Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

837results about How to "Improve washing fastness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Inkjet inks containing crosslinked polyurethanes

InactiveUS20050182154A1Increased durabilityIncrease ratingsDuplicating/marking methodsInksPolymer chemistryChemistry

Inkjet inks are described that have, as a principal component, a crosslinked polyurethane dispersoid binder additive. These inks can be used for printing on different media, and are particularly suitable for printing on textiles.

Owner:EI DU PONT DE NEMOURS & CO

Oxidizing Hair Colourant Compositions

ActiveUS20090119852A1Reduce harmAvoid hair damageCosmetic preparationsHair cosmeticsHair dyesColoring agents

Owner:WELLA OPERATIONS US LLC

Method of dyeing fabric by using dye

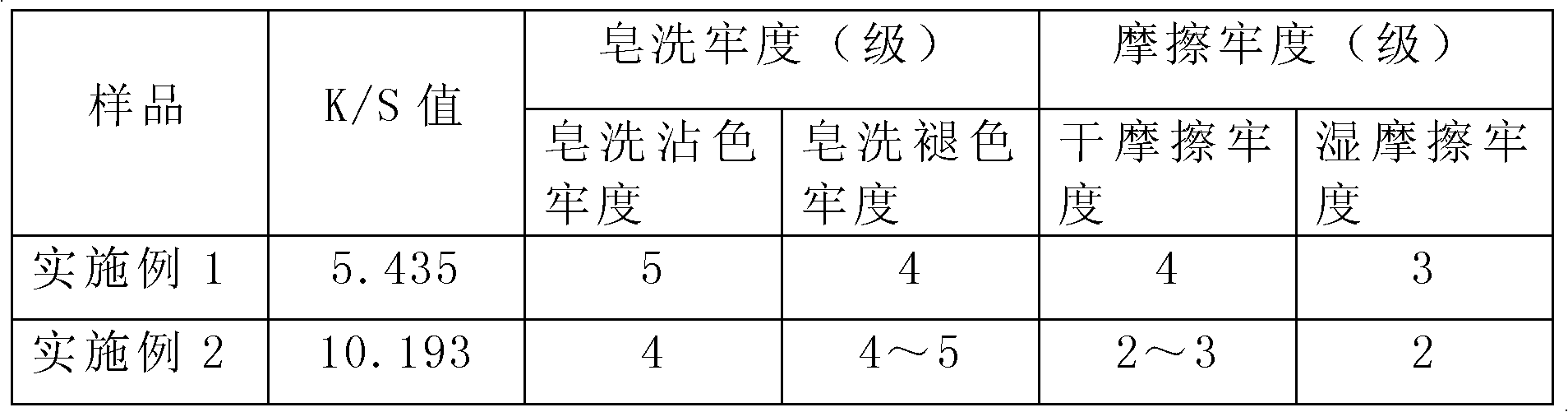

ActiveCN102535194ASoft touchImprove washing fastnessBiochemical fibre treatmentDry-cleaning apparatus for textilesTextile printerEngineering

The invention provides a method for dyeing fabric by using a dye, belonging to the technical field of textile printing and dyeing and aiming to the solve the problems of complex process, low dyeing rate, poor dyeing uniformity and poor color fastness and hand feel of dyed fabric of the existing method for dyeing the fabric by using the dye. The method comprises the following steps of: desizing the fabric, scouring, bleaching and mercerizing; adding the dye, a cationic modifier, a leveling agent, a dispersant, an alkaline reagent and a wet rubbing fastness enhancer to water, and mixing uniformly to prepare a dyeing solution; soaking the fabric into the dyeing solution, and controlling temperature and liquor ratio to dye; steaming the dyed fabric for colour fixation, washing by water and drying to finish dyeing the fabric by using the dye. The method for dyeing the fabric by using the dye is simple, ensures the high dyeing rate and the uniform dyeing, and ensures that the dyed fabric has good washing fastness and rubbing fastness and a soft feel.

Owner:台州东海翔染整有限公司

Sublimation Printing Processes and Fabric Pretreatment Compositions for Ink Jet Printing onto Arbitrary Fabrics

InactiveUS20110169901A1Outstanding washfastness to repeated launderingImprove washing fastnessTransfer printing processDyeing processTextile fiberEngineering

An ink jet printing process for sublimation printing of arbitrary textile fiber substrates, wherein the fiber materials are pretreated with an aqueous coating composition, enabling ink jet printing of natural and regenerated cellulosic fibers and blends thereof with synthetic fibers, by direct sublimation or sublimation transfer printing, applying to said fibers a novel textile coating or fabric pretreatment composition, wherein said textile coating or fabric pretreatment comprises: an aqueous dispersion of fluoropolymer particles and a non-fluoropolymer binder.

Owner:ADVANCED COMM SOLUTIONS

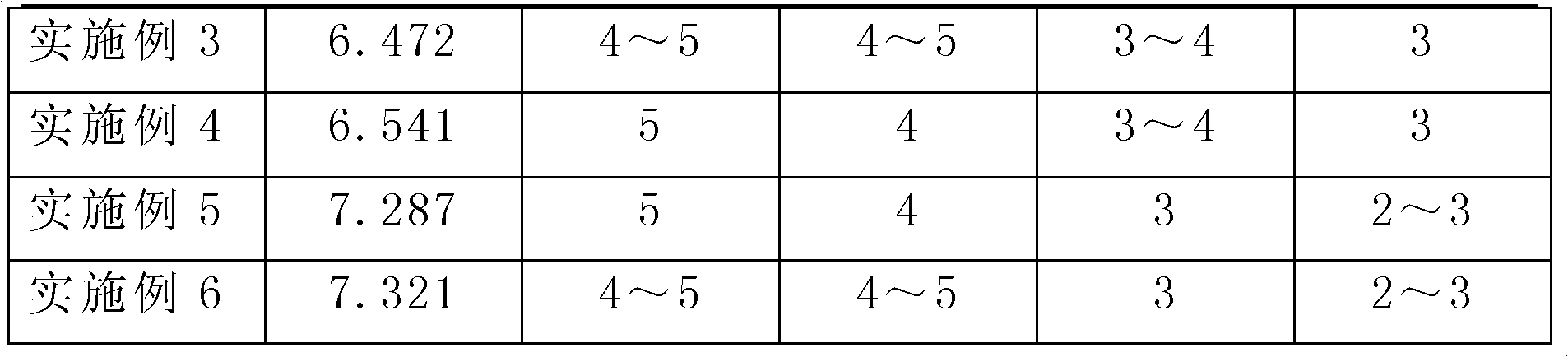

Alkali-resistant disperse dye complex

The invention discloses an alkali-resistant disperse dye complex, and relates to disperse blue BR-based alkali-resistant disperse dye complexes suitable for dyeing in a wide pH range. The complex comprises (1) alkali-resistant disperse dye blue complex, or (2) alkali-resistant disperse dye blue complex, or (3) alkali-resistant disperse dye black complex. The disperse dye complex of the invention has good dispersibility, dyeing stability and good reproducibility, and can effectively avoid the problems of stains, flaws, chromatic aberration and the like caused by dirt such as slurry, oil stain,wax and the like on fibers; and the pH value has wide range during use, dyeing can be performed in the pH range of 4.0 to 11.25, the dyed fabrics have full hue, and the dyed fabrics with predominant color fastness performance such as washing fatness, daylight fastness and the like can be obtained without reduction clearing.

Owner:HANGZHOU JIHUA JIANGDONG CHEMICAL CO LTD

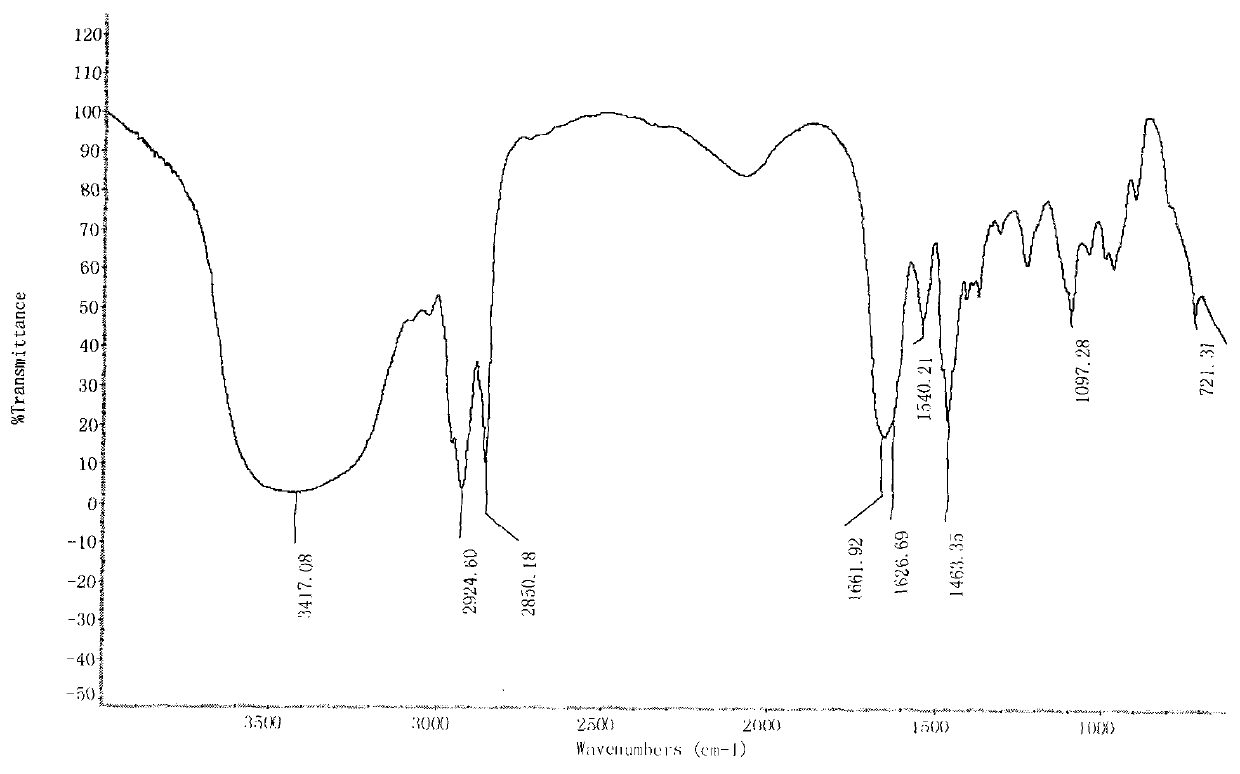

Waterproof moisture permeation polyurethane paint used for textiles and preparation method

The invention relates to waterproof moisture permeation polyurethane paint used for textiles and a preparation method. The waterproof moisture permeation polyurethane paint is prepared from methyl diphenylene diisocyanate, toluene di-isocyanate, polyether glycol (with the molecular weight of 2000), linear dihydroxylated alkylsiloxane (with the molecular weight of 1000), polyester dihydric alcohol (with the molecular weight of 2000), trimethylolpropane, chain extending agents, sealing compounds, dibutyl tin laurate and solvents through the processes of pre-polymerization reaction, chain extension reaction and sealing reaction. The production process is simple, and the products have the advantages of self-crosslinking effect, soft hand feeling, good cold resistance performance, high moisture permeation performance, high water pressure resistance and little reduction after water pressure resistance washing.

