Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1185 results about "Rice dishes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

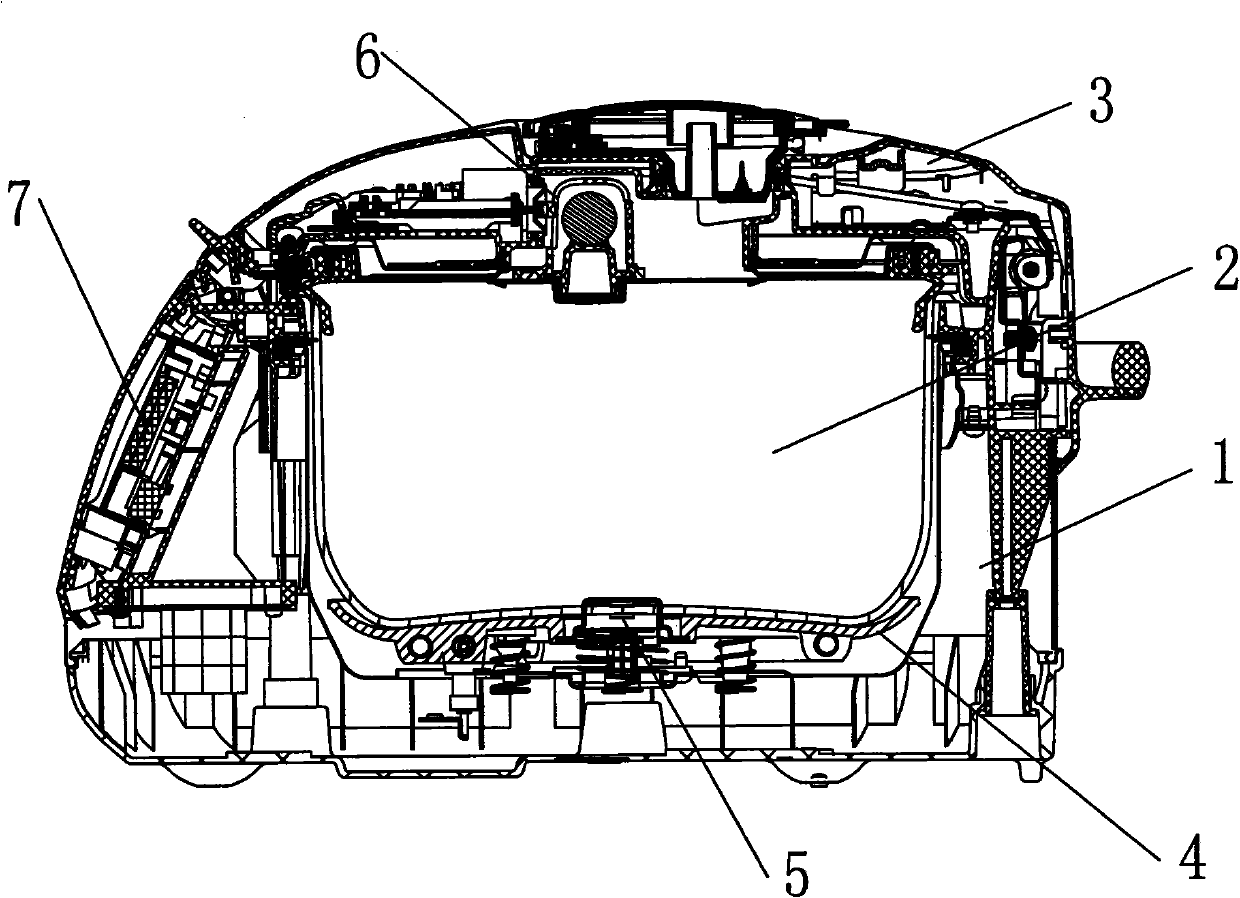

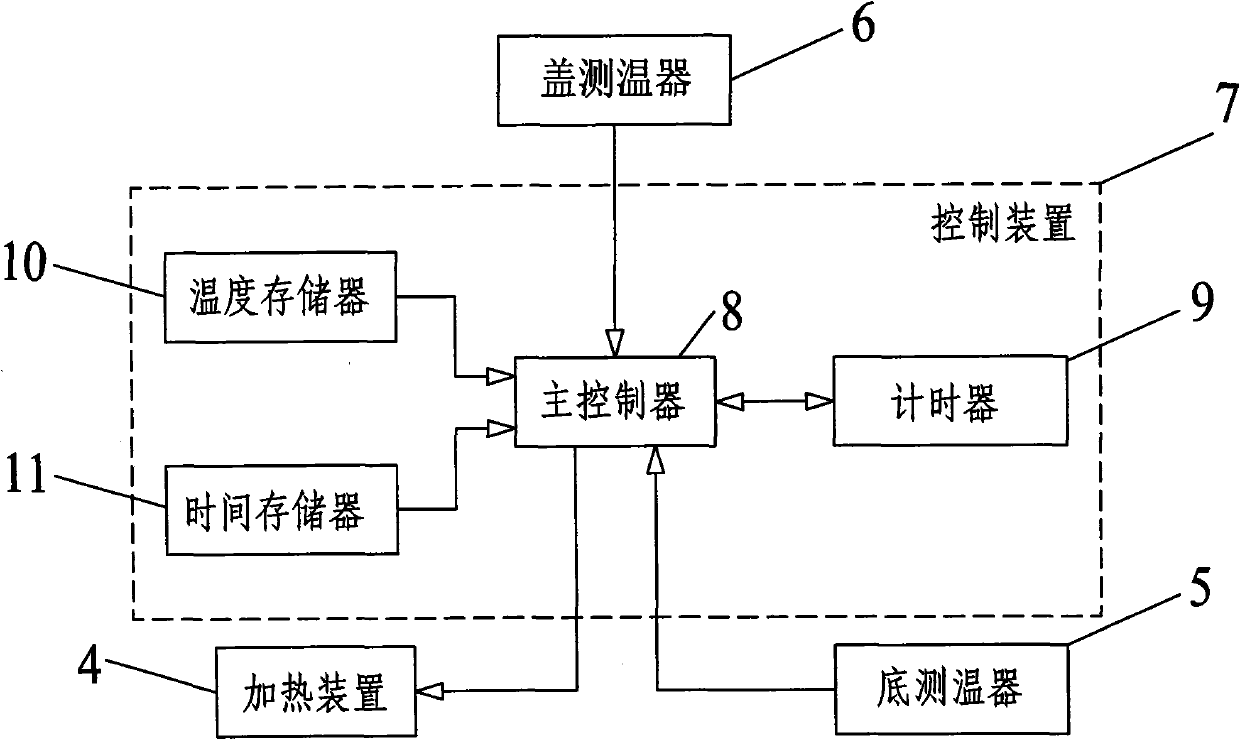

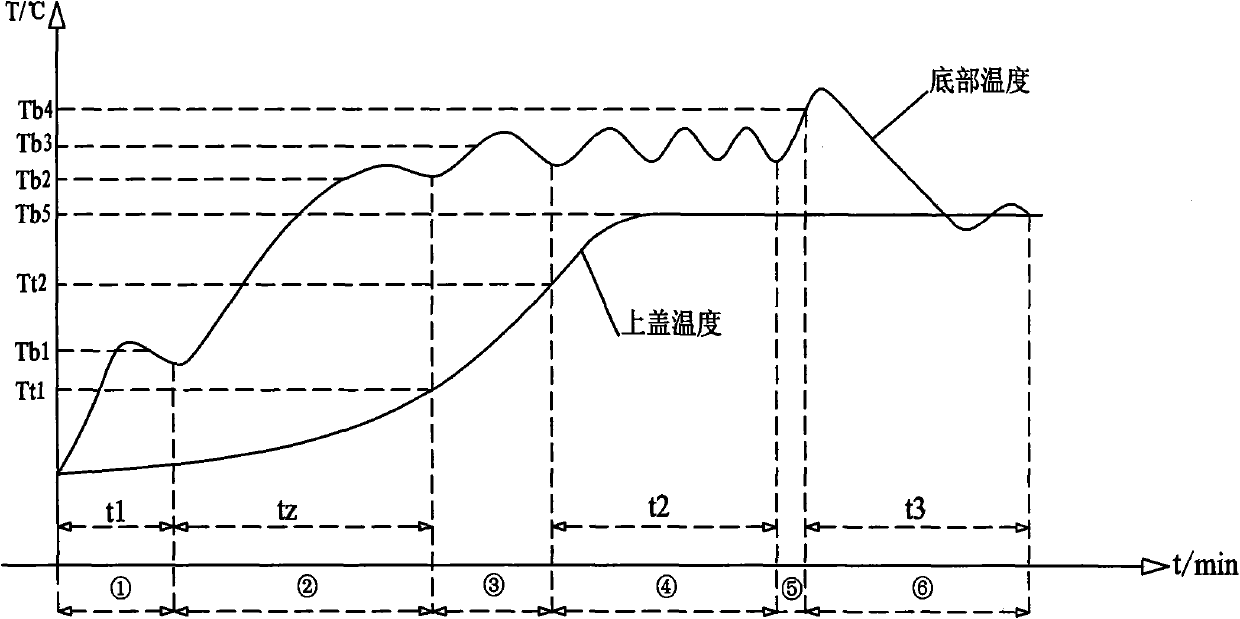

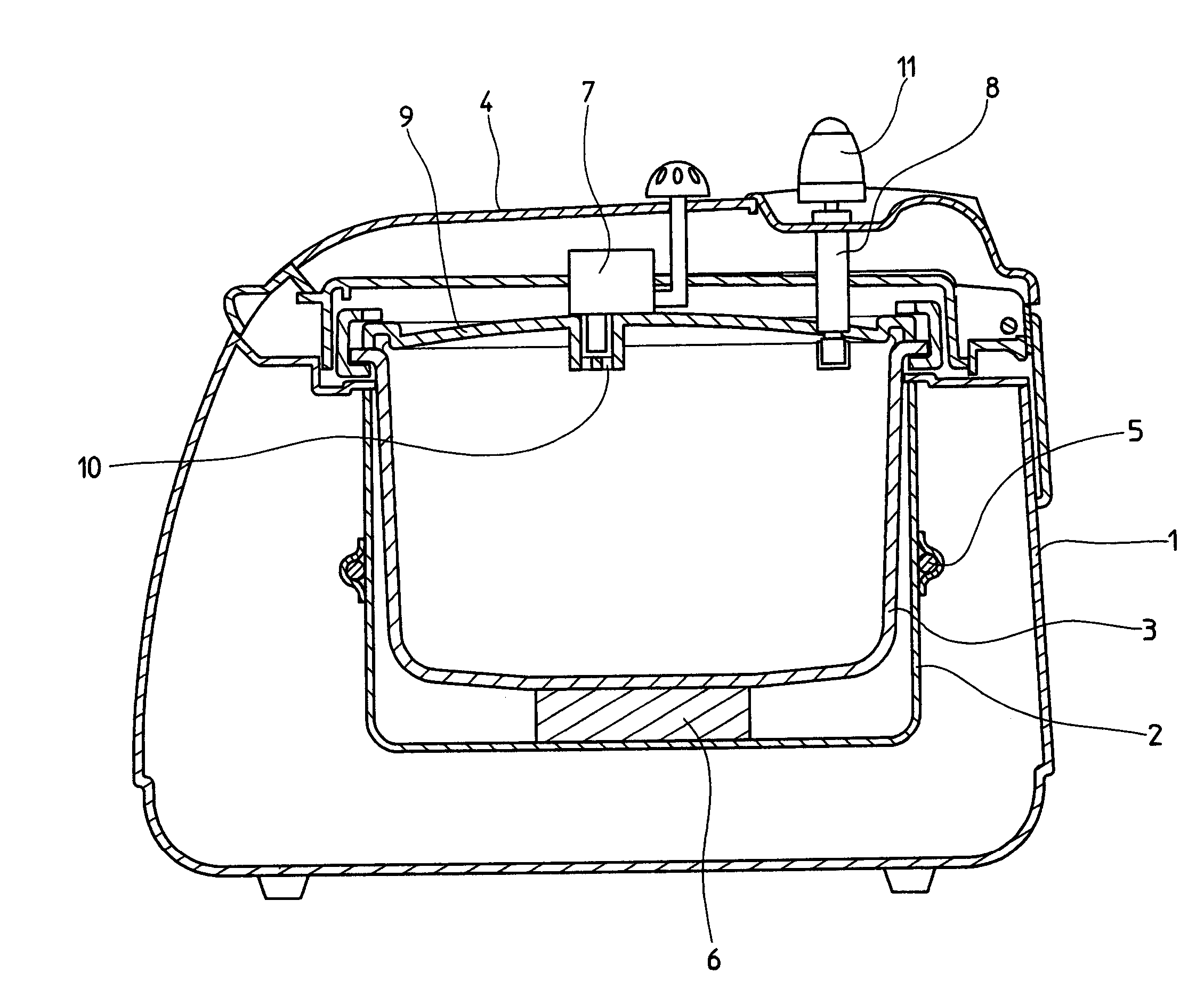

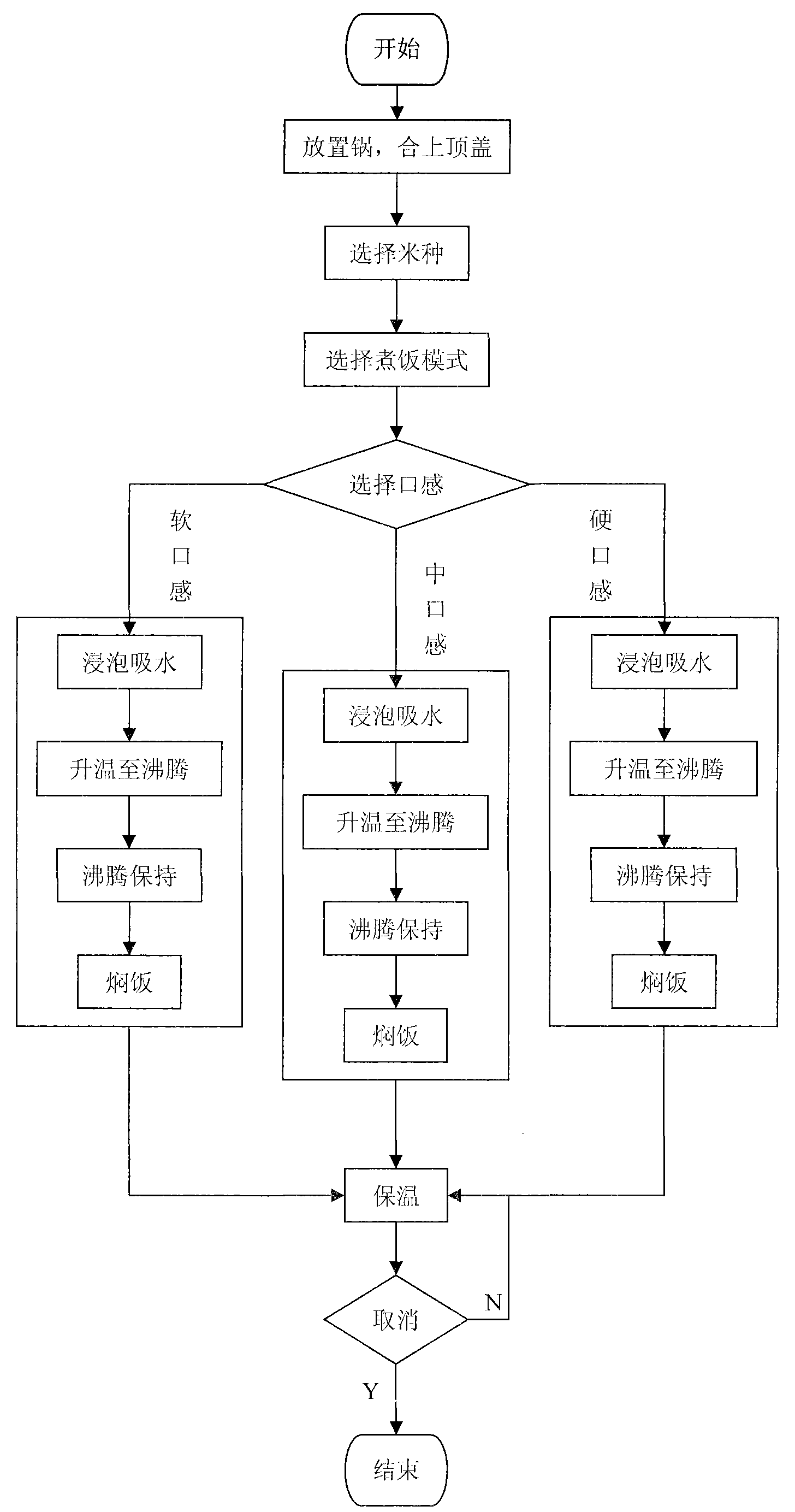

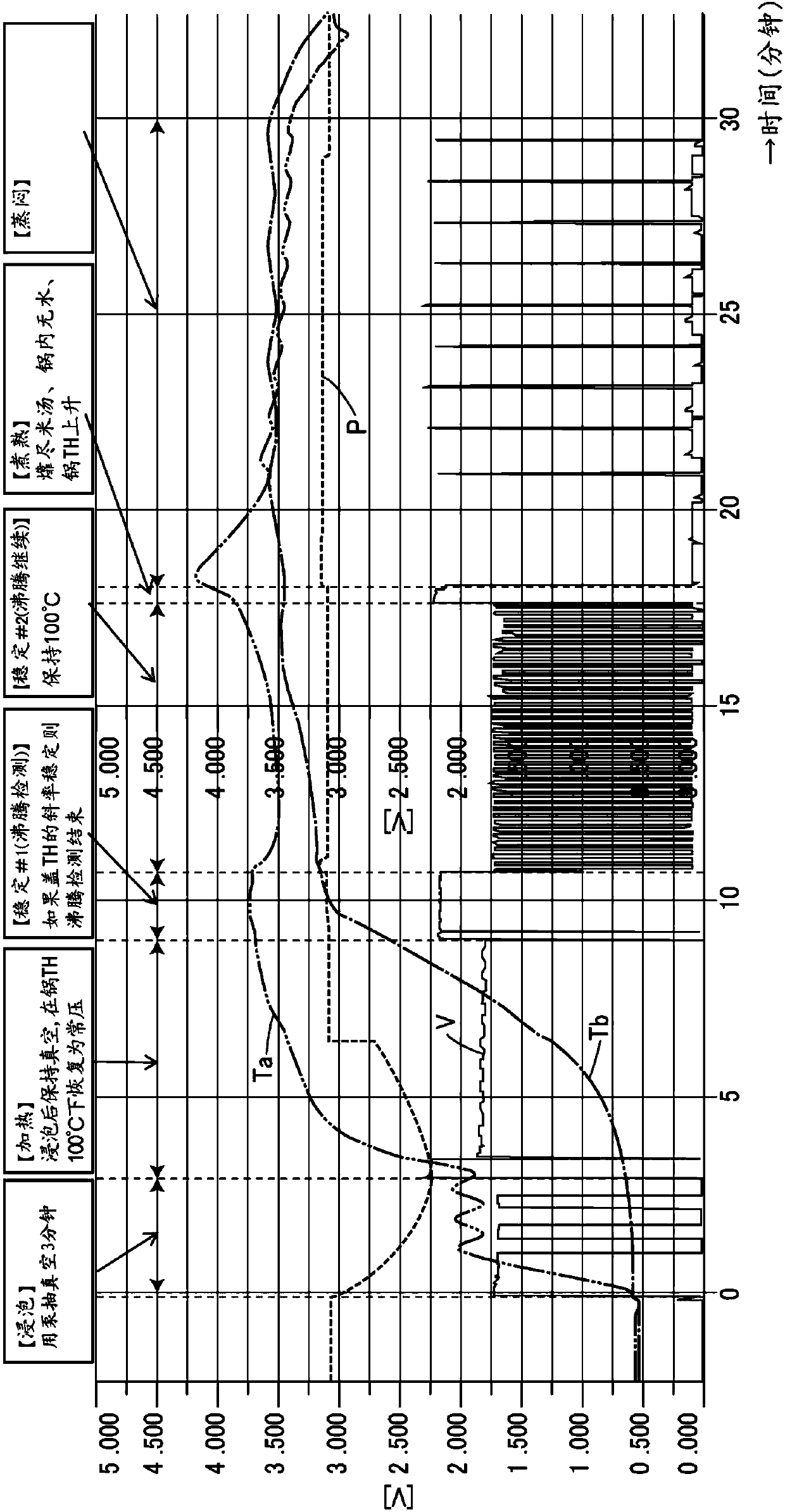

Electric cooker and rice-cooking heating control method

ActiveCN101766439ATransfer of controlEffective control transferBoiling over preventionTemperature control using electric meansThermodynamicsRice dishes

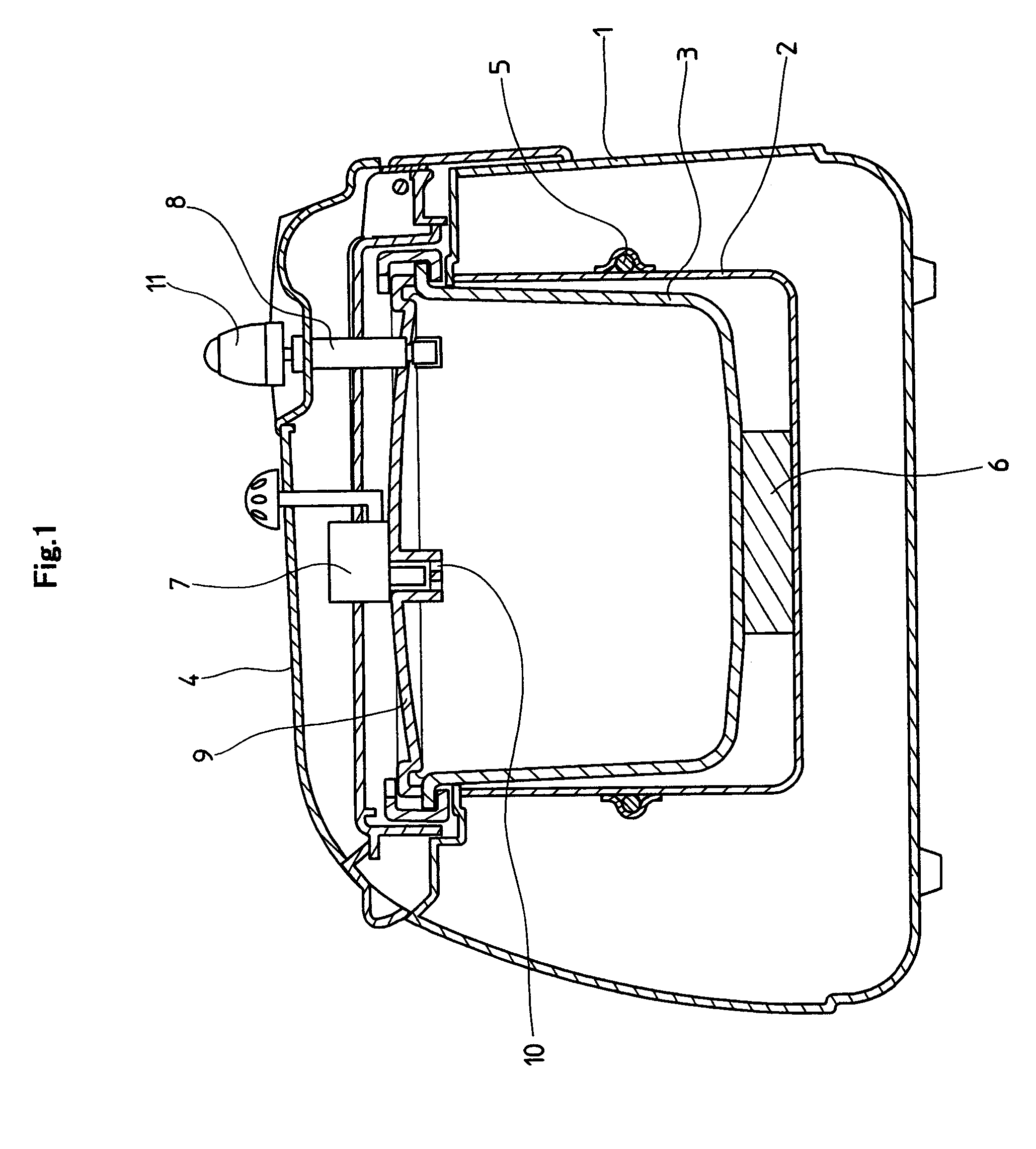

The invention relates to an electric cooker and a rice-cooking heating control method. The electric cooker comprises a cooker body, an inner container, an upper cover device, a heating device for heating the inner container and food; wherein the outside of the bottom of the inner container is provided with a bottom temperature detector for detecting temperature of the inner container, the upper cover device is provided with a cover temperature detector for detecting temperature of the upper cover and a control device for controlling rice cooking; the control device comprises a main controller and a timer and a memory respectively connected with the main controller; the output terminals of the bottom temperature detector and the cover temperature detector are connected with the input terminal of the main controller, the output terminal of the main controller is electrically connected with the heating device. The rice-cooking control method of the invention at least comprises a first heating phase, a second heating phase and a first boiling phase; wherein in the second heating phase, heating temperature and heating time of the first boiling phase is determined by heating time of the first heating phase, so that moisture of small amount of rice can be fully evaporated and overflow can be prevented; in addition, early termination of heating due to abnormal conditions at the bottom of the inner container in the case of large amount of rice can be avoided, thus ensuring enough heating to ripen the rice.

