Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

667 results about "Fluidized bed drying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

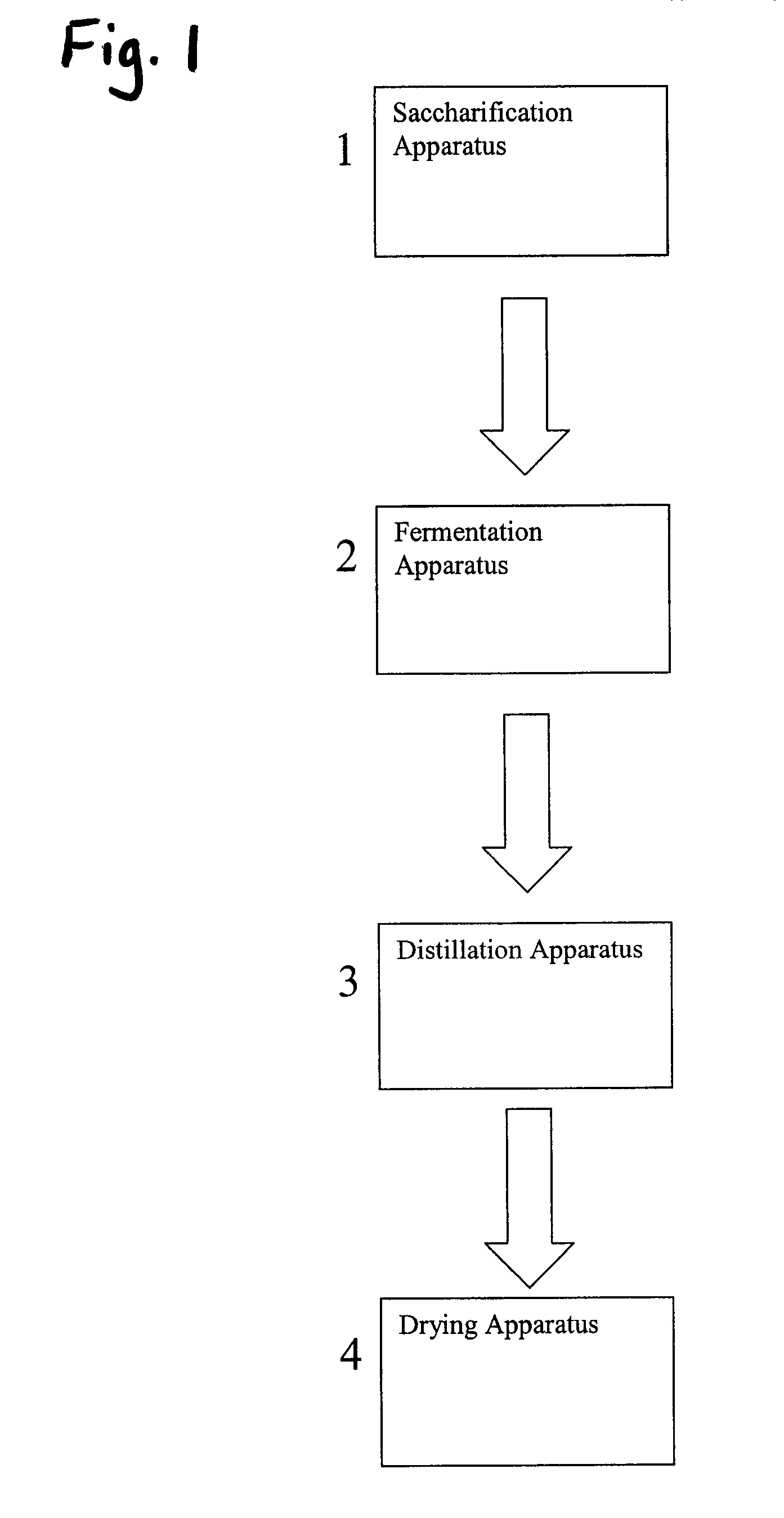

Methods and systems for producing ethanol using raw starch and fractionation

InactiveUS20070037267A1Improve the level ofImprove the immunityBiofuelsFermentationFluidized bed dryingHigh alcohol beer

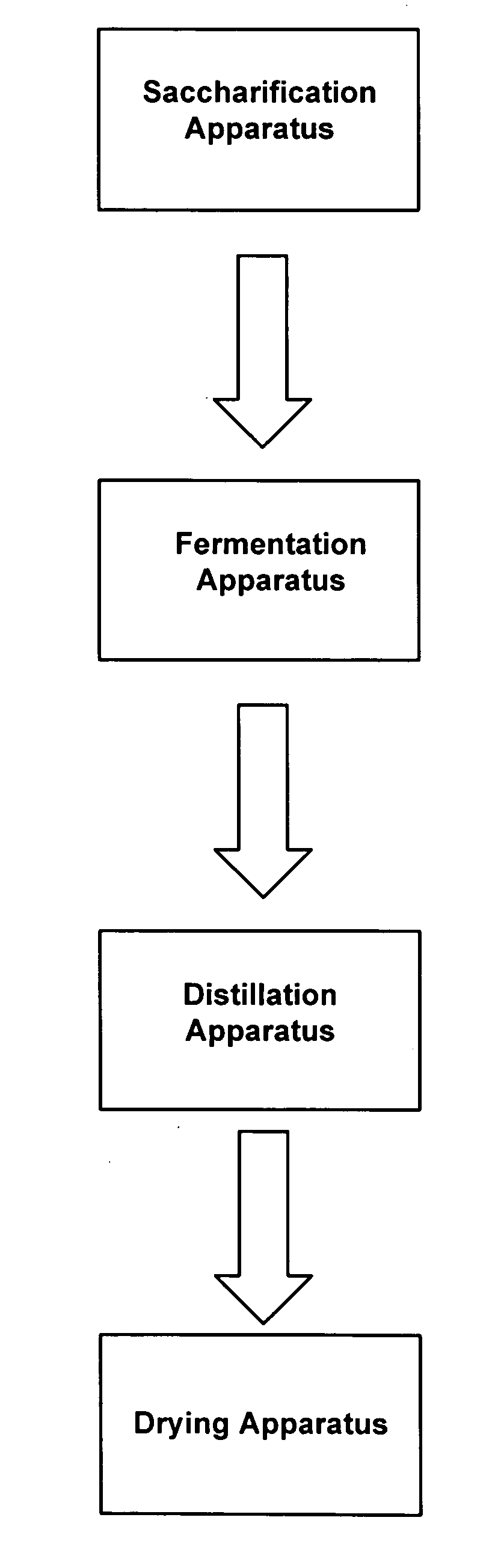

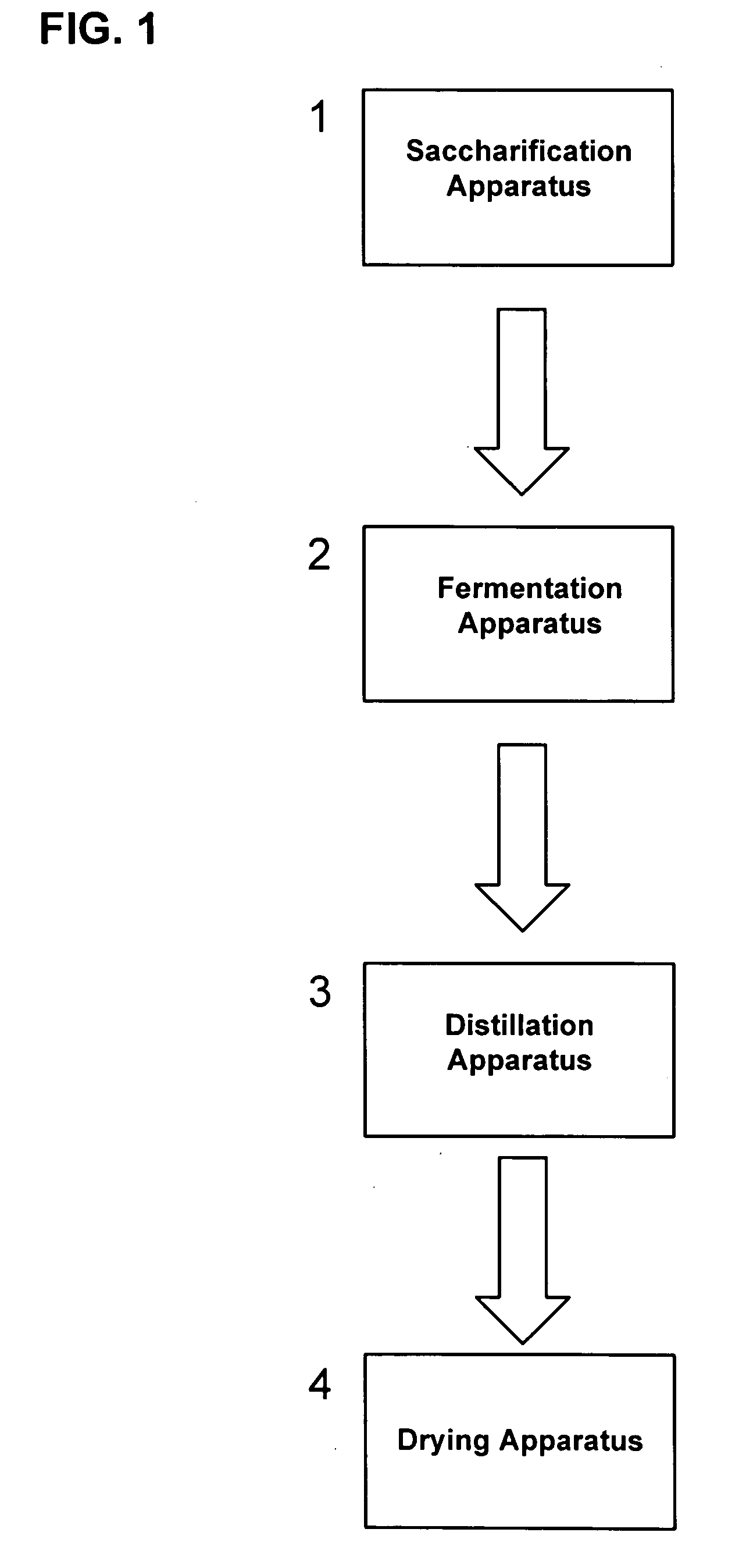

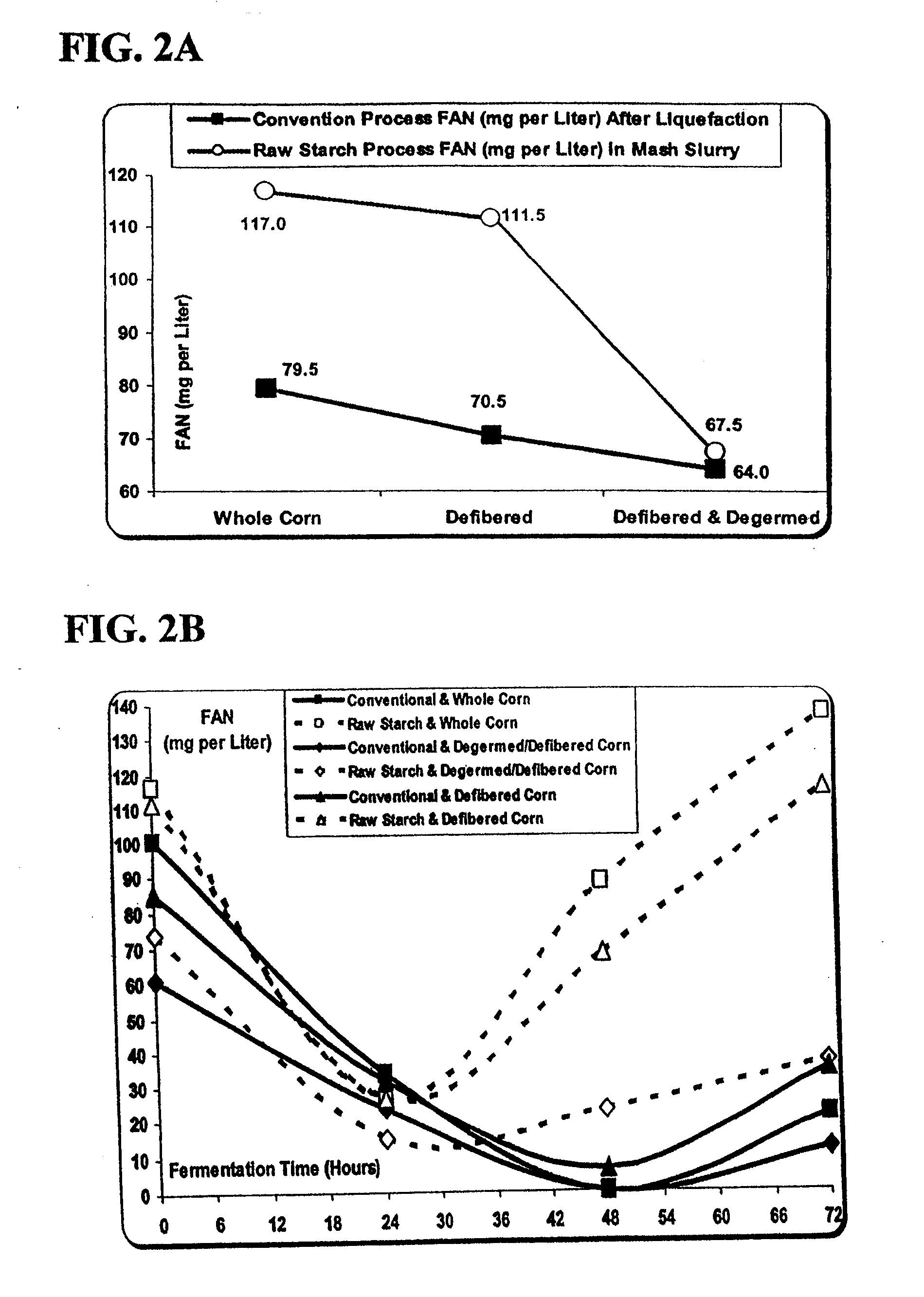

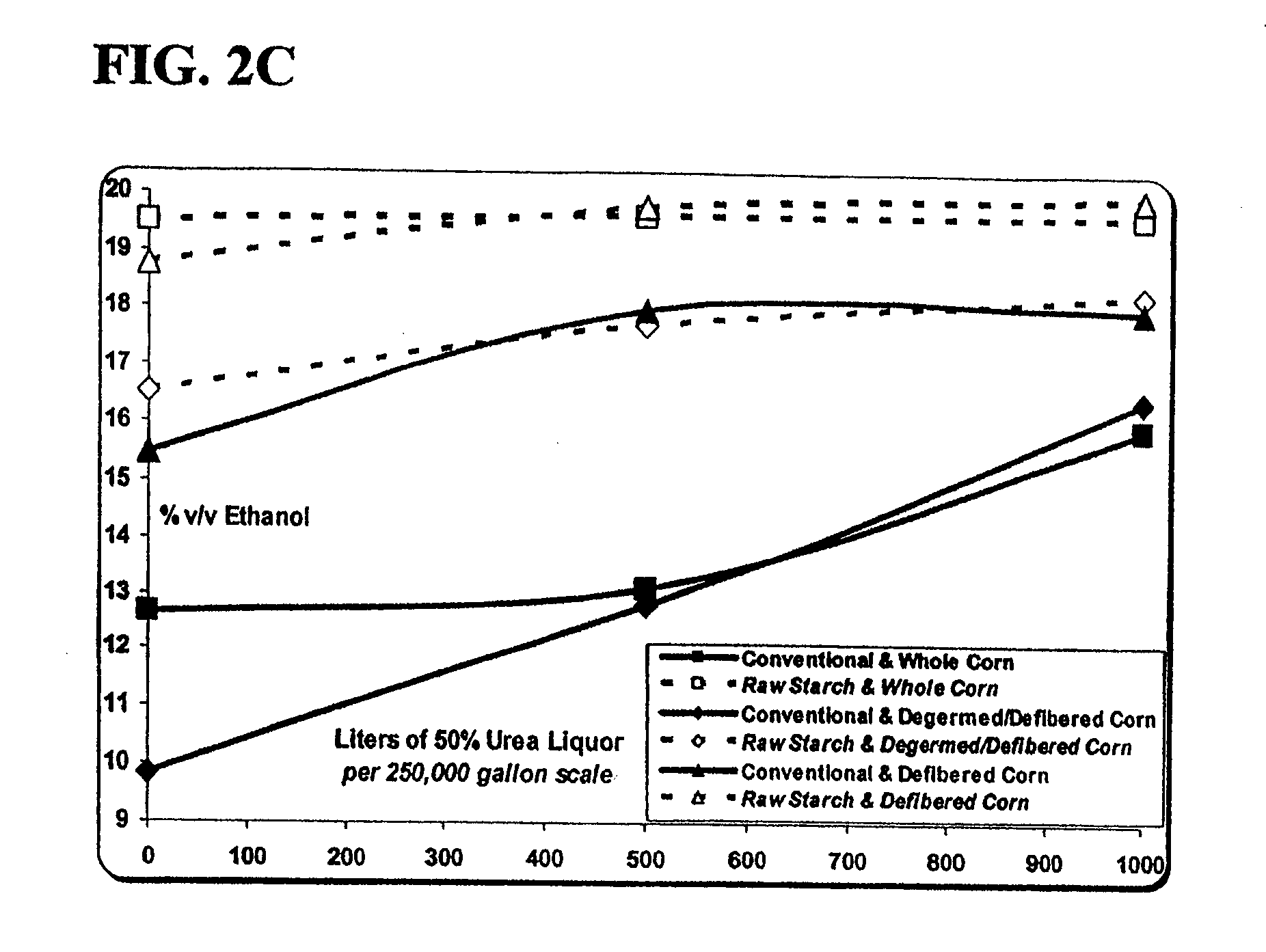

The present invention relates to methods for producing high levels of alcohol during fermentation of plant material, and to the high alcohol beer produced. The method can include fractionating the plant material. The present invention also relates to methods for producing high protein distiller's dried grain from fermentation of plant material, and to the high protein distiller's dried grain produced. The method can include drying a co-product by ring drying, flash drying, or fluid bed drying. The present invention further relates to reduced stack emissions from drying distillation products from the production of ethanol.

Owner:BROIN & ASSOC

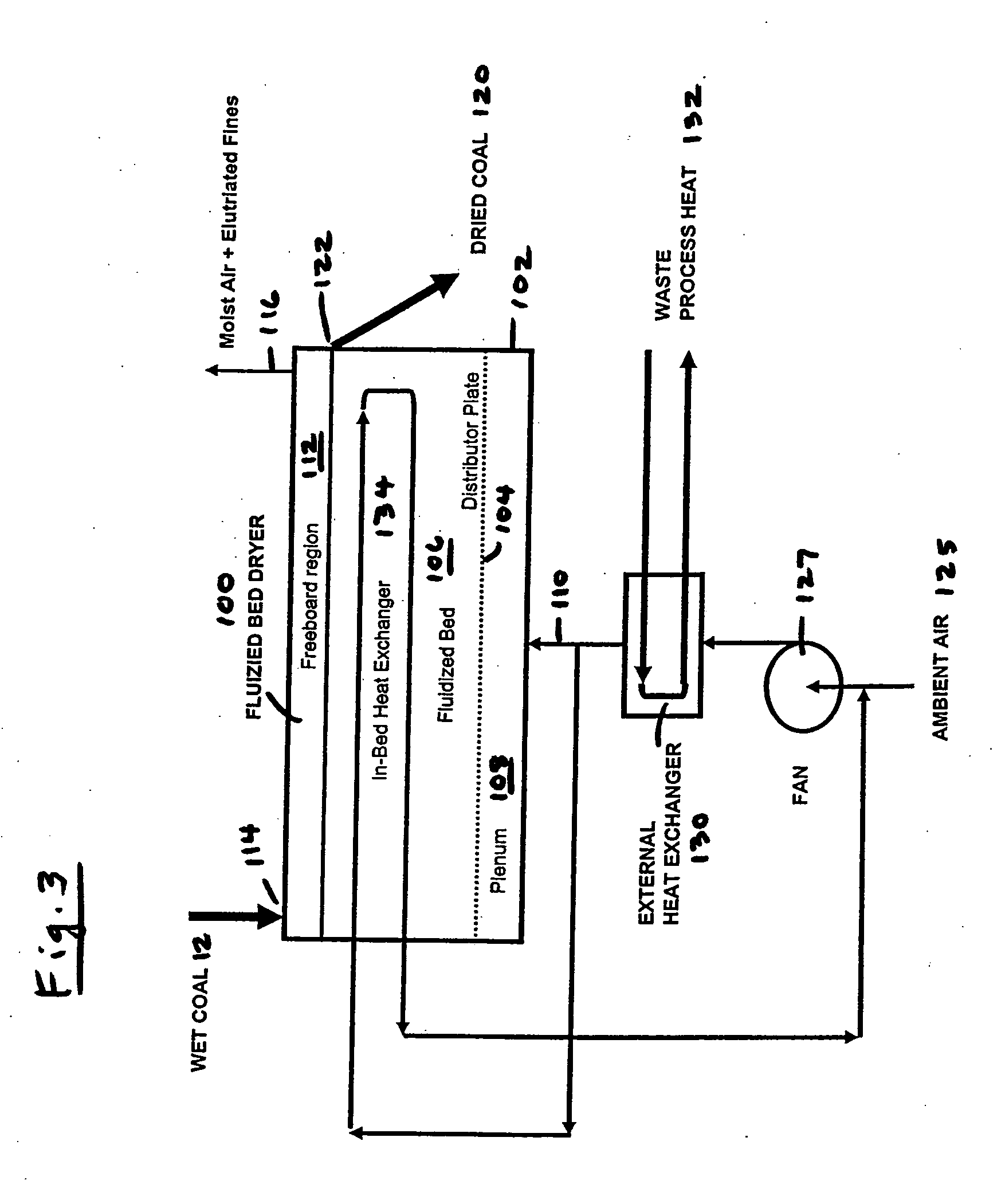

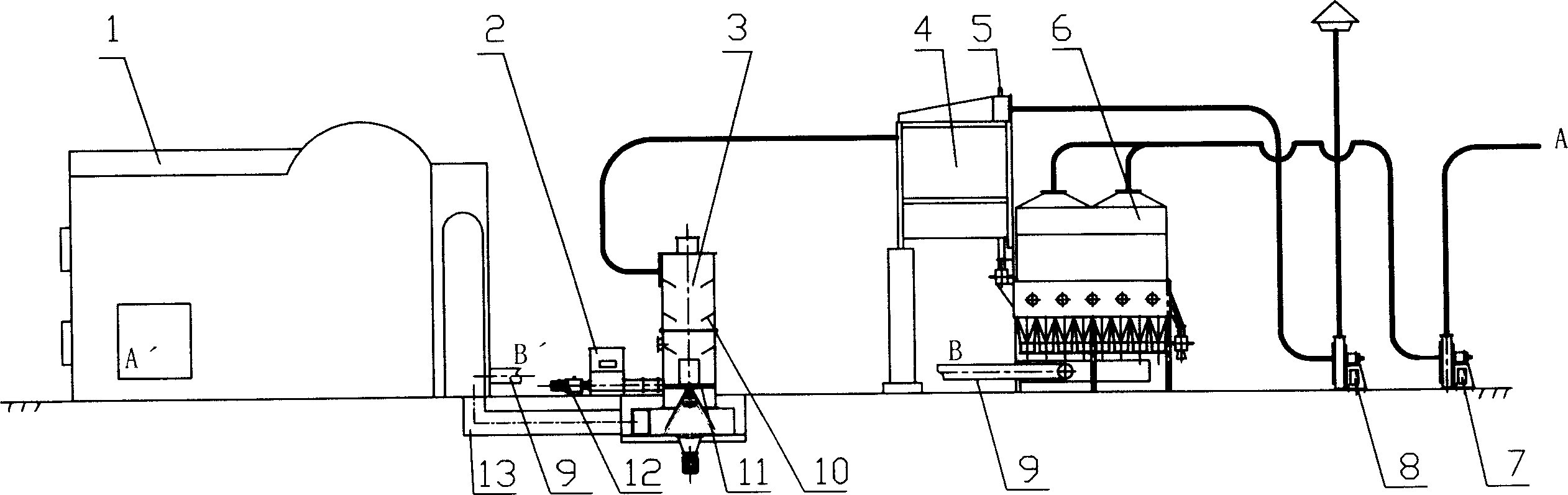

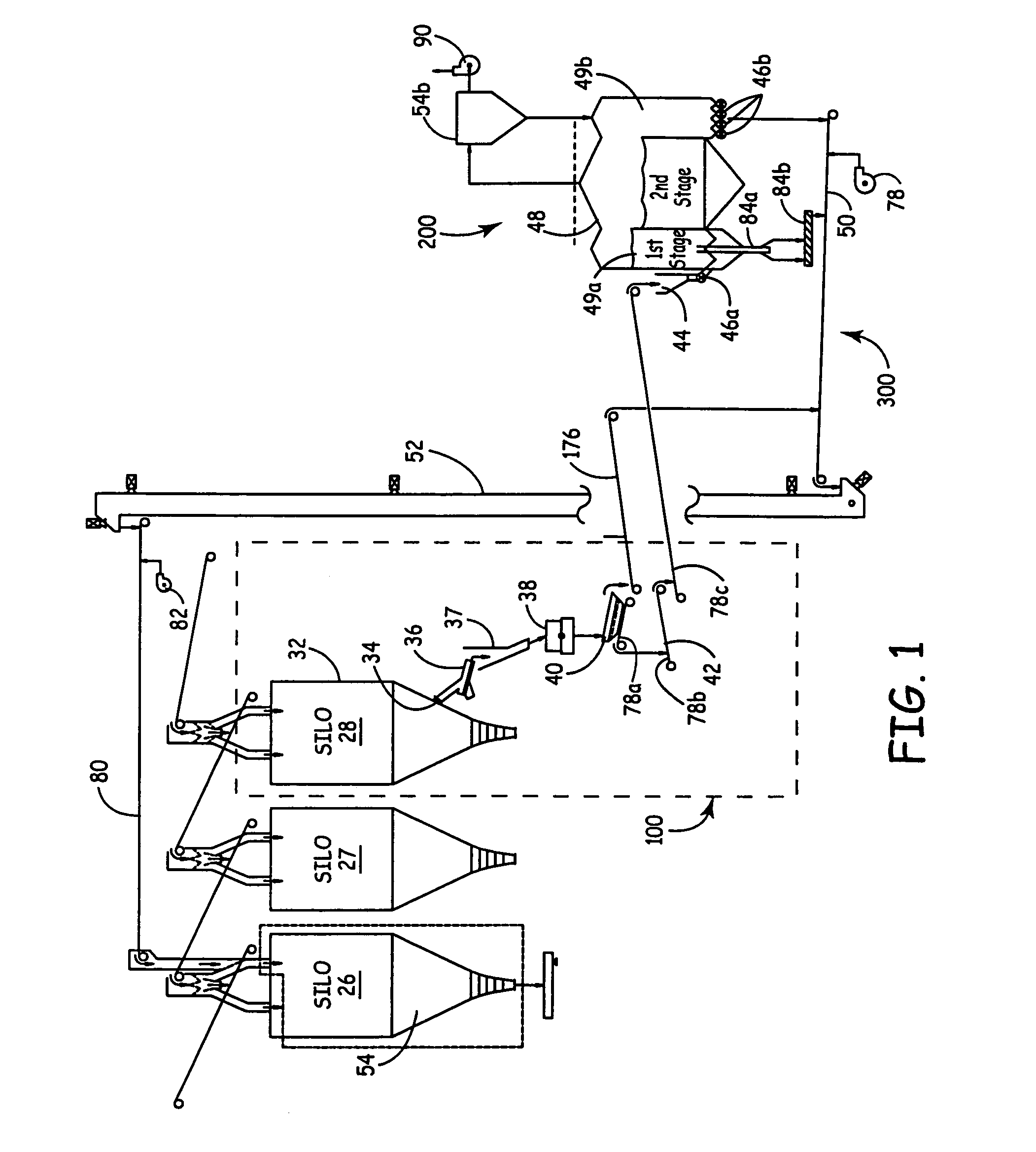

Apparatus and method of enhancing the quality of high-moisture materials and separating and concentrating organic and/or non-organic material contained therein

ActiveUS20080201980A1Processed evenly and quicklySignificant environmental benefitsDrying solid materials with heatSolid fuel pretreatmentParticulatesFluidized bed drying

The present invention harvests and utilizes fluidized bed drying technology and waste heat streams augmented by other available heat sources to dry feedstock or fuel. This method is useful in many industries, including coal-fired power plants. Coal is dried using the present invention before it goes to coal pulverizers and on to the furnace / boiler arrangement to improve boiler efficiency and reduce emissions. This is all completed in a low-temperature, open-air system. Also included is an apparatus for segregating particulate by density and / or size including a fluidizing bed having a particulate receiving inlet for receiving particulate to be fluidized. This is useful for segregating contaminants like sulfur and mercury from the product stream.

