Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

507results about How to "No warping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

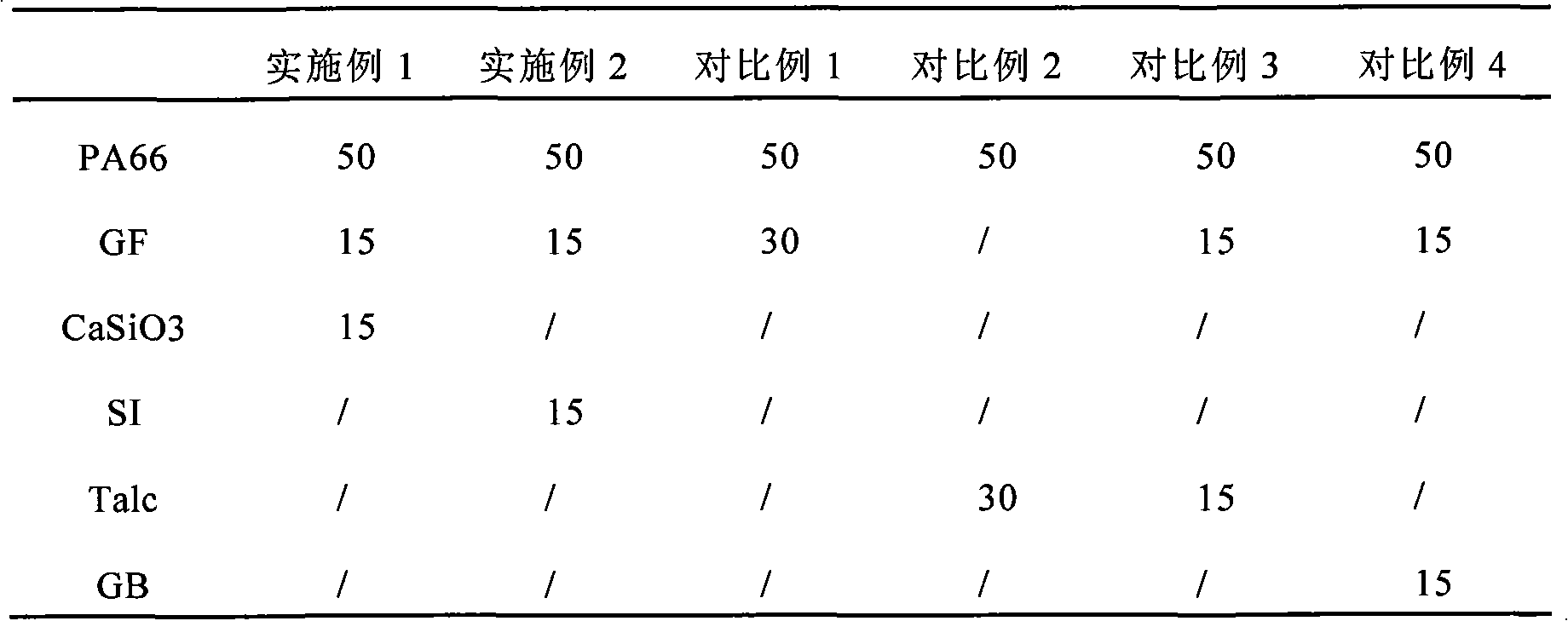

Plastic case material for breaker and preparation method thereof

ActiveCN102108204ASolve the problem of exposureHigh strengthProtective switch detailsBreaking strengthGlass fiber

The invention relates to a plastic case material for a breaker and a preparation method thereof. The material comprises the following components in parts by weight: 22-80 parts of nylon, 5-25 parts of glass fiber, 5-25 parts of needle-like filling material, 8-20 parts of fire retardant, 2-6 parts of auxiliary fire retardant and 0.1-2 parts of other auxiliaries. The preparation method comprises the following steps: evenly mixing the raw materials with a high-speed mixer at a high speed; and then bracing and pelleting the mixed materials with a screw extruder at the temperature of 220 DEG C-290DEG C to obtain the plastic case material. Compared with the prior art, the plastic case material has high breaking strength and elastic modulus, the strength of a compound material is barely influenced by a proper addition of the raw materials, and the obtained product has the advantages of no glass fiber rich surface, no buckling deformation, high strength and good heat resistance.

Owner:HEFEI GENIUS NEW MATERIALS

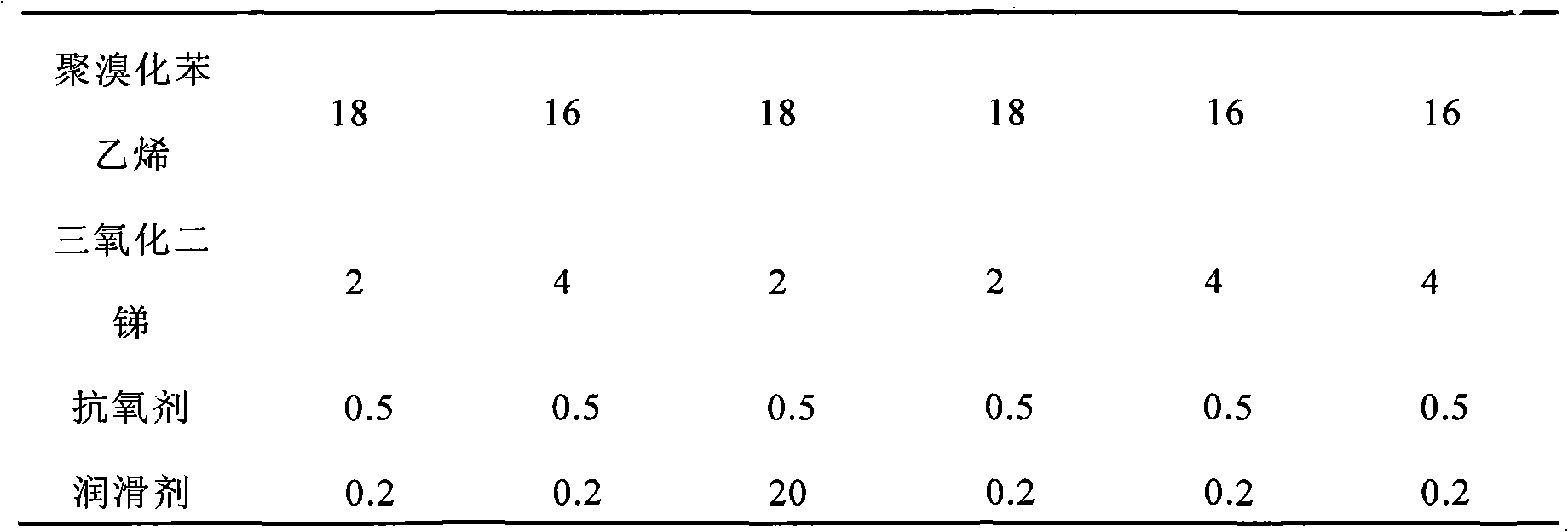

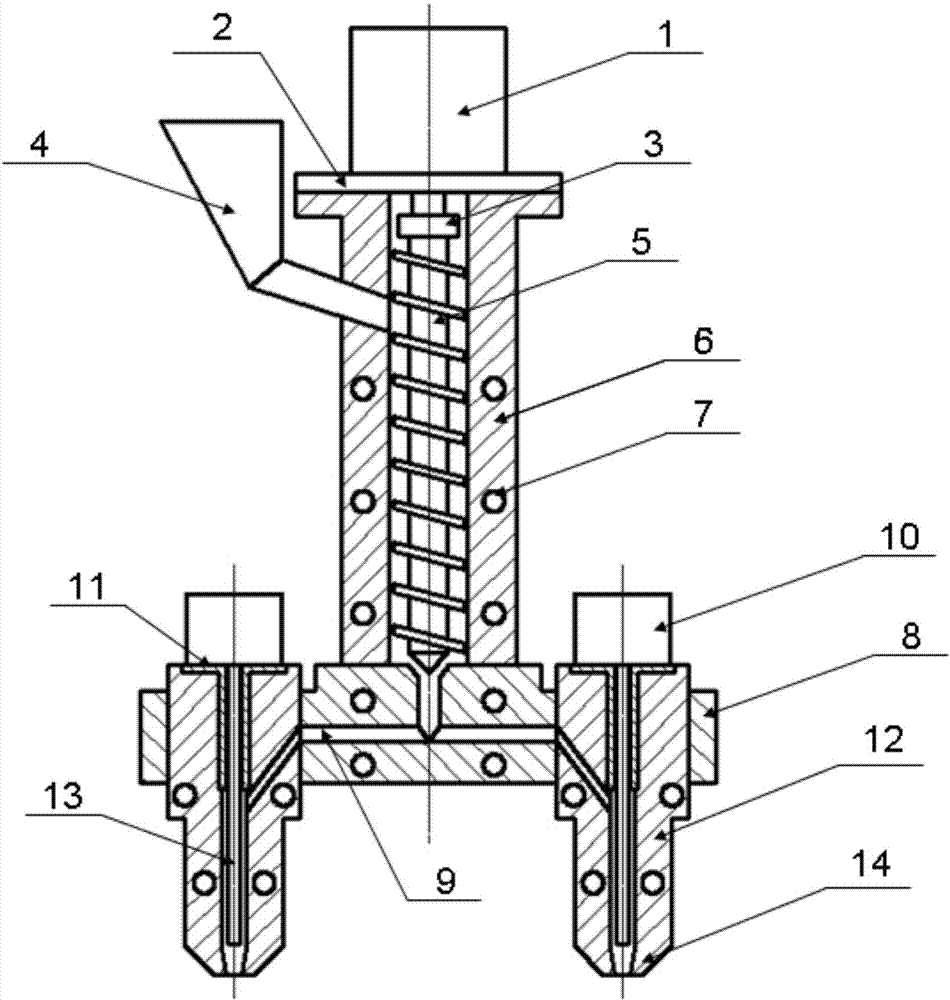

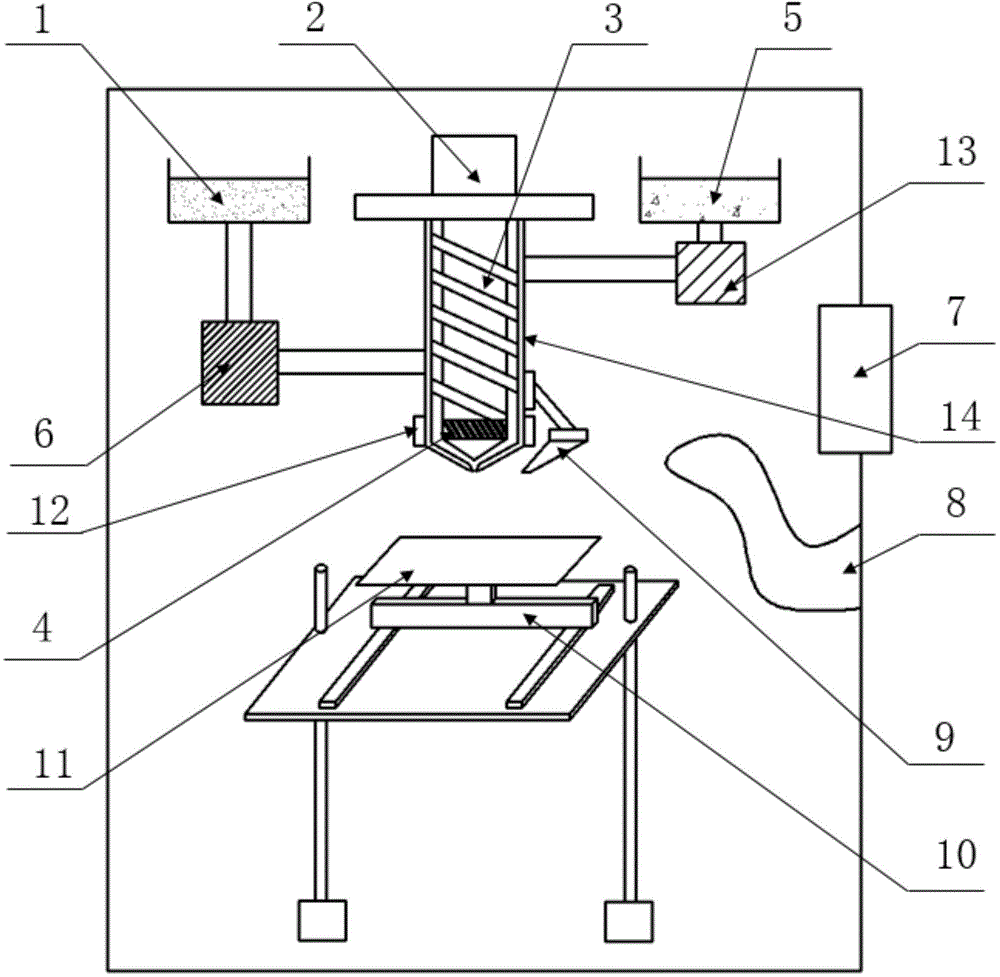

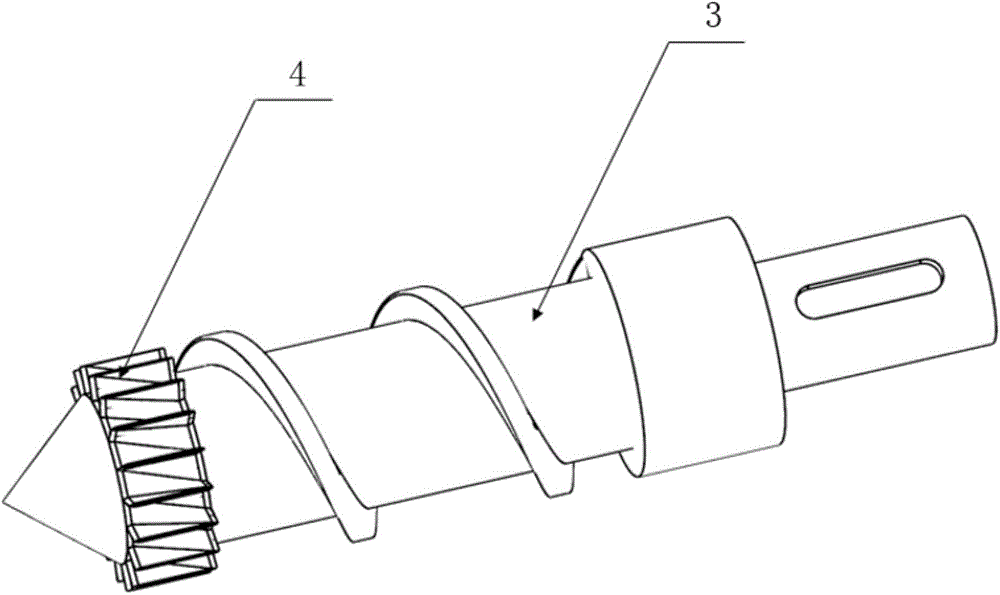

Melt differential three-dimensional printer

ActiveCN103692653ABurn out preventionConvenient Quantitative ManagementManufacturing driving meansAdditive manufacturing with liquidsHot runnerMotor drive

The invention discloses a melt differential three-dimensional printer. The melt differential three-dimensional printer mainly comprises a material melting unit, a micro-droplet jetting unit, a cylindrical-coordinate system molding unit and a rack, wherein a servo motor drives a screw rod to rotate in the material melting unit; a heater, which is fixedly arranged inside a machine cylinder, ensures that granules are entirely plastified through temperature regulation; a molten material is transmitted by the screw rod to the micro-droplet jetting unit; in the micro-droplet jetting unit, the molten material is transmitted into a valve body through a hot runner in a runner plate; a linear servo motor drives a valve needle to do reciprocating motion in the valve body so as to quantitatively and intermittently squeeze the molten material out of a nozzle to form melt micro-droplets; in the cylindrical-coordinate system molding unit, the molten micro-droplets are injected to a bearing table for cooling and deposition molding; the servo motors in the left-right direction and in the vertical direction are respectively engaged with the corresponding screw rod to rotate so as to drive the material melting unit and the micro-droplet jetting unit to move along the left-right direction and the vertical direction; a circumference servo motor drives the bearing table with a worm gear to rotate through a worm rod so as to realize three-dimensional movement under a cylindrical-coordinate system.

