Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

605 results about "Cellulose breakdown" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cellulases break down the cellulose molecule into monosaccharides (simple sugars) such as beta-glucose, or shorter polysaccharides and oligosaccharides. Cellulose breakdown is of considerable economic importance, because it makes a major constituent of plants available for consumption and use in chemical reactions.

Procedure for the production of ethanol from lignocellulosic biomass using a new heat-tolerant yeast

InactiveUS20050069998A1Low conversion rateReduce yieldFungiBiological substance pretreatmentsFiltrationSolid fraction

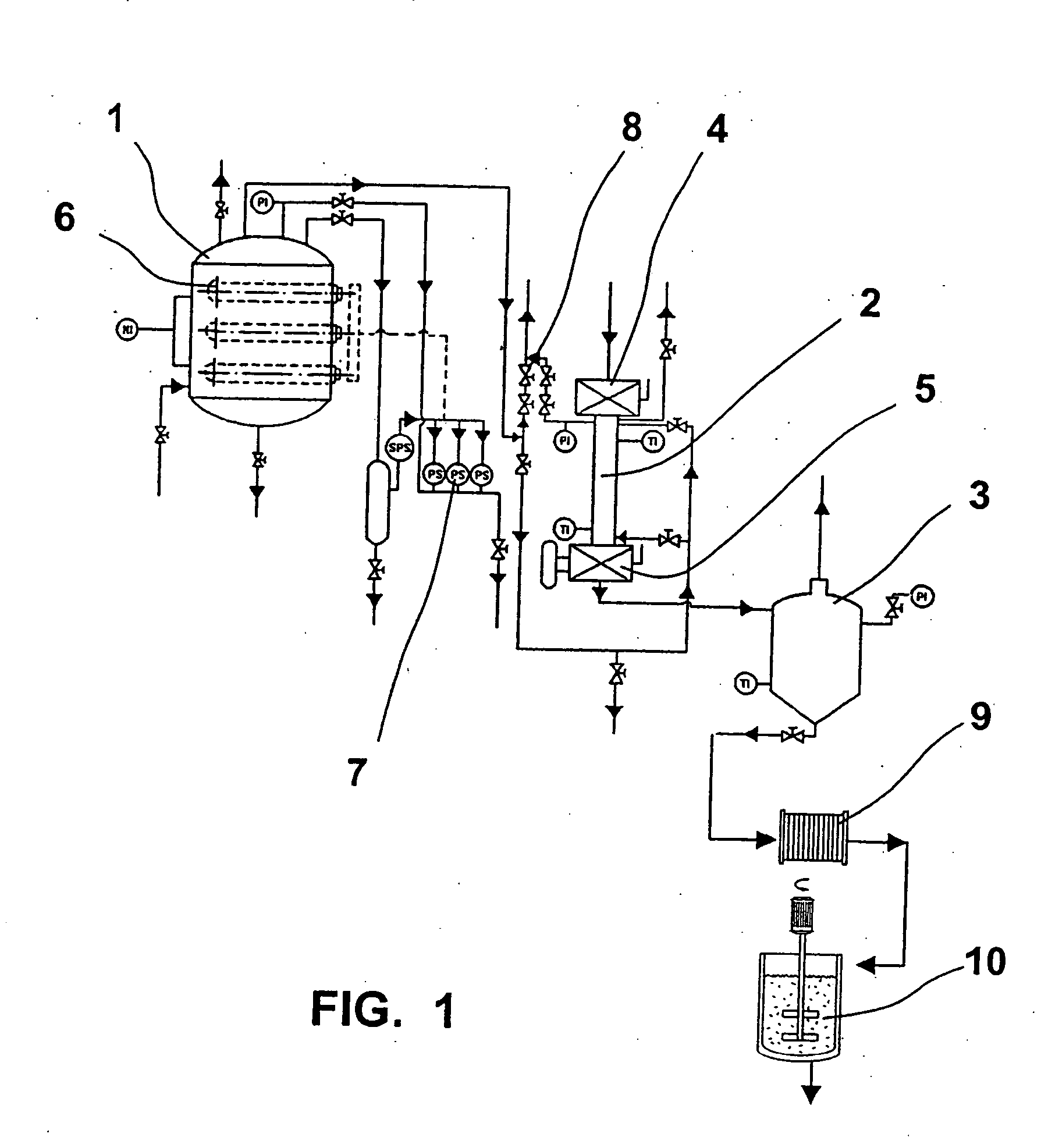

It includes the stages of grinding the lignocellulosic biomass to a size of 15-30 mm, subjecting the product obtained to steam explosion pre-treatment at a temperature of 190-230° C. for between 1 and 10 minutes in a reactor (2), collecting the pre-treated material in a cyclone (3) and separating the liquid and solid fractions by filtration in a filter press (9), introducing the solid fraction in a fermentation deposit (10), adding a cellulase at a concentration of 15 UFP per gram of cellulose and 12.6 International Units of β-glucosidase enzyme dissolved in citrate buffer pH 4.8, inoculating the fermentation deposit (10) with a culture of the heat-tolerant bacteria Kluyveromyces marxianus CECT 10875, obtained by chemical mutagenesis from strain DER-26 of Kluyveromyces marxianus and shaking the mixture for 72 hours at 42° C.

Owner:CENT DE INVESTIGACIONES ENERGETICAS MEDIO AMBIENTALLES Y TECNOLOGICAS (C I E M A T)

Construction of highly efficient cellulase compositions for enzymatic hydrolysis of cellulose

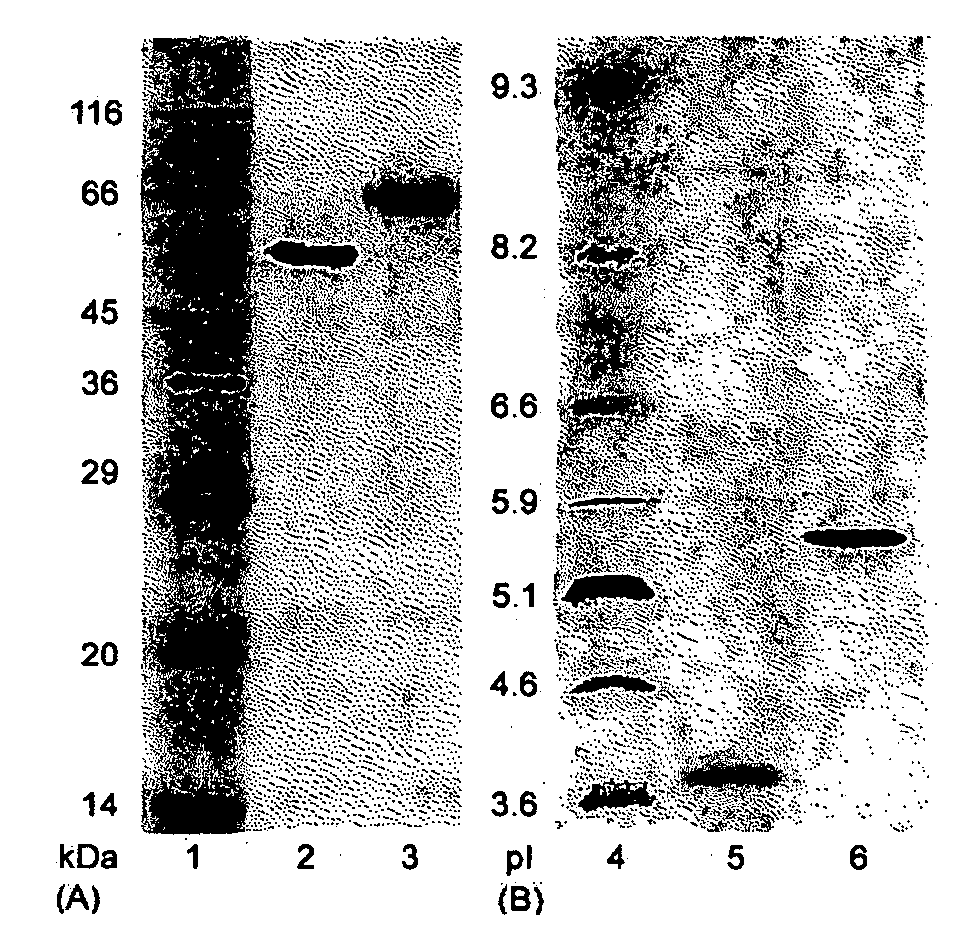

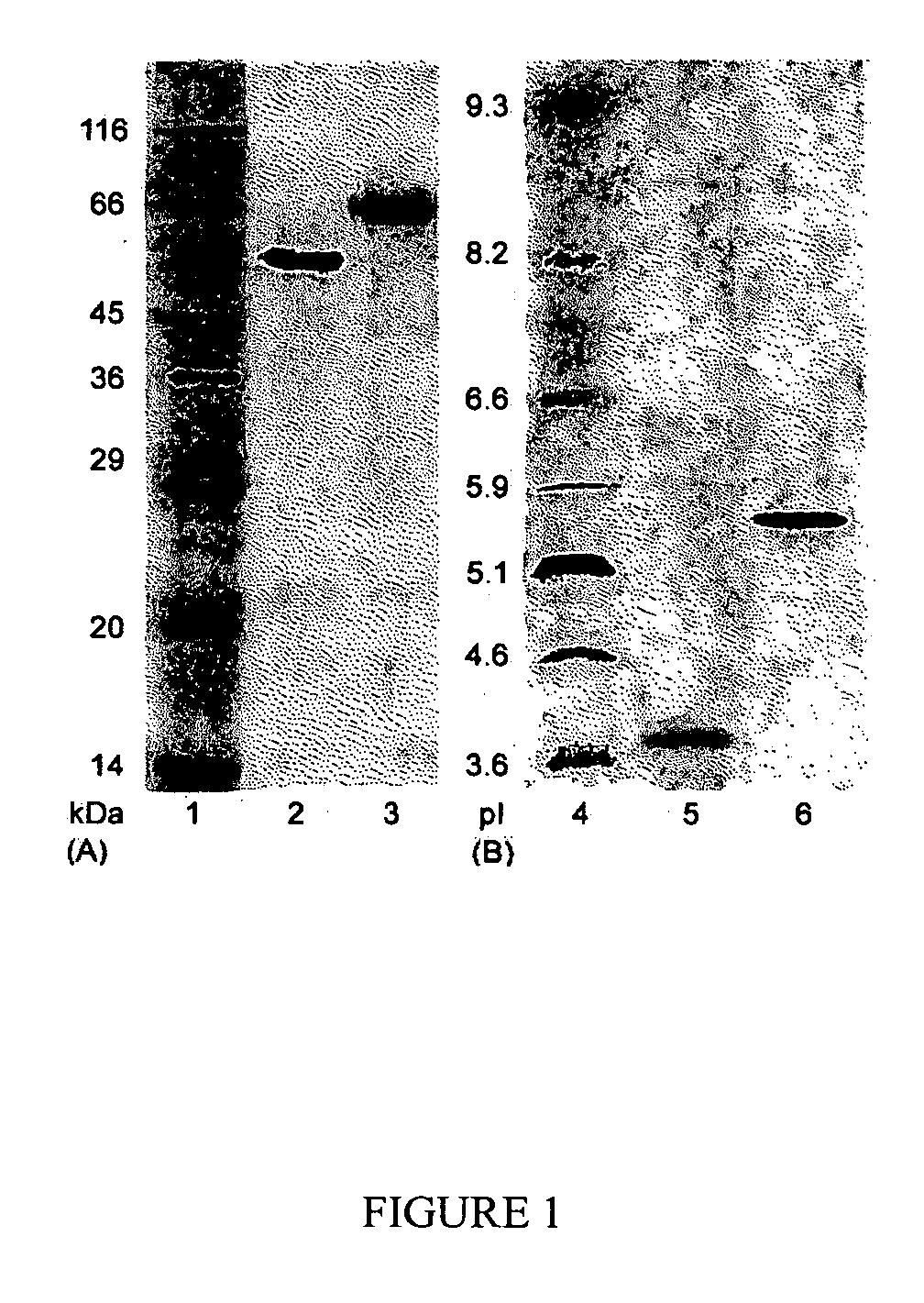

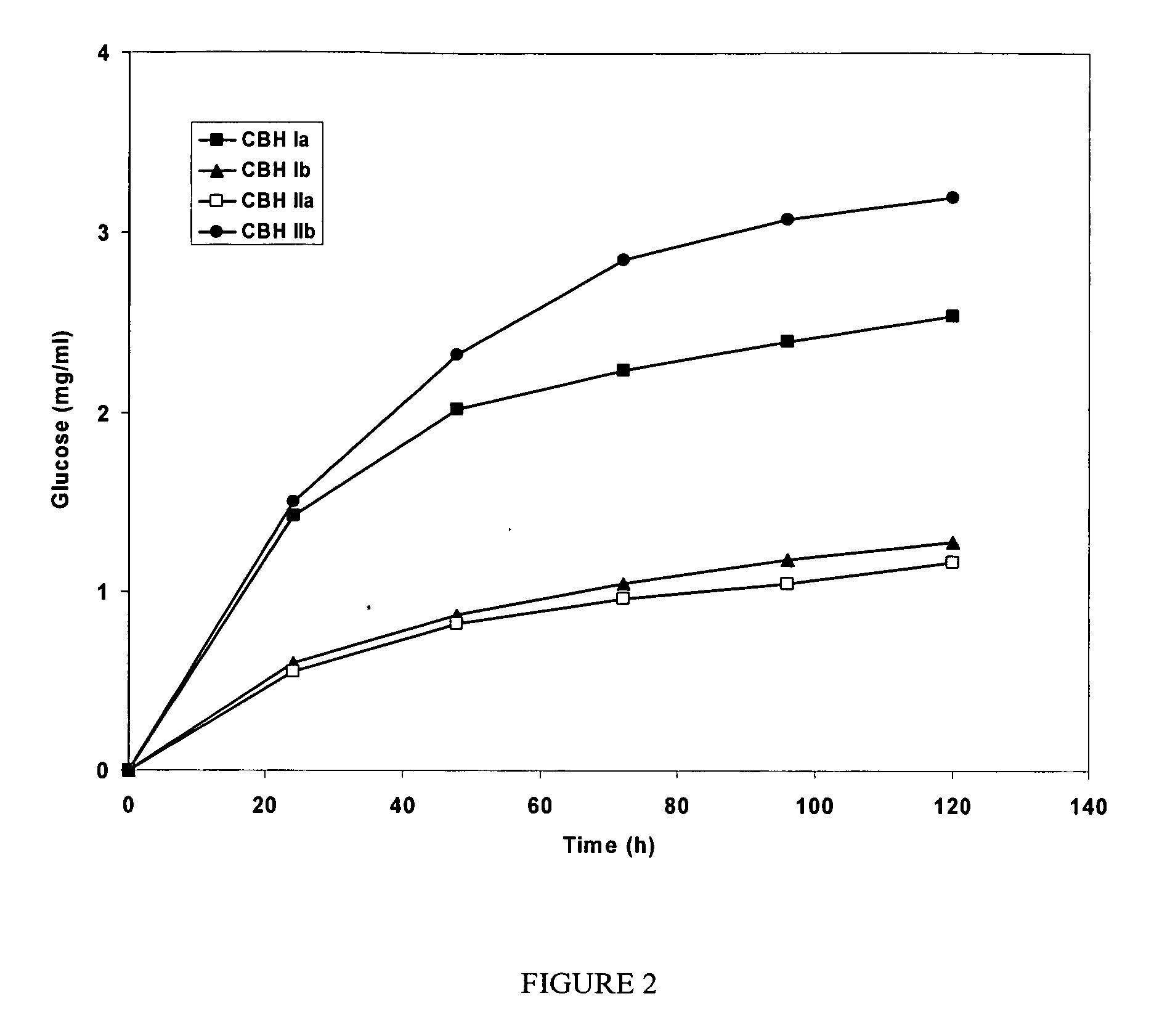

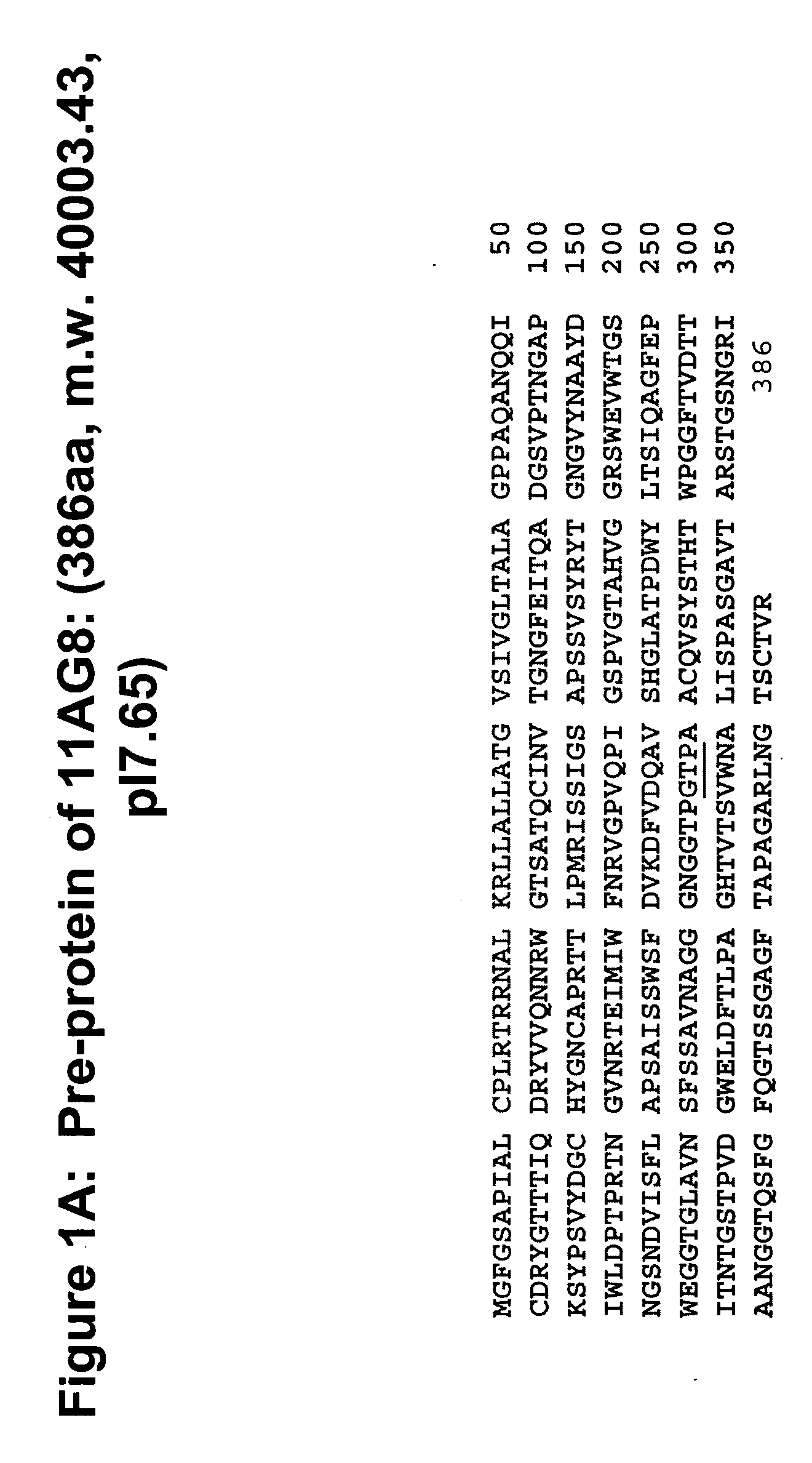

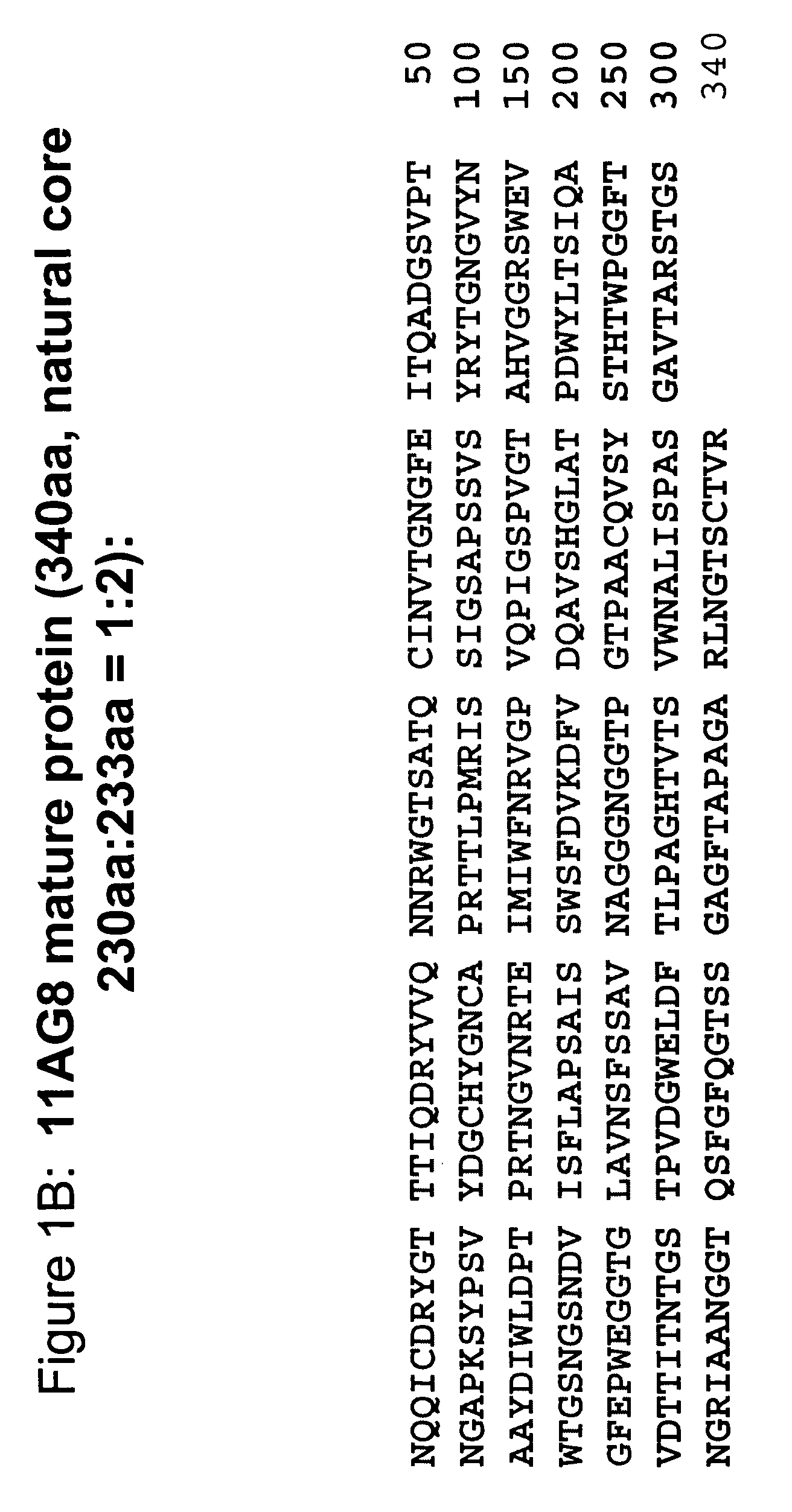

This invention provides novel enzyme compositions using newly identified and isolated C. lucknowense enzymes, including CBH Ib CBH IIb, EG II, EG VI, β-glucosidase, and xylanase II in conjunction with previously identified enzymes CBH Ia, CBH IIa (previously described as Endo 43), and EG V. These enzyme compositions demonstrate an extremely high ability to convert lignocellulosic biomass (e.g., Avicel, cotton, Douglas fir wood pretreated by organosolv) to glucose. CBH Ia and IIb, which both have a cellulose-binding module (CBM) displayed a pronounced synergism with three major endoglucanases (EG II, EG V, EG VI) from the same fungus in hydrolysis of cotton as well as a strong synergy with each other. The enzyme compositions are effective in hydrolysis of the lignocellulosic biomass.

