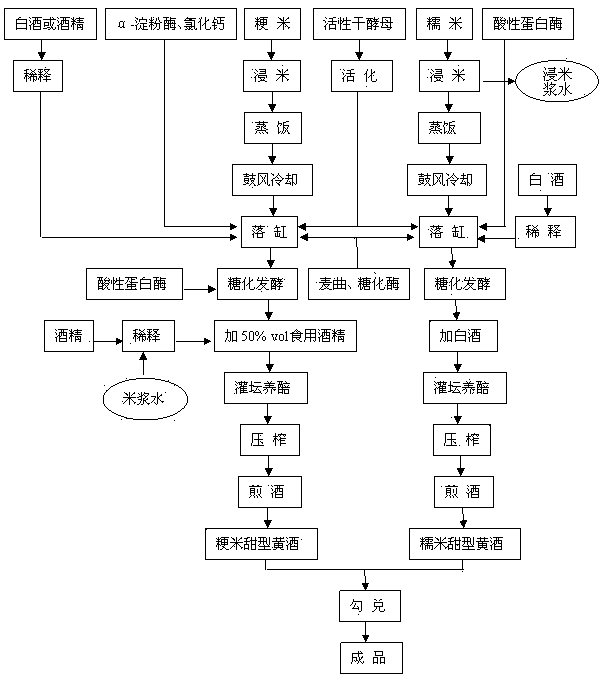

Production technology of vat fermentation sweet type yellow rice wine

A production process and technology for yellow rice wine, applied in the field of production technology of sweet yellow rice wine fermented in large tanks, can solve the problems of high labor intensity, difficult mash pressing, many operators, etc., and achieve the effects of reducing waste water discharge and saving raw material costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] One, the processing steps of glutinous rice sweet yellow rice wine among the present invention are as follows:

[0039] The amount of ingredients is calculated based on a large tank for brewing, and the ingredients for each tank are: 125kg of glutinous rice, 15kg of raw wheat koji, 60g of 100000U glucoamylase, 10g of 50000U acid protease, 180g of active dry yeast for rice wine and 130 kg of 32% vol liquor;

[0040] A1. Rice soaking: After the glutinous rice has been screened and removed, put it into a tank and soak it in water. The water surface is 10 cm above the glutinous rice layer. Soak it for 4 days, drain it, and collect part of the rice milk water for later use;

[0041] A2. Steamed rice: Steam the rice until the surface is steamed, and the rice grains are not white; the standard requirements for glutinous rice are: hard on the outside and soft on the inside, loose but not mushy, cooked but not rotten, and uniform;

[0042] A3, air-cooling: the steamed glutinous ...

Embodiment 2

[0057] One, the processing steps of glutinous rice sweet yellow rice wine among the present invention are as follows:

[0058] The amount of ingredients is calculated based on a large tank for brewing, and the ingredients for each tank are: 125kg of glutinous rice, 10kg of raw wheat koji, 80g of 100,000U glucoamylase, 15g of 50,000U acid protease, 140g of rice wine active dry yeast and 130 kg of 35% vol liquor;

[0059] A1. Rice soaking: After the glutinous rice has been screened and removed, put it into a tank and add water to soak it. The water surface is 6 cm above the glutinous rice layer. Soak it for 3 days, drain it, and collect part of the rice milk water for later use;

[0060] A2. Steamed rice: steam until the surface is steamed, and the rice grains are not white; the standard requirements for glutinous rice are: hard on the outside and soft on the inside, loose and not mushy, cooked but not rotten, and uniform;

[0061] A3, air-cooling: the steamed glutinous rice in ...

Embodiment 3

[0076] One, the processing steps of glutinous rice sweet yellow rice wine among the present invention are as follows:

[0077] Calculate the amount of ingredients based on the large tanks used for brewing, and feed each tank: 125kg of glutinous rice, 12.5kg of raw wheat koji, 70g of 100000U glucoamylase, 12.5g of 50000U acid protease, 160g of rice wine active dry yeast and 130 kg of 33.5% vol liquor;

[0078] A1. Rice soaking: After the glutinous rice has been screened and removed, put it in a tank and add water to soak it. The water surface is 8 cm above the glutinous rice layer. Soak it for 3.5 days, drain it, and collect part of the rice milk water for later use;

[0079] A2. Steamed rice: steam until the surface is steamed, and the rice grains are not white; the standard requirements for glutinous rice are: hard on the outside and soft on the inside, loose and not mushy, cooked but not rotten, and uniform;

[0080] A3, air-cooling: the steamed glutinous rice in step A2 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com