Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

230results about How to "Improve color fixation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anhydrous recycling dyeing method of activated dye

The invention relates to an anhydrous recycling dyeing method of an activated dye. The method comprises the following steps: adding the dye to a polar organic solvent; adding electrolyte and organic alkali, and dissolving, so as to obtain a dye bath, wherein the proportional relation of the dye to the polar organic solvent to the electrolyte to the organic alkali is (0.5-30g):1L:(0-10g):(0.1-30g); pre-swelling a pure cotton fabric in the polar organic solvent at 50-150 DEG C for 0.5-24 hours; then dyeing in the dye bath at 45-130 DEG C for 0.5-3 hours at the dyeing bath ratio of 1:10 to 1:50; and cleaning and drying, so as to obtain the dyed fabric. The residual dye liquid generated in the method disclosed by the invention does not contain a hydrolyzed dye, and can achieve recycling of dye liquor just by directly supplying the dye and assistants.

Owner:DONGHUA UNIV

Low-temperature dyeing and finishing technology of cottonette

InactiveCN105002730AProcess temperature changeLow processing temperatureBiochemical fibre treatmentHeating/cooling textile fabricsInorganic saltsDiastase

The invention discloses a low-temperature dyeing and finishing technology of cottonette. The technology comprises the following steps: pretreatment; preshaping; modification treatment; dyeing; mordant removing; soaping; color fixing; post-treatment; drying; shaping; calendaring; rolling. According to the technology, pretreatment is carried out through the adoption of helicase and alpha-amylase, and modification treatment is carried out before dyeing, so that the property of the cottonette is fundamentally modified, and the dye-uptake of the fabric is increased; during the dyeing procedure, large quantities of alkaline substances and inorganic salt are not used, and a levelling agent, a low-temperature dyeing accelerant, a migration inhibitor and a dispersing agent are added, so that the dye uniformity is improved; during the whole dyeing process, the temperature is lower than 80 DEG C, and the dyeing process belongs to low-temperature dyeing, so that energy consumption is reduced; self-cleaning treatment is added in post-treatment, so that the self-cleaning capacity, wrinkle resistance and water washable firmness of the fabric are improved; post-treatment is carried out through the adoption of silk fibroin and sericin, so that the pilling resistance and antistatic property of the cottonette are improved; the whole technology is environment-friendly and free of pollution.

Owner:TAICANG TIANLONG CHEM FIBER

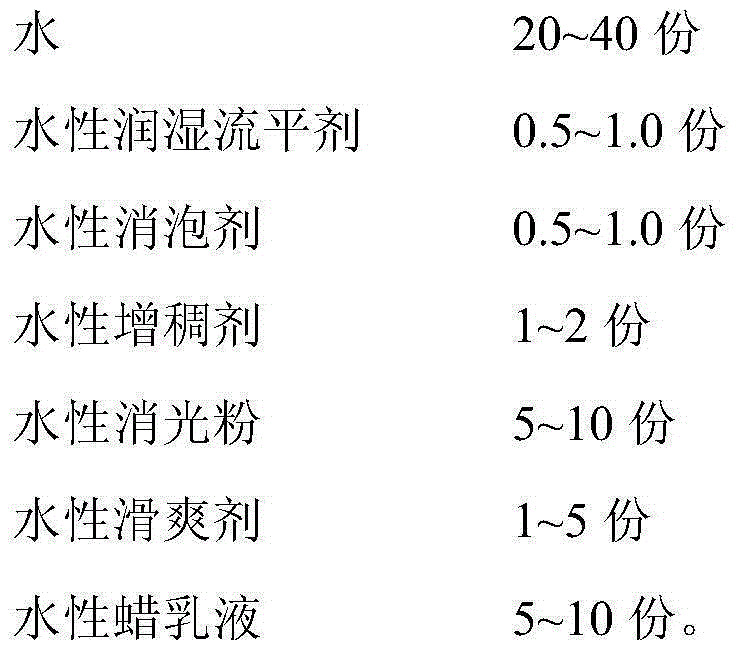

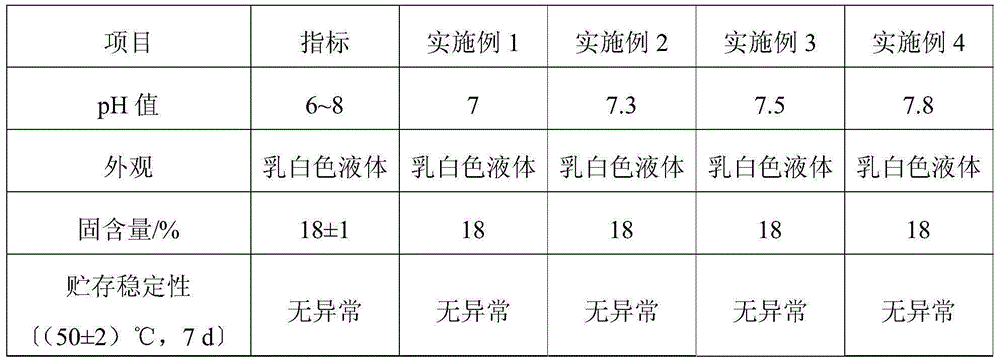

Synthetic leather surface conditioning agent

The invention provides a synthetic leather surface conditioning agent. The synthetic leather surface conditioning agent comprises, by weight, 60-80 parts of aqueous polyurethane resin, 20-40 parts of water, 0.5-1.0 part of an aqueous wetting leveling agent, 0.5-1.0 part of an aqueous antifoaming agent, 1-2 parts of an aqueous thickening agent, 5-10 parts of aqueous matting powder, 1-5 parts of an aqueous slip agent and 5-10 parts of an aqueous wax emulsion. The aqueous polyurethane surface conditioning agent has effects of dye fixation and wear resistance on the synthetic leather surface, makes synthetic leather surface fine and smooth, does not contain VOC, does not cause resource waste and environmental pollution, satisfies safety, environmental friendliness and energy saving requirements and is conducive to human health.

Owner:HEFEI KETIAN WATERBORNE TECH CO LTD +2

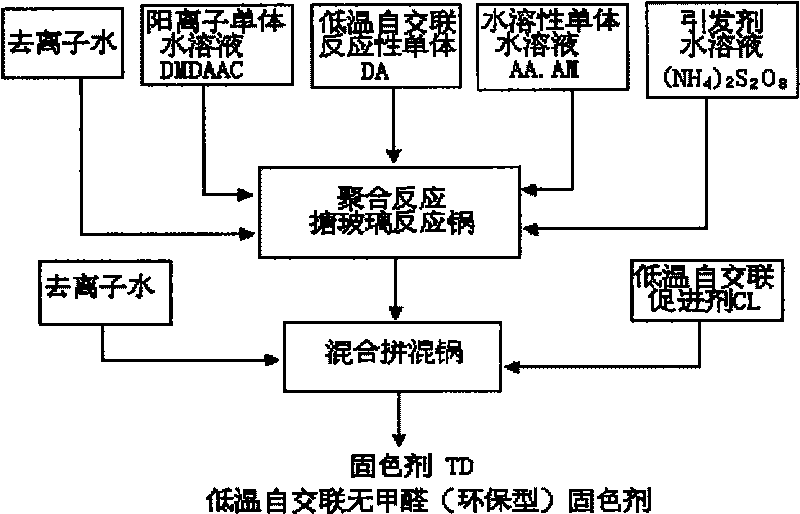

Cationic high-molecular low-temperature self-crosslinking formaldehyde-free color fixing agent and preparation method thereof

The invention relates to a cationic high-molecular low-temperature self-crosslinking formaldehyde-free color fixing agent and a preparation method. The color fixing agent is prepared from the following raw materials: dimethyl diallyl ammonium chloride containing 350 to 420kg of cationic monomer, water-soluble monomer comprising 0 to 20kg of acrylamide and 0 to 20kg of allyl amine, 10 to 20kg of low-temperature self-crosslinking reactive monomer, 10 to 20kg of low-temperature self-crosslinking accelerant, 1.0 to 2.0kg of evocating agent (ammonium persulfate) and 380 to 450kg of deionized water. The cationic high-molecular low-temperature self-crosslinking formaldehyde-free color fixing agent has the advantages that the color fixing agent can achieve ideal color-fixing effect and increase dye utilization rate, dyeing fastness and product quality. The preparation method has simple production process flow and low cost, and adopts a closed production process and special production equipment, thereby converting all input raw materials into products; and 'three wastes' (waste gas, waste water and waste residue) do not generated during the entire production course and the method is suitable for industrialized production.

