Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1279results about "Pretreatment control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

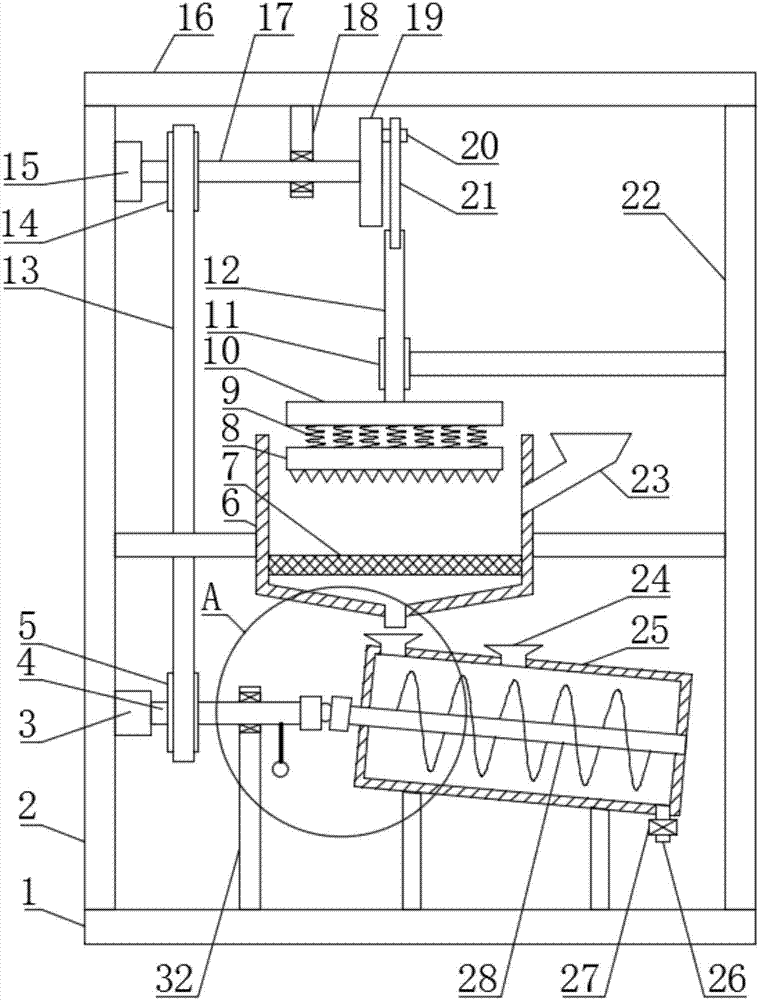

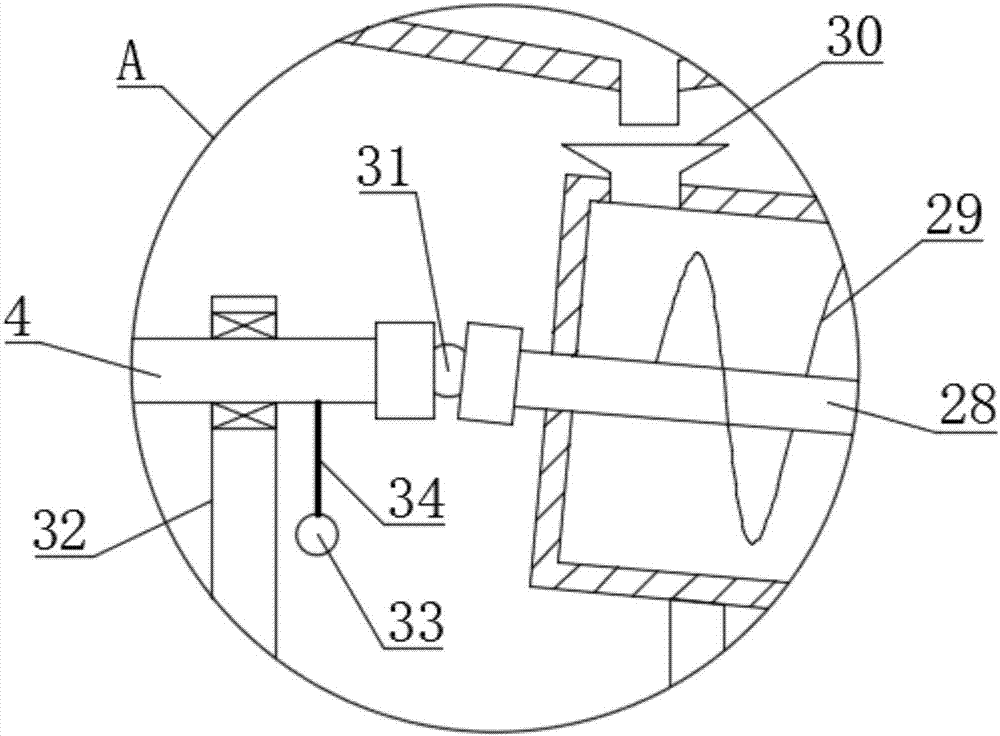

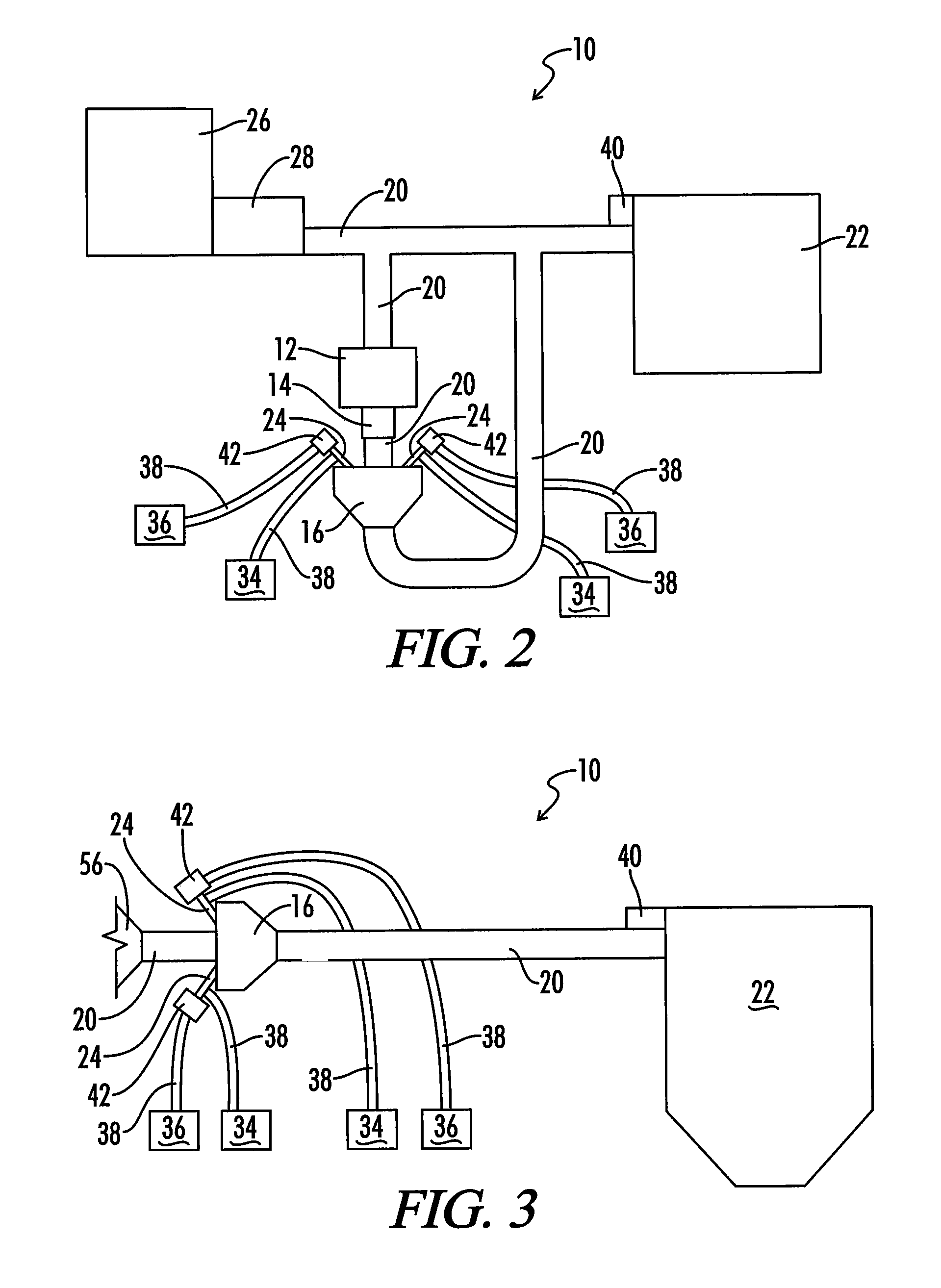

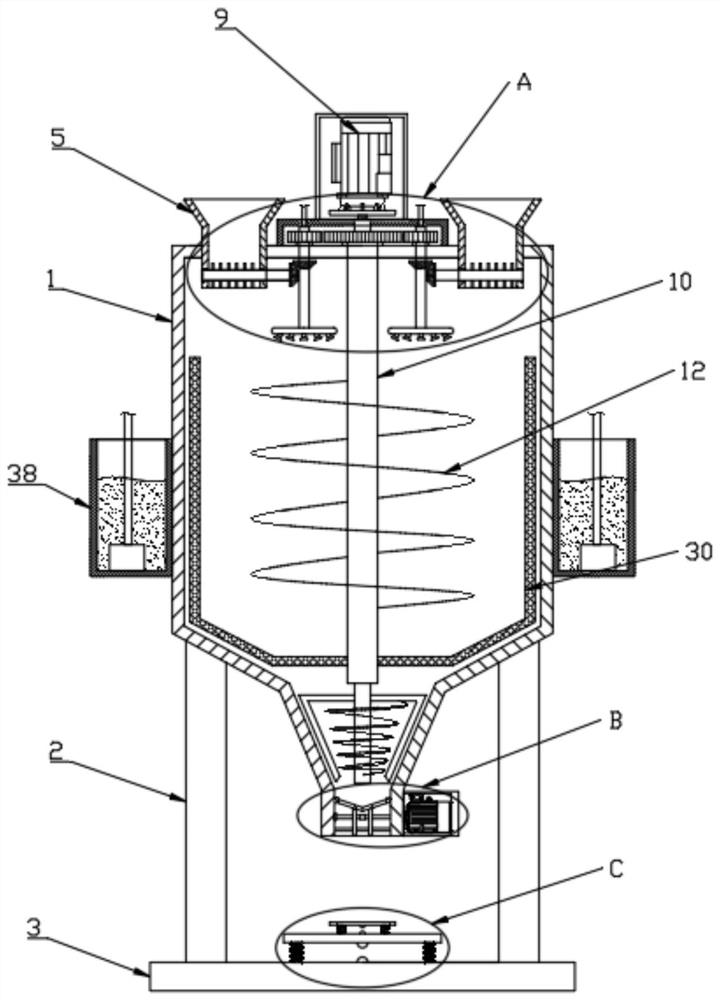

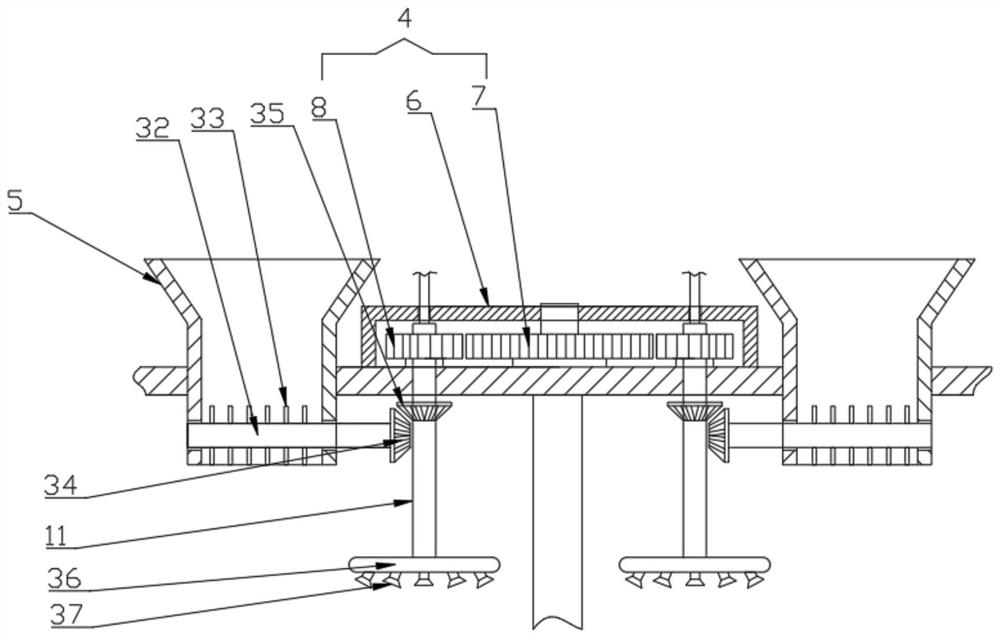

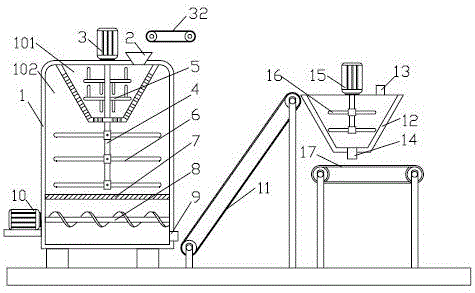

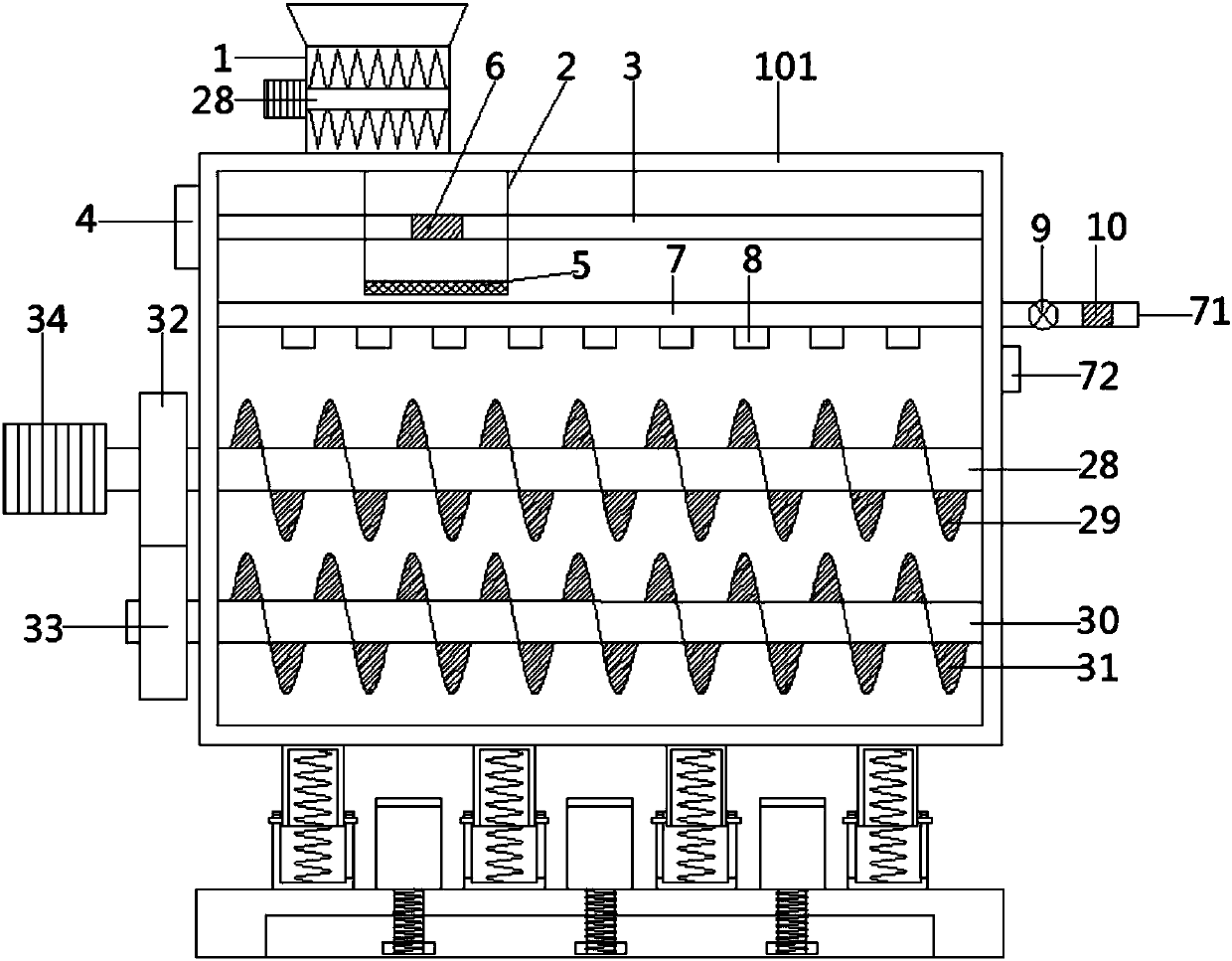

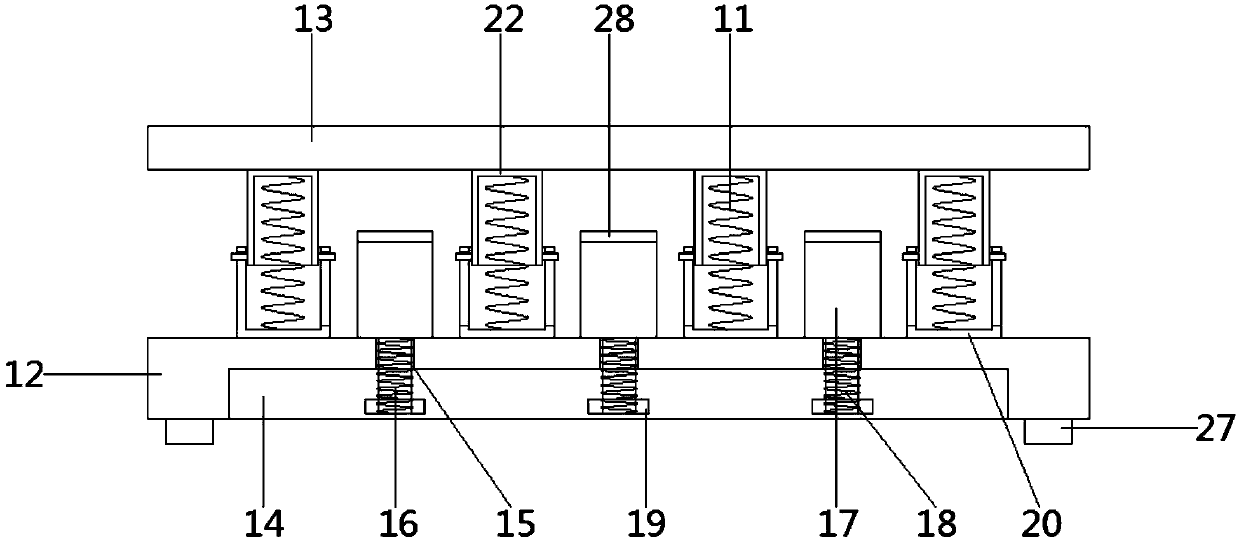

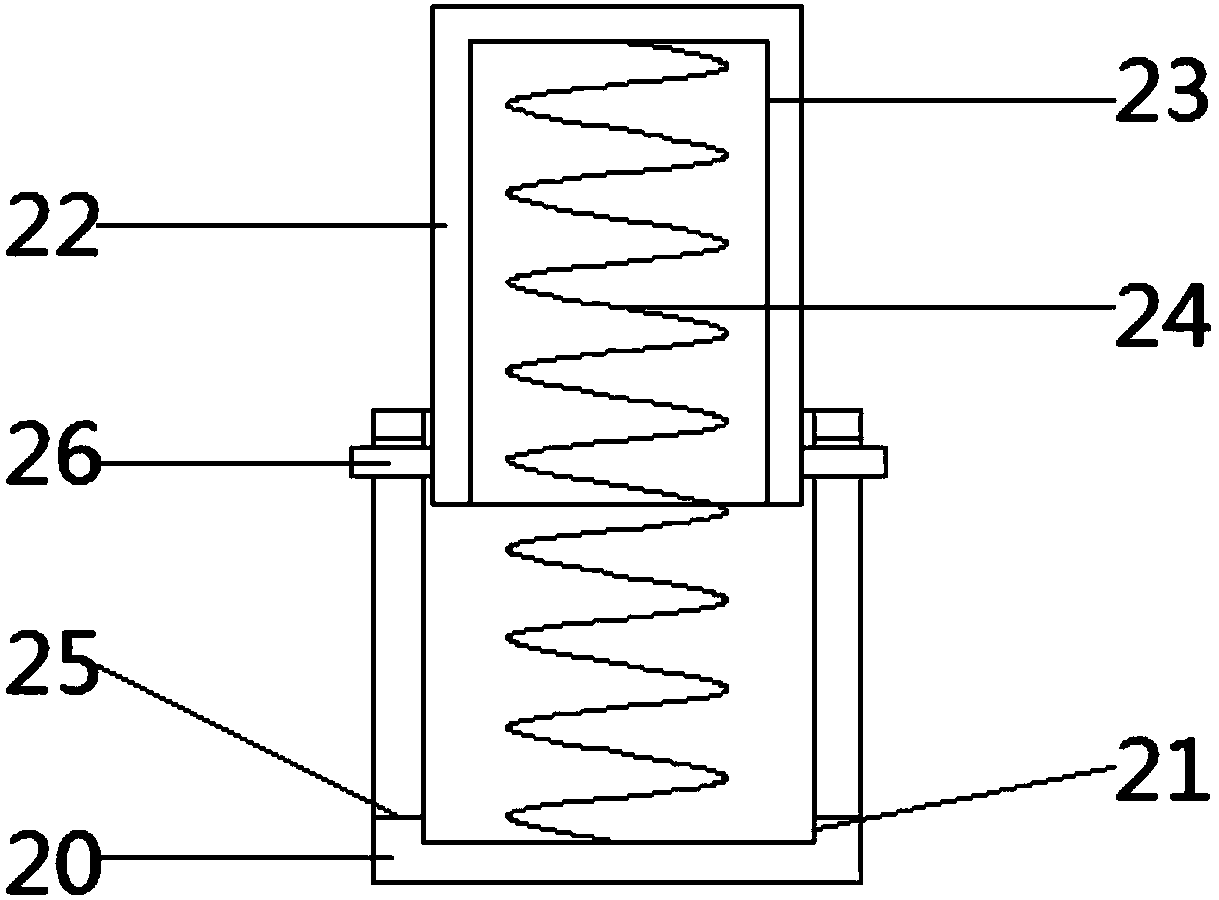

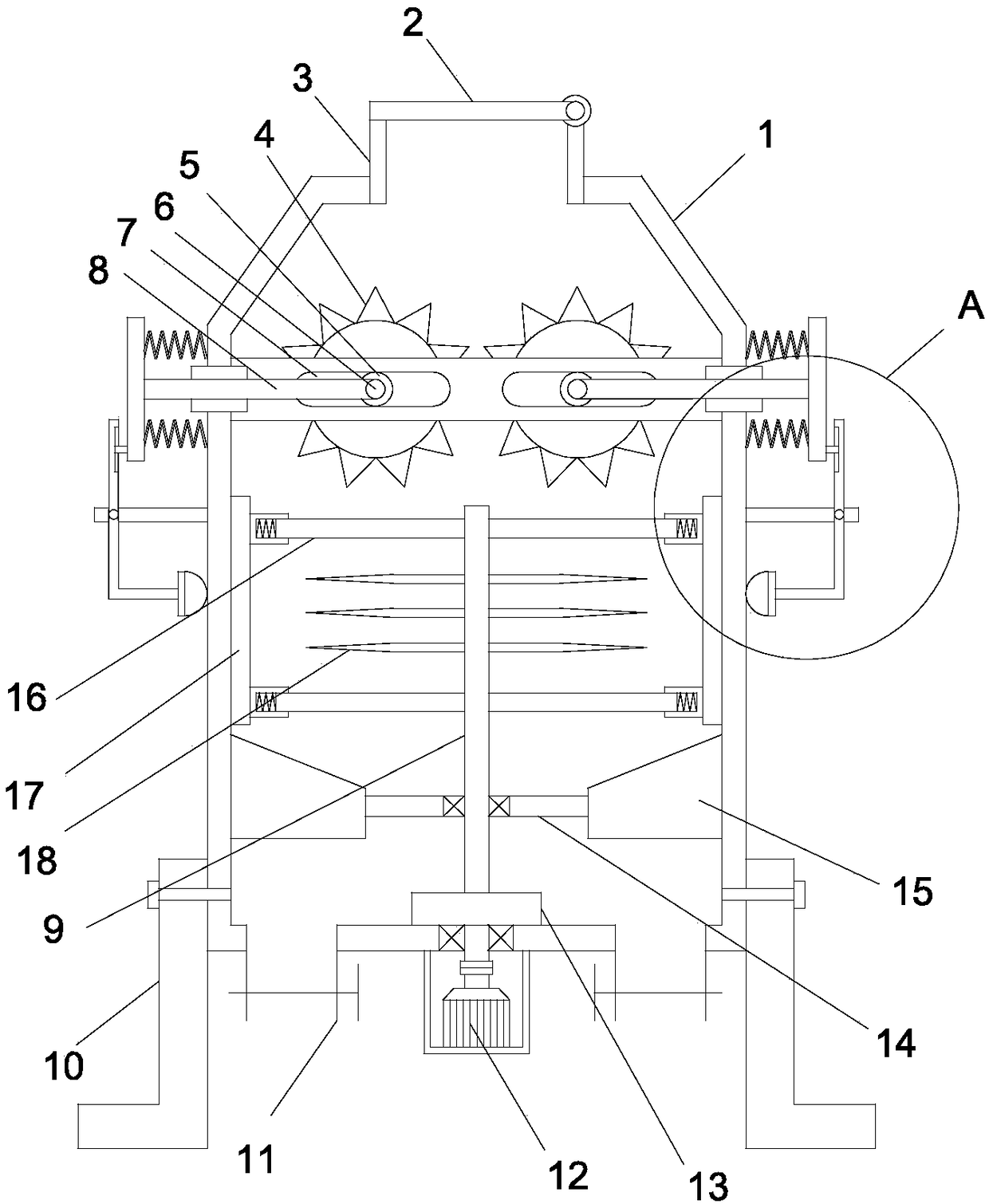

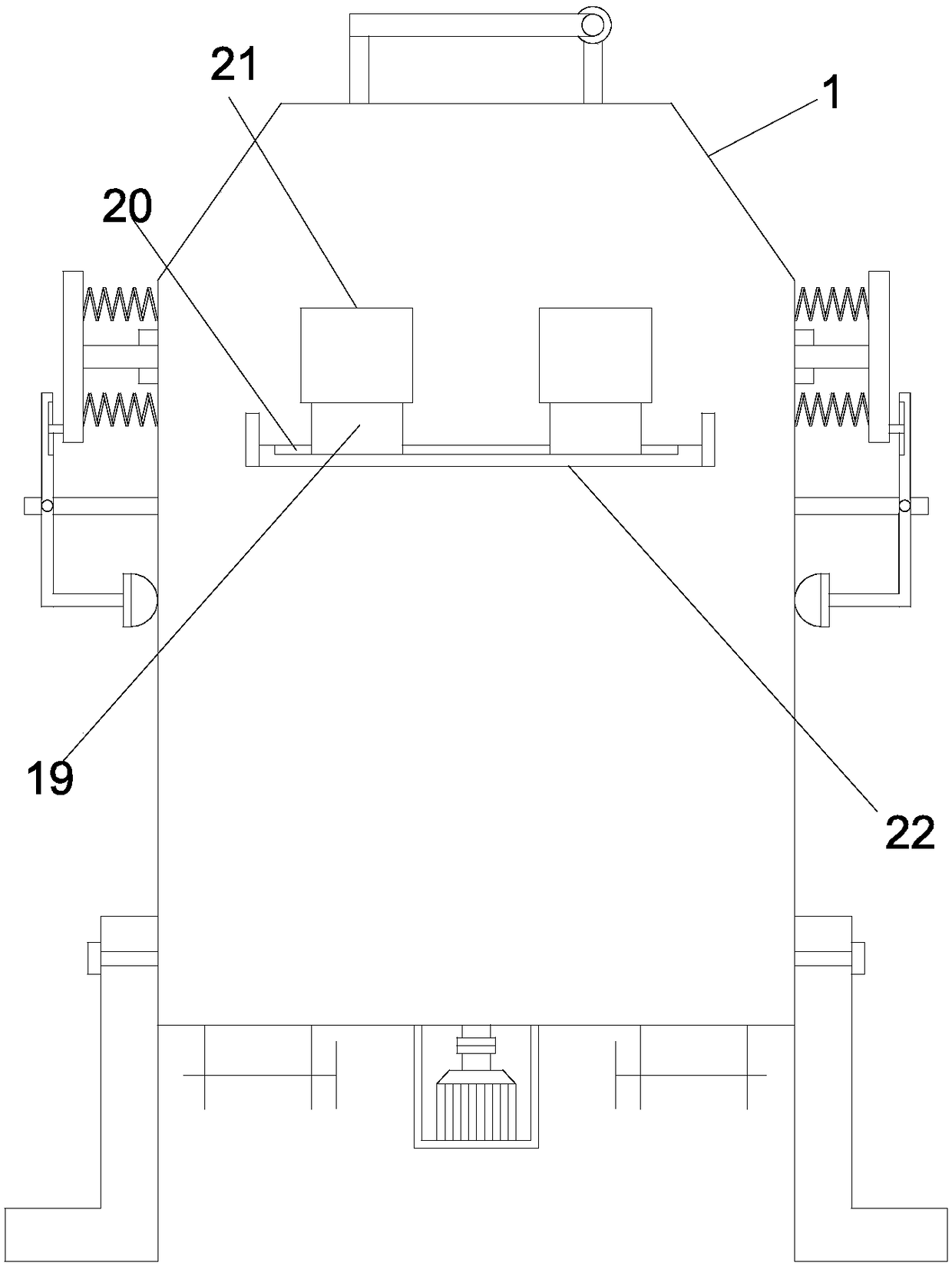

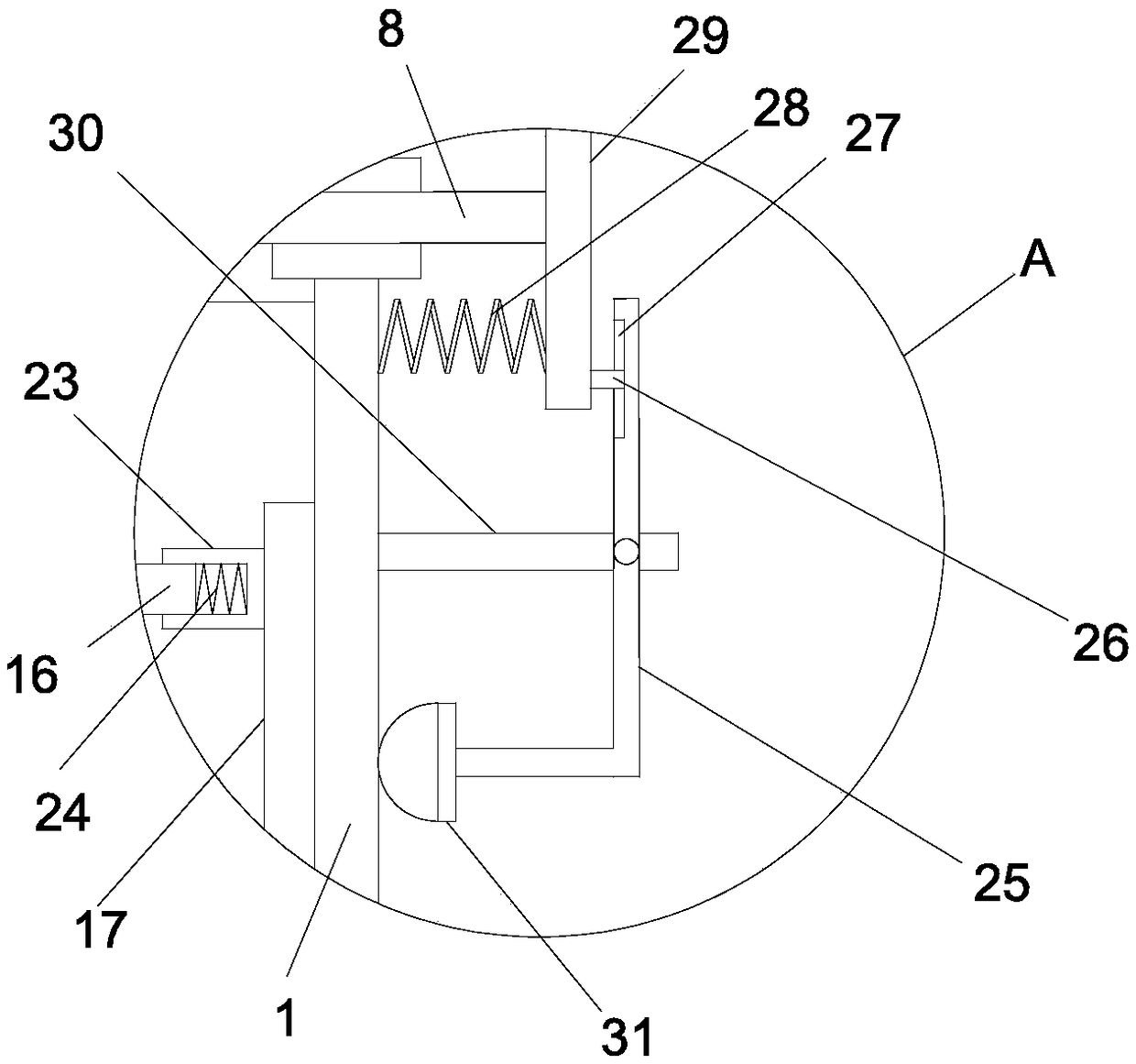

Stone-crushing concrete preparation device for buildings

InactiveCN107415049APlay a buffer roleAvoid cloggingMixing operation control apparatusPretreatment controlStone particleSpiral blade

The invention discloses a stone-crushing concrete preparation device for buildings. The stone-crushing concrete preparation device comprises a base, wherein a left supporting plate and a right supporting plate are correspondingly arranged on the left side and the right side of the base; a crushing box is fixedly arranged between the left supporting plate and the right supporting plate through a support; an extruding plate is fixedly arranged at the inner bottom of the crushing box; a marble is connected to a first rotating shaft through a snapline and positioned below the crushing box; an agitator is obliquely arranged on the base through a support, and a receiving hopper is arranged on the left side of the top of the agitator; a third rotating shaft is rotationally connected to the interior of the agitator; a spiral blade is mounted on the third rotating shaft; and the left end of the third rotating shaft penetrates the left side wall of the agitator and is connected with the right end of the first rotating shaft through a universal coupler. According to the stone-crushing concrete preparation device, the bottom of the crushing box is knocked by the marble, so that adhesion blockage is prevented; and screened stone particles directly enter the agitator to prepare concrete without manual control, so that the processing efficiency is effectively improved.

