Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

423 results about "Mordant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A mordant or dye fixative is a substance used to set (i.e. bind) dyes on fabrics by forming a coordination complex with the dye, which then attaches to the fabric (or tissue). It may be used for dyeing fabrics or for intensifying stains in cell or tissue preparations. Although mordants are still used, especially by small batch dyers, it has been largely displaced in industry by directs.

Security paper

InactiveUS6159585AAvoid the needLow compositionNon-fibrous pulp additionNatural cellulose pulp/paperOrganic solventChemical separation

A security paper indicates exposure to a solvent by a solvent resistant color signal. A metal mordant dye first co-reactant and a mordant dye second co-reactant form an organic solvent-insoluble colored reaction product when the paper is washed with an organic solvent. The metal mordant dye first co-reactant and a mordant dye second co-reactant are chemically isolated from each other so as to prevent the coordinate covalent bond from forming until the paper is washed with an organic solvent. The chemical isolation can be effected by encapsulation or other physical separation of the co-reactants. The organic solvent-insoluble colored reaction product, once formed, remains entrapped in the web when the paper is washed with an organic solvent. The chemical isolation prevents the organic solvent-insoluble colored reaction product from forming upon the application of pressure alone to the paper.

Owner:DOMTAR +1

Composition for dyeing keratin fibers and a method of dyeing hair using same

Owner:ADVANCED COSMETIC TECH

Natural hair dyeing agent prepared by plant pigment catechu and hair dyeing method thereof

The present invention relates to a hair-dying agent, in particular, it relates to a natural hair-dying agent prepared by adopting plant colour matter catechu and its hair-dying method. Said hair-dying agent includes agent A and agent B. The agent A includes (by wt%) 3-10% of plant colour matter catechu, 10-50% of organic solvent and the rest is water; and the agent B includes (by wt%) 1-5% of ferrous salt mordant, 0.2-1.0% of reduced iron powder, 1-10% of surfactant, 1-5% of thickening agent, proper quantity of acidifying agent, 0.1-0.3% of natural essence and the rest is water. The catechu is a traditional Chinese medicinal material, and has the functions of clearing away heat, astringing dampness, resisting bacteria and inhibiting bacteria.

Owner:JIANGNAN UNIV

Inkjet recording sheet

InactiveUS20020176970A1Improve abilitiesGood ink absorptionCoatingsThermographyPolyvinyl alcoholAcyl group

Disclosed is an inkjet recording sheet having a colorant-receiving layer on the surface of its support, in which the colorant-receiving layer contains at least one of compounds represented by the following general formula (1) and compounds represented by the following general formula (2), and contains a vapor-phase-process silica, a polyvinyl alcohol, a boron compound, and a mordant. In the formulae, R represents a saturated hydrocarbon group having from 1 to 12 carbon atoms, an unsaturated hydrocarbon group having from 1 to 12 carbon atoms, a phenyl group, or an acyl group, and n indicates an integer of 1 to 3. <paragraph lvl="0"><in-line-formula>RO(CH2CH2O)nH (1) < / in-line-formula><paragraph lvl="0"><in-line-formula>RO(CH2CH(CH3)O)nH (2) < / in-line-formula>

Owner:FUJIFILM HLDG CORP +1

Method for mordant printing on fabric dyed by natural vegetable dye

The invention discloses a mordant printing method on the natural plant dye dyeing cloth, which is characterized by the following: preparing printing slurry through mordant, thickener, penetrant and permeability-reducing agent; proceeding cleaning and printing disposal for slurry on the natural plant dye dyeing cloth; steaming at 120-160 deg.c for 1-5 min or baking at 130-160 deg.c at 1-5 min to fix color; proceeding watering disposal at 40-60 deg.c to dry in the 80-100 deg.c condition. The invention can improves quality of natural plant dyeing plant and added quality of cloth, which is a printing cloth with health function.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Composition For Dyeing Keratin Fibers and A Method of Dyeing Hair Using Same

A composition for dyeing keratin fibers that contains 0.1 to 30 percent of at least one substantially pure plant dye material obtained using solvent or supercritical CO2 extraction, combined with 0.01 to 5 percent of active metal in a metal or mineral salt capable of acting as a mordant as a two-part hair color system.

Owner:ADVANCED COSMETIC TECH

Textile ink composition

A textile ink composition and a method of manufacturing a textile ink composition are disclosed. The textile ink composition is formed from a cationically charged metal oxide and a dye, and is capable of durably dyeing different types of fabric. The cationically charged metal oxide is typically an oligomer, such as an alumina oligomer. A suitable alumina oligomer is aluminum chlorohydrate. Typical dyes have anthraquinone, catechol, hydroxyazo or salicylic acid groups or are mordant dyes, such as Carminic Acid, Alizarin Red, Acid Blue 45, Acid Green 41, Hematoxylin, Chromoxane Cyanine R, Calconcarboxylic Acid, Plasmocorinth B, Pyrocatechol, Acid Alizarin Violet N, Alizarin Yellow GG, Mordant Yellow 12 and Mordant Blue 9.

