Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

591 results about "Thin-film bulk acoustic resonator" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

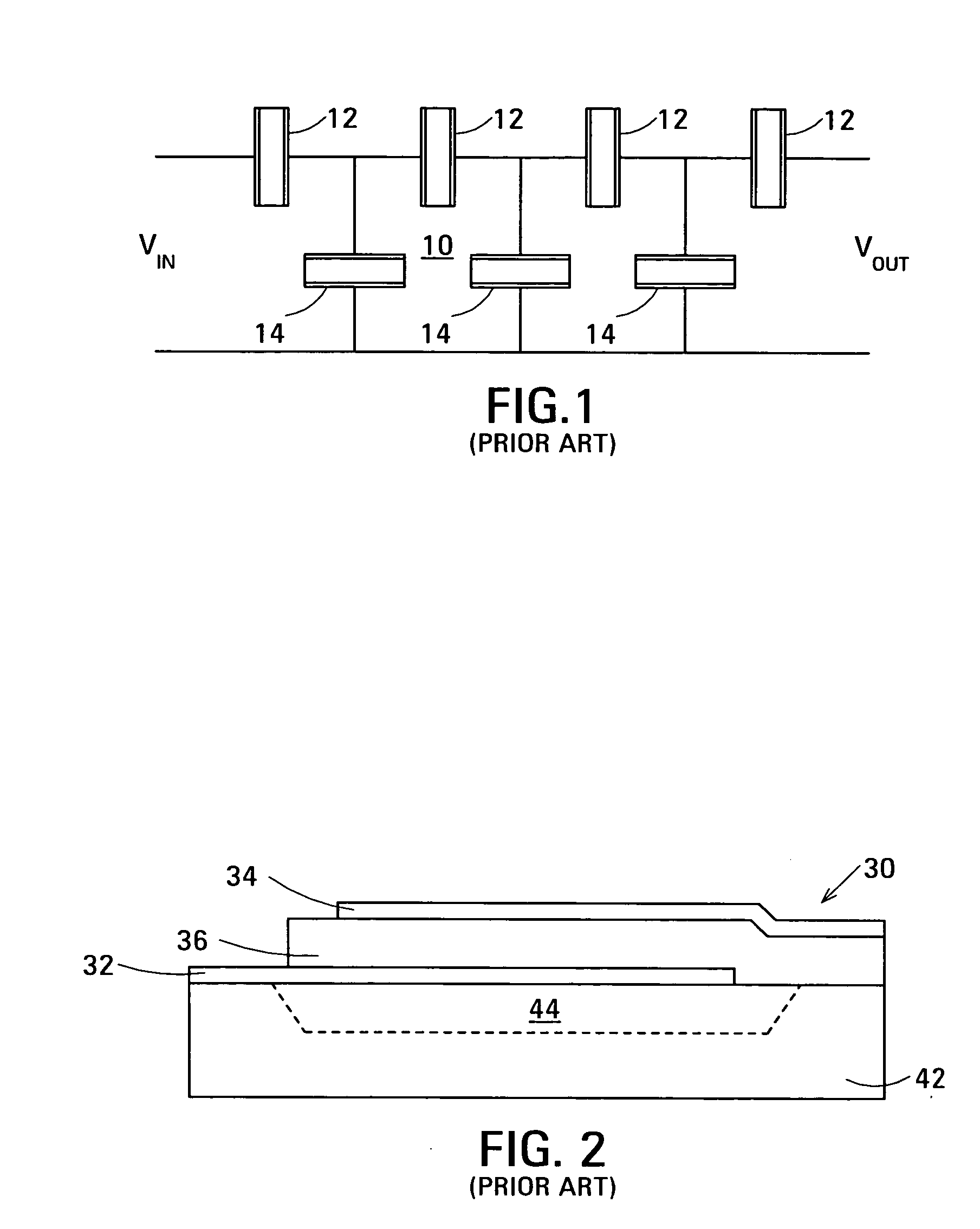

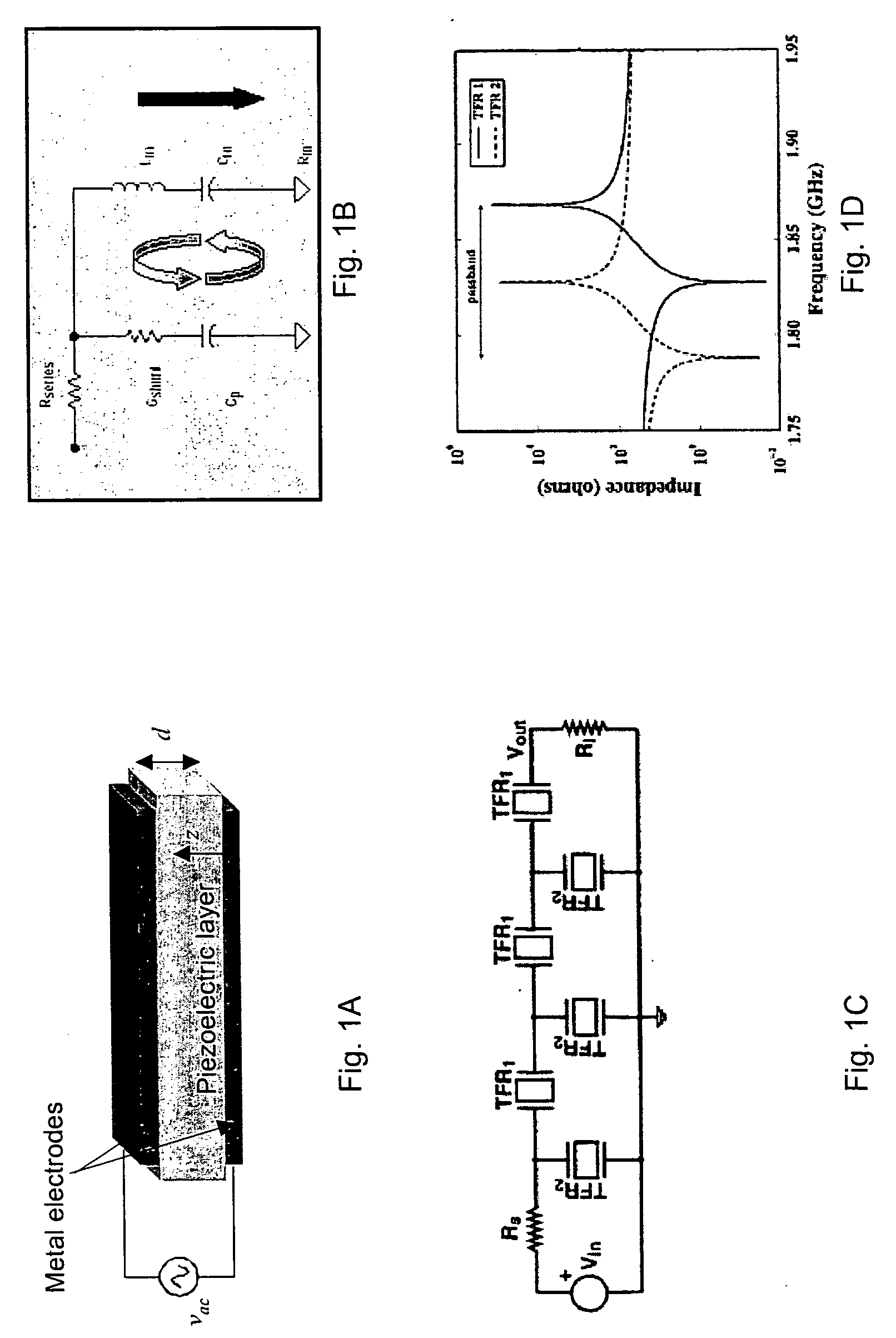

A thin-film bulk acoustic resonator (FBAR or TFBAR) is a device consisting of a piezoelectric material sandwiched between two electrodes and acoustically isolated from the surrounding medium. FBAR devices using piezoelectric films with thicknesses ranging from several micrometres down to tenth of micrometres resonate in the frequency range of roughly 100 MHz to 10 GHz. Aluminium nitride and zinc oxide are two common piezoelectric materials used in FBARs.

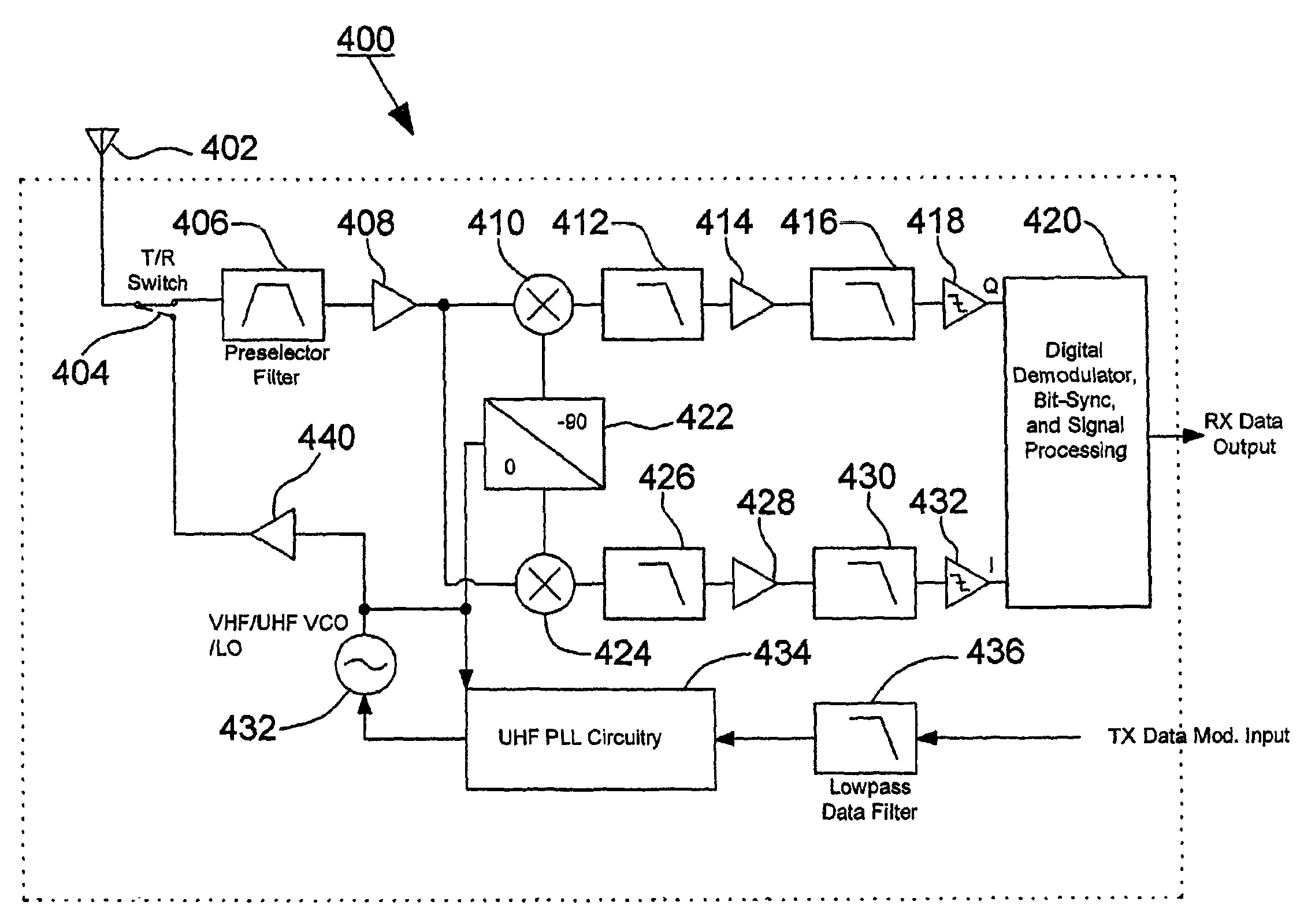

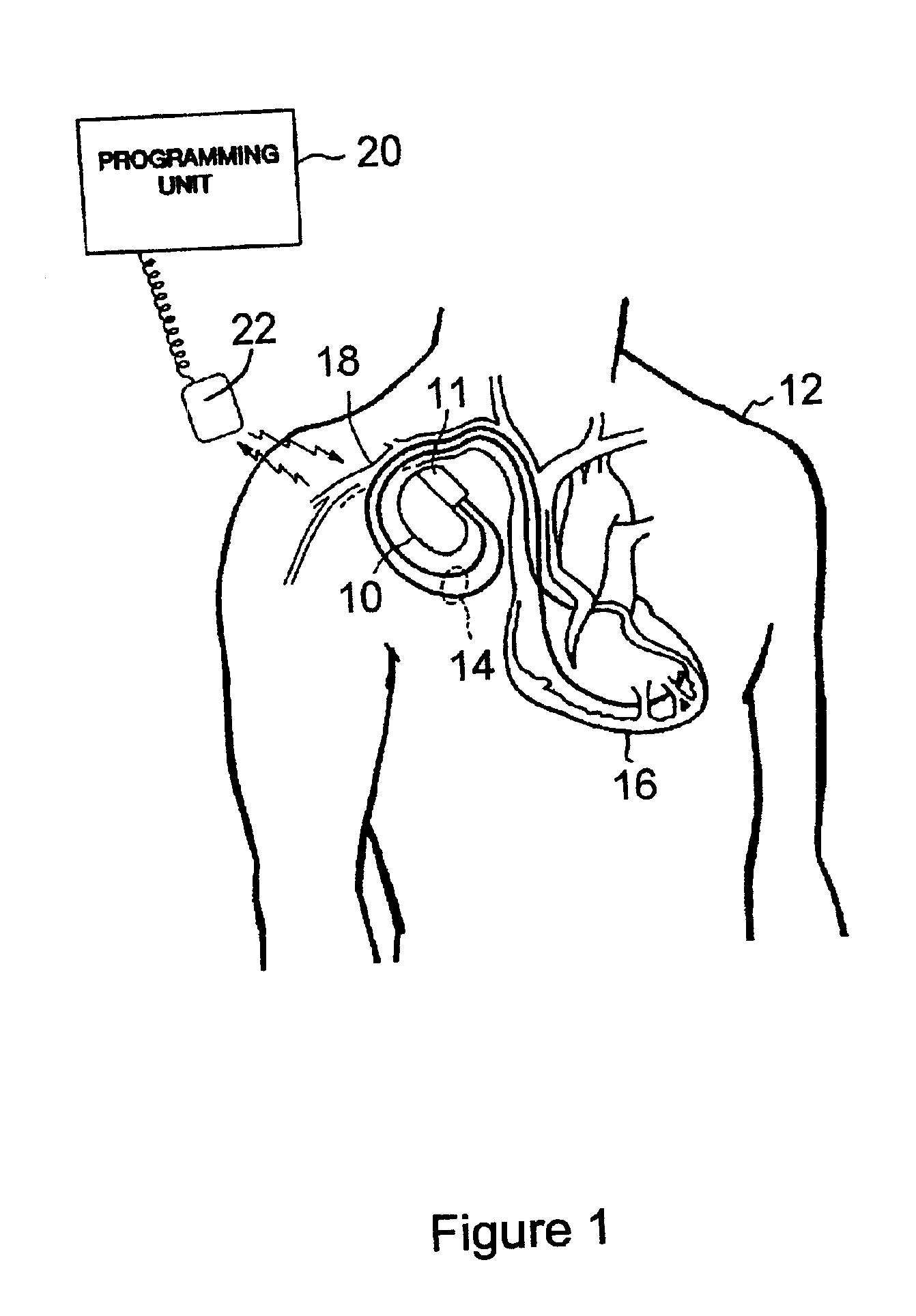

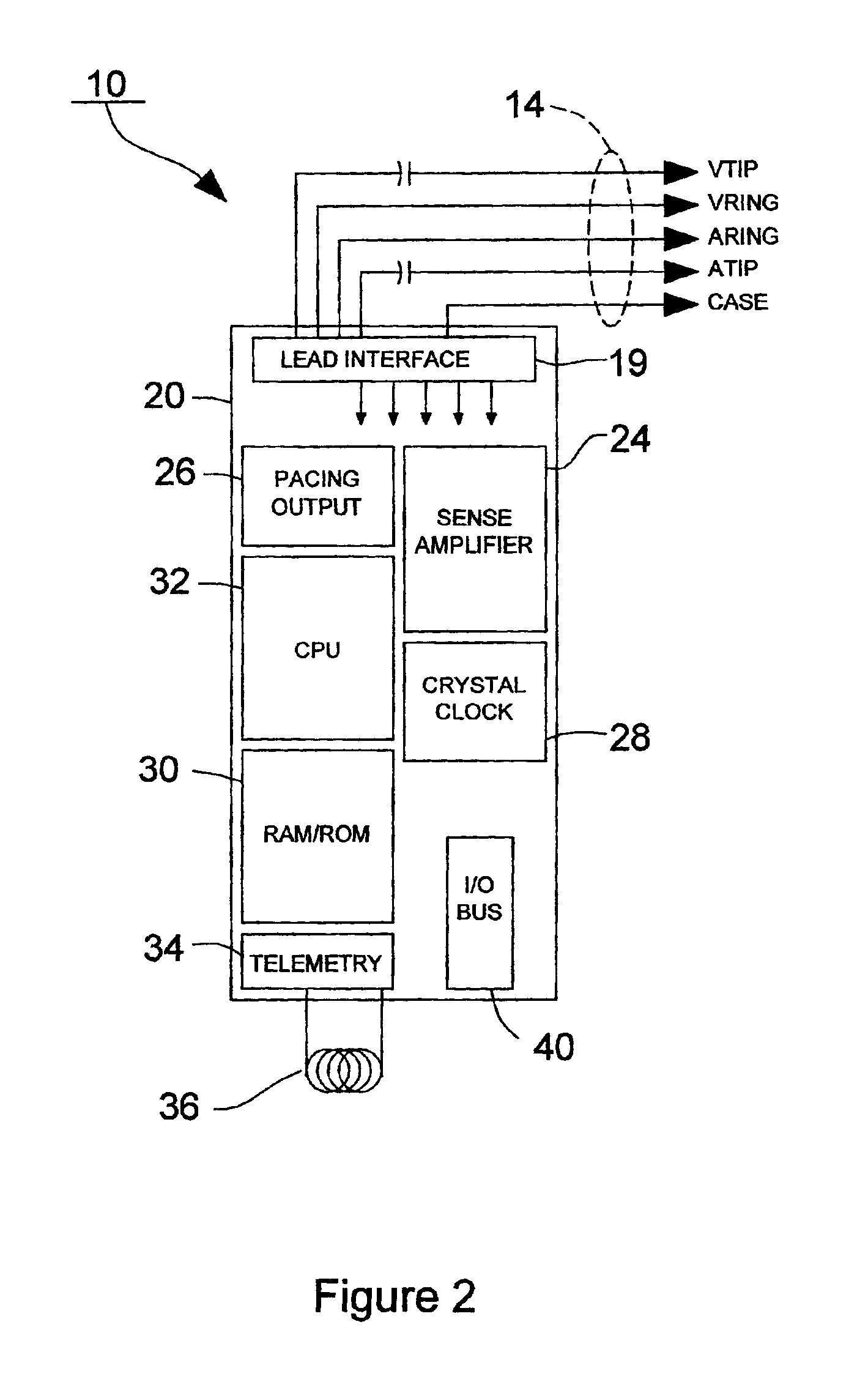

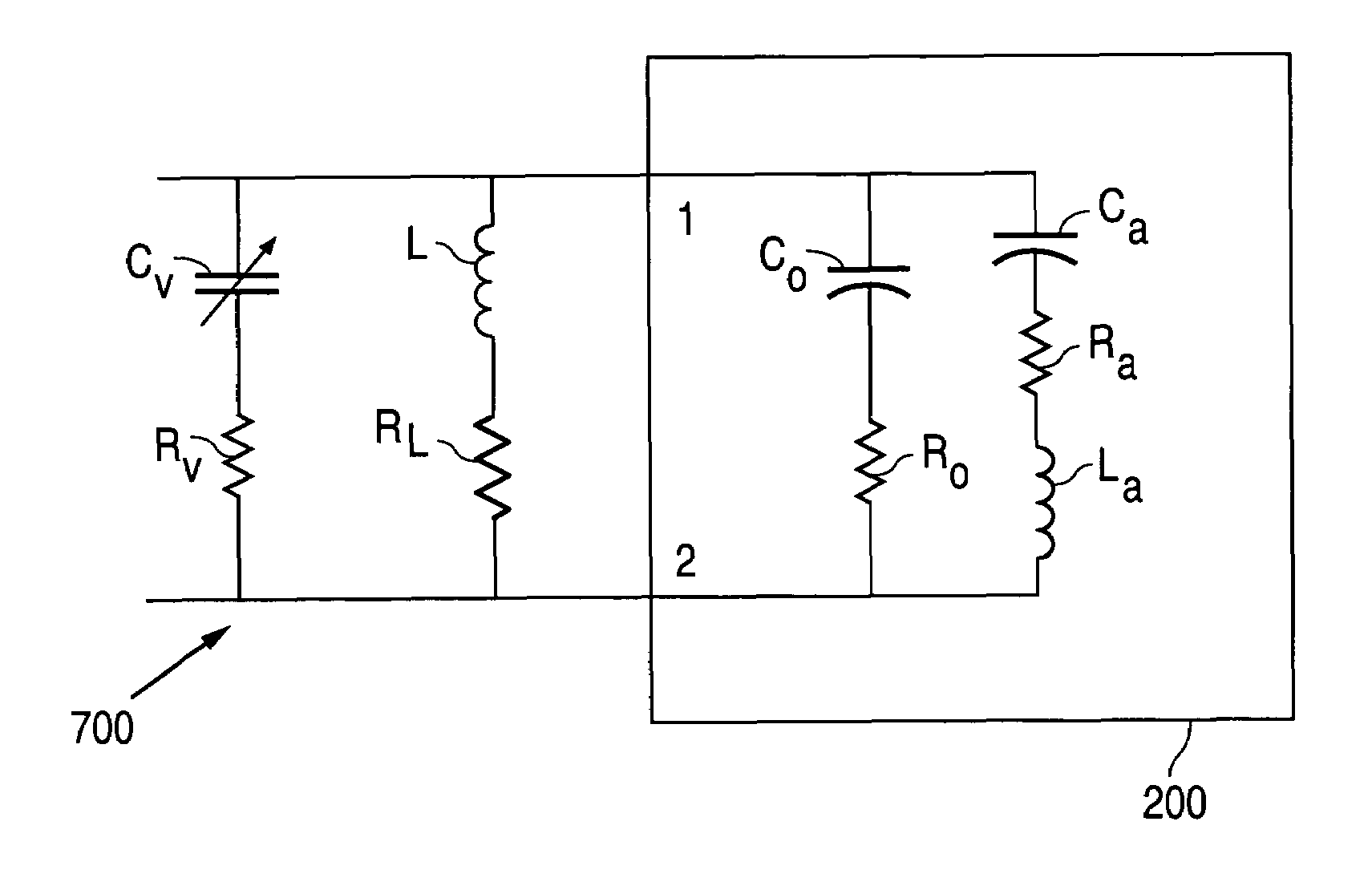

Implanted medical device telemetry using integrated thin film bulk acoustic resonator filtering

A telemetry receiver for an implantable medical device (IMD) such as a cardiac pacemaker has an RF antenna coupled to a telemetry circuit that includes an out-of-band rejection filter comprising a thin film bulk acoustic resonator filter. The telemetry circuit includes an amplifier coupled to the thin film bulk acoustic resonator filter and a demodulator coupled to the amplifier. The filter, amplifier and demodulator are all fabricated on a common integrated circuit die. A multichannel telemetry receiver for an IMD has a plurality of thin film bulk acoustic resonator bandpass filters defining individual channels. Identification of a preferred data transmission channel for communication of programming data to the IMD is determined by obtaining samples of the signals being passed by each of a plurality of thin film bulk acoustic resonator bandpass filters that define individual channels and evaluating the samples to determine the noise level for each channel.

