Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4608results about How to "Improve mixing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

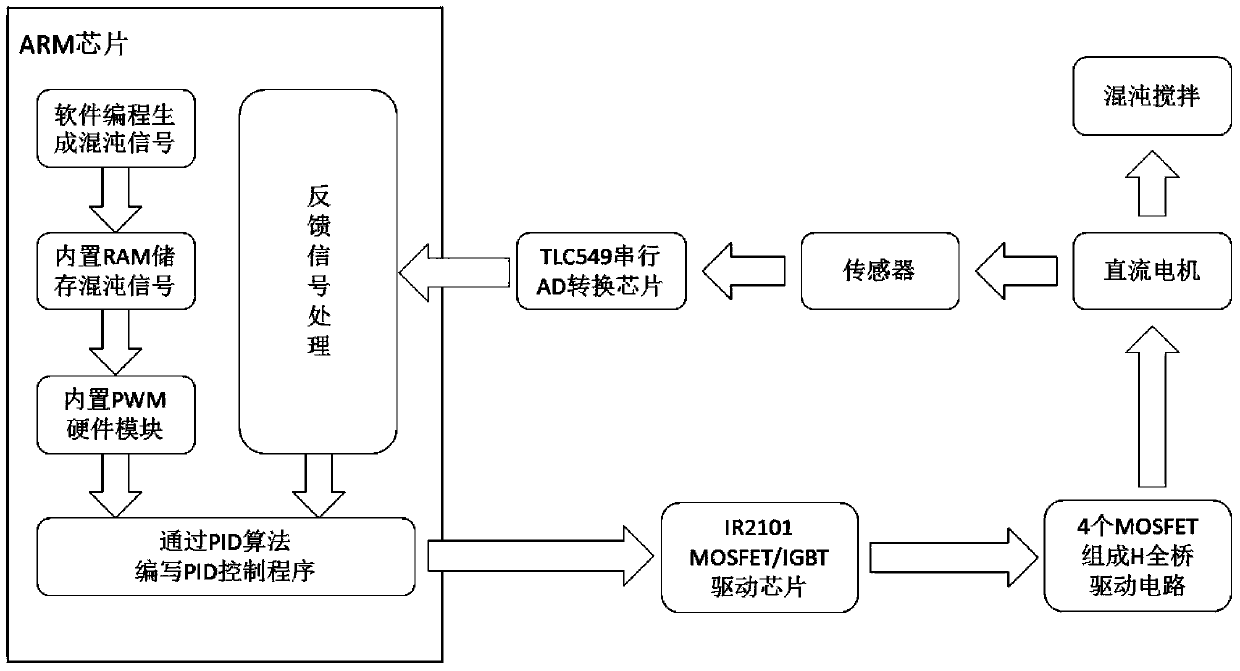

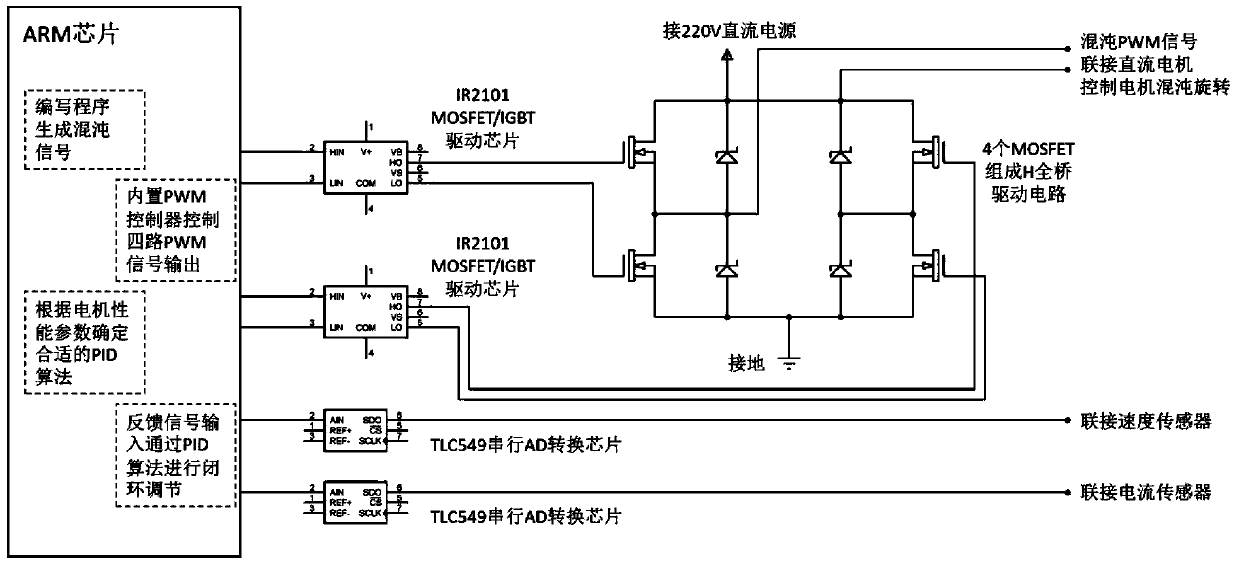

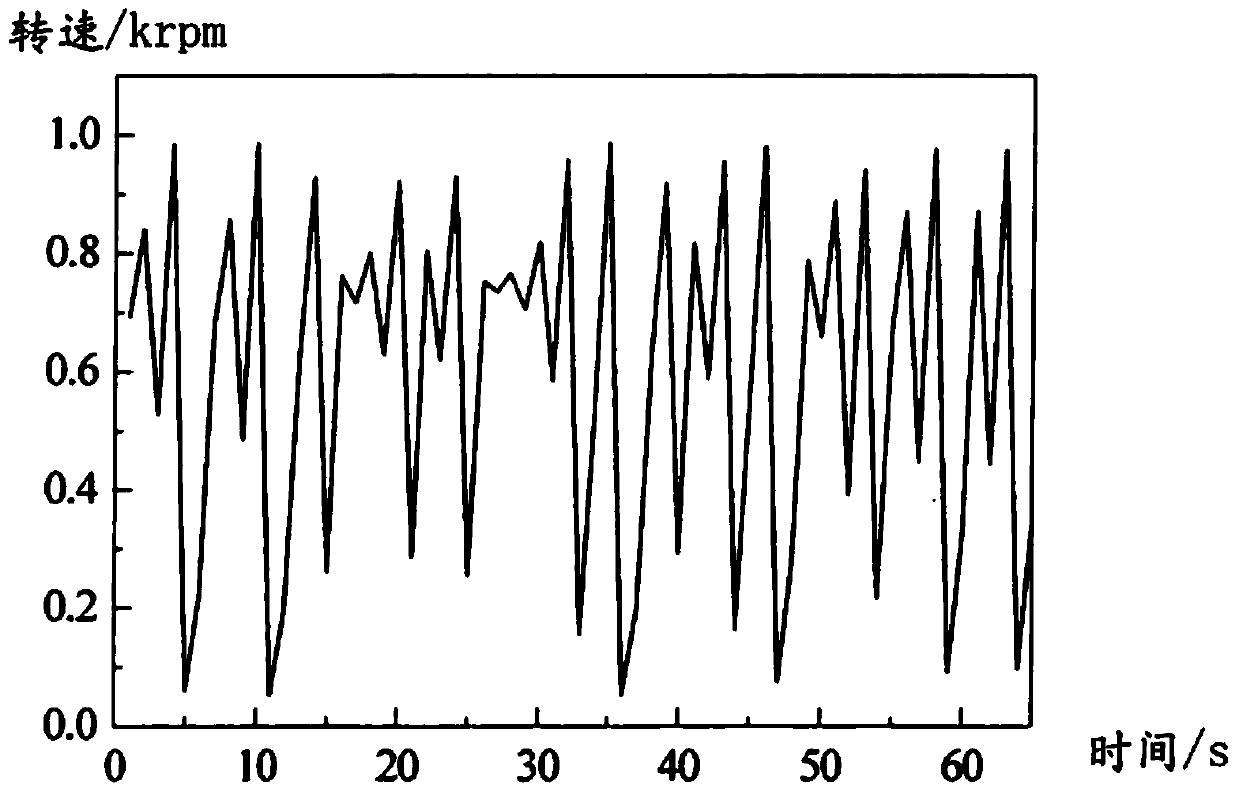

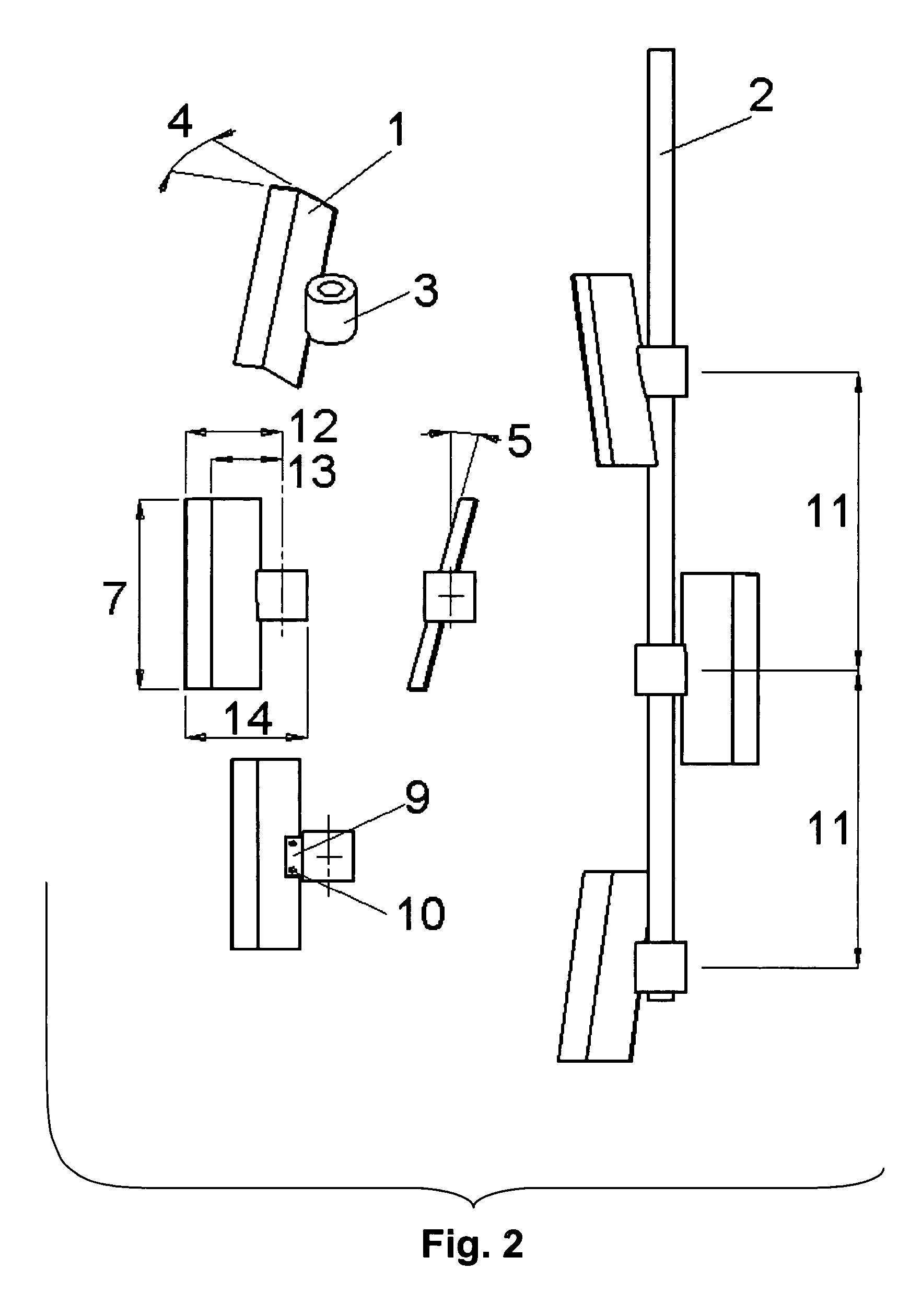

Chaotic stirring control system based on ARM (advanced RISC machine) single chip chaotic mapping control

ActiveCN103391037AChaotic speed is realized in a simple wayEasy to modifyField or armature current controlMixer accessoriesMicrocontrollerControl system

The invention discloses a chaotic stirring control system based on ARM single chip chaotic mapping control. The system comprises an ARM single chip which is connected and communicated with an input device, a drive chip and an AD (analog to digital) conversion chip respectively; the drive chip is connected with an H bridge drive circuit, the H bridge drive circuit is connected with a direct current motor, the direct current motor is connected with a chaotic stirring system, a sensor which monitors the rotating speed and a current signal of the direct current motor is arranged on the direct current motor, and the sensor is connected with the AD conversion chip. The system adopts a full digit circuit, has good stability and high reliability, can accurately control and conveniently adjust the rotating speed of the motor, is wide in application range, and can meet requirements of different stirring parameters under various work conditions.

Owner:SHANDONG UNIV

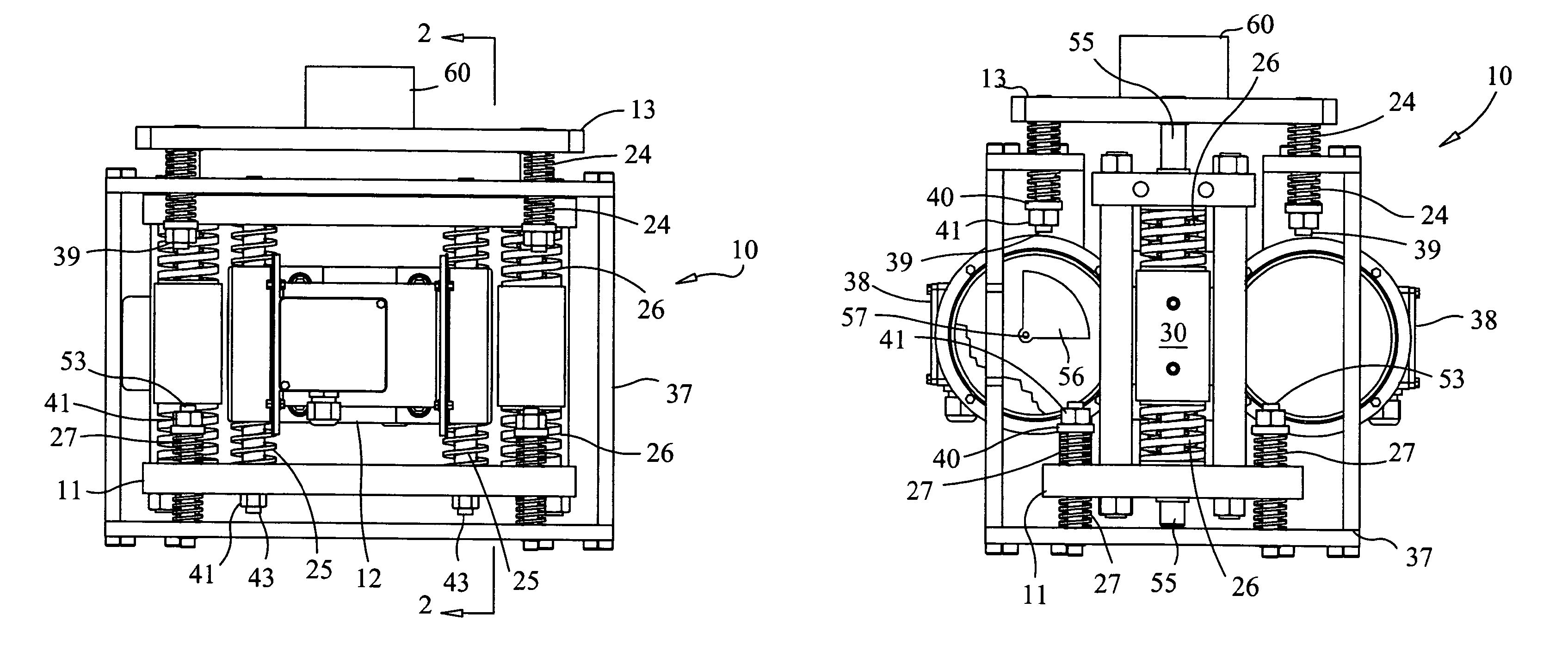

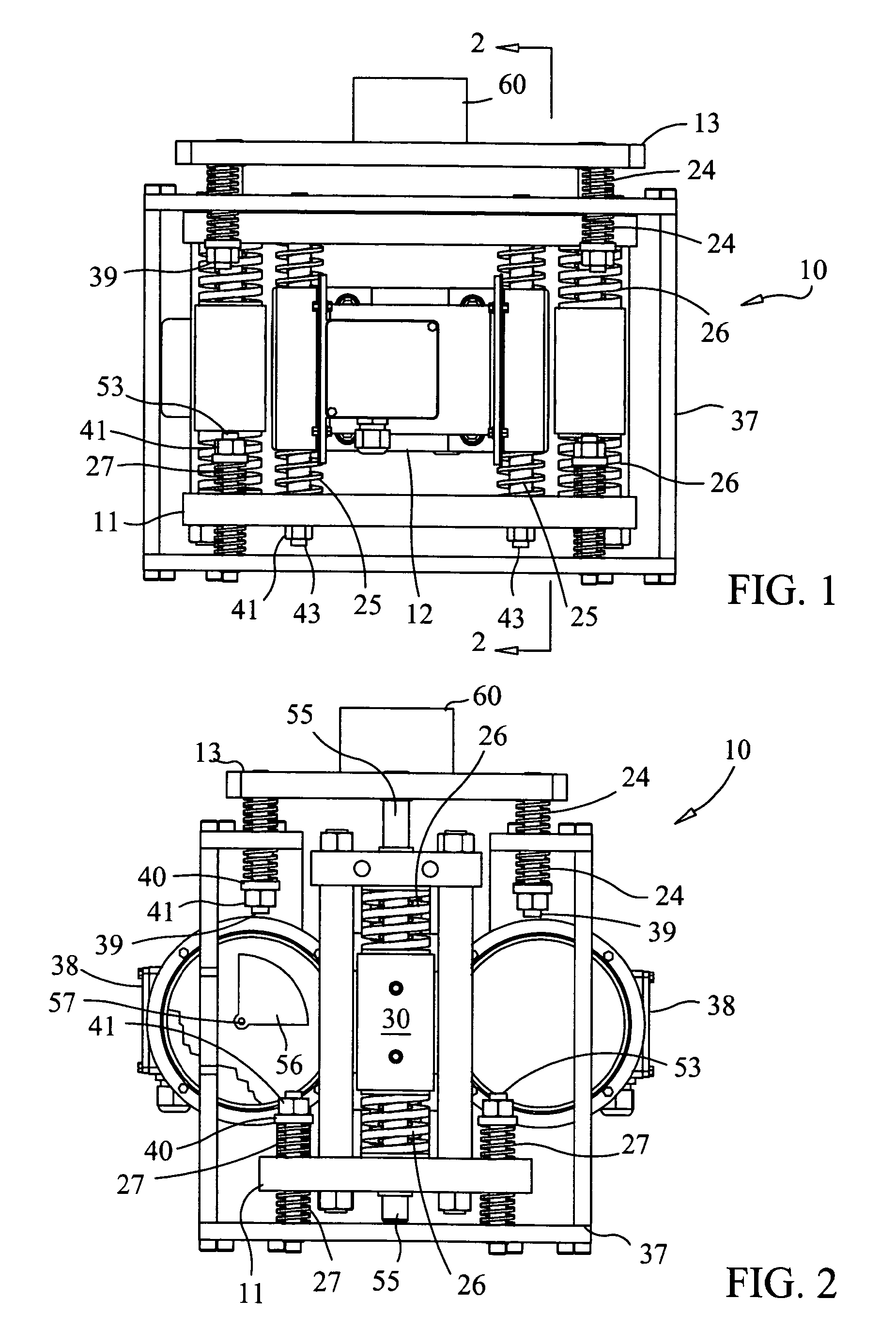

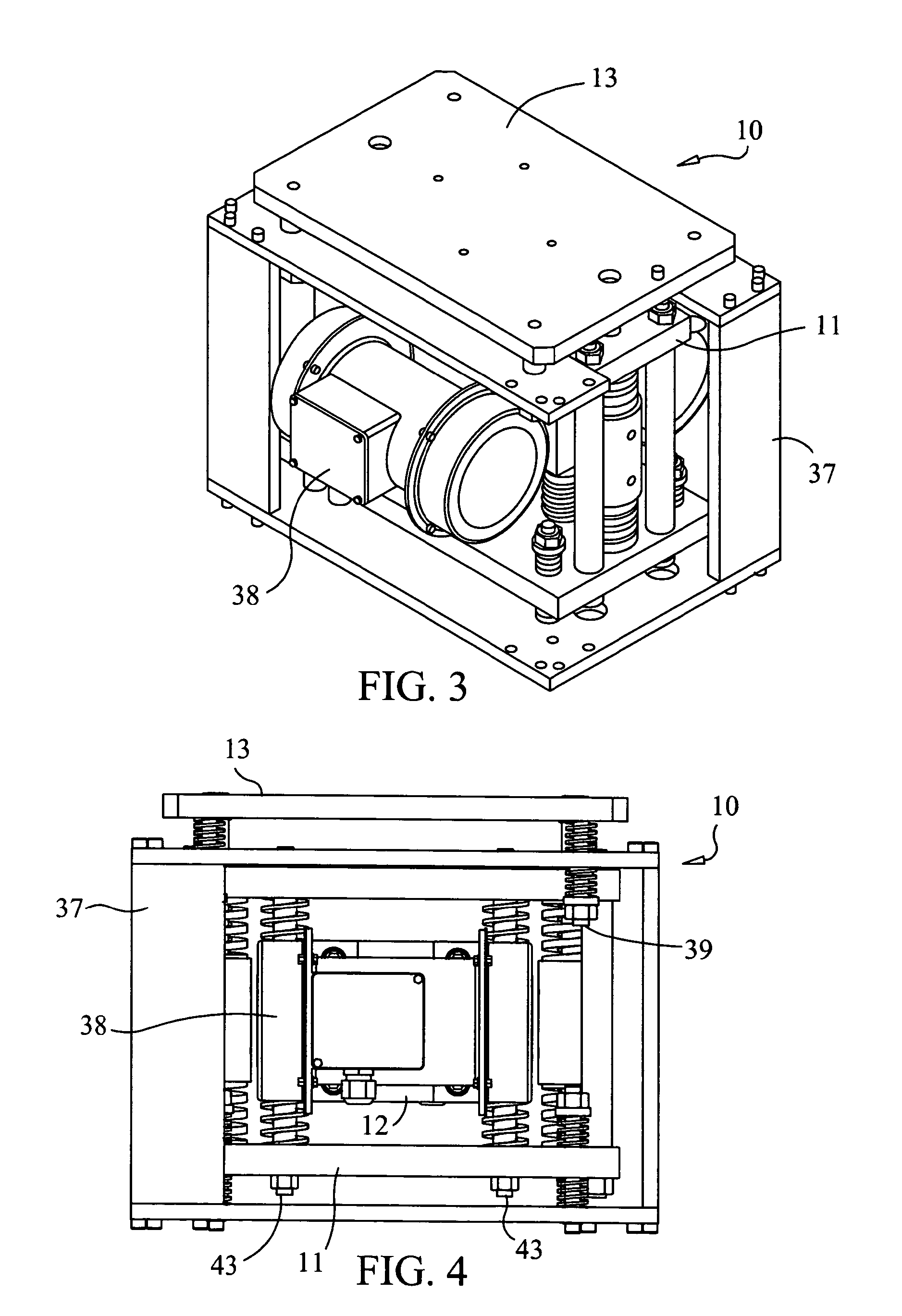

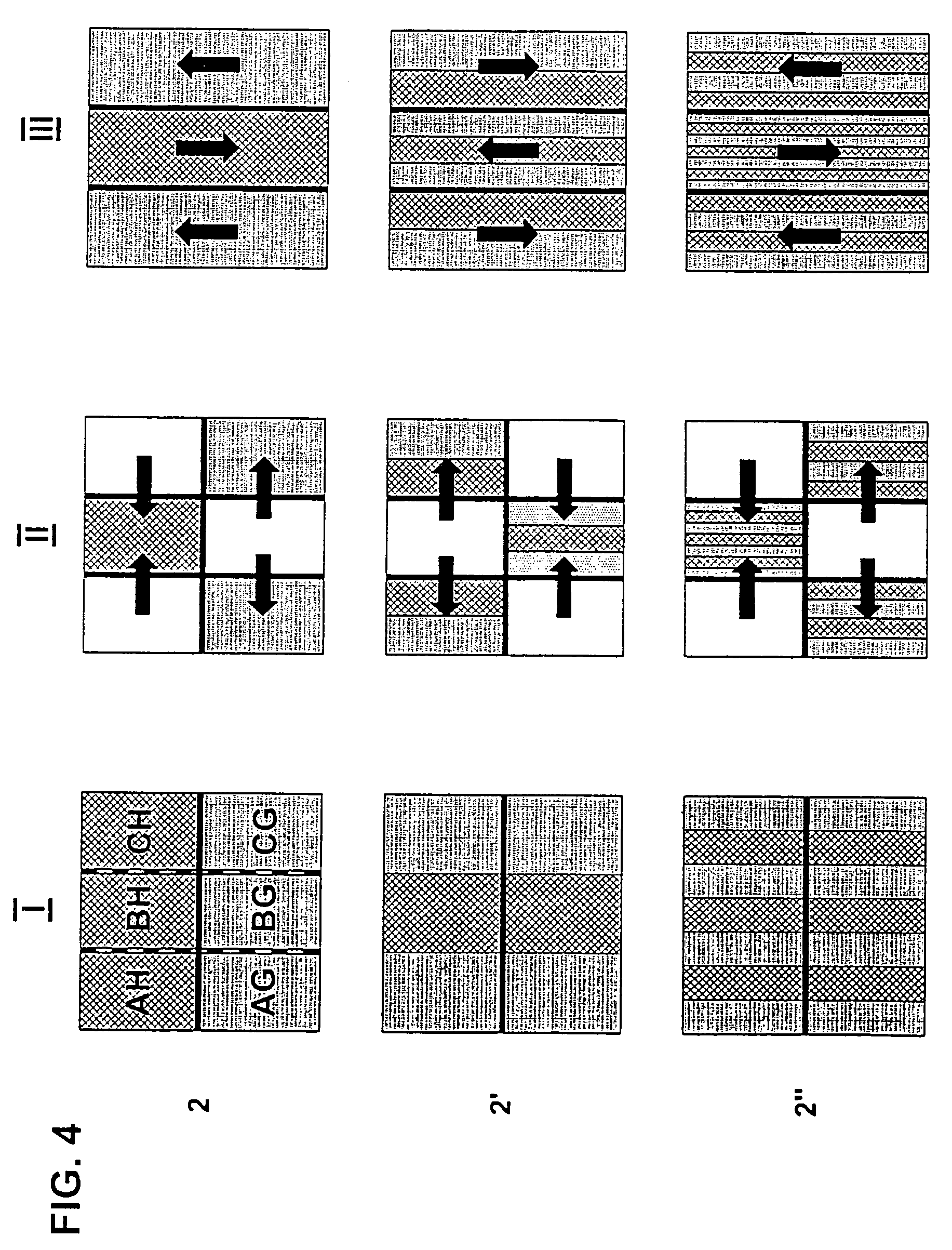

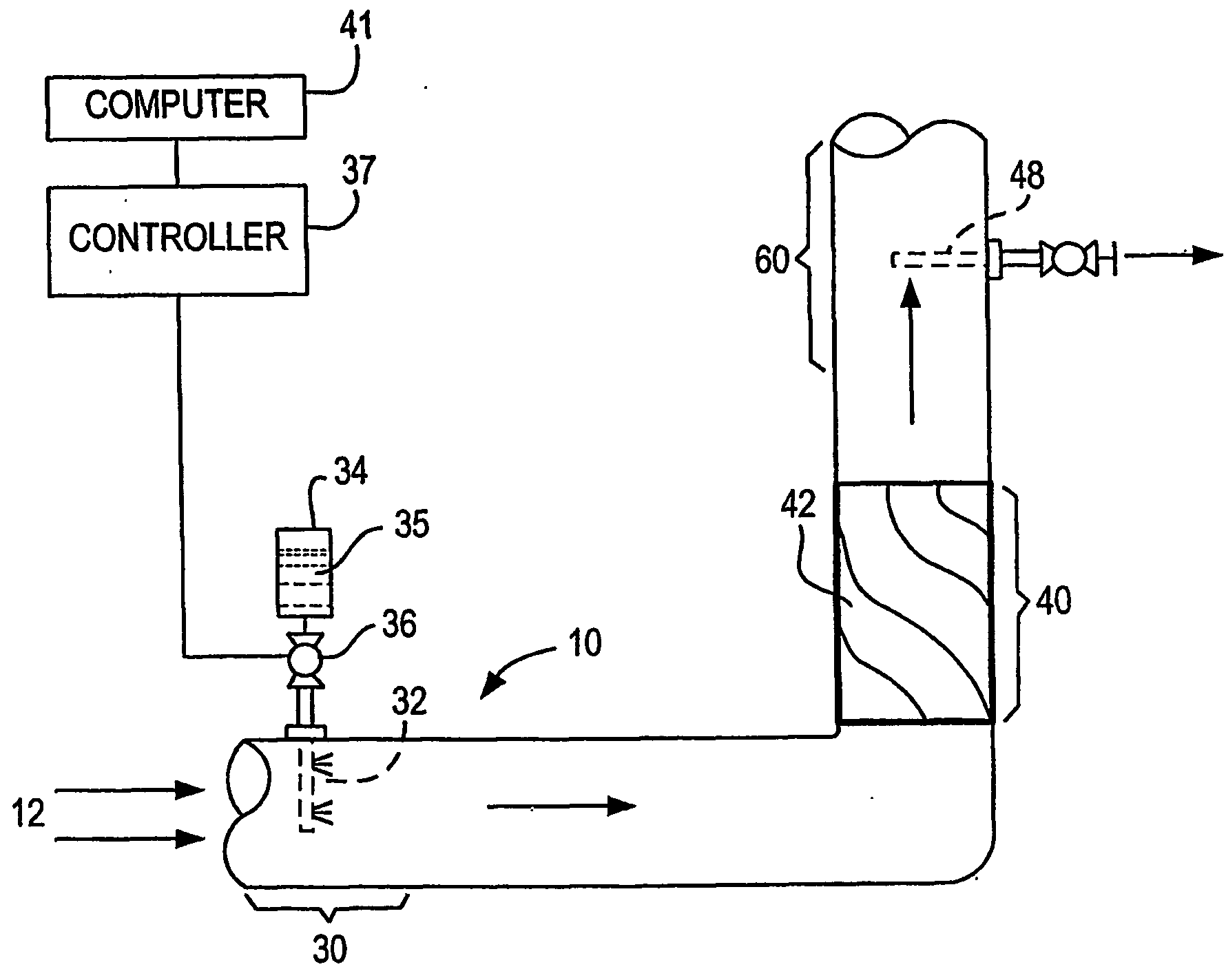

Apparatus and method for resonant-vibratory mixing

ActiveUS7188993B1Reduce the overall heightImprove bearing lifeShaking/oscillating/vibrating mixersTransportation and packagingLinear motionElectronic controller

An apparatus and method for mixing fluids and / or solids in a manner that can be varied from maintaining the integrity of fragile molecular and biological materials in the mixing vessel to homogenizing heavy aggregate material by supplying large amounts of energy. Variation in the manner of mixing is accomplished using an electronic controller to generate signals to control the frequency and amplitude of the motor(s), which drive an unbalanced shaft assembly to produce a linear vibratory motion. The motor may be a stepper motors a linear motor or a DC continuous motor. By placing a sensor on the mixing vessel platform to provide feedback control of the mixing motor, the characteristics of agitation in the fluid or solid can be adjusted to optimize the degree of mixing and produce a high quality mixant.