Owner:RAINBOW ENERGY CENT LLC

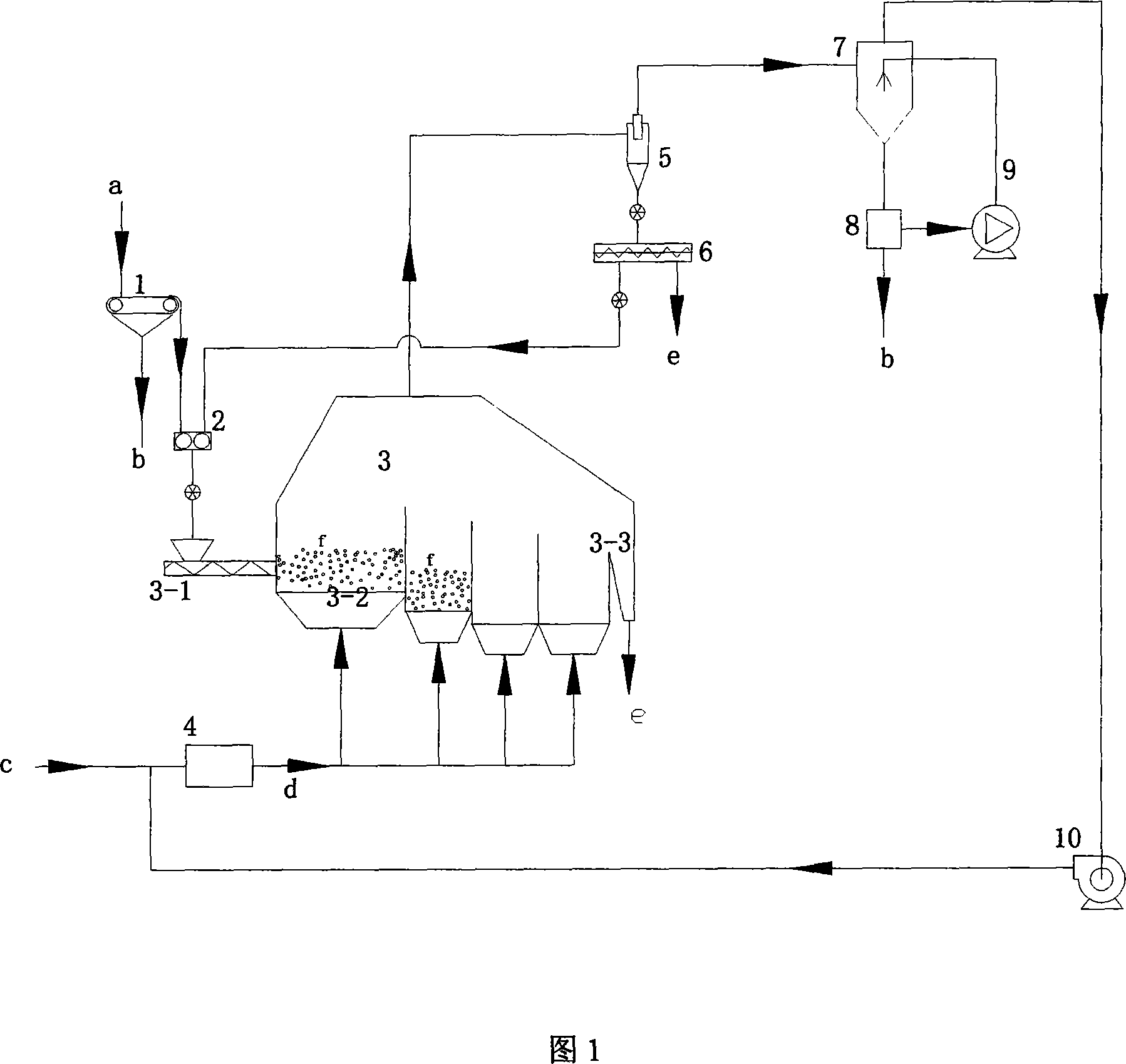

Enclosed multi-chamber fluidized bed drying method for sludge

InactiveCN101186422AUniform humidityReduce breakageSludge treatment by de-watering/drying/thickeningLiquid wasteFluidized bed drying

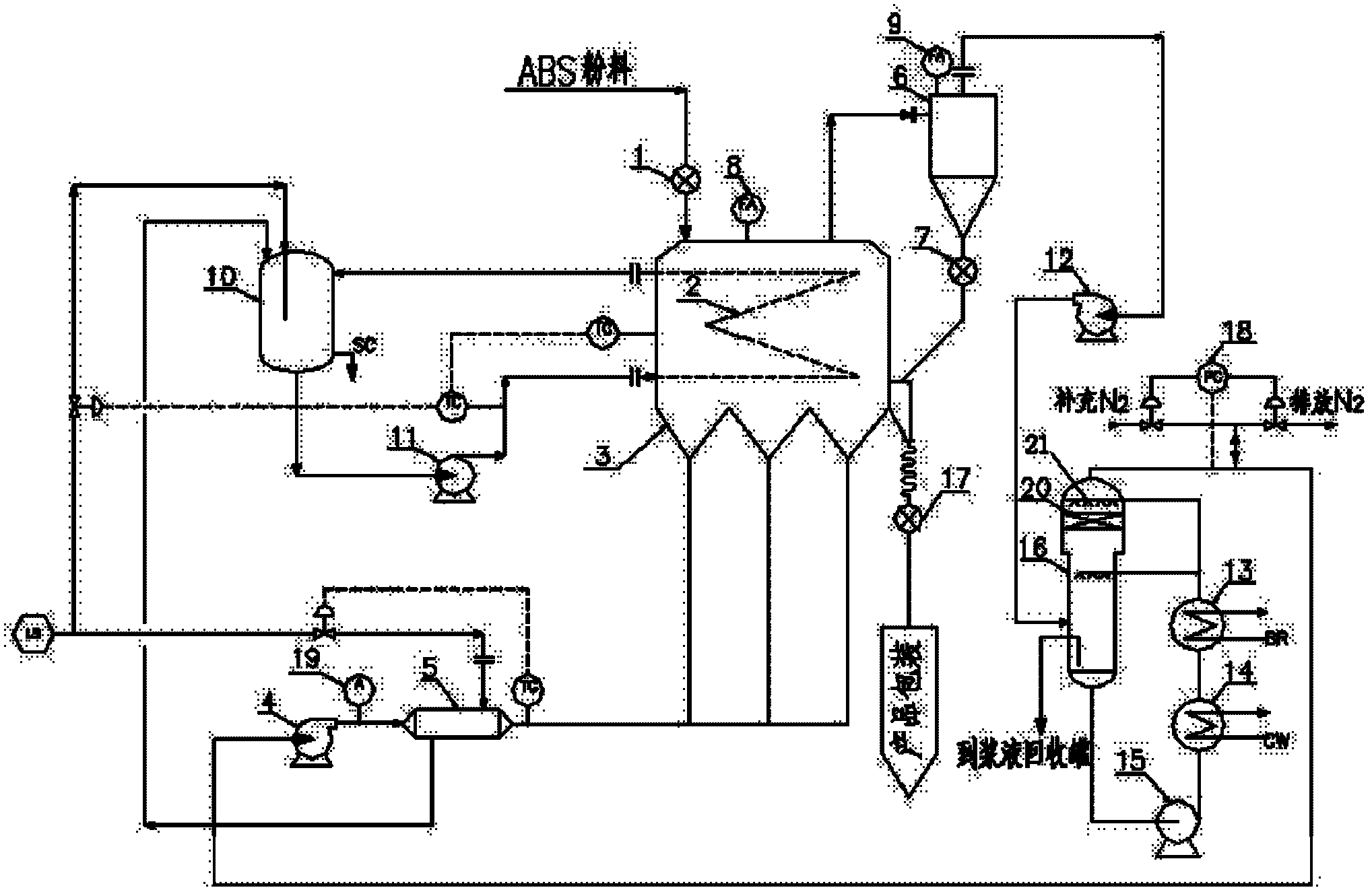

A closed multi-room fluidized bed sludge drying method is provided, which is a sludge drying method having the advantages of simple equipment structure, convenient operation, strong sludge adaptability, high thermal efficiency, safety, continuity, stability, etc. After the mechanically dewatered sludge is mixed with the back-mixed sludge, the mixture is dried room by room in an inert particles multi-room fluidized bed dryer (3). The first room and the second room of the inert particles multi-room fluidized bed dryer (3) adopt inert particles (f) as heat storage medium. Gas from a cyclone separator (5) goes through a spray tower (7) and returns into an air heating unit (4) through a circulating fan (10). Part of dried sludge (e) at the lower part of the cyclone separator (5) enters the inert particles multi-room fluidized bed dryer (3) through the back-mixing in a mixer (2). Waste liquid from the bottom of the spray tower (7) enters a waste liquid circulating pool (8), with part of waste liquid circulating into the spray tower (7) and part into a sewage treatment system.

