Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

840 results about "Sericite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sericite is the name given to very fine, ragged grains and aggregates of white (colourless) micas, typically made of muscovite, illite, or paragonite. Sericite is produced by the alteration of orthoclase or plagioclase feldspars in areas that have been subjected to hydrothermal alteration typically associated with copper, tin, or other hydrothermal ore deposits. Sericite also occurs as the fine mica that gives the sheen to phyllite and schistose metamorphic rocks.

Nano-zinc oxide coated sericite powder composite material and preparation method thereof

InactiveCN104017393AImproves UV resistanceImprove antibacterial propertiesCosmetic preparationsInorganic pigment treatmentCalcium hydroxideOrganic solvent

The invention discloses a sericite / nano-zinc oxide composite material and a preparation method thereof. The composite material is characterized in that the surface of sericite powder is coated with nano-zinc oxide. The preparation method comprises the following step: adding calcium hydroxide or calcium oxide into a mixed system of the sericite powder and zinc sulfate solution so as to directly obtain the nano-zinc oxide coated sericite powder composite material. According to the method, the sericite which is taken as a base material is a natural mineral, so that the raw material is easily available, free of pollution and low in cost; the preparation process is simple, safe, reliable and easy to control; the obtained composite material is stable in quality, and has the good dispersibility in an organic solvent and also has the excellent ultraviolet resistance and the excellent antibacterial and deodorant performance. Thus, the composite material can be applied to the field of coatings, cosmetics and the like. The method has a good potential application value in the field of synthesis of the composite material or other related sciences.

Owner:ANHUI HENGHAO SCI & TECH

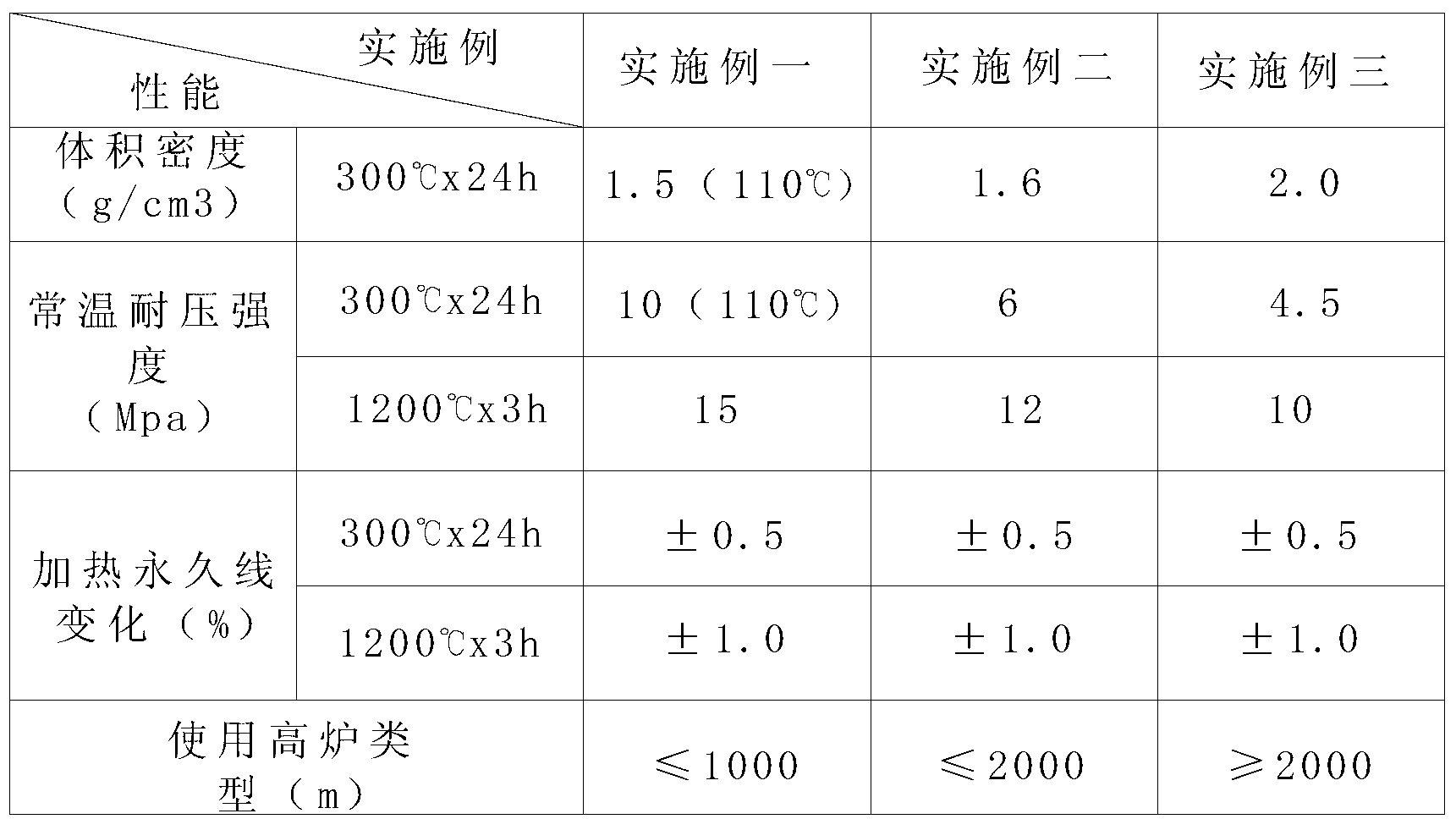

Bleed hole stemming and method for producing the same

ActiveCN101219900AGood sintered strengthEasy to openBlast furnace componentsBlast furnace detailsPyrophylliteGraphite

The invention relates to a stemming at a taphole; the weight percentages of the components are the following: 20 to 40 of corundum, 10 to 20 of silicon carbide, 3 to 10 of silicon nitride, 10 to 23 of coke powders, 1 to 5 of graphite powders, 3 to 10 of sericite, 1 to 5 of active alumina micropowders, 5 to 15 of clay, 5 to 10 of pyrophyllite, 1 to 3 of metal powders, and +15 to 25 of water-free binder. The stemming adds a plurality of materials with plasticity and good cohesiveness to cause the stemming to easily block the hole and fill interspaces, with good binding performance of new stemming and old stemming; materials with medium and high temperature expansion are added to reduce the size of the stemming contraction at high temperature, and cracks can be avoided; materials with sintering function within different temperature areas are added, so the stemming has good sintering strength in different temperature scopes; materials with high-temperature resistance and good erosion resistance are added, and thus the stemming has high strength at high temperature, washing resistance and erosion resistance.

Owner:BAOSHAN IRON & STEEL CO LTD

Underwater solventless epoxy anti-corrosive coating and preparation method thereof

InactiveCN101619189AGood flexibilityStrong adhesionAntifouling/underwater paintsPaints with biocidesEpoxyPliability

The invention relates to an underwater solventless epoxy anti-corrosive coating and a preparation method thereof. The coating contains A component and B component and comprises the following components by weight percent: 20-25% of epoxy resin E-51, 12-17% of epoxy resin E-44, 3-8% of epoxy active diluent, 3.5-5% of plasticizer, 10-16% of talcum powder, 10-15% of sericite powder, 1.0-1.6% of thixotropic agent, 2-4% of titanium dioxide, 0.5-1.0% of coupling agent, 0.5-1.2% of dispersant, 0.5-1.2% of defoaming agent, 0.1-0.5% of carbon black, 12-15% of 1085 curing agent and 5-8% of 810 curing agent; wherein, B component comprises 1085 curing agent and 810 curing agent and the remainder is A component. The preparation method comprises the following steps: separately preparing A component and B component and when using, mixing A component and B component in a weight ratio of 4:1 evenly to obtain the underwater solventless epoxy anti-corrosive coating. The invention has simple process, strong product adhesion, high mechanical strength and corrosion resistance; the coating can be especially used to coat members in water at a low temperature, has fast curing rate and good flexibility of coating film, and is hard to peel, thus being applicable to the protection of steel structures such as gates of hydroelectric power stations, sediment bottom sluices and the like and concrete structures.

