Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1030results about How to "Significant environmental benefits" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

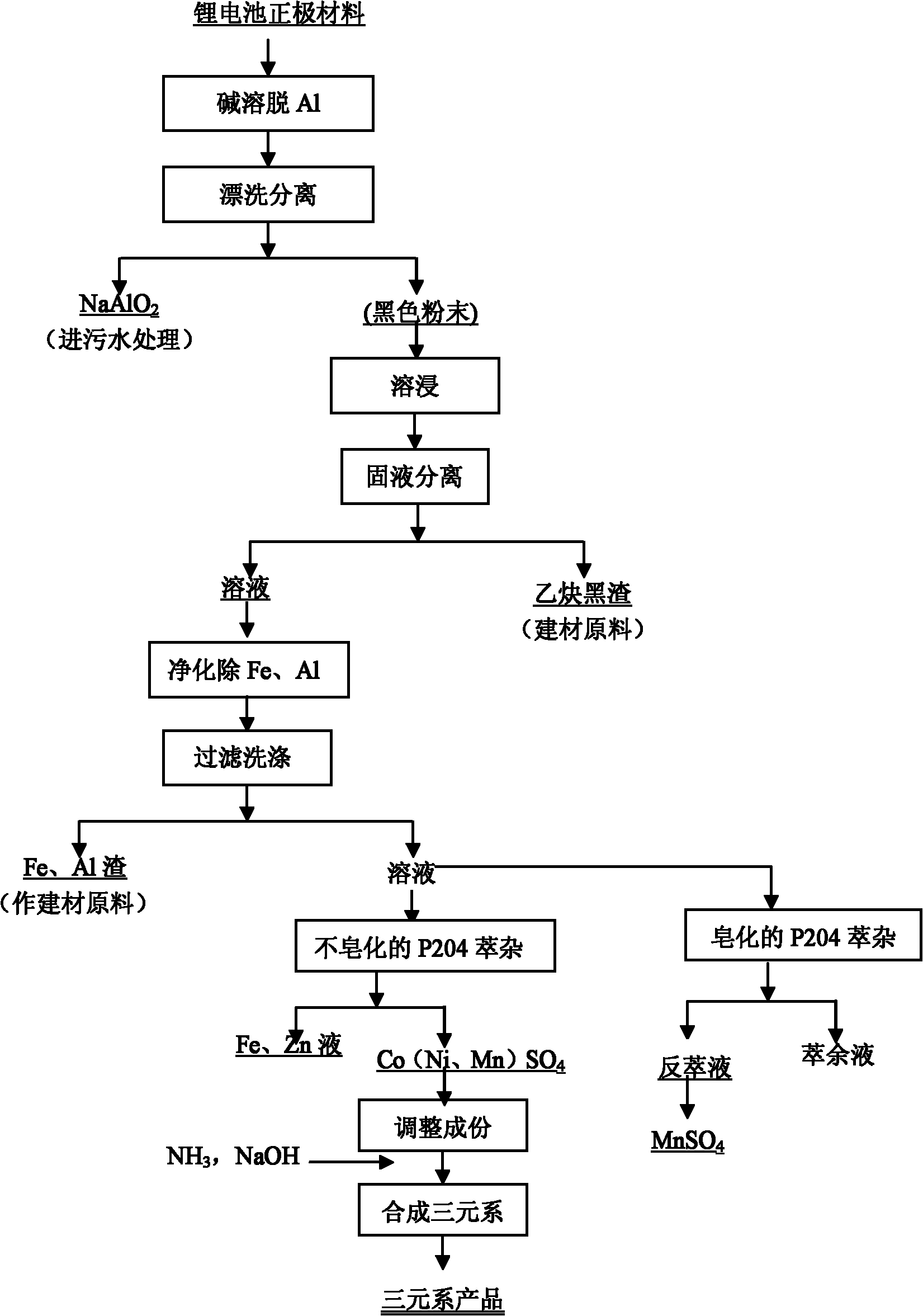

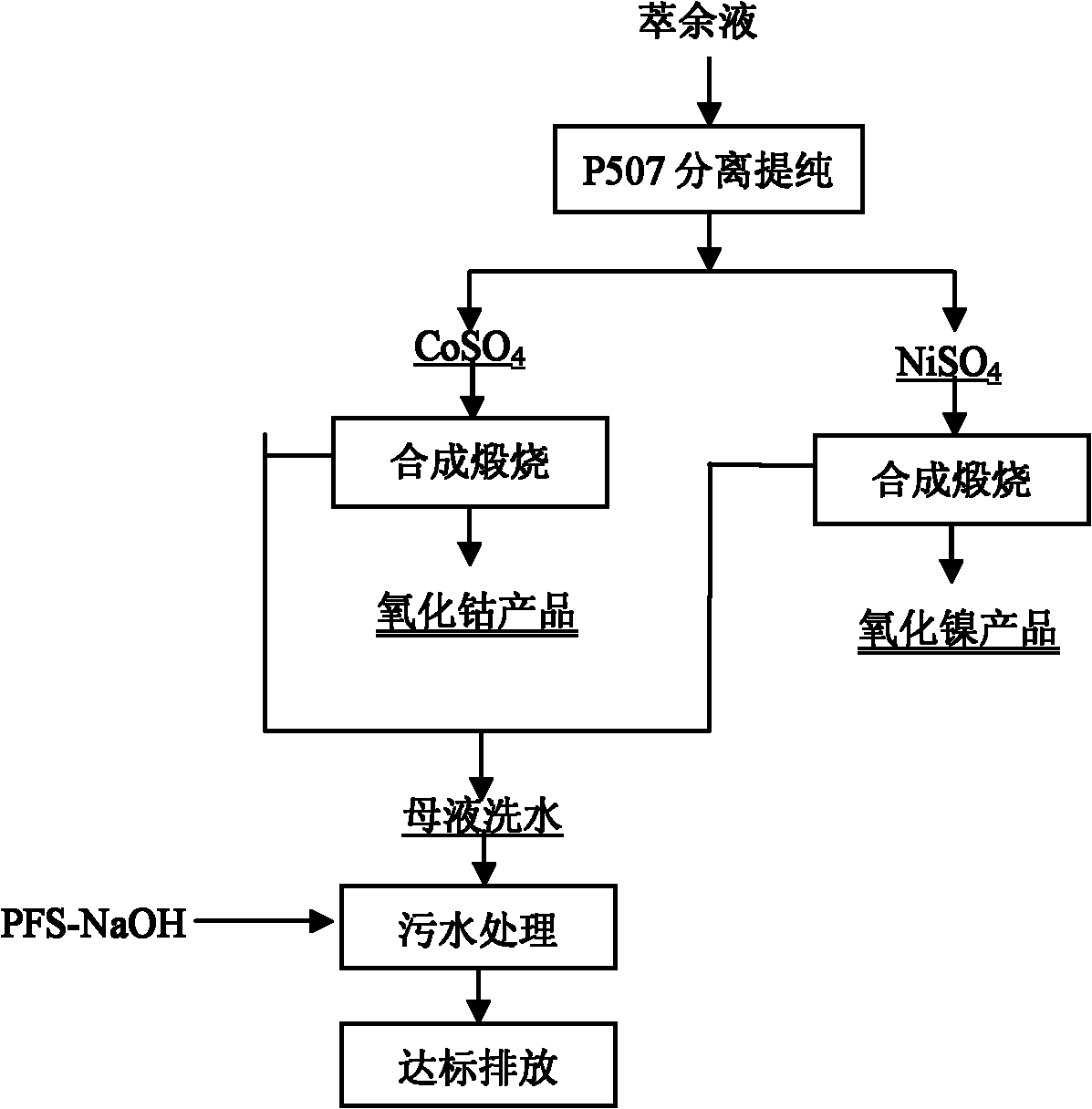

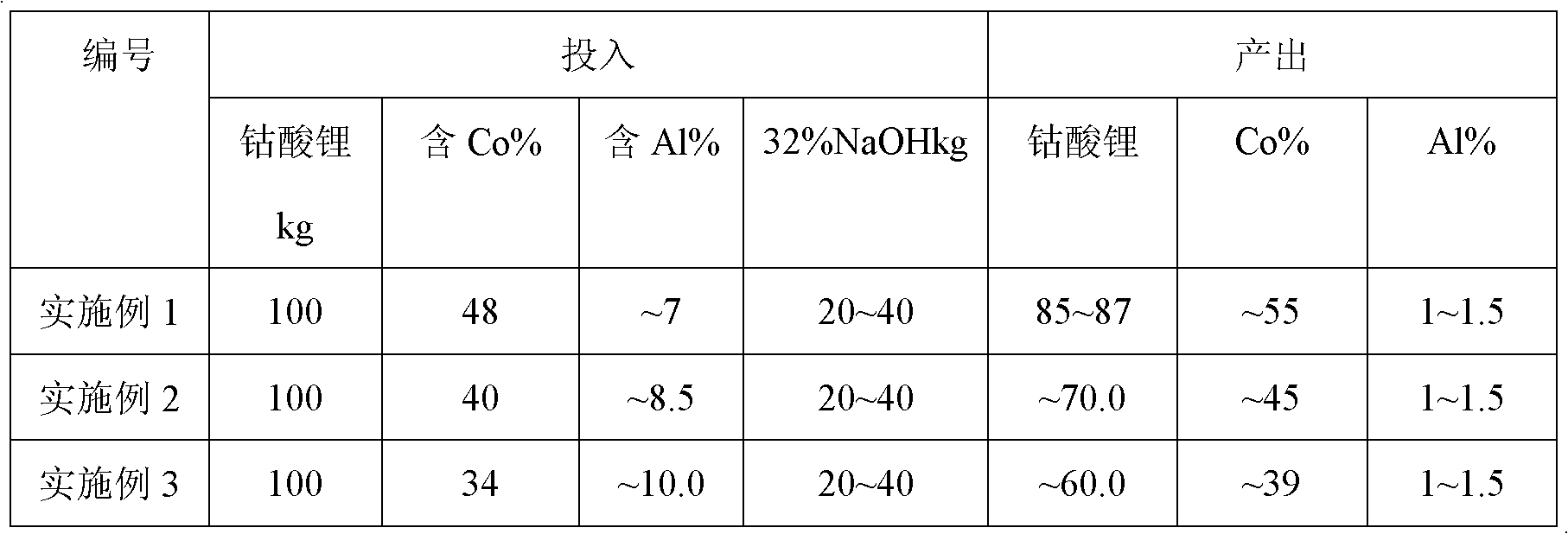

Method for recovering cobalt, nickel and manganese from waste lithium cells

ActiveCN101871048ANo pollution in the processReduce consumptionProcess efficiency improvementRecovery methodAlkaline earth metal

The invention discloses a method for recovering cobalt, nickel and manganese from waste lithium cells. Most of the conventional recovery methods can hardly guarantee the product quality. The technical scheme adopted by the invention is as follows: (1) the anode materials of waste lithium cells are immerged in low-concentration alkali solution, and because the anode materials do not react with the alkali solution, the anode materials shed from aluminum sheets to become black powder; (2) for the black powder, dilute sulfuric acid is first adopted for low-acid dissolution, Na2SO5 or Na2SO3 or Fe powder added with concentrated sulfuric acid is then adopted for reduction and dissolution, and finally, 3 to 6mol / L of sulfuric acid is adopted for high-acid dissolution; (3) solid-liquid separation is carried out on the substance obtained in step 2; (4) reagent is adopted for precipitating and deeply removing alkaline earth impurities. The method has the advantages of simple operation, low auxiliary material consumption, high product purity, high metal yield and no environment pollution, and is an ideal method for recovering cobalt, nickel and manganese from waste lithium cells.

Owner:ZHEJIANG HUAYOU COBALT +1

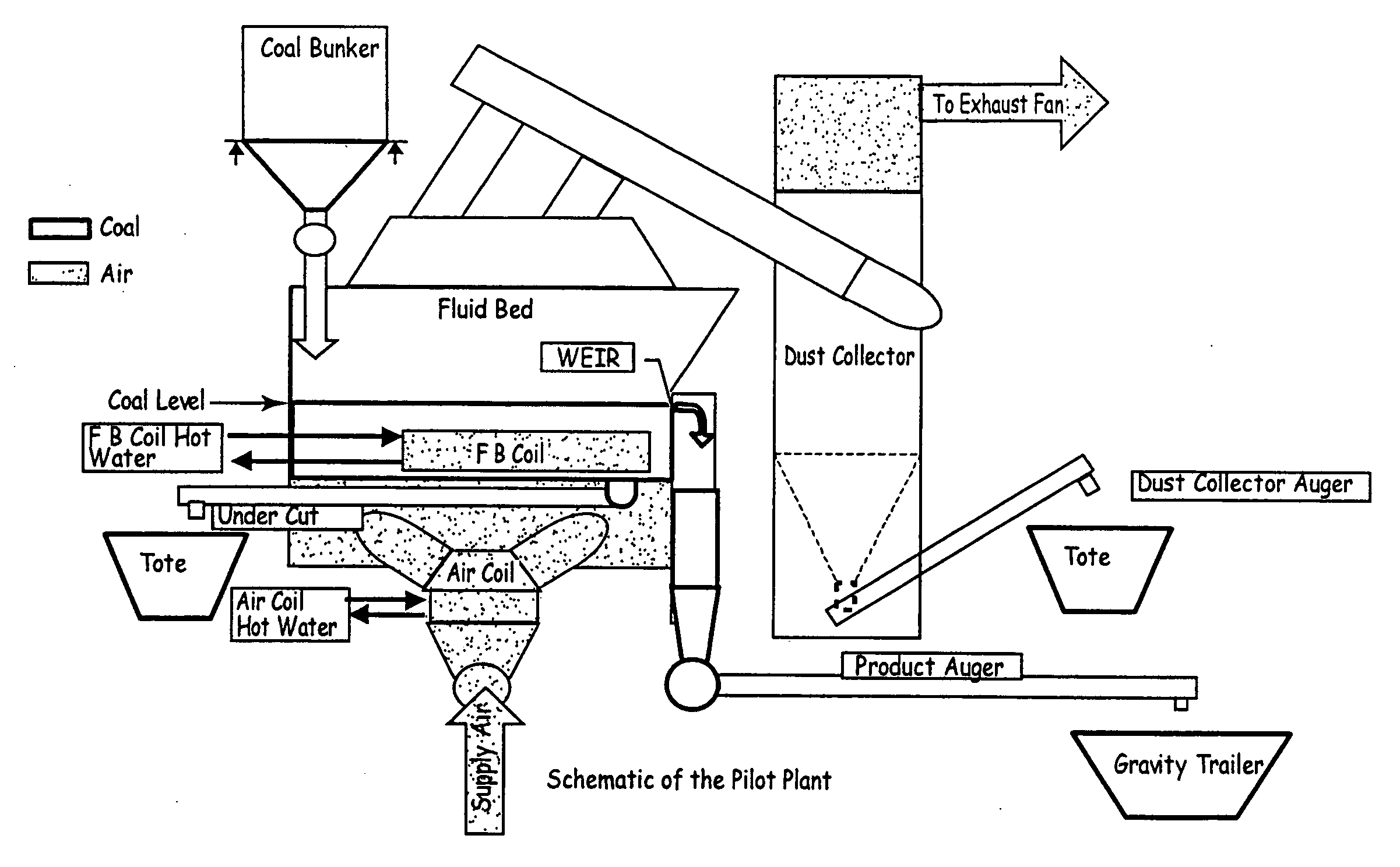

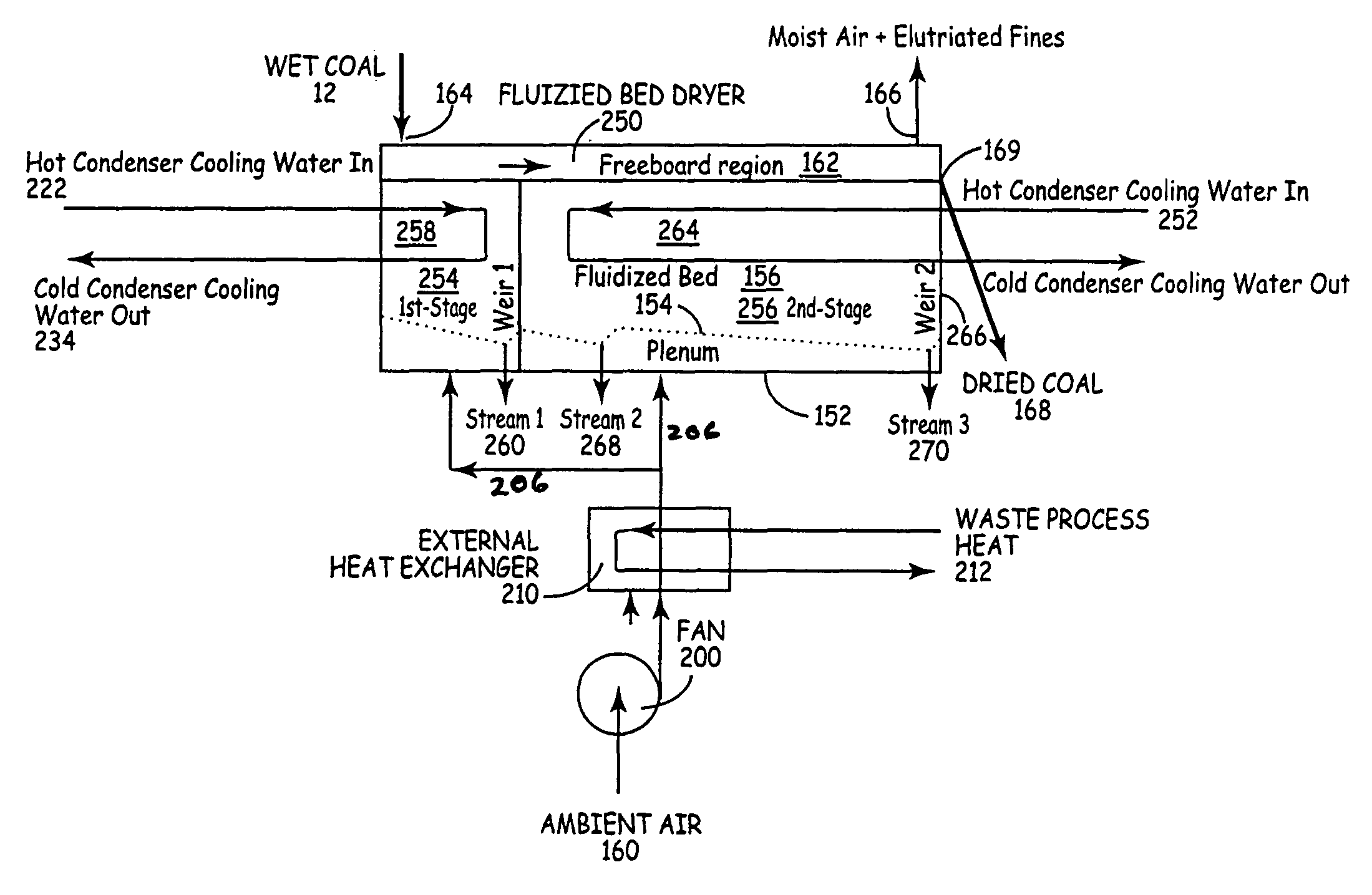

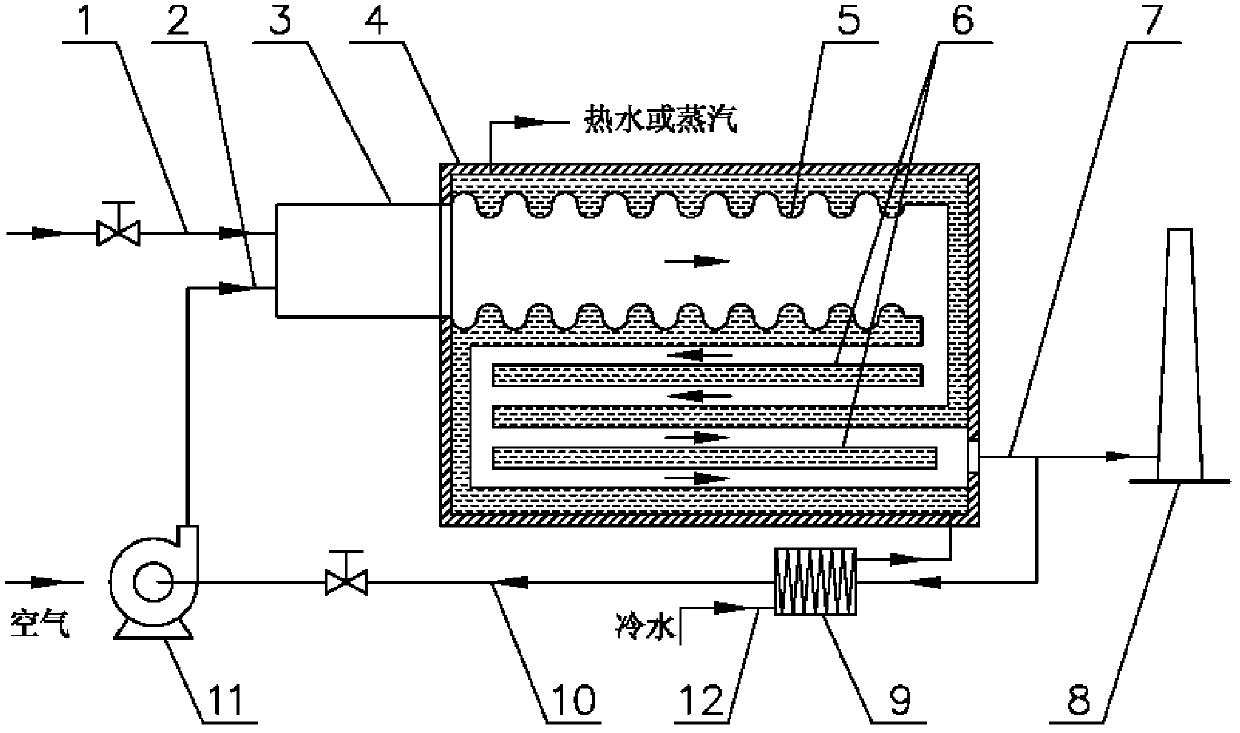

Apparatus and method of enhancing the quality of high-moisture materials and separating and concentrating organic and/or non-organic material contained therein