Owner:JIANDE BAISHA CHEM

Natural dyestuff dyeing and finishing process of polyester fabric

The invention discloses a natural dyestuff dyeing and finishing process of polyester fabric. The natural dyestuff dyeing and finishing process of the polyester fabric comprises pretreatment, preshaping, modification treatment, dyeing, mordant removing, soaping, fixation, finishing, drying, shaping, calendering and winding. According to the natural dyestuff dyeing and finishing process of the polyester fabric, helicase and alhpa-amylase are adopted to conduct pretreatment, modification treatment is radically conducted on the performance of the polyester fabric through a acetic acid aqueous solution of chitosan, hydrogen peroxide and epoxy chloropropane, and the dyeing rate of the fabric is increased; in the dyeing process, a large amount of alkaline matter and inorganic salt are not used, a levelling agent and diffusant are added, the level-dyeing property is improved, natural dyestuff is used, therefore, environmental pollution is avoided, and requirements of green environmental protection are met; modification treatment and fire-retardant treatment are conducted on the fabric through montmorillonite, and the fire resistance of the fabric is high; anti-yellowing reagents are used in the preshaping and the shaping, and the final fabric is not prone to yellowing.

Owner:TAICANG CHENGLE CHEM FIBER

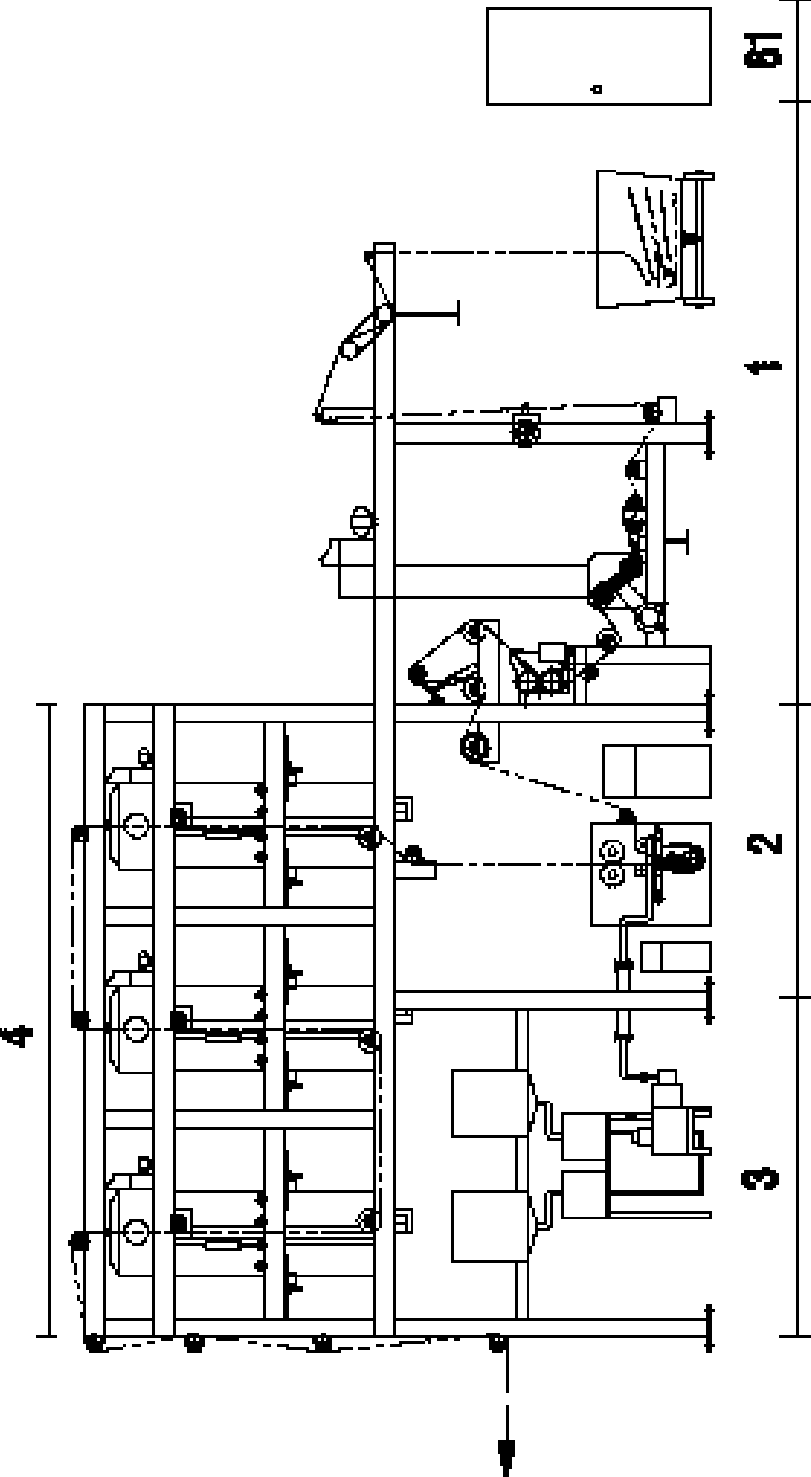

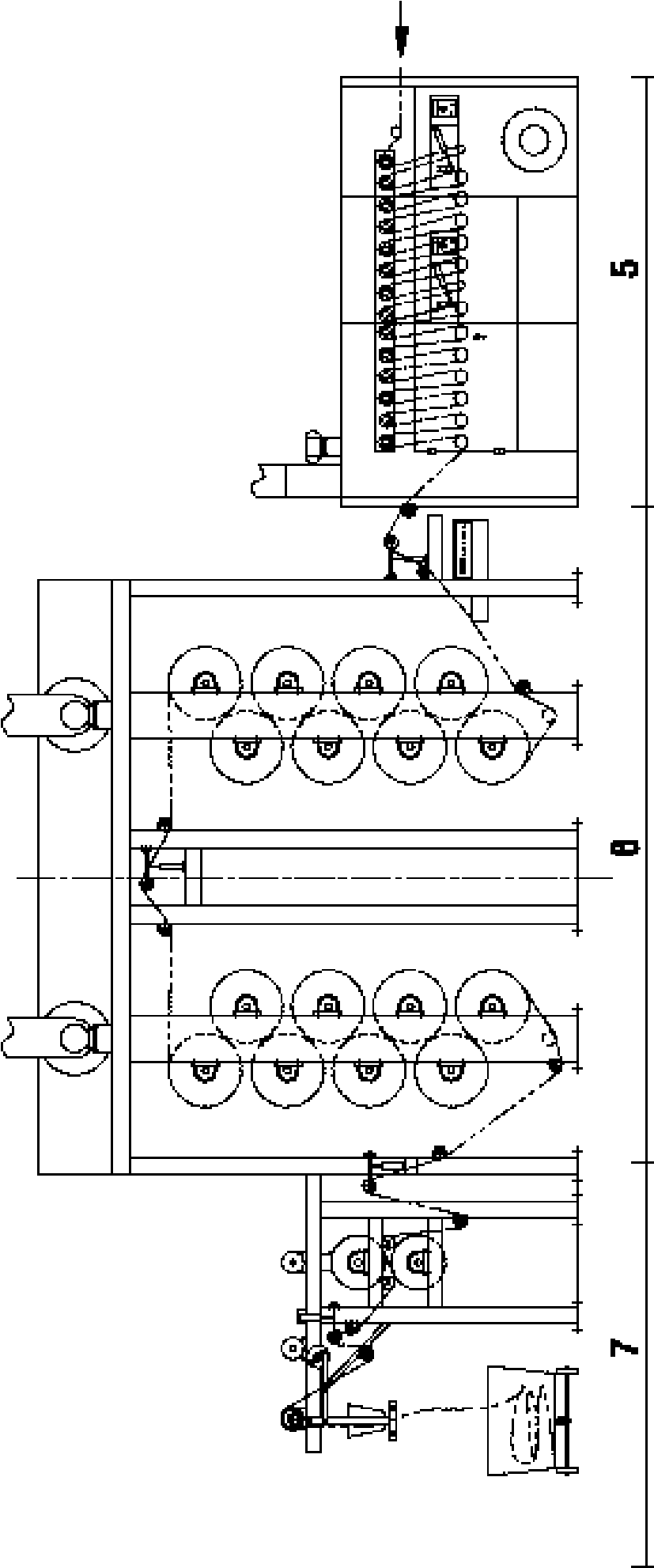

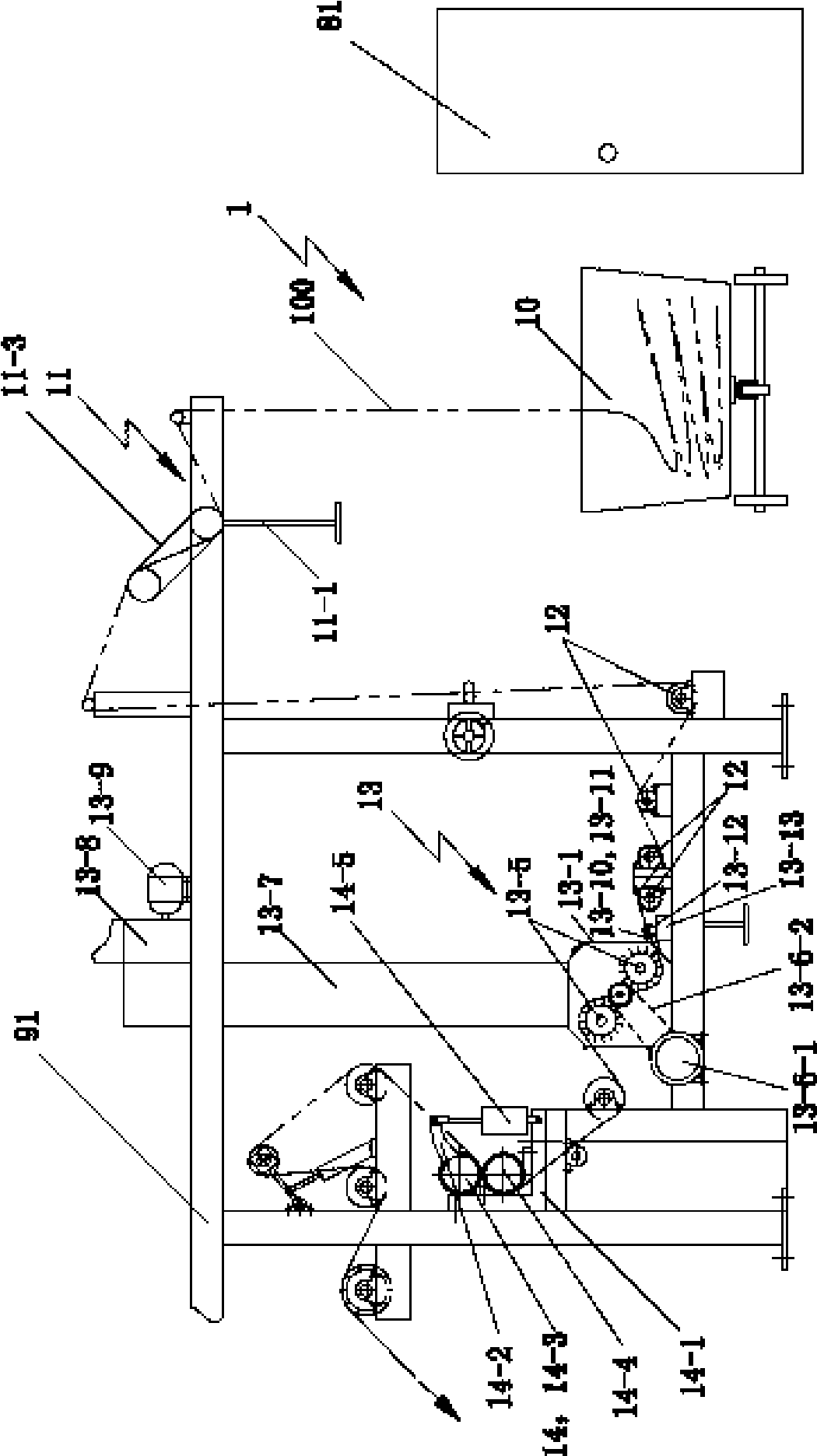

Continuous pigment dyeing pad dyer with infrared pre-baking apparatus

InactiveCN101487177AAvoid damageImprove mobilitySucessive textile treatmentsDrying solid materials with heatEngineeringPre treatment

The invention relates to a continuous paint dyeing padding machine with an infrared pre-drying device. The padding machine comprises a fabric inlet pre-processing device, a padding system, a drying system and a fabric outlet processing device which are sequentially arranged. The drying system comprises an infrared pre-drying device and a steam drying device. The infrared pre-drying device comprises two to five pre-dying mechanisms; each pre-drying mechanism comprises a pair of frame parts; and each pair of frame parts is provided with an infrared emitter. The continuous paint dyeing padding machine is characterized in that the front part of each row of infrared emitters is provided with a shielding device; when the padding machine is in use, the shielding device is arranged at a keep-clear position; and when the padding machine is in a shutdown state, the shielding device is arranged at a shielding position. Furthermore, each pair of frame parts can be arranged in a close state or an open state corresponding to the rolling of a first frame. Therefore, the padding machine has protection effect when in use, better dyeing effect and convenient maintenance.

Owner:常州慧杰电气技术有限公司

Dyeing and finishing process for linen and cotton blended fiber fabric

