Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1056results about How to "Uniform dyeing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

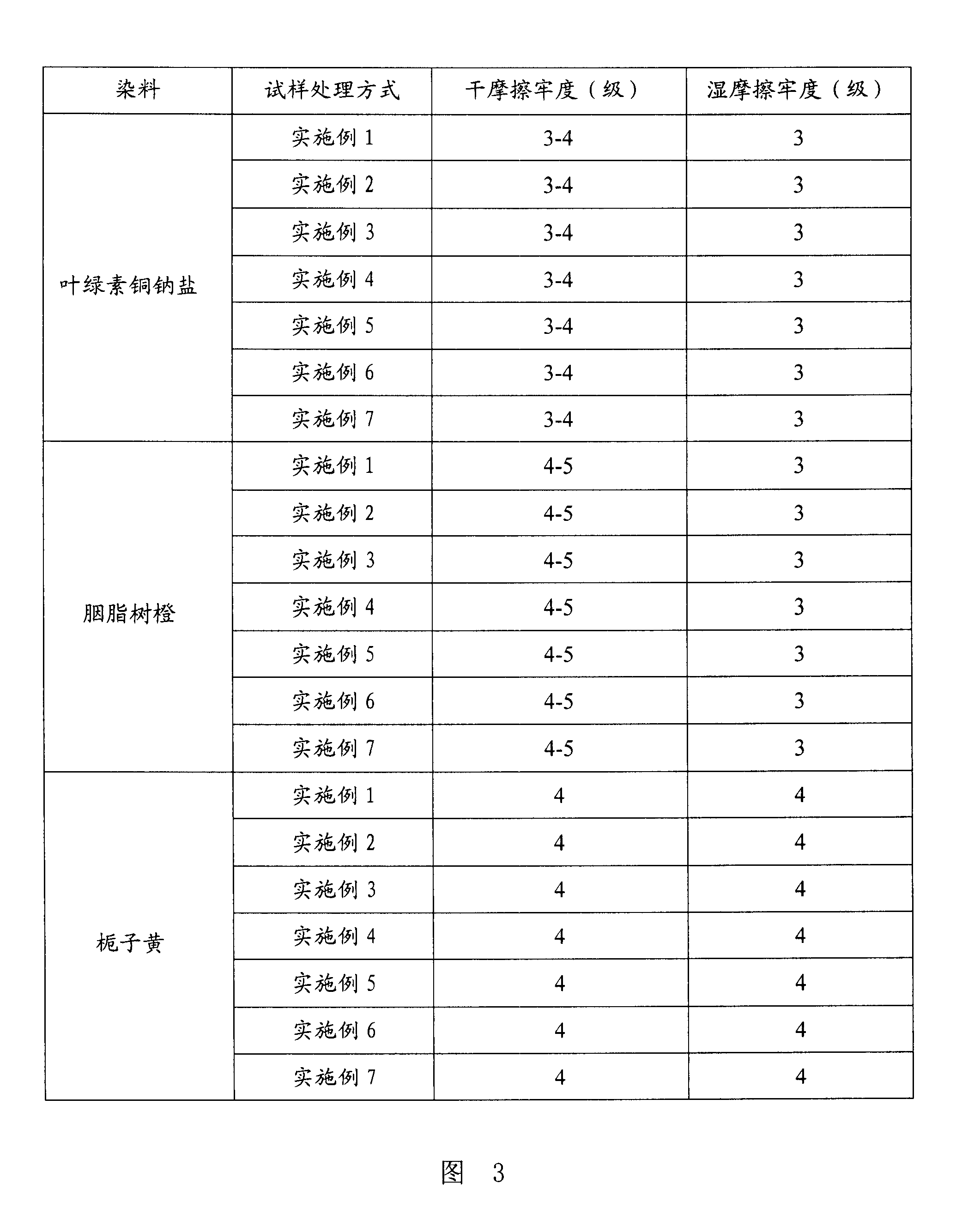

Natural dye dying method based on cotton fiber modification

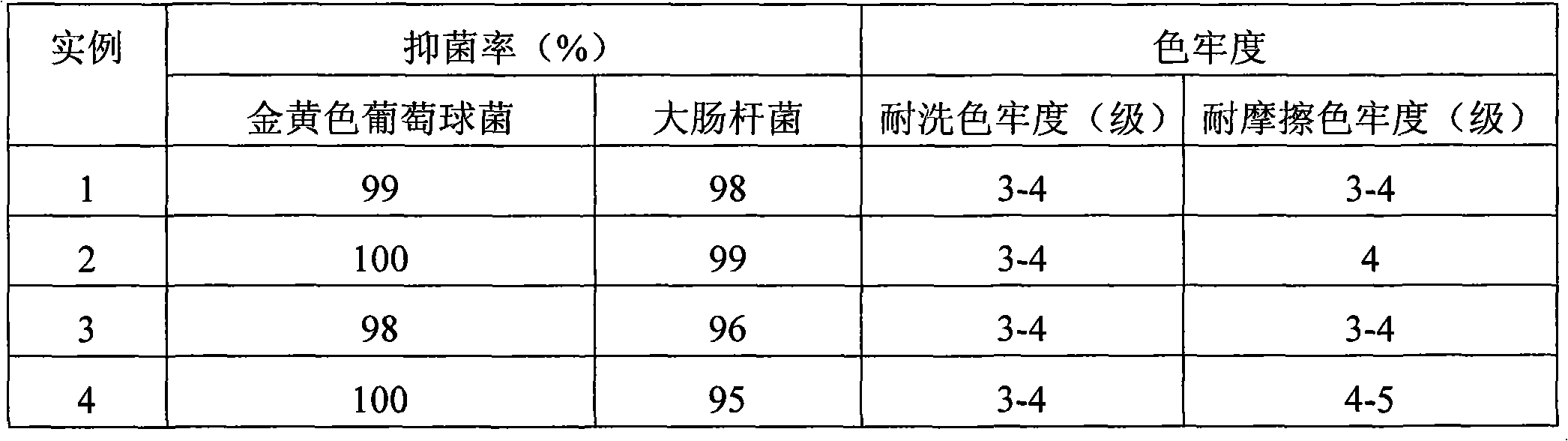

ActiveCN101187175AImprove adsorption capacityImprove dye uptakeDyeing processCotton fibreNatural dye

The invention relates to a dyeing method of natural dye material of cotton fabric, which belongs to the field of fabric dyeing and finishing technique and comprises: processing the modifying liquid by use of the modifying agent containing anode ions group, firstly modifying the cotton fabric and dyeing the fabric with the natural dyeing material, after cleaning, fulfilling the dyeing with the natural dye material of cotton fabric, wherein due to the modifying process on the cotton fabric in advance, the anode ion base is introduced into the cotton fabric to strengthen the combination ability from the cotton fabric to the natural dye material of cathode ion, which effectively improves the cotton fabric dyeing rate, color depth and dyeing evenness and distinctly improves the anti-washing and anti-abrasion firmness of the dyed cotton fabric. The process has simple operation, even dyeing and wide application prospect.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD +1

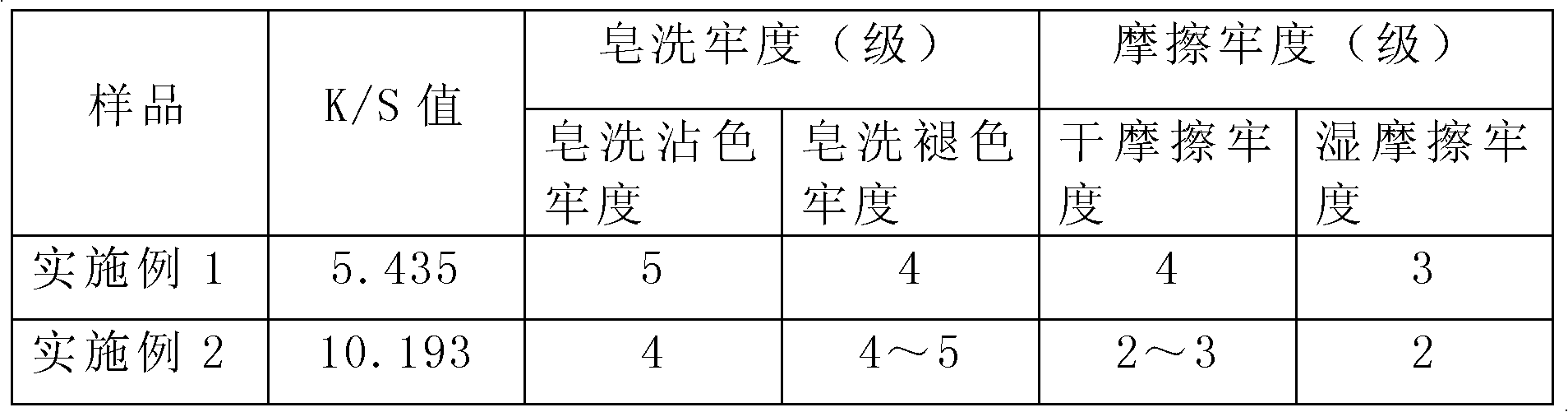

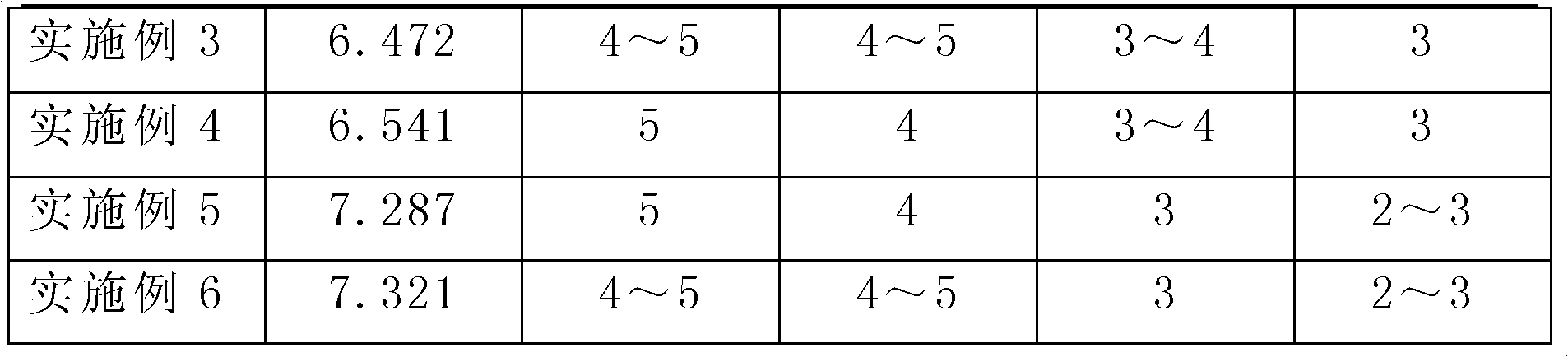

Method of dyeing fabric by using dye

ActiveCN102535194ASoft touchImprove washing fastnessBiochemical fibre treatmentDry-cleaning apparatus for textilesTextile printerEngineering

The invention provides a method for dyeing fabric by using a dye, belonging to the technical field of textile printing and dyeing and aiming to the solve the problems of complex process, low dyeing rate, poor dyeing uniformity and poor color fastness and hand feel of dyed fabric of the existing method for dyeing the fabric by using the dye. The method comprises the following steps of: desizing the fabric, scouring, bleaching and mercerizing; adding the dye, a cationic modifier, a leveling agent, a dispersant, an alkaline reagent and a wet rubbing fastness enhancer to water, and mixing uniformly to prepare a dyeing solution; soaking the fabric into the dyeing solution, and controlling temperature and liquor ratio to dye; steaming the dyed fabric for colour fixation, washing by water and drying to finish dyeing the fabric by using the dye. The method for dyeing the fabric by using the dye is simple, ensures the high dyeing rate and the uniform dyeing, and ensures that the dyed fabric has good washing fastness and rubbing fastness and a soft feel.