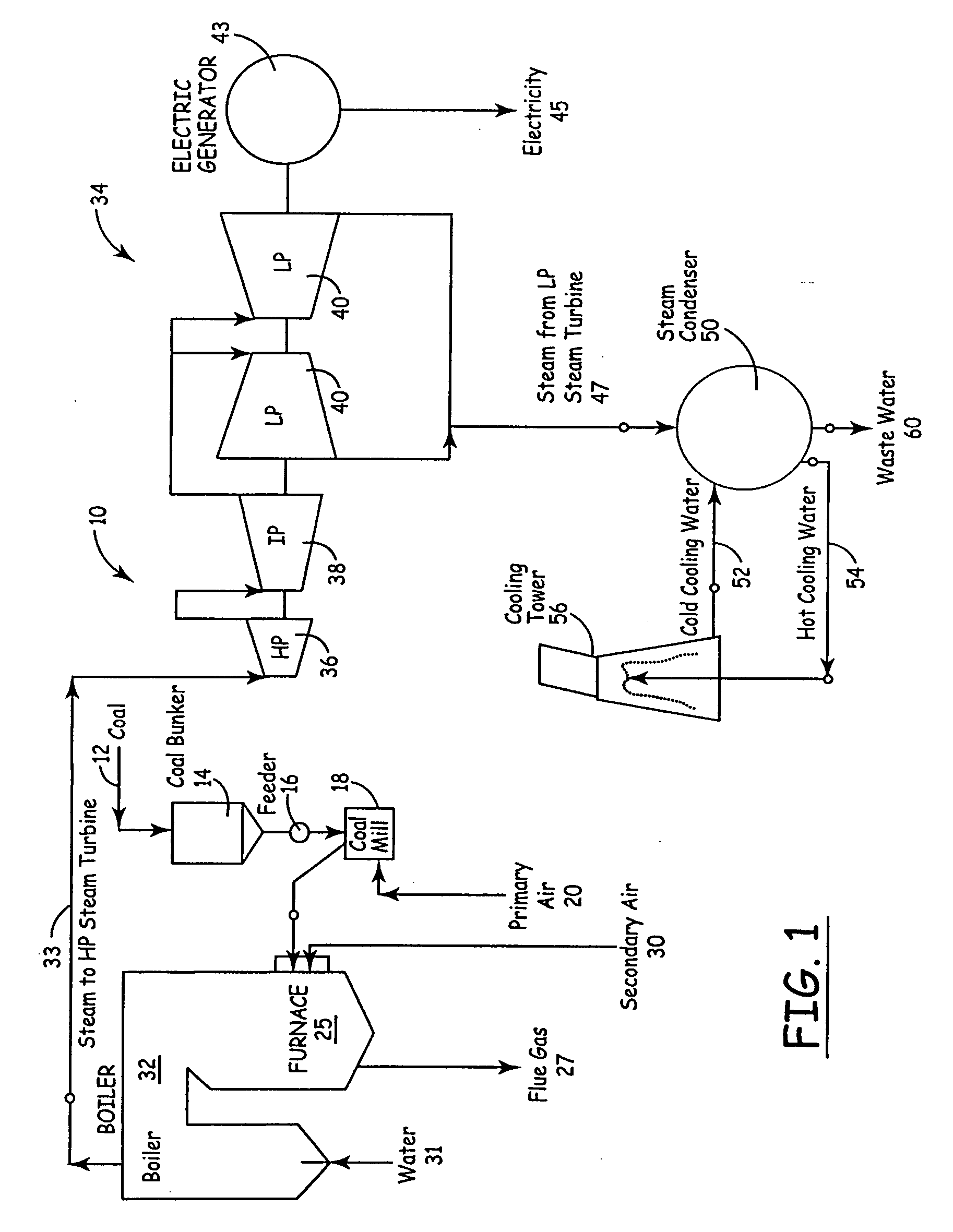

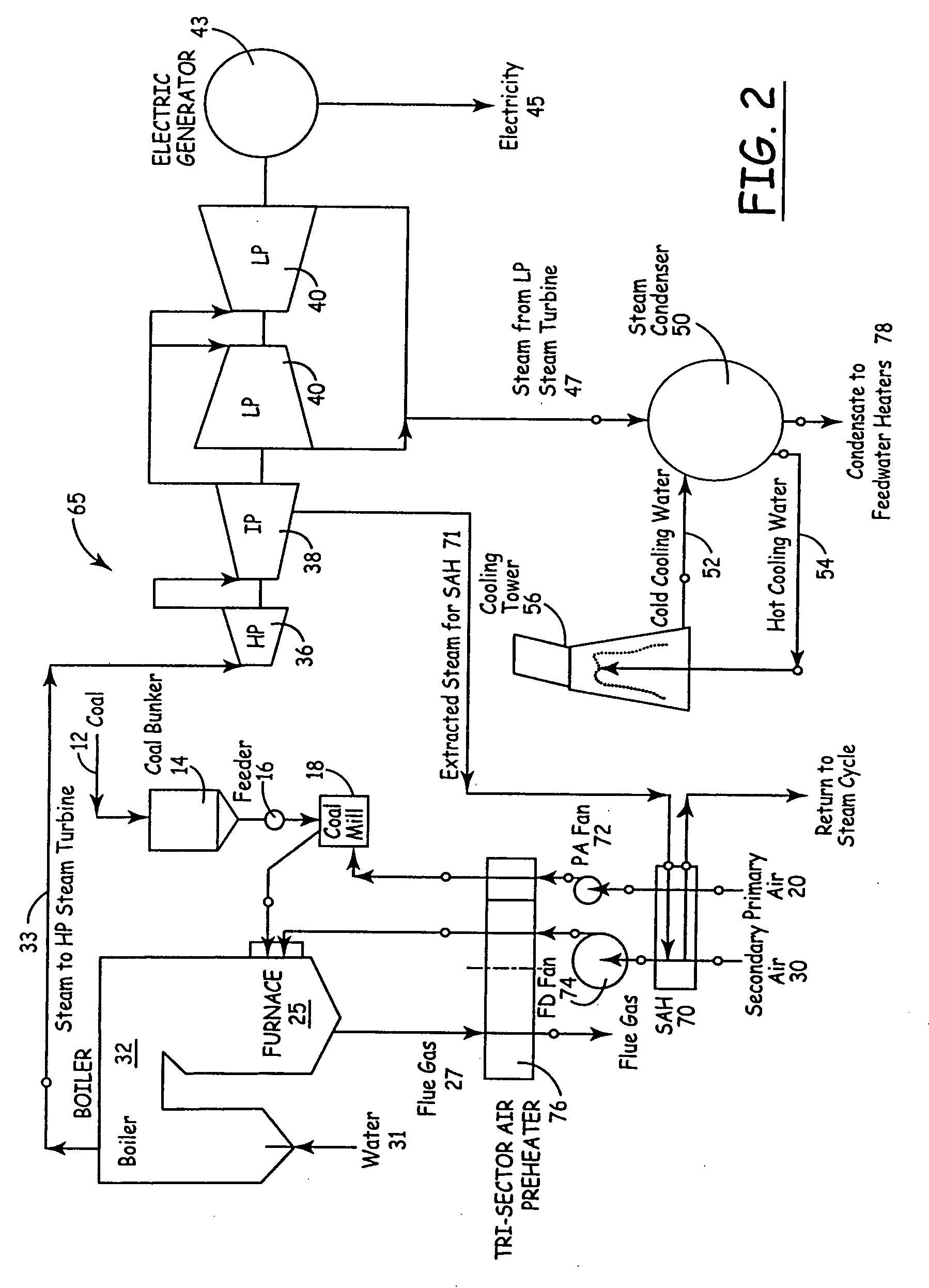

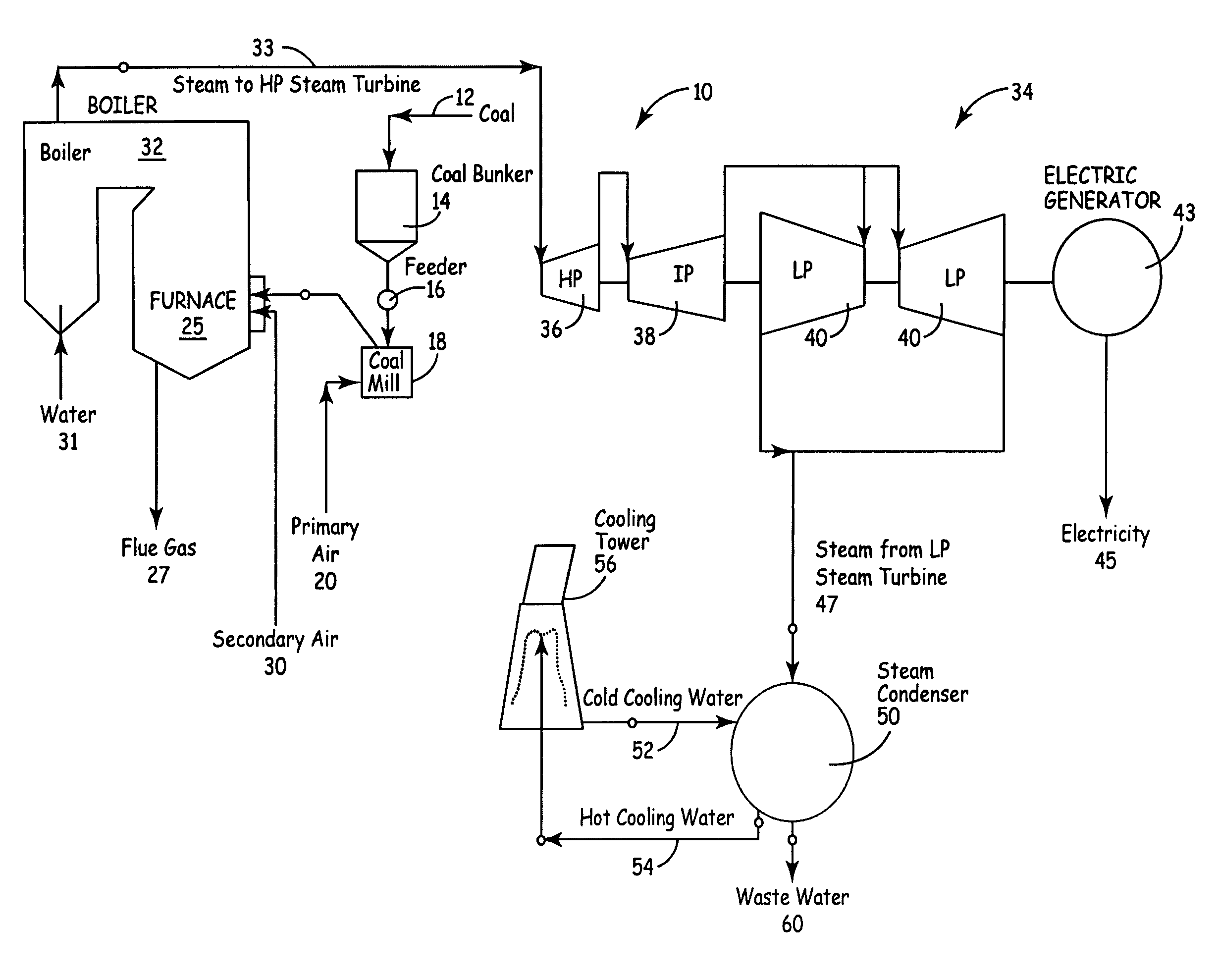

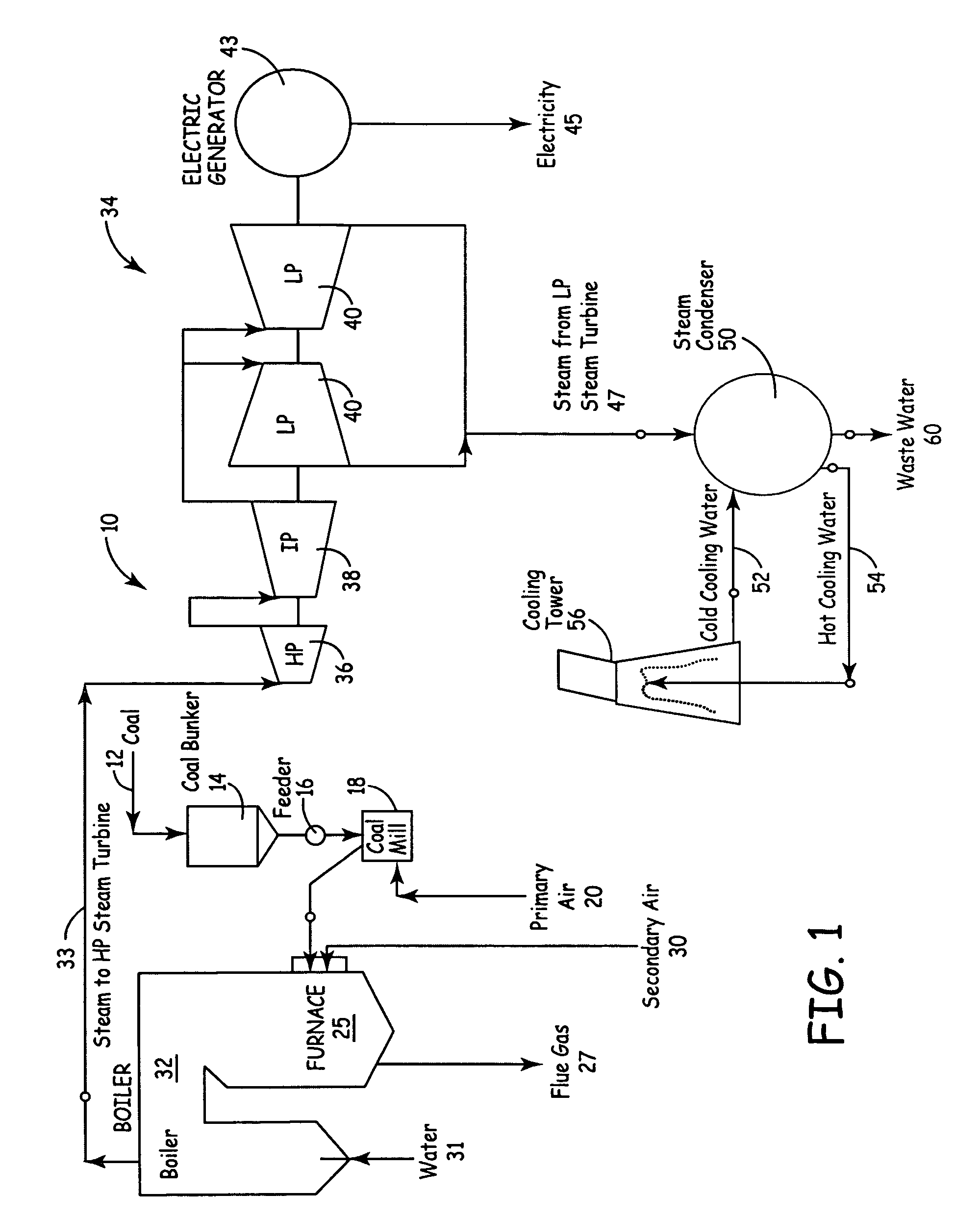

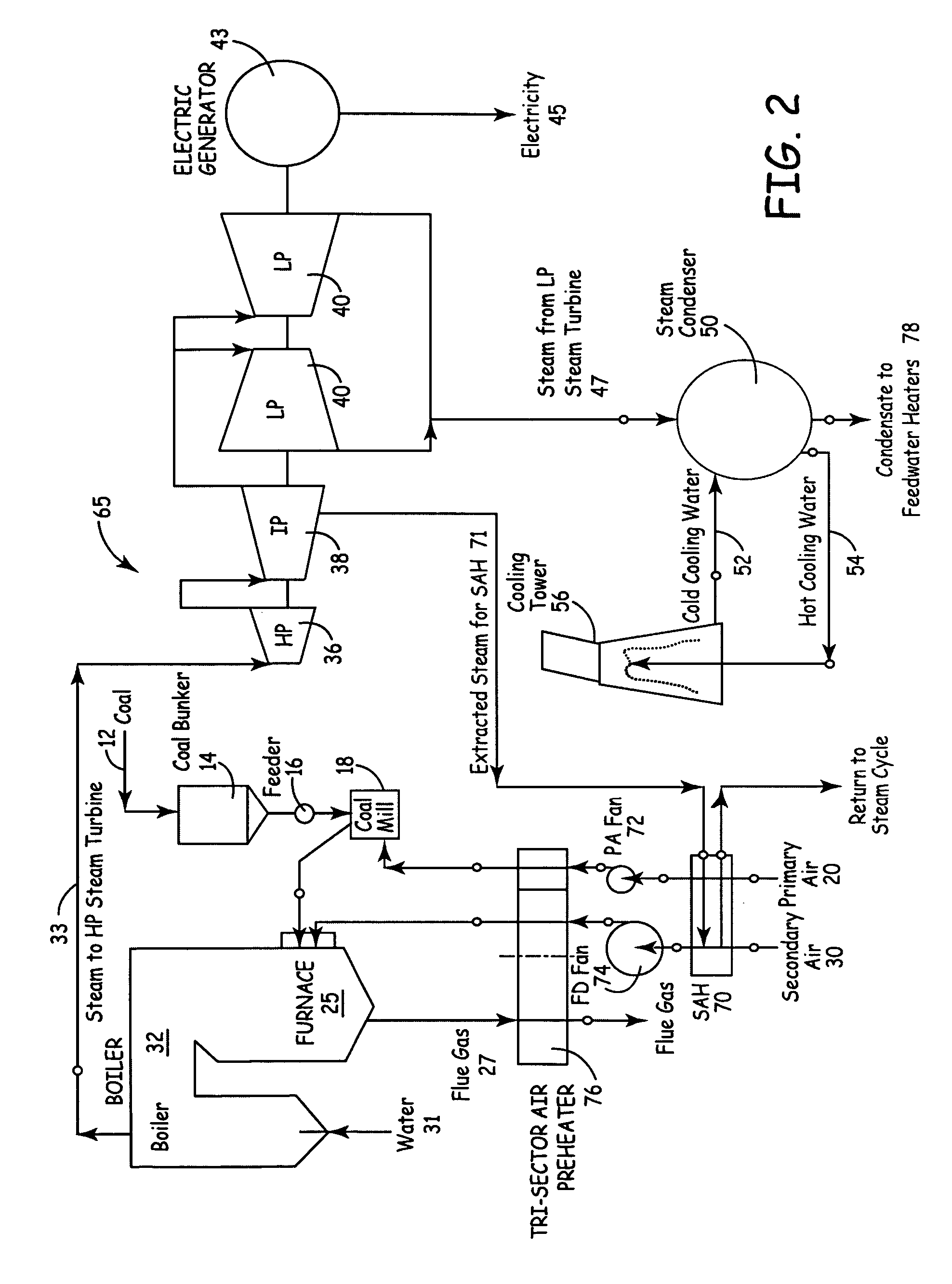

ActiveUS20080201980A1Processed evenly and quicklySignificant environmental benefitsDrying solid materials with heatSolid fuel pretreatmentParticulatesFluidized bed drying

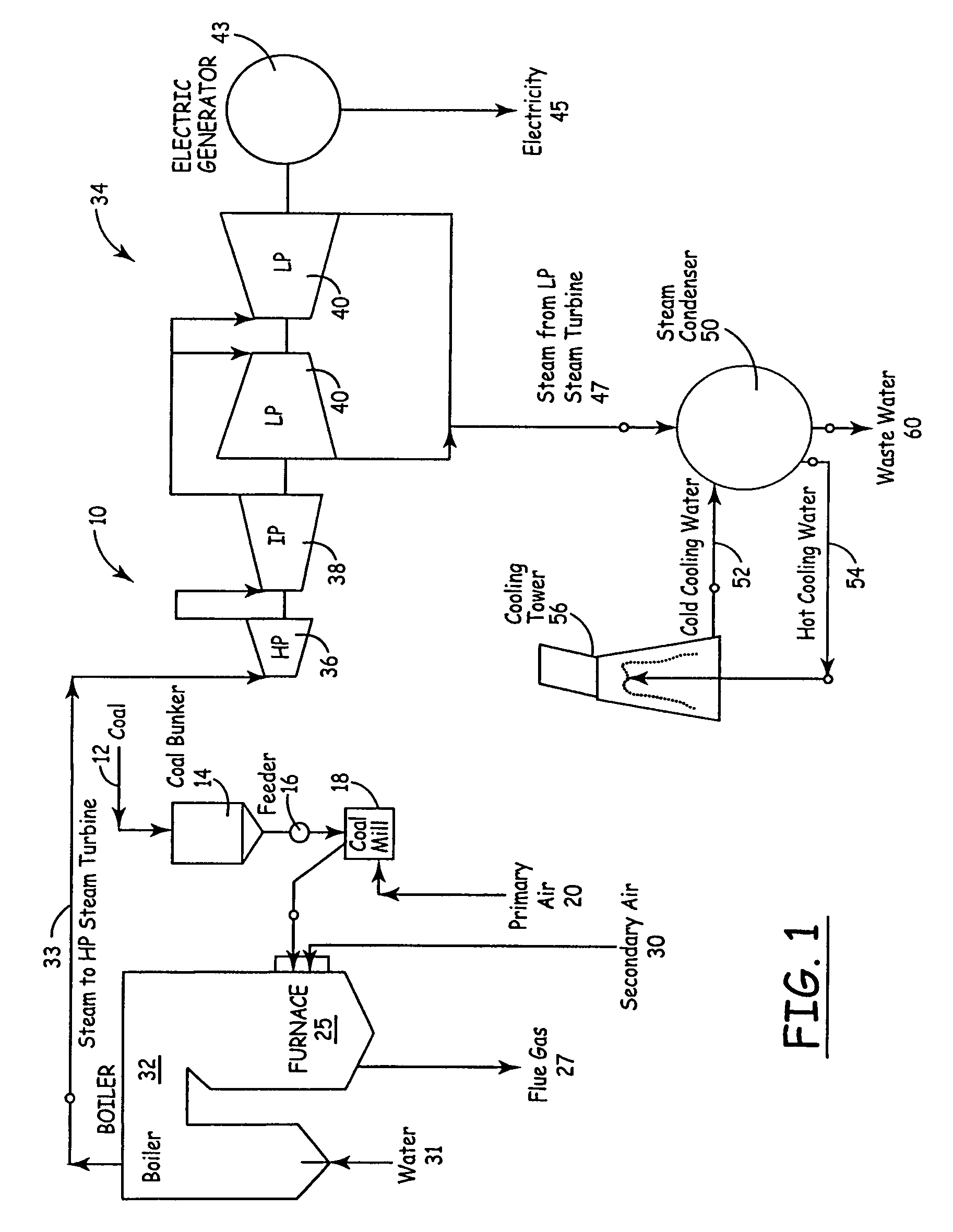

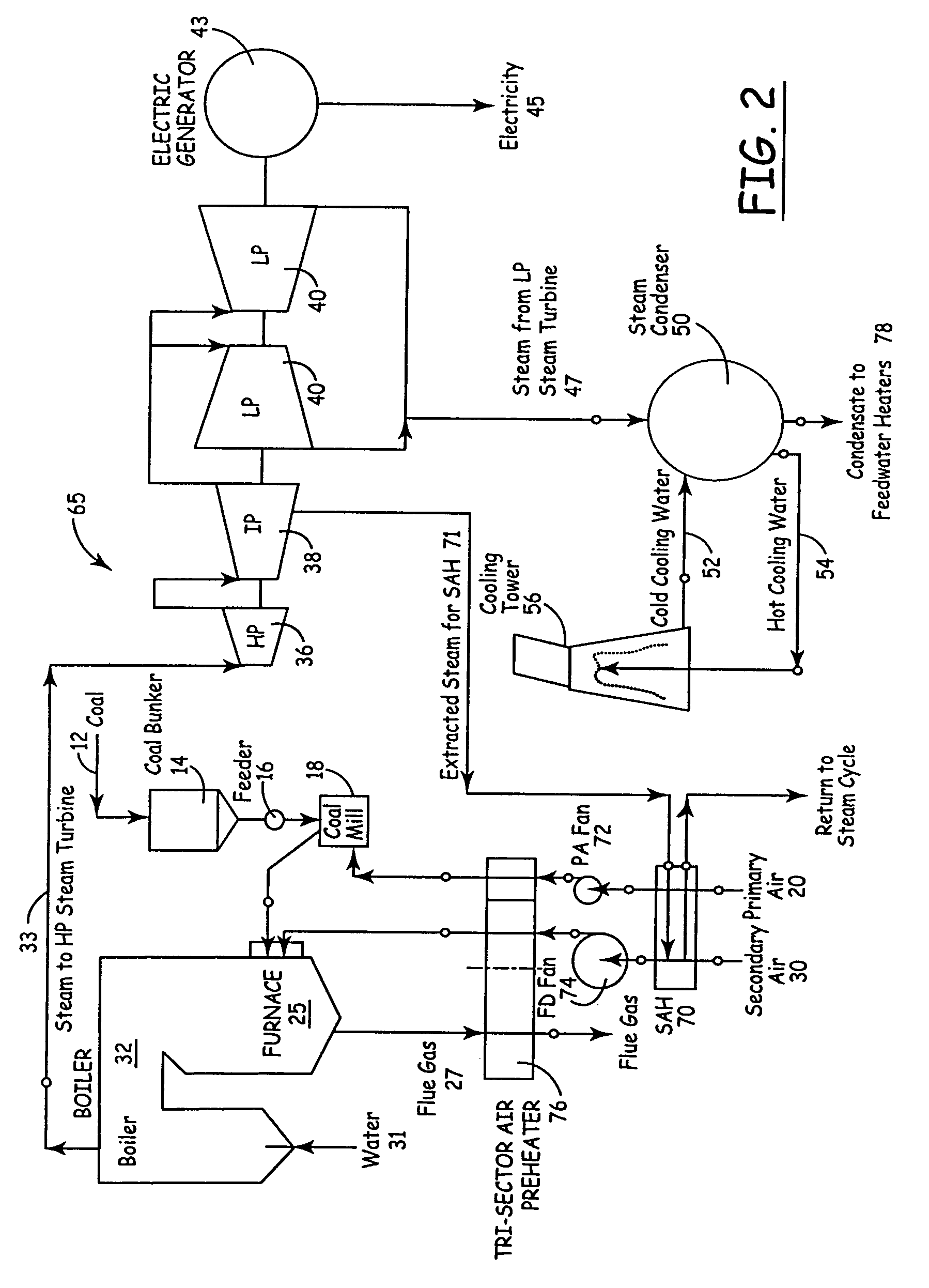

The present invention harvests and utilizes fluidized bed drying technology and waste heat streams augmented by other available heat sources to dry feedstock or fuel. This method is useful in many industries, including coal-fired power plants. Coal is dried using the present invention before it goes to coal pulverizers and on to the furnace / boiler arrangement to improve boiler efficiency and reduce emissions. This is all completed in a low-temperature, open-air system. Also included is an apparatus for segregating particulate by density and / or size including a fluidizing bed having a particulate receiving inlet for receiving particulate to be fluidized. This is useful for segregating contaminants like sulfur and mercury from the product stream.

