Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1926results about "Grain milling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

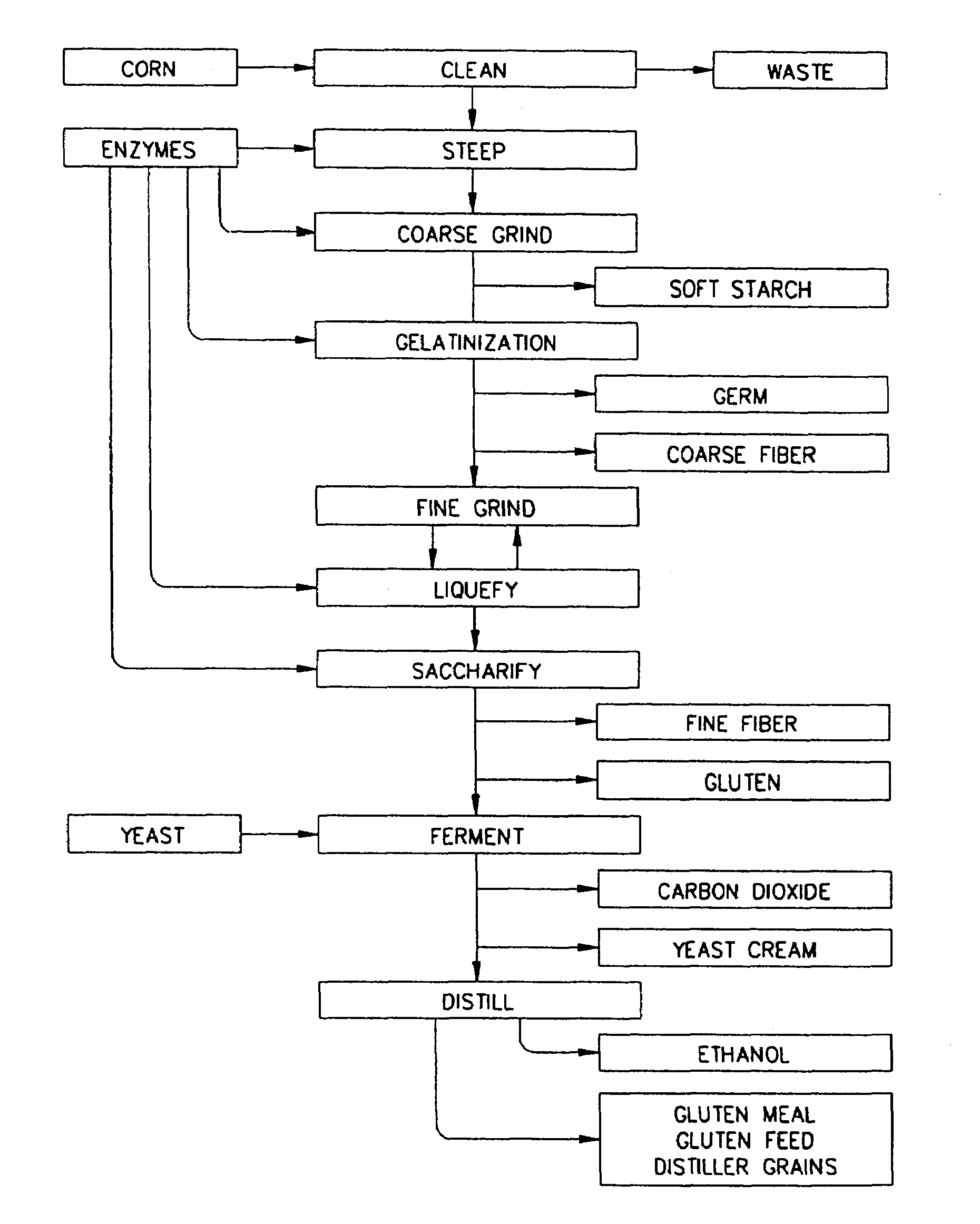

Processes for recovery of corn germ and optionally corn coarse fiber (pericarp)

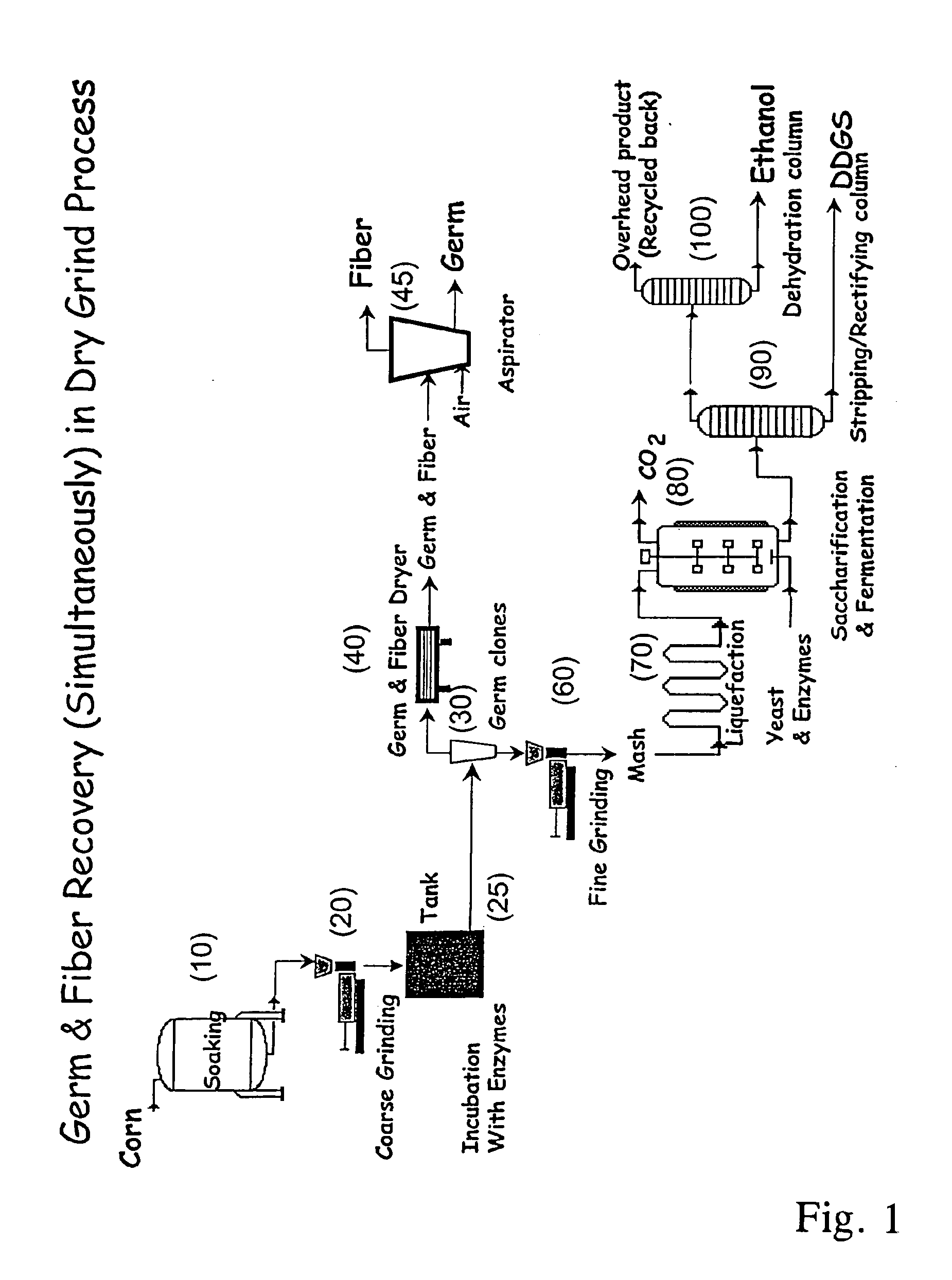

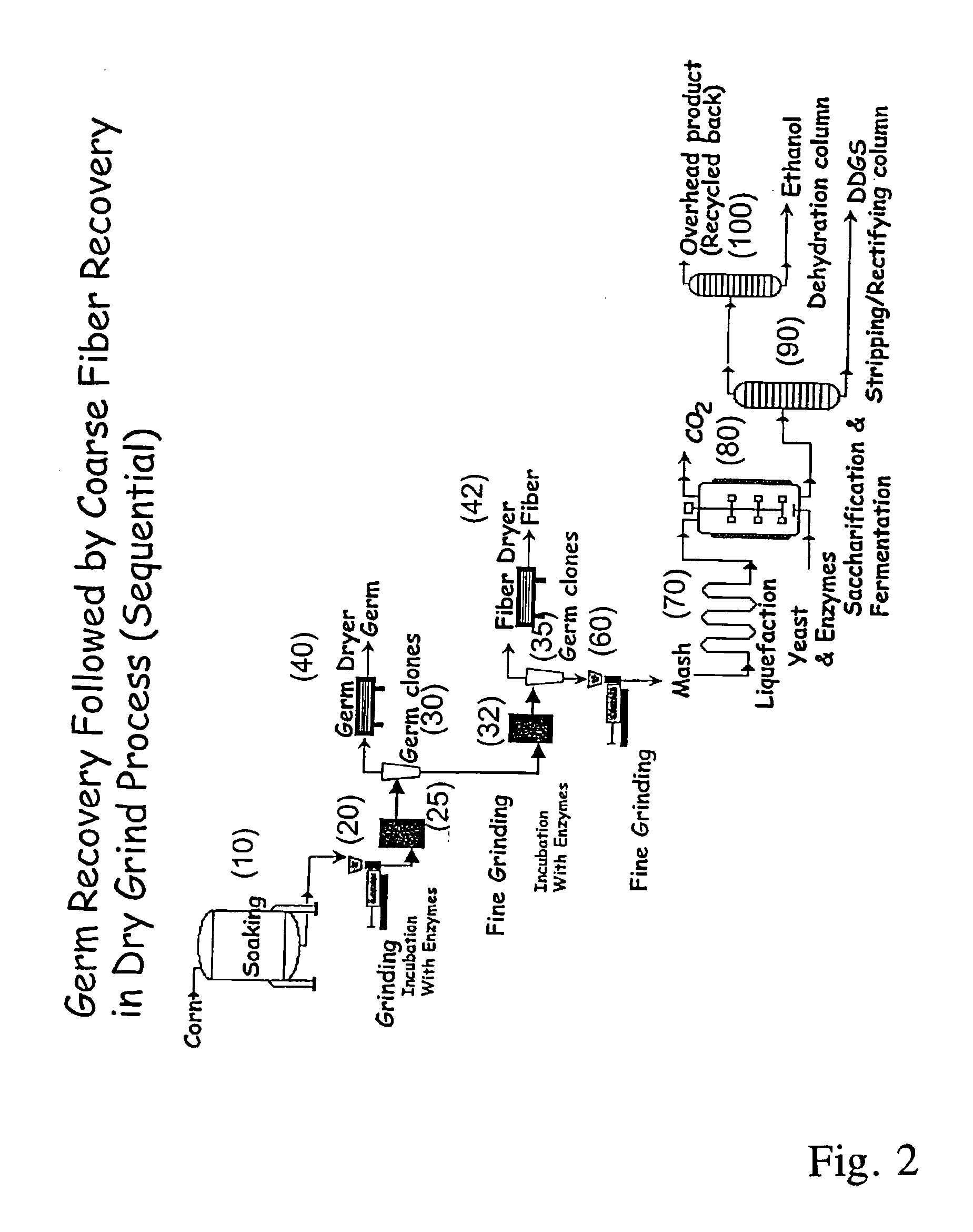

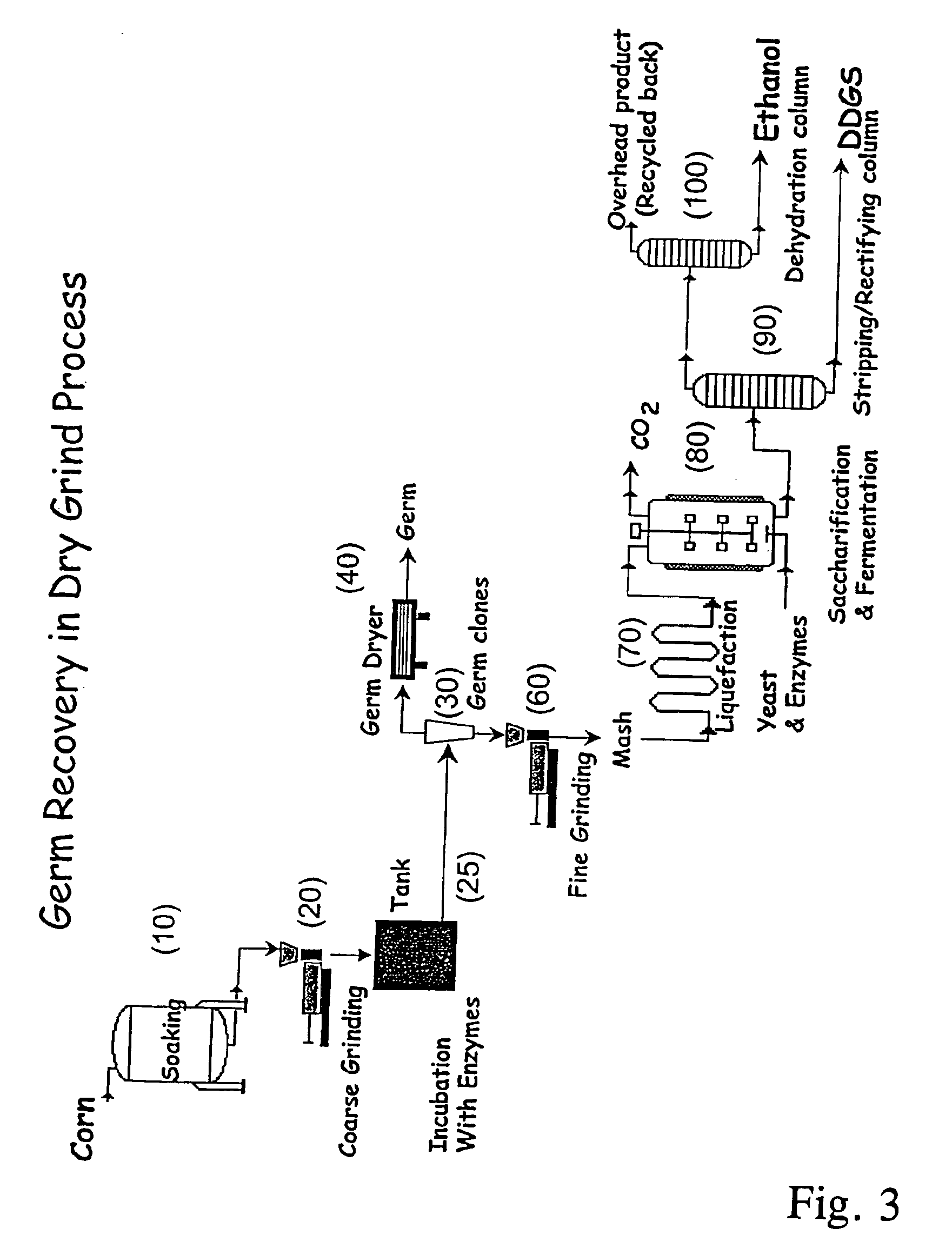

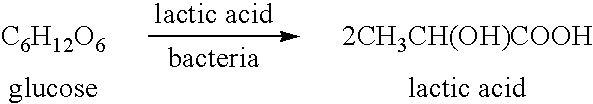

A process for recovering corn germ and corn coarse fiber from corn in a dry grind process, involving soaking corn kernels in water to produce soaked corn kernels, grinding the soaked corn kernels to produce a ground corn slurry, and incubating the ground corn slurry with at least one enzyme (amylase(s), protease(s), cell wall degrading enzyme(s), or mixtures thereof, and optionally other enzyme(s)) to increase the specific gravity of the slurry to about 10-about 16 Baume so that the corn germ and corn coarse fiber floats to the top of the slurry, recovering the corn germ and the corn coarse fiber, and optionally producing ethanol from the slurry no longer containing the corn germ and corn coarse fiber. The process does not involve the addition of starch, a salt, a sugar syrup, or mixtures thereof to the slurry.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS +1

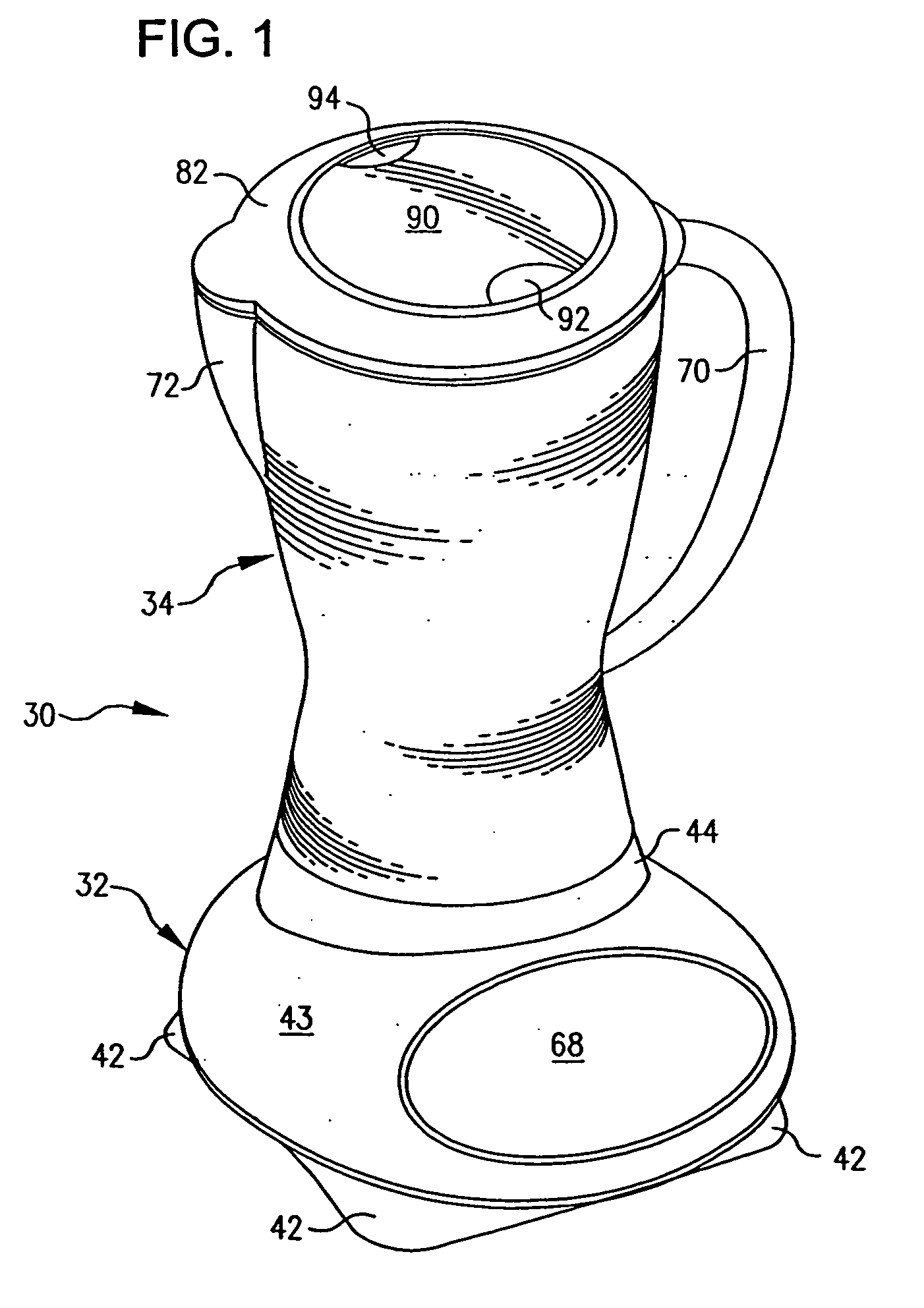

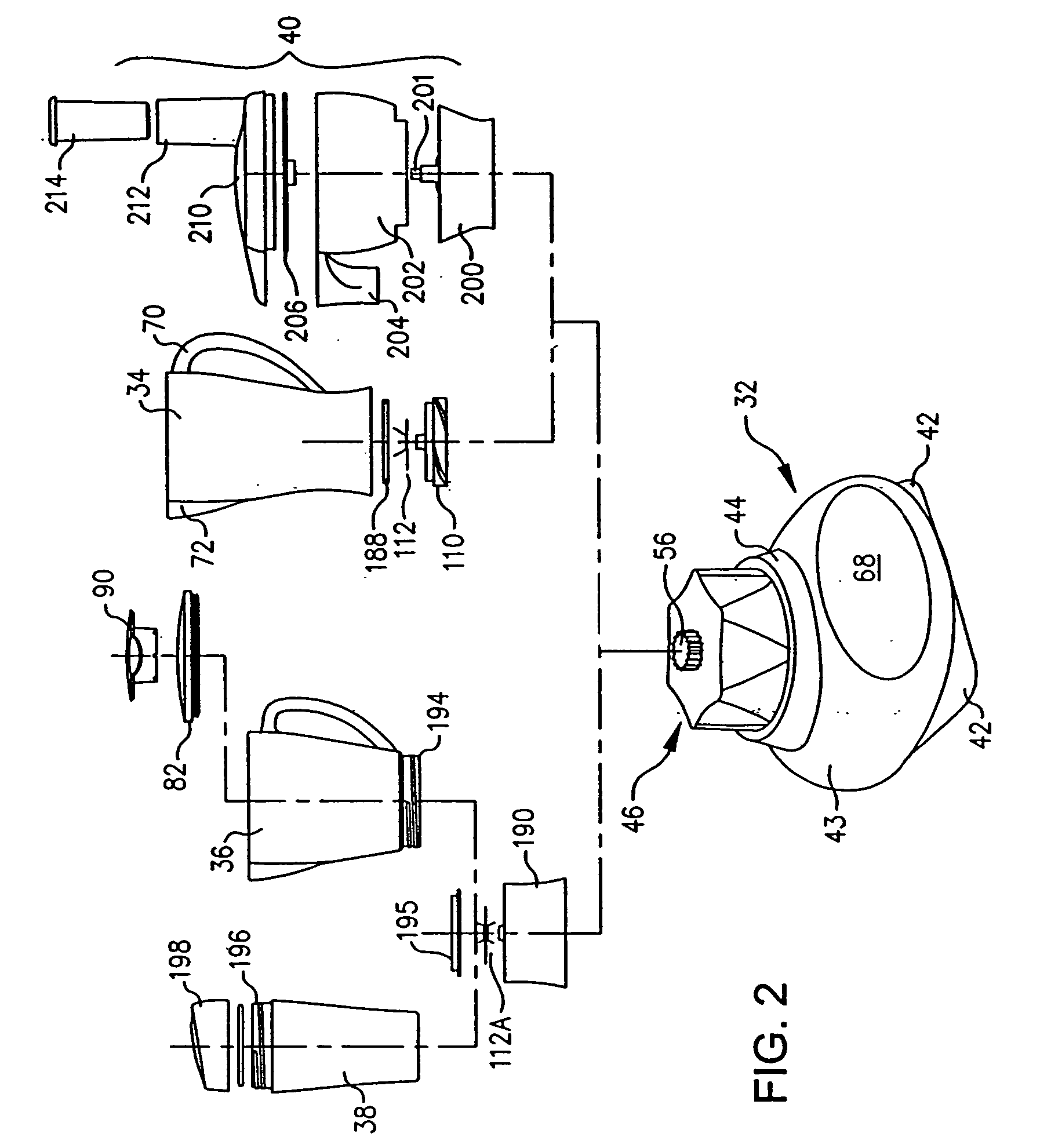

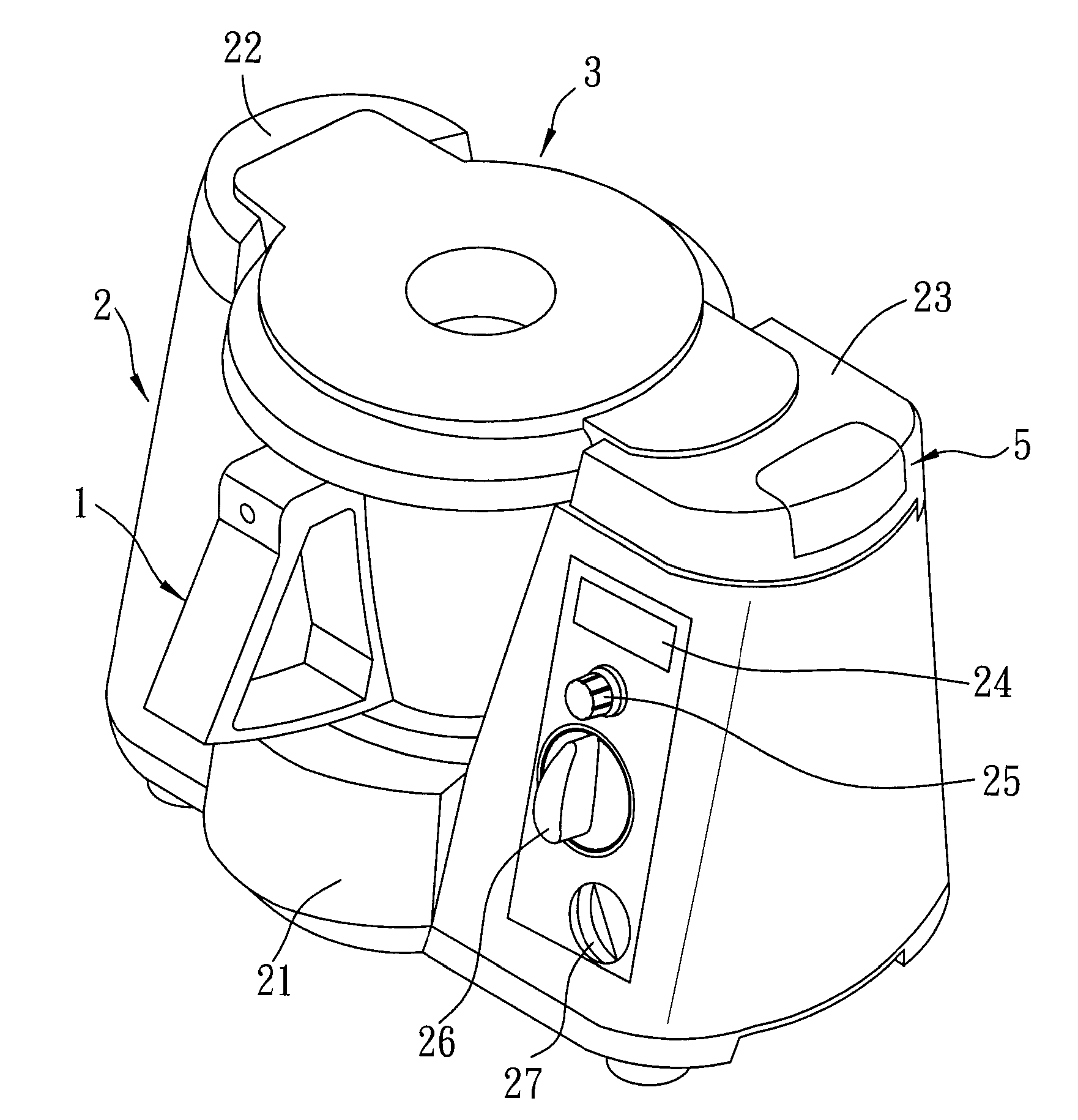

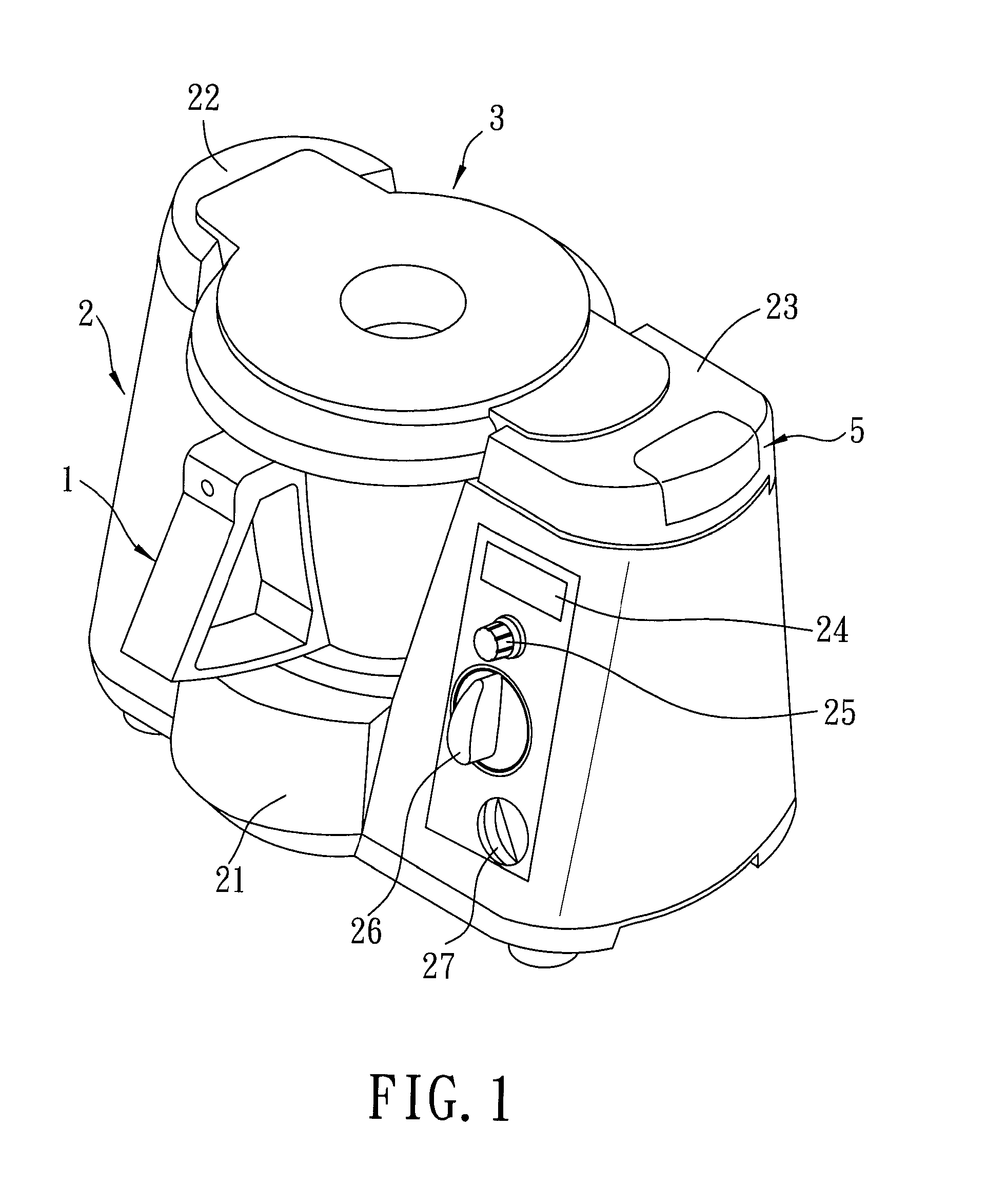

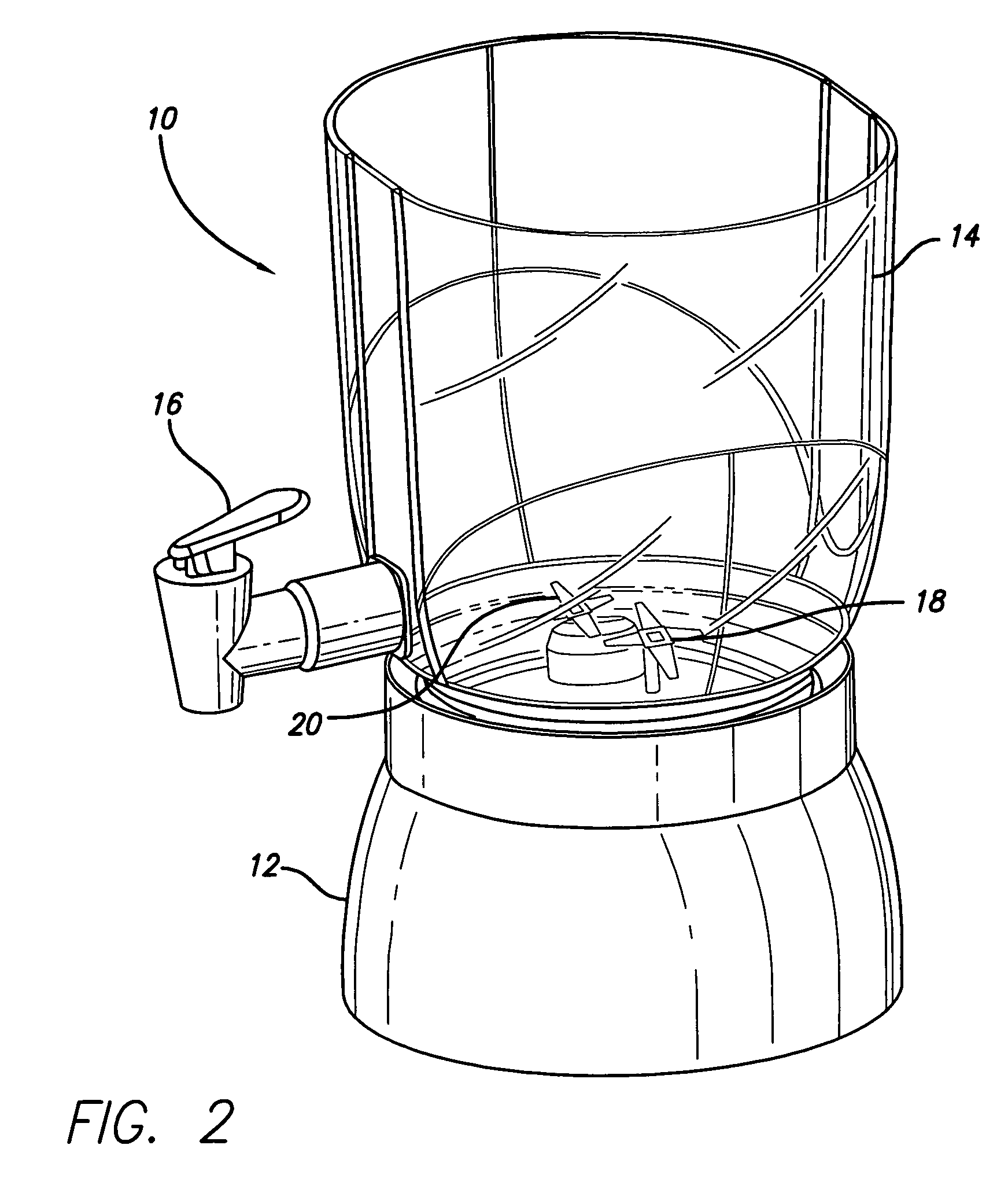

Blender base with food processor capabilities

InactiveUS20050068846A1Avoid vibrationImprove stabilityGas current separationTransportation and packagingMicrocontrollerLiquid-crystal display

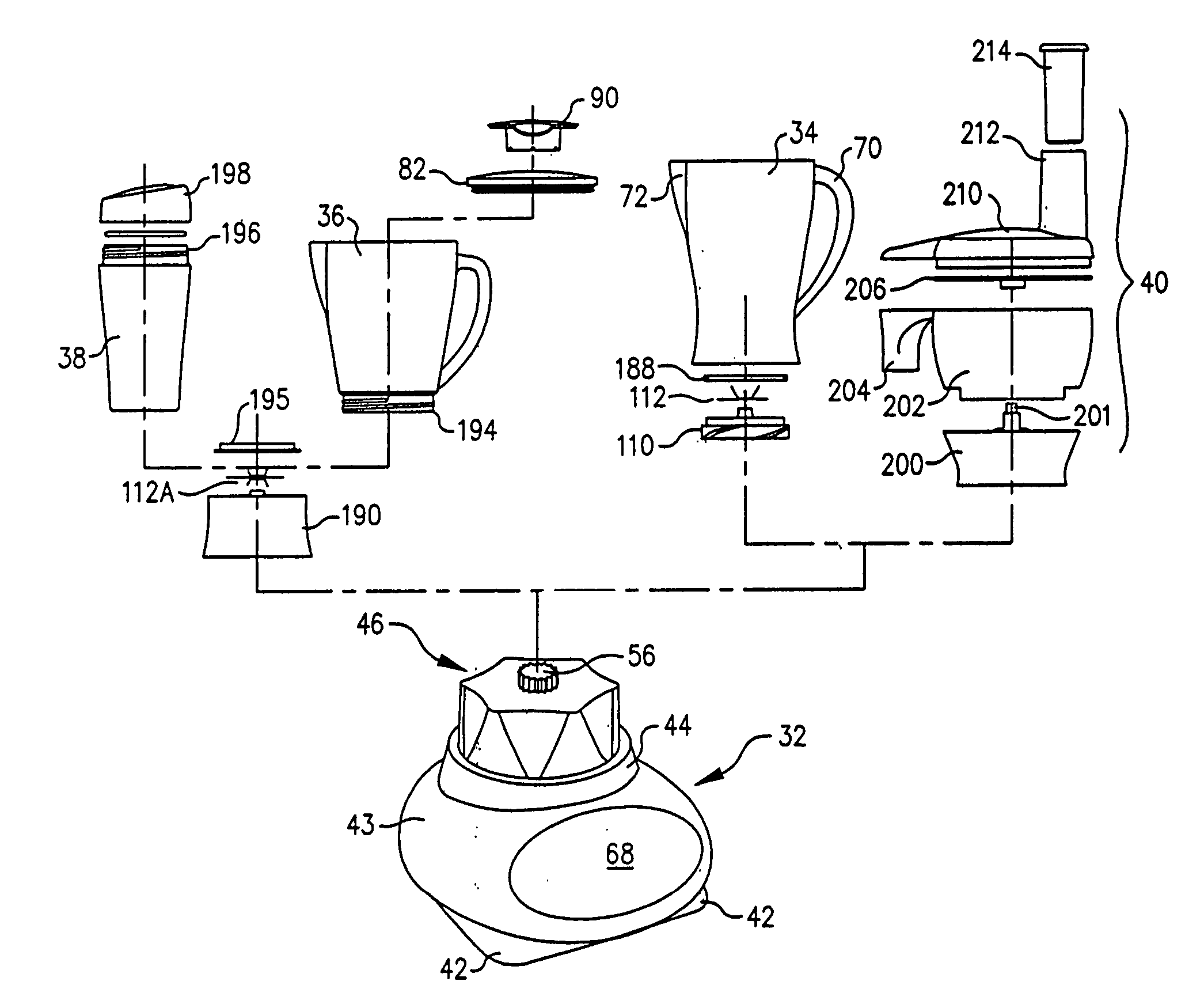

A blender base that may be used with a food processor container, a blender container, and a single use beverage container. The blender container includes a novel blade unit having a food processor-style blade and blender type blades. Programs with preprogrammed motor commands for desired operations are stored in memory and may be selected by a user on a user interface. The user interface may include a liquid crystal display, or function switches and light emitting diodes. Upon selection of a particular pre-defined function, the microcontroller retrieves the appropriate program from the read only memory and specifies the preprogrammed motor commands to accomplish the selected function.

