Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1186results about How to "Guaranteed normal rotation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

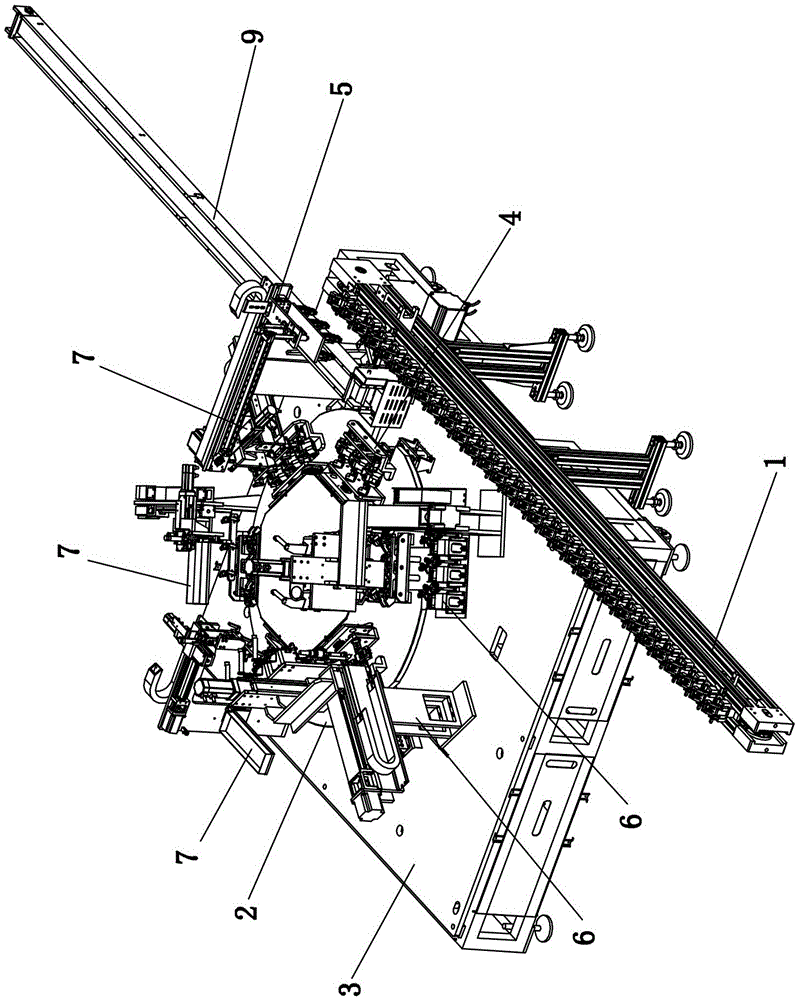

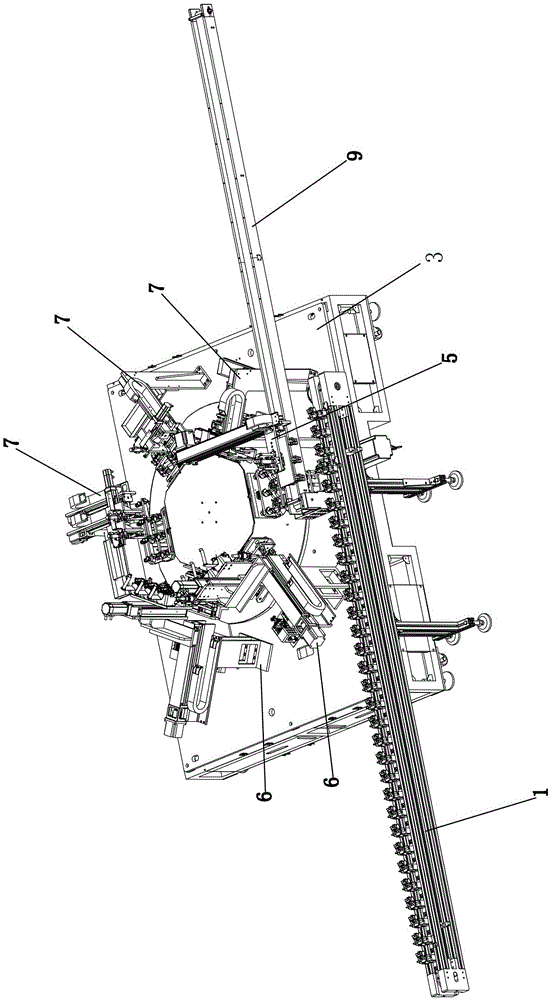

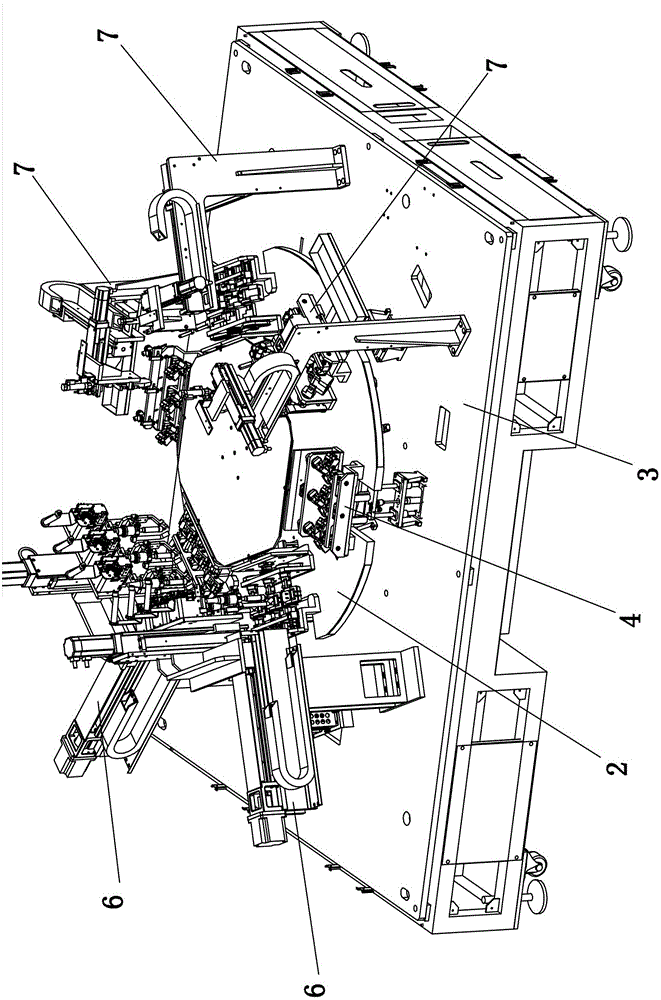

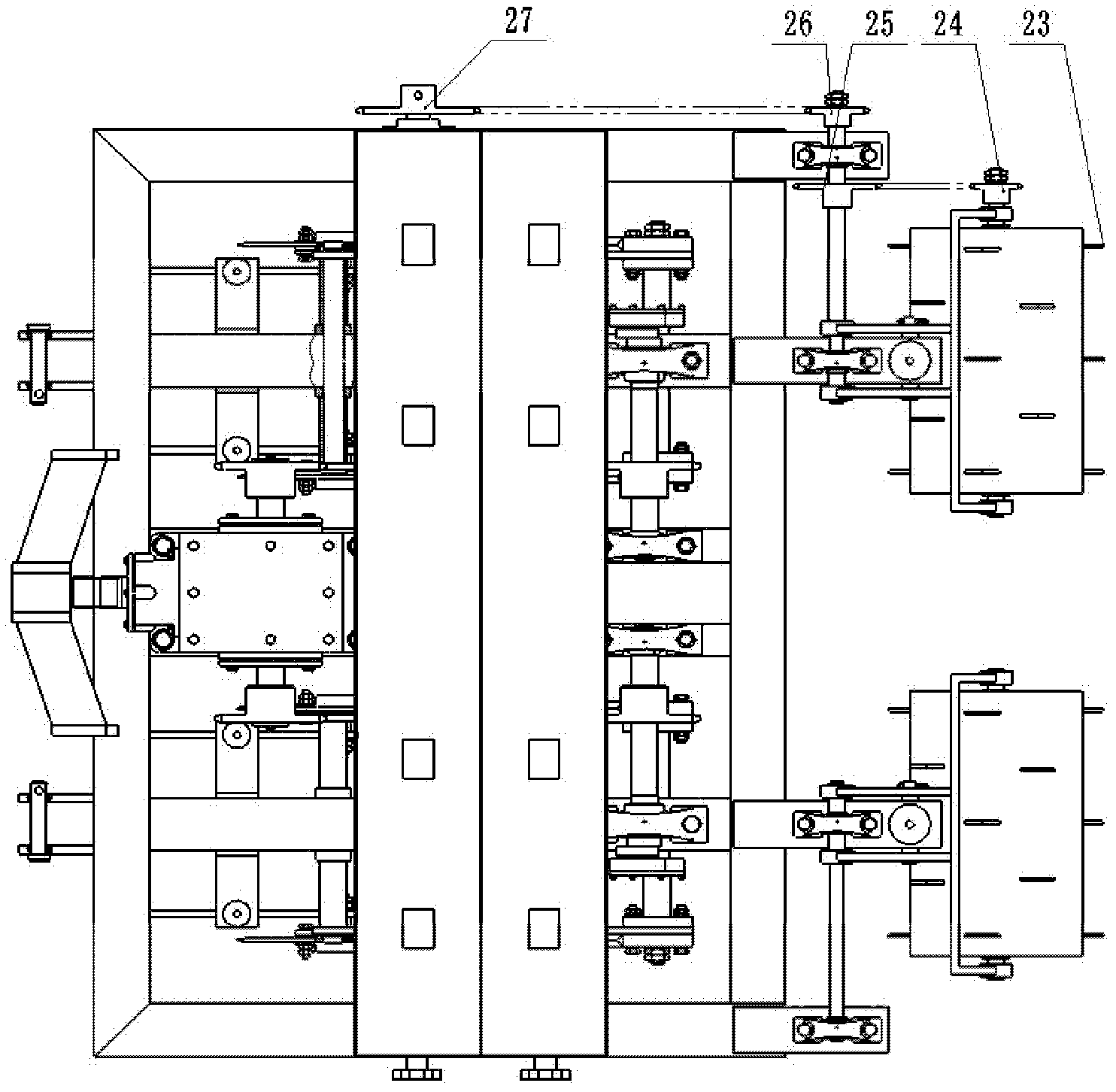

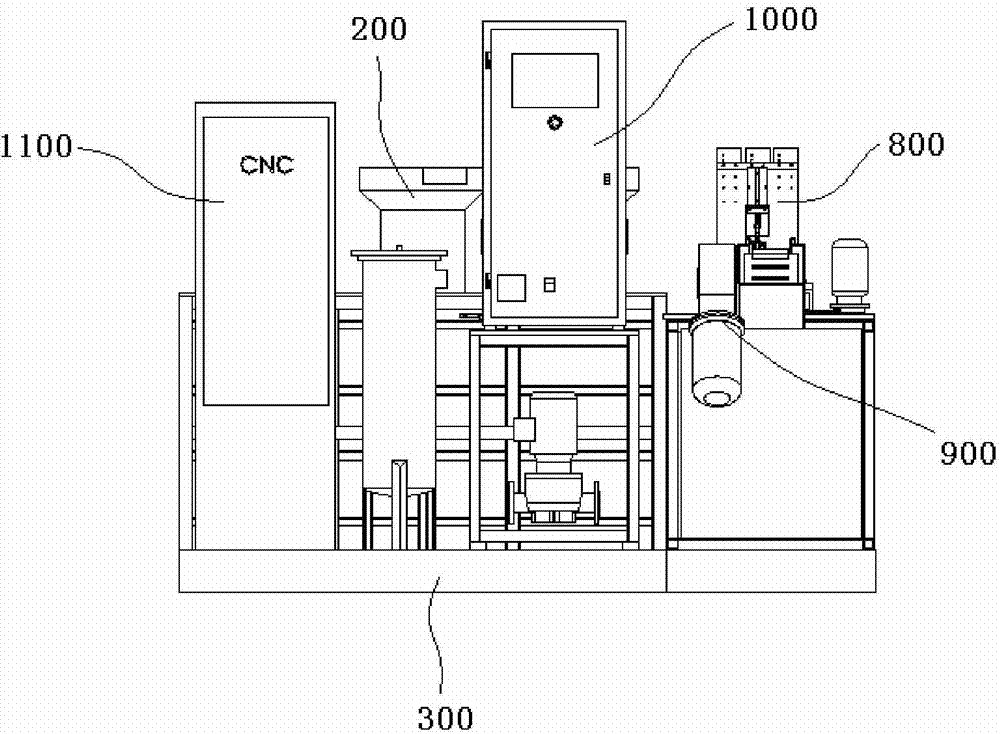

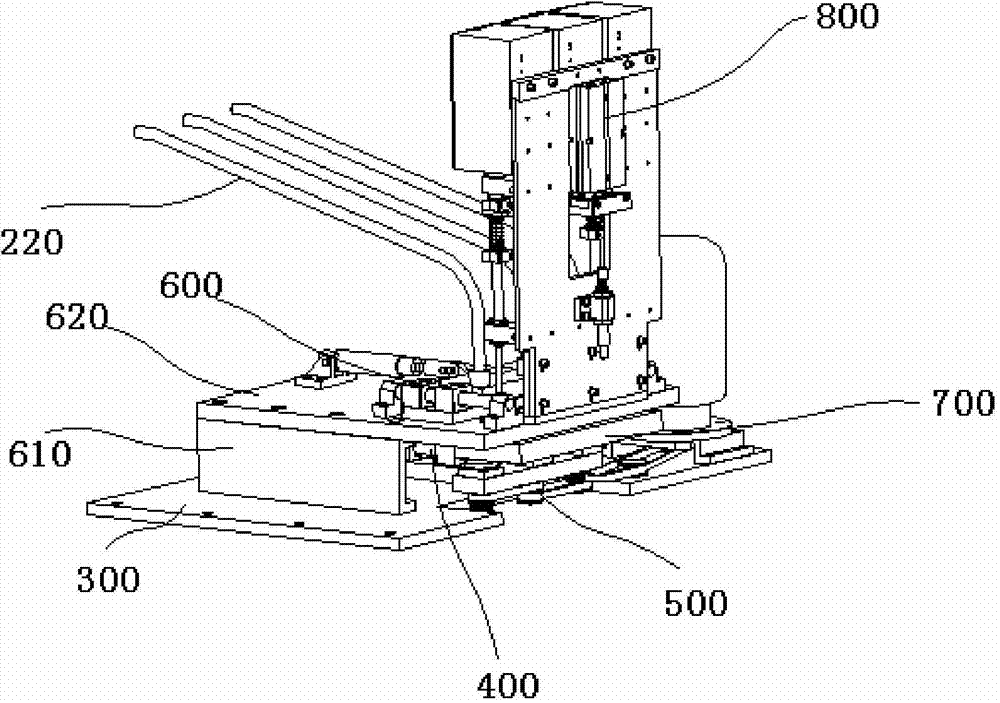

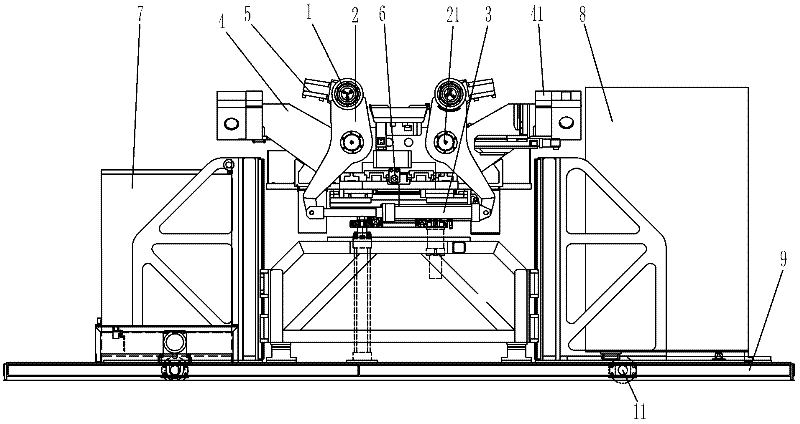

Power source automatic assembly production line and assembly process thereof

ActiveCN105583622ASave space costGuaranteed normal rotationLiquid surface applicatorsAssembly machinesProcess engineeringMachining

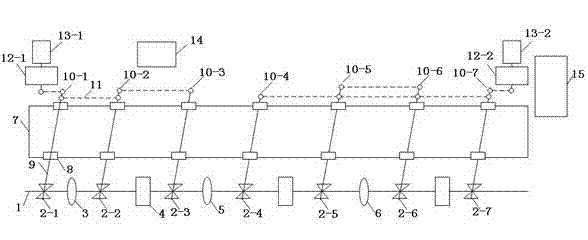

The invention discloses a power source automatic assembly production line and an assembly process thereof. The power source automatic assembly production line comprises a feeding mechanism, an assembly platform, a material conveying mechanism, welding mechanisms, adhesive dispensing mechanisms and a discharging mechanism. The feeding mechanism and the discharging mechanism are disposed on the two sides of the assembly platform correspondingly. A rotary plate is disposed in the middle of the assembly platform. Feeding and discharging stations and at least two machining stations are disposed at the edge of the rotary plate at intervals. The material conveying mechanism is disposed on the outer sides of the feeding and discharging stations. The welding mechanisms and the adhesive dispensing mechanisms are disposed on the outer sides of the machining stations. The assembly process of the power source automatic assembly production line includes the following steps that power sources are mounted and fixed inside jigs; jig loading and guiding are performed; feeding is prepared; feeding is conducted; the jigs are transferred to the machining stations; the power sources are machined; and discharging is performed. By means of the power source automatic assembly production line and the assembly process thereof, full-automatic guiding, feeding, machining and discharging are achieved, the multiple stations are combined, the power source assembly efficiency is improved, the machining accuracy is improved, and the reject ratio of products is decreased.

Owner:SHENZHEN XING GRAIN AUTOMATION CO LTD

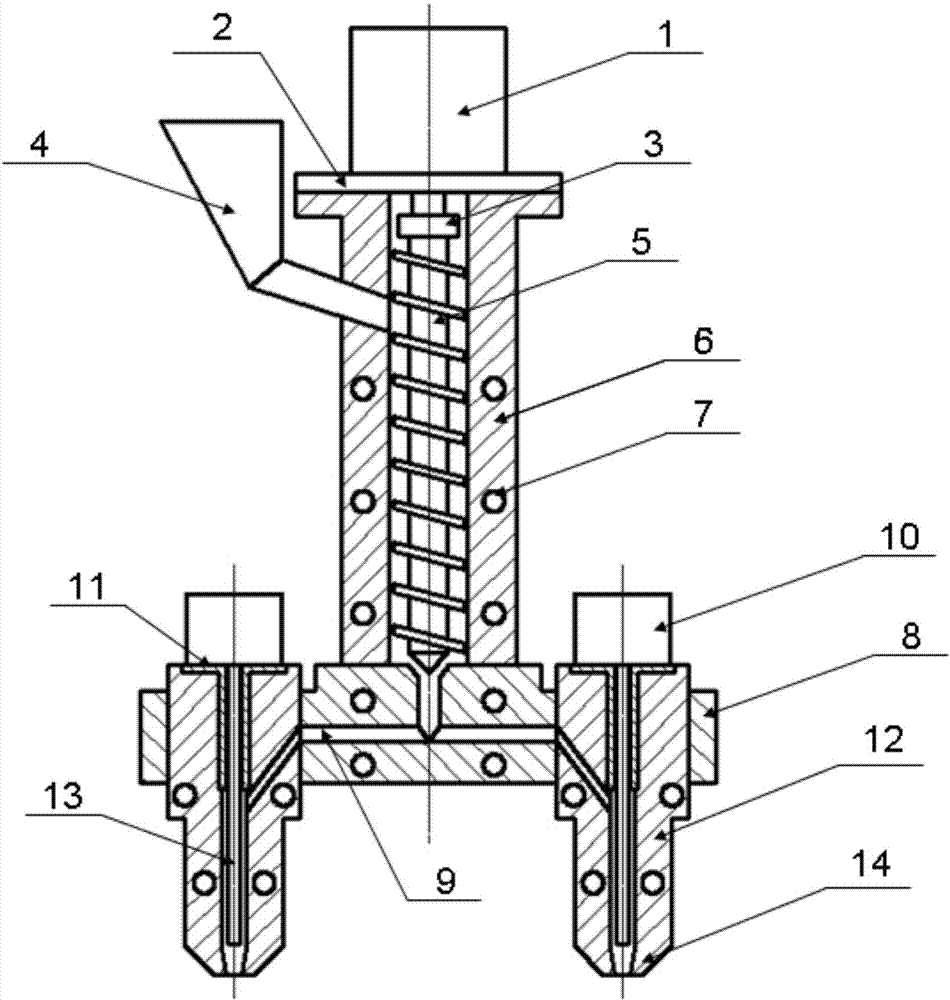

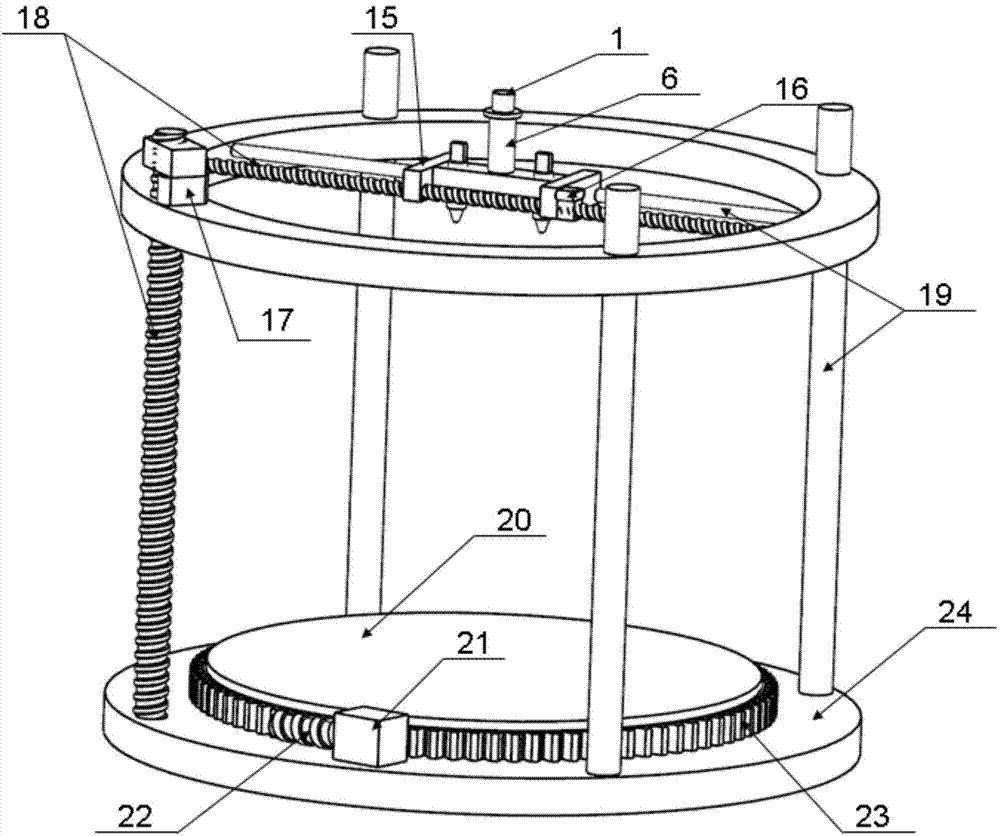

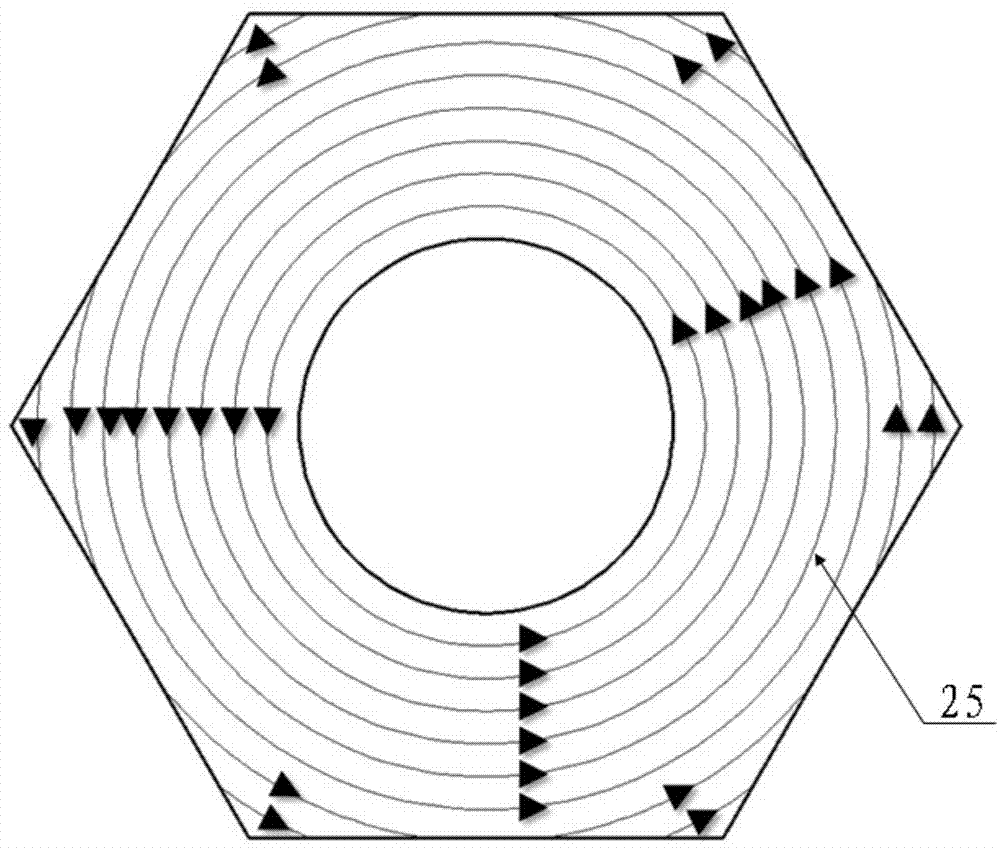

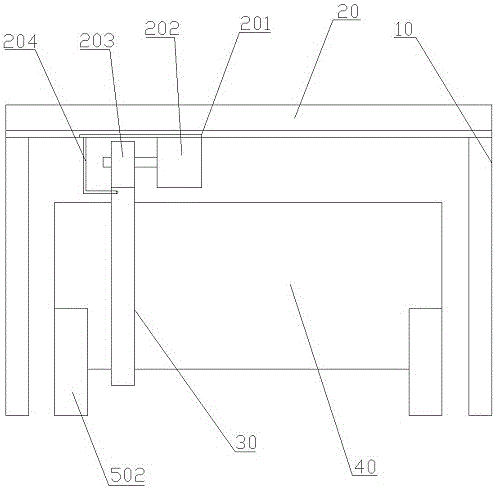

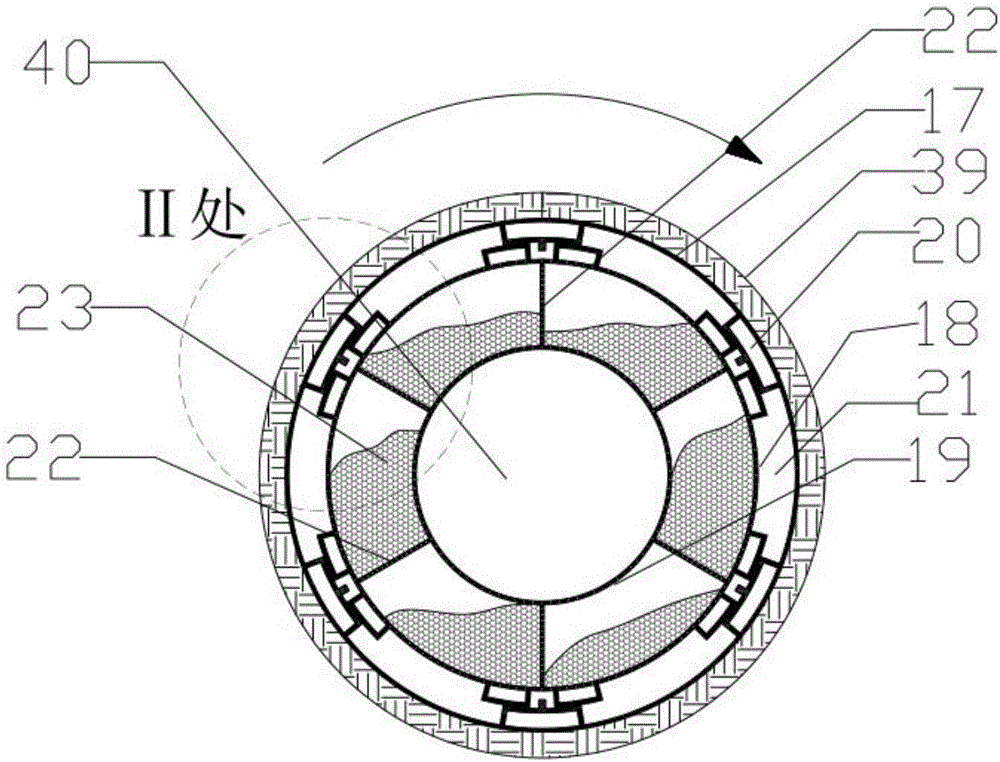

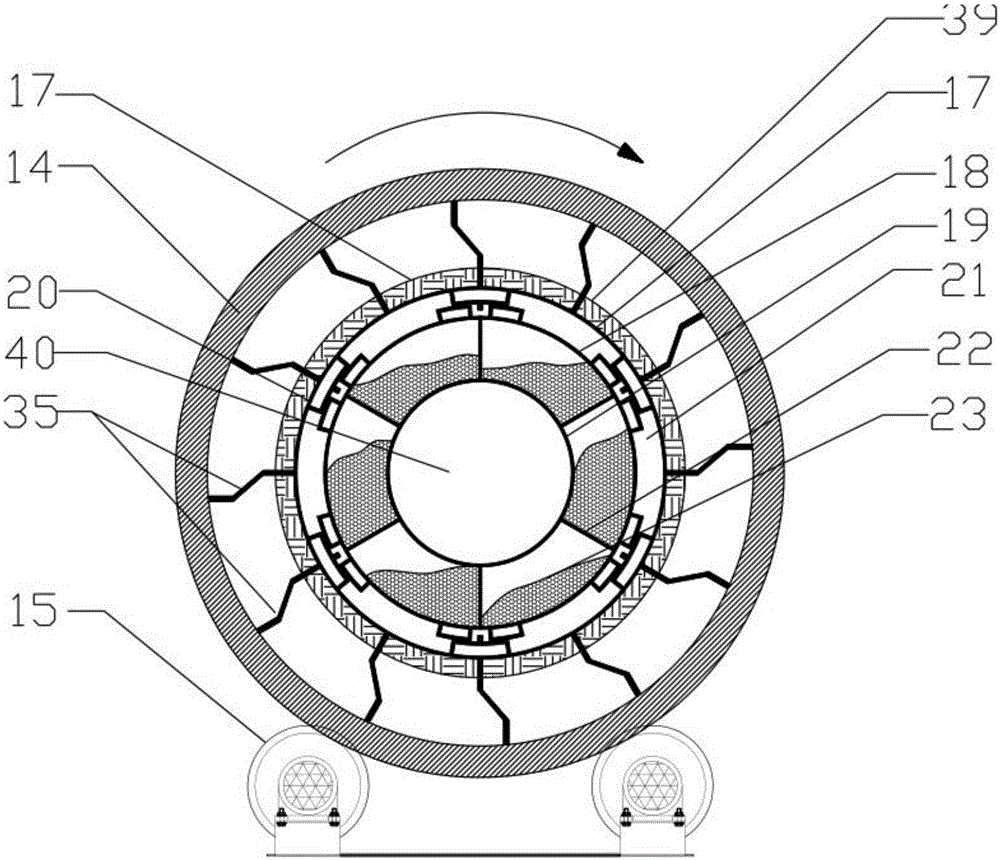

Melt differential three-dimensional printer

ActiveCN103692653ABurn out preventionConvenient Quantitative ManagementManufacturing driving meansAdditive manufacturing with liquidsHot runnerMotor drive

