Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1779 results about "Hemp fiber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hemostatic textile

ActiveUS20070160653A1Quick activationNon-adhesive dressingsPeptide/protein ingredientsLactideSisal fiber

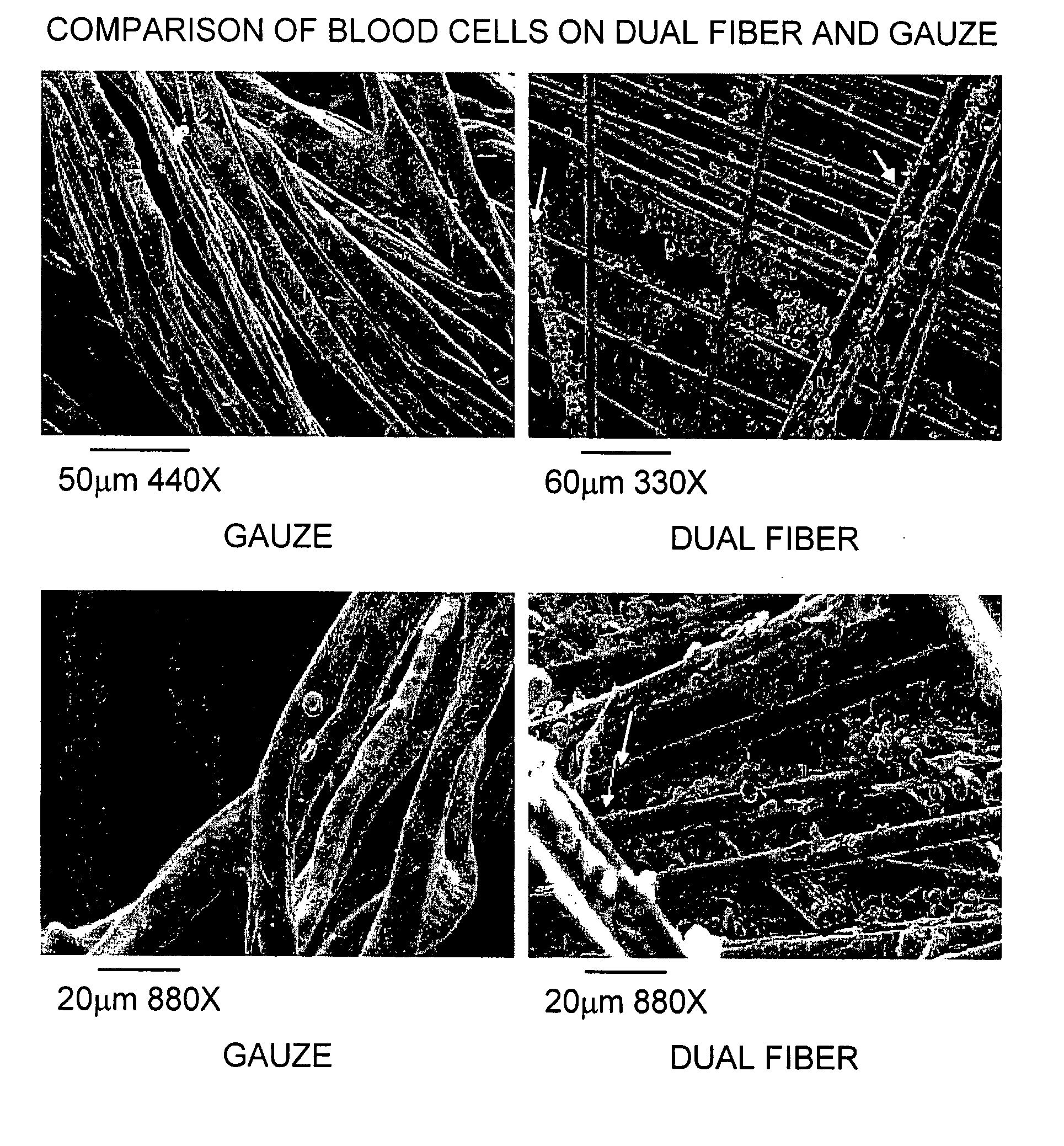

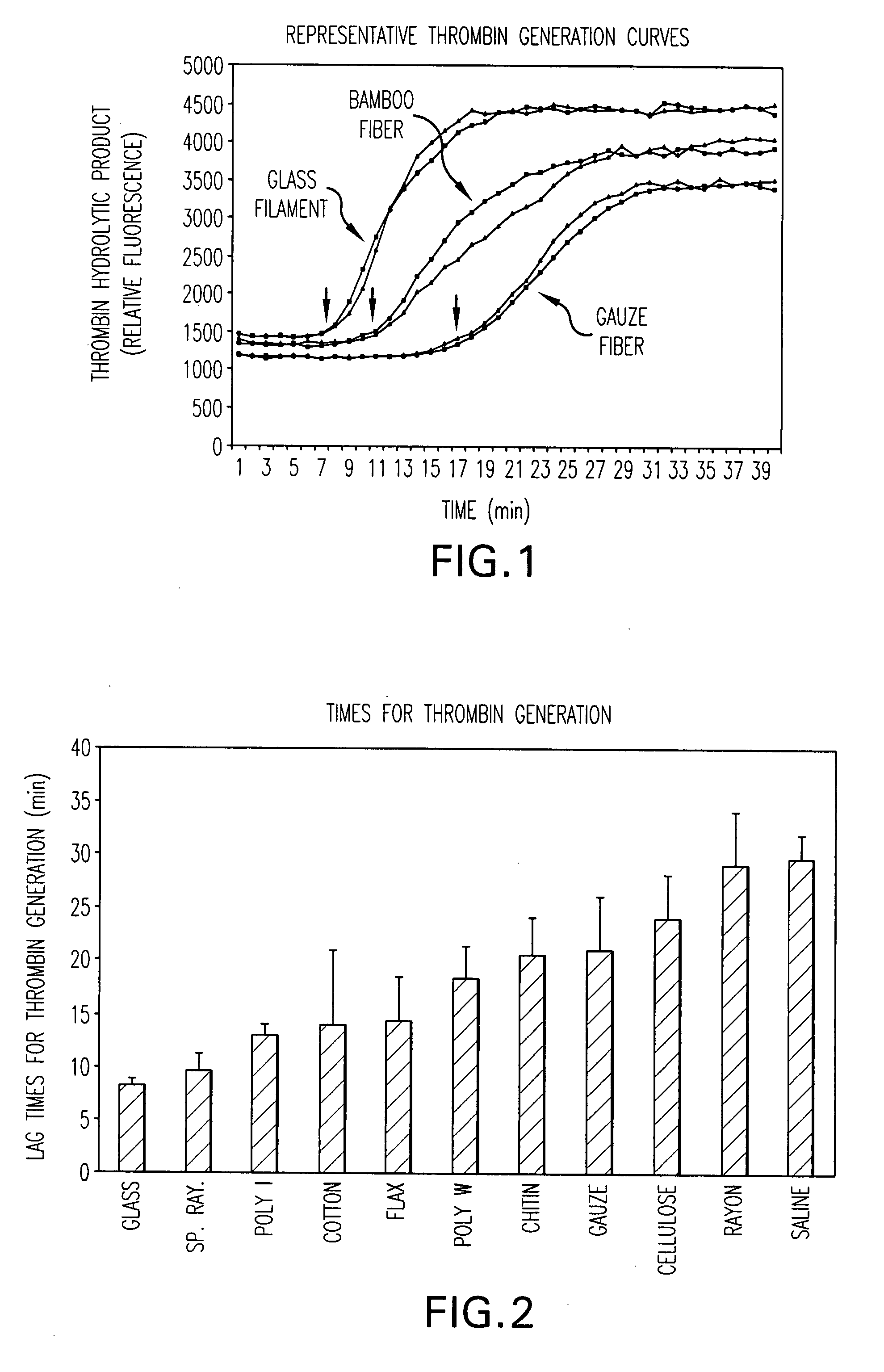

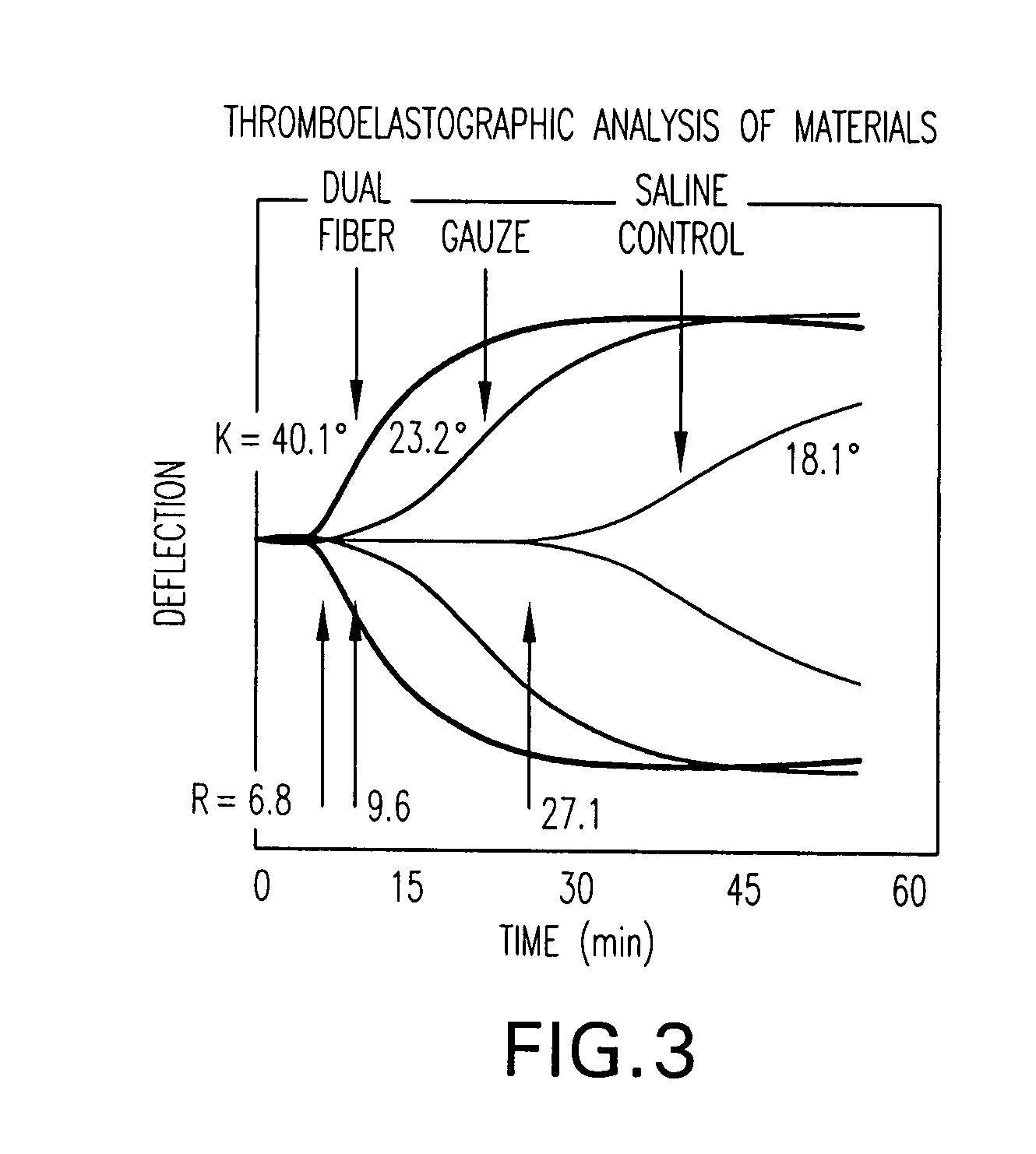

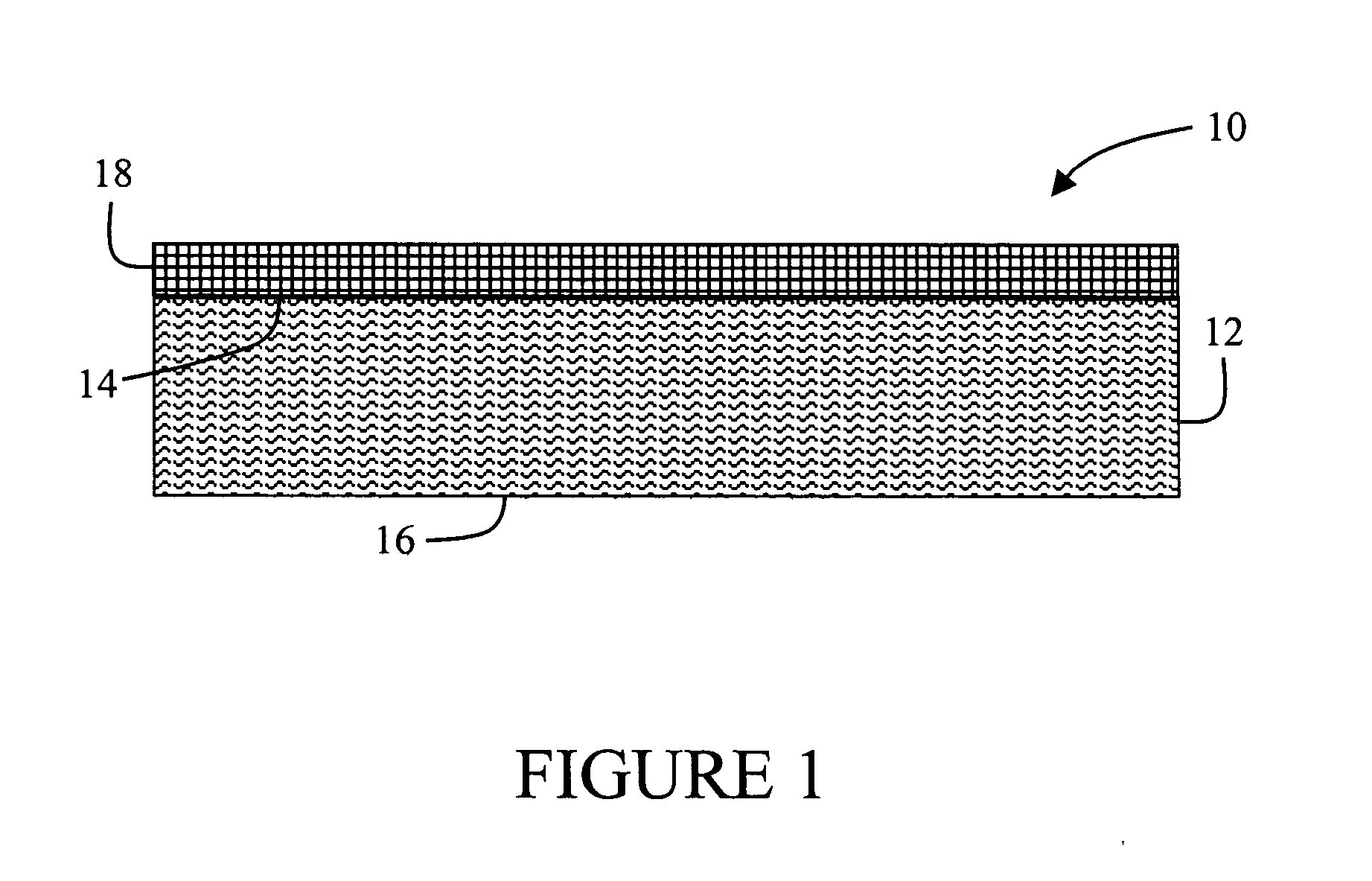

The present invention is directed to a hemostatic textile, comprising: a material comprising a combination of glass fibers and one or more secondary fibers selected from the group consisting of silk fibers; ceramic fibers; raw or regenerated bamboo fibers; cotton fibers; rayon fibers; linen fibers; ramie fibers; jute fibers; sisal fibers; flax fibers; soybean fibers; corn fibers; hemp fibers; lyocel fibers; wool; lactide and / or glycolide polymers; lactide / glycolide copolymers; silicate fibers; polyamide fibers; feldspar fibers; zeolite fibers, zeolite-containing fibers, acetate fibers; and combinations thereof; the hemostatic textile capable of activating hemostatic systems in the body when applied to a wound. Additional cofactors such as thrombin and hemostatic agents such as RL platelets, RL blood cells; fibrin, fibrinogen, and combinations thereof may also be incorporated into the textile. The invention is also directed to methods of producing the textile, and methods of using the textile to stop bleeding.