Owner:SOUTHEAST UNIV

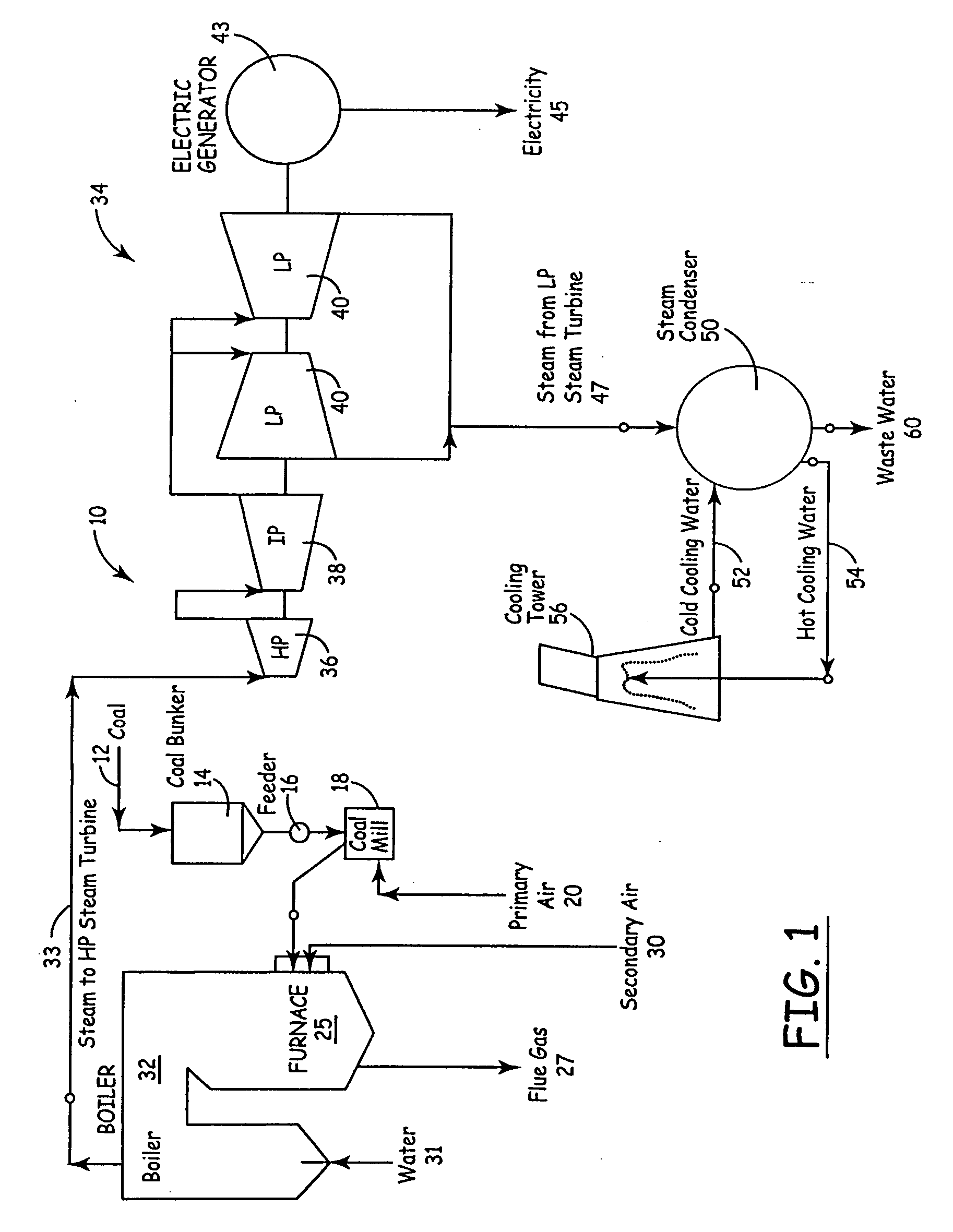

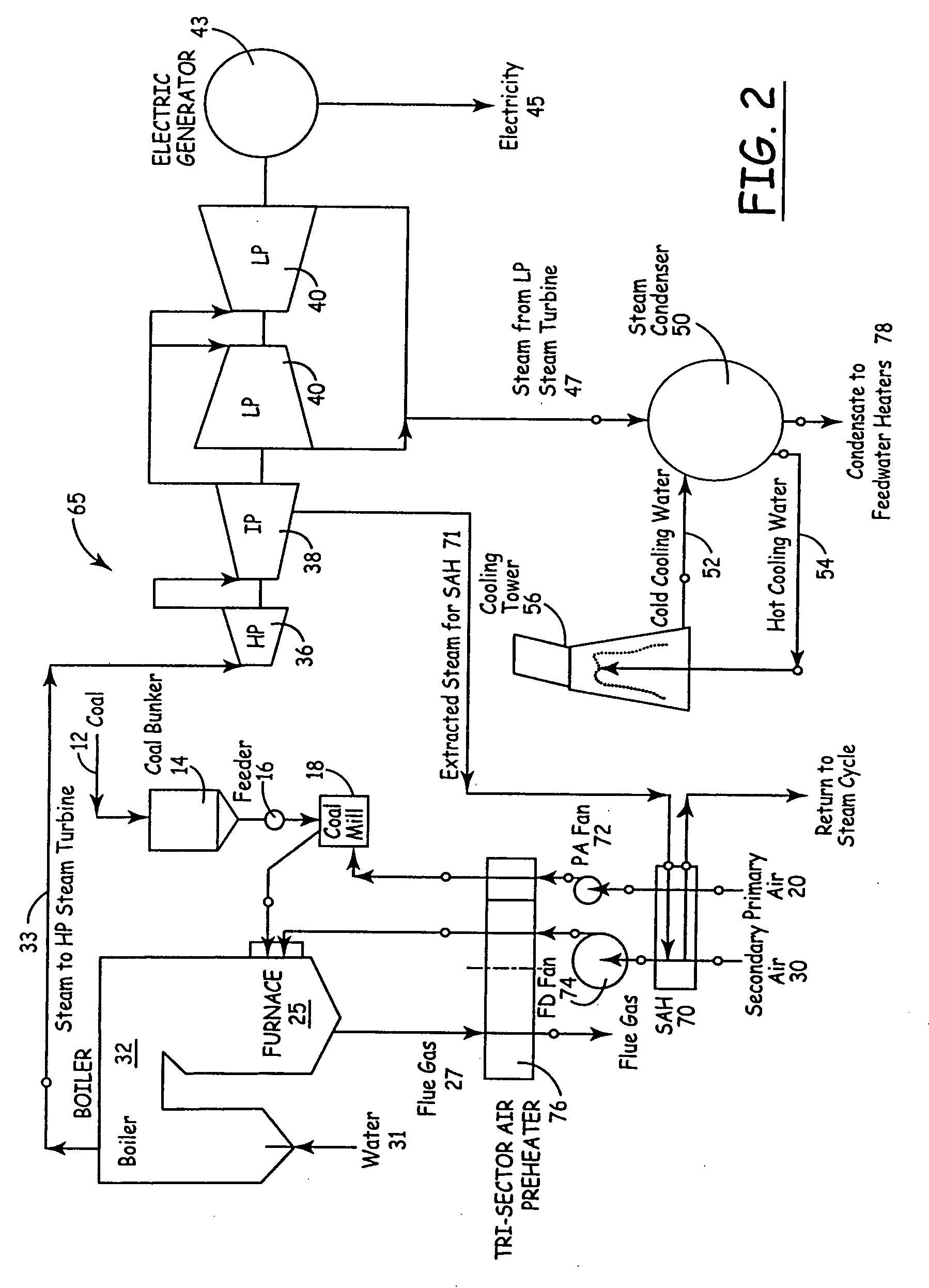

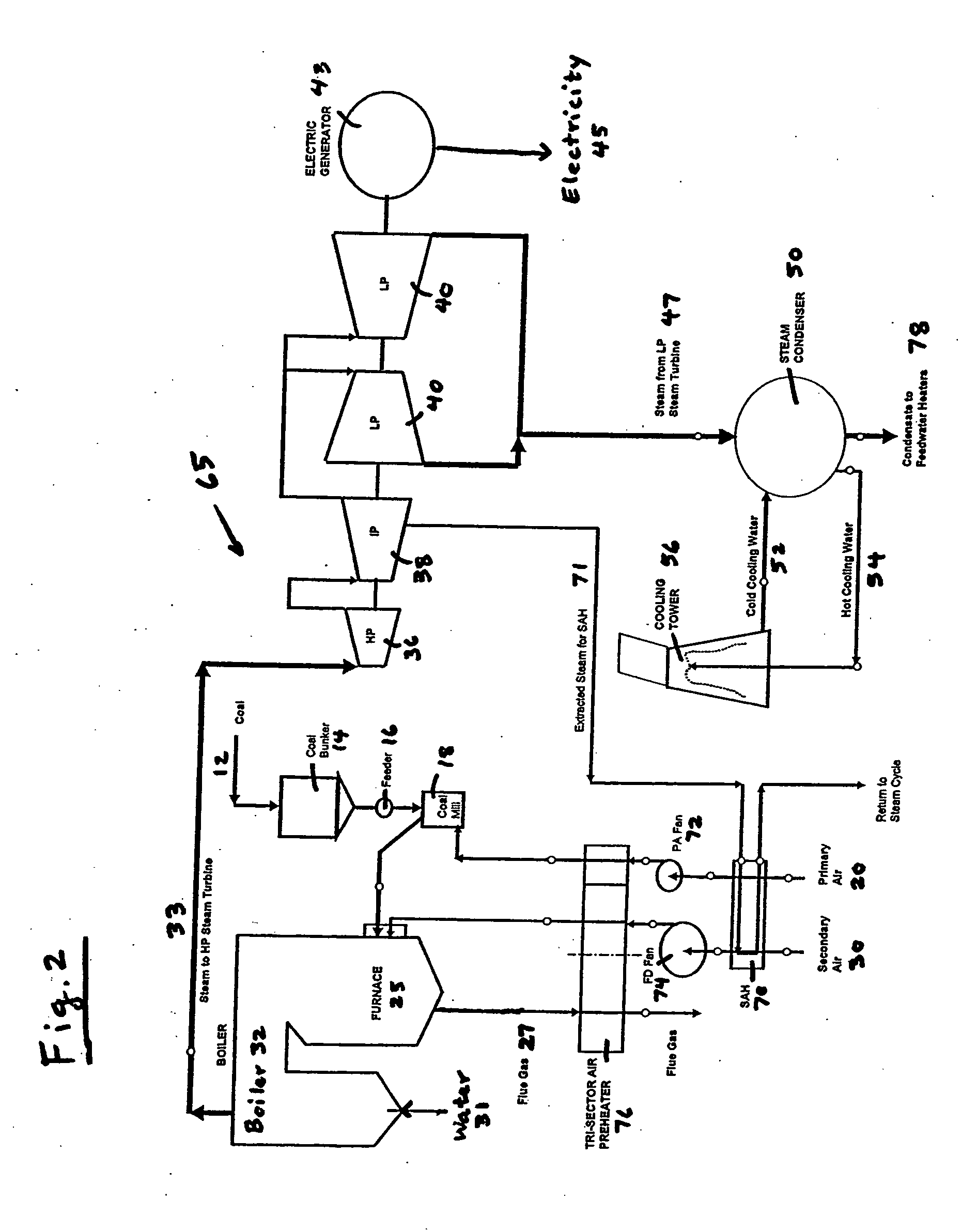

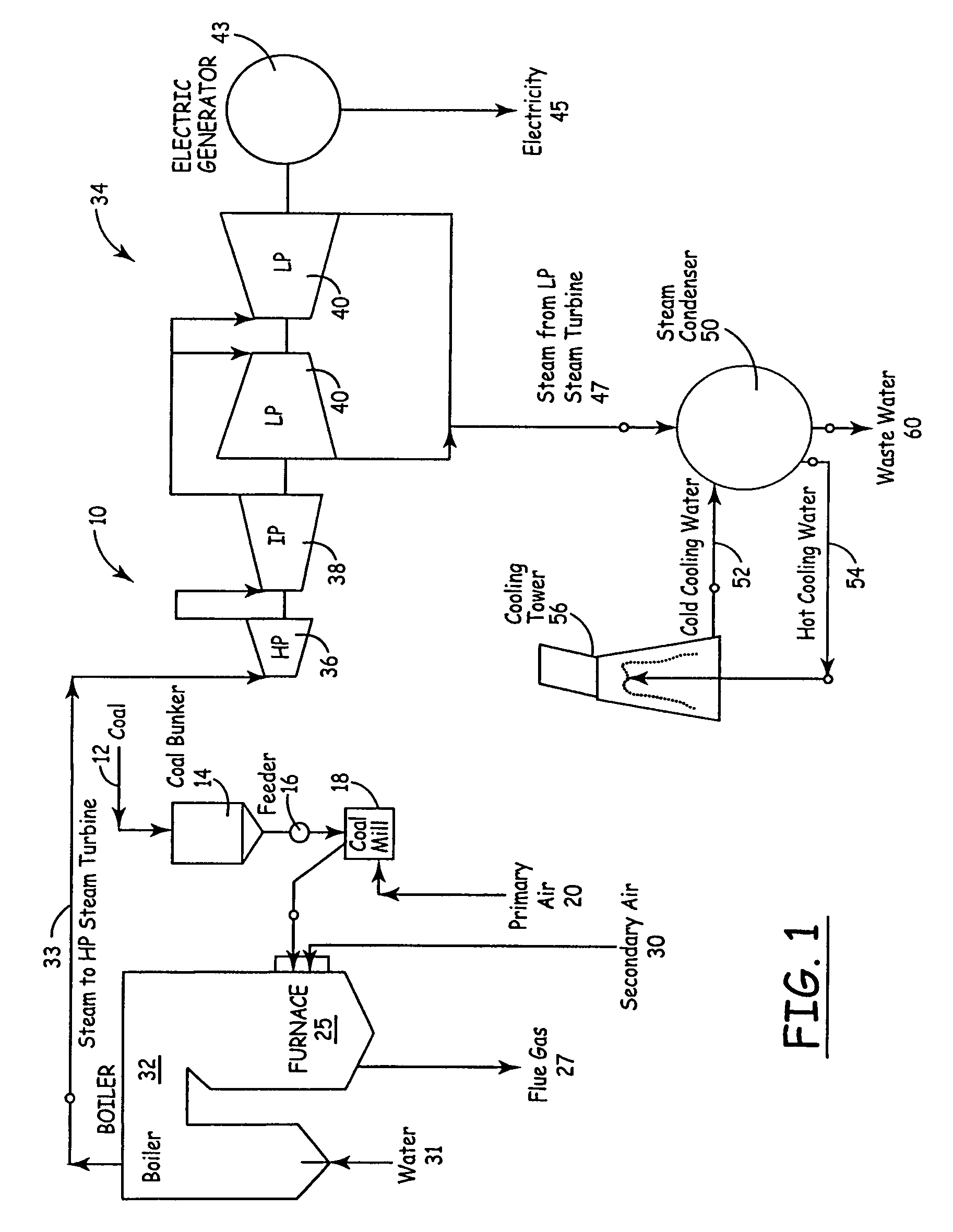

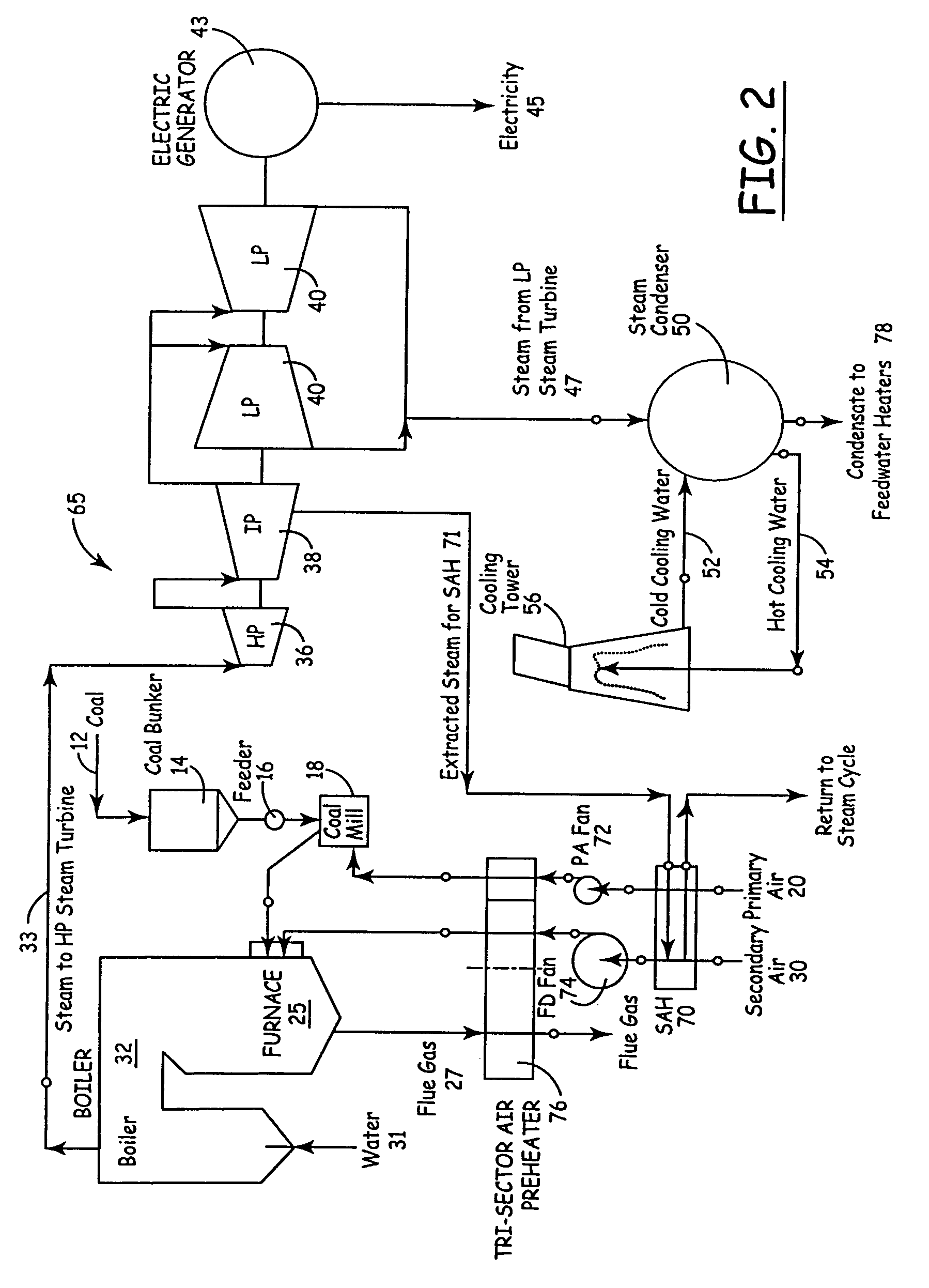

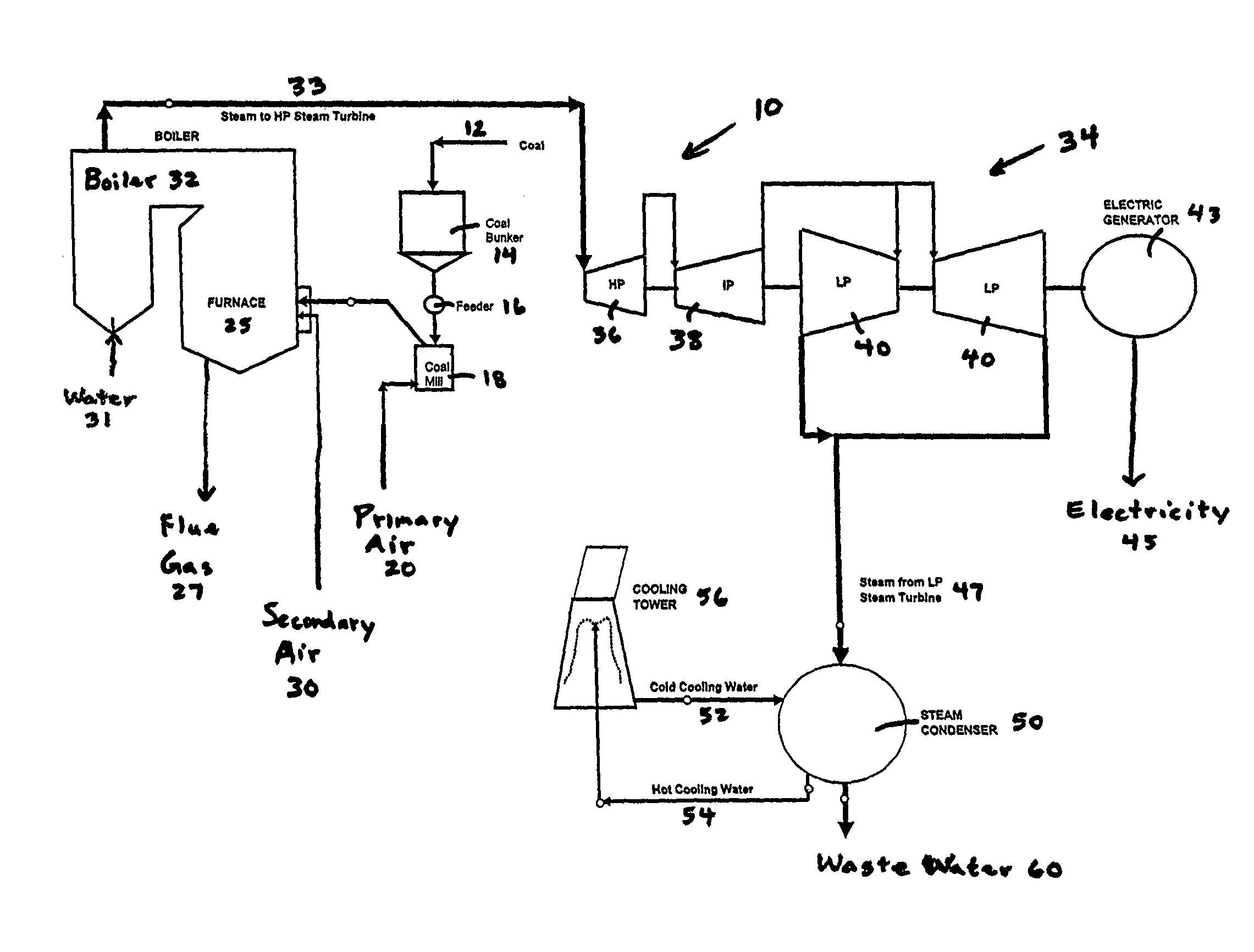

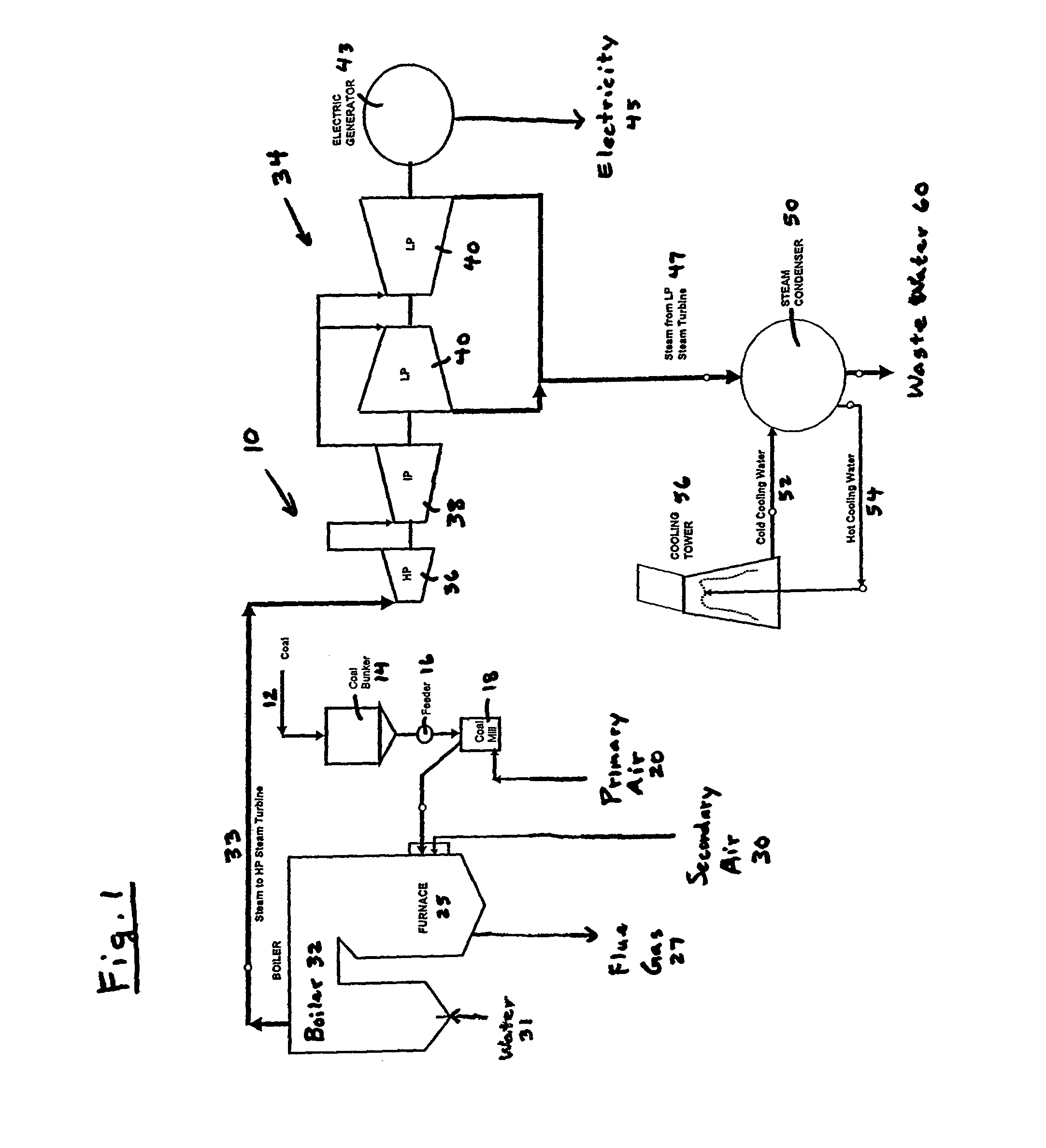

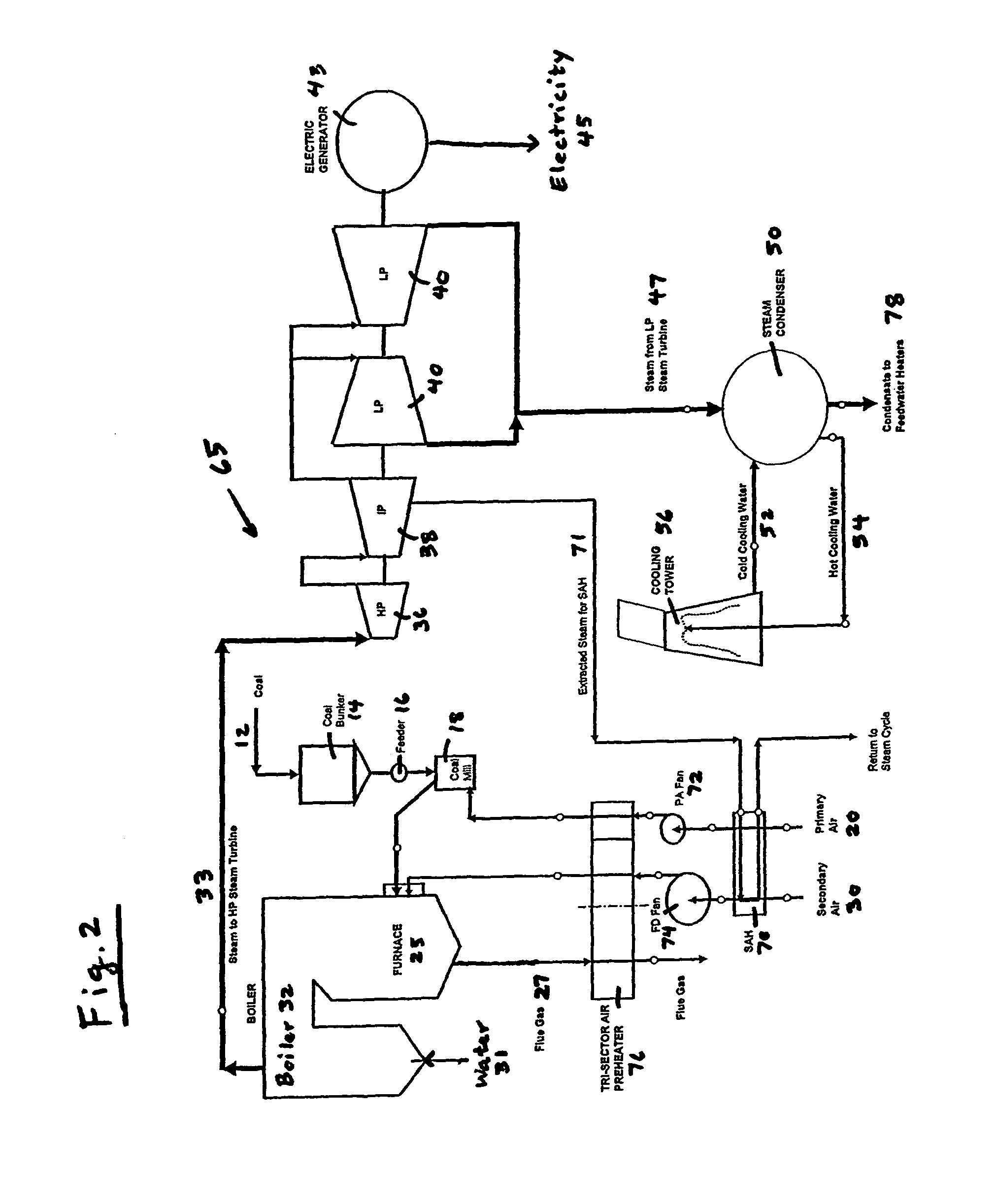

Method of enhancing the quality of high-moisture materials using system heat sources

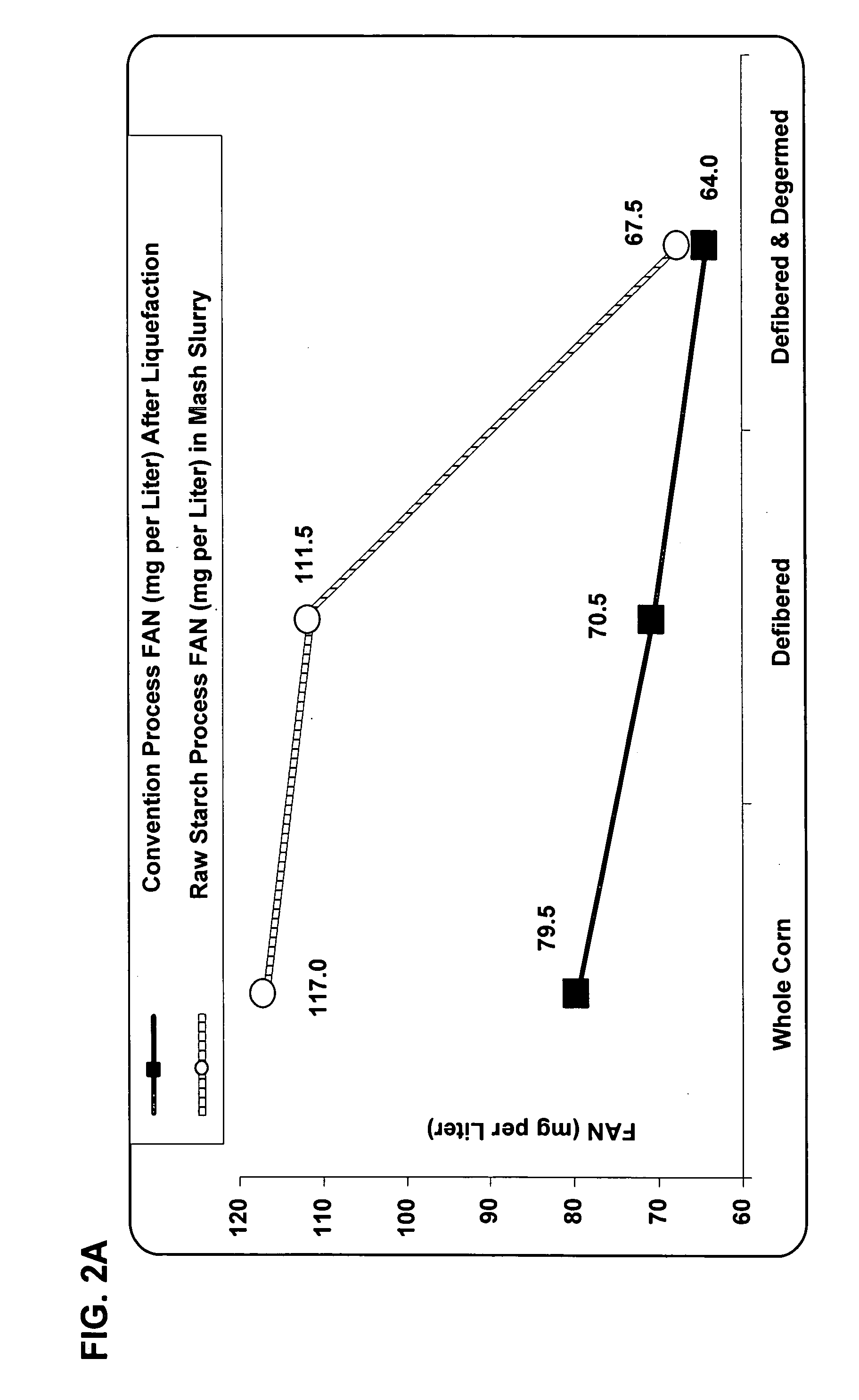

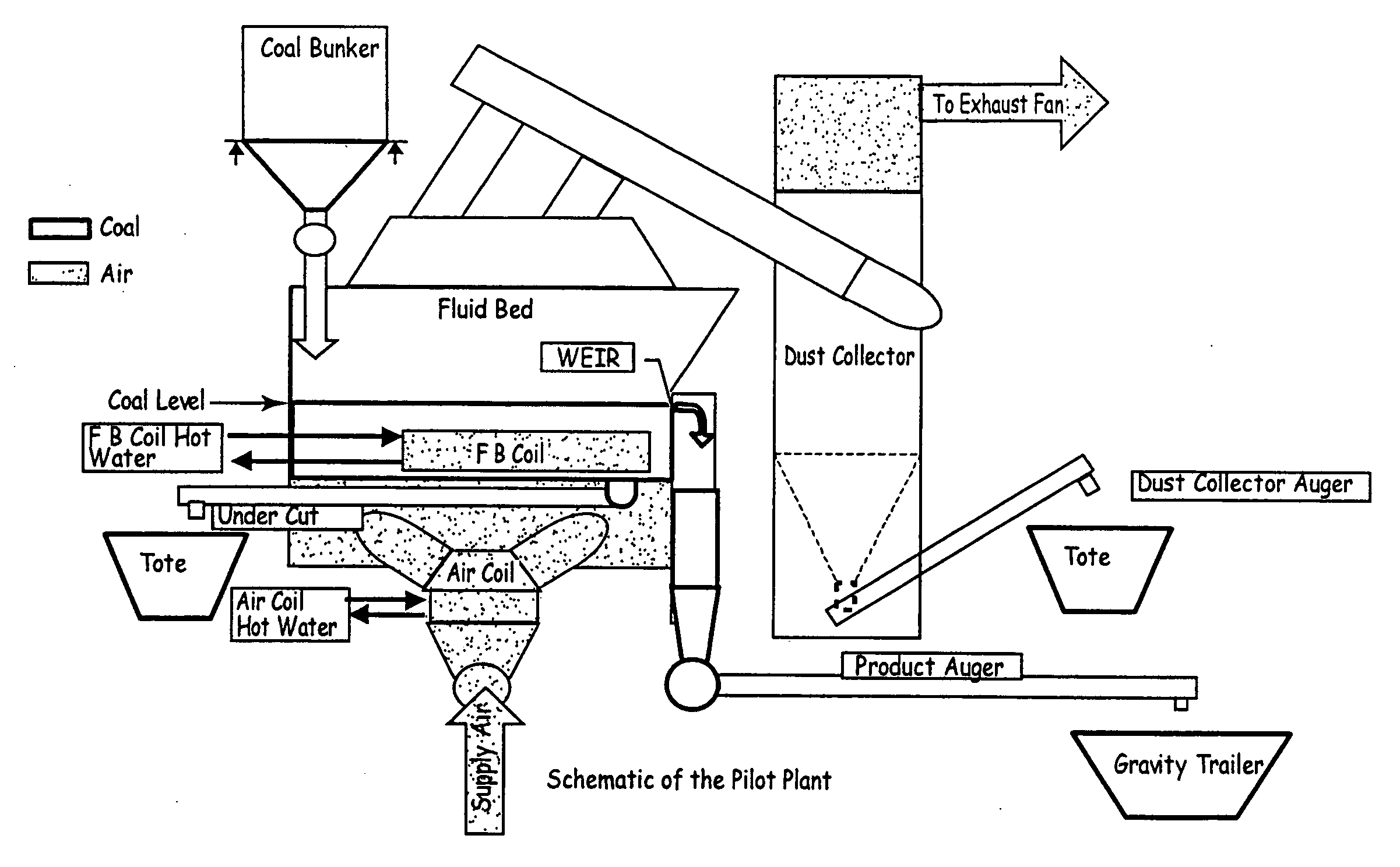

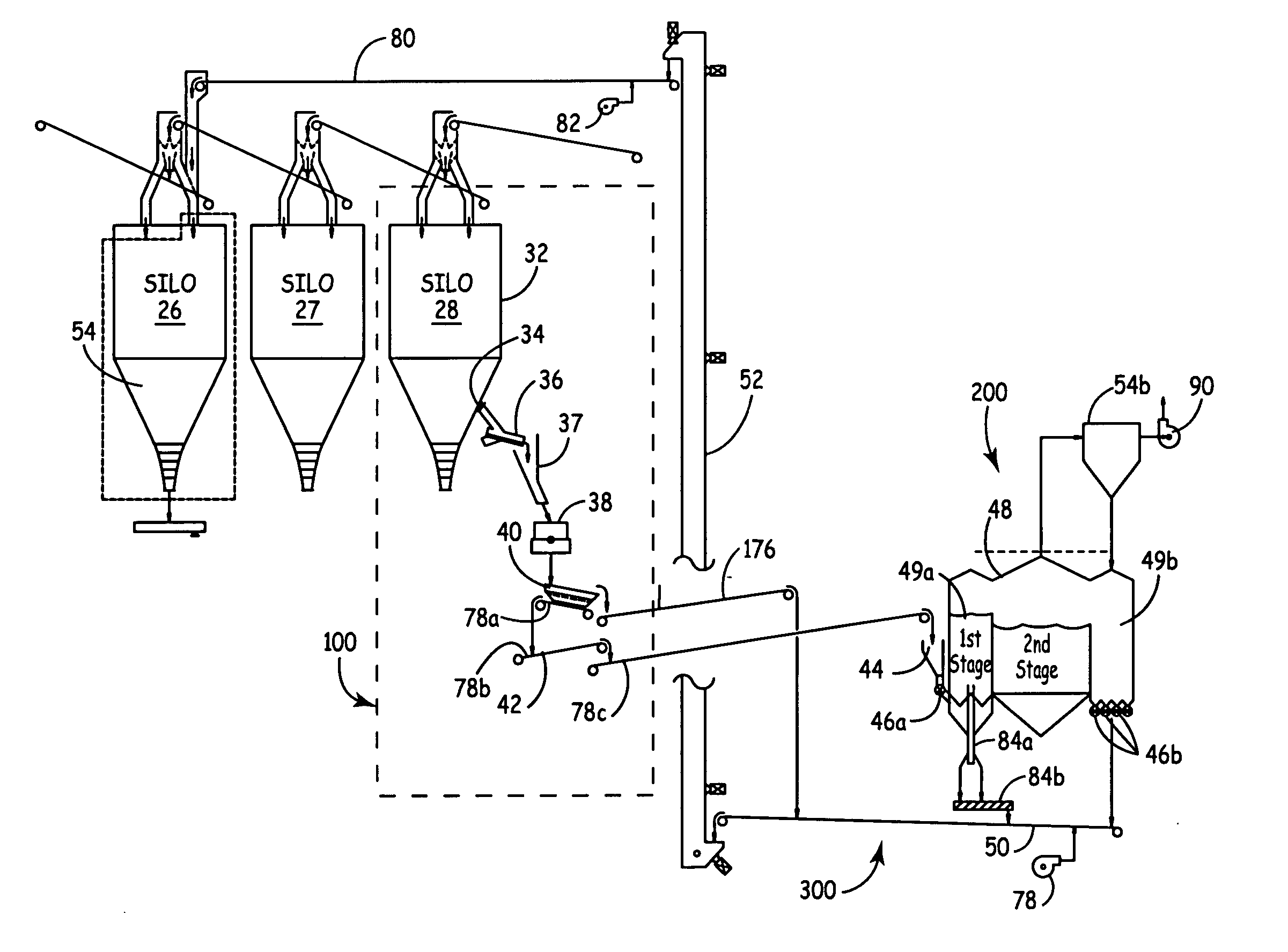

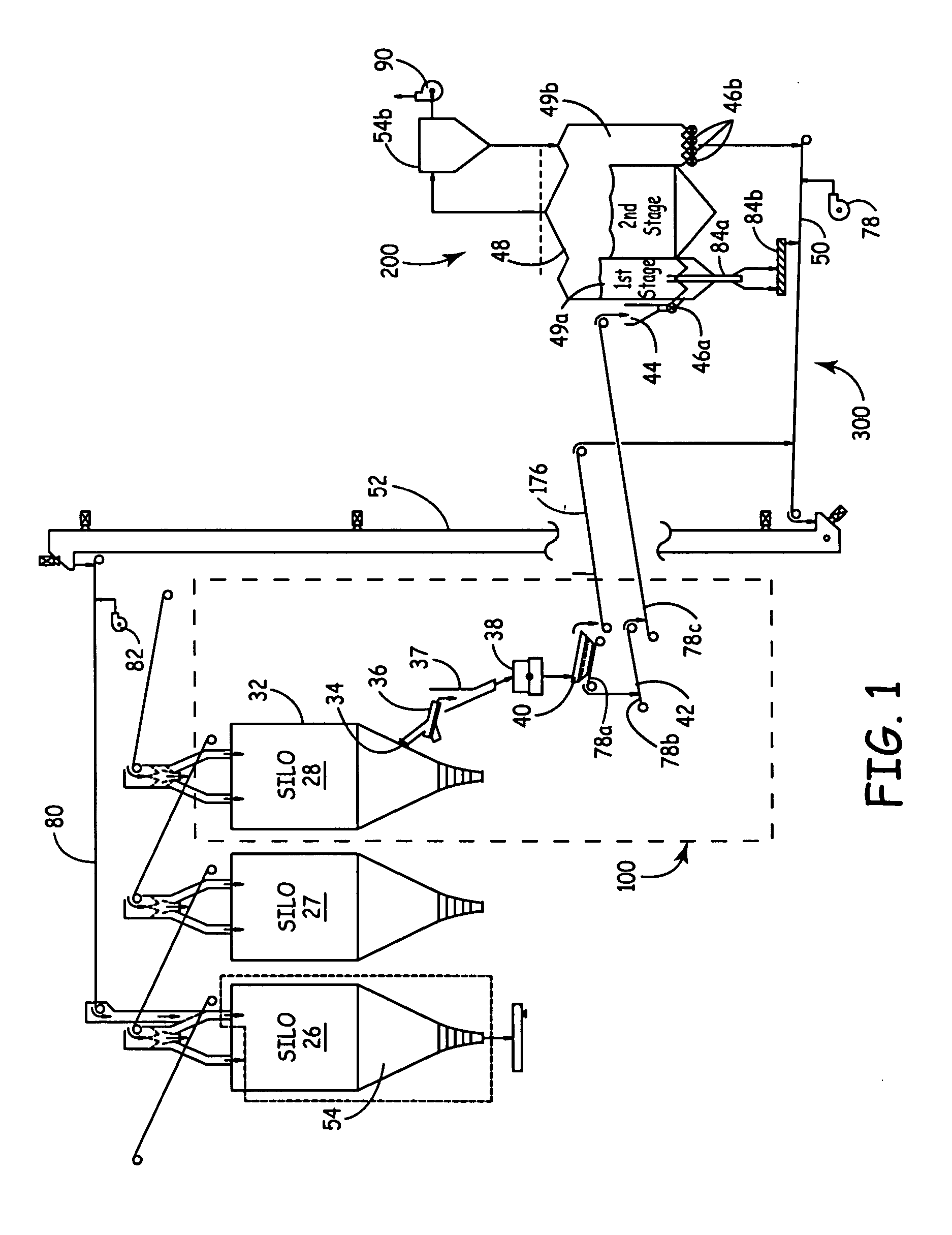

ActiveUS20060075682A1Eliminates potential harmEmission reductionDrying solid materials with heatSolid fuelsFluidized bed dryingHeat flow