Owner:MIDEA GRP CO LTD

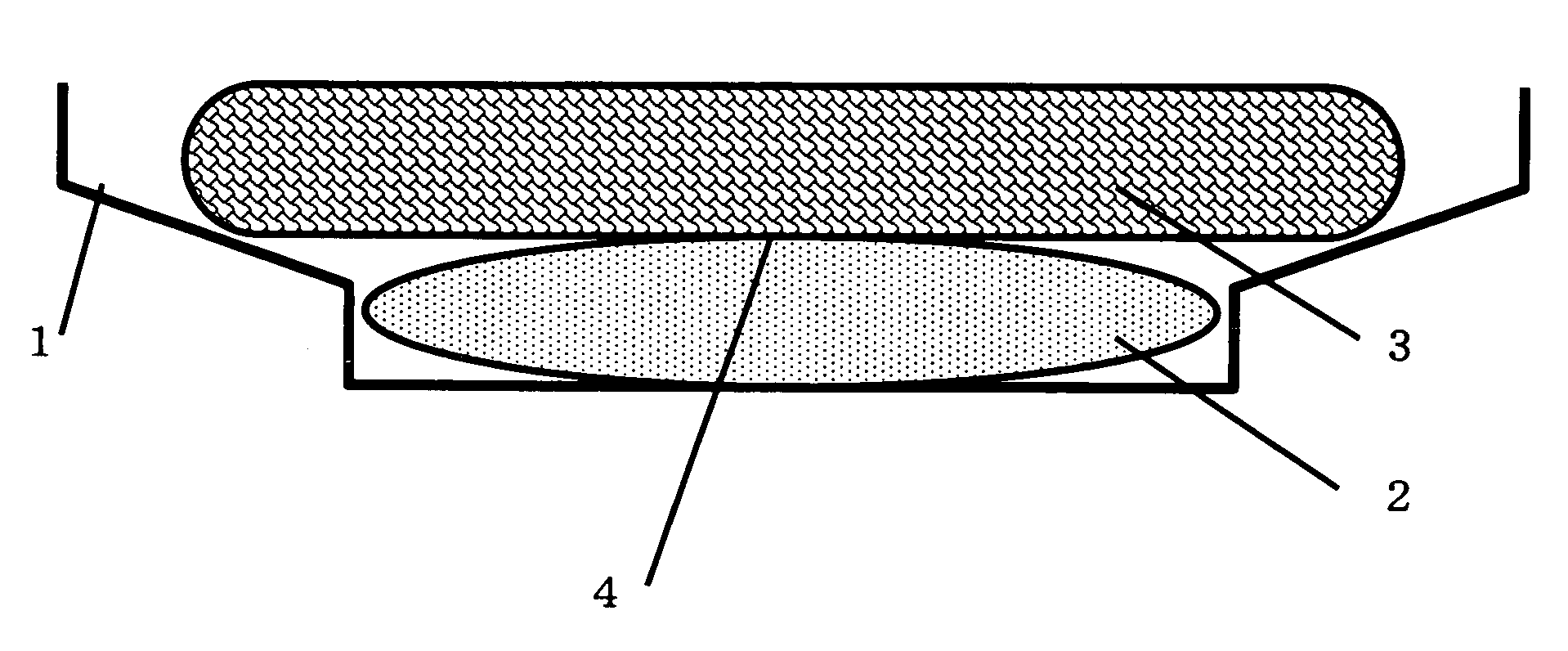

Rice cooker

InactiveUS7148451B2Short timeEliminate scatterBaking ovenPressure-cookersGamma-Aminobutyric acidRice dishes

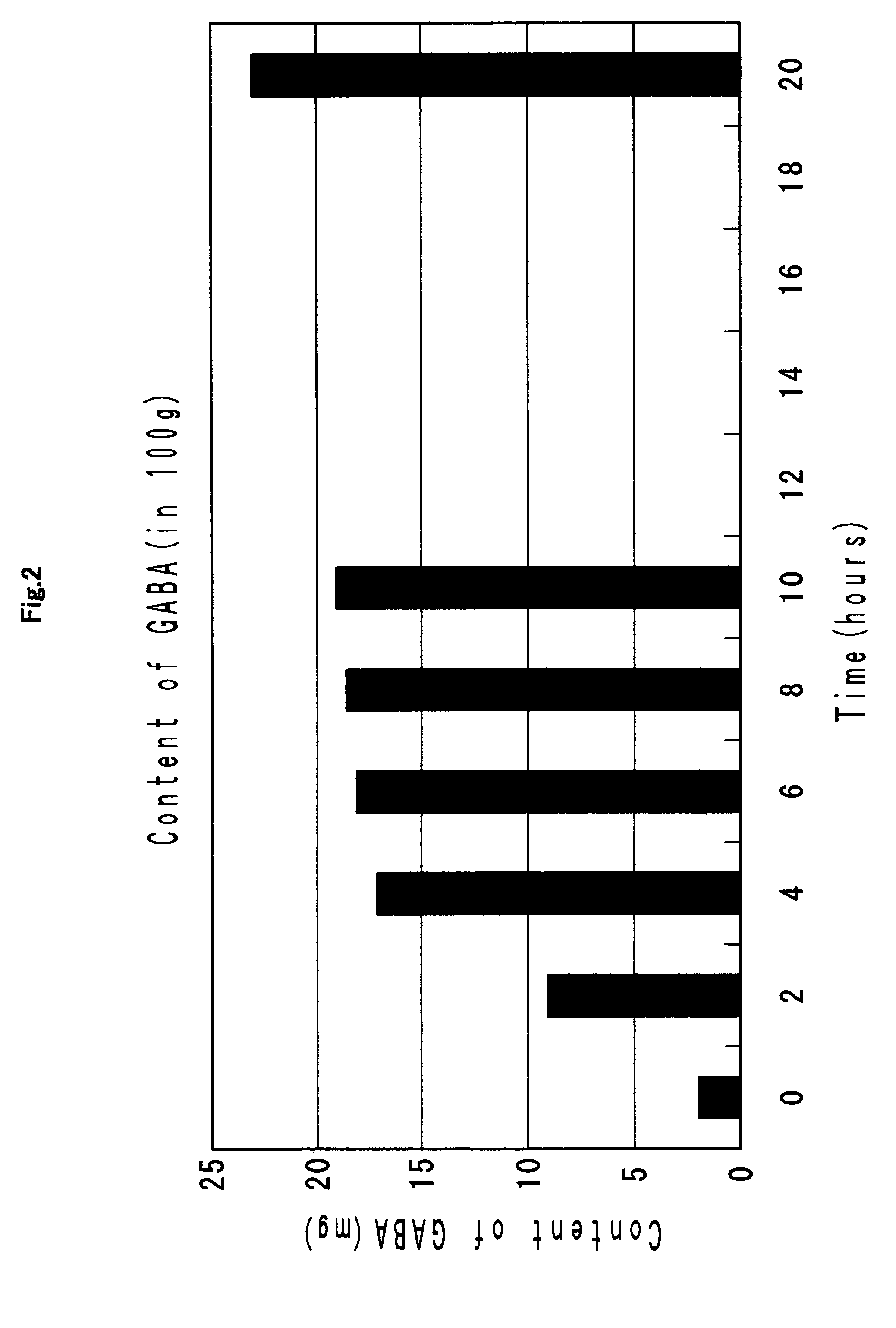

When water temperature is high and time germinating step is short, it is hard to cook freely to individual preference, and water turbidity and bad smell are likely to occur. By germinating with immersing brown rice or rice with the germ in water at 28 to 34 degrees for 3 to 6 hours in an inner pot 3, being followed by a cooking step successively, the rice can be immersed for a necessary time at low temperature, so that germinated rice with enough content of gamma-aminobutyric acid (GABA) can be obtained without causing water turbidity or bad smell.

Owner:MIYAKE INC

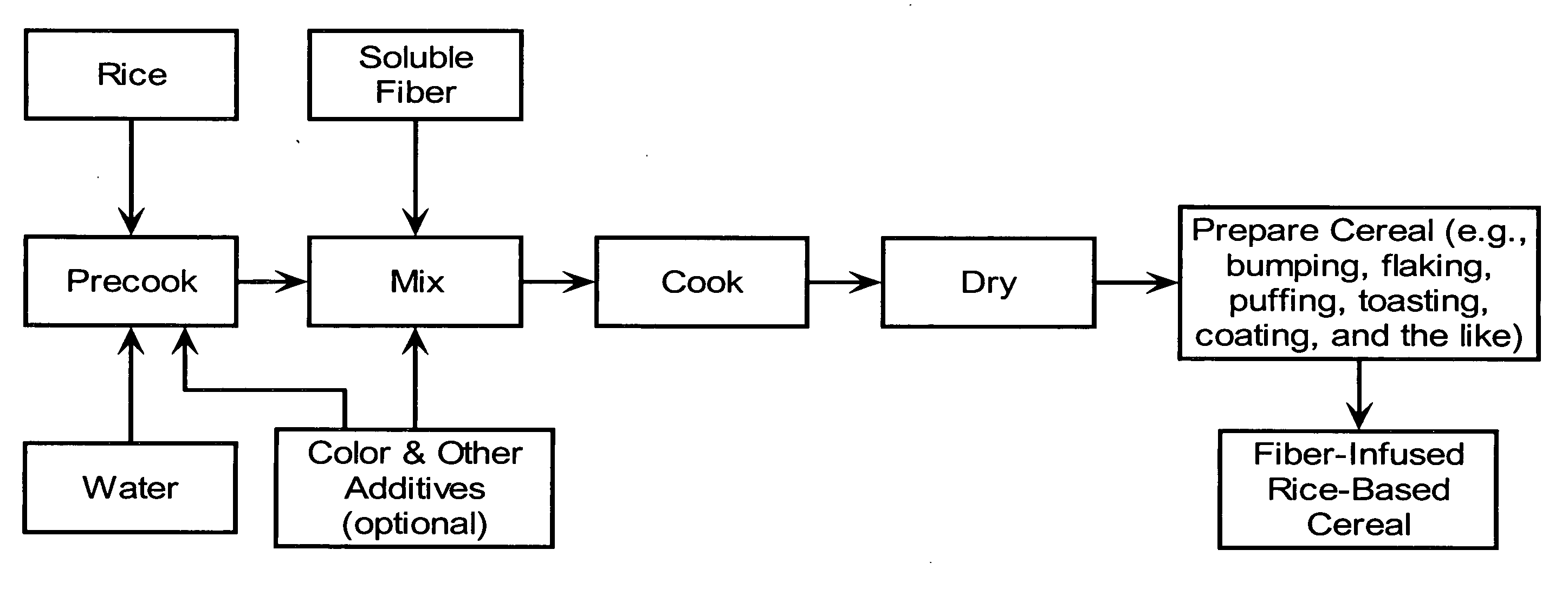

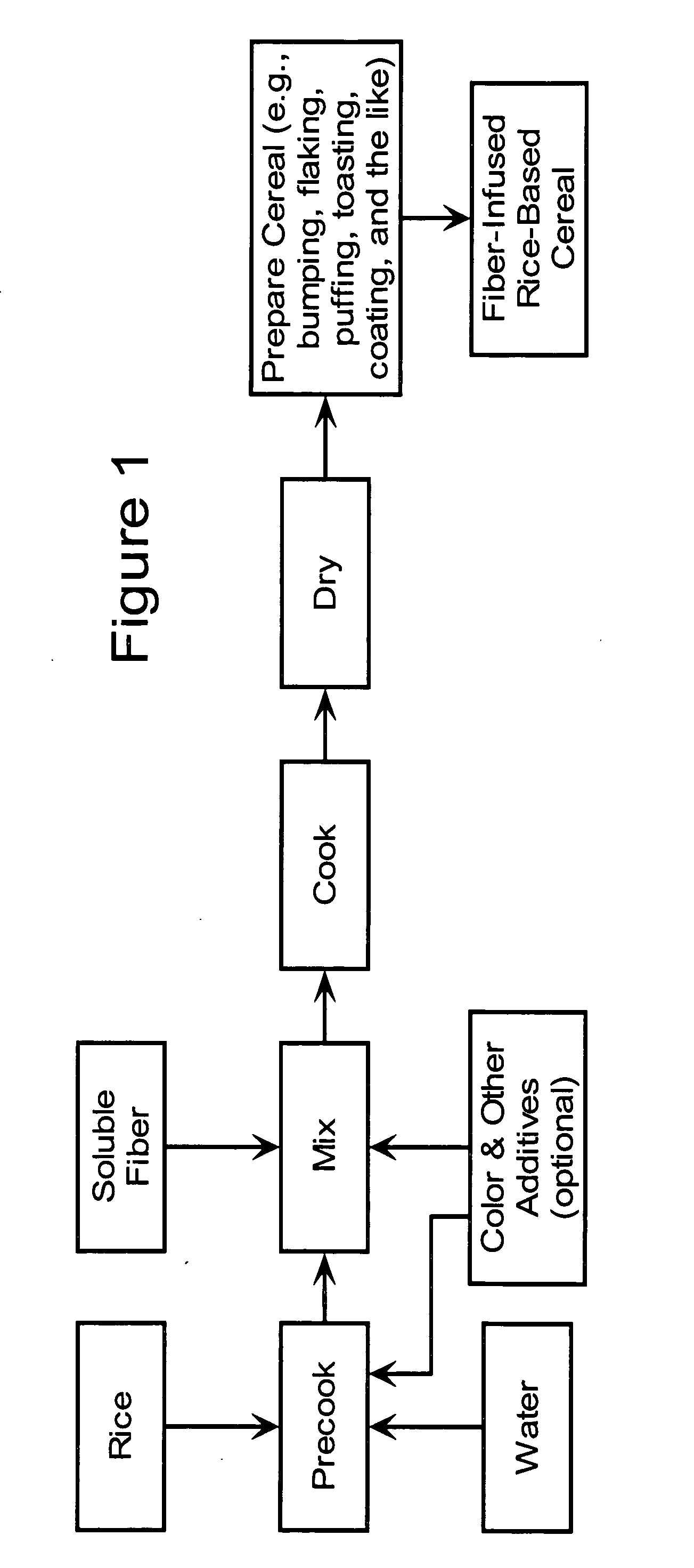

Fiber-containing rice-based cereals and methods of preparation

Methods for providing cooked rice with enhanced levels of fiber, wherein the fiber-containing cooked rice is suitable and especially adapted for use in preparing fiber-containing rice-based cereal products and especially for preparing fiber-containing puffed rice-based cereal products, are provided.