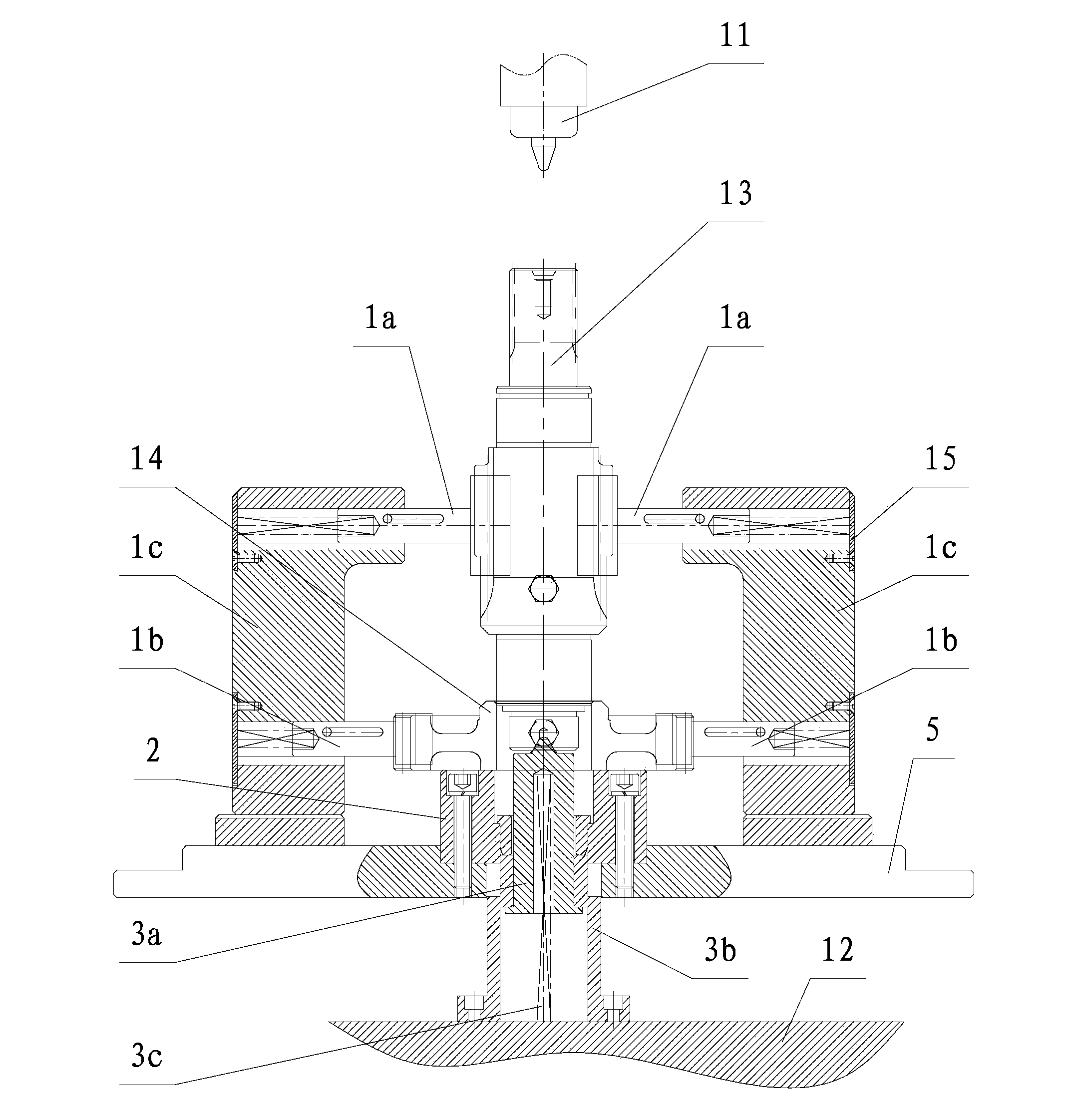

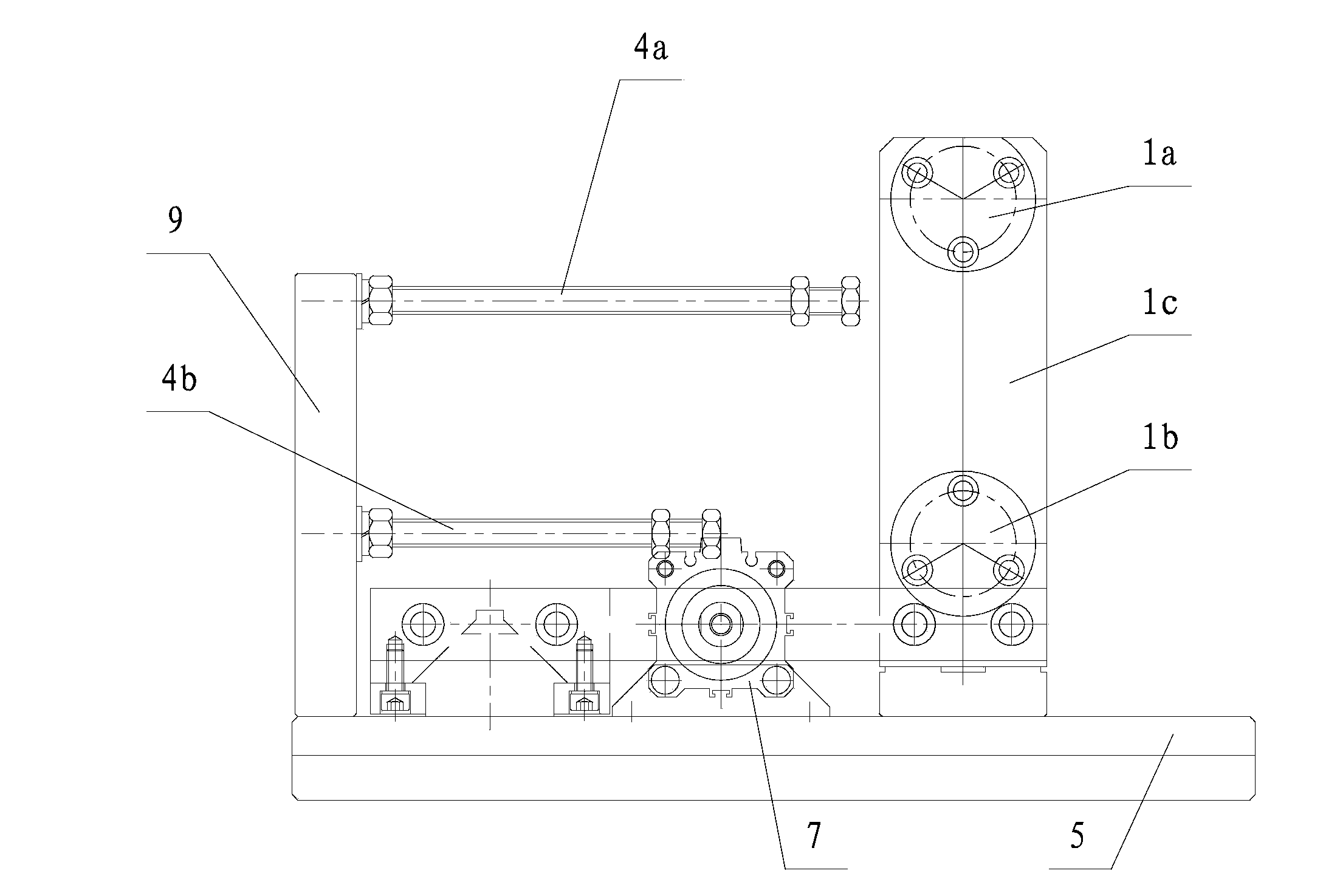

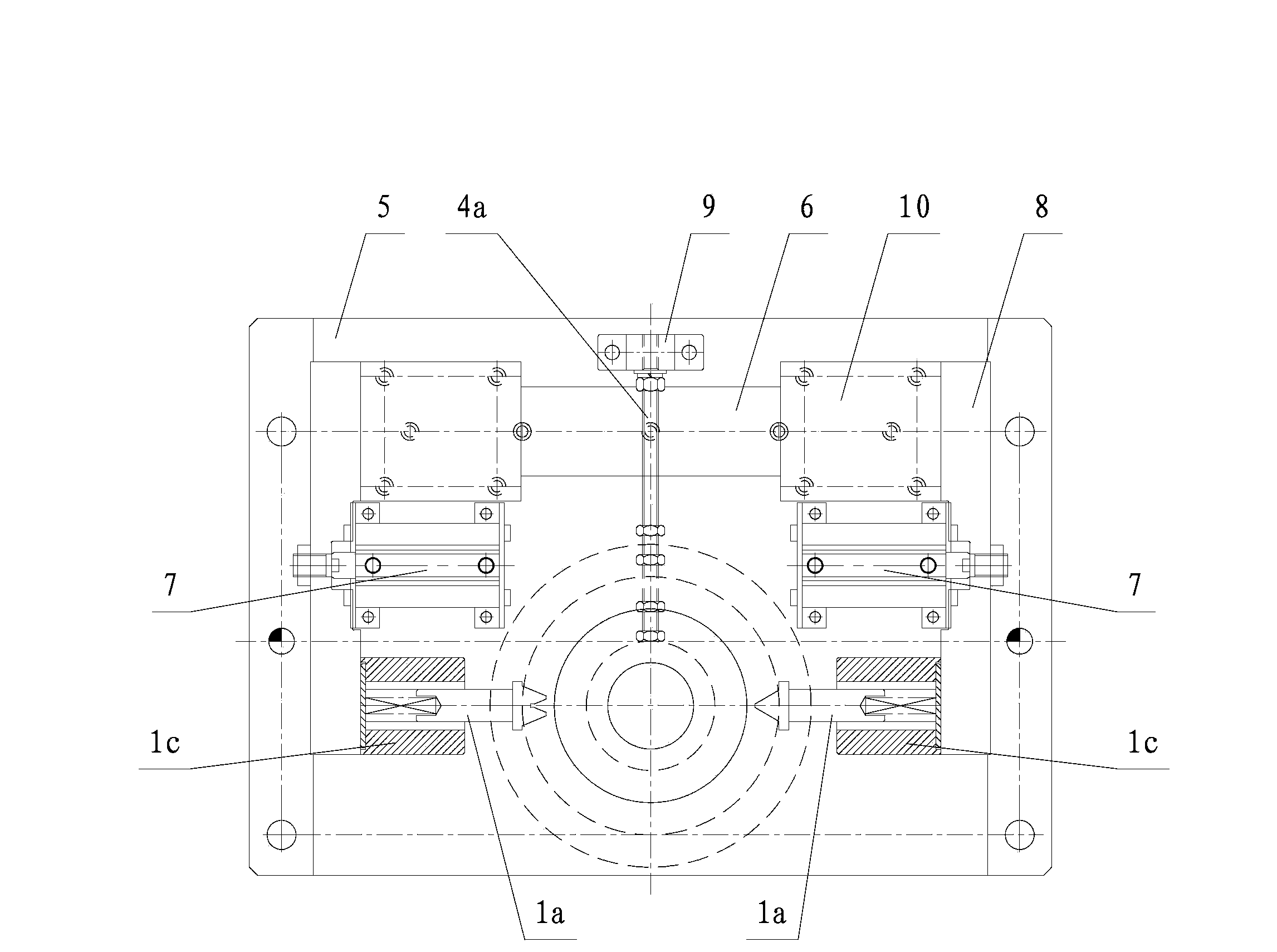

The invention discloses a melt differential three-dimensional printer. The melt differential three-dimensional printer mainly comprises a material melting unit, a micro-droplet jetting unit, a cylindrical-coordinate system molding unit and a rack, wherein a servo motor drives a screw rod to rotate in the material melting unit; a heater, which is fixedly arranged inside a machine cylinder, ensures that granules are entirely plastified through temperature regulation; a molten material is transmitted by the screw rod to the micro-droplet jetting unit; in the micro-droplet jetting unit, the molten material is transmitted into a valve body through a hot runner in a runner plate; a linear servo motor drives a valve needle to do reciprocating motion in the valve body so as to quantitatively and intermittently squeeze the molten material out of a nozzle to form melt micro-droplets; in the cylindrical-coordinate system molding unit, the molten micro-droplets are injected to a bearing table for cooling and deposition molding; the servo motors in the left-right direction and in the vertical direction are respectively engaged with the corresponding screw rod to rotate so as to drive the material melting unit and the micro-droplet jetting unit to move along the left-right direction and the vertical direction; a circumference servo motor drives the bearing table with a worm gear to rotate through a worm rod so as to realize three-dimensional movement under a cylindrical-coordinate system.

Owner:BEIJING UNIV OF CHEM TECH

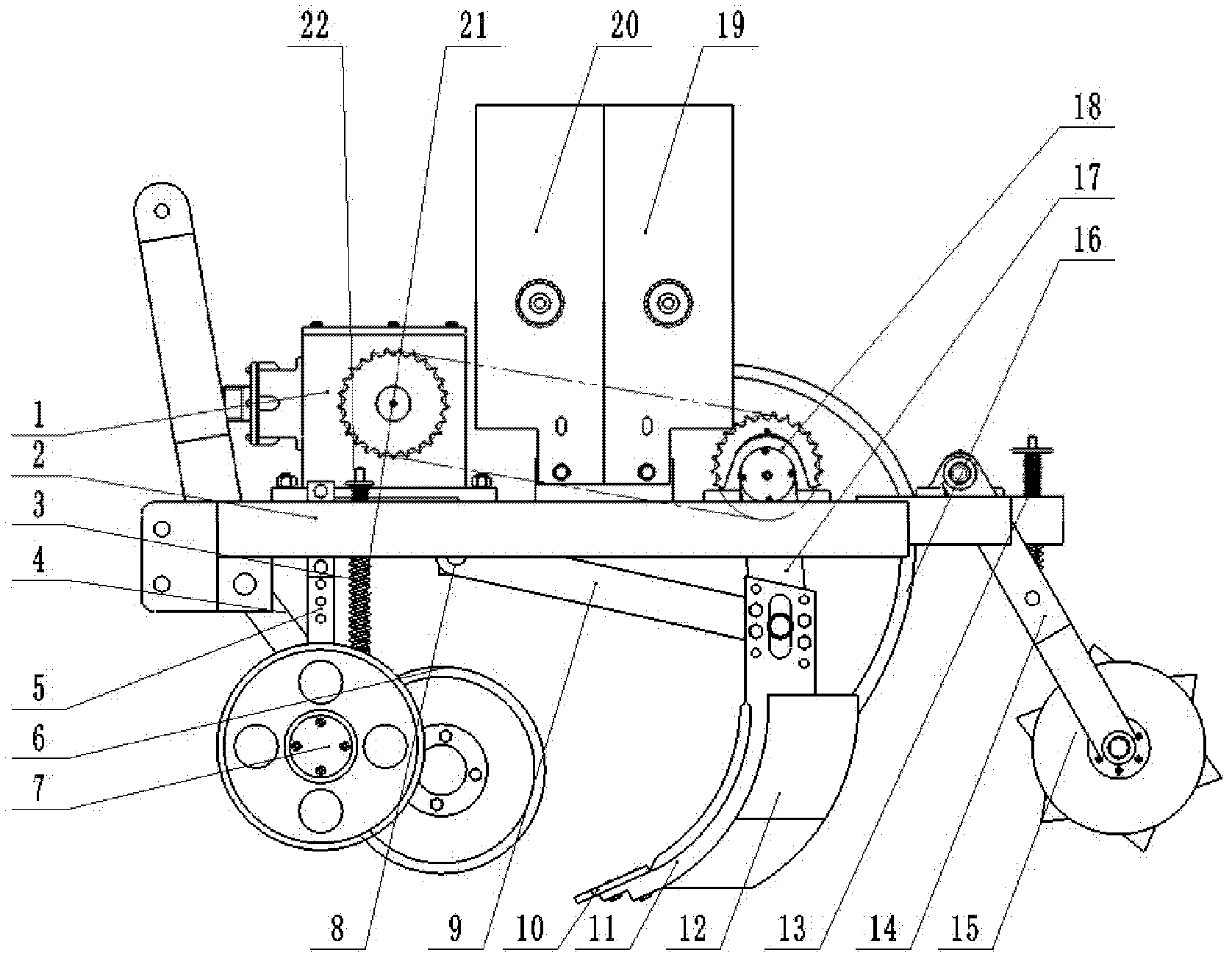

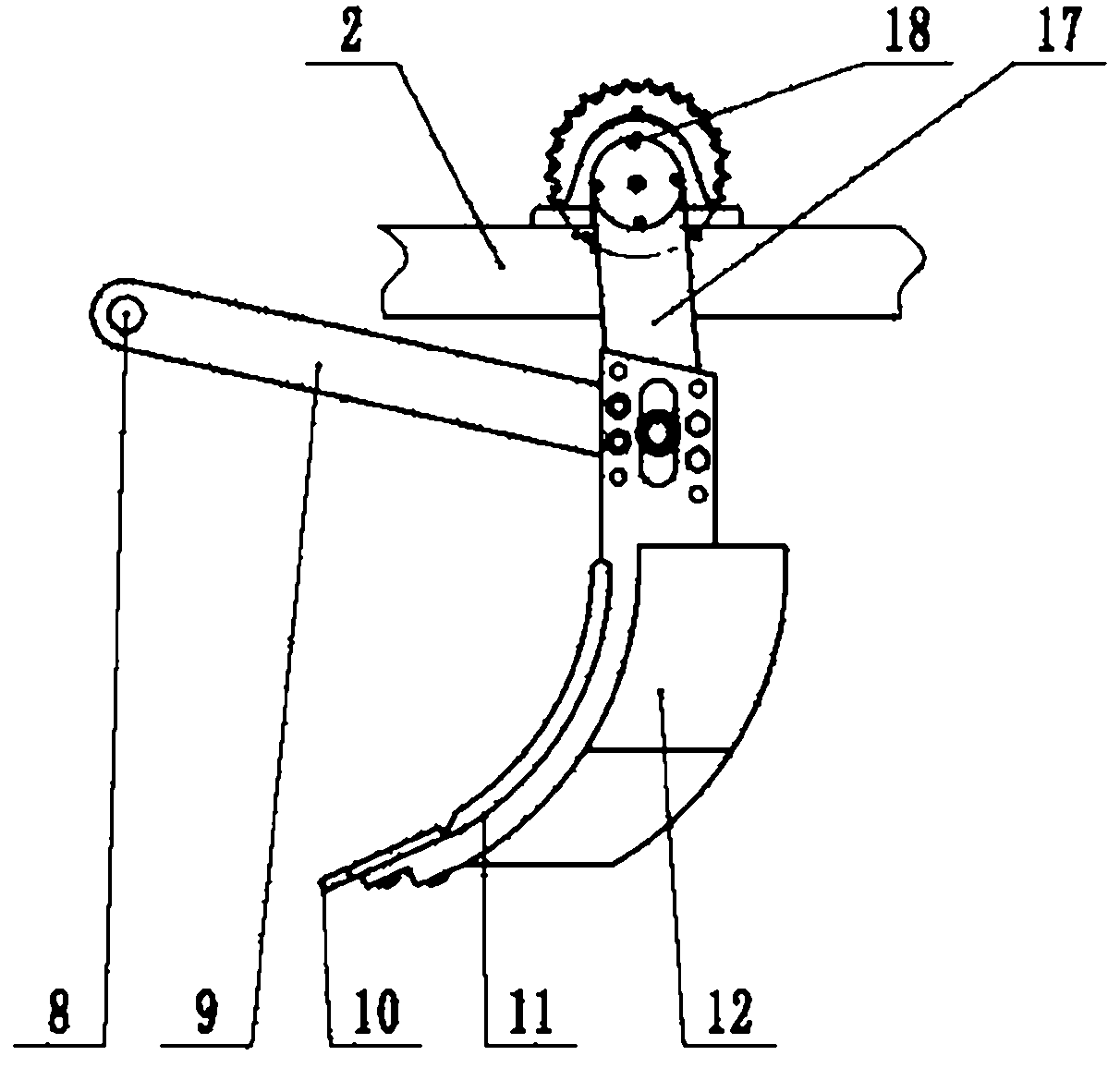

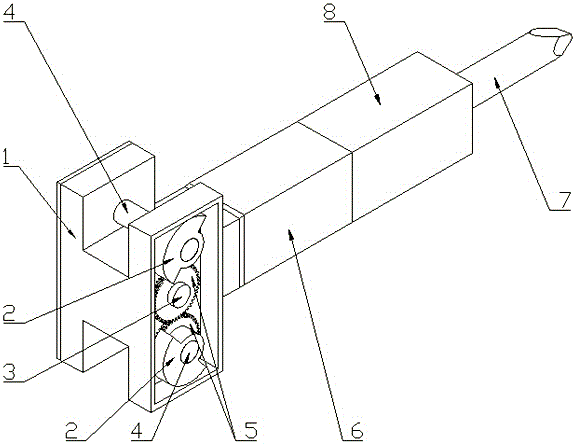

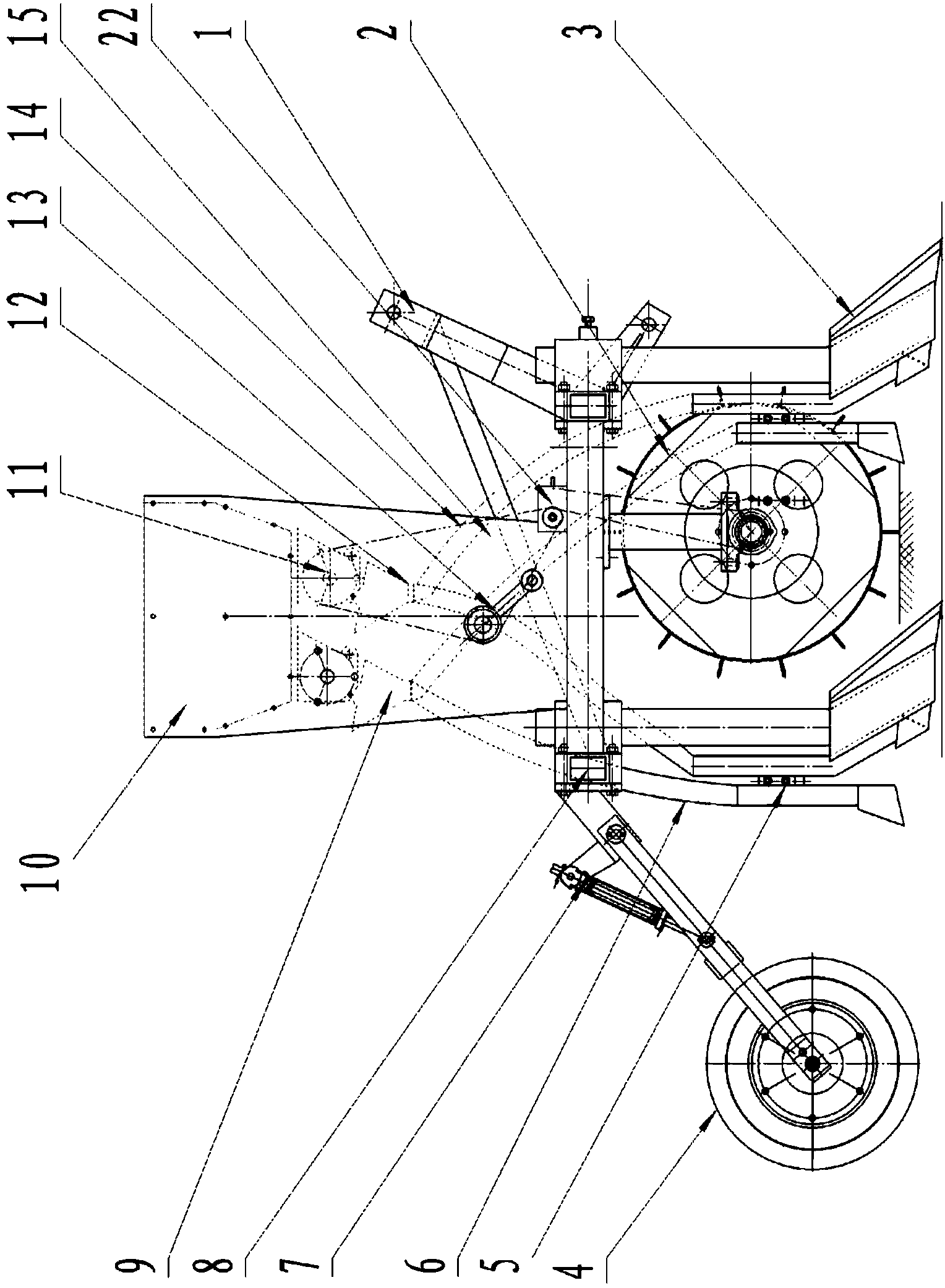

Combined remediation method for deteriorated grasslands and special grassland operating machine

The invention belongs to the technical field of the mechanized remediation of grasslands, and relates to a combined remediation method for deteriorated grasslands and a special grassland operating machine. The method comprises the following steps of: cutting roots of grass on the grasslands to be remediated, and loosening soil underground and forming seed furrows and fertilizer furrows in the soil along cutting joints; sowing and fertilizing alternately, and applying seeds and fertilizers into the corresponding furrows; and compacting the furrows. The special grassland operating machine comprises a cutting assembly, a vibratory soil loosening and furrowing assembly, a seed and fertilizing applying assembly, a compaction assembly and a depth limit assembly. By the combined remediation method and the special grassland operating machine, the root cutting, vibratory soil loosening and furrowing, sowing, fertilizer application and compaction are combined, and multiple remediation modes are combined, so the combined remediation method and the special grassland operating machine are suitable for the sowing for fertilizer application and fertilizing for resowing in the process of remediating the deteriorated grasslands with high compactness and are also applicable to farmlands with poor soil texture, and can better remediate grasslands deteriorated naturally or due to man factor.