The present invention harvests and utilizes fluidized bed drying technology and waste heat streams augmented by other available heat sources to dry feedstock or fuel. This method is useful in many industries, including coal-fired power plants. Coal is dried using the present invention before it goes to coal pulverizers and on to the furnace / boiler arrangement. Coal can be intercepted on current coal feed systems ahead of the pulverizers. Drying fuel, such as coal, is done to improve boiler efficiency and reduce emissions. A two-stage bed utilized in the process first “pre-dries and separates” the feed stream into desirable and undesirable feedstock. Then, it incrementally dries and segregates fluidizable and non-fluidizable material from the product stream. This is all completed in a low-temperature, open-air system. Elevation of fan room air temperature is also accomplished using waste heat, thereby making available to the plant system higher temperature media to enhance the feedstock drying process.

Owner:RAINBOW ENERGY CENT LLC

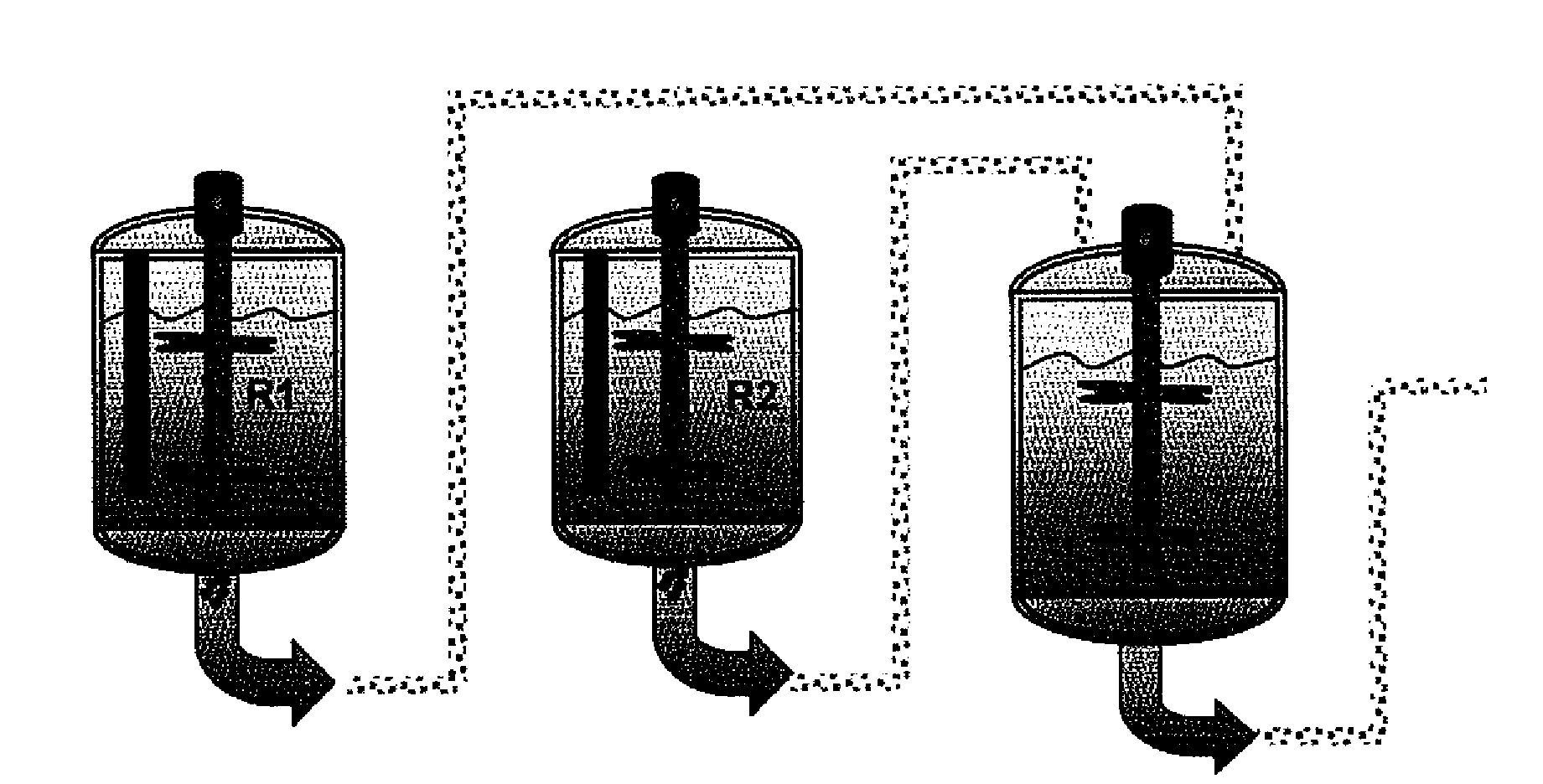

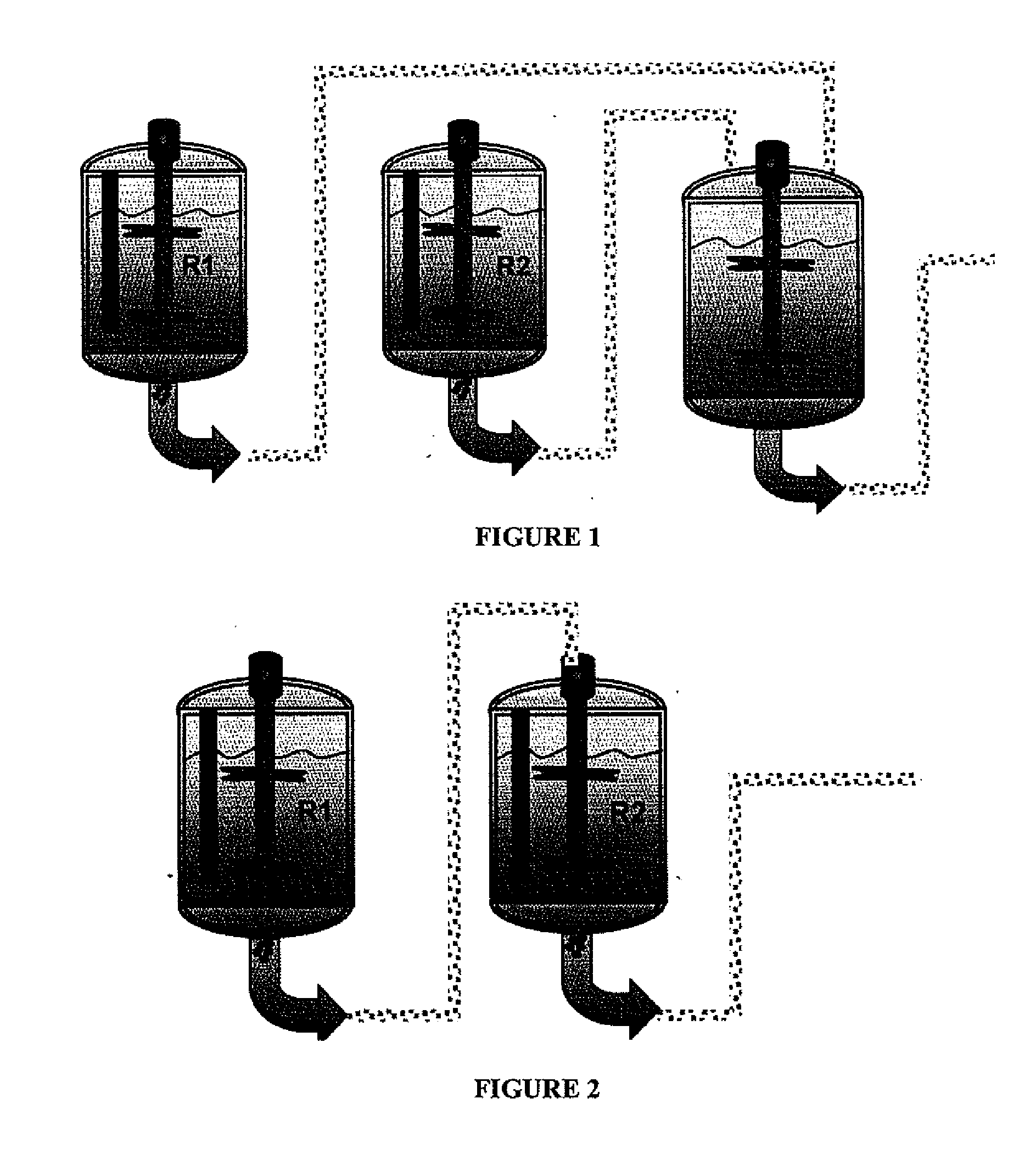

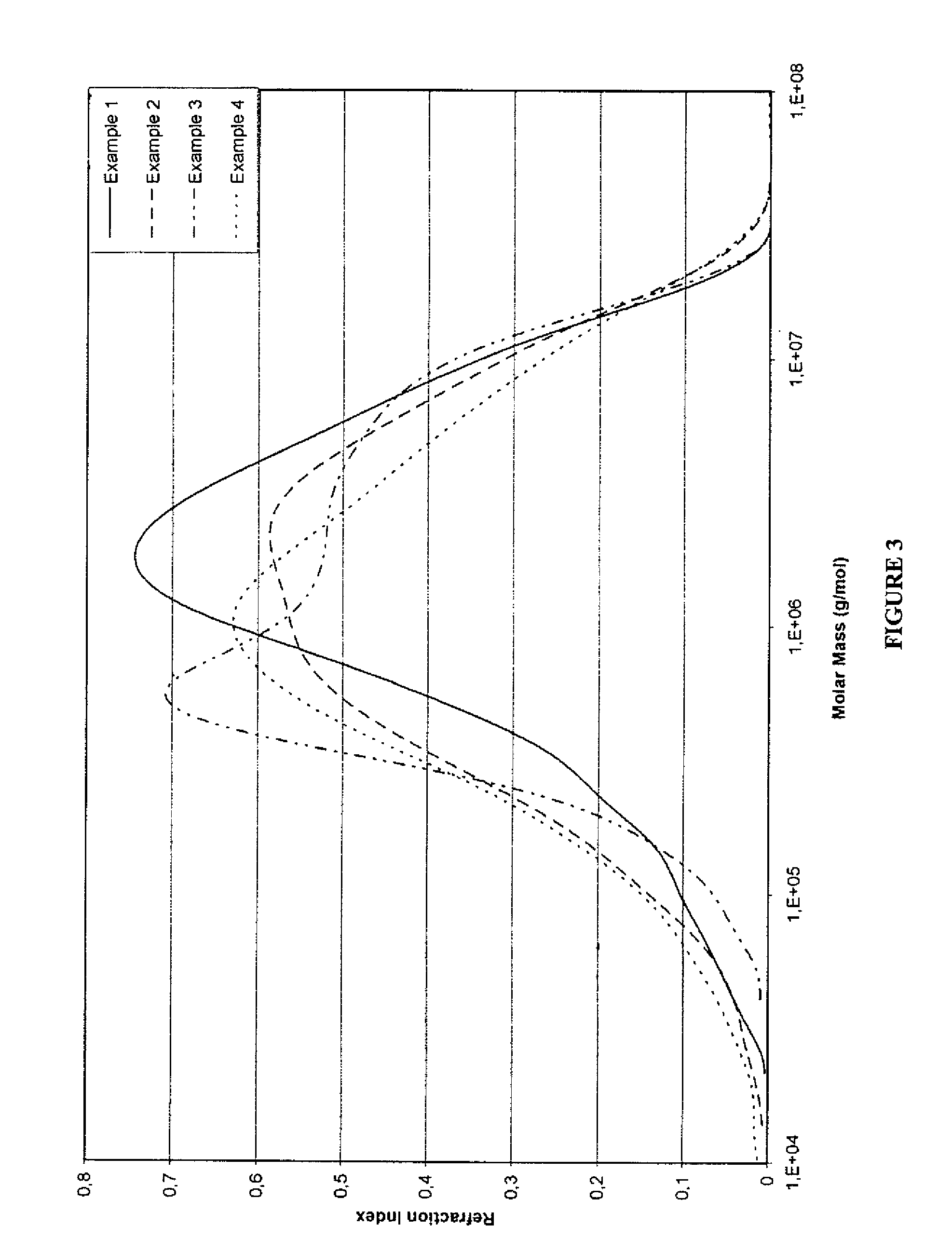

Suspension polymerization process for manufacturing ultra high molecular weight polyethylene, a multimodal ultra high molecular weight polyethylene homopolymeric or copolymeric composition, a ultra high molecular weight polyethylene, and their uses

InactiveUS20090163679A1Easy to processHigh molecular weightMonocomponent polyolefin artificial filamentFluidized bed dryingPolymer science

The present invention relates to a suspension polymerization process for the production of ultra high molecular weight polyethylene, wherein the operation is carried out in at least two reactors of the CSTR type (continuous stirring tank reactor), in a serial configuration, wherein the first reactor is fed with solvent, monomer and, optionally, comonomer; Ziegler-Natta type catalyst, said catalyst composition having a chloride concentration of at least 55%, based on its composition, and preferably more than 76%, chlorinated cocatalyst and chain growth regulator, said continuous stirring tank reactor being kept under a pressure between 0.1 to 2.0 MPa and temperature from 40° C. to 100° C., which contents of the first reactor are transferred to the subsequent reactor, by means of a pressure differential or through pumping, wherein said subsequent reactors are kept under a pressure between 0.1 to 2.0 MPa and temperature from 40° C. to 100° C., and fed with solvent, monomer, and, optionally, comonomer, catalyst, cocatalyst and chain growth regulator, the pressure and temperature in each of the reactors being different from one another up to the “nth” reactor, the number of reactors “n” varying from 2 to 4; the suspension thus obtained in reactor “n” being centrifugated for the removal of solvent and dried in a fluidized bed drier; thereby resulting in an ultra high molecular weight polyethylene homopolymeric or copolymeric composition with polydispersity greater than or equal to 6.

Owner:BRASKEM SA

Drying method of high moisture material and dryer set thereof

InactiveCN1834561AEven distribution of moisture contentReduce energy consumptionDrying solid materials with heatDrying machine combinationsThermal energyFluidized bed drying

The present invention discloses a method for drying high-wet material. Said method includes the following two steps: firstly, quickly drying high-wet material in rotary pneumatic dryer to make its water content be reduced to 25-35%, then feeding the material into fluidized bed drying machine to continuously dry said material and make its water content be less than 17%. Its drying machine unit includes rotary pneumatic dryer and fluidized bed drying machine.

Owner:王初阳

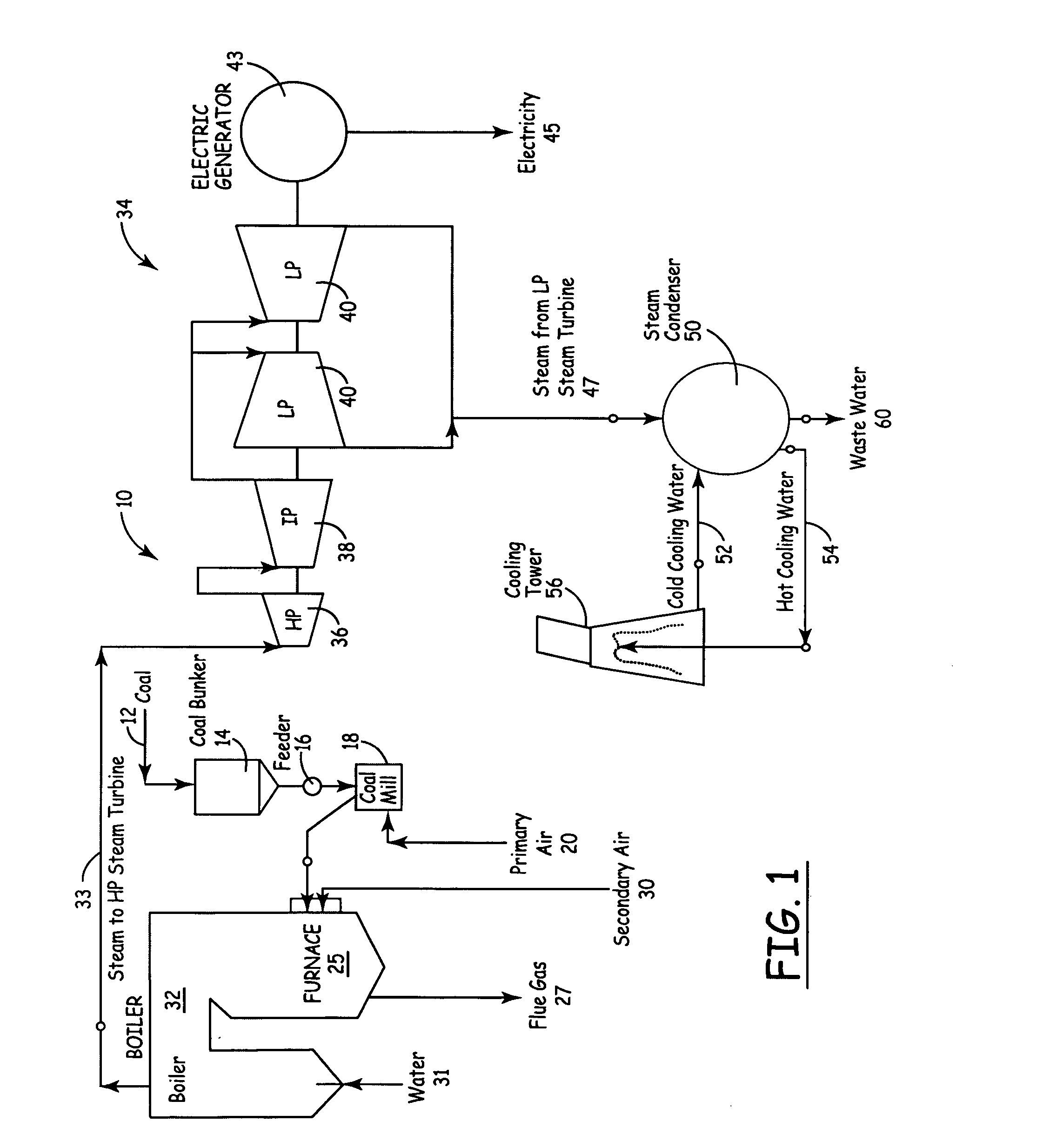

High-moisture-content lignite predrying method and system integrated with thermal power plant

InactiveCN102353237AWith drying capacityKeep dryDrying solid materials with heatFeed water supplyThermal energyFluidized bed drying

The invention discloses a high-moisture-content lignite predrying method and system integrated with a thermal power plant. In the method, lignite is dried by using hot air as a fluidizing agent and a drying medium in a fluidized bed dryer; and a heater is built in the fluidized bed dryer to supply partial heat for drying. The lignite predrying system integrated with the thermal power plant comprises the fluidized bed dryer, the heater built in the dryer, a deduster, a gas-gas heat exchanger, a gas-water heat exchanger, an air heater and a fan. According to the system, waste heat in the system and low-grade heat energy in the power plant are fully utilized to dry the lignite. By applying the method and the system disclosed by the invention, the moisture content of the lignite fed into a furnace can be reduced, the heat loss of a boiler due to exhaust gas can be reduced, and the efficiency of the lignite boiler is increased; the low-grade heat energy and waste heat resources in the thermal power plant are fully utilized, so that the consumption of high-grade energy sources in a drying process is reduced, and the power generation efficiency of a lignite power plant is increased.