Owner:QINGDAO PACIFIC OCEANEERING CO LTD

Magnetic pearlescent pigment and preparation method thereof

The invention discloses a magnetic pearlescent pigment and a preparation method thereof. The magnetic pearlescent pigment has black luster and takes a substrate with a particle diameter of 10-60mum as a cladding substrate, and the substrate is clad with Fe3O4. The preparation method of the magnetic pearlescent pigment comprises the following steps: dropwise adding ferric iron salt solution and ferrous iron salt solution to mica suspension at a certain temperature; controlling pH value for coprecipitation to deposit the precipitated ferroferric oxide evenly and compactly on the mica under the protection of inert gas; calcining in an inert atmosphere to prepare the magnetic pearlescent pigment. The prepared magnetic pearlescent pigment has a flat and compact deposition surface, high cladding rate and obvious pearlescent effect. The preparation method helps realize coprecipitation of the ferric iron and the ferrous iron and cause the ferroferric oxide to clad a sericite substrate evenly. The preparation method is suitable for the preparation of various pearlescent pigments, and a coprecipitation method and sintering atmosphere control are introduced to provide the possibility of depositing and cladding the oxides with different valences.

Owner:WENZHOU UNIVERSITY +1

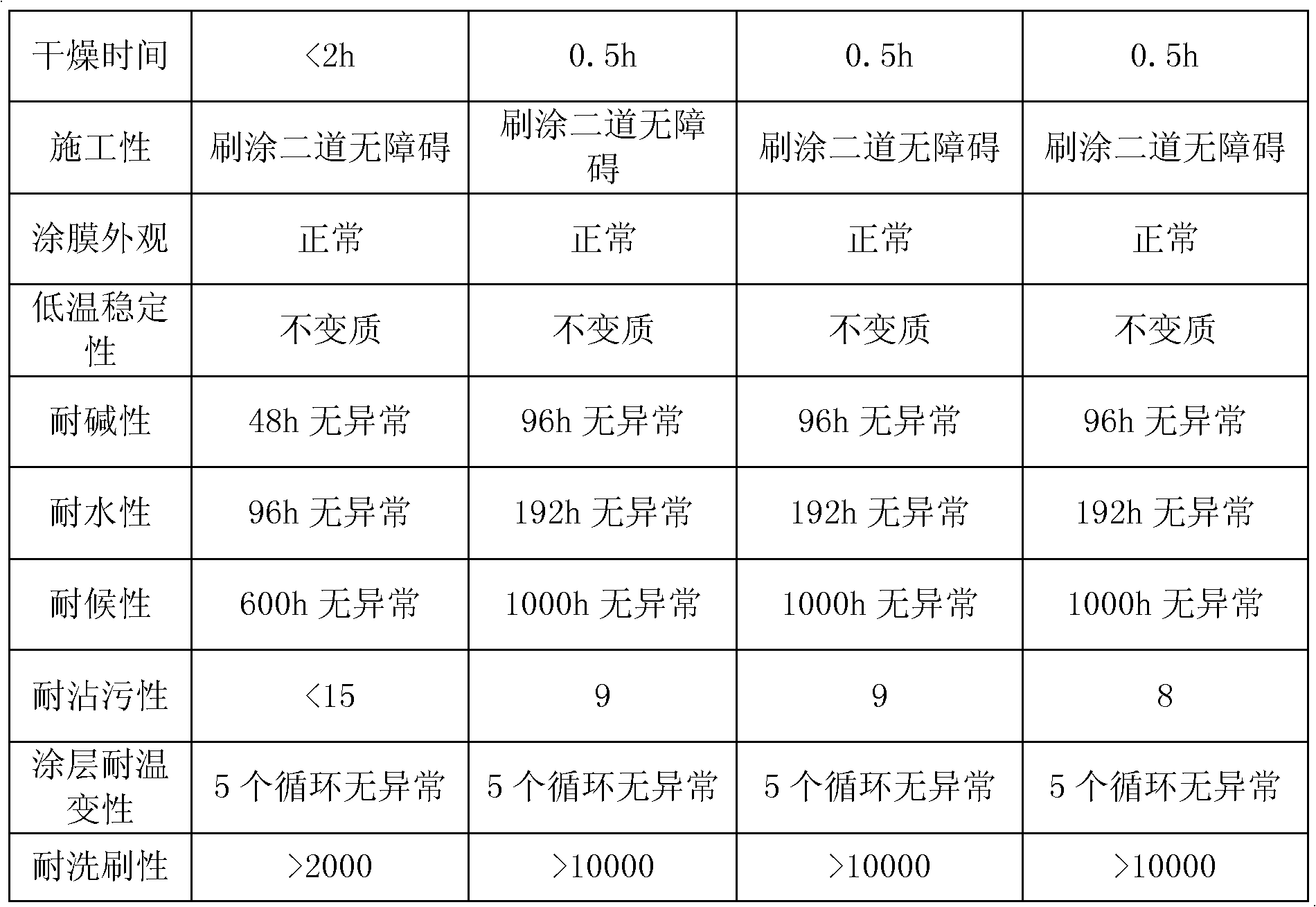

Elastic anti-fouling outer wall paint with acid rain resistance and preparation method thereof

ActiveCN101948650AStrong adhesionImprove stain resistanceAntifouling/underwater paintsPaints with biocidesAnti freezingWhite powder

The invention discloses elastic anti-fouling outer wall paint with acid rain resistance. The outer wall paint comprises the following components in percentage by weight: 10 to 20 percent of water, 0.5 to 0.8 percent of acrylic ammonium salt dispersant, 20 to 26 percent of rutile type titanium white powder, 2 to 3 percent of kieselguhr, 8 to 15 percent of superfine barium sulfate, 1 to 2 percent of sericite powder, 40 to 50 percent of self-crosslinked elastic acrylic polymer latex, 3 to 5 percent of opaque covering polymer, 1 to 2 percent of anti-freezing agent, 1 to 2 percent of film-forming aid, 0.5 to 0.8 percent of mold-proof anti-algae agent, 1 to 3 percent of organic silicon waterproof agent and 0.5 to 1.5 percent of polyurethane associated thickener. The paint has the advantages of acid rain resistance, good anti-fouling performance, excellent elasticity, mold injury resistance, good storage stability and capability of repeatedly coating a paint film.

Owner:紫荆花制漆(成都)有限公司

No-water stemming material for blast furnace taphole and its prepn

InactiveCN1810723AShorten the blasting timeExtend the tapping timeBlast furnace componentsBlast furnace detailsSlagRefractory

The present invention relates to amorphous refractory material, and is especially one kind of no-water stemming material for blast furnace taphole and its preparation process. The no-water stemming material is prepared with coke powder 15-25 wt%, clay 10-20 wt%, bauxite corundum 20-36 wt%, silicon carbide 10-20 wt%, asphalt 8-16 wt%, sericite 5-9 wt%, additive 1-5 wt% and binding agent 12-22 wt%, and through crushing, sieving, pre-mixing, rolling, kneading and extruding. The no-water stemming material has excellent plasticity and sintering performance, high strength at high and middle temperature and high slag and molten iron flush resistance, and can meet the requirement of high strength smelting in blast furnace.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Stain-resistant and oil-resistant wallpaper and preparation method thereof

The invention discloses stain-resistant and oil-resistant wallpaper. The stain-resistant and oil-resistant wallpaper comprises a substrate layer, a stain-resistant layer and an oil-resistant layer, wherein the outer periphery of the substrate layer is coated with the stain-resistant layer, and the outer periphery, far away from the substrate layer, of the stain-resistant layer is coated with the oil-resistant layer; the oil-resistant layer is prepared from the raw materials: acrylic perfluoroalkyl ester, alkyd resin, polyester resin, perfluoroalkyl acrylate, butyl acrylate, hydroxyethyl acrylate, aluminum tripolyphosphate, nano zinc borate, potassium persulfate, hydroxymethyl cellulose, nano zinc oxide, nano titanium dioxide, diatomite, magnesium hydroxide, aluminum oxide, organobentonite, sericite powder, perfluorocarbon, ferric phosphate, sodium molybdate, sodium persulfate, chlorinated paraffin, silane coupling agent KH-560, dibutyltin dilaurate, octadecyl trimethyl ammonium chloride, polyethylene glycol, fluorosilicon oil, a thickener, an antifoamer, a curing agent and modifying auxiliaries. The invention further provides a preparation method of the stain-resistant and oil-resistant wallpaper. The prepared wallpaper has excellent stain resistance and oil resistance.