Owner:BEIJING UNIV OF CHEM TECH

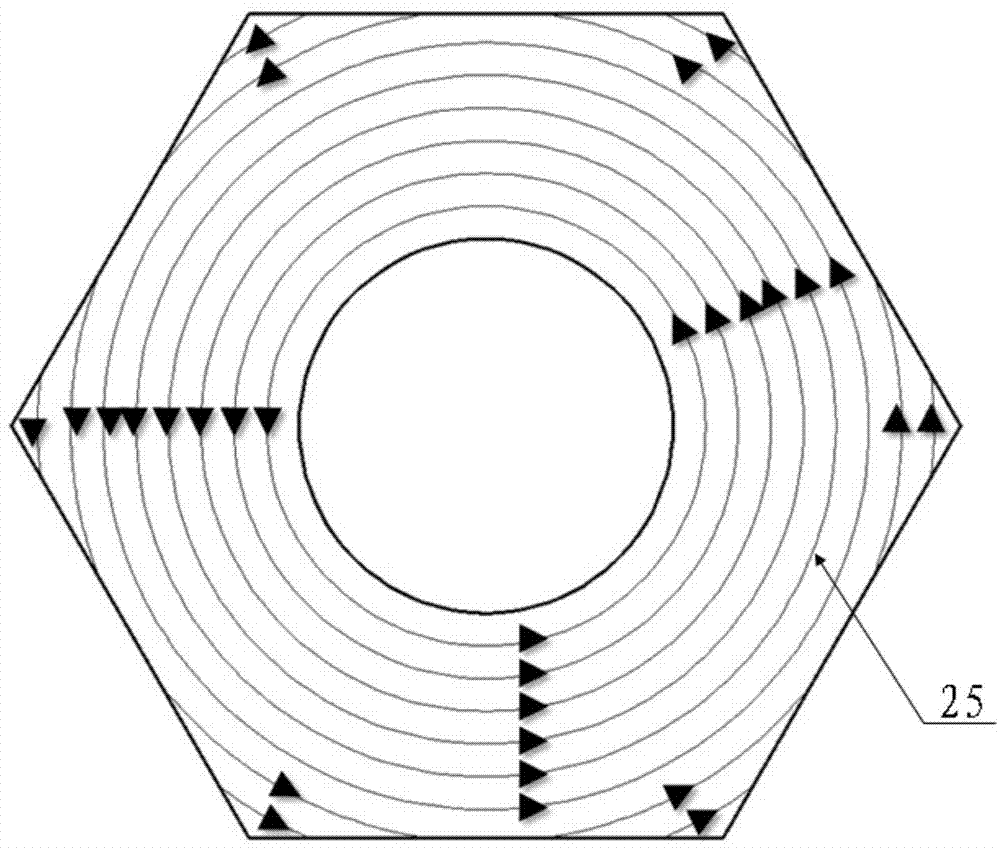

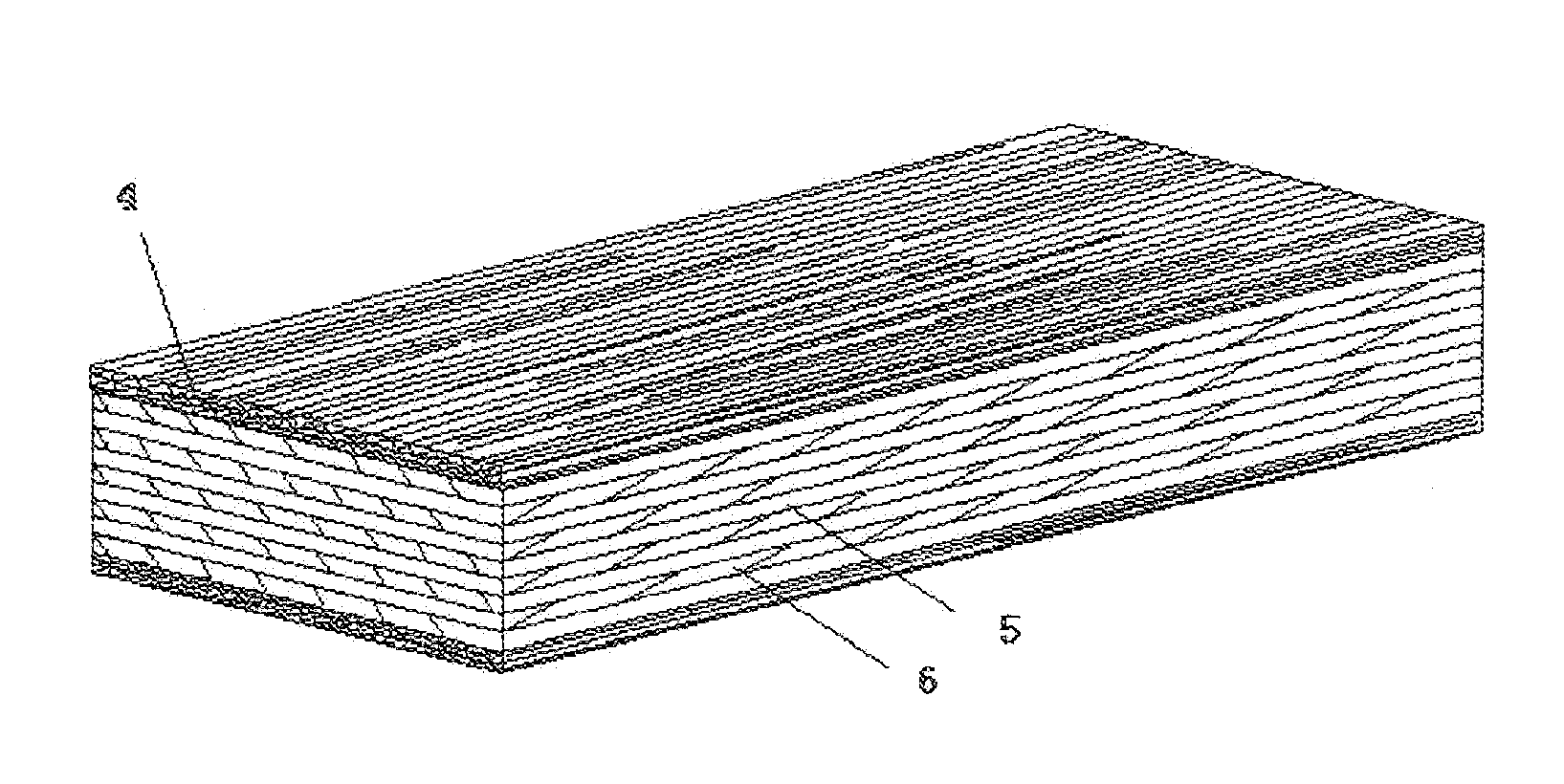

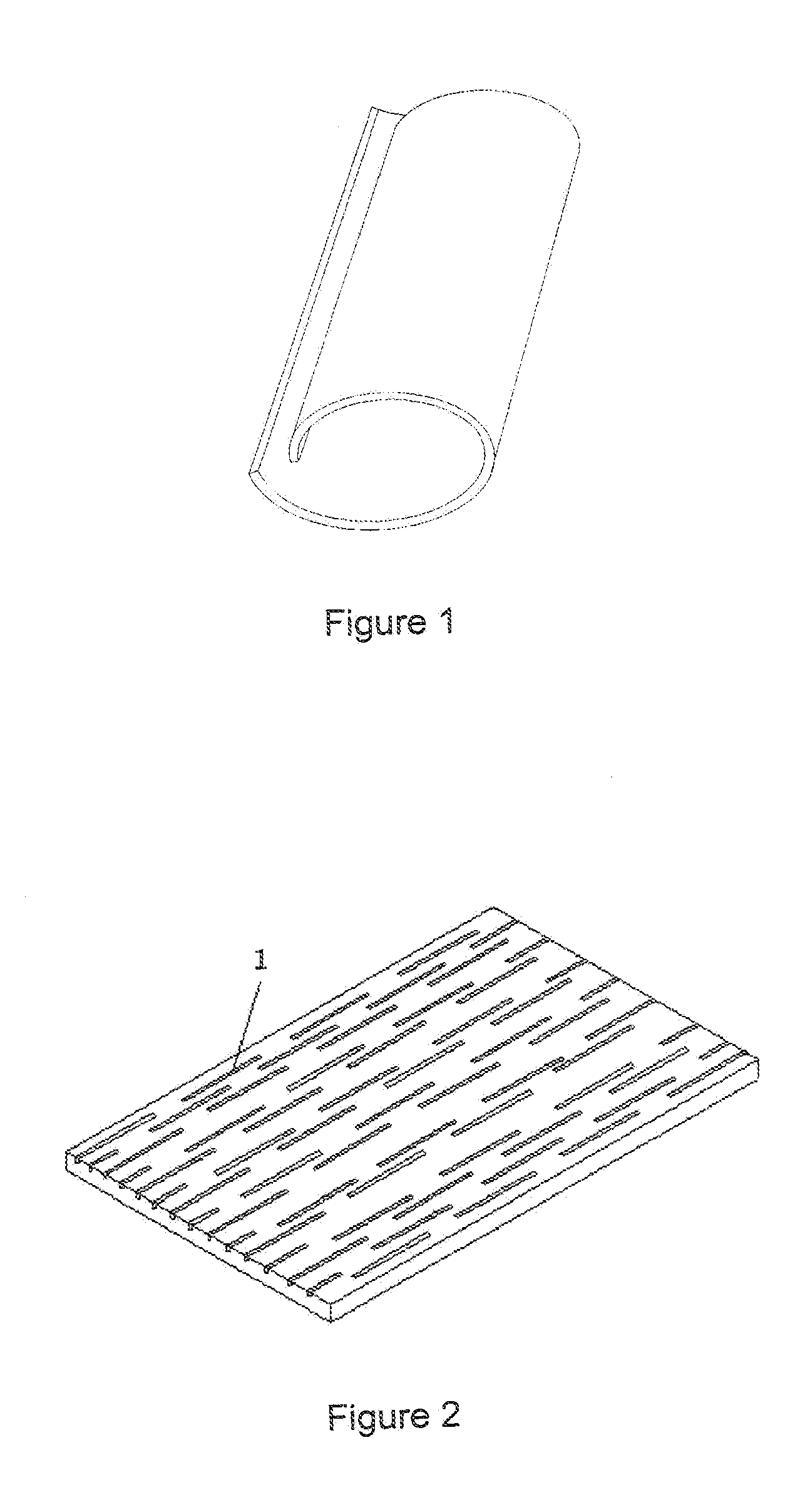

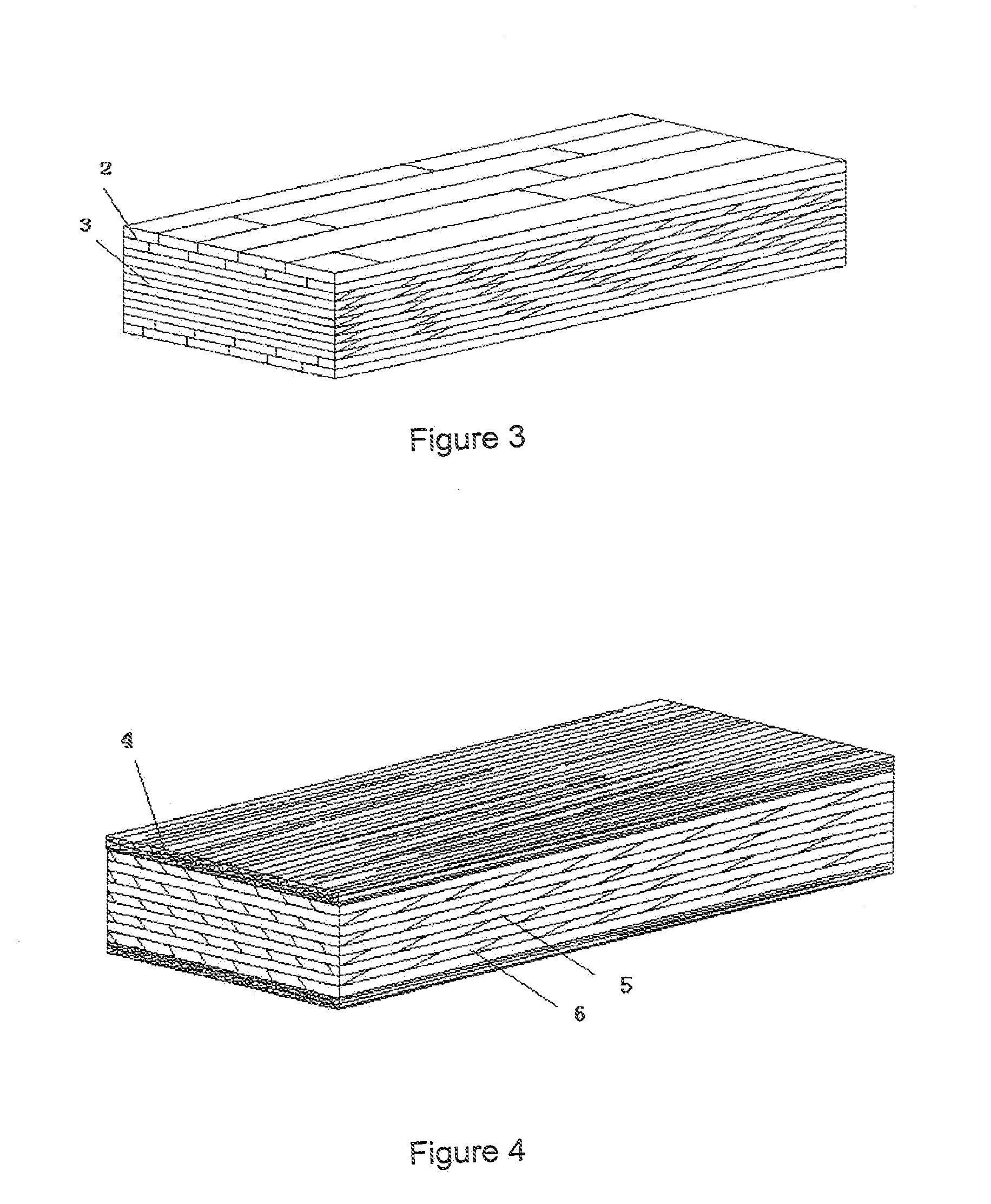

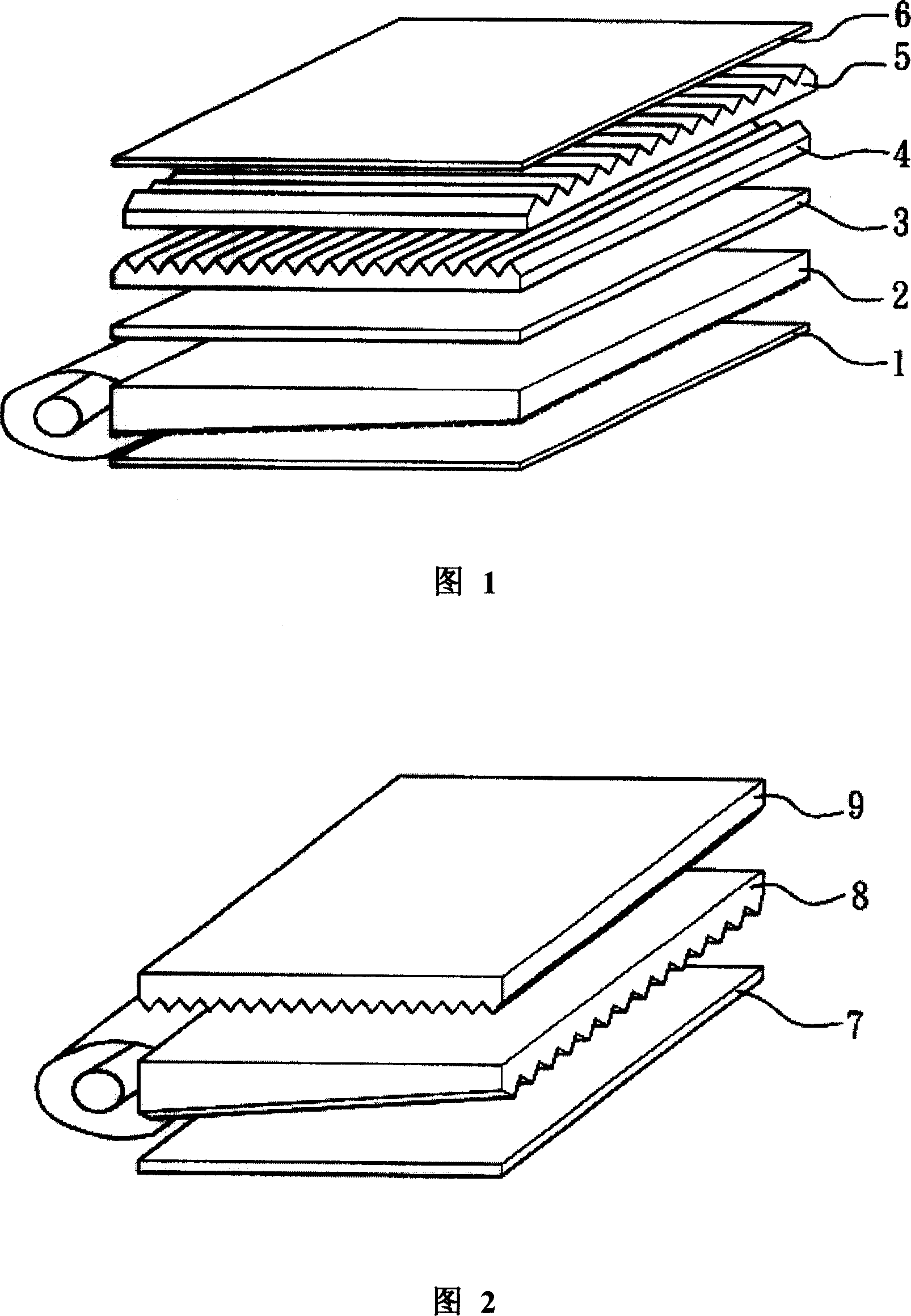

Ultra thick bamboo-wood composite panel, ultra thick solid wood composite panel and manufacturing methods thereof

InactiveUS20110274872A1Improve technologyLess amountWood veneer joiningPlant material mechanical workingLine segmentSolid wood

The present invention provides ultra-thick bamboo / wood and solid wood composite panels, comprising core board, surface board and back board; said core board is composed of ultra-thick peeling veneers with the thickness of 6 to 12 mm, both said surface board and back board are made of bamboo or wood; said core board comprises several layers of said ultra-thick veneers, and the veneers of contiguous layer are assembled with parallel structure; glue layer is arranged between contiguous said veneers, the adhesive in the glue layer is the aqueous macromolecule isocyanate adhesive; said ultra-thick veneers of the core layer are the veneers with stress degradation treatment, i.e., punctate or line segment cracks are formed along the grain of said veneer loose side in each layer. The glue spread amounts of said composite panels are obviously less than that of the existing composite panels with the same thickness, and the composite panels are without warping or deformation. The present invention also provides the manufacturing method of the above composite panels.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

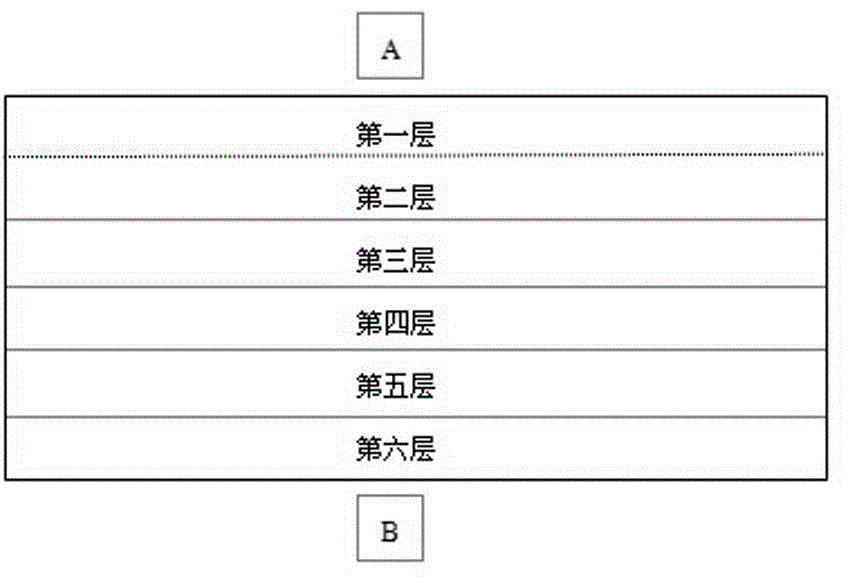

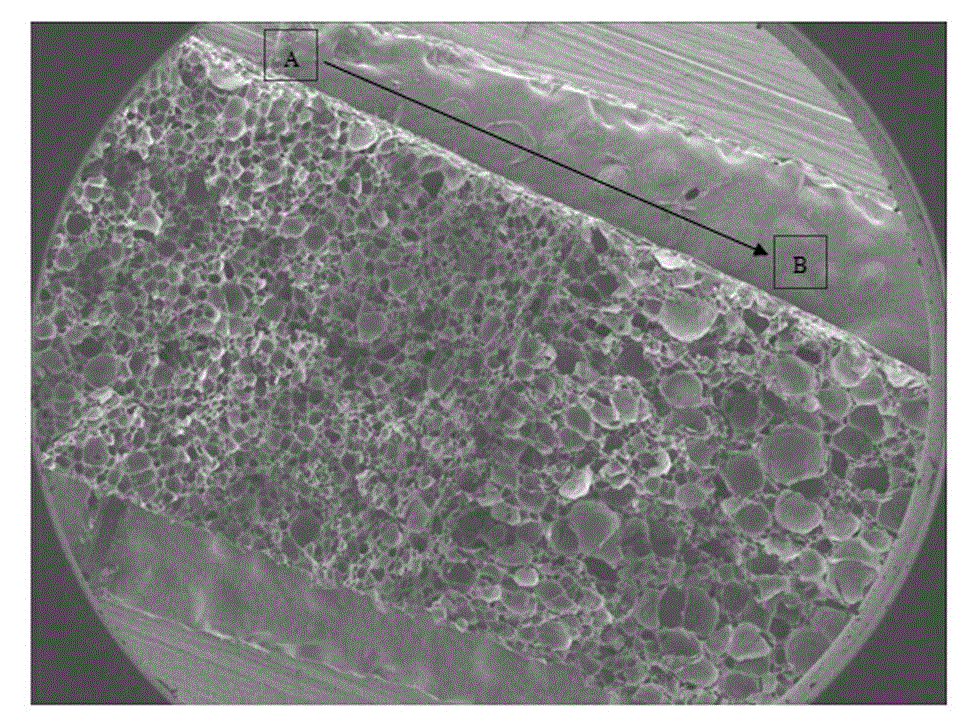

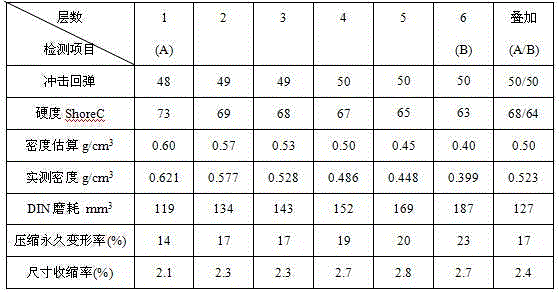

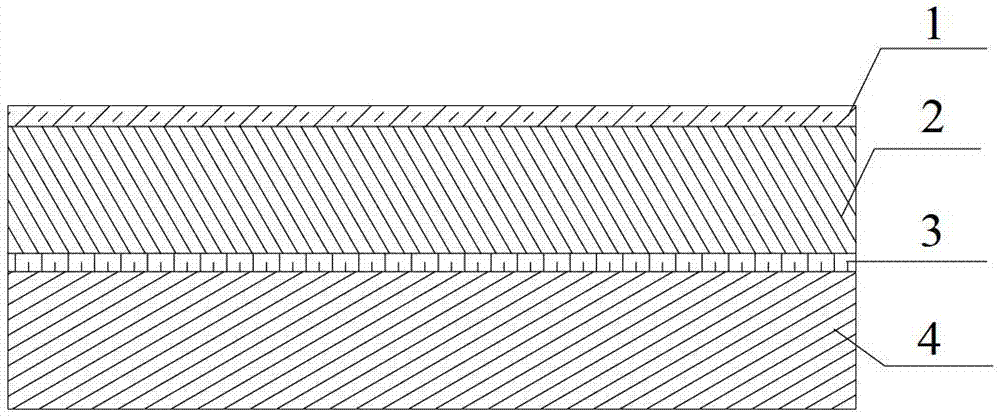

Lightweight wear-resistant density-gradient foamed sole material and preparation method thereof