Owner:MEDTRONIC INC

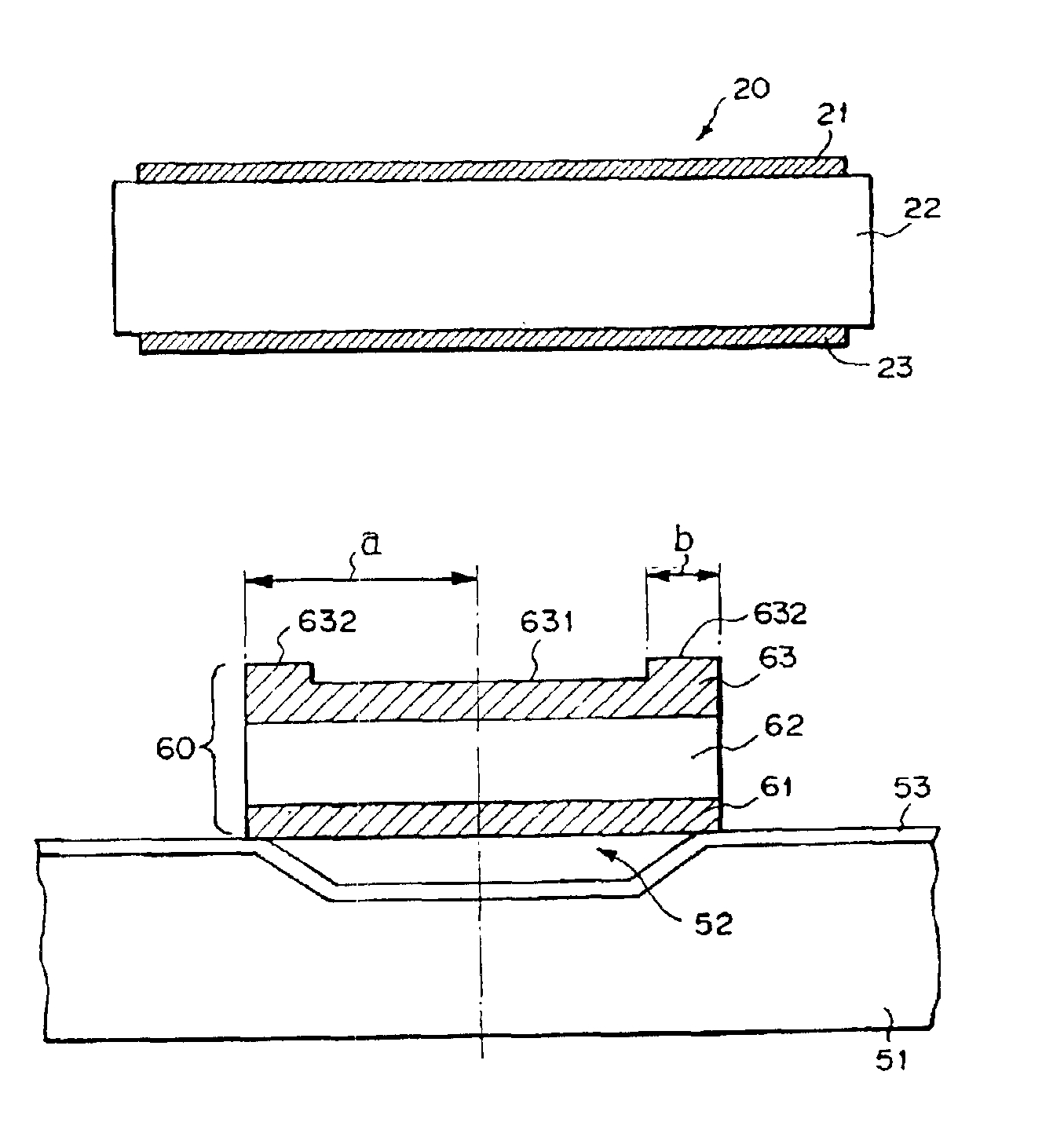

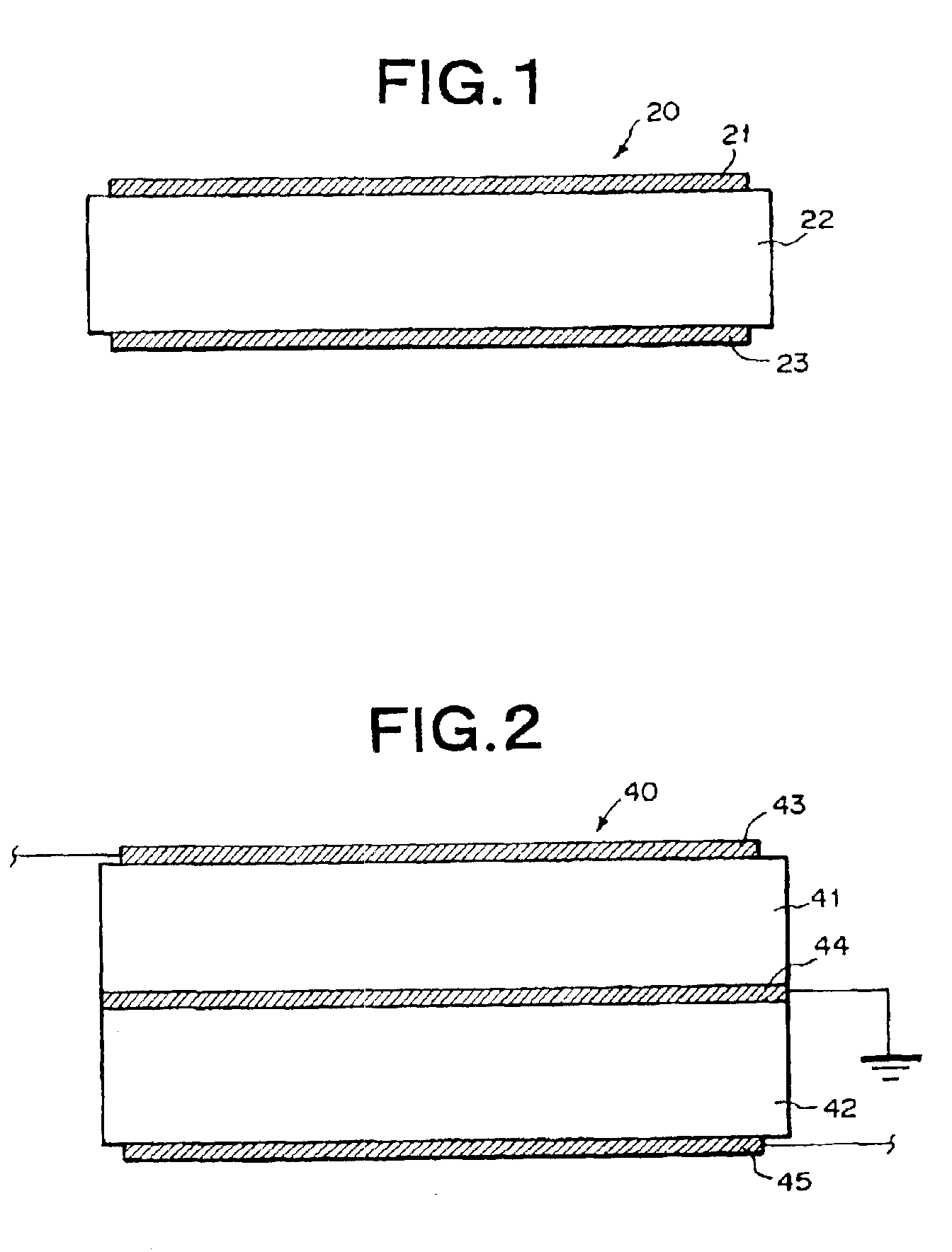

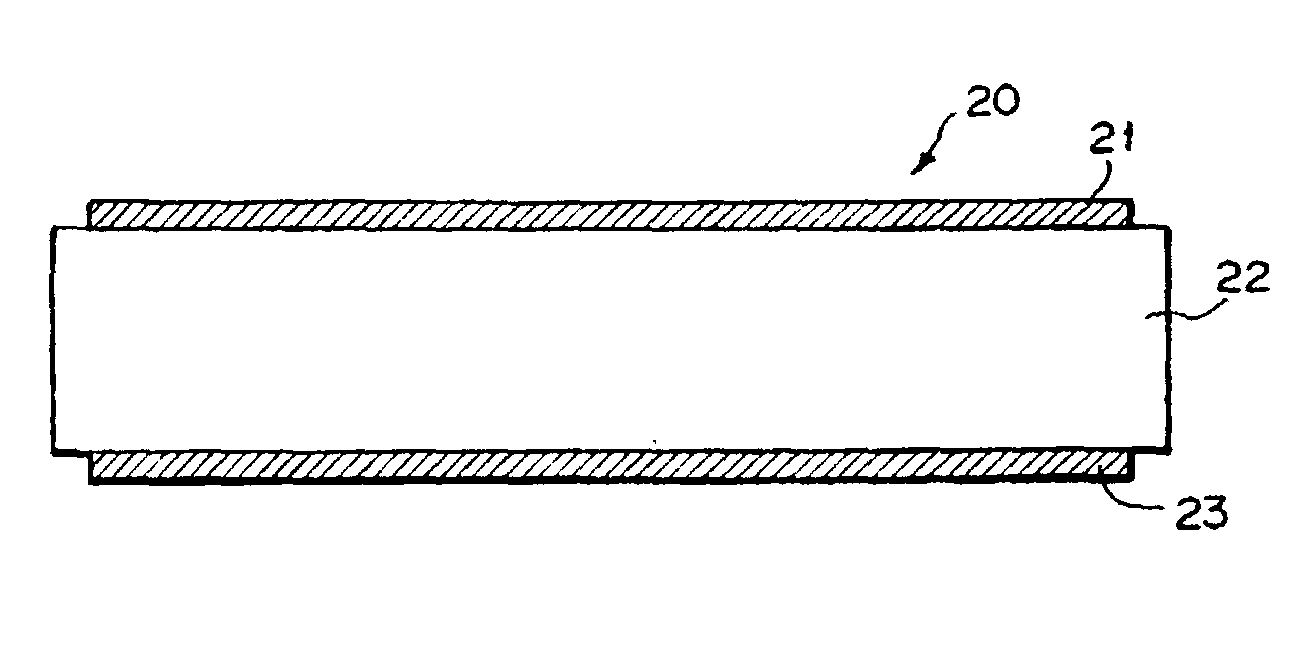

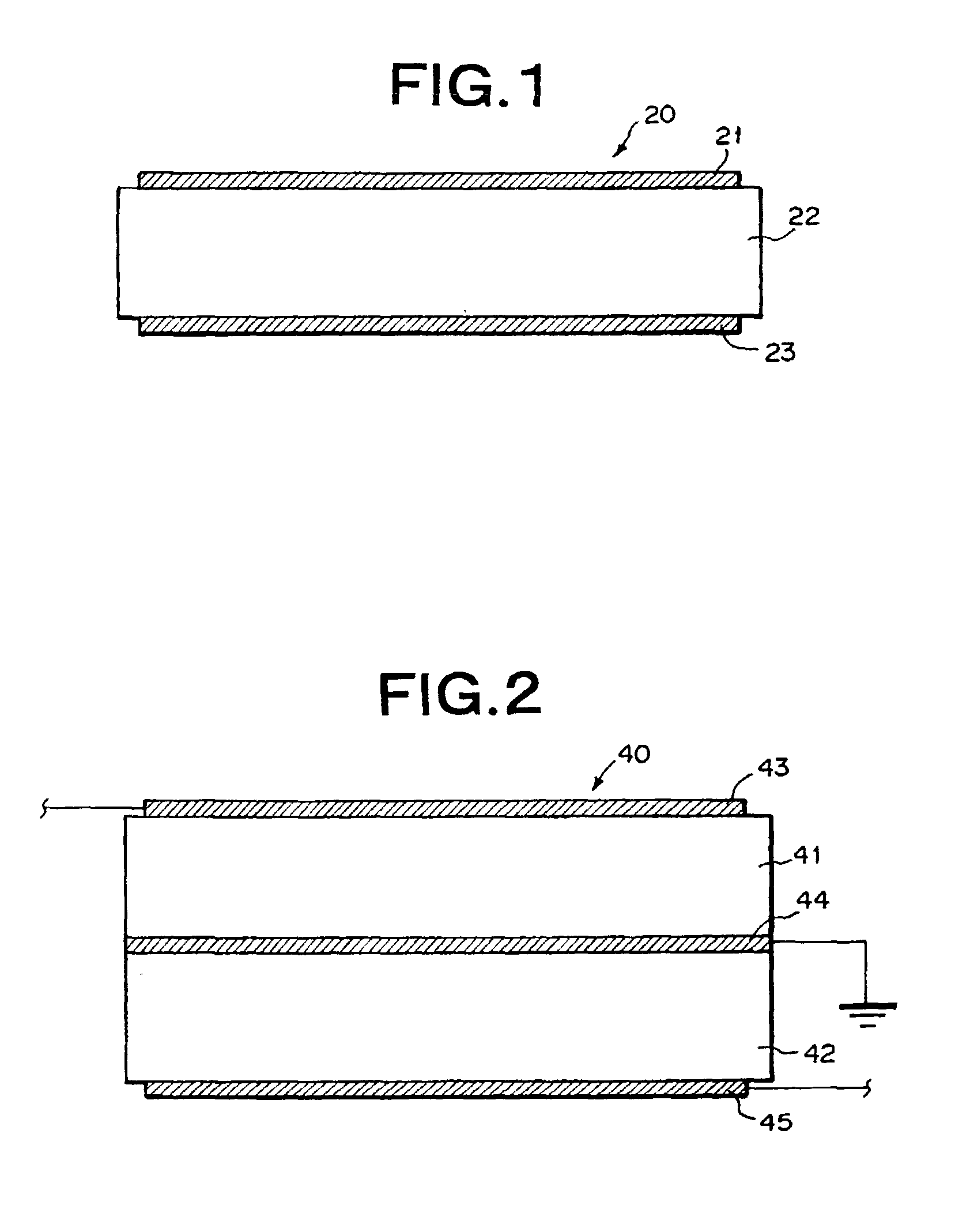

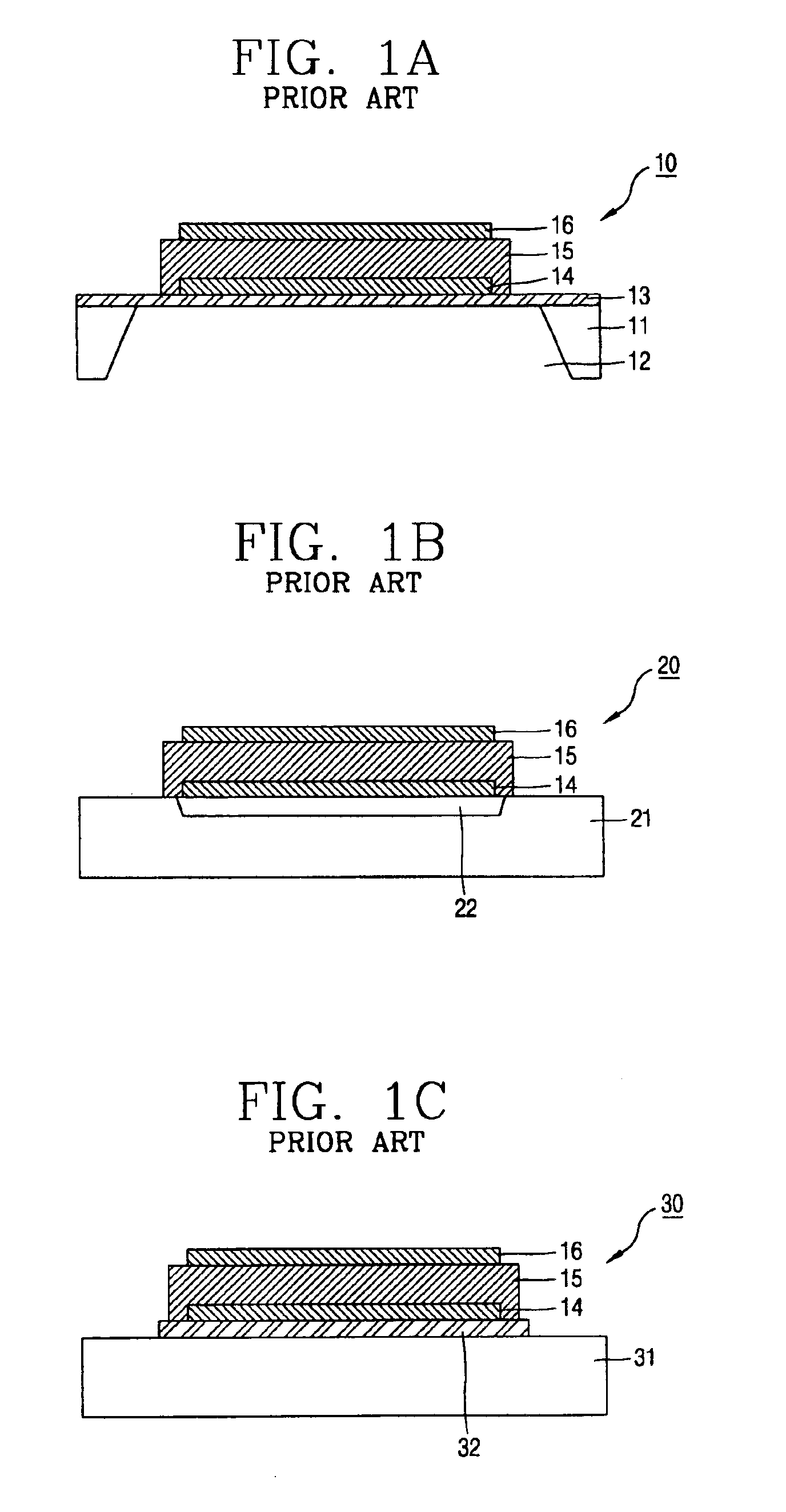

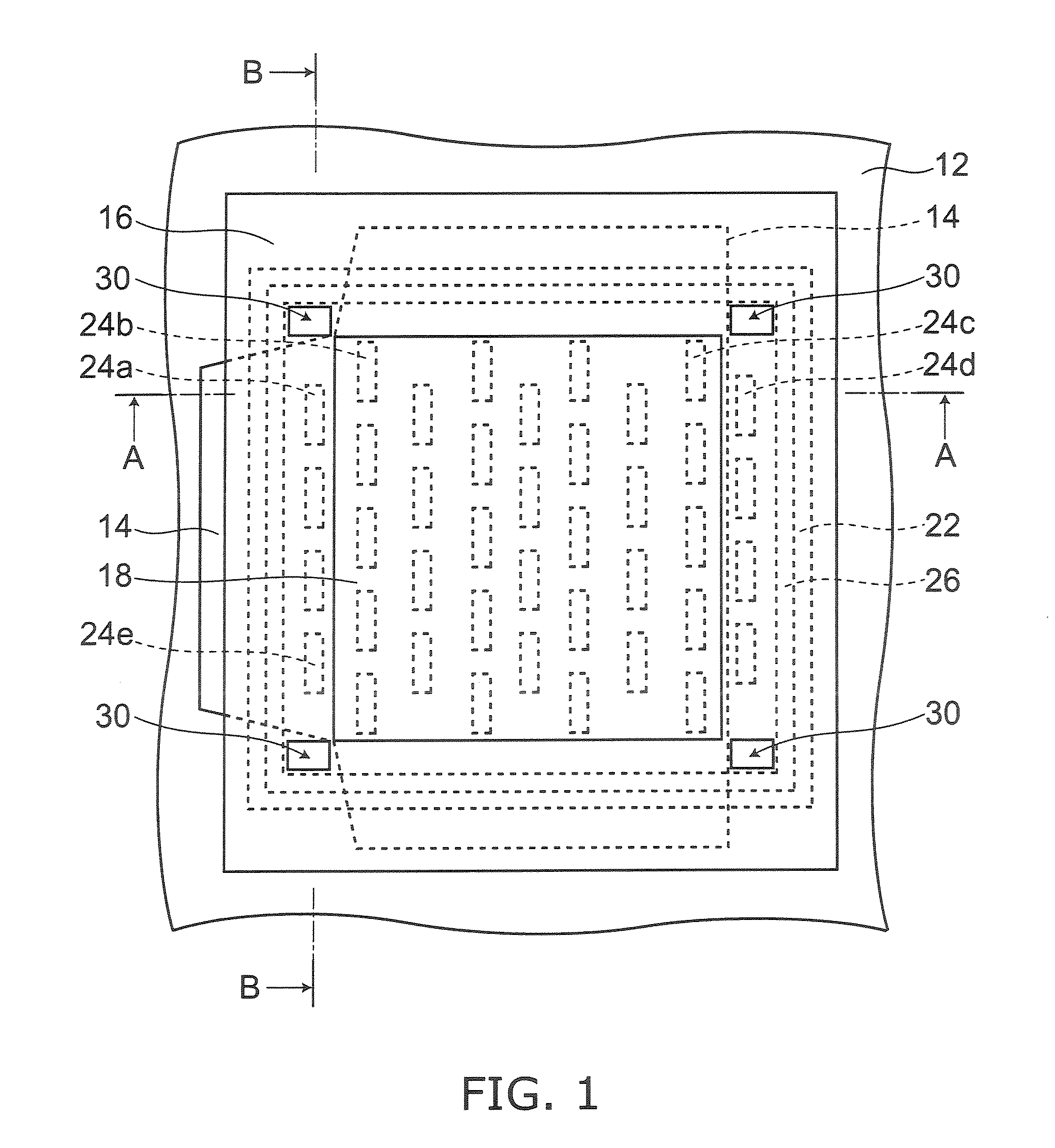

Thin film acoustic resonator and method of producing the same

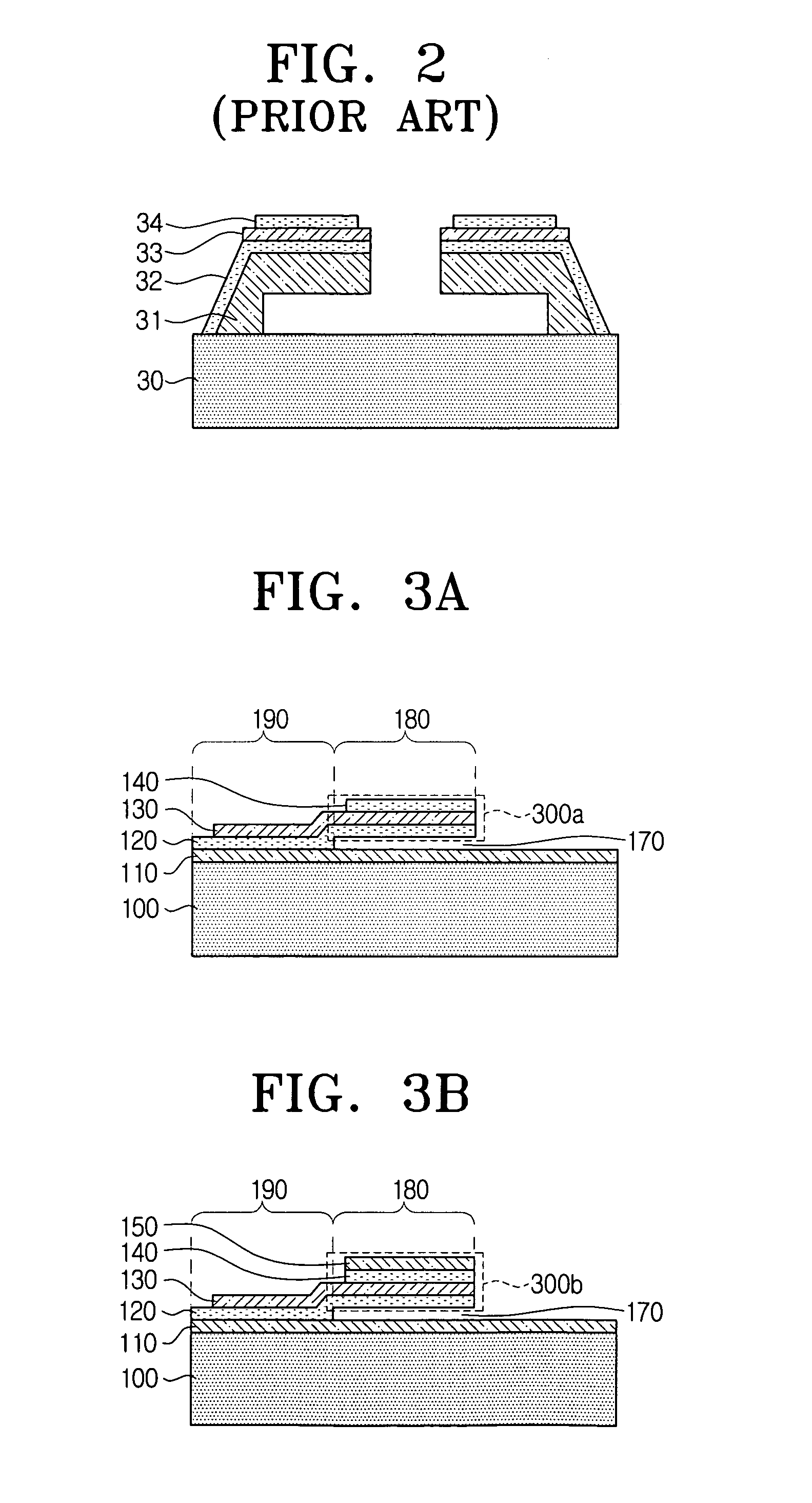

InactiveUS6842088B2Improve temperature stabilityImprovement factorNanotechPiezoelectric/electrostrictive device manufacture/assemblyThin-film bulk acoustic resonatorElectromechanical coupling coefficient

Owner:MEMS SOLUTIONS INC

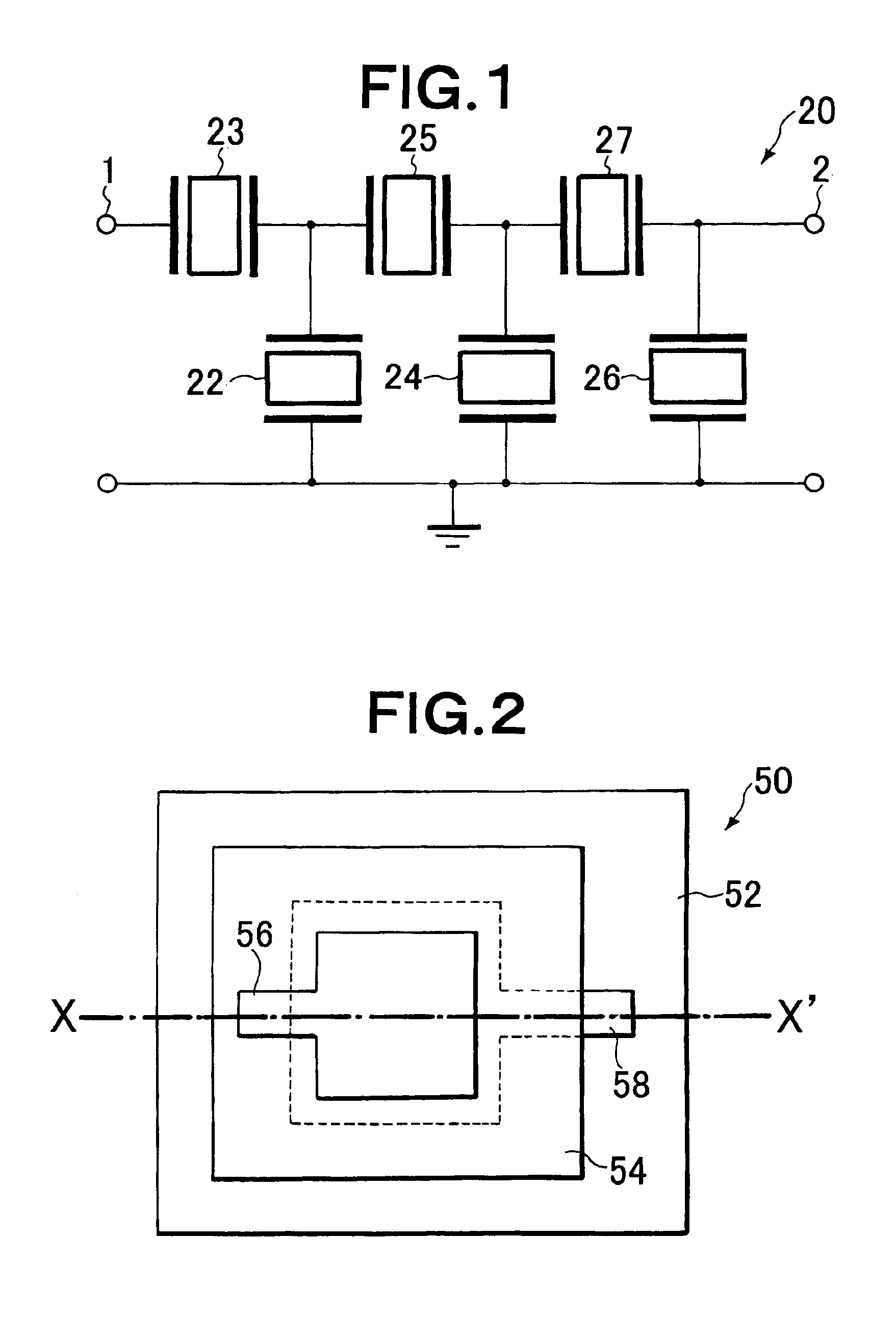

Thin film bulk acoustic resonator and method of producing the same

InactiveUS20020190814A1Improve featuresPiezoelectric/electrostrictive device manufacture/assemblyNanotechThin-film bulk acoustic resonatorElectromechanical coupling coefficient

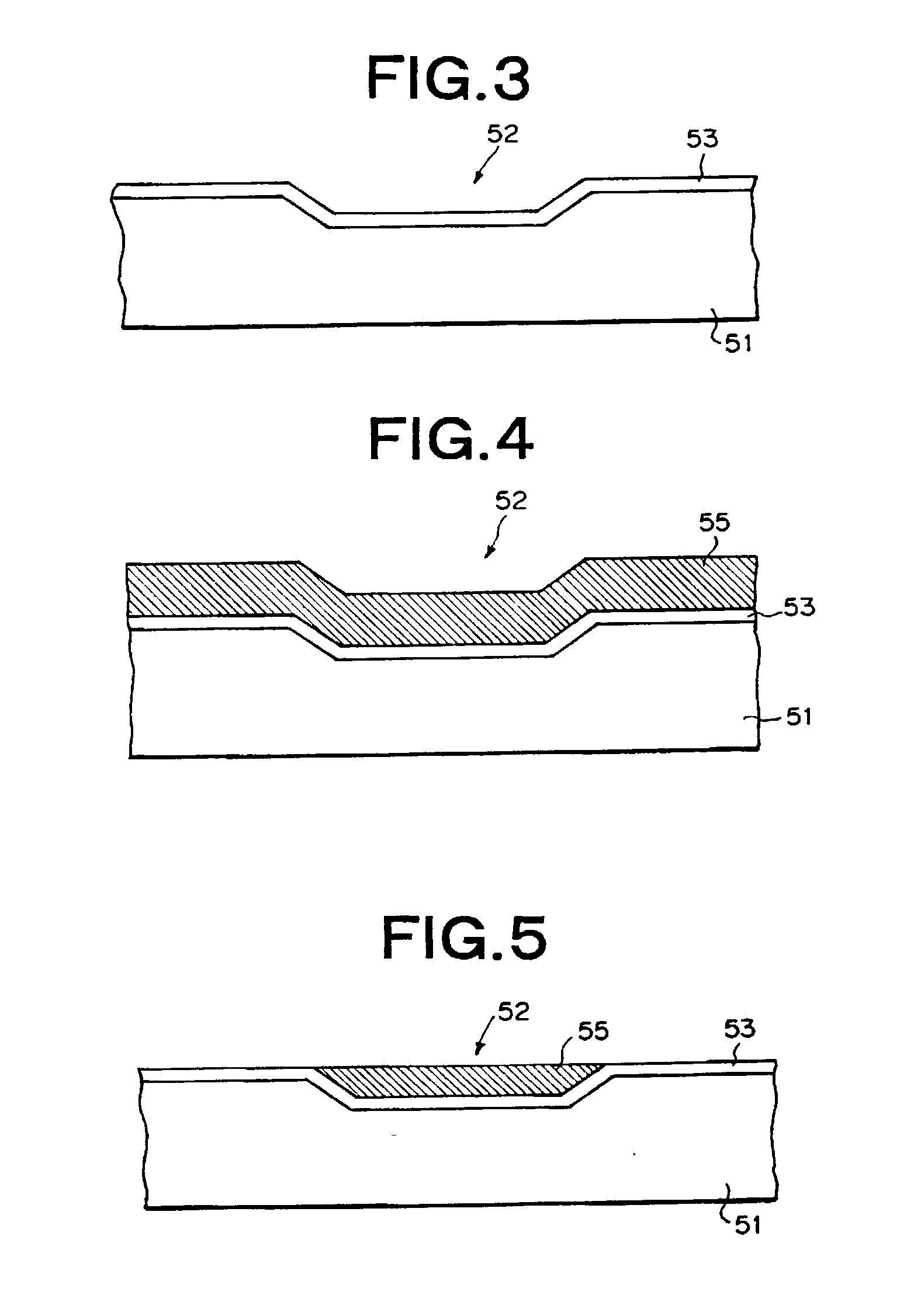

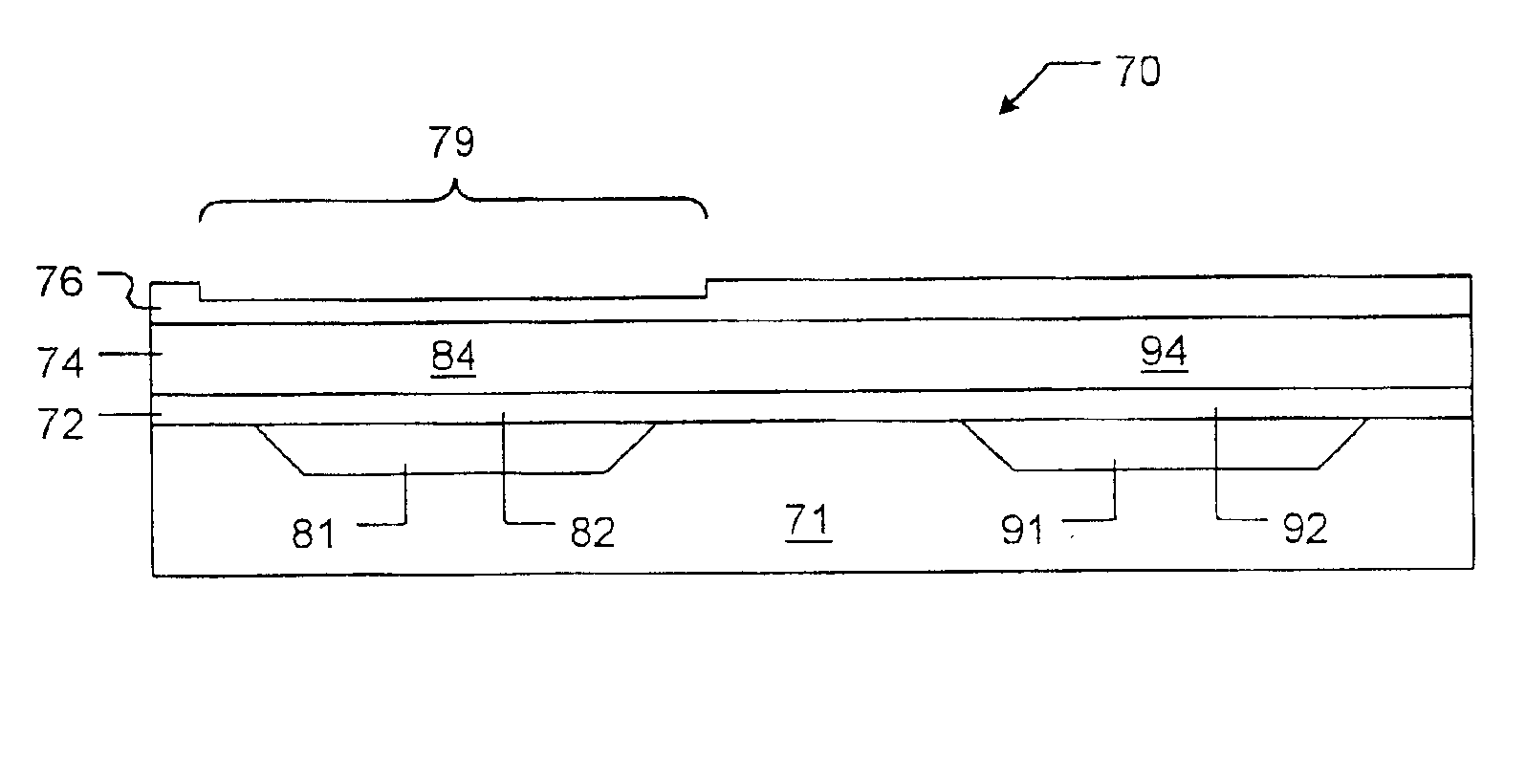

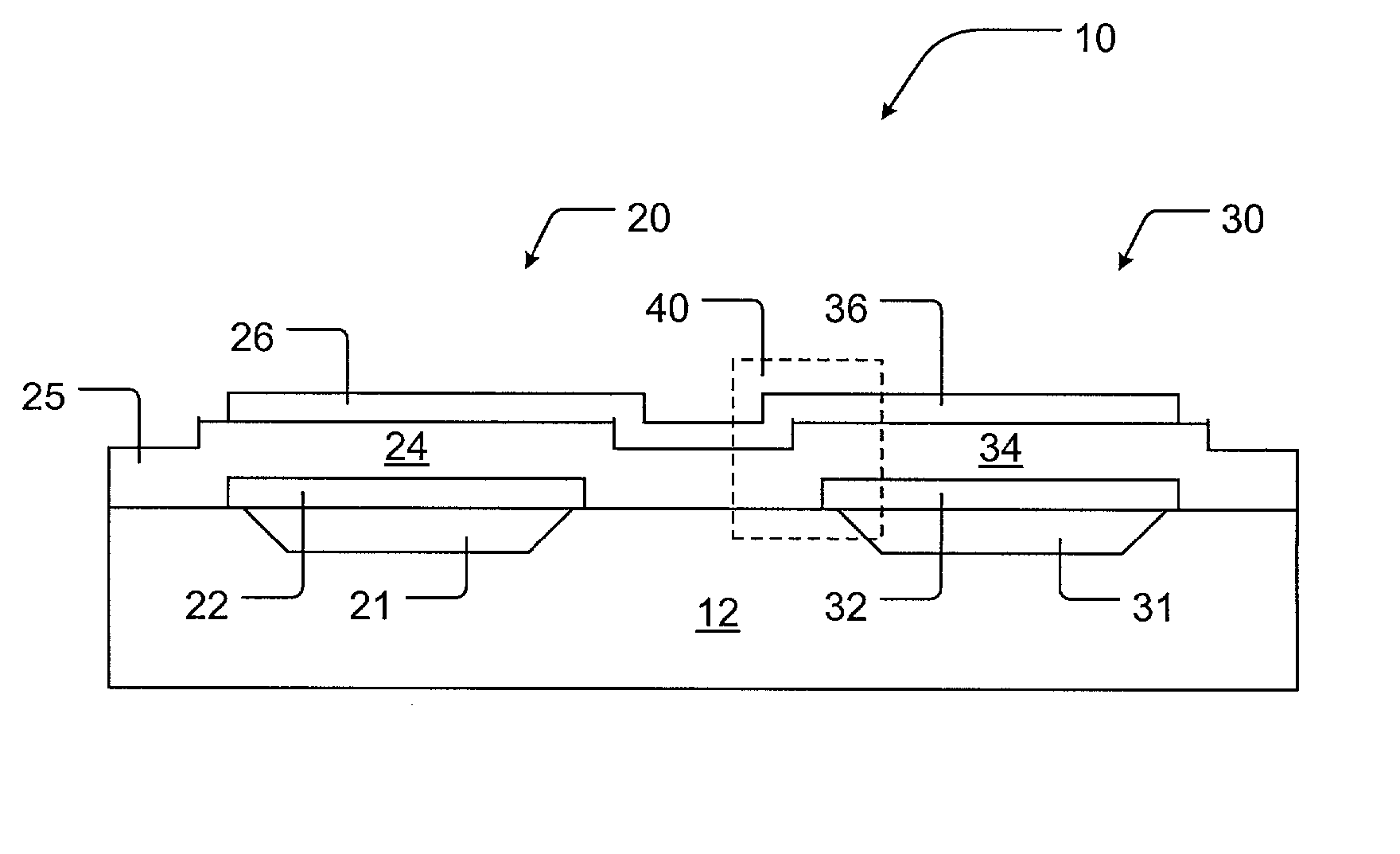

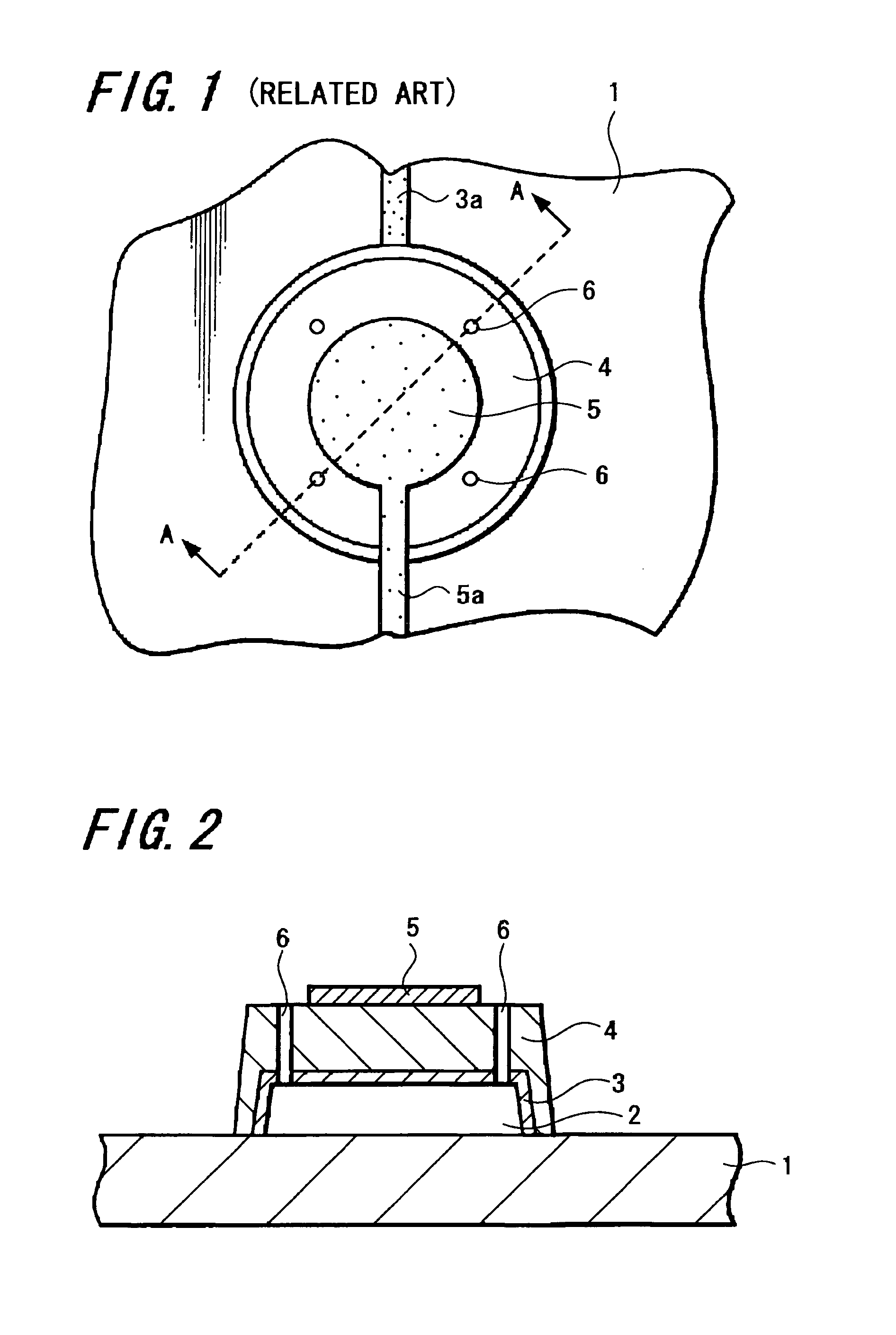

A pit (52) is formed in a substrate comprising a silicon wafer (51) on a surface of which a silicon oxide thin layer (53) is formed. A sandwich structure (60) comprising a piezoelectric layer (62) and lower and upper electrodes (61, 63) joined to both surfaces of the piezoelectric layer is disposed so as to stride over the pit (52). The upper surface of the lower electrode (61) and the lower surface of the piezoelectric layer (62) joined to the upper surface of the lower electrode are treated so that the RMS variation of the height thereof is equal to 25 nm or less. The thickness of the lower electrode (61) is set to 150 nm or less. According to such a structure, there is provided a high-performance thin film bulk acoustic resonator which are excellent in electromechanical coupling coefficient and acoustic quality factor.

Owner:MEMS SOLUTIONS INC

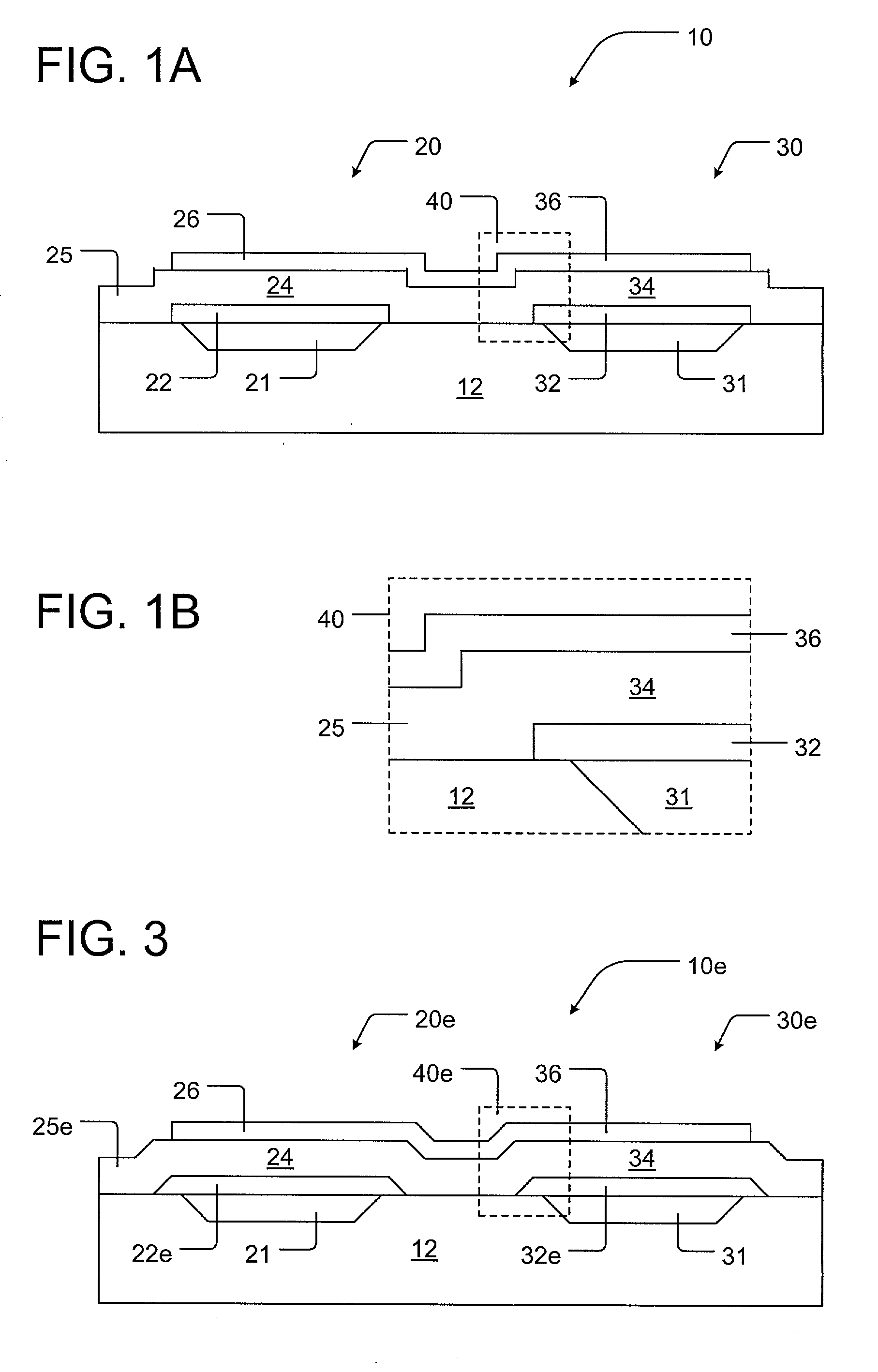

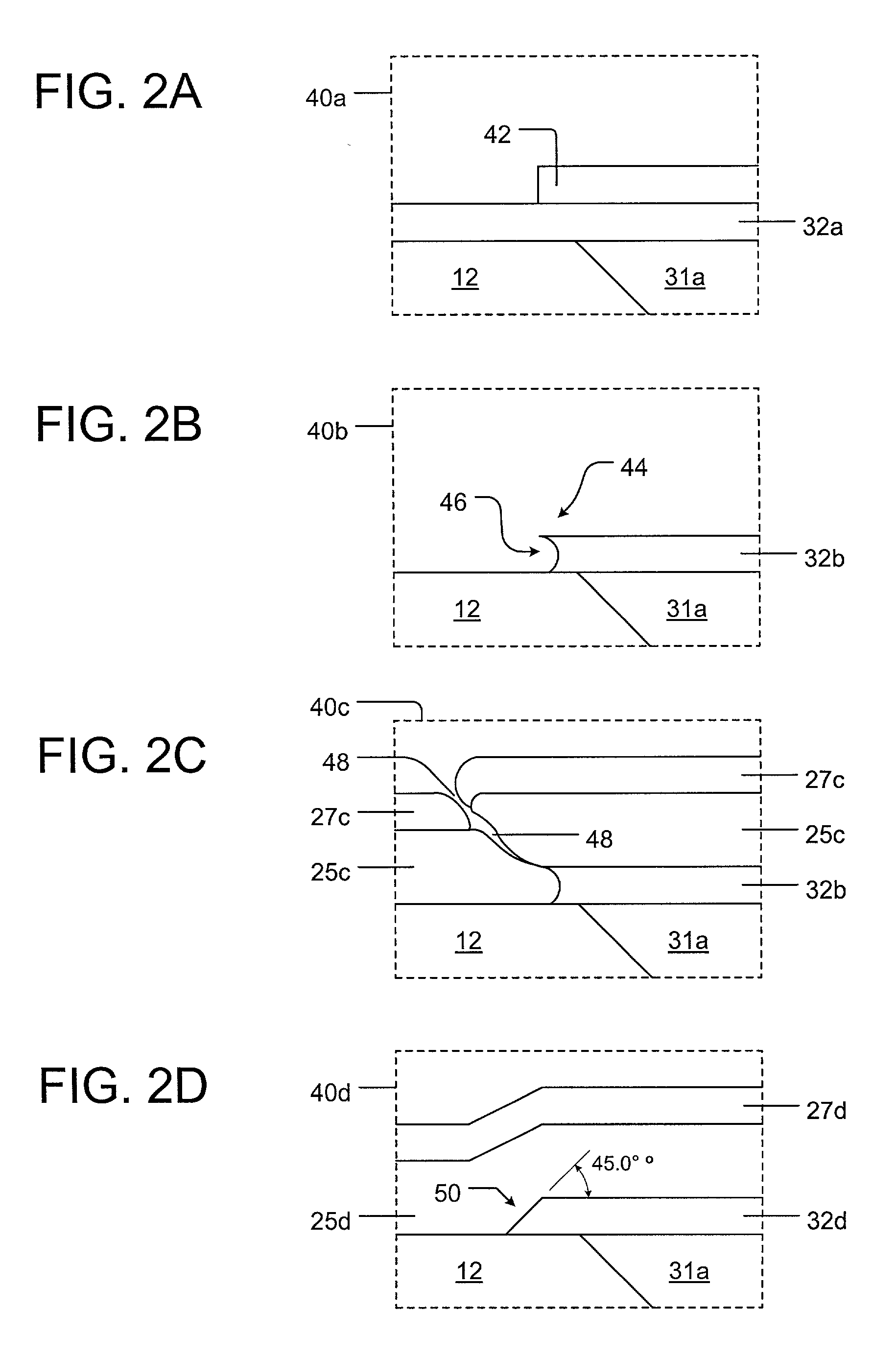

Temperature-compensated film bulk acoustic resonator (FBAR) devices

InactiveUS20050110598A1Reduce impactPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksPlanar electrodeThin-film bulk acoustic resonator

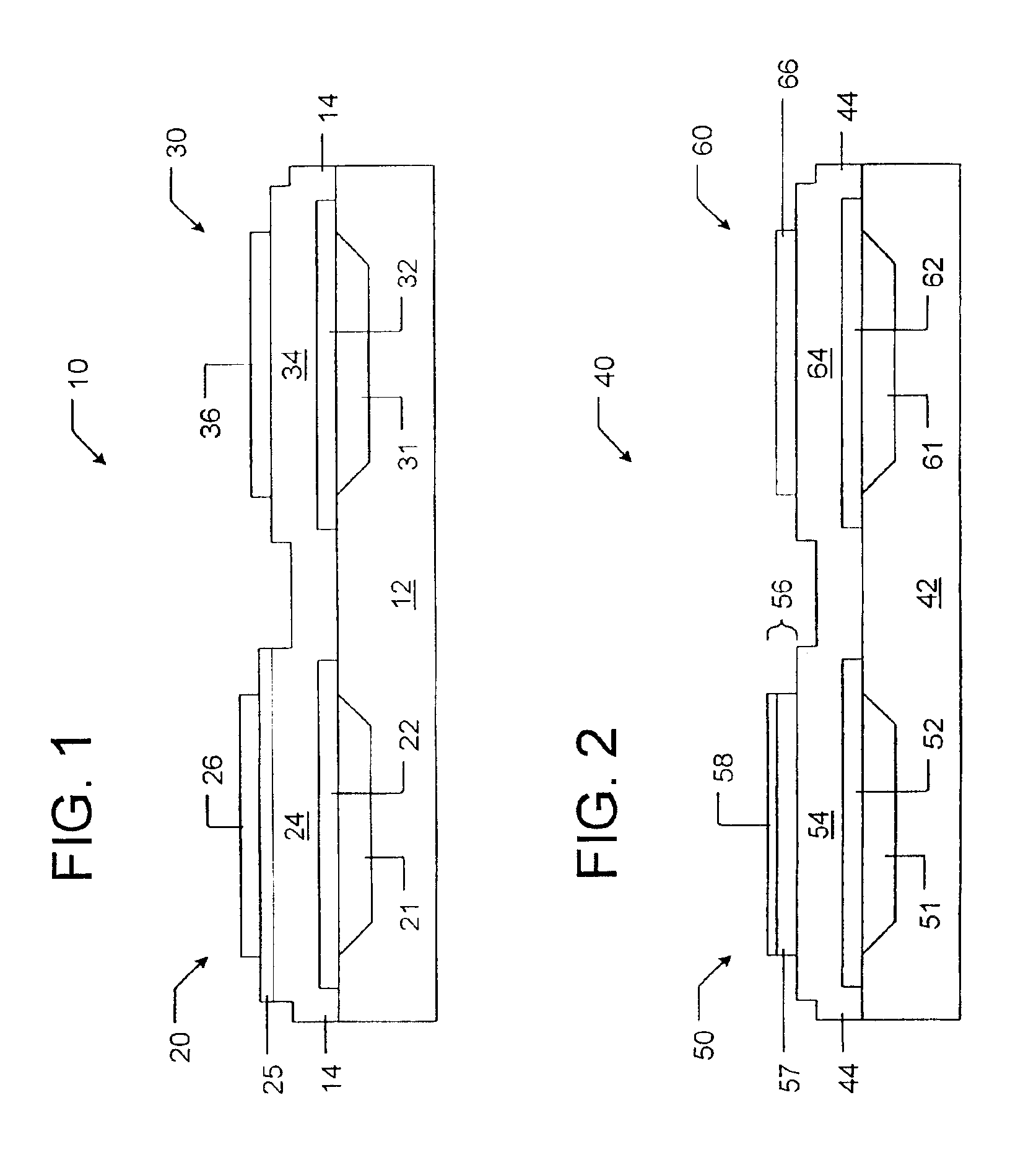

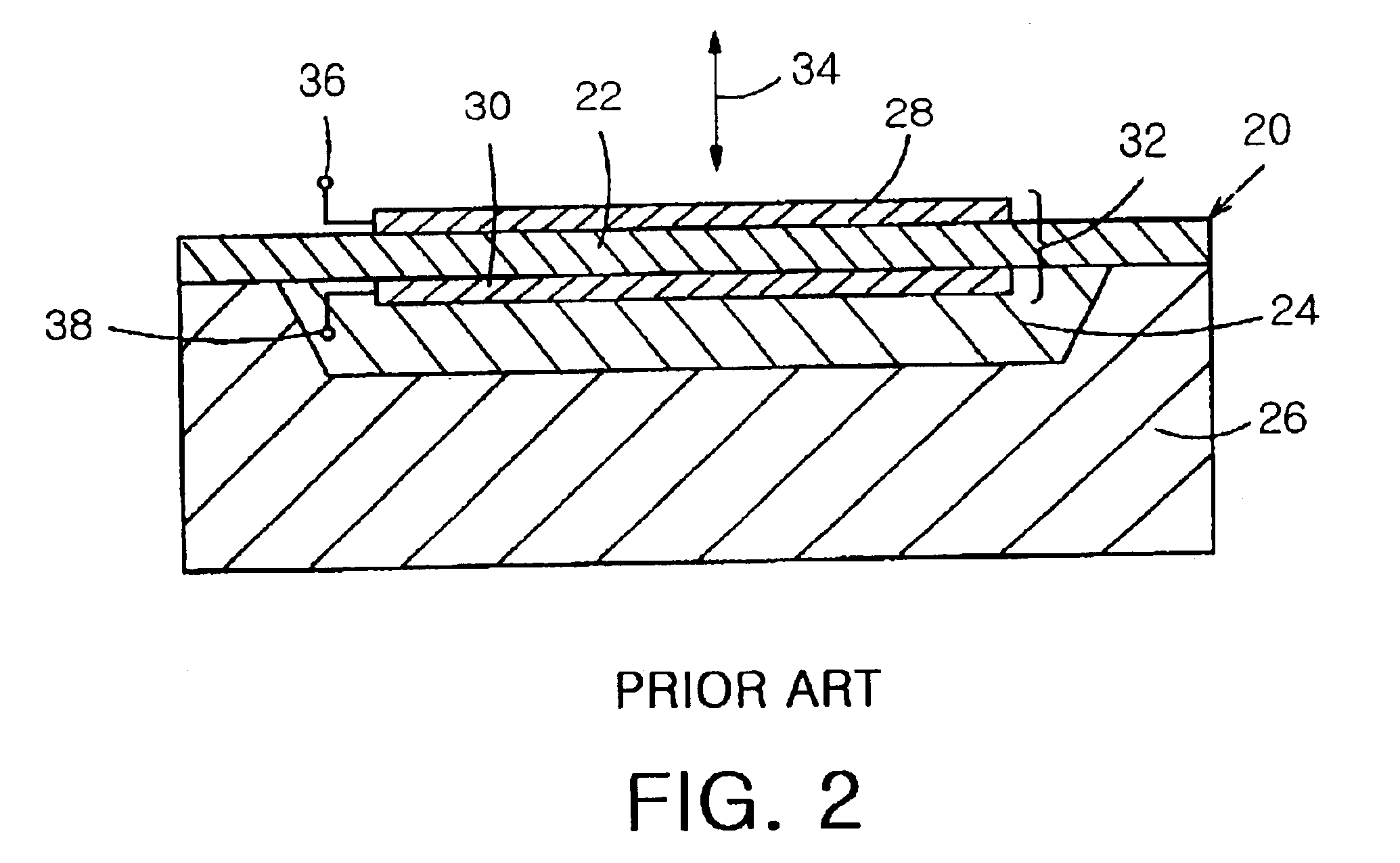

The temperature-compensated film bulk acoustic resonator (FBAR) device comprises an FBAR stack. The FBAR stack comprises an FBAR and a temperature-compensating element. The FBAR is characterized by a resonant frequency having a temperature coefficient, and comprises opposed planar electrodes and a piezoelectric element between the electrodes. The piezoelectric element has a temperature coefficient on which the temperature coefficient of the resonant frequency depends at least in part. The temperature-compensating element has a temperature coefficient opposite in sign to the temperature coefficient of the piezoelectric element.

