Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

454 results about "SISAL" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

SISAL ("Streams and Iteration in a Single Assignment Language") is a general-purpose single assignment functional programming language with strict semantics, implicit parallelism, and efficient array handling. SISAL outputs a dataflow graph in Intermediary Form 1 (IF1). It was derived from VAL (Value-oriented Algorithmic Language, designed by Jack Dennis), and adds recursion and finite streams. It has a Pascal-like syntax and was designed to be a common high-level language for numerical programs on a variety of multiprocessors.

Leaking stoppage cement slurry for well cementation and preparation method thereof

InactiveCN101857800AGood high temperature application performanceEvenly dispersedDrilling compositionCementation processSodium sulfate

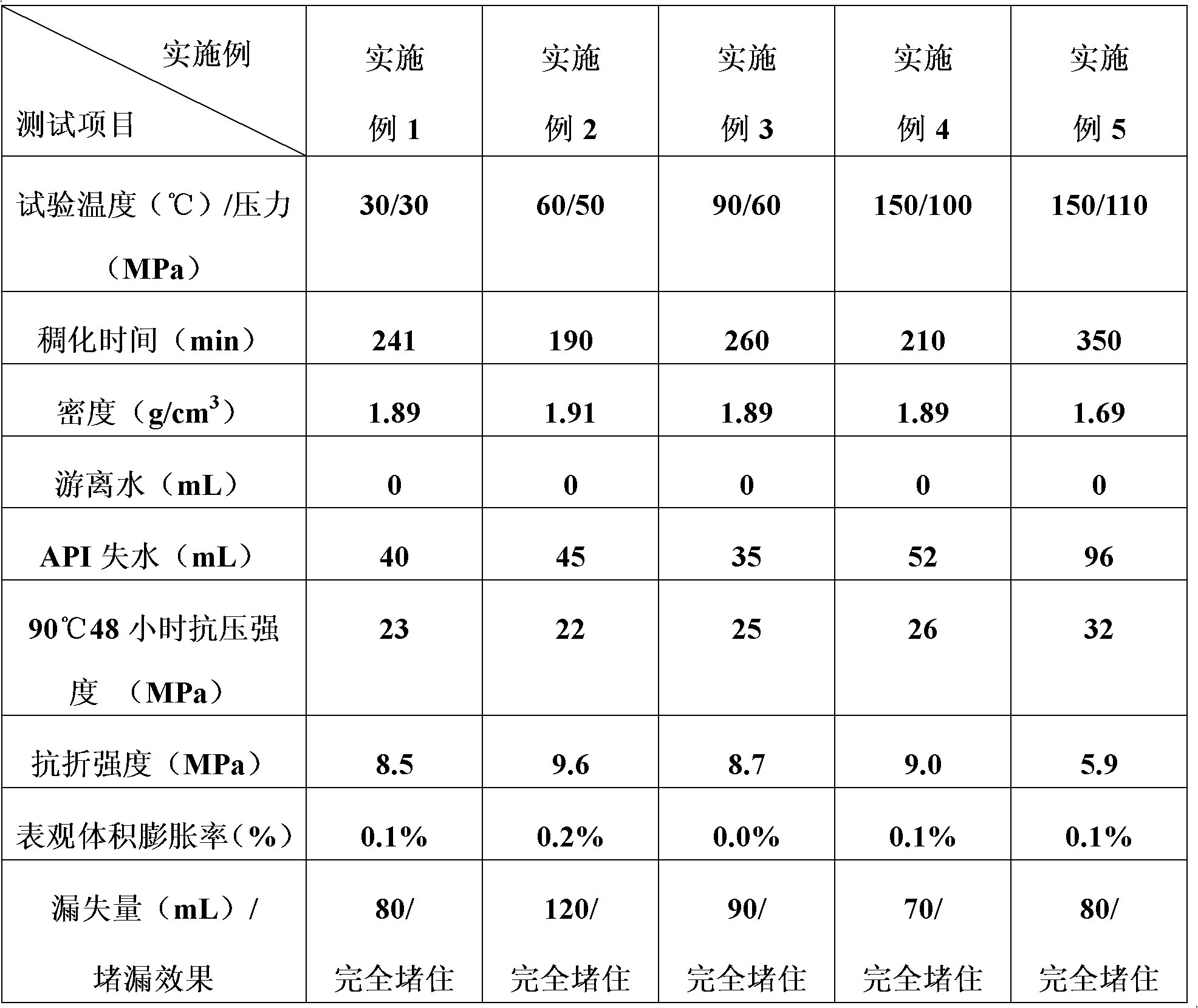

The invention relates to leaking stoppage cement slurry for well cementation and a preparation method thereof. The leaking stoppage cement slurry consists of the following components in parts by weight: 100 parts of oil-well cement, 50-150 parts of water, 0.01-8 parts of fibrilia, 1-20 parts of dispersing agent, 1-20 parts of filtrate reducer, 5-50 parts of alkali regulator, 1-10 parts of retarder and 0-1 part of defoaming agent, wherein the dispersing agent is lauryl sodium sulfate or sodium hexametaphosphate; the filtrate reducer is 2-acrylamide-2-methylpropanesulfonic acid or hydroxyethylcellulose; the alkali regulator is silicon powder; the retarder is sodium lignin sulfonate or citric acid; the defoaming agent is dimethyl silicon oil or tributyl phosphate; and the fibrilia is one or the mixture of two or more of jute, flax, hemp, ramie and sisal. The invention effectively solves the problem of leakage loss of cement slurry and inherent brittleness of set cement in the well cementation process on the premise of meeting various engineering performances required by the well cementation and provides the guarantee for subsequent operation of oil well gas.

Owner:SOUTHWEST PETROLEUM UNIV

Multipurpose pellets and method of making same

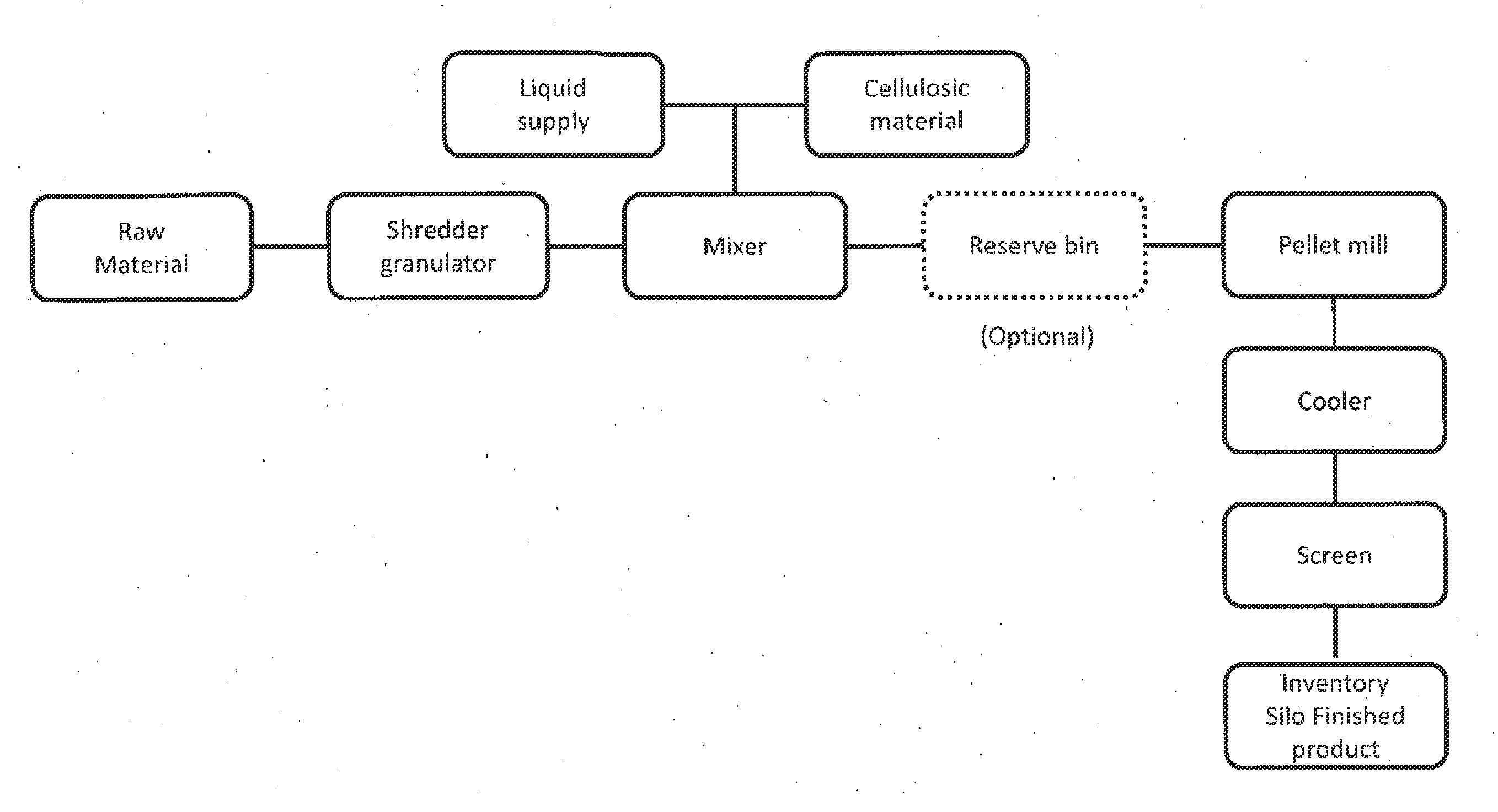

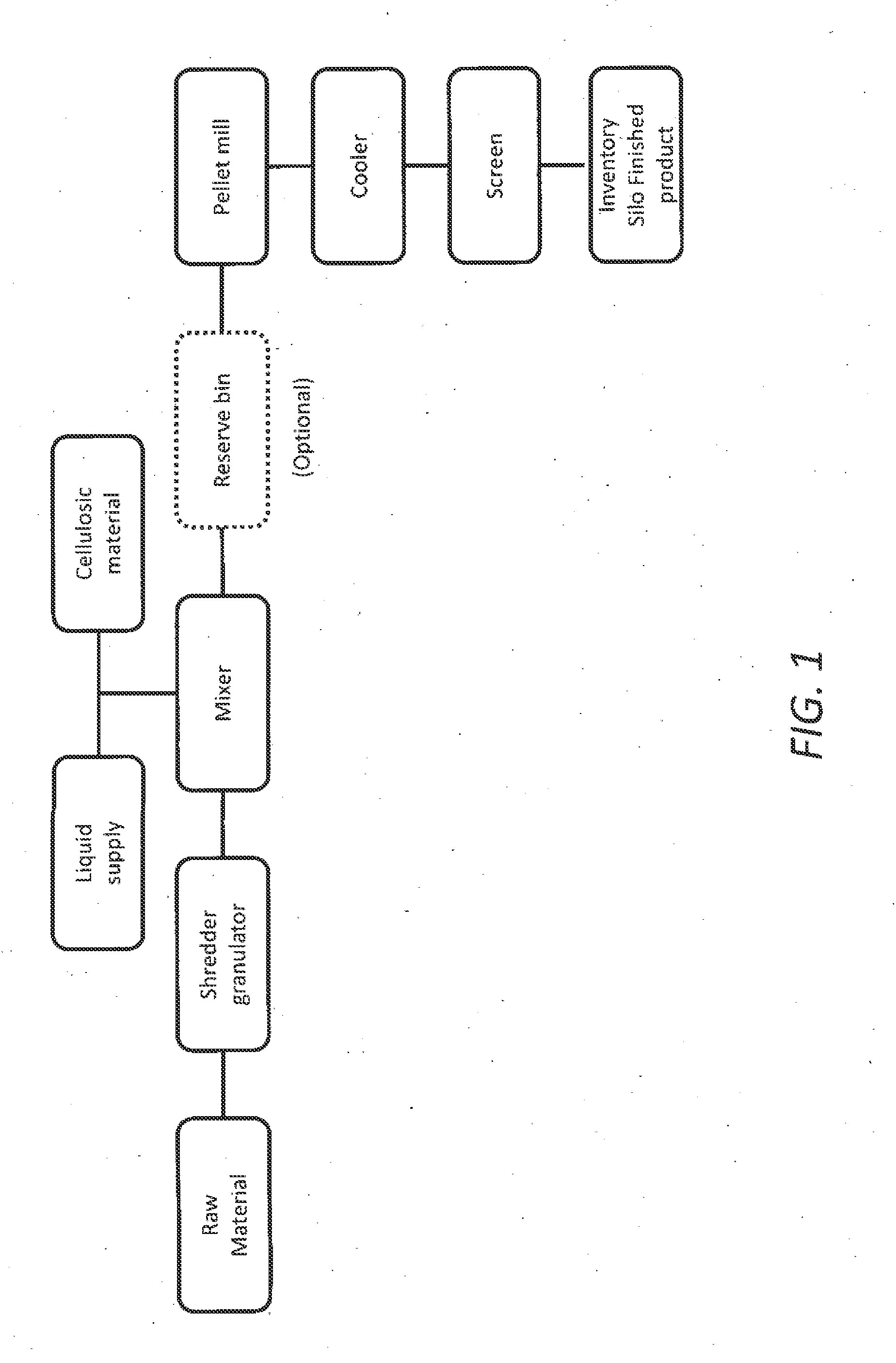

A multipurpose pellet is provided comprising: from about 0.1% to about 100% by weight of a vegetable fiber chosen from cotton, bamboo fiber, rice fiber, esparto, papaya, coir, sisal, kapok, jute, ramie, flax, roselle hemp, hemp, kenaf, abaca, soybean fiber, okra fiber, vine fiber, banana fiber, rattan and nettlesjute; and from about 99.9% to about 0% by weight of cellulosic material.