Owner:台州东海翔染整有限公司

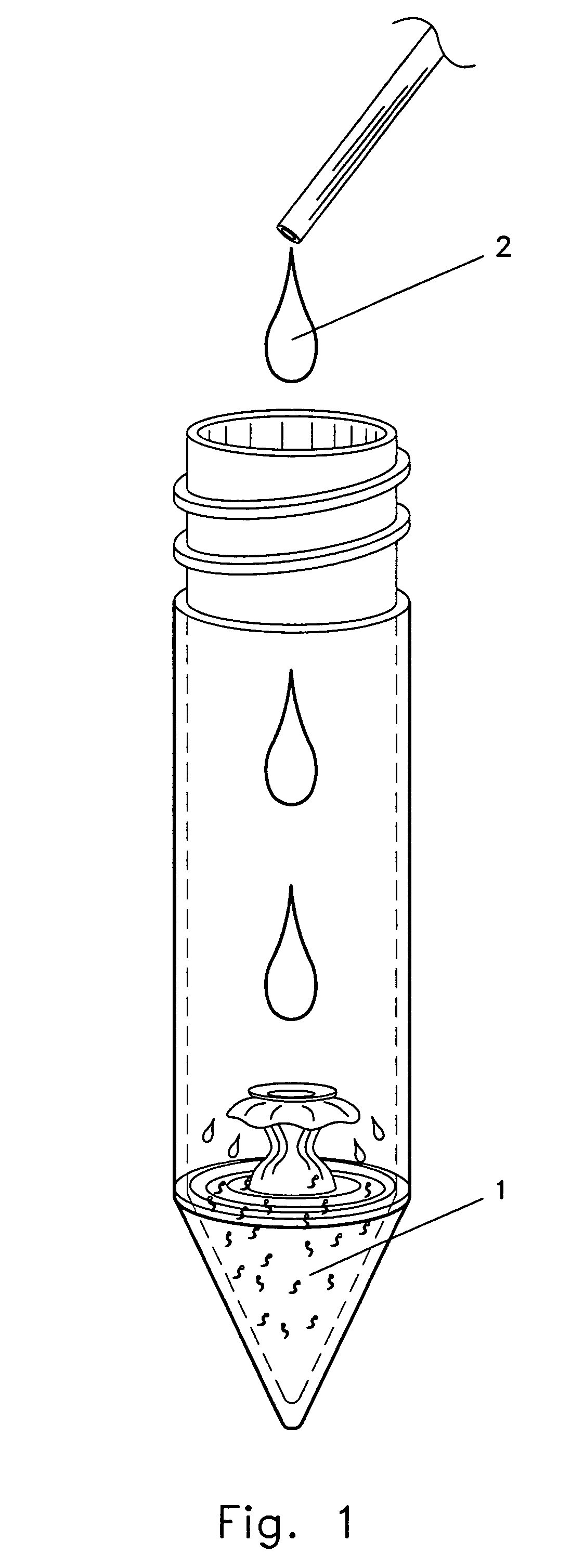

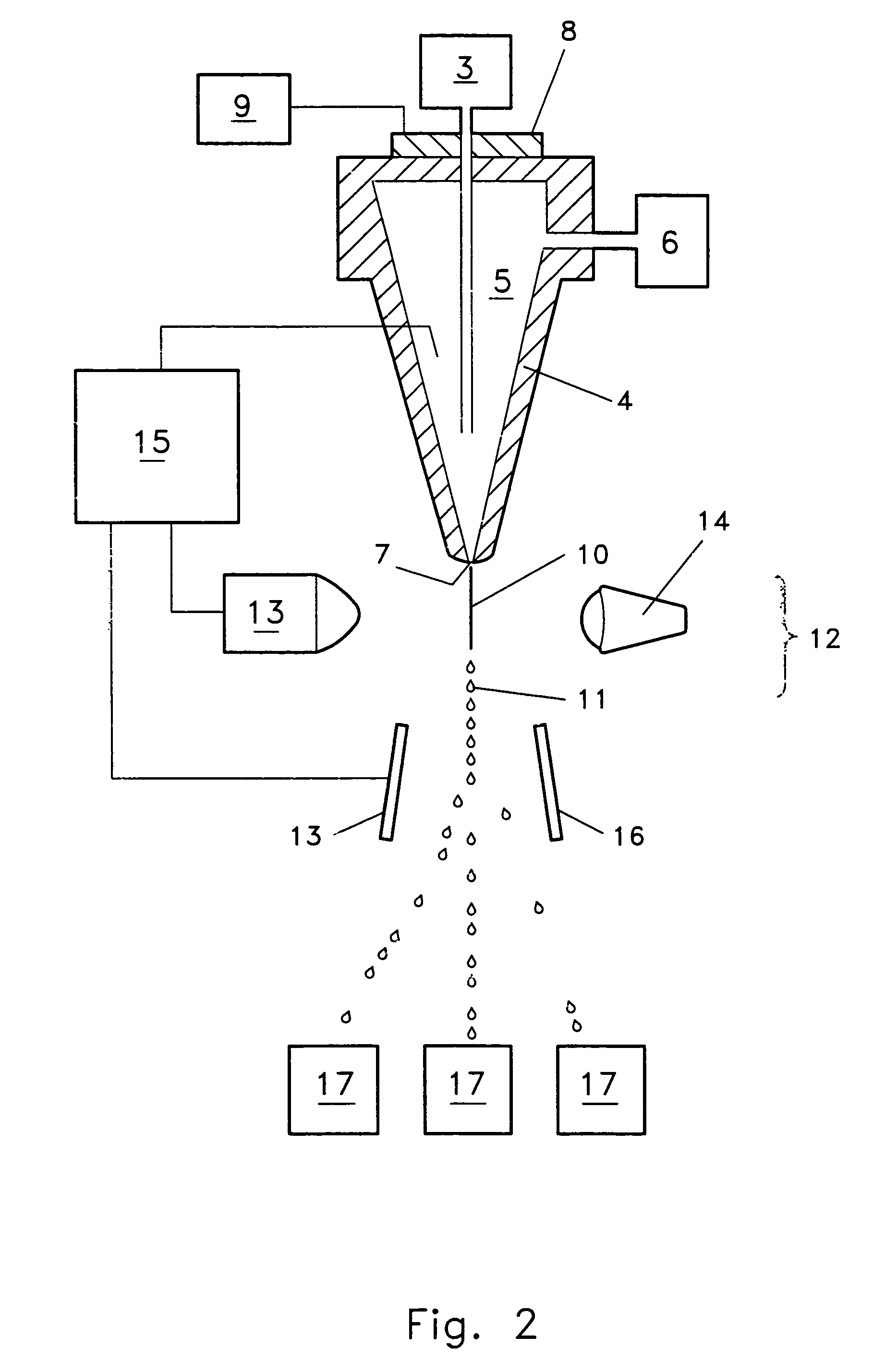

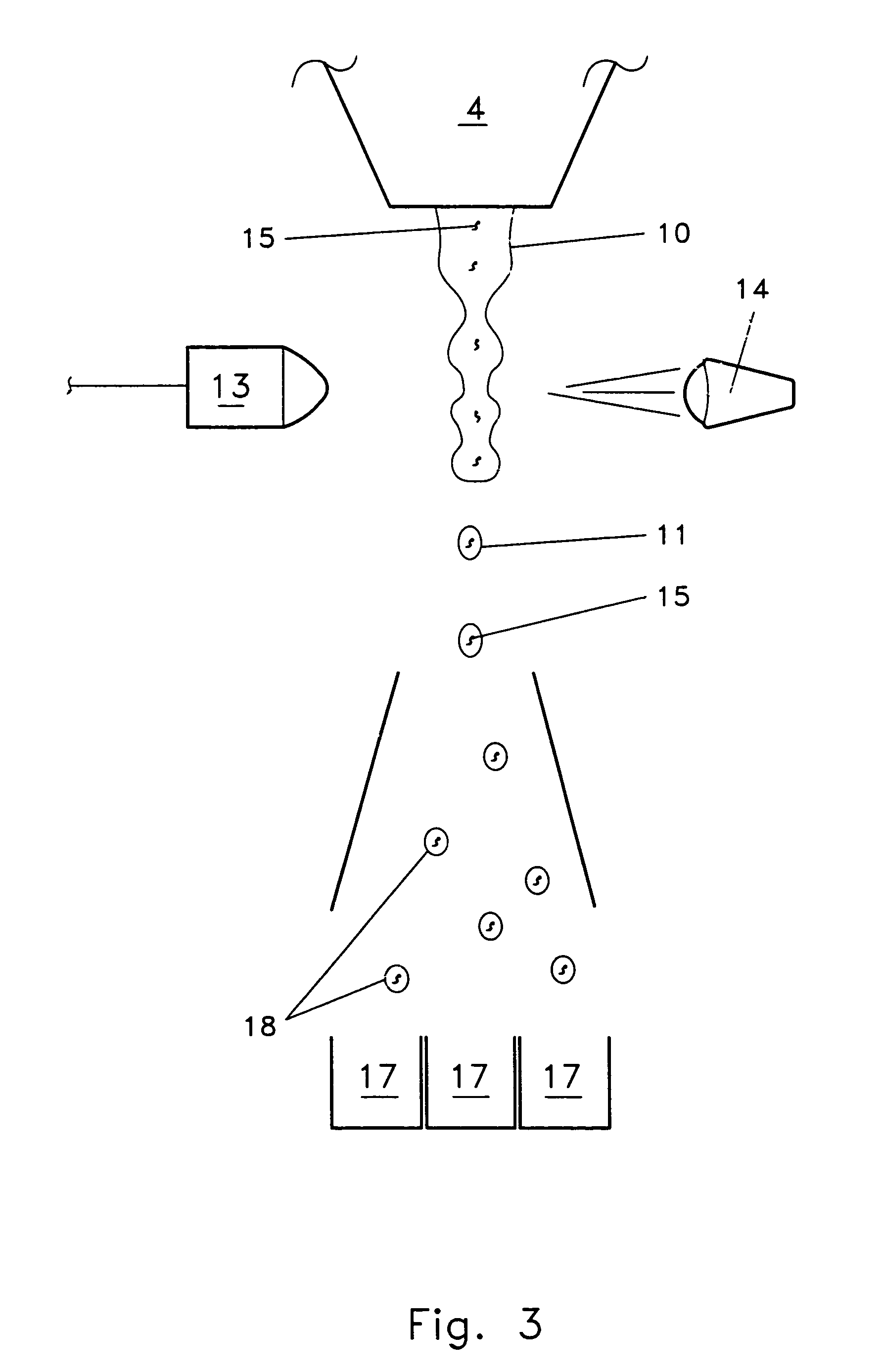

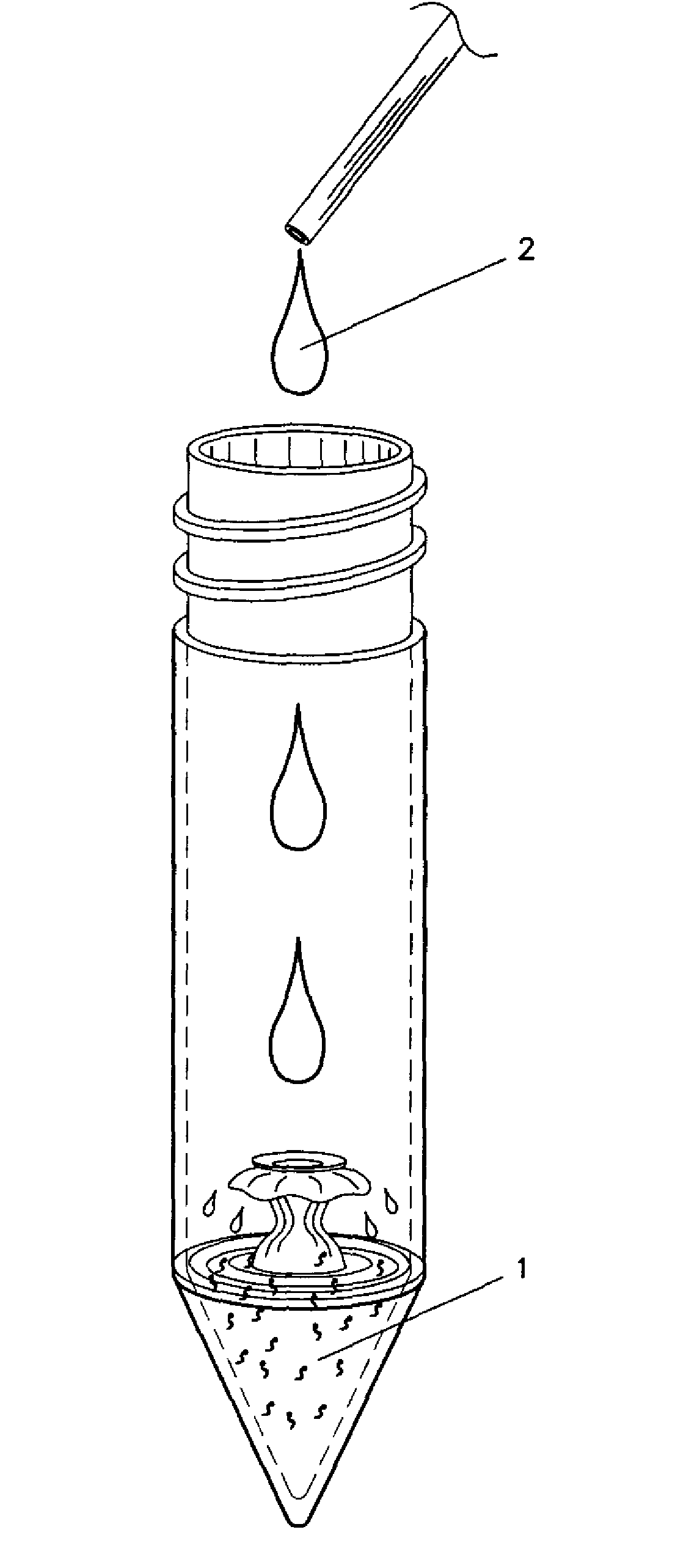

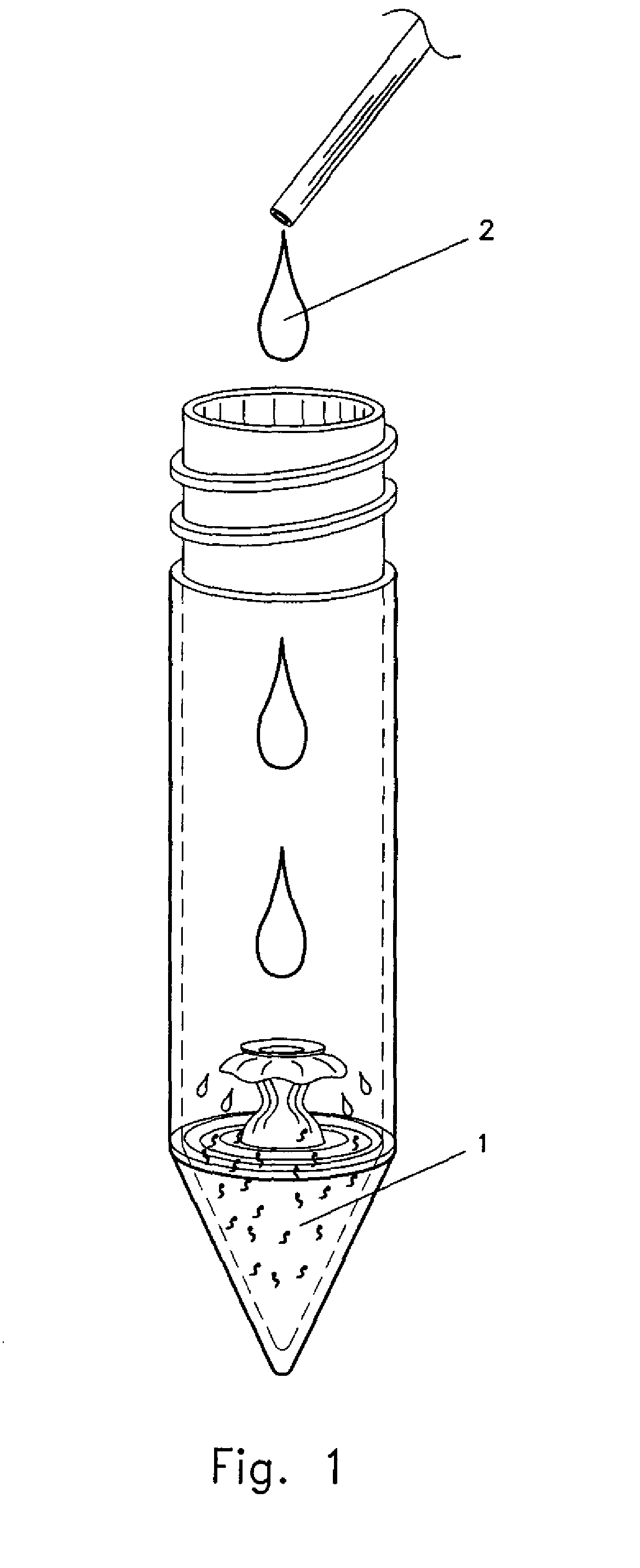

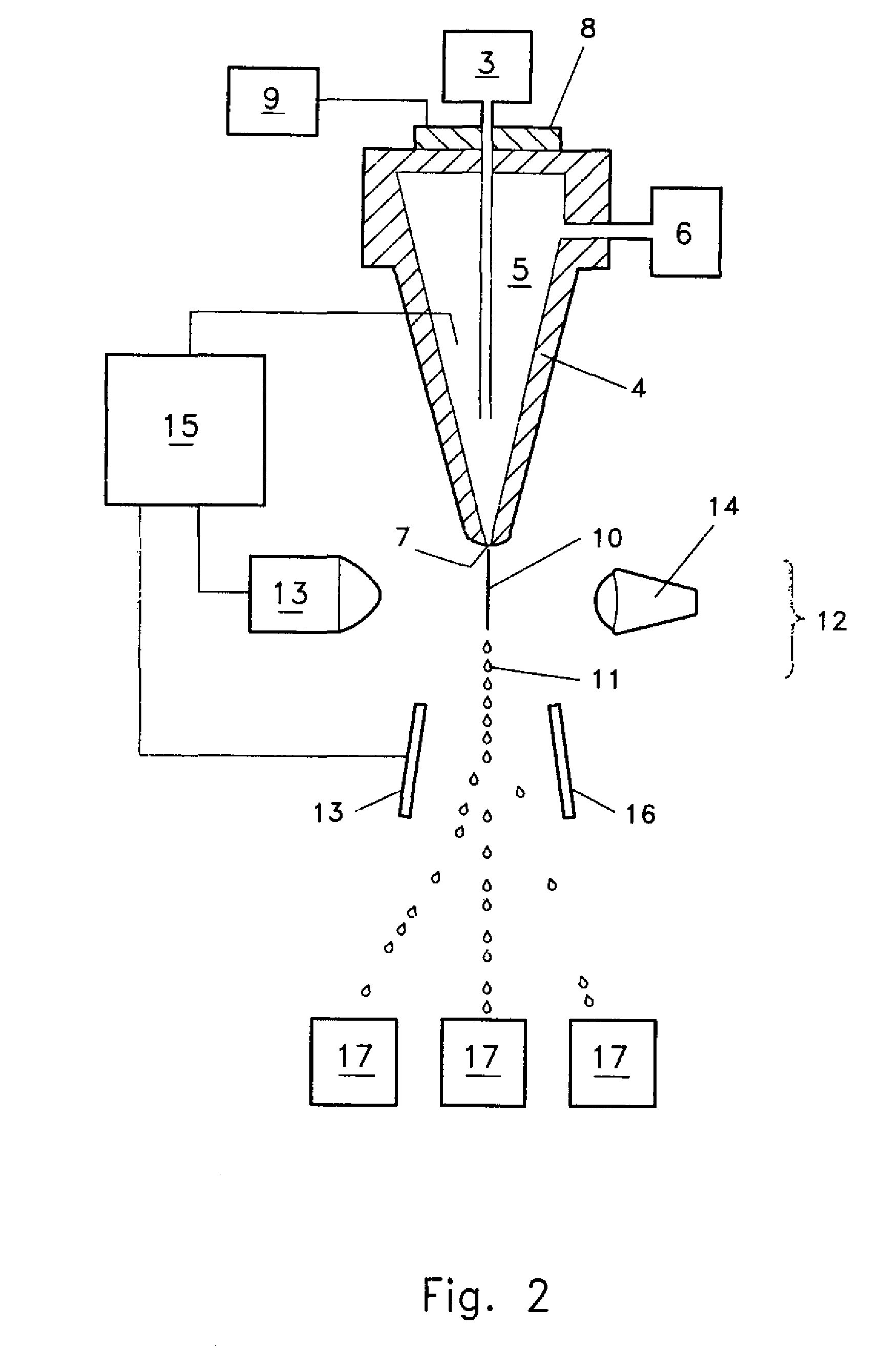

System to separate frozen-thawed spermatozoa into x-chromosome bearing and y-chromosome bearing populations

InactiveUS20040049801A1Increase the differenceReduce in quantityMicrobiological testing/measurementPreparing sample for investigationAnimal scienceStaining

Devices, compositions, and methods for handling, separating, packaging, and utilization of spermatozoa (1) that can be derived from previously frozen sperm samples collected from a male mammal. Specifically, techniques to uniformity stain (2) spermatozoal DNA even when derived from previously frozen sperm and separation techniques to separate and isolate spermatozoa even when derived from previously frozen sperm samples into X-chromosome bearing and Y-chromosome bearing populations having high purity.

Owner:XY

Separation Systems of Frozen-Thawed Spermatozoa Into X-Chromosome Bearing and Y-Chromosome Bearing Populations

InactiveUS20070042342A1Narrow range in magnitudeIncrease the differenceMicrobiological testing/measurementPreparing sample for investigationX chromosomeFreezing thawing

Devices, compositions, and methods for handling, separating, packaging, and utilization of spermatozoa (1) that can be derived from previously frozen sperm samples collected from a male mammal. Specifically, techniques to uniformly stain (2) spermatozoal DNA even when derived from previously frozen sperm and separation techniques to separate and isolate spermatozoa even when derived from previously frozen sperm samples into X-chromosome bearing and Y-chromosome bearing populations having high purity.

Owner:XY

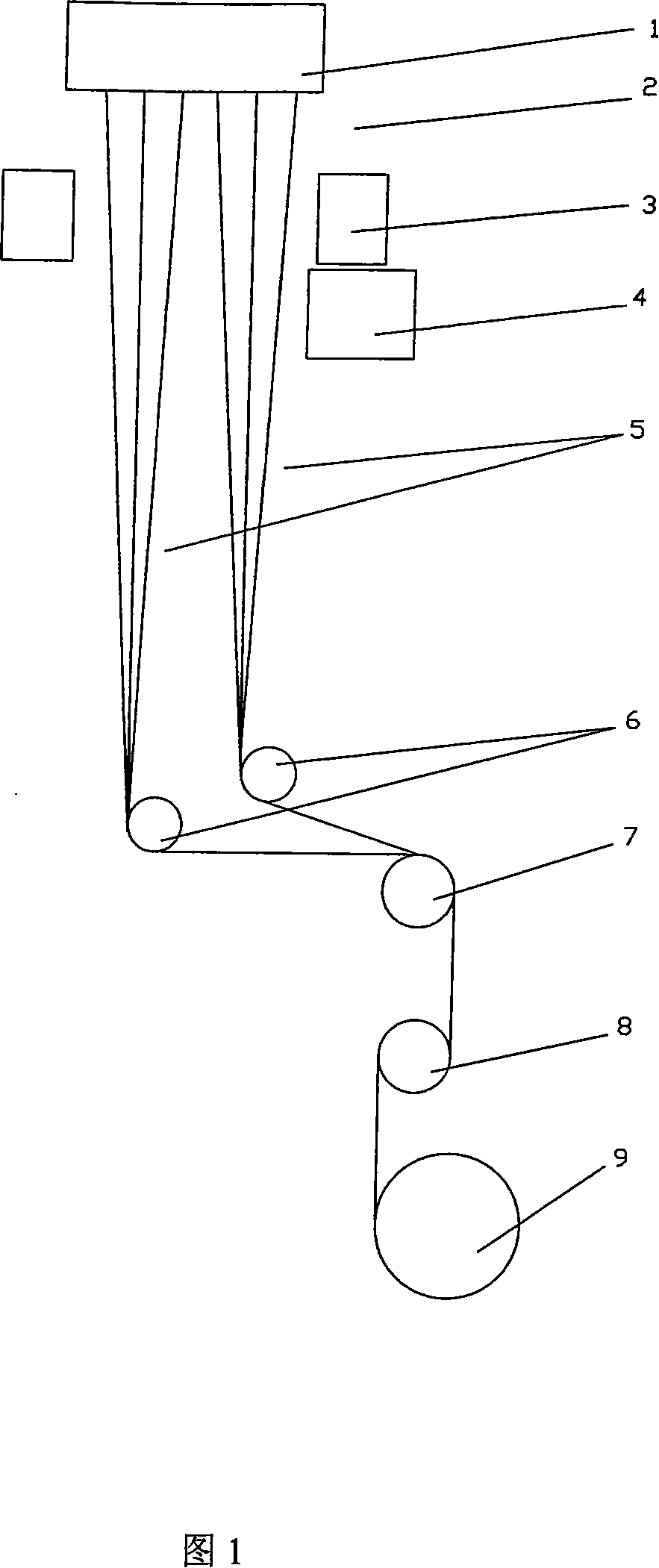

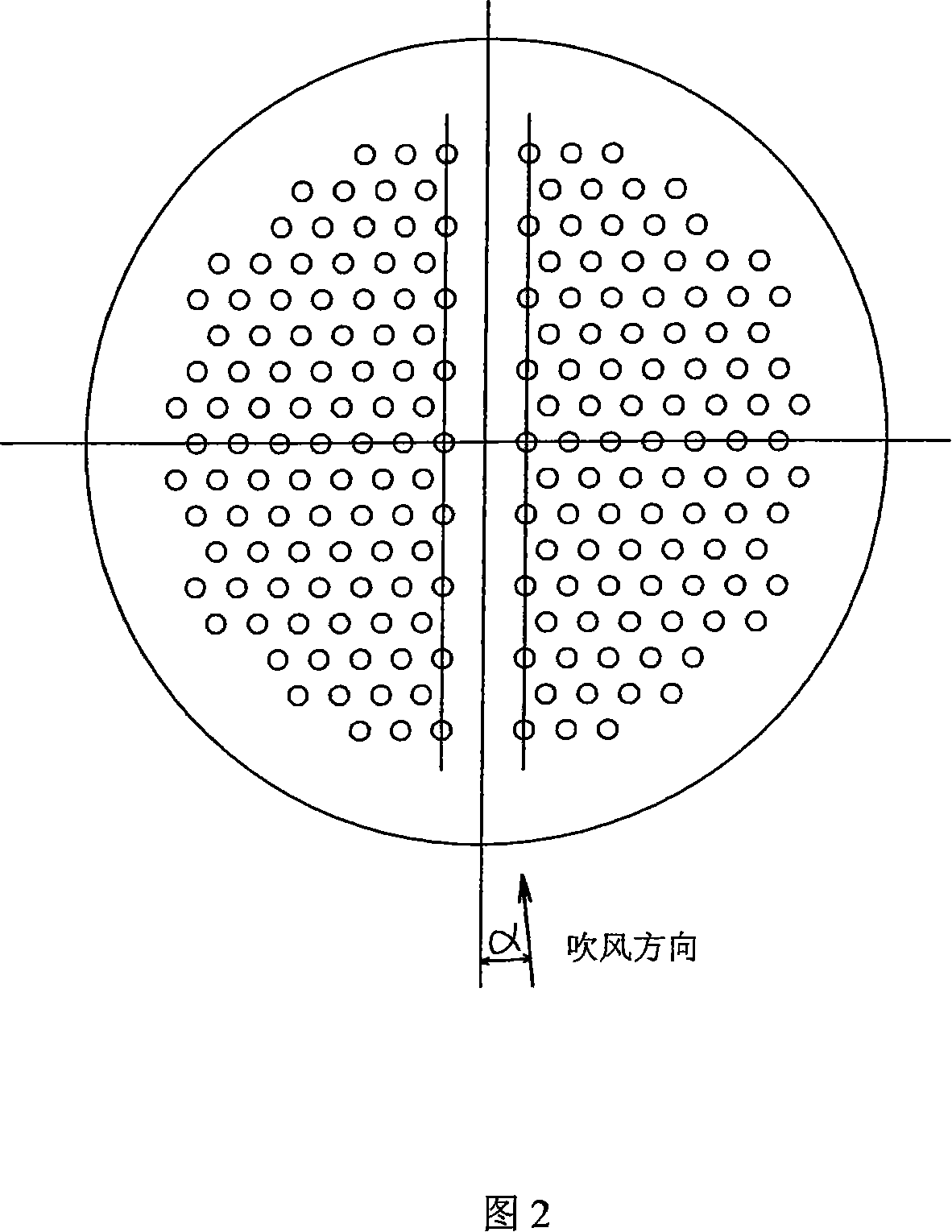

Method for preparing ultra-fine denier polyester filament yarn

InactiveCN101139735AReduce the effective areaLow costMelt spinning methodsMonocomponent polyesters artificial filamentUltra fineEngineering

The invention relates to a preparation method for super fine denier Terylene filament. The method adopts adopts cross air flow cooling process, to successfully produce a super fine denier terylene filament with monofilament size of 0.2 to 0.5 d.p.f. through adjusting calm zone height, adding a slow cooler and utilizing improved spin-spraying hole arrangement mode and oiling way during spinning process. The Terylene filament has sound spinnability and outstanding physical characteristics and processing performance.

