Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

55results about How to "Low conversion rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Procedure for the production of ethanol from lignocellulosic biomass using a new heat-tolerant yeast

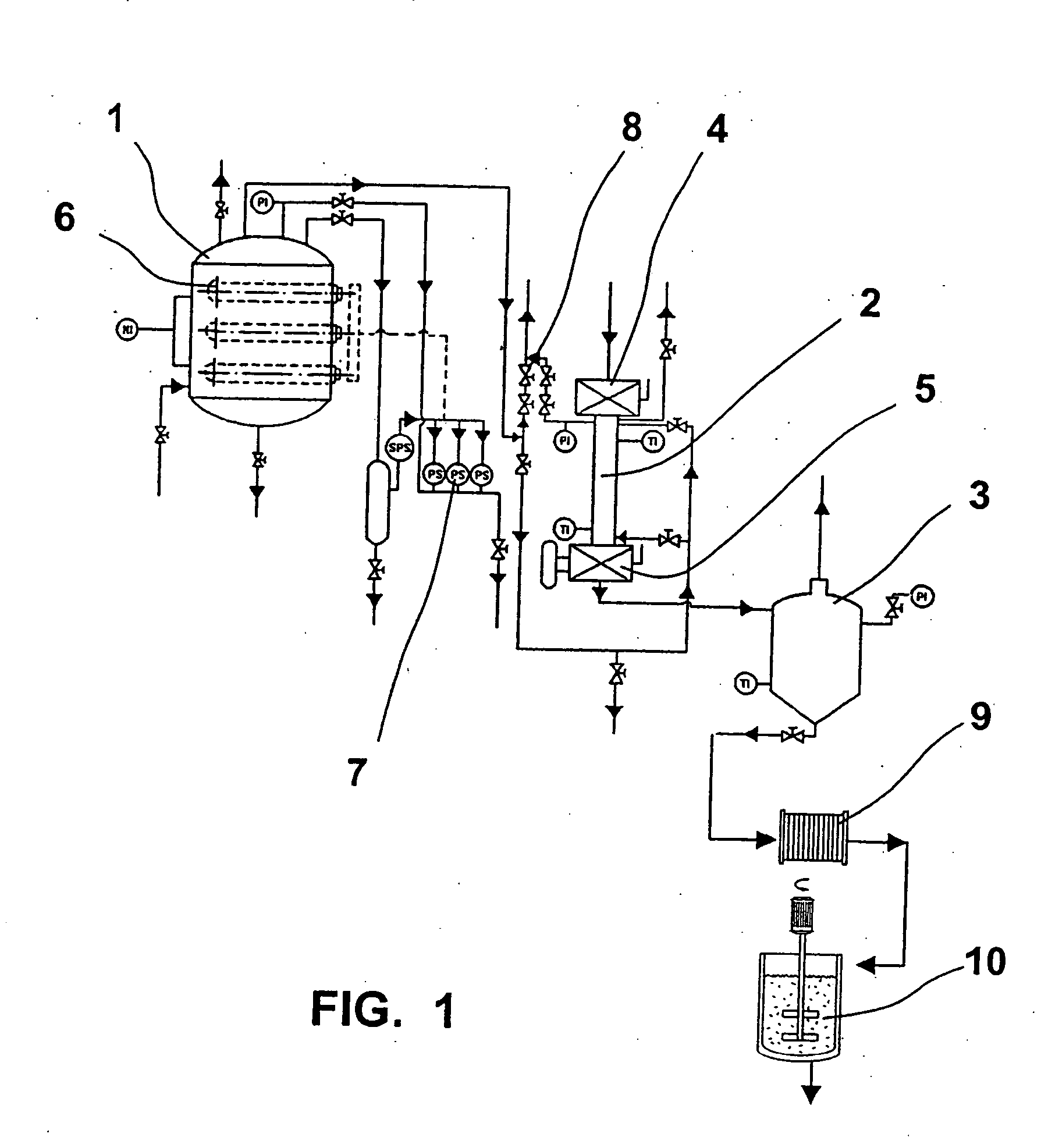

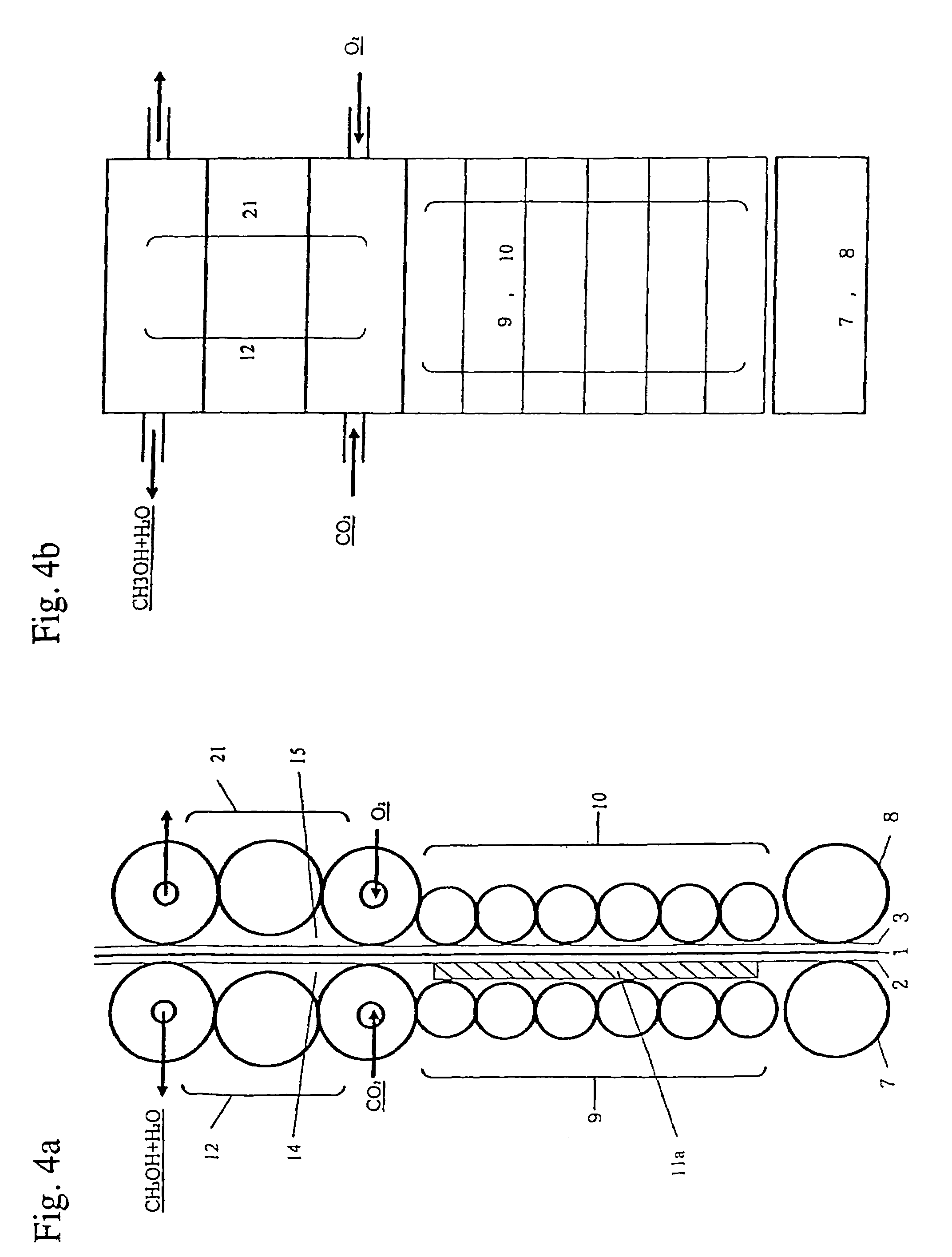

InactiveUS20050069998A1Low conversion rateReduce yieldFungiBiological substance pretreatmentsFiltrationSolid fraction

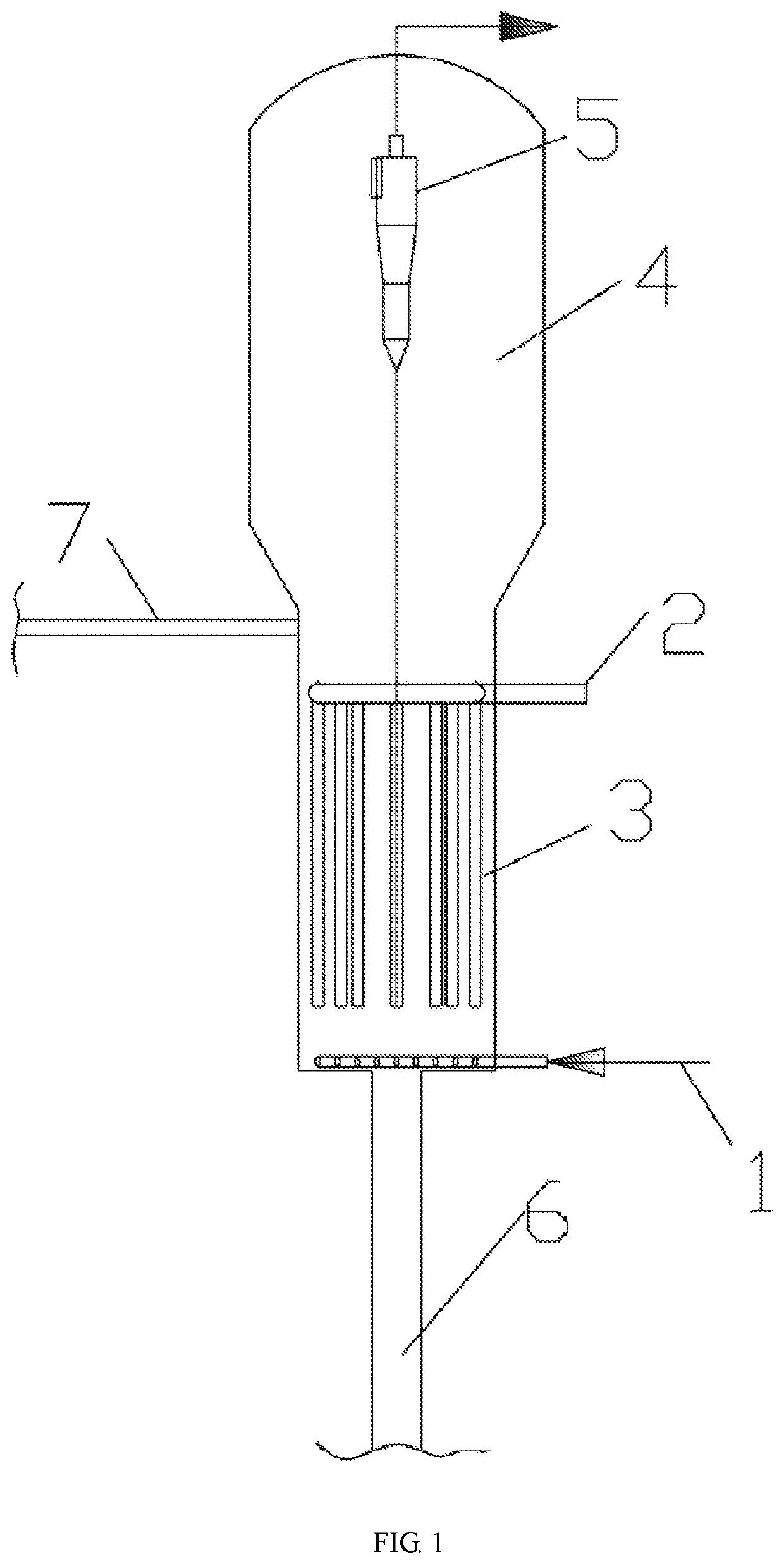

It includes the stages of grinding the lignocellulosic biomass to a size of 15-30 mm, subjecting the product obtained to steam explosion pre-treatment at a temperature of 190-230° C. for between 1 and 10 minutes in a reactor (2), collecting the pre-treated material in a cyclone (3) and separating the liquid and solid fractions by filtration in a filter press (9), introducing the solid fraction in a fermentation deposit (10), adding a cellulase at a concentration of 15 UFP per gram of cellulose and 12.6 International Units of β-glucosidase enzyme dissolved in citrate buffer pH 4.8, inoculating the fermentation deposit (10) with a culture of the heat-tolerant bacteria Kluyveromyces marxianus CECT 10875, obtained by chemical mutagenesis from strain DER-26 of Kluyveromyces marxianus and shaking the mixture for 72 hours at 42° C.

Owner:CENT DE INVESTIGACIONES ENERGETICAS MEDIO AMBIENTALLES Y TECNOLOGICAS (C I E M A T)