Owner:WULF JOHN DOUGLAS +5

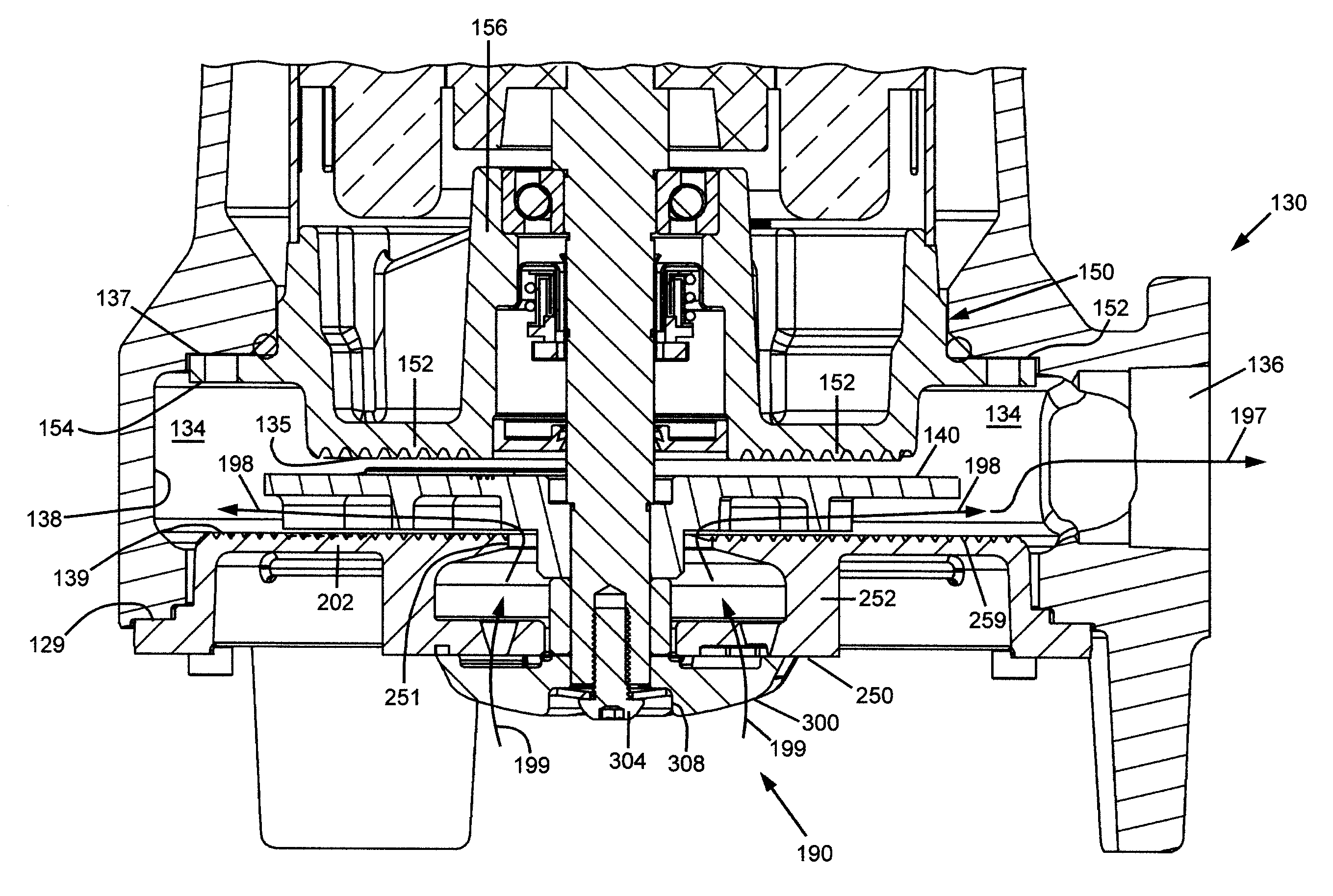

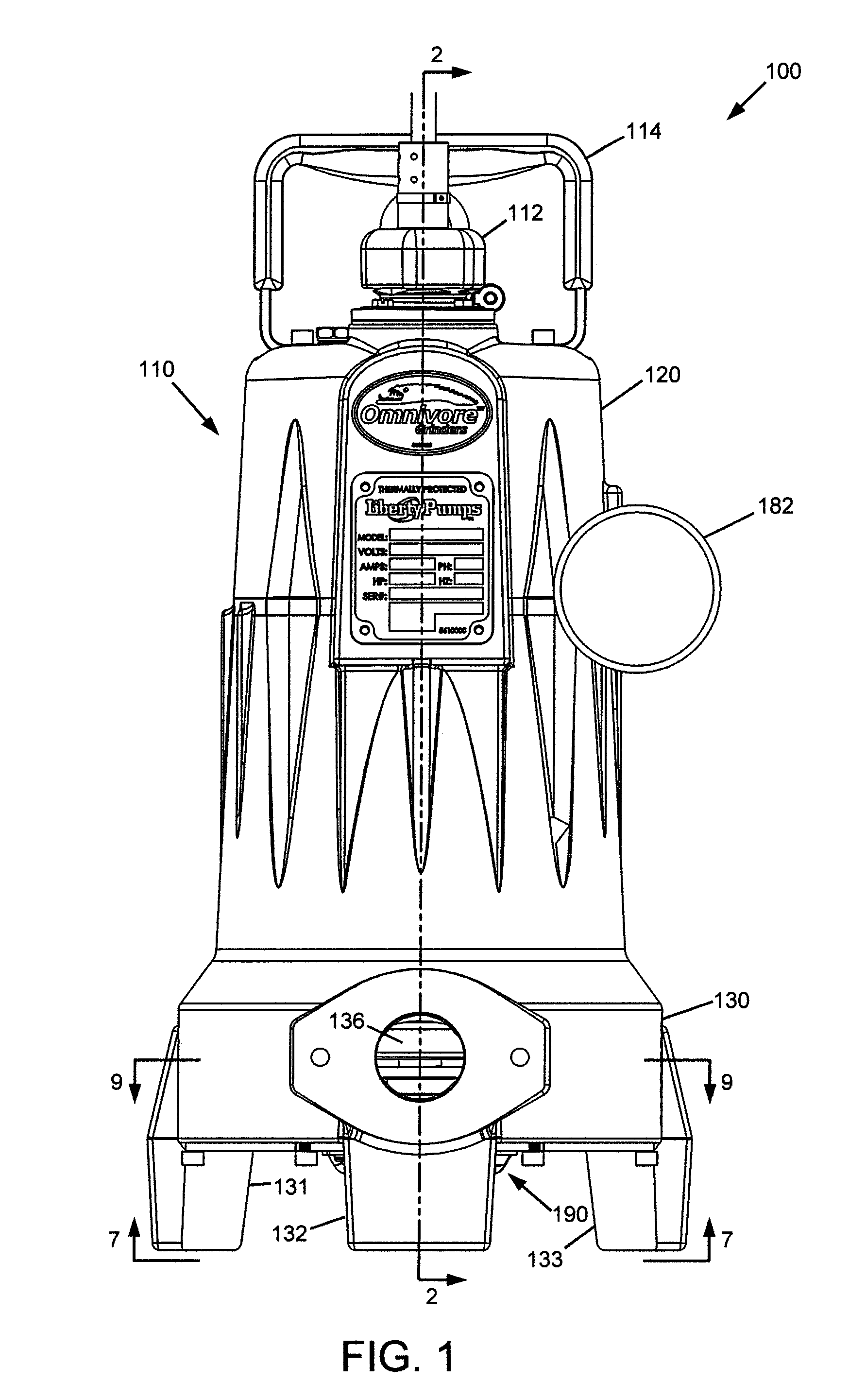

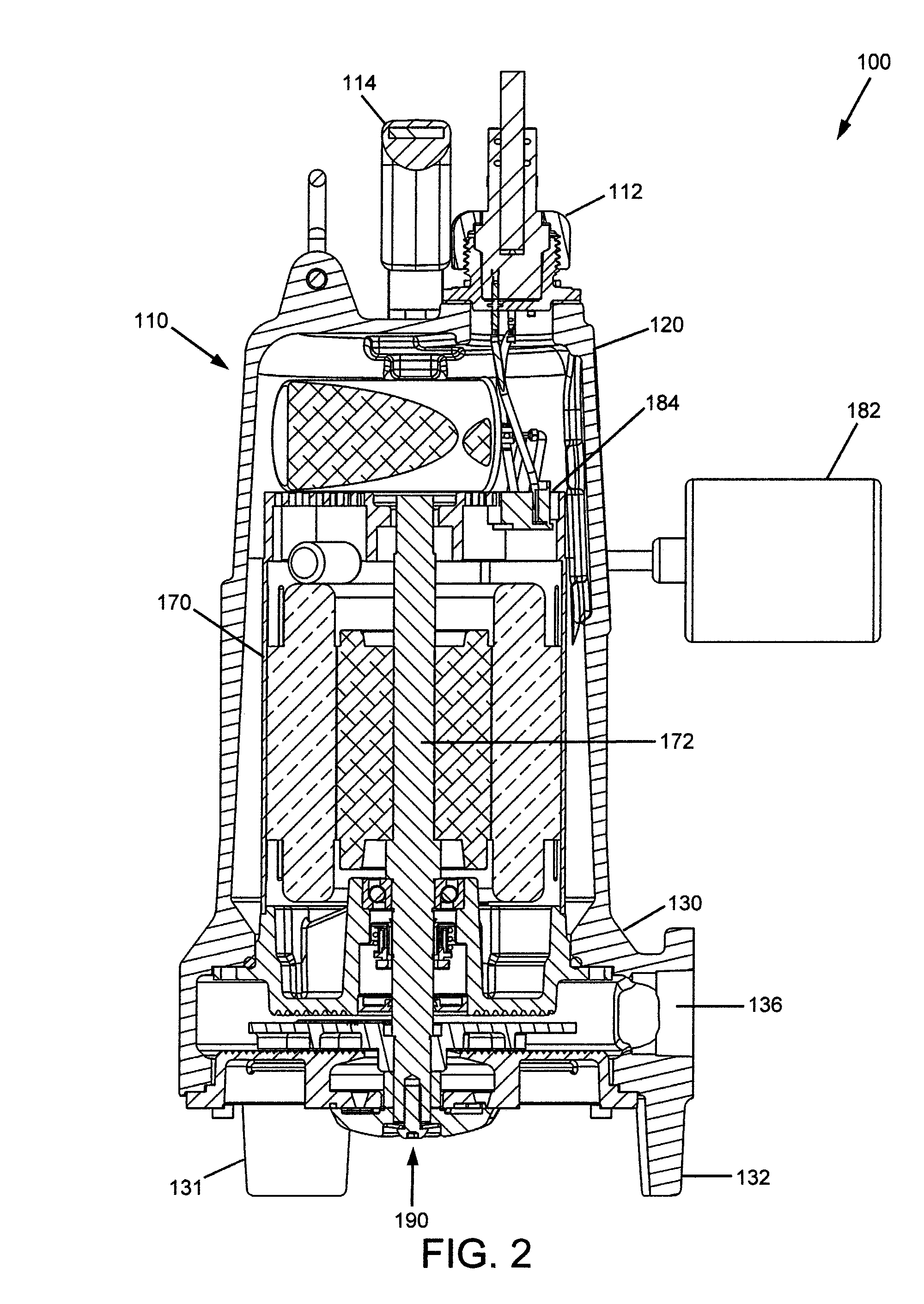

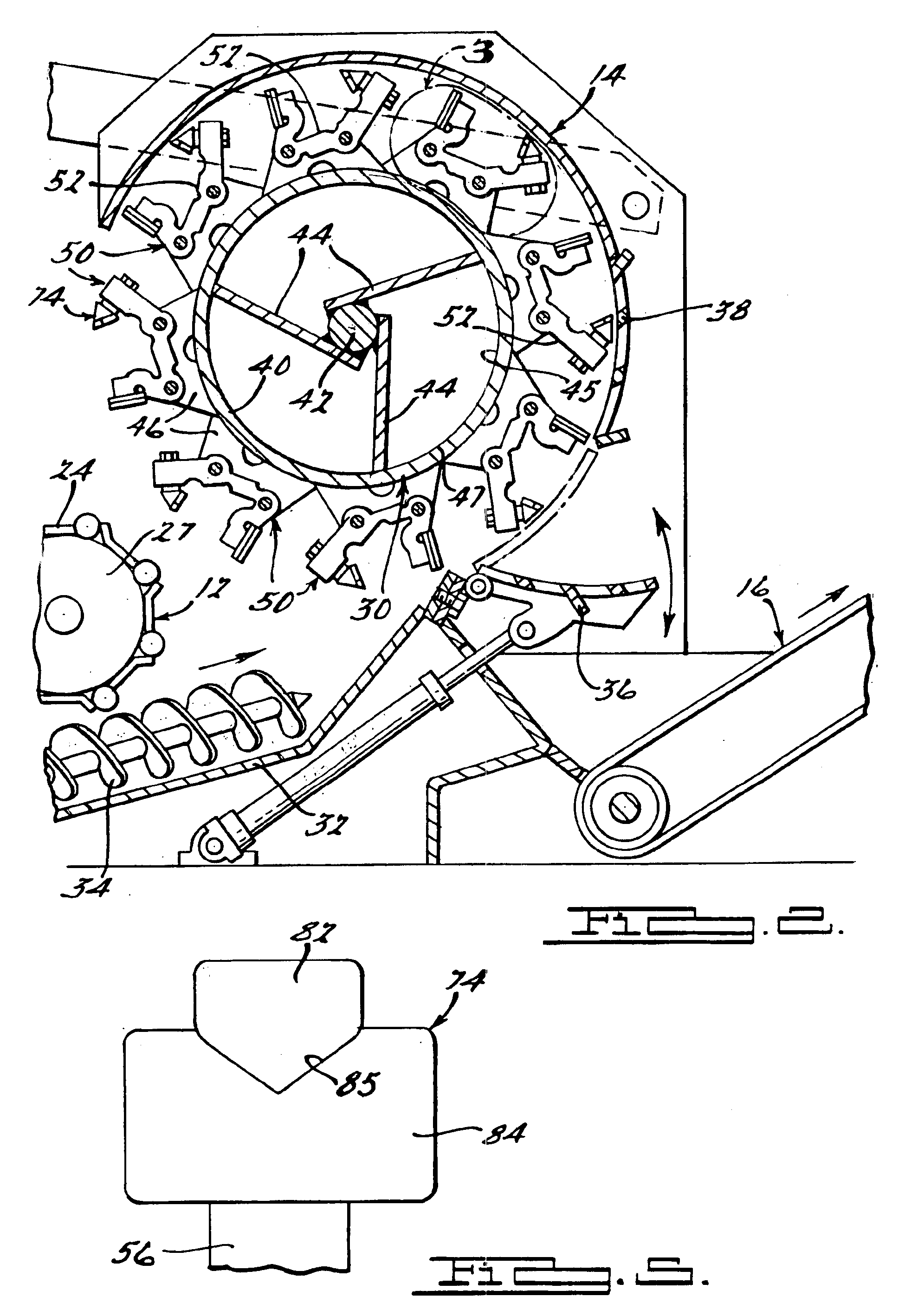

Cutter assembly for a grinder pump

A cutting assembly for a grinder pump comprised of a rotary cutter rotatable against an opposing plate cutter. The cutting edges of the plate cutter include a plurality of V-slice cutting teeth, which create bridging spaces to pinch material which is being sucked in to ports and begin cutting along the V-slice and then for cut material to pass through and onward into the volute of the pump. The rotary cutter has a ground edge with a rake angle which shears the gathered material in cooperation with the cutting edges of the plate cutter. A grinder pump including the cutter assembly is also disclosed.

Owner:LIBERTY PUMPS

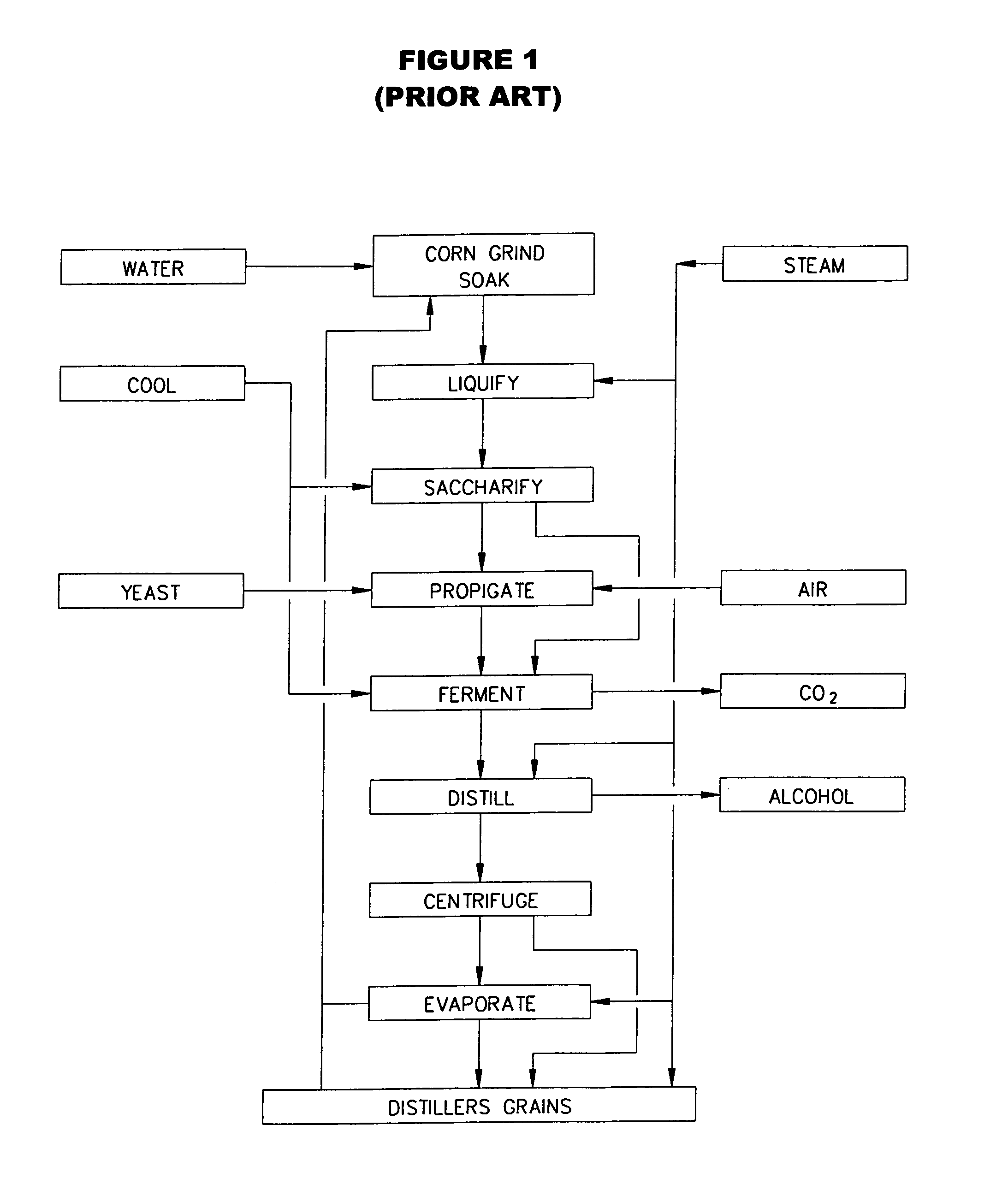

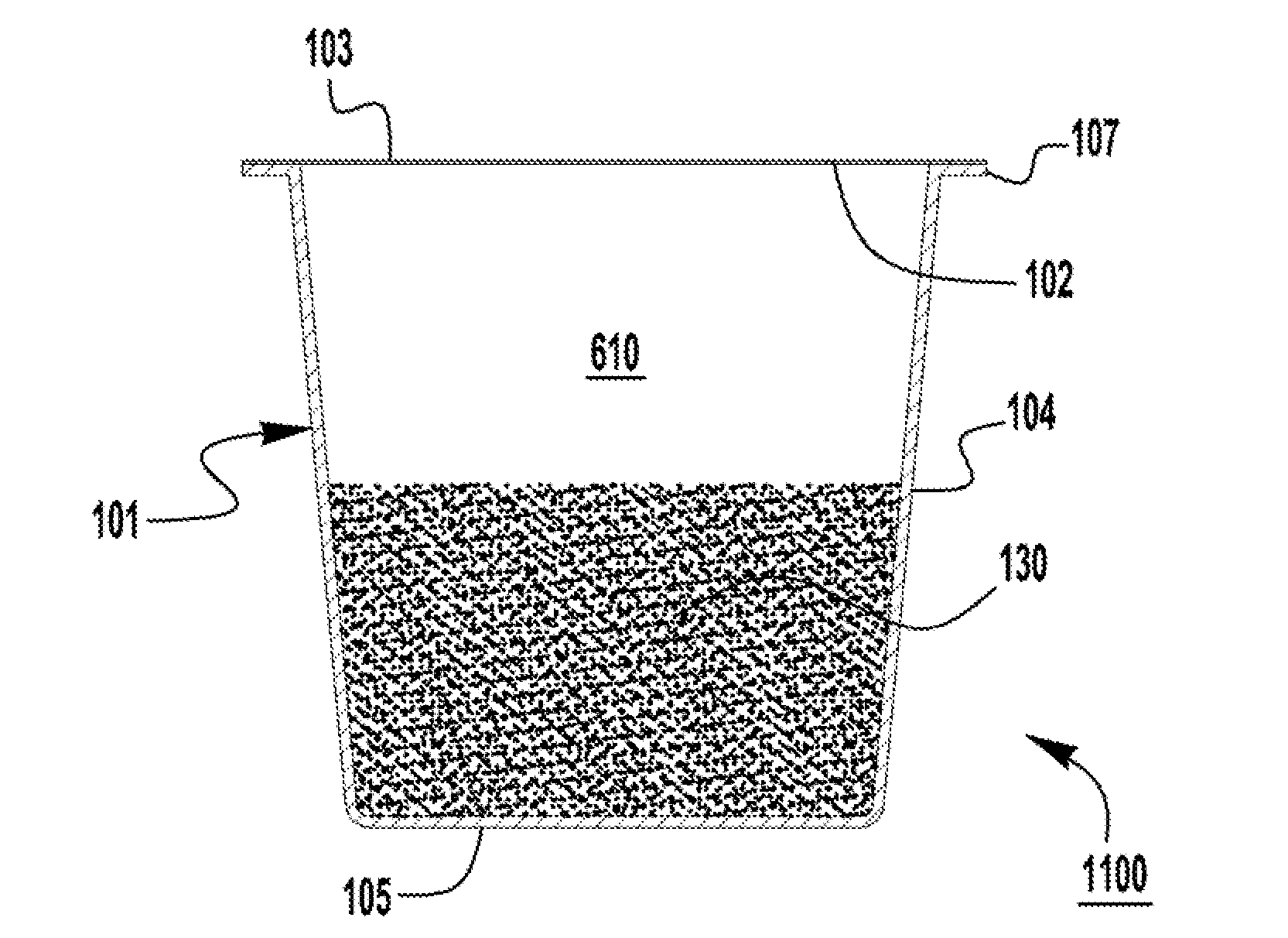

Corn refining process

InactiveUS7452425B1Quickly and efficiently producedAvoid large quantitiesJuice extractionBiofuelsSteepingSlurry

A grain containing starch, such as corn, is refined. The grain is steeped in water at a temperature of about 125 to 160° F., which water is essentially free of sulfurous acid and contains recycled enzymes from downstream processes, in a counter-current steeping reactor for about 10 to 20 hours to produce an aqueous slurry of steeped grain having a moisture content of about 40 to 50 percent. The various components of the grain are then separated and the starch is converted to ethanol.

Owner:LANGHAUSER ASSOC

Cooking utensil

Owner:HORNG ELECTRONICS CO LTD

Method of creating ultra-fine particles of materials using a high-pressure mill

Owner:CORNERSTONE TECH

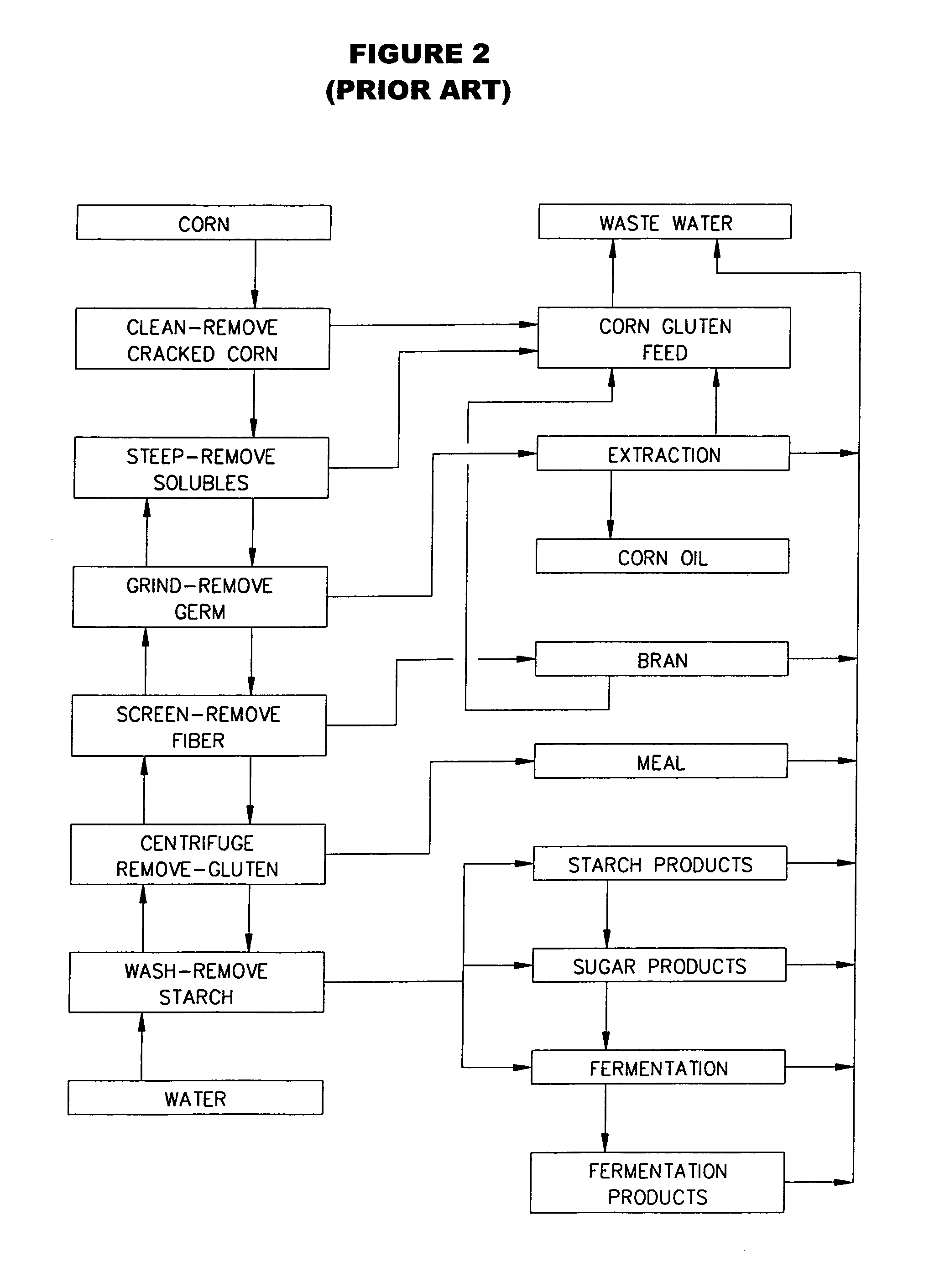

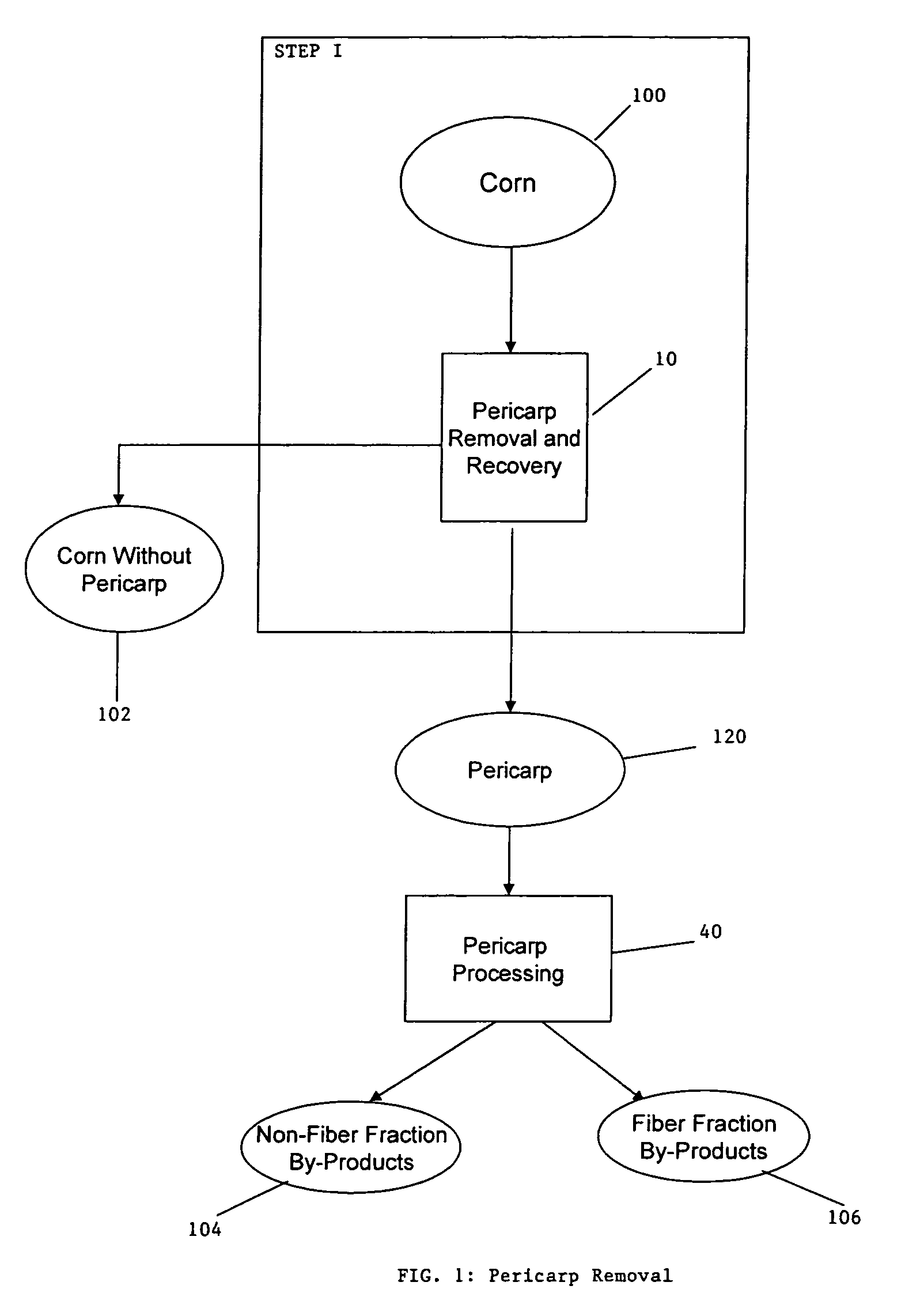

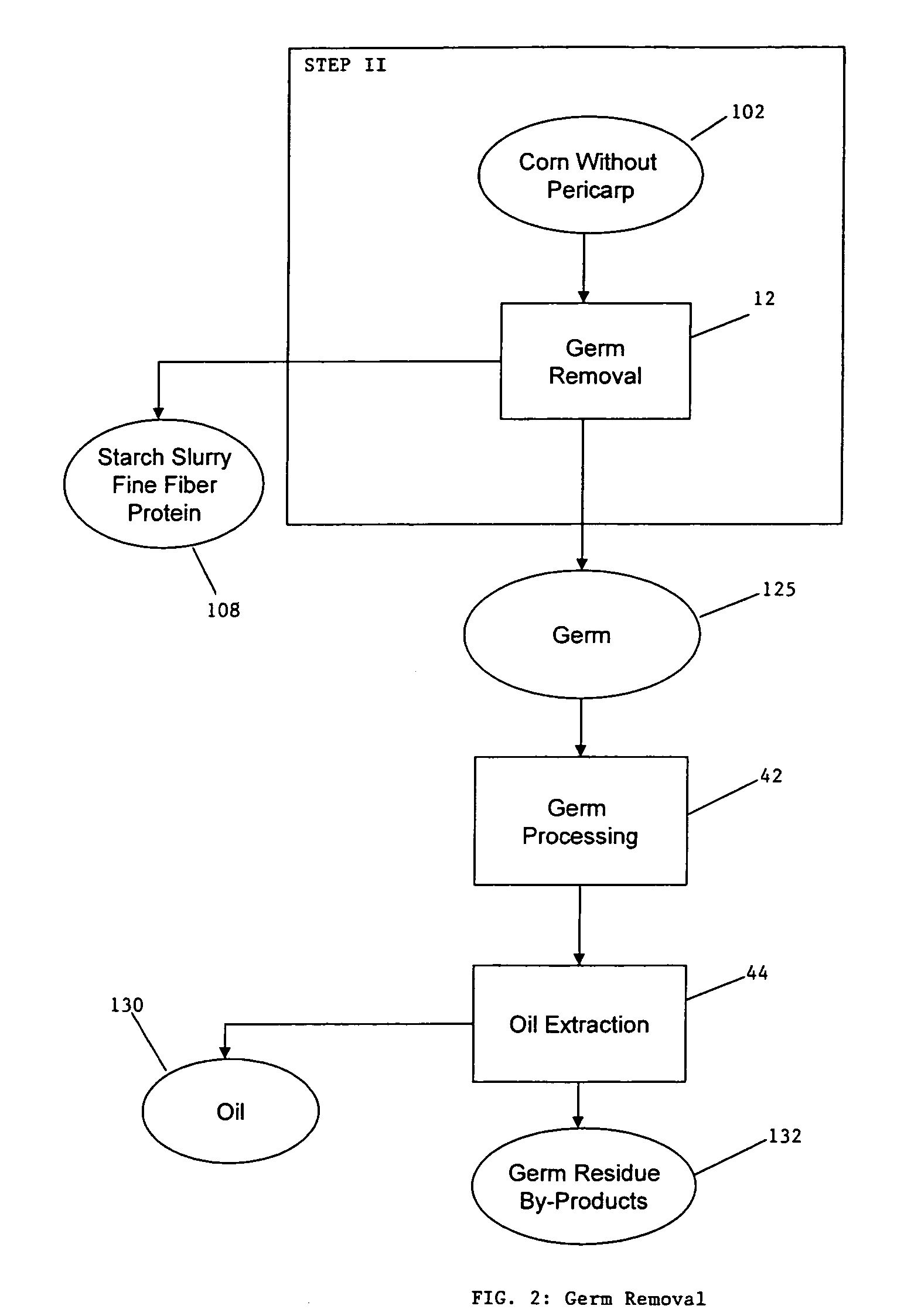

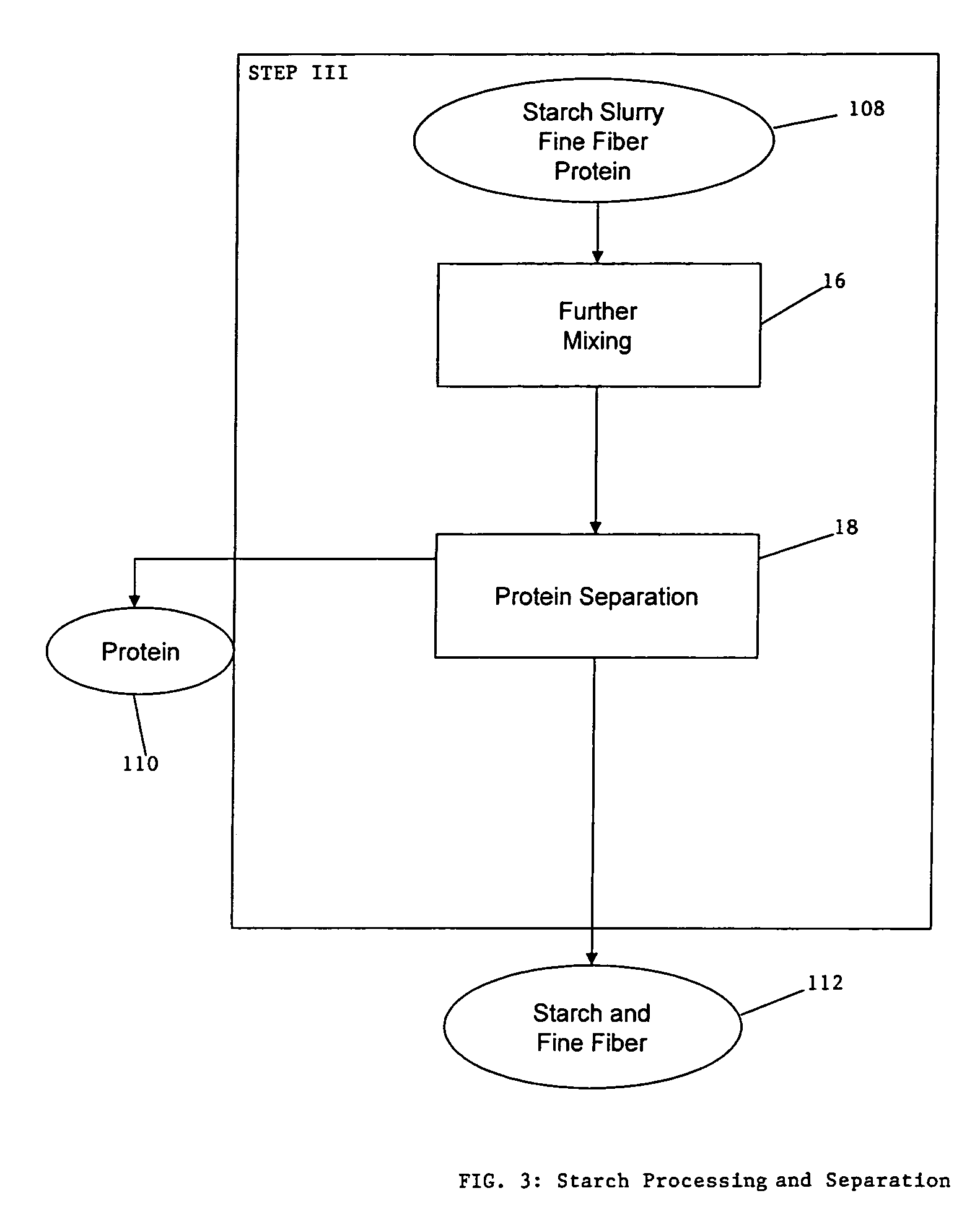

Process for the production of animal feed and ethanol and novel animal feed

A method for the production of ethanol and a modified animal feed is provided. The method replaces the starch in known corn-based animal feed with biomass fiber treated to make it more digestible by animals. The process includes wherein the pericarp and germ are removed from the corn kernel and processed for by-products. The starch and protein are also removed and separated. The starch is then fermented and distilled to ethanol and stillage. The bioavailable modified animal feed comprises the pericarp and germ removed from corn kernels and optionally by-products of the pericarp and germ processing, and lignocellulosic materials. The modified animal feed may optionally include energy materials such as animal and vegetable fats, vegetable soapstocks, or glycerin, and combinations thereof.

