Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

329 results about "Trepanning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Trepanning, also known as trepanation, trephination, trephining or making a burr hole (the verb trepan derives from Old French from Medieval Latin trepanum from Greek trypanon, literally "borer, auger") is a surgical intervention in which a hole is drilled or scraped into the human skull, exposing the dura mater, to treat health problems related to intracranial diseases or release pressured blood buildup from an injury. It may also refer to any "burr" hole created through other body surfaces, including nail beds. It is often used to relieve pressure beneath a surface. A trephine is an instrument used for cutting out a round piece of skull bone.

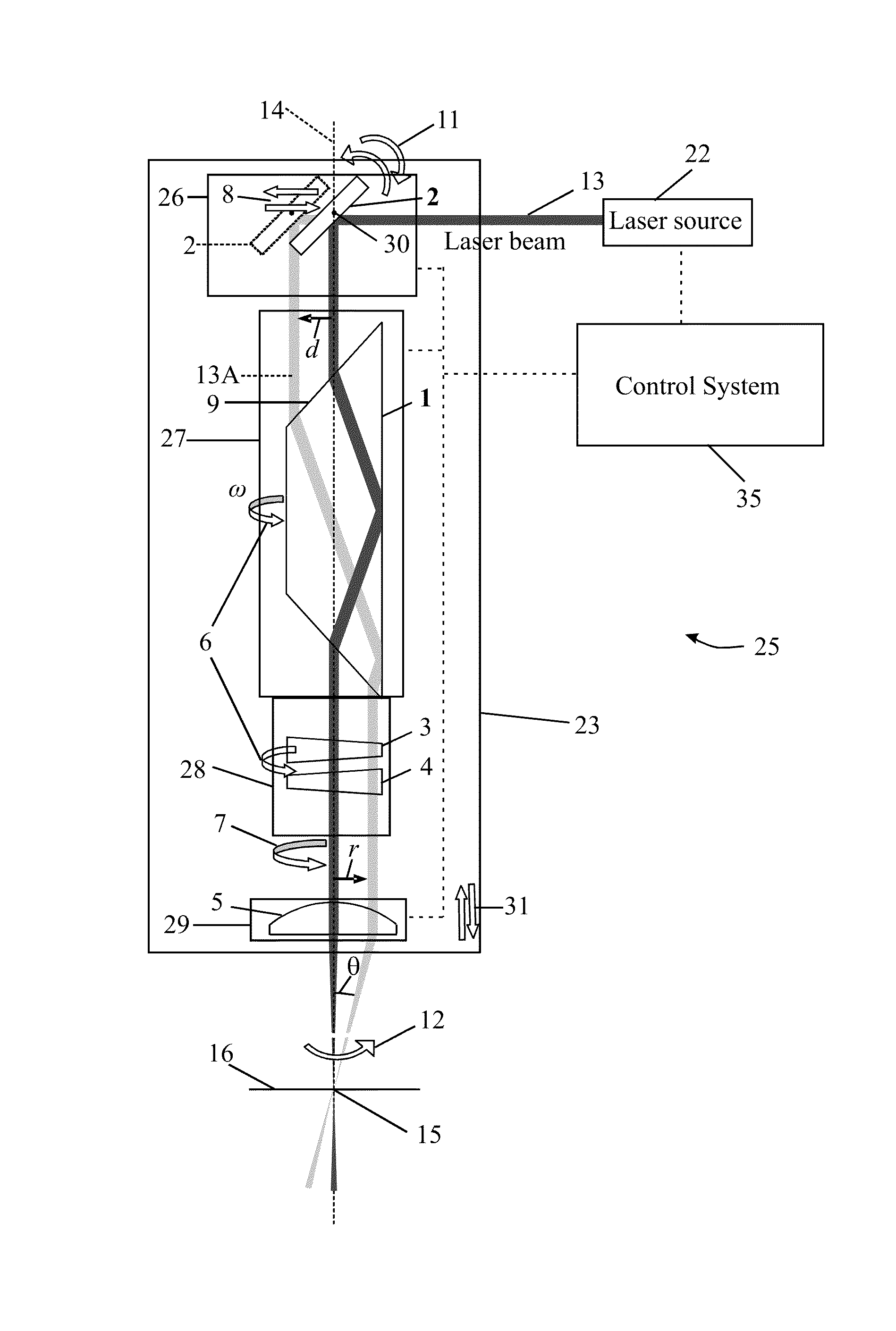

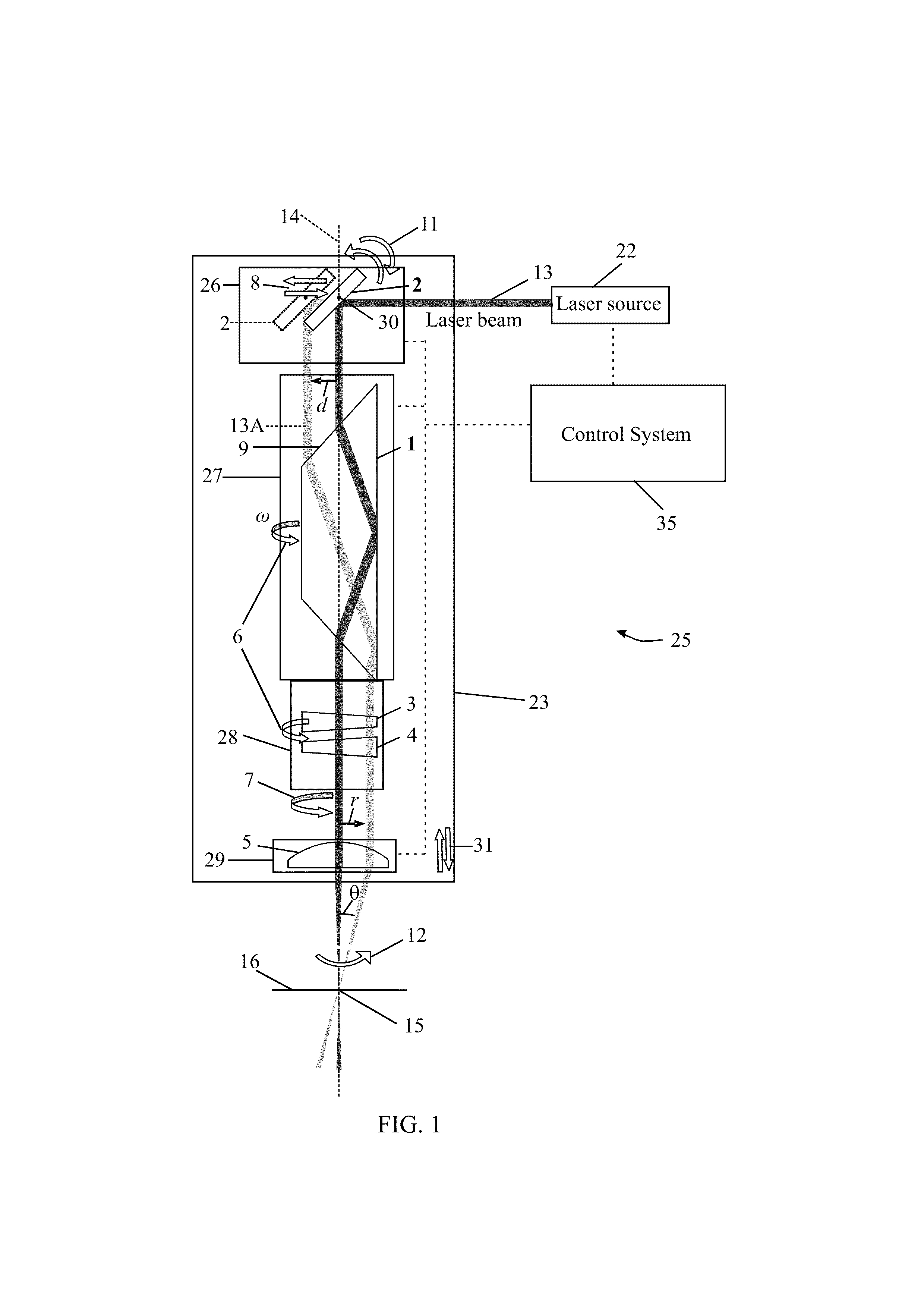

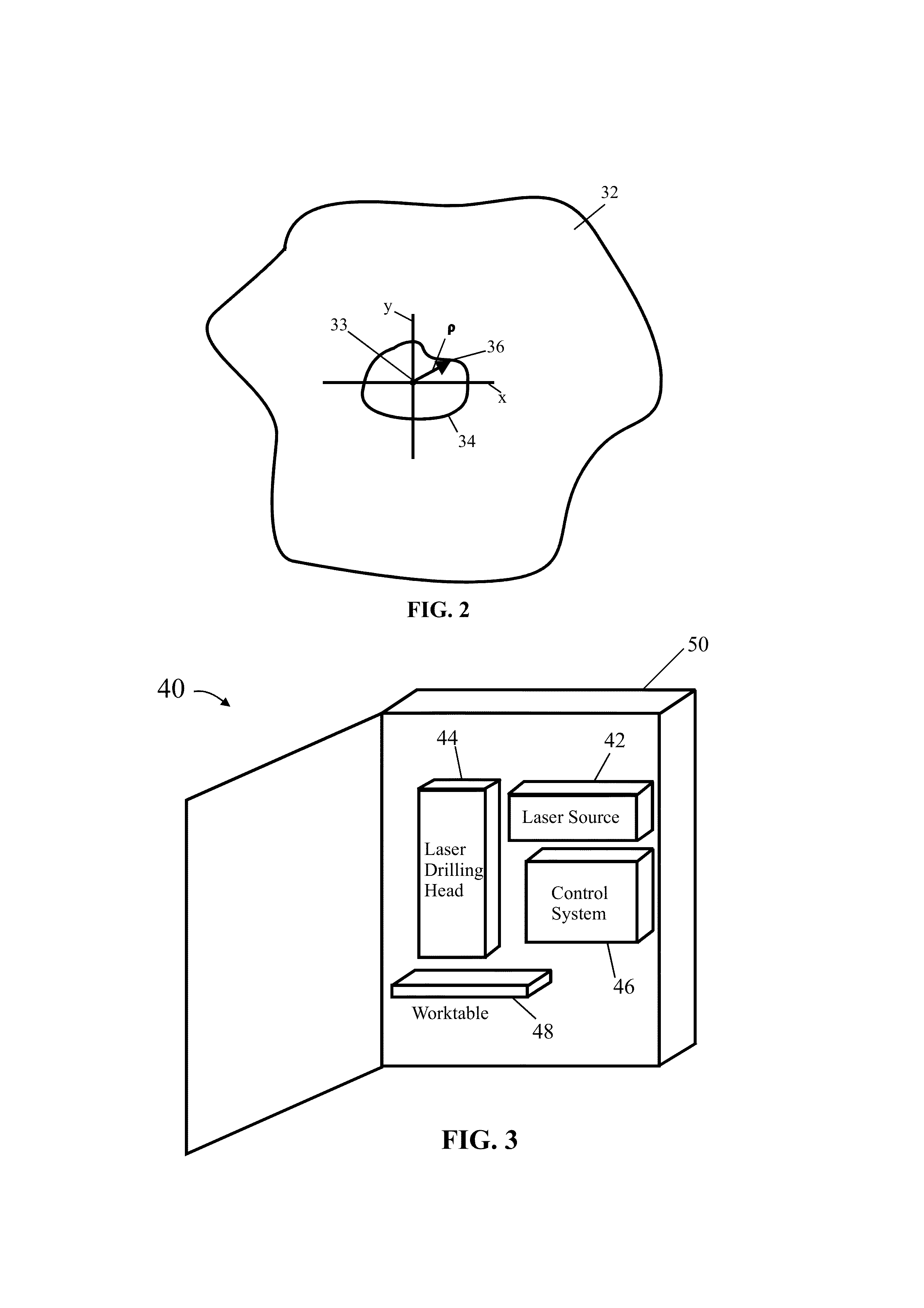

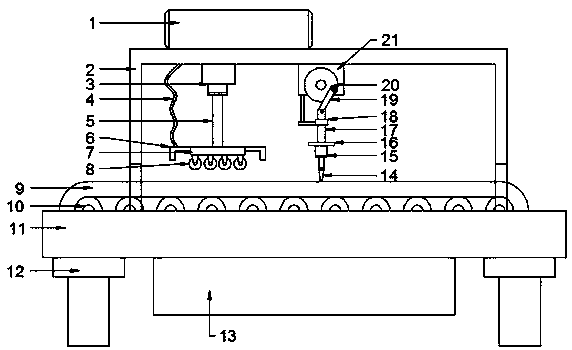

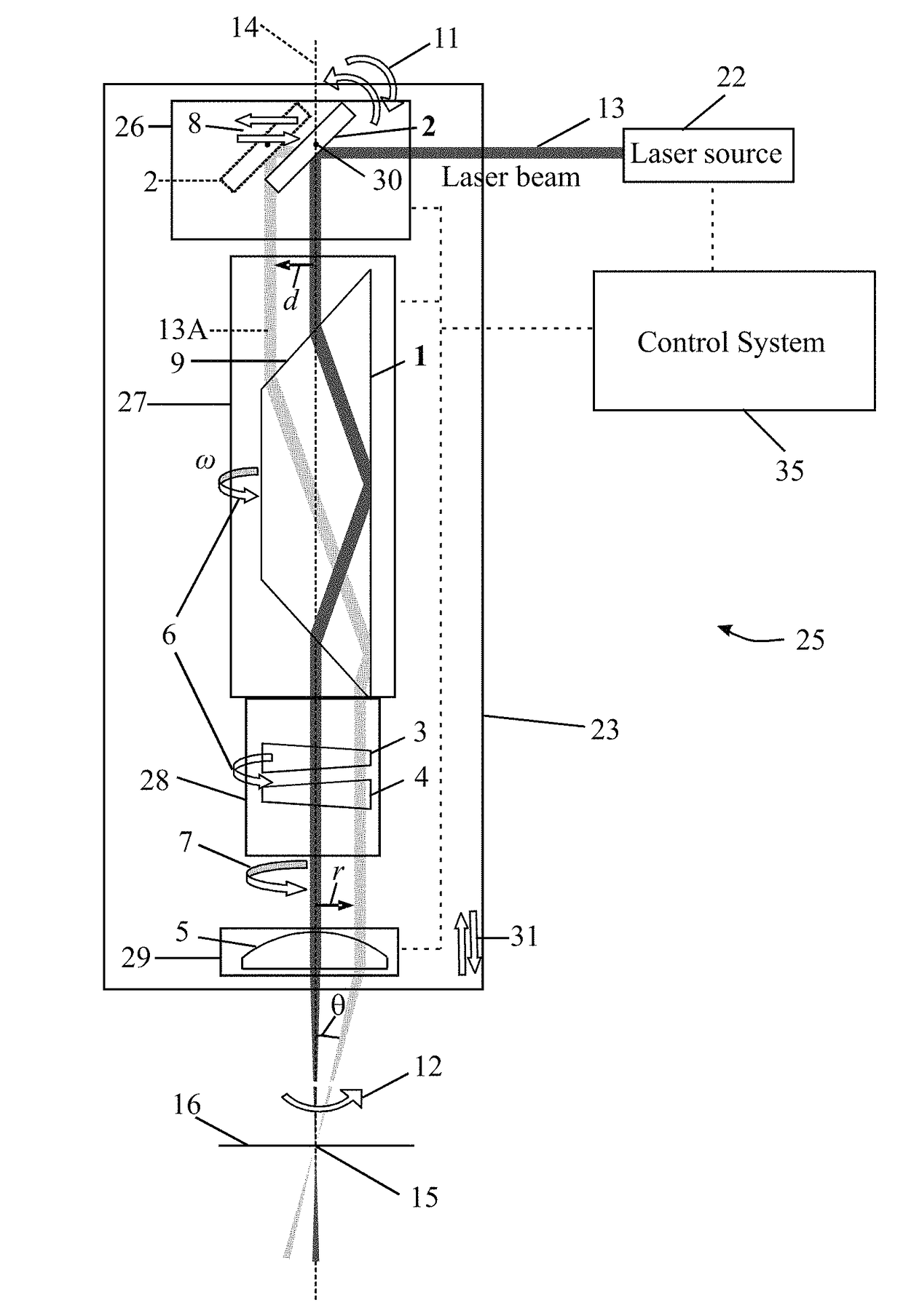

Laser Drilling and Trepanning Device