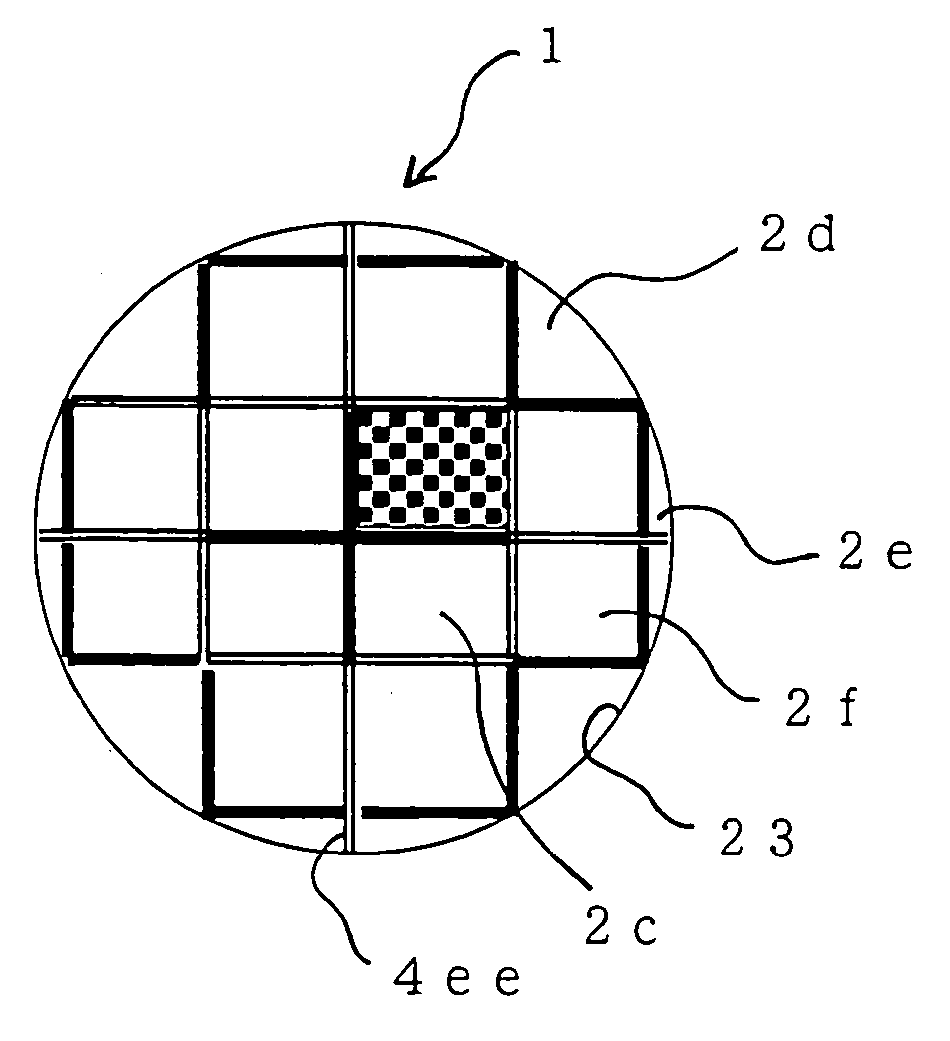

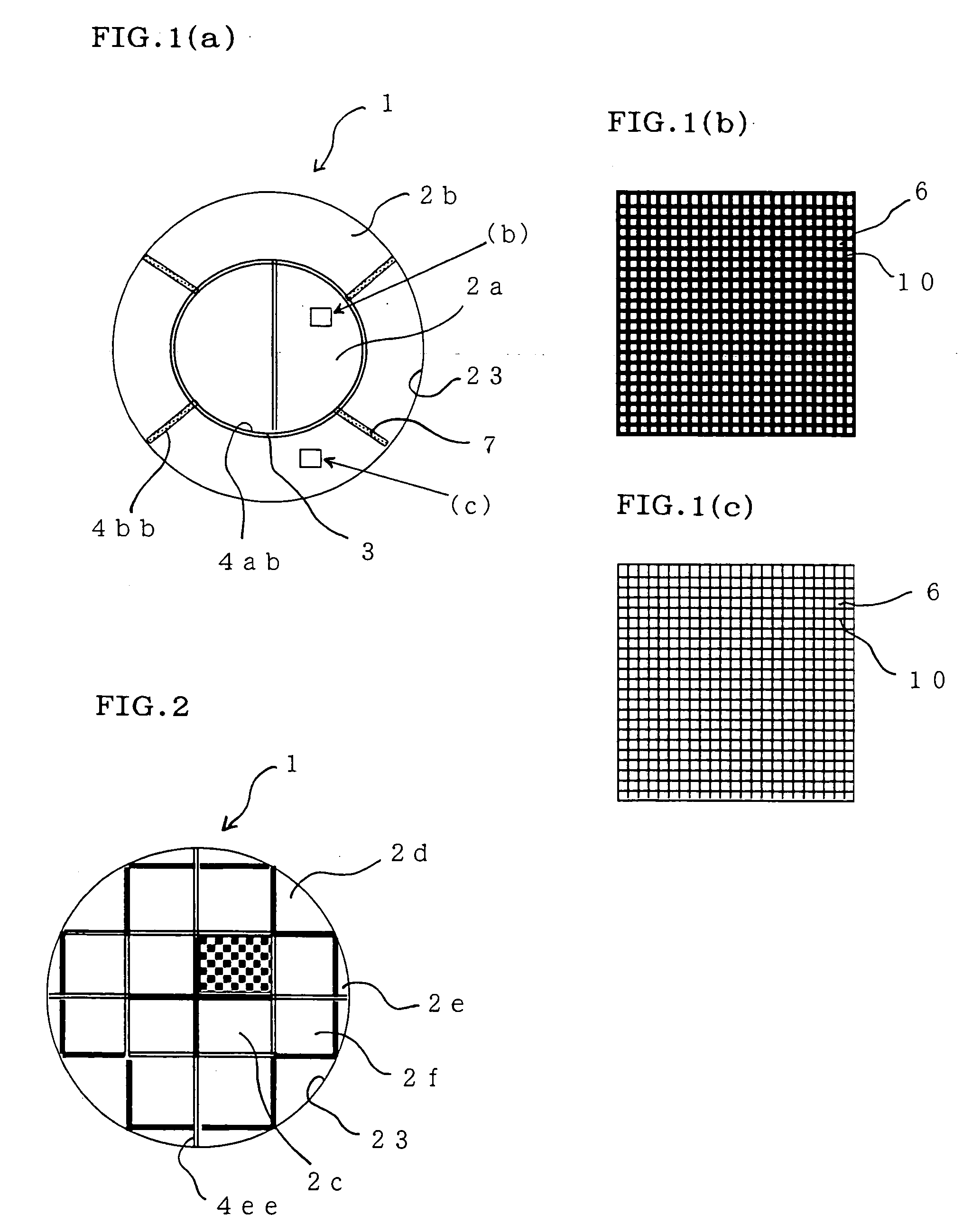

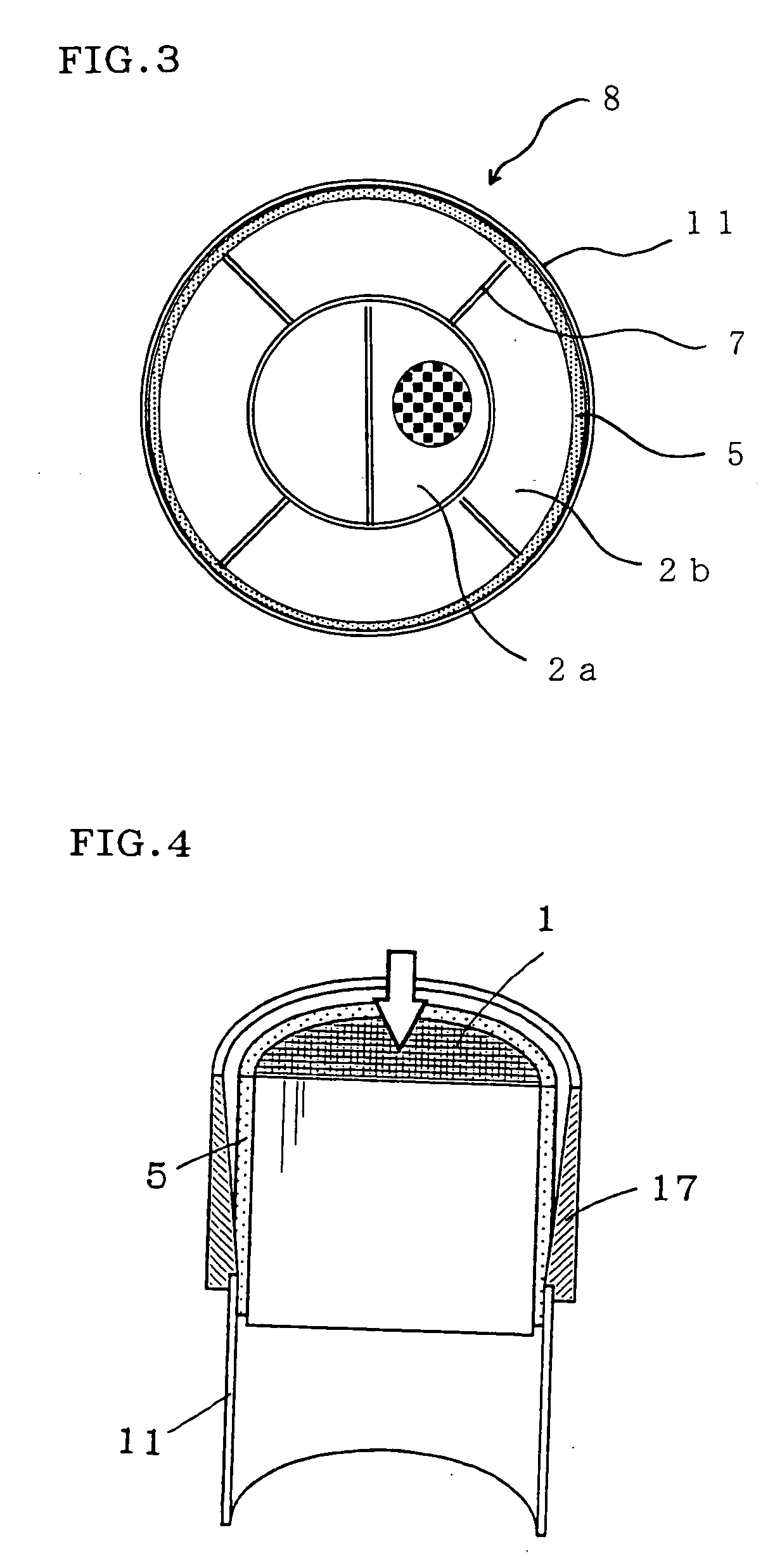

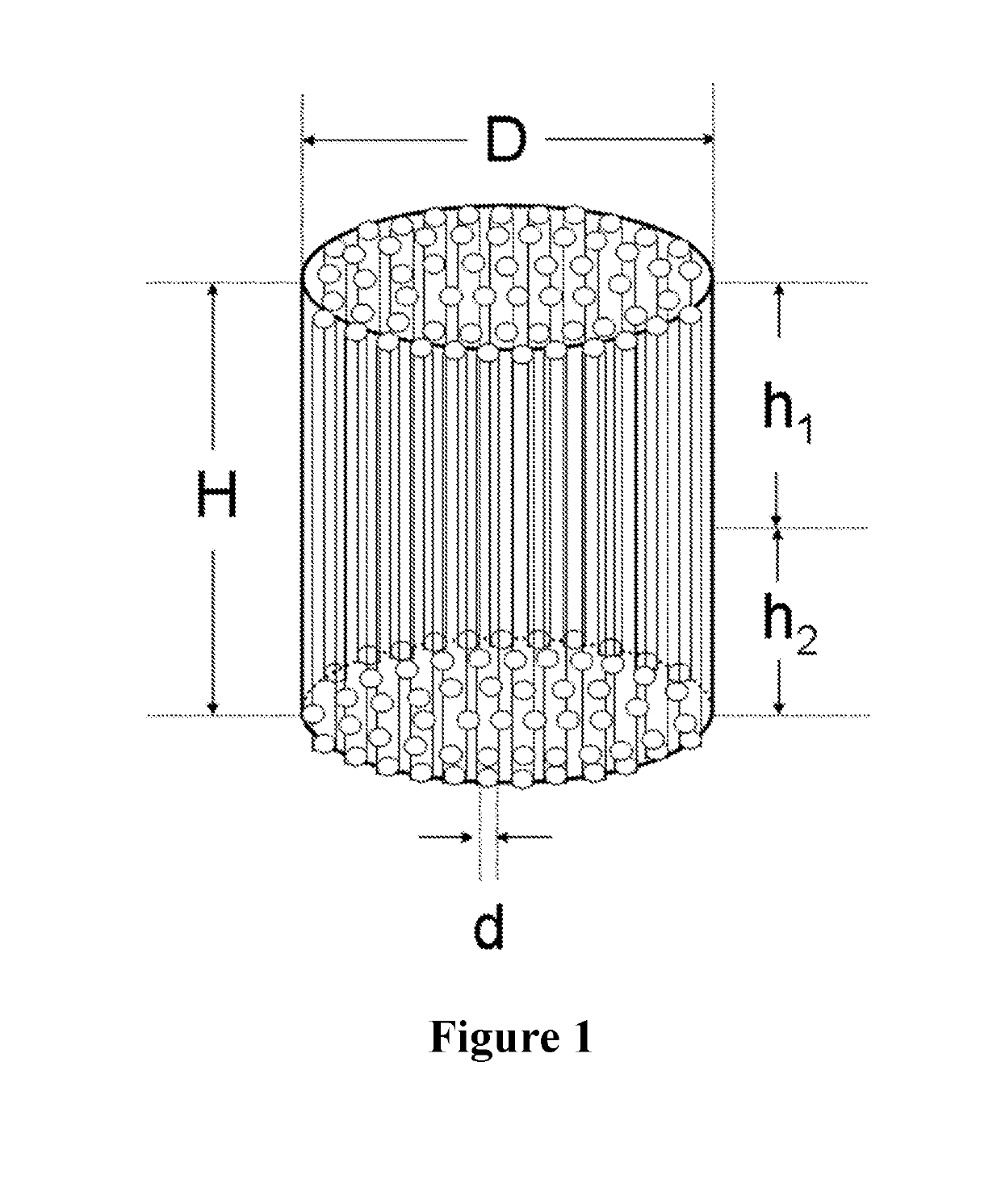

Honeycomb structural body and assembly thereof

InactiveUS20040076794A1Low efficiencySuppressing temperature increaseCombination devicesCatalyst protectionHoneycomb structureMetal

A honeycomb structural body (1) is obtained by bonding, into one piece, a plurality of honeycomb segments (2a, 2b) having a large number of through-holes (6) surrounded by partition walls (10) and extending in the axial direction. An average wall thickness of at least one honeycomb segment (2a) not constituting the outermost peripheral surface (23) of the honeycomb structural body is larger than an average wall thickness of at least one honeycomb segment (2b) constituting the outermost peripheral surface (23) of the honeycomb structural body. A honeycomb structural assembly is obtained by providing a material B having compressive elasticity on the outermost peripheral surface (23) of the honeycomb structural body (1) in a compressed state and thereby compression-holding the honeycomb structural body (1) in a metallic container. The honeycomb structural body and assembly are low in reductions in the conversion rate, purification efficiency, regeneration efficiency, etc. during the use and superior in durability against the breakage caused by thermal stress.

Owner:NGK INSULATORS LTD

Catalyst having a zeolitic core and zeolitic layer and the use of the catalyst for olefin oligomerization

InactiveUS6300536B1Raise the ratioLow degree of branchingMolecular sieve catalystsMolecular sieve catalystMolecular sieveSurface layer

A molecular sieve comprising a core having deposited thereon a surface layer, wherein the core is a zeolite containing silicon and at least one element selected from gallium and iron and the surface layer has a higher Si:Al ratio than that of the silicon:selected element ratio of the core, provides for lower branching in olefin oligomerization products.

Owner:EXXONMOBIL CHEM PAT INC

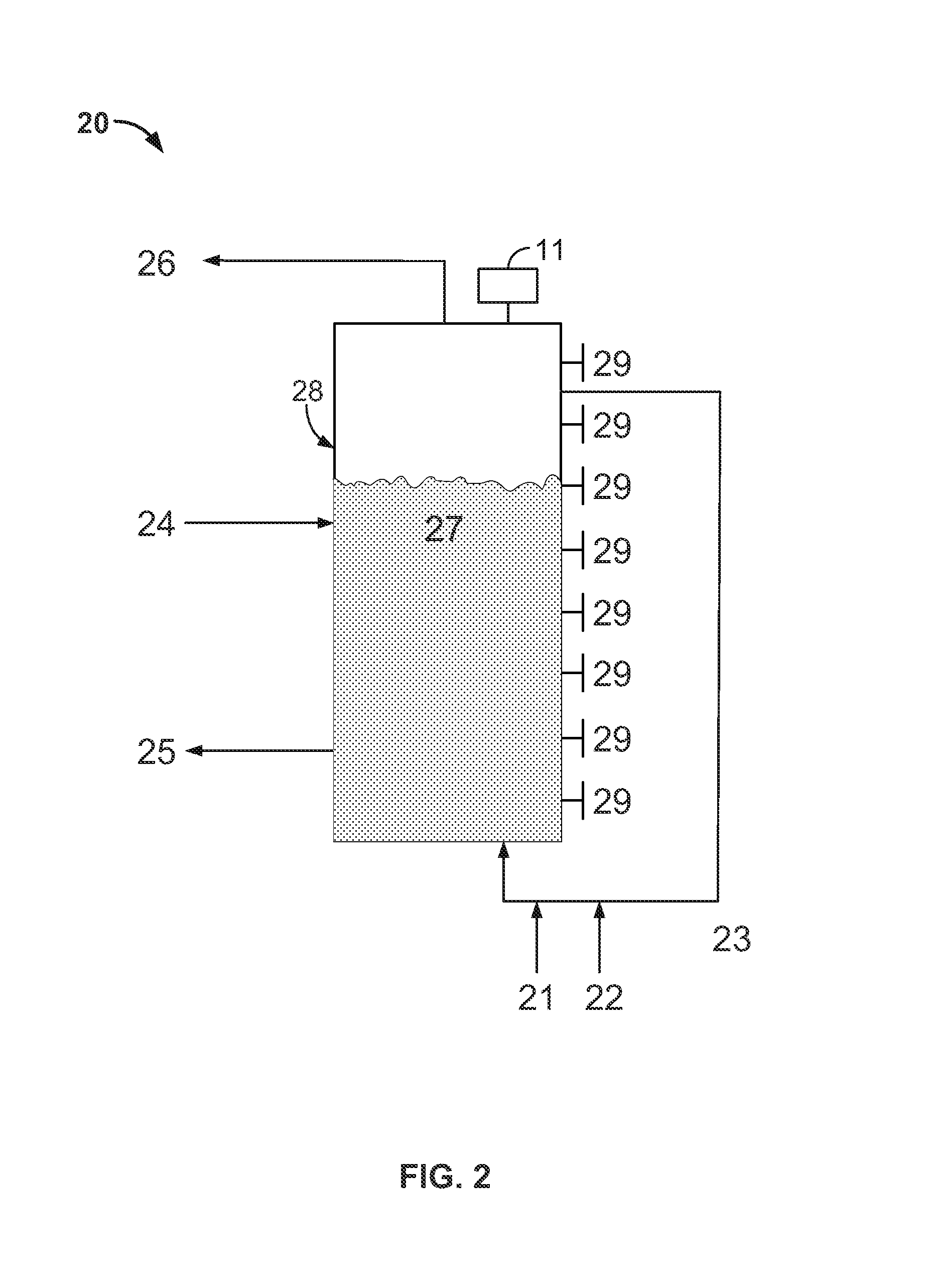

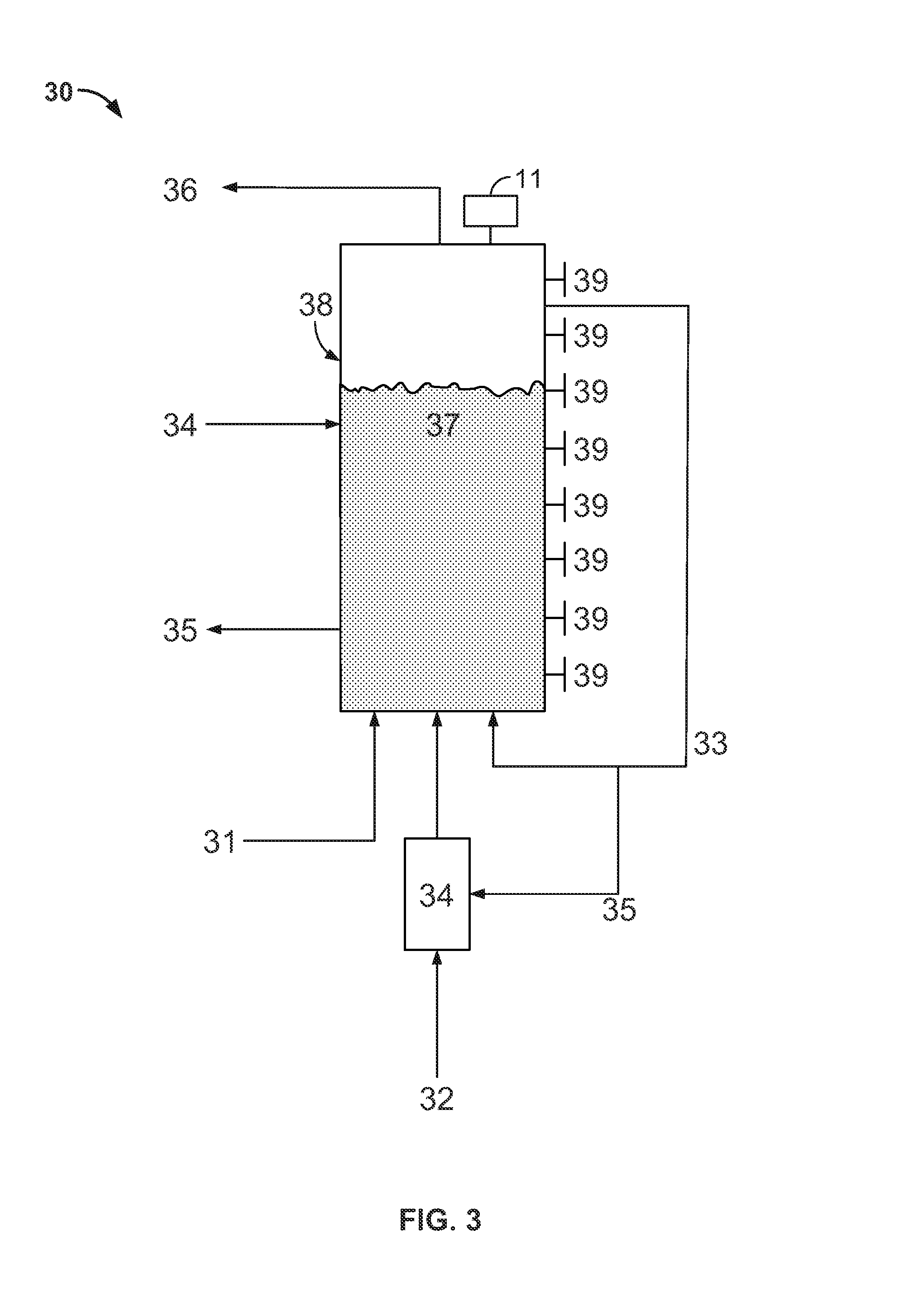

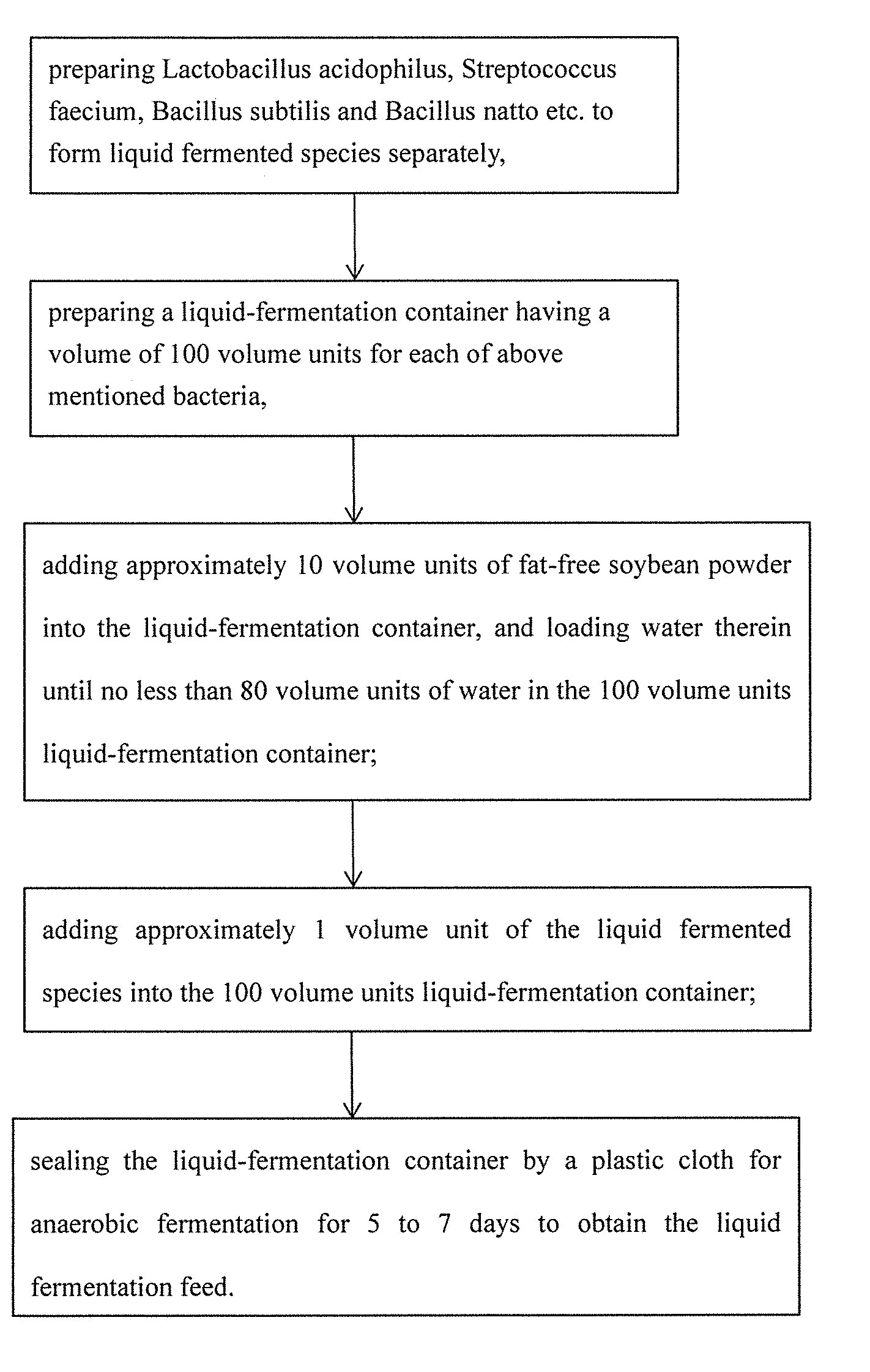

System and Method for Shrimp Aquaculture

ActiveUS20150196013A1Low conversion rateImprove survival rateClimate change adaptationPisciculture and aquariaShrimp aquacultureExposure sunlight