Owner:ARCHER DANIELS MIDLAND CO

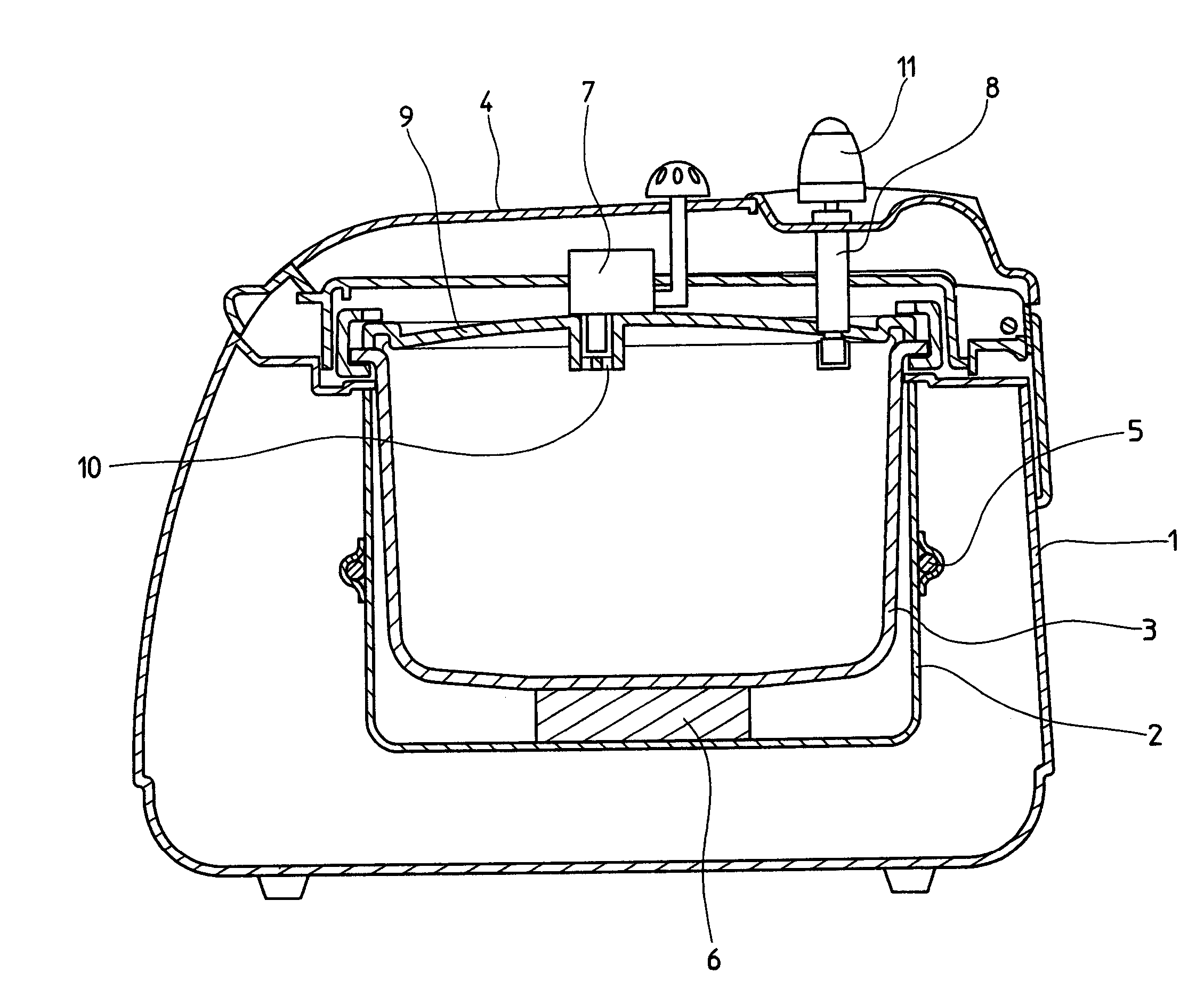

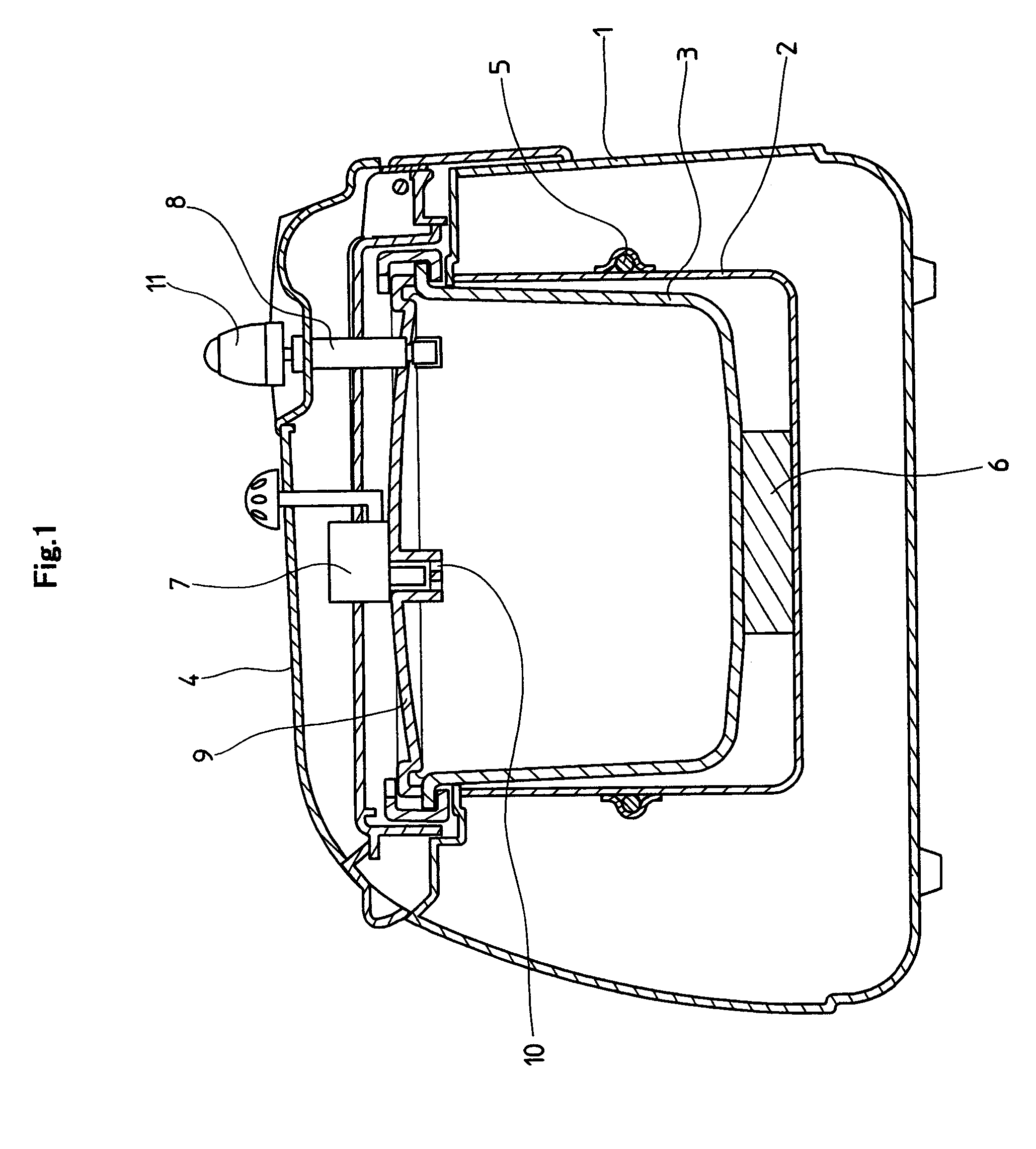

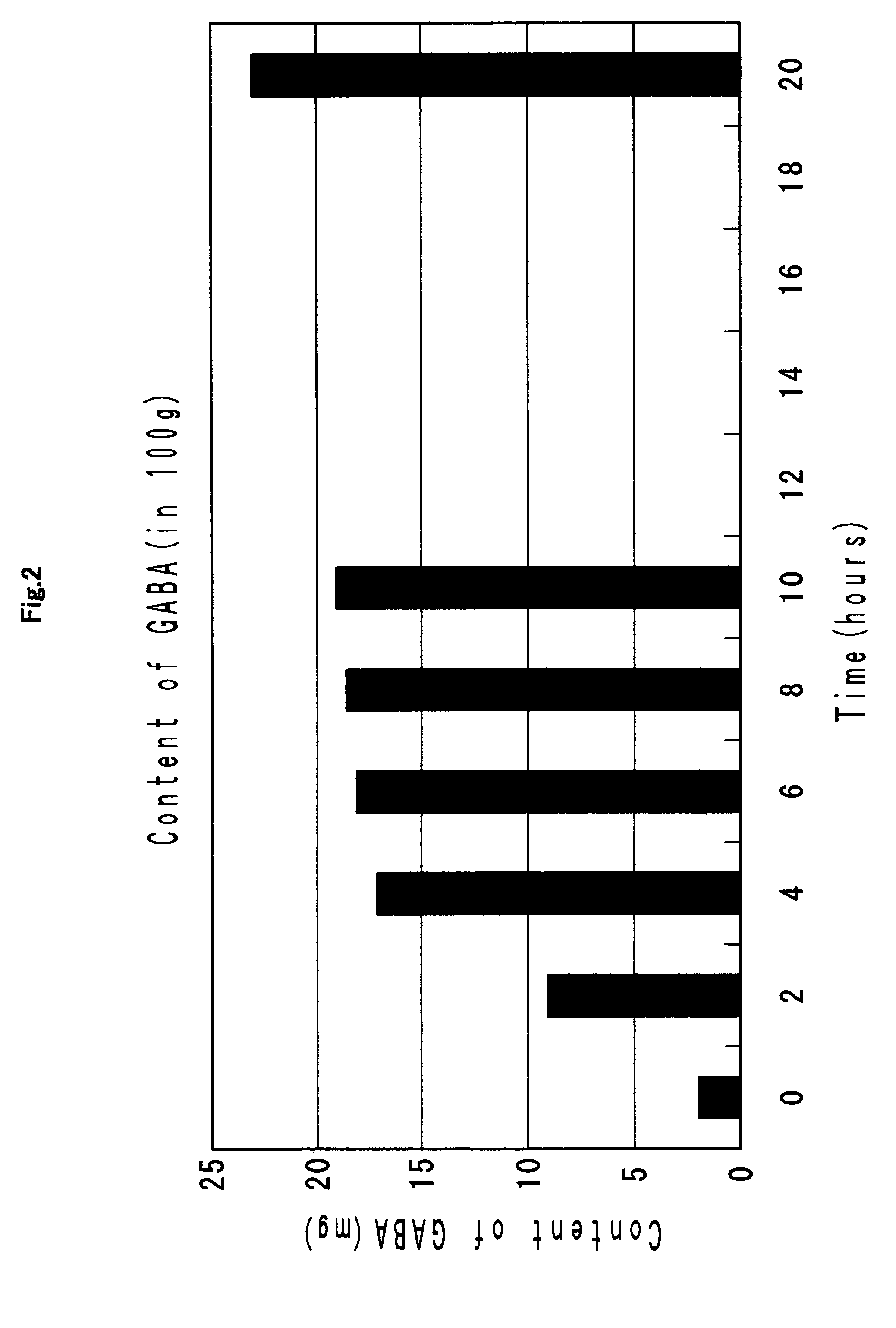

Rice cooker

InactiveUS7148451B2Short timeEliminate scatterBaking ovenPressure-cookersGamma-Aminobutyric acidRice dishes

When water temperature is high and time germinating step is short, it is hard to cook freely to individual preference, and water turbidity and bad smell are likely to occur. By germinating with immersing brown rice or rice with the germ in water at 28 to 34 degrees for 3 to 6 hours in an inner pot 3, being followed by a cooking step successively, the rice can be immersed for a necessary time at low temperature, so that germinated rice with enough content of gamma-aminobutyric acid (GABA) can be obtained without causing water turbidity or bad smell.

Owner:MIYAKE INC

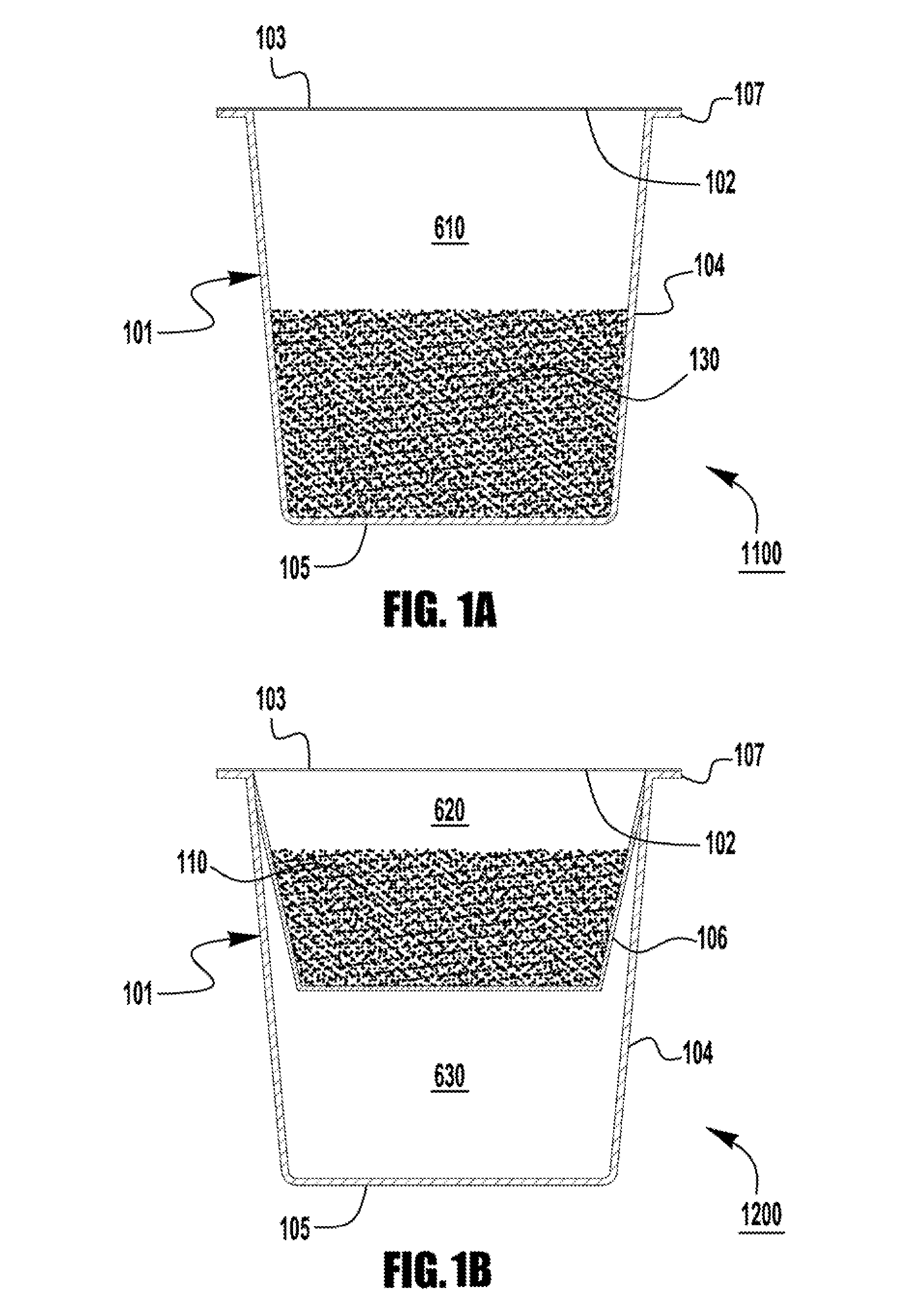

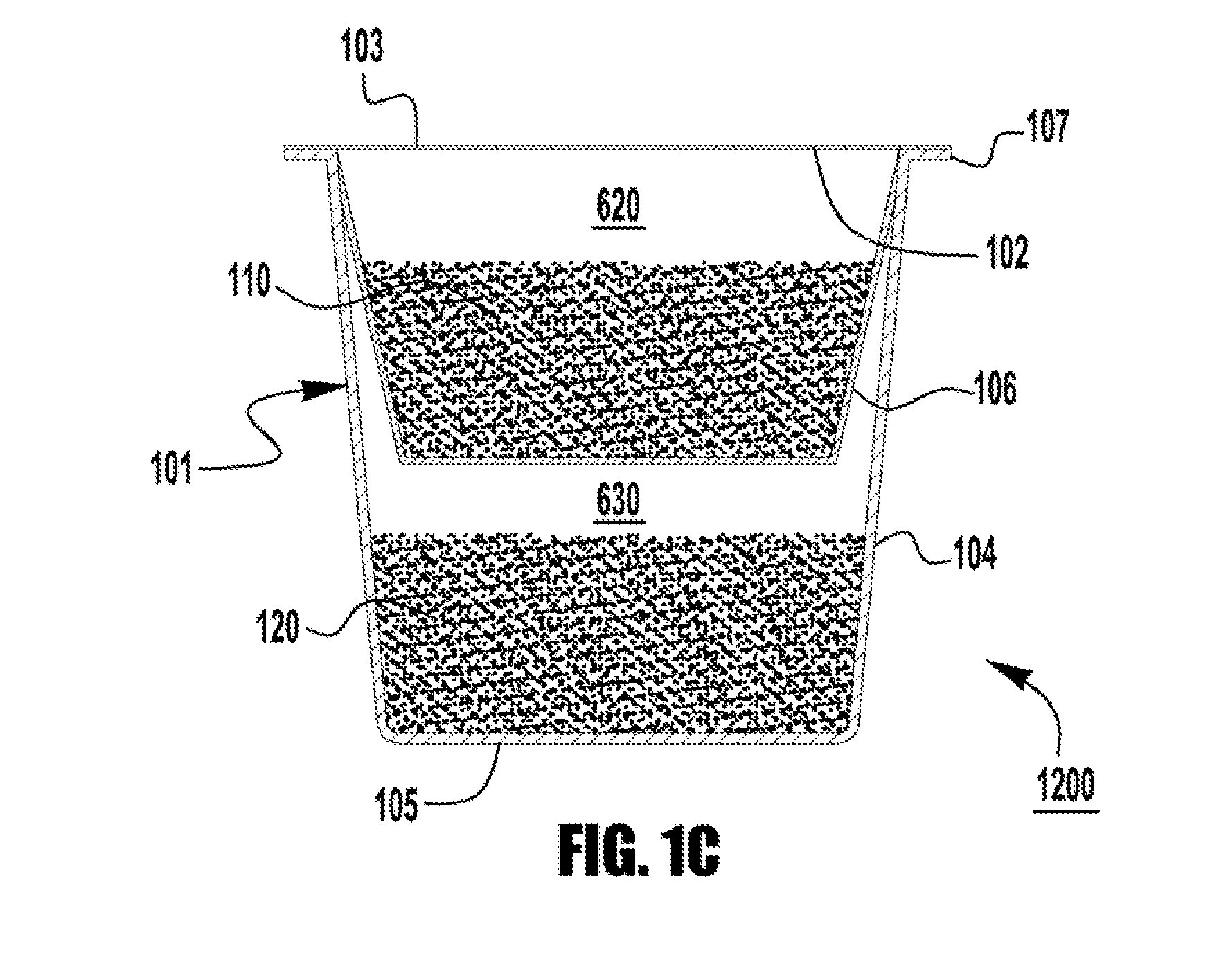

Coffee composition for use with a beverage unit and methods of using the same

The present invention provides a coffee composition for use with a single serve beverage unit. The beverage unit consists of a container having a first structure to enable the introduction of a liquid such as hot water into the container to contact the coffee composition and a second structure to enable the release of a coffee extract out of the container. The coffee composition comprises various coffee ingredients demonstrating an improved property, or an improved balance between two or more of properties, selected from aroma, strength, flavor, cup color, acidity, density, extractability, bed permeability, brewing time, yield, structural integrity, quality consistence and uniformity, and cost-effectiveness. Methods of using such coffees are also disclosed.

Owner:THE FOLGERS COFFEE

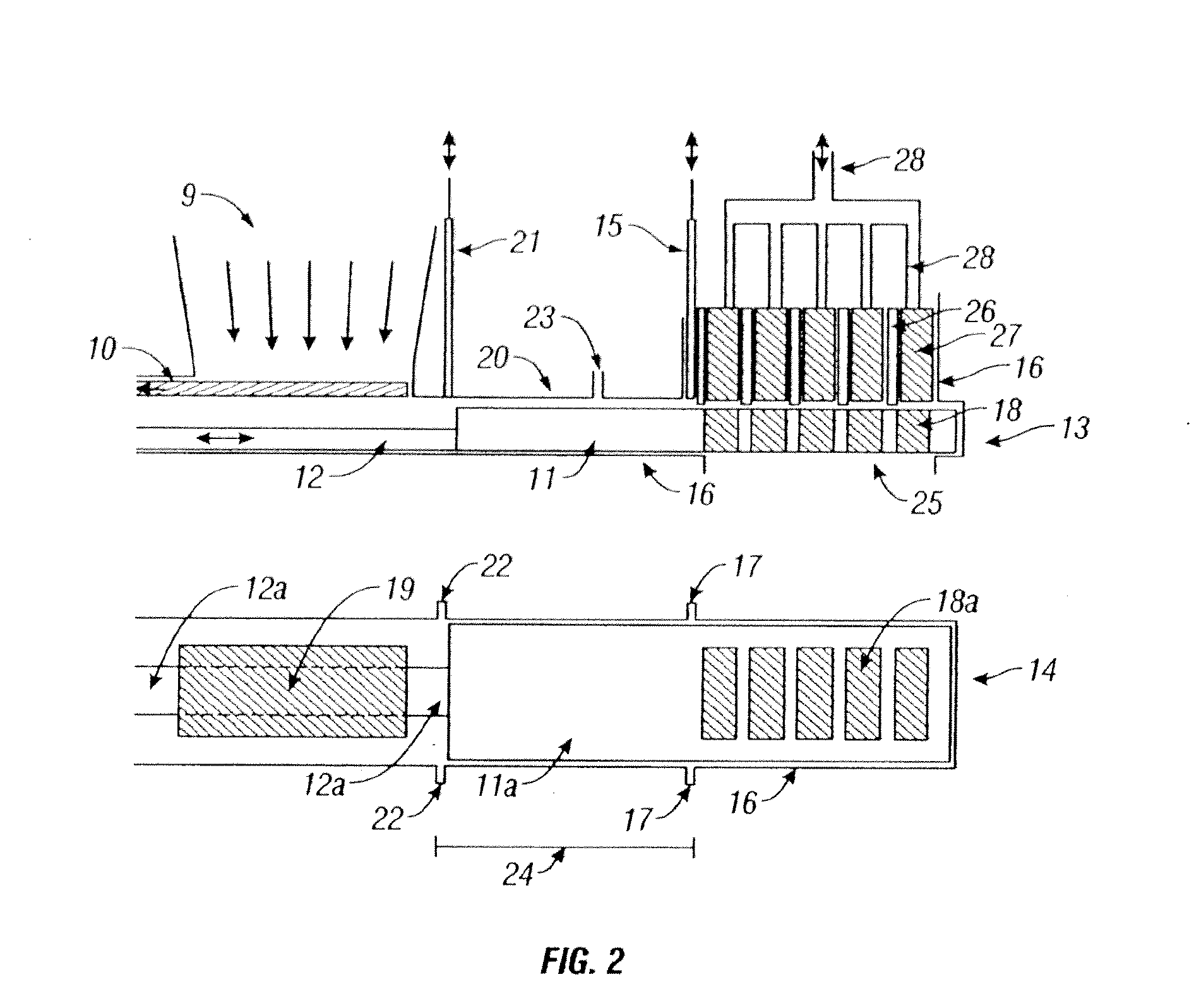

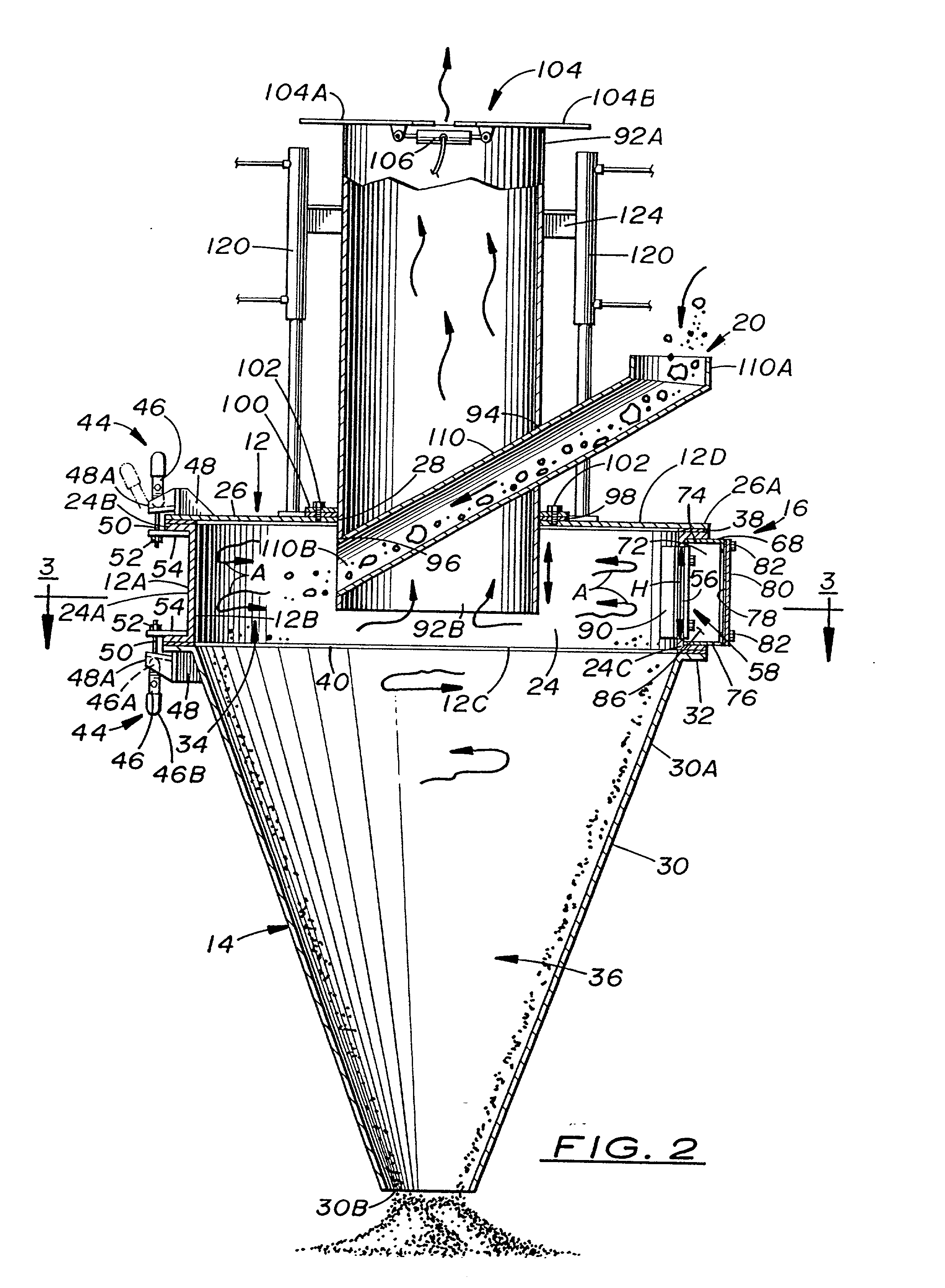

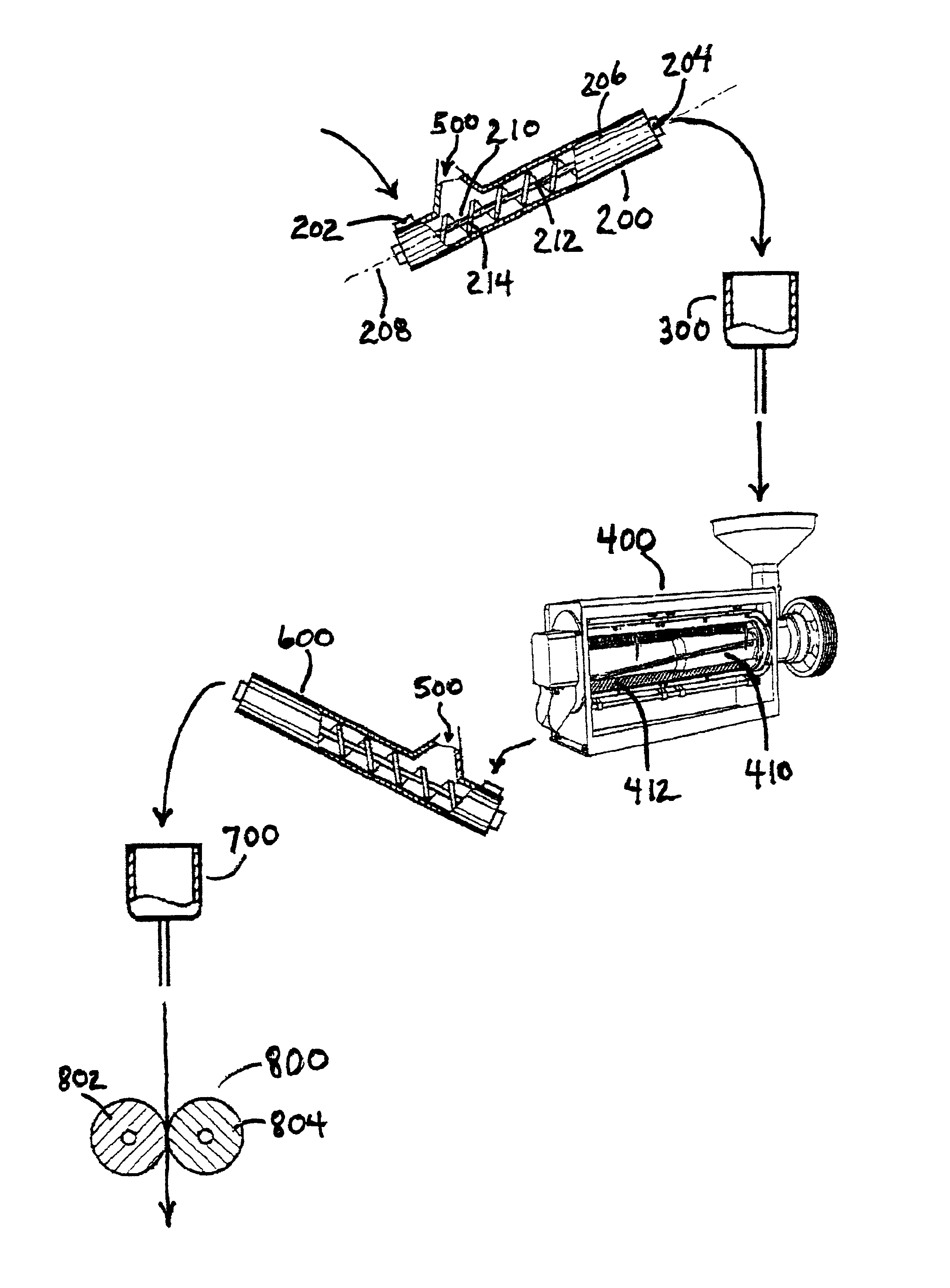

System and method for biomass fractioning

ActiveUS20110177466A1Easy inputIncrease productionDrying solid materials with heatOther heat production devicesSyngasThin sheet

A biomass fractionator and method are described for inputting ground biomass and outputting several vapor streams of bio-intermediate compounds along with syngas and biochar. In one embodiment, a method for biomass fractioning, comprises dispensing biomass into thin sheets of ground biomass; subjecting the thin sheets to ramps of temperature; and selectively collecting various groups of compounds as they are released from the thin sheets.

