Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

469results about How to "Low structural requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

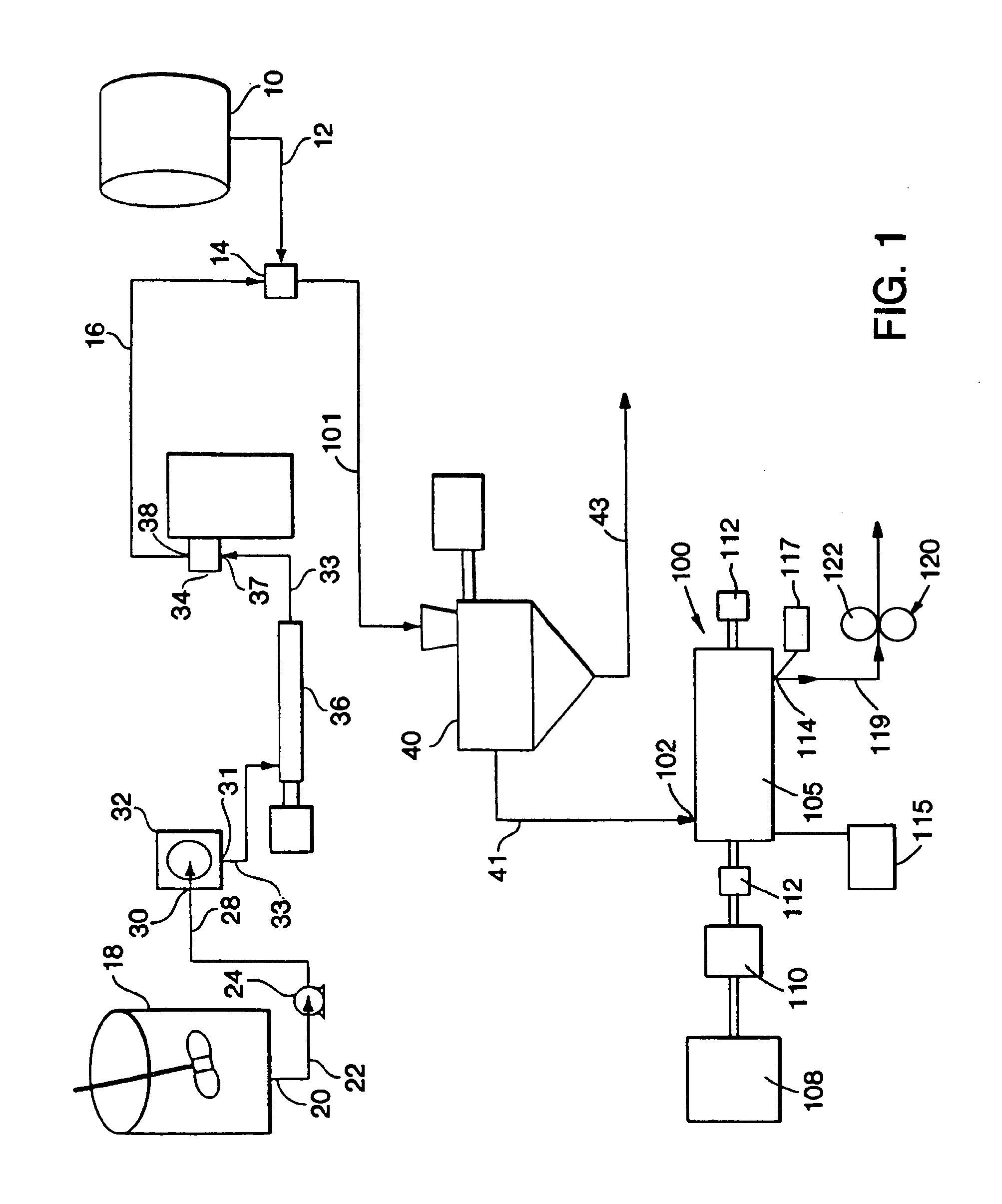

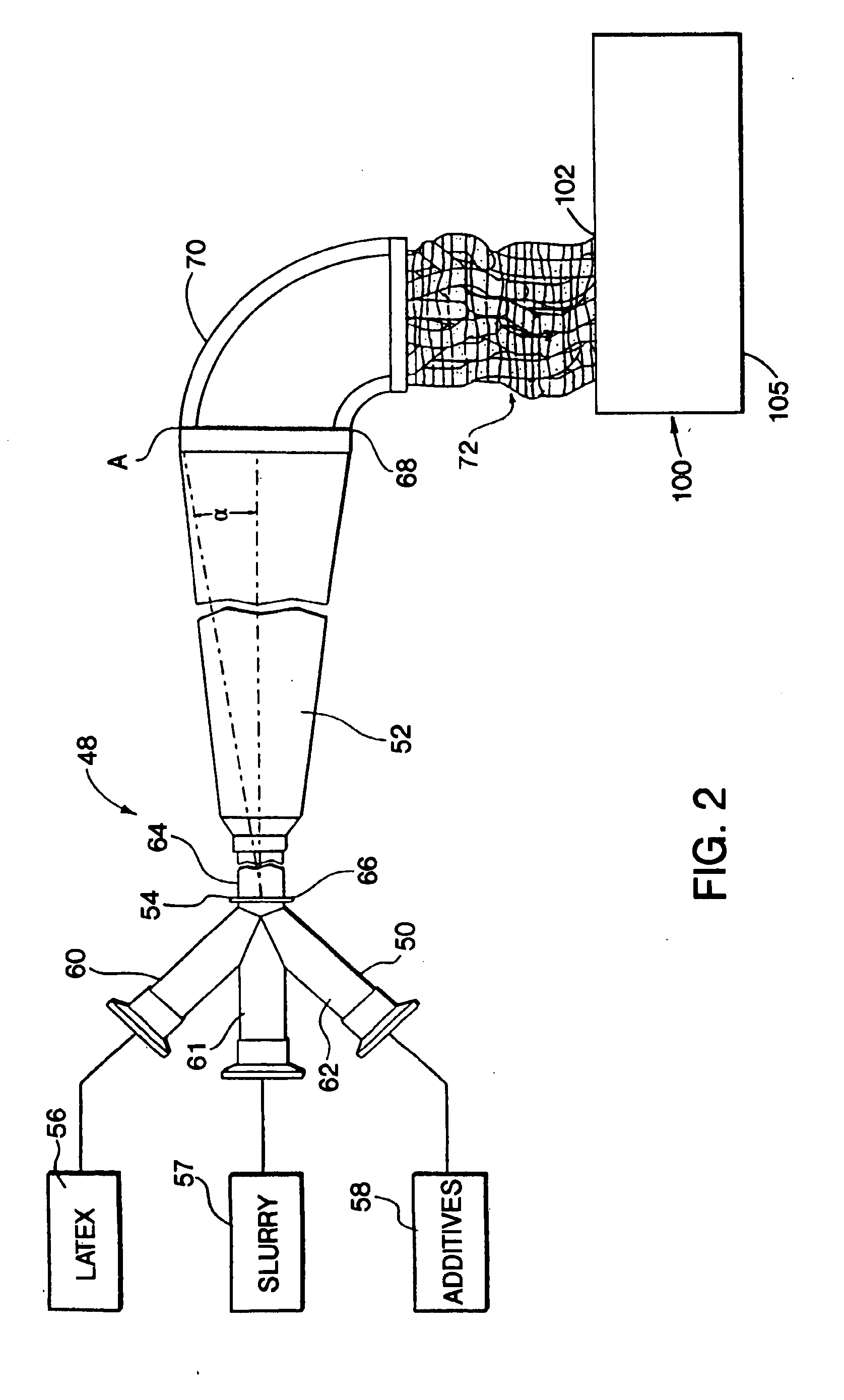

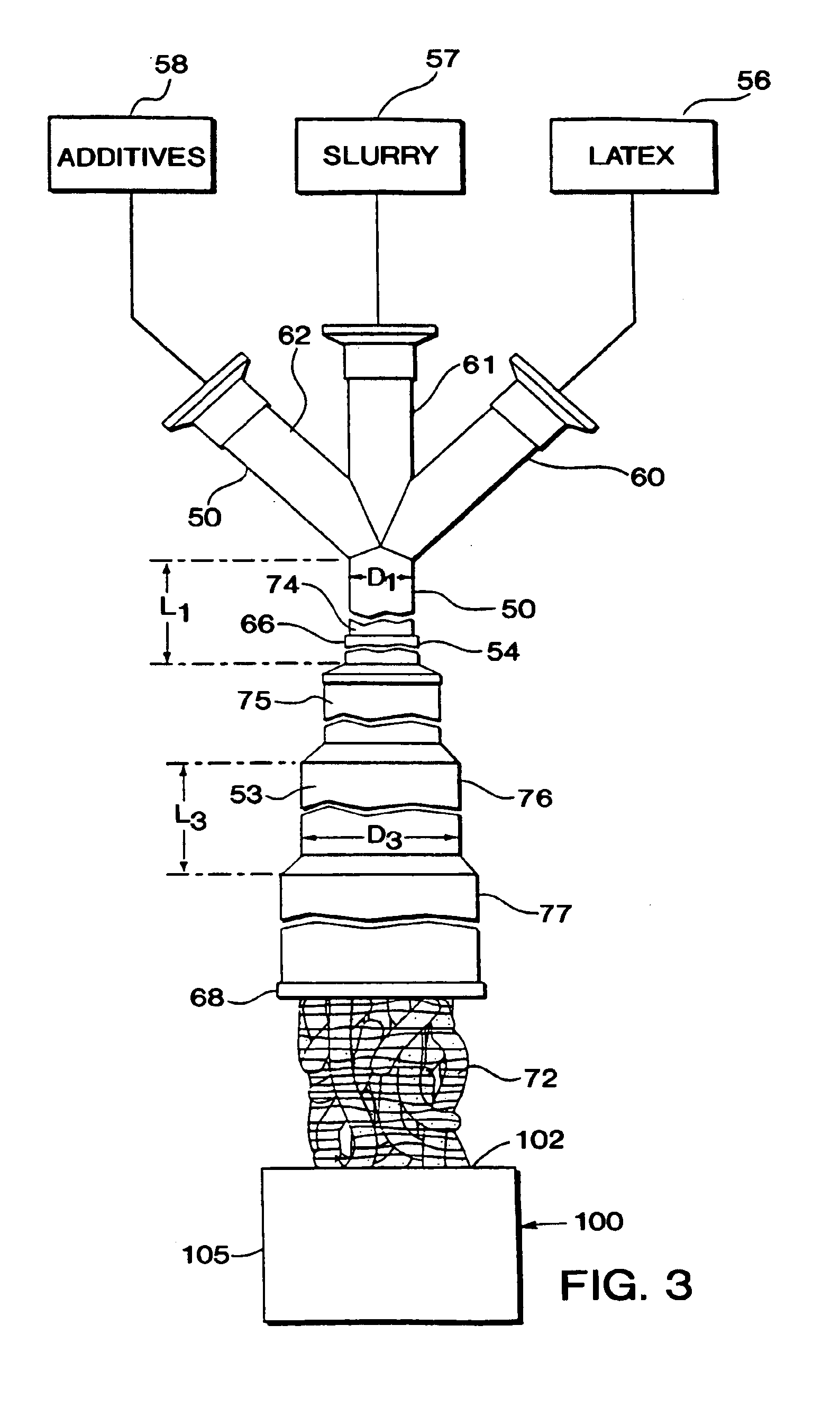

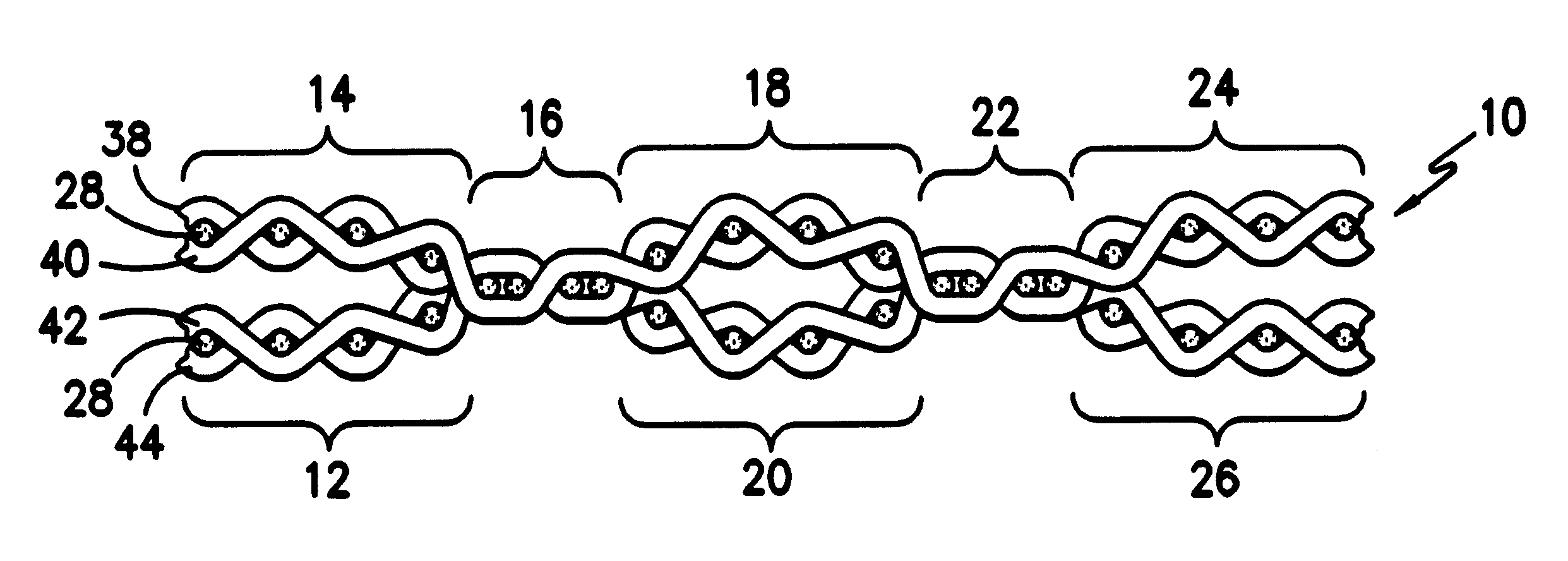

Method and apparatus for producing and treating novel elastomer composites

InactiveUS6929783B2Facilitate controlling and changing operating parameterImprove economyLiquid degasificationSpecial tyresParticulatesMasterbatch

Elastomer masterbatch is processed in a continuous compounder having multiple parallel elongate rotors axially oriented in an elongate processing chamber. Optionally, additional materials are compounded into the masterbatch, e.g., additives, other elastomeric compositions, etc. Preferably, the masterbatch then is further processed in an open mill. Excellent control of Mooney Viscosity is achieved.In certain preferred embodiments, elastomer composites are produced by novel continuous flow methods and apparatus in which fluid streams of particulate filler and elastomer latex are fed to the mixing zone of a coagulum reactor to form a coagulated mixture in semi-confined flow continuously from the mixing zone through a coagulum zone to a discharge end of the reactor. The particulate filler fluid is fed under high pressure to the mixing zone, such as to form a jet stream to entrain elastomer latex fluid sufficiently energetically to substantially completely coagulate the elastomer with the particulate filler prior to the discharge end without need of adding acid or salt solution or other coagulation step. The coagulated elastomer and particulate filler composite is fed into the aforesaid continuous compounder for processing and control of its moisture level and Mooney Viscosity. Novel elastomer composites are produced. Such novel elastomer composites combine material properties and characteristics, such as choice of filler, elastomer, level of filler loading, moisture level, Mooney Viscosity, balance between molecular weight and amount of bound rubber, and macro-dispersion not previously achieved.

Owner:CABOT CORP

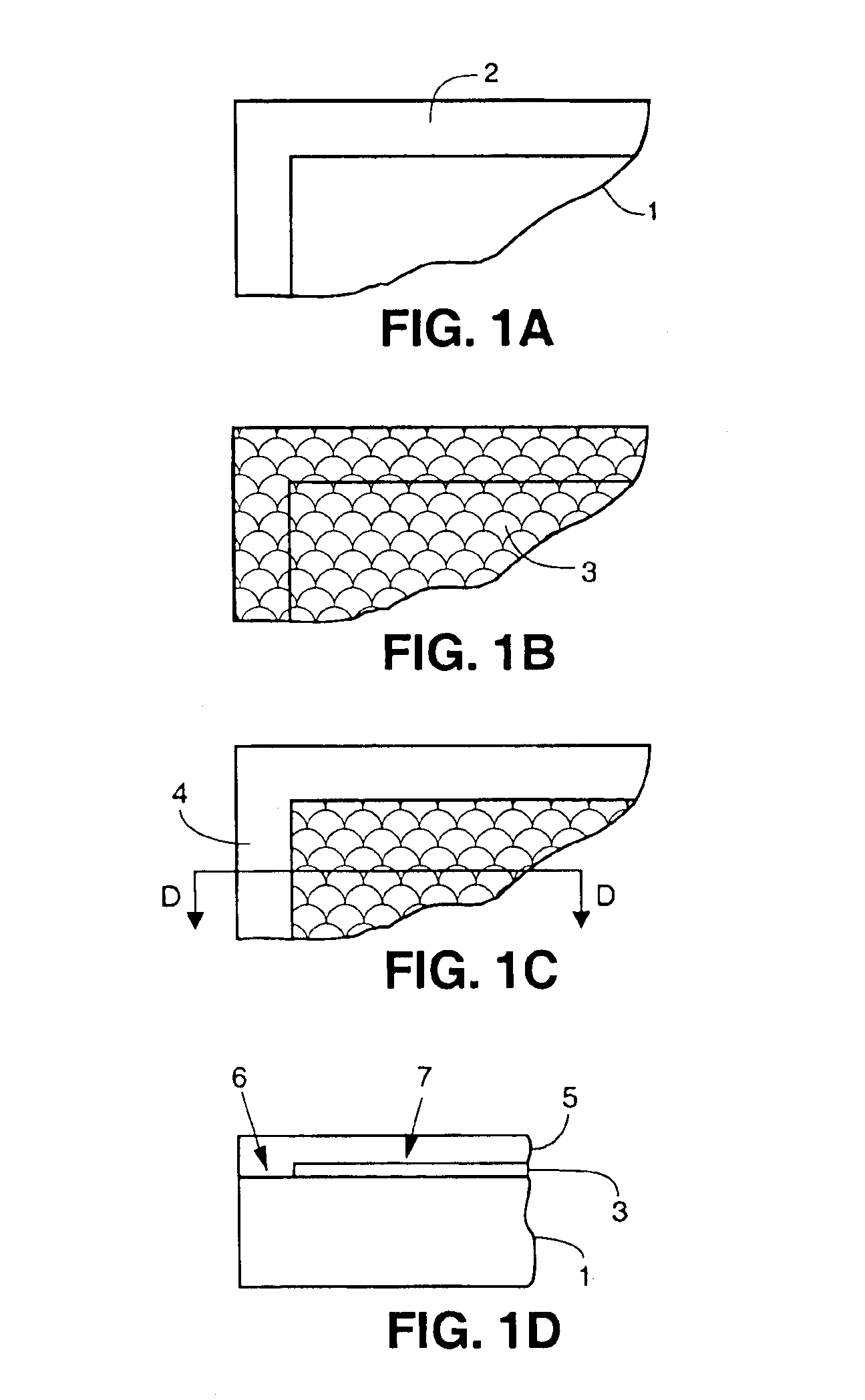

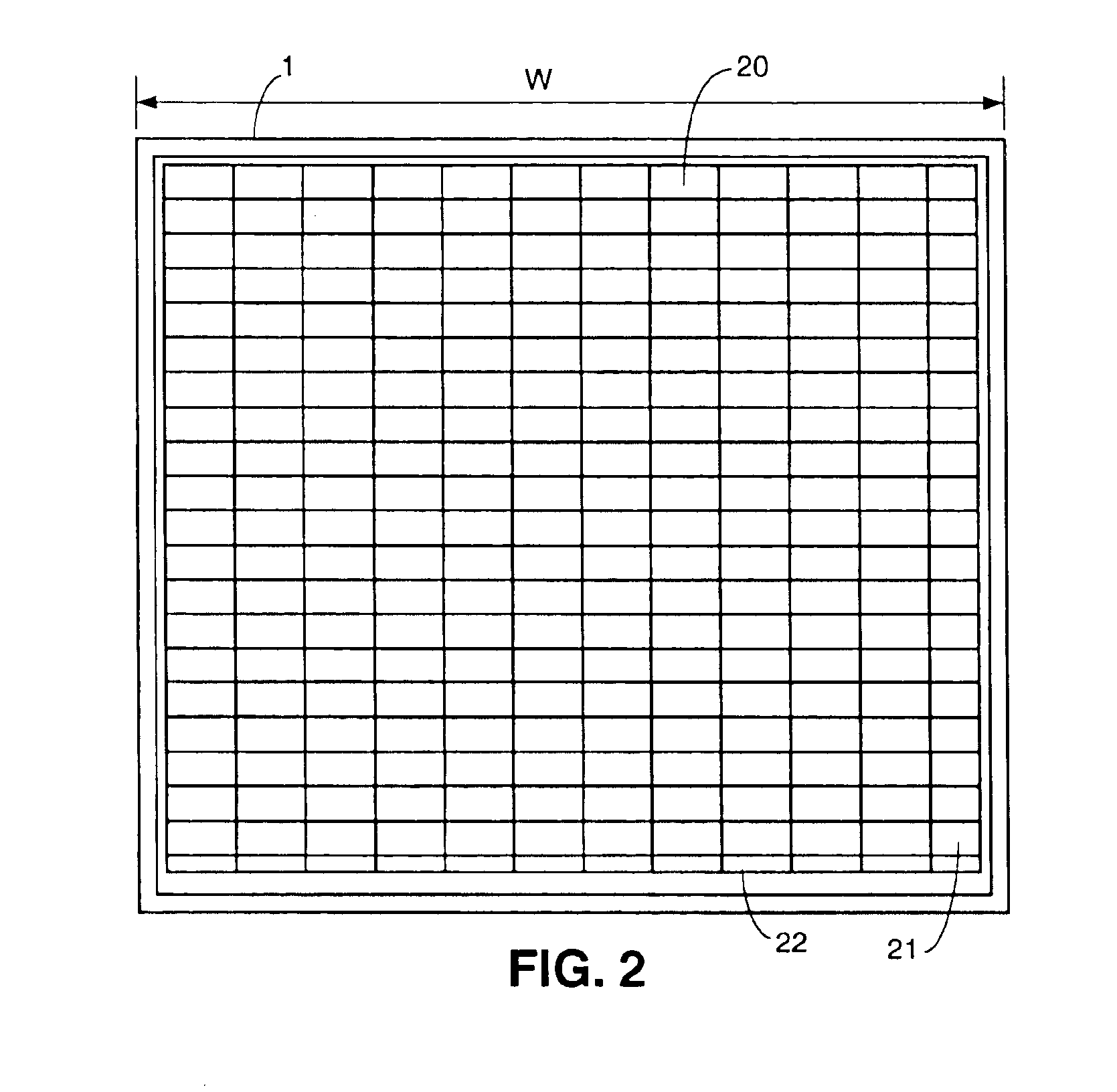

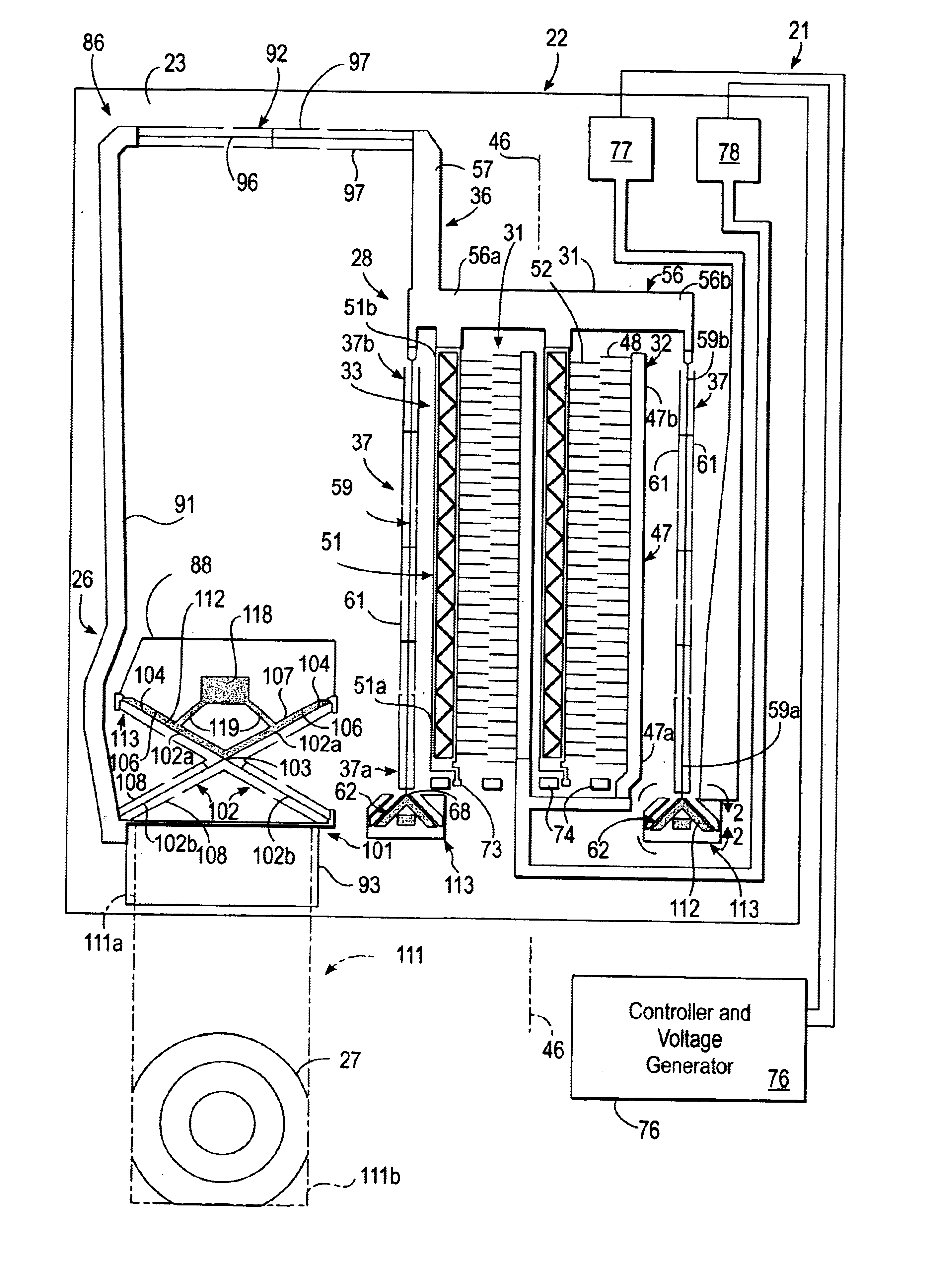

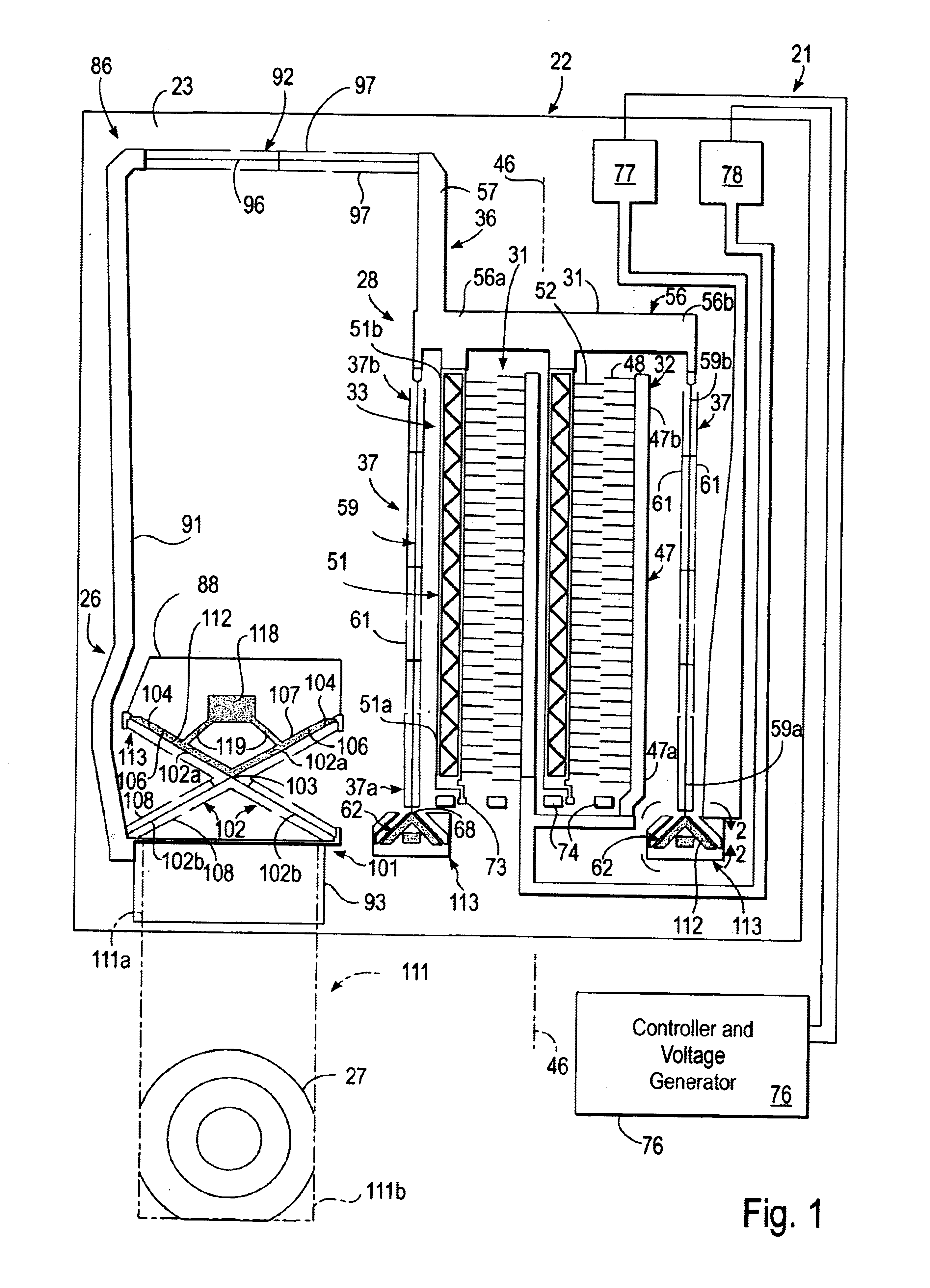

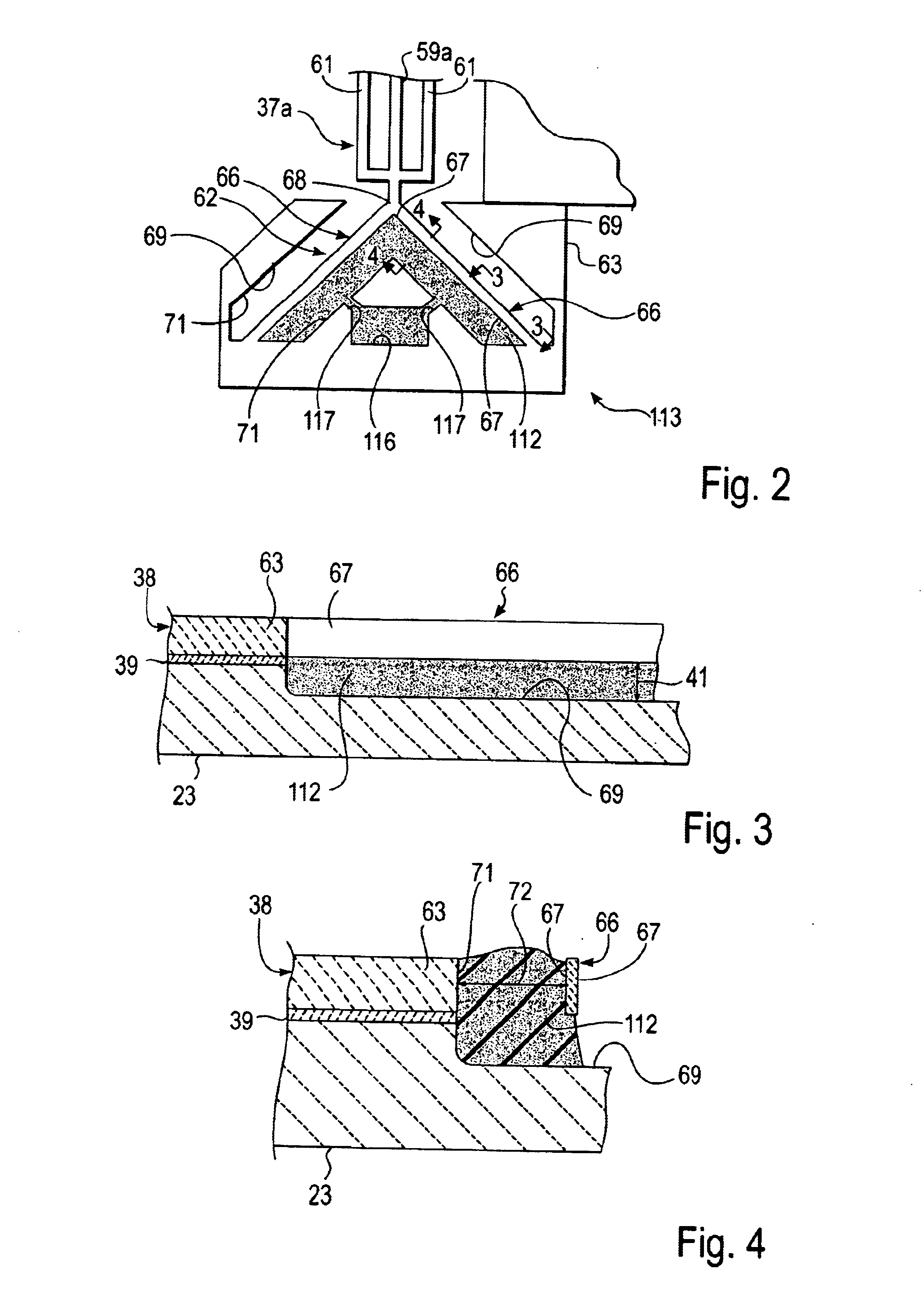

Component connections using bumps and wells

InactiveUS6881609B2Conveniently formedAccurate locationPrinted circuit assemblingFinal product manufactureHigh densityInterconnection

This specification describes techniques for fabricating connections between pairs of components. Each connection includes an array of bumps on a male component, and a matching array of wells filled with bonding material on a female component. The bump / well connections can be spaced with a pitch of less than 100 microns. One application of the invention is the attachment of electronic components to interconnection circuits or circuit assemblies to form electronic modules. The electronic components may be IC chips or high-density interconnect cables. Another application is alignment of optical components. The direct chip attachment techniques are described in the context of fabrication, assembly, test, rework, and cooling of electronic modules employing flip chip components. The preferred method is to fabricate the module on a glass carrier using a release layer so that the carrier can be removed after most of the processing is done.

Owner:SK HYNIX INC

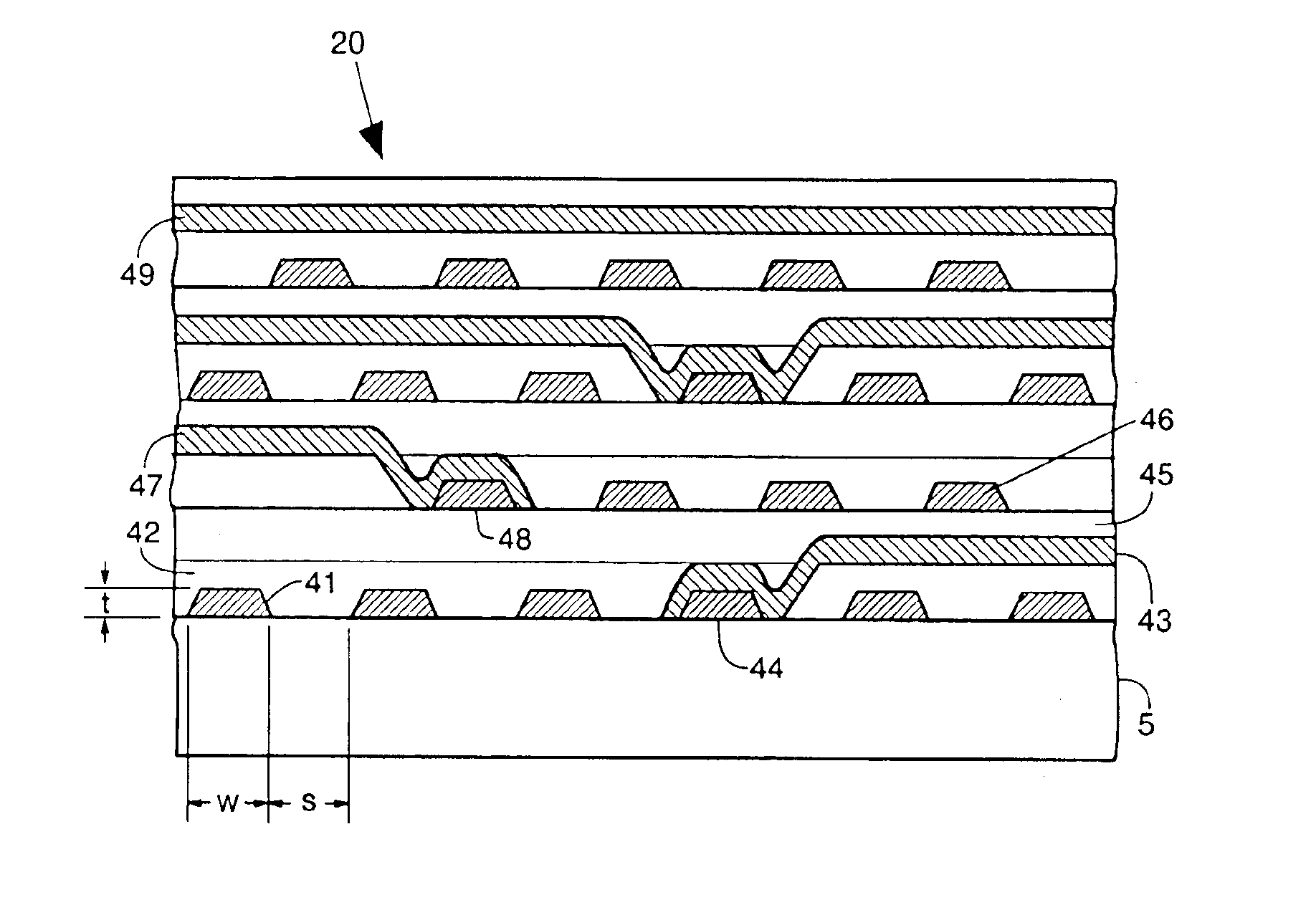

Very low effective dielectric constant interconnect Structures and methods for fabricating the same

InactiveUS7023093B2Low structural requirementsHigh mechanical strengthSemiconductor/solid-state device detailsSolid-state devicesCopper-wiringElectrical performance

A structure incorporates very low dielectric constant (k) insulators with copper wiring to achieve high performance interconnects. The wiring is supported by a relatively durable low k dielectric such as SiLk or SiO2 and a very low k and less robust gap fill dielectric is disposed in the remainder of the structure, so that the structure combines a durable layer for strength with a very low k dielectric for interconnect electrical performance.