Owner:AVAGO TECH INT SALES PTE LTD

Film acoustically-coupled transformer with increased common mode rejection

ActiveUS20050093659A1Improved common mode rejection ratioRaise the ratioImpedence networksSolid-state devicesPlanar electrodeThin-film bulk acoustic resonator

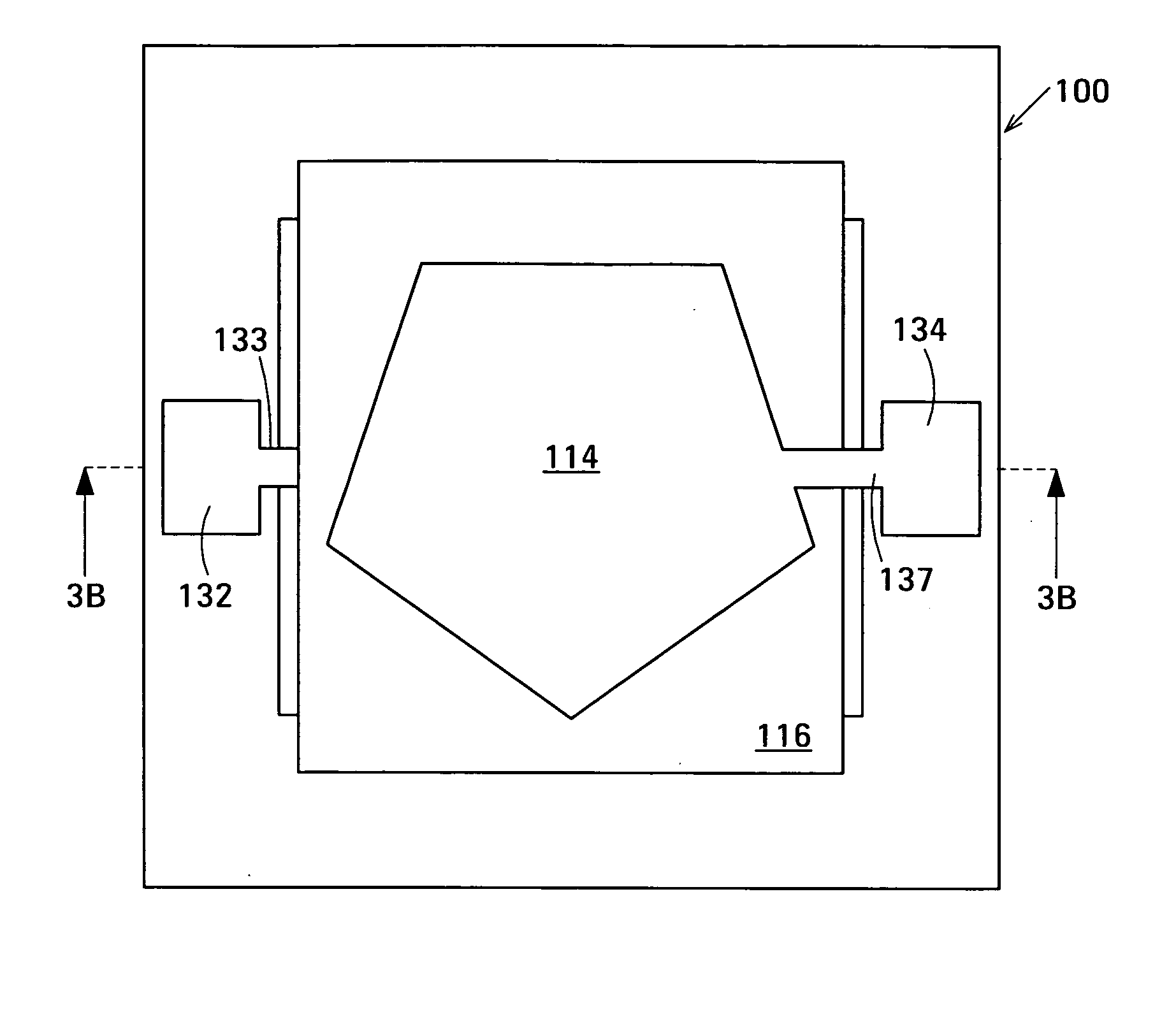

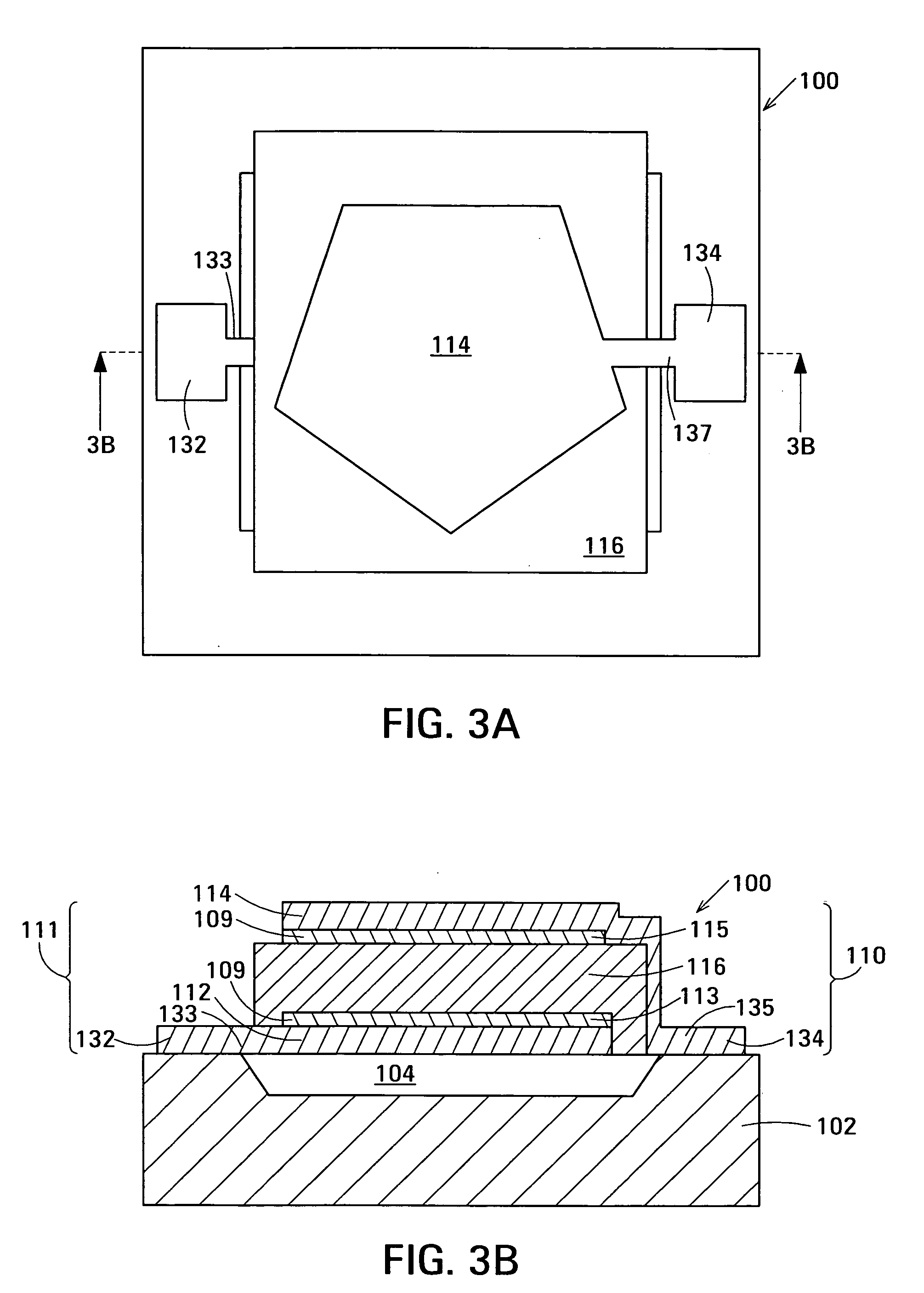

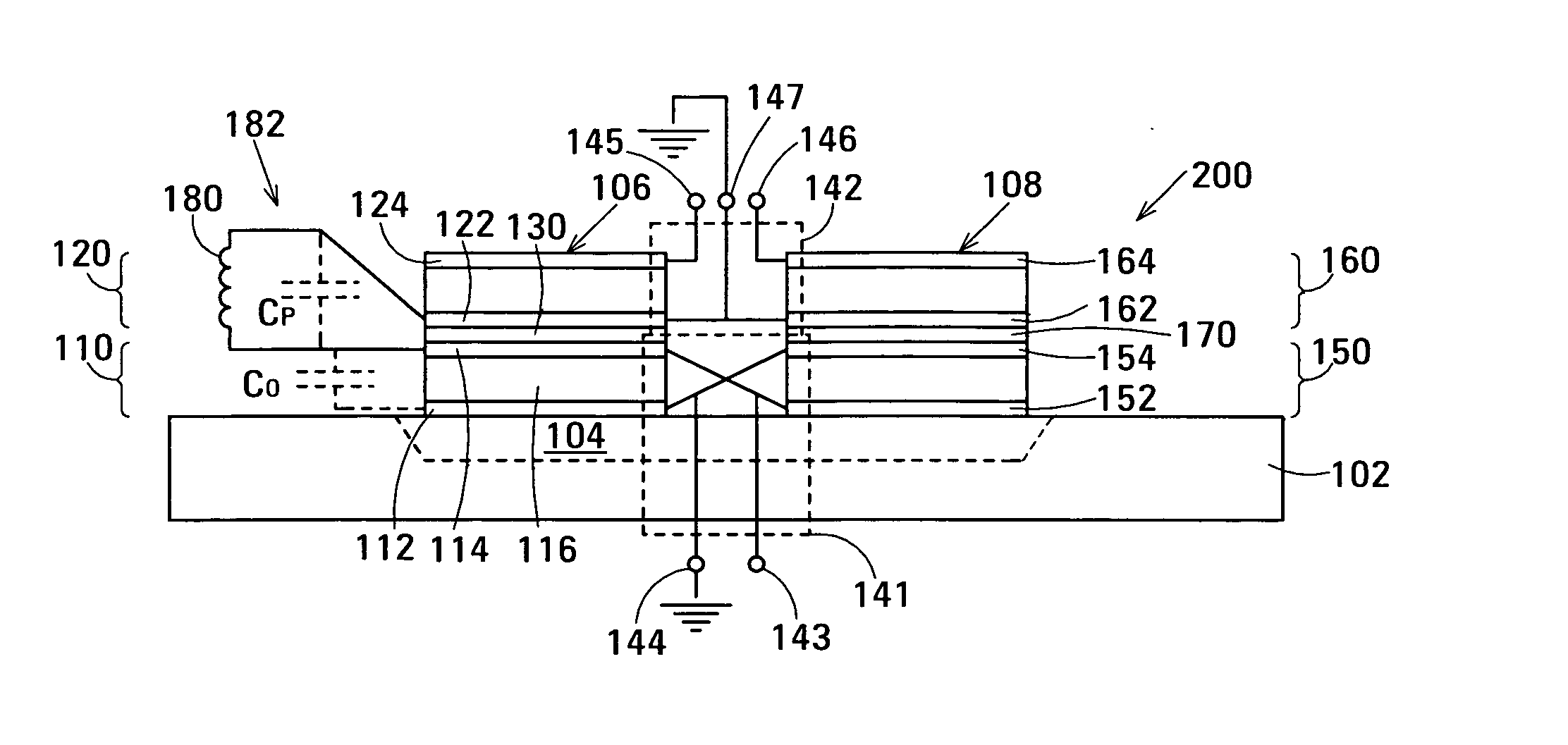

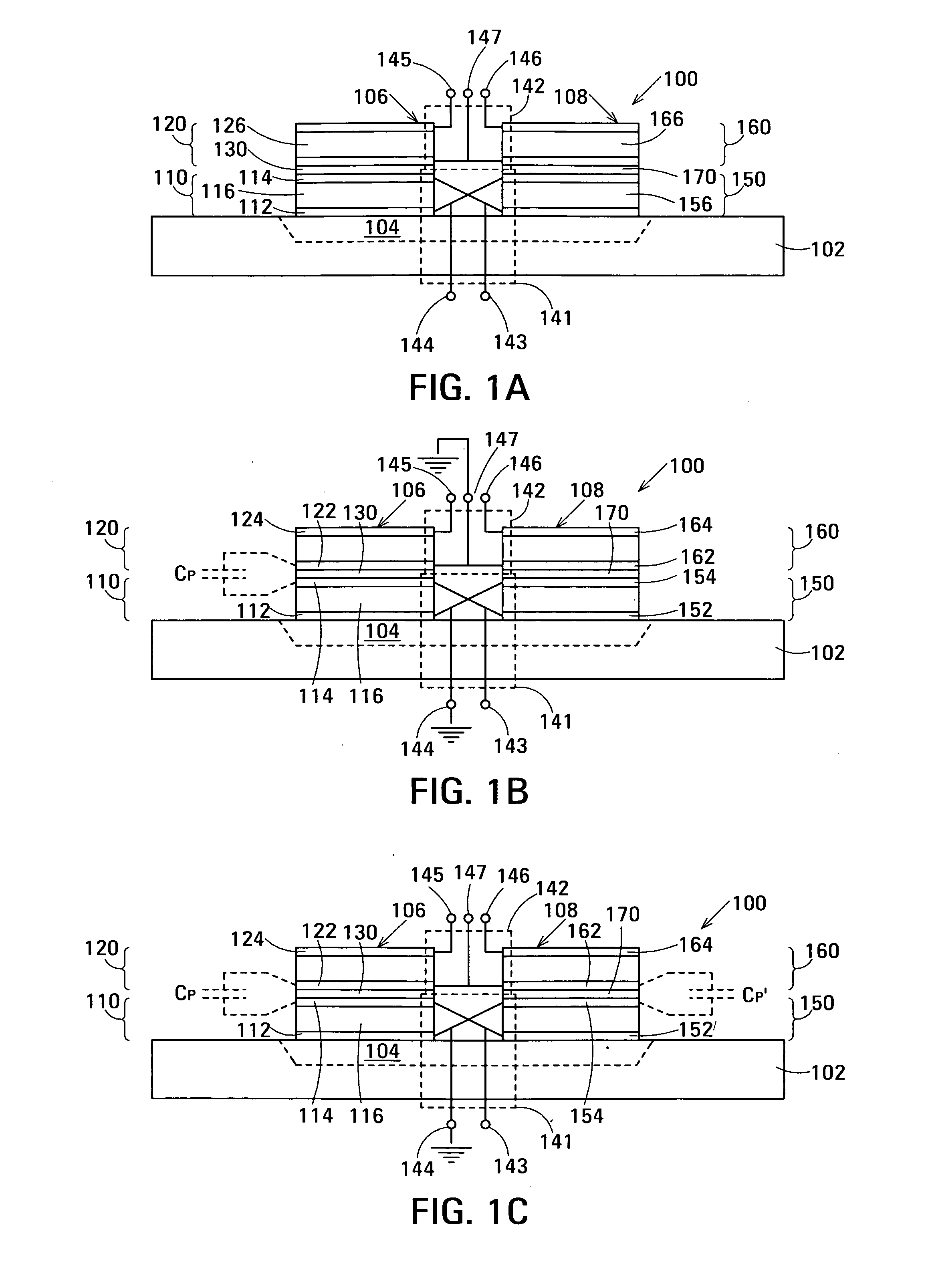

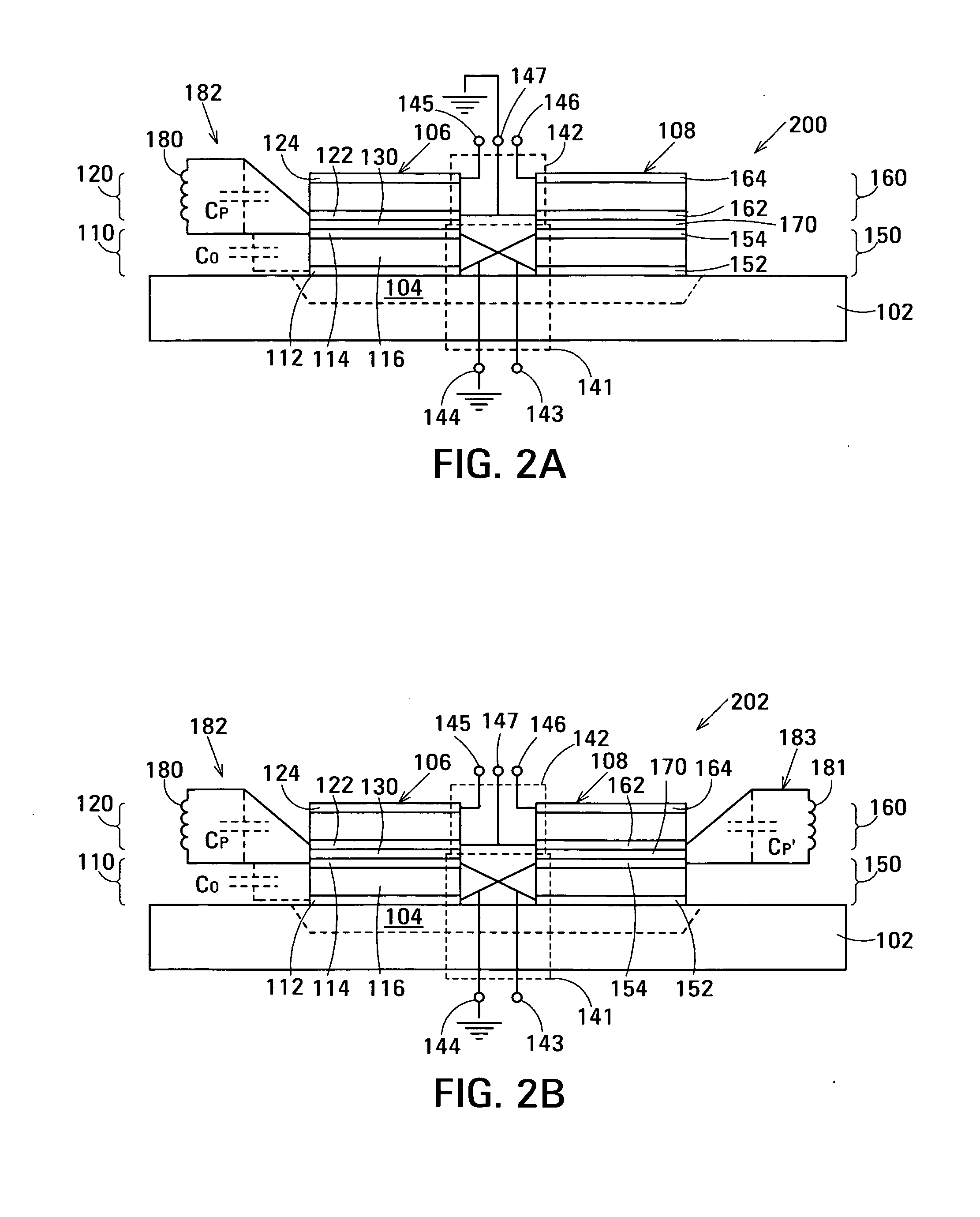

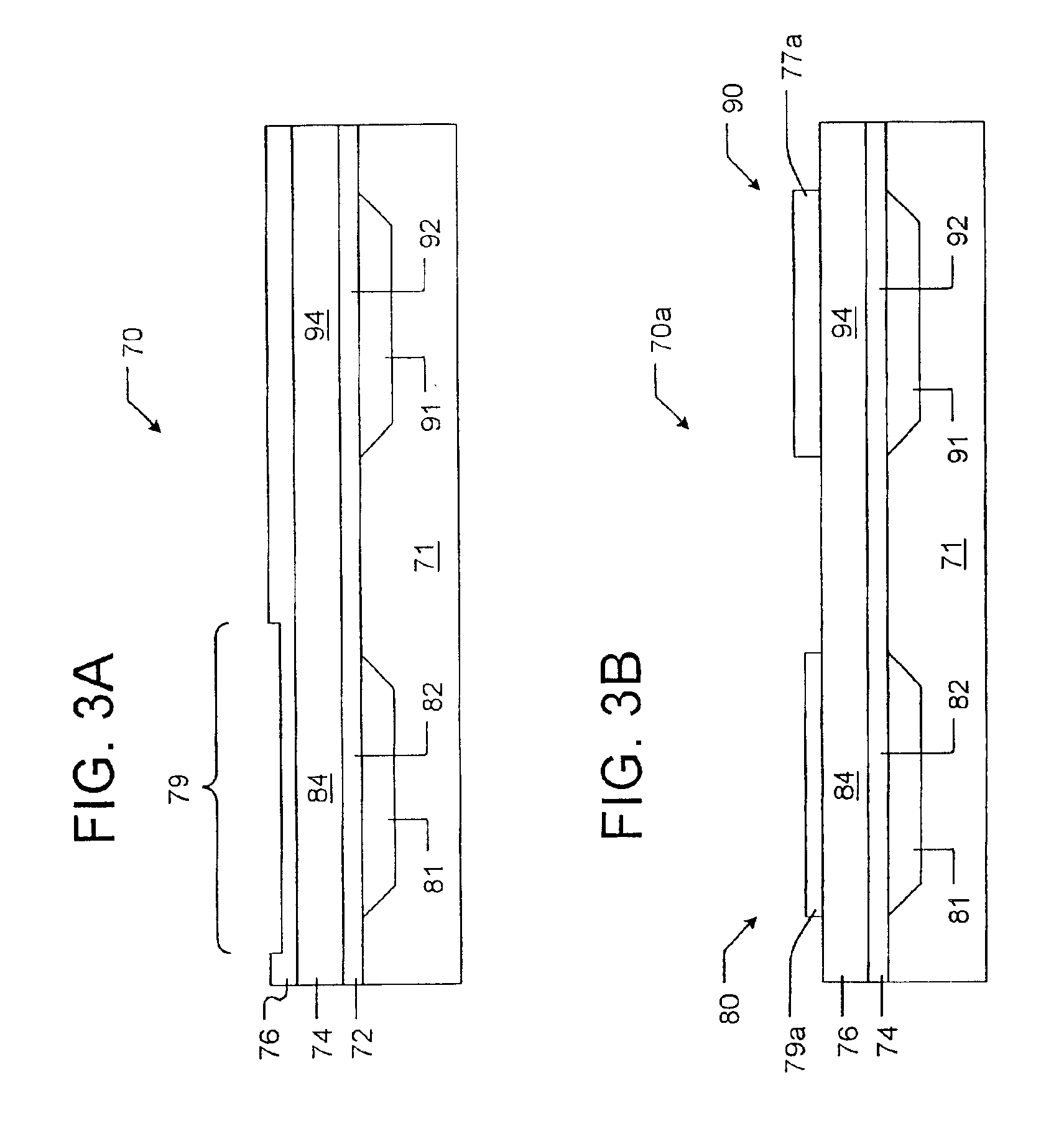

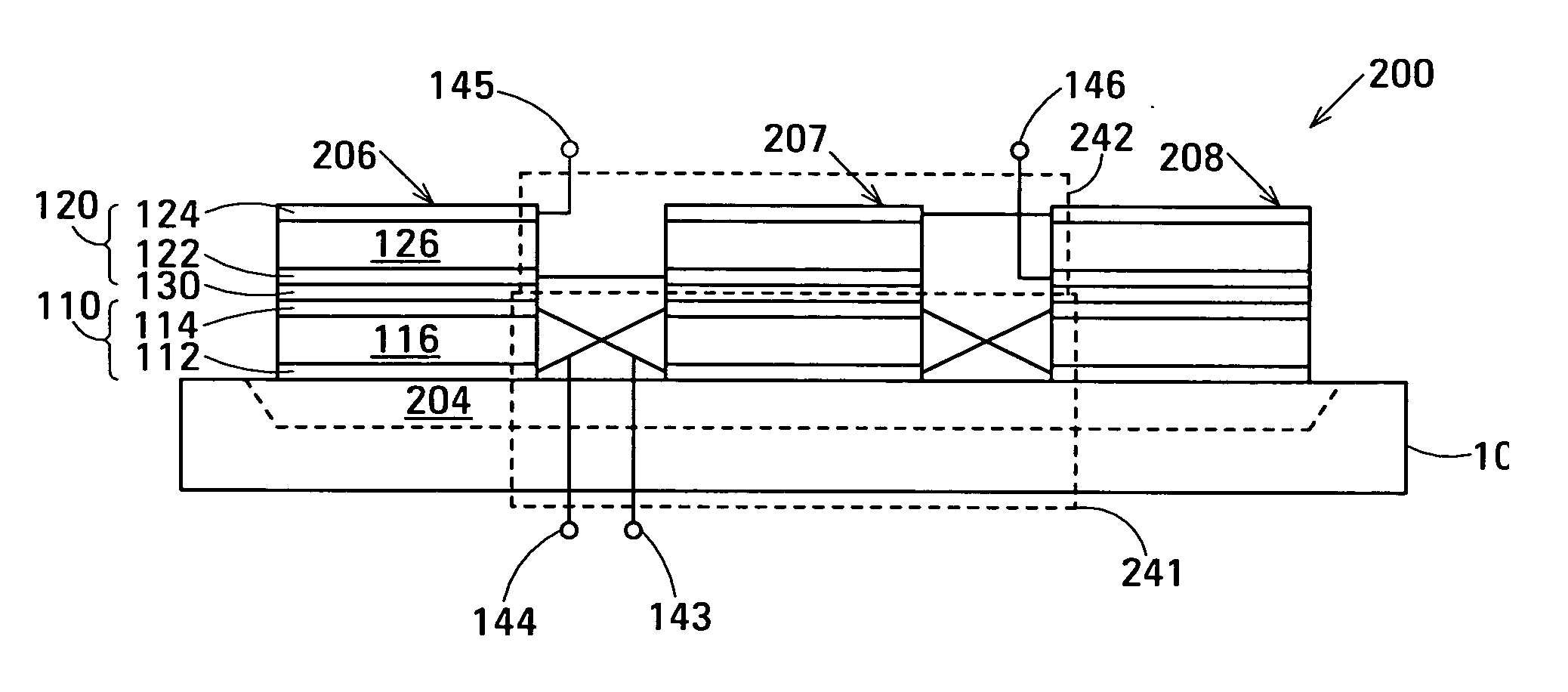

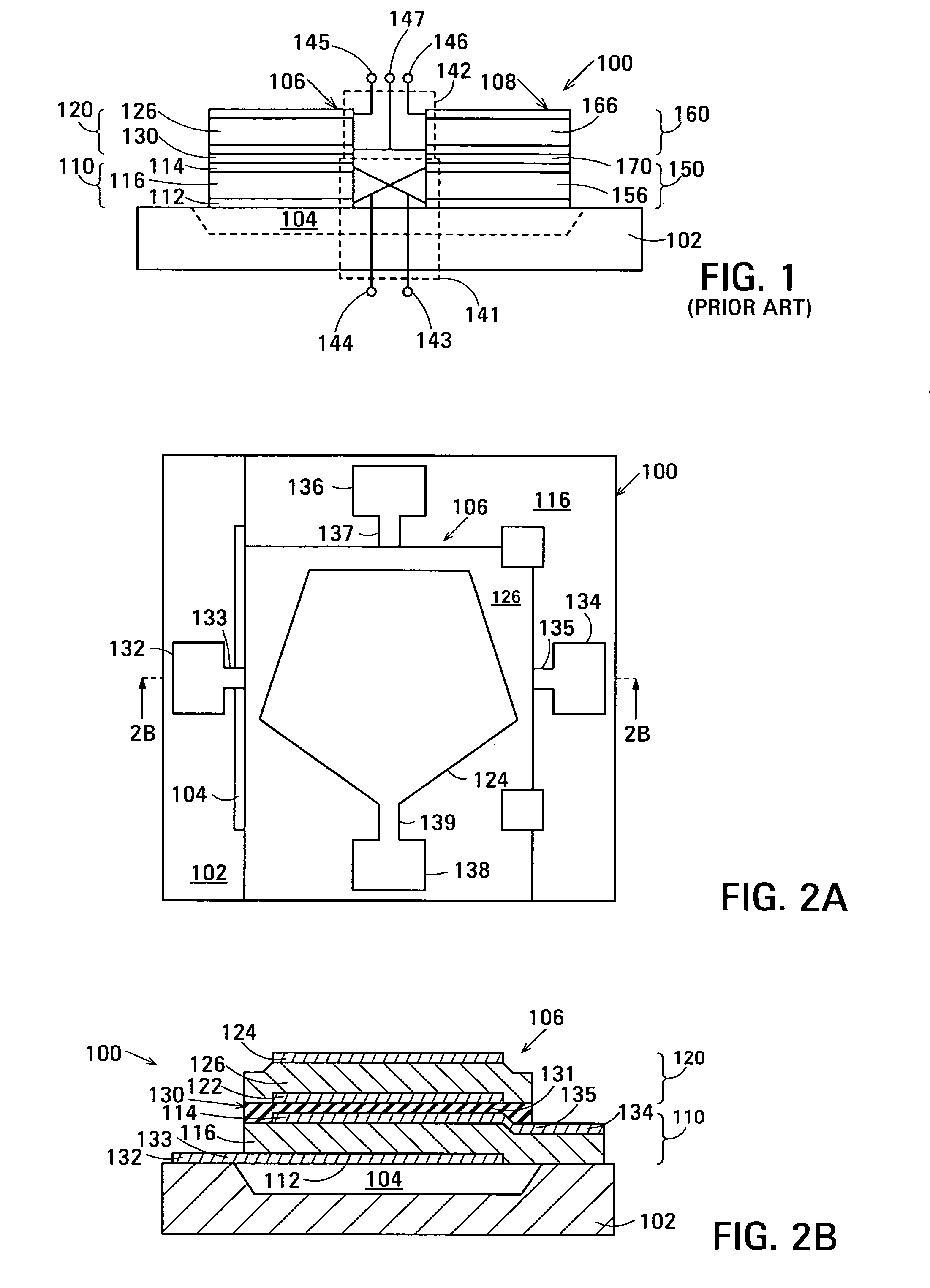

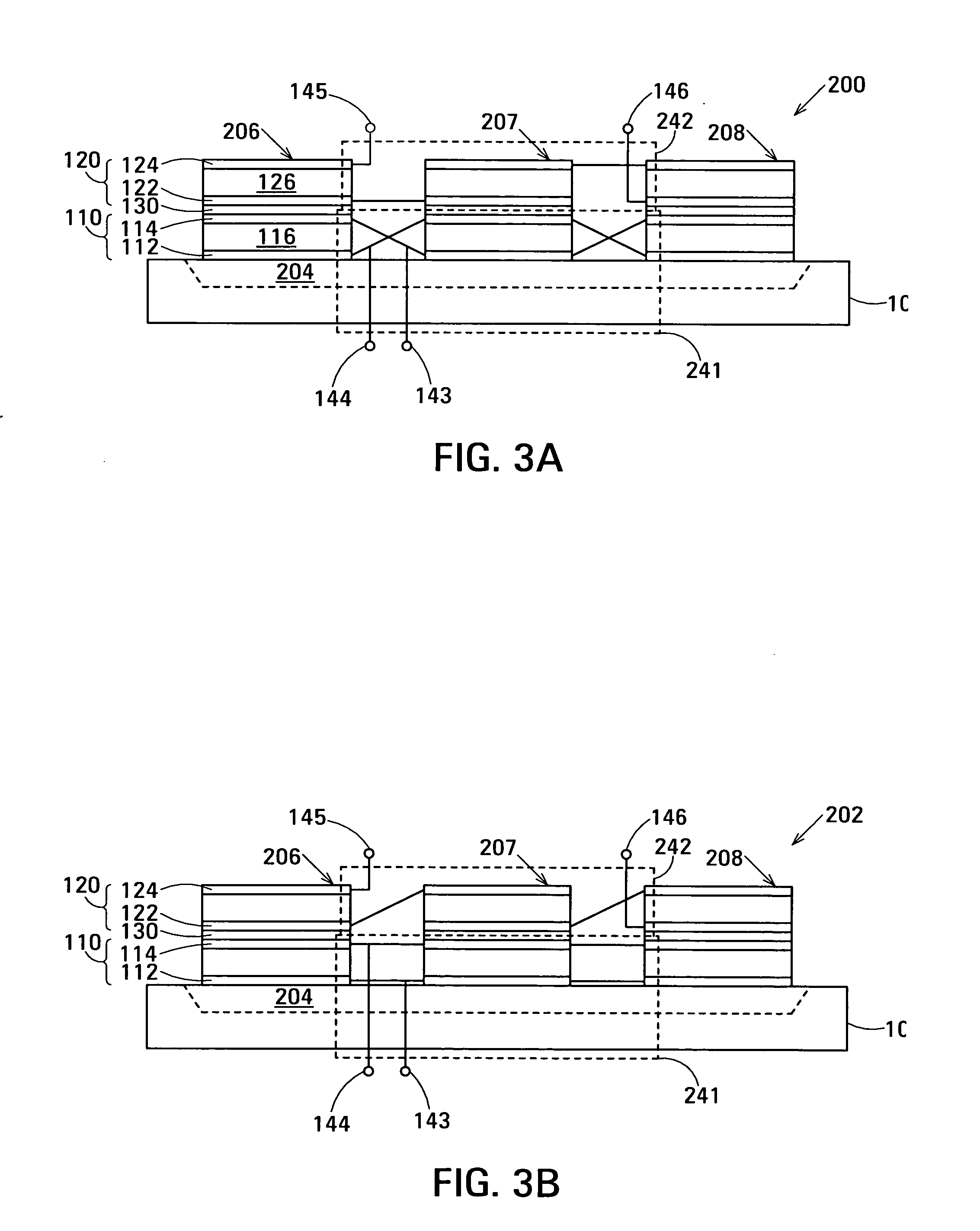

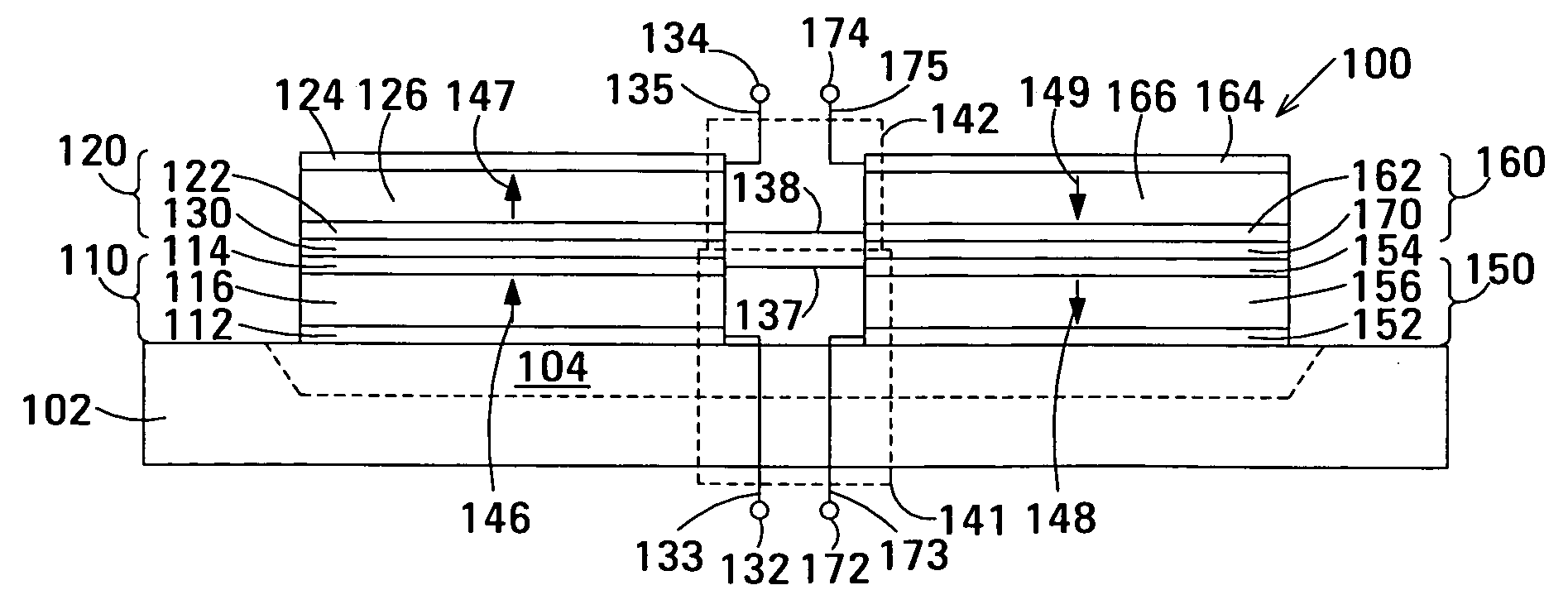

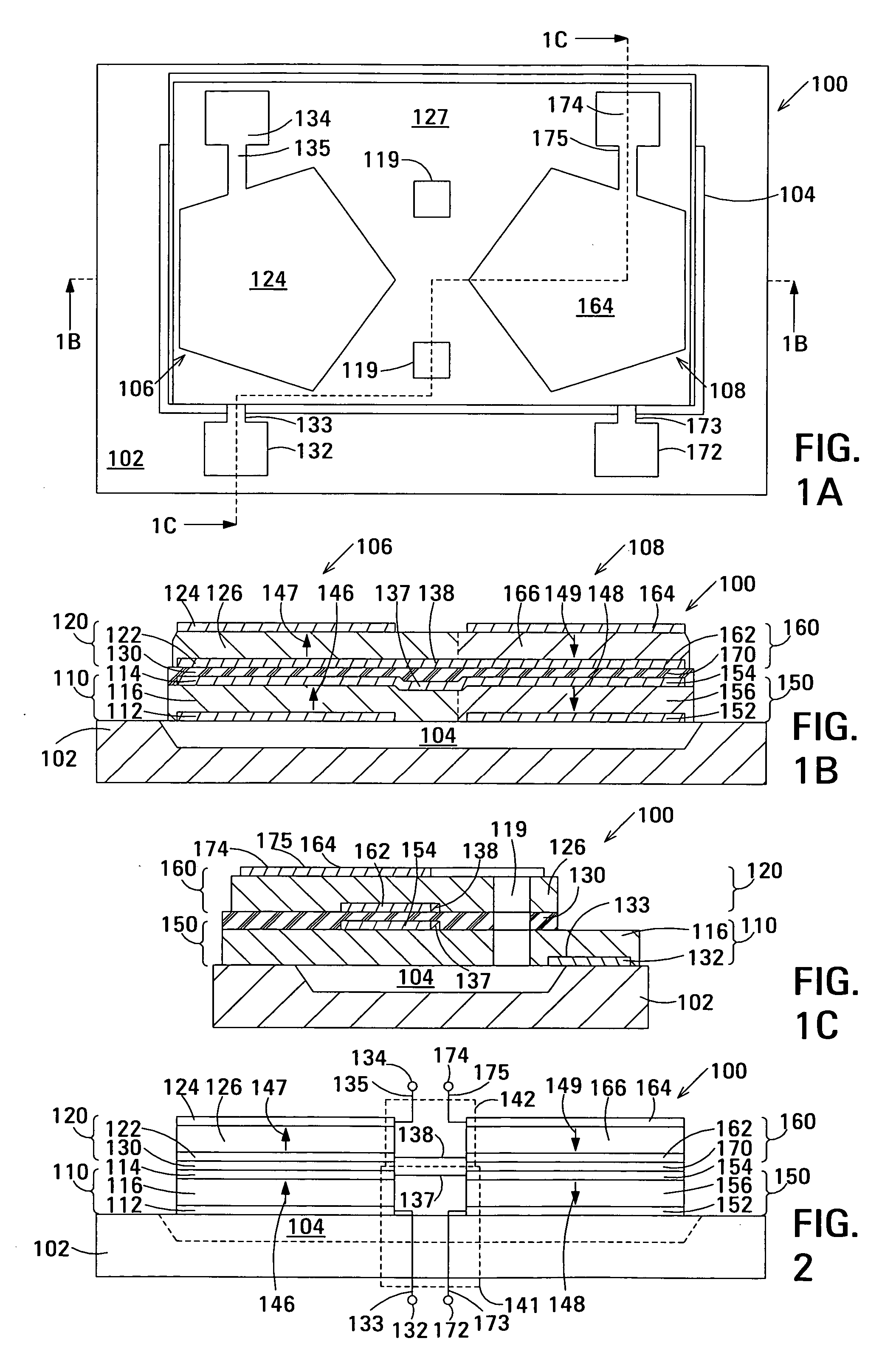

The film acoustically-coupled transformer (FACT) has a first and second decoupled stacked bulk acoustic resonators (DSBARs). Each DSBAR has a lower film bulk acoustic resonator (FBAR), an upper FBAR atop the lower FBAR, and an acoustic decoupler between them FBARs. Each FBAR has opposed planar electrodes and a piezoelectric element between the electrodes. A first electrical circuit interconnects the lowers FBAR of the first DSBAR and the second DSBAR. A second electrical circuit interconnects the upper FBARs of the first DSBAR and the second DSBAR. In at least one of the DSBARs, the acoustic decoupler and one electrode of the each of the lower FBAR and the upper FBAR adjacent the acoustic decoupler constitute a parasitic capacitor. The FACT additionally has an inductor electrically connected in parallel with the parasitic capacitor. The inductor increases the common-mode rejection ratio of the FACT.