Owner:郯城丰润粮机配件有限公司

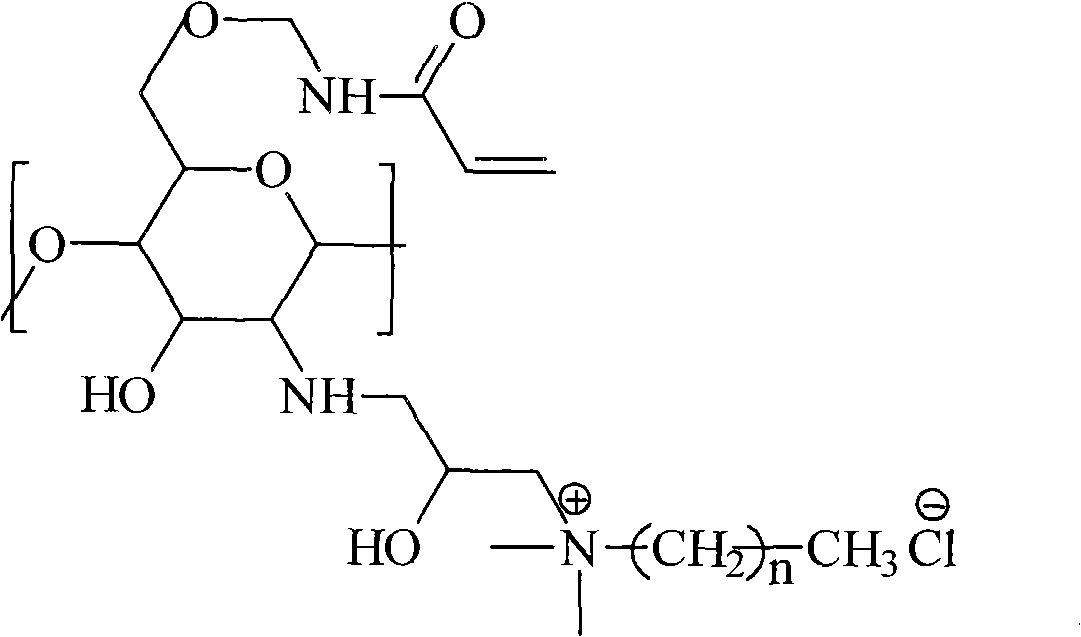

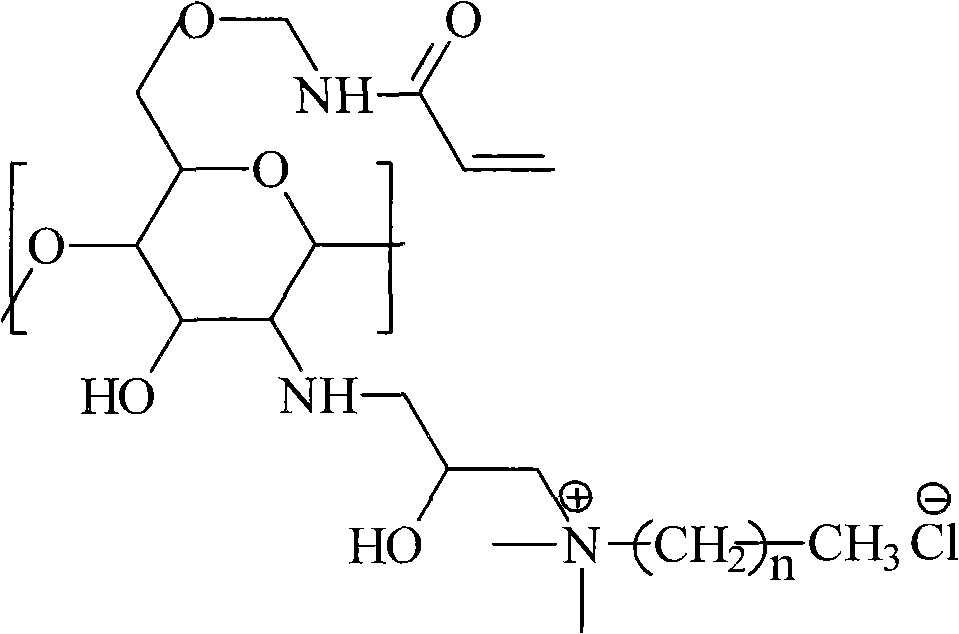

Water-soluble chitosan quaternary ammonium salt antibiotic finishing agent and preparation and application thereof

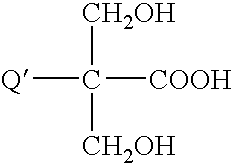

The invention relates to a water-soluble chitosan quaternary ammonium salt antibiotic finishing agent. The invention is characterized in that the antibiotic finishing agent is names as O-methacrylamide-N-hydroxypropyl alkyl dimethyl ammonium chloride chitosan and the concrete structural formula is as follows. The preparation thereof includes that: alkyl dimethyl tertiary amide and epichlorohydrin are taken as raw materials to synthesize 2, 3-epoxy alkyl dimethyl ammonium chloride, then the 2, 3-epoxy alkyl dimethyl ammonium chloride is introduce onto the ammonium group of chitosan, so as to obtain N-hydroxypropyl alkyl dimethyl ammonium chloride chitosan HDCC, and then crosslinking is carried out on the HDCC and hydroxymethyl acrylamide is carried out, thus obtaining NMA-HDCC. The quaternary ammonium salt antibiotic finishing agent contains water-soluble group and fibrous reactivity group and has good water solubility, the bacterial inhibition rate of finished cotton fabrics is close to 100%, and the finishing agent can be combined with cellulose fiber by covalent bond and is wash-resistant; and cost is low, raw material is environmental friendly, environmental pollution is less, thus having industrialization application prospect.