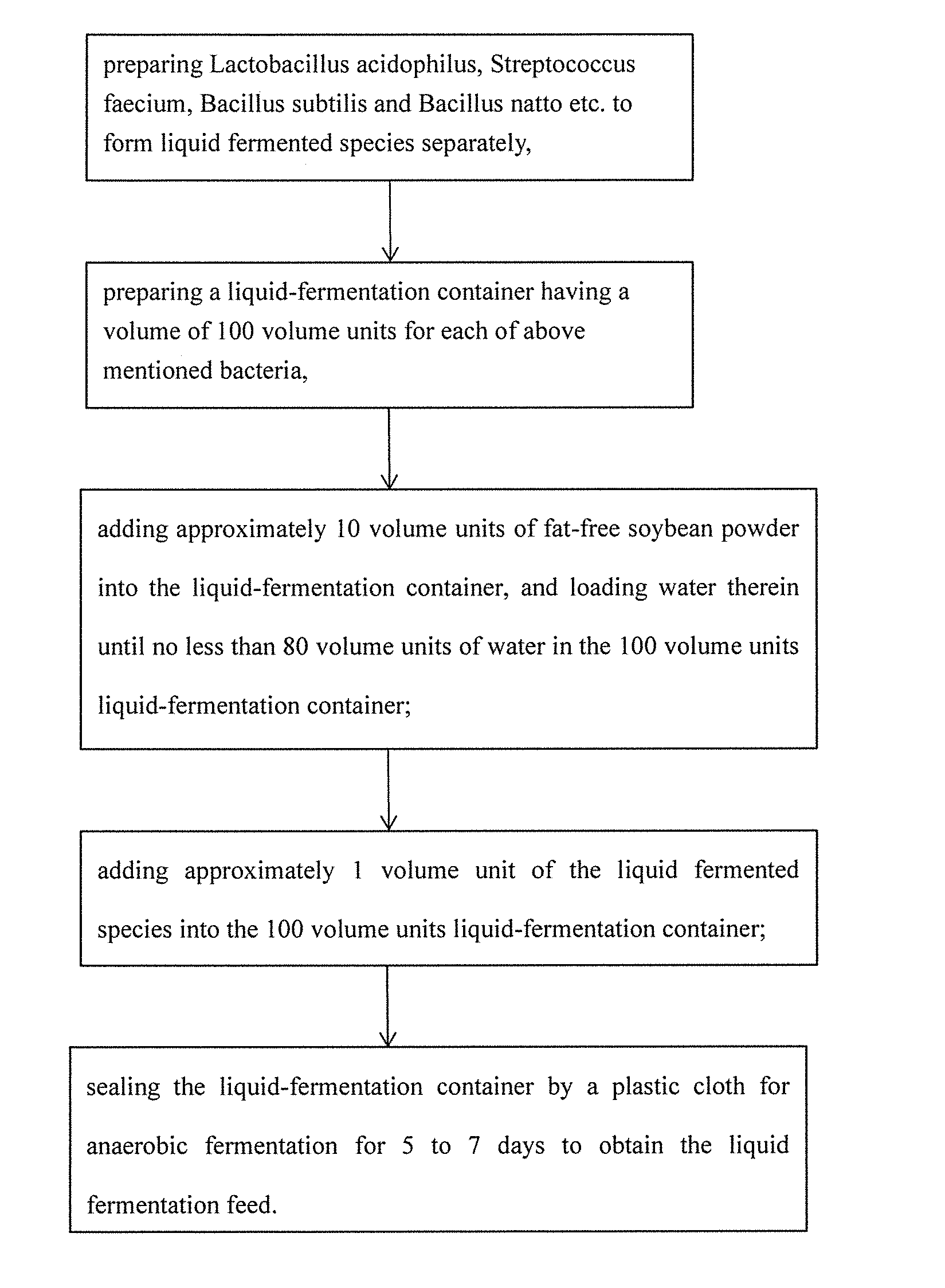

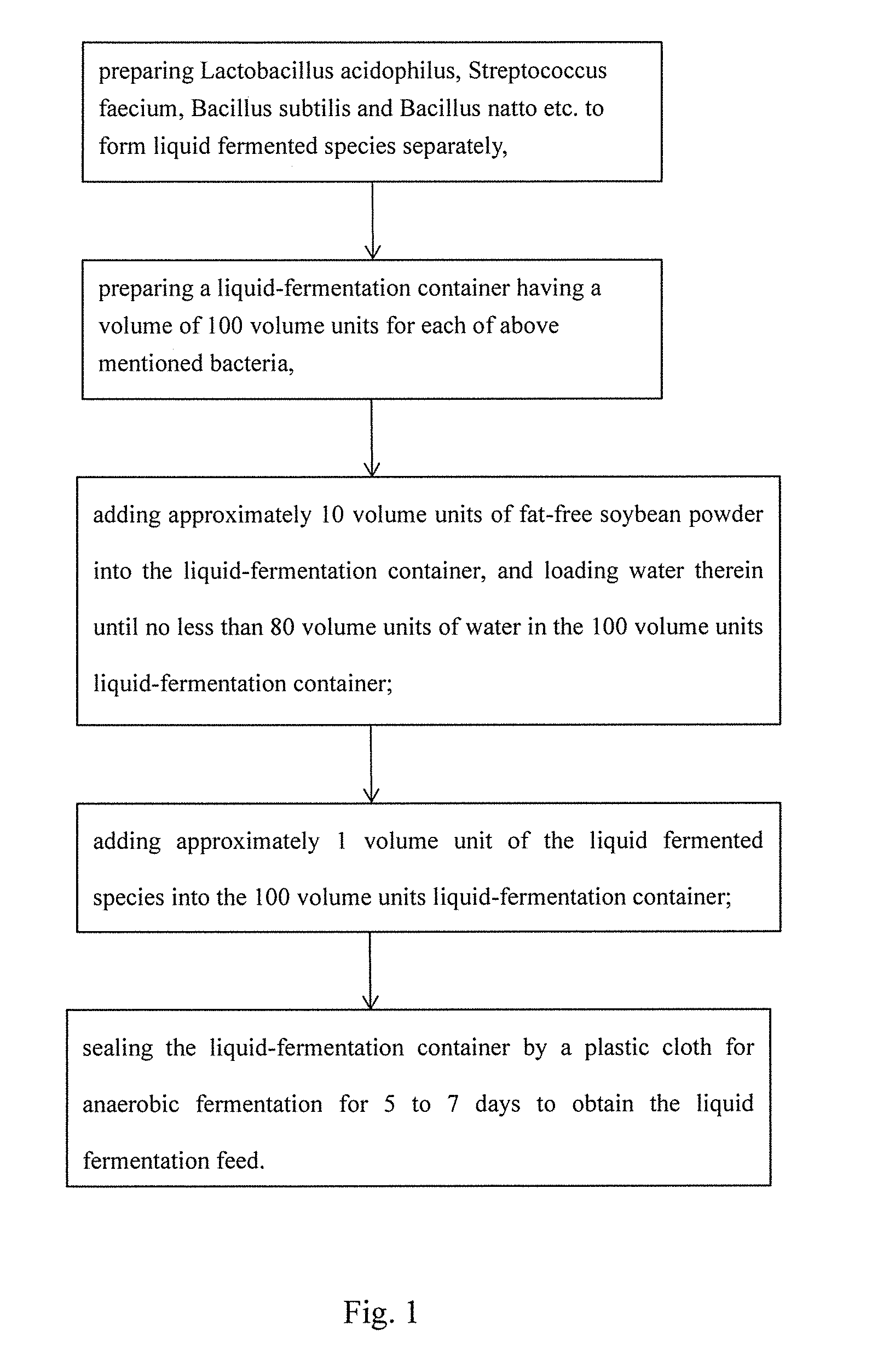

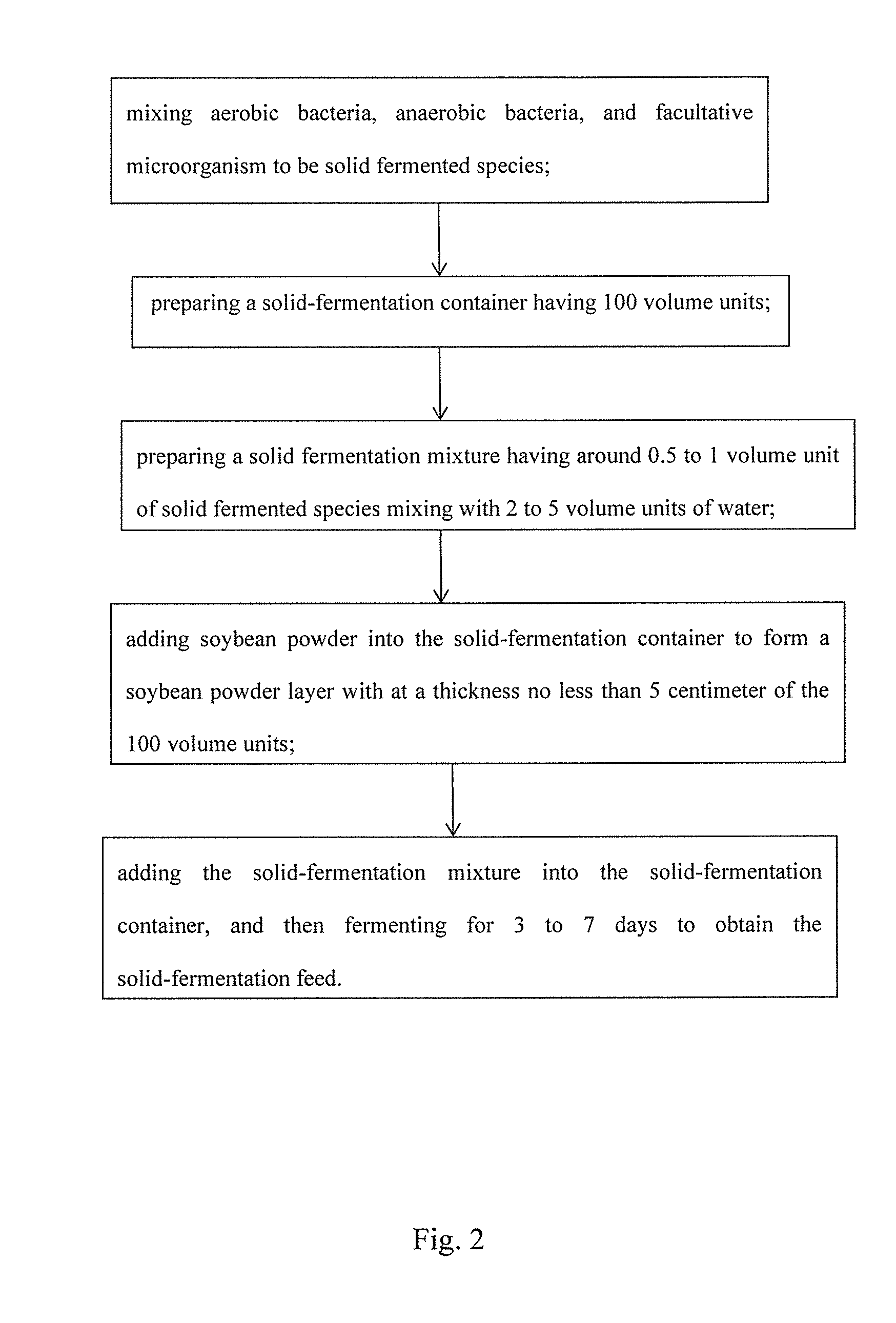

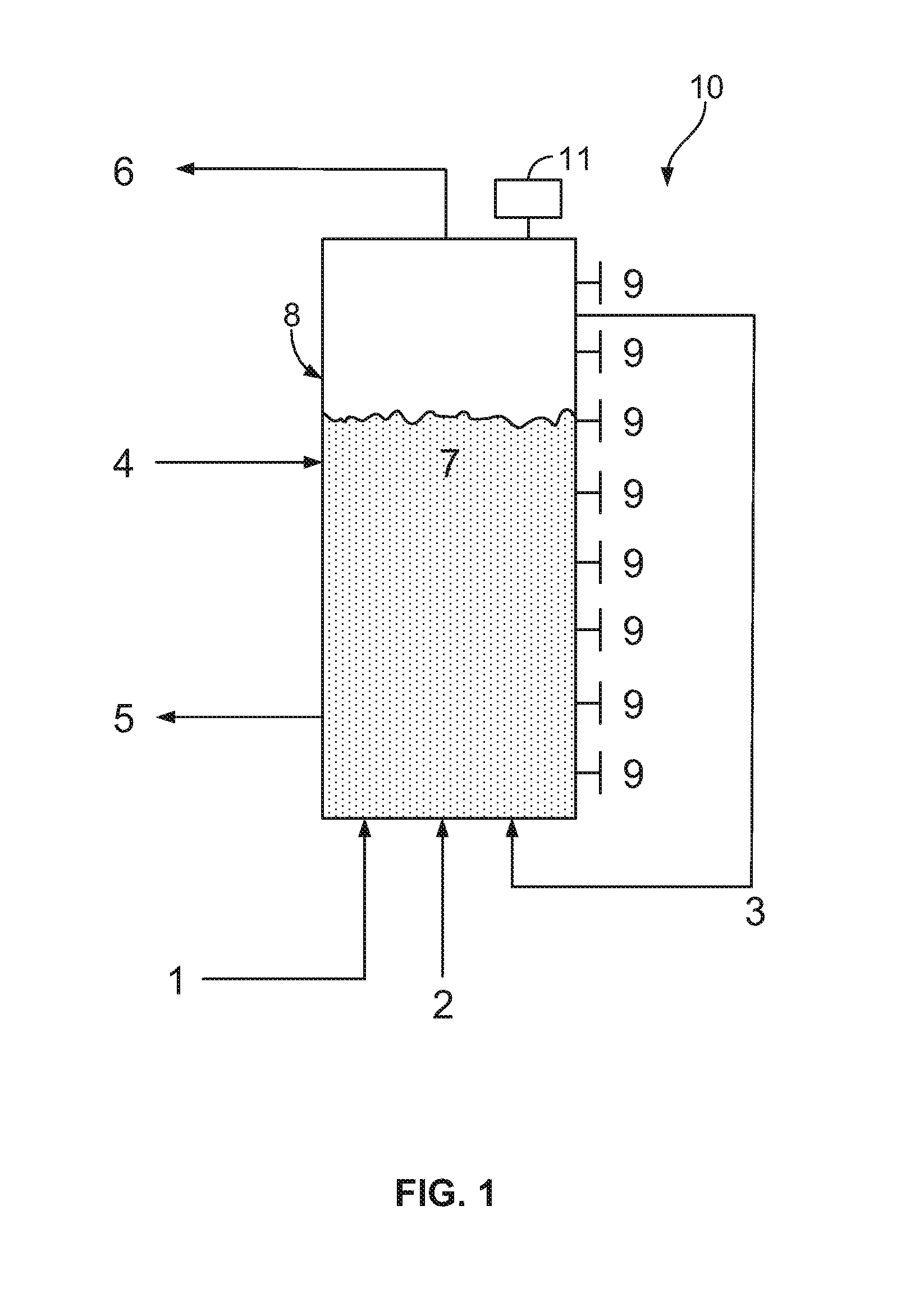

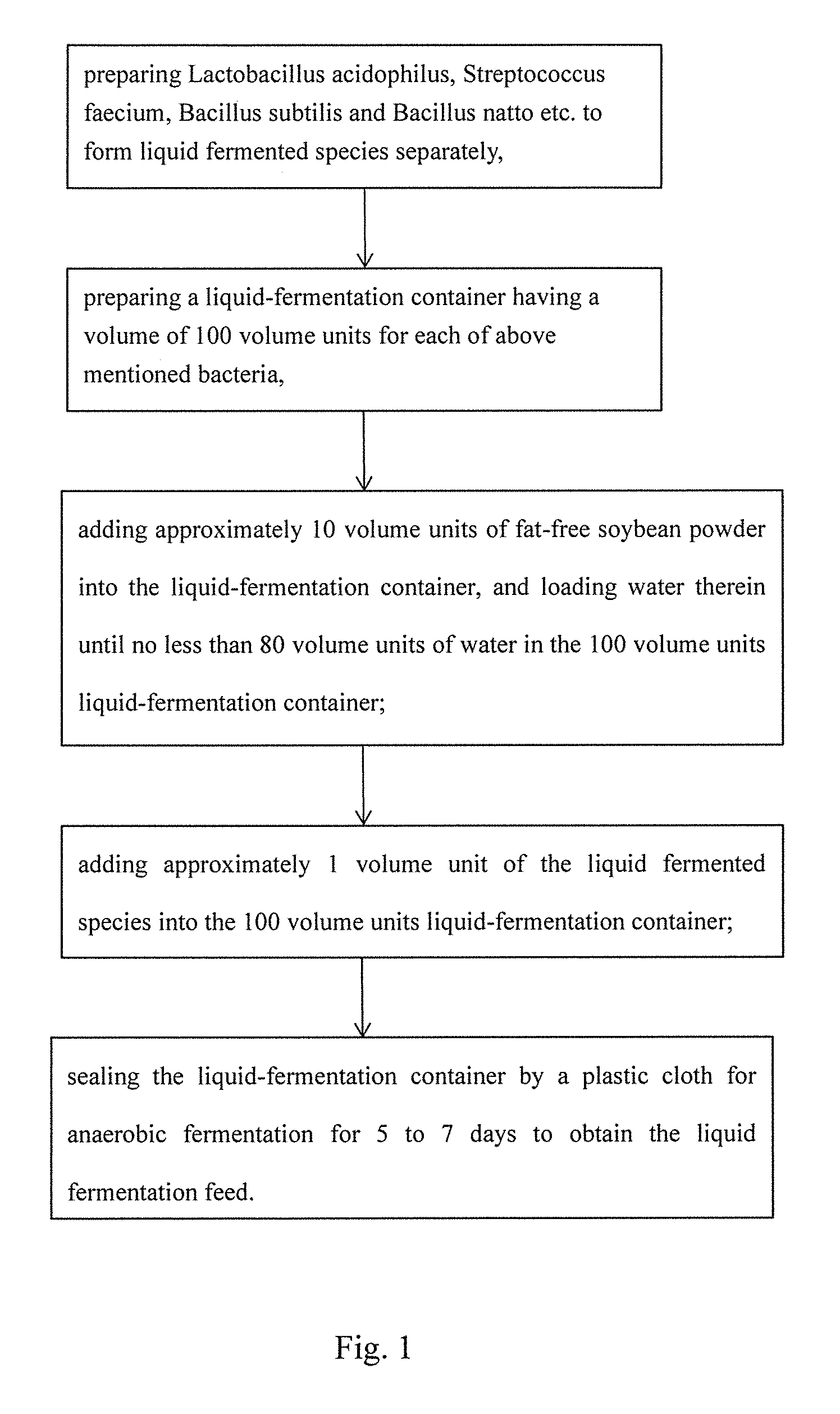

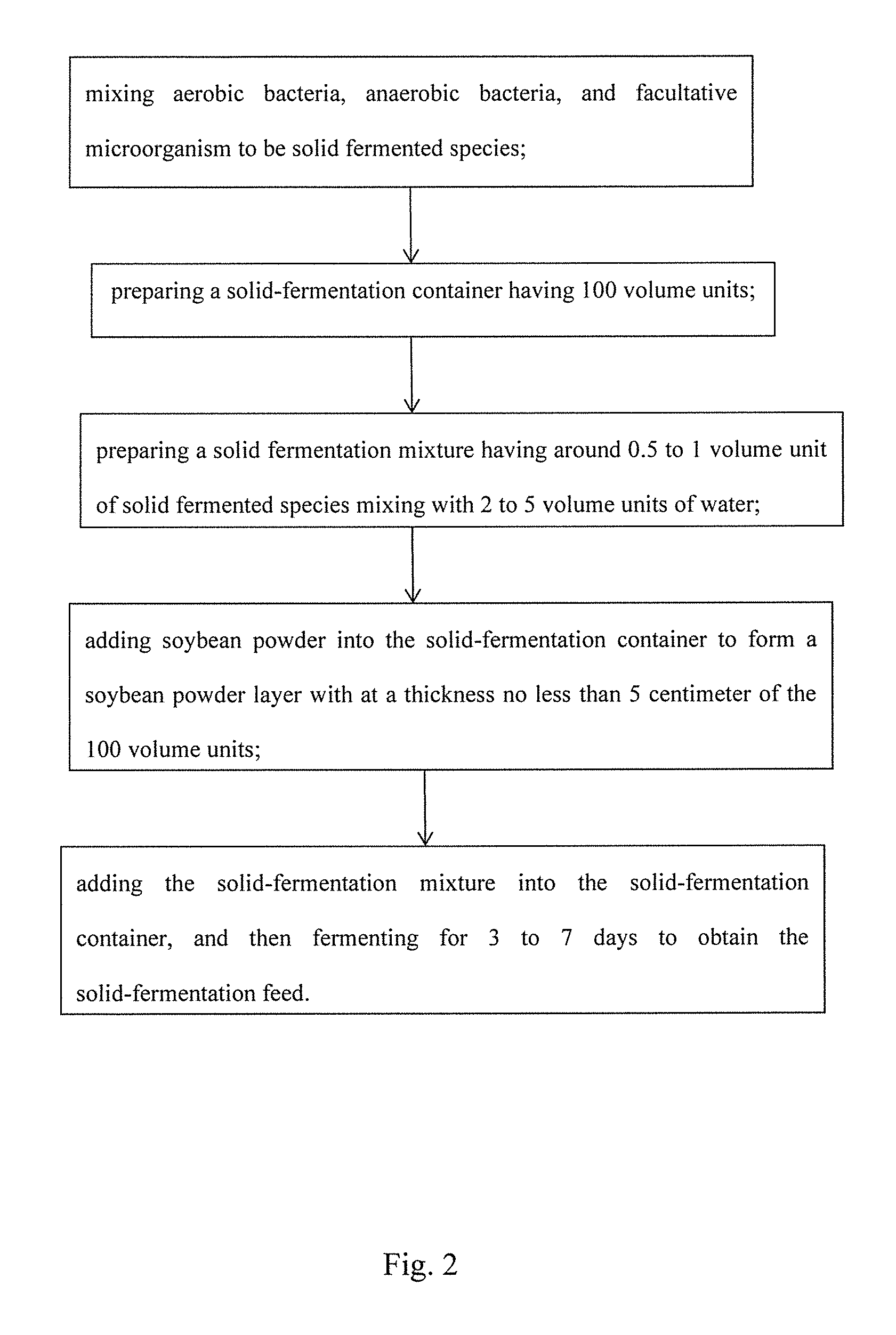

A shrimp aquaculture system includes the steps of: (1) preparing a water container; (2) exposing the water container under the sunlight, and then filling with predetermined amount of water; (3) adding 50 liter of liquid-fermentation feed into the water container at least 1 to 2 times per day; (4) adding 50 kilogram of beneficial agents into the water container once per day to obtain nursing water; (5) adding larva and young shrimp into the nursing water, and further adding a solid-fermentation feed into the nursing water, at least once a day, lasting for 0.5 to 3 months beginning on the date of adding young and larva shrimp; (6) three months later, adding regular shrimp feed containing beneficial agents into the water container; and (7) adding the amount of 1 to 3 ppm of photosynthetic bacteria into the nursing water of the water container once a day.

Owner:CHEN SHIU NAN +1

Process for producing synthetic ammonia and methanol by using coke oven gas and blast furnace gas

InactiveCN102211977ALow conversion rateNo wasteOrganic compound preparationHydroxy compound preparationCoke ovenHydrocarbon

Owner:杨皓

Recovering a caustic solution via calcium carbonate crystal aggregates

ActiveUS20150329369A1Reduce porosityHigh hardnessCalcium/strontium/barium carbonatesPulp liquor regenerationFluidized bedSlurry

Techniques for growing crystalline calcium carbonate solids such that the crystalline calcium carbonate solids include a volume of 0.0005 mm3 to 5 mm3, include a slaker to react quicklime (CaO) and a low carbonate content fluid to yield a slurry of primarily slaked lime (Ca(OH)2); a fluidized-bed reactive crystallizer that encloses a solid bed mass and includes an input for a slurry of primarily slaked lime, an input for an alkaline solution and carbonate, and an output for crystalline calcium carbonate solids that include particles and an alkaline carbonate solution; a dewatering apparatus that includes an input coupled to the crystallizer and an output to discharge a plurality of separate streams that each include a portion of the crystalline calcium carbonate solids and alkaline carbonate solution; and a seed transfer apparatus to deliver seed material into the crystallizer to maintain a consistent mass of seed material.