Owner:RAINBOW ENERGY CENT LLC

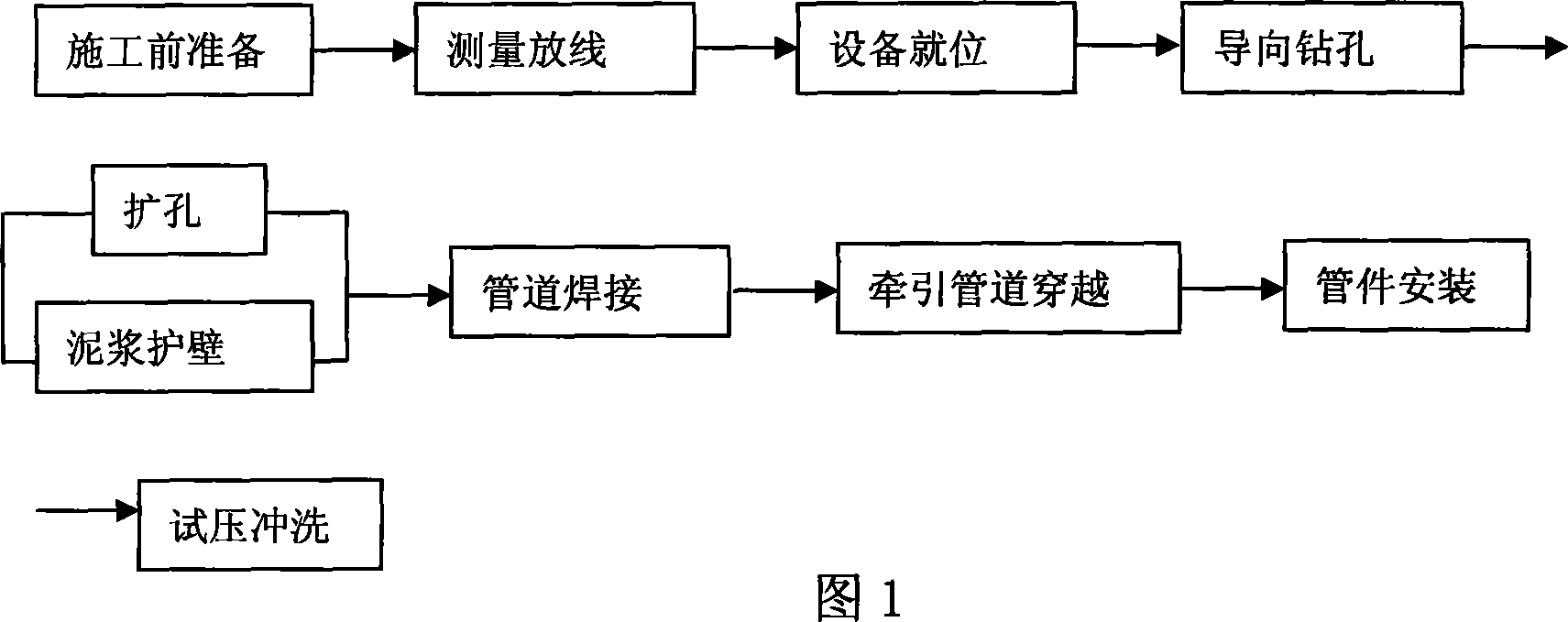

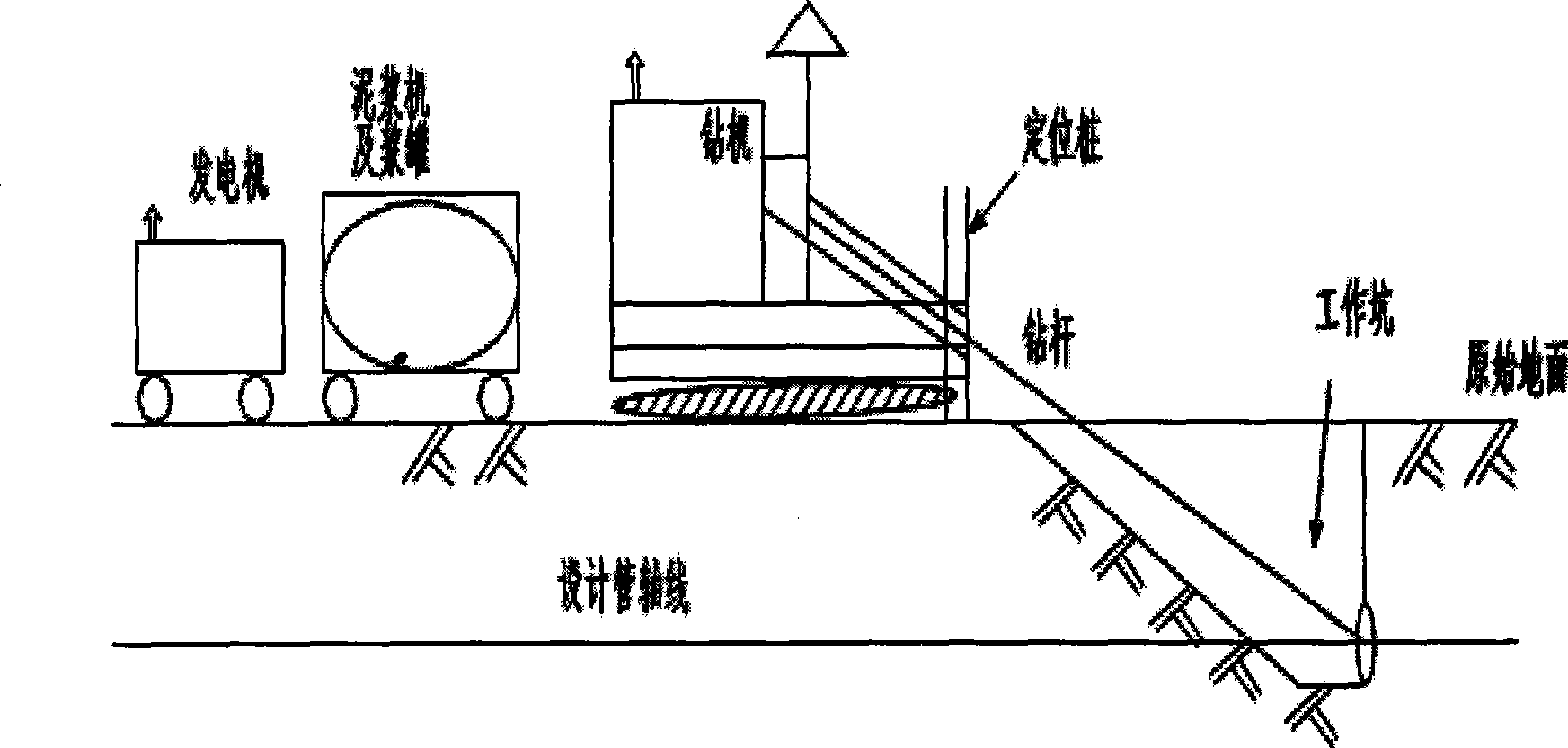

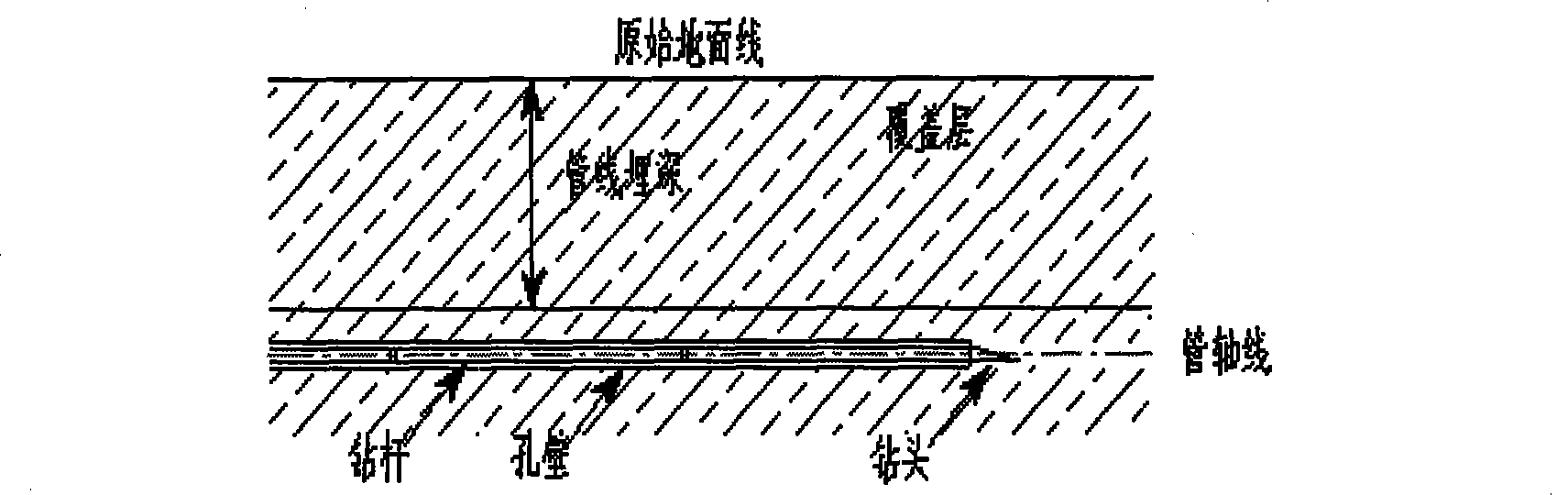

Non-digging tube-pulling construction method

InactiveCN101457853AReduce excavationReduce backfill workloadPipe laying and repairSocial benefitsGeomorphology

The invention relates to a non-excavation tube pulling construction method which comprises the following steps: (1) preparation work: understanding stratum and underground condition, calculating the number of chambering and the size of a return compandor, and formulating the control data of a pipeline midline and elevation and correction measures; (2) measuring plane surface, controlling payingoff, and measuring the elevation of each pile; (3) setting an active well, and receiving and setting a drilling machine; (4) preparing drilling fluid; (5) drilling pilot holes,; (6) adopting the compandor to chambering, cleaning the hole at the same time, and protecting walls with slurry; (7) welding the pipeline; (8) pulling the tube, and simultaneously pulling a steel tube with the same length as that of the tube; (9) casting slip and fixing; (10) mounting tubes; (11) testing pressure and flushing. The invention can effectively increases economical benefit and social benefit, and has the advantages of environmental protection and energy saving.

Owner:江苏广宇建设集团有限公司

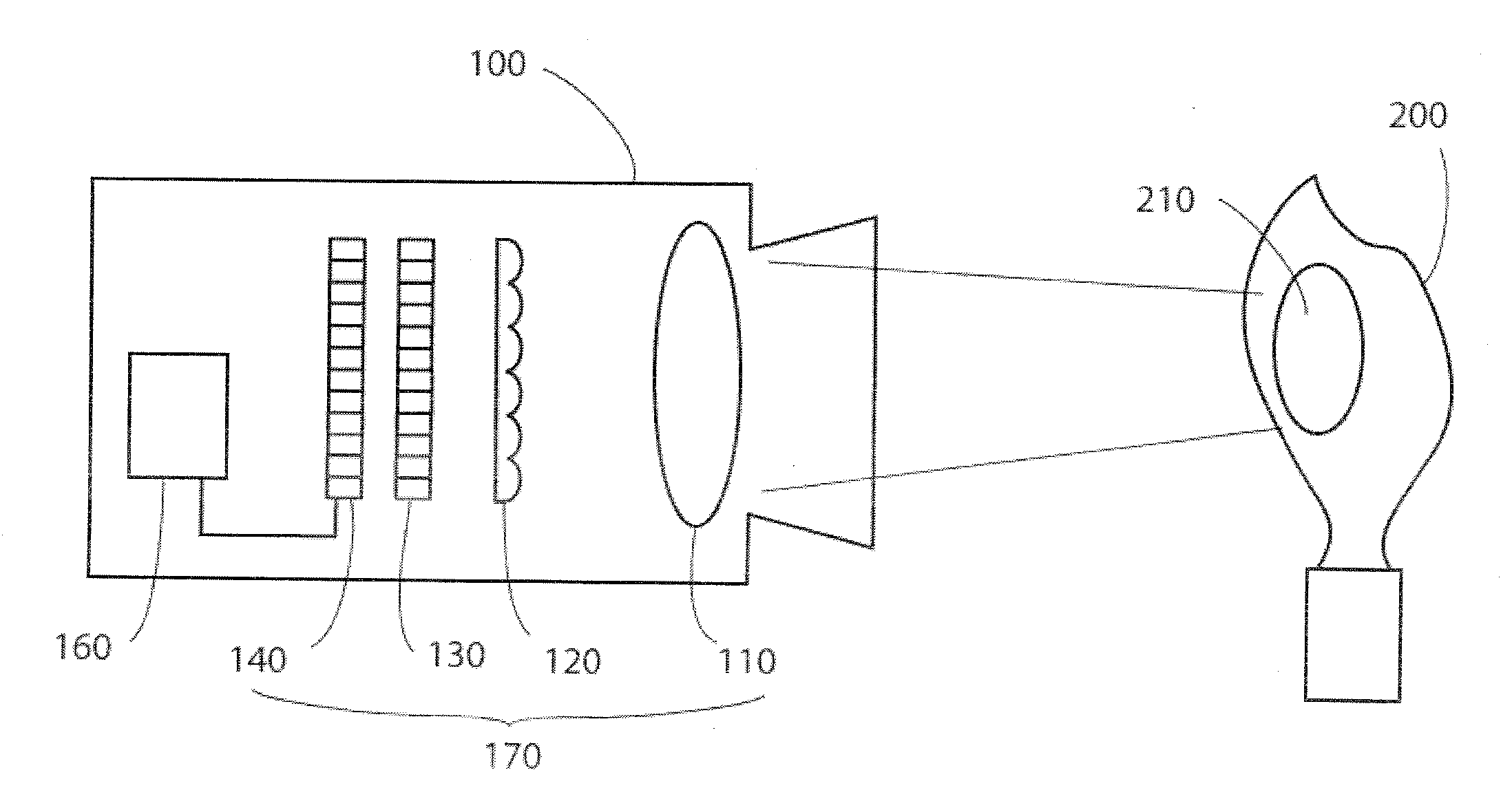

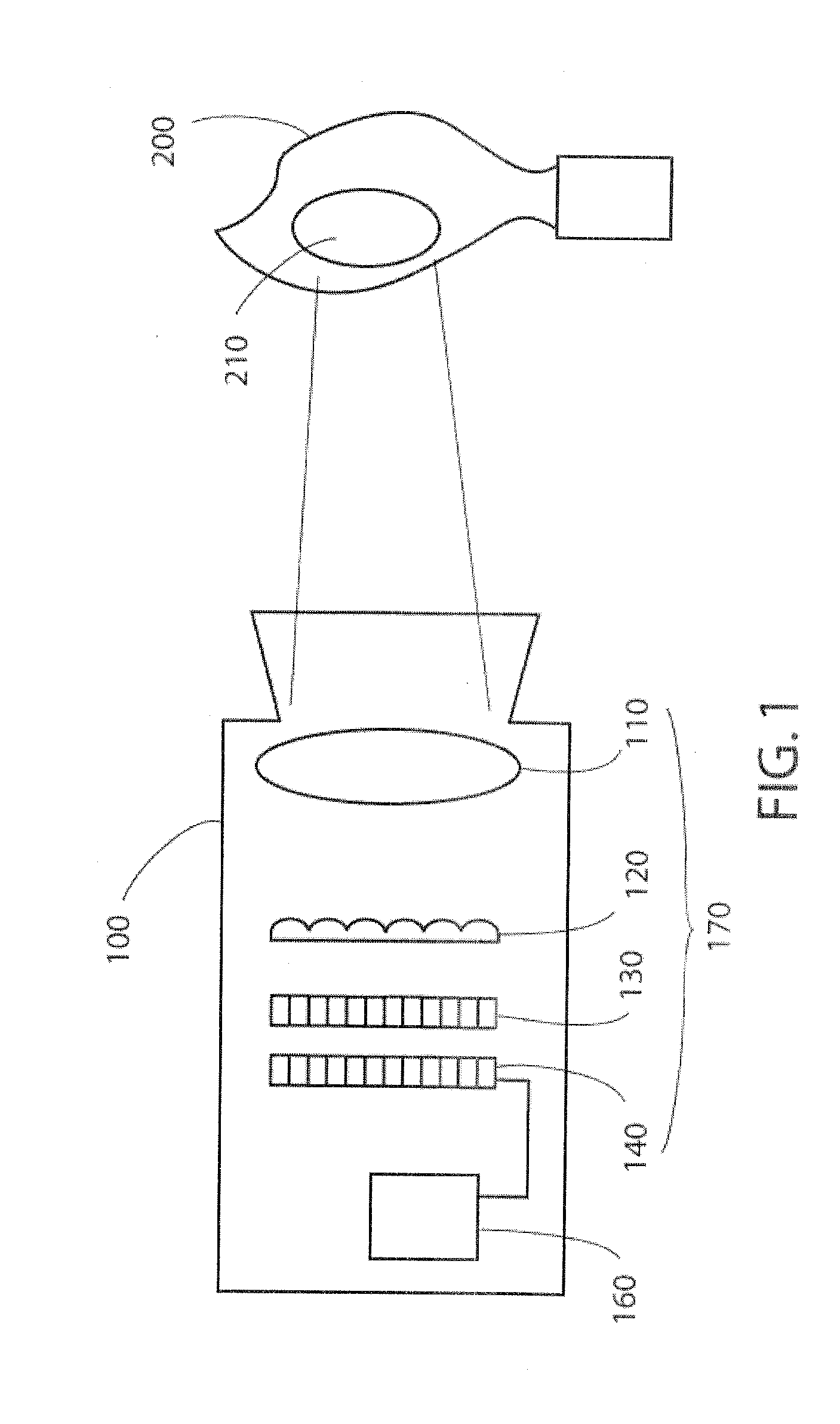

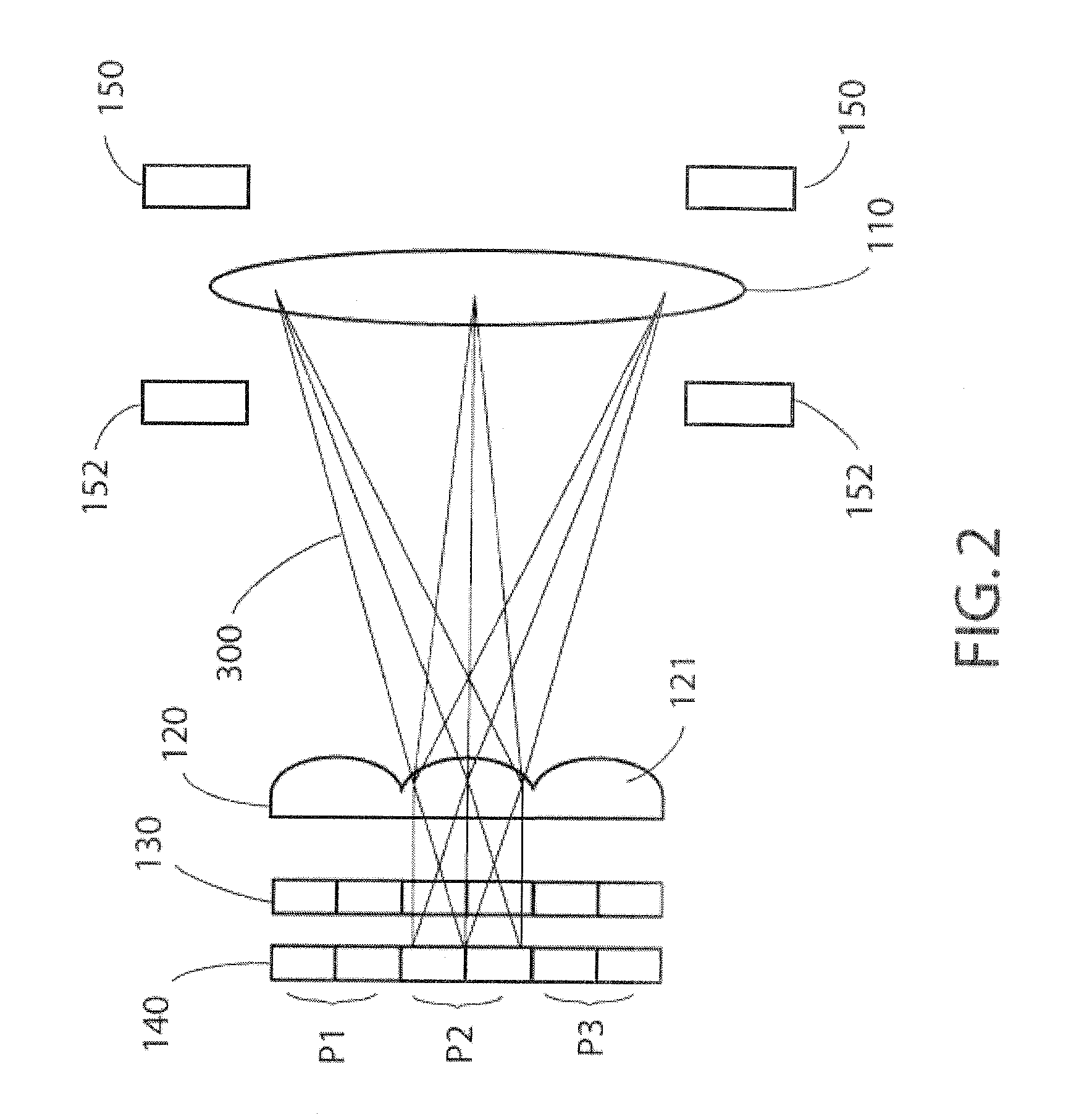

Multi-spectral infrared imaging system for flare combustion efficiency monitoring

ActiveUS20130342680A1Improve efficiencySignificant environmental benefitsTelevision system detailsSensing radiation from gases/flamesSpectral bandsCombustion

The multi-spectral imaging system for real-time measurement of combustion efficiency of an industrial flare is provided. The system includes four spectral bands, one for a hydrocarbon group (fuel), one for carbon dioxide (CO2), product of complete combustion), one for carbon monoxide (CO, product of partially completed combustion), and one for background reference. More spectral bands can be added to measure combustion efficiency of specific compounds or enhance the background reference adjustment. The analysis apparatus includes a machine readable storage medium, which provides instructions that cause the analysis apparatus to perform operations to obtain the combustion efficiency of the flare. The operations includes acquiring at least three spatially and temporally synchronized intensities from an imaging unit capturing images of the flare, and producing the combustion efficiency of the flare from said at least three intensities, and absorption coefficients of materials contained in the flare.