Owner:DANISCO US INC

Methods for degrading lignocellulosic materials

The present invention relates to methods for degrading a lignocellulosic material, comprising: treating the lignocellulosic material with an effective amount of one or more cellulolytic enzymes in the presence of at least one surfactant selected from the group consisting of a secondary alcohol ethoxylate, fatty alcohol ethoxylate, nonylphenol ethoxylate, tridecyl ethoxylate, and polyoxyethylene ether, wherein the presence of the surfactant increases the degradation of lignocellulosic material compared to the absence of the surfactant. The present invention also relates to methods for producing an organic substance, comprising: (a) saccharifying a lignocellulosic material with an effective amount of one or more cellulolytic enzymes in the presence of at least one surfactant selected from the group consisting of a secondary alcohol ethoxylate, fatty alcohol ethoxylate, nonylphenol ethoxylate, tridecyl ethoxylate, and polyoxyethylene ether, wherein the presence of the surfactant increases the degradation of lignocellulosic material compared to the absence of the surfactant; (b) fermenting the saccharified lignocellulosic material of step (a) with one or more fermentating microoganisms; and (c) recovering the organic substance from the fermentation.

Owner:NOVO NORDISKBIOTECH INC

Lignin blockers and uses thereof

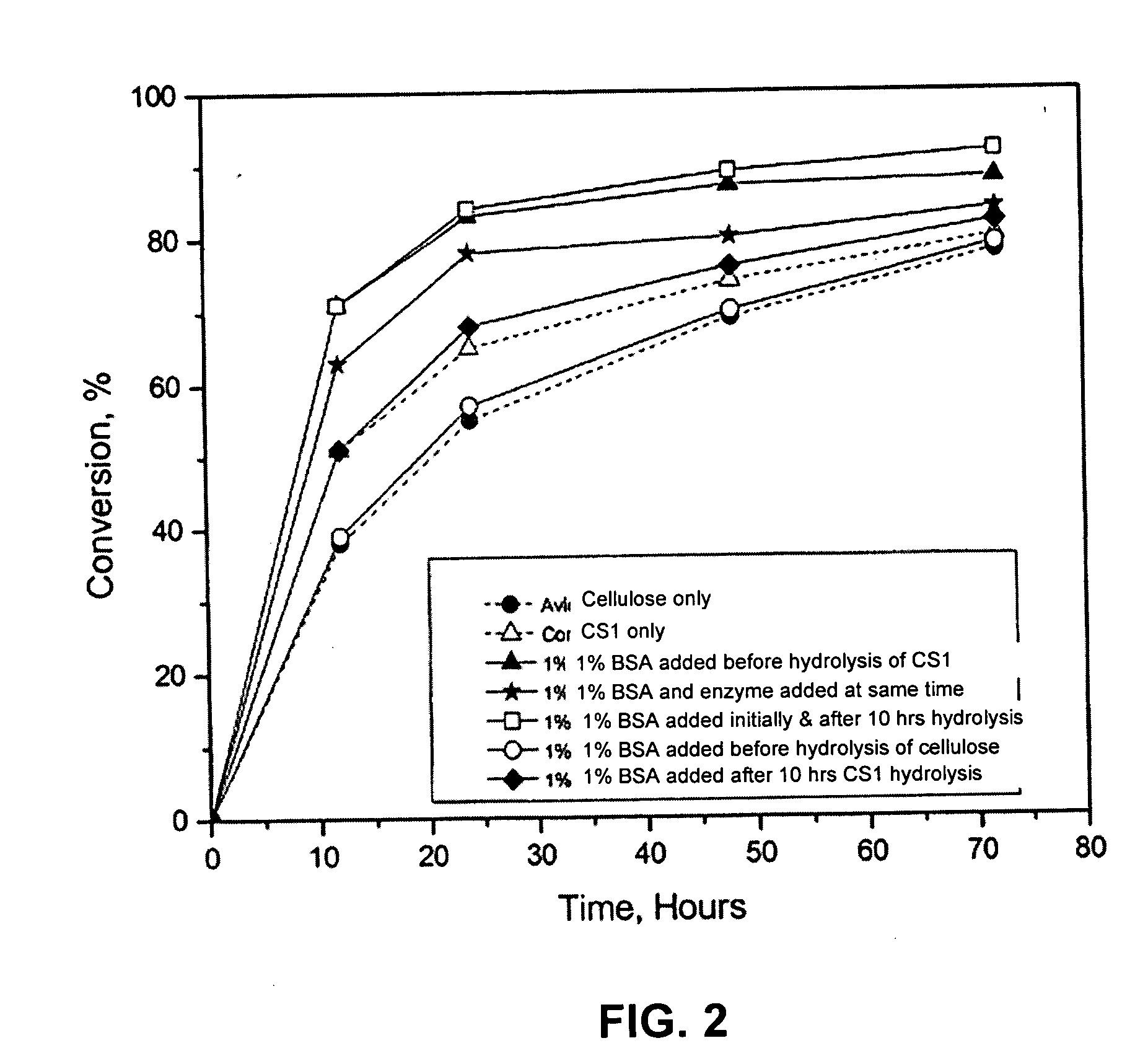

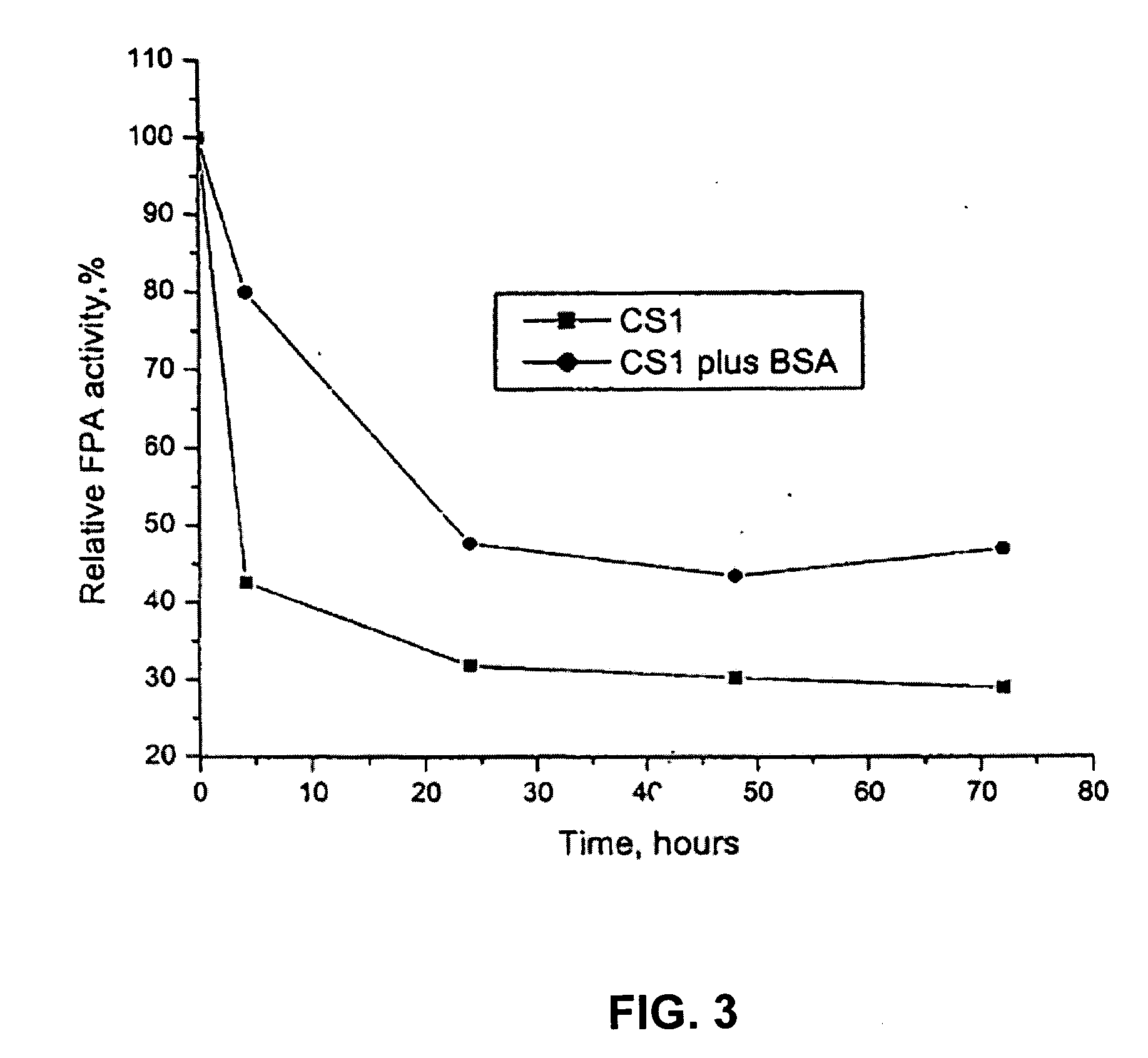

InactiveUS20060088922A1High efficiency in cellulose conversionLess of advantageProtein composition from vegetable seedsBiofuelsLignin degradationLignocellulosic biomass

Disclosed is a method for converting cellulose in a lignocellulosic biomass. The method provides for a lignin-blocking polypeptide and / or protein treatment of high lignin solids. The treatment enhances cellulase availability in cellulose conversion and allows for the determination of optimized pretreatment conditions. Additionally, ethanol yields from a Simultaneous Saccharification and Fermentation process are improved 5-25% by treatment with a lignin-blocking polypeptide and / or protein. Thus, a more efficient and economical method of processing lignin containing biomass materials utilizes a polypeptide / protein treatment step that effectively blocks lignin binding of cellulase.

Owner:TRUSTEES OF DARTMOUTH COLLEGE THE

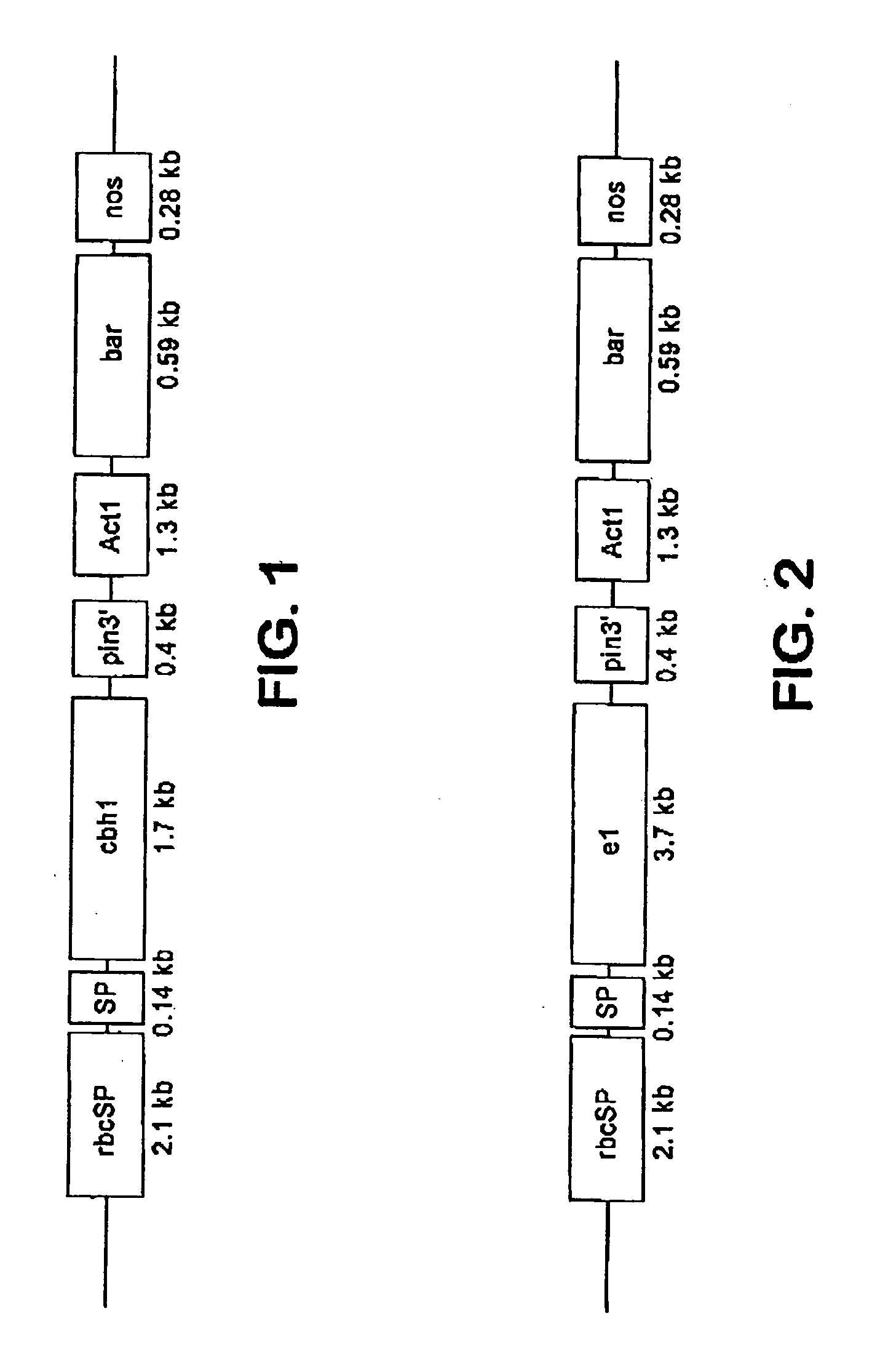

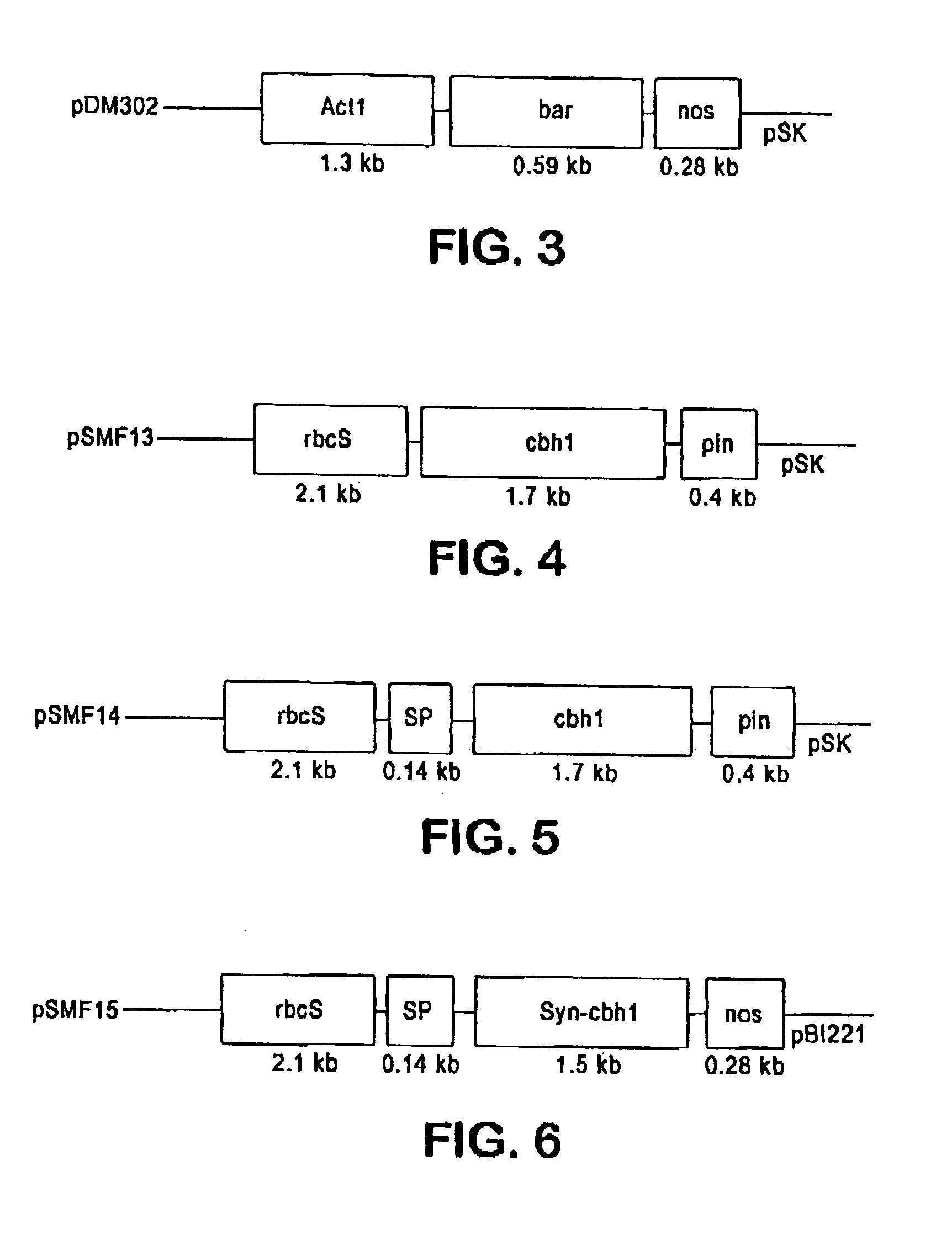

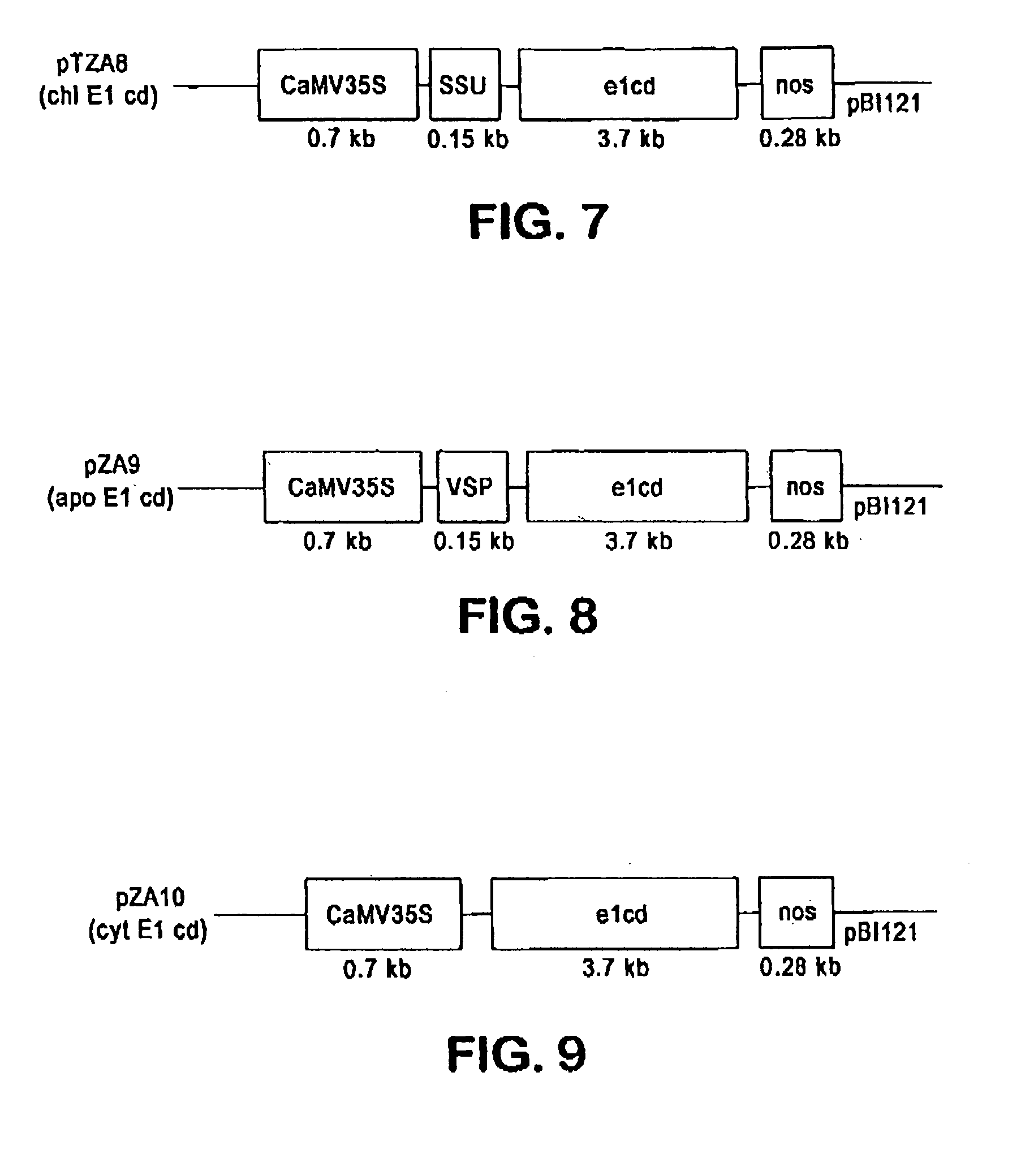

Production of beta-glucosidase, hemicellulase and ligninase in E1 and FLC-cellulase-transgenic plants

InactiveUS20070192900A1Increase biomassReduce the amount of solutionClimate change adaptationOther foreign material introduction processesAlgluceraseBeta-glucosidase

The present invention provides transgenic plants expressing one or more cell wall degrading enzymes that can degrade lignocellulose to fermentable sugars. These fermentable sugars can further be fermented to ethanol or other products. The enzymes are directed to the plastids or the apoplasts or the transgenic plant for storage. When the transgenic plants are harvested, the plants are ground to release the enzymes which then are used to degrade the lignocellulose of plant material to produce the fermentable sugars. The transgenic plants express the flowering locus c gene so that flowering is delayed and the plant biomass is increased.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