Laser drilling devices are disclosed which include a laser beam source and a laser drilling head. The laser drilling head includes a beam manipulator system in which the only dynamically moving optical element is a mirror. The mirror is dynamically and reciprocally translatable along the direction of the incoming laser beam and is also dynamically and reciprocally tiltable about an axis that is perpendicular to the nominal optical axis of the drilling head. The drilling head also includes a spinnable laser beam rotating system, a simplified compensation system, and a focusing system. The compensation system includes as its only laser beam path shifting optical elements on or two wedge plates which, if two, are fixably rotatable relative to one another in planes which are perpendicular to the nominal optical axis of the laser drilling device.

Owner:LUXCELIS TECH LLC

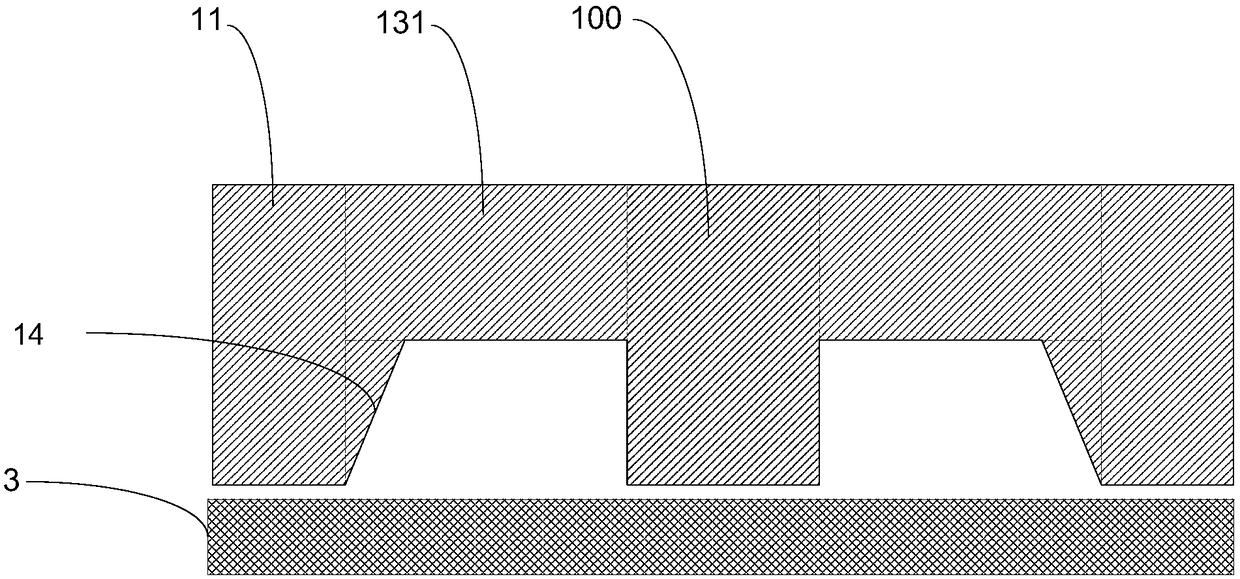

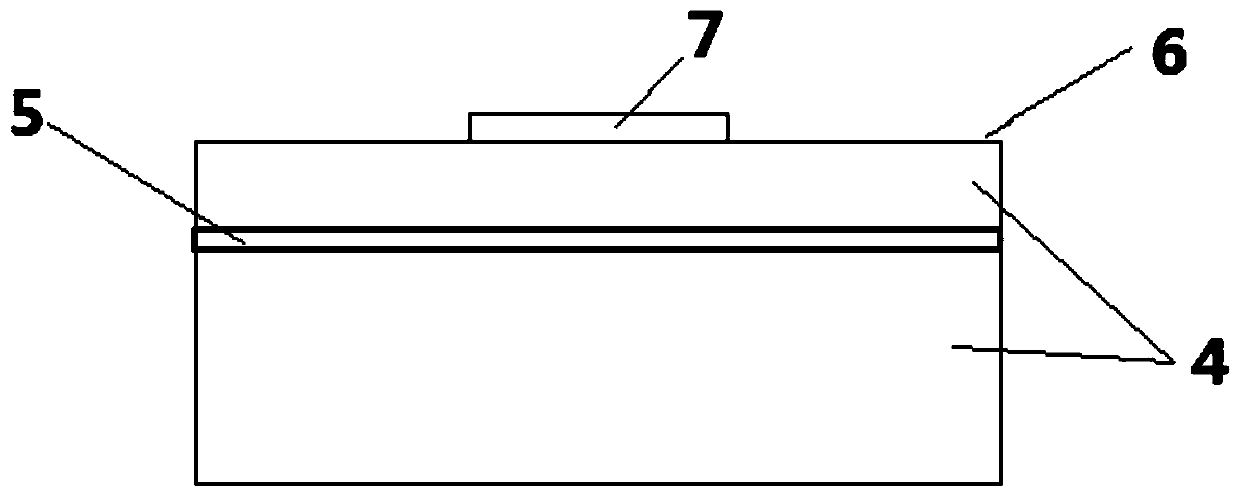

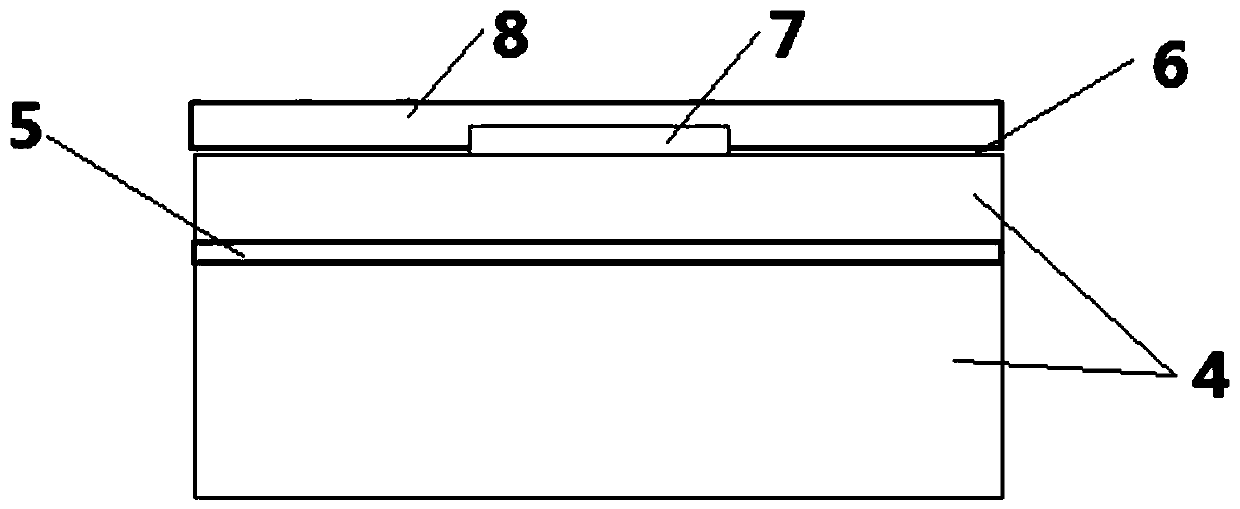

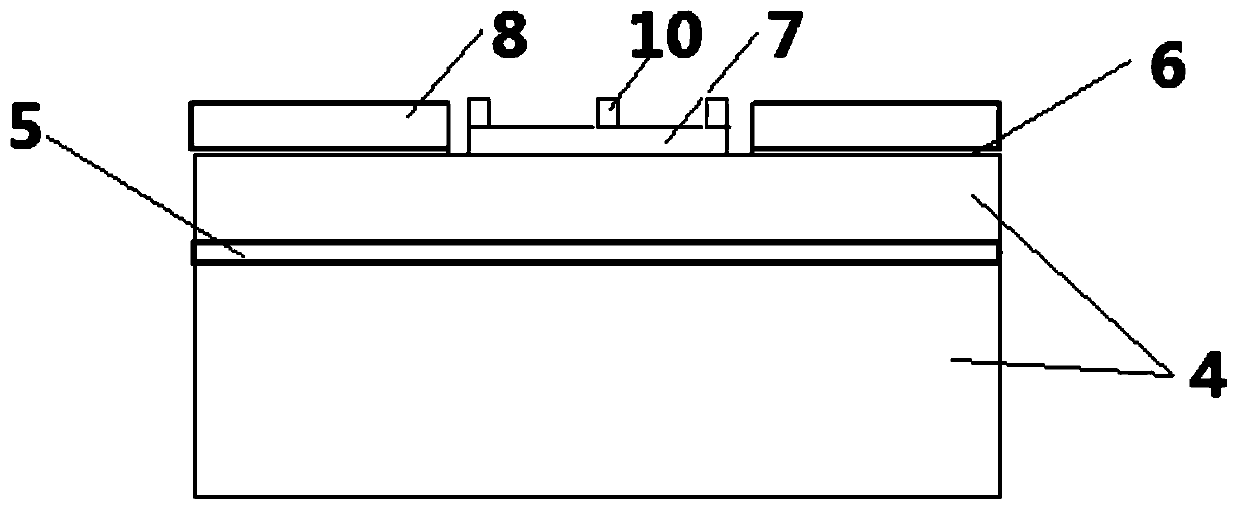

Irregularly-shaped display panel, manufacturing method thereof, display device and carrying table