Owner:PROVIDENCE PHOTONICS

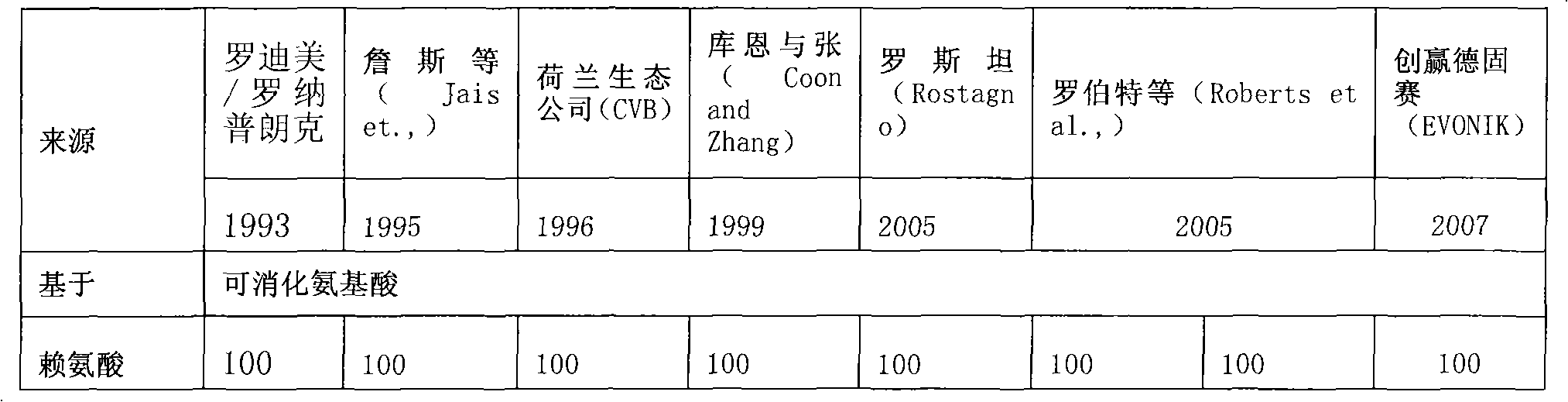

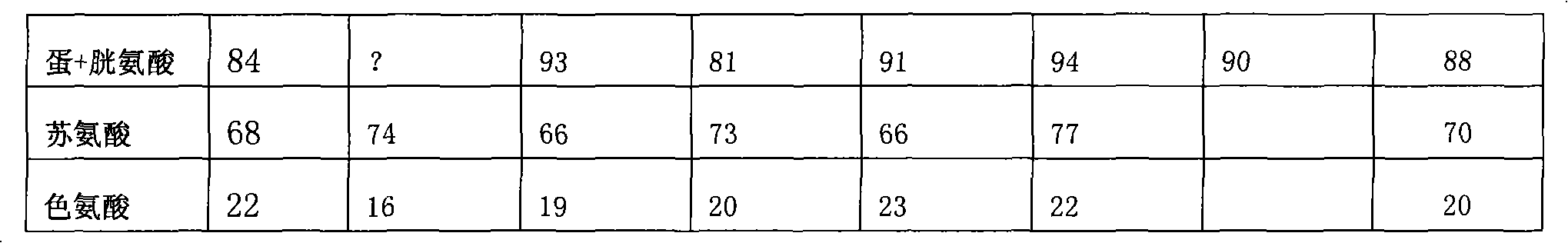

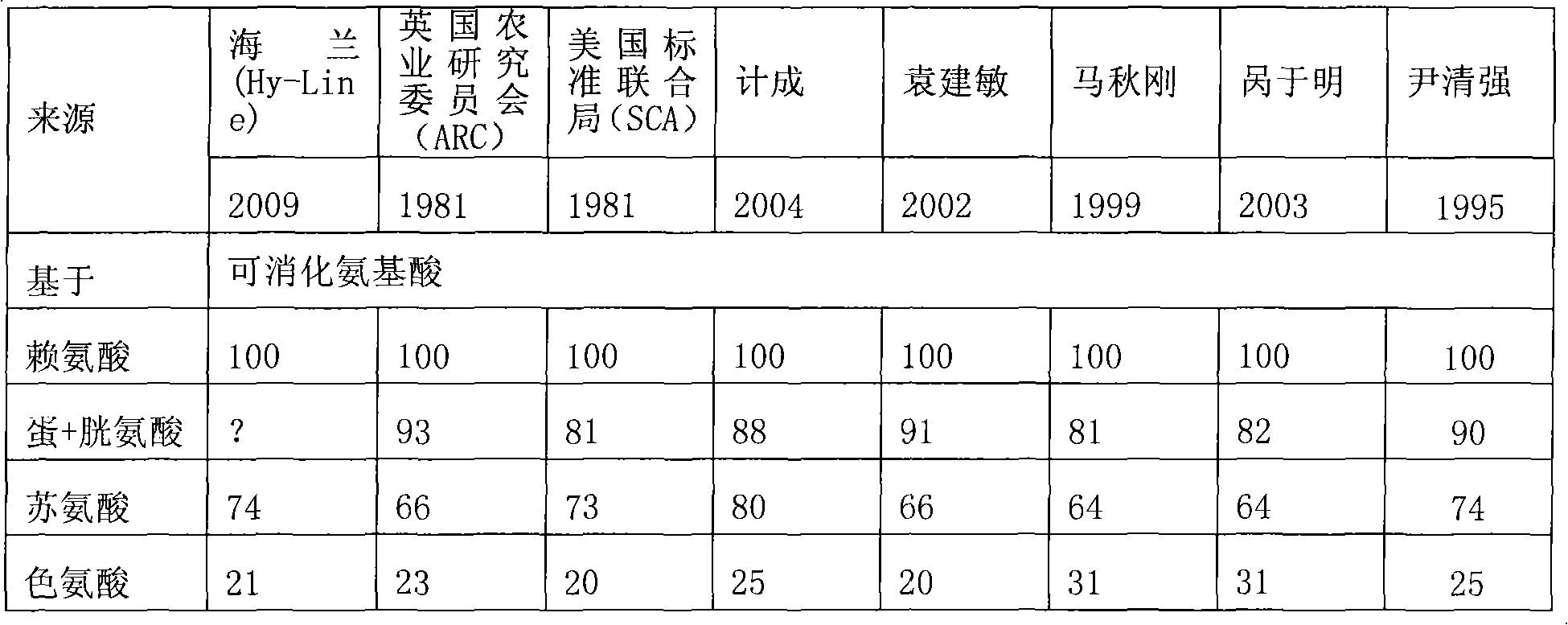

High-efficacy environment-friendly compound feed for layer hens

InactiveCN101606634AIncrease profitEmission reductionFood processingAnimal feeding stuffEconomic benefitsNitrogen

The invention relates to a high-efficacy environment-friendly compound feed for layer hens, fundamentally solving the problems of high content of crude protein, poor quality of protein and large discharge of nitrogen and phosphorus in the prior feed formulation. In the material composition of the compound feed, the balance model of digestible lysine: digestible methionine+ digestible cystine: digestible threonine: digestible tryptophan is 100:87:71:18. The invention has the advantages of reasonable design, environment protection, energy saving, improvement of laying rate, reduction of feed-egg ratio, reduction of the discharge of fecal nitrogen and fecal phosphorus and improvement of the economic benefits of enterprises.

Owner:LIAONING ZHONGYOU FEED

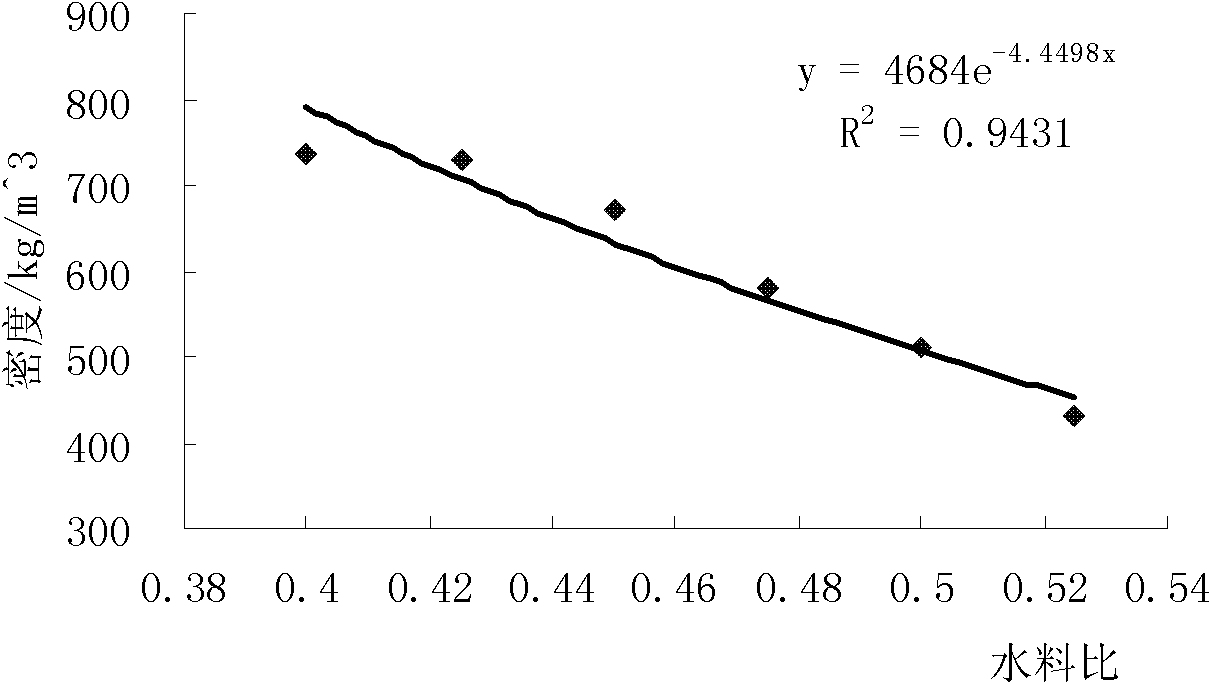

Manufacture method of environment friendly composite ceramic water-permeable brick

ActiveCN1919564AHigh strengthImprove wear resistanceSolid waste managementMixing operation control apparatusBrickComposite ceramic

The invention discloses a manufacturing method of environment-friend composite ceramic permeable brick, which comprises the following steps: adopting industrial slag with combustible substance as bottom aggregate and waste ceramic particle as layer aggregate, sieving at 10-20 order to obtain 55-65% material, sieving at 20-30 order to obtain 35-45% material, adding high-temperature adhesive and organic adhesive CMC, allocating, aging, moulding, drying, sintering.

Owner:JINGDEZHEN CERAMIC UNIV

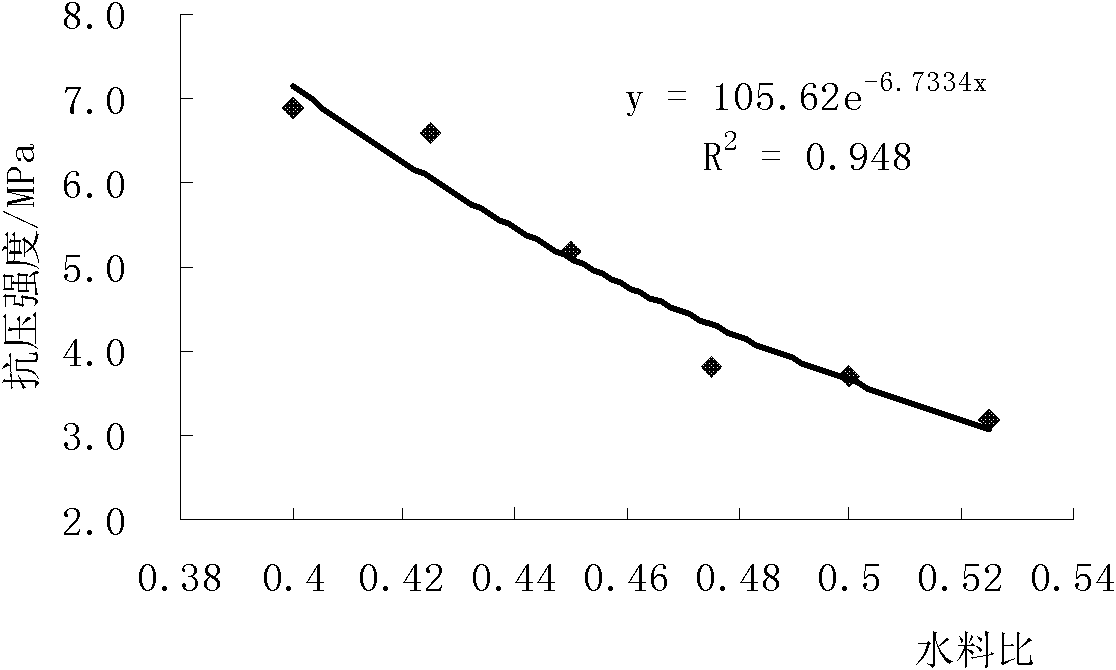

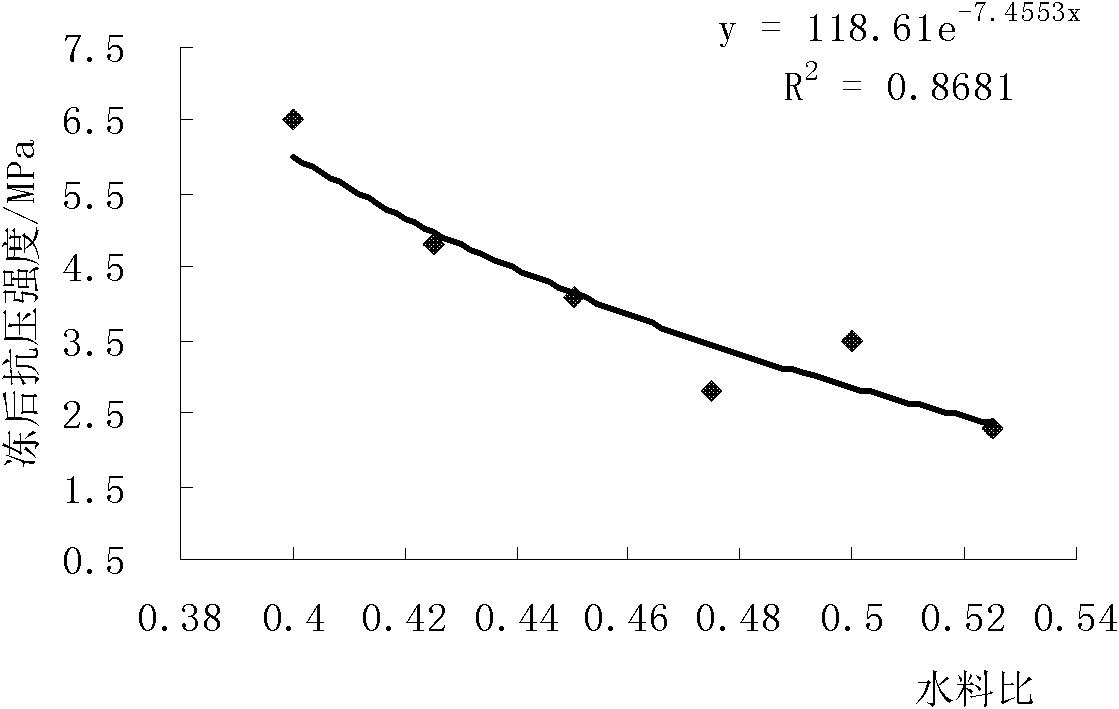

Process for preparing sludge autoclaved aerated concrete building block

InactiveCN101850574AHigh porosityMeet production requirementsSludge treatment by de-watering/drying/thickeningSolid waste managementBrickSludge

The invention belongs to the technical field of environmental engineering, and particularly relates to a process for preparing a sludge autoclaved aerated concrete building block. The process mainly comprises the following steps of: (1) quickly stirring and mixing spare dried sludge, water and lime, coal ash, cement, gypsum and aluminum powder with physical and chemical properties meeting the brick making requirements in a certain ratio and in turn; (2) feeding the mixture obtained in the step (1) into a die, and putting the die into a thermostatic curing box of 40 DEG C or 60 DEG C to perform foaming and curing for 4 hours; (3) putting the blank foamed and cured in the step (2) into an autoclave, and curing the blank for over 8 hours by adopting a stepwise buck-boost curing mode; and (4) piling the product discharged from the autoclave outdoors for over 2 days. The process can reach hazard-free and recycling treatment of urban sludge, save clay resources and save the brick making cost, and has remarkable economic, social and environmental benefits.

Owner:HUNAN UNIV OF SCI & TECH

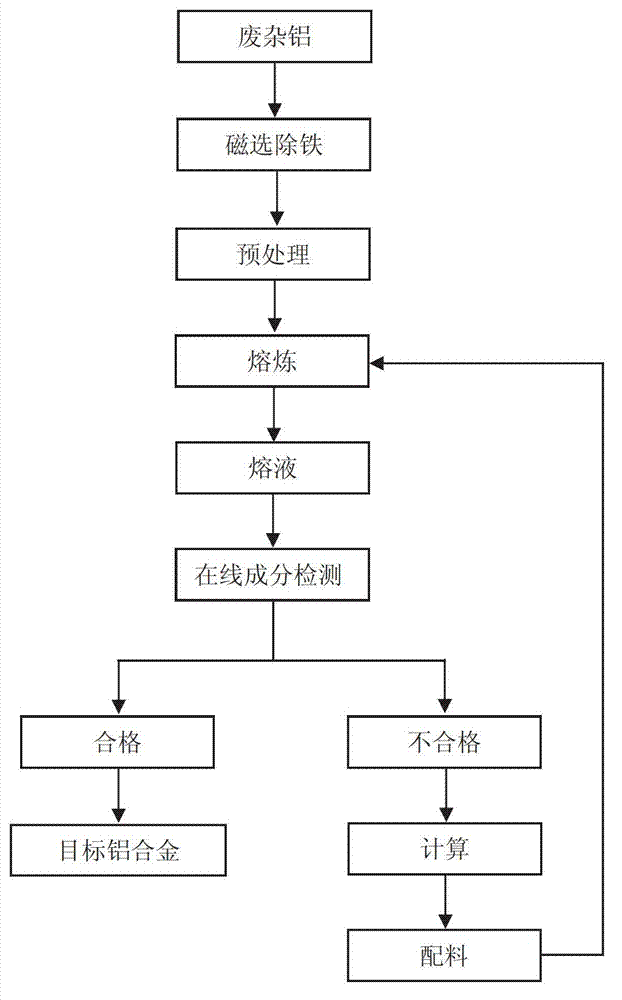

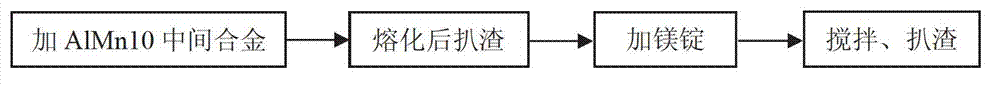

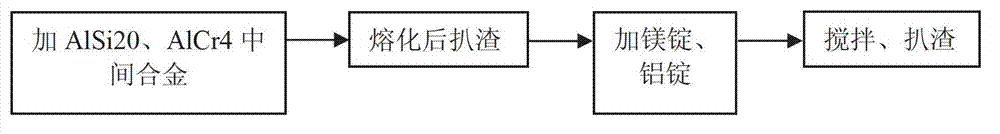

Method for regenerating aluminum alloy with target ingredient from scrap aluminum

ActiveCN103173622AAvoid pollutionEasy to detectProcess efficiency improvementCircular economyMagnetic separation

The invention discloses a method for regenerating aluminum alloy with target ingredient from scrap aluminum, relates to a scrap aluminum recycling technology and belongs to the technical field of circular economy. The technology, in which the scrap aluminum are taken as a raw material and comprises the steps of iron removal by magnetic separation, pretreatment, melting, melt ingredient detection, calculation, proportioning, and ingredient regulation for finally obtaining the aluminum alloy with the target ingredients, is developed. By adopting the method disclosed by the invention, the recycling of the scrap aluminum is achieved, and the aluminum alloy with the target ingredients can be obtained; and the method has the characteristics of no pollution, high recycling rate, easiness for realization of industrial production and obvious economic and environmental benefits.

Owner:DELTA ALUMINUM IND

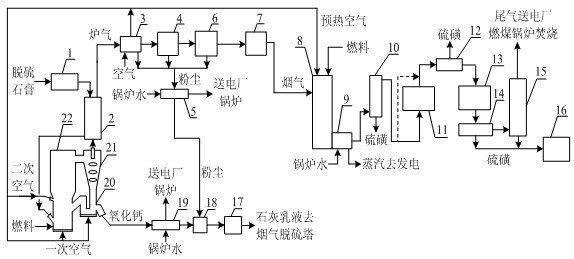

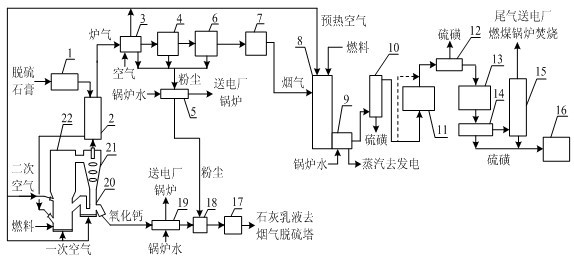

Method for preparing calcium oxide and sulfur by double-atmosphere fluidized roasting of desulfurated gypsum

InactiveCN102303883ASolve the use problemAbundant raw materialsEnergy inputSulfur preparation/purificationDust controlSulfur dioxide

The invention provides a method for preparing calcium oxide and sulfur by double-atmosphere fluidized roasting of desulfurated gypsum, belonging to the technical fields of solid pollutant treatment and in environmental protection chemical production. The method comprises the following steps: drying and dehydrating aged desulfurated gypsum, and then entering a multi-stage suspension heat exchangerfor pre-heating; entering hot-state gypsum into a circulating fluidized bed decomposition furnace, and introducing primary and secondary air for decomposition; cooling discharged hot-state calcium oxide, wherein cooled hot-state calcium oxide is used as a desulfurizer for later use; entering discharged smoke containing sulfur dioxide into the multi-stage suspension heat exchanger; removing calcium oxide dust in cooled hot smoke through multi-stage dust removing equipment; and feeding the smoke without the dust into a high-temperature-resistant high-efficiency filter for further removing the dust, and feeding clean smoke into a sulfur recovery system; and preparing the sulfur product by the processes of hot reduction, catalytic reduction, Clause reaction and the like, and feeding Clause tail gas into a coal burning boiler in a power plant for combustion. The method has the advantages of good environmental protection benefits and strong economic benefits.