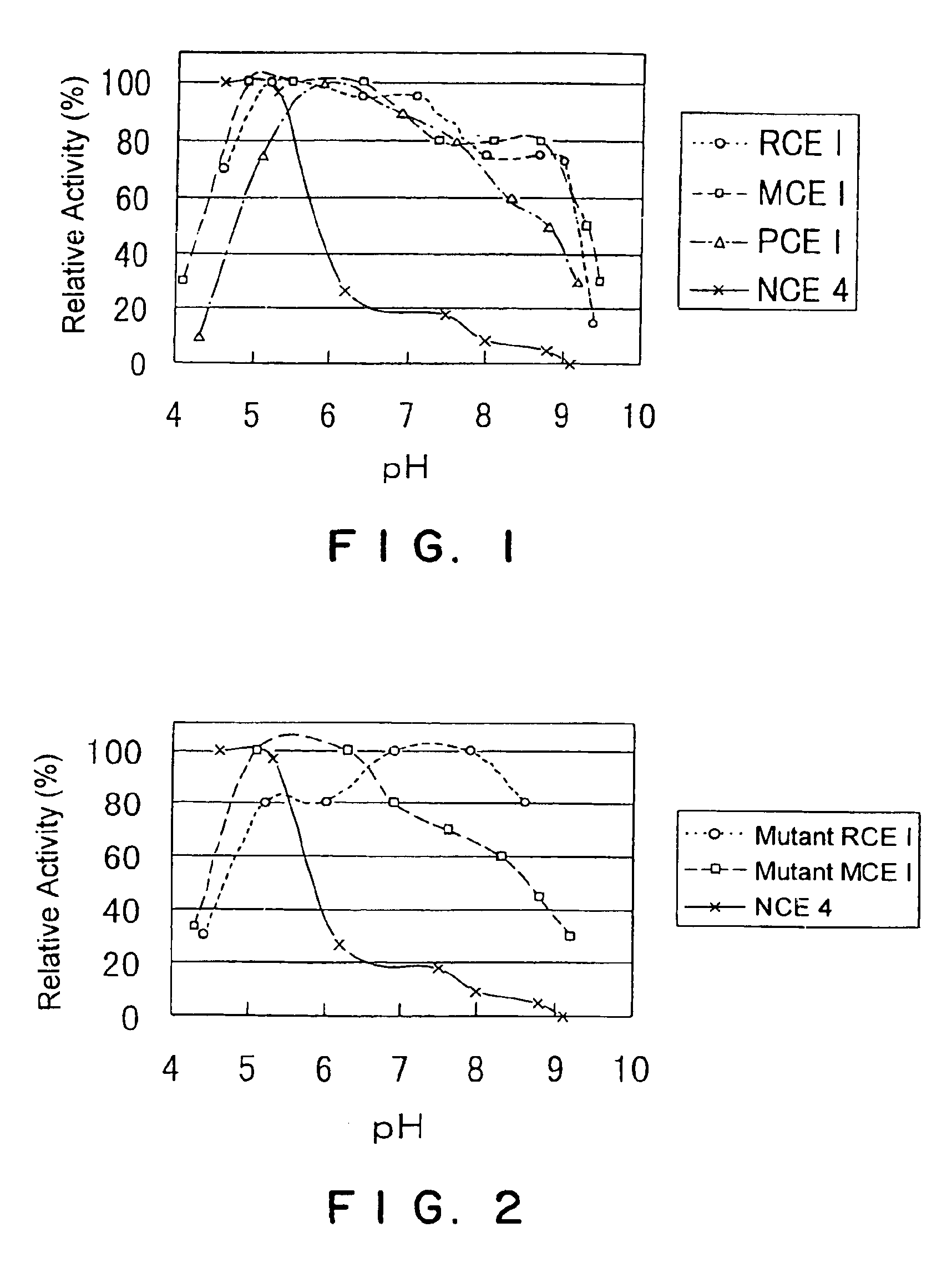

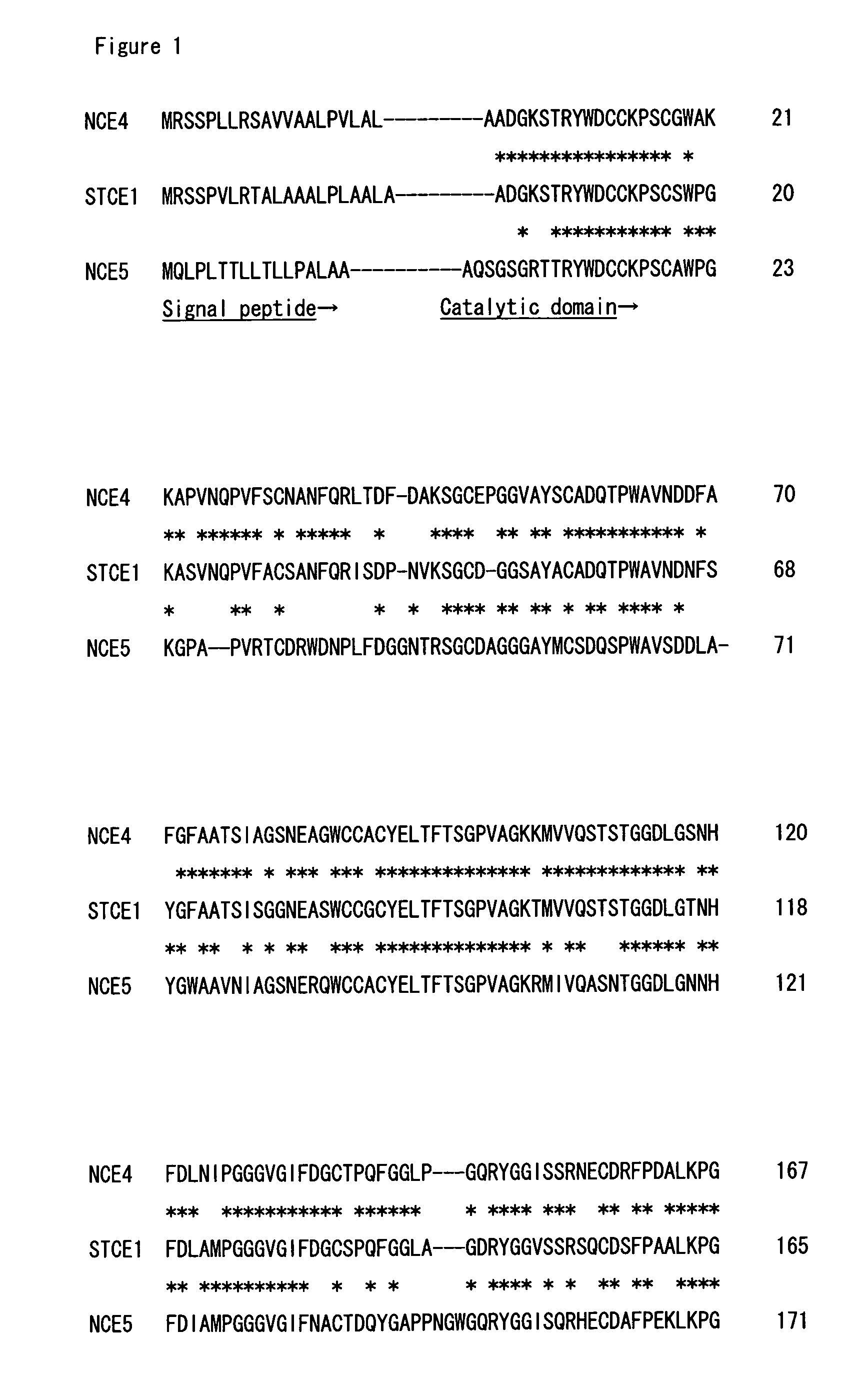

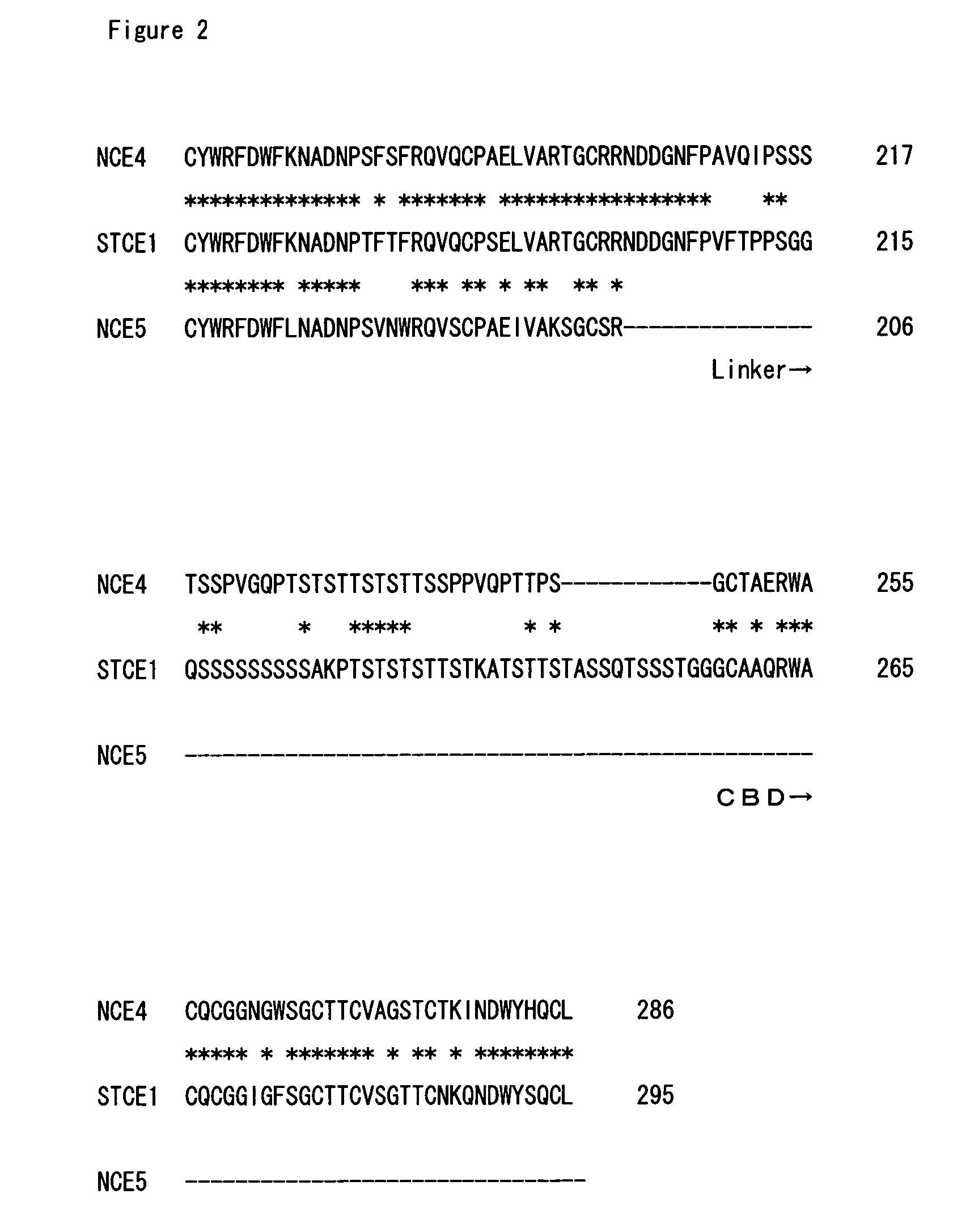

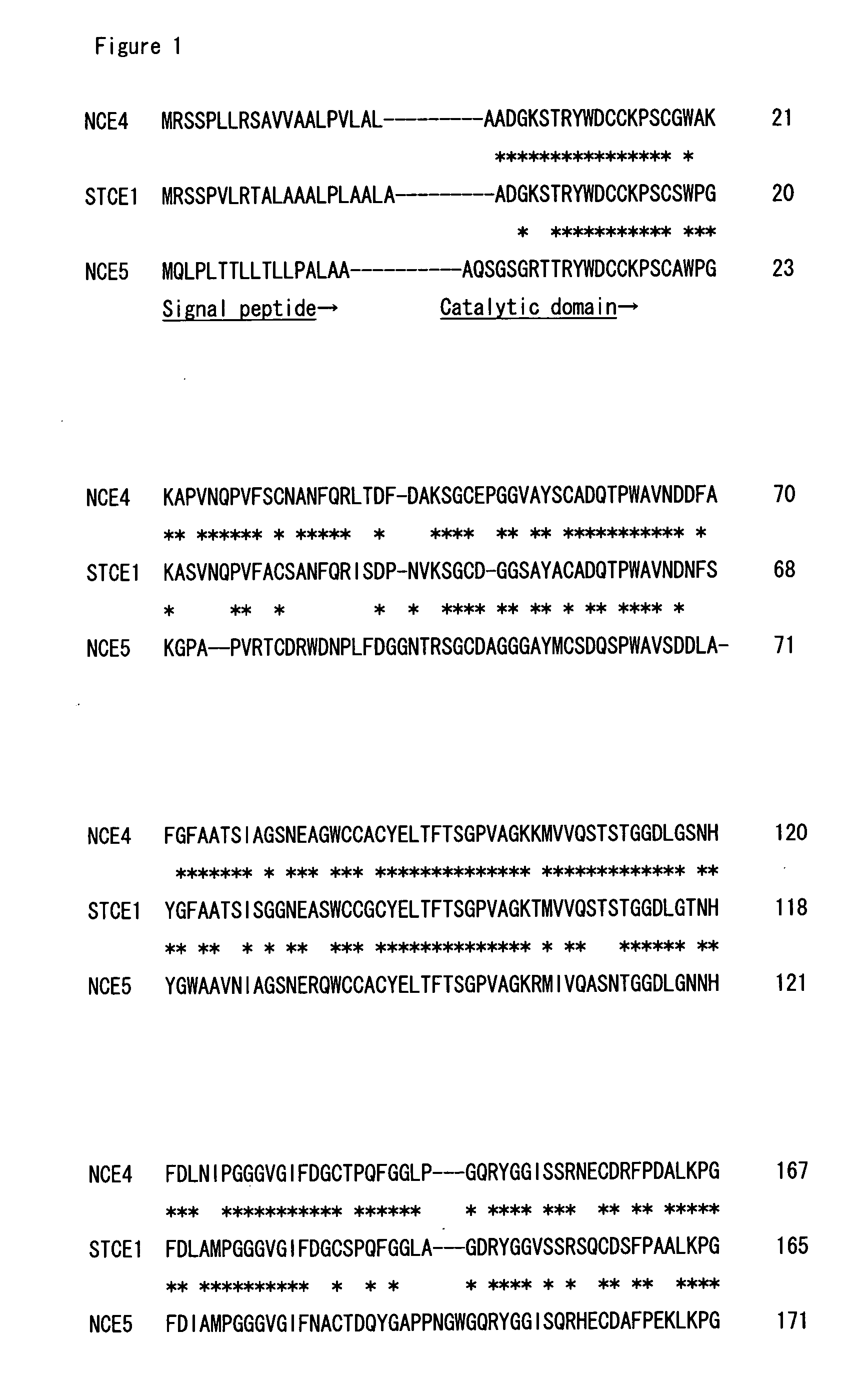

Endoglucanases and cellulase preparations containing the same

InactiveUS6921655B1High whitenessImprove freeness (drainage)Organic detergent compounding agentsBacteriaGlucanaseEndoglucanase activity

It is an object of the present invention to provide enzymes that have high endoglucanase activity and yet exhibit high activity even under alkaline conditions, and genes encoding the same. The enzyme according to the invention has the following properties: a) exhibiting endoglucanase activity; and b) capable of completely removing fuzz from regenerated cellulose fabrics at a concentration of 1 mg of the protein / L or below. The enzyme of the invention having endoglucanase activity is a protein comprising the amino acid sequence as shown in SEQ ID NO: 1, 3, 5, 7, 9 or 11; a modified protein thereof exhibiting endoglucanase activity; or a homologue of the protein or the modified protein.

Owner:MEIJI SEIKA PHARMA CO LTD

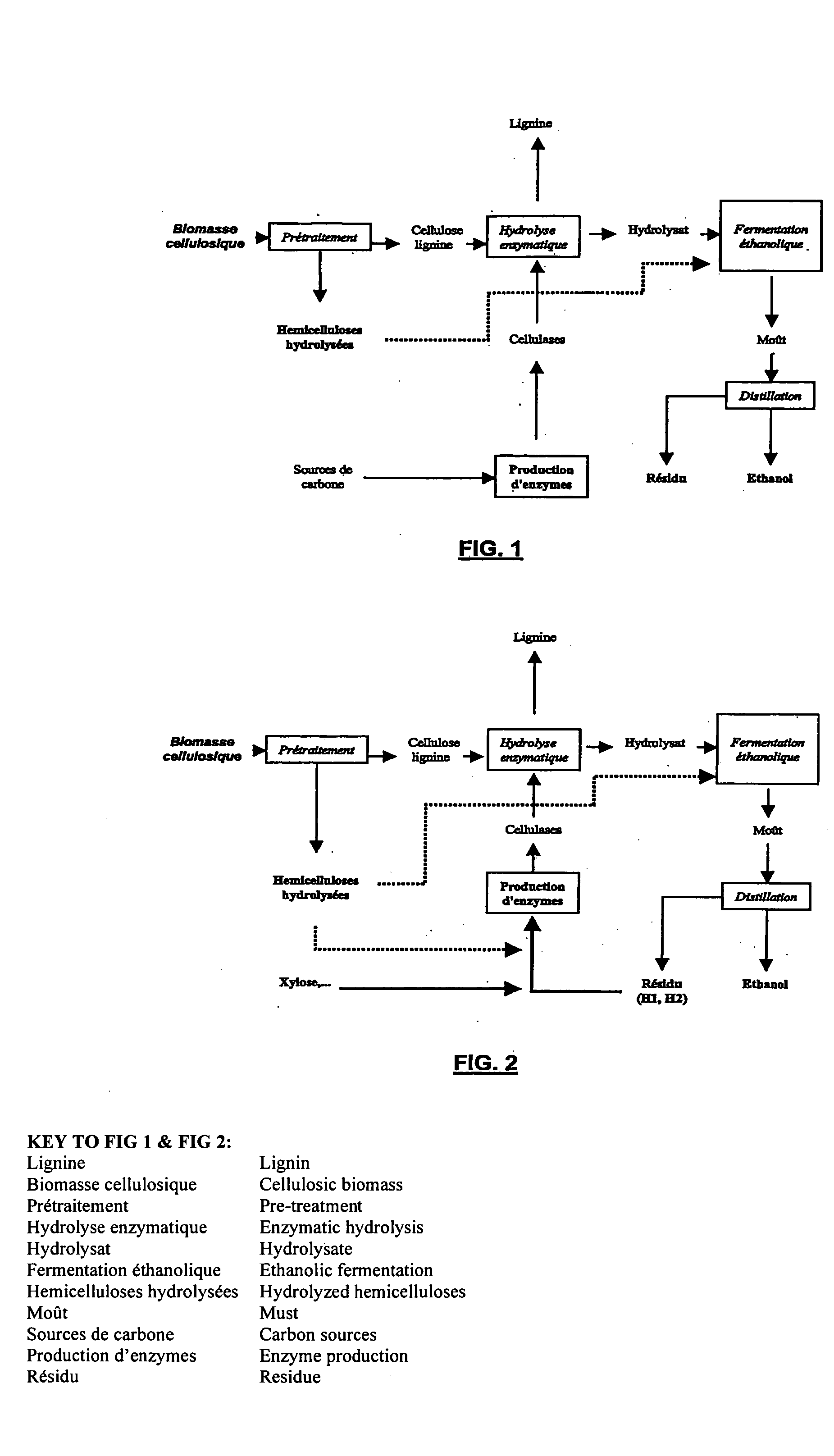

Process for the production of cellulolytic and hemicellulolytic enzymes using distillation residues from the ethanolic fermentation of enzymatic hydrolyzates of (ligno)cellulosic materials

A process for producing cellulolytic and / or hemicellulolytic enzymes uses the residue from the ethanolic fermentation of enzymatic hydrolyzates of cellulosic or ligno-cellulosic materials. This process may be integrated into a process for the production of ethanol from cellulosic or ligno-cellulosic materials which comprises the following steps: 1) chemical and / or physical pre-treatment of a cellulosic or ligno-cellulosic substrate; 2) enzymatic hydrolysis of the pre-treated substrate using cellulolytic and / or hemicellulolytic enzymes; 3) ethanolic fermentation, by a suitable alcohologenic microorganism, of the hydrolyzate from step (2) and production of a fermentation must; and 4) separation of the alcohologenic microorganism used in step (3), separation / purification of the ethanol and production of an aqueous phase constituting a residue; and in which said residue serves for the production of the cellulolytic and / or hemicellulolytic enzymes used in step 2).

Owner:INST FR DU PETROLE

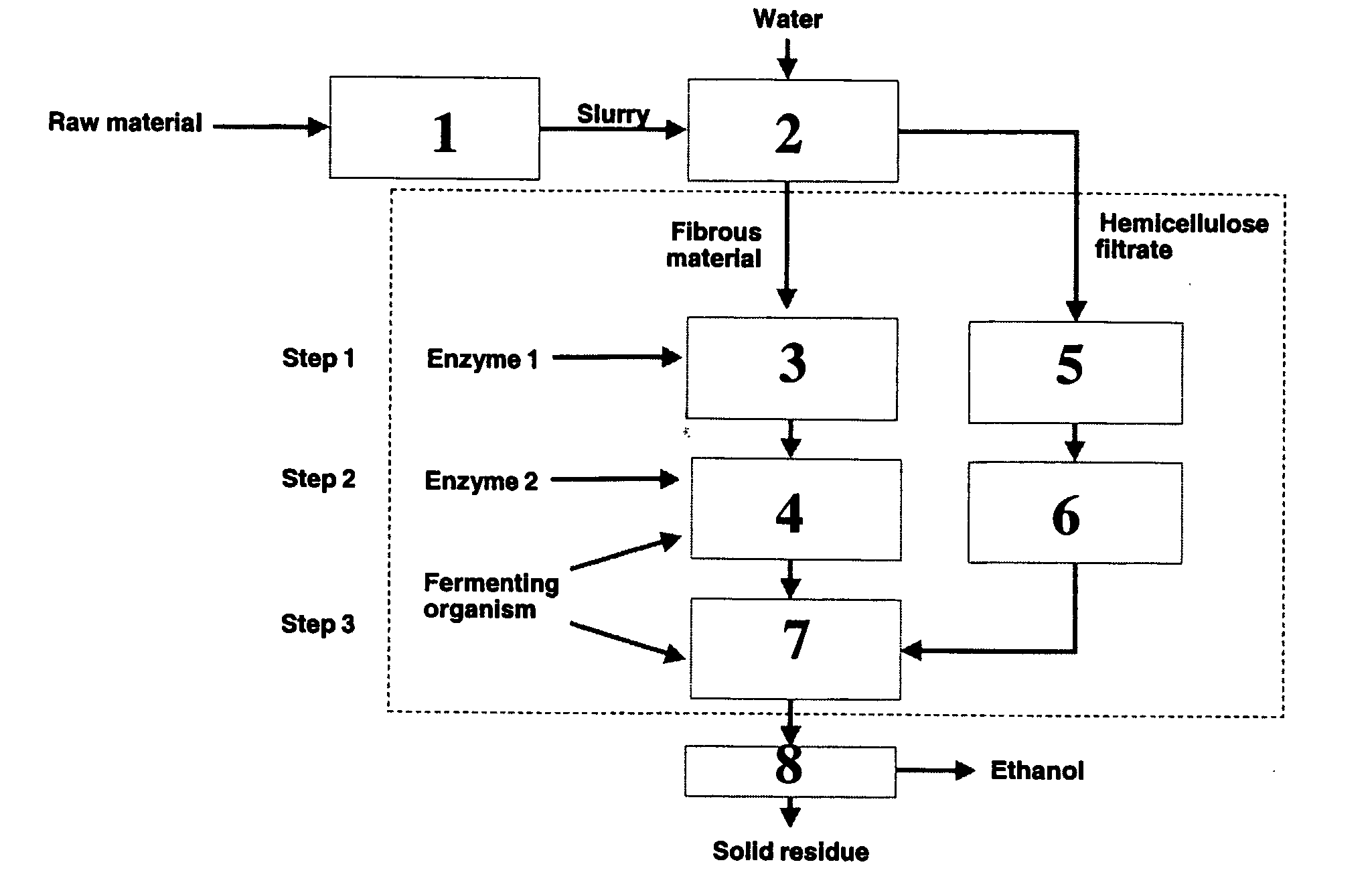

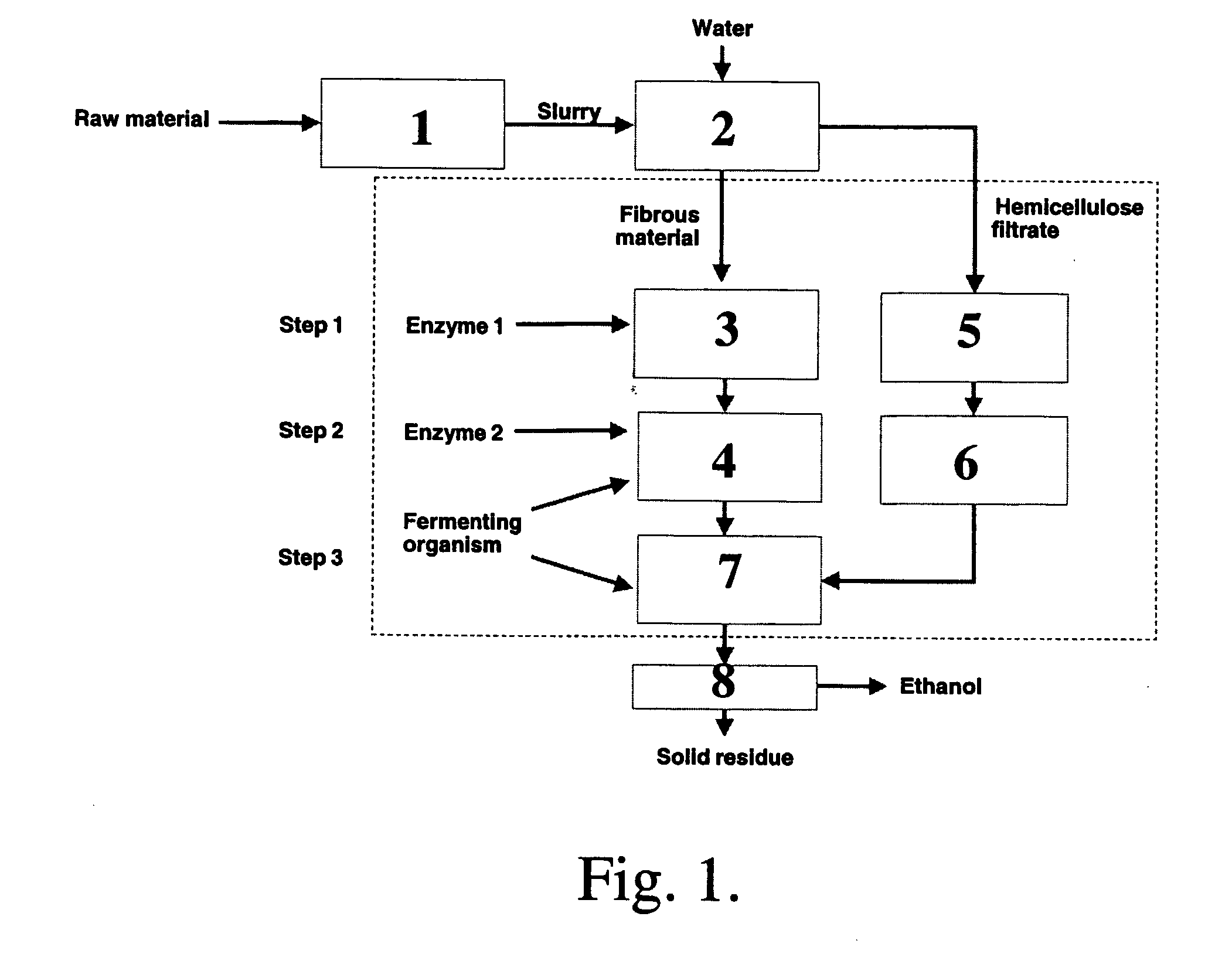

Process for Producing Ethanol

InactiveUS20080044877A1Improve efficiency and economyIncrease final ethanol concentrationBiofuelsAlcoholic beverage preparationFiberCellulose breakdown