The invention relates to a lightweight wear-resistant density-gradient foamed sole material and a preparation method thereof. The lightweight wear-resistant density-gradient foamed sole material is mainly composed of EPDM, ethylene-octene copolymer, low density polyethylene, a cross-linking agent, a filling material, a foaming agent and a foaming promoter. On the basis of foaming of EPDM, POE and LDPE and through control of a foaming ratio and density difference values of each layer of materials, a heterogeneous expandable rubber compound composed of a plurality of layers and having quasi-continuously changing performances in the thickness direction of the materials are subjected to one-shot mould pressing, foaming and moulding so as to prepare the foamed sole material, and function gradient differences of density, hardness and wear resistance are realized. Due to gradual change of density, stress concentration is mitigated, and the prepared foamed sole material does not warp. The foamed material has low density at one side close to the vola while the foamed material has high density at one side close to the outer sole, so the foamed sole material has good wear resistance, reduces the weight of the sole and has improved wearing comfortableness.

Owner:CHINA LEATHER & FOOTWEAR IND RES INST +1

Deformation-resistant high-yield-point and light zirconium boron-alumina silicate glass

ActiveCN103359934ALow densityHigh elastic modulusGlass forming apparatusSurface stressSilicate glass

The invention relates to deformation-resistant high-yield-point and light zirconium boron-alumina silicate glass and particularly relates to alumina silicate glass containing ZrO2 and B2O3. The glass has the characteristics that the elasticity modulus E is more than or equal to 60 GPa and less than or equal to 78 GPa after the glass is chemically tempered; the yield point At is more than or equal to 620 DEG C and less than or equal to 850 DEG C; the coefficient of thermal expansion (CET) is more than or equal to 7.5*10<-6> / K and less than or equal to 9.8*10<-6> / K; the density is less than or equal to 2.5 g / cm<3>; the surface pressure stress is at least 700 MPa; and the thickness of a surface stress layer is at least 25 microns. The glass has deformation resistance, is high in yield point and is light in weight.

Owner:SCHOTT GLASS TECH (SUZHOU) CO LTD

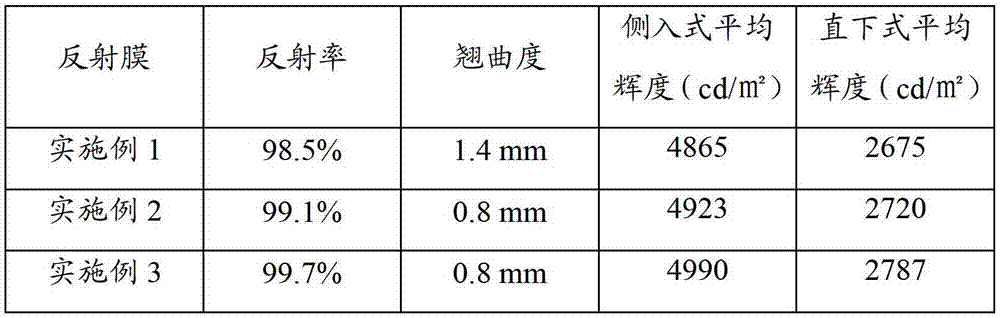

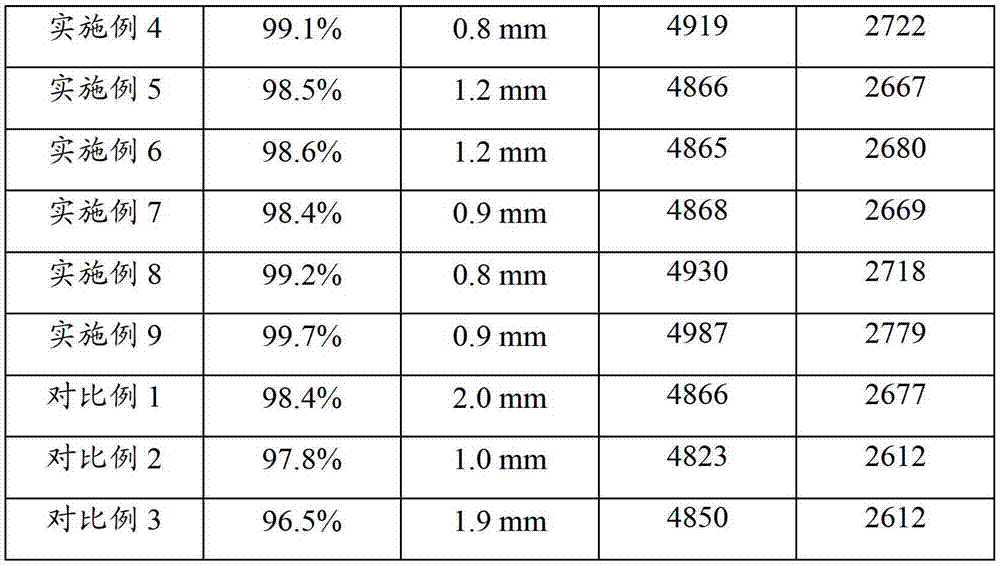

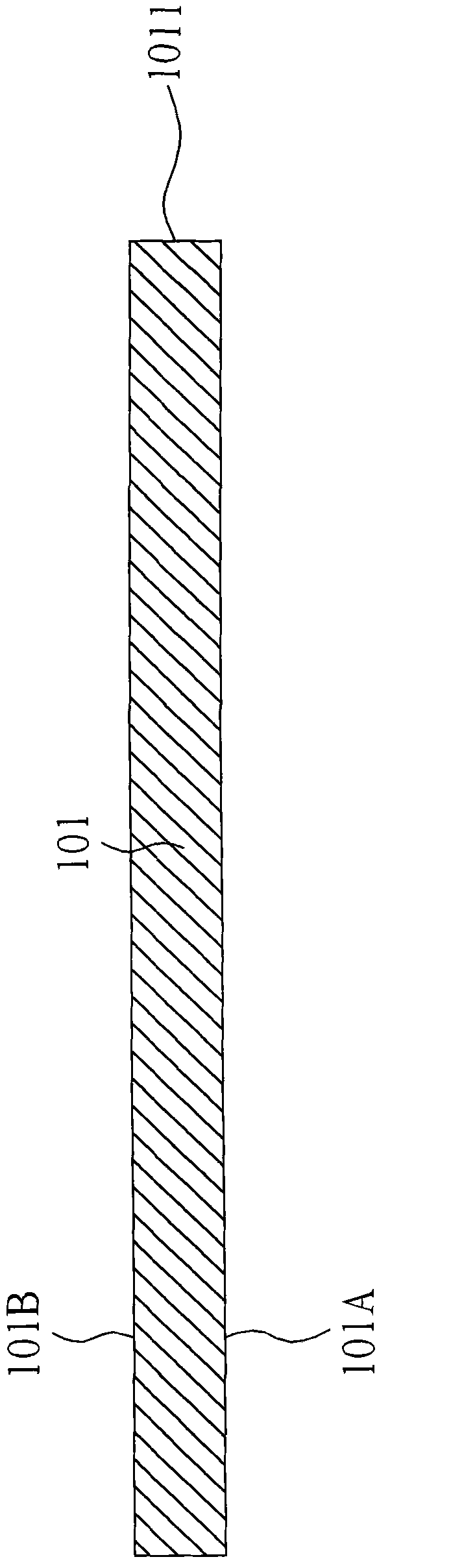

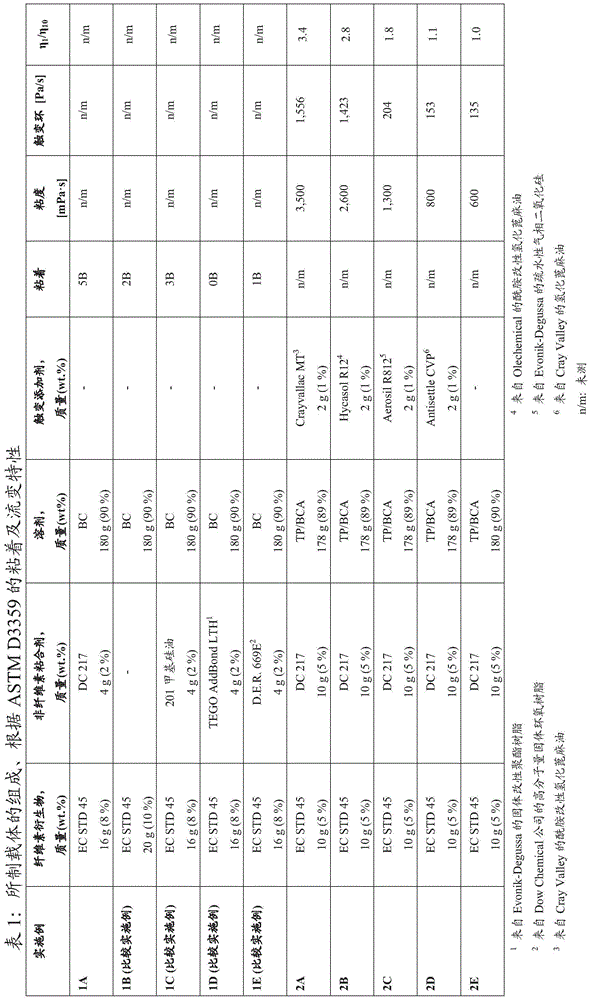

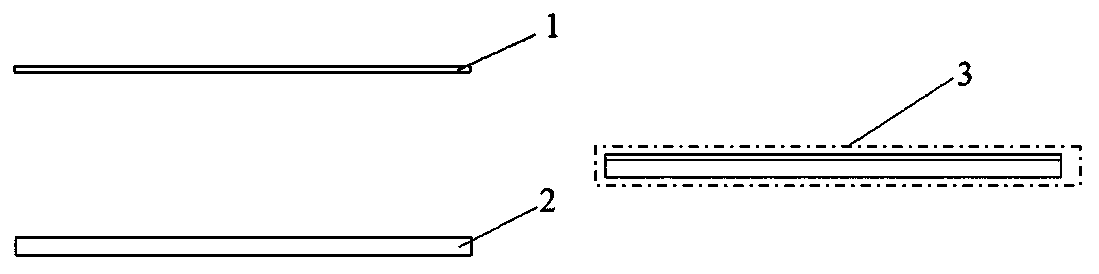

Compound optical reflecting film and preparation method thereof

ActiveCN103176229ASimple processGood dimensional stabilityMirrorsOptical articlesOptical reflectionOptical thin film

The invention relates to the technical field of optical thin films, and particularly relates to a compound optical reflecting film applied in a backlight source system and a preparation method of the compound optical reflecting film in order to overcome the defects that a conventional optical reflecting film has low reflectivity and is easy to deform. The optical reflecting film comprises a transparent film sheet and a reflecting film sheet which are bonded through a bonding agent, wherein a reflecting coating is coated on the other surface of the reflecting film sheet. The compound optical reflecting film provided by the invention has good size stability and relatively high reflectivity and is not easy to warp and deform; and according to the preparation method of the compound optical reflecting film, the process is simple and the operation is easy.

Owner:NINGBO CHANGYANG TECH

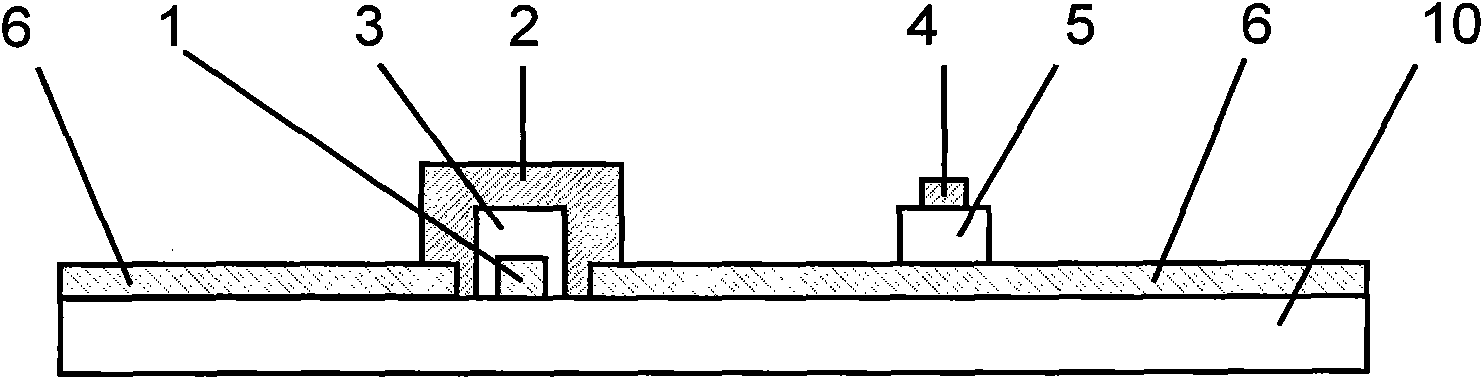

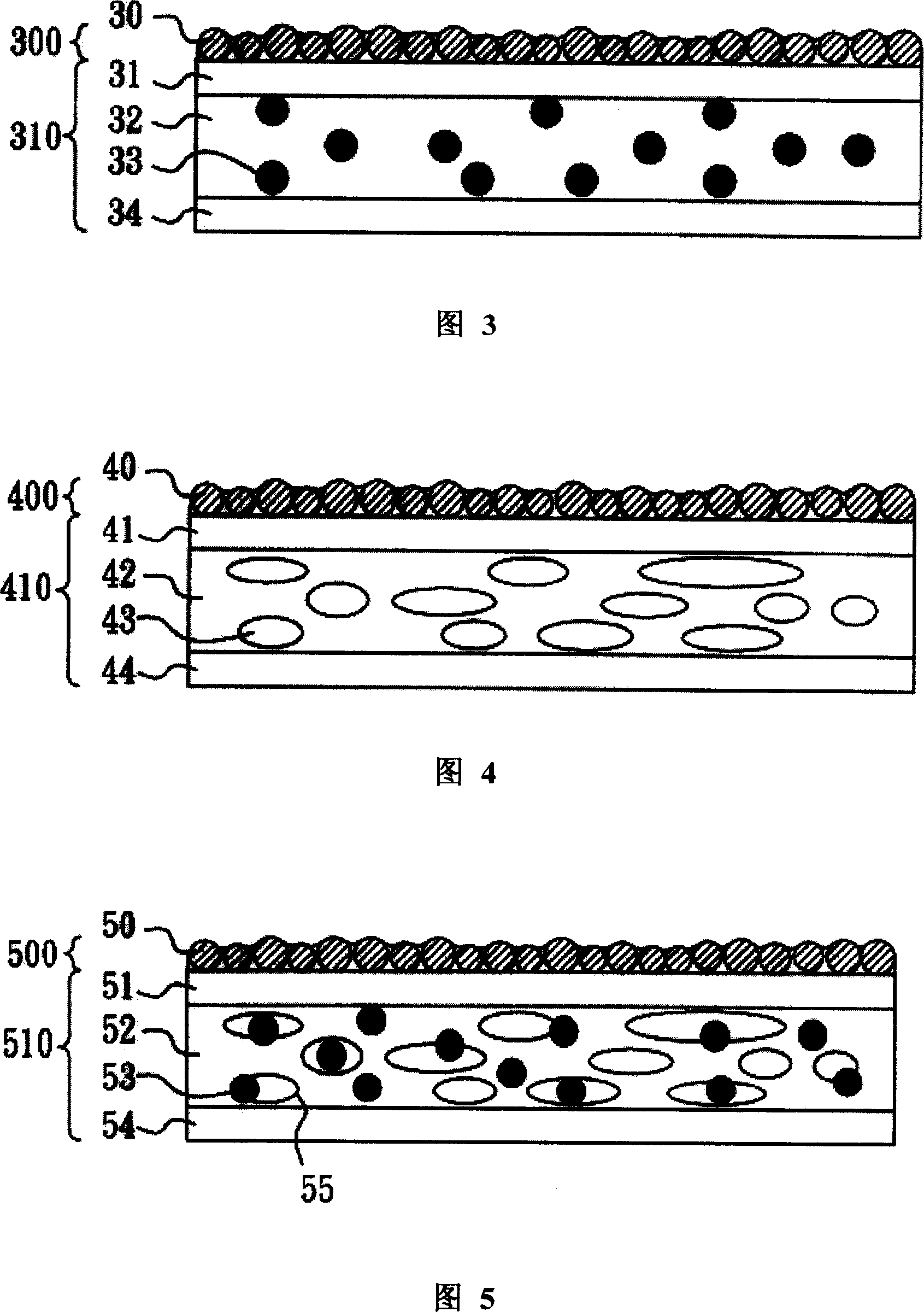

Display apparatus and manufacturing method thereof

ActiveCN102157110ANo warpingSimplify packaging stepsNon-linear opticsIdentification meansOxygenFlexible electronics

The invention discloses a display apparatus comprising a substrate, a backboard, a display medium layer, a protective layer, a driving assembly, a flexible printed circuit board and sealing glue, wherein the backboard and the display medium layer are respectively arranged on the lower and upper surface of the substrate, the protective layer covers the display medium layer to prevent negative influence on the properties of the display medium layer due to penetration of environmental water or oxygen, the sealing glue encloses the side surface of the display medium layer and the protective layer and wraps the driving assembly and part of the flexible printed circuit board. Moreover, the invention also discloses a method for manufacturing the display apparatus. The display apparatus and embodiments employing said manufacturing method do no warp under high temperature processes. Moreover, the periphery of the side surfaces of the substrate and the display medium layer, the driving assembly and the flexible printed circuit board are protected by sealing glue, thereby simplifying packaging process.