InactiveCN105063998AProcess temperature changeLow processing temperaturePhysical treatmentBiochemical fibre treatmentInorganic saltsManufacturing engineering

The invention discloses a dyeing and finishing process for linen and cotton blended fiber fabric. The dyeing and finishing process comprises preprocessing, pre-sizing, modified processing, dyeing, mordant removing, soaping, color fixing, after finishing, drying, sizing, calendaring and rolling. Helicase, scouring enzyme and alpha-amylase are used for pretreatment, modification treatment is adopted before dyeing, the performance of linen and cotton blended fabric is modified fundamentally, and the dye-uptake rate is increased; the dyeing procedure does not require a large quantity of alkaline substances and inorganic salt, a leveling agent, substitutive alkali, a migration inhibitor and a dispersing agent are added, the dye uniformity is improved, environment pollution is avoided due to use of natural dye, and requirements for environmental protection are met; self-cleaning processing is added in the after finishing procedure, and the self-cleaning capacity, the crease-resistant performance, the washing resistance and the color fastness of the fabric are improved; crease-resistance finishing is added, and the crease-resistant performance of the fabric is improved; the whole process is environment-friendly and pollution-free.

Owner:TAICANG TIANLONG CHEM FIBER

Environment-friendly dyeing and finishing technology of cotton cellulose fabric

InactiveCN105002720AHigh whitenessAvoid damagePhysical treatmentBiochemical fibre treatmentEpoxyCellulose

The invention discloses an environment-friendly dyeing and finishing technology of a cotton cellulose fabric. The technology comprises the following steps: pretreatment; preshaping; modification treatment; dyeing; mordant removing; soaping; color fixing; post-treatment; drying; shaping; calendaring; rolling. According to the technology, pretreatment is carried out through the adoption of helicase and alpha-amylase, and acetic acid aqueous solution of chitosan, hydrogen peroxide and epoxy chloropropane is adopted, so that the property of the cotton cellulose fabric is fundamentally modified, and the dye-uptake of the fabric is increased; during the dyeing procedure, large quantities of alkaline substances and inorganic salt are not used, and a levelling agent and a dispersing agent are added, so that the dye uniformity is improved; natural dye is used, so that environmental pollution is avoided, and the demand of environmental protection is met; modification treatment and fire retardant treatment are carried out on the fabric through the adoption of montmorillonite, so that the fire resistance of the fabric is high; self-cleaning treatment is added in post-treatment, so that the self-cleaning capacity, wrinkle resistance and water washable firmness of the fabric are improved; the whole technology is environment-friendly and free of pollution.