Owner:JIANGSU HENGLI CHEM FIBER

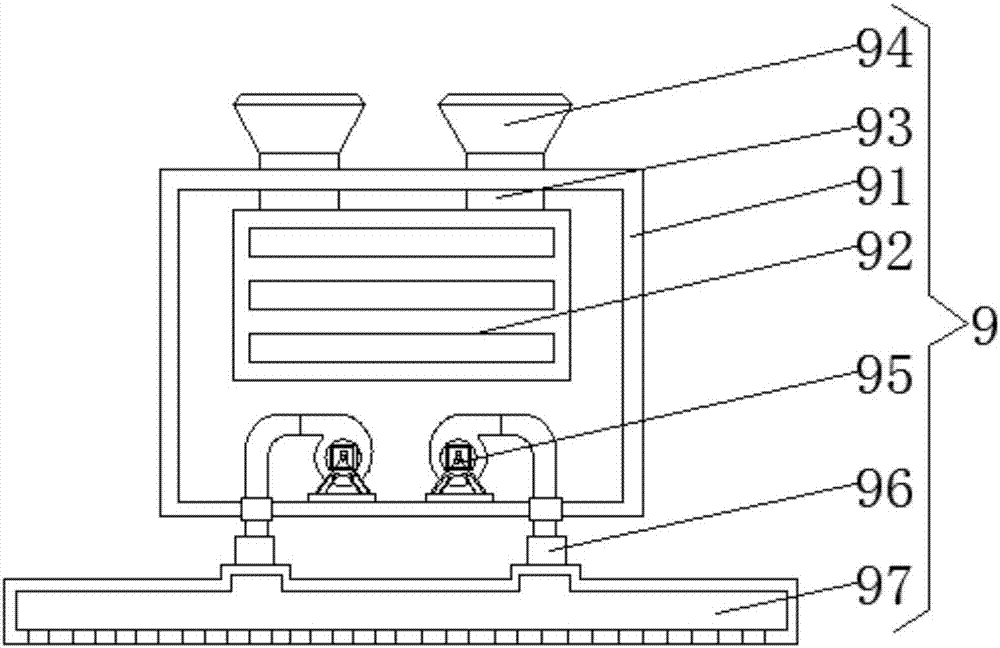

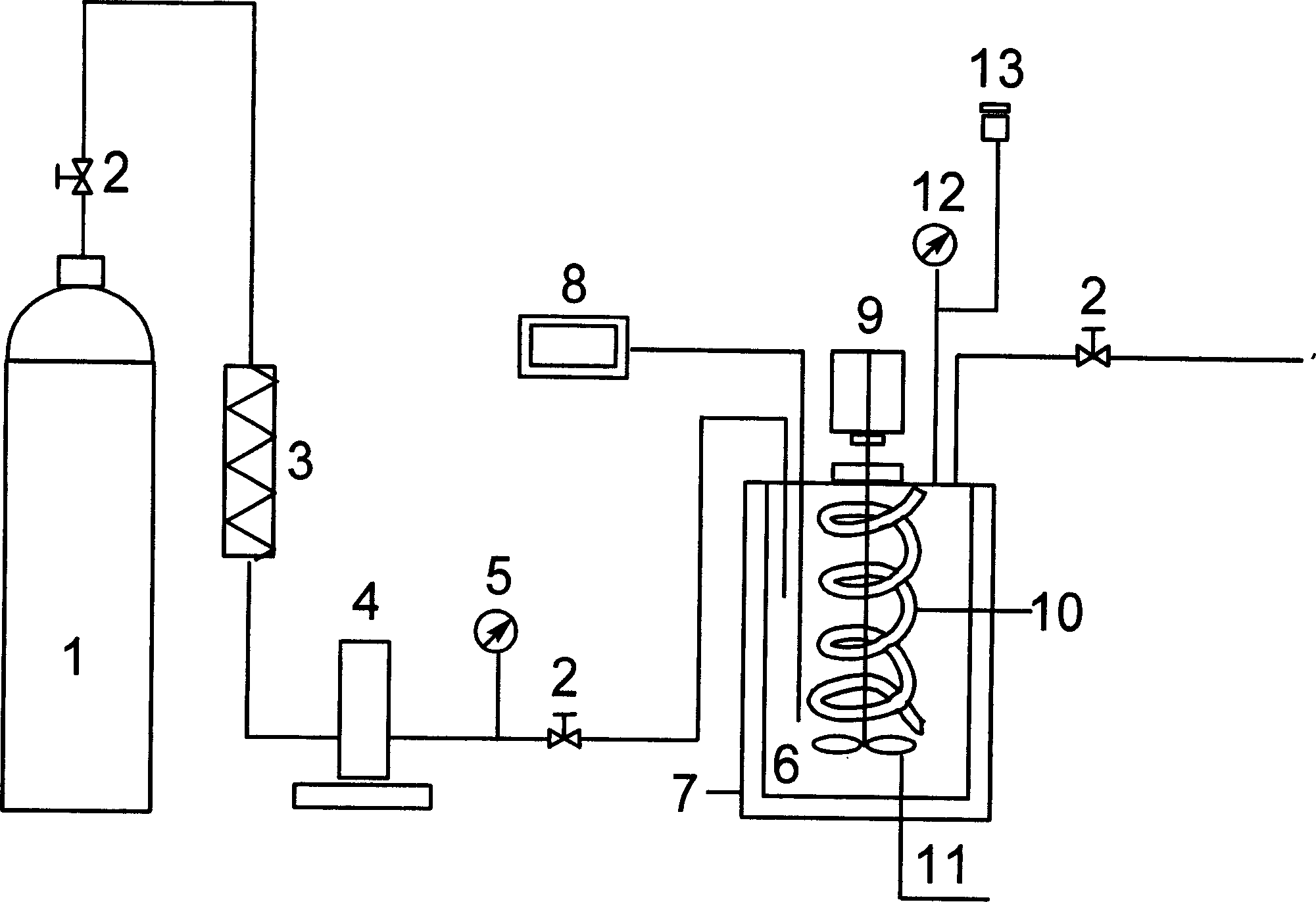

Supercritical carbon dioxide dyeing device and its process

InactiveCN1766194AReduce pollutionImprove dye uptakeSolvent treatment with solvent recoveryTextile/flexible product manufactureCo2 storageHigh pressure

The invention discloses a supercritical carbon dioxide dyeing device, which comprises mainly a CO2 storage tank (H01), a dye kettle (H06), and a dyeing kettle (H07). Wherein, the dyeing technique comprises: cooling the CO2 from HO1 into liquid to send into preheater (HO5) connected to HO6 with carbon-dioxide high-pressure pump (HO4); sending supercritical carbon dioxide to HO7 by HO6; driving the dyed carbon dioxide to pass separator (HO8) and second condenser (HO9) and return to said storage tank (HO1). This invention can recycle 100% residual dye and carbon dioxide as dyeing medium, saves water and dye resource, and reduces pollution.

Owner:DALIAN POLYTECHNIC UNIVERSITY

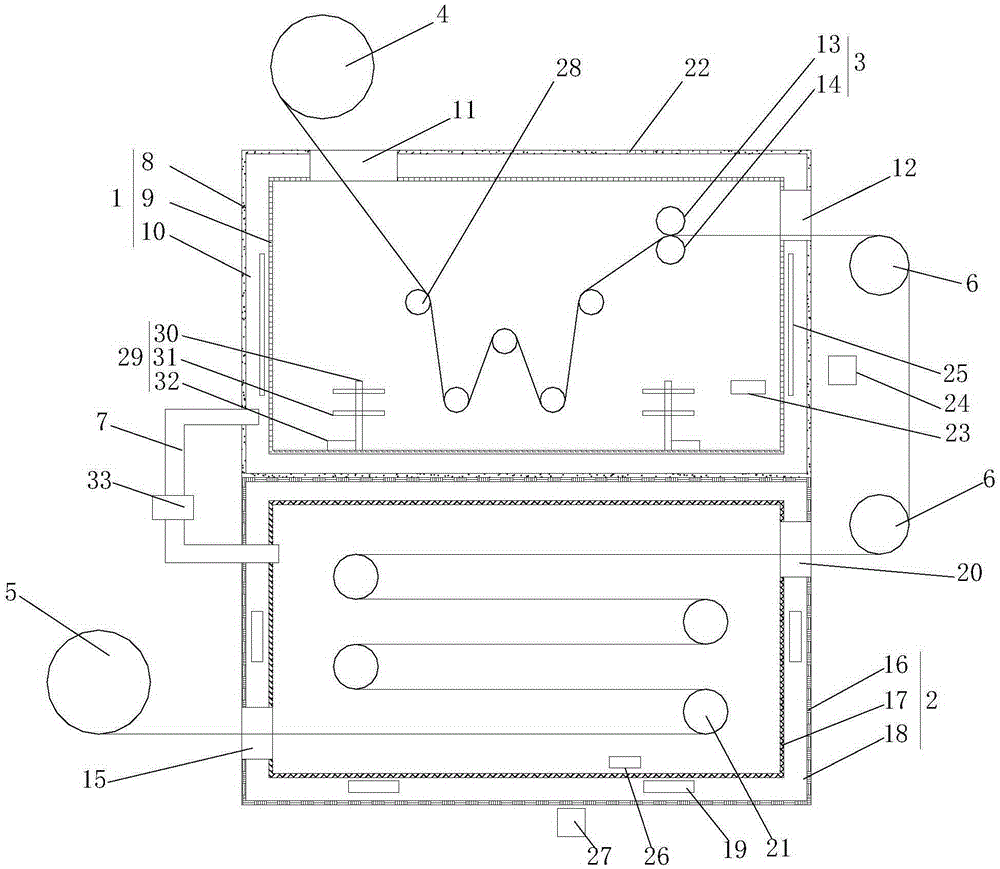

Cloth printing and dyeing device

ActiveCN105332189ADry evenlySimple structureLiquid/gas/vapor removalTextile treatment machine arrangementsEngineeringMechanical engineering

The invention provides a cloth printing and dyeing device. The cloth printing and dyeing device is used for dyeing cloth and comprises a first box, a second box, a cloth rolling roller set, a first cloth roller, a second cloth roller, transitional rollers and a communicating pipe. The first box is arranged above the second box, the body wall of the first box comprises a first outer shell, a first inner shell and a first heating cavity between the first outer shell and the first inner shell, and the cloth rolling roller set is arranged in the first box. The body wall of the second box comprises a second outer shell, a second inner shell and a second heating cavity between the second outer shell and the second inner shell, a plurality of heating pieces are arranged in the second heating cavity, and a plurality of cloth winding rollers are arranged in the second box and used for changing the direction of cloth. The first heating cavity is communicated with the interior of the second box through the communicating pipe. Exhaust holes are formed in the first outer shell and are away from the port, located in the first heating cavity, of the communicating pipe. The cloth printing and dyeing device is simple and practical in structure, uniform in dyeing and firm, and the purpose of saving energy is achieved by recycling heat.

Owner:湖州众创小微创业园企业管理股份有限公司

Polyester POY spinning finish and production method thereof

The invention discloses a polyester POY spinning finish, comprising 81-88% of lubricating agent, 3-5% of emulsifying agent, 4-7% of tow collecting agent, 3-5% of antistatic agent and 2-4% of additive by weight. The invention also discloses a production method of the polyester POY spinning finish. The product not only can endow the fibers with good processability but also is environment-friendly, overcomes the phenomenon that the finish corrodes equipment and can ideally solve the problem of easy cohesion on guide rolls during apparent cohesion and reduce fluff and broken yarns.

Owner:绍兴市上虞皇马化学有限公司

Protein cellulose viscose and preparing method thereof

ActiveCN101298708AGood protein contentImprove spinnabilityConjugated cellulose/protein artificial filamentsCellulose/protein filament chemical after-treatmentSpinningPROTEIN S HEERLEN

The invention relates to a protein viscose fiber and a preparation method thereof, belonging to the textile field and aiming at solving a technical problem about how to provide a method for adopting different animal and plant proteins as materials to prepare the protein viscose fiber. The preparation method of the protein viscose fiber includes the following steps: 1. the animal and plant proteins are degreased, decolored and deodorized to obtain animal-plant protein powder; 2. alkalization: the animal-plant protein powder is dissolved in alkaline liquor to obtain protein alkaline solution; 3. cross-linker is added into the protein alkaline solution to obtain a protein spinning liquor; 4. the protein spinning liquor is blended with a glue to be spun to obtainprotein filaments; 5. the protein filaments are washed by peroxide solution and are oiled, dried and formed into cylinder form to get the protein viscose fiber. The protein viscose fiber preparation method of the invention does not adopt any acetalation treatments to the protein filaments after spinning so as to avoid the remaining of methanal, etc. harmful matters, the technique steps are simple and can be easily operated and the manufacturing can be realized with the existing viscose fiber preparation equipment.

Owner:YIBIN GRACE GROUP CO LTD

Method for dyeing cotton fibers by using natural dye

The invention relates to a method for dyeing cotton fibers by using a natural dye, comprising the following steps of: 1) boiling the cotton fibers and drying the cotton fibers for later use; 2) modifying the cotton fibers; 3) dyeing the cotton fibers; and 4) fixing the color of the cotton fibers, wherein the dosage of a color fixing agent is 1-5% of the mass of the cotton fibers, the temperature of color fixation is 50-85 DEG C, the color fixing agent is added to the cotton fibers obtained in step 3), the time of color fixation is 20-50 min, drying is performed after water washing, and the color fixing agent can be one or two of sodium chloride, sodium sulfite, citric acid and aluminum potassium sulfate dodecahydrate. The food-grade fixing agent is selected in the method; therefore, the troubles caused by synthetic dyes and heavy metals for the health of human are solved, and the fastness of the cotton fibers can be enhanced; as a result, the dyed cotton fibers are natural and soft in color and have no harm to the human body and the environment.