Owner:LEFEBVRE ROBERT

Process for producing sisal fiber

InactiveCN101294309AImprove finenessGood flexibilityMechanical fibre separationFibre treatment to obtain bast fibreColloidHemicellulose

The method for preparing sisal fiber is characterized in that the method comprises the following steps: (1) scraping colloid in sisal leaf pulp by mechanical knocking or rolling, and removing partial lignin, hemicellulose and pectin therein; (2) pre-soaking fiber material in sulfuric solution at 30 to 80 DEG C for 1 to 3 h; (3) cleaning with circulating water to adjust pH value to 6.8 to 7.2; (4) adding the fiber material in a boiler with pressure of 0.1 to 0.2 MPa, and boiling with sodium hydroxide solution for 2 to 6 h; (5) cleaning with circulating water to adjust pH value to 6.8 to 7.2; and (6) post-treating to obtain sisal fiber. The method has the advantages that the fineness and the flexibility of sisal fiber prepared by the method are improved greatly in comparison with unprocessed crude sisal.

Owner:DONGHUA UNIV

Environment-friendly braking friction material and preparation method thereof

The invention provides an environment-friendly braking friction material containing natural plant fiber, natural mineral fiber, natural mineral powder and cardanol-based benzoxazine modified phenolic resin and a preparation method thereof. The natural plant fiber is one or a plurality of flax, ramie, jute, hemp and sisal processed by a chemical method (alkali and acid) and a physical method (high-pressure steam), the natural mineral fiber comprises needle-like limestone and basalt fiber, and the natural mineral powder comprises zircon, barite, vermiculite and graphite. The invention also provides a preparation method of the natural mineral powder and cardanol-based benzoxazine pellet and a preparation method of cardanol-based benzoxazine in-situ toughening phenolic resin.

Owner:BEIJING UNIV OF CHEM TECH

Bacillus subtilis and application thereof in sisal hemp degumming

InactiveCN101880637AExact decompositionAchieve complete degummingBacteriaMicroorganism based processesWater bathsMicrobiology

The invention discloses Bacillus subtilis and application thereof in sisal hemp degumming. The conservation number of the Bacillus subtilis B2 is CCTCCM208115. When in application, the Bacillus subtilis is used as a single strain which is inoculated in seed culture medium, is placed in a gas bath shaker or water bath shaker with temperature of 37 DEG C and is cultured for 8-12h, 2-20 percent (volume percent) of inoculation quantity is trans-inoculated in degumming culture medium when 0D600 reaches 0.6-1, fresh sisal hemp leaves are added in the degumming culture medium, culture temperature is 25-42 DEG C, the revolution of the shaker is 150-250rpm and the sisal hemp degumming can be completed in 35-55h. The invention has the advantages that the culture conditions are extensive, the growth and the reproduction are rapid, the sisal hemp degumming can be completed in 35h, the fiber is not damaged, the environment is not polluted, and the Bacillus subtilis can substitute for mechanical green removal and can be used for the pretreatment of sisal hemp before sisal hemp degumming and pulping technology.

Owner:SOUTH CHINA UNIV OF TECH

Process of preparing sodium-copper chlorophyllide and pectin with sisal residue

InactiveCN1847245ARealize comprehensive utilizationHigh economic valueCopper organic compoundsIron saltsHydrolysate

The present invention discloses comprehensive utilization of sisal residue. The wet sisal residue after fiber extraction is extruded, soaked in alcohol and filtered to obtain extracted liquid for preparing chlorophyll and extracted residue for preparing pectin. The extracted liquid after alcohol recovery is extracted with ethyl acetate to obtain chlorophyll; and the chlorophyll is reacted with copper sulfate and saponified with sodium hydroxide to obtain sodium-copper chlorophyllide. The extracted residue is ultrasonically washed, dilute hydrochloric acid washed, enzyme deactivated and hydrolyzed with 0.4 % concentration hydrochloric acid solution to obtain hydrolysate; and the hydrolysate is salted out with iron salt or copper salt, desalted, decolorized and dried to obtain pectin. The present invention raises the utilization value of sisal and is environment friendly.

Owner:GUANGXI UNIV

Method for manufacturing vegetable fiber mattress

ActiveCN101856182ABroaden sources of raw materialsReduce manufacturing costUpholstery manufactureStuffed mattressesVolumetric Mass DensityVegetable fibers

The invention discloses a method for manufacturing a vegetable fiber mattress, which uses the sisal hemp head fibers, which are made from sisal hemp heads, as a material for manufacturing the vegetable fiber mattress. In the invention, because the sisal hemp head fibers are used to manufacture the vegetable fiber mattress, a raw material source for the vegetable fiber mattress is added; and as a result, the production cost of the vegetable fiber mattress is reduced, and for the head fibers of the sisal hemp are thick and have a good naturally winding effect, the manicured vegetable fiber mattress has a small density and high breathability, avoids winding forming and has higher performance than vegetable fiber mattresses produced by mixing mountain palm or oilpalm fibers. The method of theinvention is simple, easy to implement and good in use effect.

Owner:GUIZHOU DAZIRAN TECH

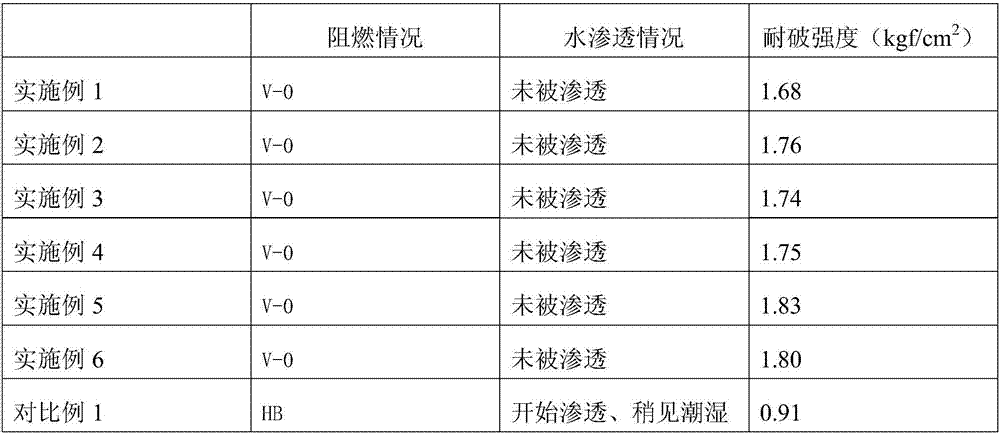

Waterproof and flame-retardant paper cone

ActiveCN106948211AHigh bromine contentImprove thermal stabilityWater-repelling agents additionReinforcing agents additionSodium metasilicateSodium Bentonite

The invention discloses a waterproof and flame-retardant paper cone, belonging to the technical field of electroacoustic products. The slurry of the paper cone is prepared by mixing and sitrring the following main raw materials in parts by weight: wood pulp, sisal hemp, cotton pulp, kapok, bulletproof fiber, wool, glass fiber, a dye, table salt, a hardening agent, a flexibilizer, a regulator, a waterproofing agent and a flame retardant, wherein the waterproofing agent is prepared through the following steps: adding acrylic rubber latex, hydroxyethyl cellulose, bentonite and sodium metasilicate according to a weight ratio of 1: (0.1-0.5): (0.2-0.5): (0.05-0.2) into water, carrying out mixing under stirring so as to form an emulsion, placing the emulsion in a stirring reflux device, and carrying out a reflux reaction for 3 to 4 hours; and the flame retardant is prepared by uniformly mixing kaolin with decabrominated dipheny ethane and antimonous oxide or magnesium hydroxide with a weight ratio of 1: (1-5) under stirring. The waterproof and flame-retardant paper cone provided by the invention has subdued sound effect and good dampproof and waterproof performances, flame retardance and mechanical performance, and is improved in use safety and prolonged in service life.

Owner:广西玉林市禹力音响配件有限公司

Epoxy soybean oil resin based rigid cellular plastic and method for preparing same

The invention discloses epoxidized soybean oil resin-matrix rigid foam plastic and a method for preparing the same. The plastic is obtained by synthesizing compositions with the following weight portions: 100 portions of epoxidized soybean oil resin, 10 to 60 portions of vinyl monomers, 1 to 6 portions of vesicant, 1 to 4 portions of foam stabilizer, 4 to 10 portions of evocating agent, 2 to 6 portions of accelerant, 2 to 10 portions of water, and 0 to 20 portions of sisal fibers. The epoxidized soybean oil resin-matrix rigid foam plastic prepared by the invention has good performance, the density is between 0.1g / cm <3> and 0.3g / cm <3>, the compressive strength is between 300 and 3500kPa, the performance approaches that of the prior thermosetting rigid foam plastic, and the plastic can be used for building materials, furniture materials, heat insulating and sound-insulating materials and so on. Reinforced fiber and main matrix resin of the plastic both derive from renewable resources, so the plastic has full biodegradation performance and is an ideal substitute for treating 'white pollution'.

Owner:SUN YAT SEN UNIV

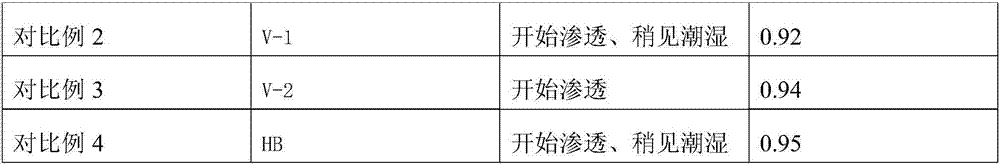

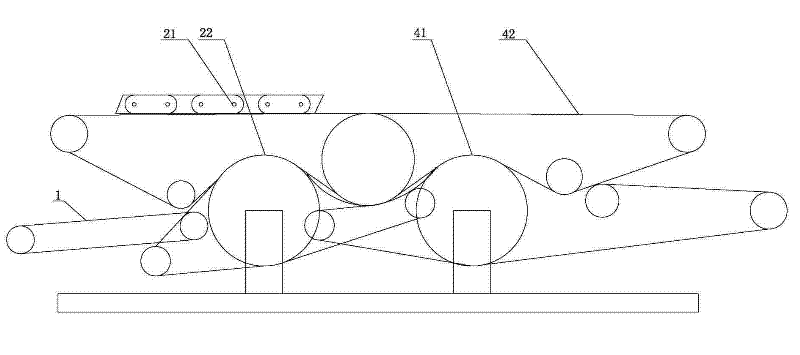

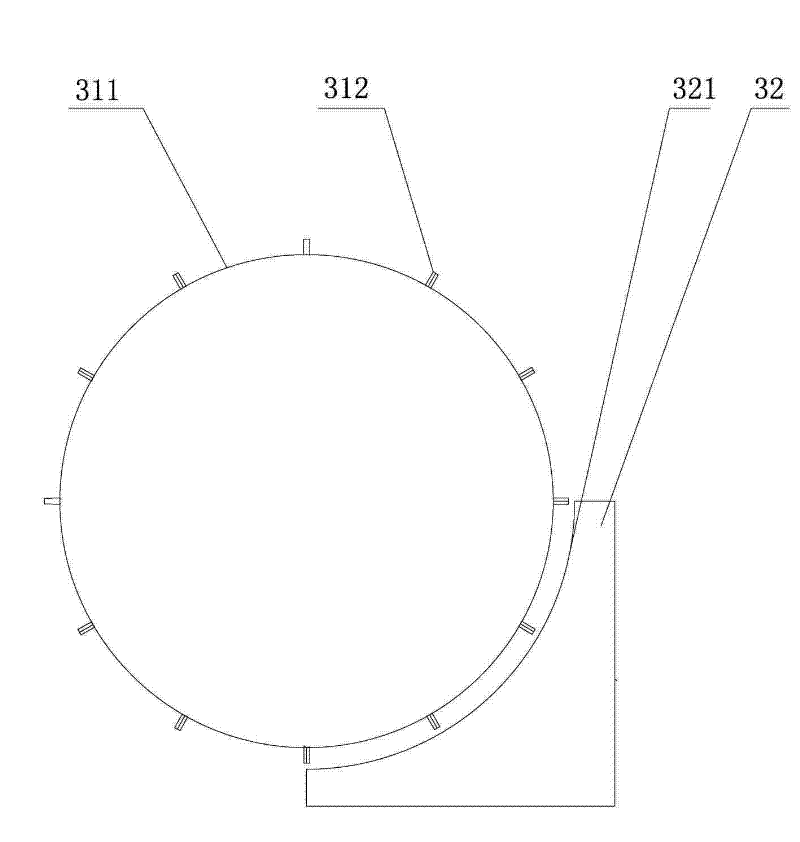

Sisal processing method and sisal scraping device thereof

InactiveCN102230229AHigh extraction rateThe draw rate does not affectMechanical fibre separationEngineeringSISAL