Owner:THE UNIV OF NORTH CAROLINA AT CHAPEL HILL +1

Composite thermoplastic sheets including natural fibers

A composite sheet material includes, in an exemplary embodiment a porous core that includes at least one thermoplastic material and from about 20 weight percent to about 80 weight percent of natural fibers based on a total weight of the porous core. The natural fibers include at least one of kenaf fibers, jute fibers, flax fibers, hemp fibers, cellulosic fibers, sisal fibers, and coir fibers.

Owner:HANWA AZDEL INC

Interior wall paint composition

The invention relates to an interior wall decorating material, in particular to a building material composition consisting of natural source materials and containing diatomite. The composition comprises the following components in percentage by weight: 20 to 40 percent of diatomite, 20 to 58 percent of shell powder, 8 to 32 percent of dolomite sand, 2 to 10 percent of casein, 5 to 12 percent of 4A zeolite powder, 3 to 8 percent of seaweed gelatine powder, 0.5 to 1.5 percent of jute fiber and 2 to 5 percent of titanium white powder. The composition fully consists of natural source materials, does not contain chemical substances of synthetic resins, and really has no volatilization, emission and pollution. Because the composition does not contain the hydraulic materials such as white cement and the like, the construction opening time is long, the stirred material can be used for long term, the construction is convenient, and the material waste is avoided. The composition can be stored for long term by packing with moisture-proof paper bags, brings convenience to producers, can be mass-produced, and enables dealers not to worry about the problem of material invalidation.

Owner:深圳市汇益德环保材料有限公司

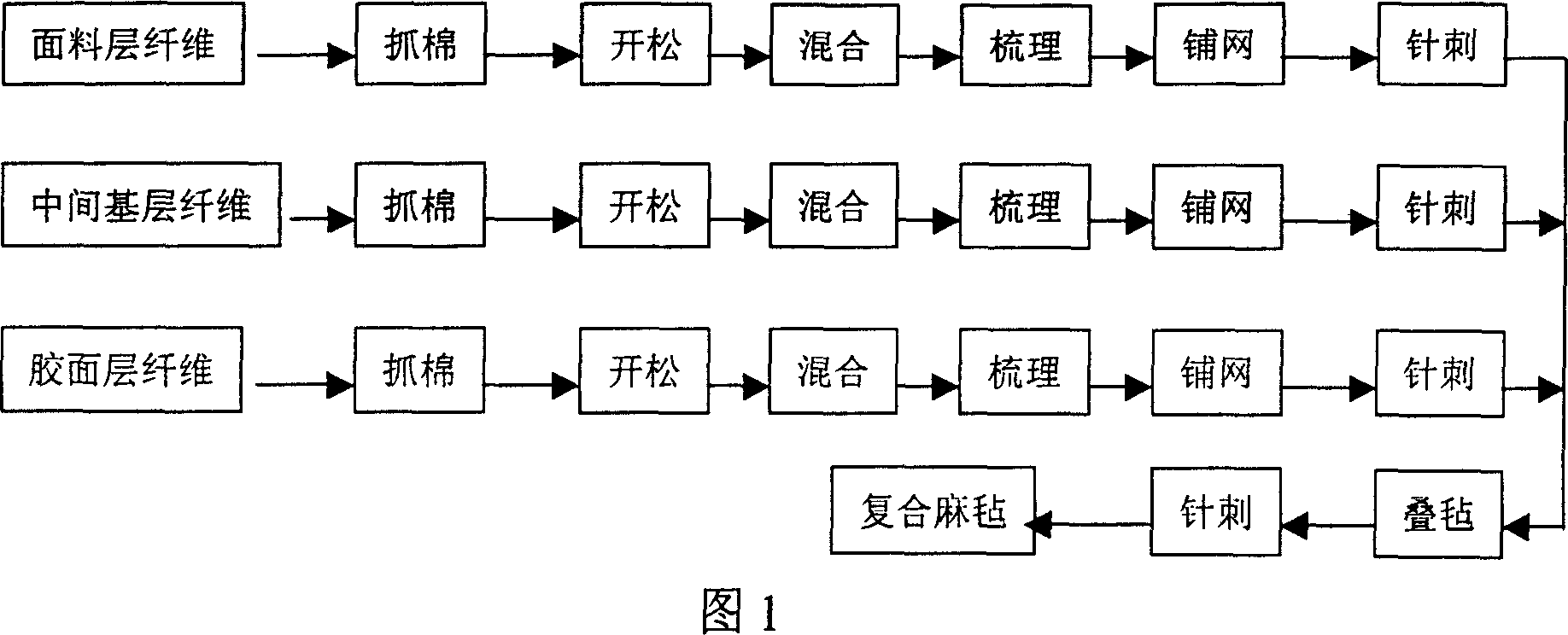

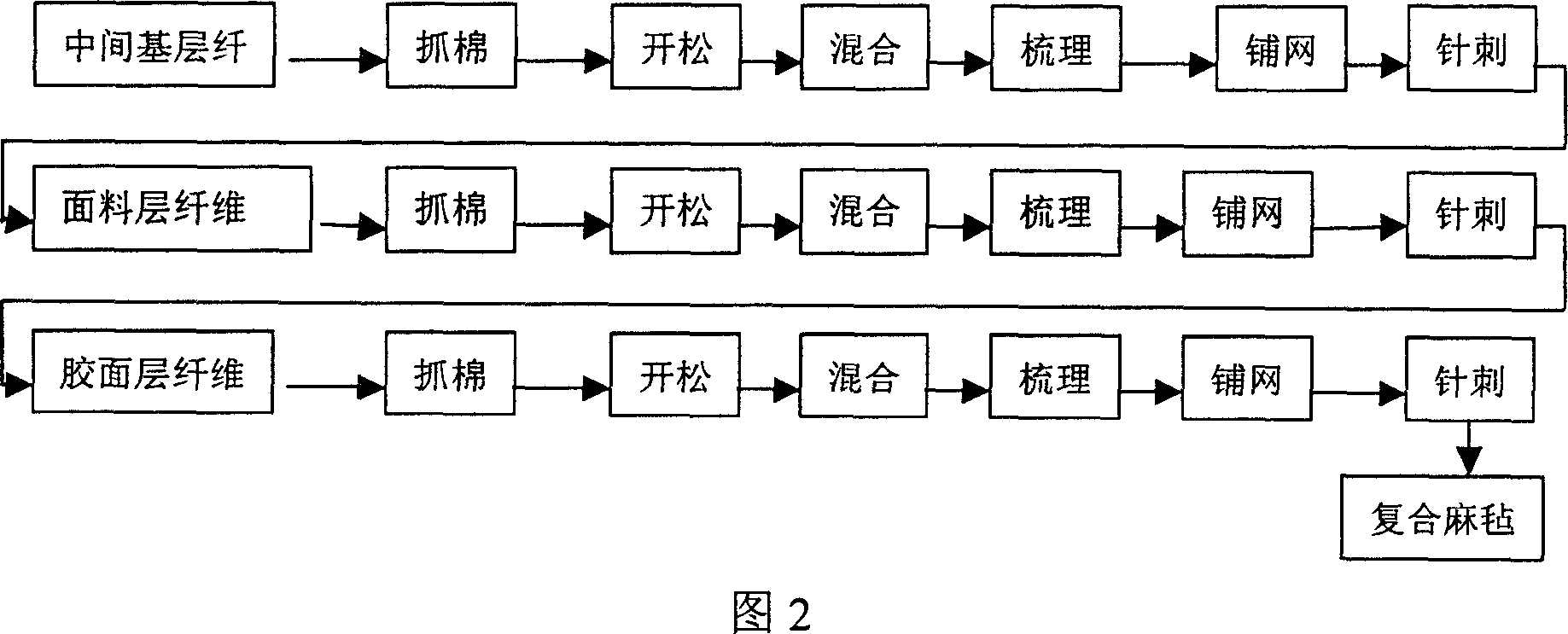

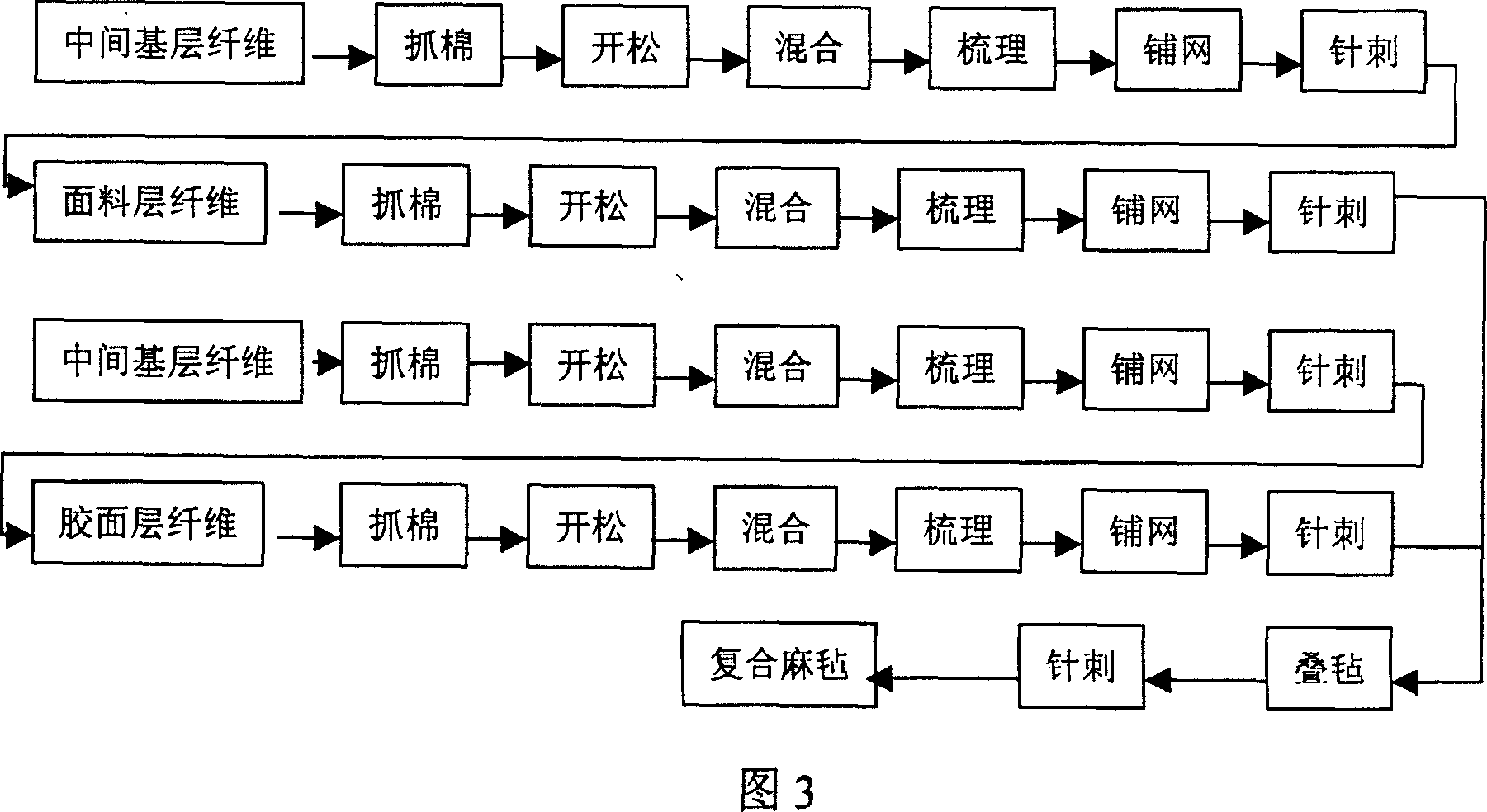

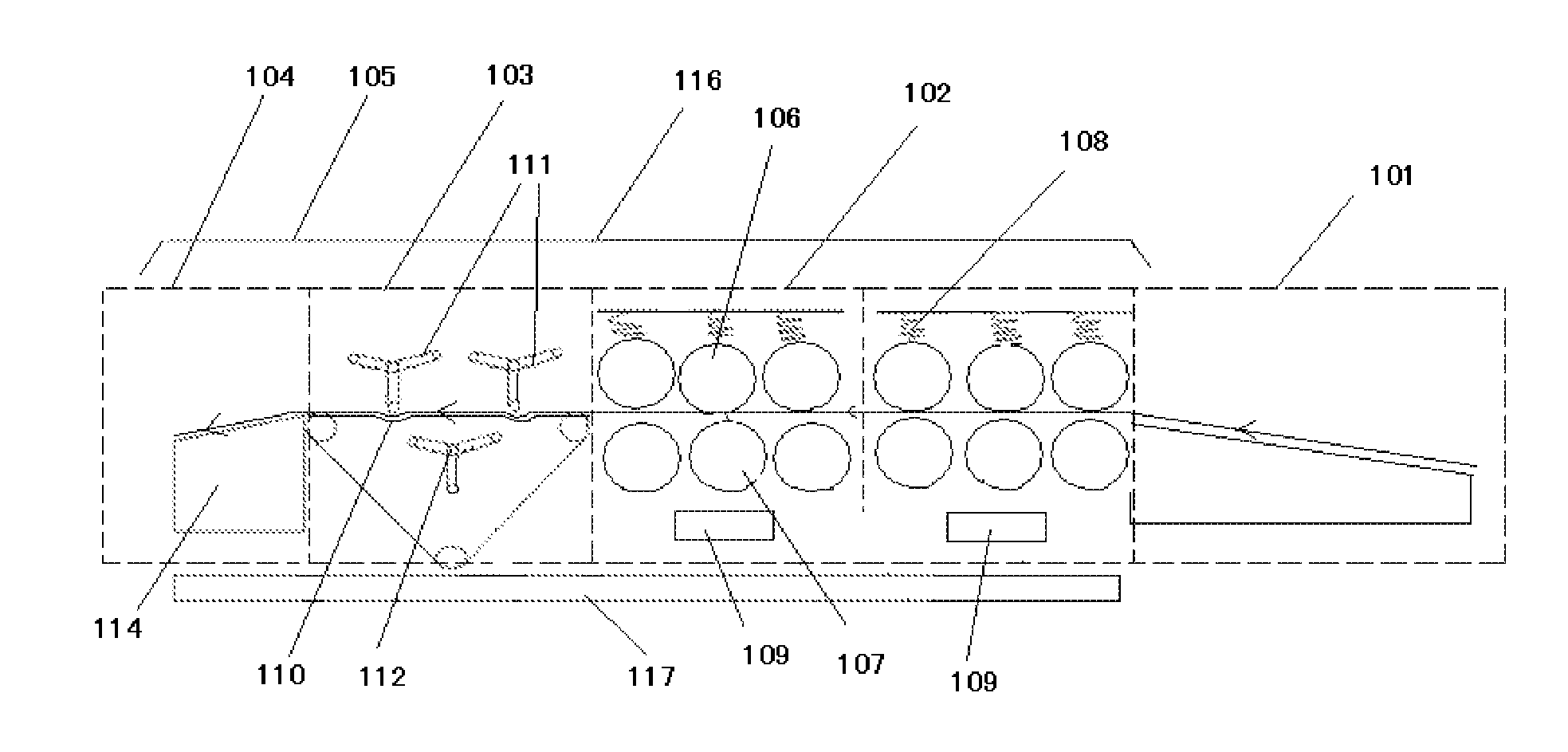

Composite board made of natural firilia for automobile inner decoration use and its producing method

ActiveCN101045310AImprove rigidityAvoid warpingWood working apparatusDomestic articlesPolyesterPolymer science

A composite bast fiber board for the internal decoration of car is composed of adhesive layer, sandwich substrate layer and surface layer, and is prepared through sequentially spreading said three layers, needling to become a composite bast felt, and hot pressing. Said sandwich substrate is made of the mixture of bast fibers (37-45%), polyester fibers (10-20%) and polypropylene fibers (35-53%).