Owner:CHINA PETROCHEMICAL CORP +1

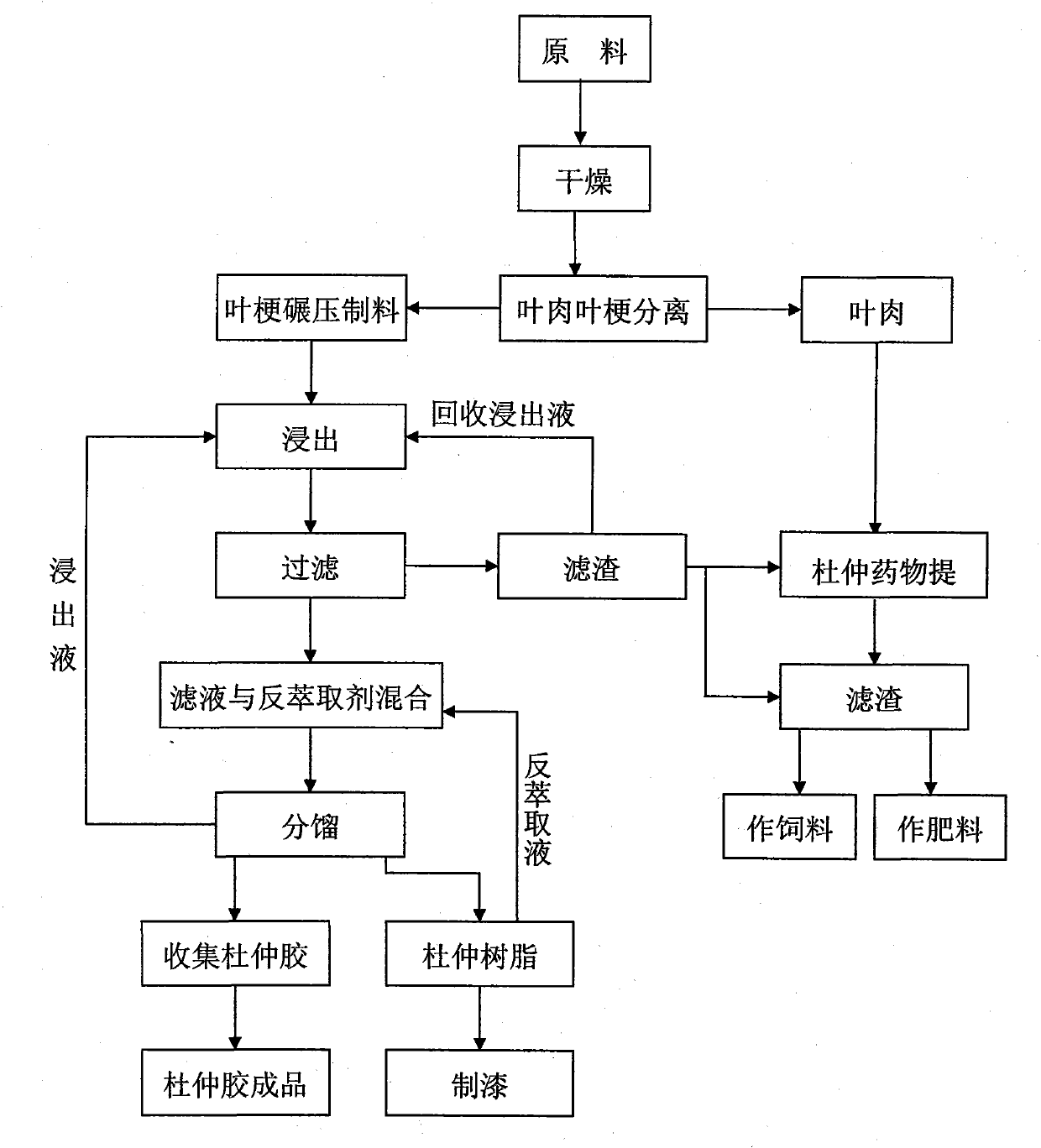

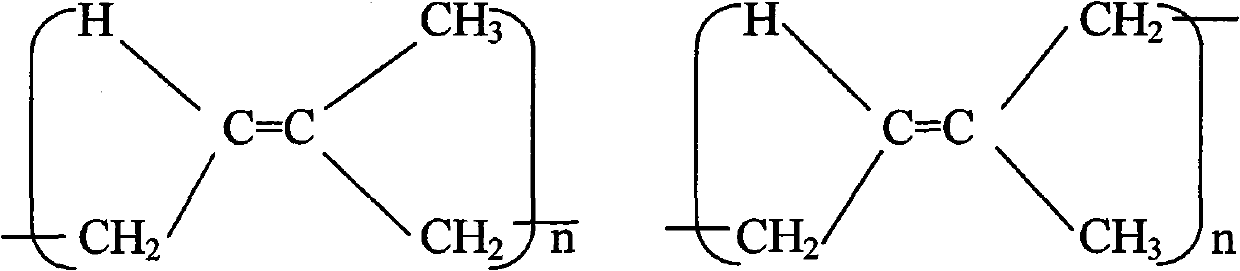

Method for continuously generating fine gutta-percha through digestion-reextraction

InactiveCN101906176AHigh extraction rateReduce consumptionNatural resin coatingsClimate change adaptationSolventDigestion

The invention relates to a method for continuously generating fine gutta-percha through digestion-reextraction. The method comprises the steps of: firstly, pre-treating folium cortex eucommiae including drying, crashing and cutting; secondly, digesting gutta-percha from folium cortex eucommiae through leach liquor; thirdly, separating gutta-percha from folium cortex resin through reextraction solution and dissolving the gutta-percha; and fourthly, post-treating materials, principally to dry the dissolved gutta-percha so as to obtain the fine gutta-percha. The method of the invention has the advantages that the leach liquor is nonflammable non-toxic agent, the gutta-percha extraction efficiency is high, the environment is prevented from being polluted, the folium cortex eucommiae is complexly used, no waste generates, the solvent is recycled, the consumption is low, the product quality is high, industrial continuous production is realized, the economic, environment-friendly and social benefits are all better than the traditional production method, and the promotional value is high.

Owner:刘志成

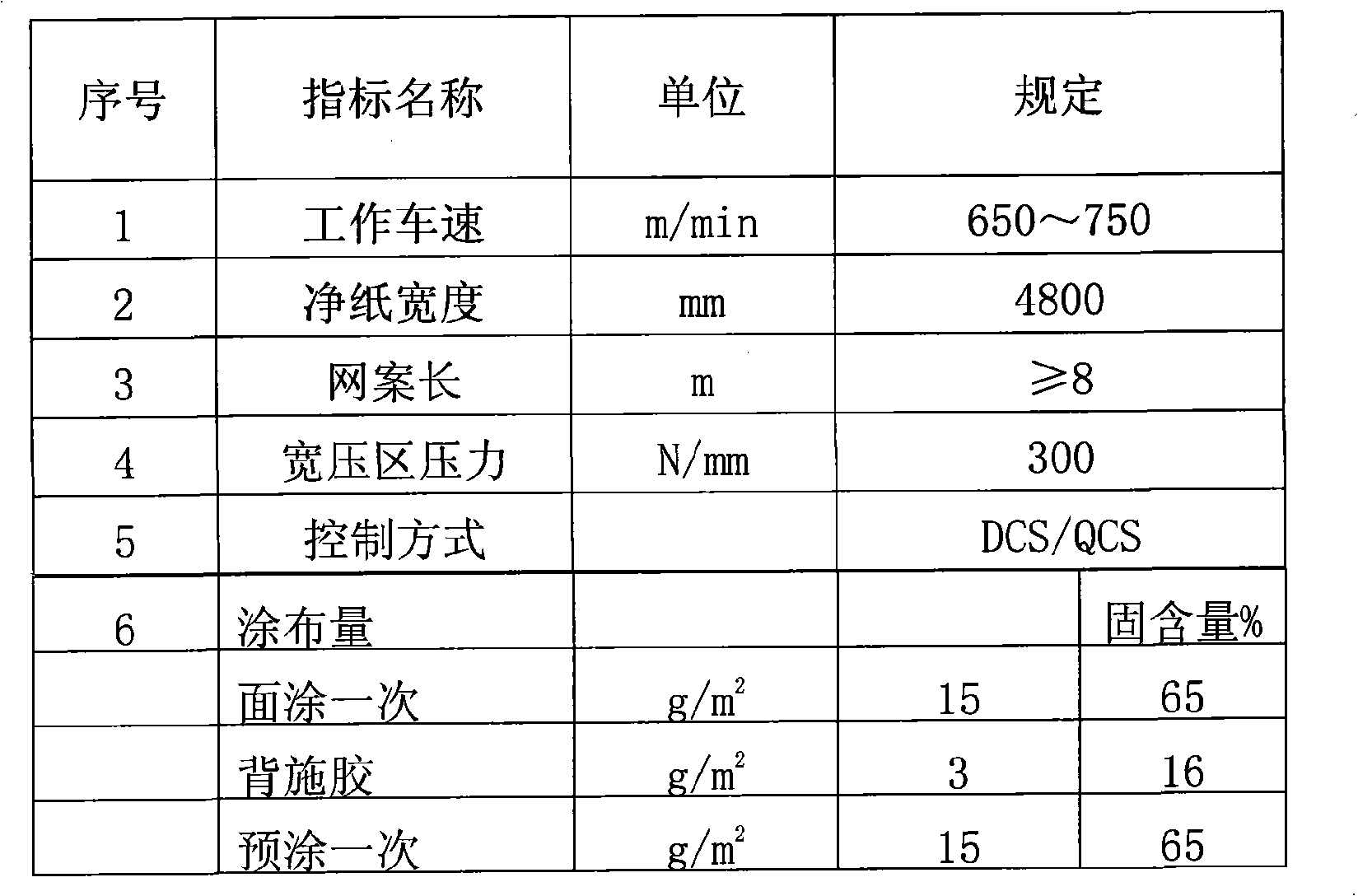

Method for producing coated kraft card board by home-made paper machine

The invention relates to technical field of coated kraft liner producing method. The producing method comprises feeding surface pulp, lining pulp, core pulp and bottom pulp pumped from machine chest of pulping workshop into respective machine chest; slushing and pressure screening the lining pulp, the core pulp and the bottom pulp by offline back water bank, then slushing and pressure screening the surface pulp by the offline back water bank after removing impurities in the surface pulp in a low concentration sand remover, finally all the pulp entering into a flow box to flow onto wire; after the pulp flowing onto wire, feeding the pulp into a coating system after forming by a four-long net forming machine, second shoe pressing, drying, glue blending, redrying, and press polishing by a two-roller hot pressing machine; feeding the coated paper into a state-regulating cylinder and a soft calendar to finish, then reeling by a horizontal paper reeling machine. The coated kraft liner producing method disclosed by the invention can greatly reduce use cost of the coated kraft liner to make the domestic market not dependent on import any longer.

Owner:ZHEJIANG YONGTAI PAPER IND GROUP

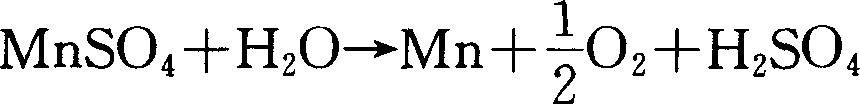

Method of manufacturing electrolytic metal manganese using titanium white waste acid and manganese dioxide ore

InactiveCN1724697ASolve pollutionImprove filtering effectPhotography auxillary processesElectrolysisSulfur

The invention relates to a method to make electrolysis manganese metal by titan white spent acid and manganese dioxide mine. The feature is that it uses the H2SO4 and Fe2+ in the titan white spent acid as assistant material, adds manganese dioxide mine and sulfur iron ore to make electrolysis manganese metal. The invention solves the environment pollution problem caused by titan white spent acid. The electrolysis manganese metal has high quality and reaches the YB / T051-2003DJMnA high purity production standard.

Owner:CENT SOUTH UNIV +1

Apparatus and method of enhancing the quality of high-moisture materials and separating and concentrating organic and/or non-organic material contained therein

ActiveUS8062410B2Processed evenly and quicklySignificant environmental benefitsDrying solid materials with heatGas current separationParticulatesFluidized bed drying

The present invention harvests and utilizes fluidized bed drying technology and waste heat streams augmented by other available heat sources to dry feedstock or fuel. This method is useful in many industries, including coal-fired power plants. Coal is dried using the present invention before it goes to coal pulverizers and on to the furnace / boiler arrangement to improve boiler efficiency and reduce emissions. This is all completed in a low-temperature, open-air system. Also included is an apparatus for segregating particulate by density and / or size including a fluidizing bed having a particulate receiving inlet for receiving particulate to be fluidized. This is useful for segregating contaminants like sulfur and mercury from the product stream.

Owner:RAINBOW ENERGY CENT LLC

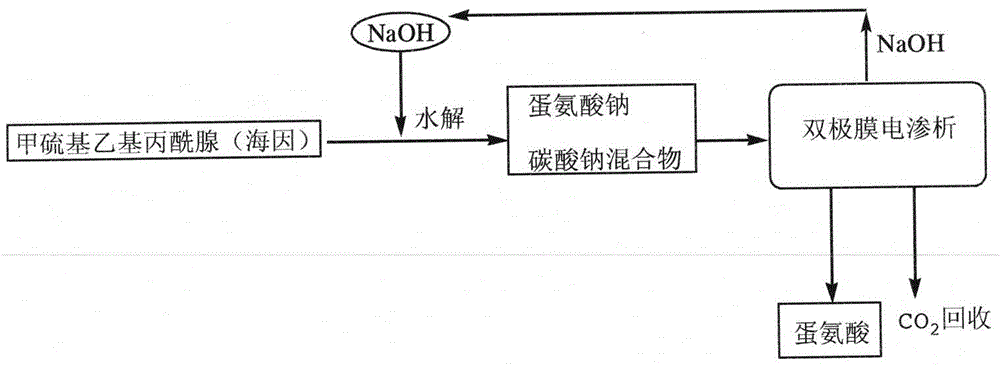

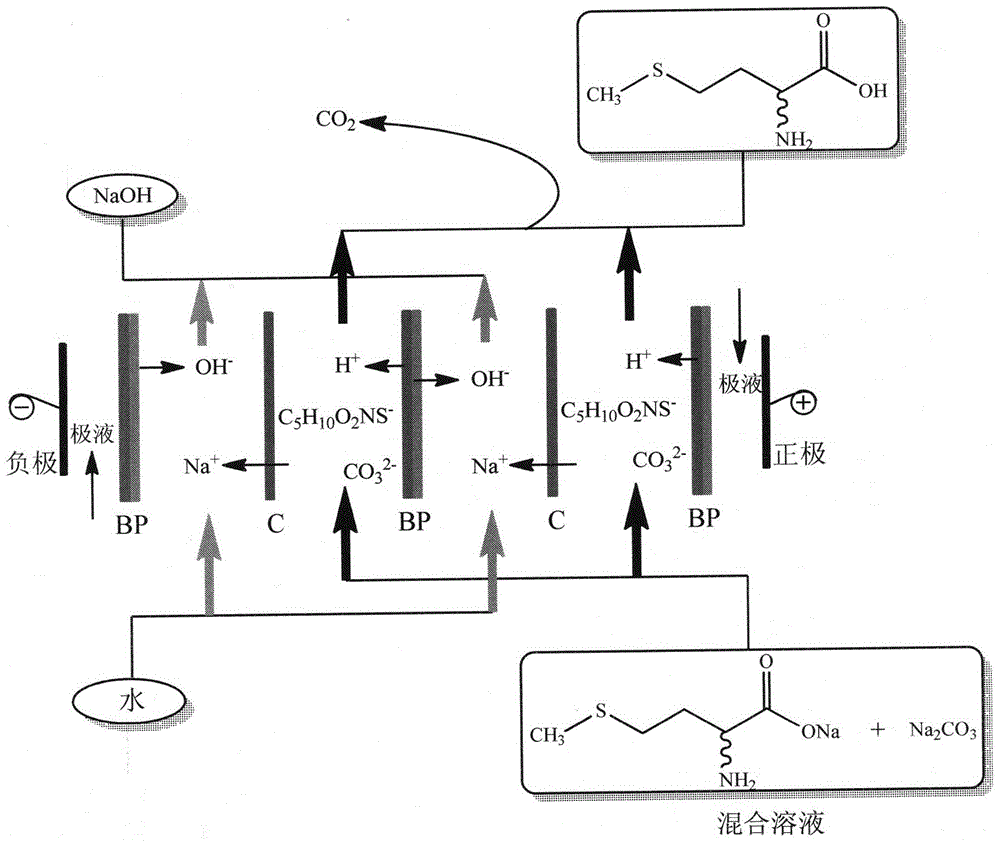

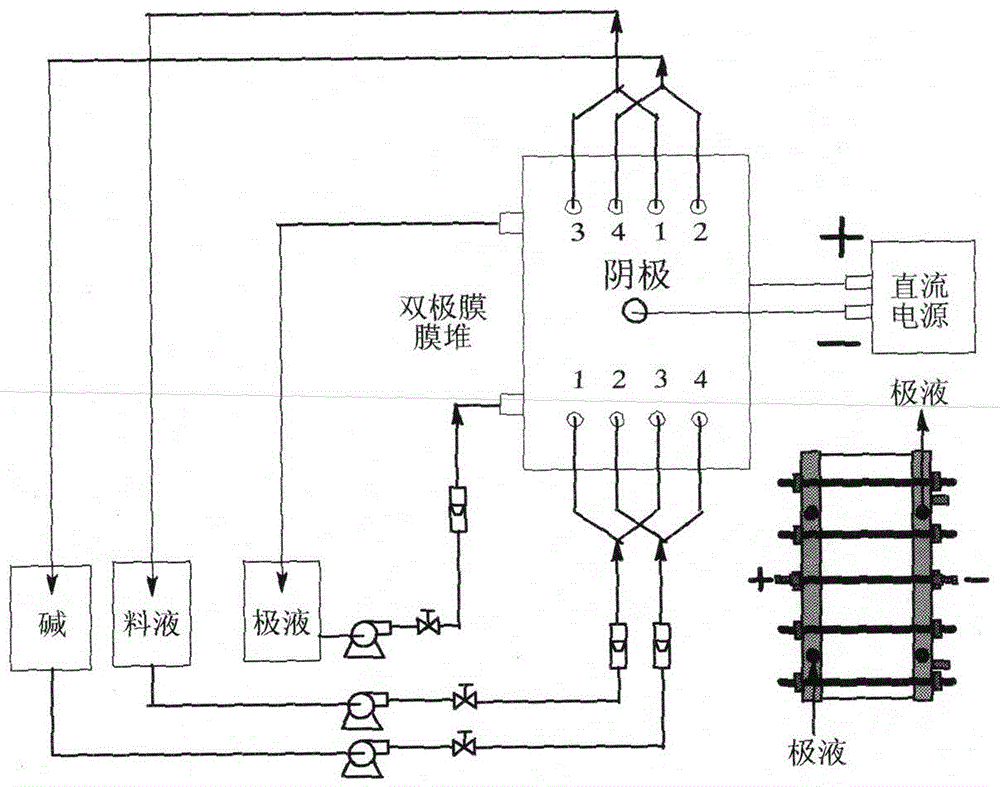

Method for preparing methionine and sodium hydroxide through bipolar membrane electrodialysis

InactiveCN103933861ARealize cleaner productionSignificant industrial application valueOrganic compound preparationAlkali metal hydroxidesMethionine recyclingHydrolysate

The invention discloses a method for preparing methionine and sodium hydroxide through applying a bipolar membrane electrodialysis technology. The method comprises the specific process: diluting a methylthioethyl hydantoin (hydantoin) hydrolysate to one-third to one-fifth of the original concentration, and filtering with a microporous filter; then pumping the hydrolysate into one of a salt chamber or a salt / acid chamber of a bipolar membrane electrodialysis device, and injecting a certain concentration of an electrolyte solution into other compartments; connecting a cathode and an anode of the bipolar membrane electrodialysis device respectively with a negative electrode and a positive electrode of a direct-current power source, starting the bipolar membrane electrodialysis device, controlling the current density of a direct-current electric field to be 50-150 mA / cm<2> and the temperature at 20-40 DEG C, and thus obtaining methionine with higher purity in an acid chamber, wherein the methionine recycling rate reaches more than 95% and the current efficiency reaches about 70%; and at the same time, collecting obtained carbon dioxide, and thus obtaining sodium hydroxide with the concentration of 4-6% in an alkali chamber. The method has the advantages of high yield, no pollution, less use of raw materials, and good application prospects.

Owner:ZHEJIANG CIRCLE TECH MEMBRANE TECH +1

Method for recovering high-purity organic salt from phosphorous-containing industrial wastewater

ActiveCN103342398ARealize resource utilizationSolve processing problemsWater/sewage treatment by heatingInorganic saltsSaline water

The invention discloses a method for recovering a high-purity organic salt from phosphorous-containing industrial wastewater. The method comprises the following steps: evaporating and concentrating the phosphorous-containing high-salt industrial wastewater to obtain an organic salt rough product; washing the inorganic salt rough product by using a washing solution; removing phosphorous from the inorganic salt rough product; keeping the washed inorganic salt rough product in contact with oxygen-containing gas at the temperature of less than or equal to 1,000 DEG C; and carbonizing to obtain the high-purity inorganic salt, wherein the washing solution is salt water or industrial wastewater with high inorganic salt content. The method realizes resource recycling of industrial salt, phosphorous in the salt is removed by the high-salt wastewater, the treatment of wastes with wastes is realized, and the economic benefit is prominent; the method has the advantages of short process flow, no wastewater discharge, incapability of producing secondary pollution which is difficult to treat, recyclability of tail gas, obvious environmental protection effect and suitability for industrial application; meanwhile, the method is widely applied; and the purification of the industrial salt can be realized by using the method for all the pesticides and even high-salt wastewater in other industries.

Owner:SHANDONG WEIFANG RAINBOW CHEM

Apparatus and method of separating and concentrating organic and/or non-organic material

ActiveUS7540384B2Processed evenly and quicklySignificant environmental benefitsGas current separationSolid fuel pretreatmentParticulatesFluidized bed

An apparatus for segregating particulate by density and / or size including a fluidizing bed having a particulate receiving inlet for receiving particulate to be fluidized. The fluidized bed also includes an opening for receiving a first fluidizing stream, an exit for fluidized particulate and at least one exit for non-fluidized particulate. A conveyor is operatively disposed in the fluidized bed for conveying the non-fluidized particulate to the non-fluidized particulate exit. A collector box is in operative communication with the fluidized bed to receive the non-fluidized particulate. There is a means for directing a second fluidizing stream through the non-fluidized particulate as while it is in the collector box to separate fluidizable particulate therefrom.

Owner:RAINBOW ENERGY CENT LLC

Open-type coal dust pollution inhibitor and method for preparing same

InactiveCN101177604AExcellent performance indexImprove performanceOther chemical processesSocial benefitsGravity flow

The invention pertains to the technical field of composite material science and environmental protection and relates to opening coal dust polluting inhibitor and the preparation method thereof. The inhibitor is the hydrophilic material compounded by a plurality of compounds, and every compound and the weight percentage thereof is that: 15-20 percent main film forming resin, 25-30 percent auxiliary film forming resin,1-2 percent thickening agent, 15-20 percent dispersant, 2-3 percent mould inhibiting antiseptic agent, 1-2 percent anti-sedimentation agent, 2 percent defoamer, 15-20 percent powder and 3-5 percent color paste. The invention adopts the theory of gravity flow mat gloss solidification, which effectively overcomes the disadvantages of uneven film forming thickness, long film forming time, poor stability of film layer, etc of original self-solidification inhibition materials. The invention has low price, and production thereof is simple and practical; in addition, the invention has remarkable economic, environmental and social benefits, and is applicable to treat raised dust pollution in the fields of shipping, power, mine, road, metallurgy, etc.