Owner:CARBON ENG LTD

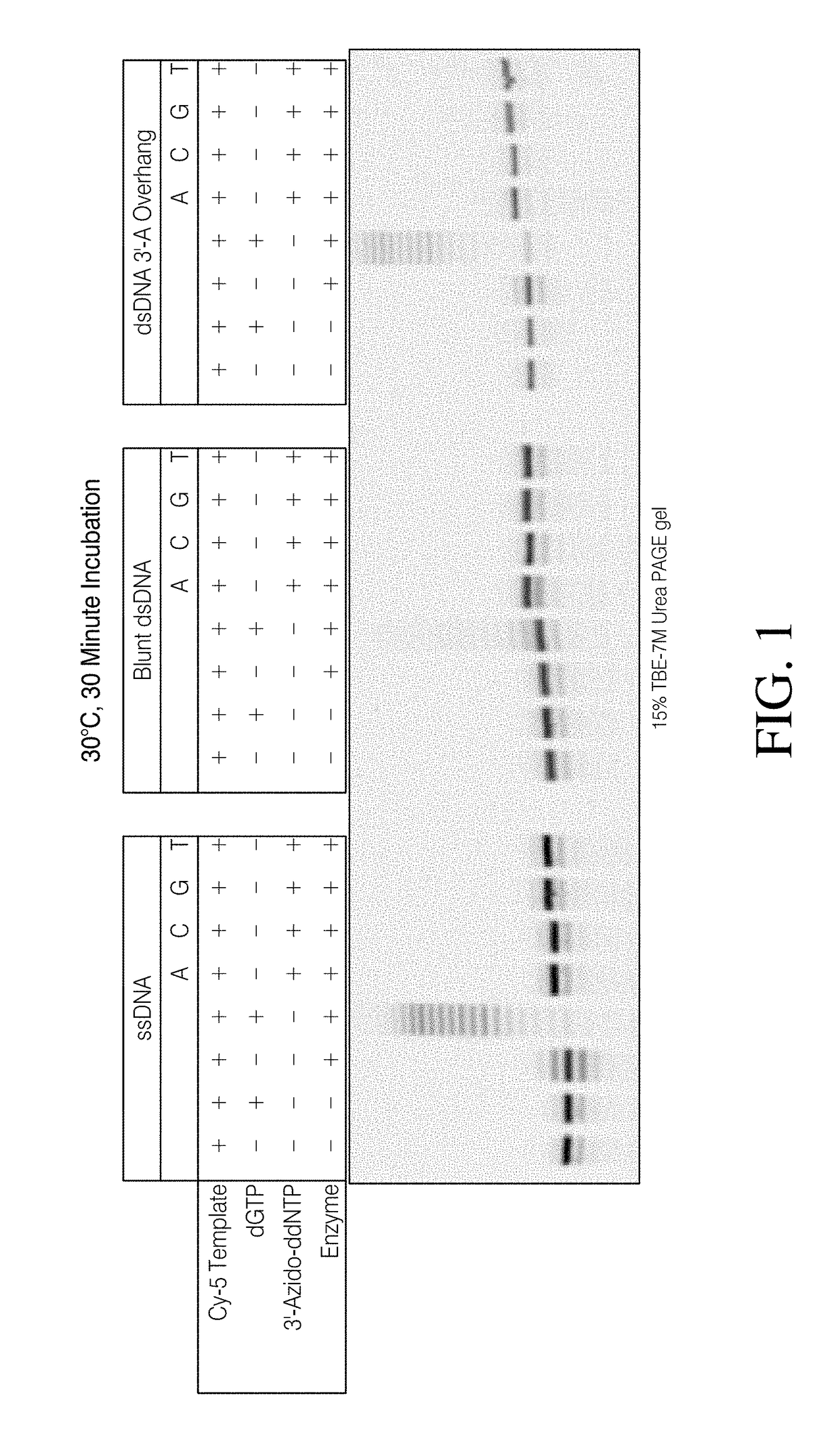

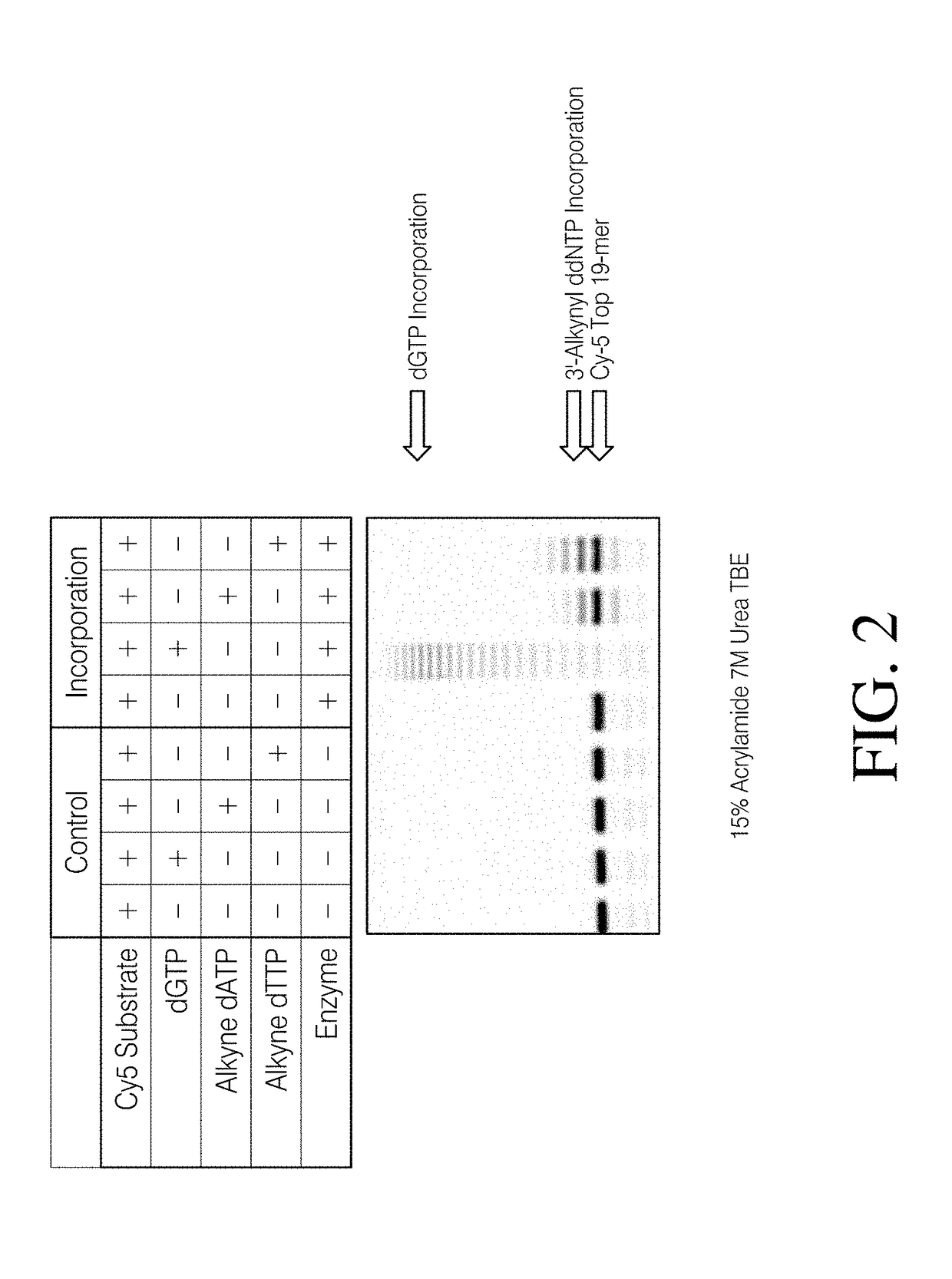

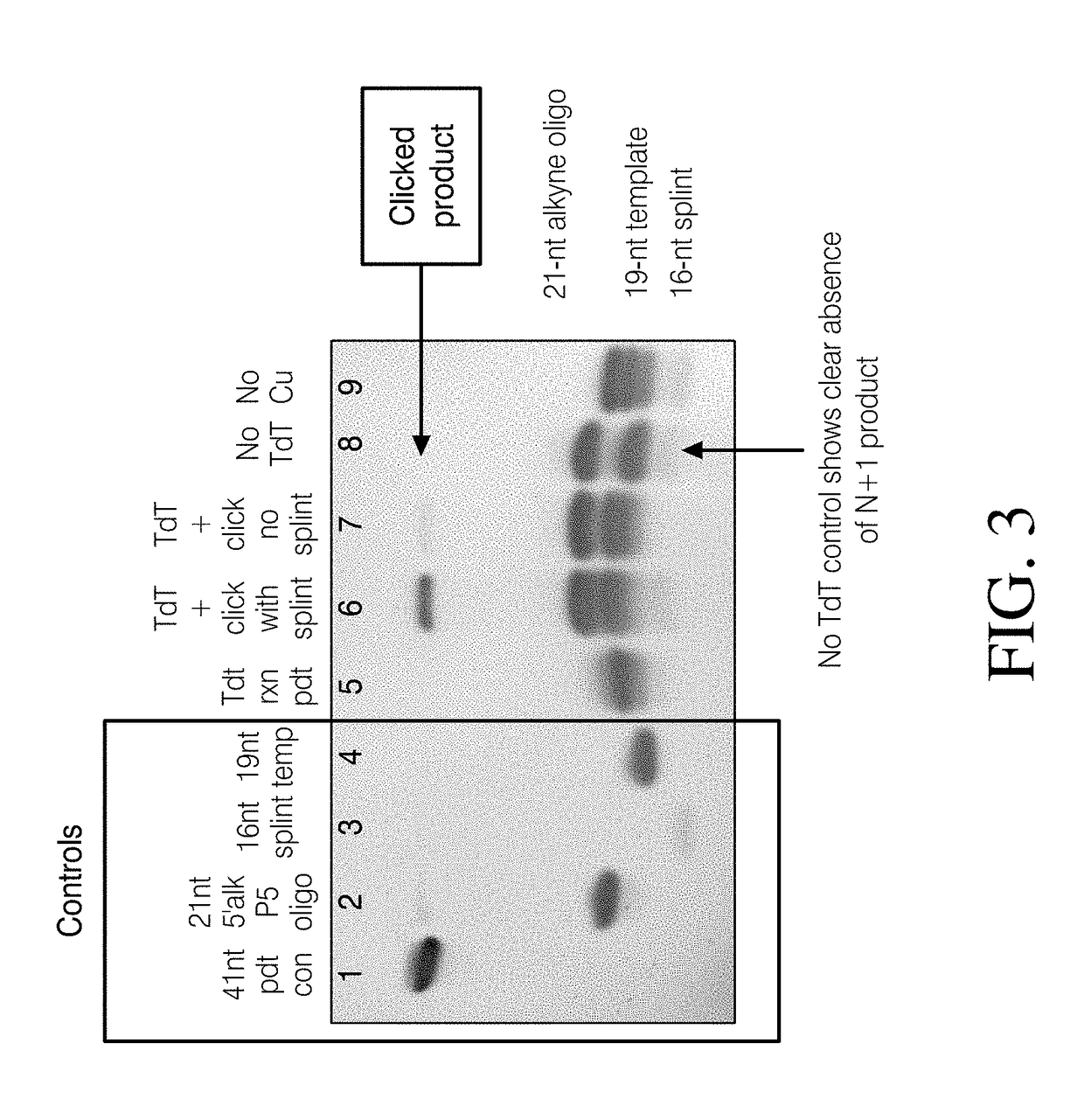

Methods for chemical ligation of nucleic acids

InactiveUS20180127816A1Improve efficiencyLower conversion rateMicrobiological testing/measurementChemical reactionChemical ligation

Provided herein are methods for preparing nucleic acid libraries, capturing DNA obtained from a limited number of cells, and selectively cleaving ssDNA or dsDNA using various chemical ligation and click chemistry reactions described herein.

Owner:ILLUMINA INC

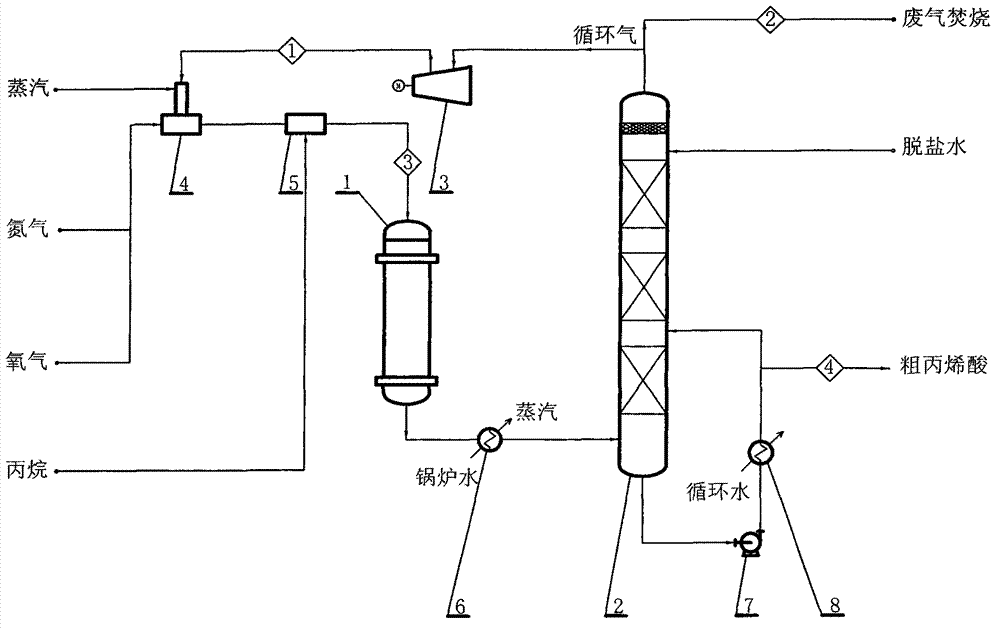

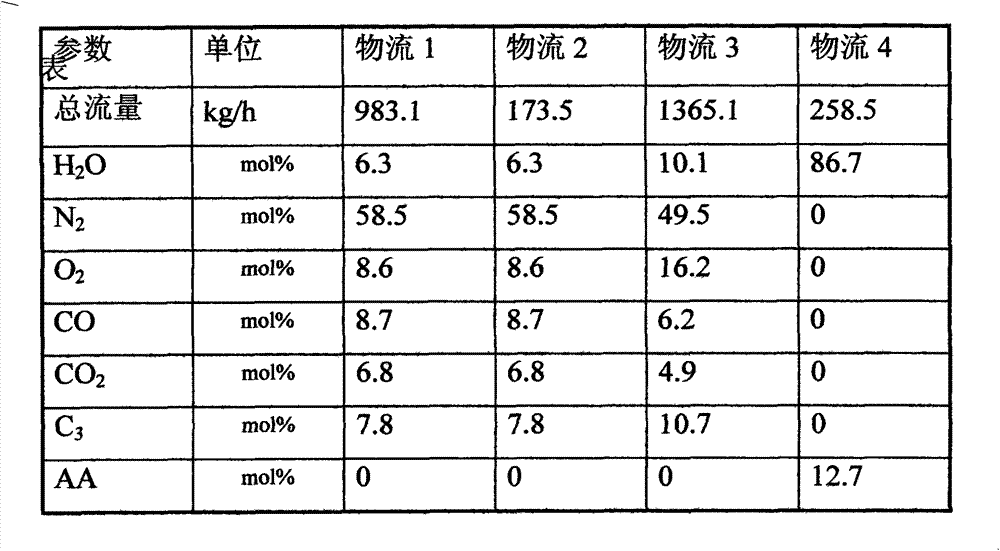

Tail gas circulating process in acrylic acid production by propane one-step method

ActiveCN103193617AReduce consumptionLow conversion rateOrganic compound preparationCarboxylic compound preparationChemistryCarbon dioxide

The invention relates to a tail gas circulating process in acrylic acid production by chemical product materials through a propane one-step method. The tail gas circulating process is characterized by comprising the following steps of: entering steam, oxygen gas and nitrogen gas from a pre-mixer and then entering a charging mixer with propane; feeding the mixture to an oxidation reactor for carrying out chemical reaction after the materials are sufficiently mixed to generate acrylic acid and carbon monoxide, carbon dioxide, acetic acid and propylene by-products; exchanging heat for the reaction products through a first cooler, enabling the heat-exchanged reaction products to enter a washing tower, and using most of emitted gases from the tower top of the washing tower as circulating gases. The tail gas circulating process has the advantages that part of the propane-containing reaction tail gases are compressed and returned to the reactor by adopting the reaction tail gas circulating process for continuously participating in the oxidization reaction, so that the consumption of the propane is reduced. If the circulation volume is extremely large, by-product Co is accumulated in a vast manner and safety hazard is generated due to extremely high CO concentration; if the circulation volume is extremely small, the total yield of the reaction is reduced, and 85% of circulated gases are preferably fed to a compressor.

Owner:中石油吉林化工工程有限公司

Process for the manufacture of catalysts used for producing para-xylene by toluene shape selective alkylation

ActiveUS20070037693A1Improve the environmentConvenient treatmentMolecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsAlkyl transferAlcohol

The present invention relates to a process for the manufacture of catalysts used for producing para-xylene by toluene shape selective alkylation. The invention is primarily used for solving the problems in the old technology, e.g., high requirements on the environment and great treatment of waste water containing organic amines when synthesizing ZSM-5 molecular sieves by using an organic amine as the template agent; small and non-homogeneous particles of the molecular sieves when synthesizing ZSM-5 molecular sieves by using an alcohol or ether as the template agent, such that the catalyst prepared thereby has low catalytic selectivity and low toluene conversion rate, etc. Said problems are better solved in the present invention by synthesizing ZSM-5 molecular sieves using the combination of organic amines and alcohols or ethers as the template agents (having a weight ratio of organic amines / alcohols=0.05-150, and organic amines / ethers=0.05-150), and modifying with organosilicon so as to obtain the catalysts. Said catalysts can be used in the industrial production of para-xylene manufactured by toluene shape selective alkylation.