ActiveCN108288634AImprove the effect of thin film encapsulationAvoid dark spots and other undesirable phenomenaSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The invention discloses an irregularly-shaped display panel, a manufacturing method thereof, a display device and a carrying table, and relates to the field of display technology. The manufacturing method comprises the following steps: manufacturing a substrate, and forming a display area, a first non-display area and a second non-display area on the substrate; carrying out cutting and hollowing on at least a part of the substrate inside a region restricted by a second retaining wall inside the second non-display area to form a first trepanning region, and putting the substrate on which the first trepanning region is formed on the carrying table; carrying out coverage on the region restricted by the second retaining wall inside the second non-display area by adopting a first mask, and evaporating an electroluminescent structure in the display area; taking down the first mask, carrying out coverage on the region restricted by the second retaining wall inside the second non-display areaby adopting a second mask, carrying out thin film packaging on the side, away from the substrate, of the electroluminescent structure to form a thin film packaging layer, and enabling a space betweena first retaining wall and the second retaining wall to be covered with the thin film packaging layer. Thus, the thin film packaging reliability of the irregularly-shaped display panel is improved.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

Display panel

InactiveCN108735094AGuaranteed reliabilityImprove ESD resistanceElectrostatic discharge protectionInput/output processes for data processingStaticsElectrostatic discharge protection

The invention discloses a display panel. The display panel is characterized by comprising a display area, a first non-display area, a trepanning, a second non-display area and an anti-static discharging protection circuit, wherein the display area is provided with multiple display units arranged in an array; the first non-display area surrounds the display area; the trepanning is formed in an areain the display area; the second non-display area is located between the display area and the trepanning, and the second non-display area is internally provided with multiple arc-shaped wirings used for being connected with corresponding data cables, gate lines and touch signal lines respectively; the anti-static discharging protection circuit comprises a suspension joint metal wiring, and the suspension joint metal wiring is arranged on the periphery of the trepanning and located in the second non-display area. The anti-static discharging protection circuit is arranged on the second non-display area so as to improve the ESD resistance capacity of the touch signal lines on the second non-display area, thereby ensuring the reliability of the display panel provided with the trepanning in thedisplay area.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

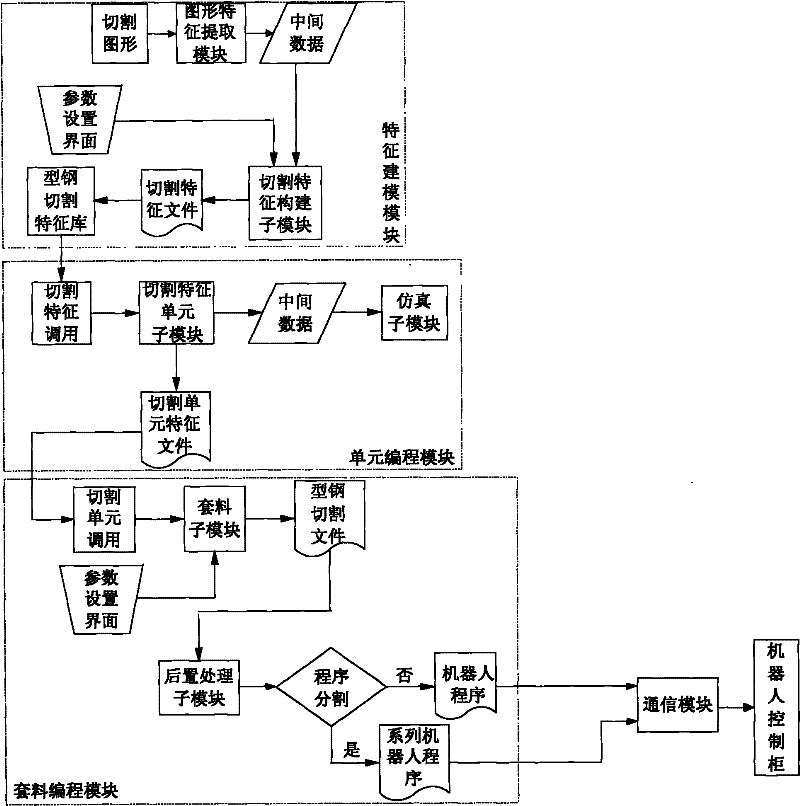

Robotic cutting method for profile steel

ActiveCN102189348AImprove cutting accuracyImprove cutting efficiencySpecial data processing applicationsWelding apparatusGraphicsDesign information

The invention discloses a robotic cutting method for profile steel, which is based on the robot offline programming. The method comprises the following steps of: reading a CAD graphics file to obtain geometrical characteristics of profile steel cutting; generating a cutting unit by a path planning and a cutting parameter design of the geometrical characteristics; determining an action parameter and a cutting parameter of a cutting gun and generating a trepanning file by a placement planning of the cutting unit on profile steel having a specific length; converting the trepanning file to be a robot executable program in accordance with the robot program format, and achieving the cutting of the profile steel. Based on the robot offline programming technology, by utilizing the designed information of CAD graphics directly, the robotic cutting precision and efficiency can be increased; the method is suitable for cutting requirements of groove-type profile steels, such as V-type, Y-type andthe like and varied-groove-type profile steel; the problem of the poor cutting quality at the edge of an angle steel or other steels is solved; the method has the characteristics of generality, flexibility, high efficiency and high precision.

Owner:HARBIN INST OF TECH

Existing subway station main structure broadening construction method

ActiveCN103469817AOpen hole precipitation method is simpleEnsure hole safetyArtificial islandsBuilding repairsSlurry wallSubway station

The invention discloses an existing subway station main structure broadening construction method. The existing subway station main structure broadening construction method comprises the following steps that firstly, bottom board trepanning dewatering construction comprises the processes that 101, dewatering well pipes are installed; 102, dewatering is conducted, and dewatering construction is conducted through the dewatering well pipes until underground water below a bottom board is reduced to the designed depth; secondly, station main structure broadening construction is conducted, and broadening construction conducted on an broadening subway station main structure comprises the processes that 201, new underground continuous wall construction is conducted; 202, broadening construction comprises the steps of broadening section division, first-period broadening-section broadening construction and second-period broadening-section broadening construction; 203, new side wall construction is conducted. The existing subway station main structure broadening construction method is simple in step, reasonable in design, convenient to achieve, low in investment cost, rapid in construction speed and good in construction effect, and effectively solves the problem that in subway station broadening construction, trepanning and dewatering are conducted on the existing bottom board with recovered water pressure difficultly.

Owner:CHINA RAILWAY FIRST GRP CO LTD +2

Wearable lower limb power-assisted mechanism

The invention provides a wearable lower limb power-assisted mechanism; a left side waist support and a right side waist support are identical and in an L-shaped structure; one ends of the waist supports are fixedly connected on two sides of a waist adjusting mechanism through a connecting flange; the side faces are tightly connected with two backside support plates through screws; the two backside support plates are vertical to the waist supports; two up-down parallel support connecting rods are screwed on the backside support plates; a control box is suspended on the support connecting rods through buckles; a waist belt penetrates trepanning in middle of the backside support plates; a hip joint driving mechanism is located below the waist supports, and screwed with connecting shafts of the other ends of left and right side waist supports; a first Femur connecting rod, a second femur connecting rod, a first femur band and a second femur band form a hip joint execution mechanism; a knee joint driving mechanism is tightly connected on the second femur connecting rod; a first shank connecting rod, a second shank connecting rod, a first shank band and a second shank band form a knee joint execution mechanism.

Owner:JIANGSU UNIV

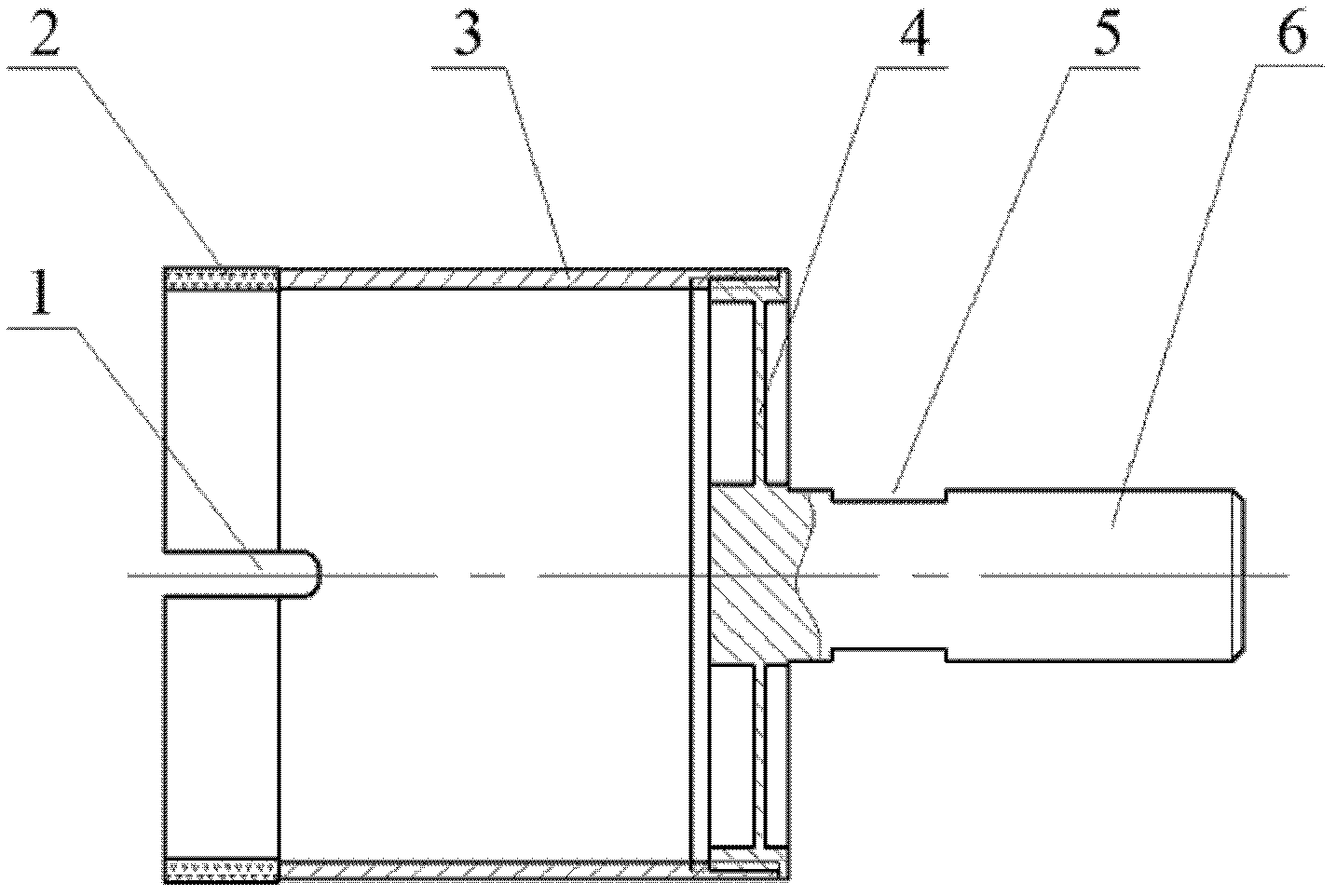

Mask device, display panel, production method of display panel and display device

ActiveCN108277473ASolve crackingSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The invention discloses a mask device, a display panel, a production method of the display panel and a display device and relates to the technical field of display. When trepanning is conducted on a packaging film layer of the display panel, the risk that the packaging film layer cracks is lowered. The mask device comprises one or more types of mask plates. Each mask plate comprises a frame shielding portion. Each frame shielding portion is provided with a material penetration area. Each material penetration area is provided with a trepanning shielding portion. Each frame shielding portion isconnected with the corresponding trepanning shielding portion through a locating shielding portion located in the corresponding material penetration area. The mask device is applied to film formationof a substrate. Under the shadow effect of a film formation process, a film layer is formed by an orthographic projection coverage area, on the substrate, of each locating shielding portion. By meansof the display panel, the packaging film layer is formed through the mask device. The mask device, the display panel, the production method of the display panel and the display device are used for forming the packaging film layer.