Owner:AU OPTRONICS CORP

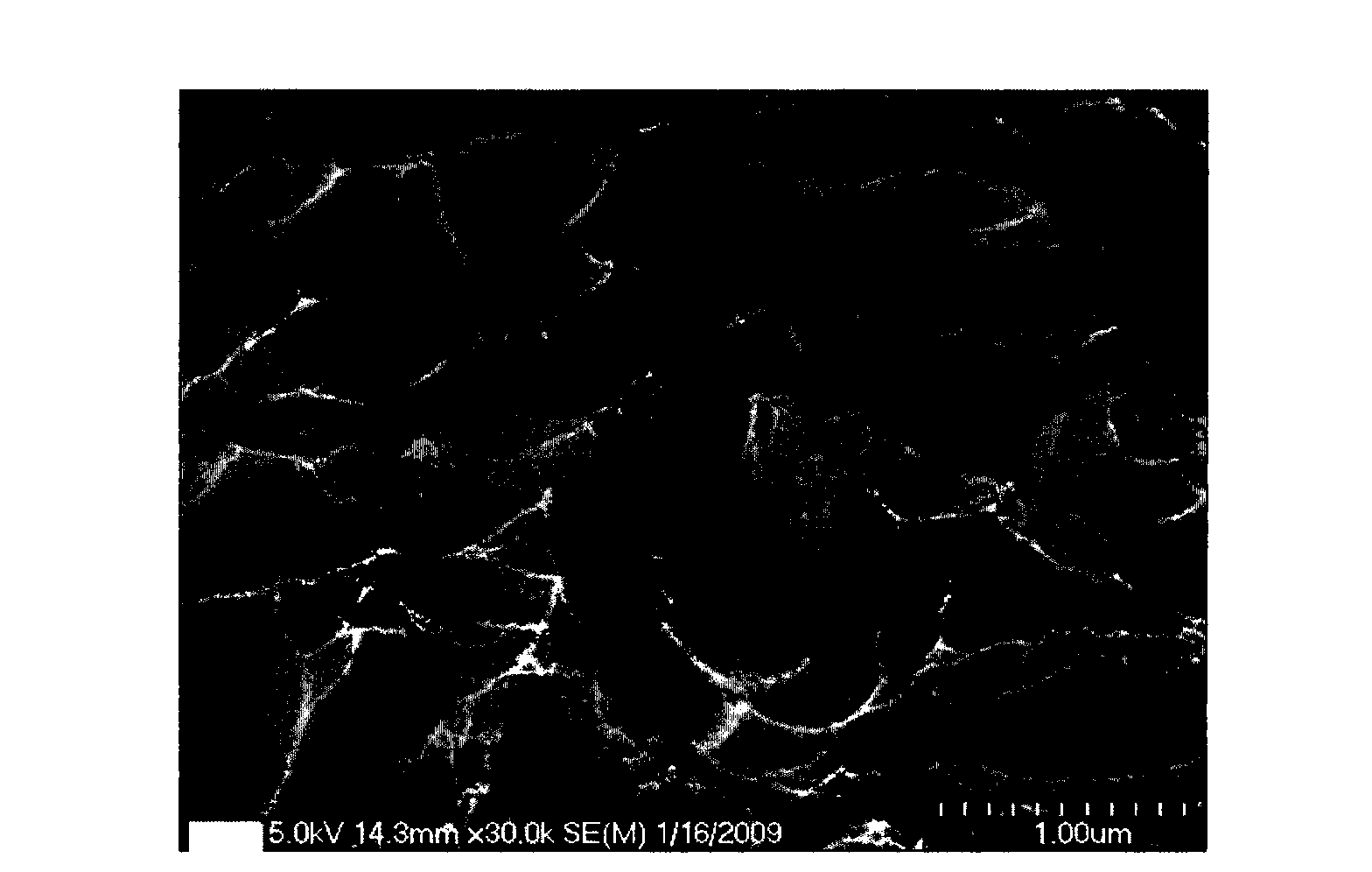

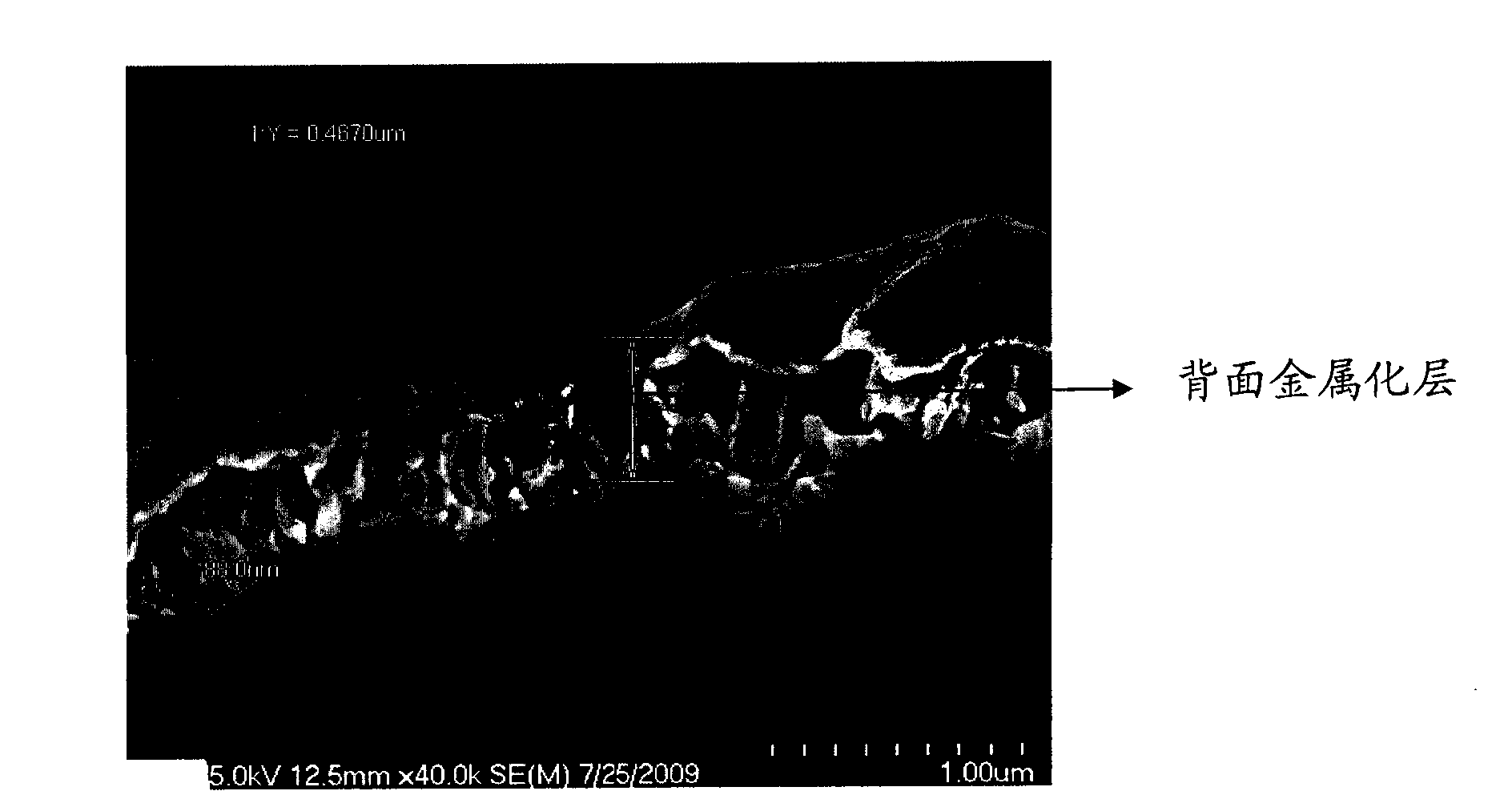

Method for processing back surface of wafer

InactiveCN102082069AQuality improvementNo warpingSemiconductor/solid-state device manufacturingSemiconductorMaterials science

The invention discloses a method for processing a back surface of a wafer, and the method is applied to the manufacturing process of a semiconductor wafer. The method comprises: thinning the back surface of the wafer to obtain a thinned wafer; placing the wafer in a mixed acid solution with a set proportion for soaking according to the surface quality of the back surface of the thinned wafer so as to acquire the surface quality satisfying the back surface metallization requirement; and carrying out back surface metallization processing on the wafer after cleaning the soaked wafer, and coating a required metal layer on the back surface of the wafer. According to the method disclosed by the invention, the surface quality of the back surface of the wafer is improved through soaking by the mixed acid, so that the warping, curling and flaking of the metallization layer of the back surface can not happen.

Owner:PEKING UNIV FOUNDER GRP CO LTD +1

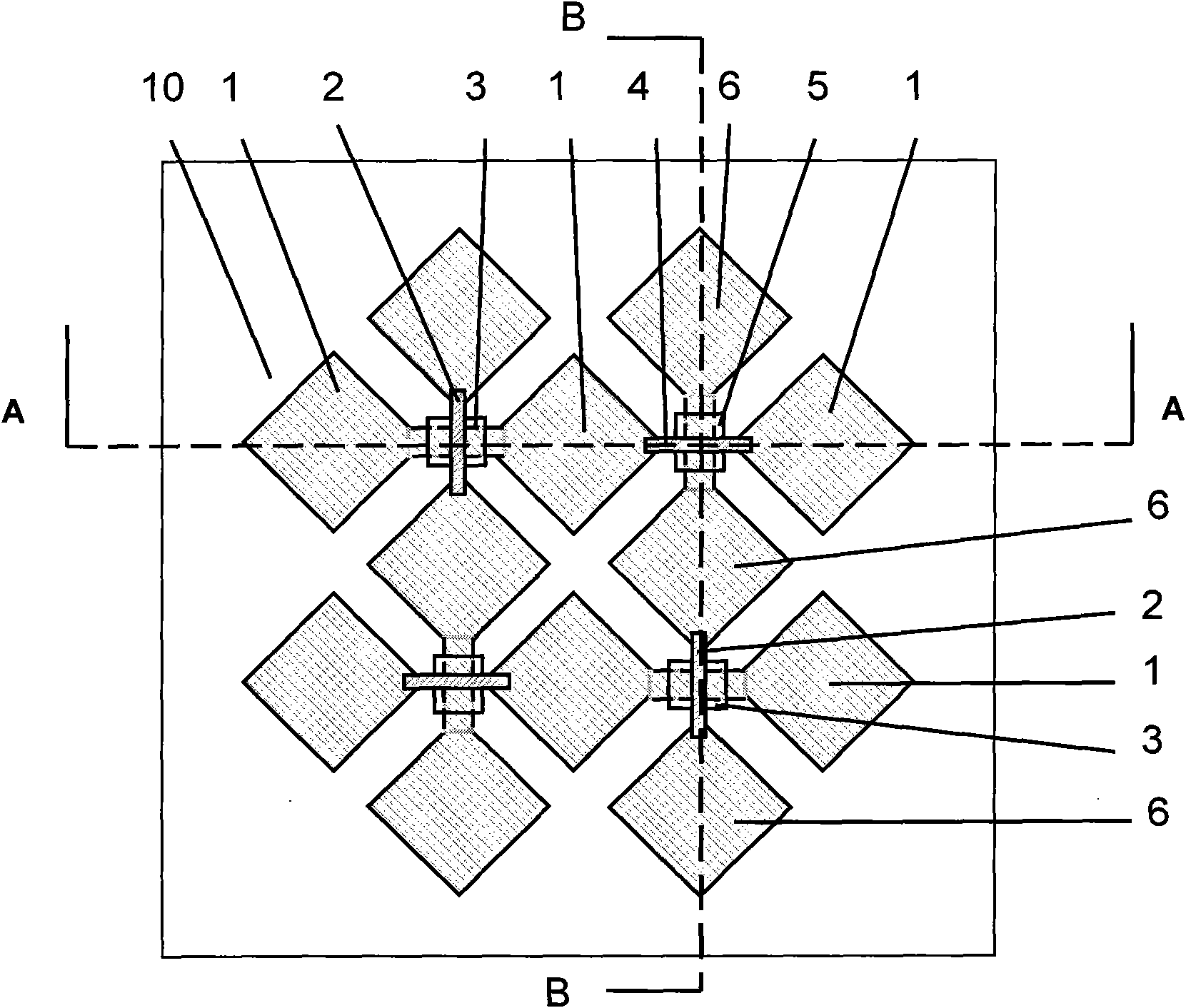

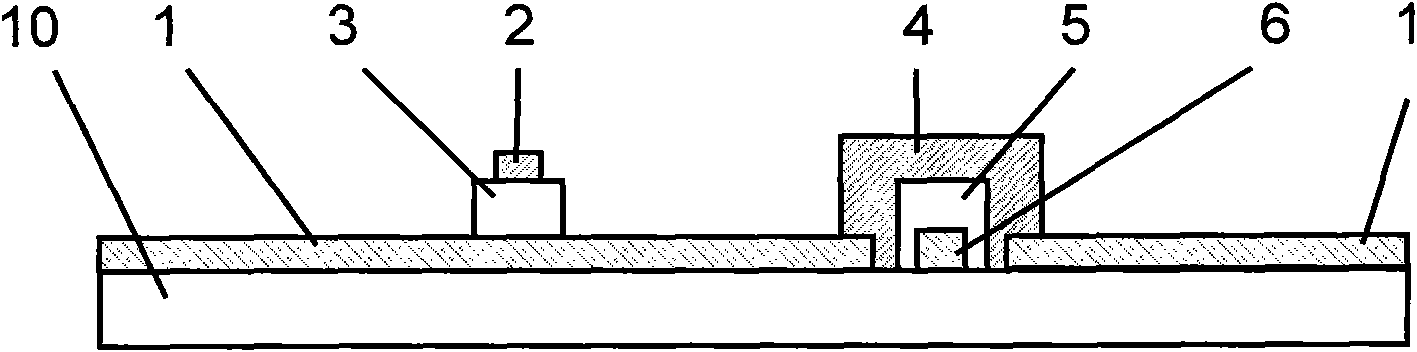

Wiring method and manufacturing method of capacitive touch screen

ActiveCN101634922AImprove product qualityAvoid chromatic aberrationInput/output processes for data processingElectrical resistance and conductanceEngineering

The invention relates to a wiring method and a manufacturing method of a capacitive touch screen, wherein the wiring method comprises the step of arranging two groups of wire transparent conducting films in X and Y directions, an insulating film and a bridging film on a basal plate, wherein the surface resistance of the bridging film is lower than the surface resistance of the transparent conducting films, an intersection structure of the transparent conducting films in the two directions comprises continuous connection and bridging connection, wherein the continuous connection structure is a continuation of transparent conducting film material at two sides of the intersection point, and the bridging connection structure has the structures that the transparent conducting film in X or Y direction is continuously connected and positioned on the basal plate at the intersection point, the transparent conducting film in the other direction is disconnected at the intersection point, the insulating film is covered on the transparent conducting films that are continuously connected at the intersection part, and the bridging film stretches over the transparent conducting films that are continuously connected at the intersection point and is covered on the insulating film and connected with the transparent conducting film disconnected at the intersection point; and the method comprises the step of manufacturing two groups of wire conducing film, the insulating film and the bridging film. The invention can avoid color difference and improve the sensitivity, the standard ratio and the quality of the touch screen.

Owner:SHENZHEN LAIBAO HI TECH

Paint composition

InactiveCN101235229AIncreased stress buffering capacityIncrease stickinessPolyester coatingsChemistryPhotoinitiator

The invention discloses a paint component, which comprises thermoplastic resin which is chosen from poly-cycloolefine resin, polyester resin, polyacrylic ester resin or polyacrylic ester mixture, radiating cured resin which comprises acrylic acid series monomer which has one or several functional groups as polymerization unit, oligomer which has ethylene unsaturated functional group, and initiating agent, wherein the weight of radiating cured resin is 220-1000 weight percentage relative to the weight of thermoplastic resin. The paint component can increase the hardness of the paint component, prevents base plate from scoring and damaging in operation, and has the properties of high transparent, and no warping.