Owner:CHINA PETROCHEMICAL CORP +1

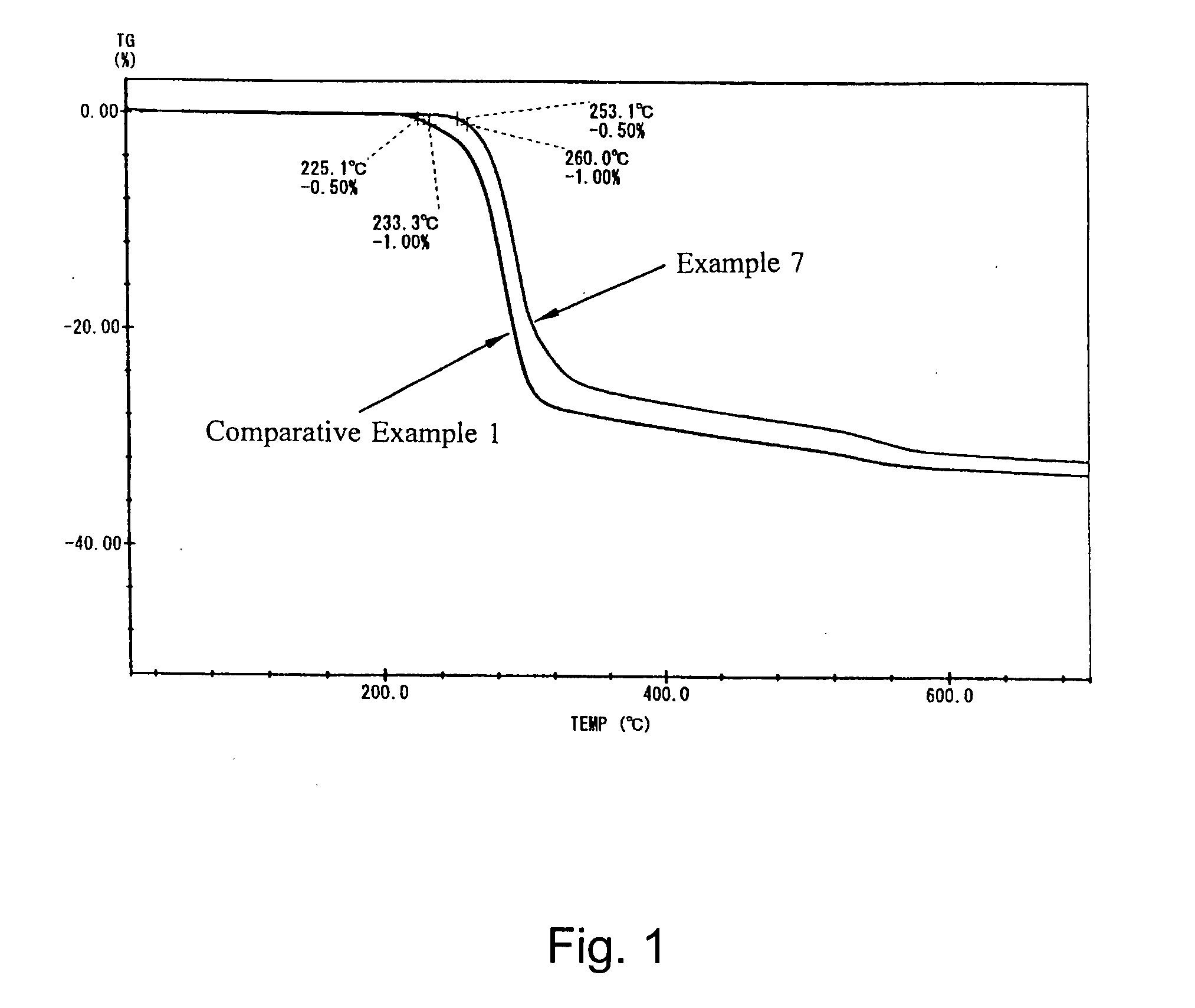

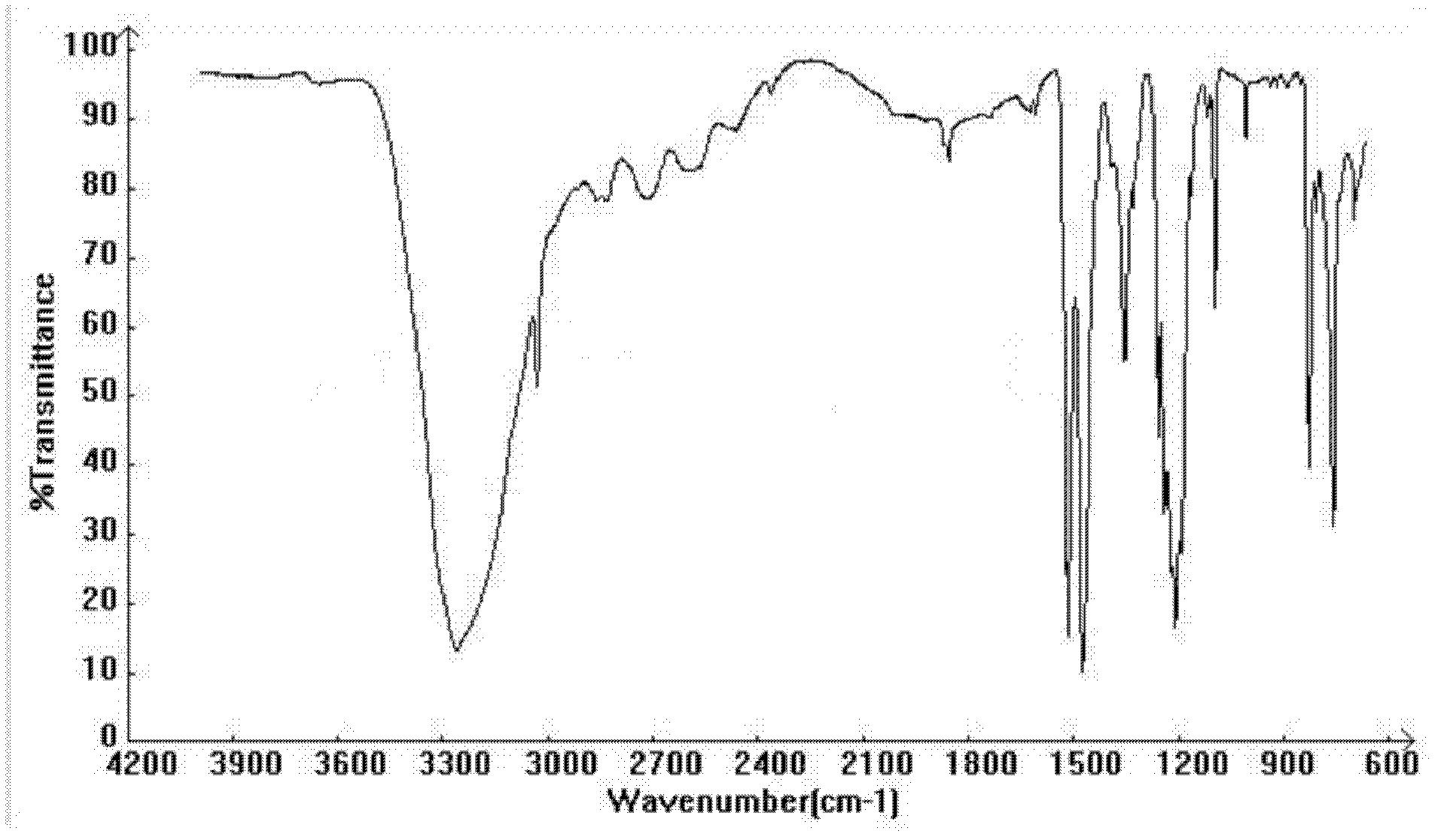

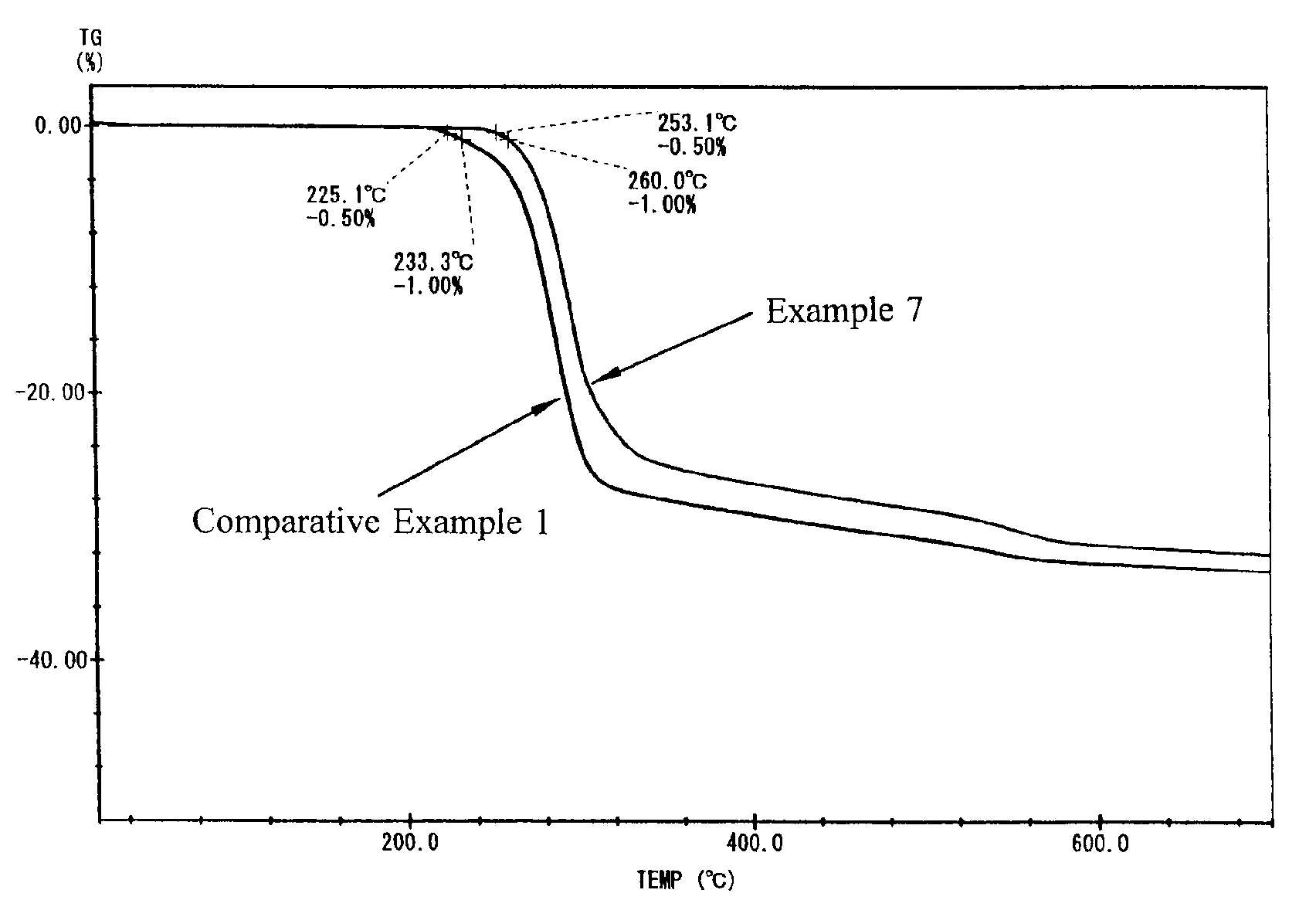

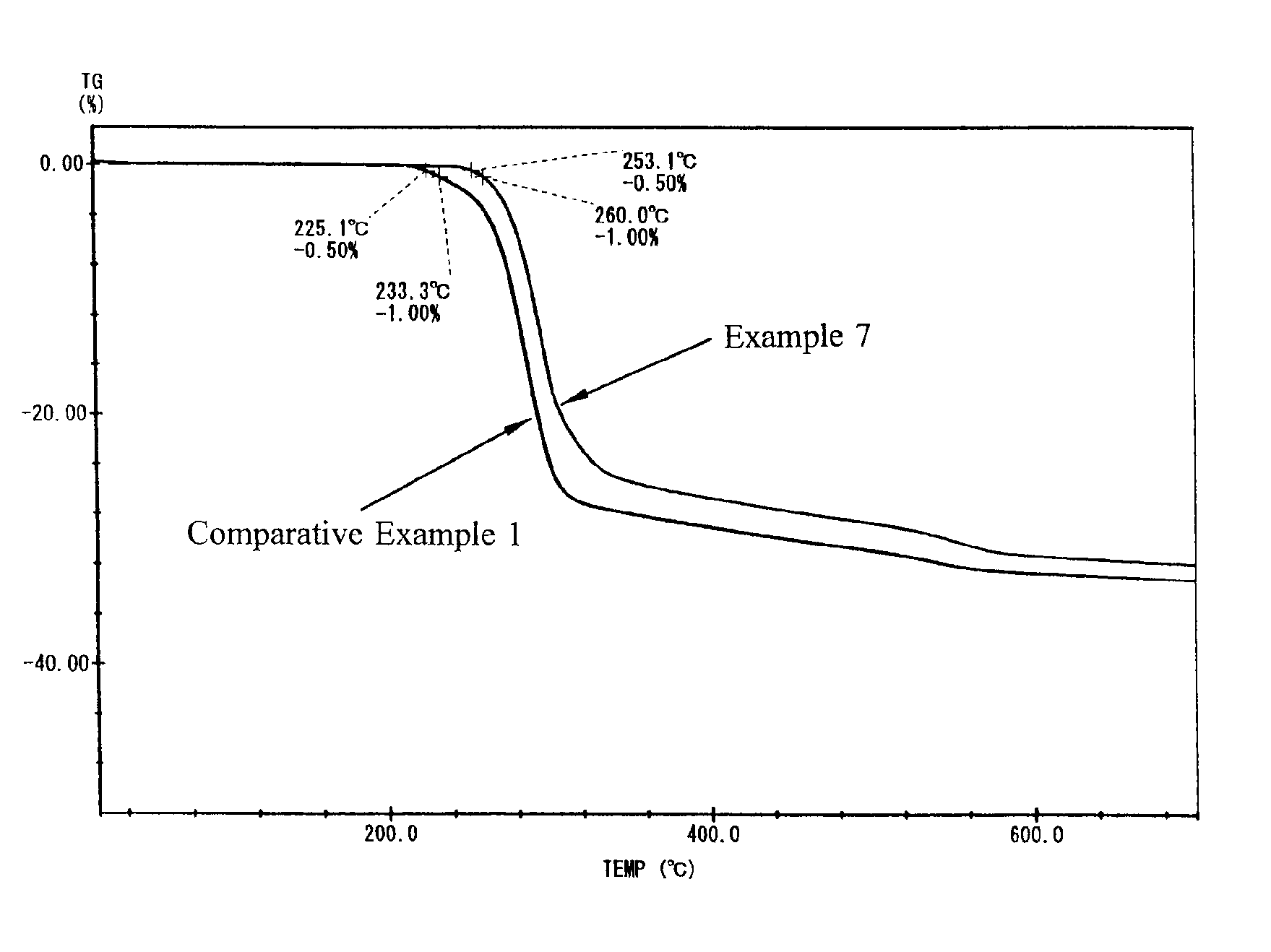

Heat-resistant aluminum hydroxide and method for preparation thereof

ActiveUS20060216226A1Improve flame retardant performanceHigh dehydration temperatureCircuit susbtrate materialsAluminium oxides/hydroxidesAluminium hydroxideFire retardant

A heat-resistant aluminum hydroxide which is prepared by subjecting a mixture of aluminum hydroxide with a reaction retardant for retarding the conversion aluminum hydroxide to boehmite, as a raw material, to the hydrothermal treatment or to pressurization and heating in a steam atmosphere; and a method for preparing a heat-resistant aluminum hydroxide which comprises subjecting a mixture of aluminum hydroxide with a reaction retardant for retarding the conversion aluminum hydroxide to boehmite as a raw material to the hydrothermal treatment, or to pressurization and heating in a steam atmosphere.

Owner:KAWAI LIME IND

Method for preparing cinnamyl alcohol through cinnamaldehyde hydrogenation

ActiveCN104974016AEliminate pollutionReduce the burden onOrganic compound preparationHydroxy compound preparationOrganic solventSolvent free

The invention relates to a method for preparing cinnamyl alcohol (COL) through cinnamaldehyde (CAL) hydrogenation. In a solvent-free system, Pt-(Ru)-Sn / TiO2 as a catalyst is used for catalyzing selective hydrogenation of CAL to prepare COL. The catalyst has relatively high activity on the hydrogenation of C=O bond of CAL and shows inertia on the hydrogenation of C=C bond of CAL and COL, and thus has high selectivity on the generated COL. When the reactants are nearly completely converted and Pt-(Ru)-Sn / TiO2 is used as the catalyst, the highest selectivity on COL reaches 93-95%. By adopting the method, the pollution of organic solvent is eliminated, the burden of the separation process is lightened, and the reaction control difficulty in large-scale production is reduced.

Owner:CHANGCHUN UNIV OF TECH

Synthesis method of hydroquinone

InactiveCN102351656BMild reaction conditionsIncrease conversion rateOrganic chemistryOrganic compound preparationPtru catalystDistillation

The invention relates to a synthesis method of hydroquinone. The method is characterized by comprising the following steps: carrying out catalytic oxidation on phenol and oxygen to generate a mixture of p-benzoquinone and o-benzoquinone, wherein a catalyst is copper and sodium complex salt; distilling to remove solvent, adding water in residual materials, and separating p-benzoquinone and o-benzoquinone by distillation; reducing separated p-benzoquinone with a reducing agent to obtain hydroquinone, filtering out hydroquinone crude product and recrystallizing so as to obtain hydroquinone crystal; and concentrating a mother liquid obtained by filtering out hydroquinone or catechol crude product to obtain an ammonium sulfate fertilizer. The synthesis method has simple process, mild reaction conditions and short reaction period, and the yield of hydroquinone in the product is larger than that of catechol.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Synthesis method of hydroquinone

InactiveCN102351656AMild reaction conditionsIncrease conversion rateOrganic chemistryOrganic compound preparationPtru catalystDistillation

The invention relates to a synthesis method of hydroquinone. The method is characterized by comprising the following steps: carrying out catalytic oxidation on phenol and oxygen to generate a mixture of p-benzoquinone and o-benzoquinone, wherein a catalyst is copper and sodium complex salt; distilling to remove solvent, adding water in residual materials, and separating p-benzoquinone and o-benzoquinone by distillation; reducing separated p-benzoquinone with a reducing agent to obtain hydroquinone, filtering out hydroquinone crude product and recrystallizing so as to obtain hydroquinone crystal; and concentrating a mother liquid obtained by filtering out hydroquinone or catechol crude product to obtain an ammonium sulfate fertilizer. The synthesis method has simple process, mild reaction conditions and short reaction period, and the yield of hydroquinone in the product is larger than that of catechol.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Monolithic catalyst used for carbon dioxide hydrogenation reaction and method for preparing same

ActiveUS20190262803A1Increase conversion rateImprove efficiencyHydrocarbon from carbon oxidesOrganic compound preparationActive componentHydrogenation reaction

A monolithic catalyst used for a carbon dioxide hydrogenation reaction and a method for preparing the same. The catalyst comprises a carrier, a coating, and active components. The carrier is a honeycomb ceramic. The coating and the active components are separately applied to honeycomb ceramic hole walls from inside to outside. Moreover, each of the honeycomb ceramic holes is divided into an upper segment and a lower segment, and different active components are separately loaded on the two segments. The method for preparing the monolithic catalyst comprises first applying a coating to a honeycomb ceramic by means of impregnation to obtain a coating-containing carrier, and then applying active components to an upper segment and a lower segment of the coating-containing carrier successively by means of impregnation to obtain the monolithic catalyst.

Owner:CHINA PETROCHEMICAL CORP +1

Catalyst for manufacturing synthesis gas and method of manufacturing synthesis gas using the same

ActiveUS20070129245A1Reduced dimensionImprove thermal efficiencyNitrogen compoundsHydrogen/synthetic gas productionAlkaline earth metalAdditive ingredient

A catalyst for manufacturing synthesis gas has a carrier and a Group VIII metal carried by the carrier. The carrier contains a first ingredient, a second ingredient and a third ingredient. The first ingredient is an oxide of at least an alkaline earth metal selected from the group of magnesium, calcium, strontium and barium. The second ingredient is an oxide of at least an element selected from the group of scandium, yttrium and lanthanoids. The third ingredient is zirconia or a substance containing zirconia as principal ingredient and has a solid electrolytic property. The carrier may be formed by forming an overcoat film on a substrate by coating. Then, the overcoat film contains the above three ingredients. A catalyst according to the invention can remarkably reduce the dimensions of the reaction facility and improve the energy efficiency of the facility.

Owner:CHIYODA CORP

Catalyst for manufacturing synthesis gas and method of manufacturing synthesis gas using the same

ActiveUS7888282B2Easily side reactionWeak acidic characteristicOrganic chemistryNitrogen compoundsAlkaline earth metalLanthanide

A catalyst for manufacturing synthesis gas has a carrier and a Group VIII metal carried by the carrier. The carrier contains a first ingredient, a second ingredient and a third ingredient. The first ingredient is an oxide of at least an alkaline earth metal selected from the group of magnesium, calcium, strontium and barium. The second ingredient is an oxide of at least an element selected from the group of scandium, yttrium and lanthanoids. The third ingredient is zirconia or a substance containing zirconia as principal ingredient and has a solid electrolytic property. The carrier may be formed by forming an overcoat film on a substrate by coating. Then, the overcoat film contains the above three ingredients. A catalyst according to the invention can remarkably reduce the dimensions of the reaction facility and improve the energy efficiency of the facility.

Owner:CHIYODA CORP

System and method for shrimp aquaculture

ActiveUS9510568B2Low conversion rateImprove survival rateClimate change adaptationPisciculture and aquariaShrimp aquacultureExposure sunlight

A shrimp aquaculture system includes the steps of: (1) preparing a water container; (2) exposing the water container under the sunlight, and then filling with predetermined amount of water; (3) adding 50 liter of liquid-fermentation feed into the water container at least 1 to 2 times per day; (4) adding 50 kilogram of beneficial agents into the water container once per day to obtain nursing water; (5) adding larva and young shrimp into the nursing water, and further adding a solid-fermentation feed into the nursing water, at least once a day, lasting for 0.5 to 3 months beginning on the date of adding young and larva shrimp; (6) three months later, adding regular shrimp feed containing beneficial agents into the water container; and (7) adding the amount of 1 to 3 ppm of photosynthetic bacteria into the nursing water of the water container once a day.

Owner:CHEN SHIU NAN +1

Process for producing dicarboxylic acids

InactiveUS20040024248A1Increased space-time yieldLow conversion rateOrganic compound preparationCarboxylic preparation by oxidationAlkaneCatalytic oxidation

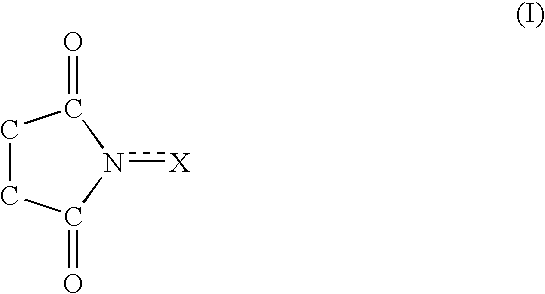

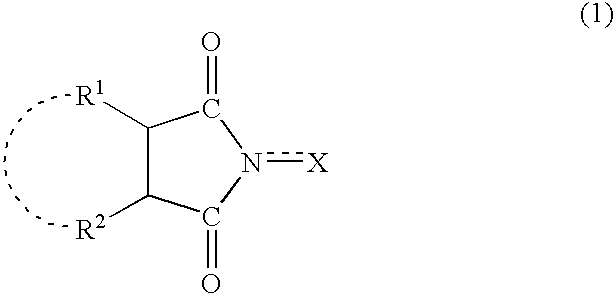

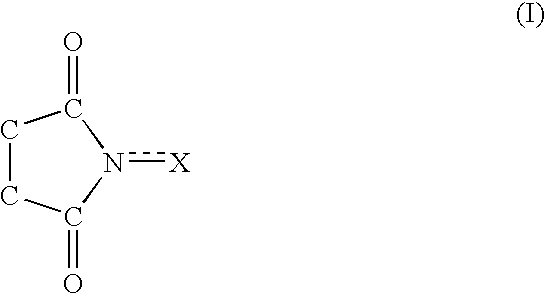

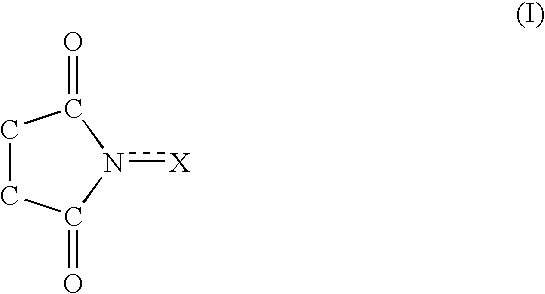

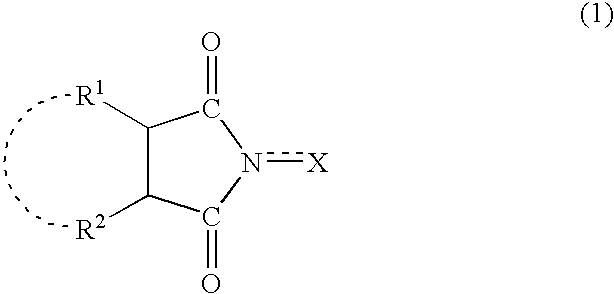

A process of the present invention produces a corresponding dicarboxylic acid by oxidative cleavage of a cycloalkane with oxygen and performs a reaction in the presence of a catalyst including an imide compound and a metallic compound, the imide compound having a cyclic imide skeleton represented by following Formula (I): wherein X is an oxygen atom or an -OR group, and wherein R is a hydrogen atom or a hydroxyl-protecting group, under conditions of a reaction temperature of 80° C. or higher and a concentration of the cycloalkane in a system of 21% by weight or more. The imide compound includes, for example, N-hydroxyphthalimide. The amount of the imide compound is, for example, from about 0.000001 to about 0.01 mole per mole of the cycloalkane. In the production of a corresponding dicarboxylic acid by catalytic oxidation of a cycloalkane with oxygen, the present invention can yield the dicarboxylic acid in a high space time yield even using a small amount of the catalyst.

