Melt differential three-dimensional printer

A three-dimensional printer and melt differentiation technology, which is applied in the direction of liquid material additive processing, processing drive device, processing and manufacturing, etc., can solve the problems of uneven plasticization, low molding accuracy, contour distortion, etc., to achieve convenient cleaning, hygiene and convenience. The effect of quantitative management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

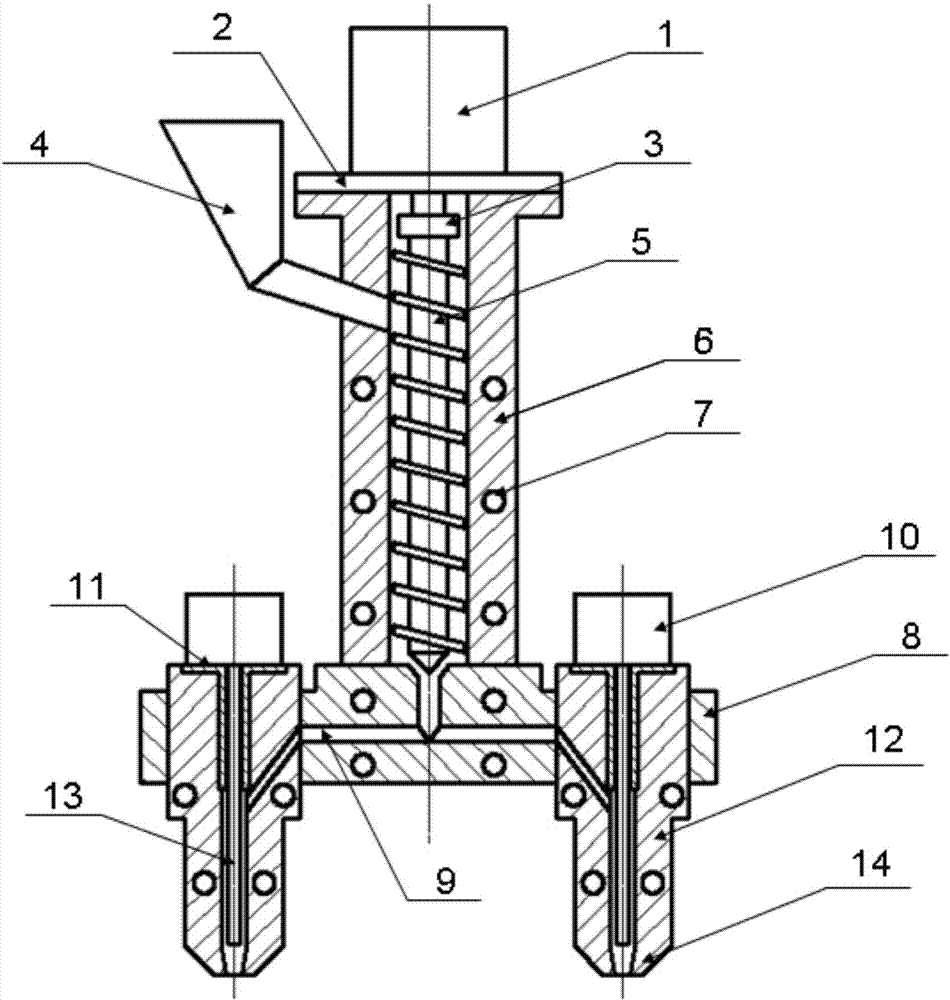

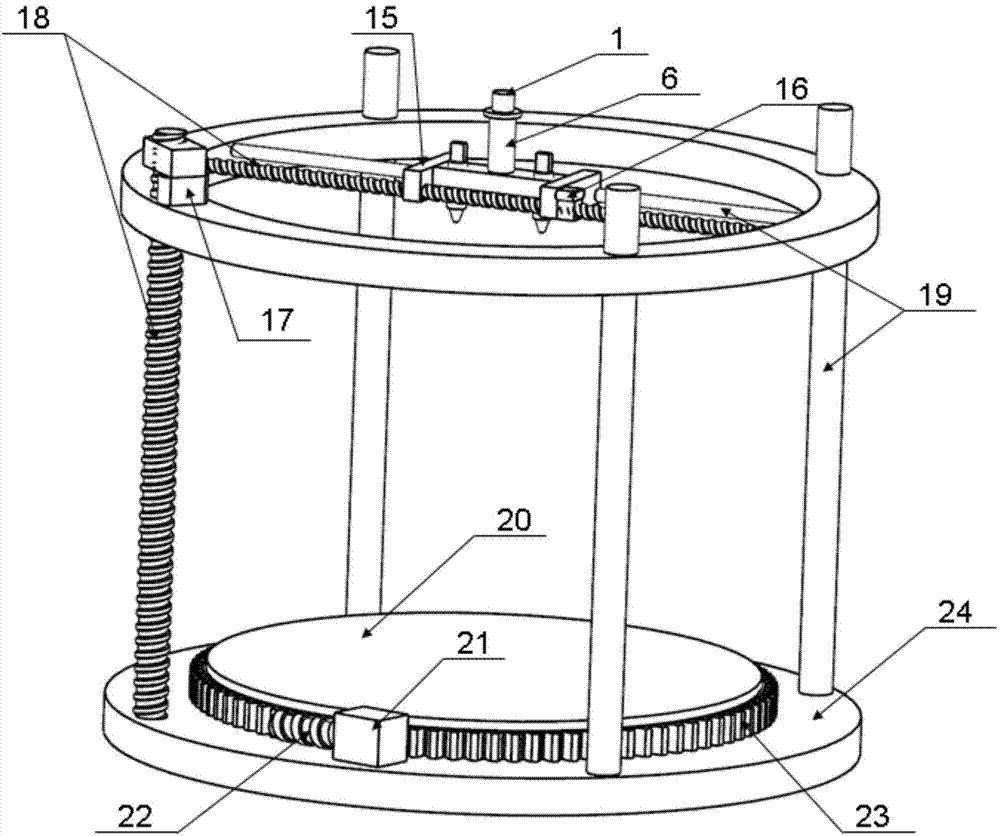

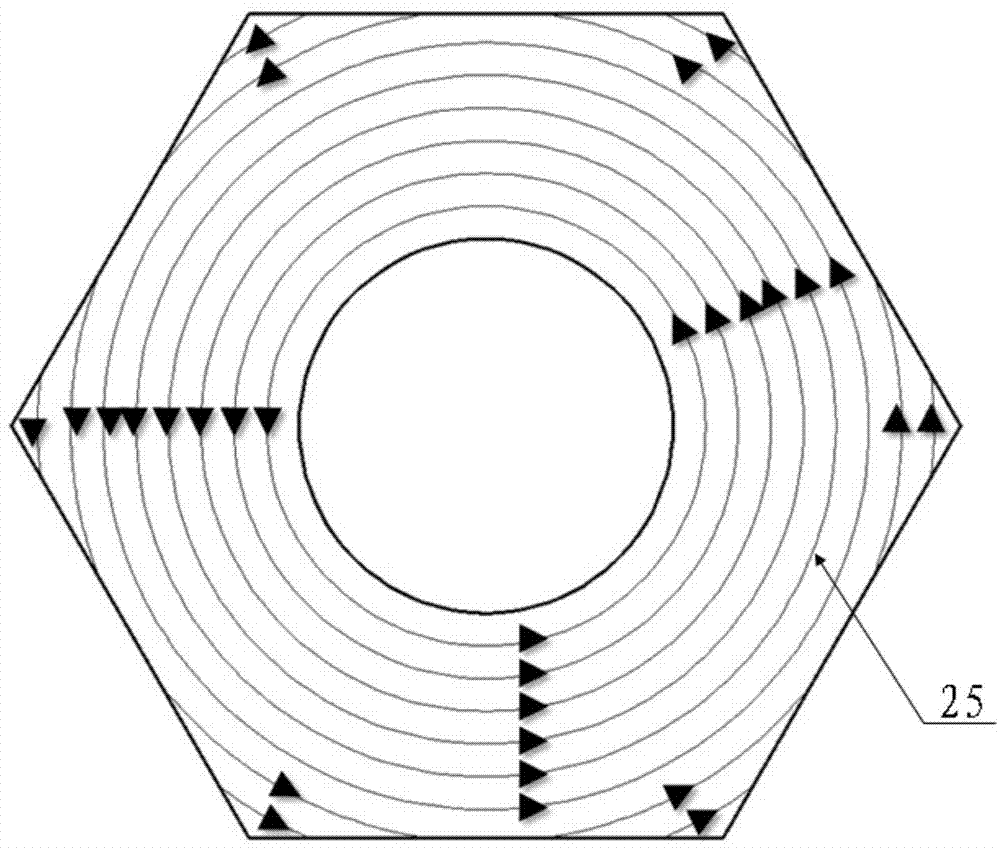

[0019] The invention provides a melt differential three-dimensional printer, which is composed of a material melting unit, a droplet ejection unit, a cylindrical coordinate system forming unit and a frame; wherein the material melting unit includes a servo motor 1, a heat insulating sleeve 2, a shaft coupling 3, and a A feed port 4, a screw 5, a barrel 6 and a heater 7; wherein the droplet ejection unit includes a runner plate 8, a hot runner 9, a linear servo motor 10, a barrier sleeve 11, a valve body 12, a valve needle 13 and a nozzle 14; The cylindrical coordinate system molding unit includes left and right servo motors 16, vertical servo motors 17, lead screws 18, guide rails 19, bearing plates 20, circumferential servo motors 21, worms 22 and worm wheels 23; barrel 6 inner cavity and hot runner 9 Through, the outer end of the flow channel plate 8 is connected with the lead screw 18 and the guide rail 19 through the connecting frame 15; the whole system is supported by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com