Owner:RESODYN ACOUSTIC MIXERS

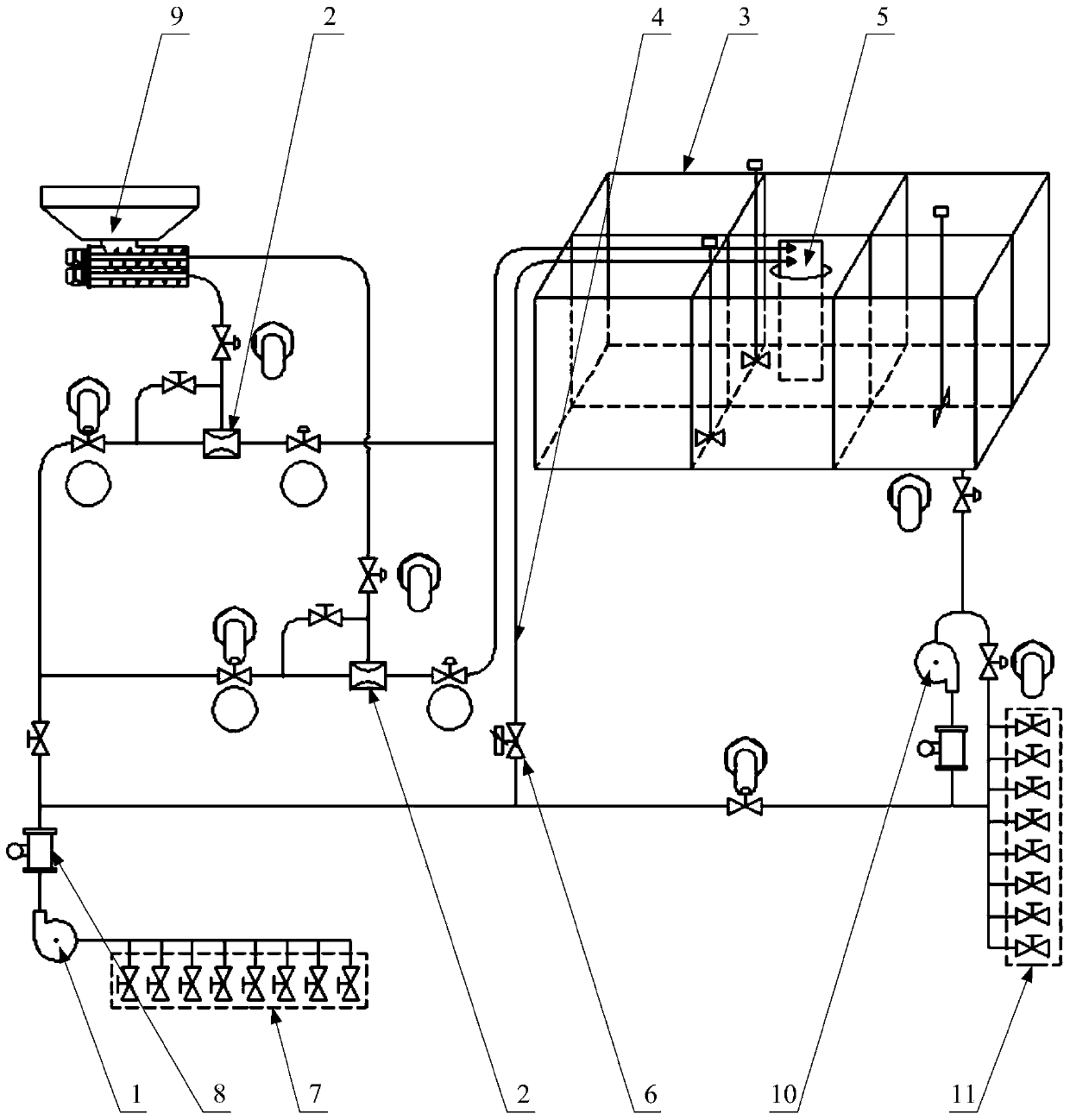

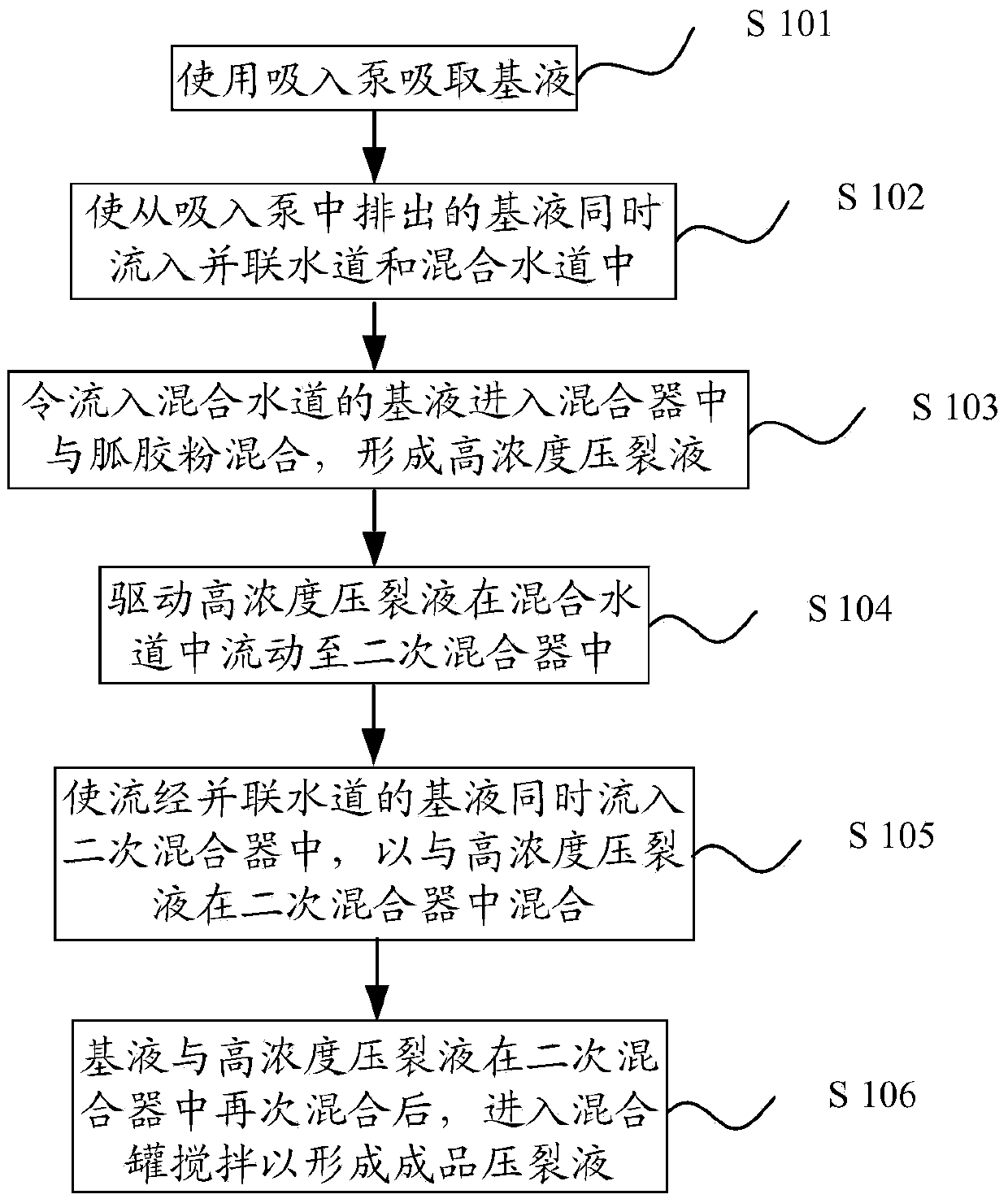

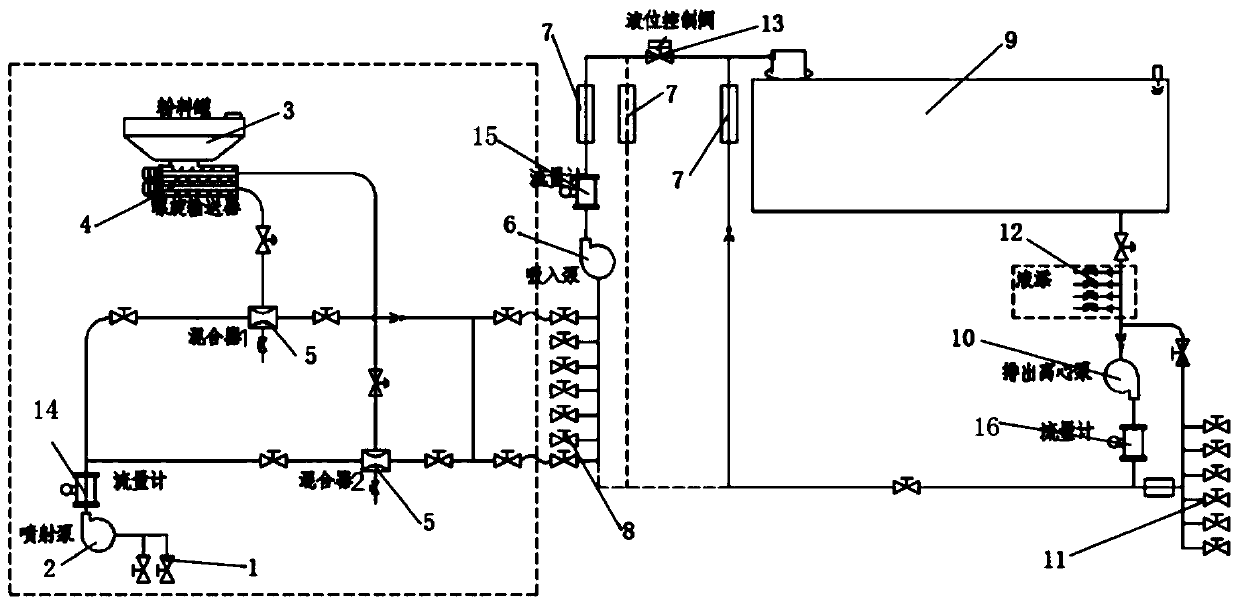

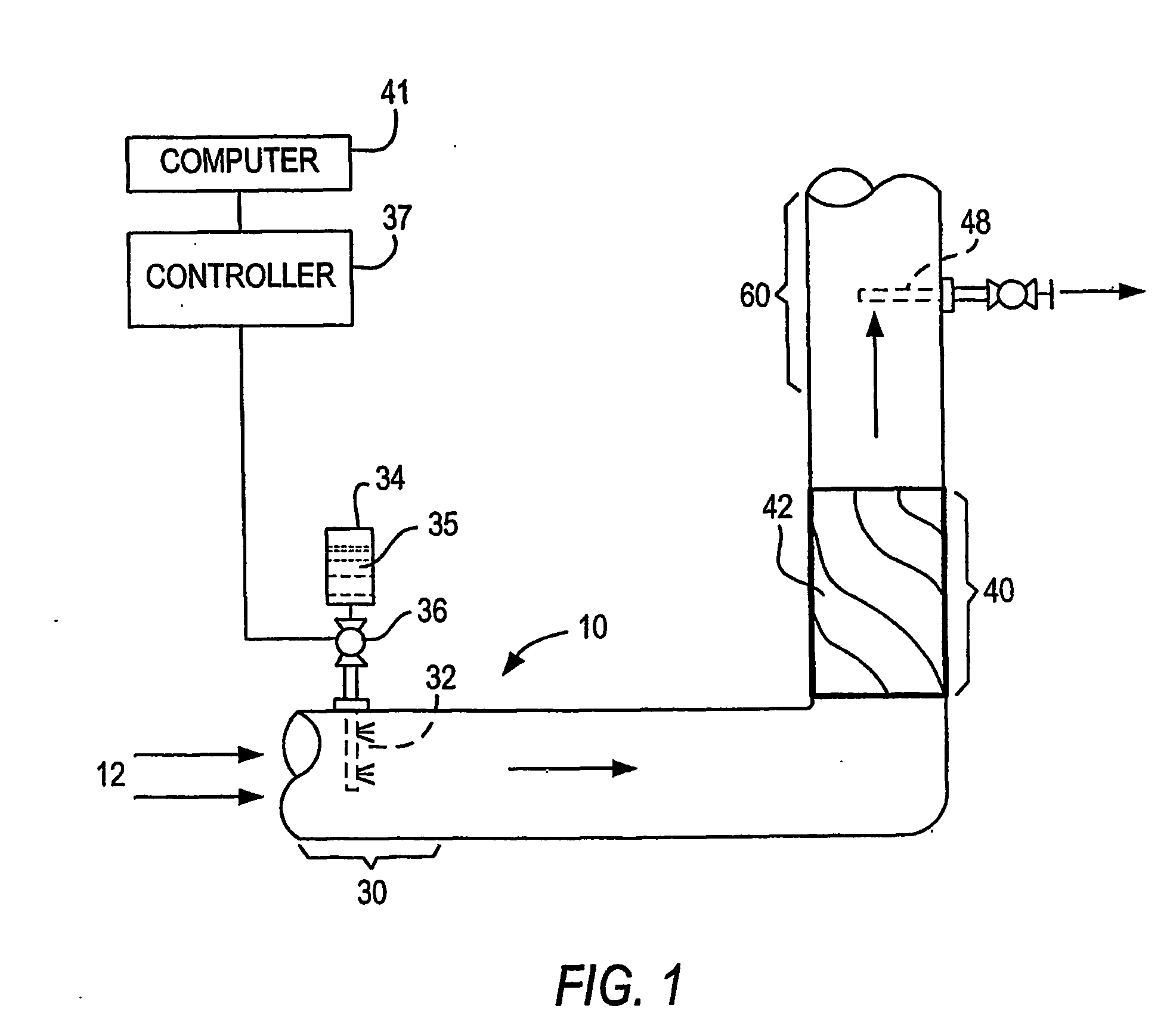

Blending system of fracturing fluid and blending technology of system

InactiveCN103990410AReduce concentrationImprove mixing efficiencyMixing methodsMixersFracturing fluidEngineering

The invention provides a blending system of a fracturing fluid. The blending system comprises a suction pump, a mixer, a mixing tank, a secondary mixer which is arranged between the mixer and the nixing tank and is used for mixing the fracturing fluid again, and a parallel-connection water channel, wherein one end of the parallel-connection water channel is communicated with the suction pump, the parallel-connection water channel and a mixing water channel of the mixer are connected in parallel, and the other end of the parallel-connection water channel is communicated with the secondary mixer. The blending system provided by the invention has the advantages that the parallel water channel is additionally arranged and is connected with the mixing water channel in parallel, a base solution is capable of simultaneously entering two routes, namely the mixing water channel and the parallel-connection water channel, not all of the base solution enters the mixing water channel, a condition that the limitation on blending efficiency is caused by the relatively small flow of the mixing water channel is avoided, the blending time is shortened, the blending energy consumption is reduced, the fracturing fluid is formed through multi-time blending in a double-route manner, the mixing uniformity is improved, and the quality of the fracturing fluid is further optimized. The invention also provides a fracturing fluid blending technology suitable for the blending system of the fracturing fluid.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

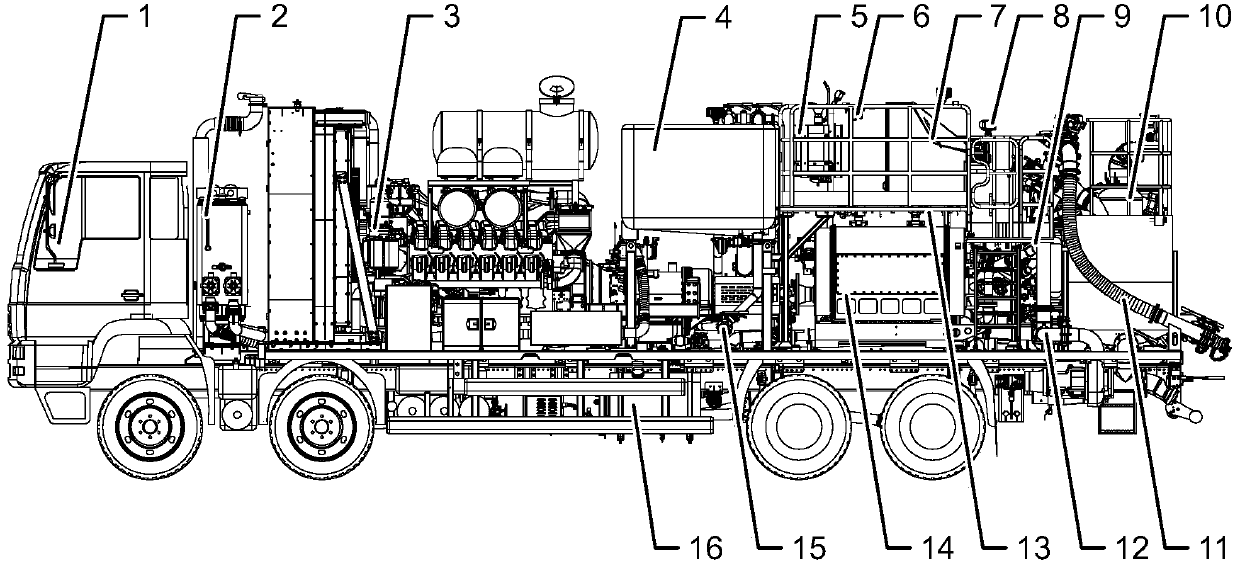

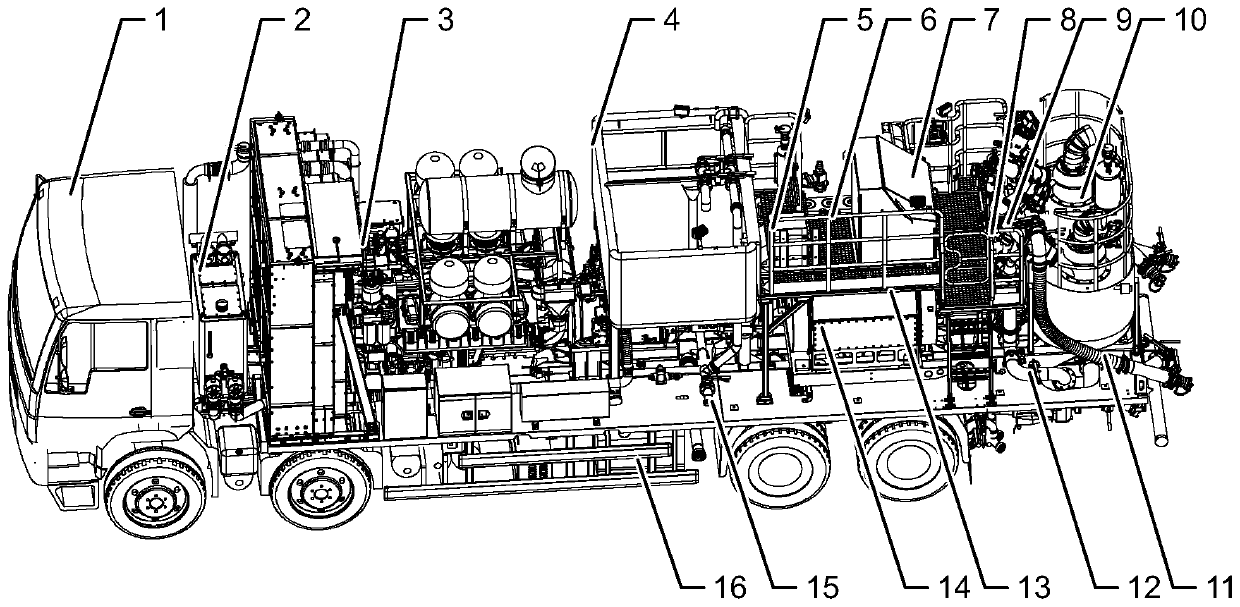

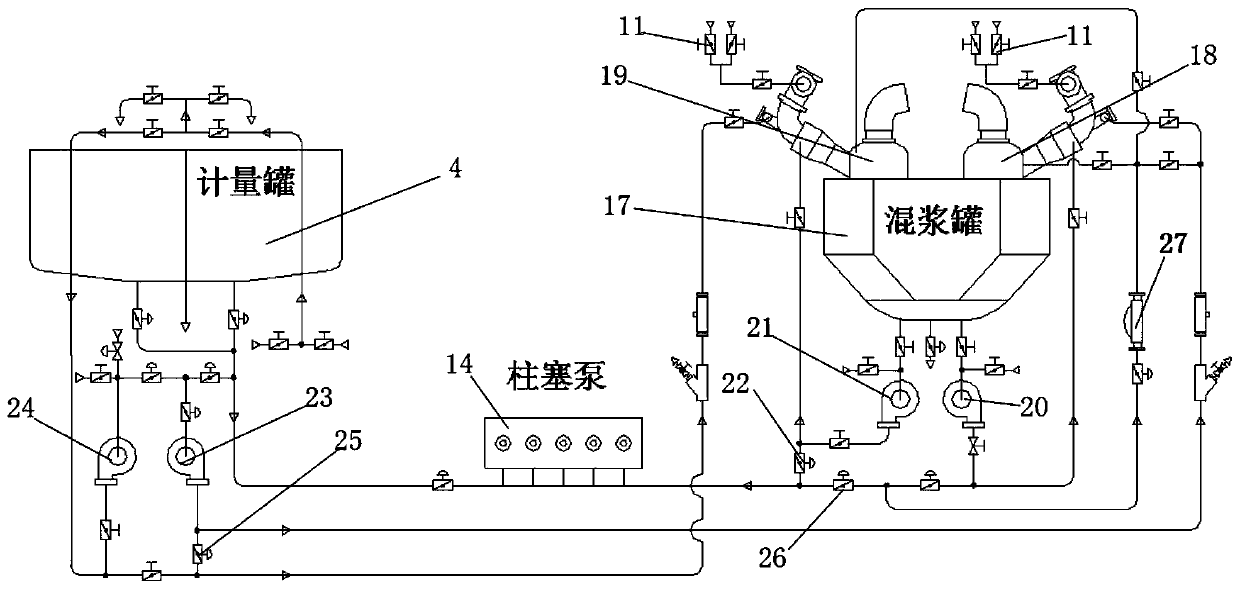

Novel ultra-large-displacement ultrahigh-pressure well cementing equipment

PendingCN111173476AIncrease pressureIncrease displacementItem transportation vehiclesSealing/packingUltra high pressureDrivetrain

The invention discloses novel ultra-large-displacement ultrahigh-pressure well cementing equipment. The novel ultra-large-displacement ultrahigh-pressure well cementing equipment comprises a loading carrier. A hydraulic system, a power transmission system, a metering tank, an electrical system, an air path system, a control system, an operating platform, a plunger pump, a clean water manifold, a mud manifold, a high-pressure manifold, a mixing system and an ash feeding manifold are mounted on the loading carrier, wherein the plunger pump is a five-cylinder plunger pump. The five-cylinder plunger pump is adopted to increase the pressure and displacement of the well cementing equipment, and the requirements of high pressure and large displacement are met; slurry mixing is carried out by double mixing devices, the mixing efficiency is improved, the stability of the slurry mixing density is improved, and the requirement of long-time uninterrupted operation is guaranteed; a mixing system pipeline is optimized, multiple sets of mixing systems are integrated on one slurry mixing tank, and the stability of the equipment is improved; and the clean water manifold is optimized, so that watersupply requirements of the multiple mixing devices can also be met at the same time by using one injection pump, and the requirement of large displacement is met.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

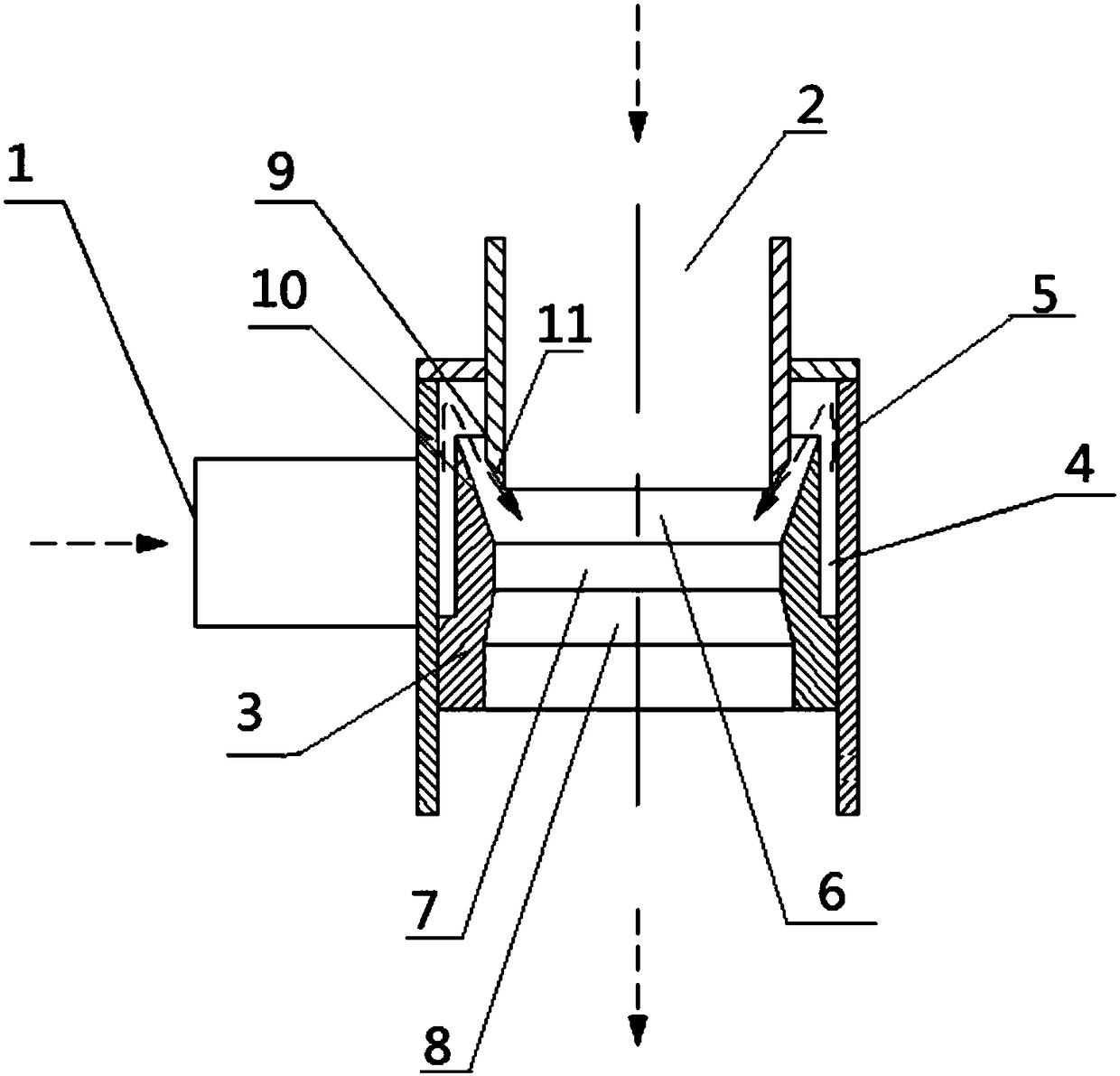

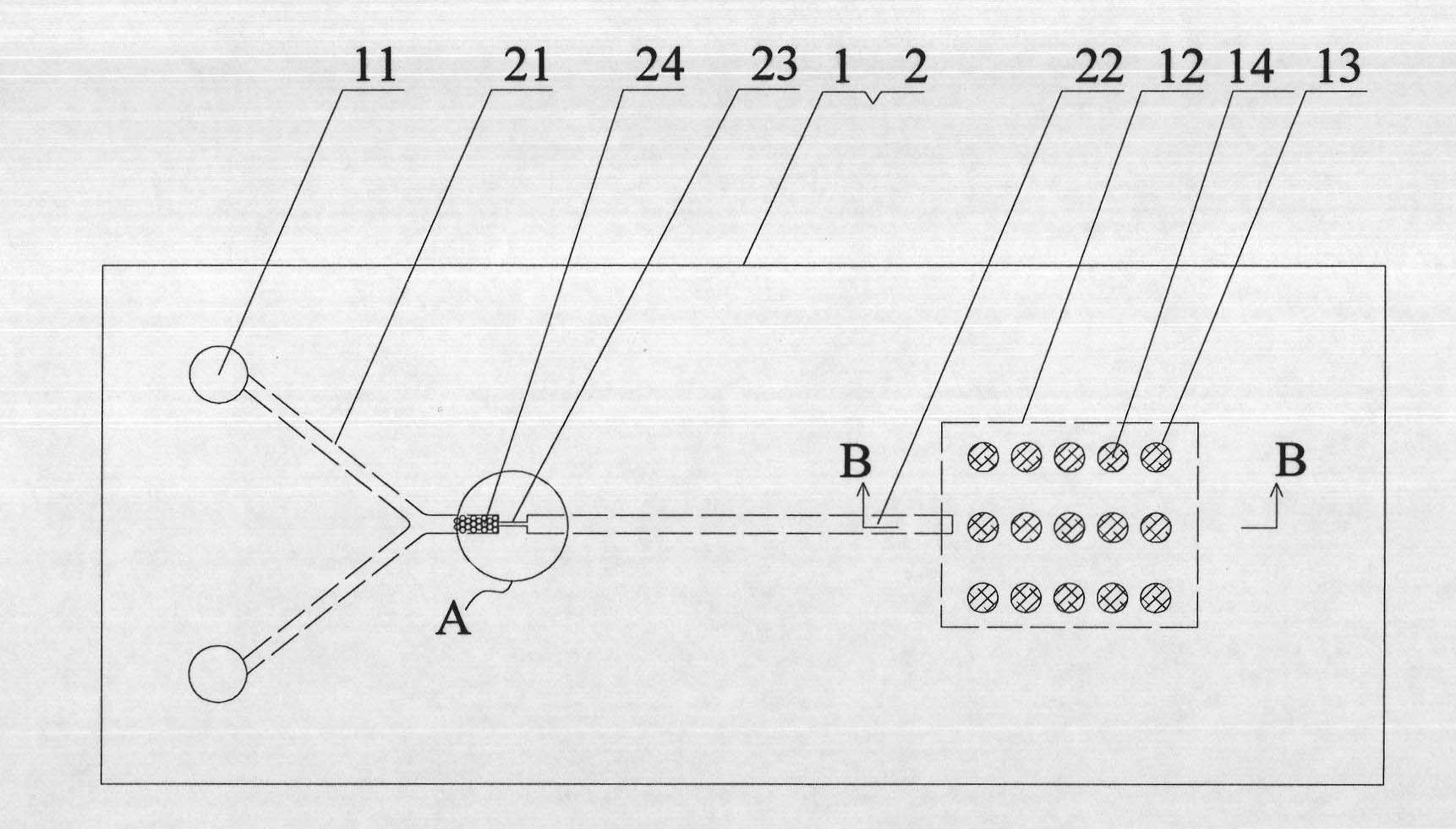

Fracturing base liquid mixer

PendingCN108371894AAchieve energy efficiency ratioCanto Efficiency RatioFlow mixersTransportation and packagingBusiness efficiencyFracture sites

The invention relates to the technical field of water-powder mixing or liquid mixing equipment in the construction operations of oil and gas fields and particularly relates to a fracturing base liquidmixer used in a construction process of an oil field fracturing site. The fracturing base liquid mixer comprises a rotational flow premixing device which comprises a liquid inlet, a feeding hole, a connecting component and an annulus, wherein the feeding hole is vertically formed, the liquid inlet is horizontally formed, the side wall of the feeding hole is connected with a sleeve, the connectingcomponent is arranged in the sleeve, the annulus is formed by the connecting component and the side wall of the feeding hole and is communicated with the liquid inlet, an oblique side is arranged atthe lower end part of the side wall of the feeding hole, an oblique plane is arranged at the upper part of the connecting component, and the oblique plane and the oblique side form certain angles witha vertical plane and are 0-80 degrees; and a reduced section, a throat pipe and a dispersion pipe are sequentially arranged at the lower part of the feeding hole. The fracturing base liquid mixer canmeet the requirements on the fracturing base liquid during large-scale operations in a fracturing operation site, the blending and mixing efficiencies are improved, the mixing quality of guanidine gum liquid is improved, and the optimal energy efficiency ratio is realized.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH

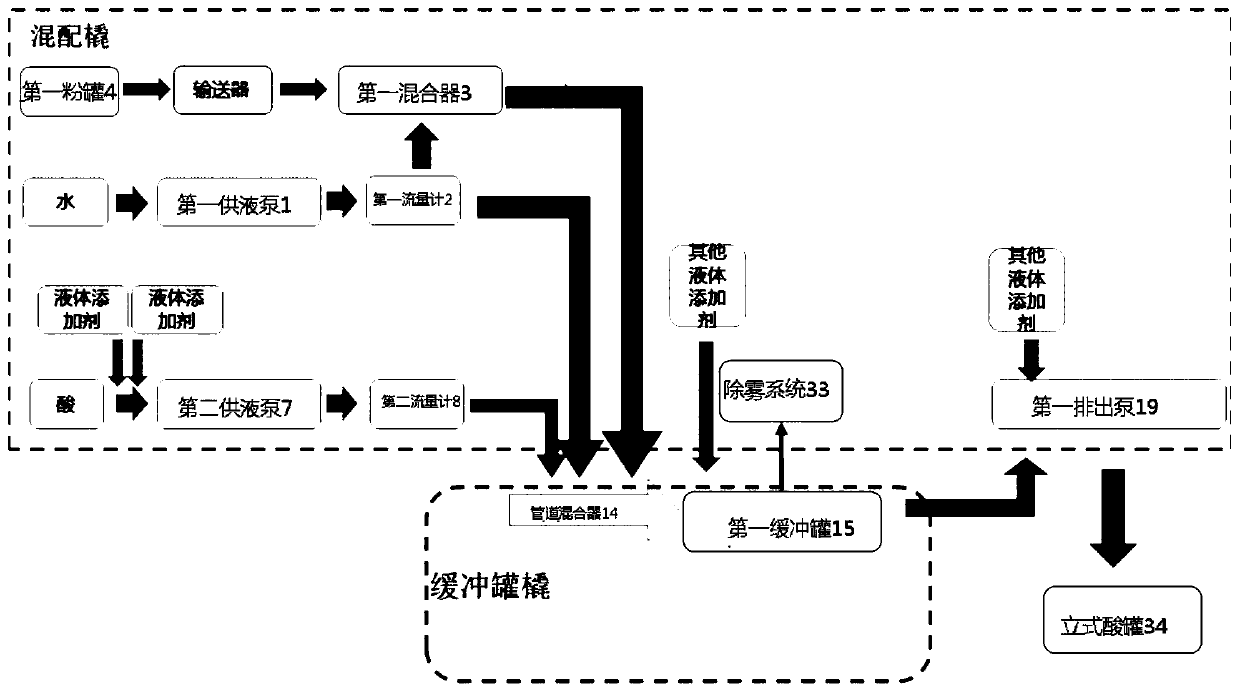

Acid liquor mixing equipment

PendingCN111151186AImprove mixing efficiencyImprove stirring efficiencyTransportation and packagingFluid removalProcess engineeringStatic mixer