Owner:铜陵华源汽车内饰材料有限公司

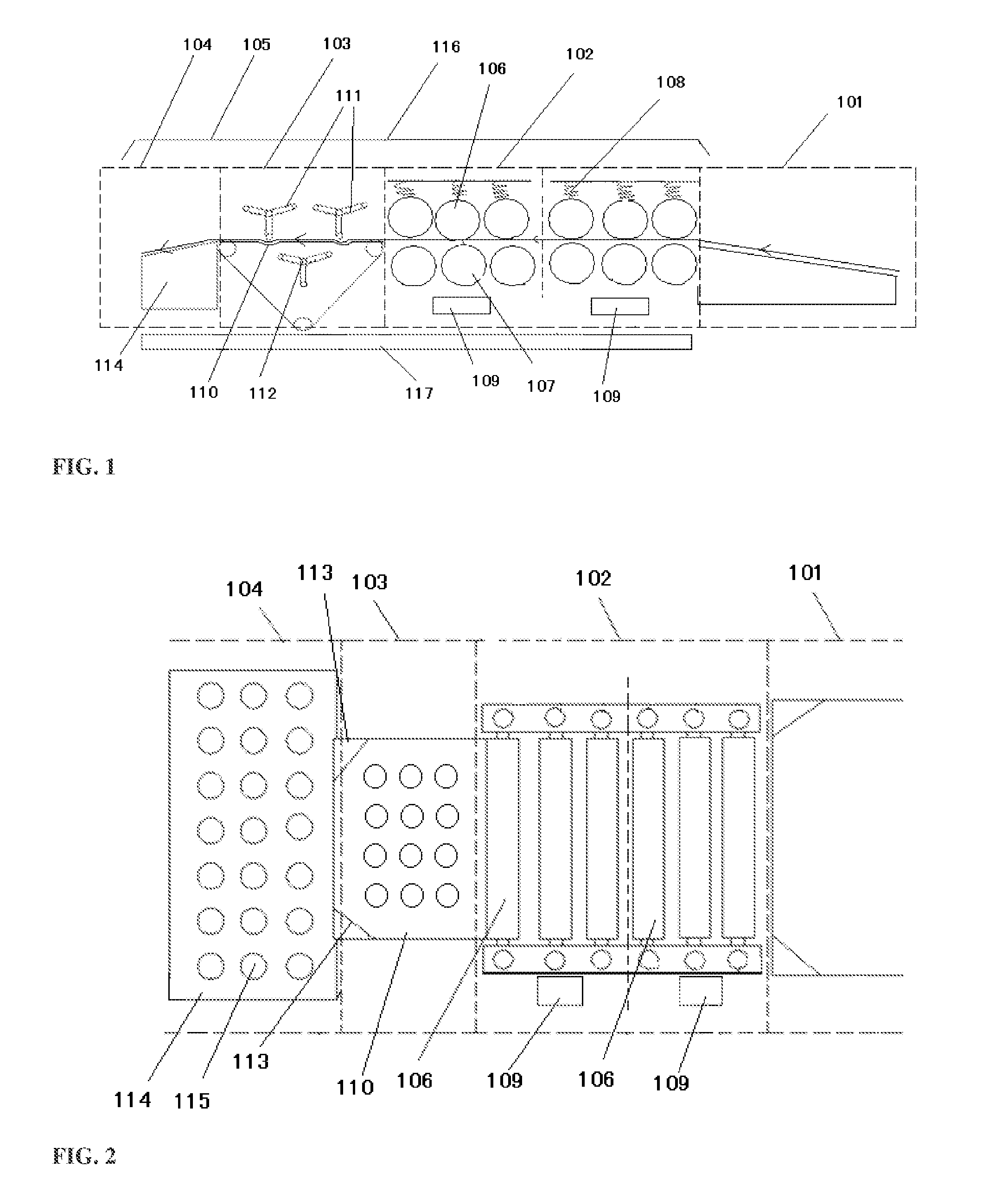

Processing Line of Bast Fiber

ActiveUS20120324677A1Improve fiber separation indexImprove biochemistry degumming uniformityMechanical impurity removalLubricating devicesCardingEngineering

A processing line of bast fiber is provided. The processing line is comprised of various devices for carding, cutting, degumming, high temperature washing, separating and water washing, softening, drying, batching and applying oil, permeating and reconditioning, stretching-breaking carding, and combing and sorting. The processing line of bast fiber can improve production efficiency, and improve the yield of long hemp fibers. Moreover, the produced fiber has stable quality and is convenient for post-processing.

Owner:WUHAN HEMP BIOLOGICAL TECH CO LTD +2

Ultraviolet-preventing antibacterial fabric and preparation technology thereof

ActiveCN103255538AImproves UV protectionImprove breathabilityFibre treatmentWoven fabricsCarbon fibersAnti bacterial

Ultraviolet-preventing antibacterial fabric comprises, by weight percentage, 10-15% of adhesive anion functional fibers, 10-15% of soybean protein fibers, 20-30% of bast fibers, 5-10% of wool fibers, 5-10% of nanometer bamboo carbon fibers, 10-15% of chitin fibers, 2-5% of nano-silver-ion fibers, 4-6% of ultraviolet-preventing finishing agents, and 2-4% of mosquito-repellent finishing agents. The ultraviolet prevention performance and air permeability of the fabric are improved, and meanwhile the fabric has effects of preventing bacteria and repelling mosquitoes. The fabric is good in application effect in home textiles, sanitary products, sports goods, health care, bacteria prevention and mosquito repellent.

Owner:广州市缔造亿百儿童用品有限公司

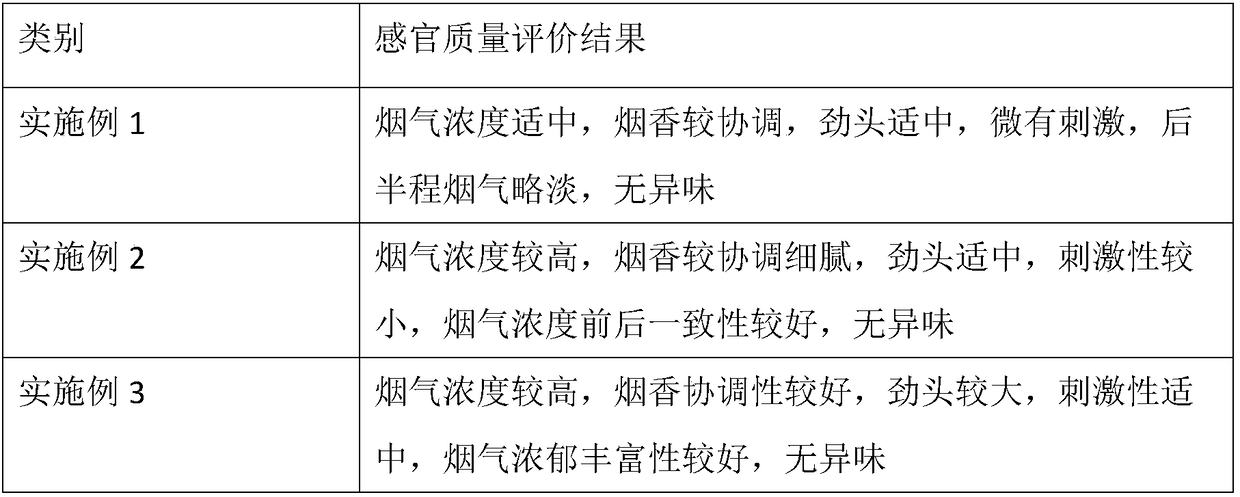

Cigarette core material for heating incombustible cigarettes and preparation method thereof

The invention provides a cigarette core material for heating incombustible cigarettes. The cigarette core material is prepared from the following components in percentage by weight: 10-50% of tobaccofiber and tobacco powder, 5-30% of wood pulp fibers, 5-30% of one or more of hemp fibers, bamboo fibers, soybean fibers, cocoon fibers, cotton fibers, polylactic acid fibers and modified cellulose fibers, 10-50% of tobacco essence, 10-30% of smoke producing agent, 1-10% of heat conduction material, 1-10% of phase change absorption material and 1-20% of paper coating component which is selected from one or more of a hydrophobic material, a microcapsule suspension and an essence suspension containing the tobacco powder. According to the cigarette core material, the heat conduction material is added, so that the heat can be uniformly conducted; the cigarette core paper is uniformly heated in the heating process; in addition, the phase change absorption material is used and is capable of achieving phase change and absorbing heat under the heated condition so as to prevent the cigarette core material paper from being locally overheated in the heating process.

Owner:NANTONG JIN YUAN NEW MATERIALS CO LTD

Heat-proof polylactic acid-starch alloy system full-biodegradation material and preparation thereof

The invention discloses temperature resistance type polylactic acid-starch alloy system whole biodegradable material and the preparation method. The temperature resistance performance of the polylactic acid can be raised above 85 DEG C by adopting the temperature resistance type polylactic acid-starch alloy system whole biodegradable material, simultaneously, fully plastic material is presented when the temperature is above 120 DEG C, the temperature resistance type polylactic acid-starch alloy system whole biodegradable material has the processing property and the practical performance of common plastics, and the applicable range of the polylactic acid is enlarged. The temperature resistance type polylactic acid-starch alloy system whole biodegradable material is made of the raw materials according to the percentage by weight: polylactic resin accounting for 50 percent to 70 percent, grafting modified starch accounting for 10 percent to 20 percent, natural hemp fiber powder accounting for 5 percent to 20 percent, superfine nucleating agent accounting for 5 percent to 20 percent, reversible cross-linking agent accounting for 1 percent to 5 percent, aliphatic chain-extending agent accounting for 1 percent to 5 percent, coupling agent accounting for 1 percent to 5 percent, plasticizer accounting for 1 percent to 5 percent, carboxy compatilizer accounting for 1 percent to 5 percent and creep resistant inorganic powder accounting for 5 percent to 20 percent.

Owner:丹阳市华东工程塑料有限公司

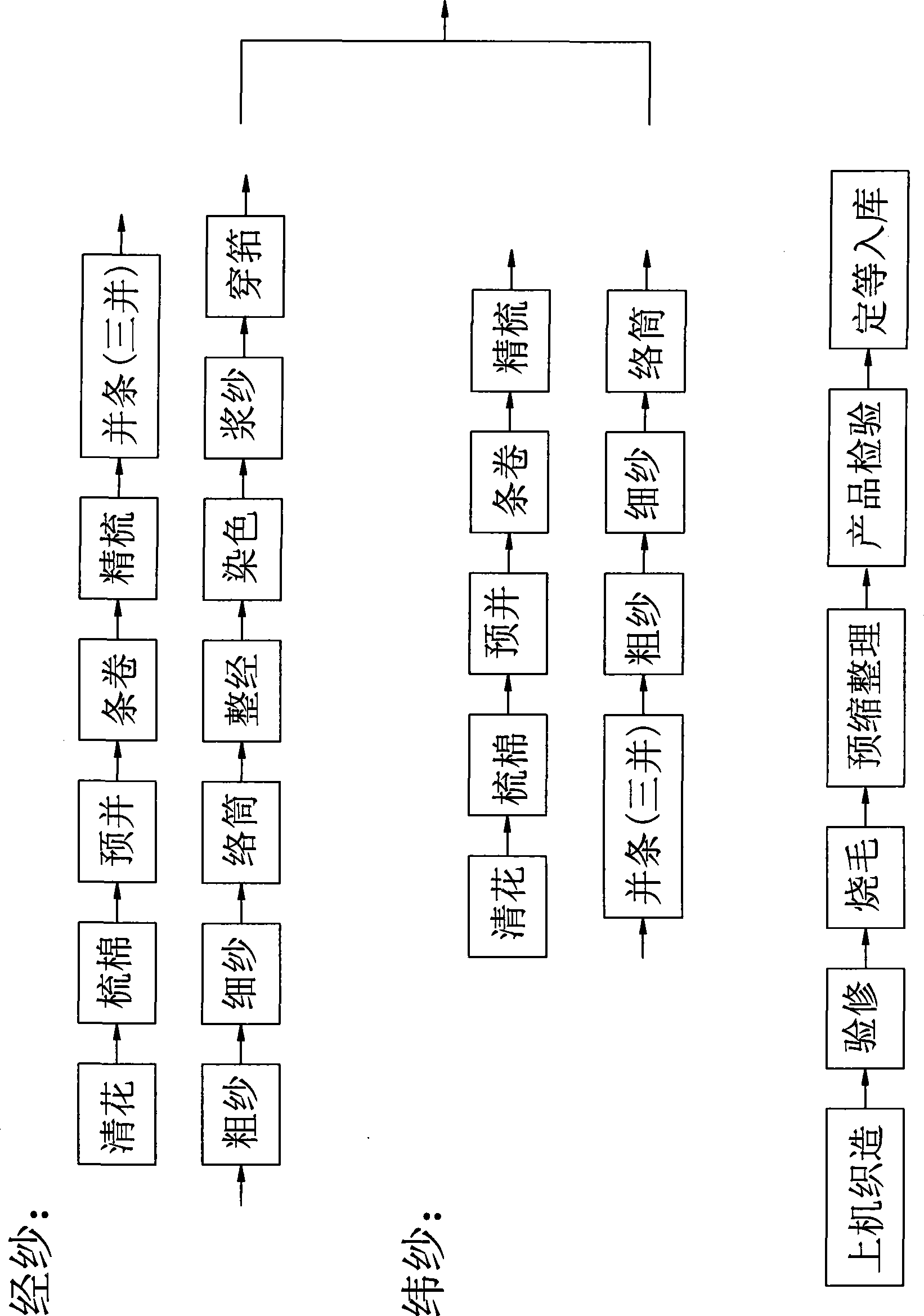

Weaving process of hemp textile product

InactiveCN101838876AHigh degree of automationEasy windingFabric breaking/softeningBiochemical fibre treatmentYarnEngineering

The invention discloses a weaving process of a hemp textile product, which comprises the process steps of winding, warping and weaving. Blended yarns bended by hemp fibers and cotton fibers are weaved by warps and wefts in the process, wherein the rotary speed of a grooved drum is 600 plus or minus 5r / min, and the ratio of hemp fibers to cotton fibers is 35:65. The process also comprises processing steps of refining, singeing, softening, drying and calendering. The hemp textile product produced by the invention has less filoplume, biodegradability, and excellent moisture absorbance and sweat release properties, keeps the natural antimicrobial and health-care functions of hemp, has good soft and comfortable properties, excellent ultraviolet resistance, radiation resistance and antibacterial properties, excellent high-temperature resistance and unique odor absorption and waste discharging properties; and the hemp textile product feels soft and comfortable compared with other hemp products, and is a new-generation environment-protection product.