Owner:COOL PLANET ENERGY SYST

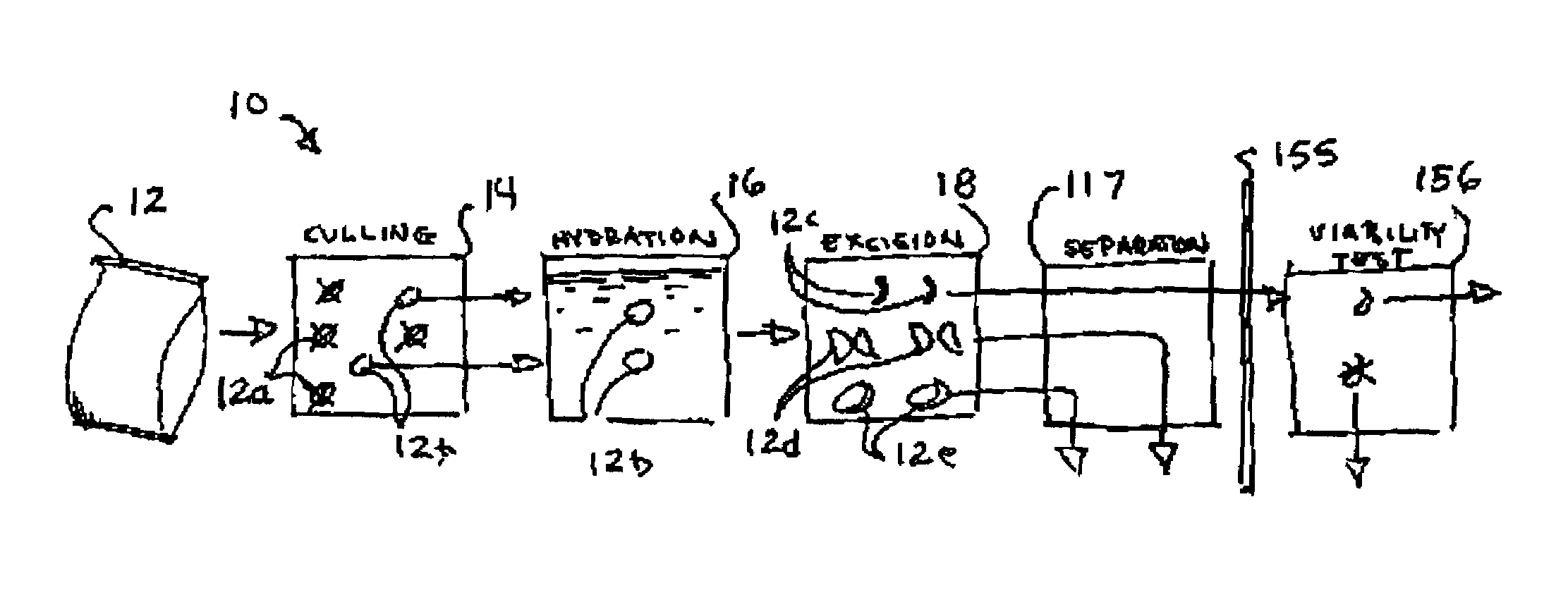

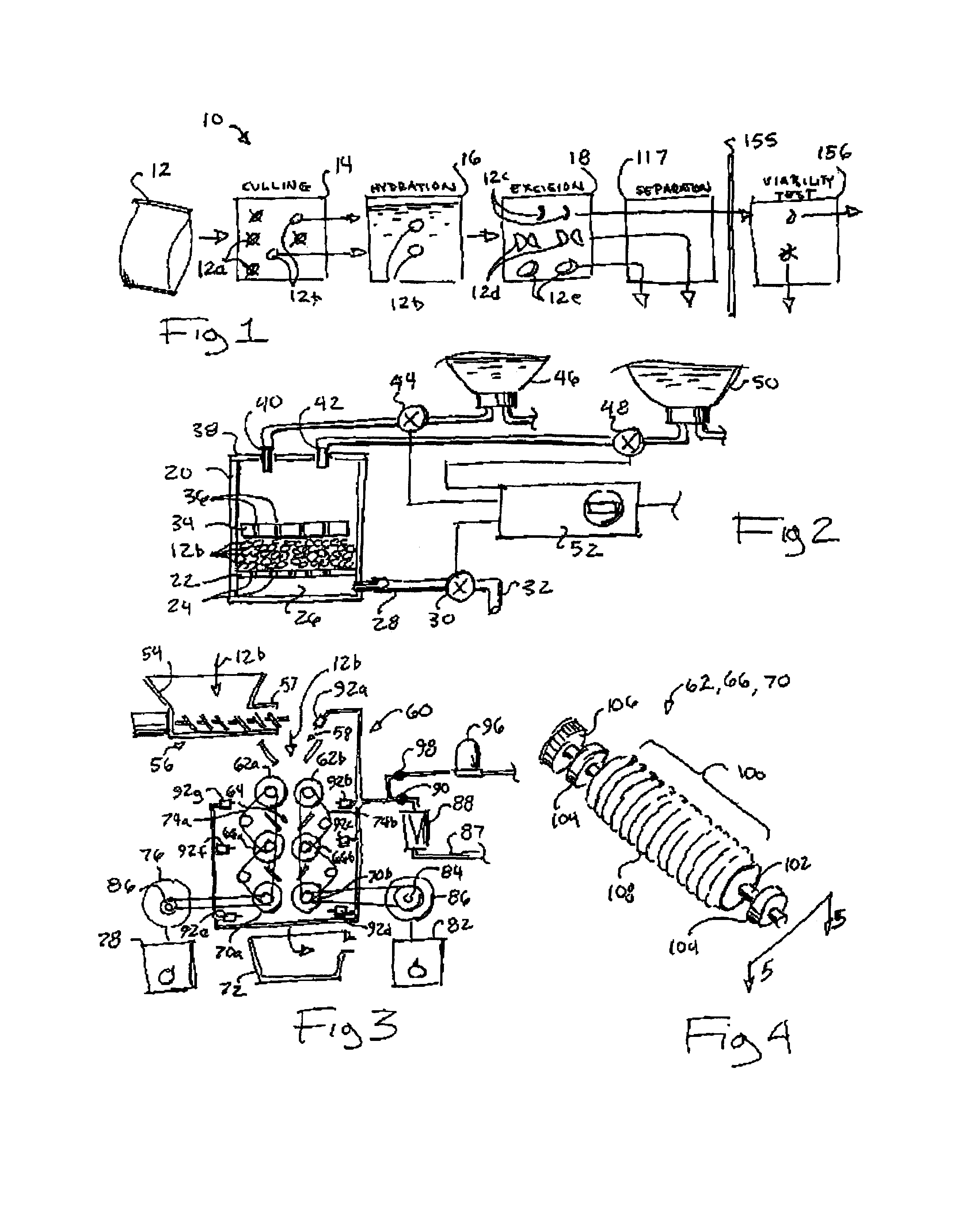

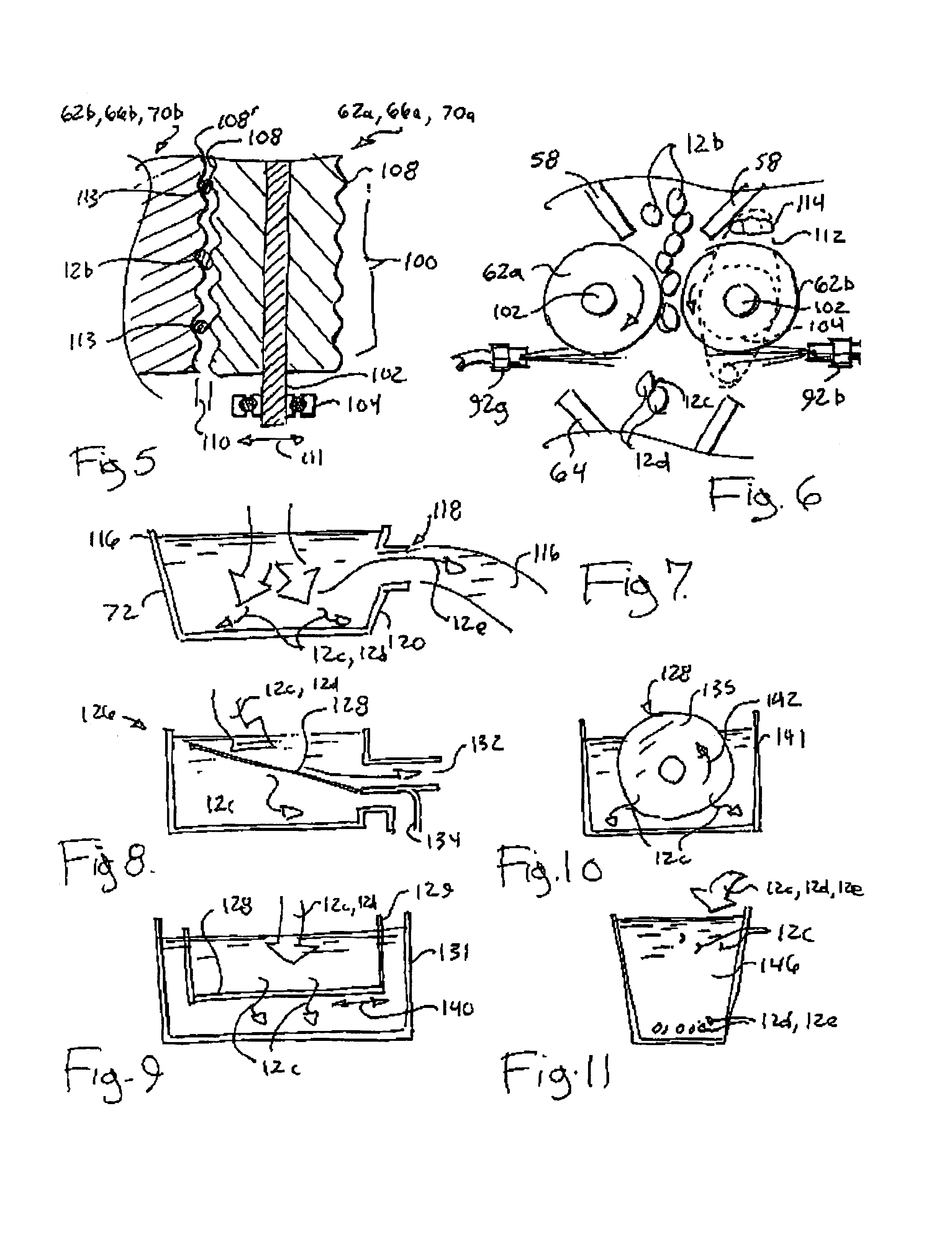

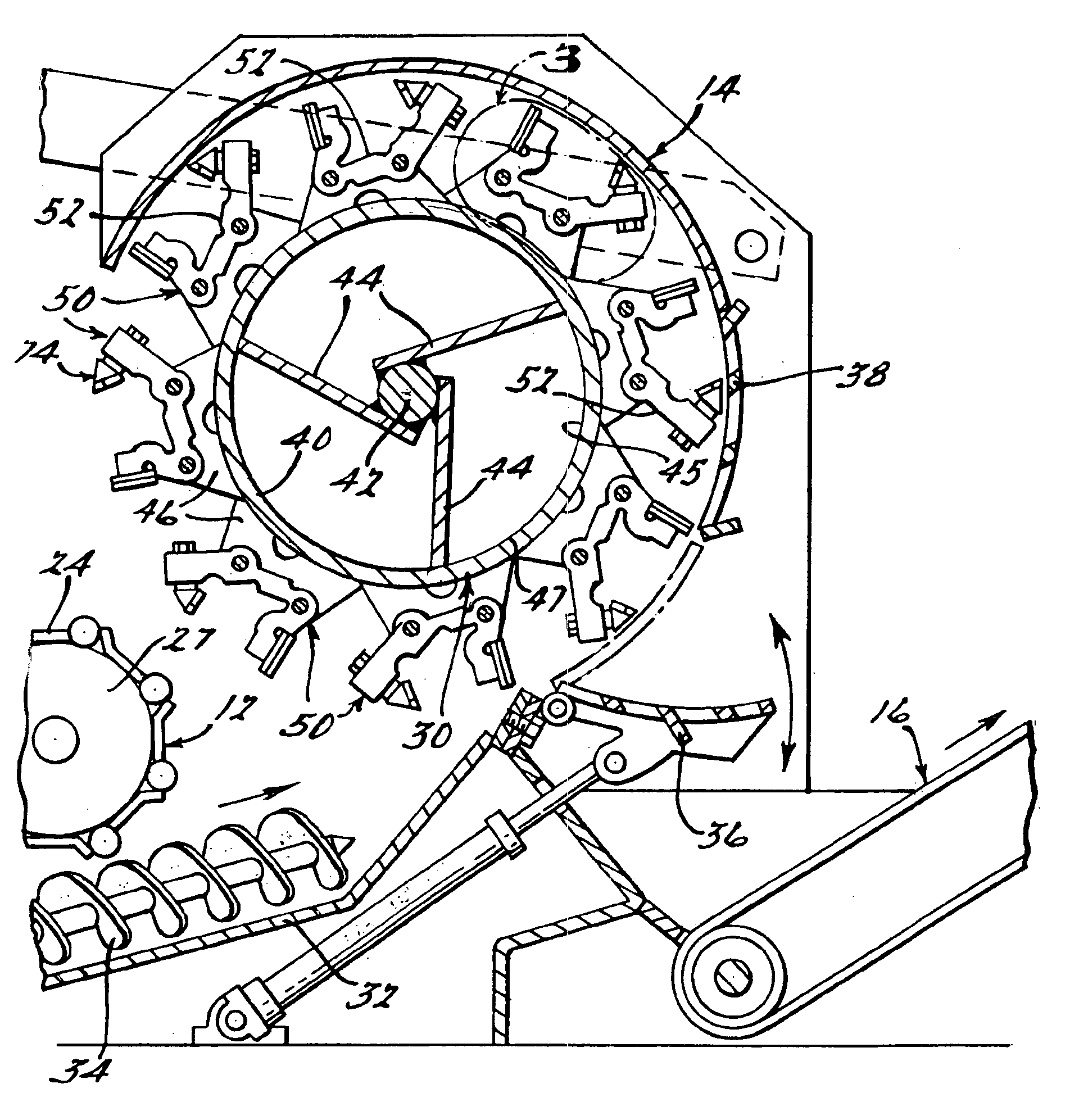

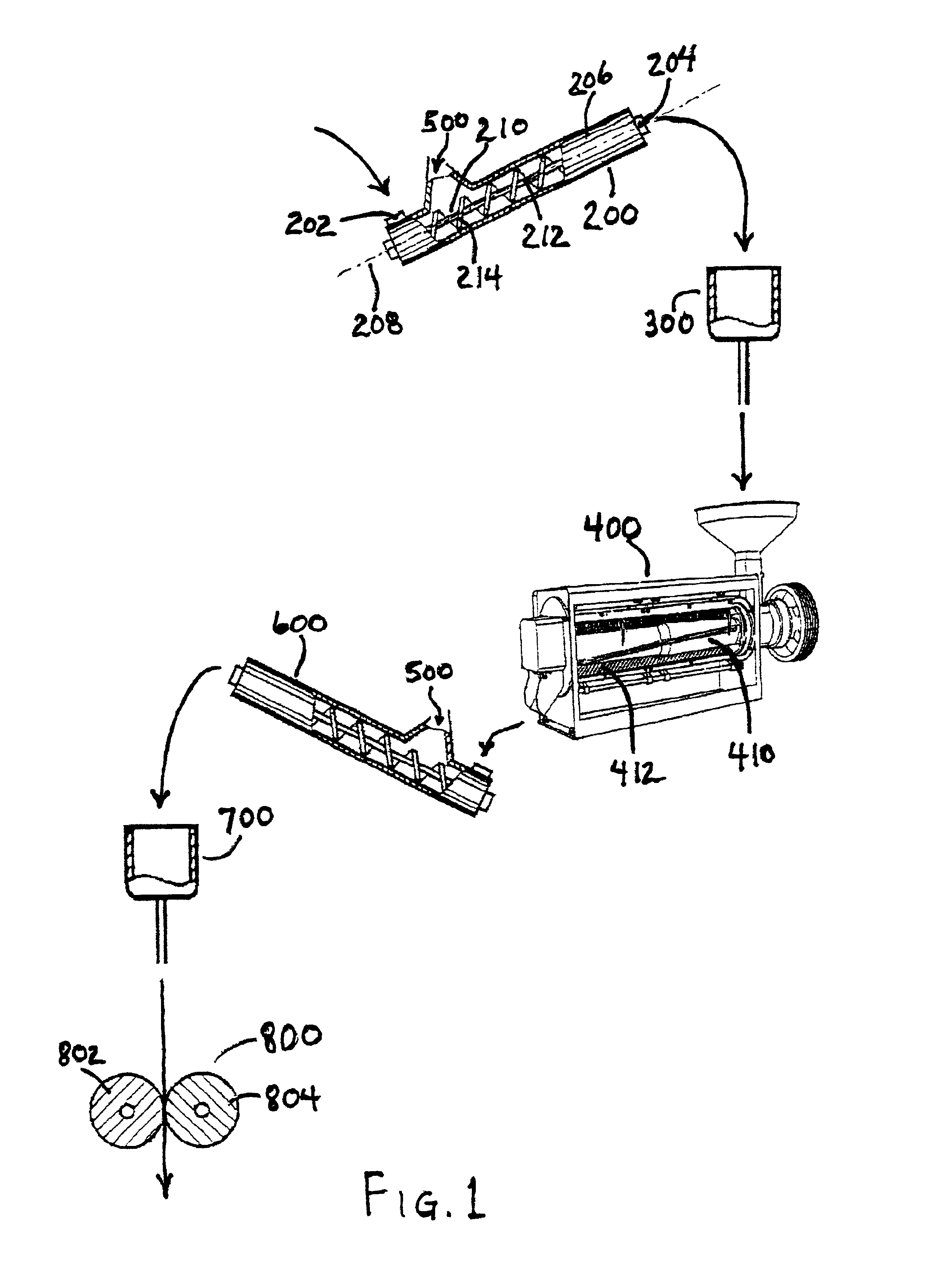

Method and apparatus for preparation of genetically transformable plant tissue

A process of mechanical separation of embryos from seeds for genetic transplantation employs counter-rotating cylinders together with one or more culling, hydration, separation, and viability testing steps to provide high-throughput of viable, transplantable tissue.

Owner:MONSANTO TECH LLC

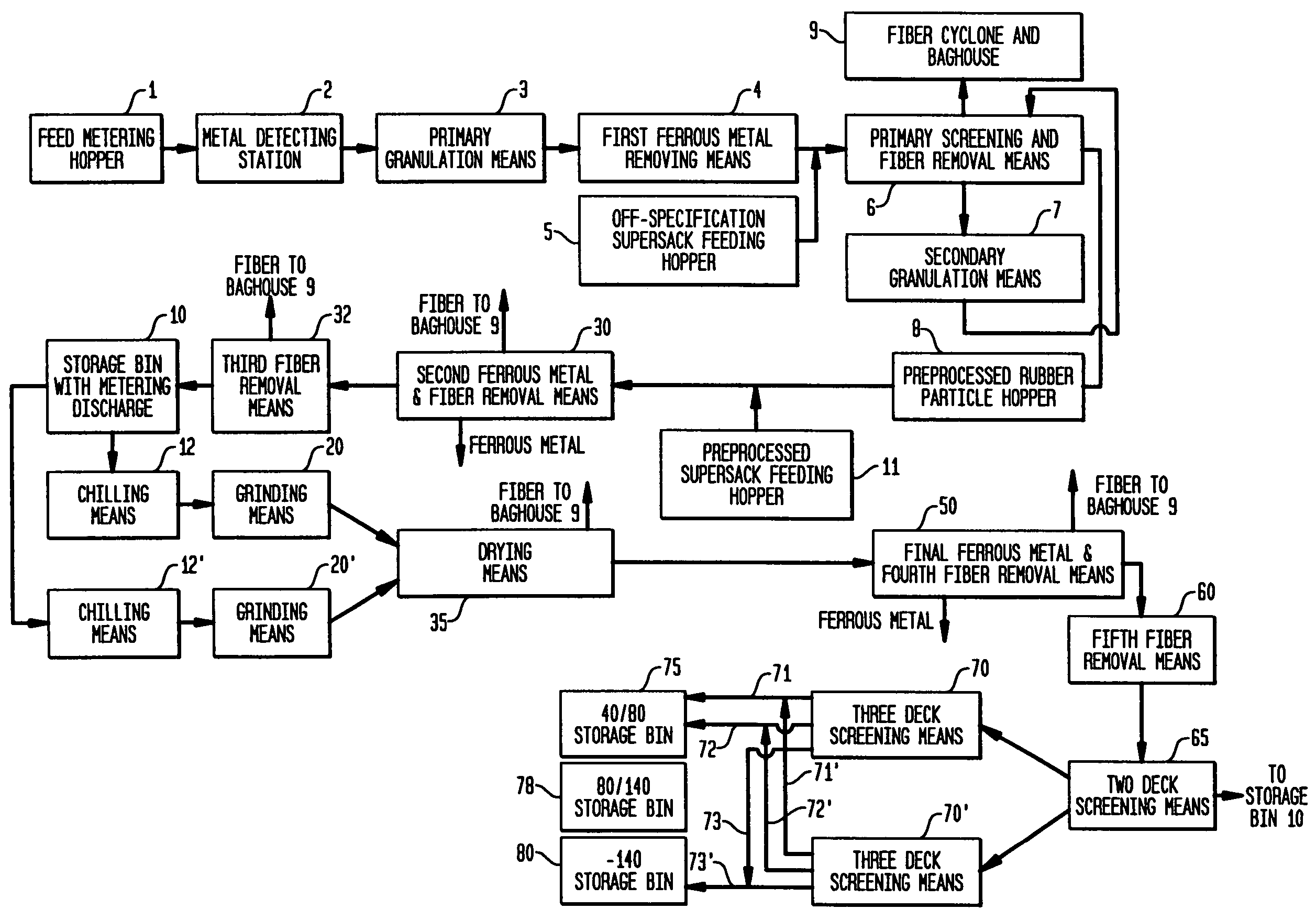

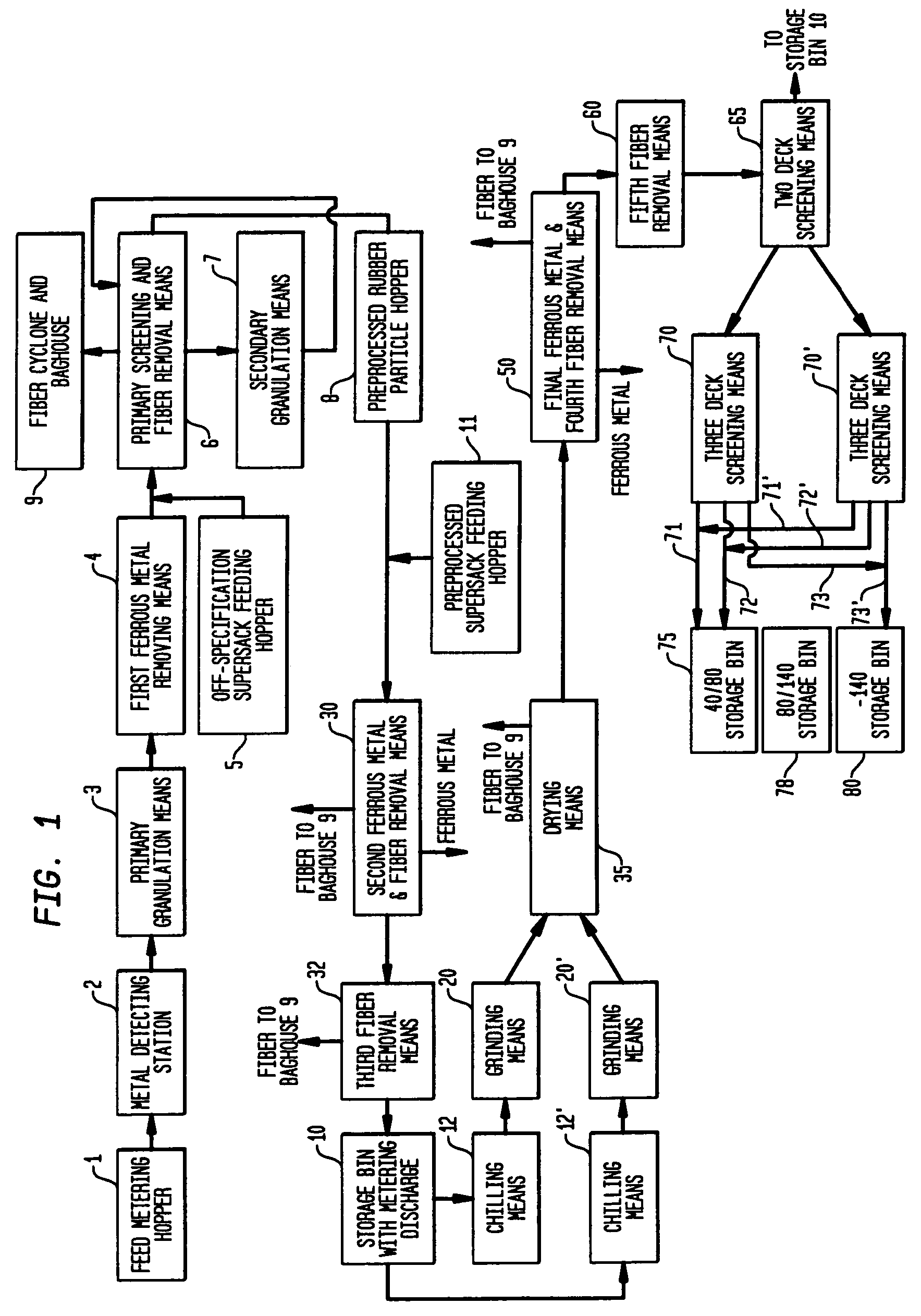

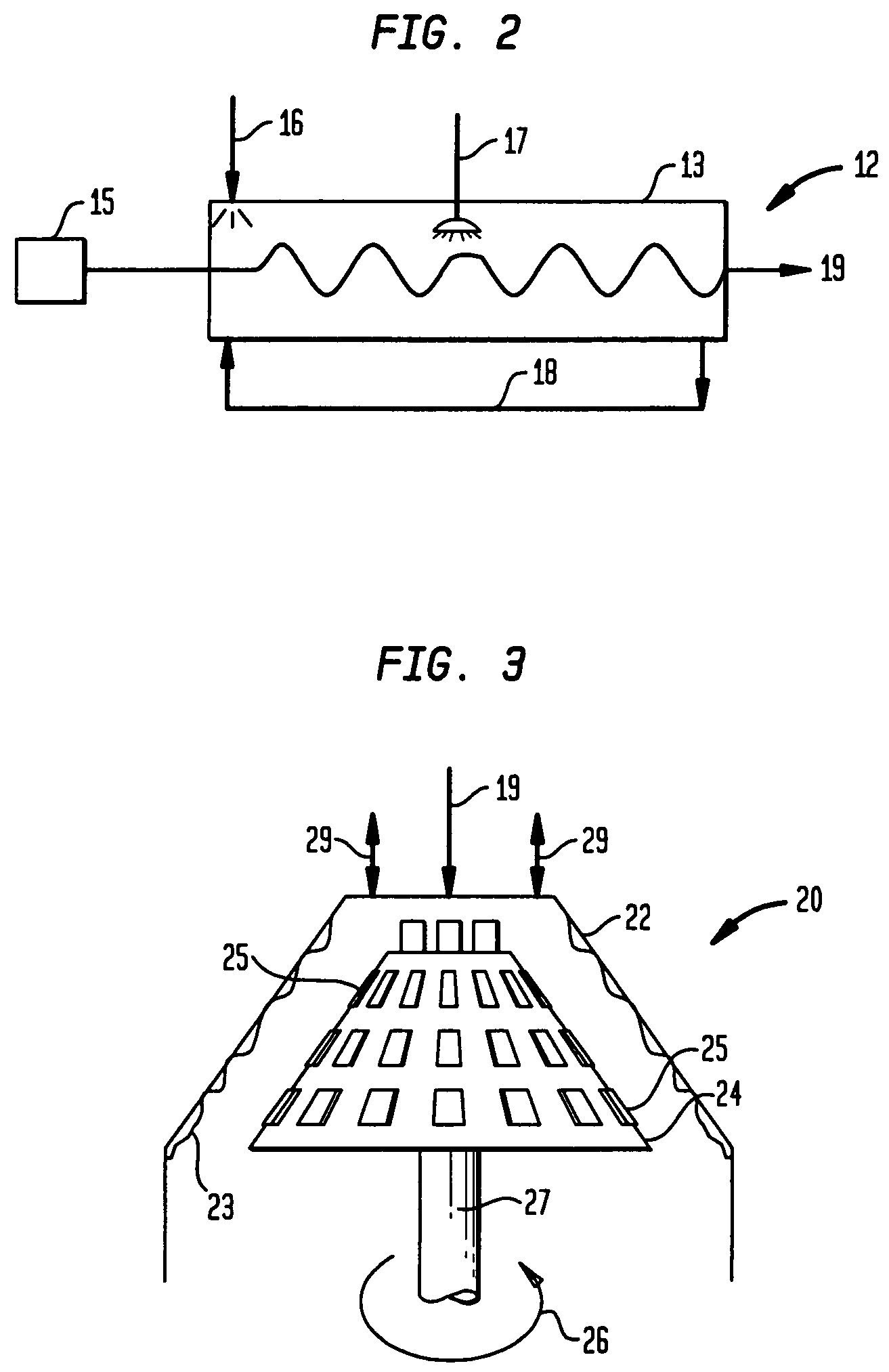

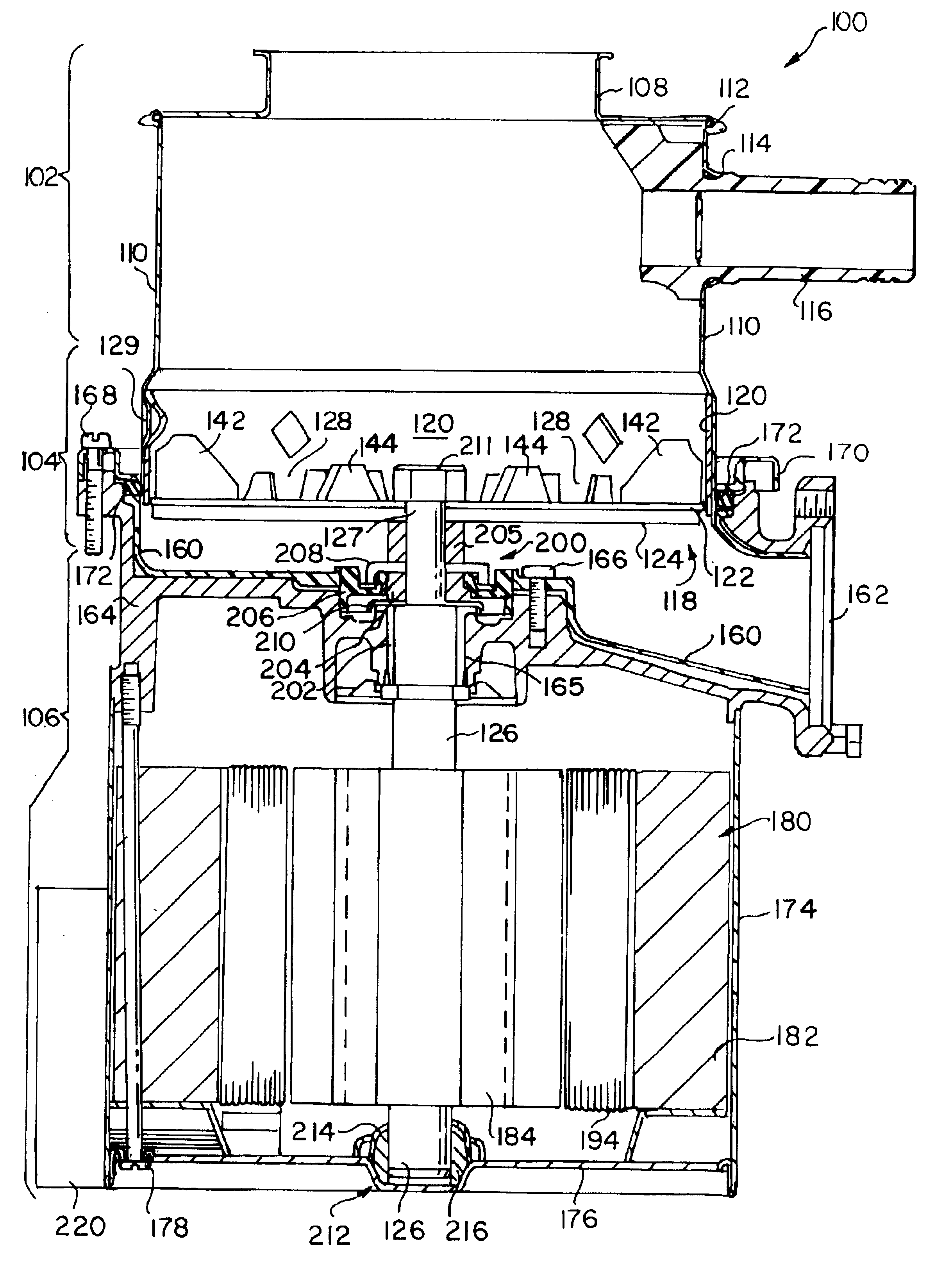

Process and apparatus for manufacturing crumb and powder rubber

A process and apparatus for manufacturing crumb and powder rubber. The process and apparatus include a cooling step, effectuated by cooling means, wherein the temperature of cryogenically cooled preprocessed rubber particles is controlled. The process and apparatus also include a grinding step, effectuated by grinding means, in which the degree of grinding, and thus the product particle size range, is controlled.

Owner:LEHIGH TECH INC

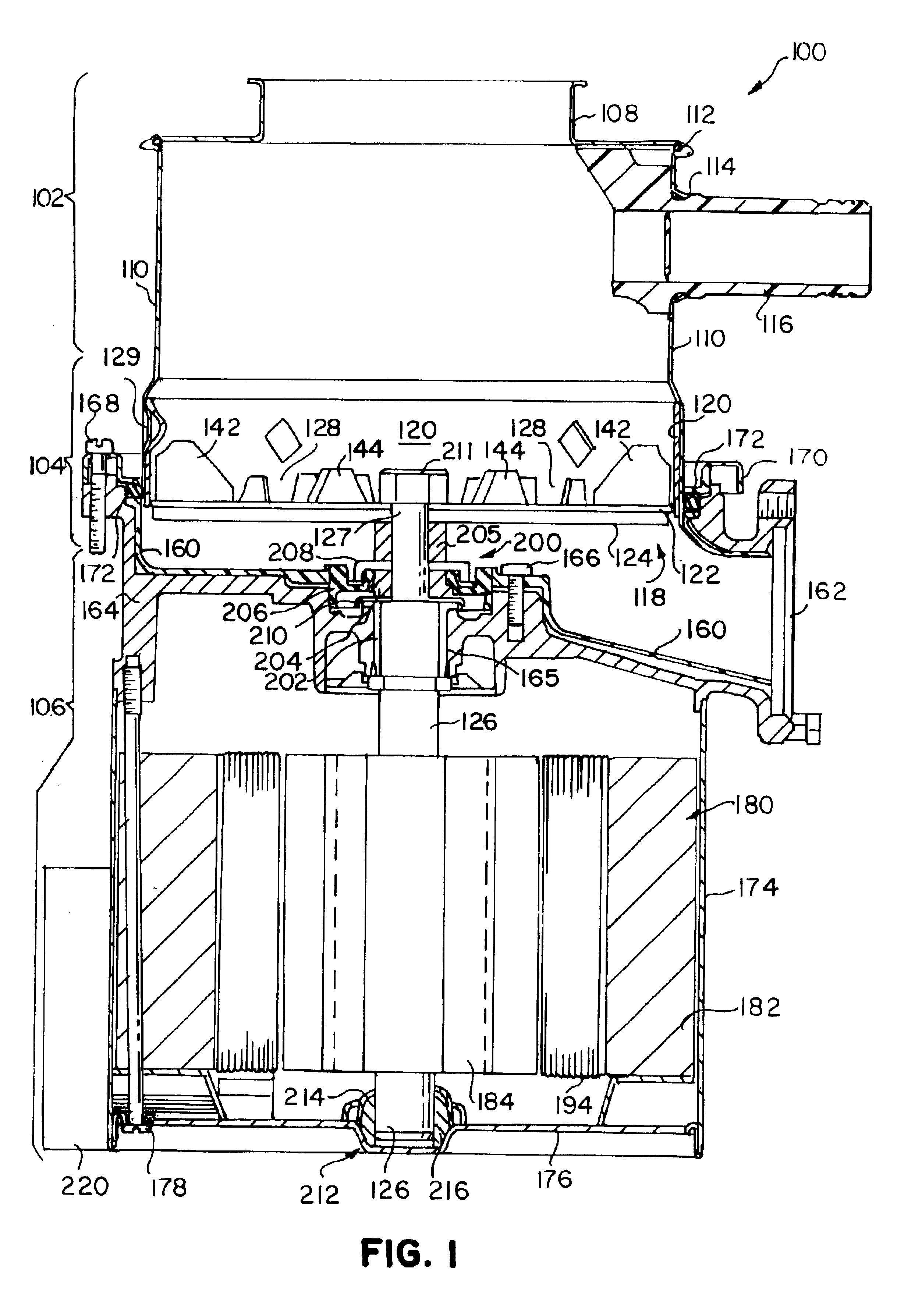

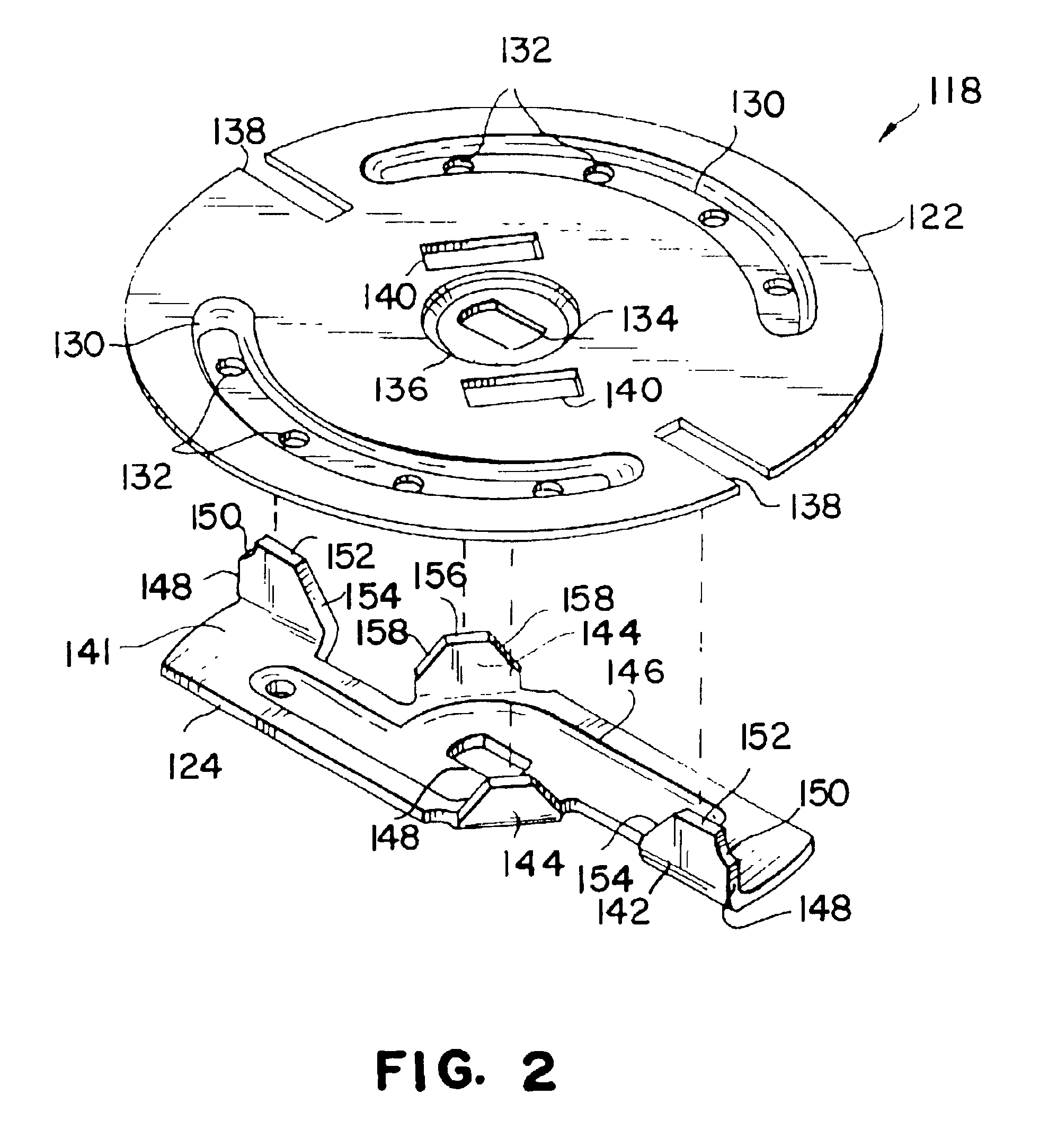

Food waste disposer having a variable speed motor

The present invention provides a food waste disposer having an upper food conveying section, a motor section, a central grinding section and a controller. The upper food conveying section includes a housing forming an inlet to receive food waste. The motor section includes a switched reluctance machine having a rotor and a stator. The rotor imparts rotational movement to a rotatable shaft. The central grinding section is disposed between the food conveying section and the motor section. The food conveying section conveys food waste to the grinding section. The grinding section includes a grinding mechanism where a portion of the grinding mechanism is mounted to the rotatable shaft. The controller is electrically connected to the stator to control the switched reluctance machine. The controller is capable of directing rotational movement to the rotatable shaft and the portion of the grinding mechanism mounted to the rotatable shaft. The controller is further capable of maintaining the rotational movement of the rotatable shaft at more than one rotational speed. The present invention also includes methods of operating a variable speed motor in different operational modes such as idle mode and anti-jamming mode.