Owner:GLOBALFOUNDRIES US INC

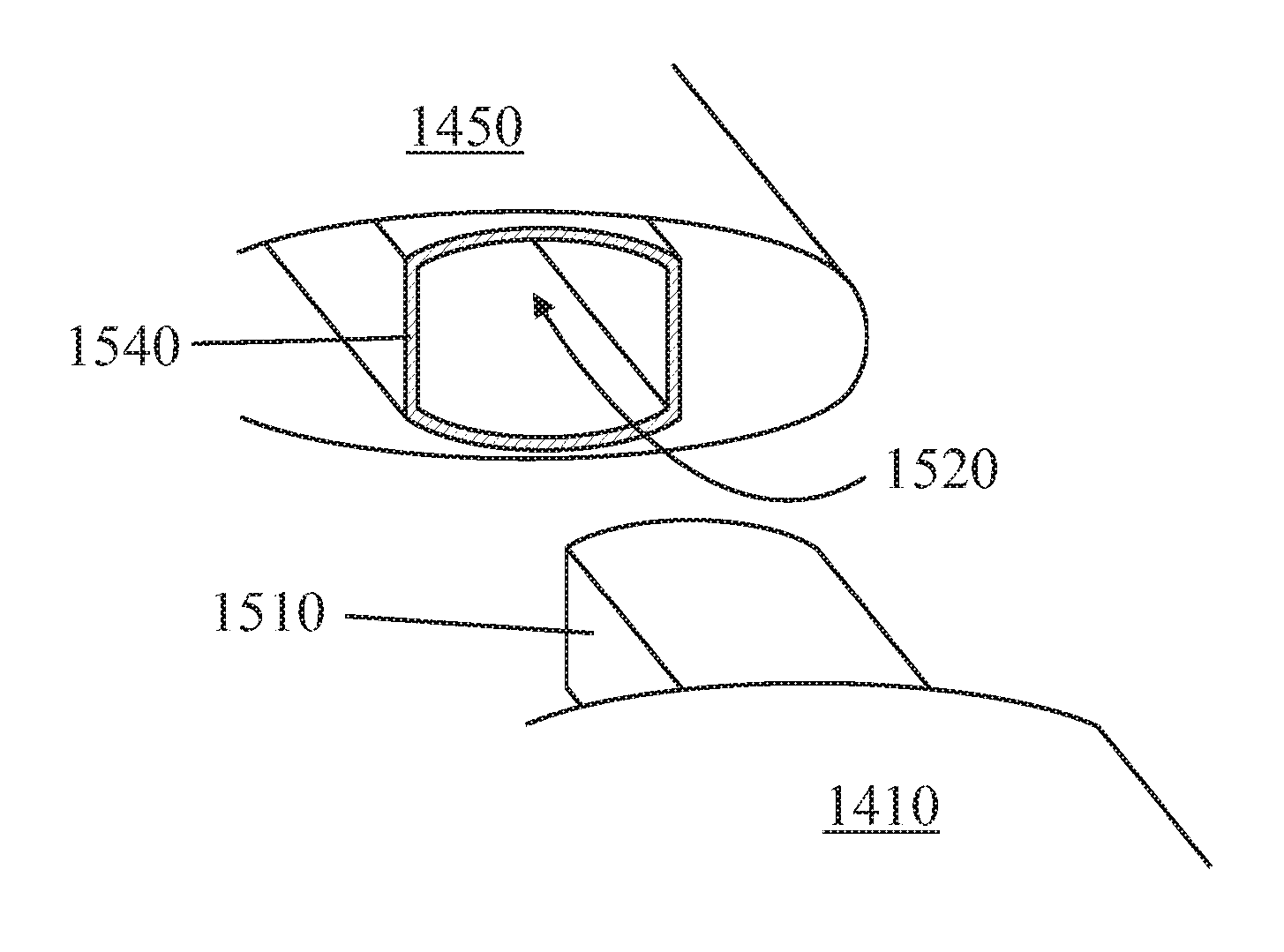

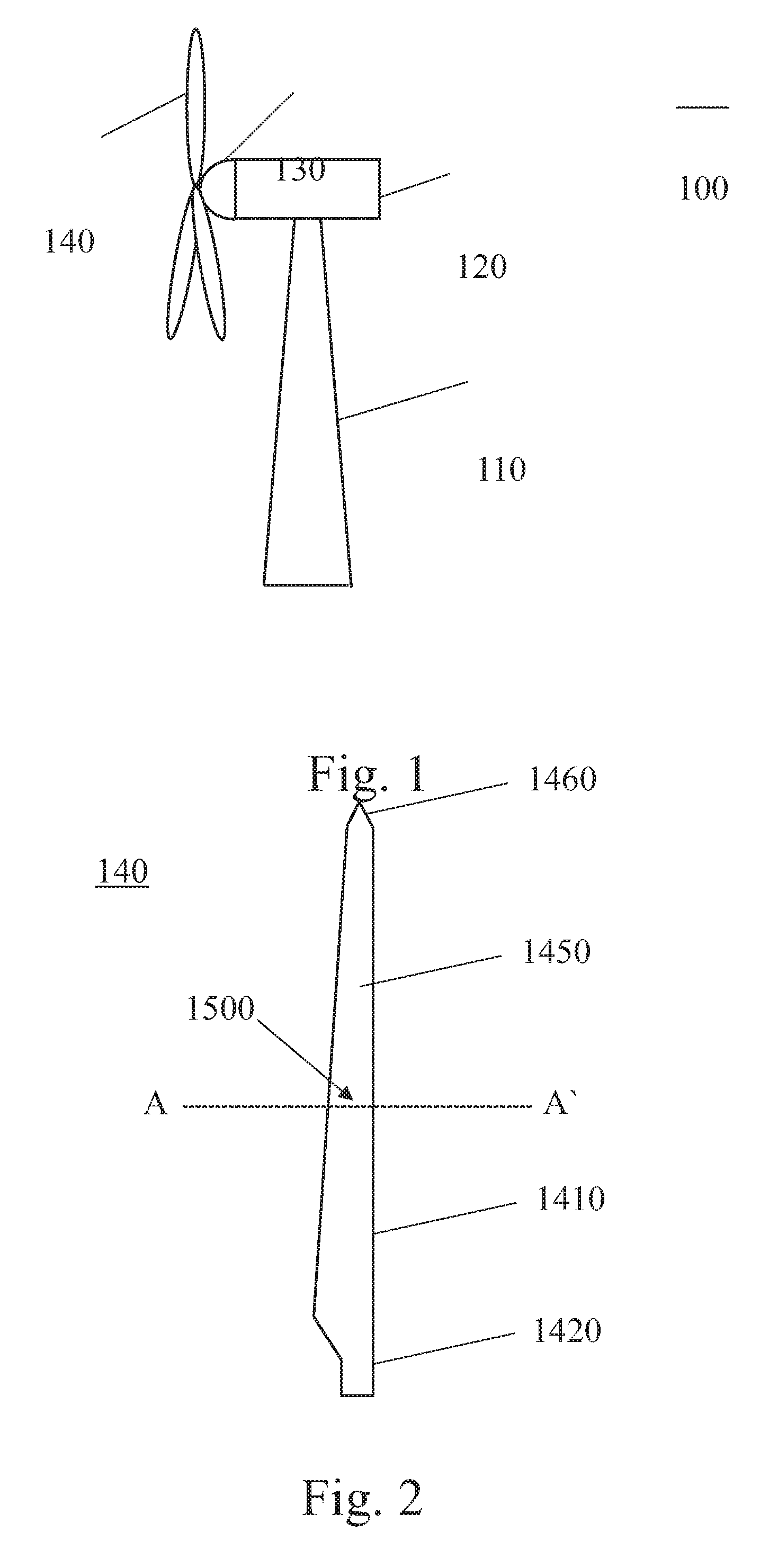

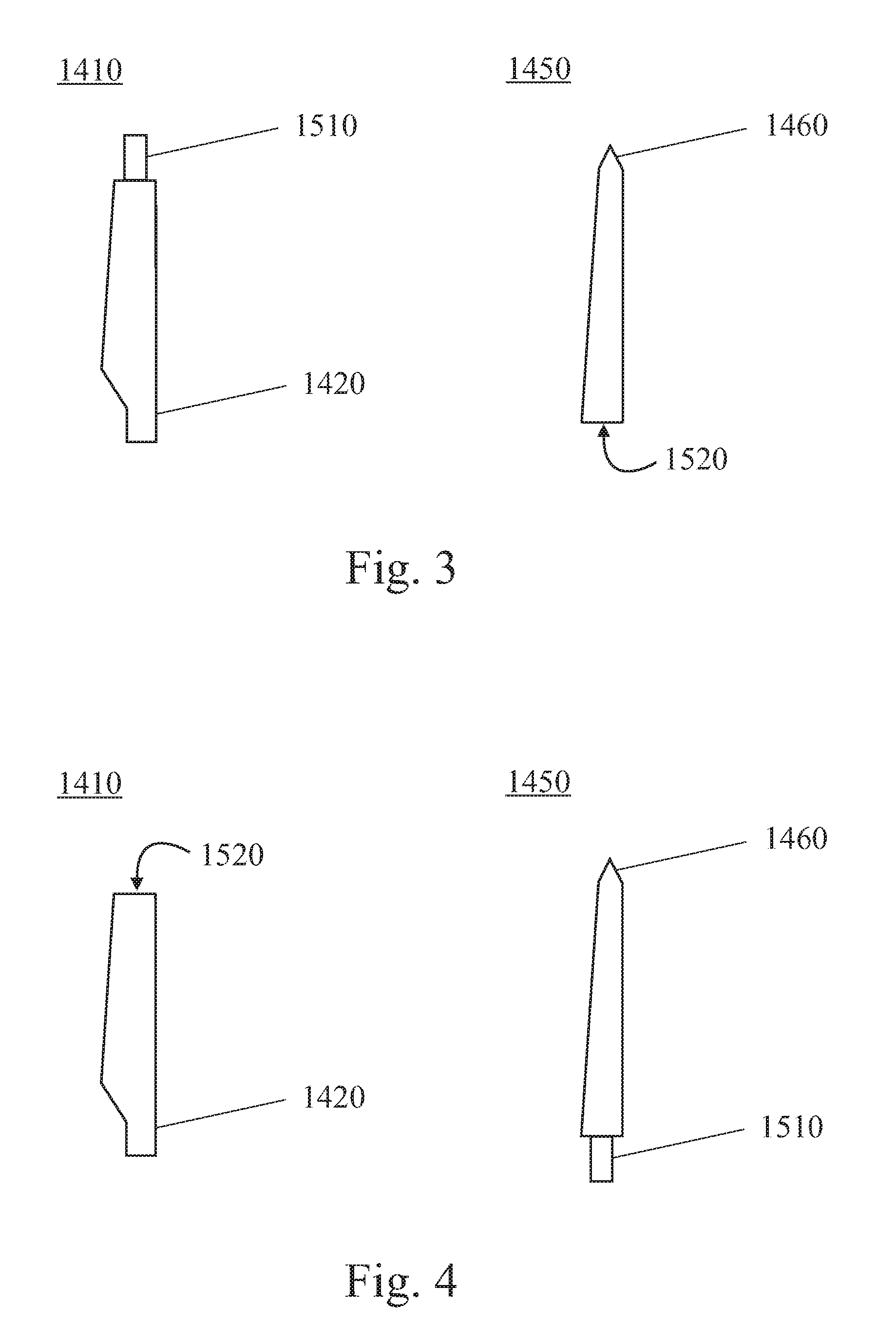

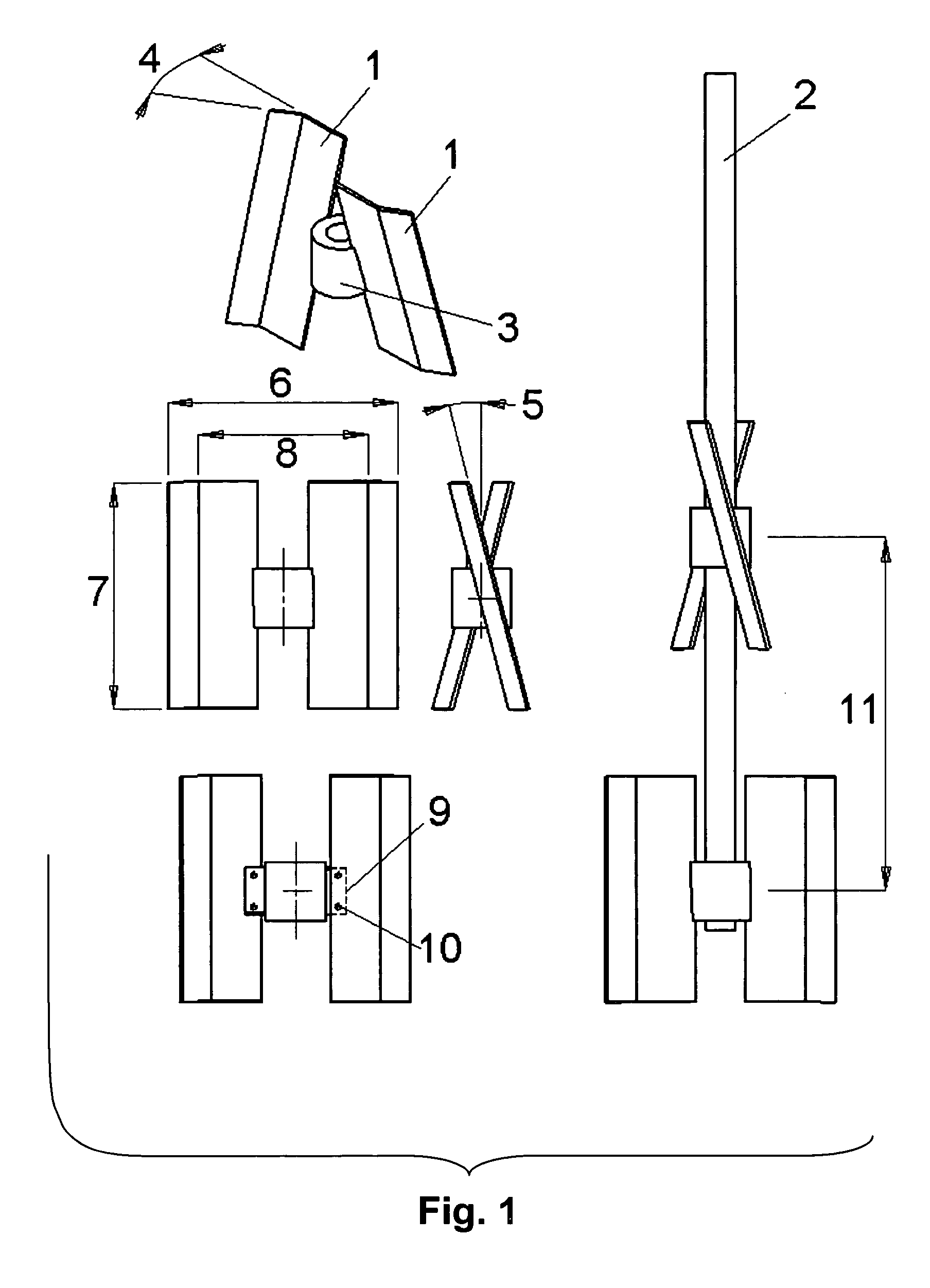

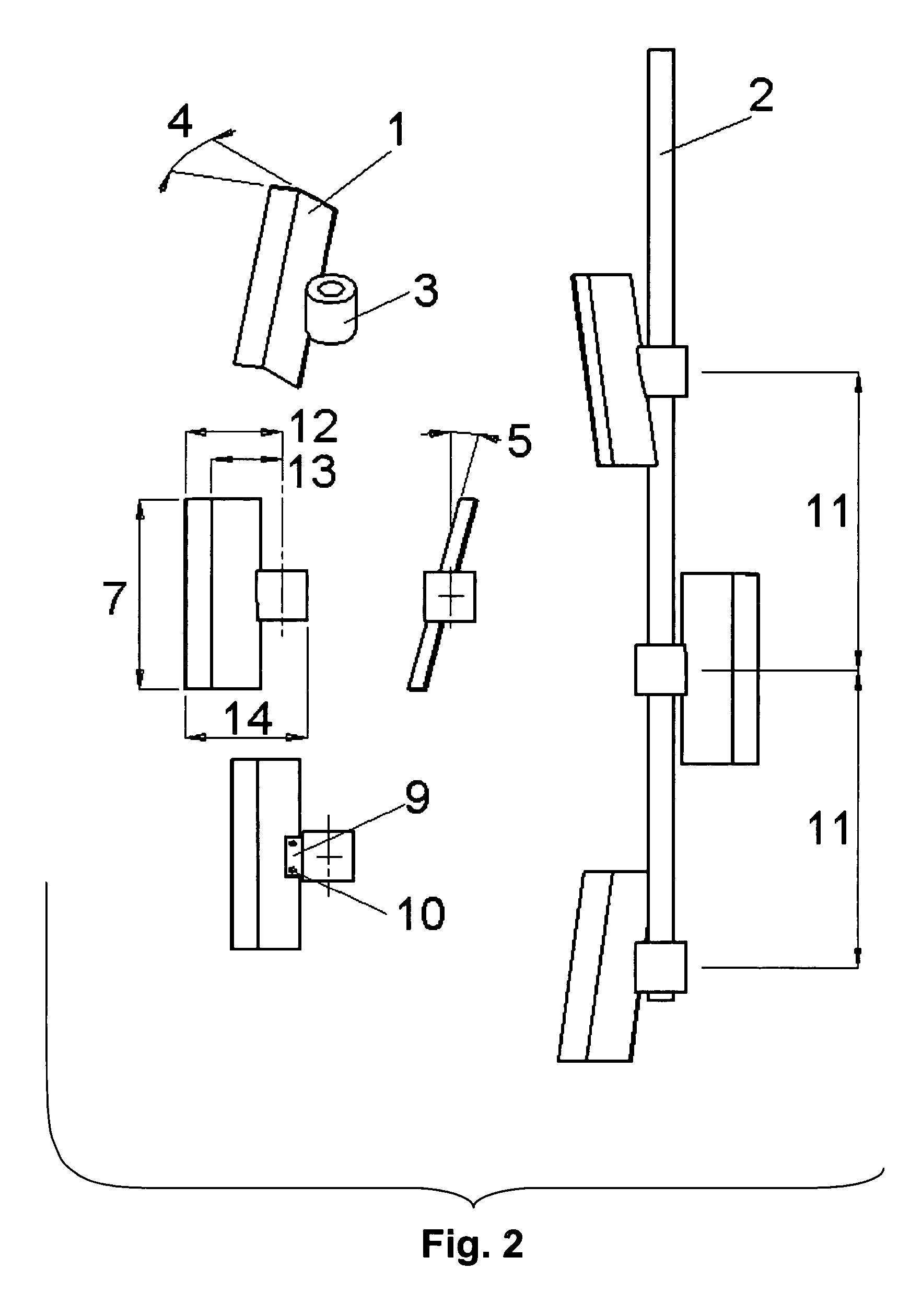

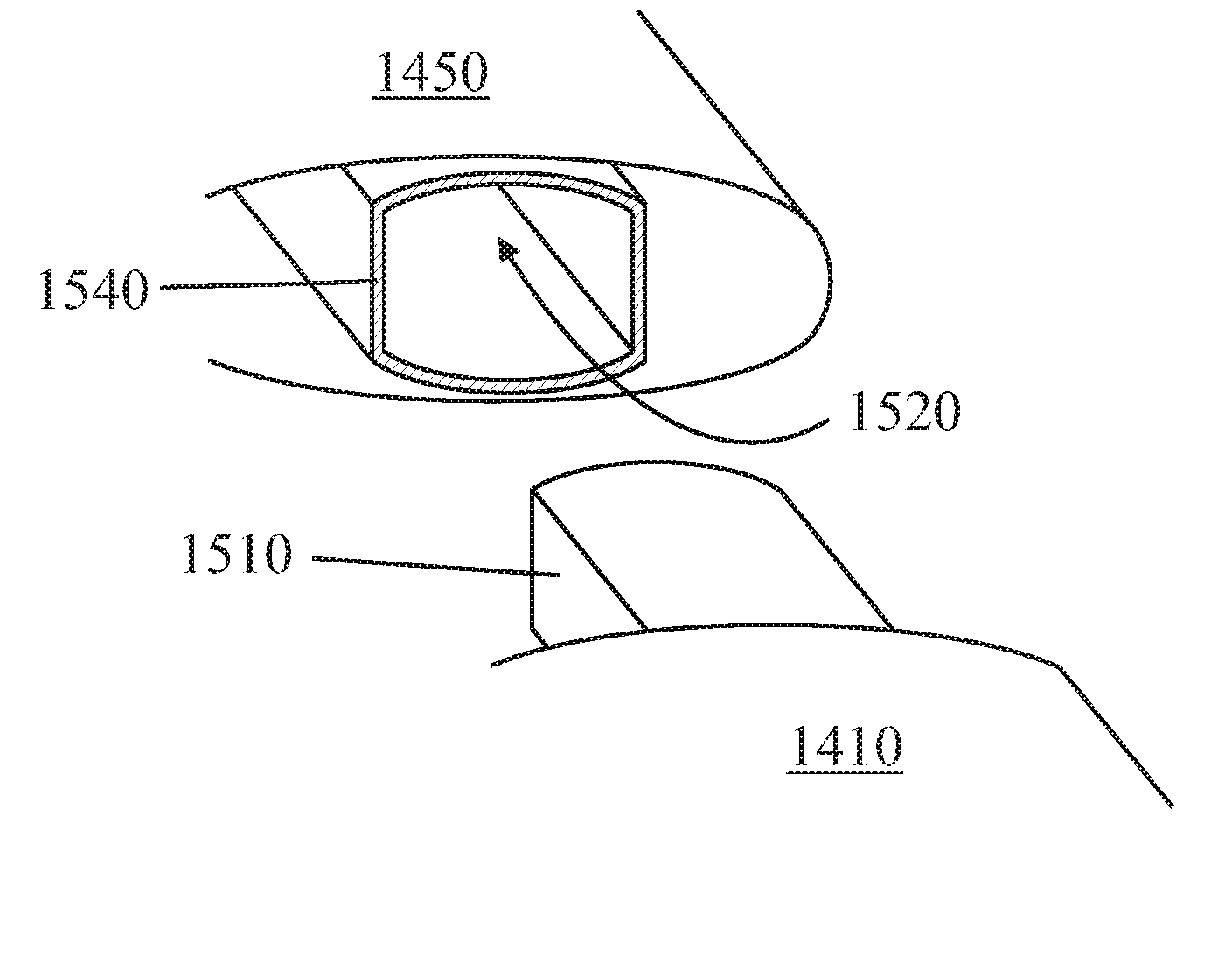

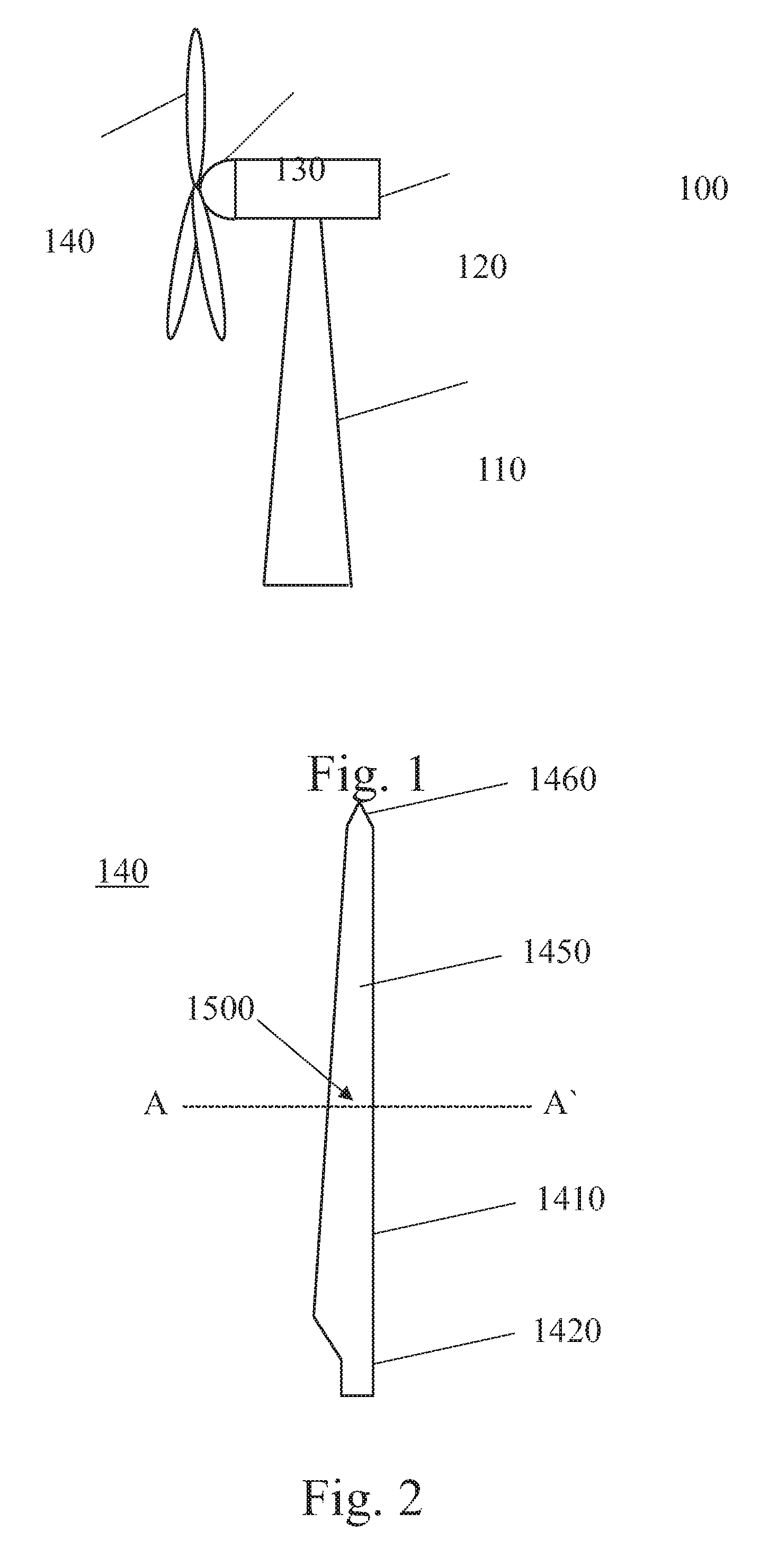

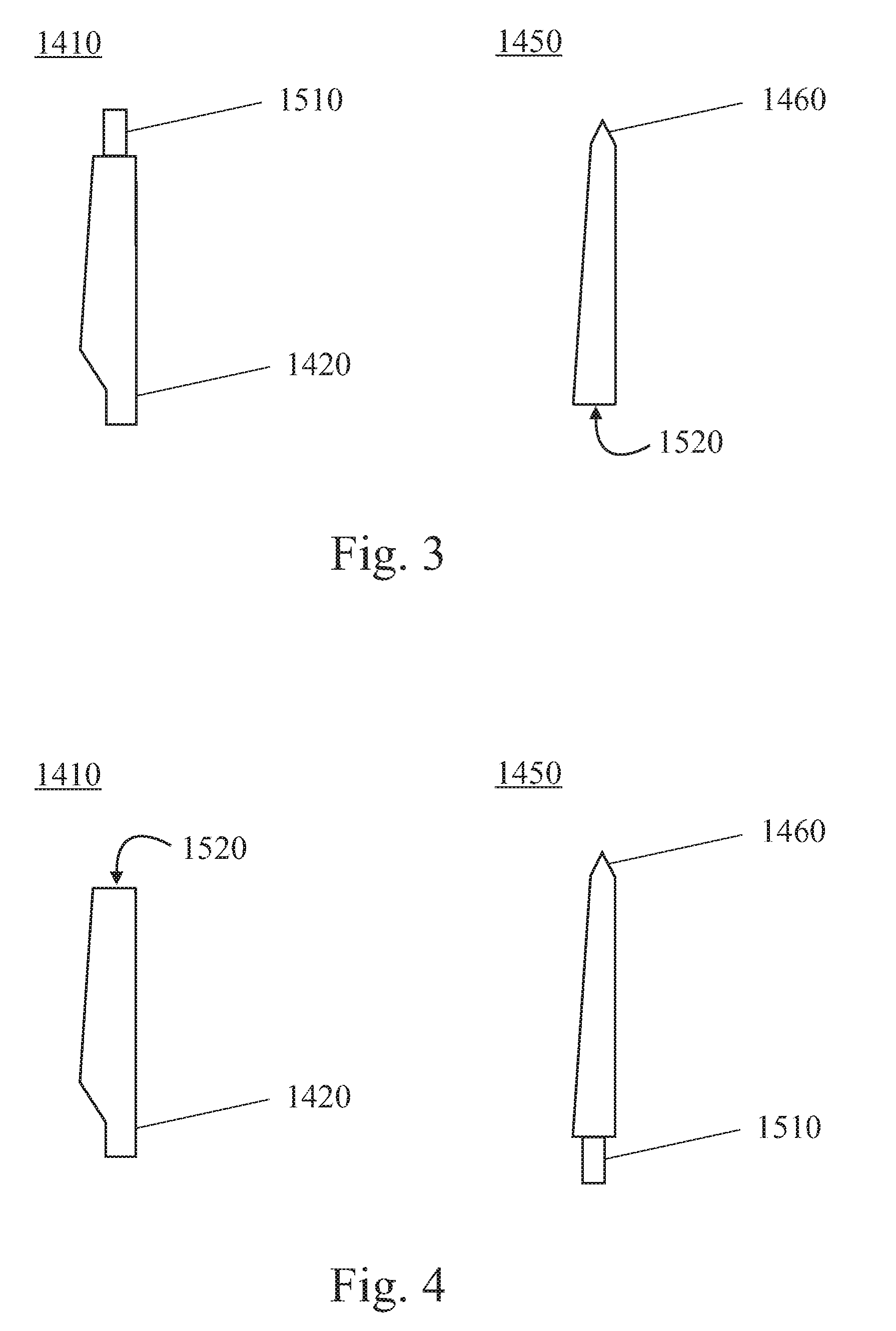

Modular rotor blade for a wind turbine and method for assembling same

ActiveUS20070253824A1Reduce lengthOperational property be not deterioratePropellersEngine manufactureTurbine rotor

A sectional wind turbine rotor blade is provided, the sectional wind turbine rotor blade having first and second blade sections, wherein the first and second blade sections are fixedly mountable to each other via a connector. Furthermore, a method for assembling a sectional wind turbine rotor blade is provided.

Owner:GENERAL ELECTRIC CO

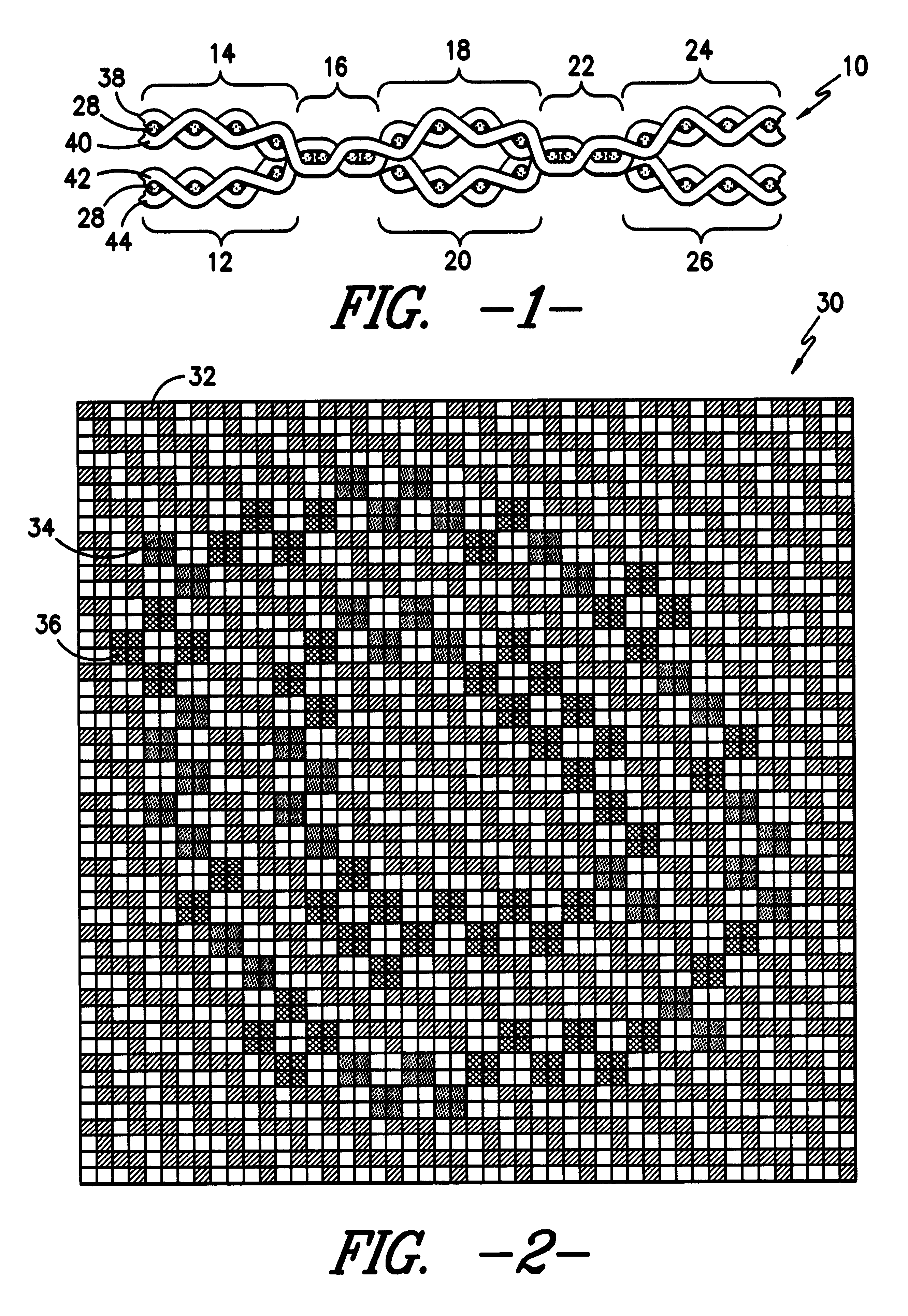

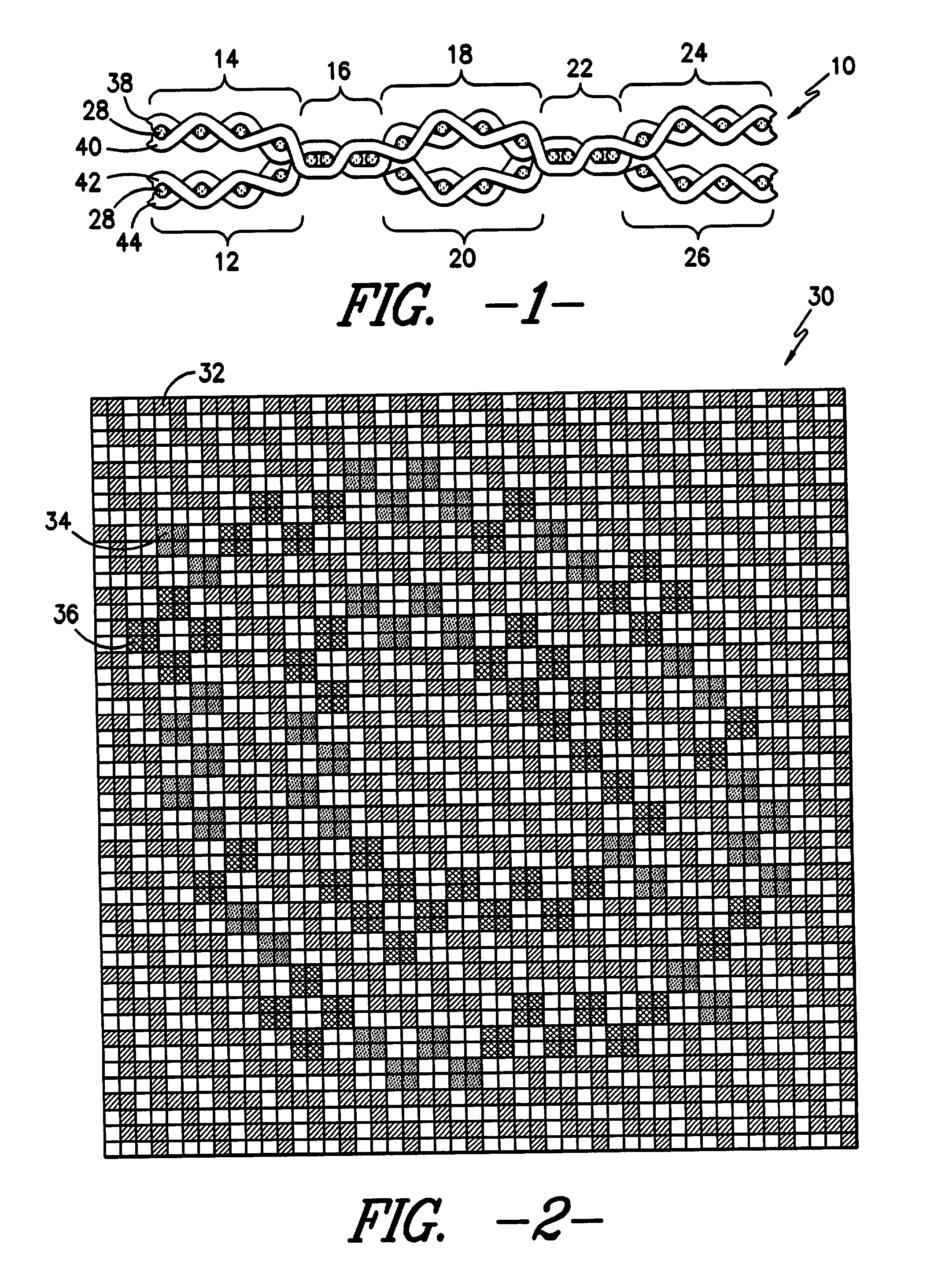

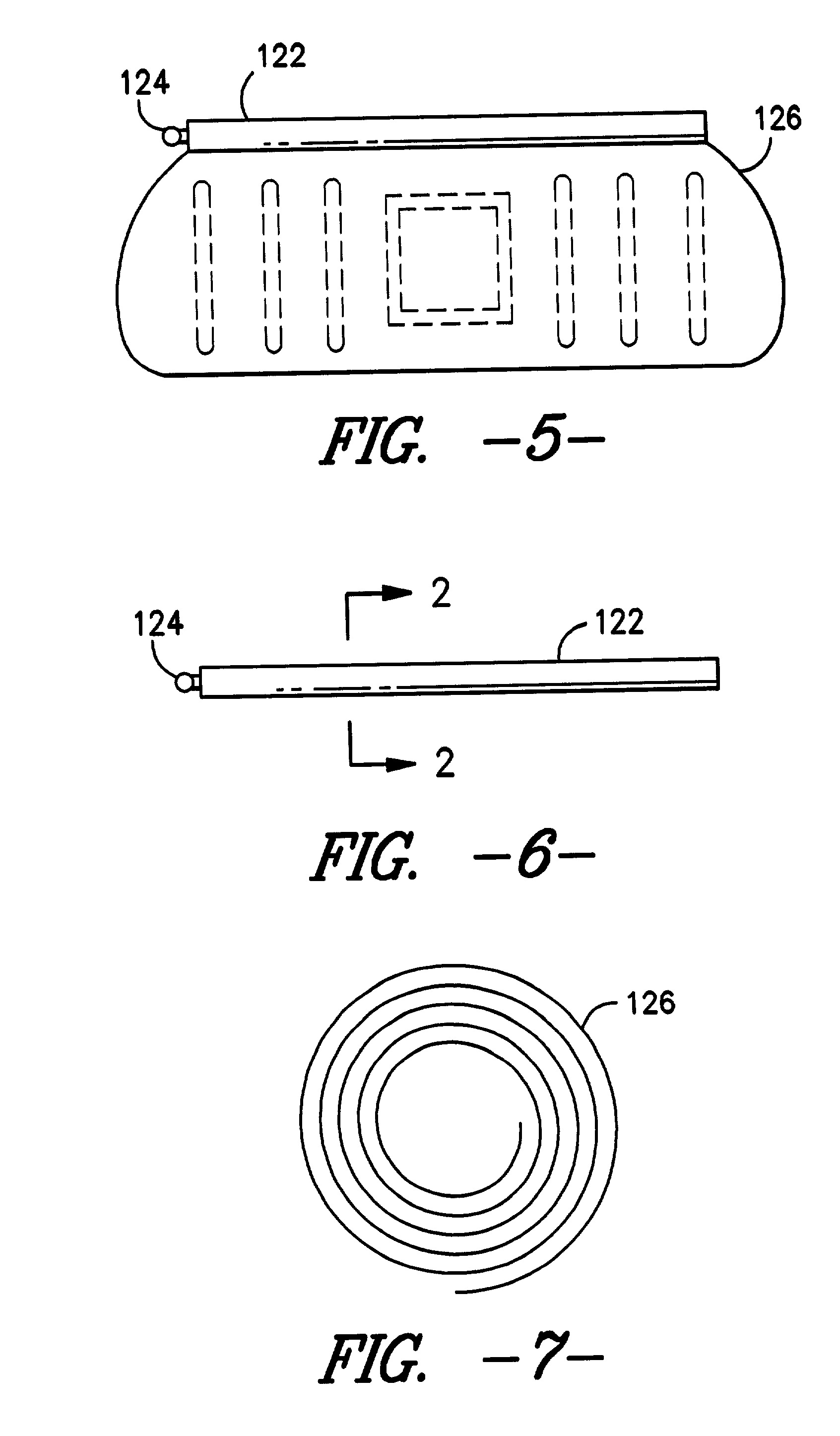

Low permeability airbag cushions having film coatings of extremely low thickness

InactiveUS6429155B1High leak-down timeReduce penetrationEnvelopes/bags making machineryPedestrian/occupant safety arrangementEngineeringNeoprene

Coated inflatable fabrics, more particularly airbags to which very low add-on amounts of coating have been applied, are provided which exhibit extremely low air permeability. The inventive inflatable fabrics are primarily for use in automotive restraint cushions that require low permeability characteristics (such as side curtain airbags). Traditionally, heavy, and thus expensive, coatings of compounds such as neoprene, silicones and the like, have been utilized to provide such required low permeability. The inventive fabric utilizes an inexpensive, very thin coating to provide such necessarily low permeability levels. Thus, the inventive coated inflatable airbag comprises a film laminated on at least a portion of the target fabric surface wherein the film possesses a tensile strength of at least 2,000 and an elongation at break of at least 180%. The film provides a low permeability airbag cushion exhibiting a leak-down time of at least 5 seconds as well as a very low packing volume (for more efficient use of storage space within a vehicle) for the target side curtain airbag.