Owner:KIMBERLY-CLARK WORLDWIDE INC

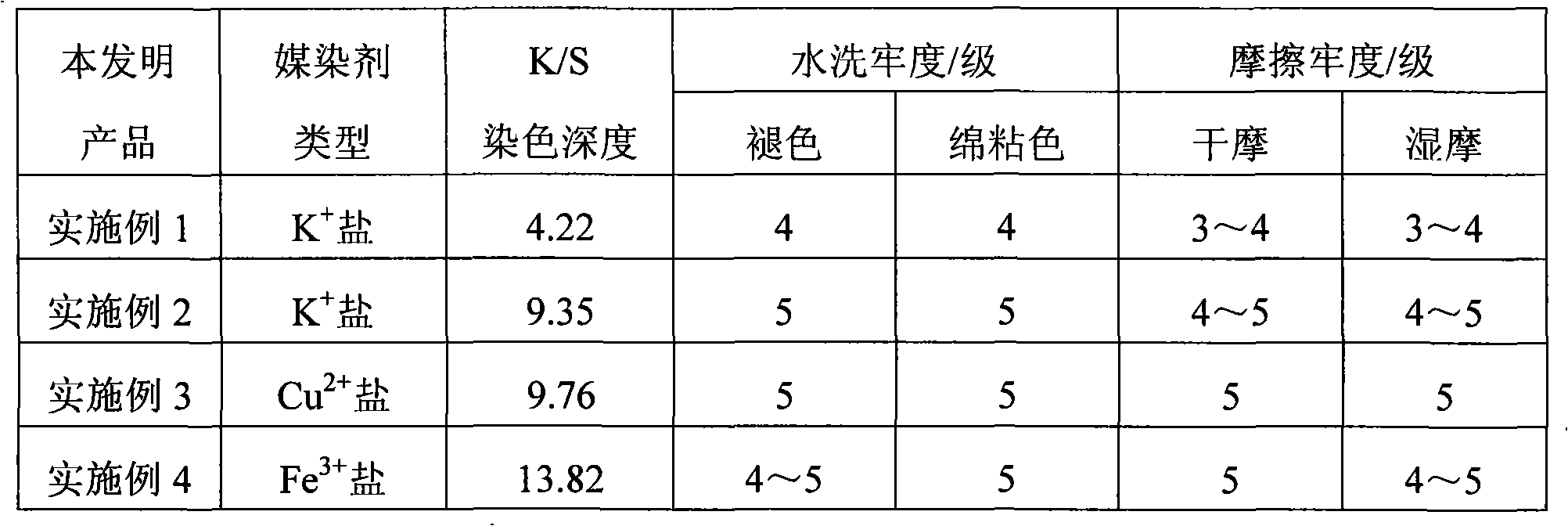

Natural dye mordanting dyeing or mordanting printing product and preparation method thereof

ActiveCN105113290AHigh color fastnessUniform base colorFibre treatmentDyeing processMordantNatural dye

The invention provides a method for preparing a natural dye mordanting dyeing or mordanting printing product. The preparation method comprises the steps of performing pretreatment on a fabric, using cation modified working solution to perform cation modification on the fabric, and obtaining cation-modified fabric; using natural dye to dye the cation-modified fabric and obtaining a natural dye dyeing fabric; using a mordant working solution or mordant working solution foam to perform mordanting dyeing or mordanting printing on the natural dye dyeing fabric at a predetermined area, performing steaming or baking at 80-180 DEG C for 10 s to 25 min, performing washing, softening and shaping, and obtaining the natural dye mordanting dyeing or mordanting printing product. The invention further provides the natural dye mordanting dyeing or mordanting printing product obtained according to the preparation method. The natural dye mordanting dyeing or mordanting printing product obtained according to the preparation method is good in color fastness and uniform in base color, the printing part is dark in color, the material loss is less, and a fabric is softer.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