Owner:BOE TECH GRP CO LTD +1

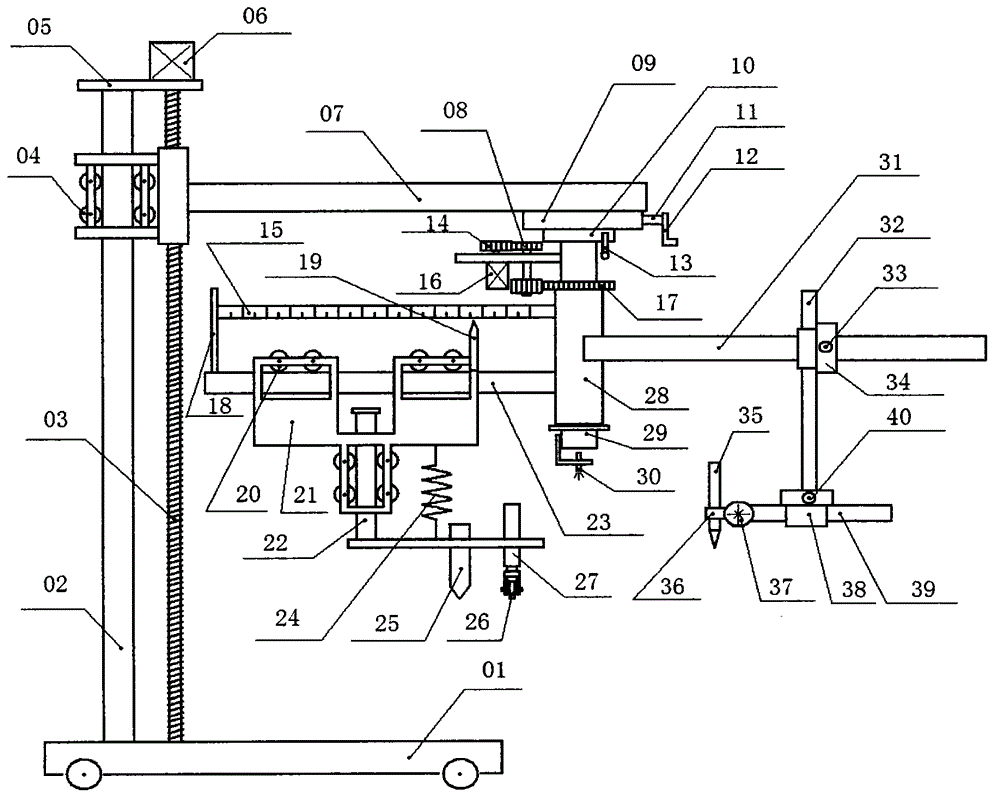

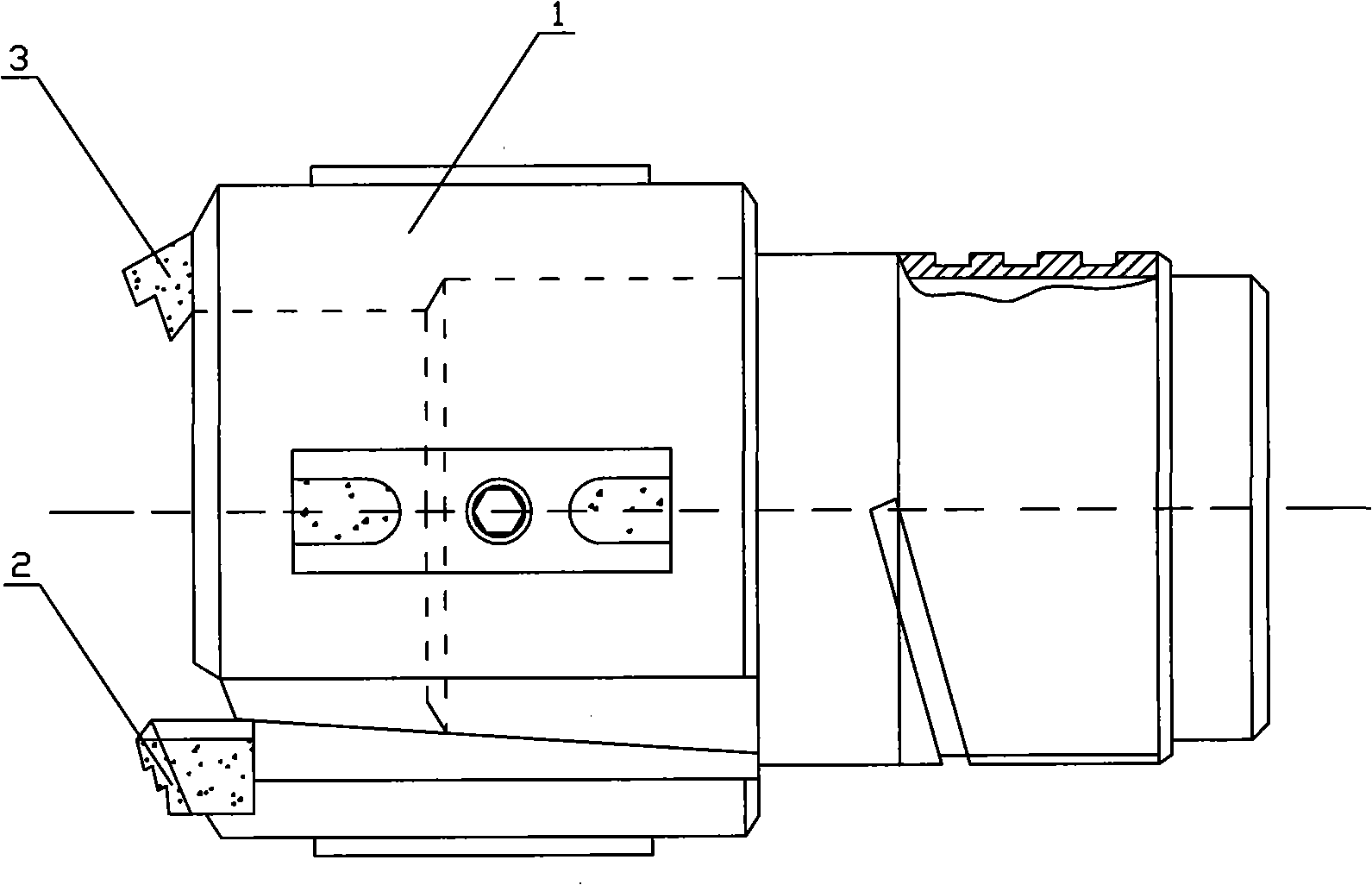

Device for scribing and trepanning cambered workpiece

InactiveCN104308826ASolve the errorSolve efficiency problemsOther workshop equipmentGas flame welding apparatusEngineeringTrepanning

The invention discloses a device for scribing and trepanning a cambered workpiece. The device comprises a base, a support, a lifting mechanism along the support, a big beam, a swing mechanism, a circle center locating mechanism, a bore diameter calibration mechanism, a scribing mechanism capable of lifting and moving left and right, and a trepanning mechanism capable of lifting and moving left and right. By adopting the device, the problems of big error, low efficiency and the like of manual scribing are solved, scribing and trepanning can be completed on the same device, and the overall production efficiency is improved.

Owner:刘哲传

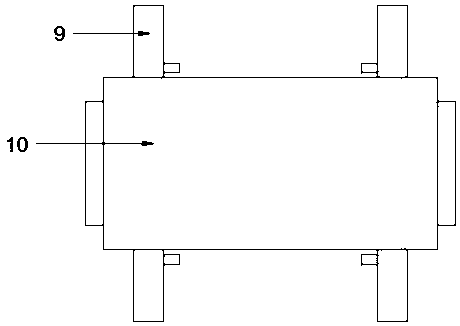

Bamboo chip trepanning and grinding integrated automation device

InactiveCN108312025ARealize transmission grindingImprove grinding efficiencyStationary drilling machinesCane mechanical workingHydraulic cylinderArchitectural engineering

The invention discloses a bamboo chip trepanning and grinding integrated automation device. The bamboo chip trepanning and grinding integrated automation device comprises grinding rollers, a workbenchand a drill bit. A conveying belt is arranged at the upper end of the workbench. In cooperation with the conveying belt, the upper end of the workbench is provided with a cavity. The conveying belt is provided with a baffle. A fixing cover is fixed to the upper end of the workbench. The four grinding rollers are arranged and are distributed on a first fixing plate in an array manner. A dust suction cover is fixed to the outer side of the first fixing plate, and the upper end of the first fixing plate is fixed to a push rod. The push rod is fixed to a hydraulic cylinder, and the drill bit is fixed to an output shaft of a first motor. The bamboo chip trepanning and grinding integrated automation device is high in grinding efficiency and quality; and meanwhile, in the grinding process, the dust suction cover can suck away fine dust generated during grinding

Owner:安吉森虎机械有限公司

Die for radially-oriented sintered NdFeB magnetic ring and production process thereof

InactiveCN103042211AIncrease profitImprove yieldInductances/transformers/magnets manufactureMagnetic polesTrepanning

A die for a radially-oriented sintered NdFeB magnetic ring comprises a magnet conducting and gathering ring, a female die, an upper pressure head assembly and a lower pressure head assembly, wherein the female die is arranged in the magnet conducting and gathering ring, the upper and lower pressure head assemblies are arranged in the female die, pressing surfaces of the upper and lower pressure head assemblies are positioned oppositely, and areas of the pressing surfaces of the upper and lower pressure head assemblies are the same with the cross section area of a female die cavity. A production process includes the steps of lifting the upper pressure assembly to the highest position, placing magnetic powder in the female die cavity, pressing the magnetic powder into a magnetic cake, removing a magnetic field, lifting the female die cavity, taking the magnetic cake out, performing isostatic pressing, trepanning and finishing the production process. Materials can be recycled, the utilization rate of the materials is high, the yield of magnetic rings is high, thin-walled parts can be produced, limitation to dimensions and shapes is small, and the amount of magnetized magnetic poles is arbitrary.

Owner:王秋安

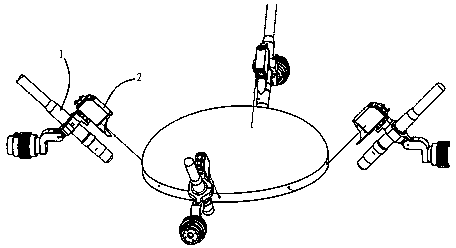

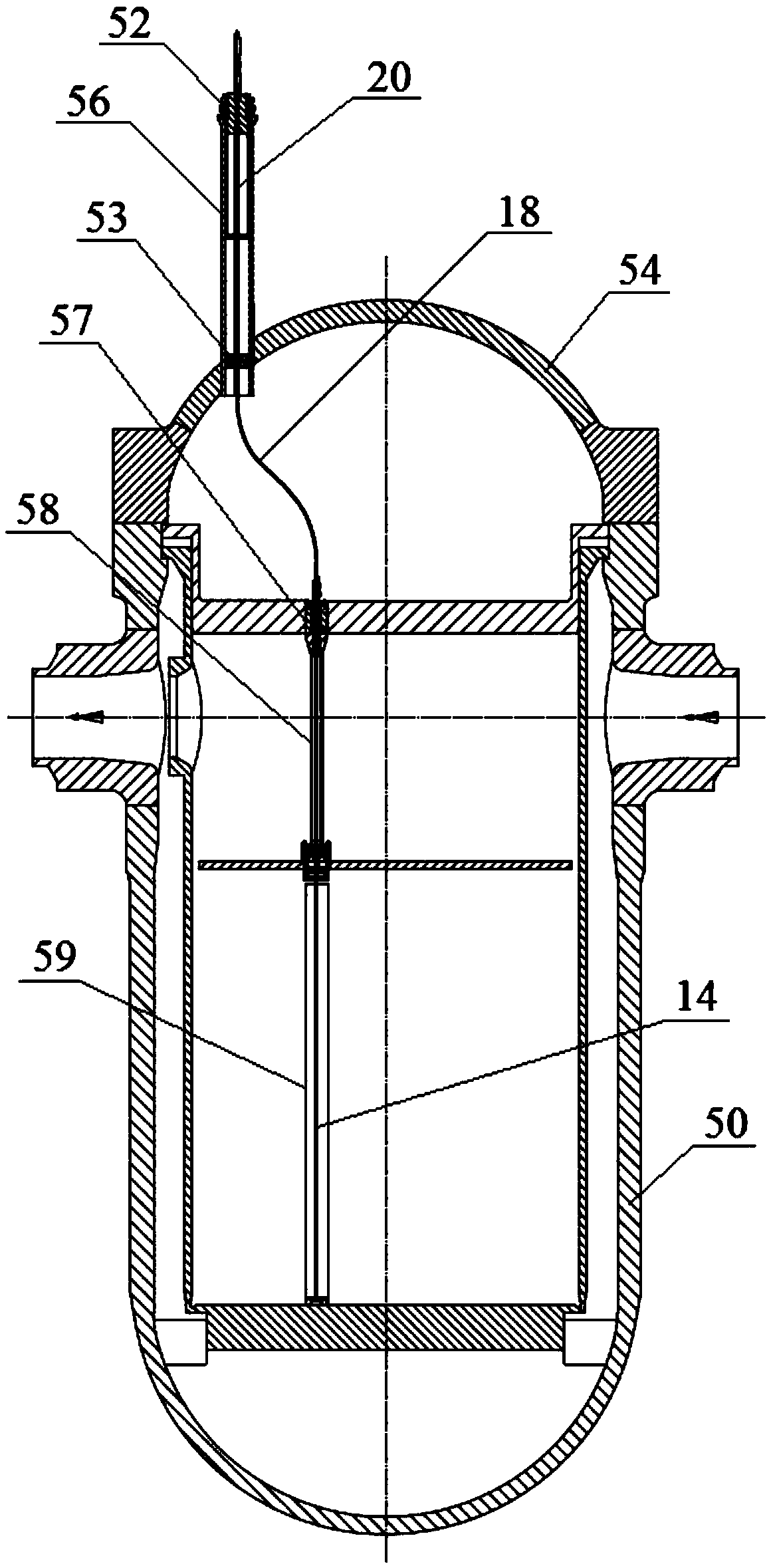

Method for cutting sealing head for automatic trepanning

ActiveCN104029206ARapid positioningFully automatedWelding/cutting auxillary devicesAuxillary welding devicesEngineeringLaser sensor

The invention discloses a method for cutting a sealing head for automatic trepanning. The method includes the following steps: S1, providing a point laser sensor, and mounting the same at the tail end of a robot; S2, providing an upper computer in communication connection with the robot, inputting cutting parameters for trepanning into the upper computer, generating a cutting task, and transmitting the cutting task to the robot; S3, automatically correcting a workpiece coordinate system, relative to the robot, of a to-be-cut workpiece to determine a pose relation between the robot and the workpiece during cutting; S4, acquiring deviation between an actual locating point of a trepanning position on the workpiece and a theoretical locating point; S5, acquiring an original track point of the trepanning position on the workpiece; S6, compensating trepanning track deviation and correcting the original track point to generate an actual track point; S7, performing trepanning cutting on the workpiece according to the actual track point acquired in S6 by the robot.