A process for producing ethanol from a fibrous lignocellulosic raw material. After pre-treatment of the raw material, the fibrous fraction is first hydrolysed at high consistency and then the modified material is subjected simultaneously to continued hydrolysis with a cellulase and to ethanol fermentation in a fermentation mixture. Fermentation is continued to convert an essential portion of the available cellulose into ethanol, then a liquid fraction containing solubilized hemicelluloses is added to the fermentation mixture and fermentation continued. By means of the invention, high fermentation rates, high ethanol concentrations and low ethanol production costs can be attained.

Owner:VALTION TEKNILLINEN TUTKIMUSKESKUS

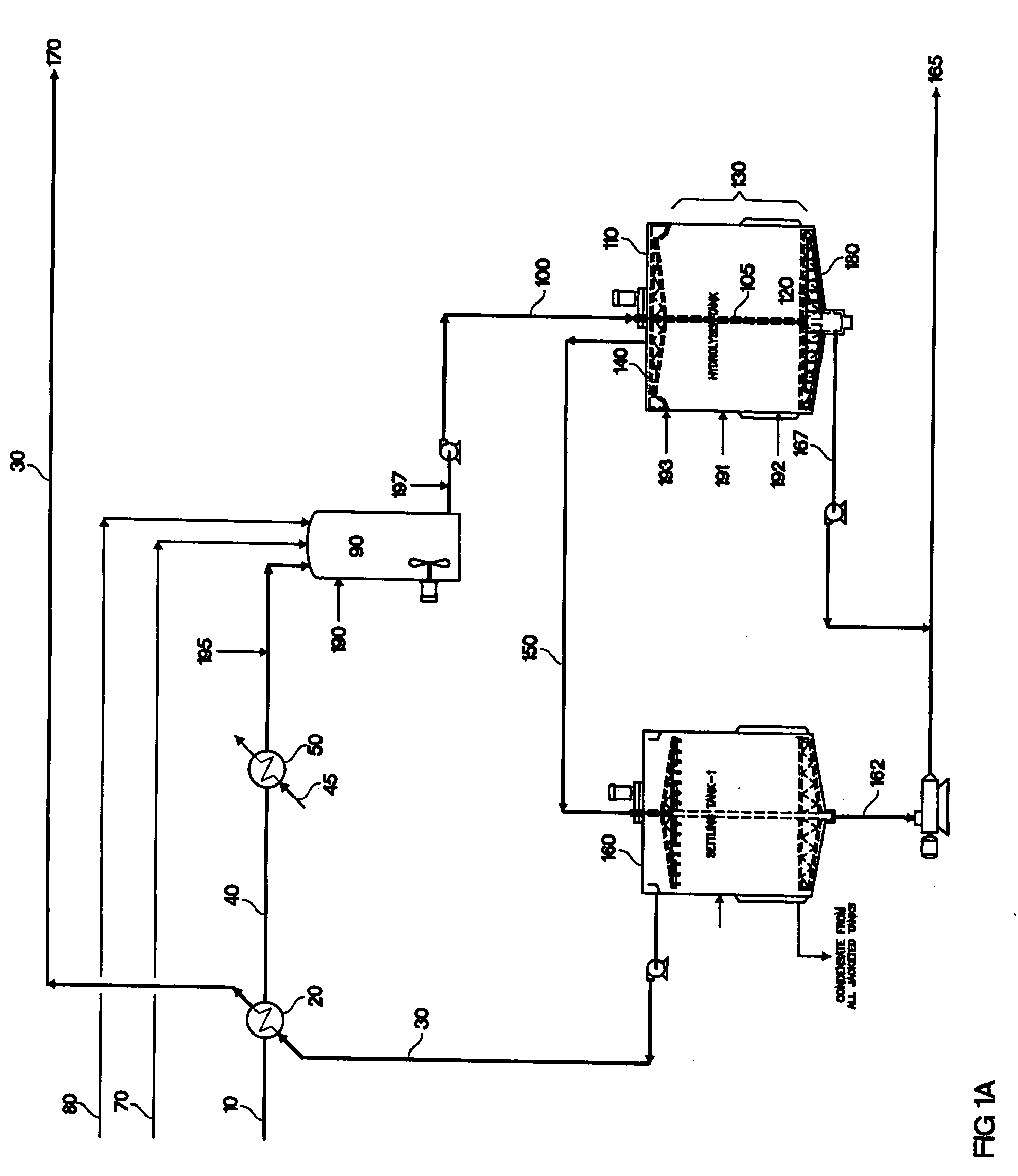

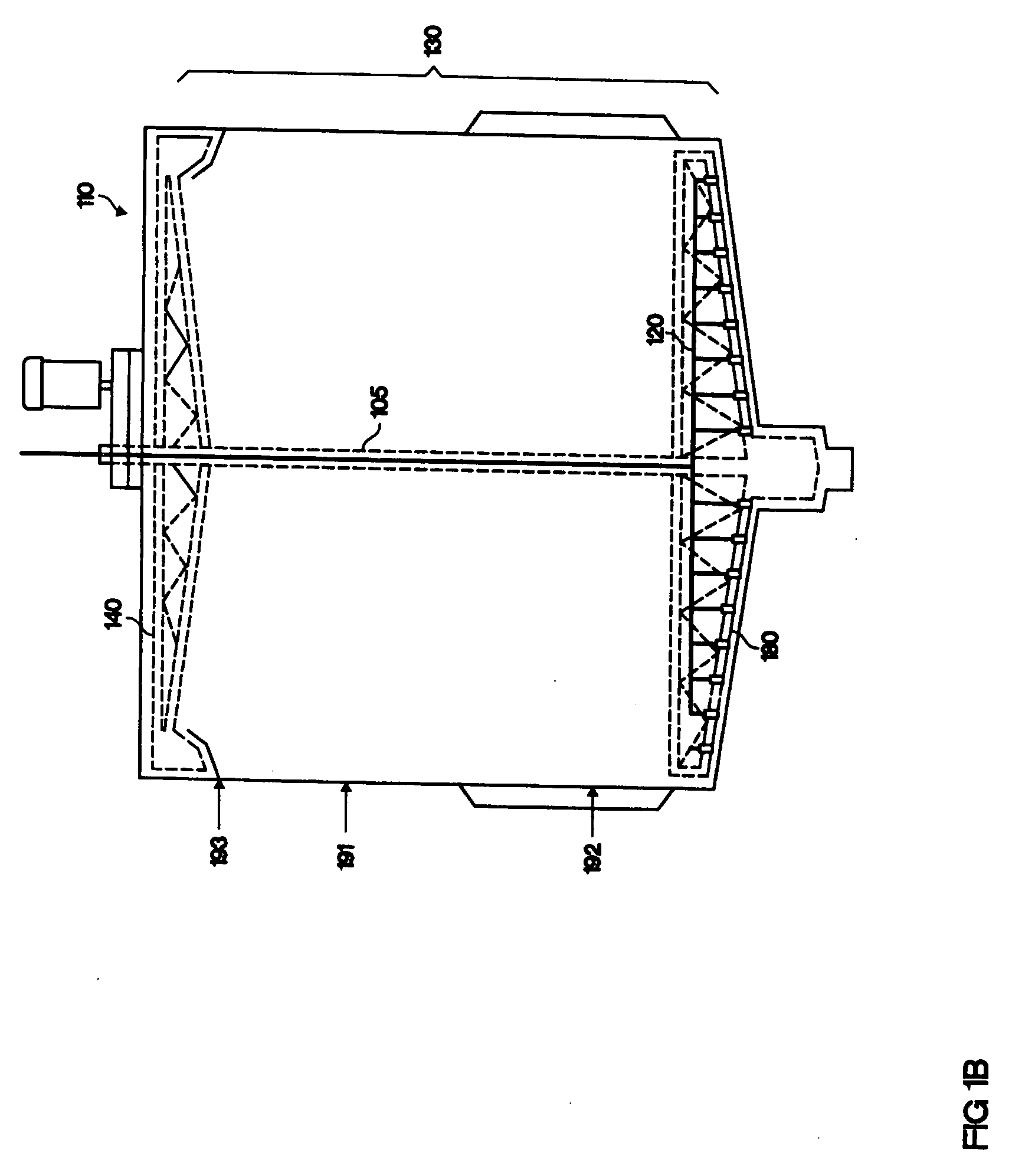

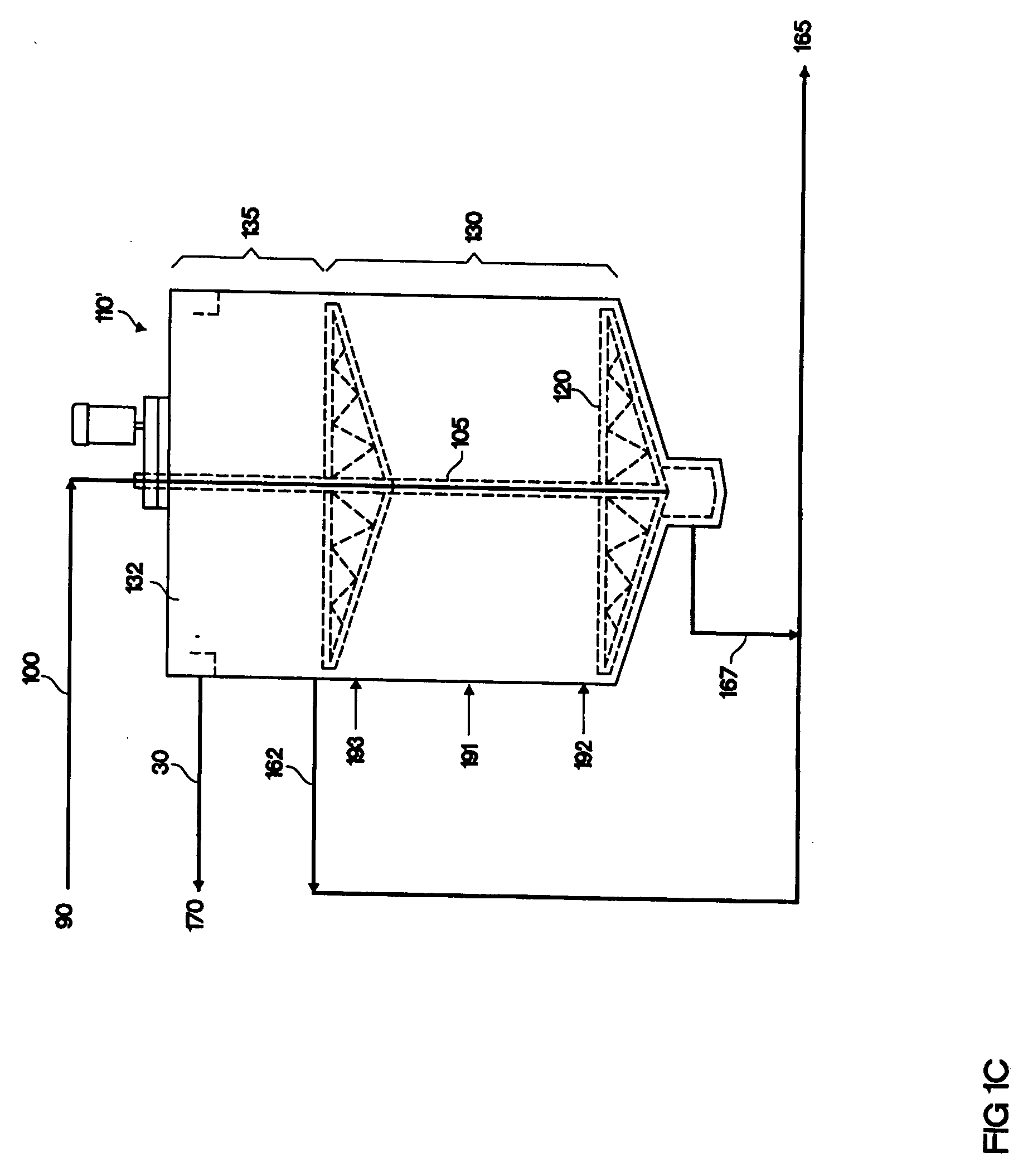

Upflow settling reactor for enzymatic hydrolysis of cellulose

InactiveUS20060154352A1Increase settlement rateEasy to operateBiological substance pretreatmentsBiofuelsEnzymatic hydrolysisHydrolysate

A process for the enzymatic hydrolysis of cellulose to produce a hydrolysis product from a pre-treated cellulosic feedstock is provided. The process comprises introducing an aqueous slurry of the pre-treated cellulosic feedstock at the bottom of a hydrolysis reactor. Axial dispersion in the reactor is limited by avoiding mixing and maintaining an average slurry flow velocity of about 0.1 to about 20 feet per hour, such that the undissolved solids flow upward at a rate slower than that of the liquid. Cellulase enzymes are added to the aqueous slurry before or during the step of introducing. An aqueous stream comprising hydrolysis product and unhydrolyzed solids is removed from the hydrolysis reactor. Also provided are enzyme compositions which comprise cellulase enzymes and flocculents for use in the process. In addition, a kit comprising cellulase enzymes and flocculent is provided.

Owner:IOGEN ENERGY CORP

Endoglucanase STCE and cellulase preparation containing the same

ActiveUS7595182B2Improvement of touch feel and appearance of fabricReduction of fuzzFungiBacteriaGlucanaseColor changes