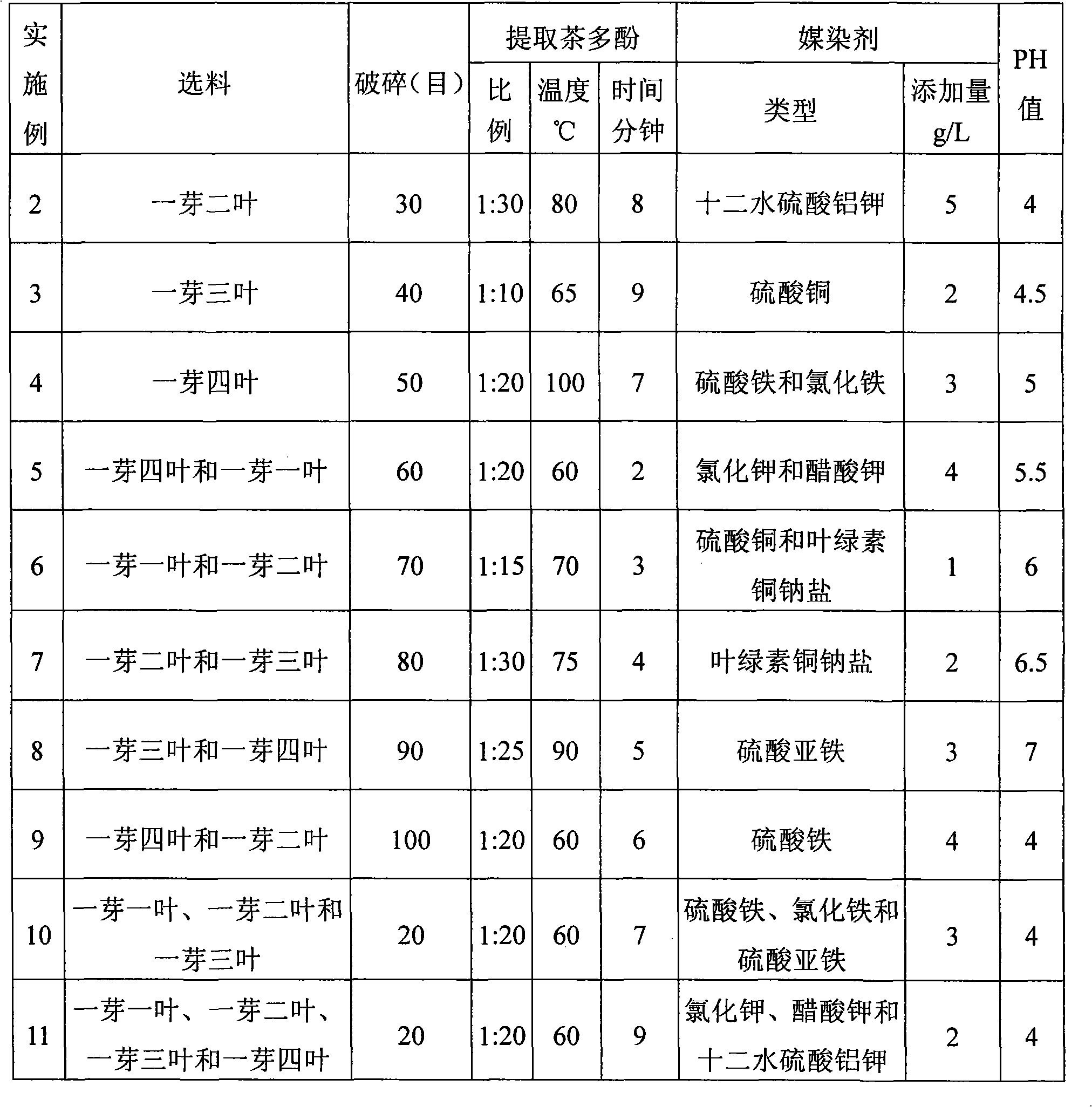

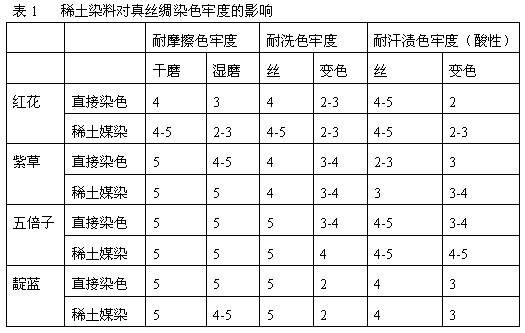

Natural staining agent, preparation thereof and application thereof to silk dyeing

The invention provides a natural coloring agent, which is characterized in that: the fresh tea leaves are used as material to extract tea polyphenol, and then the extraction liquid of the tea polyphenol is added with mordant agent, so as to form the natural coloring agent. As the natural coloring agent has rich color, good dyeing effect, good dyeing fastness (in particular wash fastness), and low production cost, the natural coloring agent has wide application, and strong practicality. The natural coloring agent also provides a preparation method of natural dyeing agent and an application at the aspect of silk fabric dyeing.

Owner:CHONGQING ACAD OF AGRI SCI

Plant hair dye taking graphene oxide as dyeing assistant and preparation method thereof

ActiveCN108030704AOvercome stabilityOvercoming low dye uptakeCosmetic preparationsHair cosmeticsEnvironmental resistanceRetention time

The invention provides a plant hair dye taking graphene oxide as a dyeing assistant and a preparation method thereof, which belong to the technical field of cosmetic industry. The plant hair dye comprises a first emulsion and a second emulsion, the first emulsion comprises the following components: 50-100 parts of plant pigment liquid, and 0.01-10 parts of graphene oxide; and the second emulsion comprises 0.5-1.5 parts of metal salt. The plant hair dye greatly reduces an application amount of a metal salt mordant, and reduces the health risk of intake of excessive heavy metals by consumers, plant pigment is employed, and a phenyl amine compound and hydrogen peroxide are not contained, which accord with requirements of safety and environmental protection; the plant hair dye has advantages of higher uniformity and better film-forming ability on hair, and effectively increases the degree of dyeing, the color retention time for hair dyeing can be longer, fading is difficulty generated, thehair is lustrous, and the hair color can be adjusted to natural black, so that beautiful black hair and health pursuit on oriental market can be better satisfied.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

Technique for dyeing silk face fabric by vegetable dye

InactiveCN101148827AAvoid damageImprove color uniformityDyeing processLiquid/gas/vapor textile treatmentDye absorptionAcetic acid

The present invention is technological process of dyeing silk fabric with vegetable dye and belongs to the field of fabric producing technology. The technological process includes the following steps: degumming silk fabric biologically with enzyme, flushing with cold water, and winding; dyeing the degummed silk fabric through adding acetic acid to regulate pH value, adding neutral phosphate and mordant, adding tea lutein as vegetable dye and heating; cold water washing, soaping, hot water washing, cold water washing, stoving, pre-shrinking to set breadth, and winding or packing. The dyeing process has high dyeing homogeneity, high stability and less damage to silk fabric.