Owner:HUAHENG WELDING

Small satellite polygonal force bearing barrel

The invention discloses a small satellite polygonal force bearing barrel which comprises a barrel body. An upper end frame is glued at the top of the upper end of the barrel body in an embedded mode, a lower end frame is glued at the bottom of the lower end of the barrel body in an embedded mode, purlin strips are arranged at corners of the barrel body, a trepanning reinforcement frame is connected to the trepanning position of the barrel body in a glued mode, and a reinforcement corner box is arranged at the upper end of the lower end frame. The small satellite polygonal force bearing barrel solves the problems that the mass of the force bearing barrel is large, inconvenience is brought to installation on the surface of the barrel body, and the structural mode is complex, and has the advantages of being simple in structure, light in weight, multiple in installation face and the like.

Owner:SHANGHAI SATELLITE ENG INST

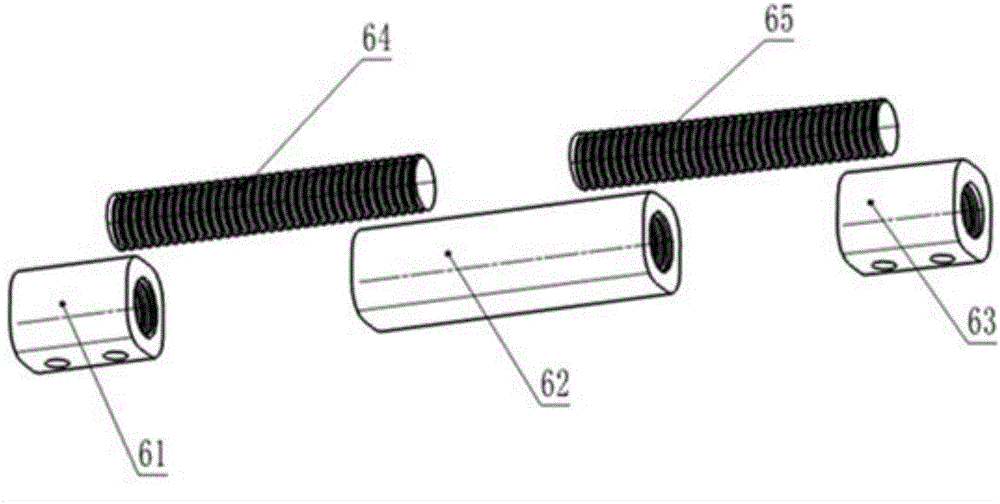

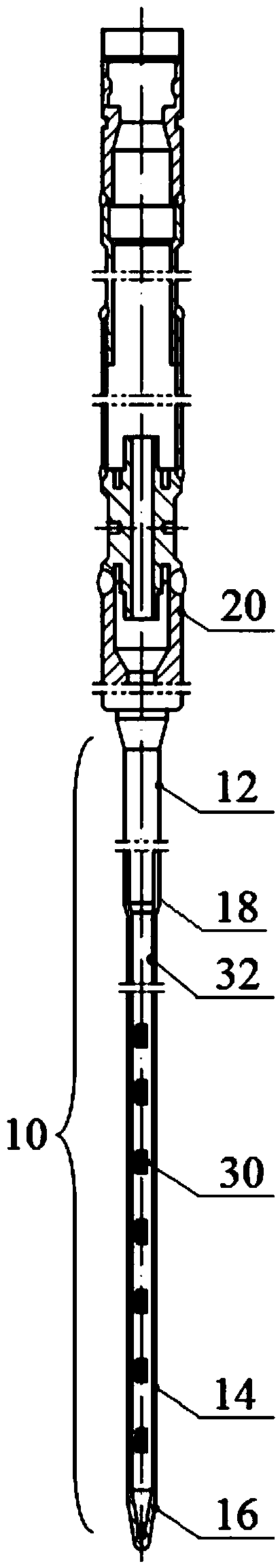

Nuclear power plant integrated in-core instrumentation assembly

InactiveCN105513657AReduce the number of openingsRealize simultaneous measurementNuclear energy generationNuclear monitoringReactor pressure vesselNuclear power

The invention discloses a nuclear power plant integrated in-core instrumentation assembly. The in-core instrumentation assembly introduces an in-core from a top cover of a reactor pressure vessel, and comprises an upper shell located outside the reactor pressure vessel, a shell located inside the reactor pressure vessel, a plurality of neutron fluence rate measurers used for detecting axial power distribution of the in-core and a thermocouple used for measuring outlet temperature of the in-core; the neutron fluence rate measurers and the thermocouple are all mounted in the shell, and the shell is used for ensuring that the neutron fluence rate measurers and the thermocouple are not in contact with a primary circuit coolant. Compared with the prior art, the nuclear power plant integrated in-core instrumentation assembly provided by the invention introduces the in-core from the top cover of the reactor pressure vessel, and meets the design requirements of advanced reactors; moreover, simultaneous measurement on the outlet temperature of the in-core and the neutron fluence rate of the in-core can be realized, and the trepanning amount of the reactor pressure vessel is reduced, so that the design safety of the reactors can be improved.

Owner:中广核工程有限公司 +1

New material surface trepanning equipment

InactiveCN107309456AHigh degree of automation integrationIncrease productivityLarge fixed membersBoring/drilling machinesElectric machineEngineering

The invention provides new material surface trepanning equipment comprising a base and a movable drilling assembly arranged at the upper end of the base. A clamp is inserted in a clamp fixing groove and clamps flocked cloth needing to be drilled through to a sliding panel. The sliding panel moves in the left and right direction through a servo motor, and then the movable drilling assembly moves through a control shaft fixed seat of the servo motor. A lifting cylinder controls a drill bit to move downwards, and at the moment, the motor controls the drill bit to rotate for drilling. The new material surface trepanning equipment is high in automation integration level, production efficiency can be improved, and the defective rate is lowered greatly. Meanwhile, the new material surface trepanning equipment adopts a multi-shaft drilling mode, the adjustability of the equipment is improved greatly, and drilling efficiency can be improved.

Owner:嘉善梦溪服饰辅料厂(普通合伙)

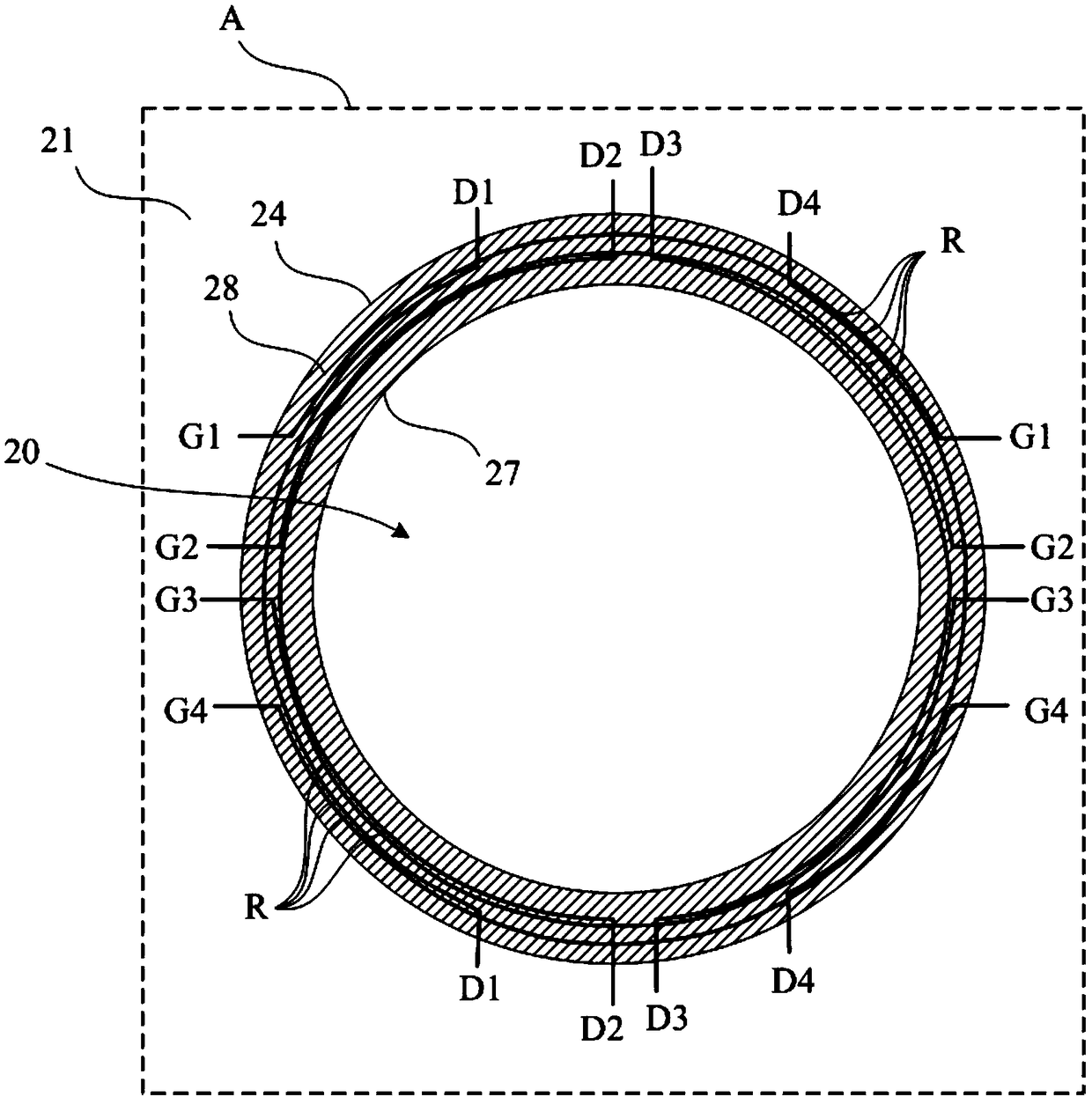

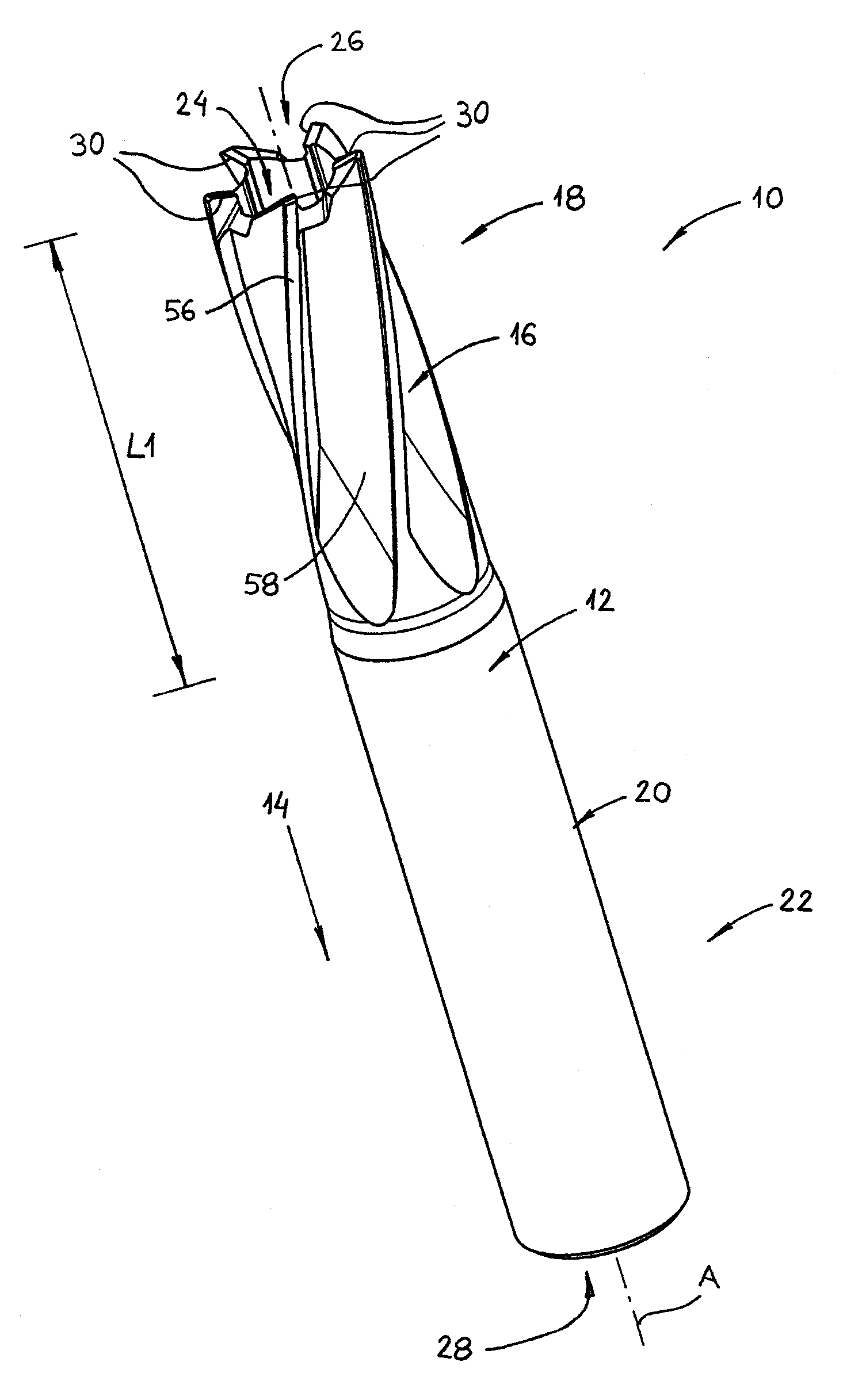

Trepanning Drill

InactiveUS20100124466A1Wood turning toolsTransportation and packagingEngineeringBiomedical engineering

A trepanning drill having a drill axis of rotation (A) and comprising a drill bore extending rearwardly from a front portion thereof. The drill body has at least two cutting edges formed in the front portion thereof. Each of the cutting edges has a cutting external edge and a cutting internal edge. A circle passing through the cutting external edge of each of the cutting edges forms an external circle having a first diameter (D1) and a first center (A1). A circle passing through the cutting internal edge of each of the cutting edges forms an internal circle having a second diameter (D2) and a second center (A2). In an end view of the trepanning drill, the first center (A1) coincides with the drill axis of rotation (A), and, the second center (A2) is offset from the drill axis of rotation (A).