Owner:SUNVIM GROUP

Environment-friendly type thermoplastic natural palm fibrilia composite base material for automobile interior decoration

The environment protecting thermoplastic composite palm and hemp fiber base material is used mainly in automobile inside decoration parts. It consists of middle base plate, facing non-woven fabric and bottom PP film compounded together, and features that the middle base plate is prepared with palm and hemp fiber in 10-30 wt%, dacron fiber in 30-40 wt% and polypropylene fiber in 40-50 wt% and through mixing and netting. The present invention is non-toxic, environment friendly, light, moisture absorbent and low in cost.

Owner:JIANGYIN YANLI AUTOMOBILE DECORATIVE PARTS

Method for producing hemp yarns through vortex spinning

ActiveCN102108574AImprove efficiencyImprove flexibilityContinuous wound-up machinesOpen-end spinning machinesYarnFibril

The invention provides a method for producing hemp yarns through vortex spinning. The method comprises the following steps: curing pretreatment of hemp fibers, a bale plucker, a bending and opening machine, an opening machine, a vibrating feed box, a lap machine, a carding machine, a pre-draw frame, a draw frame and lap machine combined, a combing machine, a draw frame and a vortex spinning machine, wherein in the step of curing pretreatment of hemp fibers, the addition of an oil feeding and conditioning soft penetrating agent is 6-8% of hemp fibrils by weight; the oil feeding and conditioning soft penetrating agent comprises 12-16% of emulsifying agent, 6-10% of softening agent and 75-79% of soft water; and the moisture regain is controlled between 12% and 15%. The method has the following advantages: the maximum count of the weaved hemp yarns can be 50; the noil rate is reduced; the flexibility, parallel straightness, spinnability and strength of the fibers are improved; the finished product rate is high; the hemp fibers are protected by adopting the methods of more opening and fewer beating and jogging; and the method lays the foundation for normal production through vortex spinning.

Owner:JIANGSU YUEDA HOME TEXTILE

Hemp fiber degumming boiling-off additive, preparing method and application thereof

InactiveCN101550607AConvenient lengthImprove finenessFibre treatment to obtain bast fibreWastewaterSURFACTANT BLEND

The present invention discloses a hemp fiber degumming boiling-off additive, a preparing method and the application thereof. The invention is characterized in that the additive is composed of two parts of organic surfactant and inorganic boiling-off additive. The additive I and the additive II are prepared through compounding the organic surfactant and inorganic boiling-off additive. Furthermore the additive I and the additive II are applied for the chemical degumming of raw hemp ramie. When the additive I and the additive II according to the invention are applied to the industrial process of chemical boiling-off degumming, not only are the xylogen content and residual adhesive rate reduced, but also the degumming effect is increased. Furthermore the boiling-off time is shortened. The dosage of NaOH and the discharge amount of polluted wastewater are reduced. Additionally, the adding of the additive according to the invention increases the whiteness and plasticity of degummed ramie. The hemp fiber degumming boiling-off additive has excellent application value.

Owner:TAIYUAN UNIV OF TECH +1

Cotton fiber and hemp fiber blended covering yarn and preparation method thereof

The invention aims to disclose a cotton fiber and hemp fiber blended covering yarn and a preparation method thereof. The covering yarn cotton fiber and hemp fiber are blended into the cotton fiber and hemp fiber blended covering yarn in a jet vortex spinning, the weight percentage of the cotton fiber is 30-50%, and the weight percentage of the hemp fiber is 50-70%. Compared with the prior art, the cotton fiber and hemp fiber blended covering yarn has the advantages of antibiosis, anti-mite, thermostability, nature and roughness, softness and comfortableness, and moisture absorption and sweat releasing, hemp cotton blended yarn is blended into the covering yarn as a yarn core, and accordingly problems of touch roughness and stiffness of fibrilia and low chromaticity are avoided, and the cotton fiber and hemp fiber blended covering yarn is achieved.

Owner:SHANGHAI SHUIXING HOME TEXTILE

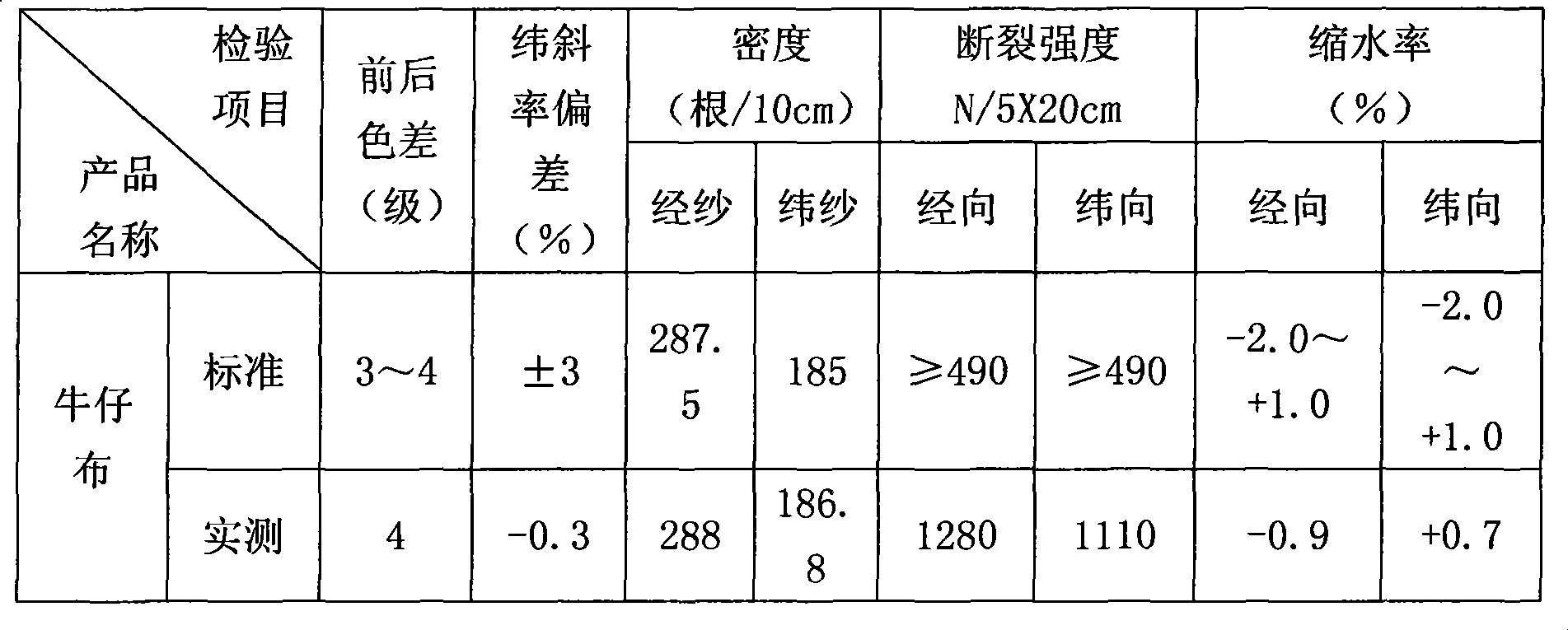

Viloft shengma smooth edge denim and production technology thereof

The invention relates to VILOFT sunn crotataria plain edge jean which comprises the following components by weight percentage: 20-40% of VILOFT fiber, 20-40% of sunn crotataria, 20-40% of one or multiple of cotton fiber, color cotton fiber, prolivon, cashmere, milk fiber, soybean fiber, tencel yarn, flax, silk, etc. In the picking process, the lap pressure is weighted, multi-combing and little beating, combing instead of beating are adopted, the speed of each beater is reduced, and the gauge of the beater and grid bars is enlarged. In the carding process, the lap is fully carded and the card sliver quota is increased; in the drawing process, the clockwise drawing process is adopted, the gauge is enlarged; the pressurizing quantity is improved and the vehicle speed is reduced, the combination process and the three blending combination process are adopted, and the first tension drawing multiple is grasped in a slightly large way; in the spinning process, large postzone roller gauge, small postzone draft multiple and small nip gauge are required, the vehicle speed is reduced, and the pressure is increased. The fabric of the jean has the advantages of environment protection, moderate elastic, soft texture, good luster and drapability, and obviously bamboo joint effect.

Owner:山东万泰创业投资有限公司

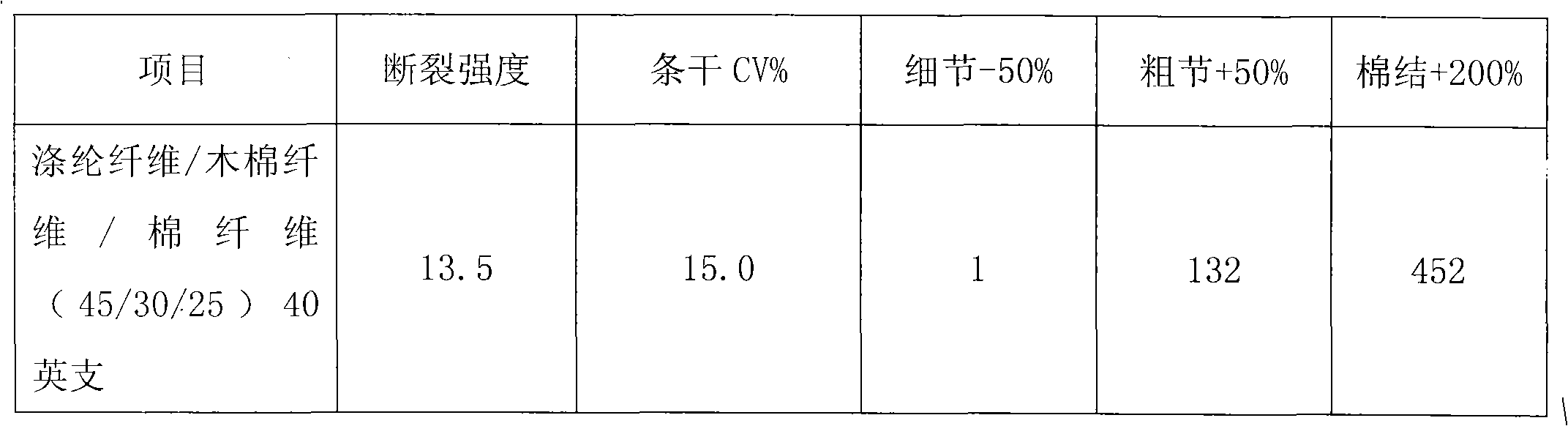

Flame retardant blended yarn and production method thereof

InactiveCN104404671AImprove flame retardant performanceIncrease added valuePhysical treatmentYarnCotton fibreSingle fiber

The invention relates to a flame retardant blended yarn and a production method thereof. According to weight percentage, the flame retardant blended yarn is formed by the following components through blending: 25-30% of flame retardant polyester filament yarns, 20-25% of flame retardant acrylic fibers, 20-30% of hemp fibers and 20-30% of cotton fibers. The production method includes: making hemp fibers and cotton fibers into card slivers respectively and tearing the card slivers into loose fibers, and making the card slivers into hemp / cotton blended combed silvers through second blowing carding in a single fiber type mixing way; making the flame retardant acrylic fibers into flame retardant acrylic card silvers; producing blended rough yarns by use of the hemp / cotton blended combed silvers and the flame retardant acrylic card silvers; producing flame retardant blended yarns by use of spun yarns in a core spun mode; producing the needed flame retardant blended yarns after plasma preprocessing and yarn flame retardant finishing. According to the flame retardant blended yarn and the production method thereof, the hemp fibers, the cotton fibers and two flame retardant fibers are selected for blending, and accordingly the produced yarns have excellent flame retardant performance as well as good antibacterial, moisture absorptive and ventilate wearing performances; the spun yarns are in the core spun mode so the tare effect is eliminated and the flame retardance is improved.

Owner:青岛博徕施纺织有限公司

Boiling-off method for bast fibre and bast fibre produced by the same

InactiveCN1772976AAchieve economyFully reflect the scientific concept of developmentVegetable materialEngineeringWater content

The present invention discloses a degumming method of bast fibre. Said method includes the following steps: soaking bast fibre in water for 40-80 min, making its water content is 60-100%, then placing the water-contained bast fibre into a steam explosion tank, making steam explosion under the condition of that its pressure is 1.3-1.7 MPa and the pressure-retaining time is 3-8 min, taking out the bast fibre, washing said bast fibre with water and drying so as to obtain the invented degummed bast fibre.

Owner:北京赛特瑞科技发展有限公司

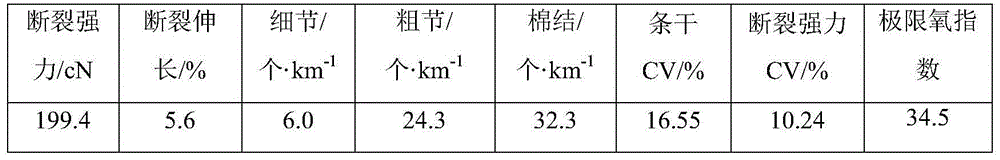

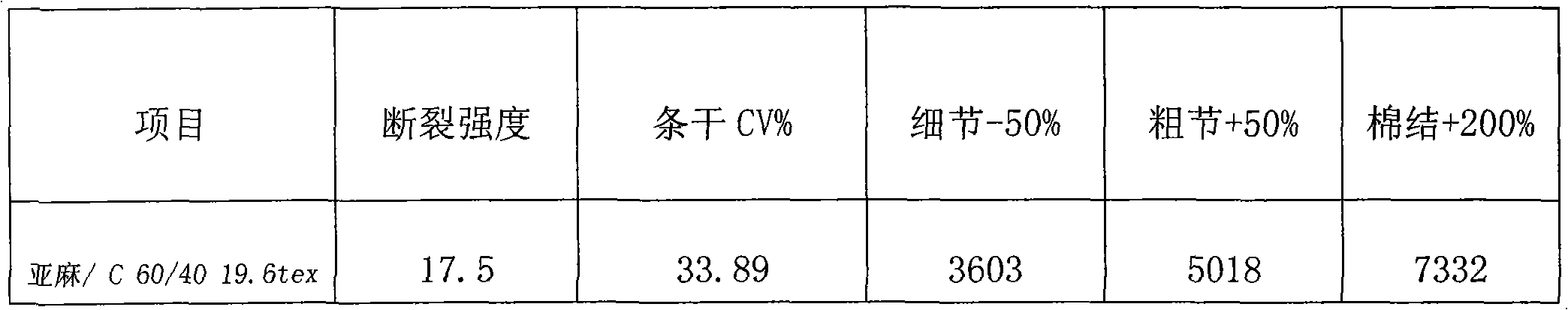

Blended yarn of flax fibers and cotton fibers and preparation process thereof

The invention discloses a blended yarn of selected flax fibers with superior count and cotton fibers and a preparation process thereof. The blended yarn consists of the flax fibers with superior count and the cotton fibers, wherein the flax fiber content accounts for 20 to 60 percent of the total weight of the blended yarn, and the cotton fiber content accounts for 40 to 80 percent of the total weight of the blended yarn. The preparation process comprises the following steps of: dividing the flax fibers with superior count and carded sliver or combed sliver into small heaps by proportioning; preparing uniform aqueous solution; and performing steps of fiber mixing, cleaning, cotton carding, drawing, roving and spinning to prepare the blended yarn of flax fibers and cotton fibers, wherein the relative humidity for the production environment of each step is 58 to 65 percent. The product produced by the invention can be made into various blended fabrics and thus provides a purely natural and comfortable textile product for the field of textile industry.