Owner:XI AN JIAOTONG UNIV

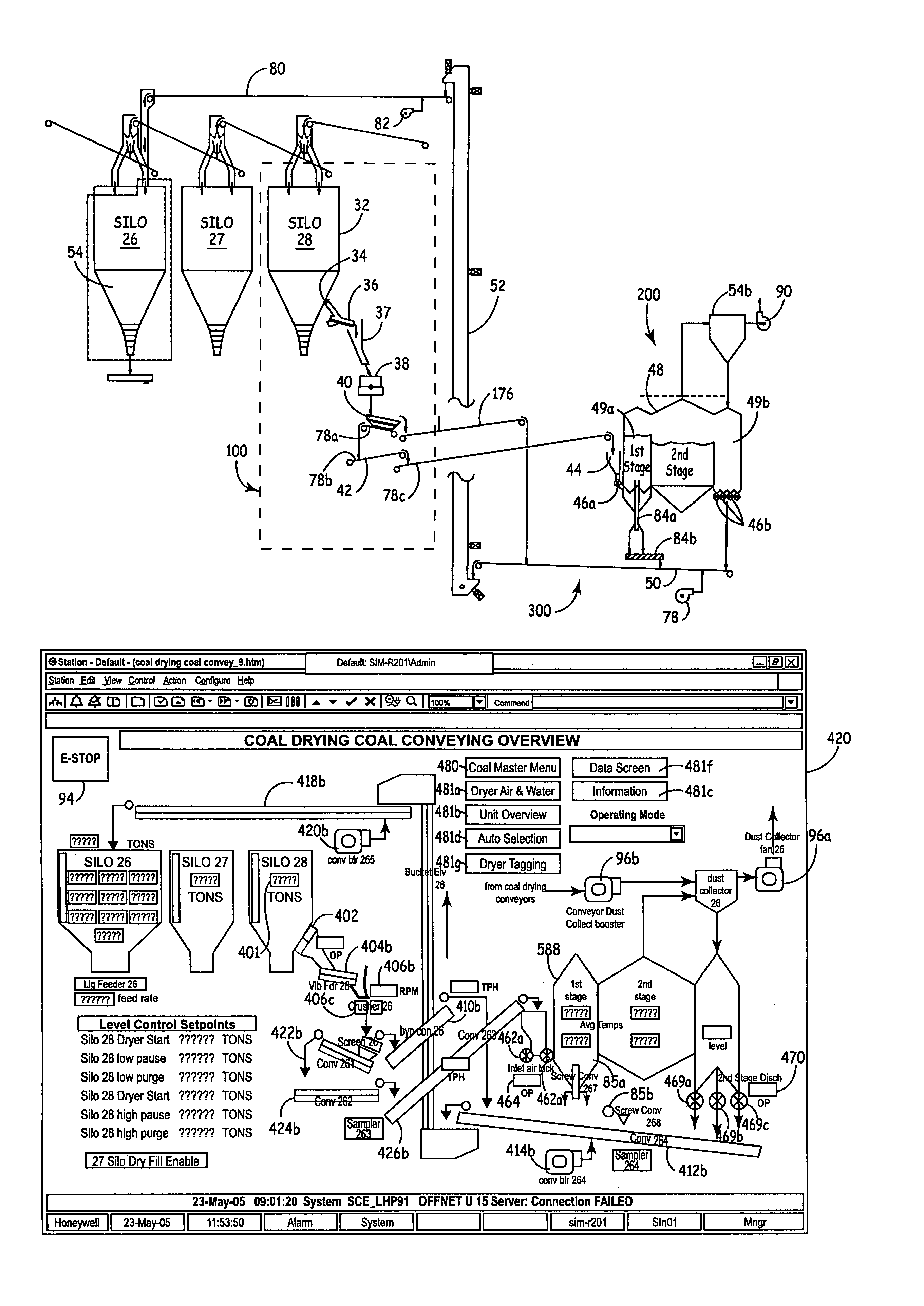

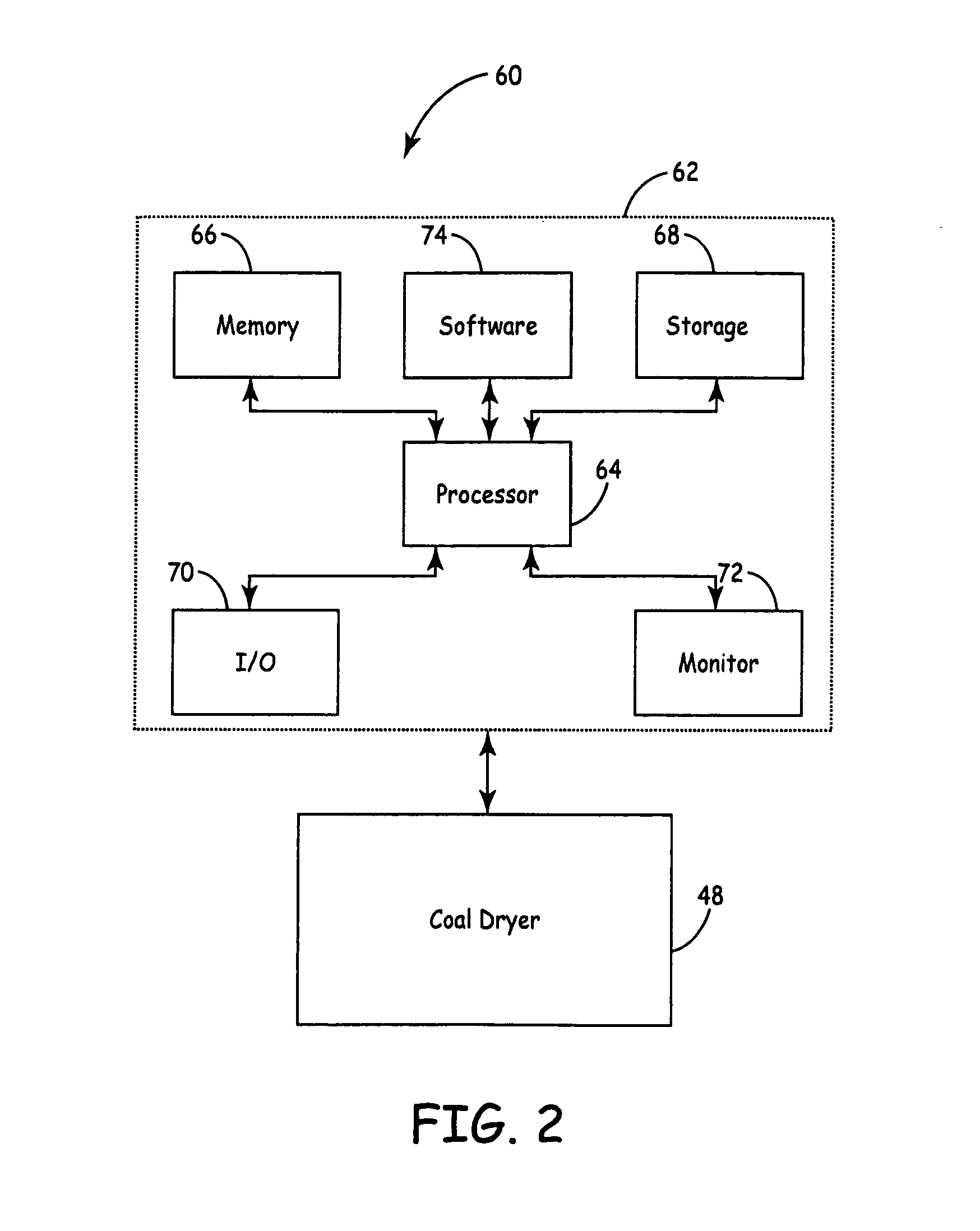

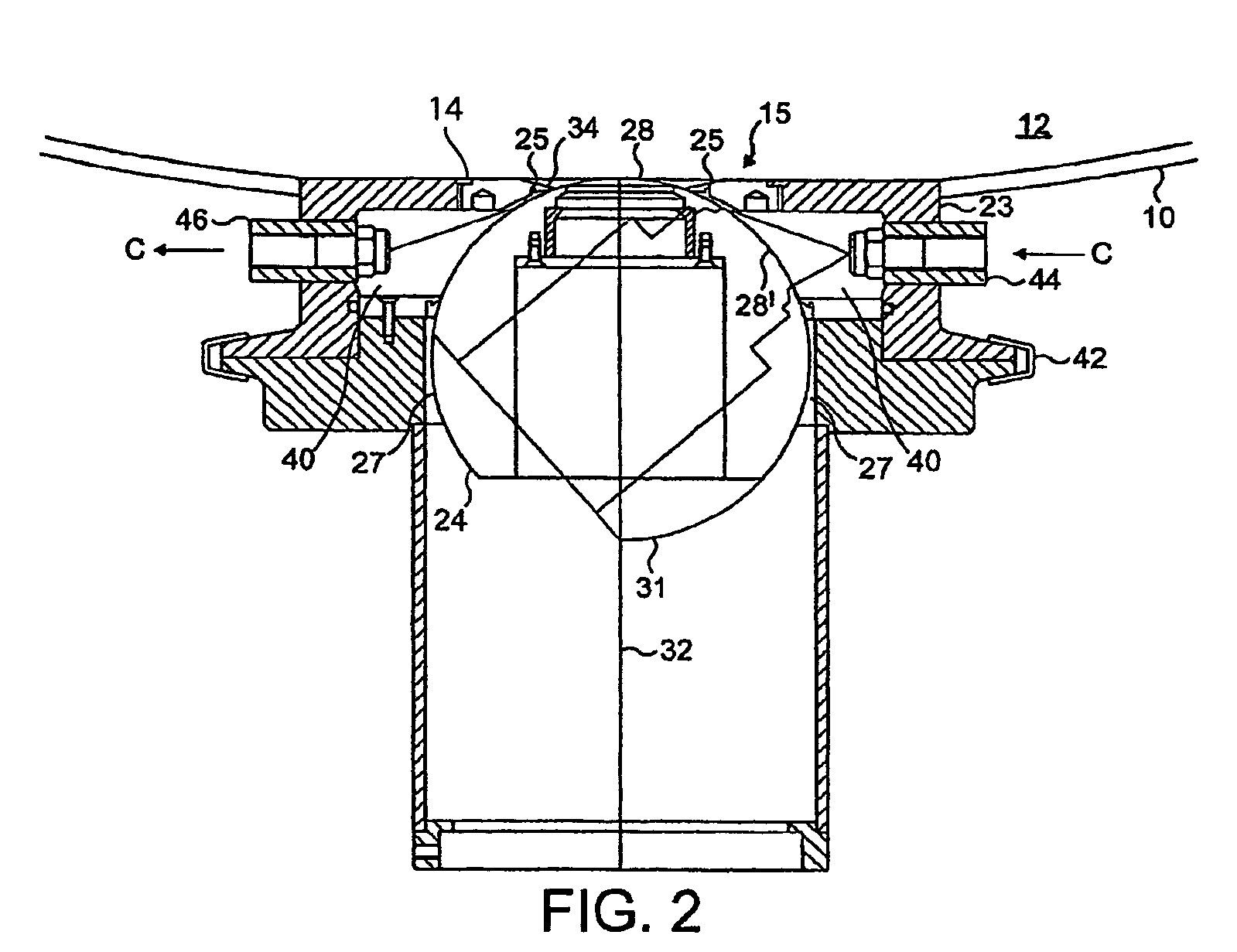

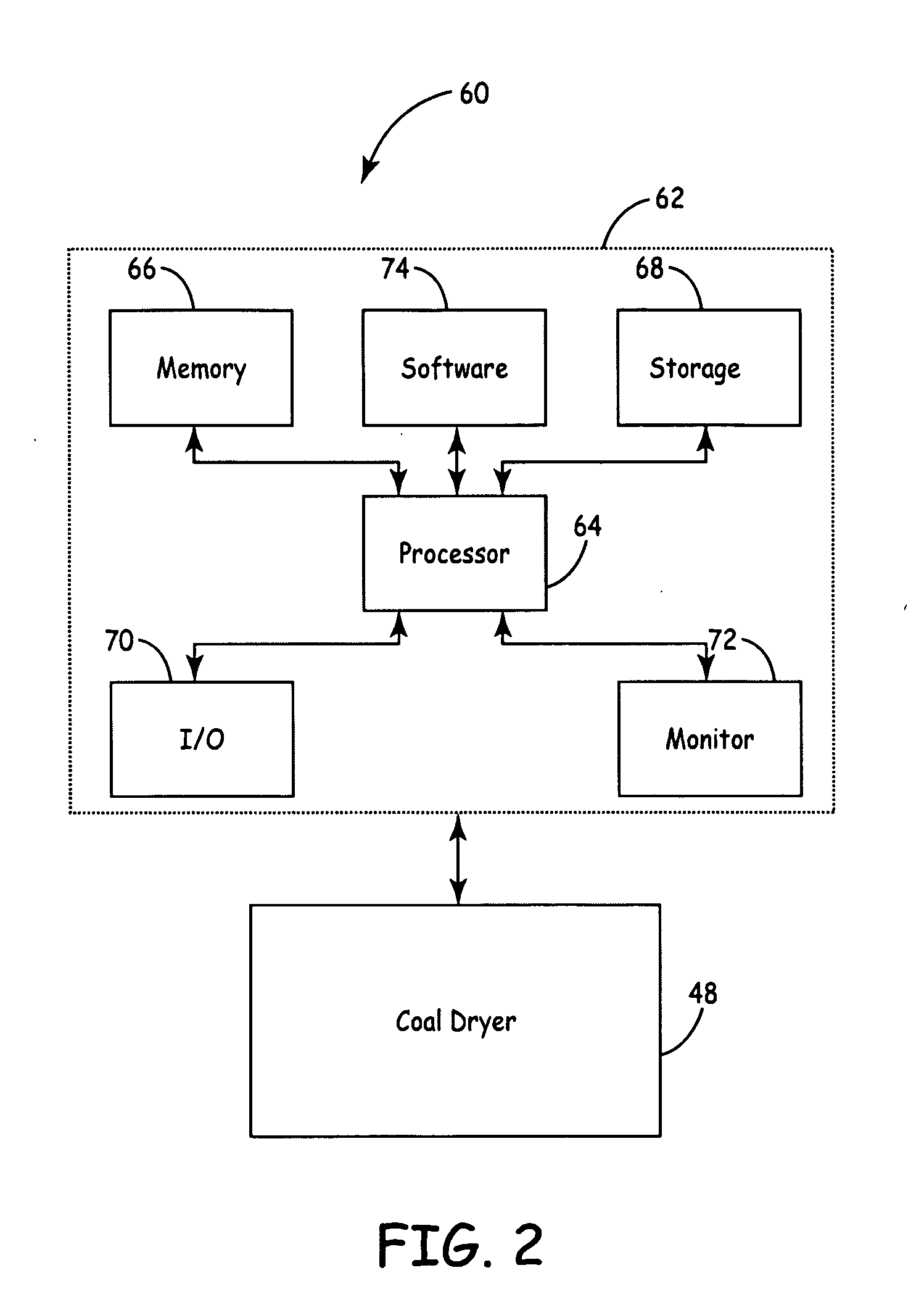

Control system for particulate material drying apparatus and process

ActiveUS7987613B2Easy to controlEasy to monitorDrying using combination processesCombustible gas coke oven heatingParticulatesFluidized bed drying

A control system for controlling the utilization of heated waste streams for fluidizing particulate matter such as coal in a fluidizing bed dryer. The control system includes a number of graphic user interfaces that allow an operator to more easily monitor and / or control the various regulator devices. The control system controls coal handling or transportation, fluid handling or flow, and the discharge of discarded or separated coal from the dryer.

Owner:RAINBOW ENERGY CENT LLC

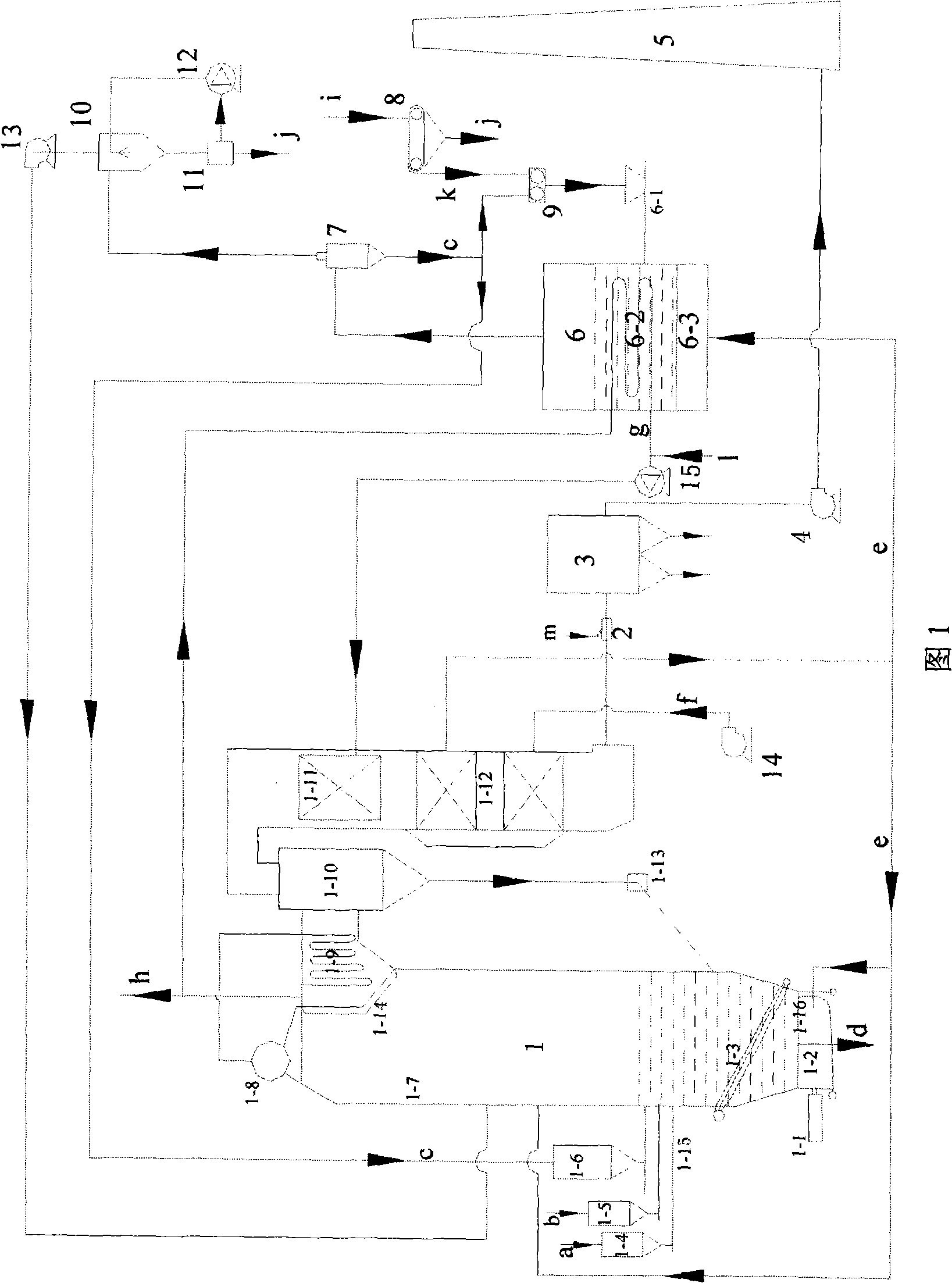

Sludge drying burning combination treatment method

ActiveCN101265008ASimple processLower the altitudeSludge treatment by de-watering/drying/thickeningIncinerator apparatusFluidized bed dryingTreatment effect

The invention relates to a sludge drying and incineration combined treatment method with good treatment effect, wide sludge adaptability, and safe and stability system. To avoid agglomeration of mechanically dewatered sludge (k) in a fluidized bed dryer (6), a part of dried sludge (c) is premixed with the mechanically dewatered sludge (k) and then fed into the fluidized bed dryer (6). The dried sludge (c) is incinerated into a circulating fluidized bed incinerator (1) to generate superheated vapor. The superheated vapor is condensed to hot water in a heat exchange tube (6-2) of the fluidized bed dryer (6) and then recycled to the circulating fluidized bed incinerator (1). The arrangement of buried pipes (1-3) and fractional air supply inside the circulating fluidized bed incinerator (1) can effectively control the lower temperature of the circulating fluidized bed incinerator (1) to prevent deflagration of dried sludge. The entire system has no emission of pollutants such as unpleasant odor, acidic gases, heavy metals and dioxin; is safe and reliable; and can operate for a long time.

Owner:JIANGSU JINSHAN SOLID WASTE RESOURCE TECH

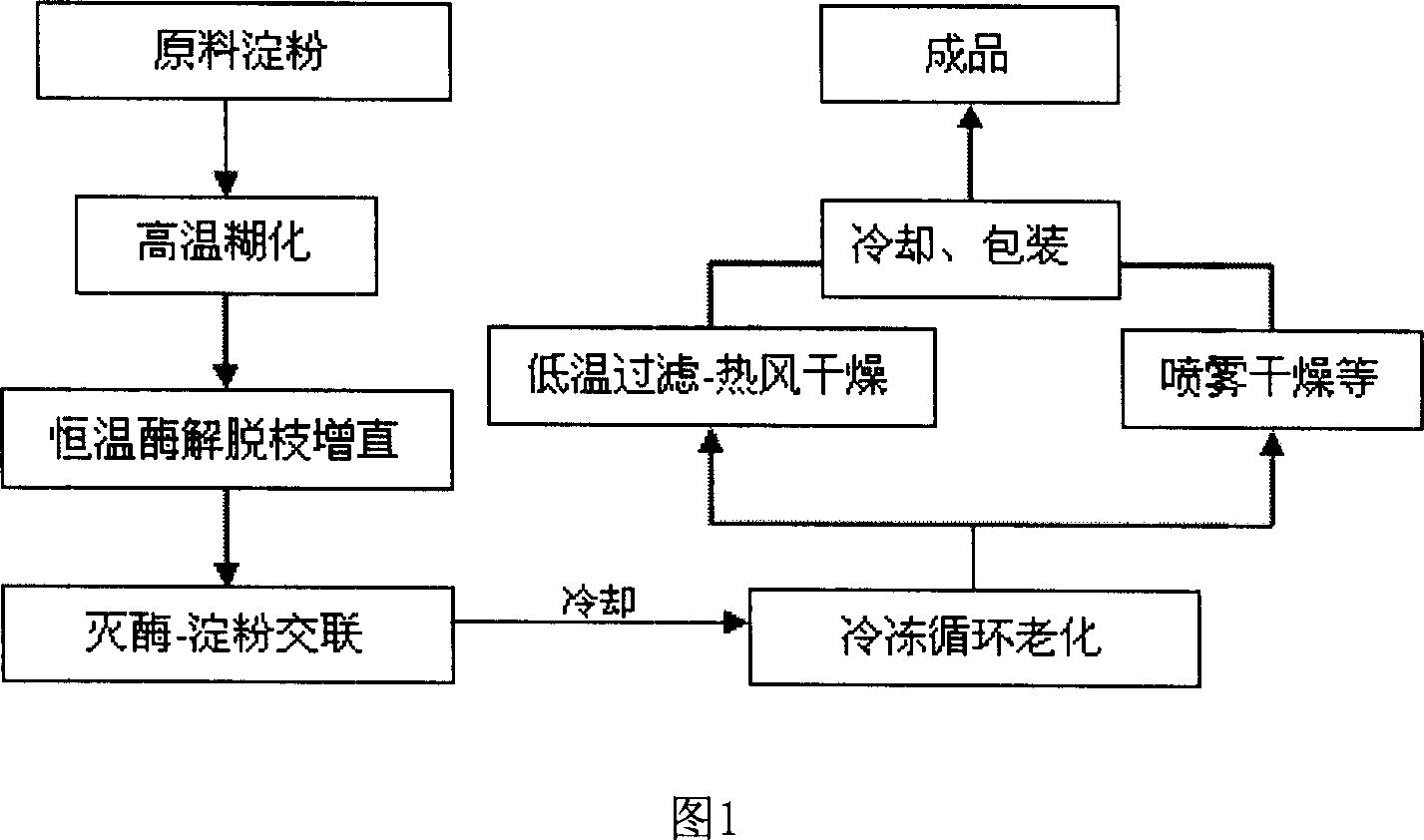

Method for promoting resistant starch content of starch

The invention discloses an improving method of resistant starch content, which is characterized by the following: adopting starch of straigt-chain starch with content more than 10% as raw material; allocating 3%-25% starch magma; gelatinizing over 78 deg. c; decomposing starch to form multiple straight-chain starch through proflavine enzyme or degrafting hydrolytic starch enzyme; using acid environment with pH value at 3. 5-6. 5 and second and third carboxylic acid functional groups of citrate to crosslink; setting the density of functional group ion at 1%-15% corresponding to starch density; adopting circulating aging technique for 3-4 times under icy point; spraying to dry starch magma; drying in the cylinder and fluid bed; filtering; drying through hot wind.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

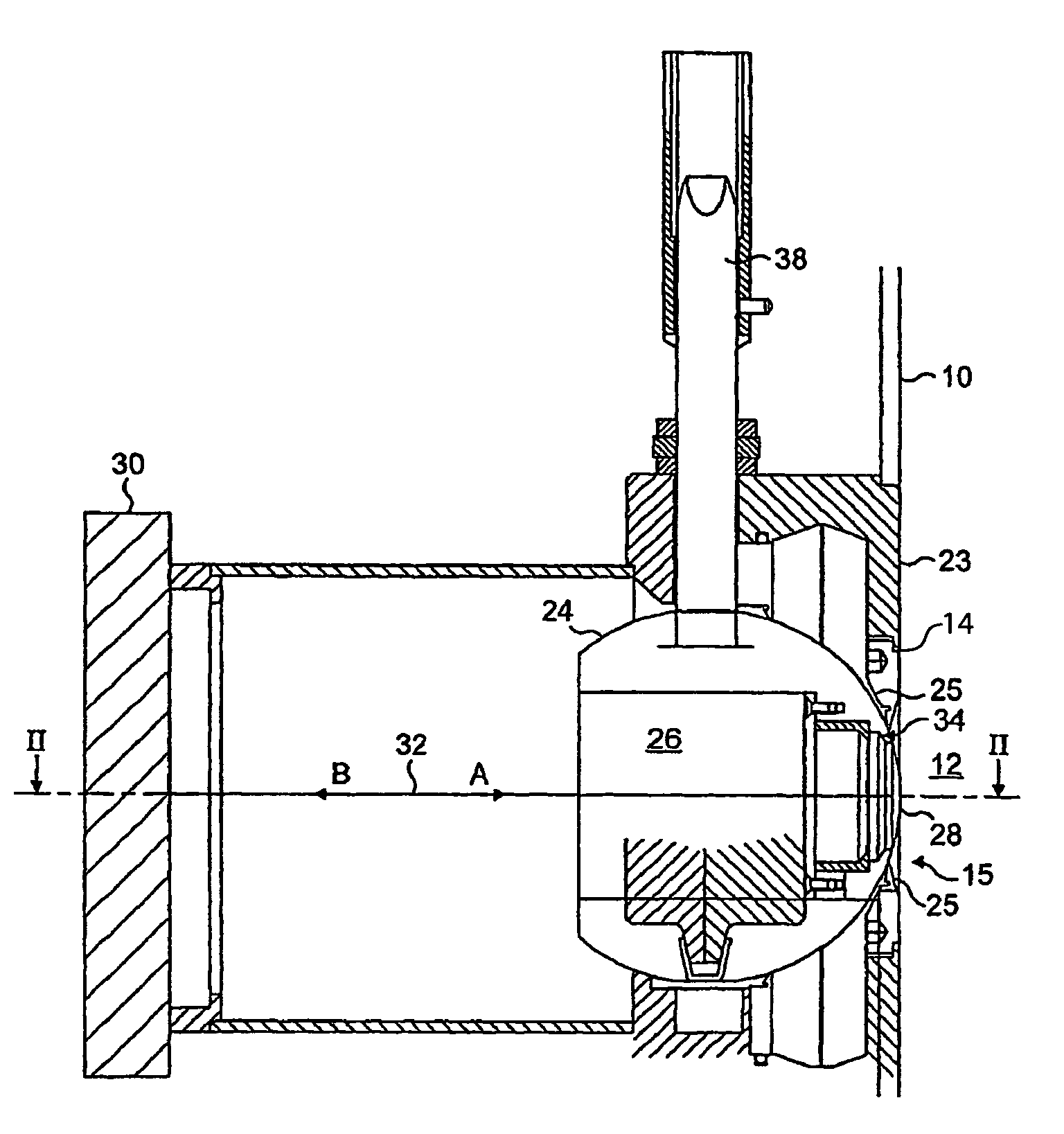

Optical window for monitoring samples

InactiveUS7145145B2Radiation pyrometryMaterial analysis by optical meansFluidized bed dryingMaterials processing

Owner:NORDSON CORP

Infant nutrition immunity formula milk powder and method of preparing the same

InactiveCN101278688APromote complexationPromote absorptionMilk preparationMilk preservationFluidized bed dryingNervous system

The invention relates to an infant nutrition immunity formula powdered milk and a production method thereof, wherein, the production method of the infant nutrition immunity formula powdered milk comprises the following steps: milk which is raw material, is preprocessed, the mixed solution of docosahexaenoic acid and arachidonic acid is prepared, ingredients are mixed, preheating, homogenizing and heating are carried out for sterilizing, decompression is carried out for concentrating, and spray-drying under negative pressure and low temperature and drying on a fluidized bed are carried out, then cooling, packing and inspecting are carried out. The infant nutrition immunity formula powdered milk manufactured by the method of the invention mainly comprises casein phosphoeptide, vitamin D3, lactoferrin, nucleotide, linoleic acid, linolenic acid, the docosahexaenoic acid, the arachidonic acid, fructo-oligosaccharide and galacto-oligosaccharide, which has the advantage of reasonable trophic structure and also ensures that various nutrient substance to be absorbed and deposited to the utmost extend, so as to promote the development of brain and nervous system, improve active immunity, improve intestinal tract micro-ecological environment and strengthen the absorption of calcium, iron and zinc as well as effectively maintain every active nutrient component during the production process.