Owner:ETERNAL MATERIALS CO LTD

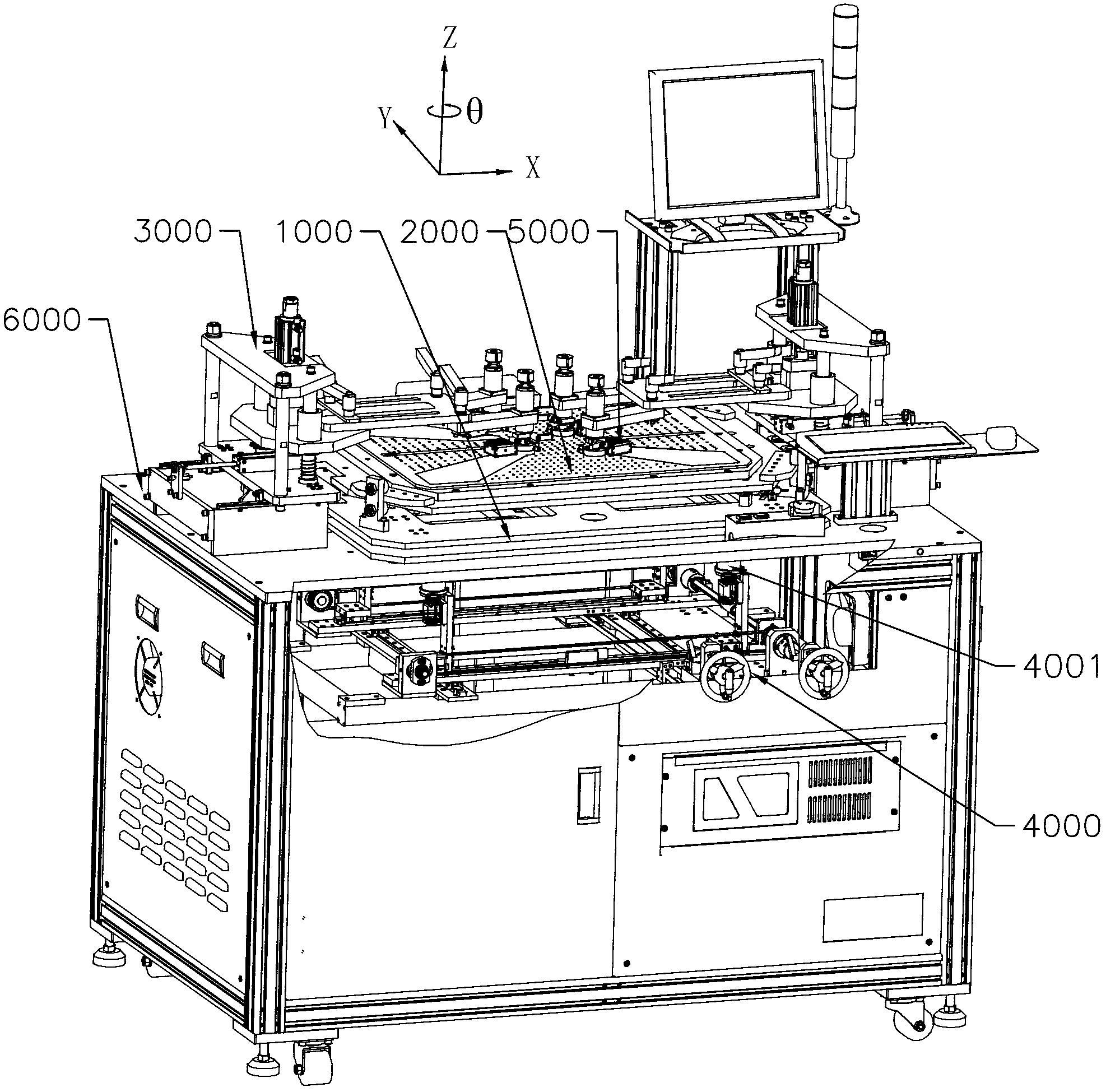

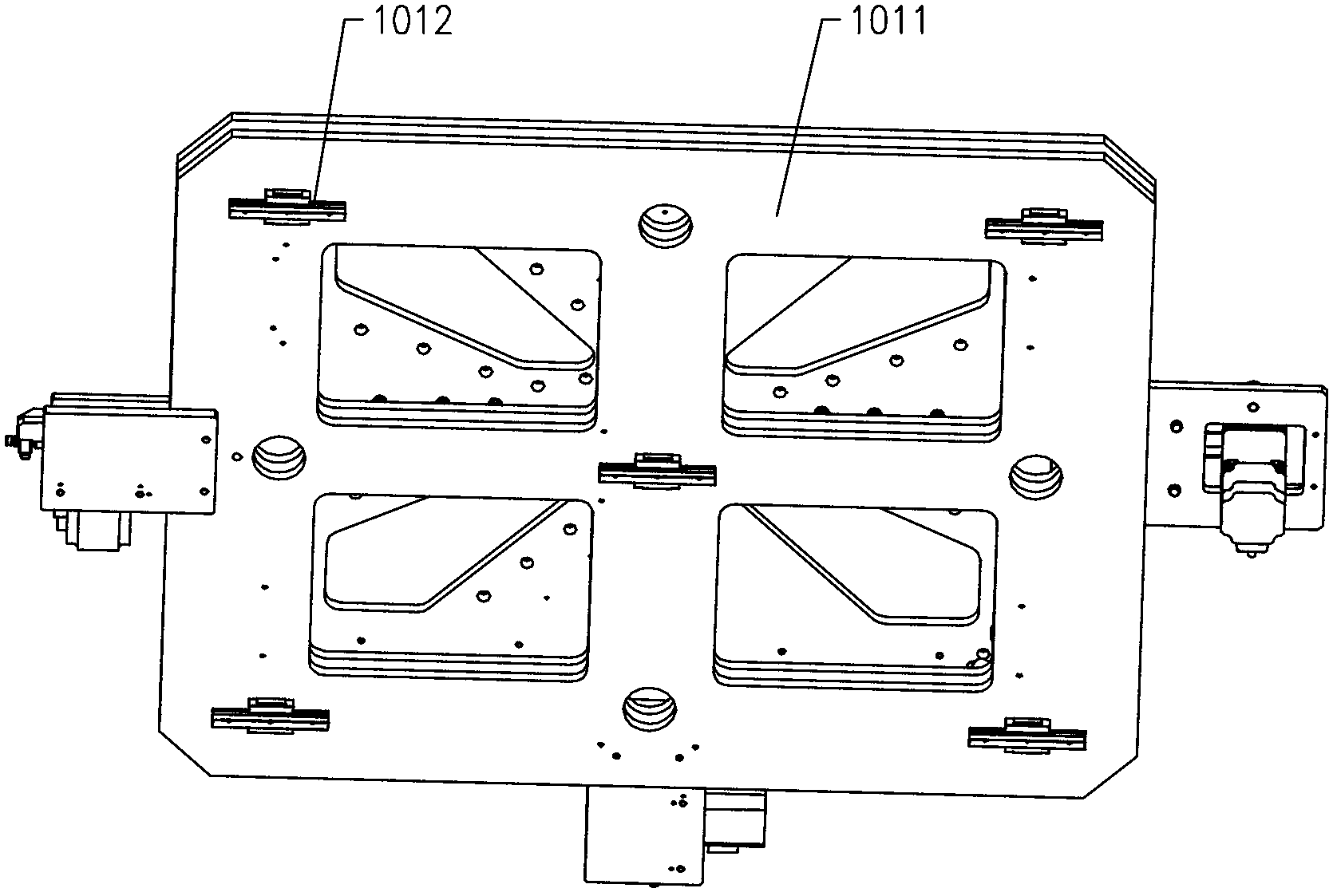

PCB and film alignment device

ActiveCN103235492AAverage errorNo warpingPhotomechanical treatmentPrinted circuit manufactureIlluminanceDiagonal

The invention discloses a PCB (printed circuit board) and film alignment device, which comprises a rack and the following parts installed on the rack: an X-Y-theta three-freedom degree adjustment mechanism; a rectangular vacuum adsorption platform fixed on the X-Y-theta three-freedom degree adjustment mechanism and used for PCB adsorption, with light transmitting parts disposed at four corners of the vacuum adsorption platform and extending along diagonal lines; two two-point compression mechanisms arranged over the vacuum adsorption platform relatively; four CCD lens that are mounted below the X-Y-theta three-freedom degree adjustment mechanism, read alignment marks at four corners of the PCB and the film through the light transmitting parts, are in rectangular arrangement and mounted on one spacing adjustment mechanism, and are in connection with a controller, the control end of which is connected to the X-Y-theta three-freedom degree adjustment mechanism; and light sources for providing illuminance conditions for the four CCD lens. The alignment device disclosed in the invention improves the alignment accuracy and alignment efficiency.

Owner:GOERTEK INC

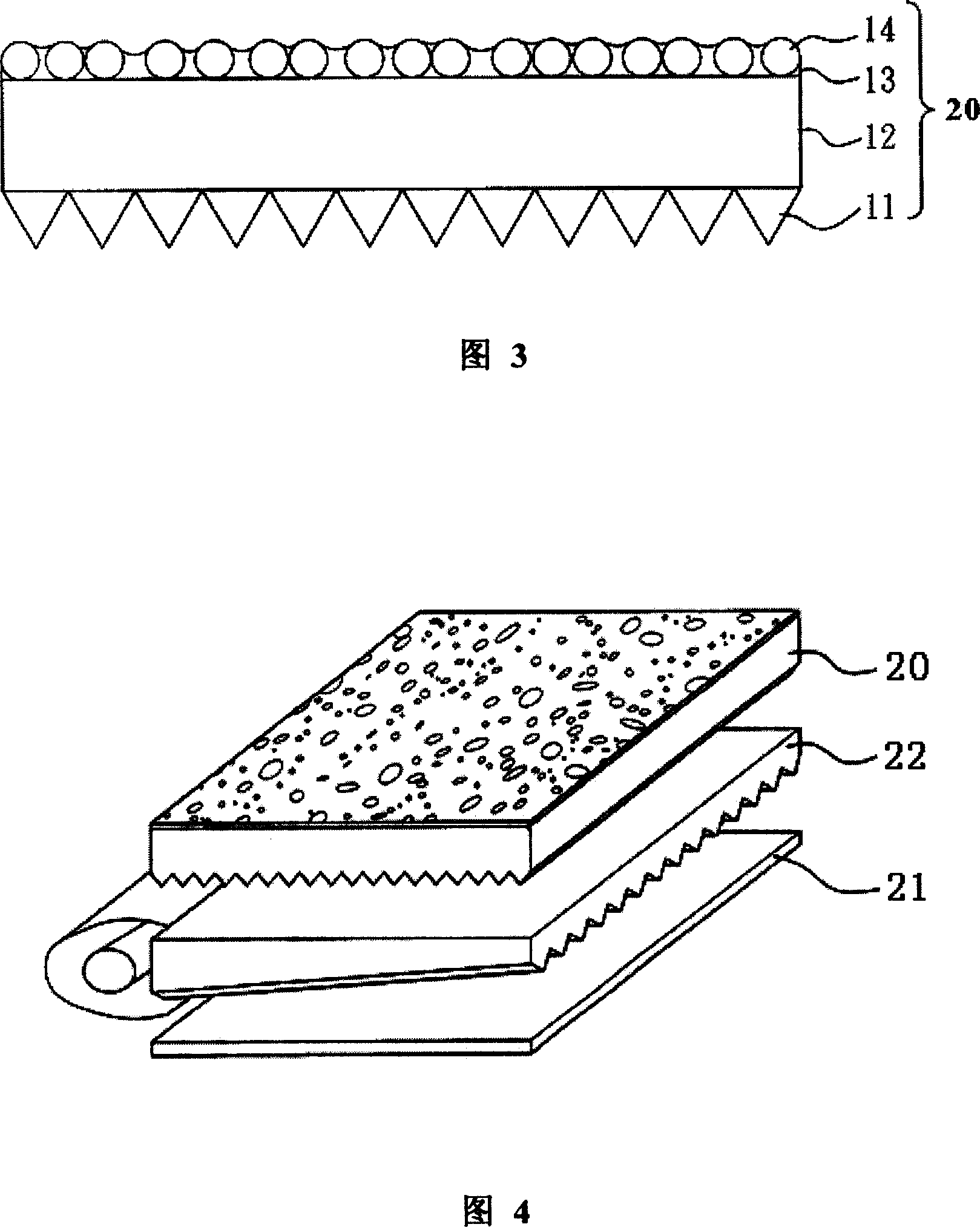

Anti scraping thin film, and liquid crystal display

InactiveCN101004461AAvoid optical propertiesHigh hardnessPrismsDiffusing elementsConvex structureLiquid-crystal display

A scratch proof film is prepared for arranging a microstructure layer at bottom side of base material and a scratch proof layer on top side of base material, setting concave-convex structure on scratch proof layer, making scratch proof layer have fog degree of 30-98% and surface resistivity of 10 to the power 8-10 Omega / „ as well as pencil hardness of 3H.

Owner:长兴光学材料(苏州)有限公司

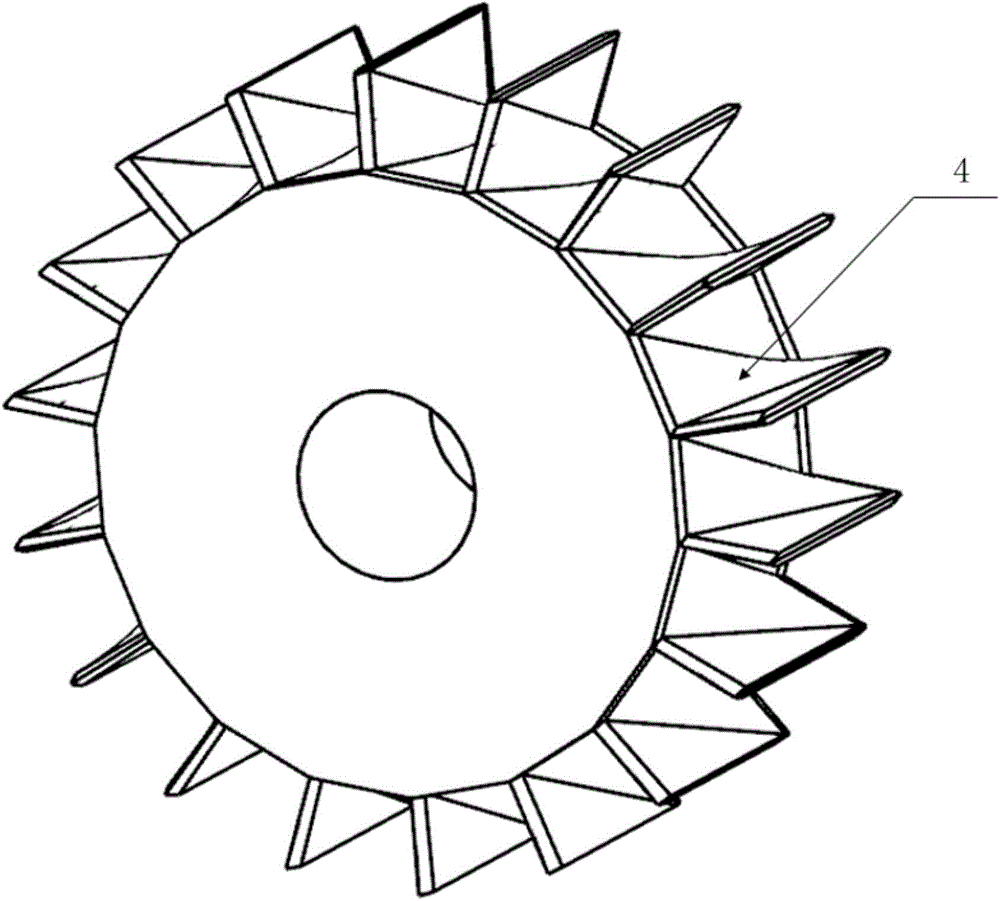

Three-dimensional forming equipment capable of preparing soft-hard compound polyurethane product

InactiveCN104786506AReduce loadImprove stabilityAdditive manufacturing apparatusPhysical healthPolyol

The invention discloses three-dimensional forming equipment capable of preparing a soft-hard compound polyurethane product. The equipment mainly consists of a material conveying unit, a screw extrusion unit, a three-dimensional forming platform unit and a safety equipment unit, wherein in the material conveying unit, a variable pump conveys an isocyanate mixture and polyol at different ratios to the extrusion unit; in the extrusion unit, a screw comprises a conveying section and a stirring section, wherein the stirring section is used for fully stirring the materials; in the three-dimensional forming platform unit, polyurethane is extruded to a carrying table to be deposited and formed. The safety equipment unit capable of preparing the soft-hard compound polyurethane product disclosed by the invention consists of an exhaust fan, an exhaust pipeline and a pair of rubber gloves; the exhaust pipeline can be used for discharging smell volatilizing in a reaction process of toluene diisocynate and polyol; by using the rubber gloves, the operator can directly take down articles from a forming platform without touch by hands. The safety forming unit is equipped, so that the safety and physical health of the operator are well protected.

Owner:BEIJING UNIV OF CHEM TECH

Log dyeing method

InactiveCN1672886ARetain structurePreserve textureWood treatment detailsPressure impregnationRoom temperatureVolumetric Mass Density

The log dyeing method is one circular hot pressing dyeing and normal temperature and pressure dyeing method on log with water content not higher than 8 % and in proper length. The log dyeing process includes the following steps: compounding acid dye aqua; soaking at room temperature for 120-480 min; dyeing at 25-120 deg.c and 10-15 Mpa under stirring for 30-60 min; lowering to room temperature; dyeing at 25-120 deg.c and 10-15 Mpa under stirring for 30-60 min; and so on until reaching the total dyeing time of 600-900 min; washing with water; drying at 25-120 deg.c to water content not higher than 8 %; and discharging. The log dyeing maintains the natural grains of log, raises the density of timber, homogenizes the color of timber, and raises the value of timber.

Owner:高凯

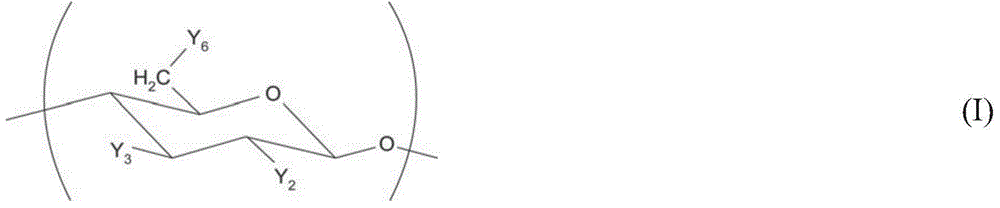

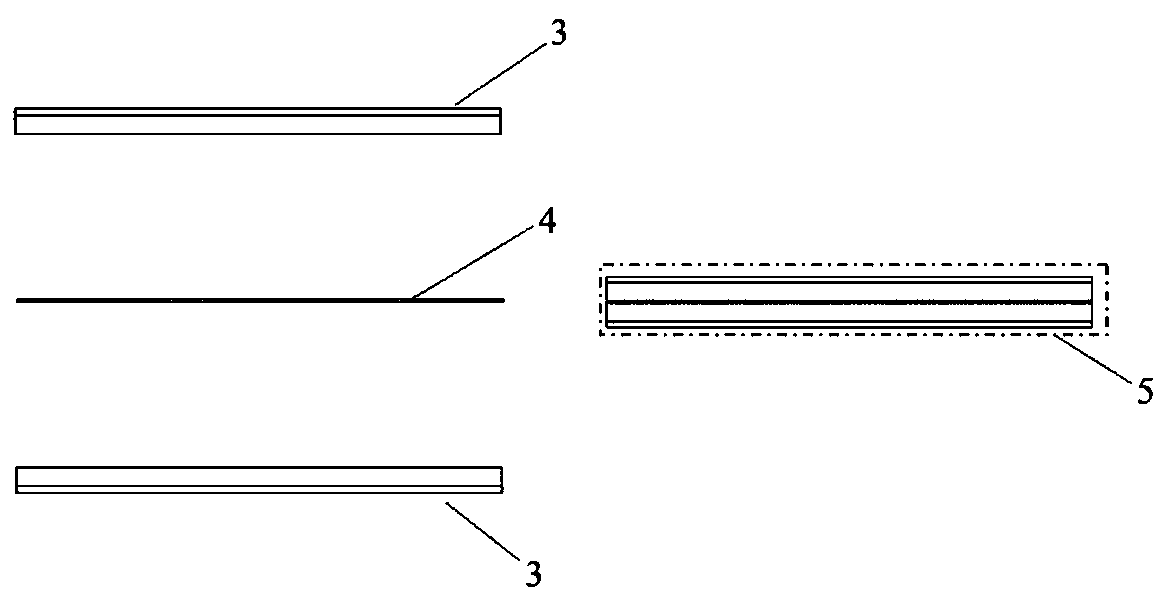

Conductive composition

InactiveCN104981911AExcellent adhesionGood dispersionApparatus for heat treatmentNon-conductive material with dispersed conductive materialParticulatesGlass particle

Disclosed is a conductive composition useful for the preparation of electrically conductive structures on a substrate comprising a plurality of metal particles, a plurality of glass particles and a vehicle comprising at least one cellulose derivative and at least one solid organopolysiloxane resin dissolved in a mutual organic solvent. The solid organopolysiloxane resin acts as adhesion promoter and assists in stably dispersing the metal and glass particles to avoid an agglomeration of such particles without degrading the rheological properties. From such conductive compositions uniform well adherent electrically conductive structures essentially free from defects in the form of cracks, bubbles or coarse particulates can be prepared on dielectric or semiconductor substrates such as silicon wafers in an efficient and cost-saving manner e.g. by screen printing, drying and sintering while inducing only low warping of the substrate. These characteristics render said conductive compositions particularly useful for the fabrication of electrodes of a semiconductor solar cell helping to increase the cell conversion efficiency.