Owner:POST HOLDINGS

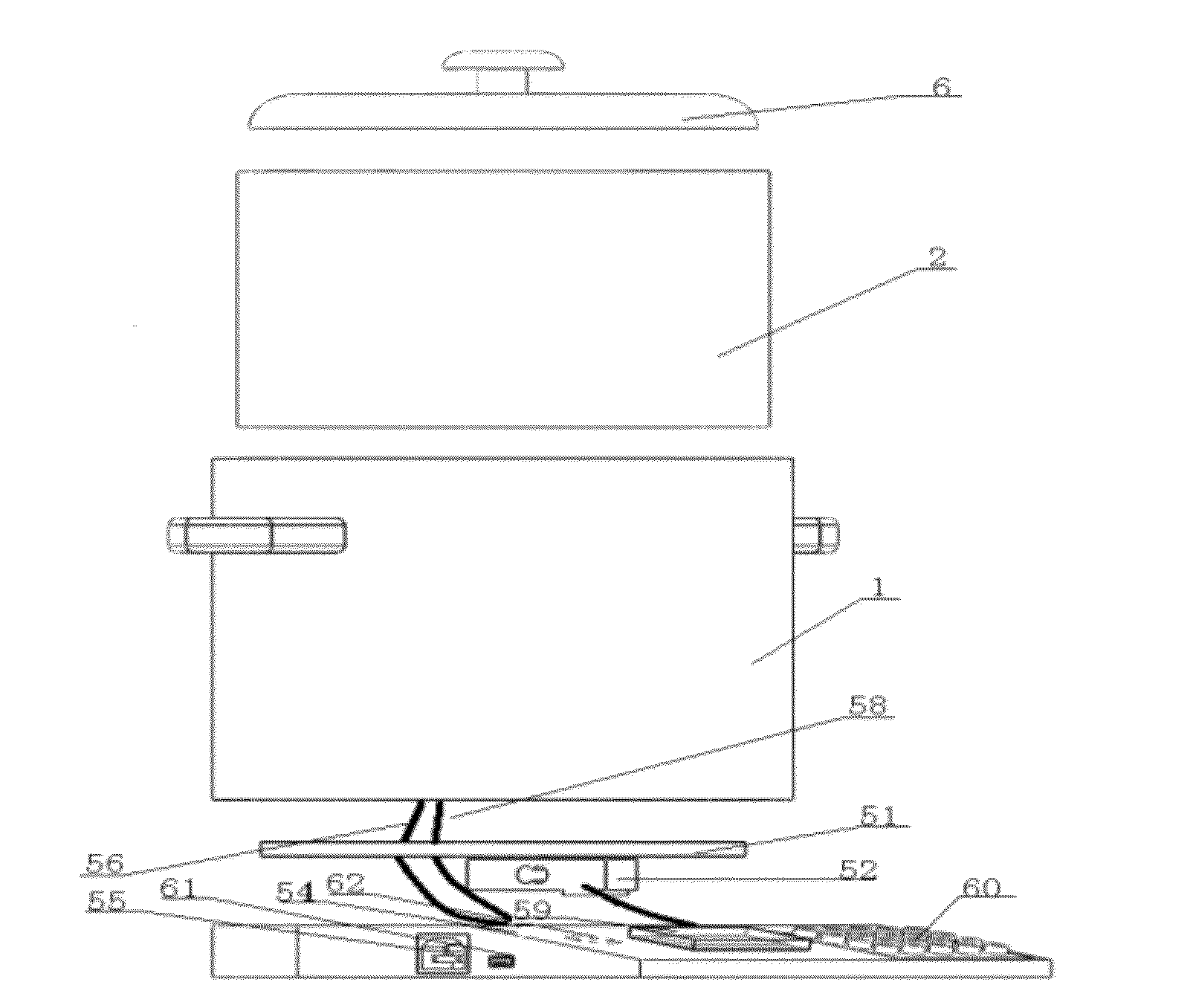

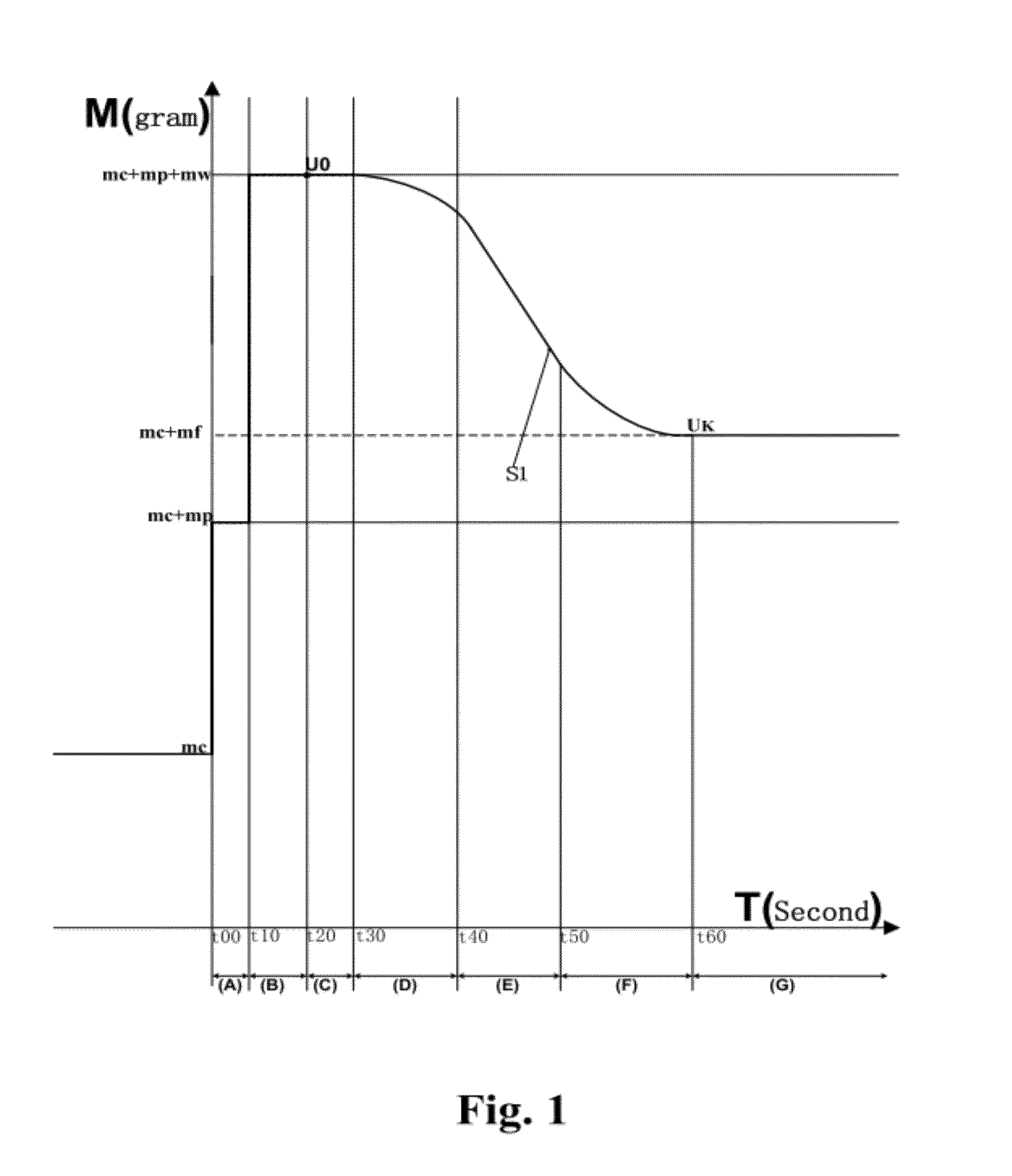

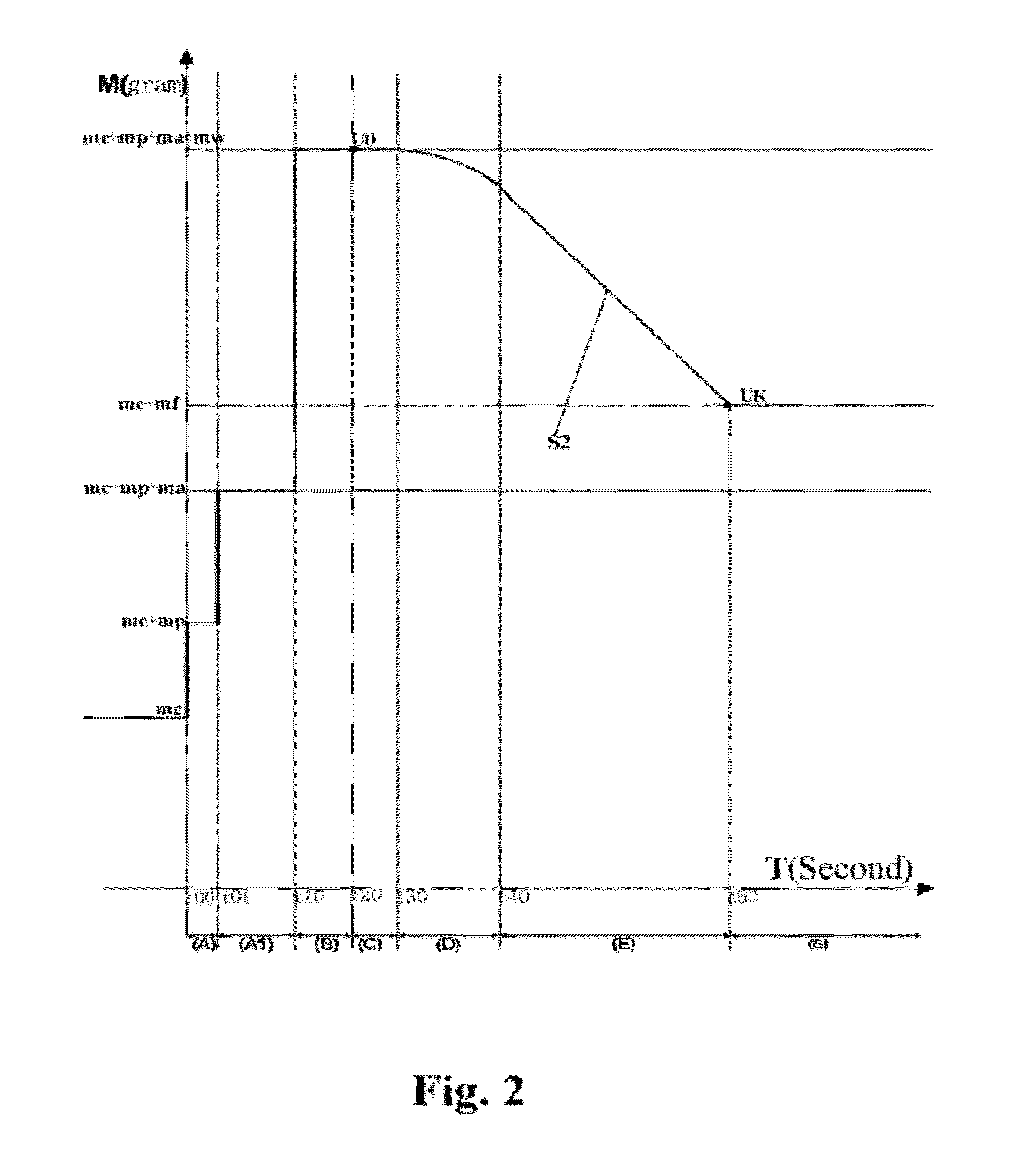

Electric heating cooker with weighing function and weighing control method thereof

ActiveUS20120321760A1Increase and decrease valueEasy to controlWeighing apparatus detailsOhmic-resistance heatingElectricityCholesterol

An electric heating cooker with weighing function and a weighing control method thereof are provided. An electronic scale (5) with weighing function is added under the traditional electric heating cooker and stores cooking experience database and food information database. It solves the problem that users aren't accurate about the amount of water to add for a given weight of ingredient. And experience curve of heating power are designed at different weight points for food such as rice or meat, and also it makes the cooker to intelligently adjust parameters according to the taste feedback of the user so as to be more closer to the user's taste for the cooking next time; additionally it is capable of showing the total and average content of heat quantity, cholesterol, protein, fat, salt and cook oil of various foods in current cooking or if there are unmatched foods.

Owner:DUO AI JIA BEIJING SCI & TECH

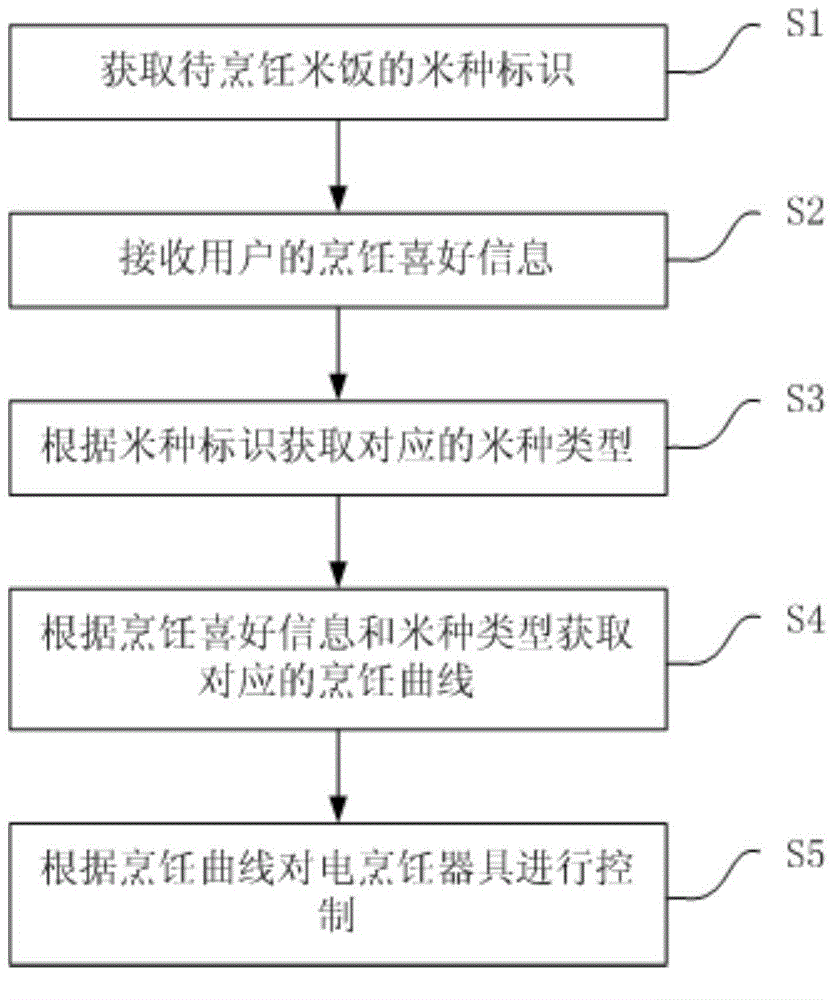

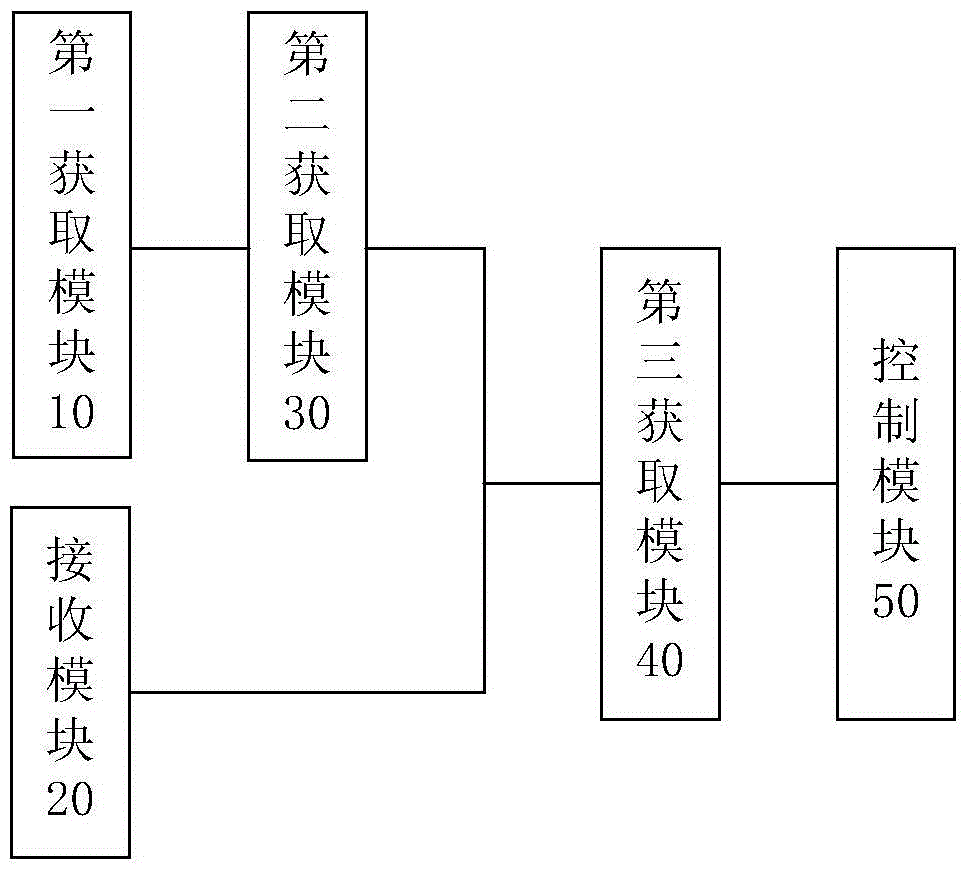

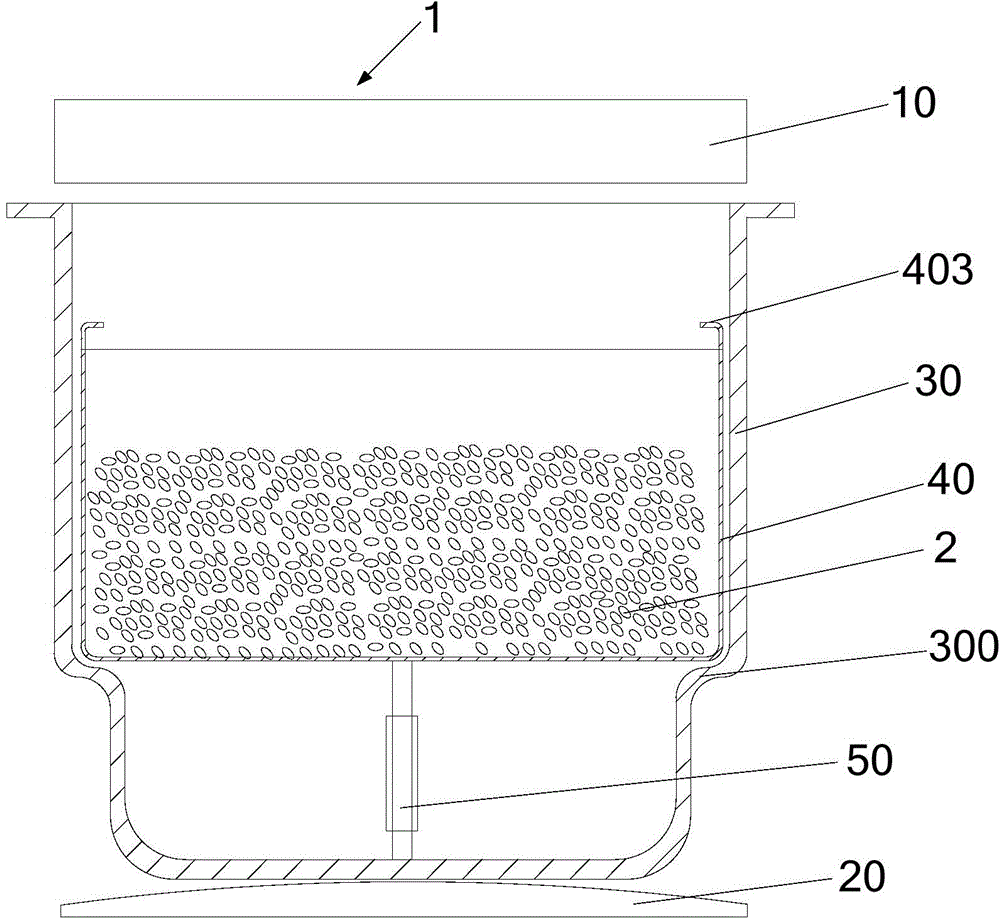

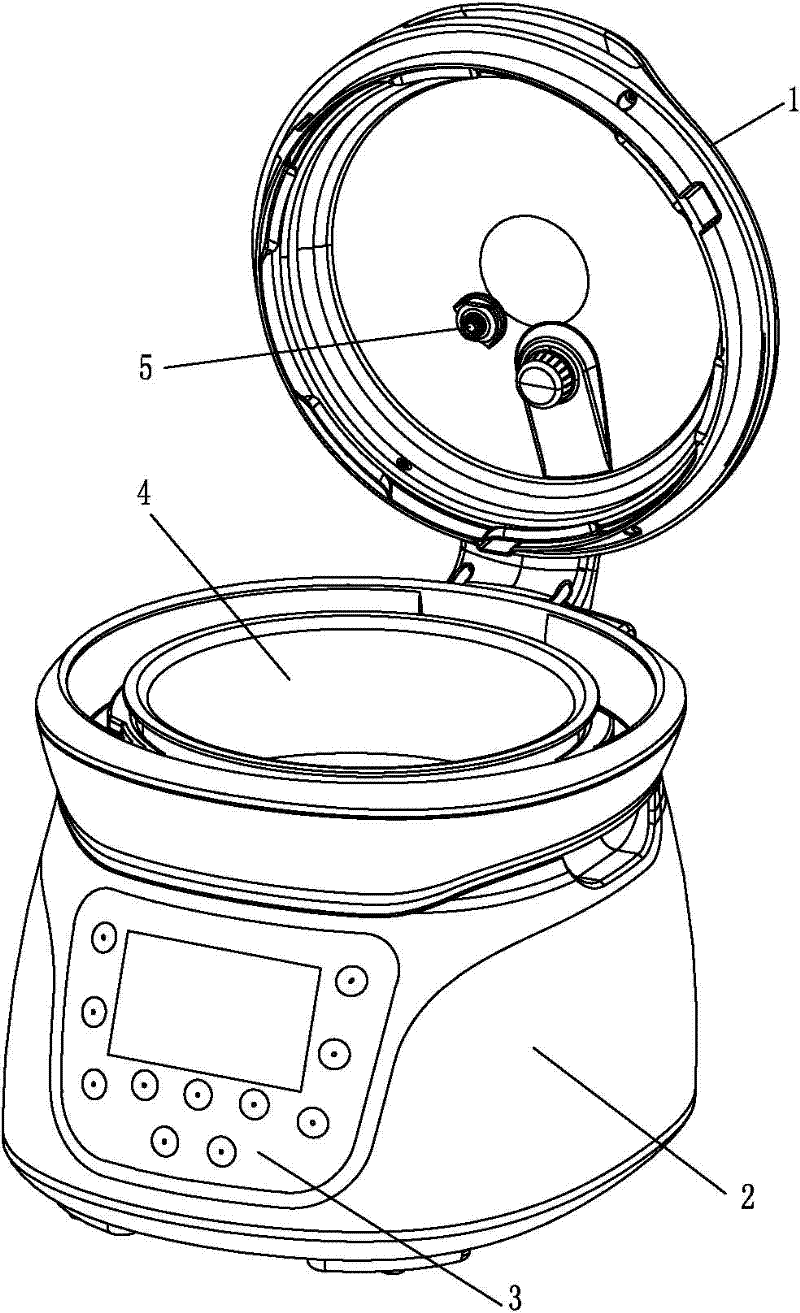

Cooking utensil, cooking control method and device of cooking utensil

InactiveCN106264068AImprove cooking resultsEasy to useSensing record carriersVessels with intergral heatingProcess engineeringCooking process

The invention discloses a cooking control method of a cooking utensil. The cooking control method comprises the following steps: acquiring a rice variety identifier of to-be-cooked rice; receiving cooking preference information of a user; acquiring the corresponding rice variety type according to the rice variety identifier; acquiring a corresponding cooking curve according to the cooking preference information and the rice variety type; and controlling the cooking utensil according to the cooking curve. With the adoption of the cooking control method, the cooking process can be controlled according to the user preference and the rice variety type, so that the cooking effect of the cooking utensil is greatly improved, and the use satisfaction of the user is greatly improved. The invention further discloses a cooking control device of the electric cooking utensil, and the cooking utensil.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD +1

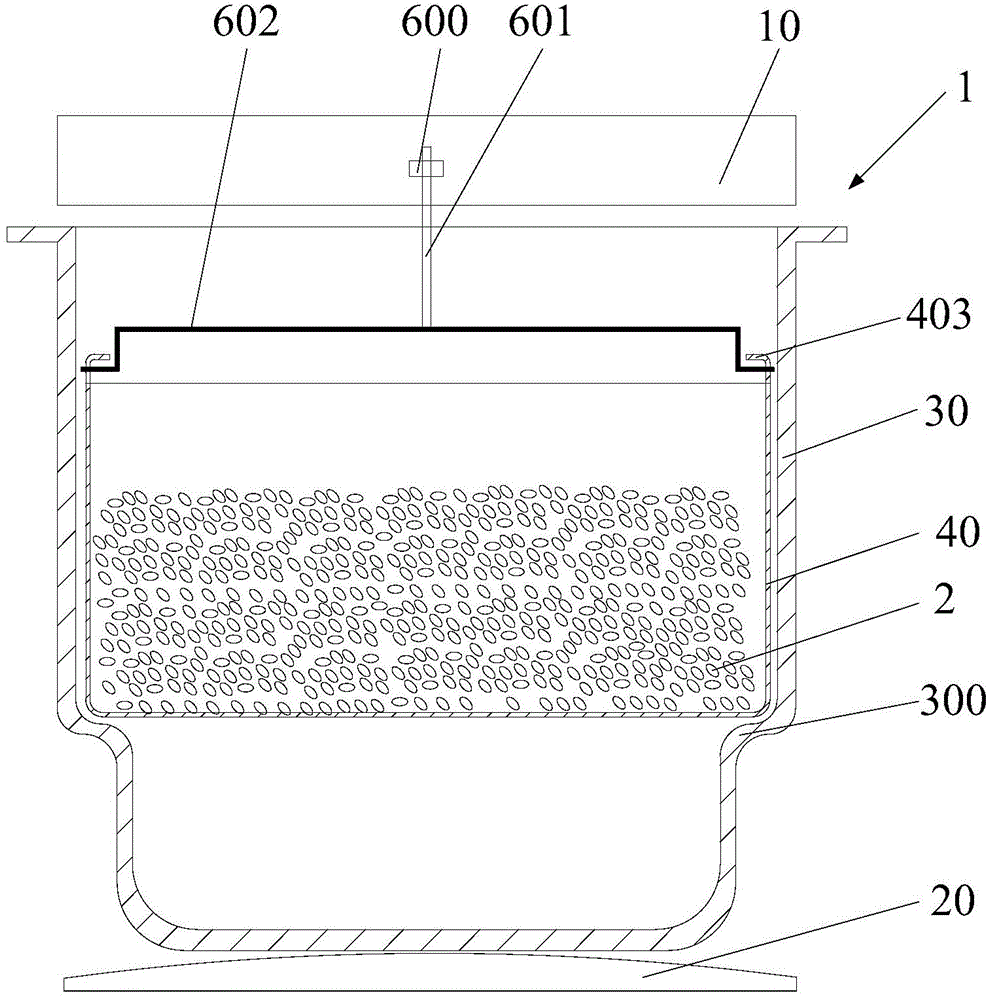

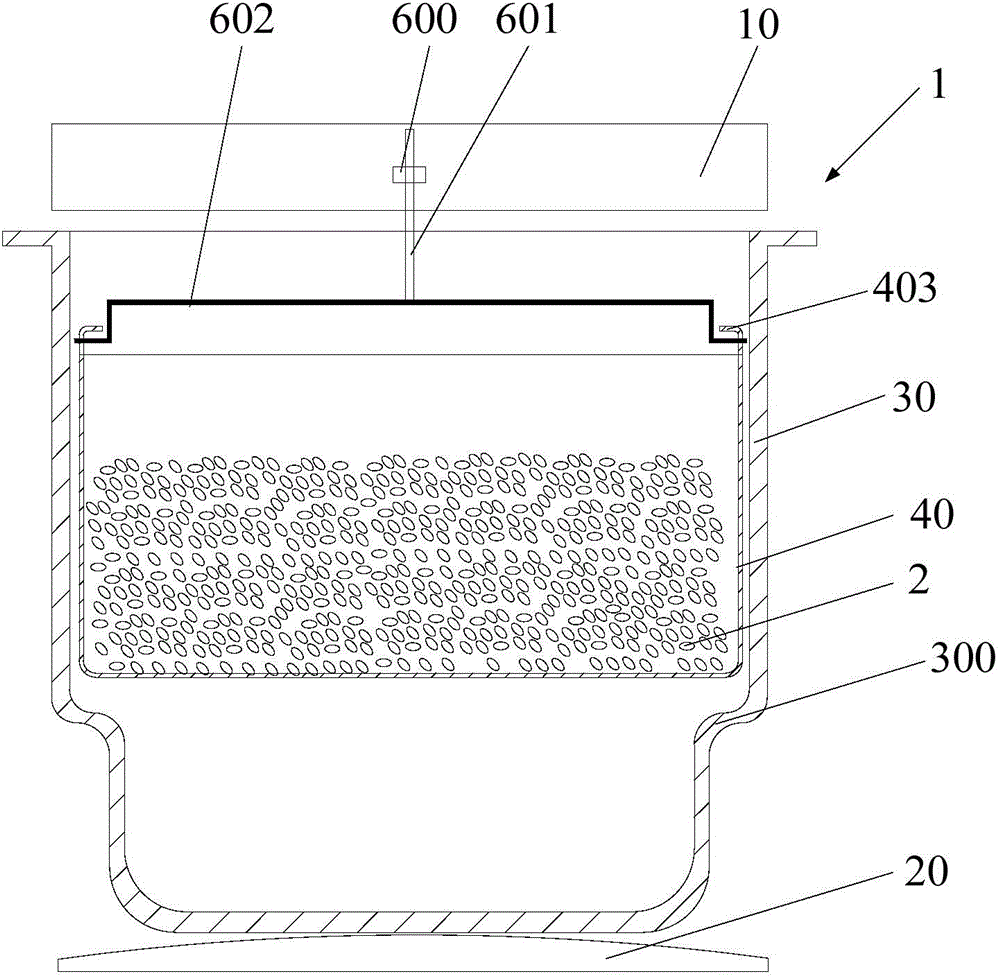

Electric cooker and control method thereof

The invention provides an electric cooker and a control method thereof. The electric cooker comprises a cooker cover, a cooker body, an inner pot, a steamer and a lifting device, the cooker cover is opened or covers the cooker body, the inner pot is placed in the cooker body, multiple through holes are formed in the steamer which is placed in the inner pot and can move relative to the same, and one end of the lifting device is connected with the cooker cover or the cooker body or the inner port while the other end of the same is connected with the steamer and can drive the steamer to move. The lifting device is arranged to drive the steamer to move to separate rice from rice soup so as to leach starch and sugar in the rice into the rice soup, so that sugar content of the rice is lowered; after the rice and the rice soup are separated, a user can get rice low in sugar content, and the rice is suitable for diabetic patients or fat patients to eat.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD +1