Owner:DONGHUA UNIV

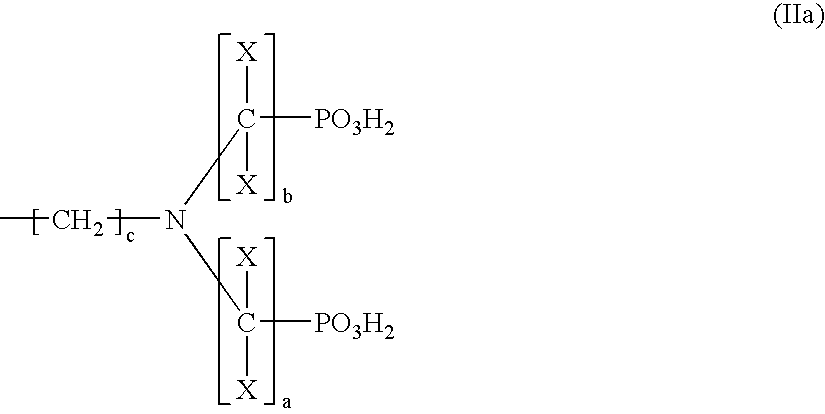

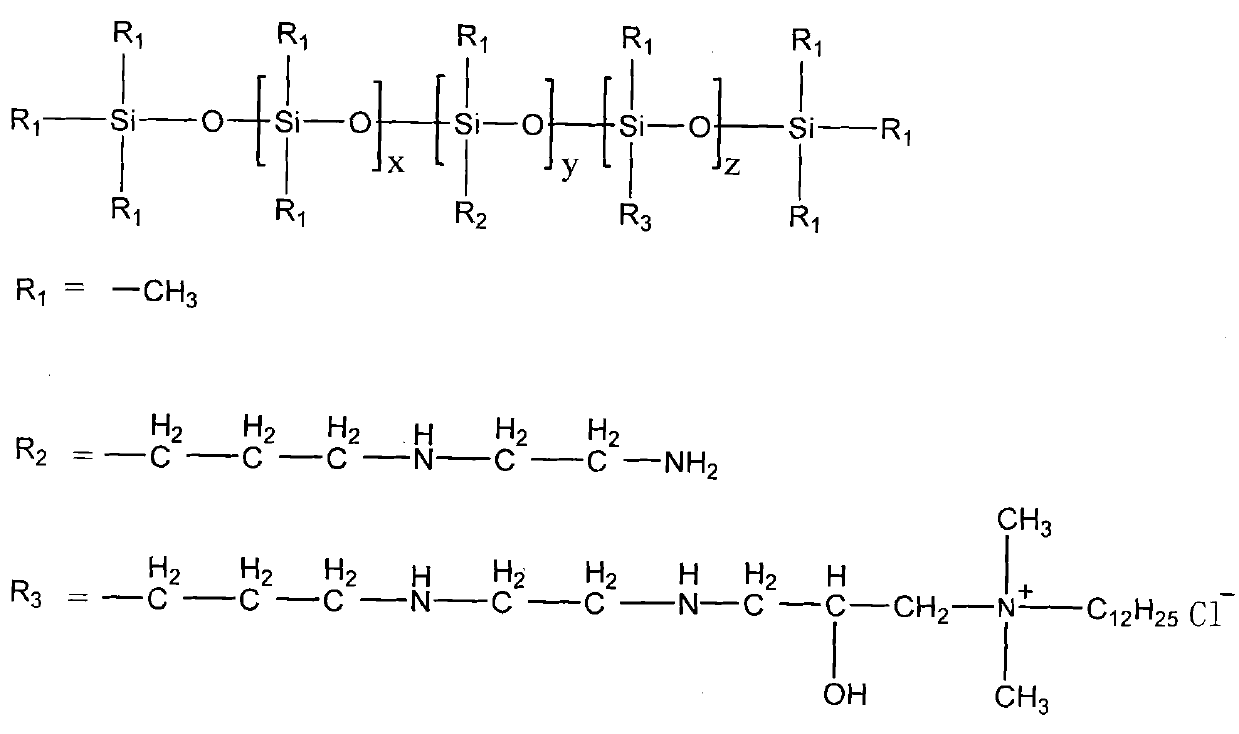

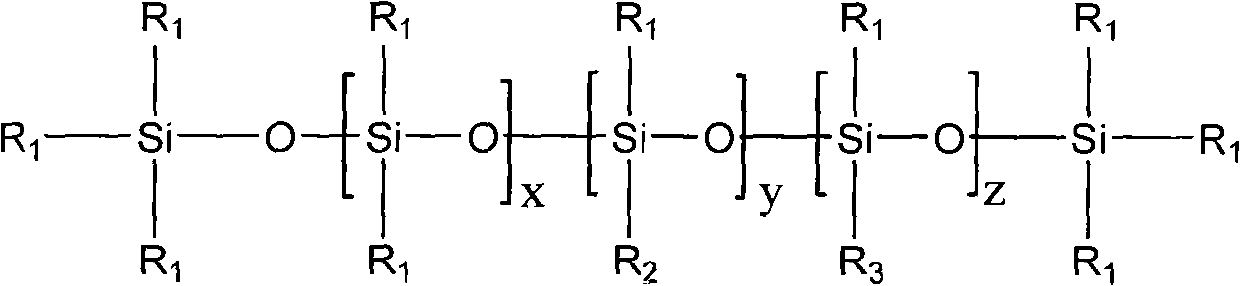

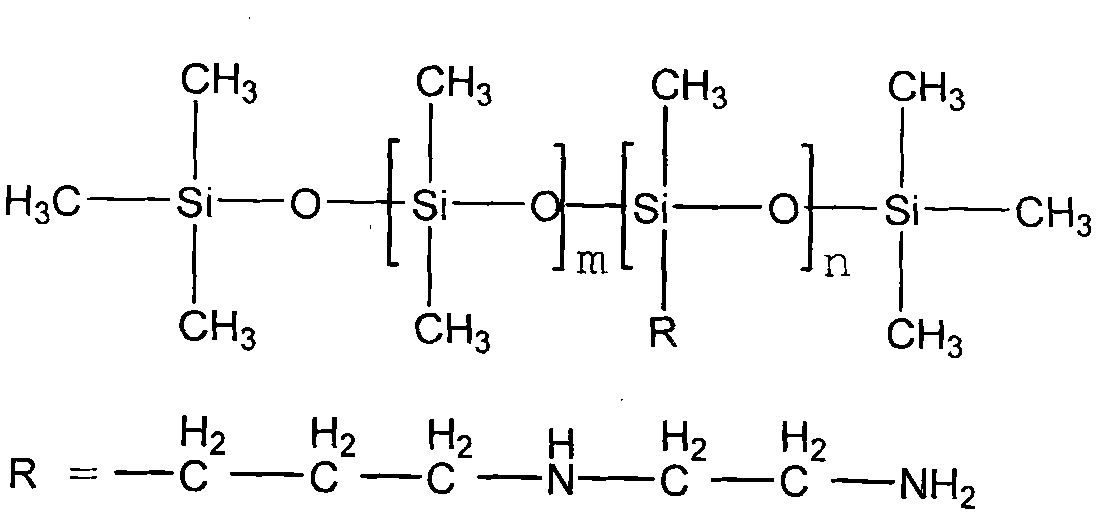

Quaternized modified amino silicone oil softener and preparation and application thereof

InactiveCN101914206AAvoid yellowingImprove hydrophilicityVegetal fibresTetramethylammonium hydroxideDisiloxane

The invention relates to a quaternized modified amino silicone oil softener and preparation and application thereof. The softener comprises the following general formula in the specification. The preparation comprises the following steps of: (1) adding octamethylcy-clotetrasiloxane into a container, adding a coupling agent N-beta-(aminoethyl)-gamma-aminopropyl methyl dimethoxysilane into the container dropwise, adding a tetramethyl ammonium hydroxide catalyst and subsequently a capping agent hexamethyl disiloxane into the container, and then performing reduced pressure distillation to obtain amino silicon oil; (2) dissolving the amino silicon oil into a solvent, adding the mixture into epichlorohydrin, stirring and heating to react under the protection of nitrogen, and removing the solvent by steaming to obtain an intermediate product; and (3) uniformly mixing N,N-dimethyl-decanamide and the solvent to obtain a mixture, stirring with heating, adding the intermediate product dropwise into the mixture under the protection of nitrogen, performing a thermostatic reaction, and removing the solvent by steaming to obtain the product. The softener of the invention has high hydrophilicity and high stability; fabric processed by the softener has excellent soft handfeel, high hydrophilicity, low yellowing, antibacterial property and the like; and the softener is simple to prepare and is suitable for industrial production.

Owner:DONGHUA UNIV

Black and blue disperse dye composition

ActiveCN101798472AWide range of applicationsGood compatibilityOrganic dyesDyeing processSunlightPhotochemistry

The invention discloses a black and blue disperse dye composition which comprises the components by weight percent: at least one 30-70% of dye monomer A shown in formula (1), at least one 15-40% of dye monomer B shown in formula (2), at least one 5-50% of dye monomer C shown in formula (3) and at least one 5-50% of dye monomer D shown in formula (4). The disperse dye composition has wide application scope of pH value, good compatibility, strong dye depth property, high color yield, good uniformity, and good sublimation fastness, washing fastness and fastness to sunlight; more importantly, the black and blue disperse dye composition has low price and convenient use, and makes up the defects of compatibility, dye depth property and tiger color of black and blue disperse dye spliced by disperse orange 288 model.

Owner:ZHEJIANG RUNTU

Disperse dye composition and application thereof

ActiveCN102031017AFull hueExcellent color fastnessOrganic dyesDyeing processPhotochemistryDisperse dye

The invention discloses a disperse dye composition and application thereof and particularly relates to a disperse dye which has good dyeing effect under an alkali condition and application thereof. The dye composition comprises a dye and an aid in a mass ratio of 1:1-1:2, wherein the dye is selected from any one or more of a dye I, a dye II, a dye III and a dye IV. The disperse dye composition can be widely applied to a full-polyester dyeing process, a synchronous polyester / cotton scouring, bleaching, dispersing and dyeing process, a polyester / cotton dispersing high-temperature active dye one-bath process, a polyester / cotton dispersing constant-temperature active dye one-bath two-step process and the like and has good dyeing effect. The disperse dye composition can realize synchronous performance of a pretreatment process and a dyeing process, can be used together with other active dyes, has wide application and contributes to shortening process time and lowering production cost.

Owner:浙江创元染料有限公司

Preparation method of formaldehyde-free active dye fixing agent

InactiveCN101768883AImprove rubbing fastnessImprove washing fastnessDyeing processUltrasound - actionTetramine

The invention relates to a preparation method of a formaldehyde-free active dye fixing agent. The compound prescription of the active dye fixing agent consists of two components, component 1 is chitosan quaternary ammonium salt produced by 3-chlorine-2-hydroxypropyl trimethyl ammonium chloride grafted with chitosan under ultrasonic, and component 2 is reactive fixing agent produced after reaction of one weight part of triethylene tetramine and three weight parts of epoxy chloropropane; the mass ratio of the component 1 and the component 2 is 1:3. The method of the invention can be applied to fixing treatment of cotton fabric dyed by active dye, can improve rubbing fastness, washing fastness and light fastness of the fabric without influence on the chromatic light and the fabric hand feel; the prepared fixing agent which is free from formaldehyde, nontoxic and environment-friendly is a novel printing and dyeing assistant.

Owner:QINGDAO UNIV

Acid soaping agent

ActiveCN101781613AImprove washing fastnessGood anti-staining effectSurface-active detergent compositionsHydrophilic monomerMaleopimaric acid

The invention discloses an addition agent acid soaping agent for dyeing. Although the conventional soaping agent composite has good soaping function, but cannot neutralize the alkaline substances which are remained on the cloth, and the cloth is washed by water for multiple times until the pH value of the cloth is close to neutral, the cloth can be used, so a great amount of water resource is wasted. Fatty alcohol polyethenoxy ether is firstly reacted with acrylic acid or maleic acid to generate a polymerization monomer with surface activity, then under the existence of the evocating agent, the polymerization monomer is polymerized with hydrophilic monomer to generate a macromolecular polymer having dispersion chelation performance, and the macromolecular polymer is compounded with the surface active agent to obtain the acid soaping agent. The prepared acid soaping agent integrates the neutralization process and the soaping process after the dyeing of the active dye, so the process flow is greatly shortened, the water is saved, the energy is saved, the emulsion dispersion chelation performance is excellent, the loose color on the texture can be easy to wash, and the staining prevention performance is excellent.