Owner:无锡汇罗新材料科技有限公司

Mordant and hair dyeing product containing same

ActiveCN101812246ANo carcinogenic potentialGuaranteed stabilityCosmetic preparationsHair cosmeticsAcetic acidHair dyes

The invention relates to a mordant for a hair dyeing product and the hair dyeing product containing the same. The mordant comprises effective amounts of ferrite, antioxygen and water; and the hair dyeing product of the invention comprises three parts, i.e. softener, dye solvent and mordant. The mordant and the hair dyeing product containing the same, provided by the invention, do not contain mercaptoacetic acid, aromatic amine compounds, such as p-phenylenediamine and the like as well as hydrogen peroxide, so that the mordant and the hair dyeing product containing the same are safe and have no stimulation. The hair dyeing product of the invention has favorable hair dyeing chroma, firmness, product stability and using convenience.

Owner:NATURAL MEDICINE INST OF ZHEJIANG YANGSHENGTANG

Natural hair dye prepared by using phytochrome curcumin and hair dyeing method of natural hair dye

InactiveCN102423286AImprove dyeing effectEasy to floatCosmetic preparationsHair cosmeticsPolyolHair dyes

The invention relates to a hair dye, in particular to a natural hair dye prepared by using phytochrome curcumin and a hair dyeing method of the natural hair dye. The hair dye comprises an agent A and an agent B, and is characterized in that: the agent A contains 0.1 to 10 weight percent of curcumin, 20 to 50 weight percent of polyol, 1 to 5 weight percent of thickening agent, 1 to 10 weight percent of surfactant and the balance of water, and the pH value is regulated to be 3 to 7; and the agent B contains 1 to 10 weight percent of metal ion mordant, 1 to 5 weight percent of thickening agent, 1 to 10 weight percent of surfactant, 0.1 to 0.3 weight percent of natural essence and the balance of water, and the pH value is regulated to be 3 to 7. The hair dyeing method comprises the following steps of: uniformly spreading the agent A on the hair when the hair is dyed, and dyeing the hair for 10 to 40min at the temperature of between normal temperature and 60 DEG C; and uniformly spreading the agent B on the hair, mordanting for 10 to 20min, cleaning the hair and blow-drying. The curcumin has a good dyeing effect and also has the effects of resisting bacteria and protecting skin. Reagents which are toxic to human bodies are not used in the hair dye, and substances which are toxic to the human bodies are also not generated in the hair dyeing process, so the hair dye is high in safety. The adopted curcumin is insoluble in water and cannot fall off easily in the washing process, so the hair dye has a good dyeing effect, and the color of the dyed hair can be kept for a long time.

Owner:JIANGNAN UNIV

Method for rapidly dyeing wool with mordant dyes

ActiveCN101942769AMeet the quality requirements for color fastnessAvoid damageDry-cleaning apparatus for textilesDyeing processFiberYarn

The invention relates to a method for rapidly dyeing wool with mordant dyes, comprising the following steps: preparing dyeing, adding low-temperature rapid dyeing assistants and dyes, raising temperature rapidly, carrying out dyeing at low temperature, adding mordants and formic acid without lowering temperature, carrying out mordanting at low temperature and carrying out aftertreatment and taking the wool out of the tank. In the invention, rapid temperature raising, lower dyeing temperature and the method of adding mordants without lowering temperature realize low-temperature rapid dyeing with mordant dyes by after-chrome dyeing. Compared with the traditional after-chrome dyeing method with mordant dyes, the method has the following advantages: fiber damage is lowered, the handfeel is good, the luster is bright, the yarn spinnability is improved, the color fastness conforms to the quality requirement of wool top dyeing color fastness and the dyeing time is shortened by 30-50%; and the method greatly reduces water, electricity, steam and labor consumption, improves the labor productivity and conforms to the requirement for low carbon economy.

Owner:JIANGSU DANMAO TEXTILE

Processing method used for dyeing wool fabric with natural dye with high colour fastness

ActiveCN105625057AGood light stabilityImprove washing fastnessDyeing processAnimal fibresColour fastnessThermal water

The invention discloses a processing method used for dyeing wool fabric with a natural dye with high colour fastness. The processing method comprises following steps: wool fabric is immersed in a treating fluid containing 0.5 to 10g / L of a wetting agent for 10 to 30min, and then is taken out from the treating fluid and dried via squeezing; the treated wool fabric is subjected to dye bath in a solution containing the natural dye and 1 to 10% (owf) of a gallnut extract, temperature is increased to 75 to 98 DEG C at a speed of 1 to 5 DEG C / min, constant temperature dyeing is carried out for 30 to 90min, and then an obtained product is taken out from dye bath and washed with water, wherein pH value of the solution ranges from 3.0 to 4.5; mordanting is carried out with a metal ion mordant, wherein mordant using amount is controlled to be 2 to 8% (owf), pH value is controlled to be 3.0 to 5.0, mordanting temperature is controlled to be 50 to 70 DEG C, and mordanting time is controlled to be 40 to 80min; high temperature steam treatment with saturated steam is carried out for 10 to 30min; fabric obtained via steaming is washed with hot water for 10 to 30min, is washed with cold water, and is subjected to dehydration and dying. The washing fastness and light fastness of the wool fabric obtained via the processing method are both relatively high.