Owner:JIHUA 3542 TEXTILE CO LTD

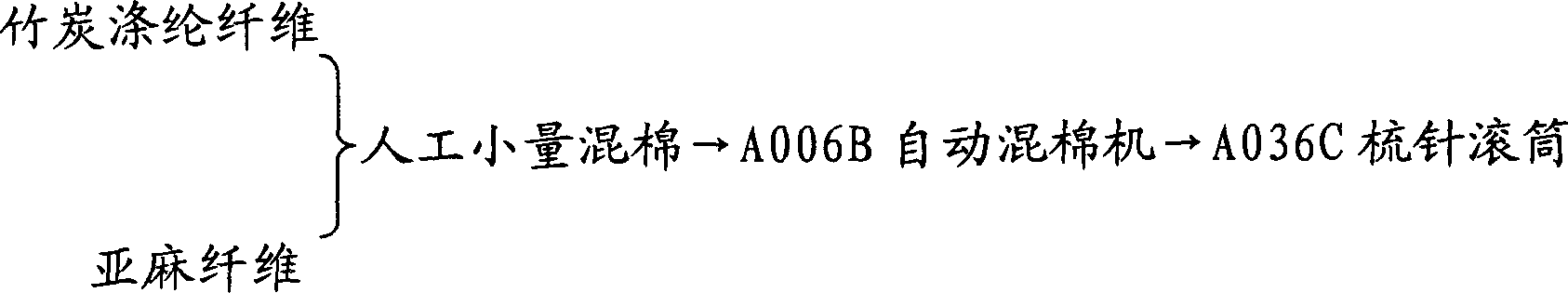

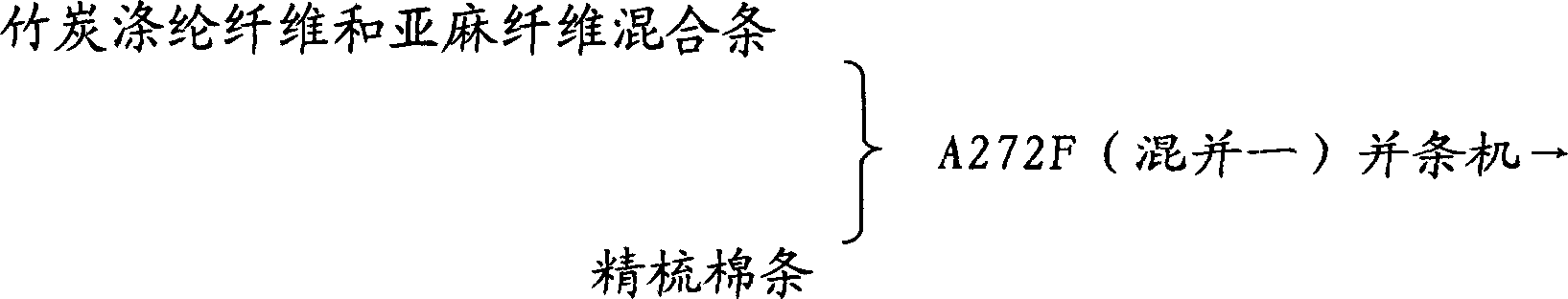

Bamboo carbon dacron fiber, flax fiber and cotton fiber blended yarn and producing method thereof

The present invention discloses a bamboo carbon polyester fibre, flax fibre and cotton fibre blended yarn and its preparation method. It is made up by using 20-40% of bamboo carbon polyester fibre, 30-40% of flax fibre and 20-50% of cotton fibre through a certain preparation process. The performance indexes of said blended yarn are as follows: single yarn breaking strength is 9.0-18.0 cN / tex, the coefficient of variation CV value of single yarn breaking strength is 8.0-22.0% and the coefficient of variation CV value of yarn evenness is 12.5-24.0%.

Owner:WUXI PAIHO TEXTILES CO LTD

Method for manufacturing Chinese hemp multi-component covering type two-sided knit fabric

ActiveCN101498074ANatural antibacterialNatural UV resistanceWeft knittingWarp knittingYarnUltraviolet

The invention relates to a manufacture method of a hemp, polycomponent, covering and double-knitted fabric, which comprises the following steps: (1), weaving 30 percent of hemp, 35 percent of terylene and 35 percent of cotton by weight percentages into hemp blended yarn with a yarn number of 40 and then weaving the hemp blended yarn with moisture-bsorbing and rapidly-drying terylene yarn into a fabric under the condition that the weight ratio of the hemp blended yarn to the moisture-bsorbing and rapidly-drying terylene yarn is 55-65 to 35-45; (2) bleaching and heating a solution at a speed of 2 DEG C / min to a temperature of 98 DEG C under the condition that a bath ratio is 1 to 12, bleaching the solution at the temperature for 30 minutes, cooling the solution at a speed of 2 DEG C / min to 25 DEG C and washing the solution for 20 minutes; (3) dyeing; and (4) post-treatment technology. The invention has the advantages that hemp fibers have wide prospects after being applied to fabrics because the hemp has natural superior characteristics of antibacterium, ultraviolet ray resistance, moisture absorbable and breathable properties, and the like, the fabric adopts the blended yarn of the hemp, the cotton and the terylene to weaken the rigidity of the blended yarn, and the hemp fabric solves the problem of scratchiness and has bright colors and high color fastness.

Owner:北京铜牛集团有限公司

Cool fiber/ hemp composite summer sleeping mat and manufacture method thereof

InactiveCN102772081AHigh color fastnessGood washing dimensional stabilityWoven fabricsYarnYarnPolyester

The invention discloses a cool fiber / hemp composite summer sleeping mat and a manufacture method thereof. The composite summer sleeping mat is a double-faced fabric structure, cool colored filament fiber yarns and hemp blended yarns are arranged on the front surface of the composite summer sleeping mat, and hemp blending yarns are arranged on the bottom surface of the composite summer sleeping mat. The cool colored filament fiber yarns are of a leather-core structure, the leather layer is blend of at least one of polymer, a jade powder body and dye, and the core layer is the polymer which is polyamide or polyester. The hemp blending yarns are formed by blending at least one of hemp fibers, viscose fibers and cotton fibers, viscose fibers and bamboo fibers. The cool colored filament fiber yarns arranged on the front surface of the cool fiber / hemp composite summer sleeping mat of the double layer structure serve as the main body, and the hemp blending fiber yarns are arranged on the bottom surface, so that cool and comfortable performance and moisture absorption performance of the summer sleeping mat are well combined when contacted with skin of a human body, and simultaneously the summer sleeping mat has antimicrobial performance, requires no dyeing during the dyeing and finishing process and produces no dyeing waste water.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME

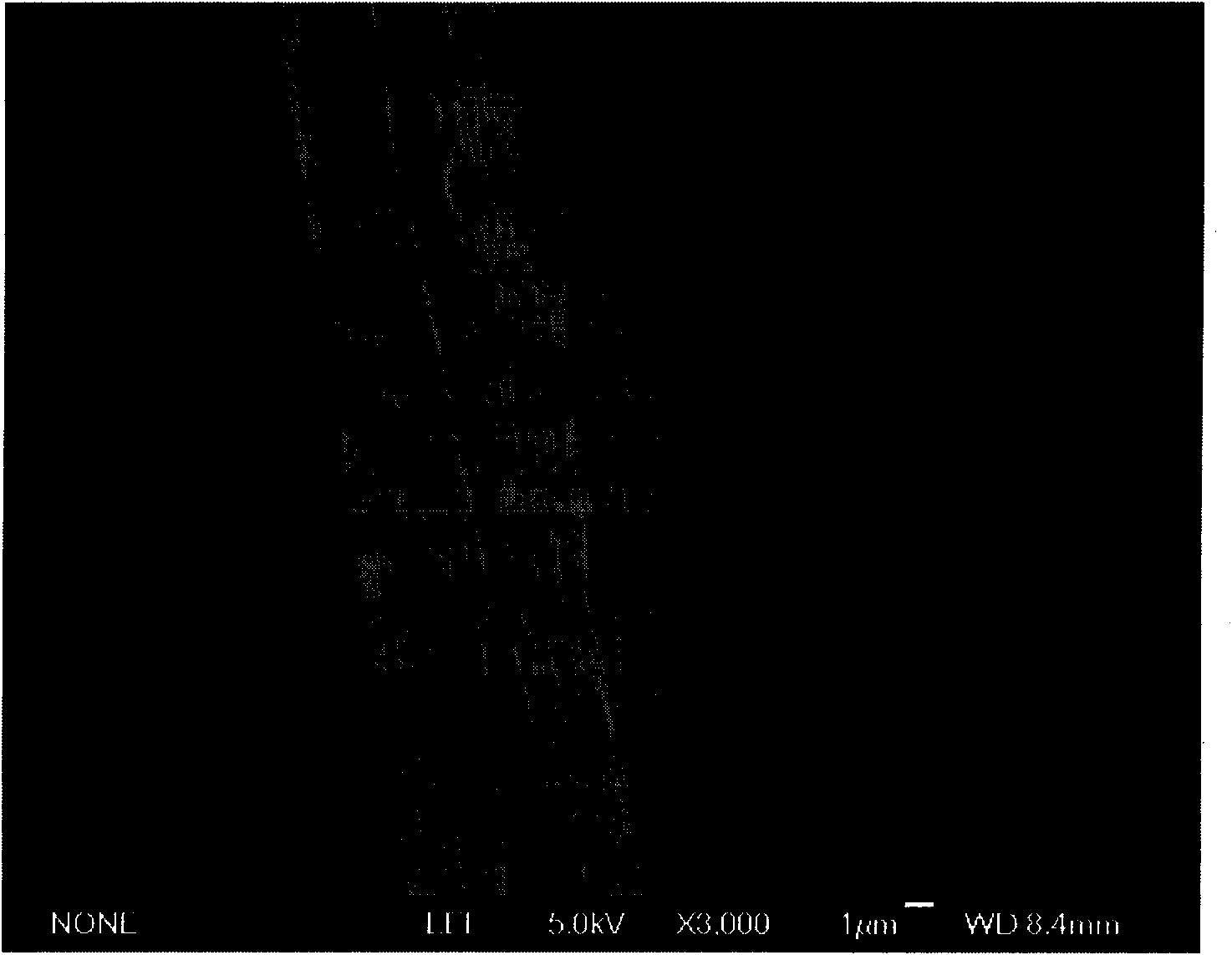

Method for preparing anesthesia activated carbon fiber

InactiveCN101230502ALarge specific surface areaWide variety of sourcesFibre chemical featuresVegetal fibresActivated carbonWater vapor

The invention provides a method of preparing a hemp activated carbon fiber, which adopts a hemp fiber or a hemp fabric as the raw material. The method includes the following steps: firstly, the hemp fiber or the hemp fabric is boiled in a pretreating solution, taken out and then dried; secondly, the obtained fiber or hemp fabric is put into a charing furnace, heated for charing under the protection of the nitrogen gas, then cooled to the room temperature and then rinsed repeatedly to be neutral; and thirdly, vapor is entered into the hemp fiber or the hemp fabric for an activation treatment, then dried after the activation treatment and finally a hemp activated carbon fiber is obtained. The specific surface area of the prepared activated carbon fiber is 680-1950m<2> / g and the yield of the activated carbon fiber is 20 to 62 percent.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME +1

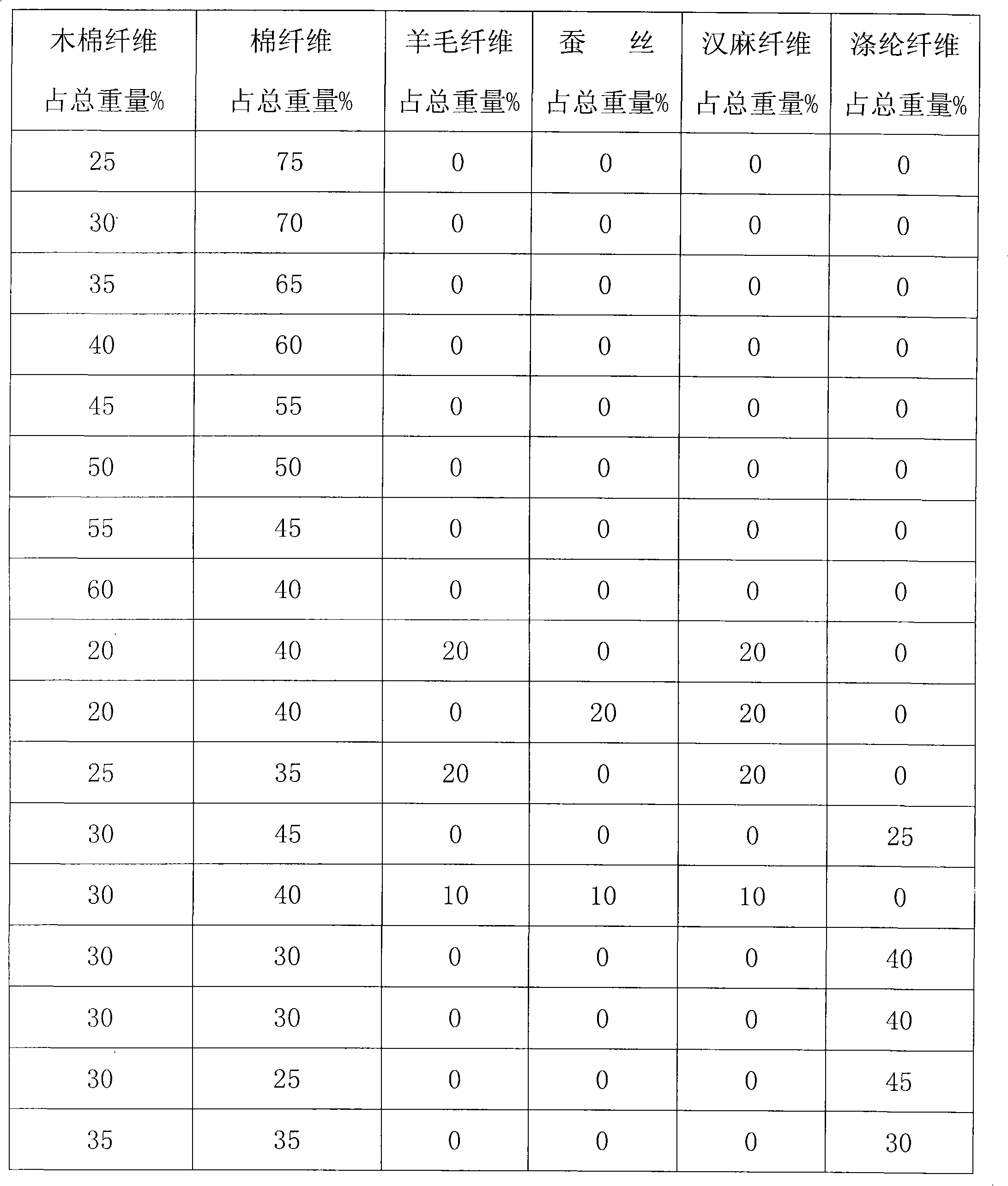

Process for manufacturing kapok fiber blended yarns

The invention discloses a process for manufacturing kapok fiber blended yarns, comprising the steps of selecting a plurality of kapok fibers, cotton fibers, wools, silks, hemp fibers and terylene fibers, wherein the content of the kapok fibers is 25-60% of the total blended yarns; the content of the cotton fibers, wools, silks, hemp fibers and terylene fibers is 40-75% of the total blended yarns; weighing the kapok fibers and other spinning fibers, dividing the fibers into small stacks, and obtaining multi-component blended yarns by mixing, blowing, cotton carding, drawing, roving and spinning, wherein the relative humidity of the production environment of each process is 60-65%; the products produced by the invention can be manufactured to be kinds of blended fabric materials; a fabric product which is pure natural, green, environment-friendly, soft and warming is increased in the spinning field.