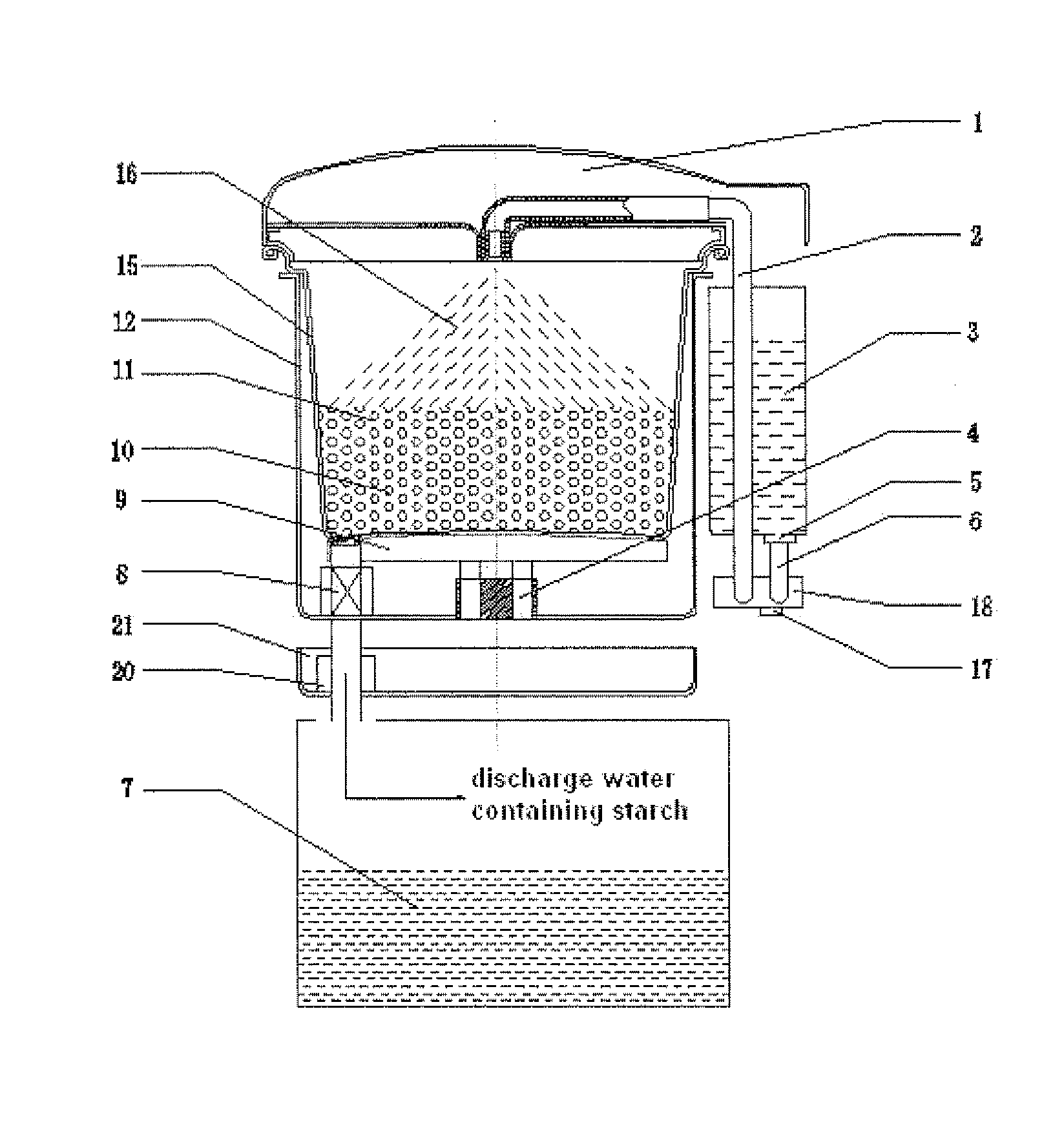

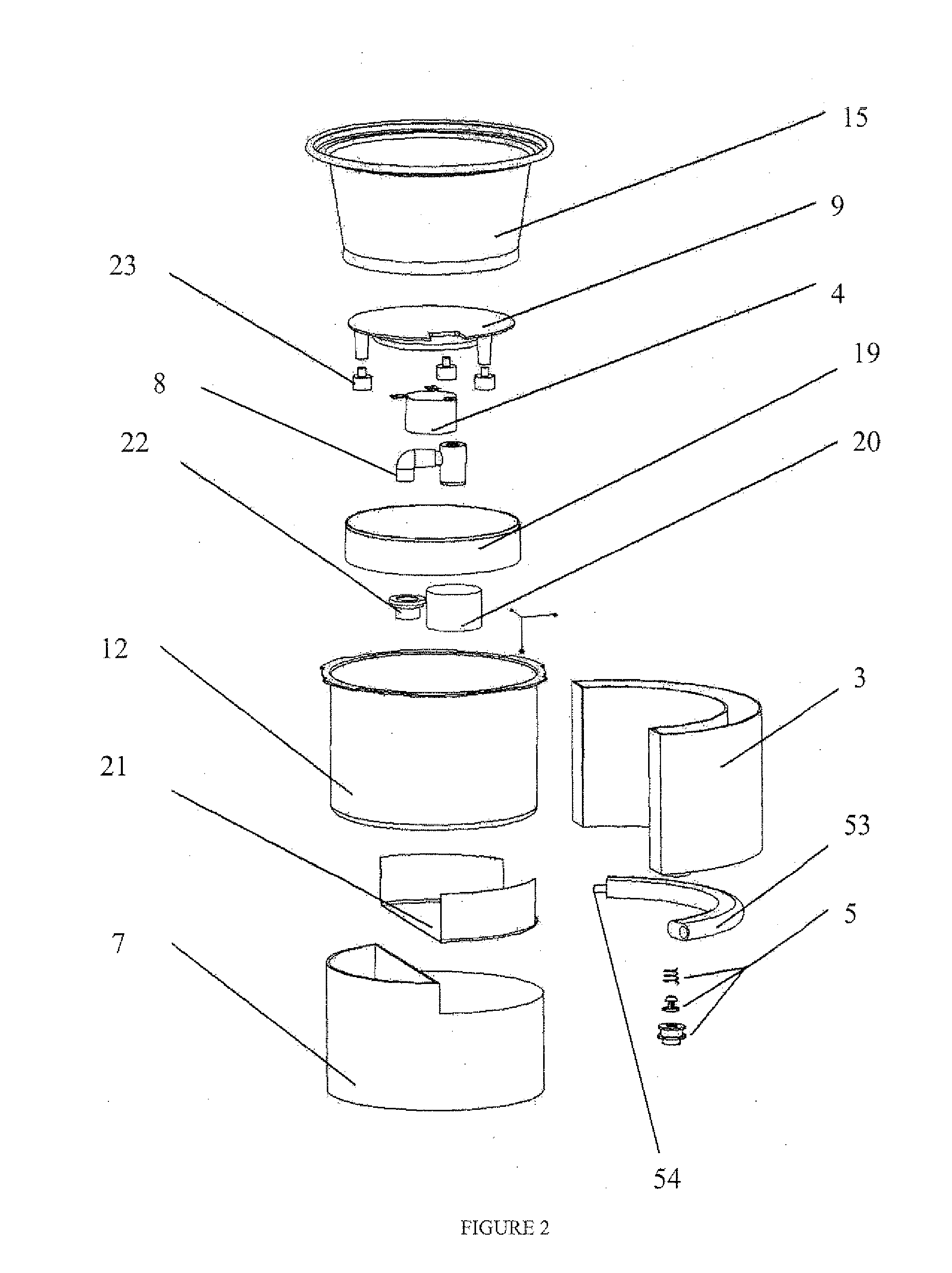

Method and apparatuses for healthy rice cooking and removing starch in rice

InactiveUS20070190221A1Reduce starch contentBeneficial to human healthWater-bath cooking vesselsRefuse receptaclesAgricultural scienceRice dishes

Method and apparatuses for healthy rice cooking and removing starch in rice is disclosed. There is provided a rice cooker, including an inner pot, an outer case with control buttons, power input terminal, a thermostat component, a control circuit, a rice cooker lid and a heater plate. The inner pot is placed inside the outer case; the heating plate, the thermostat and the control circuit are placed at the bottom of the inner pot. A starch removing device is placed between the bottom of the inner pot and the outer case, the starch removing device comprises: a heating plate, power input terminal, a thermostat component, a control circuit disposed at the bottom, a medium case inside the outer case, a water storage trough at the exterior of the medium case, a water drainage trough between the medium case and the outer case, and a evaporating tube at the bottom of the water storage trough; the ends of the evaporating tube is connected with the water storage trough and the inner pot through channels, the water drainage trough is connected with a valve and the bottom of the inner pot through channels. With the use of the rice cooker, the rice can be soaked and cleansed with flowing water before rice cooking. This process removes a portion of starch in rice, thus lowers the starch content in rice and benefits human health.

Owner:PENSONIC H K CORP

Seasoning sauce and preparation method thereof

The invention relates to a seasoning sauce and a preparation method thereof. The seasoning sauce comprises main materials, auxiliary materials, seasonings and blend oil. The preparation method comprises the following steps: cooking the blend oil to 80 DEG C, putting 1 to 3 parts of dry chili powder into a pot, and constantly stirring in moderate heat for 10 seconds; adding fermented blank beans into the pot, and stirring for 20 seconds in moderate heat; putting cooked beef dices with bean size into the pot, and frying for 15 seconds in moderate heat; mixing powdered broad bean paste, pickled chilies and chopped chilies for 3-4 times, and constantly stirring in the pot with a scoop; putting 0.5 to 1.0 part of edible salt, 0.7 to 1.2 parts of monosodium glutamate, 1.0 to 1.2 parts of chicken essence powder, 0.2 to 0.5 part of concentrated chicken broth and 2.5 to 4.5 parts of white sugar into the pot for seasoning when the temperature is 80 DEG C; and putting the rest main materials simultaneously into the pot, cooking for 40 minutes, and cooling and packaging. The seasoning sauce has the beneficial effects of transparent and bright color, pure and rich flavor and emphasized freshness, is suitable for cooked wheaten foods, rice, rice noodles, coarse cereals and the like, can be particularly used for cooking, household and business trip, can be presented for friends, and is convenient to carry.

Owner:李建峰

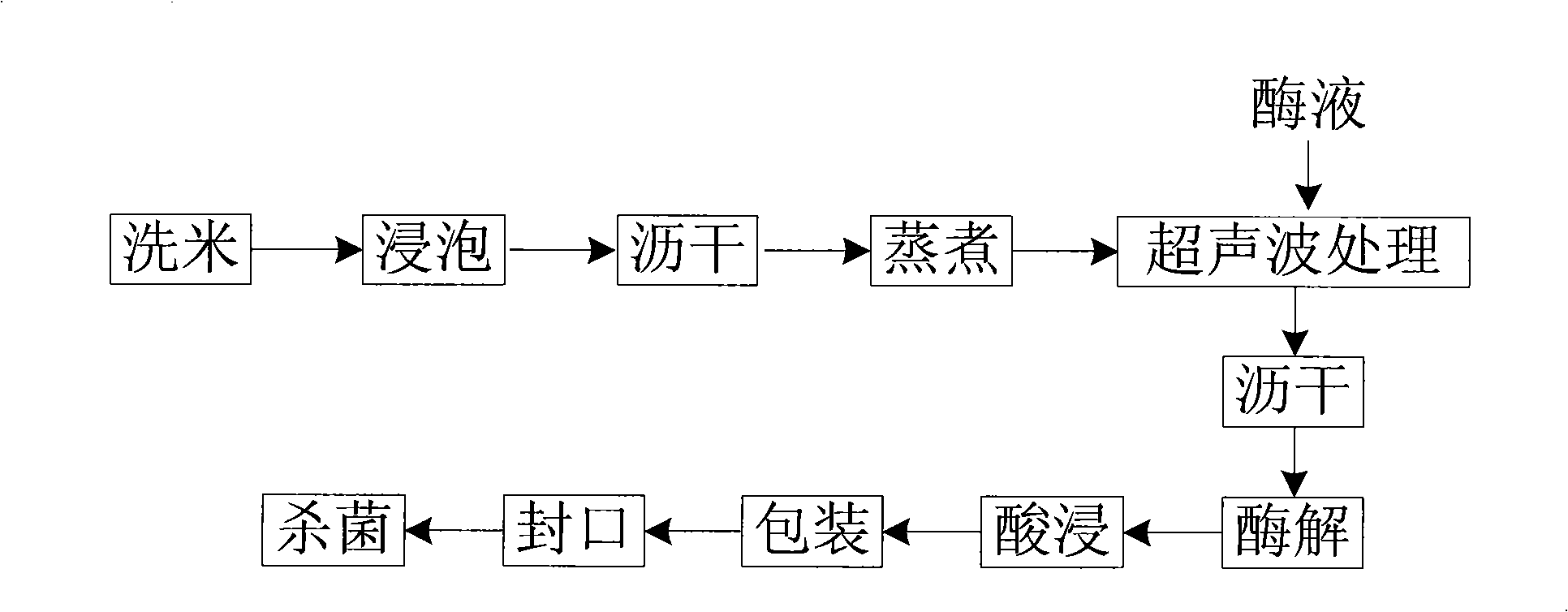

Method for producing fresh-keeping instant rice

InactiveCN101406269ASimple production processMaintain textureFood preservationFood preparationFood industryMicrowave oven

The invention provides a method for preparing fresh-keeping instant cooked rice, belongs to the technical field of agricultural product deep processing and food industry, and mainly relates to application of the ultrasonic treatment technique and the enzyme preparation in the instant cooked rice. In the method, the refined rice is used as a raw material, and the ultrasonic treatment technique and the enzyme preparation are utilized to control the aging and fresh-keeping of the instant cooked rice. The preparation method of the instant cooked rice comprises the following steps: the refined rice is washed, soaked in water, water-drained, pre-boiled, and then subjected to enzyme liquid soak and ultrasonic treatment, drainage, enzymolysis, acid soak, water drainage, packaging, sealing and sterilization to obtain the finished production of the fresh-keeping instant cooked rice. The fresh-keeping instant cooked rice prepared by the method has the advantages of low cost, convenient use and convenient eating, and can be eaten instantly or after heated; and if the hot food is needed, the rice bag is heated in boiled water or a microwave oven over medium-high heat for 1 to 2 minutes.

Owner:JIANGNAN UNIV

Crop rice and its preparation method

The present invention discloses crop rice and a preparation method of the crop rice. The crop rice is prepared with the following raw materials in weight proportions: starch base material in 2-4 portions and main crop material in 6-8 portions; the starch material is selected from potato starch, sweet potato starch, tapioca starch, maize starch, and maranta; the crop material is selected from corn, sorghum, millet, sweet potato, buckwheat, oat, kuroyone, wild oats, mung beans, red kidney beans, and pearl barley. The preparation method is: filter, clean, and crush the grains, mix with starch material, shape by extrusion, and dry, pack, and load into warehouse. The crop rice has smooth surface and even size, without any food additive or preservative, delivers good mouth feel, can be cooked with rice, and is rich in beneficial elements, Vitamin, and lysine, etc., and contain a great deal of dietary fiber, and therefore can greatly balance internal milieu. The crop rice in the present invention is available in more than 10 variants, depending on the formula, for free choice.

Owner:张昌才

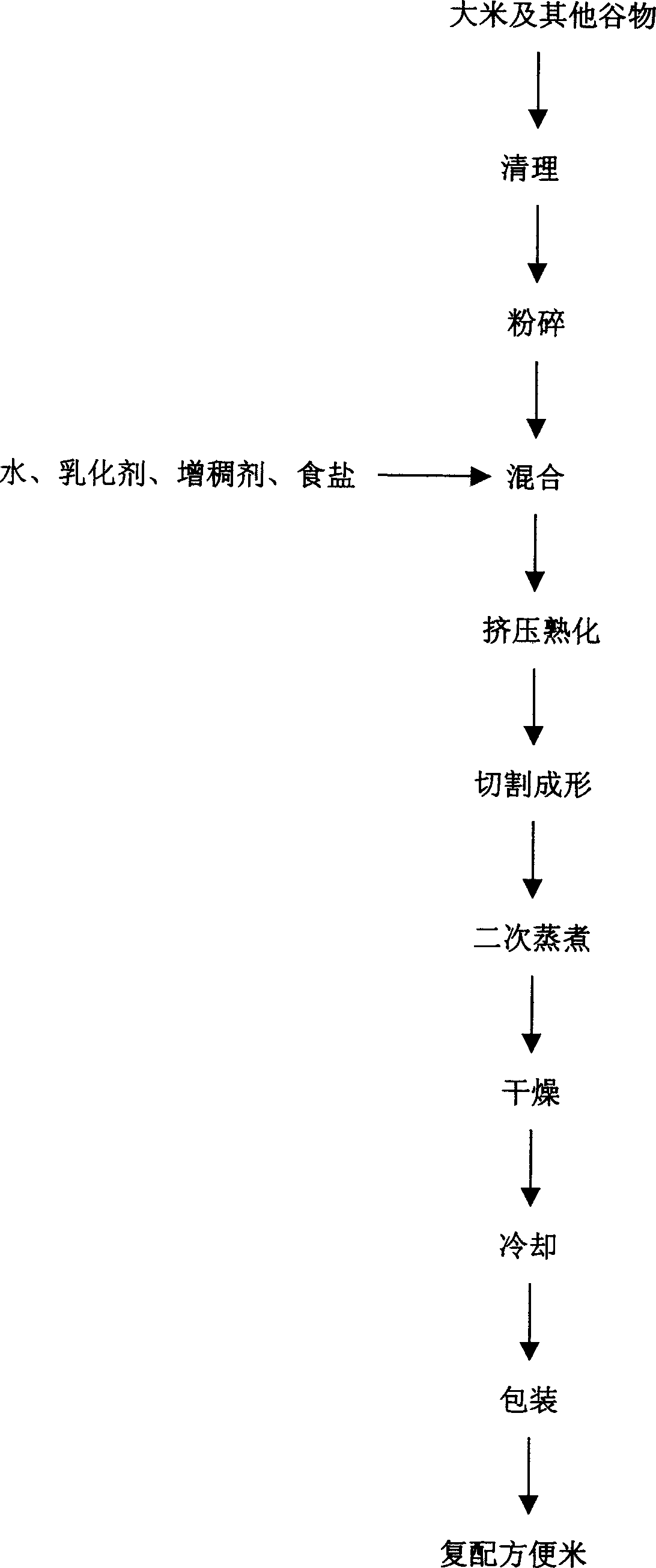

Method for preparing instant rice

InactiveCN1559276AImproved rehydration propertiesNo loss of soluble componentsFood shapingFood preparationRice dishesSoybean protein

A composite instant rice is prepared from rice, wheat flour, soybean protein, glatalin, emulsifier, thickening agent, and edible salt through pulverizing, adding food improver, mixing with water, extruding while heating, shaping, steaming again, dryingand cooling. It can be directly eaten after it is scaled by boiling water.

Owner:JIANGNAN UNIV

Indica rice crust producing process

InactiveCN1344509AUniform colorEnsure the original taste and colorFood preparationNutrient contentRice dishes

The process producing Indica rice crust includes washing rice, mixing with water in certain amount, steaming to be cooked, roasting at 175-185 deg.c for 12-16 min inside a heat conducting pressing mold comprising upper and lower mold plates as oil circulating carriers, takibng out, natural cooling and packing. The present invention produces Indica rice crust through molding heating at constant temperature without deep frying, high temperature puffing and fire roasting, and this can make the produced crust look good, smell good, be thin and be crisp and with the nutrient ingredient of Indica rice maintained.

Owner:汪林

Method for controlling rice steaming and boiling of electric rice cooker

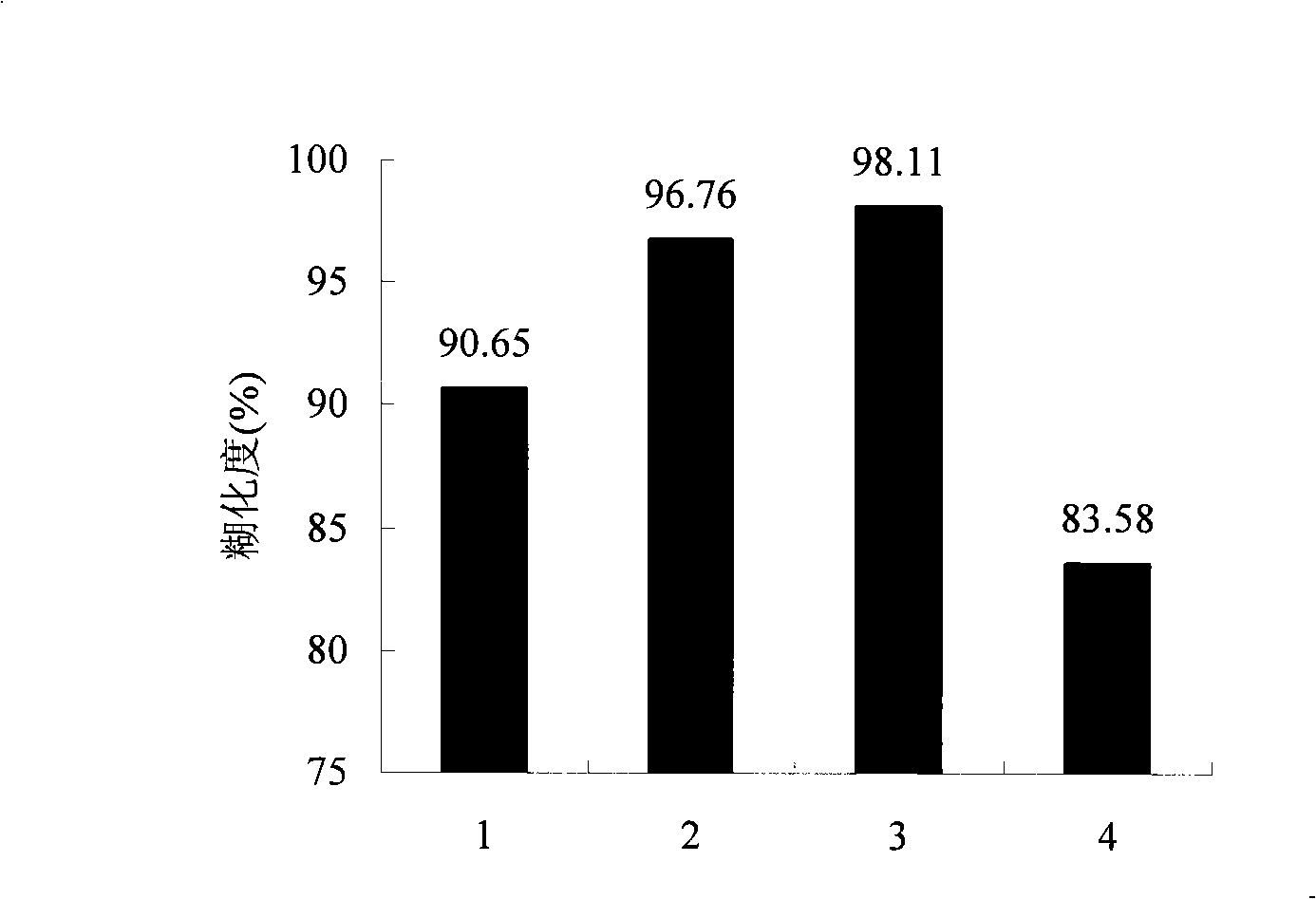

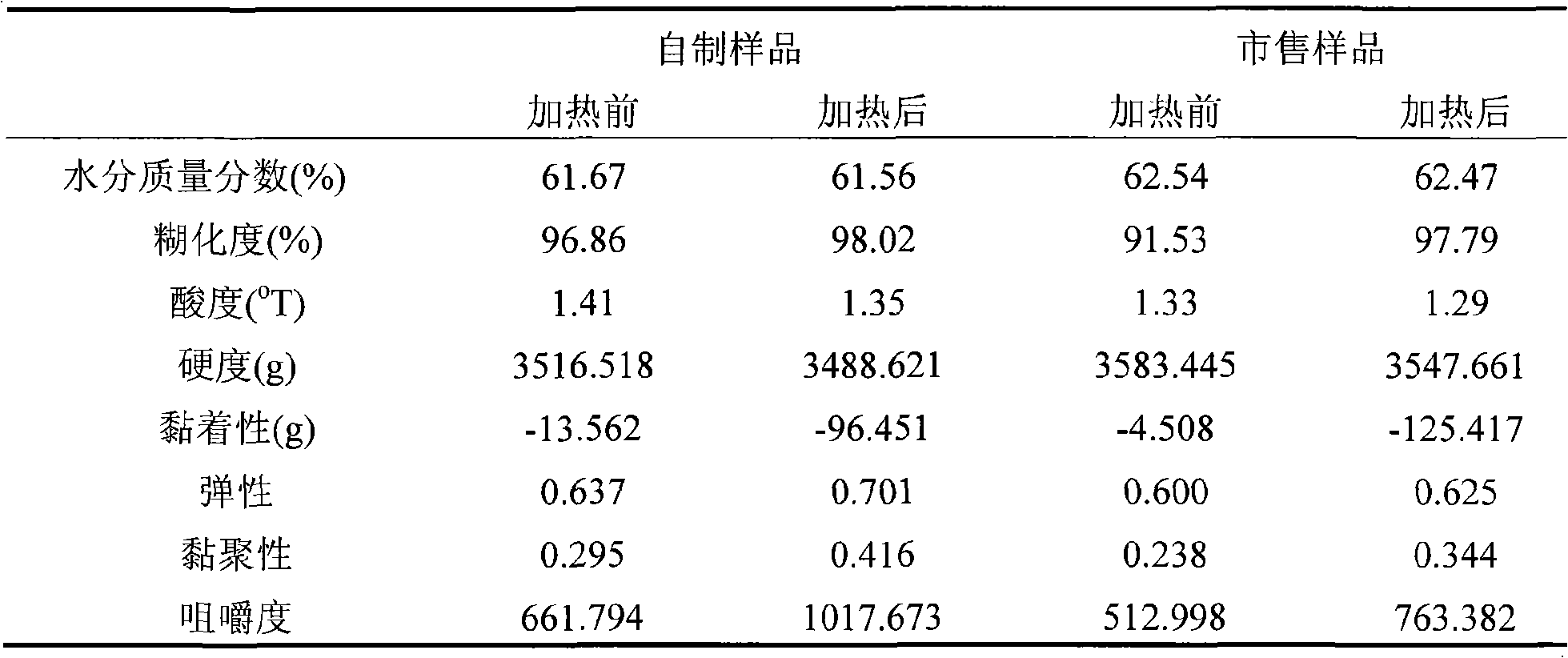

ActiveCN101587330ARaise the temperature gradientFully gelatinizedProgramme control in sequence/logic controllersWarming devicesRice dishesTemperature difference