Owner:EMERSON ELECTRIC CO

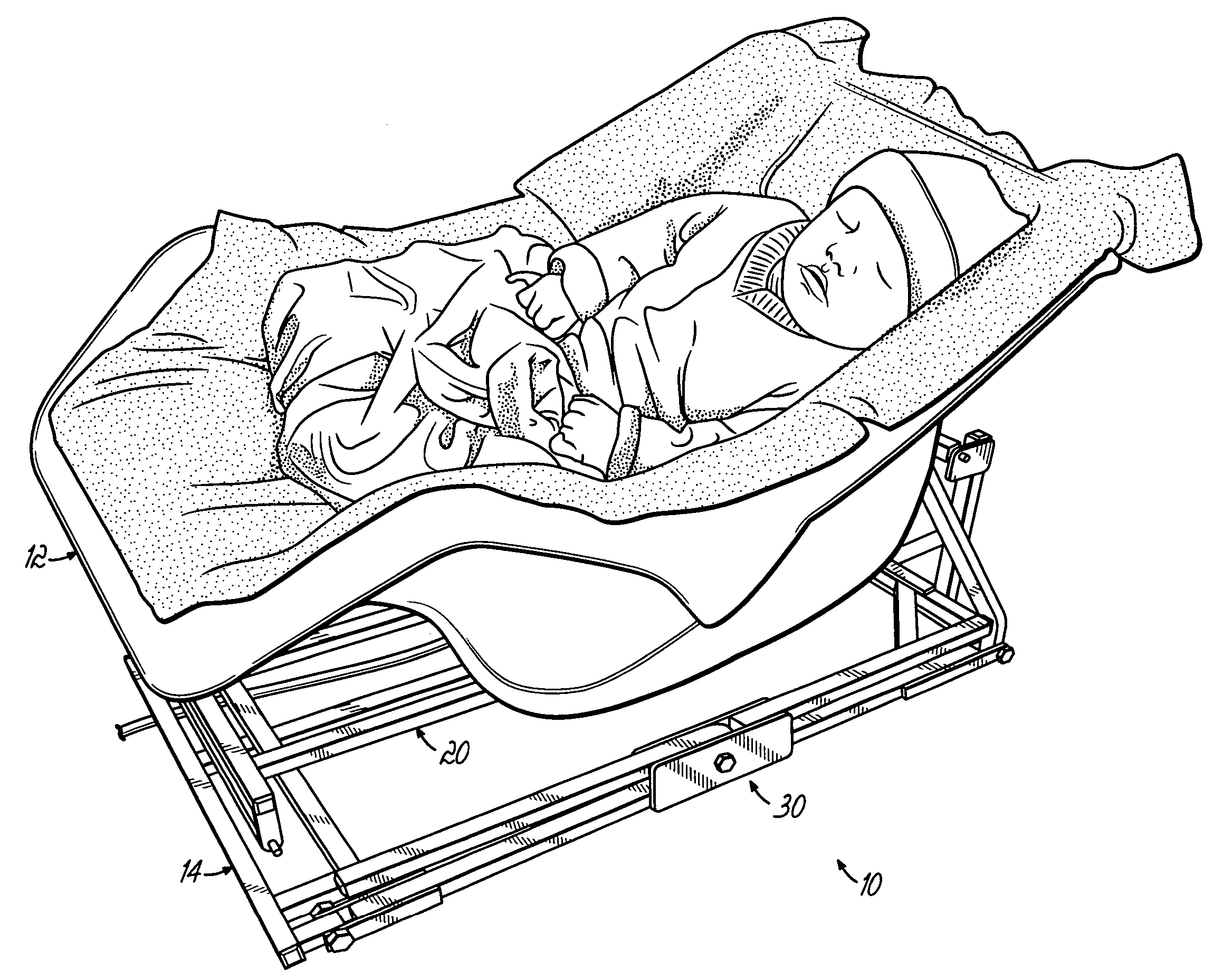

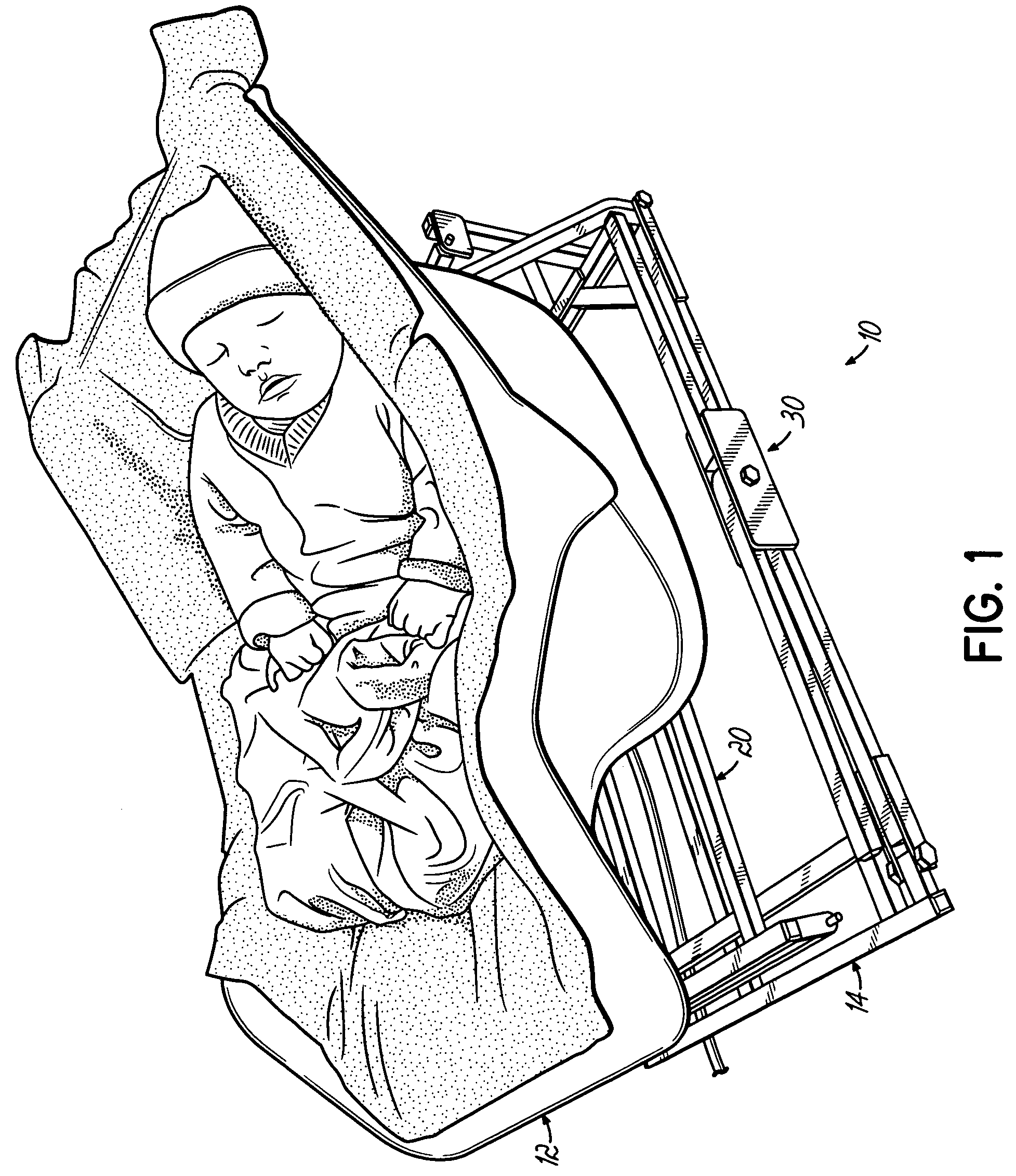

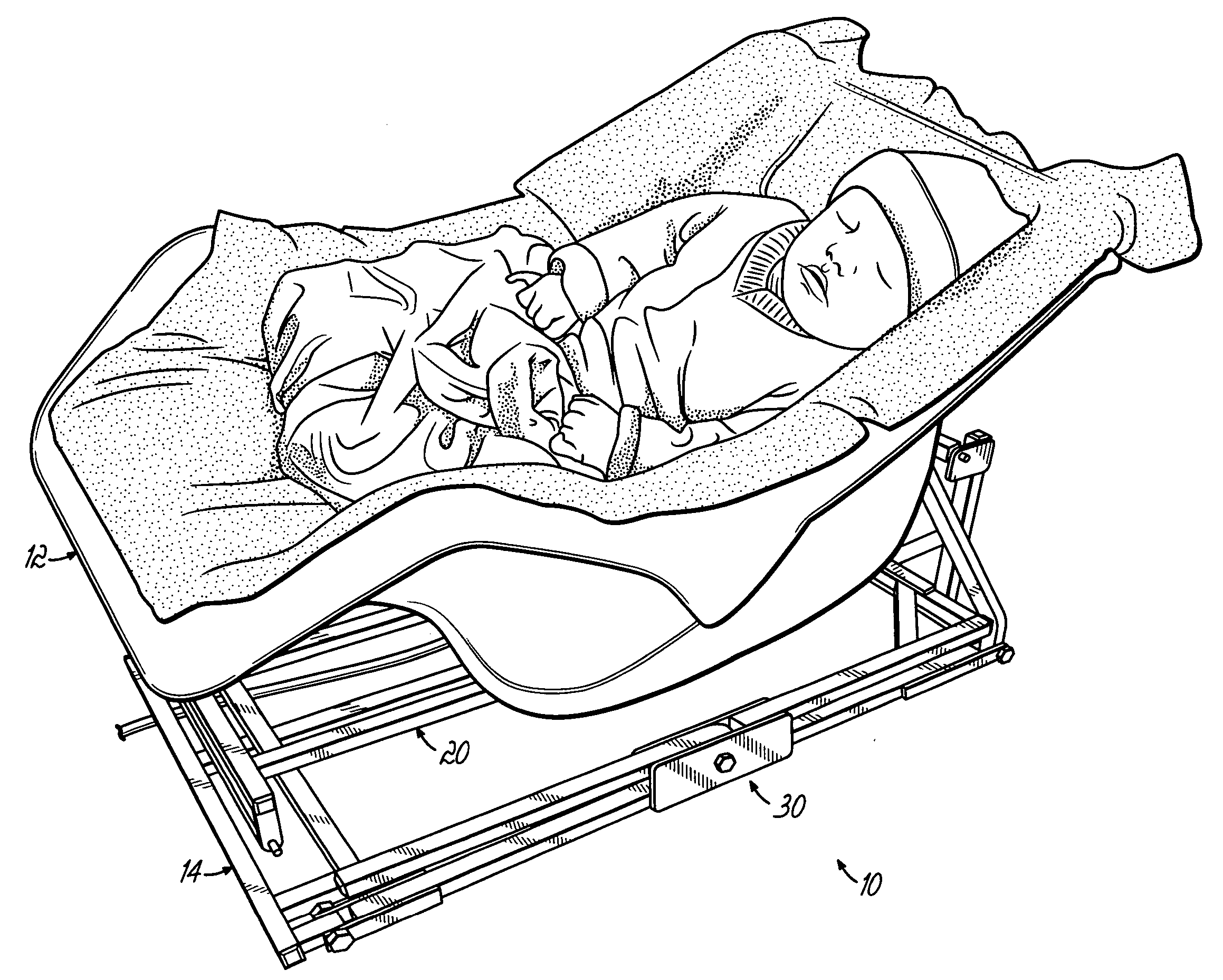

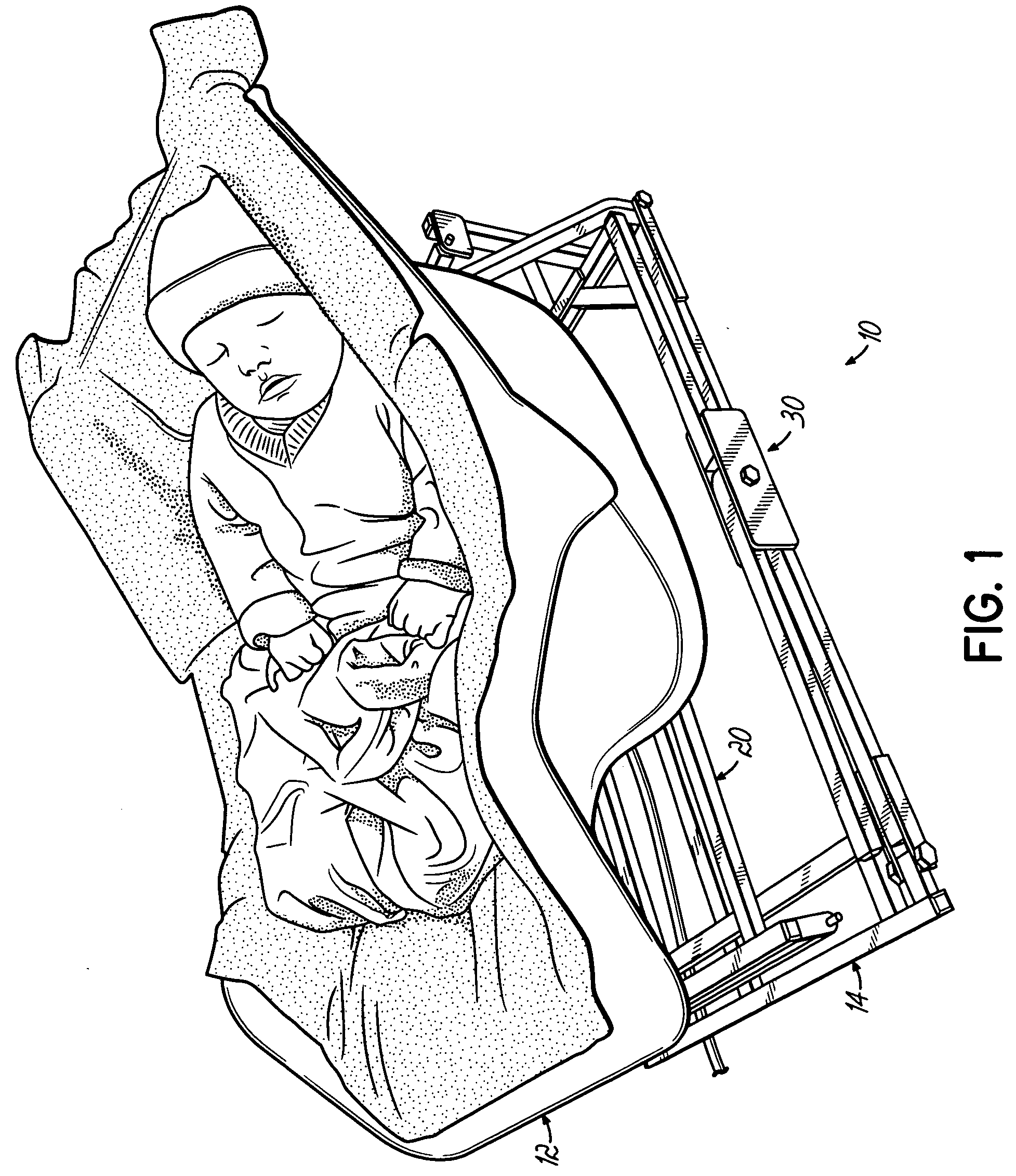

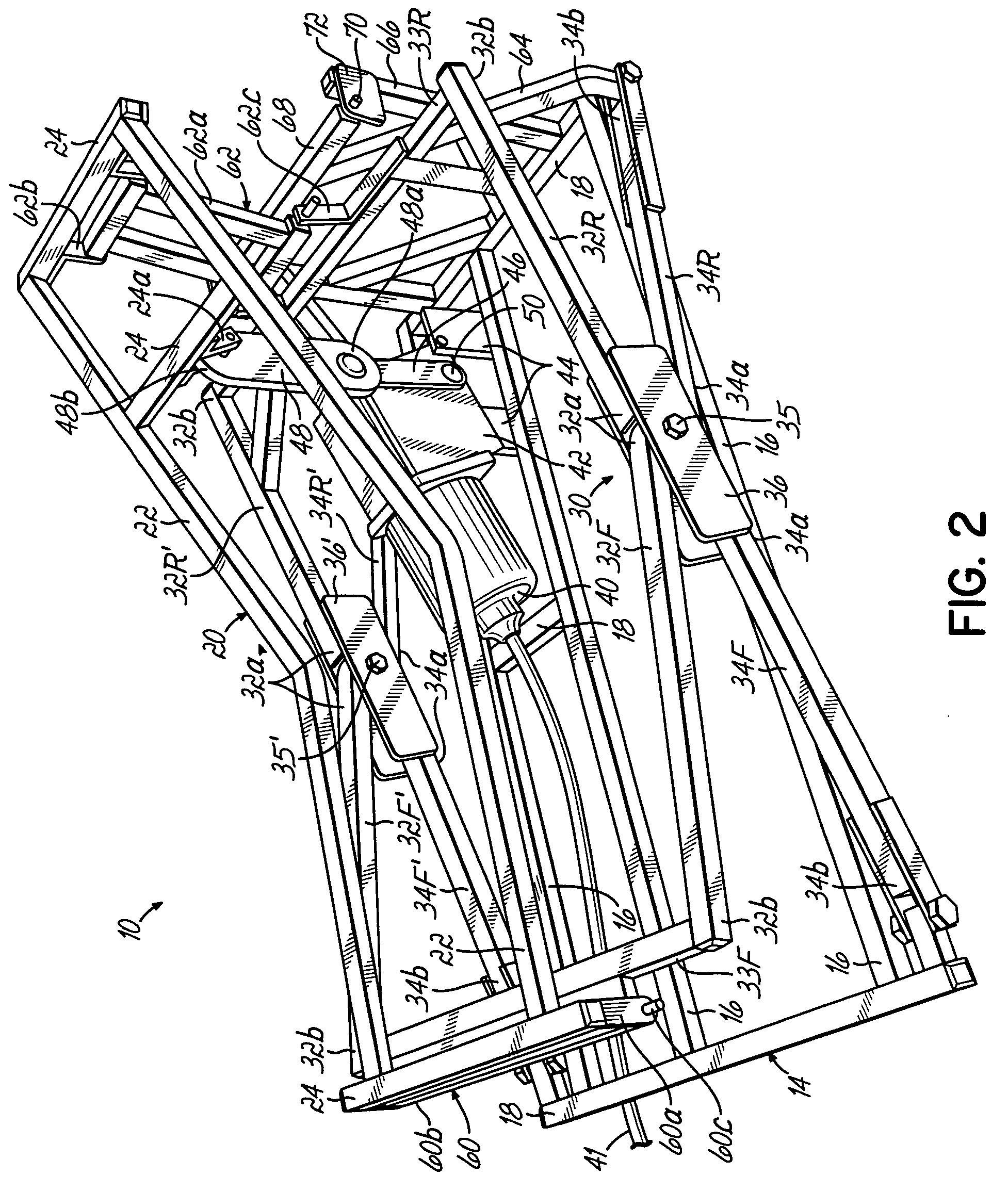

Apparatus and method for reciprocating an infant support

Owner:BLOEMER MEISER & WESTERKAMP

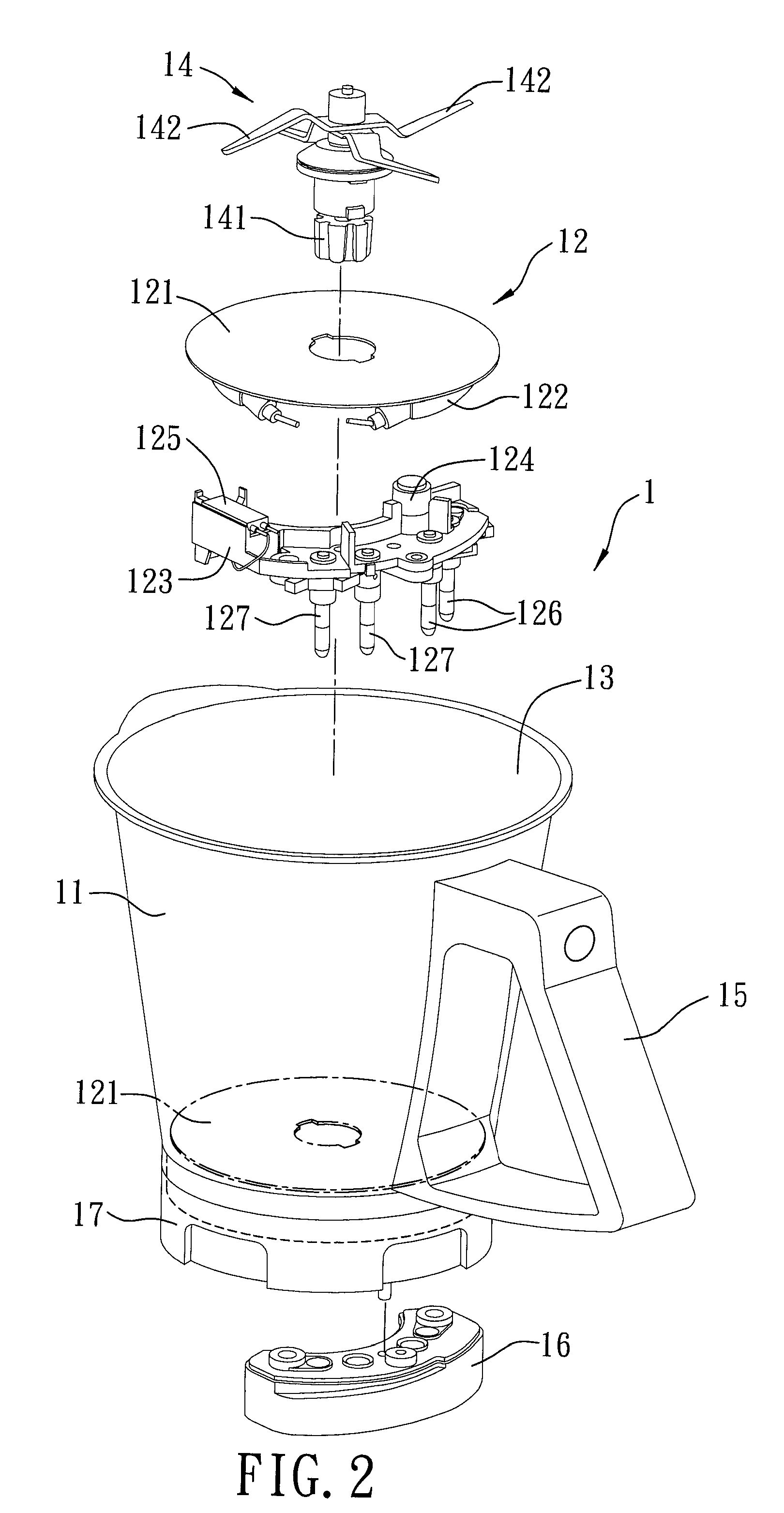

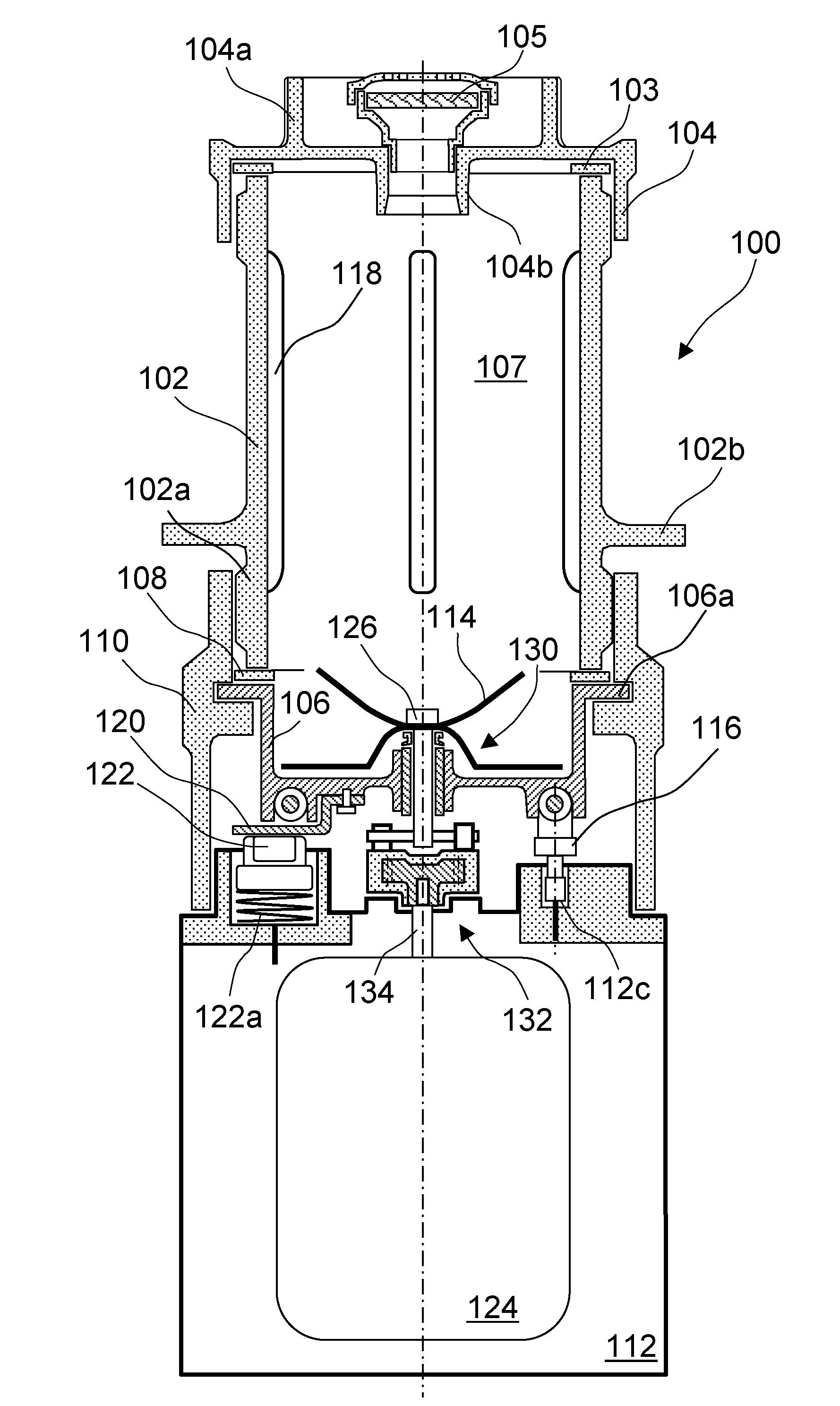

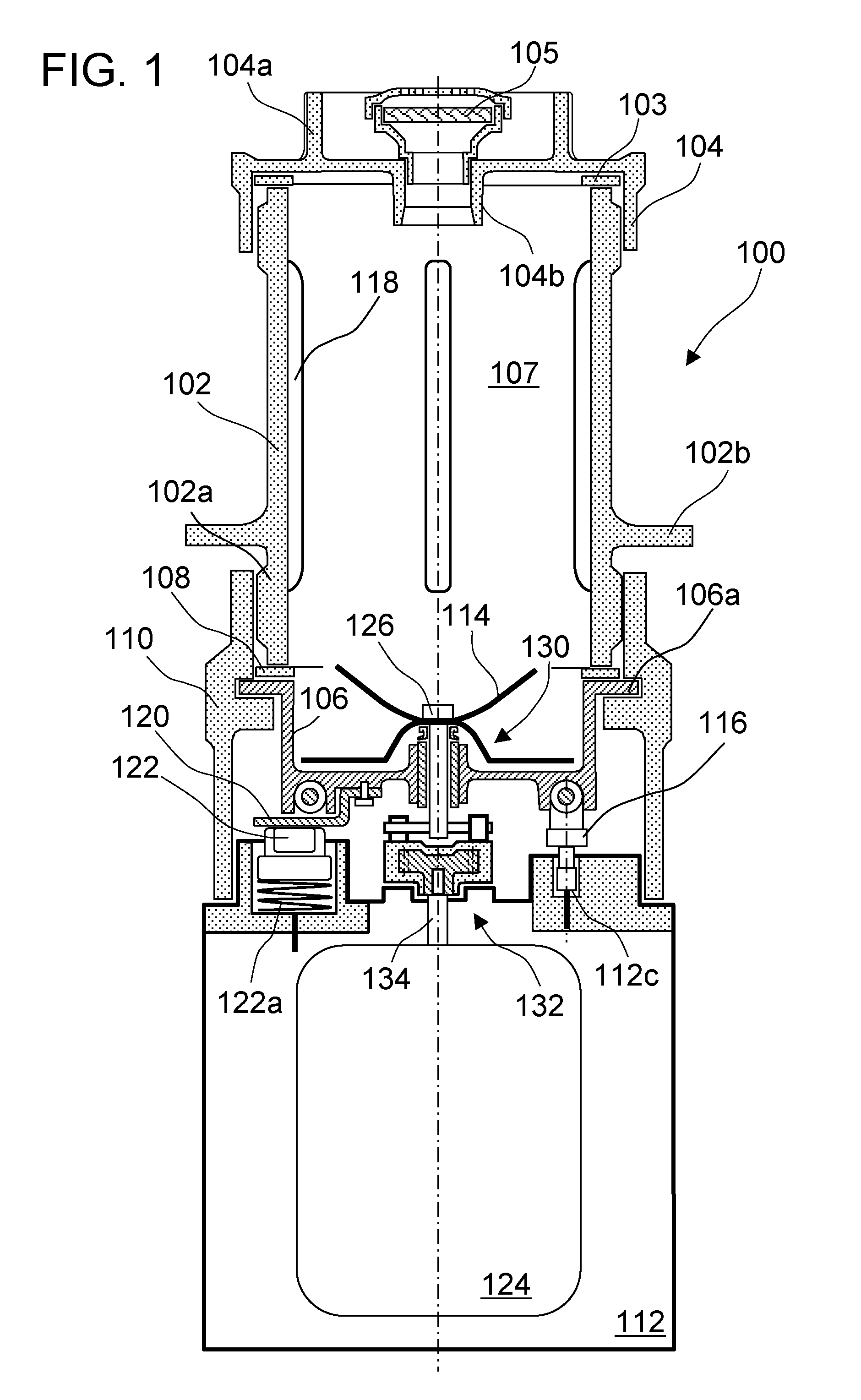

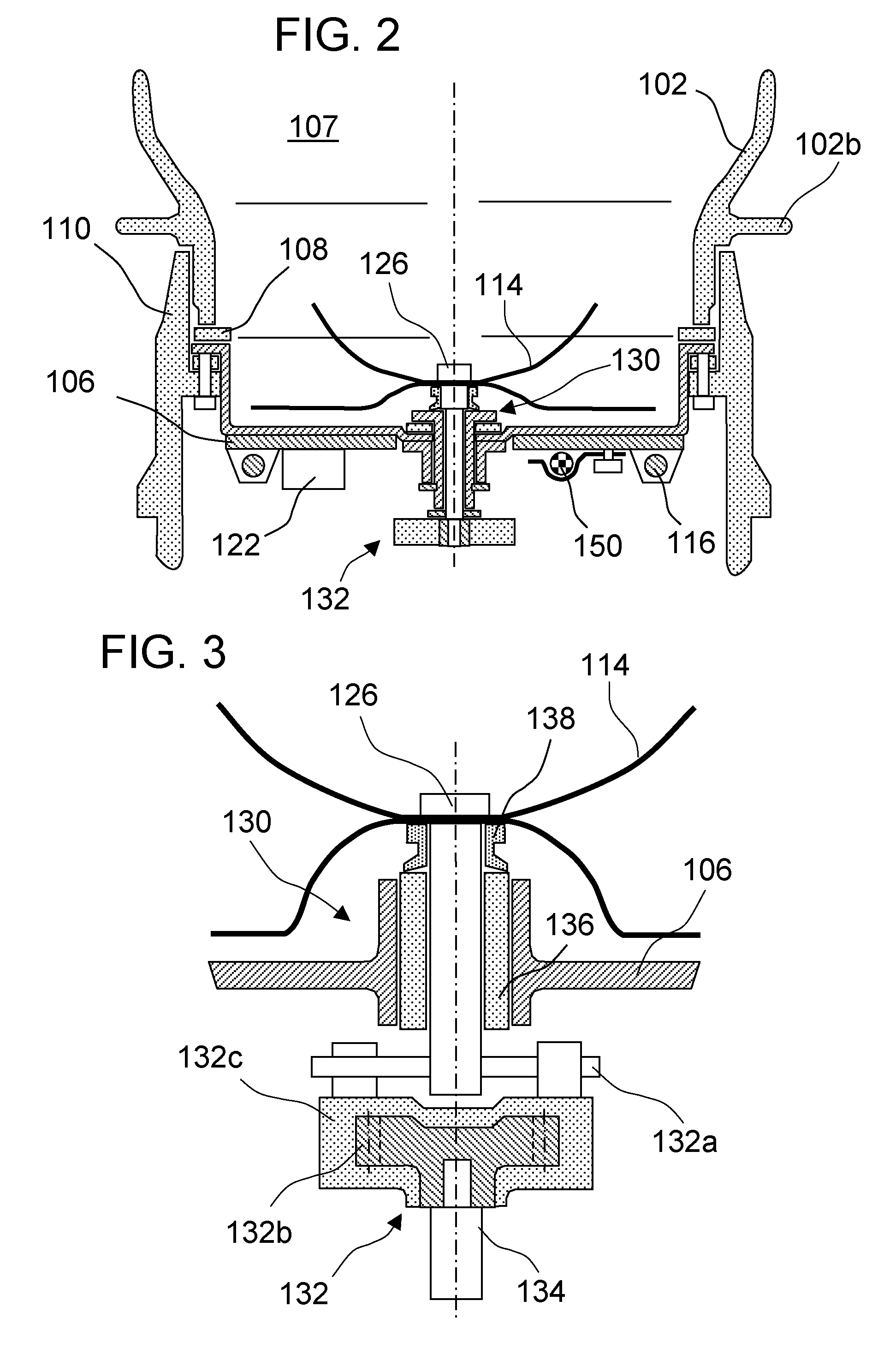

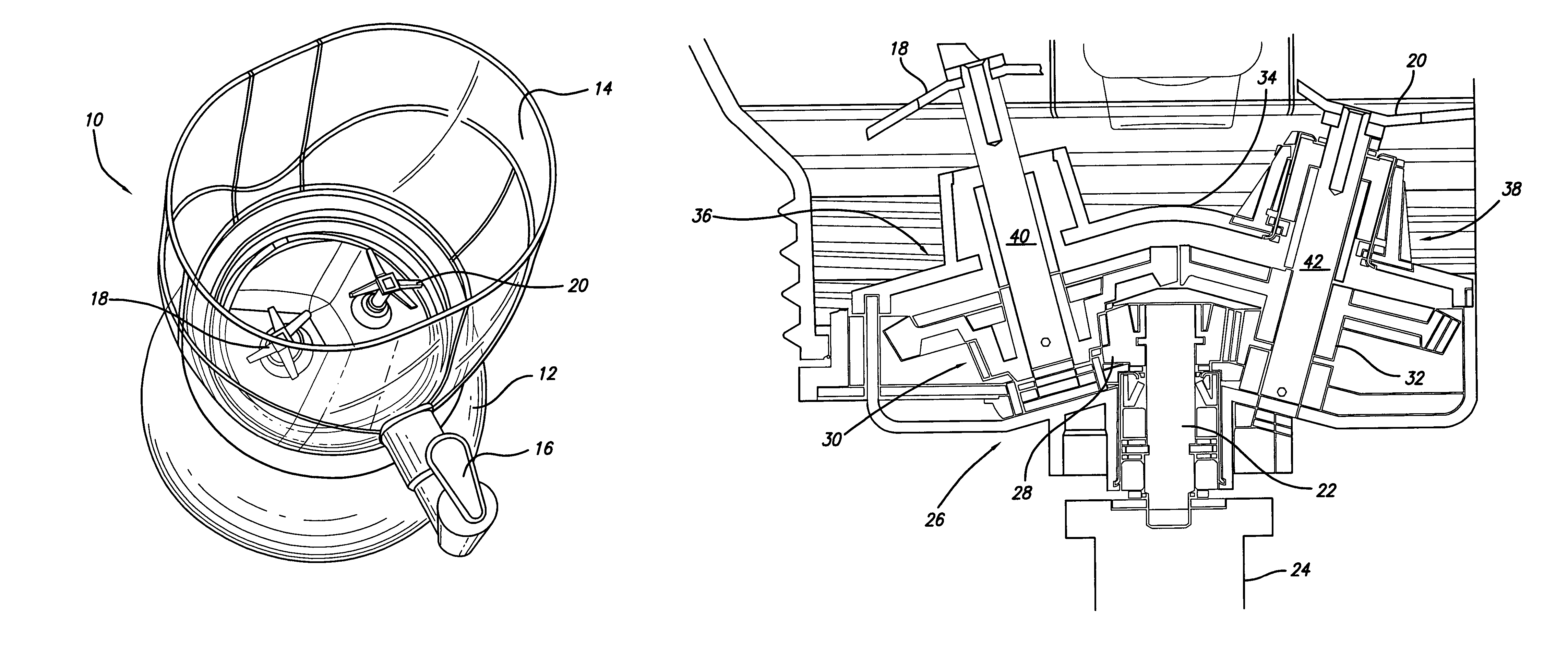

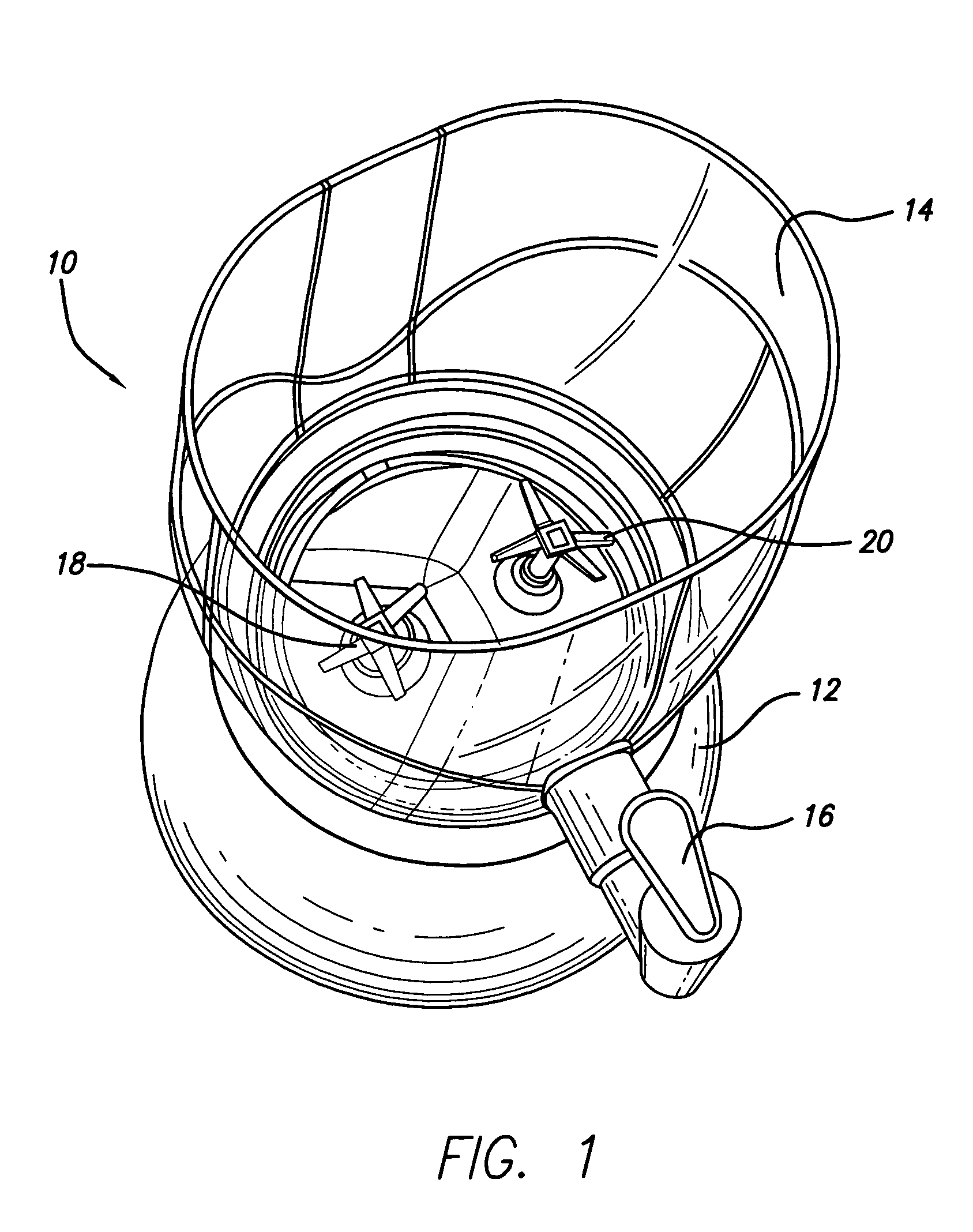

Blender

InactiveUS20090260523A1Easy to cleanOperational securityMixer accessoriesBaking plantsMechanical engineeringPosition detector

A blender (100). Blender (100) comprises a jar (102) having an open top and an open bottom for holding food, a top cap (104) for closing the open top of jar (102), a heated bottom (106) sealingly engaged with the lower end of jar (102) for forming a cooking chamber (107), blending or stirring device (114) installed inside cooking chamber (107) for blending / stirring food, a heating tube (116) fixedly installed on the bottom of heated bottom (106) for heating food, a blender base (112) disposed underneath cooking chamber (107) for supporting cooking chamber (107), a motor (124) installed inside blender base (112) and removably coupled with device (114) for driving device (114) to blend or to stir food, a jar base (110) engaged with the lower portion of jar (102) for adapting cooking chamber (107) to stand on blender base (112), and an in-position detector (128) installed inside blender base (112) for user safety protection.