Owner:HENGYUANXIANG GRP

Natural dyestuff dyeing and finishing process of polyester fabric

The invention discloses a natural dyestuff dyeing and finishing process of polyester fabric. The natural dyestuff dyeing and finishing process of the polyester fabric comprises pretreatment, preshaping, modification treatment, dyeing, mordant removing, soaping, fixation, finishing, drying, shaping, calendering and winding. According to the natural dyestuff dyeing and finishing process of the polyester fabric, helicase and alhpa-amylase are adopted to conduct pretreatment, modification treatment is radically conducted on the performance of the polyester fabric through a acetic acid aqueous solution of chitosan, hydrogen peroxide and epoxy chloropropane, and the dyeing rate of the fabric is increased; in the dyeing process, a large amount of alkaline matter and inorganic salt are not used, a levelling agent and diffusant are added, the level-dyeing property is improved, natural dyestuff is used, therefore, environmental pollution is avoided, and requirements of green environmental protection are met; modification treatment and fire-retardant treatment are conducted on the fabric through montmorillonite, and the fire resistance of the fabric is high; anti-yellowing reagents are used in the preshaping and the shaping, and the final fabric is not prone to yellowing.

Owner:TAICANG CHENGLE CHEM FIBER

Dyeing method for common goldenrod herb natural dye

The invention relates to a dyeing method for a common goldenrod herb natural dye. The dyeing method comprises the following steps: preparing a 2 to 20 g / I common goldenrod herb dye, and setting a dyeing temperature of 40 to 100 DEG C, a bath ratio of 1:50 to 200 and dyeing time of 10 to 90 minutes; taking a 2 to 20 g / I mordant solution, and setting a mordanting temperature of 40 to 100 DEG C and mordanting time of 10 to 90 minutes; and adding a mordant before or after natural fiber yarn or natural fiber textile is added into common goldenrod herb dye liquor or simultaneously when the natural fiber yarn or the natural fiber textile is added into the common goldenrod herb dye liquor for one-bath dyeing. The method uses the prior textile dyeing device for direct dyeing without adding devices or increasing cost. The textile dyed by the method is soft, primitive and simple and natural color, and has good dye fastness, no fading, no discoloring, good reproducibility, and chromatic aberration around a half level. The method is suitable for the industrialized production, and has no toxicity, no harm and no pollution.

Owner:DONGHUA UNIV

Ink jet recording element

InactiveUS6110585AEffect light fadePrevents bronzingSynthetic resin layered productsElectrography/magnetographyColloidal silicaSilicon dioxide

An ink jet recording element comprising a support having thereon the following layers: a) a cationic mordant for an anionic dye; b) a nonionic or amphoteric material compatible with a) and c); c) colloidal silica; and d) a hydrophilic overcoat in an amount of at least about 0.25 g / m2; wherein either a) or c) can be directly on the support, b) is always between a) and c), and d) is the outermost layer.

Owner:EASTMAN KODAK CO

Madder dye extracting process and its usage in dyeing mercerized wool and mercerized wool fabric

InactiveCN1810889AReduce the chance of occurrenceImprove uniformityNatural dyesDyeing processSodium bicarbonatePhosphate

The present invention is madder dye extracting process and its usage in dyeing mercerized wool and mercerized wool fabric. The madder dye extracting process includes the following steps: washing madder root as material, fermentation at 20-50 deg.c for 20í½30 hr, and extracting madder dye through heating at 70-90 deg.c and condensing evaporated gas for 0.5-1.5 hr. The dyeing process includes two steps: the first step of ecological pre-treatment of mercerized wool or mercerized wool fabric in treating liquid comprising sodium bicarbonate, coconut oil biethyl alcohol acrylamine as detergent and neutral organic phosphate in certain proportion at 20-60 deg.c and bath ratio of 1:20-50 for 10-60 min; and the second step of harmless mordant dyeing of the pre-treated mercerized wool or mercerized wool fabric. The present invention has rich dye resource, good dyeing effect and less damage of mercerized wool.