Owner:TAICANG CHENGLE CHEM FIBER

Dyeing and finishing process for polyamide fabric

InactiveCN105177987AProcess temperature changeLow processing temperatureBiochemical fibre treatmentUltrasonic/sonic fibre treatmentPolyamideAmmonium chloride mixture

The invention discloses a dyeing and finishing process for polyamide fabric. The provided process comprises pretreatment, pre-setting, modified processing, dyeing, soaping, dye fixation, post-finishing, drying, setting, calendering and rolling. Supersonic waves are employed for pretreatment, fabric is subjected to low temperature plasma processing before the dyeing step, then 2,3-epoxy propyl trimethyl ammonium chloride is employed for modification processing of the fabric, the dyeing degree of the fabric is raised, and difficulty of the subsequent dyeing step is lowered. During the dyeing step, a lot of alkaline substances and inorganic salt are not used, natural dyes are employed, colophony powder is added as a dye-fixing agent, the dye-fixing effect is enhanced, environment pollution is avoided, and green environmental protection requirements are met. Montmorillonite is employed for modification processing and flame retardation processing of the fabric, and thus the flame retardation of the fabric is high. Anti-yellowing reagents are used both in the pre-setting and setting steps, and thus the final fabric is not easy to turn yellow.

Owner:TAICANG TIANLONG CHEM FIBER

Flax fabric dyeing and finishing process

InactiveCN104988768AReduce pollutionAvoid damageUltrasonic/sonic fibre treatmentDyeing processInorganic saltsMontmorillonite

The invention discloses a flax fabric dyeing and finishing process including pretreatment, pre-sizing, modification treatment, dyeing, soaping, color fixation, post-finishing, drying, sizing, calendering, and coiling. Ultrasonic waves are used for pretreatment, and at the same time, the modification treatment step is added; in the dyeing process, a large amount of alkaline substances and inorganic salts are not used, natural dyes are used, and at the same time, a colophony powder is added as a color fixing agent, so that the color fixing effect is enhanced, besides, the environmental pollution is avoided, and the requirements of environmental protection are met; montmorillonite is used for modification treatment and flame retardant treatment on the fabric, so that the flame retardancy of the fabric is high; and an anti-yellowing reagent is used in the processes of pre-sizing, sizing and post-finishing, so that a final fabric does not easily turn yellow.

Owner:太仓市宝明化纤有限公司

Disperse/activated one-emulsion paste printing dye and printing technology thereof

The invention discloses a disperse / activated one-emulsion paste printing dye, mainly prepared from the following components: composite paste slurry, an alkaline agent, reserve salt, urea, activated dye, disperse dye and water, wherein the composite paste is mainly prepared from the following components: 60% of sodium alginate, 20-30% of sodium polyacrylate, 5-15% of polyethylene glycol 2000 and 5% of polyvinyl pyrrolidone. A printing technology of the one-emulsion paste printing dye comprises the steps of printing, drying, baking (at the temperature of 180 DEG C for 7 minutes), washing by cold water, washing by alkaline water (at the temperature of 95 DEG C for 3 minutes), washing by hot water (at the temperature of 80-90 DEG C), washing by cold water, neutralizing and drying; after that, carrying out post-boarding and tentering. The disperse / activated one-emulsion paste printing dye successfully solves the problems that a disperse dye and an activated dye are poor in compatibility during one-emulsion paste printing, the paste pH value is sensitive to the disperse dye, the disperse dye and the activated dye are low in color yield percentage and serious in white ground contamination, a cloth cover effect is poor since the disperse dye and the activated dye are large in dyeing difference of fibers, and the like; the printing technology is more reasonable in process, clean and environment-friendly in production and stable in product quality.

Owner:ZHEJIANG JIAXIN SILK

Fabric formaldehyde-free fixing agent

InactiveCN103669050AImprove color fixationHigh color fastnessDyeing processColour fastnessPolymer science

The invention discloses a fabric formaldehyde-free fixing agent. The fixing agent comprises the following raw materials in parts by mass: 10-15 parts of poly dimethyl diallyl ammonium chloride, 15-18 parts of 2-hydroxypropyltrimethyl ammonium chloride chitosan, 25-34 parts of water, 20-25 parts of ethanol and 5-10 parts of fatty alcohol polyoxyethylene ether. The fixing agent disclosed by the invention has an excellent fixation effect, and can effectively improve colour fastness of fabric dyes and wet rubbing fastness in the processes of dyeing and printing. The fabric treated by the fabric formaldehyde-free fixing agent does not discolor.

Owner:NANTONG TONGZHOU DISTRICT CHUANJIANG TOWN SUNWORLD DYNASTY HOME TEXTILE DESIGN STUDIO

Aramid fabric high-efficiency dyeing and finishing process

InactiveCN104988711AImprove hydrophilicityImprove dye uptakePhysical treatmentFibre typesInorganic saltsProcess engineering

The invention discloses an aramid fabric high-efficiency dyeing and finishing process including modification treatment, scouring and dyeing in one bath, soaping, color fixation, post-finishing, drying, sizing, calendering, and coiling. According to the dyeing and finishing process, before the dyeing process, a fabric is subjected to low temperature plasma treatment, then the fiber fabric is subjected to modification treatment with 2,3-epoxypropyltrimethylammonium chloride and chitosan, and thus the fabric dyeing degree is increased, and the difficulty of the subsequent dyeing steps is reduced; at the same time, ultrasonic treatment is adopted during modification treatment, so that the time is saved and the treatment efficiency is improved; with adopting of scouring and dyeing in one bath, the efficiency is increased, and the cost is reduced; in the dyeing process, a large amount of alkaline substances and inorganic salts are not used, natural dyes are used, and at the same time, a colophony powder is added as a color fixing agent, so that the color fixing effect is enhanced, besides, the environmental pollution is avoided, and the requirements of environmental protection are met; and with increase of anti-yellowing finishing, a final fabric does not easily turn yellow.

Owner:TAICANG SHUANGYU CHEM FIBER CO LTD

Dyeing and finishing process of polyester and cotton blended fiber fabric

InactiveCN105063997AHigh whitenessAvoid damageSucessive textile treatmentsBiochemical fibre treatmentPolyesterFiber

The invention discloses a dyeing and finishing process of polyester and cotton blended fiber fabric. The process comprises pretreatment, presetting, modification treatment, dyeing, mordant removal, soaping, color fixing, after finishing, drying, sizing, calendaring and rolling. Snailase and alpha-amylase are adopted for pretreatment, modification treatment is adopted before dyeing, the polyester and cotton blended fabric is modified fundamentally, and the dye-uptake of the fabric is increased; in the dyeing procedure, fewer alkaline substances and inorganic salt are used, a dye leveler, substitution alkali, a migration inhibitor and a diffusant are added, the dye leveling performance is improved, natural dye is used, environmental pollution is avoided, and the environment-friendly requirement is met; self-cleaning treatment is added during aftertreatment, and the self-cleaning capacity, the crease-resistant performance, the wash durability and color fastness are improved; silk fibroin and sericin are adopted for afterfinish, and the anti-pilling performance and the antistatic performance of the fabric are provided; the whole process is environment-friendly and pollution-free.

Owner:TAICANG TIANLONG CHEM FIBER

Method for willow artwork dyeing through natural indigo pigment

ActiveCN107253249AGood colorGood spotlightRadiation/waves wood treatmentWood treatment detailsSteepingDistillation

The invention discloses a method for willow artwork dyeing through a natural indigo pigment. The method comprises the following aspects that (1) indigo extraction is conducted, specifically, a plant raw material is subjected to crushing, fermentation, water soluble extraction and low-temperature drying, and the indigo pigment is prepared; (2) acid-alkali steeping is conducted, specifically, a hydrochlric solution with the concentration being 0.3-0.4% and a sodium hydroxide solution with the concentration being 0.25-0.3% are used to steep a willow artwork correspondingly; (3) cooking for impurity removal is conducted, specifically, impurities in the willow artwork is removed through cooking; (4) steaming for dyeing is conducted, specifically, the indigo pigment with the mass being 11-13% that of distillation boiler water is added, and steam dyeing is conducted; (5) low-temperature drying is conducted, specifically, the dyed willow artwork is dried; (6) infrared color fixing is conducted, specifically, the willow artwork is wrapped through mixed slurry and placed under infrared lamplight with the illumination intensity being 470-520 lux for color fixing; (7) ultraviolet inspection is conducted, specifically, the willow artwork subjected to color fixing is placed under an ultraviolet lamp, and the color fixing condition is inspected; and (8) tung oil layer coating is conducted, specifically, the willow artwork qualified after inspection is coated with tung oil, and after drying, the willow artwork with the natural indigo pigment is prepared.