Owner:PENG ZHENG

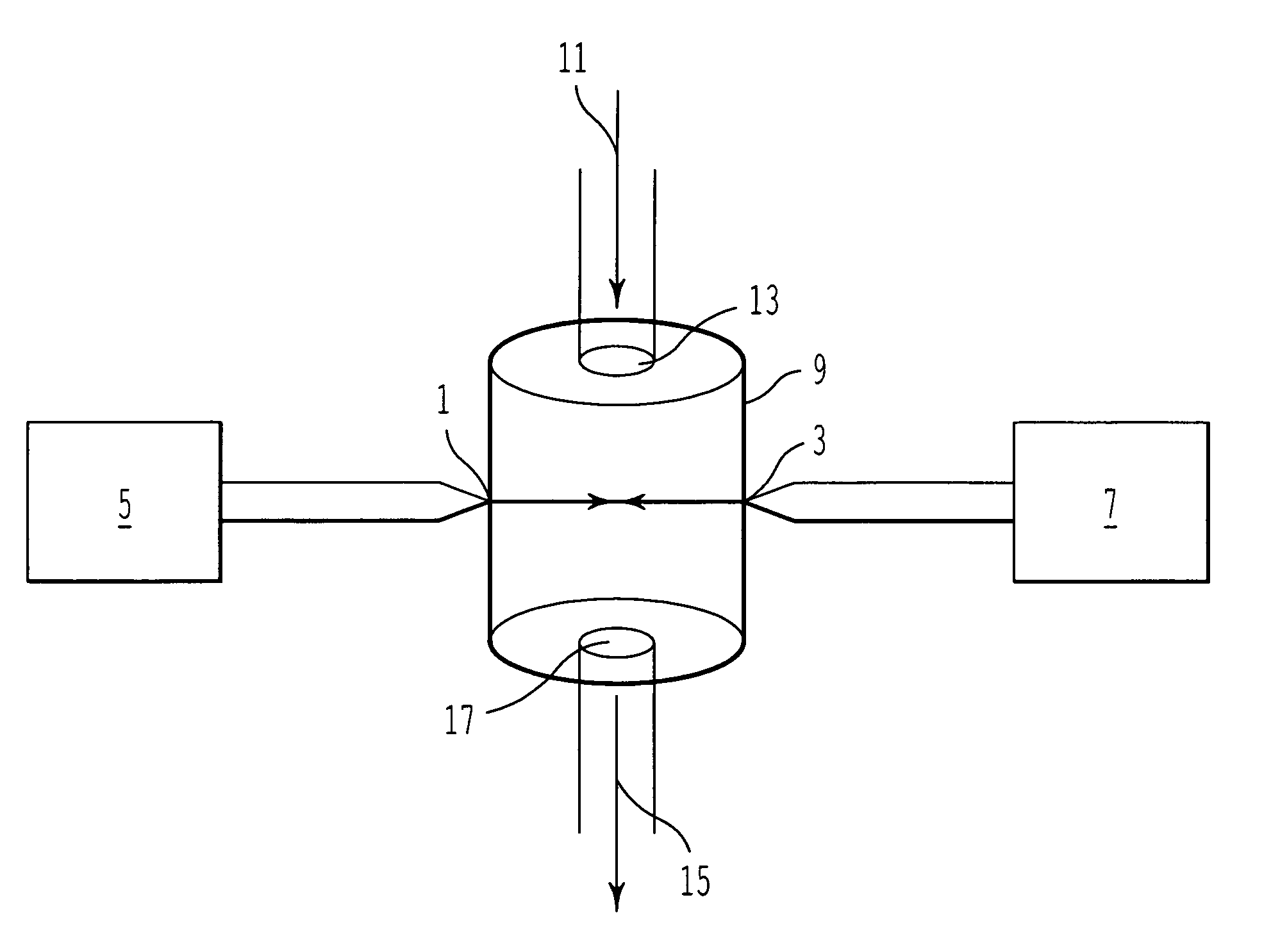

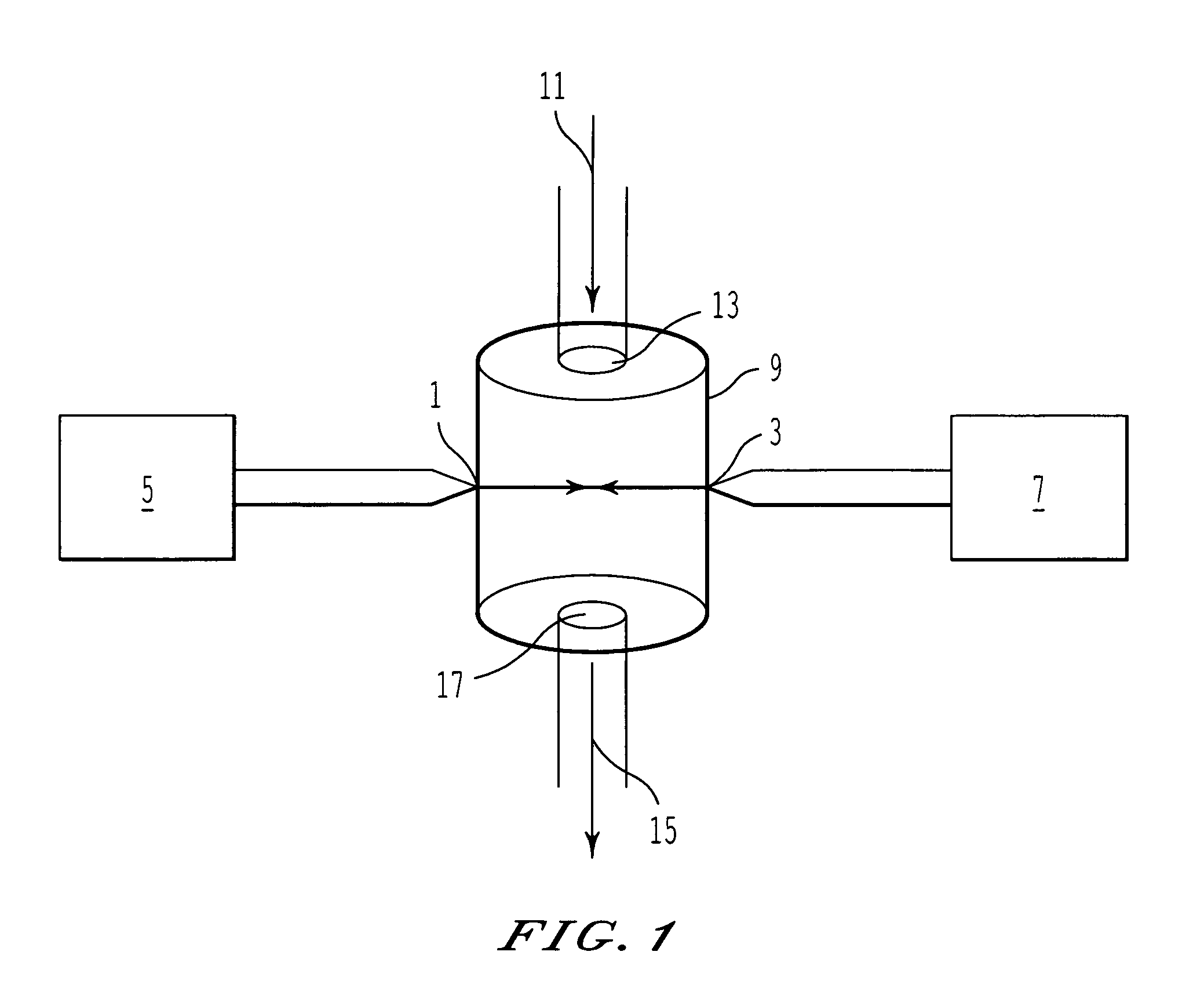

Process for producing dispersions

InactiveUS6991190B2Simple and economic isolationGas current separationFlow mixersWater vaporAtmosphere

A finely divided, stable dispersion of a solid is produced by: spraying at least two streams of a preliminary dispersion, each through a separate nozzle by pumps, onto a collision point in a reactor chamber enclosed by a reactor housing; passing water vapor through an opening into the reactor chamber so that a vaporous atmosphere consisting mainly of water vapor prevails in the reactor chamber; and removing the finely divided dispersion and a) vapor, b) partially condensed vapor consisting mainly of water or c) a combination of a) and b) from the reactor chamber by excess pressure of an incoming water vapor on the gas inlet side; wherein the solid has an average particle size of from 10 nm to 10 μm.

Owner:EVONIK DEGUSSA GMBH

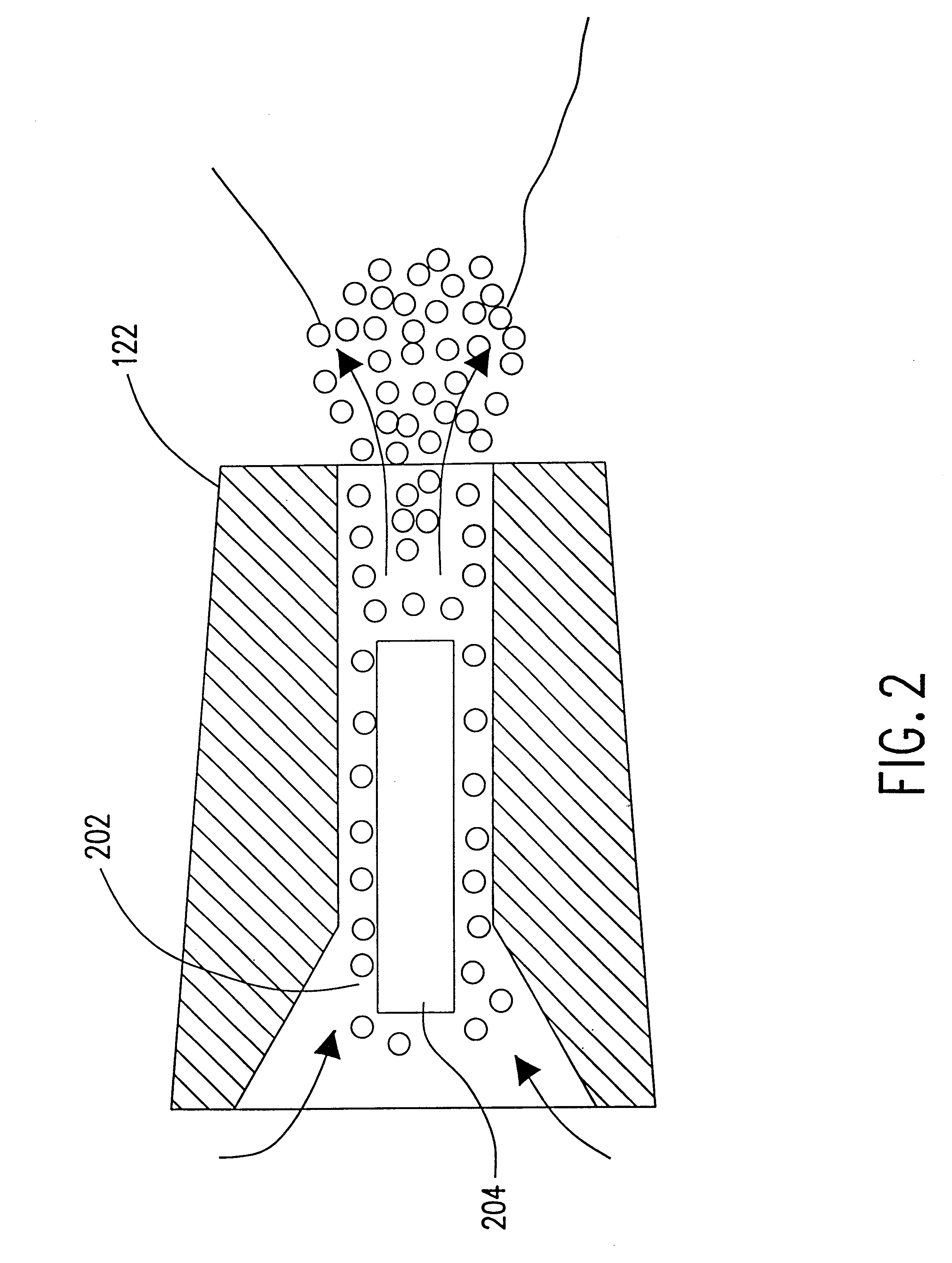

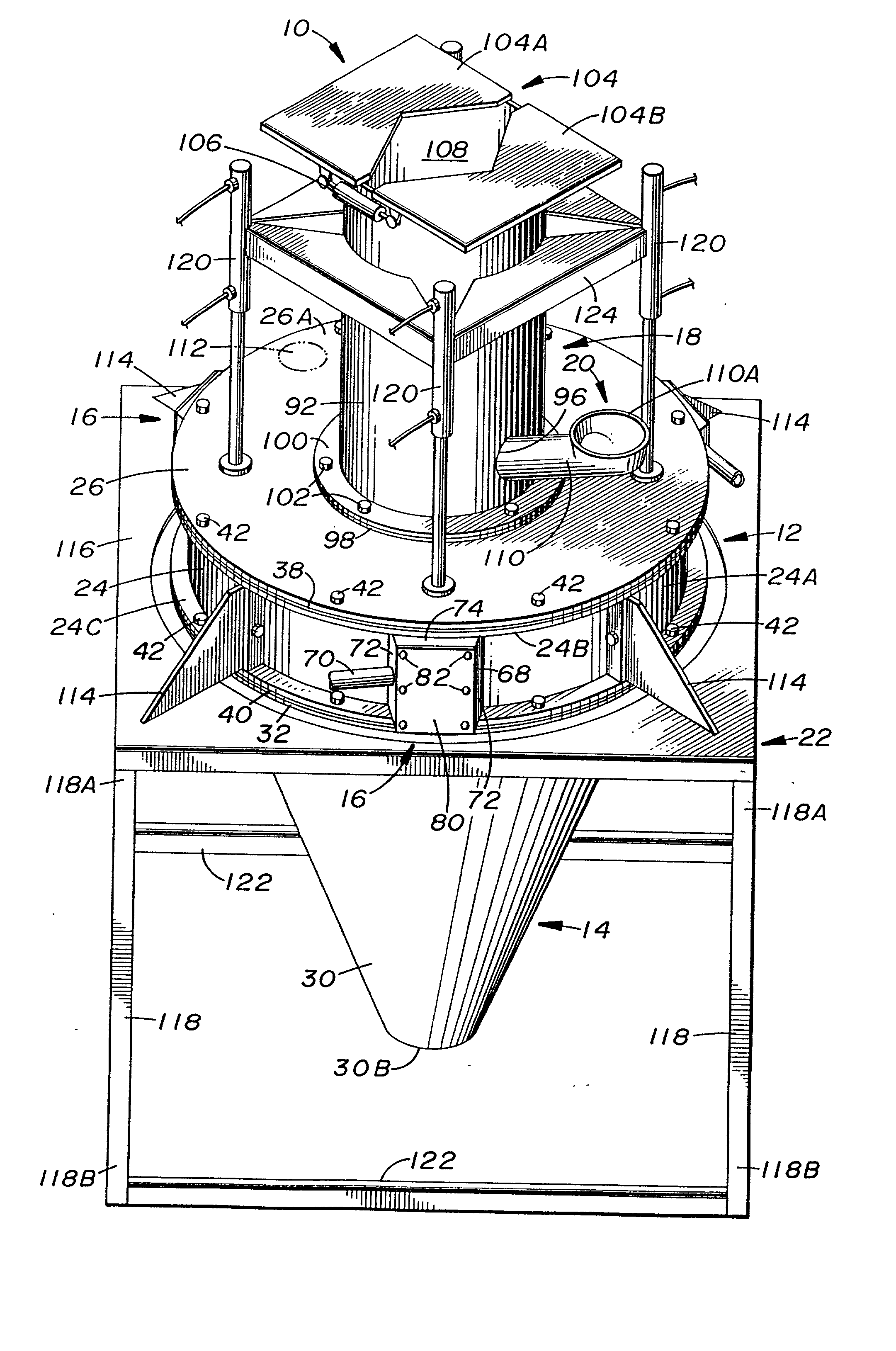

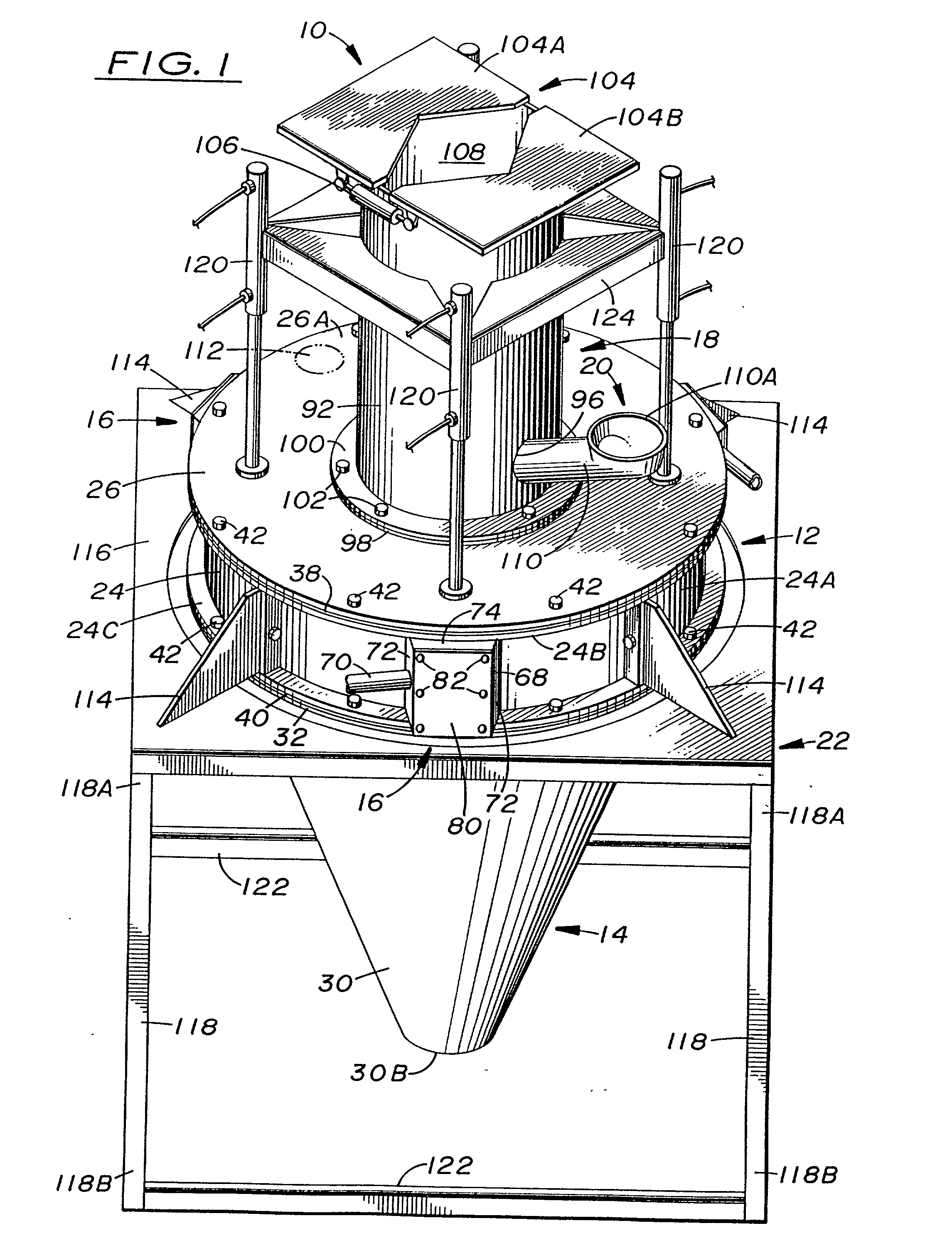

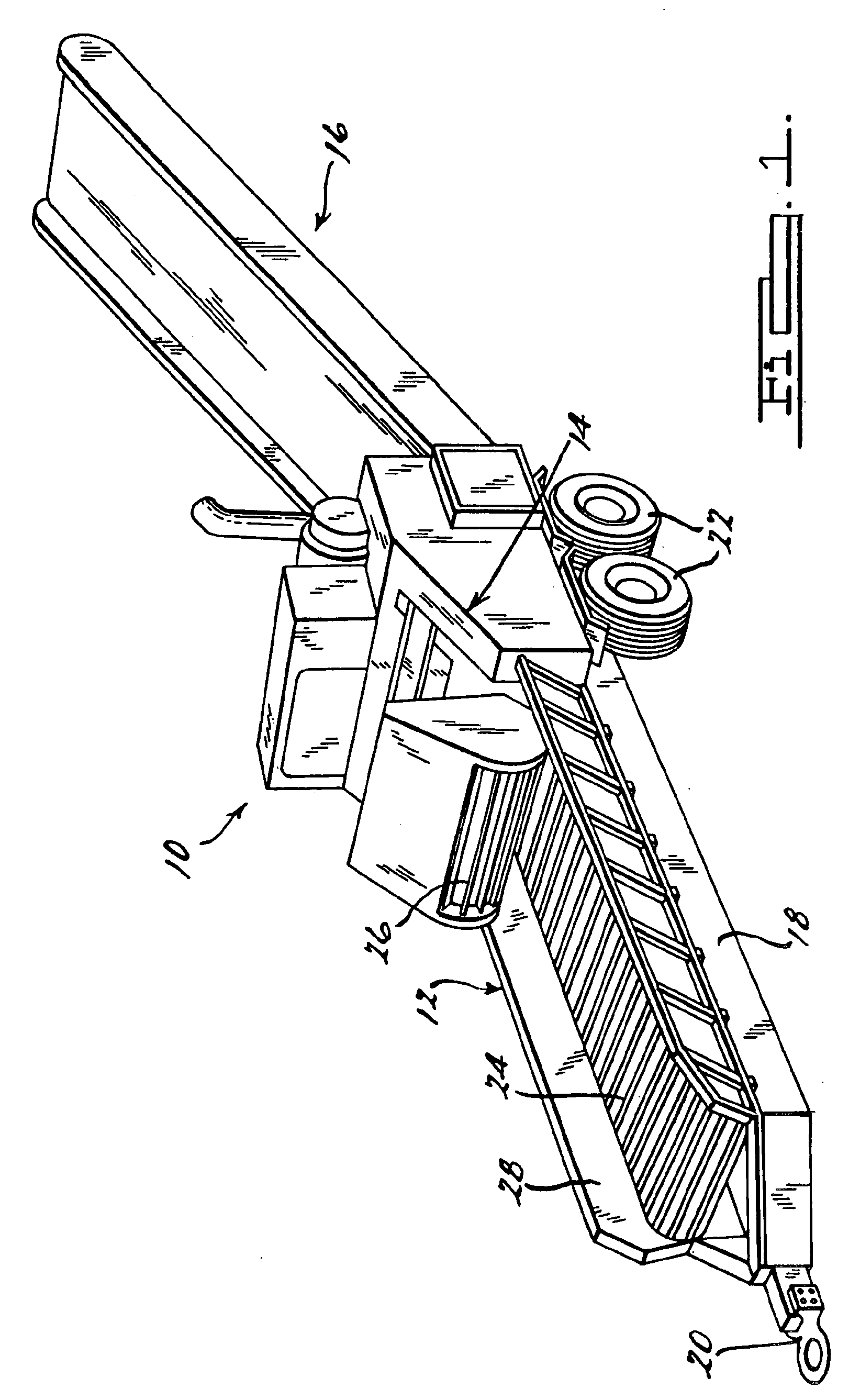

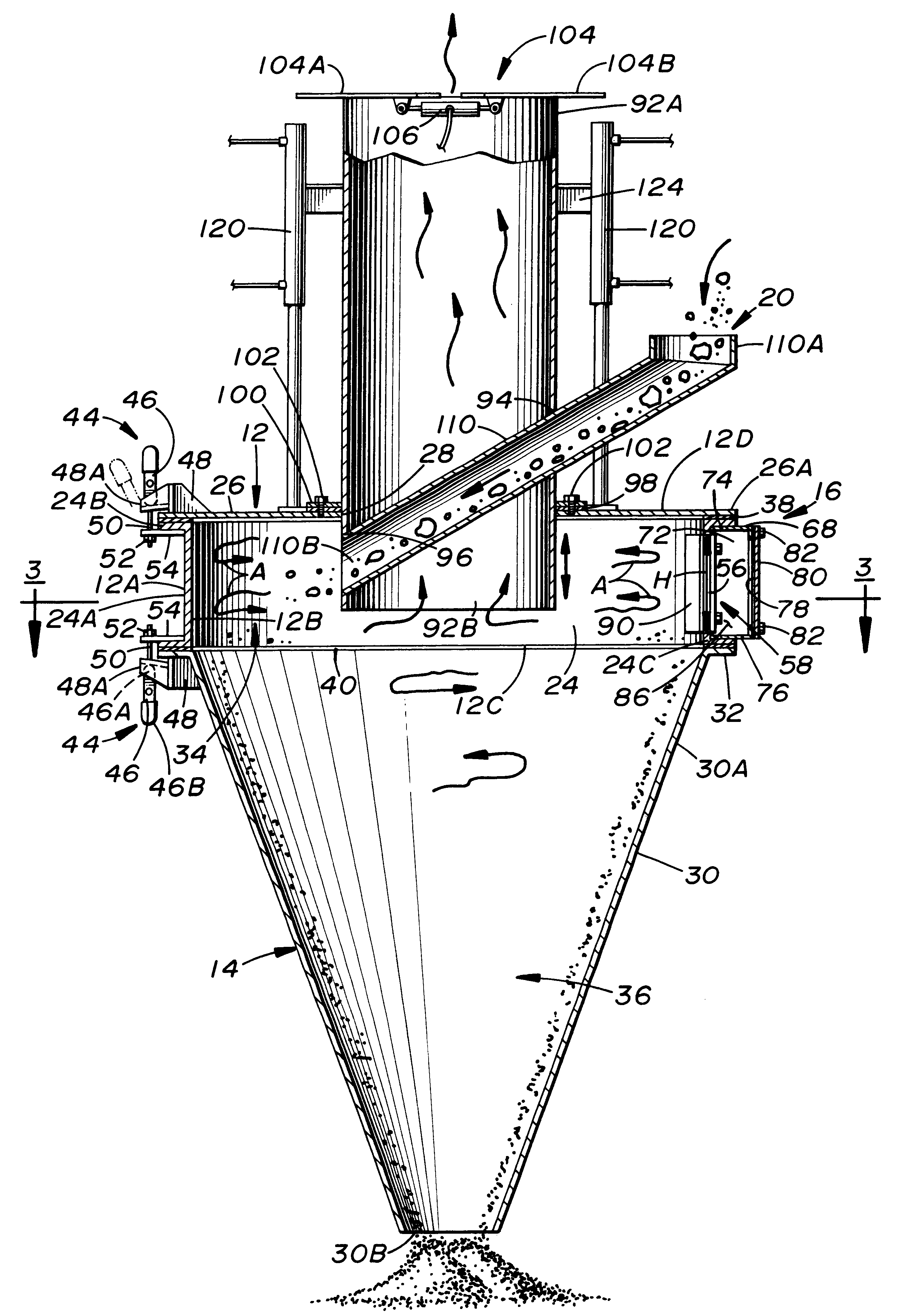

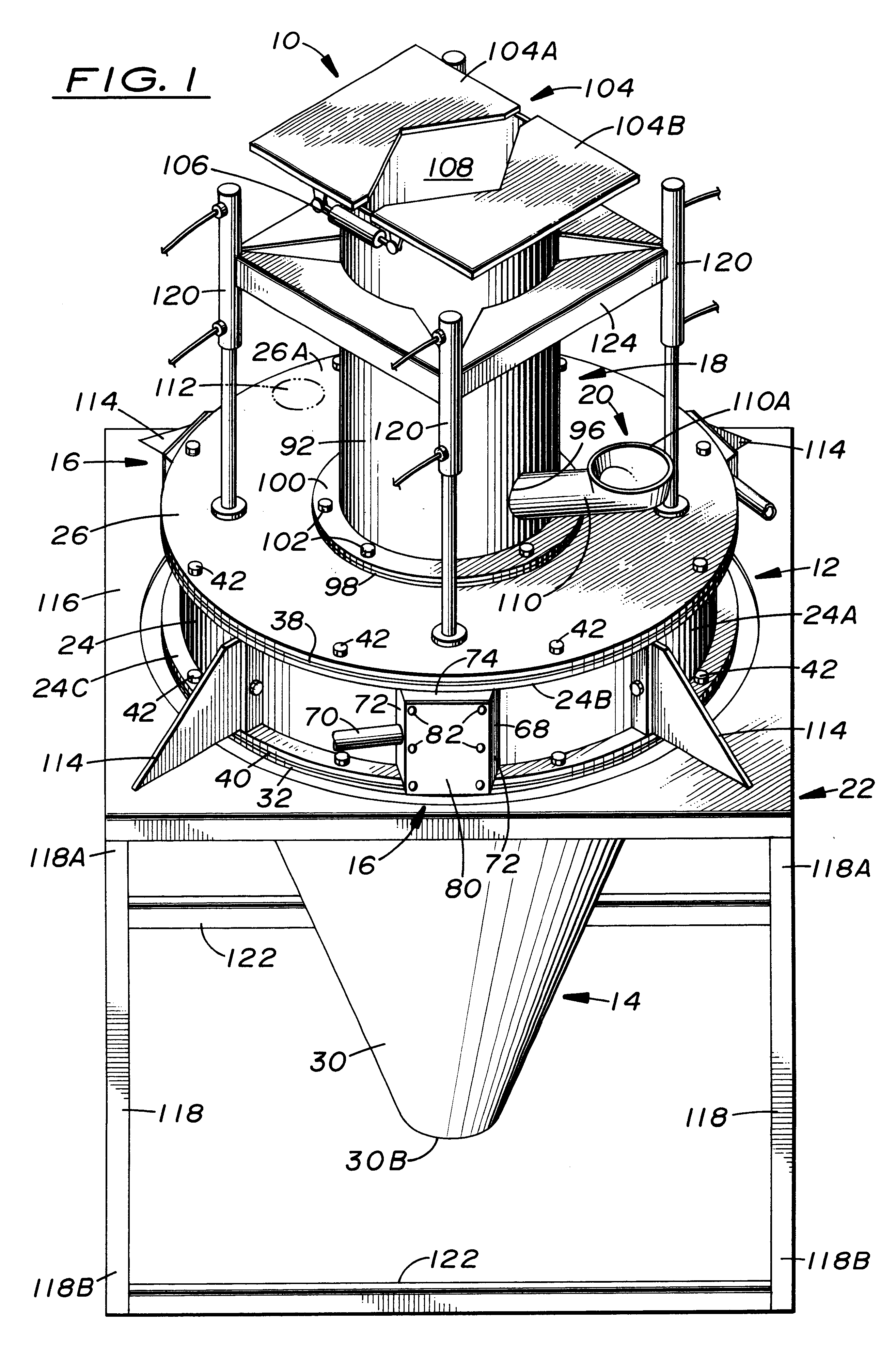

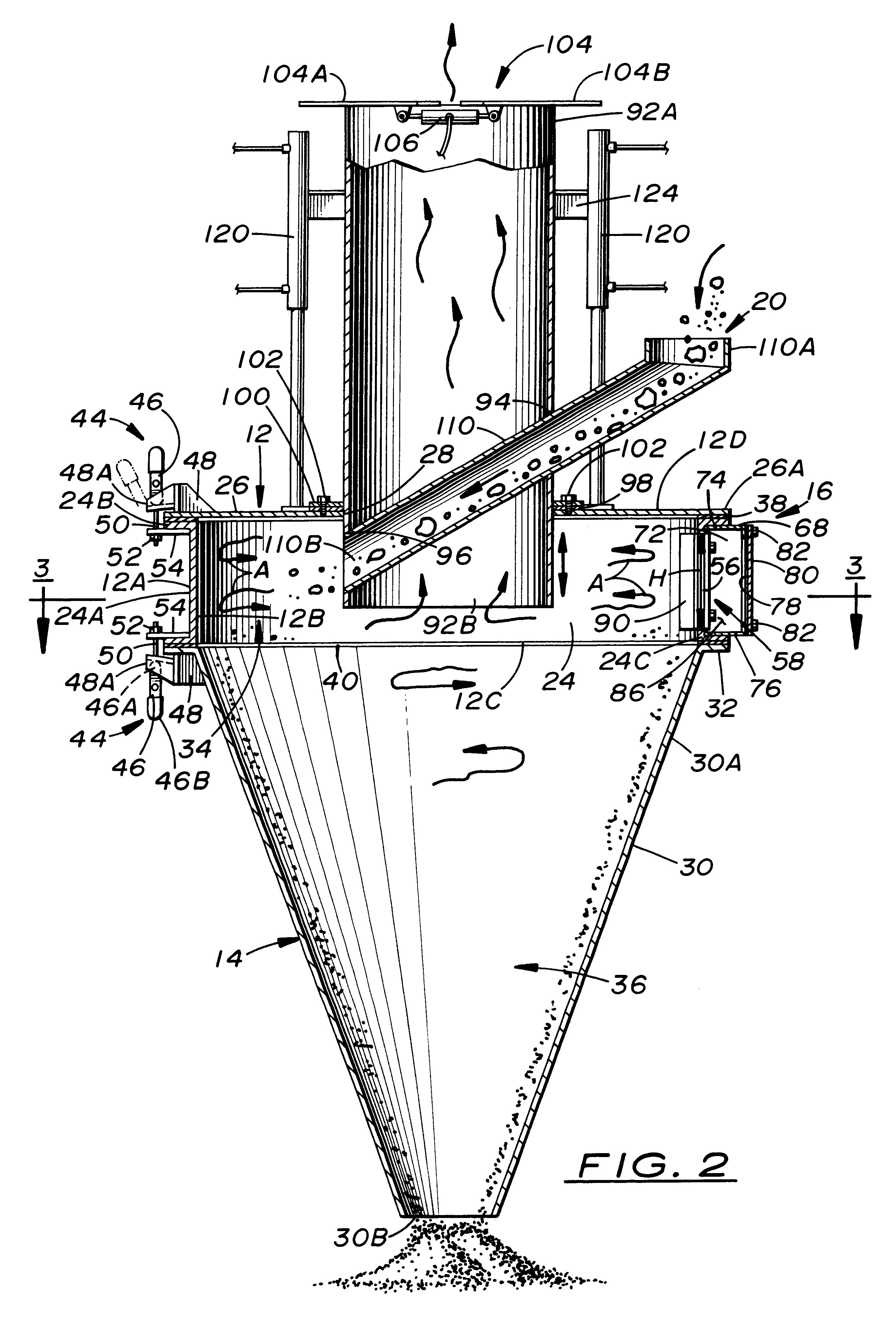

Apparatus and method for circular vortex air flow material grinding

InactiveUS20020027173A1Easy constructionEliminate needGas current separationGrain millingEngineeringAirflow

A material grinding apparatus (10) includes an annular upper enclosure (12) defining an upper chamber (34) into which material to be ground is introduced from above, a conical lower enclosure (14) defining a lower chamber (36) and supported in tandem with the upper enclosure (12), and one or more angled slots (56) defined in the sidewall of the upper enclosure (12) through which compressed air is introduced relatively circumferentially into the upper chamber (34) so as to generate a circular vortex flow of air and material in the upper enclosure (12) for grinding and drying to take place. The air flow is exhausted by a pipe (92) through an upper end of the upper enclosure (12) and the dried ground material is discharged through an open lower end of the lower enclosure (14). The lower enclosure (14) is a downward continuation and extension of the upper enclosure (12) so as not to extend upwardly into nor past the upper chamber (34) thereof.

Owner:VORTEX DEHYDRATION TECH

Selective nixtamalization process for the production of fresh whole corn masa, nixtamalized corn flour and derived products

InactiveUS6265013B1Keep for a long timeShorten the timeDough treatmentBakery productsCorn flourNixtamalization

A process for the production of fresh masa, nixtamalized flour and derived produts is disclosed. Water-lime cooking of pericarp fractions of the corn, and appropriate hydration of the germ and endosperm fractions of the corn is achieved to prepare fresh masa, nixtamalized corn flour and derived products. The pericarp fractions are cooked with lime and water at a temperature between about 50° C. to about 300° C. The germ and endosperm fractions are hydrated with water. The pericarp fractions and the germ-endosperm fractions are milled separately, and the milled pericarp, germ and endosperm fractions are then mixed for producing fresh corn masa. The fresh corn masa can be dehydrated and milled for producing nixtamalizaed corn flour. Also, the pericarp, germ and endosperm fractions can be dried in order to produce nixtamalized corn flour.