Owner:李小强

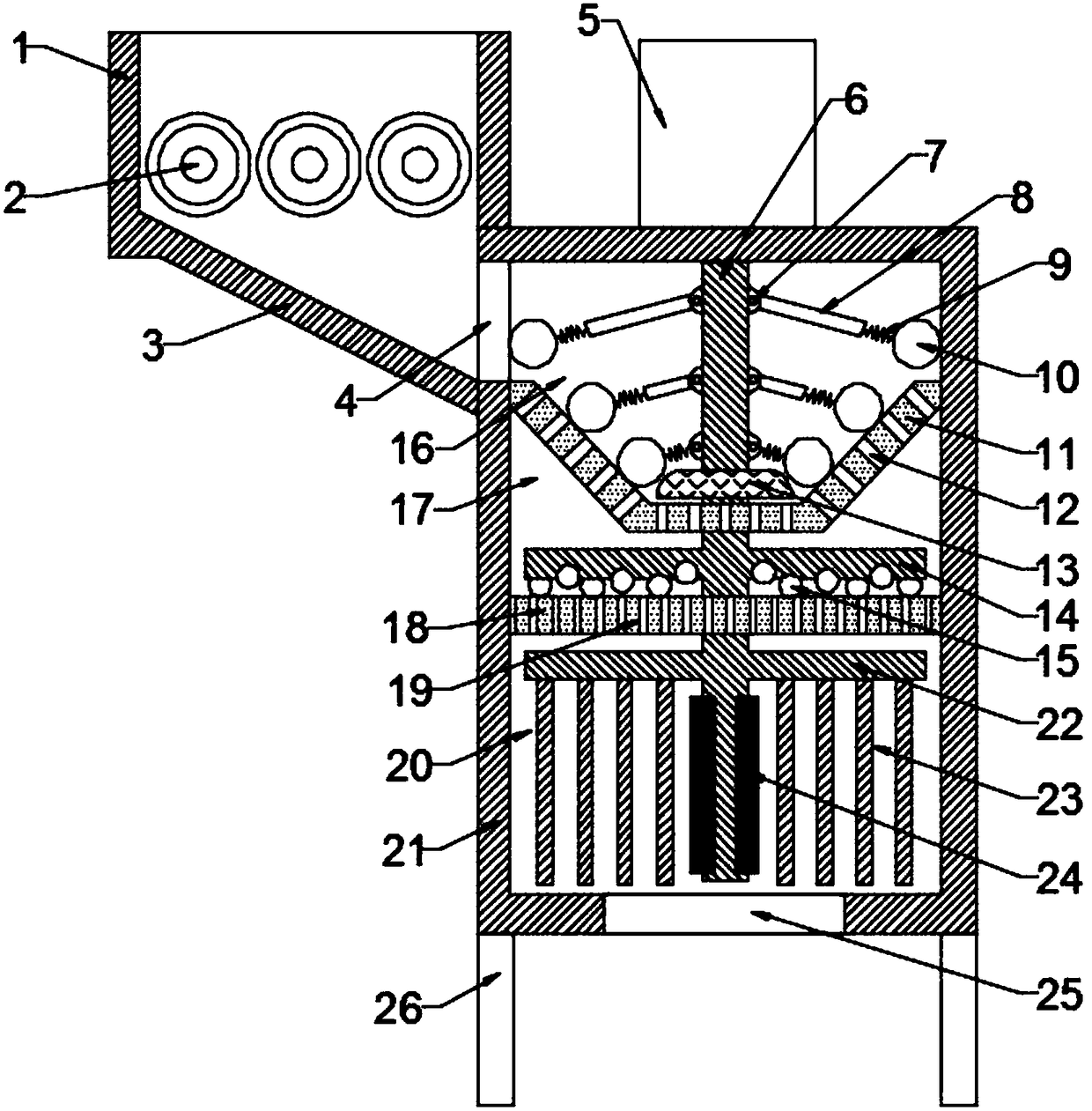

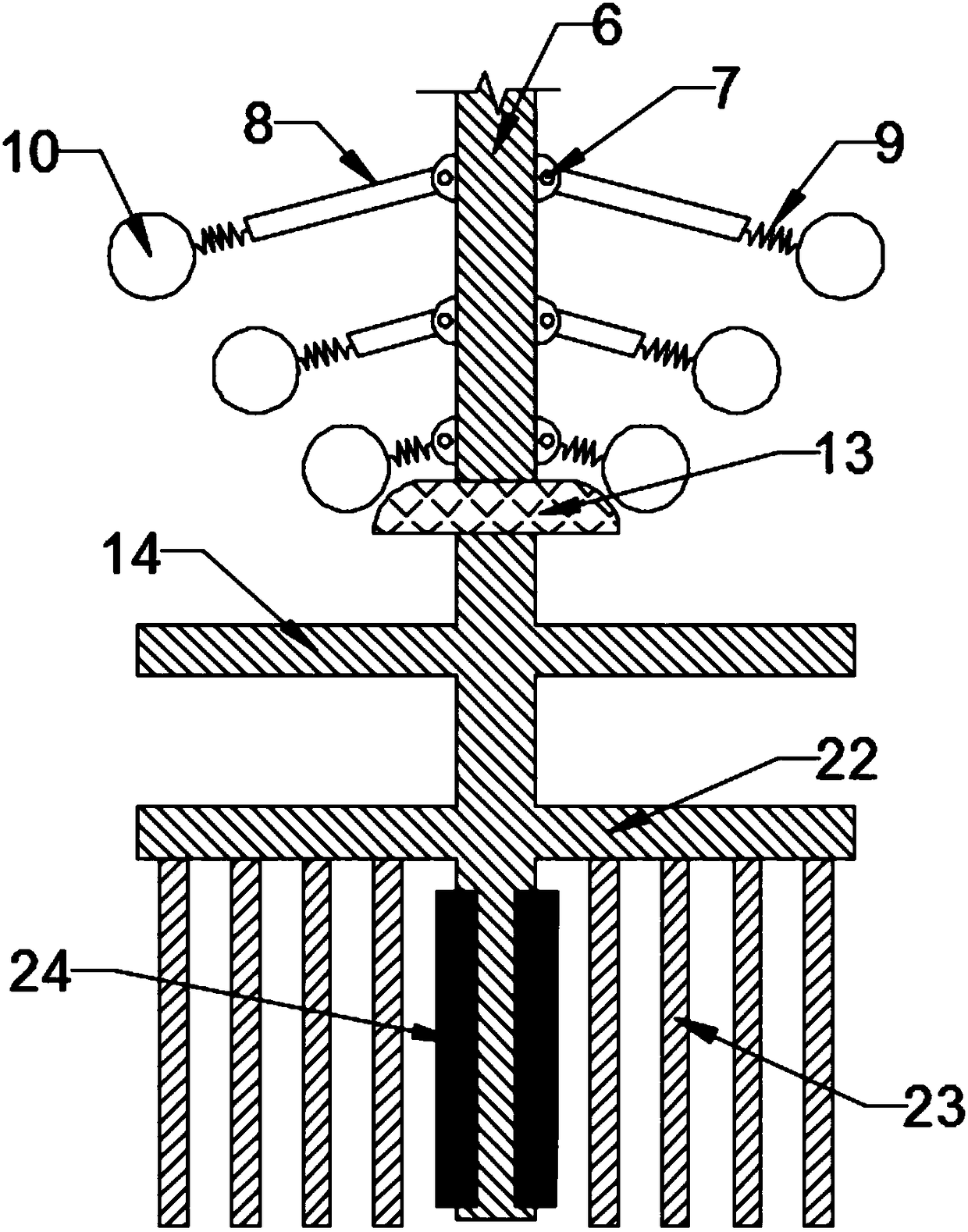

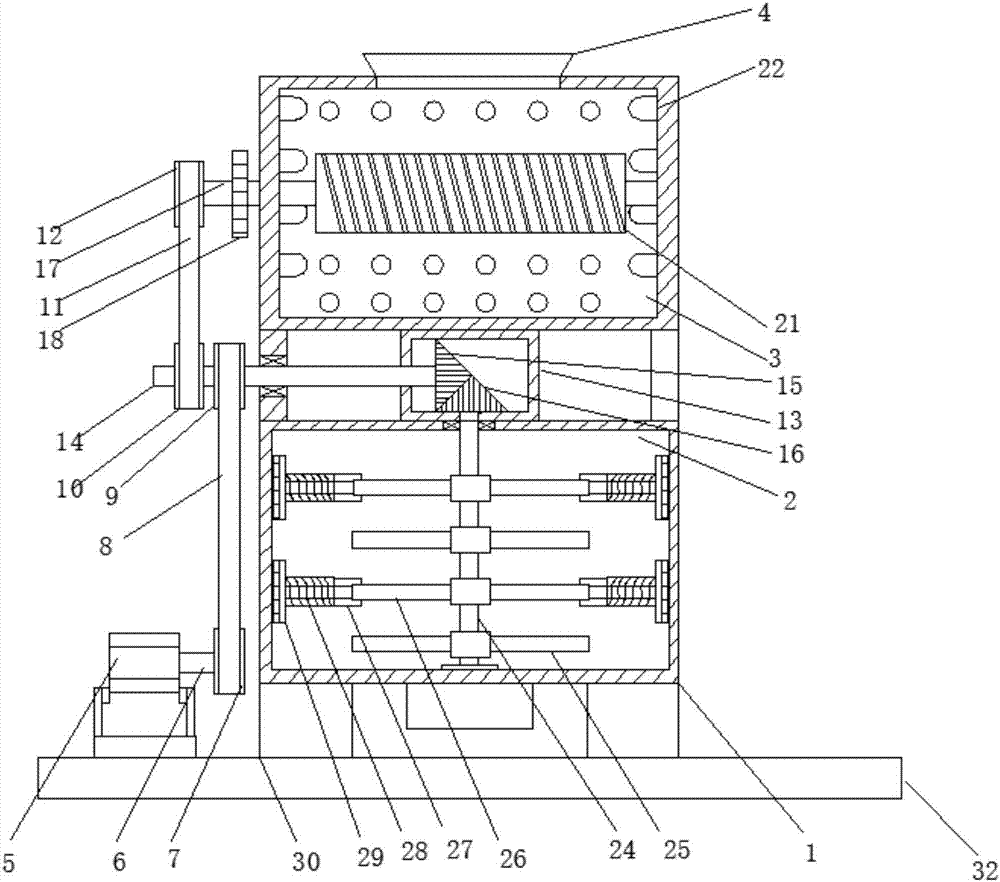

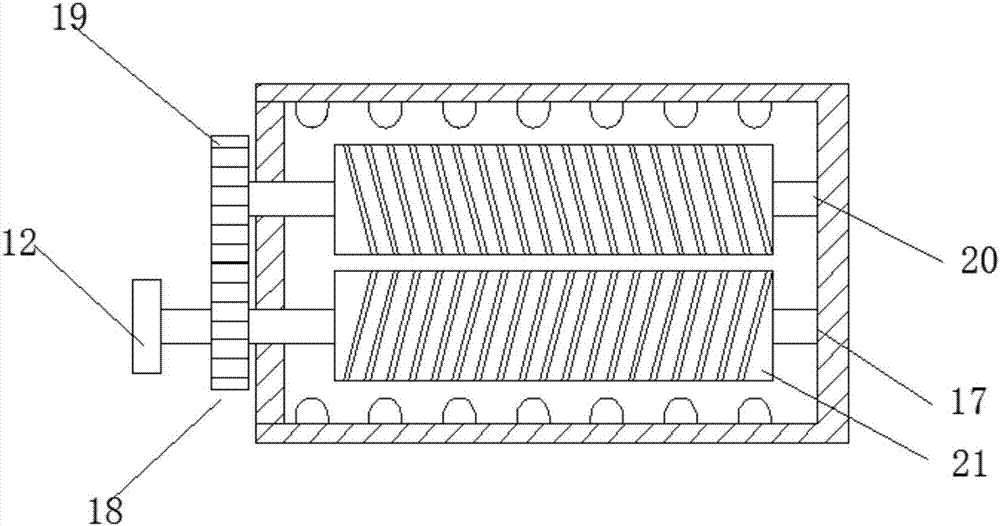

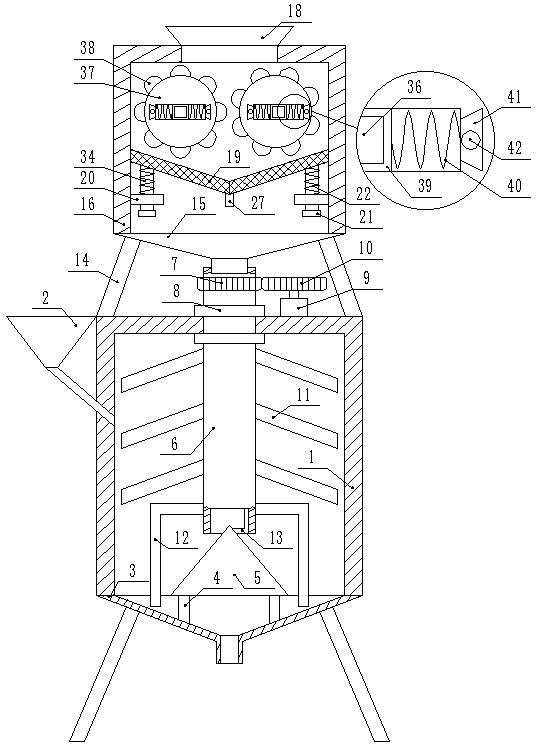

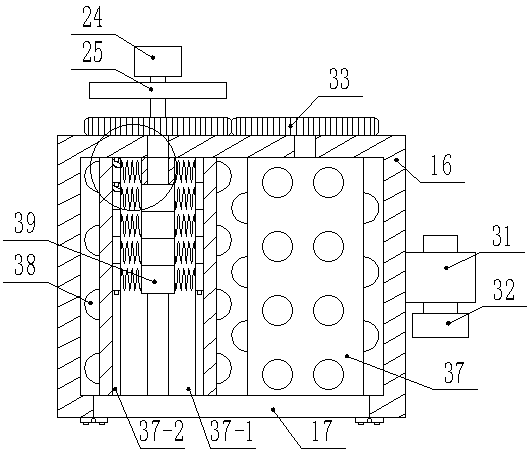

Integrated crushing and grinding equipment for cement raw material

InactiveCN108579983AEasy to addFully groundMixing operation control apparatusPretreatment controlEngineeringRaw material

The invention discloses integrated crushing and grinding equipment for a cement raw material, and aims to solve the problem of inconvenient raw material processing of a existing cement plant in the prior art. The integrated crushing and grinding equipment is technically characterized in that the integrated crushing and grinding equipment comprises a feeding hopper, a crushing mechanism, grinding balls, grinding pills and a tank body, wherein a grinding hopper and a filter plate are connected to the interior of the tank body and sequentially divide the interior of the tank body into a first grinding cavity, a second grinding cavity and a mixing cavity from top to bottom; hinged seats are fixed on side walls of a rotating shaft of the first grinding cavity and connected to one ends of connecting rods; the other ends of the connecting rods are connected to one ends of springs; the other ends of the springs are connected to the grinding balls; the grinding balls are propped against the inner wall of the grinding hopper; a pushing rod is fixedly connected to a rotating shaft in the second grinding cavity; the plurality of grinding pills are arranged in the second grinding cavity. The integrated crushing and grinding equipment has the advantages that the structure is stable, the crushing effect is good, it is guaranteed that a material is fully ground and processed, the grain sizes of the ground material are the same, and raw material production and processing by the cement plant are facilitated.

Owner:王少平

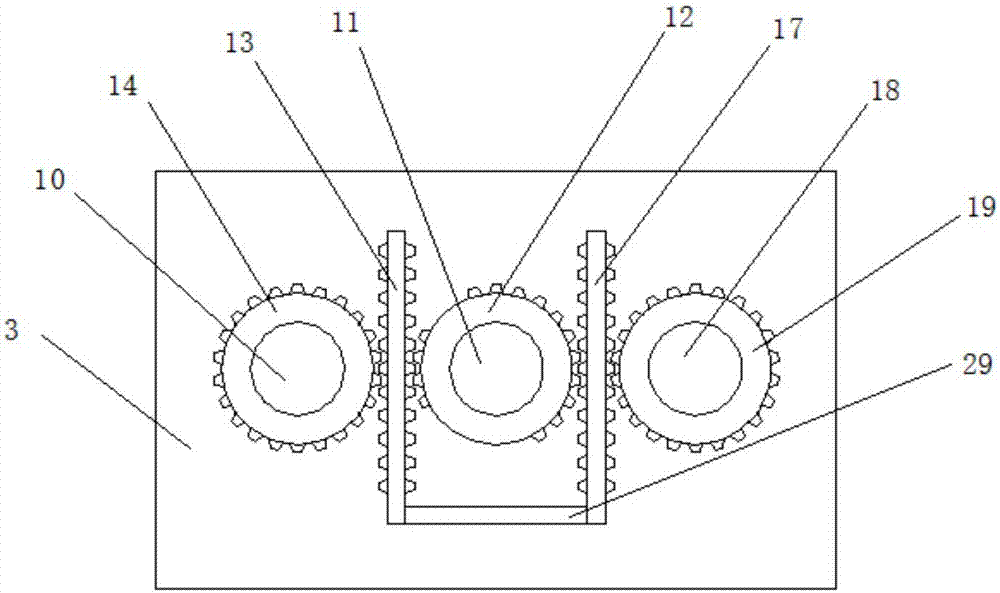

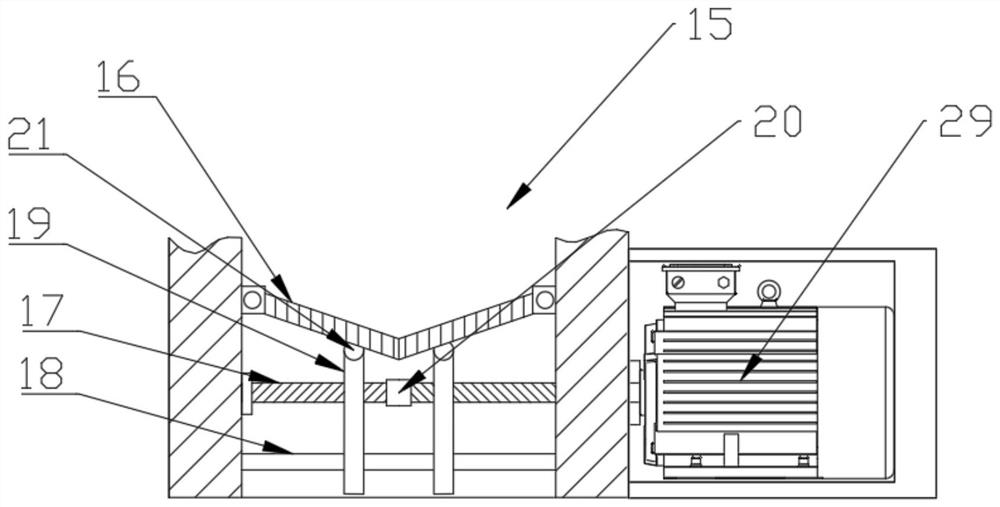

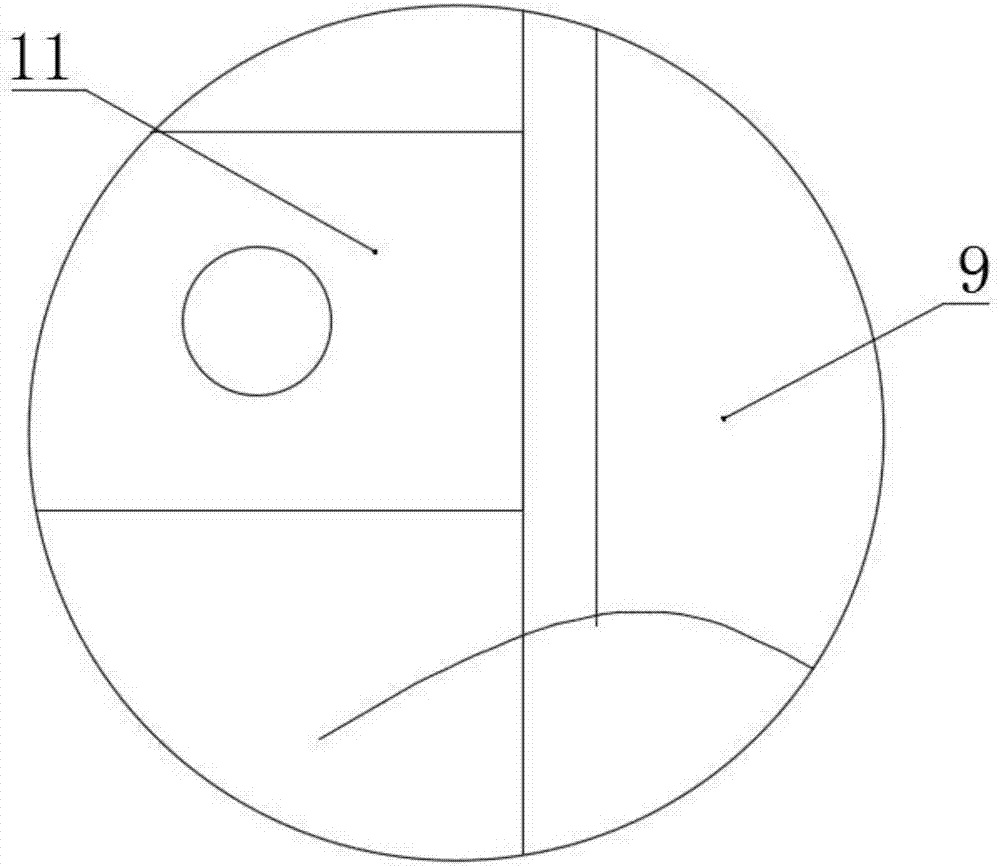

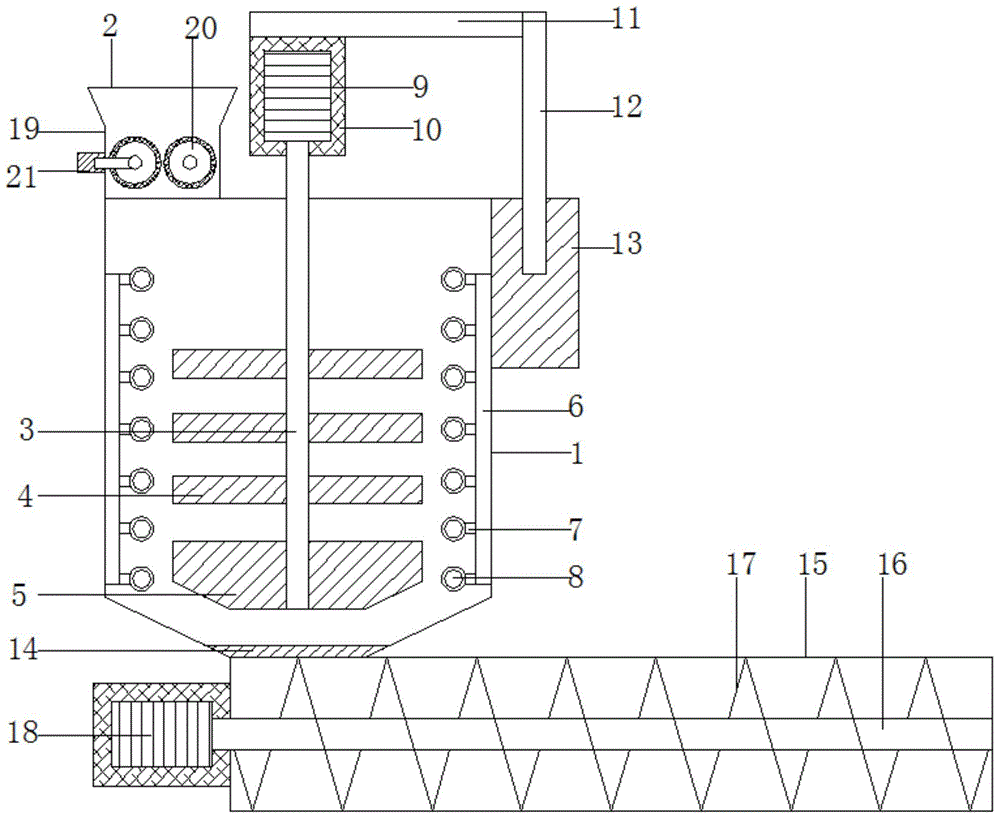

Swing-type concrete block crushing, mixing and stirring device

InactiveCN107336355AImprove processing efficiencyAffectMixing operation control apparatusPretreatment controlEngineeringDrive motor

The invention discloses a swing type concrete block crushing and mixing device, which comprises a bottom plate, a side plate, a top plate and a mixing drum. Double-sided rack and right double-sided rack, the mixing drum is provided with a rotating shaft coaxial with it, the top of the rotating shaft is provided with a left gear, the left gear meshes with the left double-sided rack, and the mixing drum A sieve plate is installed inside, and the sieve plate divides the mixing drum into a crushing chamber and a mixing chamber. A crushing rod is arranged on the shaft section of the rotating shaft in the crushing chamber and on the side wall of the crushing chamber, and a crushing rod is arranged on the crushing rod. The blade is provided with a mixing rod at the bottom of the rotating shaft in the mixing chamber. The invention has the advantages of simple structure, continuous crushing and mixing of concrete blocks, improved working efficiency, sufficient and uniform crushing and mixing, high mixing and crushing efficiency, simple operation and strong practicability.