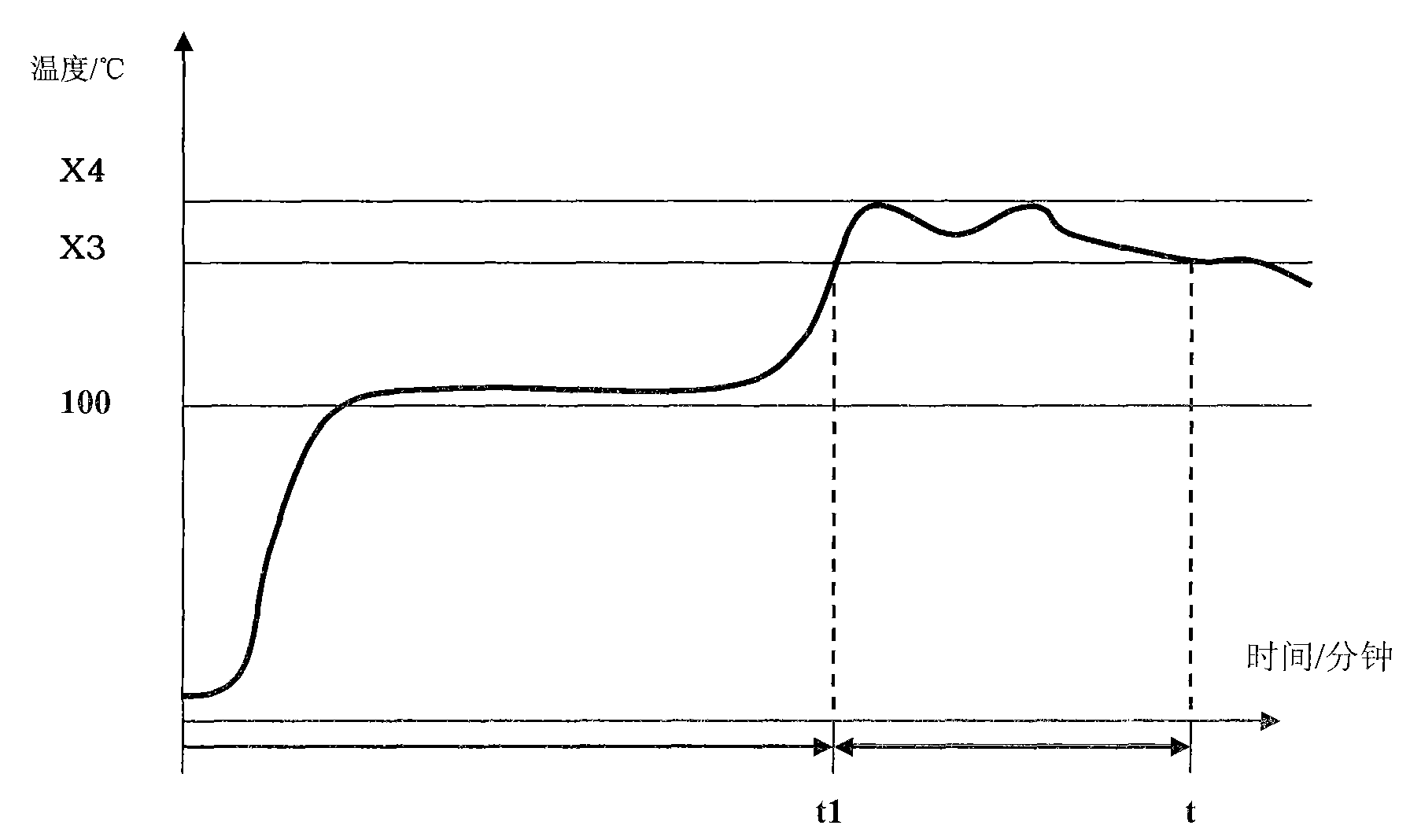

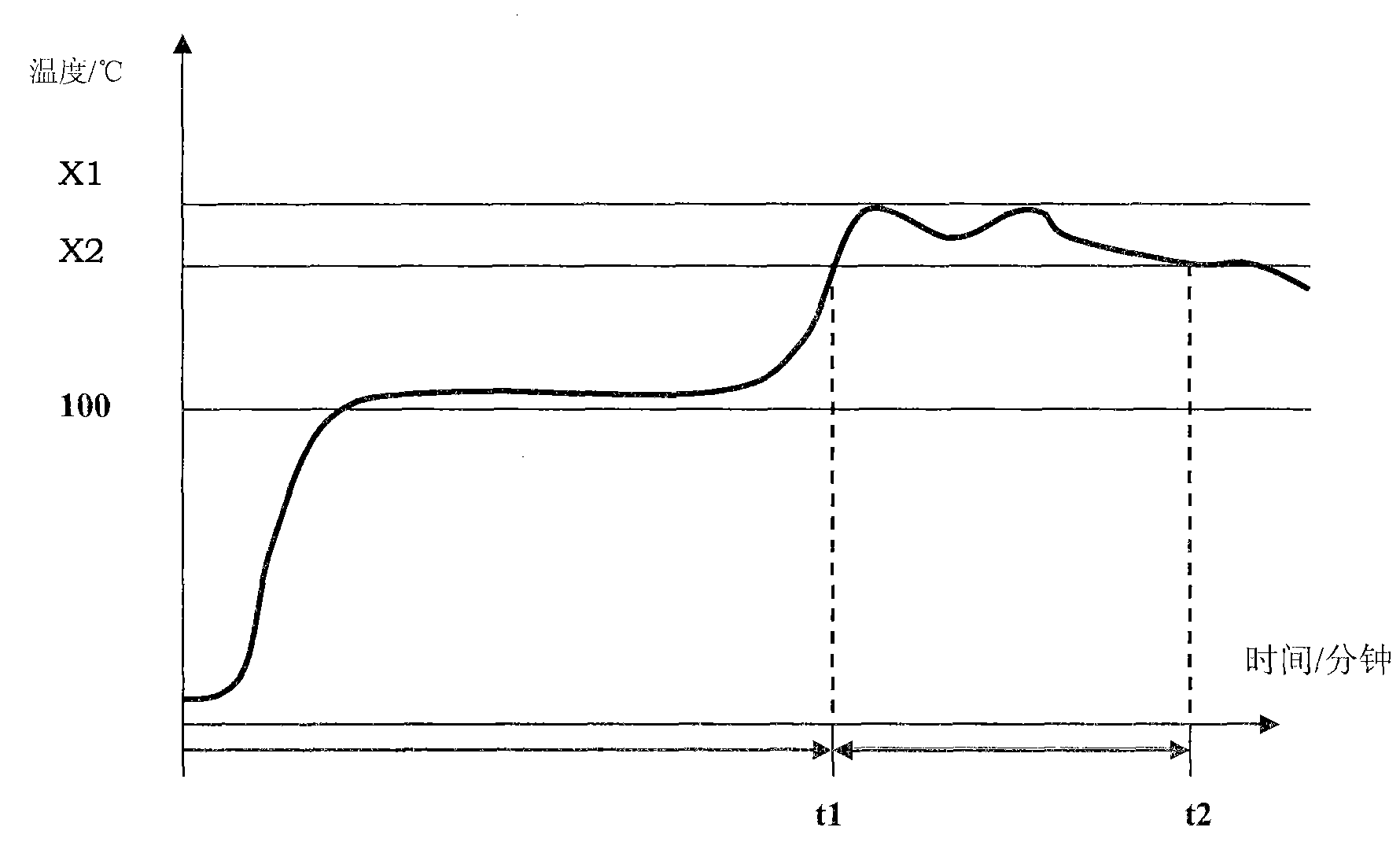

The invention relates to a method for controlling the rice steaming and boiling of an electric rice cooker, which comprises the following steps: (1) confirming the boiling maintenance time t and the boiling maintenance temperature X of the electric rice cooker according to different rice kinds and mouth feeling; (2) starting the electric rice cooker and soaking, dewatering, heating and boiling rice according to a set procedure; (3) achieving the boiling maintenance temperature X= 130-165 DEG C after time t1=15-35 min and maintaining boiling in the electric rice cooker for the maintenance time t=6-10 min; and (4) cooking the rice after achieving the maintenance time t. The invention provides the method for controlling the rice steaming and boiling of the electric rice cooker, which controls the temperature and the time in the process of boiling maintenance, improves a temperature difference between the electric rice cooker and rice boiling, enables the rice to be fully gelatinized and enables water to be fully vaporized and absorbed by rice grains, thereby boiling the rice with high quality.

Owner:ZHEJIANG SUPOR ELECTRICAL APPLIANCES MFG CO LTD

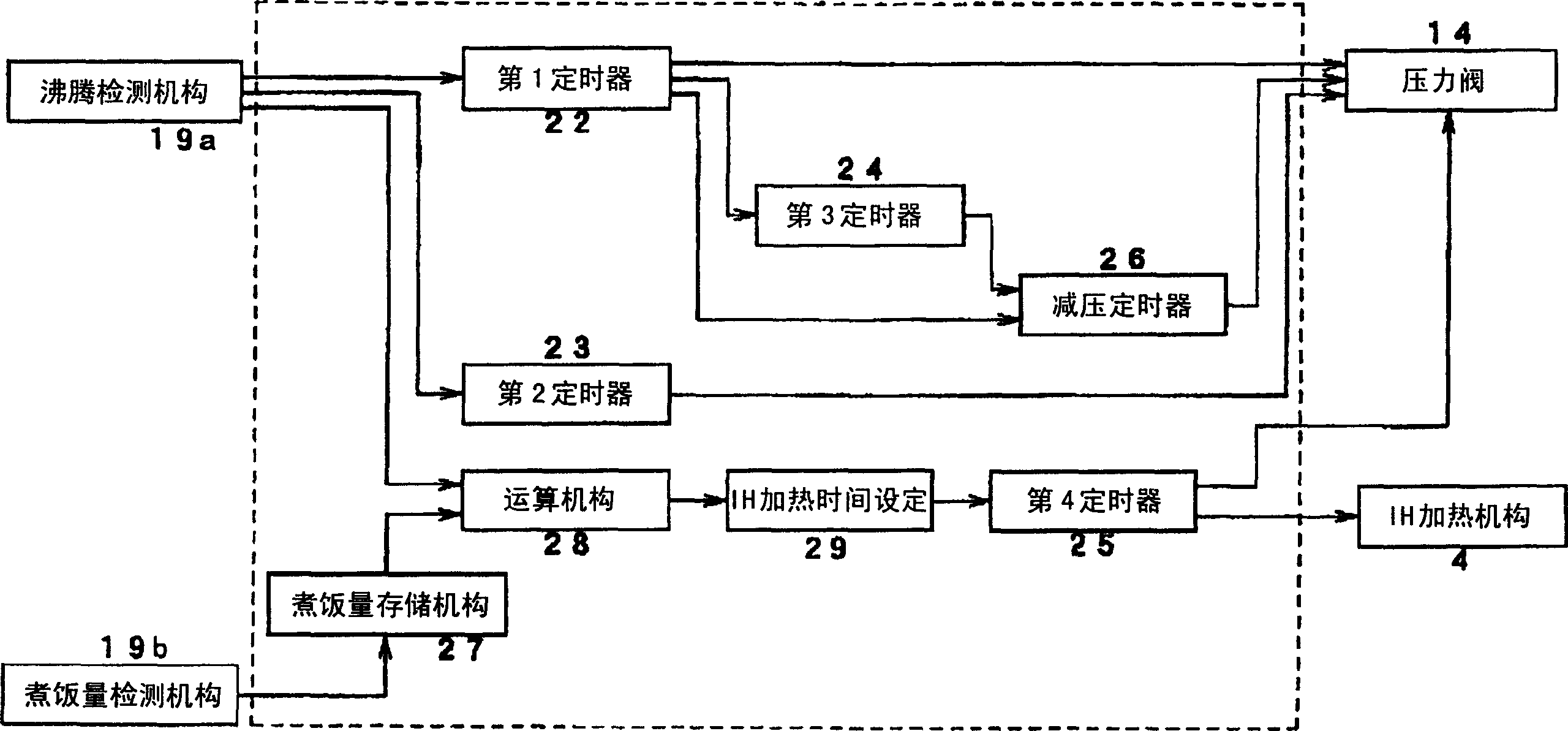

Rice cooker

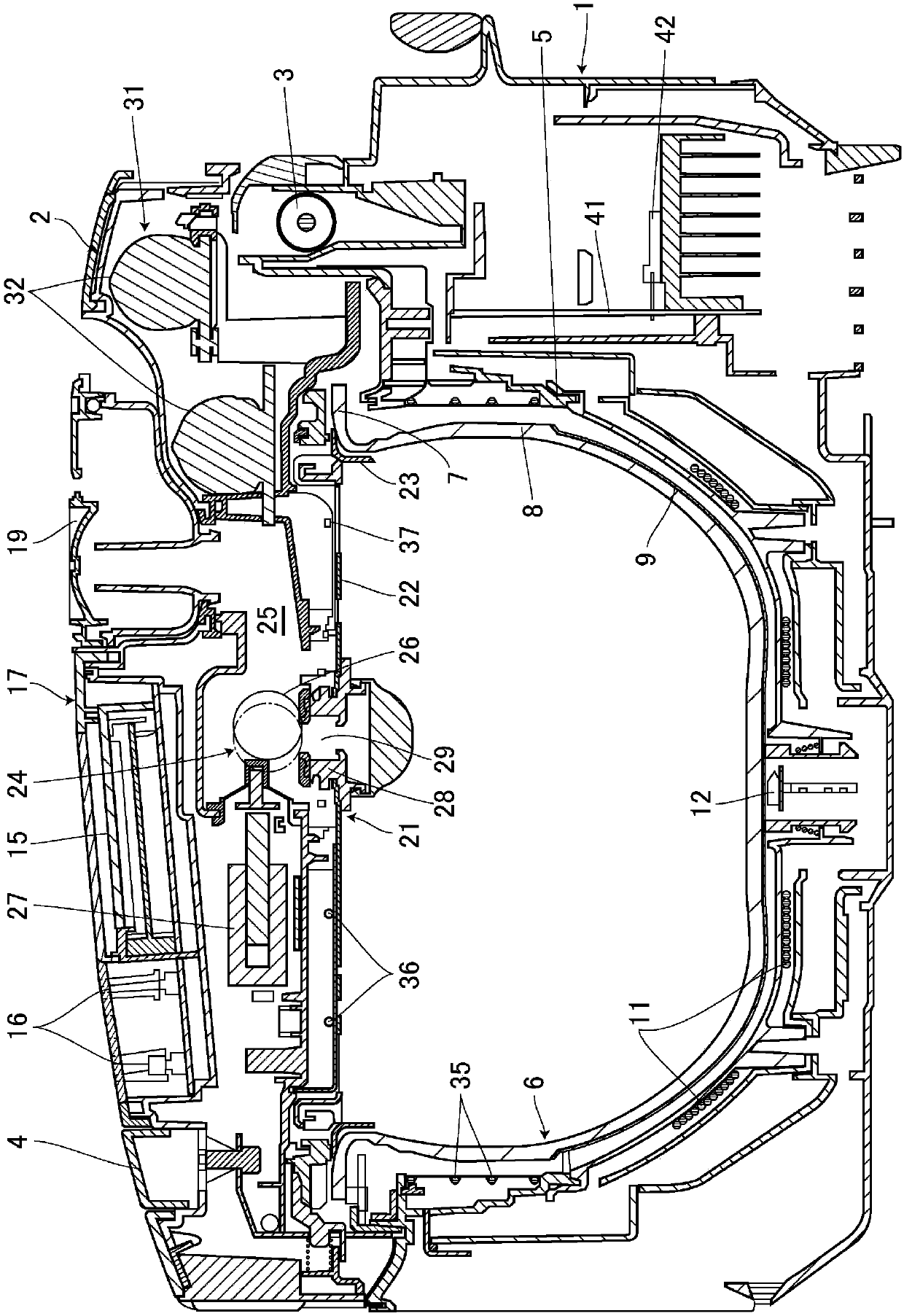

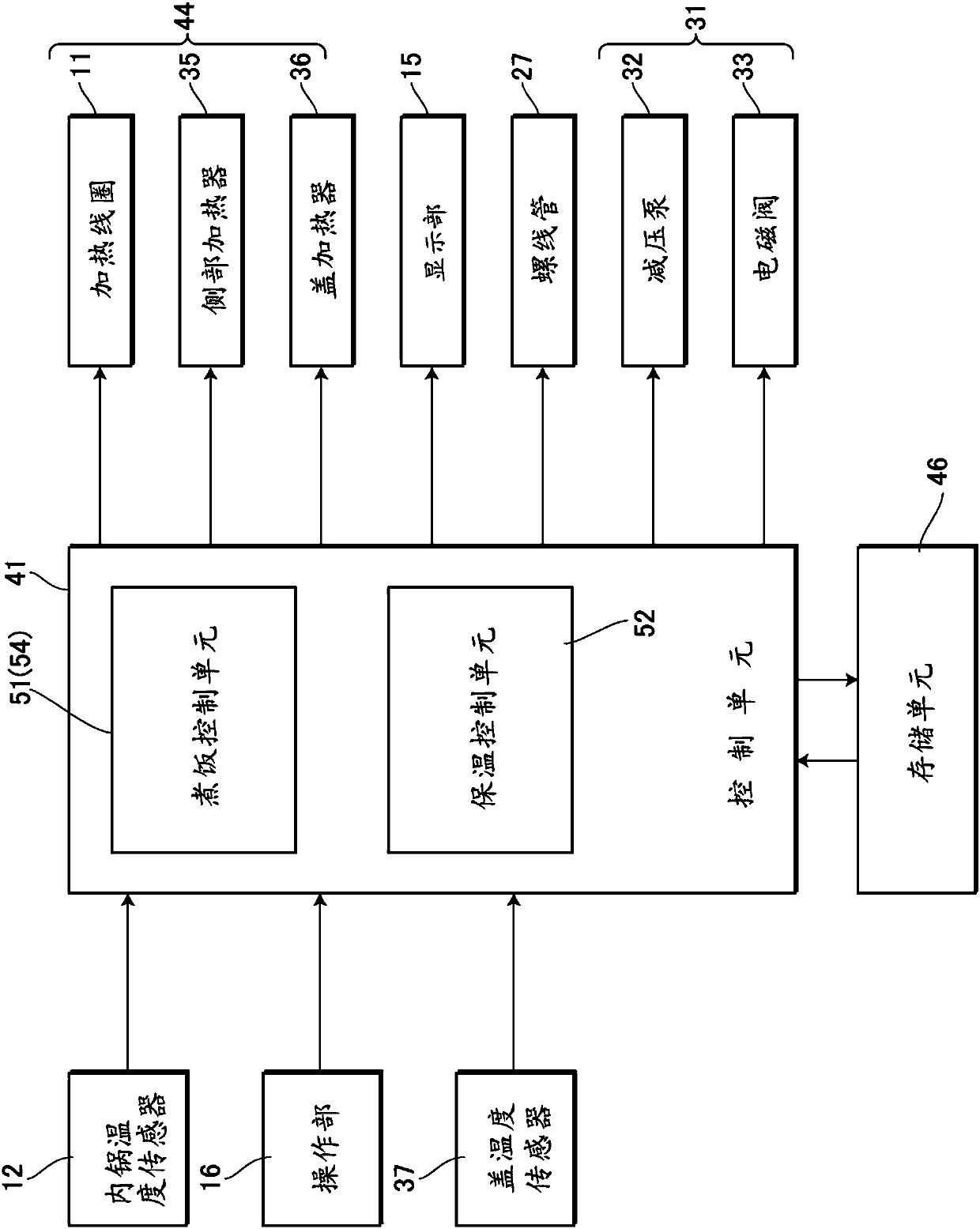

ActiveCN108013747AFully absorbedStay decompressedPressure-cookersTime-controlled ignitorsRice dishesEngineering

The invention provides a rice cooker which takes less time to cook and can provide delicious rice. According to the invention, the rice cooker includes a control unit 41 which enables a to-be-cooked object to be in a decompression state in the immersing process in which water absorption of rice is promoted, and remains the decompression state in the heating process that follows the immersing process until the to-be-cooked object boils in the decompression state. The control unit 41 controls a heating unit 44 and a decompression unit 31 so as to cook and heat the to-be-cooked object with specified pressure. Therefore, the to-be-cooked object is decompressed and boiled as rice is gelatinized at a temperature of 60-100 DEG C, and rice grains are rolled and water can be absorbed by the rice grains to the core within a short time.