Owner:CHINA AGRI UNIV

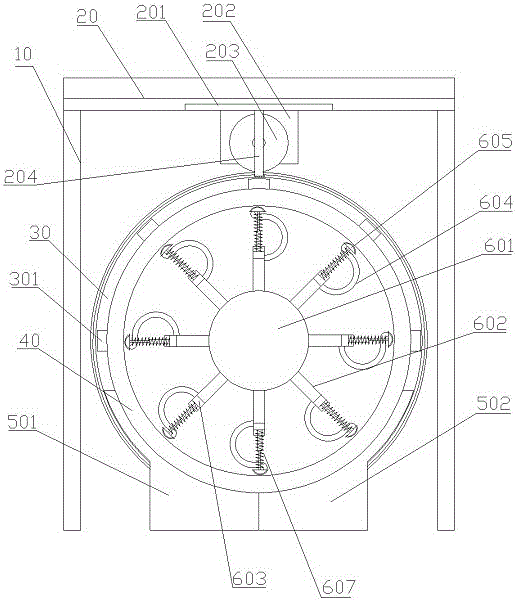

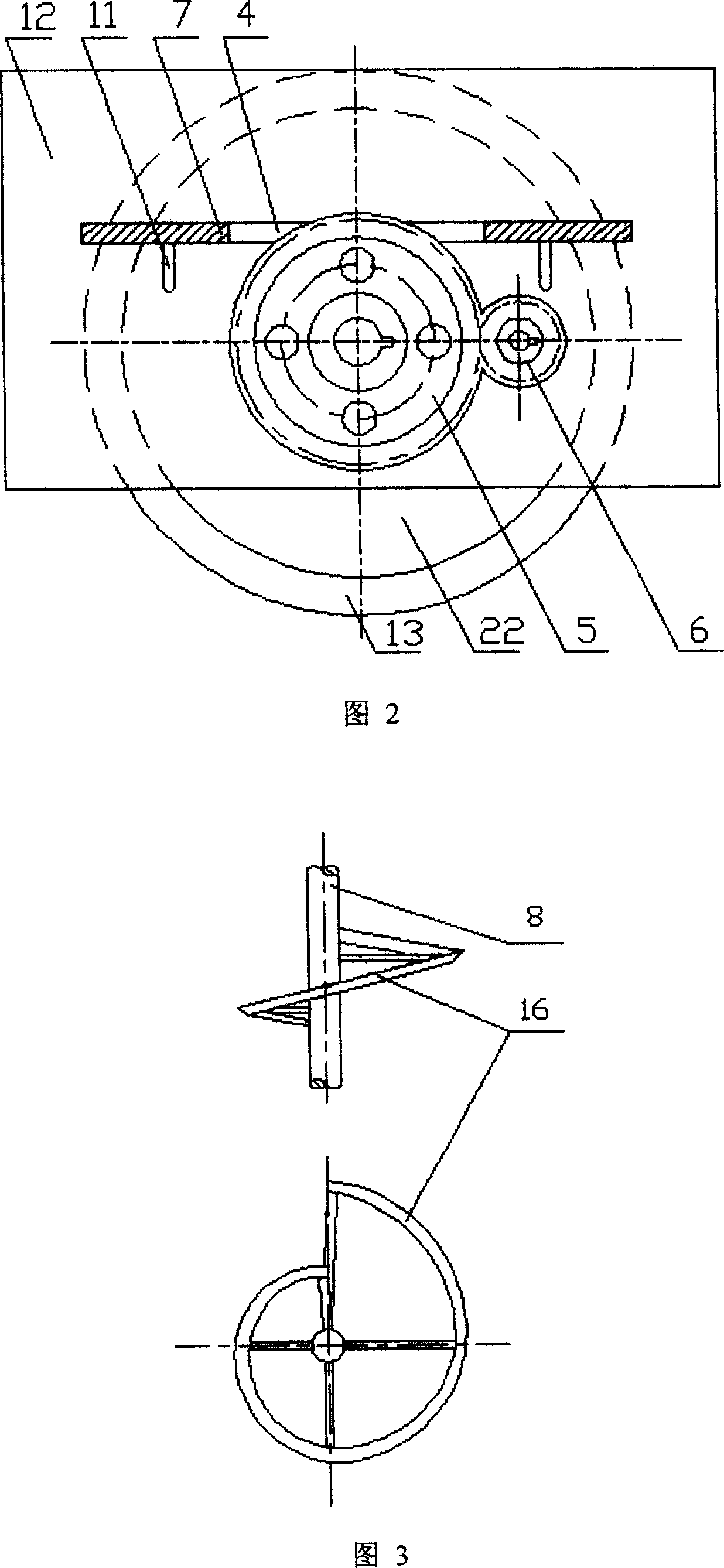

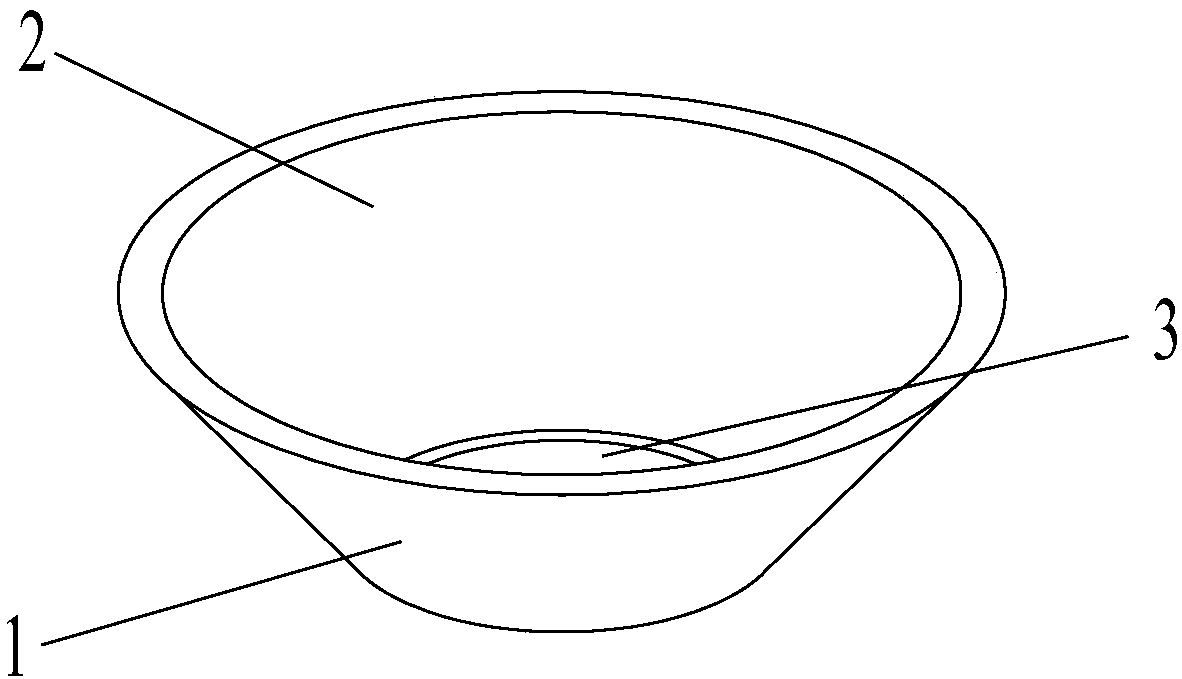

Leaching tank having adjustable double shaft stirring device

The invention provides a leaching tank having an adjustable double shaft stirring device. The leaching tank comprises a tank body with the bottom provided with a residue discharging hole, a tank cover, a stirring shaft, stirring paddles and driving mechanisms, the stirring shaft comprises an internal shaft and an external shaft having a common axis, the lower end of the internal shaft is provided with an auxiliary stirring paddle, the lower end of the external shaft is provided with a main stirring paddle, the driving mechanism of the internal shaft is a first motor, the driving mechanism of the external shaft comprises a second motor, a small gear and a large gear, the small gear is connected with the large gear, the large gear is sleeved outside the external shaft, the small gear is engaged with the large gear, the outside of the external shaft is provided with a boss, and the external s haft is arranged on the tank cover through the boss. The stirring device comprises independent work double shaft, and the rotating directions and the rotating speeds of the shafts can be independently set as needed in order to guarantee the full stirring of a slurry.

Owner:WUHAN UNIV OF SCI & TECH

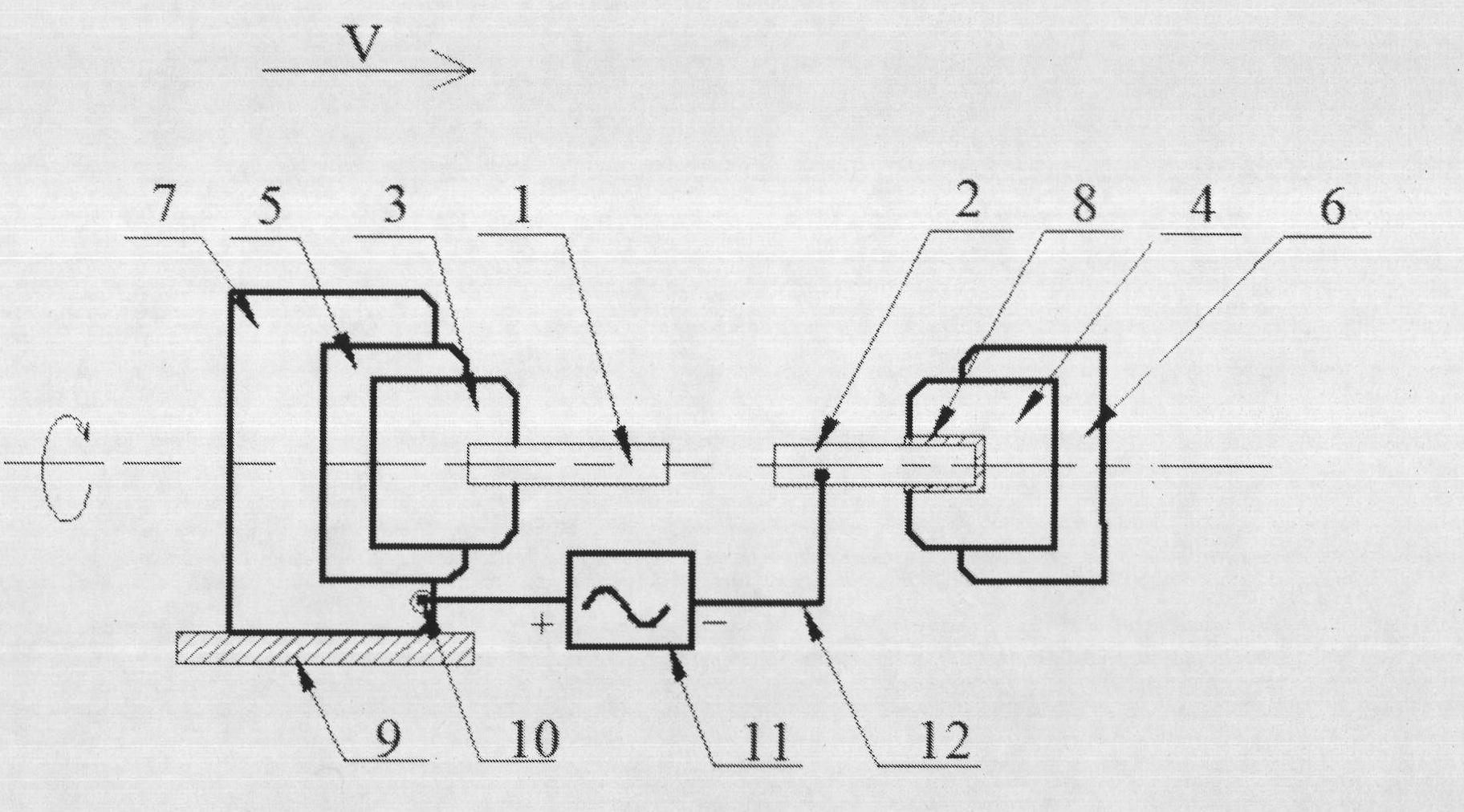

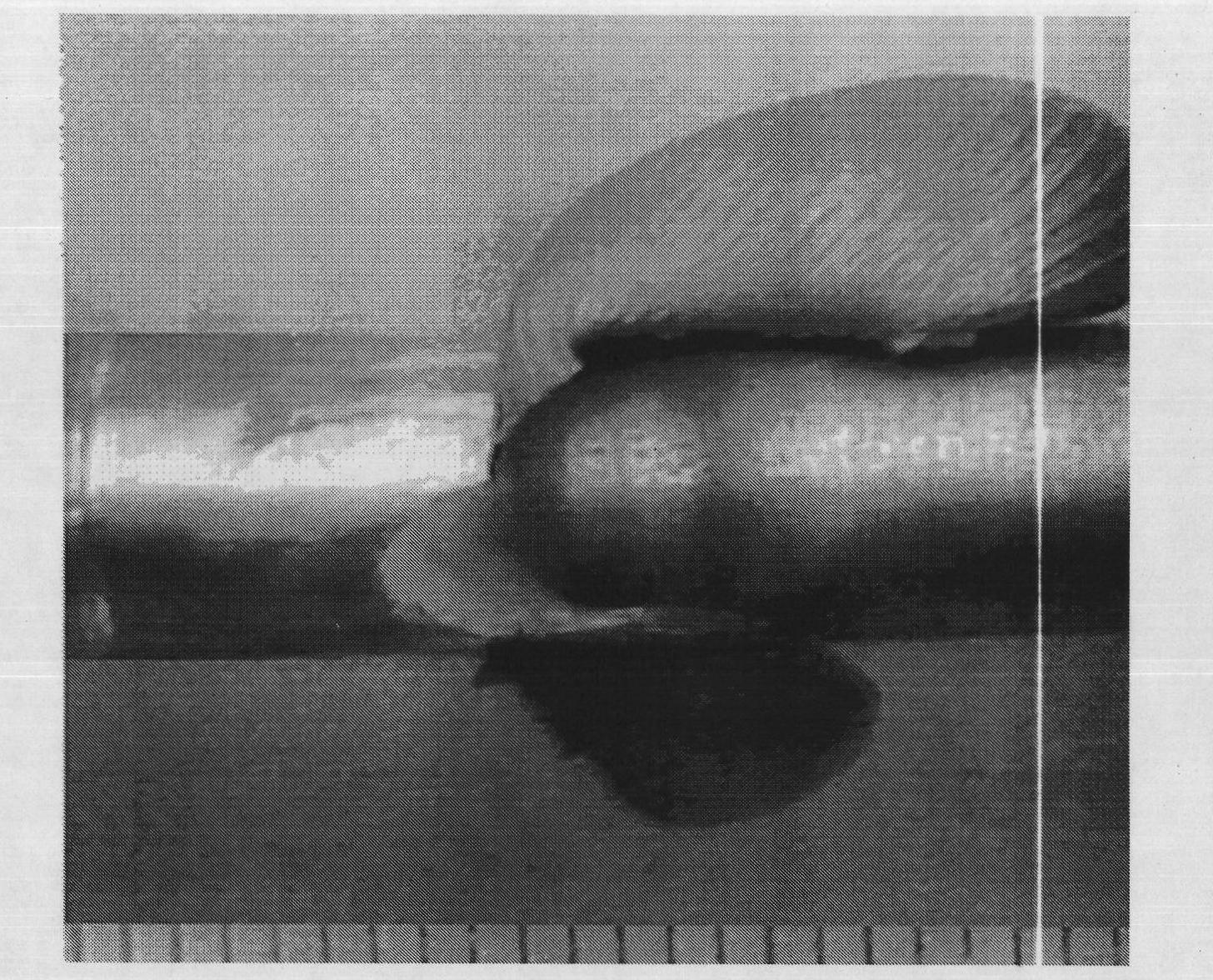

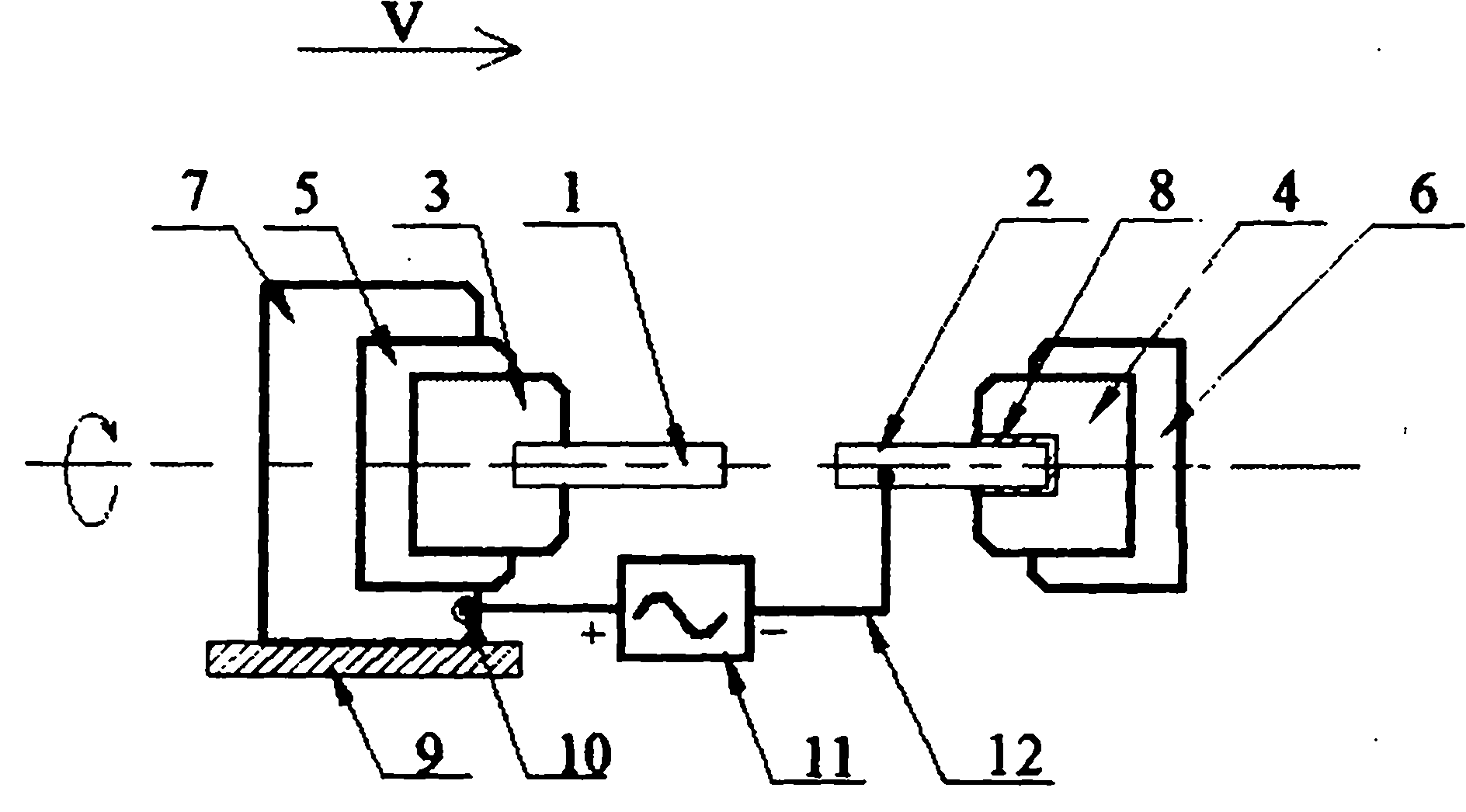

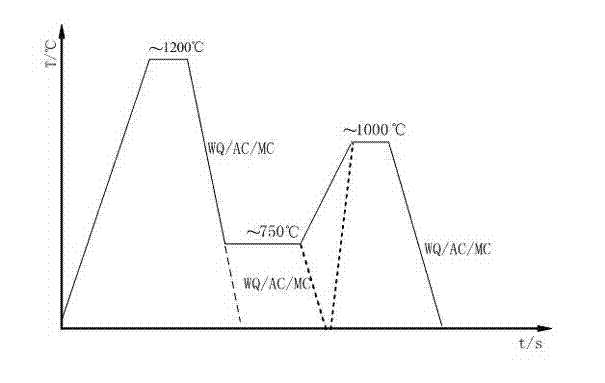

Current-carrying inertial axial friction composite welding method and equipment thereof

InactiveCN101829853AGuaranteed normal rotationGuaranteed electrical conductivityResistance welding apparatusNon-electric welding apparatusFriction weldingElectrical resistance and conductance

The invention relates to a current-carrying inertial axial friction composite welding method and equipment thereof. In the inertial axial friction welding process, a unique current loading method without an electric brush is adopted, current is introduced into a friction welding head to enable a friction interface to generate resistance heat, and the resistance heat and friction heat form a friction composite heat source for together heating joints and carrying out friction and plastic deformation to realize the purpose of welding through the method and the equipment. The method and the equipment can shorten the heating time of friction welding, improve the production efficiency of welding, the friction pressure, the power of a main shaft and the special requirements for the capacity of a friction welding machine, can adopt resistance heat to carry out heat treatment after welding and preheating before welding on welding seams and improve the structure property of joints, and are especially suitable for friction welding of rotator joints of high-melting point and high-hardness dissimilar materials, small-size pipes or bars and the like.

Owner:CHONGQING UNIV

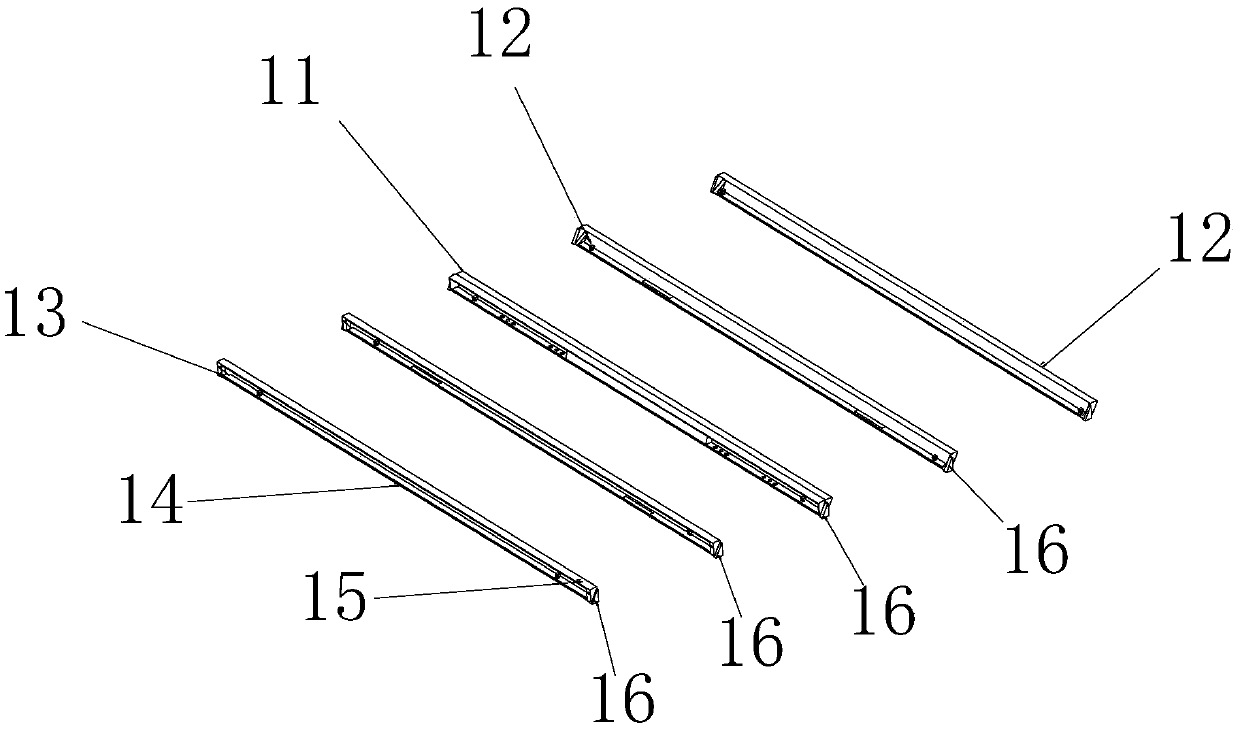

Kerbstone thickness-fixing multi-face fine polishing machine

InactiveCN103624643APolishing flexibleFlexible polishingPlane surface grinding machinesProduction lineElectric motor

The invention provides a kerbstone thickness-fixing multi-face fine polishing machine which comprises a machine frame, an electric motor, a triangular belt and a polishing head and further comprises at least two rotating joints, an adjusting disc and a fixator. The rotating joints can ensure that the machine frame can rotate, the adjusting disc can adjust the height of the polishing head, and the fixator can replace the polishing head and fix the polishing head. The invention further comprises a production line which can conduct fine polishing on the plurality of side faces of kerbstone at one time, and the production line comprises at least two kerbstone thickness-fixing multi-face fine polishing machines, a movable working table, a fixing block and a guide rail. The kerbstone thickness-fixing multi-face fine polishing machine and the production line which can conduct fine polishing on the side faces of the kerbstone at a time and can conduct machining on the faces of the kerbstone at a time, cost is saved, and economic efficiency is improved.

Owner:许春雷

Hydraulic breaking hammer

InactiveCN105275037AAvoid the phenomenon of difficulty in pressing downPlay a role in energy storageSoil-shifting machines/dredgersEngineeringCylinder block

The invention discloses a hydraulic breaking hammer which comprises the components of a drill rod seat, a drill rod, a drill rod front sleeve, a drill rod back sleeve, a cylinder body, a piston, a nitrogen chamber sealing sleeve, a crankcase, a crankshaft, a connecting rod, a connecting rod piston, a motor, an eccentric wheel, a reversing valve, an energy accumulator, a valve plate, etc. One end, which is far from the drill rod, of the piston is dynamically connected with the eccentric wheel though the connecting rod, the crankshaft and the gear. One end of the crankshaft is connected with the motor. A sealed chamber for storing gas is arranged between the piston and the cylinder. The valve plate is mounted on the crankshaft. The hydraulic breaking hammer aims to settle problems of high difficulty in downward pressing a nitrogen explosion hammer, large hydraulic impact, incapability of stopping oil supply from a pump in a stroke period without oil consumption, no enough impact force caused by insufficient flow in a full-hydraulic hammer or a gas-liquid hammer, complicated structure, and large hydraulic impact force.

Owner:赵德朝

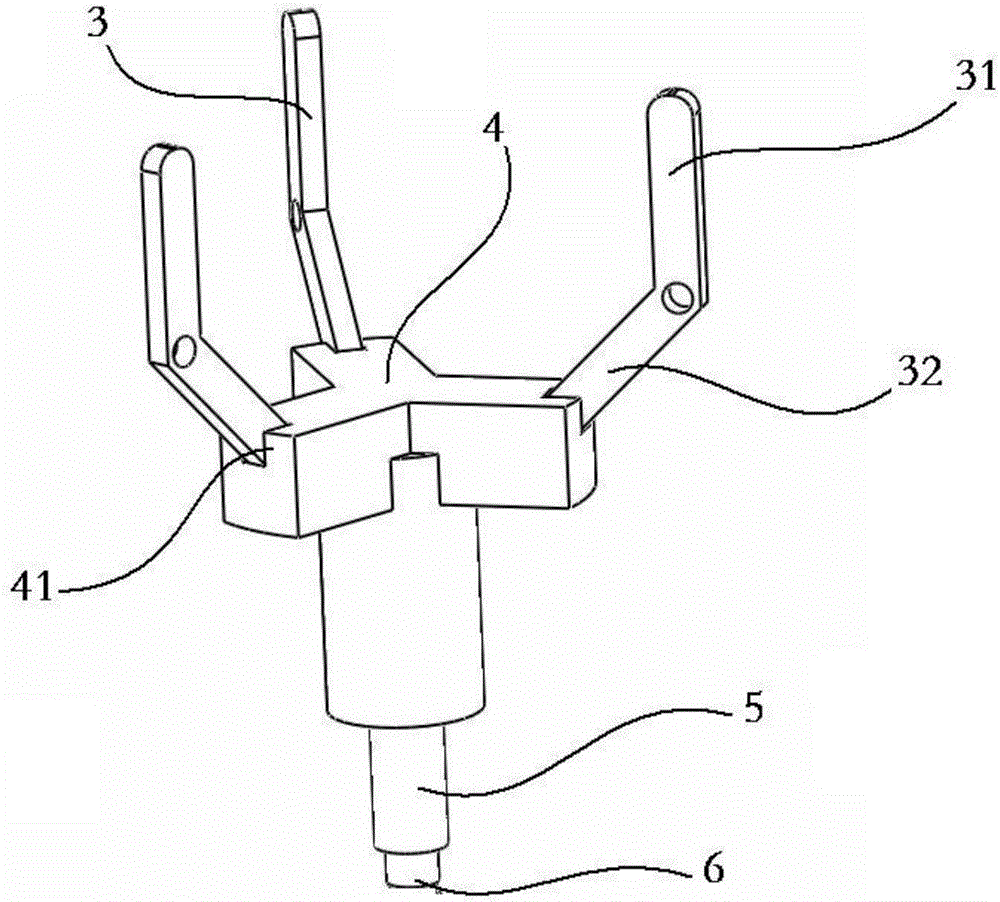

Self-adaptive under-actuated turning three-finger robot clamping jaw

The invention belongs to the field of robot clamping jaws, and specifically relates to a self-adaptive under-actuated turning three-finger robot clamping jaw. The clamping jaw comprises a clamping jawshell, a drive module, a first finger module, a second finger module and a third finger module, wherein the drive module is installed in the clamping jaw shell and comprises a first drive motor, a second drive motor, a first power transmission system, a second power transmission system and three drive rods, the three finger modules are distributed circumferentially and are distributed at three sides of the top of the clamping jaw shell, each finger module comprises a finger base, a first finger section and a second finger section, the first drive motor drives the three finger modules to finish a grasp action through the first power transmission system, the second drive motor drives the second finger module and the third finger module to rotate along respective axis through the second power transmission system so as to acquire corresponding gestures of different finger modules. The clamping jaw can grasp a target object adaptively, has a large stroke, grasps stably, and has a graspingand self-locking function.