Owner:MEIJI SEIKA KAISHA LTD

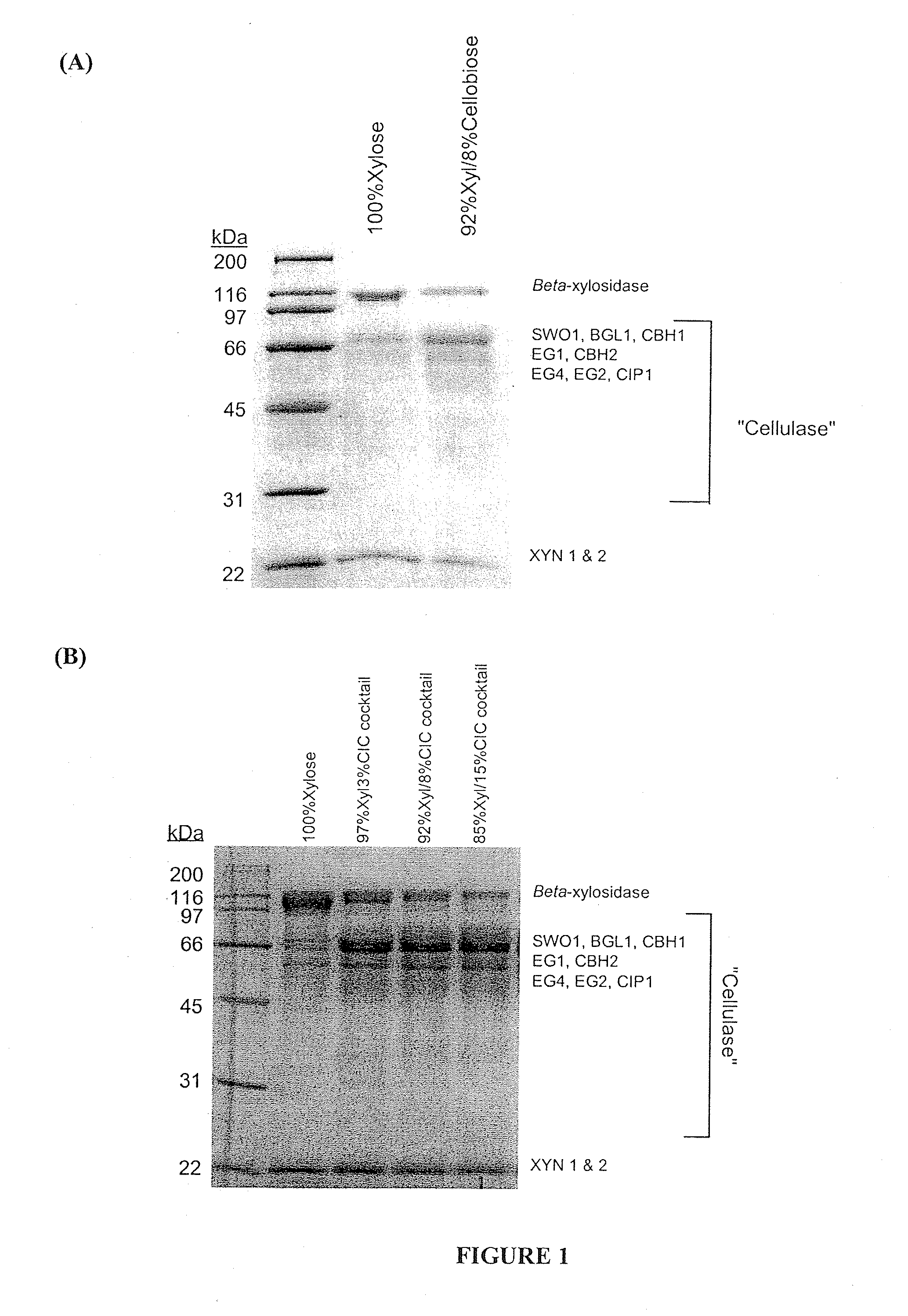

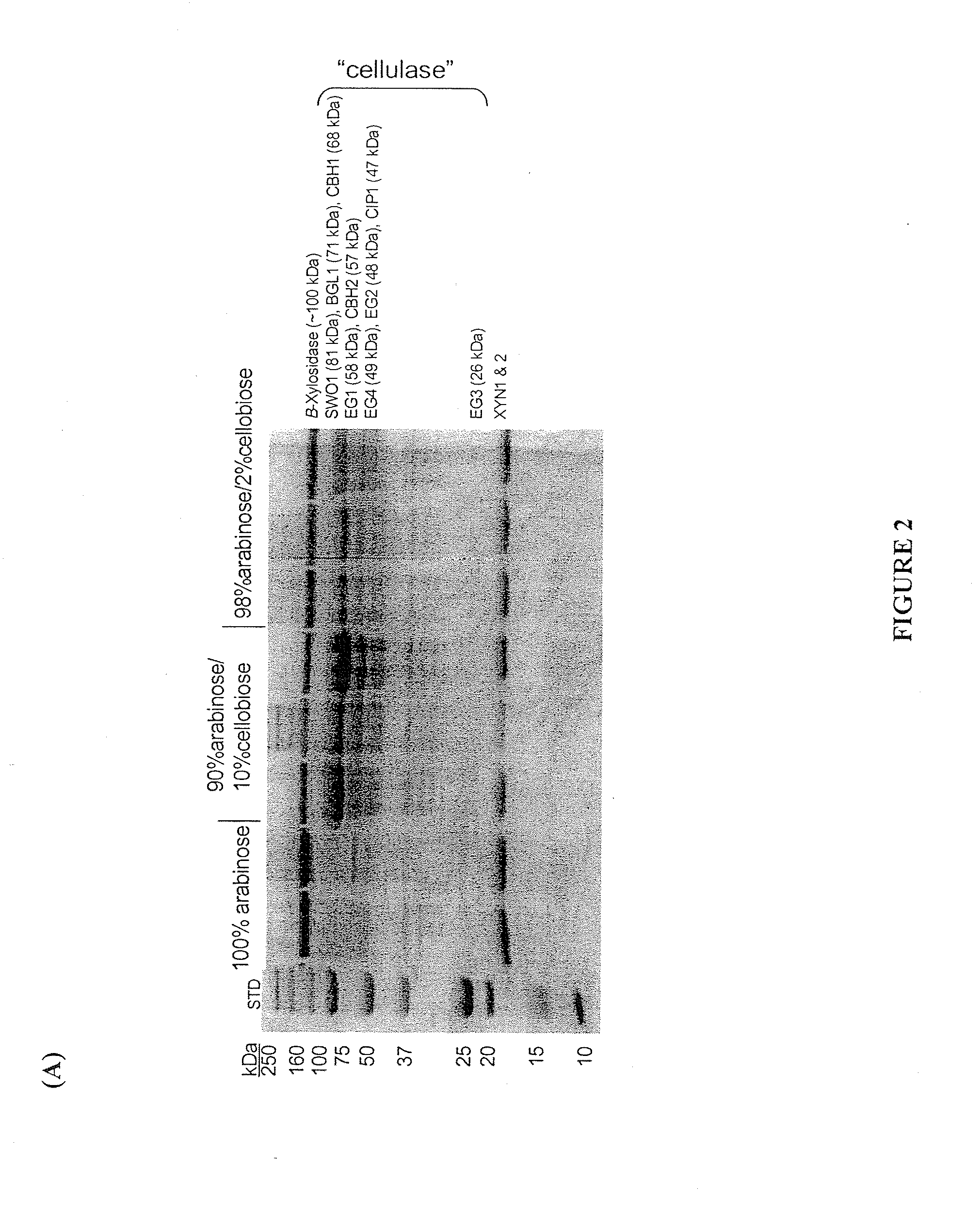

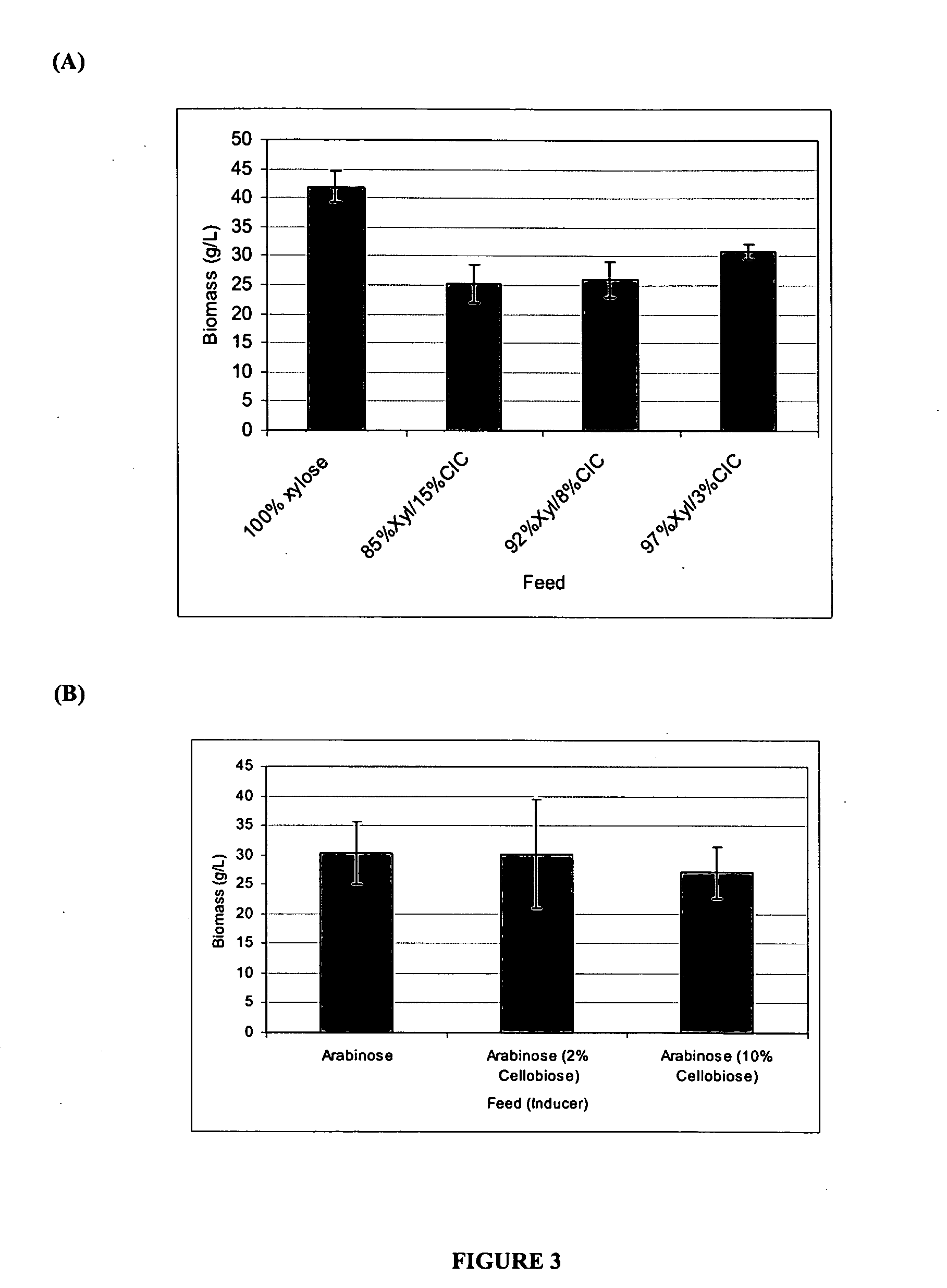

Method for cellulase production

A fermentation process using hemicellulose-derived carbohydrates for the production of cellulase mixtures with a high proportion of cellulases relative to hemicellulases is provided. The cellulases produced by the process of the invention are further characterized by high specific productivity. The resulting cellulase mixtures comprise at least two times more cellulase than hemicellulase and are useful for the hydrolysis of cellulosic substrated, particularly, pretreated lignocellulosic substrate.

Owner:IOGEN ENERGY CORP

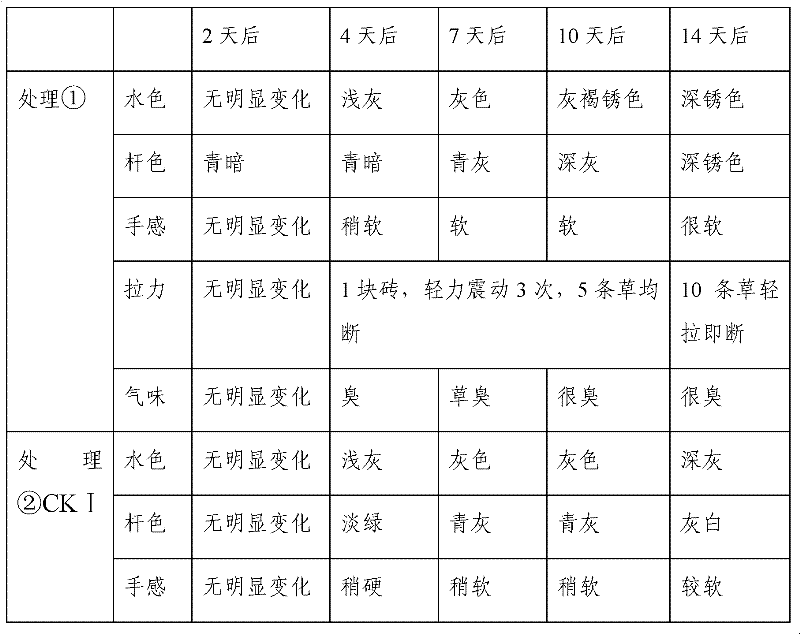

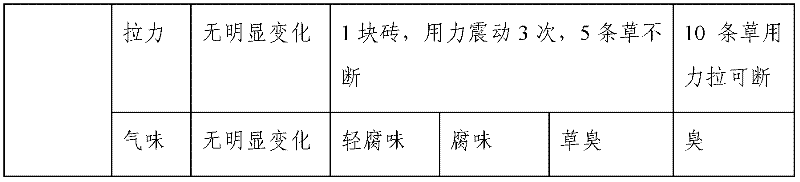

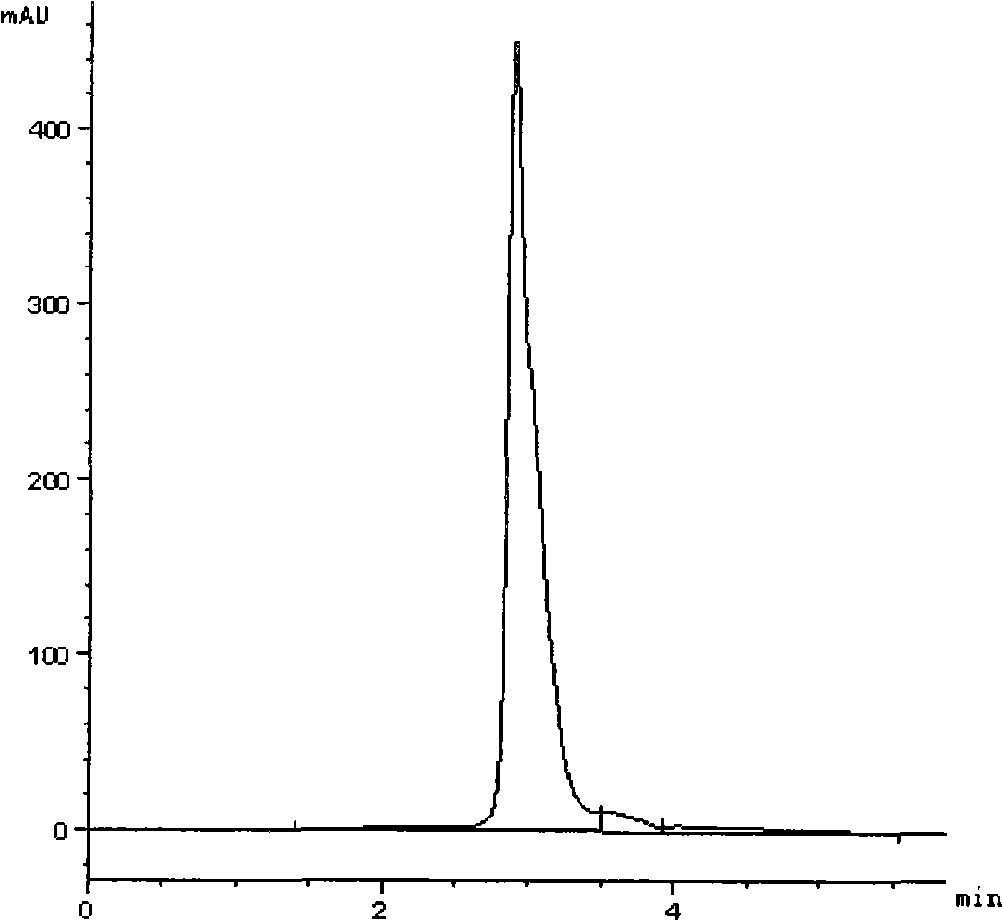

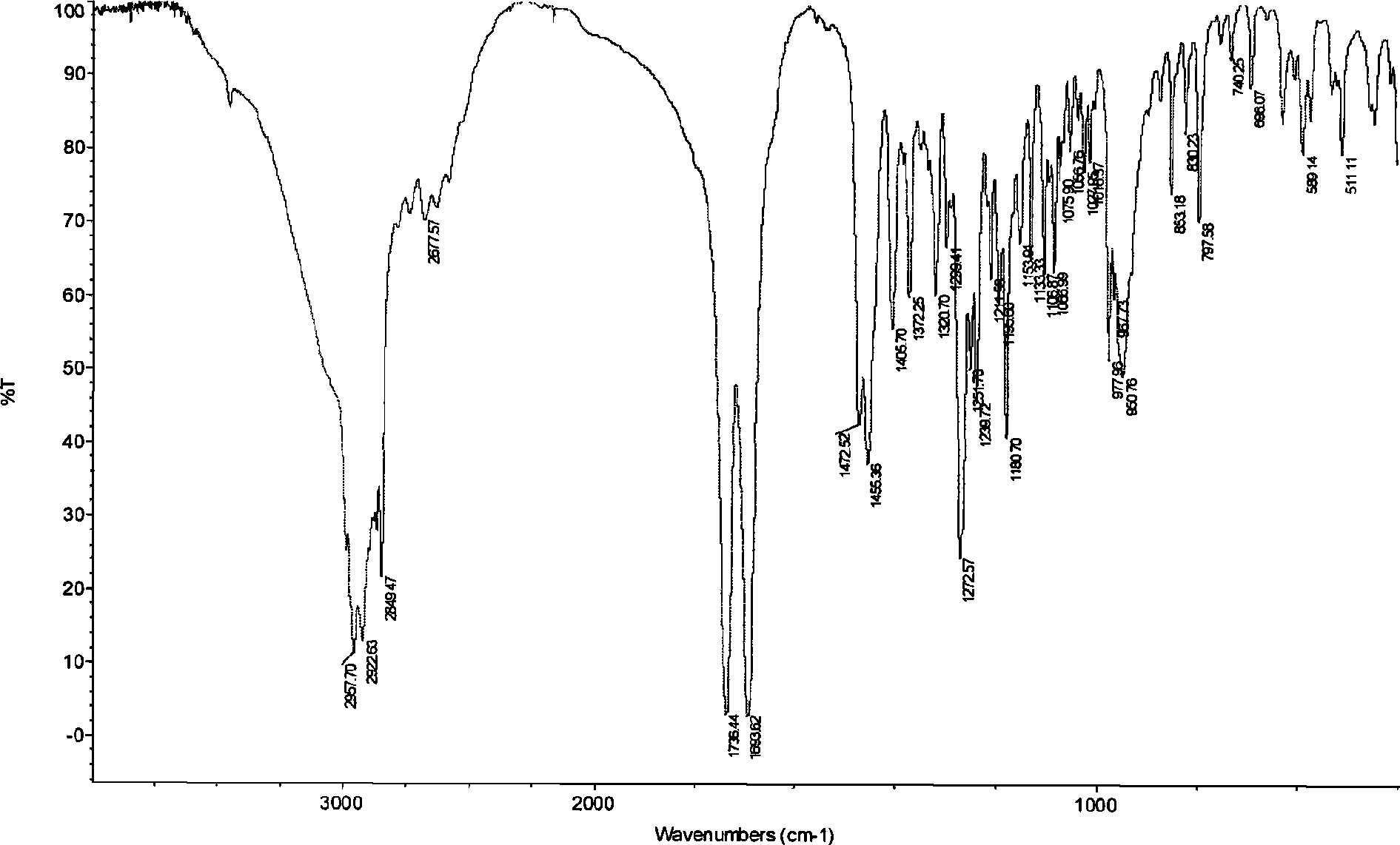

Bacillus licheniformis and application thereof in promotion of cellulose degradation

InactiveCN101892182APromote degradationHigh nutritional valueBio-organic fraction processingBacteriaBacillus licheniformisNutritive values

The invention discloses bacillus licheniformis and application thereof in the promotion of cellulose degradation. The invention provides the bacillus licheniformis J15CGMCC No.3905. Fermentation liquor obtained by fermenting the bacillus licheniformis J15 is the cellulose degradation enzymic preparation of the invention. The bacillus licheniformis J15 can be used for degrading cellulose and preparing compost. By degrading straws with cellulose decomposition bacteria, the bacillus licheniformis has the advantages of improving the nutritive value and the utilization value of the straw, along with high nutritive value, reproducibility, environmental friendliness, less energy consumption and the like. By inoculating the cellulose decomposition bacteria to the high temperature compost, cellulase content in the composting process can be obviously increased, the degradation of the cellulose and the decomposition of the compost can be promoted and the quality of the compost can be improved.