Owner:JIHUA 3542 TEXTILE CO LTD

Degumming method of fabric

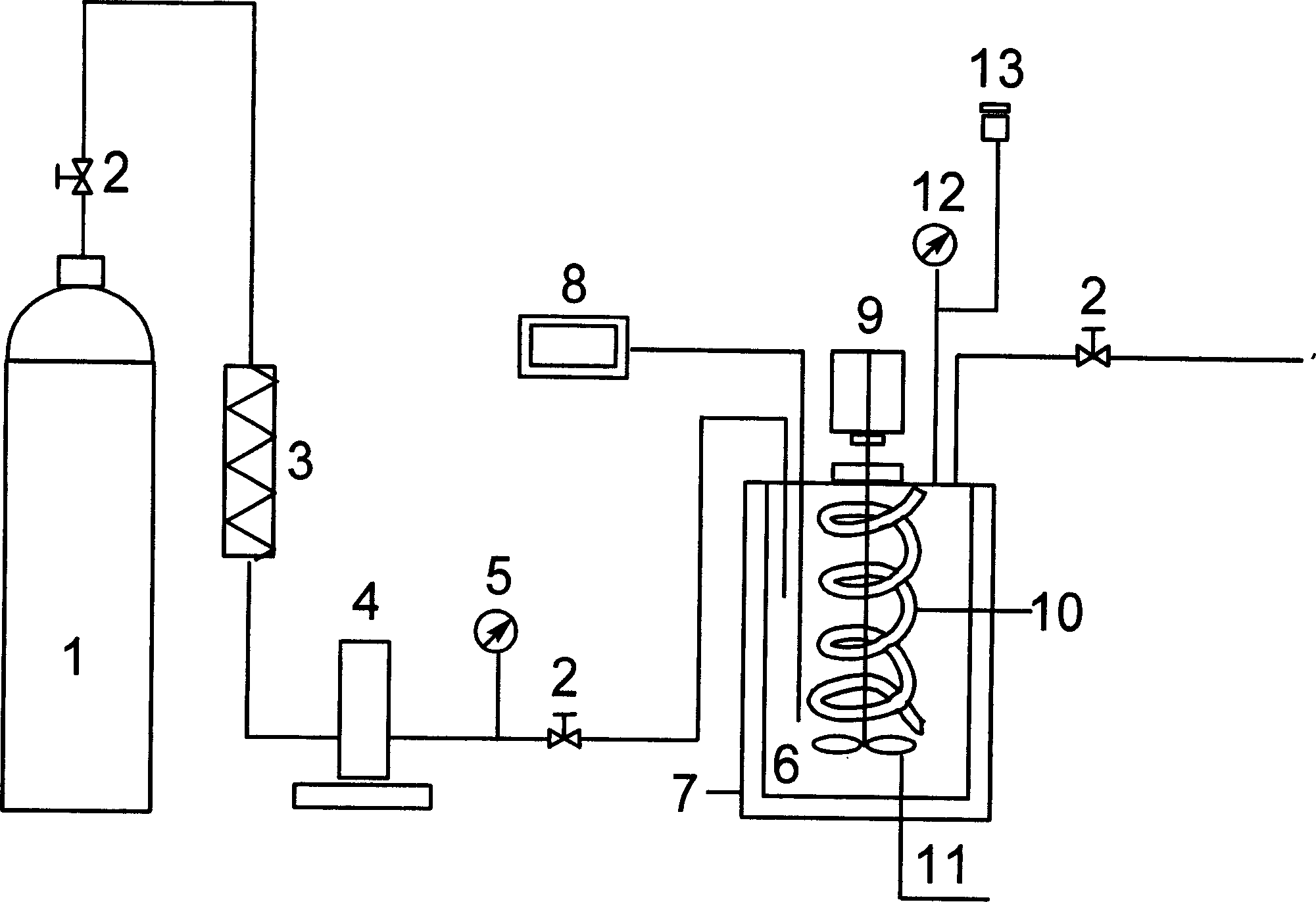

The invention relates to a degumming method for hemp fiber, in particular to a method for combined application of chemical with super critical CO2 fluid degumming. Wherein, before carrying out super critical CO2 fluid degumming, the hemp fiber first goes through chemical treatment, then super critical degumming is carried out under low and hi pressure respectively. The invention can obviously reduce the non-cellulose composition for example lignin, etc. in hemp fiber, is of an ideal degumming effect, with obviously improved cellulose ratio, very good softening effect of fiber, hence improved process quality of hemp fiber; the invention additionally overcomes the shortcoming associated with prior degumming way such as high pollution, etc., and is of high economic efficiency.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME

Technology for dyeing ramie fiber with overcritical carbon dioxide method

The invention relates to a new process of supercritical CO2 dyeing of ramie fiber, using ramie fiber as raw material, swelling by NaOH solution and modifying by benzoyl chloride, and dyeing with dispersive dye in supercritical CO2 medium by supercritical fluid technique. And its advantages: it is a clean producing process; the dyed ramie fiber has characters of bright color, short dyeing flow, dyeing uniformity, good color intensity, low synthetic cost, and remarkable economic and environmental protection benefits. And it also reveals a process device implementing the dyeing method, suitable to spread and apply in spinning and weaving, and printing and dyeing enterprises.