Owner:MILLIKEN & CO

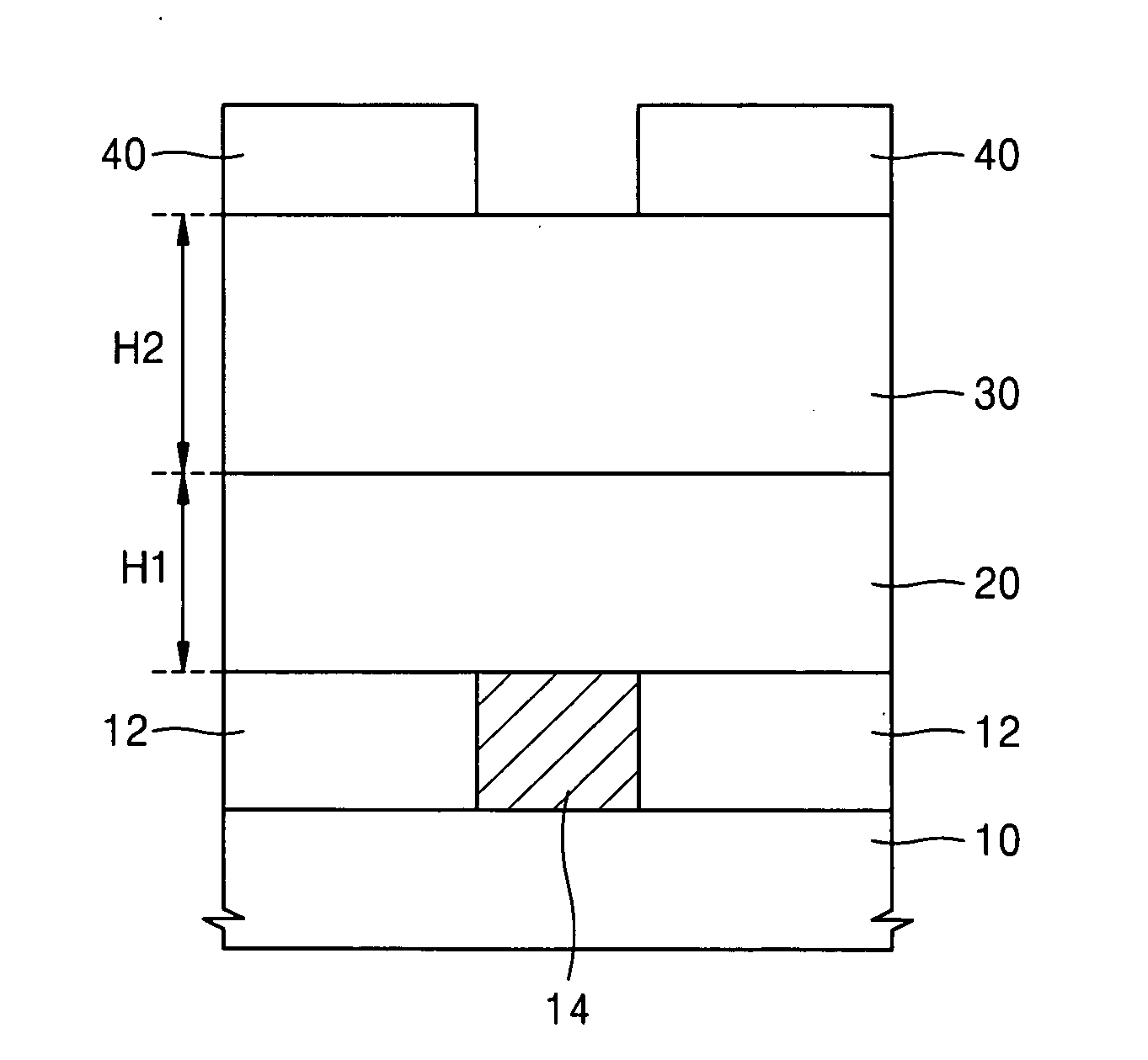

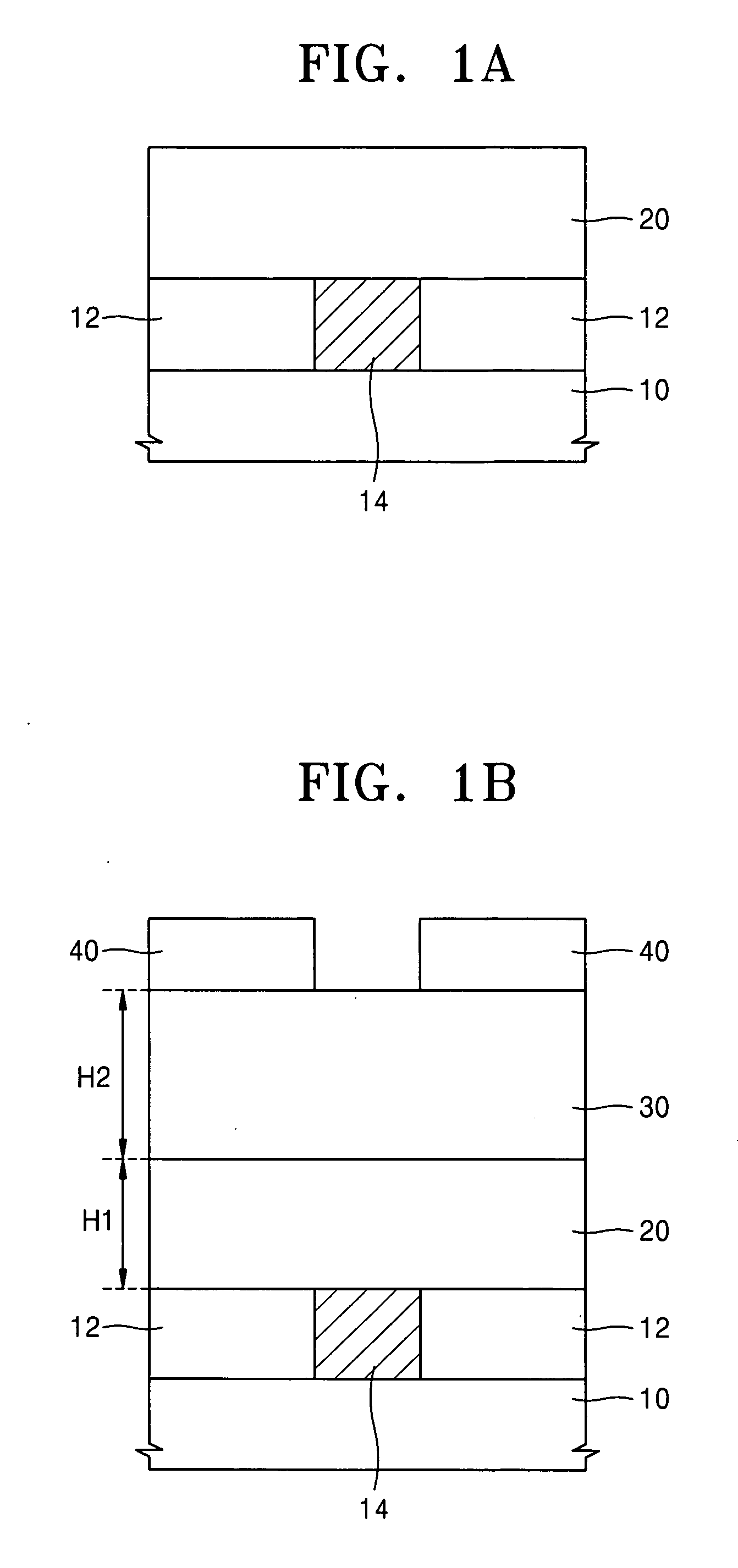

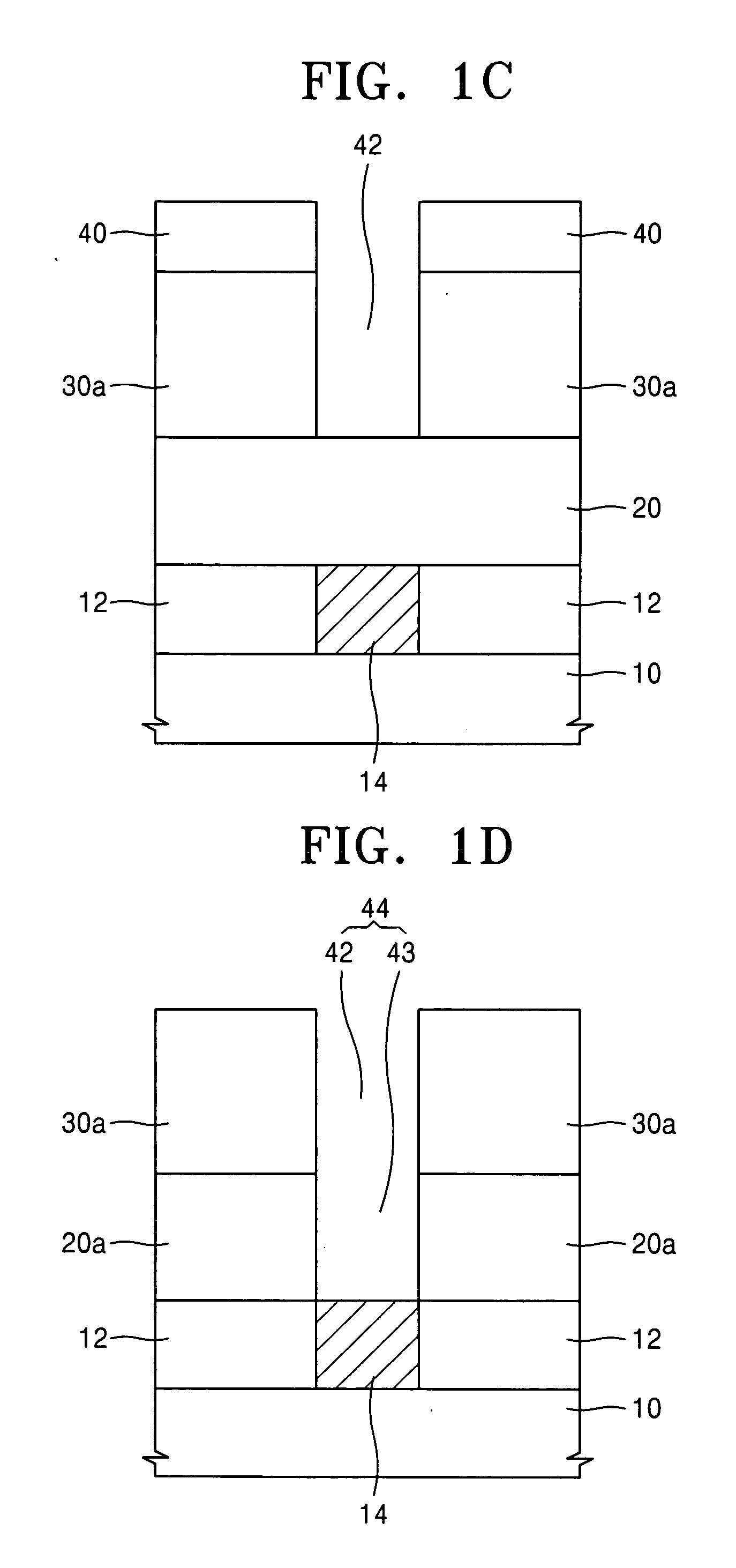

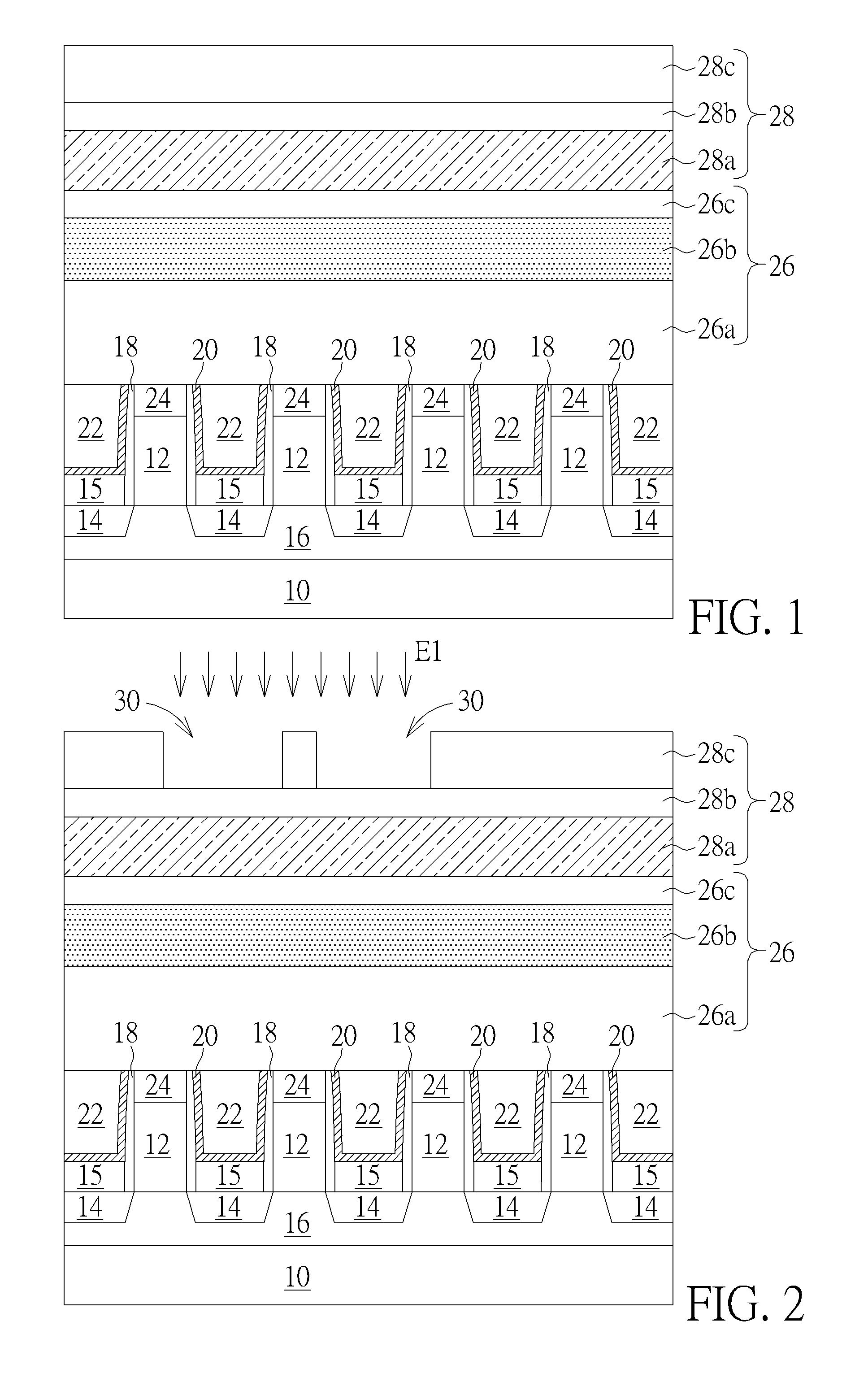

Method of manufacturing a semiconductor memory device

InactiveUS20050287738A1Increase heightGreat outer diameterSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringDielectric layer

A method of manufacturing a semiconductor memory device includes forming a carbon-containing layer on a semiconductor substrate, forming an insulating layer pattern on the carbon-containing layer, the insulating layer pattern partially exposing an upper surface of the carbon-containing layer, dry-etching the exposed portion of the carbon-containing layer, to form a carbon-containing layer pattern for defining a storage node hole, forming a bottom electrode inside the storage node hole, forming a dielectric layer on the bottom electrode inside the storage node hole, the dielectric layer covering the bottom electrode, and forming an upper electrode on the dielectric layer inside the storage node hole, the upper electrode covering the dielectric layer.

Owner:SAMSUNG ELECTRONICS CO LTD

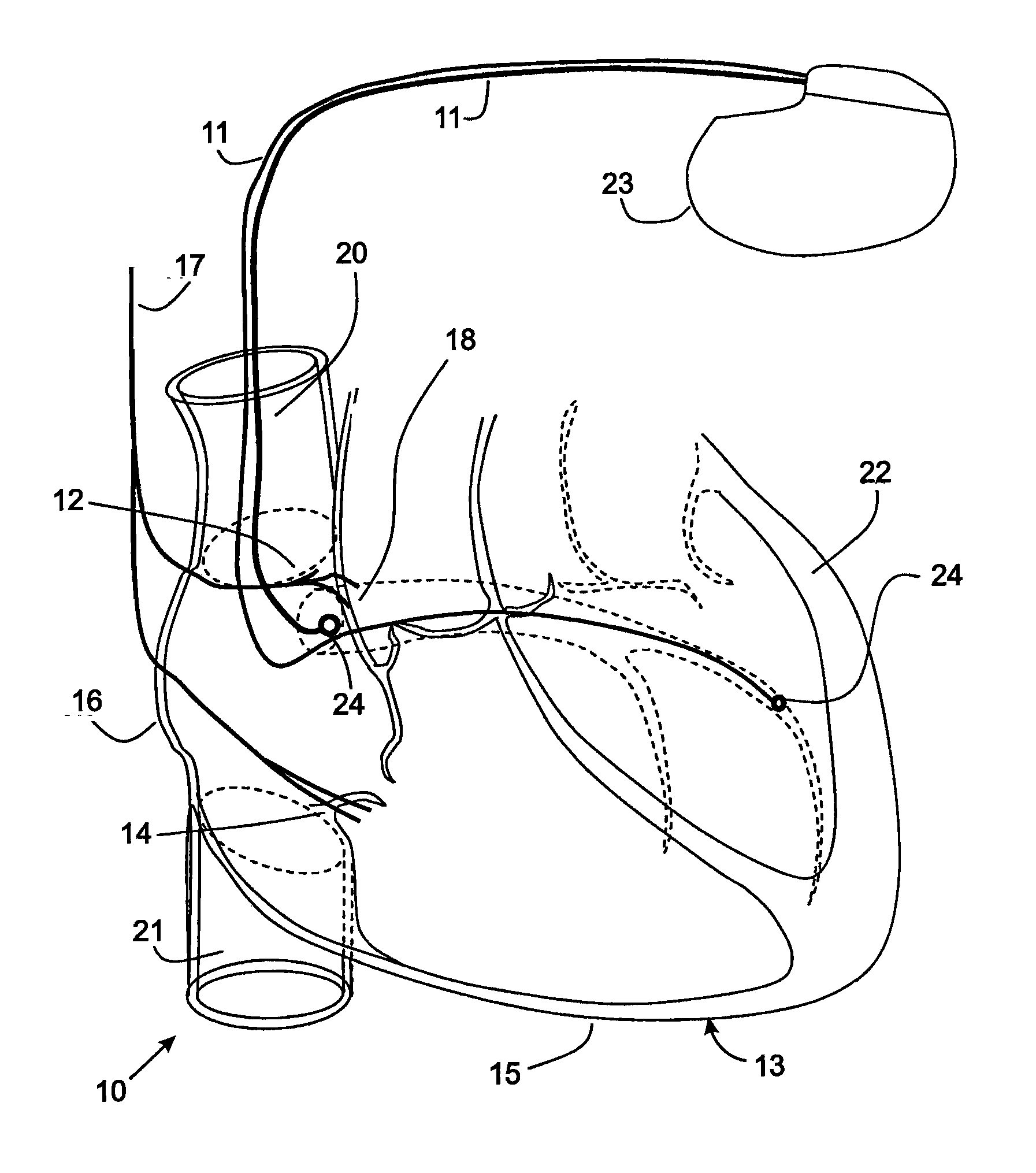

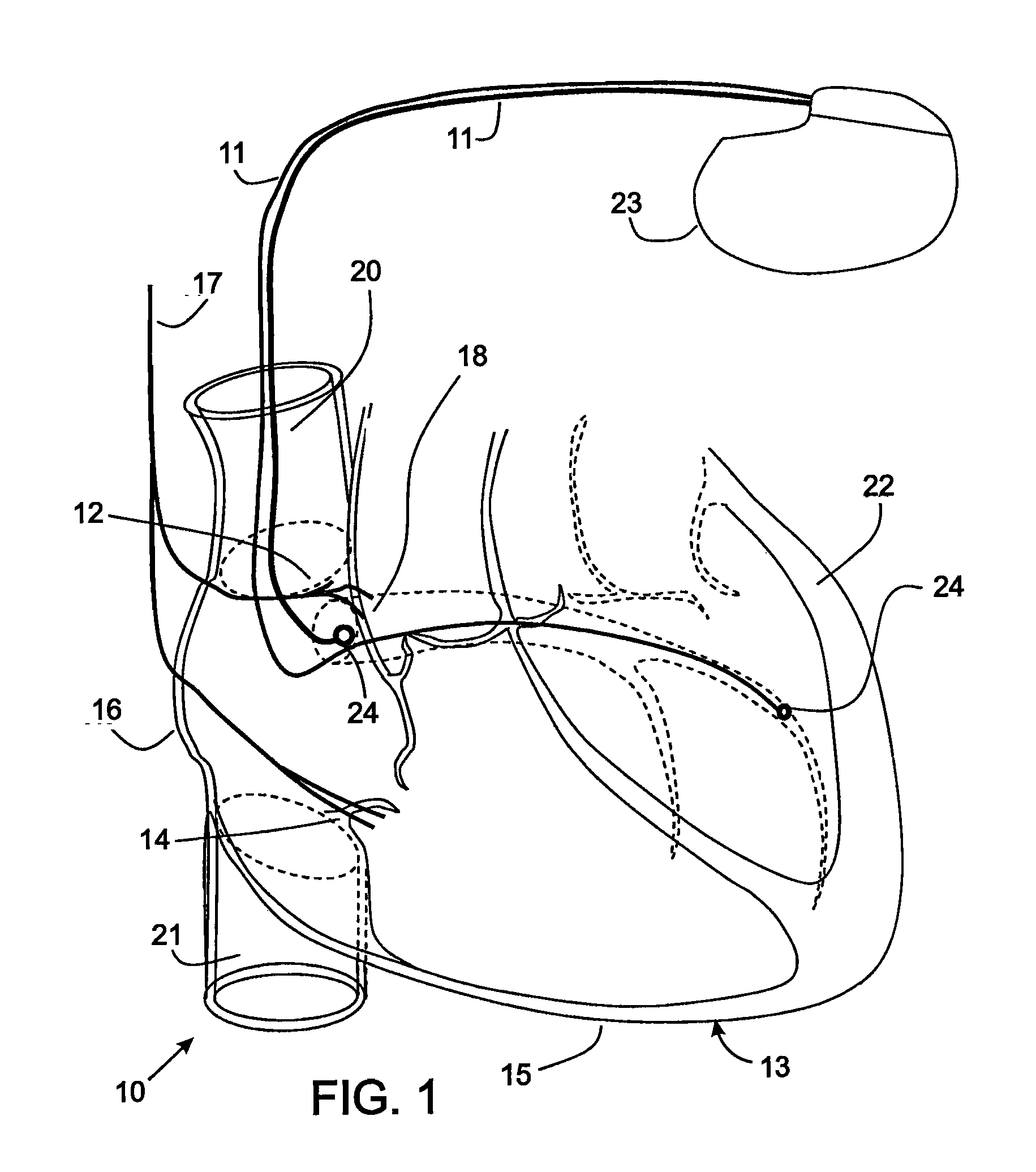

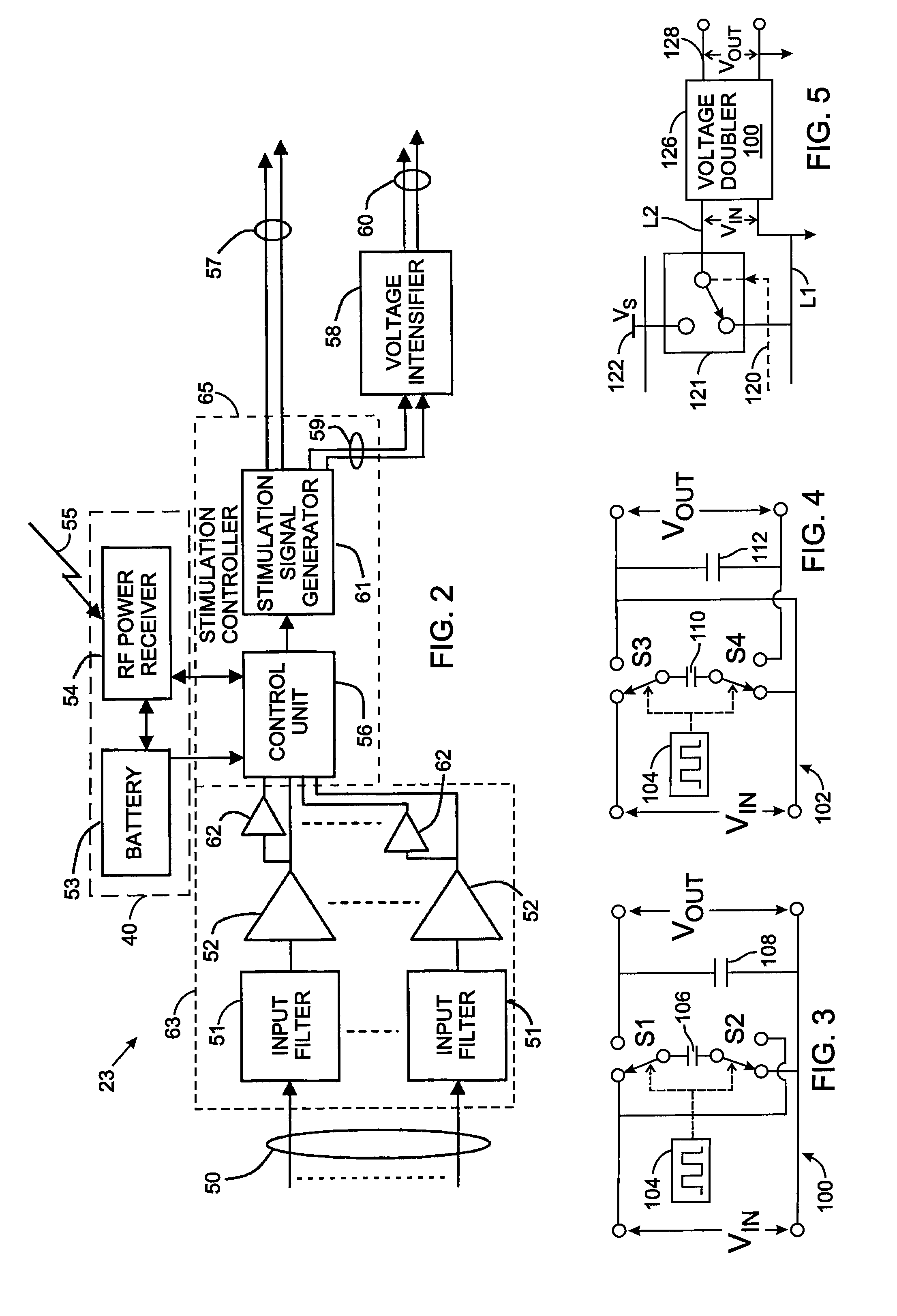

Implantable digital device for tissue stimulation

InactiveUS20080281368A1Power Loss MinimizationLower impedanceHeart defibrillatorsHeart stimulatorsHigh energyDigital device

An implantable vagal stimulation device with high-energy efficiency and novel data sensing is provided for use in a wide variety of applications where neural stimulation is required, including human heart rate control. The stimulation device uses low-impedance circuitry and digital waveforms to minimize energy losses, thereby requiring a relatively small battery. Front-loaded, passive filtering is employed to reduce electromagnetic noise sensitivity, leaving a clear physiological signal without degradations. This physiological signal is processed by a derivative zero transition detector (DZD), which is immune to variations in input signal dynamic range unlike traditional methods. Information that the DZD receives can be then interpreted and used along with an algorithm to execute appropriate vagal nerve stimulation.

Owner:KENERGY INC

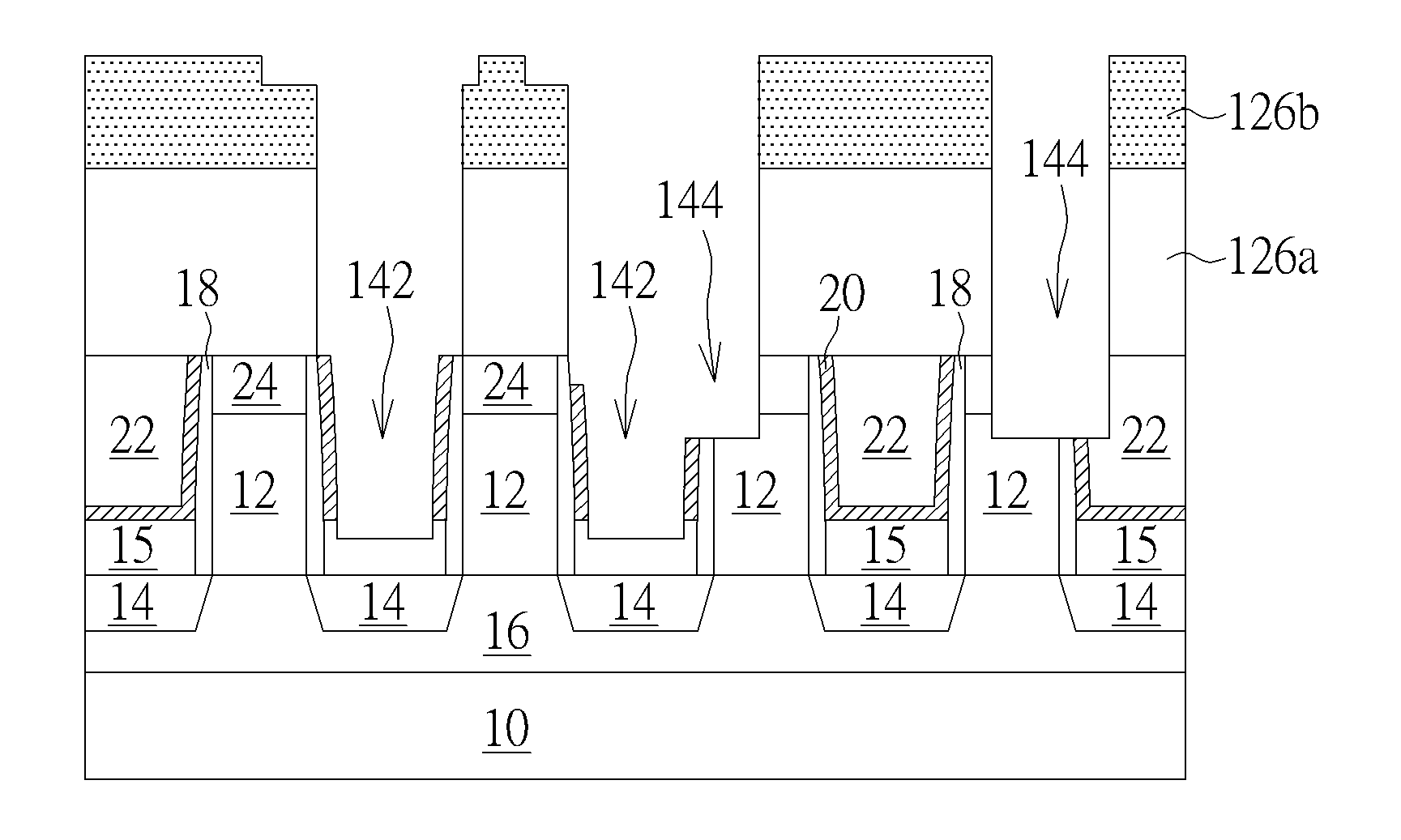

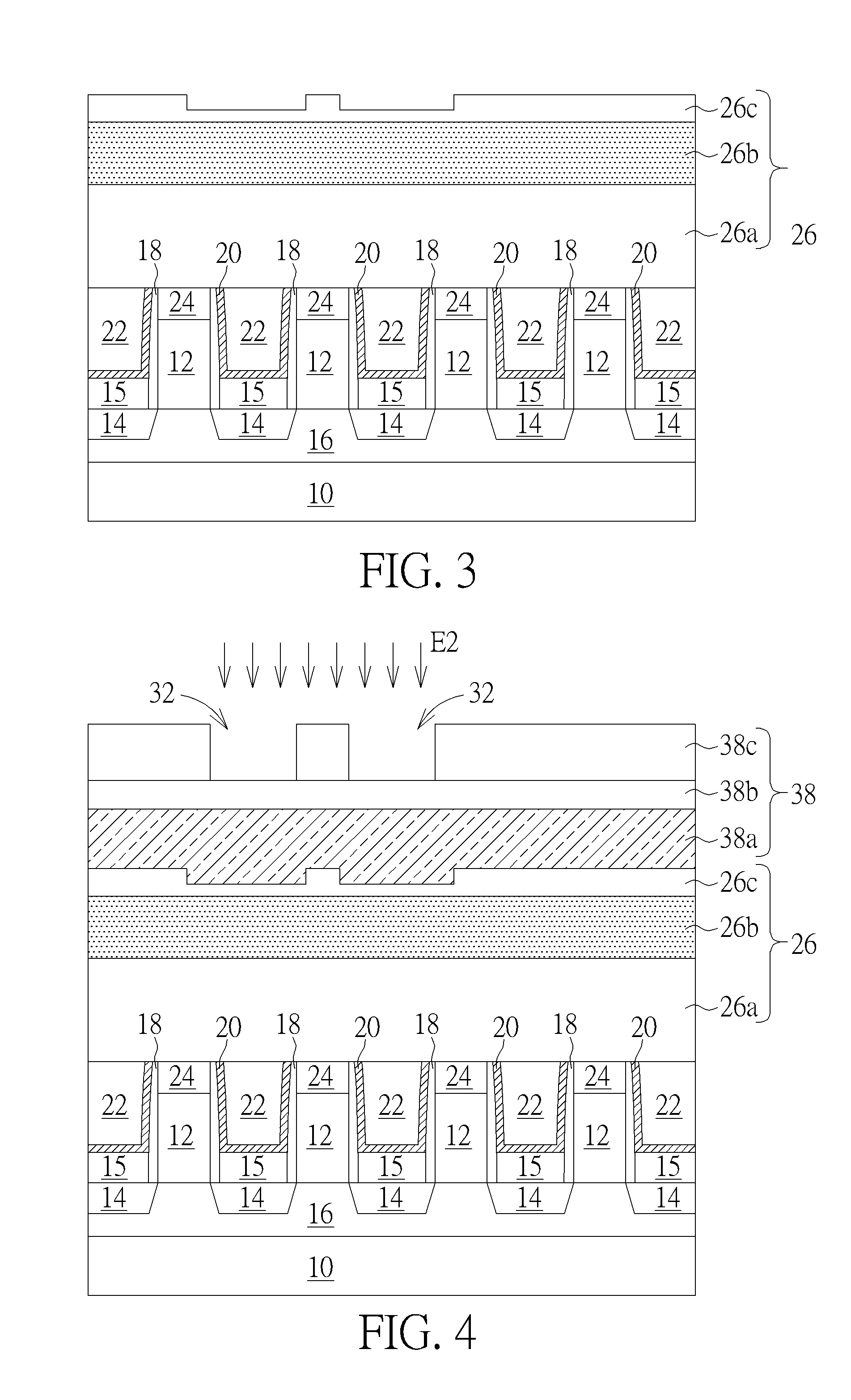

Manufacturing method for forming a semiconductor structure

ActiveUS20140349476A1Reduce manufacturing stepsLow structural requirementsSemiconductor/solid-state device detailsSemiconductor/solid-state device manufacturingPhotolithographyPhotomask

The present invention provides a manufacturing method of a semiconductor device, at least containing the following steps: first, a substrate is provided, wherein a first dielectric layer is formed on the substrate, at least one metal gate is formed in the first dielectric layer and at least one source drain region (S / D region) is disposed on two sides of the metal gate, at least one first trench is then formed in the first dielectric layer, exposing parts of the S / D region. The manufacturing method for forming the first trench further includes performing a first photolithography process through a first photomask and performing a second photolithography process through a second photomask, and at least one second trench is formed in the first dielectric layer, exposing parts of the metal gate, and finally, a conductive layer is filled in each first trench and each second trench.