Owner:ISCAR LTD

Clamping and trepanning die for hardware

InactiveCN105903808AExtended service lifeAffect machining accuracyPerforating toolsMetal-working feeding devicesWear resistantTrepanning

The invention discloses a clamping and trepanning die for hardware. The clamping and trepanning die comprises a lower die body and an upper die body. The lower die body is located under the upper die body. The clamping and trepanning die further comprises horizontal transverse air cylinder sets, a horizontal longitudinal air cylinder set, vertical air cylinder sets and compression rings. A workpiece fixing table used for installing a workpiece is arranged in the middle of the lower die body. The horizontal transverse air cylinder sets and the horizontal longitudinal air cylinder set are fixedly installed on the periphery of the upper end face of the lower die body. Air cylinder telescopic rods of the horizontal transverse air cylinder sets and the horizontal longitudinal air cylinder set face the workpiece fixing table. The vertical air cylinder sets are installed on the lower end face of the upper die body. The lower sides of the vertical air cylinder sets are fixedly connected with the upper surfaces of the compression rings, and each of the lower end faces of the compression rings and the upper end face of the workpiece fixing table are coated with an ultra-hard wear-resistant coating. The clamping and trepanning die for the hardware is reasonable in structure, the machining and positioning precision of the workpiece is improved, the workpiece is prevented from deforming, the service life is long, and the labor intensity is greatly reduced.

Owner:JIAXING HENGTAI METAL PROD

Cavity type bulk acoustic wave resonator with pillar and preparation method thereof

The invention provides a cavity type bulk acoustic wave resonator with a support column and a preparation method of the cavity type bulk acoustic wave resonator. The method comprises the following steps of: taking a piezoelectric single crystal wafer which is subjected to ion implantation and is provided with a bottom electrode; forming a plurality of supporting columns on one side, with the bottom electrode, of the piezoelectric single crystal wafer; forming a cavity at the gap of supporting columns, taking the substrate, bonding the substrate with one side of the piezoelectric single crystalwafer with the cavity, carrying out heat treatment on the substrate after bonding, stripping a film of the piezoelectric single crystal wafer, and producing a top electrode on the stripped side of the piezoelectric single crystal wafer to obtain the piezoelectric single crystal wafer. According to the technical scheme provided by the invention, a sacrificial layer does not need to be grown, etching and trepanning are not carried out on the thin film, the mechanical strength of the device is improved, and the thin film is not easily damaged; the cavity structure is formed before film formation, the rate of finished products is high, residues left by etching after film formation do not exist, and the influence of incomplete release on the device does not need to be considered.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

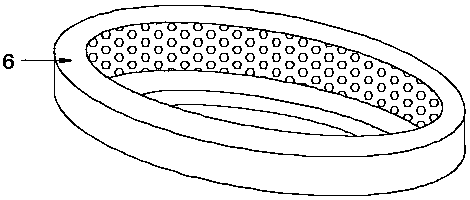

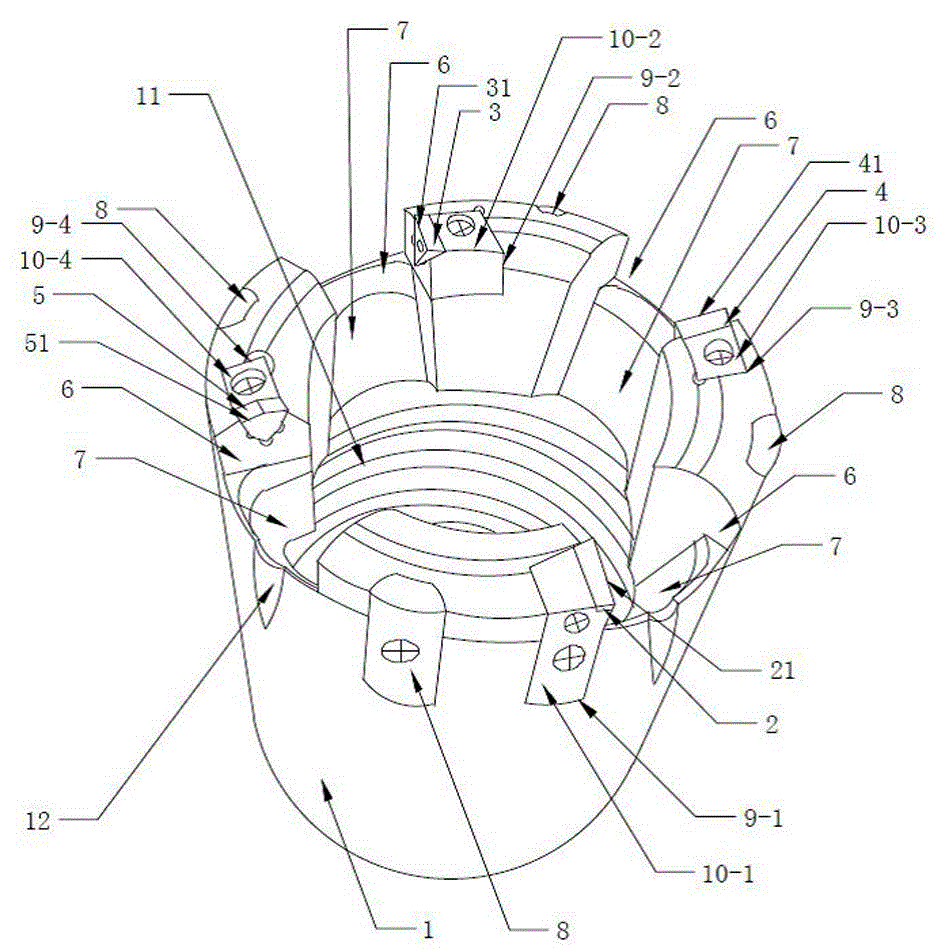

Trepanning tool with self-air cooling and chip removing functions

ActiveCN102211217AReduce frictionReduce the temperatureTransportation and packagingTrepanning drillsImpellerEngineering

The invention discloses a trepanning tool with self-air cooling and chip removing functions. The upper end face of the trepanning tool is provided with an impeller with blades; the impeller consists of more than two blades with an angle in the shapes of a flat surface or a curved surface; the inclination angle is in a clockwise direction or an anticlockwise direction according to outward exhaust or inward suction; the trepanning tool has a split structure, namely comprises a cutter handle with the impeller and a trepanning head with a diamond abrasive, which are in threaded connection; a cutting part with abrasive particles consists of super-hard abrasive particles subjected to electroplating or hot-pressing sintering; the thickness of the cutting part is greater than that of a barrel wall substrate; and the end face of the cutting part is provided with more than two chip removing grooves. The trepanning tool can obviously reduce friction between cuttings and a cutter, and between the cuttings and a material substrate, reduces the temperature of a cutting area, timely takes the cuttings away, effectively slows down the blockage of the cutter, and fulfills the aim of low-damage and high-efficiency processing; meanwhile, the manufacturing cost and the using cost of the cutter can be obviously reduced due to the split structure.

Owner:DALIAN UNIV OF TECH

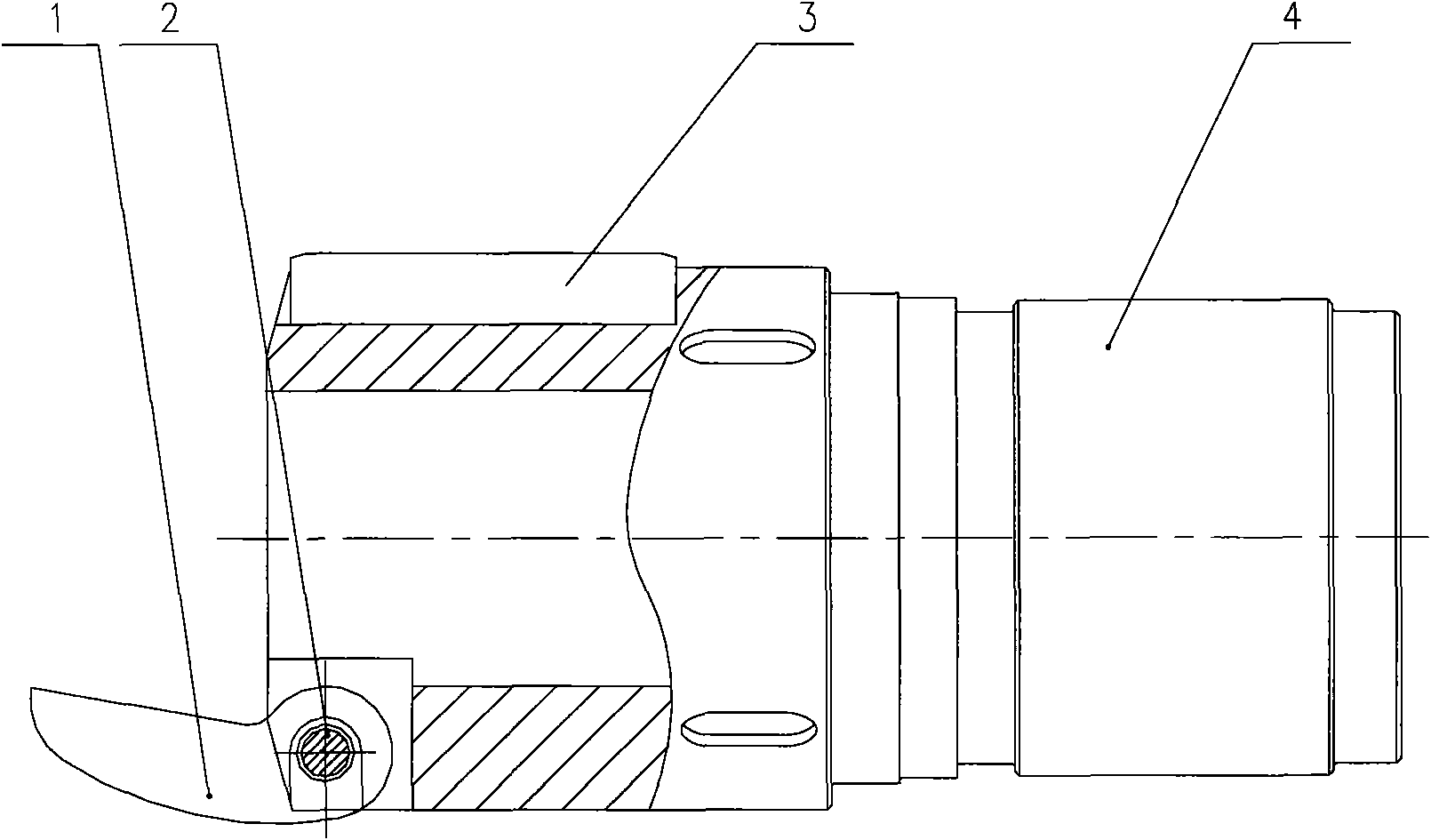

Trepanning tool

InactiveCN104148709AReduce cutting forceIncrease feed rateTransportation and packagingTrepanning drillsEngineeringCutting force

The invention discloses a trepanning tool. By the adoption of the structural design, the cutting force is lowered, the amount of feed is increased, cutting efficiency is improved, and cutting stability is improved. The mode is that an inner cutter, a middle cutter and an outer cutter are adopted to conduct cutting working on different circumferences of a shaft body to be machined; a main cutting edge of the inner cutter and a main cutting edge of the outer cutter are arranged in an inclined mode; a chip splitting cutter is arranged; an inner clipping cutter, a middle clipping cutter and an outer clipping cutter are optimized, and the structure parameters, position parameters and other parameters of the chip splitting cutter are optimized.