Owner:HAILAN GRP +1

Method for dyeing protein fiber and fabric thereof with natural dye extracted from grape seeds

The invention relates to a method for dyeing with a dye extracted from a grape beverage and grape seeds as waste resources in wine industry processing, which is characterized in that a grape seed pigment solution is adopted to dye protein fiber fabrics such as wools, silks and the like with a directly dyeing method or an aluminium ion and iron ion pre-mordant dyeing method. A dyeing technology has the following parameters: the bath ratio of (25-50):1, a dye bath pH value of 3-5, the grape seed dosage of 1-6 percent (o.w.f), dyeing temperature of 30 DEG C, temperature rise rate of 1-3 DEG C / min, temperature rising to 80-100 DEG C and insulation time of 60-120min. The aluminium ion and iron ion pre-mordant dyeing method is characterized by comprising the following steps of, firstly, carrying out pre-mordant dyeing on the protein fiber fabrics by adopting aluminium ions and iron ions, and putting the protein fiber fabrics such as the wools, the silks and the like into a grape seed pigment dye bath to dye. Fabrics in different colors can be obtained by adopting different mordants. The invention can efficiently utilize grape seed waste resources and expand the application field of completely nontoxic grape seed pigments.

Owner:JIANGNAN UNIV

Environmental-friendly cotton fabric dyeing

InactiveCN104099788AReduce consumptionThe production process is briefBiochemical fibre treatmentDyeing processAfter treatmentPulp and paper industry

The invention discloses an environmental-friendly cotton fabric dyeing. The cotton fabric dyeing comprises the following steps: (1) pretreatment: putting grey cloth into lukewarm water to conduct pre-moistening; adding a pretreatment agent; adjusting pH value to conduct scouring and bleaching; conducting hot washing and cool washing; drying; dyeing; conducting fixation; putting the grey cloth after the pretreatment in the step (1) into water of which the bath ratio is 1:(20-30) in ordinary temperature; adding natural dyestuff, a dispersant, a mordant and a dyeing auxiliary to dye for 20 min; elevating temperature for dyeing for 20-40 min; reducing temperature and adding a fixing agent to conduct fixation; (2) after-treatment: putting the cotton fabric after dyeing into water of which the bath ratio is 1:8 at ordinary temperature; adding soap berry saponin to soak for 10-20 min; washing the cotton fabric; drying. The dyeing is simple and short in production technology, greatly shortens pretreatment time, reduces manufacturing cost, is high in fastness, easy to wash and low in water consumption, and reduces pollution to environment.

Owner:WUXI XINDA DYEING MACHINE FACTORY

Lotus leaf dyestuff and its extraction method and method of dyeing wool and wool fabric using said

A lotus leaf dye is extracted from lotus leaves. Its extracting process is also disclosed. A method for using said lotus leaf dye to dye wool or wool fabric includes ecological pretreating, modifying wool by the composite enzyme consisting of subtilisin and papain, and mordant dyeing. Its advantage is high dyeing effect.