Owner:HANGZHOU TRANSFAR FINE CHEM CO LTD +2

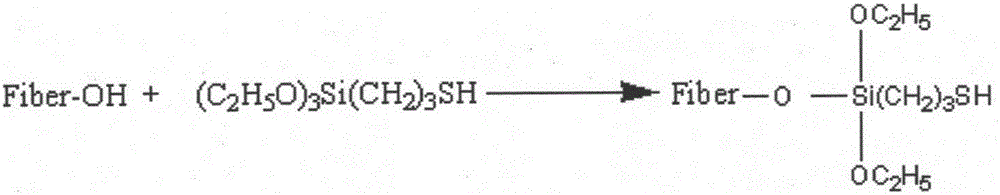

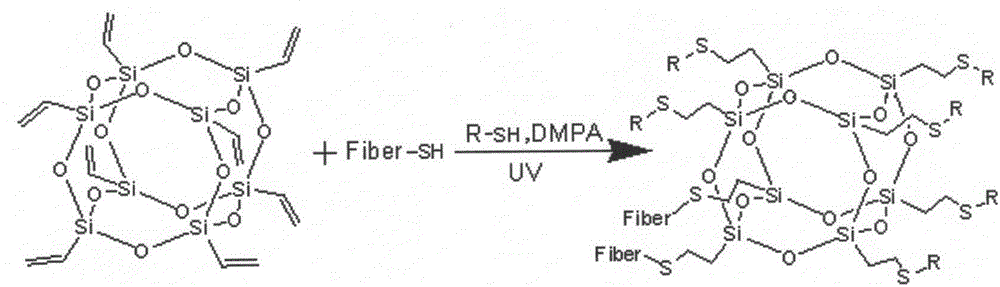

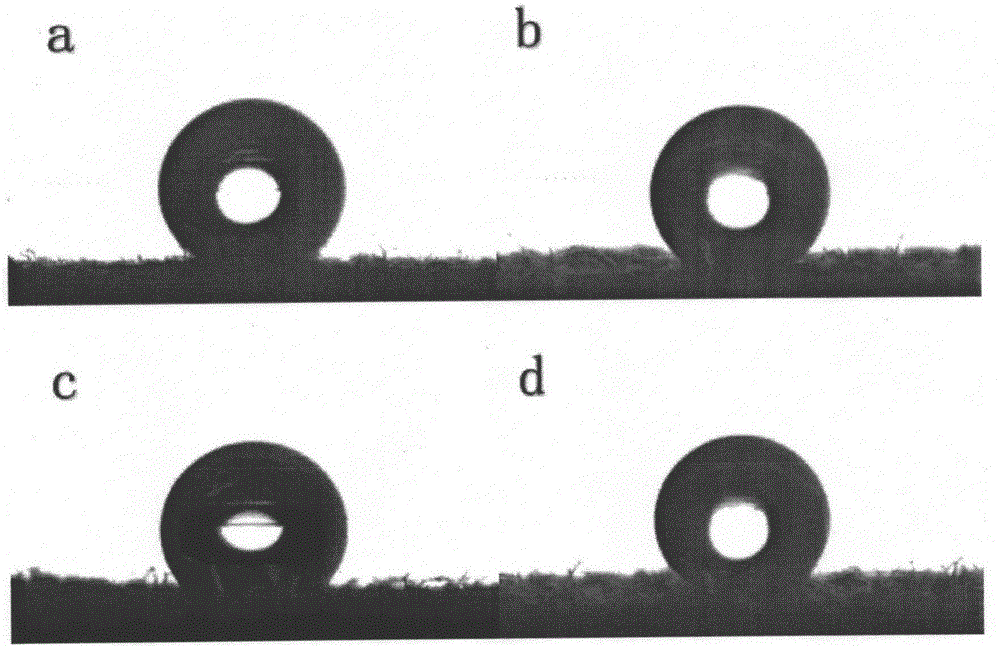

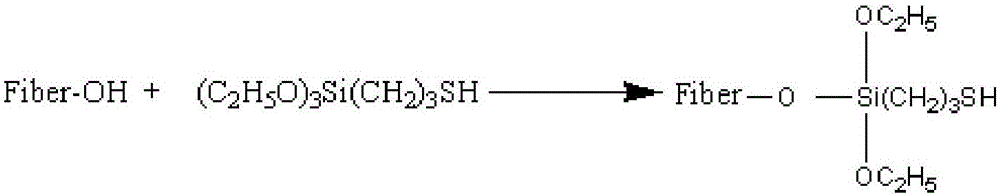

Ultraviolet curing reaction-based fluoride-free and water-repellent finishing method of cotton fabric

InactiveCN106637959AImprove water repellency durabilityHigh activityPhysical treatmentLiquid repellent fibresAcetic acidTriethoxysilane

The invention discloses an ultraviolet curing reaction-based fluoride-free and water-repellent finishing method of cotton fabric. The method comprises the steps of putting the cotton fabric into 3-mercaptopropyl triethoxysilane ethyl acetate solution and carrying out mercapto modification to obtain pretreated cotton fabric; dipping the cotton fabric subjected to mercapto modification into vinyl polyhedral oligomeric silsesquioxane solution, and obtaining the fluoride-free and water-repellent cotton fabric, which has a surface with an approximate super-hydrophobic effect, under the ultraviolet curing condition. The reaction is based on the principle of click chemistry, so that a static contact angle is basically remained unchanged after soaping treatment is carried out. Furthermore, according to a test method of AATCC 22-2005 waterproof spray test, the waterproof spray test score of the cotton fabric subjected to water-repellent finishing reaches 95. The ultraviolet curing reaction-based fluoride-free and water-repellent finishing method of the cotton fabric is simple in operation and high in efficiency, obvious in water-repellent effect under the condition that a finishing agent is fluoride-free, and high in finishing washing fastness.

Owner:DONGHUA UNIV

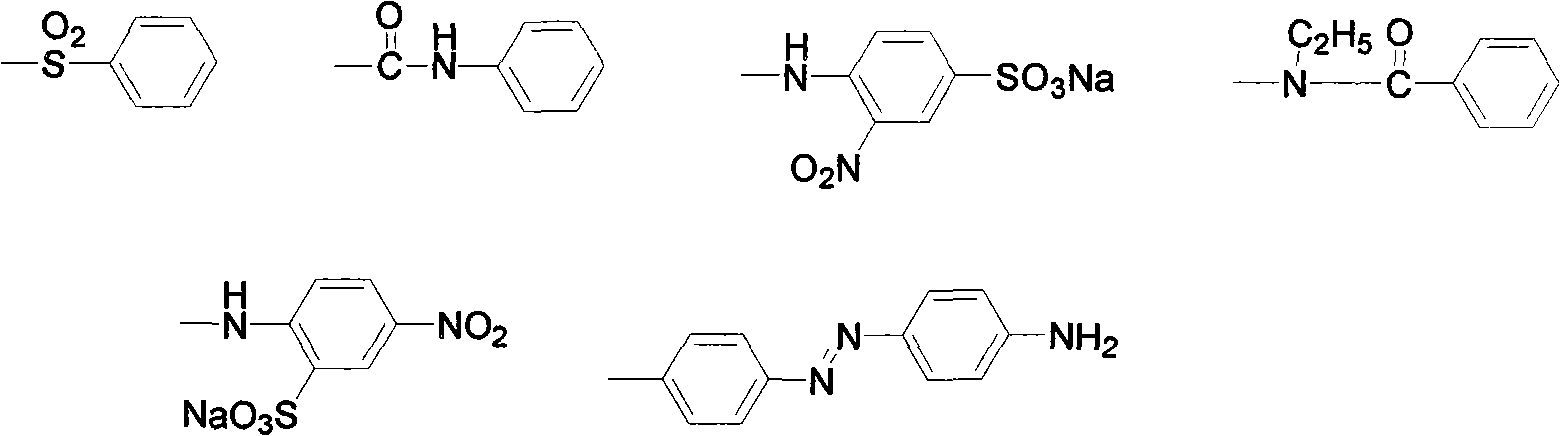

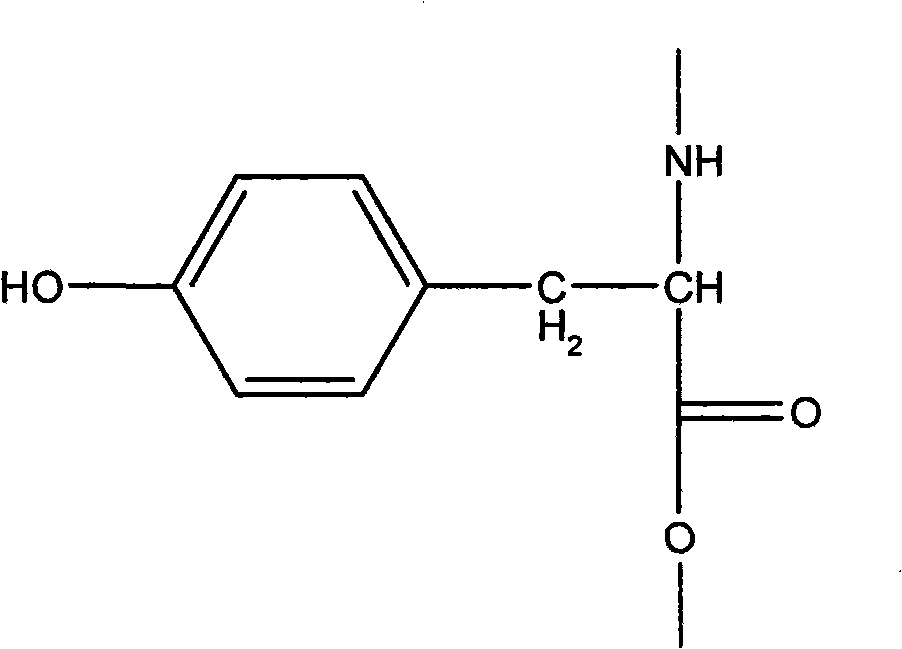

Dyeing method of protein material

The invention discloses a dyeing method of protein material. Arylamine compound is diazotized and then is directly coupled with tyrosine segment in protein molecule, so as to generate coloured substance containing azo bond; dosage of arylamine compound is equivalent to 0.1-5% of weight of protein material, and dyeing bath ratio is 1:20-100. Arylamine compound is taken as colour base and diazotized and then is directly coupled with tyrosine segment in protein molecule, and coloured substance connected with main chain by covalent bond in protein molecule, thus realizing dyeing on protein material and obtaining various colours by selecting arylamine colour bases in different structures. The dyeing method has the advantages of low energy consumption, less pollution and high colour fastness. The protein fiber fabric obtained by the method has higher wet-processing fastness; and the dyed protein powder also has higher fastness. The invention also provides a new dyeing method for protein material.