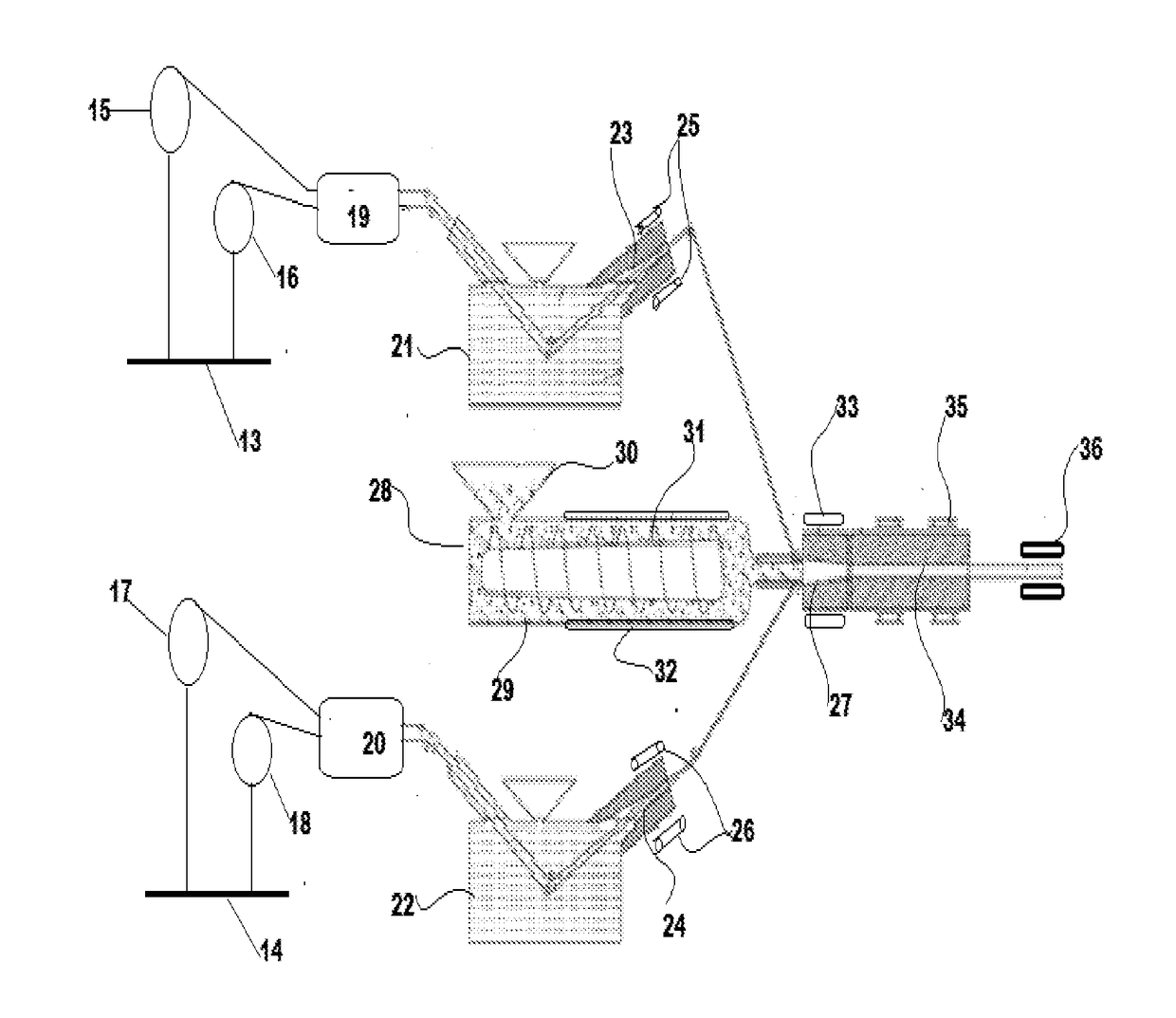

The invention discloses a sisal processing method and a sisal scraping device thereof. The sisal processing method comprises the steps of: 1) arranging sisals and quantitatively feeding; 2) neatly spacing blades of the sisals; 3) stretching and conveying; 4) scraping the sisals: firstly clamping the base parts of the blades of the sisals; then scraping the tip parts of the blades of the sisals; clamping scraped tip fibre parts; and completely scraping the base parts of the remainder blades of the sisals; 5)squeezing water of straight fibres; 6) drying the straight fibres; and 7) packing and warehousing. The sisal scraping device comprises a sisal arranging and conveying mechanism, a first sisal clamping mechanism, a first knife ball mechanism, a second sisal clamping mechanism and a second knife ball mechanism; the base parts of the blades of the sisals are clamped by the first sisal clamping mechanism and are conveyed forwards; the tip parts of the blades of the sisals are scraped by the first knife ball mechanism; the scraped edge fibre parts are clamped by the second sisal clamping mechanism and are conveyed forwards; and the base parts of the blades of the sisals are scraped by the second knife ball mechanism. According to the invention, the extraction rate of the straight fibres and the comprehensive quality of the fibres are improved; and the production cost is reduced.

Owner:湛江农垦第二机械有限公司

Method for preparing pectin by using waste sisal dregs

The invention discloses a method for preparing pectin by using waste sisal dregs. By utilizing the waste sisal dregs as raw materials, the method for preparing the pectin comprises the steps of pretreatment of the raw materials, enzyme inactivation, water rinsing, microwave assisted acid water extraction, extracting solution treatment and concentration, alcohol precipitation, filtration and drying. Compared with the prior art, the method has the advantages of: 1, high pectin yield, low impurity content, simple process, low energy consumption and easy large batch production of the pectin; 2, short extraction time and high yield by using the microwave for assisting in the extraction during the decomposition of the acid water; low energy consumption, low impurity content and easy industrialization by using the membrane separation technology for filtrate concentration; and light color of the obtained product and no need of color removal by using the freeze drying technology for the drying process. The pectin obtained by the method is low methoxyl pectin and has the advantages of good solubility and easy formation of gel.

Owner:GUANGXI UNIV

Renewable nonwoven carpet

InactiveUS20060257616A1Various aesthetic effectUniform colorSynthetic resin layered productsFloor coveringsDecompositionFiber type

A carpet constructed from a biodegradable nonwoven face layer and a backing layer that is biodegradable and / or recyclable. The face layer comprises a needle-punched nonwoven web formed from a blend of different fiber types each of which is biodegradable, the blend comprising face fibers having a relatively high decomposition temperature and thermally activatable binder fibers having a thermal activation temperature lower than the decomposition temperature of the face fibers. The binder fibers bind to one another and to the face fibers. The face fibers can comprise one or more types of fibers that are biodegradable. Suitable fiber types include but are not limited to wool, hemp, cotton, polylactic acid, jute, flax, kanaf, sisal, rayon, and silk. The binder fibers in some embodiments of the invention comprise low-melt polylactic acid.

Owner:STOWE PHARR MILLS PHARR YARNS

Machinable light weight sisal-based concrete structural building material

InactiveUS6881257B2Improve plasticityImprove workabilitySolid waste managementCeramic shaping apparatusSludgeSISAL

A machinable light weight sisal-based concrete structural building material and a method of making the same are disclosed. The material includes short sisal fibers in a range from about 22% (v / v) to about 33% (v / v); a cement in a range from about 12% (v / v) to about 22% (v / v); and perlite in a range from about 51% (v / v) to about 59% (v / v). The method includes the steps of mixing an amount of cement with an amount of perlite to form a solid mixture; adding water and mixing water with the solid mixture to form a sludge; adding an amount of sisal fibers and mixing the sisal fibers into the sludge to form an uniform final composition; and pouring the final composition into a mold and setting the final composition to a solid form structural building material. The produced structural building material can be machined, screwed, cut, and nailed.

Owner:BEAUBOEUF SEYMOUR

Production method of art paper containing crude fibers

The invention relates to a production method of art paper containing crude fibers, which comprises the steps: preparing slurry, manufacturing by a paper machine, drying before sizing, sizing on a surface, drying after sizing, slitting, packaging and the like. Commercial bleached sulfate chemical wood pulp and sisal yarn are selected as raw materials; the raw materials comprises the following components in percentage by weight: 50-70% of softwood pulp boards, 10-30% of sisal yarns and 20-30% of hardwood pulp boards; beating processing is carried out by a beater; the beating degree of the slurry is 35-36 degrees SR; the wet weight is 4-5g; a polyvinyl alcohol aqueous solution is used as sizing liquid for surface sizing; and the concentration of polyvinyl alcohol is 5-6%, and the temperature of the surface sizing liquid is 55-60 DEG C. The production method provided by the invention is easy to implement and simple in formula of the surface sizing liquid; the surface of the obtained paper product is rough; the crude fibers protrude on the paper surface; and the processed paper is high in bulk, high in strength, high in stiffness and good in natural texture of coming back to earth.

Owner:SHANDONG KAILI SPECIAL PAPER

Method for processing rhizoma gastrodiae seeds by germination bacteria

InactiveCN102783324AOvercome the quality degradation problemSeed and root treatmentHorticultureSeeds sourceSISAL

The invention discloses a method for processing rhizoma gastrodiae seeds by germination bacteria, belonging to an agricultural technology. The method is used for generative propagation of rhizoma gastrodiae and can be used for overcoming the defects that the existing processing method is low in germination percentage and is difficult to meet production requirements. The method comprises the steps of selecting mother hemp, storing the mother hemp, cultivating sisal hemp, artificially pollinating, collecting seed, separating and cultivating strains, preparing a seedbed and accelerating germination. The method has the beneficial effects that the germination percentage of the rhizoma gastrodiae seed which processed by the invention and is sowed in good time can be up to 30-50% and is 3-5 times higher than that of generative propagation in the past; natural quality of large seed quantity in the rhizoma gastrodiae fruit is combined; a lot of excellent seed sources can be provided for production of the rhizoma gastrodiae by the existing generative propagation mode, so that the production of the rhizoma gastrodiae by generative propagation has economic and technical valuable significances, and the problem of quality degradation of the rhizoma gastrodiae seed by the generative propagation mode is overcome.

Owner:JILIN AGRICULTURAL UNIV

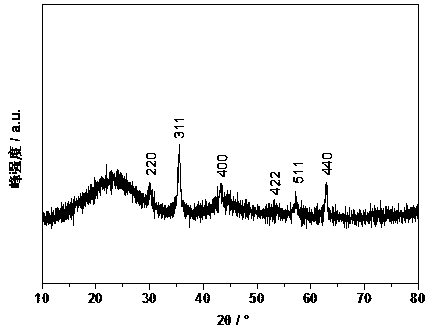

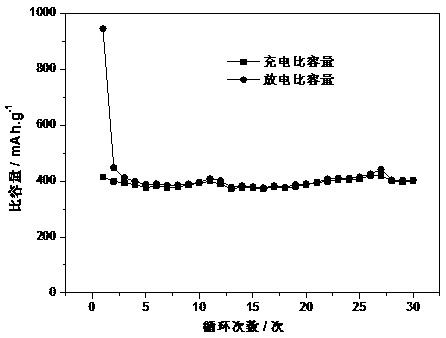

Preparation method for cathode material of nano ferroferric oxide/sisal hemp carbon lithium ion battery

The invention discloses a preparation method for a cathode material of a nano ferroferric oxide / sisal hemp carbon lithium ion battery. The preparation method comprises the following steps: (1) carbonizing washed and dried sisal hemp fibers under an inert atmosphere, and crushing to obtain sisal hemp carbon powder; (2) dissolving an iron source into water and adding the sisal hemp carbon powder; adding a precipitant and carrying out oil-bath reaction for a period of time; washing and filtering to obtain a cathode material precursor; and (3) calcining the cathode material precursor under the inert atmosphere to obtain black solid powder, namely the cathode material of the nano ferroferric oxide / sisal hemp carbon lithium ion battery. An electrochemical test shows that the cathode material of the nano ferroferric oxide / sisal hemp carbon lithium ion battery prepared by the invention has high capacity and good circulation stability; the specific capacity can be 414mAh / g when the battery is charged for the first time and is obviously better than a theoretical specific capacity (372mAh / g) of a graphite cathode material. After the battery is circularly charged for 30 times, the specific capacity can still be maintained to 401mAh / g and is 96.9% of the initial charging specific capacity, so that the circulating stability is good.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