Owner:INST POLITECNICO NACIONAL MEXICAN INSTION OF HIGHER EDUCATION

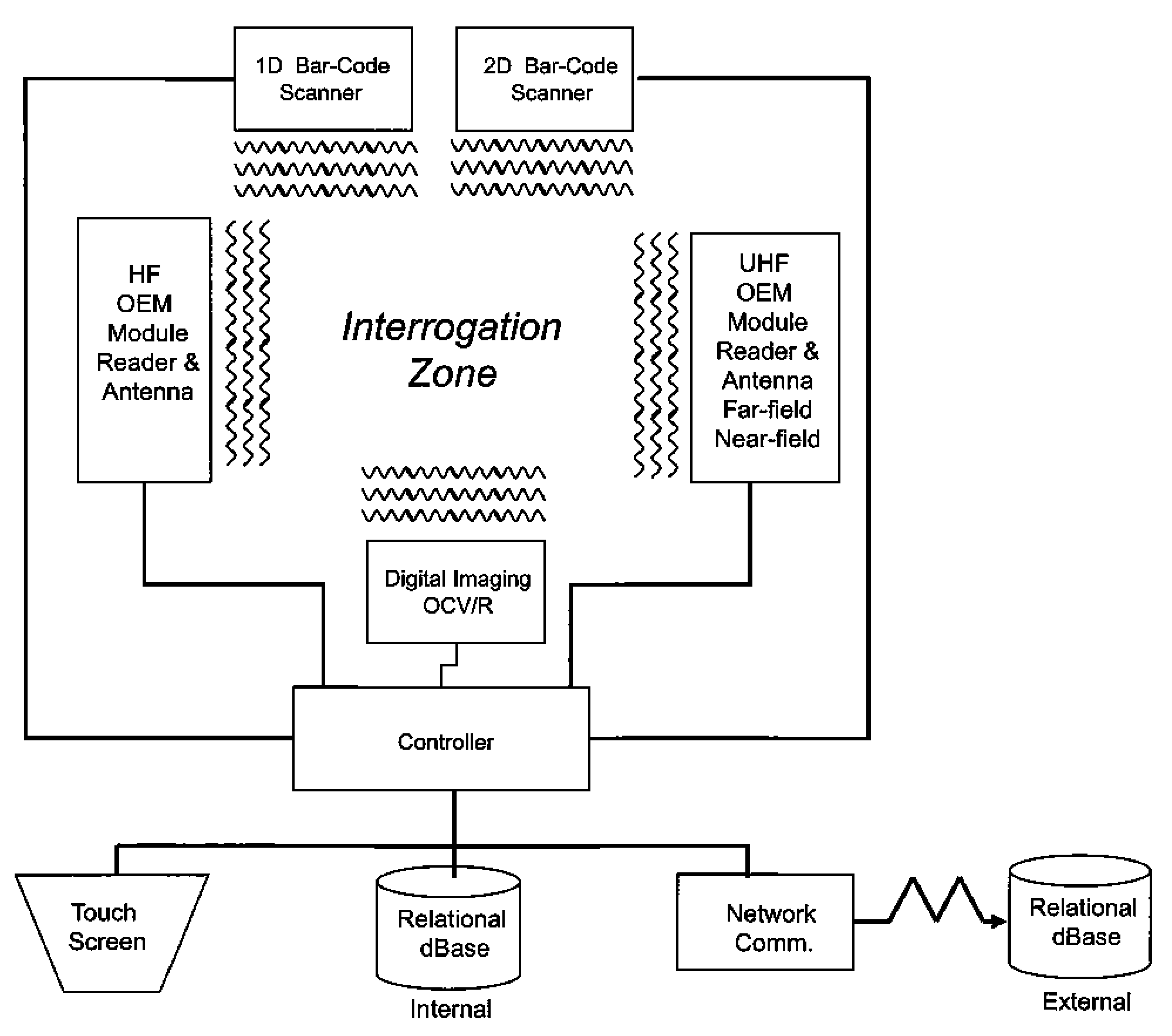

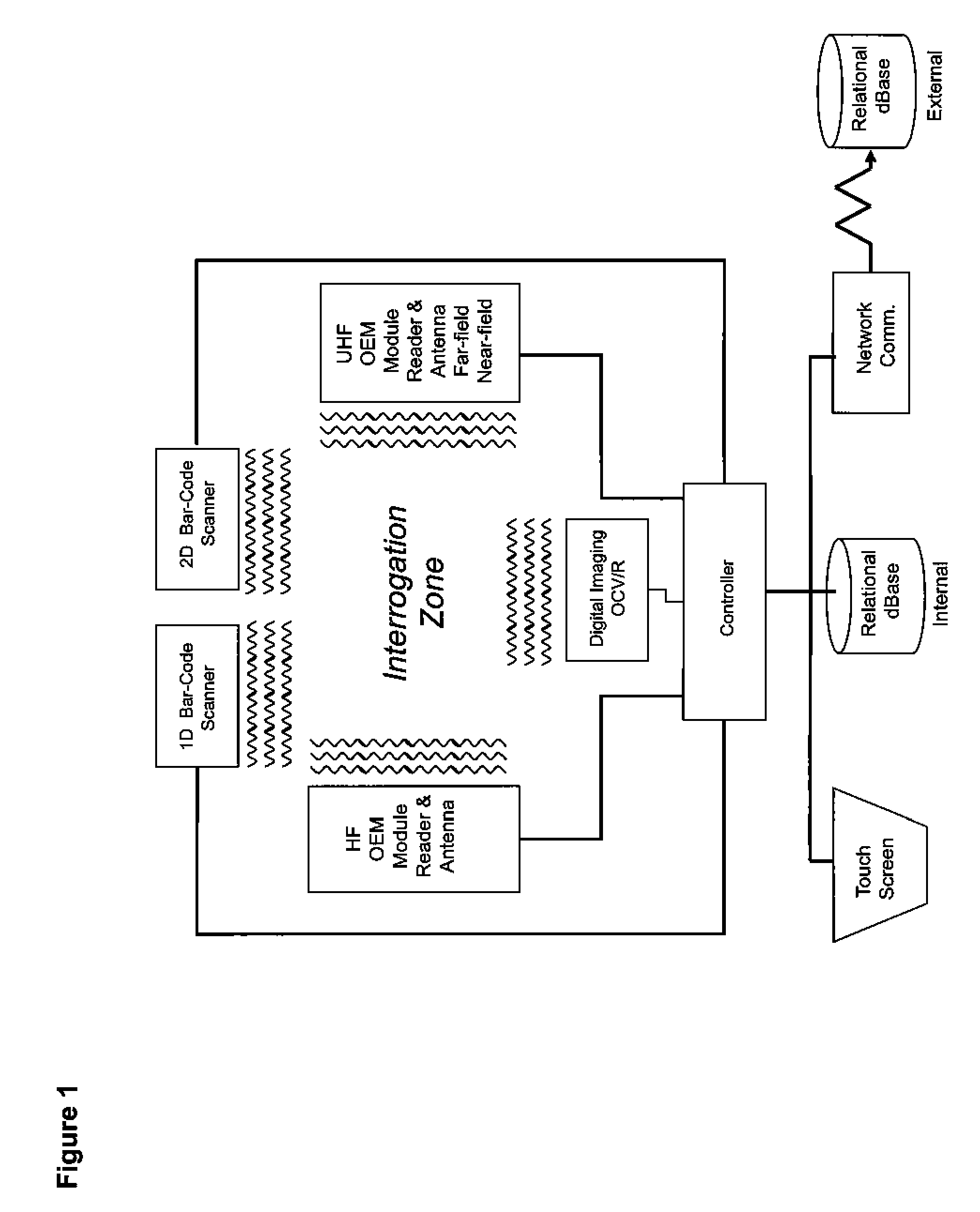

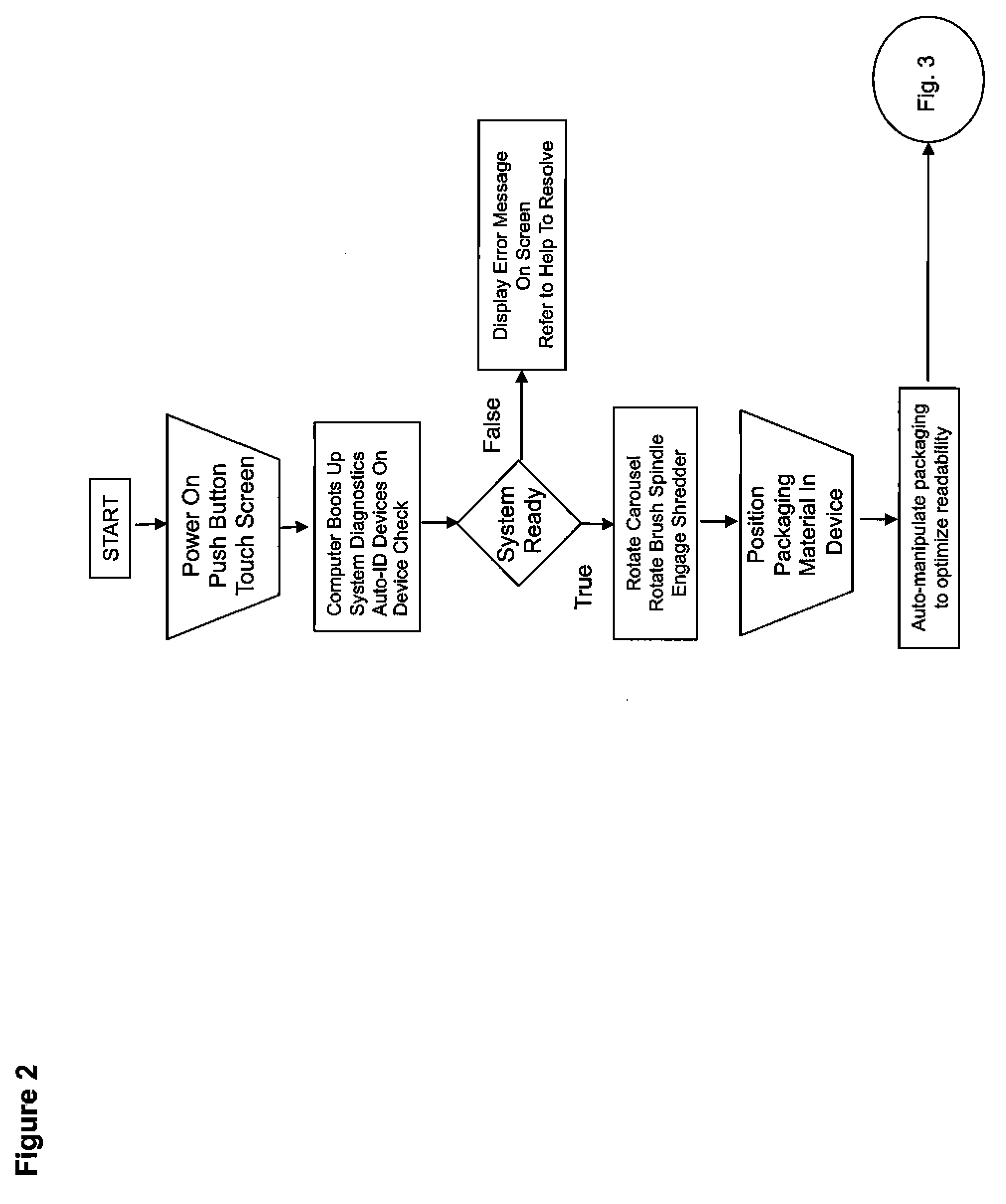

Systems and processes for tracking items

ActiveUS20090267740A1Telemetry/telecontrol selection arrangementsGas current separationDrug productWorld Wide Web

Systems and processes for tracking the status of an item are disclosed. Systems and processes for decommissioning identifying information from pharmaceutical product containers are disclosed.

Owner:RECLAIM RX

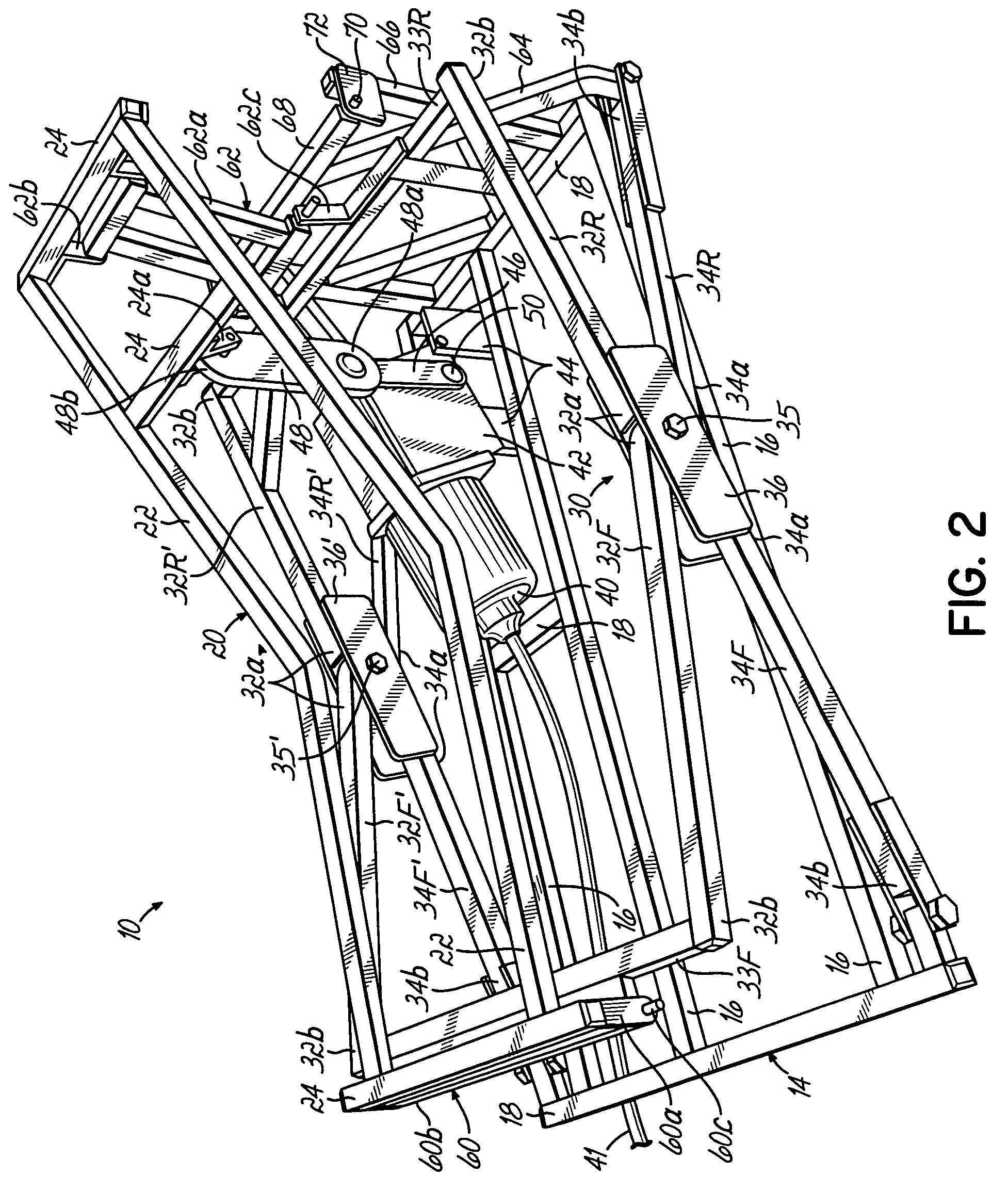

Apparatus and method for reciprocating an infant support

ActiveUS20050091743A1Uniform loadSmooth and efficient operation of apparatusCradleSofasReciprocating motionEngineering

An apparatus for reciprocating an infant support comprises a frame and a receiving member supported above the frame for substantially vertical reciprocating movement. The receiving member is configured to receive the infant support and, in one embodiment, is coupled to the frame by a reciprocating assembly configured to constrain the motion of the receiving member in a substantially vertical direction. A motive device coupled to the receiving member reciprocates the receiving member relative to the frame. The apparatus may also include a counterbalance mechanism configured to offset the load of the infant and the infant support on the motive device.

Owner:BLOEMER MEISER & WESTERKAMP

Food products containing whole chia seed or a gluten-free agglutinant derived therefrom and methods of making same

Food products containing whole chia seeds or a gluten-free agglutinant derived therefrom are made by mixing a food material with water, adding whole chia seeds or an agglutinant derived therefrom in an agglutinating amount, and reducing the water activity of the mixture. Other ingredients such as honey, syrups, and sprouted grains can also be mixed with the chia seeds. The gluten free varieties are of especial value for those individuals who are allergic to the gluten in wheat and other grains.

Owner:FITZPATRICK MICHAEL

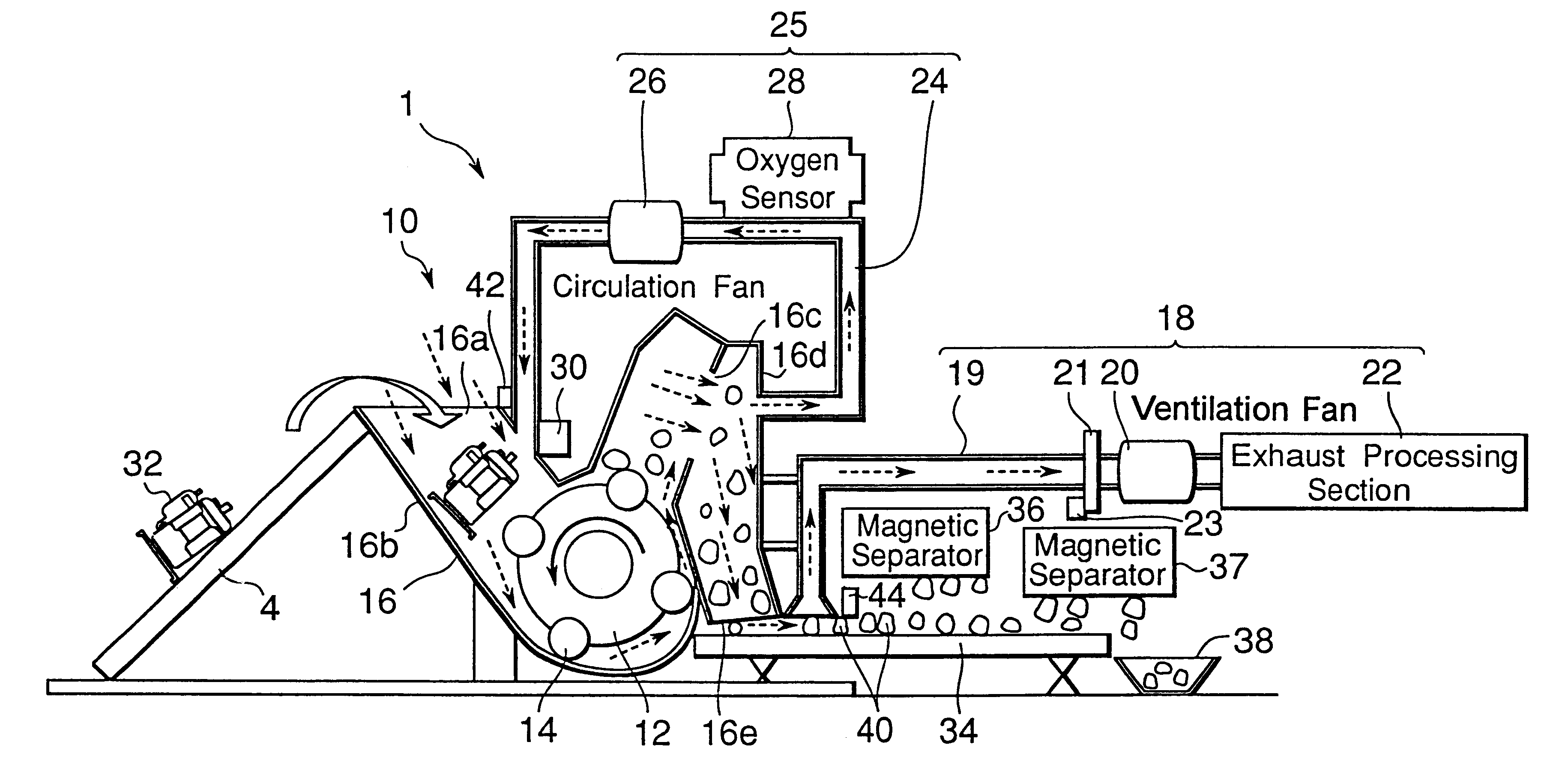

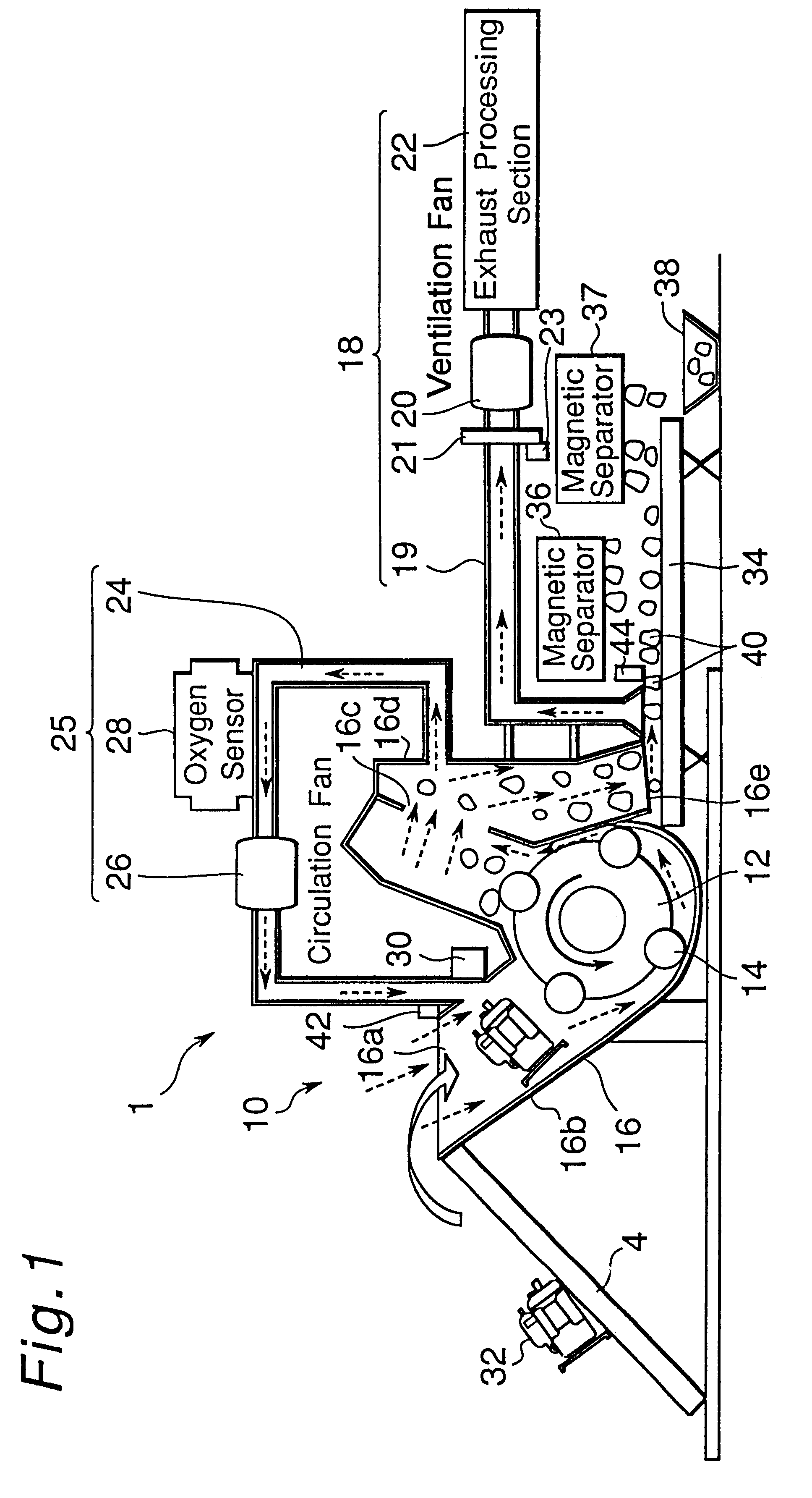

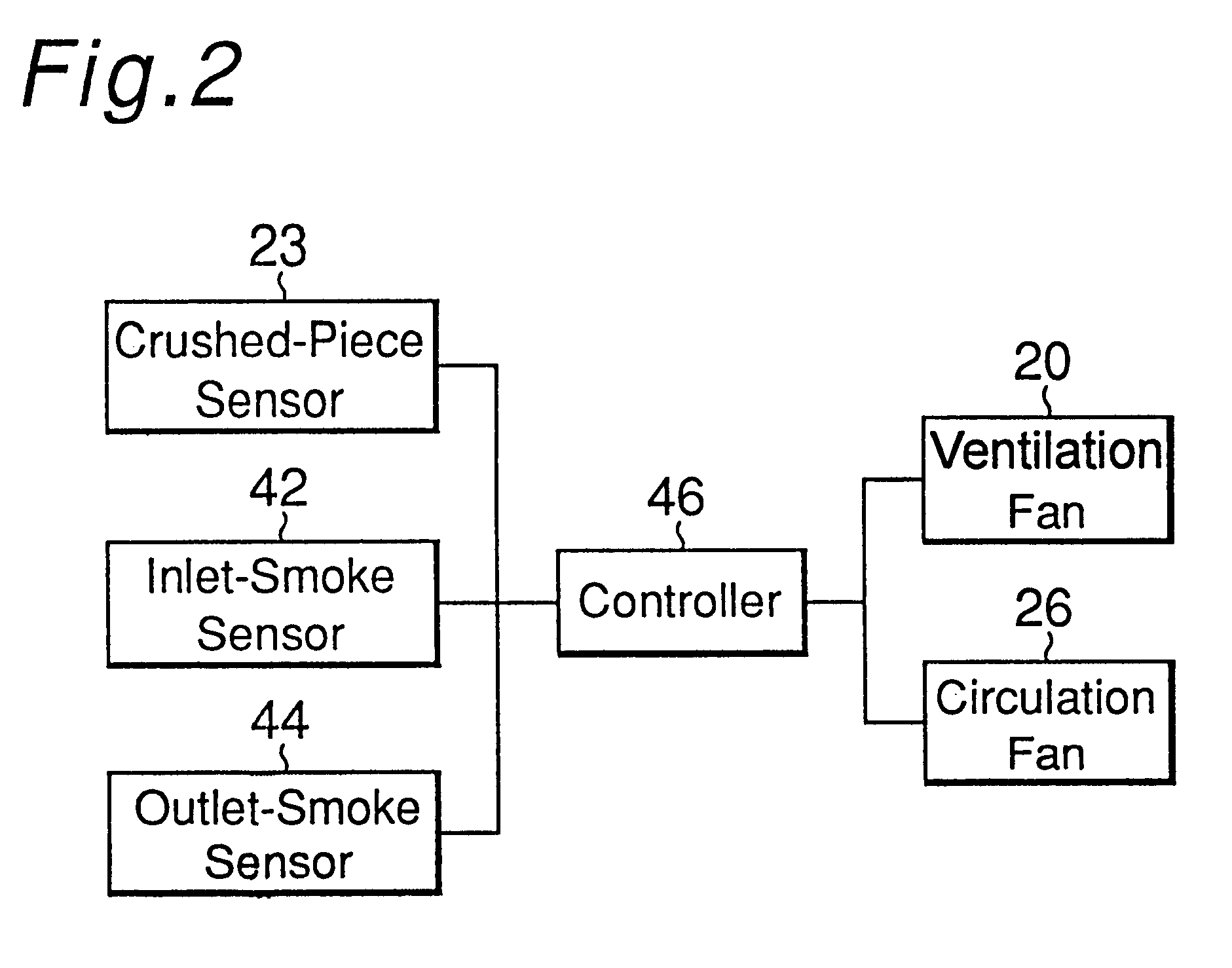

Apparatus for crushing waste products and method of operating the same

InactiveUS6390396B1Reduce outgassingGuaranteed uptimeGas current separationSolid waste disposalWaste productProduct gas

Owner:PANASONIC CORP

Method of producing fermentation-based products from corn

InactiveUS7083954B2Excellent extractabilityIncrease usable surface areaProtein composition from vegetable seedsClimate change adaptationCorn mealFermentation

Corn oil and corn meal obtained from corn are included in useful products. A method for producing fermentation-based products comprises combining corn meal with water and an enzyme, and mixing the combination with a micro-organism capable of fermenting a carbon source to produce a fermentation-based product. The corn meal is produced by cracking whole corn, conditioning the whole corn and extracting the whole corn to produce corn meal without flaking the corn during processing. The corn grain process generally includes the steps of cracking corn grain having a total oil content of from about 3% by weight to about 30% by weight and extracting a corn oil from the cracked corn grain.

