High-efficiency multielement compound foliage selenium fertilizer and preparation technique thereof

A multi-component compound and foliage technology, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problems of inappropriate types of chelating agents, neglect of nutrient absorption rate, poor water solubility, etc., and achieve excellent raw material compatibility and high nutrient absorption efficiency , the effect of high nutrient active ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

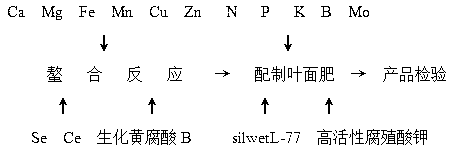

Method used

Image

Examples

Embodiment 1

[0065] The components of the invention include: macroelements, moderate elements, trace elements, chelating agents, selenium elements, rare earth elements, active organic matter, growth regulators, and surfactants.

[0066] The raw material of large amount of elements refers to nitrogen source, phosphorus source and potassium source, and its specific composition and proportion of the total amount

[0067] Do as follows:

[0068] The nitrogen source is composed of urea and ammonium nitrate in a weight ratio of 1:1 3.0g / L

[0069] The phosphorus source is selected from potassium dihydrogen phosphate 2.0g / L

[0070] Potassium source selected from potassium pyrophosphate 15.0g / L

[0071] The medium element raw materials refer to calcium sources and magnesium sources, and their specific compositions and proportions in the total amount are as follows:

[0072] Calcium source selected from calcium nitrate 5.0g / L

[0073] Magnesium source is selected from magnesium sulfate 15.0g / L...

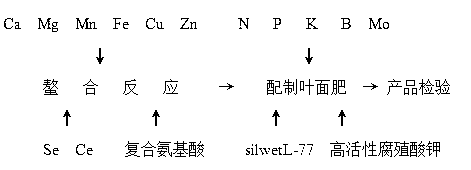

Embodiment 2

[0097] same reason

[0098] The present invention includes the following components: macroelements, moderate elements, microelements, chelating agent, selenium,

[0099] Rare earth elements, active organic compounds, growth regulators, surfactants.

[0100] The raw material of large amount of elements refers to nitrogen source, phosphorus source and potassium source, and its specific composition and proportion of the total amount

[0101] Do as follows:

[0102] The nitrogen source is urea plus 2~3g / L paraformaldehyde (solid formaldehyde) 10g / L in proportion

[0103] The phosphorus source is selected from potassium dihydrogen phosphate 10g / L

[0104] Potassium source is selected from potassium acetate 10g / L

[0105] The medium element raw materials refer to calcium sources and magnesium sources, and their specific compositions and proportions in the total amount are as follows:

[0106] Calcium source selected from calcium nitrate 10g / L

[0107] Magnesium source is sele...

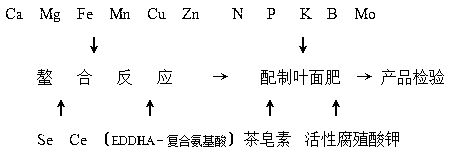

Embodiment 3

[0127] same reason

[0128] The invention includes the following components: macroelements, moderate elements, trace elements, chelating agents, selenium elements, rare earth elements, active organic matter, growth regulators, and surfactants.

[0129] The raw material of large amount of elements refers to nitrogen source, phosphorus source and potassium source, and its specific composition and proportion of the total amount

[0130] Do as follows:

[0131] The nitrogen source is composed of urea and ammonium nitrate in a weight ratio of 1:1 7g / L

[0132] The phosphorus source is selected from potassium dihydrogen phosphate 6g / L

[0133] Potassium source selected from potassium pyrophosphate 12g / L

[0134] The medium element raw materials refer to calcium sources and magnesium sources, and their specific compositions and proportions in the total amount are as follows:

[0135] Calcium source selected from calcium nitrate 7g / L

[0136] Magnesium source is selected from ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com