Owner:冯威

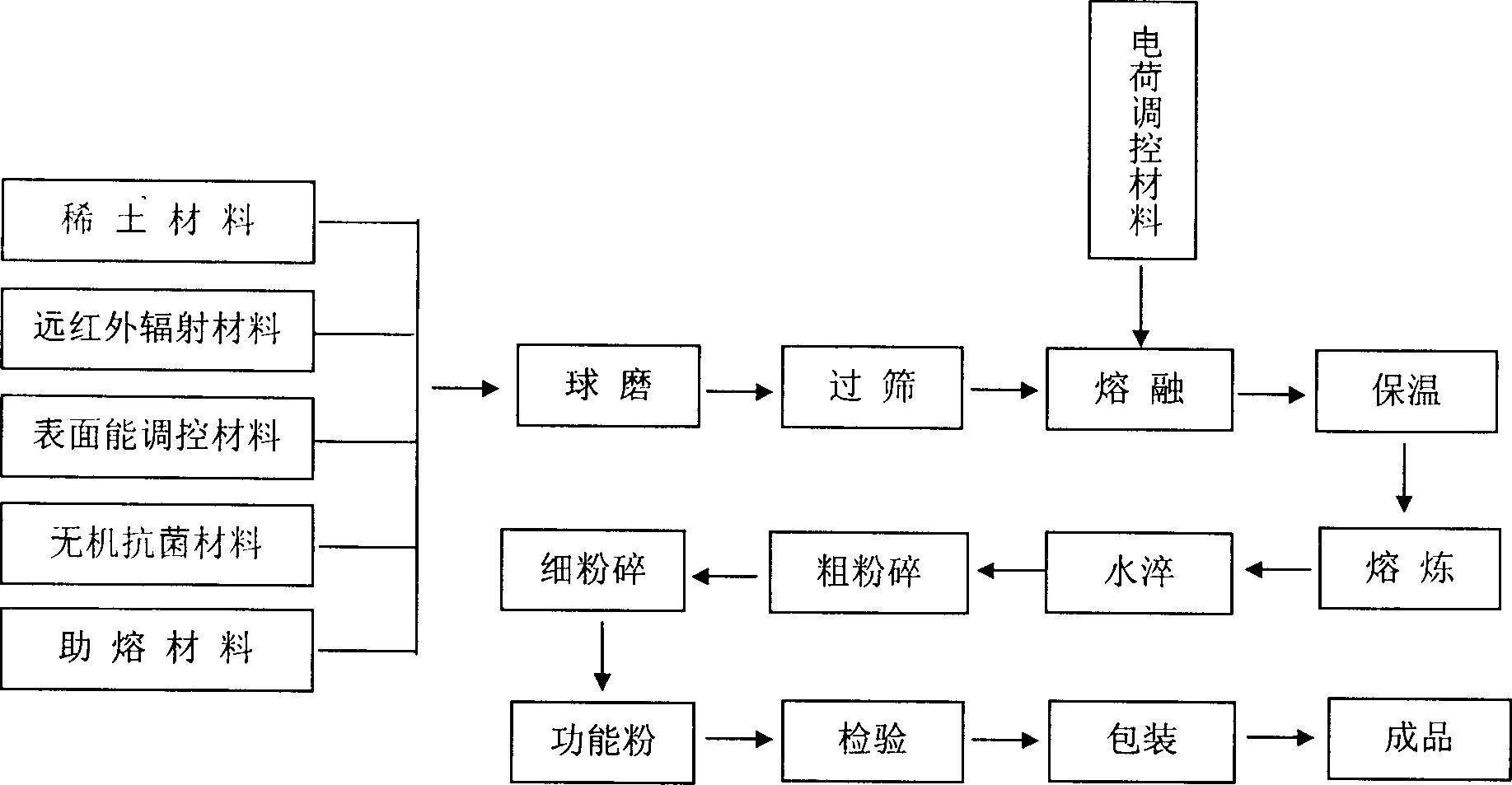

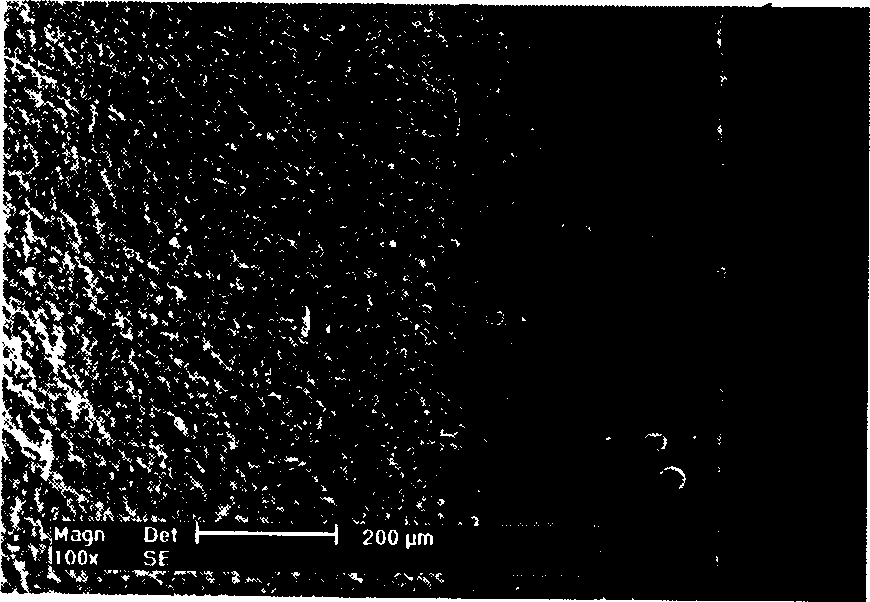

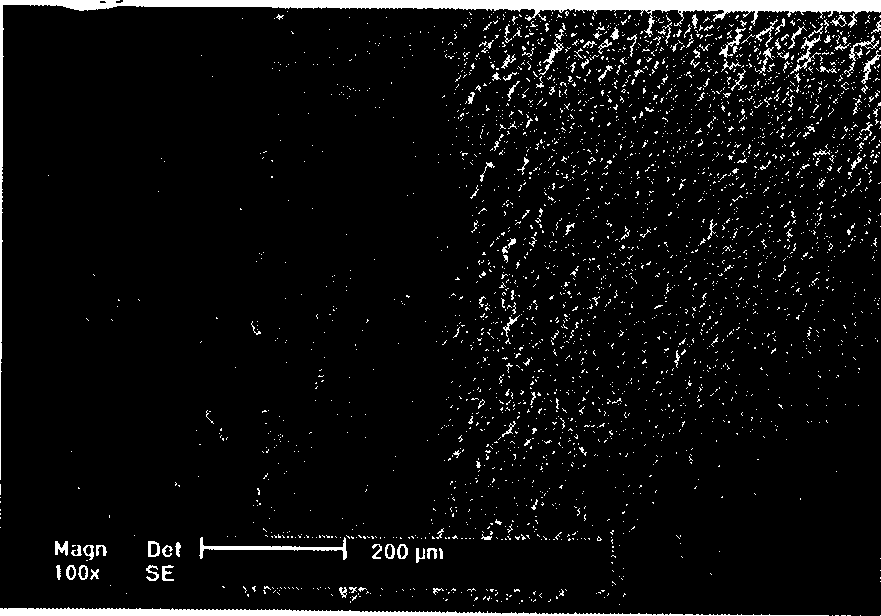

Super hydrophilic functional ceramic material easy to be cleaned and preparation technique

The present invention relates to a super hydrophilic easy-to-clean function ceramic material which can be used for producing easy-to-clean anti-bacterial high-grade ceramic product. Its raw material composition includes (by male%) 2-10% of rare earth material, 25-40% of far infrared radiation material, 10-30% of surface energy regulating material, 2-10% of electric change regulating and controlling material, 6-15% of flux material and 2-15% of inorganic anti-bacterial material. Said invention also provides its preparation process and its application method.

Owner:淄博博纳科技发展有限公司 +1

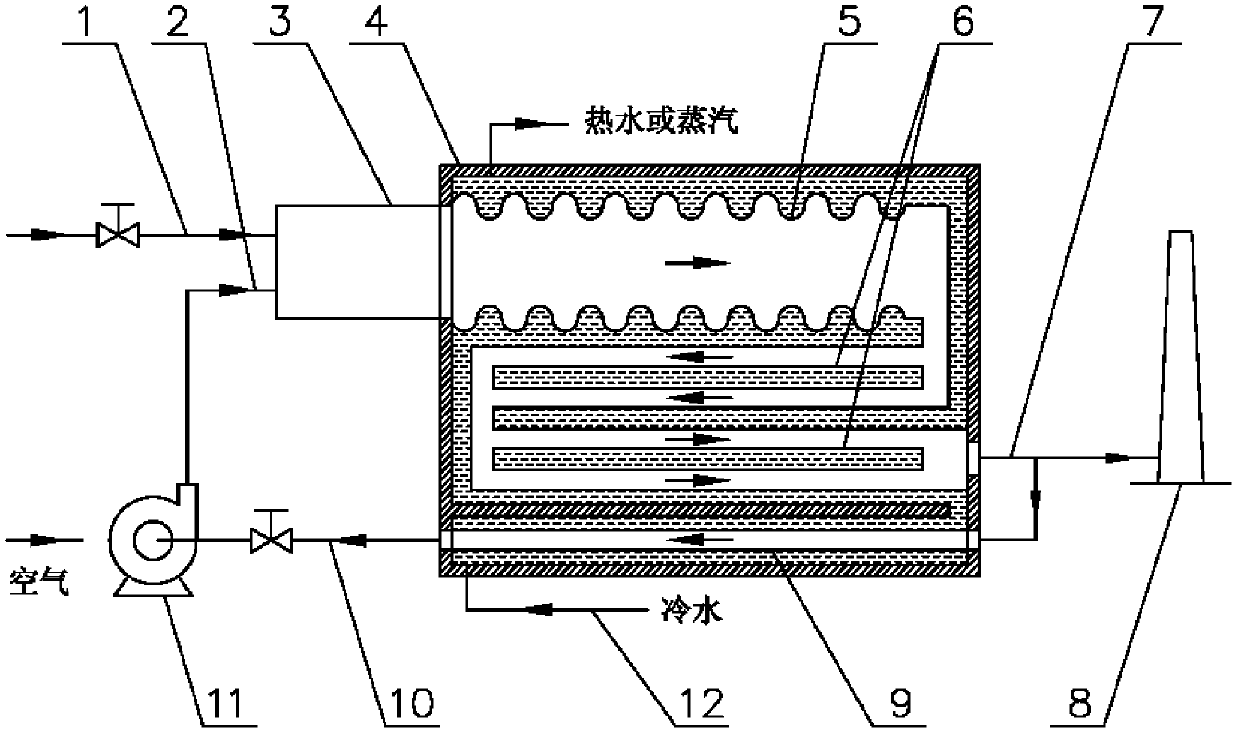

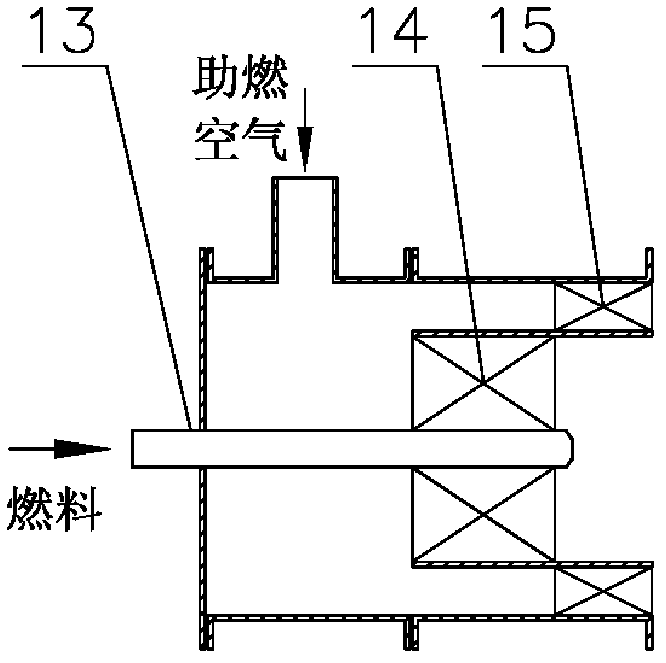

Fuel oil/gas boiler for reducing emission of nitric oxides and method

ActiveCN102635852AReduce the temperatureWide stable rangeBurnersCombustion technology mitigationLow nitrogenFuel oil

The invention relates to a fuel oil / gas boiler for reducing emission of nitric oxides and a method, belonging to the technical fields of energy saving and emission reduction and boilers. The fuel oil / gas boiler for reducing emission of nitric oxides comprises a fuel pipeline, a combustion-supporting air pipeline, a low-nitrogen combustor, a boiler body, a smoke discharging pipeline, a chimney, a smoke circulating pipeline, a combustion-supporting fan and a water inlet pipe. Compared with the common boiler, the fuel oil / gas boiler has the advantages of reducing radiation heat exchange area by 30-50%, and increasing heat convection area by 15-25%; and 15-25% of boiler low-temperature smoke enters the combustion-supporting fan after passing through a smoke circulating cooler and the smoke circulating pipeline, and is mixed with fresh air to be used as combustion-supporting air to enter the low-nitrogen combustor. According to the invention, on the premise of no reduction of the heat efficiency of the fuel oil / gas boiler and no increase of operation cost, the emission of the nitric oxides of the fuel oil / gas boiler can be reduced by 20-50%.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