Owner:CHINA AGRI UNIV

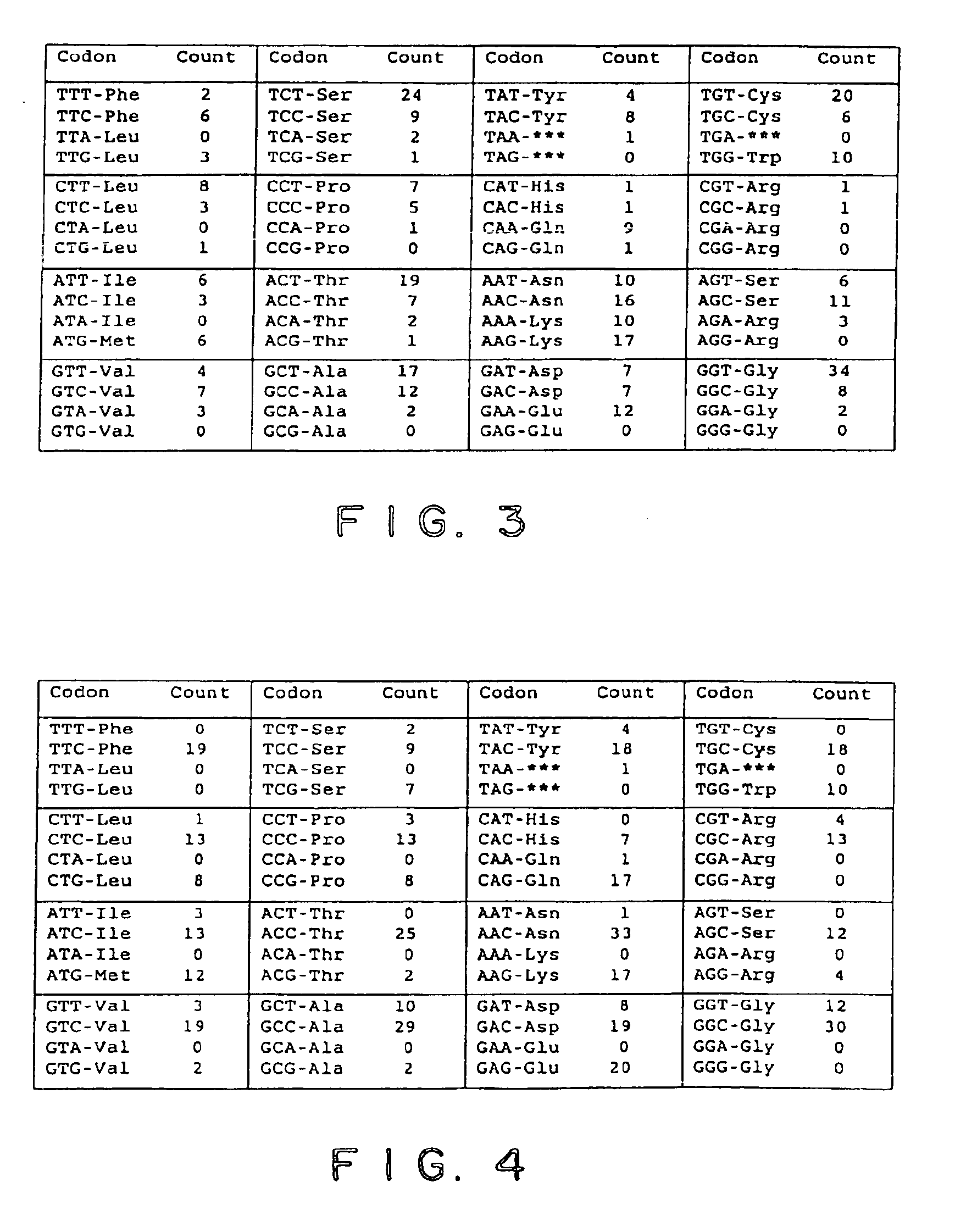

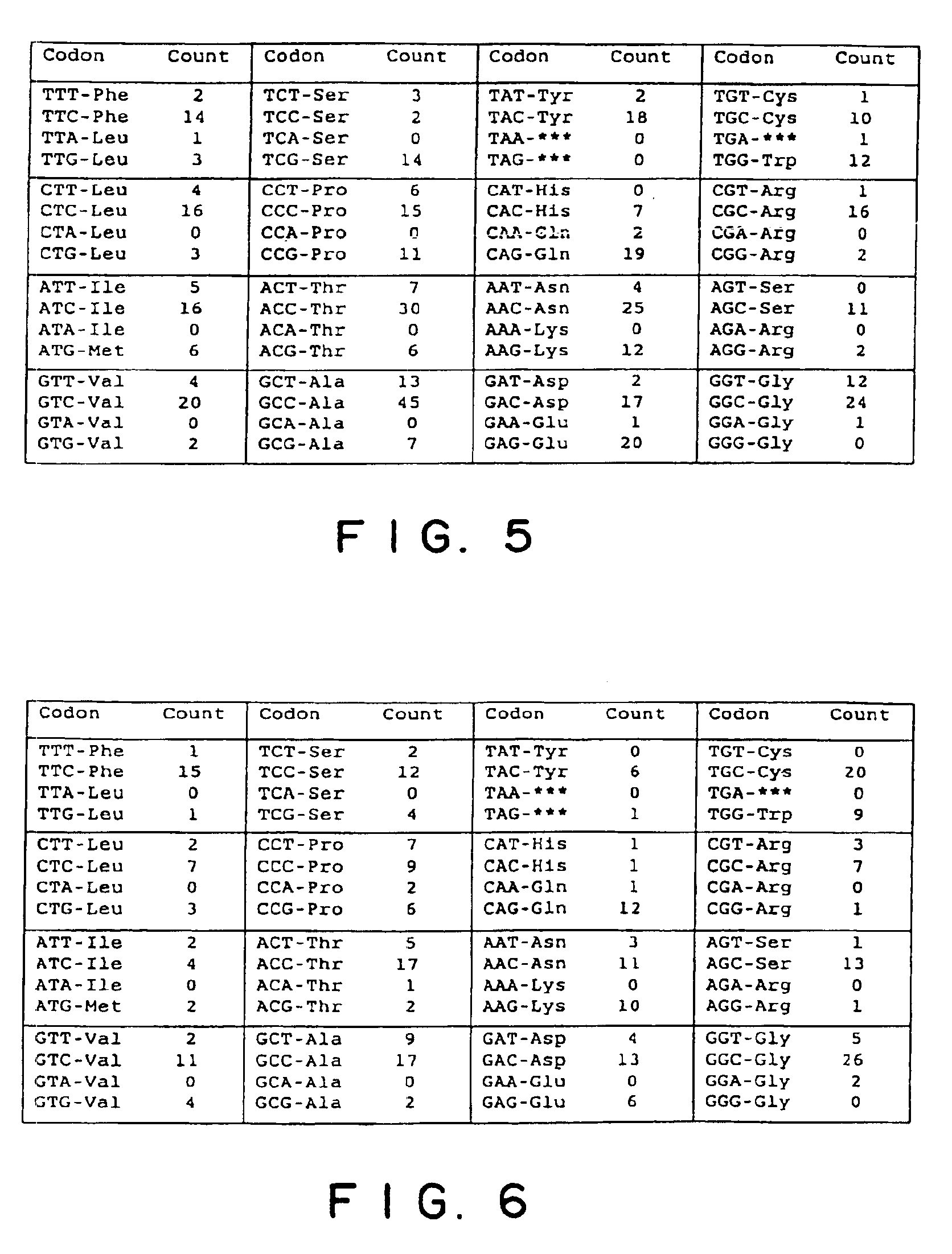

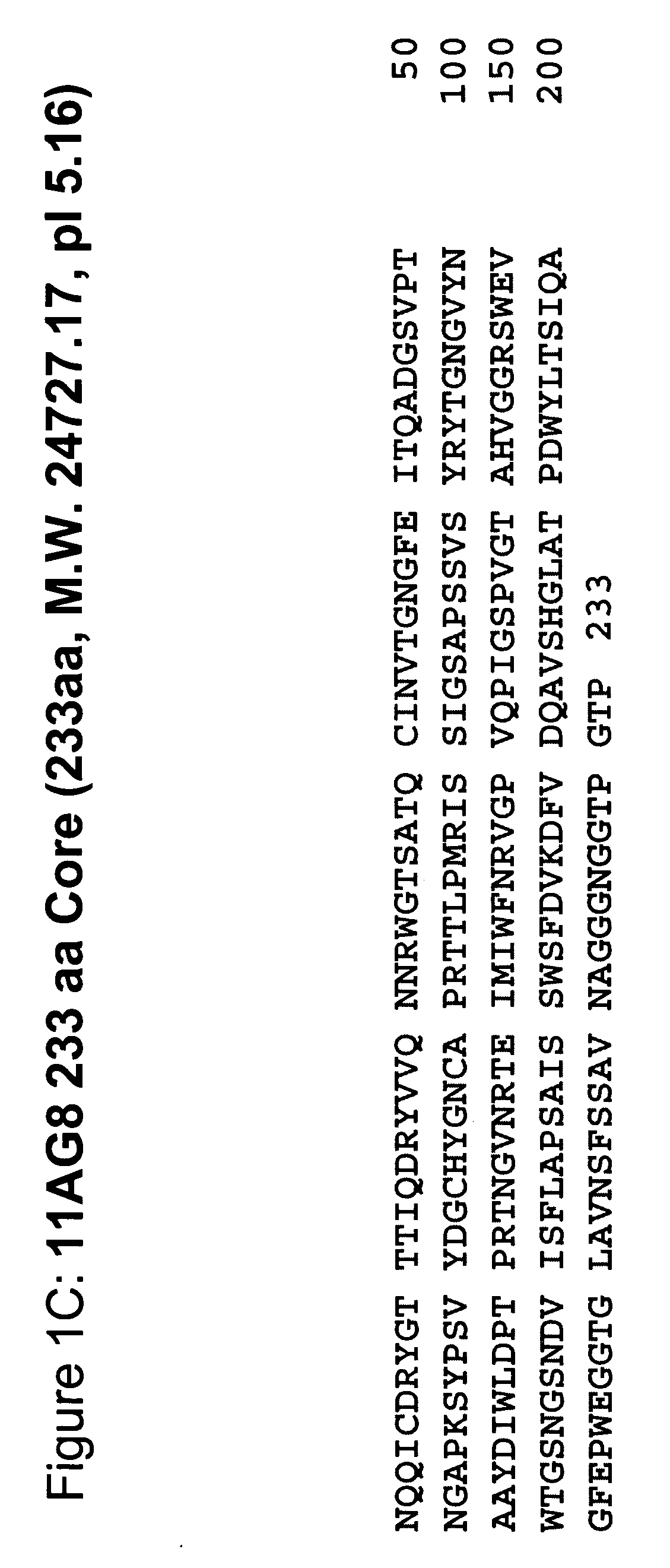

Neutral cellulase catalytic core and method of producing same

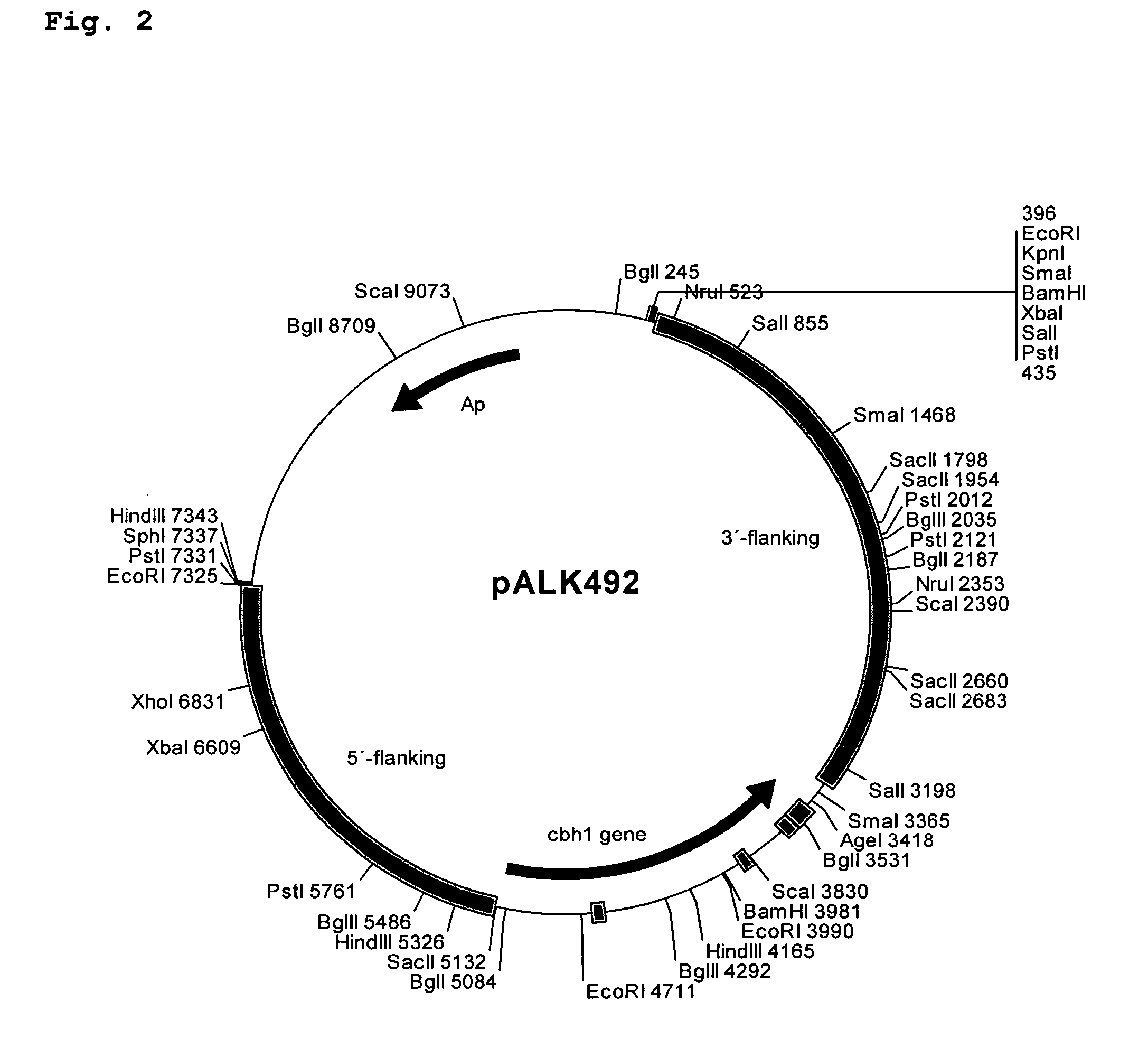

InactiveUS20060154843A1Reduce redepositionEasy to wearBacteriaFermentationHigh level expressionCellulose breakdown

The present invention relates to the cloning and high level expression of novel cellulase proteins or derivatives thereof in the in a host cell. Further aspects of the present invention relate to transformants that express the novel cellulases, and expression vectors comprising the DNA gene fragments or variants thereof that code for the novel cellulases derived from Actinomycete using genetic engineering techniques. The present invention is also directed to novel cellulase compositions and methods of use therefore in industrial processes. In particular, the present invention is related to treating textiles with a novel cellulase derived from Actinomycete spp. The present invention also relates to the use of cellulase derived from Actinomycete spp. to enhance the digestibility of animal feed, in detergents, in the treatment of pulp and paper and in the production of starch and treatment of by-products thereof.

Owner:GENENCOR INT INC

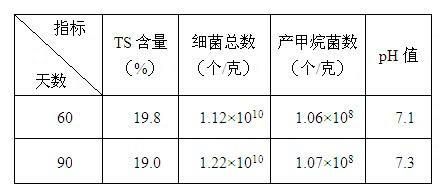

Preparation method of methane dry fermentation compound bacterial preparation

InactiveCN102559499AReduce volumeLow costBacteriaMicroorganism based processesBiotechnologyCellulose

The invention discloses a preparation method of a methane dry fermentation compound bacterial preparation, which comprises the following steps: mixing fermentation substrate with an inoculum which is compound bacteria composed of cellulose decomposing bacteria, proteolytic bacteria, fat decomposing bacteria, hydrogen-producing aceogenic bacteria, sulfate reducing bacteria and methanogenic archaea, adjusting the water content and pH of the mixed materials to 70-80% and 7.0 respectively, performing anaerobic fermentation under the condition of 35 DEG C plus or minus 2 DEG C for 60-90 days to obtain methane dry fermentation compound bacterial preparation. The preparation method of the invention can prepare compound bacterial preparation with a relatively complete methane fermentation function, and the total number of microbial cells and methanogenic archaea cells in the bacterial preparation are at least 10*10<10> / g and 1.0*10<8> / g respectively. Using the compound bacterial preparation as an inoculum of methane dry fermentation can reduce the starting time, and the fermentation process is stable and easy to control.

Owner:BIOGAS SCI RES INST MIN OF AGRI

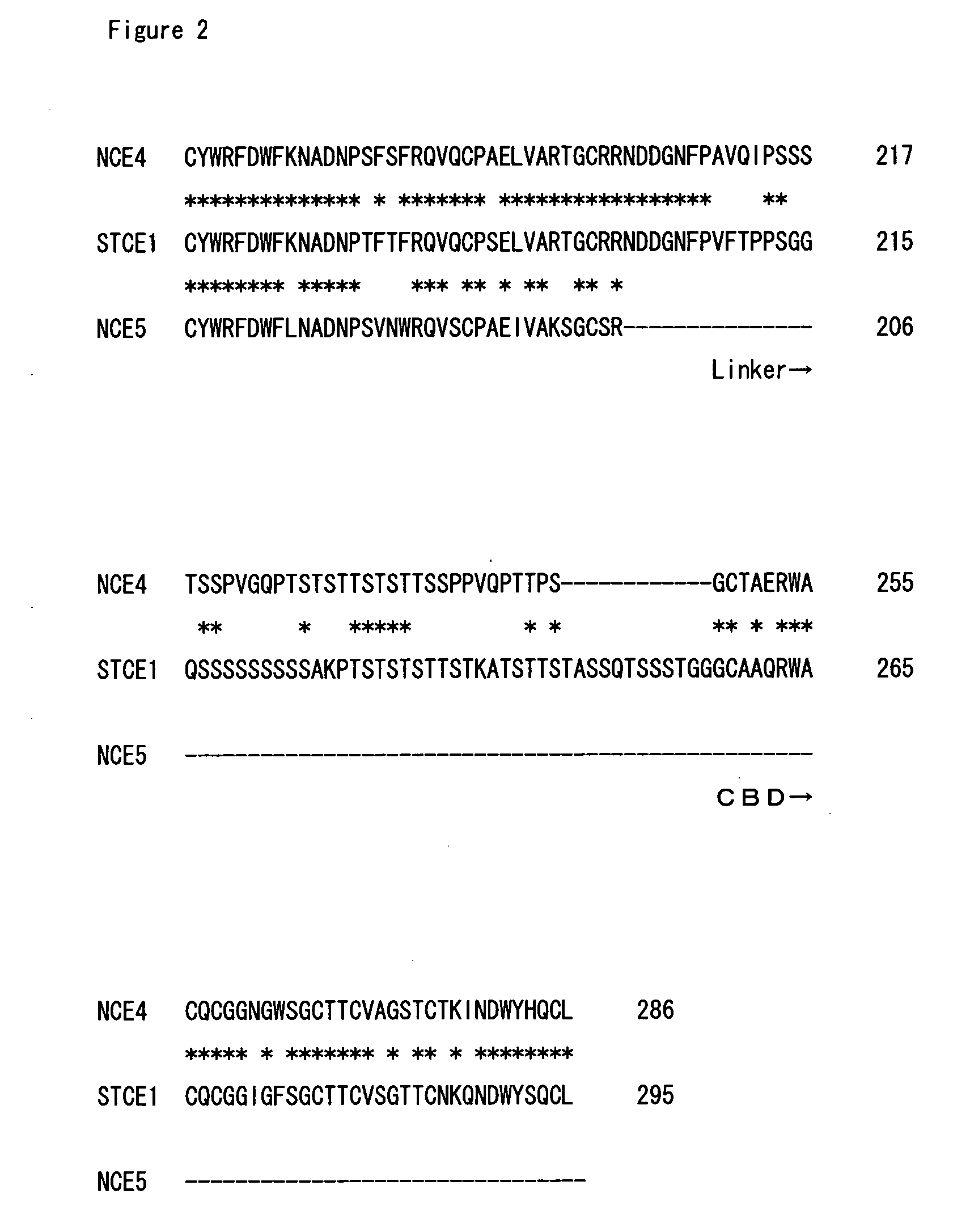

Endoglucanase stce and cellulase preparation containing the same

ActiveUS20070111278A1Improvement of touch feel and appearance of fabricReduction of fuzzFungiBacteriaGlucanaseStaphylococcus aureus

A novel endoglucanase derived from Staphylotrichum coccosporum, a polynucleotide encoding the endoglucanase, and a cellulase preparation containing the endoglucanase are disclosed. The endoglucanase or cellulase preparation is available for a washing use or fabric processing, such as a color clarification of a cellulose-containing fabric, a reduction of fuzz, an improvement of the touch feel and appearance of the fabric, providing a localized color change to the fabric, or a reduction of stiffness.

Owner:MEIJI SEIKA KAISHA LTD

Liquid detergent composition

The present invention provides a liquid detergent composition, comprising: (a) a cleaning effective amount of an enzyme preferably selected from a proteolytic enzyme, an amylolytic enzyme, a lipolytic enzyme, a cellulolytic enzyme and mixtures thereof; (b) from 0.001 to 3% by weight of a perfume composition, not containing a perfume component selected from the group consisting of saturated and unsaturated linear aldehydes, lilial, cyclal c, vanillin, citral, cinnamic aldehyde, pulegone, terpinolene, gamma terpinene, alpha methylionone; (c) from 0.002 to 1% by weight of an antioxidant; and (d) a fatty acid soap in an amount of at most 4% by weight. Said detergent composition was found to have favourable storage stability characteristics.

Owner:CONOPCO INC D B A UNILEVER

Cellulase preparation containing nonionic surfactant and method of treating fiber

InactiveUS20030021949A1Large thicknessEfficiently formedInternal combustion piston enginesDispersed particle filtrationParticulatesFiber

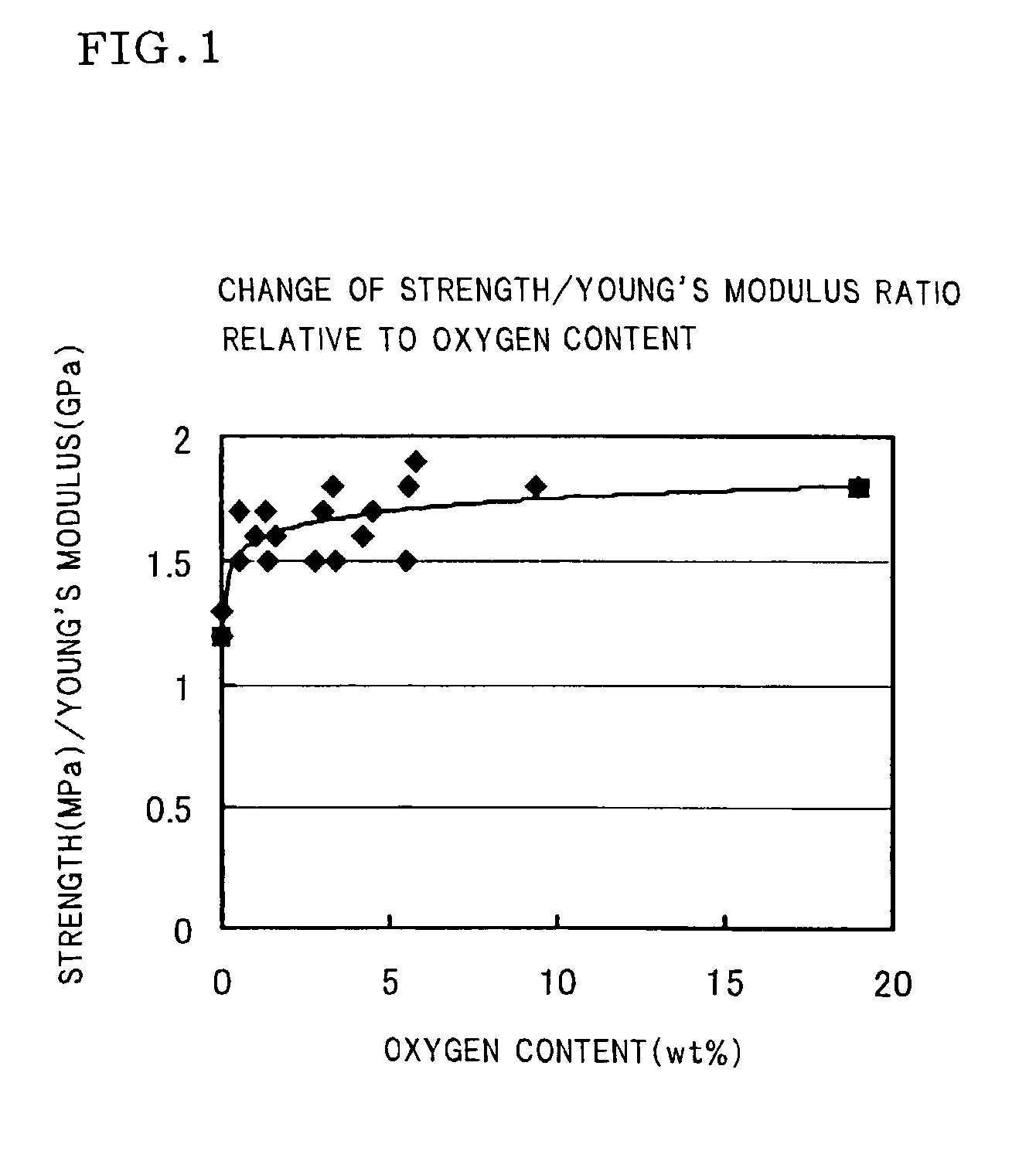

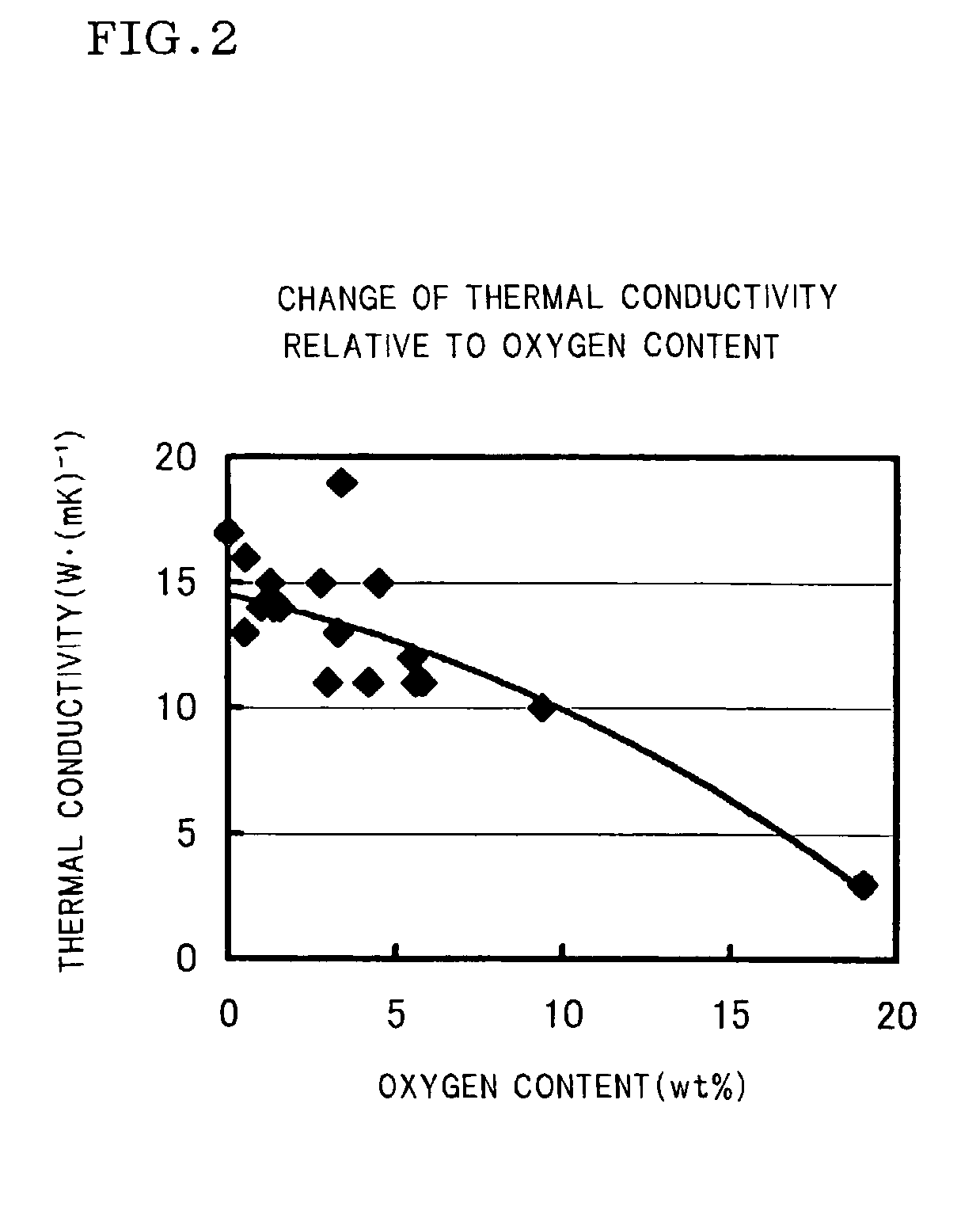

It is directed to a silicon carbide-based porous body, wherein said body is a porous one which contains silicon carbide particles as an aggregate and metallic silicon, and has an oxygen-containing phase at the surfaces of silicon carbide particles and / or metallic silicon or in the vicinity of the surfaces thereof. The silicon carbide-based porous body contains refractory particles such as silicon carbide particles or the like and yet can be produced at a relatively low firing temperature at a low cost, has a high thermal conductivity, and is superior in oxidation resistance, acid resistance, chemical resistance to ash and particulates.

Owner:NGK INSULATORS LTD

Soluble straw decomposing agent, its preparation method and application

ActiveCN102351578AReasonable mix of typesStrong complementarityOrganic fertilisersDecompositionPlant Sources

The invention provides a soluble straw decomposing agent, its preparation method and application. The soluble straw decomposing agent comprises by weight: 10-20 parts of a composite bacterial agent, 20-50 parts of nutrients, 2-5 parts of a plant source emulsification penetrant, and 25-68 parts of a soluble carrier. The composite bacterial agent contains cellulose decomposition bacteria, protein decomposition bacteria, and nutrient bio-control growth-promoting bacteria. The invention also provides a preparation method of the above soluble straw decomposing agent. The soluble straw decomposing agent provided in the invention is in a powder form and is fully soluble in water, and also can be applied through both scattering and spraying, thus being suitable for mechanized operation. The soluble straw decomposing agent provided in the invention can substantially speed up degradation of a plurality of crop straw, promote crop growth, and prevent a lot of crop diseases and pests.

Owner:HUNAN TAIGU BIOTECH

Method for preparing isosteviol and sophorose at the same time

ActiveCN101497633AIncrease profitEmission reductionSugar derivativesOrganic compound preparationCellulose breakdownInducer

The invention discloses a method for hydrolyzing stevioside with rich sources by using acid and synchronously preparing two products with high added values, namely isosteviol and sophorose. An isosteviol product is a medicine with functions of reducing blood sugar, regulating lipid, and the like, the sophorose is a most effective inducer for producing cellulase from strains such as trichoderma, and the like, and the two products have broad application prospect respectively. The method is characterized in that by controlling appropriate conditions, the two high added value products with important industrial application value and medical value, namely the isosteviol and the sophorose are synchronously prepared, and a one-step hydrolysis method is adopted.

Owner:巴州正达绿源生物科技有限公司

Condensed multi-enzyme medical cleaning agent

InactiveCN102071113AQuick breakdownQuick clearNon-ionic surface-active compoundsDetergent compounding agentsGlycerolCleansing Agents

The invention relates to a condensed multi-enzyme medical cleaning agent. The cleaning agent contains surfactants, a detergent auxiliary agent, a solubilizing agent, an enzymic preparation, a foam inhibitor and a preservative, wherein the surfactants are a non-ion surfactant and an anion surfactant. The cleaning agent comprises the following formula components in percentage by weight: 5 to 10 percent of alkoxyl fatty alcohol, 3 to 5 percent of alkyl polylucoside, 5 to 10 percent of alkanol polyether, 5 to 10 percent of sodium xylene sulfonate, 0.5 to 1.5 percent of sodium sulfate, 0.5 to 1 percent of calcium chloride, 2 to 4 percent of disodium ethylene diaminetetraacetate, 5 to 10 percent of hydrogenated castor oil, 6 to 12 percent of dipropylene glycol monomethyl ether, 5 to 10 percent of glycerol, 2 to 6 percent of proteinase, 1 to 5 percent of amylase, 1 to 5 percent of lipase, 0.5 to 1 percent of cellulase, 0.1 to 0.5 percent of methylparaben and propyl hydroxybenzoate preservative, 0.1 percent of essence, 0.1 percent of pigment and the balance of deionized water. Through the cleaning agent, all the biological residues adhered in and out of a medical apparatus can be quickly and effectively decomposed and cleaned and aluminum oxide playing a role in protection on the metal surface layer is not damaged.