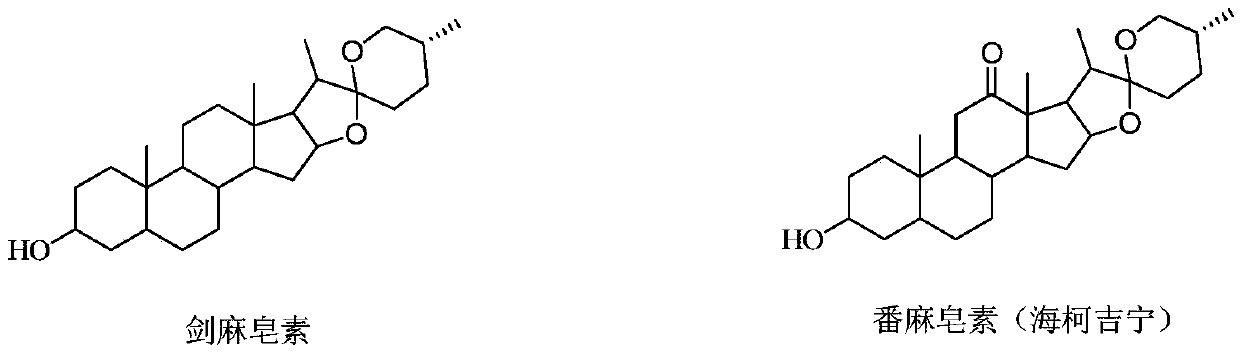

Method for extracting tigogenin from squeezed juice of sisal residue

The invention discloses a method for extracting tigogenin from squeezed juice of sisal residue. The method for extracting tigogenin from squeezed juice of sisal residue disclosed by the invention comprises the following steps: squeezing juice by squeezing fresh sisal residue to obtain squeezed juice of sisal; filtering by filtering the squeezed juice of sisal and removing coarse residue to obtain a coarse residue filter liquor; centrifuging by centrifuging the filter liquor to obtain a transparent liquor; fermenting by naturally fermenting the transparent liquor at normal temperatures to obtain a sisalagenin fermentation liquor; centrifuging by centrifuging the fermentation liquor to obtain a sisal paste; carrying out acidolysis by adding the sisal paste and concentrated sulfuric acid into a reaction kettle, heating and carrying out acidolysis on the sisalagenin; drying by neutralizing sulfuric acid in an acidolysis liquor by using calcium hydroxide, heating and drying in vacuum, and crushing to obtain powdery tigogenin crude product; and purifying by extracting the sisalagenin in crude saponin by using hot ethanol, filtering, concentrating and stewing in vacuum, centrifuging and collecting saponin crystals, heating and drying to obtain finished products of tigogenin. The tigogenin extracted by the method for extracting tigogenin from squeezed juice of sisal residue disclosed by the invention has the advantages of good quality, high purity, less energy consumption, simple process, high recovery rate, energy conservation, environmental friendliness and the like.

Owner:GUANGXI NANJIAN BIOTECH

Sheet laminating preparation method for sisal fiber reinforced polypropylene composite material

The present invention adopts the sisal hemp fiber as fiber raw material, and uses the nonwoven fabric of thermoplastic resin PP, film, powder material and its fiber as resin base body, and adopts thefollowing steps: pretreating sisal hemp fiber and making it into fiber felt, hot-pressing and forming, selecting and using a certain number of fiber felts, delaminating and sand wiching pp nonwoven fabric or film, under the condition of a certain temp. and pressure hot-pressing and forming or mixing PP fiber (PP powder) directly with sisal hemp fibre, making them into fiber felt and then hot-pressing and forming so as to obtain the invented sisal hemp fiber reinforced polypropylene composite material.

Owner:SUN YAT SEN UNIV

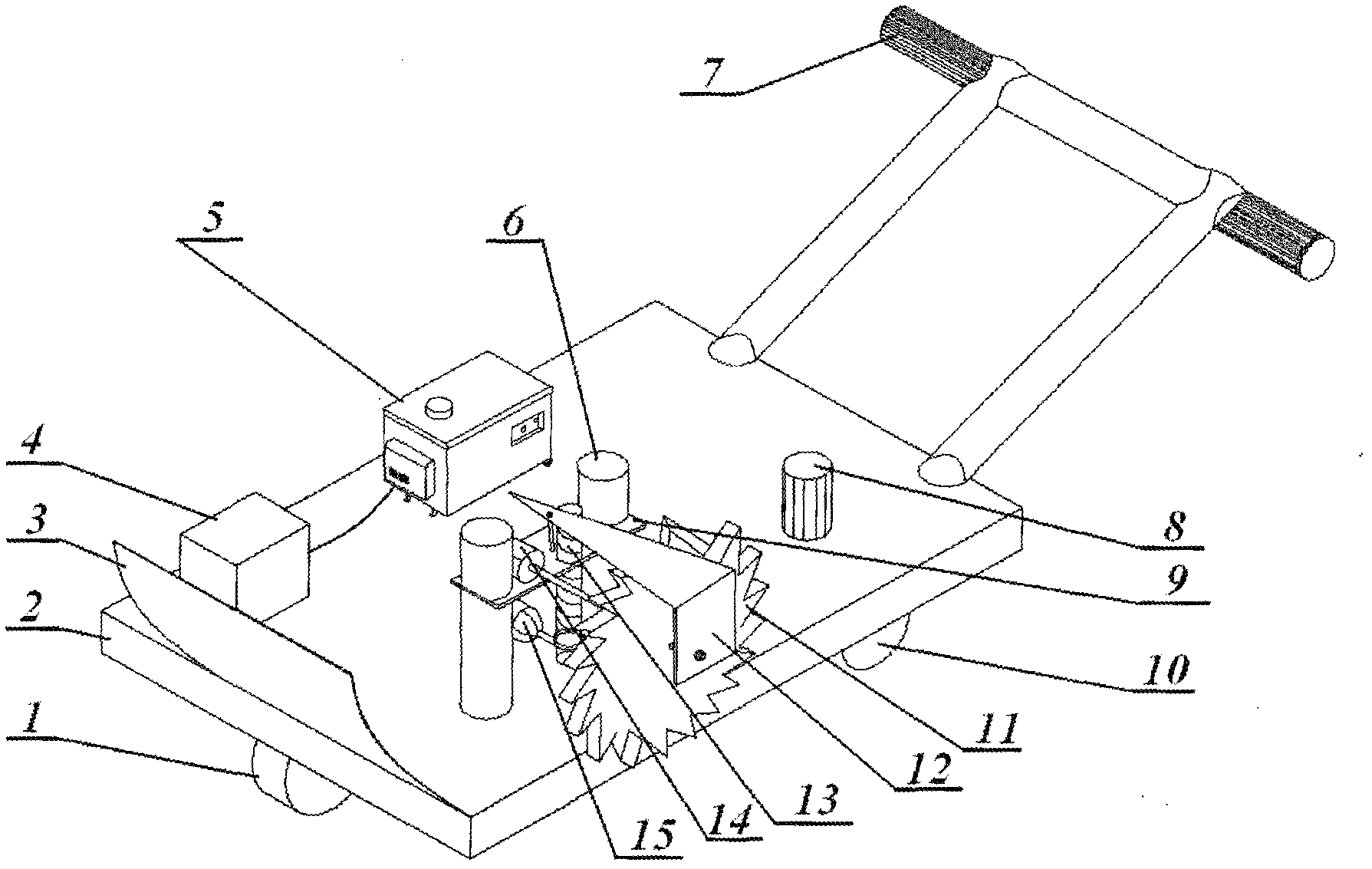

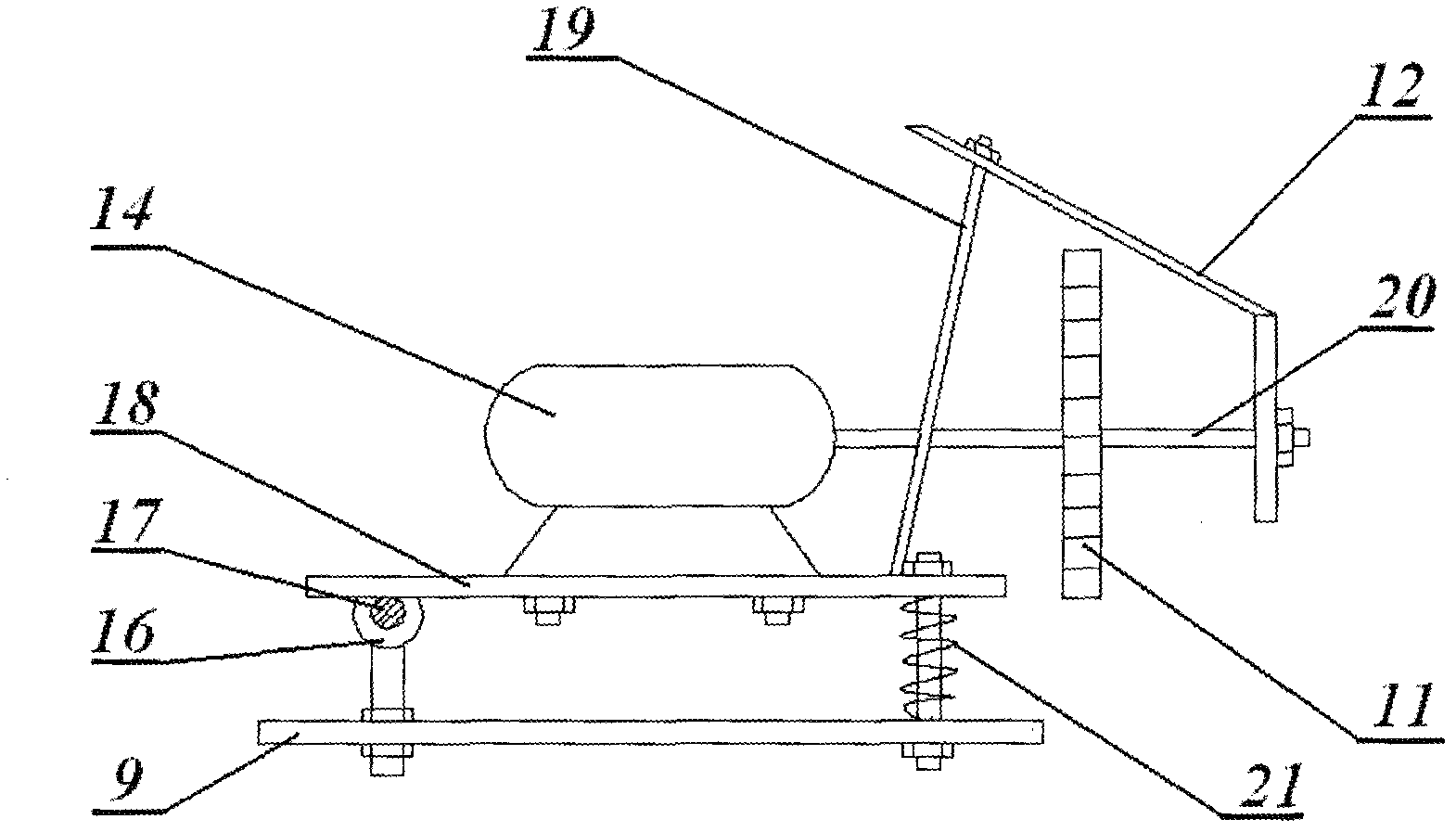

Sisal harvester

The invention discloses a sisal harvester. A small diesel generator (5) is installed on a small platform lorry, which provides power for the whole sisal harvester; the sisal harvester is provided with a dicing saw blade (11); the dicing saw blade (11) is driven through a main servo motor (14) to rotate; the main servo motor (14) is installed on a lifting bottom plate (9), the height of which can be adjusted; the main servo motor (14) is in flexible connection with the lifting bottom plate (9); a guide protective cover (12) is arranged outside the dicing saw blade (11); one end of the guide protective cover (12) is connected with a motor supporting plate (18) through a guide protective cover supporting rod (19); the other end of the guide protective cover (12) is connected with a saw blade shaft (20) through a bearing; and a sisal collector (3) is arranged at the lower front part of the dicing saw blade (11). The sisal harvester is also provided with a lifting servo motor (15), a lead screw (13), a vertical column (6), a control box (4) and a driving servo motor (8). The sisal harvester has the benefits that sisal harvesting mechanization is realized, the sisal harvester is simple and convenient to operate, the harvesting efficiency is high, and the sisal harvesting cost is greatly reduced.

Owner:HAINAN UNIVERSITY

Composite coated fertilizer having high utilization rate and high plant absorption rate and preparation method thereof

InactiveCN104108981AGood sustained release effectImprove fertilizer efficiencyFertilizer mixturesEnvironmental resistanceAbsorption rate

The invention discloses composite coated fertilizer having a high utilization rate and a high plant absorption rate and a preparation method thereof. The composite coated fertilizer is prepared from 15-19 parts by weight of potassium chloride, 1-2 parts by weight of borax, 1-2 parts by weight of ammonium molybdate, 2-3 parts by weight of ferrous sulphate, 44-49 parts by weight of waste molasses, 2-3 parts by weight of polyepoxysuccinic acid, 25-29 parts by weight of sisal hemp fibers, 26-29 parts by weight of urea, 22-26 parts by weight of diammonium phosphate, 6-9 parts by weight of medical stone, 7-9 parts by weight of vermiculite powder, 40-45 parts by weight of wheat bran, 34-38 parts by weight of bagasse, 5-7 parts by weight of EM microbial inoculum, 7-9 parts by weight of a soil conditioner and a proper amount of water. The composite coated fertilizer has effects of improving effects, promoting nutrient absorption of plants and improving soil hardening. Through use of mineral components such as medical stone, the composite coated fertilizer is safe and environmentally friendly, and substantially improves nitrogen, phosphorus and potassium absorption utilization rates of plants. Through urea coating, the composite coated fertilizer has good slow release effects and lasting fertilizer efficiency.