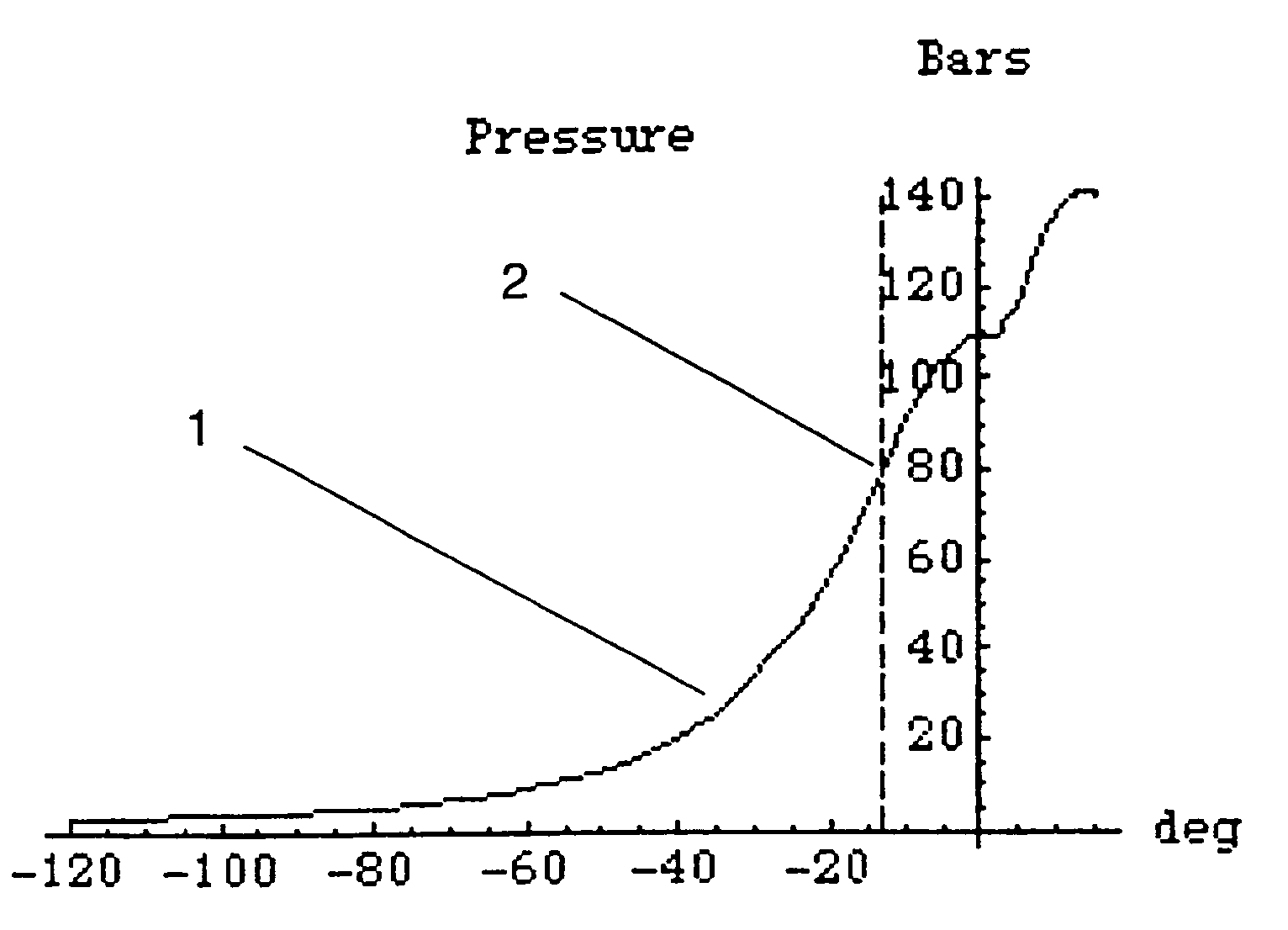

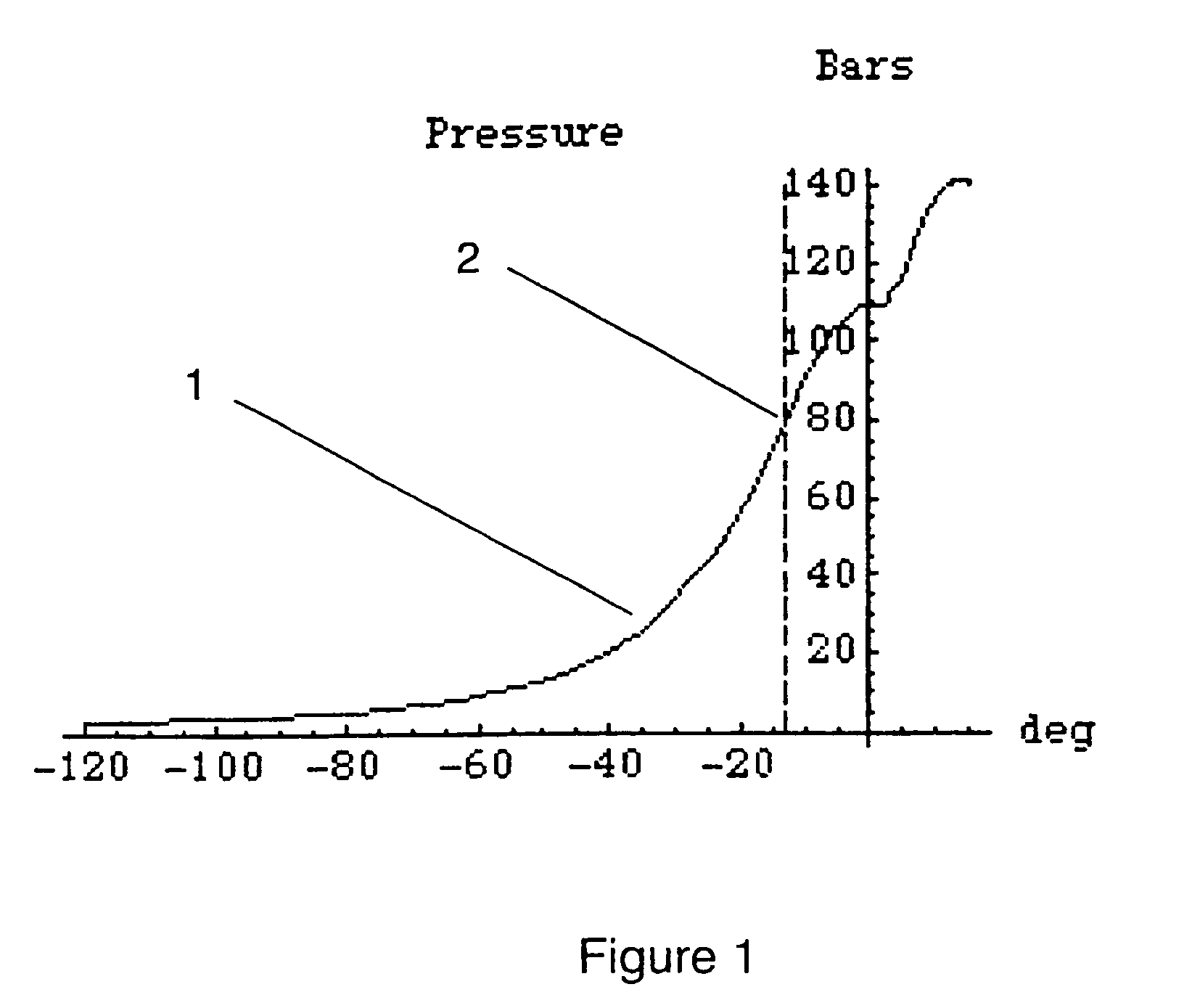

Method to determine TDC in an internal combustion engine

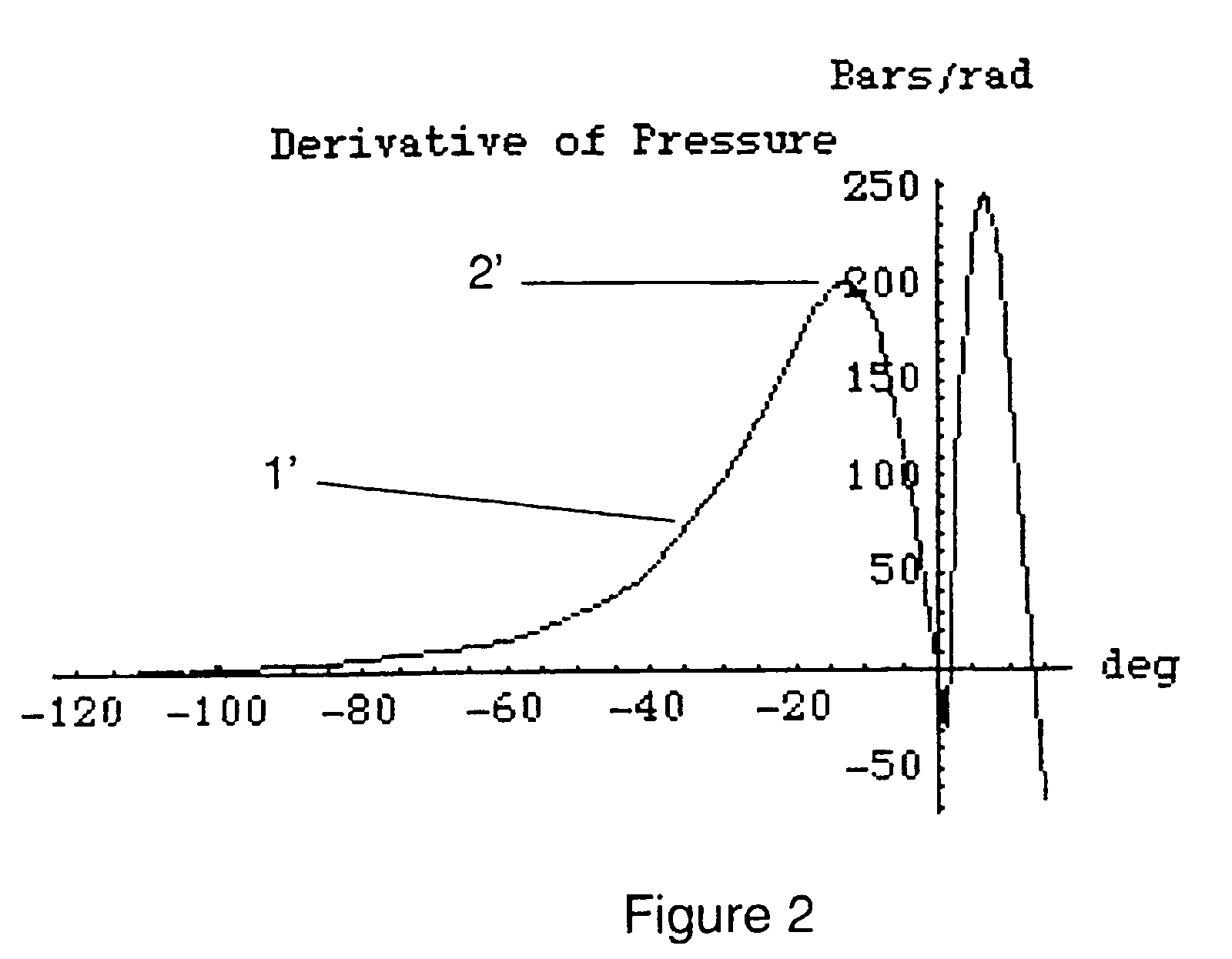

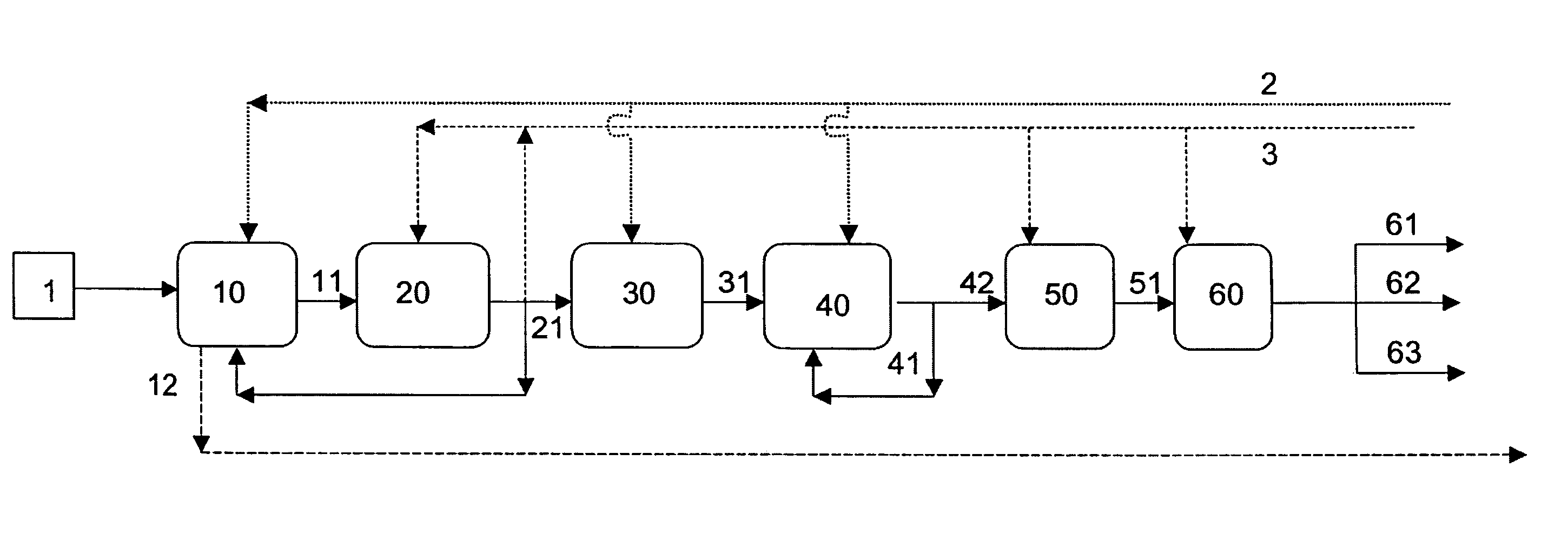

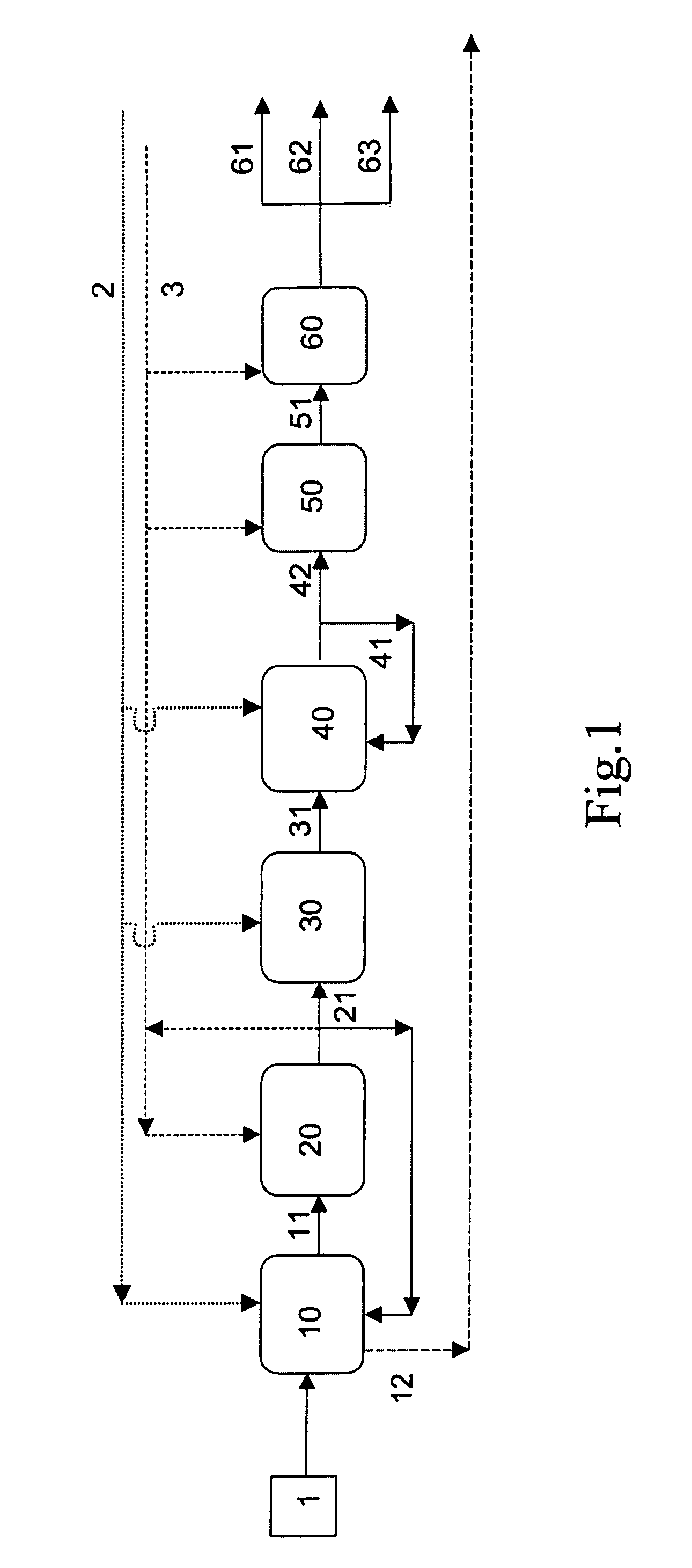

InactiveUS7117080B2Efficient developmentHigh in technologyInternal-combustion engine testingAnalogue computers for vehiclesInternal combustion engineFlywheel

A method and apparatus for accurately determining TDC in a cylinder of an internal combustion engine. Gas pressure is measured in the cylinder relative to crank angle, giving rise to a curve of gas pressure with crank angle. An offset is found by first computing the angular position of an inflexion point of the compression pressure curve measured as a function of the crank angle, and then computing the offset as the difference between the angular position of a piston in the cylinder and a theoretical value for said angular position of the piston dependent on a known or measured flywheel angle. The value of TDC corrected by the offset is then used to calculate a value of work output such as the Indicated Mean Effective Pressure (IMEP) which may be used for diagnostic and / or control purposes.

Owner:ABB (SCHWEIZ) AG

Process for the manufacture of base oil

ActiveUS7795484B2Significant environmental benefitsReduce impactHydrocarbon by hydrogenationCarboxylic acid esters preparationDistillationHeteroatom

A feedstock originating from renewable sources is converted to branched and saturated hydrocarbons without heteroatoms in the base oils distillation range by converting the fatty acids to olefins, which are subsequently oligomerised.

Owner:NESTE OIL OY

Method for producing flavourings cooking wine

ActiveCN101130730ASimple processEasy to operateAlcoholic beverage preparationFood preparationYeastWork in process

The invention discloses a manufacturing method of flavouring cooking wine, which comprises the following steps: adopting yellow water, squeezing liquid of distiller's grain, wine end and special cavity wine as raw material; predisposing the raw material; boiling; dispensing; filtering; blending the yellow water and distiller's grain with weight rate at 1. 5-5: 1 to do basylous action through hypercritical CO2 extraction; adding 0. 05-0. 1% aromatic yeast in the slurry; culturing at 30 deg. c for 2-5d; adding the cultured slurry into 0. 1-0. 5%. composite condiment material to boil 10-20 min; cooling to 33-35 deg. c to add 20-50% wine end to blend to produce the semi-product; dispensing the semi-product with special cavity wine and edible salt according to the standard of SB / T10416-2007 flavouring cooking wine. The invention prevents environmental pollution of yellow water, wine end and distiller's grain to realize maximum resource transition utility, which saves a large amount of grain and simplifies the technique and operation with low cost and rapid effect in comparison with traditional brewing technique.

Owner:SICHUAN TUOPAI SHEDE WINE

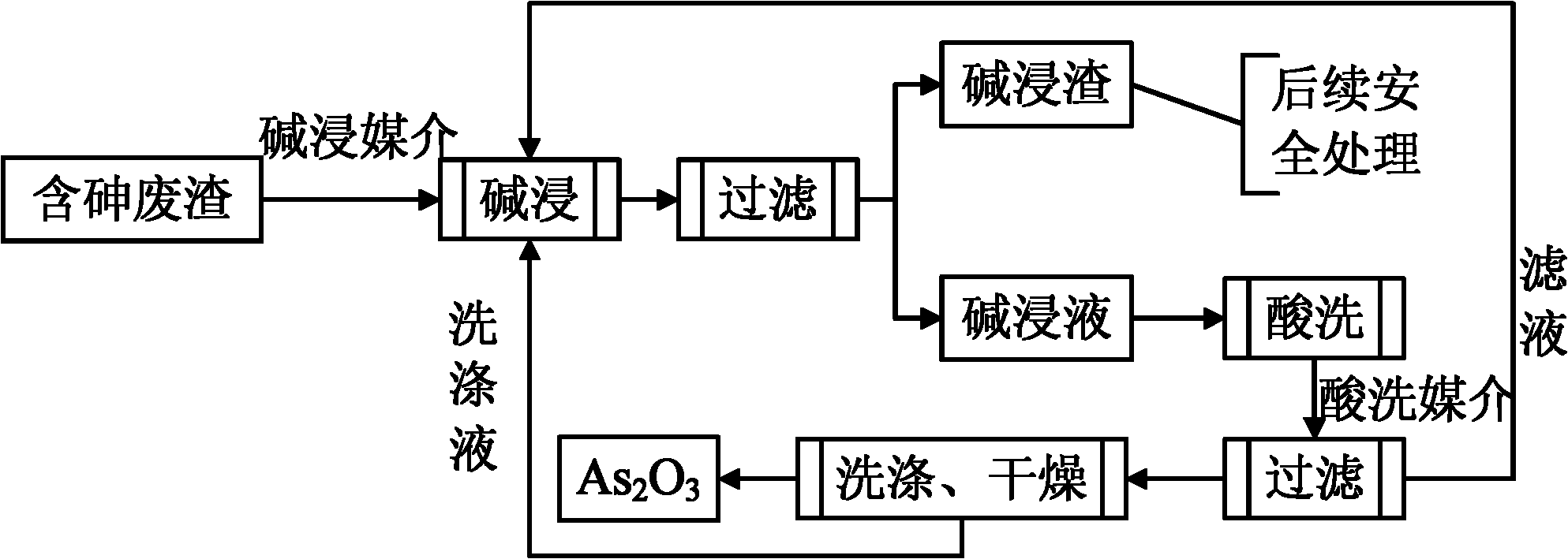

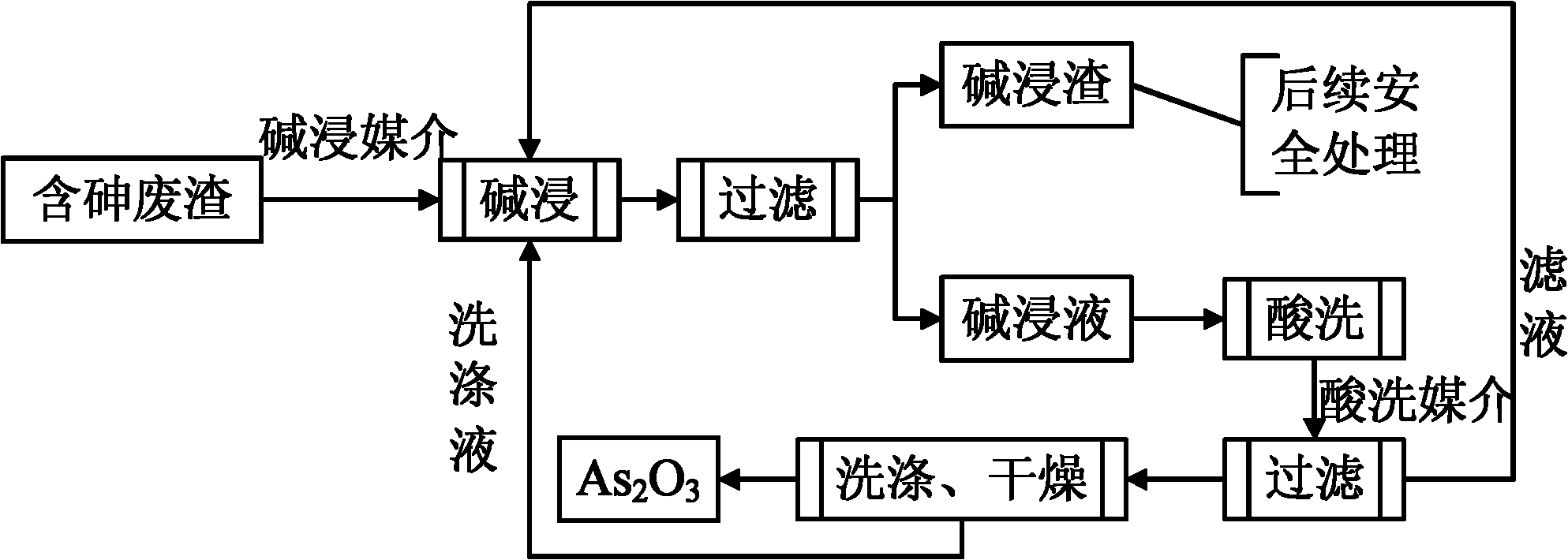

Method for recycling arsenic-containing waste residues

ActiveCN101954370APollution controlSimple processSolid waste disposalArsenic compoundsAcid washingPollution

The invention relates to a method for recycling arsenic-containing waste residues, which comprises the two steps of the alkaline leaching of the arsenic-containing waste residues and acid-washing separation of extract. The method comprises the following specific steps of: mixing the arsenic-containing waste residues, an inorganic strong alkaline solid and an alkaline leaching medium according to a certain ratio, reacting for 10 to 180 minutes by mechanically stirring and then filtering, and performing safe landfill in the subsequent process, wherein compared with the quality of non-processed residues, the quality of filter residues is reduced by 80 to 98 percent; adding filter liquor into concentrated acid for acid washing at the temperature of between 10 and 25 DEG C for 1 to 2 hours, wherein the added amount of an acid-washing medium is 5 to 10 volume percent of the alkaline leaching solution; filtering the mixture, and after washing filter residues with 0.02 to 1 percent dilute acid, drying to obtain As2O3 powder (the purity is over 95 percent); and returning acid-washing filter liquor and dilute acid washing liquor to the alkaline leaching step. The method has the advantages of simple process, convenience of operation, low cost, small secondary pollution and the like, and at the present, arsenic-containing waste residues pour in the environment, the method has the obvious economic, social and environmental benefits.

Owner:TONGJI UNIV

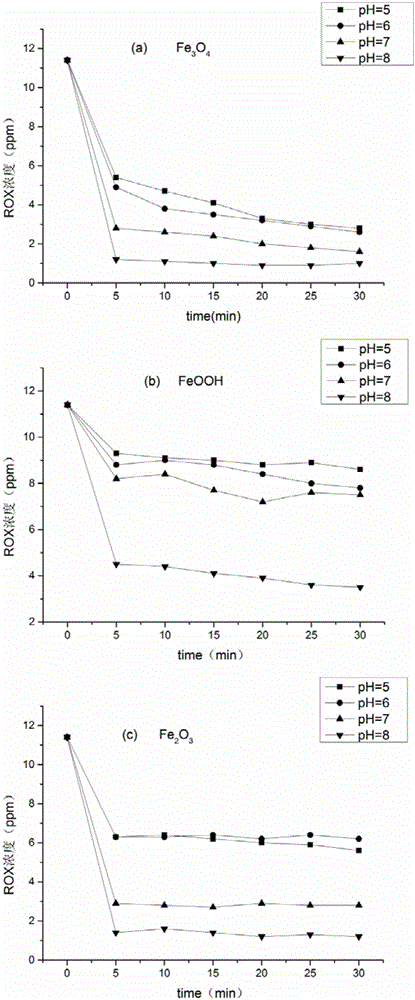

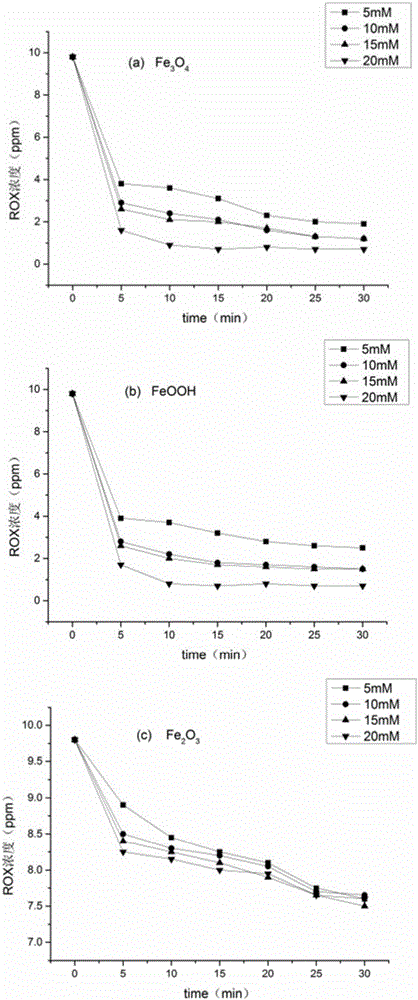

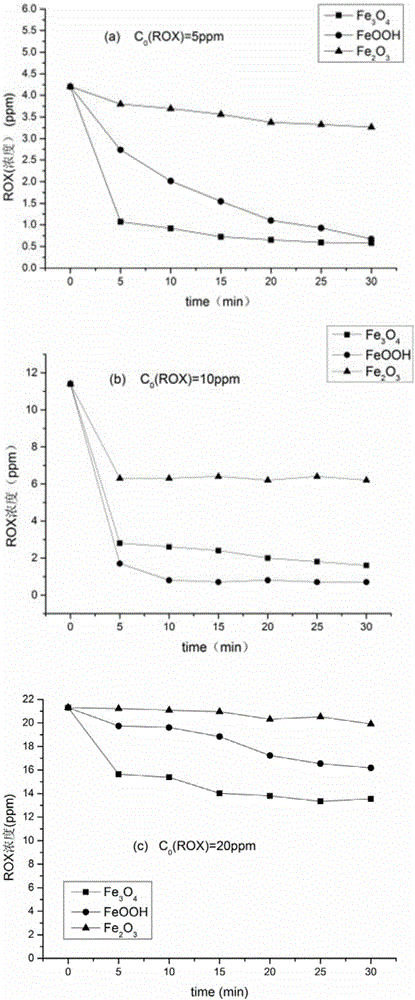

Method for treating arsenic-containing wastewater by using multiphase Fenton system based iron oxide

InactiveCN106277278AImprove adsorption capacityEfficient degradationWater treatment compoundsWater contaminantsBinding stateOrganoarsenic compounds

The invention discloses a method for treating arsenic-containing wastewater by using a multiphase Fenton system based on iron oxide. The method is characterized in that firstly, the pH of the arsenic-containing wastewater is adjusted to range from 2.0 to 9.0, then an iron oxide catalyst and a hydrogen peroxide oxidizing agent are added, so that an organic arsenic compound completes form transformation from organic arsenic to inorganic arsenic in the multiphase Fenton system based on the iron oxide, meanwhile, released inorganic arsenic forms Fe-As chemical coordinate bonds through binding state iron central atoms on the surface of the iron oxide to be effectively adsorbed, and the arsenic pollutant in the arsenic-containing wastewater is removed. Degradation from organic arsenic to inorganic arsenic and adsorption of the inorganic arsenic can be finished simultaneously in one step, the iron oxide serves as an efficient adsorption material of the inorganic arsenic as well as a Fenton reaction catalyst for degrading the organic arsenic to the inorganic arsenic, and the treatment cost of the organic arsenic wastewater is effectively reduced while the reaction efficiency and the operation simplicity are greatly improved.

Owner:HEFEI UNIV OF TECH

Processing method for cephalosporin dreg

ActiveCN103146761AEasy to handleDeal with economical and thoroughWaste based fuelSludge processingActivated sludgeResource utilization

The invention discloses a processing method for cephalosporin dreg. The processing method comprises the following process steps of: (A) thermal alkaline hydrolysis and separation treatment: uniformly mixing cephalosporin dreg, water and alkali, carrying out constant-temperature alkaline hydrolysis reaction, and carrying out solid-liquid separation at a certain temperature after the constant-temperature alkaline hydrolysis reaction, so as to obtain sediments to be standby; and (B) anaerobic digestion treatment: inoculating anaerobic activated sludge into an anaerobic fermentation tank, mixing the sediments obtained in the step (A) with excess sludge produced by utilizing wastewater biological treatment, injecting the mixture into the fermentation tank, carrying out constant-temperature stirring, and carrying out biogas residue discharging and feeding during fermentation. According to the processing method for the cephalosporin dreg, drug residues in the cephalosporin dreg can be completely removed, the problem that the anaerobic fermentation of single cephalosporin dreg cannot be effectively sustained is solved, and the reduction and innocent treatment to the cephalosporin dreg are realized; and biogas residues produced during the processing process can be used for preparing raw materials of organic fertilizers, the produced sewage gas can be used as clean fuels, and safe and effective disposition and resource utilization to the cephalosporin dreg are realized.

Owner:河北华药环境保护研究所有限公司

Method for treating a substrate made of animal fibers with solid particles and a chemical formulation

ActiveUS20160040260A1Easy to useShorten the construction periodTanning treatmentPre-tanning chemical treatmentFiberProcedure Agents

The invention discloses a method for treating an animal substrate comprising: agitating the moistened animal substrate with a treatment formulation and a solid particulate material in a sealed apparatus wherein the treatment formulation comprises a tanning agent or a tannery process agent. The method can comprise applying the tanning agent or tannery process agent to the animal substrate wherein at least some of the agent so applied originates from the treatment formulation. There is also disclosed an animal substrate obtained by the method. The treatment formulation can be aqueous.