Owner:SHENZHEN DH ROBOTICS TECH CO LTD

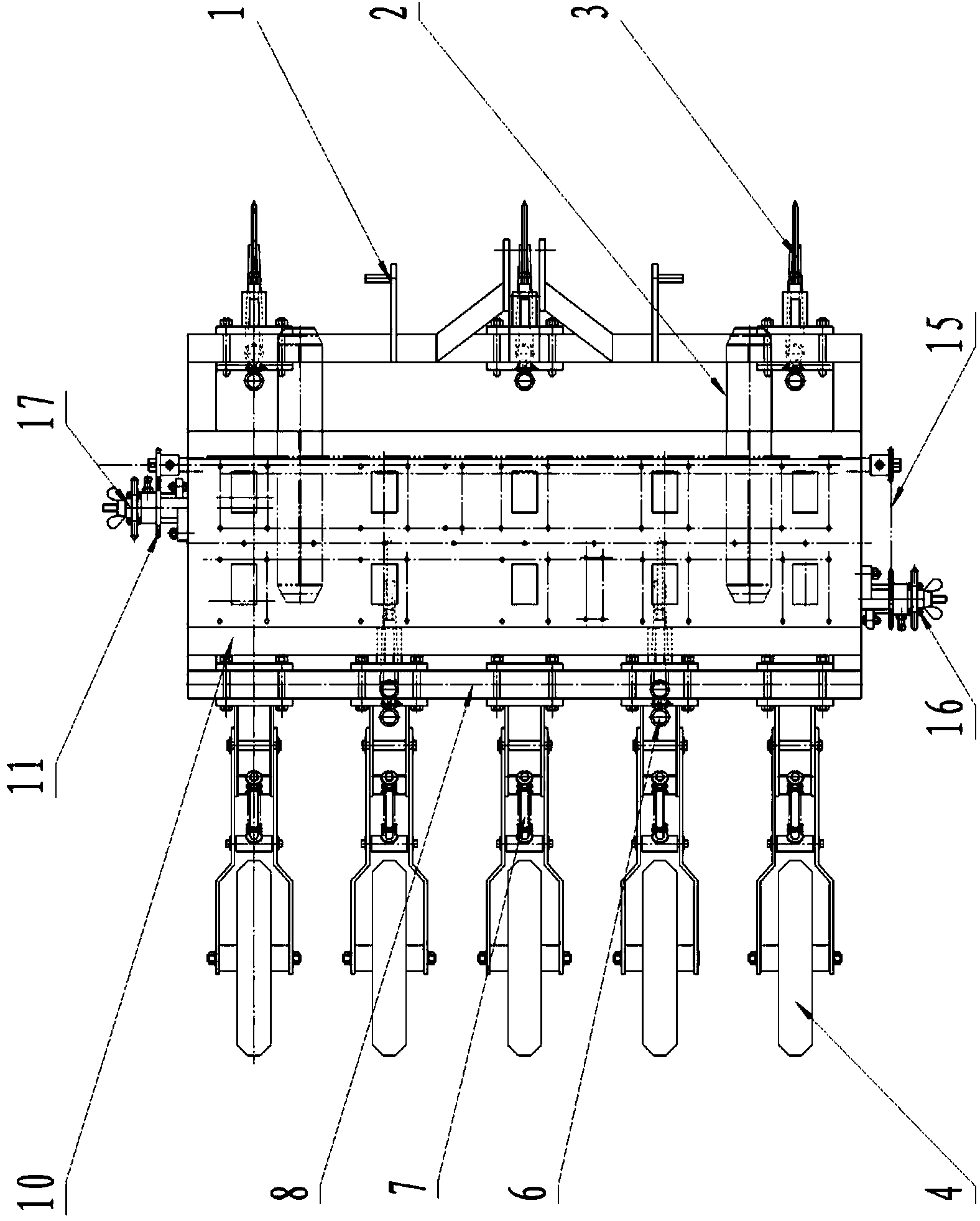

Coarse cereal seeding machine for no-tillage seeding

ActiveCN103444317ASimple structureSimple and fast operationPlantingFurrow making/coveringAgricultural engineeringSoil horizon

The invention discloses a coarse cereal seeding machine for no-tillage seeding. The coarse cereal seeding machine comprises a rack, a fertilizer apparatus, a seed sowing device, a seed manure box, a stubble breaking and ditching device, a suppression mechanism, ground wheels and transmission mechanisms. The machine adopts a stubble breaking, ditching, seed manure applying and seeding single body, a suppression wheel mechanism single body, a high ground clearance and large spacing transverse beam rack and the various transmission mechanisms for intensively changing speeds so as to realize stubble breaking and ditching, seed manure application, and semi-precision no-tillage seeding of wheat, corns, coarse cereals and small-grain pasture seeds. Particularly, the problems of crop stubble winding and blockage, hilling, mixed seed manure application, difficult burying of the ditching device, much disturbance to a soil layer, unevenness of a soil covered ground surface, large traction resistance and the like in the no-tillage seeding process are solved. The machine is simple in structure and easy to operate, has multiple purposes, is low in manufacturing cost and is suitable for specialized households of planting, and small and medium-sized farms to popularize and apply.

Owner:呼和浩特市得利新农机制造有限责任公司

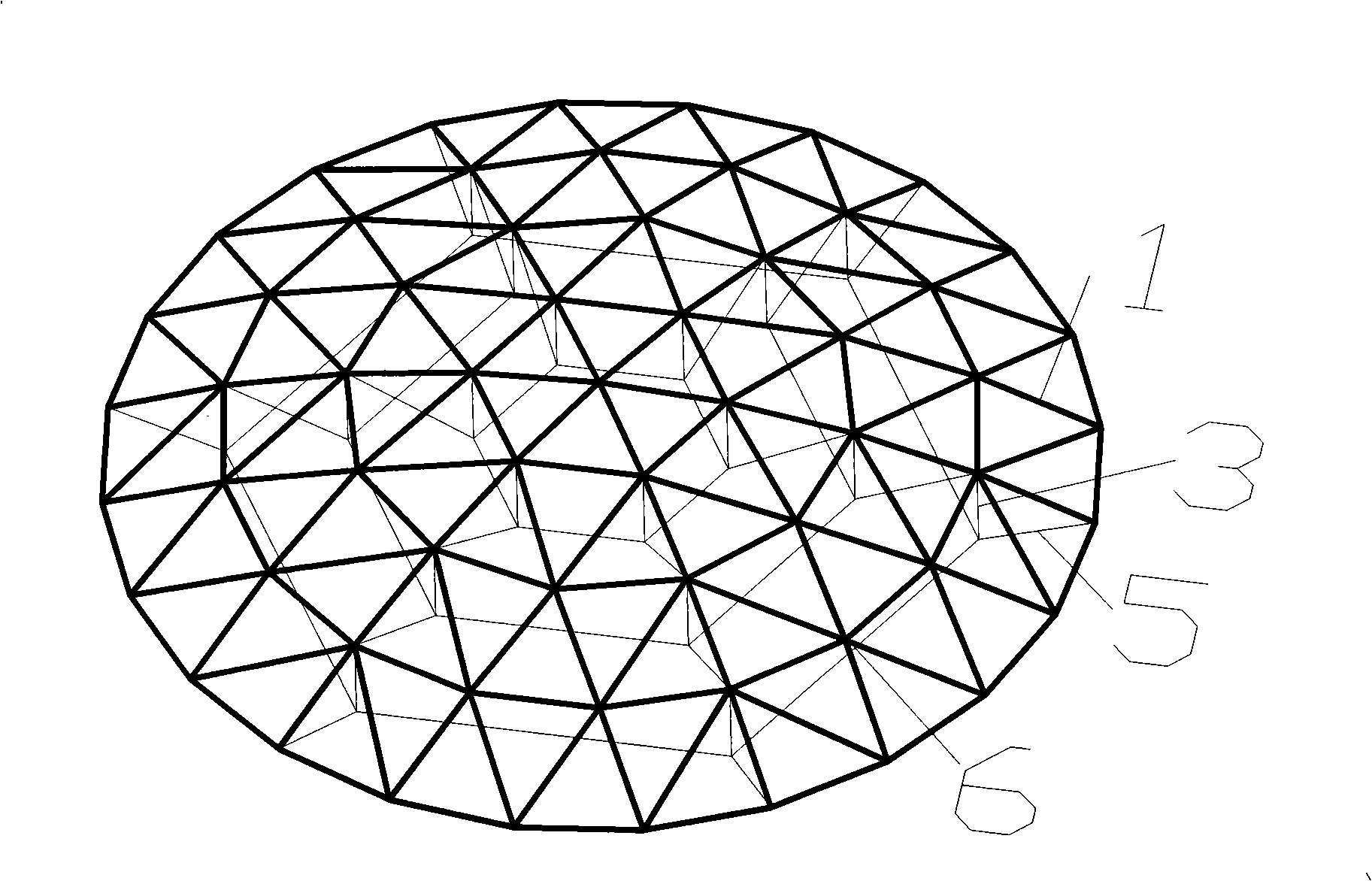

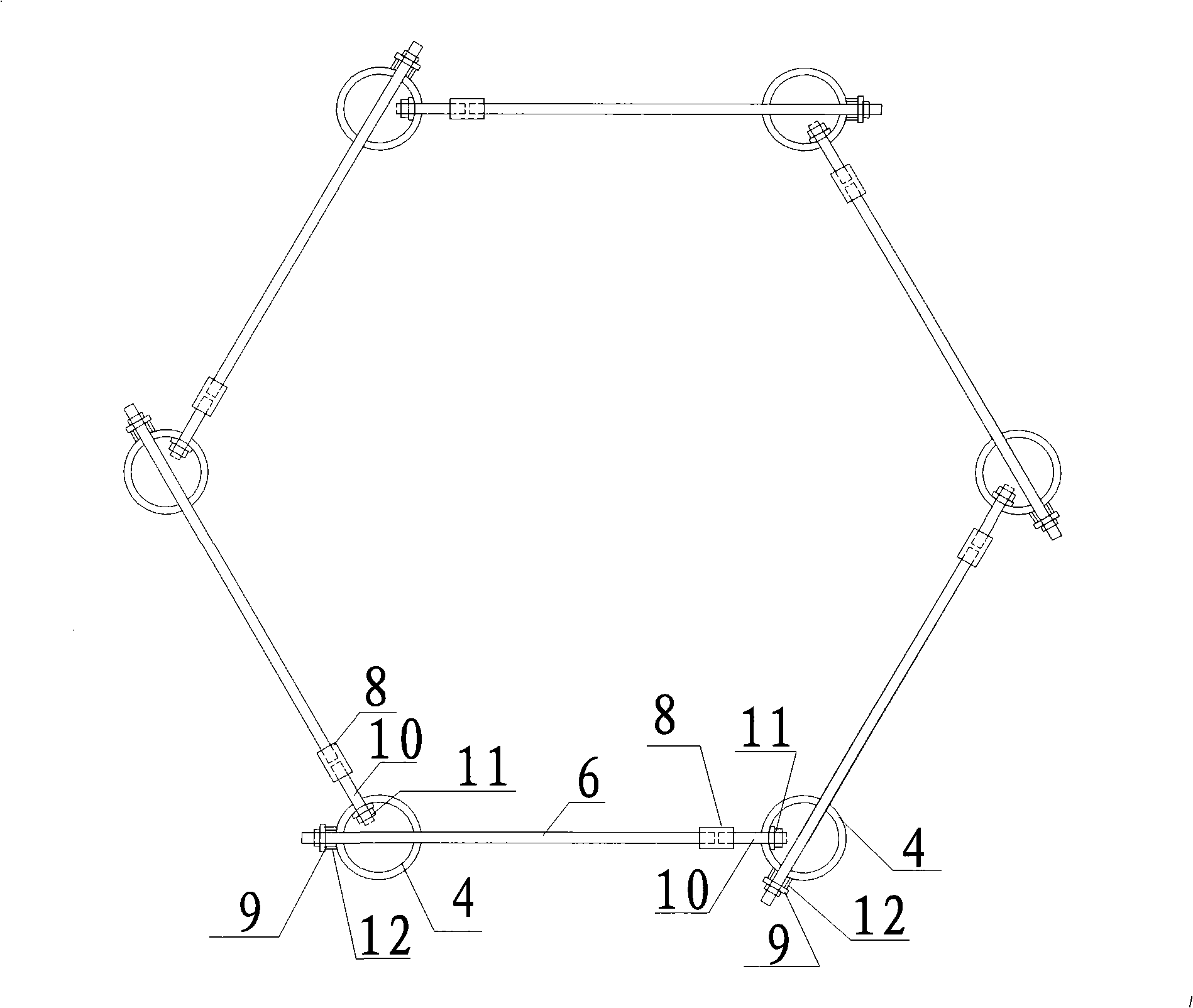

Connecting structure for suspendome

InactiveCN101314972AEasy to processEasy to installBuilding roofsArched structuresSpherical jointScrew thread

The invention discloses a connecting structure used for a suspend-dome structure. The suspend-dome structure is a structure formed by connecting an upper chord single-layer spherical reticulated shell, an oblique cable and hoop cables through a vertical compression rod. In the connecting structure, the oblique cable, the hoop cables and the vertical compression rod are connected with each other through a welded hollow spherical joint. The welded hollow spherical joint forms three holes in the horizontal hoop cable direction, wherein two holes allow one hoop cable to penetrate the welded hollow spherical joint and be anchored through a cast anchor, the other hole allows a washer inside the welded hollow spherical joint to be anchored with a screw cap to form a connecting cable head, and the connecting cable head is connected with a threaded sleeve through the other hoop cable; the welded hollow spherical joint forms the other hole in the oblique cable direction, the washer used inside the welded hollow spherical joint is anchored with the screw cap to form the other connecting cable head, and the connecting cable head is connected with the hoop cables through the threaded sleeve. After the connecting structure is adopted, the construction of the suspend-dome structure is very convenient, the cable force can be adjusted times and again, and the disadvantage that the cable force in the prior suspend-dome structure engineering is difficult to be consistent with the theoretical value can be overcome.

Owner:ZHEJIANG UNIV

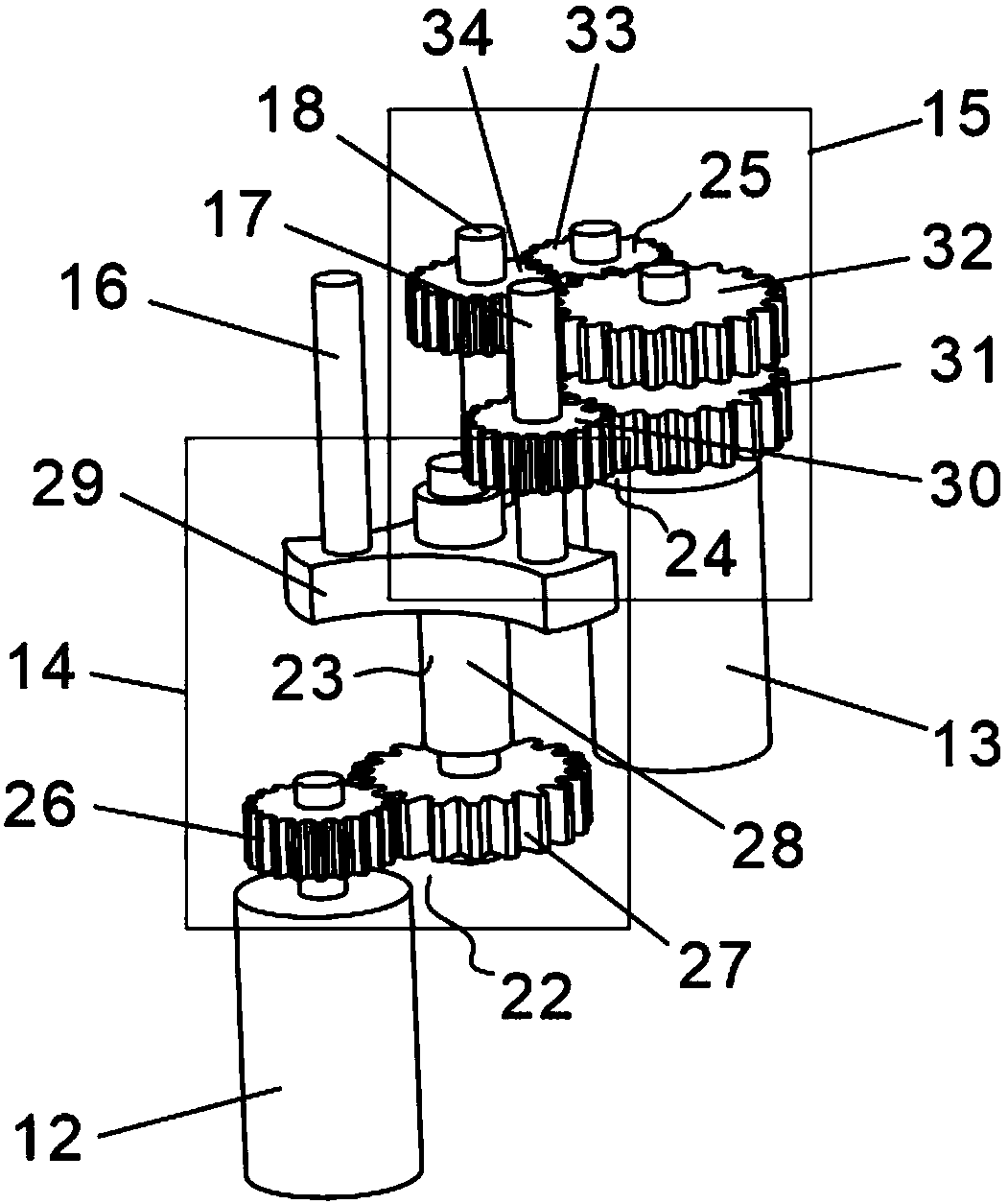

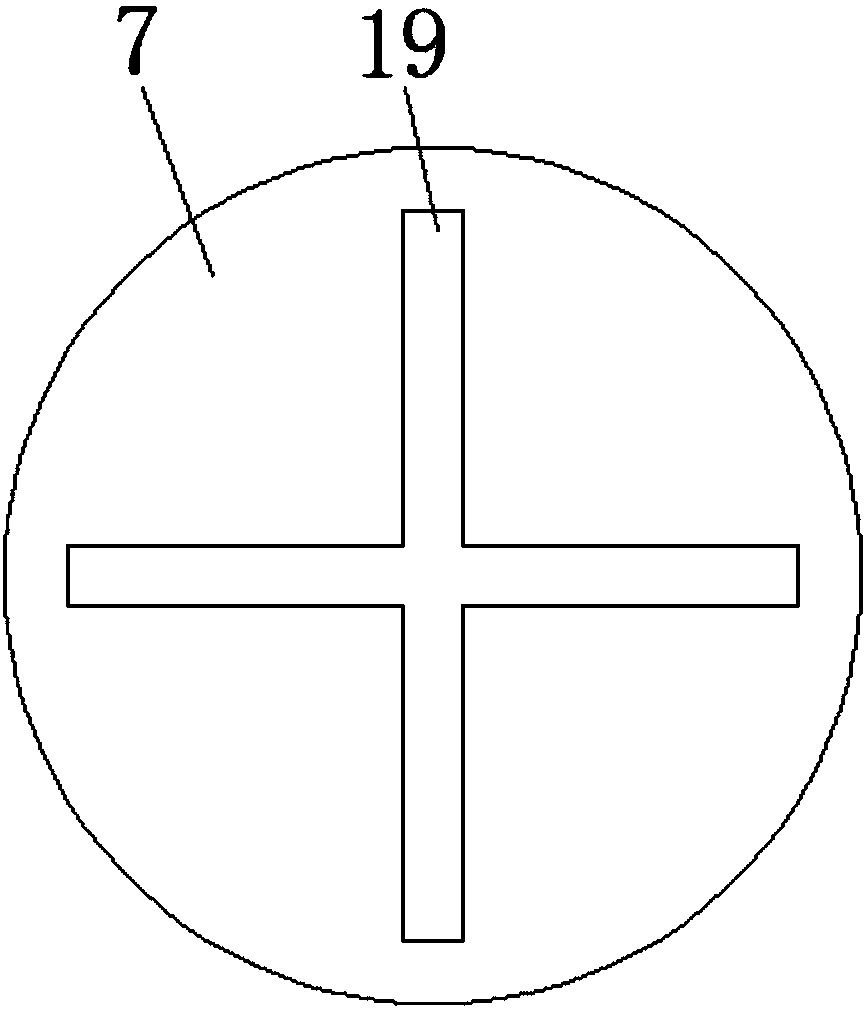

Driving mechanism driving moving pieces to move back and forth on installation base in radial direction and chuck

ActiveCN106112038ARealize radial push and pullThe mechanical transmission process is simple and reliableChucksMechanical transmissionEngineering

The invention discloses a driving mechanism driving moving pieces to move back and forth on an installation base in the radial direction and a chuck. The driving mechanism comprises stirring pieces and a driving assembly. The stirring piece can rotate relative to the installation base and rotate in the plane determined by the radial direction of the moving pieces corresponding to the stirring pieces and the axial direction of the installation base, and the stirring pieces are connected with the corresponding moving pieces. The driving assembly is provided with stirring piece connecting parts, wherein distribution of the stirring piece connecting parts is consistent with that of the stirring pieces. The stirring pieces are hinged to the corresponding stirring piece connecting parts. When the driving assembly moves back and forth in the axial direction of the installation base, the stirring pieces are driven to rotate to drive the moving pieces to move back and forth in the radial direction of the installation base. According to the driving mechanism driving the moving pieces to move back and forth on the installation base in the radial direction and the chuck, a mechanical transmission assembly is simple in structure, stable and reliable, and non-interference rotation of the chuck can be achieved.

Owner:BEIJING XUANYU INTELLIGENT TECH CO LTD

Spraying method for coating on inner wall of pipeline

ActiveCN106670085AEasy to placeRealize transmissionLiquid surface applicatorsCoatingsEngineeringCentrifugal force

The invention relates to the field of surface treatment, and particularly discloses a spraying method for a coating on the inner wall of a pipeline. According to the spraying method, a magnetic spraying device is adopted, and a coating device in the magnetic spraying device is placed in the pipeline; a first magnet mounted on a driven gear can attract a second magnet, a connecting rod connected with the second magnet is pulled at the same time, a sliding block is made to move in a branch pipe, a discharging port between the branch pipe and a corrugated pipe is not blocked any more in the moving process of the sliding block, and paint in a paint storage box can flow into a storage cavity of the second magnet accordingly; and when the driven gear rotates, the second magnet is driven to rotate at the same time, the whole coating device is made to rotate accordingly, paint in the coating device flows out from a spraying port of the second magnet under the effect of centrifugal force in the rotating process and then is sprayed onto the inner wall of the pipeline, and the inner wall of the pipeline is coated. By adoption of the scheme, the inner wall of the pipeline can be sprayed.

Owner:CHONGQING YONGCHUAN DISTRICT TAIXING MACHINERY FACTORY

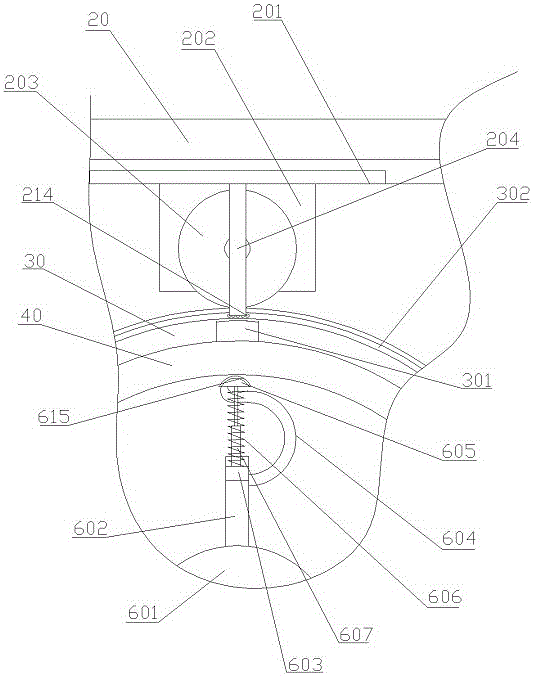

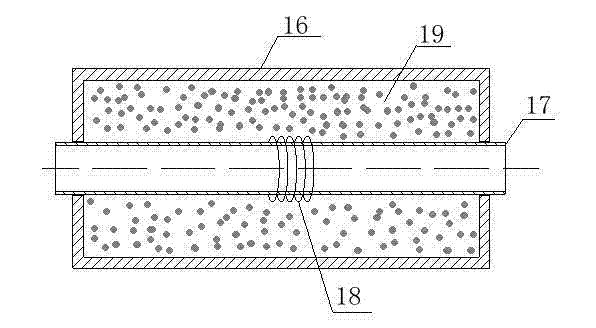

Intermediate frequency induction heat treatment device for steel tubes, and heat treatment method of the same

InactiveCN102363835AFast heatingSmall grain sizeIncreasing energy efficiencyFurnace typesTemperingTransformer

The invention belongs to the technical field of heat treatment for steel tubes, particularly, relates to an intermediate frequency induction heat treatment device for steel tubes, and a heat treatment method of the same. In the intermediate frequency induction heat treatment device, at least 7 pairs of bearing pedestals are mounted on a long steel bracket, one shaft lever is fixed on each pair ofbearing pedestals, one end of each shaft lever is provided with a bipyramidal carrier roller, and a preheating furnace, a cooling box, a heating furnace, the cooling box, a tempering furnace and the cooling box are orderly arranged between each two bipyramidal carrier rollers; the other end of each shaft lever is provided with a gear, and the gear is connected with the gear at the output end of areduction box through a leading chain, and drives other gears through the leading chain; the reduction box is connected with a motor via a coupling; a quenching transformer is connected with the preheating furnace, the heating surface and the tempering furnace, and a master control device is connected with the motor. The intermediate frequency induction online heat treatment device provided by the invention takes the intermediate frequency induction power as the heat source for heating and takes the electric energy as the heating energy, has high heating speed, and is simple and convenient tooperate and easy to use.