Owner:AVAGO TECH INT SALES PTE LTD

Method for producing thin film bulk acoustic resonators (FBARs) with different frequencies on the same substrate by subtracting method and apparatus embodying the method

InactiveUS6874211B2Piezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesThin-film bulk acoustic resonatorAcoustics

A method for fabricating a resonator, and in particular, a thin film bulk acoustic resonator (FBAR), and a resonator embodying the method are disclosed. An FBAR is fabricated on a substrate by reducing mass from a top electrode layer. For a substrate having multiple resonators, mass is reduced from only selected resonator to provide resonators having different resonance frequencies on the same substrate.

Owner:AVAGO TECH INT SALES PTE LTD

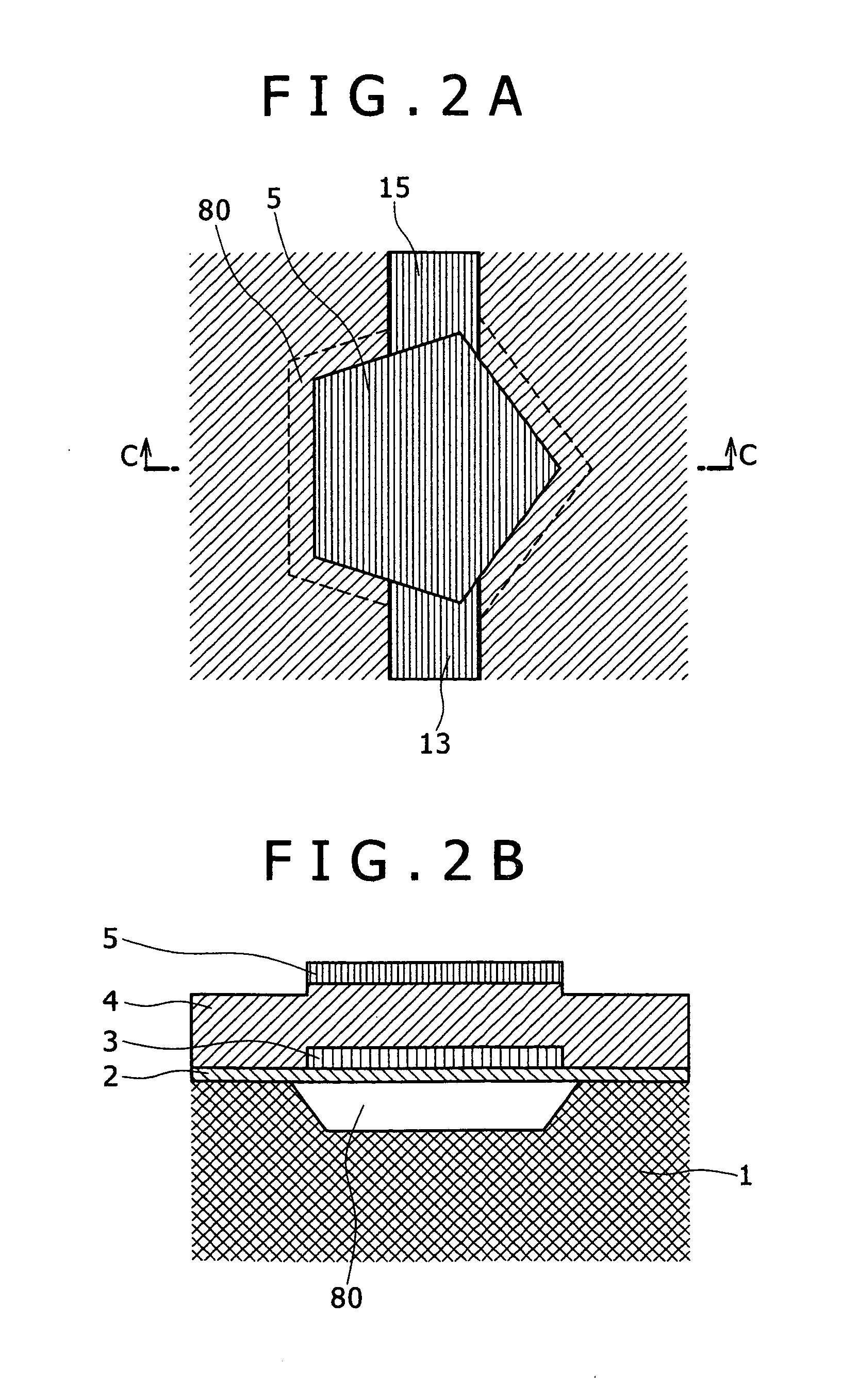

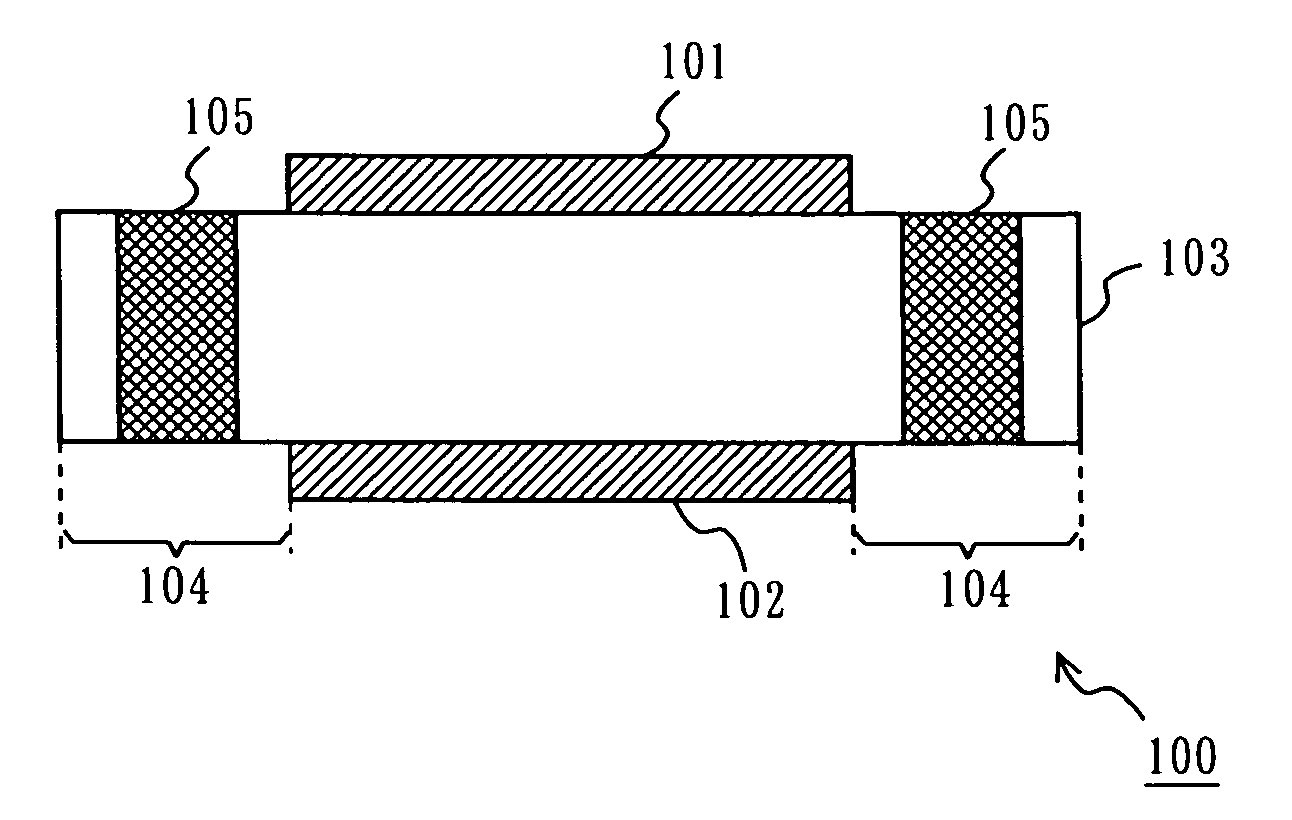

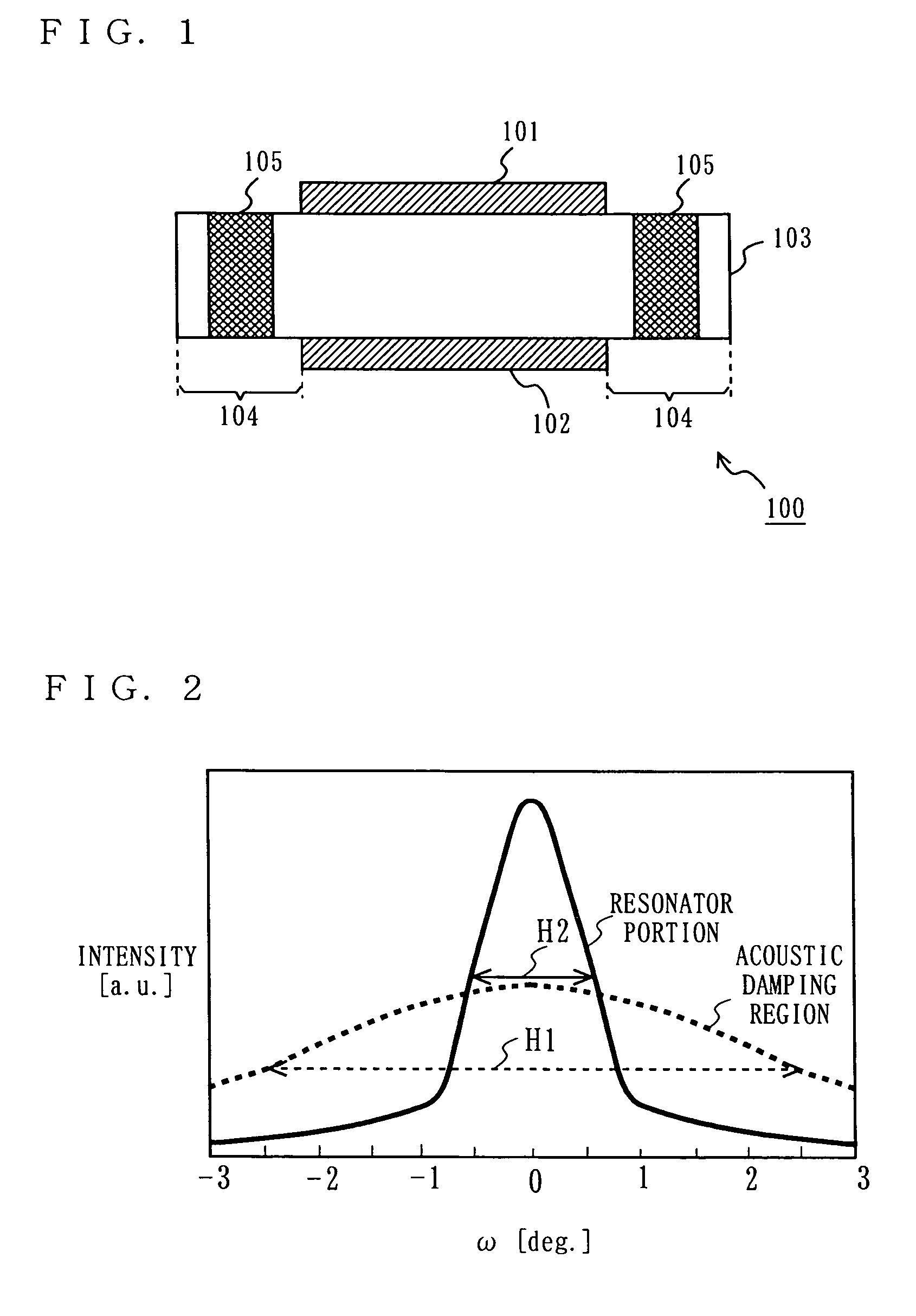

Thin film bulk acoustic resonator, method for producing the same, filter, composite electronic component device, and communication device

InactiveUS20050057324A1Sacrificing design freedomImprove filter characteristicsImpedence networksThin-film bulk acoustic resonatorAcoustic wave

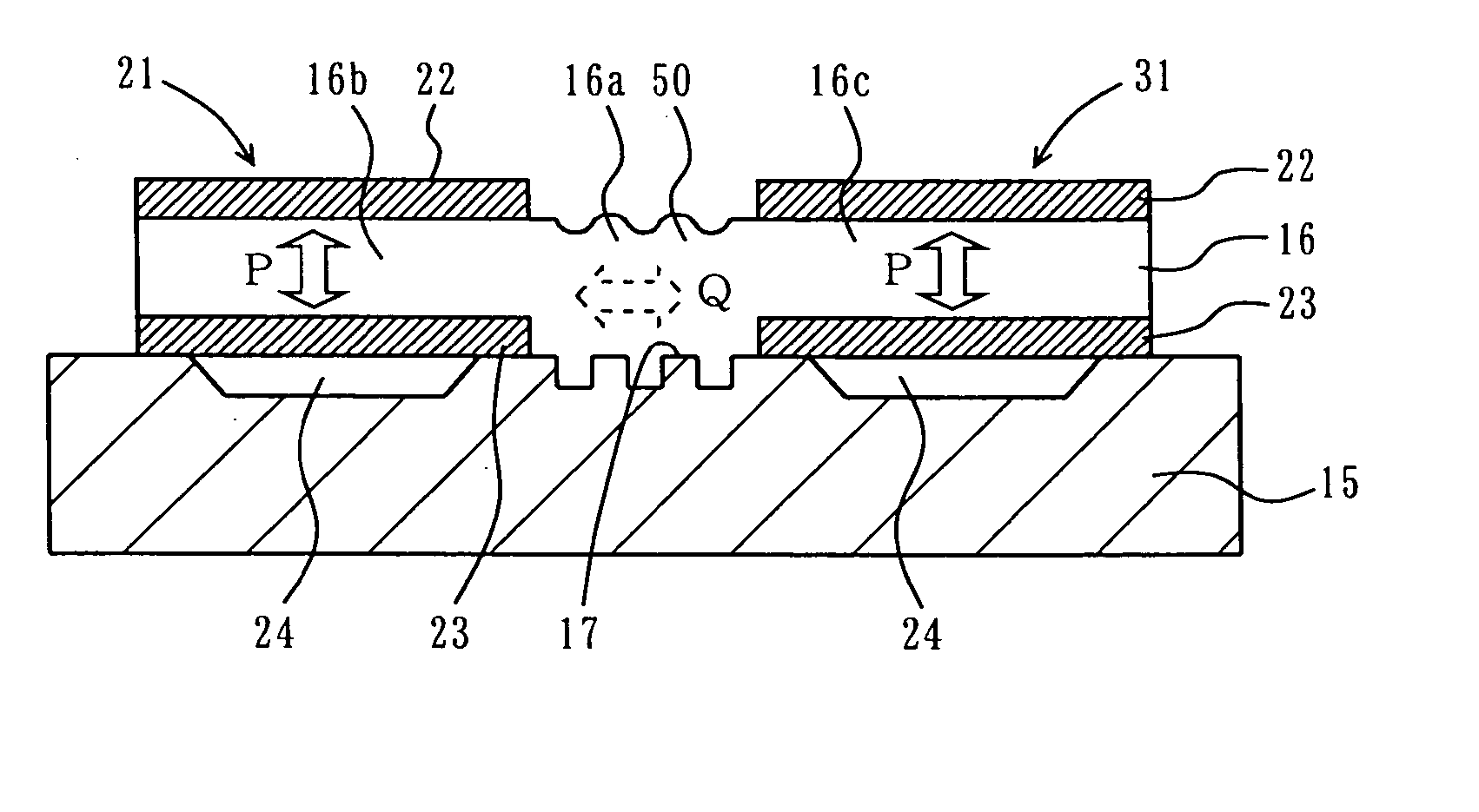

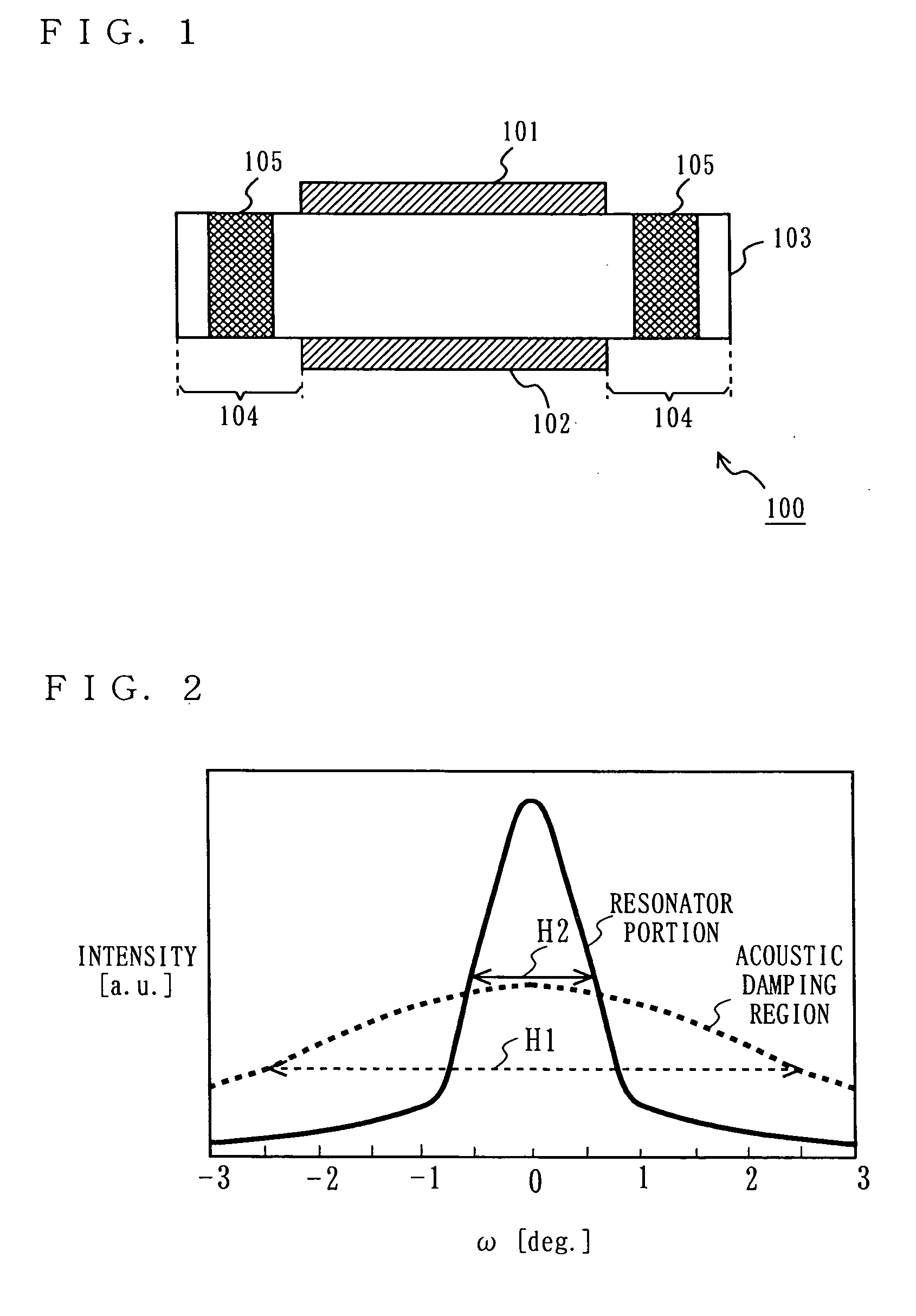

A thin film bulk acoustic resonator includes a piezoelectric film, and a pair of electrodes between which the piezoelectric film is interposed. The piezoelectric film includes an outer region extending outwards from at least a portion of the periphery of a resonator portion composed of the pair of electrodes and the piezoelectric film. The outer region includes, in at least a portion thereof, an acoustic damping region for damping acoustic waves.

Owner:PANASONIC CORP

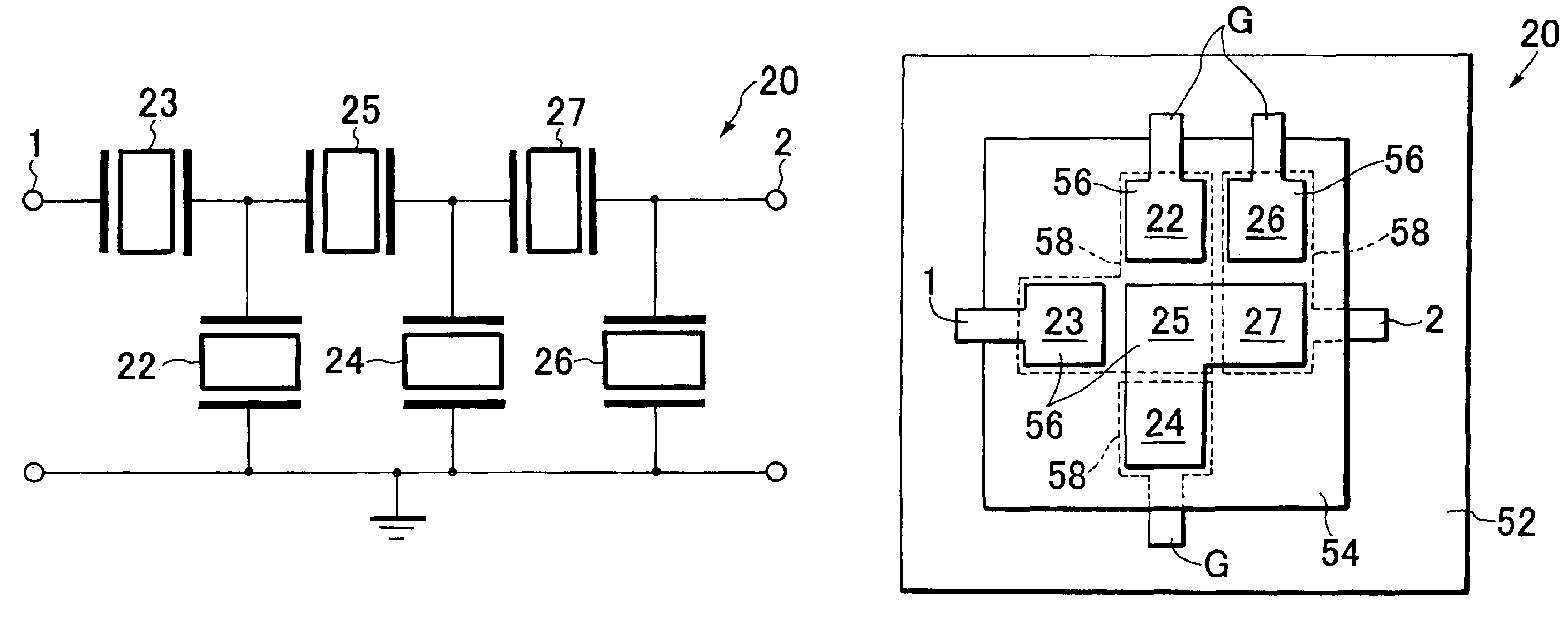

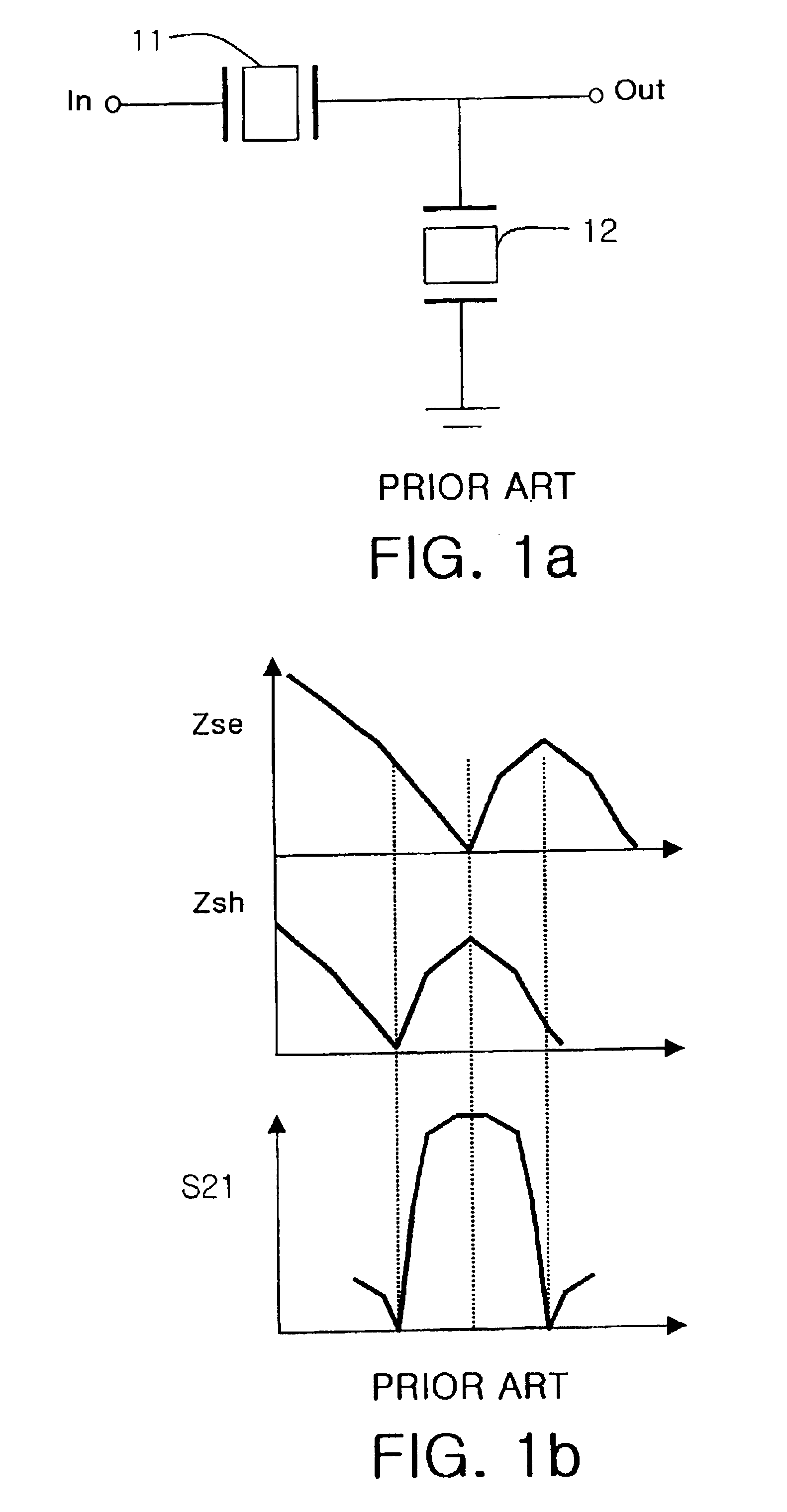

Band-pass filter using film bulk acoustic resonator

ActiveUS6885262B2Increase in size of filterDeteriorating characteristic in insertion lossImpedence networksThin-film bulk acoustic resonatorBand-pass filter

A band-pass filter has a ladder-type circuit including first and second terminals whose characteristic impedances are Z0, and series elements and shunt elements disposed between a first terminal and a second terminal, each of the series elements and shunt elements containing a film bulk acoustic resonator. Assuming that characteristic impedance of any one of the series elements is Z1 and that characteristic impedance of any one of the shunt elements is Z2, the characteristic impedances Z0, Z1, and Z2 have a relation of 1<(Z1 / Z0)<2, preferably 1.3<(Z1 / Z0)<1.7, and 0.5<(Z2 / Z0)<1, preferably 0.6<(Z2 / Z0)<0.8.

Owner:MEMS SOLUTIONS INC

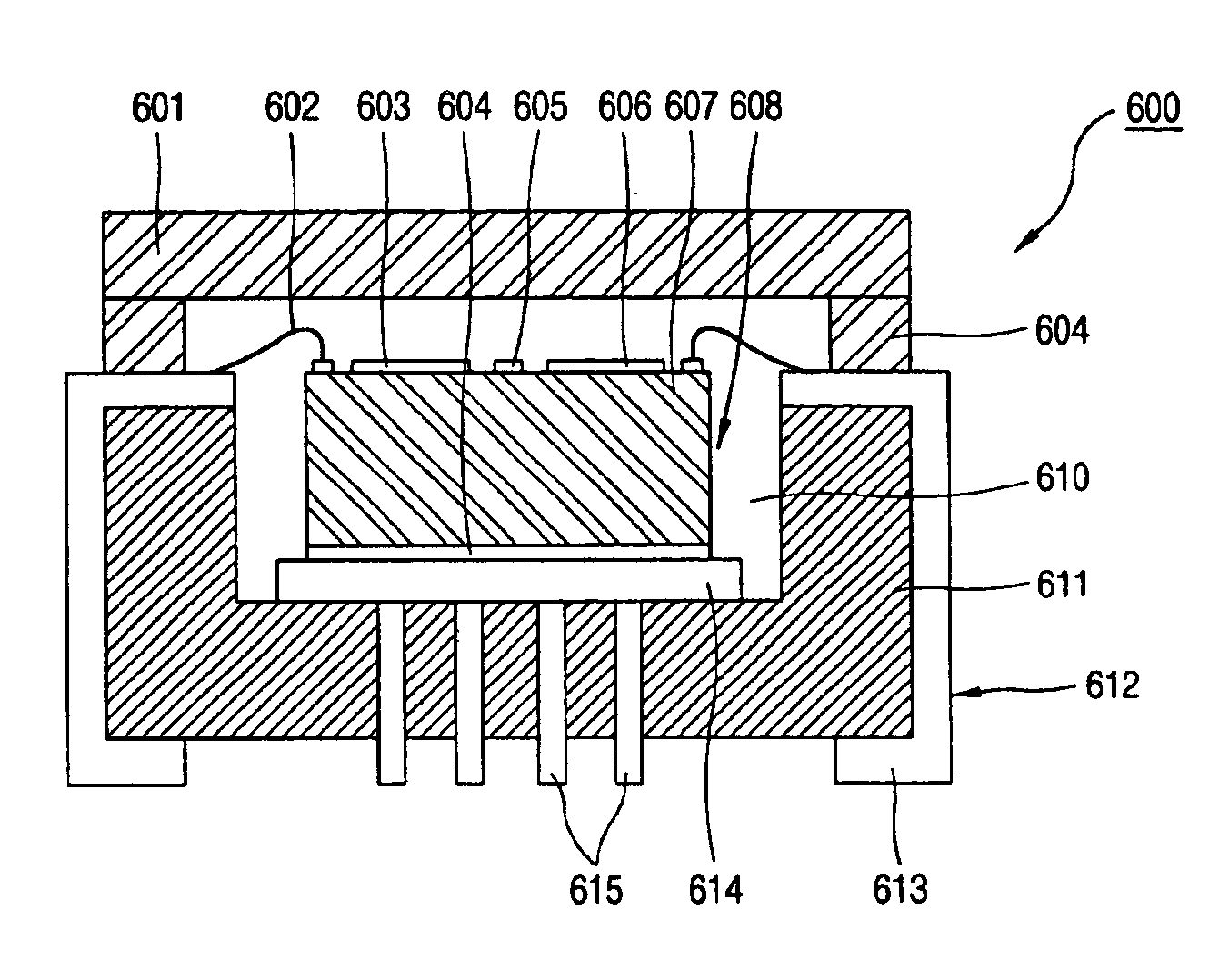

Duplexer filter having film bulk acoustic resonator and semiconductor package thereof

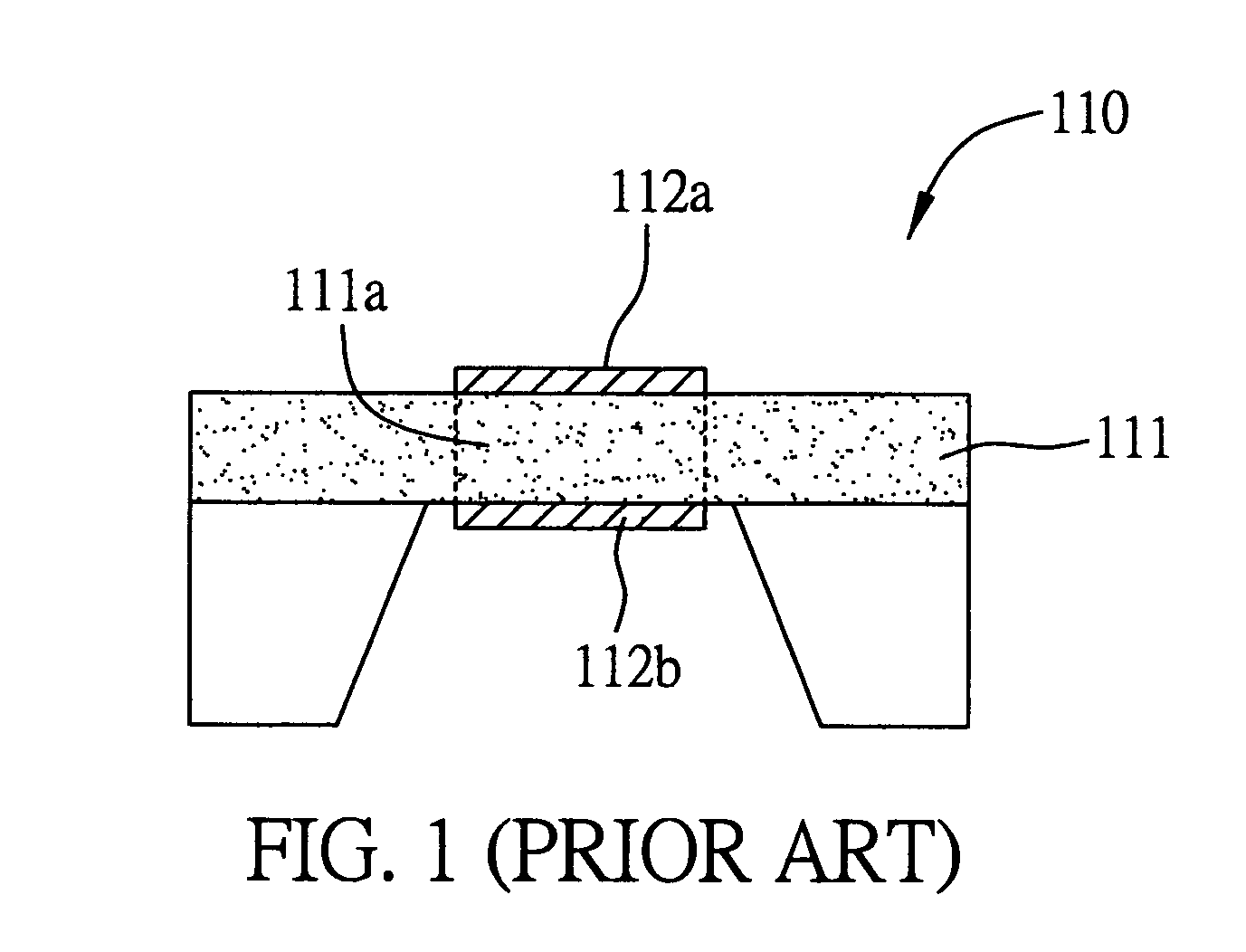

InactiveUS6911708B2Excellent Adhesive PropertiesStructuredImpedence networksPiezoelectric/electrostriction/magnetostriction machinesThin-film bulk acoustic resonatorSemiconductor chip

Disclosed are a film bulk acoustic resonator, a duplexer filter having the same, and a semiconductor package thereof. The film bulk acoustic resonator comprising: a semiconductor substrate; a lower electrode more than two layers formed at an upper surface of the semiconductor substrate; a piezoelectric layer deposited on an upper surface of the lower electrode with a certain thickness; and an upper electrode more than two layers formed at an upper surface of the piezoelectric layer, has an excellent bonding characteristic. The duplexer filter can microminiaturize a size thereof by integrating a film bulk acoustic filter formed by connecting the plurality of film bulk acoustic resonators serially and in parallel and peripheral passive elements of the film bulk acoustic filter into one semiconductor chip. Also, the semiconductor package is suitable for the duplexer filter.