Owner:铜陵市银树生态养殖有限责任公司

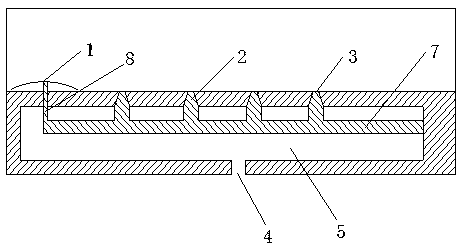

Novel sisal/synthetic fiber composite structure oil-containing steel wire rope core and preparation method thereof

The invention discloses a novel sisal / synthetic fiber composite structure oil-containing steel wire rope core and a preparation method thereof. The method includes the steps of 1, formation of sisal / polyester sirofil yarn; 2, formation of high-strength, high-modulus and low-elongation polyester filament yarn; 3, formation of ultrahigh-molecular-weight polyethylene filament yarn; 4, formation of sisal / polyester sirofil yarn and polyester yarn plied yarn; 5, formation of sisal / polyester sirofil yarn and ultrahigh-molecular-weight polyethylene filament yarn plied yarn; 6, formation of the novel sisal / synthetic fiber composite structure steel wire rope core. According to the method, sirofil spinning is adopted in the spinning process, the high-strength, high-modulus and low-elongation polyester filament yarn and the ultrahigh-molecular-weight polyethylene filament yarn are added in the plied yarn and rope making process, and an online oiling device is additionally arranged in sisal spinning and yarn making equipment. Ultrahigh-molecular-weight polyethylene filaments in the yarn are pretreated, and polyester filaments and the ultrahigh-molecular-weight polyethylene filaments with special sections are adopted.