Owner:NORTHEASTERN UNIV LIAONING

Automatic tooth aligning tool fixture

InactiveCN103878716AGuaranteed Angle RequirementsGuaranteed normal rotationWork holdersMetal working apparatusGear toothEngineering

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

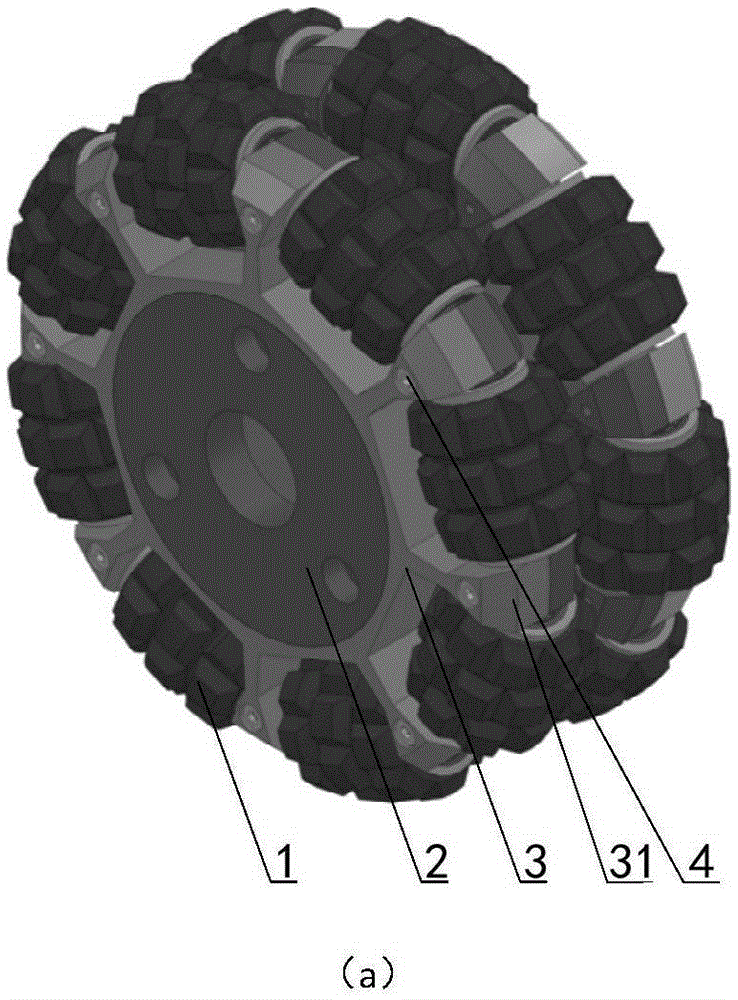

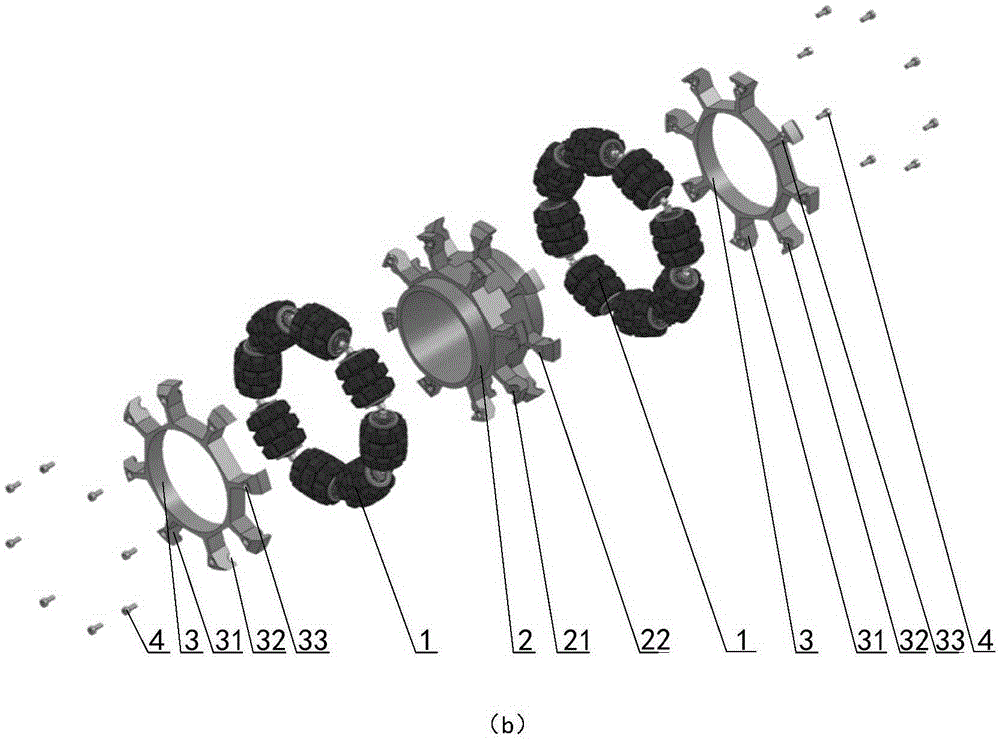

Omnidirectional wheel

The invention provides an omnidirectional wheel which comprises a plurality of driven wheels, a wheel hub and two end covers, wherein each driven wheel comprises a support shaft, a support sleeve, a rubber sleeve, two linings and two bearings; the support shaft sequentially passes through one lining, one bearing, the support sleeve, the other bearing and the other lining; the two bearings are clamped at two ends of the support sleeve, so that the support sleeve can not generate displacement in radial and axial directions relative to the support shaft; the outer ring of each bearing can rotate relative to the support shaft, and the inner ring of each bearing is relatively fixed with the support shaft; and one side of each lining is clamped in the wheel hub, and the other side of each lining clamps the inner ring of each bearing. The omnidirectional wheel provided by the invention overcomes the defects that the existing omnidirectional wheel is poor in motion control precision and the driven wheels stall and are not convenient to disassemble and assemble.

Owner:NAT UNIV OF DEFENSE TECH

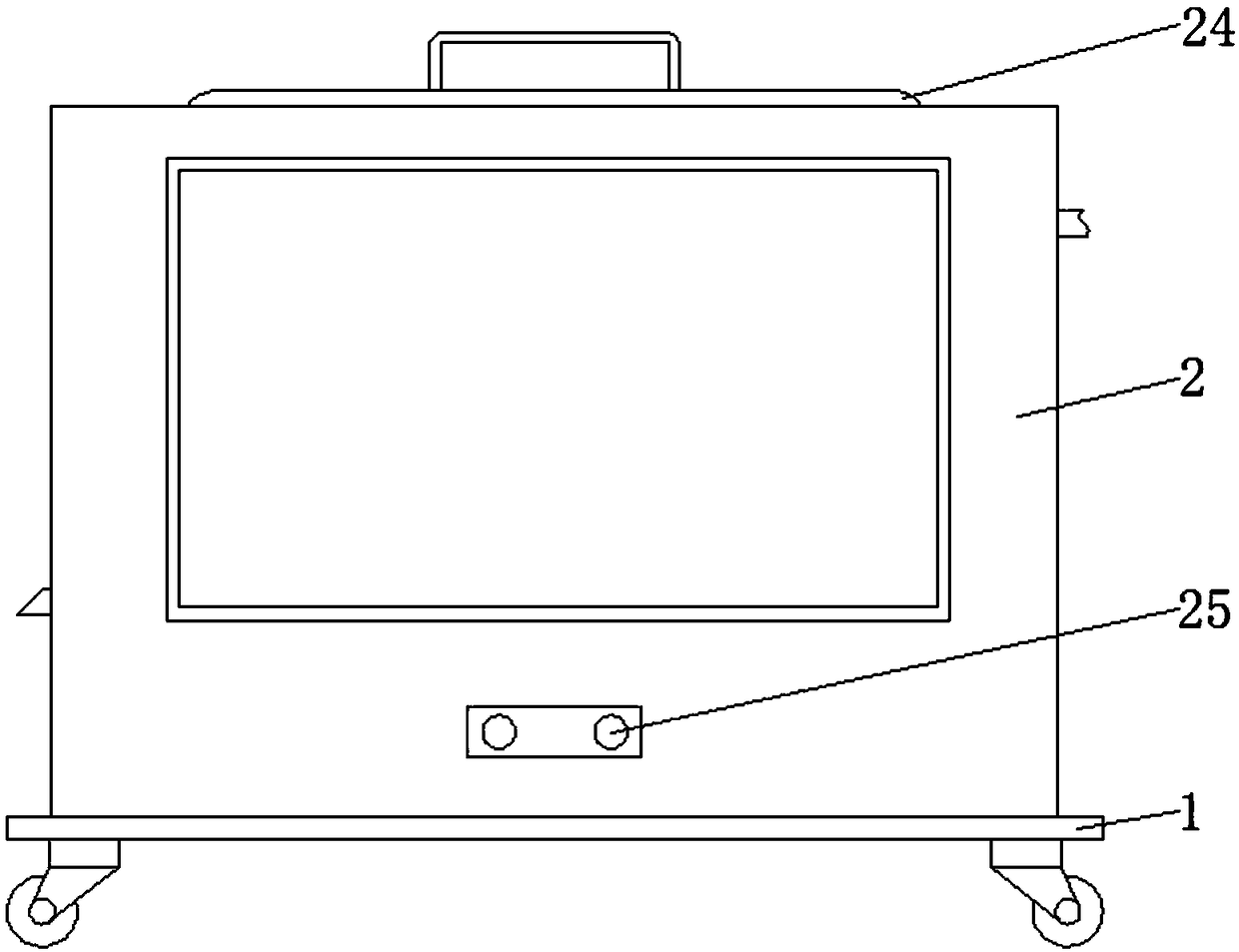

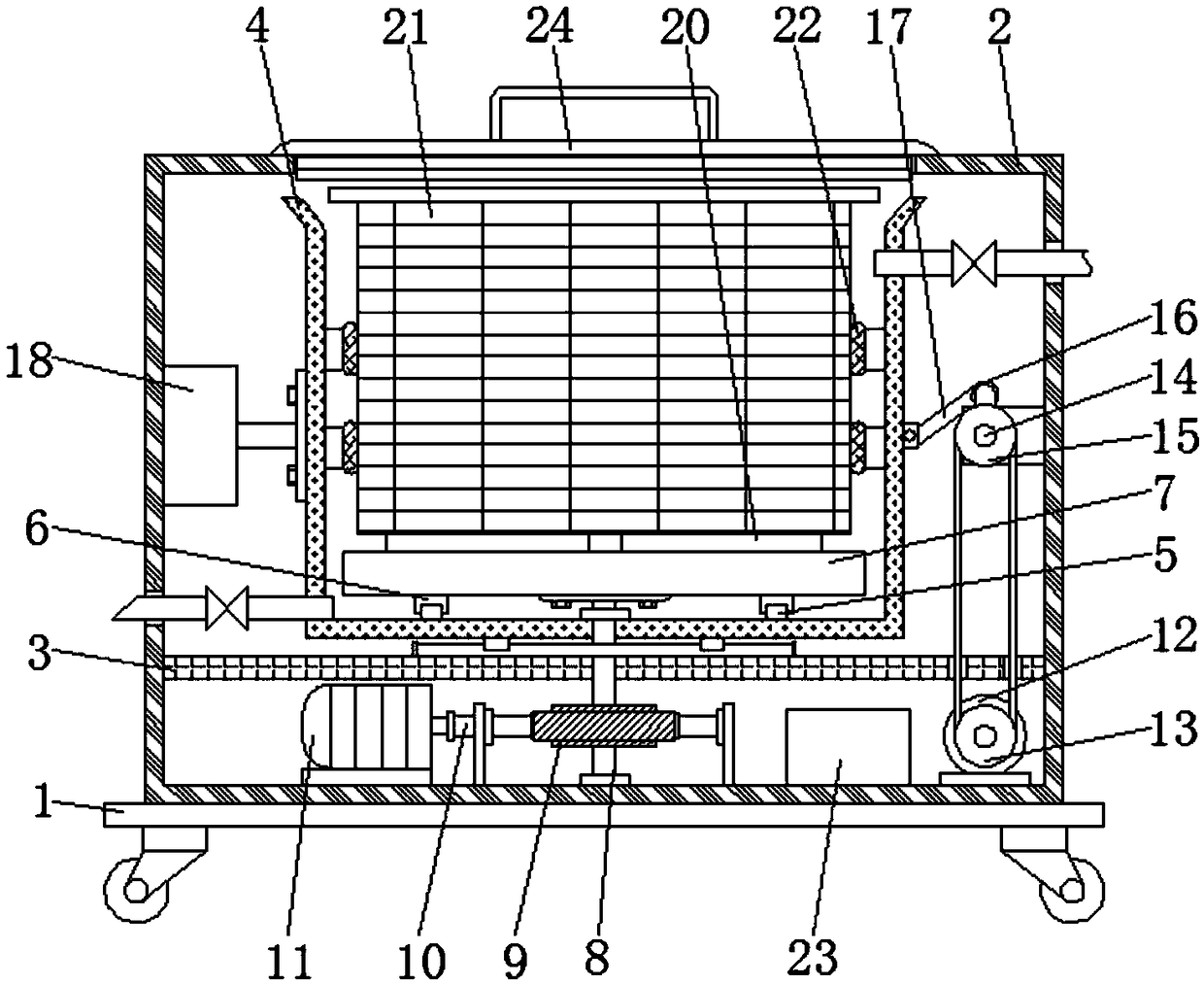

Cleaning device for hardware precision parts

InactiveCN108080345AEasy to cleanFast and efficient cleaning of precision hardware partsCleaning using liquidsBlock matchMachining

The invention discloses a cleaning device for hardware precision parts, and relates to the technical field of hardware precision part machining equipment. The cleaning device comprises a bottom plate,wherein a cleaning case is fixedly connected to the top of the bottom plate, a separation plate is fixedly connected between the two sides of the inner wall of the cleaning case, a cleaning cylinderis fixedly connected to the top of the separation plate, annular sliding rails are fixedly connected to the bottom of the inner wall of the cleaning cylinder, a sliding block matched with each annularsliding rail is slidably connected to the top of the annular sliding rail, and a rotating circular plate is fixedly connected to the tops of the sliding blocks. According to the cleaning device for the hardware precision parts, the cleaning effect is greatly improved, the cleaning efficiency is improved, production personnel do not need to spend a large amount of time cleaning the hardware precision parts, the working load of the production personnel is better relieved, comprehensive cleaning can be conducted on the hardware precision parts rapidly and efficiently, and therefore the production personnel can conduct the cleaning work on the hardware precision parts conveniently.

Owner:方建松

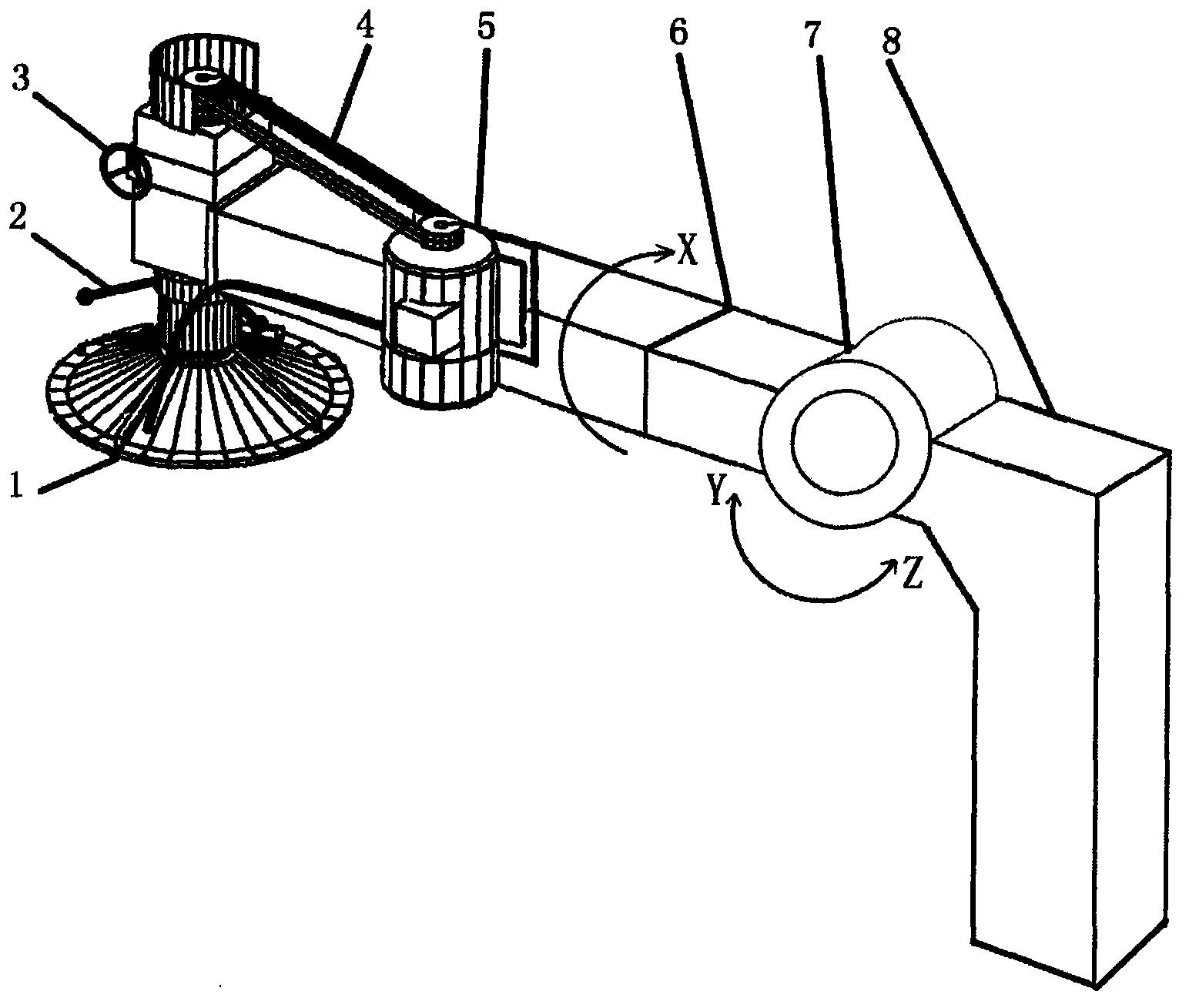

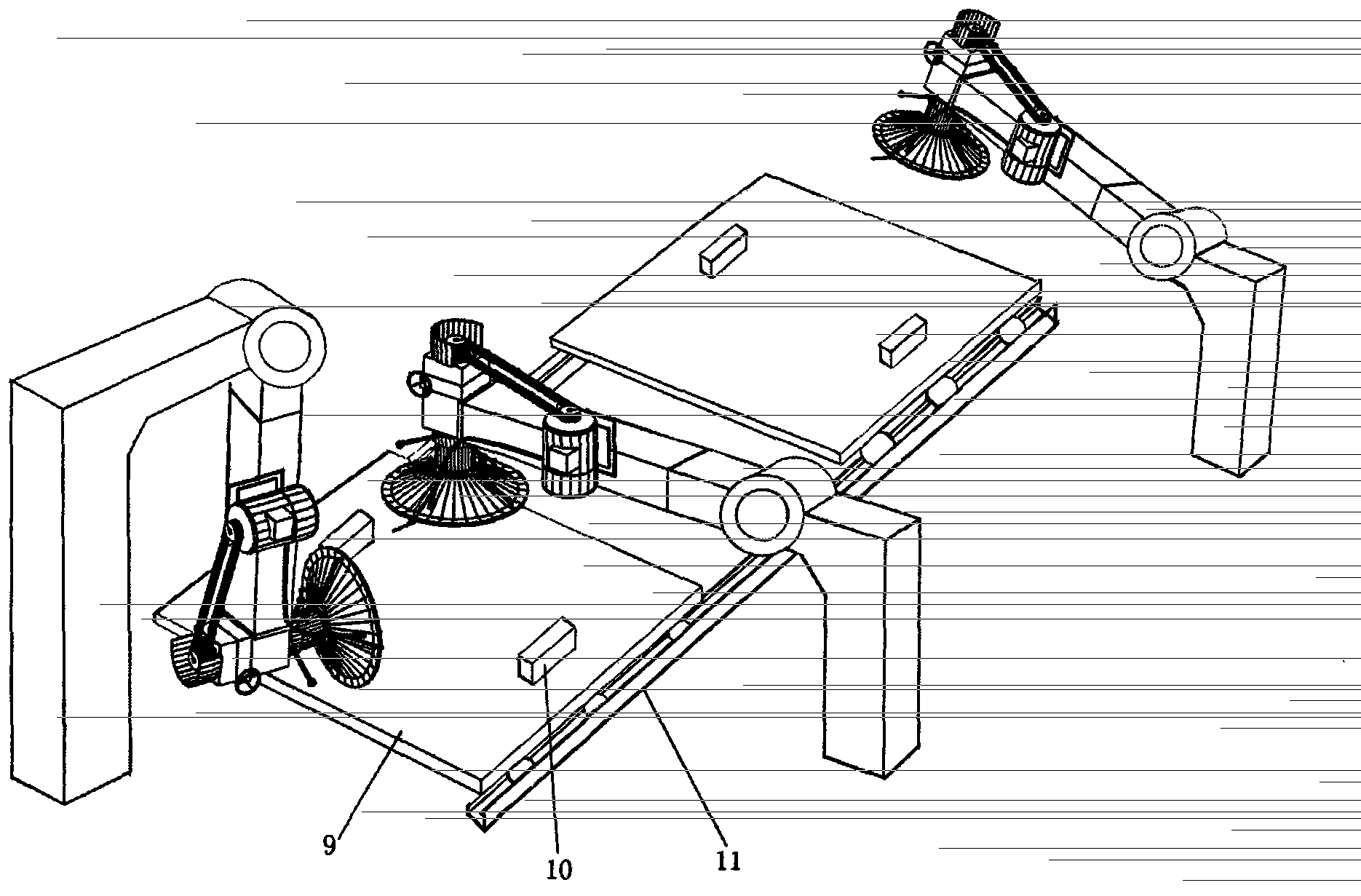

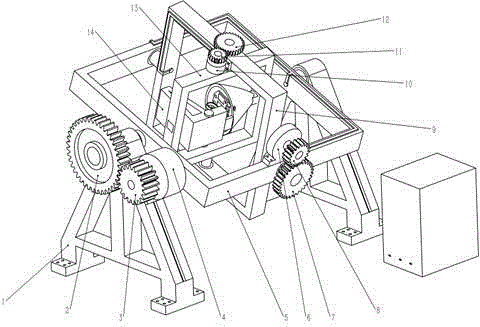

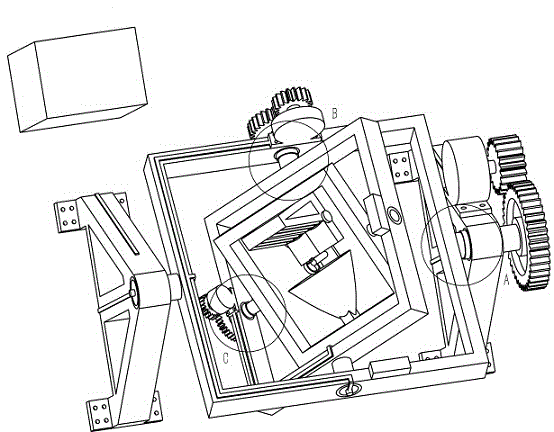

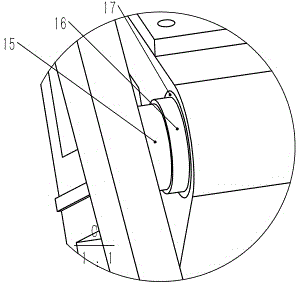

Flight simulator

InactiveCN104916185AReal flight experienceGuaranteed normal rotationCosmonautic condition simulationsSimulatorsFlight experienceFlight simulator

The invention provides a flight simulator, which comprises a frame part, a motor driving part, a control module part, a line part and a sensor part, and has the beneficial effects that the flight simulator can achieve rotation in any one angle of an X, a Y and a Z shafts in a cartesian coordinate system compared with a flight simulator which is arranged by utilizing a space parallel mechanism, and most really simulates flight attitude during flight process. Three rotating rings are prevented from being disturbed with each other during the movement process through a design that the three rotating rings are nested with each other, and can be guaranteed to rotate around own axial lines. Lines are guaranteed to be normally connected during the process by using electric slip rings, and can not be coiled together. The flight simulator can most really simulate change of space attitude when flying, and brings most real flight experience for operators.

Owner:冯圣冰

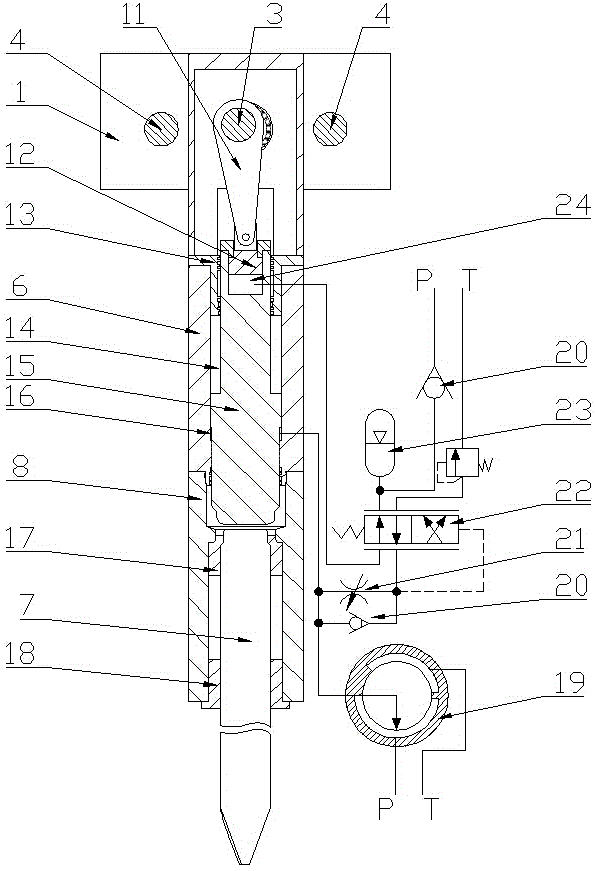

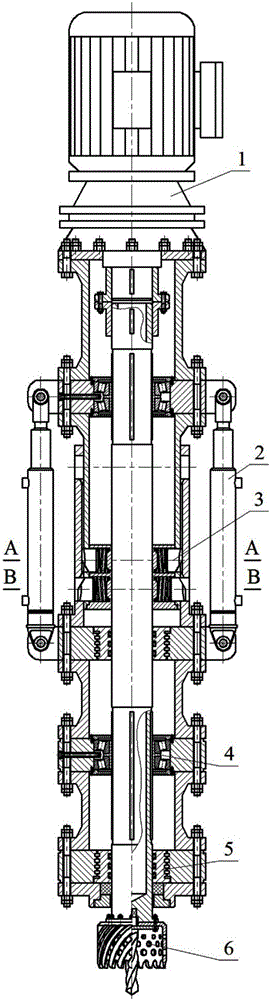

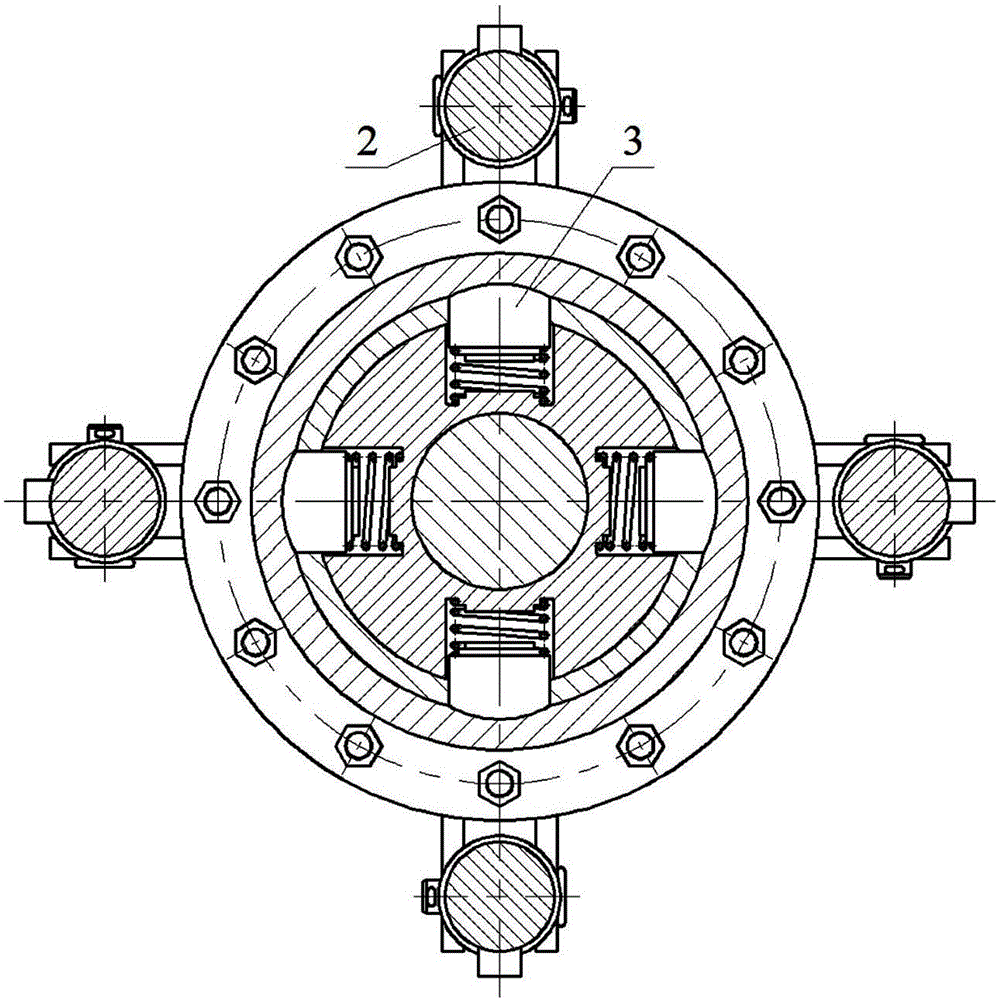

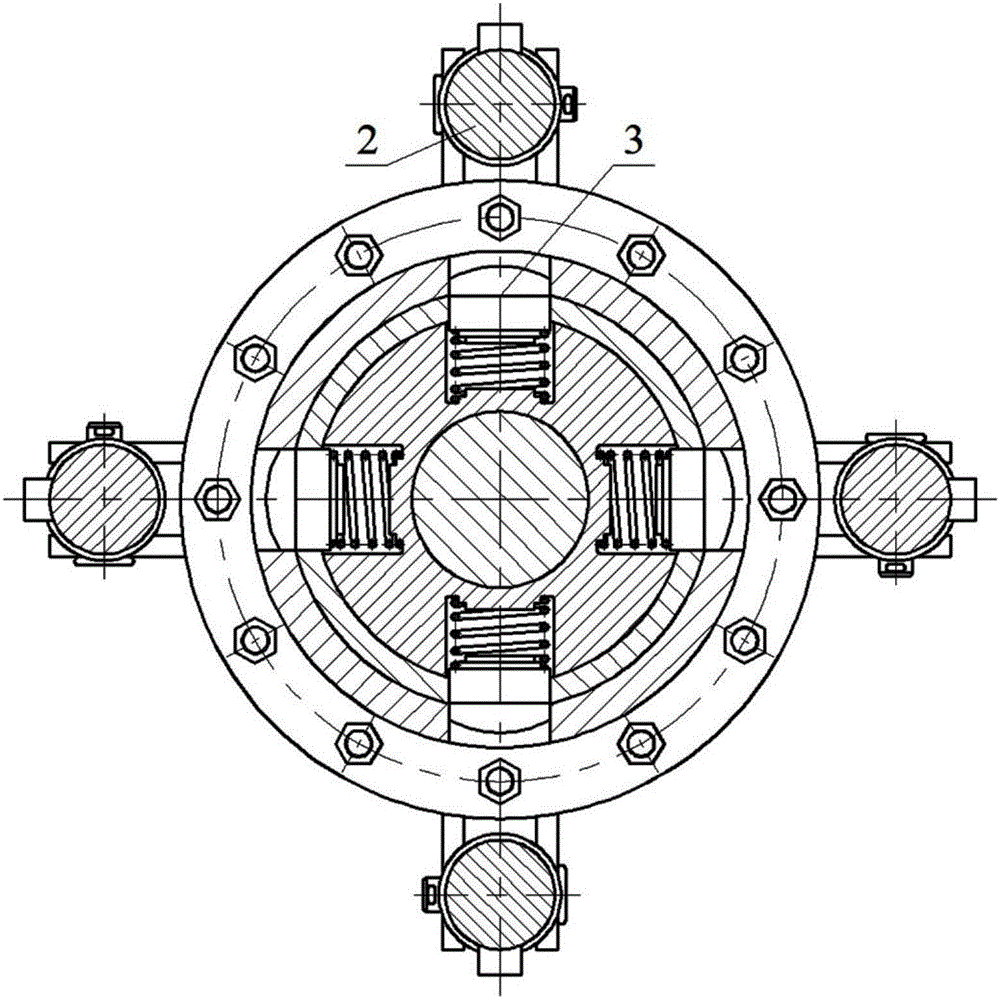

Hydraulic spinning underwater pressure double drill trepanning device

ActiveCN106270641AGuaranteed normal rotationGuaranteed sealing performanceBranching pipesBoring/drilling machinesEngineeringLimiter