Owner:LG ELECTRONICS INC

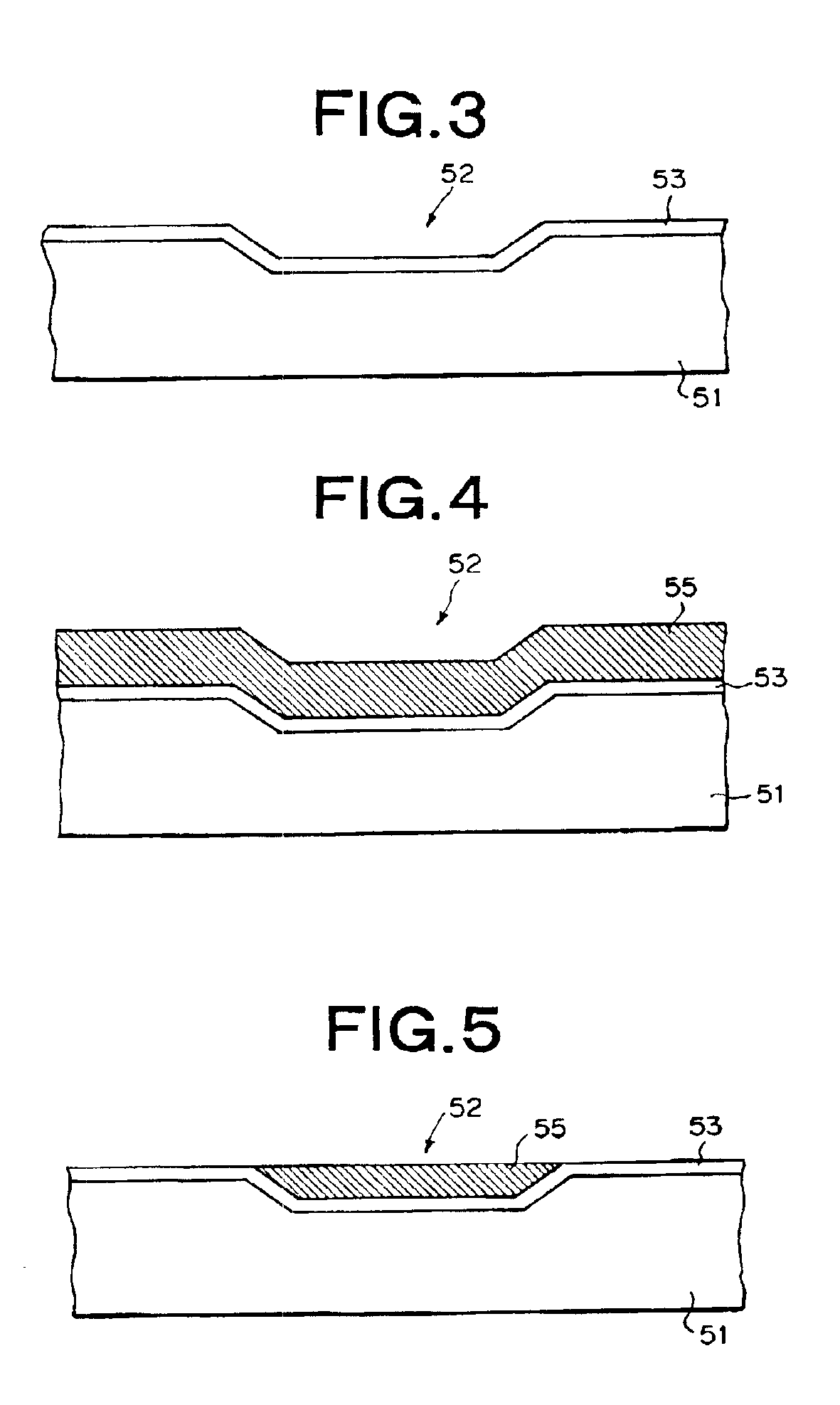

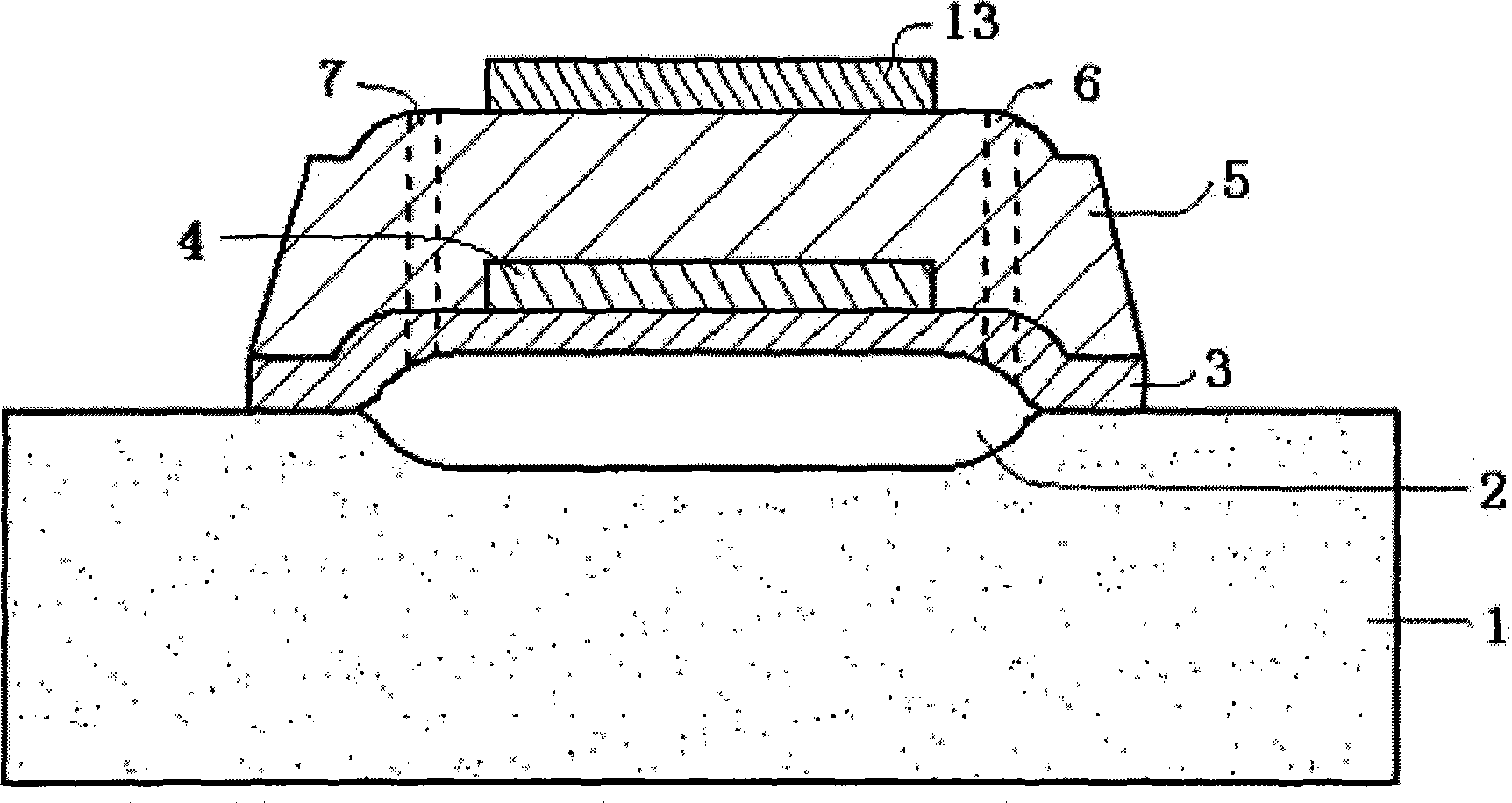

Film bulk acoustic wave resonator and preparation method thereof

InactiveCN101465628AHigh application frequencyReduce the requirements of the manufacturing process for equipmentImpedence networksThin-film bulk acoustic resonatorBulk acoustic wave

The invention discloses a thin film bulk acoustic wave resonator which comprises a substrate, a buffer layer, a piezoelectric layer and electrodes, and is characterized in that 1. A smooth concave groove and the buffer layer are arranged on the upper end surface of the substrate; the buffer layer crosses the concave groove and forms an air gap provided with a smooth upper convex edge with the substrate, and completely covers the air gap; the height of the lower top surface of the air gap is less than that of the substrate, and the air gap has flat surface and even change edge; 2. The edge of the buffer layer, which is contacted with the air gap and is close to the substrate is in smooth and outer-convex shape; the piezoelectric layer is arranged on the buffer layer; the electrodes include a bottom electrode and a top electrode; the bottom electrode is arranged in the piezoelectric layer on the buffer layer; the top electrode is arranged on the piezoelectric layer. The thin film bulk acoustic wave resonator has ingenious structure; a FBAR with stable structure and low loss can be fabricated on the substrate through the method, and the CMP process is avoided, so the thin film bulk acoustic wave resonator can be integrated into a CMOS chip conveniently.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

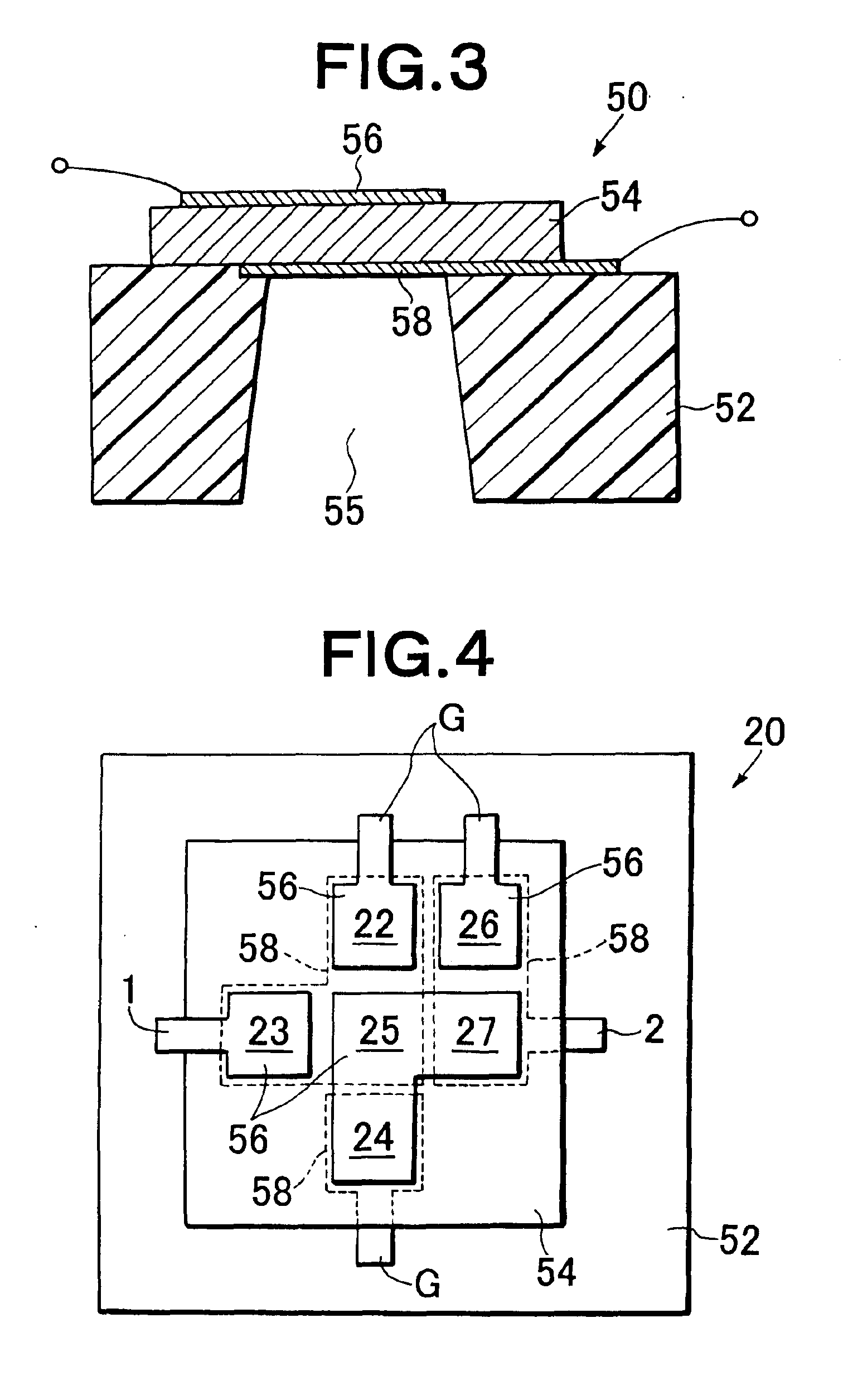

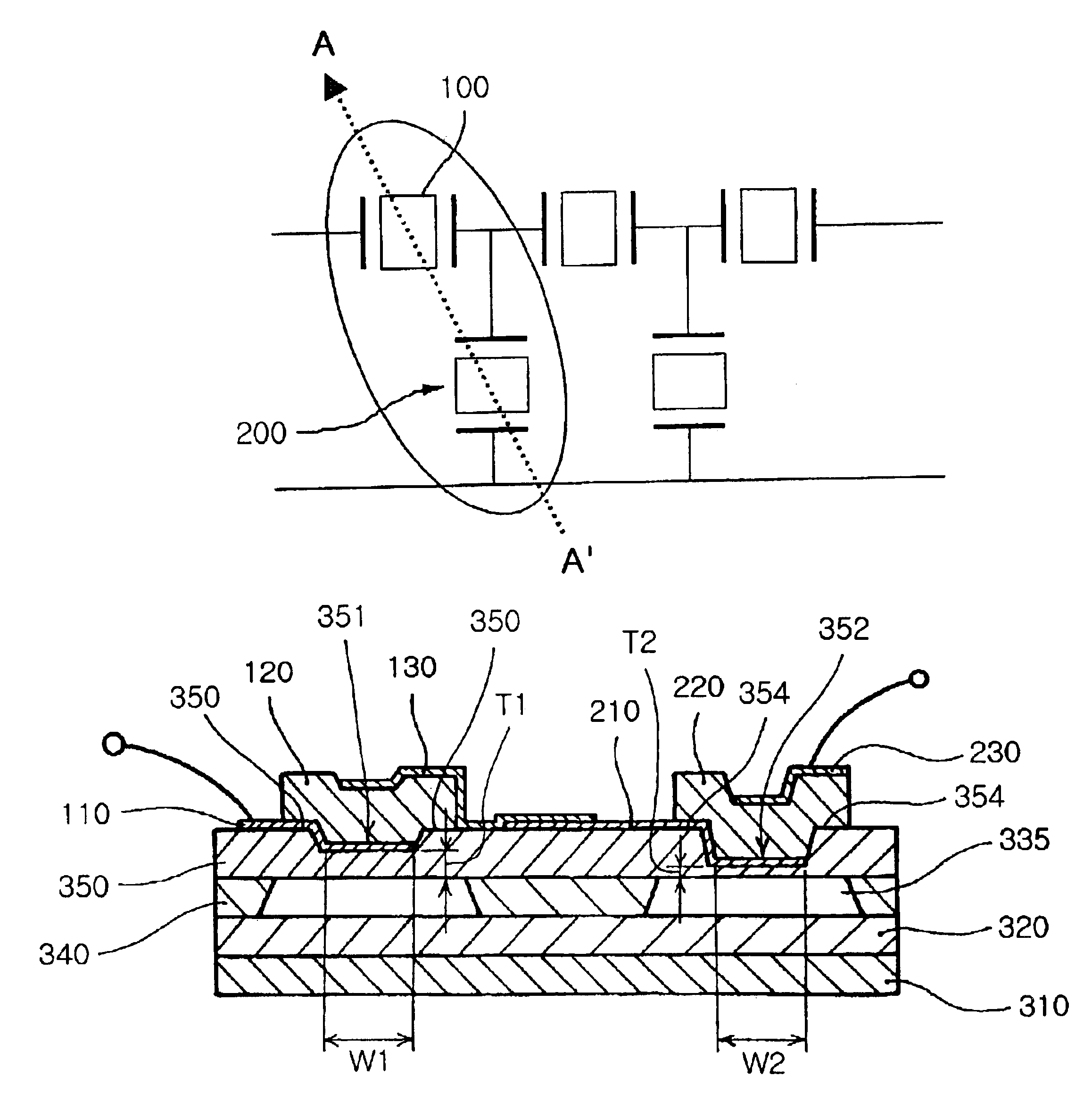

Impedance transformation ratio control in film acoustically-coupled transformers

ActiveUS20050128030A1Multiple-port networksSolid-state devicesThin-film bulk acoustic resonatorPlanar electrode

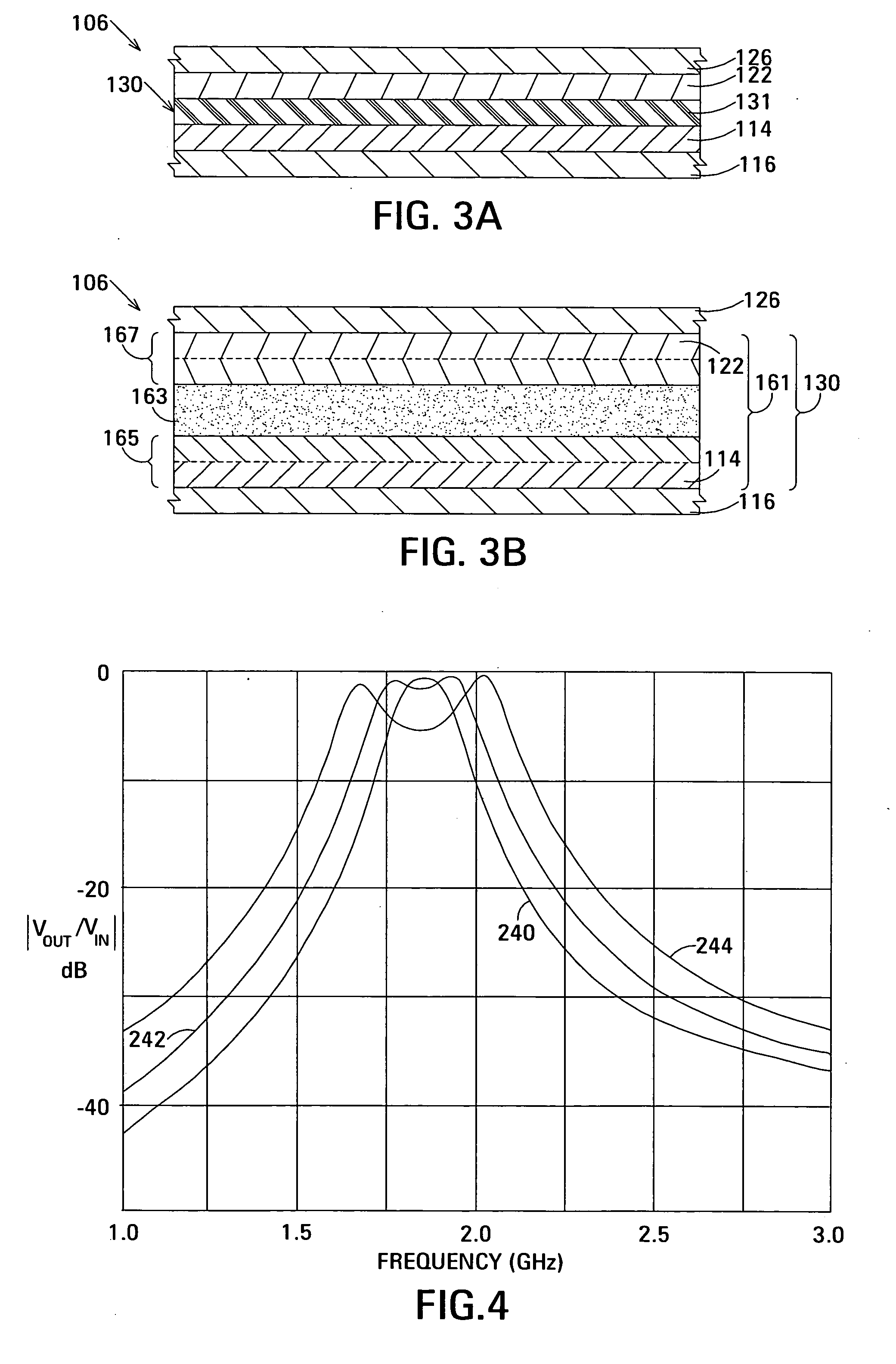

The film acoustically-coupled transformer (FACT) has decoupled stacked bulk acoustic resonators (DSBARs), a first electrical circuit and a second electrical circuit. Each of the DSBARs has a lower film bulk acoustic resonator (FBAR), an upper FBAR and an acoustic decoupler. The upper FBAR is stacked on the lower FBAR and the acoustic decoupler is located between the FBARs. Each FBAR has opposed planar electrodes and a piezoelectric element between the electrodes. The first electrical circuit interconnects the lower FBARs. The second electrical circuit interconnects the upper FBARs. The FBARs of one of the DSBARs differ in electrical impedance from the FBARs of another of the DSBARs. The FACT has an impedance transformation ratio greater than 1:m2, where m is the number of DSBARs. The actual impedance transformation ratio depends on the ratio of the impedances of the FBARs.

Owner:AVAGO TECH INT SALES PTE LTD

Film acoustically-coupled transformers with two reverse c-axis piezoelectric elements

ActiveUS20050093396A1Low insertion lossSolve insufficient bandwidthImpedence networksPiezoelectric/electrostriction/magnetostriction machinesThin-film bulk acoustic resonatorPlanar electrode

Embodiments of an acoustically-coupled transformer have a first stacked bulk acoustic resonator (SBAR) and a second SBAR. Each of the SBARs has a lower film bulk acoustic resonator (FBAR) and an upper FBAR, and an acoustic decoupler between the FBARs. The upper FBAR is stacked atop the lower FBAR. Each FBAR has opposed planar electrodes and a piezoelectric element between the electrodes. The piezoelectric element is characterized by a c-axis. The c-axes of the piezoelectric elements of the lower FBARs are opposite in direction, and the c-axes of the piezoelectric elements of the upper FBARs are opposite in direction. The transformer additionally has a first electrical circuit connecting the lower FBAR of the first SBAR to the lower FBAR of the second SBAR, and a second electrical circuit connecting the upper FBAR of the first SBAR to the upper FBARs of the second SBAR.

Owner:AVAGO TECH INT SALES PTE LTD

Film bulk acoustic resonator (FBAR) and the method of making the same

InactiveUS20030141946A1Reduces void and discontinuityImpedence networksThin-film bulk acoustic resonatorAcoustic wave

An apparatus having a thin film bulk acoustic resonator (FBAR) with positively sloped bottom electrode and a method of making the same is disclosed. The resonator has a bottom electrode, a top electrode, and core material. The bottom electrode includes a positively sloped edge. To make the apparatus including the resonator, first, a bottom electrode layer is deposited. Then, the bottom electrode layer is dry etched to fabricate a bottom electrode having a positively sloped edge. Next, a core layer is fabricated above the bottom electrode. Finally, a top electrode is fabricated over the core layer.

Owner:AGILENT TECH INC

Film bulk acoustic resonator (FBAR) device

InactiveUS6842089B2Stable structureImprove featuresPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksThin-film bulk acoustic resonatorAcoustics

Disclosed are a film bulk acoustic resonator (FBAR) device and a method for fabricating the film bulk acoustic resonator (FBAR) device. The film bulk acoustic resonator (FBAR) device comprises a membrane layer having a plurality of active regions and provides different resonant frequencies by providing different thicknesses of the active regions of series resonators and shunt resonators, and by controlling the thicknesses, respectively. A plurality of the film bulk acoustic resonator (FBAR) devices having different resonant frequencies are manufactured on a substrate, thereby simultaneously manufacturing a transmission filter and a reception filter on the same substrate. Further, the film bulk acoustic resonator (FBAR) device has a stable structure and excellent characteristics.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Film bulk acoustic resonator

InactiveUS6936837B2Maximum couplingHigh bandwidthImpedence networksBulk negative resistance effect devicesThin-film bulk acoustic resonatorAlkaline earth metal

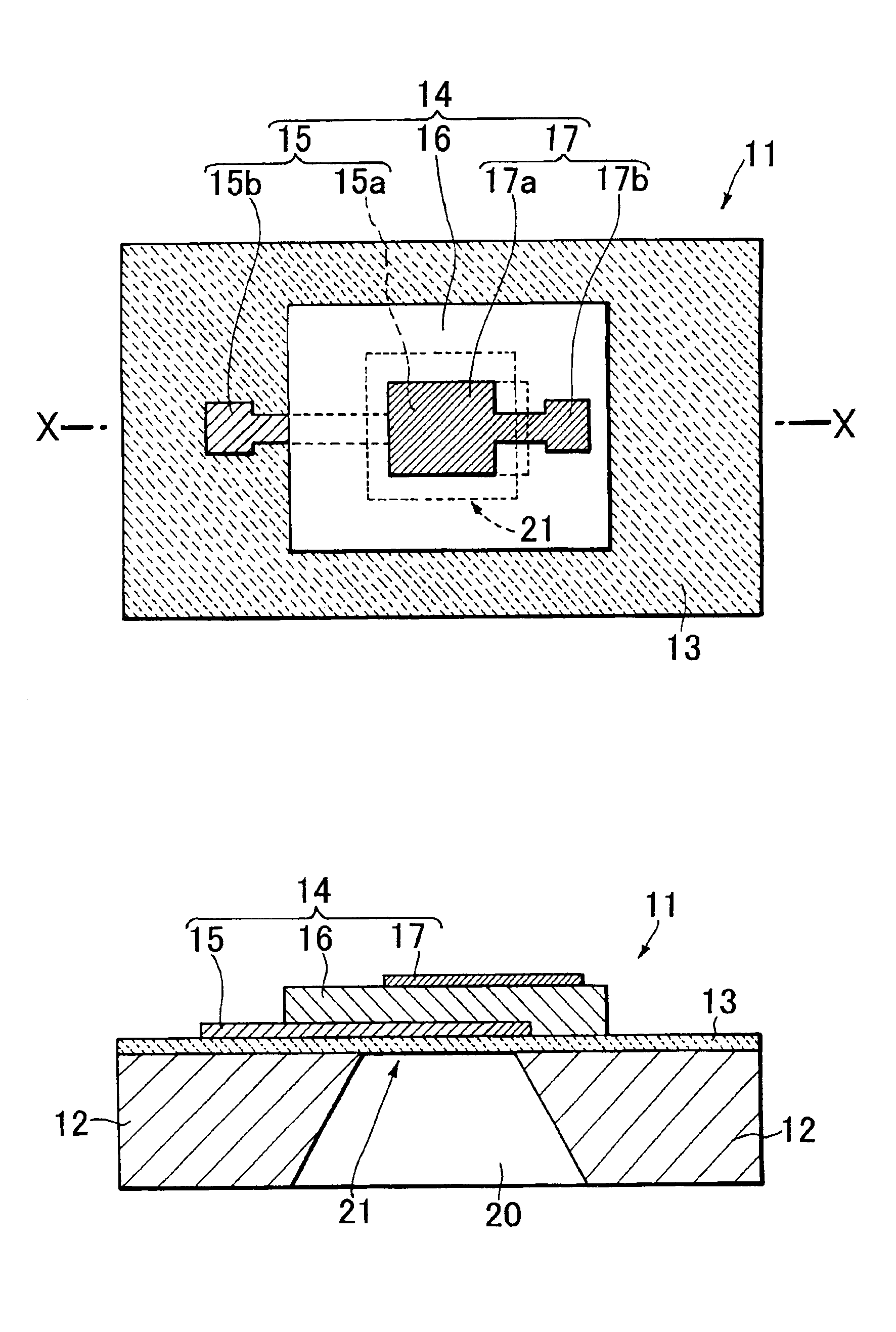

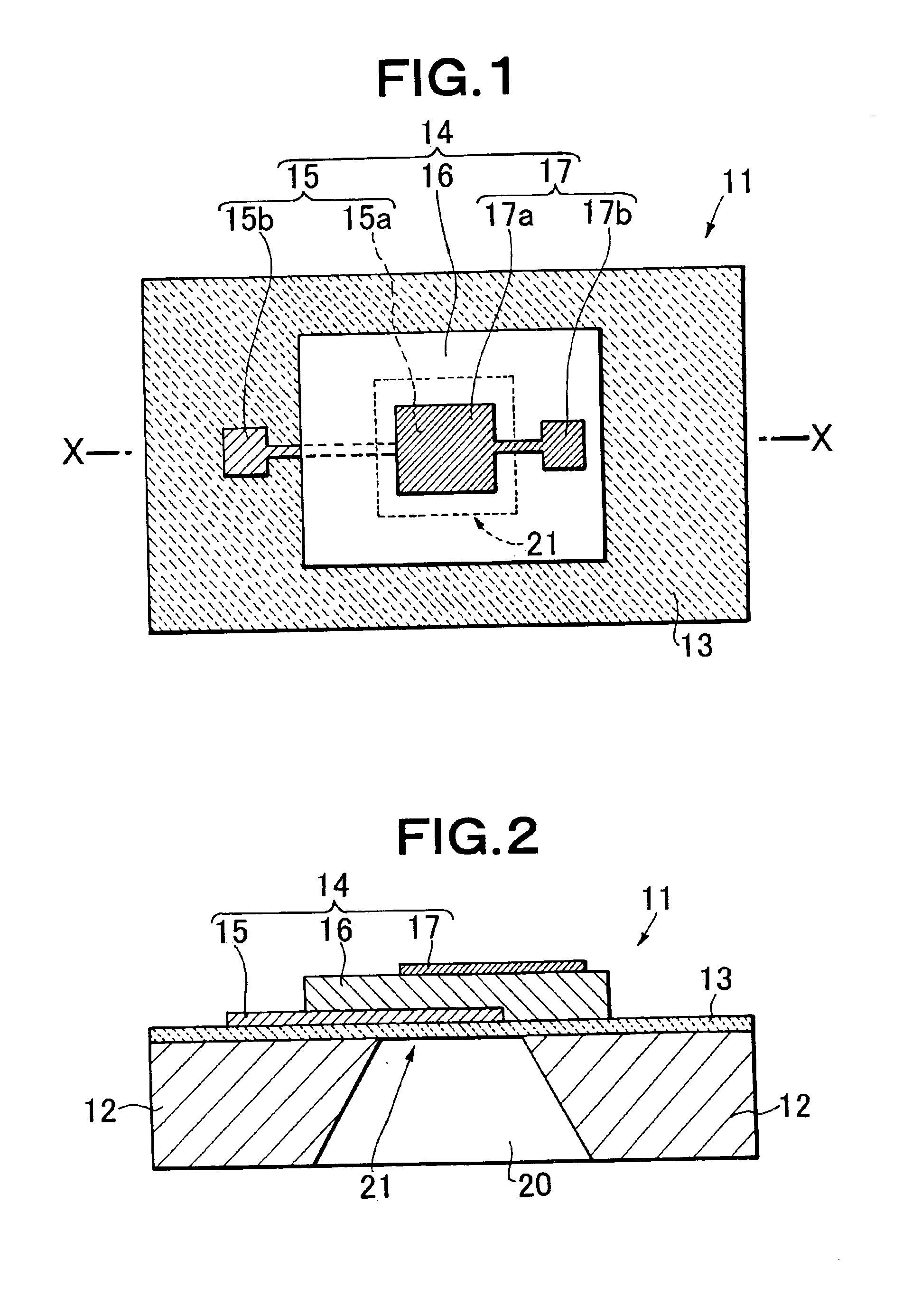

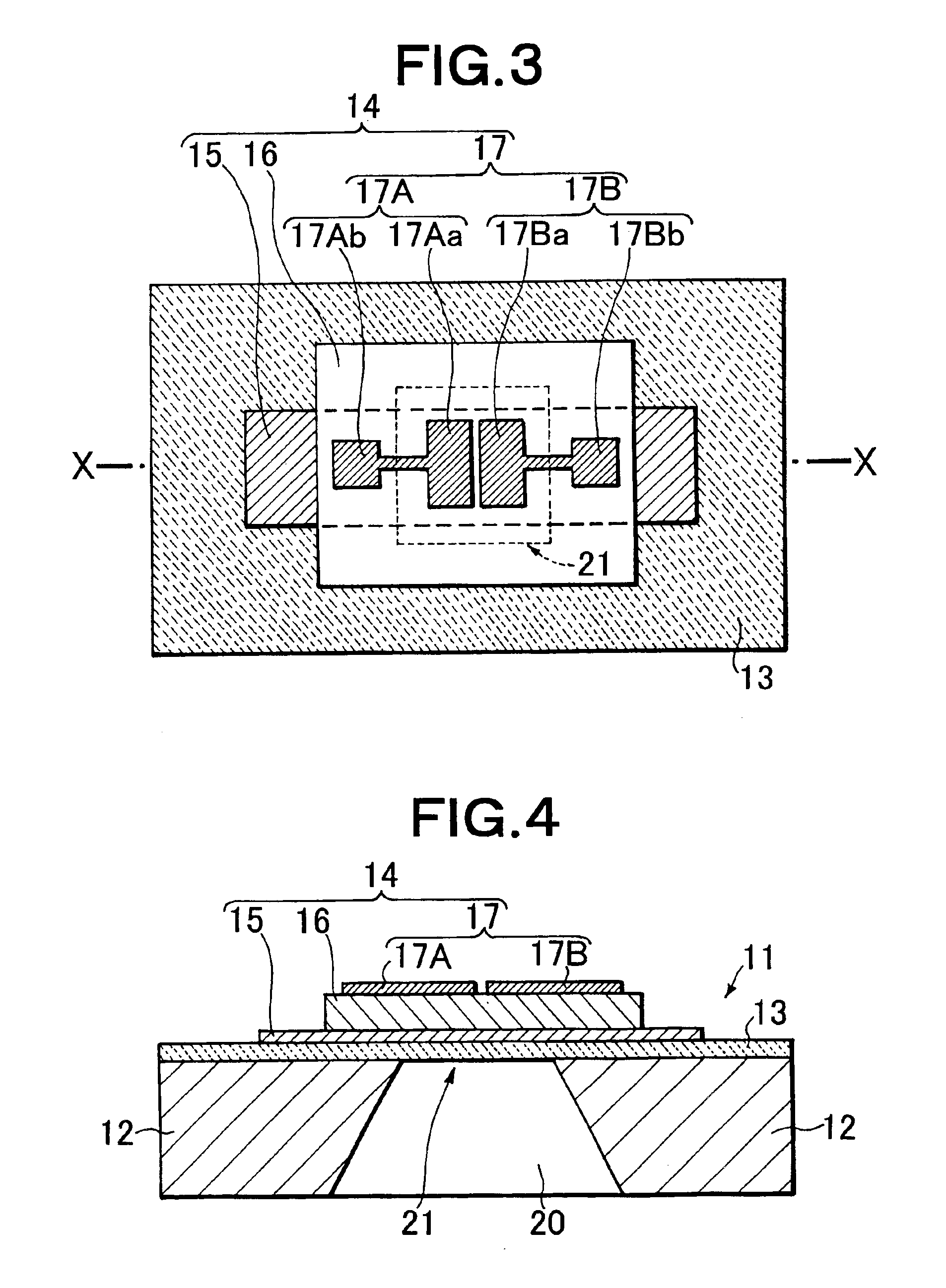

A thin film bulk acoustic resonator comprises a substrate (12) of a silicon single crystal, a base film (13) formed on the substrate (12) and composed of a dielectric film mainly containing silicon oxide, and a piezoelectric stacked structure (14) formed on the base film (13). A vibratory section (21) composed of a part of the base film (13) and a part of the piezoelectric stacked structure (14). The piezoelectric stacked structure (14) includes a lower electrode (15), a piezoelectric film (16), and an upper electrode (17) formed in this order from below. The substrate (12) had a via hole (20) in the region corresponding to the vibratory section (21). The via hole forms a space for allowing vibration of the vibratory section (21). The piezoelectric film (16) is an aluminum nitride thin film containing 0.2 to 3.0 atom % of alkaline earth metal and / or a rare earth metal. Thus, the thin film bulk acoustic resonator has a high performance such as a large electromechanical coupling coefficient, an excellent acoustic quality factor (Q) and an excellent frequency-temperature characteristic.