Owner:阜南县宏达工艺品厂

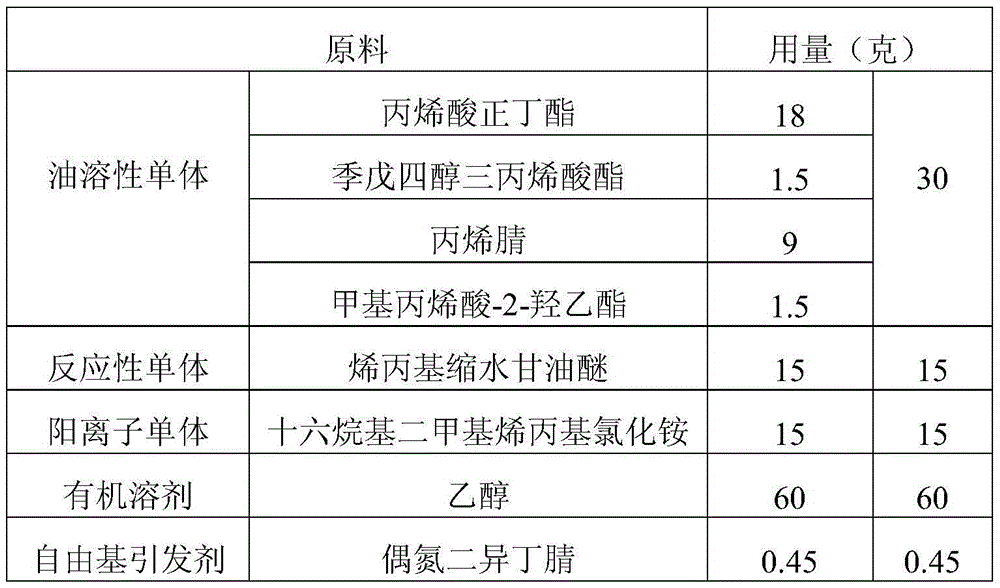

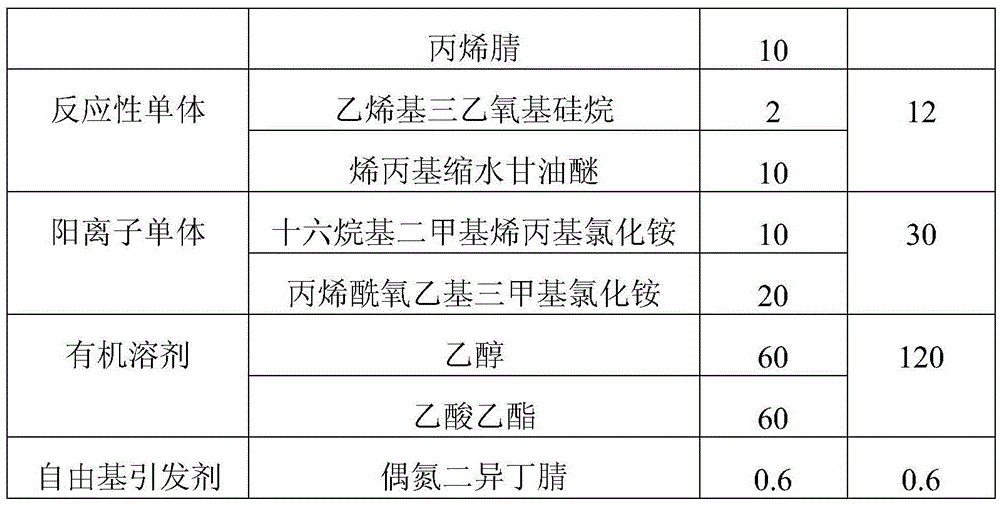

Cationic color fixing agent and preparation method and application thereof

The invention provides a cationic color fixing agent and a preparation method and application thereof. The cationic color fixing agent is obtained by polymerization reaction of an oil-soluble monomer, a cationic monomer and a reactive monomer in a solvent under the action of a radical initiator, wherein the oil-soluble monomer is one or the combination of several of styrene, acrylonitrile and acrylate; the cationic monomer is one or the combination of acryloxyethyl alkyl quaternary ammonium salt and / or allyl alkyl quaternary ammonium salt; the reactive monomer is one or the combination of several of allyl glycidyl ether, hydroxyl-containing acrylics, vinyl trimethoxy silane, vinyl triethoxy silane, acrylamide, crylic acid and methacrylic acid. The cationic color fixing agent is insoluble in water and can be dissolved in a weak polar solvent and / or non-polar solvent; besides, after non-aqueous solvent dyeing of reactive dyes, the cationic color fixing agent can be directly used in the on-going fixing process without washing.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Low-temperature dyeing and finishing technology for bamboo fiber fabric

InactiveCN105019250AAvoid damageLower processing temperaturePhysical treatmentBiochemical fibre treatmentAmylaseFiber

The invention discloses a low-temperature dyeing and finishing technology for bamboo fiber fabric. The low-temperature dyeing and finishing technology includes the steps of pretreatment, preshaping, modification treatment, dyeing, mordant removal, soaping, color fixation, after finishing, drying, shaping, calendering and rolling. Helicase, scouring enzyme and alpha-amylase are adopted for pretreatment, modification treatment is adopted before dyeing, the performance of the bamboo fiber fabric is modified fundamentally, and the dye-uptake rate of the fabric is increased; as in the dyeing working procedure, alkaline substance and inorganic salts are not used in quantity, and a levelling agent is added, the dyeing levelness is improved; environment pollution is avoided by using natural dyestuff, which meets the requirement for environmental protection; as self-cleaning treatment is added in after treatment, the self-cleaning capacity, crease-resistant performance and wash-resisting firmness of the fabric are improved; crease-resistant finishing is added, and therefore the crease-resistant performance of the fabric is improved; the whole technology is environmentally friendly and free from pollution.