Owner:ZHEJIANG SCI-TECH UNIV

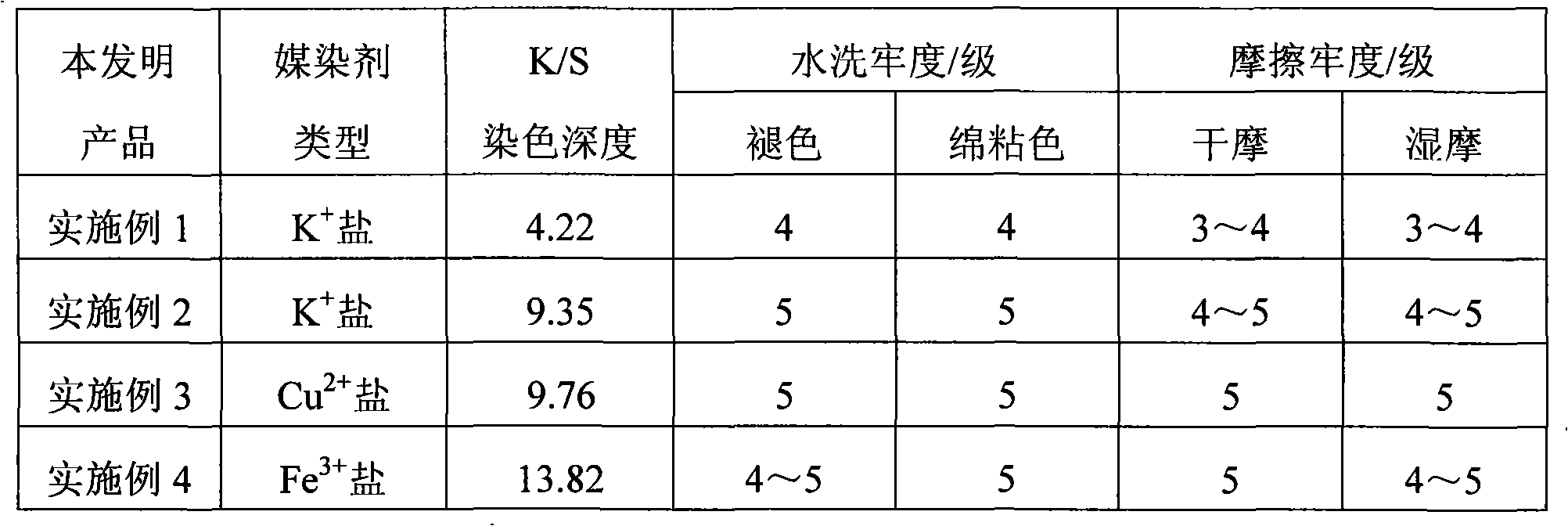

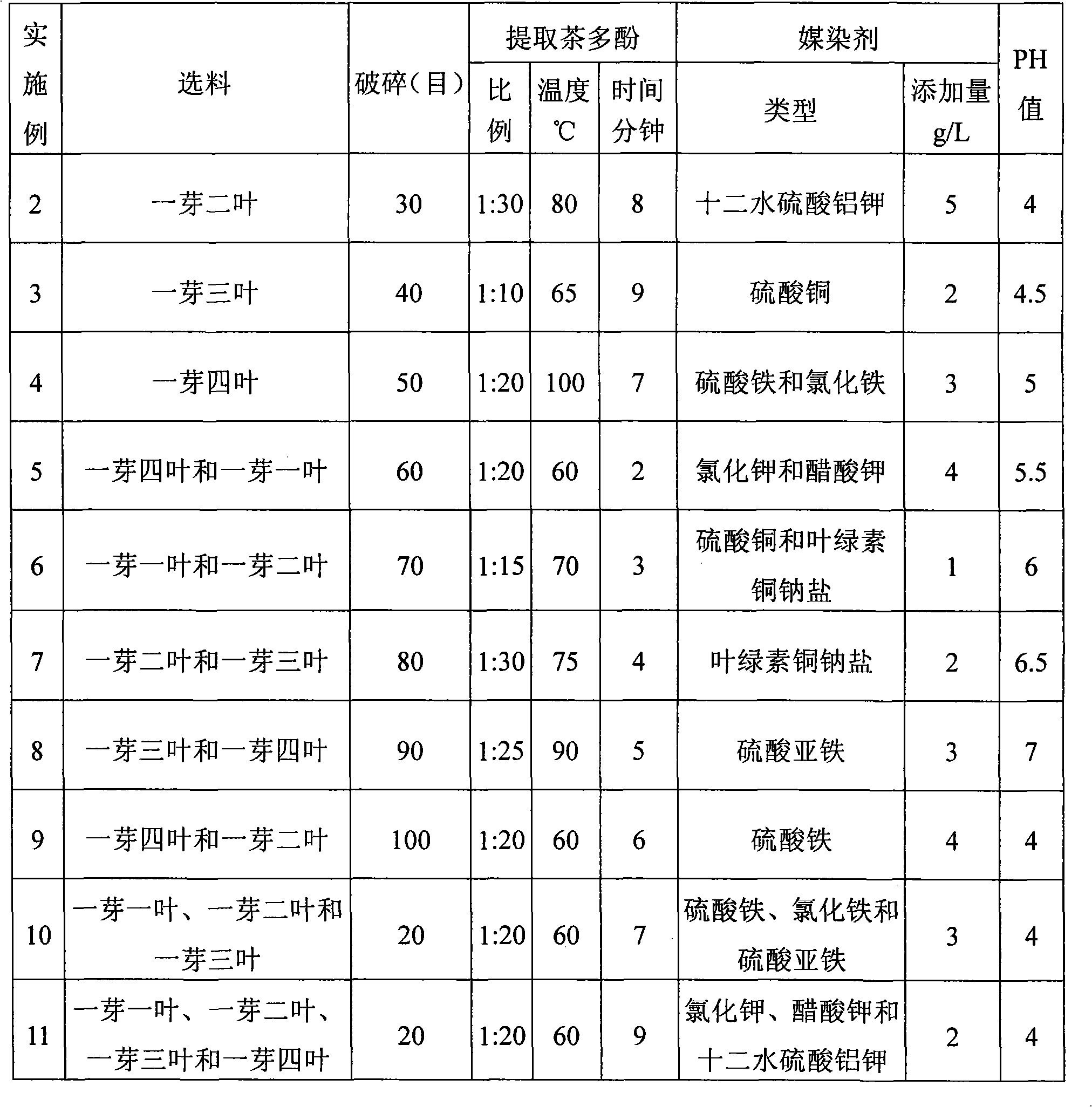

Natural staining agent, preparation thereof and application thereof to silk dyeing

The invention provides a natural coloring agent, which is characterized in that: the fresh tea leaves are used as material to extract tea polyphenol, and then the extraction liquid of the tea polyphenol is added with mordant agent, so as to form the natural coloring agent. As the natural coloring agent has rich color, good dyeing effect, good dyeing fastness (in particular wash fastness), and low production cost, the natural coloring agent has wide application, and strong practicality. The natural coloring agent also provides a preparation method of natural dyeing agent and an application at the aspect of silk fabric dyeing.

Owner:CHONGQING ACAD OF AGRI SCI

Ink jet ink, ink set and method of printing

InactiveUS20070259989A1Improve stabilityGood jetting characteristicInksCoatingsPrinting inkEngineering

Owner:EI DU PONT DE NEMOURS & CO

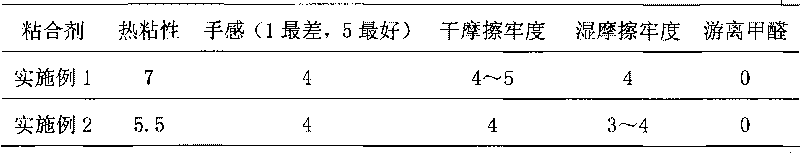

Anti-sticking soft dope printing adhesive and preparation method

The invention discloses anti-sticking soft dope printing adhesive and a preparation method. The adhesive comprises the following raw materials in percentage by mass: 25 to 50 percent of soft monomer, 6 to 20 percent of hard monomer, 0.8 to 5 percent of emulsifying agent, 0.1 to 0.25 percent of initiator, 0.05 to 0.5 percent of buffer, 0.04 to 0.2 percent of thiol and 40 to 65 percent of deionized water. The preparation method comprises the following steps: adding 1 / 8 to 1 / 6 of the soft monomer, the hard monomer and a functional monomer of the raw materials, total emulsifying agent and total deionized water into a reactor, stirring and emulsifying the mixture for 30 to 40 minutes at the room temperature, heating the mixture to between 50 and 65 DEG C, and adding the thiol and the initiator into the reactor; and beginning dripping the mixed monomer, preserving the heat for 2 hours at the temperature of between 50 and 65 DEG C after the dripping is finished, heating the mixture to 70 DEG C, preserving the heat for half an hour, and cooling a product to the room temperature, and discharging the product. The anti-sticking soft dope printing adhesive has the advantages that: the adhesive has excellent washing fastness, super-soft handfeel, environmental protection and no brittleness or after tack, overcomes the defects of hot sticking and poor handfeel of acrylic ester, has many available thickening agent categories, and easily mixes size.

Owner:SHANGHAI JAROS NEW MATERIAL +1

Yellow disperse dye capable of dyeing in acid and alkaline baths

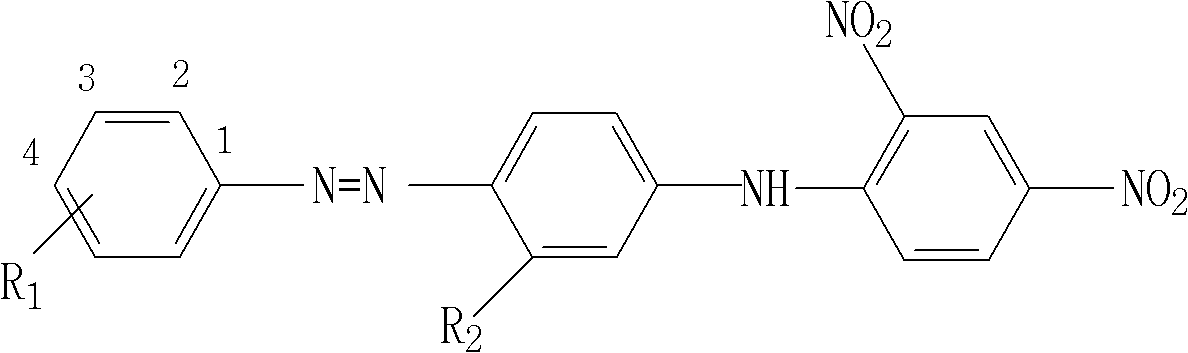

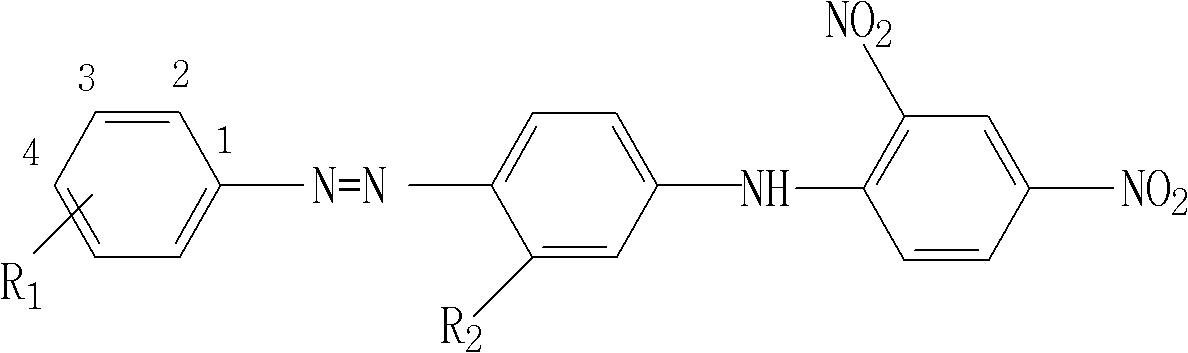

ActiveCN102250485AGuaranteed to run throughQuality improvementMonoazo dyesDisperse dyeStructural formula

The invention relates to a yellow disperse dye capable of dyeing in acid and alkaline baths. The structural formula of the yellow disperse dye is shown in the specification, wherein, R1 is CH3, OCH3, OC2H5 or NHCOCH3; R2 is CH3 or NHCOR3; and R3 is H, CH3 or C2H5. The dye provided by the invention can be used for dyeing and printing of terylene and blended fabrics thereof, and especially is suitable for high-temperature high-pressure dyeing. In weak acid and strong alkaline baths (pH = 4.0-14), the yellow disperse dye can acquire the same dyeing shade and depth, and has good reproducibility and excellent sublimation and washing fastness.

Owner:PENGLAI JIAXIN DYES & CHEM

One-bath, multi-color dyeing method for multi-component superfine fibers

The invention relates to a one-bath, multi-color dyeing method for multi-component superfine fibers. At present, the two-bath, two-step method is usually adopted as the dyeing method for multi-component superfine fibers, the flow is long, the production cost is high, a great deal of time and energy are consumed, and the production efficiency is low. Colors are matched according to the coloring laws of dyes and fibers, i.e., with superfine polyester fibers, superfine polyester-cotton compound fibers and cationic dyeable superfine polyester fibers as materials and disperse dye, acid dye and cationic dye as dyes, multi-color schemes are combined and mixed; and by means of the sequential arrangement of feeding, the preparation and usage of anti-setting agent and a multi-stage heating process realizing the separate dyeing of the fibers corresponding to the dyes, the one-bath, multi-color dyeing of the multi-component superfine fibers are realized. The products dyed by the method disclosed by the invention have two or more different colors and good washing fastness and rubbing fastness, and are vivid, the dyeing effect is equal to the dyeing effect of the two-bath method, however, the dyeing process is simplified, and the consumption of chemicals, water and steam is reduced.