Owner:安徽易有墙纸有限公司

Flame-retardant reflection insulation paint and preparation method thereof

The invention provides flame-retardant reflection insulation paint comprising the components of: 35-50wt% of acrylic emulsion comprising phosphate ester group, 10-25wt% of rutile-type titanium dioxide, 1-8wt% of sericite, 2.5-15wt% of heat-reflective insulation powder, 5-20wt% of hollow glass microspheres, 10-15wt% of water, and 2-20wt% of auxiliary agents. In the acrylic emulsion comprising phosphate ester group, phosphorus element content accounts for 0.9-1.8% of the mass of the acrylic emulsion comprising phosphate ester group. The invention also provides a preparation method of the flame-retardant reflection insulation paint. The flame-retardant reflection insulation paint provided by the invention has reflective insulation performance, flame resistance, good dispersity, and storage stability.

Owner:BYD CO LTD

Epoxy anticorrosive paint for underwater steel

InactiveCN102719174AStrong adhesionPromote environmental protectionAntifouling/underwater paintsPaints with biocidesSolvent freeSolvent

The invention discloses epoxy anticorrosive paint for underwater steel. Liquid epoxy resin DER351 is used as base materials, liquid polysulfide rubber JLY-121 is used as toughening agent, pentanediol glycidyl ether 6286 is used as diluents, aluminum tripolyphosphate, zinc phosphate and iron oxide red are used as active rustproofing pigment, micaceous iron oxide, sericite and precipitated barium sulphate are used as filler, cashew shell oil modified phenolic aldehyde and modified fatty amine are used as curing agents, silane coupling agent 1121 is used as adhesion promoter, and solvent-free bicomponent epoxy anticorrosive paint for underwater steel is prepared by the normal preparation process under the cooperation of functional auxiliaries. The epoxy anticorrosive paint for underwater steel has fine environment friendliness, can be brushed or scraped at rusted damp interfaces of underwater steel, can be quickly cured to form films, excellent in coating adhesive power, capable of removing, converting and stabilizing rusts, high in resistance to impact, abrasion and corrosion and widely applicable to corrosion resistance of various underwater steel facilities.

Owner:BEIJING GUOTAI RUIHUA DIATOMS APPL TECH

Anti-freezing anti-seepage anti-cracking concrete and preparation method thereof

The invention discloses anti-freezing anti-seepage anti-cracking concrete and a preparation method thereof, wherein the anti-freezing anti-seepage anti-cracking concrete comprises, by weight, 300-315 parts of cement, 340-360 parts of medium sand, 430-450 parts of coarse sand, 800-850 parts of broken stone, 135-160 parts of fly ash, 50-60 parts of mineral powder, 160-175 parts of water, 5-10 parts of a water reducing agent, 1-5 parts of an air entraining agent, 5-10 parts of water glass, 5-10 parts of modified polypropylene fiber, 50-55 parts of modified rubber particles, and 55-70 parts mixed stone powder, wherein the mixed stone powder is prepared by carrying out drying treatment and grinding treatment on dolomite, slag, ceramsite and sericite powder according to a mass ratio of 1:0.5-0.8:1.1-1.5:0.6-0.9. According to the present invention, the anti-freezing anti-seepage anti-cracking concrete has advantages of strong freezing resistance, good impermeability, good crack resistance and high strength.

Owner:西安新意达建筑制品有限公司

Molding sand and preparation method thereof

InactiveCN103521681AGood collapsibilityImprove adhesionFoundry mouldsFoundry coresSodium metasilicateSodium Bentonite

The invention discloses molding sand. The molding sand is characterized by being prepared from the following materials in parts by weight: 200-240 parts of quartz sand, 30-35 parts of sericite, 60-70 parts of kaolin, 30-40 parts of calcium carbonate, 10-15 parts of coke powder, 10-15 parts of clays, 2-4 parts of titanium dioxide, 4-5 parts of aluminum oxide powder, 20-30 parts of argil, 3-4 parts of asphalt, 10-15 parts of bentonite, 3-4 parts of ammonium dihydrogen phosphate, 4-5 parts of sodium metasilicate, 2-3 parts of sodium dodecyl benzene sulfonate and an appropriate amount of water. According to the invention, the quartz sand, the sericite and the kaolin are used and roasted to achieve abundant pores and good gas permeability, moreover, mobility is good, and grinding of added calcium carbonate, clay, titanium dioxide, asphalt, and the like is combined, so that the molding sand has excellent cohesiveness, plasticity and heat stability, and also has high collapsibility. The molding sand material disclosed by the invention is fine and uniform; a casting piece produced by the molding sand has a smooth surface and a few flaws.