Owner:TAICANG TIANLONG CHEM FIBER

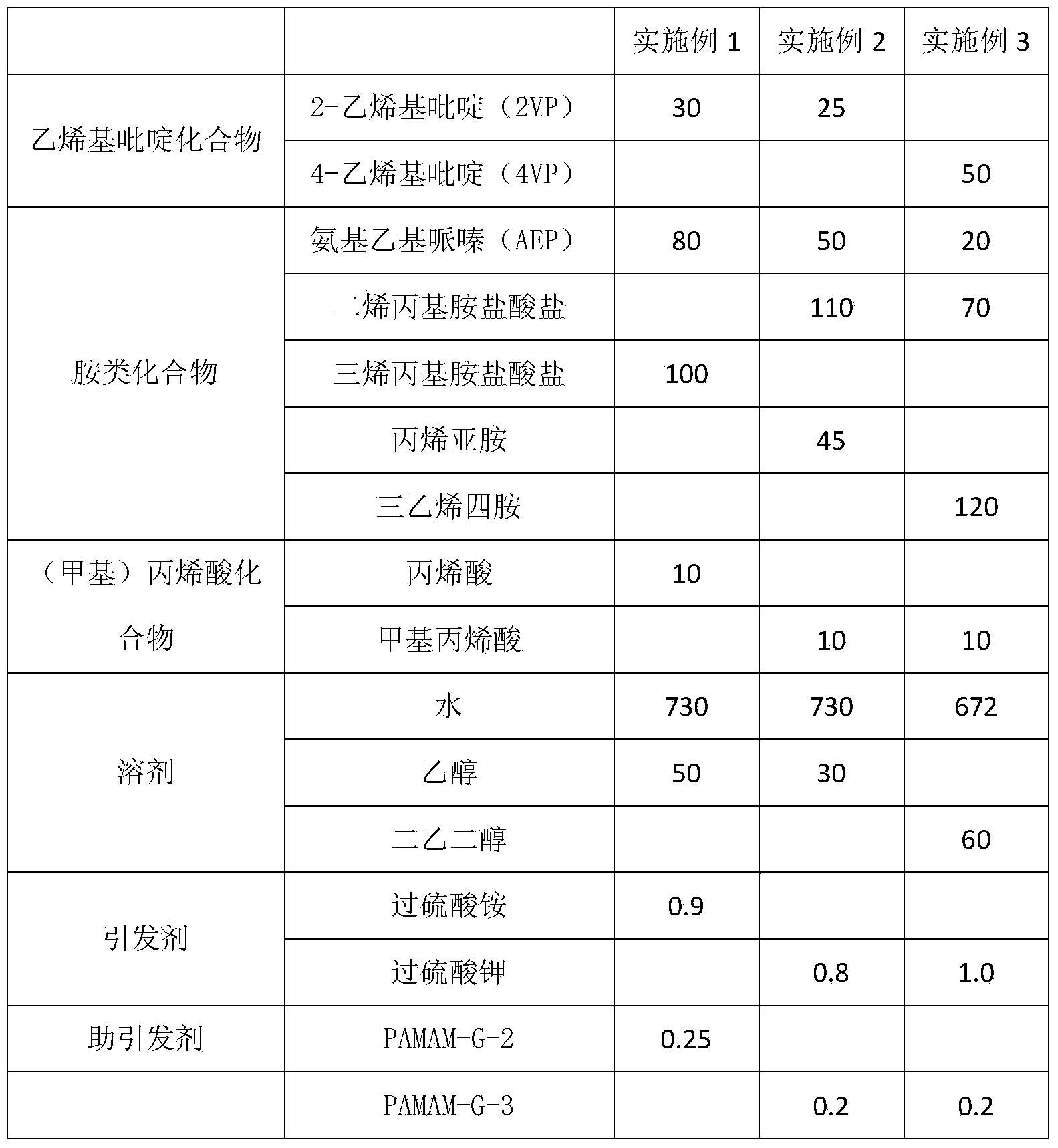

Preparation method for hydrophilic dye-fixing agent for reactive dyeing

ActiveCN104313926ADoes not affect hydrophilicityDoes not affect the feelDyeing processRadical initiatorDyeing

The invention relates to a preparation method for a hydrophilic dye-fixing agent for reactive dyeing. According to the method, vinylpyridine, amine monomers and acrylate monomers have a polymerization reaction when radical initiators and assisting initiators exist, and the hydrophilic dye-fixing agent is obtained. The hydrophilic dye-fixing agent prepared with the method has an excellent dye-fixing effect, meanwhile, the hygroscopicity and the hydrophilia of cotton fabric are not affected, and a good hand feeling is achieved.

Owner:SHANGHAI ARGUS NEW MATERIAL CO LTD

Dyeing and finishing process for modal fabric

InactiveCN104975499AReduce pollutionAvoid damageBiochemical fibre treatmentHeating/cooling textile fabricsInorganic saltsProcess engineering

The invention discloses a dyeing and finishing process for modal fabric. The process comprises the procedures of pretreatment, pre-setting, modification treatment, dyeing, soaping, fixation, after-finishing, drying, sizing, calendering and rolling. According to the invention, pretreatment is carried out by adopting ultrasonic wave, and a step of modification treatment is added; in the dyeing procedure, a base substituent SA is used, use of a large quantity of alkaline substances and inorganic salt is avoided, nature dye is adopted, and colophony powder is added as a fixing agent, so that the color fixing effect is enhanced, environmental pollution is avoided, and the requirement of green environmental protection is met; furthermore, montmorillonoid is adopted to carry out modification treatment and flame retardant treatment on the fabric, so that the flame retardancy of the fabric is high. According to the invention, a yellowing-resisting reagent is used in the procedures of pre-setting, sizing and after-finishing, so that the final fabric cannot become yellow easily.

Owner:TAICANG CHENGLE CHEM FIBER

Alkali-fast aldehyde-free colour stabilizer and method for preparing the same

InactiveCN101492888AImprove wet fastnessImprove the composite fastness to sweat and lightDyeing processEpoxyAdditive ingredient

The invention relates to a color fixing agent and a preparation method thereof. An alkaline-resisting aldehyde-free color fixing agent is a cationic polymer formed by the polymerization reaction of acrylamide, butyl acrylate and epoxy chloropropane. A method for preparing the alkaline-resisting aldehyde-free color fixing agent comprises the ingredients as follows: 10%-35% of acrylamide, 15%-45% of butyl acrylate, 10%-40% of epoxy chloropropane, 5%-13% of hydrochloric acid and 0.1%-1.5% of an initiating agent; and comprises the following steps: adding acrylamide and butyl acrylate under normaltemperature and raising the temperature; adding epoxy chloropropane at 60 DEG C and maintaining the temperature for 10-18 minutes; raising the temperature to 80 DEG C to add the initiating agent and maintaining the temperature for 30 minutes; raising the temperature to the range from 120 DEG C to 130 DEG C, and persistently reacting for 3-4 hours; adding hydrochloric acid for acid cleaning, temperature reduction, neutralization and discharging to obtain the alkaline-resisting aldehyde-free color fixing agent. The invention is quite strong in resisting alkaline and high temperature, is free from color variation when treating the fabrics, and has no influence on chlorine fastness, light fastness and perspiration-light fastness.

Owner:上海德桑精细化工有限公司

Antique tusche and new preparation method thereof

InactiveCN101787234AIncrease the sense of thicknessAvoid ambiguityInksGranularityTraditional medicine

The invention relates to an antique tusche and a preparation method thereof. The antique tusche comprises the components by weight percent: 75-85 bone glue solution, 3-25 oily fume, 0.05-0.5 powdery spice and 0.5-5 traditional Chinese medicine liquid, wherein the bone glue solution is prepared by mixing bone glue and water according to a certain mass ratio, heating to 110-120 DEG C, decocting for 20-50h, and filtering; the oily fume is light powder solid and has the granularity less than 1 micron; the powdery spice is prepared by grinding musk and borneol with the mass ration of 2: 8 and sieving by a 200-mesh sieve; the traditional Chinese medicine liquid is prepared by decocting Chinese herbal medicines; and the preparation method of the antique tusche comprises the steps of: evenly mixing the bone glue solution, the oily fume, the musk, the borneol and the traditional Chinese medicine liquid, and dispersing the mixture into paste with the fineness less than 15 microns and the viscosity of 0.01-200 Pa. S; and the antique tusche is used for writing or printing painting and calligraphy works.

Owner:北京今鼎新化文化有限公司 +1

High-fixation high-flame retardation polyester fabric dyeing and finishing technology

InactiveCN105113286AProcess temperature changeLow processing temperatureFibre typesUltrasonic/sonic fibre treatmentPolyesterFlame resistance

The invention discloses a high-fixation high-flame retardation polyester fabric dyeing and finishing technology. The technology comprises pre-treatment, pre-setting, modification treatment, dyeing, soaping, dye fixation, after finishing, drying, setting, calendering and rolling. Supersonic wave is used for pre-treatment and a modification treatment process is used. In dyeing, a lot of alkaline substances and inorganic salts are avoided, natural dye is adopted and colophony powder is used as a dye-fixing agent so that dye fixation effects are improved, environmental pollution is avoided and environmental protection requirements are satisfied. Through modification and flame retardation treatment on the fabric by montmorillonite, fabric fire resistance is high. Through the dyeing and finishing technology, the high-fixation high-flame retardation polyester fabric is obtained.

Owner:太仓市宝明化纤有限公司

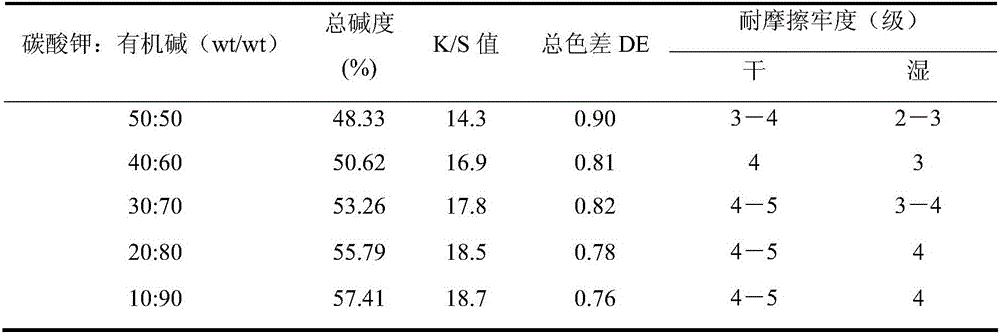

Novel substitutive alkali and preparation method thereof

Disclosed is novel substitutive alkali. The novel substitutive alkali is prepared from, by weight, 73-82% of organic alkali and potassium carbonate, 10-15% of buffer agent and 8-12% of additive. The novel substitutive alkali has the advantages that wet rubbing fastness values of the novel substitutive alkali and sodium carbonate are close, the wet rubbing fastness values are up to Grade IV when the novel substitutive alkali is used for cotton fabrics dyed by reactive dark blue SGE and reactive blue SPR dyes and fixed, and the novel substitutive alkali is up to or superior to fixation performance of highly-condensed dyeing substitutive alkali and the sodium carbonate.