Owner:DAICEL CHEM IND LTD

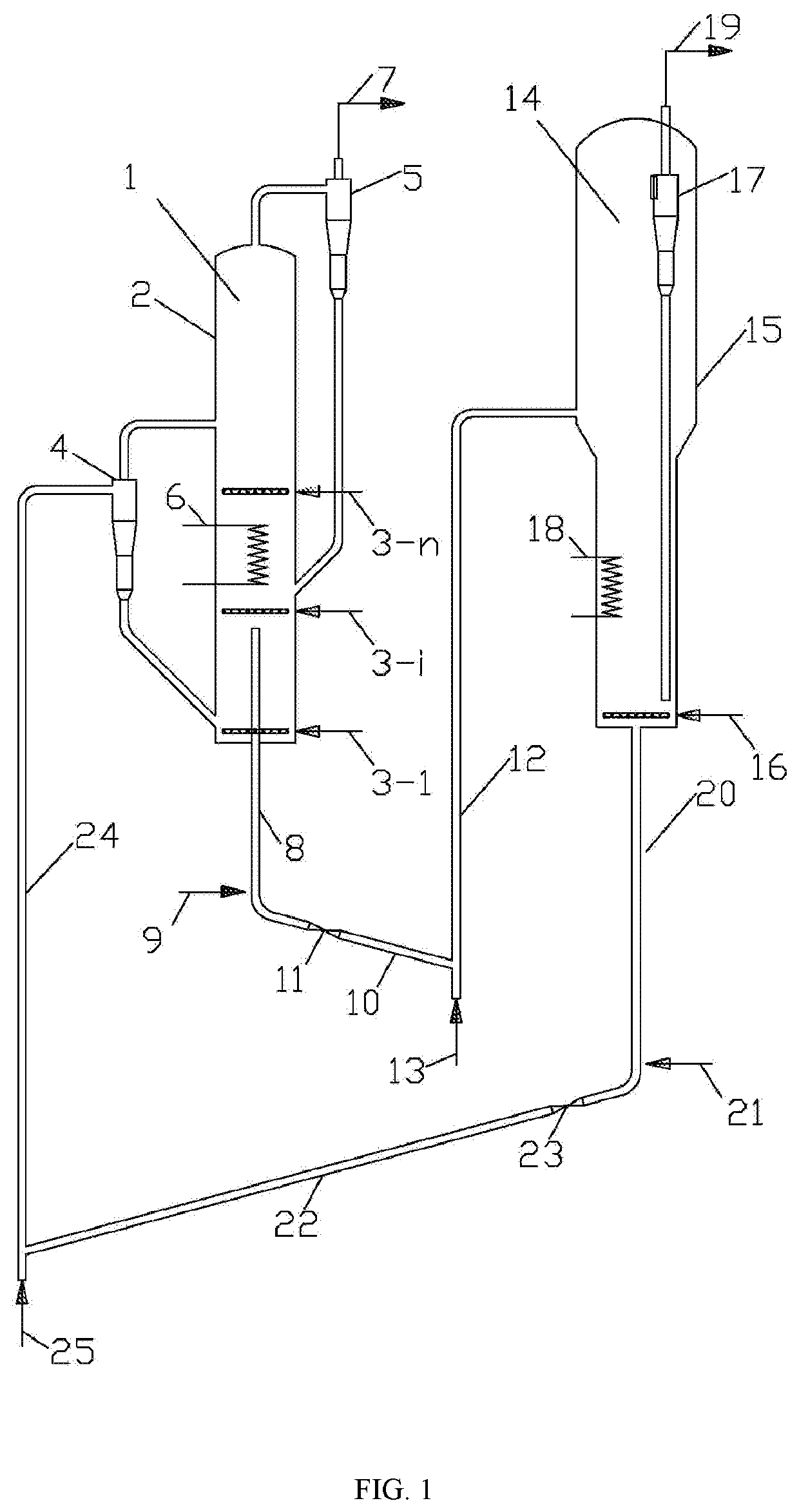

Device and method for preparing para-xylene and co-producing light olefins from methanol and/or dimethyl ether and toluene

ActiveUS20200179891A1Conversion of of of lightSelectivity of lightMolecular sieve catalystCatalystsXylyleneFluidized bed

Disclosed are a fast fluidized bed reactor, device and method for preparing para-xylene and co-producing light olefins from methanol and / or dimethyl ether and toluene, with the reactor, device and method being capable of solving or improving the problem of competition between an alkylation reaction and an MTO reaction during the process of producing the para-xylene and co-producing light olefins from toluene and methanol, thus achieving a synergistic effect between the MTO reaction and the alkylation reaction. By controlling the mass transfer and reaction, the competition between the alkylation reaction and the MTO reaction is coordinated and optimized to achieve a synergistic effect, thereby increasing the conversion rate of toluene, the yield of para-xylene and the selectivity of the light olefins. The fast fluidized bed reactor comprises a first reactor feed distributor and a plurality of second reactor feed distributors, the first reactor feed distributor and the plurality of second reactor feed distributors are sequentially arranged along the gas flow direction in a reaction zone of the fast fluidized bed reactor.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

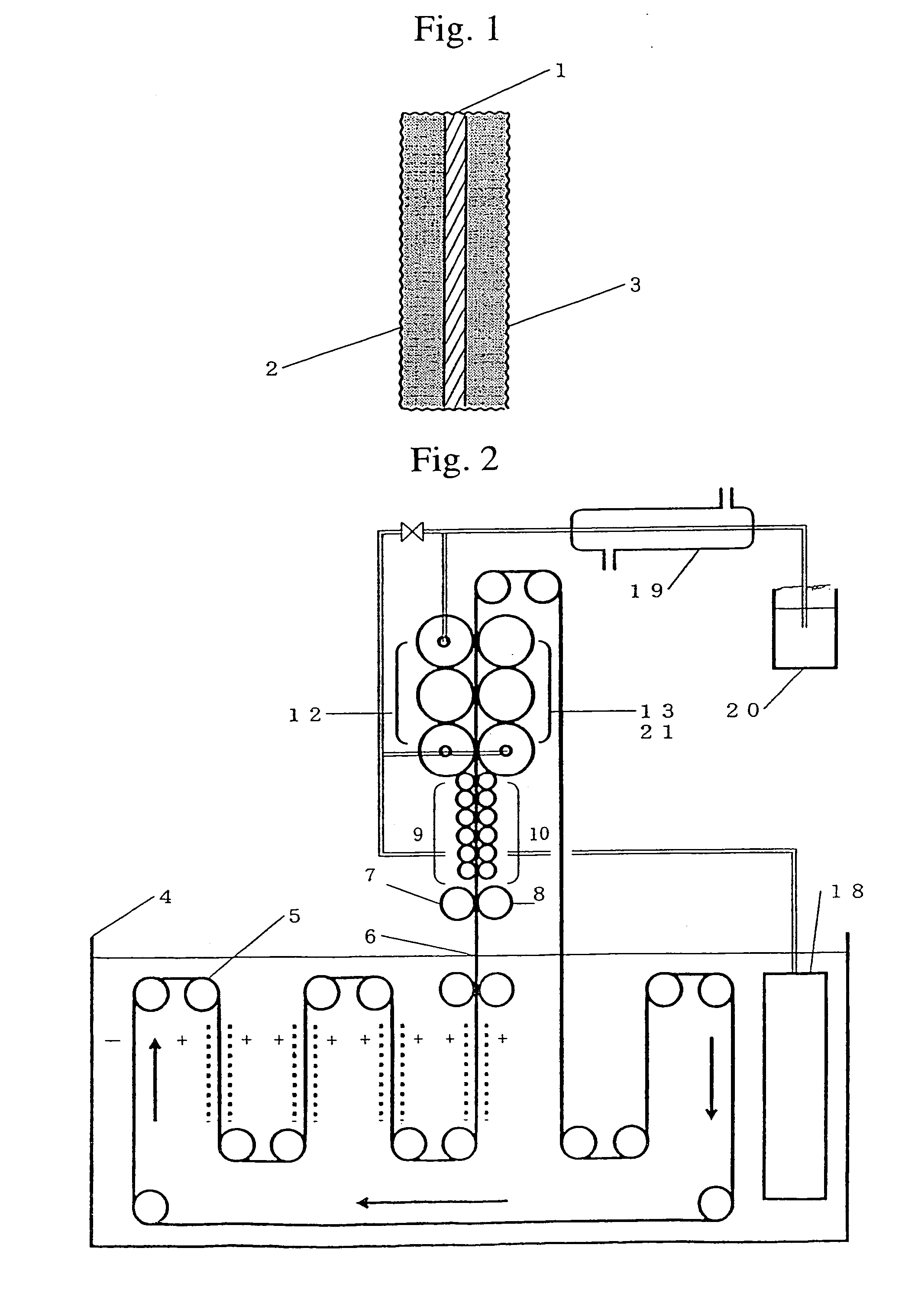

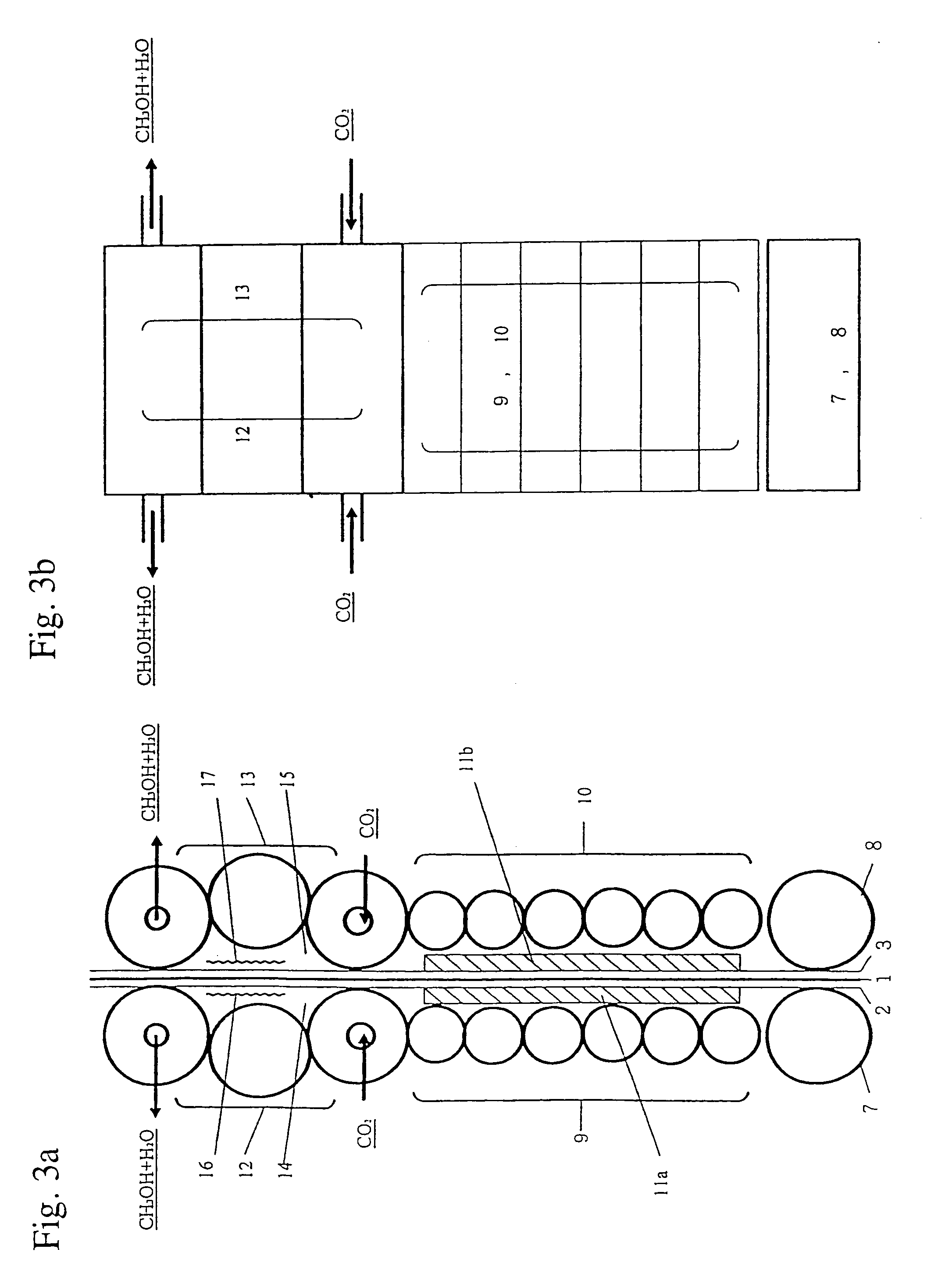

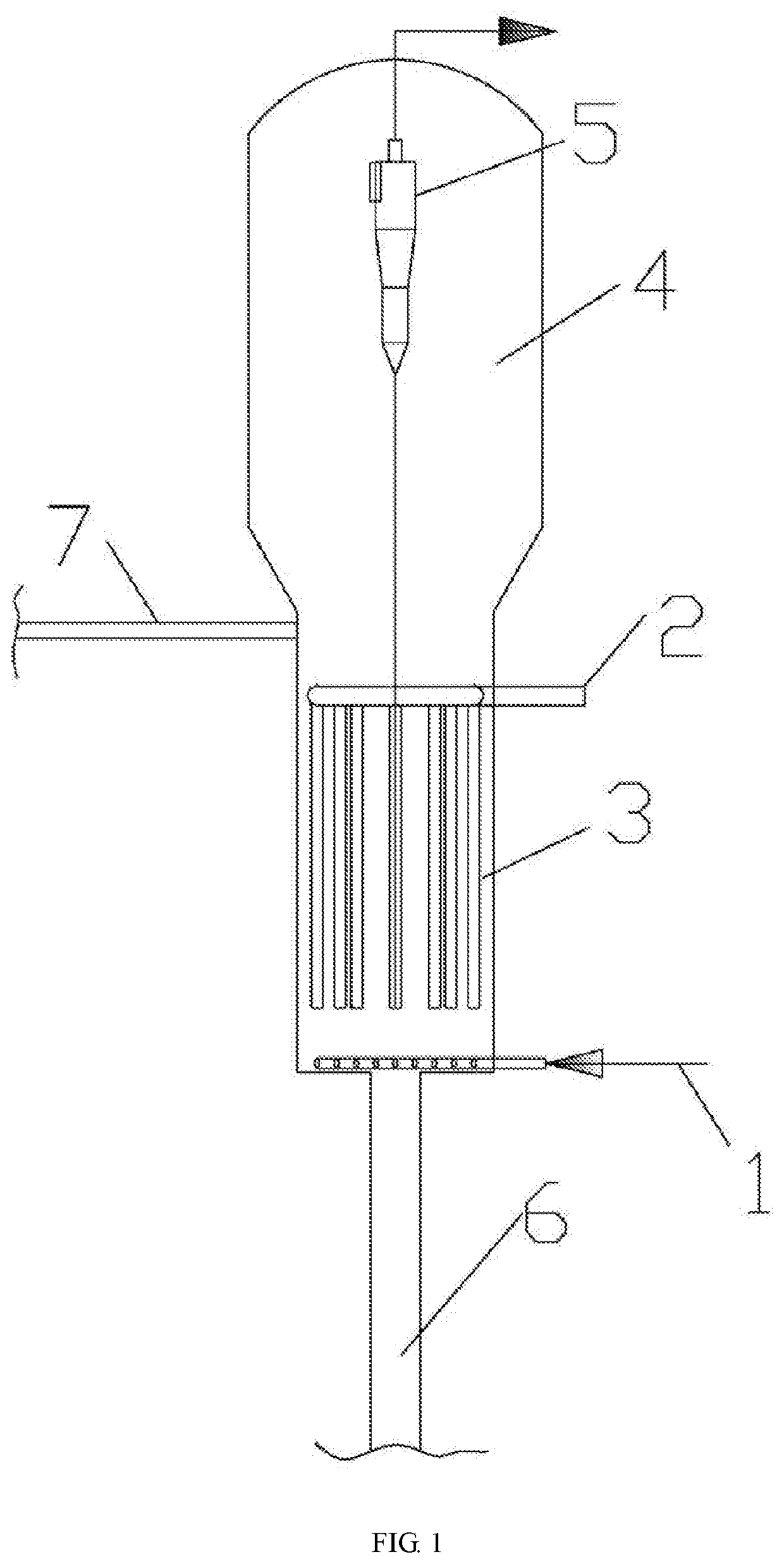

Method for hydrogenating carbon dioxide, treating apparatus, and basic material for hydrogenation

InactiveUS7064150B2Good effectAvoid small quantitiesElectrolysis componentsOrganic compound preparationElectrochemical responseHydrogen

A process for hydrogenating carbon dioxide to generate methanol. In the process, a strip of copper base plate is transported by the groups of rotating drive rollers to deposit porous metallic zinc on the copper base plate. Hydrogen is generated from the porous metallic zinc upon electrochemical reactions in the inner space sealed with the above groups of rollers. Simultaneously, zinc oxide and copper oxide catalysts are formed on the porous metallic zinc. Carbon dioxide is introduced into the sealed inner space under high-temperature and high-pressure to generate methanol by hydrogenation.

Owner:MATSUI

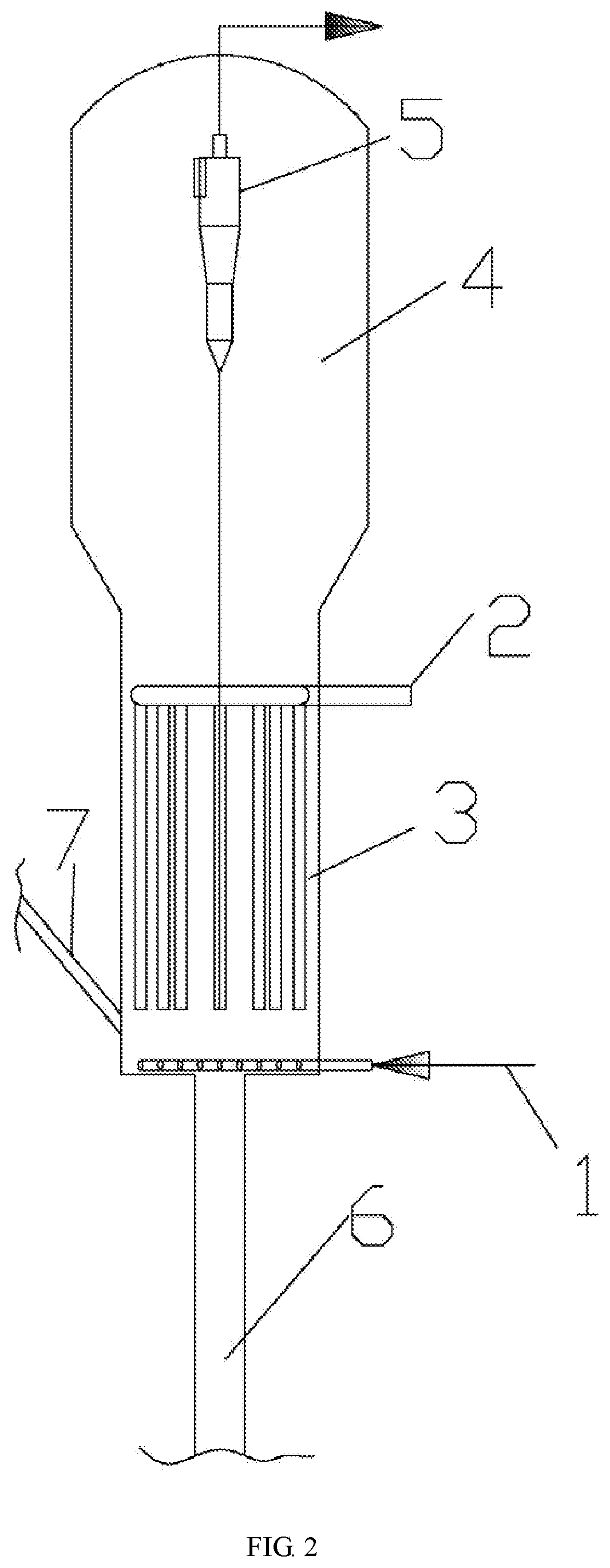

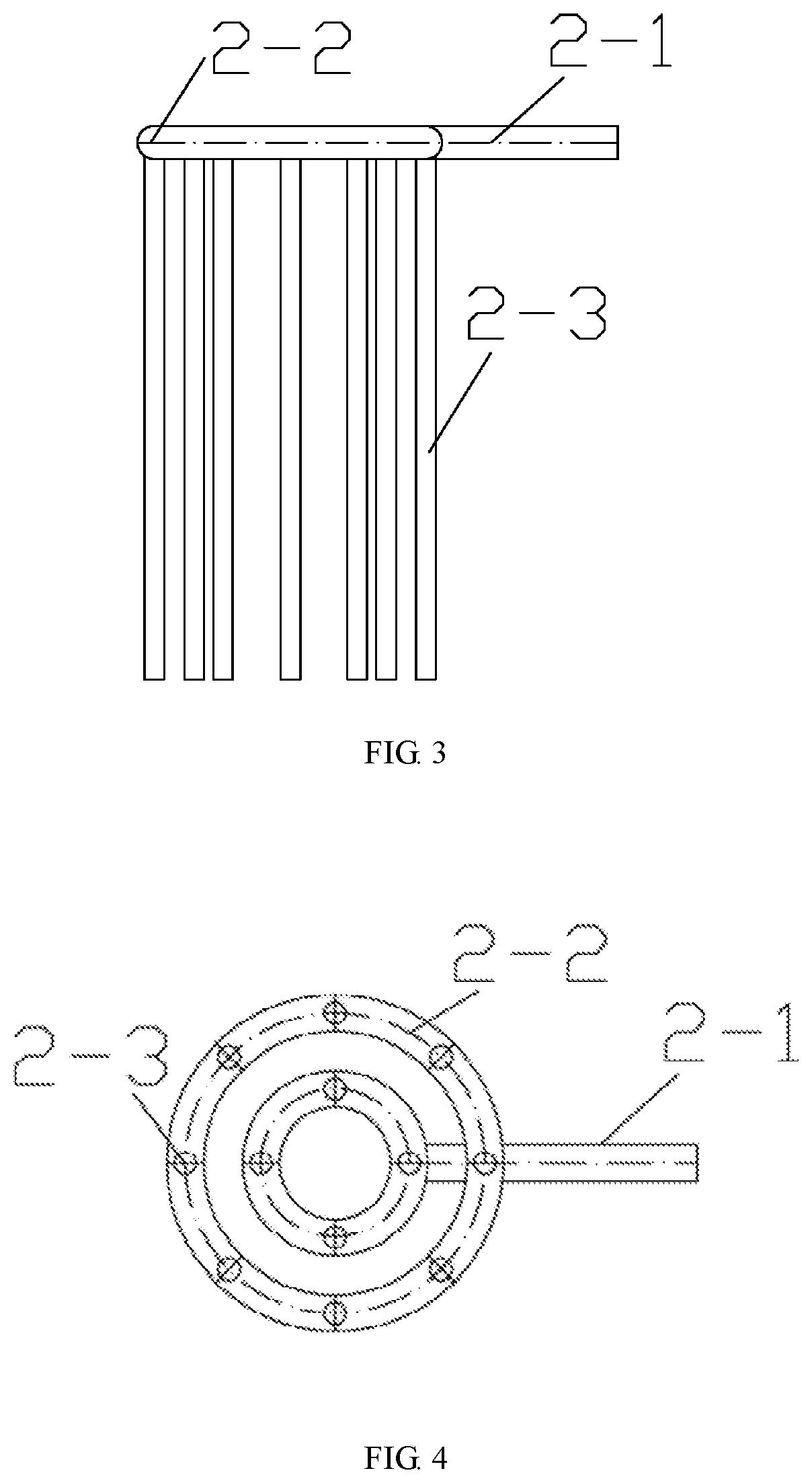

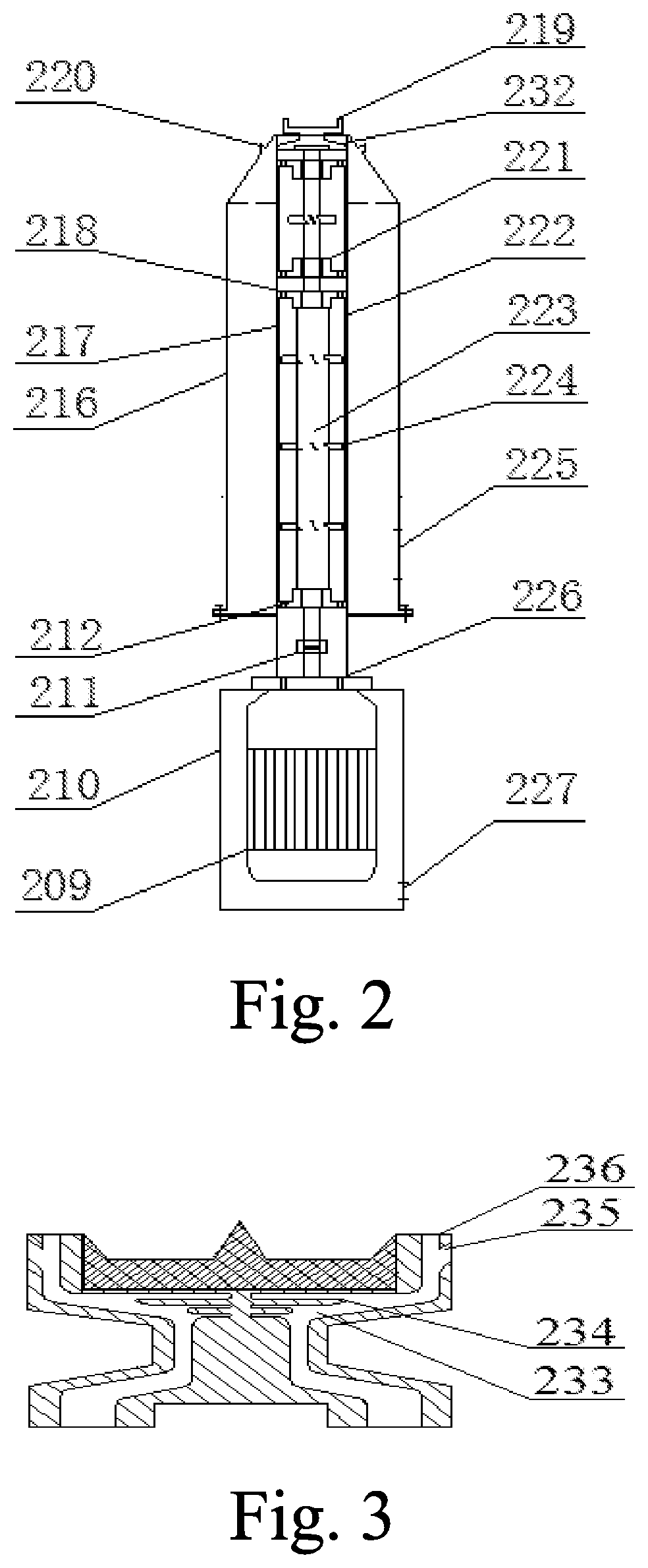

Fluidized bed gas distributor, reactor using fluidized bed gas distributor, and method for producing para-xylene and co-producing light olefins