Owner:UNITED MICROELECTRONICS CORP

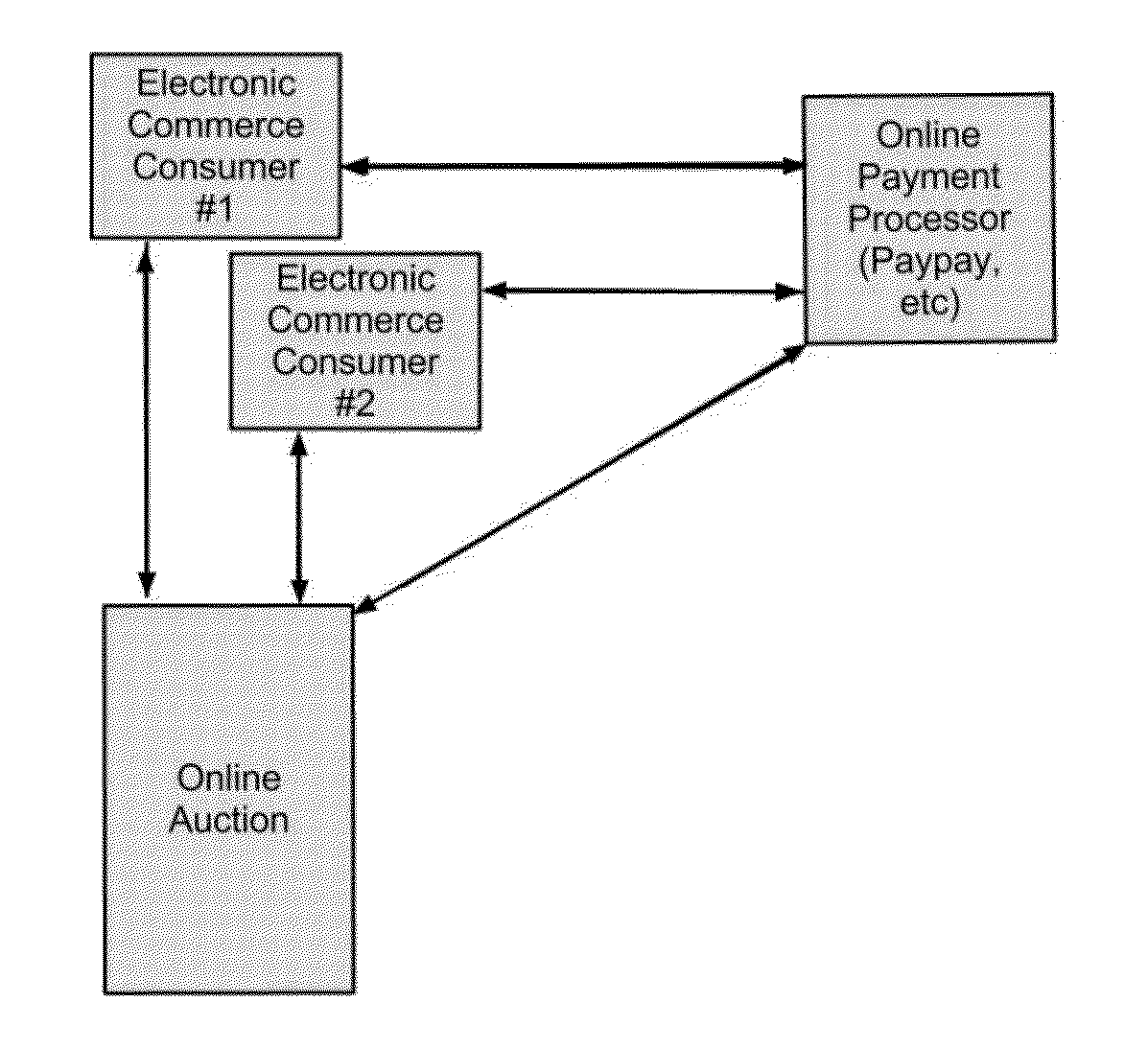

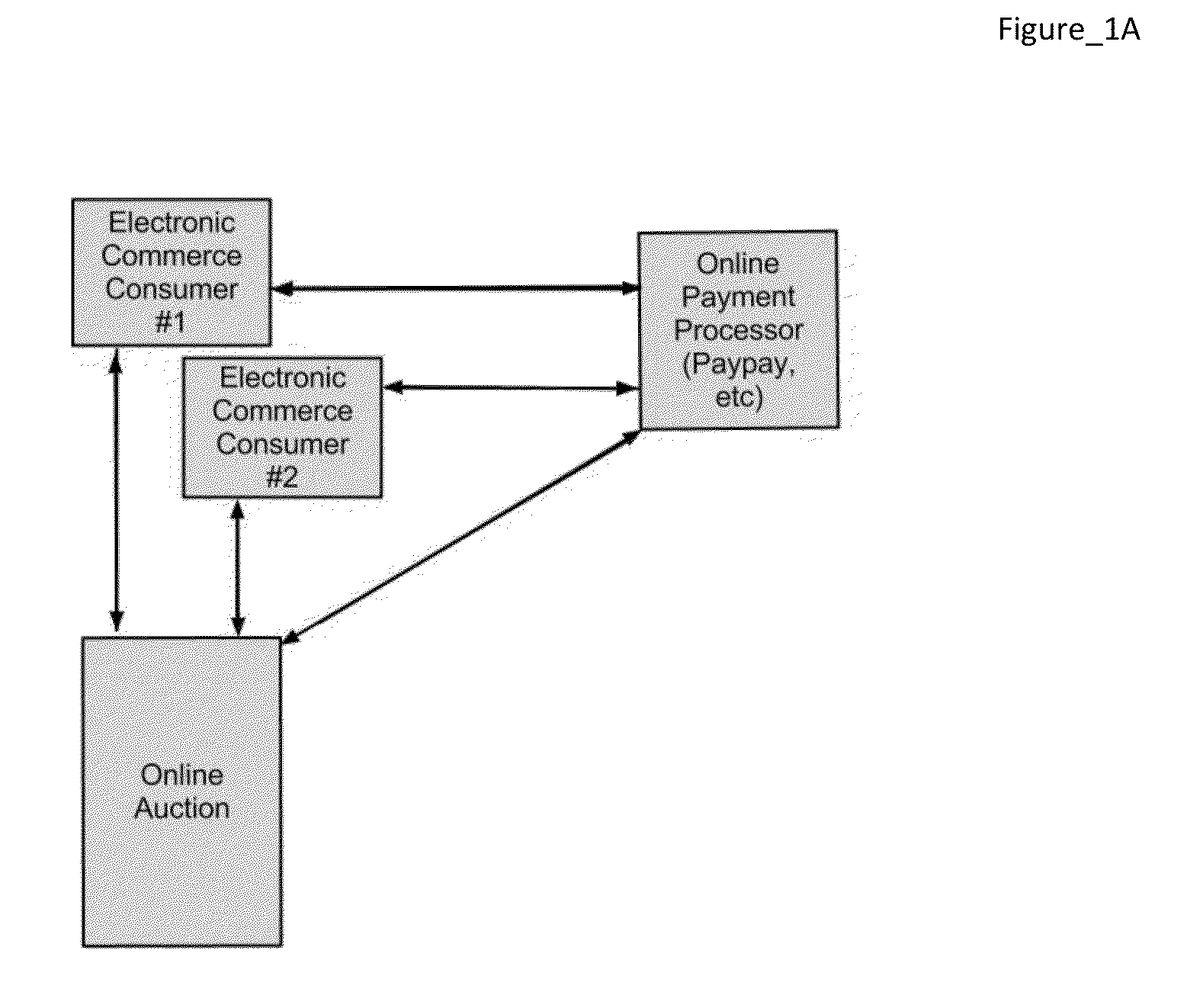

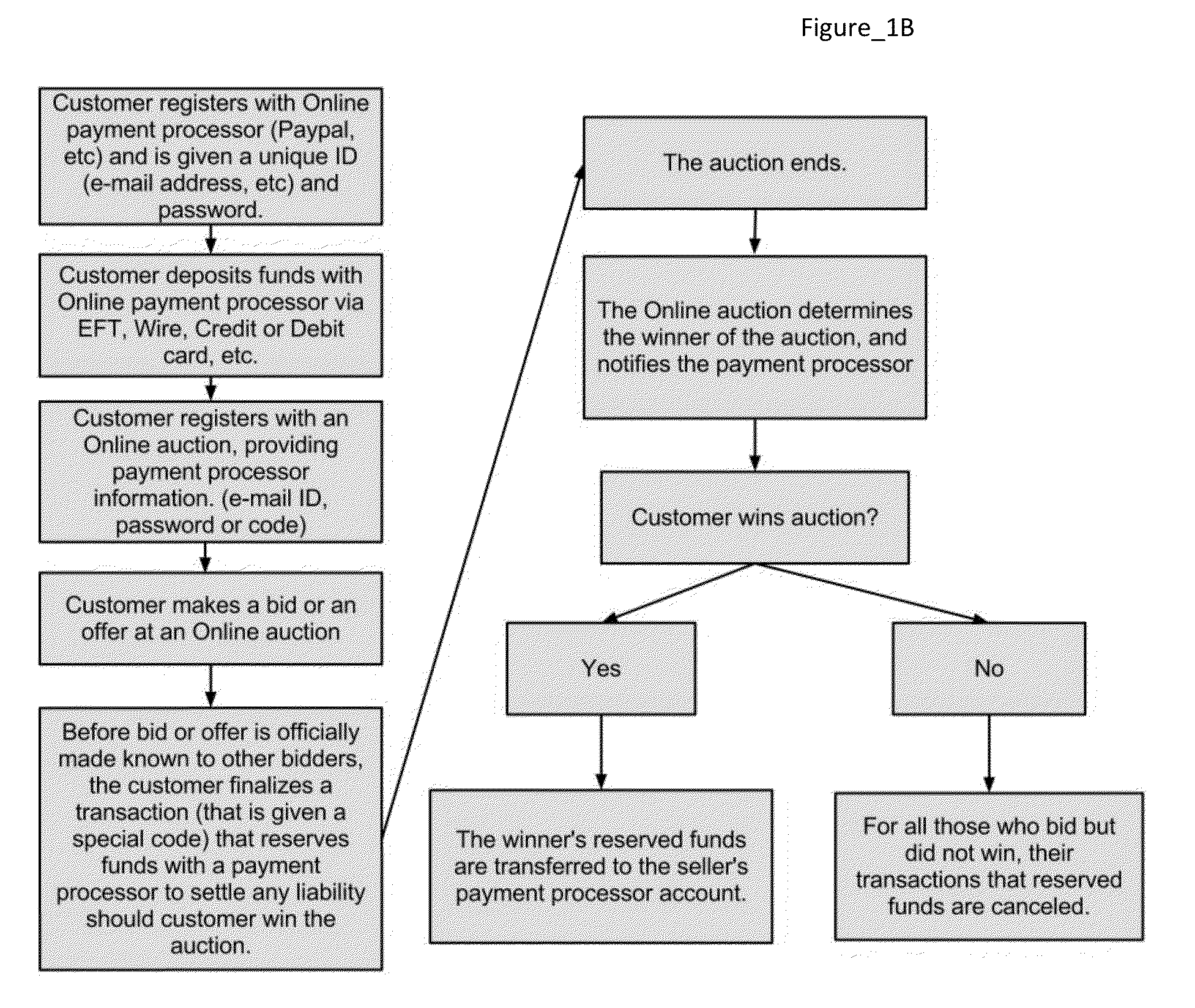

Systems and methods to process online monetary payments dependent on conditional triggers involving future events

InactiveUS20130041773A1Low structural requirementsLow fee structurePre-payment schemesBuying/selling/leasing transactionsSoftwarePayment

The present invention is a system to process online monetary payments between end-users whose payments are dependent on conditional triggers involving future events, such as winning bids / offers in an auction or a trading exchange. In the system, bids and offers are backed by actual funds which are held in reserve, enabling instantaneous payments upon the close of an event. The system contains methods to be included in online auction and trading exchange software applications. These methods would allow end-users of online auctions and trading exchanges to send and receive payments directly to one another.