Acid liquor mixing equipment comprises a buffer system, a pipeline mixing pipe system and an output system. The pipeline mixing pipe system is communicated with the buffer system and is used for mixing materials in a pipe and spraying the mixed material to the buffer system. The buffer system is connected with the output system and is used for outputting the stirred mixed material in real time through the output system. Materials are mixed in the pipe through a spraying system, the efficiency of the mixing and stirring process can be improved through one or more of a spraying mixer, a three-way mixer, a static mixer, a rotational flow mixer and the like, rapid stirring and mixing can be achieved, and prepared acid liquor is output in real time through the output system connected with a stirring system. Through the connection of the pipeline mixing pipe system, the stirring system and the output system, the two processes of acid liquor preparation and acid liquor output can be continuously carried out, and the production efficiency is improved.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

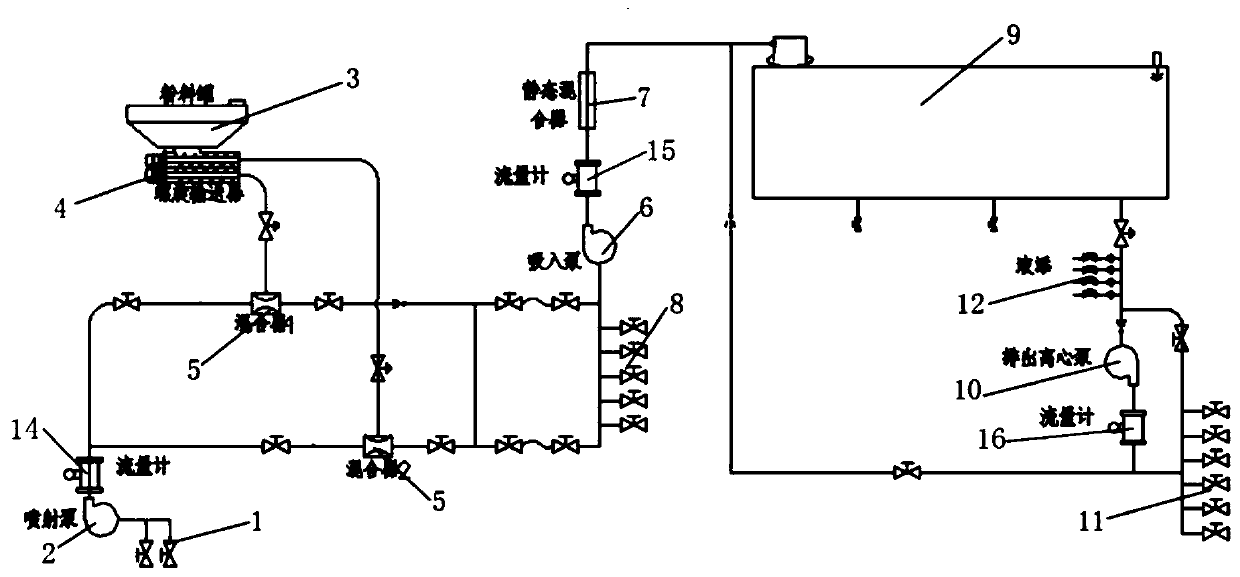

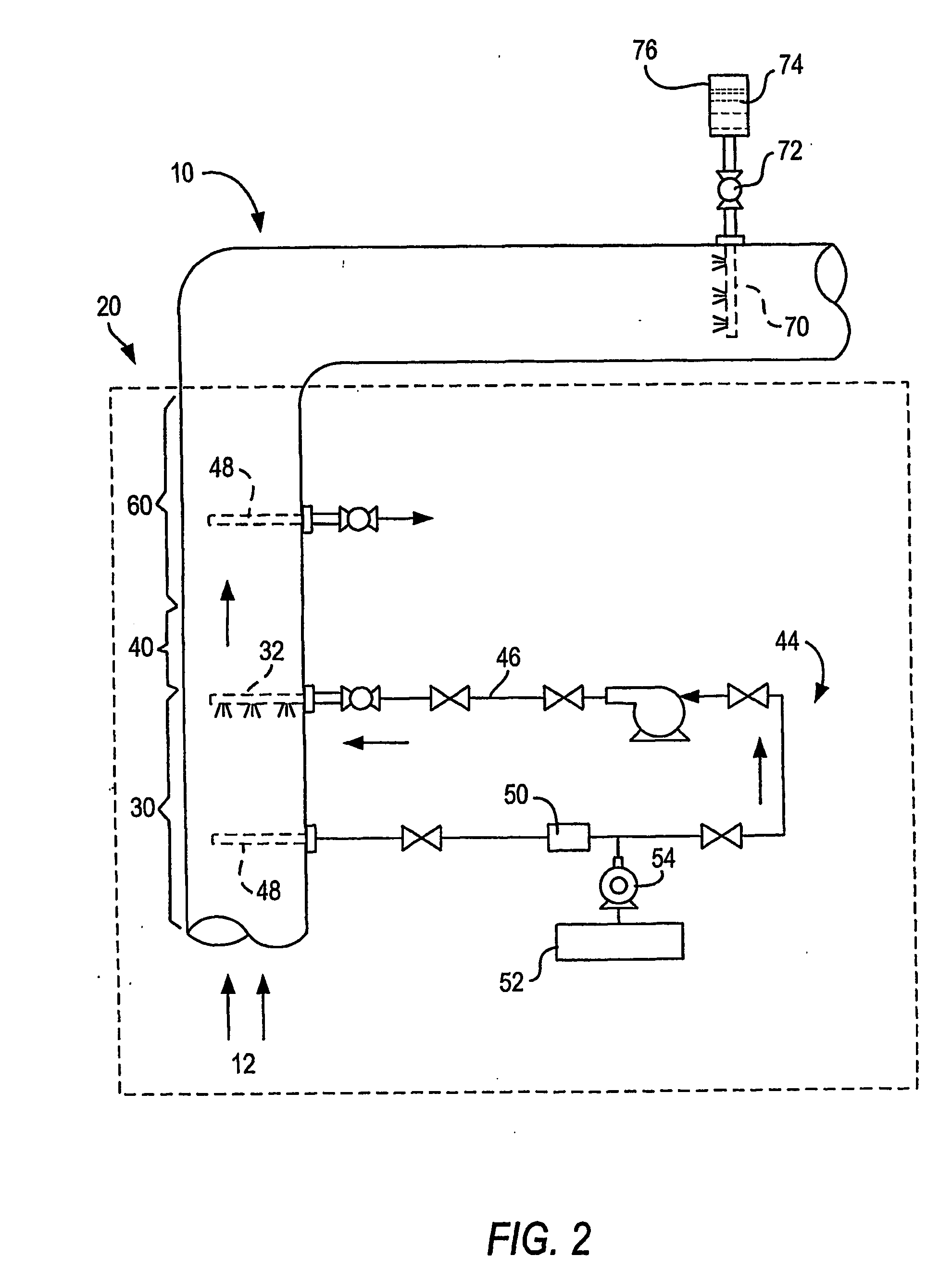

Mixing system

PendingCN110787667AImprove mix qualityImprove mixing efficiencyTransportation and packagingMixing methodsEngineeringStatic mixer

The invention discloses a mixing system. The mixing system comprises a mixing module and an output module, the mixing module comprises a first liquid inlet header, an injection pump, a powder tank anda mixer, the first liquid inlet header is connected with the injection pump, the injection pump is connected with the mixer, and the powder tank provides powder for the mixer; the output module comprises a second liquid inlet header, a suction pump, a second flowmeter, a static mixer, a mixing tank and a liquid discharge manifold, and the second liquid inlet header, the section pump, the second flowmeter, the static mixer, the mixing tank and the liquid discharge manifold are sequentially connected; an outlet of the mixer of the mixing module is connected with an inlet of the suction pump ofthe output module through a valve, and the mixing module and the output module can be used respectively or used in combination as a complete set. The mixing system has the beneficial effects that thesecond liquid inlet header and the static mixer are arranged, mixing with large discharge capacity and high quality can be completed with low energy consumption; and the mixing system is flexible in disassembly and assembly.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

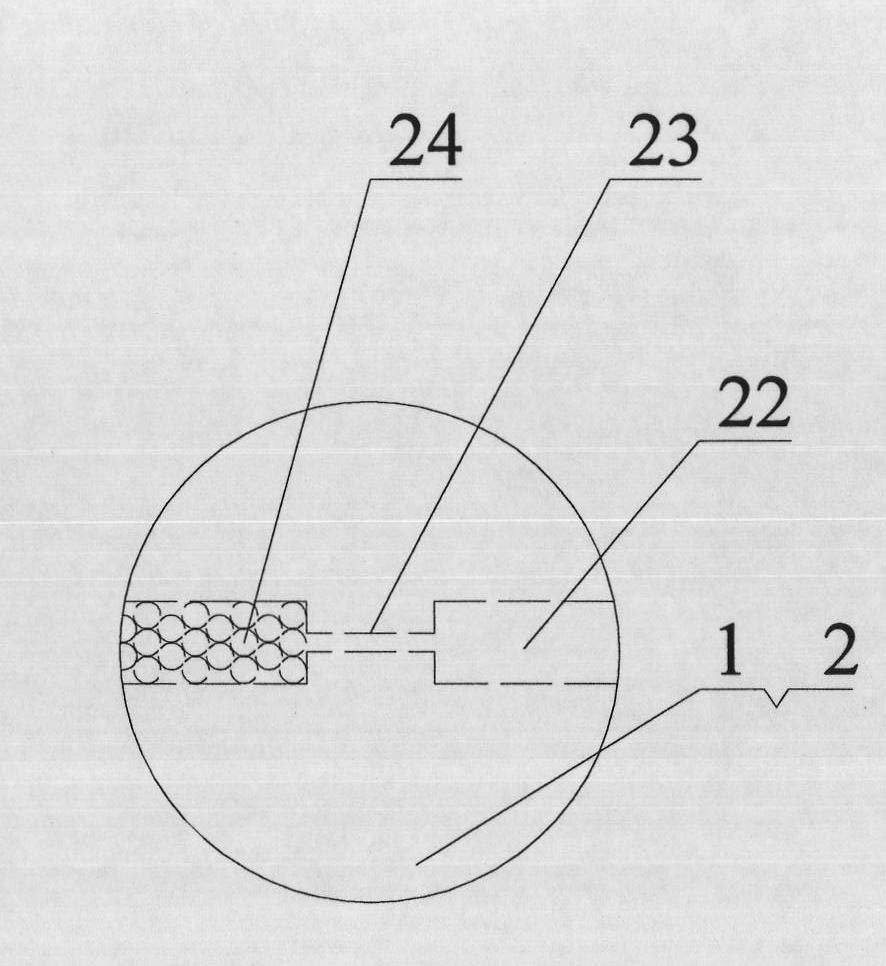

Micro fluid control chip and preparation method and application thereof

InactiveCN101817495AReduce volumeVolume stabilityPrecision positioning equipmentSolid-state devicesFluid controlVolumetric Mass Density

The invention belongs to the technical field of micro fluid control, particularly disclosing a micro fluid control chip and a preparation method and application thereof. One side of the chip is provided with a plurality of sample introduction holes, each sample introduction hole is communicated with a sample introduction runner; after meeting, each sample introduction runner is communicated with a main runner; the main runner is provided with a narrow runner; a micro-sphere of which the size is 0.5-1.5 mm is filled in front of the inlet of the narrow runner; the outlet of the main runner is communicated to a waste liquid tank arranged at the other side of the chip. The preparation method mainly comprises: firstly preparing a PDMS substrate; then, preparing a PDMS cover plate with an upper groove; sticking the substrate onto the cover plate to obtain a semi-finished product of the chip; carrying out modified treatment on each runner in the semi-finished product of the chip; finally, putting the micro-sphere in, controlling the charge quantity, and finishing production. The micro fluid control chip of the invention has high solution mixing efficiency, stable solution flow rate, small volume, convenient carrying and relatively simple manufacturing; when being used for detecting the density of triphosadenine, the micro fluid control chip has the advantages of high sensitivity, favourable detection effect and the like and can not be affected by environment humidity.

Owner:HUNAN UNIV

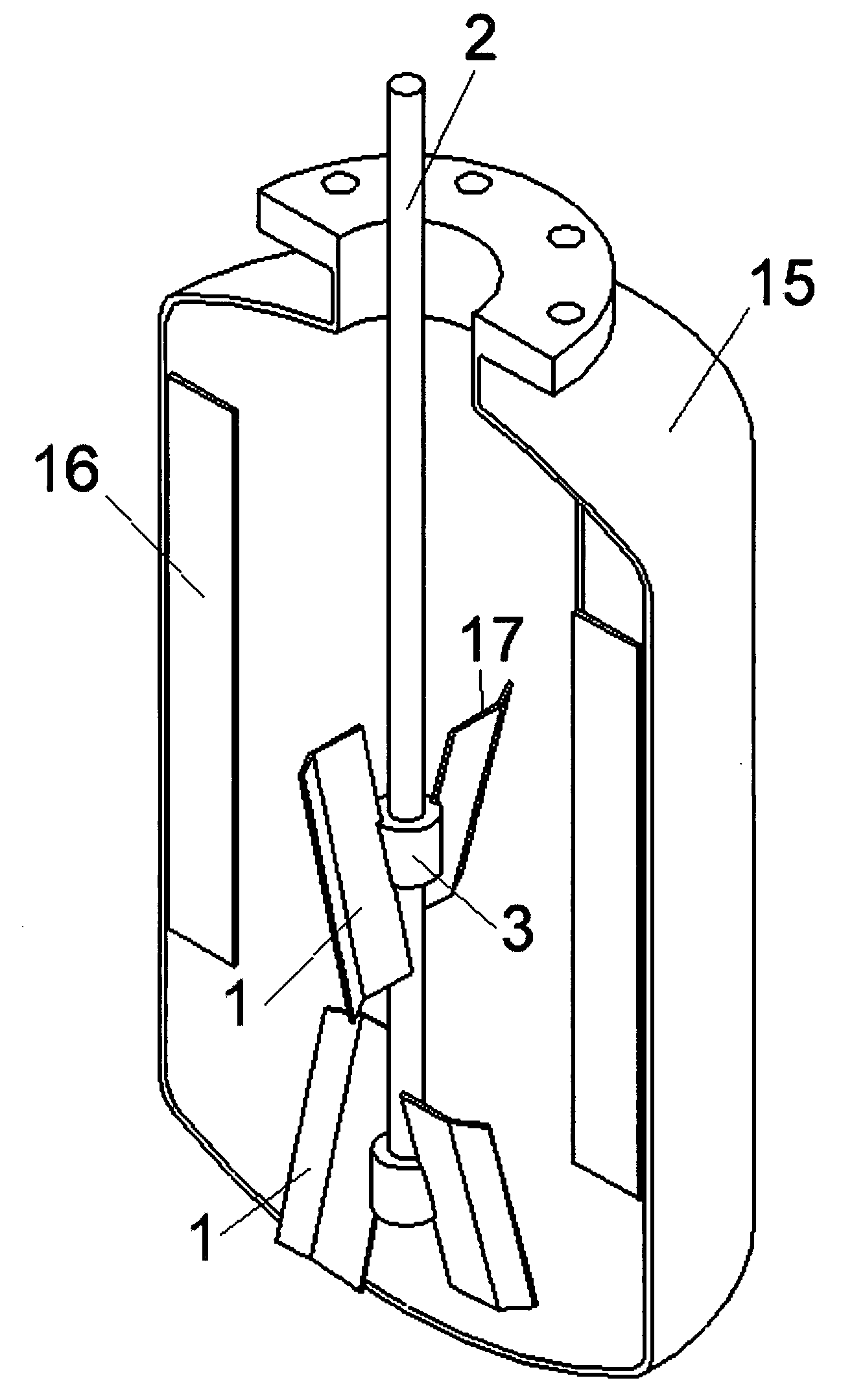

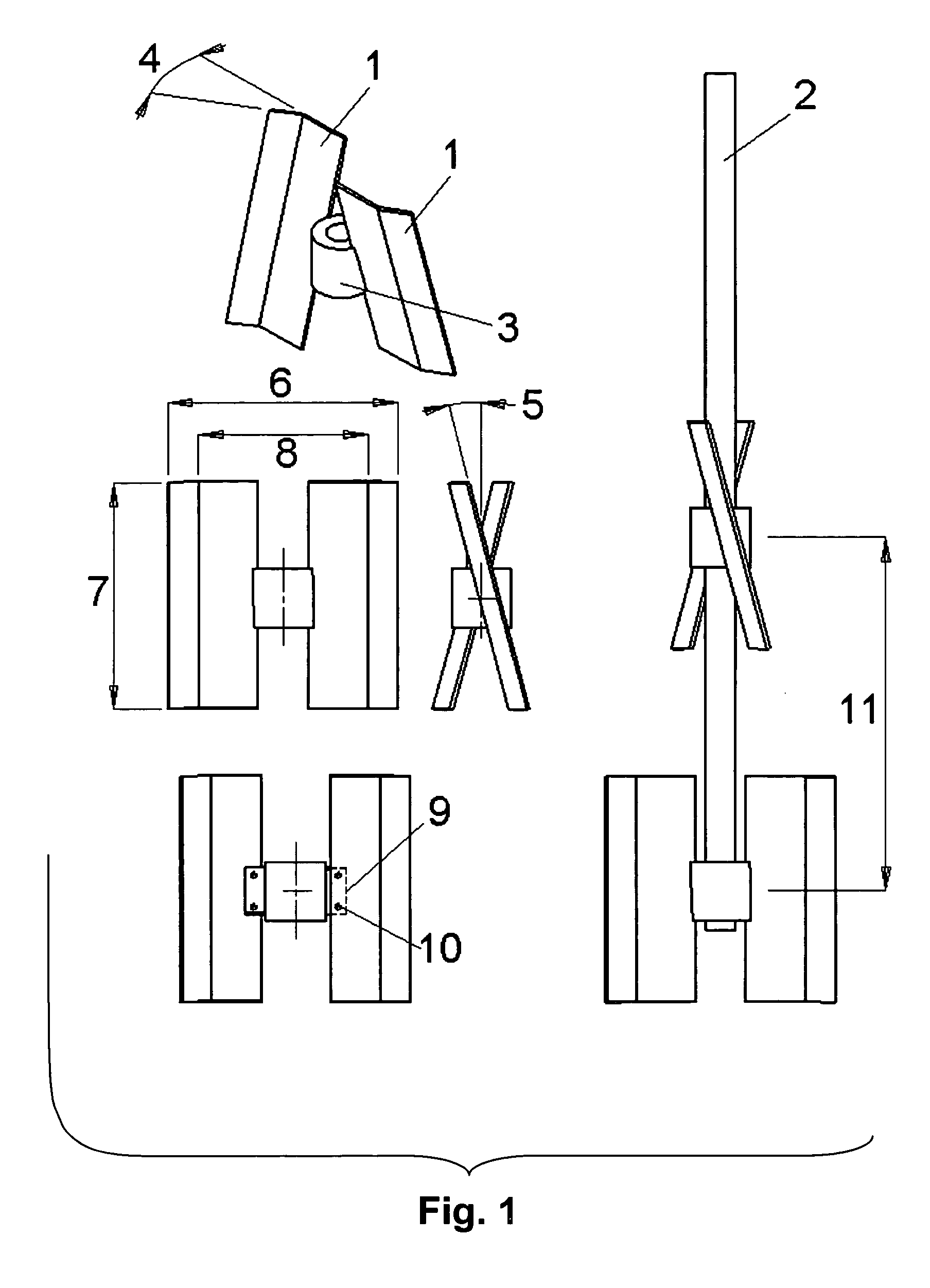

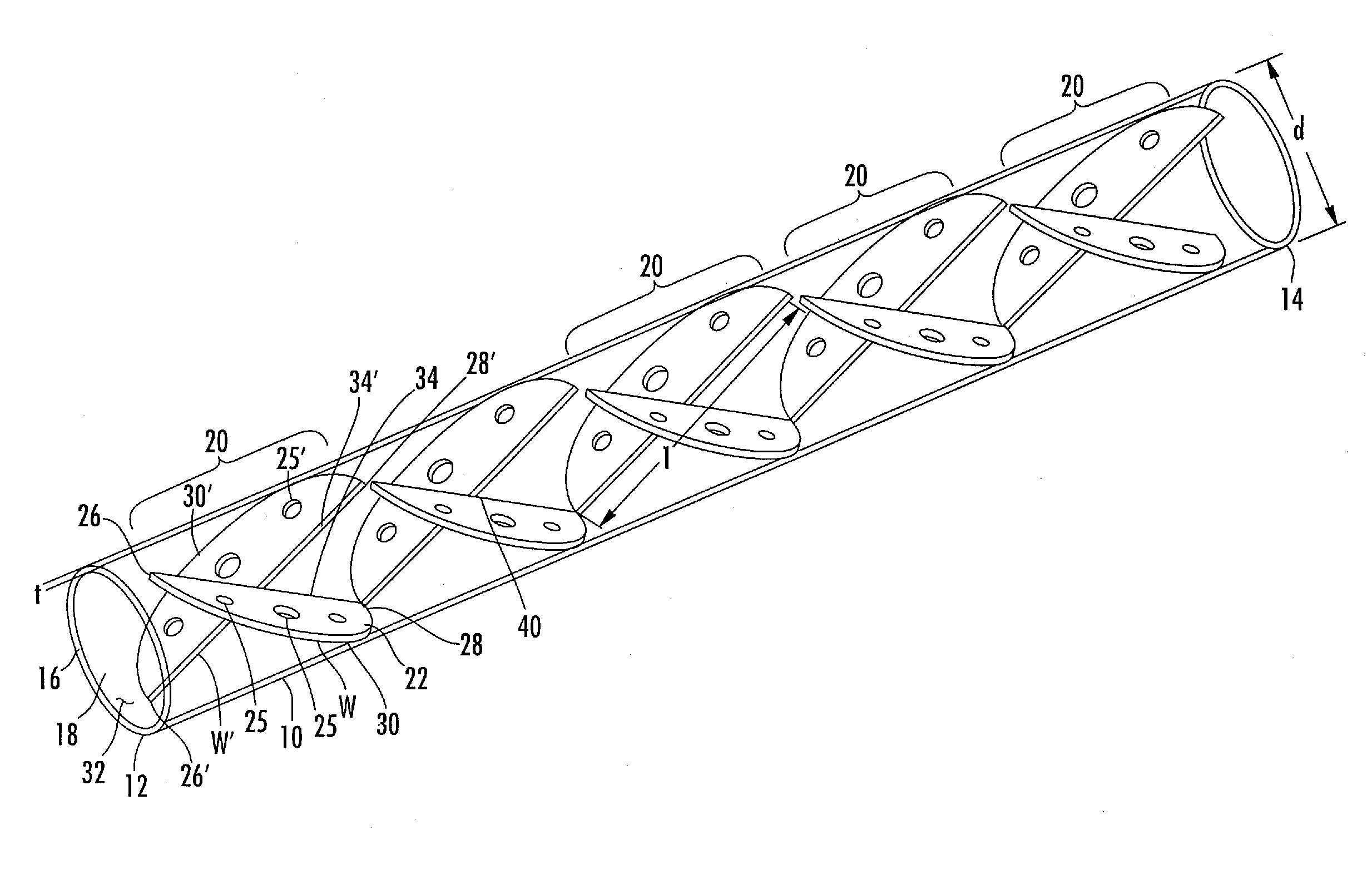

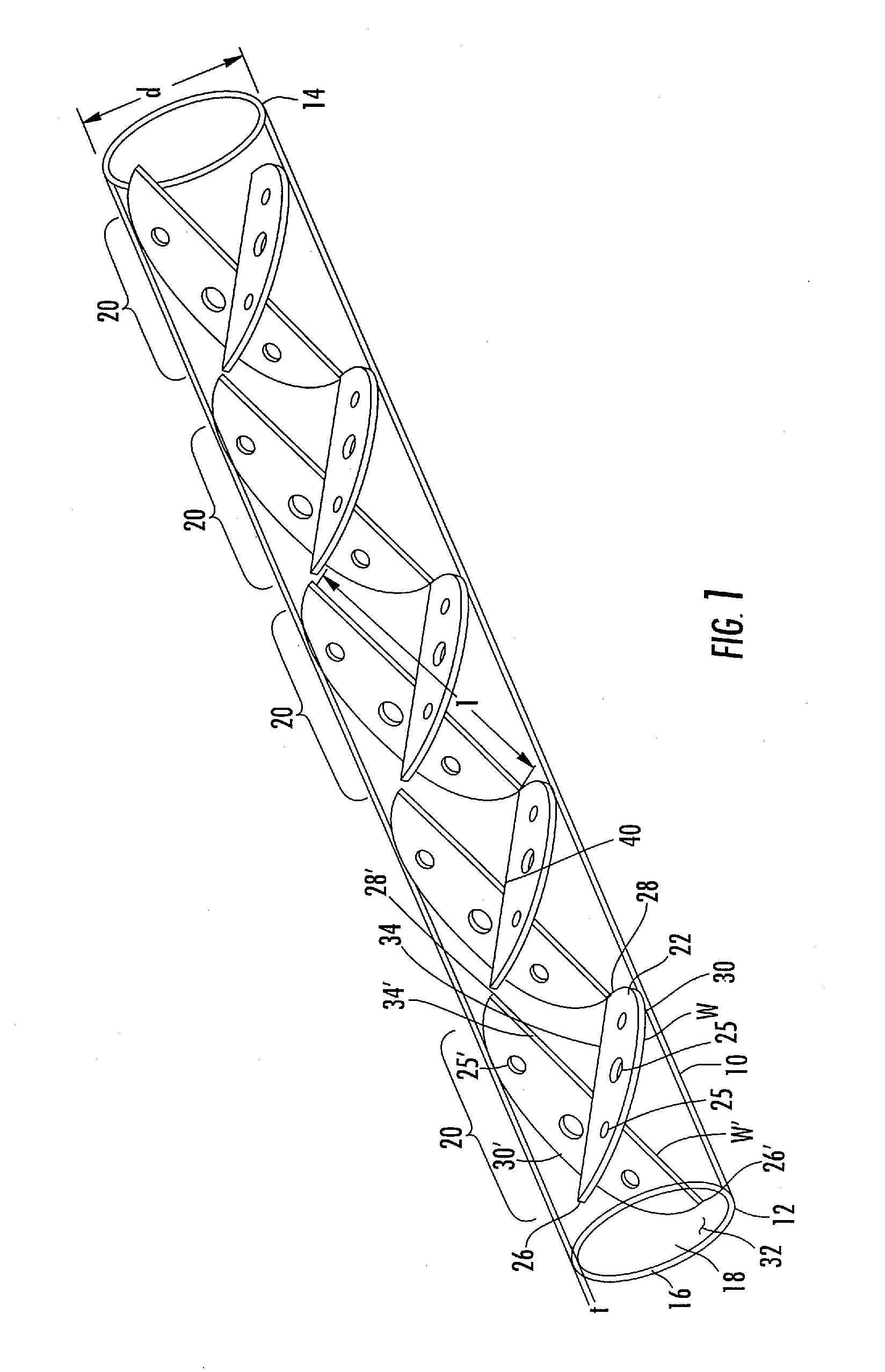

Low shear impeller

ActiveUS20050007874A1Promote stratificationImprove mixing efficiencyFlow mixersTransportation and packagingImpellerDrive shaft

One or more mixing impellers is carried on a driving shaft received in a mixing vessel. Impeller blades are angularly and / or axially distributed on the shaft and can be single staggered axially-spaced blades or groups of two or more placed angularly around the shaft, e.g., diametrically opposite. Each blade has a radially inner flat plate sloped to produce axial flow, preferably at about 15° from parallel to the rotation axis. An outer plate is joined to the inner plate at a bend line with an angle of about 20° located at about 70% of the outside diameter of the impeller path.