Owner:CHANGZHOU MYSUN BIOLOGICAL MATERIALS

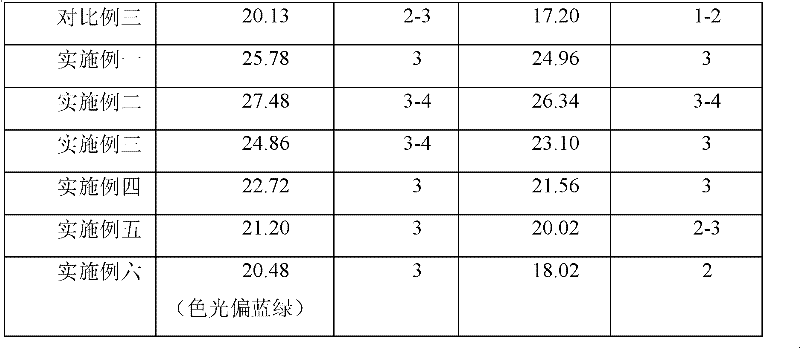

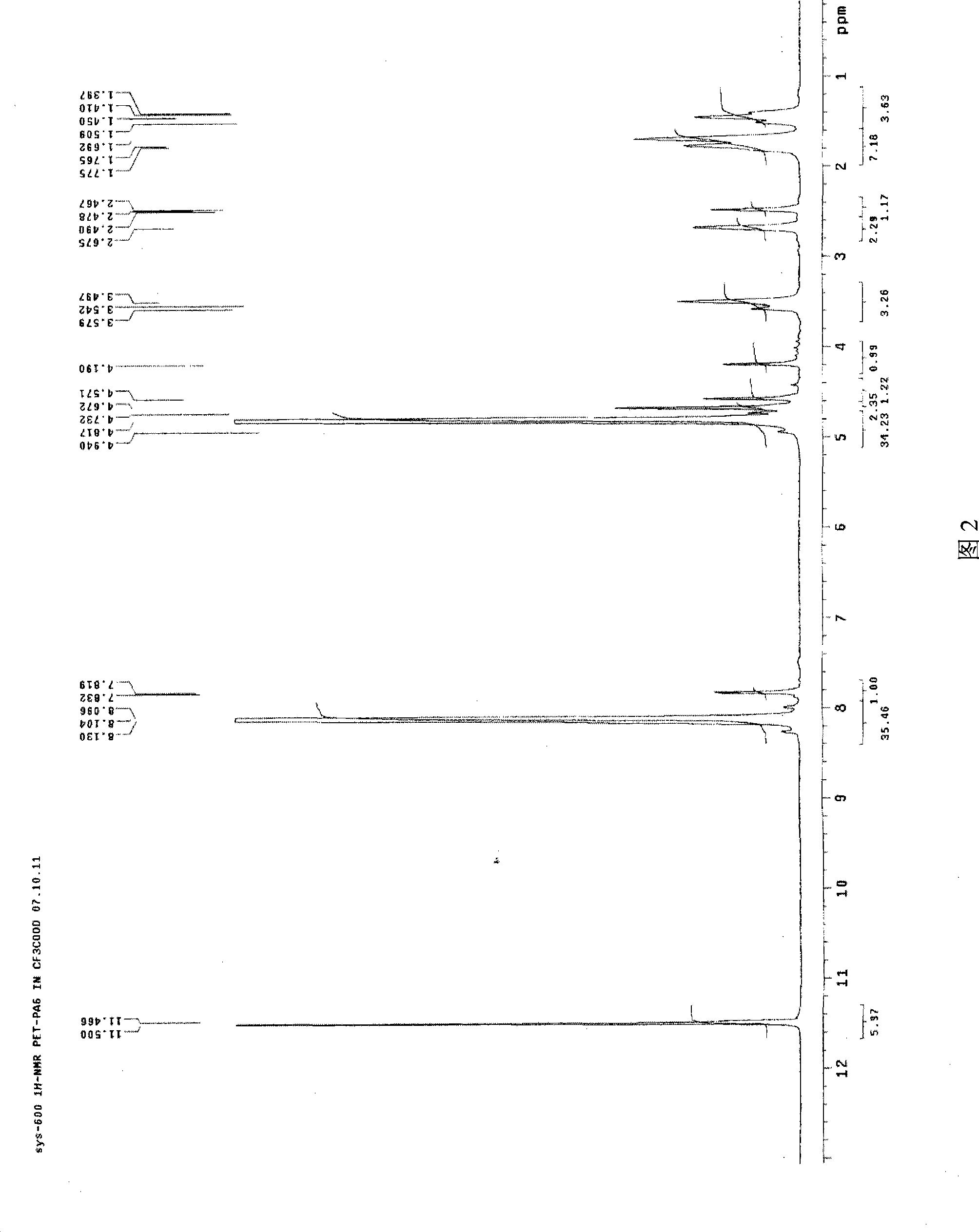

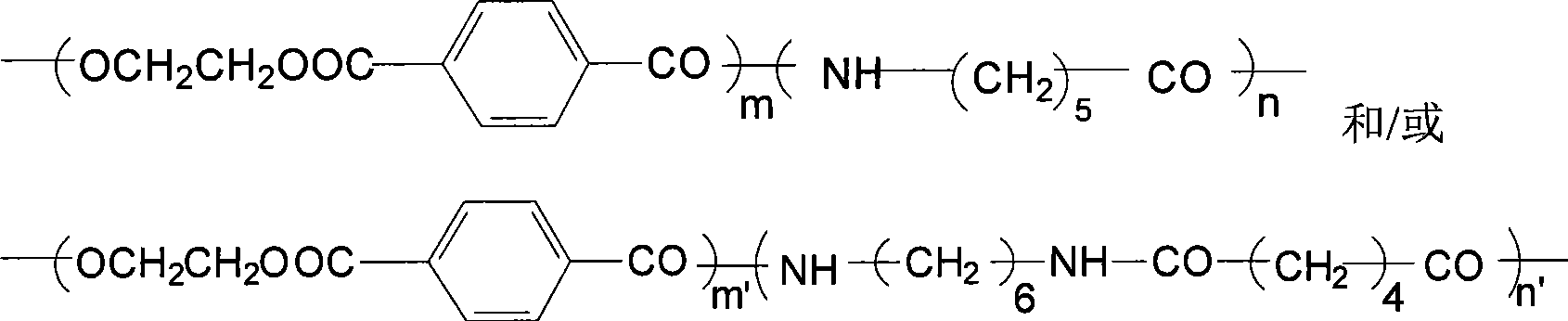

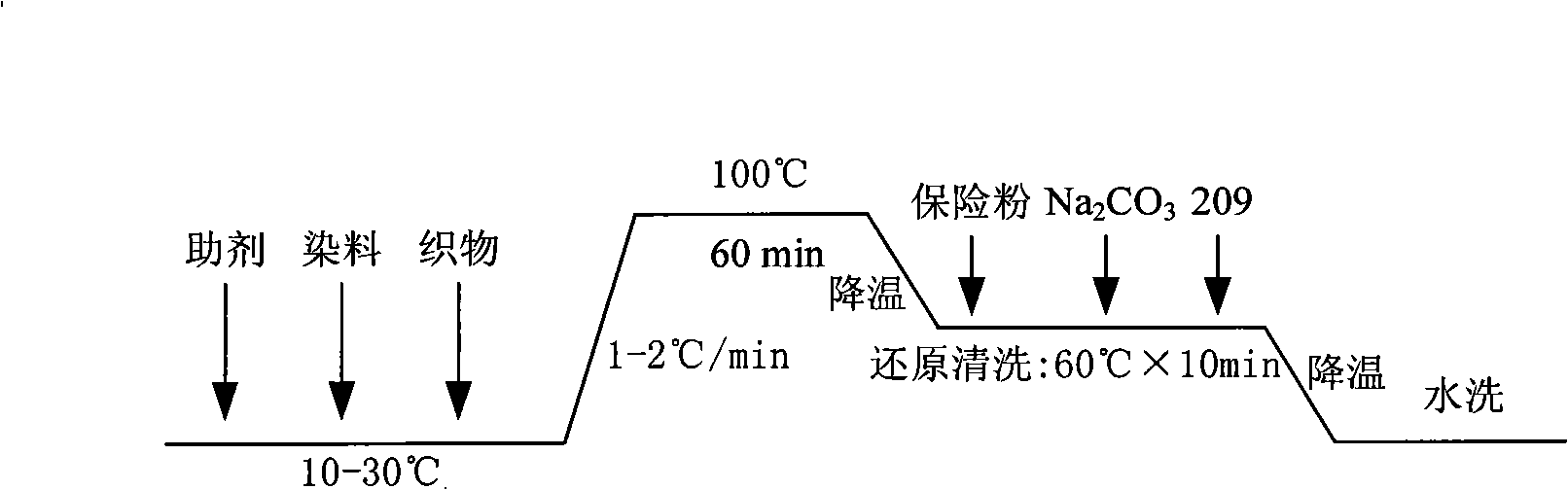

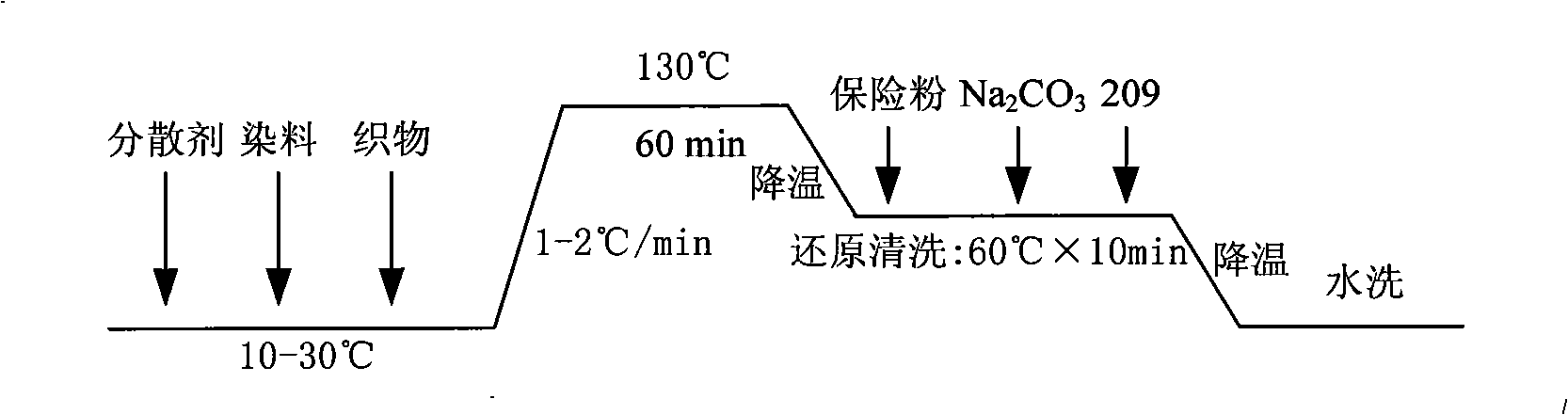

Acidic dyeable polyester and method for preparing acidic dyeable polyester and fiber thereof

ActiveCN101450990AUniform dyeingAffinityMonocomponent copolyesters artificial filamentDyeing processFiberFormate

The invention relates to acidic dyeable polyester and a method for preparing acidic dyeable polyester chip and fiber. The method comprises the steps of performing transesterification or esterification to p-phenyl dimethyl formate or p-phenyl dicarboxylic acid and glycol, adding polyamide such as nylon 6 and / or nylon 66 during polyester polymerization so as to prepare polyester chip, drying the polyester chip and using a conventional spinning machine to spin so as to prepare the polyester fiber used for the dyeing of acid dye. The polyester fiber thoroughly solves the problem that polyester and polyamide are not compatible, ensures uniform dyeing of acid dye, and enables spinning workstage to proceed smoothly. In addition, as the preparation of the polymer adopts a process similar to polyester polymerization for polymerization on a common polyester polymerization device, the method is simple to operate, easy to perform industrial production and low in cost.

Owner:CHINESE TEXTILE ACAD

Biological protein hair fiber preparation method by dissolving animal hair and cellulose material mixture

InactiveCN1884642AReduce lossesReduce direct lossesConjugated cellulose/protein artificial filamentsCelluloseAdjuvant

The invention discloses a biological protein wool fiber preparing method, which comprises the following steps: blending animal fur and fiber to produce soluble liquid in the ion liquid with positive and negative ion of fusing condition at 100 deg.c and positive ion to form salt; solidifying in the water, carbinol, alcohol, cyanoethyl or (NH4)2SO4 solution; adding adjuvant in the soluble liquid; solidifying in the water, carbinol, alcohol, cyanoethyl or 30 percent (NH4)2SO4 solution; evolving biological protein fur fiber.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

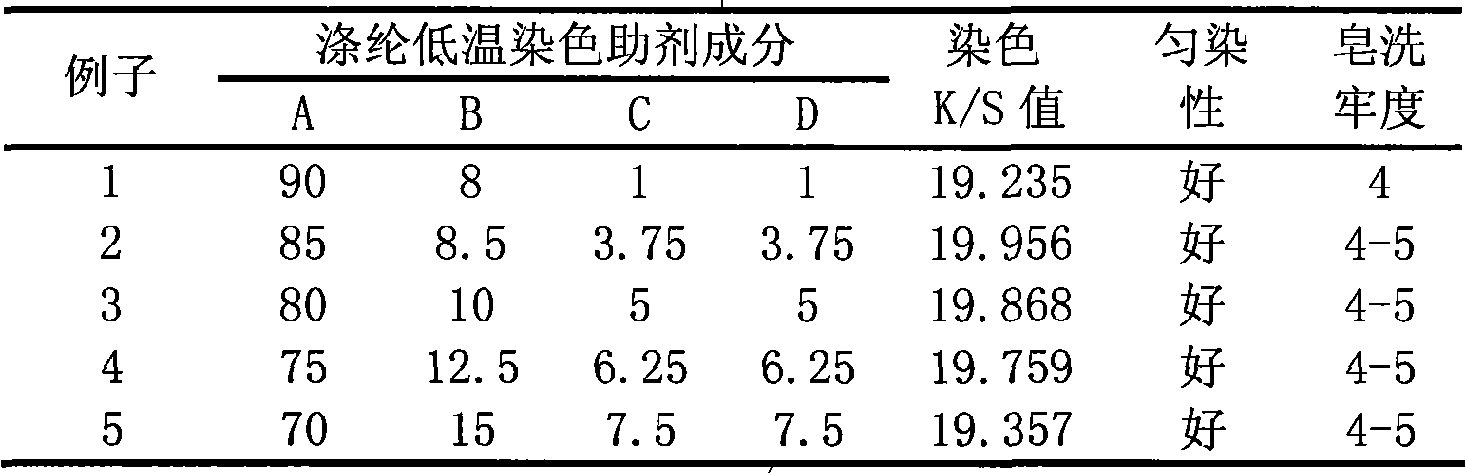

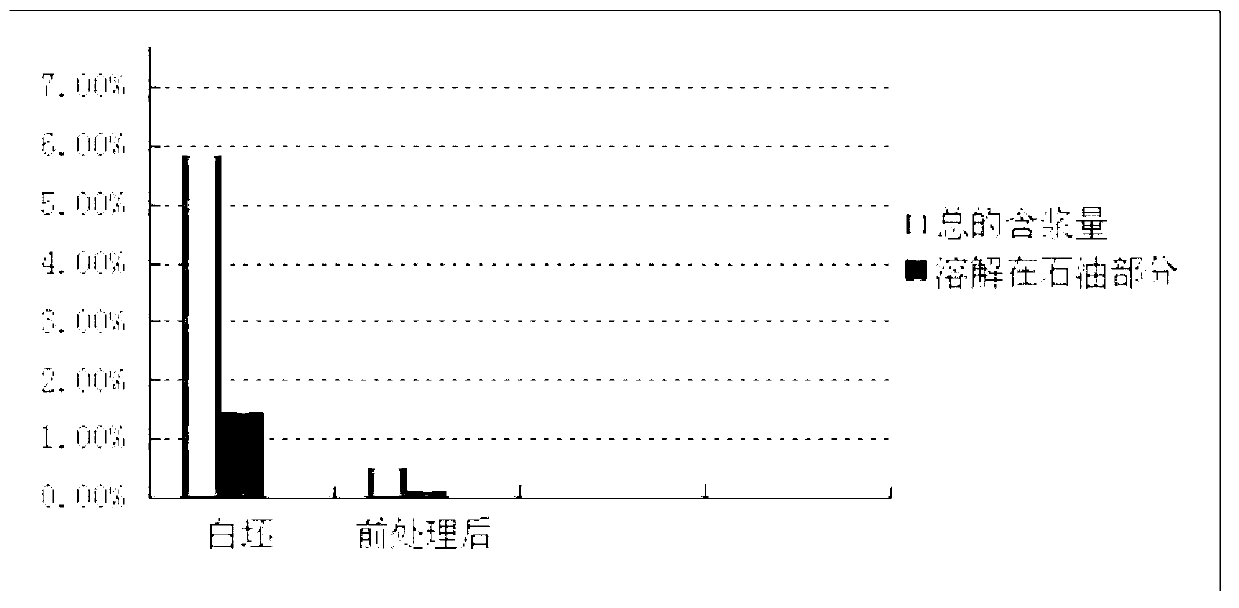

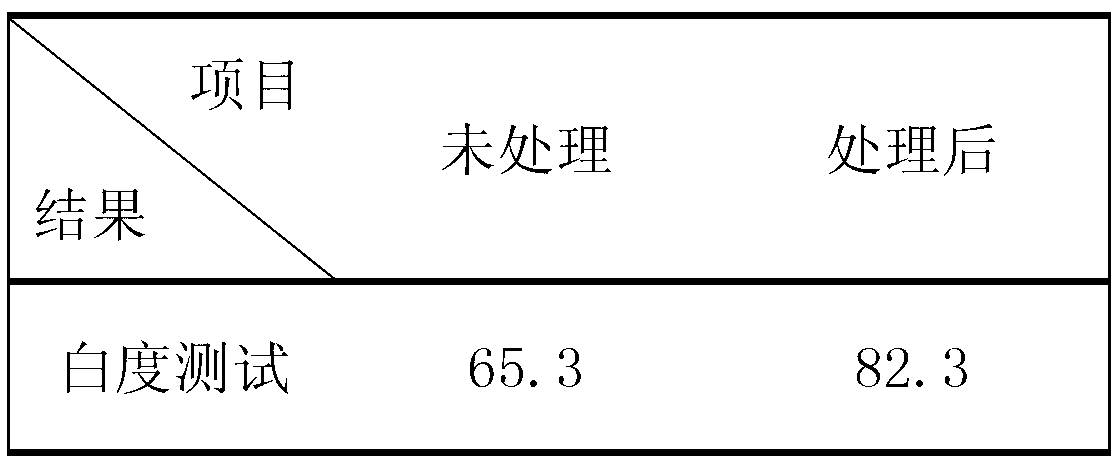

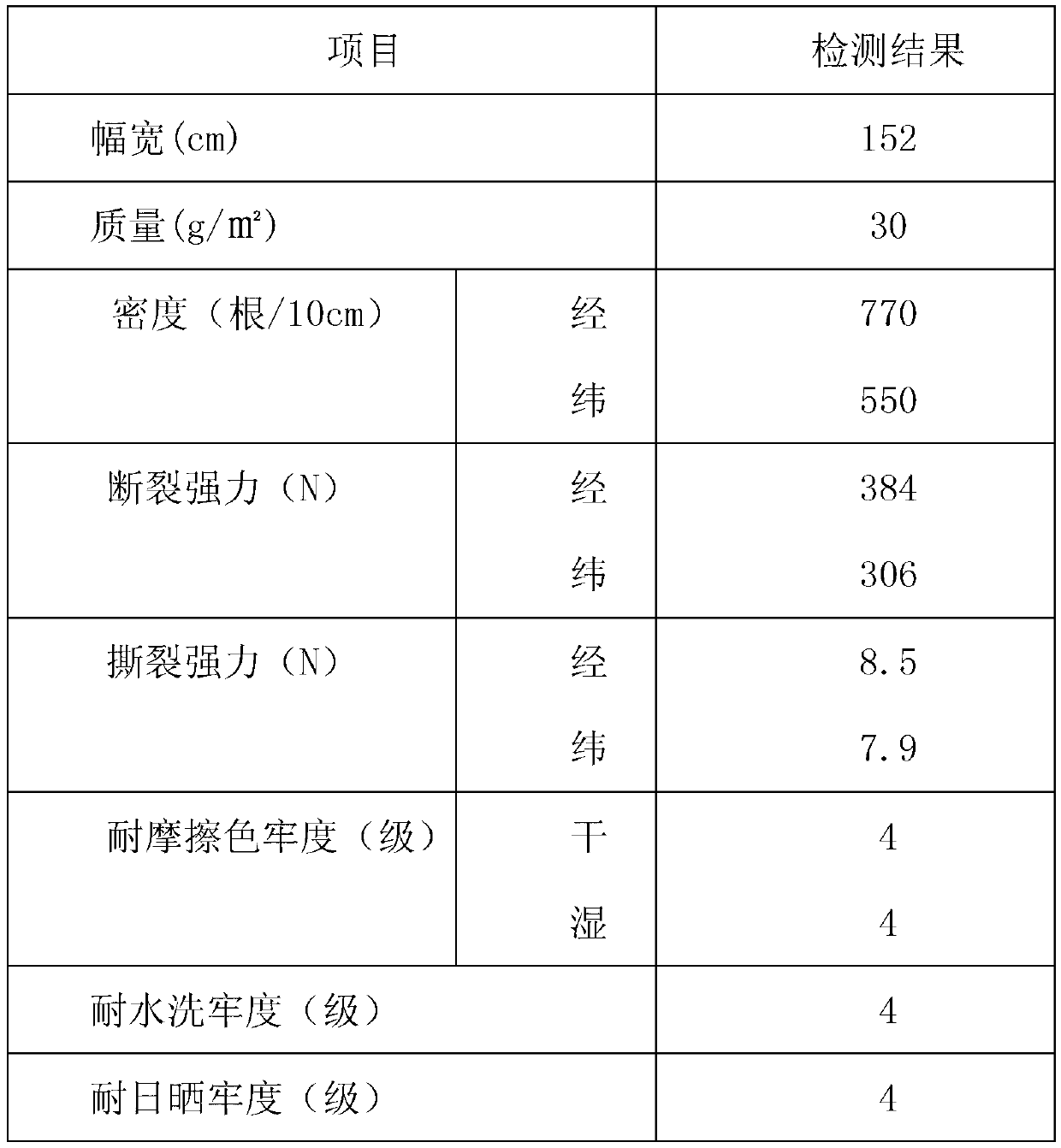

Environment-friendly type terylene low temperature dyeing assistant with alkyl phthalic imide as vector and preparation thereof

The invention discloses an environment-friendly terylen low-temperature dyeing auxiliary agent taking alkyl phthalimide as a carrier and a preparation method thereof. The compositions in percentage by weight of the dyeing auxiliary agent are: 70 to 90 percent of alkyl phthalimide compound, 8 to 15 percent of concentrated emulsion 8206, 1 to 7.5 percent of castor oil polyoxyethylene ether sulphonated matter and 1 to 7.5 percent of alkyl phenol polyoxyethylene ether, wherein the alkyl phthalimide is takes as the carrier; and the concentrated emulsion 8206, the castor oil polyoxyethylene ether sulphonated matter and the alkyl phenol polyoxyethylene ether are takes as an emulsifying agent. The environment-friendly terylen low-temperature dyeing auxiliary agent is used in low-temperature dyeing of terylen and terylen-containing textile fabrics; moreover, the dyeing auxiliary agent not only has the characteristics of nontoxicity, tastelessness, environmental protection and low cost, etc., but also has the advantages of high dye uptake, excellent level dyeing property, high dyeing fastness and wide application range, etc., thereby meeting the requirements of low-temperature dyeing production of terylen-containing textile fabrics.