Owner:NANTONG CITY TONGZHOU DISTRICT DADA HEMP TEXTILE +1

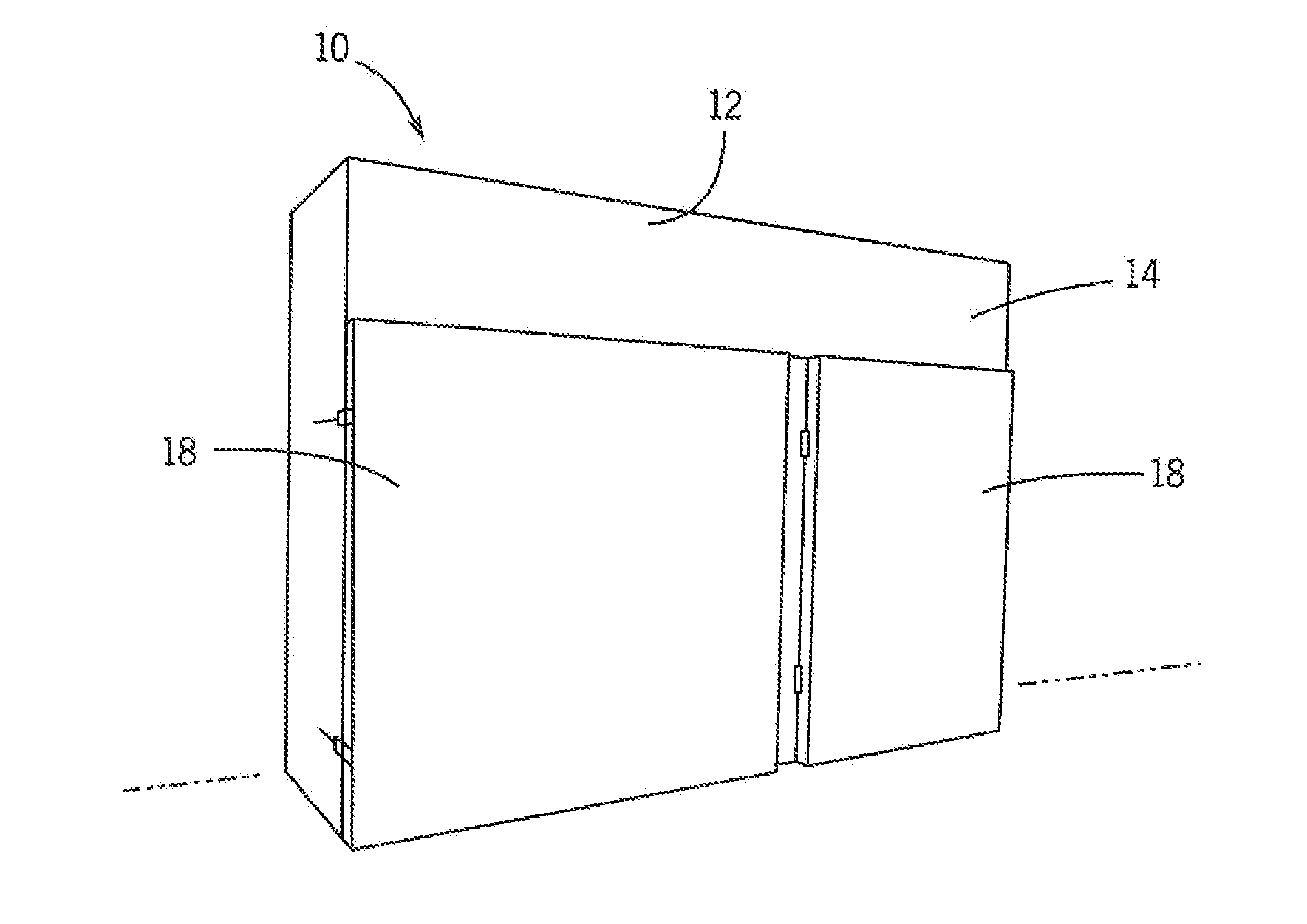

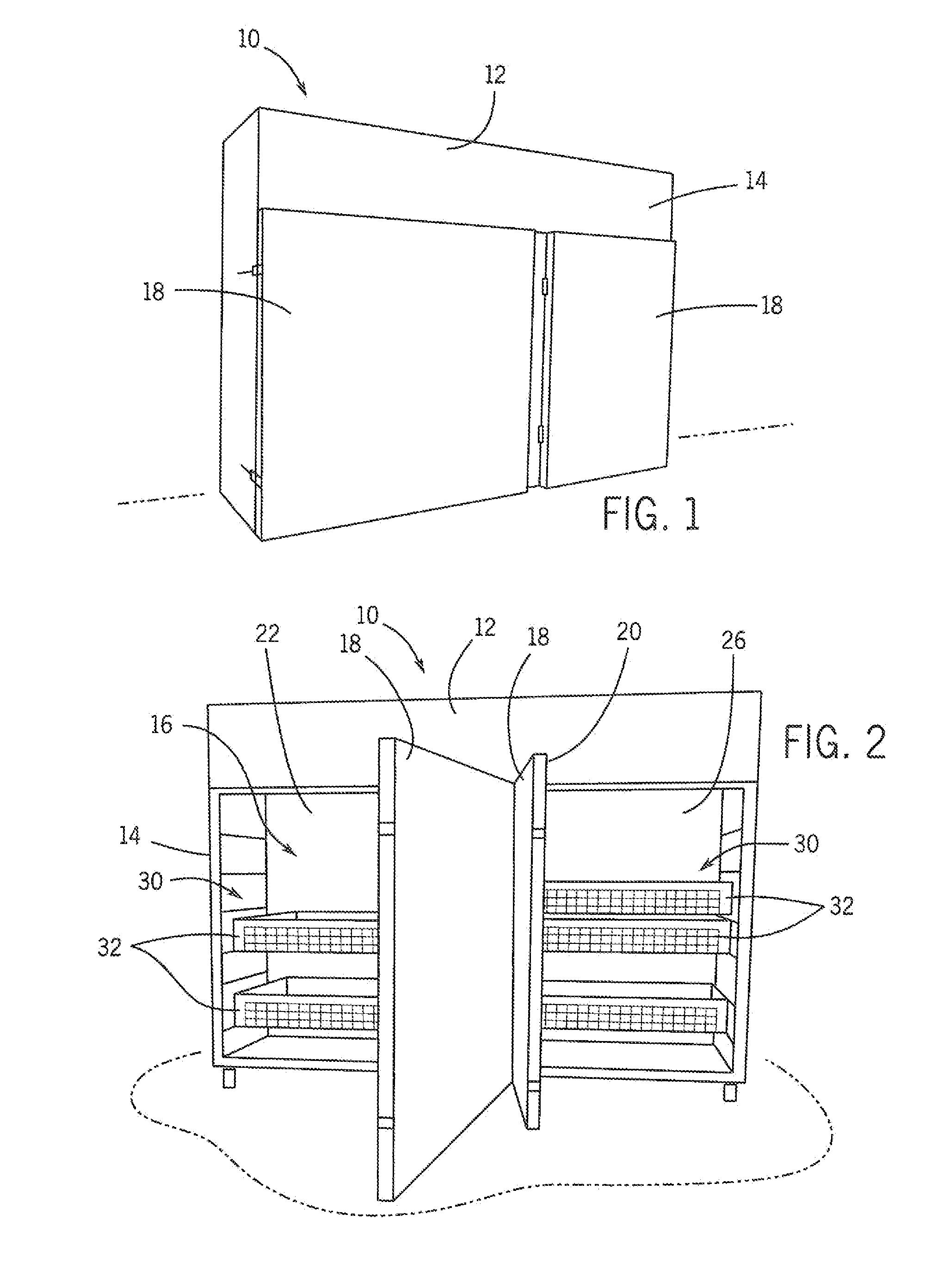

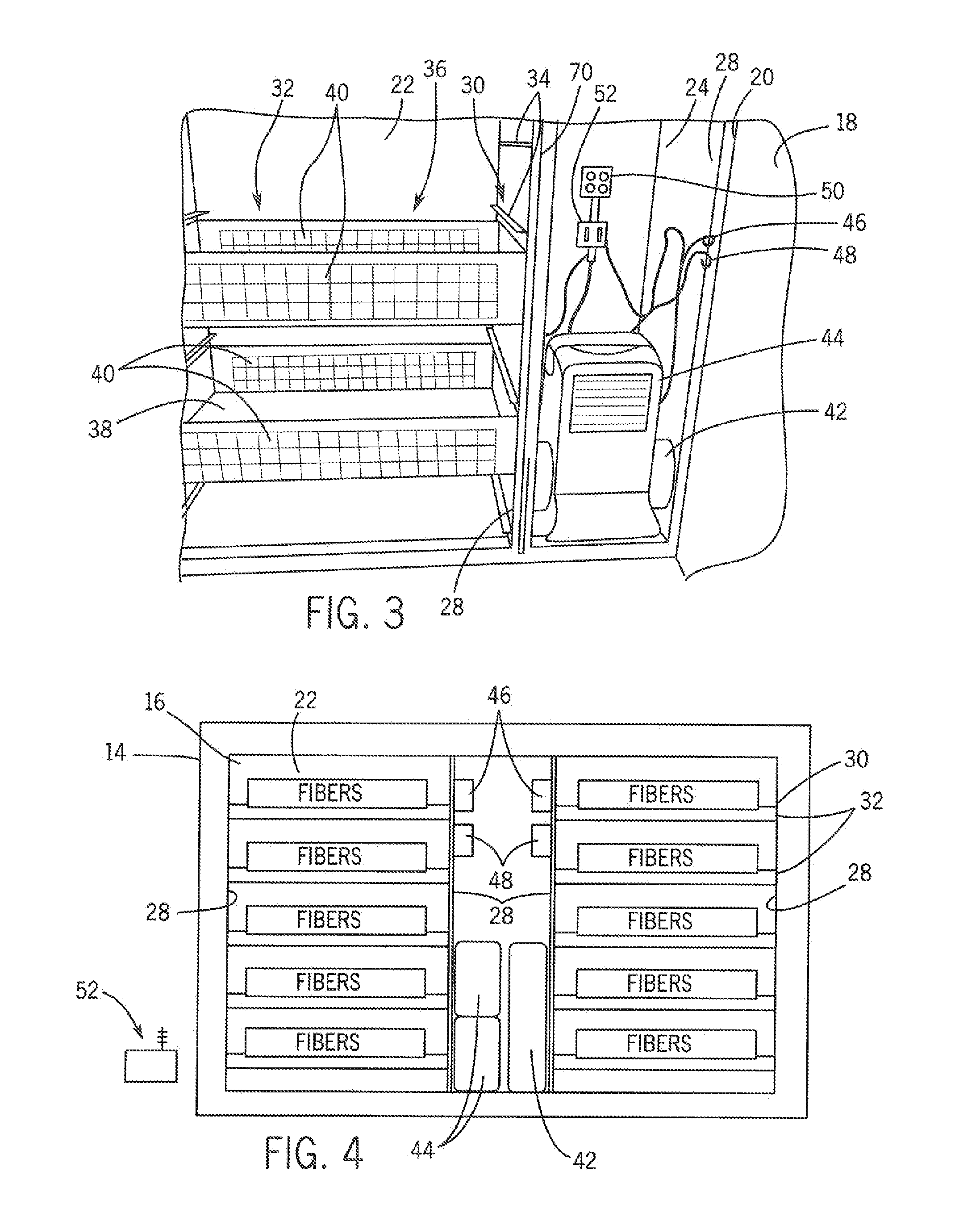

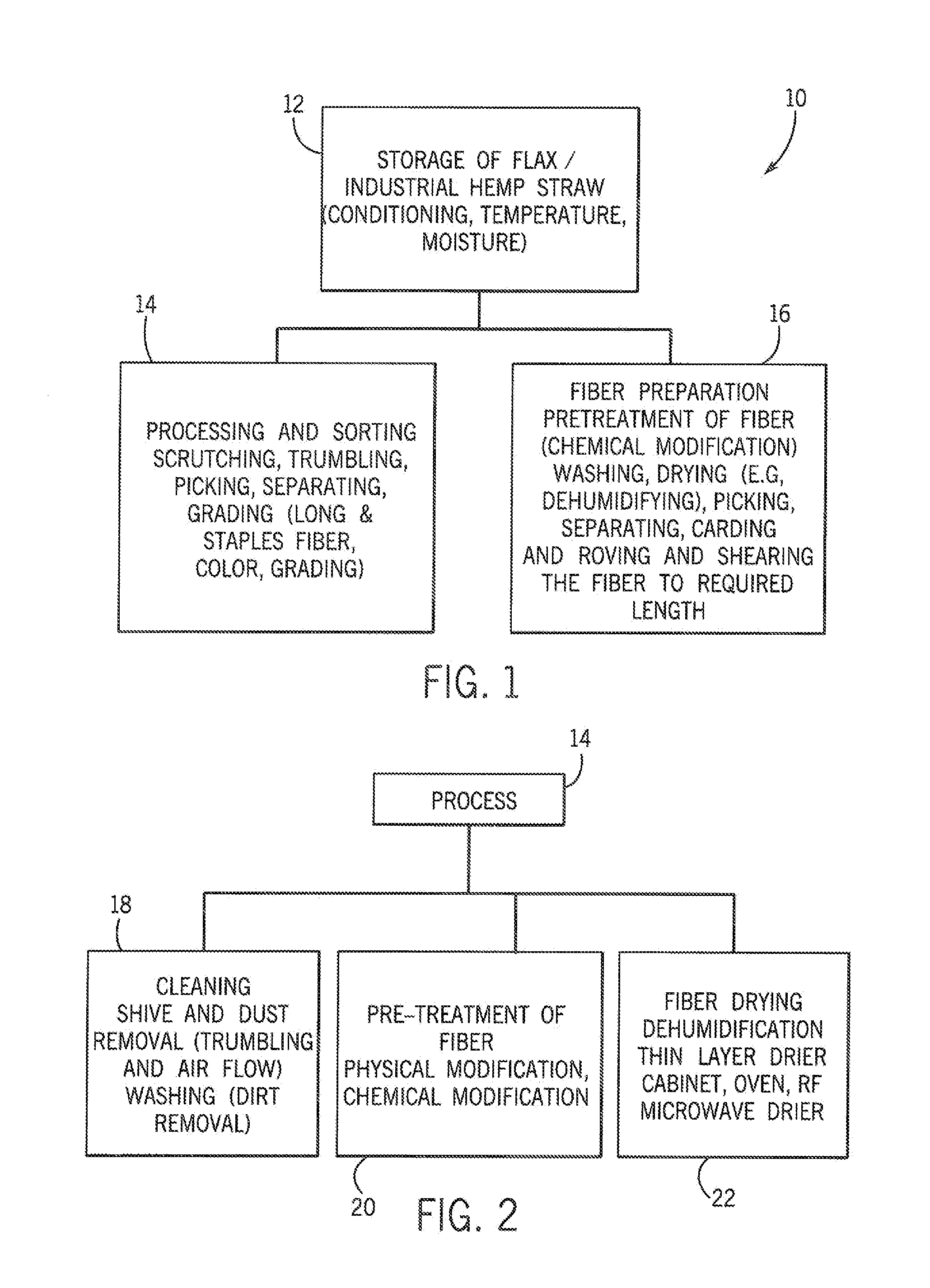

Dehumidification System And Method Used For Drying Fibers

ActiveUS20150252515A1Easy to useReduces/prevents fiber discoloration and odor and decomposition of fiberDrying solid materials with heatDrying gas arrangementsPolymer scienceDecomposition

A system and method is provided for drying for fibers or fibrous materials, such as flax, hemp, jute, sisal, banana and coir, among others by dehumidifying the fibers in a temperature and humidity-controlled environment. The dehumidification system does not detrimentally affect the fiber's properties (e.g., strength) by evenly drying the fibers and not subjecting the fibers to repeated high temperature environments, allowing the fibers to be used in more biocomposite applications, such as a reinforcement material. Also the dehumidification method reduces / prevents fiber discoloration, odor, and decomposition.

Owner:CNH IND CANADA

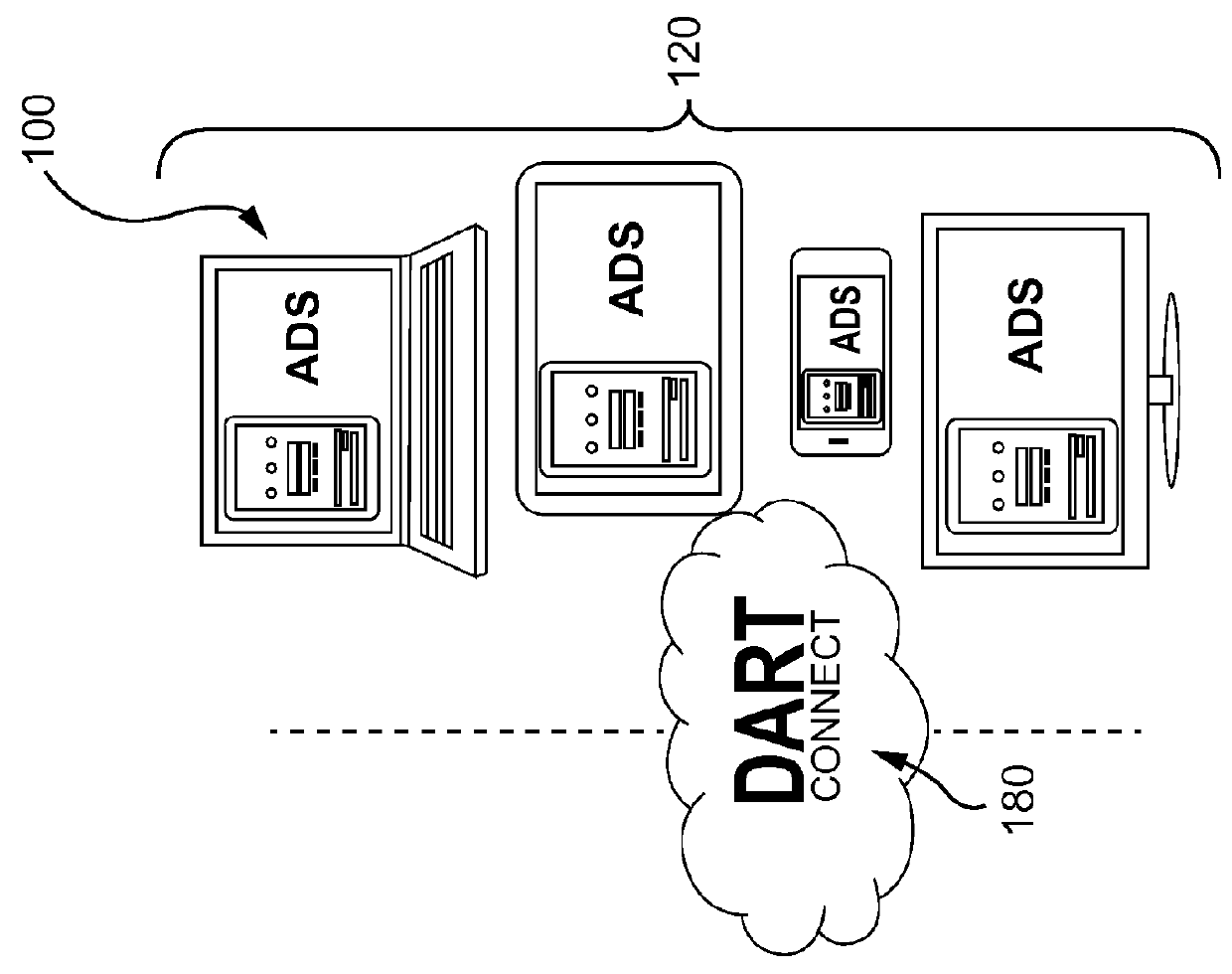

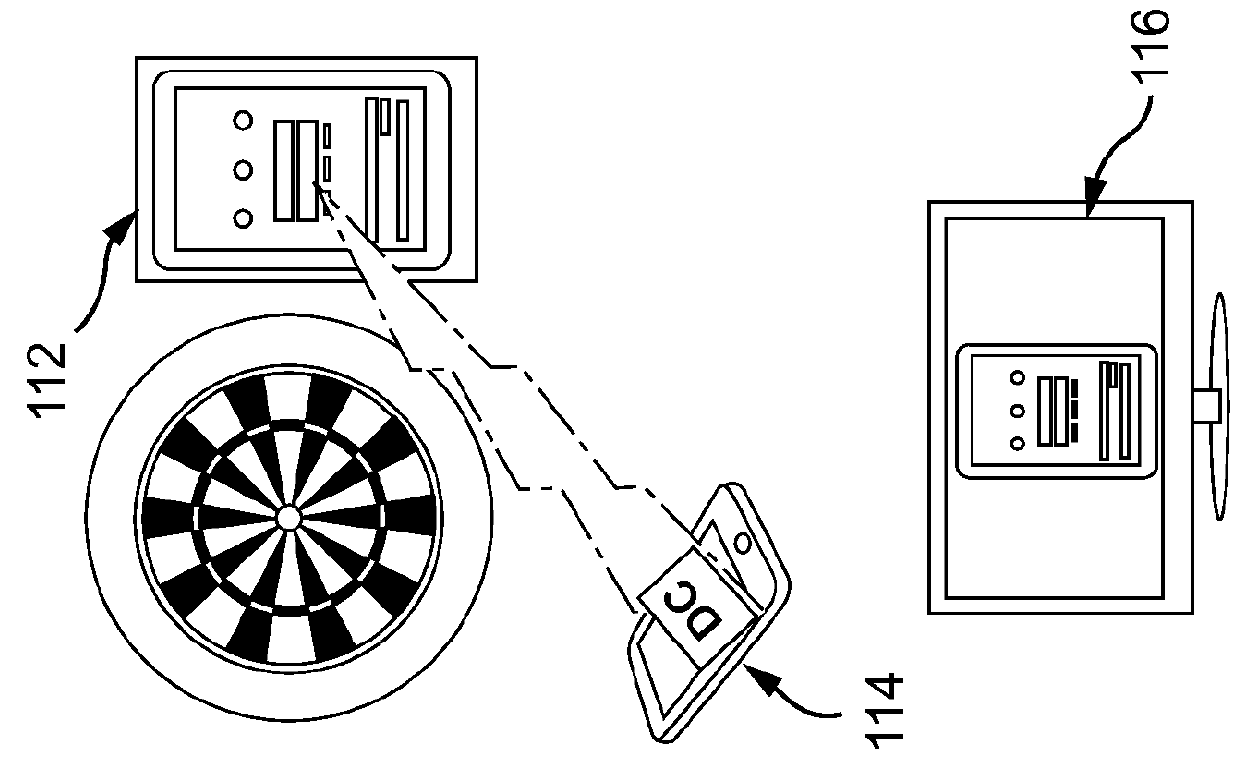

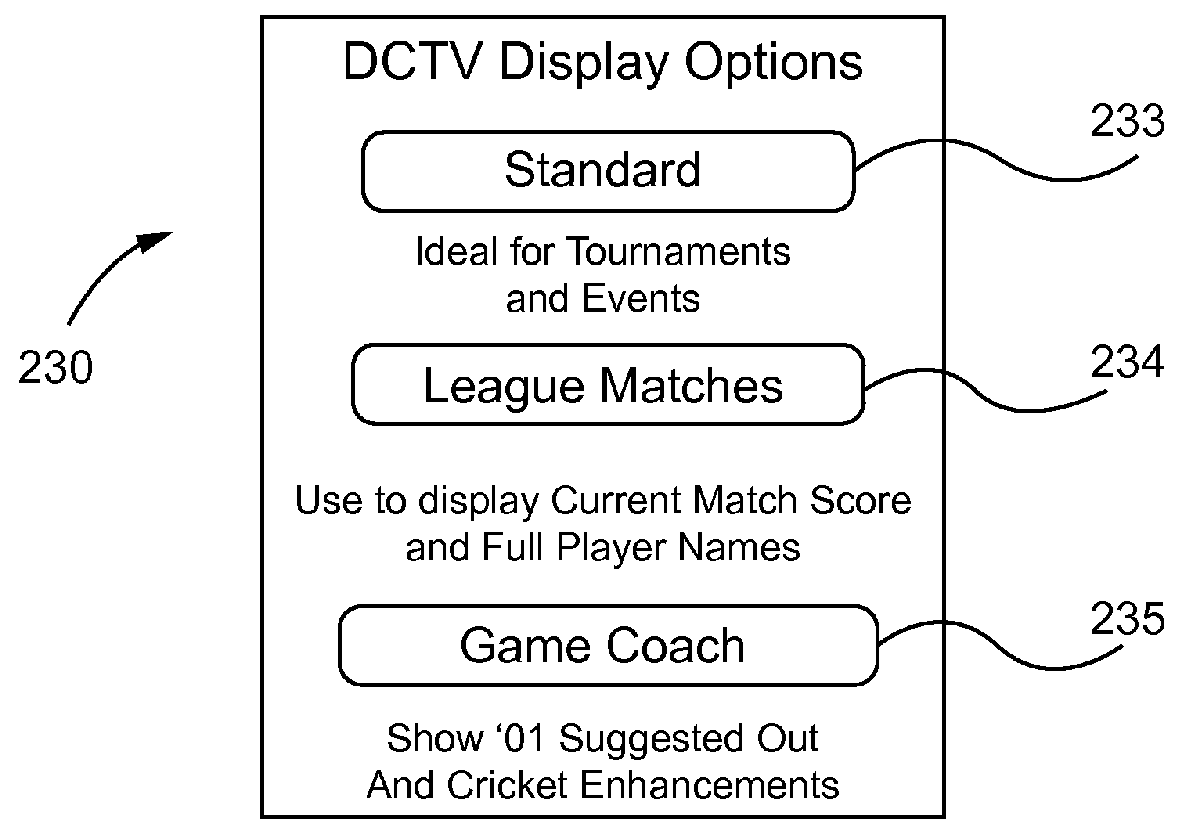

Dart scoring system

ActiveUS20160054103A1Quickly and easily calculatedIncrease experienceAmmunition projectilesThrow gamesSISALHuman–computer interaction

A dart game system comprising a steel-tipped dart, a sisal dart board, at least one first mobile computing scoring device comprising a scoring interface, and a remote mobile computing device adapted to receive the scoring interface from the at least one scoring device for display of real-time dart game scores at a remote location.