Owner:HAILAN GRP +1

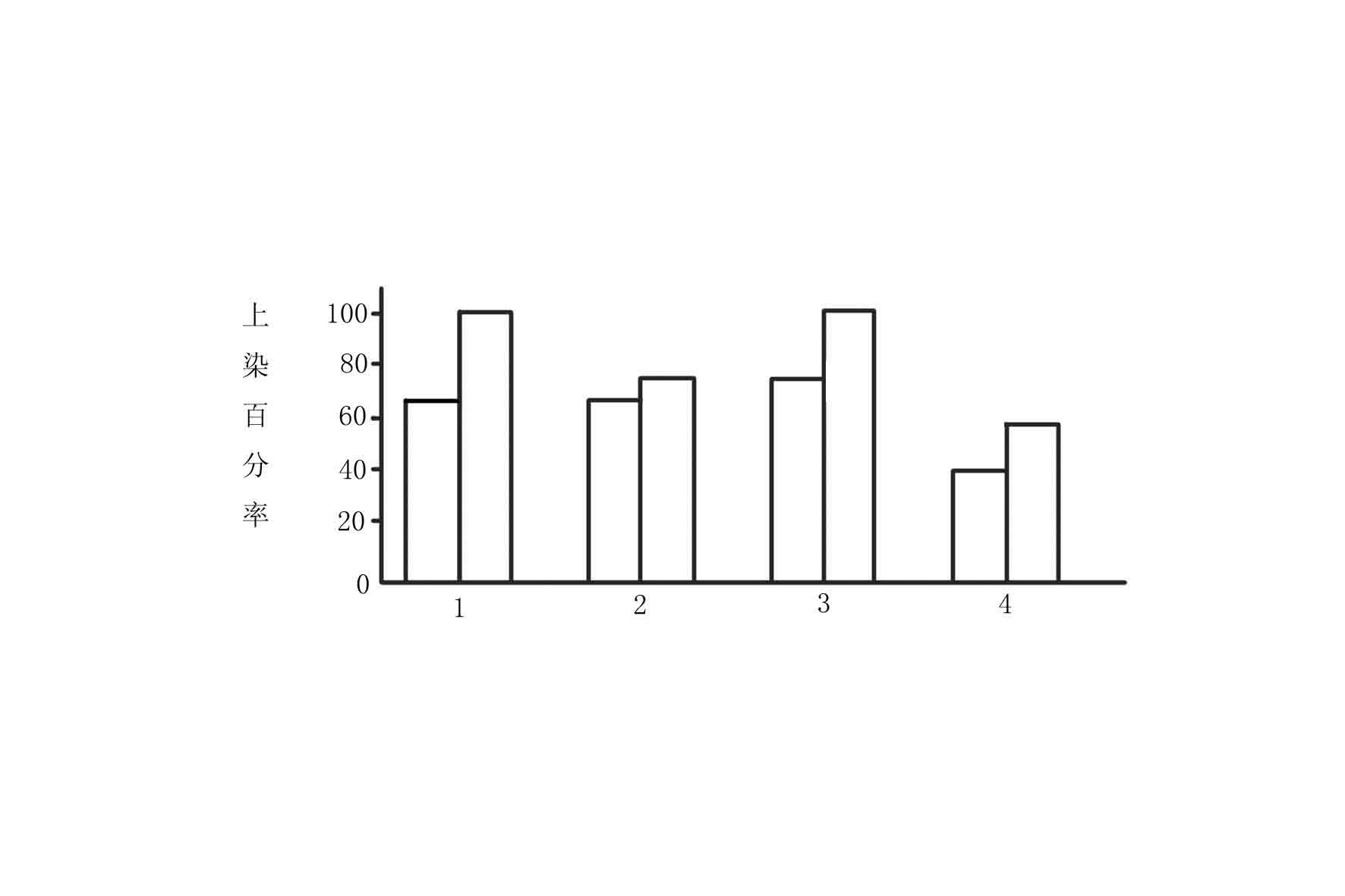

Rare earth mordant dyeing method for kapok fiber and textile thereof

InactiveCN102561063AImprove dyeing effectPromote infectionBleaching apparatusDyeing processState of artKapok fiber

The invention relates to a rare earth mordant dyeing method for kapok fibers and textiles thereof. The method comprises the following steps: pre-treating kapok textile so as to remove some waxy xubstances, impurities and the like on the surface of the kapok fiber and achieve certain whiteness; and then adding a complexing rare earth mordant into a dye bath of the pretreated kapok textile, and mordant dyeing the kapok textile. Compared with the prior art, according to the dyeing method of the invention, the dyeing of the kapok fibers and textiles thereof is not limited to direct dyes and can also be used for other anionic dyes such as reactive dyes and the like, and the problems of low rate of dye-uptake, poor level-dyeing property, poor deep-color dyeing effect, poor dyeing fastness and the like are overcome.

Owner:SHANGHAI UNIV OF ENG SCI

Method for dyeing silk broadcloth by using plant dye solution extracted from lily

InactiveCN102587153ASafe to takeIncrease added valueDry-cleaning apparatus for textilesNatural dyesFiltrationPollen

The invention discloses a method for dyeing silk broadcloth by using the pollen of lily as a natural dye and belongs to the technical field of textile dyeing and finishing. The method comprises the following steps of: soaking fresh or dried dark-red lily pistil, heating and performing suction-filtration to obtain a dye solution; adding silk broadcloth fabric which is refined, and dyeing the silk broadcloth fabric; and adding different mordants for mordanting and thus obtaining silk fabric with different colors. The method has the advantages of low cost, simple process, high performance, high additional value, non-allergic and non-carcinogenic to skin, and the like; raw materials are inexpensive, easy to get, and reproducible; and taking of dyeing products is safe. Particularly, by taking plant ash as a mordant, pollution is avoided. The method is environment-friendly and energy-saving, and clothes which are made of fabric dyed by using the method are natural, environment-friendly and nonirritating to the skin.

Owner:ZHEJIANG IND POLYTECHNIC COLLEGE

Dyeing and finishing process of polyester-nylon composite fiber fabric

InactiveCN105019237AHigh whitenessAvoid damageBiochemical fibre treatmentHeating/cooling textile fabricsPolyesterInorganic salts

The invention discloses a dyeing and finishing process of polyester-nylon composite fiber fabric. The dyeing and finishing process of the polyester-nylon composite fiber fabric comprises pretreatment, preshaping, modification treatment, dyeing, mordant removing, soaping, fixation, finishing, drying, shaping, calendering and winding. According to the dyeing and finishing process of the polyester-nylon composite fiber fabric, helicase and alhpa-amylase are adopted to conduct pretreatment, the modification treatment is conducted before dyeing, modification is conducted on performance of the polyester-nylon fabric radically, and the dyeing rate of the fabric is increased; in the dyeing process, a large amount of alkaline matter and inorganic salt are not used, a levelling agent, substitution alkali, migration inhibitor and diffusant are added, the level-dyeing property is improved, natural dyestuff is used, therefore, environmental pollution is avoided, and requirements of green environmental protection are met; self-cleaning treatment is added in finishing, and the self-cleaning capacity, crease resistant property and fastness to washing of the fabric are improved; the whole process is environmentally friendly and free of pollution.

Owner:TAICANG TIANLONG CHEM FIBER

Inkjet receiver

InactiveUS20090122127A1High absorption rateHigh image densityDuplicating/marking methodsTypewritersInorganic particlesSilica gel

An inkjet receiver having upon a support an ink-receiving pack which comprises an image-receiving layer of a binder and 0.5 to 10 g / m2 of an inorganic particulate material, of which at least 70% by weight is alumina, and an second layer of a binder and 10 to 40 g / m2 of an inorganic particulate material, of which at least 65% is fumed silica and / or silica gel, and an optional third layer having up to 30 g / m2 of an inorganic particulate that is mostly calcium carbonate, the receiver demonstrating excellent printing properties, gloss and absorption rate, whilst being relatively economical and simple to manufacture. Optional inclusion of mordant in the image-receiving layer provides an effective universal glossy receiver.