Owner:XEROS LTD

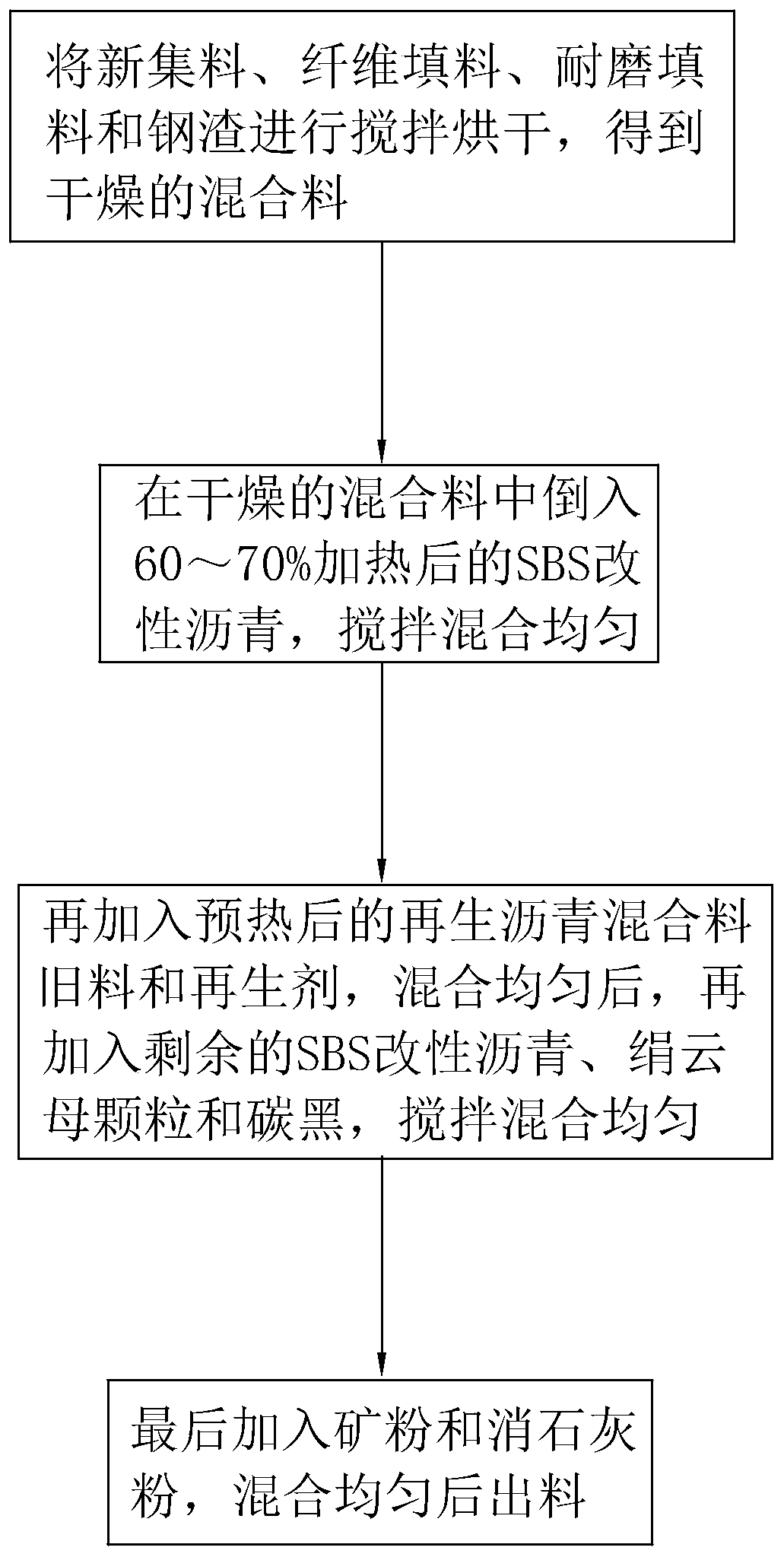

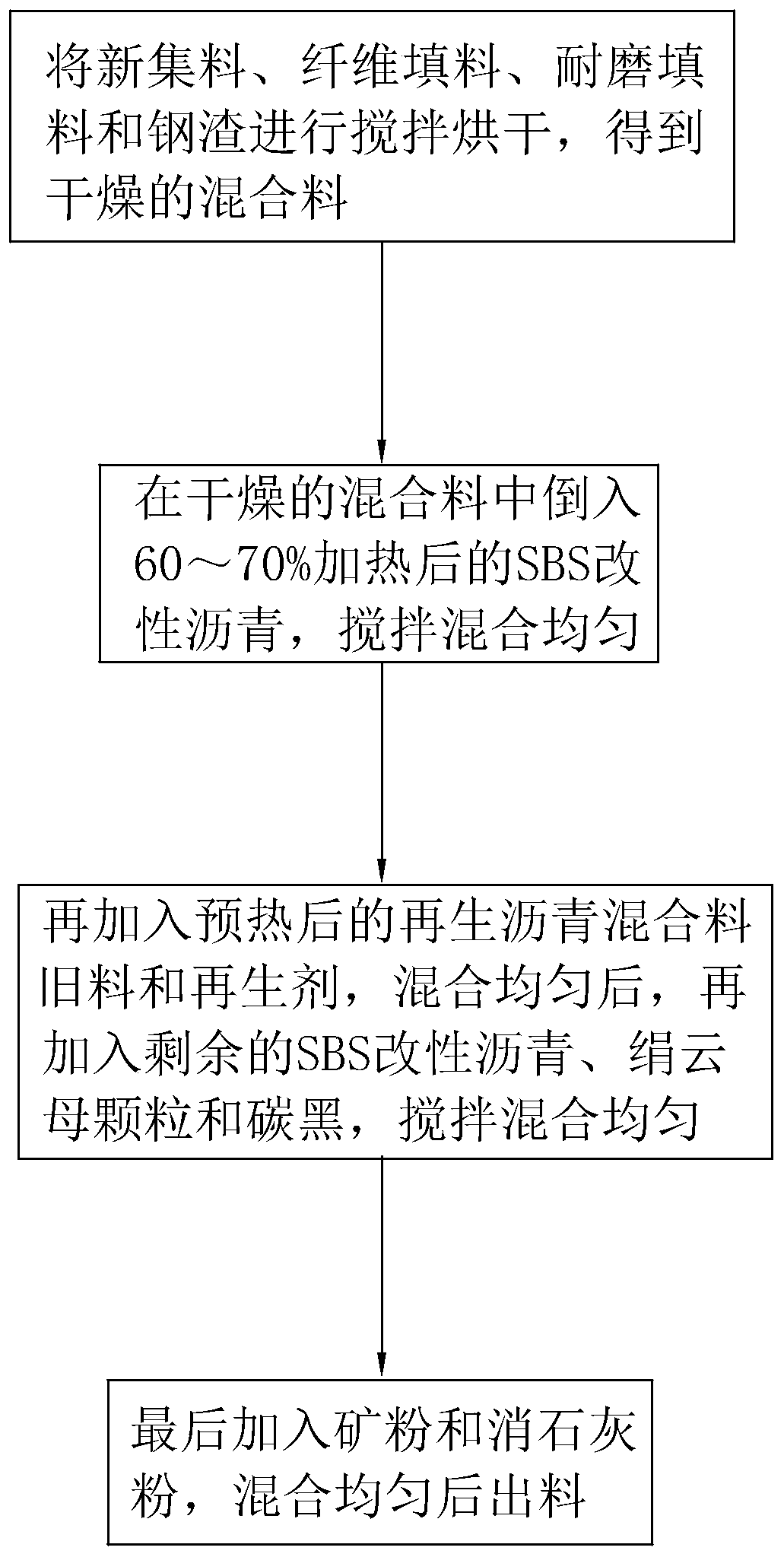

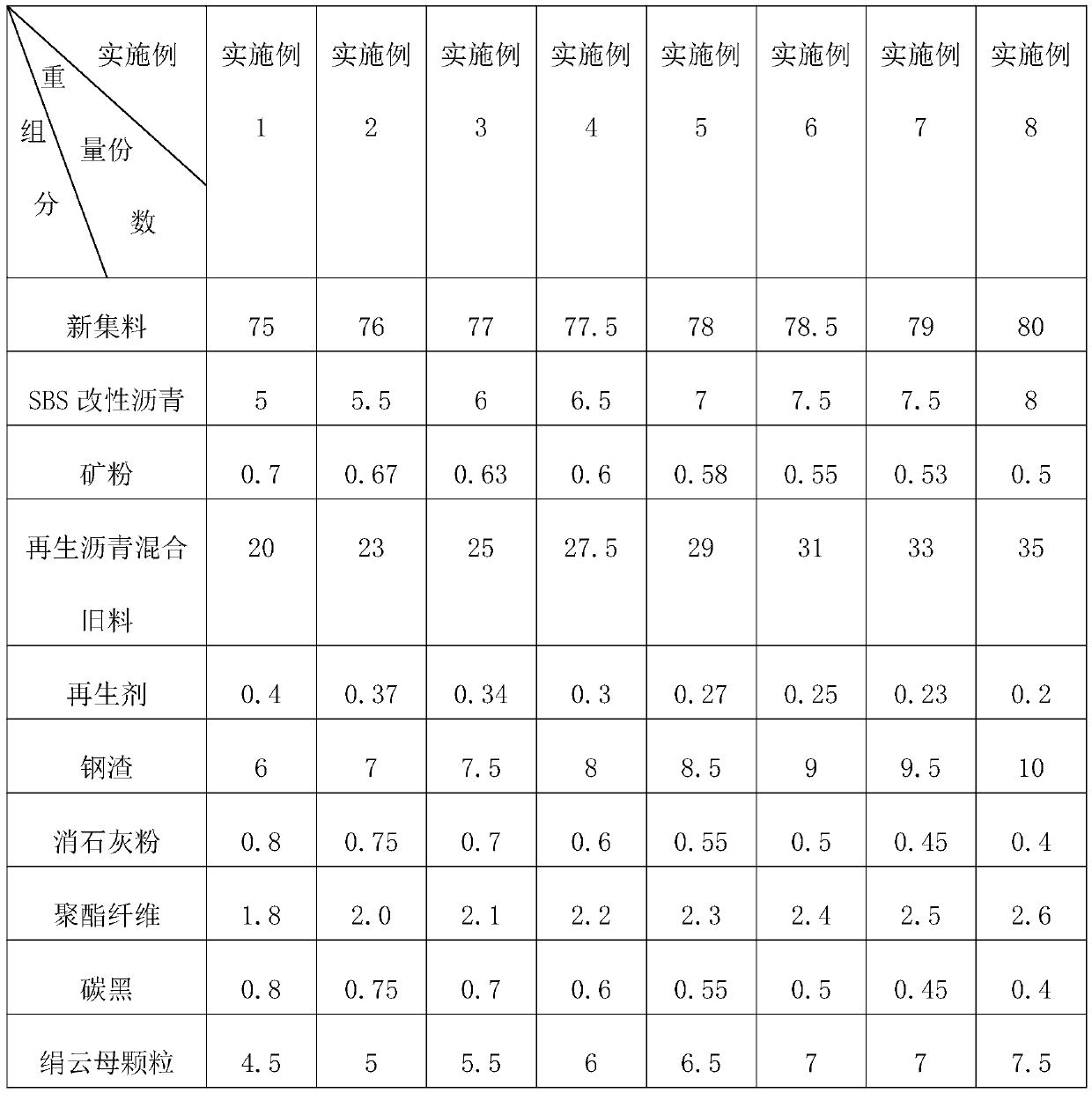

Abrasion-resistant recycled asphalt concrete and preparation process thereof

The invention discloses an abrasion-resistant recycled asphalt concrete and a preparation process thereof, relates to the technical field of asphalt concrete processing, and solves the problem that asphalt concrete pavement is prone to ageing due to frequent temperature changes and is prone to large abrasion during use. The abrasion-resistant recycled asphalt concrete comprises the following components in parts by weight: 75 to 80 parts of new aggregate, 5 to 8 parts of SBS modified asphalt, 0.5 to 0.7 part of mineral powder, 20 to 35 parts of a recycled asphalt mix old material, 0.2 to 0.4 part of a regenerating agent, 6 to 10 parts of steel slag, 0.4 to 0.8 part of hydrated lime powder, 1.8 to 2.6 parts of fiber filler, 0.5 to 1.5 part of abrasion-resistant filler, 0.4 to 0.8 part of carbon black, 4.5 to 7.5 parts of sericite particles. The abrasion-resistant recycled asphalt concrete in the invention has good stability in the use process, is not easy to age due to intermittent friction heat generated between the abrasion-resistant recycled asphalt concrete and a wheel, and is not easy to greatly wear.

Owner:上海宝新特种沥青混凝土有限公司

Technology for using steel dregs

InactiveCN1560283AIncrease added valueImprove the effect of iron removalRecycling and recovery technologiesSlagTubes types

The invention is a new environmental-protection using process of steel slags, crushing the slags by a multi-stage crushing system, and then adopting progressive iron magnetic separation system to make magnetic separation and screening process; drying the tail slags after eliminating the irons and transferring in a tube-type mill for powder milling; eliminating the irons from the fine powder by magnetic separation system, and separating the powder by a high-performance powder separator and a box-type dust cleaning device, and the separated fine powder is steel slag micropowder product, and the rough material is returned to the tube-type mill for milling fine, and the specific area of the product is greater than 450 sq m / kg. The mcropowder can act as a mixture of high-activity concrete of building material systems. Its advantages: the iron eliminating effect of the process is good and it can produce the steel slag micrpowder product, increasing the added-value of the product.

Owner:LAIWU IRON & STEEL GRP

Method for removing arsenic, antimony and copper by refining raw lead

InactiveCN102011015AGood for physical and mental healthTo overcome the poor effect of removing arsenic, antimony and copperProcess efficiency improvementIngotCopper

The invention discloses a method for removing arsenic, antimony and copper by refining raw lead. The invention aims to provide the method for removing the arsenic, antimony and copper by refining the raw lead. The method is characterized by comprising the following steps of: A, putting raw lead ingots into an open lead melting pot, and heating the raw lead ingots to the temperature of between 450 and 850 DEG C for melting lead into lead liquid; B, putting aluminum or aluminum alloy into the lead liquid obtained in the step A, fully mixing the aluminum or the aluminum alloy and the lead liquid with stirring, and generating scum which floats to the surface of the lead liquid; C, fishing the scum, namely fishing the scum generated in the step B after stirring to obtain the lead liquid removed with arsenic, antimony and copper; and D, casting ingots, namely casting the ingots by using the impurity removed lead liquid obtained in the step C to obtain lead ingots removed with the arsenic, antimony and copper. The method is mainly used for removing the arsenic, antimony and copper by refining the raw lead.

Owner:ZHUZHOU SMELTER GRP

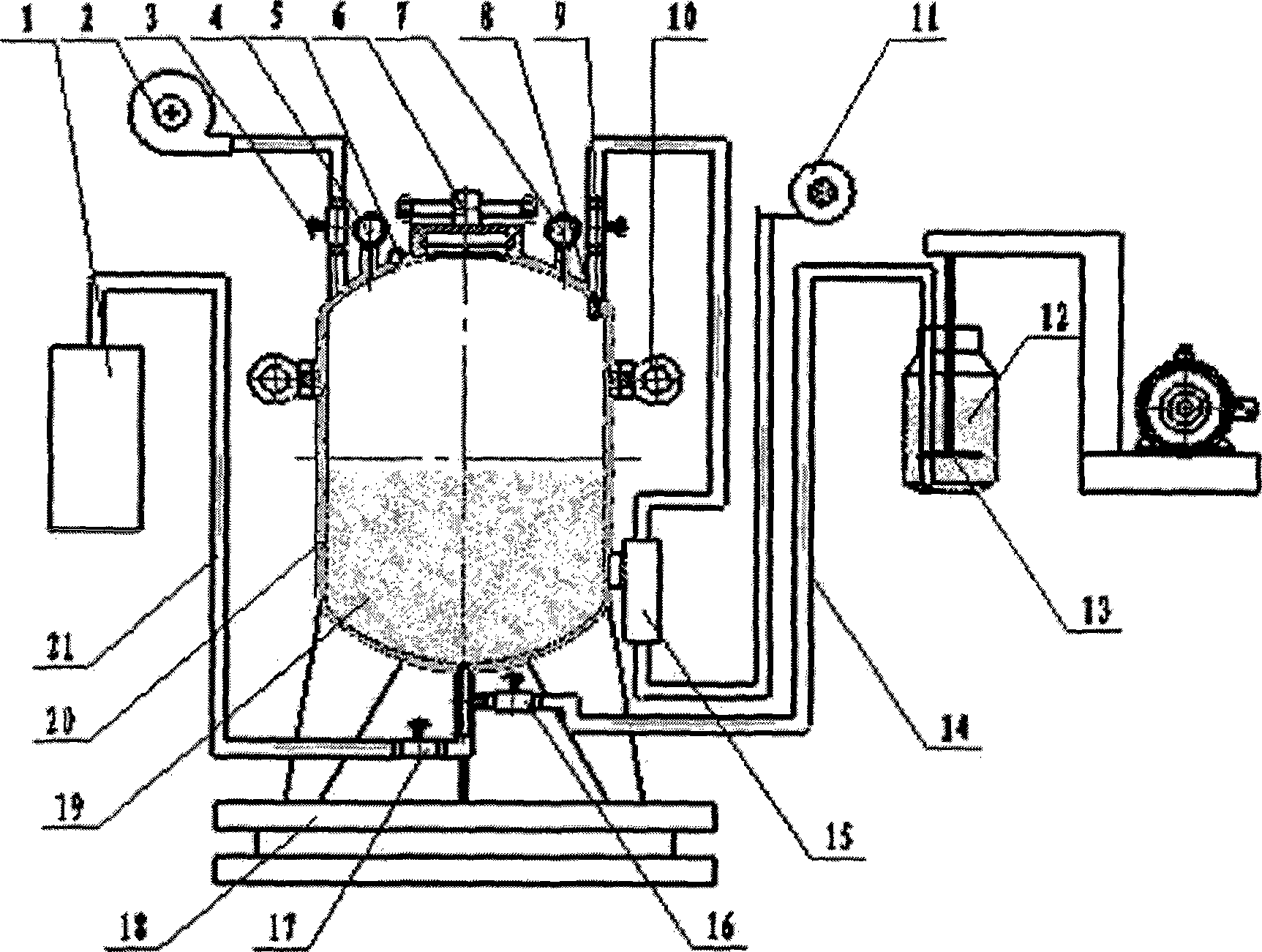

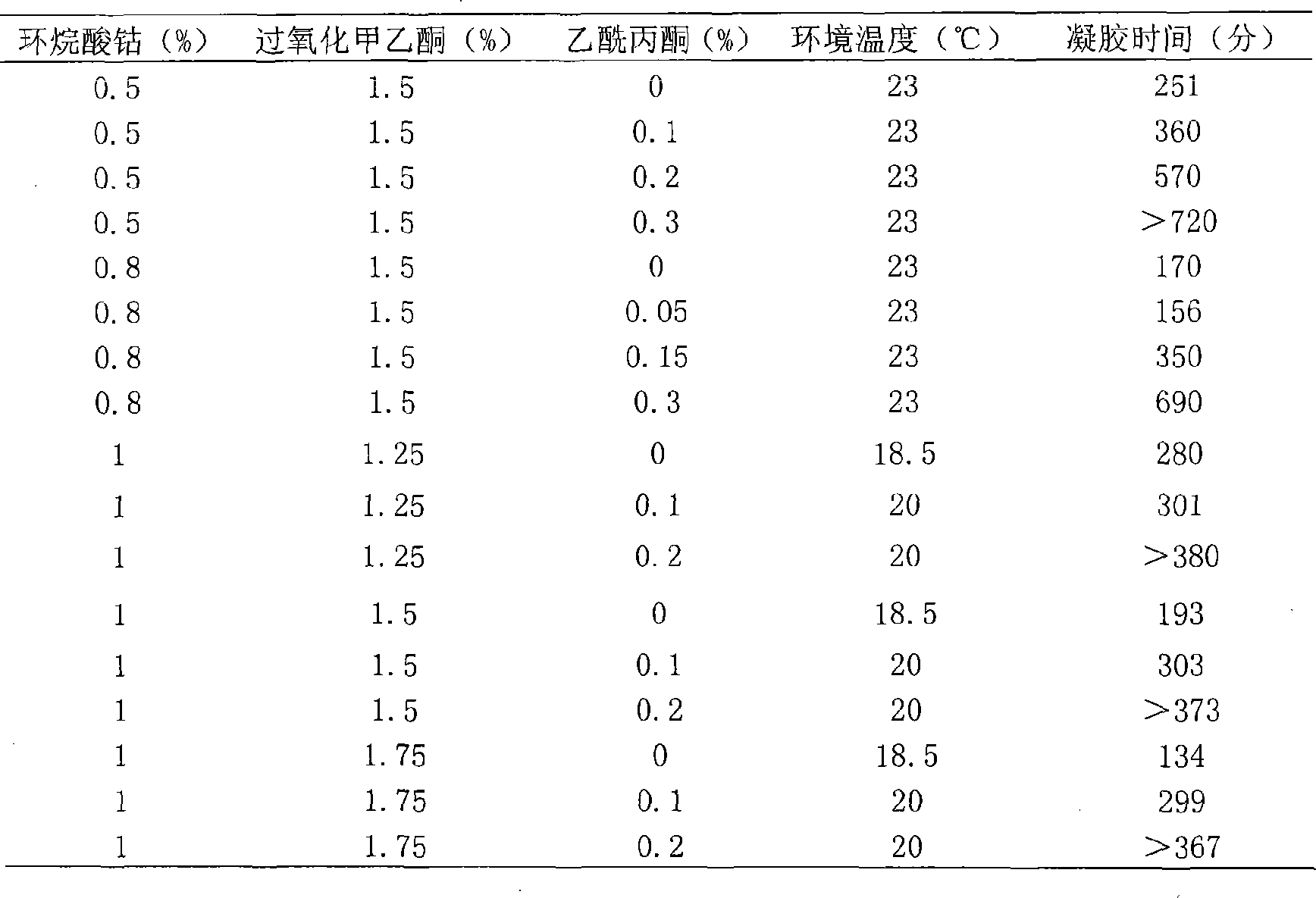

Re-injection process and equipment for poured resin adhesive solution when discharging air bubbles during composite material RTM molding process

The invention discloses a process for re-injecting resin adhesive liquid discharged from exhaust bubble in composite material RTM moulding process and a device thereof; the process comprises the steps as follows: the resin adhesive liquid is filtered by a screen mesh and collected to a material barrel added with retarder to be stirred; the evenly stirred resin adhesive liquid is sucked into a tank under the pull of vaccum, the tank is vacuumized and de-foaming is carried out on the resin adhesive; pressure is injected into the tank in which the resin adhesive liquid is stored after de-foaming, under the effect of the pressure, the resin adhesive liquid after de-foaming is injected into a mould; meanwhile pressure is continuously injected into the tank at the filling speed of 5-2000g / min; finally residual resin adhesive liquid in the empty tank after filling and in the pipeline connecting the mould with the tank is cleaned. The pipeline is positioned between the mould and the tank. The device comprises a sealed tank, a discharge nozzle connected with the tank, an air inlet pipeline, the mould and the material barrel. The invention can effectively reduce the production cost, save energy and reduce emission, and reduce the emission of waste material; in addition, the invention has remarkable economic and social benefits and is conducive to popularization and application.

Owner:北京玻钢院复合材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com