Owner:AUSTRALIA DIVINE DAIRY

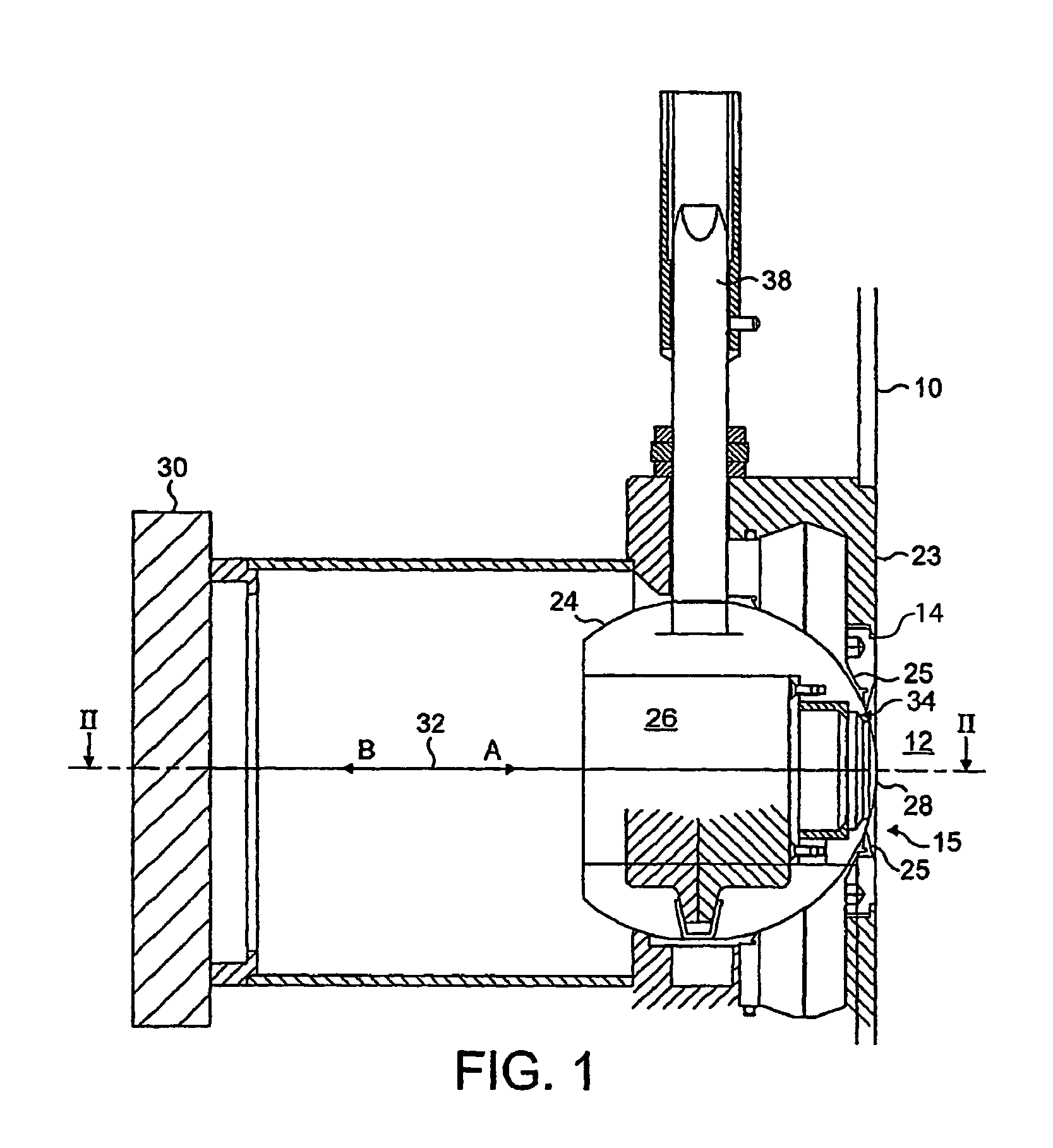

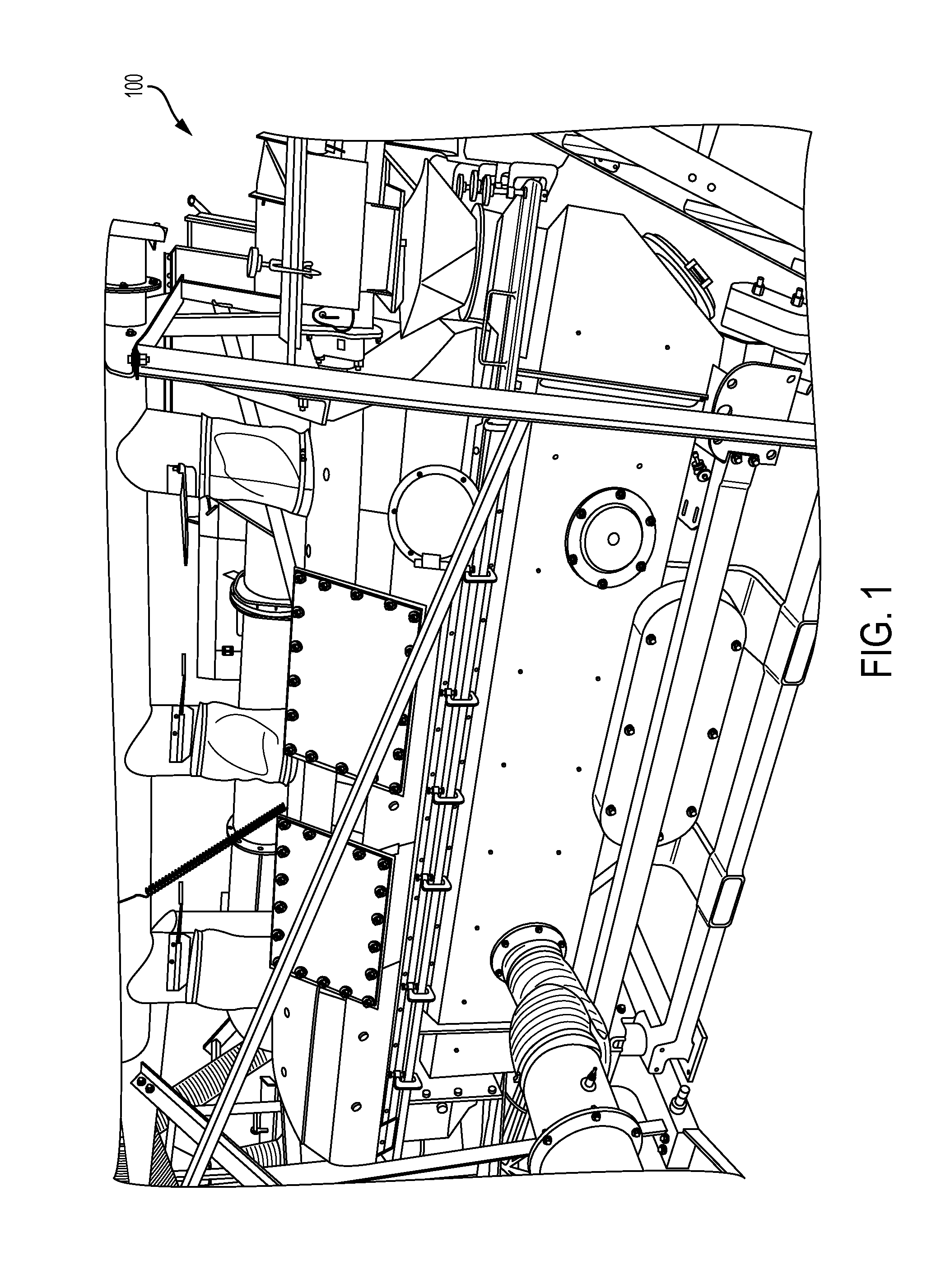

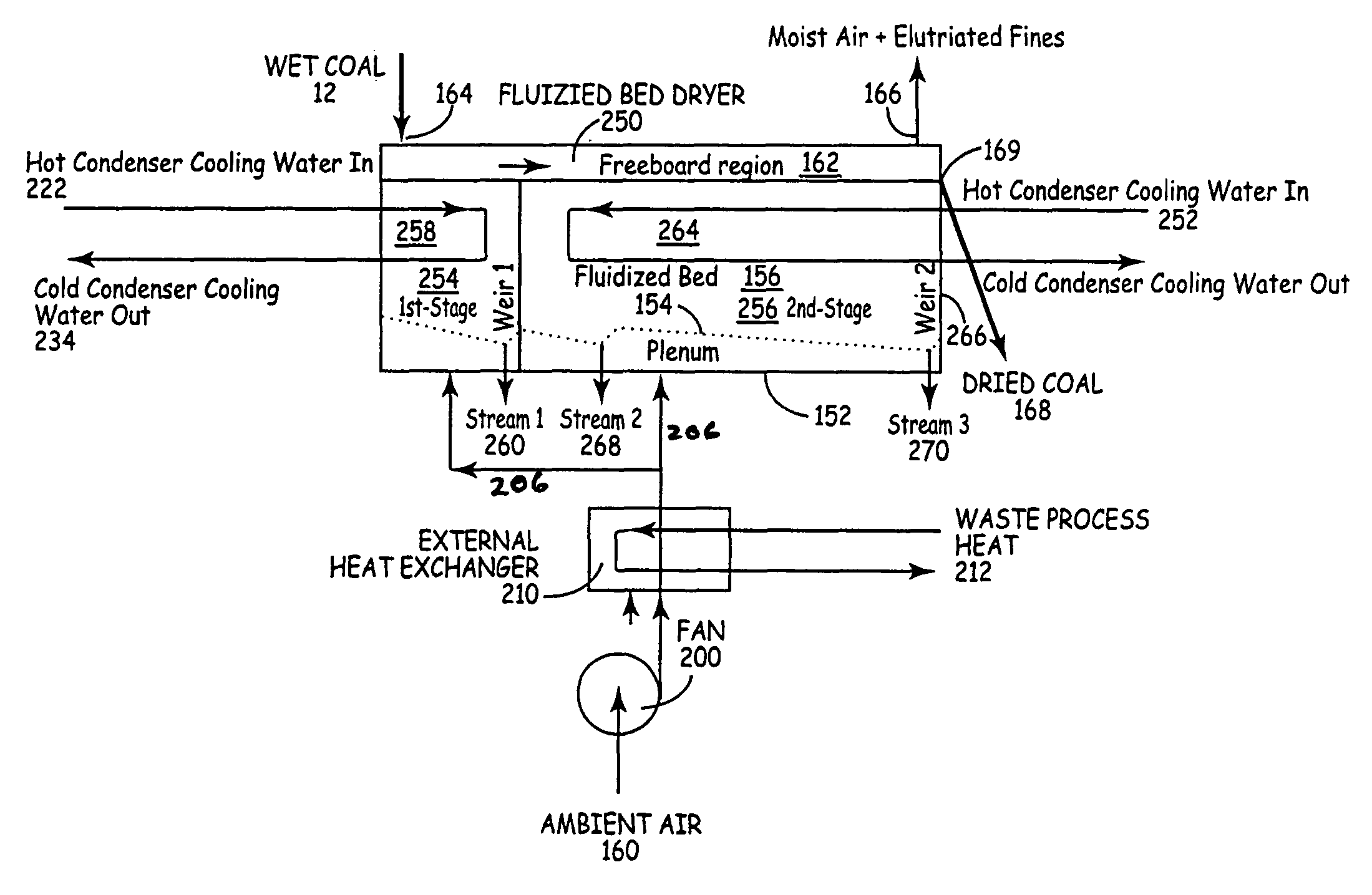

Apparatus for heat treatment of particulate materials

ActiveUS20060107587A1Reduce operating costsIncrease dryer efficiencyDrying solid materials with heatSolid fuelsParticulatesFluidized bed drying

The present invention constitutes a heat treatment apparatus like a fluidized-bed dryer for heat treating a particulate material in a low temperature, open-air process. Preferably, available waste heat sources within the surrounding industrial plan operation are used to provide heat to the dryer. Moreover, conveyor means contained within the dryer can remove larger, denser particles that could otherwise impede the continuous flow of the particulate material through the dryer or plug the fluidizing dryer. This invention is especially useful for drying coal for an electricity generation plant.

Owner:RAINBOW ENERGY CENT LLC

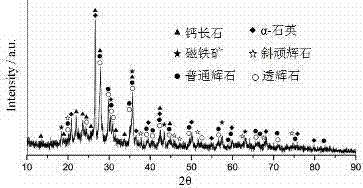

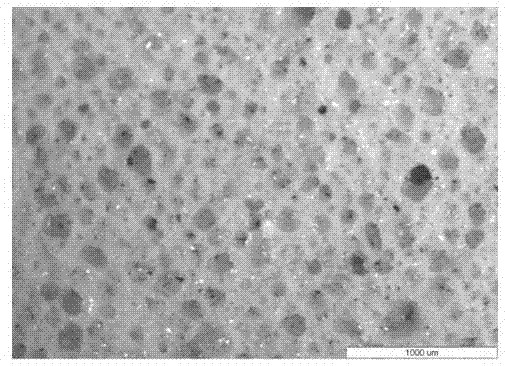

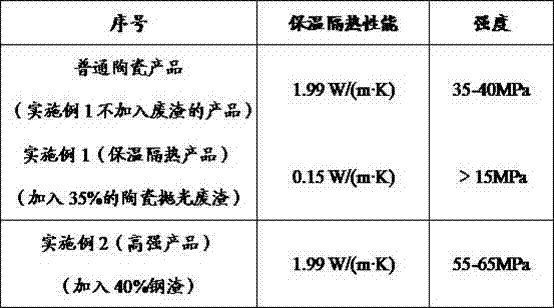

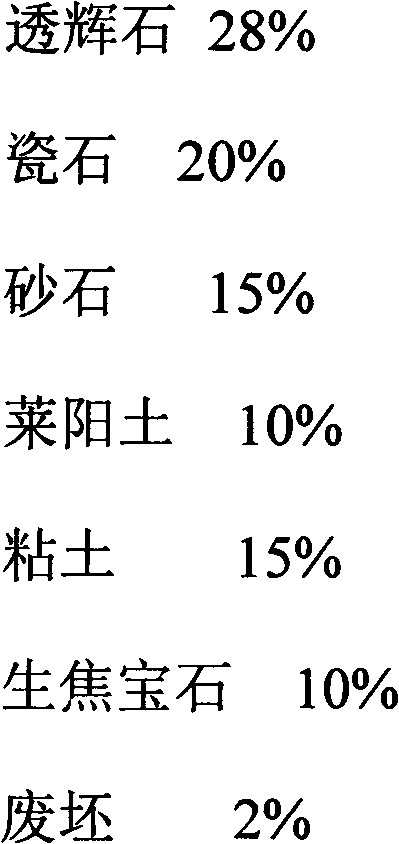

Architectural ceramic prepared from industrial solid waste through dry method and process for preparing architectural ceramic

ActiveCN103570340AReduce the cost of degummingSave the drying processCeramic materials productionClaywaresFluidized bed dryingThermal insulation

The invention discloses architectural ceramic prepared from industrial solid waste through a dry method and a process for preparing the architectural ceramic. The architectural ceramic comprises the following components in percentage by mass: 30-60% of solid waste, 40-70% of ceramic raw material and 1-3% of ceramic additive, wherein the ceramic raw material is selected from one or a composition of multiple of clay raw material, feldspar raw material or talc, and the ceramic additive is one or a combination of multiple of sodium tripolyphosphate, sodium silicate, ammonium chloride, ammonium citrate, sodium humate, sodium lignin sulfonate sodium, ethylenediamine tetraacetic acid disodium and edetic acid. After being pretreated, the granules of the solid waste are fine and are mixed evenly in a dry mixing manner and a spray drying manner and are directly used for pressing of green bricks or stored in a bin for standby, so that the ball milling energy consumption and the peptization cost are reduced, the humidification pelleting and fluidized bed drying procedures are omitted, the formula can be quickly adjusted according to the functional characteristics of the architectural ceramic, the process is simple and convenient to control, and the architectural ceramic has such good properties as heat preservation, thermal insulation and high strength.

Owner:FOSHAN OCEANO CERAMICS +1

Novel production method for glutamic acid

ActiveCN102703537AReduce lossesLess waste waterOrganic compound preparationMicroorganism based processesHigh concentrationFluidized bed drying

The invention discloses a novel production method for glutamic acid, belonging to the technical field of the production of amino acid. The novel production method for the glutamic acid comprises the following steps of: removing thalli and insolubles by means of high-speed disc separation; evaporating and concentrating separated glutamic acid material liquid through a multi-effect plate type evaporator at low temperature, wherein the generated secondary steam condensed water is used for fermentation ingredients of the glutamic acid; performing continuous isoelectric extraction on the glutamic acid in the evaporated glutamic acid concentrated solution; absorbing the glutamic acid by making supernatant fluid pass through ion exchange columns; performing isoelectric reextraction on the analyzed glutamic acid; inputting high-concentration wastewater into a fertilizer workshop for producing fertilizer; squeezing heavy phase (mycoprotein) through a plate frame, and granulating; and drying through a fluid bed, and thus producing high-protein feed. The novel production method for the glutamic acid has the advantages of low unit consumption of liquid ammonia and sulfuric acid, high extraction yield of the glutamic acid, less ion exchange investment and the like; and meanwhile, the purity of the extracted glutamic acid is high, sodium glutamate can be produced without crystalloblast, resources are fully used in the whole process, the aims of energy conservation and consumption reduction are achieved, and the novel production method for the glutamic acid has a wide application prospect.

Owner:HULUNBEIER NORTHEAST FUFENG BIOTECHNOLOGIES CO LTD

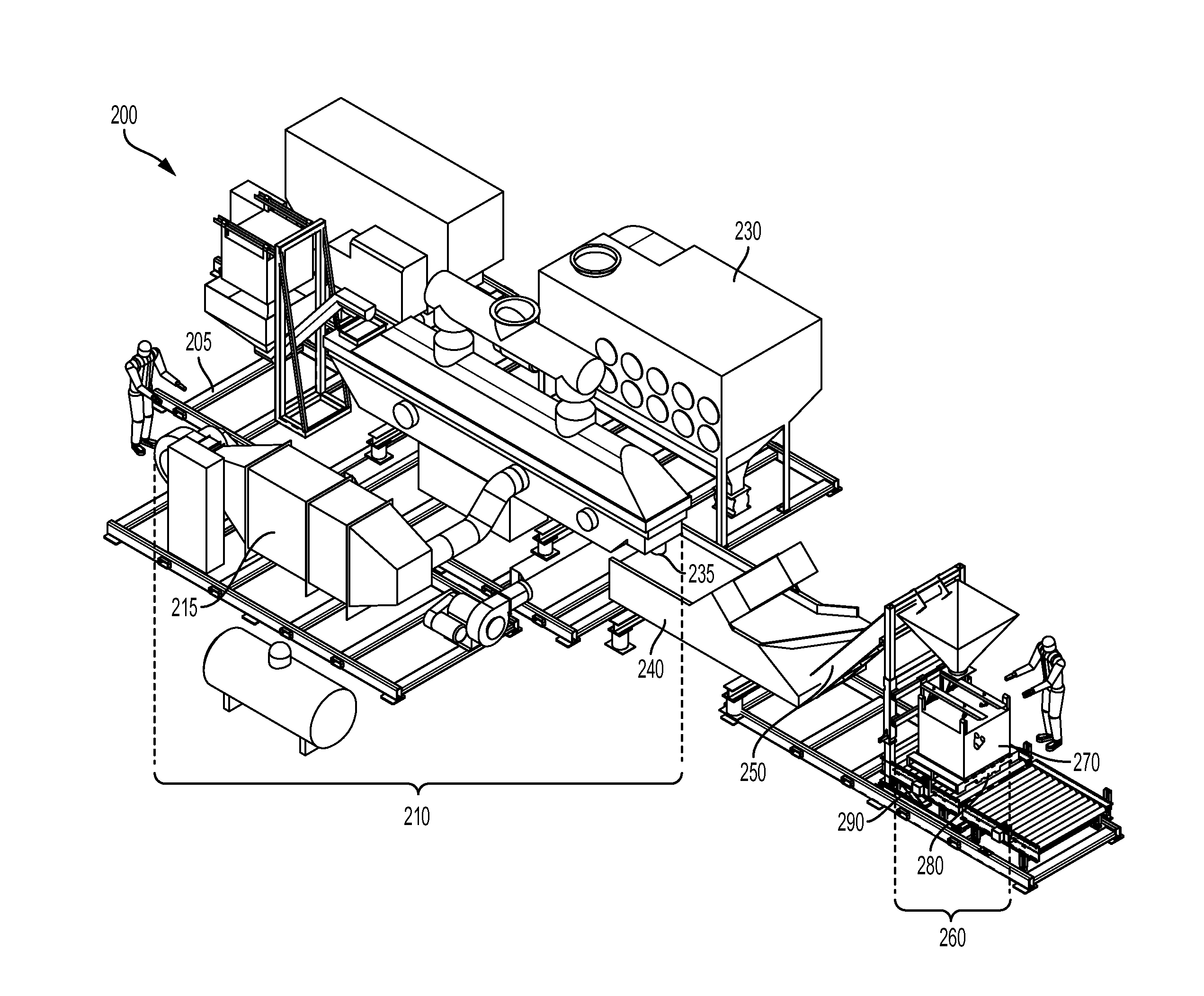

Method and system for processing and recycling infill material of artificial turf

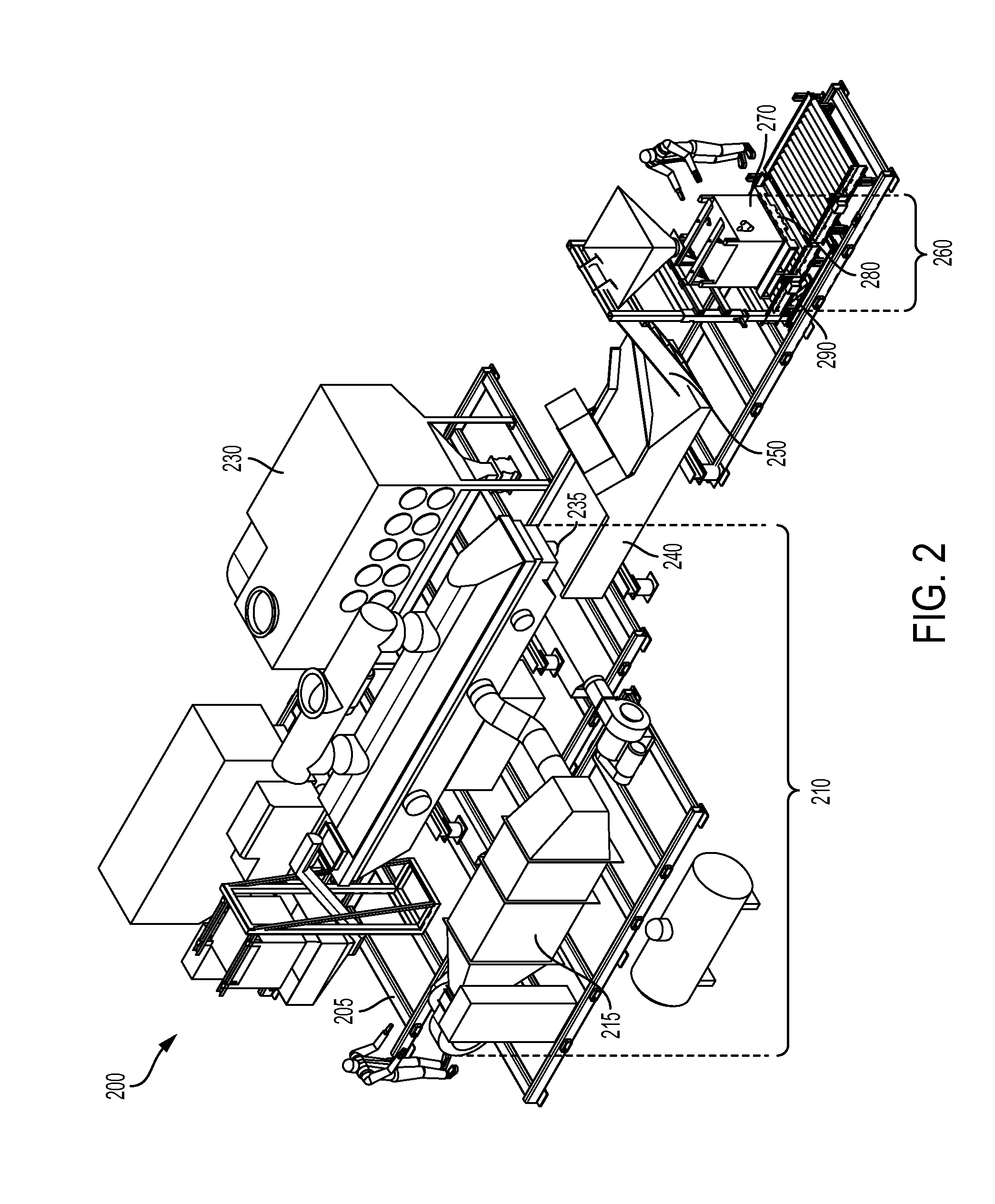

ActiveUS20150209830A1High strengthEasy to set upDrying solid materials with heatGas current separationFluidized bed dryingEngineering

A method and system for processing and recycling infill material of artificial turf. The invention includes drying extracted infill material through a fluid bed dryer, the fluid bed dryer passes a process gas through a bed of solids via a perforated plate. The dried infill material is processed using a plurality of vibrating screens to remove excessively large or small particles from the infill material. The plurality of vibrating screens may be a set of progressively finer mesh screens. The processed infill material is separated by density. The density of the infill material may be determined by a high intensity, uniform sheet of laminar airflow. The separated infill material is discharged and is ready to be used again in another artificial turf. In one embodiment, the infill material includes at least one of graded sand, granulated styrene-butadiene rubber, cork, organic infill, thermoplastic elastomers, or ethylene propylene diene monomers.

Owner:TARKETT INC

Control system for particulate material drying apparatus and process

ActiveUS20060112588A1Maximize productionMaximize efficiencyCombustible gas coke oven heatingDrying solid materials with heatParticulatesFluidized bed drying

A control system for controlling the utilization of heated waste streams for fluidizing particulate matter such as coal in a fluidizing bed dryer. The control system includes a number of graphic user interfaces that allow an operator to more easily monitor and / or control the various regulator devices. The control system controls coal handling or transportation, fluid handling or flow, and the discharge of discarded or separated coal from the dryer.