Owner:周口科技职业学院

Polyamide fabric modifying, dyeing and finishing process

InactiveCN105019266AProcess temperature changeLow processing temperatureBiochemical fibre treatmentFibre typesPolyamideDyeing

The invention discloses a polyamide fabric modifying, dyeing and finishing process. The process comprises the steps of pretreatment, pre-setting, modification treatment, dyeing, soaping, color fixing, after treatment, drying, setting, calendering and rolling. Helicase and alpha-amylase are adopted for carrying out pretreatment, mixed liquor of nanometer titanium dioxide, gamma-(2, 3-epoxypropoxy) trimethoxypropylsilane and caprolactam is adopted for modifying performance of polyamide fabric fundamentally, and the dye-uptake rate of the fabric is increased; in the dyeing working procedure, a large number of alkaline substances and inorganic salts are not used, a leveling agent and a dispersing agent are added, and dyeing levelness is improved; meanwhile, as rosin powder is added to serve as a color fixing agent, the color fixing effect is enhanced, environmental pollution is avoided, and the requirement for environmental protection is met; moreover, montmorillonite is adopted for carrying out modifying and flame retarding on the fabric, and therefore the fire retarding property of the fabric is high; anti-yellowing reagents are used in the presetting and setting steps, and therefore the final fabric is not prone to yellowing.

Owner:TAICANG CHENGLE CHEM FIBER

Modified cationic waterborne polyurethane color fixing agent and preparation method thereof

The invention discloses a preparation method of a modified cationic waterborne polyurethane color fixing agent, and belongs to the technical field of textile color fixing agents. The preparation method comprises the following steps: (1) carrying out a quaternization reaction, (2) carrying out a reaction on a polyurethane prepolymer, and (3) carrying out an end-capping and emulsification reaction to obtain the modified cationic waterborne polyurethane color fixing agent with semitransparent appearance, blue light exhibition and solid content of 30-40%. The preparation process disclosed by invention is simple. Firstly, a part of diisocyanate groups obtained after the reaction of the polyurethane prepolymer is inactivated by using an end-cappingreagent, and then the waterborne polyurethane color fixing agent is generated by self emulsifying. The color fixing agent is applied to a color fixation post-treatment process of dyed cotton fabrics, so that the color fixation effect is good, rubbing fastness and soaping fastness are obviously improved, the color change of the dyed fabric is small, and the hand feeling is soft. Meanwhile, the prepared color fixing agent does not contain formaldehyde, so that relatively high economic benefit and environmental benefit are achieved.

Owner:SHAANXI UNIV OF SCI & TECH

Efficient dyeing and finishing process for chemical fiber fabric

InactiveCN104975498AImprove hydrophilicityImprove dye uptakeHeating/cooling textile fabricsDry-cleaning apparatus for textilesInorganic saltsFiber

The invention discloses an efficient dyeing and finishing process for a chemical fiber fabric, which comprises the procedures of modification treatment, one-bath scouring dyeing, soaping, fixation, after finishing, drying, sizing, calendering and rolling. According to the invention, pretreatment is carried out by adopting ultrasonic wave; before the procedure of dyeing, the fabric is subjected to low-temperature plasma treatment, and then 2, 3-glycidyl trimethyl ammonium chloride is adopted for carrying out modification treatment on the fiber fabric, so that the degree of dyeing of the fabric is increased, and the difficulty of subsequent dyeing step is lowered; since one-bath scouring dyeing is adopted, the efficiency is increased, and the cost is lowered; in the dyeing procedure, use of a large quantity of alkaline substances and inorganic salt is avoided, nature dye is adopted, and colophony powder is added as a fixing agent, so that the color fixing effect is enhanced, environmental pollution is avoided, and the requirement of green environmental protection is met; furthermore, montmorillonoid is adopted to carry out flame retardant treatment on the fabric, so that the flame retardancy of the fabric is high. According to the invention, a yellowing-resisting reagent is used in the procedure of sizing, so that the final fabric cannot become yellow easily.

Owner:TAICANG TIANLONG CHEM FIBER

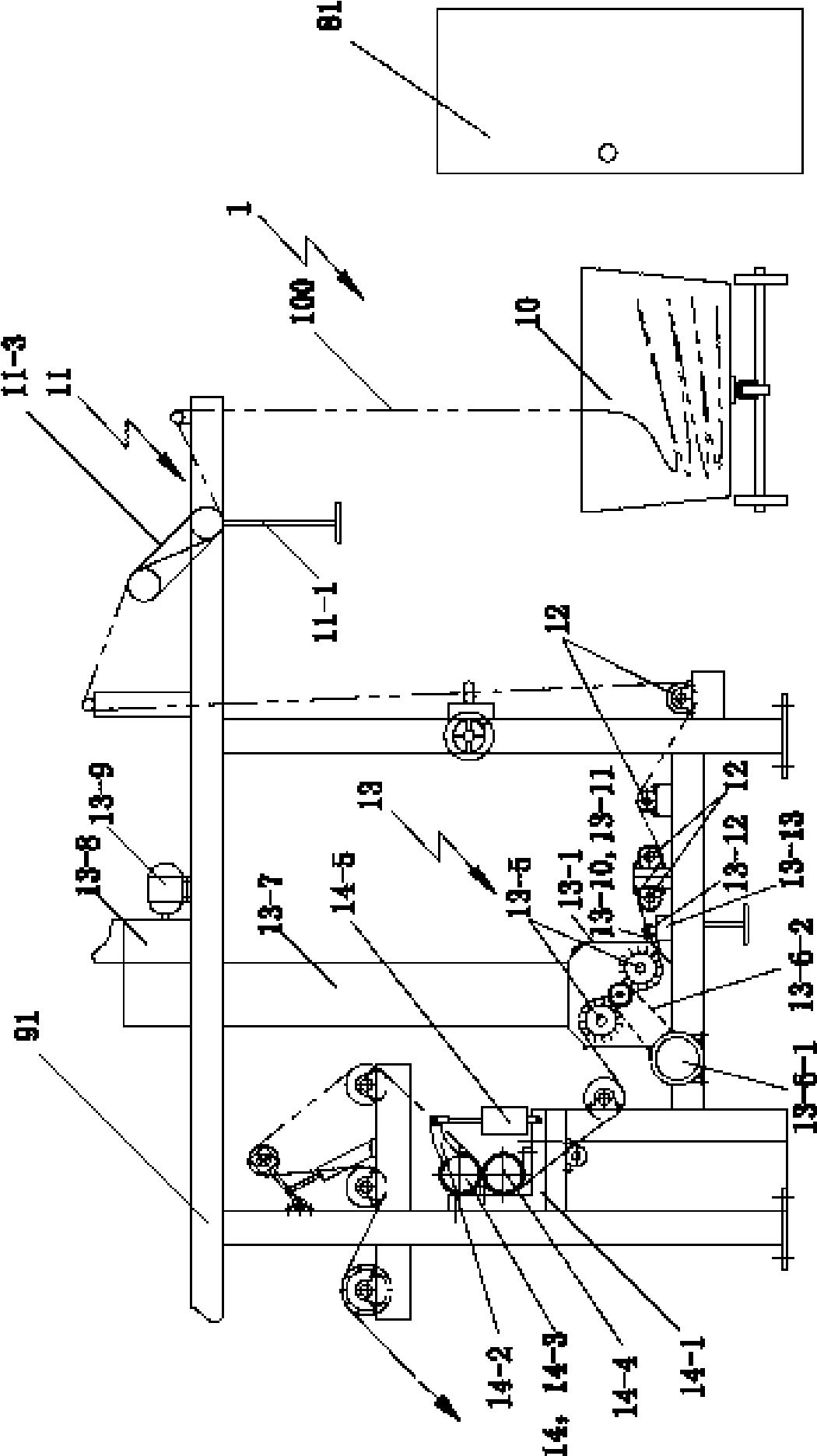

Temperature control atomization yarn dyeing process and system thereof

ActiveCN105088582AEmission reductionEasy to dyeSucessive textile treatmentsTextile treatment by spraying/projectingYarnEngineering

The invention discloses a single yarn dyeing process and system. The system comprises an unwinding mechanism, a guide roller mechanism, a wetting mechanism, a spray dyeing mechanism, a drying mechanism and a winding and rewinding mechanism. Dyeing steps comprise procedures of yarn rewinding and unwinding, yarn humidity adjusting, yarn dyeing, drying, yarn rewinding and forming, and the like, wherein in a dyeing process, a temperature control high-frequency atomization dyeing process is adopted, dyeing effects of more efficiency and more stable chromaticity can be achieved by adjusting atomization chamber temperature and atomization chamber humidity during dyeing, and a dyeing effect of more evenness can be achieved by adjusting yarn humidity before dyeing. By adopting the dyeing process and system, the dyeing course is simple, dyeing permeation is even, the course is continuous, the operation is simple, the yield is high, water consumption and sewage drainage are less, energy consumption is low, loss is less, and economic benefit can be greatly improved.