Owner:ZHEJIANG SCI-TECH UNIV +1

Dyeing and finishing method of superfine denier nylon fabric

ActiveCN103132349AHave affinityReduce initial dyeing speedFibre typesDry-cleaning apparatus for textilesCooking & bakingColour fastness

The invention discloses a dyeing and finishing method of superfine denier nylon fabric, belongs to the field of processing on the superfine denier nylon fabric, and aims at solving the problems that dyeing defect and uneven dyeing of the superfine denier nylon fabric are easily generated in the dyeing process. The method disclosed by the invention comprises the steps of: cold heaping, open-width desizing, pre-setting, dyeing, performing fixation, baking and molding a finished product. An anionic leveling agent disclosed by the invention has affinity on nylon, and can generate an unexpectedly dyeing effect on the fiber together with anionic dye. Thus, the initial dyeing speed of the dye is reduced, so as to achieve a uniform dyeing effect; and the fold resistance of the fabric is improved when the craping style of the fabric is kept by presetting the desized fabric. By using the dyeing and finishing method, the dyeing process is even, the color and the luster are good, the colour fastness is good, and the like; and the dyeing defect can not be generated, and the fabric processed by using the method accords with the requirements of superior products specified by the standard of GB / T17253-2008 'synthetic filament yarn fabric'.

Owner:SHENGHONG GRP CO LTD

Low-temperature dyeing and finishing technology of cottonette

InactiveCN105002730AProcess temperature changeLow processing temperatureBiochemical fibre treatmentHeating/cooling textile fabricsInorganic saltsDiastase

The invention discloses a low-temperature dyeing and finishing technology of cottonette. The technology comprises the following steps: pretreatment; preshaping; modification treatment; dyeing; mordant removing; soaping; color fixing; post-treatment; drying; shaping; calendaring; rolling. According to the technology, pretreatment is carried out through the adoption of helicase and alpha-amylase, and modification treatment is carried out before dyeing, so that the property of the cottonette is fundamentally modified, and the dye-uptake of the fabric is increased; during the dyeing procedure, large quantities of alkaline substances and inorganic salt are not used, and a levelling agent, a low-temperature dyeing accelerant, a migration inhibitor and a dispersing agent are added, so that the dye uniformity is improved; during the whole dyeing process, the temperature is lower than 80 DEG C, and the dyeing process belongs to low-temperature dyeing, so that energy consumption is reduced; self-cleaning treatment is added in post-treatment, so that the self-cleaning capacity, wrinkle resistance and water washable firmness of the fabric are improved; post-treatment is carried out through the adoption of silk fibroin and sericin, so that the pilling resistance and antistatic property of the cottonette are improved; the whole technology is environment-friendly and free of pollution.

Owner:TAICANG TIANLONG CHEM FIBER

Dual-purpose modification process for native breed sheepskin leather

InactiveCN102839236AHas softnessIncrease shrinkage temperatureTanning treatmentPre-tanning chemical treatmentExtensibilityWork in process

The invention discloses a dual-purpose modification process for native breed sheepskin leather. The process sequentially comprises the following steps of processing native breed sheepskin semi-finished products: (1) classifying skin; (2) returning water; (3) soaking; (4) softening; (5) pickling; (6) performing chromium aluminum tanning; (7) performing tanning post-processing; (8) performing chrome retanning; (9) performing chrome retanning before dyeing; and (10) dyeing. According to the dual purpose modification process, commercially available native breed semi-finished skin (namely white skin) is processed, and the native breed semi-finished skin is tanned by increasing aldehyde aluminum tanning particularly, so that the extensibility of the native breed sheepskin can be effectively improved, the problem of dyeing defects is solved, and the uniformity in the post dyeing is ensured. The dual purpose modification process is matched with other steps and appropriate additives, and each additive is added according to reasonable additive amount, so that the final products have good handfeeling, high tearing resistance and high fullness, and the quality of the native breed sheepskin leather is greatly improved.

Owner:桐乡市雄鹰皮草股份有限公司

Low-temperature dyeing process of fiber fabric

ActiveCN103966867AGuaranteed functionAvoid damageFibre treatmentDyeing processFiberProcess engineering

The invention provides a low-temperature dyeing process of a fiber fabric. The low-temperature dyeing process comprises the processes of pretreatment, pre-sizing, dyeing, reduction clearing, fixing, softening treatment, drying, sizing, calendaring and rolling. In the dyeing process, the highest temperature does not exceed 100 DEG C, mild dyeing is carried out by using a gradual warming method and pH value regulation is carried out through a buffer solution, so that a proper acid environment required during the dyeing is satisfied and the dyeing effect is excellent; during the dyeing, a leveling agent is added to ensure that the dyeing is uniform; anhydrous sodium sulphate is added to postpone the dyeing process of the pigment and the temperature rises slowly at the same time, so that the uniform dyeing is ensured; a smoothing agent is added to prevent the scratching and local fibrillation; a penetrant and a diffusant are added to ensure that the penetration and the diffusion of the dyeing are relatively good; by means of the strict control in the aspects of temperature, acid, auxiliaries, time and the like, the low-temperature dyeing process of the fiber fabric has the advantages that the dyeing firmness is high, the dyeing is uniform, the dyeing stability is good and the effect is excellent at low temperature.

Owner:绍兴洁彩坊印染有限公司

Dyeing technology of nylon-imitating high-elastic polyester yarn

InactiveCN103498350AImprove featuresEnsure stabilityFibre typesHeating/cooling textile fabricsTextile printerPolyester

The invention relates to the technical field of textile printing and dyeing, and provides a dyeing technology of a nylon-imitating high-elastic polyester yarn. According to the dyeing technology, by combining of low-elastic polyester and twisting into high-elastic polyester, the nylon yarn dyeing problem can be solved and an elastic hand feeling effect of the nylon yarn can be achieved, and the dyeing technology comprises a polyester yarn dyeing preprocessing process, a yarn reeling process, high temperature preforming, a dyeing process, a reduction cleaning process, a finishing process and a dehydration drying process.

Owner:福建锦丰印染有限公司

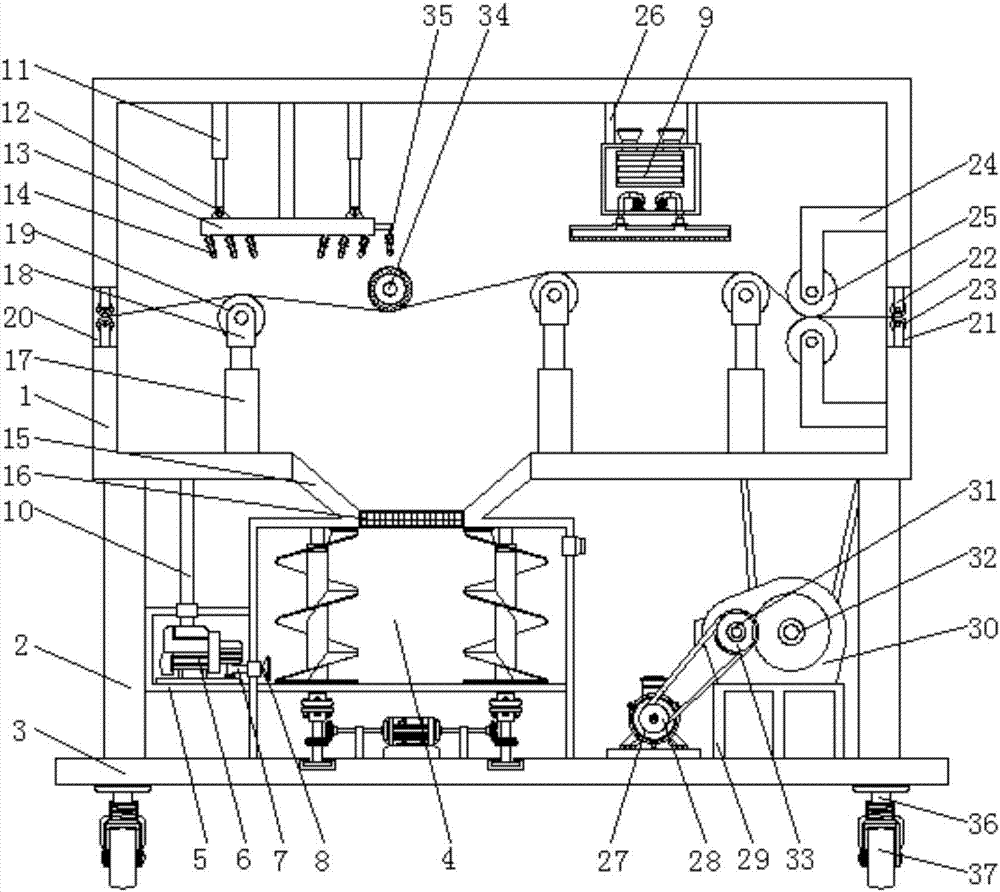

Spraying, dyeing and drying device for textile fabric

InactiveCN107574602AStir fully and evenlyStir wellTextile treatment machine arrangementsLiquid/gas/vapor removal by gas jetsEngineeringUltimate tensile strength

The invention discloses a spraying, dyeing and drying device for textile fabric. The device comprises a tank body, supporting vertical plates which are mutually symmetric are fixedly connected to twosides of the bottom of the tank body, and a bottom supporting plate is fixedly connected to the bottoms of the two supporting vertical plates; a dye stirring device is fixedly connected to the left side of the top of the bottom supporting plate, a liquid pumping pump placement tank is fixedly connected between the surface of the left side of the dye stirring device and the surfaces of the right sides of the supporting vertical plates, and a liquid pumping pump is fixedly connected to the bottom of the inner wall of the liquid pumping pump placement tank; a liquid pumping pipe is communicated with the right side of the liquid pumping pump. The invention relates to the technical field of textile machinery equipment. According to the spraying, dyeing and drying device for the textile fabric,the problems of high dyeing cost, environmental pollution, low use ratio and low cloth dyeing effect of an existing drying device for the textile fabric are solved, the use efficiency of dye is effectively improved, the device is safe and environmentally friendly, the pollution to the environment is lowered, manual operation is not needed, the labor intensity is lowered, and the economic efficiency is improved.

Owner:HUZHOU BOREN TEXTILES

Technology for dyeing ramie fiber with overcritical carbon dioxide method

The invention relates to a new process of supercritical CO2 dyeing of ramie fiber, using ramie fiber as raw material, swelling by NaOH solution and modifying by benzoyl chloride, and dyeing with dispersive dye in supercritical CO2 medium by supercritical fluid technique. And its advantages: it is a clean producing process; the dyed ramie fiber has characters of bright color, short dyeing flow, dyeing uniformity, good color intensity, low synthetic cost, and remarkable economic and environmental protection benefits. And it also reveals a process device implementing the dyeing method, suitable to spread and apply in spinning and weaving, and printing and dyeing enterprises.

Owner:SHAANXI NORMAL UNIV

Hematoxylin eosin staining solution and preparation method thereof

ActiveCN103725040ALong validity periodEfficient removalPreparing sample for investigationOrganic dyesHematoxylin stainAlcohol

The invention provides a hematoxylin eosin staining solution, comprising a hematoxylin staining solution and an eosin staining solution, wherein the hematoxylin staining solution comprises hematoxylin, an alumium salt, an oxidizing agent, benzalkonium chloride, an alcohol, a weak acid and water; the eosin staining solution comprises eosin, Biebrich scarlet, flame red B, water and ethanol. The invention also provides a preparation method of the hematoxylin eosin staining solution, and a dyeing method thereof. When the hematoxylin eosin staining solution provided by the invention is used for dyeing slices, the effects of clear background, distinct gradation, good dyeing effect, easy slice reading, not easy fading and convenience for long-term storage can be achieved.

Owner:无锡市江原实业技贸有限公司

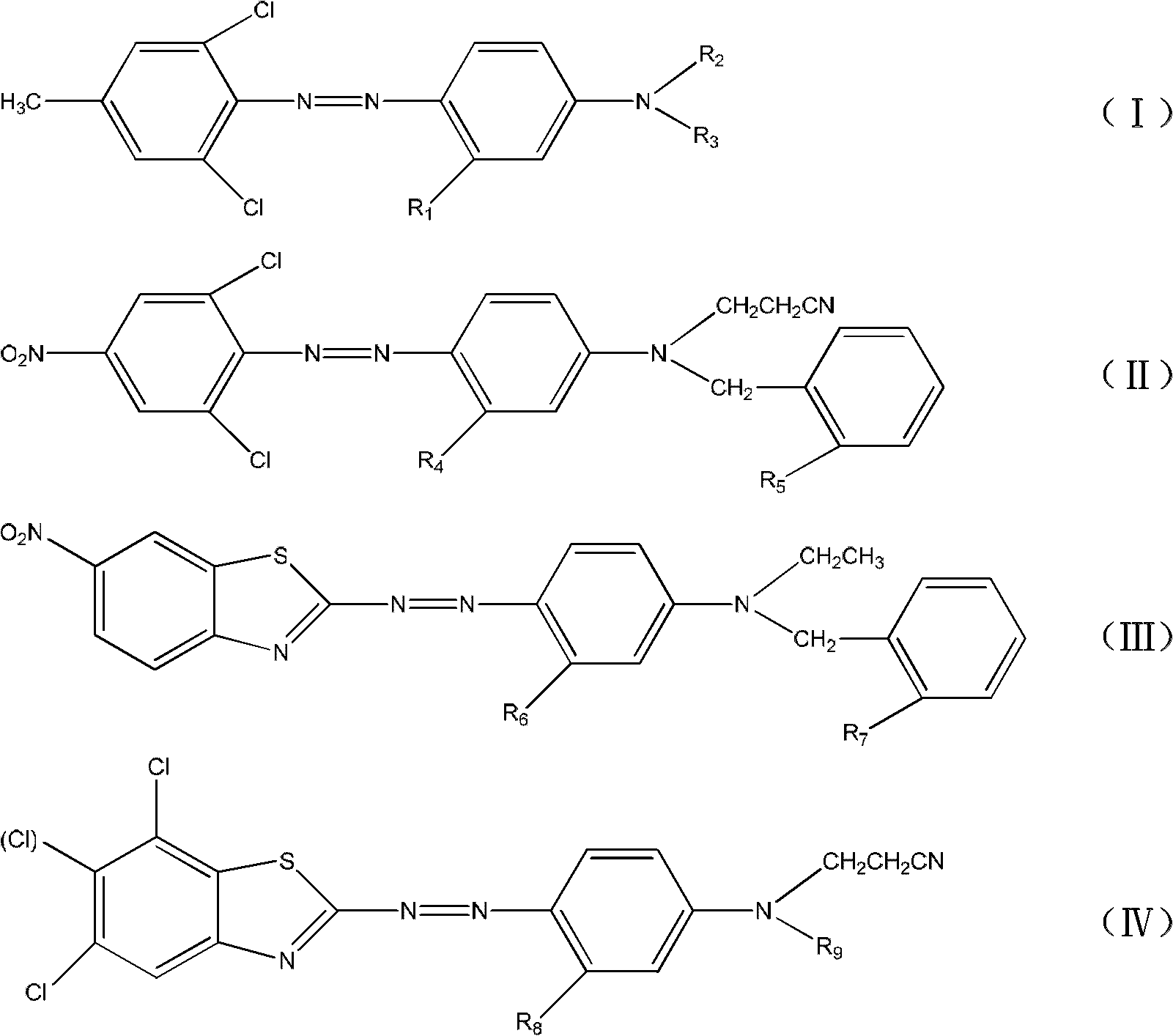

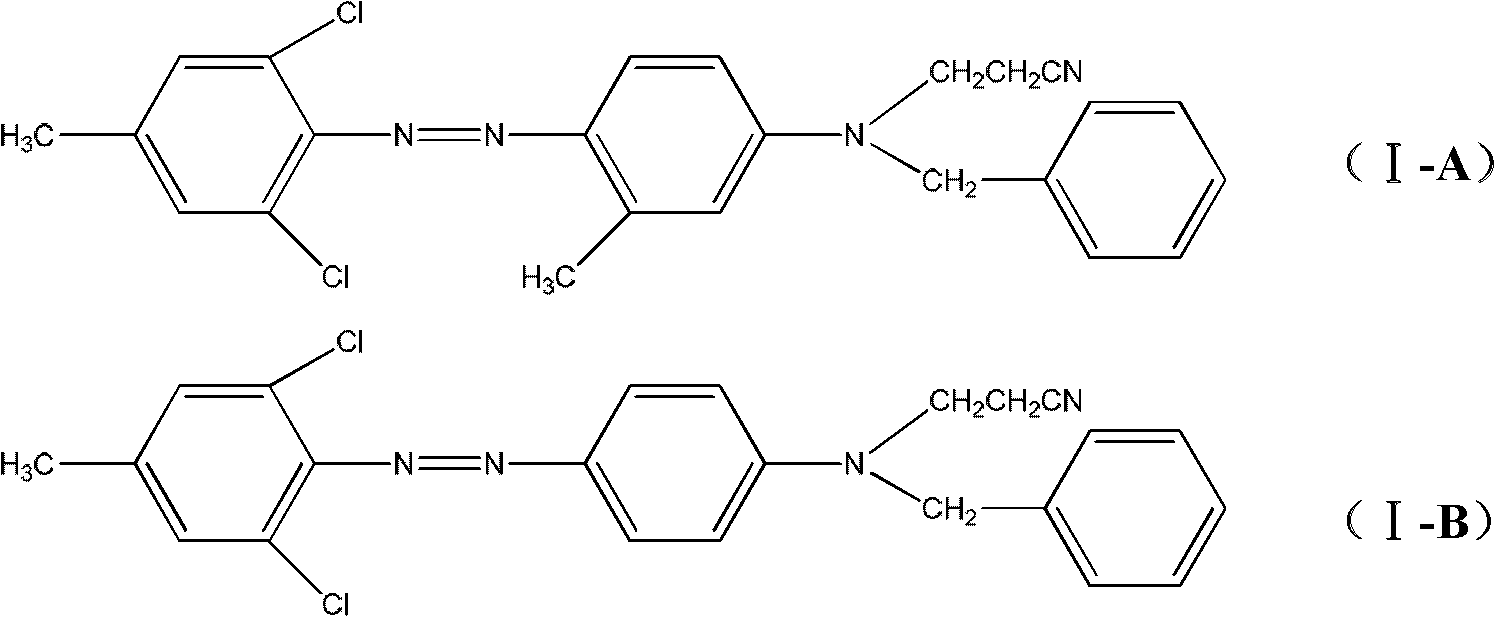

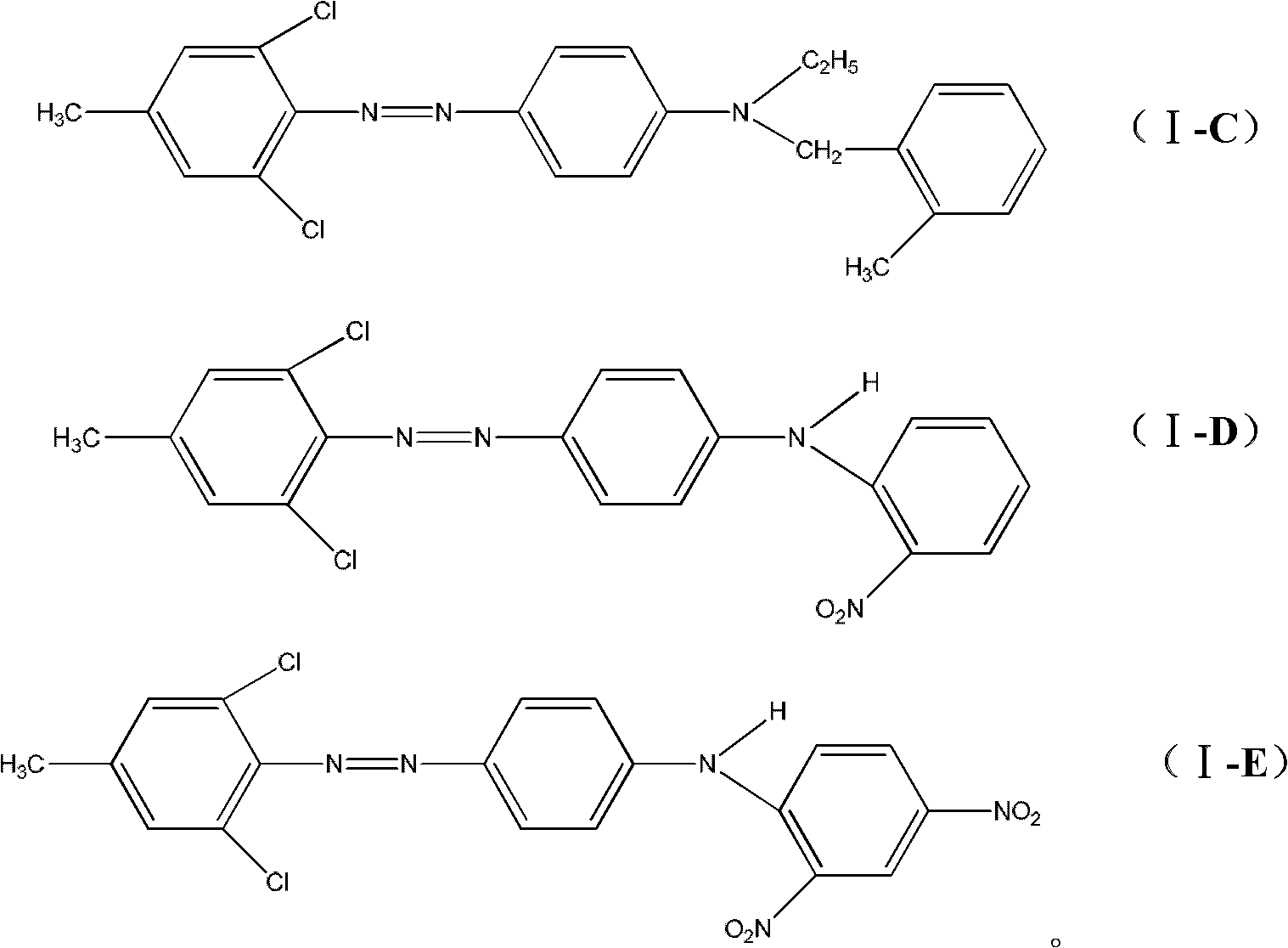

Oxidation-resistant disperse dye composition and preparation and application thereof