Owner:徐宏汇 +1

Process for preparing fucoidan by enzymatic hydrolysis of brown algae

The enzymically hydrolysis process of preparing fucan sulfate with brown algae includes the following steps: compounding composite cellulase with cellulase and pectase; enzymolyzing brown algae material via adding the composite water and cellulase at pH 6.0-8.0 for 50-80 min; heating at 90-100 deg.c in water bath for 3-4 hr, cooling to room temperature and centrifuging to obtain supernatant; adding alcohol to the supernatant to produce precipitate and centrifuging to obtain the second supernatant; adding alcohol to the second supernatant to produce precipitate and collecting the precipitate; washing the precipitate and vacuum freeze drying to obtain white powder. The said process has high extraction rate, low product cost, and less environmental pollution.

Owner:DALIAN FISHERIES UNIVERSITY

Preparation method of activated carbon by utilizing corncob hydrolysis residue

InactiveCN101837973ASolve the problem of effective transformation and utilizationTake advantage ofFermentationCelluloseCarbonization

The invention discloses a preparation method of activated carbon by utilizing corncob hydrolysis residue, which belongs to the technical field of functional sugar production. The process comprises four steps of removing cellulose, carbonization-activation, washing and drying and grinding. The preparation process utilizes the corncob hydrolysis residue after enzymolysis by cellulase to prepare the activated carbon for producing xylose (or xylitol), which can not only meet the demands of self-production and reduce the production cost but also be sold as a commodity to acquire economic benefits directly, thus realizing a great leap from high residue discharge amount to zero discharge in the xylitol production, reducing the environmental protection pressure, creating economic benefits and meeting the national requirements of energy saving, emission reduction and sustainable development.

Owner:FUTASTE PHARM CO LTD

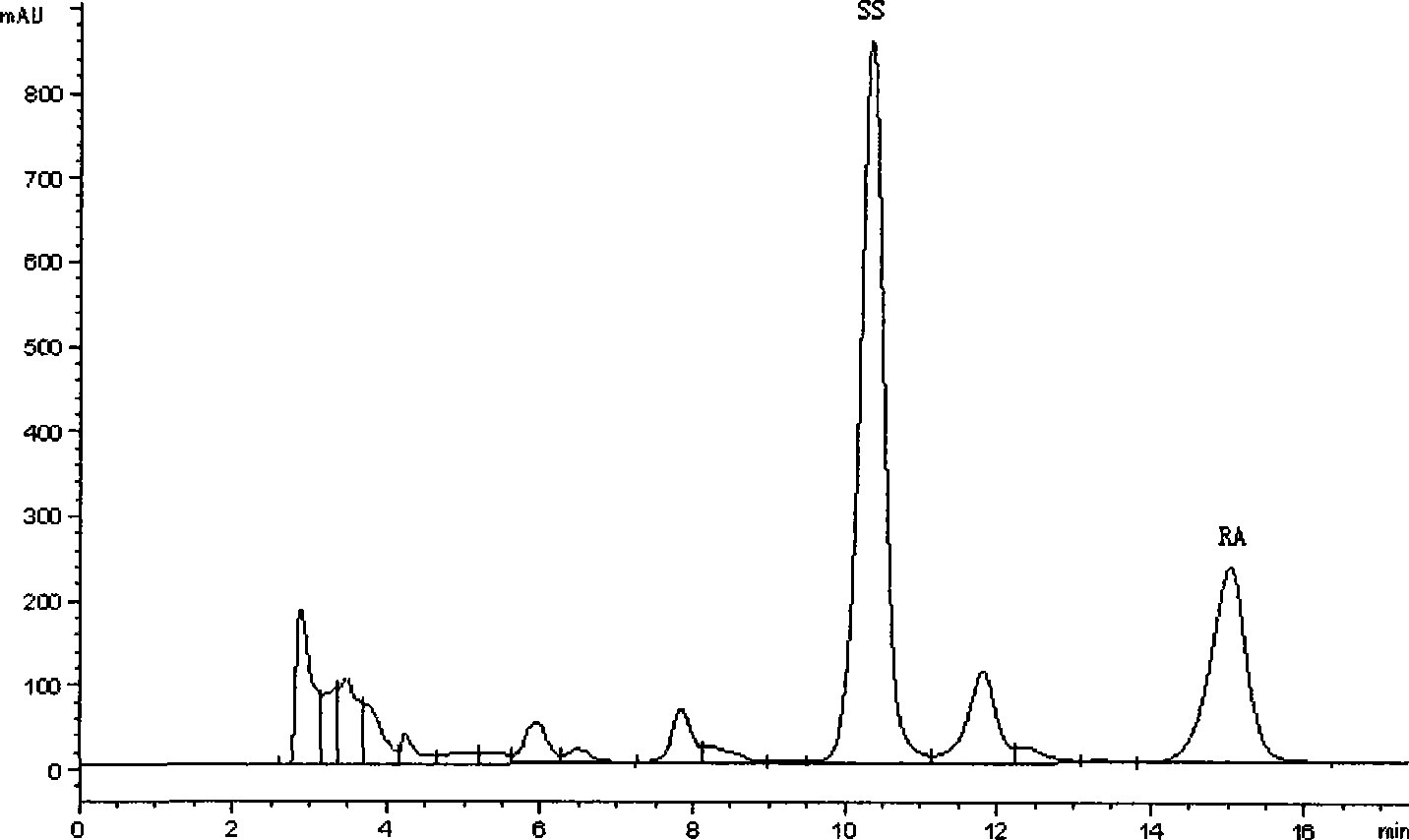

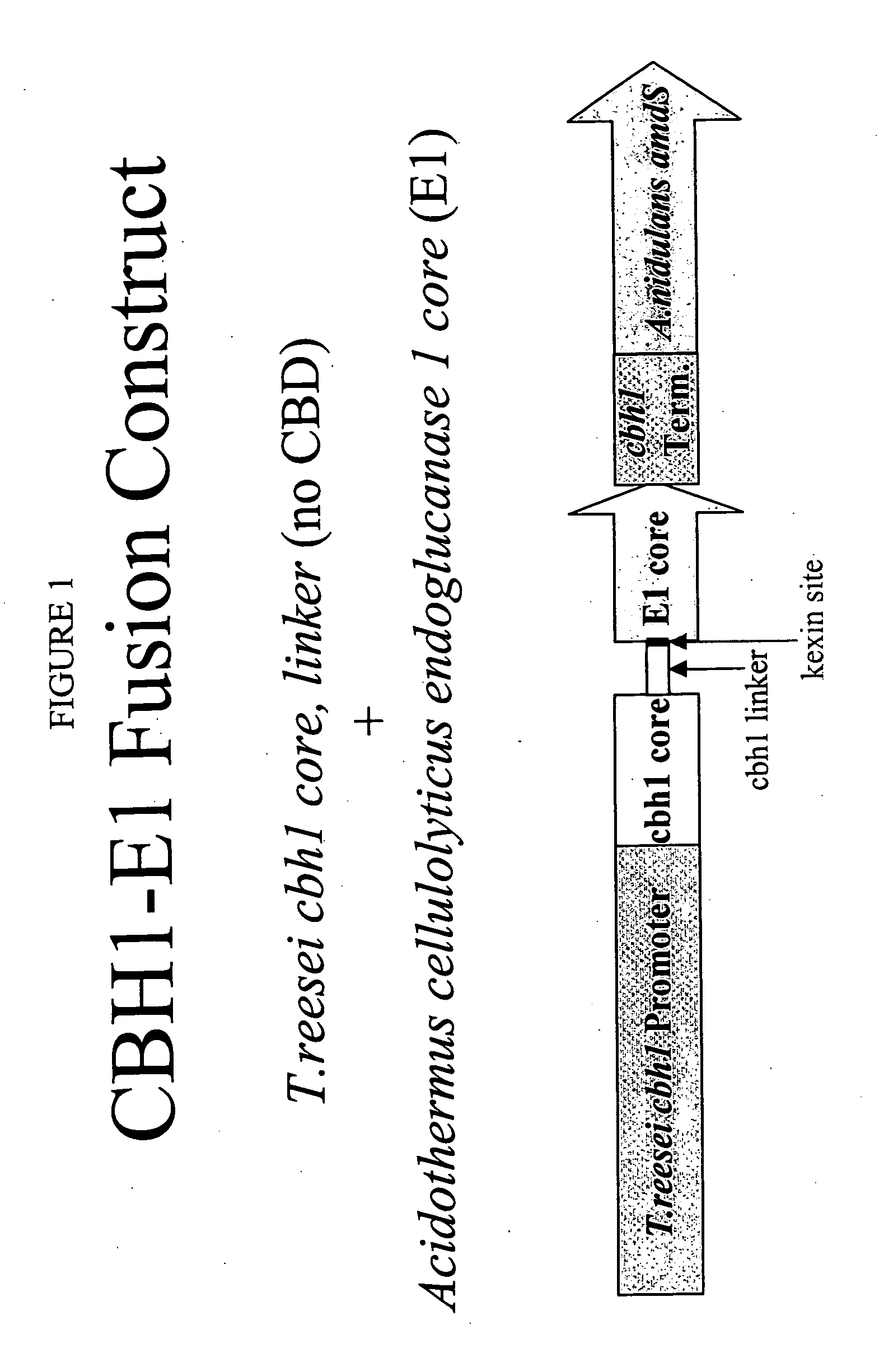

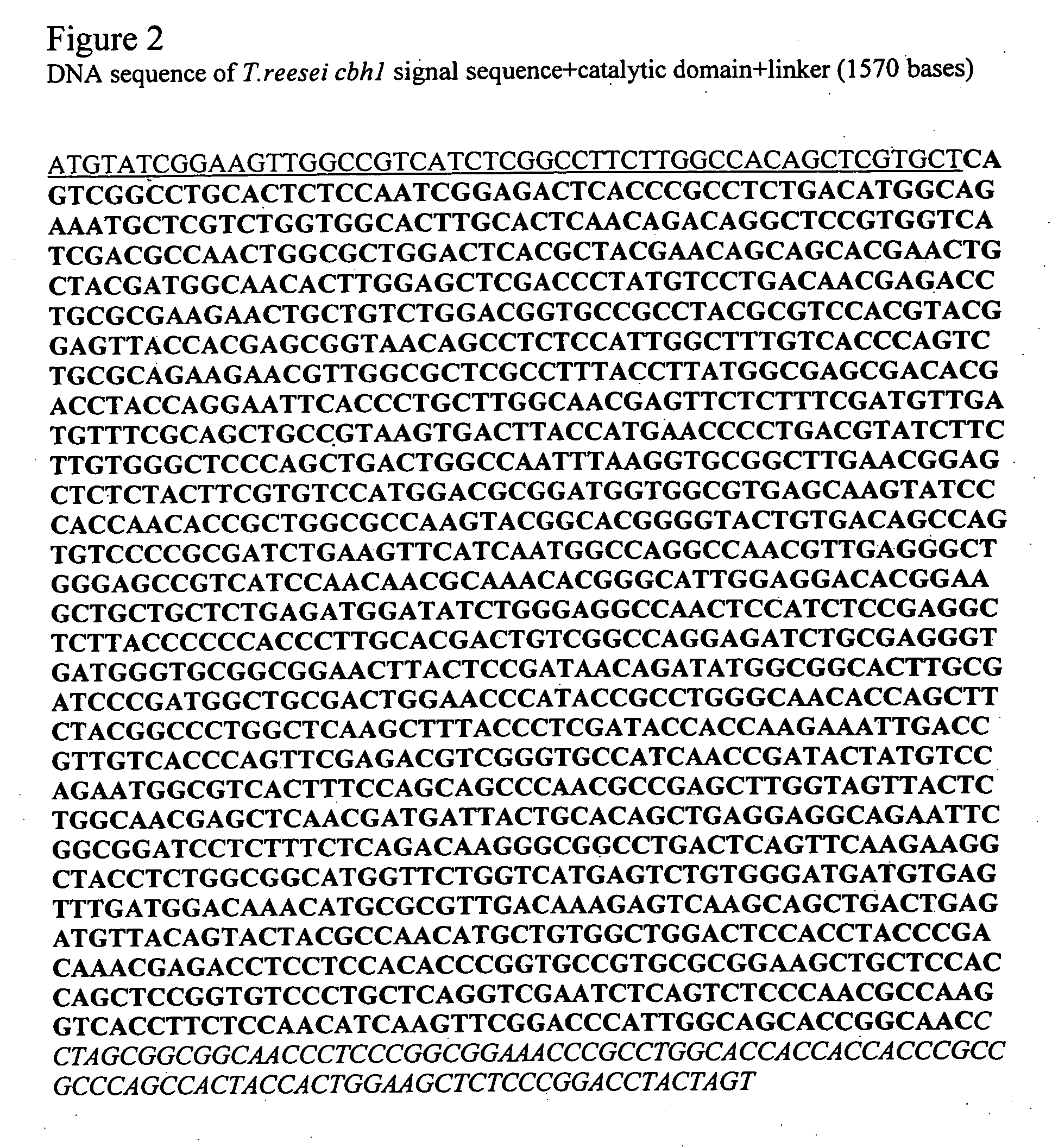

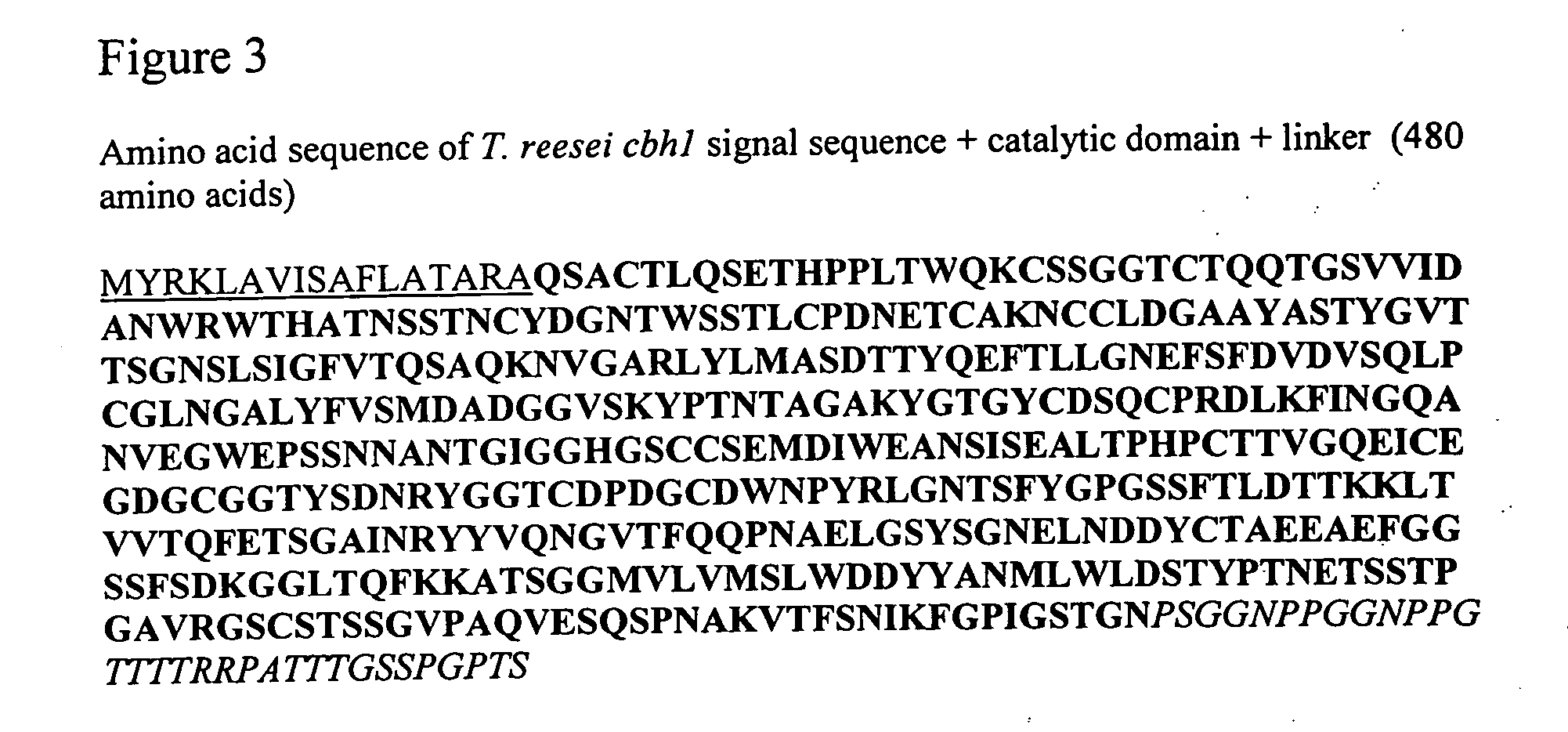

Exo-endo cellulase fusion protein

The present invention relates to a heterologous exo-endo cellulase fusion construct, which encodes a fusion protein having cellulolytic activity comprising a catalytic domain derived from a fungal exo-cellobiohydrolase and a catalytic domain derived from an endoglucanase. The invention also relates to vectors and fungal host cells comprising the heterologous exo-endo cellulase fusion construct as well as methods for producing a cellulase fusion protein and enzymatic cellulase compositions.

Owner:DANISCO US INC

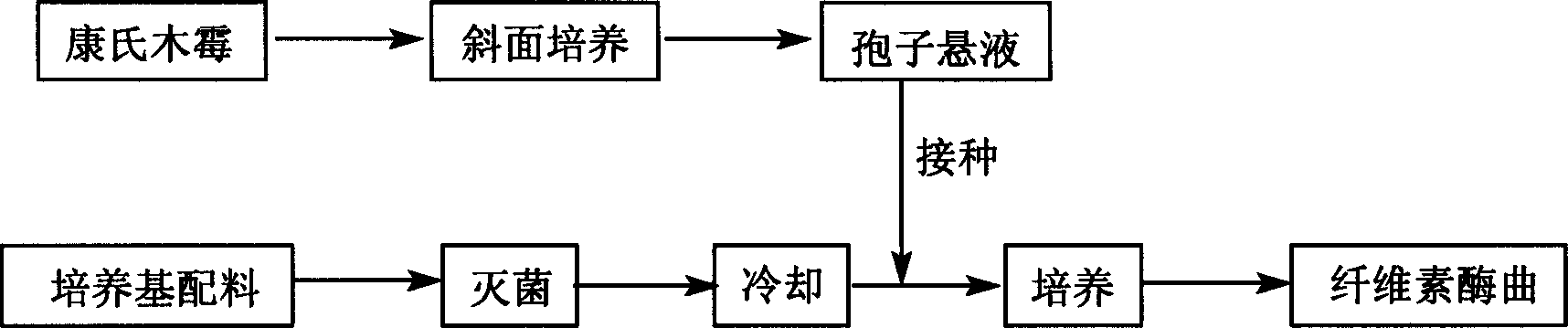

Method for preparing lactic acid and feedstuff concurrent with crop straw fermentation

InactiveCN1594584AReduce manufacturing costReduce energy consumptionFood processingAnimal feeding stuffCelluloseFilter paper

The invention relates to crop stalk fermentation and lactic acid and quality fodder preparation method. The synchronous diastatic fermentation provided by the invention is: adding in pretreated stalk of 2-3 times water in weight, 121 DEG C sterilizing, adding cellulase leaven (step 2 prepared), enzyme activity of cellulase leaven of total substrate amounting to 42-50IU / g in cellulose filter paper enzyme activity, inoculating activated high temperature resistant lactobacillus, inoculating volume is 5-10% of total substrate, fermenting 72-108 hours in 45-50 DEG C condition, adjusting substrate pH to 5.0-6.0 during fermenting. The invention shortens greatly of fermentation time, promotes the fermentation effiency. The 72-108 hours synchronous fermentation can produce 6-8g lactic acid and 60-70g quality fodder every 100g dry stalk. The invention has merits of low cost, low investment, no pollution, little energy consumption, high resource exploitation.

Owner:HARBIN INST OF TECH

Method for preparing champignon polypeptide powder

ActiveCN101709320AImprove overall utilizationReduce wasteFermentationProteinase activityInstant noodle

The invention discloses a method for preparing champignon polypeptide powder, which comprises the following steps of: crushing mushroom fruit bodies, taking mushroom fruit body powder, and mixing the mushroom fruit body powder with water; adding cellulase into the mixture to perform enzymolysis for 1 to 2 hours, and then adding protease into the mixture to perform enzymolysis for 3 to 6 hours; and inactivating the enzymes, concentrating an enzymolysis solution, adding a flavoring agent into the enzymolysis solution, and embedding and drying the mixture to obtain a product. The product prepared by the method has high amino acid content, rich nutrients and high freshness, and not only can be applied to conditioning essence reactive perfume bases, but also can be applied to the industries of bio-pharmaceuticals, nutritional health products, domestic flavoring materials, instant noodle seasonings, puffed foods, bakery foods, meat processed products and the like; besides, the method has the advantages of high utilization rate of mushrooms, less waste and low production cost, is suitable for processing a large amount of products, and is a good method for the deep processing of the mushrooms.