Owner:NUTRITION & BIOSCIENCES USA 1 LLC

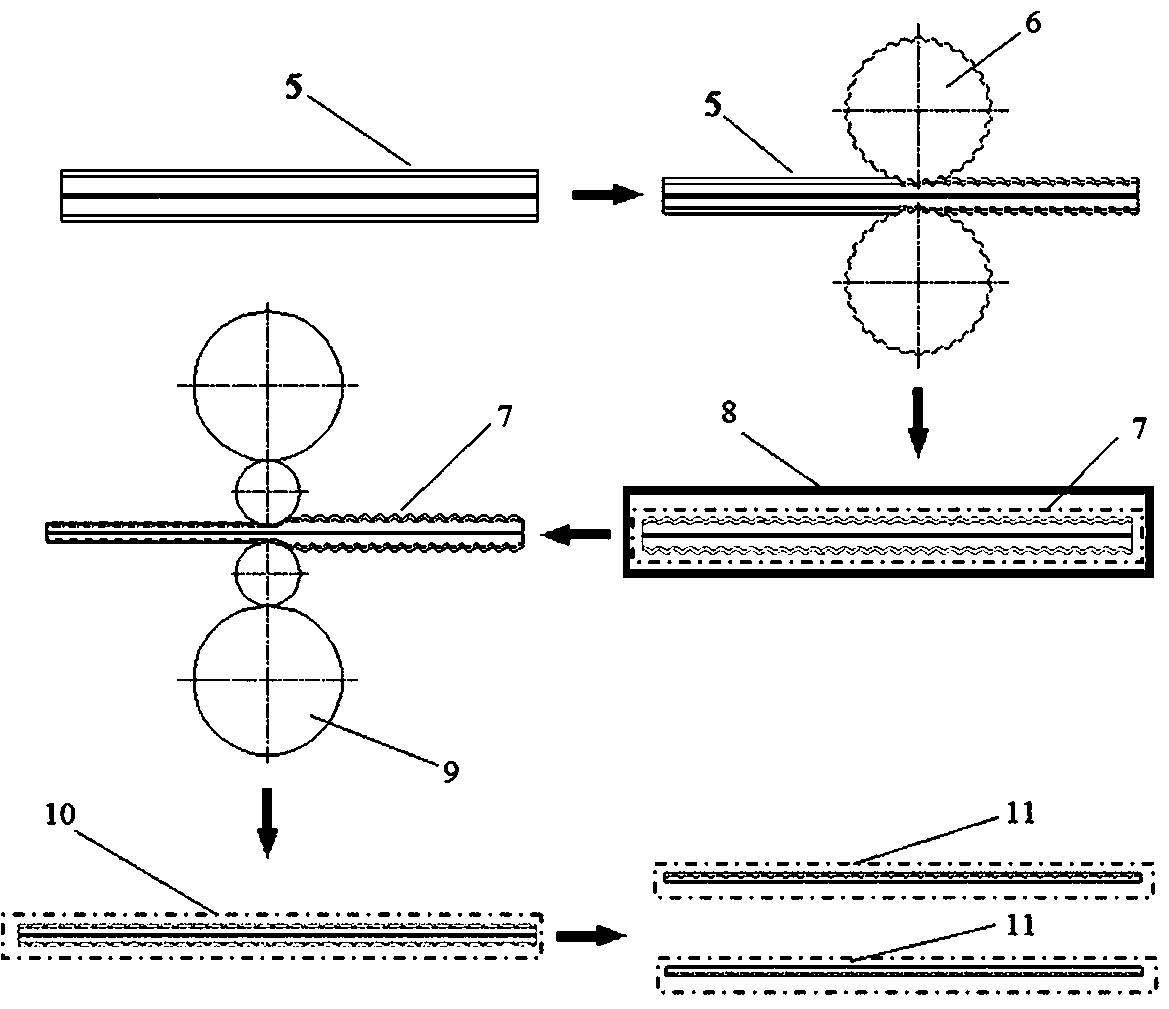

Method for smoothing continuous ply rolling of metal-based composite plates

InactiveCN108971226AImprove straightnessNo warpingAuxillary arrangementsMetal rolling arrangementsComposite filterComposite plate

The invention belongs to the field of rolling of metal composite plates, and particularly relates to a method for smoothing continuous ply rolling of metal-based composite plates. The method comprisesthe steps of rolling a blank by using a two-roll mill with corrugated rolls on the top and the bottom to obtain a corrugated composite plate of which the upper surface and the lower surface are corrugated; carrying out annealing treatment; heating or cooling the annealed composite plate to a required temperature according to process requirements; and rolling and flattening the composite plate byusing a two-roll mill or four-roll mill with common flat rolls on the top and the bottom to obtain a corrugated flattened composite plate of which the upper surface and the lower surface are planes. During first-pass rolling through the corrugated rolls, rolling force changes in a stepped manner, thus, large stress can be generated at a position of a trough of a rolled piece, metallurgical bondingof metals is promoted and is gradually diffused towards two sides, during second-pass rolling through the flat rolls, the original wave crest position with small stress can generate peak stress againdue to increasing of rolling reduction, and metallurgical bonding on a whole contact surface is promoted again.

Owner:TAIYUAN UNIV OF TECH

Nano shell powder ecological functional flatly painted coating

The invention relates to environmental protection paint, in particular to nano shell powder ecological functional flatly painted coating. The coating is prepared from shell powder (calcined), ash-calcium, kaolin, heavy calcium carbonate, hydrated magnesium silicate, titanium dioxide, vinyl acetate, hydroxyethyl cellulose, polyving akohol, polydimethylsiloxane, a water reducer and a defoamer. The coating solves the problem that indoor ornament or decoration paint is not environment-friendly. The coating has the characteristics that the coating is antifungal, purifies the air, prevents mildew, adopts a spiral pore structure, is 3.0mm in press coating thickness and high in glossiness, does not has obvious color aberration, is resistant to shock, abrasion, water, high and low temperature weather and aging, and ensures that the service life of a product reaches more than 20 years.

Owner:通化市星赛尔生物科技有限公司

Functional gradient foamed sole material and preparation method thereof

The invention relates to an insole material of a sneaker and a preparation method thereof, and particularly relates to a functional gradient insole material of the sneaker and the preparation method thereof. The sole material mainly comprises ethylene-vinyl acetate copolymer (EVA), ethylene-octene copolymer (POE), a crosslinking agent, a filler, a foaming agent, and a foaming promoter. Two-layer or multi-layer heterogeneous expandable rubber compound of which the performance continuously changes in the thickness or length direction of the material is foamed and molded to prepare the foamed sole material in a once mold pressing manner on the basis that EVA and POE are foamed. The foamed sole material has the advantages that (1) the functionality (for example, rebound resilience and hardness) of the prepared foamed sole material forms gradient change along the thickness direction, the hardness of the foamed material at one side near pelma is small, the rebound resilience is high, energy feedback is facilitated, the foamed material at one side near outsoles is large and the elasticity is low so as to provide enough support, thus, the foamed sole material is more comfortable to wear in maximal extent; (2) compared with the comfortable foamed sole material in the market at present and the preparation method, the material cost of the binder is saved, labor charges are saved, the molding period is shortened, and environment protection is facilitated.

Owner:CHINA LEATHER & FOOTWEAR IND RES INST

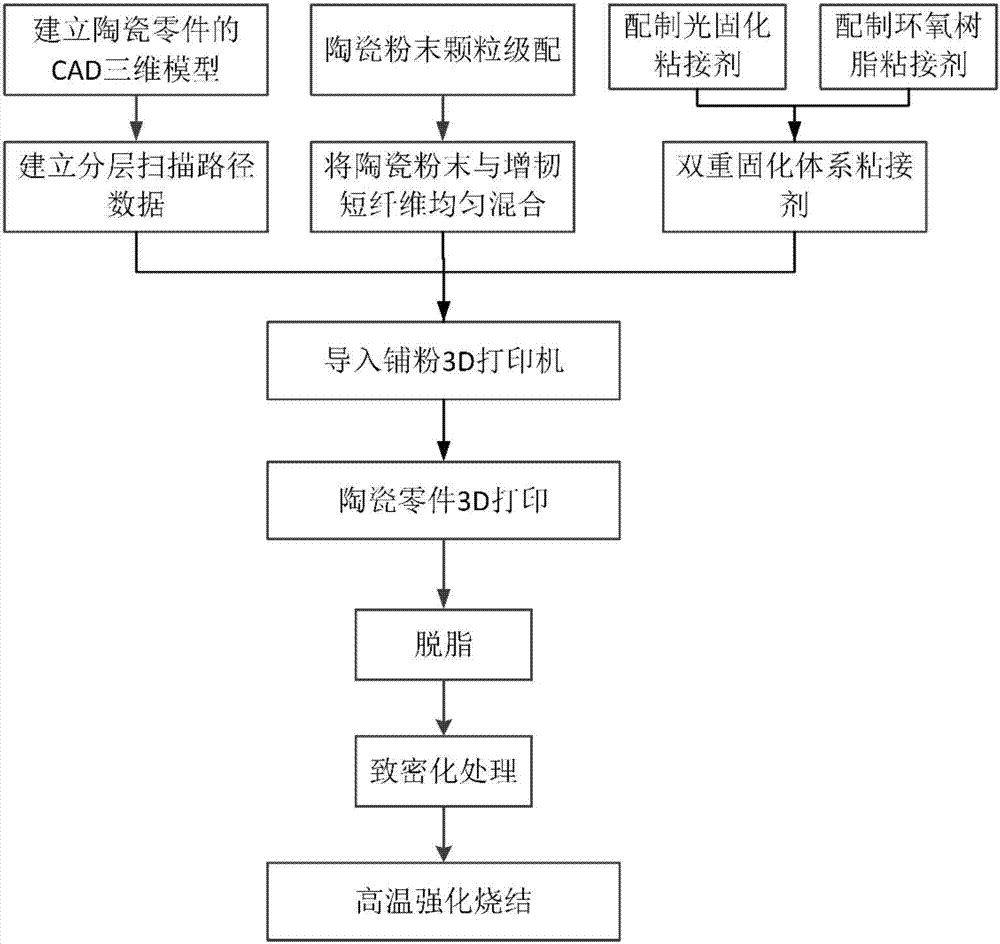

Ceramic part 3D (three dimensional) printing method based on adhesives of dual curing systems

InactiveCN107098715AWon't clogImprove curing efficiencyAdditive manufacturing apparatusSolubilityDual cure

The invention discloses a ceramic part 3D (three dimensional) printing method based on a photocuring adhesive. In a first curing system, a photosensitive resin-based adhesive solidifies quickly under the irradiation of ultraviolet light, bonds powder so as to take shape and has high curing efficiency; only when the photosensitive resin-based adhesive encounters the ultraviolet light, the photosensitive resin-based adhesive solidifies; and as the photosensitive resin-based adhesive is not likely to encounter the ultraviolet light in a spray nozzle, the photosensitive resin-based adhesive is not likely to solidify and block the printing spray nozzle. In a second curing system, an epoxy resin-based adhesive can also solidify quickly by adding polymercaptan serving as a solidification triggering agent; and as the epoxy resin and the polymercaptan triggering agent are in different spray nozzles and do not contact with each other, the epoxy resin-based adhesive is not likely to solidify and block the spray nozzle. As the adhesives of the dual curing systems are resin-based adhesives and no water is added all the time in the preparation process, the adhesives of the dual curing systems can be used for bonding water-solubility ceramic powder; and the green bodies of ceramic parts formed by the dual curing systems have very high strength and forming accuracy.

Owner:XI AN JIAOTONG UNIV

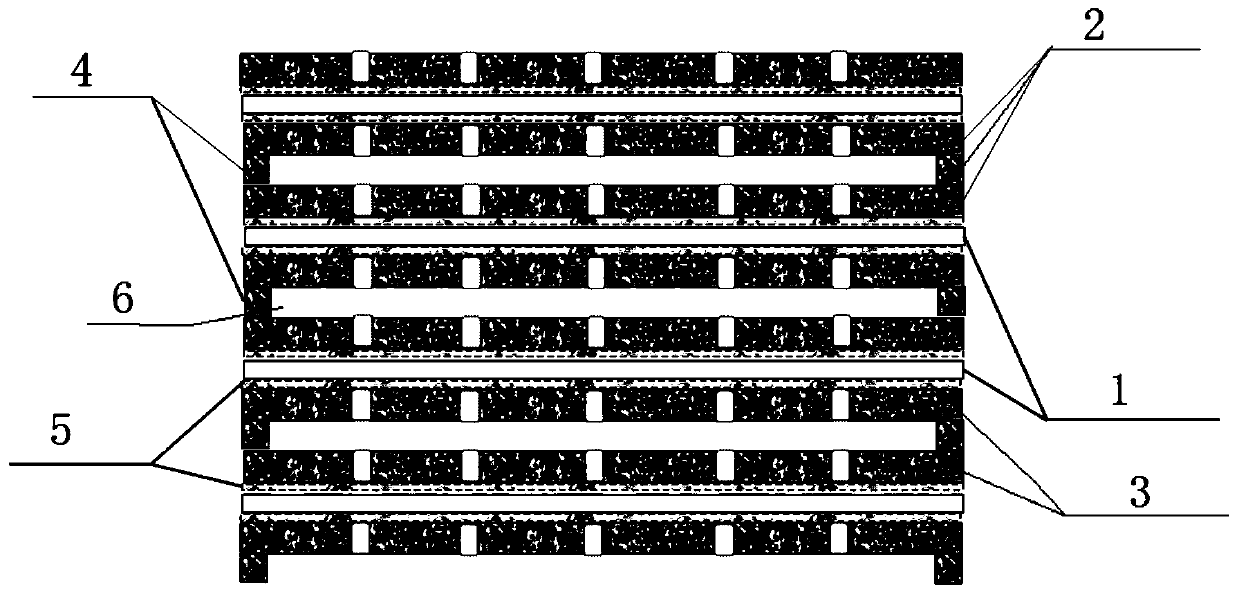

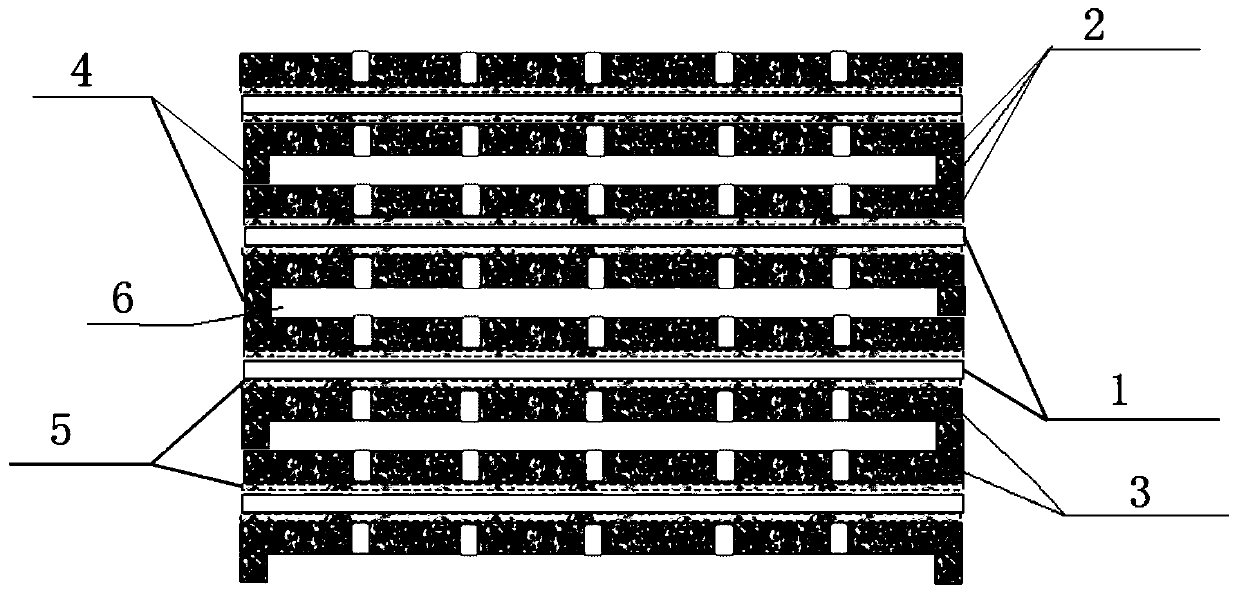

High-thermal-conductivity silicon nitride ceramic substrate and preparation method thereof

ActiveCN109987944AReduce grain boundary phase contentImprove thermal conductivityGraphiteMechanical property

The invention belongs to the technical field of high-thermal-conductivity silicon nitride ceramic substrates, and particularly relates to a high-thermal-conductivity silicon nitride ceramic substrateand a preparation method thereof. The high-thermal-conductivity silicon nitride ceramic substrate is formed by stacking a plurality of silicon nitride tape casting biscuits layer by layer, a middle layer is arranged between every two adjacent silicon nitride tape casting biscuits, each middle layer is composed of two graphite plates and two graphite strips which are located between two ends of thetwo graphite plates respectively to form a cavity, the graphite plates are provided with a plurality of holes communicating with the cavities, and slurry separation layers are arranged between the graphite plates and the corresponding silicon nitride tape casting biscuits. The silicon nitride ceramic substrate prepared by the preparation method disclosed by the invention is relatively good in purity and performance, and particularly has relatively high heat conductivity and excellent mechanical properties.

Owner:TSINGHUA UNIV +1

Material used for manufacturing handle of refrigerator door and preparation method thereof

ActiveCN103044862AIncrease the number of door openingsImprove mechanical propertiesRefrigerator carAcrylonitrile

The invention relates to a material used for manufacturing a handle of a refrigerator door and a preparation method thereof. The material composition comprises the following components in parts by weight: 40-83 parts of polybutylene terephthalate, 5-25 parts of acrylonitrile- styrene-acrylonitrile composition, 10-35 parts of glass fiber, 3-20 parts of crystal whisker, 2-10 parts of a compatilizer, 0.03-2 parts of an antibacterial agent, 0.01-2 parts of a lubricating agent and 0.01-2 parts of other auxiliaries; and the components are mixed in the formula, and then extrusion pelleting is carried out by virtue of an extruding machine, so that the material composition product is obtained. Compared with the prior art, the material composition provided by the invention is subjected to moulding and processing, the prepared handle of the refrigerator door is smooth and produces no warpage on the surface, no glass fiber is exposed, dimensional stability is good, and the prepared handle of the refrigerator door is resistant to scraping and has excellent antibacterial property.