Owner:PHILADELPHIA GEAR

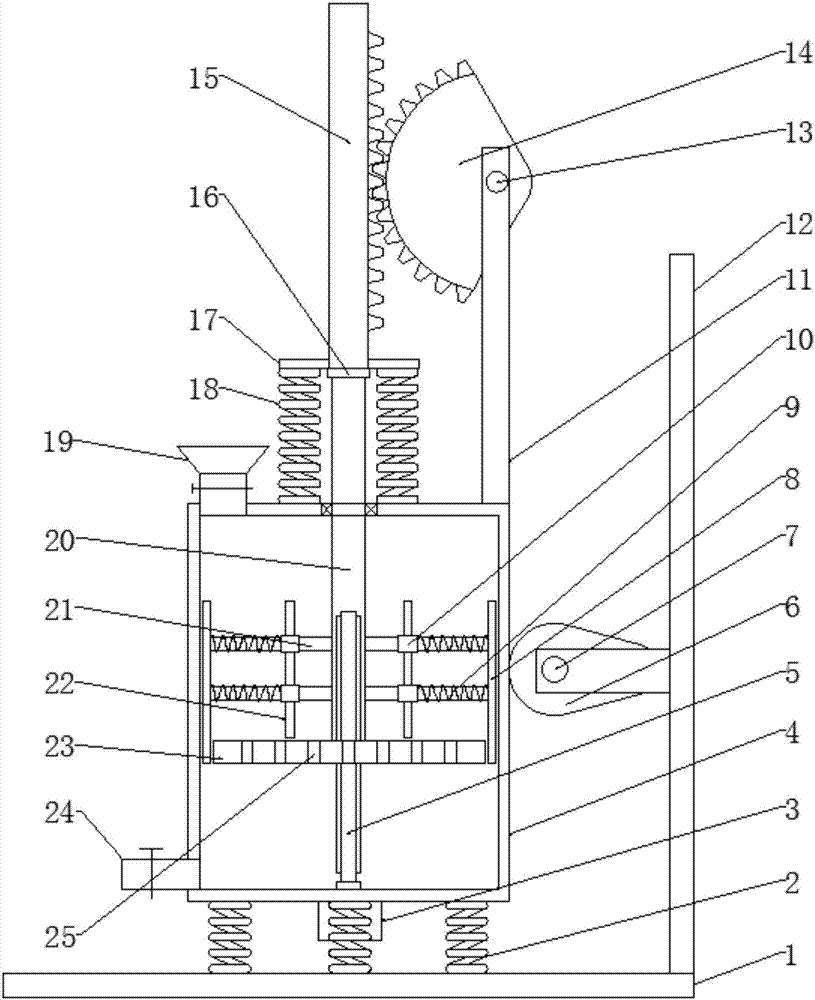

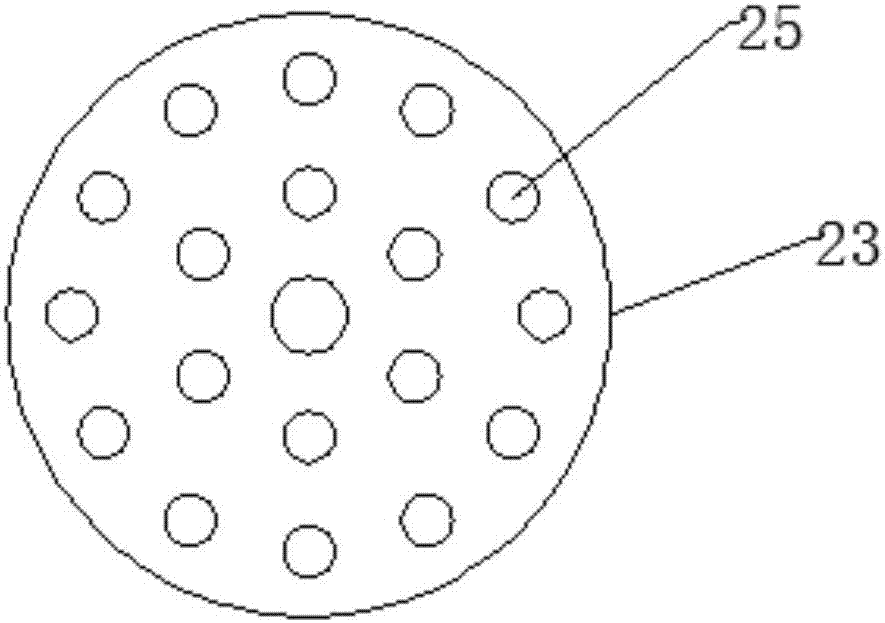

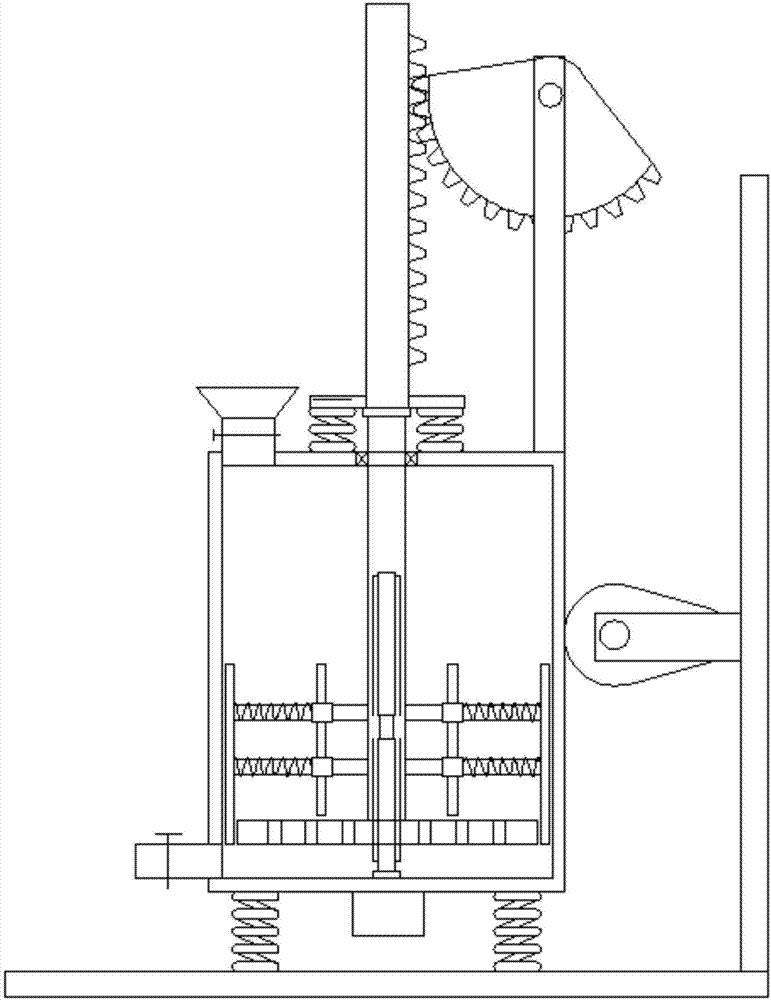

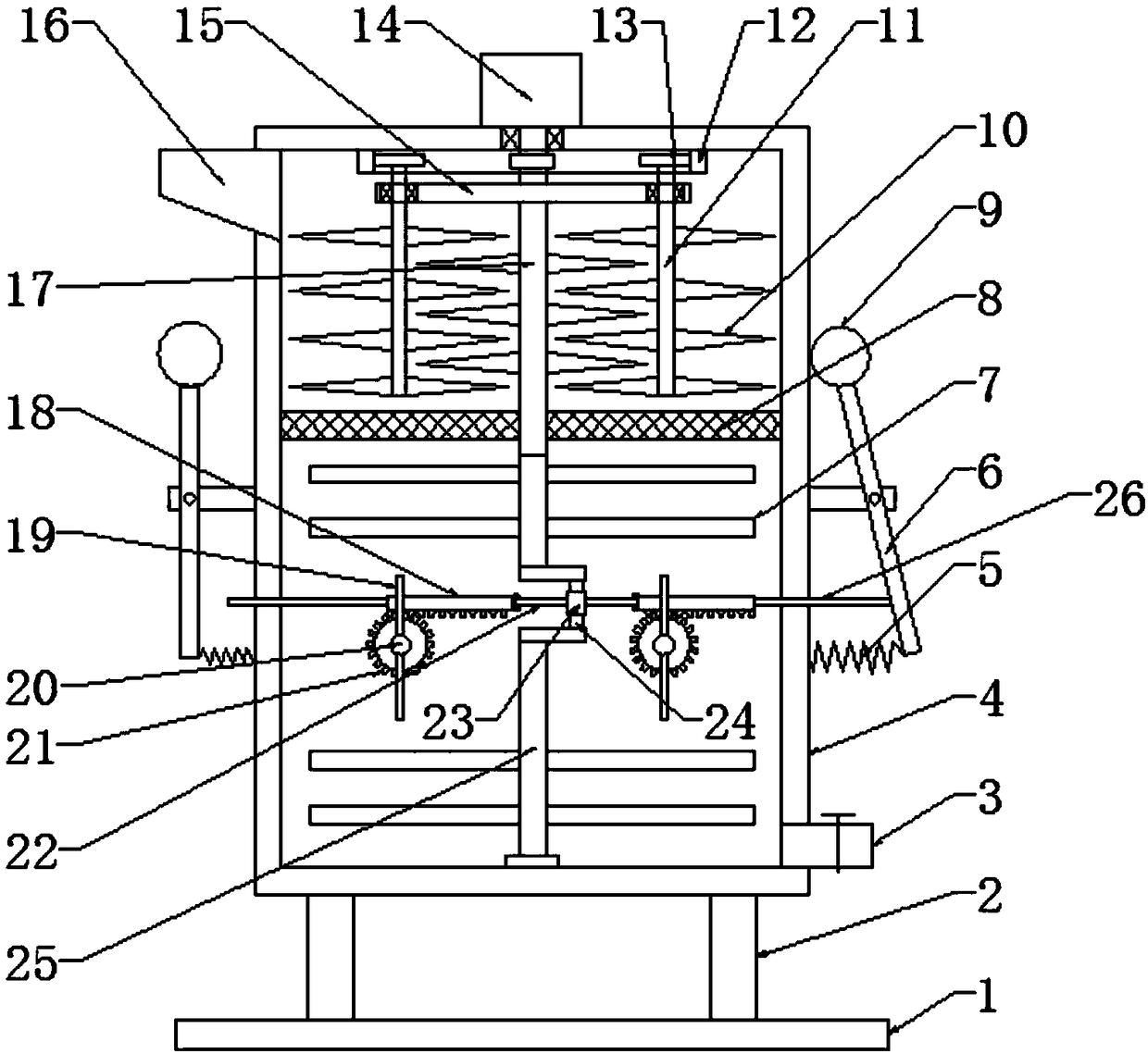

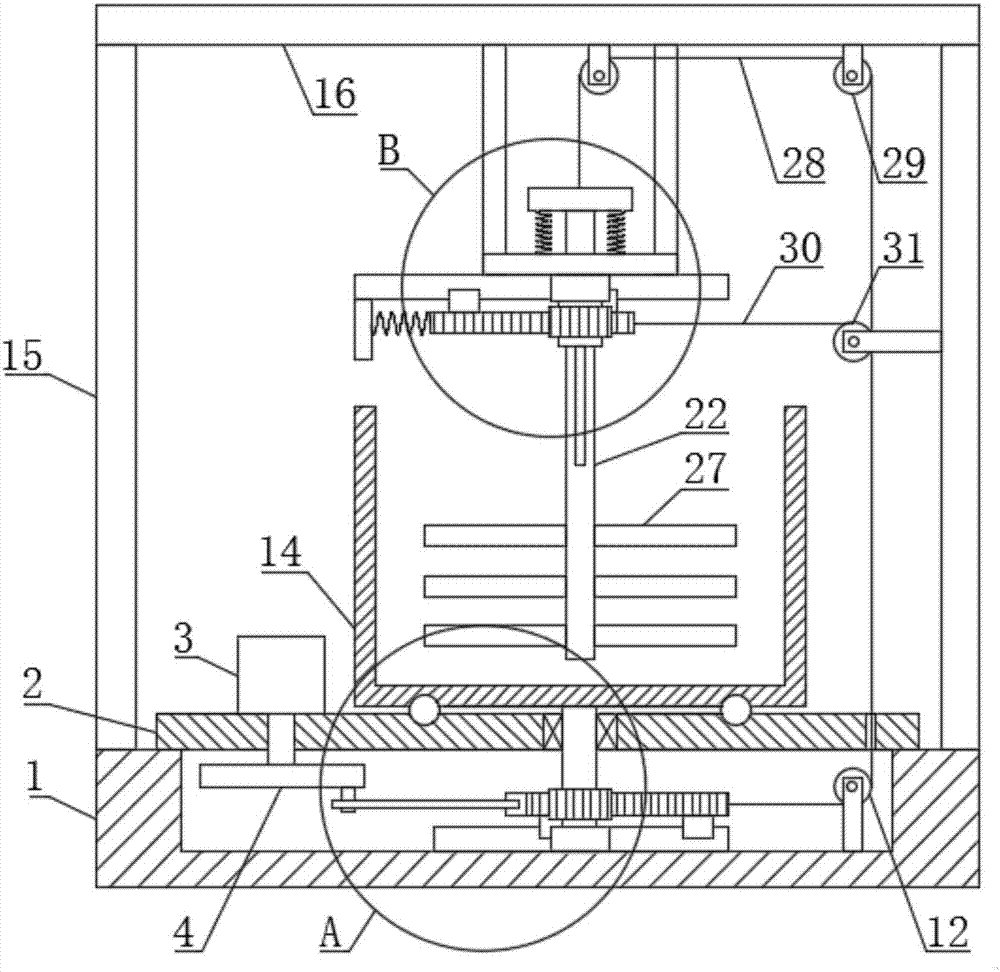

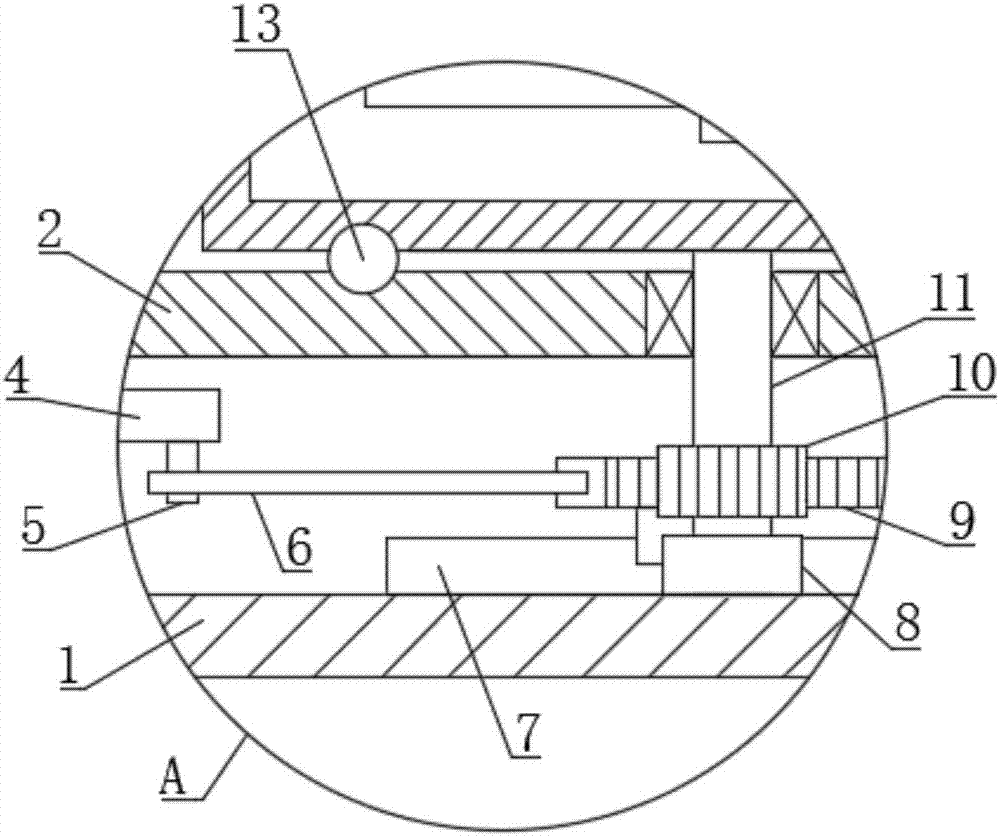

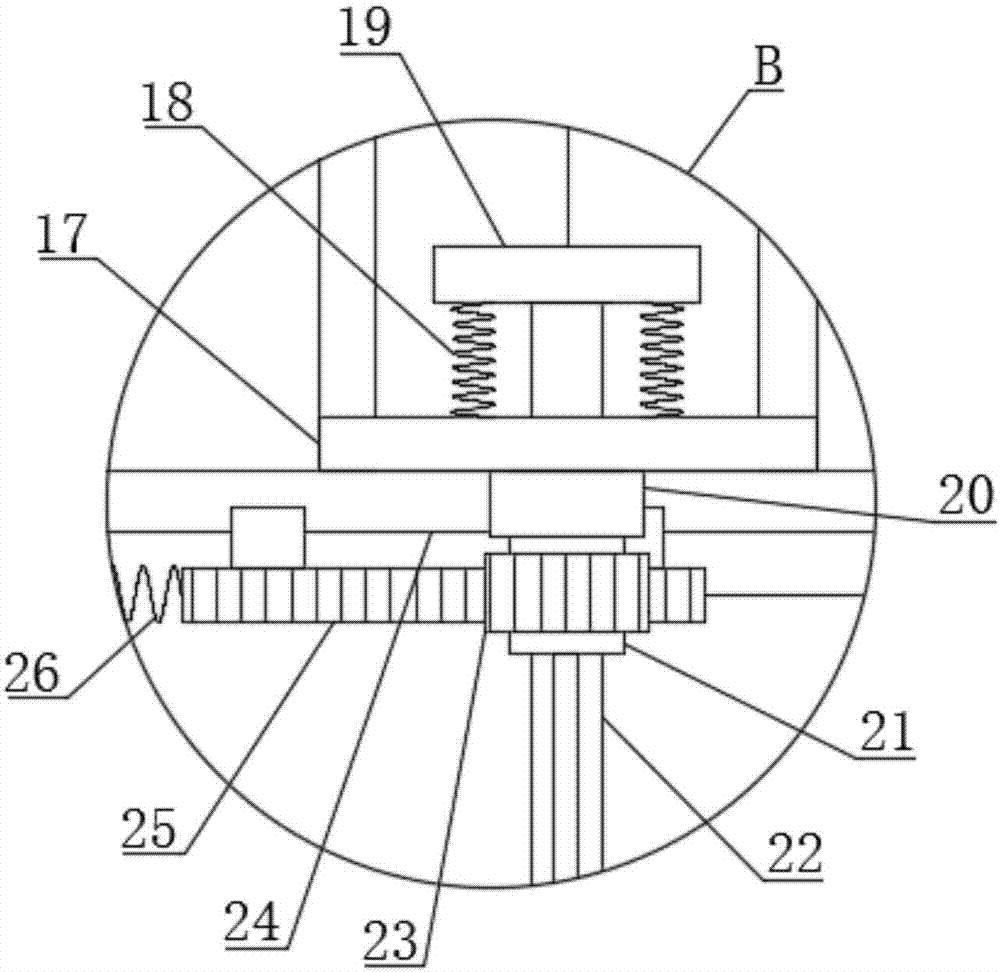

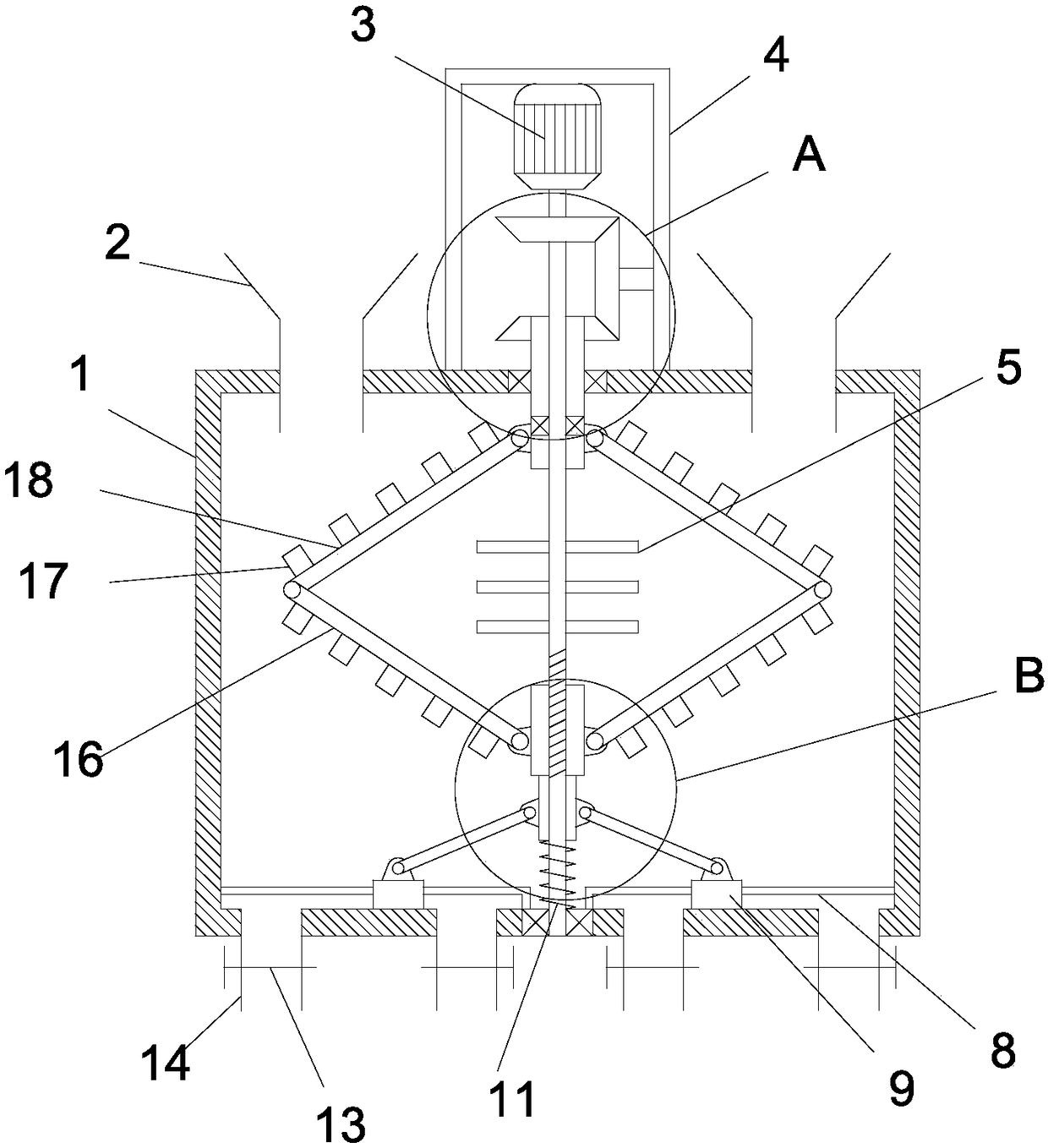

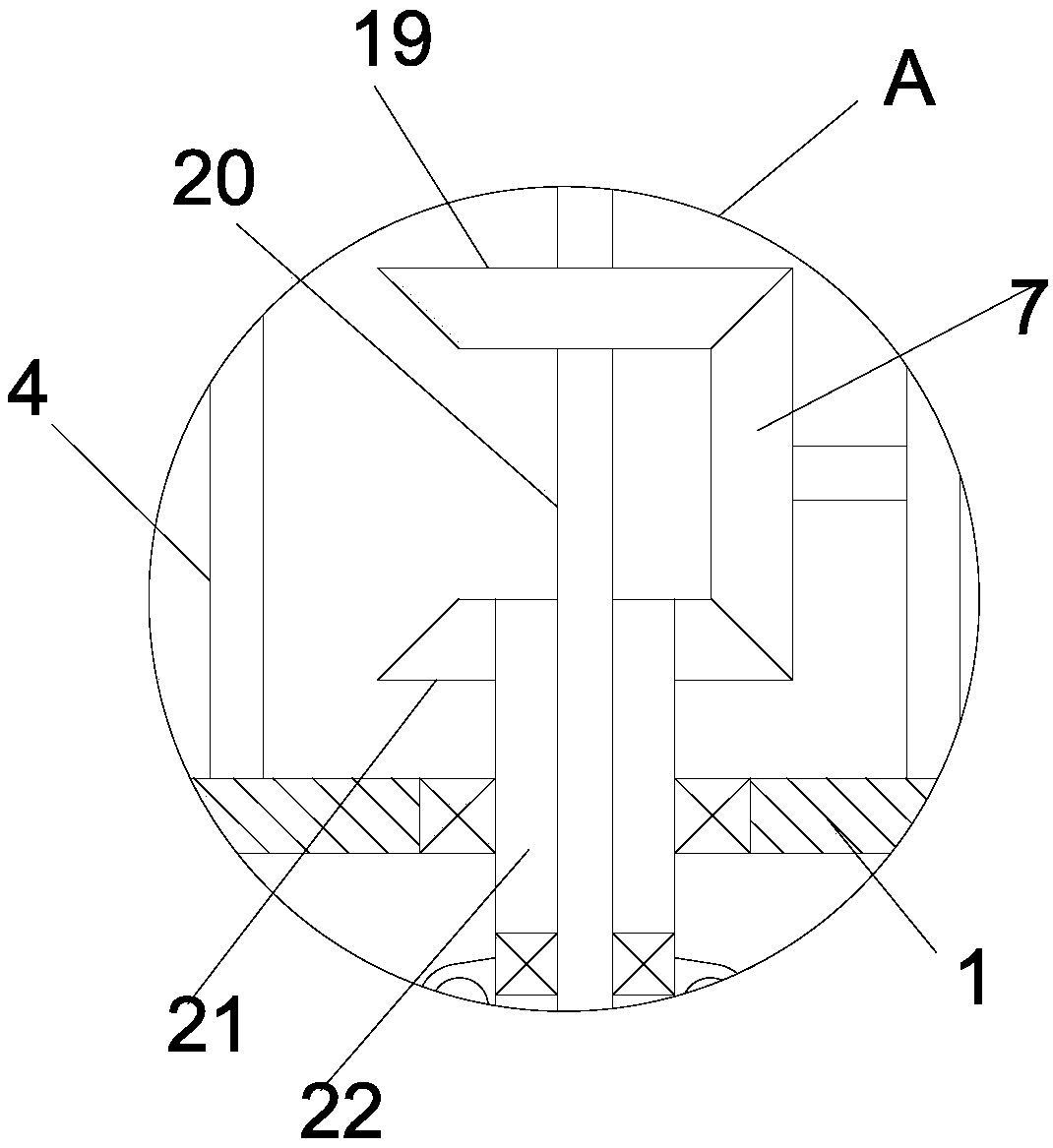

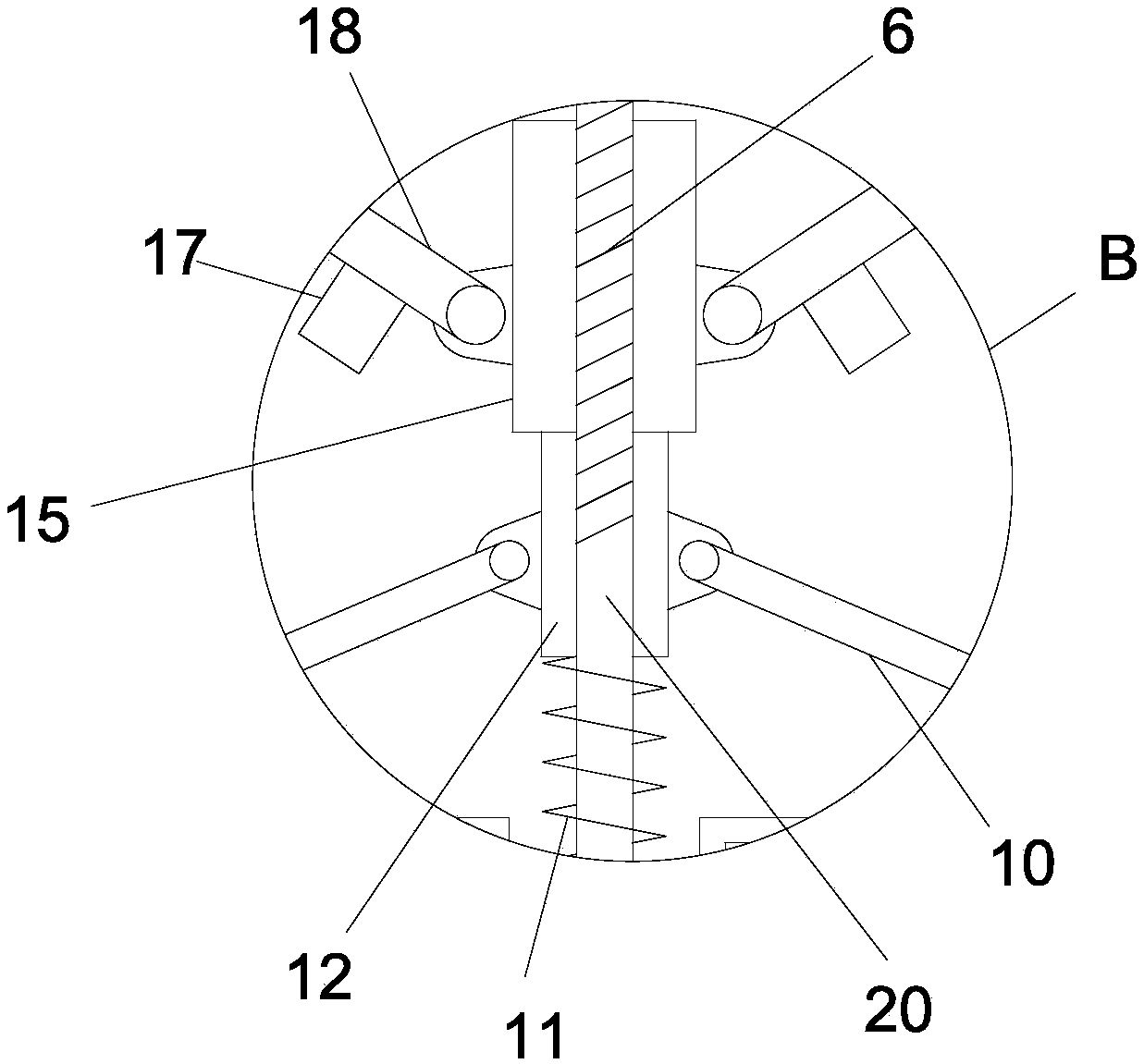

Device for uniformly stirring and mixing coating for buildings

PendingCN107469709AWell mixedAvoid wastingShaking/oscillating/vibrating mixersTransportation and packagingEngineeringCam

The invention discloses a device for uniformly stirring and mixing a coating for buildings. The device comprises a base plate, a stirring barrel, a first spring, a hollow shaft, a rack, a limiting block, a second spring, a fan-shaped gear, a first motor, an extruding plate, a stirring rod, a variable frequency motor, a spline shaft, a lateral plate, a second motor and a cam. The variable frequency motor, the spline shaft, the hollow shaft, the stirring rod, a scraper, a slide sleeve, a stirring support rod and a third spring are arranged on the device disclosed by the invention; the stirring support rod is driven to move left and right by the slide sleeve under the cooperation effect of the parts, so that the stirring efficiency is increased and the coating is more uniformly mixed; the first motor, the fan-shaped gear, the rack and the extruding plate are arranged on the device; the stirring rod is driven to move up and down under the cooperation effect of the parts so as to further increase the stirring efficiency, and meanwhile, the coating in the stirring barrel is continuously circulated in the up-and-down motion process of the extruding plate, so that the stirring and uniform mixing efficiency is further increased and the mixing is more uniform; and the second motor, the cam and the first spring are arranged on the device, so that the stirring barrel is continuously shaken and the coating is more fully and uniformly mixed.