Owner:SHAANXI NORMAL UNIV

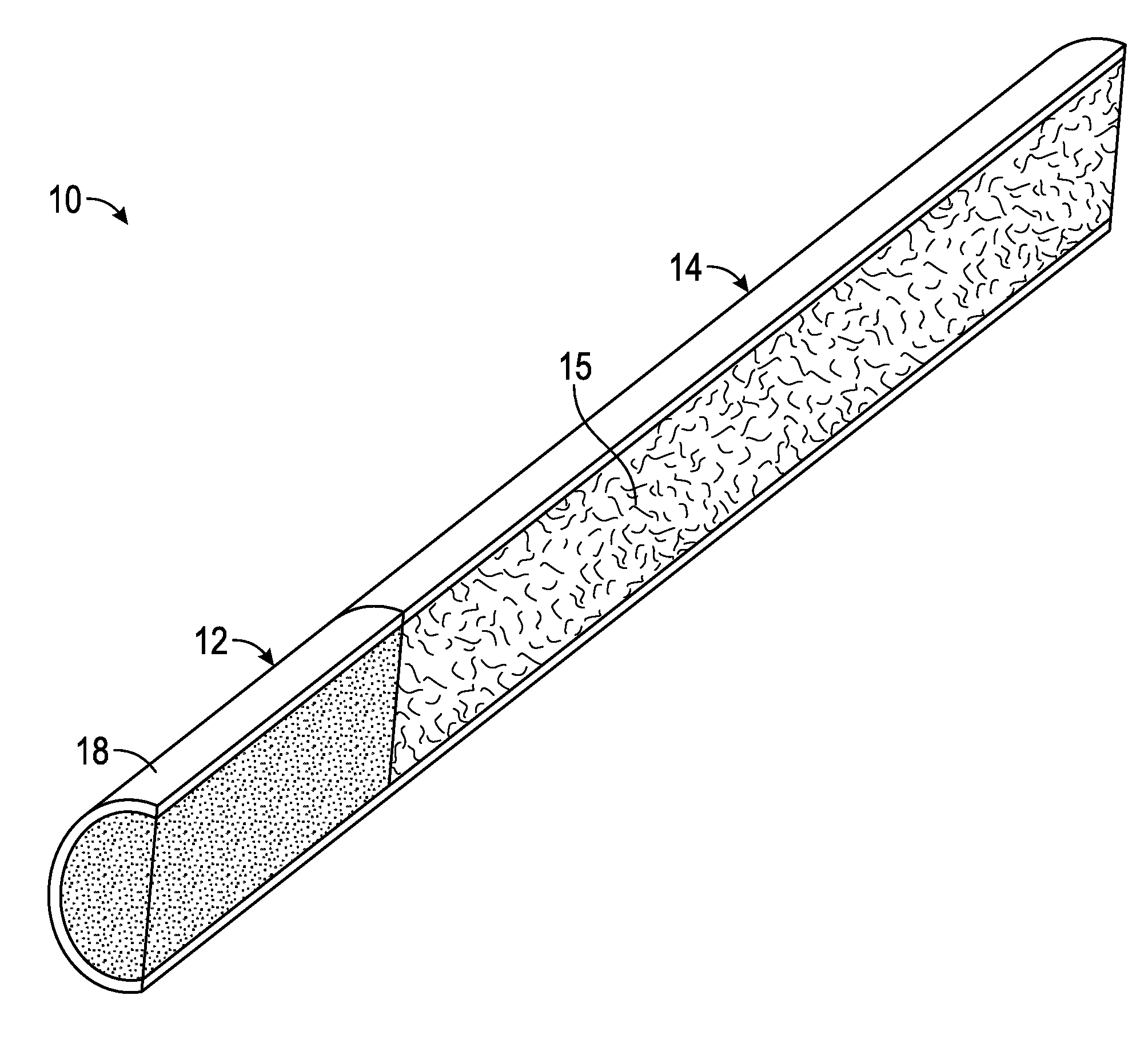

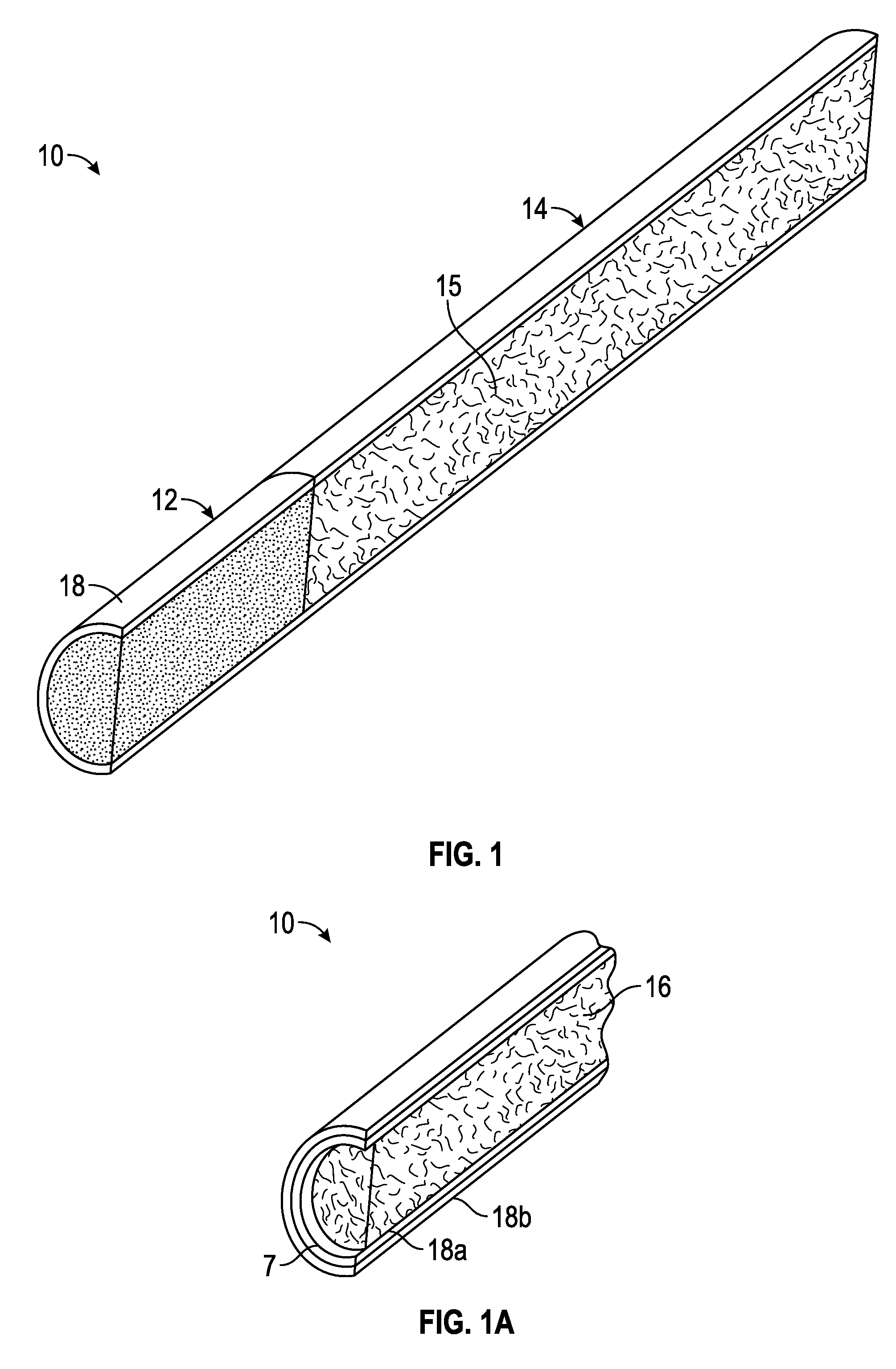

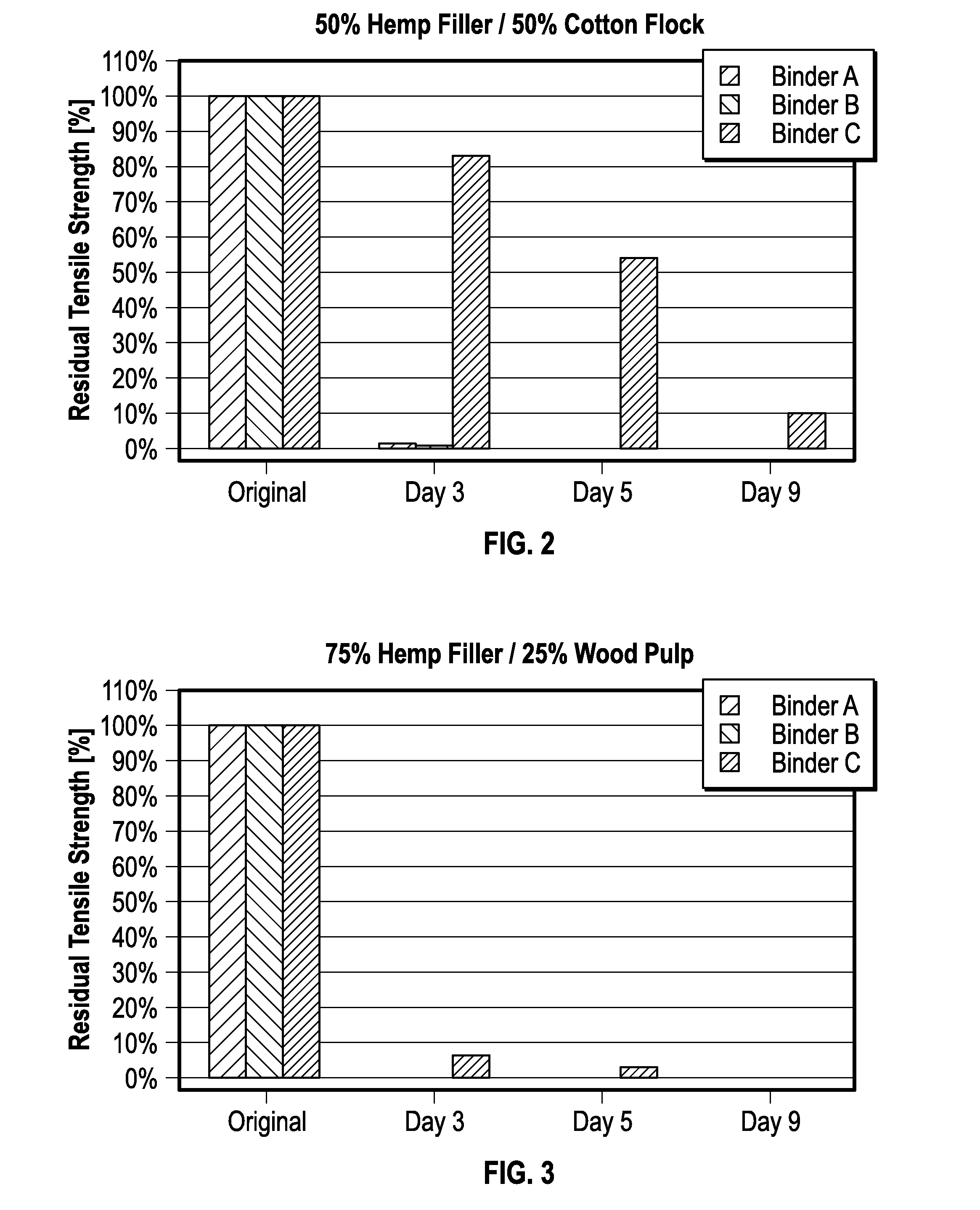

Biodegradable cigarette filter tow and method of manufacture

InactiveUS20150374030A1Promotes quick dispersibilitySimple methodNon-fibrous pulp additionTobacco treatmentPolymer scienceSisal fiber

A biodegradable cigarette filter tow includes a mixture of at least two or more natural materials selected from the group consisting of hemp fiber, flax fiber, abaca fiber or pulp, sisal fiber or pulp, wood pulp, and cotton fiber or cotton flock. The mixture may also include regenerated cellulose fibers. The mixture may include a natural binder or may be hydroentangled.

Owner:GREENBUTTS LLC

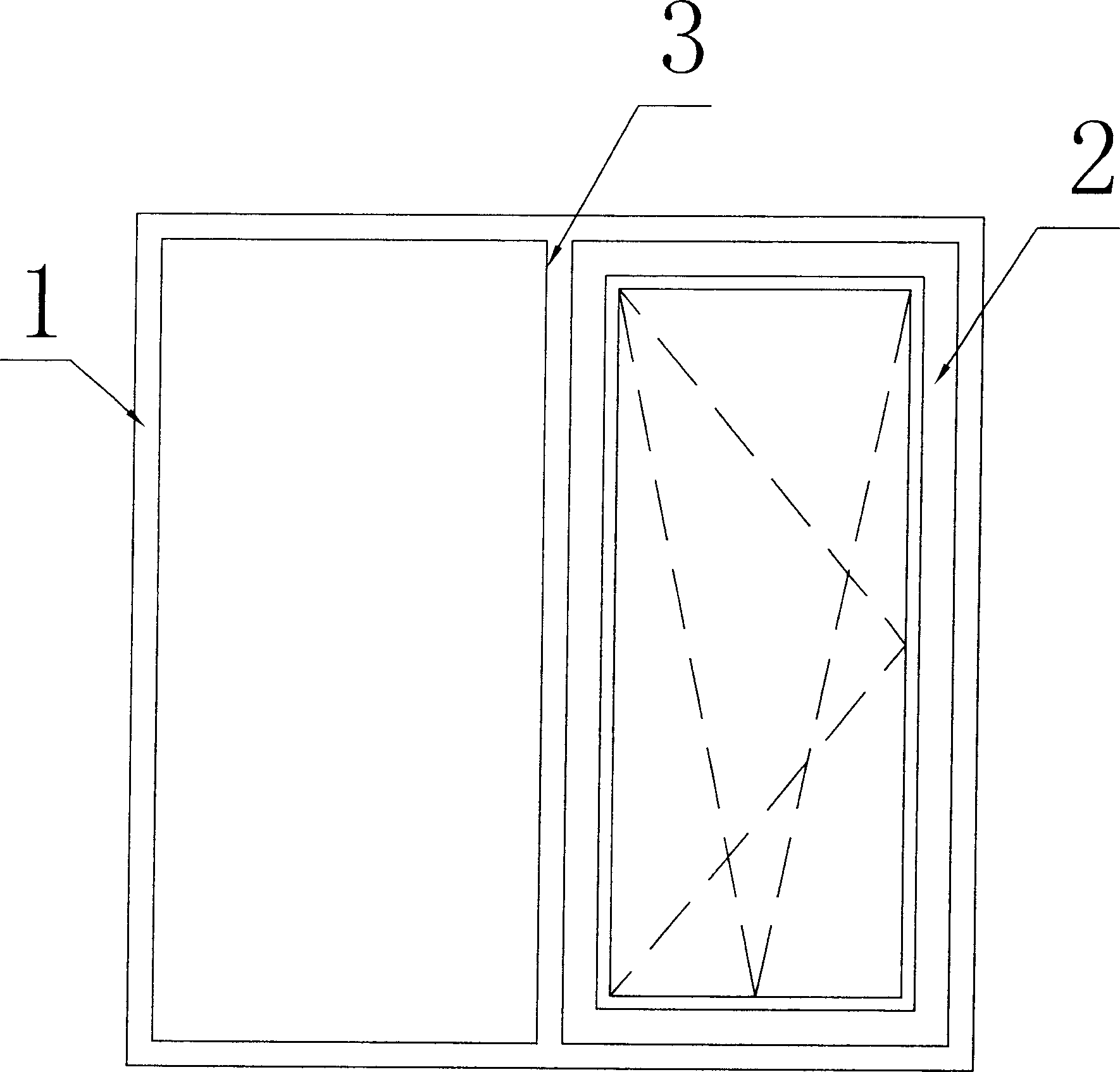

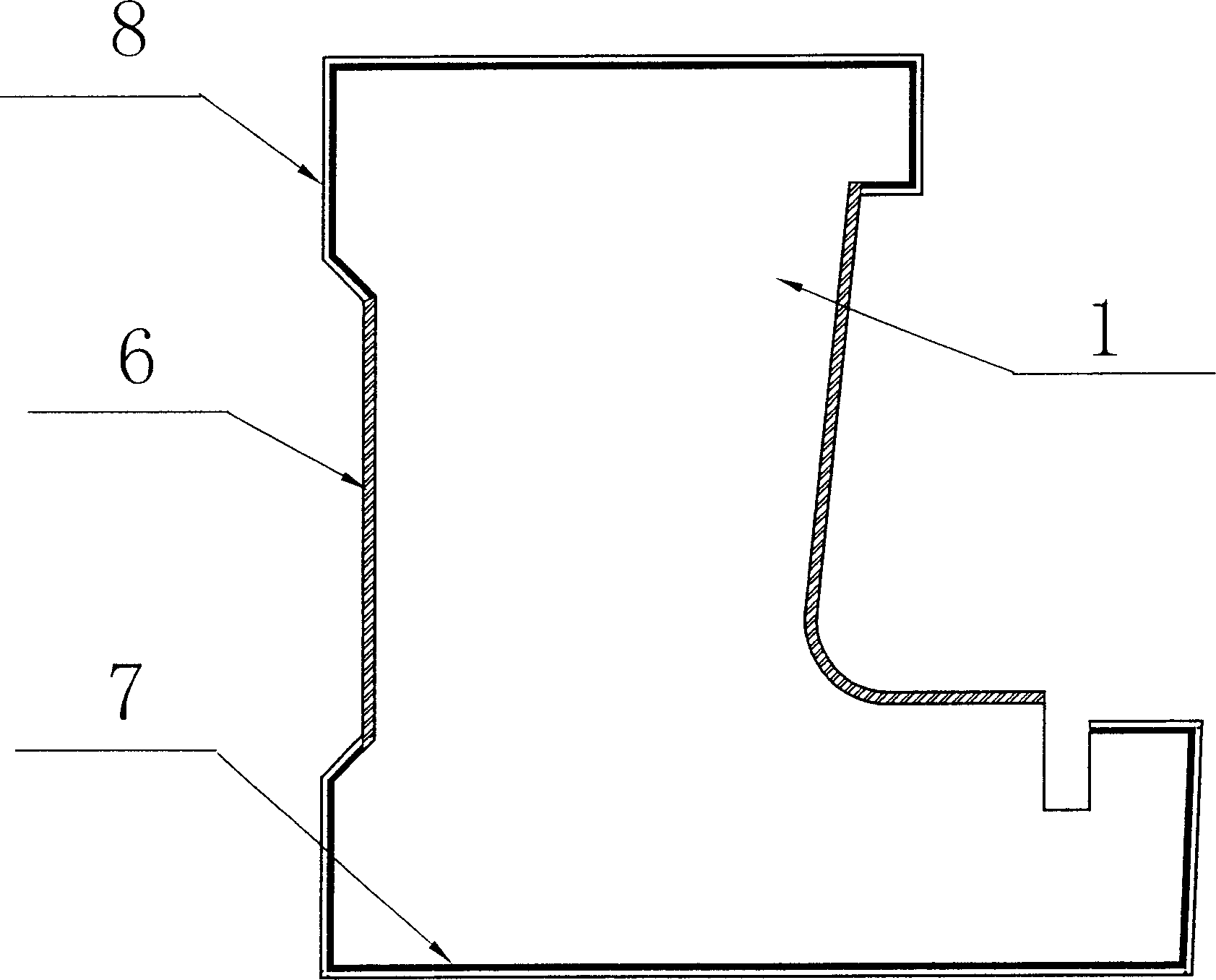

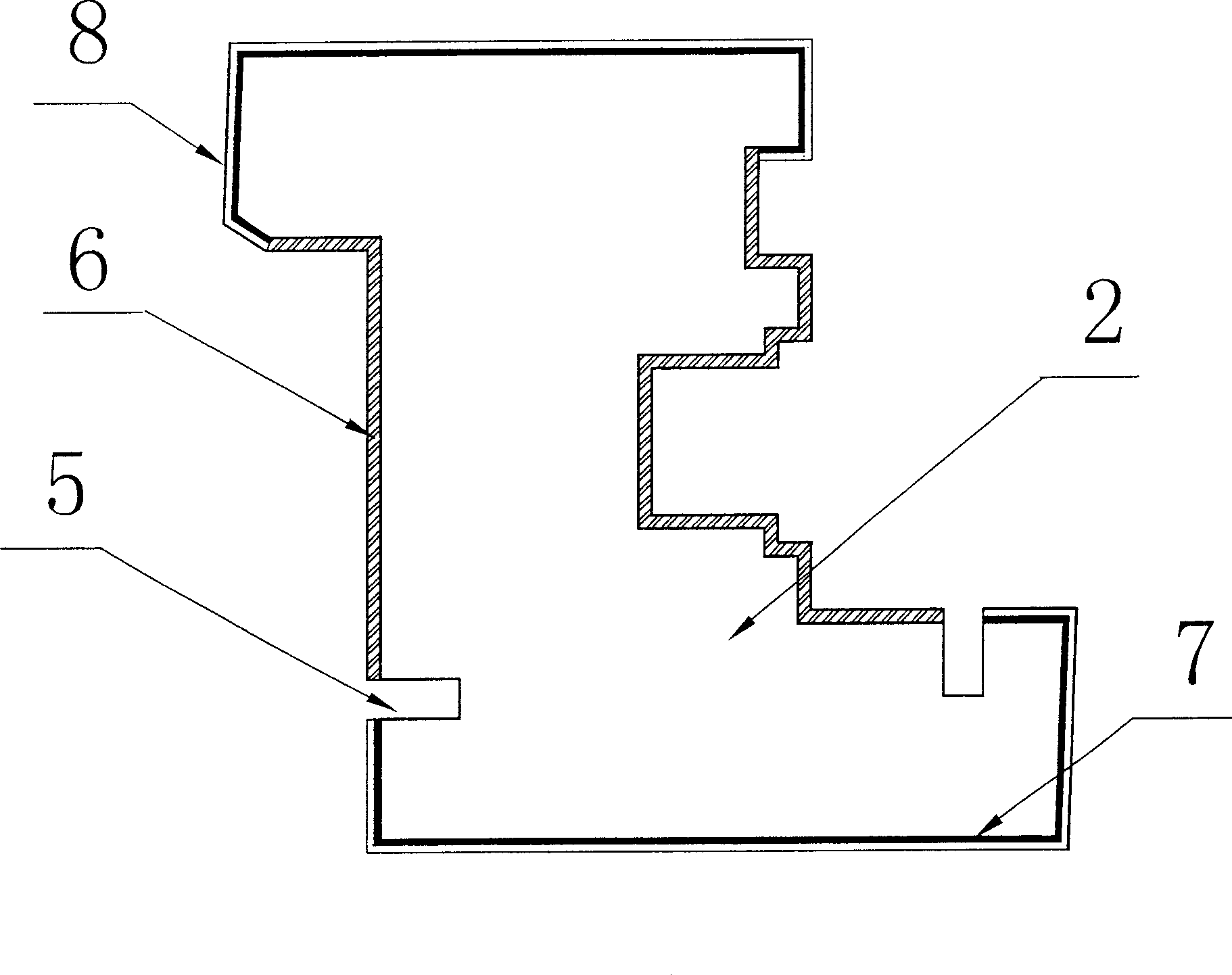

Environmental-protective and regenerative solid wooden plastic door and window and its production

This invention is a kind of regenerative environmental protecting type solid core wooden door and window. It is combined with frame structural section, sector structural section, middle frame structural section and sealing strips. The structural sections are solid core structural section. Their side faces are coated with plastic layer. The indoor face and outdoor face are coated with aluminum-coated layer through glue line. The main raw materials of the said solid core structural sections are regenerative polyolefine resin, plant fiber filler and auxiliary agent. The said regenerative polyolefine resin is the mixture of regenerative polypropylene and regenerative polyethylene. The plant fiber filler is wood fiber powder, hemp fiber powder, bamboo fiber powder, grass fiber powder, chaff powder or straw fiber powder. This invention decreases environmental pollution. It will not generate harmful gas when being heated. It also increases the anti-ultraviolet radiation, aging resistance and heat insulating performances.