Owner:CHANGSHA KEYUE ENTERPRISE MANAGEMENT CONSULTING CO LTD

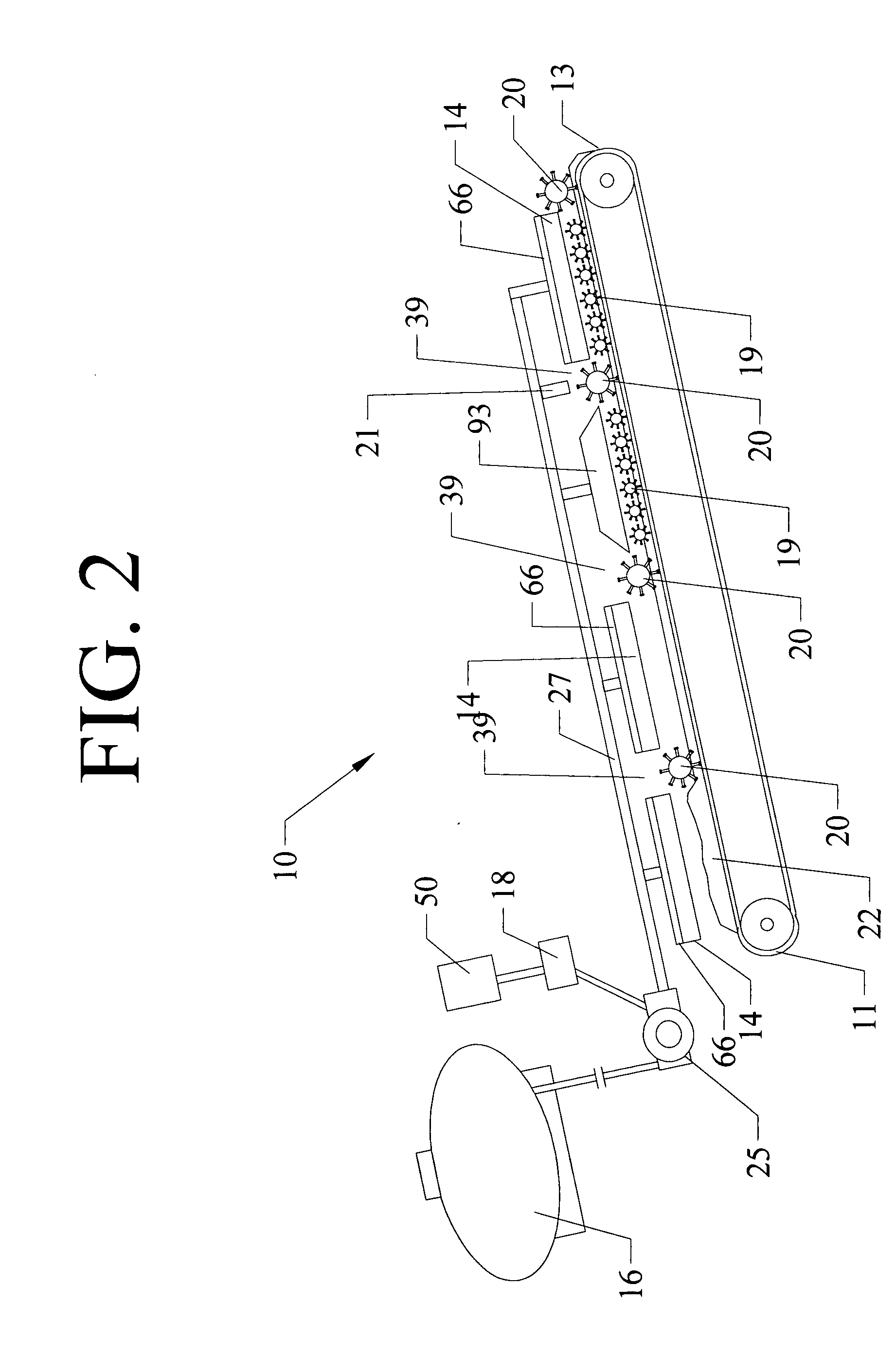

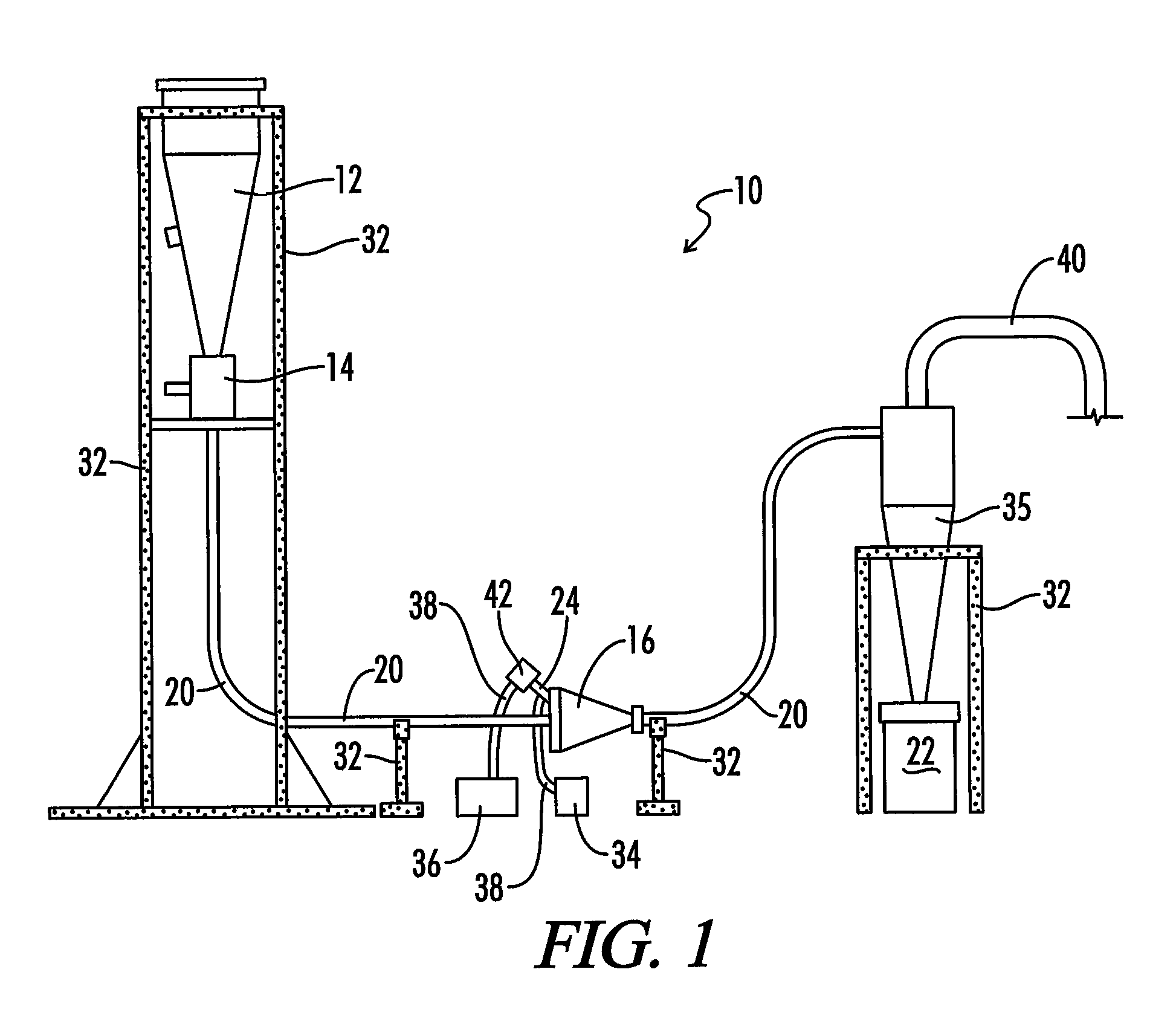

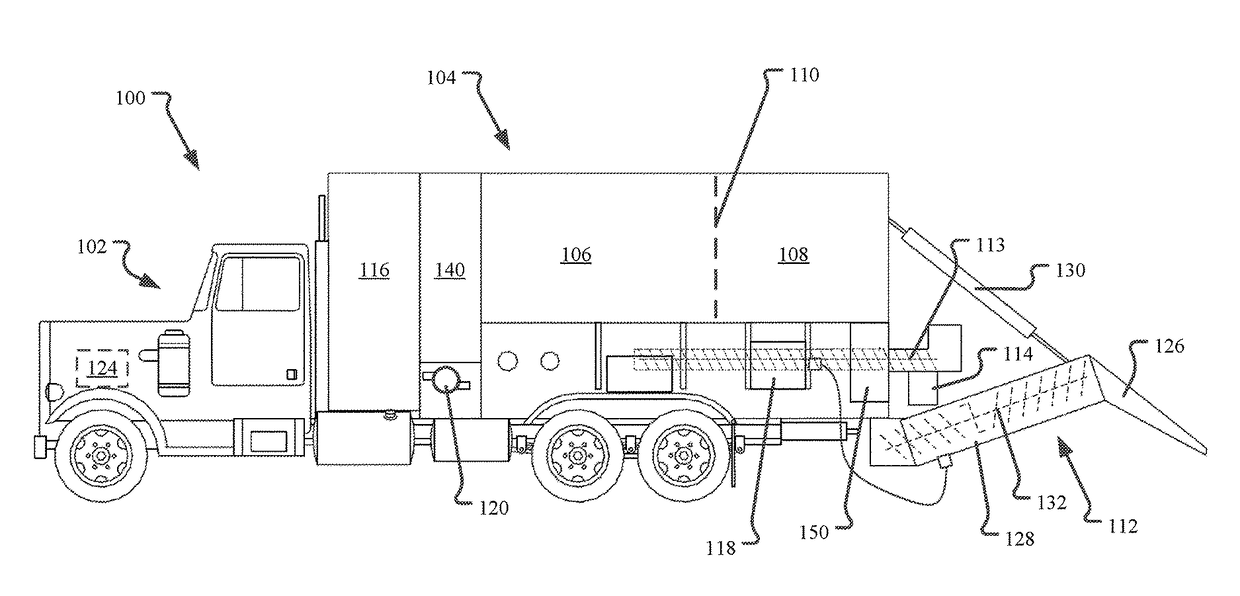

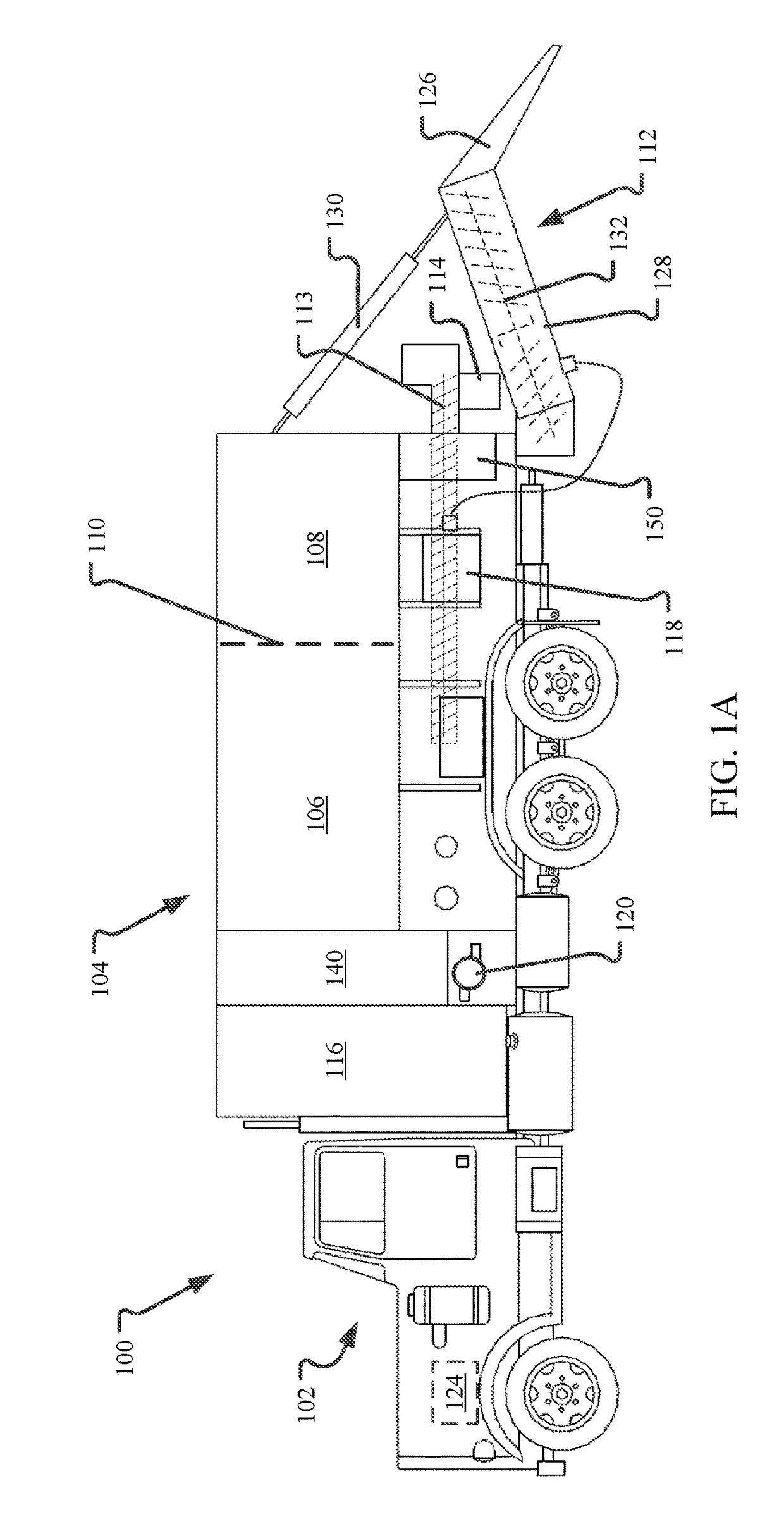

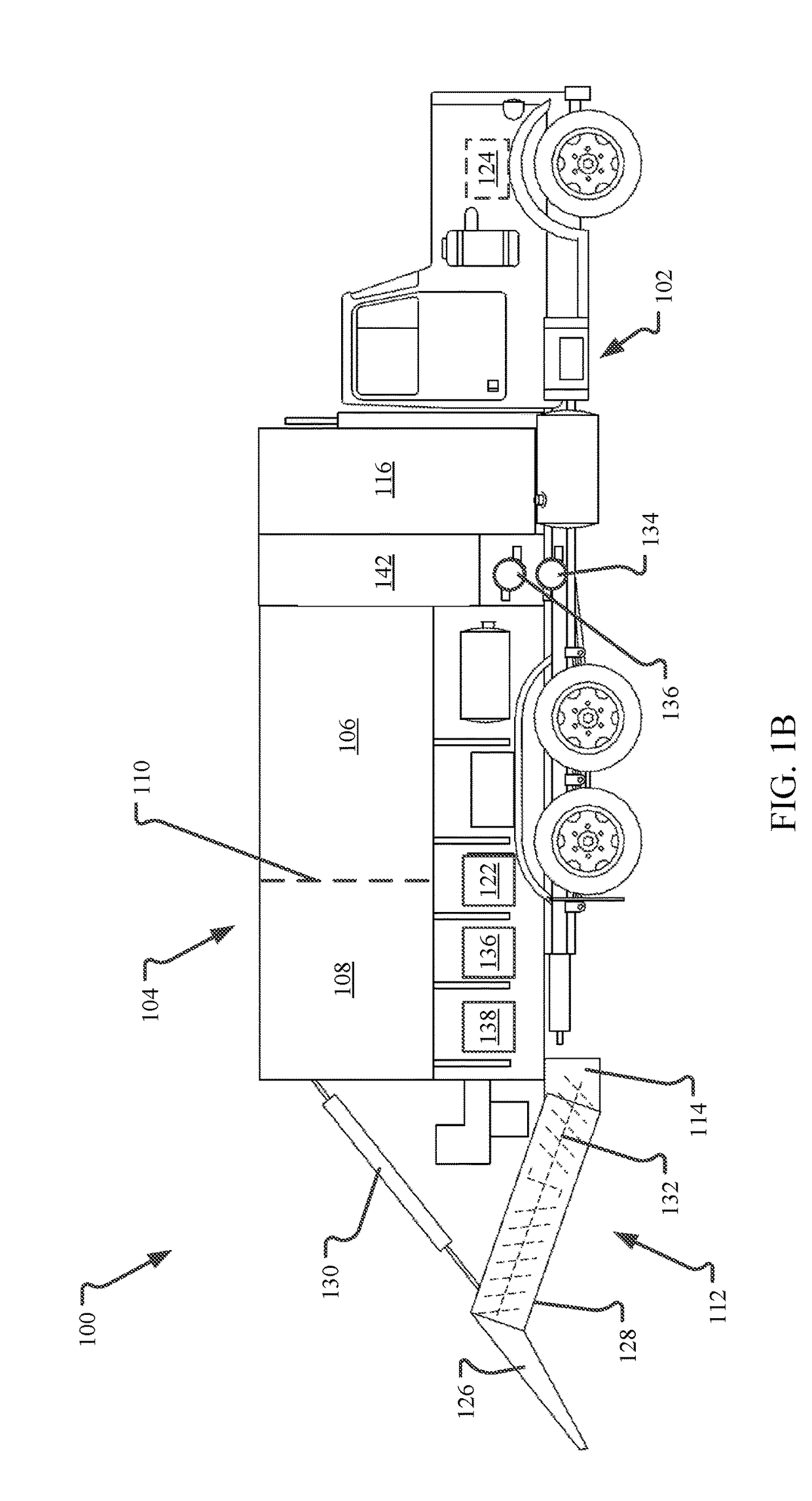

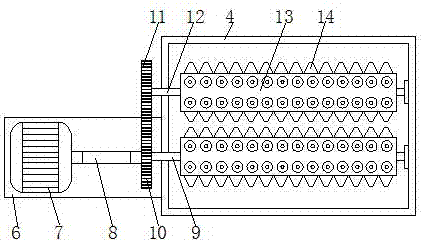

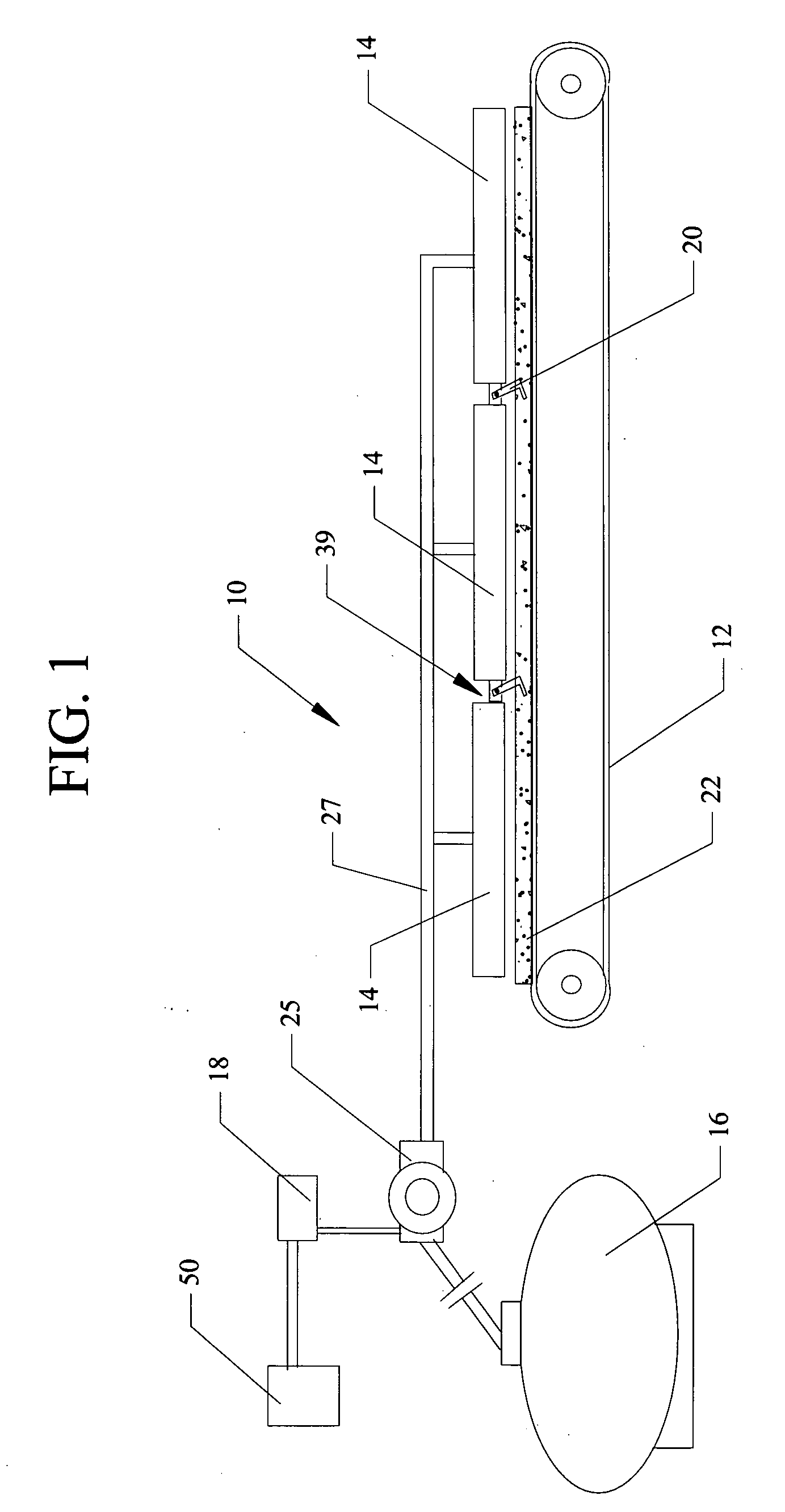

Aggregate pre-heating systemsand method

InactiveUS20110129296A1Improve accuracyImprove consistencyIn situ pavingsDrying solid materials with heatEngineeringConveyor belt

A portable system for heating aggregate material, especially reclaimed asphalt pavement (RAP), a portable system for producing asphalt, a portable system for continuously repaving roadway, and a method for continuously repaving roadway. Each system includes a conveyor belt, at least one infrared chamber disposed in substantially parallel relation to the conveyor belt at a distance sufficient to allow infrared heating of the aggregate material, a source of fuel, a fuel control in communication with the infrared chamber, and at least one mixer disposed between the infrared chamber and the conveyor belt and dimensioned and disposed relative to the conveyor belt so as to mix the aggregate material during heating and drying.

Owner:VAN VELSOR WESLEY

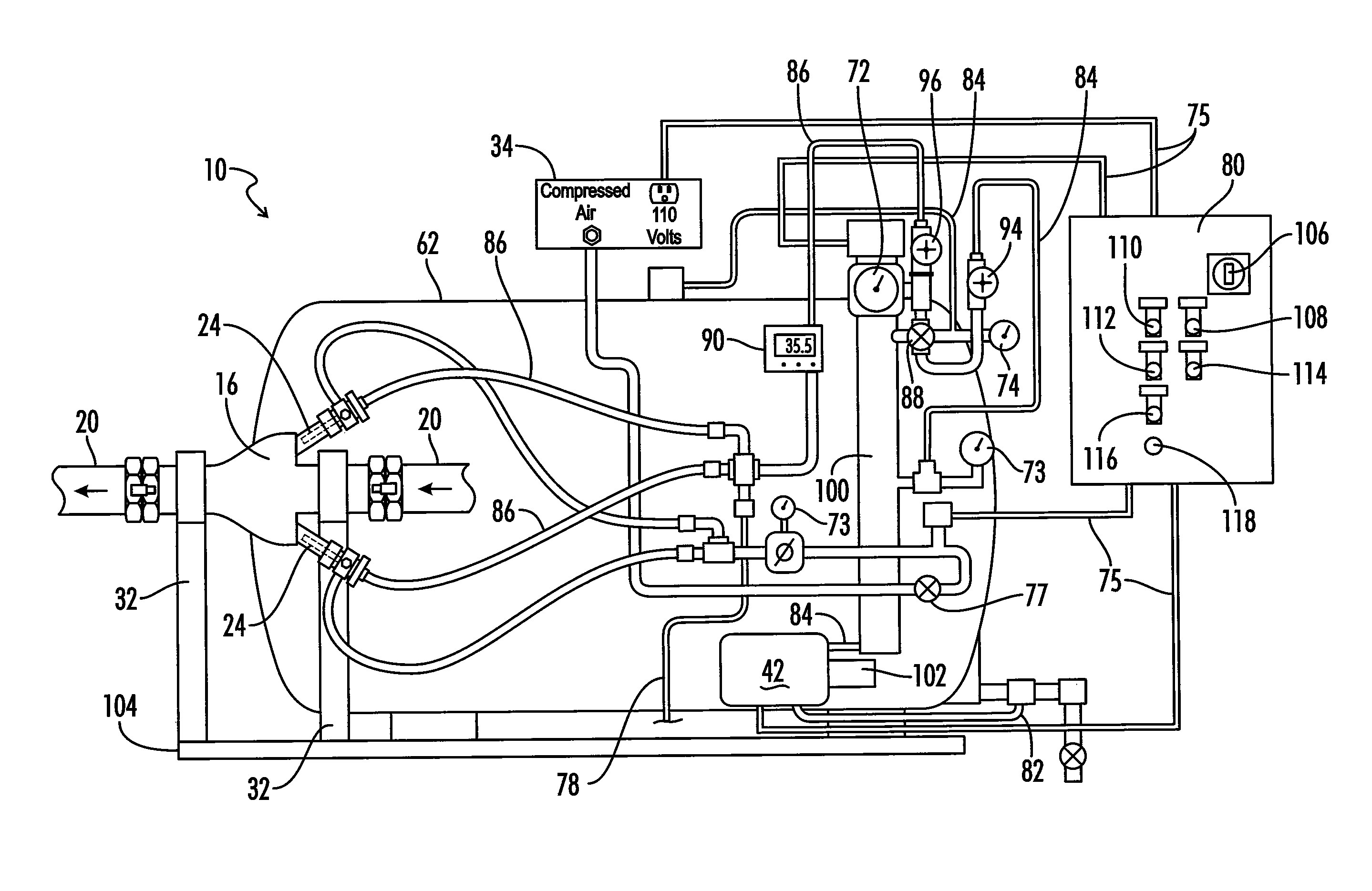

Fly ash treatment system and method of use thereof

ActiveUS7942566B1Sufficient rateQuickly and efficiently treatingSolid waste managementFlow mixersTruckFly ash

The present invention provides a system for treating fly ash and a method of use thereof. The system and method allow for the quick and consistent application of a chemical entity to fly ash so that the characteristics of the fly ash are changed in order to allow use of the fly ash in a new capacity. One specific example is the use of treated fly ash in concrete. The system disclosed herein may be used to treat fly ash as it is produced at a coal-burning power plant or as it is unloaded from a pneumatic truck.