Owner:HEFEI CITY TENVER PRECISION CASTING

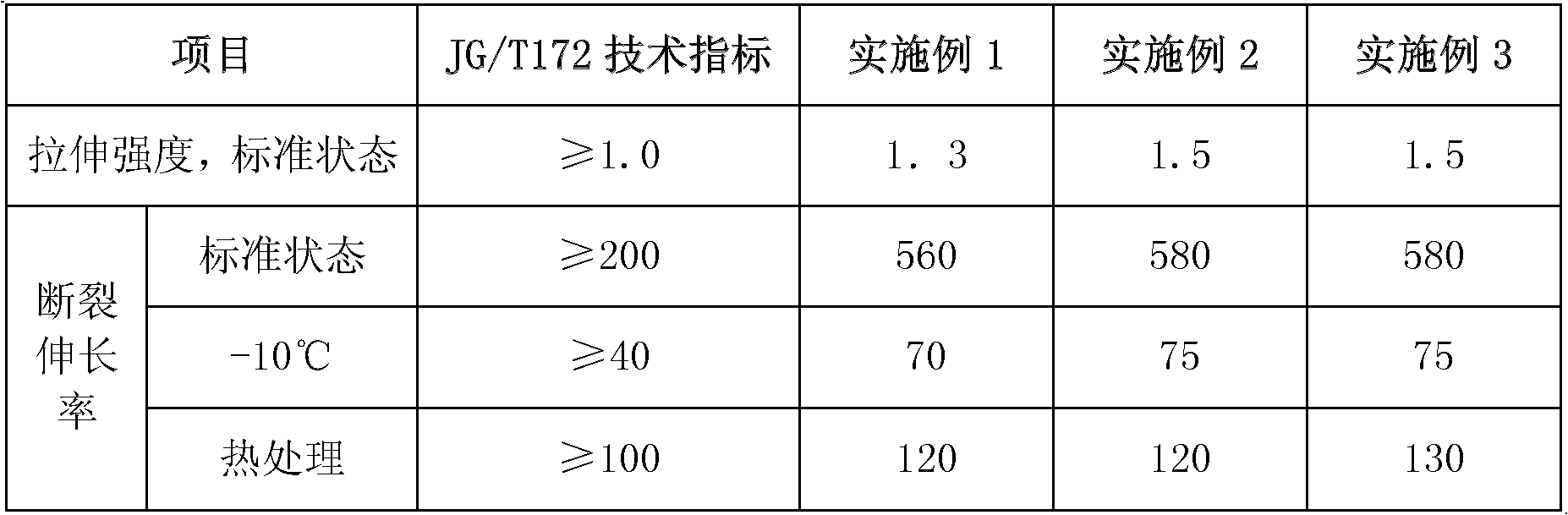

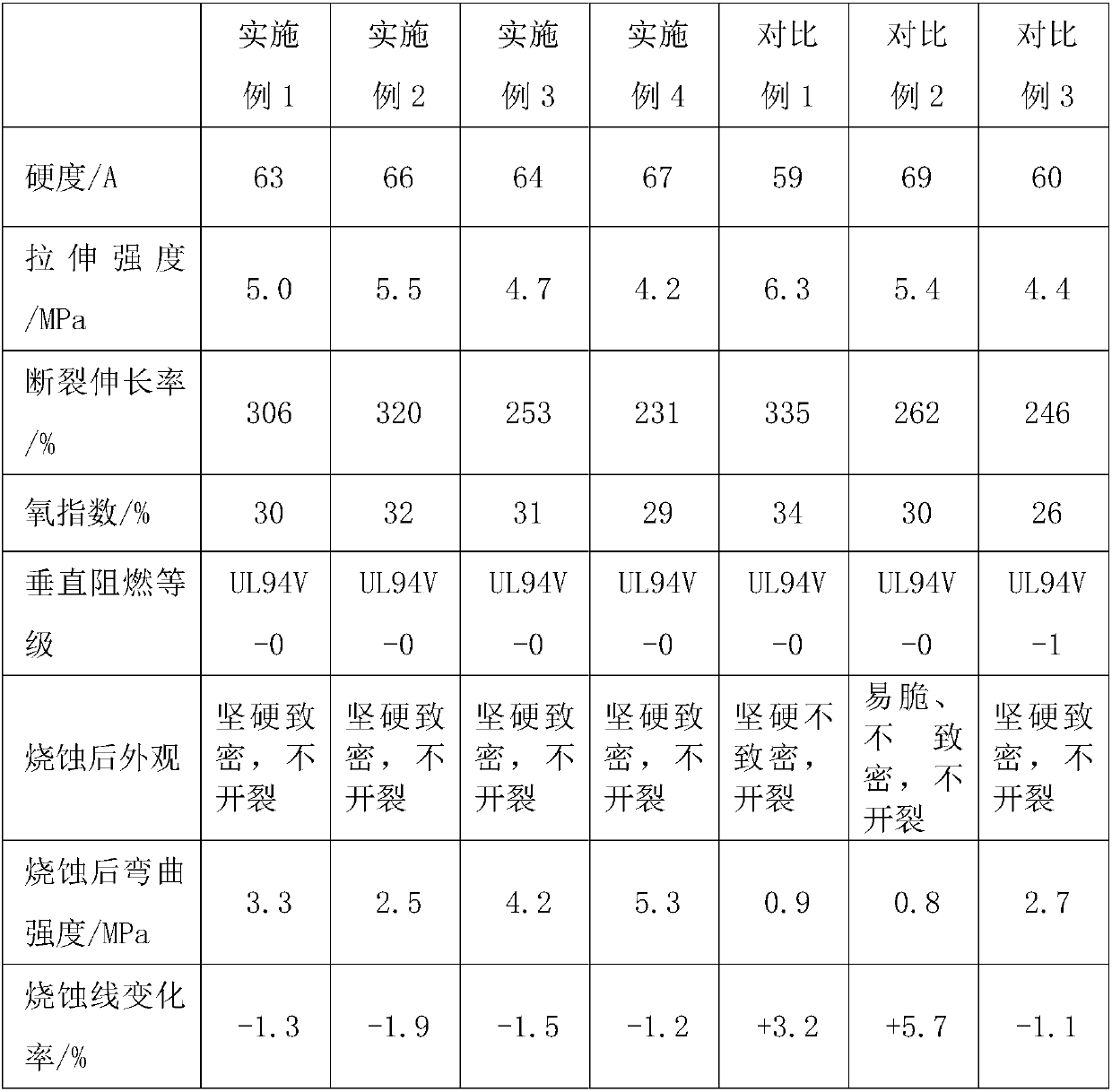

Ceramic flame-retardant and fireproof silicone rubber and preparation method thereof

The invention discloses ceramic flame-retardant and fireproof silicone rubber and a preparation method thereof. The silicone rubber contains the following components in parts by weight: 100 parts of raw silicone rubber, 10-50 parts of white carbon black, 10-100 parts of aluminum hydroxide, 10-50 parts of low-melting-point glass powder, 10-100 parts of sericite powder, 1-20 parts of hydroxyl silicone oil, 1-20 parts of hexamethyl disilazane, 0.1-3 parts of a platinum compound and 0.1-5 parts of a vulcanizing agent. The silicone rubber is good in flame retardance, excellent in mechanical property, safe and environmentally friendly, has good mechanical strength and insulating property after being ablated, is capable of preventing burnt objects from being damaged and keeping a circuit completefor a long time and can play a good fireproof role.

Owner:GUANGDONG POLYSIL TECH CO LTD

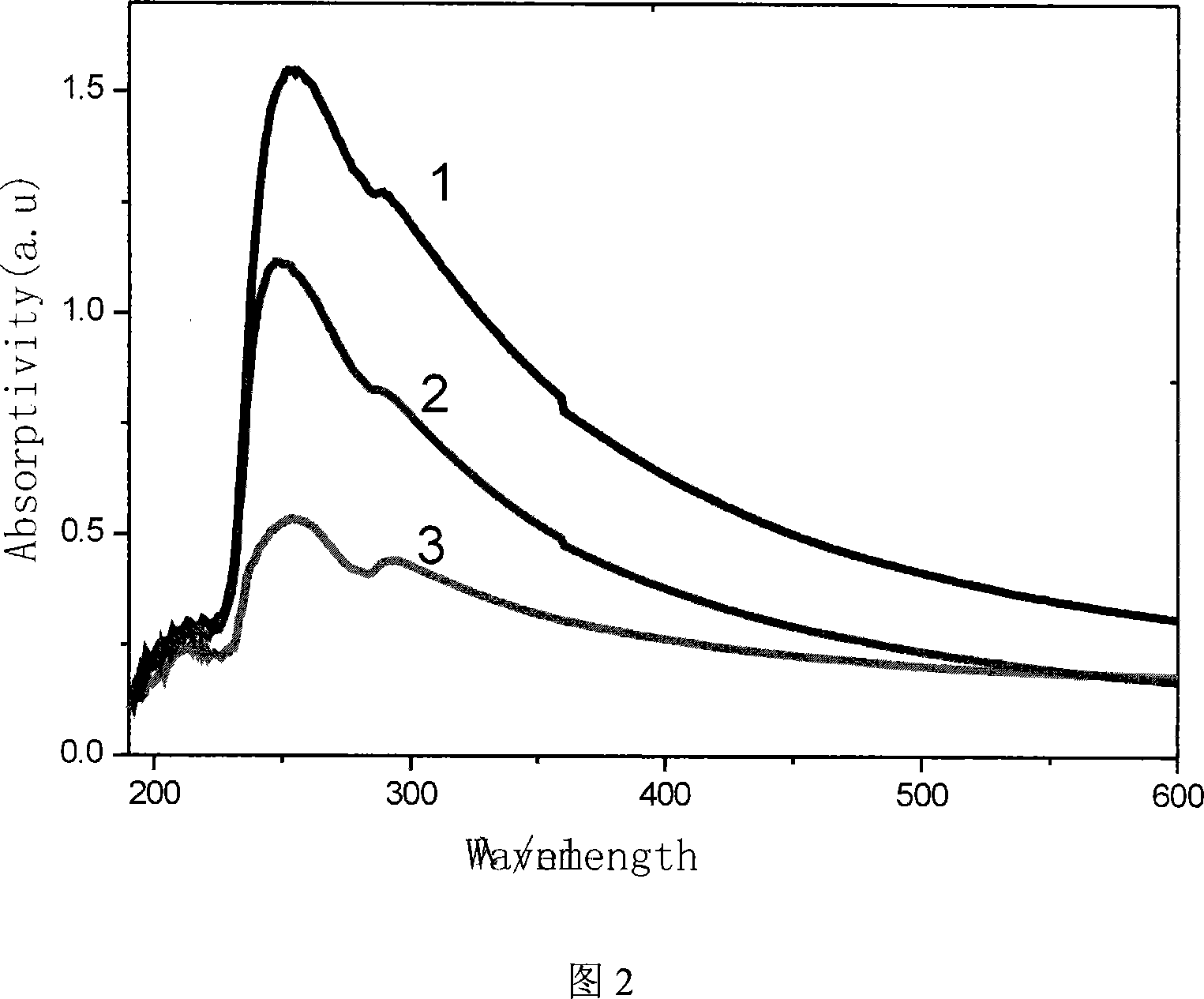

Method of preparing sericite ultraviolet radiation screening agent

InactiveCN101058679AGood coating effectGood dispersionOther chemical processesInorganic pigment treatmentChlorideVolumetric Mass Density

The invention discloses a making method of ultraviolet masking agent of sericite mica, which comprises the following steps: 1) preparing fined sericite mica; 2) activating the sericite mica powder; 3) adding water in the sericite mica to form the suspension with density at 2. 5-5%; adjusting the pH value to 2. 0-2. 5 through alcaine as system C; 4) allocating titanic chloride solution with density at 10-15%; adding zinc chloride in the titanic chloride solution; making the molar rate of Zn and Ti at 1: 2; obtaining the solution D; 5) dripping the solution D into the system D; controlling the pH value to 7. 0; 6) filtering the sediment; washing; drying at 95 deg. c; 7) grinding the drier; placing the drier in the electric furnace at 600 deg. c for 2-3h; 8) grinding the sintered material; beating to 10-15um; obtaining the product.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