The invention provides a hydraulic spinning underwater pressure double drill trepanning device which is applied to submarine pipeline nonstop trepanning operation. The hydraulic spinning underwater pressure double drill trepanning device is organically combined with a submarine pipeline connection device; a hydraulic feeding system provides axial propelling power according to a hydraulic multi-power feeding mechanism and realizes the effect of hydraulic spinning of a double drill cutter by depending on a guide mechanism; a trepanning assembly provides trepanning power and transmits the trepanning power to the double drill cutter through a rotating hollow drill rod; automatic centering in a spinning process of the hollow drill rod is ensured by a self-centering device according to an automatic centering mechanism; the double drill cutter adopts an inner drill bit and an outer drill bit which are arranged coaxially; pressure double drill trepanning operation including inner drill location first and outer drill trepanning later is carried out on a submarine pipeline; a two-way limiter realizes the effect of automatic two-way limiting in a drill bit trepanning process according to an upper and lower reversible locking mechanism; the sealing in a spinning process of the hollow drill rod is ensured by a seal assembly according to a packing and labyrinth multiple seal technology; and a trepanning control system remotely and automatically regulate and control an overpressure working condition of the seal assembly during operation.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

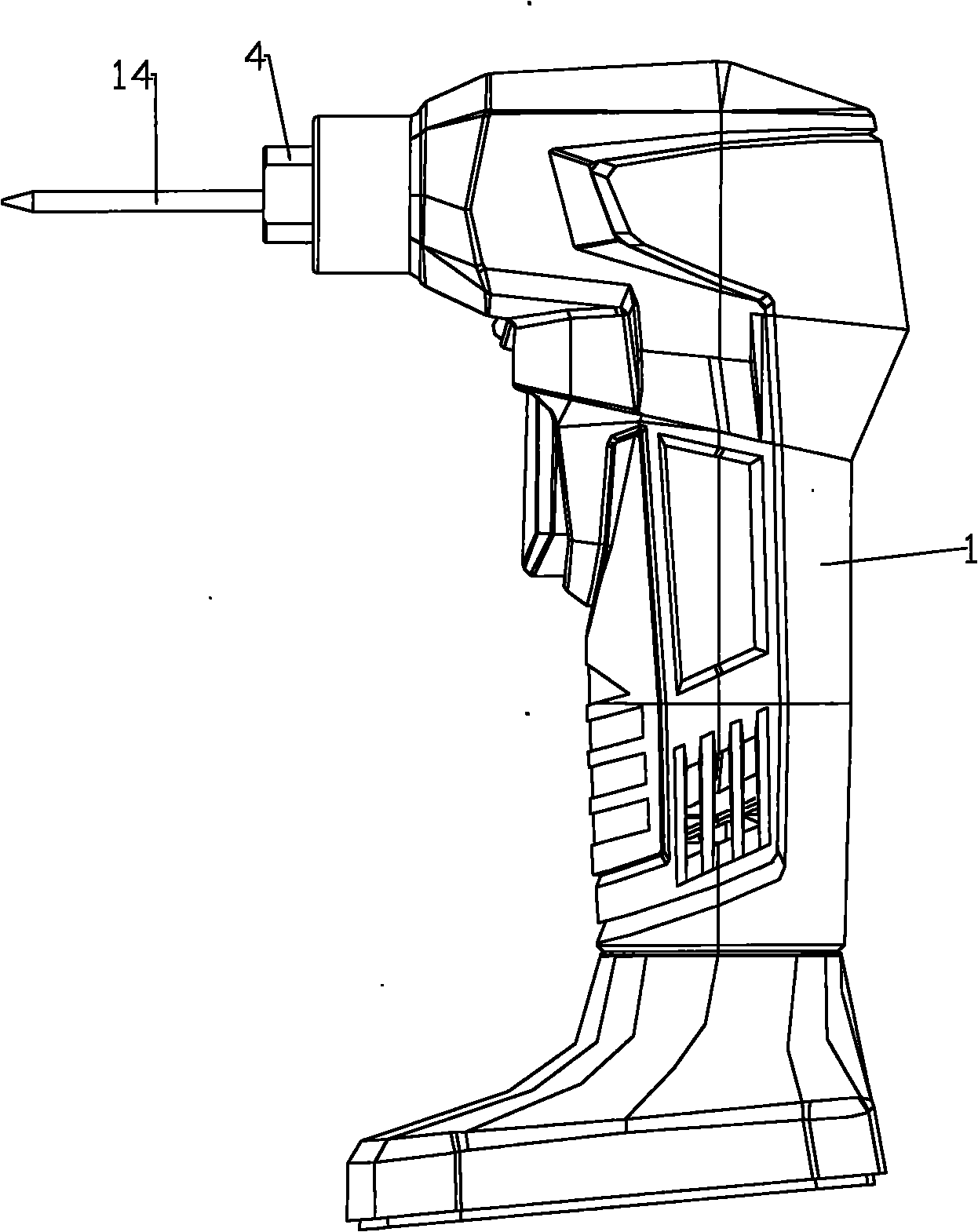

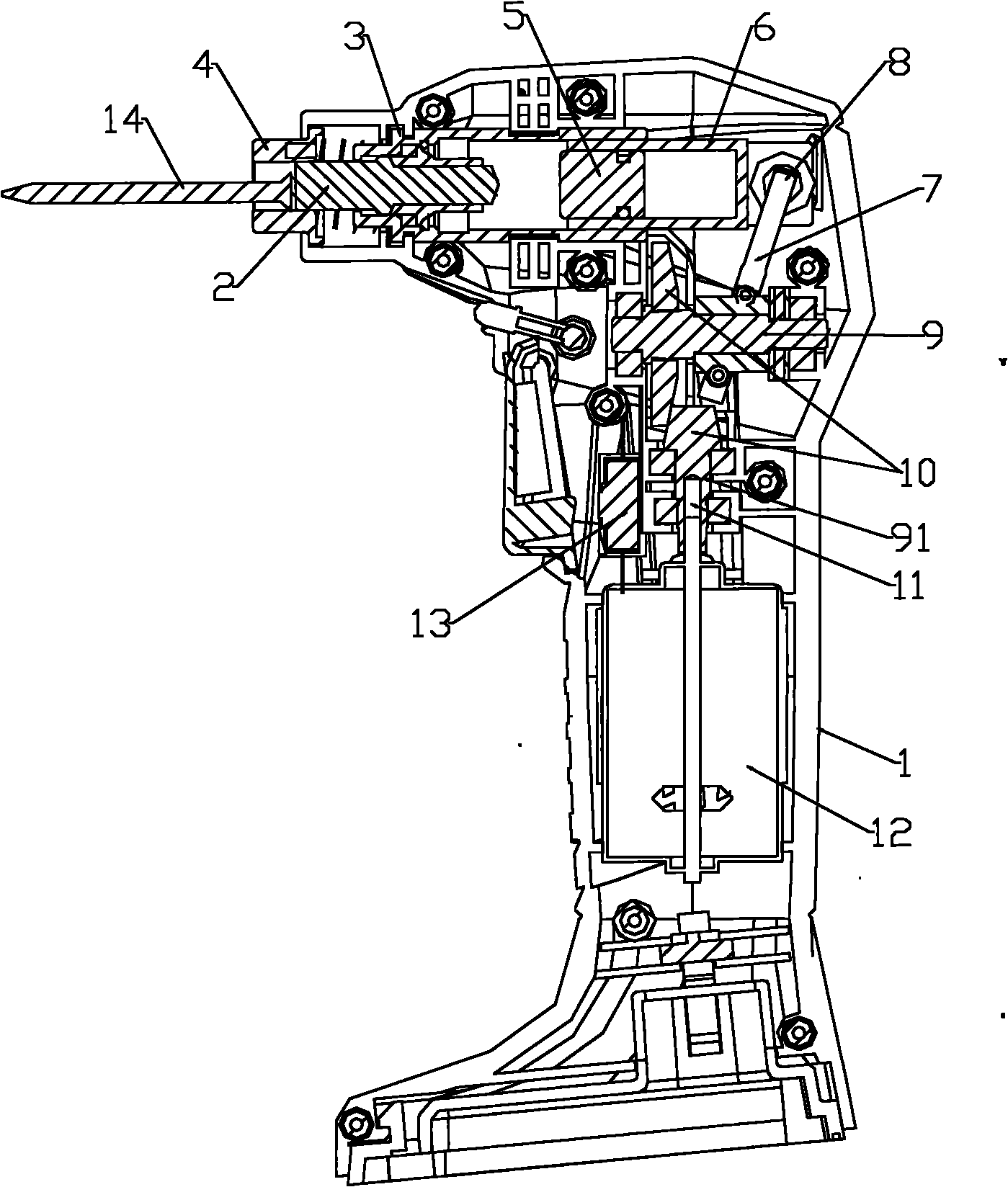

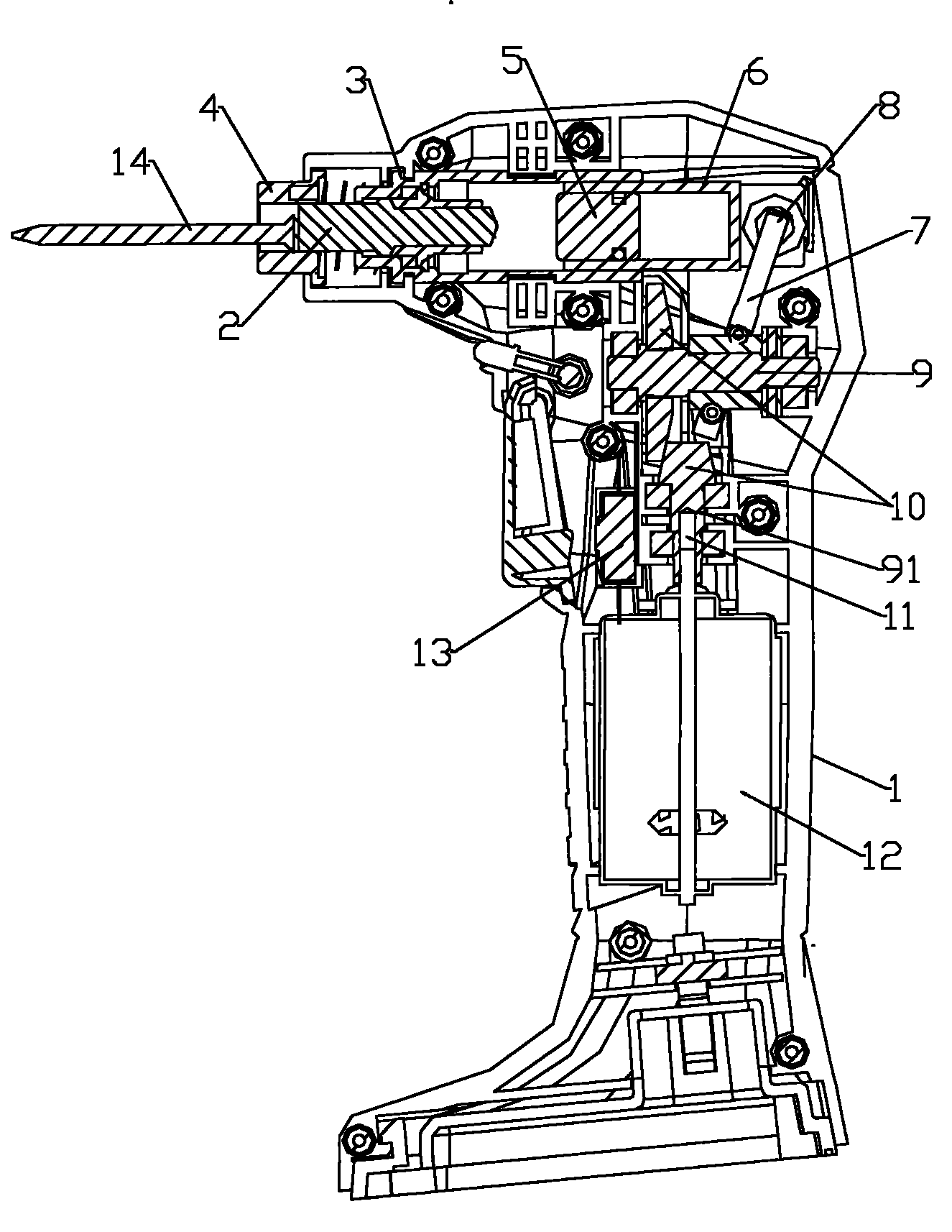

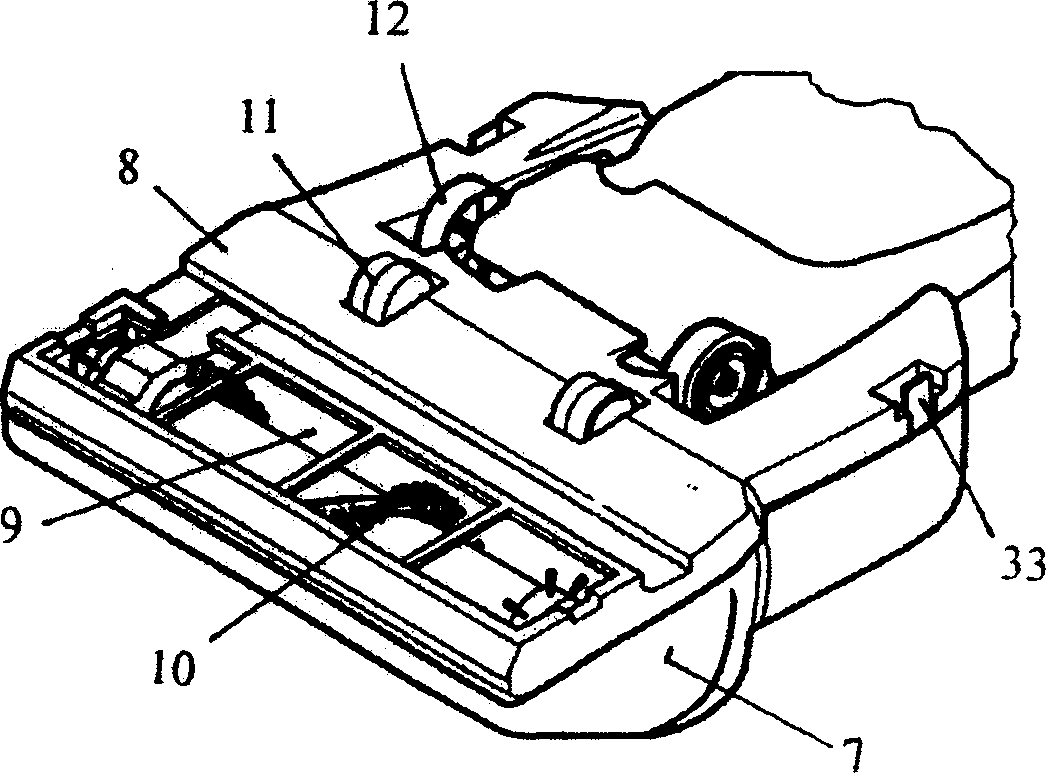

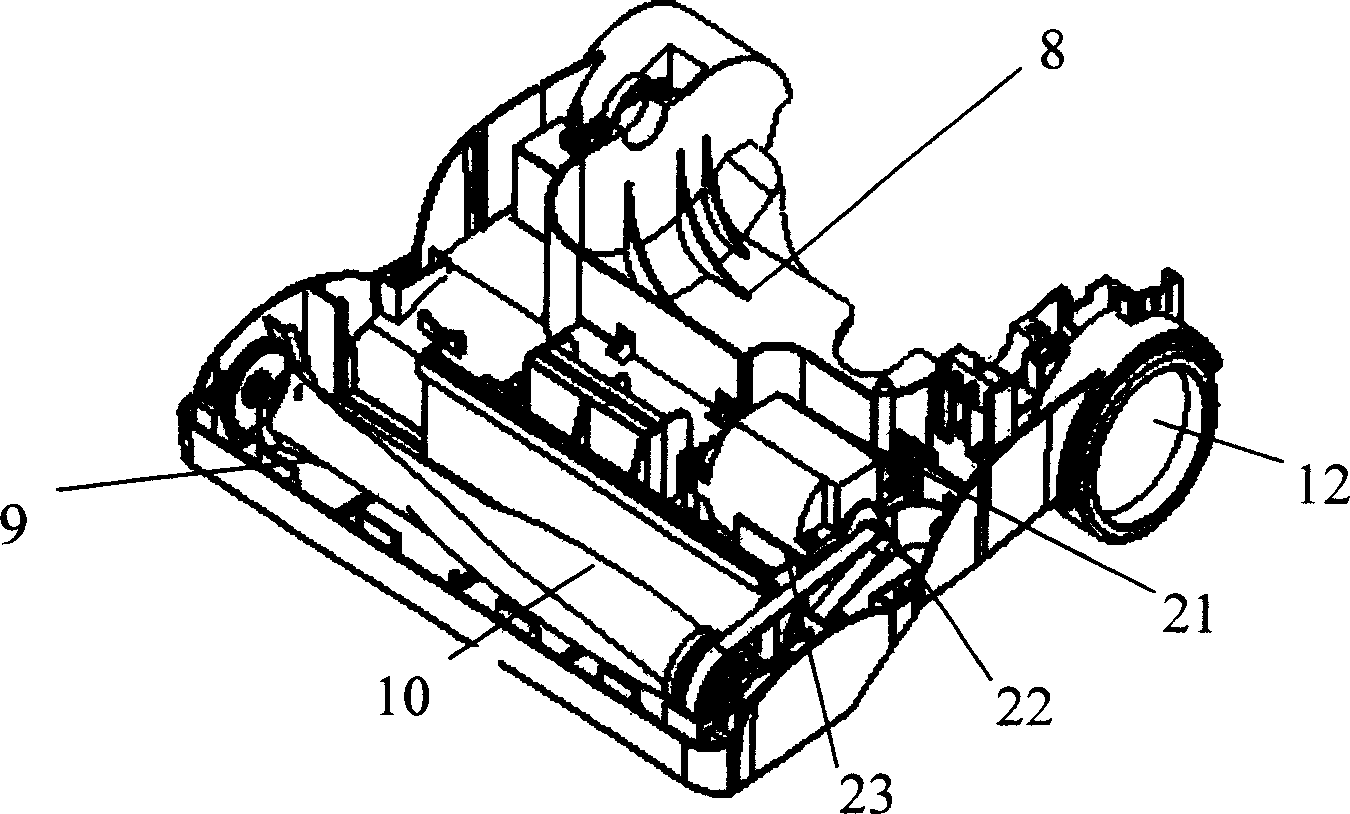

Nailing gun

The invention discloses a nailing gun which comprises a shell cavity and a motor, wherein the shell cavity is formed by carrying out involution on a left half shell and a right half shell; a rotary-linear motion conversion transmission mechanism is arranged in the shell cavity; the motor is connected with a piston through the rotary-linear motion conversion transmission mechanism; a nail striking pin for nailing is arranged in a gun mouth of the nailing gun and fixed in a cylinder body; the piston is mounted in the cylinder body; an axial cavity with an opening at one end of the axial cavity is arranged in the piston; an air hammer is mounted in the axial cavity of the piston; the gun mouth is also provided with a nail accommodating port formed by an indention structure; and the axis of the nail accommodating port is coaxial with that of the nail striking pin. By utilizing the structure provided by the invention, a continuous hammering function is realized in a compact space, and the energy utilization efficiency is improved; continuous efficient striking on a nail can be achieved, thereby effectively avoiding the trouble that the nail cannot be nailed by a single-shot nailing gun under certain working conditions; and moreover, as the nail is stricken by the air hammer, the striking force is great.

Owner:JIANGSU HEHUI POWER TOOLS CO LTD

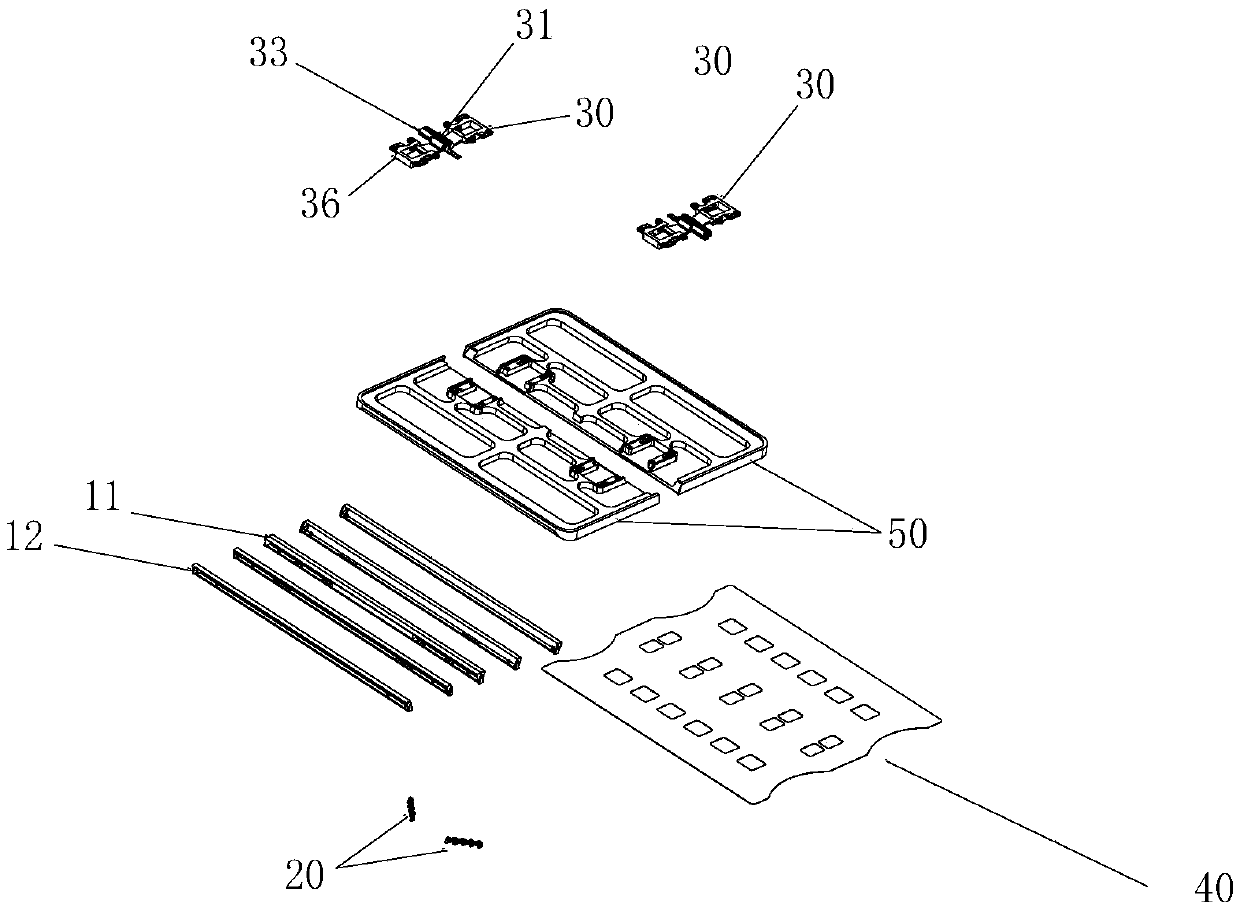

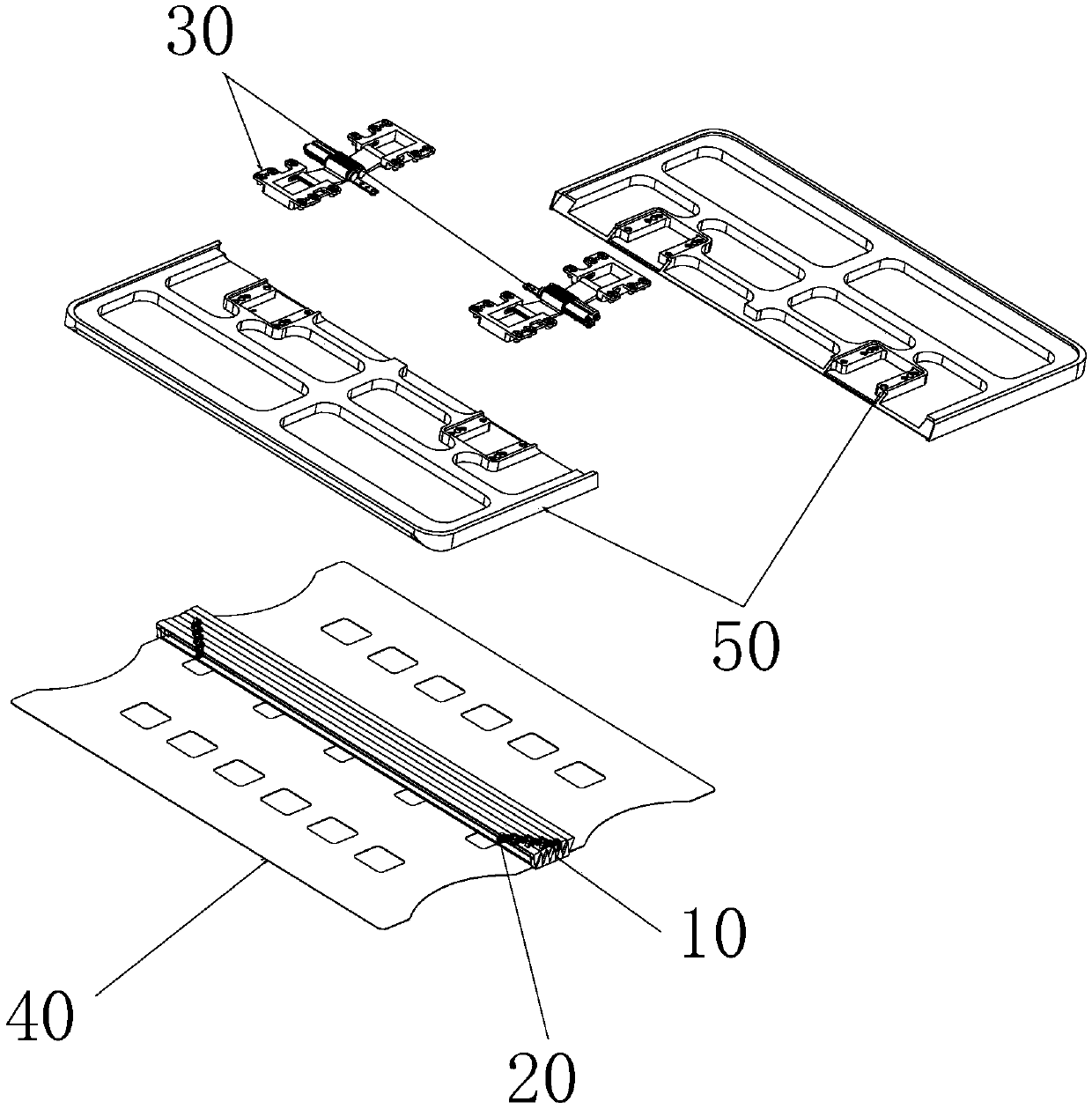

Folding mechanism for flexible screen

PendingCN109256048AGuaranteed normal rotationNot subject to extrusionIdentification meansThin slabSacroiliac joint

The invention discloses a folding mechanism for a flexible screen. The folding mechanism comprises an elastic thin plate and a bending joint assembly matched with the elastic thin plate, and more thanone group of synchronous sliding hinge mechanisms. The bending joint assembly comprises a plurality of joint units, each joint unit comprises a supporting framework, a lower side plate and an upper side plate, the tangent lines of the upper side plate and the lower side plate present a certain included angle, and when the lower side plates of the joint units are horizontally placed side by side,every two adjacent upper side plates are partially overlapped. Triangular limit blocks are installed on the two end faces of the joint units correspondingly, and each synchronous sliding hinge mechanism comprises a plurality of synchronous sliding hinge units which are hinged to each other. According to the folding mechanism for the flexible screen, by making design of the bending joint assembly similar to 'lobster joints', outer elastic thin sheets are attached to the outer side faces of the 'lobster joints', the fact that the joint units rotate around contact points is ensured, in the bending process, the inner and outer sides are bent synchronously and coaxially.

