Cavity type bulk acoustic wave resonator with pillar and preparation method thereof

A bulk acoustic wave resonator and pillar technology, applied in the direction of electrical components, impedance networks, etc., can solve the problems of low film quality, cavity corrosion residue, etc., and achieve the effects of less damage, high yield, and reduced complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] The preparation method of the cavity-type BAW resonator with pillars in this embodiment includes the following steps:

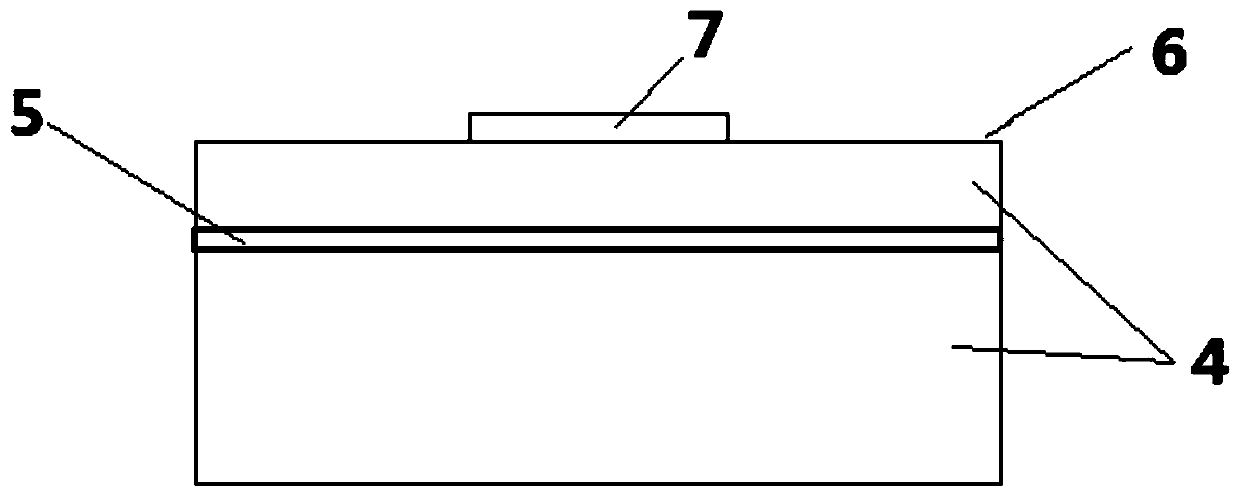

[0058] (a) Take a piezoelectric single crystal wafer, the piezoelectric single crystal wafer is a lithium tantalate wafer, perform ion implantation on the piezoelectric single crystal wafer to form an ion damage layer, and the implanted ions are H ions , the energy of implanted ions is 195KeV, and the implantation dose is 6×10 16 / cm 2 , the ion beam current is 1μm / cm -2 , the implantation depth is 6 μm to obtain a pyroelectric material, and then photolithography forms a pattern to be grown on the injection surface of the obtained pyroelectric material, and then utilizes magnetron sputtering to grow electrodes, the electrode material is Au, and finally passes through acetone Wash off the excess part to obtain a piezoelectric single crystal wafer with ion implantation and a bottom electrode, the thickness of the bottom electrode is 100nm; figure 1 Sh...

Embodiment 2

[0073] The preparation method of the cavity-type BAW resonator with pillars in this embodiment includes the following steps:

[0074] (a) Take a piezoelectric single crystal wafer, the piezoelectric single crystal wafer is a lithium tantalate wafer, perform ion implantation on the piezoelectric single crystal wafer, the implanted ions are As ions, the energy of the implanted ions is 500KeV; the implantation depth is 1.8 μm to obtain a pyroelectric material, and then grow an electrode on the injection surface of the obtained pyroelectric material by magnetron sputtering, the electrode material is Au, and then prepare a mask, and finally etch After removing the excess part, a piezoelectric single-crystal wafer with ion implantation and a bottom electrode can be obtained, and the thickness of the bottom electrode is 100nm;

[0075] (b) taking a piezoelectric single crystal wafer that has undergone ion implantation and has a bottom electrode, and forming a plurality of pillars on ...

Embodiment 3

[0080] The preparation method of the cavity-type BAW resonator with pillars in this embodiment is prepared by the same method as that of Embodiment 1, except that the upper surface area of the bottom electrode is larger than the upper surface area of the cavity.

[0081] Figure 9 It is a structural schematic diagram of the ion-implanted piezoelectric single crystal wafer obtained in step (b) and having a bottom electrode.