ActiveUS20200188869A1Improve conversion rateSignificant differenceMolecular sieve catalystsMolecular sieve catalystPtru catalystFluidized bed

Disclosed are a fluidized bed gas distributor and a fluidized bed reactor, the fluidized bed reactor comprising a first distributor (1) and a second distributor (2), wherein the first distributor (1) is located at the bottom of a fluidized bed, and second distributor (2) is located downstream of a gas from the first distributor (1). Also disclosed is a method for producing a para-xylene and co-producing light olefins, the method comprising the following steps: material stream A enters a reaction zone (3) of a fluidized bed reactor from a first gas distributor (1); material stream B enters the reaction zone (3) of the fluidized bed reactor from a second gas distributor (2); and the reactants are brought into contact with a catalyst in the reaction zone (3) to generate a gas phase stream comprising para-xylene and light olefins.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Co-firing method of full-body ink-jet black golden flower full-polished bricks and common archaized bricks

Owner:广西蒙娜丽莎新材料有限公司

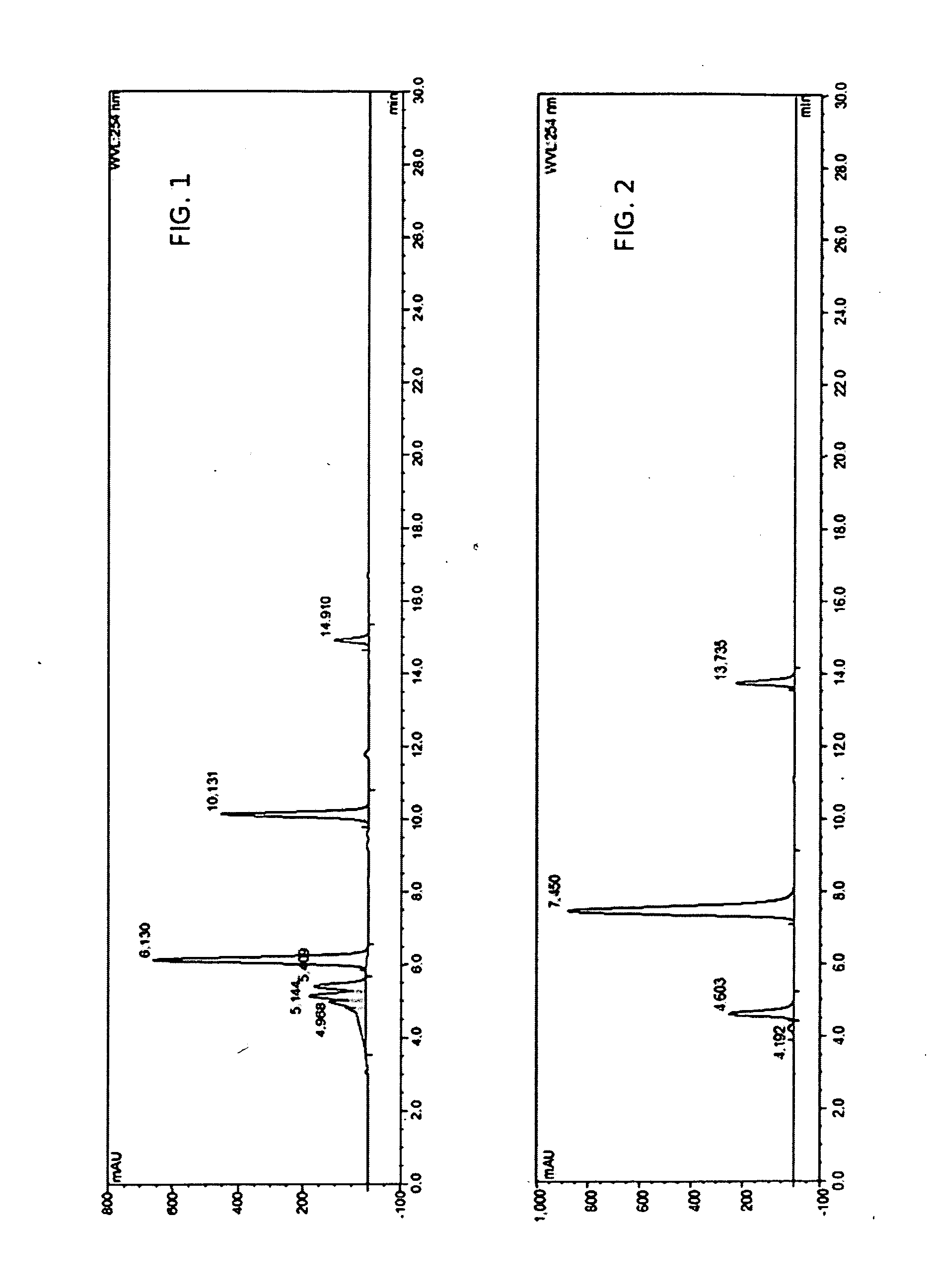

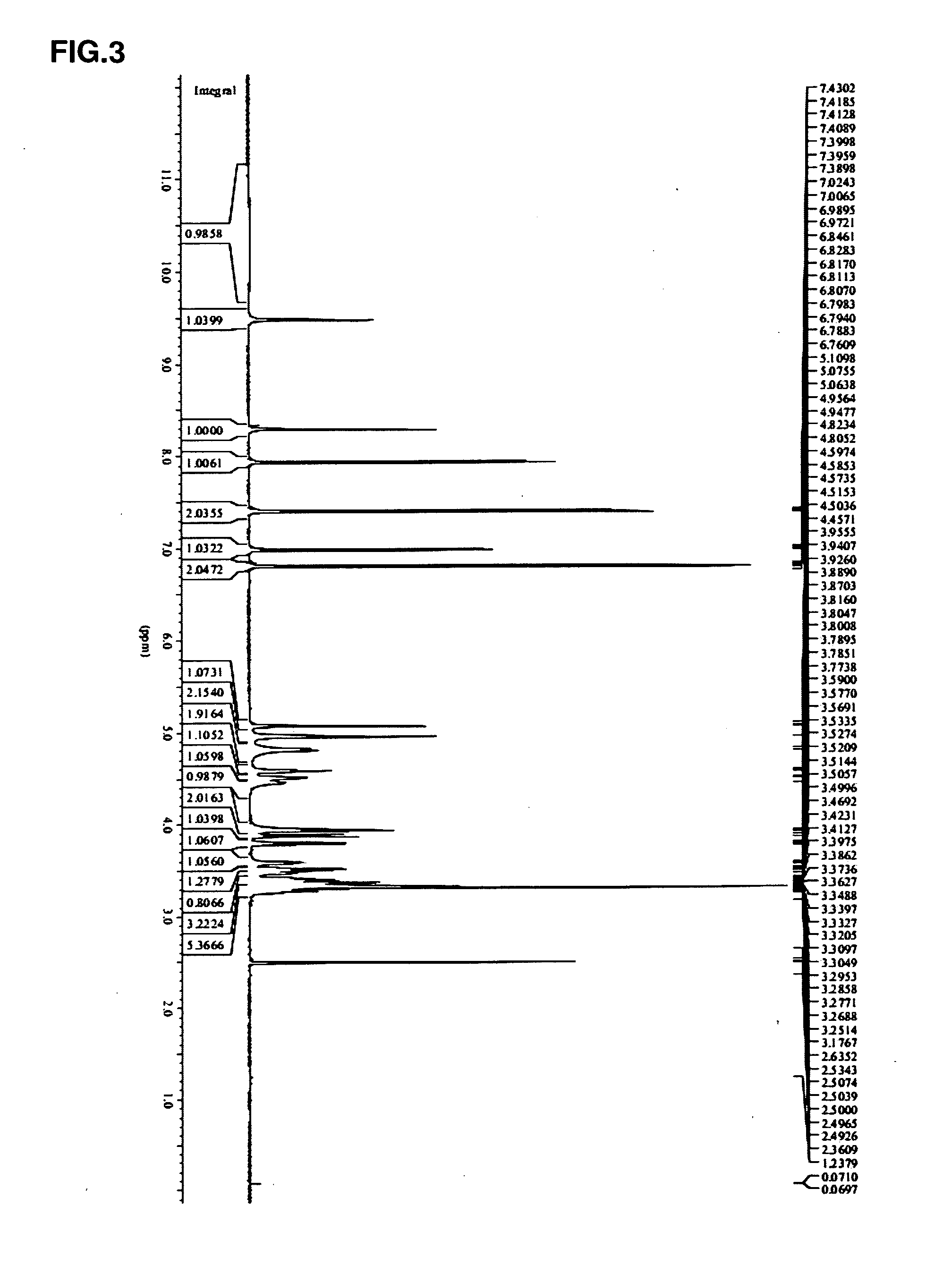

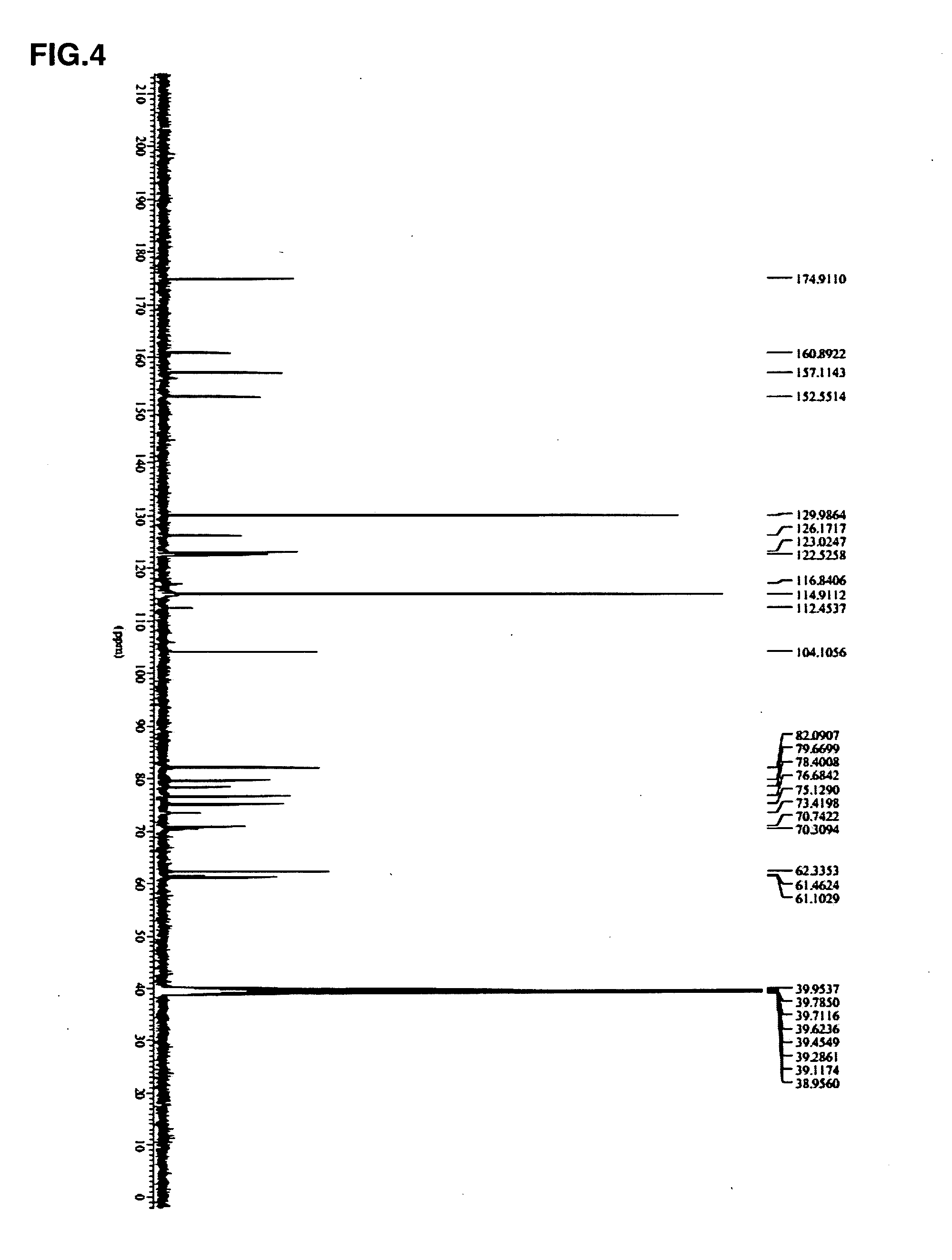

Fructosylated puerarin, and preparation method and use thereof

InactiveUS20130190266A1Easy to useExpand sourceBiocideSugar derivativesAcute myocardial ischaemiaPuerarin

Fructosylated puerarin being converted from puerarin by a bioconversion method conducted in an aqueous phase or nonaqueous phase system, including monofructosyl-(2,6)-puerarin, bifructosyl-(2,6)-puerarin, trifructosyl-(2,6)-puerarin, tetrafructosyl-(2,6)-puerarin and pentafructosyl-(2,6)-puerarin. Tests have shown that the oligosaccharylated puerarin is effective to treat acute myocardial ischemia, and can markedly suppress in vitro the proliferation of human breast cancer cell strain MDA-MB-23 and human chronmyelogenors leukemia cell strain K562, and it has a low toxicity.

Owner:BALLY GAMING INC +1

Supported catalyst and method for preparing light olefin using direct conversion of syngas

ActiveUS20210347710A1Promote activation and conversionImprove conversion rateHydrocarbon from carbon oxidesMolecular sieve catalystsSyngasPtru catalyst

A supported catalyst for preparing light olefin using direct conversion of syngas is a composite catalyst and formed by compounding component I and component II in a mechanical mixing mode. The active ingredient of component I is a metal oxide; and the component II is a supported zeolite. A carrier is one or more than one of hierarchical pores Al2O3, SiO2, TiO2, ZrO2, CeO2, MgO and Ga2O3; the zeolite is one or more than one of CHA and AEI structures; and the load of the zeolite is 4%-45% wt. A weight ratio of the active ingredients in the component I to the component II is 0.1-20. The reaction process has an extremely high light olefin selectivity; the sum of the selectivity of the light olefin comprising ethylene, propylene and butylene can reach 50-90%, while the selectivity of a methane side product is less than 7%.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Heat-resistant aluminum hydroxide and method for preparation thereof

ActiveUS8138255B2High dehydration temperatureImprove flame retardant performanceCircuit susbtrate materialsAluminium oxides/hydroxidesAluminium hydroxideHeat treated

A heat-resistant aluminum hydroxide which is prepared by subjecting a mixture of aluminum hydroxide with a reaction retardant for retarding the conversion aluminum hydroxide to boehmite, as a raw material, to the hydrothermal treatment or to pressurization and heating in a steam atmosphere; and a method for preparing a heat-resistant aluminum hydroxide which comprises subjecting a mixture of aluminum hydroxide with a reaction retardant for retarding the conversion aluminum hydroxide to boehmite as a raw material to the hydrothermal treatment, or to pressurization and heating in a steam atmosphere.

