Super hydrophilic functional ceramic material easy to be cleaned and preparation technique

A functional ceramic and hydrophilic technology, applied in the field of super hydrophilic and easy-to-clean functional ceramic materials, can solve the problems of drainage, water resource pollution, and inability to kill it

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

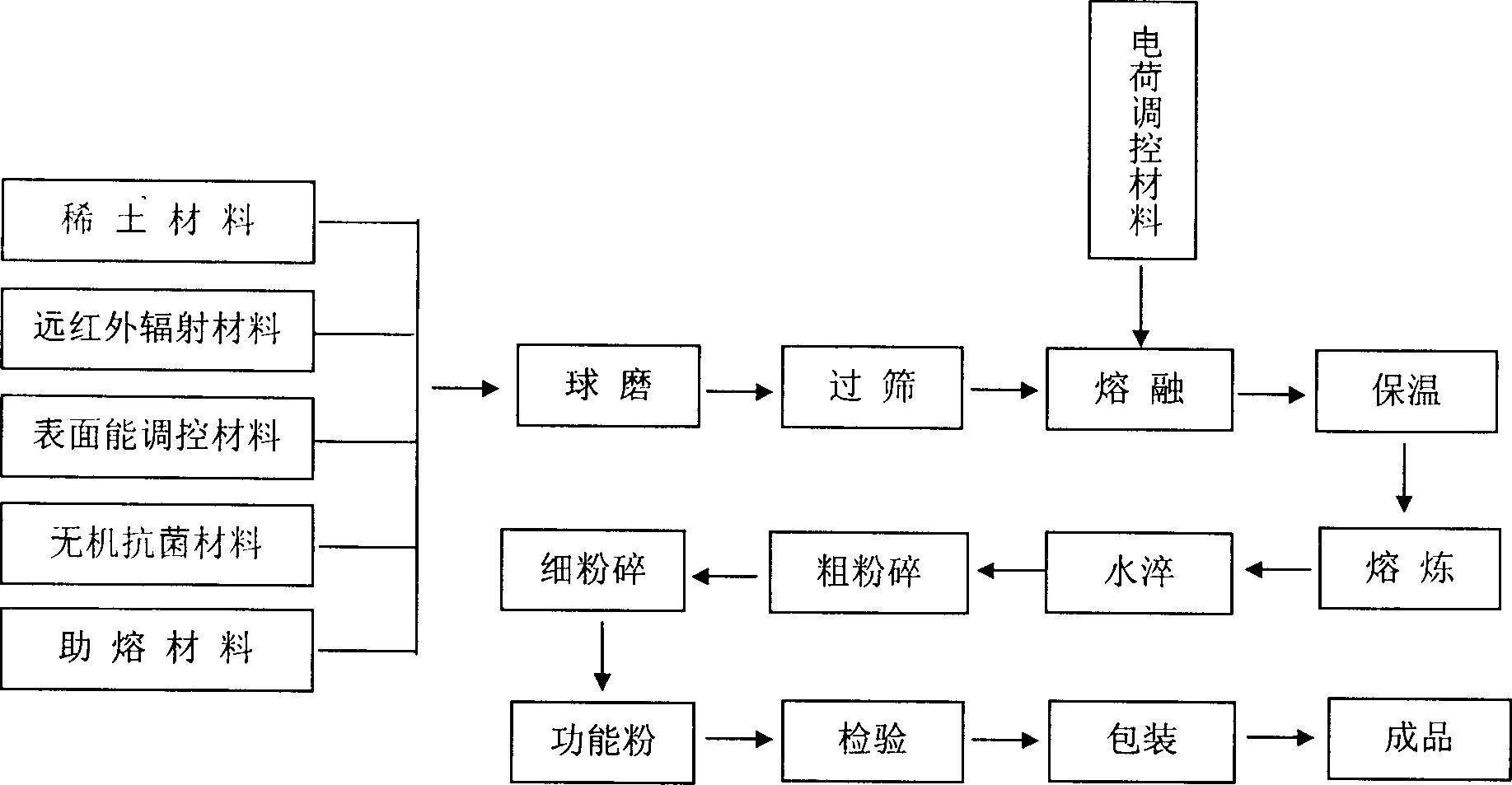

Method used

Image

Examples

Embodiment 1

[0072] The super-hydrophilic and easy-to-clean functional ceramic material of the present invention is prepared from the following raw materials in a molar ratio:

[0073] 5% cerium nitrate, 35% silicon oxide, 30% alumina, 10% tourmaline with a particle size of 5-15 microns, 10% potassium oxide, and 10% inorganic composite antibacterial agent.

[0074] The preparation process is that cerium nitrate, silicon oxide, aluminum oxide, potassium oxide and the inorganic composite antibacterial agent produced and sold by this application unit are mixed and ball milled for 8 hours, and then tourmaline powder is added for later ball milling for 12 hours, and heated and melted to 1250. ±20°C, heat preservation for 2 hours, quenched with tap water at regular temperature to form a frit, and then crushed to form the ultrafine hydrophilic and easy-to-clean functional ceramic powder material of the present invention with a particle size of 1-8 microns.

Embodiment 2

[0076] The super-hydrophilic and easy-to-clean functional ceramic material of the present invention is prepared from the following raw materials in a molar ratio:

[0077] 10% cerium nitrate, 40% silicon oxide, 25% alumina, 5% tourmaline with a particle size of 5-15 microns, 12% potassium oxide, and 8% inorganic composite antibacterial agent.

[0078] The preparation process is the same as that in Example 1, and the control parameters are respectively: the mixed ball milling for 5 hours in the early stage, the ball milling for 20 hours in the later stage, the melting temperature of 1300±20°C, and the holding time for 1.5 hours.

Embodiment 3

[0080] The super-hydrophilic and easy-to-clean functional ceramic material of the present invention is prepared from the following raw materials in a molar ratio:

[0081] 6% cerium oxide rare earth material, ultrafine rutile titanium oxide powder with a particle size of less than 5 microns, 40% far infrared radiation material, 30% magnesium oxide surface energy adjustment material, tourmaline charge control material with a particle size of 5-15 microns 4%, sodium oxide fluxing material 12%, inorganic composite antibacterial agent 8%.

[0082] The preparation process is to mix and ball mill rare earth materials, far-infrared radiation materials, surface energy adjustment materials, flux materials and inorganic antibacterial materials for 8 hours, then add tourmaline powder for later ball milling for 16 hours, and heat and melt to 1300±20℃ , Heat preservation for 2 hours, water quenched into frit, crushed into powder product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com