Owner:RAINBOW ENERGY CENT LLC

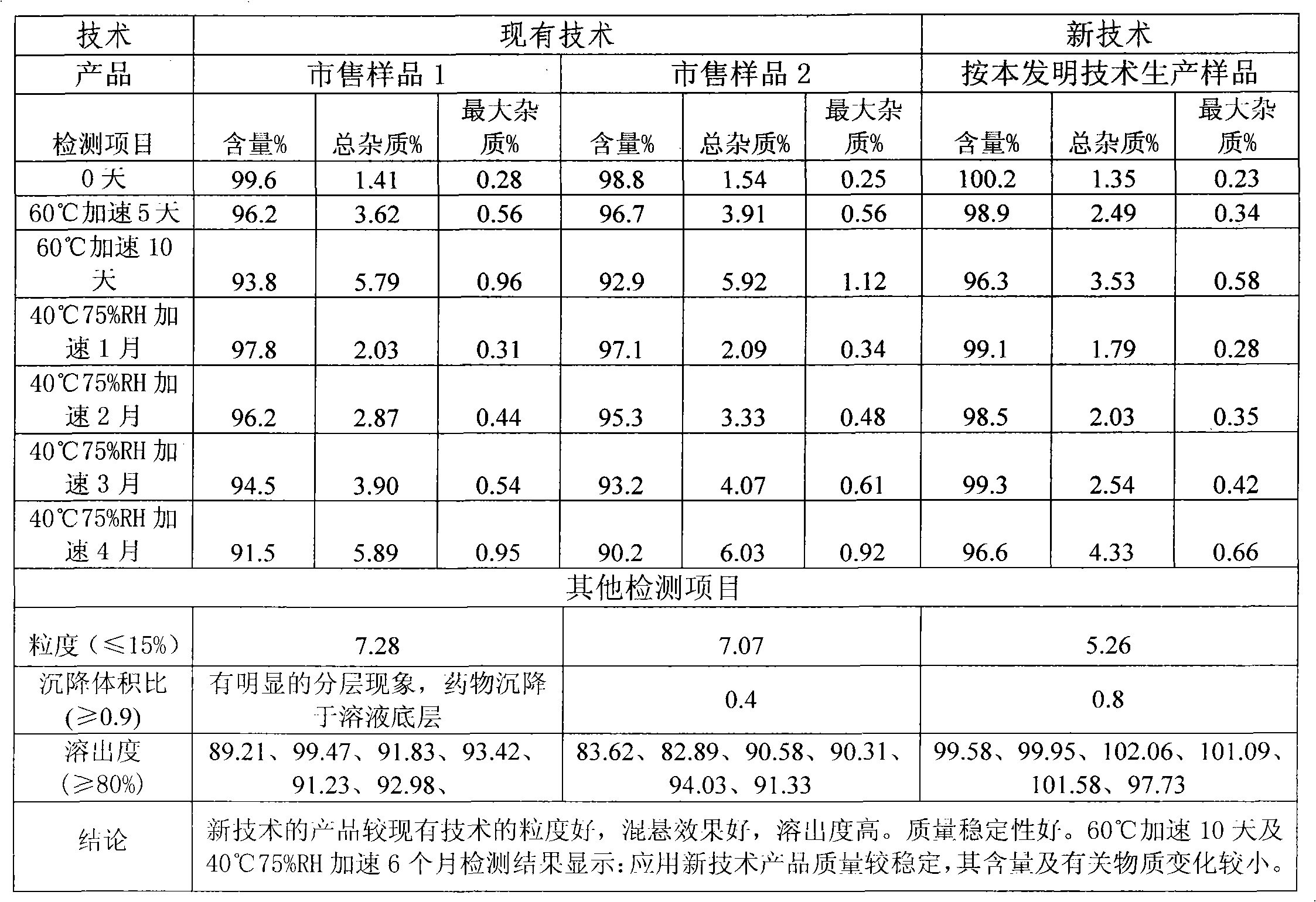

Cephalosporin suspension granule and preparation method thereof

ActiveCN101816635AGranularityAvoid damageAntibacterial agentsOrganic active ingredientsFluidized bed dryingAdditive ingredient

The invention discloses a cephalosporin suspension granule of which the formula composition comprises drug active ingredients, excipient, suspending agent, disintegrating agent, flavoring agent, coloring agent, stabilizing agent, adhesive and spice. The granule takes cefixime, cefprozil, cefaclor or cefdinir as the main drug ingredient, disintegrating agent and suspending agent with a certain quantity are added into the formula to ensure that the effective ingredients are dissolved out, and the solution has favorable suspending effect. Meanwhile, the invention also discloses a preparation method of the cephalosporin suspension granule, which adopts the wet granulation method to prepare granules and adopts the fluidized bed drying method to dry. The invention adopts the fluidized bed drying technology, so that compared with the traditional oven drying, the invention has the advantages of short drying time, small influence on active matter quality and the like, not only ensures product quality but also improves production efficiency. The granule prepared by the formula of the invention has solid granularity and lowers damage to the granule by fluidized drying.

Owner:广东恒健制药有限公司

Apparatus and method of enhancing the quality of high-moisture materials and separating and concentrating organic and/or non-organic material contained therein

ActiveUS8062410B2Processed evenly and quicklySignificant environmental benefitsDrying solid materials with heatGas current separationParticulatesFluidized bed drying

The present invention harvests and utilizes fluidized bed drying technology and waste heat streams augmented by other available heat sources to dry feedstock or fuel. This method is useful in many industries, including coal-fired power plants. Coal is dried using the present invention before it goes to coal pulverizers and on to the furnace / boiler arrangement to improve boiler efficiency and reduce emissions. This is all completed in a low-temperature, open-air system. Also included is an apparatus for segregating particulate by density and / or size including a fluidizing bed having a particulate receiving inlet for receiving particulate to be fluidized. This is useful for segregating contaminants like sulfur and mercury from the product stream.

Owner:RAINBOW ENERGY CENT LLC

Nutrition bar and process of making components

InactiveUS7220442B2Fruit and vegetables preservationProteins working-up by texturisingFluidized bed dryingPea protein

A nutrition bar which incorporates protein in the form of nuggets having high levels of selected proteins. By use of the nuggets of the invention, nutrition bars are formulated to have elevated levels of protein, yet good taste and other organoleptic properties. The nuggets according to the invention include greater than 50 wt % of a non-soy protein selected from the group consisting of milk protein, rice protein and pea protein, especially between 51 wt % and 99 wt %, more preferably between 52 wt % and 95 wt %, most preferably 55 wt % or above. The milk protein is preferably whey protein.The nuggets of the invention are preferably made using an extrusion process wherein the extrusion temperature is moderated so as to avoid damage to the whey proteins and concomitant off-taste. In this preferred process according to the invention, extrusion is conducted at temperatures of from 60 to 140° C., after which the protein is dried using a belt / conveyor drier or a fluid bed drier. In an alternate method of making the nuggets according to the invention, a lower extrusion temperature of up to 90° C. is used and one or more supercritical fluids are injected prior to extrusion to form a puffed product.

Owner:SLIM FAST FOODS

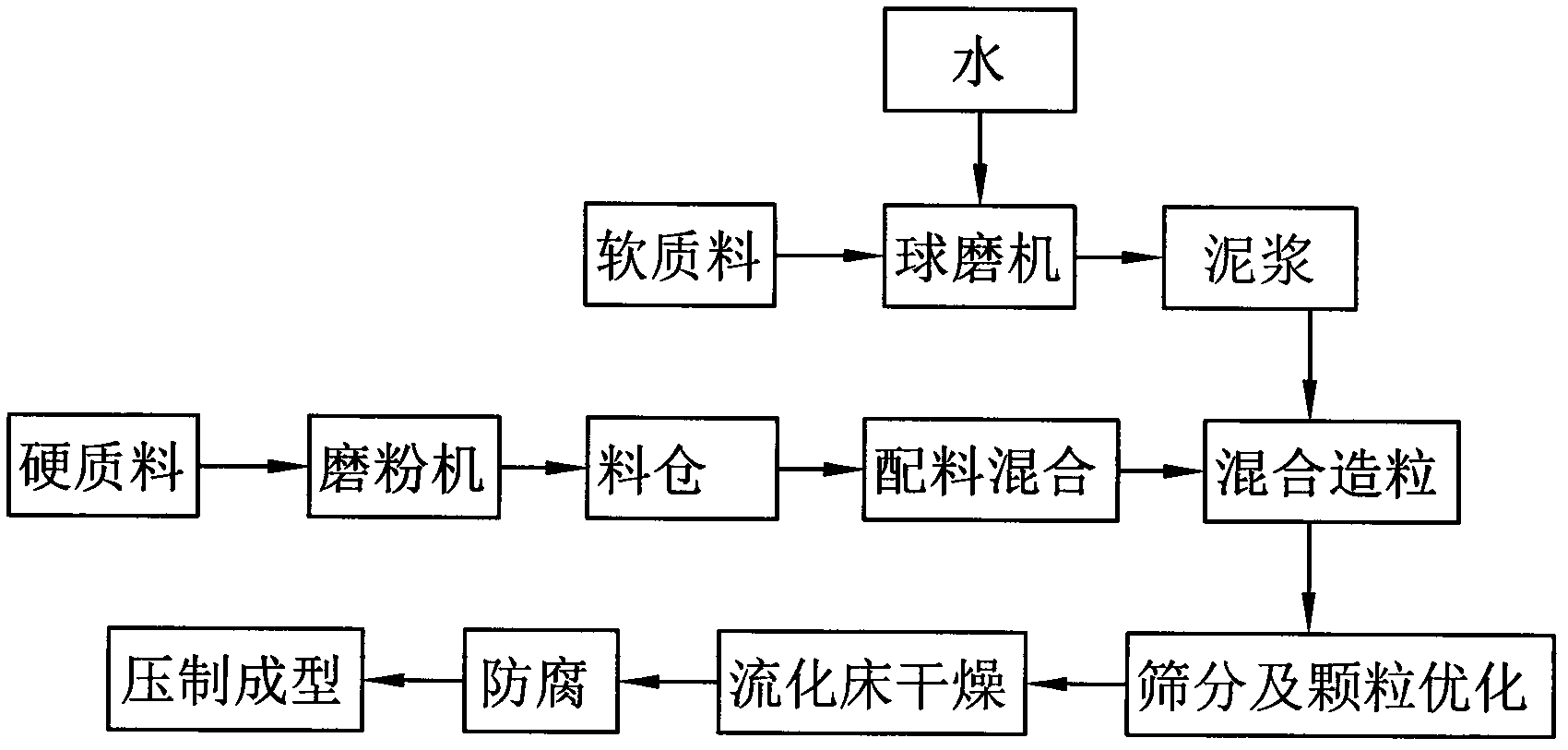

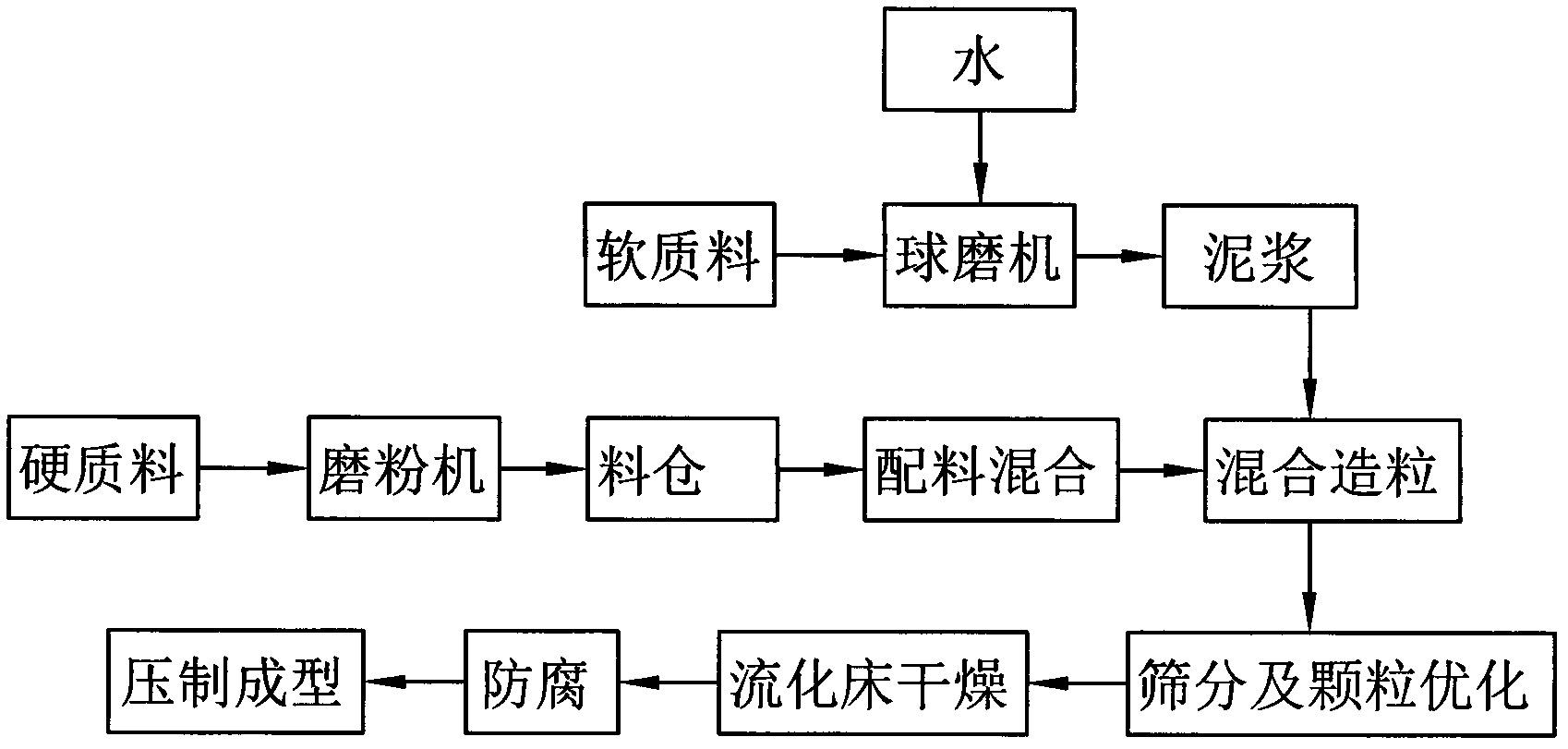

Energy-saving dry powder production method for building ceramics

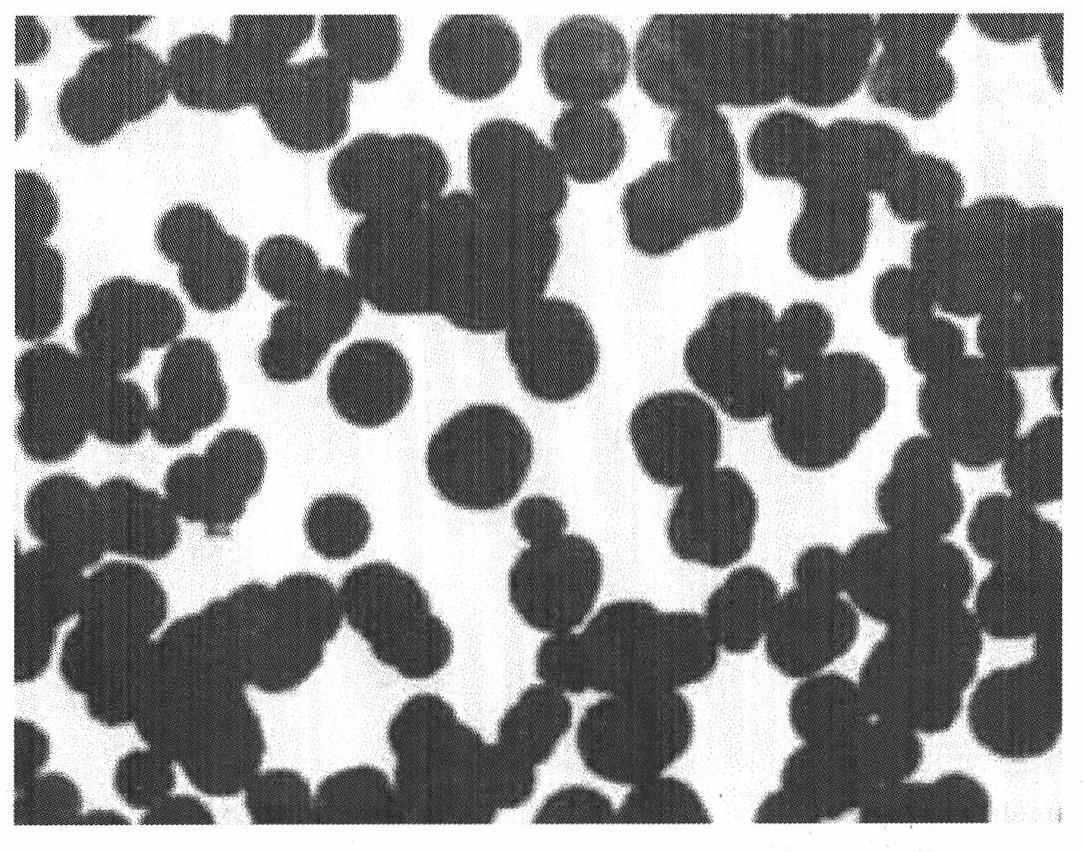

The invention relates to an energy-saving dry powder production method for building ceramics. The method is characterized in that the method includes the following steps: (1) hard materials and soft material in a green body formula are separated; (2) a ball mill is used for processing the soft material with high moisture content into slurry with 40 to 70 percent of moisture content for later use; (3) a pulverizer is used for respectively processing the hard materials into fine powders meeting requirement and conveying the fine powders into respective bins; (4) according to the green body formula, an automated batching system is used for mixing the processed fine hard material powders in batches according to proportion; and the prepared slurry as humidizer and the mixed fine hard material powders are forcibly mixed and granulated in a mixing granulator; (5) after granulation, granules are screened and optimized, and are then dried into the needed granular powder in a fluidized-bed dryer, and the granular powder can be used after being aged for 24 hours. The invention has the advantages of energy saving, consumption reduction and little pollution.

Owner:SHANDONG ECON ENERGY SAVING TECH

Phenolic resin activated carbon microballon and rapid preparation method thereof

The invention provides a phenolic resin activated carbon microballon and a rapid preparation method thereof. The rapid preparation method comprises the following steps of: preparing a phenolic resin microballon with a certain size by carrying out spray drying or fluidized bed drying on water-soluble phenolic resin or spirit soluble phenolic resin; thermocuring the microballon; carrying out temperature-rising carbonization on a curing sample in an inert atmosphere; mixing the curing sample (or a carbonized sample) with an active agent; then carrying out temperature-rising carbonized activation in the inert atmosphere; and carrying out cooling, washing, acid washing and washing to obtain a phenolic resin based activated carbon microballon. The invention has the advantages of wide raw material source, low price, simple process, high yield, uniform grain diameter of products, controllable sphere diameter and specific area and convenient industrial implementation.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