Owner:DARTCONNECT

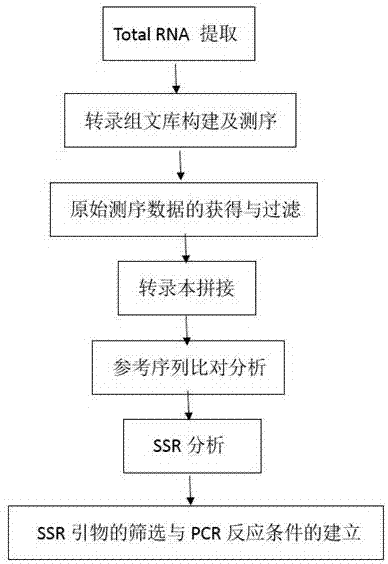

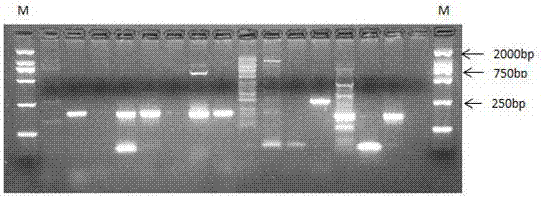

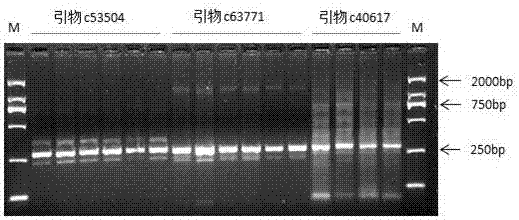

Method for developing SSR (Simple Sequence Repeat) primers of sisal hemp based on transcriptome sequencing

ActiveCN107201408AImprove development efficiencyFill the scarce gapsMicrobiological testing/measurementHybridisationAgricultural scienceTotal rna

The invention discloses a method for developing SSR (Simple Sequence Repeat) primers of sisal hemp based on transcriptome sequencing and belongs to the technical field of molecular biology. A preparation method of the SSR primers comprises the following five steps: extracting Total RNA (Ribonucleic Acid) and constructing a transcriptome library; carrying out transcriptome sequencing and sequence quality analysis; carrying out transcript assembly and SSR labeling analysis; designing the SSR primers; carrying out PCR (Polymerase Chain Reaction) amplification on the primers and electrophoresis analysis on amplified products. According to the method disclosed by the invention, a transcriptome sequence of the sisal hemp at a certain specific period is obtained by using a transcriptome sequencing method; then the SSR labeling analysis is carried out by bioinformatics analysis software, and further the SSR labeled primers of the sisal hemp are developed; the labeling and developing efficiency is high, and the blank of scarce SSR labels of the sisal hemp at present is filled up.

Owner:SOUTH SUBTROPICAL CROPS RES INST CHINESE ACAD OF TROPICAL AGRI SCI

Preparation method of sisal hemp carbon fiber photocatalyst

ActiveCN107252696AGuaranteed normal transmissionImprove photocatalytic performancePhysical/chemical process catalystsWater/sewage treatment by irradiationPorous carbonAdsorption effect

The invention relates to the field of catalytic materials for waste water treatment, and discloses a preparation method of a sisal hemp carbon fiber photocatalyst. The preparation method comprises the following steps: firstly, calcinating sisal hemp into porous carbon fiber with strong adsorption effect, and loading titanium dioxide nanoparticles and molybdenum disulfide quantum dots onto porous carbon by adopting a sol-gel method to obtain a tri-compounded porous carbon material. Through the photocatalyst, not only can the energy gap of titanium dioxide be reduced, but also the transfer efficiency of electrons can be enhanced, the visible light response range of the catalyst can be extended, and the modified titanium dioxide photocatalyst has response to visible light with wavelength of more than or equal to 460nm. According to the preparation method, the high-efficiency utilization of resources can be realized by fully utilizing natural sisal hemp, thus meeting green ecological concept. The preparation method of chemically modified sisal hemp carbon fiber photocatalyst is simple in technology, low in cost, and applicable to industrial production.

Owner:TONGXIANG BEITE TECH CO LTD

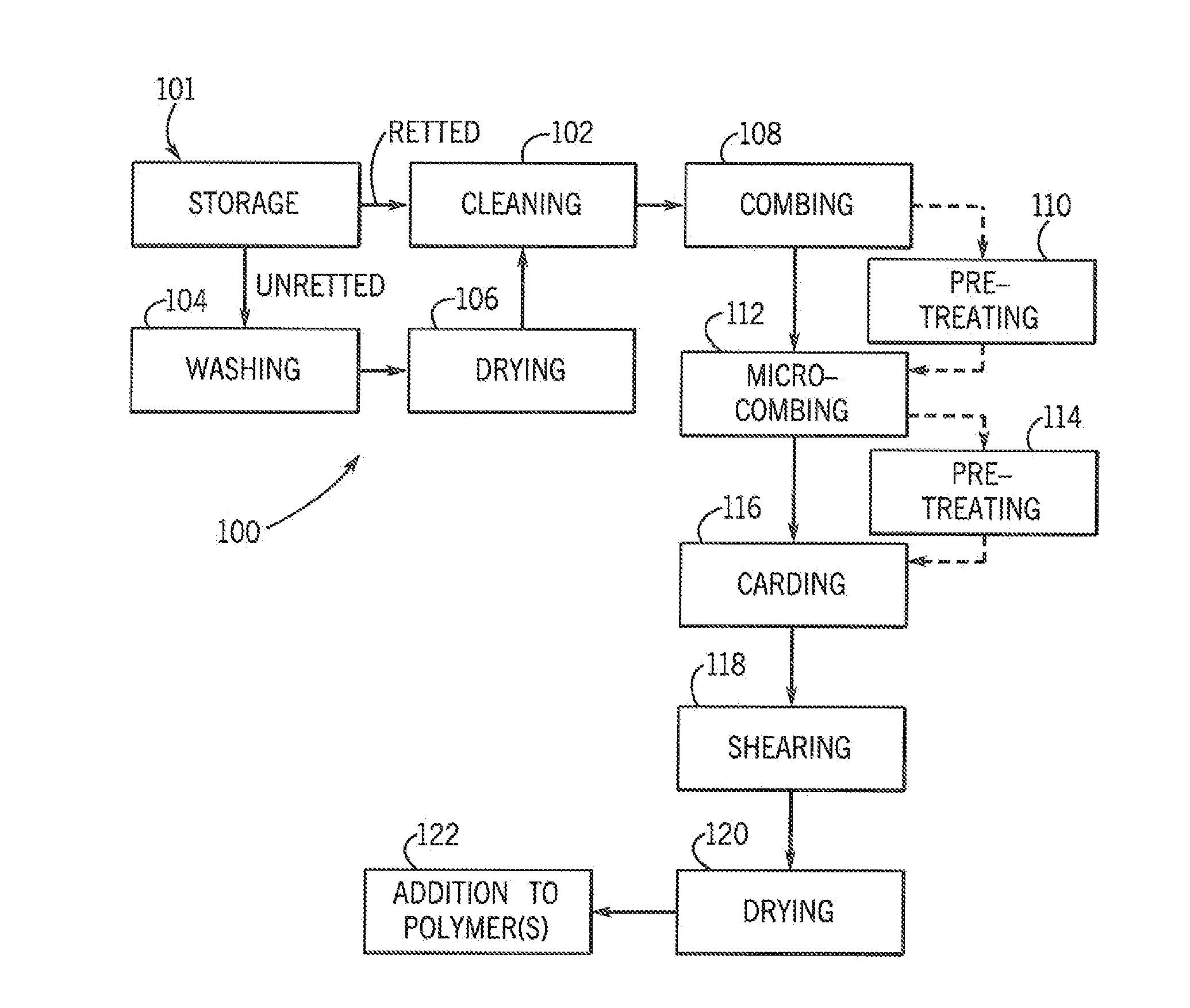

Method To Process Oilseed Flax Fiber For Use In Biocomposite Materials

ActiveUS20150166745A1Retention strengthOptimizationMechanical impurity removalFibre cleaning/opening by air draught arrangementsFlax fiberSISAL

A method and system for the production of fibers for use in biocomposites is provided that includes the ability to use both retted and unretted straw, that keeps the molecular structure of the fibers intact by subjecting the fibers to minimal stress, that maximizes the fiber's aspect ratio, that maximizes the strength of the fibers, and that minimizes time and energy inputs, along with maintaining the fibers in good condition for bonding to the polymer(s) used with the fibers to form the biocomposite material. This consequently increases the functionality of the biocomposites produced (i.e. reinforcement, sound absorption, light weight, heat capacity, etc.), increasing their marketability. Additionally, as the disclosed method does not damage the fibers, oilseed flax straw, as well as all types of fibrous materials (i.e. fiber flax, banana, jute, industrial hemp, sisal, coir) etc., can be processed in bio composite materials.