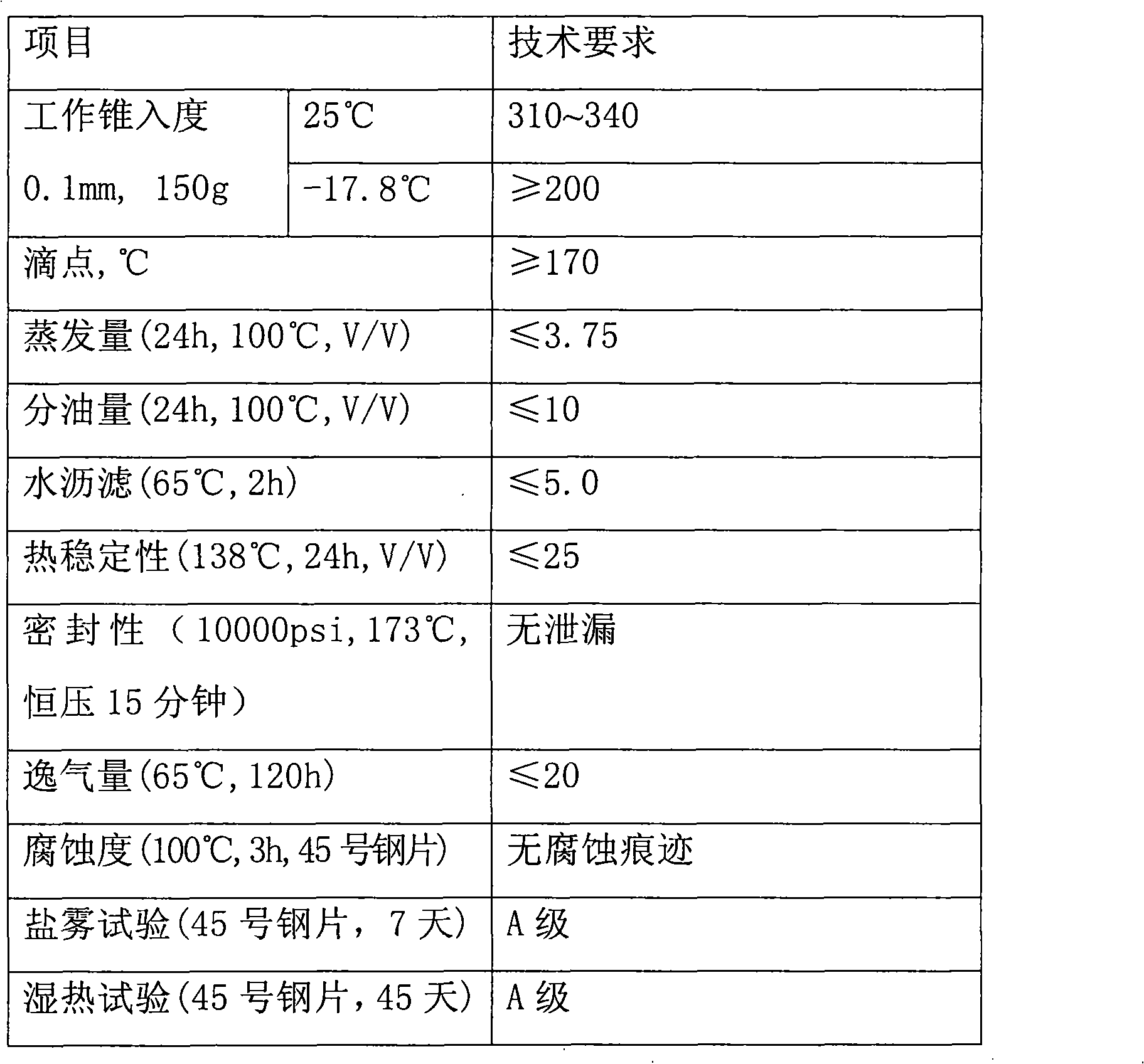

API oil sleeve thread sealing grease composite and preparation method thereof

ActiveCN101565648AImprove low temperature fluidityMechanical automatic spraying effect is goodOther chemical processesAdditivesWear resistantPetroleum

The invention provides an API oil sleeve thread sealing grease composite. The components of the composite include 40-50 percent of basic grease, 5-10 percent of dimethyl silicon oil, 16.5-20 percent of crystalline graphite powder, 6-9 percent of polyfluortetraethylene, 0.5-1.0 percent of expansion graphite powder, 1-2 percent of white carbon black, 3-4 percent of sericite in powder, 3-4 percent oflight calcium carbonate and 10-15 percent of tin bronze powder according to the percentage accounting for in the weight of the sealing grease composite. The invention also provides a preparation method of the API oil sleeve thread sealing grease composite. The invention has the beneficial effects that among the components of the sealing grease composite, synthetic oil is taken as a substitute formineral oil, and therefore the low temperature fluidity of the basic grease is improved to facilitate the brush application in winter. The addition of high performance antirust to the basic grease ensures that pipe threading does not rust when oil sleeves and pipes are stored outside in long term. Without zinc powder added but with the consumption of copper powder increased and other wear-resistant materials added, the high temperature lubricity of the grease is guaranteed and the pipe threading of the oil sleeves and pipes is prevented from thread gluing when screwing together. With novel high efficiency sealing materials added in the components of the sealing grease composite, the leak tightness of the grease is guaranteed.

Owner:TIANJIN PIPE GROUP CORP

Elastic napping coating for thermal insulating external wall

The invention relates to external wall elastic napping coating with thermal insulating function. The coating consists of the following components in percentage by weight: 40 to 50 percent of elastic acrylic emulsion, 10 to 15 percent of titanium white, 1 to 2 percent of freeze proof agent, 0.3 to 0.8 percent of defoamer, 0.1 to 0.15 percent of bacteriacide, 0.1 to 0.15 percent of wetting agent, 0.5 to 1 percent of film-forming additive, 0.1 to 0.2 percent of cellulosic thickener, 0.1 to 0.4 percent of dispersing agent, 1 to 1.5 percent of alkali swelling thickener, 3 to 5 percent of hollow glass microspheres, 5 to 8 percent of expanded perlite, 2 to 5 percent of vermiculite, 3 to 5 percent of sericite, 5 to 8 percent of coal ash filler, and 10 to 20 percent of water. Besides decorating and protection functions of conventional external elastic napping coating, the coating has the special function of thermal insulation.

Owner:苏州圣广泰国际贸易有限公司

Weather-resistant epoxy polyurethane anticorrosive paint and preparation thereof

InactiveCN101298535AGood weather resistanceStrong adhesionAnti-corrosive paintsPolyurea/polyurethane coatingsGas phaseSiloxane

The invention relates to a weather resistant epoxy-polyurethane anti-corrosion coating and a manufacturing method thereof, which adds phenol-A epoxy resin, bisphenol-F epoxy resin, hydroxyl contained saturated polyester resin and fluorocarbon resin into the mixed solvent of dimethylbenzene, n-butyl acetate, methyl isobutyl ketone and butanone; then adds rutile type titanium pigment, saponite, sericite in powder, polyacrylate co-polymer, polymethyl alkyl siloxane, benzotriazole, gas phase silica and iso-caprylic acid znic to make the fluid A of the weather resistant epoxy-polyurethane anti-corrosion coating while adds fatty group polyisocyanate into the mixed liquor of anhydro-dimethylbenzene and the n-butyl acetate to make fluid B, and mix the two components during application. The invention can be applied to the preservation of the surfaces of outdoor steel structures, pipes and concrete requiring weather resistance, light aging resistance and acid, alkali and salt corrosion resistance.

Owner:TIANJIN BO XING ENG SCI & TECH LIMITED COMPANY OF CNPC +1

High-temperature-hot-water corrosion resisting coating

InactiveCN101892010AGood high water resistanceImprove water resistanceAnti-corrosive paintsHigh resistanceThermal water

The invention relates to a high-temperature-hot-water corrosion resisting coating, in particular to a corrosion resisting coating containing an epoxy-modified silicone resin. The coating can be applied to the internal wall coating corrosion resistance of a geothermal hot water pipeline, a heat exchanger pipe and a hot water conveying pipeline and comprises a component A and a component B, whereinthe component A consists of the following materials in percentage by mass: 50 to 60 percent of epoxy-modified silicone resin, 22 to 30 percent of mica oxidation iron ash, 9 to 14 percent of sericite,2 to 4.5 percent of talcpowder, 0.2 to 0.5 percent of dispersant and 0.1 to 0.4 percent of defoamer; and the component B comprises 2 to 6 mass percent of curing agent. The coating of the invention has the advantages of curing at normal temperature, high water resistance, high-temperature stability, cost reduction, stable structural performance in geothermal hot water of 120 DEG C and high resistance to high-temperature-hot-water corrosion.