Owner:EASTMAN KODAK CO

Chinlon dyeing process adopting natural dye

InactiveCN104695241AReduce pollutionAvoid damageFibre typesHeating/cooling textile fabricsColour fastnessFiber

The invention provides a chinlon dyeing process adopting natural dye. The method comprises the steps of pretreatment, presetting, dyeing, soaping, fixation, softening treatment, drying, setting and rolling. The natural dye, alizarin, is adopted, rare earth chloride is adopted as dye mordant, the dyeing effect is better, the washability is greatly enhanced, and meanwhile dyed chinlon fibers have the good antibacterial property. The washing and fixation process is added, the dyeing firmness is good, environment-friendly formaldehyde-free TCD-R is adopted in the fixation process, chinlon is dried step by step after fixation, and the firmness of the chinlon is greatly improved. The softening treatment process is added, the color fastness and softness of fabric are improved, the roughness of the fabric is reduced, and the fabric is fluffy and elastic.

Owner:TAICANG TIANLONG CHEM FIBER

Method for dyeing chitosan fabrics by vegetable dyes

The invention discloses a method for dyeing chitosan fabrics by vegetable dyes, which comprises the following steps of: 1) performing a preprocessing process, namely performing dyeing preprocessing on the chitosan fabrics; 2) performing a dyeing process, namely putting the chitosan fabrics subjected to the preprocessing process into a dyeing machine, adding water in a bath ratio of 1:(10-30), adding carbonate and / or hydrocarbonate to regulate the pH value, adding the vegetable dyes, adding anhydrous sulfate, heating to the temperature of between 90 and 110 DEG C, maintaining the temperature for 30 to 60 minutes, discharging dye liquor, washing, and taking the fabrics out of a dye vat; and 3) performing postprocessing process, dehydrating, drying, sizing, and sizing a woollen blanket. The chitosan fabrics are dyed by the dyeing method without using a mordant, so the dyeing method is energy-saving and environment-friendly; and compared with the chitosan fabrics dyed by the other conventional methods, the chitosan content is less in loss, namely the loss is controlled within 15 percent. Simultaneously, the uniformity and stability of dyeing are improved.

Owner:上海嘉麟杰纺织科技有限公司

Environment-friendly dyeing and finishing technology of cotton cellulose fabric

InactiveCN105002720AHigh whitenessAvoid damagePhysical treatmentBiochemical fibre treatmentEpoxyCellulose

The invention discloses an environment-friendly dyeing and finishing technology of a cotton cellulose fabric. The technology comprises the following steps: pretreatment; preshaping; modification treatment; dyeing; mordant removing; soaping; color fixing; post-treatment; drying; shaping; calendaring; rolling. According to the technology, pretreatment is carried out through the adoption of helicase and alpha-amylase, and acetic acid aqueous solution of chitosan, hydrogen peroxide and epoxy chloropropane is adopted, so that the property of the cotton cellulose fabric is fundamentally modified, and the dye-uptake of the fabric is increased; during the dyeing procedure, large quantities of alkaline substances and inorganic salt are not used, and a levelling agent and a dispersing agent are added, so that the dye uniformity is improved; natural dye is used, so that environmental pollution is avoided, and the demand of environmental protection is met; modification treatment and fire retardant treatment are carried out on the fabric through the adoption of montmorillonite, so that the fire resistance of the fabric is high; self-cleaning treatment is added in post-treatment, so that the self-cleaning capacity, wrinkle resistance and water washable firmness of the fabric are improved; the whole technology is environment-friendly and free of pollution.

Owner:TAICANG CHENGLE CHEM FIBER

Method for dyeing pure silk by regarding rare earth material as mordant

InactiveCN102605652AIncrease the percentage of dyeingAdd depthBleaching apparatusDyeing processOrganic chemistryMordant

The invention relates to a method for dyeing pure silk by regarding a rare earth material as a mordant. The adopted technical scheme is as follows: taking a bleaching liquor according to a bath ratio of 1: (25-35) and pre-treating at a temperature of 90 DEG C; washing the pre-treated pure silk with a water washing liquor for twice to three times; dewatering and drying the pure silk; taking a dye liquor according to a bath ratio of 1: (25-35), adjusting pH of the dye liquor to 3-3.5, heating the dye liquor to 50 DEG C; adding the dried pure silk in the dye liquor and heating to 90 DEG C at a temperature rise speed of 2 DEG C per each minute, keeping the heat for 30-40 min and then cooling to 70 DEG C; and adding a rare-earth solution to soak the pure silk for 10-15 min, then heating to 90 DEG C at a temperature rise speed of 2 DEG C per each minute, keeping the heat for 30-40 min, washing with clear water for twice to three times, dewatering and drying. By adopting the method for dyeing the pure silk by regarding the rare earth material as the mordant, disclosed by the invention, color fastness requirements needed by the production of green environment-friendly textiles not only can be satisfied, but pollution from the traditional mordants to the environment can also be avoided.

Owner:YINGKOU LANGSHIDUO SILK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com