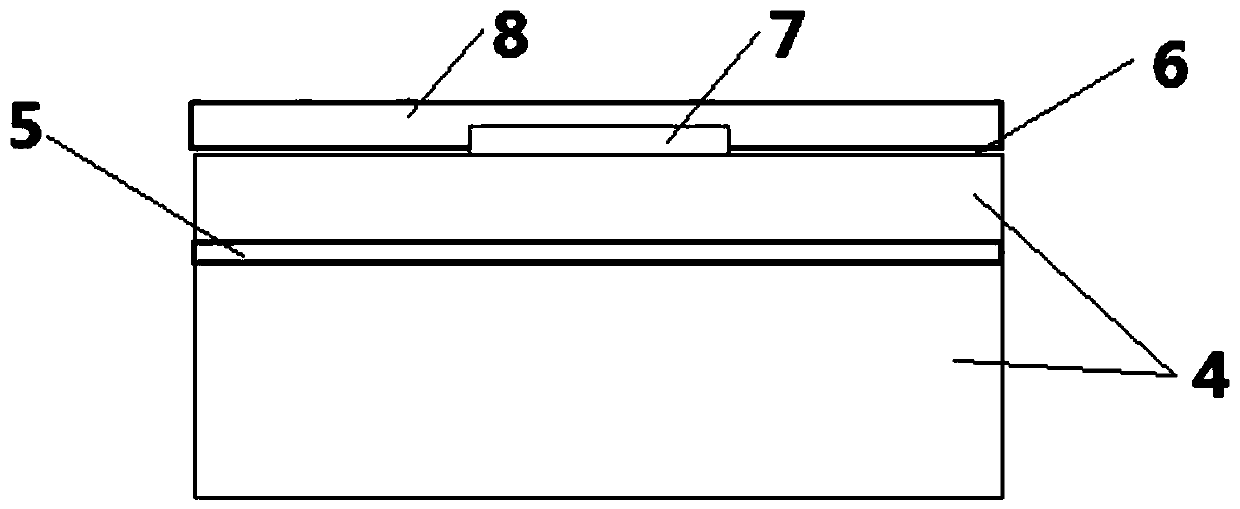

[0082] Figure 10 It is a structural schematic diagram of a piezoelectric single crystal wafer with pillars and cavities formed in the gaps between the pillars in step (b);

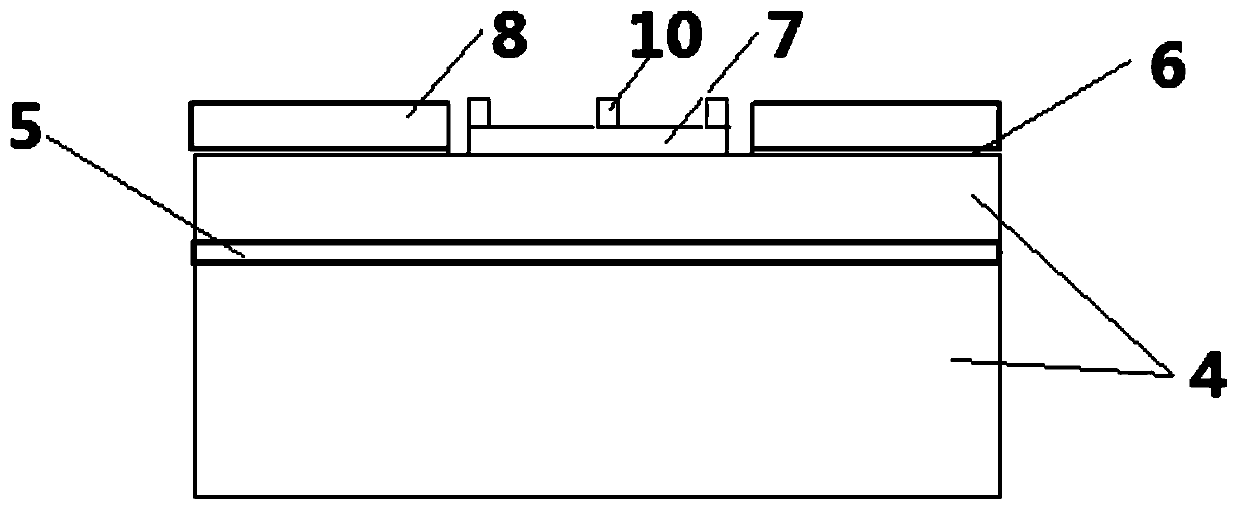

[0083] Figure 11 It is a structural schematic diagram of a cavity-type bulk acoustic wave resonator with pillars in step (d);

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com