Owner:TOSHIBA HOME TECHNOLOGY

Pretreatment method for edible coarse cereals of grains, beans and tubers

InactiveCN102511741AReduce hardnessImprove water absorptionFood preparationPretreatment methodFreeze-drying

The invention relates to a pretreatment method for edible coarse cereals of grains, beans and tubers. The method is applicable to production of mixed coarse cereals of grains, beans and tubers and to production of products which can be cooked with rice without soaked in advance. The method is characterized by comprising the following steps: (1) soaking coarse cereals of grains and beans with 1 to 3 times by mass of water having a temperature of 10 to 50 DEG C until the coarse cereals have a water content of 30 to 80%, peeling the coarse cereals, cutting the coarse cereals into dices with a side length of 2 to 8 mm and draining water; (2) precooling obtained coarse cereal dices in a freezer for 1 to 8 h and controlling the temperature of the coarse cereal dices to be in a range of -18 DEG C to -50 DEG C; and (3) carrying out vacuum freeze drying on the precooled coarse cereal dices for 8 to 25 h, with temperature controlled to be in a range of -15 DEG C to -30 DEG C. Compared to the prior art, the invention has the following beneficial effects: edible coarse cereals and mixed beans which have undergone vacuum freeze drying have reduced hardness and improved water absorbability; nutrients in and flavor of original mixed beans are retained, the requirement for rapid cooking of the mixed beans is achieved, and the mixed beans are applicable to cooking of mixed bean rice and production of mixed bean snack food.

Owner:NINGXIA JIADAO HALAL FOOD

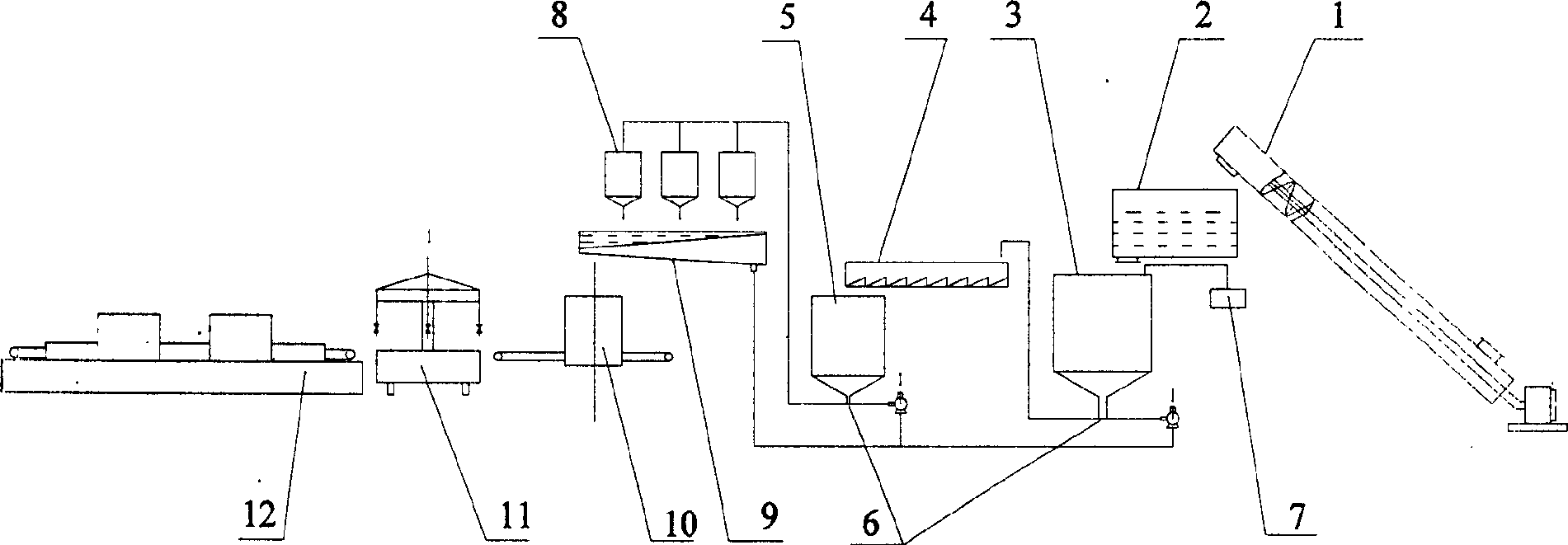

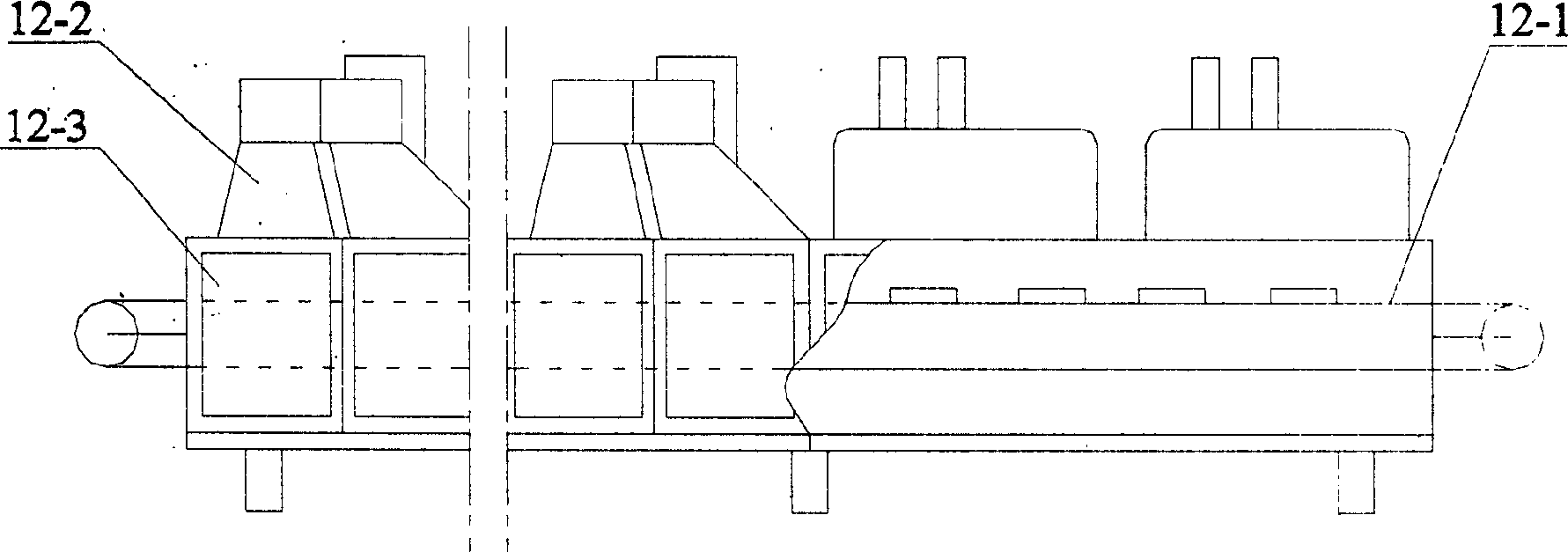

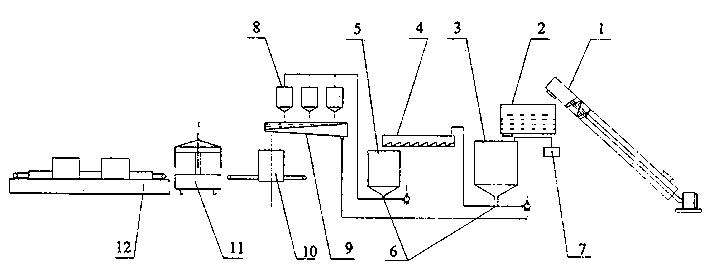

Method and device for continuously cooking rice

A technology for continuously cooking rice includes such steps as washing rice, immersing, quantitatively loading in boxes, microwave cooking and outputting rice in boxes. Its apparatus is composed of screw conveyer, high-position rice tank, rice washer, redox washer, jet-type sprayer, step impurities remover, rice immersing container, oblique rich dropper, quantitative loaders of rice and water, and continuous microwave cooker. Its advantages are high speed, high utilization rate of heat energy, and high productivity.

Owner:SOUTH CHINA UNIV OF TECH

Minor cereal confected rice jointly cooked with rice and processing method of minor cereal confected rice

InactiveCN104642936AImprove water absorptionImprove gelatinizationFood preparationPolygonum fagopyrumAdditive ingredient

The invention relates to minor cereal confected rice which is jointly cooked with rice and a processing method of the minor cereal confected rice. The minor cereal confected rice meets nutritional requirements on 'Chinese dietary guide' and is prepared based on a formula obtained by linearly planning demand on cereal energy caused by a human body. Raw materials in the formula are several of sorghum, foxtail millet, buckwheat, oat, barley, black rice, broom corn millet, glutinous broom corn and coix seed and are pretreated. The processing method of the minor cereal confected rice comprises the following steps: firstly screening minor cereals, removing impurities, soaking or atomizing and modifying the minor cereals, draining off, carrying out microwave puffing, carrying out hot-air drying, cooling, and carrying out mixed loading. The minor cereal confected rice has the advantages that the nutrients of refined grains and minor cereals are supplemented each other, and daily energy demand of a consumer is met; meanwhile, the minor cereals are processed by utilizing a microwave puffing technology, the original nutritional ingredients of food are maintained to the utmost extent, the processing time is short, and puffing, drying and sterilizing techniques can be completed at the same time; besides, rice and the minor cereals can be jointly cooked, and a complex operation that the minor cereals need to be cooked firstly and then rice is added and cooked with the minor cereals when people want to eat minor cereal rice at present is eliminated, so that the minor cereal confected rice is convenient and practical.

Owner:JILIN AGRICULTURAL UNIV

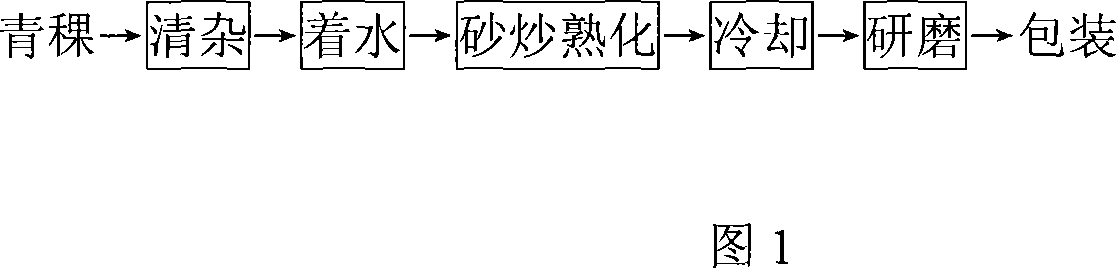

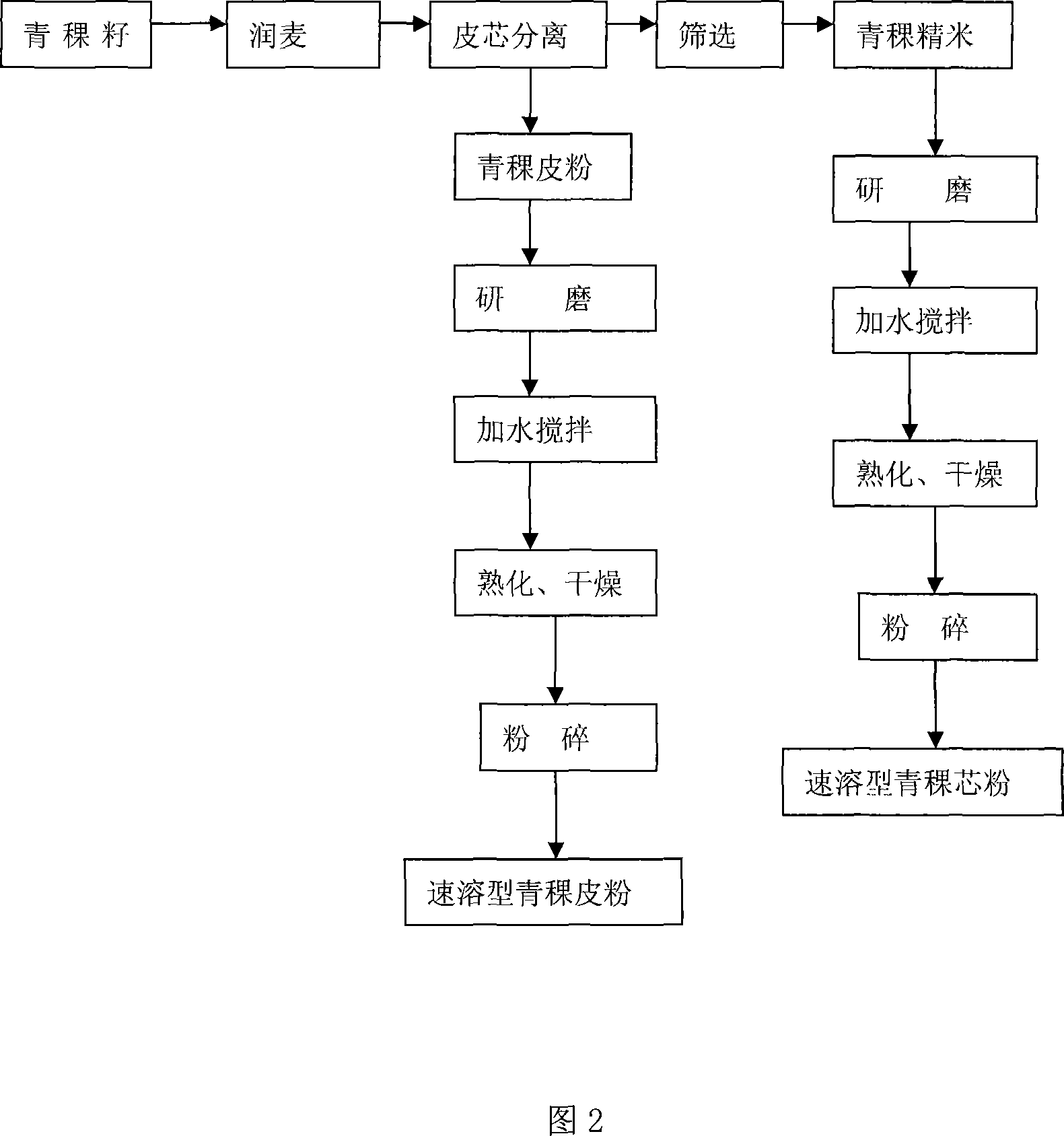

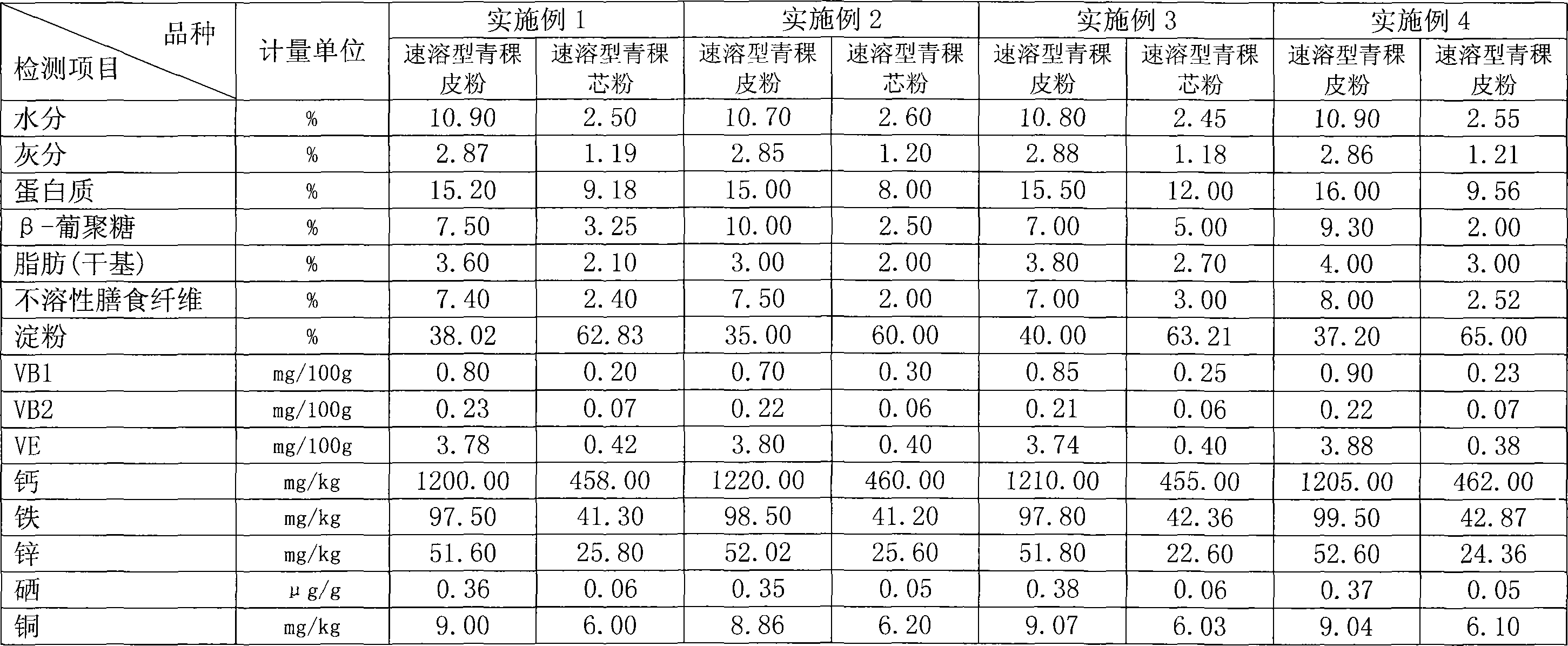

Deep-processing method and product of highland barley wild oat

ActiveCN101049135AIncreased beta-glucan contentHigh technology contentFood preparationVitaminDeep processing

A technology for processing the highland barley includes such steps as washing highland barley grains, removing impurities, wetting, peeling, screening to obtain the peel and grains, preparing the instant peel powder which contains protein, unsaturated fatty acid, edible fibers, vitamins, minerals and beta-glucosan, and refining the grains, which can be used to cook staple food.