Owner:WM CCP SOLUTIONS

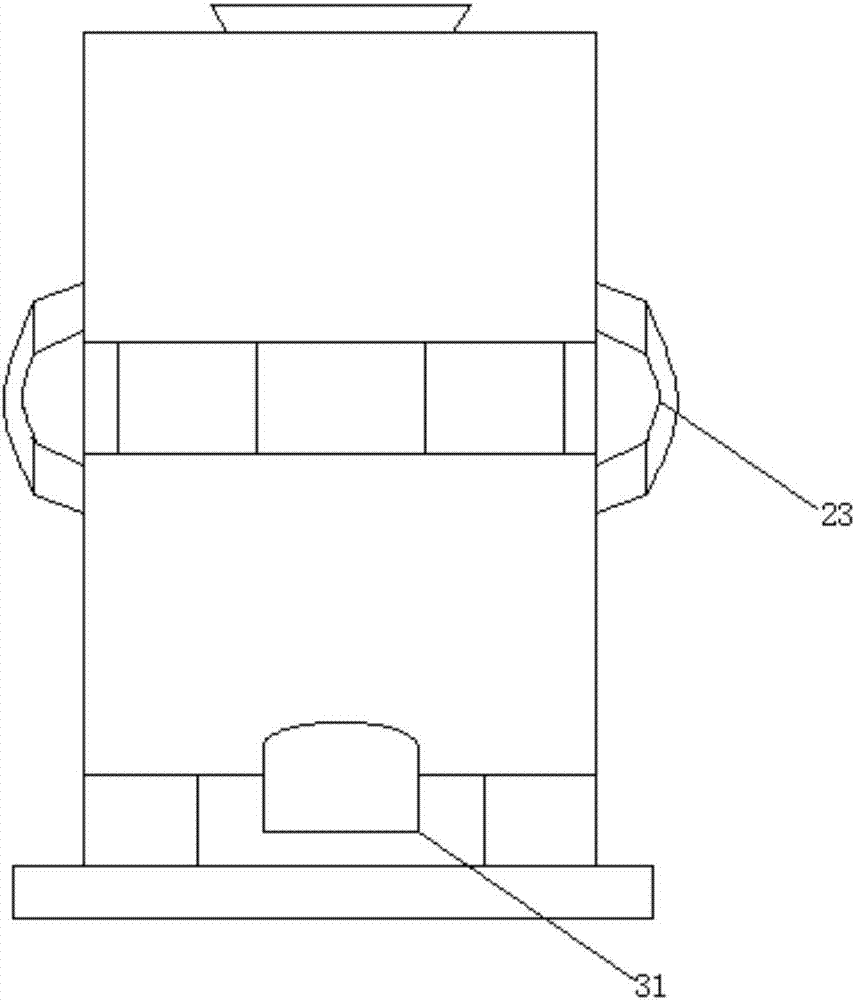

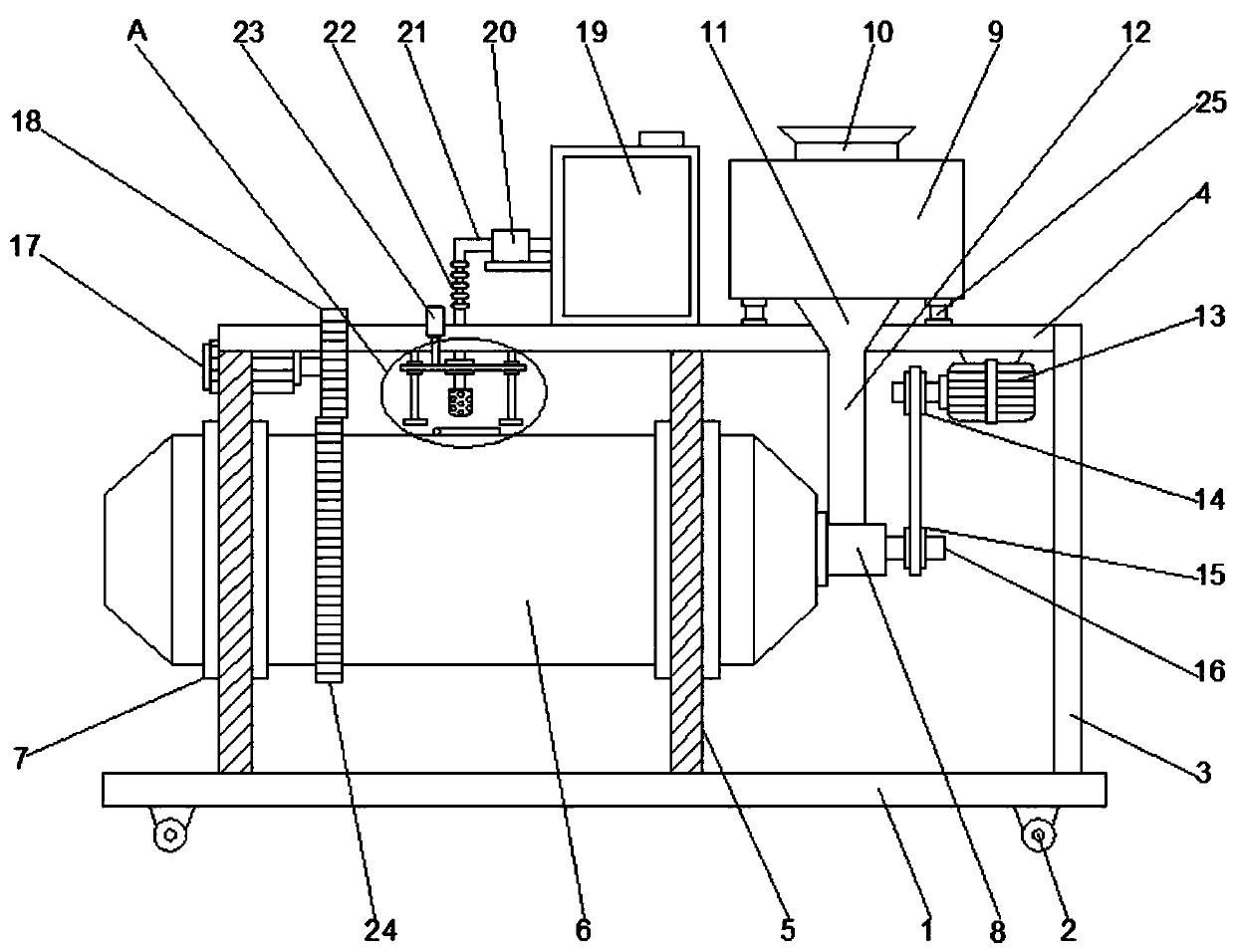

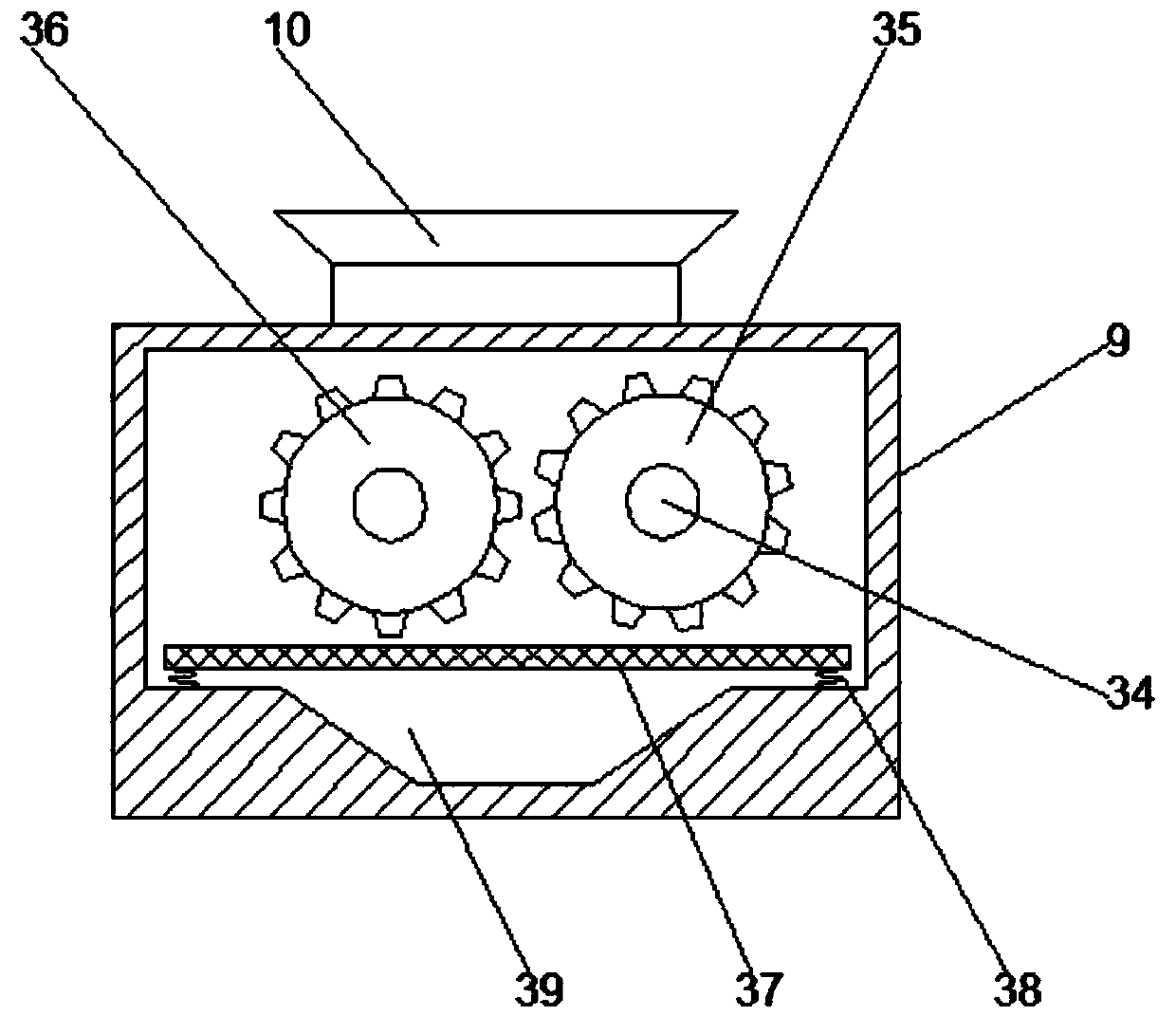

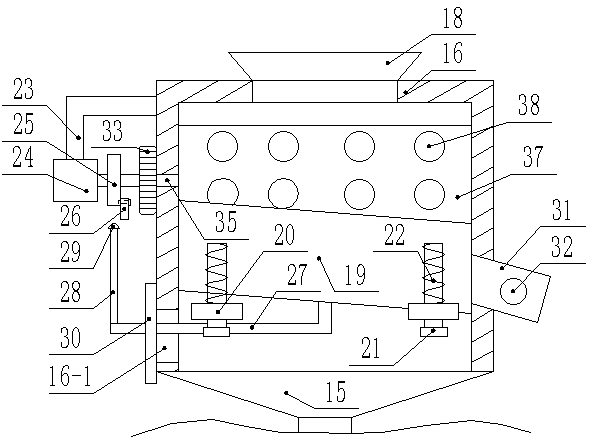

Crushing and stirring device for building cement

InactiveCN107297819AAvoid erectionImprove qualityMixing operation control apparatusPretreatment controlDrive wheelDrive shaft

The invention discloses a crushing and stirring device for building cement, which comprises a frame and a base. The frame includes a stirring box and a crushing box. The right end of the rotating shaft is equipped with a driving wheel, the middle position of the frame is horizontally provided with a first transmission shaft, the left end of the first transmission shaft is equipped with a primary driven wheel and a secondary driven wheel, and the driving wheel and the primary driven wheel They are connected by the first belt, the second transmission shaft and the third transmission shaft are horizontally arranged in the crushing box, the second transmission shaft and the third transmission shaft are horizontally parallel, and the left end of the second transmission shaft is installed with The third-stage driven wheel, the second-stage driven wheel and the third-stage driven wheel are connected through the second belt; the beneficial effect of the present invention is: the transmission structure of the belt and the gear is utilized, the working motor is reduced, and the operation safety is improved , fully milled and crushed to improve the quality of the material.

Owner:黄瀚

Self-cleaning type concrete stirring equipment for building

InactiveCN110228138AQuality improvementStir wellMixing operation control apparatusHollow article cleaningEngineeringCushion

The invention discloses self-cleaning type concrete stirring equipment for building. The self-cleaning type concrete stirring equipment comprises a base, moving wheels and a stand column, the four moving wheels are arranged at the bottom of the base, the four moving wheels are uniformly distributed in a rectangular shape, the stand column is arranged on the right side of the upper surface of the base, a top plate is arranged at the top end of the stand column, the upper surface of the top plate is correspondingly provided with a crushing box and a water tank, the four corners of the bottom ofthe crushing box are connected with the upper surface of the top plate through damping cushions, and a feeding port is formed in the top end of the crushing box. During use, sand and stones are throwninto the feeding port, a third motor is started, so that a first crushing roller and a second crushing roller rotate to crush the sand and stones, the crushed sand and stones fall on a screen, the qualified sand and stones can pass through the screen to fall into a material guiding groove, and can pass through a discharging pipe to enter a feeding pipe, due to the fact that vibrating springs arearranged at the bottom of the screen, the unqualified sand and stones can be bounced up by the vibration power to be continuously crushed.

Owner:史海军

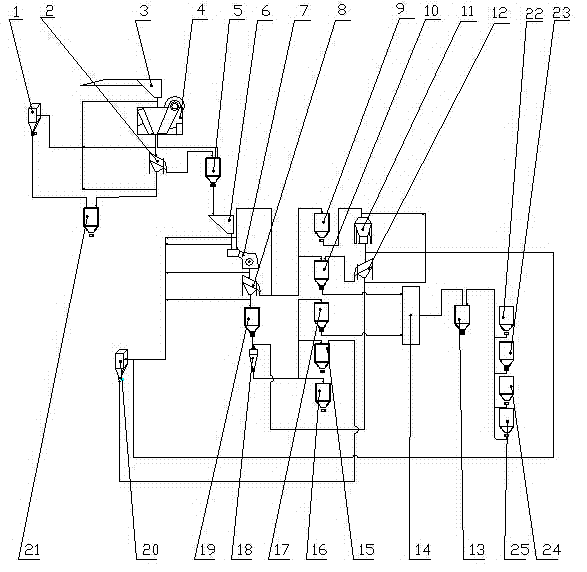

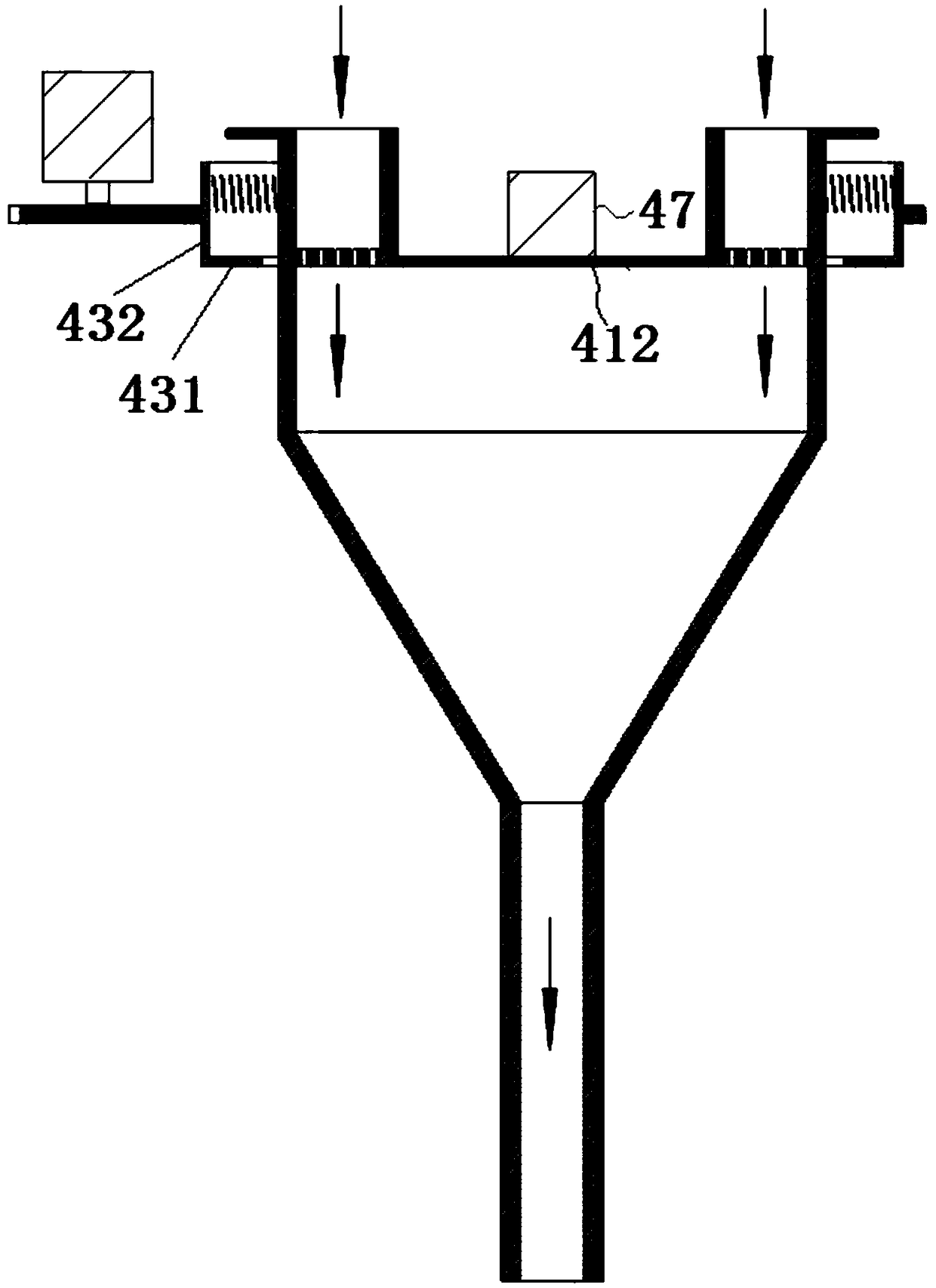

Aggregate and concrete production equipment and aggregate and concrete production process

ActiveCN104493980AKeep healthyMixing operation control apparatusPretreatment controlLow voltageControl signal

The invention discloses aggregate and concrete production equipment. The aggregate and concrete production equipment comprises a DCS central control system which is used for controlling an earth material low-voltage pulse dust collator, an earth sieve, a jaw crusher feeder, a jaw crusher, a buffer bin, an impact crusher feeder, an impact crusher, a circular vibrating sieve, a sand making storage bin, a finished product bin, a sand making machine, a circular finished product vibrating sieve, a stirring station, a material distributing bin, a fine powder bin, a medium powder bin, a sand bin, a V selector, a mixing bin, a low-voltage powder pulse dust collector, an earth bin, a sealing carrying belt, a field meter, a cement bin, a mineral powder bin, a coal ash bin, an additive bin and a water tank through a control signal. An aggregate and concrete production process comprises the following processes: a crushing process by adopting the jaw crusher; a crushing process by adopting the impact crusher; a sorting process by adopting the circular vibrating sieve; a sand making process; a centralized dust collecting process; and a finished product conveying and loading process. The aggregate and concrete production equipment and the aggregate and concrete production process have the advantages that dust during full-automatic sealing production is little, the environment is protected and the harm on body health is avoided.

Owner:山东连银山环保建材有限公司

Volumetric mobile powder mixer

ActiveUS20170080601A1Transportation and packagingMixing operation control apparatusSolid componentEngineering

This disclosure describes volumetric mobile powder mixer (VMPM) systems and methods for VMPM operation and use. The VMPM is providing with a number of storage compartments (or bins) for liquid or solid ingredients including at least one powder storage bin, a powder transport system, a dust handling system, a solid / liquid mixing system, a cellular foam generator, a product delivery system, and a controller capable of monitoring the delivery and mixing of each of the ingredients, as well as the discharge of the final product. The controller determines if the proper mixture is being discharged by the VMPM and, if not, alerts the VMPM operator. In an automated embodiment, the VMPM controller is also configured to independently control the delivery and mixing of each of the ingredients, as well as the delivery of the final product.

Owner:EAGLE STRONG INVESTMENTS LLC

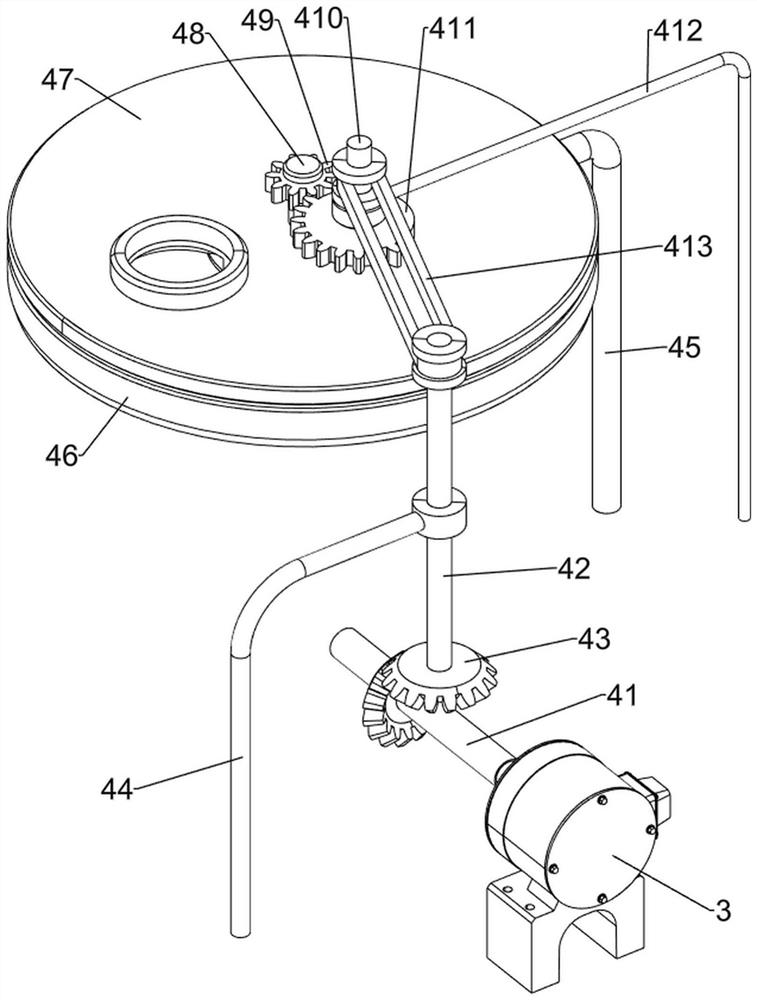

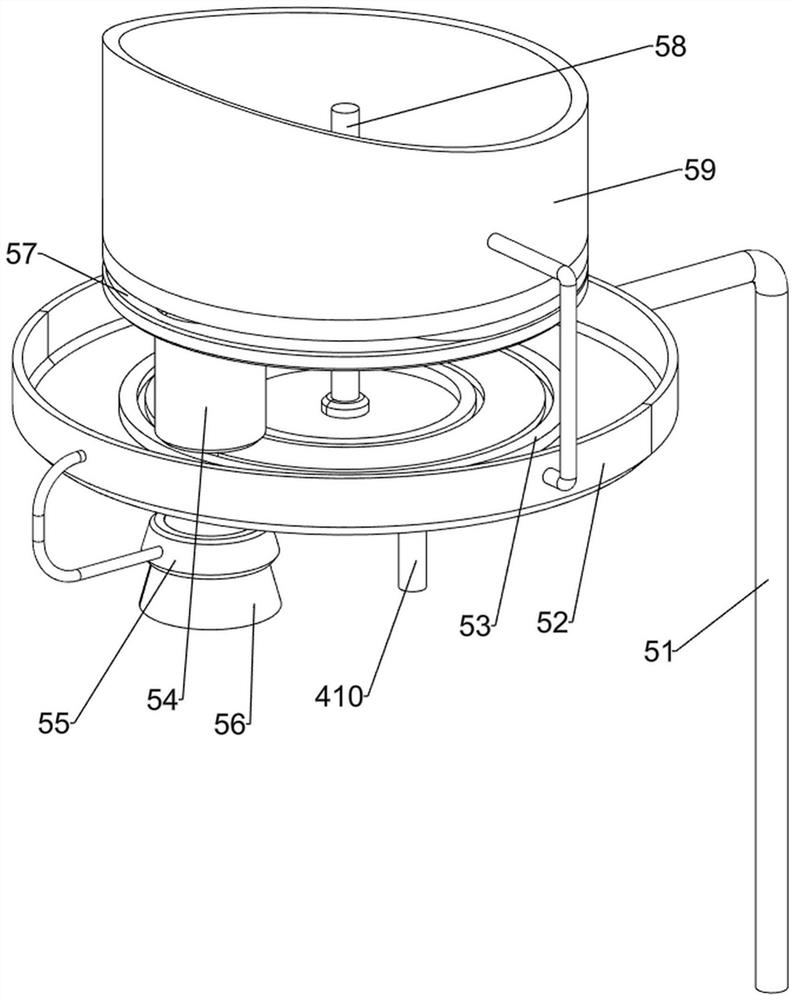

Mixing device facilitating discharging for concrete processing

PendingCN111844449ARealize quantitative nestingPrevent overflowDischarging apparatusMixing operation control apparatusGear wheelElectric machinery

The invention discloses a mixing device facilitating discharging for concrete processing. The mixing device comprises a stirring tank, a driving mechanism is arranged at the top of the stirring tank,feeding channels are symmetrically formed in the positions, located on the two sides of the driving mechanism, of the top of the stirring tank, a discharging channel is formed in the bottom of the stirring tank, and a discharging mechanism is arranged in the discharging channel. According to the mixing device, through arranging the driving mechanism, when a motor rotates, a first gear is meshed with a second gear, so that a first rotating shaft rotates, a first bevel gear is meshed with a second bevel gear, a third rotating shaft rotates, and a guide rod is matched, so that a concrete raw material is smoothly guided into the stirring tank; and through arranging the discharging mechanism, a first annunciator and a second annunciator, quantitative discharging of the mixing device is achieved, the situation that concrete overflows out of a hopper due to misoperation of workers is avoided, resources are saved, and the working intensity of the workers is reduced.

Owner:夏梅

Concrete slurry stirring and processing device for bridge construction

InactiveCN107322800AHeating up fastHigh activityMixing operation control apparatusPretreatment controlBlade plateSlurry

The invention discloses a concrete slurry mixing and processing equipment for bridge construction, which comprises a mixing shell, the outer wall of the mixing shell is provided with a heating coil arranged in a spiral shape, and the inside of the mixing shaft is provided with a Hollow structure and several small spraying holes are opened on the outer wall of the shaft body, a flow control switch and a small water pump are installed on the body of the water delivery pipeline, and plate-type stirring blades are respectively arranged on both sides of the upper and lower shaft body of the mixing shaft And the spiral mixing blade, the end of the horizontal support rod is equipped with a strip scraper, the upper part of the mixing shell is also fixedly equipped with a premix conveyor, and the lower end of the hydraulic telescopic rod is equipped with a universal roller through a connecting sleeve. The invention can achieve rapid temperature rise, realize automatic cleaning of the inner cavity after work, fully stir, improve the mixing effect of subsequent materials, facilitate moving and positioning, and save time and effort.