ActiveCN102660146AImprove oxidation resistanceWide concentration rangeFibre treatmentOrganic dyesDisperse dyeYELLOW DYE

The invention relates to an oxidation-resistant disperse dye composition and preparation and an application thereof. The oxidation-resistant disperse dye composition comprises the combination of any 2-4 of a yellow dye shown as a general formula (I), an orange dye shown as a general formula (II), a blue dye shown as a general formula (III) and a red dye shown as a general formula (IV), not more than two types of dyes are shown as each general formula; and the oxidation-resistant disperse dye composition is applied to pre-treatment dyeing of dacron or polyester-cotton blended fabrics. The disperse dye composition can be used for dyeing polyesters and blended fabrics thereof under the strong oxidative condition that the mass concentration of H2O2 is 0.1-0.5 percent, and an obtained fabric has the advantages of stable chromatic light, bright color, neat cloth cover and excellent fabric style; and according to the disperse dye composition, pretreatment and one-bath and one-step dyeing of polyester fiber or blended fabrics thereof are realized, efficiency is increased, production cost is reduced, and dyeing waste water is reduced.

Owner:ZHEJIANG WANFENG CHEM +1

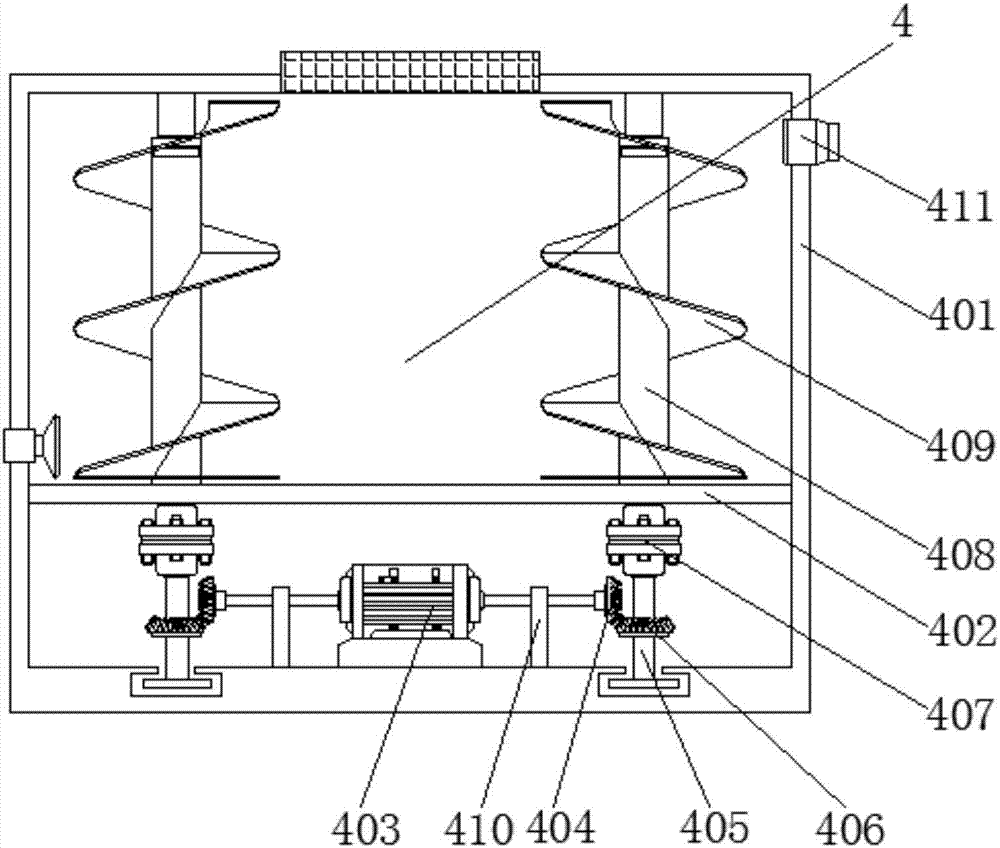

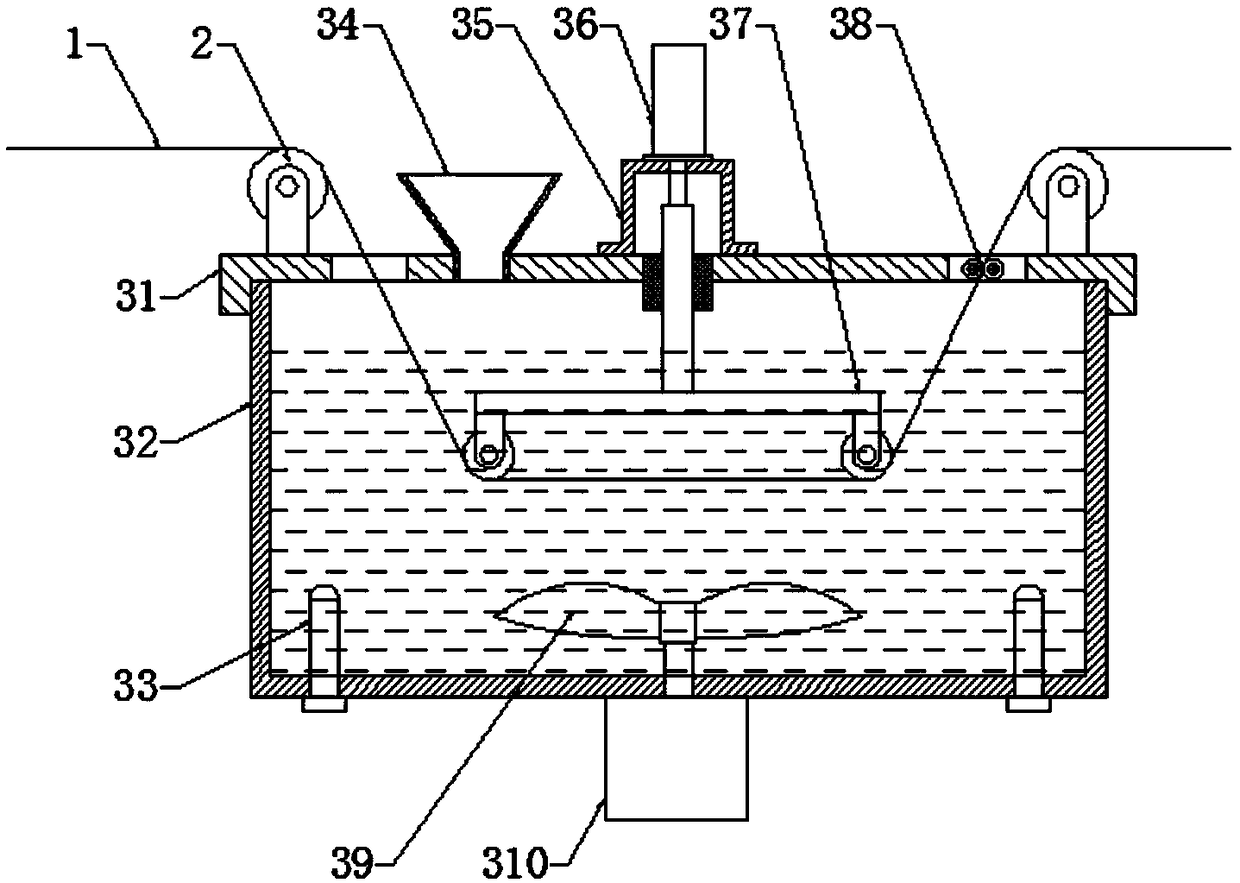

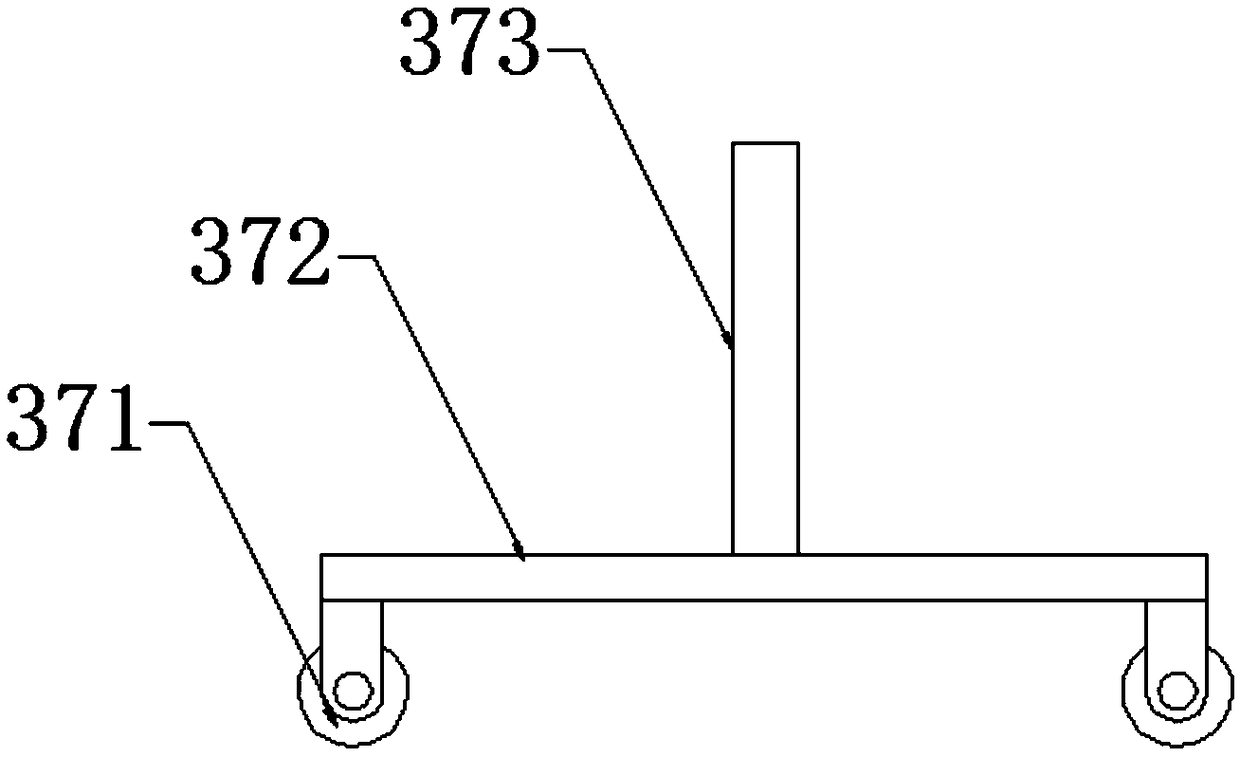

Polyester yarn dyeing device and method

InactiveCN109281097ARealize flow dyeingRealize streamlined dyeing processLiquid/gas/vapor open-width material treatmentSucessive textile treatmentsPolyesterYarn

The invention discloses a polyester yarn dyeing device and method. The polyester yarn dyeing device comprises polyester yarn, a dyeing mechanism, a washing mechanism and a drying mechanism; the washing mechanism and the drying mechanism are arranged on one side of the dyeing mechanism in sequence, the polyester yarn penetrates through the dyeing mechanism, the washing mechanism and the drying mechanism in sequence, and yarn guide wheels are arranged at the left and right ends of the upper surface of the dyeing mechanism and the left and right ends of the upper surface of the washing mechanismrespectively. According to the polyester yarn dyeing device and method, the polyester yarn is subjected to flow dyeing through the yarn guide wheels and dyeing guide wheels of the dyeing mechanism, surface dye of the polyester yarn is washed through the washing mechanism, finally, the polyester yarn is dried through the drying mechanism, and thus flow dyeing processing of the polyester yarn is achieved; no repeated dyeing operation is needed, and time and labor are saved; meanwhile, extruding rollers extrude out redundant dye carried by the polyester yarn, redundant dye is prevented from beingcarried out, and thus resource waste is greatly reduced.

Owner:福建省天和纺织实业有限公司

Natural dyestuff dyeing and finishing process of polyester fabric

The invention discloses a natural dyestuff dyeing and finishing process of polyester fabric. The natural dyestuff dyeing and finishing process of the polyester fabric comprises pretreatment, preshaping, modification treatment, dyeing, mordant removing, soaping, fixation, finishing, drying, shaping, calendering and winding. According to the natural dyestuff dyeing and finishing process of the polyester fabric, helicase and alhpa-amylase are adopted to conduct pretreatment, modification treatment is radically conducted on the performance of the polyester fabric through a acetic acid aqueous solution of chitosan, hydrogen peroxide and epoxy chloropropane, and the dyeing rate of the fabric is increased; in the dyeing process, a large amount of alkaline matter and inorganic salt are not used, a levelling agent and diffusant are added, the level-dyeing property is improved, natural dyestuff is used, therefore, environmental pollution is avoided, and requirements of green environmental protection are met; modification treatment and fire-retardant treatment are conducted on the fabric through montmorillonite, and the fire resistance of the fabric is high; anti-yellowing reagents are used in the preshaping and the shaping, and the final fabric is not prone to yellowing.