Owner:MUSE RANDALL FR

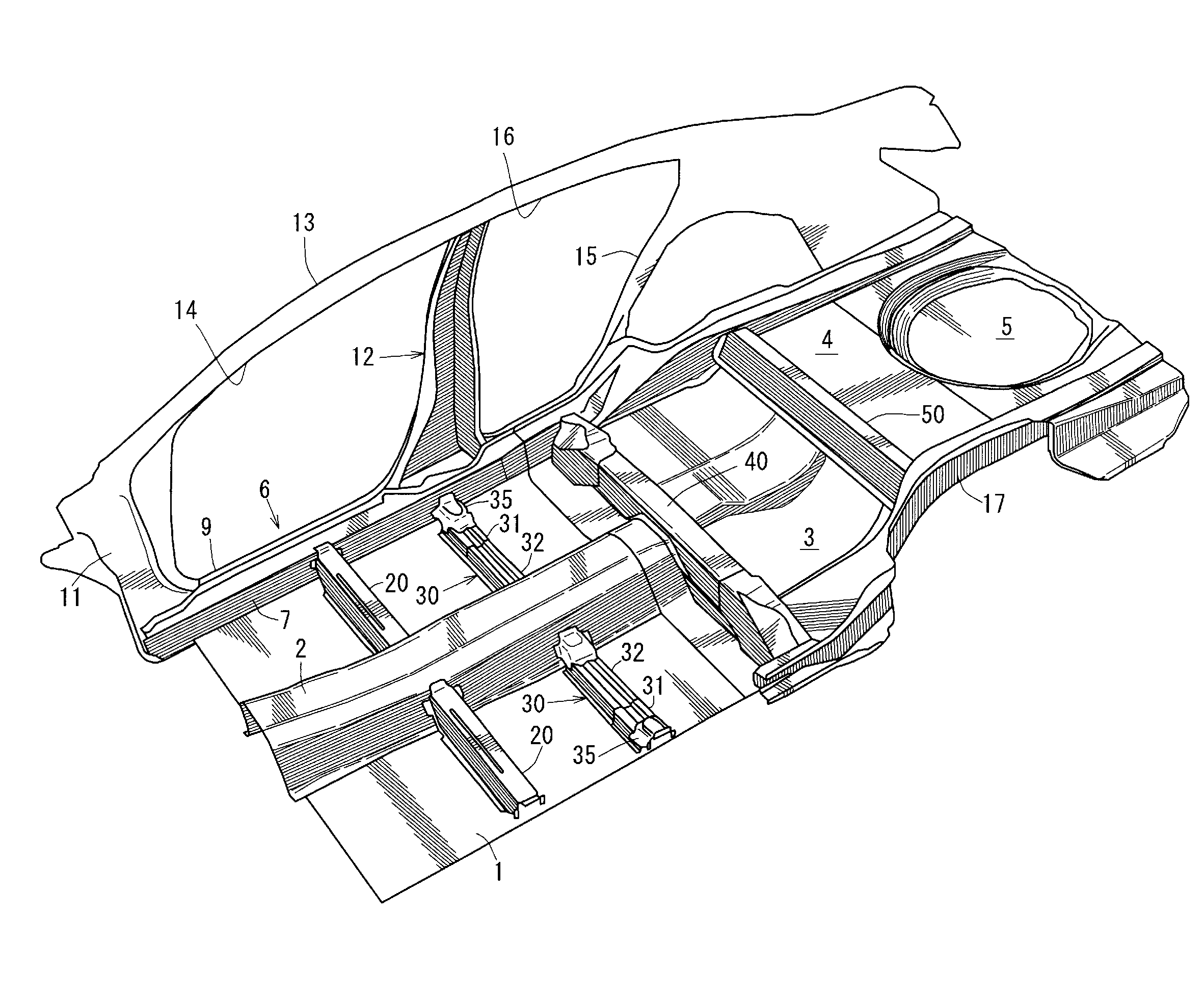

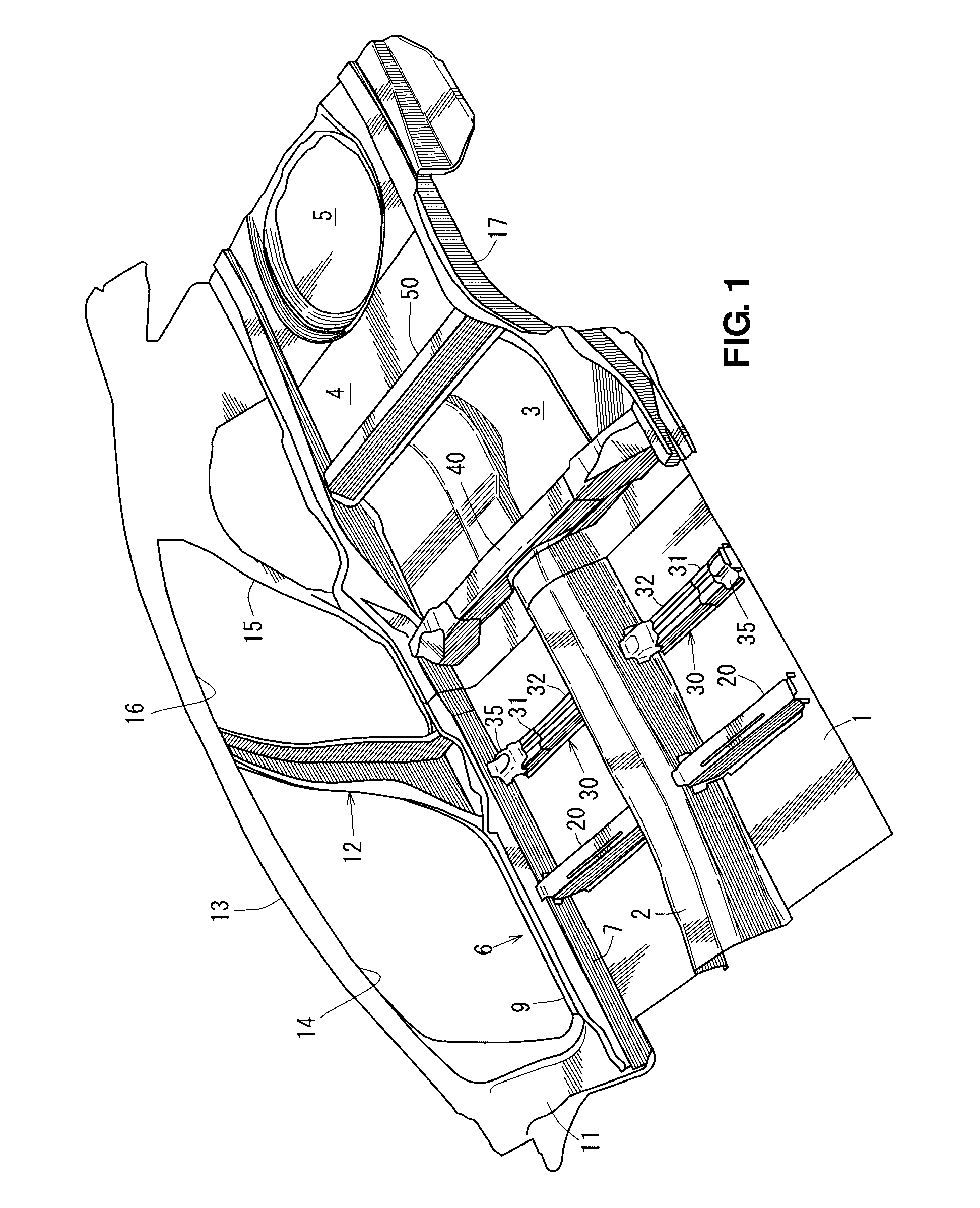

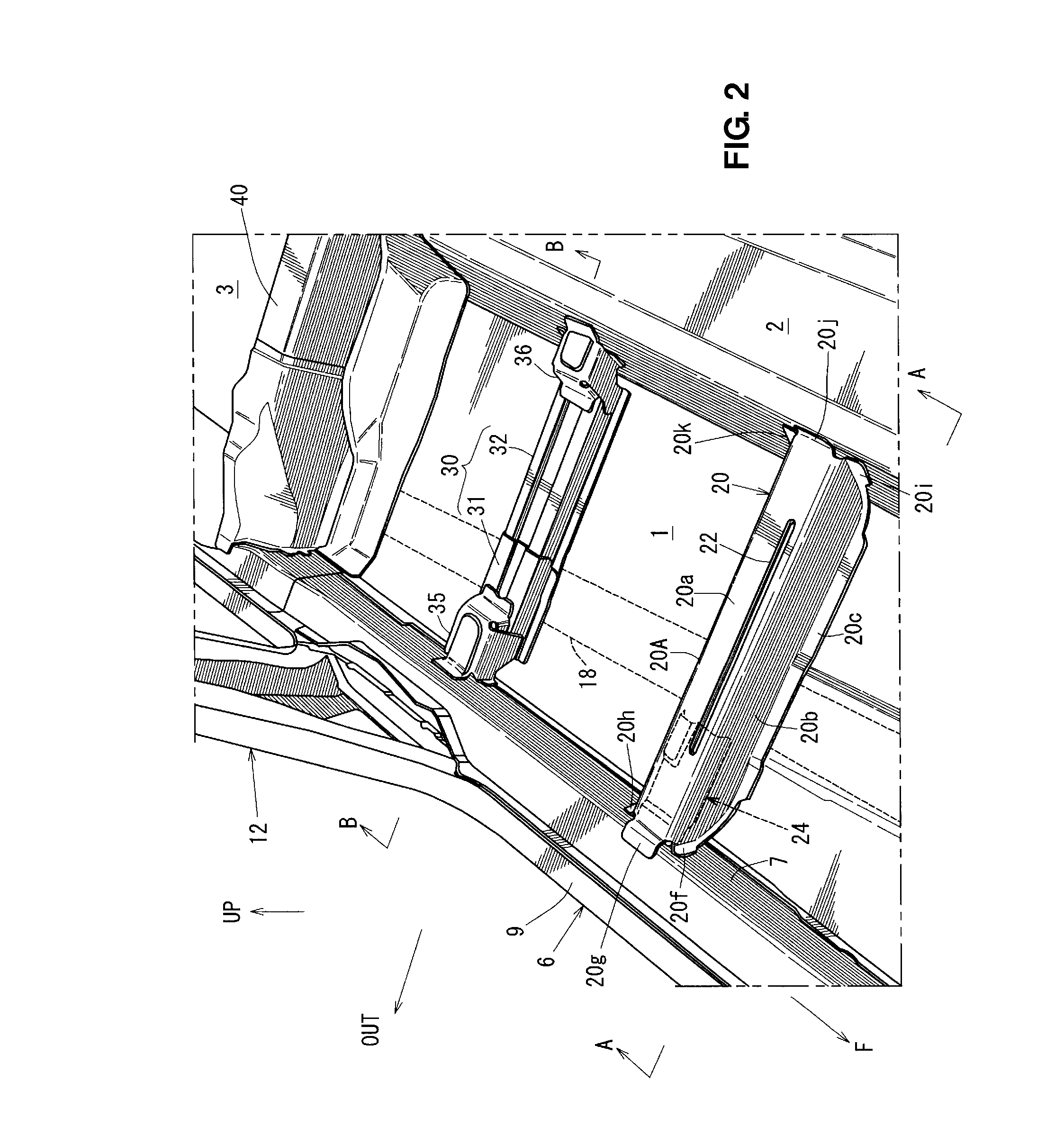

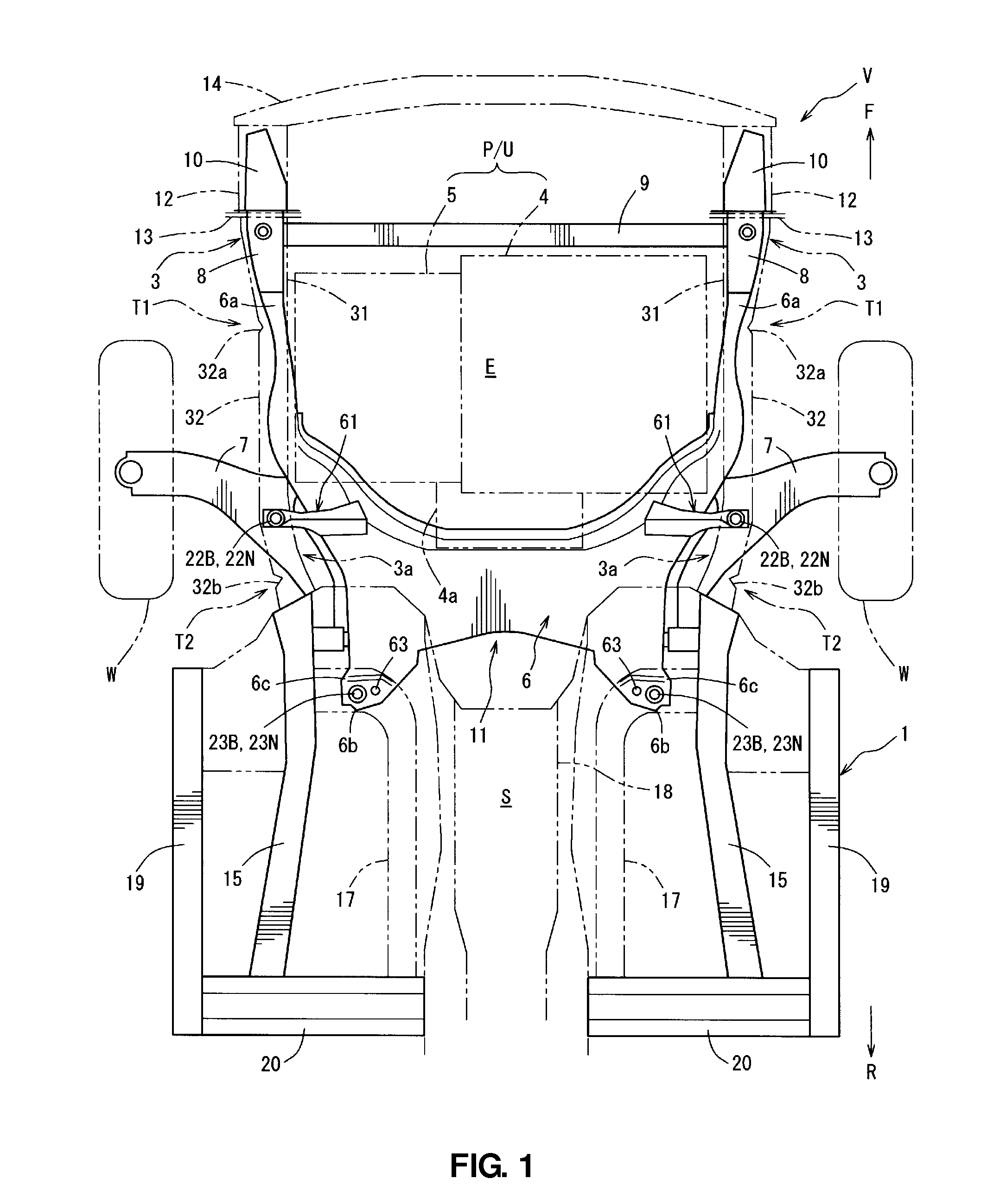

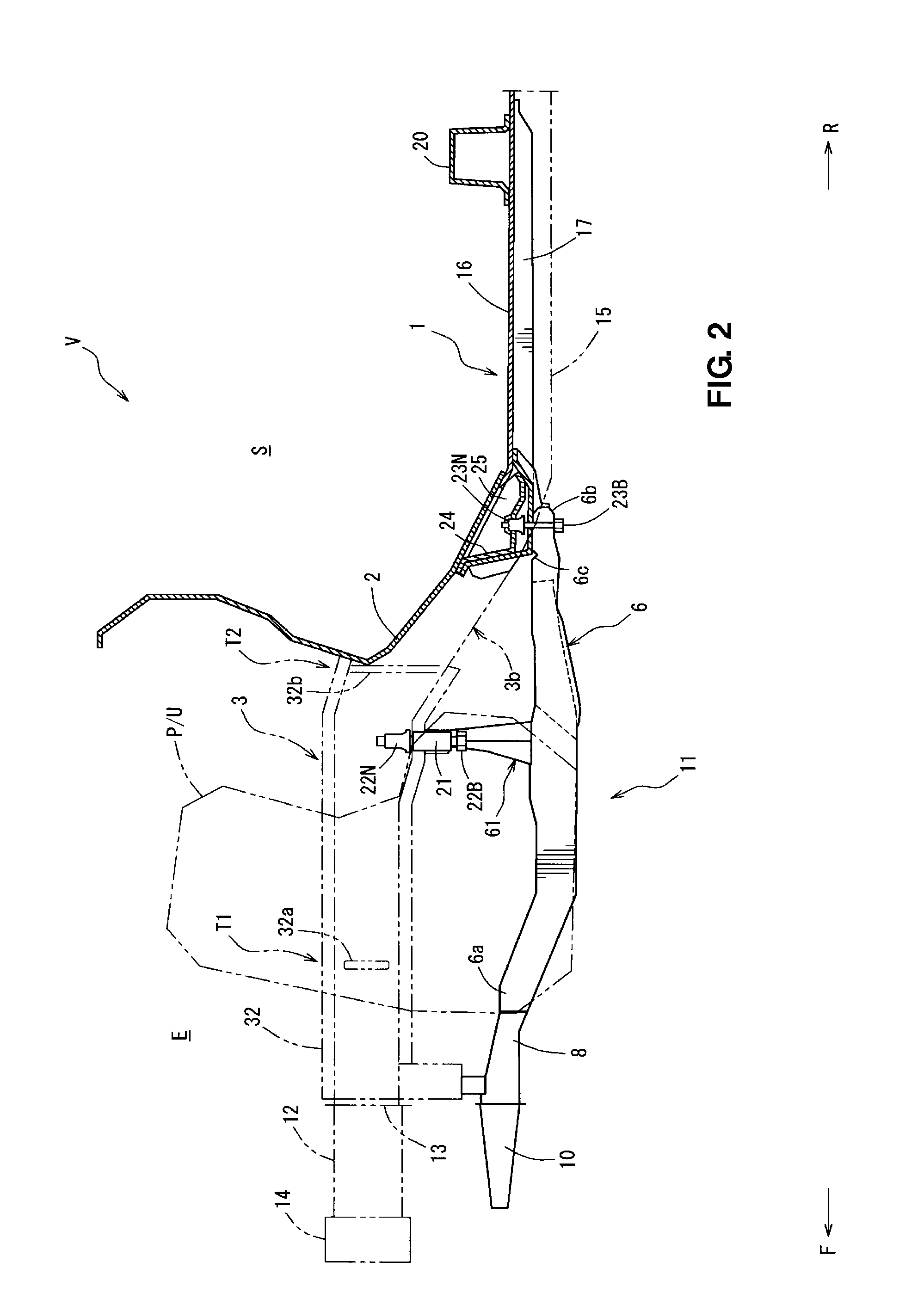

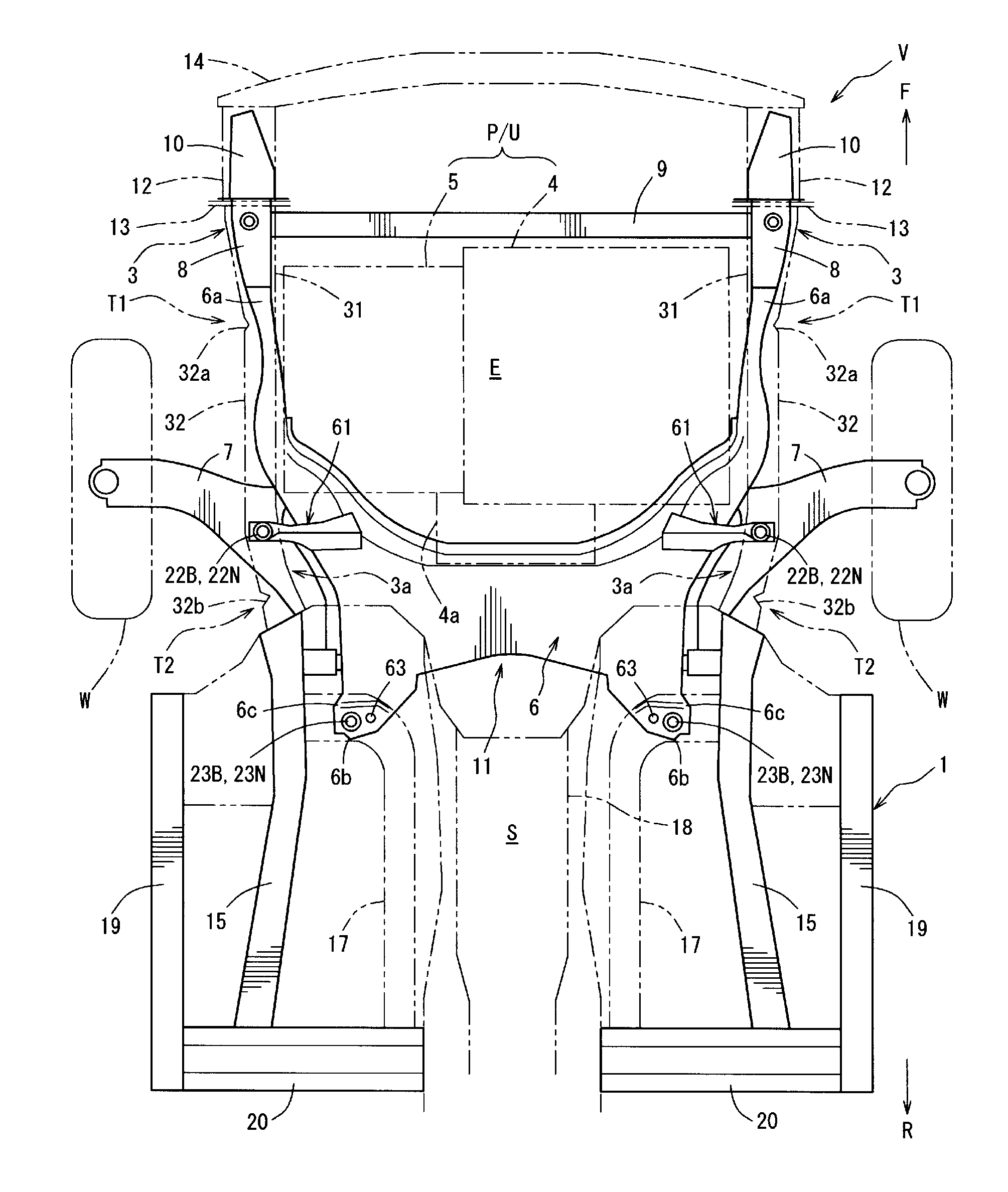

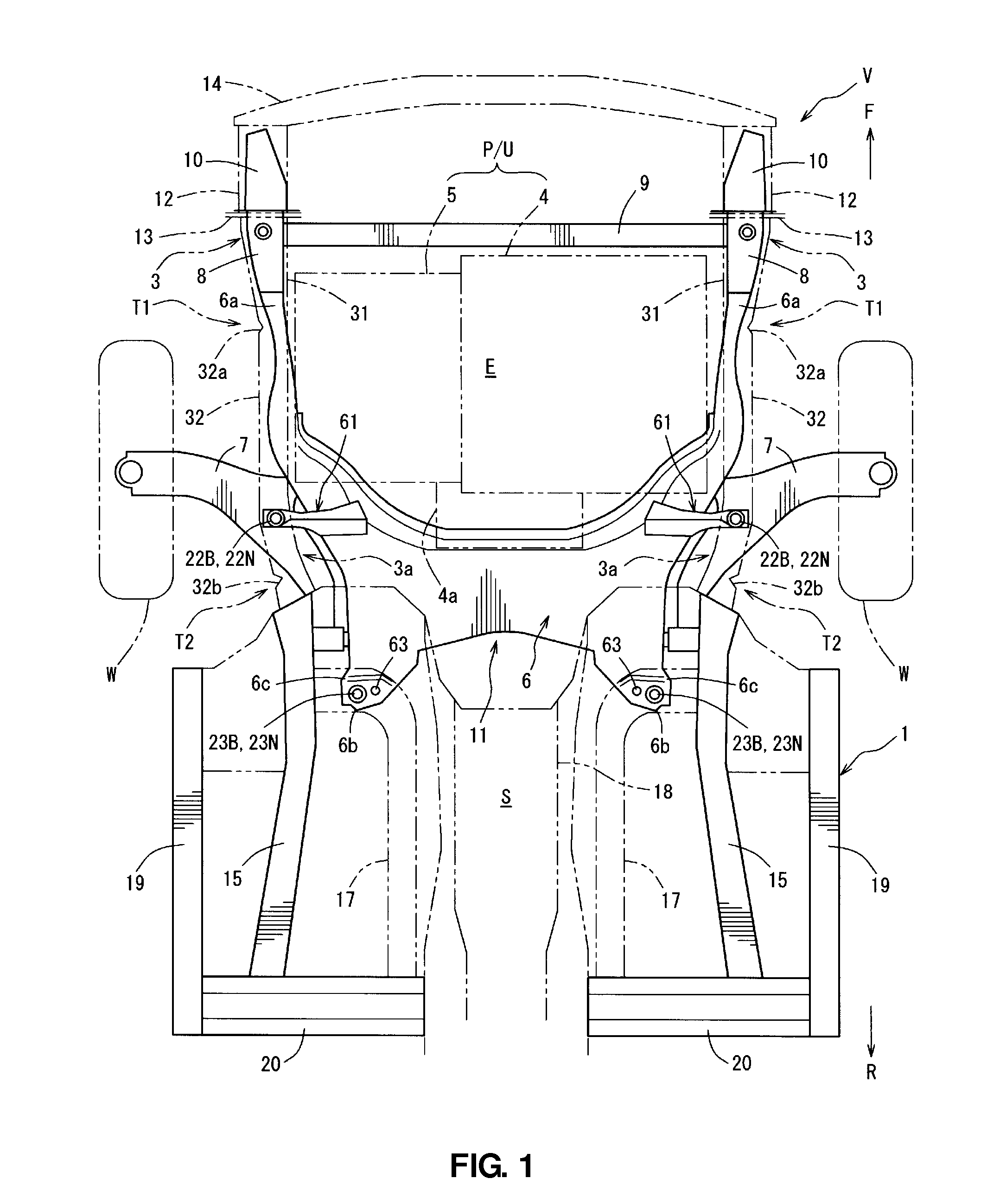

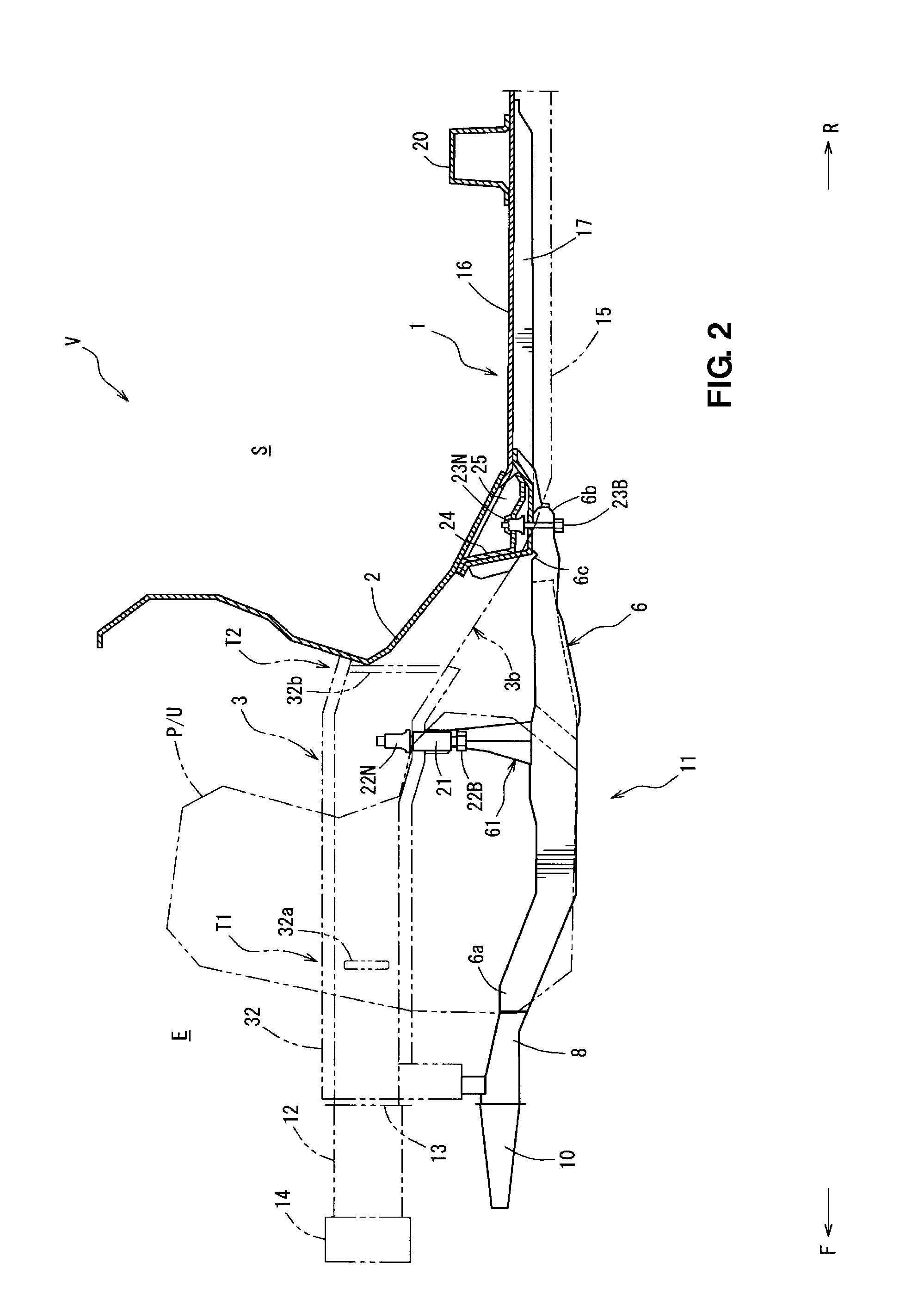

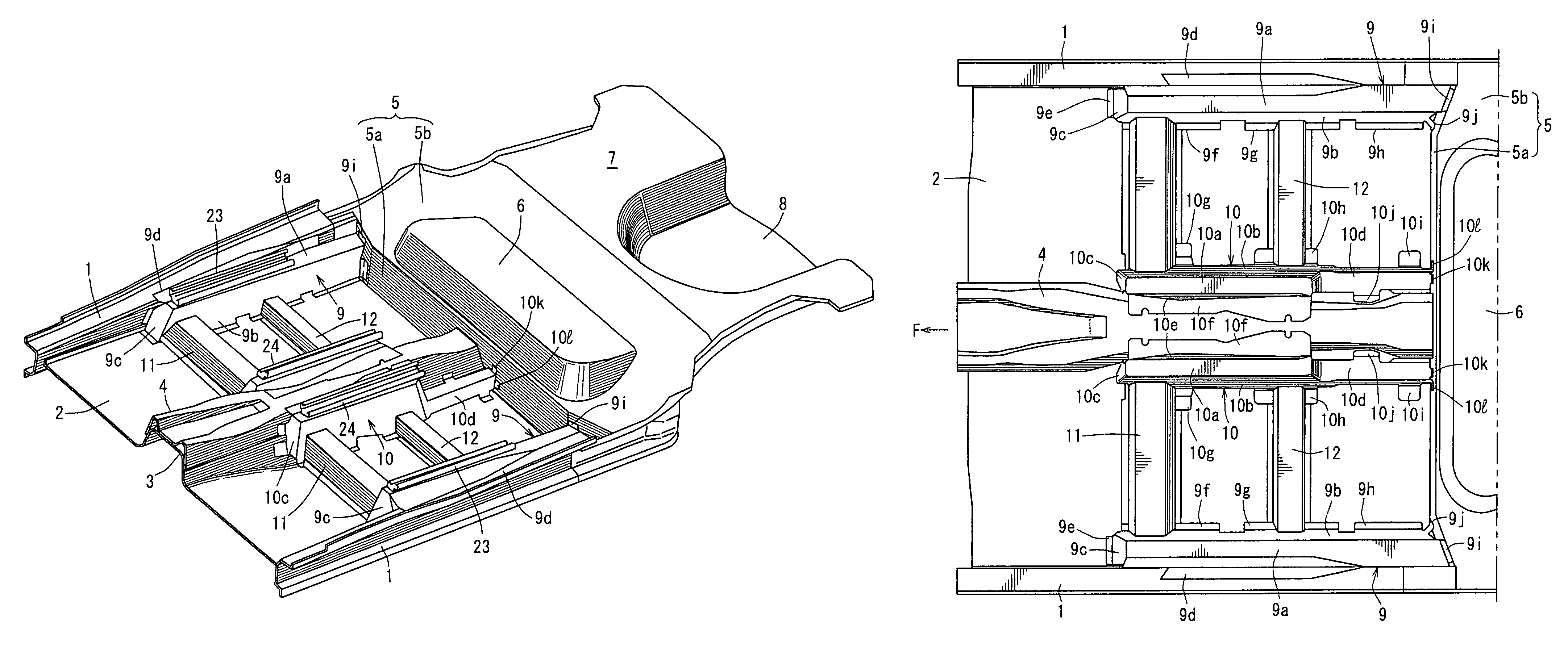

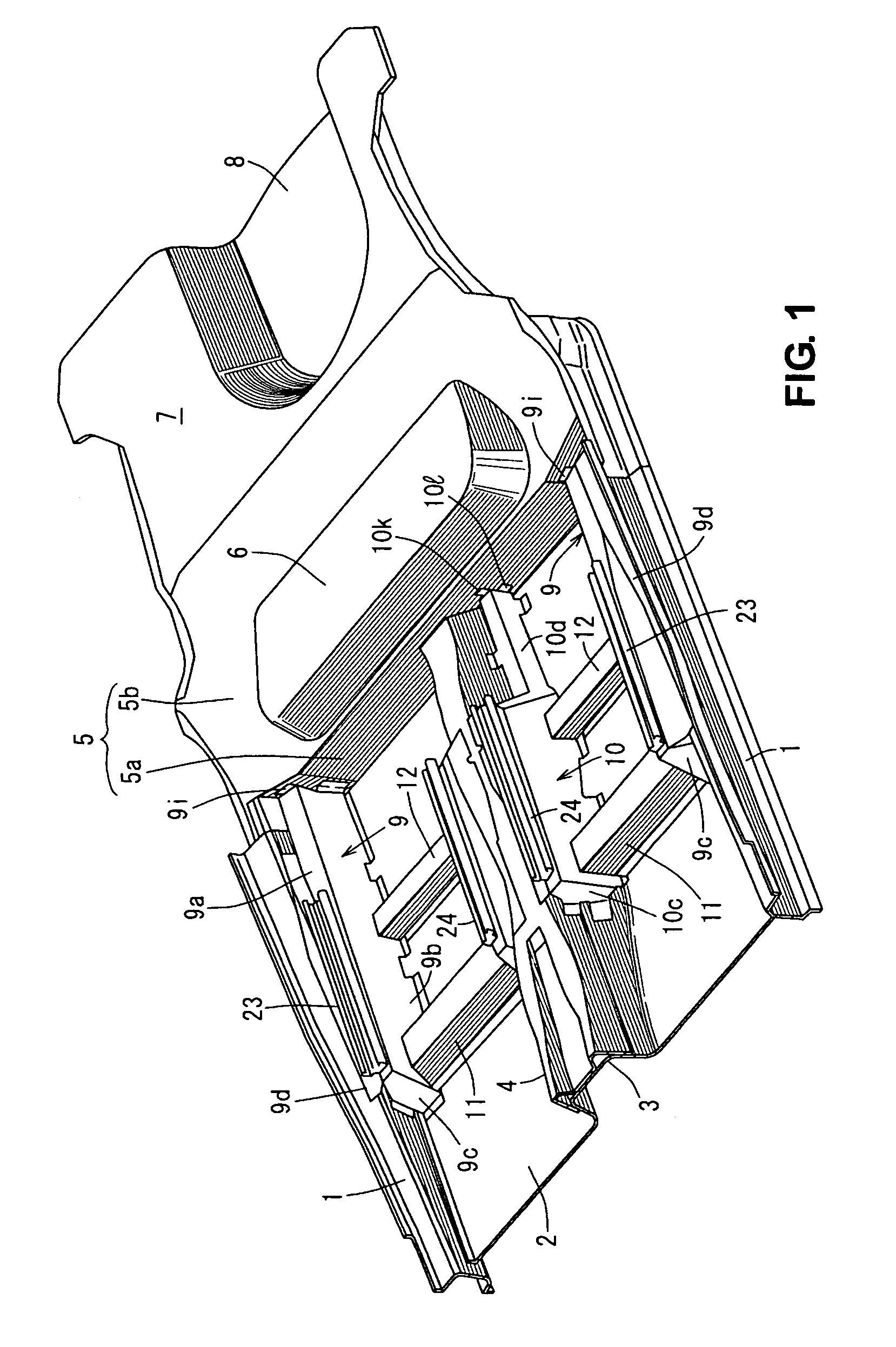

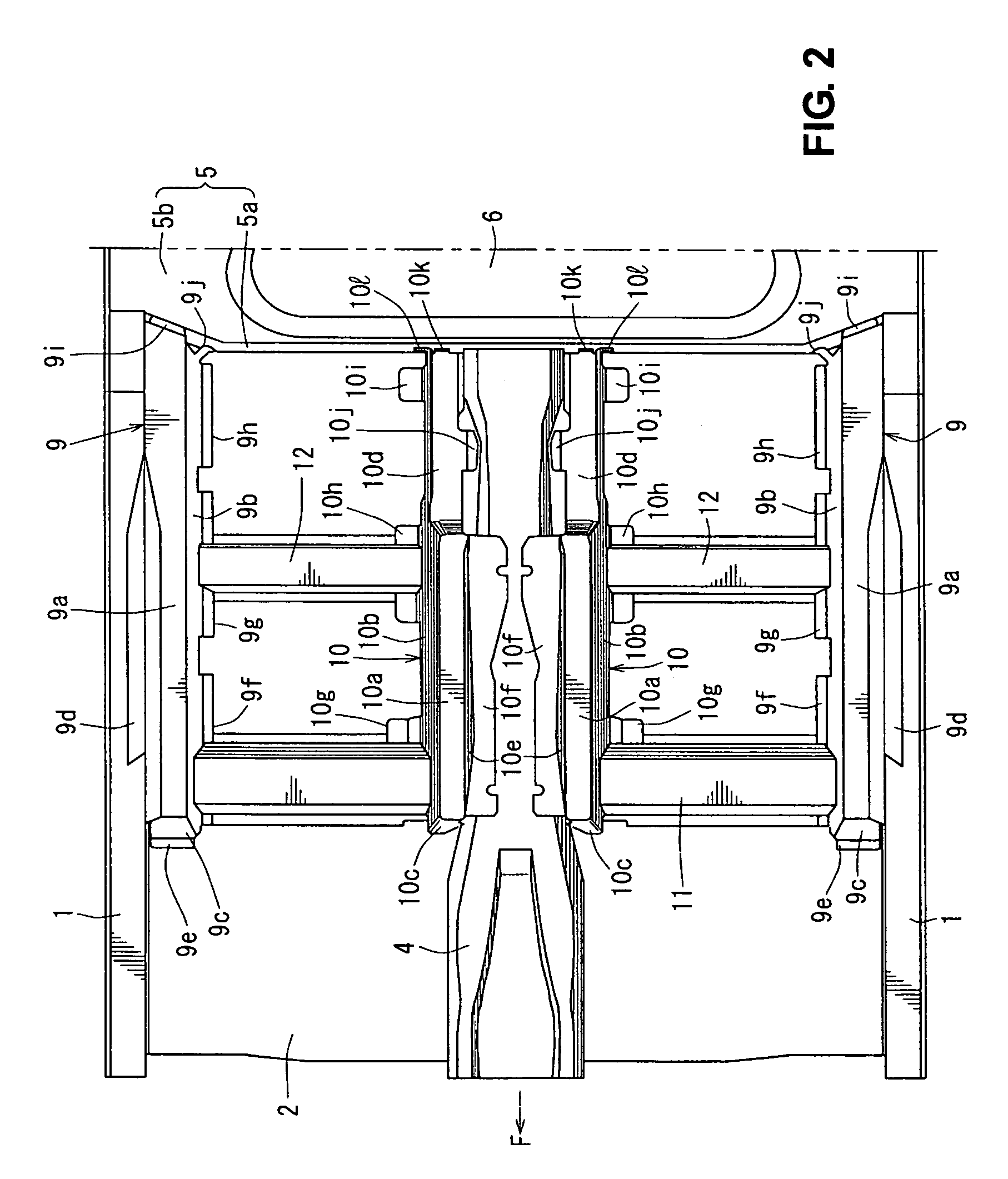

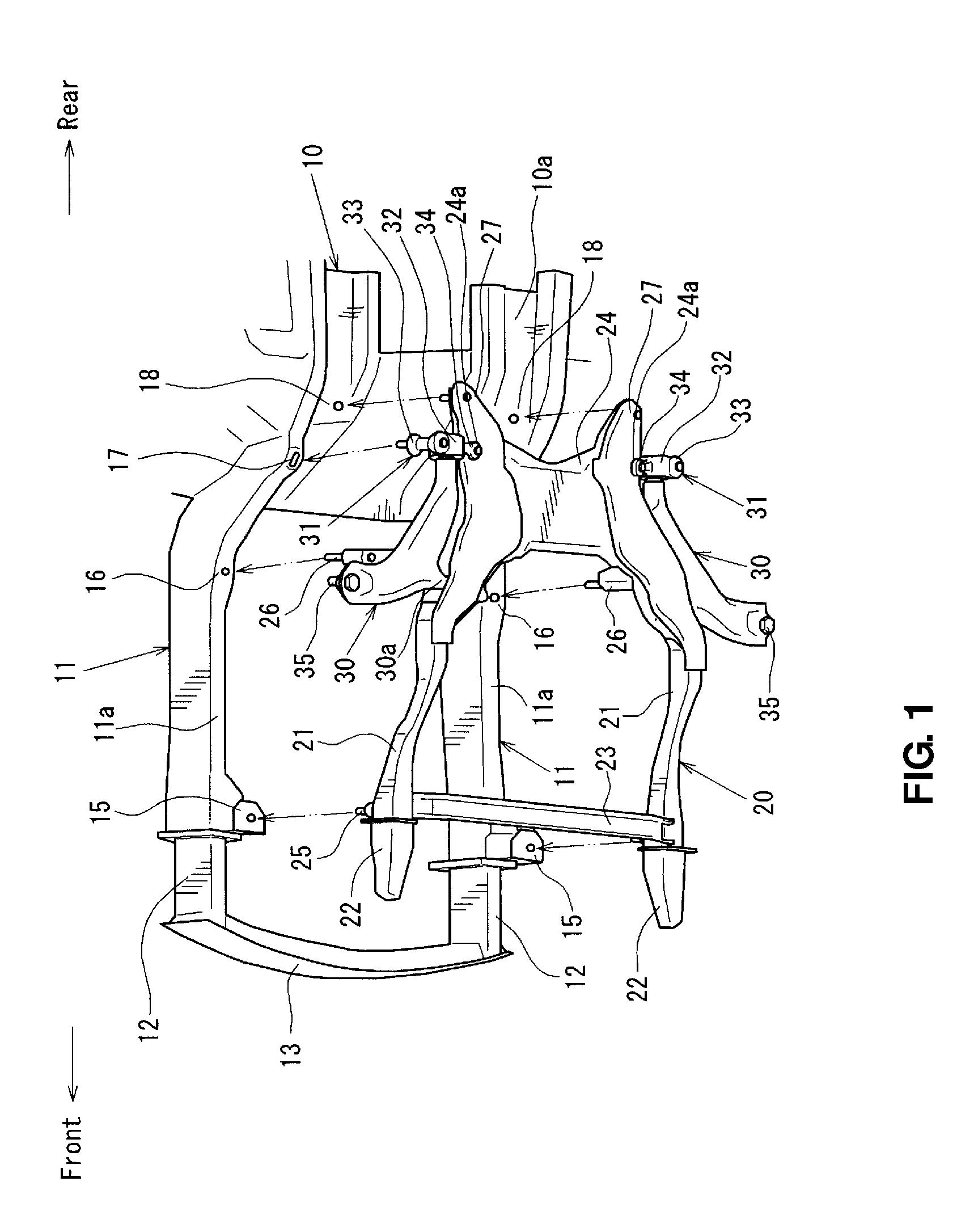

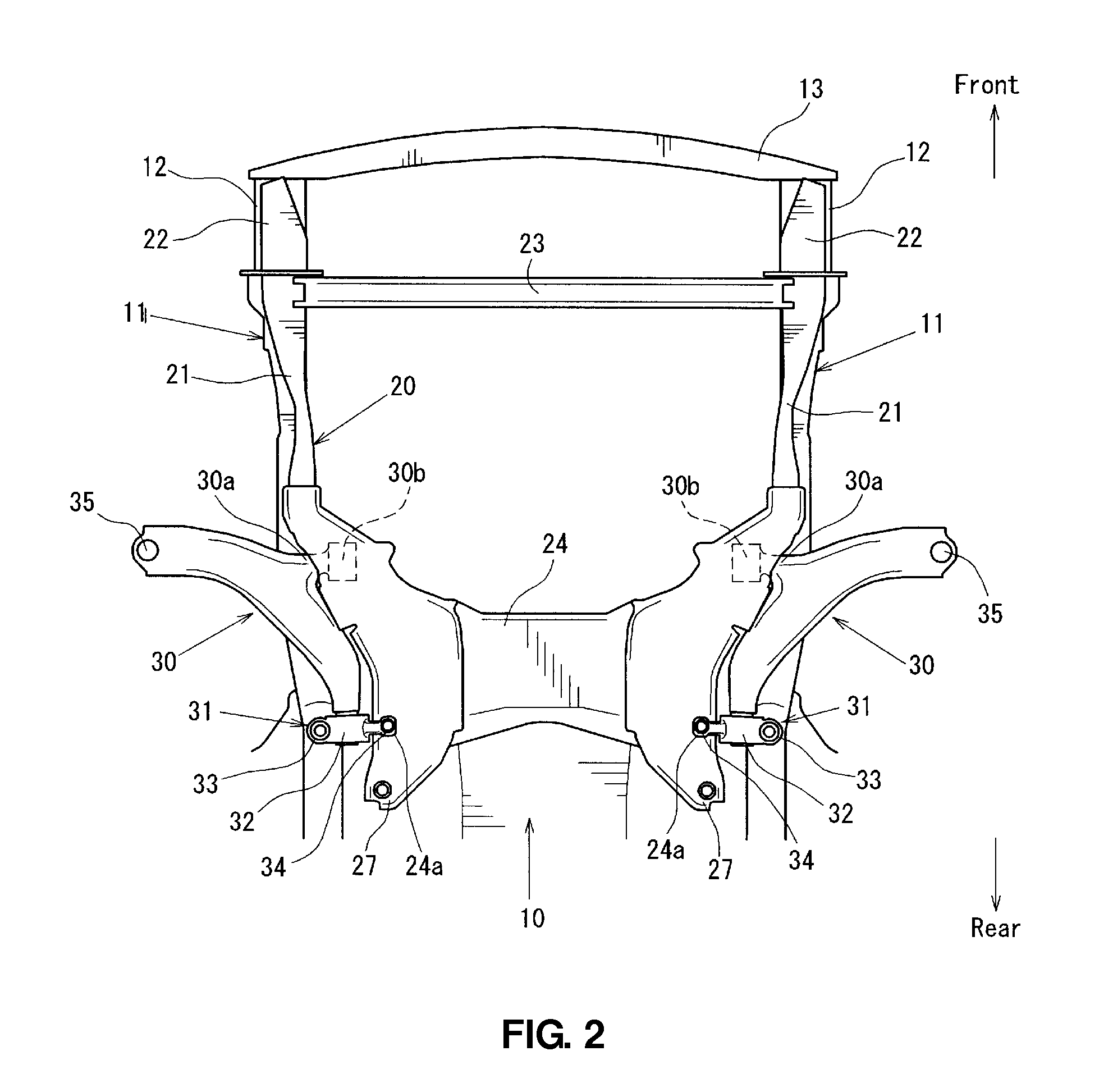

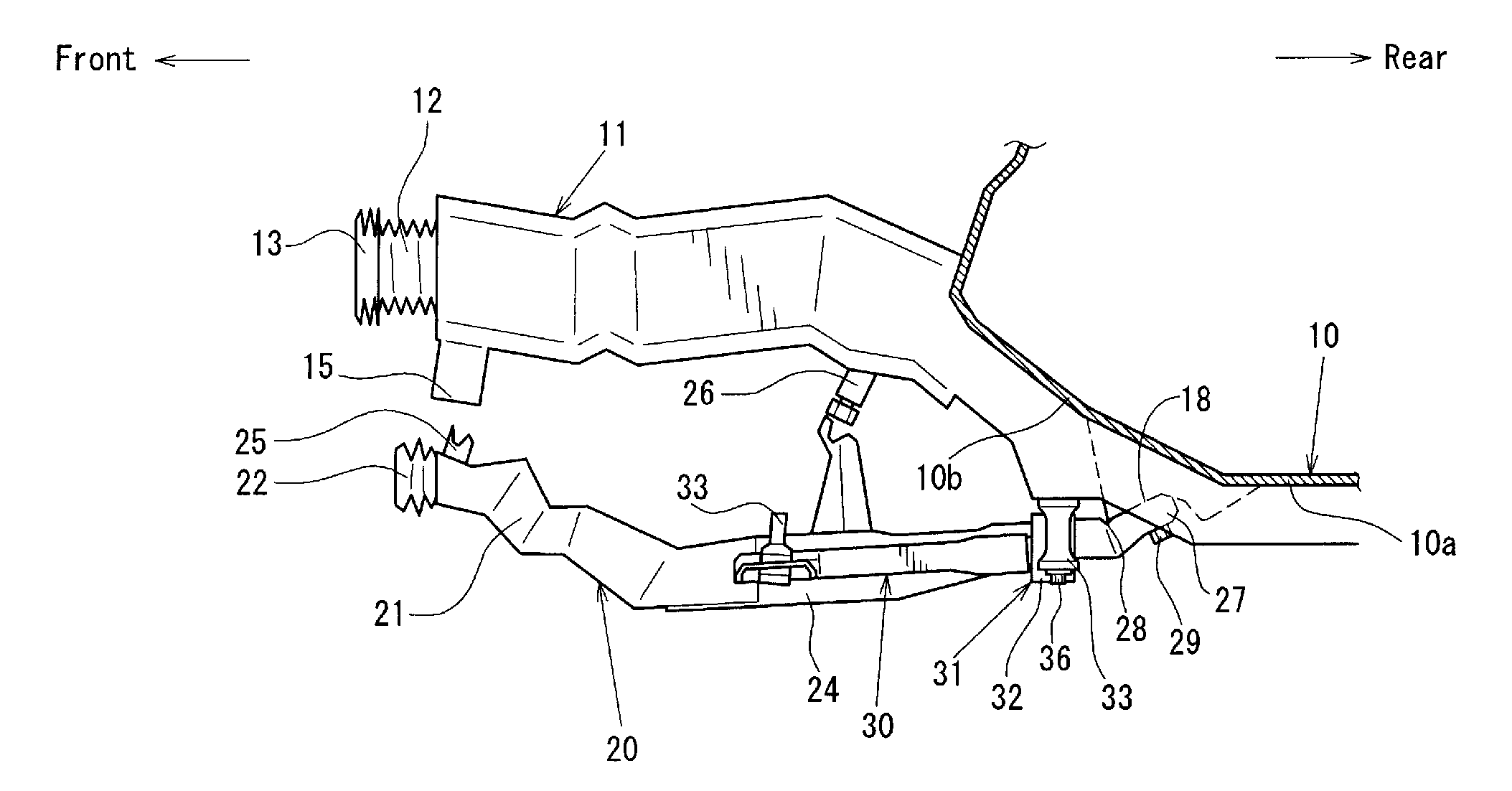

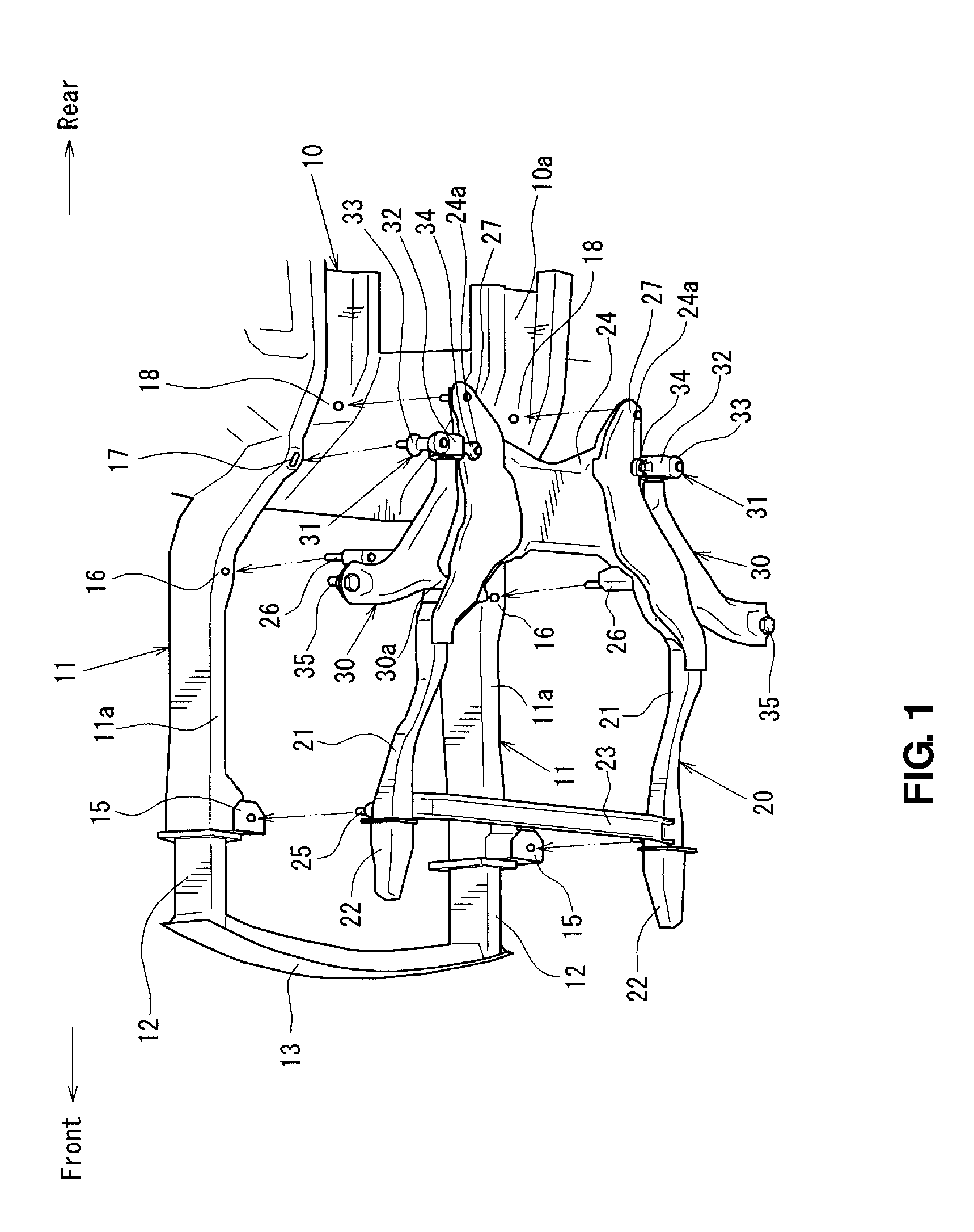

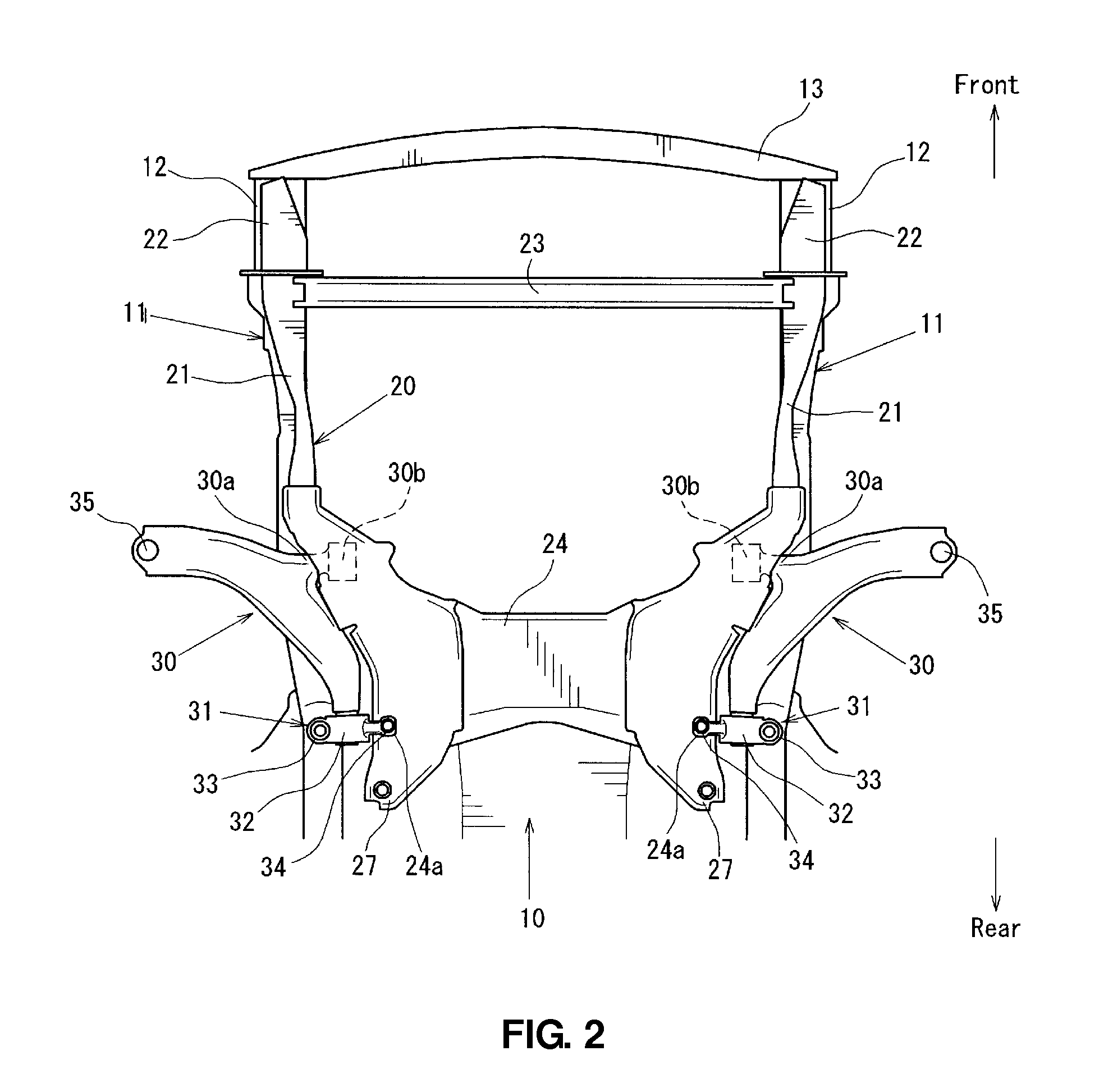

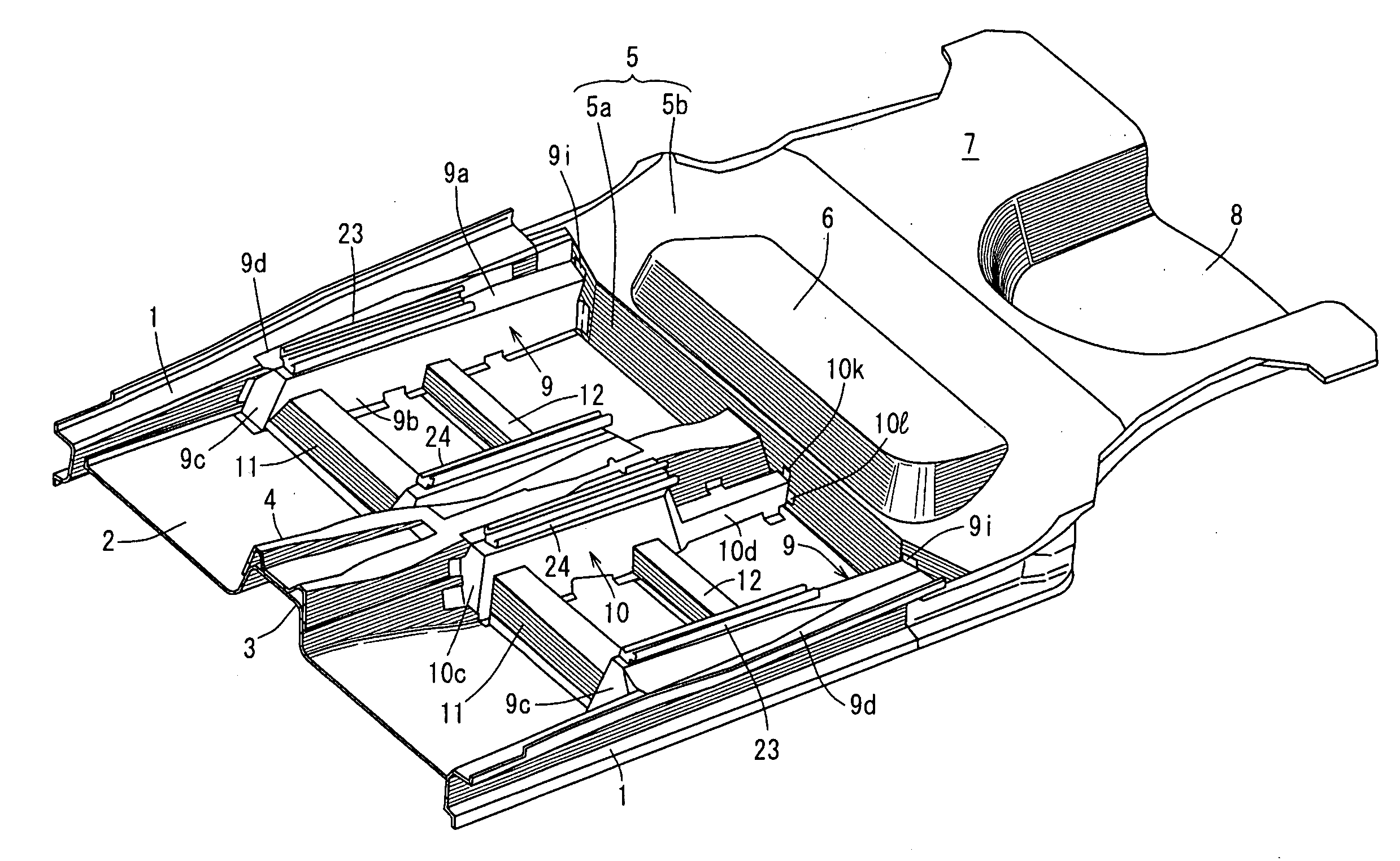

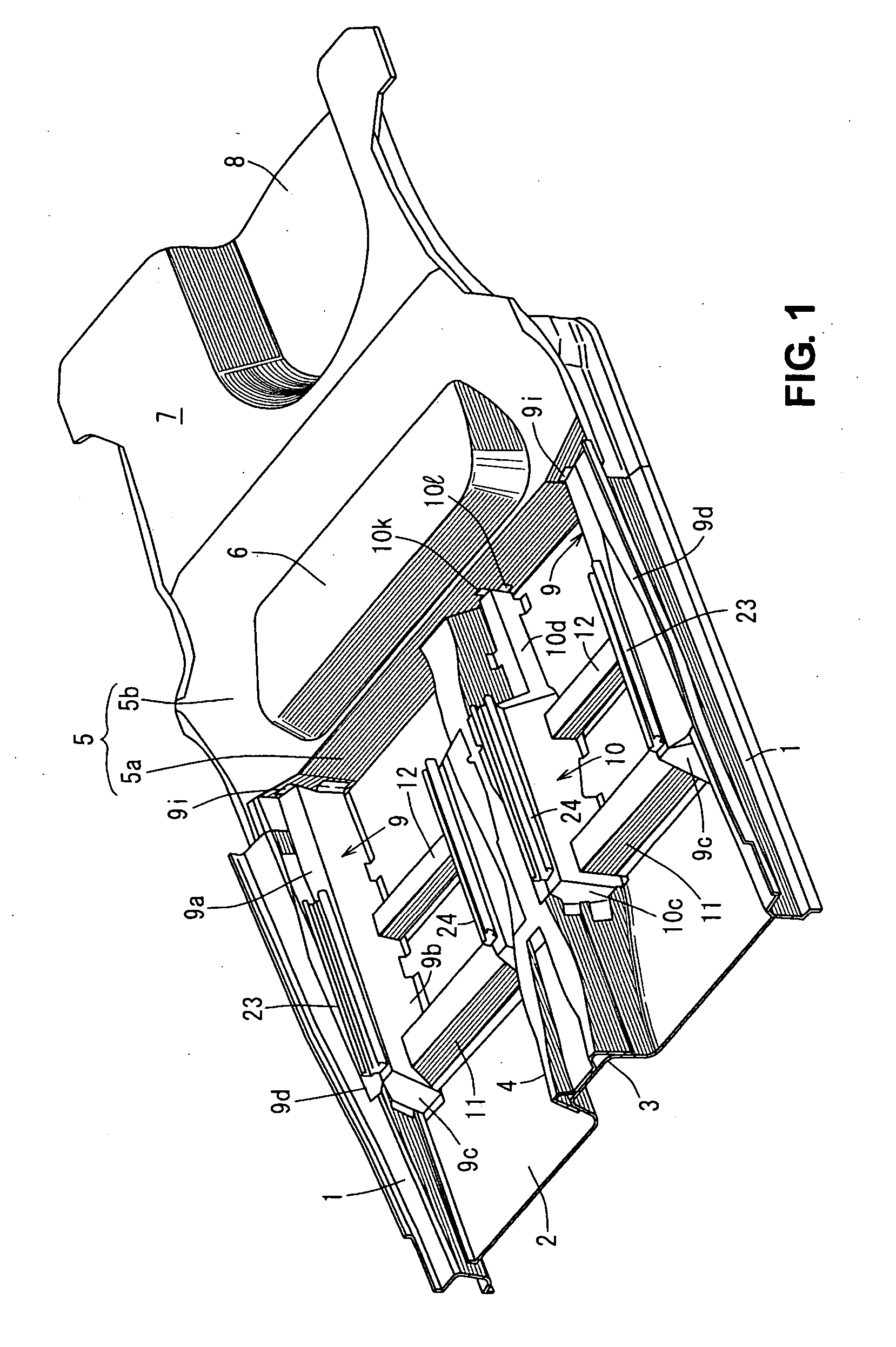

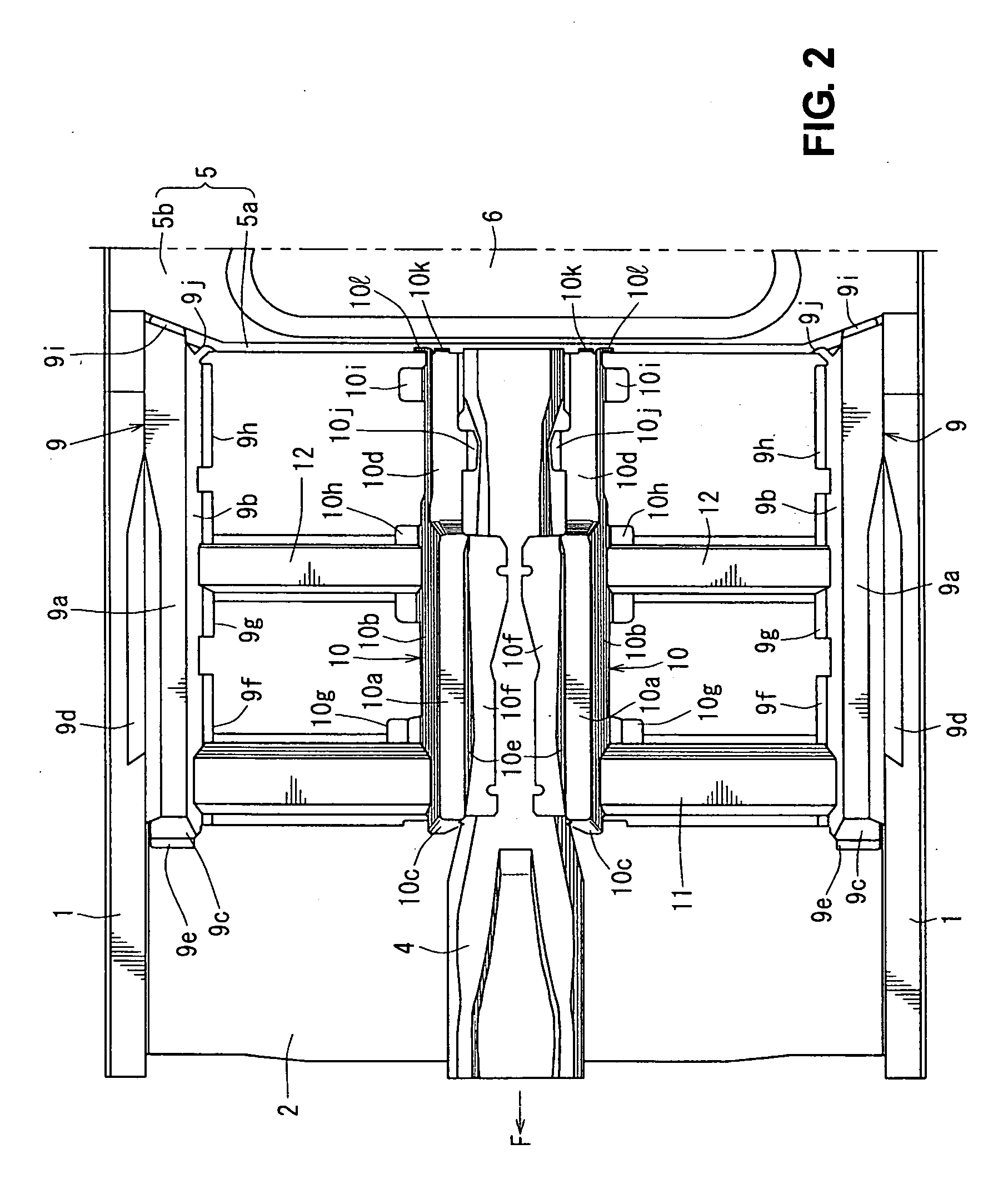

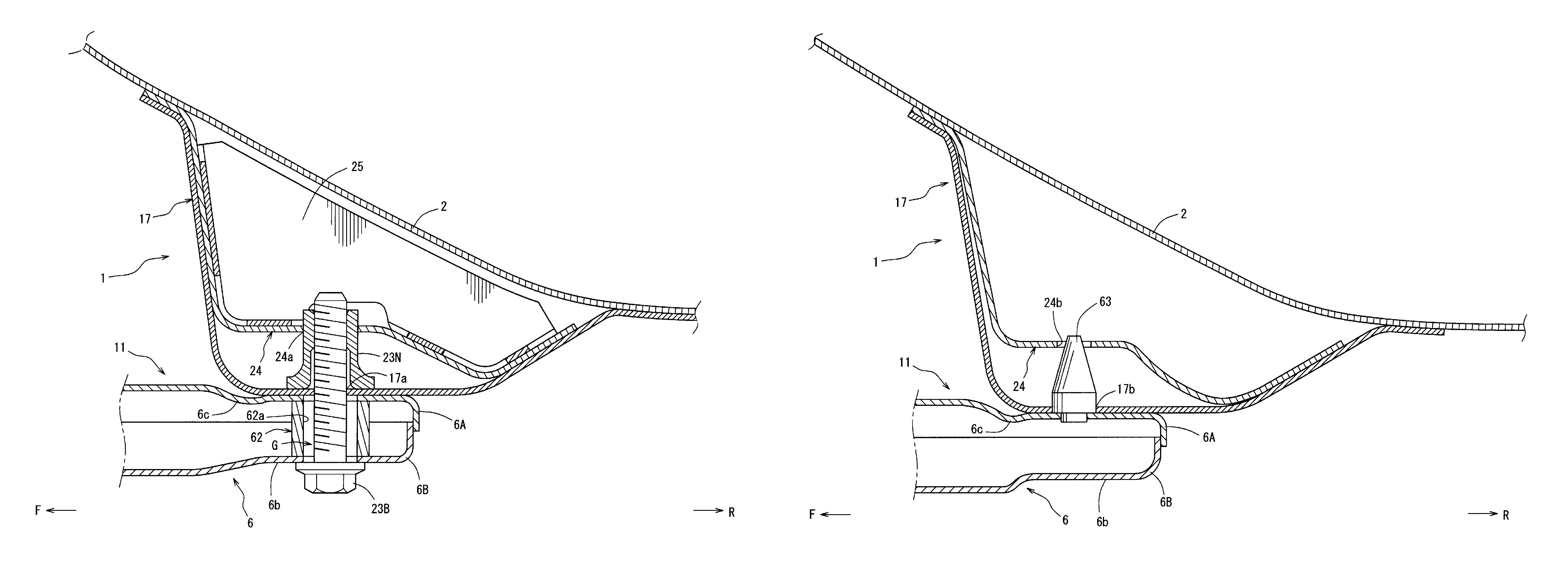

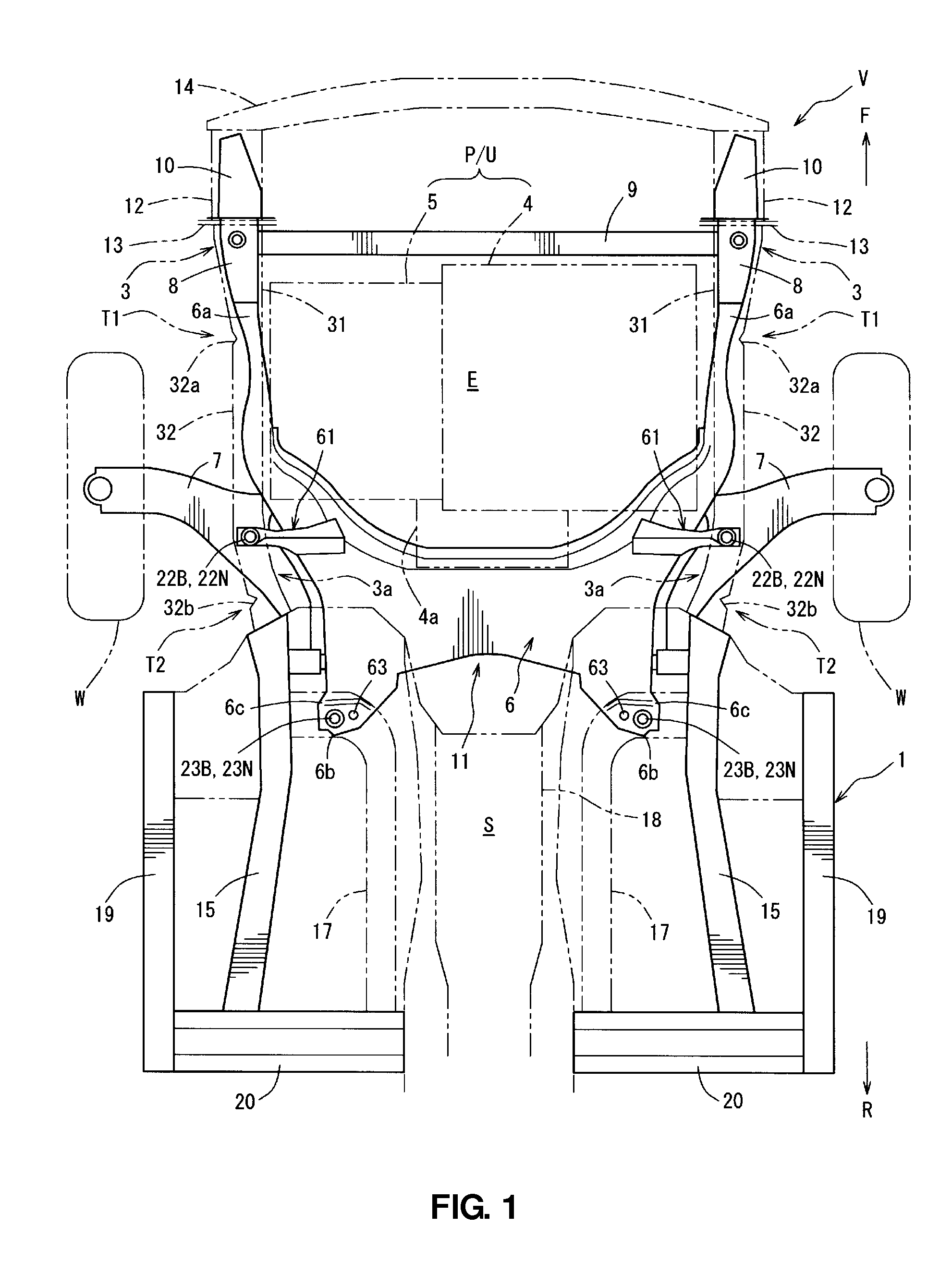

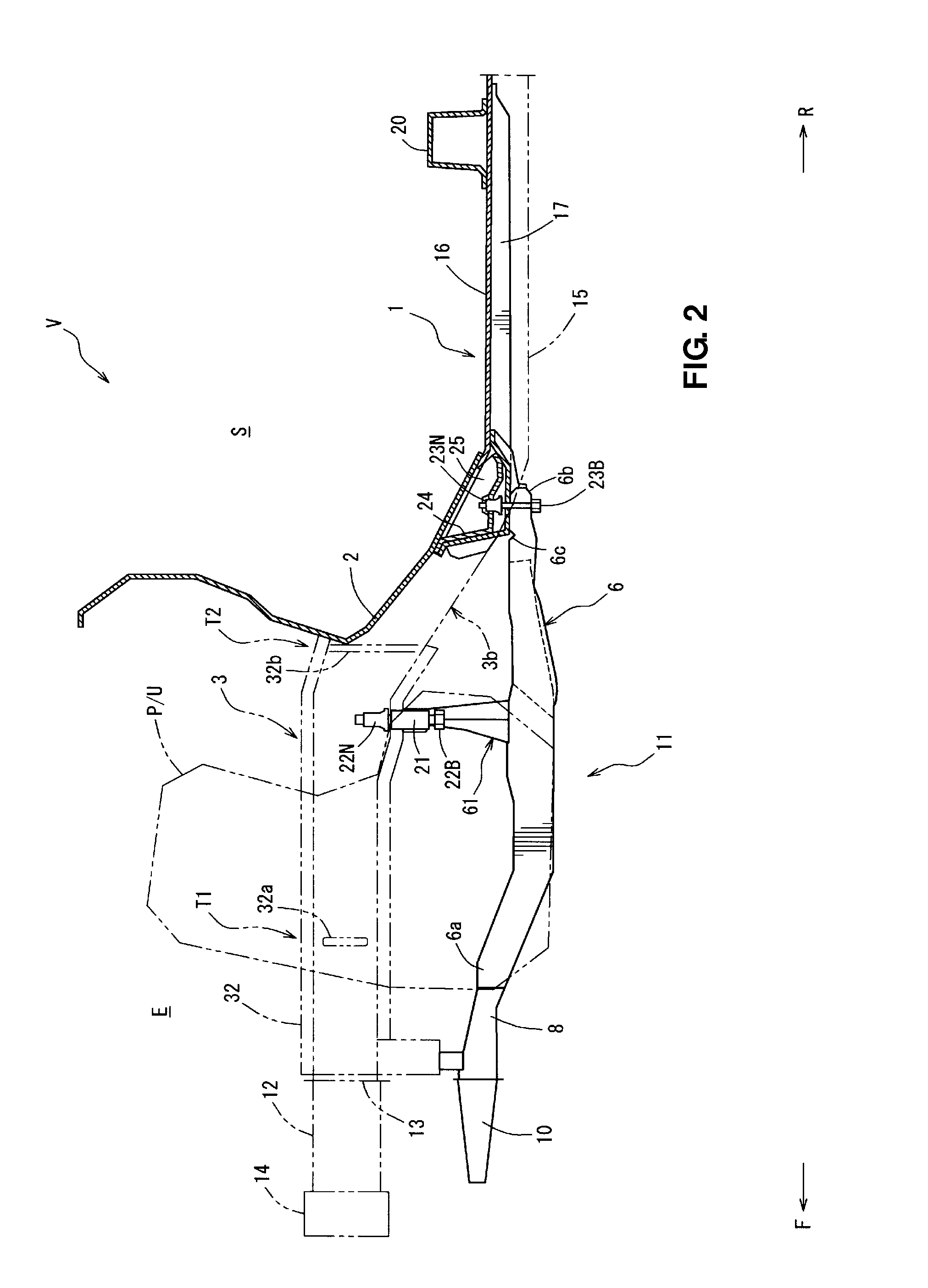

Lower vehicle-body structure of vehicle

ActiveUS20100237659A1Low structural requirementsVehicle seatsUnderstructuresSide impactMechanical engineering

A reinforcing member is provided at a lower-outside corner of a side-sill reinforcement so as to extend in the vehicle longitudinal direction including a connection portion of the side sill to a center pillar for straining deformation of the corner. A deformation promoting portion which is provided at an upper portion of the side-sill reinforcement at a specified position which corresponds to the connection portion for prompting deformation of the upper portion of the side-sill reinforcement. Accordingly, a lower vehicle-body structure of a vehicle which can properly restrain the side sill and the center pillar from coming toward the vehicle inside at the vehicle side crash can be provided.

Owner:MAZDA MOTOR CORP

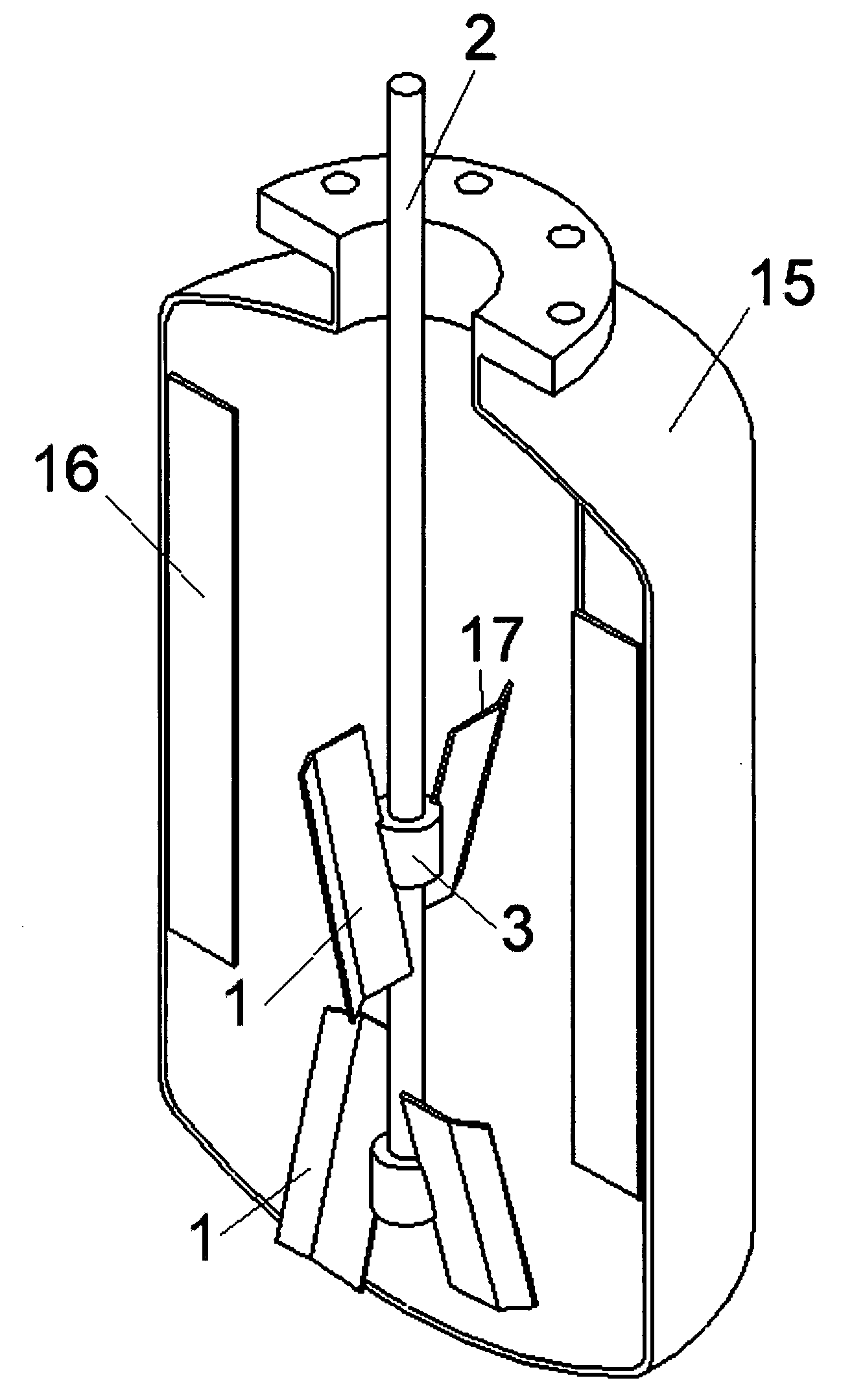

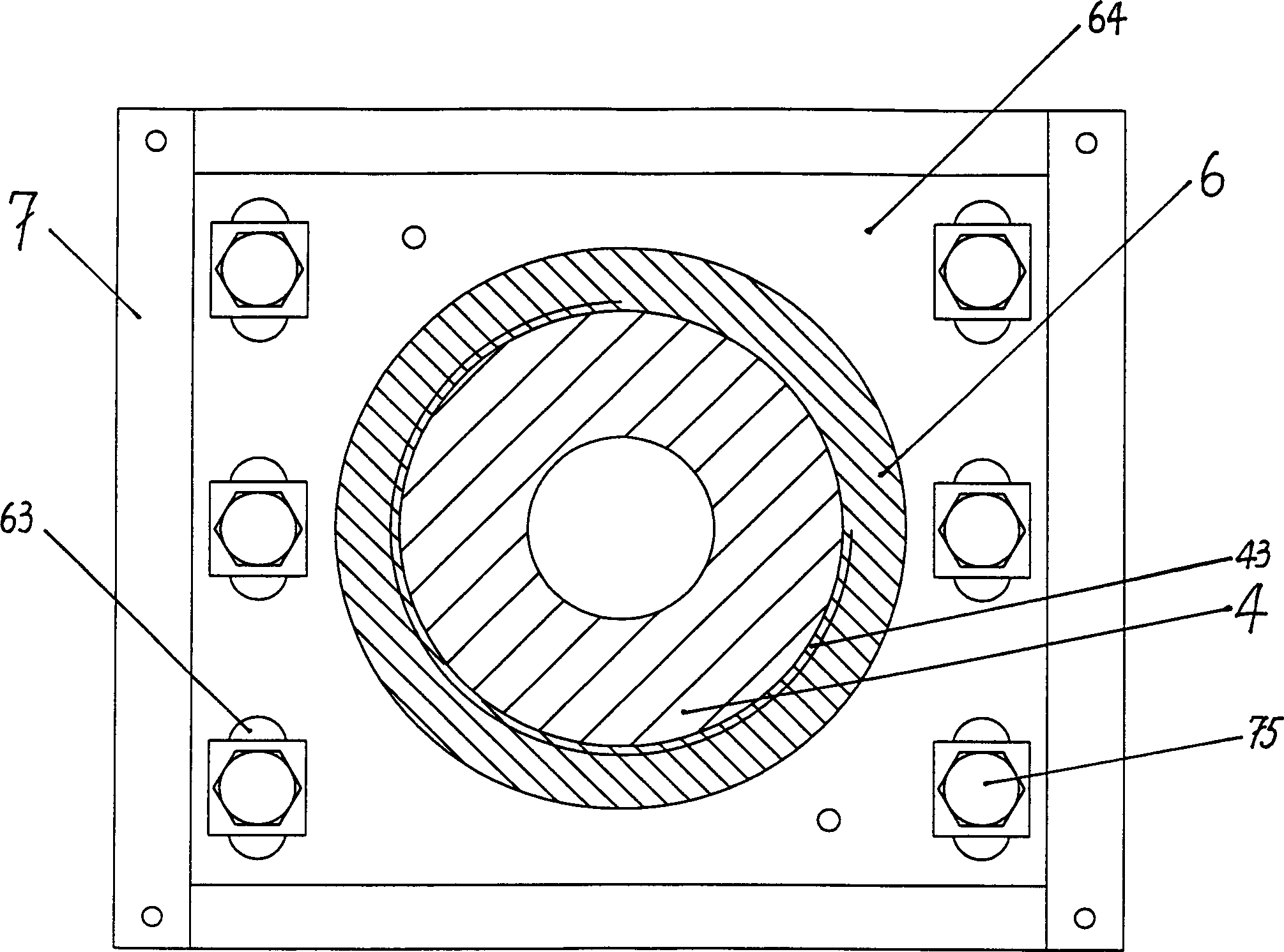

Low shear impeller

ActiveUS20050007874A1Promote stratificationImprove mixing efficiencyFlow mixersTransportation and packagingImpellerDrive shaft