Owner:ZHENGZHOU UNIV

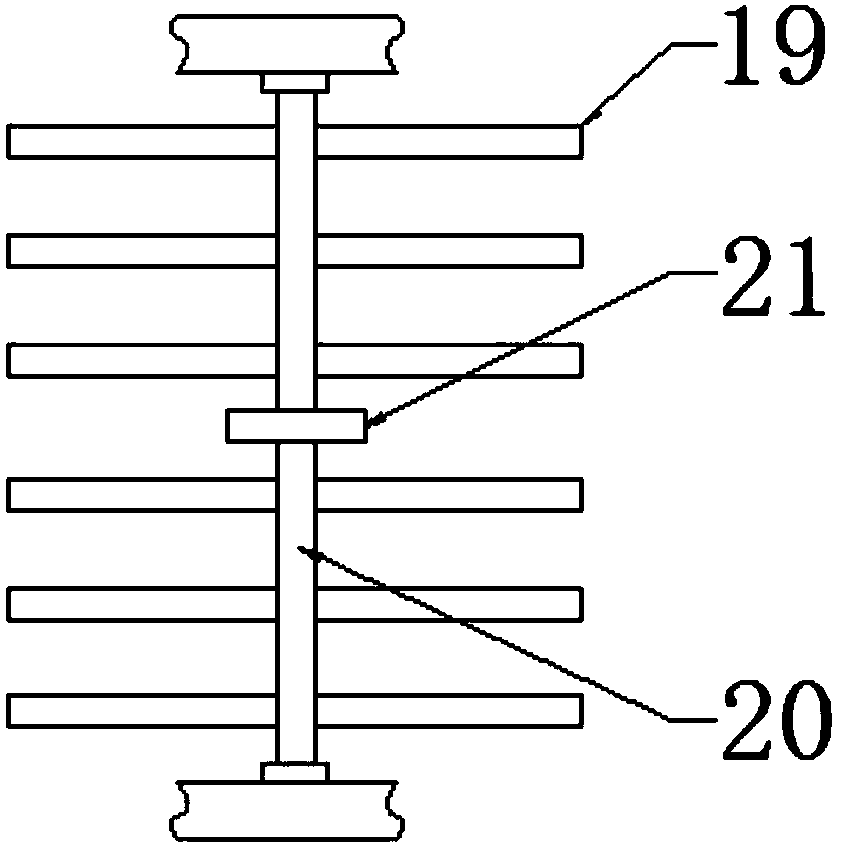

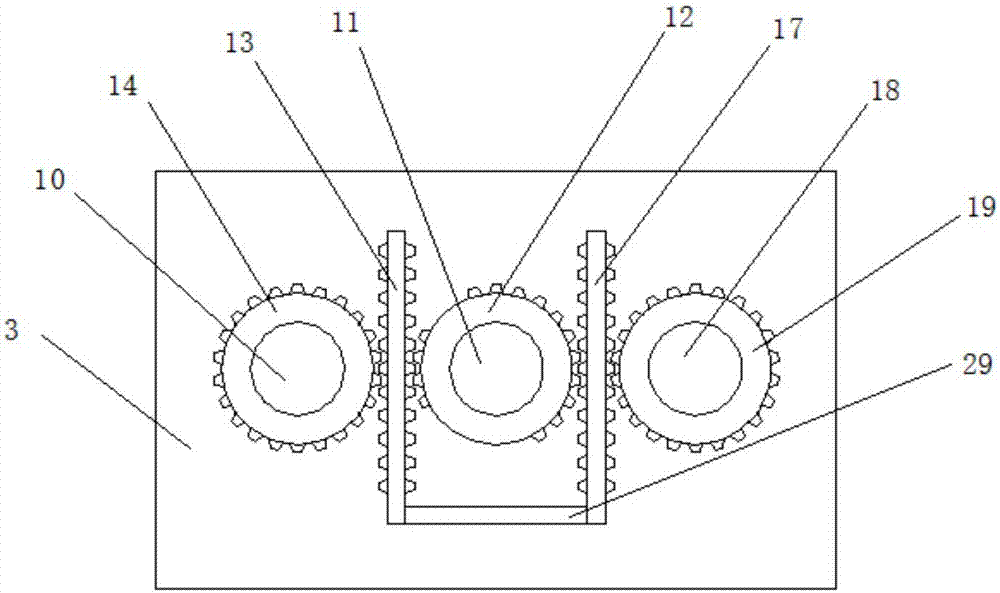

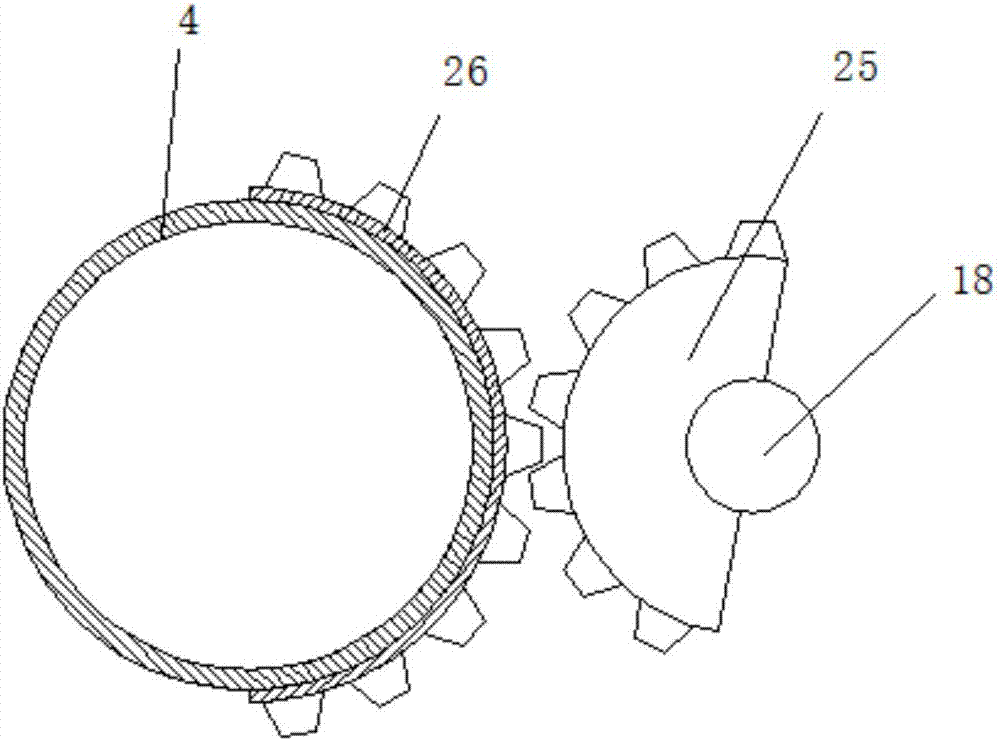

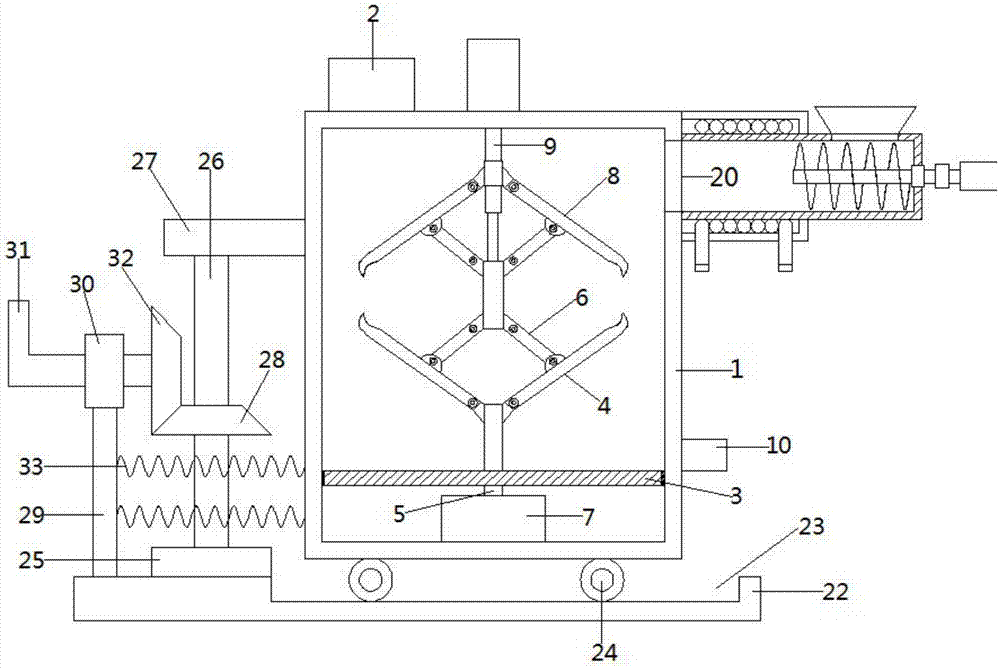

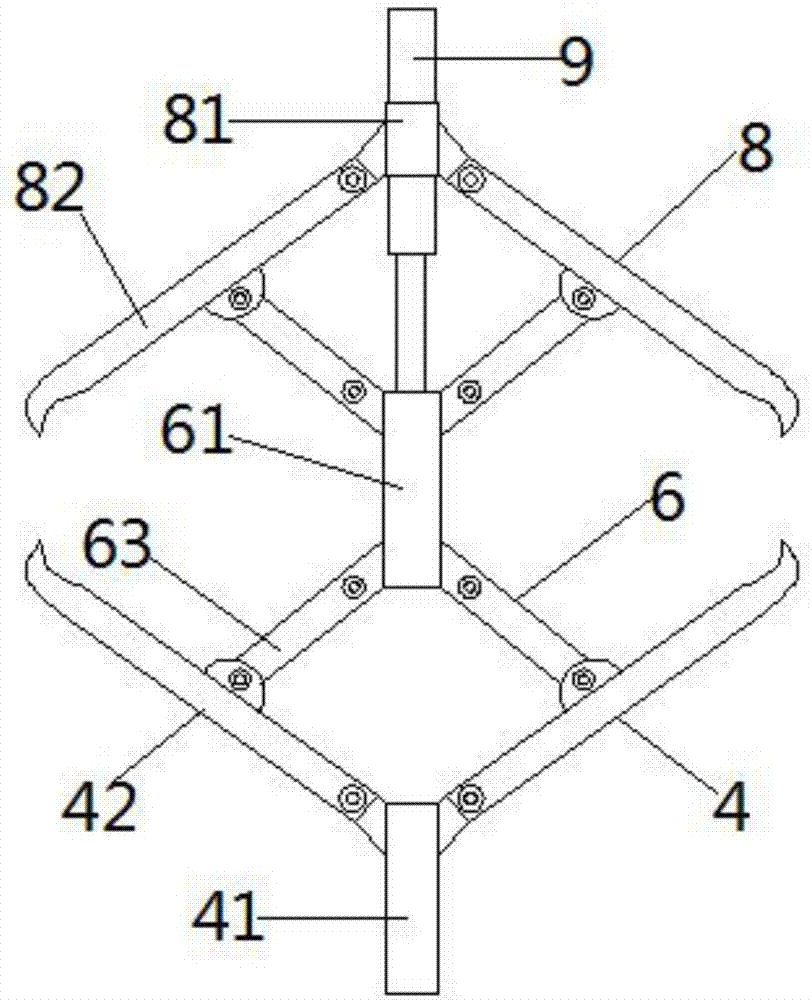

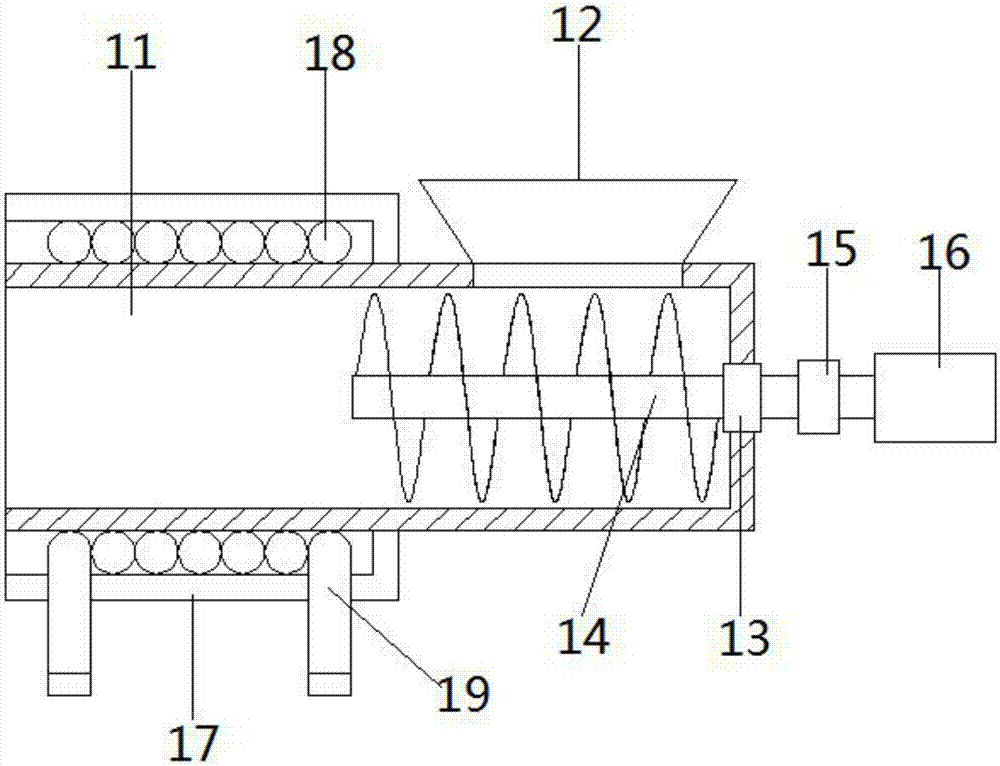

Crushing and stirring integrated equipment for feed production

InactiveCN108142969AMix well and evenlyAvoid vibrationFeeding-stuffTransportation and packagingKnife bladesCrankshaft

The invention discloses crushing and stirring integrated equipment for feed production. The crushing and stirring integrated equipment comprises a bottom plate, a stirring tank, a motor, a first rotating shaft, a mesh screen, a supporting plate, second rotating shafts, first gears, inner gear rings, a first crushing blade, second crushing blades, a crankshaft, a connecting rod journal, racks, second gears, third rotating shafts and knocking devices, wherein each knocking device comprises a swinging rod, a spring and a knocking ball. According to the crushing and stirring integrated equipment disclosed by the invention, the motor, the first rotating shaft, the second rotating shafts, the first gears and the inner gear rings are arranged and cooperate with each other to sufficiently and uniformly crush feed raw materials, so that the crushing efficiency is improved; the crankshaft, the connecting rod journal, the racks, the second gears and the third rotating shafts are arranged, so thatthe stirring manners are diversified, the stirring and mixing efficiency is improved, and the mixing of feeds is more sufficient and uniform; and the knocking devices are arranged, so that the situation that too many feeds are stuck to the side walls of the stirring tank, and waste is generated can be avoided.

Owner:ZHENGZHOU LIFUAI BIOLOGICAL TECH CO LTD

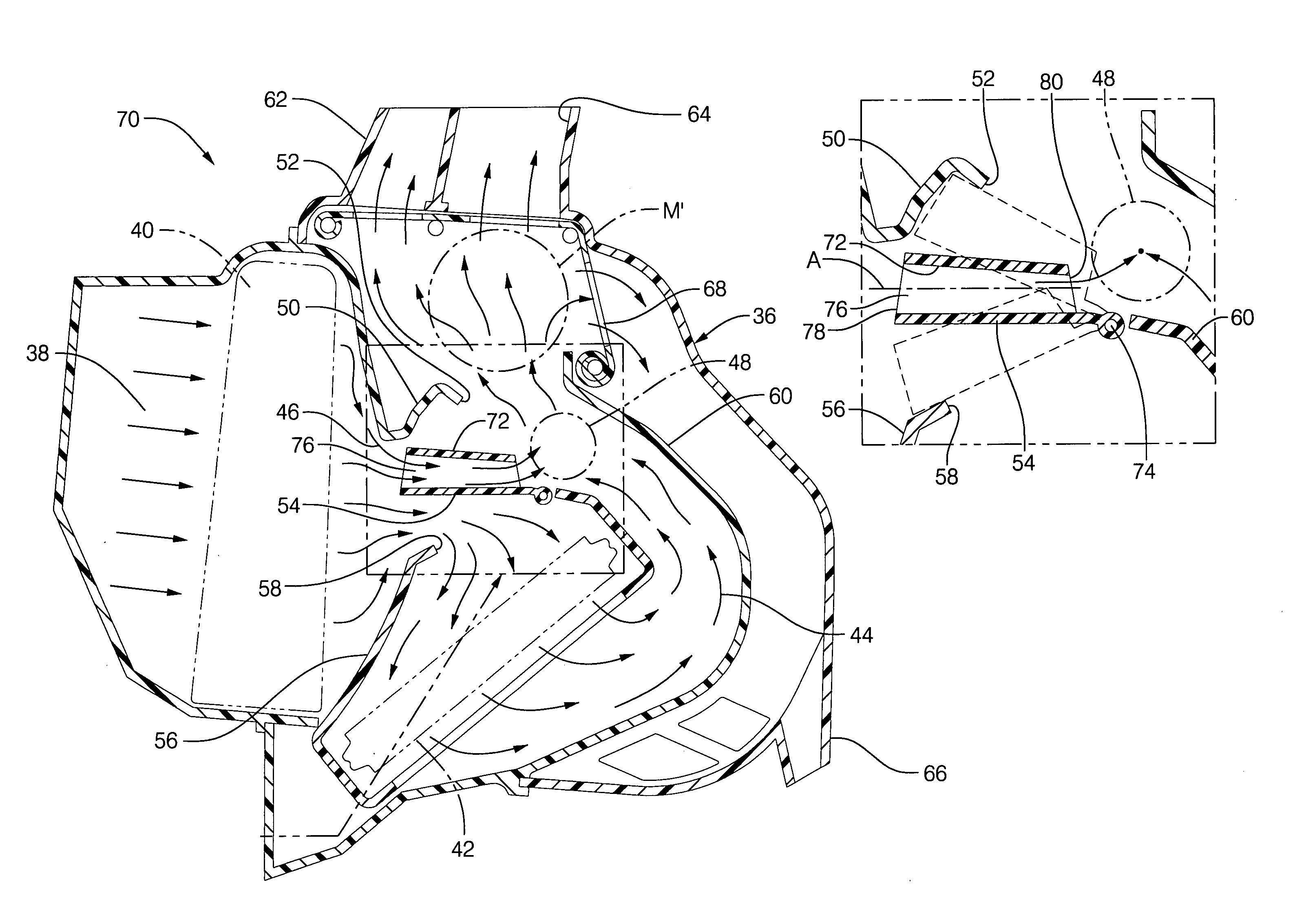

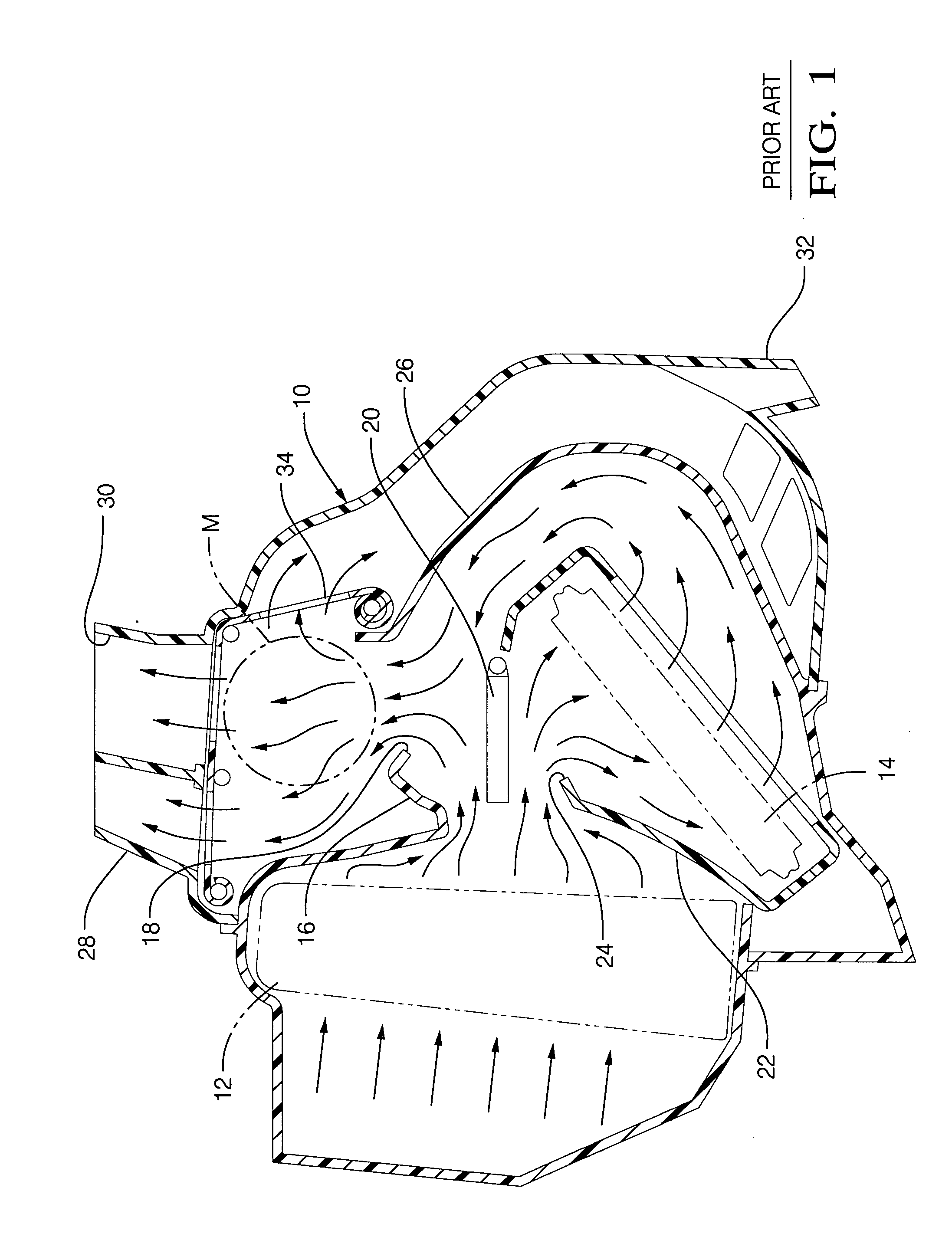

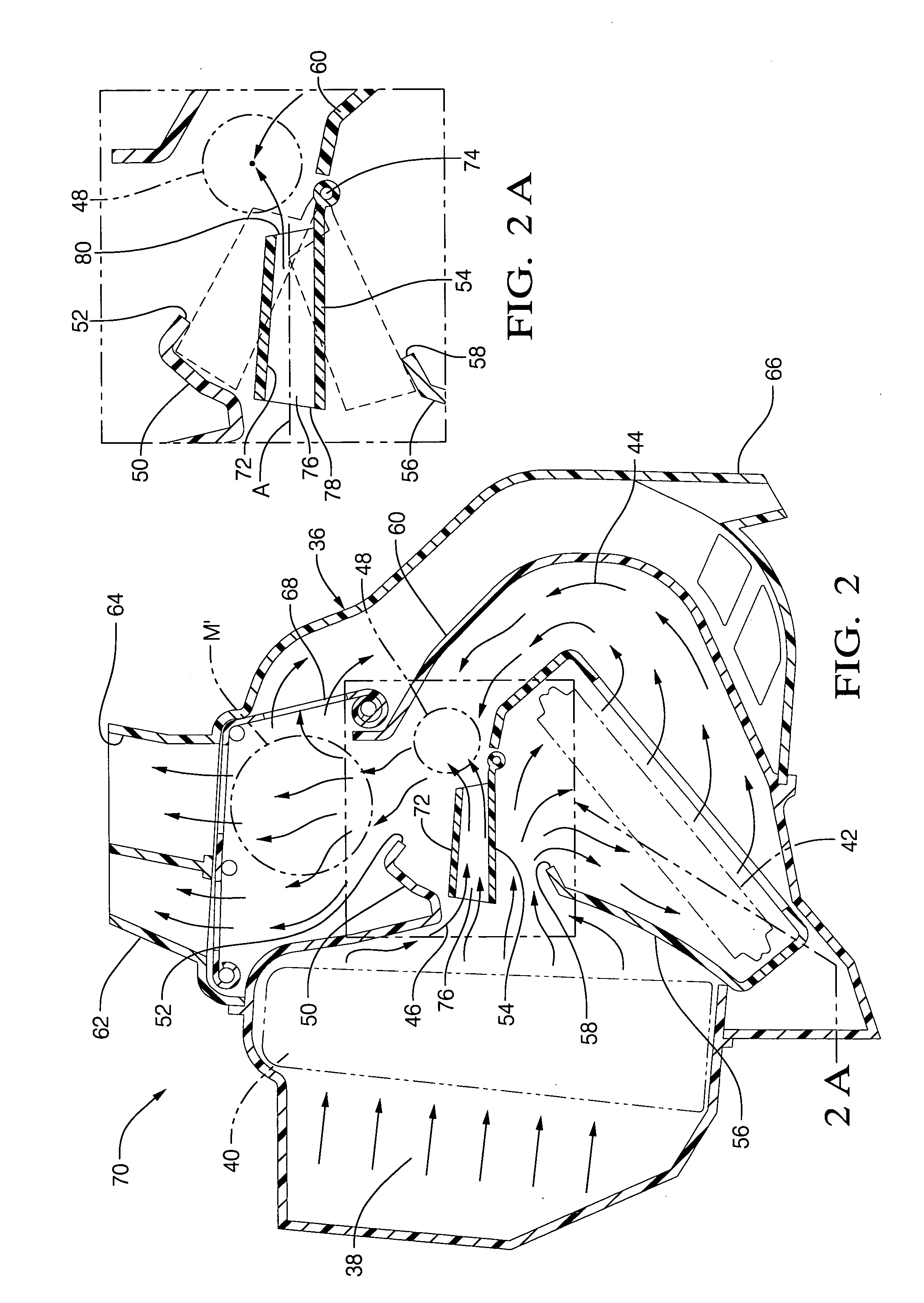

Box vane mixing element for automotive heating, ventilating and air conditioning system

InactiveUS20080200110A1Prevent foggingGood mixingAir-treating devicesVehicle heating/cooling devicesEvaporatorAirflow

An HVAC housing assembly includes a novel structure to aid the mixing of hot and cold air downstream of the evaporator and heater core. One or more variable nozzles are carried for displacement with the temperature door for accelerating some of the cold air stream through an internal housing opening and varying the cold air stream impingement angle with the hot air stream at their point of confluence to establish secondary mixing sites and substantially improving the resulting heat transfer coefficient.

Owner:DELPHI TECH INC

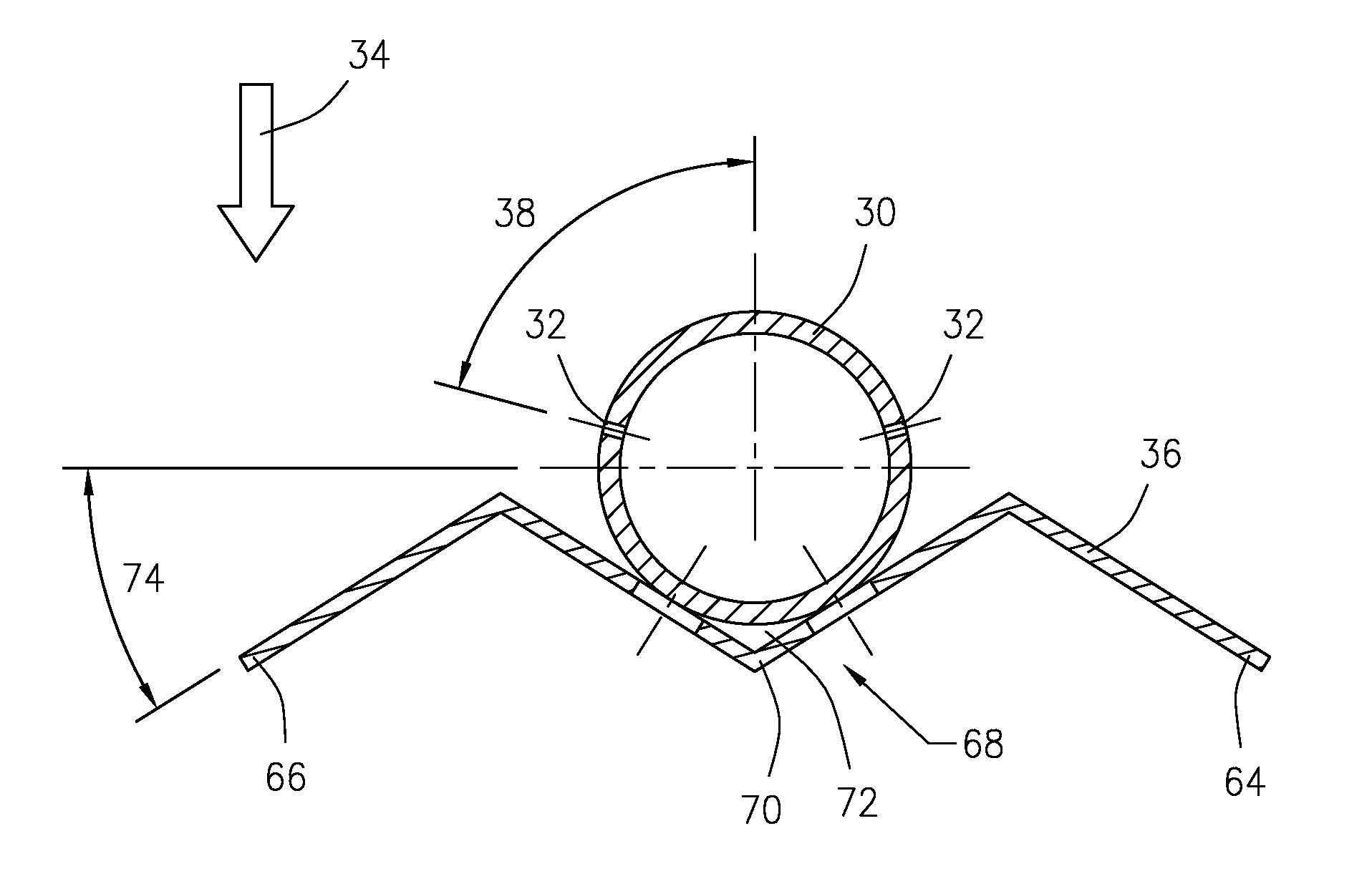

Ammonia injection grid for a selective catalytic reduction system

An ammonia injection grid for a selective catalytic reduction (SCR) system that provides uniform distribution of ammonia to the SCR catalyst in NOx reduction systems for heat recovery steam generation systems, packaged boilers, simple cycle catalyst systems and fired heaters for superior operational efficiency. The ammonia injection grid includes an injection tube having at least one nozzle for injecting ammonia into a flow of flue gas. The ammonia injection grid also includes a corrugated turbulence enhancer associated with the injection tube to generate turbulent wake to enhance turbulent mixing.