Owner:NAT INST OF ADVANCED IND SCI & TECH +1

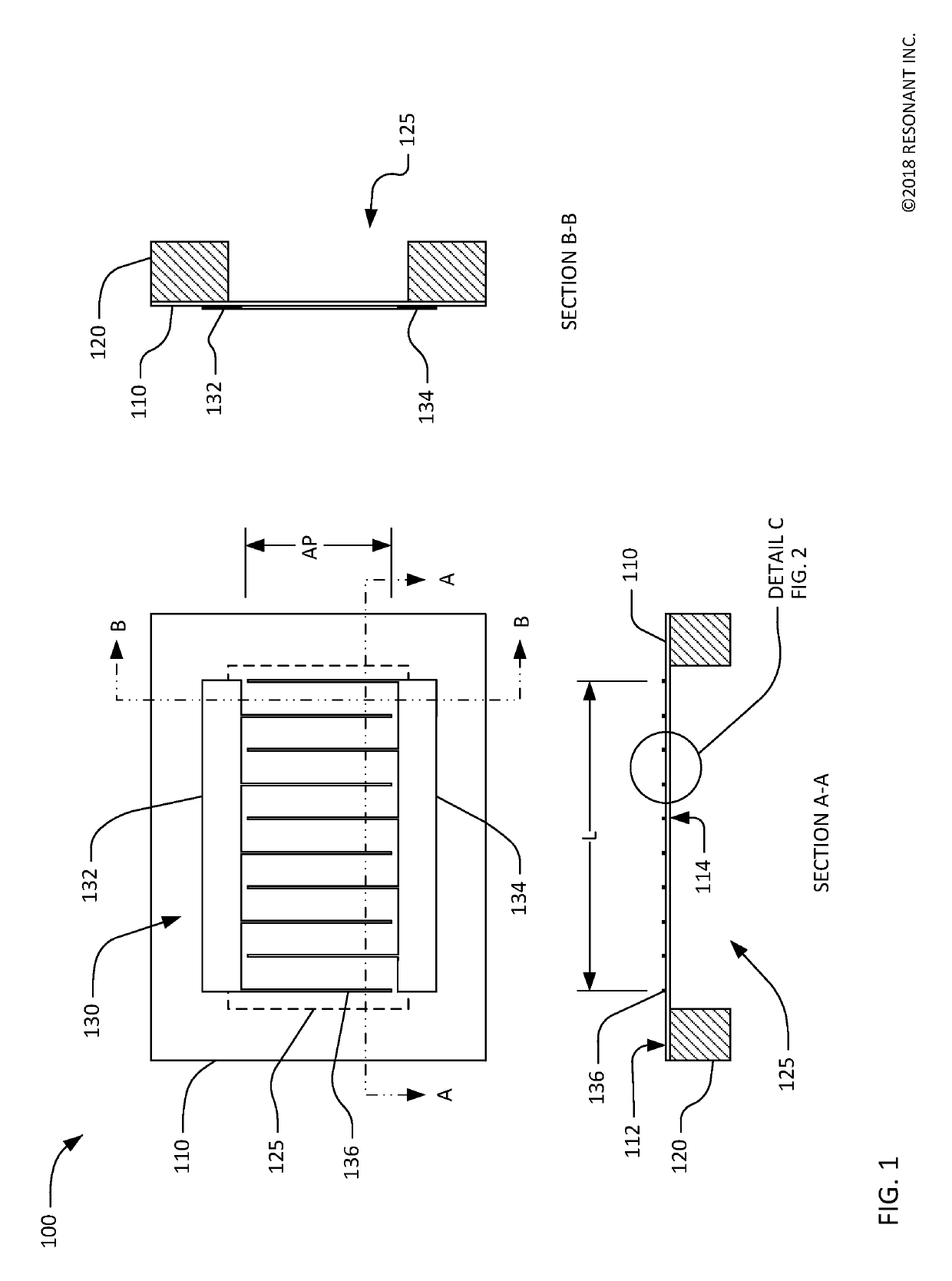

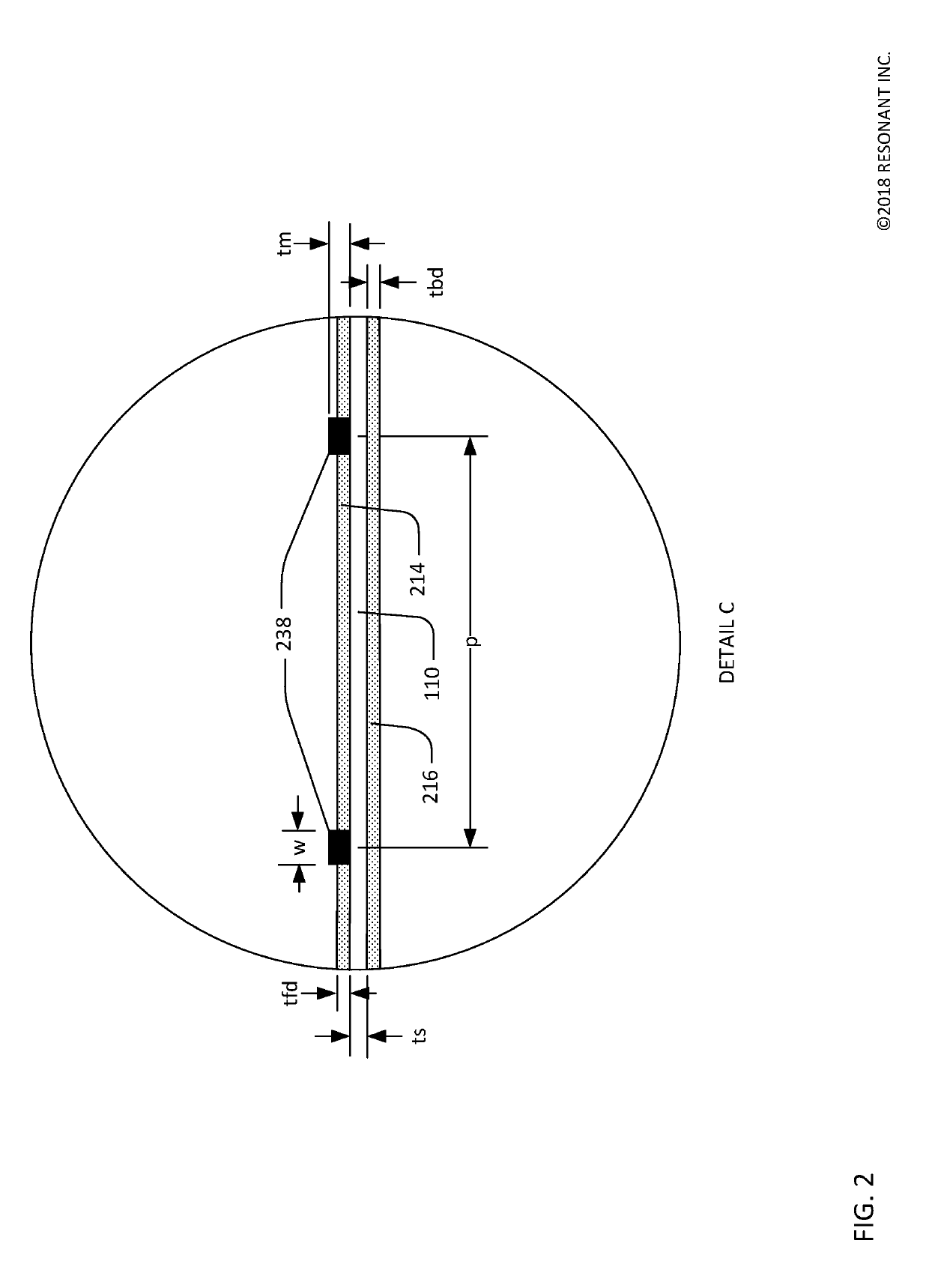

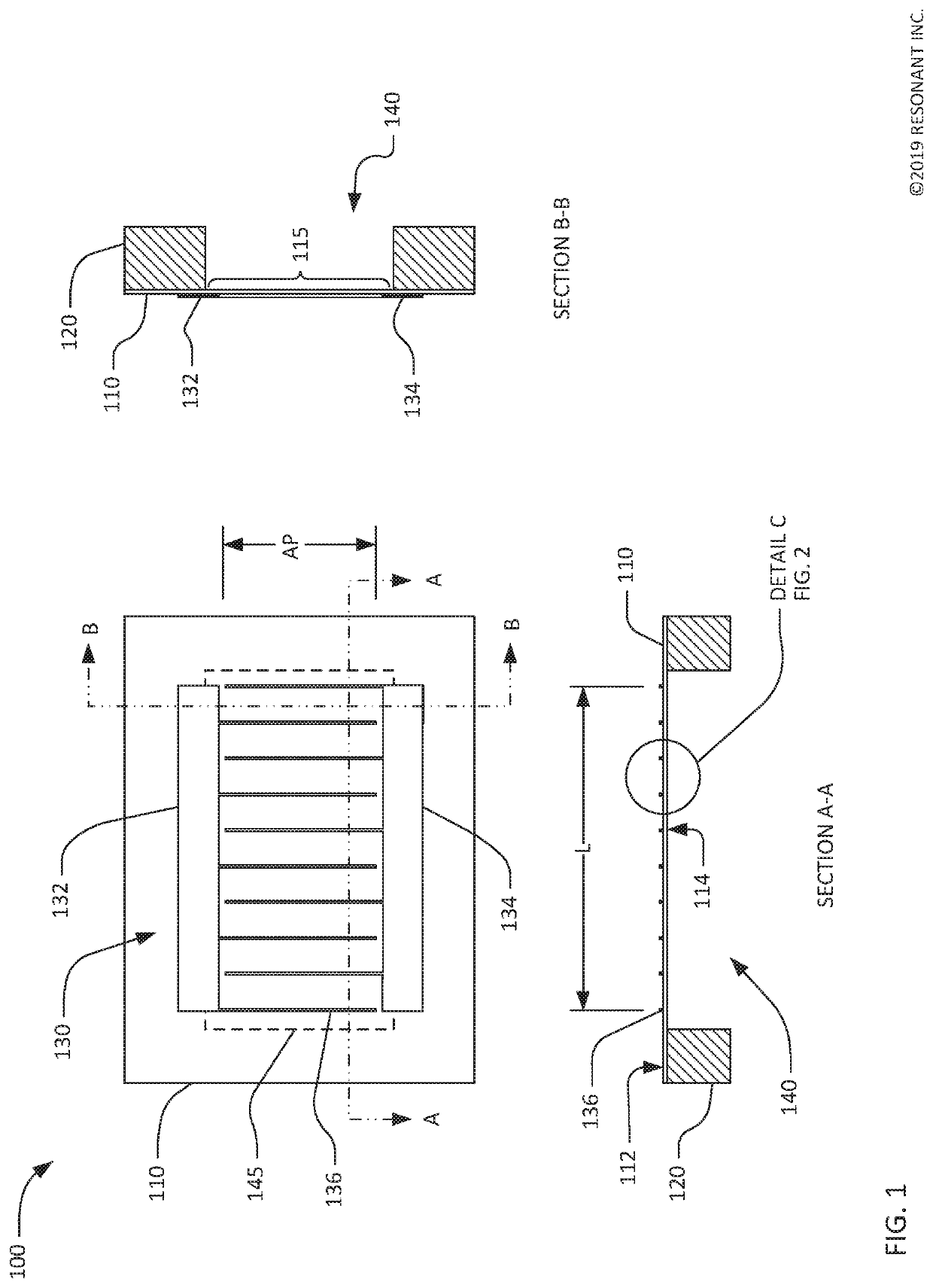

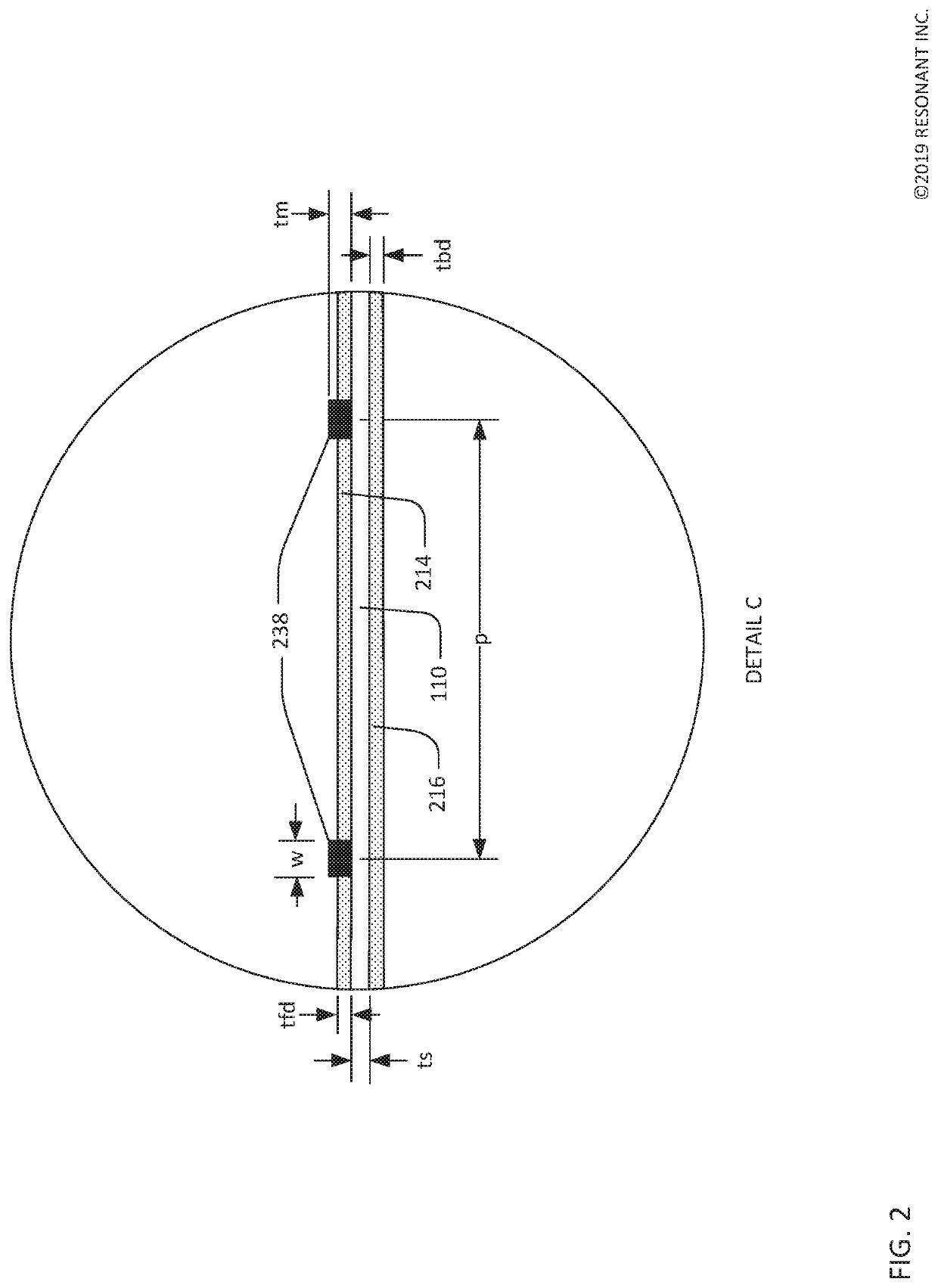

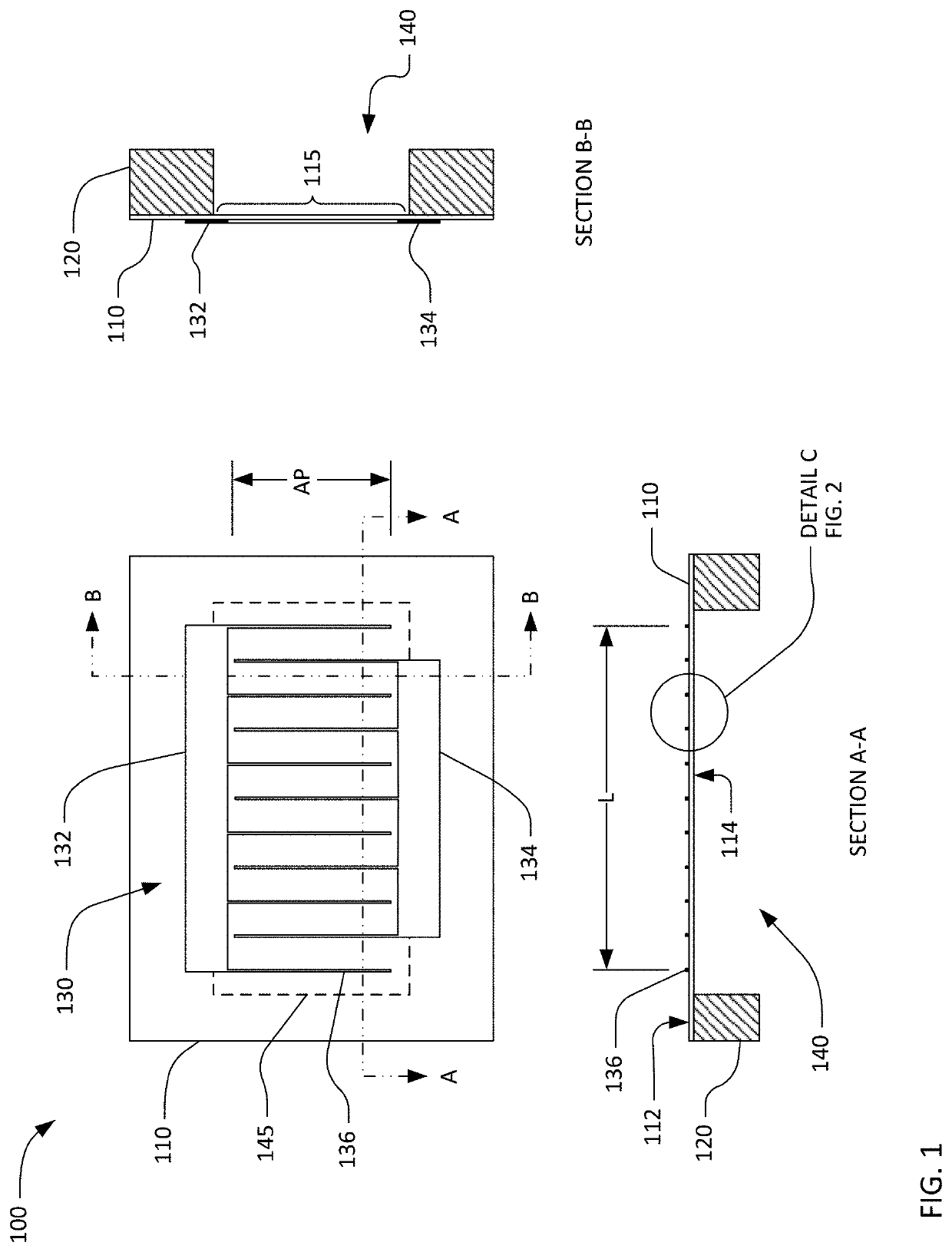

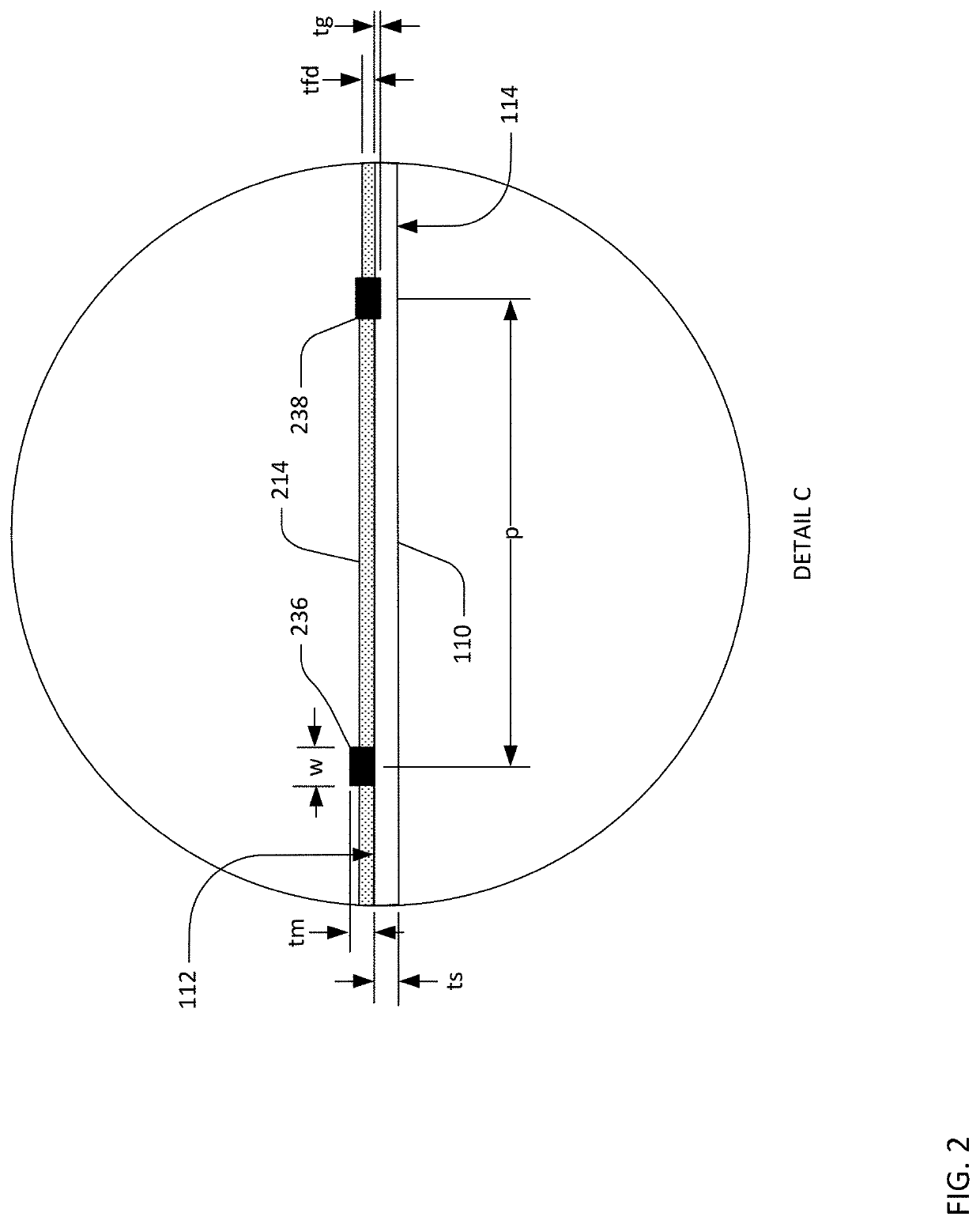

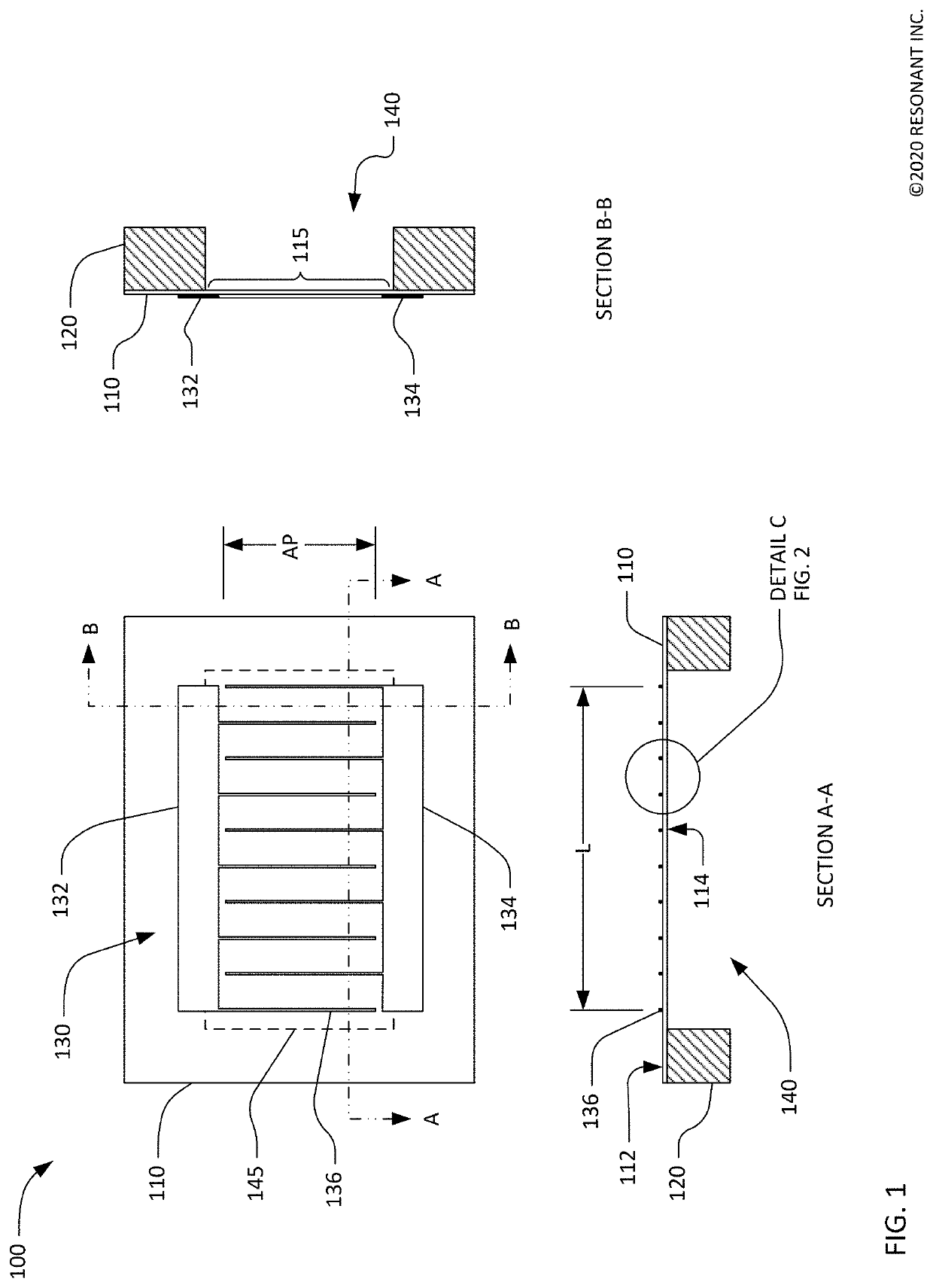

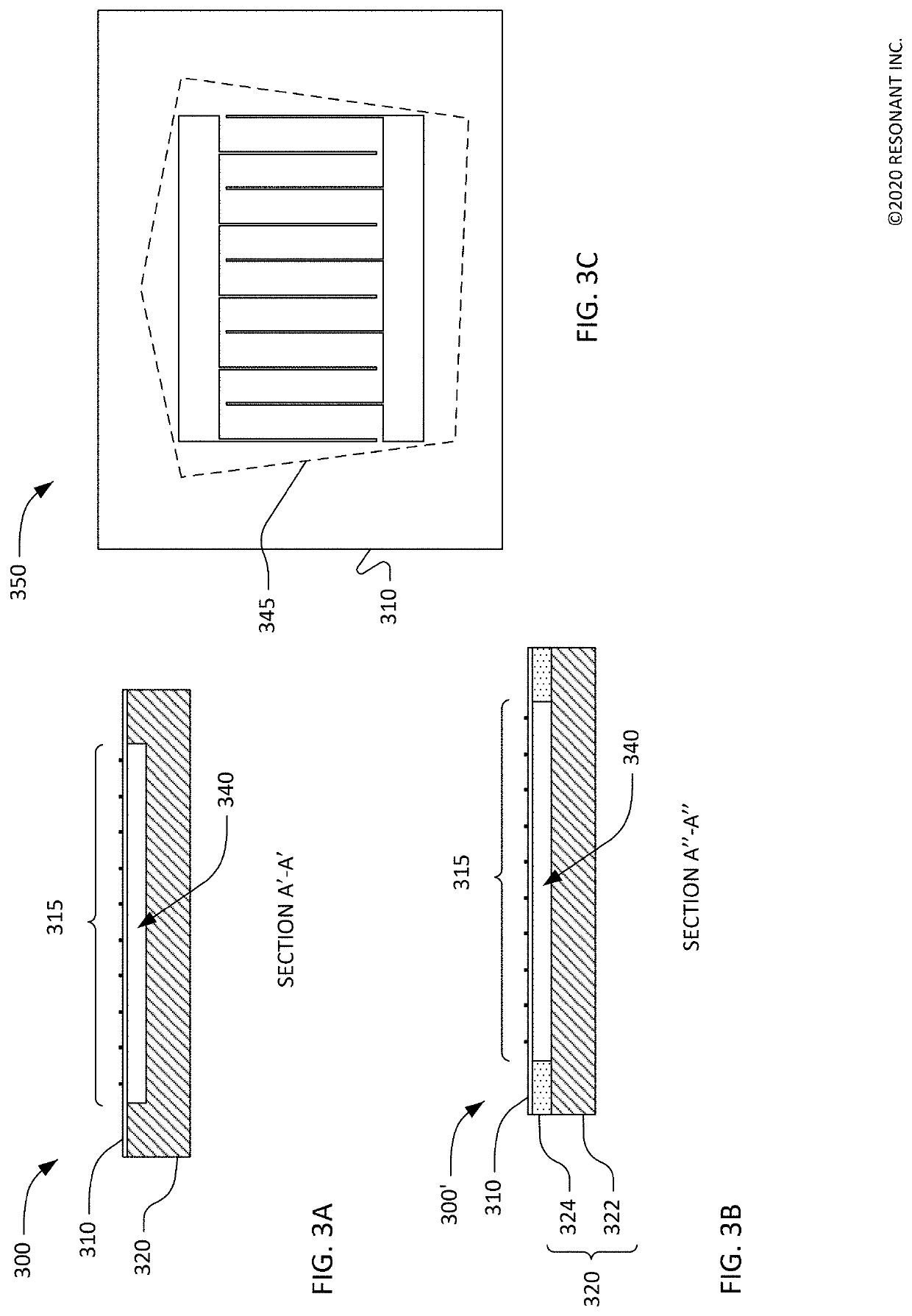

Transversely-excited film bulk acoustic resonator

ActiveUS10491192B1Impedence networksPiezoelectric/electrostrictive/magnetostrictive devicesThin-film bulk acoustic resonatorAcoustics

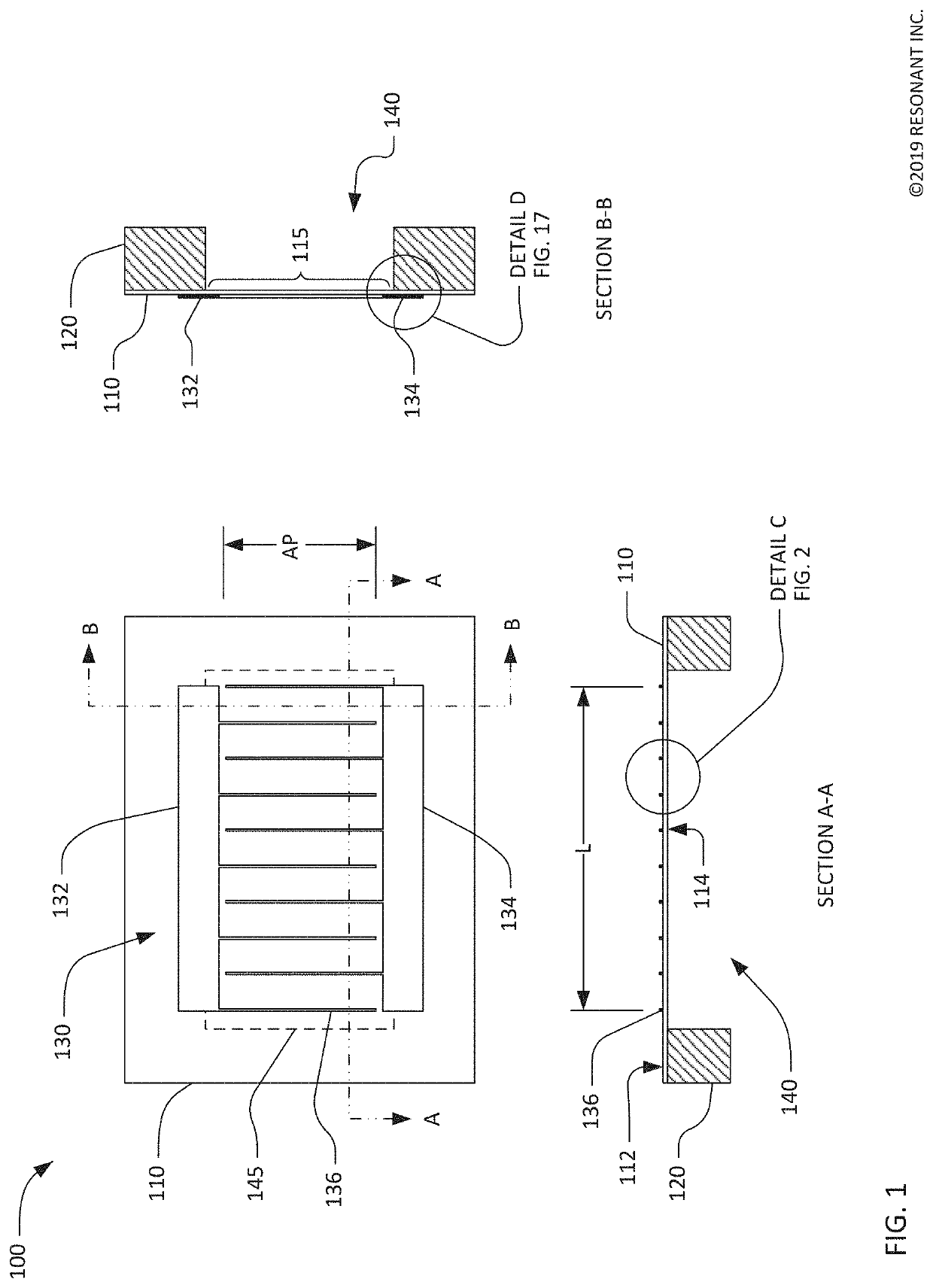

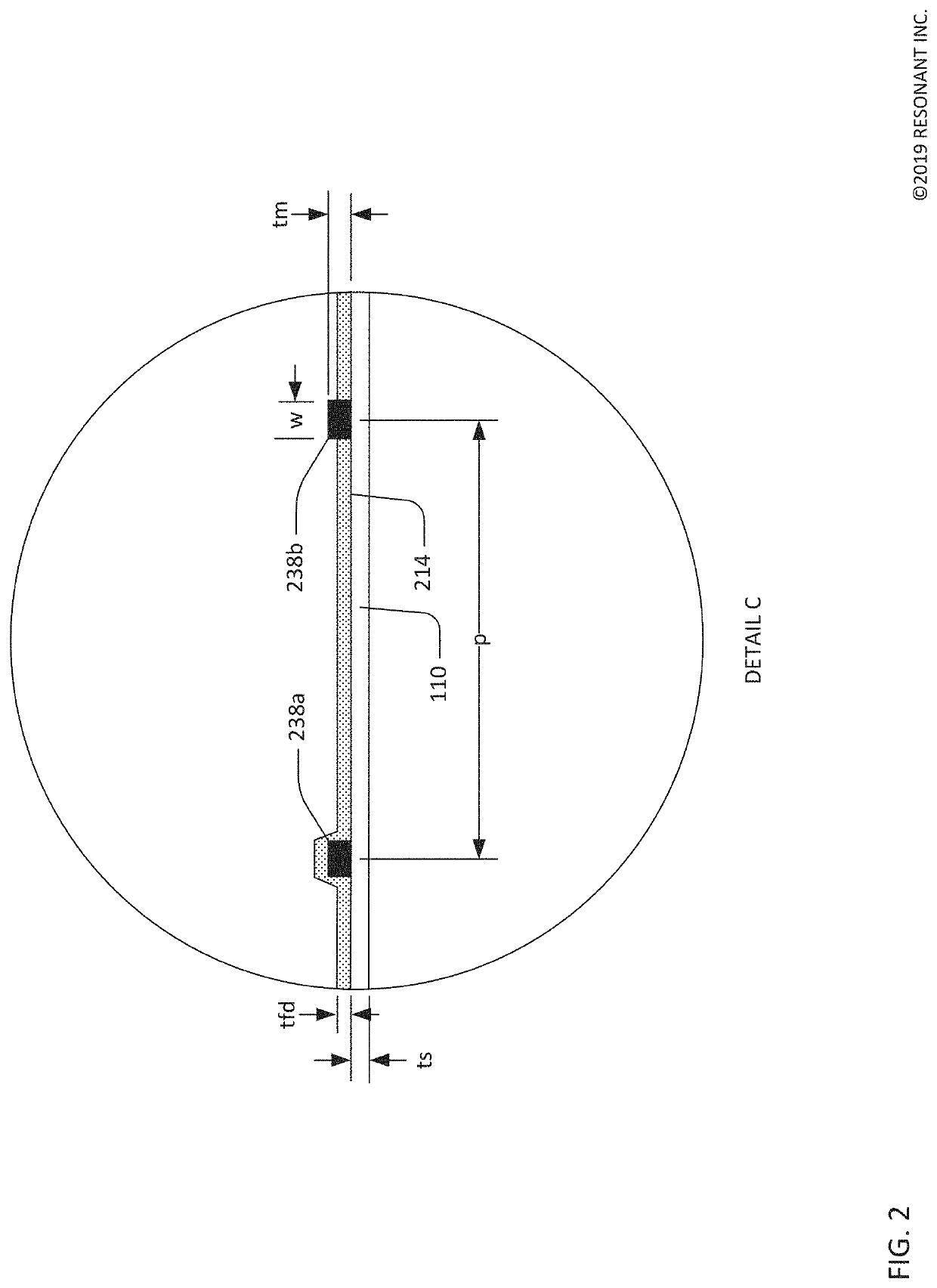

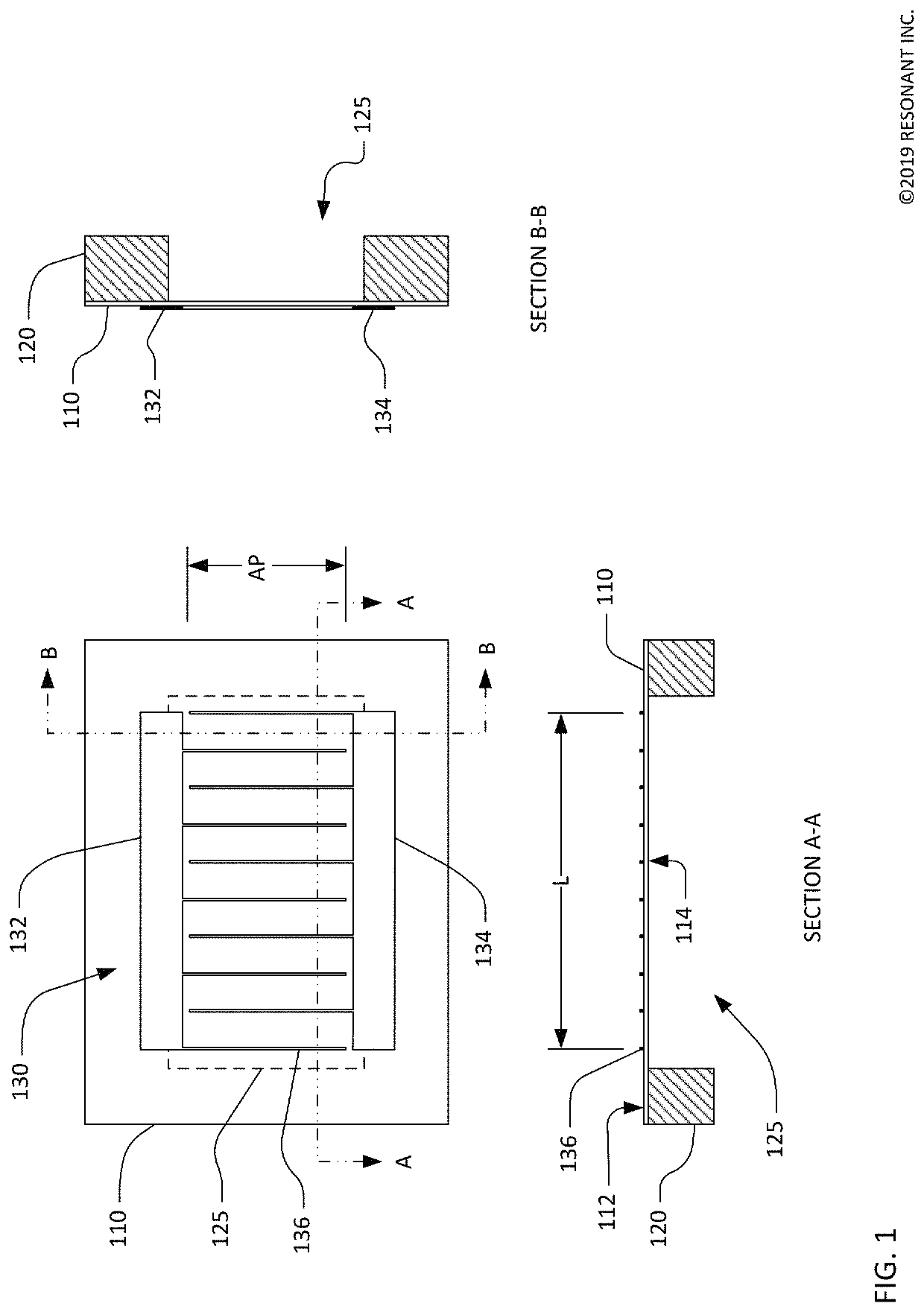

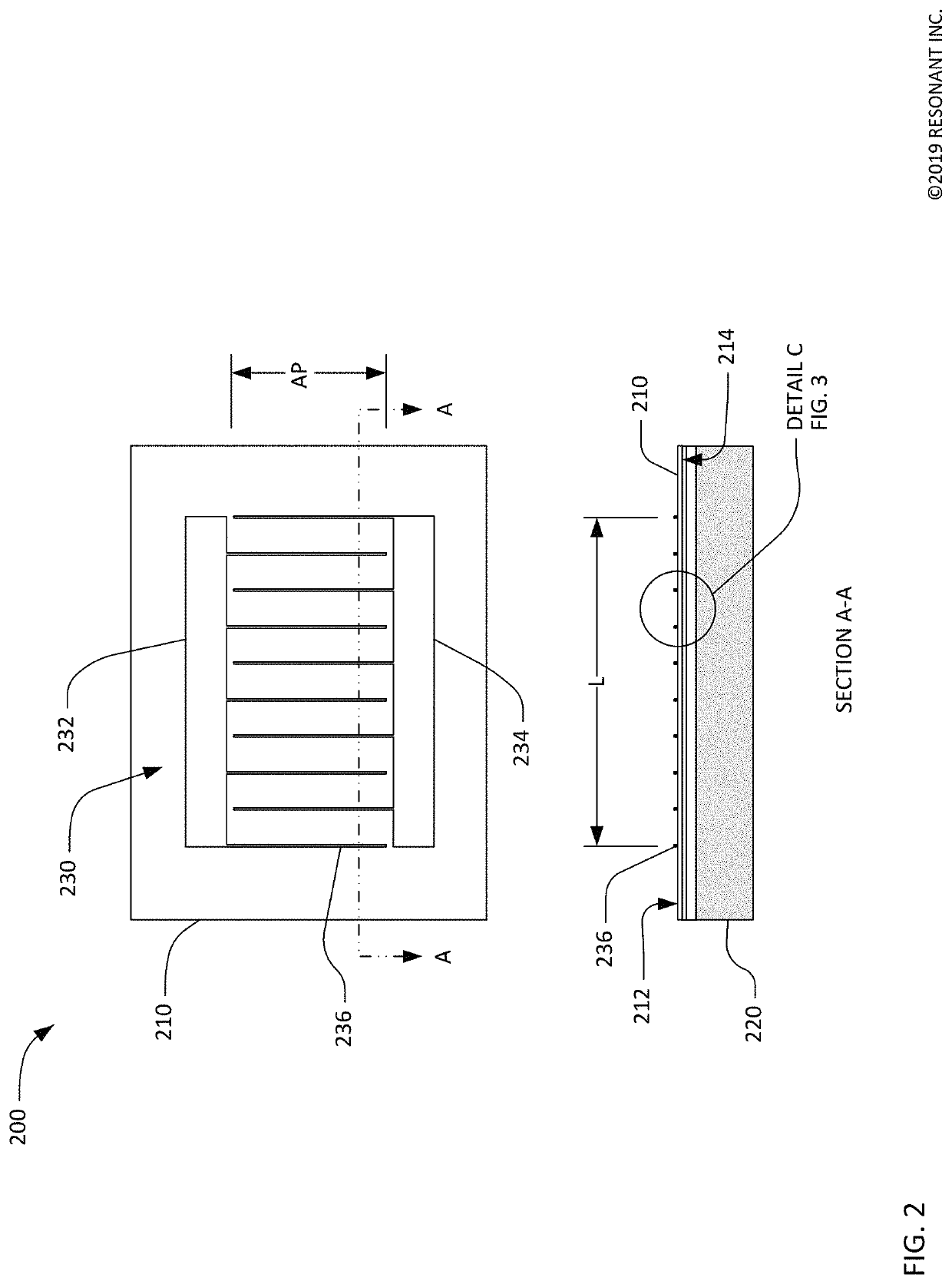

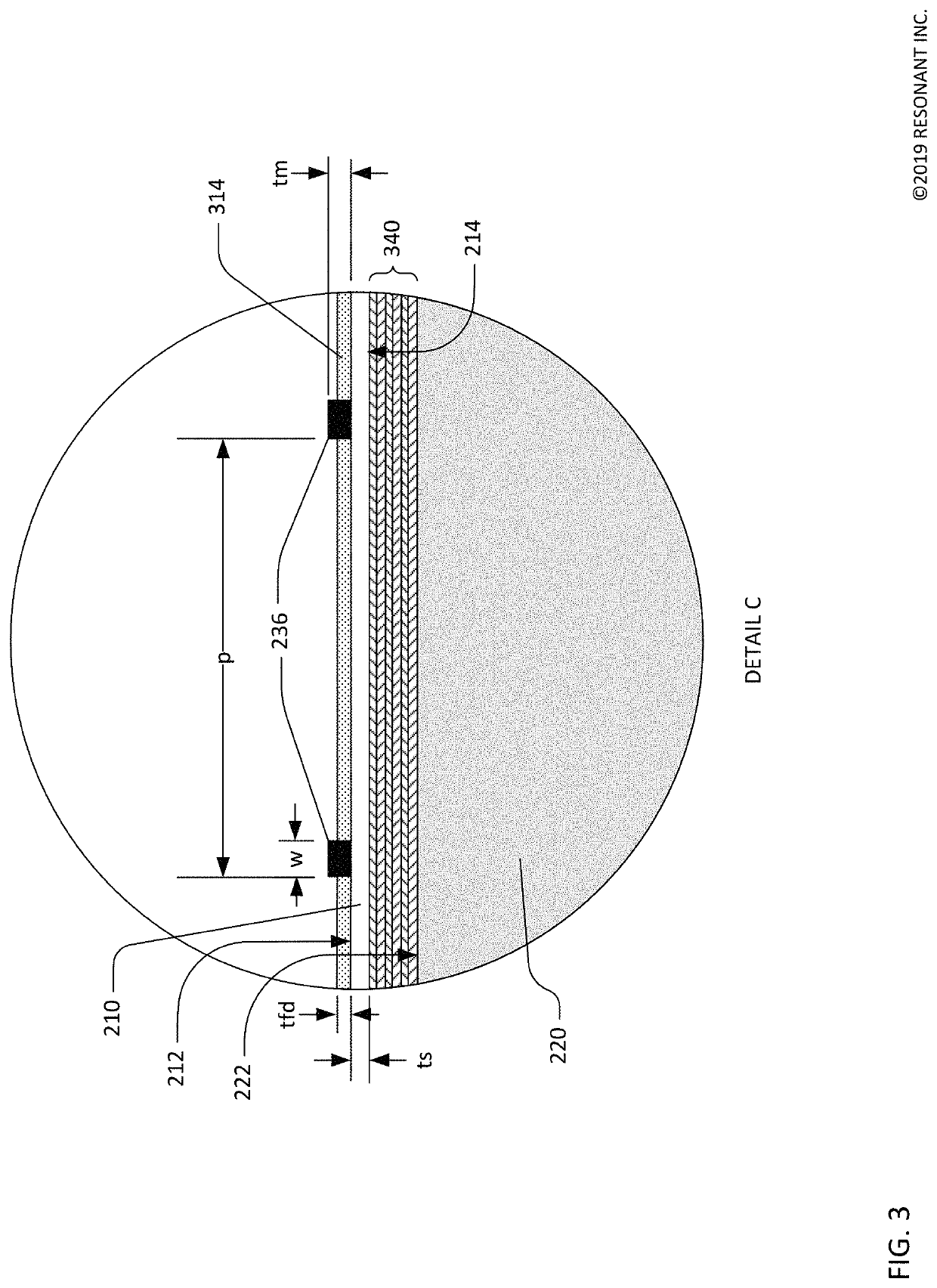

Acoustic resonator devices and filters are disclosed. An acoustic resonator includes a substrate and a piezoelectric plate having parallel front and back surfaces, the back surface attached to the substrate. An interdigital transducer (IDT) is formed on the front surface of the piezoelectric plate such that interleaved fingers of the IDT are disposed on a portion of the piezoelectric plate suspended over a cavity formed in the substrate.