Owner:西藏春光食品有限公司

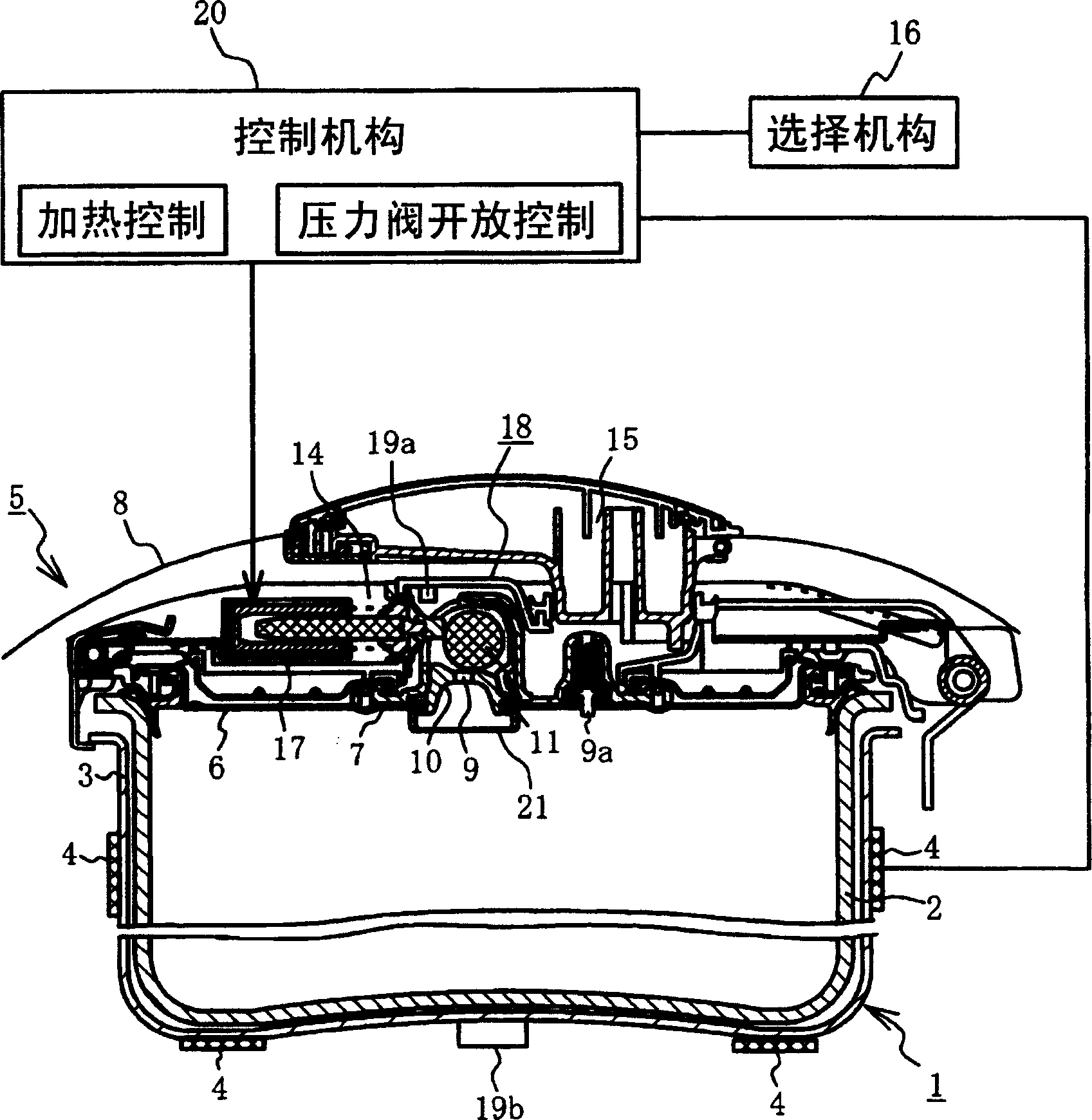

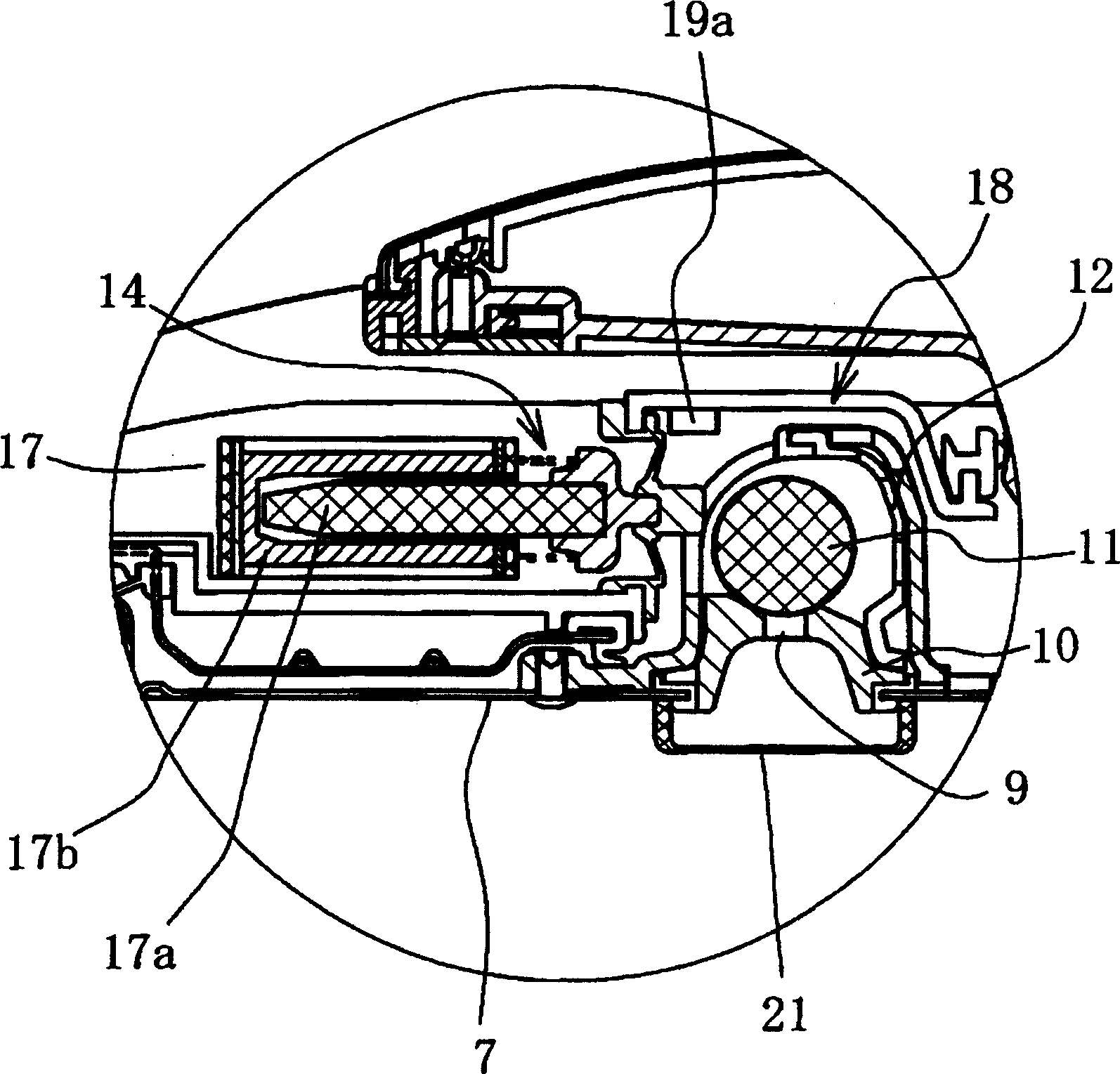

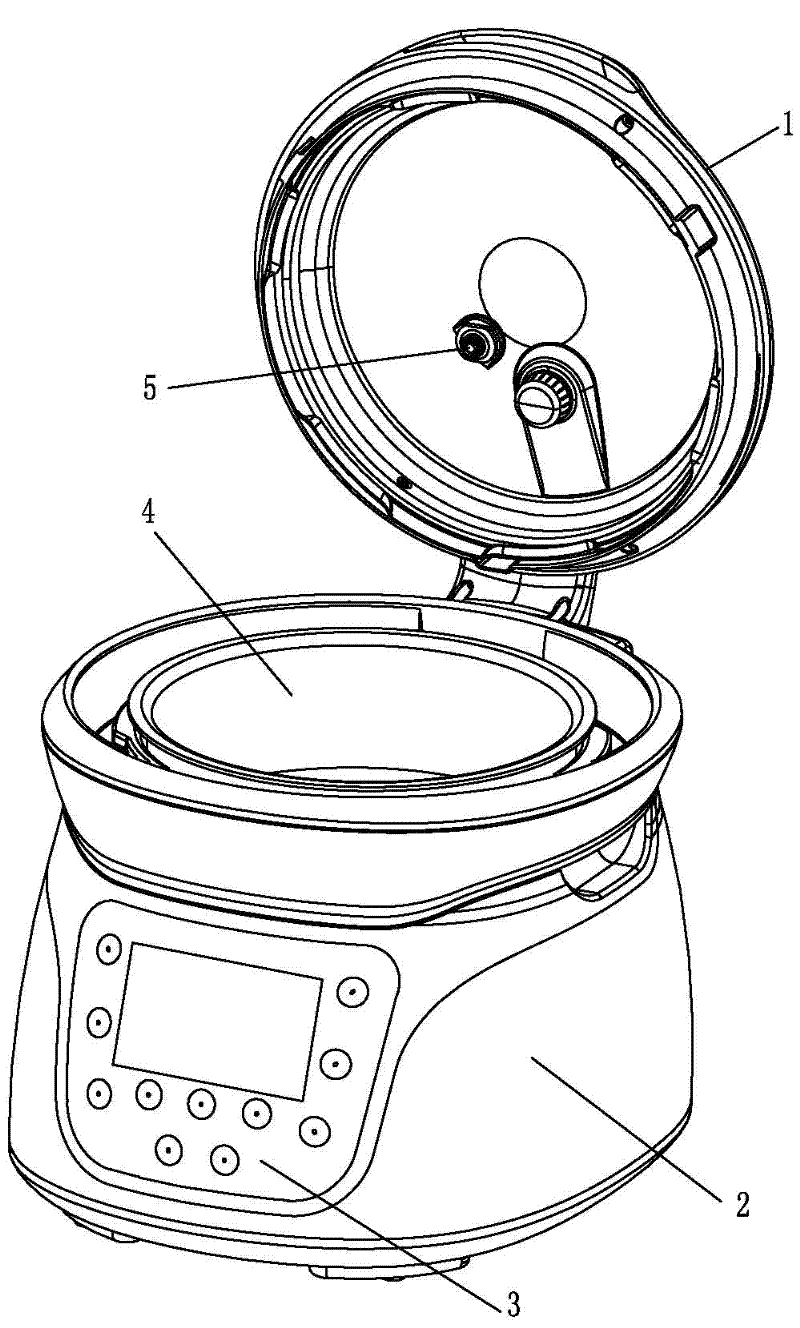

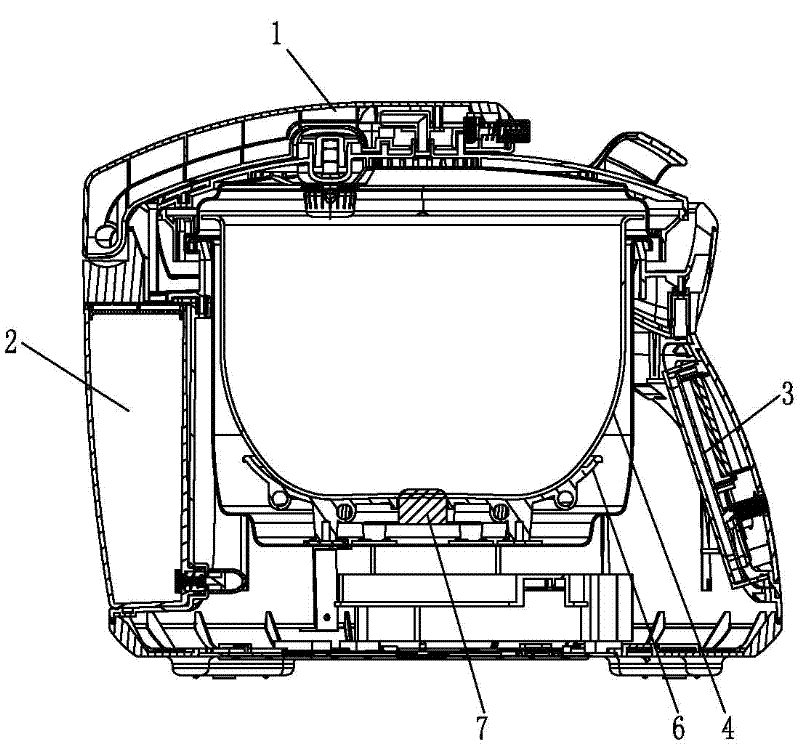

Rice cooker

This rice cooker is equipped with a pot to house water and rice, a heating means, a pressure valve to make the inside of the pot communicate with the outside air or cut off, and a control means for the heating means and the pressure valve. The rice to be cooked is processed by a starting-up process to rapidly heat rice and then a boiling keeping process wherein the rice to be cooked is heated by the heating means when the pressure valve is open.The invention provides a rice cooker in which rice can be sufficiently agitated during boiling and uniformly cooked, and the upper face of cooked rice is flat causing visual artistic effect after rice is completely cooked.

Owner:SANYO ELECTRIC CO LTD +1

An electric pressure cooker for finely cooking rice and its control method

ActiveCN102293584AAvoid overcookedGreat tasteAuxillary controllers with auxillary heating devicesPressure-cookersThermodynamicsRice dishes

The invention discloses an electric pressure cooker for finely cooking rice and a control method thereof. The electric pressure cooker for finely cooking rice comprises a cover body, a cooker body, an inner tank, a heating disk, and a control device for controlling the heating disk to heat or stop heating; the control device comprises a soft fire heating process module, a low-temperature water-absorption process module, a medium-temperature water-absorption process module, a big fire heating process module, a sufficient boiling process module and a rick-stewing process module. The control method for finely cooking rice comprises a preparation process, a soft fire heating process, a medium-temperature water-absorption process, a big fire heating process, a sufficient boiling process and a rice-stewing process. In different heating process stages, different control temperatures and heating time are adopted according to the rice characteristics so that each grain of rice can sufficiently absorb water from outside to inside to guarantee the edible quality of the rice grains such as grain form, color, taste, flavor and the like; since the adopted heating manner mainly is an intermittent heating form, the finely cooked rice has better edible quality and contains more nutrient components.

Owner:GUANGDONG LUBY ELECTRONICS

Frozen food with seasoning liquid

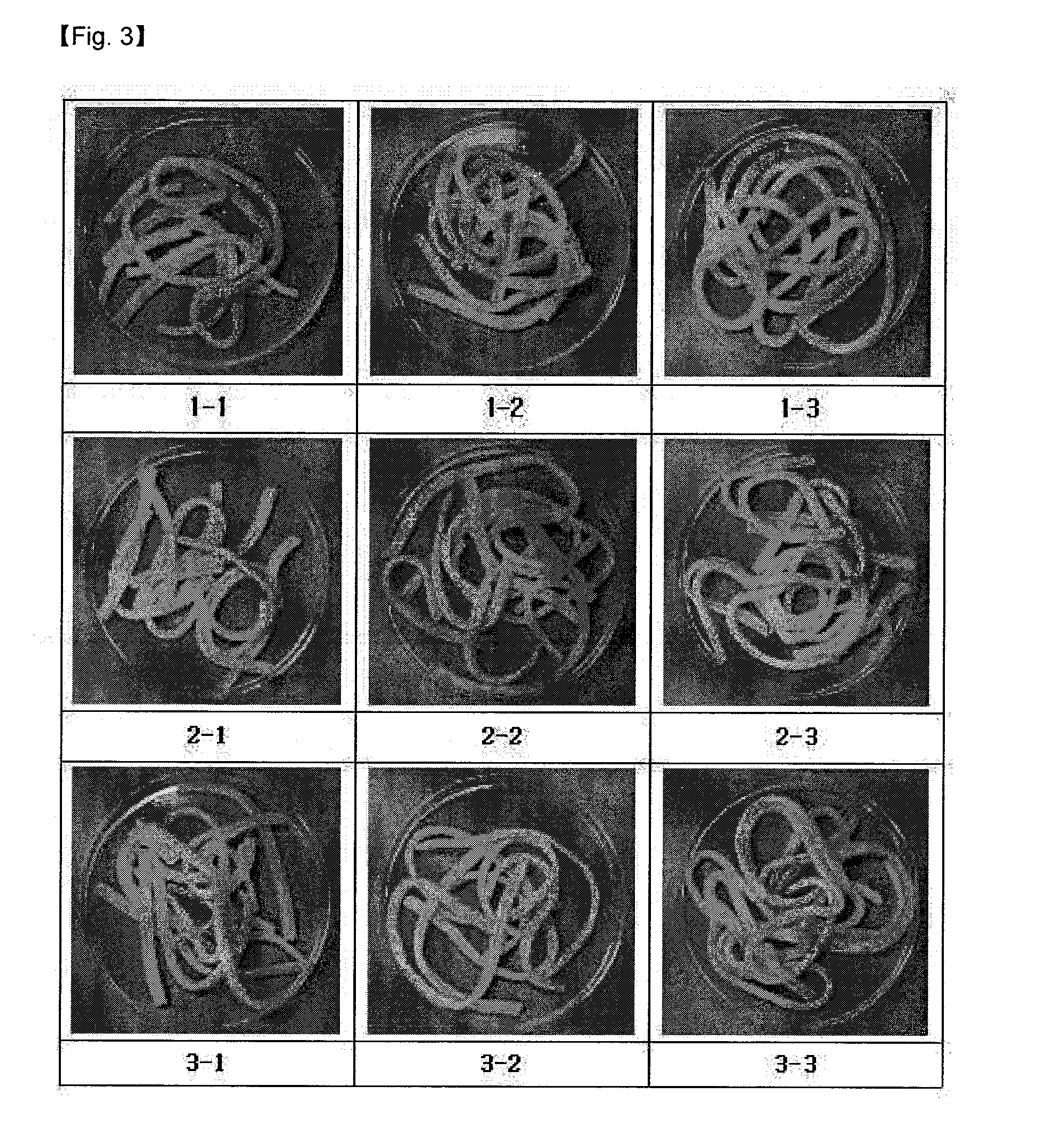

InactiveUS20050281919A1Reduced migration of waterGood lookingConfectionerySweetmeatsRice dishesCooked food

Frozen foods which contain a seasoning liquid, having a specified viscosity, and a main food arranged in a container in that order minimize the migration of water from the seasoning liquid to the main food (e.g., noodles and boiled rice), afford cooked foods which have excellent appearance when plated on a dish, are capable of saving a person time for conducting miscellaneous affairs after the food is heated and cooked, and do not entail a high packaging cost. The seasoning liquid is arranged in a container of a predetermined shape, and then a main food is placed thereon in the mentioned order, so as to prevent the seasoning liquid and main food from being united as one when the food is manufactured and thawed.

Owner:AJINOMOTO CO INC

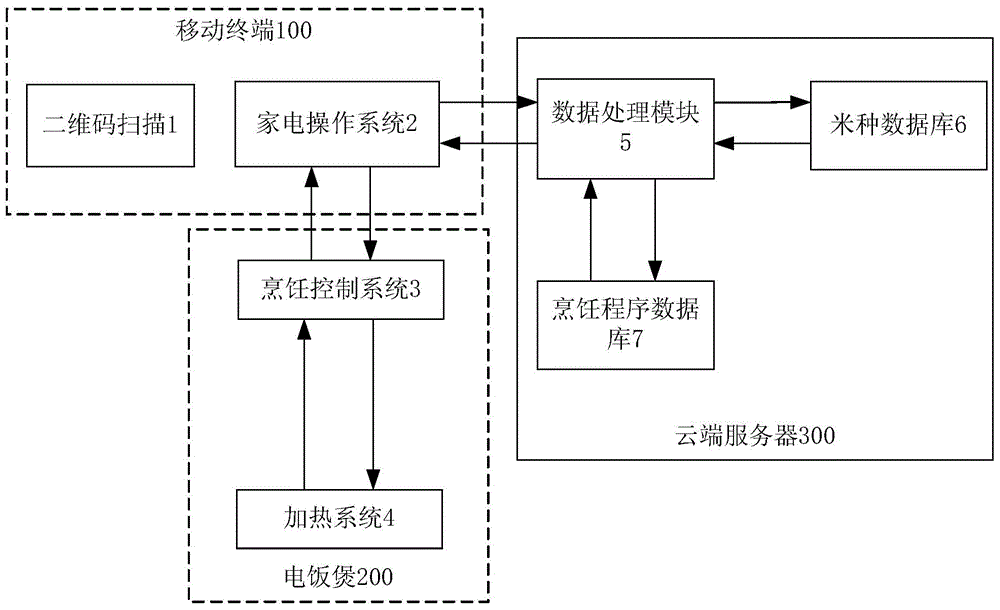

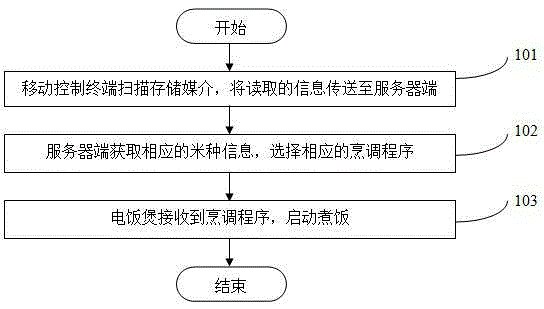

Method for automatically selecting cooking program according to rice category and cloud electric cooker system applying method

InactiveCN105380498AFeature releaseRefinement of the production processCooking vesselsFlavorComputer terminal

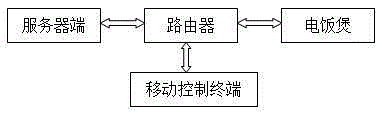

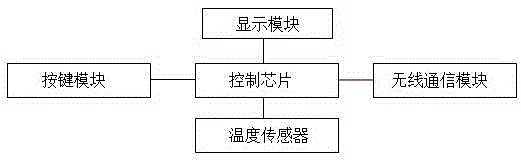

The invention discloses a method for automatically selecting a cooking program according to the rice category and a cloud electric cooker system applying the method. The method comprises the following steps that a mobile control terminal scans a storage medium and transmits read information to a server end; the server end obtains corresponding rice category information according to the information read by the mobile control terminal, selects the corresponding cooking program and transmits the cooking program to an electric cooker; the electric cooker receives the cooking program and starts to cook. By means of the method, the rice category information is obtained by scanning a two-dimension code, a cooking program can be customized for each type of rice according to different types of food materials, rice which is delicate in mouthfeel is cooked out, cooking can be completed conveniently and efficiently, the function of cooking out different flavors out of different types of rice can be achieved for a customer, and cooking experience of a user is improved; the rice characteristics can be effectively released, the advantages of the rice are embodied to the greatest extent, and the rice cooking process is refined.

Owner:SHANGHAI CHUNMI ELECTRONICS TECH CO LTD +1

Production method for instant rice

InactiveCN102232522ASpecial nutritional propertiesDoes not raise blood sugarFood preparationRice dishesWater activity

The invention relates to a production method for instant rice. The method is characterized in that: a raw material of rice is subjected to screening, elutriating, immersing, cooking and separating to obtain cooked rice; hot air is adopted for the first drying to obtain the cooked rice having a moisture content of 30-40%; the cooked rice having a moisture content of 30-40% contacts a osmotic solution comprising functional sugar and gravy salt to carry out a osmotic treatment; then the hot air is adopted for the second drying to obtain the cooked rice having a moisture content of 15-20%, a water activity of 0.55-0.65 and a rehydration time of 8-10 min. According to the present invention, the osmotic solution containing the functional sugar is provided for carrying out the osmotic treatment for the cooked rice, the osmotic solution is uniformly dispersed in the cooked rice, such that the cooked rice has characteristics of specific nutritive peculiarity, high moisture content and low water activity. In addition, after rehydrating, the cooked rice has characteristics of good quality, complete grains of the cooked rice, no hard center and good springiness.

Owner:JIANGNAN UNIV

Method for processing vinasse fish

InactiveCN101095532AUnique aromaRemove fishy smellMeat/fish preservation by heatingMeat/fish preservation using acidsYeastMicroorganism

The invention discloses a method for processing fish pickled with grains, which comprises following steps: cleaning fresh fish pickled with grains, eliminating fish organs, cutting into blocks, salting fish blocks, drying, fermenting, vacuum packing and disinfecting. The fermentation comprises following steps: loading rice into container, adding Chinese yeast into rice with its weight being 1-2% of that of rice, stirring evenly, putting dried fish block with its weight being 60-100% of that of rice into container and embedding them in rice, sealing container, fermenting for 45-55 hours at 26-30 Deg. C, anaerobic fermenting for 45-55 hours at 26-30 Deg. C, and getting fish pickled with grains. The fish block and rice are used as nitrogen and carbon source for fermentation, the fish block absorbs the vinous flavor and the substance in fish is volatilized out after fermentation and anaerobic fermentation process, and the fish smell is removed off at the same time.

Owner:NINGBO UNIV

Preparation method of five-colored steamed rice

InactiveCN103478605AShorten the timeAvoid secondary pollutionFood thermal treatmentNatural extract food ingredientsVaccinium bracteatumRice dishes

Belonging to the field of food deep processing, the invention relates to a preparation method and process of five-colored steamed rice. The basic process of the five-colored instant steamed rice consists of: subjecting rice to dip dyeing, steaming, rice blending, hot filling, and vacuum packaging, thus obtaining a finished product. The method is characterized in that: polished round-grained rice, glutinous rice or germinated brown rice is adopted as the raw material, natural pigments derived from different plants are employed to dye the rice into different colors, the juice of caulis spatholobi is used to dye the rice red, the juice of Peristrophe roxburghiana is used to dye the rice purple, the juice of Vaccinium bracteatum Thunb leaves is used to dye the rice black, the juice of curcuma longa is used to dye the rice yellow, and a part of undyed rice (white) is retained to constitute five colors. In the invention, a vacuuming penetration technology is employed, the rice dyeing rate is accelerated, and the process time is shortened. With a high degree of industrialization, the method produces the five-colored steamed rice with the characteristics of aromatic flavor, rich nutrition, and strong health care. As the plants for dyeing all contain abundant functional components, the nutrition and health care components of the steamed rice are increased. The five-colored steamed rice can serve as both a staple food and a leisure health food.

Owner:NANJING AGRICULTURAL UNIVERSITY

Gluten additives for rice bakery and preparation method thereof

InactiveUS20120207880A1Simple structureIncrease volumeMilk preparationLeguminous plant bakery productsWheat breadWheat allergy

The present disclosure provides: (a) a composition for preparing gluten-free wet rice noodle, rice cake, baked rice confectionery, rice cookie and rice bread, (b) gluten-free wet rice noodle, rice cake, baked rice confectionery, rice cookie and rice bread, and (c) a method for preparing the same. The present disclosure not only provides superior gustatory sensation over wet wheat noodle, wheat cake, baked wheat confectionery, wheat cookie and wheat bread but also provides well-being diet cake for health improvement in terms of nutrition since intake of sugar and sweet substances as well as fats can be reduced. In addition, the present disclosure will find useful applications in the well-being health food industry and the agricultural processed food industry since wheat allergy can be avoided owing to the absence of wheat and the gluten-free food is of great help to patients with celiac disease or atopy.