Owner:CALLIDUS TECH

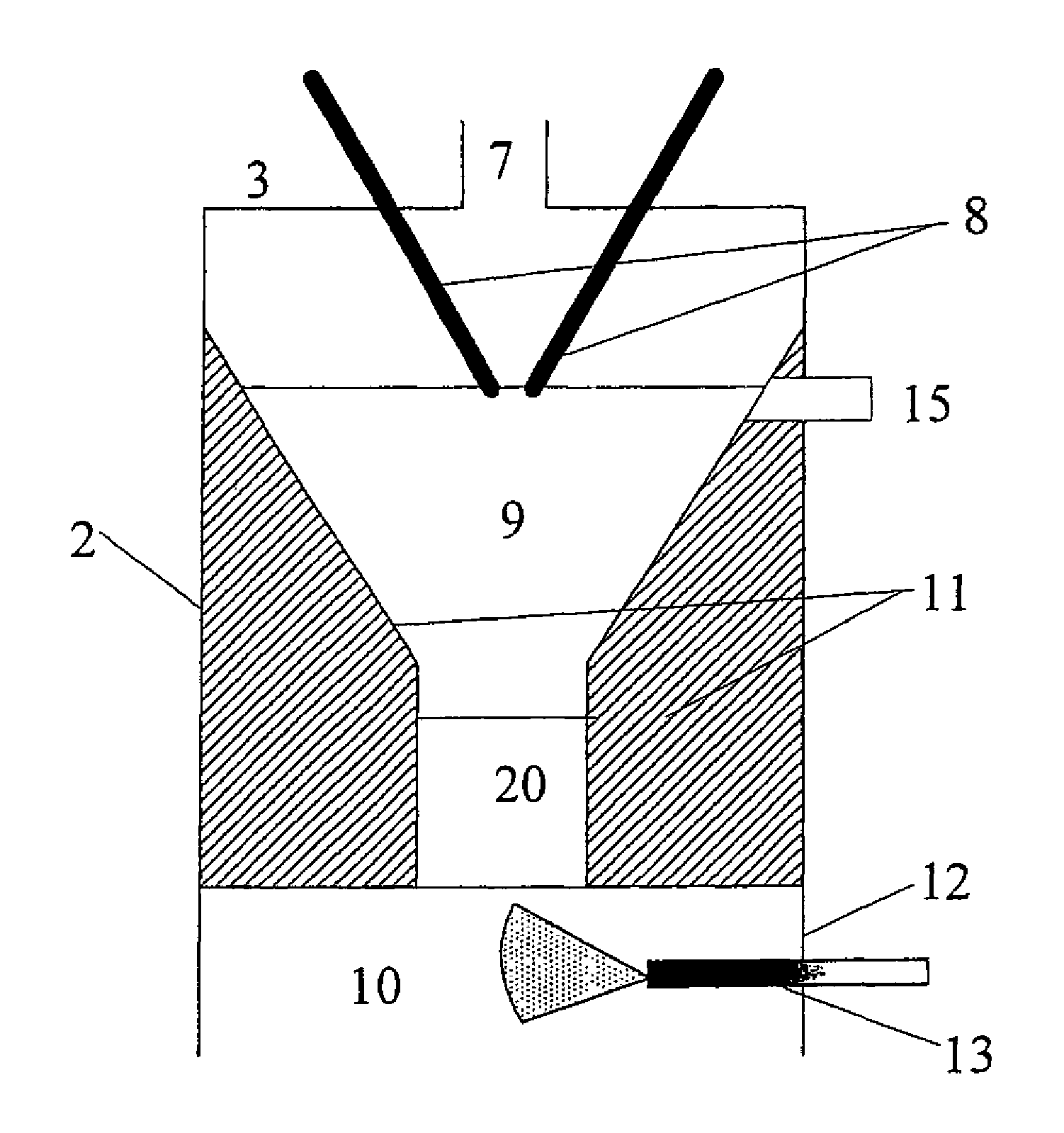

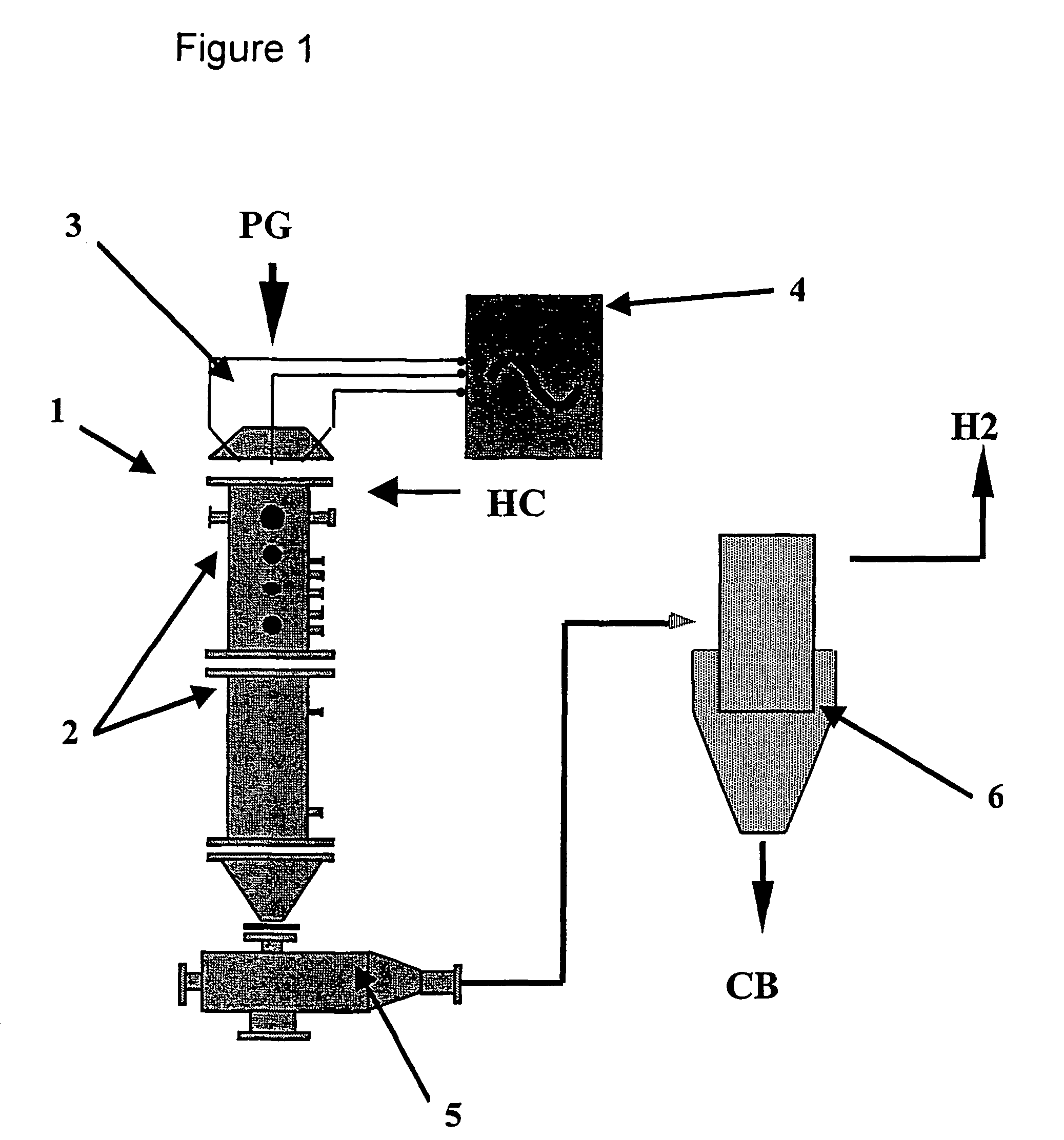

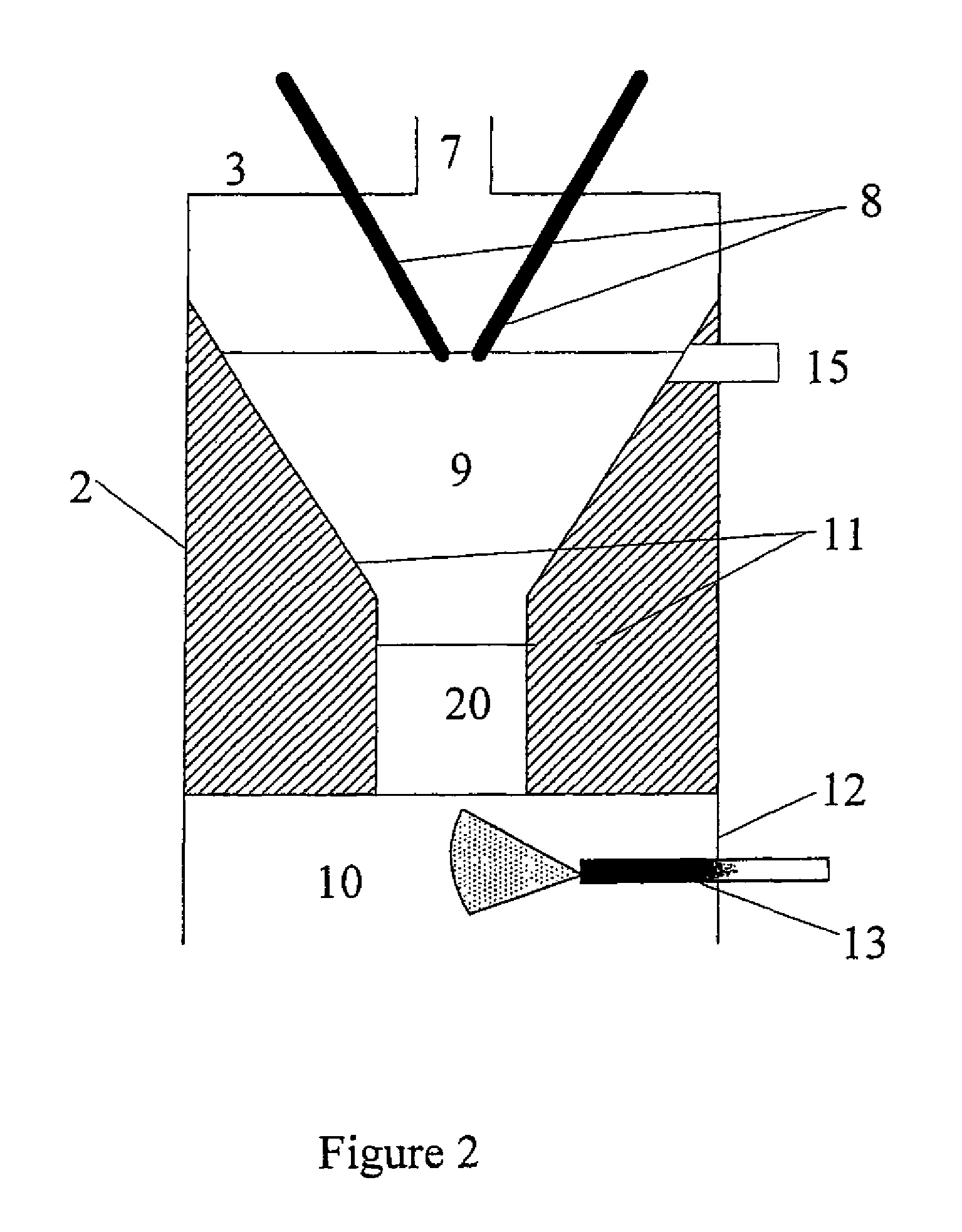

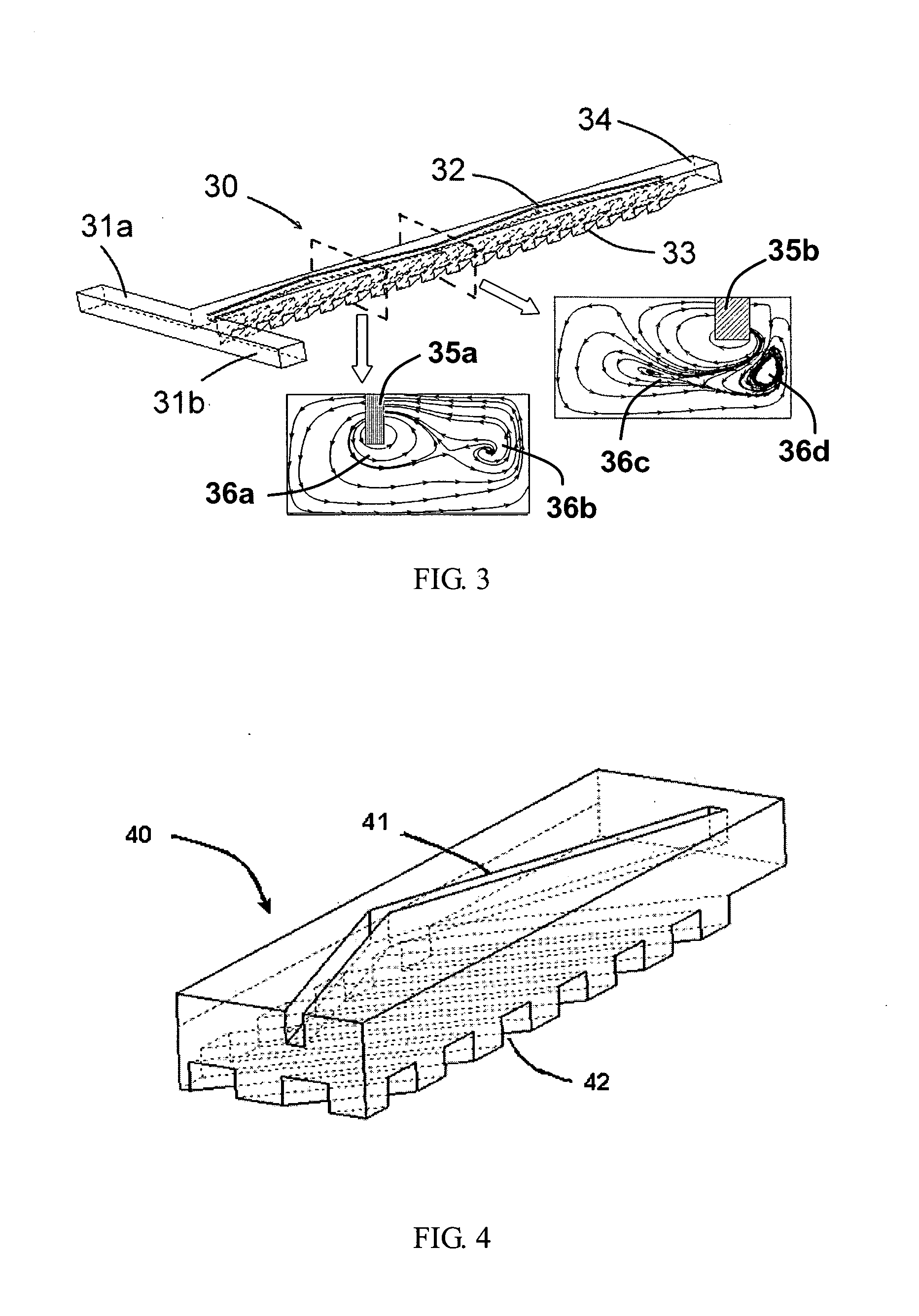

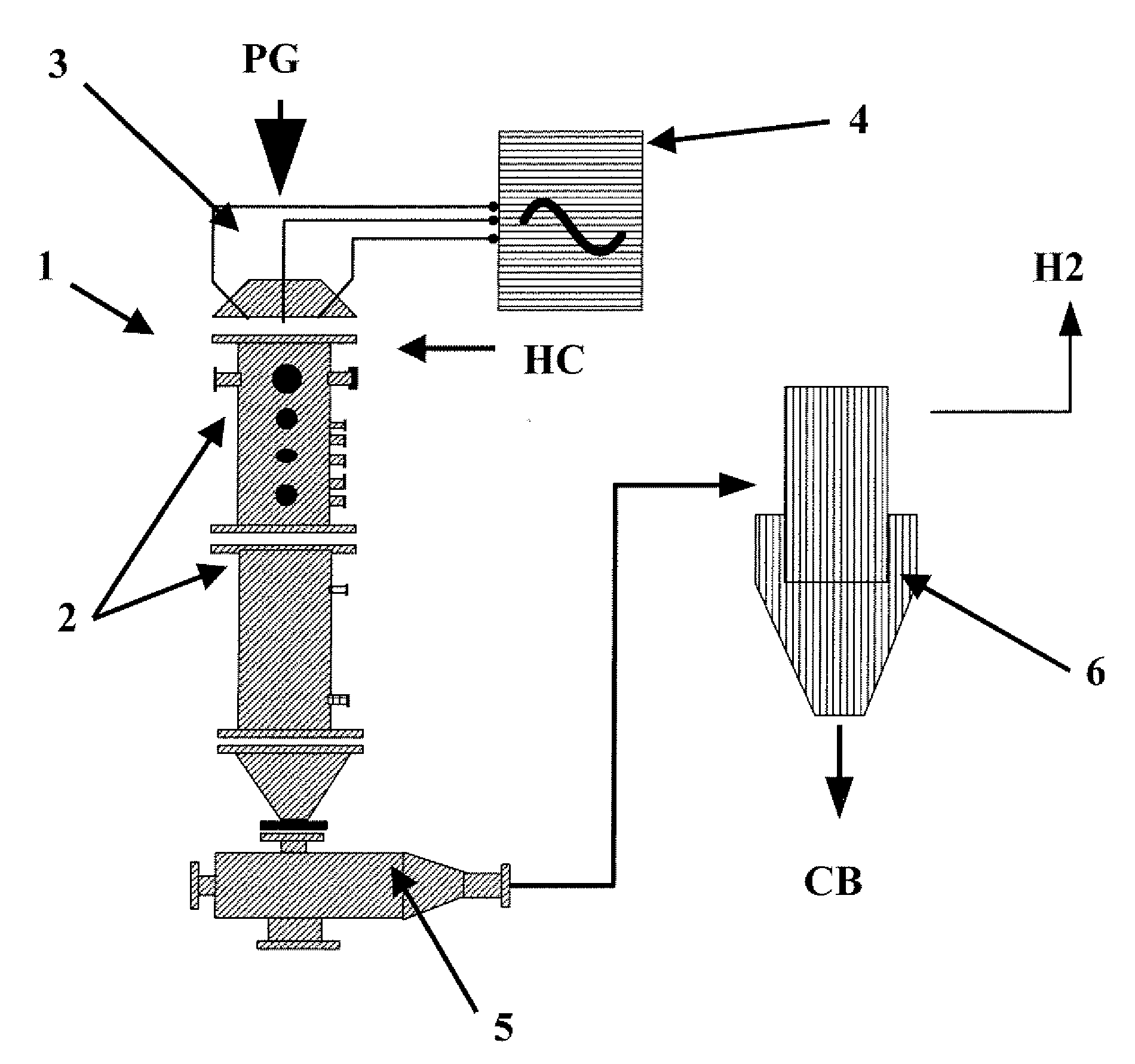

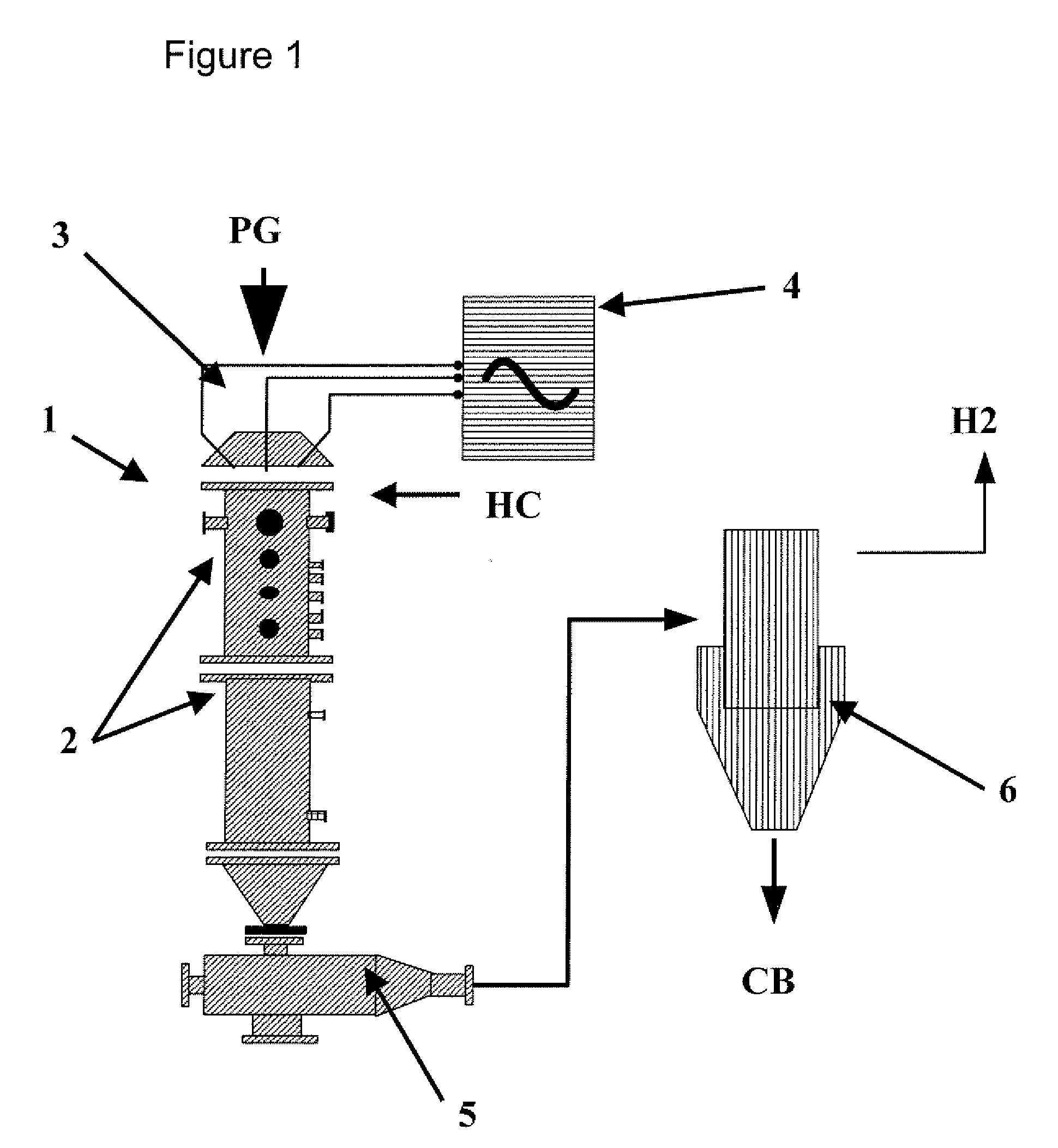

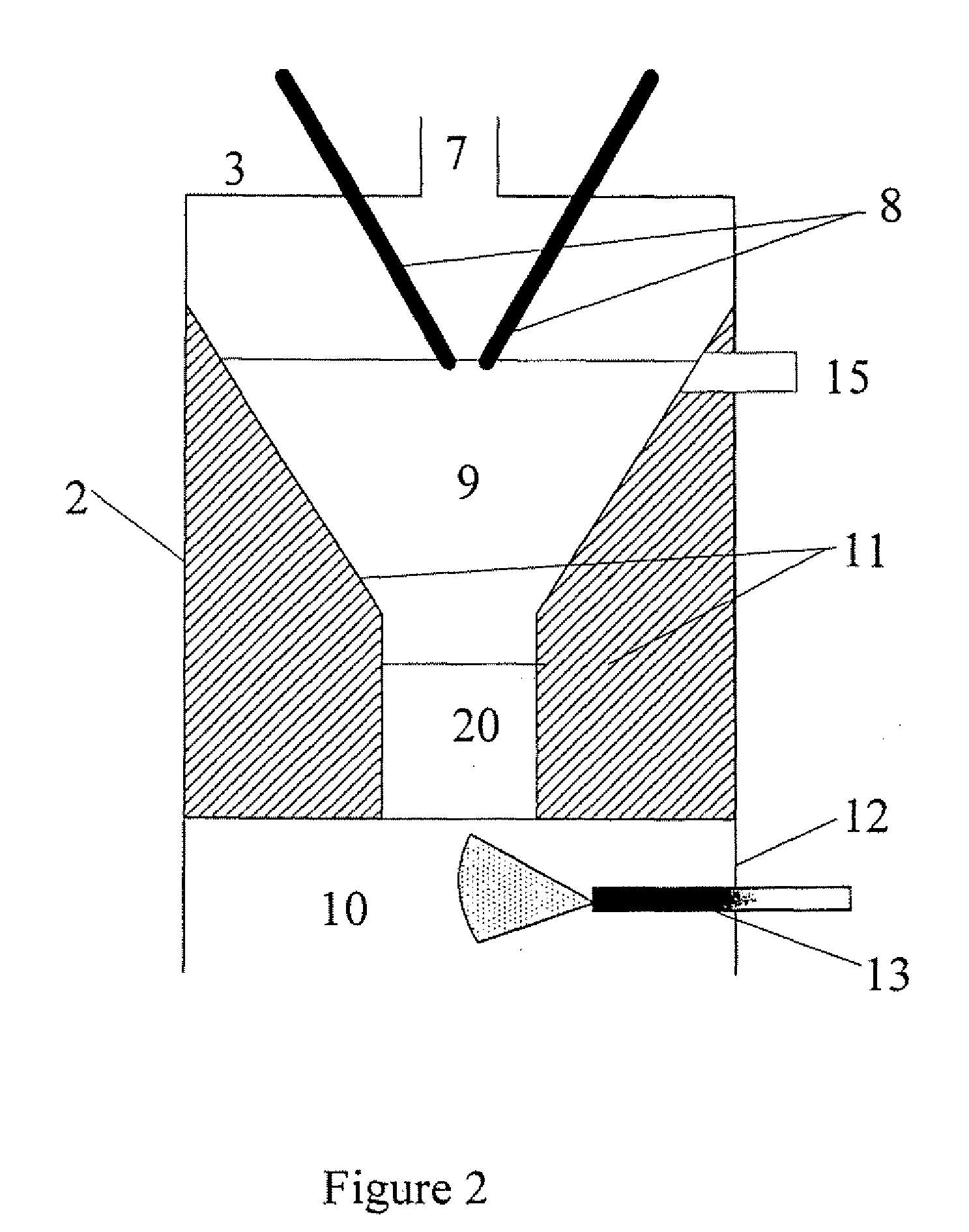

Device and method for converting carbon containing feedstock into carbon containing materials, having a defined nanostructure

InactiveUS7452514B2Improve conversion efficiencyEasy to controlMaterial nanotechnologyPigmenting treatmentPlasma GasesNanostructure

Apparatus and process for producing carbon black or carbon containing compounds by converting a carbon containing feedstock, comprising the following steps: generating a plasma gas with electrical energy, guiding the plasma gas through a venturi, whose diameter is narrowing in the direction of the plasma gas flow, guiding the plasma gas into a reaction area, in which under the prevailing flow conditions generated by aerodynamic and electromagnetic forces, no significant recirculation of feedstock into the plasma gas in the reaction area recovering the reaction products from the reaction area and separating carbon black or carbon containing compounds from the other reaction products.

Owner:ТІМКАЛ SА

Swing-type concrete block crushing, mixing and stirring device

InactiveCN107336355AImprove processing efficiencyAffectMixing operation control apparatusPretreatment controlEngineeringDrive motor

The invention discloses a swing type concrete block crushing and mixing device, which comprises a bottom plate, a side plate, a top plate and a mixing drum. Double-sided rack and right double-sided rack, the mixing drum is provided with a rotating shaft coaxial with it, the top of the rotating shaft is provided with a left gear, the left gear meshes with the left double-sided rack, and the mixing drum A sieve plate is installed inside, and the sieve plate divides the mixing drum into a crushing chamber and a mixing chamber. A crushing rod is arranged on the shaft section of the rotating shaft in the crushing chamber and on the side wall of the crushing chamber, and a crushing rod is arranged on the crushing rod. The blade is provided with a mixing rod at the bottom of the rotating shaft in the mixing chamber. The invention has the advantages of simple structure, continuous crushing and mixing of concrete blocks, improved working efficiency, sufficient and uniform crushing and mixing, high mixing and crushing efficiency, simple operation and strong practicability.

Owner:CHANGSHA KEYUE ENTERPRISE MANAGEMENT CONSULTING CO LTD

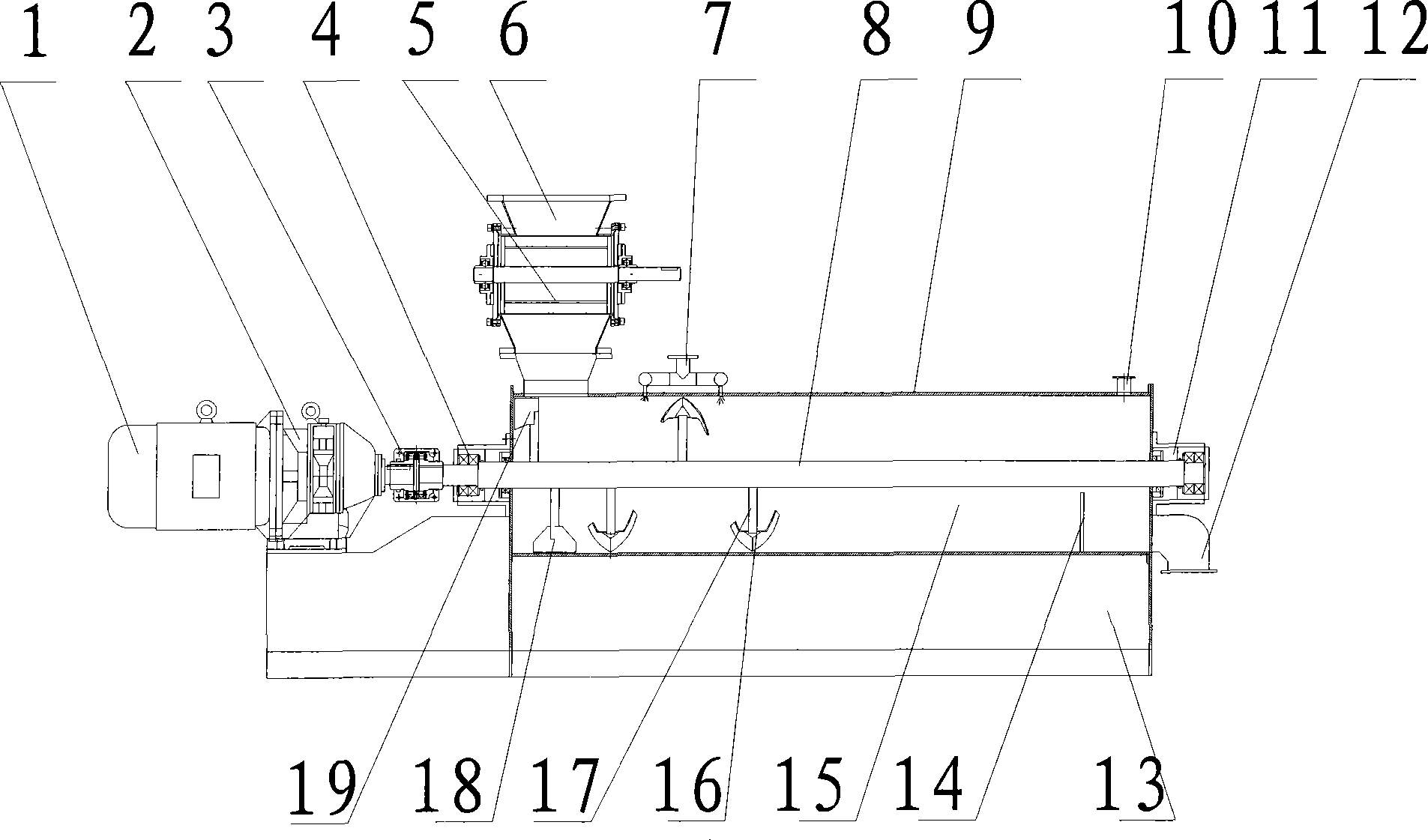

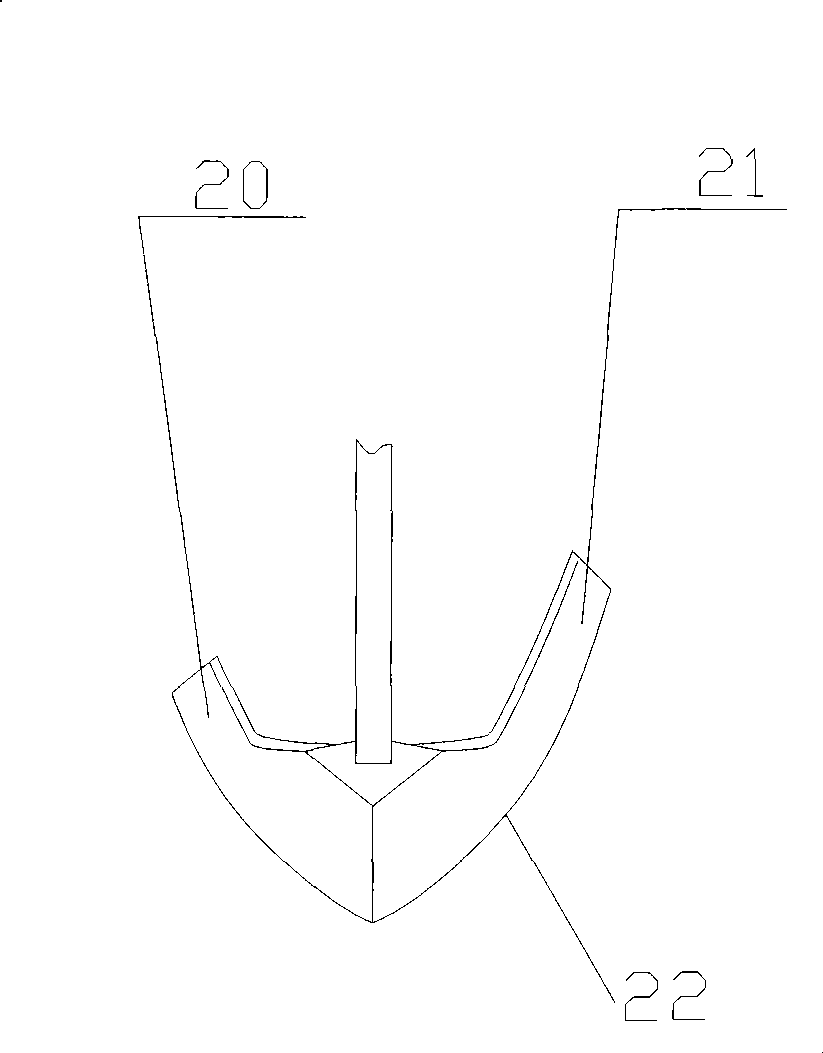

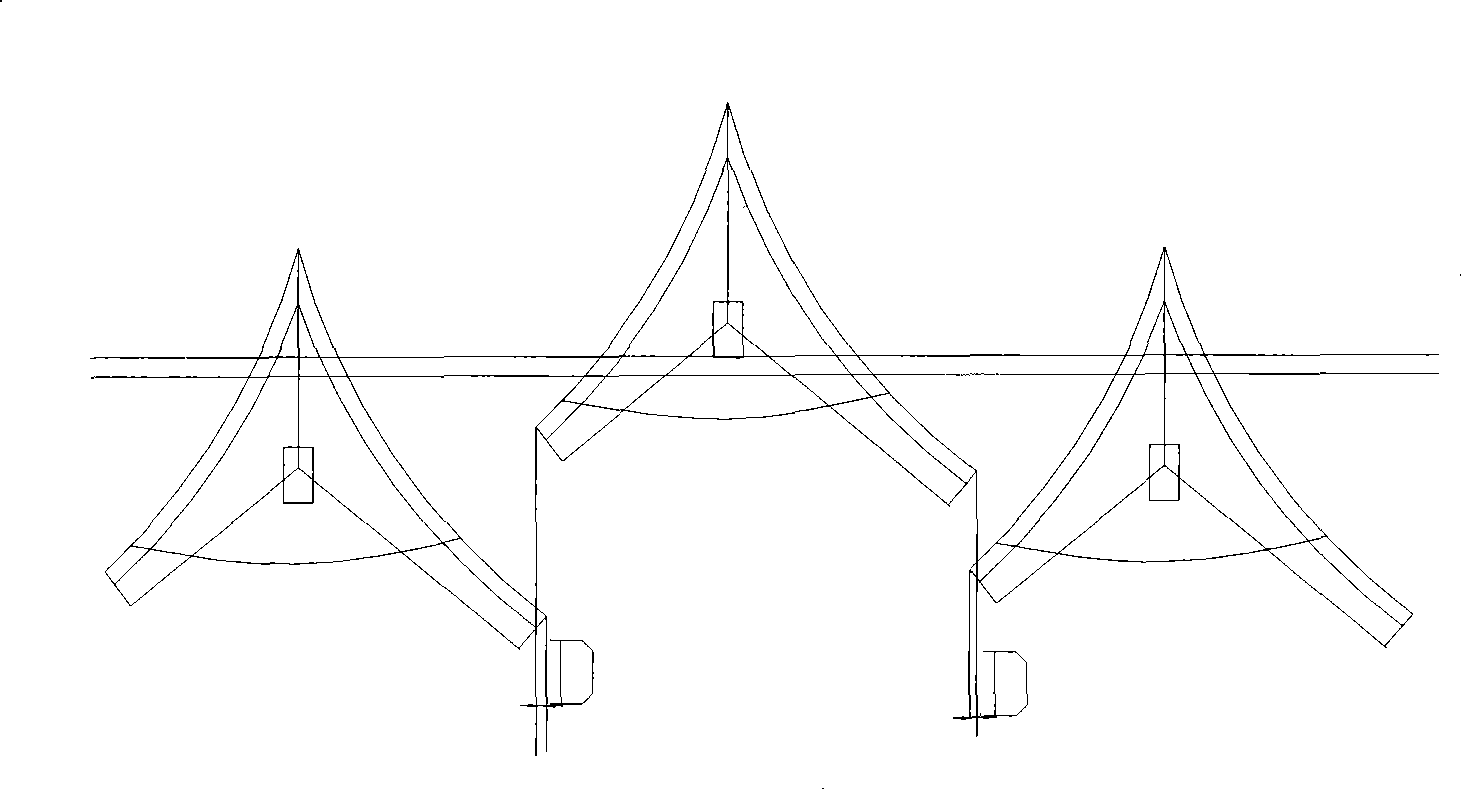

Horizontal solid-liquid mixing device and application thereof

InactiveCN101444705AWell mixedQuality improvementRotary stirring mixersMixing methodsChemical industryRotary valve

The invention relates to a horizontal solid-liquid mixing device and the application thereof. The mixing device comprises a motor, a reduction gearbox, a ratcheting, a front bearing end, a rotary valve, a solid feeding hole, a liquid feeding hole, a mixer shaft, a mixing cylinder, an exhaust hole, a rear bearing end, a discharge hole, a solid-liquid mixing room, a drawing template, a plough coulter, a fixed link of the plough coulter and a baffle; wherein, the drawing template is fixed on the mixer shaft and arranged under the solid feeding hole, the plough coulter is fixed on the mixer shaft by the fixed link of the plough coulter, a plowshare of the plough coulter forms an angle with the mixer shaft, the baffle is arranged inside the mixing cylinder, and a gap is arranged at the position of a contact surface between the baffle and the cylinder in front of the discharge hole. Compared with the prior art, the horizontal solid-liquid mixing device can fully mix two phases of solid and liquid within a short time, has high mixing efficiency, low energy consumption and even material mixing, does not produce 'powder balls' generated by mixing the powder and the liquid, is good in continuous operation effect and can be widely applied to industries such as petroleum, chemical industry, coal chemical industry, food, medicine, etc.

Owner:SHANGHAI RES INST OF CHEM IND +1

Multi-direction high-efficiency feed mixing device

InactiveCN107456906AWell mixedImprove mixing efficiencyRotating receptacle mixersShaking/oscillating/vibrating mixersMotor shaftSpeed reduction

The invention discloses a multi-direction high-efficiency feed mixing device. The multi-direction high-efficiency feed mixing device comprises a base, wherein a groove is arranged in the base; a support plate is arranged at the top part of the base; a speed reduction motor is arranged at the top part of the support plate; a motor shaft at the bottom end of the speed reduction motor penetrates through the support plate and is connected with a rotary disc; the right side of the bottom part of the rotary disc is rotationally connected with a connecting rod through a pin shaft; a first slide rail is arranged at the bottom part of the groove in the base; the upper part of the first slide rail is glidingly connected with a first gear rack through a slide block, and the left end of the first gear rack is hinged to the right end of the connecting rod; the bottom part of the groove in the base is rotationally connected with a first rotary shaft through a first bearing with a base, a first gear is arranged on the first rotary shaft and is engaged with the first gear rack, and the top end of the first rotary shaft penetrates through the support plate and is fixedly connected with a mixing box. The multi-direction high-efficiency feed mixing device has the advantages that the speed reduction motor is used as a power source to drive in working, so that the operation is simple, and the convenience in control and use is realized; the rotary disc is rotated, and then the mixing box is positively and reversely rotated, so that the feed is more sufficiently mixed, and the uniformity of the feed in mixing is effectively improved.

