Technology for dyeing ramie fiber with overcritical carbon dioxide method

A ramie fiber, carbon dioxide technology, applied in the direction of dyeing, textile and papermaking, can solve the problems of high temperature and high pressure, and achieve the effects of low dyeing pressure, uniform dyeing and low comprehensive cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

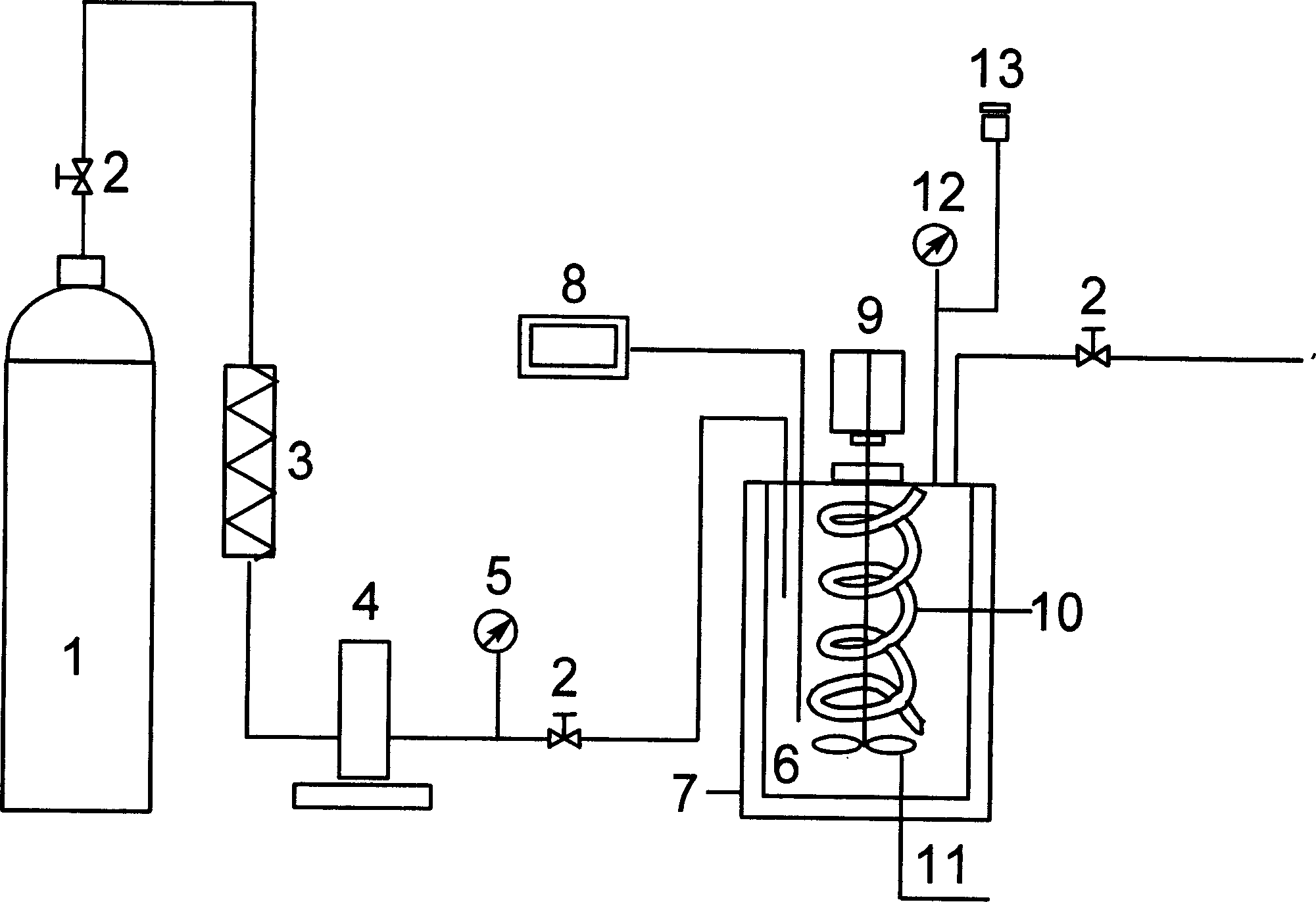

Image

Examples

Embodiment 1

[0022] Swelling treatment: ramie fibers are treated with 15% sodium hydroxide solution to eliminate polarity and partial hydrogen bonds, reducing the crystallinity of fibers. At room temperature, treat for 150 minutes.

[0023] Modification treatment: ramie fibers are treated with benzoyl chloride to introduce hydrophobic benzoyl groups. At room temperature, treat for 30 minutes.

[0024] Disperse dyes (the amount of dyestuff is 5.0% of the weight of the fiber) are charged into the autoclave, and then the ramie fibers are fixed in the autoclave. Turn on the refrigeration compressor to let the liquid carbon dioxide flow out from the steel cylinder and enter the autoclave through the high-pressure pump. Pressurize to 3-4MPa, raise the temperature to 90°C, pressurize again to the predetermined pressure of 15MPa, start stirring, and dye for 120 minutes.

[0025] After the dyeing time is up, carbon dioxide is discharged, and when the pressure is reduced to normal pressure, the d...

Embodiment 2

[0027] Swelling treatment: 20% of the ramie fiber is treated with sodium hydroxide solution to eliminate polarity and partial hydrogen bonds, reducing the crystallinity of the fiber. At room temperature, treat for 90 minutes.

[0028] Modification treatment: ramie fibers are treated with benzoyl chloride to introduce hydrophobic benzoyl groups. At room temperature, process for 20 minutes.

[0029] The disperse dye (the amount of the dyestuff is 3.0% of the weight of the fiber) is loaded into the autoclave, and then the ramie fiber is fixed in the autoclave. Turn on the refrigeration compressor to let the liquid carbon dioxide flow out from the steel cylinder and enter the autoclave through the high-pressure pump. Pressurize to 3-4MPa, heat up to 110°C, pressurize again to the predetermined pressure of 18MPa, start stirring, and dye for 150 minutes.

[0030] After the dyeing time is up, carbon dioxide is discharged, and when the pressure is reduced to normal pressure, the dy...

Embodiment 3

[0032] Swelling treatment: 25% of the ramie fiber is treated with sodium hydroxide solution to eliminate polarity and partial hydrogen bonds, reducing the crystallinity of the fiber. At room temperature, treat for 60 minutes.

[0033] Modification treatment: ramie fibers are treated with benzoyl chloride to introduce hydrophobic benzoyl groups. Incubate for 10 minutes at room temperature.

[0034] Disperse dyes (the amount of dyestuff is 2.5% of the weight of the fiber) are packed into an autoclave, and then the ramie fibers are fixed in the still. Turn on the refrigeration compressor to let the liquid carbon dioxide flow out from the steel cylinder and enter the autoclave through the high-pressure pump. Pressurize to 3-4MPa, raise the temperature to 130°C, pressurize again to the predetermined pressure of 20MPa, start stirring, and dye for 90 minutes.

[0035] After the dyeing time is up, carbon dioxide is discharged, and when the pressure is reduced to normal pressure, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical temperature | aaaaa | aaaaa |

| critical pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com