Owner:HEFEI GENIUS NEW MATERIALS

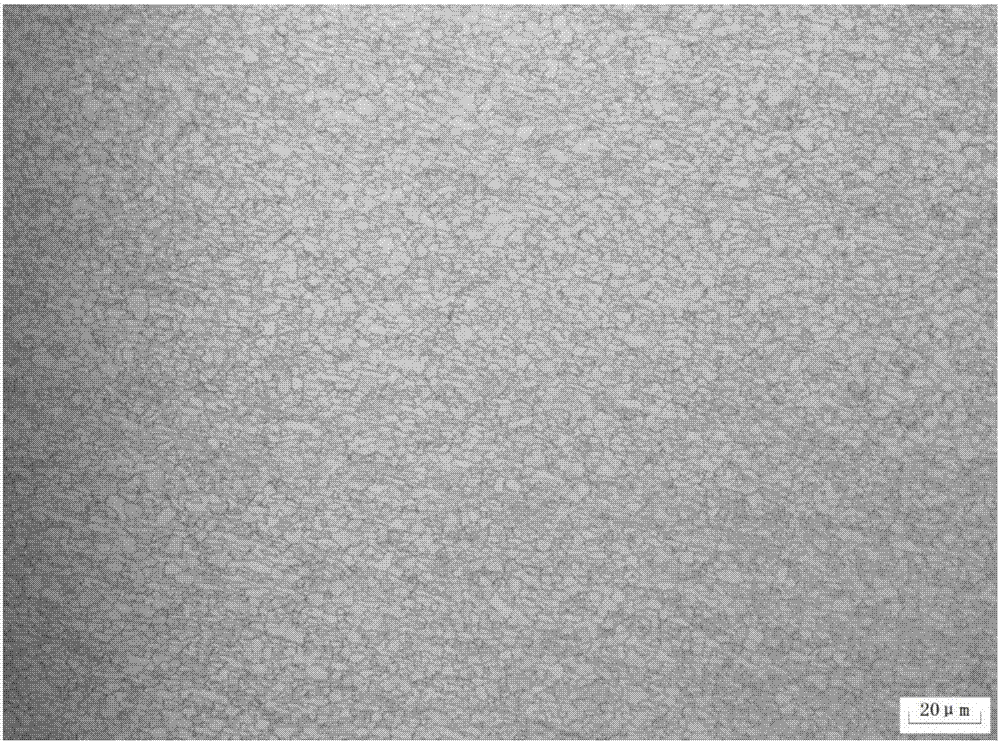

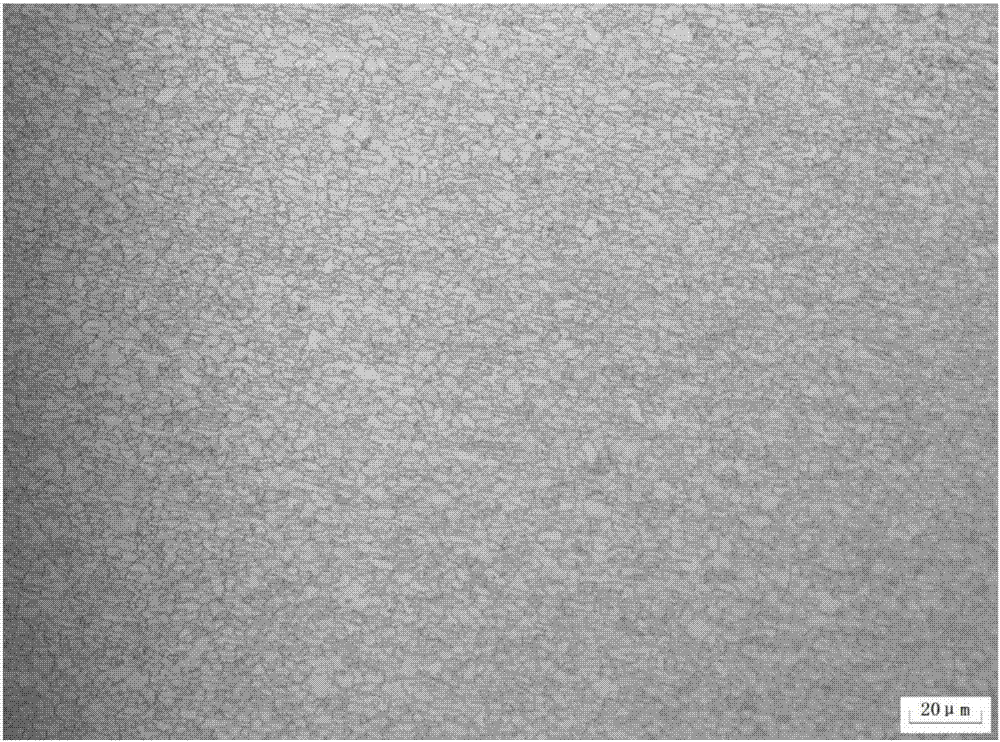

Processing method of SP700 titanium alloy sheet for superplastic forming

ActiveCN106955893AImprove consistencyImprove stabilityForging/pressing devicesMetal rolling arrangementsBeta phaseWater cooling

The invention belongs to the technical field of processing of titanium alloy materials, and relates to a processing method of an SP700 titanium alloy sheet for superplastic forming. The processing method comprises step I, carrying out heating number casting around a beta phase transformation point, and carrying out water cooling to obtain an intermediate billet; step II, carrying out first hot rolling, so as to obtain a first hot rolled plate blank; step III, carrying out second hot rolling, so as to obtain a second hot rolled plate blank; step IV, carrying out intermediate annealing treatment; step V, carrying out cold rolling, so as to obtain a hot rolled plate blank; and step VI, carrying out annealing treatment on a finished product, so as to obtain the SP700 titanium alloy sheet of which the thickness is 0.5 mm to 1.2 mm. According to the processing method, operation is simple, the technology is stable and controllable, and the prepared SP700 titanium alloy sheet is uniform in structure, fine in grains and good in performance consistency, and meets the relative technological requirement of superplastic forming.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

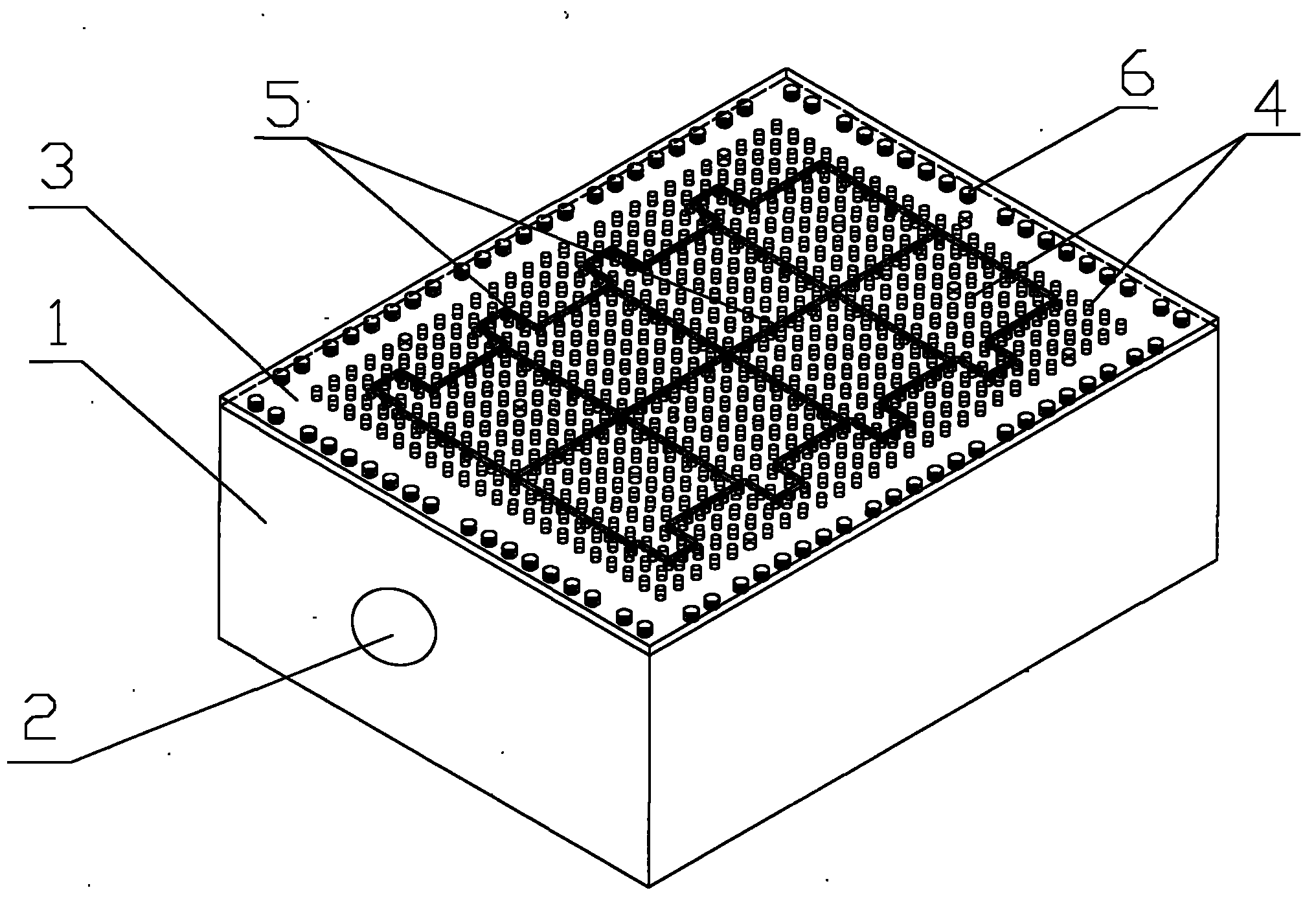

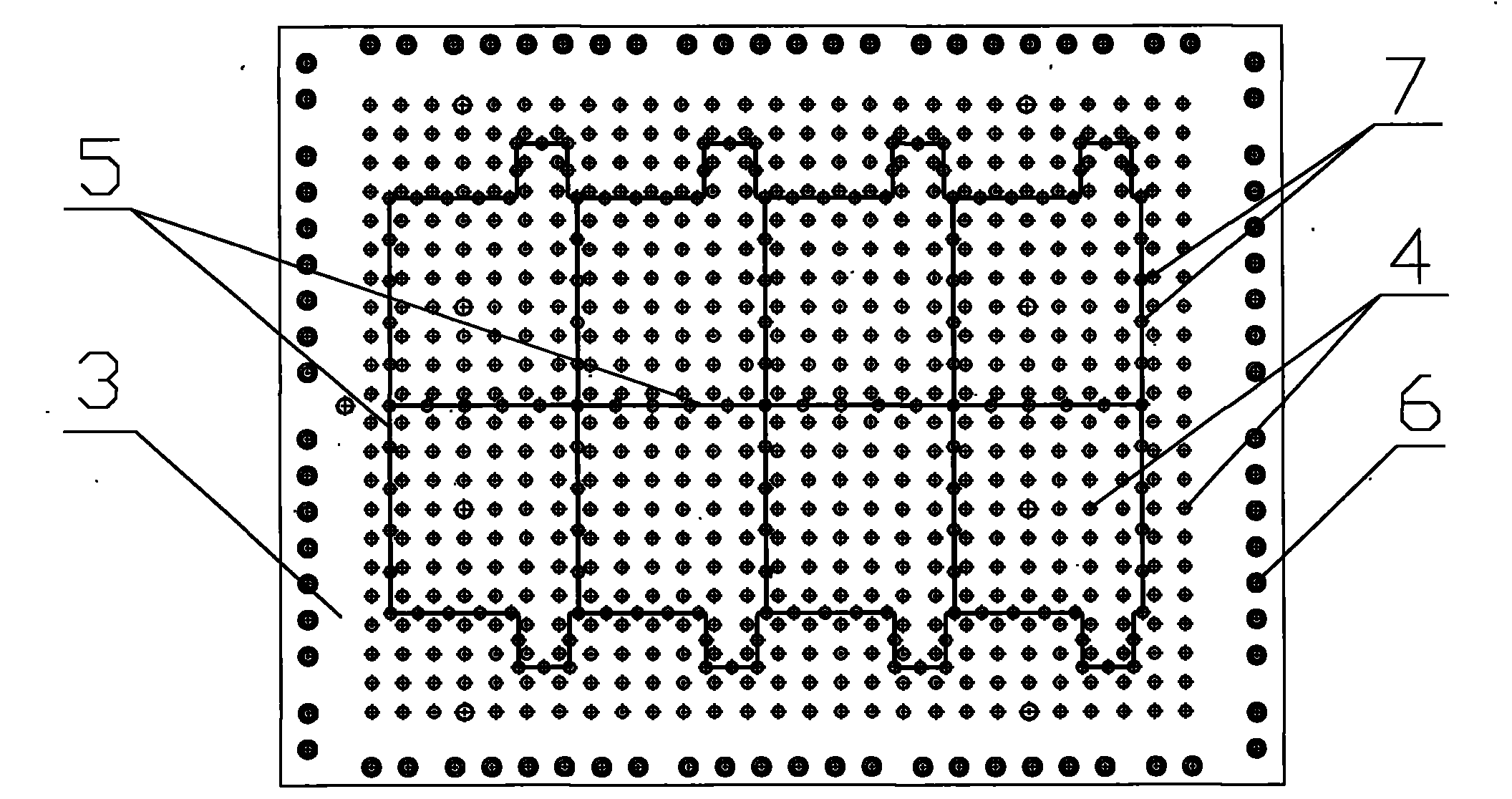

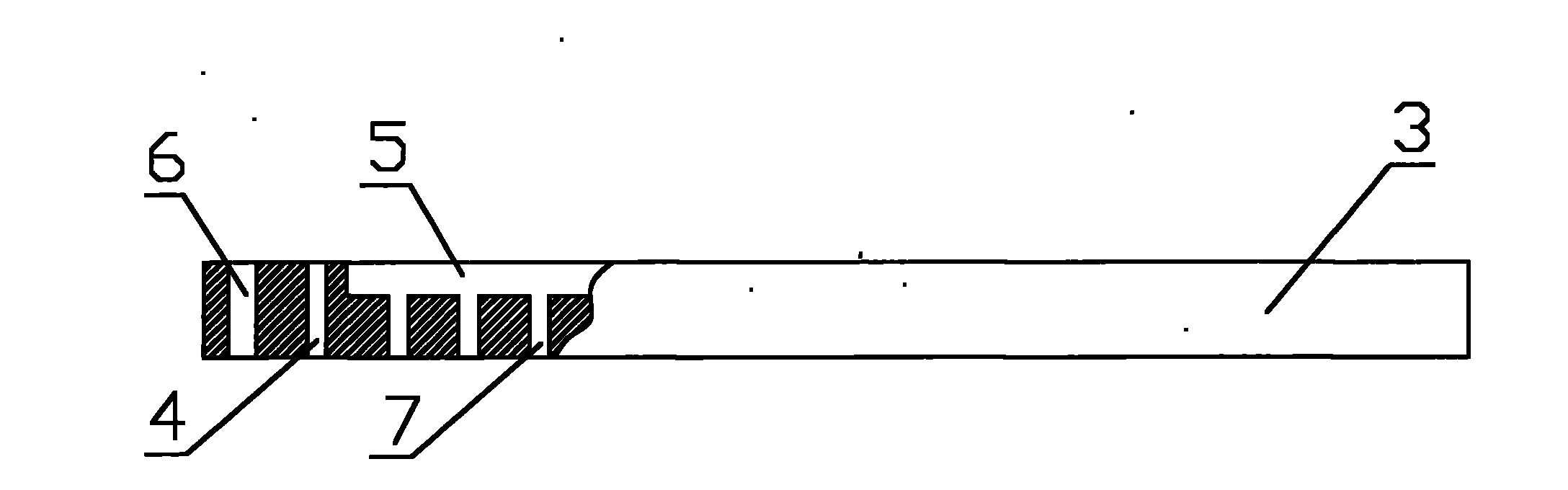

Vacuum adsorption device of battery pole piece

InactiveCN101774087ANo warpingNo situationLaser beam welding apparatusPlanar substrateElectrical battery

The invention provides a vacuum adsorption device of a battery pole piece, which is suitable for laser cutting operation and has simple structure and strong practicality. The device comprises a sealed cavity which is provided with vents communicated with a vacuum generator; the key point is that the top surface of the cavity is a plane substrate provided with plural adsorption through holes; the substrate is provide with an indent clearance groove along the cutting line of the battery pole piece; the cavity and the vacuum generator form a vacuumizing device; under the vacuumizing action of the vacuum generator, the battery pole piece can be tightly adsorbed on the substrate without lifting and bending or collapsing; the substrate is provided with the indent clearance groove along the cutting line of the battery pole piece, thus avoiding the uneven substrate as the substrate is cut and scratched when laser light beams cut the substrate during laser cutting, ensuring the cutting quality of subsequent battery pole pieces, and prolonging the service life of the substrate. The device has simple and reasonable structure, favorable adsorption effect and better popularization and application values.

Owner:CHERY AUTOMOBILE CO LTD

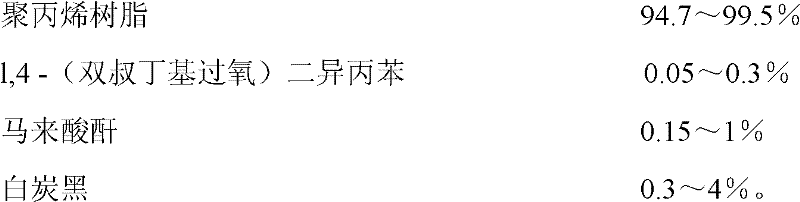

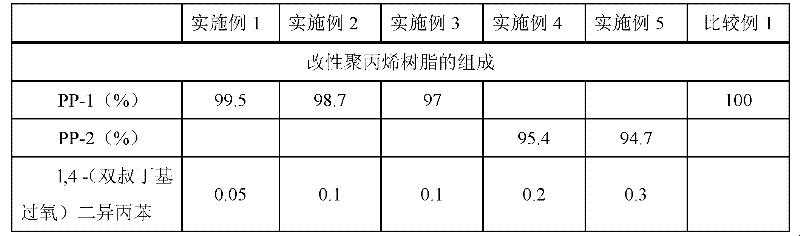

Low-VOC (volatile organic compound) long glass fiber reinforced polypropylene composite material and preparation method thereof

The invention discloses a low-VOC (volatile organic compound) long glass fiber reinforced polypropylene composite material and a preparation method thereof. The composite material comprises the following components by weight percent: 10-60% of long glass fiber arranged parallel to particle length and 90-40% of modified polypropylene resin, wherein the modified polypropylene resin is prepared by carrying out reaction and extrusion on known commercialized polypropylene resin through melting and kneading equipment such as a two-screw extruder. The preparation method has the beneficial effects that high-flowability polypropylene resin does not need to be singly produced or purchased in advance, and the production process is simplified. The prepared low-VOC long glass fiber reinforced polypropylene composite material has the beneficial effects of good apparent performance, no exposed glass fiber, no warping, good heat resistance, and easiness for processing. The product prepared by the method has the advantages of good low-VOC diffusion property and good mechanical properties such as good stretch and bending strengths and good impact resistance.