Owner:广州传味传美信息科技有限公司

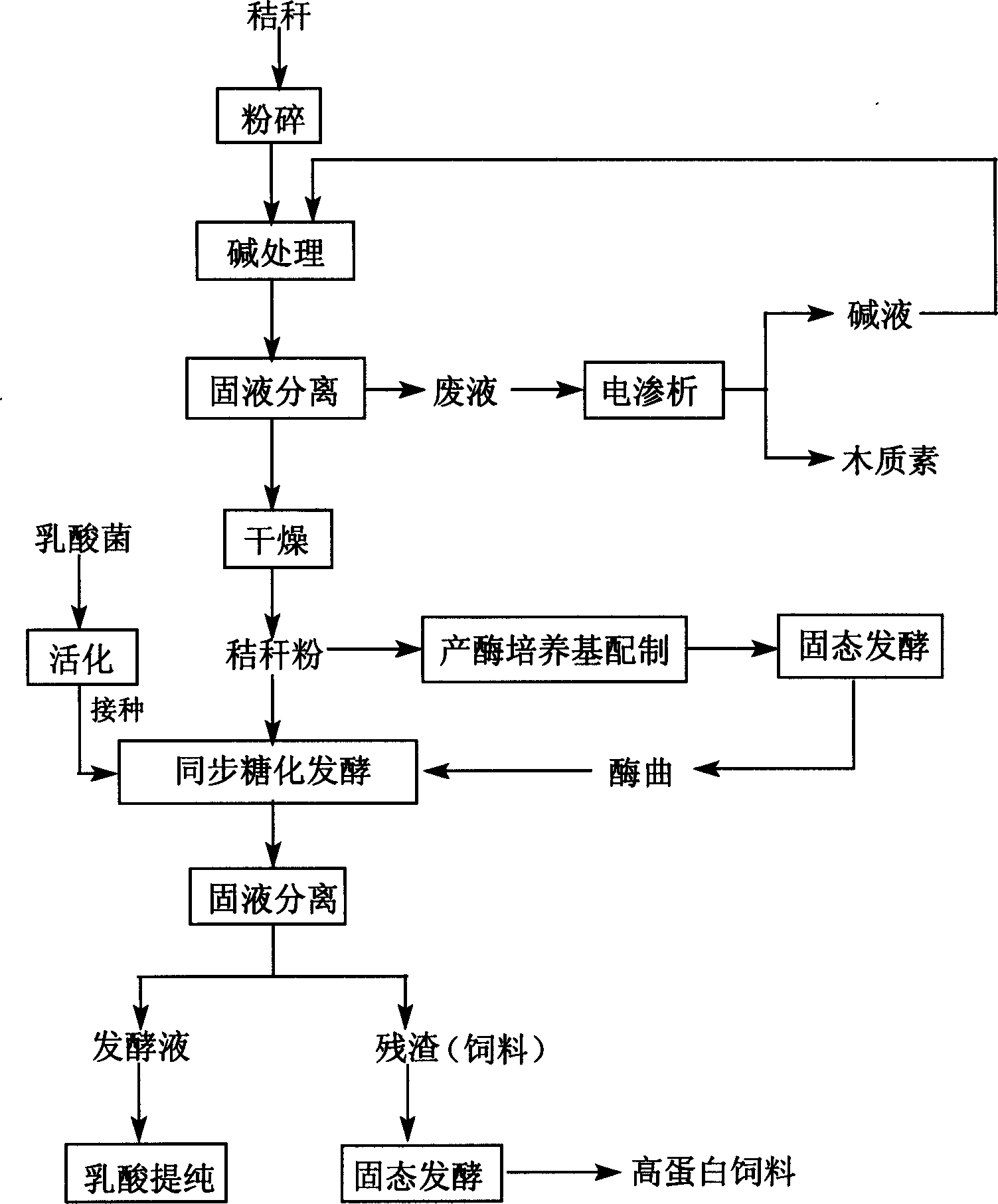

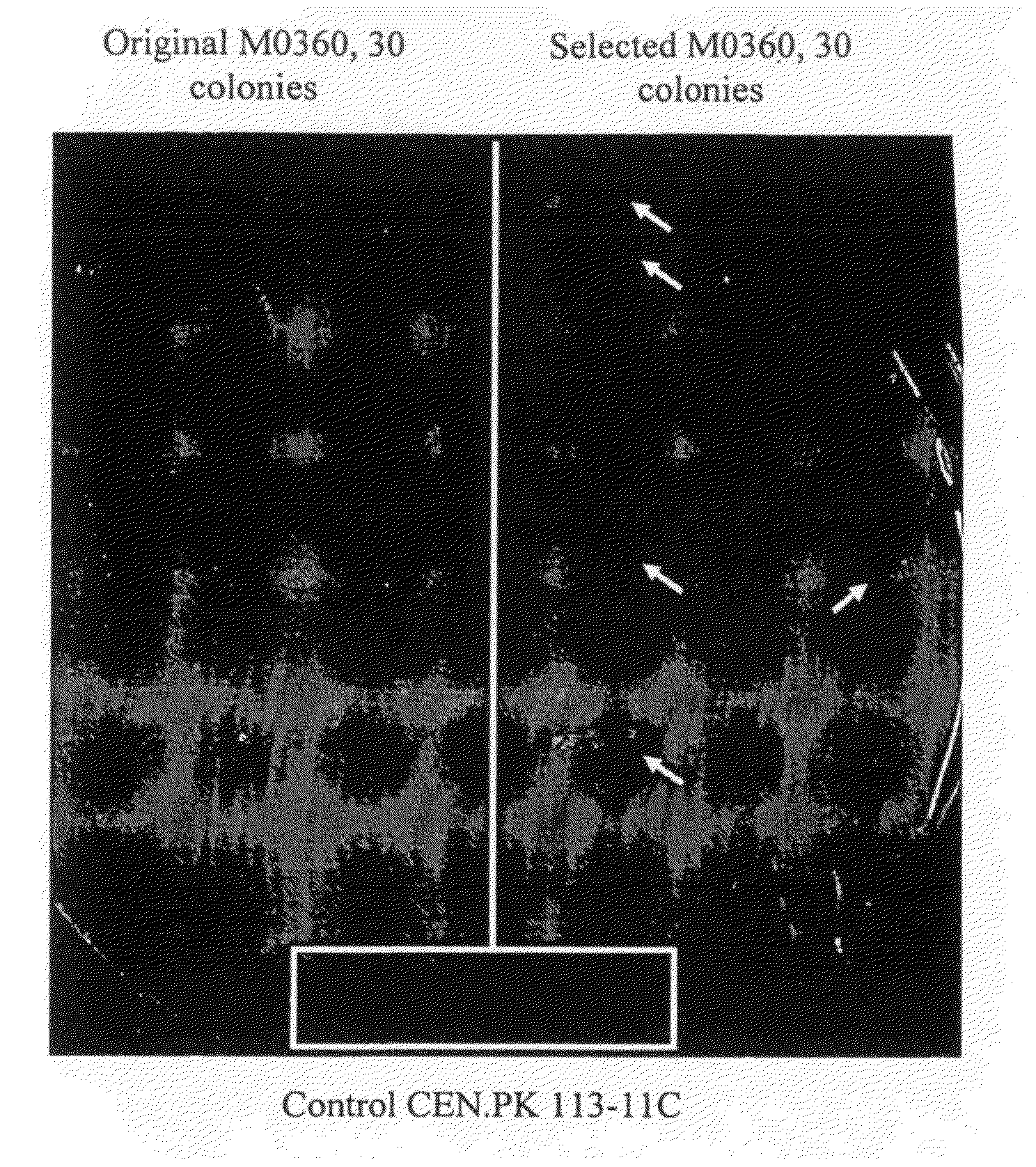

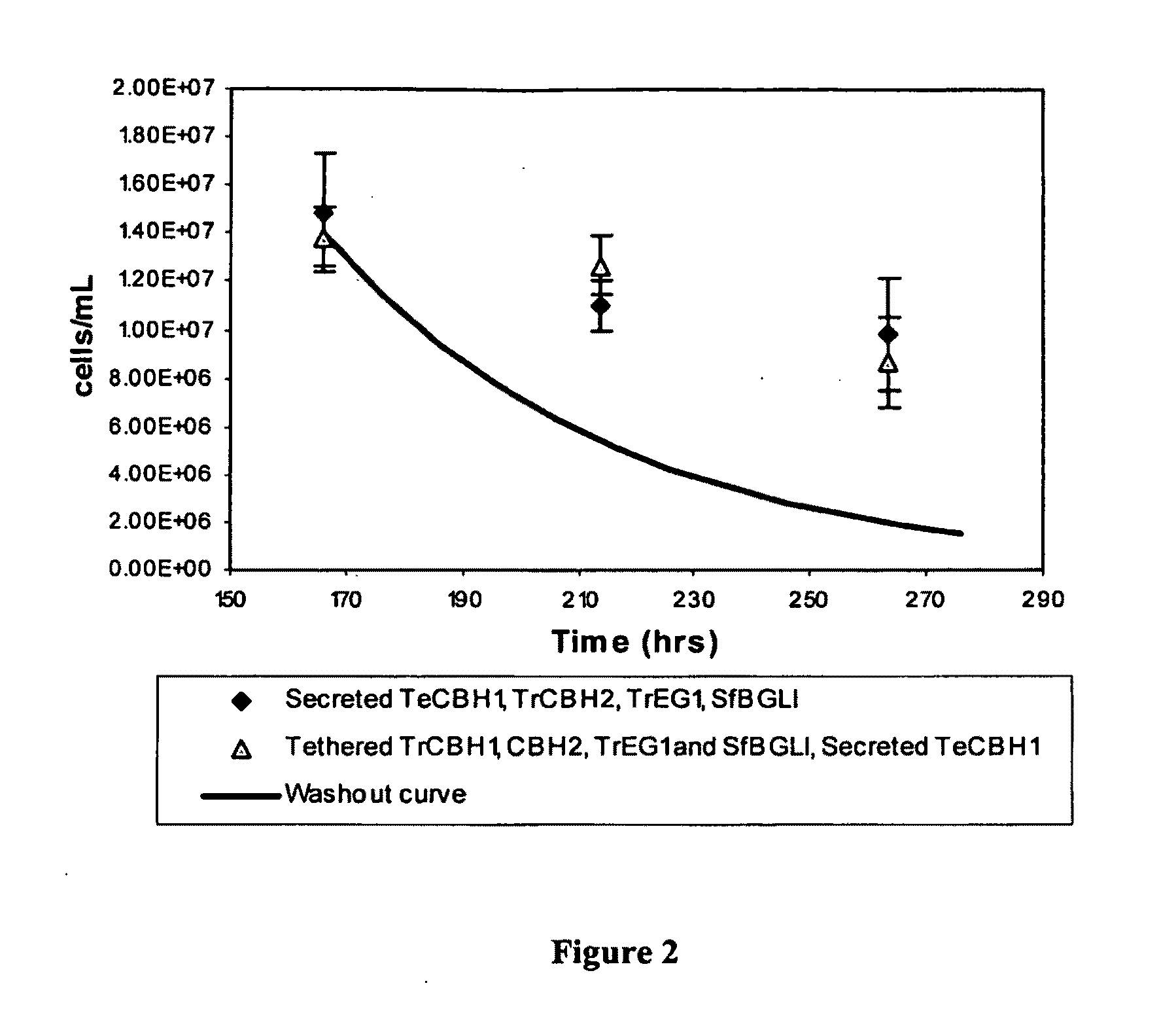

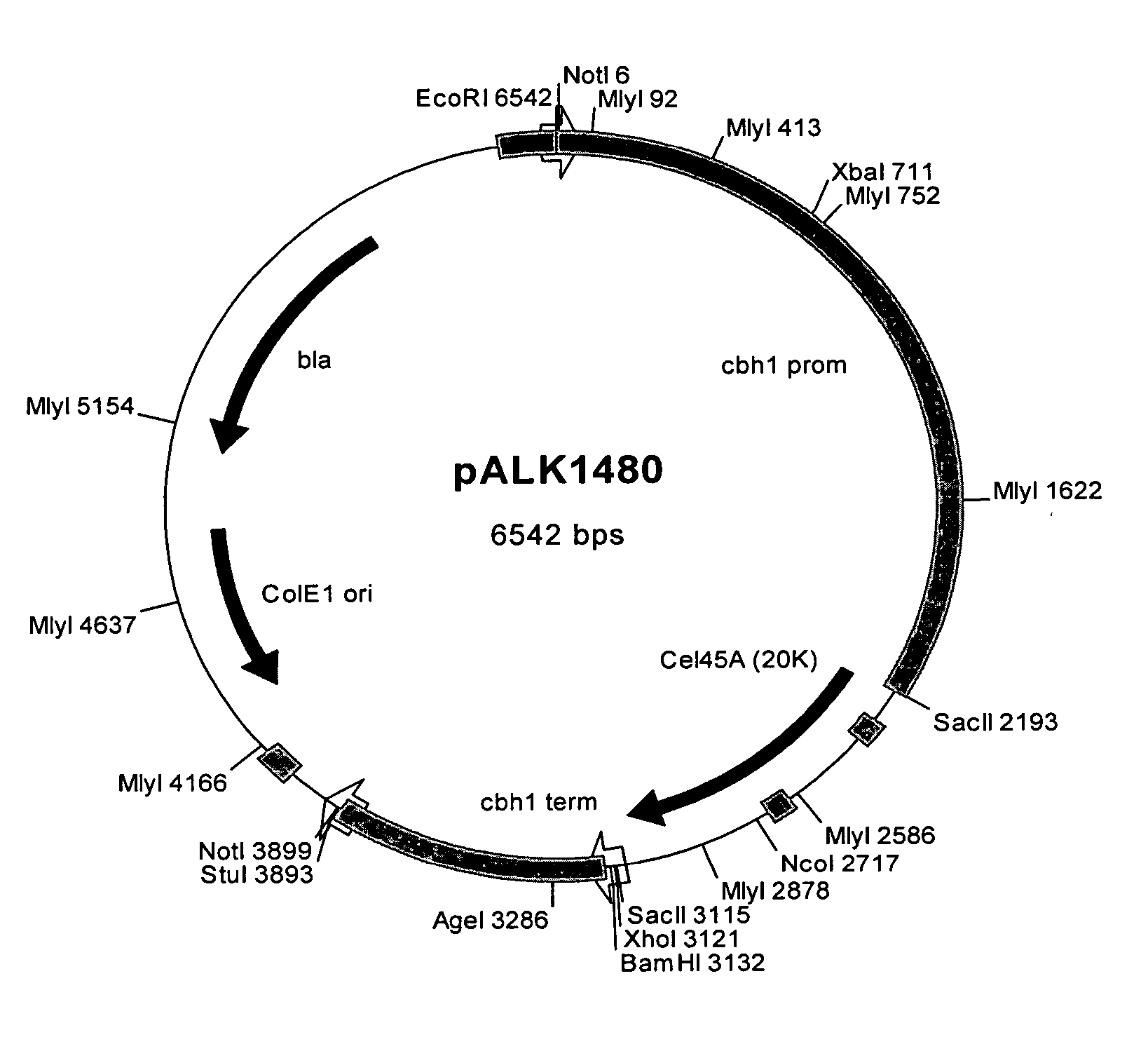

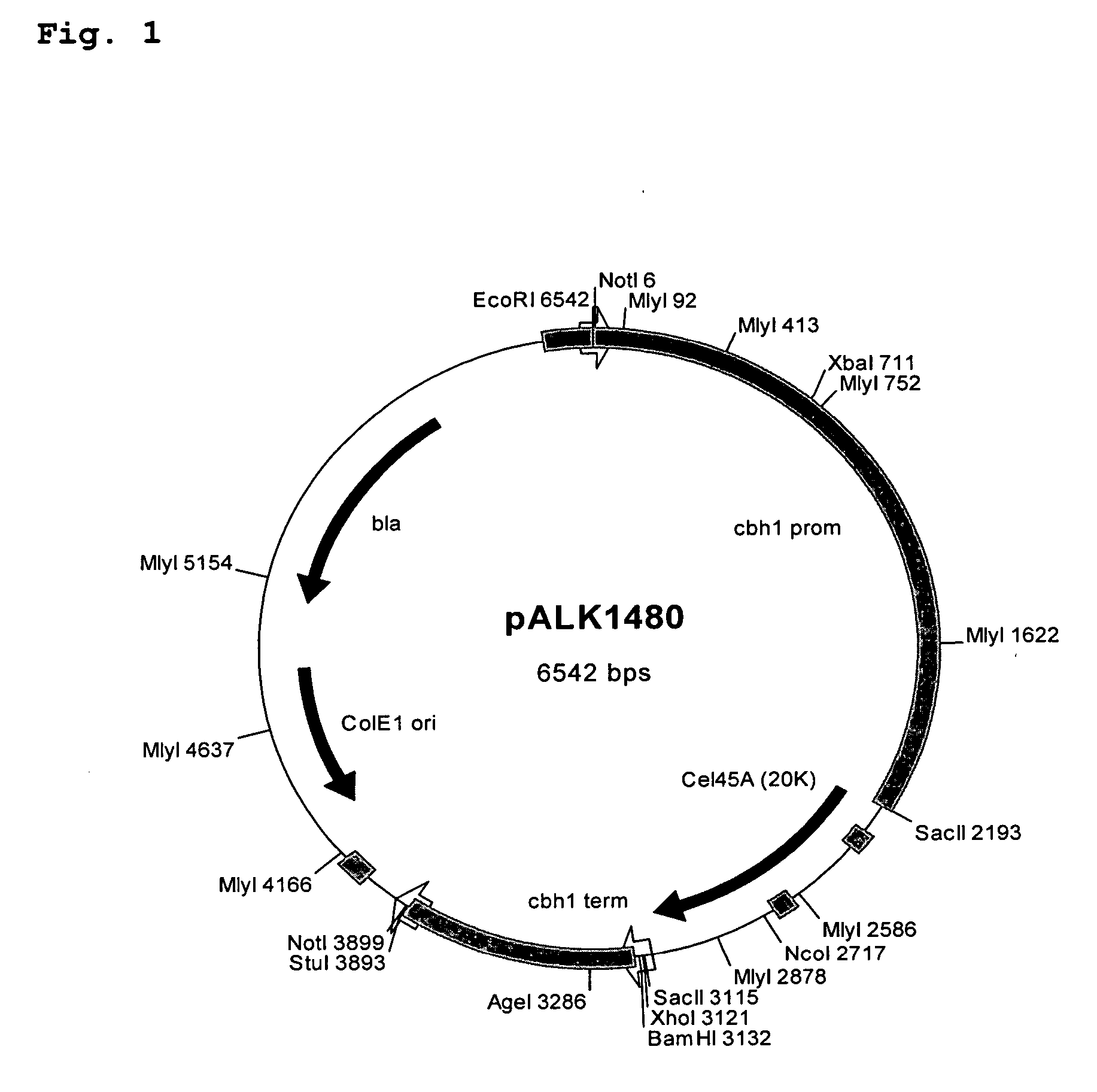

Construction of Protrophic/Celluloytic Yeast Strains Expressing Tethered and Secreted Cellulases

ActiveUS20110189744A1Improve abilitiesImprove reproductive abilityFungiAntibody mimetics/scaffoldsYeast strainMicrobiology

The present invention is directed to the construction of prototrophic, cellulo lytic strains of Saccharomyces cerevisiae with tethered and secreted cellulases and selection-based improvement of growth on cellulose by these strains. In some embodiments, host cells of the invention are able to produce ethanol using crystalline cellulose as a sole carbon source.

Owner:LALLEMAND HUNGARY LIQUIDITY MANAGEMENT LLC

Method for manufacturing purple corn anthocyanin

ActiveCN101037702AImprove use valueHigh-quality pigment productsFermentationHydrolysisBeta-Cyclodextrins

The invention provides a preparing method of purple corn cyanidin, using purple corn plant as material, first hydrolysis of material by cellulase, regulating pH value by citric acid in the hydrolysis process; then leaching by adding water and / or alcohol, or alcohol water solution in acidic environment which maintaining by citric acid leaching system; separating the leached material and collecting extracting solution; condensing the extracting solution as required to get purple corn cyanidin extracting solution; and, controlling temperature lower than 70 DEG C in whole manufacture process. Adding beta-cyclodextrin or maltodextrin, spray drying to get microcapsule product containing purple corn cyanidin. By using the method of this invention, purple corn cyanidin has high extractability, and obtained products at least contain more than six kinds of anthocyanin or derivant components thereof.

Owner:BEIJING ACADEMY OF AGRICULTURE & FORESTRY SCIENCES

Novel cellulases and their uses

ActiveUS20060246566A1Improve performanceImprove stabilitySugar derivativesSurface-active detergent compositionsCellulose breakdownChemistry

The present invention provides novel cellulase fusion proteins, preparations of cellulase fusion proteins and compositions of cellulase fusion proteins. The present invention further provides cellulase expression vectors, host cells expressing cellulase and methods for preparing such vectors and cells. Uses of cellulases, cellulase preparations and cellulase compositions in the textile, detergent, pulp and paper industries are also provided.

Owner:AB ENZYMES OY

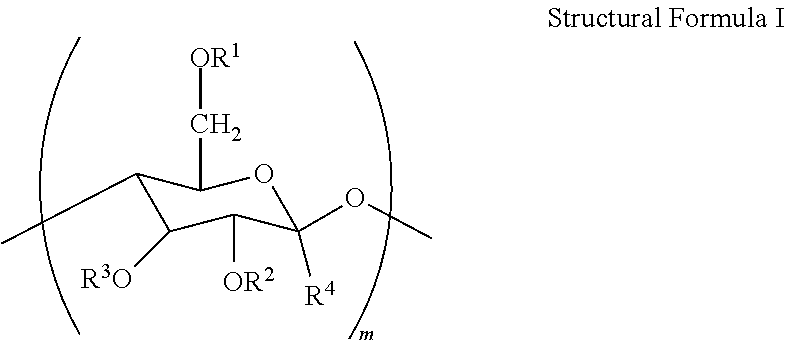

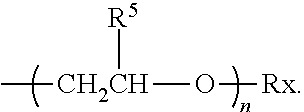

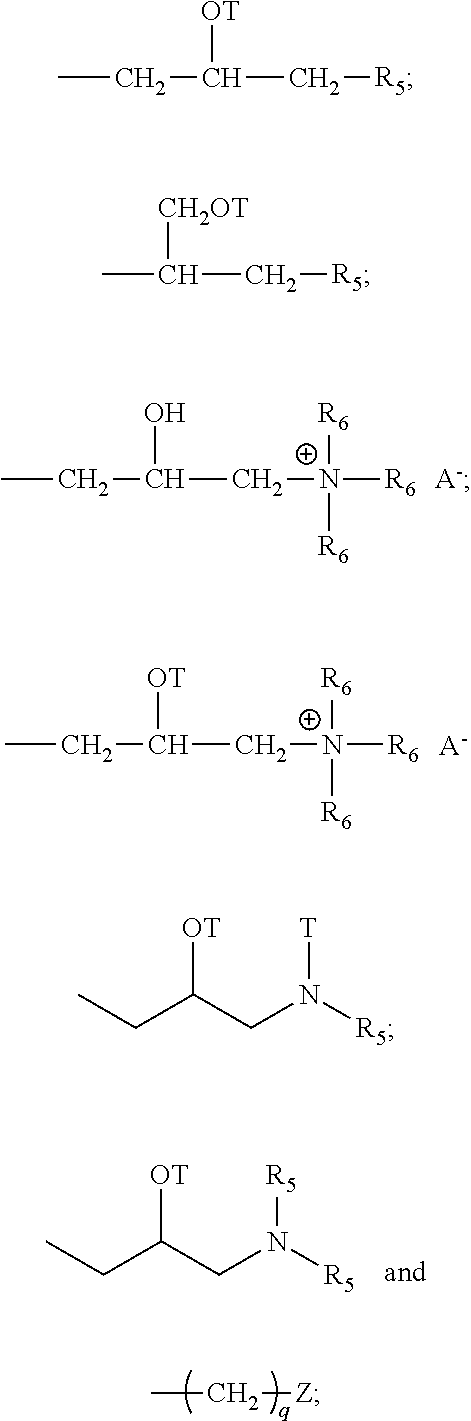

Stable Compositions Comprising Cationic Cellulose Polymers and Cellulase

InactiveUS20110319310A1Good benefitImprove performanceNon-surface-active detergent compositionsDetergent compounding agentsPolymer scienceWater soluble

The need for a stable, compact composition providing improved fabric care benefit, that is also convenient to use, can be met by incorporating a cationic cellulose polymer and cellulase enzyme into a non-aqueous composition. The non-aqueous composition can be made even more convenient to use, by encapsulating in a water-soluble or dispersible film to form a unit-dose article. Such unit dose articles provide improved fabric feel in addition to improved colour maintenance.

Owner:THE PROCTER & GAMBLE COMPANY

Enzymatic detergent composition and method for degrading and removing bacterial cellulose

InactiveUS6020293AReduce riskMinimize ecological harmInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsWater solubleCellulose breakdown

This invention relates to an enzymatic detergent drain cleaner composition containing: 0.015-20 wt % of an acid cellulase enzyme having hydrolytic activity specific to beta -glucosidic bonds; 1-70 wt % of a water soluble carbonate salt; 1-70 wt % of a water soluble acid that reacts in an aqueous medium with the carbonate salt to form carbon dioxide that dissolves in the aqueous medium; 0.1-10 wt % of a surfactant; and 0.05-5 wt % of a thickening agent. This detergent composition may be used as an enzymatic detergent drain cleaner or in a method for removing or preventing bacterial cellulose deposits in an aqueous system at a solution temperature of up to about 60 DEG C. and a pH of about 2 to about 7.

Owner:KAY CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com