Owner:山东恒泰纺织有限公司

Low-temperature dyeing and finishing technology of cottonette

InactiveCN105002730AProcess temperature changeLow processing temperatureBiochemical fibre treatmentHeating/cooling textile fabricsInorganic saltsDiastase

The invention discloses a low-temperature dyeing and finishing technology of cottonette. The technology comprises the following steps: pretreatment; preshaping; modification treatment; dyeing; mordant removing; soaping; color fixing; post-treatment; drying; shaping; calendaring; rolling. According to the technology, pretreatment is carried out through the adoption of helicase and alpha-amylase, and modification treatment is carried out before dyeing, so that the property of the cottonette is fundamentally modified, and the dye-uptake of the fabric is increased; during the dyeing procedure, large quantities of alkaline substances and inorganic salt are not used, and a levelling agent, a low-temperature dyeing accelerant, a migration inhibitor and a dispersing agent are added, so that the dye uniformity is improved; during the whole dyeing process, the temperature is lower than 80 DEG C, and the dyeing process belongs to low-temperature dyeing, so that energy consumption is reduced; self-cleaning treatment is added in post-treatment, so that the self-cleaning capacity, wrinkle resistance and water washable firmness of the fabric are improved; post-treatment is carried out through the adoption of silk fibroin and sericin, so that the pilling resistance and antistatic property of the cottonette are improved; the whole technology is environment-friendly and free of pollution.

Owner:TAICANG TIANLONG CHEM FIBER

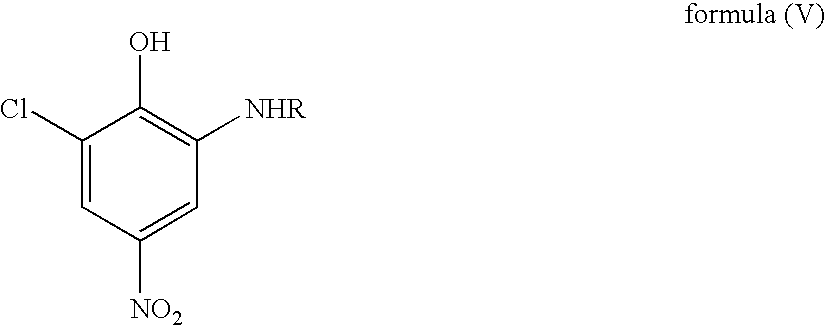

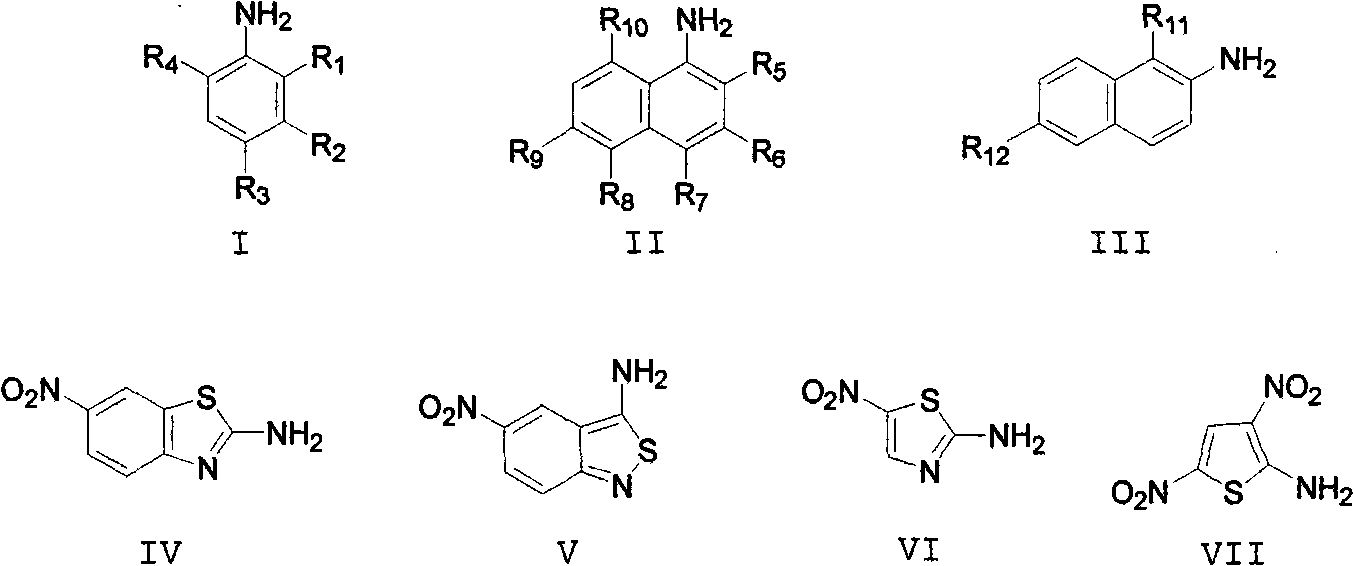

High-fastness blue-to-black disperse dye composition and dye product

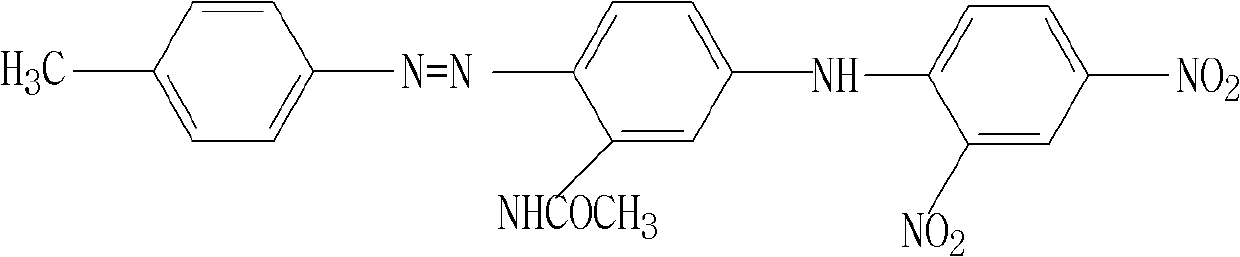

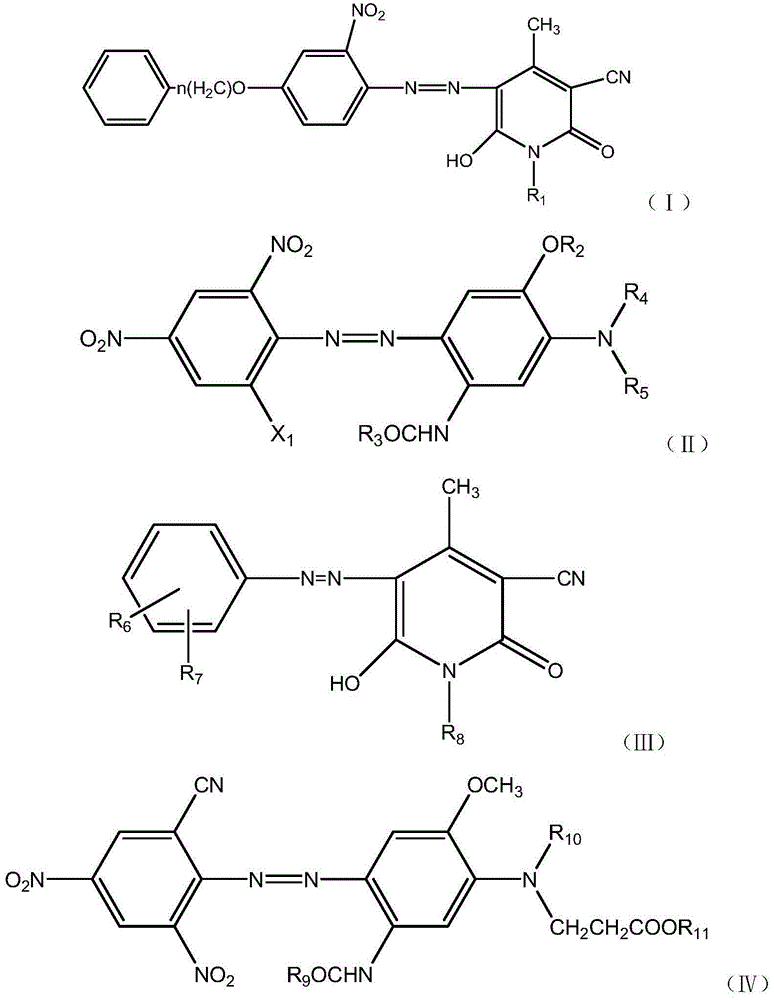

InactiveCN104559316AGood thermal migration resistanceImprove washing fastnessOrganic dyesDisperse dyeRubbing

The invention relates to a disperse blue-to-black dye composition and dye product. The composition is mainly composed of a component A, a component B, a component C, a component D and a component E, wherein the component A is selected from one or more of compounds disclosed as Formula (I), the component B is selected from one or more of compounds disclosed as Formula (II), the component C is selected from one or more of compounds disclosed as Formula (III), the component D is selected from one or more of compounds disclosed as Formula (IV), and the component E is selected from one or more of compounds disclosed as Formula (V). The dye product is mainly composed of the composition and assistants. When being used for hydrophobic fiber material dyeing and after-finishing, the dye product has excellent fastness to washing and fastness to rubbing, and is very suitable for printing and dyeing of high-grade textiles.