One or more mixing impellers is carried on a driving shaft received in a mixing vessel. Impeller blades are angularly and / or axially distributed on the shaft and can be single staggered axially-spaced blades or groups of two or more placed angularly around the shaft, e.g., diametrically opposite. Each blade has a radially inner flat plate sloped to produce axial flow, preferably at about 15° from parallel to the rotation axis. An outer plate is joined to the inner plate at a bend line with an angle of about 20° located at about 70% of the outside diameter of the impeller path.

Owner:PHILADELPHIA GEAR

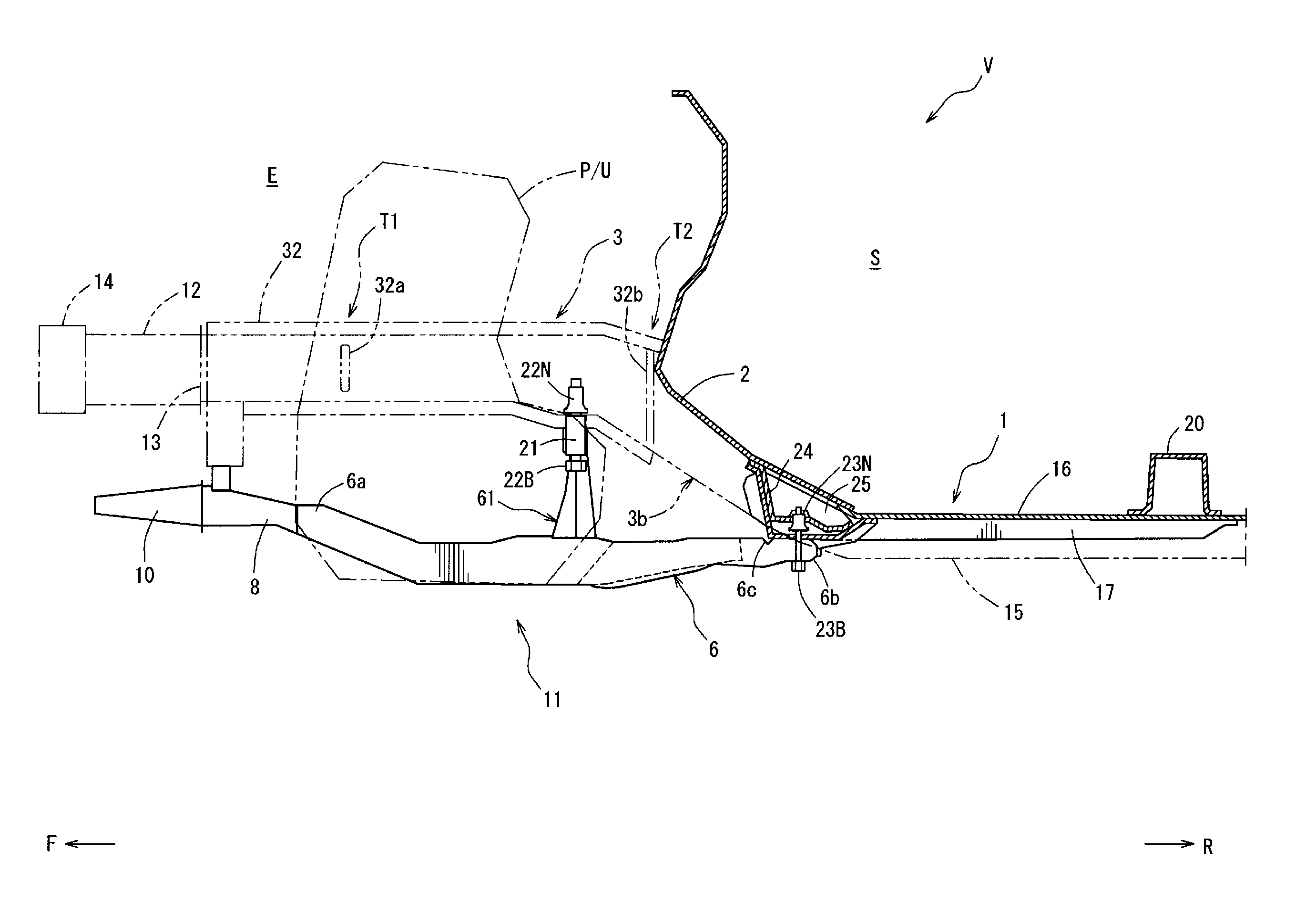

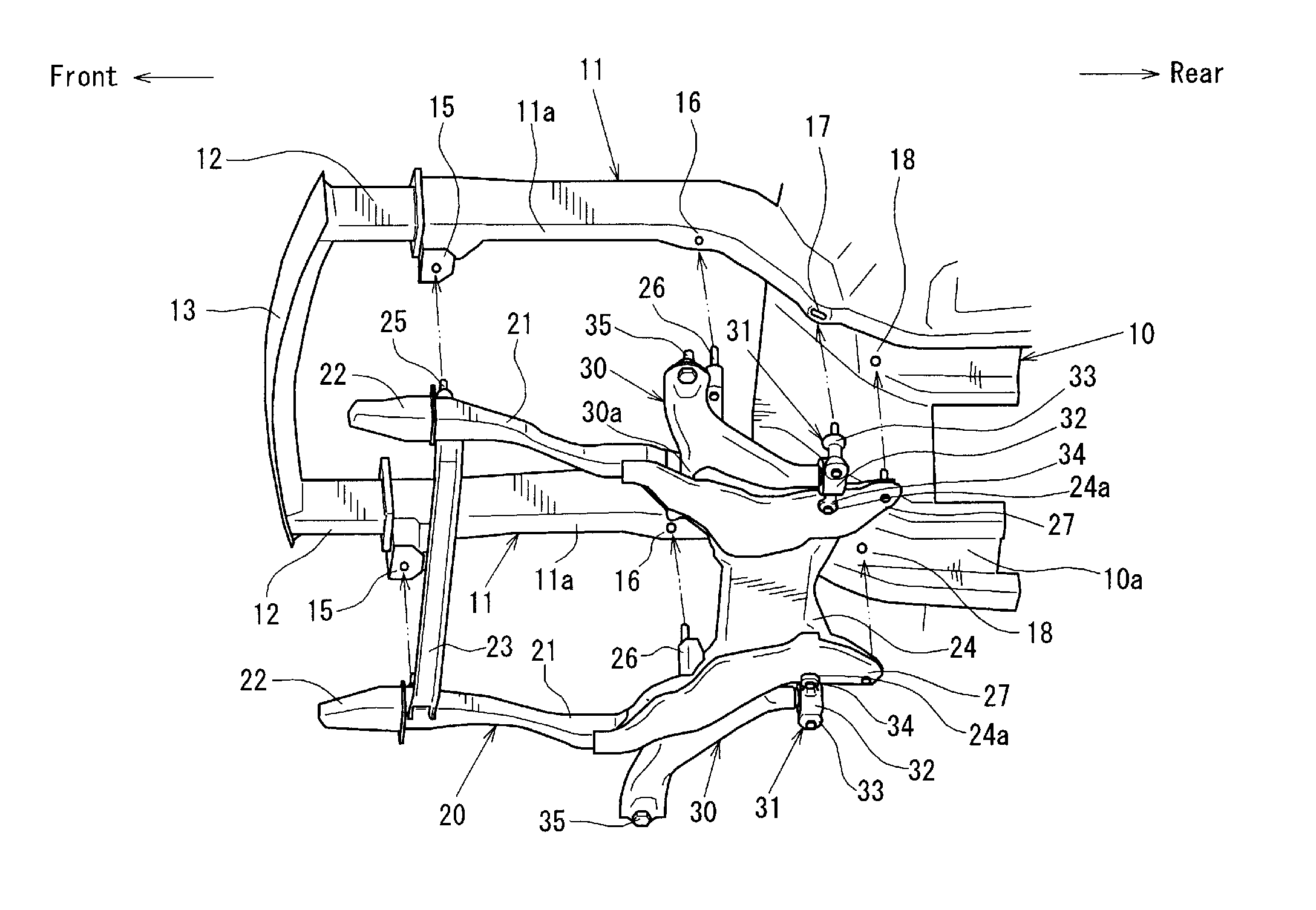

Lower structure of automotive vehicle

InactiveUS8490988B2Low structural requirementsAvoid loadSteering linkagesUnderstructuresEngineeringMechanical engineering

Owner:MAZDA MOTOR CORP

Damped micromechanical device

InactiveUS6787969B2Low structural requirementsControl the damping of micromechanical devicesAcceleration measurement using interia forcesSolid-state devicesEngineering

Owner:COHERENT INC

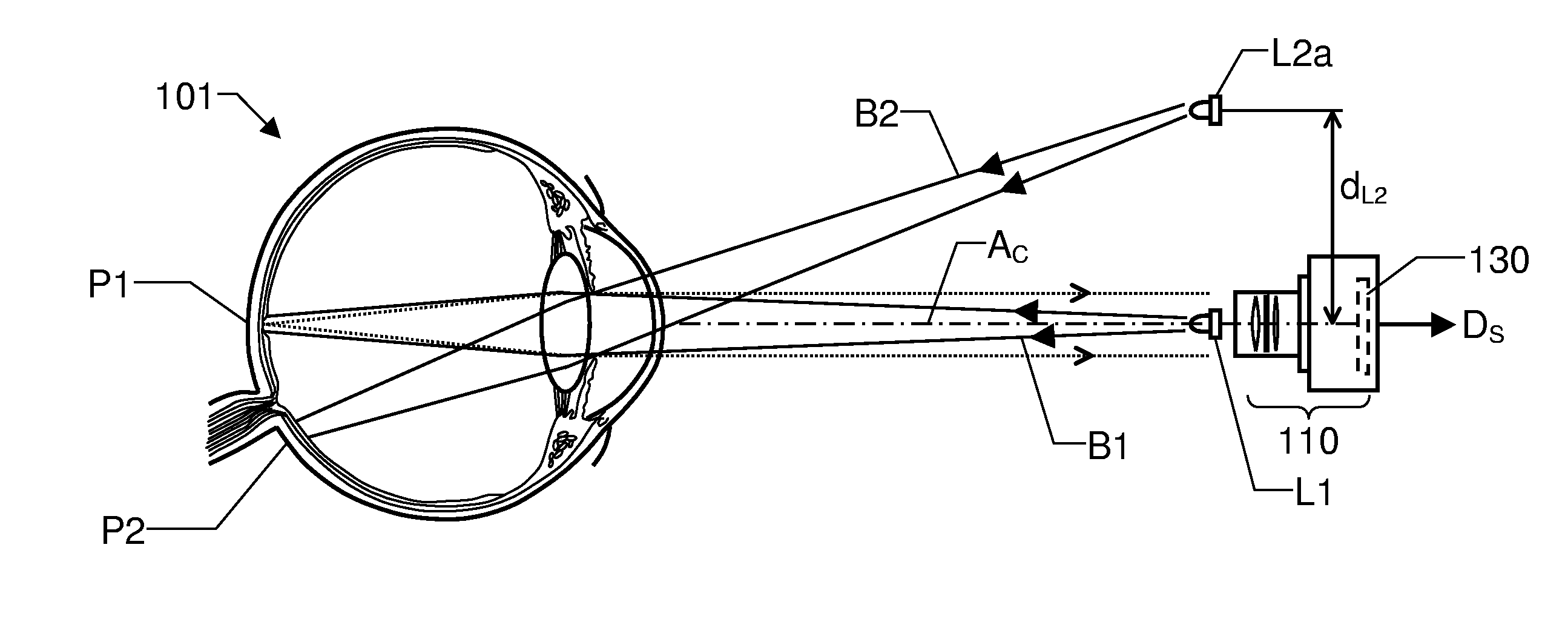

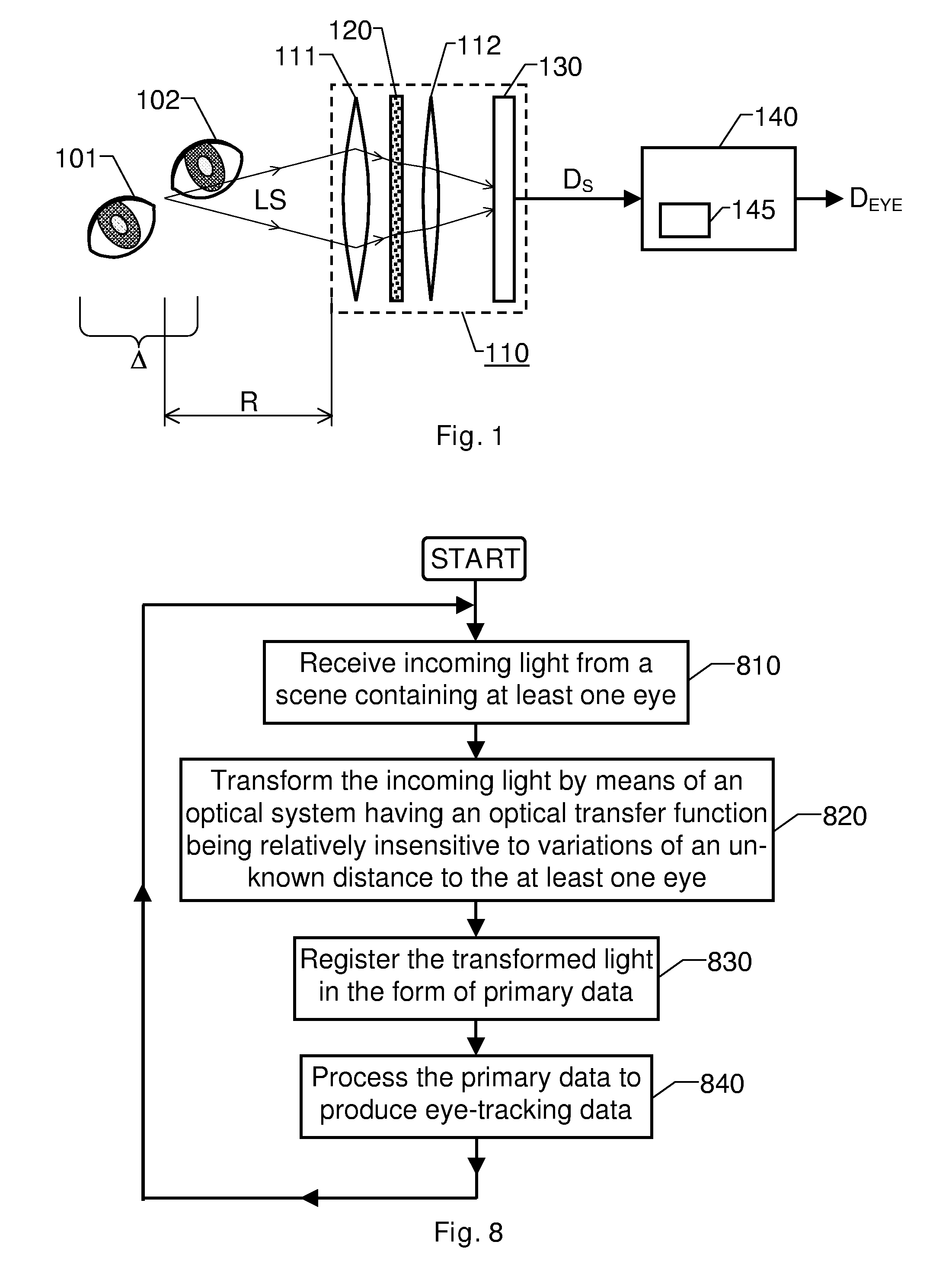

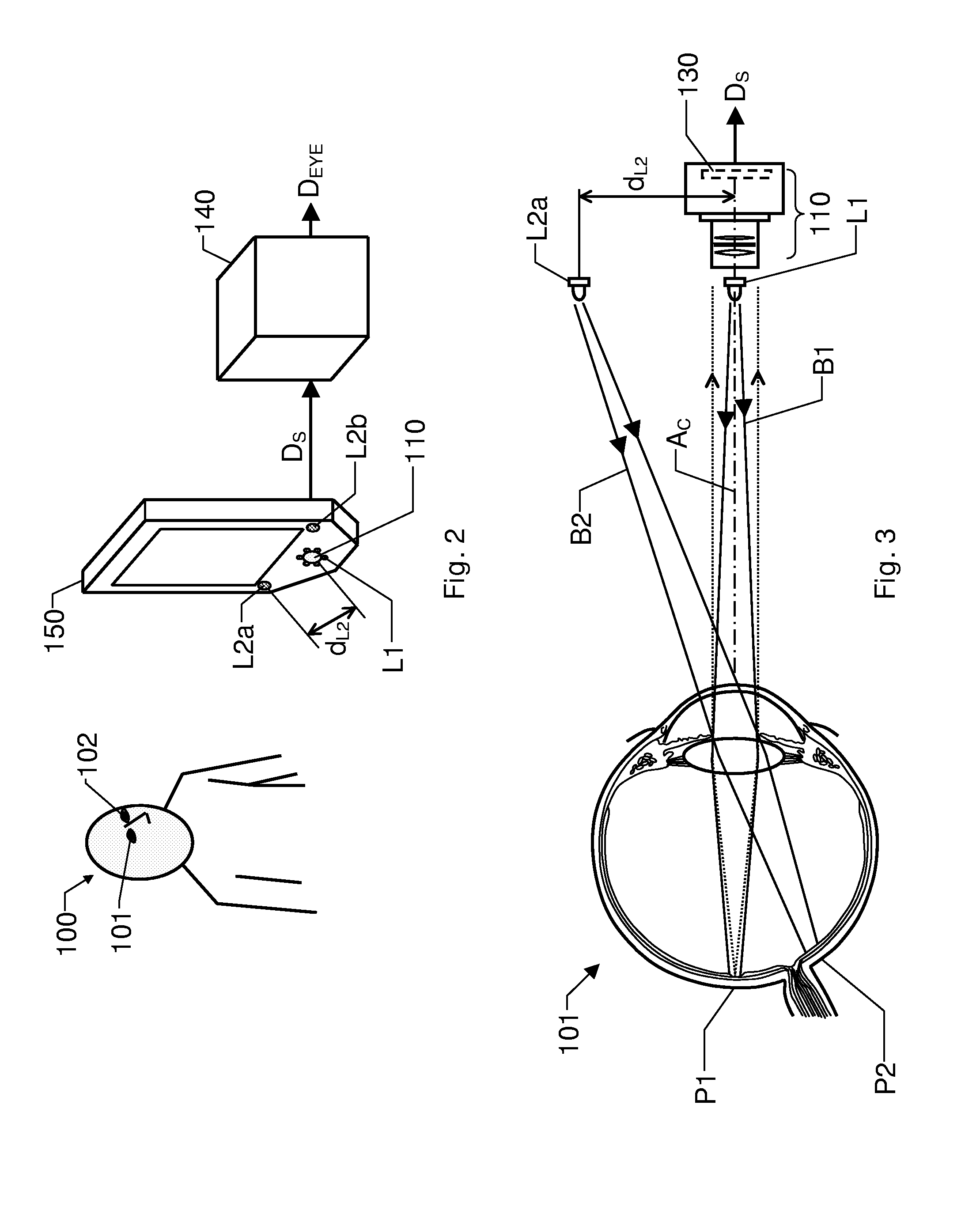

Eye Tracker Having an Extended Span of Operating Distances

ActiveUS20080284980A1Reliable automatic eye trackingSignificant changeImage analysisAcquiring/recognising eyesSignal transfer functionGaze directions

The present invention relates to automatic registration and tracking of the eyes of at least one subject. An optical system, including a lens structure, a mask and an image sensor, receives incoming light from a scene containing the subject and directs at least a portion of this light towards the image sensor, which registers spatially distributed light and thus produces primary data. The mask is adapted to alter a basic optical transfer function of the lens structure and the image sensor into an enhanced optical transfer function, which is substantially less sensitive to variations of an unknown distance between the optical system and the subject than the basic optical transfer function. The processing unit is adapted to receive the primary data and process this data to produce resulting eye-tracking data representing a position estimate of the at least one eye and / or a gaze direction for the at least one eye.