Owner:童贤波

Concrete mixer for building

InactiveCN109676789AReduce generationProtect healthMixing operation control apparatusPretreatment controlEngineeringAtmospheric pressure

The invention provides a concrete mixer for a building, and relates to the technical field of building machines. The concrete mixer for the building comprises a mixing box, two supports are fixedly arranged on the top of the mixing box, according to the concrete mixer for the building, through an exhaust fan, a dust suction pipe, an air suction cover, a filter net and an air outlet pipe, when a person puts concrete burdening from a feeding hopper or carries out mixing work, the exhaust fan pumps out dusty air in the mixing box through the dust suction pipe, due to the fact that the air pressure in the mixing box is smaller than the air pressure outside the stirring box, air outside the mixing box carries out dust on the periphery of the mixing box and enters the mixing box from the feedinghopper, meanwhile, through a water pump, a water inlet pipe, a water outlet pipe, a spraying disc and nozzles, the water pump sprays exterior air to the interior of the mixing box through the nozzles, and dust is settled. In conclusion, according to the concrete mixer for the building, in the mixing work process, generated dust is greatly reduced, and the health of a person can be conveniently ensured.

Owner:扬州程航机械制造有限公司

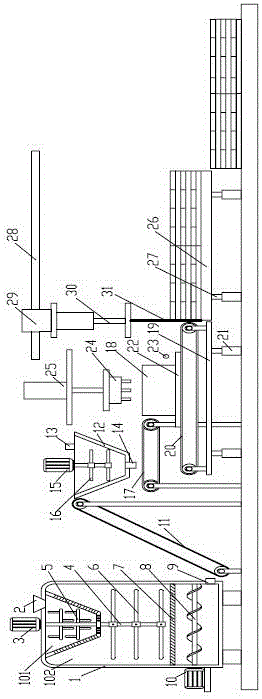

Construction material molding production line

InactiveCN106827220ATake advantage ofReduce pollutionDischarging arrangementDischarging apparatusProduction lineEngineering

The invention relates to a building material molding production line, which includes a feeding unit, a molding unit and a feeding unit; the feeding unit includes a crushing mechanism, a first conveying mechanism, a mixing mechanism and a second conveying mechanism; the crushing mechanism is located in the first conveying mechanism At the feed end, the mixing mechanism is located at the discharge end of the first conveying mechanism, and the second conveying mechanism is located at the discharge end of the mixing mechanism; the forming unit includes a forming box, a third conveying mechanism, a supporting platform, a first cylinder, a supporting plate, an infrared A sensor, a die head and a second cylinder; the blanking unit includes a blanking platform, a third cylinder, a slideway mechanism, a slide, a driving mechanism, a fourth cylinder and a blanking plate. The building material molding production line proposed by the present invention reduces the amount of soil and environmental pollution, and can realize automatic loading and unloading during the production process, with small human intervention factors in the process, low labor intensity, strong continuity, high processing efficiency, and automation High degree.

Owner:和县圣大新型建筑材料有限责任公司

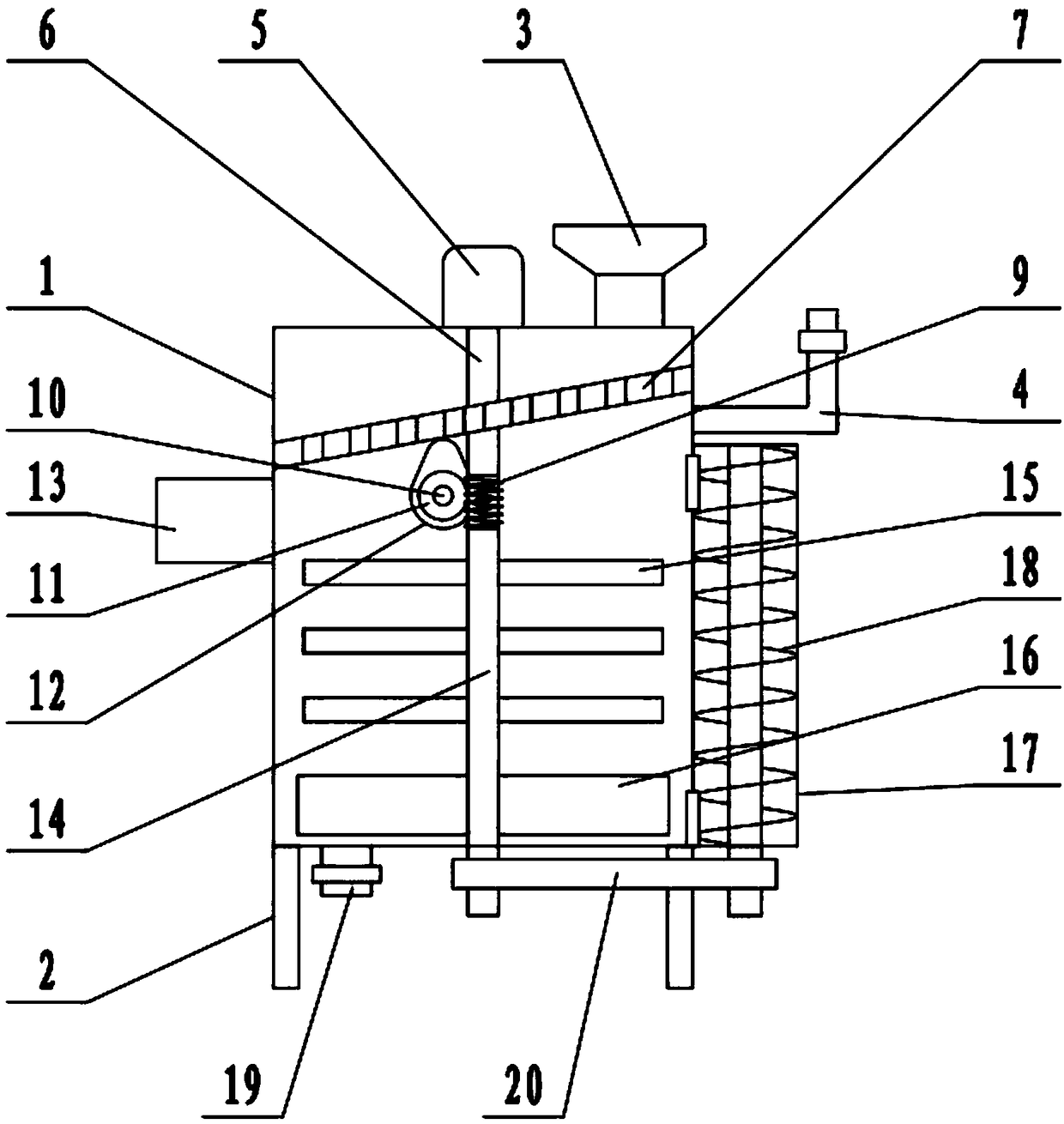

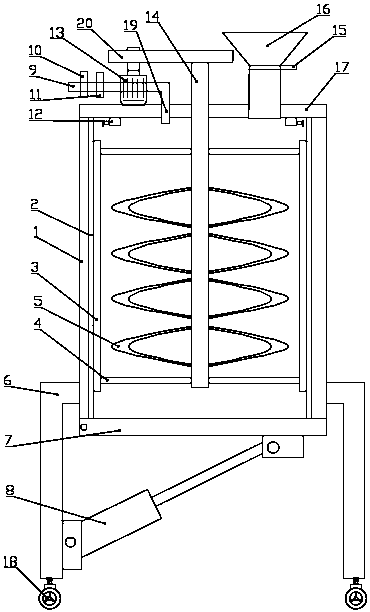

Stirring device for building construction

InactiveCN110861214AStir wellQuality improvementSievingScreeningRotational axisArchitectural engineering

The invention discloses a stirring device for building construction. The stirring device for building construction comprises a stirring barrel, the top end of a crushing barrel fixedly communicates with a feeding pipe, the two side walls of a barrel body are symmetrically and fixedly connected with second springs, two dovetail grooves are located on the two sides of a second through groove and communicate with the second through groove, a plurality of dovetail blocks are arranged in each dovetail groove in a attached and sliding mode, the other ends of the second springs are fixedly connectedwith the side walls of the dovetail blocks, one sides of the dovetail blocks are provided with blind holes, the other sides of the dovetail blocks are fixedly connected with inserting rods matched with the blind holes, the inserting rods are made of a Fe3O4 material, a first rotating shaft and a second rotating shaft are connected in a welded mode, and the model of a three-phase asynchronous motoris Y2-80M2-4S150. The device is diversified in function and high in practicability, concrete can be fully stirred and then can be uniformly mixed, the quality of the finished product is improved, stones with different hardness can be crushed and screened according to different requirements, so that the utilization rate of the stones is improved, then the quality of the concrete is indirectly improved, the labor intensity is reduced, and the building use requirement is met.

Owner:ZHEJIANG COLLEGE OF CONSTR

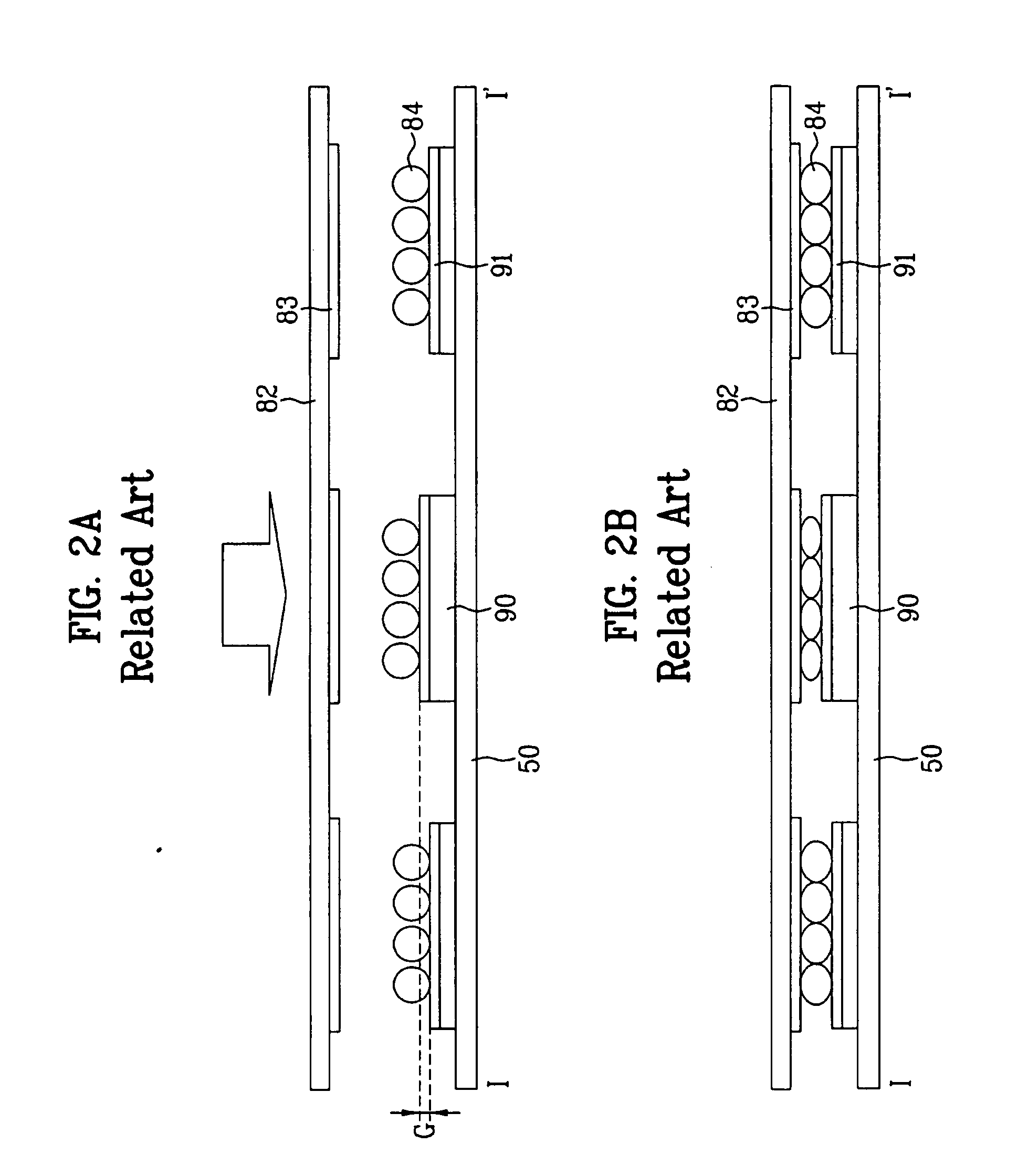

Chip on glass type liquid crystal display device and method for fabricating the same

ActiveUS20050243234A1Prevent abnormal contactSolid-state devicesPretreatment controlAdhesiveEngineering

A chip on glass type liquid crystal display device and a method for fabricating the same are provided in which a surface of a pad electrode for attaching a flexible printed circuit film is embossed to increase an adhesive force between a pad electrode and a flexible printed circuit film, thereby ensuring contact between the pad electrode and the flexible printed circuit film. Unit pixels in an active region contain thin film transistors formed at intersections of gate lines and data lines. A pad electrode is formed in an inactive region. An embossing pattern is formed on the pad electrode. An adhesive is provided on the pad electrode including the embossing pattern and an external drive circuit part is connected to the pad electrode by the adhesive.

Owner:LG DISPLAY CO LTD

Concrete mixing and stirring device capable of mixing uniformly

InactiveCN106863605AWell mixedAvoid stickingMixing operation control apparatusPretreatment controlGear wheelEngineering

The invention discloses a uniformly mixed concrete mixing and stirring device, which comprises a bottom plate, the upper surface of the bottom plate is fixedly connected with a vertical plate, and one side of the vertical plate is fixedly connected with a feeding box through a connecting plate, and the feeding A feeding sleeve is sleeved in the opening opened on the top of the box, and one side of the feeding box is fixedly connected with a motor through a carrier plate, and the output end of the motor is fixedly connected with one end of the first U-shaped rod. The other end of the U-shaped rod is fixedly connected with one end of the driving rotating rod, and the driving gear is sleeved on the driving rotating rod. In the present invention, through the improvement of the rolling roller and the use of the toggle lever, when the motor drives the rolling roller to rotate through the driving gear and the driven gear, the sand and cement can be rolled through the toggle lever arranged on it. Thereby, it is possible to prevent sandstone and concrete from being bonded together, and when the stirring rod rotates, it can drive the telescopic rod to rotate, so that the scraper can scratch the inside of the mixing box.

Owner:章德昌

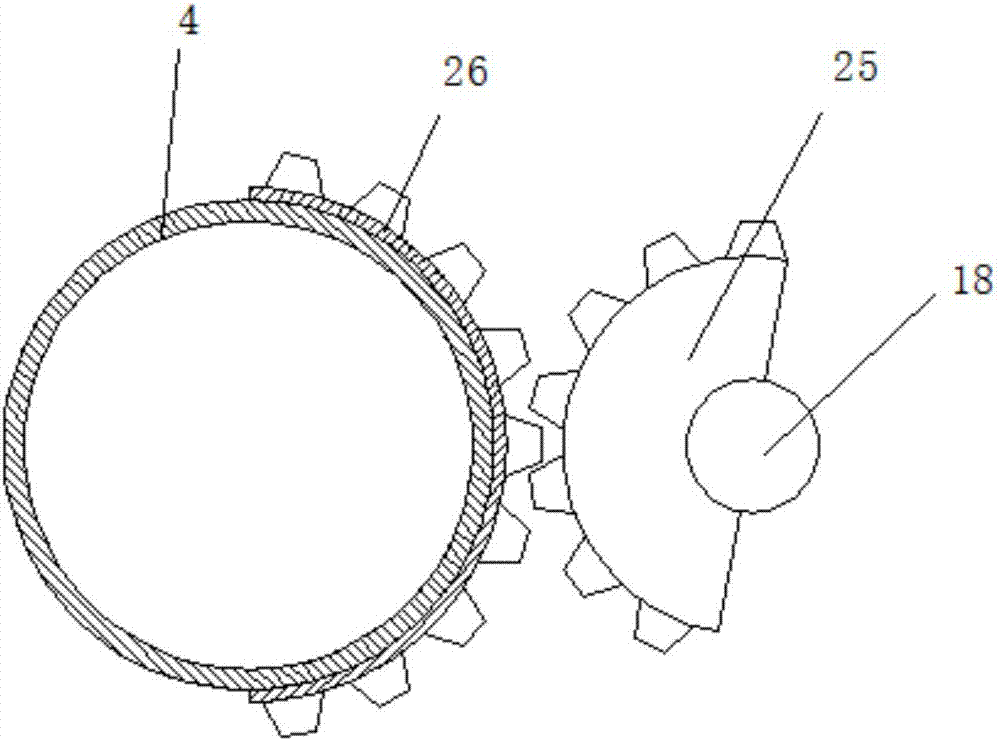

Full-automatic concrete mixing equipment capable of realizing proportioning

InactiveCN111702952AScientific and reasonable structureEasy to useMixing operation control apparatusPretreatment controlElectric machineGear wheel

The invention discloses full-automatic concrete mixing equipment capable of realizing proportioning. The full-automatic concrete mixing equipment is characterized in that a bottom frame is fixedly connected to the bottom end of a mixing drum, a discharging opening is fixedly connected to the position, corresponding to the top of the bottom frame, of the outer end of the mixing drum, a gravel feeding mechanism is fixedly connected to one side of the top end of the mixing drum, the other side of the top end of the mixing drum is fixedly connected with a cement feeding mechanism, the side edge ofthe outer end of the mixing drum is fixedly connected with a water control mechanism, and a stirring mechanism is embedded inside the mixing drum. The equipment is scientific and reasonable in structure and safe and convenient to use; the gravel feeding mechanism is arranged, a rotating motor drives first rotating rods to rotate, and through cooperation of transmission gears, two first rotating rods drive two rough grinding rollers to rotate together to crush gravel, and meanwhile, through belt transmission, the two first rotating rods drive the two second rotating rods to rotate together, sothat the two fine grinding rollers are driven to rotate, and the gravel and cement mixing effect is improved.

Owner:李彦红

Small concrete mixer with screening function

The invention discloses a small concrete mixer with a screening function. The small concrete mixer comprises a tank body, stabilizer blades, a feeding opening, a water inlet pipe, stirring rods and adischarging opening; a motor is fixedly connected to the upper surface of the tank body, an upper rotating shaft is fixedly connected to the shaft extending end of the motor, a screening plate is arranged inside the tank body, a worm is fixedly connected to the lower end of the upper rotating shaft, a driven shaft is arranged on the left side of the worm and is sleeved with a worm gear and a cam,and a lower rotating shaft is fixedly connected to the lower end of the worm; the multiple stirring rods are distributed on the lower rotating shaft, a circulation barrel is fixedly connected to the right side wall of the tank body, the screening plate is used for screening concrete aggregate, impurities like dinas in large size cannot pass through the screening plate, the impurities in large sizeare removed, and the concrete grout quality is guaranteed; the screening plate vibrates up and down, concrete raw materials are screened, and the screening efficiency is improved; and the stirring rods are used for stirring concrete, a scraping plate is used for pushing the concrete grout into the circulating barrel through the circulated feeding opening, and the stirring efficiency is improved.

Owner:COMMON TECH DEV CO LTD

Ceramic production raw material grinding treatment equipment

InactiveCN112452427ARealize the effect of grinding treatmentRealize the effect of automatic feedingMixing operation control apparatusPretreatment controlGear wheelElectric machinery

The invention discloses ceramic production raw material grinding treatment equipment. The ceramic production raw material grinding treatment equipment comprises a bottom plate, a motor, a grinding mechanism and a discharging mechanism, wherein a workbench is arranged on the bottom plate; the motor is arranged on the bottom plate, the grinding mechanism is arranged on the bottom plate, and the grinding mechanism is connected with an output shaft of the motor; and the discharging mechanism is arranged on the bottom plate, and the discharging mechanism is connected with the grinding mechanism. According to the ceramic production raw material grinding treatment equipment, a first incomplete gear is intermittently engaged with a first spur gear, so that the first spur gear intermittently rotates to drive a third rotating shaft to rotate, the third rotating shaft drives a grinding plate to rotate, and the effect that the grinding plate grinds mixed production raw materials in a discharging plate is achieved; the grinding mechanism drives the discharging mechanism to operate, and the effect of automatic discharging of the mixed production raw materials is achieved; and two second water pipes are driven to rotate through a first rotating shaft and a seventh rotating shaft, then mud mixing rods are driven to rotate, the mud mixing rods can uniformly stir raw material powder sprayed by water in a mud mixing box, and the mud mixing effect is achieved.

Owner:李伟

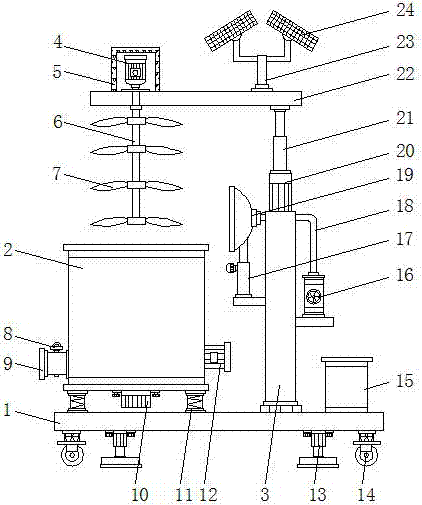

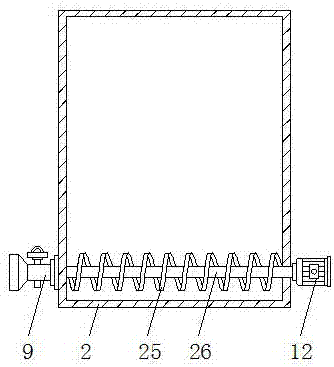

Concrete stirring device for building construction

InactiveCN107379256AEffective absorption and removalAvoid pollutionDischarging apparatusMixing operation control apparatusArchitectural engineeringSolar cell

The invention discloses a concrete stirring device for building construction. The concrete stirring device comprises a base, a stirring barrel and a supporting cross beam; rolling wheels are installed at the four corners of the bottom of the base, the stirring barrel and a supporting column are arranged on the top of the base, a dust collector is installed on the side wall of the supporting column, and a dust collection hood is connected to the dust collector through a dust collection pipe; an electric cylinder is installed at the top end of the supporting column and connected with the supporting cross beam through a ball screw, the supporting cross beam is provided with a stirring motor and a support frame, and solar cell panels are installed at the top end of the support frame. According to the concrete stirring device for building construction, flying dust generated in the stirring process can be effectively sucked and removed, and the condition that the flying dust floats around to pollute the environment is avoided; solar energy in the environment can be utilized to provide electric energy for running of the whole device through the solar cell panels installed on the support frame, and energy conservation and environment protection are achieved; in addition, materials can be automatically conveyed out when discharging is conducted, manual operation is not needed, and therefore the labor intensity is greatly reduced.