Owner:MURATA MFG CO LTD

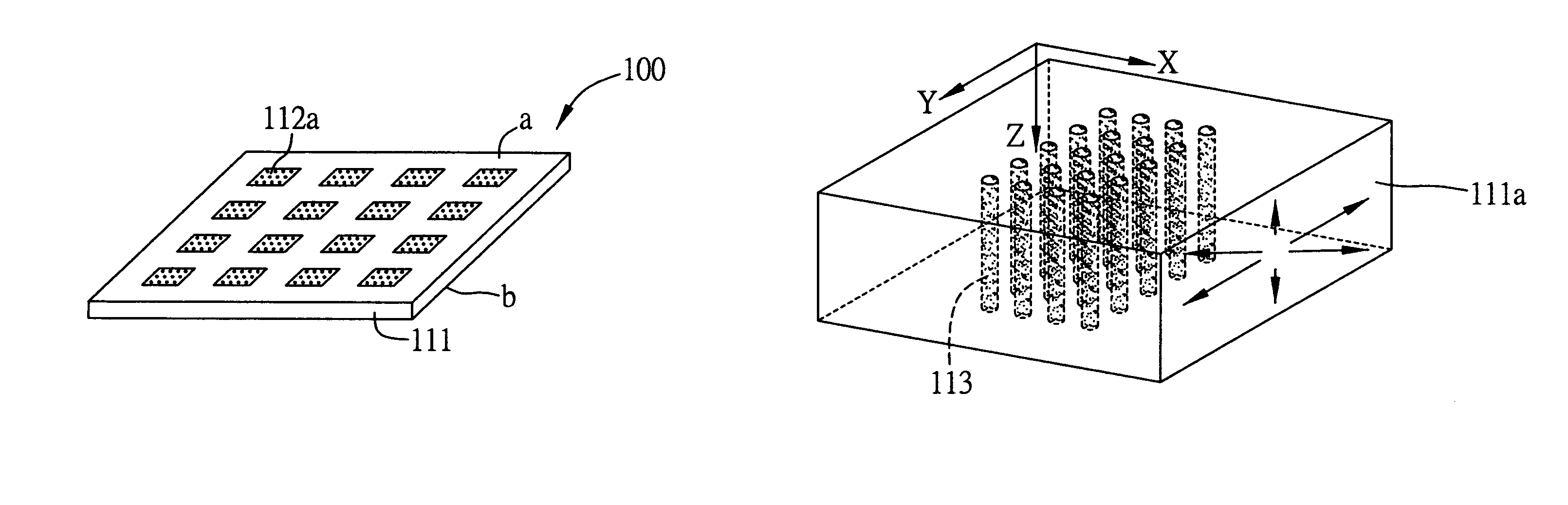

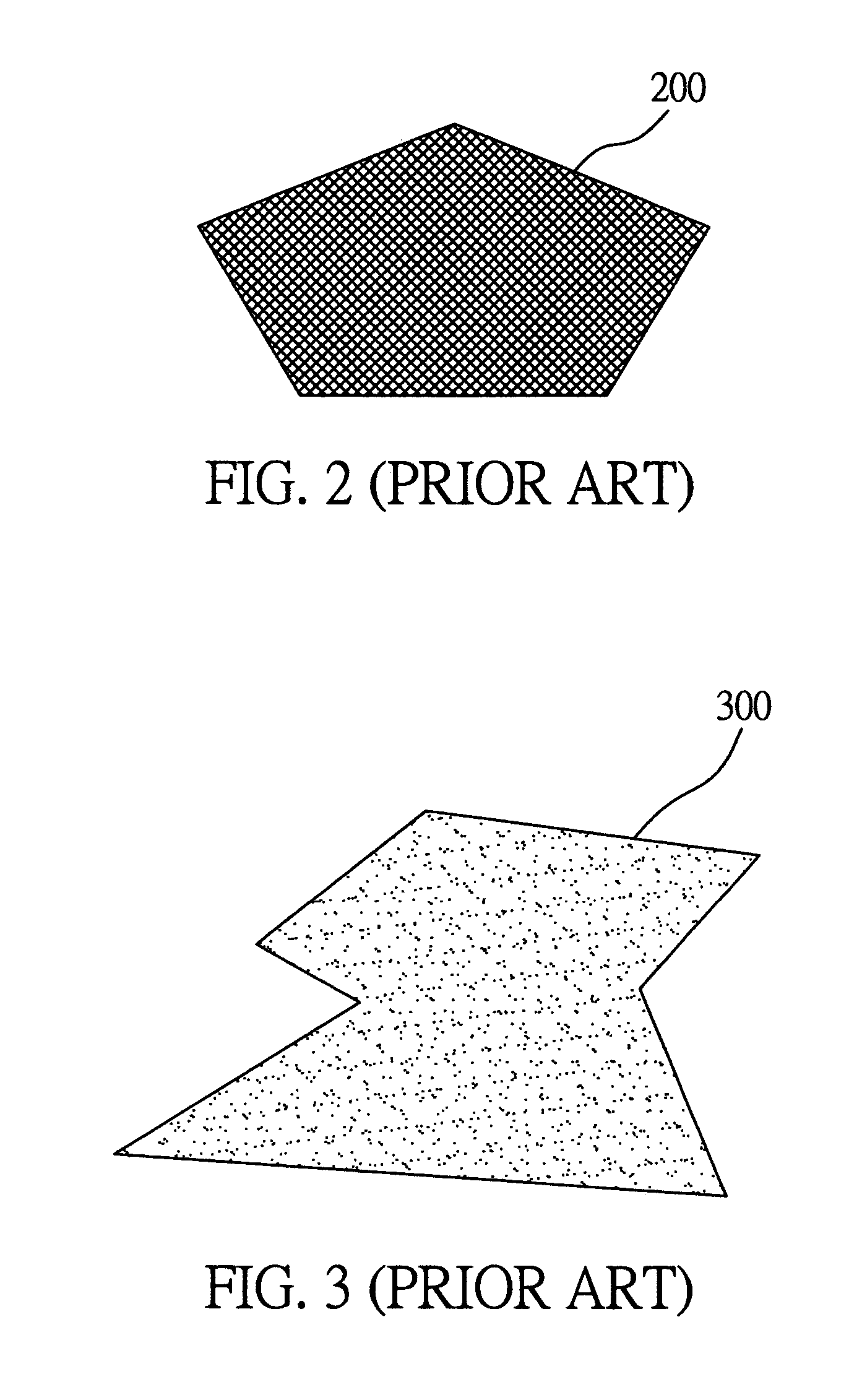

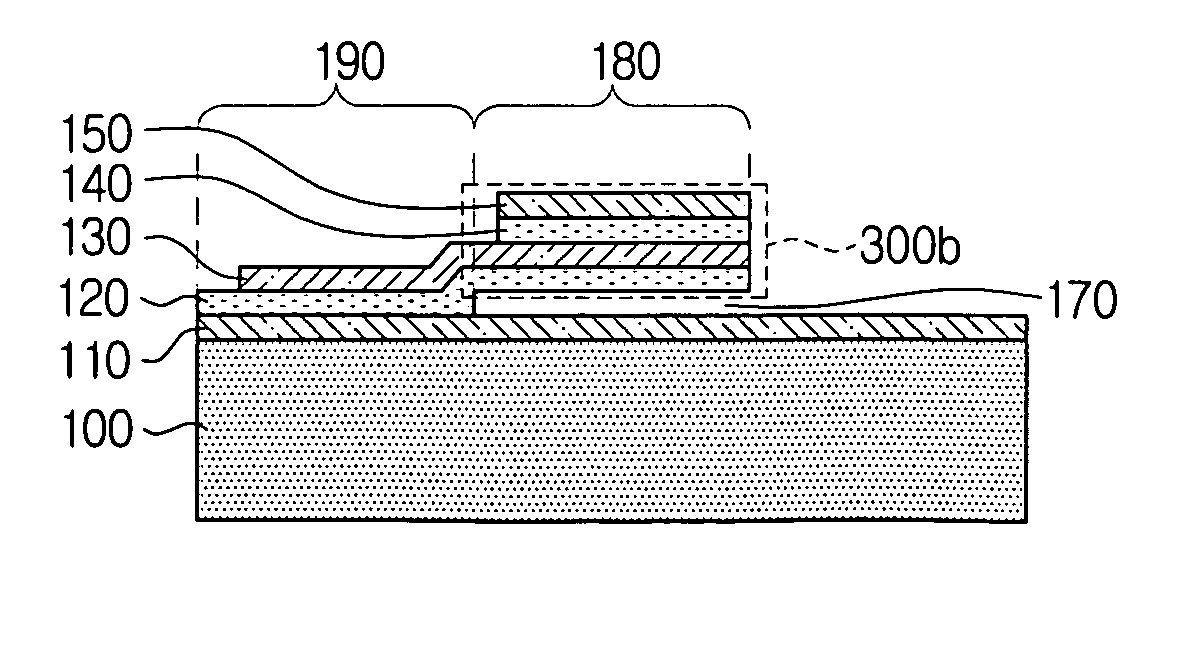

Noise suppression method for wave filter

ActiveUS7057476B2Eliminate signalWeaken energyPiezoelectric/electrostriction/magnetostriction machinesImpedence networksThin-film bulk acoustic resonatorHarmonic vibration

A noise suppression method of a wave filter used to eliminate standing wave signal interferences in the acoustic wave filter consisted by a plurality of film bulk acoustic resonators (FBARs). The method is to provide a plurality of scatterers in the structured consisted by the FBARs, thereby creating an band-gap structure due to the material characteristics difference, which consequently generates a destructive interfering effect to the transverse higher harmonics vibration within a specific operating frequency range, and ultimately decreases or even eliminates any parasitic effects. Therefore, within the operation frequency range of this band-gap structure, abnormal signals created by any transverse wave modes cannot exist. In addition, an acoustic shield can be provided by phononic crystal structures between different FBARs, thus acoustic shielding any mutual interference within the operation frequency range.

Owner:IND TECH RES INST

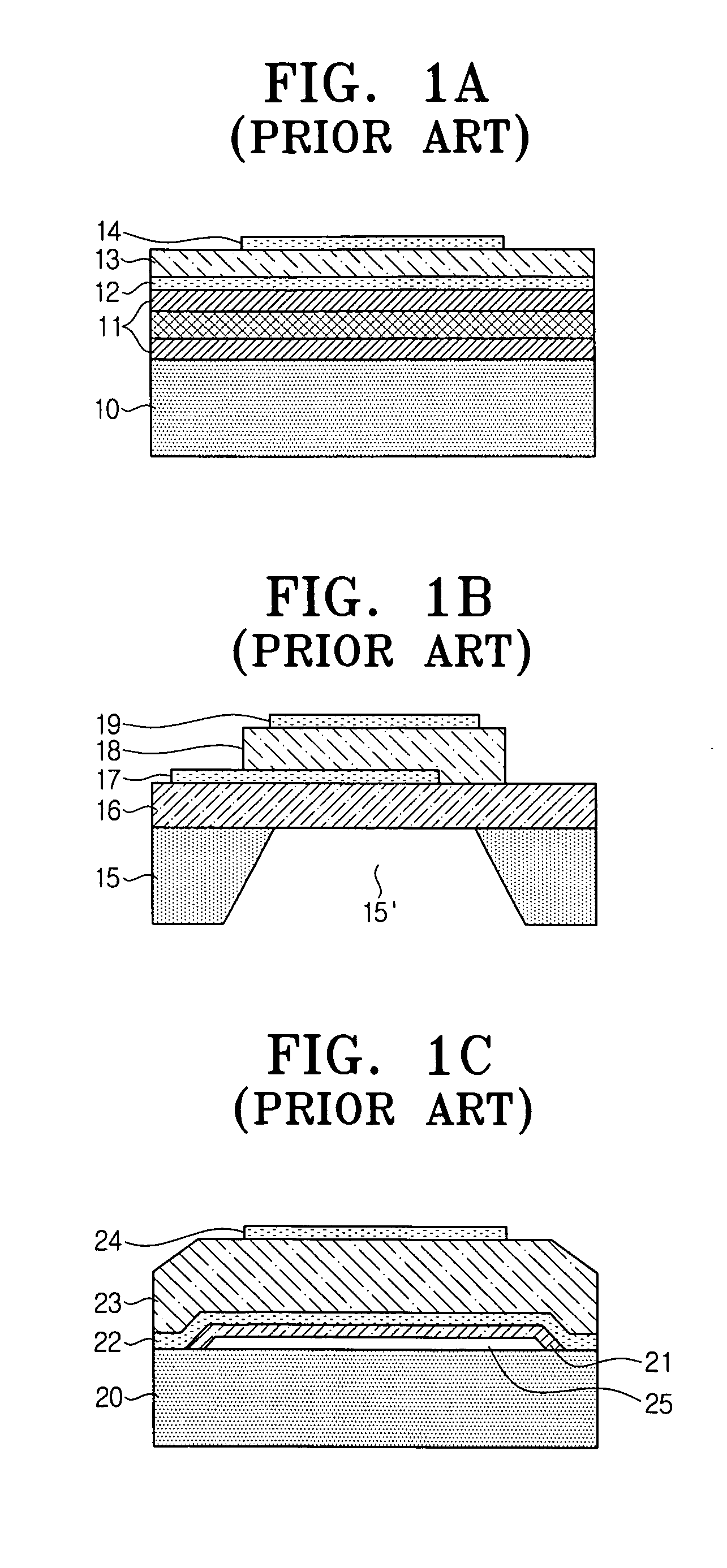

Method for fabricating cantilevered type film bulk acoustic resonator and film bulk acoustic resonator fabricated by the same

ActiveUS20050034822A1Simpler FBAR fabricationAvoid damagePiezoelectric/electrostrictive device manufacture/assemblyImpedence networksThin-film bulk acoustic resonatorDielectric layer

A method for fabricating a film bulk acoustic resonator (FBAR) includes depositing a dielectric layer on a substrate, providing a sacrificial layer on part of the dielectric layer; providing a bottom electrode on part of the sacrificial layer on part of the dielectric layer; providing a piezoelectric layer on the bottom electrode; patterning a top electrode on the piezoelectric layer; and removing the sacrificial layer. The substrate may have a cavity receiving the sacrificial layer. As a result, a cantilevered resonator having an air gap between the bottom electrode and the dielectric layer may be simply fabricated.

Owner:SAMSUNG ELECTRONICS CO LTD

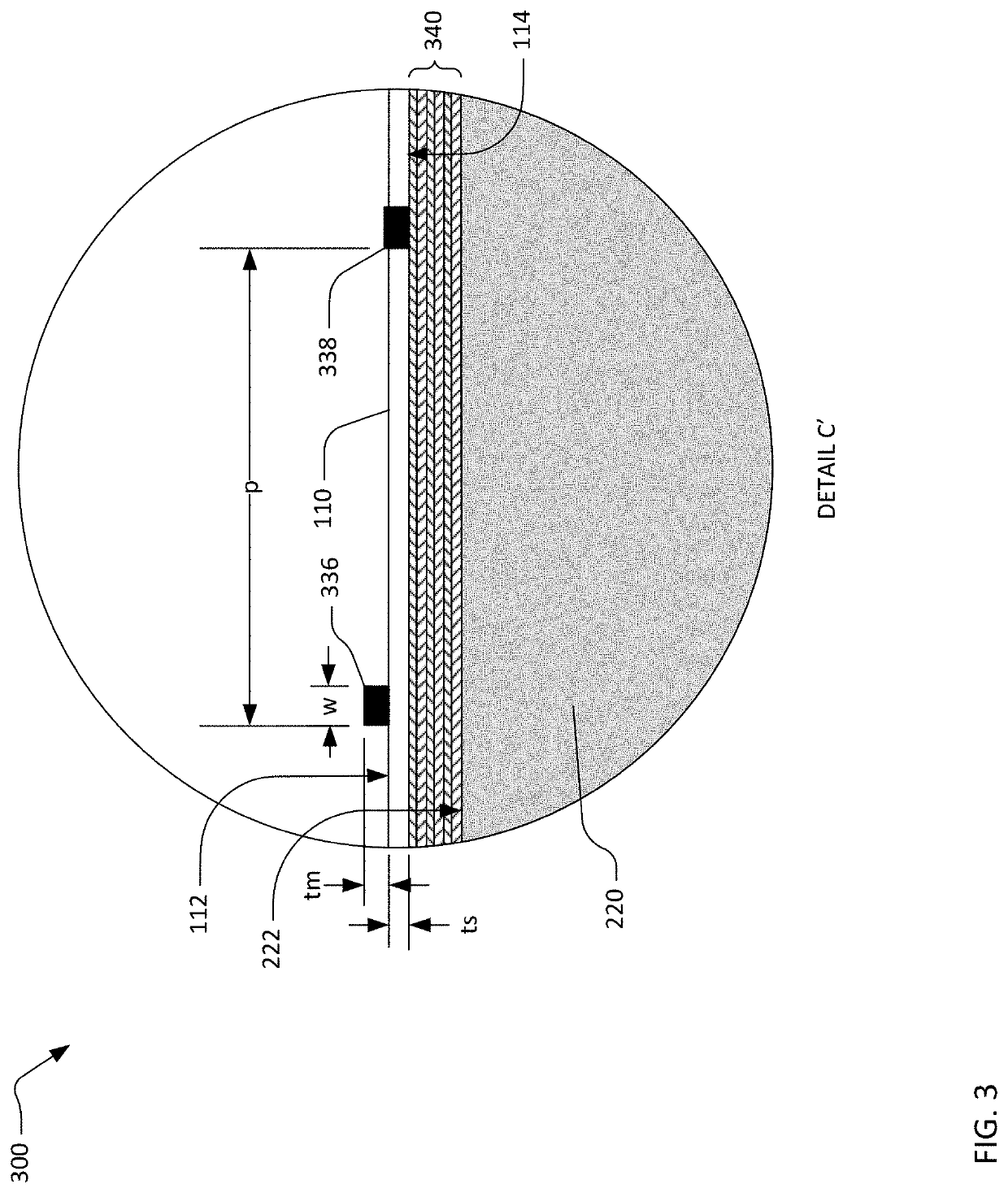

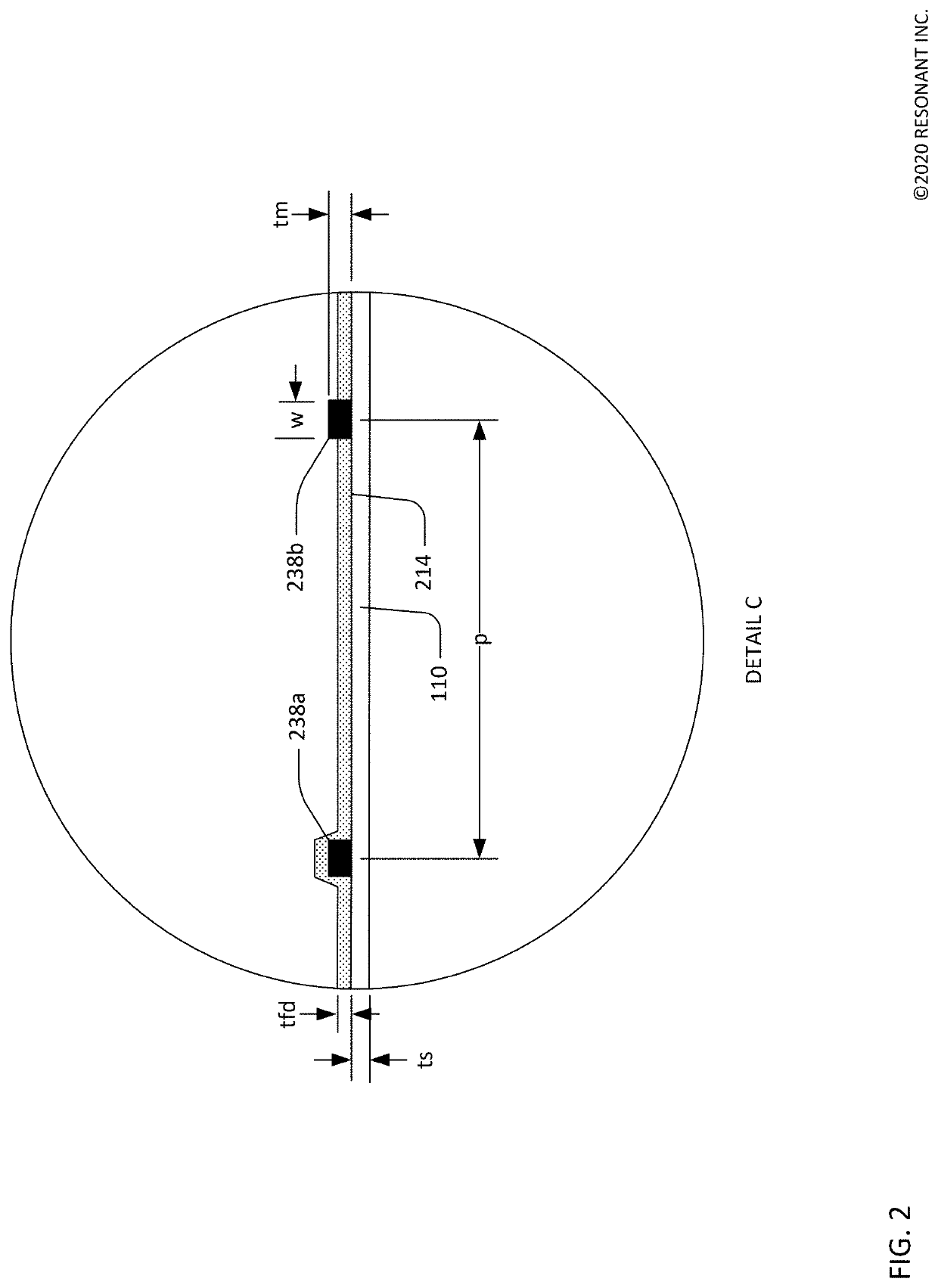

Transversely-excited film bulk acoustic resonators for high power applications

There is disclosed acoustic resonators and filter devices. An acoustic resonator includes a substrate having a surface and a single-crystal piezoelectric plate having parallel front and back surfaces, the back surface attached to the surface of the substrate except for a portion of the piezoelectric plate forming a diaphragm that spans a cavity in the substrate. An interdigital transducer (IDT) is formed on the front surface of the single-crystal piezoelectric plate such that interleaved fingers of the IDT are disposed on the diaphragm. The IDT is configured to excite a primary acoustic mode in the diaphragm in response to a radio frequency signal applied to the IDT. A thickness of the interleaved fingers of the IDT is greater than or equal to 0.85 times a thickness of the piezoelectric plate.

Owner:MURATA MFG CO LTD

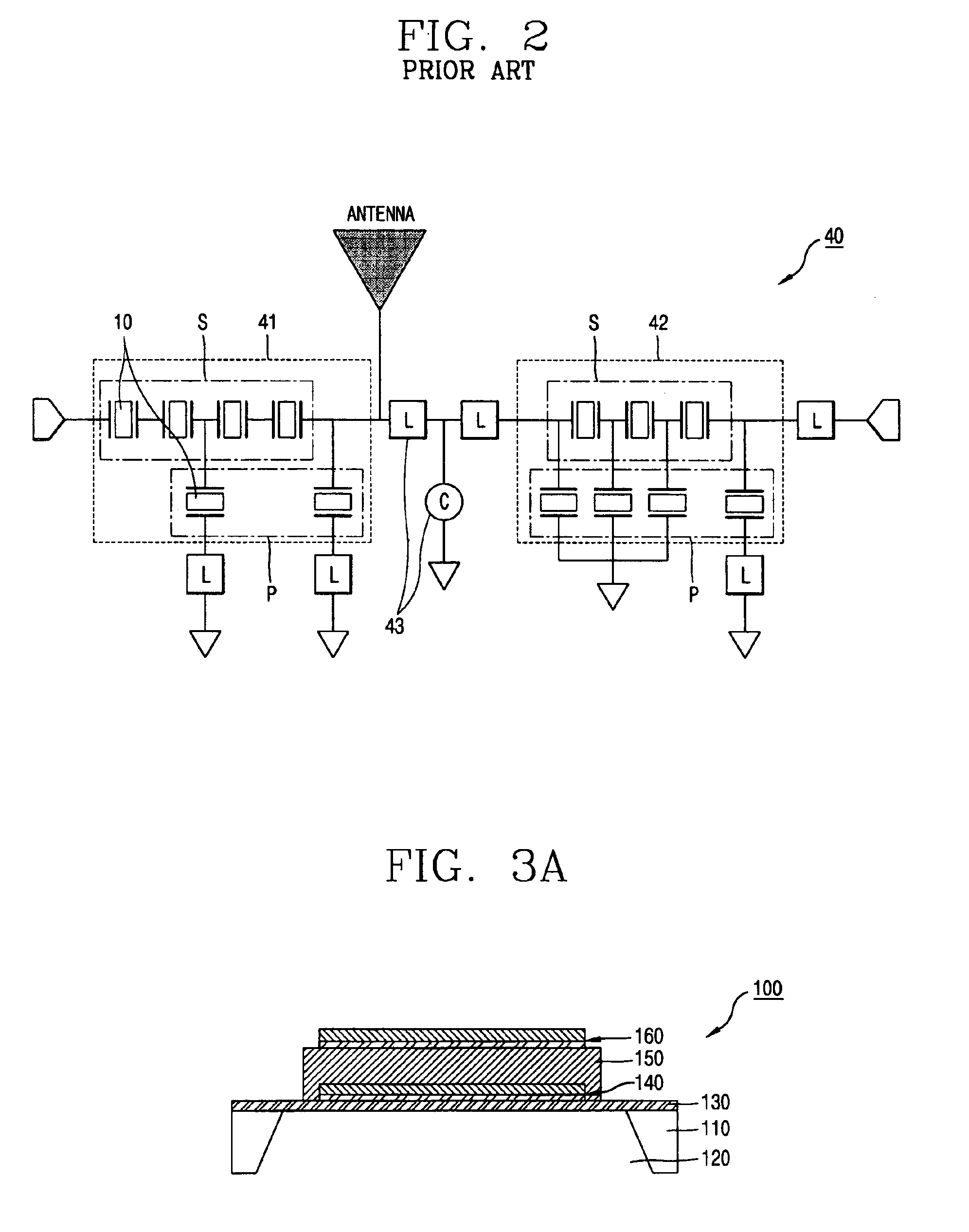

Duplexer

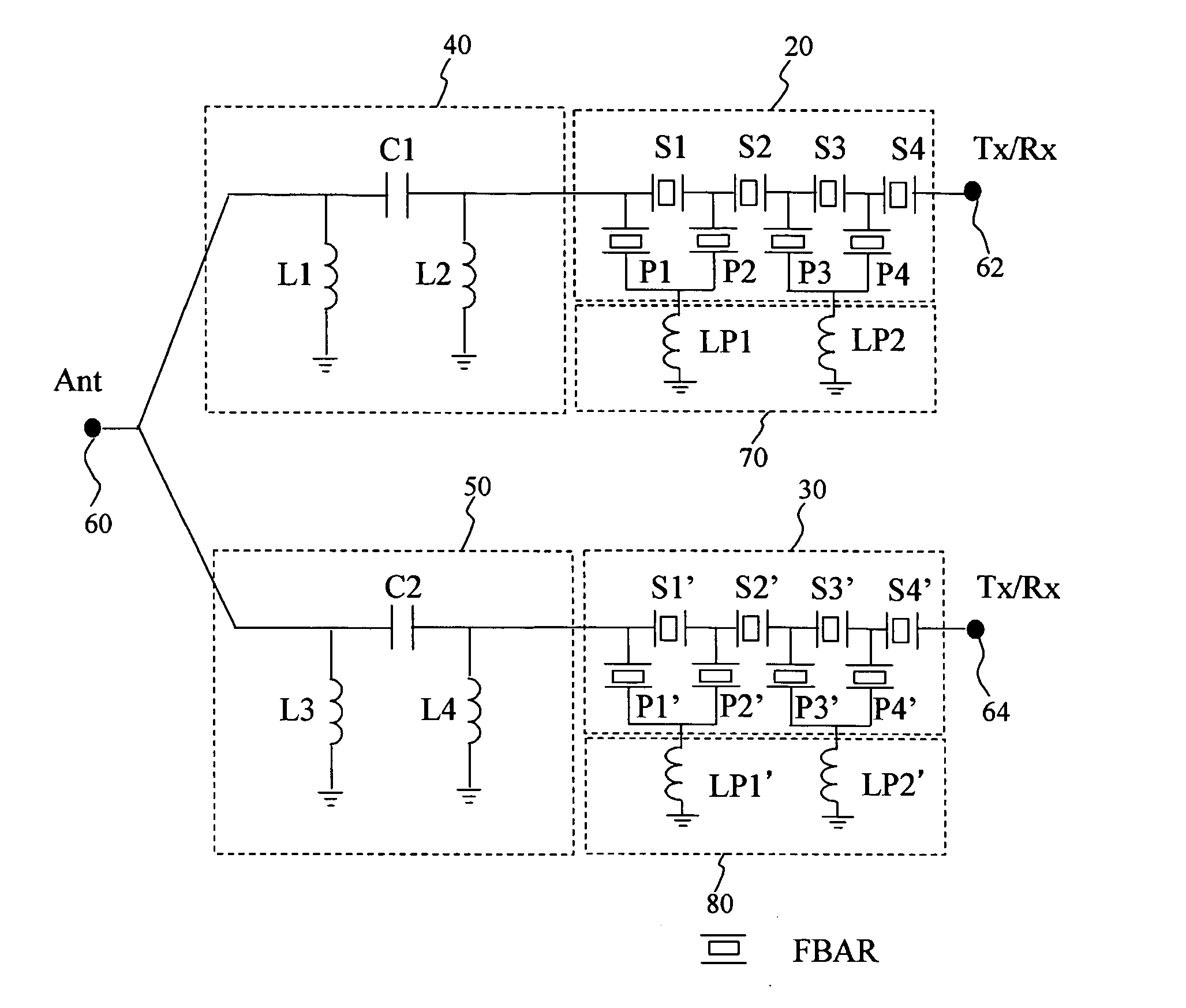

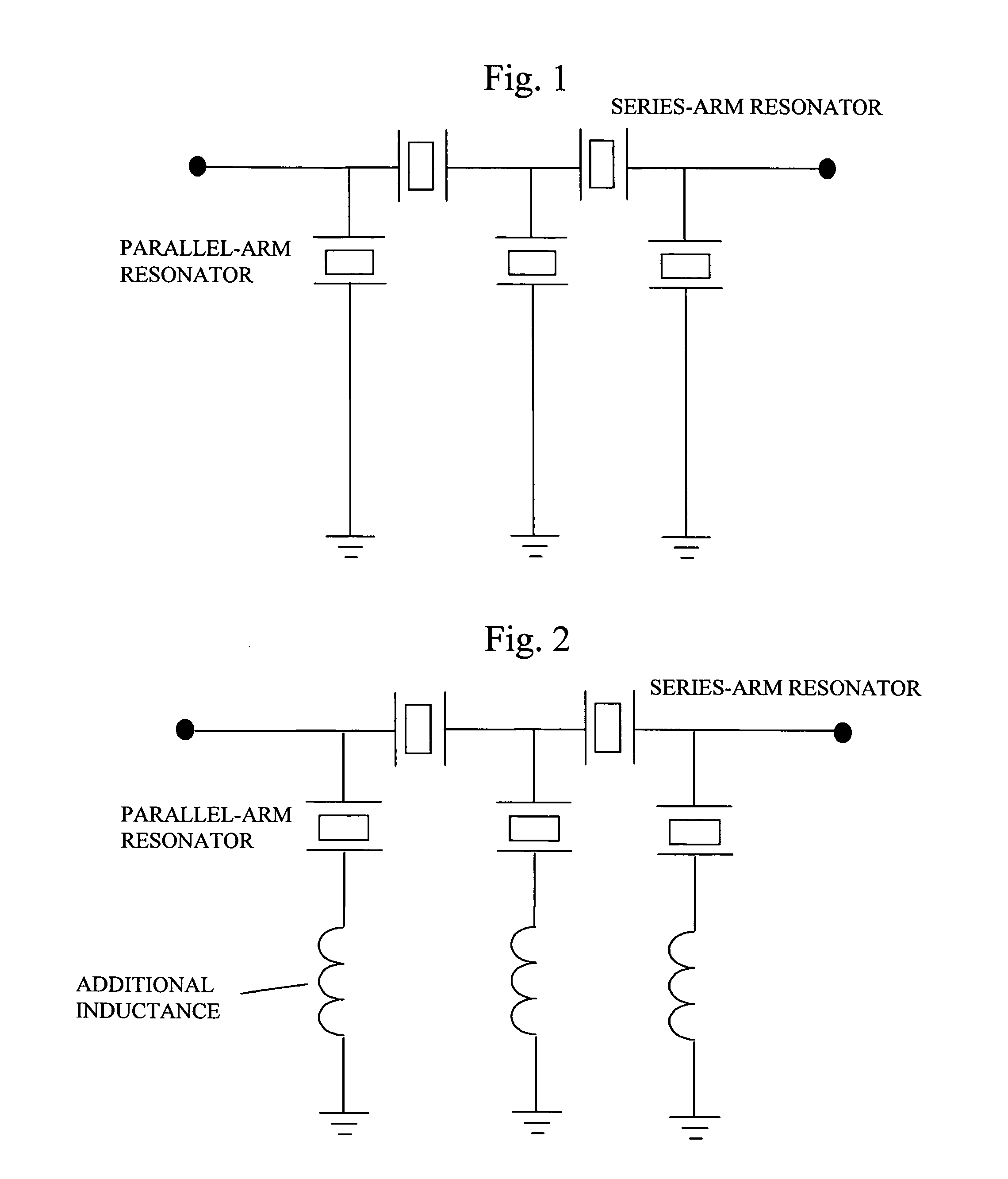

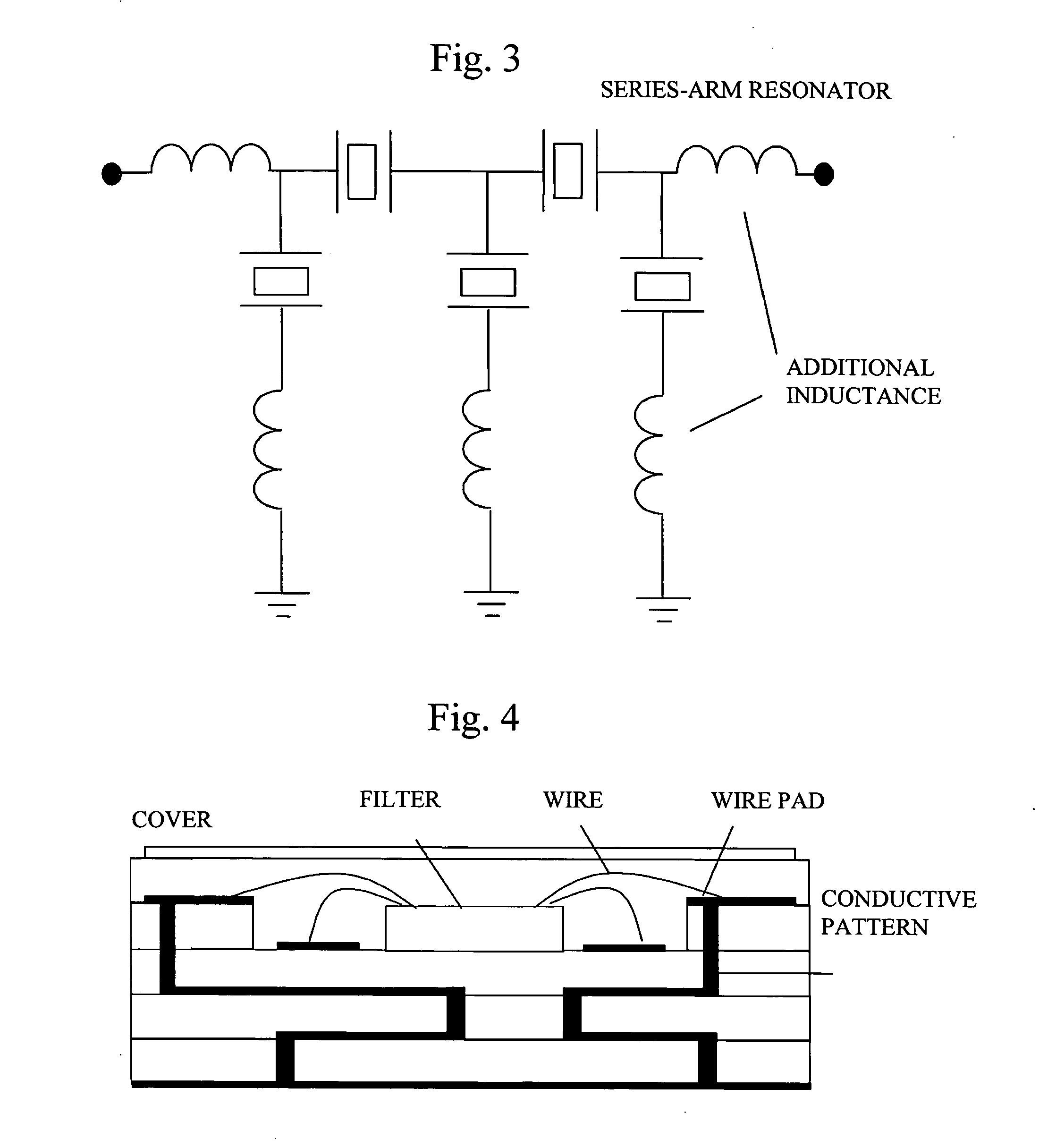

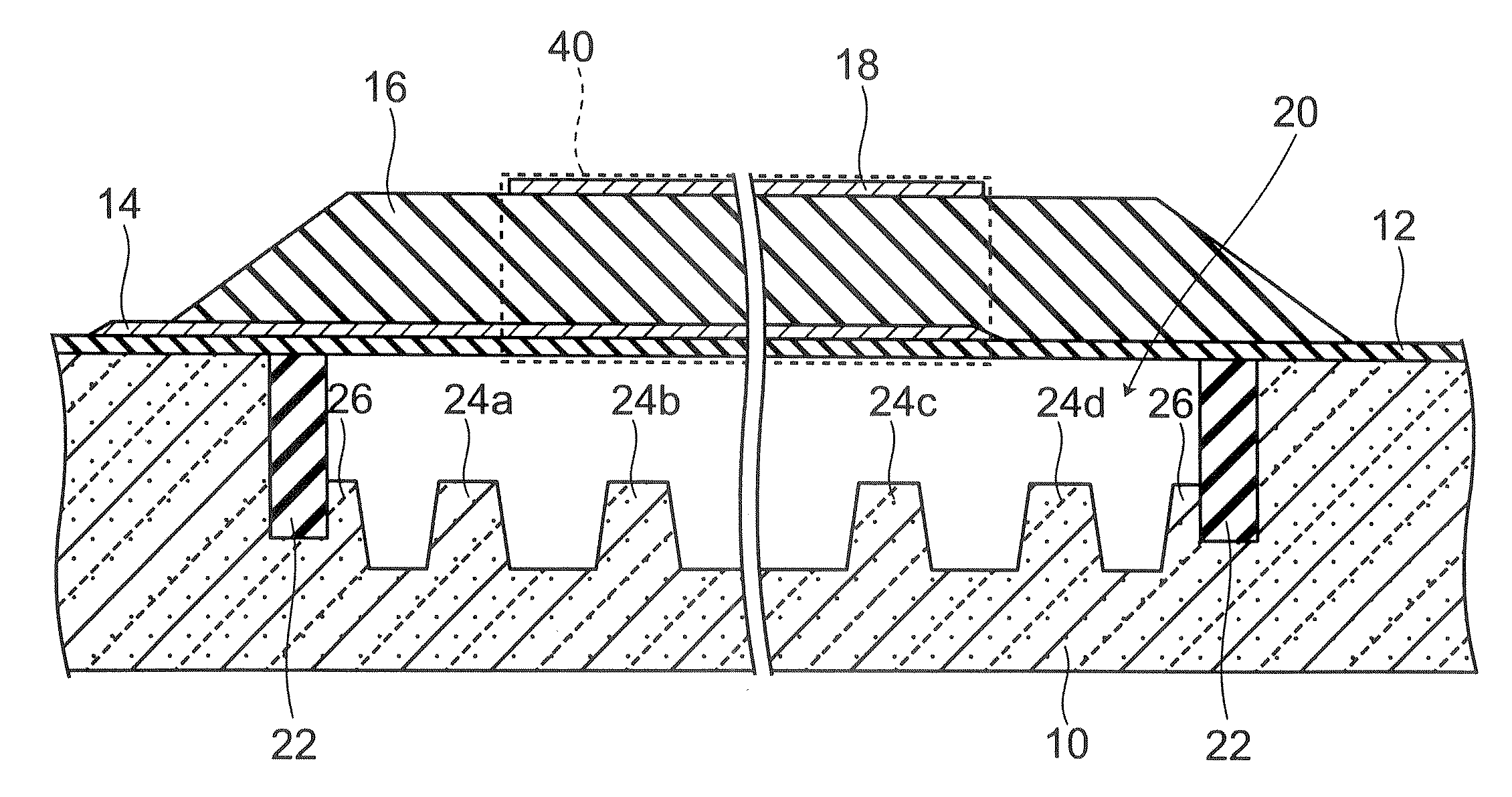

ActiveUS20060066419A1Improve featuresMultiple-port networksPiezoelectric/electrostrictive/magnetostrictive devicesThin-film bulk acoustic resonatorInductor

A duplexer includes: first and second filters including film bulk acoustic resonators (FBARs) arranged in a ladder form; first and second integrated-passive devices (IPDs) provided between a common terminal and the first and second filters; and a substrate on which the first and second filters and the first and second IPDs are mounted. The substrate includes conductive patterns that realize inductances connected between the first and second filters and ground. The first and second IPDs includes inductors connected to the first and second filters.