Owner:SHANGHAI PRET COMPOSITES

Preparation method of silicon chip metallographic specimen

InactiveCN102607916ANo warpingNo brokenPreparing sample for investigationOrganic solventAcrylic resin

The invention discloses a preparation method of a silicon chip metallographic specimen. The preparation method comprises the following steps: (1) proportioning and mixing acrylic resin powder and a liquid curing agent uniformly according to instructions, adding an organic solvent with the weight of 5-25% of the total weight of the acrylic resin powder and the liquid curing agent, and mixing uniformly to prepare a cold inserted agent; (2) placing a silicon chip on the bottom of a silicon gel cold inserted mold, pouring the cold inserted agent prepared in the step (1), and curing; and (3) carrying out polishing and corrosion treatment on the cured metallographic specimen, wherein the organic solvent is ethanol, glycol or isopropanol. The preparation method of the silicon chip metallographic specimen disclosed by the invention has the advantages that the metallographic specimen of the ultra-thin and fragile silicon chip can be prepared, structure morphologies such as dislocation with clear materials are obtained, the phenomena of wrapping, crashing and the like of the ultra-thin silicon chip in specimen insertion and polishing processes are avoided, the problem that the micro scratch of the ultra-thin silicon chip is difficult to remove is solved, and the metallographic specimen of the ultra-thin silicon chip is prepared successfully.

Owner:SUZHOU XIEXIN INDAL APPL INST

Ink composition for 3D ink-jet printing, ink kit and preparation method thereof

The invention provides an ink composition for 3D ink-jet printing, an ink kit and a preparation method thereof. The ink composition comprises the following components in parts by weight: 45-75 parts of an acrylic acid oligomer, 20-45 parts of an acrylic monomer, 1-9 parts of an ultraviolet photoinitiator, 0.2-10 parts of aids and 0-4 parts of a coloring agent, wherein the acrylic acid oligomer is selected from one or more of polyurethane acrylate, polyester acrylate and polyether acrylate. At the temperature of 25 DEG C, the viscosity of the ink composition is 25-70cps; at the temperature of 40-60 DEG C, the surface tension of the ink composition is 20-35dyn; and under at least one temperature of 40-60 DEG C, the viscosity of the ink composition is 9-14.5cps. The ink composition disclosed by the invention is simple in constitution, and the service life of a printing head can be prolonged. Moreover, the curing process is simple, emission of VOCs (Volatile Organic Compounds) is avoided, pollution is eliminated, and buckling deformation is avoided in the preparation.

Owner:ZHUHAI SAILNER 3D TECH CO LTD

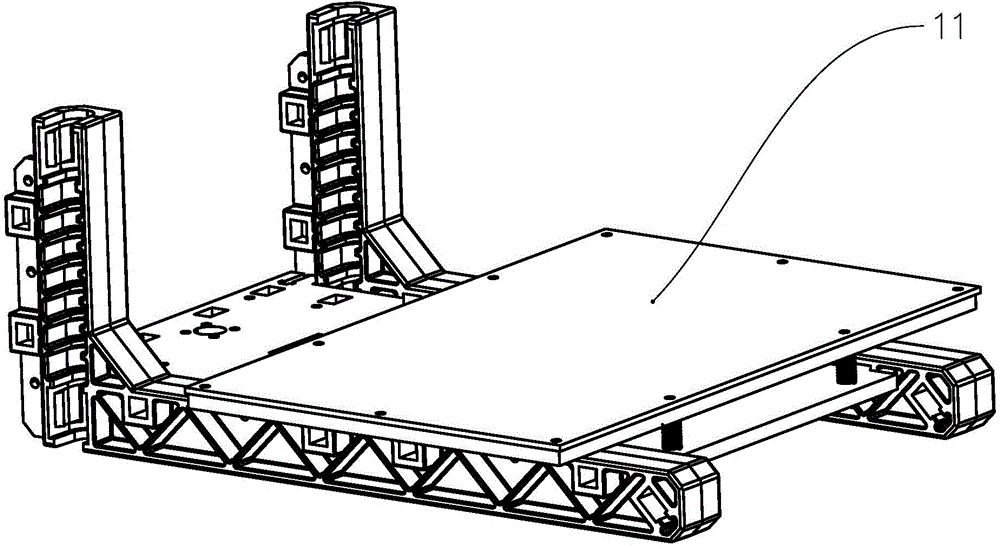

Three-dimensional printer, printing workbench applied to three-dimensional printer, paint, film and preparation method

ActiveCN104827665AGood anti-warping effectExtended service lifeAdditive manufacturing apparatusCoatingsAdhesion forceAcrylic resin

The present invention provides a printing workbench applied to a three-dimensional printer. The printing workbench successively comprises a heating layer, a glass layer and a film layer. The film layer is formed by 12 parts of heterocyclic acrylic resin by mass and 24-28 parts of weak solvent resin by mass. After the printing process, the heating layer stops heating, and the temperature of the film layer is cooled gradually to the room temperature. At this time, the adhesion force between the contact surfaces of the film layer with a to-be-printed object is lowered to a minimum value. Therefore, a user can easily and conveniently take out the to-be-printed object, while the integrity of the film layer is not damaged at all. Therefore, the service life of the film layer is prolonged. The film layer can be applied to three-dimensional printing materials, such as ABS, PA, PC and the like, and is high in universality.

Owner:PRINT RITE UNICORN IMAGE PROD CO LTD

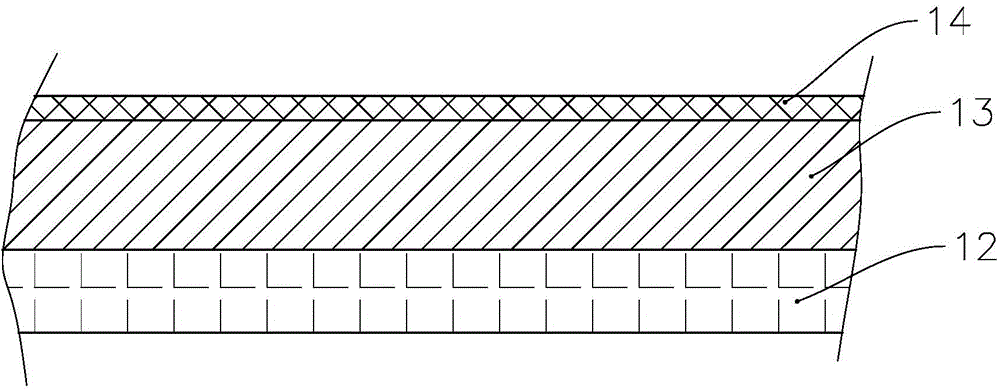

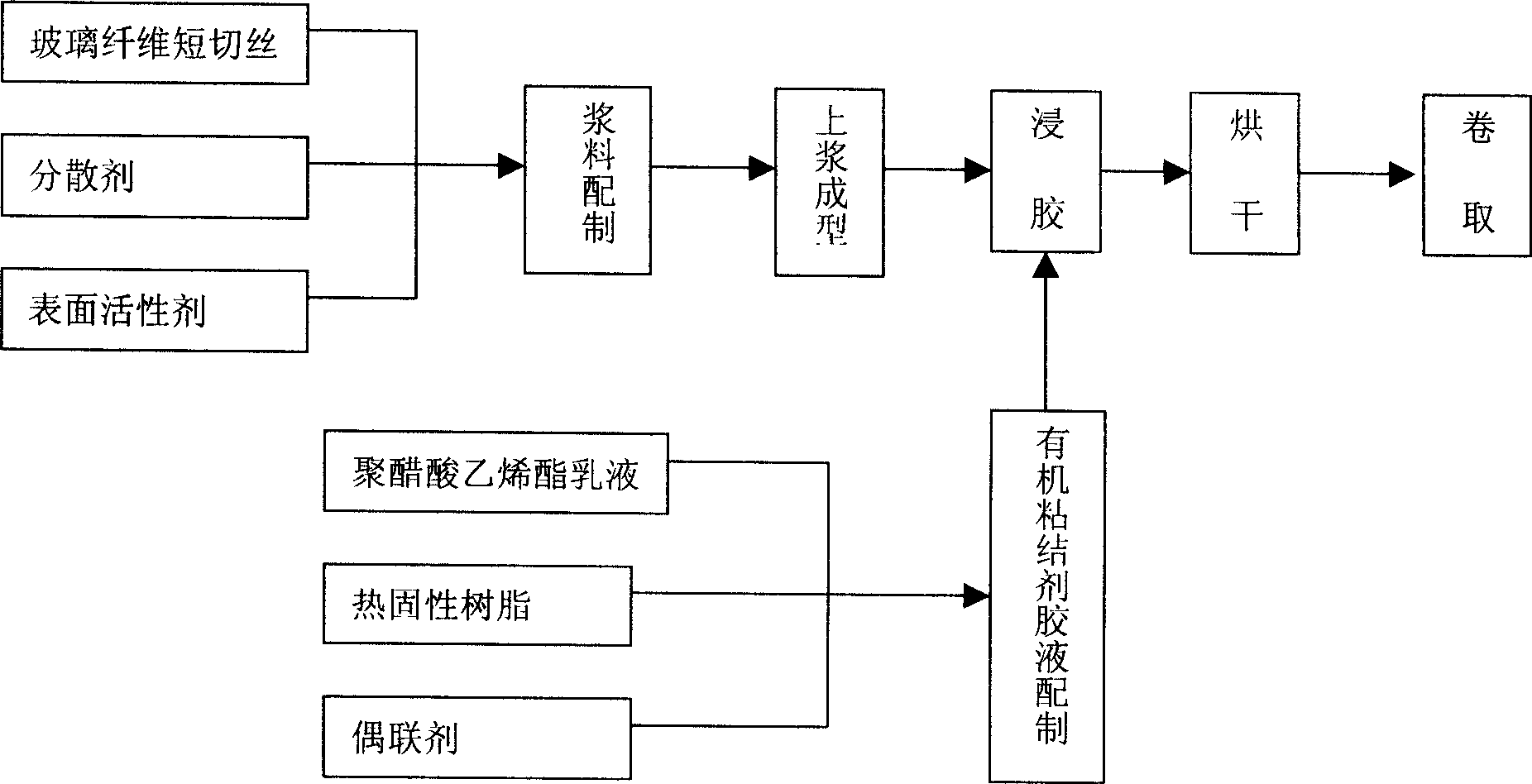

Glass fiber thin felt for plastic floor leather base material and preparation method thereof

The invention discloses a thin felt with glass fiber for the substrate of plastic floor ant the manufacturing method, comprising short-cut silk of glass fiber, dispersant, surfactant and organic binder. Said short-cut silk of glass fiber is middle-alkali or non-alkali, the diameter is 9-10 mum and the length is 6-12mm. Said dispersant is thickener belonging to cellulose acetate. Said surfactant is quaternary ammonium cationic surfactants. The organic binder is the mixture of polyethylene acetate emulsion thermosetting resin, KH560 coupling agent and water. Said thin felt with glass fiber is produced by wet technology, which comprises producing stock, preparing slurry, sizing forming, dipping and drying so on. The product is provided with high compactness, even thickness, widely applied temperature, and no-deformation under high temperature. The plastic floor surface with the felt as the substrate, is provided with flat and smooth, no shrinkage deformation, no-bending, no mildewing and stable dimension.

Owner:樊福定

Antiscraping optical film and use thereof

InactiveCN101021644AImprove antistatic performanceExcellent hardness propertiesNon-linear opticsOptical elementsAntistatic agentLiquid-crystal display

The invention provides an anti-scratching optical film and its use. And its characters: at least a surface of its substrate is coated with antistatic anti-scratching layer whose surface resistivity is 108-1012 Ohm / sq and which has the hardness of pencil of 3H or above, according to the measurement by JIS K5400 standard method. And it has low volumetric shrinkage, unable to warp but having good antistatic performance and high hardness, applied to advertising lamp boxes or plane displays and other light source devices, especially applied to an LCD provided with ''V-channel'' light guide plate as anti-scratching reflective film at the bottom of the light guide plate.

Owner:长兴光学材料(苏州)有限公司

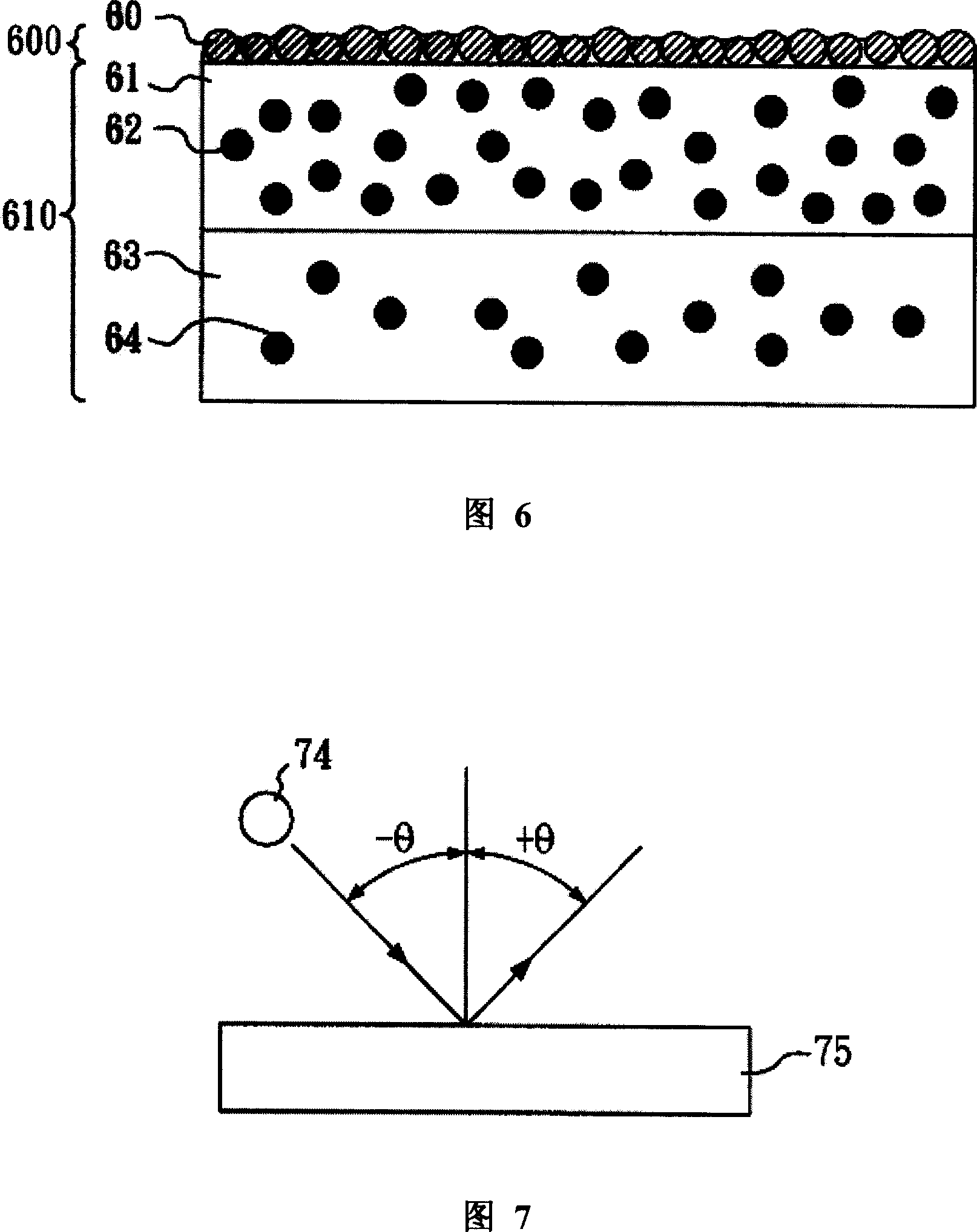

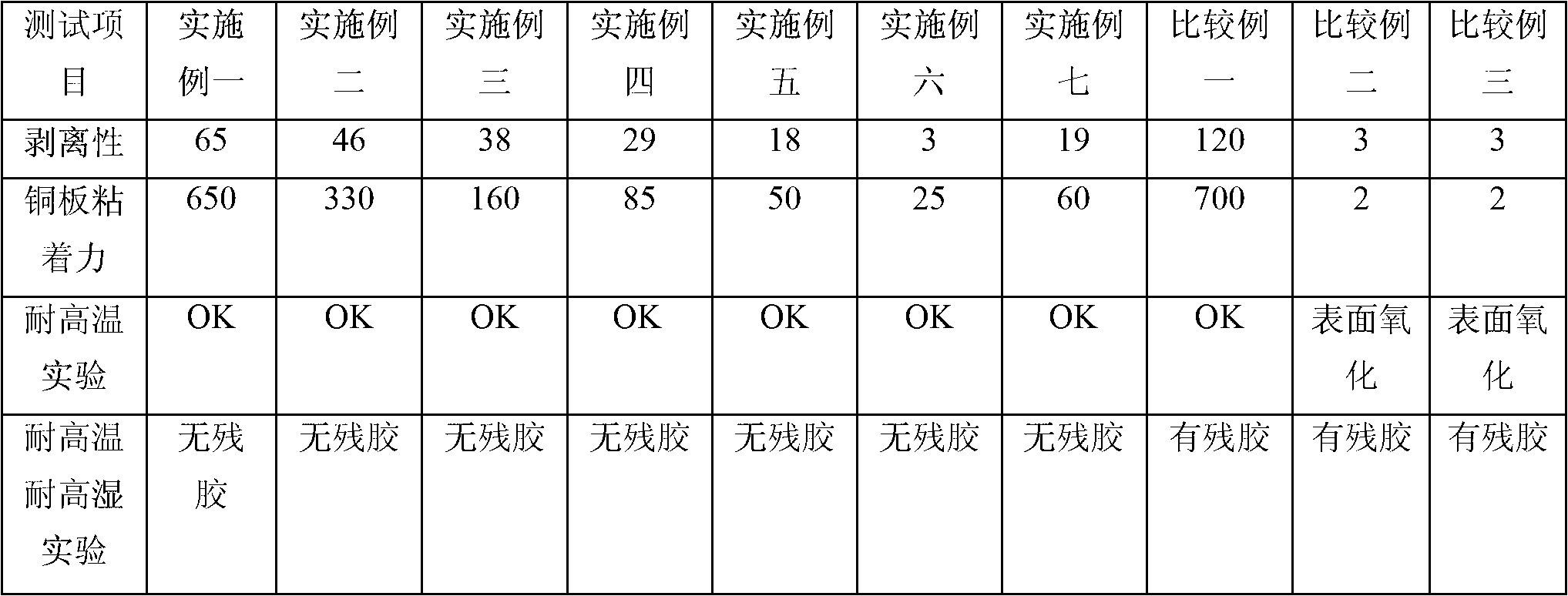

High-temperature resistant protecting film of electronic circuit board

ActiveCN103009734ANo shrinkageNo warpingFilm/foil adhesivesSynthetic resin layered productsHybrid typeTectorial membrane

The invention relates to a high-temperature resistant protecting film of an electronic circuit board. The high-temperature resistant protecting film comprises a base material layer and an adhesive layer coated on the base material layer. The high-temperature resistant protecting film is characterized in that the adhesive layer is composed of the following components in parts by weight: 100 parts of mixed type organic silicon raw rubber, 0.1-5 parts of polydimethylsiloxane and 0.1-5 parts of Pt catalyzer. Compared with the prior art, according to the high-temperature resistant protecting film, the mixed type organic silicon raw rubber is adopted so that the protecting film can be automatically wetted and pasted on the surface of a pasted object, the protecting film can not contract or raise after being pasted for more than 200 hours at the high temperature of 250 DEG C, and the surface of the pasted object does not have oxidation, pollution or residual adhesive.

Owner:NINGBO SOKEN CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com