Owner:ZHEJIANG LONGSHENG GROUP

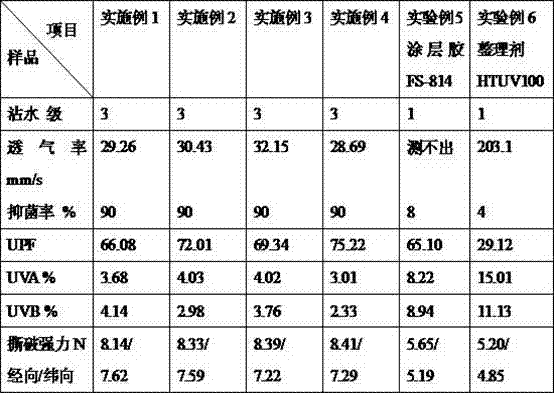

Waterproof air-permeable antibacterial anti-ultraviolet reinforced coating adhesive for textile and preparation method of waterproof air-permeable antibacterial anti-ultraviolet reinforced coating adhesive

ActiveCN104727151AGuaranteed waterproof performanceAntimicrobial GuaranteeFibre treatmentPolyesterWater based

The invention provides waterproof air-permeable antibacterial anti-ultraviolet reinforced coating adhesive for textile and a preparation method of the waterproof air-permeable antibacterial anti-ultraviolet reinforced coating adhesive. The adhesive is prepared by mixing the following raw materials in parts by weight: 65-68 parts of a water-based polyurethane waterproof permeable adhesive, 10-15 parts of polyethylene glycol having the average molecular weight of 600, 2-3.5 parts of a TDI tripolymer curing agent, 3-4 parts of anionic amino silicon oil emulsion, 5-7 parts of an anionic or non-ionic fluorine-containing waterproof agent, 5-7 parts of a phenylamide anionic antibacterial deodorant agent, 1.5-2.5 parts nano-zinc oxide powder and 1-2 parts of nano-titanium dioxide powder. The coating adhesive is simple and convenient to produce and convenient to use, has good waterproof color fastness, and is suitable for 10D-20D polyester, chinlon cloth fabric functional coatings.

Owner:DANDONG UNIK TEXTILE

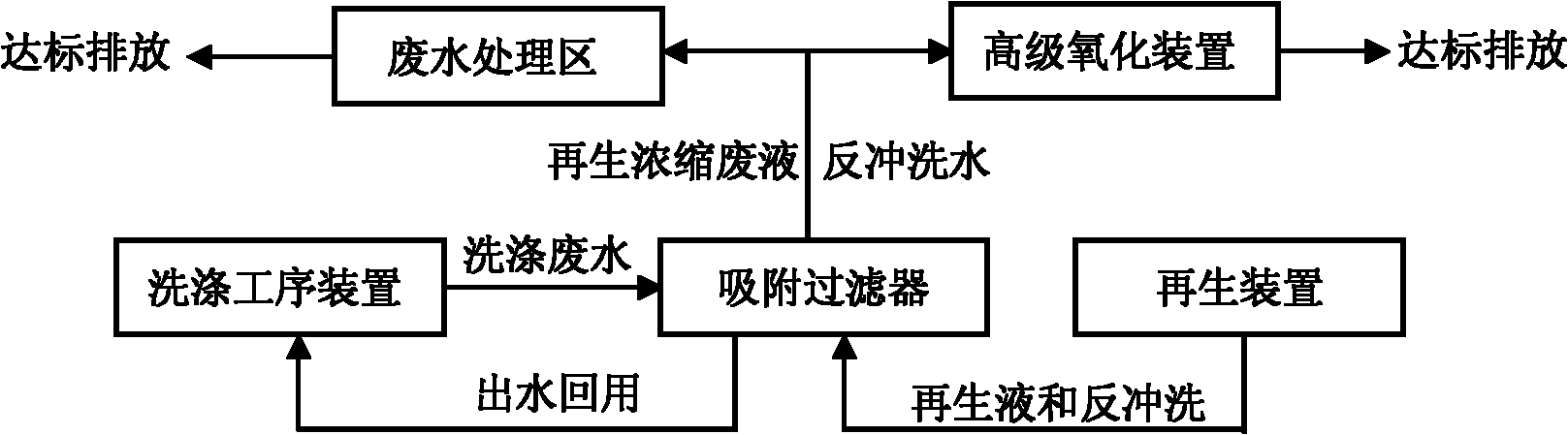

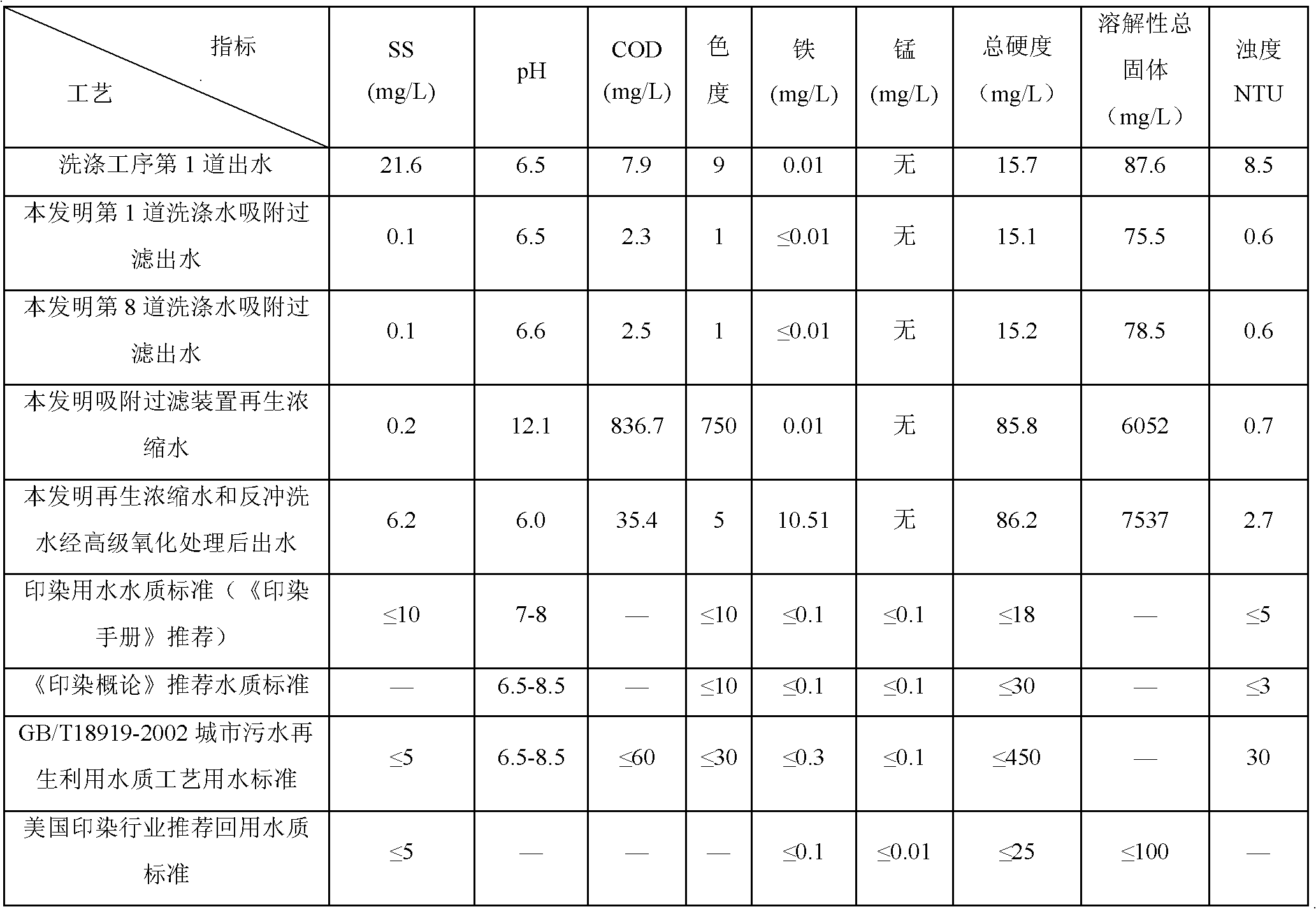

A method and device for treating and reusing waste water from on-line printing, dyeing and washing

ActiveCN102276010AImprove washing fastnessImprove cleaningWater/sewage treatment by irradiationWater/sewage treatment by ion-exchangeWater solubleTreated water

The invention relates to a method for on-line treatment and recycle of printing and dyeing washing waste water and a device thereof, and the method comprises the following steps: treating printing and dyeing washing waste water by an adsorption filtration device (3), recycling the treated water in a washing procedure (1) directly, allowing an adsorption medium to be adsorbed saturatedly, performing regeneration by a regeneration device; allowing the regenerated waste liquid and the waste water after backwashing to enter a superior oxidation area for further oxidation and degradation, discharging after the water reaches the standard. The device comprises a water inlet pipe and a water outlet pipe, and also comprises three parts of an adsorption filtration device (3), a regeneration device (2), and a superior oxidation device (4). The method of the invention has simple operation and management, low equipment investment and running cost, and is convenient for popularization and application; During the adsorption filtration process of the invention, no chemical reagent is needed to be added, and no secondary pollution is caused, and thus no additional effect on dyeing quality is caused; The invention is applicable to the on-line treatment and recycle of dyeing washing waste water of anionic or cationic water-soluble dyes such as active dyes, acid dyes, weak-acid dyes, basic dyes, etc.

Owner:DONGHUA UNIV +1

Printing

ActiveUS20140147576A1Good light fastnessImprove washing fastnessRadiation pyrometryScattering properties measurementsConfocalLength wave

Owner:INOVINK

Environment-protection coating printing adhesive and its preparing method

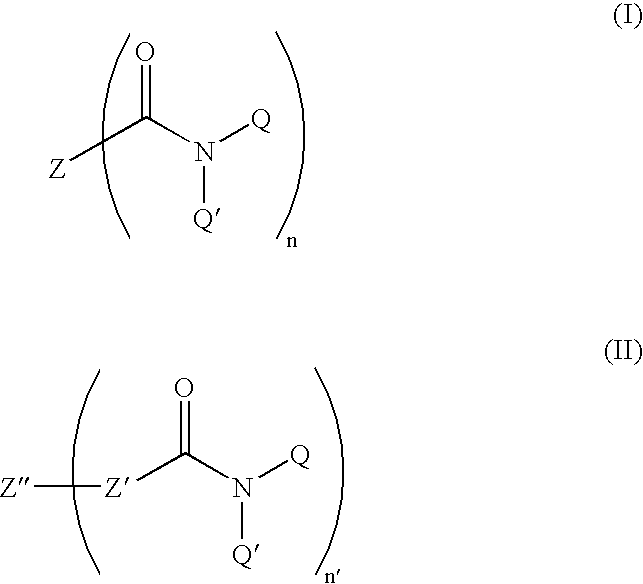

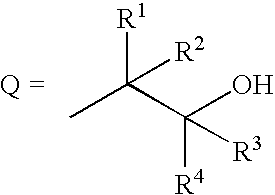

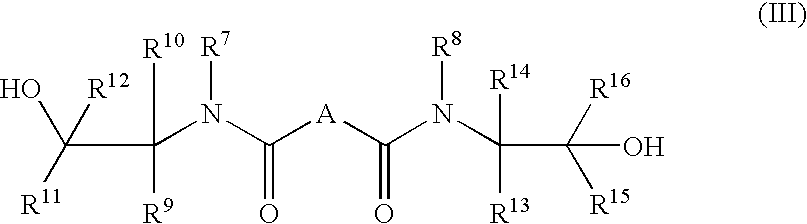

InactiveCN1936172AGood compatibilityUniform sizePolyureas/polyurethane adhesivesPolyurea/polyurethane coatingsSal ammoniacPolymer science

The invention relates to an environment protecting resin-bonded pigment printing adhesive that is made up according the following steps: adding 0.5-1% polyacrylic acid salt into polyurethane acrylic ester emulsion, adjusting pH value to 7-8 to gain cream, and the viscosity is 30-60Pa.S. The preparation of polyurethane acrylic ester emulsion includes the following steps: gaining end ethenyl polyurethane performed polymer from polyether glycol, isocyanic ester and auxiliary agent, mixing the preformed polymer with acrylic ester monomer and water to make dispersing liquid, irradiating for 30-50 minutes at 1.5-2.5KGy radiation dose. The content of formaldehyde is below 5ppm and APEO below 5ppm in the adhesive. The product is environment protection.