Owner:BEIJING UNIV OF CHEM TECH

Novel stemming at tap hole

The invention discloses novel stemming at a tap hole. The stemming comprises the components in parts by weight as follows: 5-25 parts of corundum, 5-25 parts of high aluminum aggregate, 10-30 parts of silicon nitride combined with silicon carbide, 2-3 parts of silicon nitride iron, 5-15 parts of coke powder, 8-20 parts of clay, 1-5 parts of crystalline flake graphite, 5-10 parts of pyrophyllite, 4-7 parts of sericite, 5-10 parts of magnesium-aluminum spinelle, 2-4 parts of active alumina micro powder, 1-3 parts of metal powder and 15-20 parts of external composite binding agent. The composite binding agent comprises tar, modified phenolic resin and an organic solvent. The volume ratio of tar, modified phenolic resin to the organic solvent in the composite binding agent is 1:3:1. According to the invention, with the adoption of the composite binding agent formed by mixing tar and modified phenolic resin, smoke generated is less, the same plasticity to be combined with tar is met, the opening performance is good, the pressure resisting thermal shock resistance is good, and the adhesion strength is high. The depth of the tap hole can be prolonged and the furnace cylinder can be protected, the tapping time is prolonged, and the number of casts every day is reduced.

Owner:长兴云峰炉料有限公司

Diatom ooze wall material with high content of diatomite and preparation method thereof

The invention provides a diatom ooze wall material with high content of diatomite and a preparation method thereof, relating to a diatom ooze wall material and a preparation method thereof, and solving the problem that existing diatom ooze wall materials have poor using effects. The diatom ooze wall material is prepared from diatomite, dispersible latex powder (21#), hydroxypropyl methyl cellulose, Portland cement, ash calcium powder, attapulgite powder, white washed quartz sand, sericite powder, zeolite powder, flax fibers, nano ZnO powder, nano silver particles, hydrophobic organic silicon powder and inorganic pigments. The method comprises the steps of I. weighing the raw materials; II. mixing the raw materials uniformly to obtain diatom ooze powder, and packaging the diatom ooze powder with a moisture-barrier bag, thus completing preparation. The diatom ooze wall material has high content of diatomite (volume content is not less than 60%), has various performance indexes meeting the national requirements for diatom ooze wall materials, and is an efficient and environment-friendly indoor decoration material. The method for preparing the diatom ooze wall material with high content of diatomite is simple and convenient to operate and can achieve industrialization.

Owner:CHANGBAI KOREAN AUTONOMOUS COUNTY GSUNY DIATOMITETECH CO LTD +1

Waterless stemming for blast furnace

InactiveCN1523120AImprove workabilityEasy to squeeze outBlast furnace componentsBlast furnace detailsAnthraceneContraction rate

The present invention provides an anhydrous stemming for blast furnace. Its composition includes (wt%) coarse brown corundun 1-4%, fine brown corundum 2-5%, coarse mullite 7-15%, fine mullite 9-20%, coke powder 15-20%, clay 10-19%, silicon carbide 7-11%, sericite 5-8%, bitumen 2-4% and anthracene oil 15-25%. It has good working property, stable high temperature resistance, excellent caking property, quick agglutinating property, low ton-iron stemming consumption, low contraction rate and high strength, it can raise tap up-to-standard rate to 100% from original 61.5%, can raise production safety of blast furnace, and can raise smelting strength.

Owner:WUKUN STEEL

Glass fiber reinforced polypropylene compound material and preparation method thereof

The invention relates to a glass fiber reinforced polypropylene compound material and a preparation method thereof. The glass fiber reinforced polypropylene compound material comprises the following raw materials: 20-40% of copolymerized polypropylene I, 20-40% of copolymerized polypropylene II, 5-25% of compatibility agent, 0.2-1% of coupling agent, 1-30% of glass fiber, 1-20% of sericite and 0.1-0.4% of antioxidant, wherein the copolymerized polypropylene I is high-impact copolymerized polypropylene with the impact strength of more than 80 J / m; the copolymerized polypropylene II is high-rigidity copolymerized polypropylene with the flexural modulus of more than 1200 Mpa; the diameter of the glass fiber is 8-17 microns; and the particle size of the sericite is 800-1250 meshes. According to the glass fiber reinforced polypropylene compound material, the effect of very low warpage and even no warpage can be achieved on the premise of keeping high heat resistance and high rigidity.

Owner:ECOVACS ROBOTICS (SUZHOU ) CO LTD

Method of producing modified acrylic acid roofing waterproof paint

PendingCN101153180AWateryWaterproof and anti-seepageAntifouling/underwater paintsPaints with biocidesUltravioletCarvacryl acetate

The present invention discloses a preparation method of modifying acrylic acid waterproof dope for house face; 0.01 portion of sodium hexametahposphate is added into water for milling. 0.2 portion of sericite powder, 0.1 portion of silicon lime powder, 0.1 portion of titanium powder are added to be milled; after grinded for two times, 0.2 portion of pure acrylic acid ester latex, 0.1 portion of watercraft polyurethane latex, 0.2 portion of organic silicon latex, 0.1 portion of ethylene-polyvingl acetate emulsion, 0.01 portion of glycol, 0.01 portion of dibutyl phthalate and 0.001 portion of sodium pentachlorophenate are added for milling. And finally, 0.01 portion of organic silicon defoamer agent is added to be milled so as to obtain the present invention. The present invention has the advantages of innocuous, inodorous and non-pollution. The present invention has water-hating performance. The present invention can bear or endure the irradiation of ultraviolet radiation. In addition, the present invention is characterized in anti-aging, much stronger adhesion intension, waterproof, seepy-resisting, heat-resisting and cold-resisting. The present invention has much better extending ability; the present invention has the advantages of cool construction and can be coated directly.