Owner:北京大龙东升门窗幕墙工程有限公司

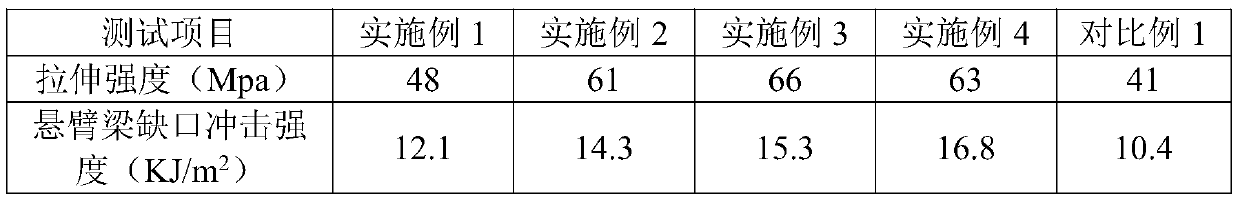

High-toughness full-degradable composite material

The invention provides a high-toughness full-degradable composite material, which is mainly prepared by blending the following components in parts by weight: 100 parts of biodegradable matrix resin; 1-60 parts of modified bio-based fiber; 1-8 parts of a compatilizer; 1-5 parts of a lubricant and 0-5 parts of a coupling agent; wherein the biodegradable matrix resin is one or a composition of more than two of PBAT, PCL, PLA, PBS, PBSA, PPC, PBST, PHB, PHA, PVA and PHBV, wherein the modified bio-based fiber comprises hydrophobic modification of the bio-based fiber or / and coupling modification ofthe bio-based fiber, the bio-based fiber is fibrilia, and the fibrilia is one or more of hemp fiber, flax fiber, sisal fiber and palm fiber. The modified plant fiber disclosed by the invention has a remarkable reinforcing and toughening effect on the bio-based matrix resin, and the interface compatibility and the interface bonding force of the modified plant fiber and the bio-based matrix resin are improved.

Owner:佰信(福建)新材料科技有限公司

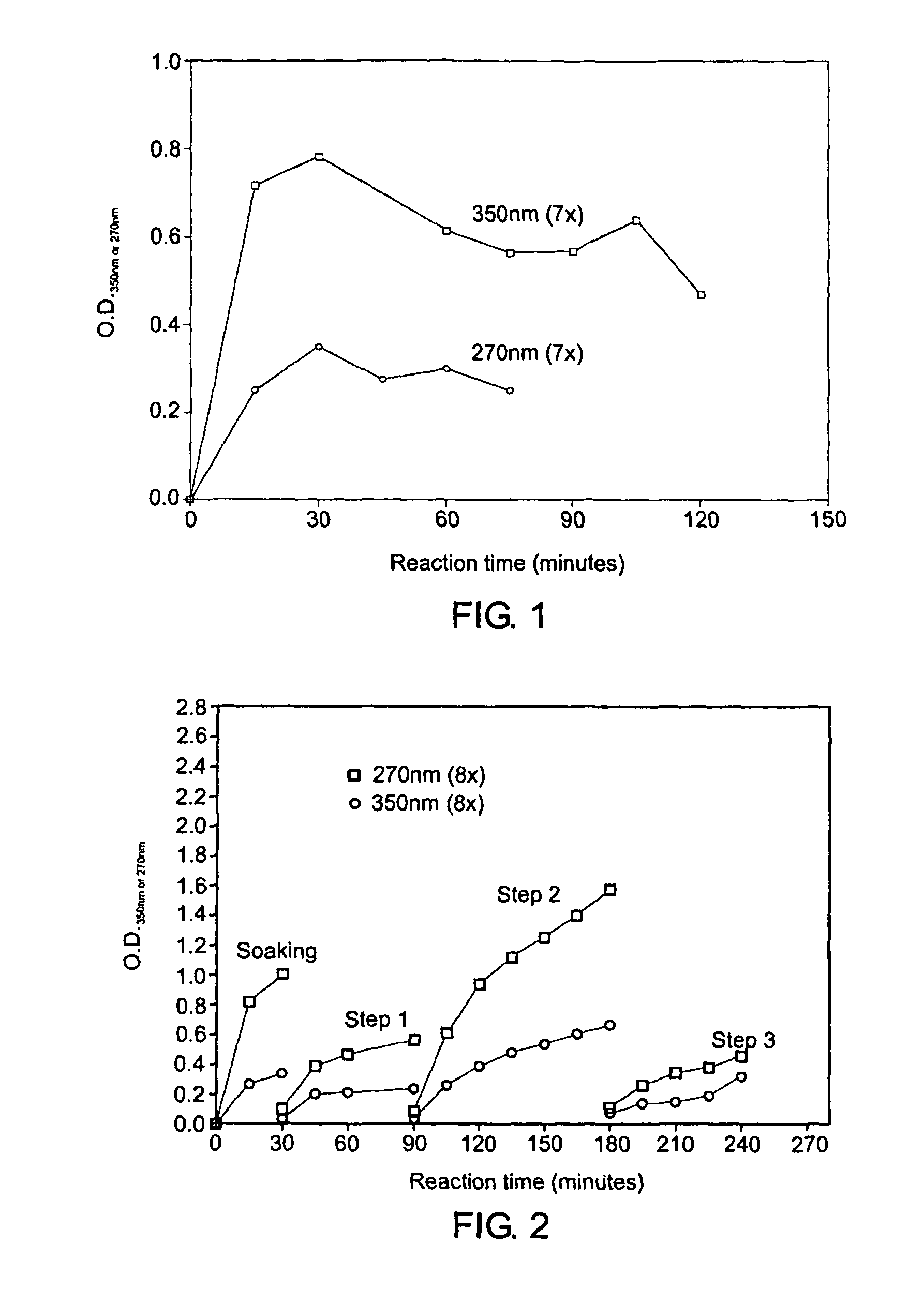

Extraction of hemp fibers

InactiveUS8591701B2Improve efficiencyEfficient extractionDigestersPulping with organic solventsPectinaseCellulose

Owner:NAT RES COUNCIL OF CANADA

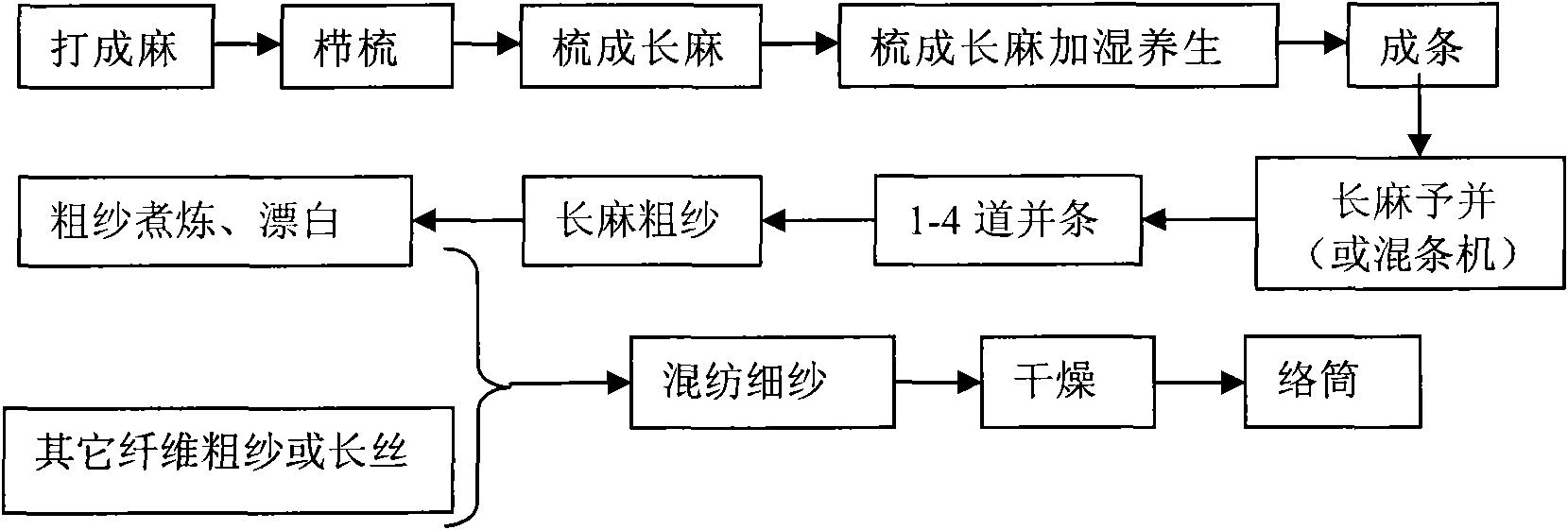

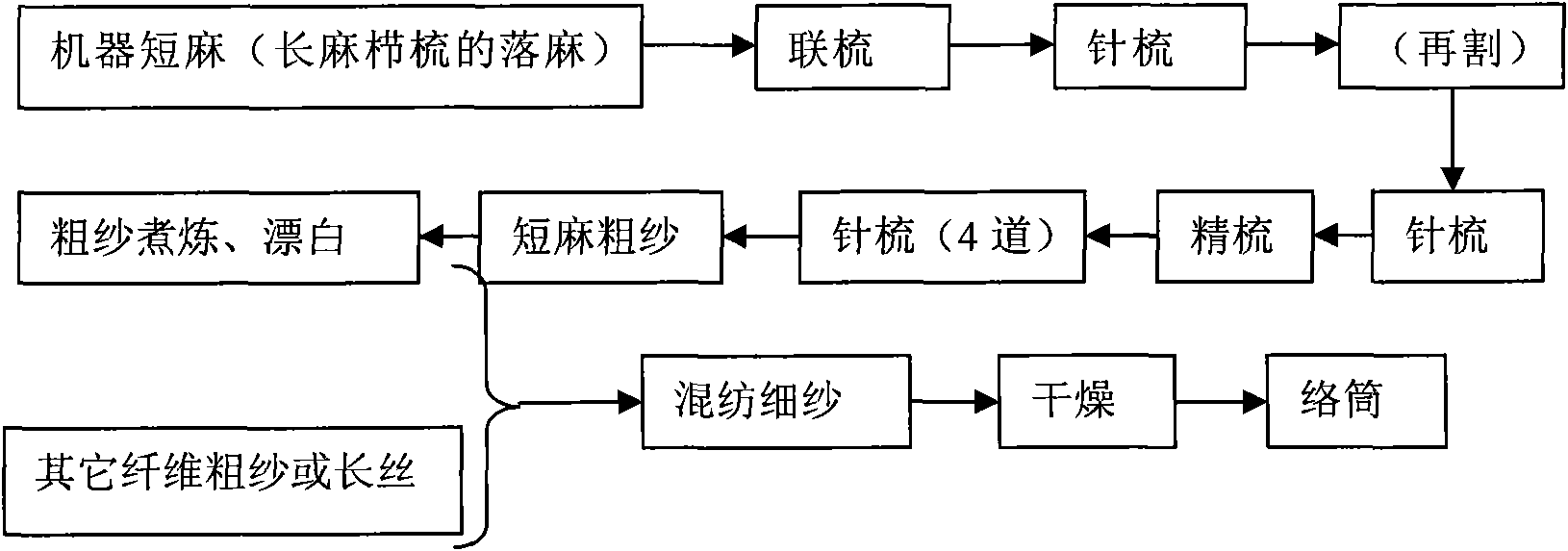

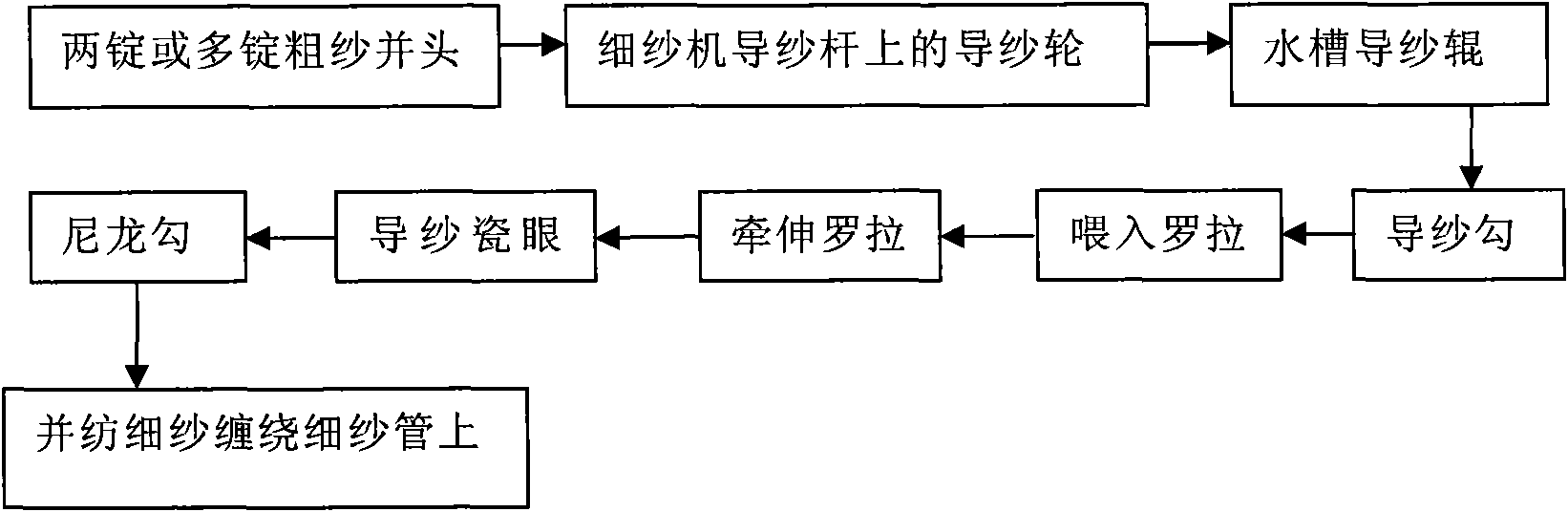

Blending method using hemp fiber as main material

InactiveCN101871147AIncrease the degree of splittingImprove impurity removalHackling machinesBleaching apparatusImpurityMaterials science

The invention relates to a blending method using a hemp fiber as a main material. The method comprises the following steps of: firstly, processing the hemp fiber into rovings; secondly, mixing the roving yarns of the hemp fiber with the rovings or filaments of other fibers in proportion to form bunch yarns; and finally, spinning the mixed bunch yarns in the second step into spun yarns. The blending method has the advantages of improving the disintegration degree of the hemp fiber and removing impurity without damaging the performance of the blended fibers, ensuring a high spinning yam count and quality of the blended yarns and greatly improving the quality of the blended yarns of the hemp fiber along with simple process.

Owner:肇融亚麻纺织有限公司

Process for producing sisal fiber

InactiveCN101294309AImprove finenessGood flexibilityMechanical fibre separationFibre treatment to obtain bast fibreColloidHemicellulose

The method for preparing sisal fiber is characterized in that the method comprises the following steps: (1) scraping colloid in sisal leaf pulp by mechanical knocking or rolling, and removing partial lignin, hemicellulose and pectin therein; (2) pre-soaking fiber material in sulfuric solution at 30 to 80 DEG C for 1 to 3 h; (3) cleaning with circulating water to adjust pH value to 6.8 to 7.2; (4) adding the fiber material in a boiler with pressure of 0.1 to 0.2 MPa, and boiling with sodium hydroxide solution for 2 to 6 h; (5) cleaning with circulating water to adjust pH value to 6.8 to 7.2; and (6) post-treating to obtain sisal fiber. The method has the advantages that the fineness and the flexibility of sisal fiber prepared by the method are improved greatly in comparison with unprocessed crude sisal.

Owner:DONGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com