Owner:合肥安大天辐新材料有限公司 +1

Water-repellent, oil-repellent, sun-proof, anti-bend torsion and cold-resistant matt-leather-membrane aqueous coating adhesive for textiles and preparation method of matt-leather-membrane aqueous coating adhesive

ActiveCN104831540AAssociative functionCombined with styleFibre treatmentIsooctyl acrylatePolymer science

The invention relates to a water-repellent, oil-repellent, sun-proof, anti-bend torsion and cold-resistant matt-leather-membrane aqueous coating adhesive for textiles and a preparation method of the matt-leather-membrane aqueous coating adhesive. The preparation method comprises the steps of emulsifying isooctyl acrylate, isobornyl methacrylate, glycidyl methacrylate, trifluoroethyl methacrylate, vinyl trimethoxysilane, hydroxypropyl acrylate, fatty alcohol ethoxylate XL90 and dodecyl benzene sulfonate to trigger polymerization, and compounding a thickening agent, namely an associated polyurethane flatting rheological agent, a cross-linking agent, namely terminated isocyanate, a flatting agent, namely polymethyl urea resin and silicon dioxide with the particle size of 2-7 microns, so as to obtain the matt-leather-membrane aqueous coating adhesive.

Owner:DANDONG UNIK TEXTILE

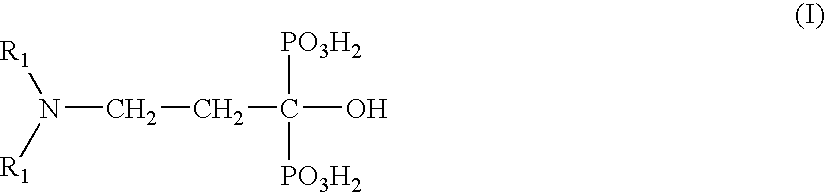

Method for producing cation modified polyurethane color stabilizer

The invention discloses a modified polyurethane color fixing agent of basic ion, which is prepared by PEG600, PPG2000, TDI, DMPA, methyl ethyl ketone, calcium trisodium diethylenetriamine pentoacetate, epichlorohydrin, acetone, isopropanol, sodium bisulfite, water and glacial acetic acid. The process for preparation comprises polyurethane prepolymerization reaction, modified chain extending reaction, blocking reaction, emulsion reaction, removing solvent and the like. The modified polyurethane color fixing agent of ion of the invention can form net-shaped cross bonding with woven fabric, and the invention adopts sodium acid sulfite to be blocking agent, which guarantees that when in application, enough isocyanate bonds are supplied to form chemical crosslinking with hydroxyl group and carboxy group with cloth surface, the invention improves various color stabilities of dyed fabric, meanwhile, the invention keeps soft hand feeling of fabric.

Owner:NANTONG UNIVERSITY +1

Fluoride-free water-repellent textile fabric finishing method based on ultraviolet light curing reaction

InactiveCN106592222AImprove water repellency durabilityEasy to operateLiquid repellent fibresVegetal fibresOrganic solventSilanes

The invention relates to a fluoride-free water-repellent textile fabric finishing method based on an ultraviolet light curing reaction. The method comprises the steps that a textile fabric is cleaned and then subjected to sulfydryl modification; vinyl cage-type silsesquioxane and sulfydryl silane or vinyl cage-type silsesquioxane and alkyl sulfhydryl are dissolved into an organic solvent, and ultrasonic oscillation is conducted to obtain a mixed solution; a photoinitiator is added, and ultrasonic oscillation is conducted to obtain a finishing solution; the textile fabric obtained after sulfydryl modification is steeped in the finishing solution, ultraviolet curing, cleanign and drying are conducted, and then the finished textile fabric is obtained. According to the method, operation is easy, the efficiency is high, and under the fluoride-free condition of a finishing agent, the water-repellent effect is obvious, and the treated washable fastness is high.

Owner:DONGHUA UNIV

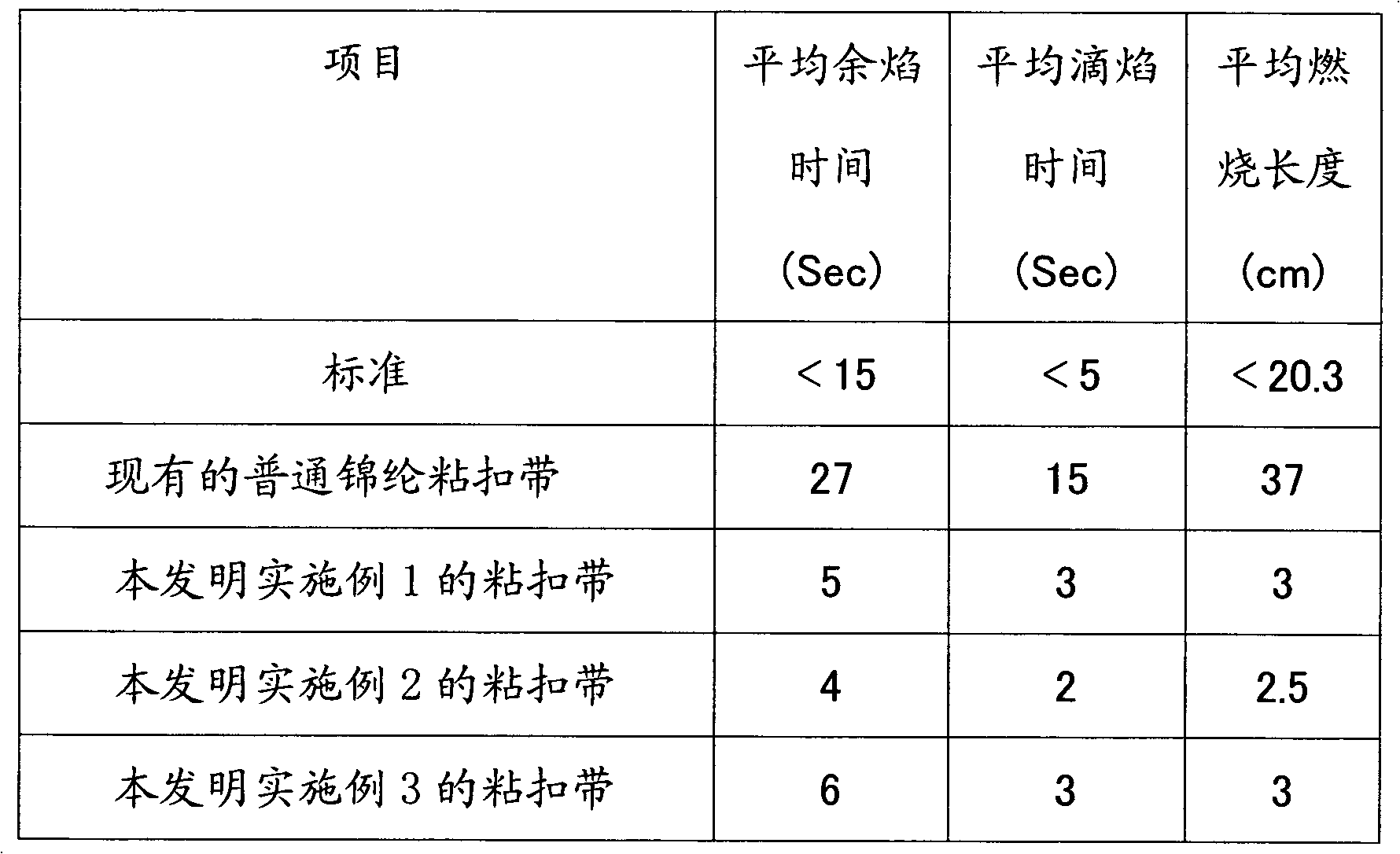

Method for manufacturing halogen-free, washing-resistant and flame retardant polyamide hook and loop fastener

ActiveCN102182058ASolve the problem that the washing fastness does not meet the requirementsImprove securityFibre typesVisibilityToxic gas

The invention relates to a method for manufacturing a halogen-free, washing-resistant and flame retardant polyamide hook and loop fastener. The method comprises the following steps: preparing a flame retardant finishing working solution; carrying out flame-retardant finishing on the polyamide hook and loop fastener and dehydrating the polyamide hook and loop fastener; preparing flame retardant viscose; spraying the flame retardant viscose on the front of the hook and loop fastener; coating the flame retardant viscose on the back of the hook and loop fastener; and drying and baking the hook and loop fastener. The dyes and chemicals, flame retardant finishing agents and resins which are used in the production process of the hook and loop fastener do not contain halogen or heavy metals. Compared with the prior art, the hook and loop fastener not only improves the flame retardant effect, reduces the toxic gases released in the combustion process, has high visibility, conforms to the standard of the Boeing company in America and improves the safety of personnel and transportation when being used for transportation, but also can be washed and reused and simultaneously solves the problem that the fastness to washing can not meet the requirement when the popular flame retardants on the market are directly used for manufacturing the halogen-free and flame retardant polyamide hook and loop fastener.

Owner:WUXI PAIHO TEXTILES CO LTD

High-fastness turquoise blue disperse dye composition

The invention provides an environment-friendly and economical high-fastness turquoise blue disperse dye composition with bright colored light, good leveling property, good elevating power and excellent washing fastness and sublimation fastness. The high-fastness turquoise blue disperse dye composition mainly comprises the following components in parts by weight: 50-90 parts of a component A shown by a formula (I), 0.1-10 parts of a component B shown by a formula (II) and 0.1-45 parts of a component C shown by a formula (III). After being commercialized, the turquoise blue disperse dye composition provided by the invention can be ground to be in a liquid state by a sand mill or a grinder, and can be in the shape of powder or particle after being subjected to spray drying, so that the turquoise blue disperse dye composition is suitable for dyeing of polyester and a blended fabric thereof, and particularly suitable for dyeing of a spandex blended fabric, and has the characteristics of good elevating power, small contamination to spandex, excellent washing fastness, excellent color fastness to sublimation and the like.

Owner:ZHEJIANG LONGSHENG GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com