Owner:宁波新材料科技城犀鸟工业设计有限公司

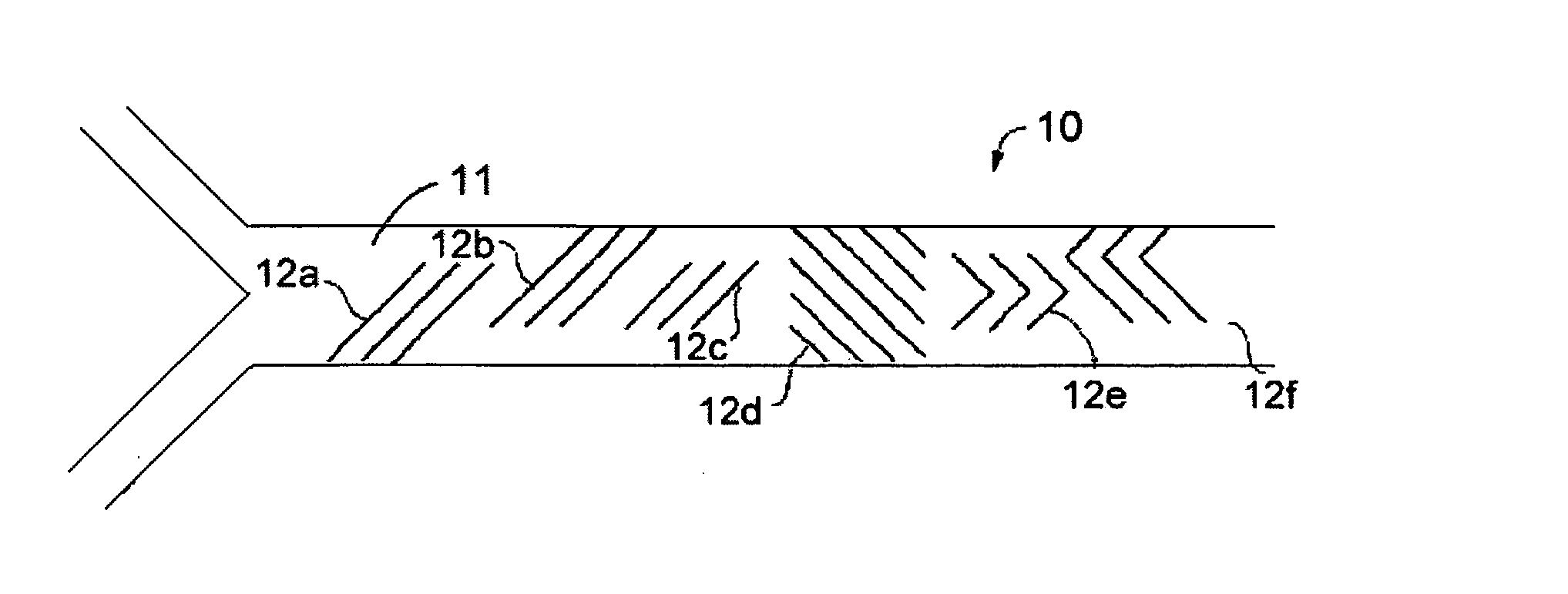

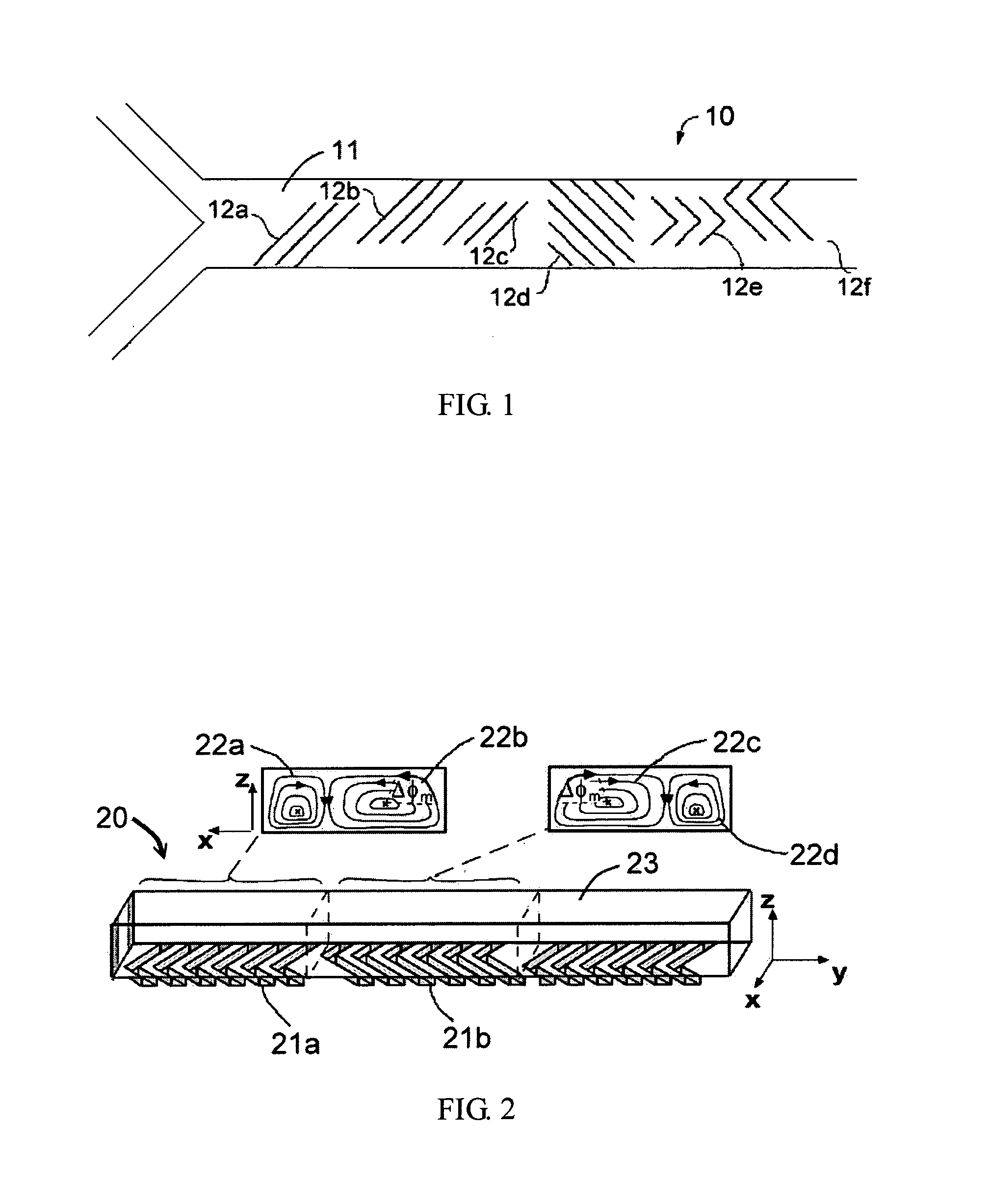

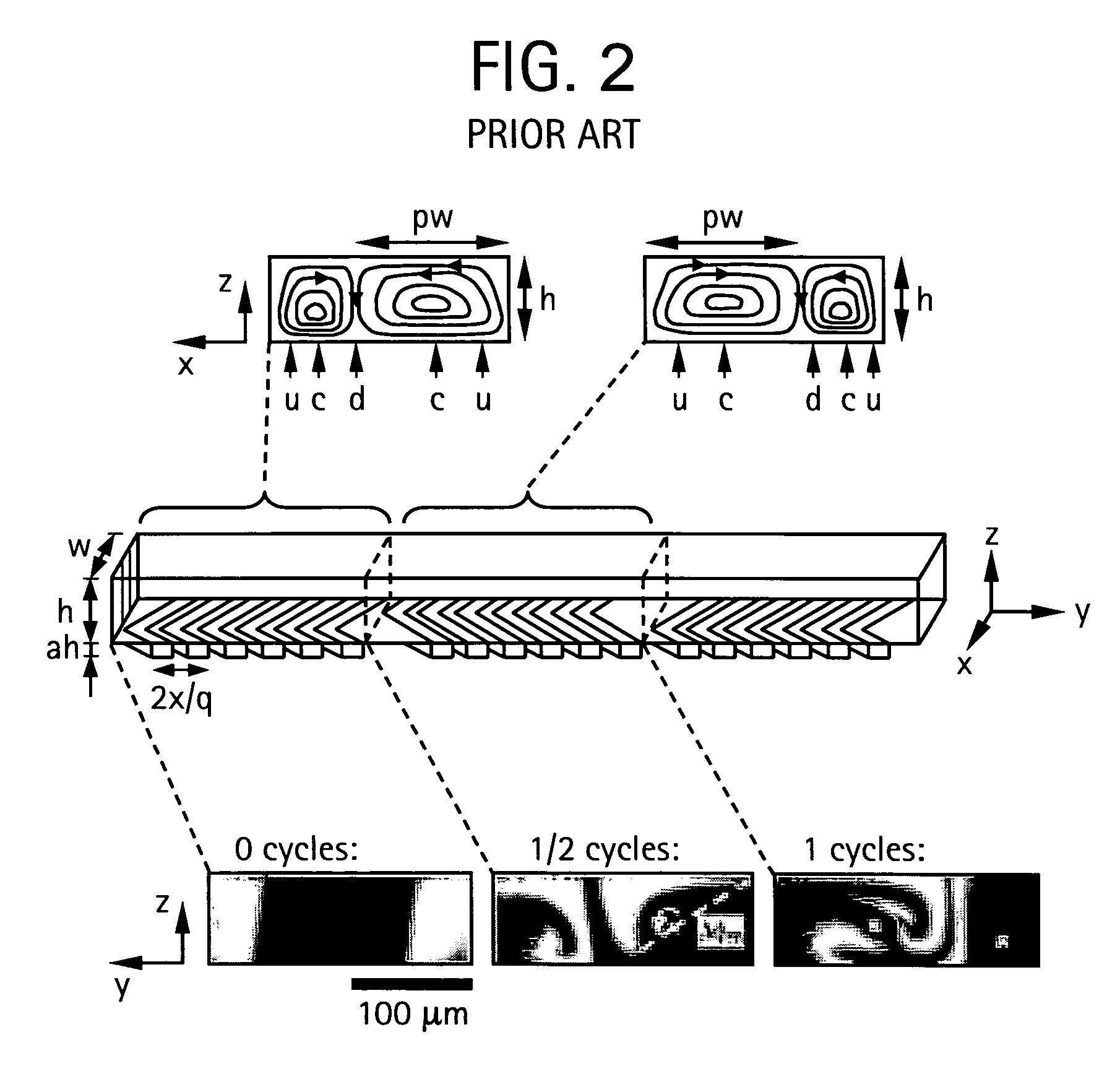

Twin-vortex micromixer for enforced mass exchange

InactiveUS20070263485A1Well mixedImprove mixing efficiencySemi-permeable membranesOther chemical processesShortest distanceLab-on-a-chip

The present invention discloses a vortex-modulation based micromixer for enforced mass exchange. The micromixer of the present invention comprises a mixing chamber with grooves on one wall thereof and a special-shape barrier on another wall. As different fluids are injected into the mixing chamber respectively from two inlets of the micromixer, the grooves and barriers of the micromixer of the present invention create the constructive interferences to form the active-like agitation of the fluid. For every groove, the flux passed by can be increased via its high pressure gradient. Understandably, the mixing efficiency of the fluids can be greatly improved within a very short distance. At last, the outlet of the micromixer is located in the downstream of the mixing chamber and further is able to connect with other elements. The present invention is entirely a passive micromixer and no additional energy is required. The present invention can apply to a continuous chemical analysis, particularly to a lab-on-a-chip or a micro total analysis system.

Owner:NATIONAL TSING HUA UNIVERSITY

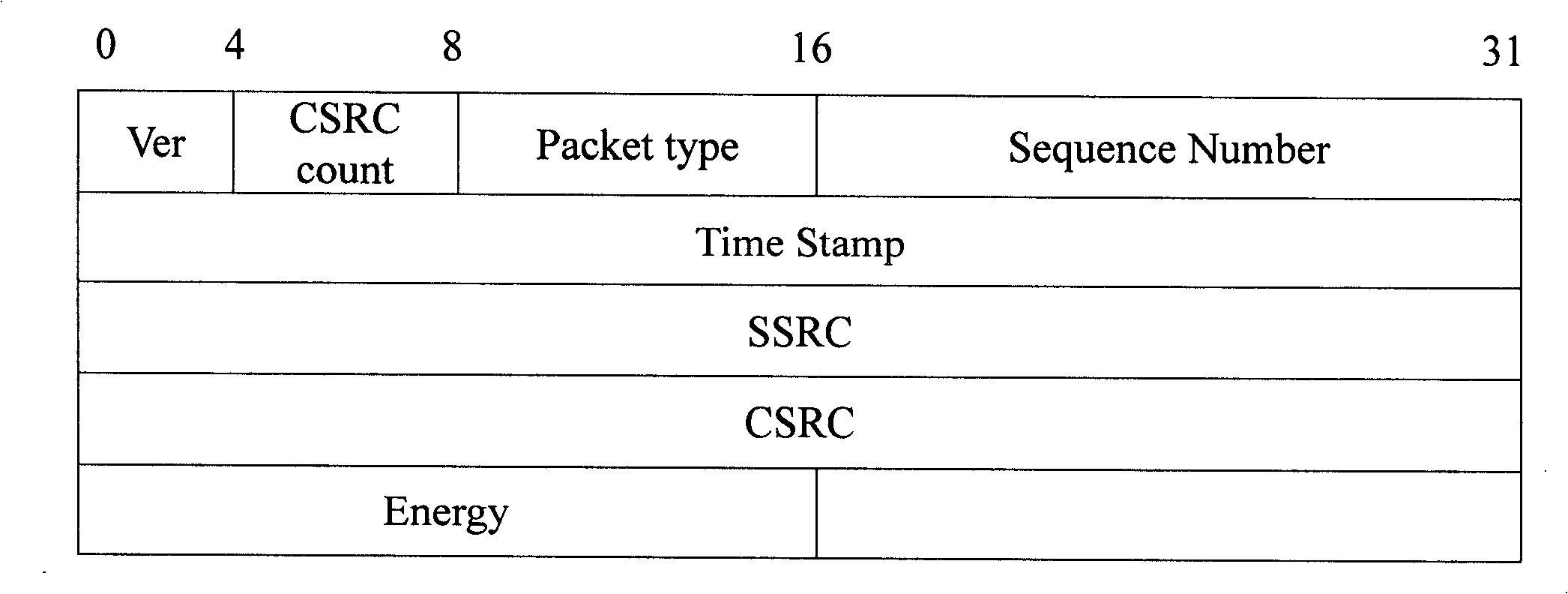

Distributed type tone mixing system in multimedia conference

InactiveCN101252452AReduce CPU loadReduce latencySpecial service provision for substationSpecial service for subscribersVideo serverClient-side

Owner:杭州红杉赛联通讯技术有限公司

Device and method for converting carbon containing feedstock into carbon containing materials having a defined nanostructure

InactiveUS20090142250A1Improve conversion efficiencyEasy to controlMaterial nanotechnologyPigmenting treatmentProduct gasPlasma Gases

Apparatus and process for producing carbon black or carbon containing compounds by converting a carbon containing feedstock, comprising the following steps: generating a plasma gas with electrical energy, guiding the plasma gas through a venturi, whose diameter is narrowing in the direction of the plasma gas flow, guiding the plasma gas into a reaction area, in which under the prevailing flow conditions generated by aerodynamic and electromagnetic forces, no significant recirculation of feedstock into the plasma gas in the reaction area recovering the reaction products from the reaction area and separating carbon black or carbon containing compounds from the other reaction products.

Owner:ТІМКАЛ SА

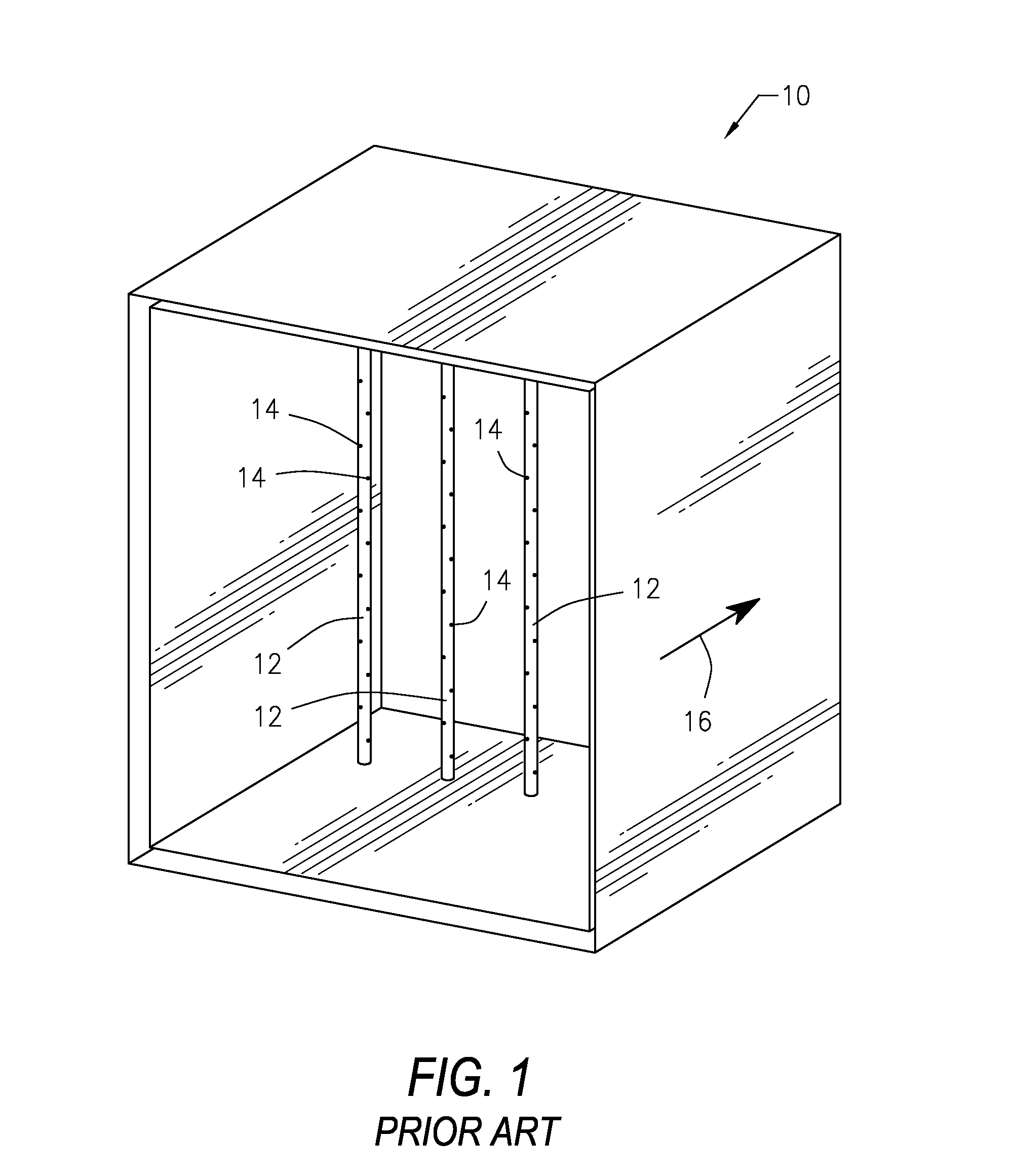

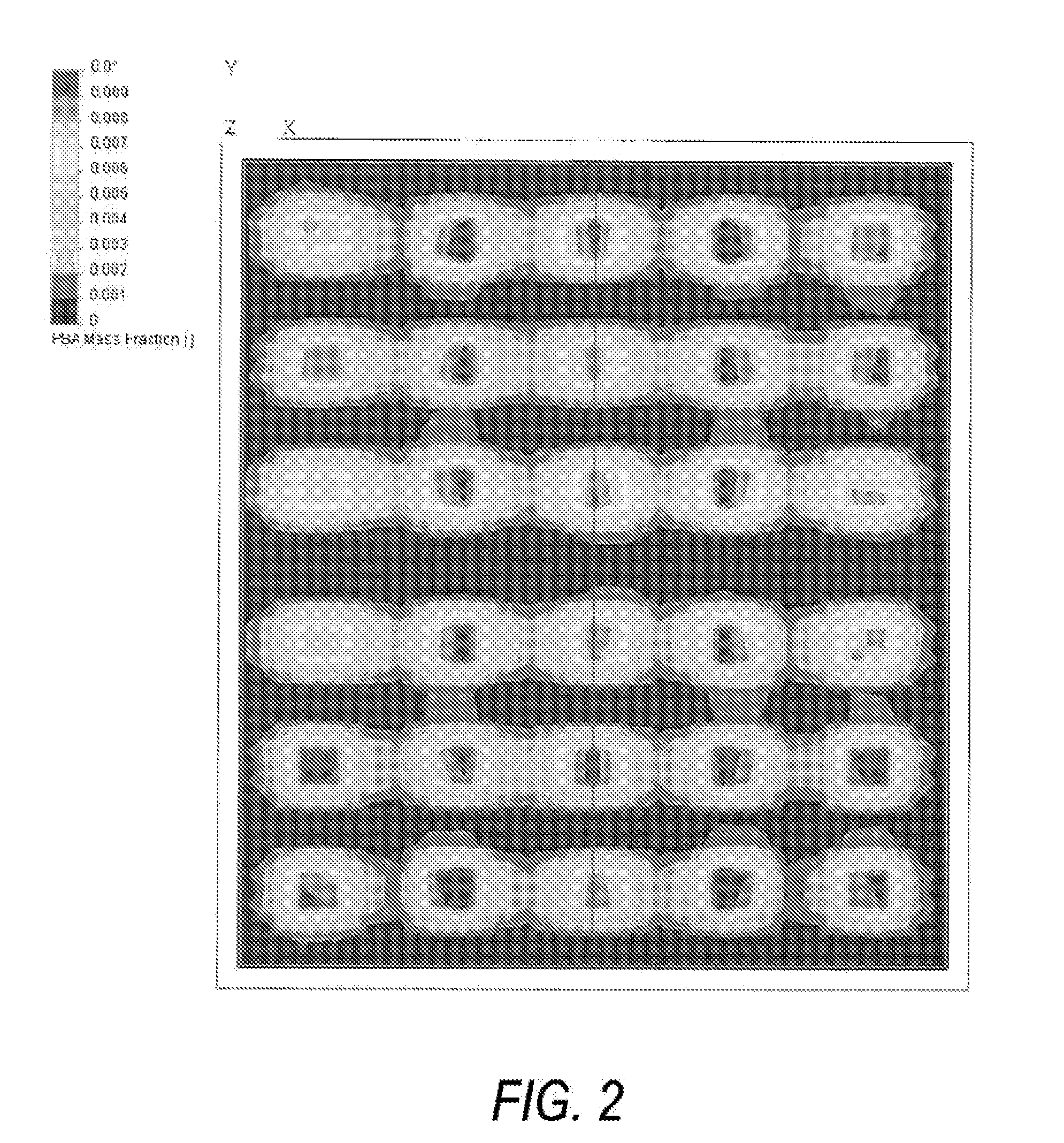

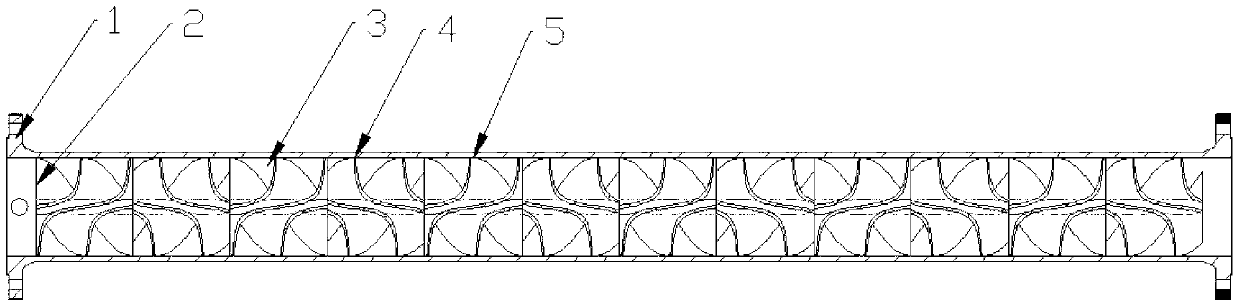

Microstructure designs for optimizing mixing and pressure drop

ActiveUS20050276160A1Efficient mixingImprove mixing efficiencyFlow mixersOther chemical processesContinuous flowEngineering

A class of designs is provided for a mixer in micro reactors where the design principle includes at least one injection zone in a continuous flow path where at least two fluids achieve initial upstream contact and an effective mixing zone (i.e. adequate flow of fluids and optimal pressure drop) containing a series of mixer elements in the path. Each mixer element is preferably designed with a chamber at each end in which an obstacle is placed (thereby reducing the typical inner dimension of the chamber) and with optional restrictions in the channel segments. The obstacles are preferably cylindrical pillars but can have any geometry within a range of dimensions and may be in series or parallel along the flow path to provide the desired flow-rate, mixing and pressure-drop. The injection zone may have two or more interfaces and may include one or more cores to control fluids before mixing.

Owner:CORNING INC

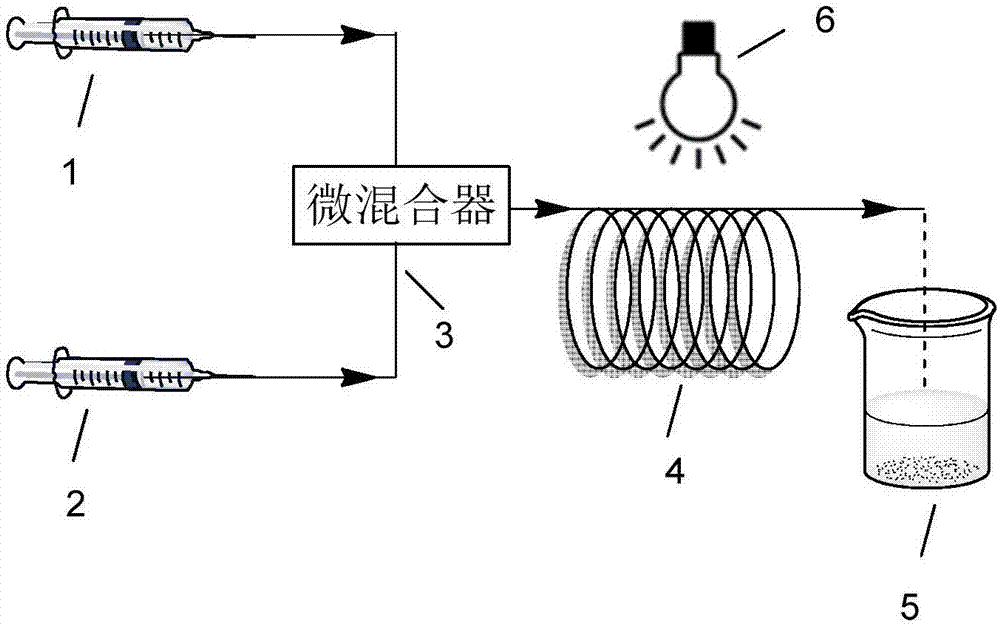

Method for preparing polymer by micro-scale photo-induced organic catalysis

ActiveCN106893015AImprove mixing efficiencyImprove mass transfer efficiencyChemical/physical/physico-chemical processesChemical/physical/physico-chemical microreactorsMicroreactorPolymer science

The invention discloses a method for preparing a polymer by micro-scale photo-induced organic catalysis. The method comprises the following steps: using alkyl halide as an initiator in a microreactor; and using an organic small molecule as a catalyst to catalyze atom-transfer radical-polymerization, so as to prepare the polymer. Compared with the prior art, the method provided by the invention has advantages of high reaction speed, controllable molecular weight and molecular weight distribution of a polymerization product, no residue, and wide application in fields of optoelectronic materials and biomedical materials.

Owner:NANJING UNIV OF TECH

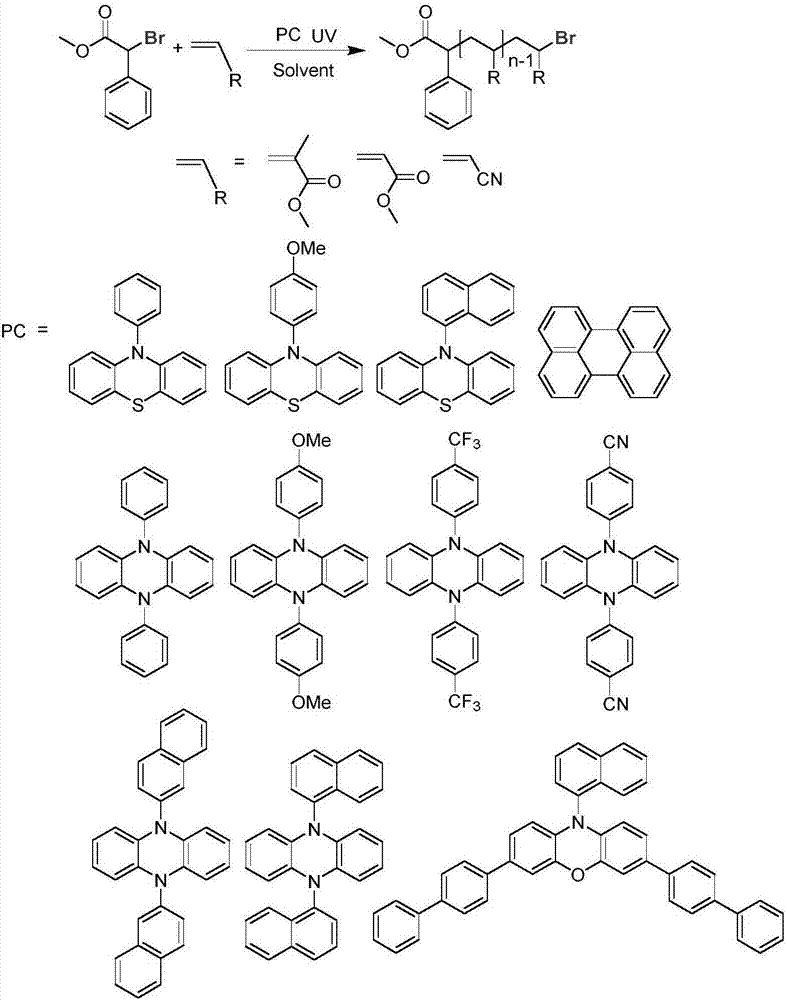

Spiral static mixer

The invention discloses a spiral static mixer which is applied to mixing of multiple materials and particularly mixing of high-viscosity materials. The spiral static mixer comprises a shell, mounting flanges, left rotating blades and right rotating blades and is characterized in that the mounting flanges are respectively arranged at the two ends of the shell, the left rotating blades and the right rotating blades are in multiple-spiral blade structures and sequentially and alternately arranged from an inlet of the shell to an outlet of the shell, the adjacent left rotating blades and right rotating blades are fixedly connected at the periphery in a staggering manner, and a washing lifting ring is connected at one end of a blade group formed by the left rotating blades and the right rotating blades. The spiral static mixer provided by the invention has the advantages of simple structure, high mixing efficiency, convenience and fastness in installation, low cost, convenience in washing and suitability for long-time working; a mixed blade unit can be replaced; and the spiral static mixer is more widely applied to mixing of the high-viscosity materials in the chemical engineering industry.