Owner:JIANGYIN LEGAO ENERGY EQUIP

Method for bushing repairing of thread hole

The invention discloses a method for bushing repairing of a thread hole, and belongs to the technical field of mechanical part repairing treatment. The method comprises following steps that S1, chambering for defect removing is achieved, the thread hole A to be repaired is chamfered to the pre-designed bushing size, the defect part is removed, a 30 to 60-degree chamfer is reamed on the edge opening part of the thread hole A; S2, a filling part is prepared, a material the same with or similar to base metal is selected, and a filling part matched with the thread hole A is turned; S3, the threadhole is filled; S4, welding is carried out, according to the welding parameters, the filling part is welded on the chamfering part, full welding chamfering is carried, and in the welding process, welding deforming is controlled; S5, primary leveling is carried out; S6, a set screw is assembled; S7, secondary leveling is carried out; and S8, trepanning is carried out. The method has the beneficialeffects that thread deforming of a new thread hole in the assembling process can be avoided, an original bolt can be still used, the detaching of the original size can be kept, the workpiece integration is improved, and the anti-vibration property and the anti-tensile property of a workpiece are optimized.

Owner:DEYANG DONGQI POWER STATION EQUIP

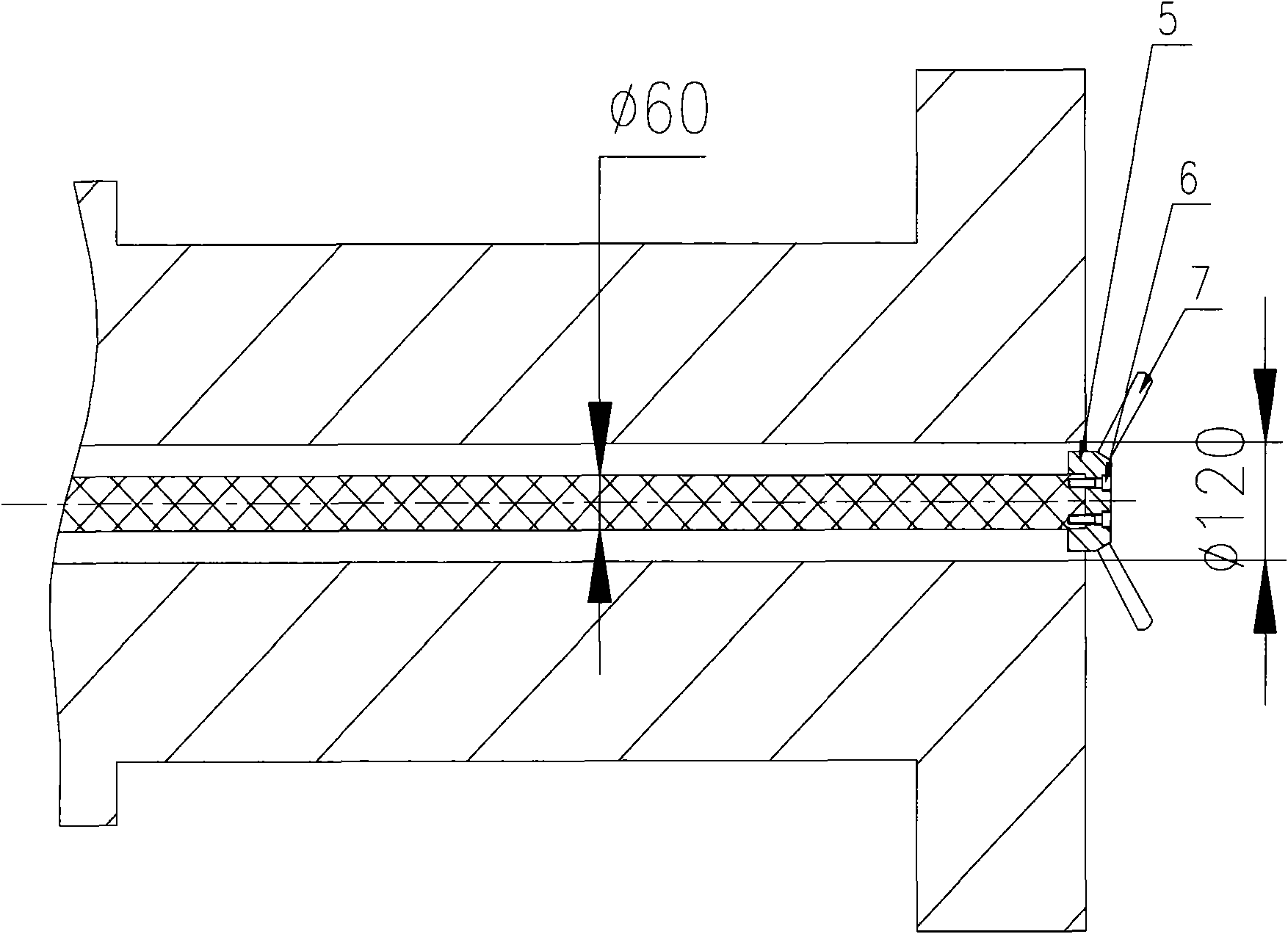

Trepanning sampling method of blind hole of ultralong deep hole and cut-off tool

The invention discloses a trepanning sampling method of a blind hole of an ultralong deep hole, which can be used for taking a core rod with a hole diameter of 60 mm and a length of 1500-4000 mm out of a blind hole with a hole diameter of 120 mm and solving the problem of trepanning sampling of the blind hole of the ultralong deep hole of a super-critical generator. The trepanning sampling methodcomprises the following steps of: firstly, trepanning a blind hole of an ultralong deep hole with a hole diameter D and a core rod hole diameter d at the sampling end of a workpiece by using a trepanning drill rod; and secondly, installing a cut-off tool on the head of the trepanning drill rod, transporting the cut-off tool to the appointed blind hole deeply to carry out cut-off operation, and cutting the core rod off from the blind hole. The invention also discloses the cut-off tool for the trepanning sampling of the blind hole of the ultralong deep hole.

Owner:SHANGHAI HEAVY MACHINERY PLANT

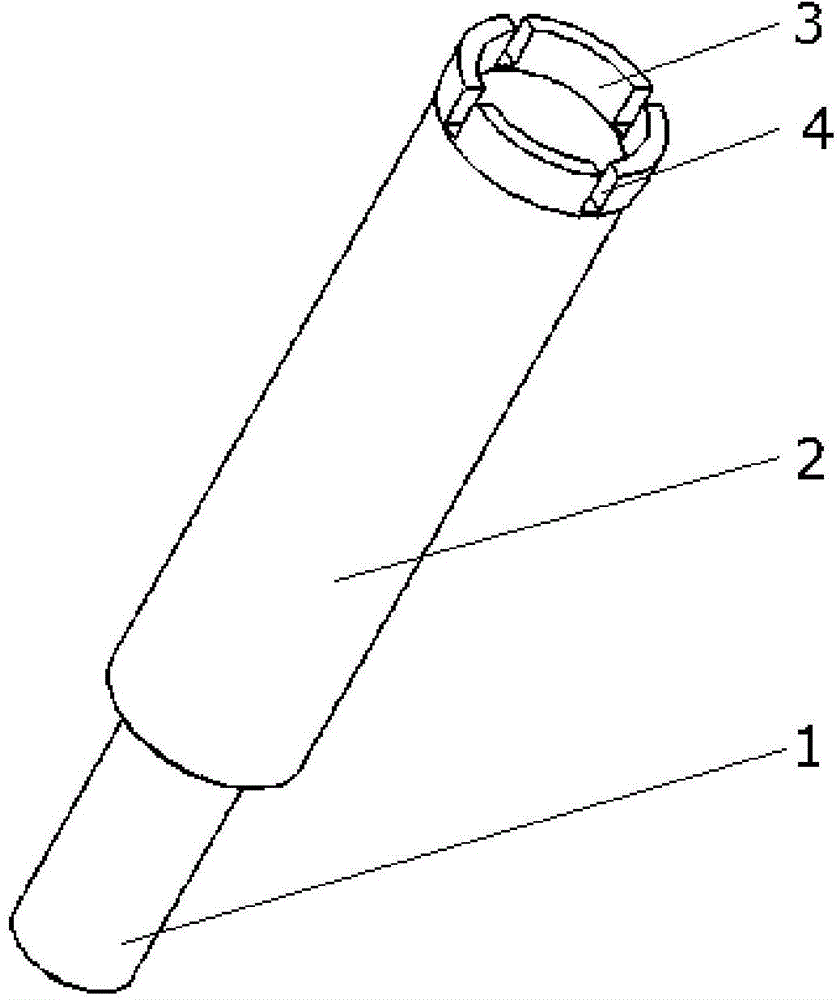

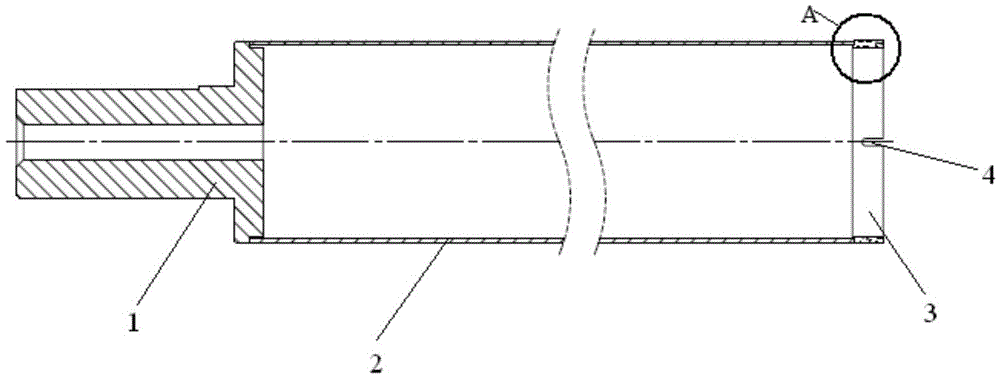

Diamond trepanning drill bit for sapphire crystal bar taking and preparing method of diamond trepanning drill bit

The invention belongs to the technical field of ultra-hard material tool manufacturing, and discloses a diamond trepanning drill bit for sapphire crystal bar taking and a preparing method of the diamond trepanning drill bit. The diamond trepanning drill bit comprises a joint, a drill pipe and a diamond tool bit, wherein the joint is arranged on a main shaft of a sapphire crystal bar taking machine; the drill pipe is in a tubular shape; the bottom end of the drill pipe is connected with the joint; the diamond tool bit is in an annular shape and is integrally formed; and the bottom end of the diamond tool bit is connected with the top end of the drill pipe through laser welding, so that a hollow cavity is formed by the drill pipe and the diamond tool bit. The preparing method of the diamond trepanning drill bit comprises the following steps including a diamond tool bit rough processing and preparing step, a welding step and a fine processing and preparing step. Through the scheme, the goal of improving the concentricity of the concentricity and the drill pipe is achieved.