Owner:SHANGHAI FUTURE HIGH-TECH CO LTD

Bearing rolling needle and rolling column quenching machine tool

ActiveCN104726680AImprove processing efficiencyLow costFurnace typesHeat treatment furnacesEngineeringInductor

The invention discloses a bearing rolling needle and rolling column quenching machine tool. The bearing rolling needle and rolling column quenching machine tool comprises a loading mechanism, a quenching mechanism, at least one heating inductor, a photoelectric detection mechanism, a quenching water tank discharging system, a heating and loading system and a machine tool motor numerical control system, wherein the loading mechanism comprises a bed body frame and a vibration loading and guide mechanism arranged on the bed body frame, the quenching mechanism comprises a base, a retreating and blanking mechanism arranged on the base, a workpiece positioning and rotation driving mechanism arranged on the base and a front-and-back loading sliding plate mechanism arranged above the retreating and blanking mechanism, and the vibration loading and guide mechanism is connected with the front-and-back loading sliding plate mechanism through a guide pipe; the heating inductor is arranged on the workpiece positioning and rotation driving mechanism; the photoelectric detection mechanism is arranged above the front-and-back loading sliding plate mechanism, and the photoelectric detection mechanism is responsible for detecting the existence and absence of a workpiece and the height position of the workpiece; and the quenching water tank discharging system, the heating and loading system and the machine tool motor numerical control system are arranged on the base and positioned below the heating inductor. The bearing rolling needle and rolling column quenching machine tool disclosed by the invention can automatically realize loading, unloading, heating and cooling and has no need of artificial participation.

Owner:SHANGHAI HEATKING INDUCTION TECH CORP

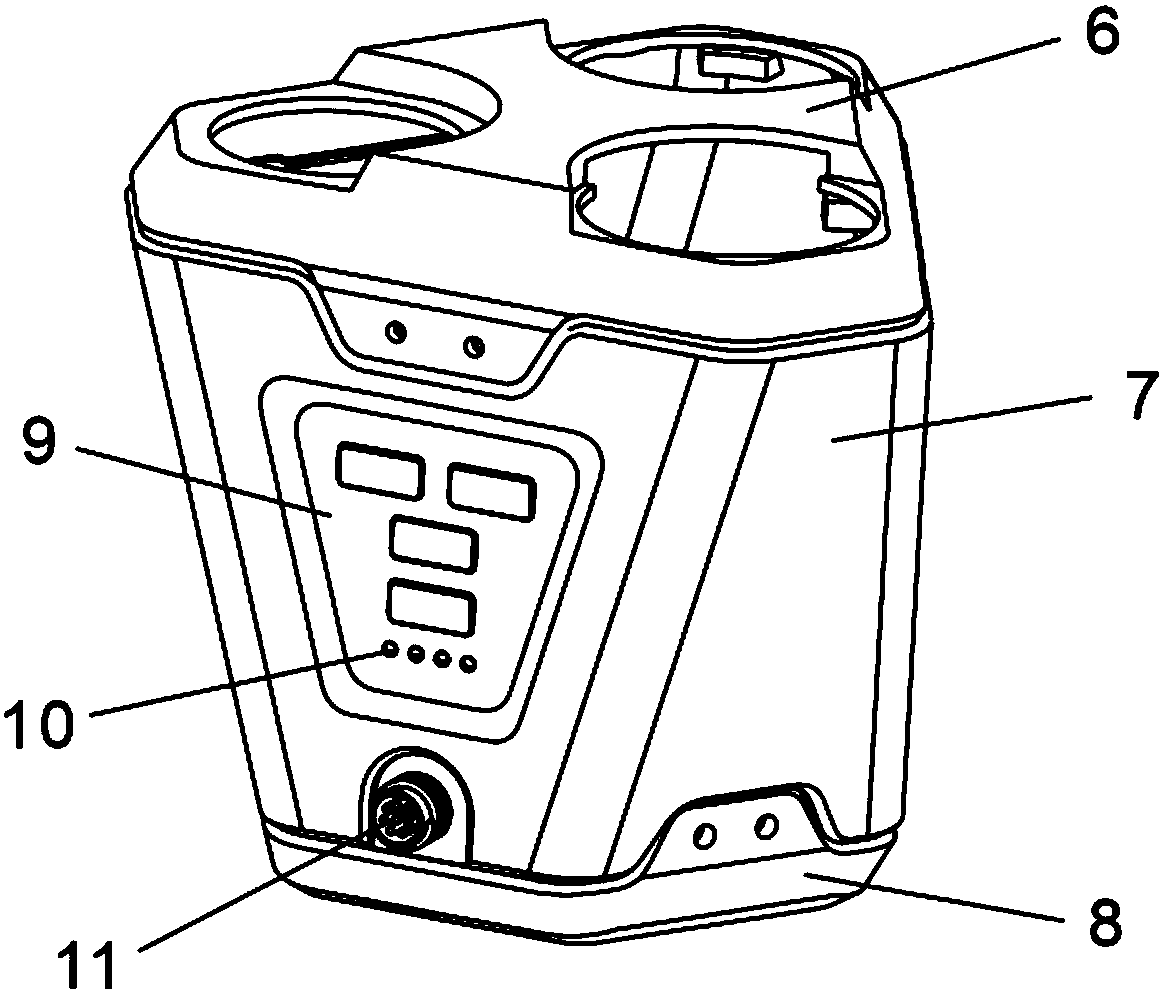

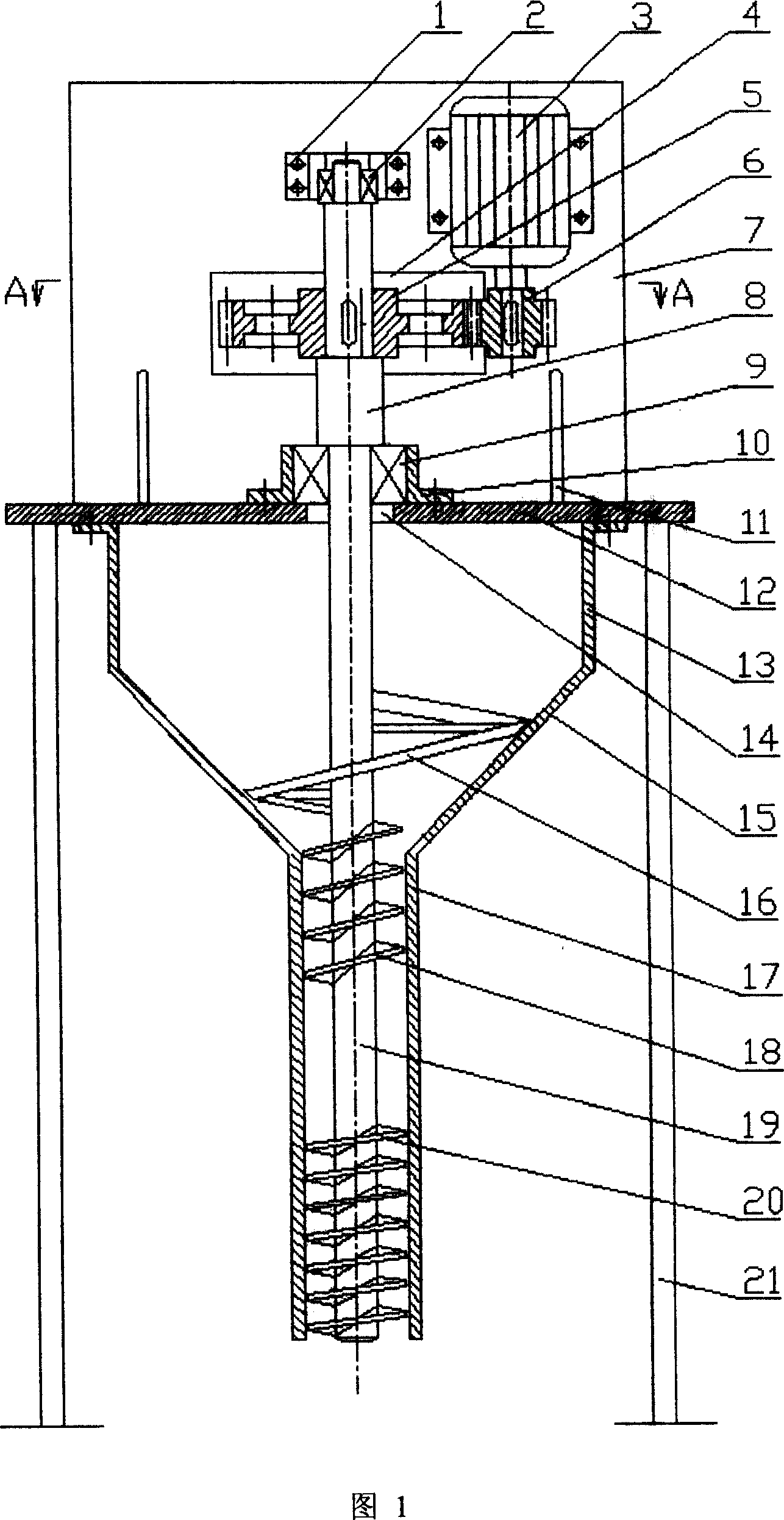

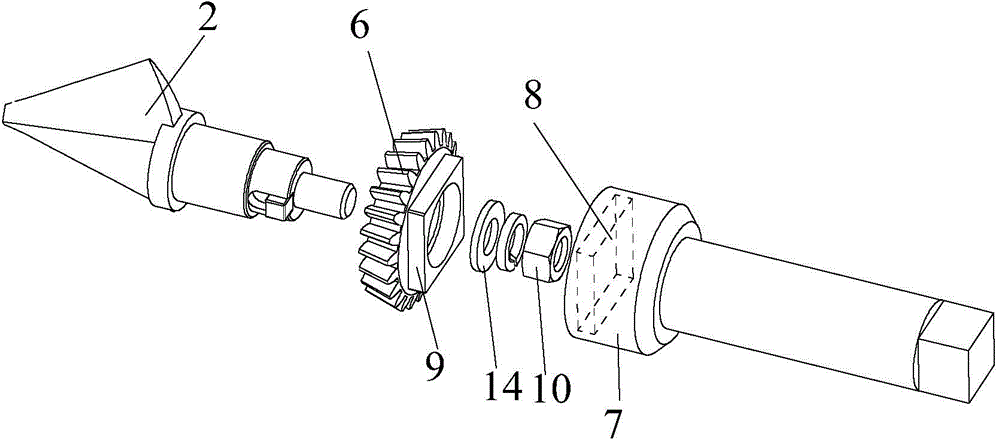

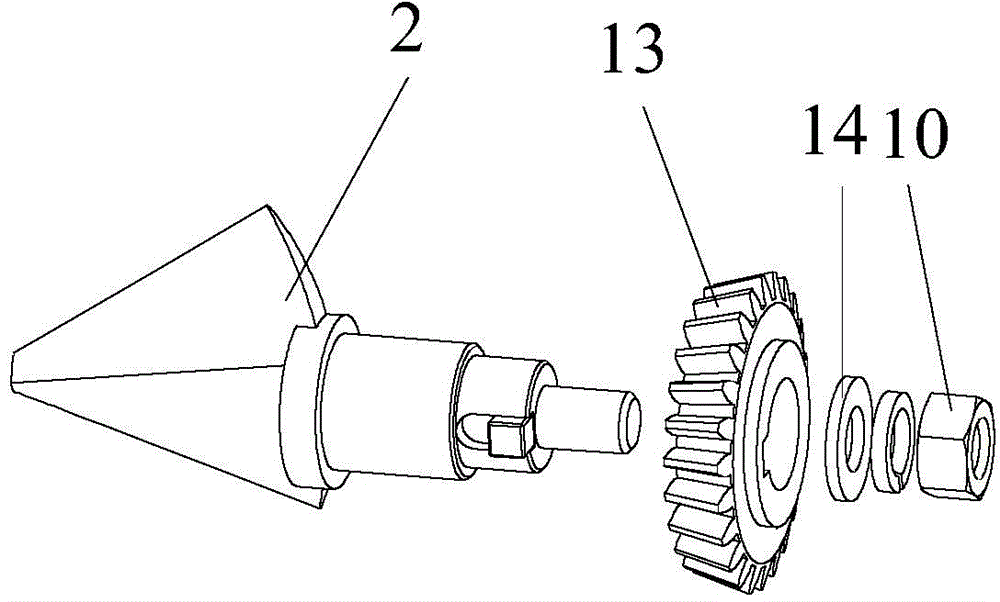

Pressurization trace quantity helix powder feeding equipment

InactiveCN101012031AGuaranteed normal rotationTo achieve the purpose of sealed deliveryToothed gearingsPackagingColloidEngineering

The pressurized micro spiral powder feeder drives the screw shaft through drive mechanism by generators, hopper and material outlet pipe integrated under the lower surface of the support platform, featuring in its being load bore by support platform and positioned by the middle up shaft bearing, vertically going through the insert hopper of the round hole, the lower end sticking to the material output pipe in arm shape, blender at the screw shaft of the corresponding position of the conical sectional hopper, intermittently fixing two sections spiral vanes with different pitches, lower spiral vane pitch smaller than the pitch of the upper spiral vane, leaving a section of emptiness between the spiral shaft of the spiral vanes. It is simple and compact in structure, adjustable in feeding quantity, even and stable in pressurized transportation.

Owner:UNIV OF SCI & TECH OF CHINA

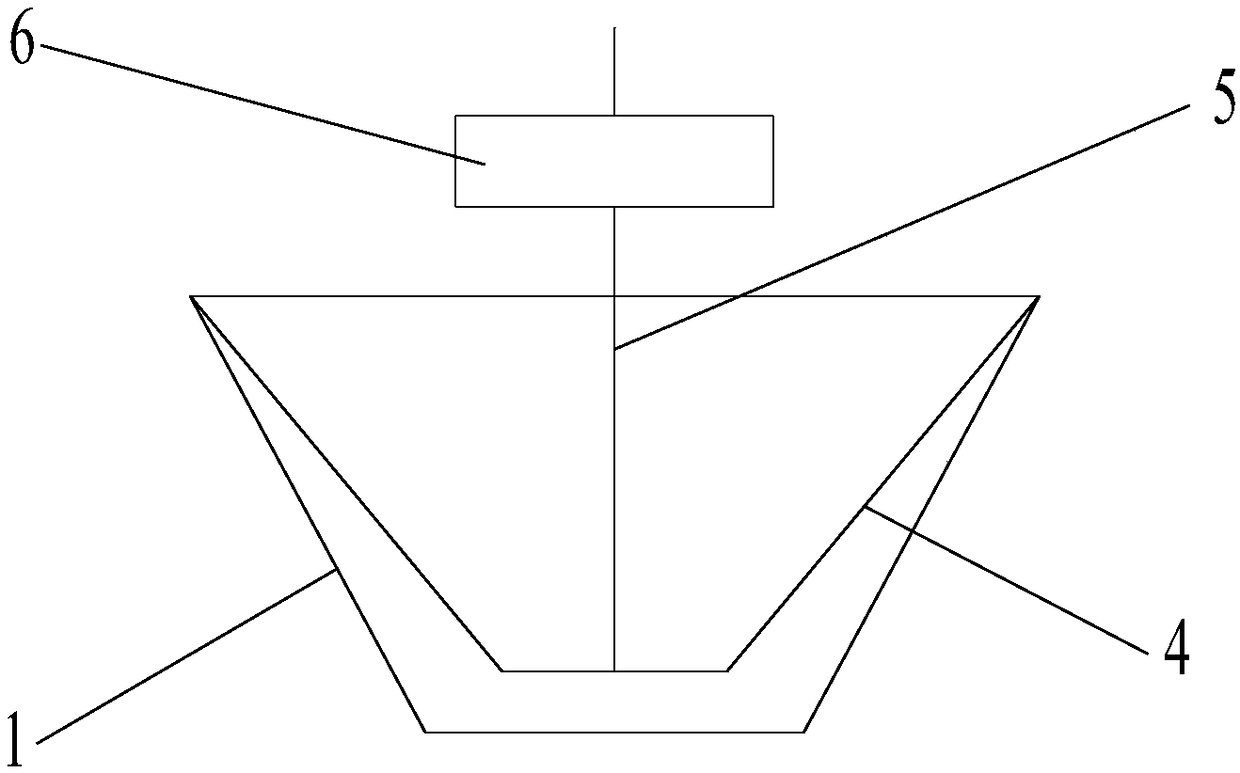

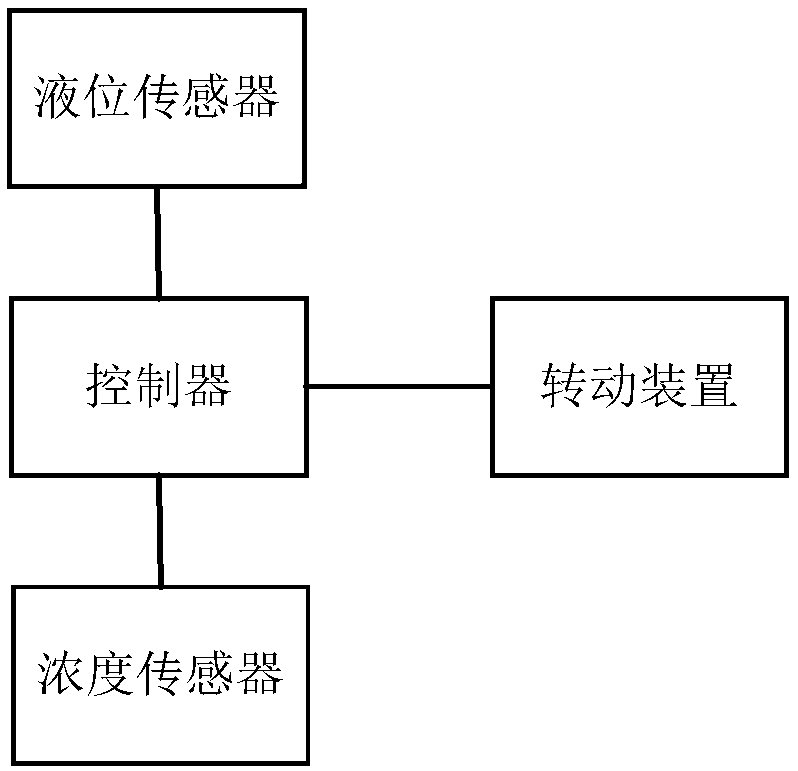

Extracted liquid filtering device

PendingCN108096873ASpeed up filteringReduce blockageSolid solvent extractionMoving filtering element filtersEngineeringLiquid level sensor

The invention relates to an extracted liquid filtering device. The extracted liquid filtering device comprises a circular truncated cone-shaped housing; the internal part of the circular truncated cone-shaped housing is hollow; the upper end and the lower end of the circular truncated cone-shaped housing are provided with openings; the opening on the upper end is an upper circular hole, and the opening on the lower end is a lower circular hole; a circular truncated cone-shaped filter screen is arranged in the circular truncated cone-shaped housing; the height of the circular truncated cone-shaped filter screen is smaller than or equal to that of the circular truncated cone-shaped housing; the upper end external edge of the circular truncated cone-shaped filter screen is pressed against theinternal edge of the upper circular hole; the center of the bottom wall of the circular truncated cone-shaped filter screen is detachably provided with a vertical rod; the vertical rod is connected with a transmission device; a liquid level sensor and a concentration sensor are arranged on the internal wall of the circular truncated cone-shaped filter screen; the transmission device, the liquid level sensor, and the concentration sensor are connected with a controller through electric connection respectively. The above design is capable of accelerating extracted liquid filtering speed; when the circular truncated cone-shaped filter screen is blocked, it is not necessary to pump out the unfiltered extracted liquid; and processing efficiency is increased.

Owner:荆州市宏达生物科技股份有限公司

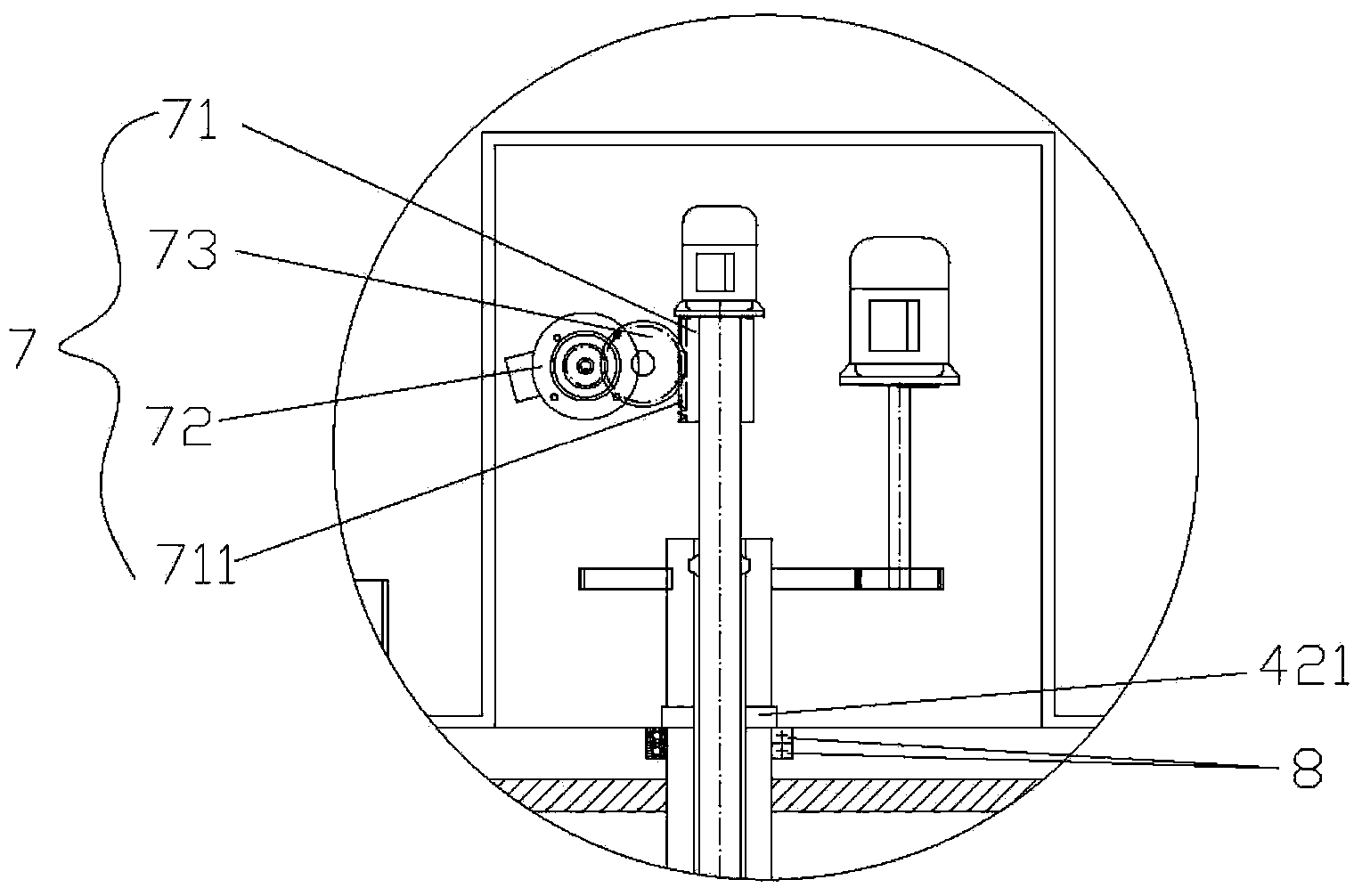

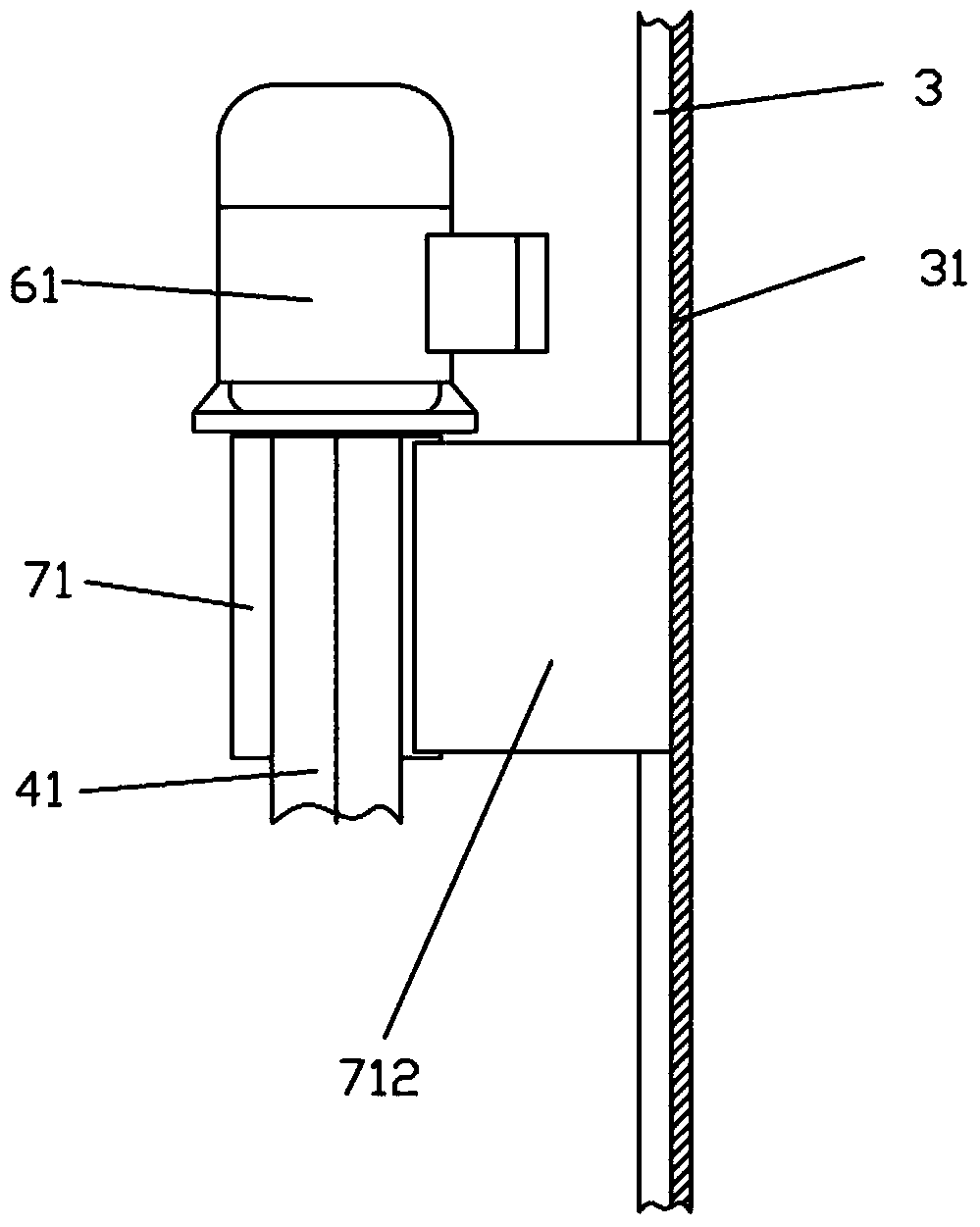

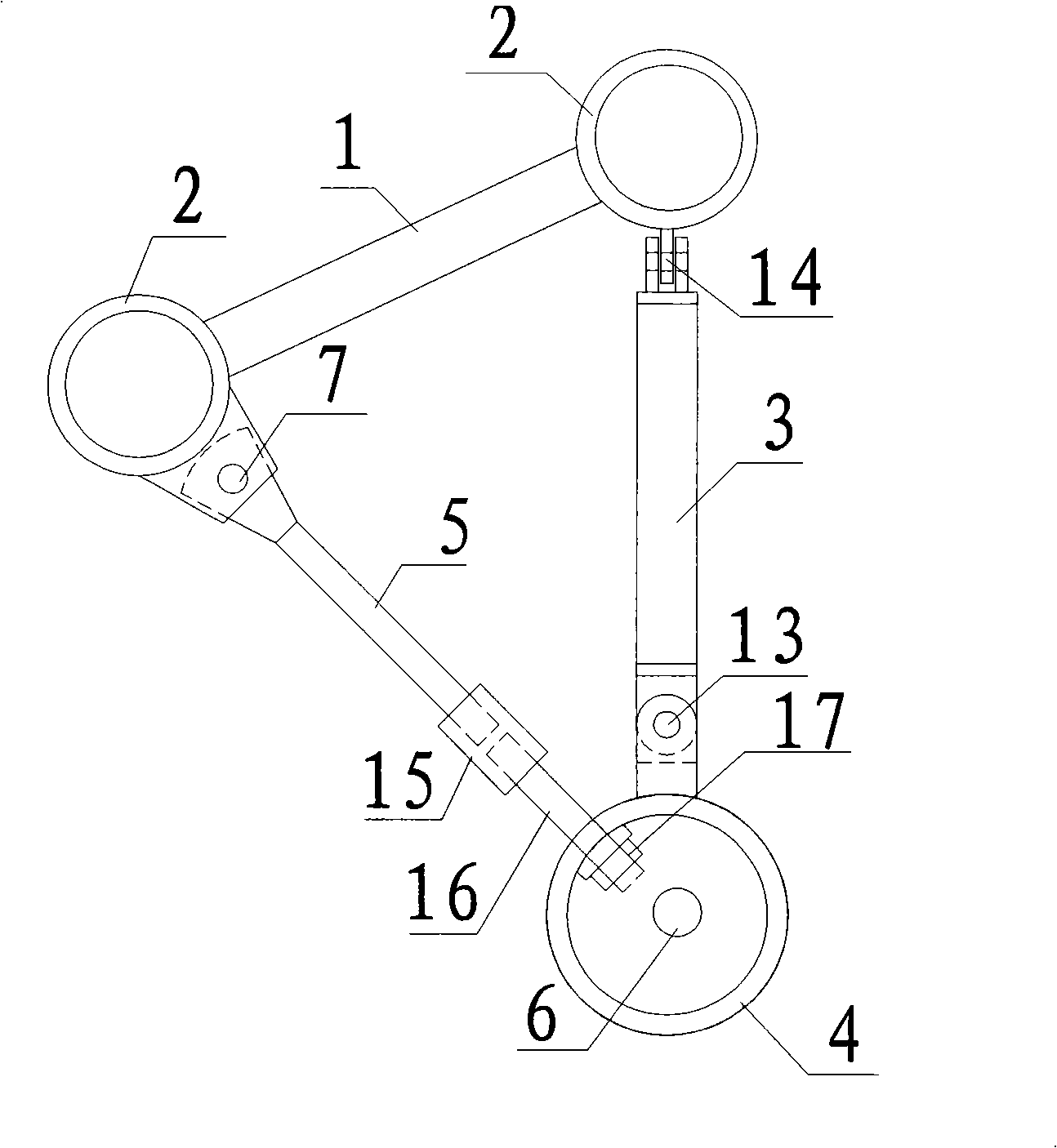

On-line top wheel device

ActiveCN102269660AGuaranteed normal rotationSimple structureRailway vehicle testingMotor driveIntegrated design