Owner:TAICANG CHENGLE CHEM FIBER

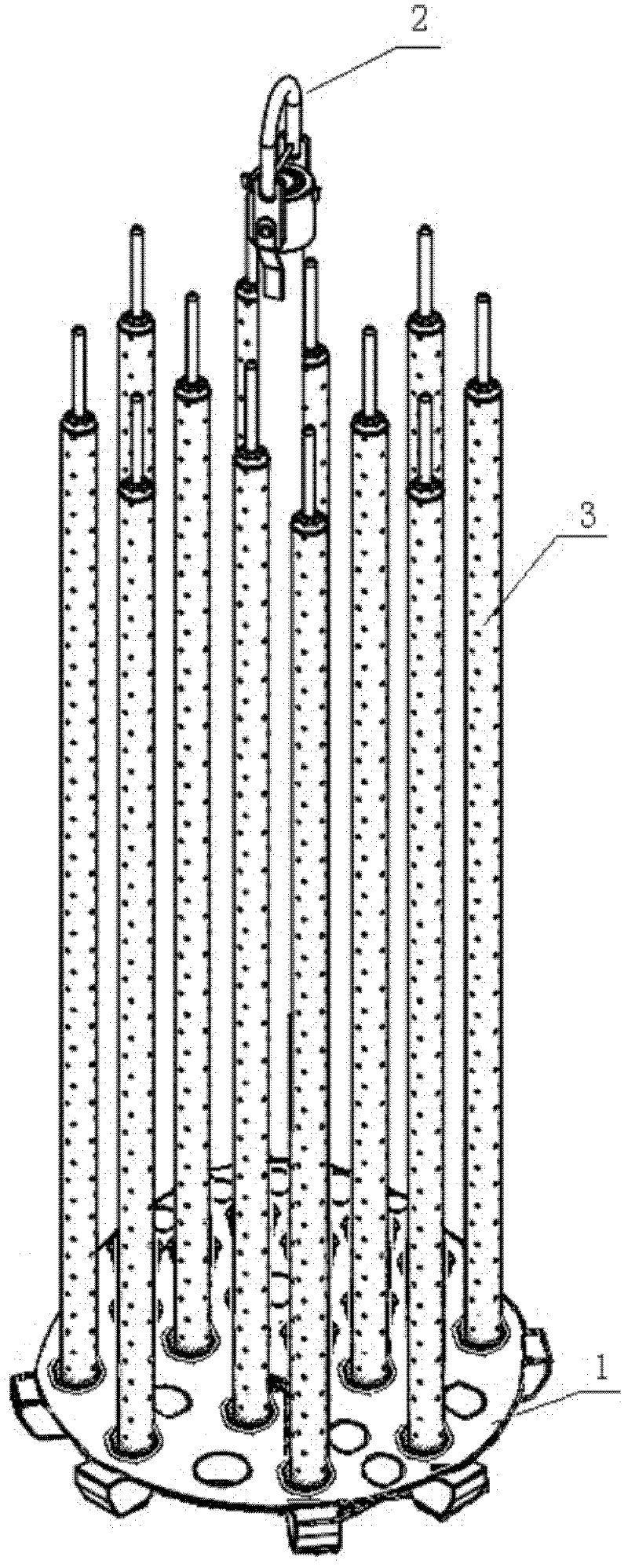

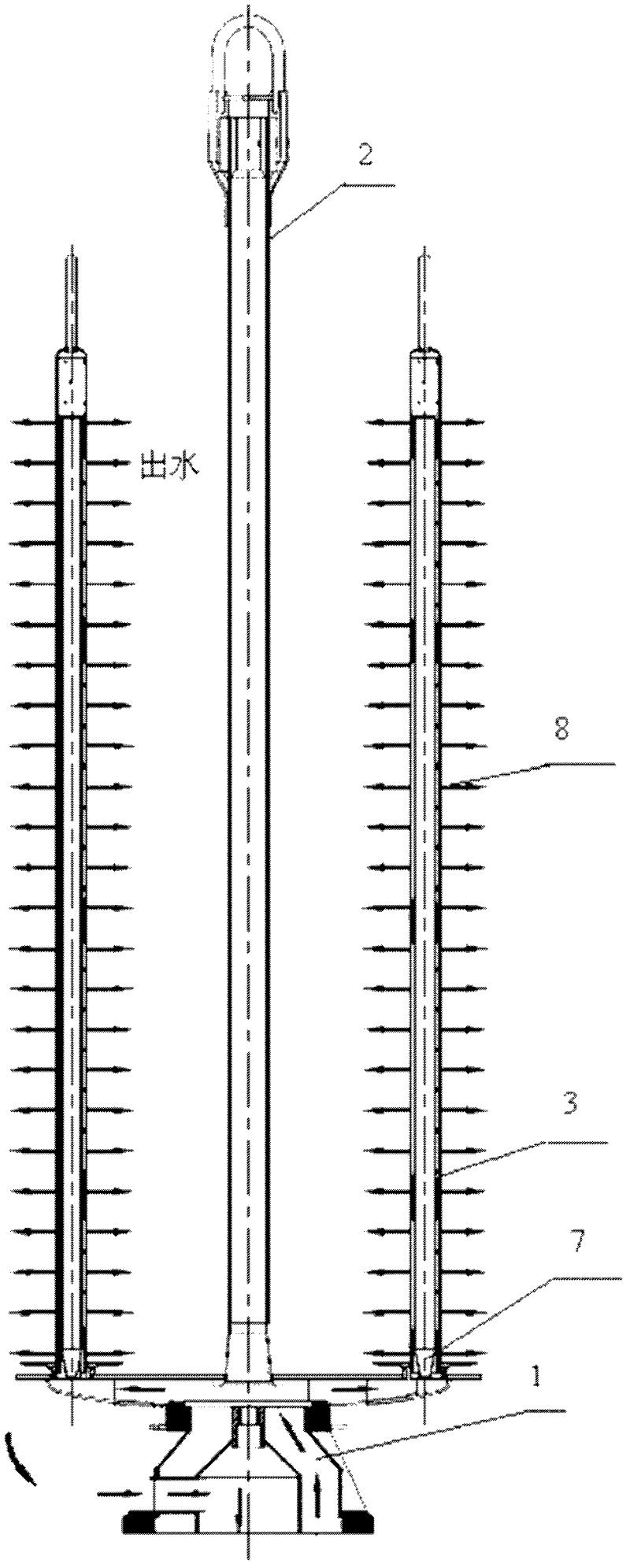

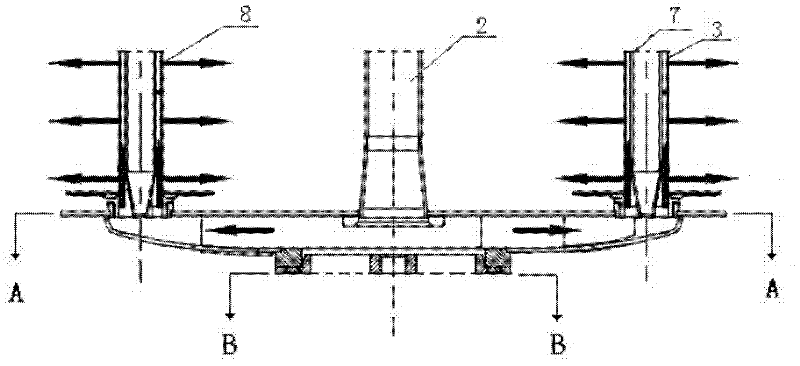

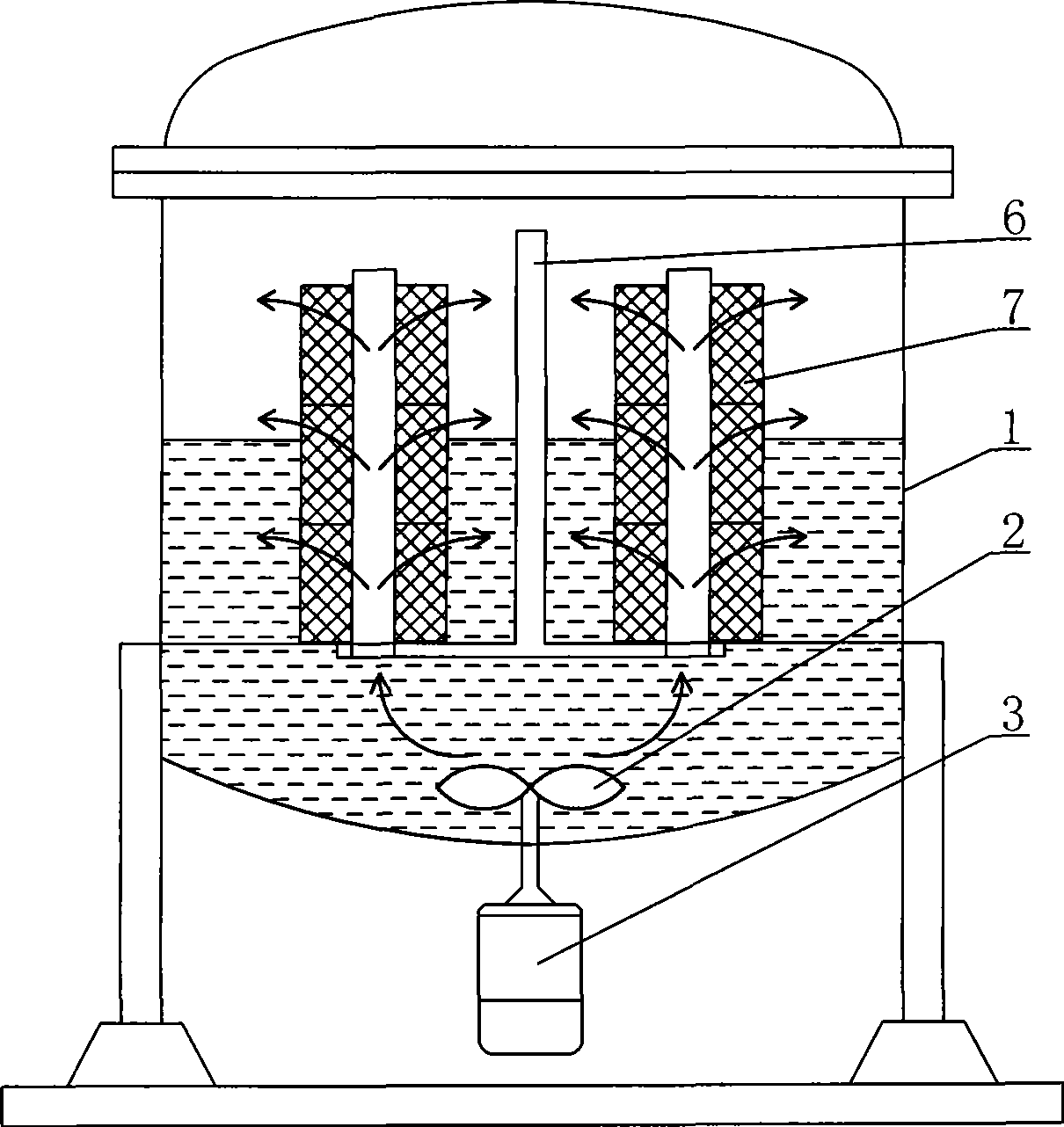

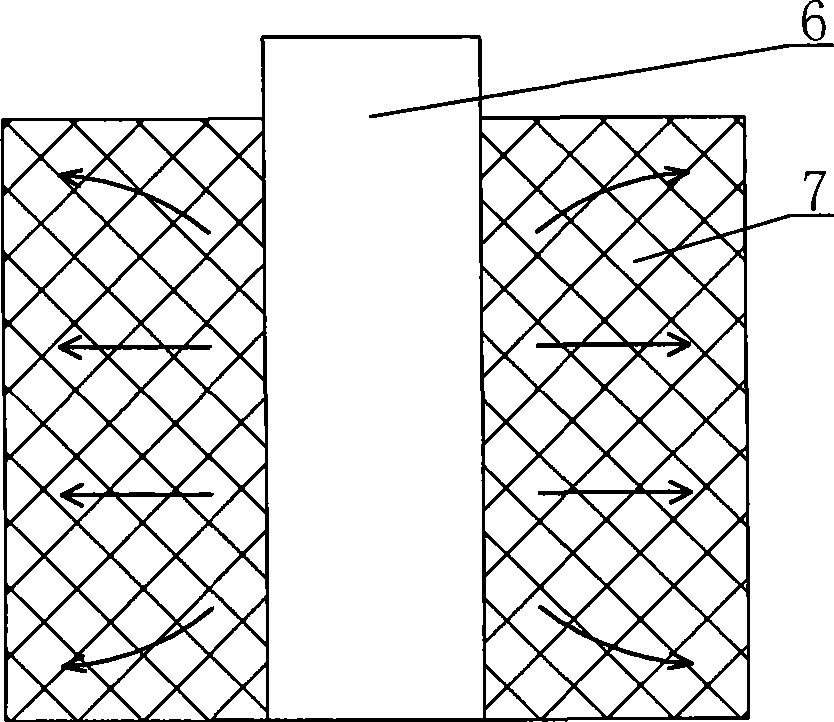

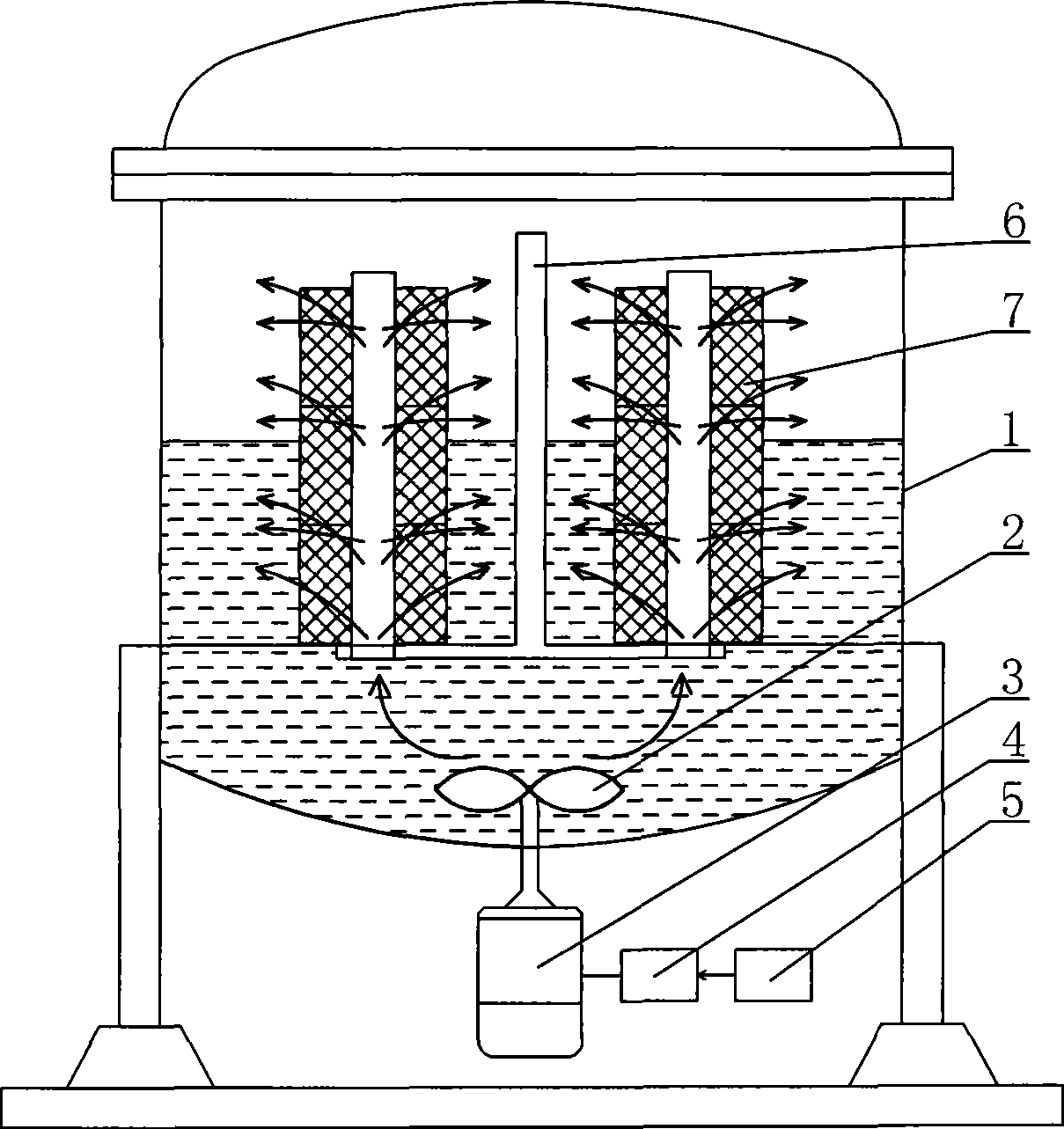

A creel device for an ultra-low liquor ratio yarn dyeing machine

InactiveCN102296436AReduce the cross-sectional areaGuaranteed coaxialityTextile treatment carriersLiquid/gas/vapor yarns/filaments treatmentWater bathsYarn

The invention discloses a creel device of a yarn dyeing machine with an ultra-low bath ratio, which comprises a sand table, a suspender and a yarn rod, wherein the upper surface of the sand table is in a disk shape; the lower end of the sand table is in a cavity structure; the yarn rod is in a hollow barrel structure; a water drum is arranged in the barrel of the yarn rod and is in a hollow or solid columnar structure; the center line of the yarn rod and the center line of the water drum are same; the ratio of the hollow internal diameter of the yarn rod and the external diameter of the waterdrum is 10:7-9; and the barrel of the yarn rod is evenly provided with a plurality of water outlets along the circumference of horizontal cross sections of different heights. The hollow barrel of theyarn rod disclosed by the invention is provided with the water drum, which is favorable for reducing the volume of dye liquor in the yarn rod and for reducing a water bath ratio; under the same main pump power, the water drum is favorable for improving the practical lift of a pipeline relatively, the flow rate of the dye liquor in the yarn rod is improved, the levelling property of cheeses of upper layers and lower layers can be better guaranteed, and the one-time success rate for dyeing is improved; and from the bottom to the top, the water outlets on the barrel of the yarn rod at the outer side of the water drum are thicker at the higher place of the yarn rod, which is favorable for realizing the purpose of even dye transfer.

Owner:高勋绿色智能装备(广州)有限公司

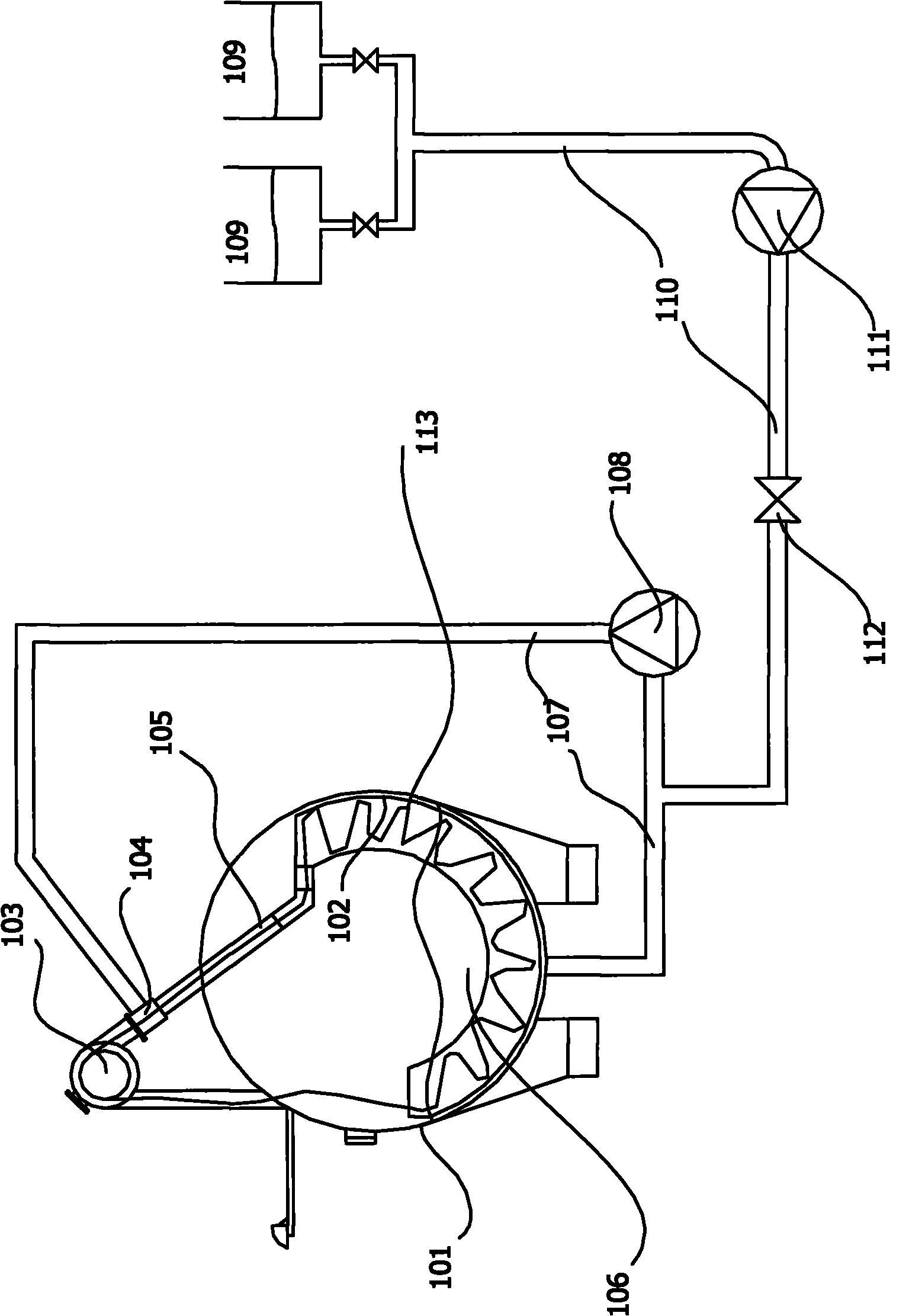

High-temperature high-pressure air flow dyeing machine

InactiveCN101280496AFully contactedReduce consumptionTextile treatment containersLiquid/gas/vapor treatment of propelled fabricsAir filterHigh pressure

The invention relates to a high temperature and high pressure air flow dyeing machine, in which the high pressure air flow is utilized for the dyeing of textiles after the dyeing atomization, which comprises a cylinder, a lifting wheel, and a feed cylinder and is characterized in that the cylinder is in a horizontal arrangement and internally provided with a dye vat. The upper wall of the cylinder corresponded to both ends of the dye vat is provided with two openings. The inside of one opening is provided with a cloth placing mechanism, and the upper part of the other opening is provided with a wheel shell communicated with the position between two openings through pipelines. The lifting wheel is disposed inside the wheel shell. The inside of the pipeline between the wheel shell and the cloth placing mechanism is provided with a nozzle and a spray head. The outside of the cylinder is provided with a heat exchanger, a feed pump and a fan. The lower part of the cylinder is provided with a backflow mechanism. The heat exchanger is provided with an inlet and an outlet. The outlet thereof is connected to a nozzle through the pipelines, and the inlet thereof is communicated with the feed cylinder, which is communicated to the bottom cavity of the cylinder through the feed pump, the backflow mechanism and the pipelines. The air outlet of the fan is linked with the spray head, and the air inlet of the fan is communicated to the cylinder through an air filter. With the adoption of such a dyeing machine to dye textiles, the production costs can be reduced.