Owner:BEIJING GANG YAN DIAMOND PROD CO +1

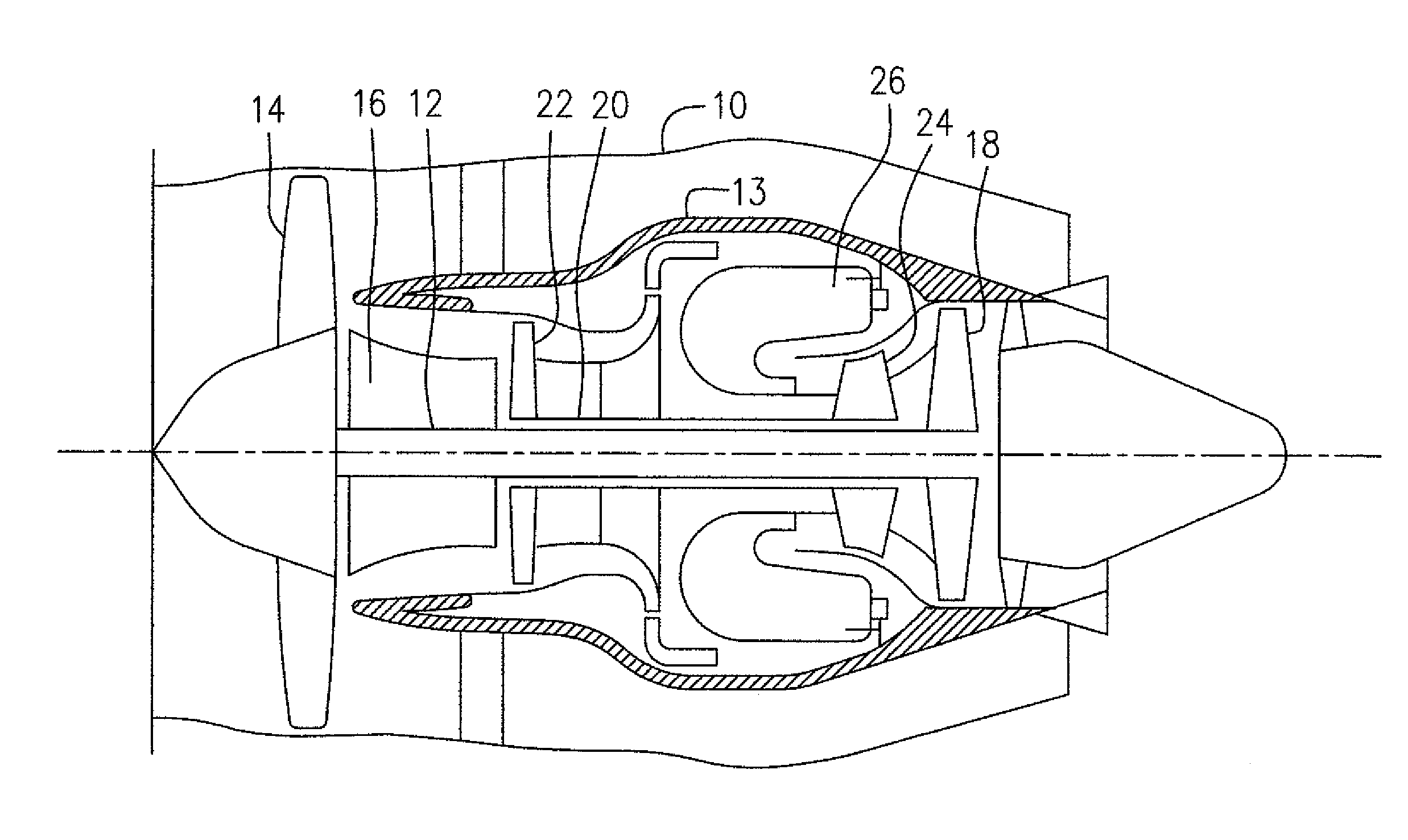

Laser drilling methods of shallow-angled holes

A method for providing a shallow-angled hole through a metal component, such as a turbine combustor, includes a step of applying a pulse laser beam to drill a section of the hole substantially within a thermal barrier coating of the component in a trepanning concept. A further step is conducted to apply the pulse laser beam through the completed section of the hole to further drill through a base metal of the component to complete the formation of the hole extending through the component.

Owner:PRATT & WHITNEY CANADA CORP

Laser drilling and trepanning device

Laser drilling devices are disclosed which include a laser beam source and a laser drilling head. The laser drilling head includes a beam manipulator system in which the only dynamically moving optical element is a mirror. The mirror is dynamically and reciprocally translatable along the direction of the incoming laser beam and is also dynamically and reciprocally tiltable about an axis that is perpendicular to the nominal optical axis of the drilling head. The drilling head also includes a spinnable laser beam rotating system, a simplified compensation system, and a focusing system. The compensation system includes as its only laser beam path shifting optical elements one or two wedge plates which, if two, are fixably rotatable relative to one another in planes which are perpendicular to the nominal optical axis of the laser drilling device.

Owner:HIMILE CNC MASCH TOOL (SHANDONG) CO LTD

Method for rectifying deviation of large storage tank by jack-up

InactiveCN107100215AFree from destructionControl precisionFoundation repairTreatment effectDeformation monitoring

The invention relates to a method for rectifying the deviation of a large storage tank by jack-up. The method specifically comprises the following steps that firstly, a deformation monitoring system is established, wherein the deformation monitoring system is used for monitoring degree of storage tank sedimentation, monitoring storage tank displacement and monitoring deep soil deformation; secondly, a storage tank foundation is reinforced; thirdly, the storage tank is filled with water and pre-pressed; and fourthly, the deviation of the storage tank is rectified by jack-up. The method is suitable for most of building structure forms and various foundation soil, and the operation space is small; in the method, due to the fact that grouting pipe trepanning and grouting are conducted from the periphery of a building structure, the building structure is not damaged; through monitoring synchronous with construction, the precision of rectifying deviation by jack-up can be effectively controlled; and after foundation reinforcing and deviation rectifying, all loads are applied to meet the using requirement, and the treatment effect is very visual.

Owner:CHINA GASOLINEEUM ENG

Taper degree mounting type off-centering machine cutting ferrule material drill

InactiveCN101318233AImprove cutting performanceReduce vibrationTransportation and packagingBoring/drilling machinesEngineeringProduct processing

The invention provides a taper mounted type eccentric machine trepanning drill which comprises a cutter body, an outer cutter, an inner cutter, a shim, a guidance key, an elastic key, an oil resisting rubber jointing, an oil inletting clearance, a chip removal clearance, a machine card cutter holder and a machine card taper screw. The chip removal clearance is provided with an eccentric machine card of the cutter holder in a coattail shape; the outer cutter and the inner cutter are arranged in the eccentric machine card in a coattail shape at the front part of the machine card cutter holder respectively by machine card taper screw; the tail part of the machine card cutter holder is in a cylinder shape and the upper part of the cylinder is provided with inclined surface in shape of a umbrella with the gradient slope of 2 to 5; the machine card cutter holder tightly fastens the inclined surface in shape of a umbrella in the installing hole of the cutter body by screws; the outer cutter and the inner cutter are provided with at least one chip splitting table respectively; the outer edge of the cutter body is tightly provided with two guiding keys and two elastic keys by screws. The trepanning drill has the advantages of good cutting property, less vibration and good chip breaking effect, can meet the demand of product processing size and can reduce the roughness of the products on the basis of high-speed cutting.

Owner:田栽亮

Device and method for microleak identification of coal-powder boiler or circulating fluidized bedboiler

InactiveCN108645571AImprove compatibilityReduce economic lossFluid-tightness measurement using fluid/vacuumMeasurement pointEngineering

The present invention discloses a device and a method for microleak identification of a coal-powder boiler or a circulating fluidized bedboiler. The device comprises a hearth flue, a dust remover, aninduced draft fan, a chimney, a computer, trepanning measurement points, a thermocouple, a hygrometer and a PLC system. The two sides of the heating surface in the hearth flue are provided with the plurality of trepanning measurement points, the trepanning measurement points are internally provided with protective casings; the thermocouple and the hygrometer are respectively arranged in the protective casings to measure the temperatures and the humidities of different heating surfaces in real time and transmit the measurement values into the PLC system through cables; the PLC system is connected with the computer, the PLC system is configured for data analysis and processing, an analysis result can be displayed on the computer in a curve mode, if the humidity curve trend of a certain pointor the humidity difference of some two points reaches a threshold value, leakage alarm is emitted, and the positions of the heating surfaces are confirmed to perform furnace shutdown maintenance. Thedevice and the method for microleak identification of a coal-powder boiler or a circulating fluidized bedboiler can discover problems and can emit alarm when the leakage amount is little, and can discover the preliminary position of the leak surface.

Owner:高振宇 +3

Mobile terminal and manufacturing method thereof

The application relates to a mobile terminal and a manufacturing method thereof. The mobile terminal comprises a display screen, a shell, a motherboard and a functional module; wherein the shell comprises a middle frame and a back shell; the middle frame is connected with the display screen as a whole, and no matching gap exists between the middle frame and the display screen; the back shell is connected with the middle frame at the side farther from the display screen; the display screen, the middle frame and the back shell are enclosed together to form a closed cavity; and the motherboard isconnected with the functional module, and both the motherboard and the functional module are arranged in the closed cavity. In the mobile terminal disclosed by the application, since no matching gapexists between the display screen and the middle frame, and the back shell is connected with the middle frame, the back shell, the display screen and the middle frame are enclosed together to form theclosed cavity; therefore, the outside water vapor or dust cannot enter the closed cavity, thereby being well waterproofed and dustproof, and improving the use effect of the mobile terminal. Meanwhile, the setting avoids the limitation of the trepanning of the conventional mobile terminal to the setting area of the display screen of the mobile terminal, therefore, the display area of the display screen can be made as large as possible, and the screen ratio is increased.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

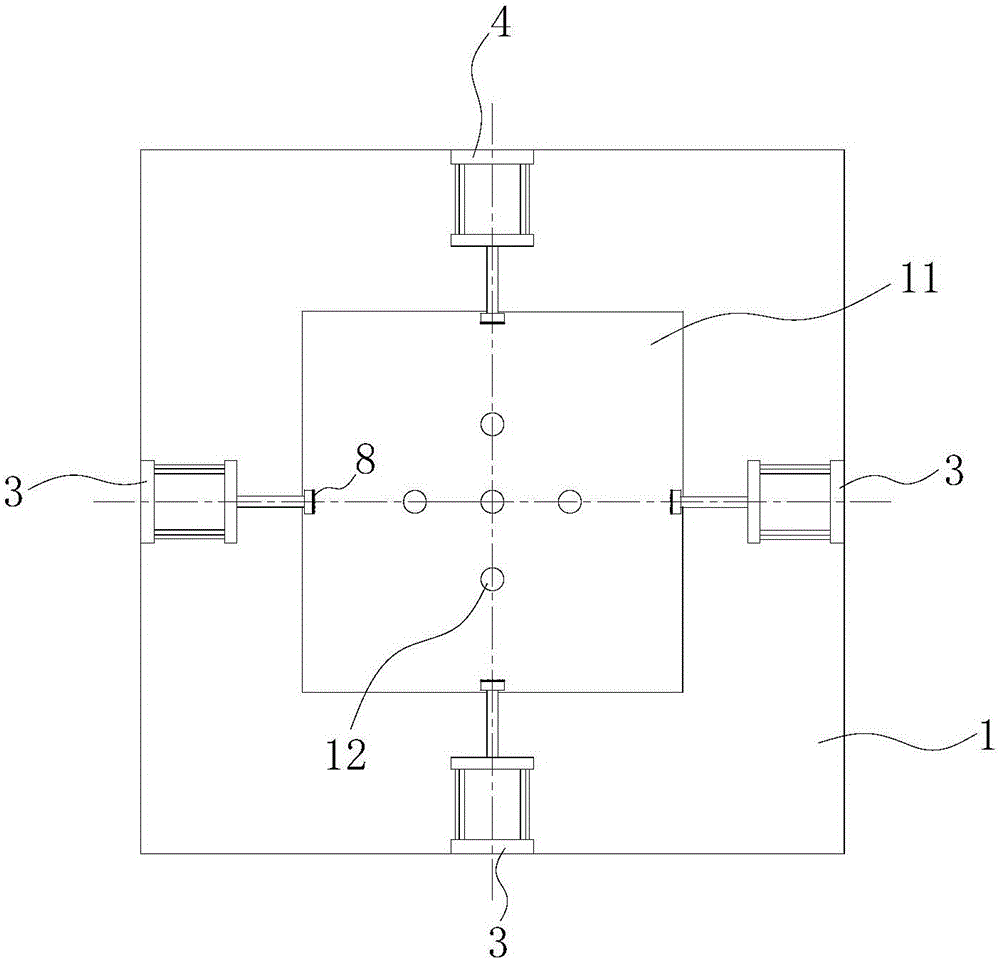

Underground hole drilling and trepanning azimuthal angle measurement system and method

ActiveCN104088626AReduce the difficulty of position adjustmentAngle adjustableConstructionsLight sensingDrill site

The invention discloses an underground hole drilling and trepanning azimuthal angle measurement system and method. The system comprises a line marking device and a measurement host. Two line light source emitting devices on the line marking device generate two emitting planes, the first emitting plane is used for being aligned to a center line of a roadway, the second emitting plane intersects with a light sensing face on the measurement host to form a sensing straight line, the included angle between the light sensing straight line and a set shaft of the measurement host and a self inclination angle are measured thorough a processing system inside the measurement host, and therefore the hole drilling and trepanning azimuthal angle is calculated. The line marking device can be arranged according to drill sites, is installed at a time and used repeatedly, does not need to be moved and adjusted frequently, does not need to be manually operated after being installed and fixed, and can achieve continuous real-time measurement which cannot be achieved through various original examination methods. Due to the fact that the projection of the central line of the roadway on the horizontal plane is horizontally moved to the position easy to utilize, the hole drilling azimuthal angle can be more rapidly and visually measured.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

P-type crystalline silicon solar cell preparing method

ActiveCN107644925ASolve front passivationSolving Metallization ProblemsFinal product manufactureSemiconductor devicesScreen printingP type silicon

The invention discloses a P-type crystalline silicon solar cell preparing method. The method comprises the steps that phosphorus diffusion is carried out on the front of a P-type silicon wafer after texturing, and an acquired phosphorus diffusion layer forms an emitter junction; the phosphorus diffusion layer is thermally oxidized to form a tunnel oxide layer; a polycrystalline silicon thin film with the thickness range of 5 nm to 20 nm is deposited on the tunnel oxide layer; wound plating and a wound expansion layer on the back of the P-type silicon wafer are removed, and a silicon nitride thin film is deposited on the front; a silicon nitride and alumina laminated thin film is deposited on the back of the P-type silicon wafer, and laser trepanning is carried out; and screen printing andsintering are carried out. According to the P-type crystalline silicon solar cell preparing method, the problems of front passivation and metallization of P-type crystalline silicon and the problem oflight absorption of the polycrystalline silicon thin film in a passivated contact structure are solved, and the cell conversion efficiency is improved.

Owner:ZHEJIANG JINKO SOLAR CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com