Owner:KAWAI LIME IND

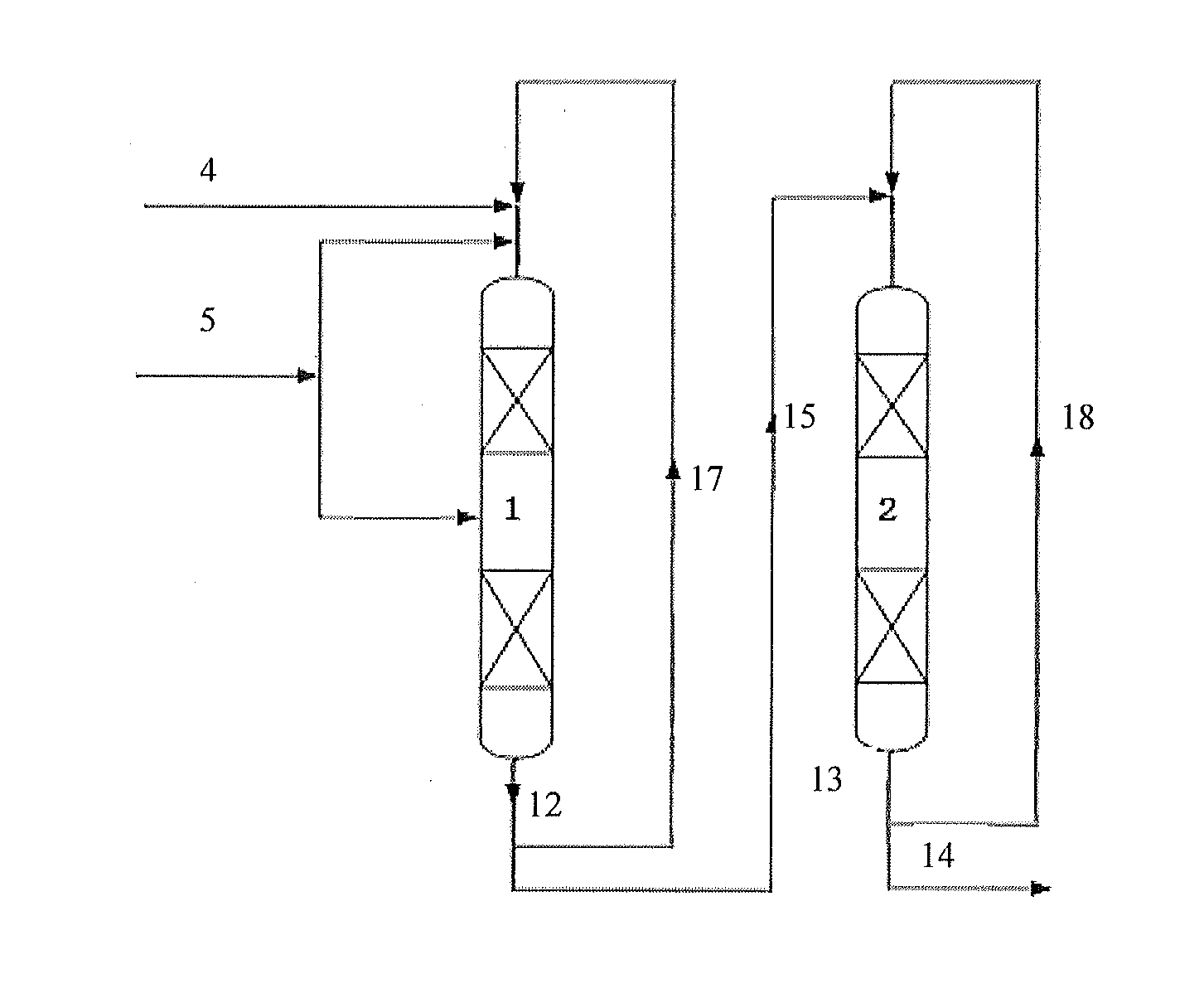

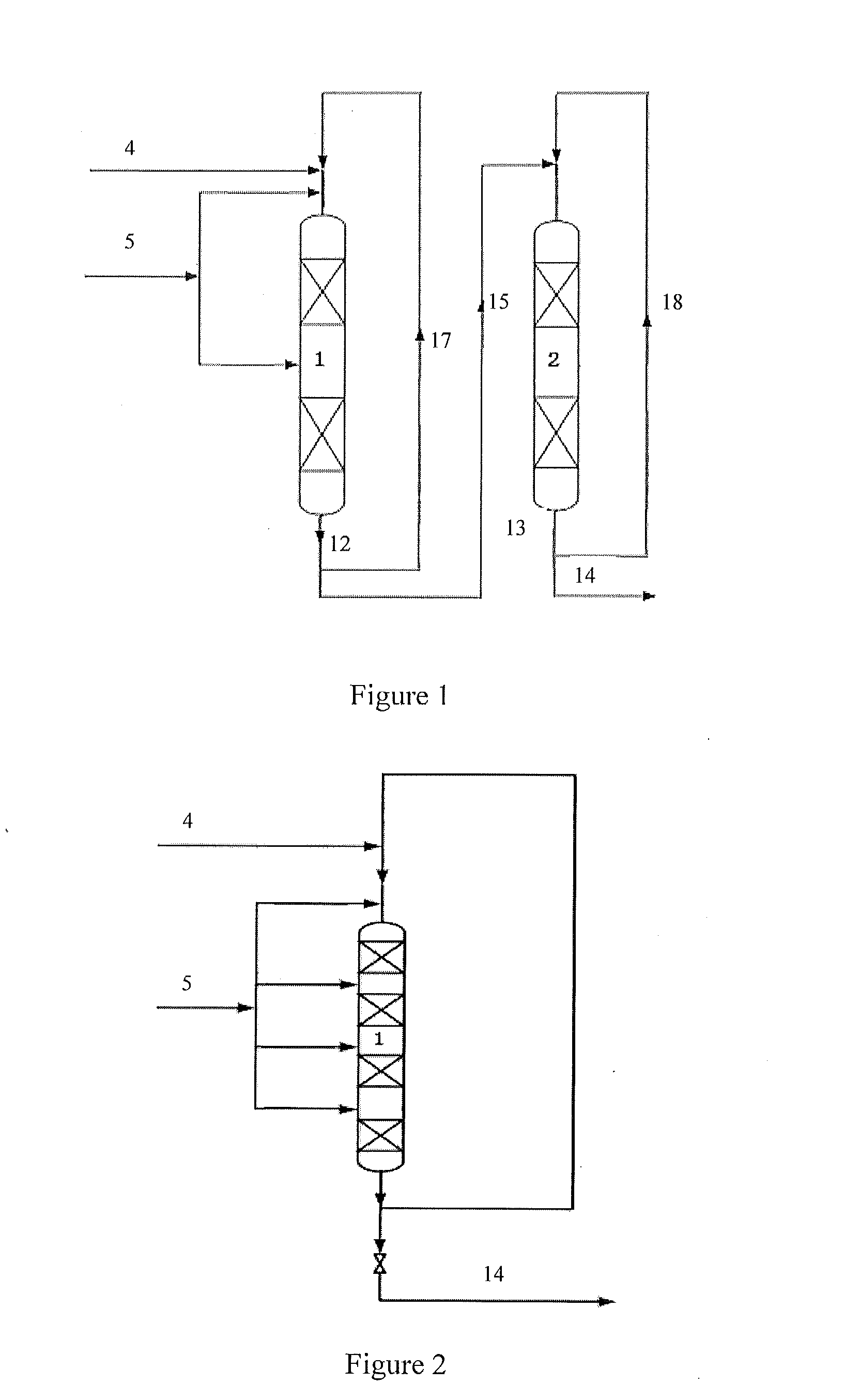

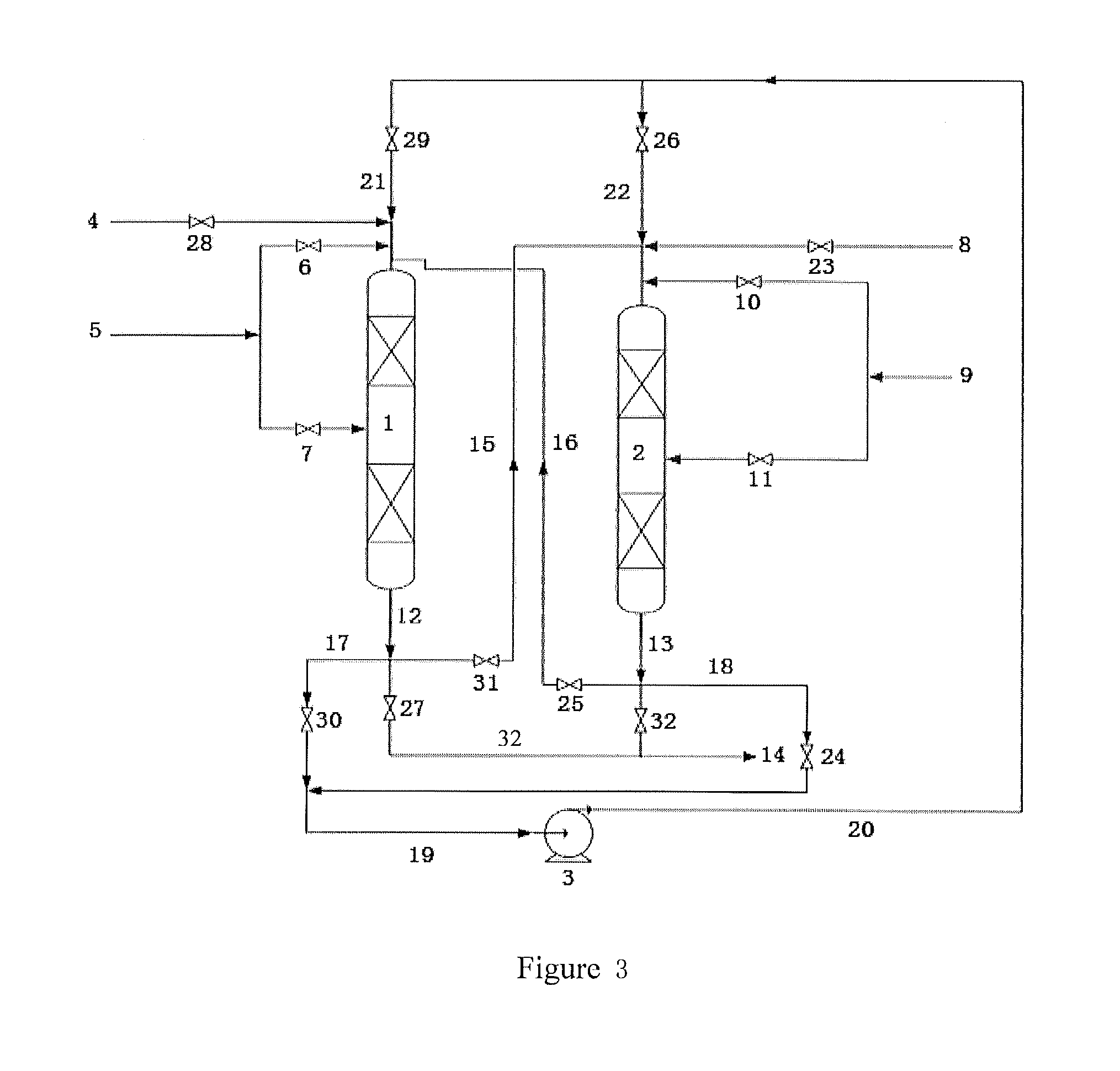

Method for producing isopropyl benzene from benzene and propylene

ActiveUS20150119619A1Improve technical effectReduce contentMolecular sieve catalystsMolecular sieve catalystReaction zoneAlkylation

A method for producing isopropyl benzene includes the following steps. Step A: feeding a first stream containing benzene and a first stream containing propylene into a first reaction zone to contact a first catalyst for alkylation, and obtaining a first stream containing isopropyl benzene from the first reaction zone, dividing the first stream containing isopropyl benzene into a stream Ia and a stream IIa, the stream Ia circulating back into the first reaction zone and the stream IIa entering into a second reaction zone, having the stream entering the second reaction zone to contact a second catalyst for alkylation, and obtaining a second stream containing isopropyl benzene from the second reaction zone, and purifying at least a partial stream IIIa of the second stream containing isopropyl benzene, and obtaining a product isopropyl benzene.

Owner:CHINA PETROCHEMICAL CORP +1

Process for producing dicarboxylic acids

InactiveUS7015356B2Increased space-time yieldLow conversion rateOrganic compound preparationCarboxylic preparation by oxidationReaction temperatureCarboxylic acid

A carboxylic acid is produced by oxidative cleavage of a cycloalkane with oxygen and performs a reaction in the presence of a catalyst including an imide compound and a metallic compound, the imide compound having a cyclic imide skeleton represented by the following Formula (I): wherein X is an oxygen atom or an —OR group, and wherein R is a hydrogen atom or a hydroxyl-protecting group, under conditions of a reaction temperature of 80° C. or higher and a concentration of the cycloalkane of 21% by weight or more.

Owner:DAICEL CHEM IND LTD

Process for one-pot liquefaction of biomass or coal and biomass

ActiveUS20190359892A1Low conversion rateHigh energy consumptionLiquid carbonaceous fuelsLiquid hydrocarbon mixture productionHydrogenSlurry

Disclosed is a process for the one-pot liquefaction of a biomass or coal and a biomass, the process comprising: first preparing a slurry containing a catalyst, a vulcanizing agent and a biomass (and coal), and then introducing hydrogen gas into the slurry to carry out a reaction. Preparing the slurry comprises: subjecting a biomass (and coal) sequentially to drying, a first pulverization, compression and a second pulverization, then mixing same with a catalyst and a vulcanizing agent to obtain a mixture, and adding the mixture to an oil product for grinding and pulping to obtain a biomass slurry. By means of the treatment process of subjecting the straw firstly to compression and then to a second pulverization, the volume of the straw is greatly reduced, thereby facilitating the dispersion thereof in the oil product, increasing the concentration of the reaction material, and improving the delivery amount of the biomass per unit time by means of a pump; Furthermore, the conversion rate of the biomass is also improved.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Fluidized bed gas distributor, reactor using fluidized bed gas distributor, and method for producing para-xylene and co-producing light olefins

ActiveUS10967350B2Improve conversion rateSignificant differenceMolecular sieve catalystsMolecular sieve catalystPtru catalystFluidized bed

Disclosed are a fluidized bed gas distributor and a fluidized bed reactor, the fluidized bed reactor comprising a first distributor (1) and a second distributor (2), wherein the first distributor (1) is located at the bottom of a fluidized bed, and second distributor (2) is located downstream of a gas from the first distributor (1). Also disclosed is a method for producing a para-xylene and co-producing light olefins, the method comprising the following steps: material stream A enters a reaction zone (3) of a fluidized bed reactor from a first gas distributor (1); material stream B enters the reaction zone (3) of the fluidized bed reactor from a second gas distributor (2); and the reactants are brought into contact with a catalyst in the reaction zone (3) to generate a gas phase stream comprising para-xylene and light olefins.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

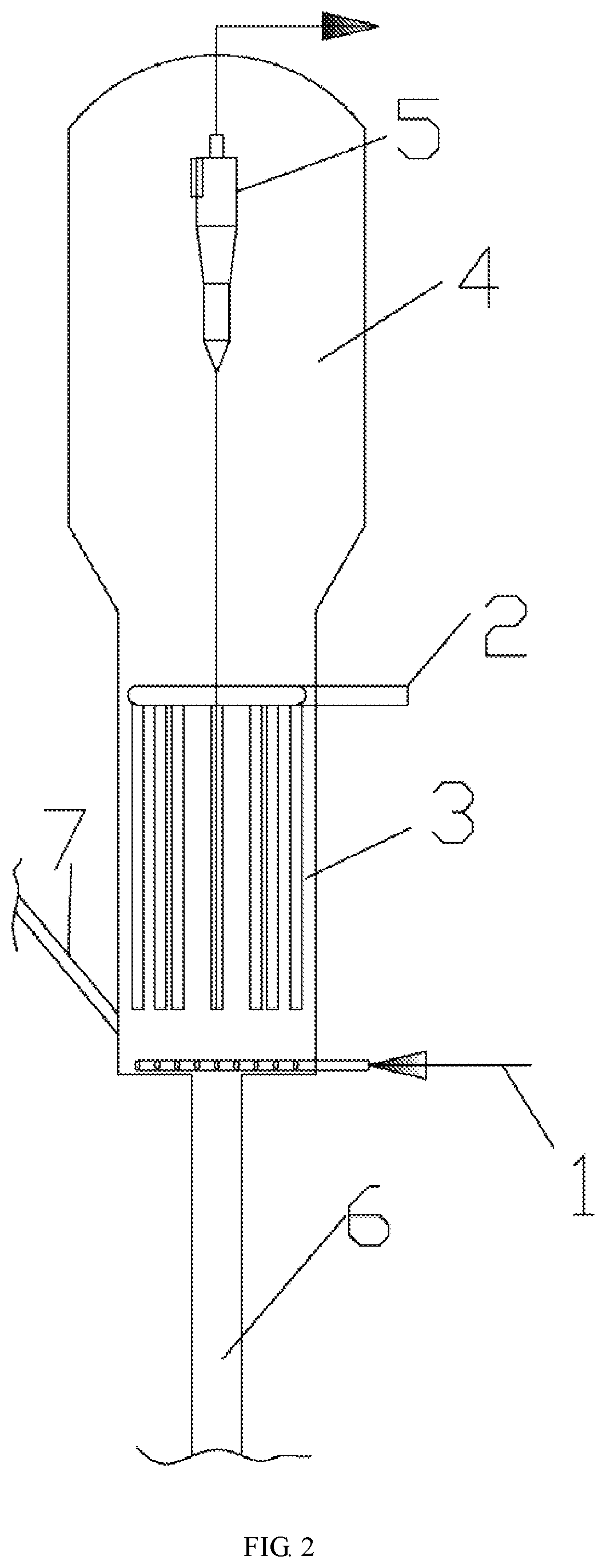

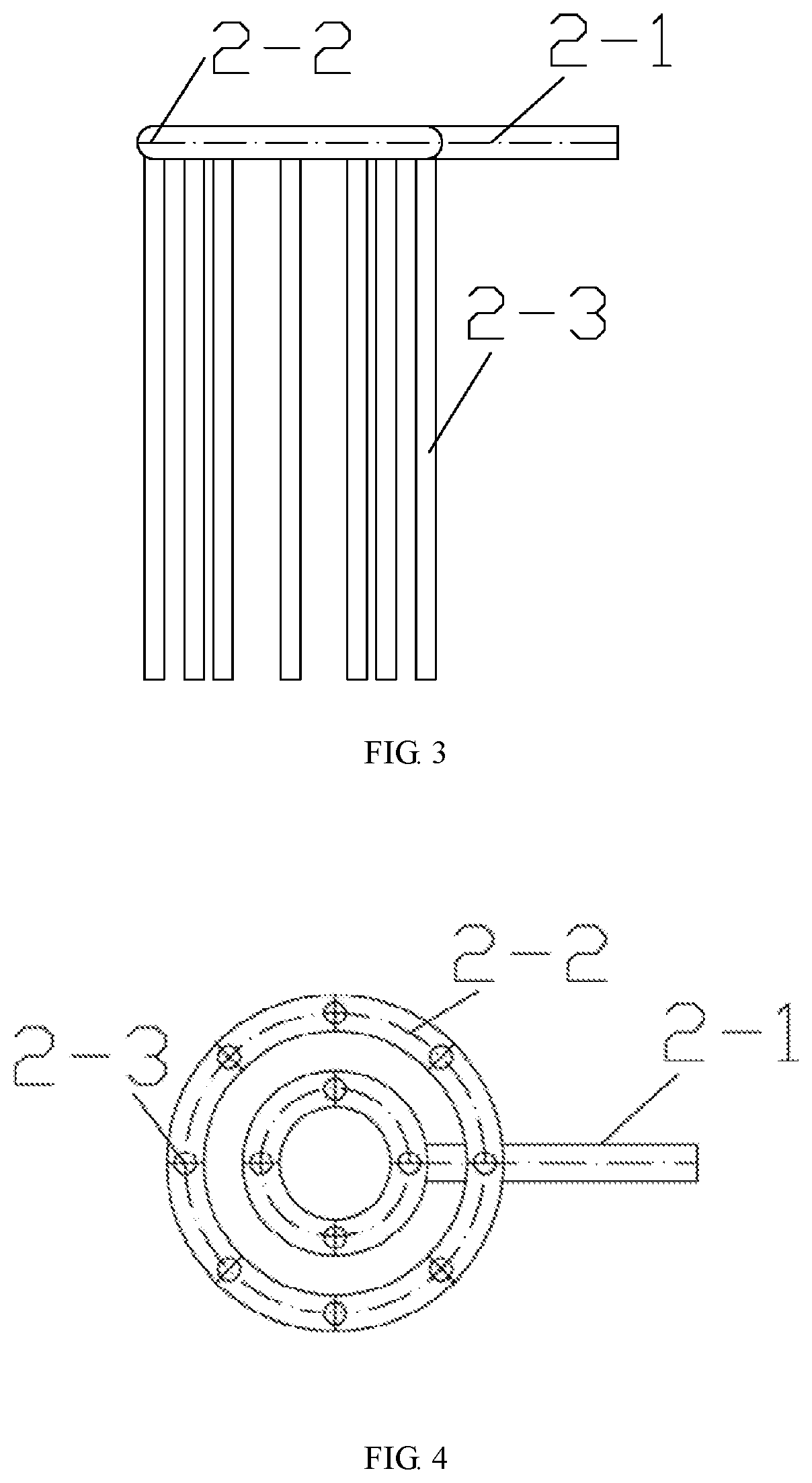

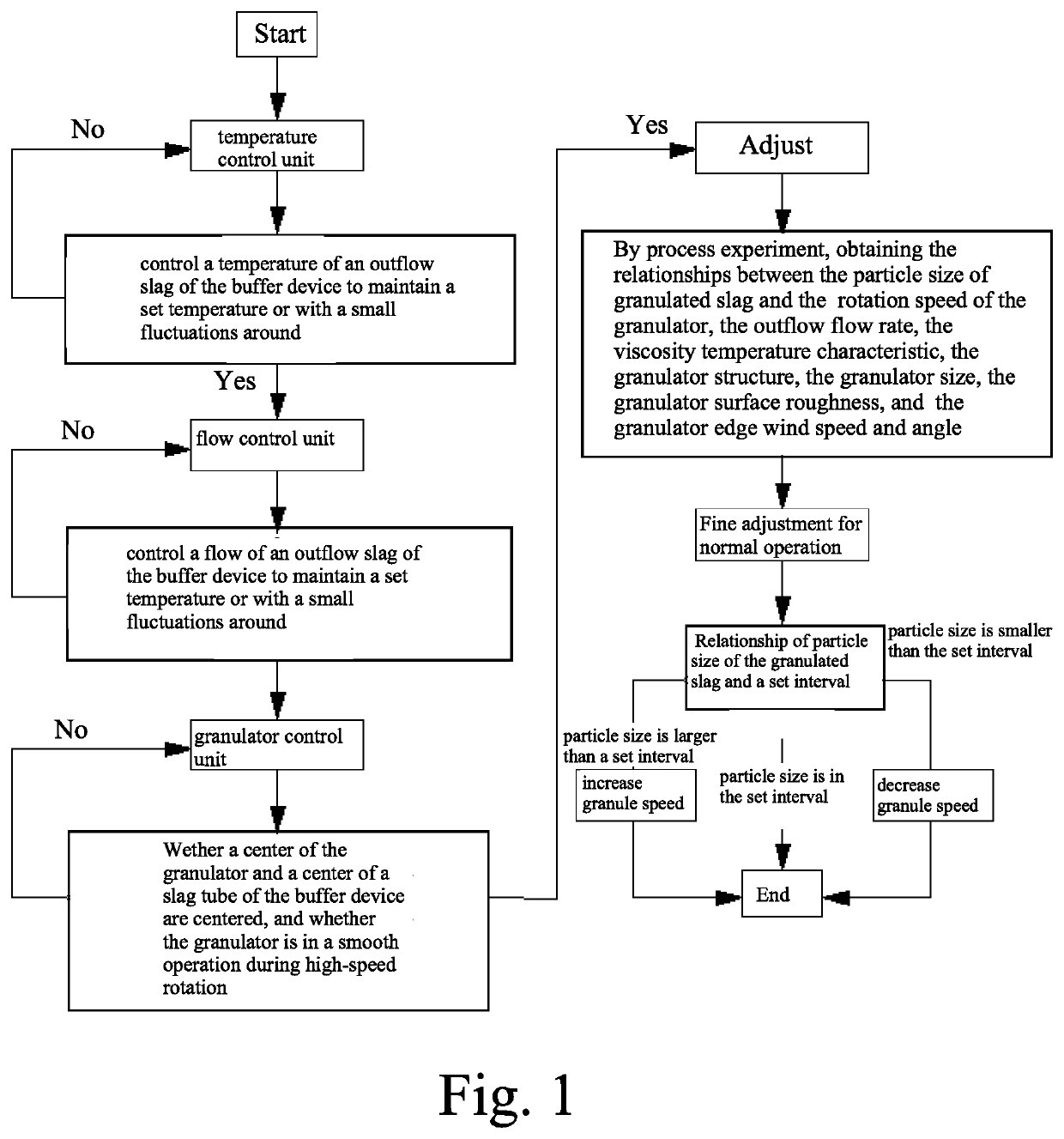

Method for controlling particle size of dry centrifugal granulated slag particles from liquid slag

InactiveUS20200208230A1Lower conversion rateLow rate of transitionRecycling and recovery technologiesTemperature controlLiquid slag

A method for controlling a particle size of dry centrifugal granulated slag from liquid slag, which is based on a dry centrifugal granulation system for liquid slag, wherein the dry centrifugal granulation system for the liquid slag includes: a temperature control unit, a flow control unit, and a granulator control unit; wherein the temperature control unit is configured to control a high-temperature slag in the liquid slag buffer device to maintain a first set temperature range, and control a temperature of an outflow slag of the buffer device to maintain a second set temperature range; a flow control unit configured to control a flow rate of the high-temperature slag flowing out of the buffer device in a set range to ensure smoothness of the flow; a granulator control unit configured to ensure a smooth operation of the granulator during high-speed rotation.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com