Owner:RENESSEN

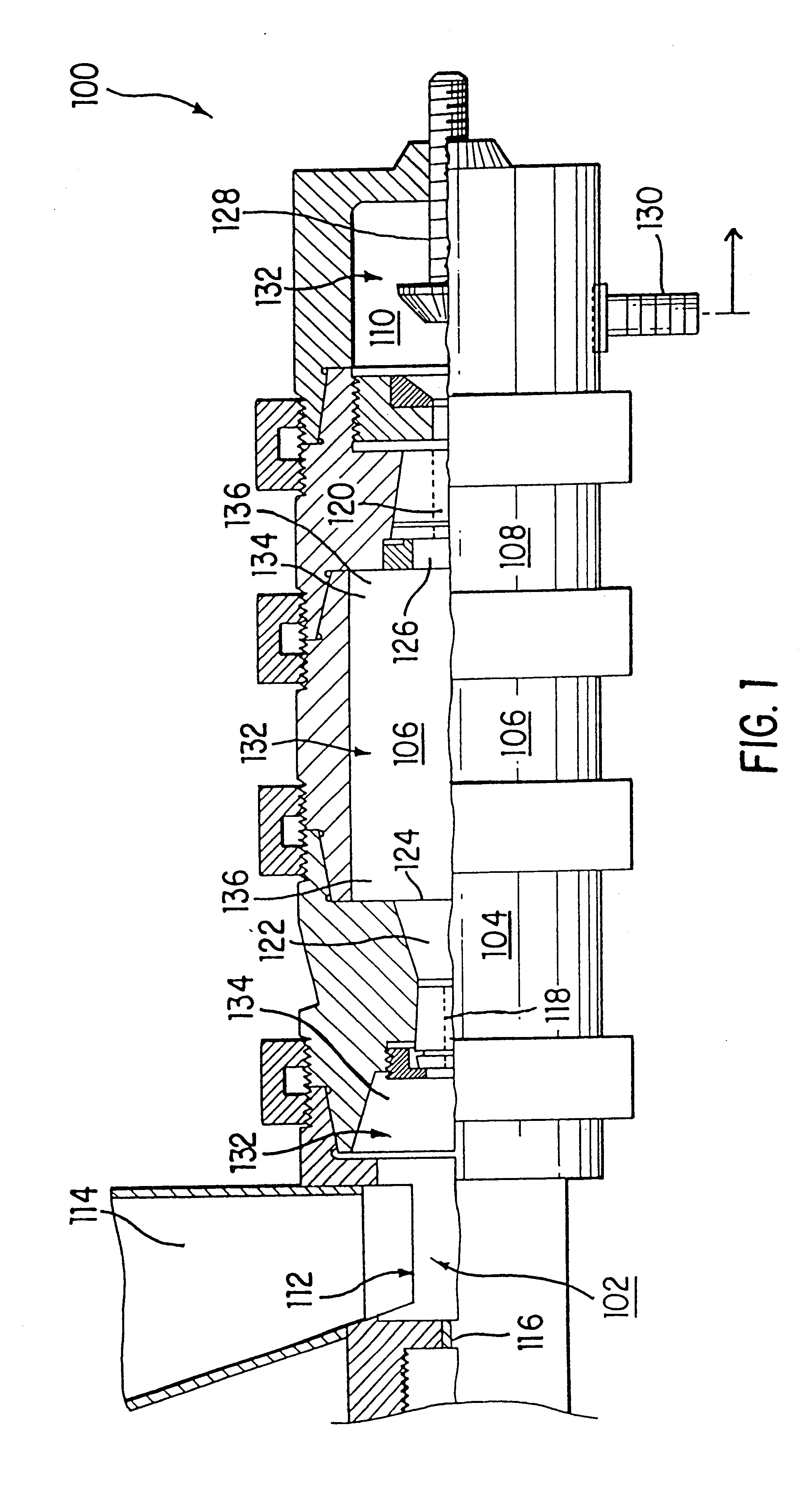

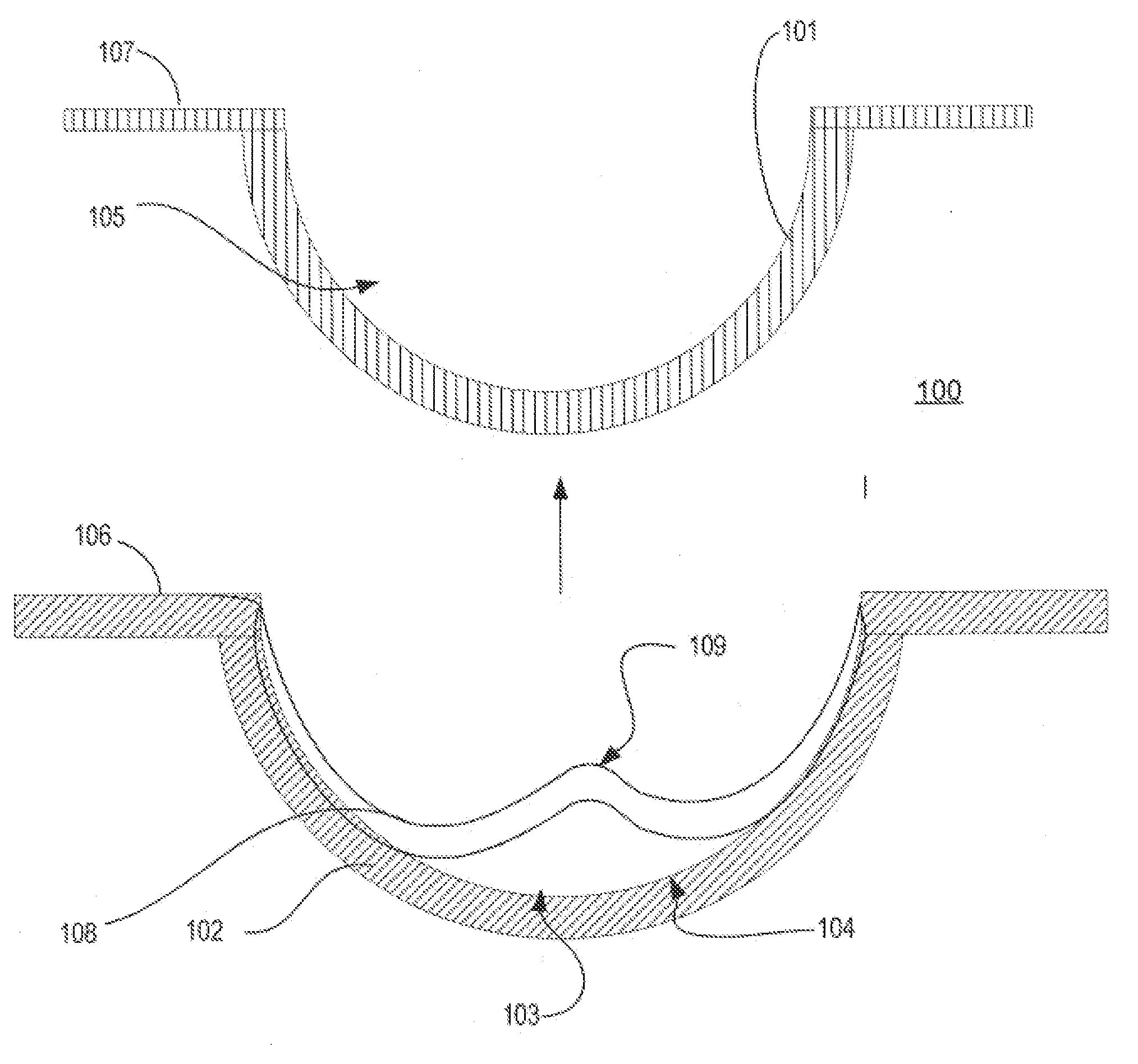

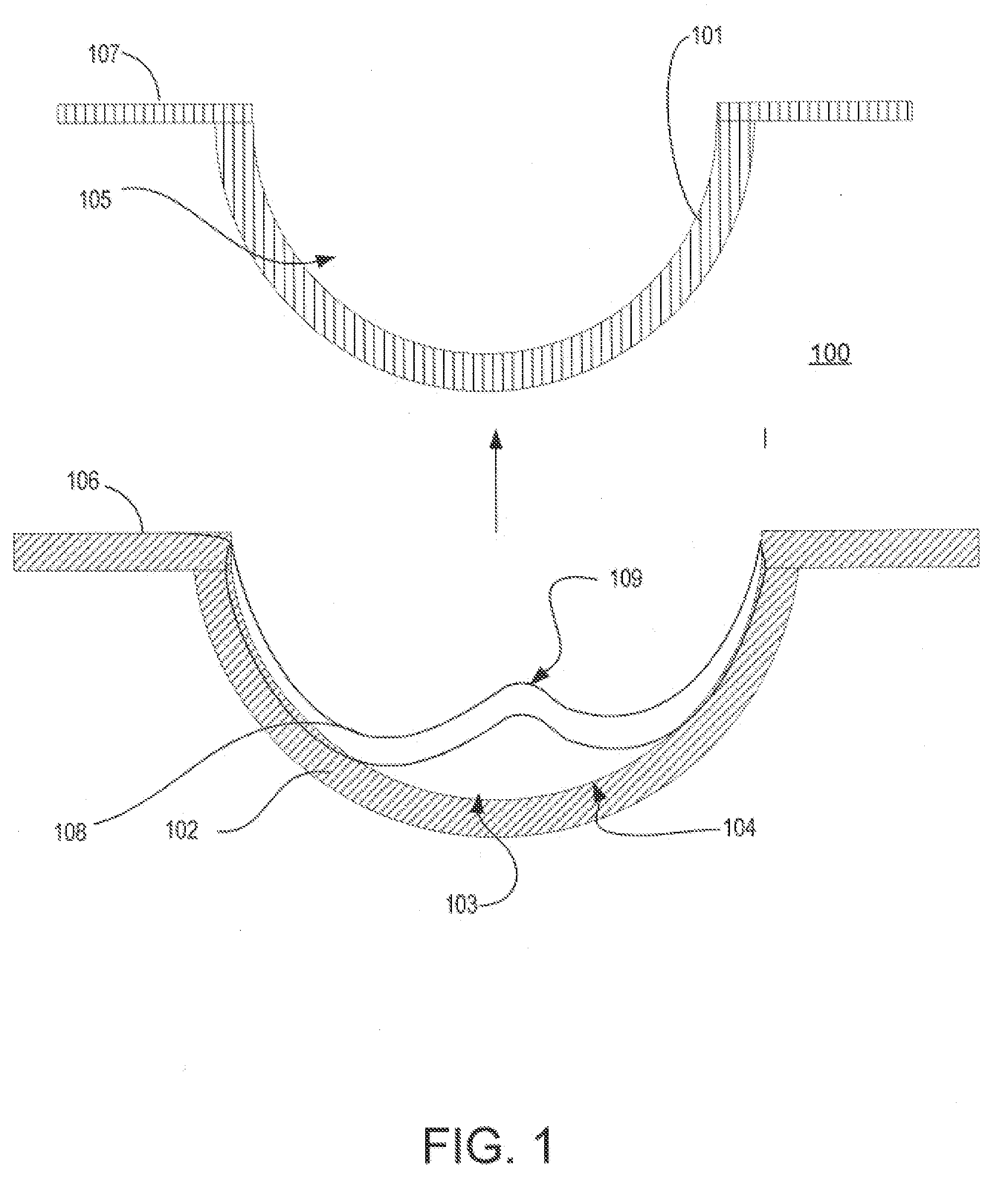

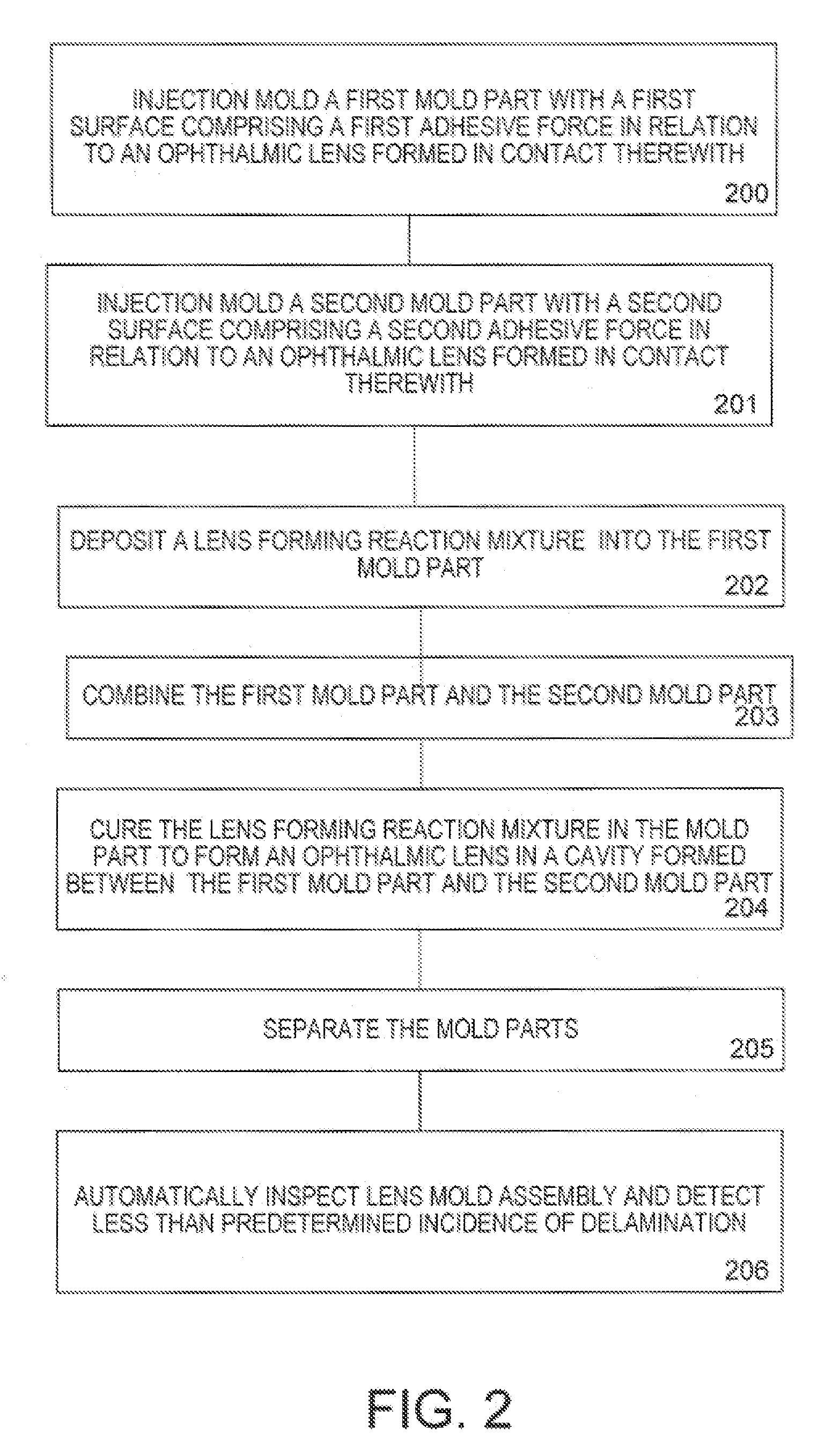

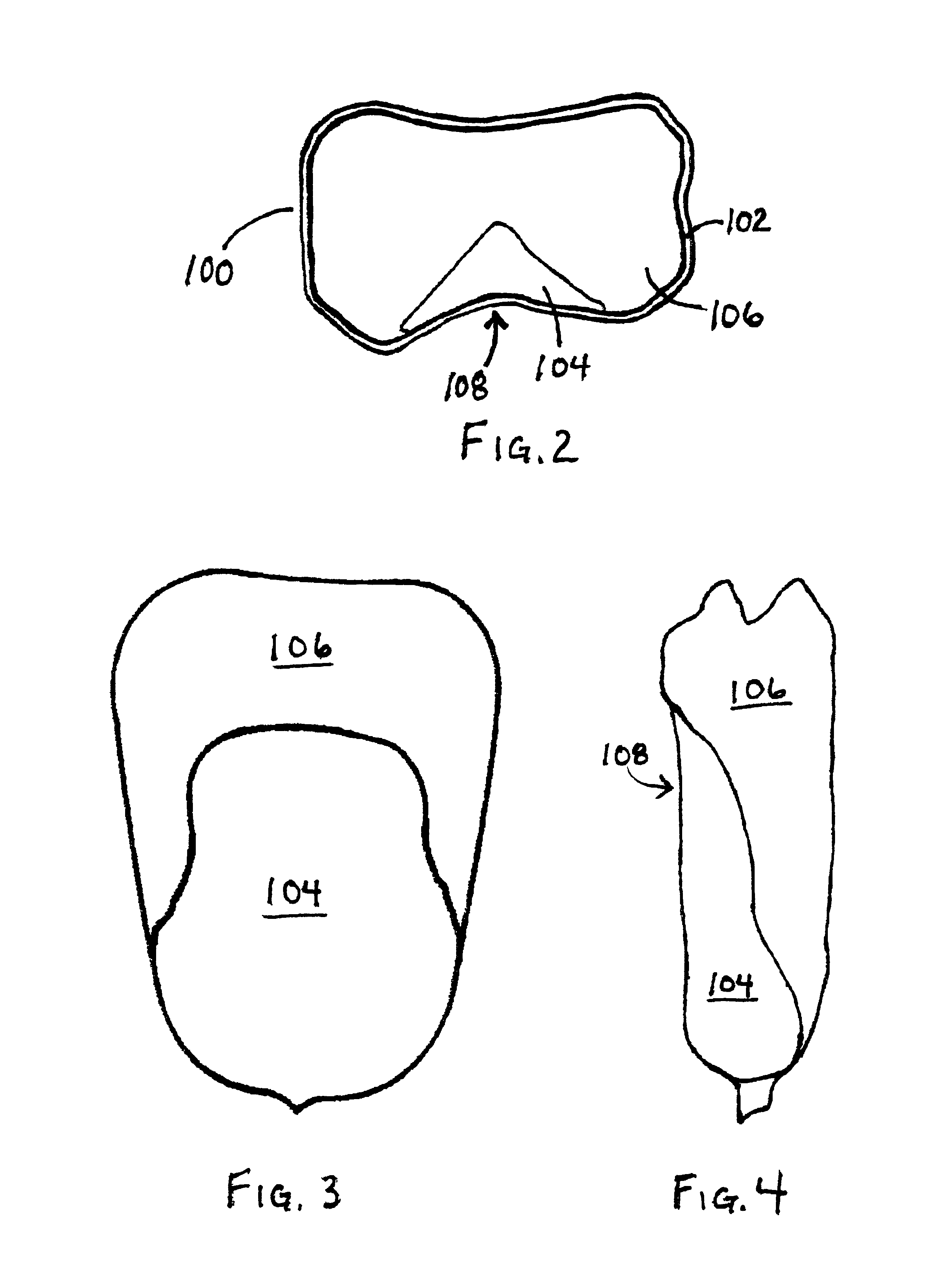

Decreased lens delamination during ophthalmic lens manufacture

The present invention includes molds for forming ophthalmic lenses, such as contact lens. In particular, the present invention relates to apparatus, molds and methods for fashioning an ophthalmic lens with a mold assembly that includes a two or more mold parts and an adhesion differential between a surface of each mold part in the lens forming area as the surface relates to the ophthalmic lens.

Owner:JOHNSON & JOHNSON VISION CARE INC

Process and apparatus for comminuting silicon

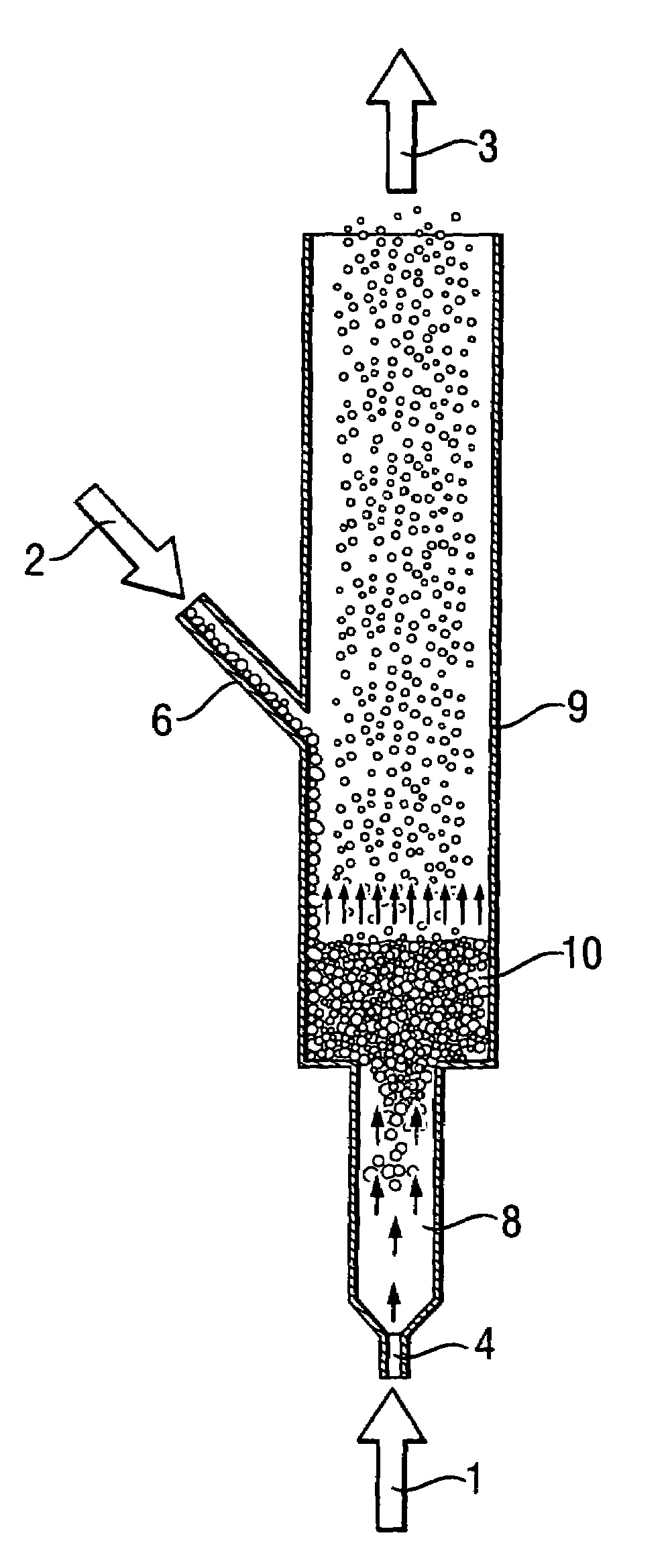

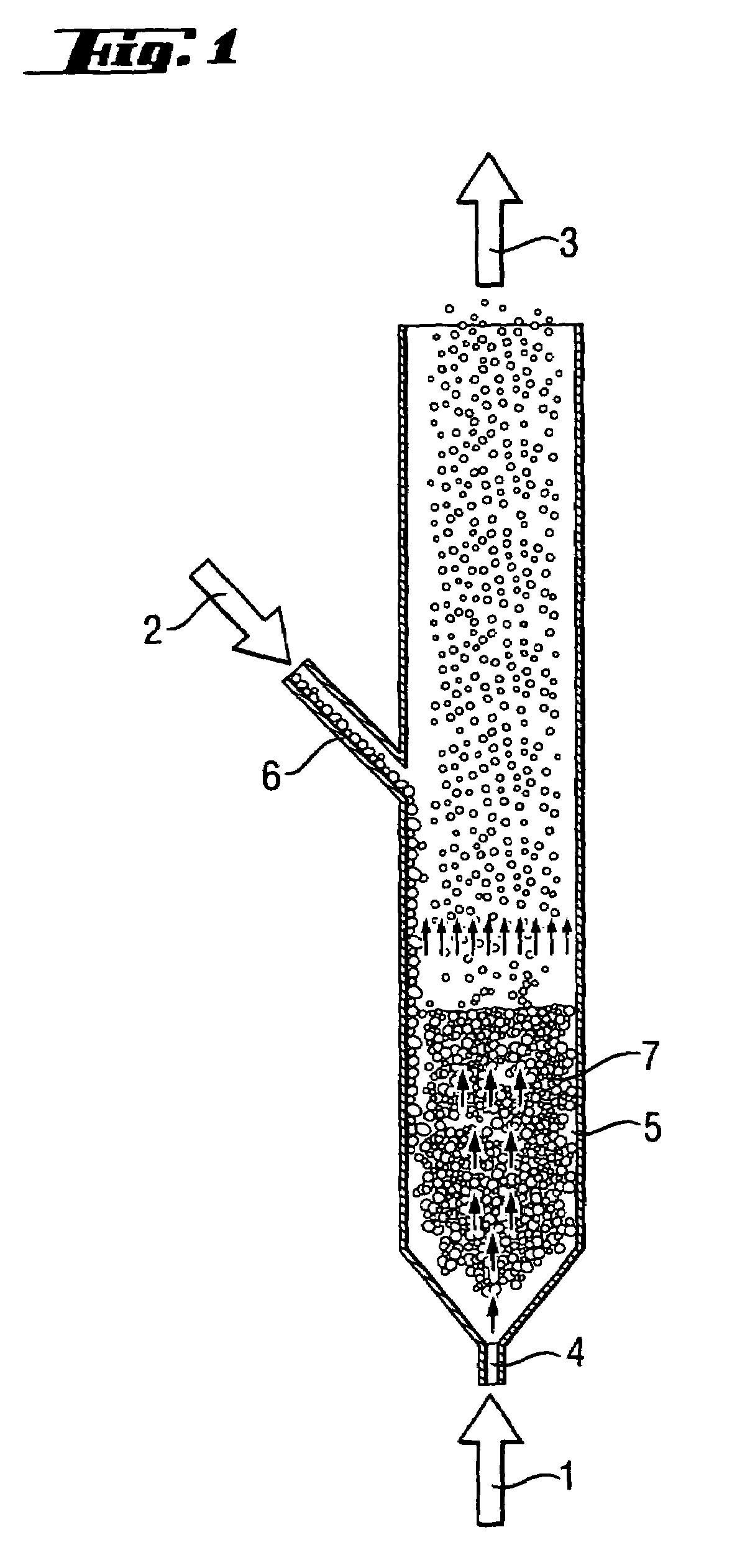

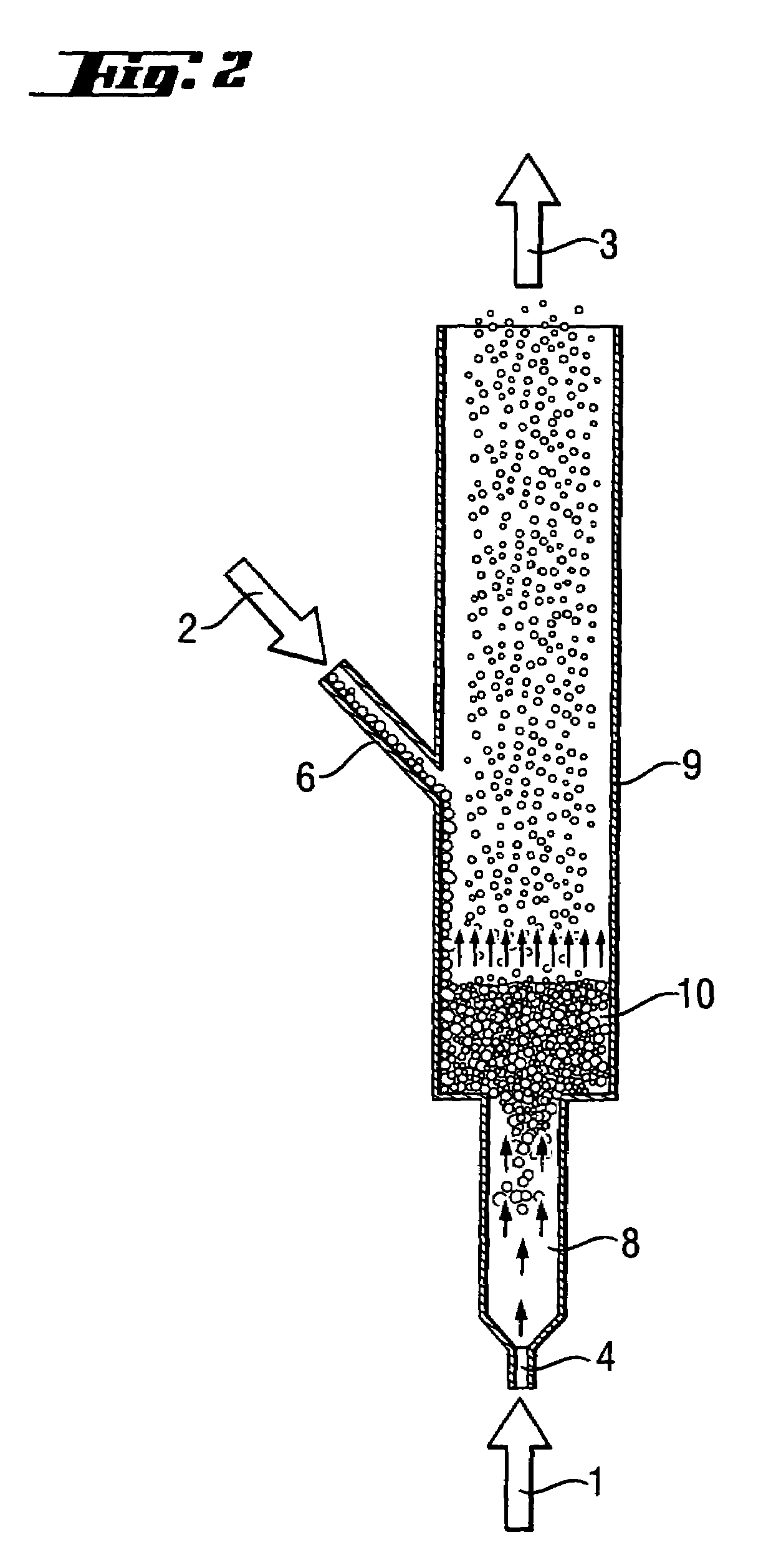

An apparatus for producing silicon seed particles having a size of from 50 μm to 1000 μm from silicon granules having a size of from 300 μm to 5000 μm, comprising a vertically disposed jet chamber with a low cross sectional area and a jet nozzle at the base of the jet chamber through which a milling gas stream is introduced into the chamber; a larger cross section countercurrent gravity separator adjoining the jet chamber, and an inlet for silicon granules, wherein the jet chamber has a length sufficient to allow the milling gas stream to widen to the cross section of the jet chamber.

Owner:WACKER CHEM GMBH

Multi-functional tool assembly for processing tool of waste processing machine

A multi-functional tool assembly for a processing tool of a waste processing machine includes a tool holder for attachment to a rotor assembly of the waste processing machine. The multi-functional tool assembly also includes a multi-functional tool attached to the tool holder to reduce waste material and to aggressively output the reduced waste material from the rotor assembly of the waste processing machine.

Owner:BANDIT IND

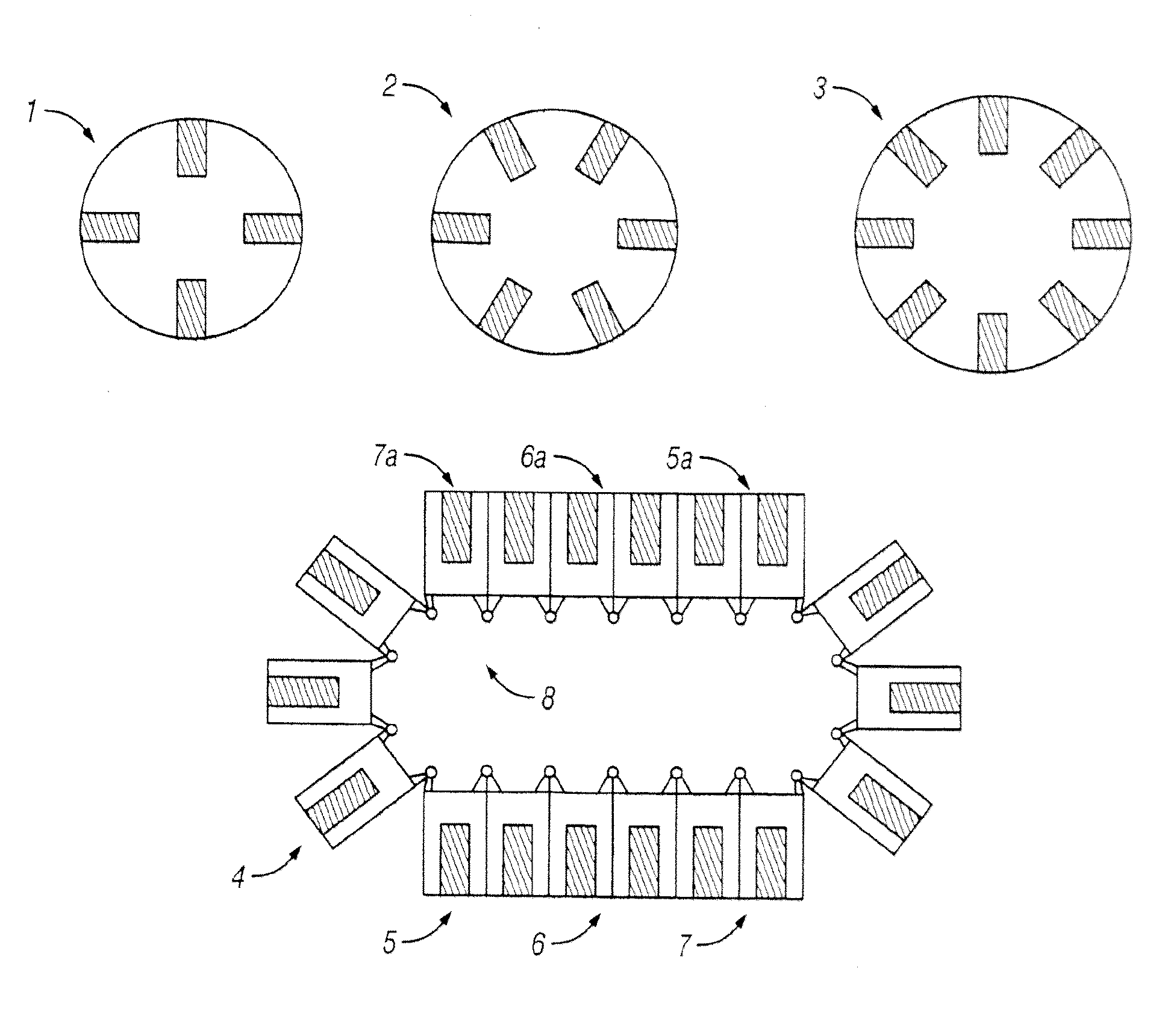

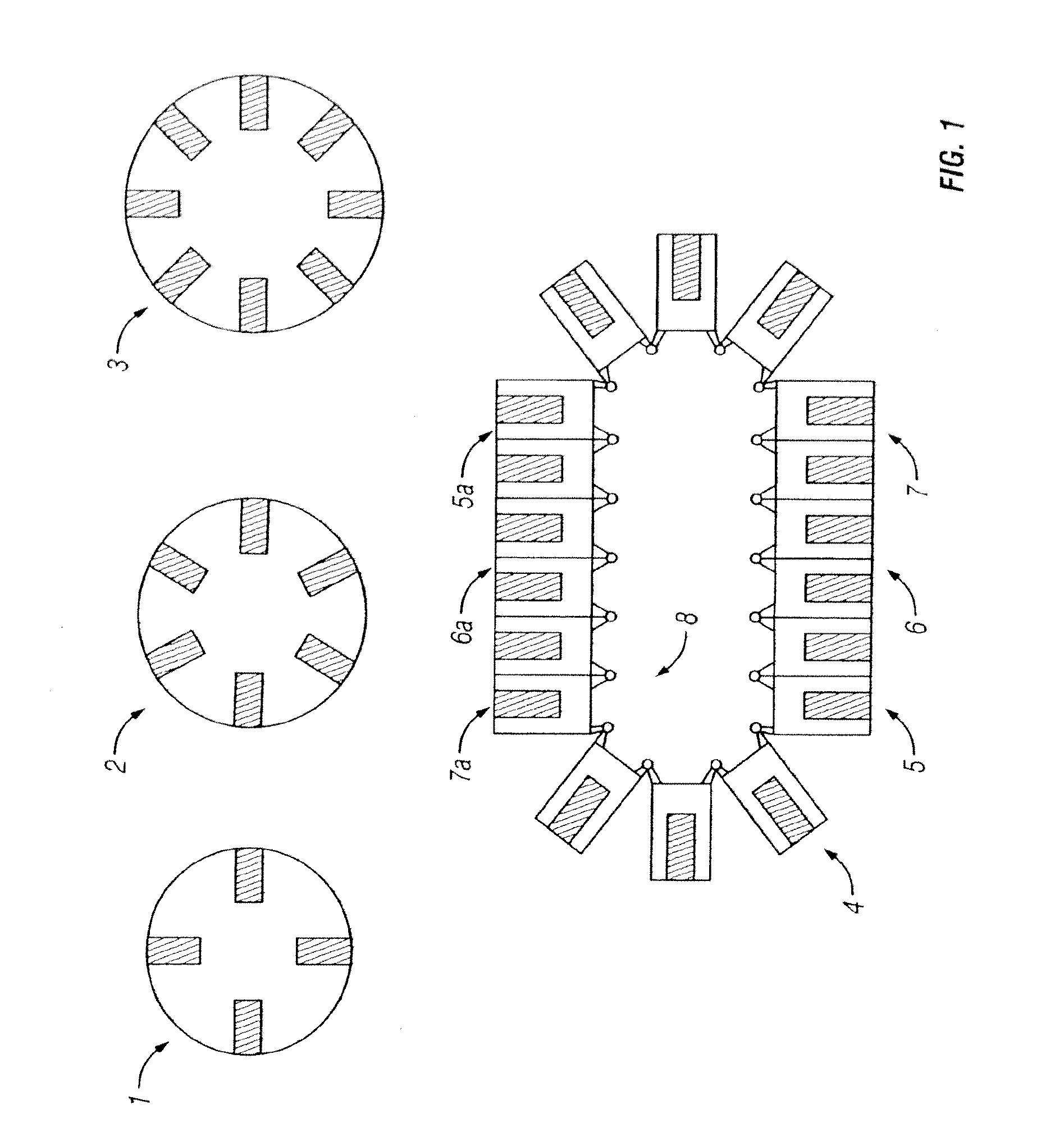

Multiple blade blender apparatus

A multi-blade blender is disclosed having a drive shaft, a gear system, and at least two blade assemblies. Each blade assembly includes a blade affixed to an end of a blade shaft. The blade shafts of the first, second and third blade assemblies are angled from the vertical position toward the container wall. The gear system engages at least one of the blade assemblies. The drive shaft engages the gear system and causes the blade assemblies to rotate in operation.

Owner:IDEAL LIVING HLDG

Apparatus and method for circular vortex air flow material grinding

Owner:POLIFKA RUTH

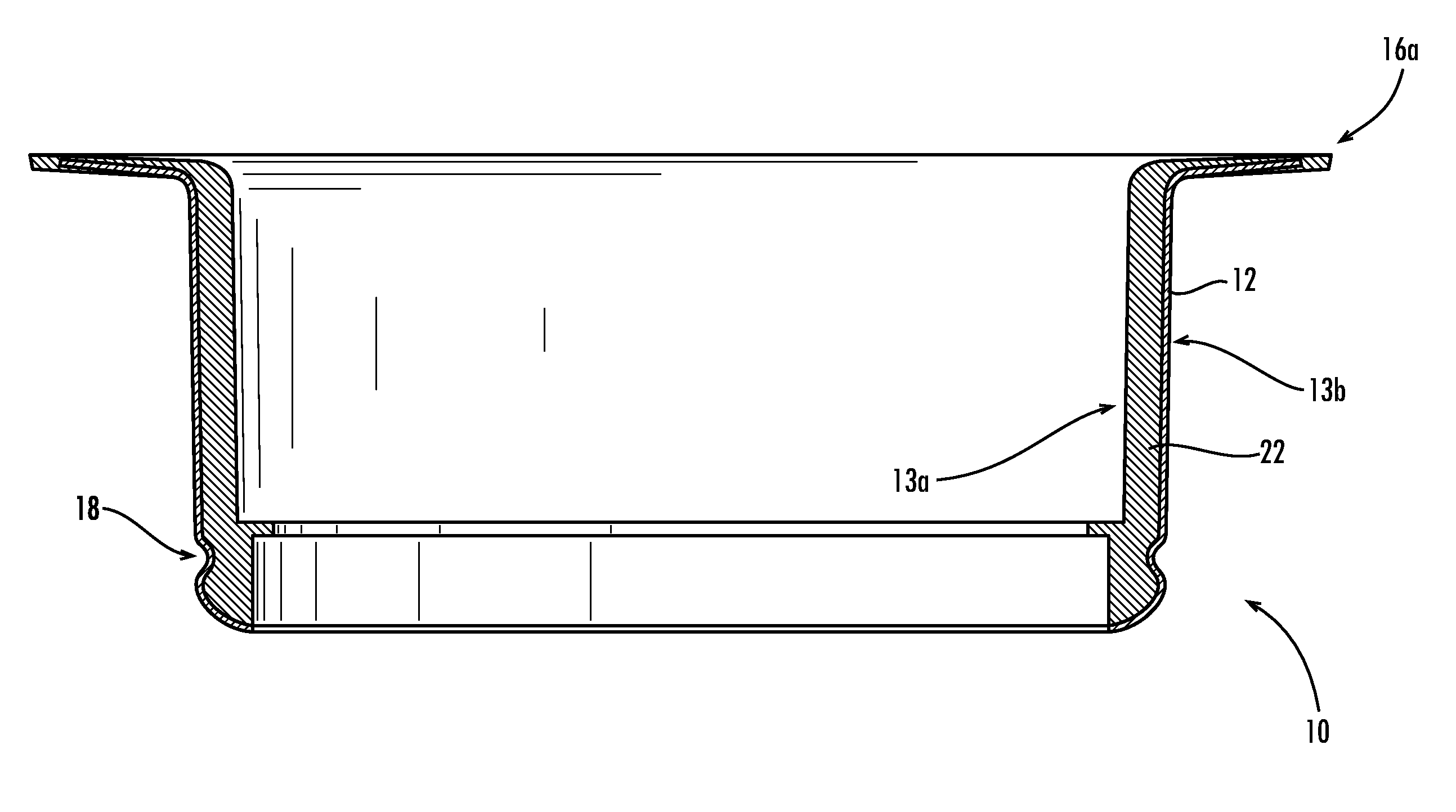

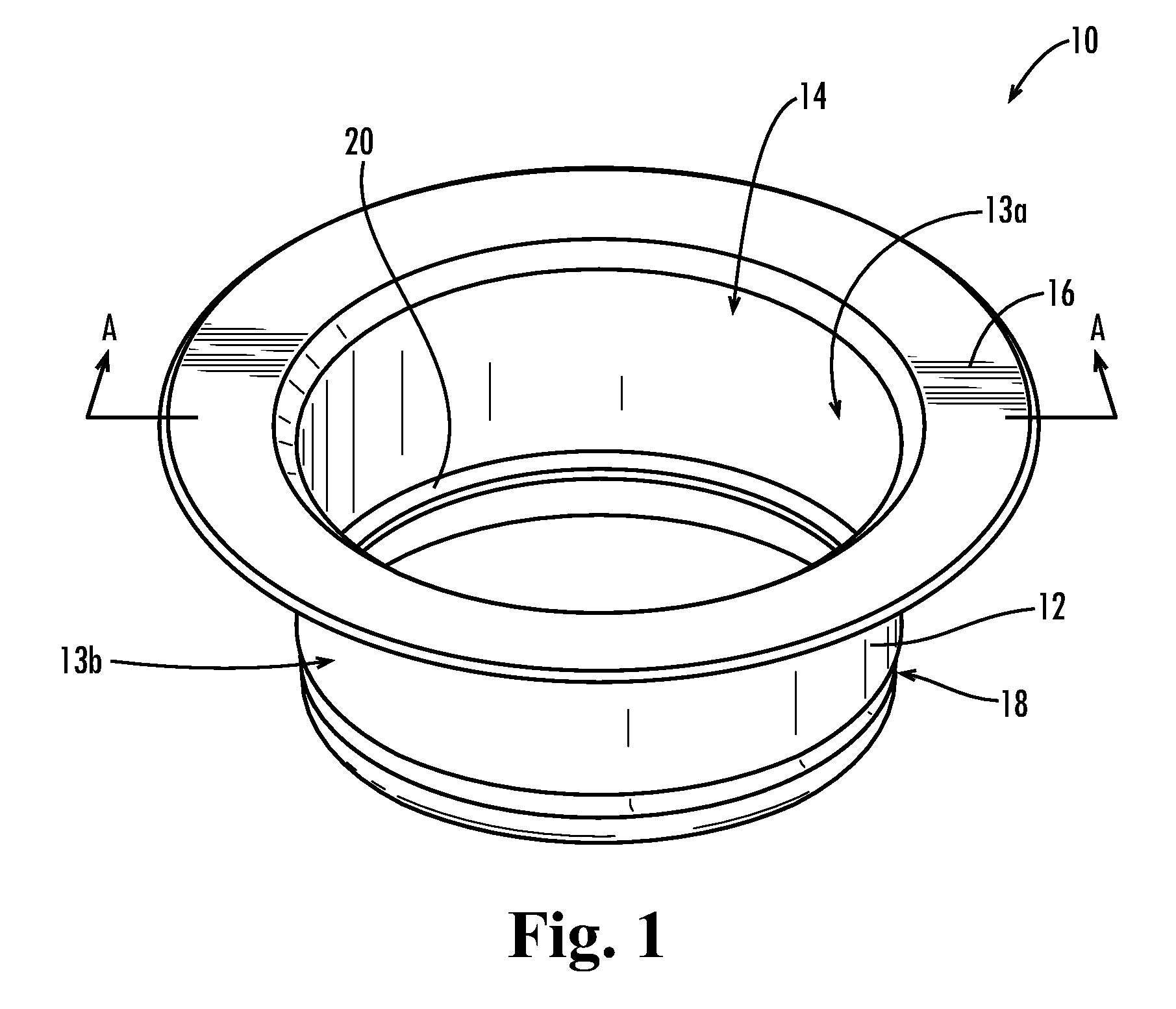

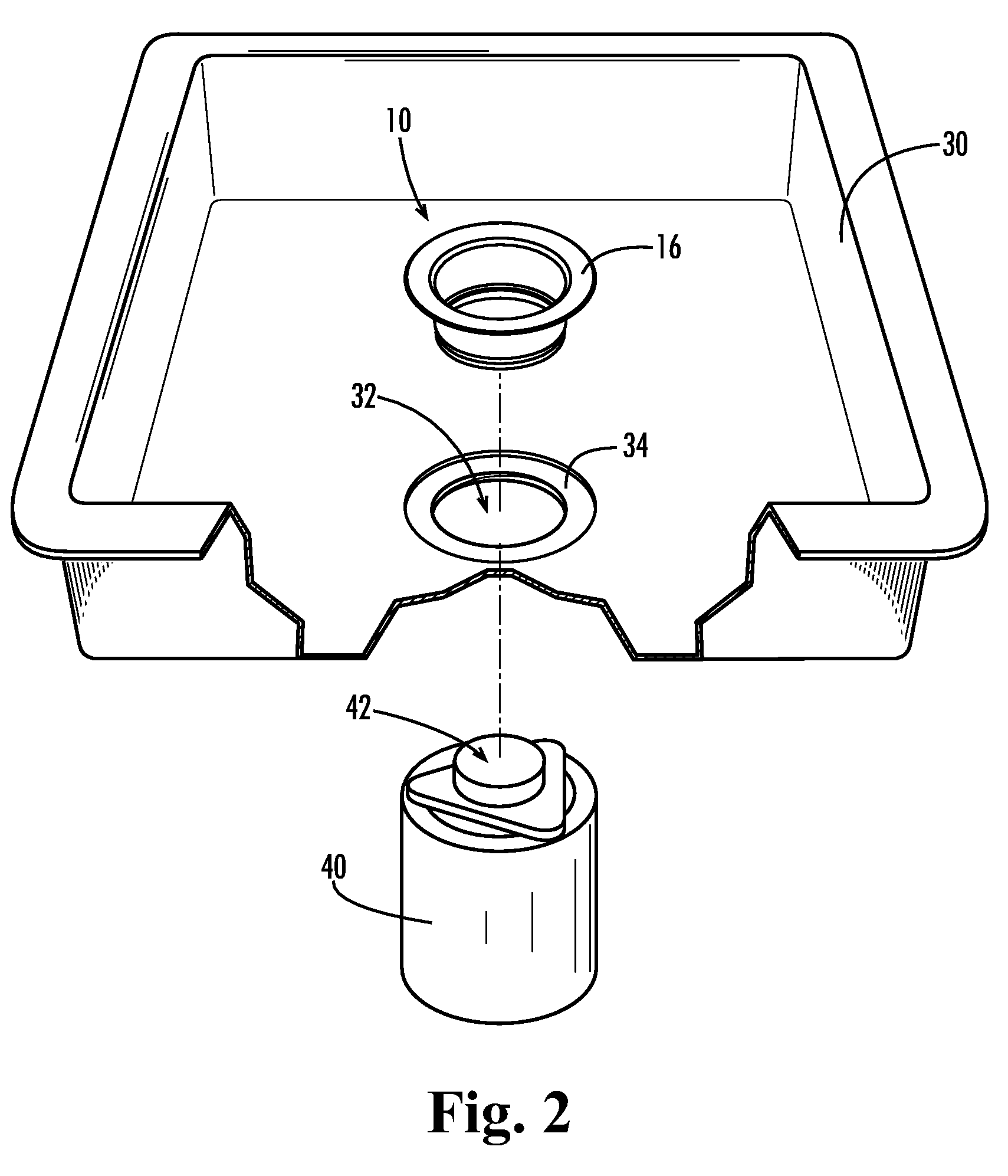

Decorative disposer flange and strainer assembly

A sink flange for use in conjunction with a sink drain. The flange includes a flange body and a flange lip. The flange body is substantially vertical having a top end and a bottom end. The bottom end defines a flange passage therethrough. The flange lip is annular having a top side and a bottom side, which radially extends out of the top end of the flange body. The flange passage and flange lip are at least coated with a polymer.

Owner:OPELLA

Corn degermination process

InactiveUS6936294B2Increase productionYield maximizationGrain huskingGrain polishingSurface velocityEngineering

Owner:SATAKE USA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com