Owner:ZHONGHONG (TIANJIN) IND CO LTD

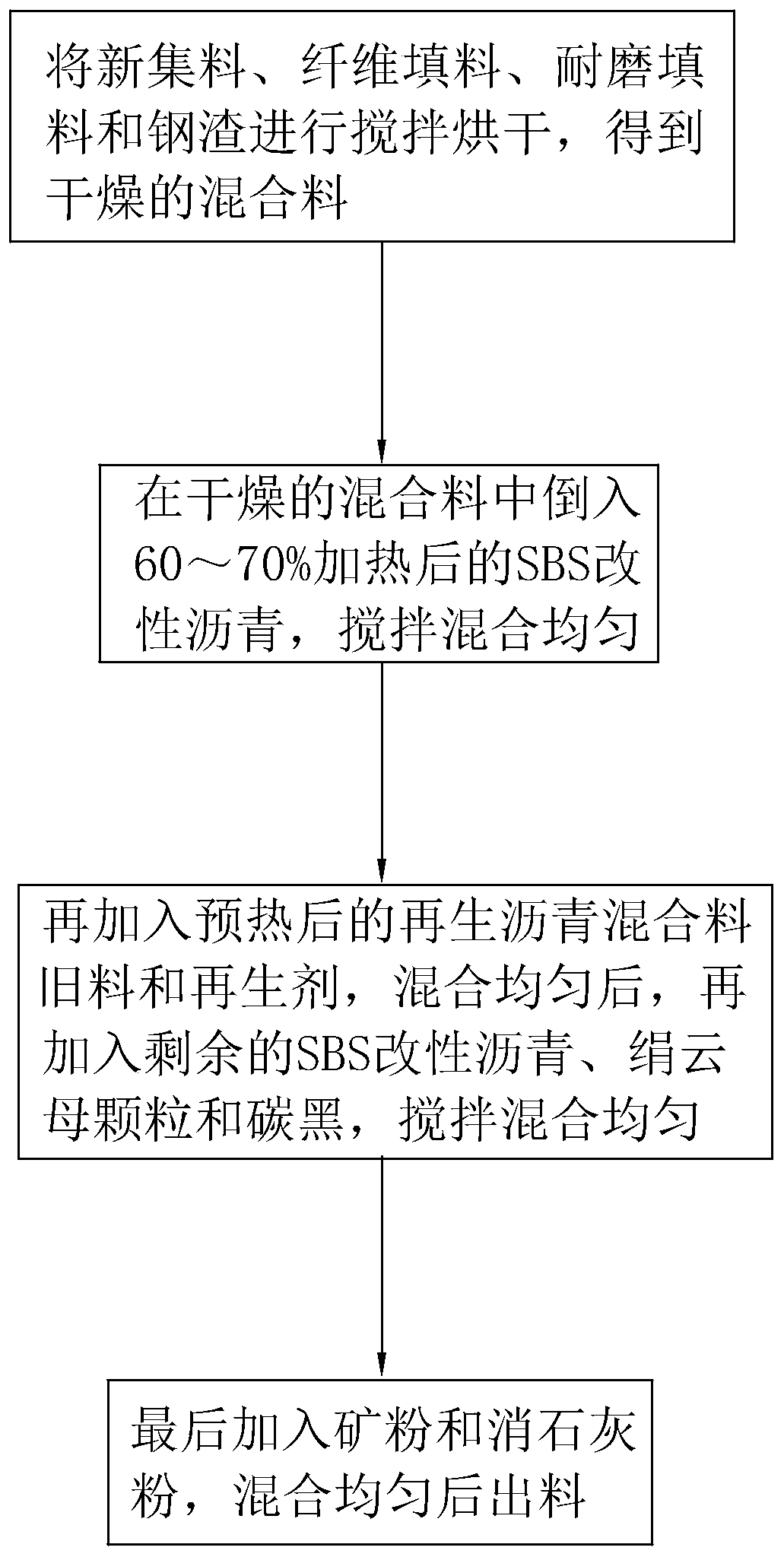

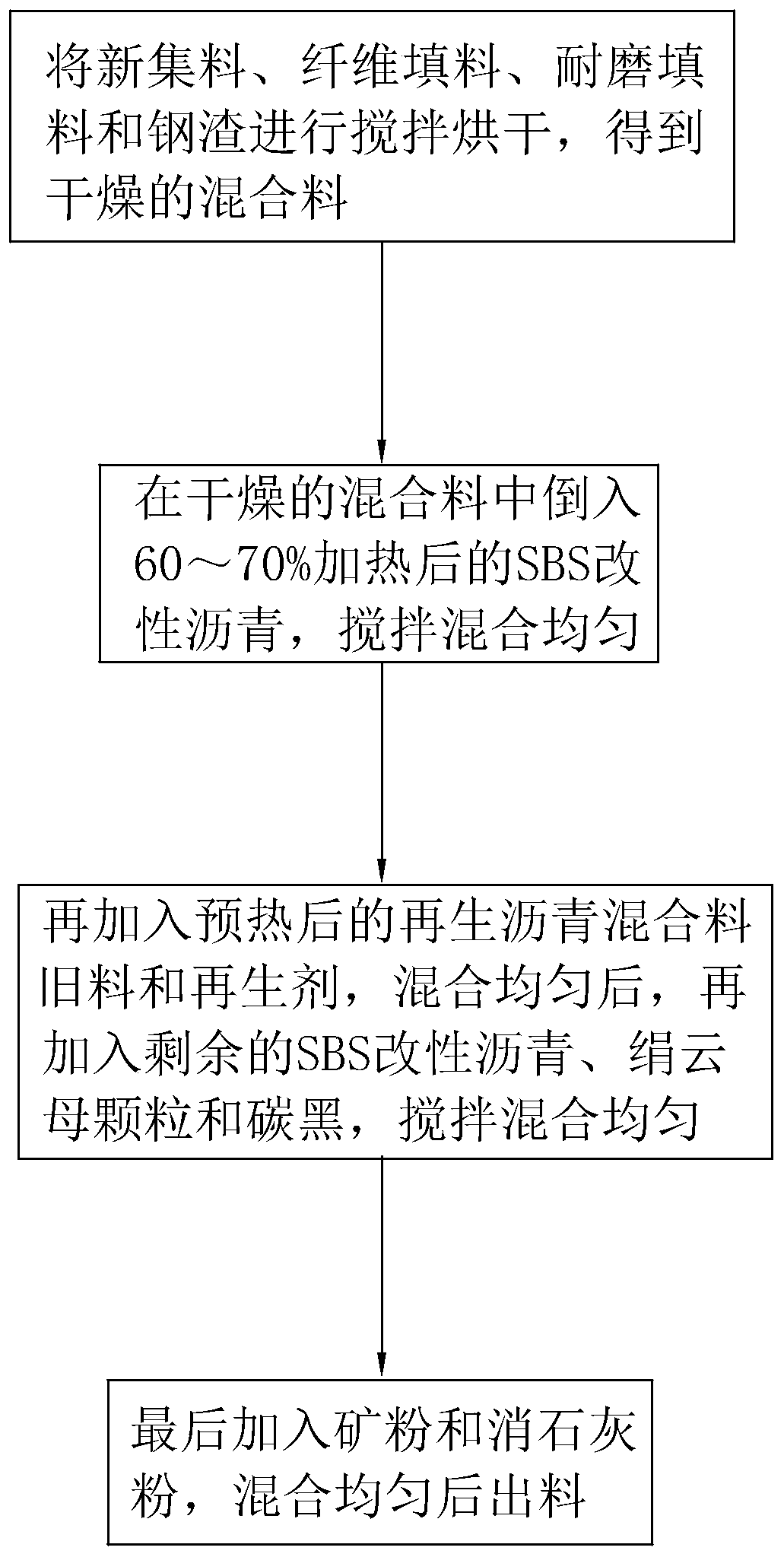

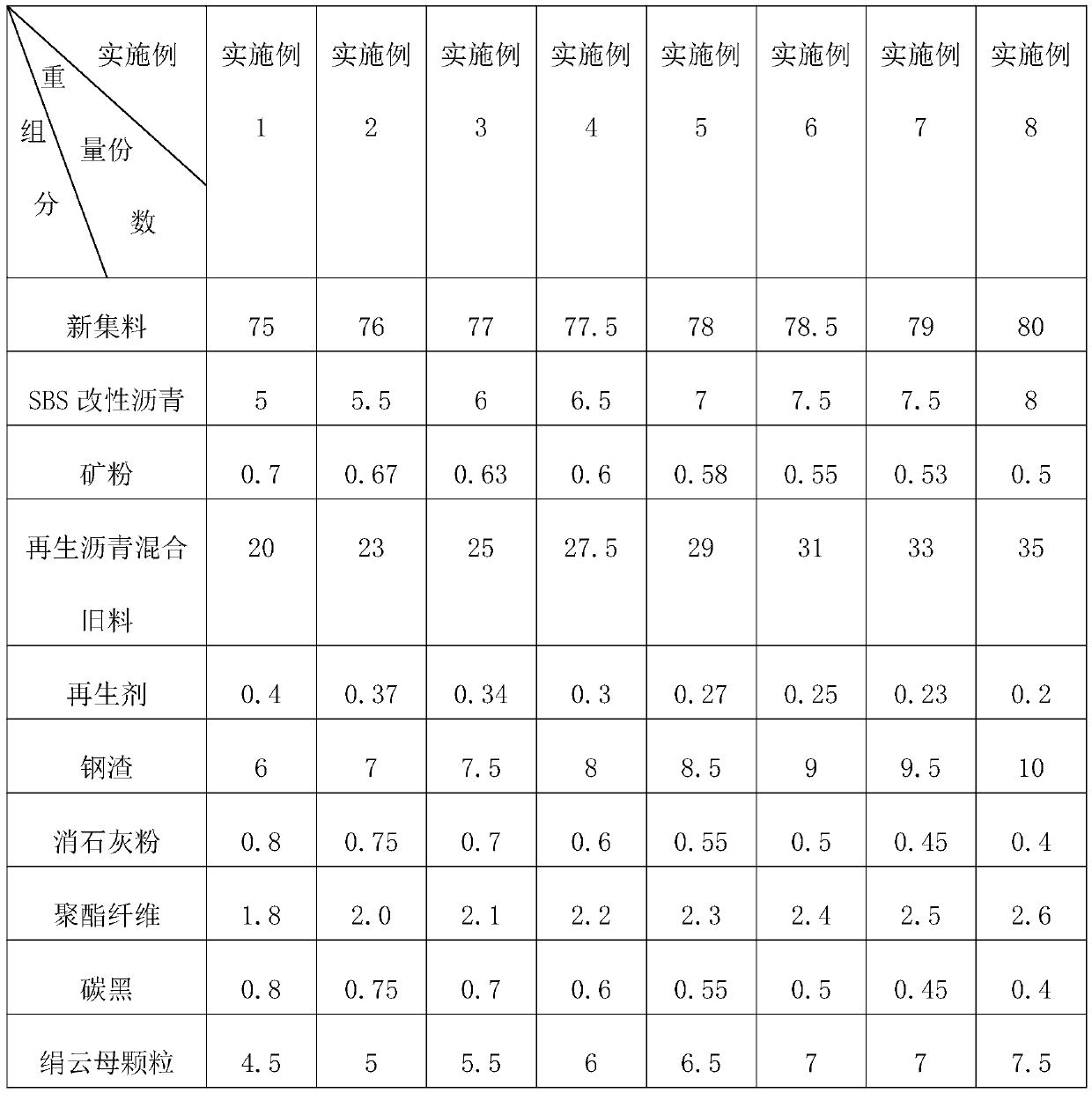

Abrasion-resistant recycled asphalt concrete and preparation process thereof

The invention discloses an abrasion-resistant recycled asphalt concrete and a preparation process thereof, relates to the technical field of asphalt concrete processing, and solves the problem that asphalt concrete pavement is prone to ageing due to frequent temperature changes and is prone to large abrasion during use. The abrasion-resistant recycled asphalt concrete comprises the following components in parts by weight: 75 to 80 parts of new aggregate, 5 to 8 parts of SBS modified asphalt, 0.5 to 0.7 part of mineral powder, 20 to 35 parts of a recycled asphalt mix old material, 0.2 to 0.4 part of a regenerating agent, 6 to 10 parts of steel slag, 0.4 to 0.8 part of hydrated lime powder, 1.8 to 2.6 parts of fiber filler, 0.5 to 1.5 part of abrasion-resistant filler, 0.4 to 0.8 part of carbon black, 4.5 to 7.5 parts of sericite particles. The abrasion-resistant recycled asphalt concrete in the invention has good stability in the use process, is not easy to age due to intermittent friction heat generated between the abrasion-resistant recycled asphalt concrete and a wheel, and is not easy to greatly wear.

Owner:上海宝新特种沥青混凝土有限公司

Epoxy resin modified silica sol based high-temperature-resistant hydrophobic coating and preparation method thereof

The invention discloses an epoxy resin modified silica sol based high-temperature-resistant hydrophobic coating which is composed of the following components in percentage by mass: 60-65% of epoxy resin modified silica sol, 7-9% of rutile titanium dioxide, 8-12% of glass dust, 9-10% of sericite powder, 0.5-1% of organic bentonite and 9-14% of butyl acetate. The preparation method is implemented through the following steps of: preparing epoxy resin modified silica sol firstly, reacting gamma-triethoxypropylsilane with epoxy resin, and then adding tetraethoxysilane for carrying out hydrolytic condensation; adding filler and a solvent in the prepared product in proportion, and carrying out high-speed mixing and grinding on the obtained mixture until the fineness of the obtained product is below 50 mu m so as to obtain the coating disclosed by the invention. A film prepared by dying and solidifying the coating disclosed by the invention has the advantages of good mechanical properties, excellent hydrophobic properties, good high temperature resistance and weather resistance, and the like. The coating is applicable to the high-temperature-resistant protection and decoration of metal substrates such as aluminum plates, tinplate and steel plates.

Owner:JIANGSU UNIV OF SCI & TECH

Environment-friendly stemming for blast furnace taphole and preparation method thereof

InactiveCN101613213AReduce tar contentImprove protectionBlast furnace componentsCeramic shaping apparatusInorganic phosphateSocial benefits

The invention discloses an environment-friendly stemming for a blast furnace taphole and a preparation method thereof, which is prepared by the following raw materials according to weight percentage content: 35-50% of bauxite or hard clay or fused alumina with thickness of 0.2-3mm, 1-5% of modified powder resin, 1-5% of high-temperature pitch, 3-8% of inorganic phosphate, 1-20% of silicon carbide, 10-20% of coke powder, 3-10% of sericite, 2-8% of cyanite and 3-8% of tar oil. The preparation method comprises the following steps: weighting each raw material according to the above formula, adding into a heating stirrer for stirring and mixing and molding by using a friction press after mixing. The invention adopts the mixture of organism and inorganic substance as a binder to prepare the stemming, thus greatly reducing the component content of tar oil which pollutes environment, being favor of environmental protection and having remarkable social benefit, and can be hardened quickly.

Owner:HENAN GENGSHENG REFRACTORIES

Heat-insulating coating for external wall

InactiveCN104745013ALow viscosityImprove liquidityReflecting/signal paintsHydroxyethyl celluloseDefoaming Agents

Owner:GUANGXI JIKUAN SOLAR ENERGY EQUIP +1

Scratch-resistant outdoor powder paint

ActiveCN106366892AImprove shielding effectHigh visible light transmittancePolyurea/polyurethane coatingsPowdery paintsArchitectural glassWater based

