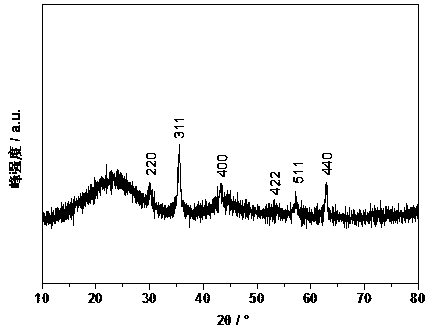

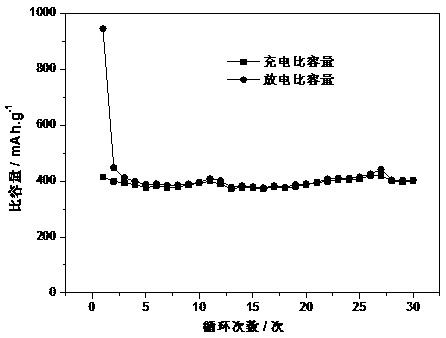

Preparation method for cathode material of nano ferroferric oxide/sisal hemp carbon lithium ion battery

A technology of ferric oxide and lithium-ion batteries, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as short service life, high cost, and poor safety, and achieve high specific capacity, abundant sources, and good circulation The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] (1) The sisal fiber was cleaned and dried and placed in a vacuum tube resistance furnace, carbonized for 1 hour in a nitrogen atmosphere with a gas flow rate of 40ml / min, the carbonization temperature was 900°C, and the heating rate was 3°C / min. The sisal charcoal was obtained after natural cooling; then the sisal charcoal was ball milled at a speed of 35 r / s for 5 hours to obtain sisal charcoal powder with an average particle size of 300 mesh.

[0022] (2) Add 1g of ferrous chloride and 1g of sisal charcoal powder obtained in step (1) into 100ml of water, then add 1g of urea while stirring, stir and react in a constant temperature oil bath at 95°C for 50 minutes, filter, and use Wash with ionic water until pH = 7, then wash again with absolute ethanol, place in the air for 12 hours, and finally vacuum dry at 80°C for 24 hours to obtain a negative electrode material precursor.

[0023] (3) Put the negative electrode material precursor obtained in step (2) into a vacuum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com