Owner:MECHANICS RES & DESIGN ACAD SICHUAN PROV

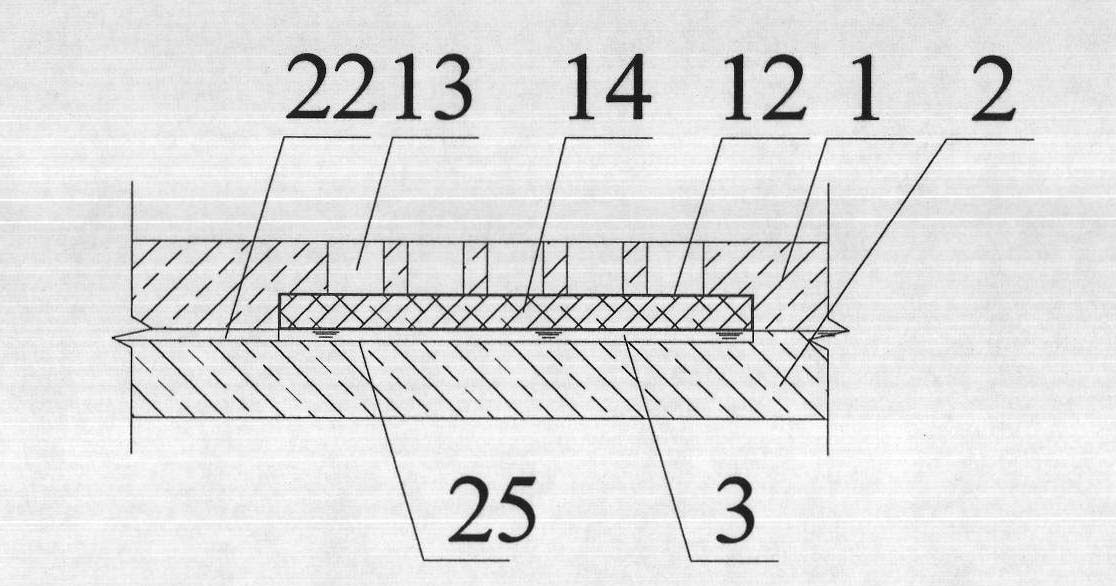

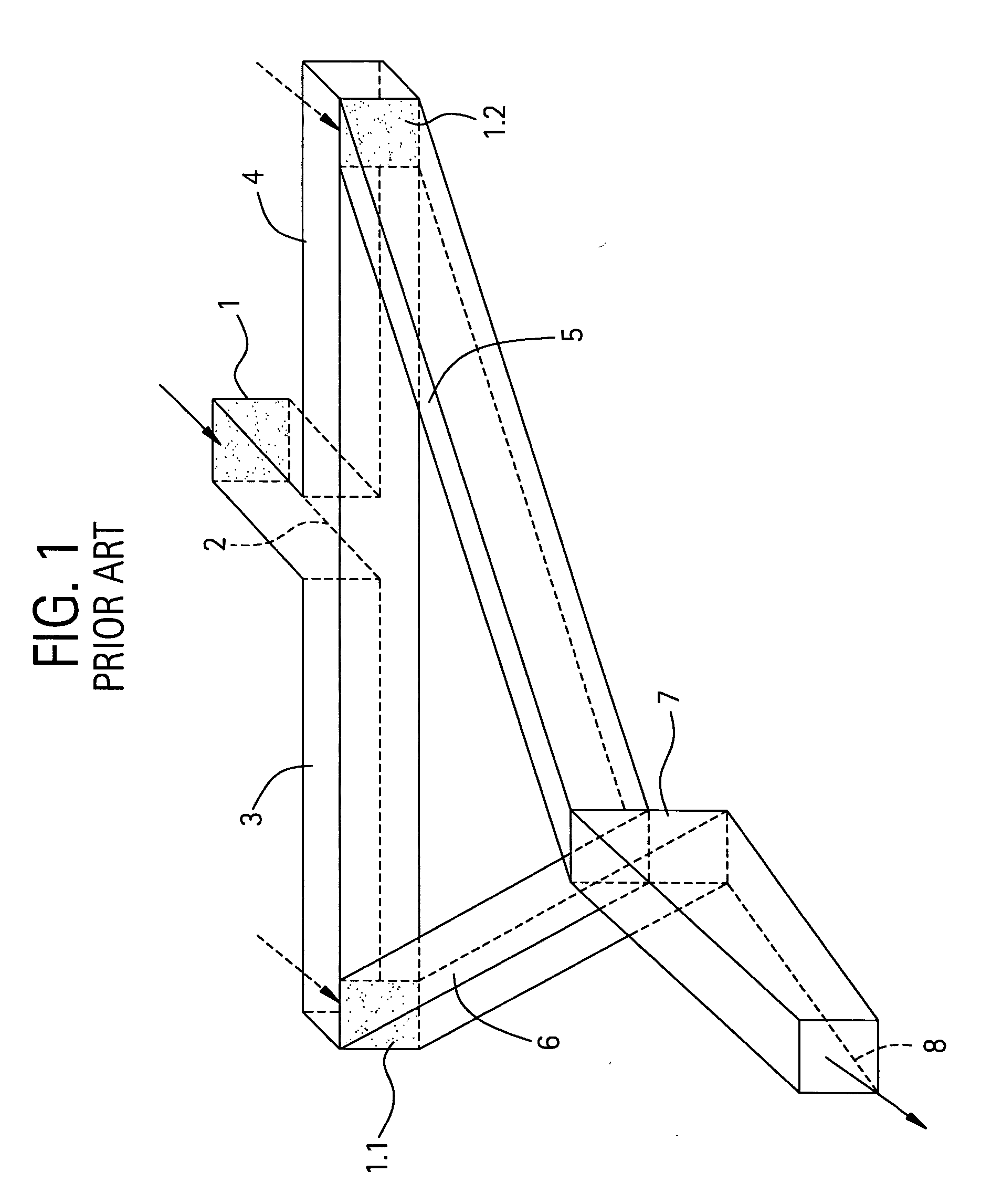

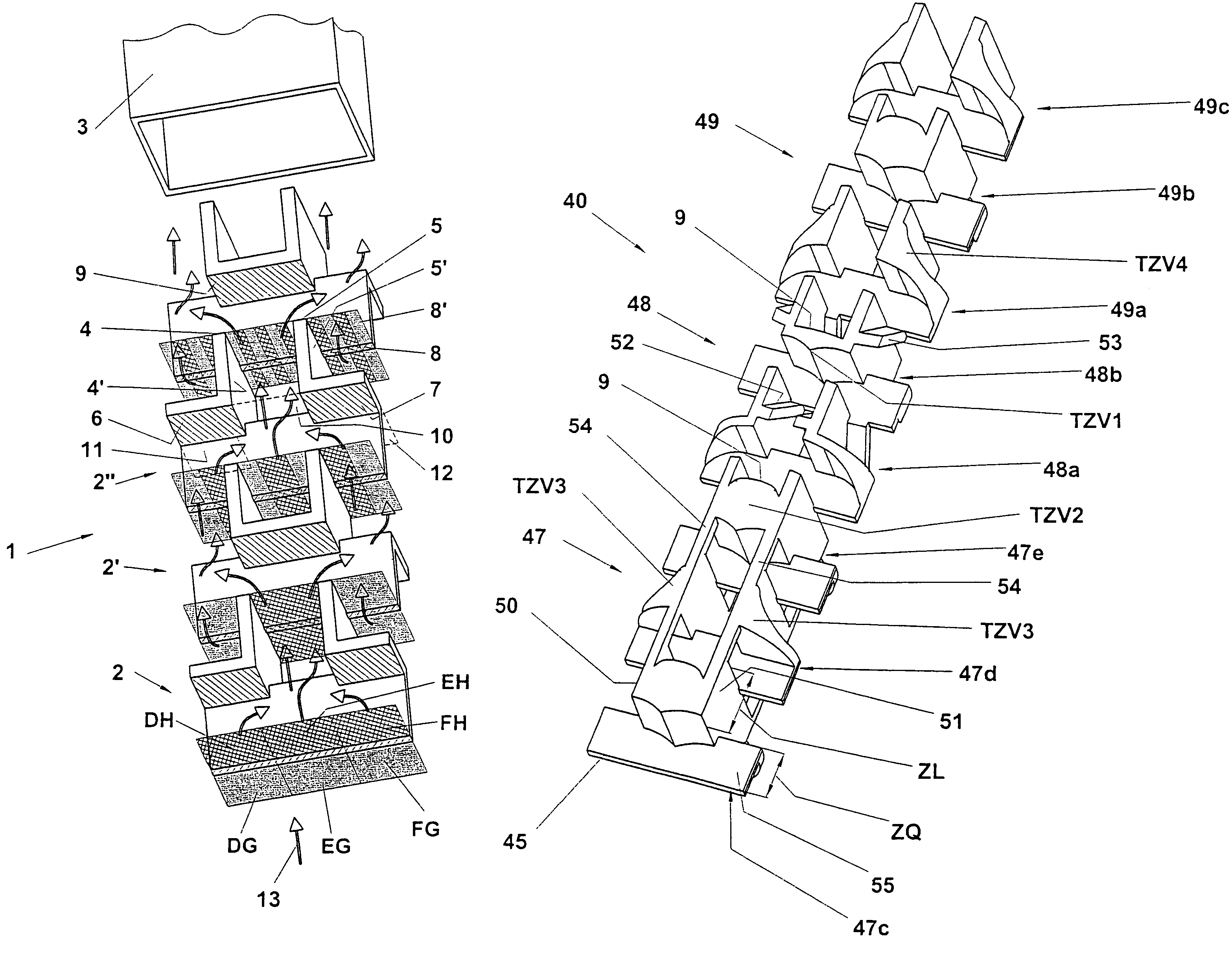

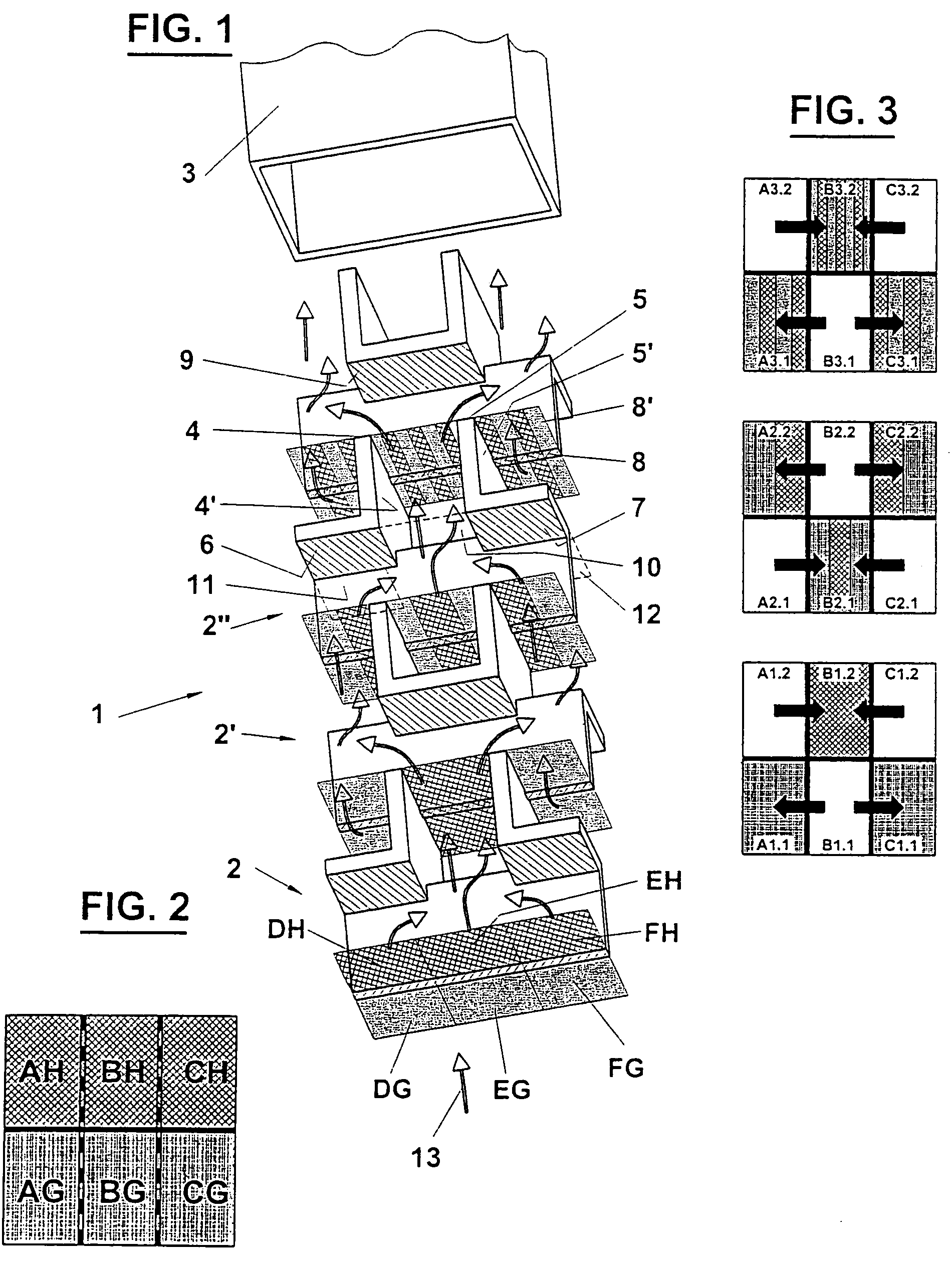

Static mixer

InactiveUS7325970B2Improve mixing efficiencyReduce dead volumeFlow mixersTransportation and packagingDead volumeEngineering

The static mixer comprising mixing elements for separating the material to be mixed into a plurality of streams and a mechanism for the layered junction of the same, a transversal edge and guide walls that extend at an angle to said transversal edge, as well as deflecting elements arranged at an angle to the longitudinal axis and provided with openings, includes mixing elements comprising a transversal edge and a following transversal guide wall and at least two guide walls with lateral end sections and at least one bottom section disposed between said guide walls, thereby defining at least one opening on one side of said transversal edge and at least two openings on the other side of said transversal edge. In addition to a high mixing efficiency and a low pressure drop, a mixer of this kind provides reduced dead volumes and is thus more effective than mixers of the prior art.

Owner:MEDMIX SWITZERLAND AG

Liquid mixing device capable of rapidly mixing materials

InactiveCN107349852AExtended range of mixingChange fixed mixShaking/oscillating/vibrating mixersRotary stirring mixersEngineeringDrive motor

Owner:林红英

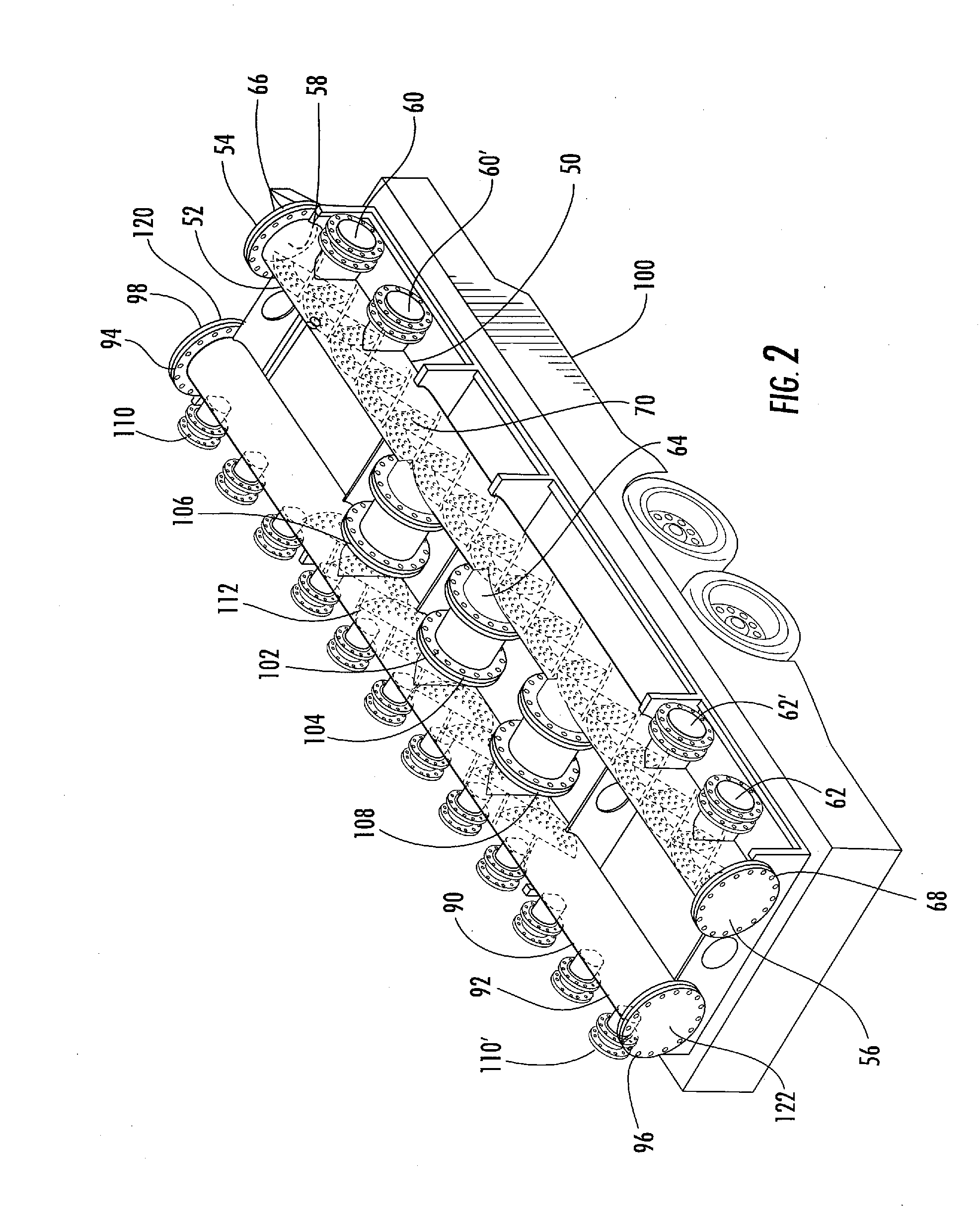

Portable hydrodynamic cavitation manifold

ActiveUS20110305104A1Improve mixing efficiencyIncrease flow rateFlow mixersTransportation and packagingCavitationEngineering

A portable hydrodynamic cavitation manifold assembly formed from cylindrical tubes having flow-through chambers for collection and distribution of fluids. Each chamber includes a series of baffle units each unit formed from a first plate defined by a first end spaced apart from a second end by a length. The first plate includes a curved outer edge sized to follow the inner side wall of the chamber and a straight inner edge extending from the first end to the second end along the approximate center line of the chamber and positioned at a 45 degree angle relative to the longitudinal length of the tube. A second plate, forming a mirror image of the first plate, is also positioned at a 45 degree angle relative to the longitudinal length of the tube and at a 90 degree angle to the first plate. Each plate includes a plurality of apertures sized to control the velocity of the fluid flow, each aperture having edge walls to induce constriction for hydrodynamic cavitation mixing of fluids.

Owner:BRISBEN WATER SOLUTIONS

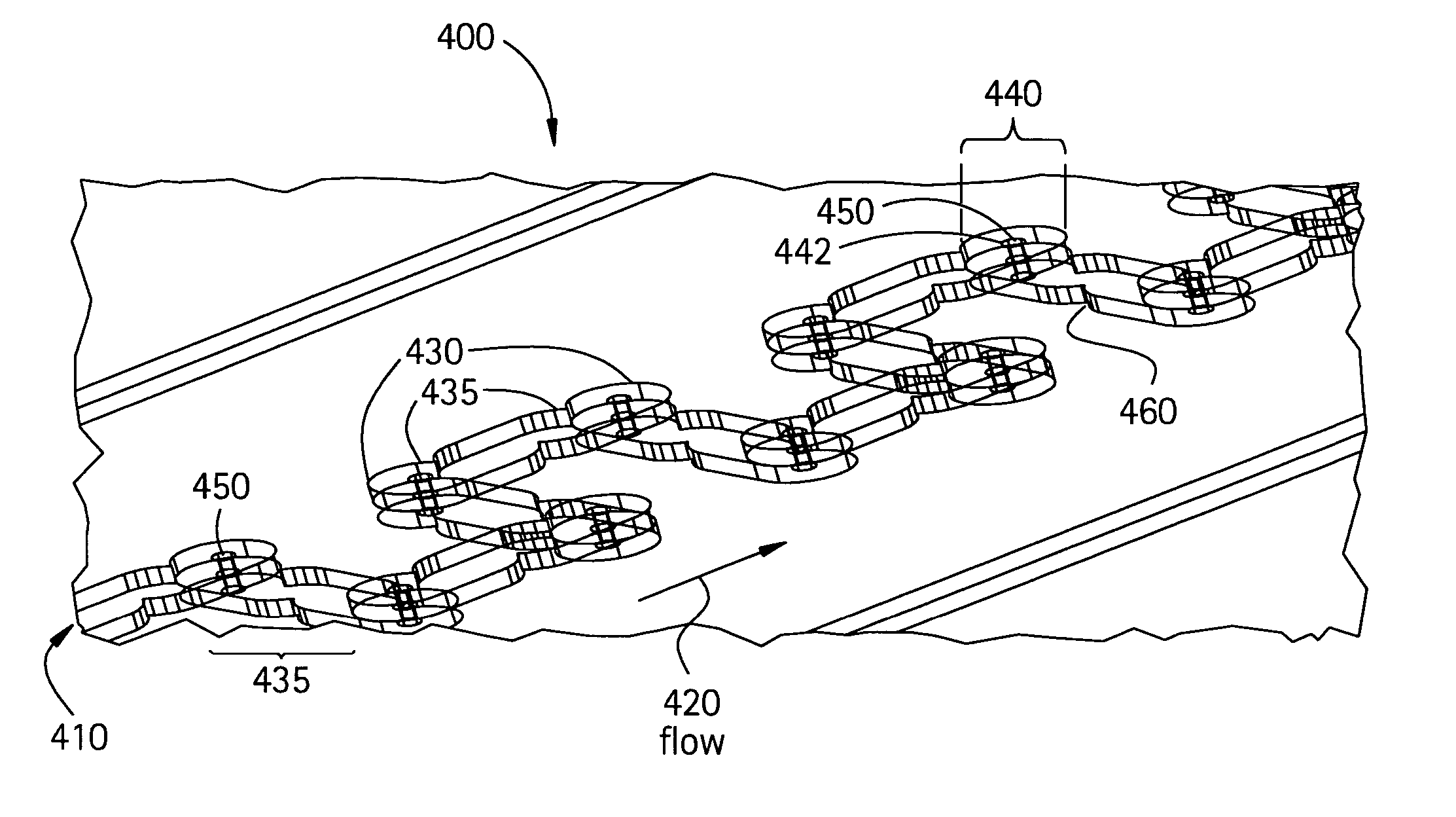

Multi-phase fluid sampling method and apparatus

ActiveUS20060141637A1Accurate and economicalReliable and accurate multi-phase fluid flow measurementWithdrawing sample devicesBiological testingStream flowSurface-active agents

The invention provides a method for producing a homogenous sample of a pressurized fluid stream flowing in a pipeline, the fluid stream consisting of a majority component of hydrocarbon gas, the remainder consisting of one or more hydrocarbon liquids and water in the form of vapor, aerosols, droplets and / or liquid streams, the method includes the steps of: a. injecting one or more surface active agents into the fluid stream in an injection zone at a rate that is sufficient to form a uniform foam of the gas and the one or more hydrocarbon liquids and water components; b. mixing the one or more surface active agents with the fluid stream in a mixing zone to form a uniform foam composition flowing in the pipeline downstream of the mixing zone; c. withdrawing a portion of the foam composition from the pipeline at a sampling point; d. passing the portion of the foam composition withdrawn through a sampling loop; and e. removing a sample of predetermined volume of the foam composition from the sampling loop for analysis.

Owner:SAUDI ARABIAN OIL CO

Multi-element feed raw material mixing device

ActiveCN108311005AImprove mixing efficiencyShaking/oscillating/vibrating mixersFeeding-stuffEngineeringSlide plate

The invention discloses a multi-element feed raw material mixing device which comprises a main body, wherein a motor rack is fixedly mounted on the main body; a clockwise and counterclockwise rotationmotor is fixedly mounted on the motor rack vertically; a stirring shaft is fixedly mounted on the output shaft of the stirring motor vertically; the surface of the stirring shaft is in threaded sleeve connection with a threaded sleeve; two upper turnover plates are symmetrically hinged with a rotating sleeve; two guide rods which are symmetrically arranged are fixedly mounted inside the main bodyhorizontally; the guide rods are sleeved with sliding plates in a horizontal sliding manner; the sliding plates are propped against the inner bottom surface of the main body; a plurality of dischargetubes are arranged at the bottom of the main body vertically; valves are mounted on the discharge tubes. Through up and down closure and opening of the upper turnover plates and lower turnover platesof the device, turnover and mixing of feed can be achieved; meanwhile, the upper turnover plates and the lower turnover plates can be rotated along with the rotation of the rotating sleeve, and stirring blades can be rotated along with the stirring shaft. Therefore, feed raw materials can be turned over up and down and rotated and stirred as well, and the feed mixing efficiency can be greatly improved.

Owner:河南正本清源科技发展股份有限公司

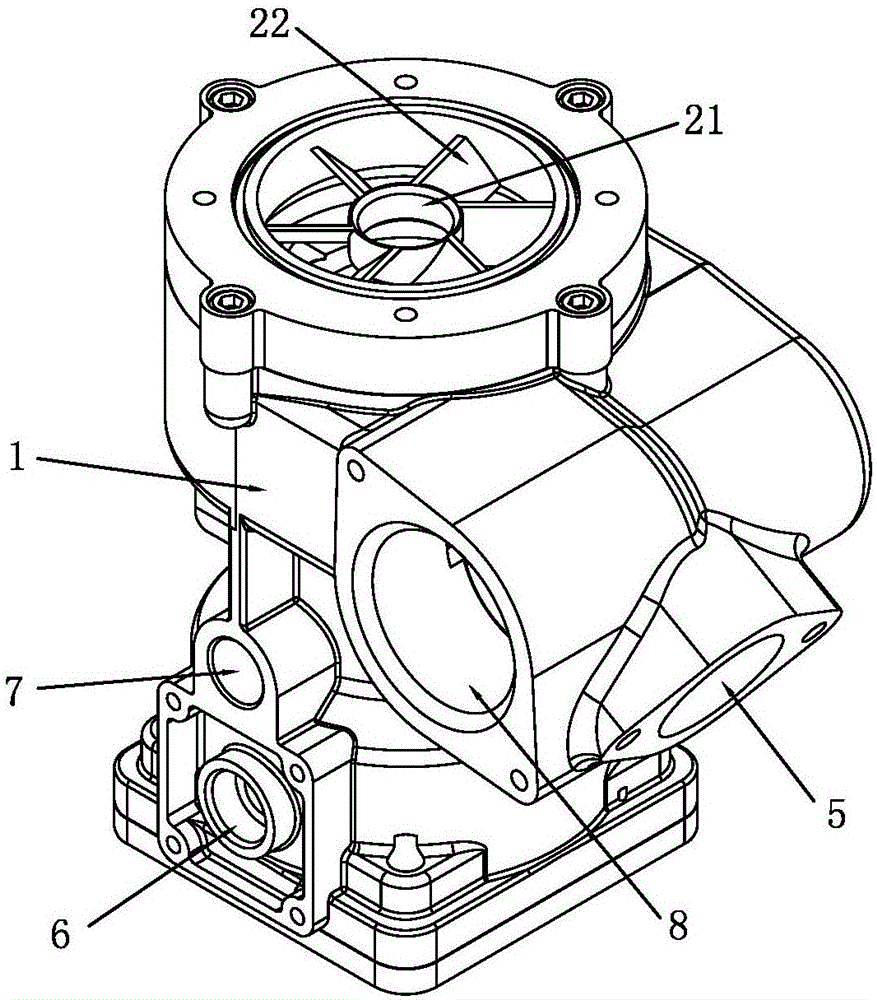

Mixer for gas engine and exhaust gas recirculation (EGR) mixer

ActiveCN106762245AGuaranteed uptimeImprove gas utilization efficiencyInternal combustion piston enginesExhaust gas recirculationProcess engineeringExhaust gas recirculation

The invention discloses a mixer for a gas engine and an exhaust gas recirculation (EGR) mixer. The mixer for the gas engine comprises a through mixer body. A turbulent flow body is arranged at an air inlet of the mixer body. A gas core is arranged at an air outlet of the mixer body. An EGR core is arranged between the turbulent flow body and the gas core. An exhaust gas inlet and a gas inlet are formed in the mixer body. The EGR core communicates with the exhaust gas inlet. The gas core communicates with the gas inlet. The mixer for the gas engine is suitable for various kinds of gas engines, the mixing efficiency is high, operation of the engine is more stable, and the utilization efficiency of gas is higher. Requirements for periphery conditions are lower than those of independent gas mixers and EGR mixers, the total cost is lower, safety and reliability are achieved, the sealing performance is good, and the mixer for the gas engine and the EGR mixer have great market application value.

Owner:成都耐尔特科技有限公司

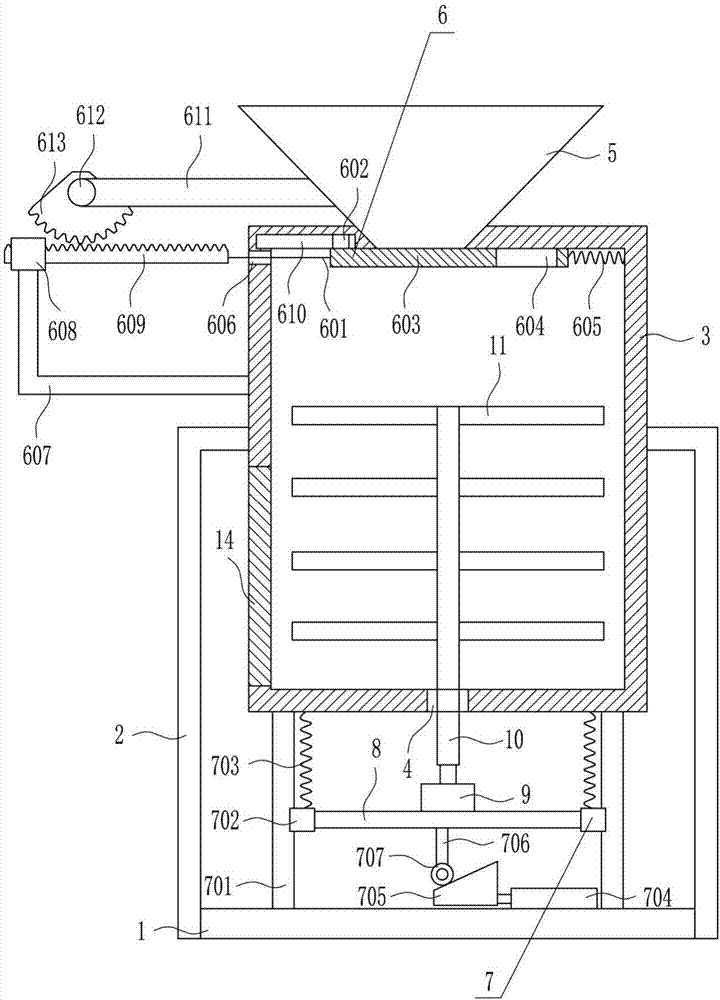

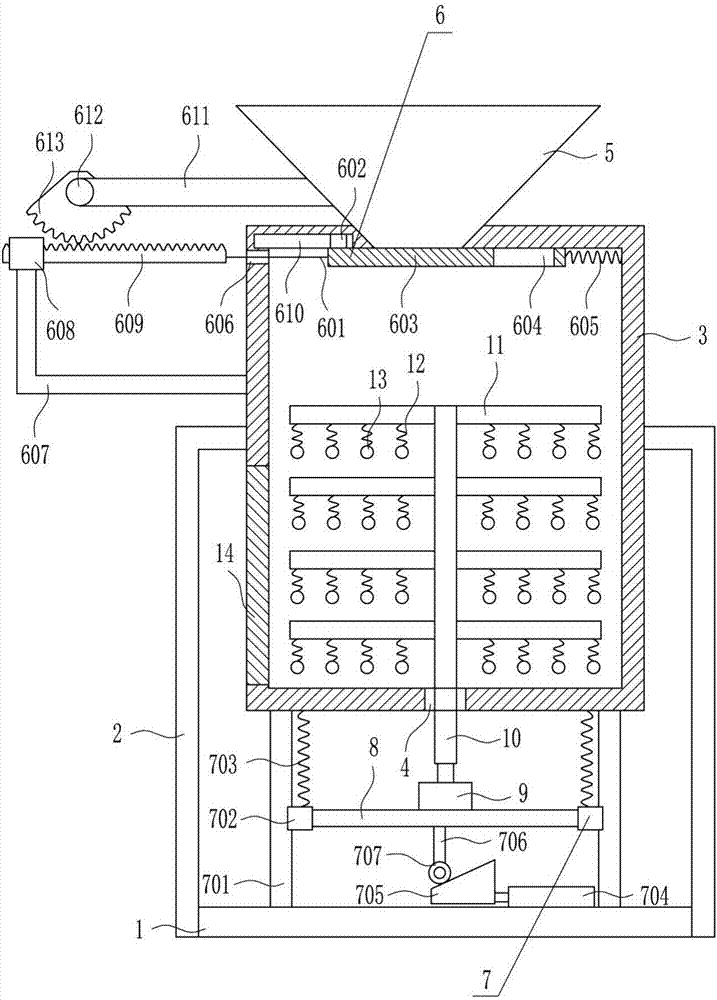

Sintering raw material mixing device for smelting

The invention relates to equipment for smelting, in particular to a sintering raw material mixing device for smelting. The sintering raw material mixing device for smelting is capable of saving time and labor, improving the mixing efficiency and the mixing effect, is easy to operate and is convenient to use. The device comprises a base, seven-shaped plates, a box body, a feeding hopper, an intermittent feeding device, an up-down moving device and the like, wherein the left side face and the right side face of the base each are connected with one seven-shaped plate through a bolt, the box body is connected between the two seven-shaped plates through bolts, a guide hole is formed in the middle of the bottom of the box body, a box door is arranged on the lower portion of the left side of the box body, the feeding hopper is installed on the top of the box body, and the lower side of the feeding hopper is provided with the intermittent feeding device. The device moves up and down while mixing blades rotate, and thus the mixing effect is improved.

Owner:安阳市新普钢铁有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com