Owner:唐佳伟

Method for dyeing cotton fabric with tea dye and finishing liquor used by method

InactiveCN103451963ARealize green environmental protectionHas antibacterial propertiesDyeing processVegetal fibresAcetic acid solutionClean water

The invention discloses a method for dyeing a cotton fabric with tea dye and finishing liquor used by the method. The method comprises the following process steps of (1) crushing tea leaves, and adding clean water to extract the tea dye; (2) preparing the finishing liquor from the following materials in parts by weight: 1-5 parts of chitosan powder, 20-25 parts of a glacial acetic acid solution with the concentration being 4%, and 1000 parts of water, namely firstly adding the glacial acetic acid solution with the concentration being 4% into the chitosan powder gradually, simultaneously stirring uniformly, adding water, and mixing uniformly to obtain the finishing liquor; (3) finishing the cotton fabric with the finishing liquor in an immersing and rolling method; and (4) dyeing the cotton fabric finished by the finishing liquor. The method disclosed by the invention has the advantages that not only can the dyeing depth and fastness of the dyed cotton fabric be improved, but also the antibacterial effect and the clean and environment-friendly effects can be achieved.

Owner:CHANGZHOU TEXTILE GARMENT INST

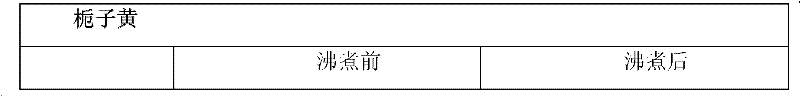

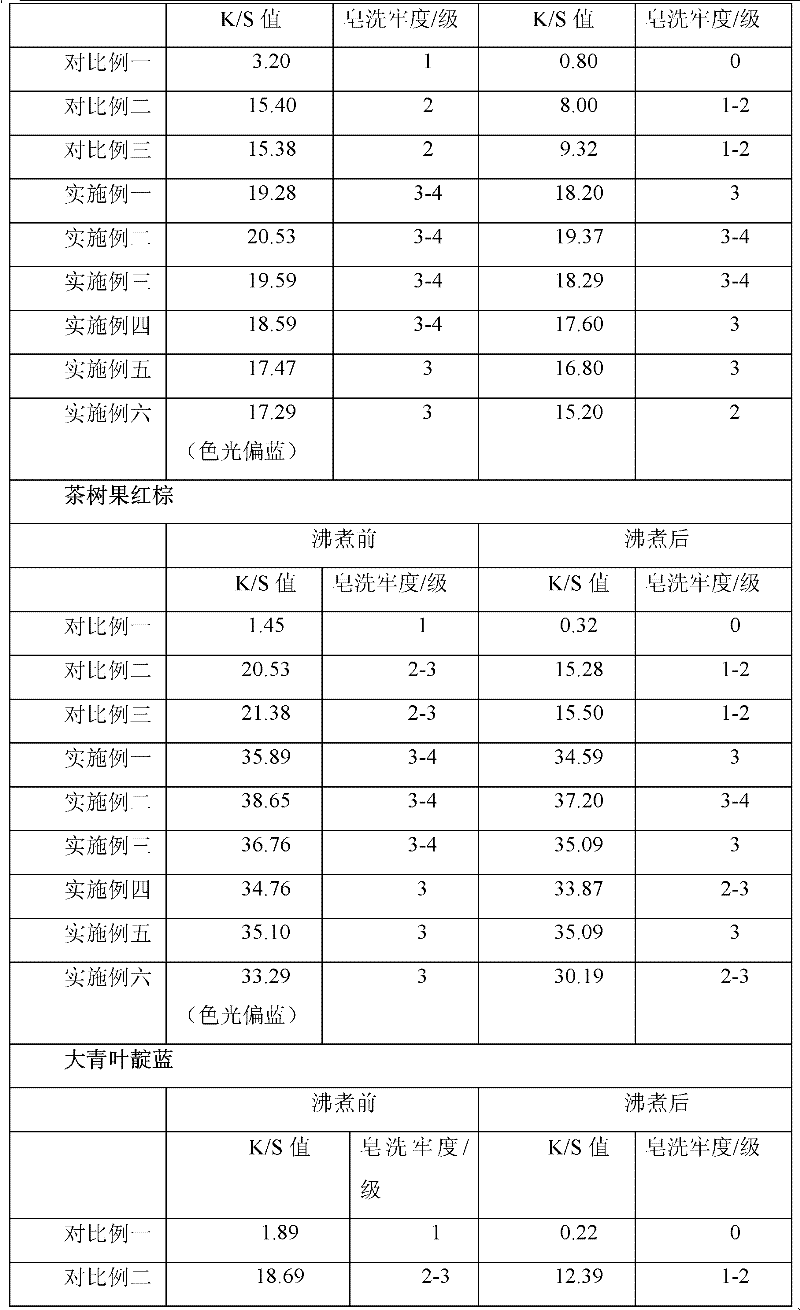

Method for dying cotton fiber by utilizing tea vegetable dye

ActiveCN101956334AHas antibacterial effectHigh color fastnessDyeing processVegetal fibresFiberSocial benefits

The invention provides a method for dying cotton fiber by utilizing tea vegetable dye. In the method, natural tea vegetable dye is extracted from fresh tea leaves, and is utilized to dye cotton fiber by different mordanting methods. After being dyed by the method the invention, the cotton fiber has the advantages of good dyeing color fastness, more color spectrums and good bacteriostatic effect. Through the method, multiple colors can be dyed, the color and lustre are soft, archaic and natural, thus people can feel natural and healthy; the dyed cotton fiber has the characteristics of good dyeing fastness, washing and wear resistance, strong repeatability and uniform dyeing; the existing dyeing equipment is used to dye directly without adding equipment and increasing cost; the method is environmentally friendly and is beneficial to human health; and the method can be applied to clean production of textile industry and can realize large-scale production. The method can efficiently use resources of summer tea and autumn tea, develop and produce tea-dyeing cotton textiles which are environmentally friendly and have archaic, simple and elegant colors and bacteriostatic effect, and the market prospect is broad, thus being capable of not only generating great economic benefits but also obtaining great social benefits.

Owner:TEA RES INST CHINESE ACAD OF AGRI SCI +1

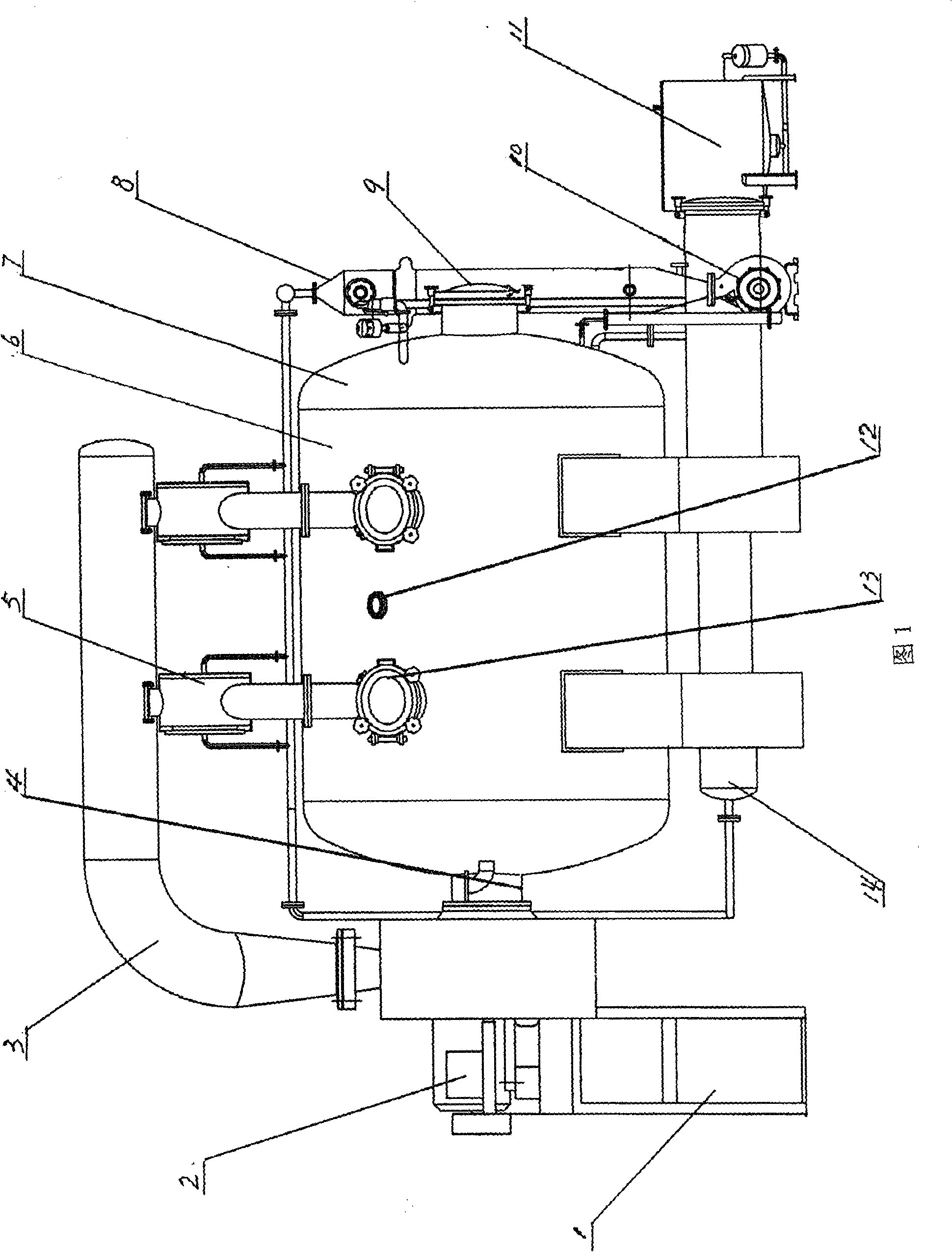

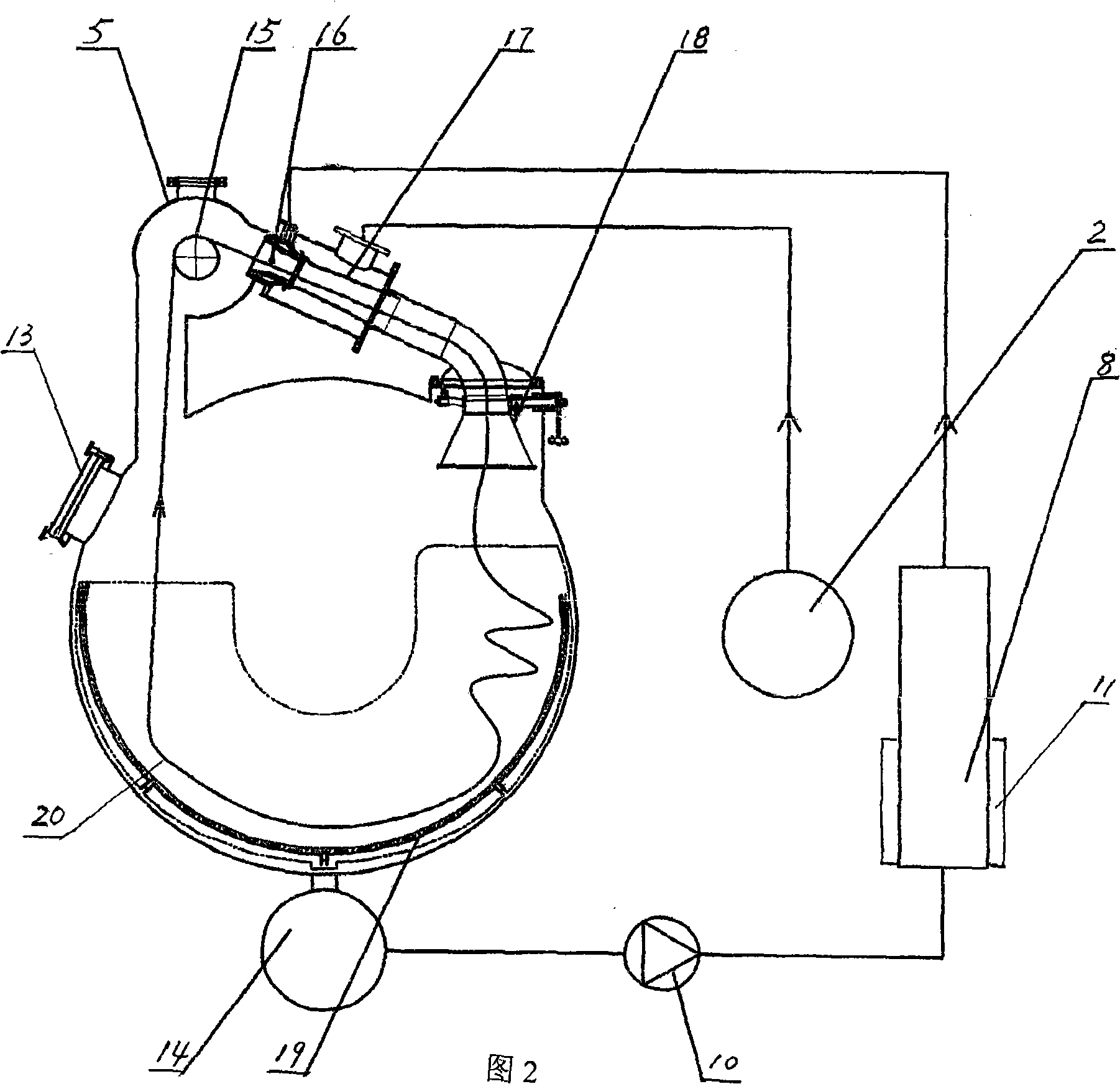

Turbulent current type cheese dyeing method and apparatus thereof

ActiveCN101440559AAvoid opacity and internal and external differencesSave electricityTextile treatment containersLiquid/gas/vapor treatment of definite length materialsDyeingYarn

The invention belongs to the technical field of dyeing textile material, and relates to a turbulence type cheese dyeing method. The cheese is dipped in dye vat, in which dye liquor cyclically flows, for dyeing, and the dye liquor cyclically flows in the amplitude changed turbulence mode in the dye vat. A turbulence type cheese dyeing device comprises a dye vat accommodating the dye liquor, the dye vat is provided with a main pump driving the dye liquor to cyclically flow, and the main pump drives the dye liquor to flow cyclically in the amplitude changed turbulence mode in the dye vat. The dye liquor cyclically flows in the amplitude changed turbulence mode, thereby maximally making the dye liquor evenly pass through the cheese without a dead angle, and avoiding the occurrence of impermeable dyeing and inside-and-outside difference. As a method of making even dye only by increasing pump speed is saved, the aim of energy conservation is achieved. Because a motor of the main pump operates with changed rotation speed, the power is saved by 30 to 50%. Moreover, the problems of low strength and excessive hairy feather due to impact of liquid flow on yarn are solved, and the strength of the original fabric is maintained.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

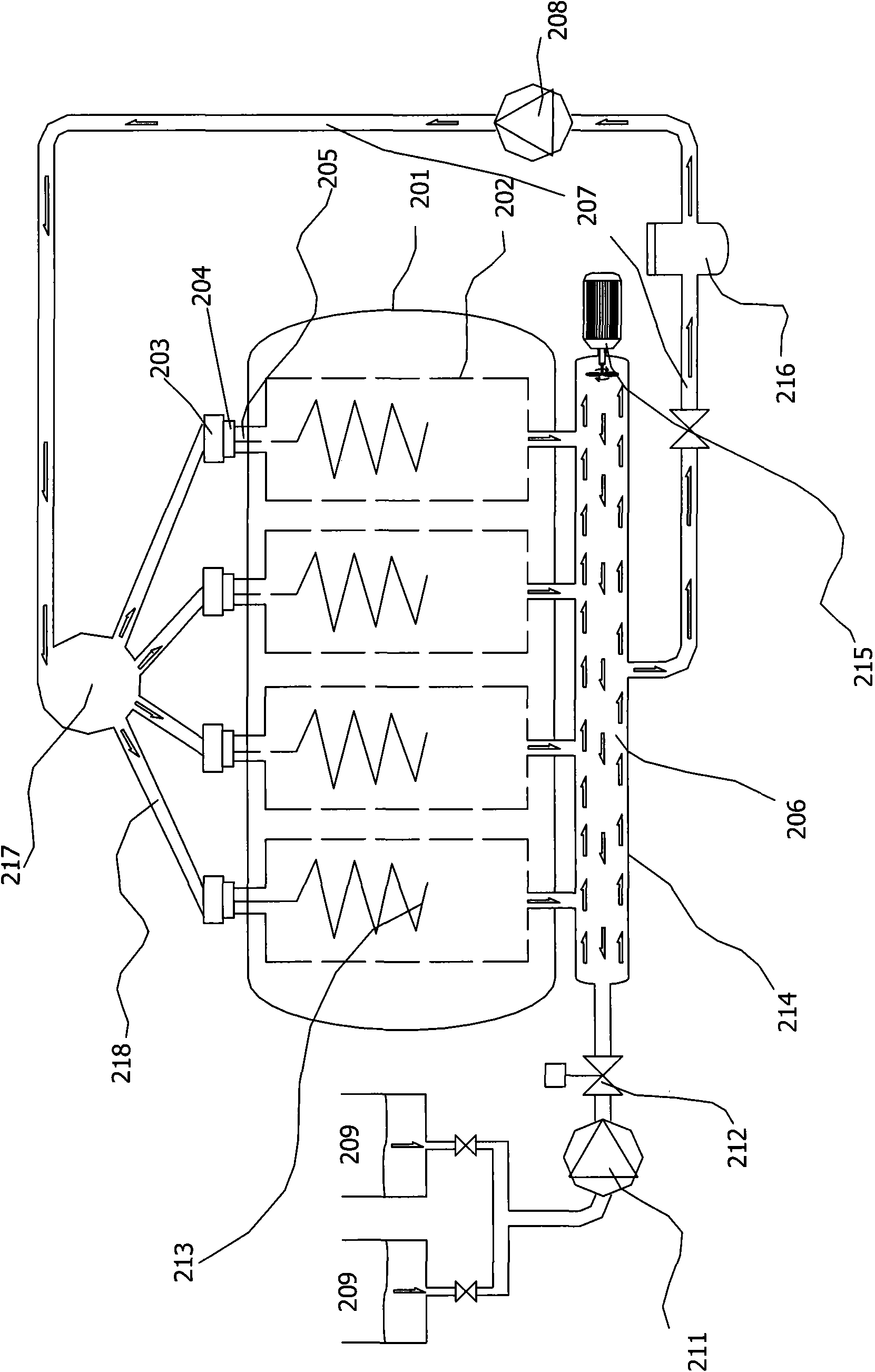

Overflow dyeing machine

InactiveCN101962887ASimple structureWell mixedTextile treatment containersLiquid/gas/vapor treatment of propelled fabricsLiquid storage tankEngineering

The invention discloses an overflow dyeing machine. The overflow dyeing machine comprises a main machine body (201), wherein a dye vat (202) is arranged in the main machine body (201); a cloth lifting pulley (203) is arranged outside the main machine body (201); nozzles (204) are arranged over the main machine body (201); the outlet of the dye vat (202) is communicated with the inlets of the nozzles (204) through a circulation pipeline (207); the outlet of a chemical material vat (209) is communicated with the circulation pipeline (207); a liquid storage tank (214) is also arranged on the circulation pipeline (207); the liquid storage tank (214) is communicated with the outlet of the chemical material vat (209) and the outlet of the dye vat (202) respectively; and a main pump (208) is arranged on the circulation pipeline (207) which connects the outlet of the liquid storage tank (214) and the inlets of the nozzles (204). The overflow dyeing machine provided by the invention has the advantages that: the structure is simple; a dyeing liquid is uniformly mixed; due to the liquid supply balance among the plurality of nozzles, surface contamination of a fabric and blockage of the nozzles is effectively prevented and dyeing is more uniform; the working efficiency is improved; and the technical time is shortened.

Owner:田立法

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com