The invention discloses a scratch-resistant outdoor powder paint which is composed of the following raw materials in parts by weight: 5-8 parts of modified sericite, 10 parts of silicon dioxide, 8-15 parts of modified nano tin tungsten oxide, 5 parts of barium sulfate, 7 parts of titanium dioxide, 1-3 parts of dispersing aid, 1-3 parts of leveling agent, 0.05-1 part of defoaming agent, 1 part of polytetrafluoroethylene wax, 30 parts of water-based polyurethane resin and 30 parts of organic silicon resin. The paint is suitable for heat insulation on the surfaces of building glass, vehicle glass and cement, can shield ultraviolet and infrared light, and has the advantages of favorable heat-insulating property, favorable scratch resistance, stable coating performance and simple preparation technique.

Owner:广东捷宇粉体涂料有限公司

High heat conductive insulating impregnated resin used for air reactor and preparation method thereof

InactiveCN101864145AReduce temperature riseImprove thermal conductivityPlastic/resin/waxes insulatorsCoils manufactureEpoxySericite

The invention discloses a high heat conductive insulating impregnated resin used for an air reactor and a preparation method thereof. The impregnated resin comprises the following components in parts by weight: 100 parts of epoxy resin, 5-25 parts of flexibilizer, 75-100 parts of curing agent, 0.30-0.80 part of curing accelerator and 85-300 parts of inorganic powder, wherein the inorganic powder is selected form one or more than two of silica micropowder, aluminium oxide powder and sericite powder. The preparation method comprises the following steps: sequentially feeding the epoxy resin, the curing agent and the flexibilizer into a kettle and stirring; feeding the inorganic powder while heating to 50-60 DEG C, evenly stirring, and carrying out decompression and defoaming at the temperature of 60-75 DEG C until no air bubble is released; and while cooling to 40-50 DEG C, carrying out vacuum release, adding the curing accelerator, and evenly stirring to obtain the solvent impregnated resin. Compared with the prior art, the solvent impregnated resin preparation method of the invention is simple, the production cost is low, the obtained impregnated resin has high coefficient of heat conductivity, and the temperature rise of the reactor is low.

Owner:桂林五环电器制造有限公司

Transparent glass thermal-insulation and heat-preservation coating

InactiveCN102086329AEqualized scatteringUniform absorptionEpoxy resin coatingsEpoxyThermal insulation

The invention discloses transparent glass thermal-insulation and heat-preservation coating, which is prepared from the following materials in percentage by weight: 30 to 40 percent of elastic acrylic acid emulsion, 5 to 7 percent of epoxy resin, 10 to 15 percent of hollow glass microspheres, 8 to 12 percent of a functional filler (wet-process sericite powder), 15 to 20 percent of kaolin, 0.8 to 1.2 percent of anti-ultraviolet absorbent, 0.5 to 0.7 percent of dispersing agent, 3 to 5 percent of ethanol, 8 to 12 percent of water, 0.3 to 0.5 percent of wetting agent, 0.4 to 0.6 percent of defoamer, 0.1 to 0.3 percent of antibacterial agent, 0.2 to 0.45 percent of mildew preventive, 1.5 to 2.5 percent of flatting agent and 0.8 to 1.2 percent of thickener. The transparent glass thermal-insulation and heat-preservation coating is used as glass coating, has high transparency, does not give off harmful gas, is stable and durable and has good ultraviolet and infrared ray scattering and absorption effects.

Owner:杨卓卫

Process for comprehensively recovering ferrum, molybdenum and sericite from gold concentrator tailings

InactiveCN103433124AQuality improvementAdvanced technologyFlotationWet separationSericiteMaterials science

The invention relates to a mineral separating process for recovering useful components in tailings and particularly relates to a process for comprehensively recovering ferrum, molybdenum and sericite from gold concentrator tailings. The ferrum, molybdenum and sericite in the gold concentrator tailings are sufficiently recovered by using primary grinding, primary magnetic separation and secondary flotation processes, the recovery rate of Fe in the obtained magnetic concentrate is larger than 75%, the recovery rate of Mo in a molybdenum concentrate is larger than 70%, and the recovery rate of the sericite in a sericite concentrate is larger than 61%. The process provided by the invention is advanced, stable in operation and capable of increasing the utilization efficiency of resources of the gold concentrator tailings.

Owner:JIANGXI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com