Owner:唐云龙

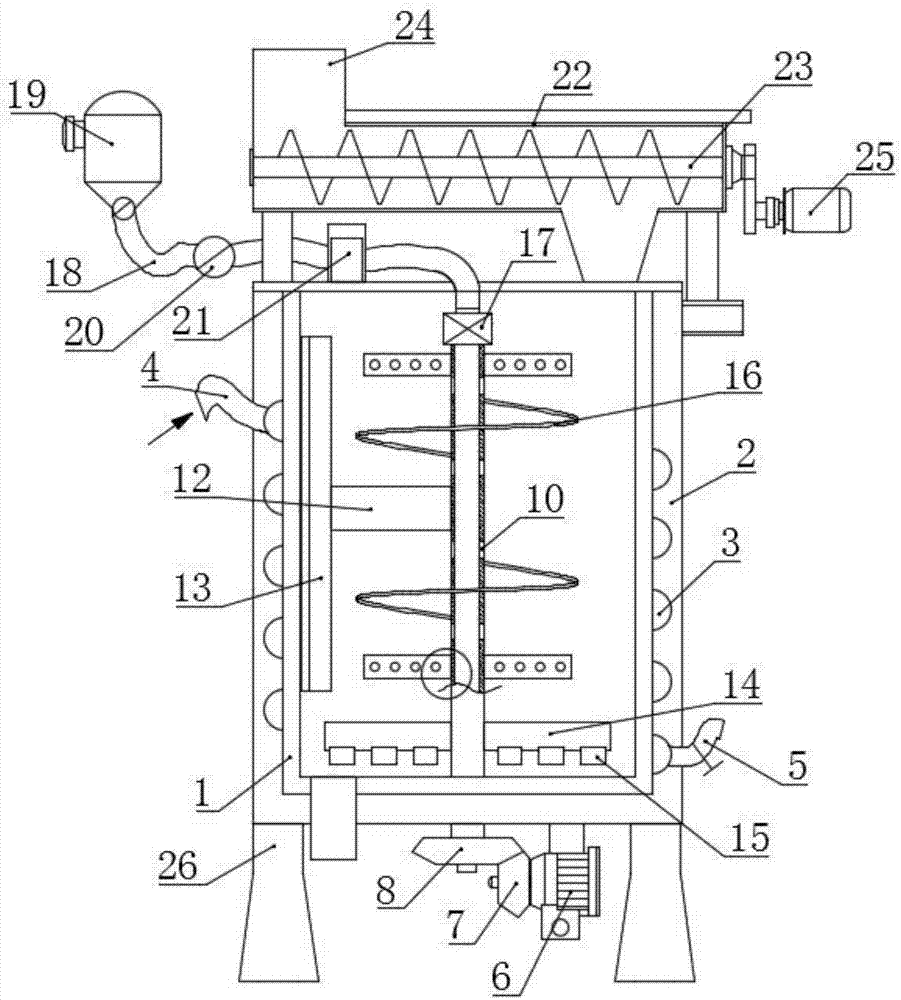

Efficient stirring device for building mortar production

InactiveCN107696275AStir quicklyImprove work efficiencyMixing operation control apparatusPretreatment controlMotor driveElectric machinery

The invention discloses a high-efficiency stirring device for the production of building mortar, which comprises a mixing drum. A feeding hopper is arranged on the left side of the upper side of the mixing drum. A pre-crushing mechanism is arranged inside the feeding hopper. There is a sliding bar, the left and right ends of the sliding bar are installed on the inner wall of the mixing drum, and the electric slider is slidably connected to the sliding bar, and the electric slider is slidably connected to the sliding bar. The invention is a high-efficiency mixer for the production of construction mortar. The stirring device is convenient for adding slurry and additives, and can pre-crumble the mortar raw materials to ensure the quality of the mortar. It can automatically feed water and control the water intake, reducing the intensity of manual operation. The stirring shaft is used for stirring, which is driven by a motor, which improves the stirring efficiency and makes the stirring more fully and evenly. In addition, it can effectively absorb shock and adjust the size of its amplitude. It is equipped with a spring to make it have a telescopic function and increase the shock resistance. efficiency.

Owner:史佩瑶

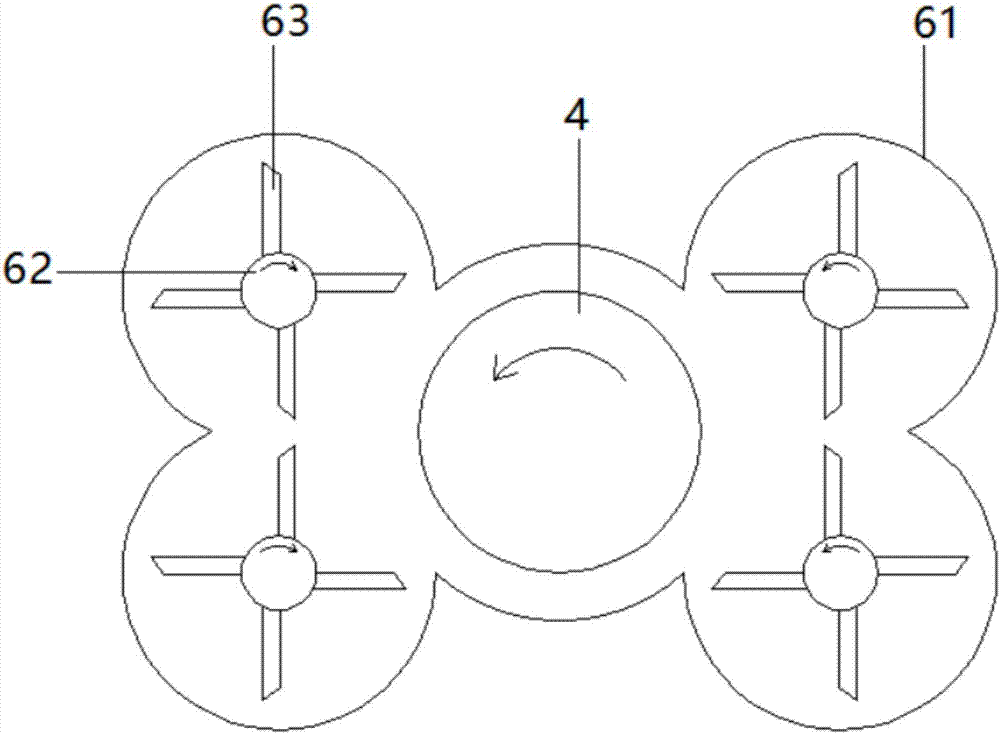

Efficient mixing device for concrete mixing

InactiveCN108189236ARealize repeated tappingPromote shock dropMixing operation control apparatusPretreatment controlSmall amplitudeMixing tank

The invention discloses an efficient mixing device for concrete mixing. The efficient mixing device comprises a mixing tank; supporting frames are vertically and fixedly arranged at the bottom of themixing box; a fixing plate is horizontally and fixedly arranged in the mixing box; dispersing rotating rollers are coaxially and fixedly arranged on rotating shafts; sliding shafts penetrating throughthe mixing box in a sliding mode are horizontally and fixedly arranged on sliding sleeves; and motors II are fixedly arranged at the upper ends of limiting blocks. According to the efficient mixing device, concrete entering the mixing box can be subjected to rotary dispersing through rotation of the dispersing rotating rollers, when the dispersing rotating rollers disperse concrete mortar, left and right small-amplitude shaking can be realized due to vibration, so that clockwise and anticlockwise rotation of the dispersing rotating rollers can be realized, repeated knocking on the mixing boxcan be realized, the concrete adhering to the inner wall of the mixing box can be promoted to be vibrated into the mixing box, the scraper plate scrapes the concrete on the inner wall of the mixing box, and therefore the phenomenon that stirring and mixing are not sufficient due to the fact that the concrete adheres to the inner wall of the mixing box can be avoided, and the stirring and mixing efficiency of the concrete can be effectively improved.

Owner:SUZHOU RUISHUO ENVIRONMENT TECH CO LTD

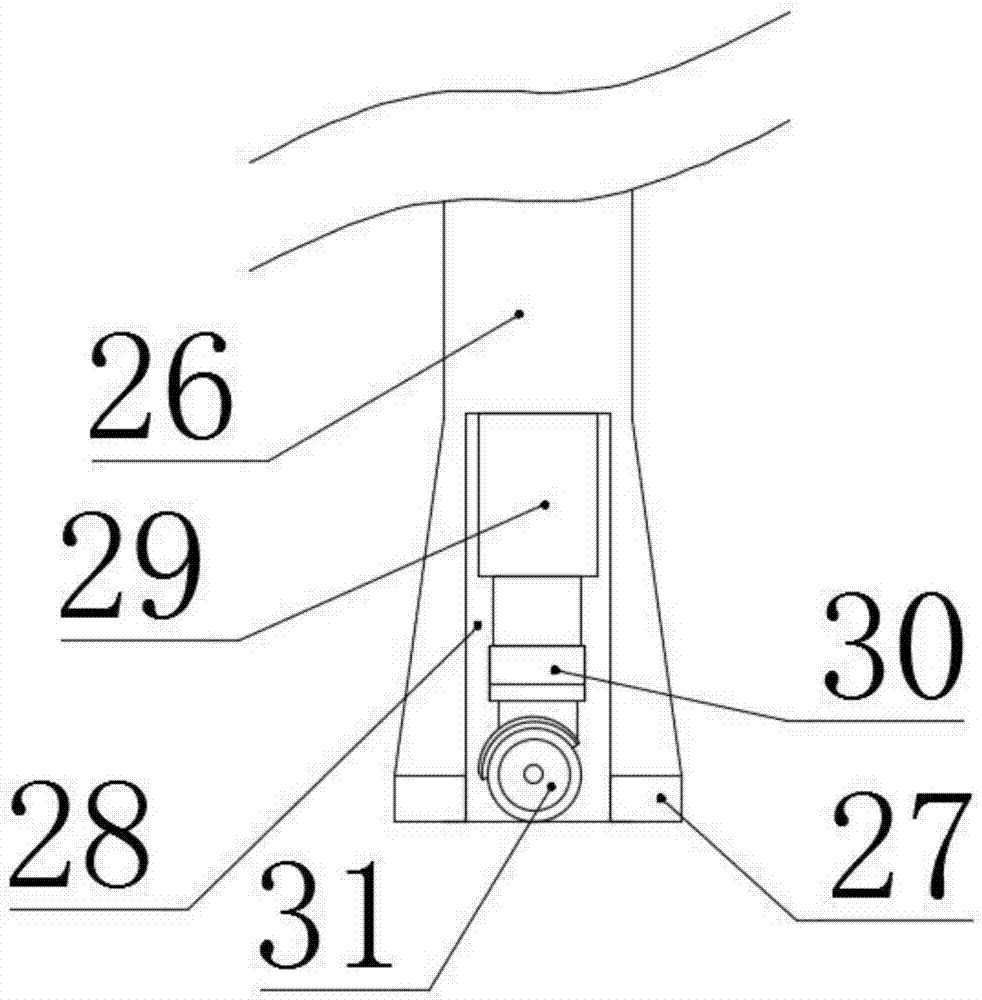

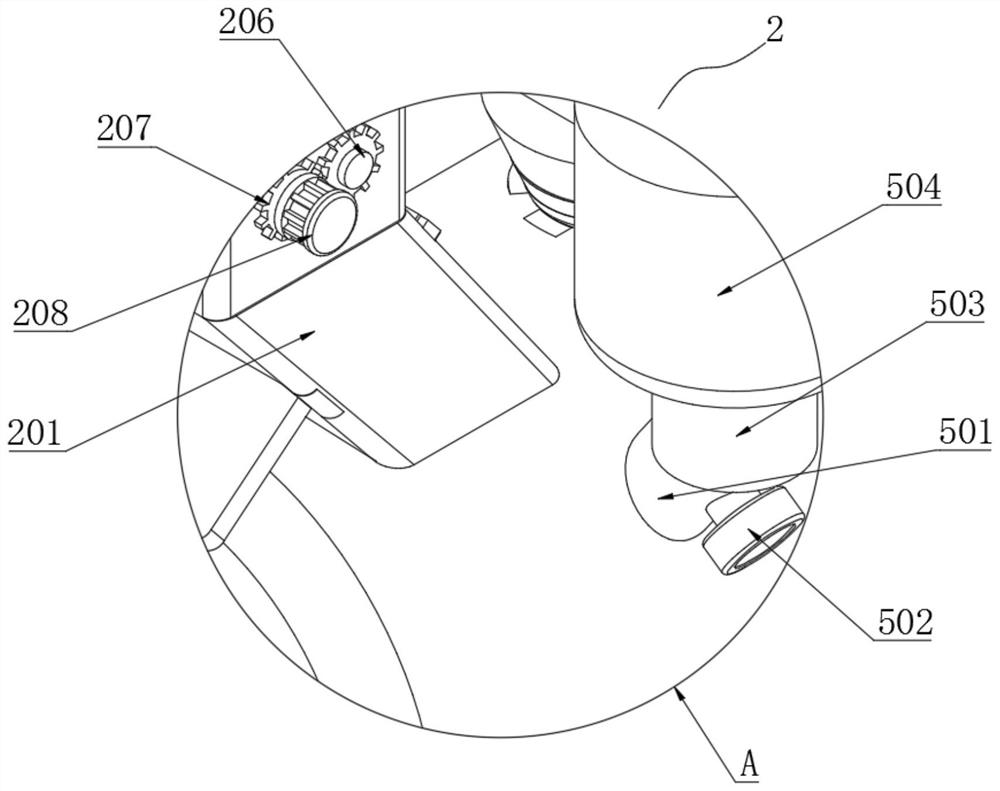

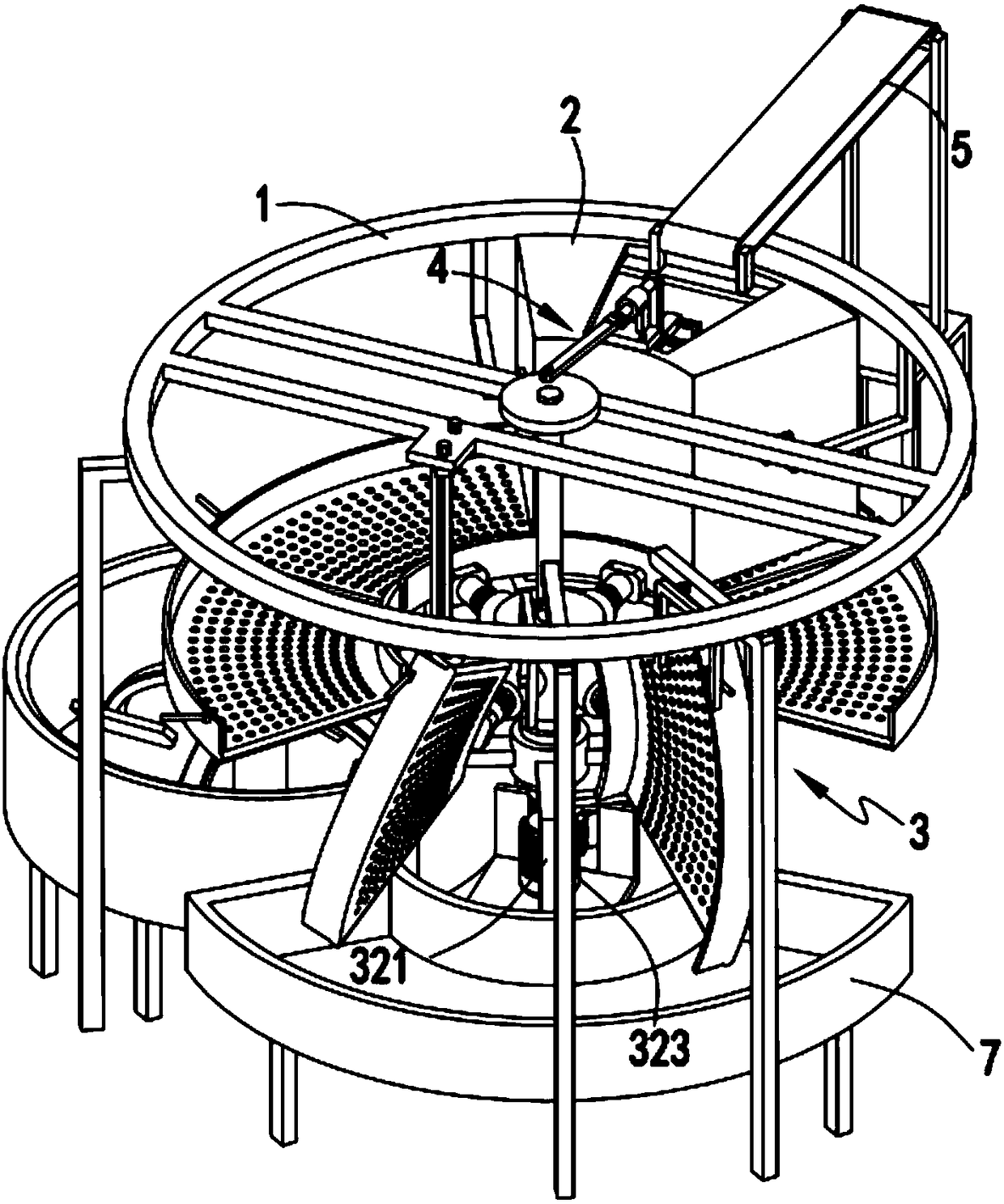

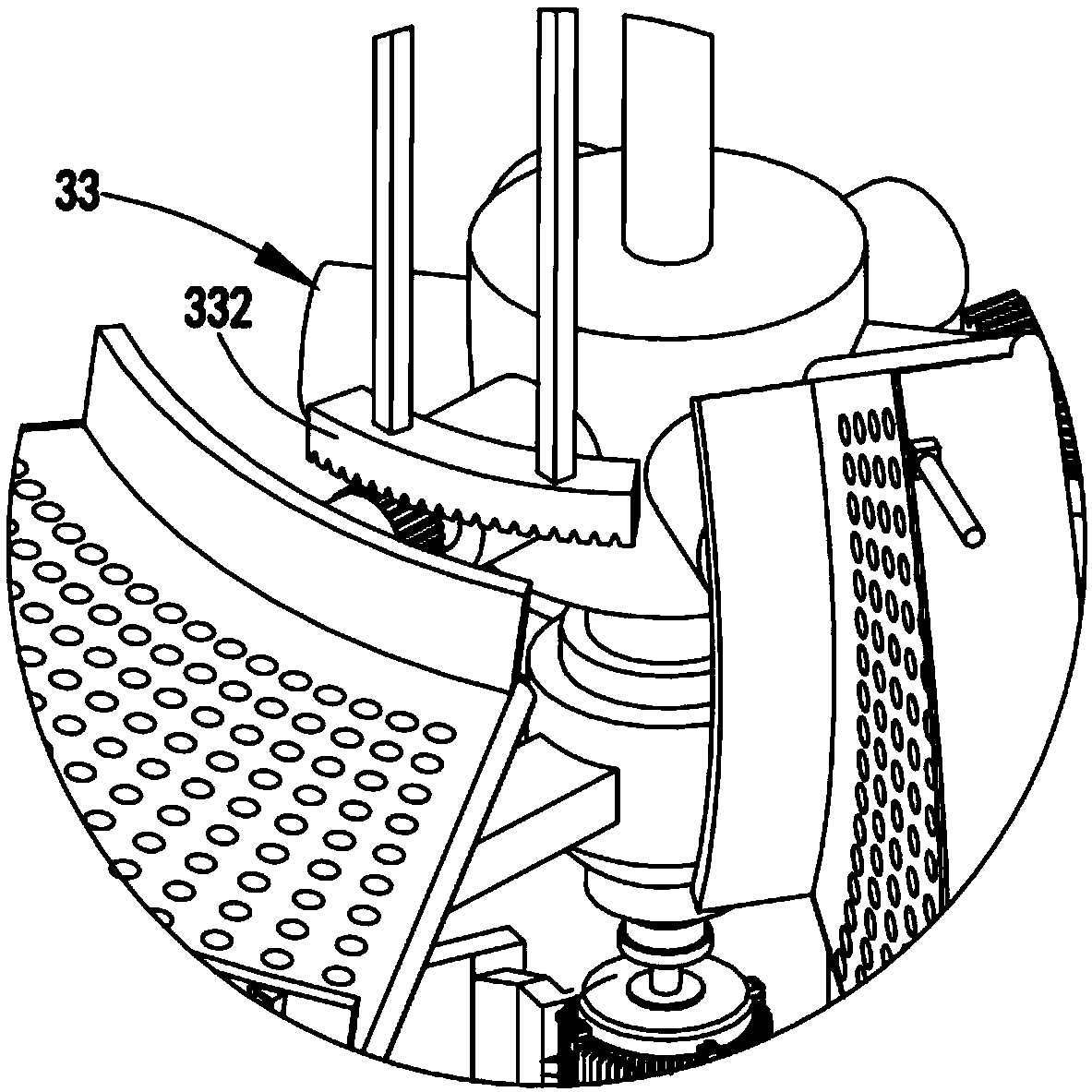

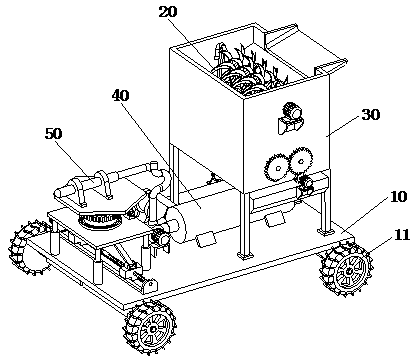

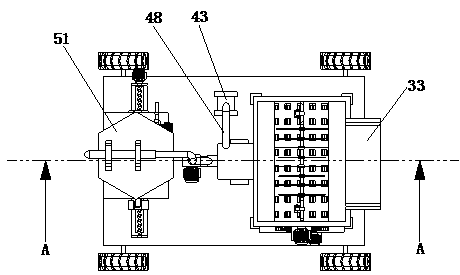

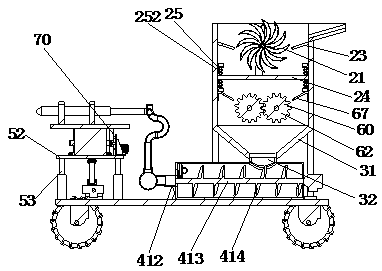

Concrete preparation processing equipment and processing technology thereof

The invention relates to concrete preparation processing equipment and a processing technology thereof. A production line comprises a machine frame, wherein a material screening bucket is arranged onthe machine frame, and a rotary screening device is arranged under the material screening bucket. The rotary screening device comprises a plurality of screening assemblies, a rotary mechanism and a turnover mechanism, wherein the screening assemblies are arranged in the peripheral direction in an array mode, the rotary mechanism is used for driving the screening assemblies to perform circular motion and penetrate through the bottom of the material screening bucket, and the turnover mechanism is used for driving the screening assemblies to turn over. The materials in the material screening bucket are screened when the screening assemblies penetrate through the bottom of the material screening bucket, the turnover mechanism drives the turnover of the screening assemblies to complete the primary screening, so that the large particle materials left on the screening assemblies after screening fall off. A material shaking mechanism is further arranged on the machine frame, and the material shaking mechanism enables the large particle materials left on the screening assemblies to fall off through the method of knocking the screening assemblies. The concrete preparation processing equipment and the processing technology thereof solves the problem of low screening efficiency, poor screening effect, low degree of automation of the equipment and consumption of manpower when raw materialsof concrete are screened in the prior art.