Owner:TOBII TECH AB

Lower structure of automotive vehicle

InactiveUS20110198889A1Restrain collision loadLow structural requirementsVehicle seatsSteering linkagesEngineeringMechanical engineering

A suspension cross member comprises a middle-portion attaching member which extends upwardly from a suspension cross member body, and a pipe-shaped attaching member which is supported at a support portion provided at an upper portion of the middle-portion attaching member. A side portion, in a vehicle width direction, a front portion and a rear portion, in a vehicle longitudinal direction, of a side face portion of the attaching member are supported at the support portion. A lower portion of the attaching member is supported at the support portion with a specified support rigidity, in the vehicle longitudinal direction, which is lower than that of the supporting of the side portion, the front portion or the rear portion of the side face portion of the attaching member.

Owner:MAZDA MOTOR CORP

Low permeability side curtain airbag cushions having extremely low coating levels

InactiveUS20010005660A1Reduced packaging volumeLong leak-downEnvelopes/bags making machineryPedestrian/occupant safety arrangementElastomerEngineering

Coated inflatable fabrics, more particularly airbags to which very low add-on amounts of coating have been applied, are provided which exhibit extremely low air permeabilities. The inventive fabrics are primarily for use in automotive restraint cushions which require low permeability characteristics (such as side curtain airbags). Traditionally, heavy, and thus expensive, coatings of compounds such as neoprene, silicones and the like, have been utilized to provide such required low permeability. The inventive fabric utilizes an inexpensive, very thin coating to provide such necessary low permeability levels. Thus, the inventive coated airbag possesses a coating of at most 3.0 ounces per square yard, most preferably about 0.8 ounces per square yard, and exhibits a leak-down time (a measurement of the time required for the entire amount of gas introduced within the airbag at peak pressure during inflation to escape the airbag at 10 psi) of at least 5 seconds as well as very low packing volumes (for more efficient use of storage space within a vehicle). All coatings, in particular elastomeric, preferably, though not necessarily, non-silicon coatings, and coated airbags meeting these criteria are intended to reside within the scope of this invention.

Owner:MILLIKEN & CO

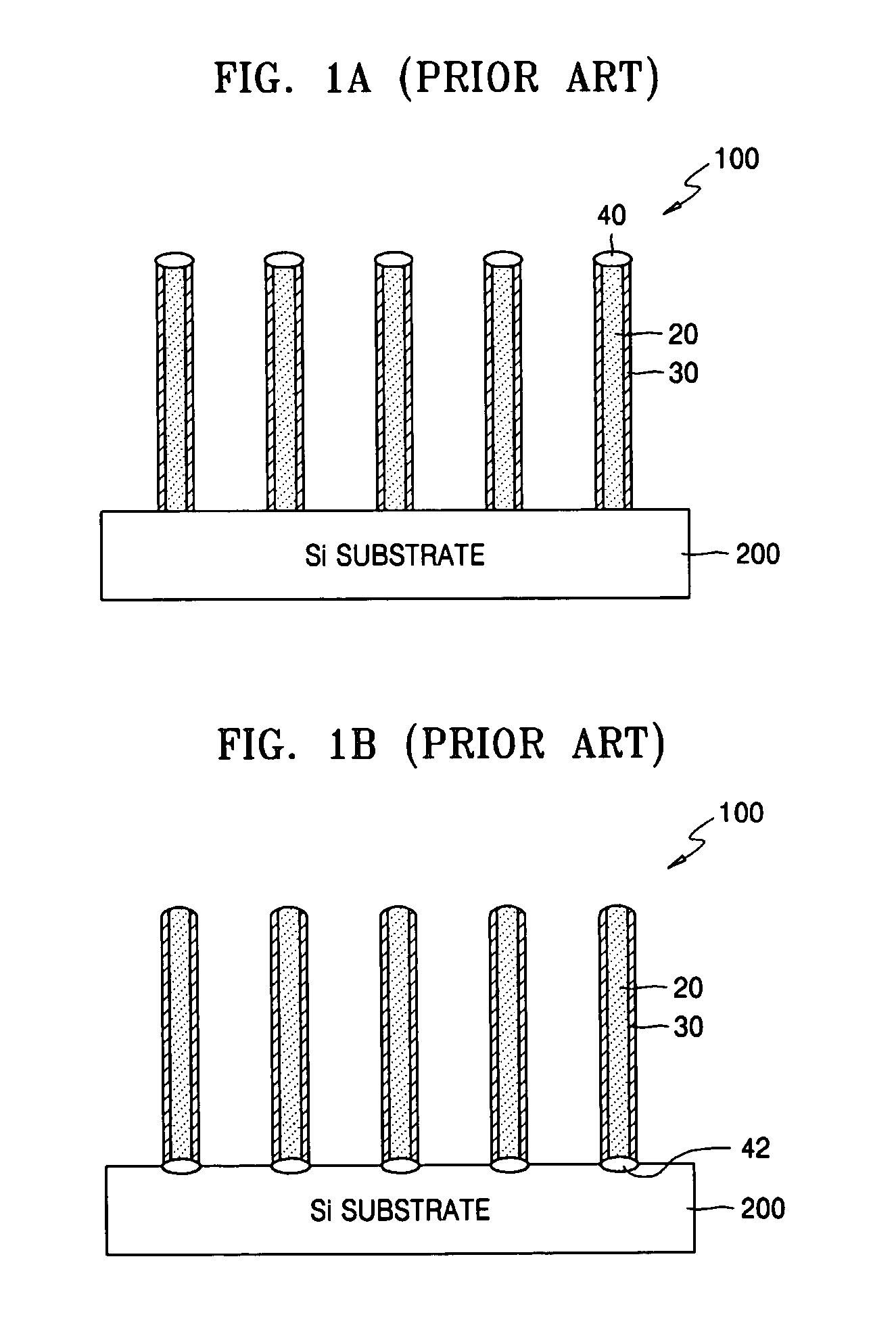

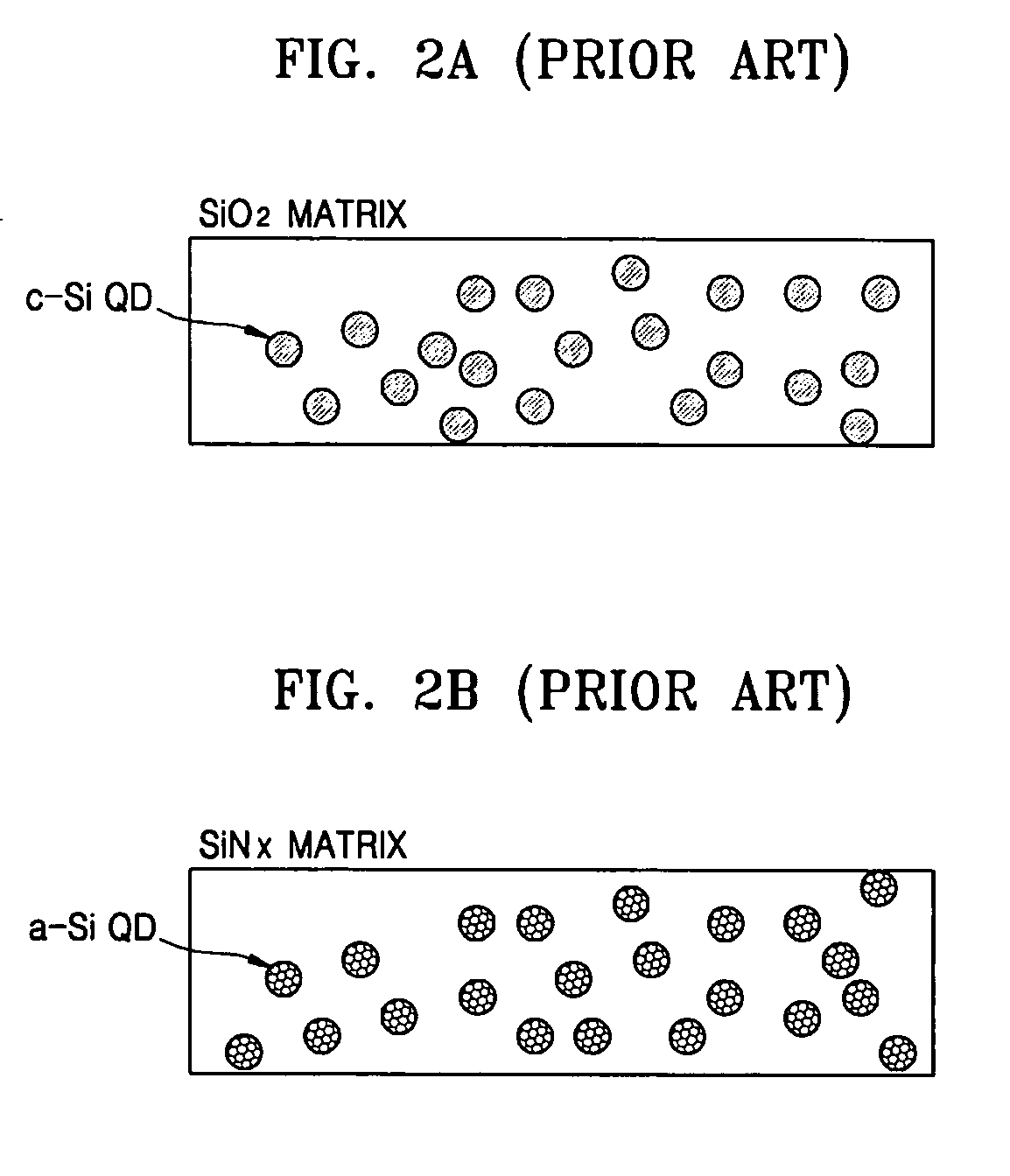

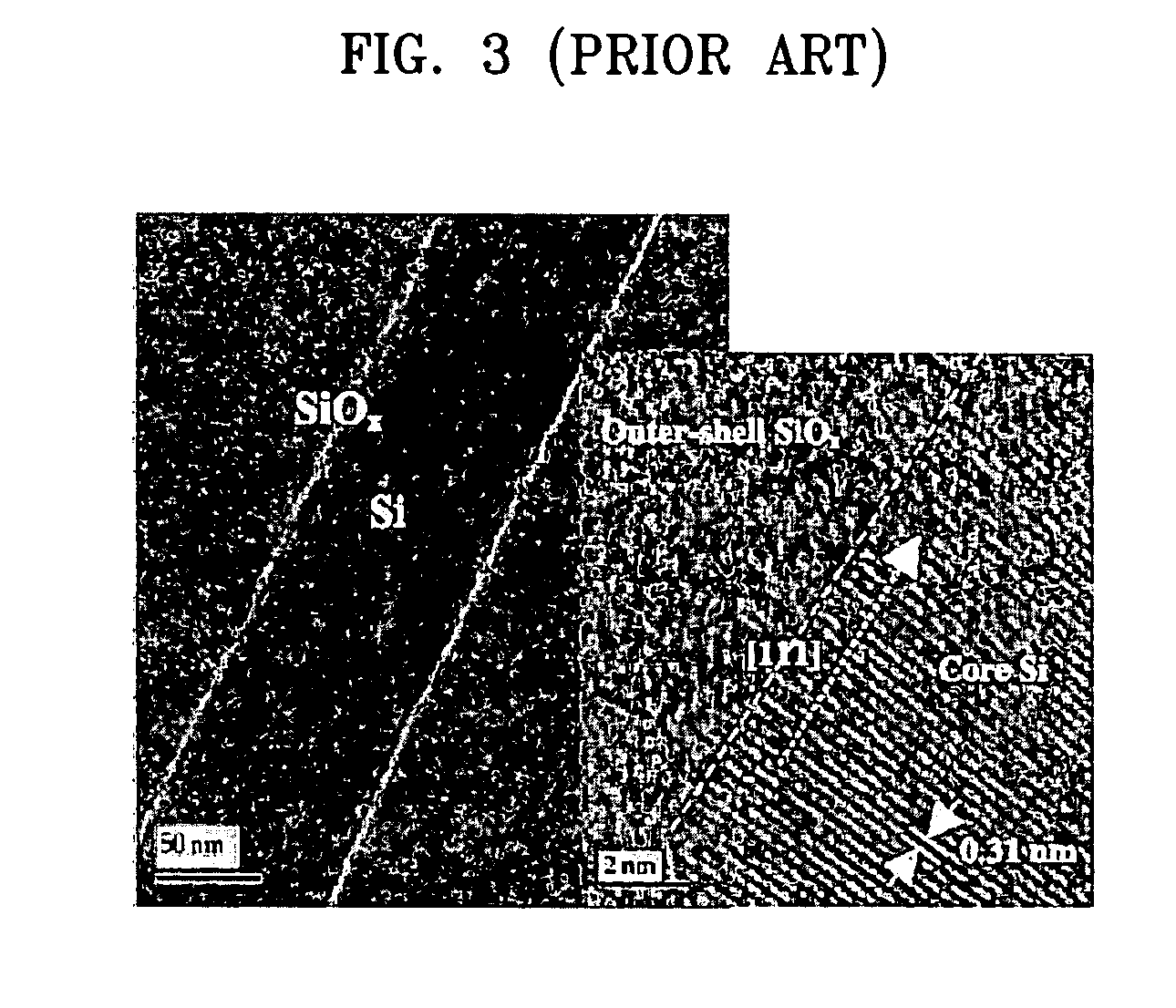

Silicon nano wire having a silicon-nitride shell and method of manufacturing the same

InactiveUS20060182966A1Excellent luminous propertiesEasy to controlMaterial nanotechnologyPolycrystalline material growthSilicon nanowiresOptoelectronics

Silicon nano wires having silicon nitride shells and a method of manufacturing the same are provided. Each silicon nano wire has a core portion formed of silicon, and a shell portion formed of silicon nitride surrounding the core portion. The method includes removing silicon oxide formed on the shell of the silicon nano wire and forming a silicon nitride shell.

Owner:SAMSUNG ELECTRONICS CO LTD

Regulatable supporter

InactiveCN1382873ASmooth rotationPrevent looseningBridge structural detailsConnectionsMechanical engineeringLocknut

A regulatable supporter is composed of top plate, top seat, ball hinge, screw piles, locking nuts, base of screw pile, locking screw and base, and can be regulated vertically and horizontally in stepless mode. Its advantages are less compression and high precision.

Owner:SHANGHAI MAGLEV TRANSPORTATION DEVELOPMENT CO LTD

Modular rotor blade for a wind turbine and method for assembling same

ActiveUS7654799B2Shorten the lengthReduce shipping costsPropellersEngine manufactureWind forceTurbine rotor

A sectional wind turbine rotor blade is provided, the sectional wind turbine rotor blade having first and second blade sections, wherein the first and second blade sections are fixedly mountable to each other via a connector. Furthermore, a method for assembling a sectional wind turbine rotor blade is provided.

Owner:LM WIND POWER US TECH APS

Lower vehicle body structure of vehicle

InactiveUS7434871B2Low structural requirementsPrecise layoutVehicle seatsUnderstructuresEngineeringMechanical engineering

There is provided a lower vehicle body structure, in which a floor panel is provided between a pair of side sills extending longitudinally, a tunnel portion extending longitudinally is provided at a central portion of the floor panel, and a seat is provided between the side sill and tunnel portion, wherein there are provided a seat support member outer to support the seat, which extends longitudinally inside the side sill, and a plurality of cross members extending in the vehicle width direction with a specified distance therebetween longitudinally, outside end portions of which are connected to the seat support member outer and inside end portions of which are connected to the tunnel portion. Accordingly, both layout of the seat and sufficient vehicle body rigidity against a vehicle side crash can be provided.

Owner:MAZDA MOTOR CORP

Lower vehicle-body structure of vehicle

InactiveUS8480102B2Improving attachment rigidityLow structural requirementsVehicle seatsSteering linkagesEngineeringMechanical engineering

Owner:MAZDA MOTOR CORP

Lower vehicle-body structure of vehicle

InactiveUS20110316295A1Improving attachment rigidityFully absorbedSteering linkagesUnderstructuresVehicle frameEngineering

Owner:MAZDA MOTOR CORP

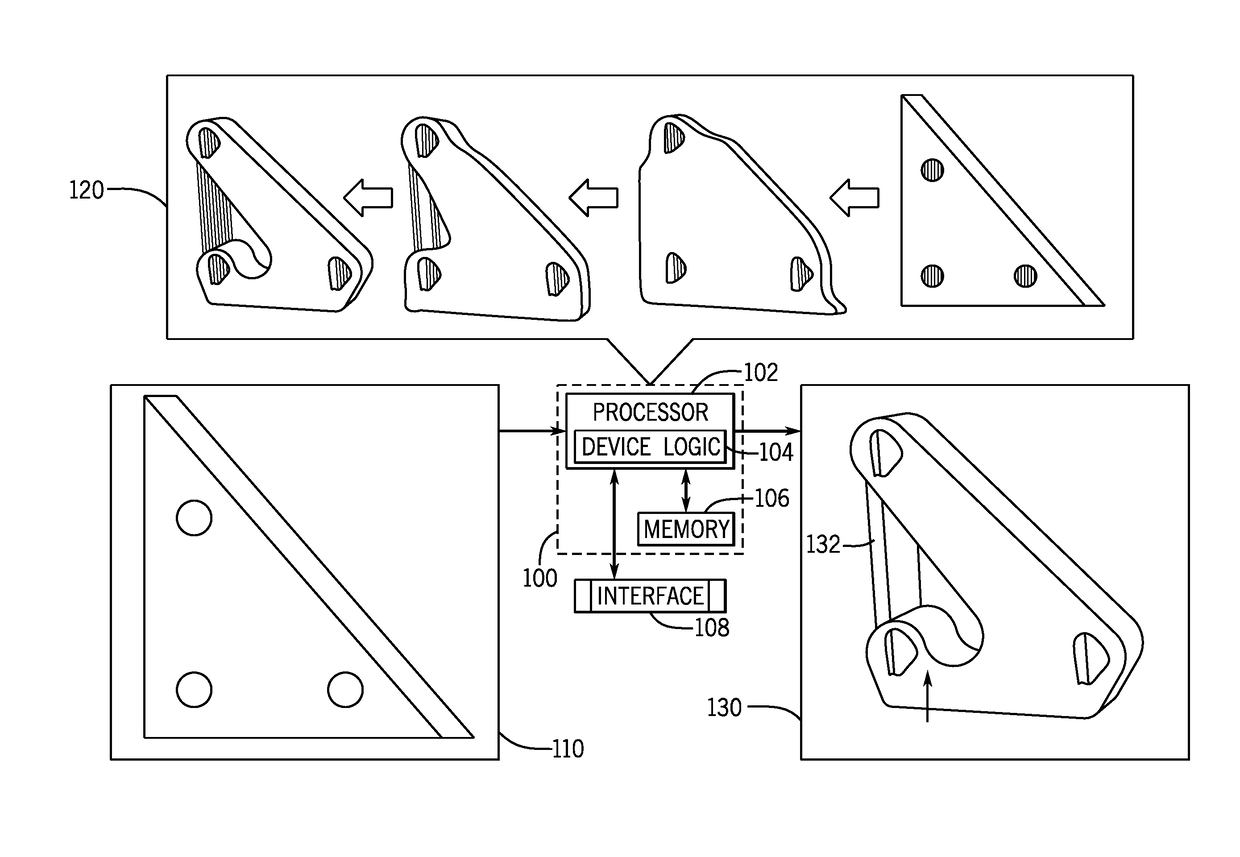

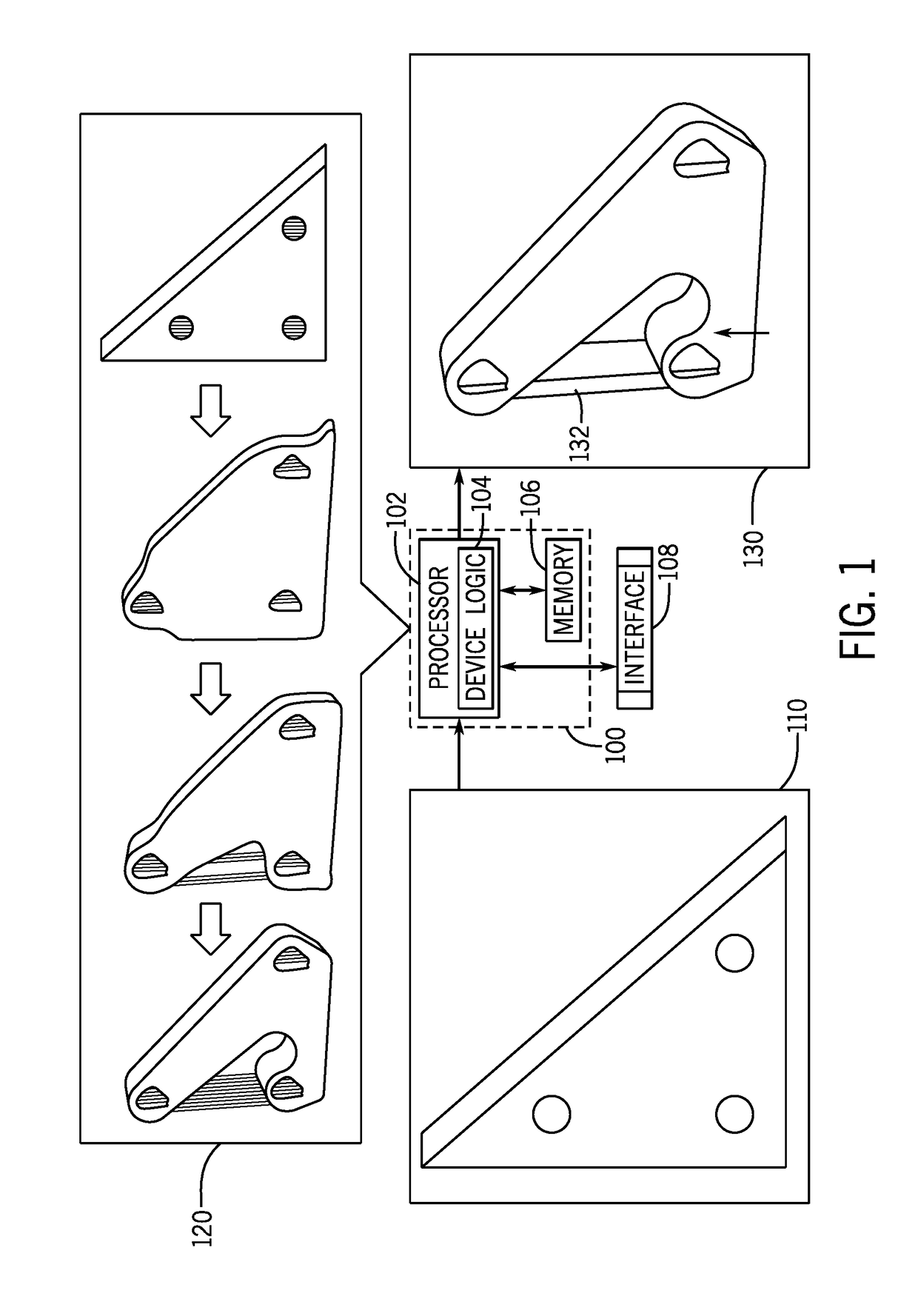

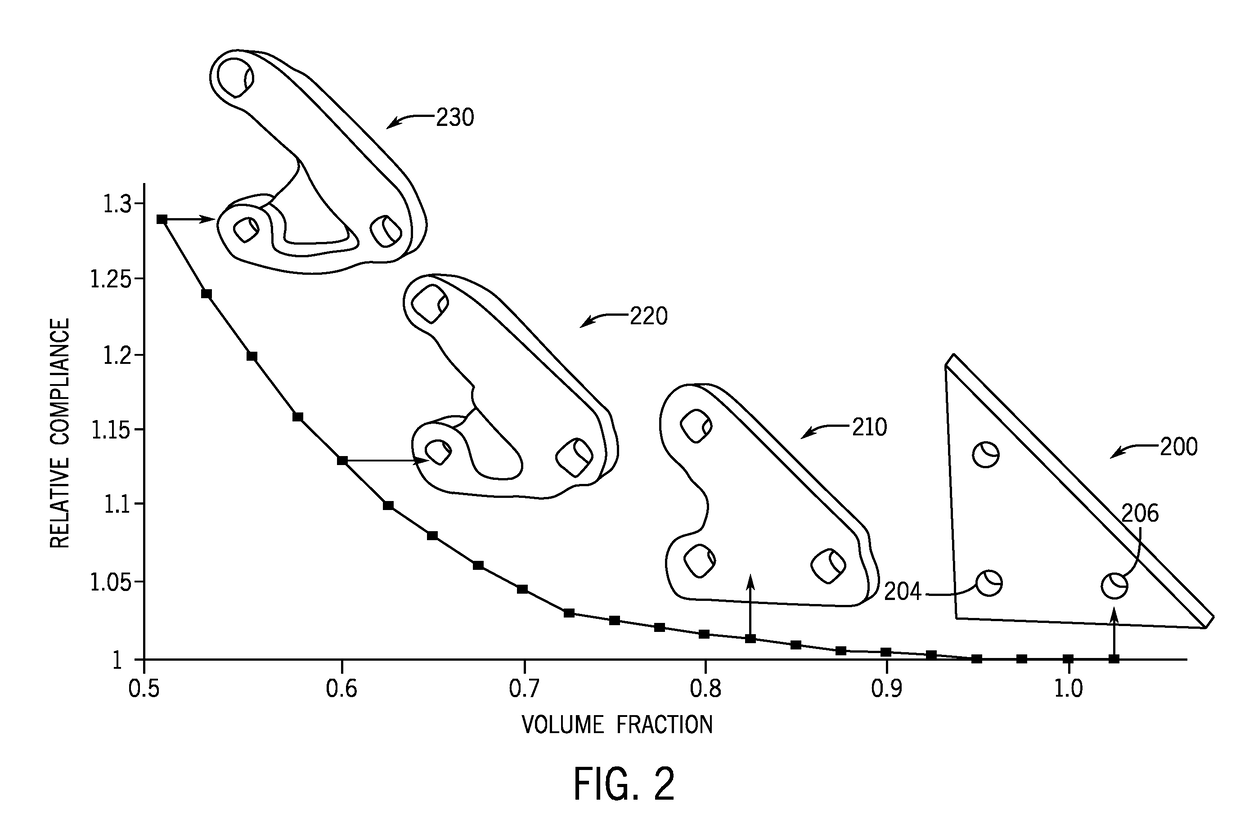

Support structure constrained topology optimization for additive manufacturing

ActiveUS20180079149A1Reduced support structure requirementSpeed up design and engineering processProgramme controlAdditive manufacturing apparatusComputer generationEngineering

Systems and methods for generating designs of objects for additive manufacturing (AM) include a topological optimization framework that facilitates optimized computer generated designs requiring significantly reduced support structures. Towards this end, the concept of ‘support structure topological sensitivity’ is introduced. This is combined with performance sensitivity to result in a TO framework that maximizes performance, subject to support structure constraints. The robustness and efficiency of the proposed method is demonstrated through numerical experiments, and validated through fused deposition modeling, a popular AM process.

Owner:WISCONSIN ALUMNI RES FOUND

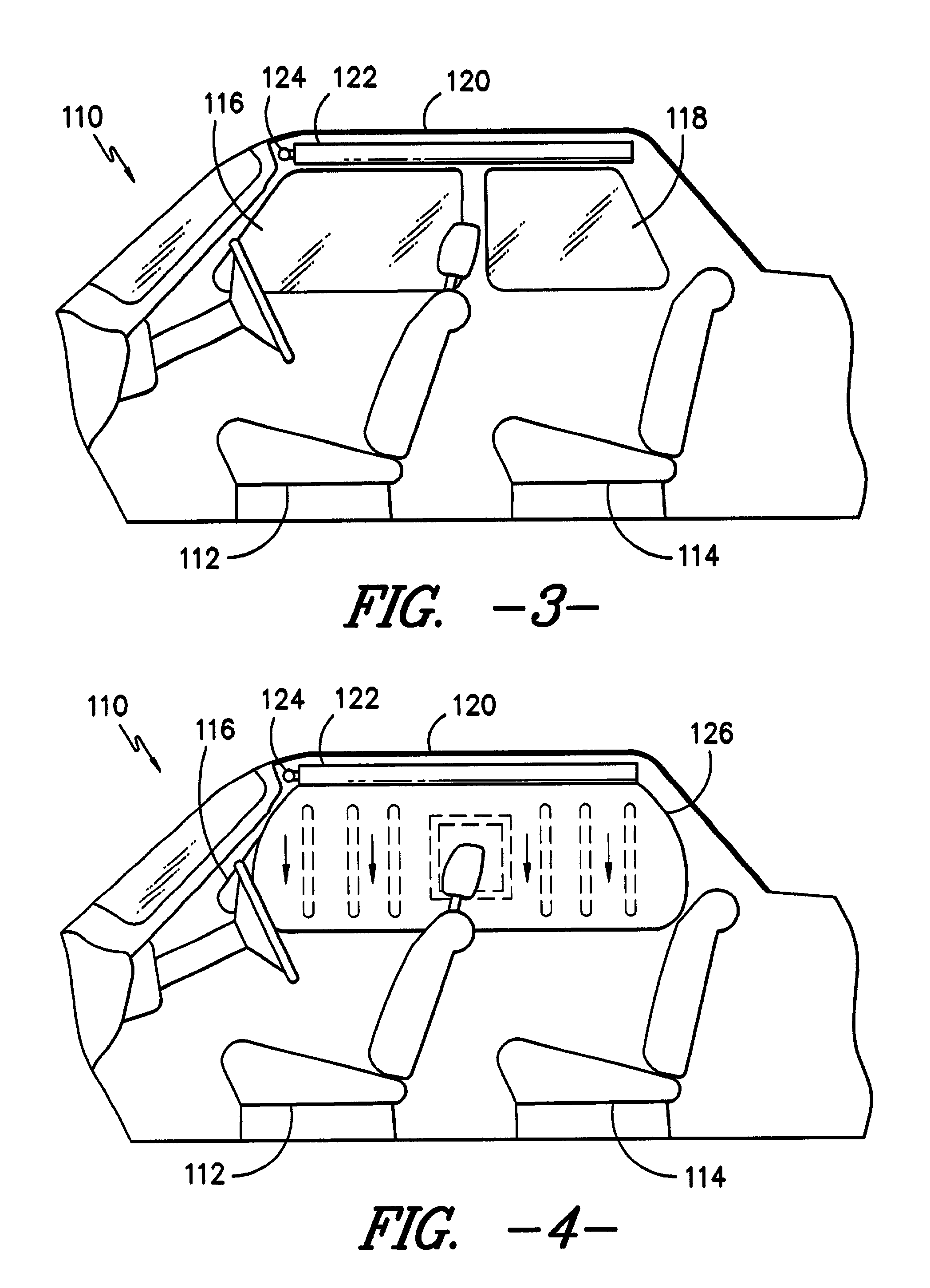

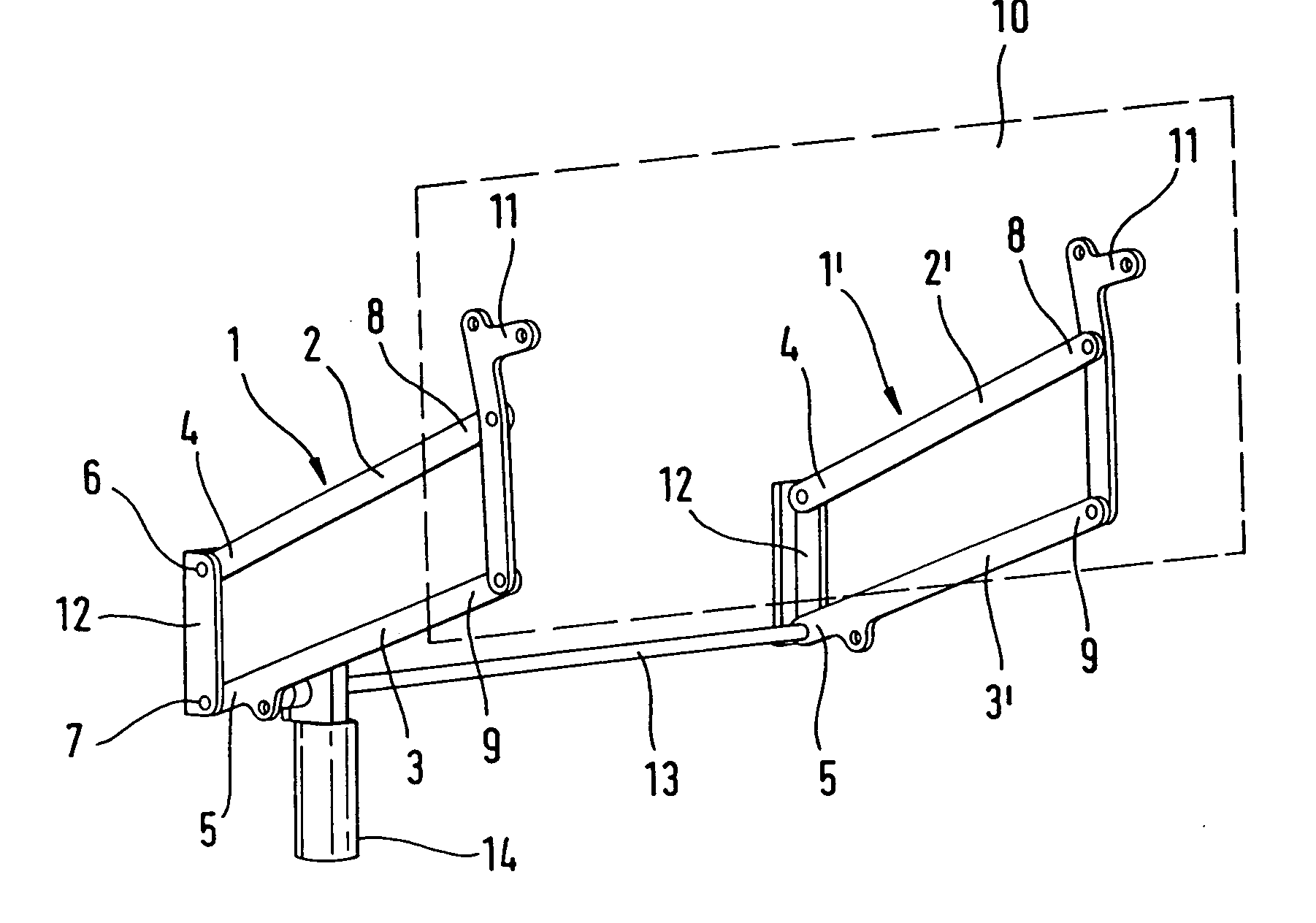

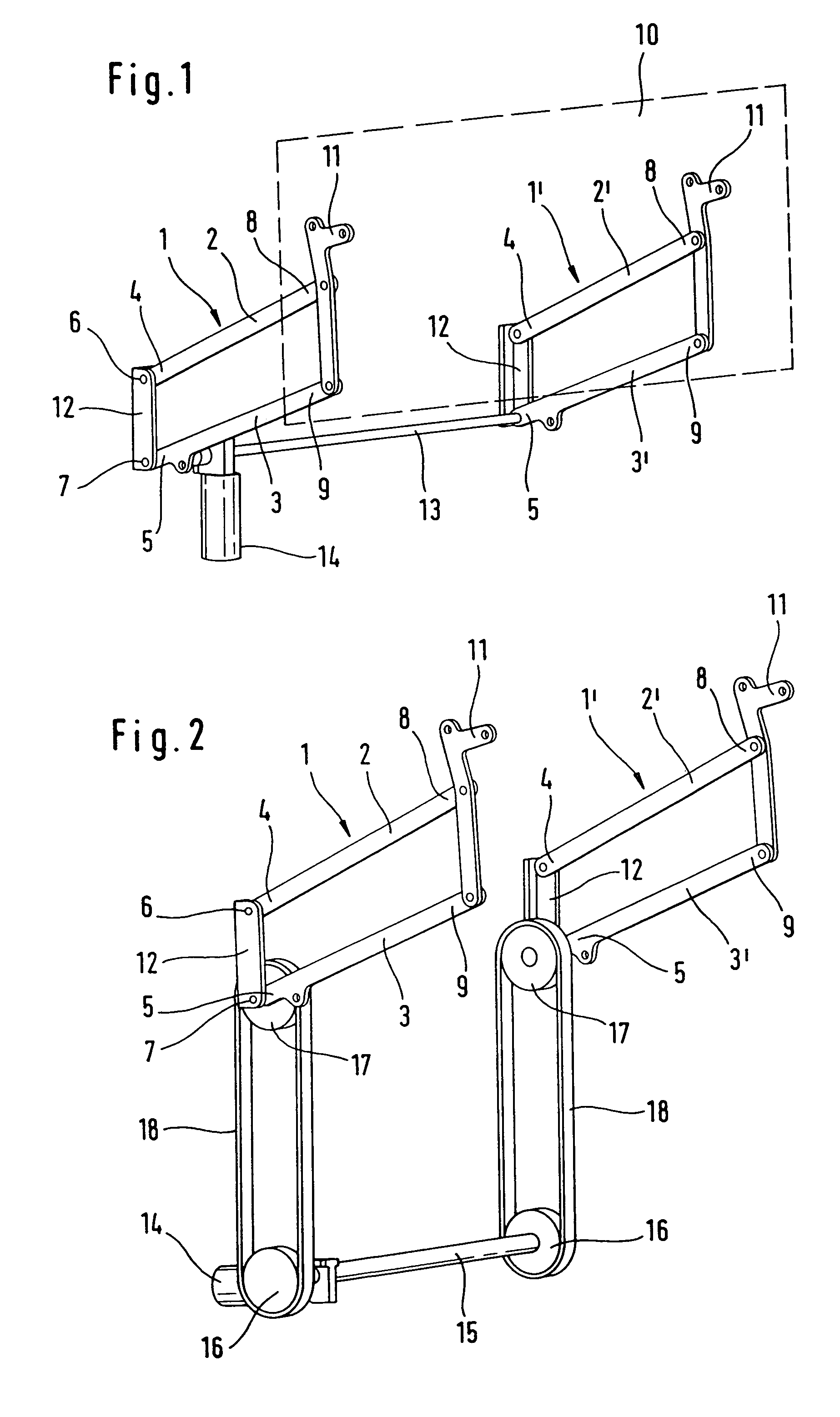

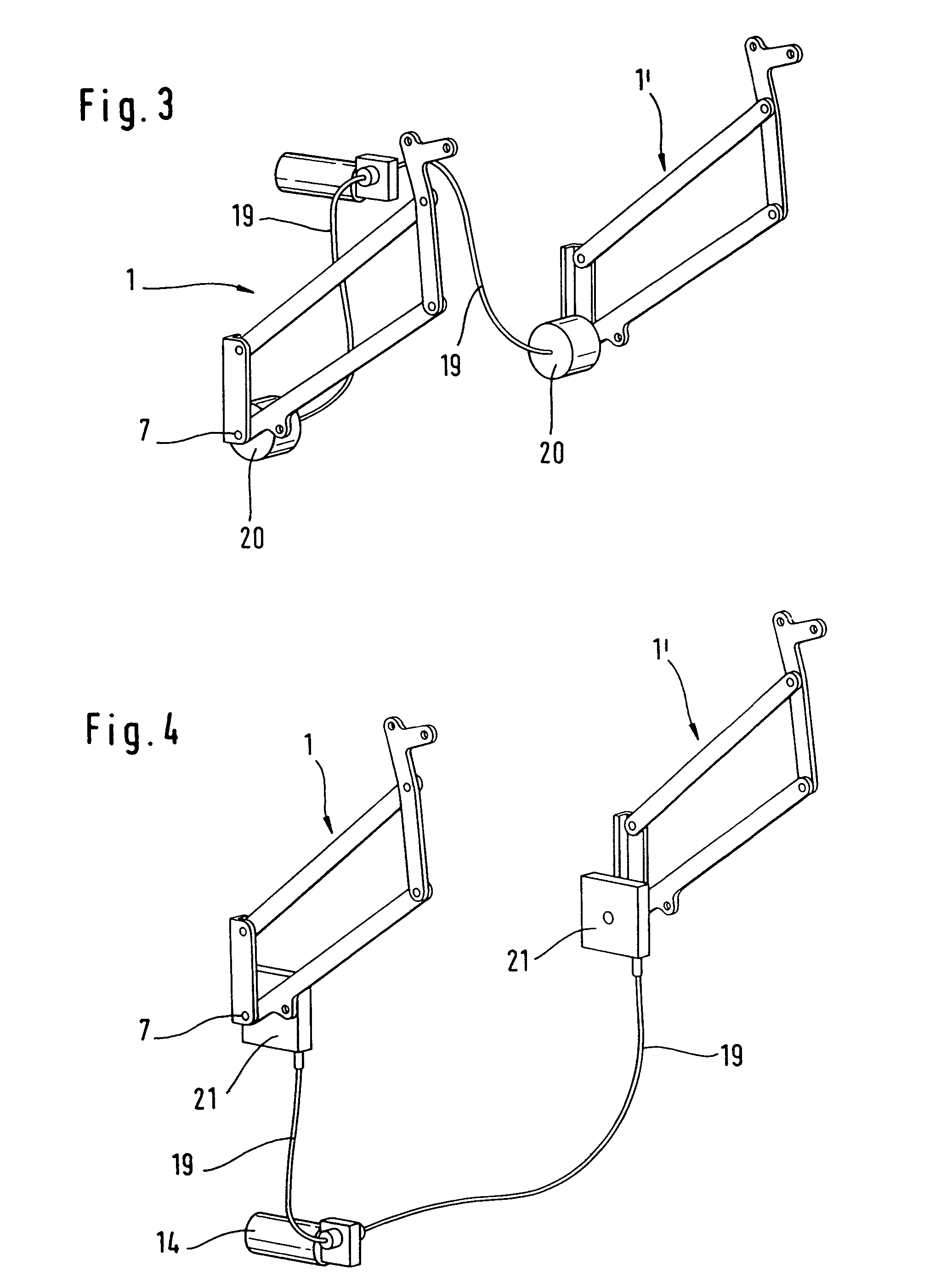

Drive for opening and closing a vehicle flap

ActiveUS7143548B2Avoid distortionLow structural requirementsSuperstructure subunitsMonocoque constructionsMobile vehicleEngineering

A flap drive for a flap includes two identical lever joint arrangements which are arranged in pairs at a distance from one another. The flap can be moved out of its closing position into its opening position and back by the flap drive. In this case, the lever joint arrangements are articulated pivotably with one of their ends in each case on a side region of the flap and with their other ends at a fixed location on the motor vehicle. The mutually corresponding pivot axes of the articulation points extend coaxially to one another. Movement transmission devices for the pivotable drive of a driven lever of each lever joint arrangement are guided by a common motive drive unit, the driven levers being articulated at a fixed location on the motor vehicle.

