Biodegradable cigarette filter tow and method of manufacture

a cigarette filter and biodegradable technology, applied in the direction of filtration separation, tobacco, separation processes, etc., can solve the problems of unfavorable environmental protection, unfavorable environmental protection, and unfavorable environmental protection, and achieve the effect of promoting rapid dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

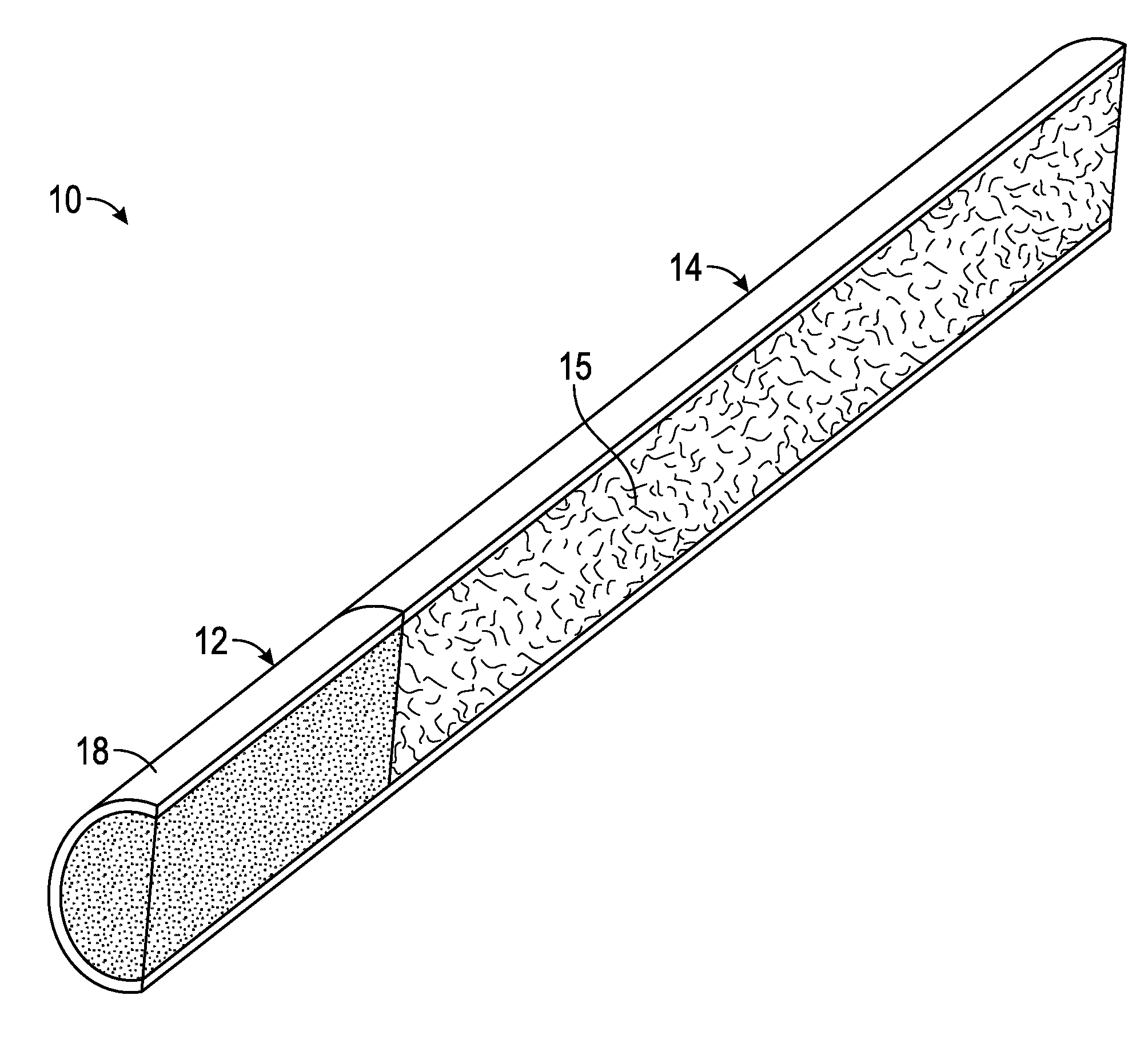

Image

Examples

example manufacturing process

[0110]In one embodiment, a fibrous web (wetlaid nonwoven or wetlaid paper) of the fiber composition described above is formed by a wetlaid or paper making process. The process involves dispersion of fibers in water, delivery of the fiber dispersion to the formation wire of a wetlaid or papermaking machine (flat wire, incline wire, cylindrical mold machine, etc.). The technical differences between the processes are well known and described in literature. The concept is based on the fibers in the form of dispersion in water being deposited on the formation wire (aperture belt) and subsequent removal of excess water from the fiber layer by a suction system. The selection of the machinery, setting of process parameters, and addition of process additives depend on the type and morphology of fibers involved in the process. The process parameters are set to provide sufficient fiber dispersion, uniform deposition of fibers on the forming wire, fiber orientation in the fibrous web and areal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com