Owner:临泉县三合商品混凝土有限公司

Grouting ejection device for coal mine tunnel

InactiveCN110344851ABroken and meticulousFully brokenUnderground chambersDischarging apparatusSolenoid valveSlurry

The invention discloses a grouting ejection device for a coal mine tunnel and belongs to the technical field of mortar ejection equipment. The grouting ejection device for the coal mine tunnel comprises a vehicle body, a mortar uniform-crushing mechanism, a stirring box, an ejected mortar conveying mechanism and a mortar ejection mechanism. Four travelling wheels distributed in matrix are arrangedat the bottom of the vehicle body. The mortar uniform-crushing mechanism comprises a primary crushing assembly, a smashing assembly and a filter screen. The primary crushing assembly is arranged above the smashing assembly. A discharging hopper communicating with the interior of the stirring box is arranged at the bottom of the stirring box. A material conveying pipeline is arranged at the bottomof the discharging hopper. A feeding nozzle is arranged at the right end of the stirring box. A solenoid valve is arranged on the material conveying pipeline. The grouting ejection device for the coal mine tunnel has the beneficial effects that through the mortar uniform-crushing mechanism, filtering of larger mortar particles can be achieved, and repeated crushing operation can be conducted on the mortar particles; meanwhile, shaking of the filter screen can also be achieved; and in addition, through the mortar ejection mechanism, a mortar ejection head is capable of conducting mortar ejection operation on slopes of the coal wall.

Owner:胡立宇

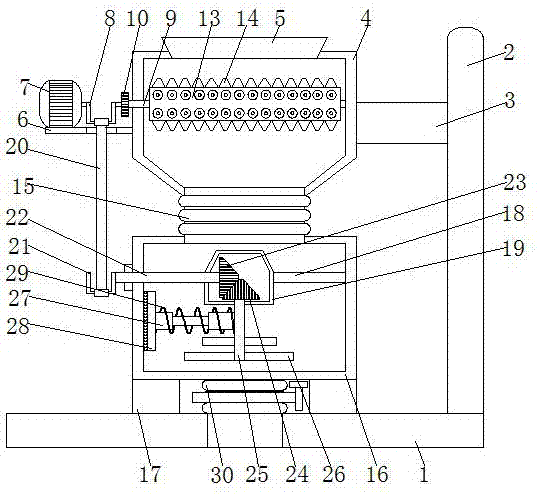

Efficient concrete stirrer with crushing device

InactiveCN104960092AQuality improvementQuality assuranceDischarging apparatusMixing operation control apparatusHydraulic cylinderEngineering

The invention discloses an efficient concrete stirrer with a crushing device. The efficient concrete stirrer comprises a stirring barrel, a spiral conveying barrel and a crushing cavity. A feeding hopper is arranged at the left end of the upper side of the stirring barrel. The lower side of the feeding hopper is connected with the crushing cavity. Two crushing rollers are arranged inside the crushing cavity side by side. A crushing gap is arranged between the two crushing rollers. According to the efficient concrete stirrer with the crushing device, concrete is stirred in the horizontal direction and the vertical direction at the same time through stirring blades, a stirring plate and stirring wheels. A hydraulic cylinder is utilized for driving a stirring mechanism to move up and down to perform stirring, the stirring effect and the working efficiency of the stirrer are greatly improved, and the quality of the concrete is guaranteed; automatic discharging is achieved through a bolt conveying mechanism, concrete continues to be stirred in the discharging process, and the working efficiency of the stirrer is improved; in addition, the noise of the stirrer is low in the working process, concrete raw materials can be sufficiently crushed, and the size of crushed particles can be controlled.

Owner:苏晓玲

Practical building stirrer

InactiveCN108297281AEasy to moveReduce wearTransportation and packagingMixing operation control apparatusWear resistantEngineering

The invention discloses a practical building stirrer. The practical building stirrer comprises a main body. A wear-resistant layer is arranged on the inner wall of the main body. An upper cover plateis arranged on the upper portion of the main body and provided with a water inlet opening, a motor, a rotating shaft and an upper cover plate body. A first rotating wheel is arranged on the rotating shaft, and a second rotating wheel is arranged on the motor. A stirring device is arranged on the rotating shaft. Connecting rods are arranged at the upper end and the lower end of the rotating shaft.The other ends of the connecting rods are arranged on two scraping plates. Support legs are arranged on the lower portion of the main body and used for supporting the main body. Universal wheels are arranged at the bottoms of the support legs. A discharging plate is arranged at the bottom o the main body through hinges. An extending-and-contracting device is arranged at the bottom of the other endof the discharging plate and mounted on the discharging plate through hinges. The other end of the extending-and-contracting device is mounted at the bottoms of the support legs through hinges. The practical building stirrer is simple in structure, convenient to discharge, capable of achieving self-leaning and long in service life.

Owner:陈伟平

Stirring equipment used for municipal construction

InactiveCN107053470AExtended service lifeAchieve circular flowMixing operation control apparatusPretreatment controlElectric machineryWaste management

The invention discloses stirring equipment used for municipal construction. The equipment comprises an equipment body. A feeding barrel is arranged on the upper side of the equipment body. A feeding hopper is arranged at the left end of the upper side of the feeding barrel. A feeding mechanism is arranged in the feeding barrel and comprises a feeding screw and a screw blade arranged on the outer wall of the feeding screw. The left end of the feeding screw is connected with a motor. A pre-crushing mechanism is arranged on a right section of the feeding barrel. According to the stirring equipment used for municipal construction, automatic feeding can be achieved, raw materials are pre-crushed in the feeding process, the stirring efficiency is improved, circulating flowing of concrete is achieved through vertical moving of vibro-rammers and the guiding effect of an inner barrel, stirring screws are used for stirring the concrete and driving the concrete to rise in the stirring process, and the stirring effect is greatly improved; and in addition, a damping bracket can be used for achieving effective shock absorption and prevention, and the service life of the stirring equipment is prolonged.

Owner:FUNAN GAOFUXING INTELLIGENT TECH CO LTD

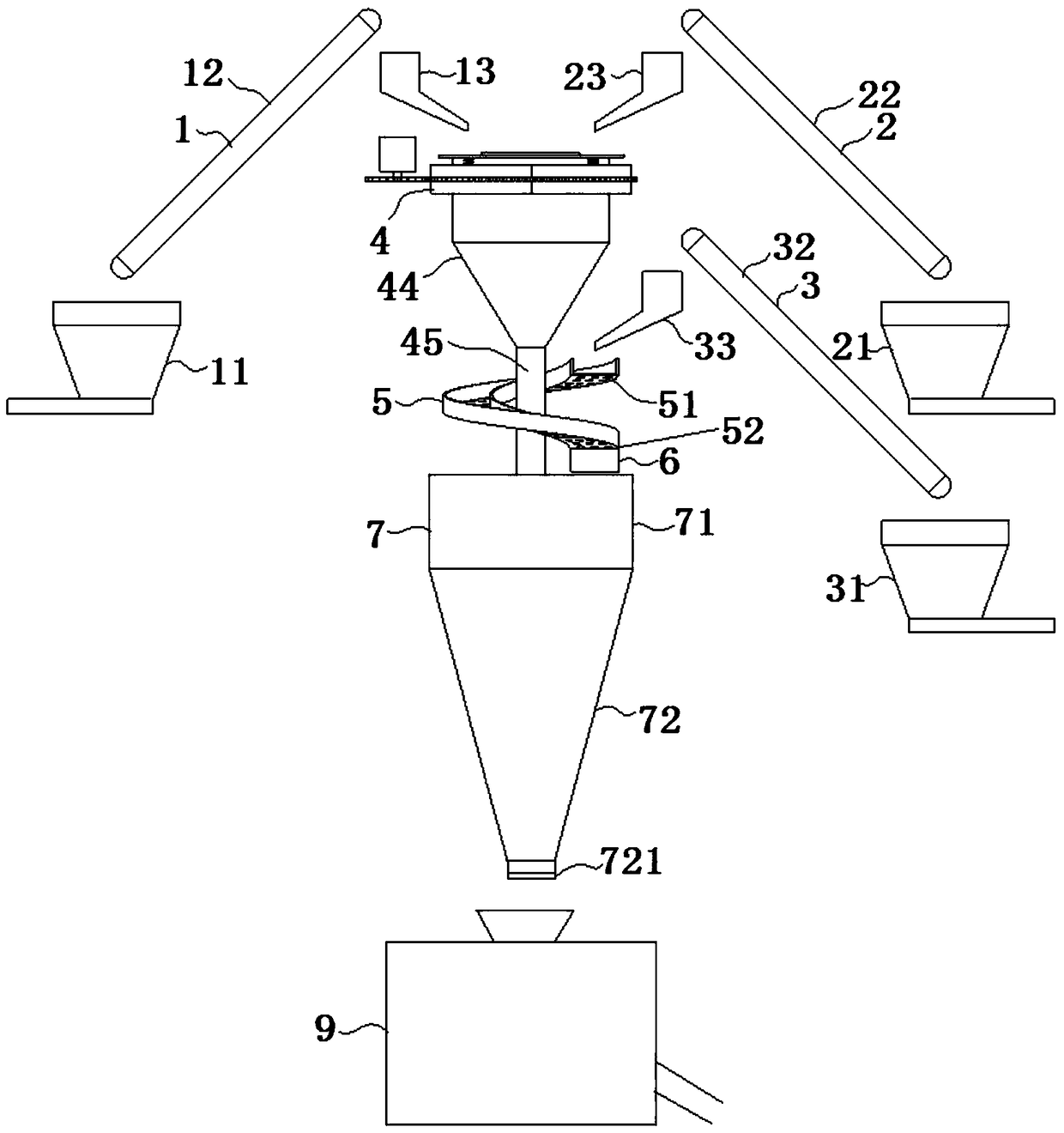

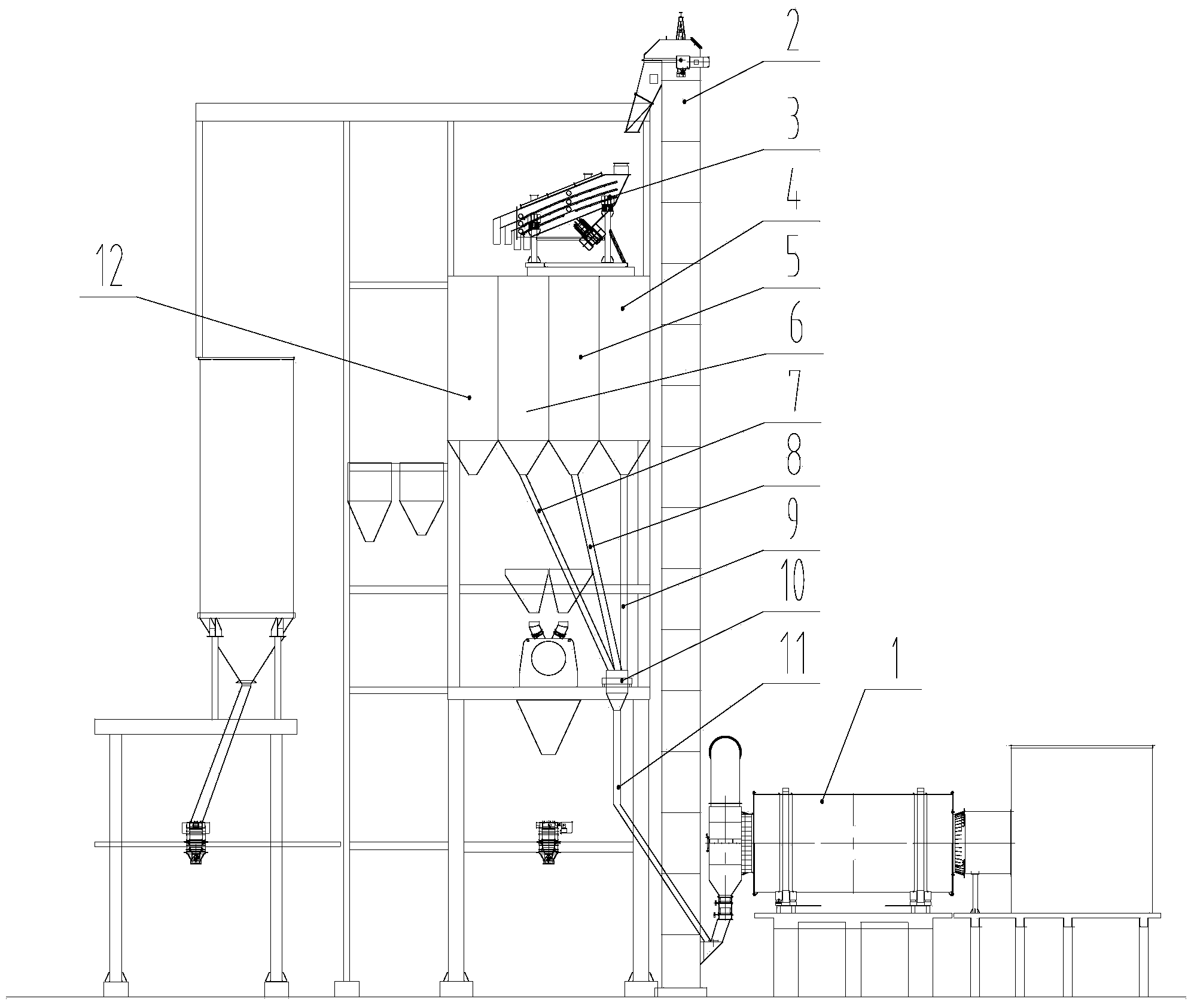

Concrete production system and production method thereof

ActiveCN109366742AImprove the quality levelShorten mixing timeMixing operation control apparatusPretreatment controlMaterials scienceRaw material

The invention discloses a concrete production system and a production method thereof. The concrete production system comprises a sand feeding device, a cement feeding device, a gravel feeding device,a sand-cement mixing device, a gravel screening spiral material guide groove, a sand-cement-gravel mixing device and a concrete mixer; the sand feeding device can supply raw material sand required byconcrete to the sand-cement mixing device, the cement feeding device can supply raw material cement required by the concrete to the sand-cement mixing device, and the sand-cement mixing device can mixthe supplied sand with the supplied cement; and the gravel feeding device can be used for screening raw material gravel required by the concrete through the gravel screening spiral material guide groove and then supplying the gravel to the sand-cement-gravel mixing device, the sand-cement-gravel mixing device can be used for mixing the mixed sand and cement with the gravel, and then the mixture is stirred by the concrete mixer to form the concrete. According to the concrete production system and the production method thereof, the mixing uniformity of all the raw materials required by the concrete is ensured, and the quality grade of the concrete is improved.

Owner:江西信源建材科技集团有限公司

Aggregate preheating system, kit and method

InactiveUS20070268778A1Reduce amountAmount of timeDischarging apparatusTransportation and packagingEngineeringMechanical engineering

A system, kit and method for preheating aggregate supplied to a drying drum uses in the HMA manufacturing process. The system includes a conveyor belt, at least one infrared chamber disposed in substantially parallel relation to the conveyor belt at a distance sufficient to allow infrared heating of the aggregate material, a source of fuel, a fuel control in communication with the infrared chamber, and at least one mixer disposed between the infrared chamber and the conveyor belt and dimensioned and disposed relative to the conveyor belt so as to mix the aggregate material during pre-drying.

Owner:VELSOR WESLEY VAN

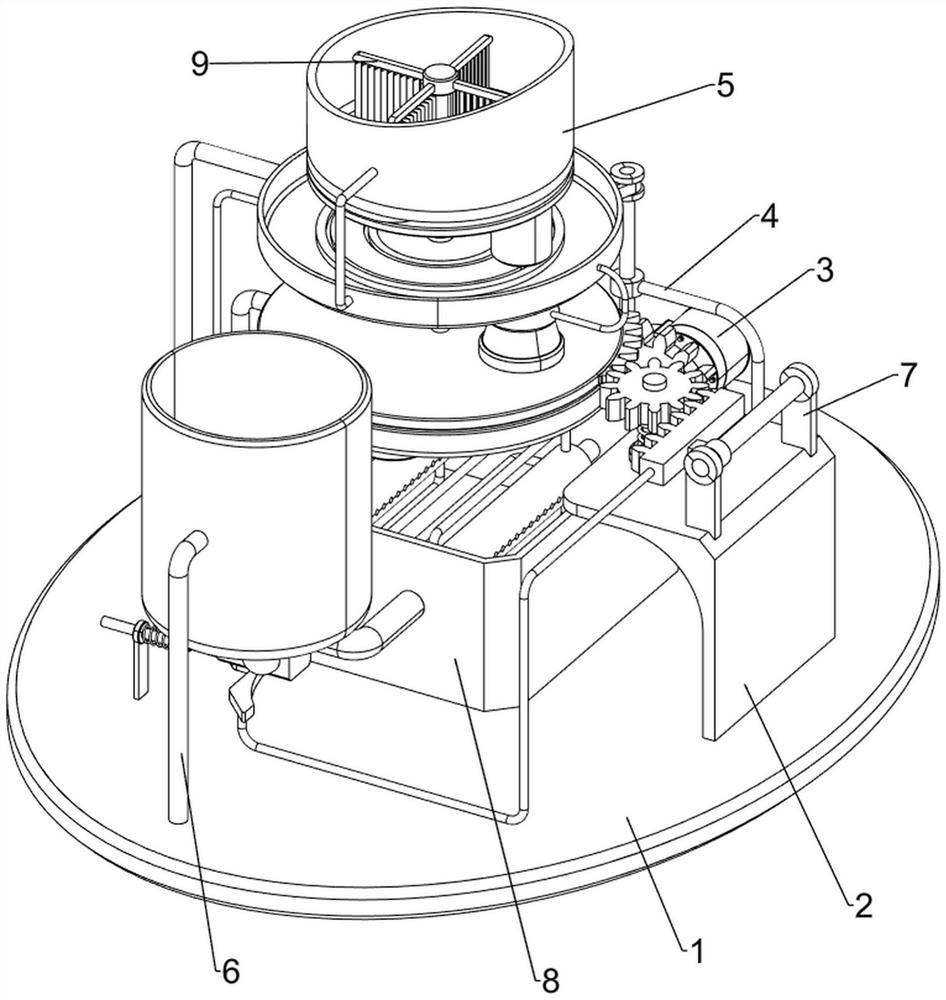

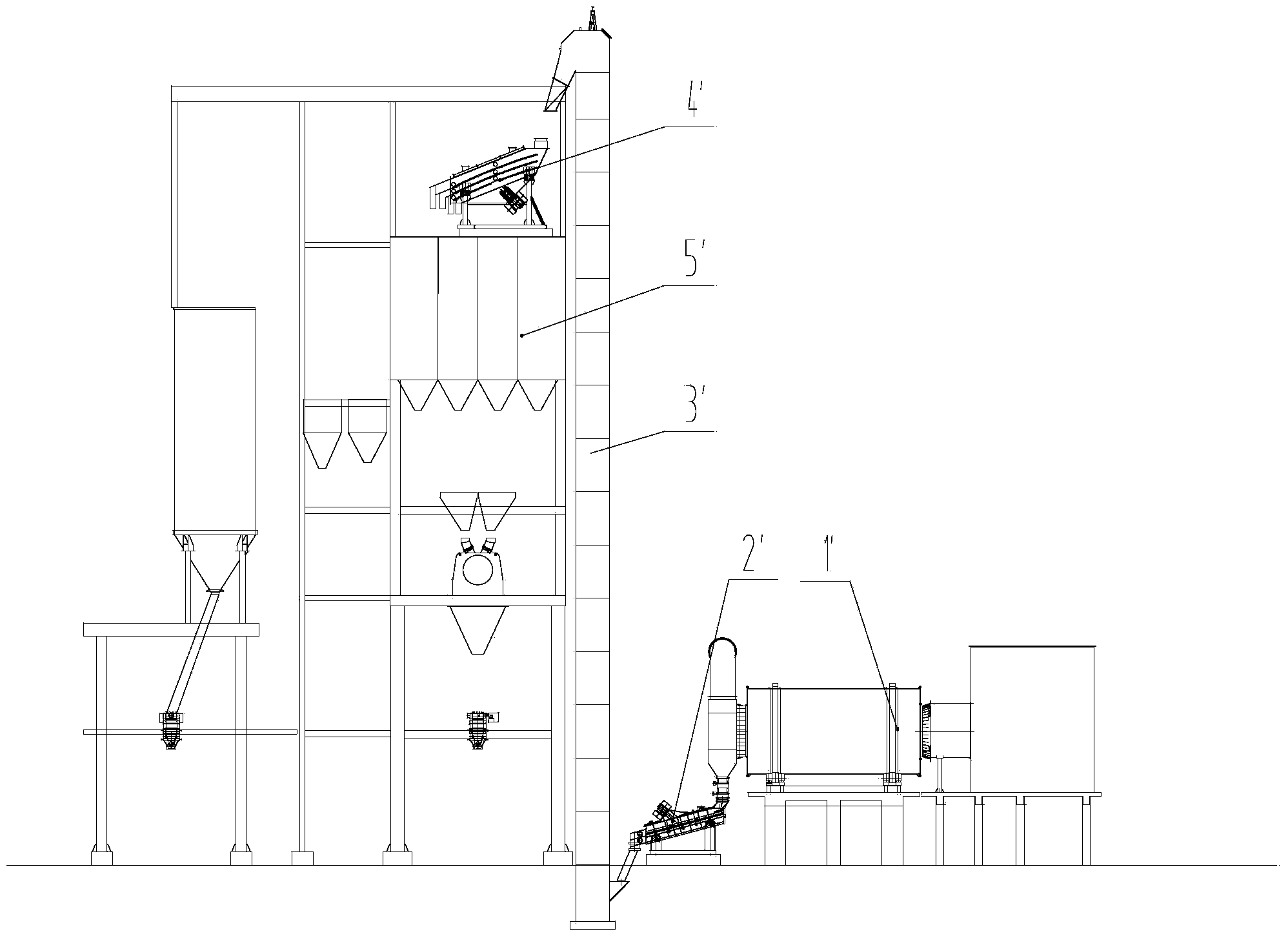

Dry-mixed mortar stirring station and screening and crushing system thereof

The invention discloses a dry-mixed mortar stirring station and a screening and crushing system thereof. The screening and crushing system comprises a dry sand elevator, a vibrating screen, at least two storing bins, valves, feeding pipes, a crushing machine and a material returning pipe, wherein the vibrating screen is used for receiving sand output from the dry sand elevator; the at least two storing bins are used for storing sand output from the vibrating screen, a first storing bin of the at least two storing bins is used for storing fine sand, and second storing bins of the at least two storing bins are used for storing sand the grain diameter of which is greater than that of the fine sand; the upper ends of the feeding pipes are connected with the second storing bins and are also provided with the valves, and the lower ends of the feeding pipes are connected with a feed hole of the crushing machine; the upper end of the material returning pipe is connected with a discharge hole of the crushing machine, and the lower end of the material returning pipe is in butt joint with a feed hole of the dry sand elevator. The screening and crushing system provided by the invention is capable of fully utilizing the sand the grain diameter of which is greater than that of the fine sand, and a problem that a large number of waste materials are wasted or / and medium-coarse sand is likely to overfill a bin is avoided.

Owner:SANY AUTOMOBILE MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com