Owner:STABILUS

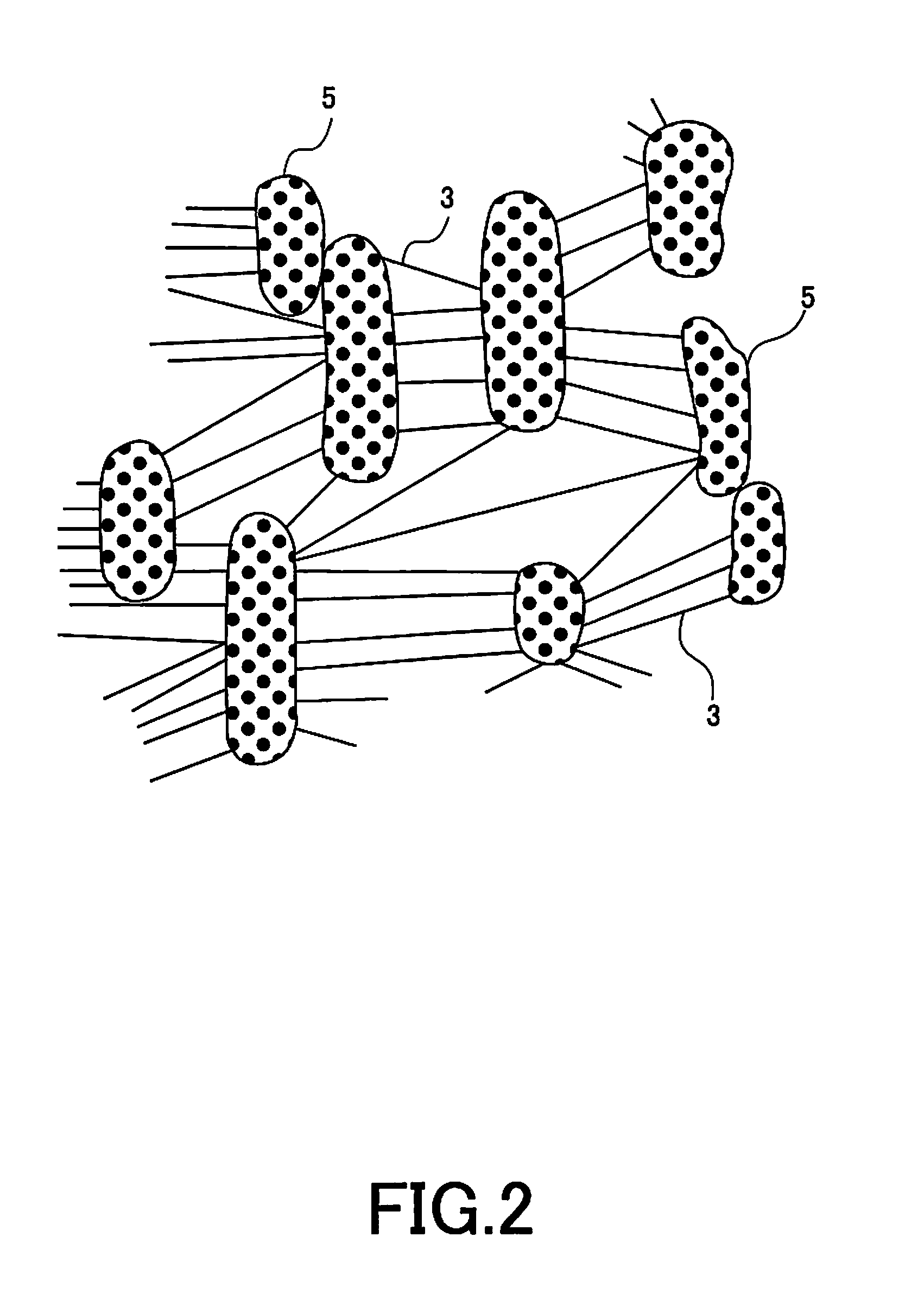

Carbon black

InactiveUS6290767B1Low structural requirementsReduction in carbon black throughputPigmenting treatmentMaterials sciencePigment

Carbon blacks doped with elements that are not carbon, wherein pairs of carbon atoms have been replaced by iso-electronic pairs of elements or combinations of elements. They can be used as a pigment or filler in rubber, plastics, paints, inks or the like.

Owner:UBS AG

Lower vehicle body structure of vehicle

InactiveUS20070126264A1Sufficient vehicle body rigidityLow body structureVehicle seatsUnderstructuresEngineeringMechanical engineering

There is provided a lower vehicle body structure, in which a floor panel is provided between a pair of side sills extending longitudinally, a tunnel portion extending longitudinally is provided at a central portion of the floor panel, and a seat is provided between the side sill and tunnel portion, wherein there are provided a seat support member outer to support the seat, which extends longitudinally inside the side sill, and a plurality of cross members extending in the vehicle width direction with a specified distance therebetween longitudinally, outside end portions of which are connected to the seat support member outer and inside end portions of which are connected to the tunnel portion. Accordingly, both layout of the seat and sufficient vehicle body rigidity against a vehicle side crash can be provided.

Owner:MAZDA MOTOR CORP

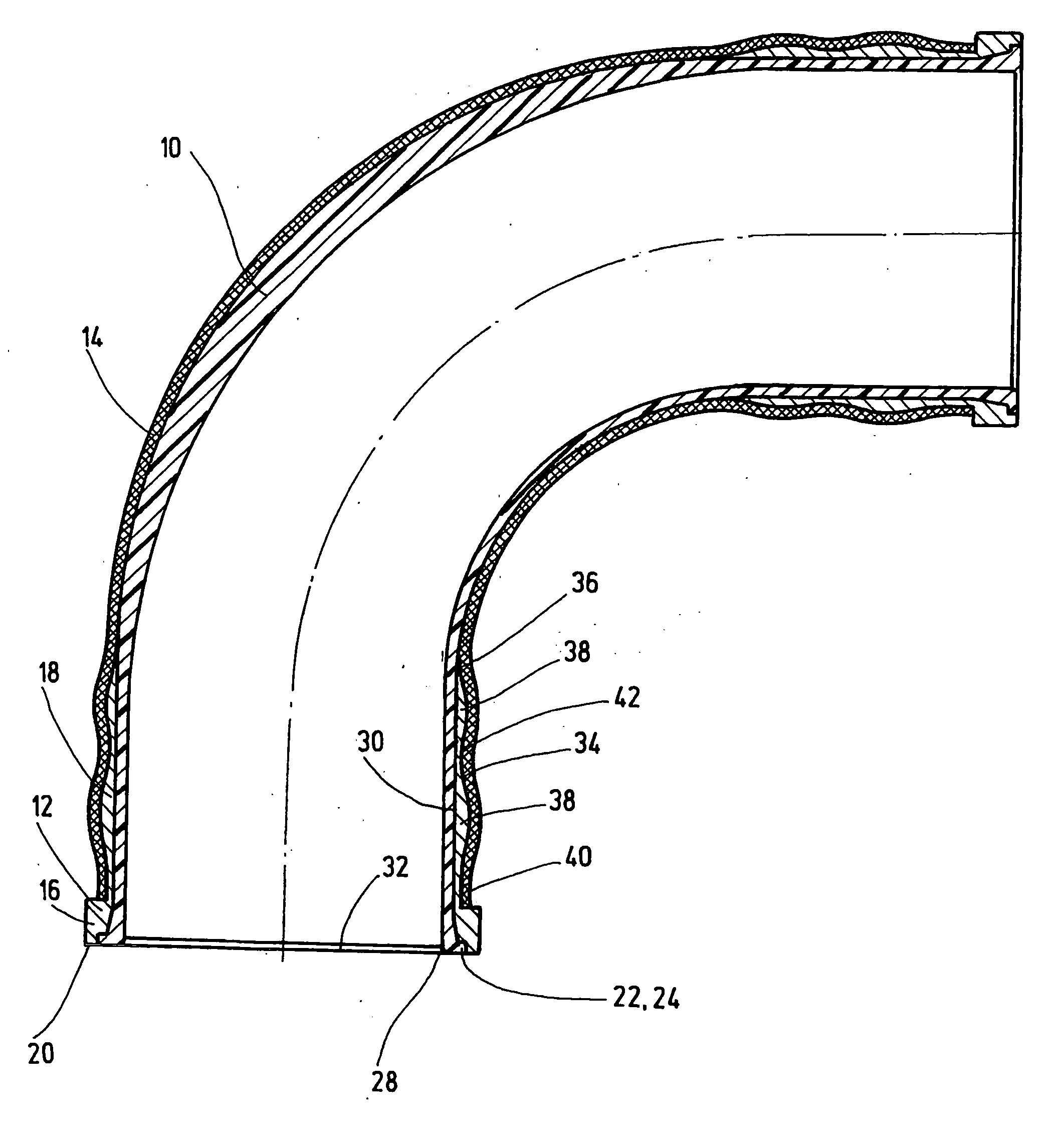

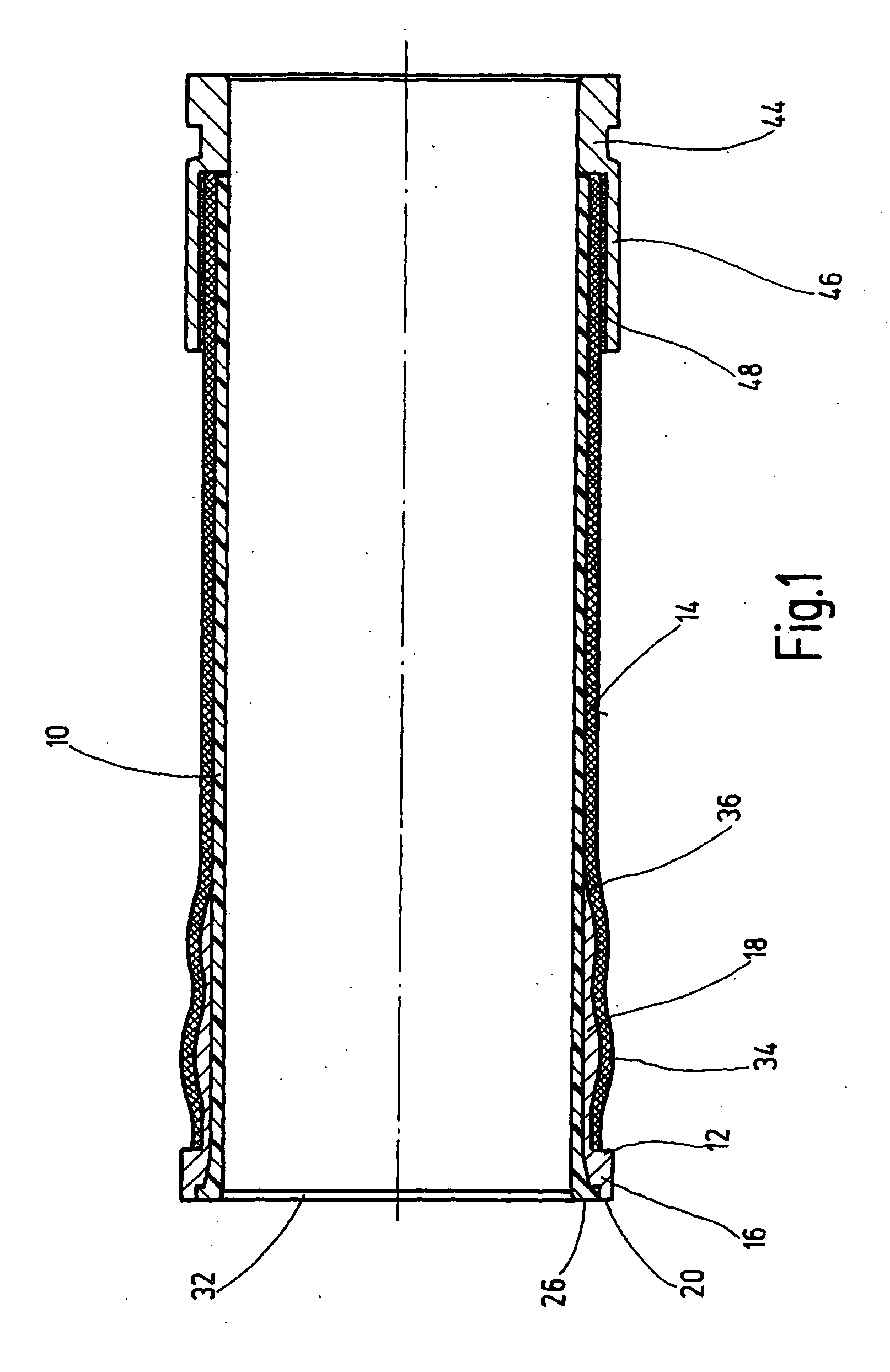

Tube for transporting high-viscosity materials

ActiveUS20060054231A1Low structural weightEasy to assembleFlanged jointsFlexible pipesPlastic materialsEngineering

Transport pipe for high viscosity materials, in particular for concrete. The transport pipe includes an inner pipe (10) made of an abrasion-resistant plastic, at least one metallic joint element (12), as well as a reinforcing jacket (14) which envelops at least the internal pipe. In order to ensure a reliable and enduring joint between inner pipe and joint element, it is proposed in accordance with the invention, that the radially projecting collar of the joint element is defined by a ring-shaped end face (20) and by a thereto joined ring step (22) extending radially towards the inside of the pipe and recessed axially from the ring-shaped end face, and wherein the plastic material of the inner pipe (10) engages in the ring step (22) from the inside of the pipe.

Owner:XPERION

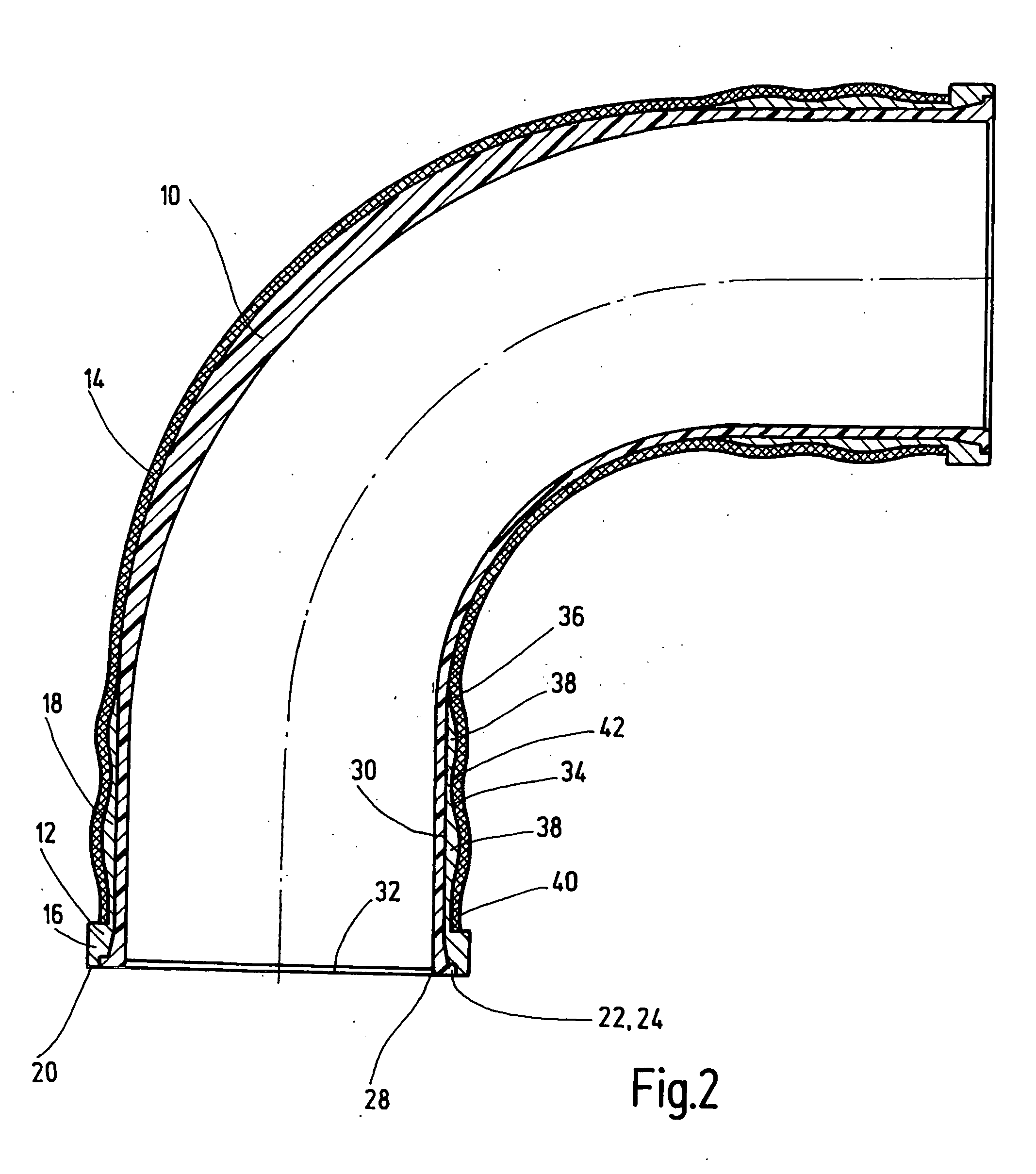

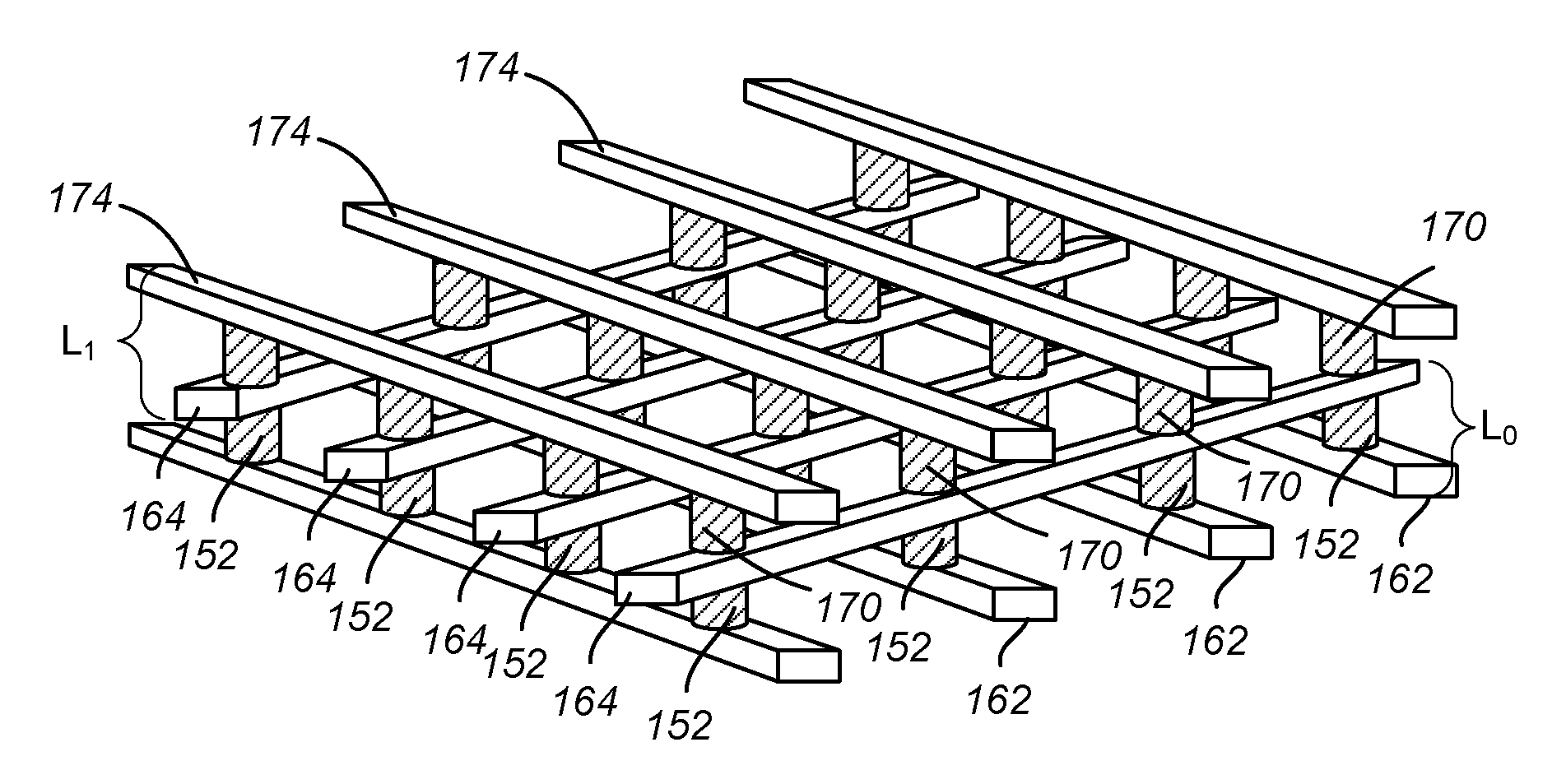

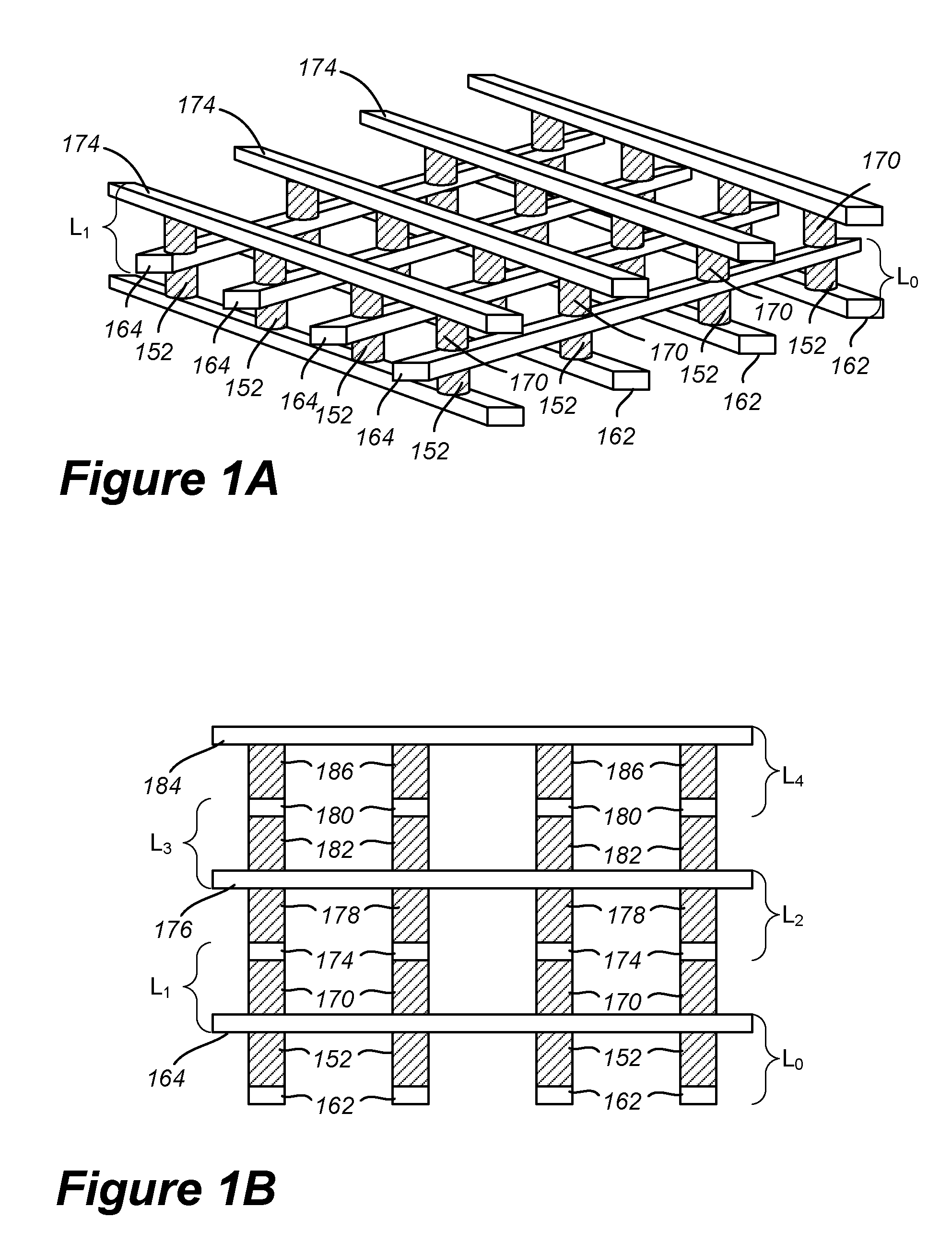

Self-Aligned Three-Dimensional Non-Volatile Memory Fabrication

ActiveUS20100124813A1Low structural requirementsElectrolytic capacitorsDecorative surface effectsEngineeringElectrical conductor

A self-aligned fabrication process for three-dimensional non-volatile memory is disclosed. A double etch process forms conductors at a given level in self-alignment with memory pillars both underlying and overlying the conductors. Forming the conductors in this manner can include etching a first conductor layer using a first repeating pattern in a given direction to form a first portion of the conductors. Etching with the first pattern also defines two opposing sidewalls of an underlying pillar structure, thereby self-aligning the conductors with the pillars. After etching, a second conductor layer is deposited followed by a semiconductor layer stack. Etching with a second pattern that repeats in the same direction as the first pattern is performed, thereby forming a second portion of the conductors that is self-aligned with overlying layer stack lines. These layer stack lines are then etched orthogonally to define a second set of pillars overlying the conductors.

Owner:SANDISK TECH LLC

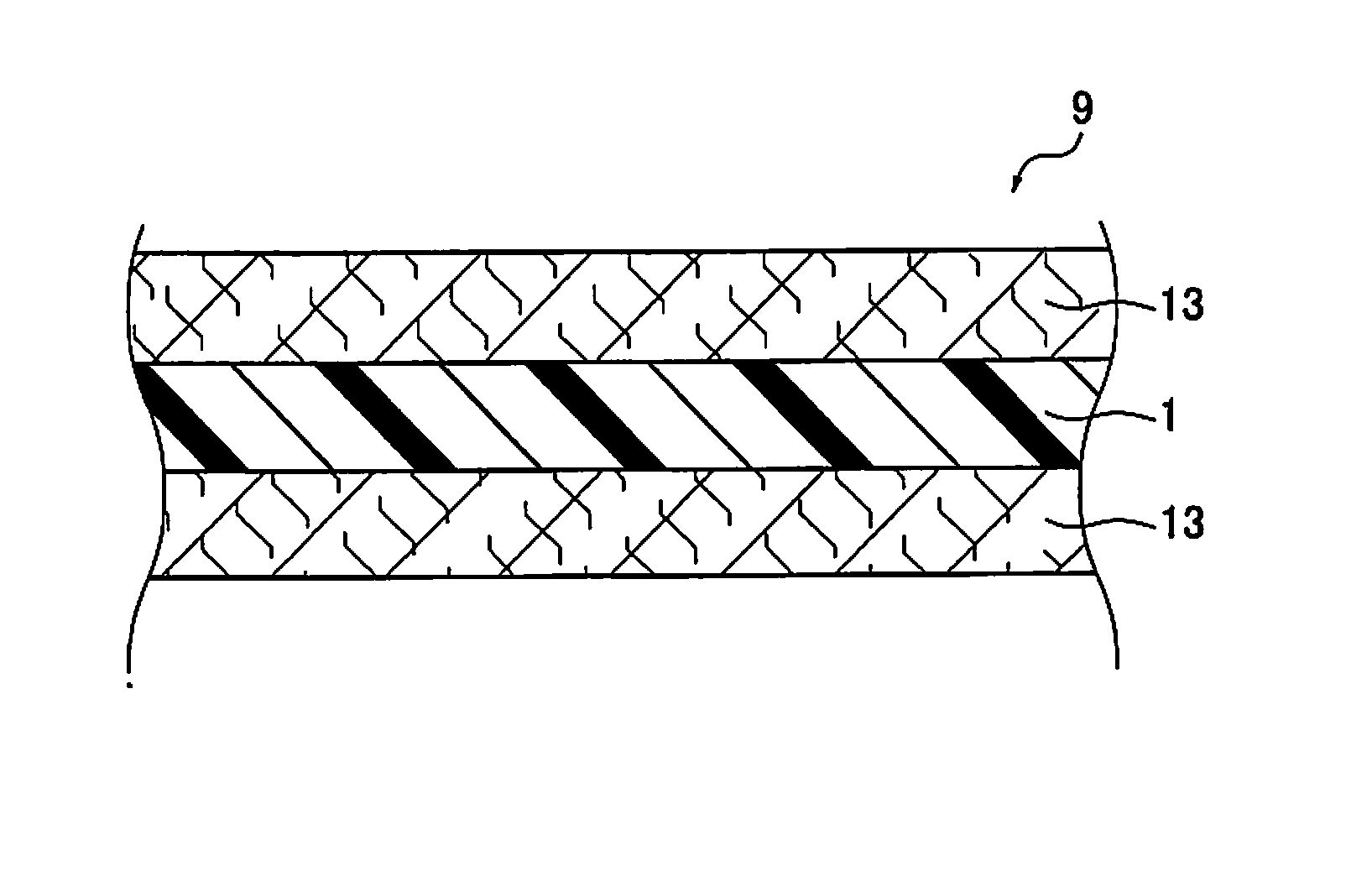

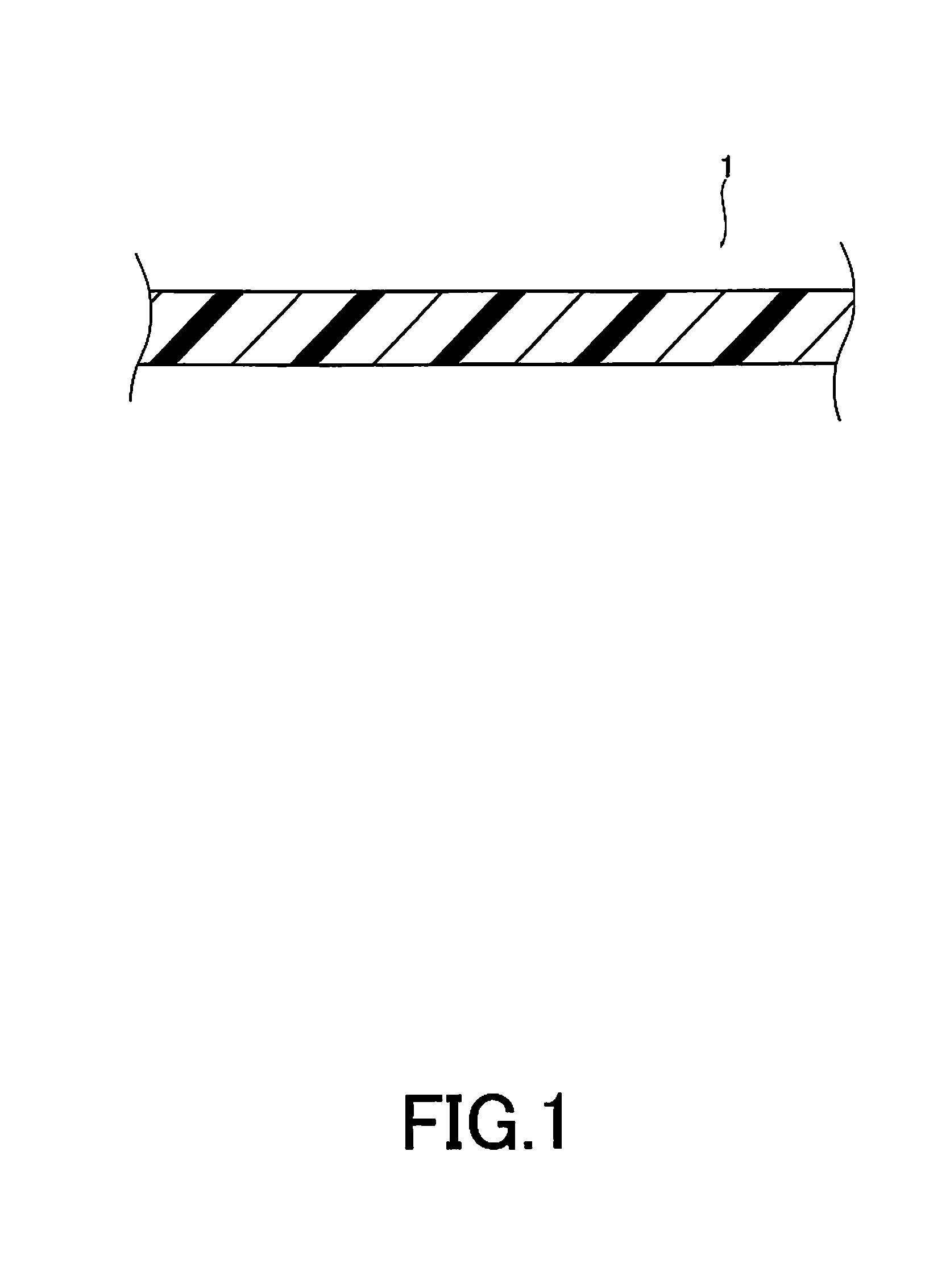

Composition having PTFE as main component, mixed powder, material for molding, filtering medium for filter, air filter unit, and a method for manufacturing a porous membrane

ActiveUS20150082757A1Improve breathabilityDecrease in filter performance is suppressedCombination devicesSemi-permeable membranesAir filterPorous membrane

A composition, a mixed power and a material for molding have polytetrafluoroethylene as a main component. Each includes polytetrafluoroethylene that can be fibrillated, a non-hot melt processable component that is not fibrillated, and a hot melt processable component with a melting point of lower than 320° C. that is not fibrillated. The hot melt processable component is contained at equal to or more than 0.1% by weight but less than 20% by weight of a total weight. A filtering medium for an air filter includes a porous membrane made of these components, and an air permeable support. The porous membrane is manufactured, by mixing these components, extruding the mixture, rolling and drawing.

Owner:DAIKIN IND LTD

Lower structure of automotive vehicle

ActiveUS8267429B2Low structural requirementsAvoid loadSteering linkagesUnderstructuresEngineeringPower unit

Owner:MAZDA MOTOR CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com