Owner:上海帆绣机电科技有限公司

Wool and cashmere printing and dyeing auxiliary

The invention relates to the field of production auxiliaries of wool products, in particular to a wool and cashmere printing and dyeing auxiliary. The wool and cashmere printing and dyeing auxiliary comprises sodium carboxy methyl cellulose, sodium diethylhexyl sulfosuccinate, citric acid, ethylene oxide, amino silicon oil, di-rhamnolipid, peroxidase and deionized water. The wool and cashmere printing and dyeing auxiliary comprises, by mass, 10-15 parts of sodium carboxy methyl cellulose, 3-8 parts of sodium diethylhexyl sulfosuccinate, 12-16 parts of citric acid, 8-14 parts of ethylene oxide, 5-10 parts of amino silicon oil, 3-6 pars of di-rhamnolipid, 1-3 parts of peroxidase and 40-60 parts of deionized water. According to the wool and cashmere printing and dyeing auxiliary, due to the combination ratio of the carboxy methyl cellulose, the citric acid and the amino silicon oil, dyeing and fixation of the dye on a wool and cashmere product are effectively improved, color fastness is improved, the color increasing and protecting performance can be improved, and the dyeing effect is ensured.

Owner:TONGXIANG PUYUAN WOOLEN KNITTING TECH SERVICE CENT

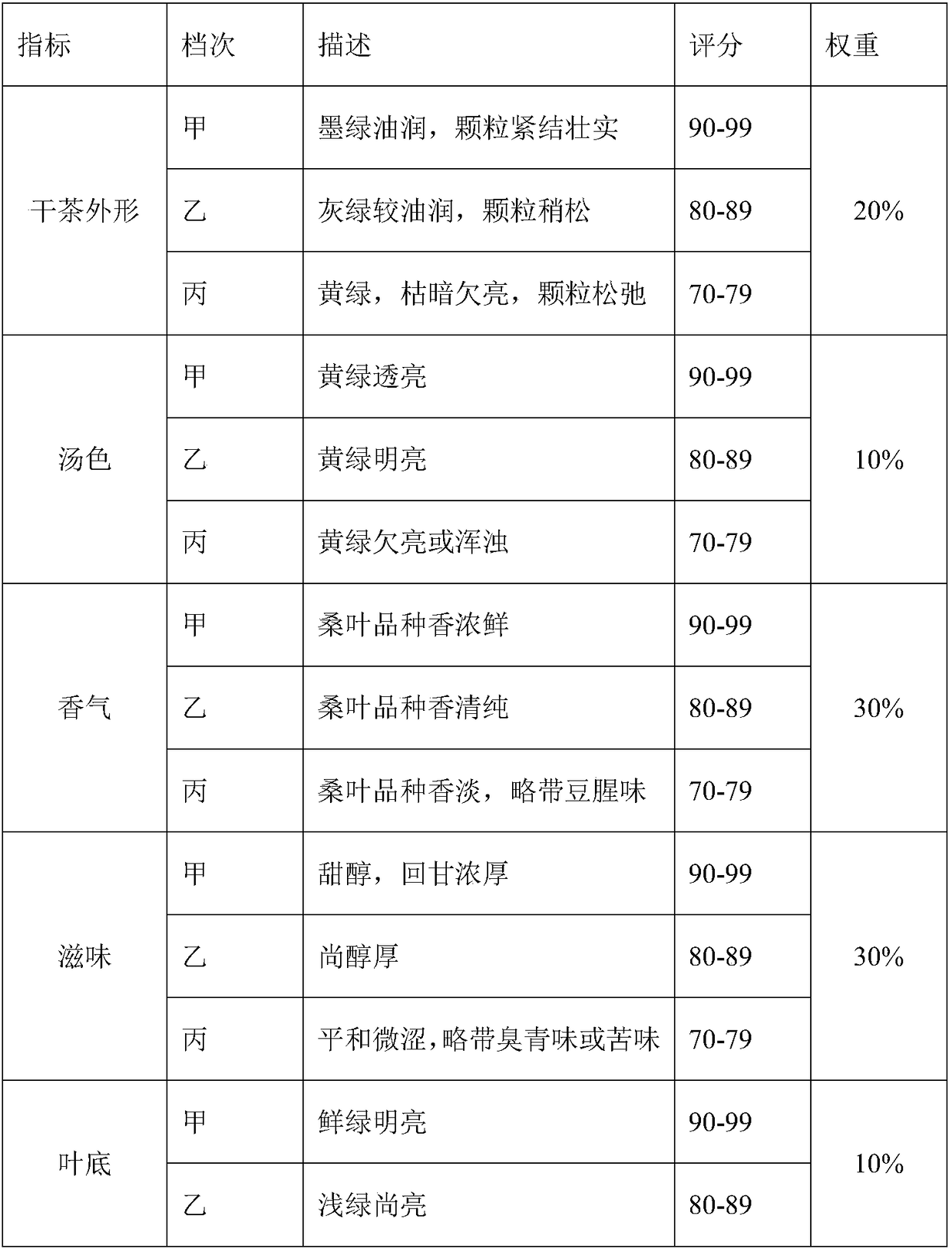

Mulberry leaf green-tea and preparation technology thereof

ActiveCN108432923AThe particles are tight and strongDark green oily colorTea substituesEpigallo-catechin gallateBiology

The invention provides mulberry leaf green-tea and a preparation technology thereof, and specifically relates to the technical field of tea preparation. The preparation technology of the mulberry leafgreen-tea comprises the following steps: a. Picking fresh mulberry leaves; b. withering the picked mulberry leaves; c. cutting the withered mulberry leaves into strips; d. carrying out drum fixation;e. carrying out spreading-cooling; f. carrying out secondary microwave fixation; g. carrying out cooling and water-regaining; h. carrying out rolling; and i. carrying out stir-frying and shaping. Thestep of withering moisture in the mulberry leaves, the fixation temperature and the rolling methods in the preparation technology are optimized so that the prepared mulberry leaf green-tea has uniquecharacteristic varietal aroma of mulberry leaves, and is tight and compact in granules, dark green and oily in color and lubricant in color and luster, yellowish green, translucent and bright in soupcolor, sweet and pure in taste, and mellow in after taste; moreover, the preparation technology of the mulberry leaf green-tea is stable and controllable in preparation processes, high in productionefficiency, and suitable for large-scale production.

Owner:柳城县国营伏虎华侨农场茶厂

Continuous pigment dyeing pad dyer with padding system

InactiveCN101487176AWell mixedAchieve dyeing effectSucessive textile treatmentsDrying solid materials with heatFiberPulp and paper industry

The invention belongs to a continuous paint dyeing padding machine with a padding system. According to the successive sequence, the dyeing padding machine is provided with a fabric feeding pre-processing device, a padding system, a drying system and a fabric outlet processing device; the padding system comprises a padding device and a proportional liquid supply device; the proportional liquid supply device comprises a measuring pump motor, two liquid supply devices, a mixer and a liquid inlet pipe; and a liquid storage box of one liquid supply device contains cation modifier and the liquid storage box of the other liquid supply device contains paint color paste. When in use, the cation modifier and the paint color paste pass by a corresponding measuring pump by a certain proportion, are subsequently mixed in the mixer to form composite dye solution, and then flow in a dipping trough continuously along the pipeline; the composite dye solution used for dipping the textile is the just mixed composite dye solution; before the modifier generates cohesion with the paint color paste, the modifier is attached to the solid fiber and generates the modification function; furthermore, the paint color paste is also attached to the solid fiber and better dyeing effect can be obtained after the post-processing.

Owner:常州市东高染整有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com