Owner:IND FOUND OF CHONNAM NAT UNIV

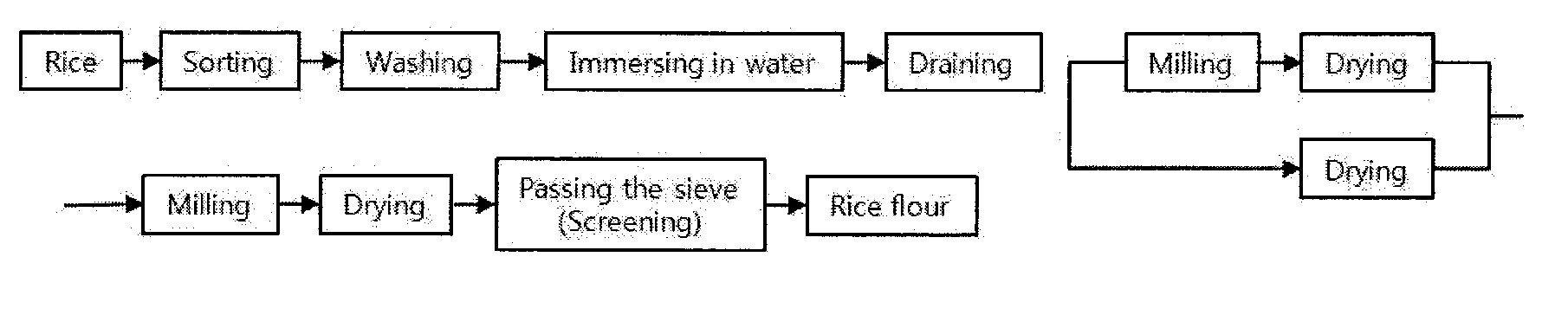

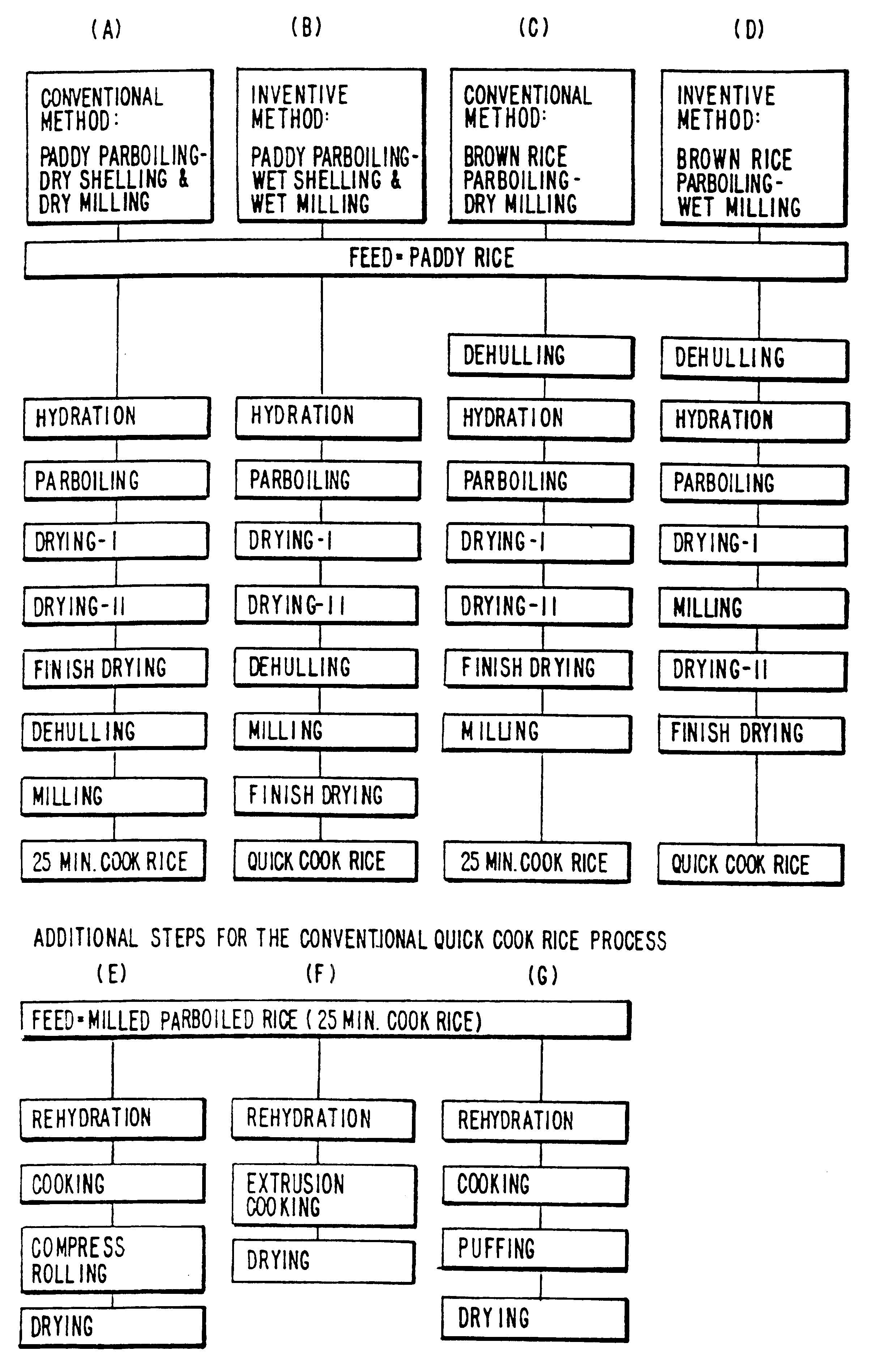

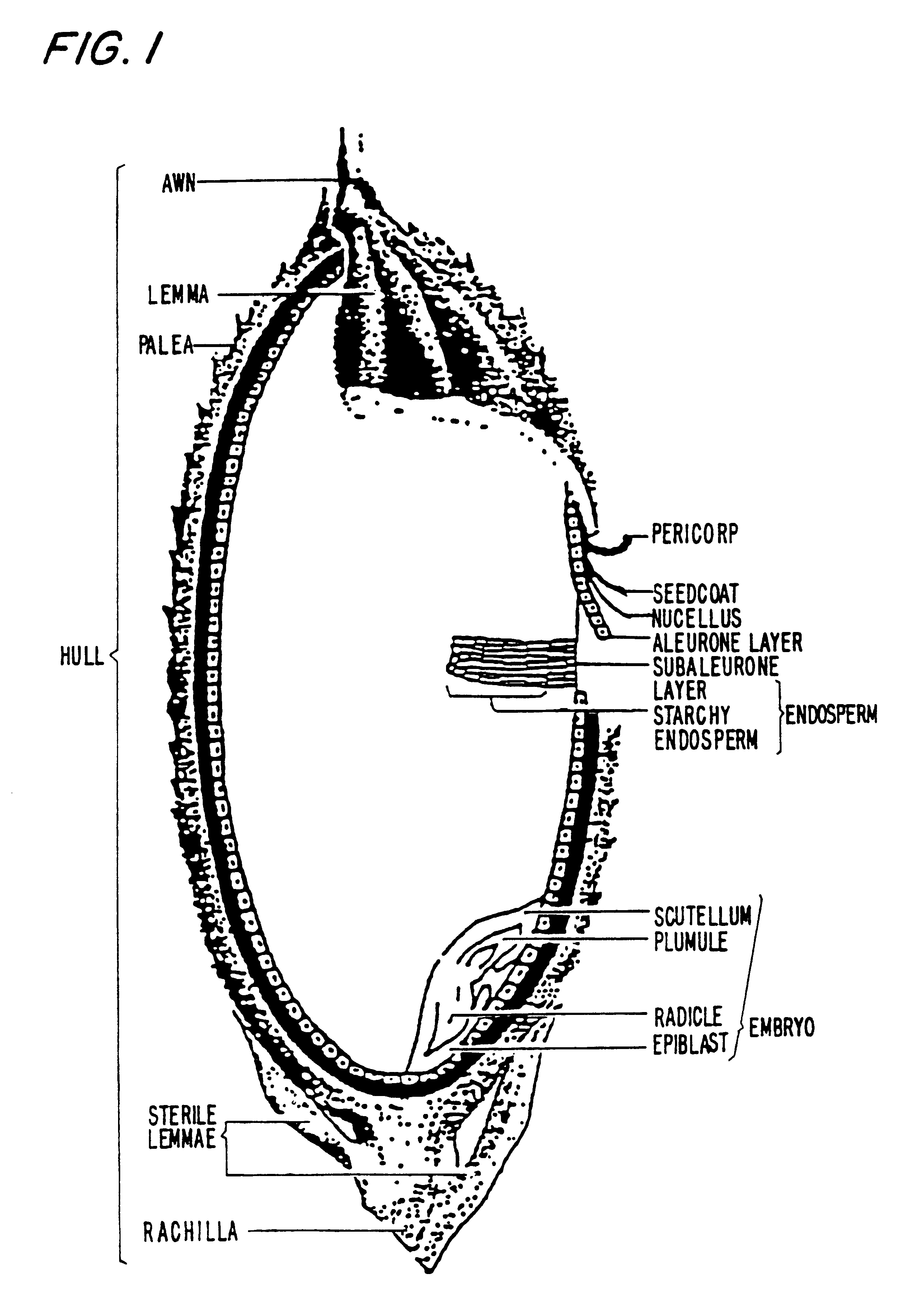

Method of making quick cooking and instant rice

InactiveUS6416802B1Reduce cooking timeImprove water absorptionMilk preservationDough treatmentRice dishesEngineering

The invention provides a process for the preparation of quick cooking rice having a natural appearance and smooth mouthfeel. The rice is produced by mechanically manipulating wet rice at a moisture content of from more than 17% to 32% by weight, preferably by wet milling the rice to remove the bran, followed by drying. The wet milling results in a product with quick cooking properties, superior cook yield and eating properties. The mechanically manipulated wet rice can also be instantized after the wet flexing step to produce an instant rice. Accordingly, the invention provides quick cooking and instant rices obtainable by the claimed processes.

Owner:UNCLE BENS

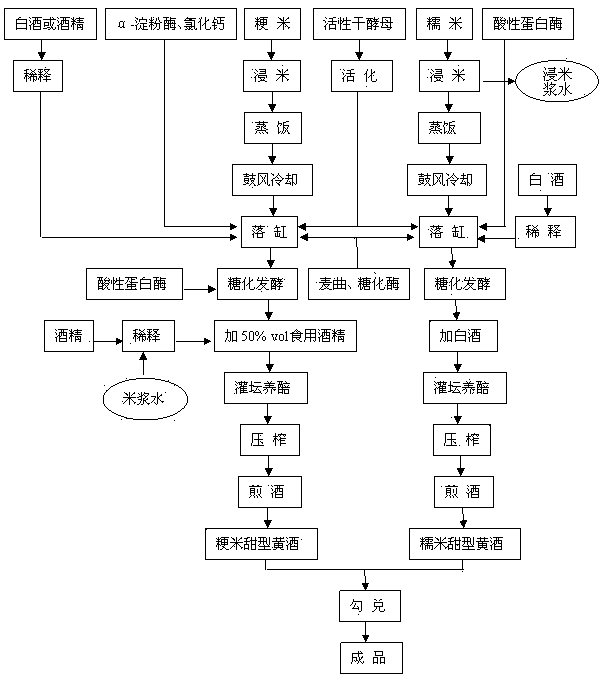

Production technology of vat fermentation sweet type yellow rice wine

The invention relates to a production technology of vat fermentation sweet type yellow rice wine. The production technology comprises a technology for brewing sticky rice sweet type yellow rice wine by taking sticky rice as a raw material, and a technology for brewing polished round-grained rice sweet type yellow rice wine by taking polished round-grained rice as a raw material, and the sweet type yellow rice wine is prepared by blending the sticky rice sweet type yellow rice wine with polished round-grained rice sweet type yellow rice wine in a certain weight ratio. By taking a part of polished round-grained rice as the raw material, the cost of raw materials is saved; steeped rice is only required for draining mixed starch without flushing and the steeped rice is not required for spraying water for cooling, so that a great amount of water for production is saved and the emission of waste water can be greatly reduced; nest forming operation is omitted, operations are simplified, labor force can be saved and the labor intensity can be lightened; by adding a proper amount of enzyme preparations, the utilization ratio of raw materials can be improved; a part of rice pulp is utilized to reduce emission.

Owner:绍兴国家黄酒工程技术研究中心有限公司

Production process of grain boiled rice

InactiveCN101869241AHigh degree of simulationEasy to eatFood preparationFluidized bed dryingCellulose

The invention discloses a production process of grain boiled rice, in particular to a production process of high-biofidelity grain boiled rice. The grain boiled rice can be prepared by mixing, extruding, forming, drying, baking and cooling a raw material, wherein the raw material is at least one grain or grain flour and comprises 49-100 percent of starch, 0-16 percent of protein, 0-12 percent of cellulose, 0-9 percent of grease and 0-14 percent of water. The drying adopts fluidized bed drying or hot air drying and is carried at 60-120DEG C for 10-60min, so that the water content of the formed rice grains by extruding is tempered to be 8-15 percent from 25-30 percent after extruded; and the baking is carried by using an oven at 180-270DEG C for 2-5min and aims at secondarily curing the tempered rice grains, enabling the gelatinization degree of the rice grains to be more than 92 percent and simultaneously forming a porous structure. The grain boiled rice solves the problems of troublesome edible process or difficult rehydration, poor mouthfeeling after rehydration and poor biofidelity of the rice grains existing in traditional convenient rice and makes up the defects of the prior art.

Owner:HENAN JIUYI FOODS

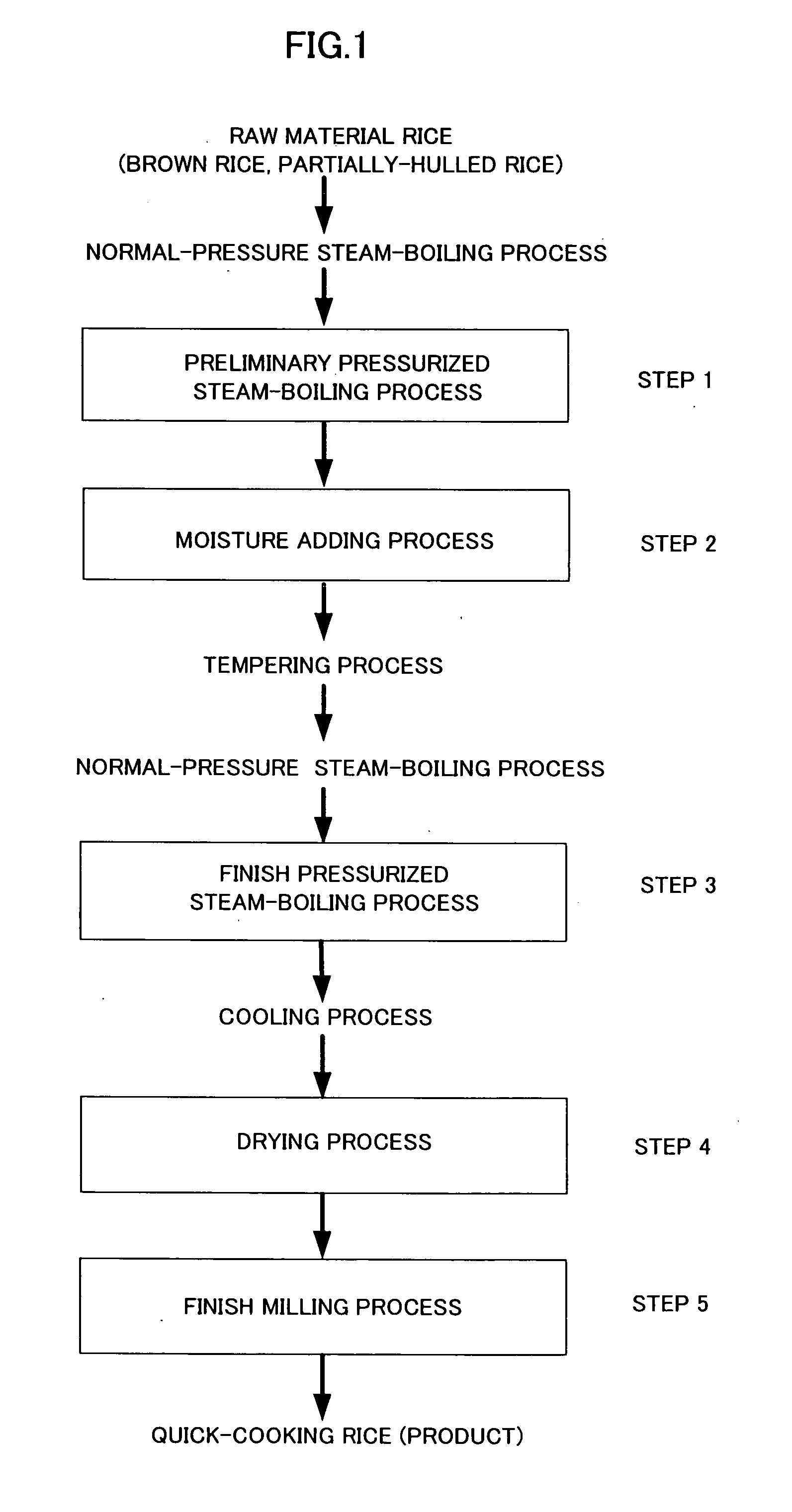

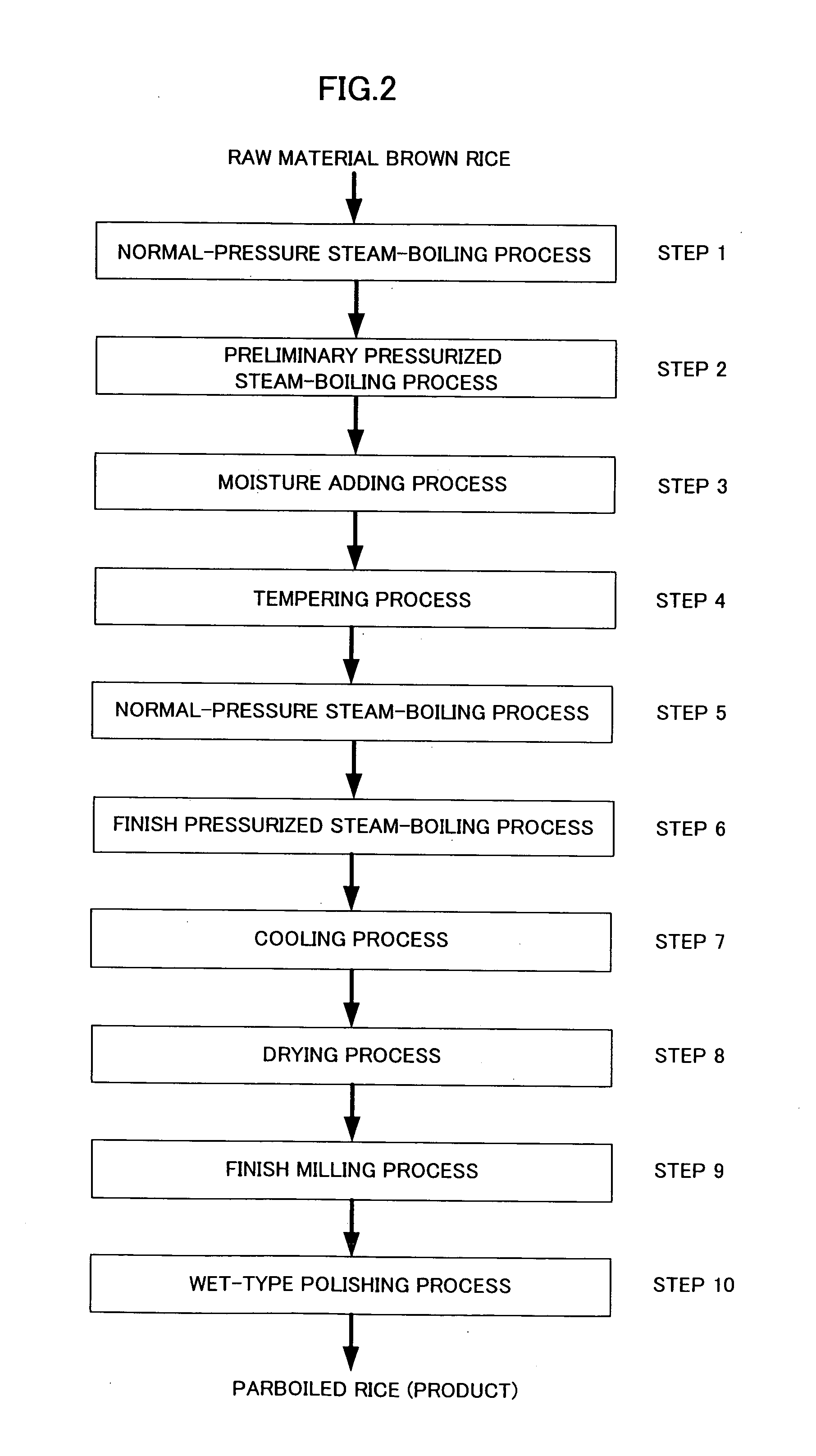

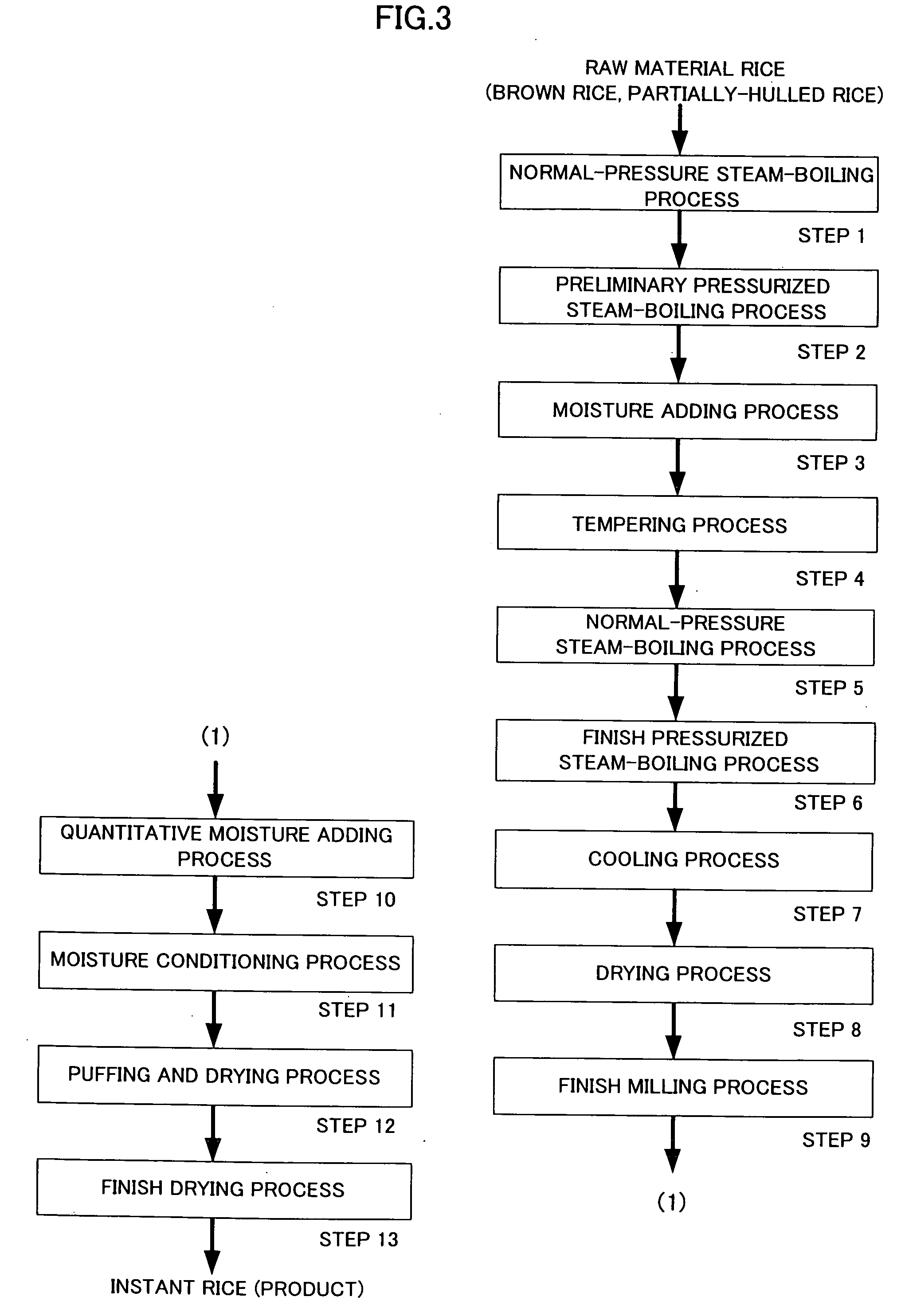

Method for producing quick-cooking rice and quick-cooking rice produced by the method

InactiveUS20100323087A1Quality improvementExtension of timeMeat/fish preservation by heatingFood shapingRice dishesBoiling process

Raw material rice (brown rice and partially-milled rice) is subjected to a preliminary pressurized steam-boiling process to form an alpharized layer on the surface of the raw material rice, and then a moisture adding process is performed. Since the surface of the raw material rice is alpharized to become stiff with the preliminary pressurized steam-boiling process, even rapid moisture addition does not cause a crack in the raw material rice. Therefore, water absorption can be quickly achieved to a target moisture content, thereby reducing a moisture adding time. Also, with no crack, quick-cooking rice with an excellent outer appearance of rice as a product and without a drain of nutrients in rice grains at the time of rice cooking.

Owner:SATAKE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com