The invention discloses an online rotating wheel jacking device, which comprises a swing arm group, rotating wheels, and a first expansion device, wherein the swing arm group comprises two swing arms hinged to a frame; the rotating wheels are arranged on the tops of the swing arms, and are connected with a servo motor; two ends of the first expansion device are hinged with bottoms of the two swing arms. The first expansion device drives the swing arms to rotate, and the rotating wheels on the swing arms jack an online wheel pair off a rail surface. The servo motor drives the rotating wheels to rotate, and the rotating wheels drive the online wheel pair to rotate through contact friction force, so that the wheel pair to be detected is rotated at the required speed. The online rotating wheel jacking device is not interfered with objects at the bottoms of various motor train units and rolling stocks, and can adapt to any contour dimensions of the various motor train units and rolling stocks in an application limit. The online rotating wheel jacking device has a concise structure, high bearing capacity, high stability, safety and reliability, and effectively solves the problem of an online wheel pair jacking and rotating integrated design.

Owner:CHENGDU LEAD SCI TECH CO LMT +5

Roller type drying and sintering or roasting device

InactiveCN106679366AAutomatic separationEven heat absorptionRotary drum furnacesDrying gas arrangementsEngineeringNet shape

The invention relates to a roller type drying and sintering or roasting device which comprises a kiln body and a drive device. A drying roller comprises a kiln body outer shell, a net-shaped outer sleeve and a net-shaped inner sleeve from outside to inside in the radial direction of the drying roller. The inner wall of the kiln body outer shell and the outer wall of the net-shaped outer sleeve are connected through a plurality of sliding drive shifting blocks evenly distributed in the circumferential direction, and rotary drive is carried out. A powder chamber is formed by a space between the kiln body outer shell and the net-shaped outer sleeve. The net-shaped outer sleeve and the net-shaped inner sleeve are connected through a plurality of net-shaped partitions spirally extending in the length direction of the kiln body. A space between the net-shaped outer sleeve and the net-shaped inner sleeve is divided by the partitions into a plurality of drying or roasting (sintering) material chambers distributed in the circumferential direction. An inner sleeve air chamber is formed by a space in the inner sleeve. The device has the beneficial effects that material drying is even, thorough and fast; the manmade pellet (spherical block) damage rate is low; the device investment is reduced; the productivity is greatly improved; and energy saving and emission reduction are realized.

Owner:唐竹胜

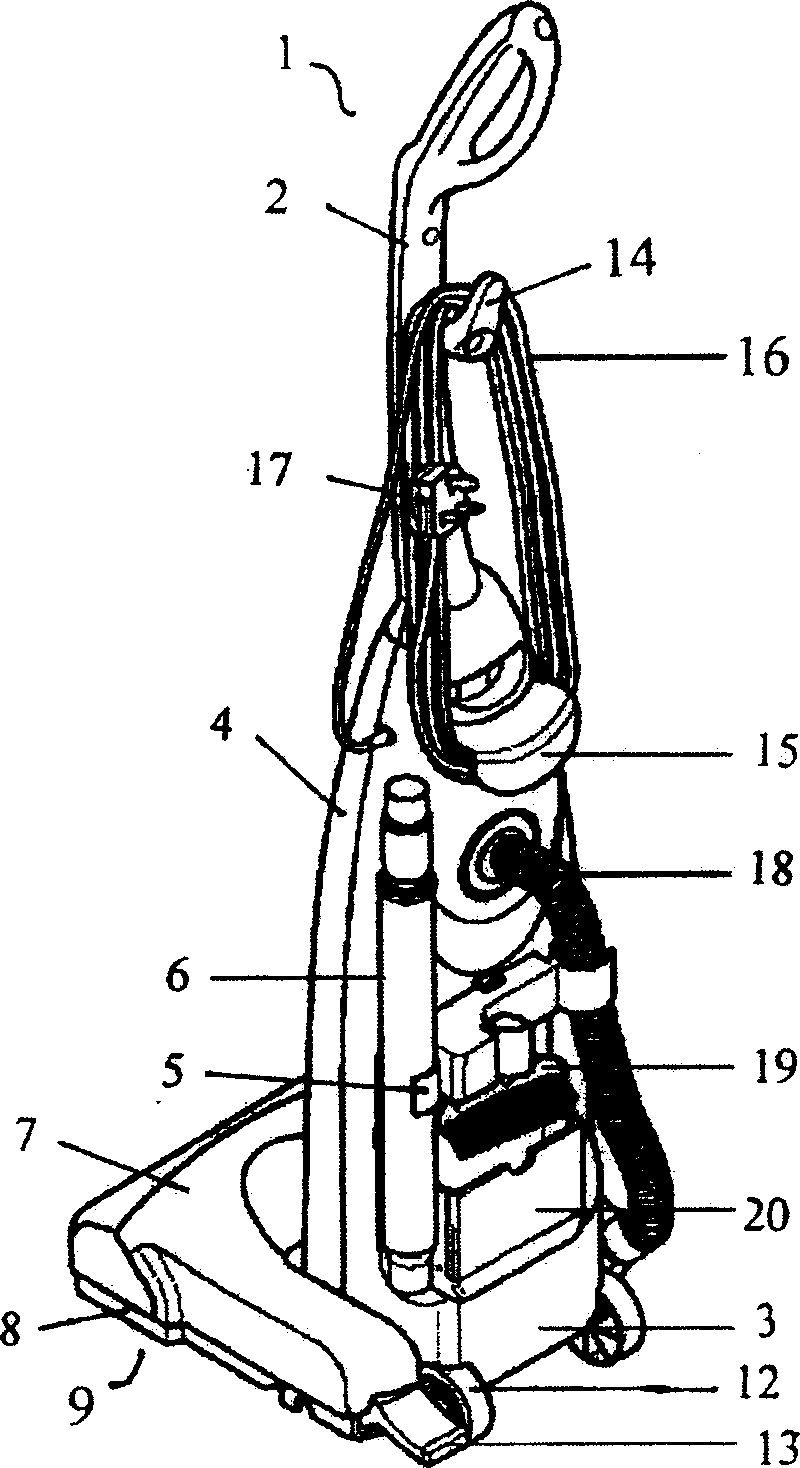

Rolling brush connecting structure of vertical vacuum cleaner

InactiveCN1887171AGuaranteed normal rotationExtended service lifeSuction nozzlesForeign matterBristle

The present invention discloses one kind of rolling brush connecting structure for vertical vacuum cleaner as one hand supported vacuum cleaner. The rolling brush connecting structure includes rotatable right and left connecting parts connected to the right and left end cap of the suction nozzle separately, roller, and bristles set spirally on the roller. It features the end cap protecting rings set in the right and left end cap installing units to hold the end bosses and the end bosses in the right and left connecting units to form inclined slot. The present invention has low possibility of dust and other foreign matters to enter to the end cap installing units so as to ensure the normal rotation and long service life of the rolling brush.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Guide vane component, centrifugal compressor and air conditioner

InactiveCN104564833AGuaranteed normal rotationHigh control precisionPump componentsPumpsEngineeringMechanical engineering

The invention discloses a guide vane component, a centrifugal compressor and an air conditioner. The guide vane component comprises a flow guider (1), guide vanes (2), a driving ring (3) and a driving mechanism, wherein the guide vanes (2) are distributed along the circumference of the flow guider (1); first gears are arranged at vane tail ends of the guide vanes (2); the driving ring (3) sleeves the flow guider (1); a second gear (5) meshed with the first gears of the guide vanes (2) is arranged on one side, facing to the guide vanes (2), of the driving ring (3); the driving mechanism is in driving connection with the driving ring (3), so as to drive the driving ring (3) to rotate. According to the guide vane component provided by the invention, control precision is high and stabilizing performance is excellent.

Owner:GREE ELECTRIC APPLIANCES INC +1

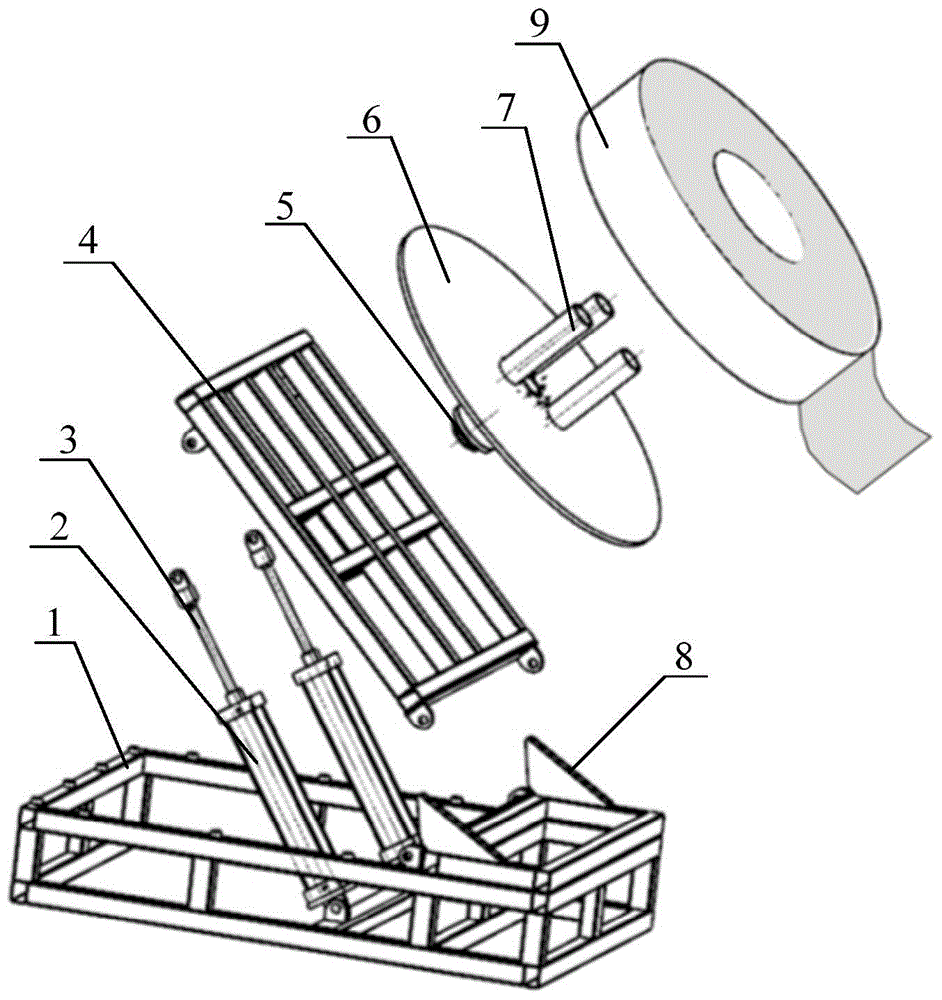

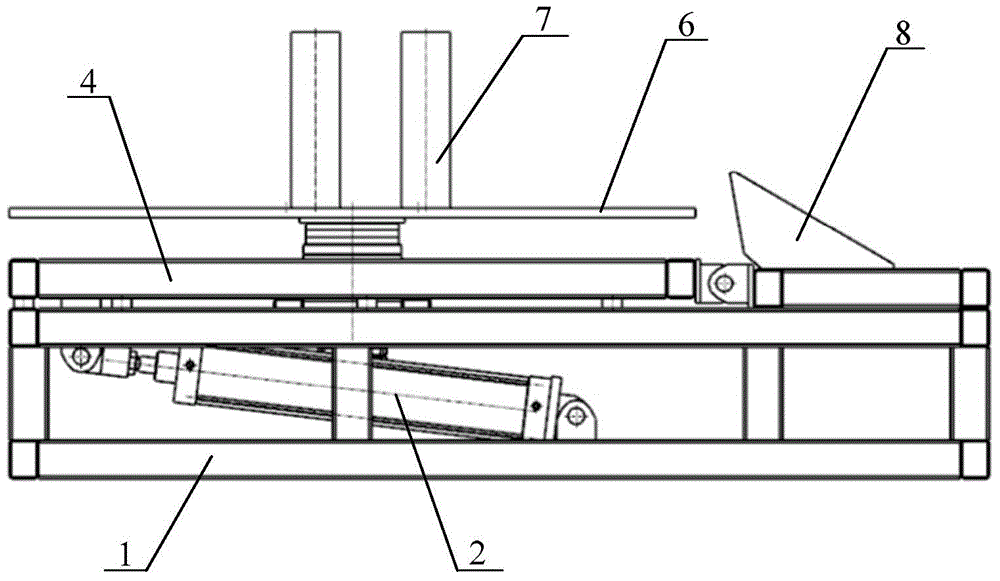

Coil stock unrolling feeding device

The invention discloses a coil stock unrolling feeding device. The coil stock unrolling feeding device is characterized by comprising a base (1), a rotary support (4) with one end connected to the base (1), and a rotary table (6) which is arranged on the support (4) and can rotate, fixing columns (7) are fixed to the rotary table (6), and the base (1) is provided with a power device pushing the support (4) to rotate. The coil stock unrolling feeding device is simple in structure and low in cost. According to the coil stock unrolling feeding device, the loading work can be finished within a very short time, the coil stock loading difficulty can be lowered, one-time loading success is ensured, and therefore the material loss, the occupational injury hidden danger and other accidental situations are reduced, safety and reliability are achieved, meanwhile, the input of manpower and material resources is reduced, accordingly, cost is reduced, and the coil stock unrolling feeding device is suitable for usage and popularization.

Owner:CHENGDU HELE DOORS

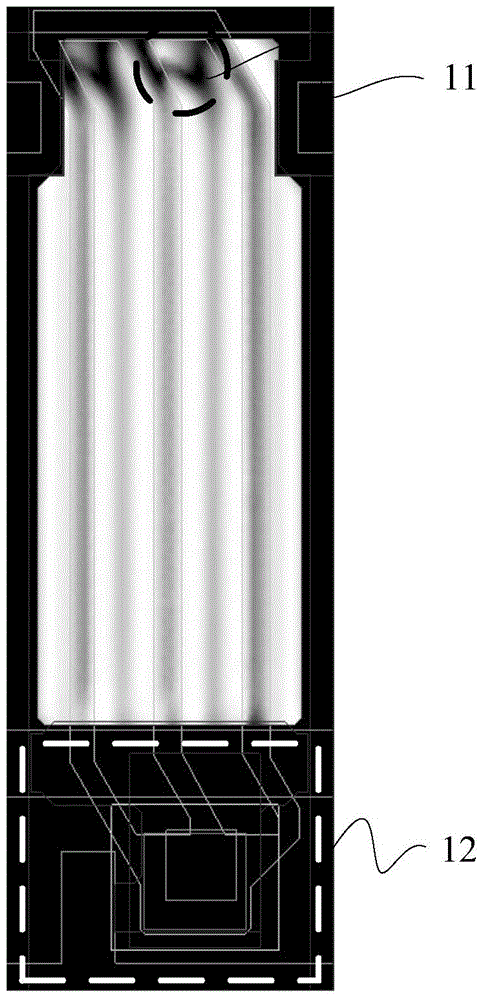

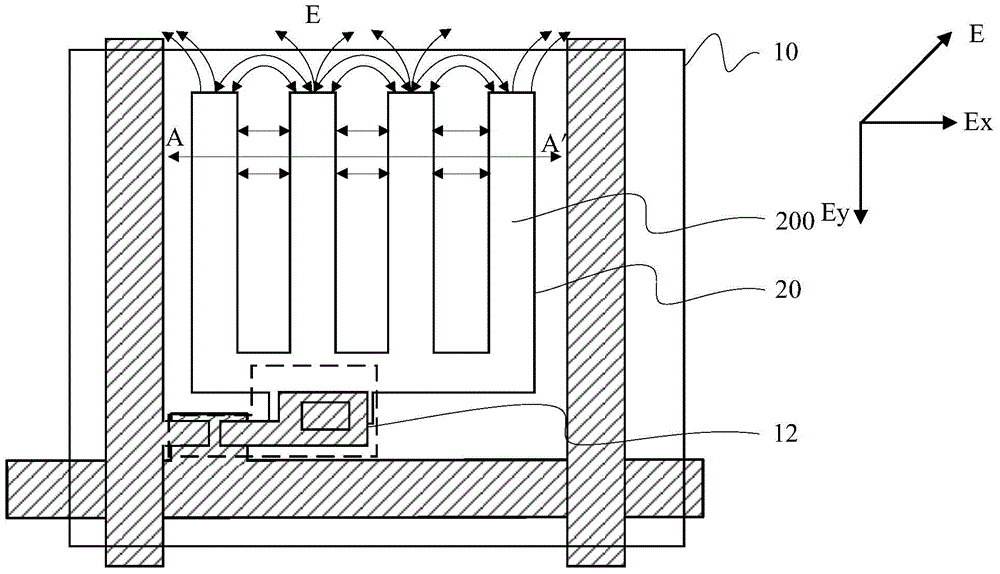

Pixel unit structure, array substrate structure and liquid crystal display device

ActiveCN103913910AAvoid problemsGuaranteed normal rotationNon-linear opticsArray data structureLiquid-crystal display

The invention discloses a pixel unit structure, an array structure and a liquid crystal display device to solve the problem of poor display effect of a liquid crystal display device in the prior art. The pixel unit structure comprises a first electrode, a second electrode and shielding electrodes, the first electrode is of a faceted structure, a first insulating layer is formed on the first electrode, the second electrode is formed on the first insulating layer and comprises a plurality of strip electrodes which are arranged at intervals, and the shielding electrodes are arranged at the tail ends of the strip electrodes of the second electrode. By the aid of the technical scheme, when the pixel unit structure has electric signals, an Ey-direction electric field generated at the tail ends of the strip electrodes of the second electrode is shielded owing to the shielding electrodes, so that domain lines are effectively avoided, display molecules corresponding to all display areas of the pixel unit structure can rotate according to a preset mode, and image display effects are improved.

Owner:XIAMEN TIANMA MICRO ELECTRONICS +1

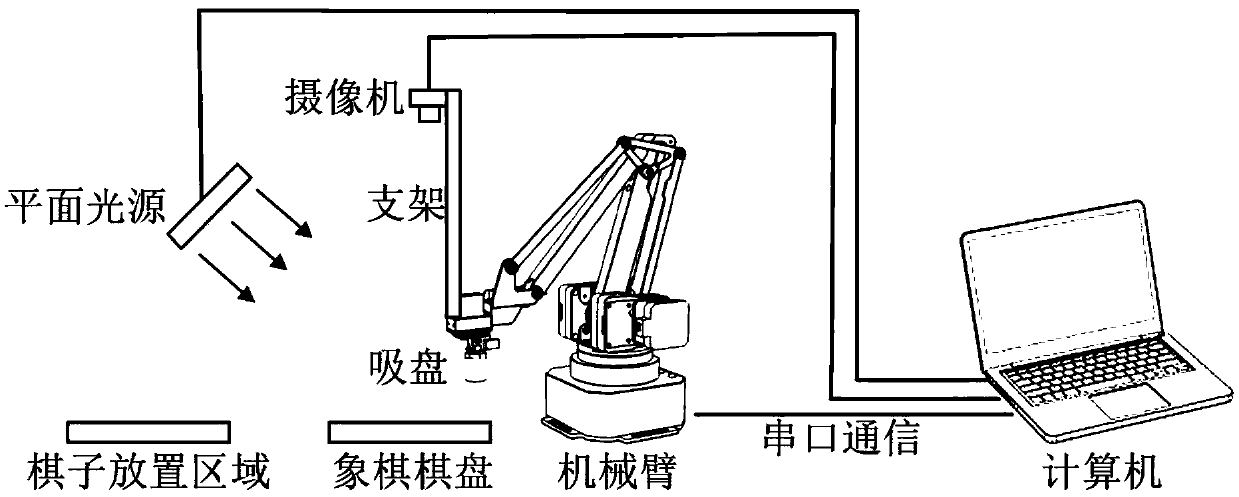

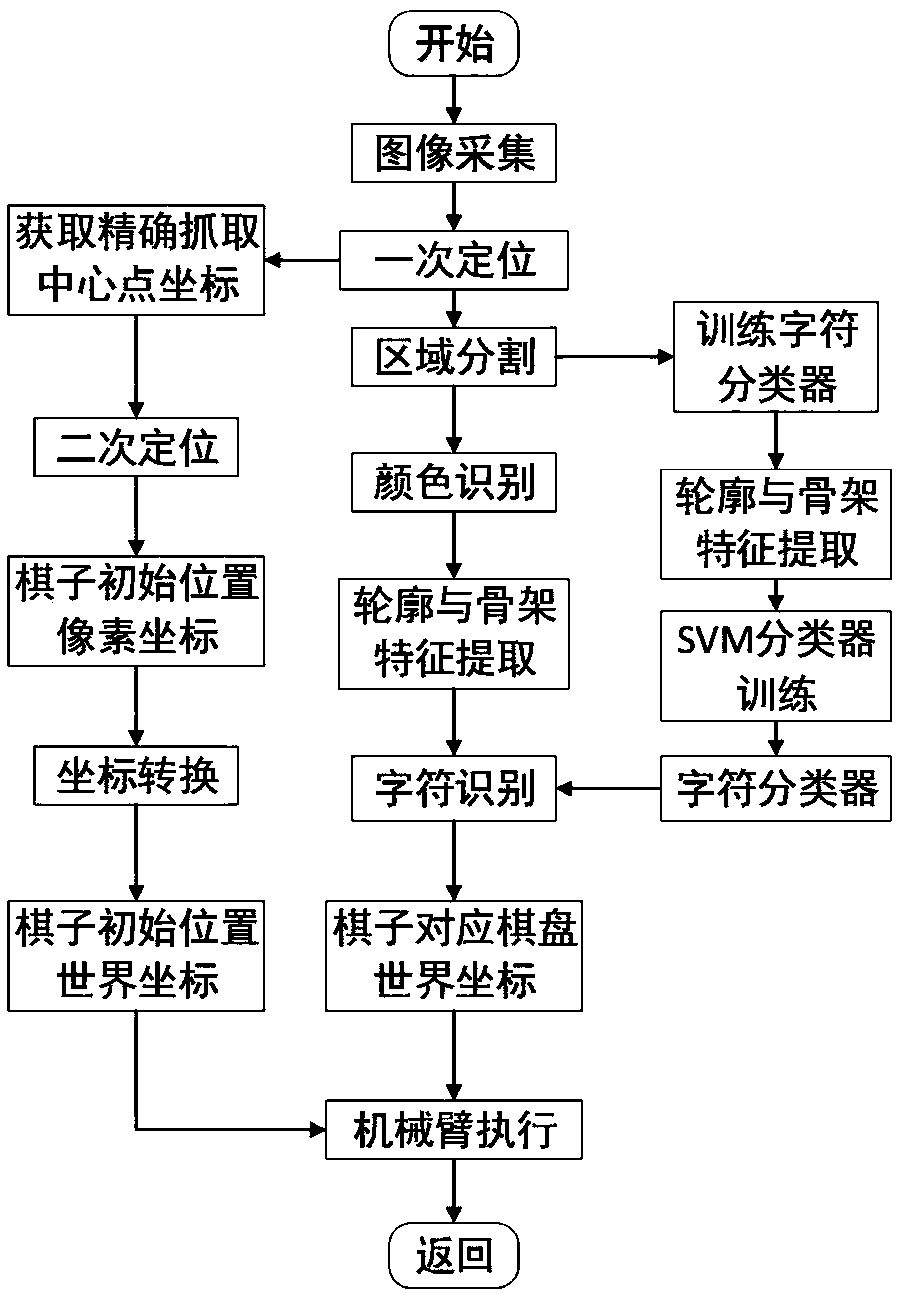

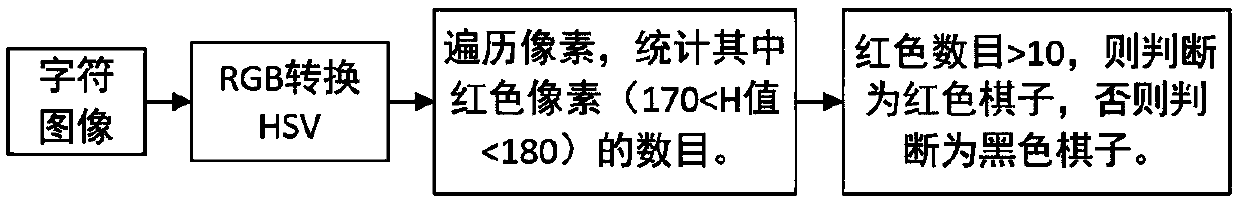

Robot chess opening arranging method and system based on target outline and skeleton characteristics

The invention discloses a robot chess opening arranging method and system based on target outline and skeleton characteristics. In the method, a chess piece positioning and identifying method of primary coarse positioning, region segmentation, secondary accurate positioning and extraction based on the target outline and skeleton characteristics combined with a SVM multi-classifier part is provided, and the automatic arranging function at the opening stage of an intelligent chess robot is achieved. The system is formed by a common Chinese-chess chessboard, chess pieces, a uArm four-degree-of-freedom mechanical arm, a sucking disc, a camera, a light source, a control system based on a PC and the like; the whole system is simple in structure and easy and convenient to operate, the full-automatic arranging function of the robot can be completed before man-machine chess playing is conducted, and the system has the good stability in the relatively-complex environment.

Owner:HUNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com