Owner:CNH IND CANADA

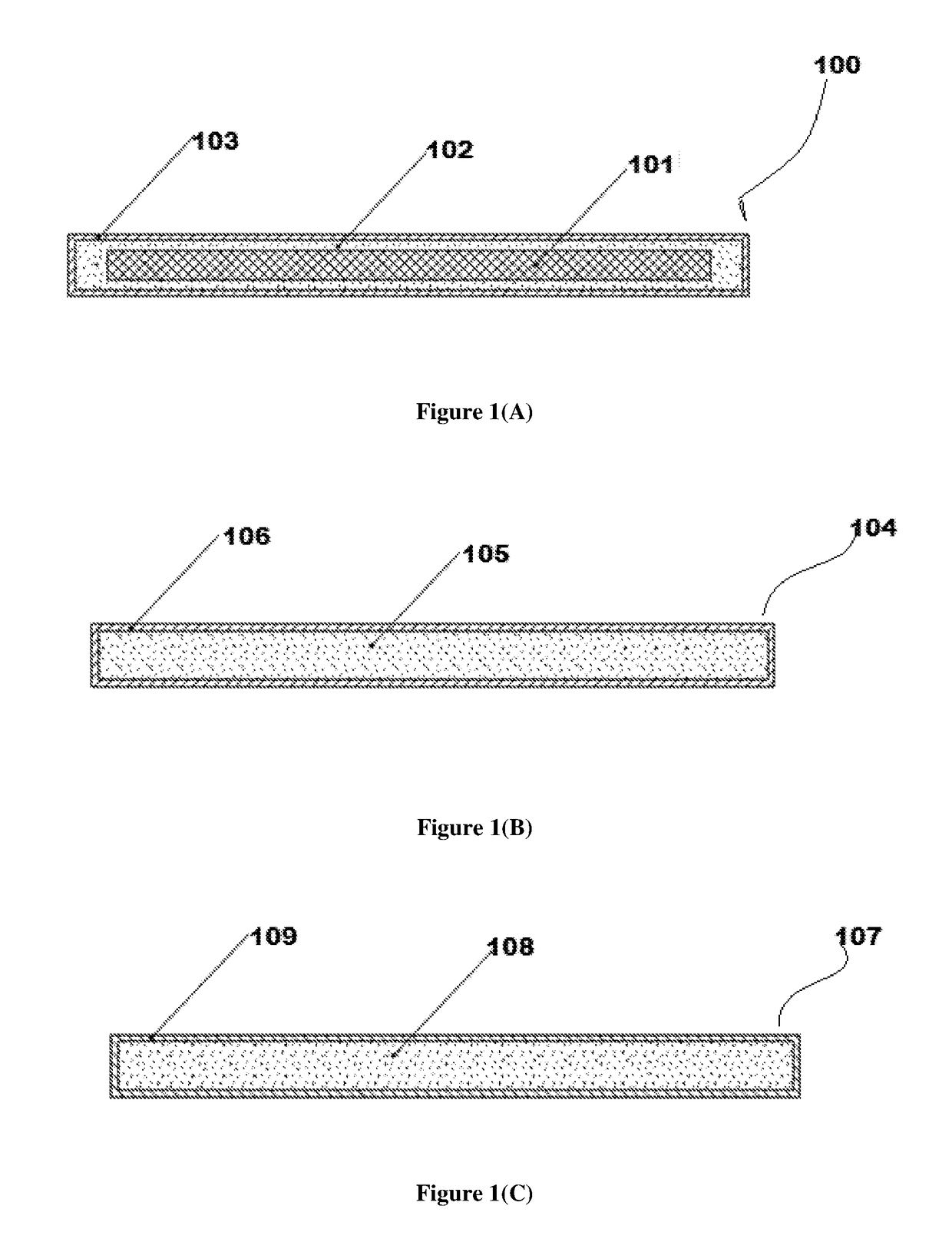

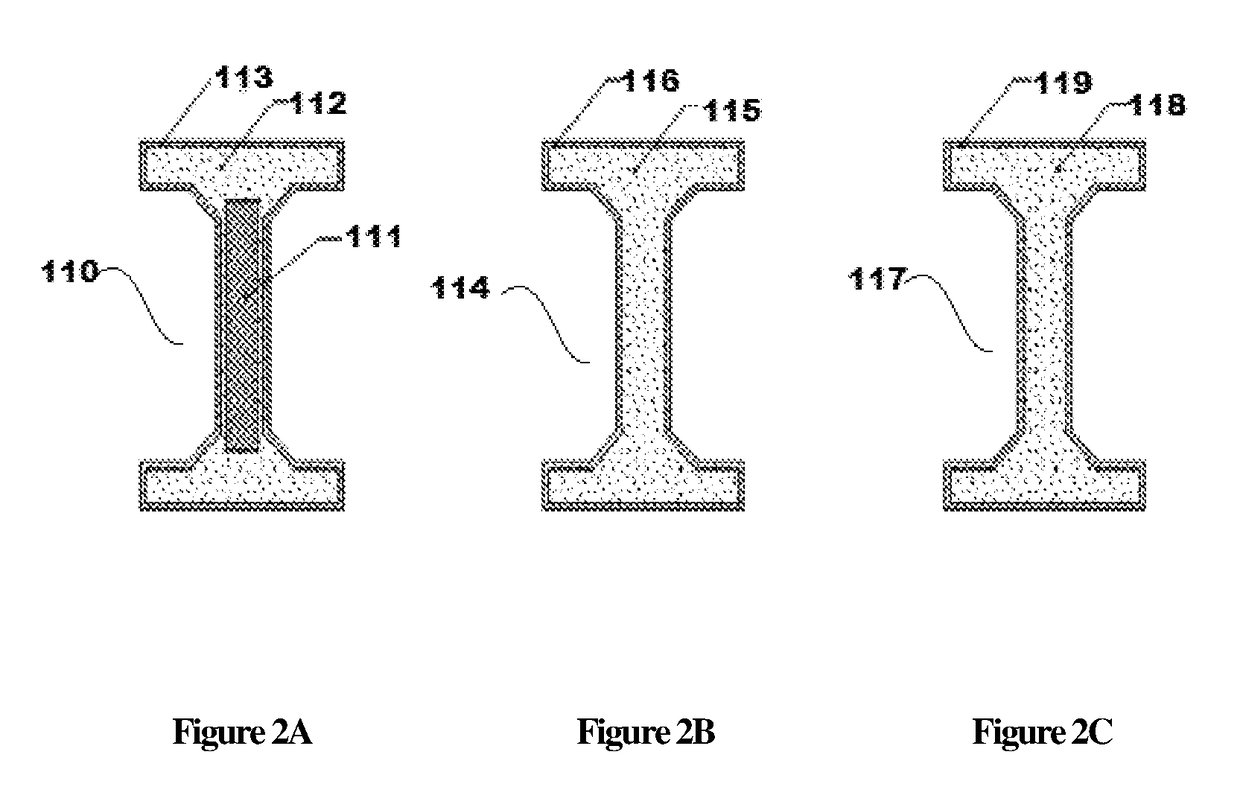

System of continuous pultrusion method for manufacturing of bio-composite products; process and products thereof

ActiveUS20180311915A1Eliminate material wasteEfficient and cost-effectiveSynthetic resin layered productsGirdersPolyesterFlexural strength

Bio-composite pultruded products (100, 104, 107, 110, 114, 117) either in “I” profile or “Plate” profile of higher cross sectional area where said products consisting essentially natural fibres selected from hemp, jute, sisal and. flex as core impregnated with a resin system comprise of at least one resin, curing system comprising a curing agent and an accelerator, a filler, a thinner, pigment or any other additives; encapsulated between bi-directionally and / or uni-directionally oriented synthetic fabric selected from polyester, carbon, aramid, glass, basalt and mixtures thereof impregnated with said resin system are provided. in another bio-composite pultruded products either of “I” profile or “Plate” profile of higher cross sectional area where said products consisting of plank of short fibers bagasse premixed with the said resin system as core is enclosed between the natural fibers selected from hemp, jute, sisal and flex impregnated with the resin system which is further enclosed between bi-directionally and / or uni-directionally oriented synthetic fabric selected from polyester, carbon, aramid, glass, basalt and mixtures thereof impregnated with the resin system. The system and method for the preparations of said bio-composite pultruded products, are also illustrated herein. These products lead to a significant reduction in weight and reduction in density with higher stiffness and bending strength. The present bio-composite products are encapsulated by fabrics in the peripheral area brings more integrity uniformity of jute materials. This leads to a significant cost reduction in a without sacrificing much tensile strength.

Owner:SP ADVANCED ENG MATERIALS PVT LTD

Manufacturing process for anti-bacterial and allergy-free textile fabric

InactiveCN105239250ASoft textureWear cool and comfortableSolvent-treatmentFabric breaking/softeningYarnPectinase

The invention discloses a manufacturing process for an anti-bacterial and allergy-free textile fabric. The fabric is made of the raw materials in the following weight parts: 9-14 parts of bamboo charcoal fibers, 15-25 parts of activated carbon fibers, 20-25 parts of apocynum venetum fibers, 10-20 parts of corduroy fibers, 6-10 parts of dacron, 5-8 parts of alkaline pectinase, 5-8 parts of bi-palmitoyl quadrol sodium dipropionate, 4-8 parts of tea saponin, 7-15 parts of chinlon, 9-13 parts of gabardine, 6-11 parts of bamboo fibers, 5-10 parts of fully drawn yarns, 5-8 parts of sisal hemp, 7-15 parts of jeans flocking, 10-20 parts of sheep wool, and 10-17 parts of cotton fibers. The textile fabric is woven by using various fiber materials, and can effectively absorb various dusts and has excellent sterilization and anti-bacterial effects. The textile fabric has effective allergy-free effect. The fabric is soft in texture, and is breathable and absorbs moisture, and the fabric is cool and comfortable to wear.

Owner:NANSHING CORP

Method for preparing active carbon from caudex of sisal

InactiveCN1480396AIncrease the areaLarge hole volumeCarbon compoundsManufacturing technologyWater vapor

A process for preparing activated carbon from sisal hemp stem includes immersing, charring and activating with steam under protection of N2, water washing and baking. Its advantages are large specific surface area, rich mesopore (40-70%), better adsorbability and a certain redox power.

Owner:SUN YAT SEN UNIV

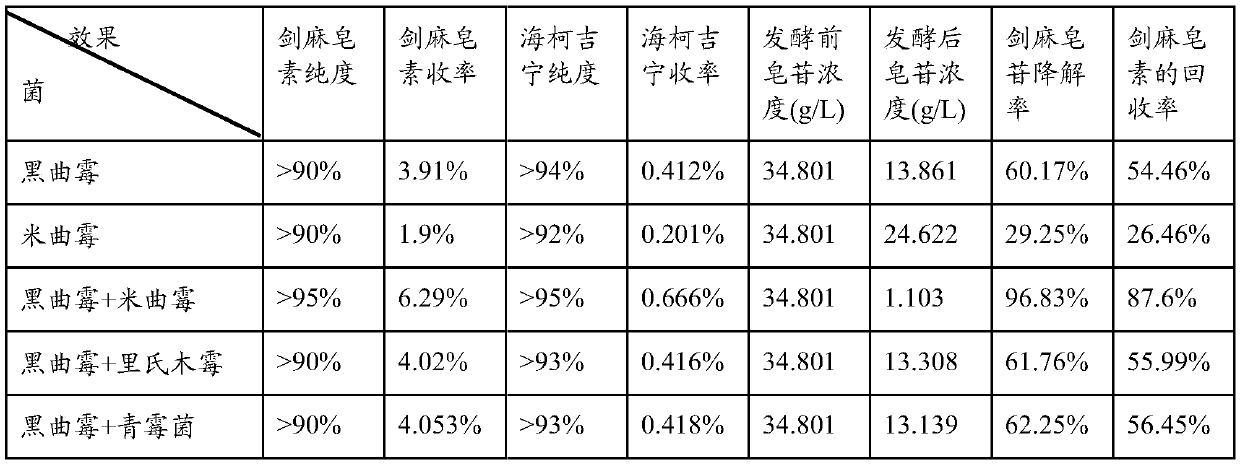

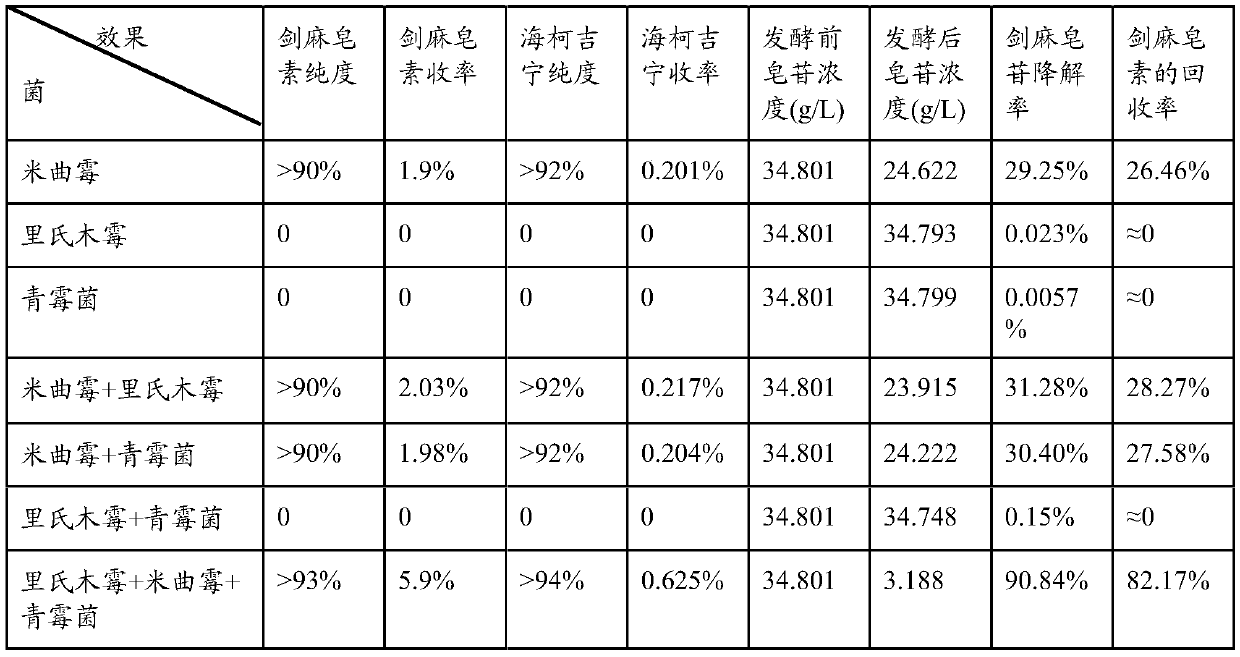

Method for extracting tigogenin and/or hecogenin with composite bacteria method

ActiveCN105506051ATake advantage ofReduce pollutionMicroorganism based processesFermentationPectinaseCellulose breakdown

The invention discloses a method for extracting tigogenin and / or hecogenin with a composite bacteria method. The method comprises steps as follows: pectin in agave sisal dregs is hydrolyzed with pectinase and cellulase, saponin in the sisal dregs is released while the viscosity of the sisal dregs is reduced, and then the released saponin is effectively degraded by the aid of compound enzyme produced from mould composition after fermentation. The method can be used for extracting tigogenin or hecogenin from the sisal dregs, can be used for extracting tigogenin and hecogenin from the sisal dregs simultaneously, and has the advantages of simplicity in operation, mild extraction conditions, small environmental pollution, high product yield and purity, low cost and the like.

Owner:北京颐方生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com