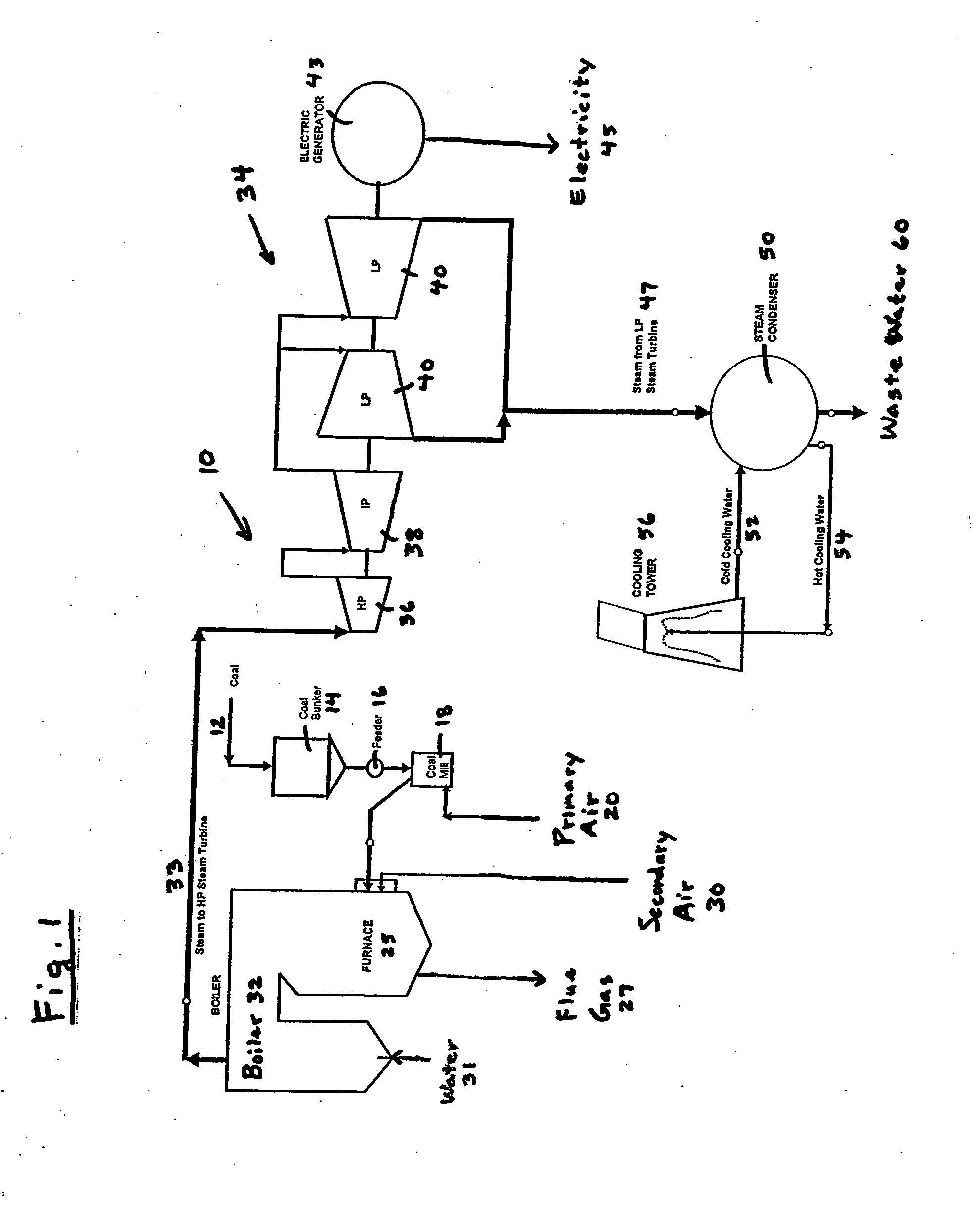

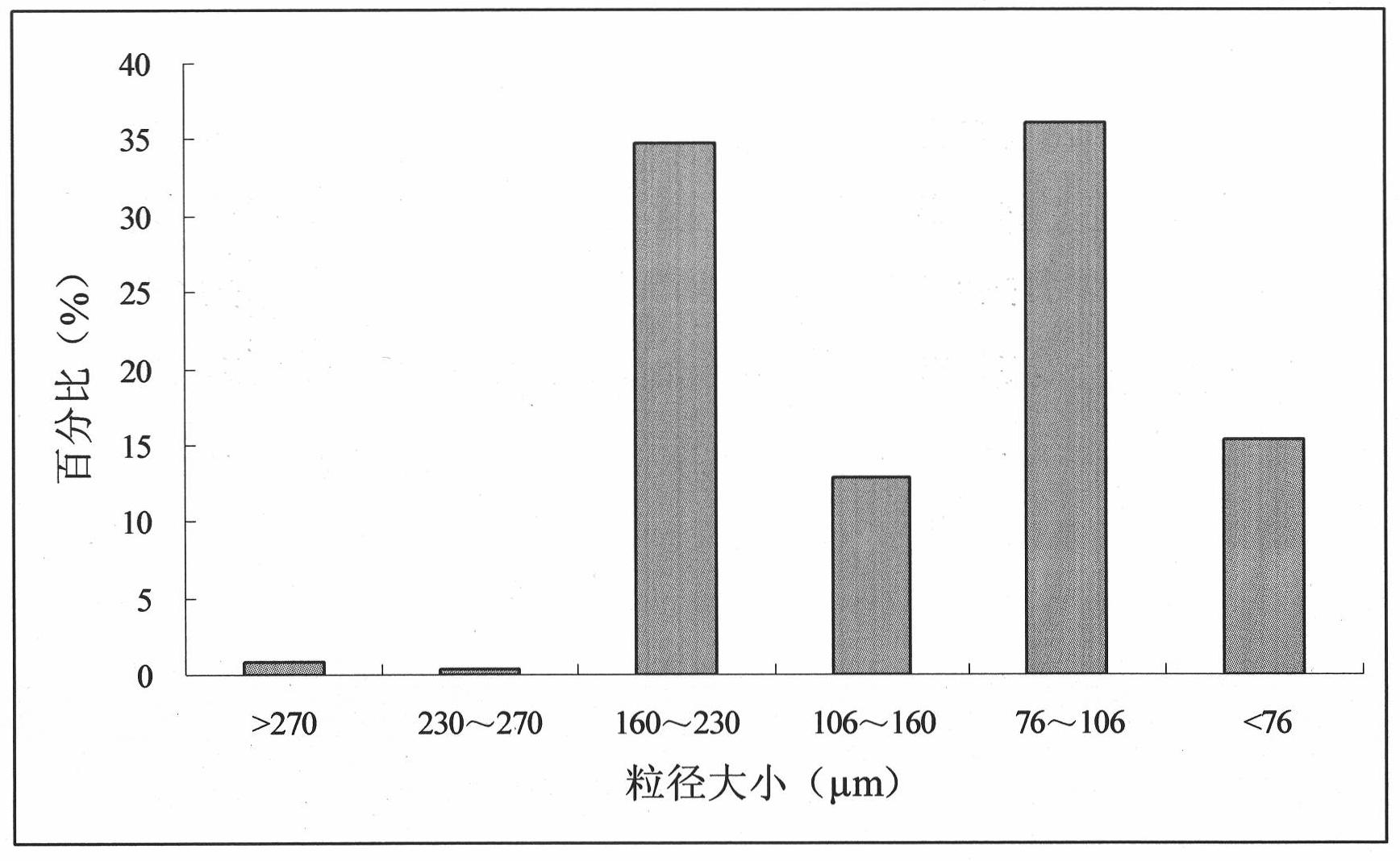

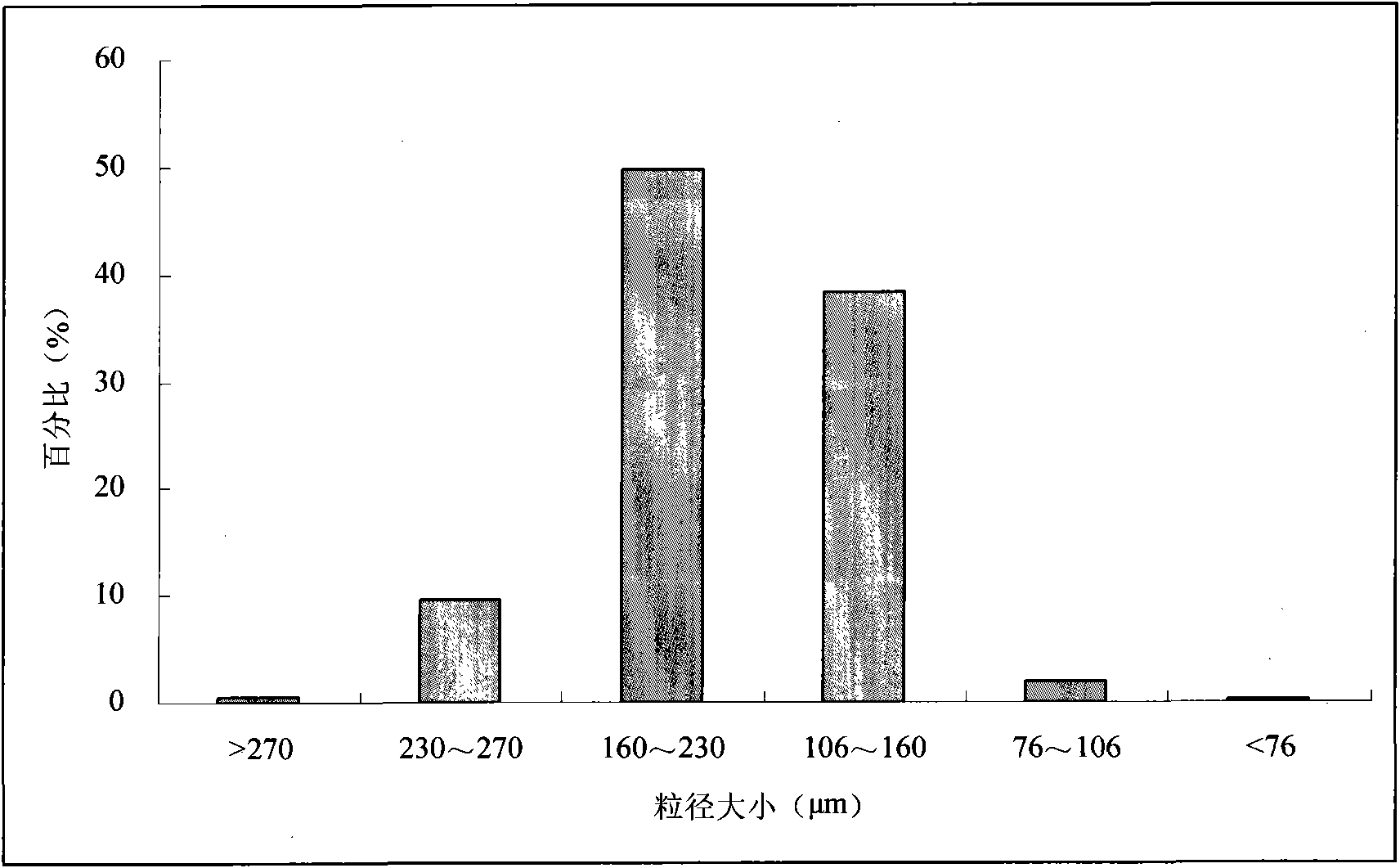

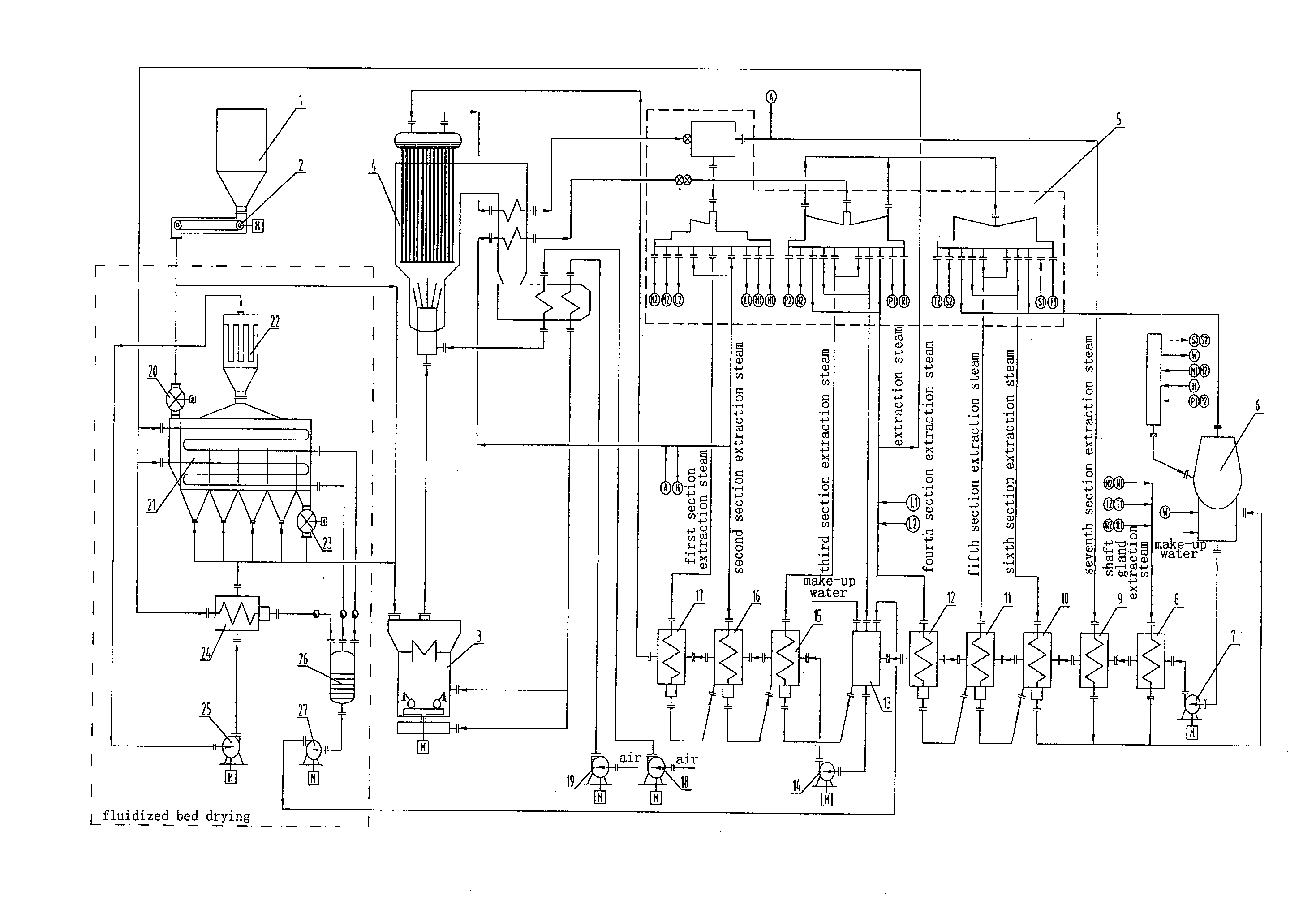

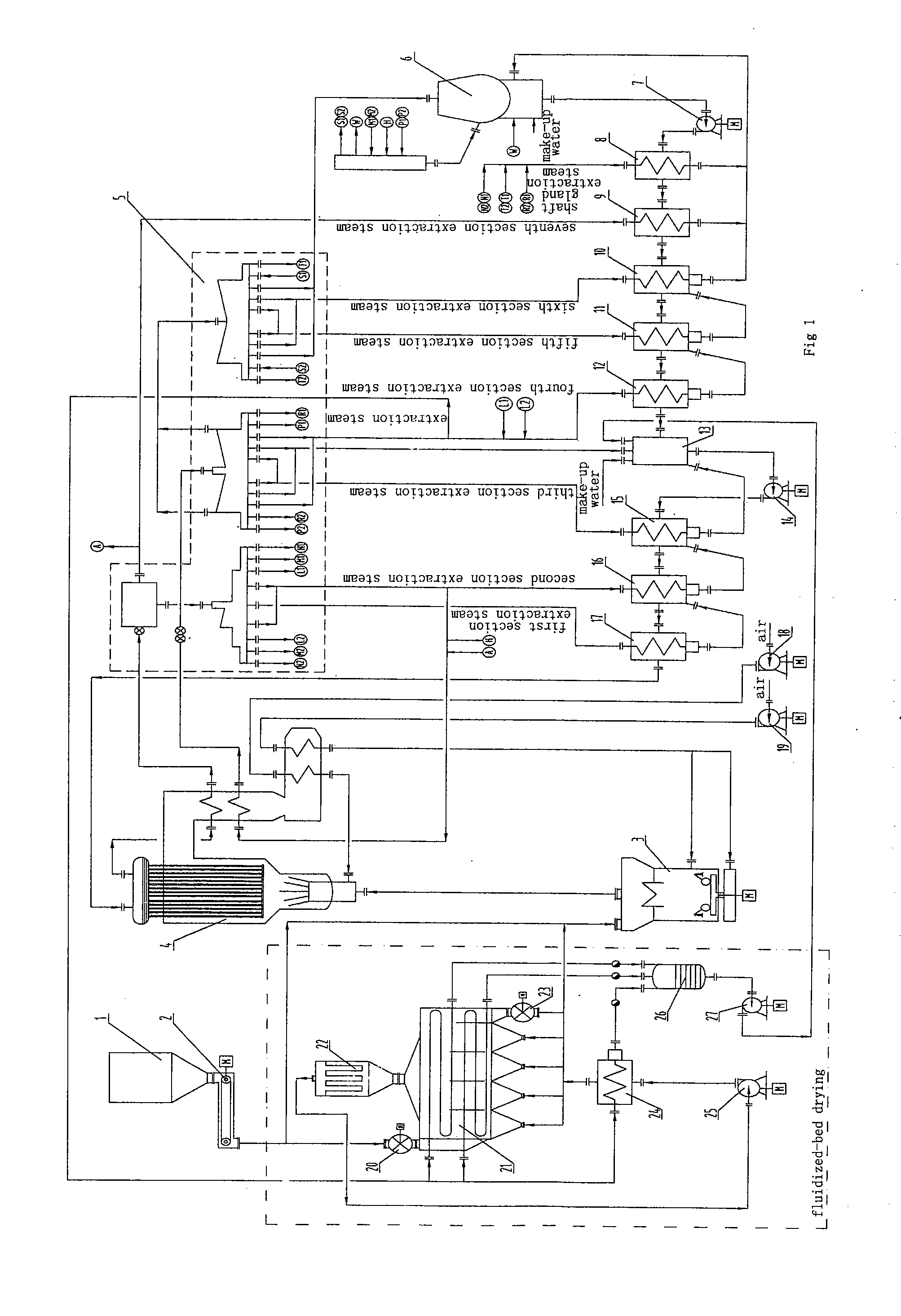

Process for reducing coal consumption in coal fired power plant with fluidized-bed drying

ActiveUS20110220744A1Reduce coal consumptionRemarkable effectFuel feeding arrangementsDrying solid materials with heatFluidized bed dryingProcess engineering

The present invention relates to a process for reducing coal consumption in coal fired plant with fluidized-bed drying, namely a fluidized-bed drying system is provided between a coal powder bunker as well as a weighing belt and a coal grinding mill of the prior coal fired boiler generating set, and superheated steam which has done partial work is extracted from an steam turbine and used as a drying medium, moisture contained in the coal powder is evaporated with sensible heat and latent heat of the superheated steam, water resulted from the condensation of the superheated steam is fed into a deaerator of the steam turbine via a condensate pump for recirculation. The present invention has advantages of reducing coal consumption and saving coal, recovering residual heat, reducing emission of carbon dioxide and adopting to the national industrial policy on energy saving and emission reduction.

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION +1

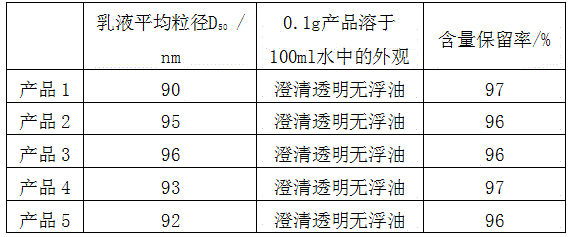

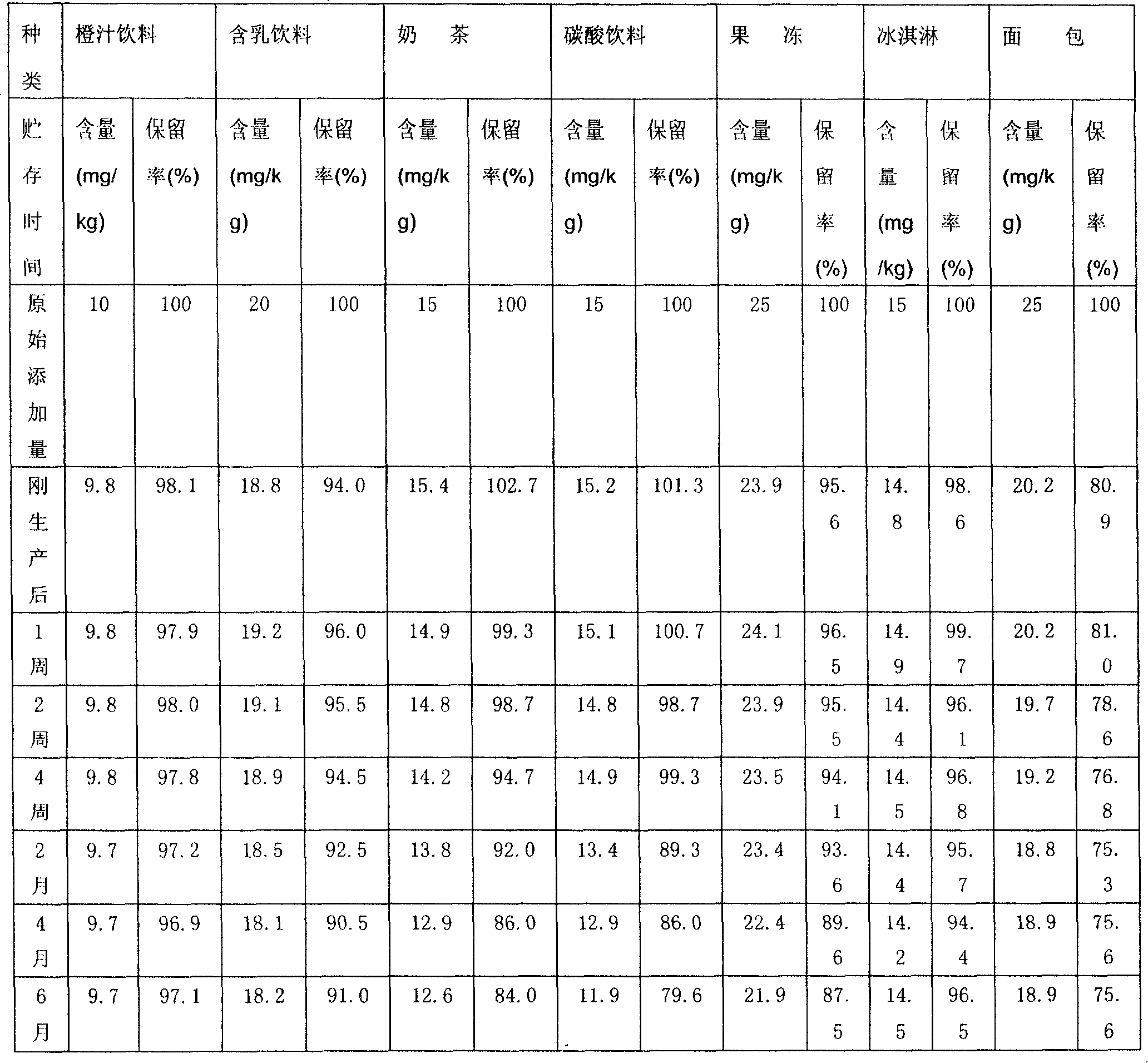

Preparation method of highly-stable and cold water-soluble natural astaxanthin microcapsule preparation

ActiveCN105596314AHigh embedding rateOvercoming poor pressure resistanceCosmetic preparationsOrganic active ingredientsFluidized bed dryingAntioxidant

The invention relates to a preparation method of a highly-stable and cold water-soluble natural astaxanthin microcapsule preparation. The method concretely comprises the following steps: uniformly mixing astaxanthin oil, an oil-soluble antioxidant and a water-soluble emulsifier under a heating condition to prepare an oil phase; adding a wall material, a water-soluble antioxidant and a filler to purified water, stirring and dissolving above added materials, and adjusting the pH value of the obtained solution to prepare a water phase; and adding the oil phase to the water phase, uniformly stirring the water phase and the oil phase, grinding the obtained mixture through a sand mill, and carrying out one-step granulation on the obtained emulsion through a cold spraying-starch fluidized bed drying technology to obtain the microcapsule preparation with the particle size of 40-100 meshes. The content reservation rate of the microcapsule preparation disposed at 40DEG C under RH of 75% for 6 months is greater than 95%, and 0.1g of the microcapsule preparation is dissolved in 100ml of water to form a clear, transparent and floating oil-free solution, so the microcapsule preparation can be applied in beverages and other aqueous foods.

Owner:CHENGUANG BIOTECH GRP HANDAN CO LTD

Method of enhancing the quality of high-moisture materials using system heat sources

ActiveUS8579999B2Improve efficiencyIncrease heatDrying solid materials with heatSolid fuelsFluidized bed dryingMoisture

The present invention harvests and utilizes fluidized bed drying technology and waste heat streams augmented by other available heat sources to dry feedstock or fuel. This method is useful in many industries, including coal-fired power plants. Coal is dried using the present invention before it goes to coal pulverizers and on to the furnace / boiler arrangement. Coal can be intercepted on current coal feed systems ahead of the pulverizers. Drying fuel, such as coal, is done to improve boiler efficiency and reduce emissions. A two-stage bed utilized in the process first “pre-dries and separates” the feed stream into desirable and undesirable feedstock. Then, it incrementally dries and segregates fluidizable and non-fluidizable material from the product stream. This is all completed in a low-temperature, open-air system. Elevation of fan room air temperature is also accomplished using waste heat, thereby making available to the plant system higher temperature media to enhance the feedstock drying process.

Owner:RAINBOW ENERGY CENT LLC

Method for preparing lutein water-soluble dry powder

ActiveCN101177540AMultiple smallImprove solubilityNatural dyesFood preparationSolubilityFluidized bed drying

The invention discloses a preparation method of food-grade lutein water-soluble dry powder. The content of the all-trans isomer of the active ingredient in the product obtained by the existing method is low, and the structure is amorphous, which affects the coloring effect or bioavailability of the product. The steps of the present invention are as follows: after mixing lutein crystals with a low-boiling, volatile organic solvent with high solubility to lutein crystals, heating and dissolving to obtain an oil phase; mixing denatured starch with water, heating and dissolving, and cooling to obtain an aqueous phase ; The oil phase is slowly added to the water phase under stirring to obtain an emulsified mixed solution; the emulsified mixed solution is uniformed through a high-pressure homogenizer, so that the particle size of the emulsion reaches the nanometer level; the organic matter in the emulsion system is removed by conventional separation methods Solvent; use spray drying method or spray-starch fluidized bed drying method to remove water in the emulsion to obtain dry powder. The invention greatly increases the all-trans content of the active ingredients in the final product, is all amorphous, and has good coloring and nutritional strengthening effects.

Owner:ZHEJIANG MEDICINE CO LTD XINCHANG PHAMACEUTICAL FACTORY

Chlorinated polyethylene drying process

The present invention discloses one chlorinated polyethylene drying process. The chlorinated polyethylene drying process with hot air as drying medium includes the first stage of pulse airflow drying and the second stage of fluidized bed drying to dry chlorinated polyethylene with 30-55 % water content into product with 0.3 % below water content. The present invention has simple drying apparatus, high heat efficiency, low water content in product and other advantages.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

Preparation method for cellulose crystal susceptible to re-dispersion after drying

InactiveCN103275336AReduce drying energy consumptionInhibition of agglomerationFluidized bed dryingActive agent

The invention discloses a preparation method for a cellulose crystal susceptible to re-dispersion after drying, which comprises selection and using for cellulose crystal materials and non-ionic surface active agents; and a preparing and drying processing method for cellulose crystal suspending liquid materials, wherein the cellulose crystal materials comprise different types of cellulose crystals obtained by different cellulose sources and different processing methods; and the non-ionic surface active agents are APG, poly ethylene glycol, and polypropylene glycol. The preparation method comprises the following steps: mixing and stirring one of the non-ionic surface active agents and one of cellulose crystal suspending liquid to obtain the cellulose crystal suspending liquid materials; the cellulose crystal suspending liquid materials are subjected to drying processing by a fluid bed dryer or a spray dryer to obtain granulated, particulate, or powdered cellulose crystals which can disperse in an aqueous phase system quickly; and obtaining a particle size distribution, which can maintain original properties of the cellulose crystals, is similar to that of the original cellulose crystals after re-dispersing. Therefore, the cellulose crystals capable of re-dispersion provide convenience for the storage, the transportation, and the follow-up application.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

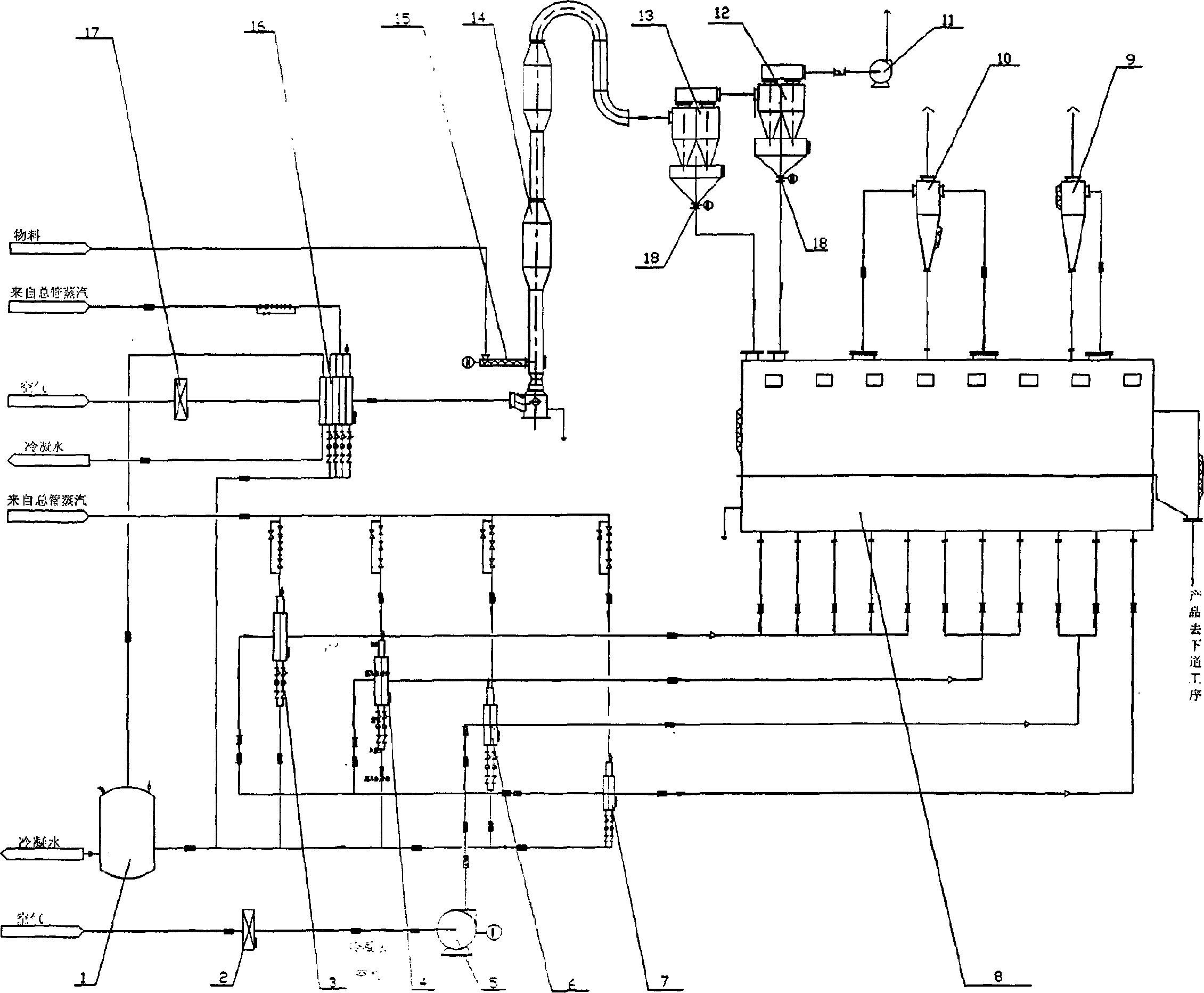

ABS powder drying method

ActiveCN102626965AEasy to separateImprove securityDrying solid materials with heatDrying gas arrangementsFluidized bed dryingNitrogen

The invention provides an ABS powder drying method, comprising a step of powder drying and a step of powder recovery. In the step of powder drying the technology of utilization of waste heat of condensed water comprises conveying the steam condensed water in a nitrogen heater to a buffer hot water tank as heating medium hot water in a heater. A slurry recovery tank is connected to a bottom portion of a washing tower. The upper portion diameter of the washing tower is slightly bigger than the bottom portion diameter. No filling material and no tray floor are arranged inside the washing tower. The washing tower is provided with a demister, and second spray water in the upper portion of the washing tower. A split-range controller is arranged on the top portion of the washing tower. A first fire extinguishing device is installed in a fluidized bed dryer. A second fire extinguishing device is installed at the exit port of a cyclone separator. An oxygen detector is installed at a nitrogen inlet side of the nitrogen heater. The method of the invention has the advantages of full utilization of the waste heat, energy saving and consumption reduction, heat utilization efficiency improvement, short process flow, reduction of powder loss, reduction of equipment investment, high operation flexibility and stability in the whole technology process, a good ABS separating effect, and good safety performance.

Owner:CHINA TIANCHEN ENG +3

Methods and systems for producing ethanol using raw starch and fractionation

ActiveUS20110111085A1Tea extractionMicrobiological testing/measurementFluidized bed dryingHigh alcohol beer

Owner:POET RES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com