Owner:TAIYO YUDEN KK

Film bulk acoustic resonator and method of manufacturing same

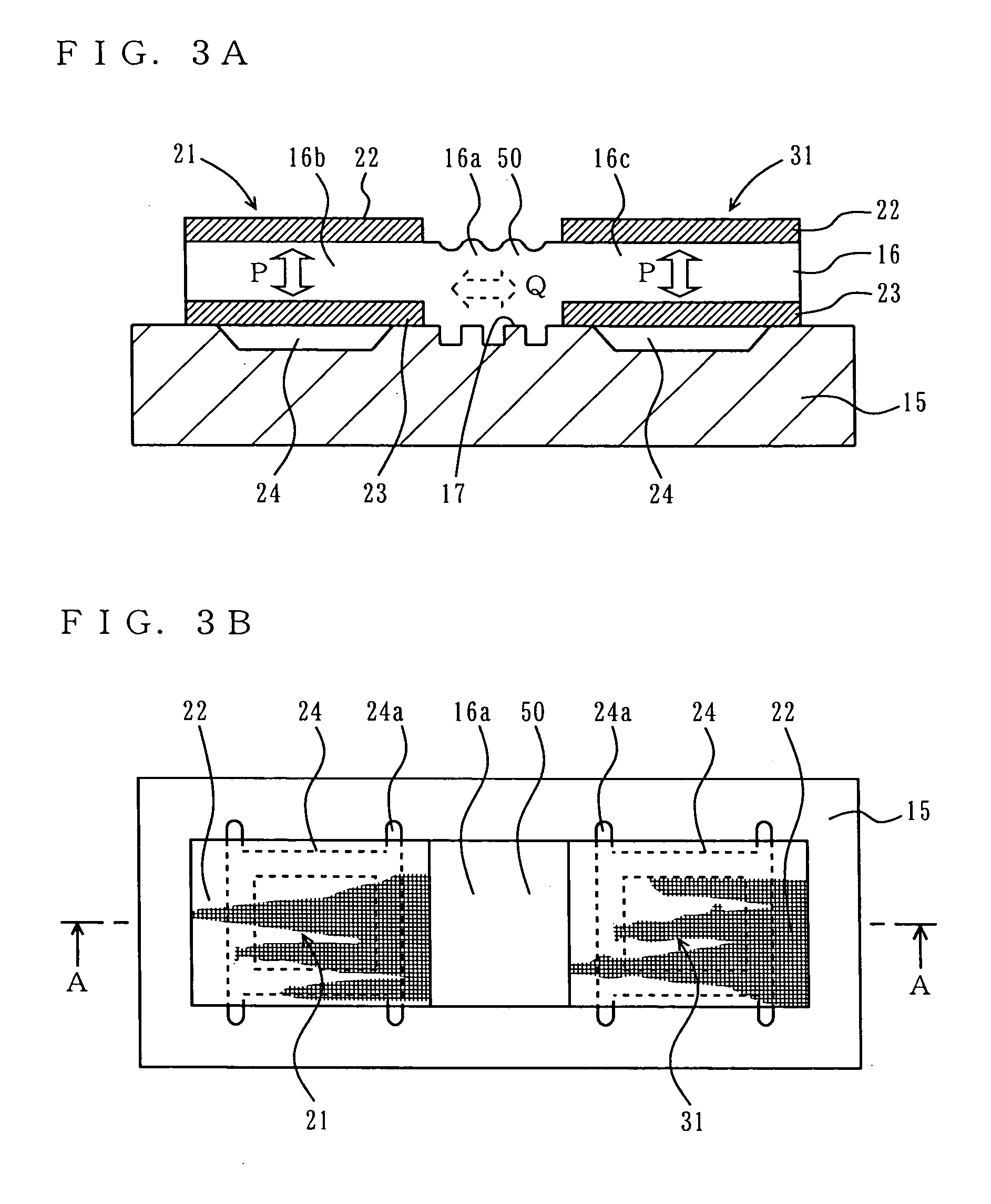

InactiveUS20070194863A1Piezoelectric/electrostrictive device manufacture/assemblyImpedence networksThin-film bulk acoustic resonatorPhysics

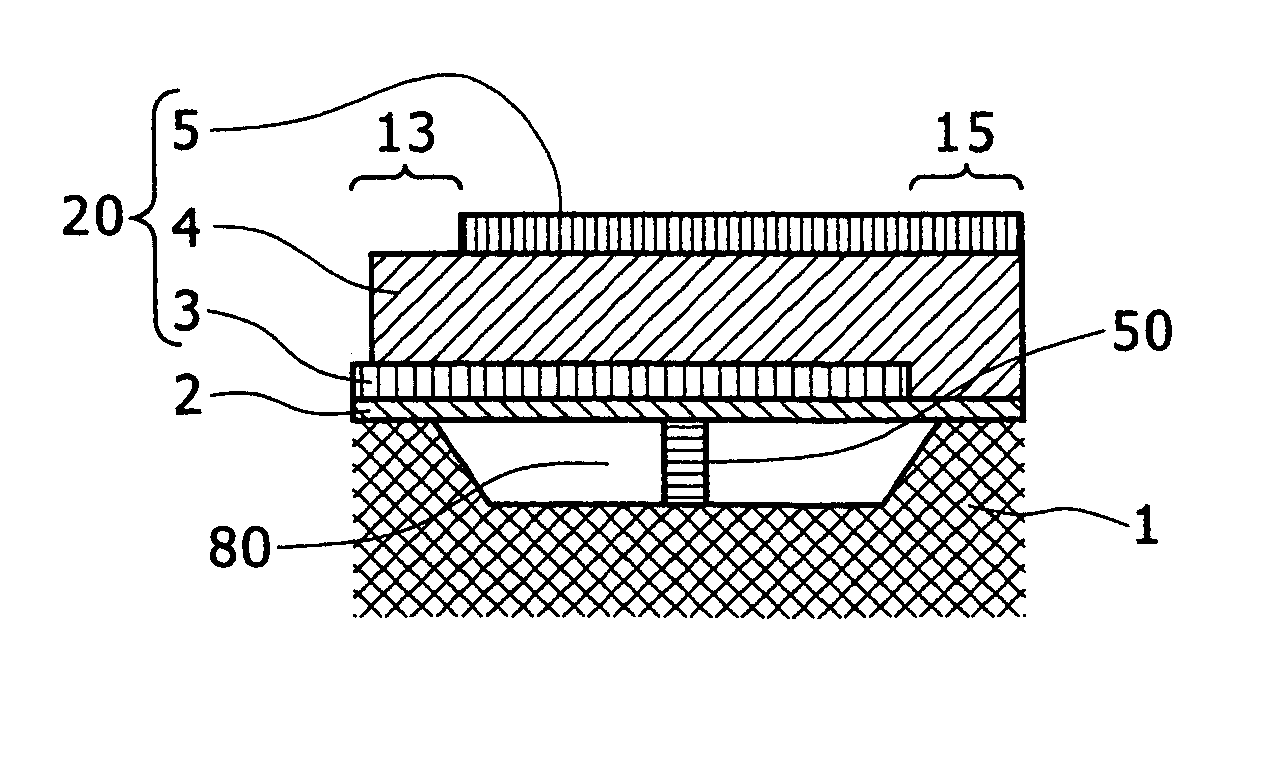

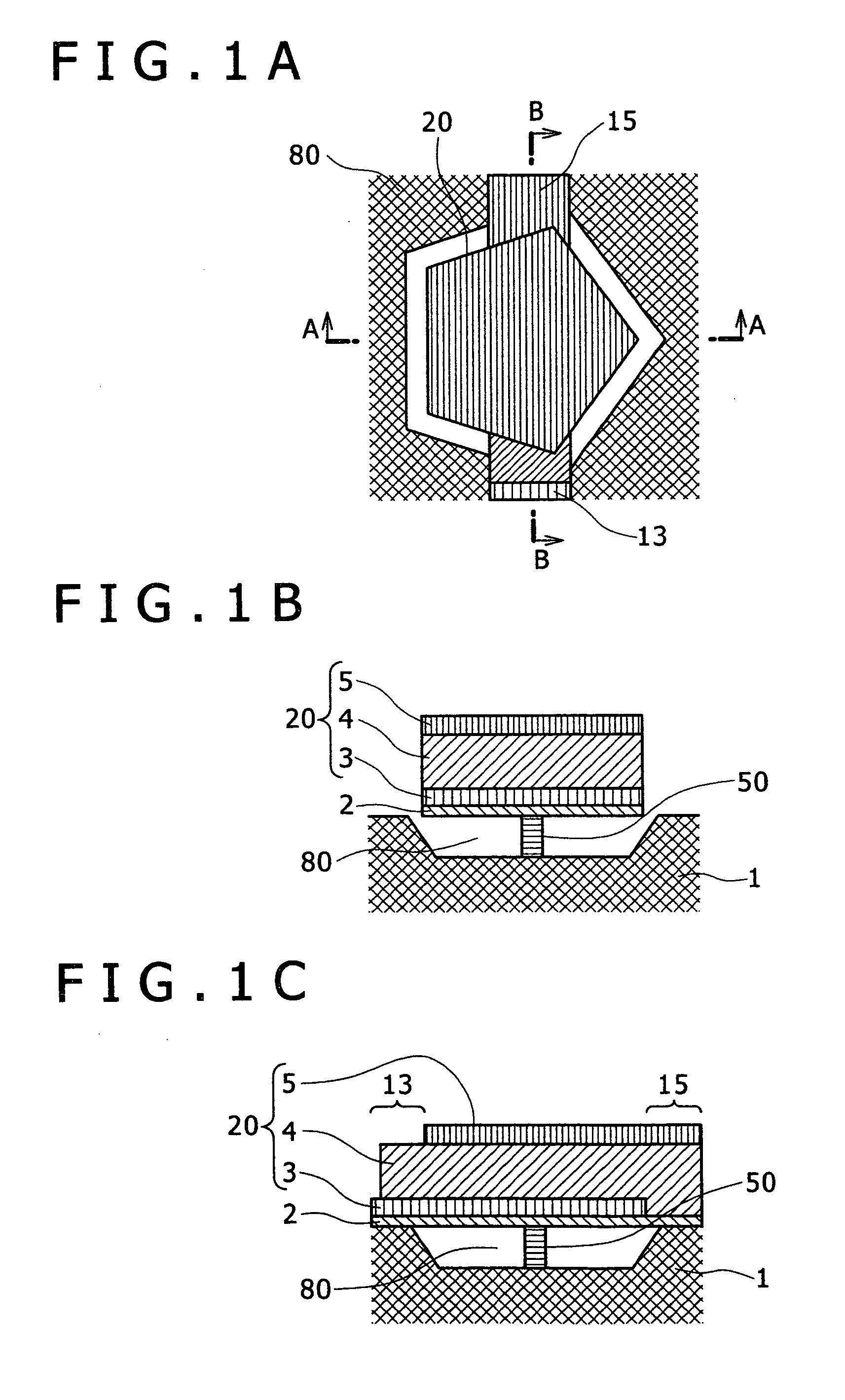

A film bulk acoustic resonator includes: a substrate having; a lower electrode extending; a piezoelectric film provided on the lower electrode; an upper electrode opposed to the lower electrode and provided on the piezoelectric film; and a plurality of protrusions. The substrate has a cavity in a surface thereof. The lower electrode extends above the cavity from an upper surface of the substrate. The protrusions are provided below the lower electrode in the cavity.

Owner:KK TOSHIBA

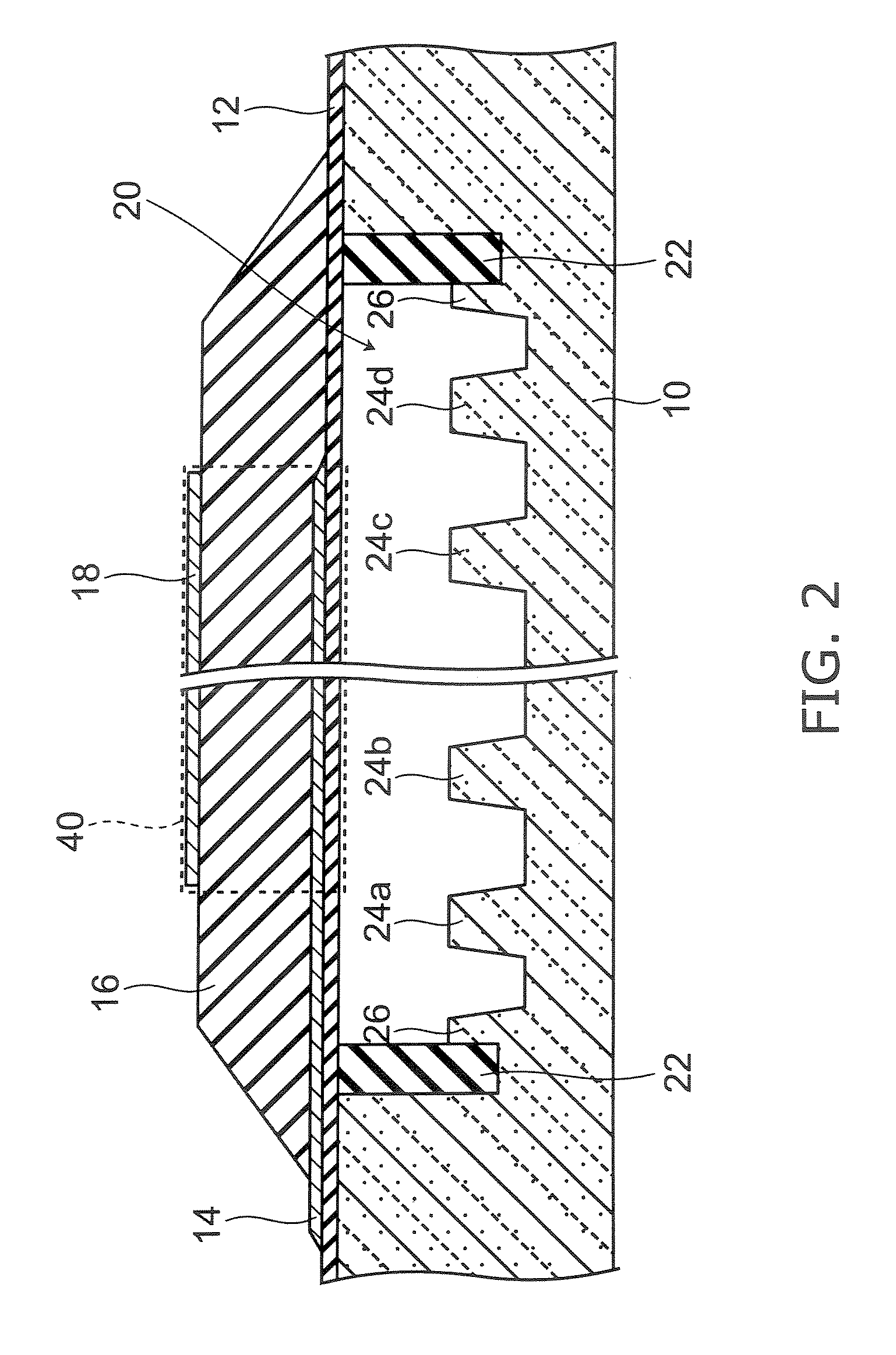

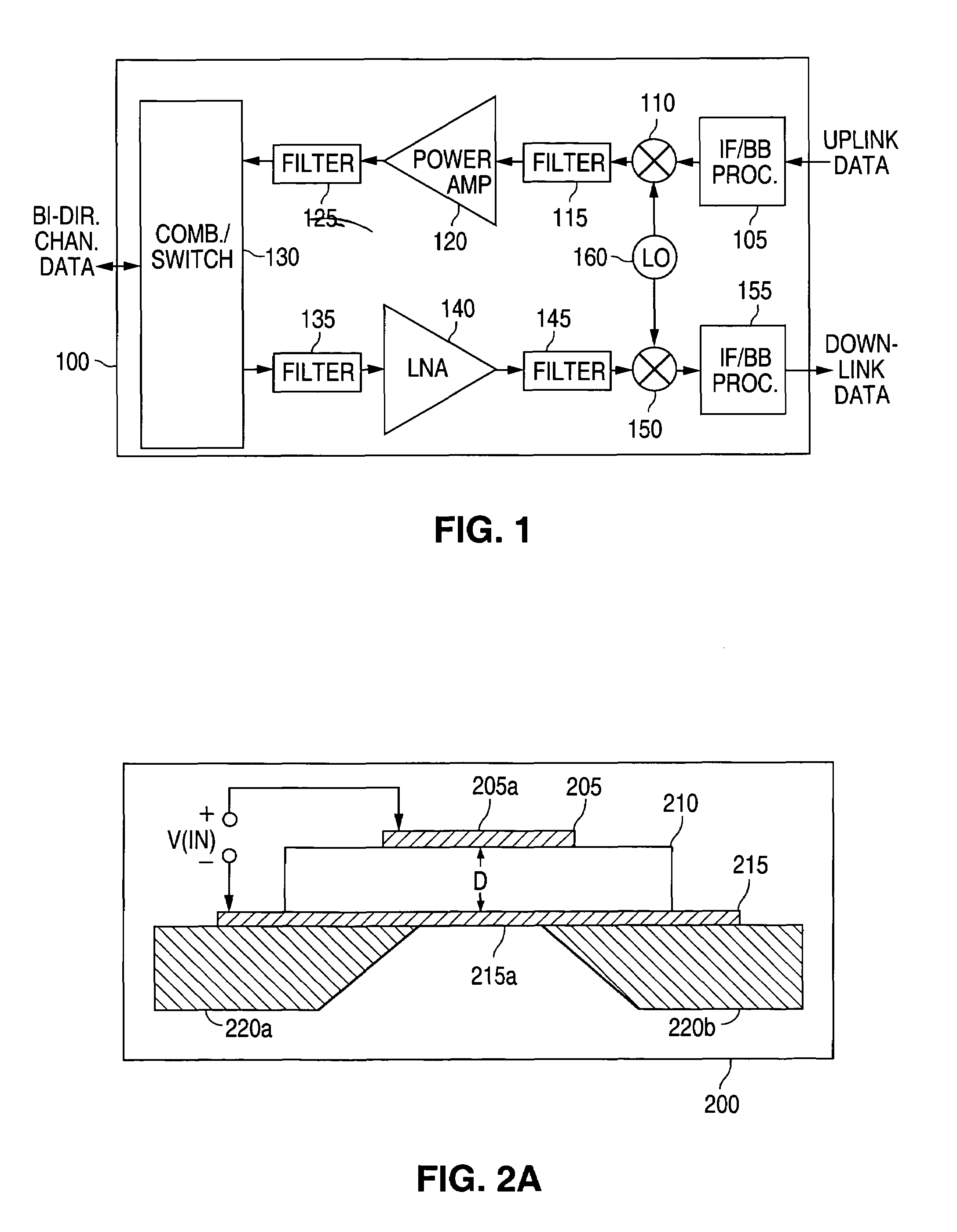

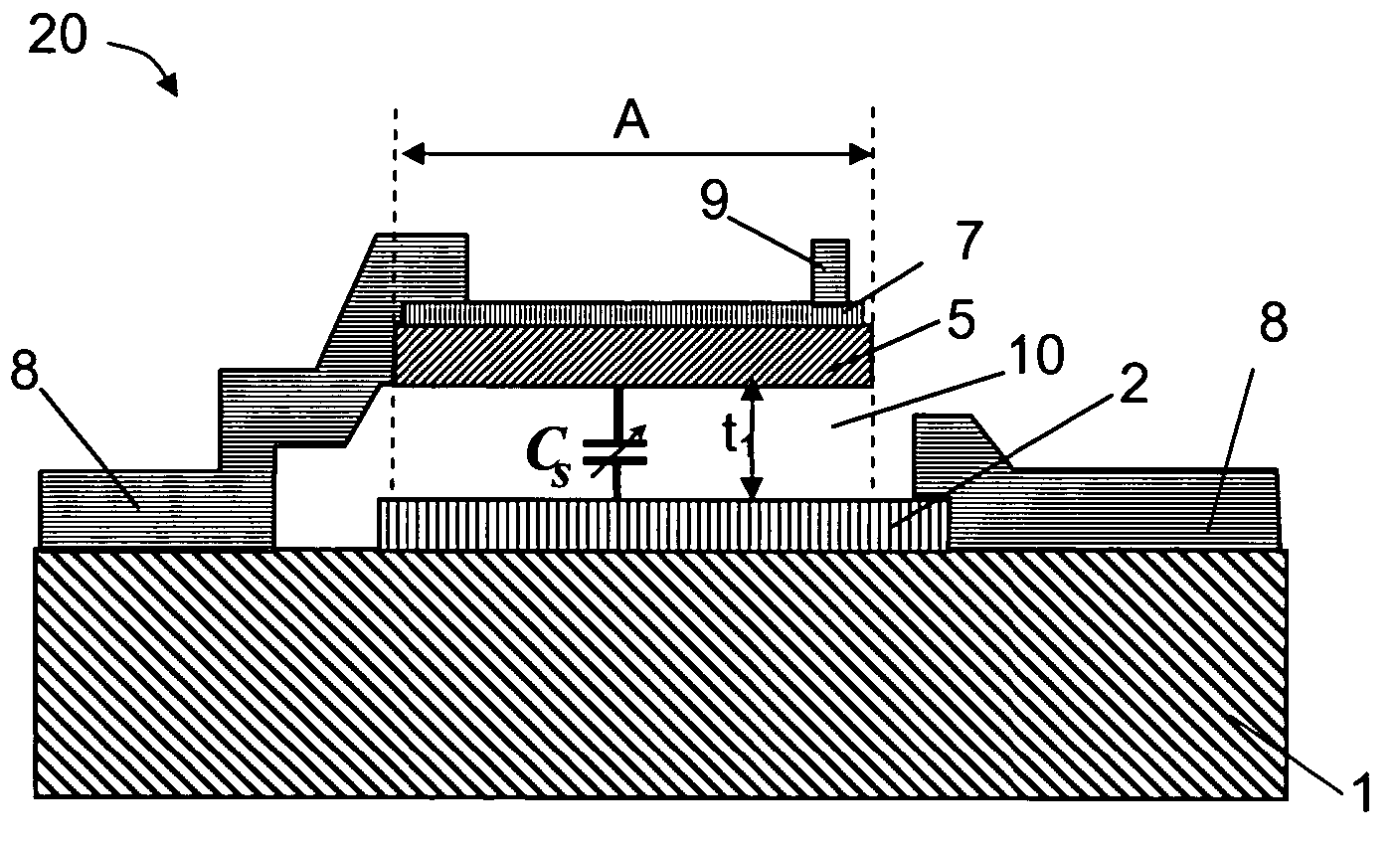

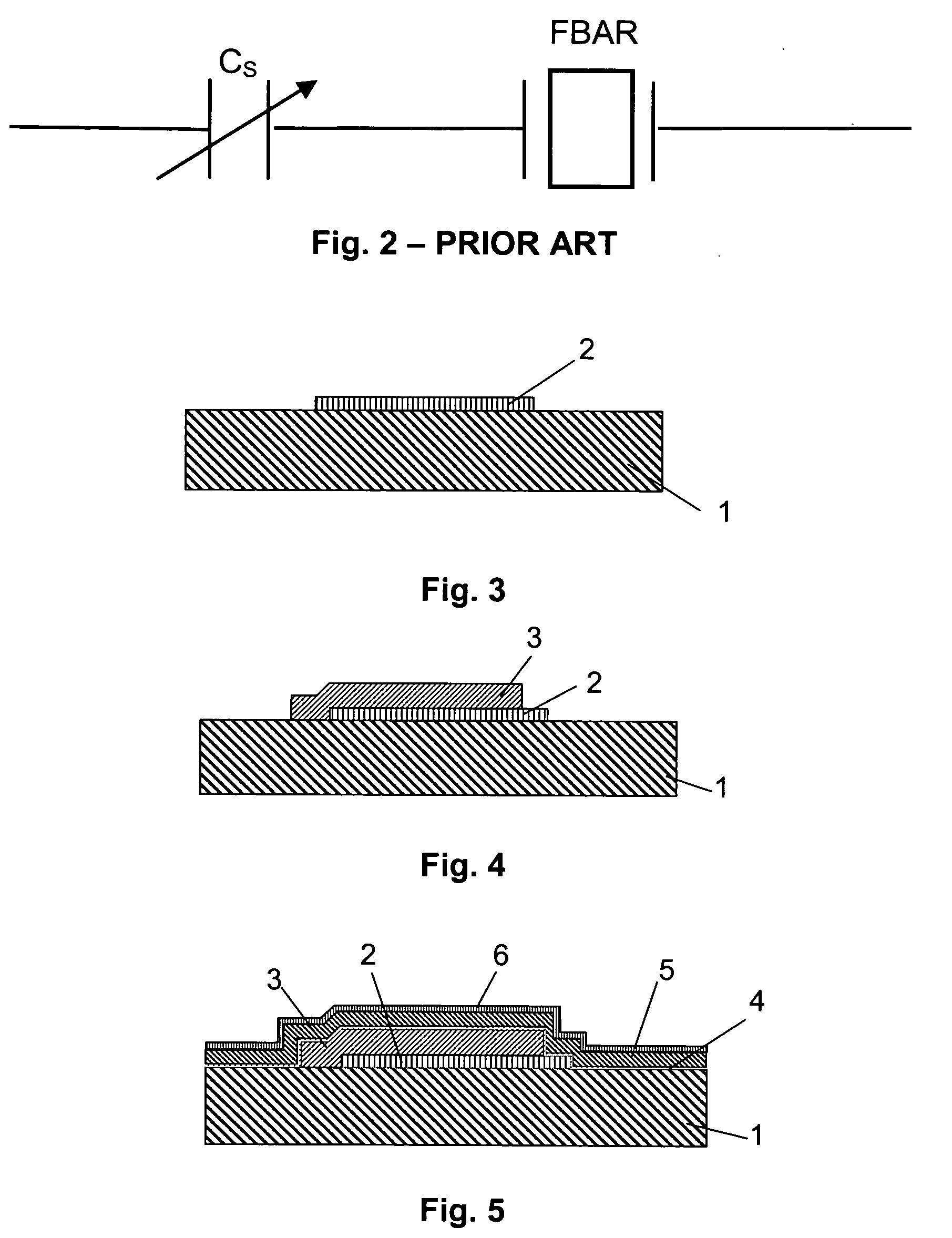

Apparatus and method for extending tuning range of electro-acoustic film resonators

InactiveUS7030718B1Increase spacingExceeding initial spacingImpedence networksElectric pulse generatorThin-film bulk acoustic resonatorAcoustic wave

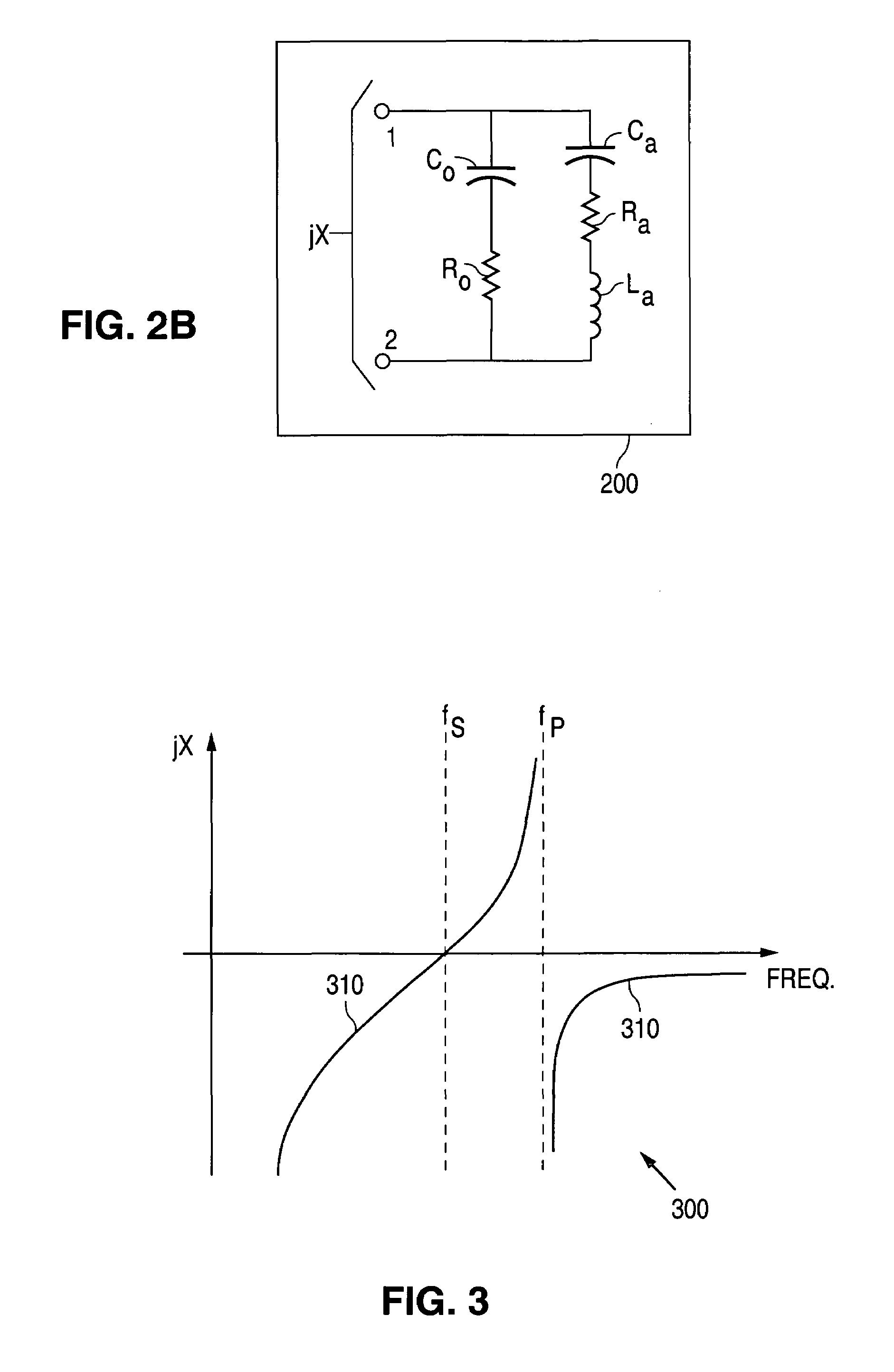

A tuning circuit for adjusting an oscillation frequency of an oscillator circuit. The tuning circuit comprises a film bulk acoustic wave resonator (FBAR) having a series resonance frequency and a parallel resonance frequency, and an inductor coupled in series or parallel with the film bulk acoustic wave resonator. The series connection of the inductor and FBAR decreases the series resonance frequency. The parallel connection of the inductor and the FBAR increases the parallel resonance frequency. The tuning circuit further comprises a varactor coupled in series or parallel with the inductor and the FBAR combination. The varactor tunes the oscillation frequency over the increased tuning range.

Owner:NAT SEMICON CORP

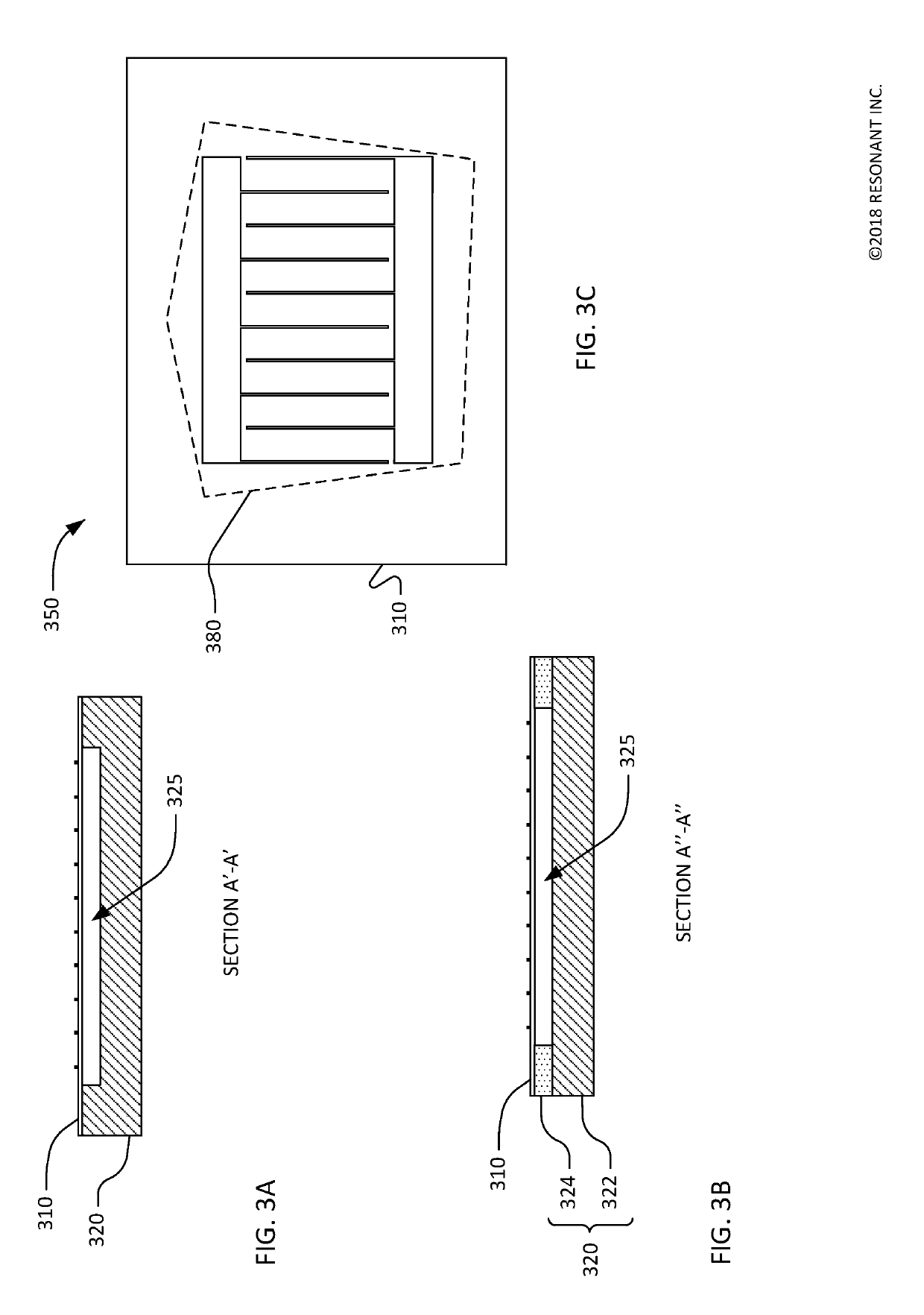

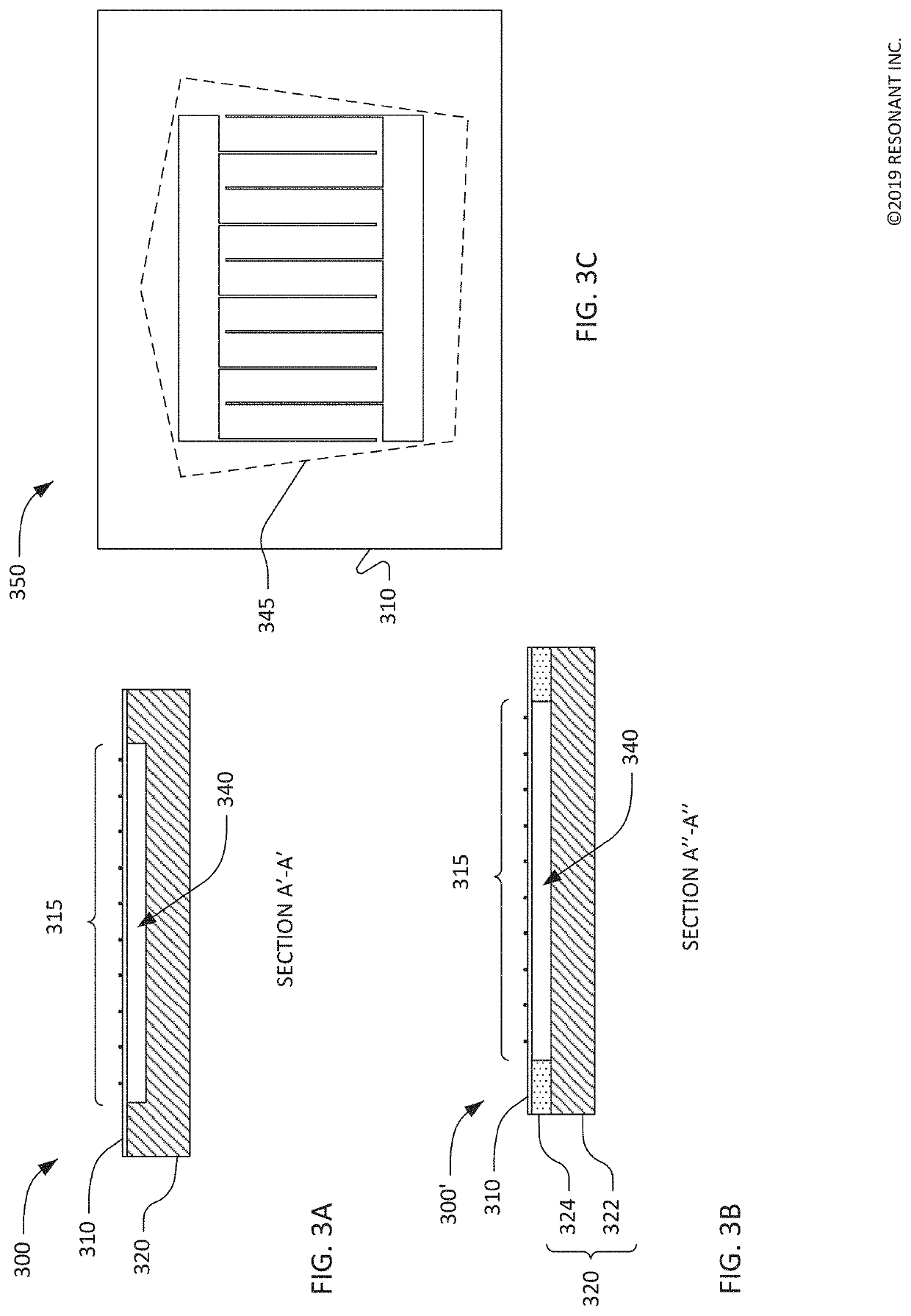

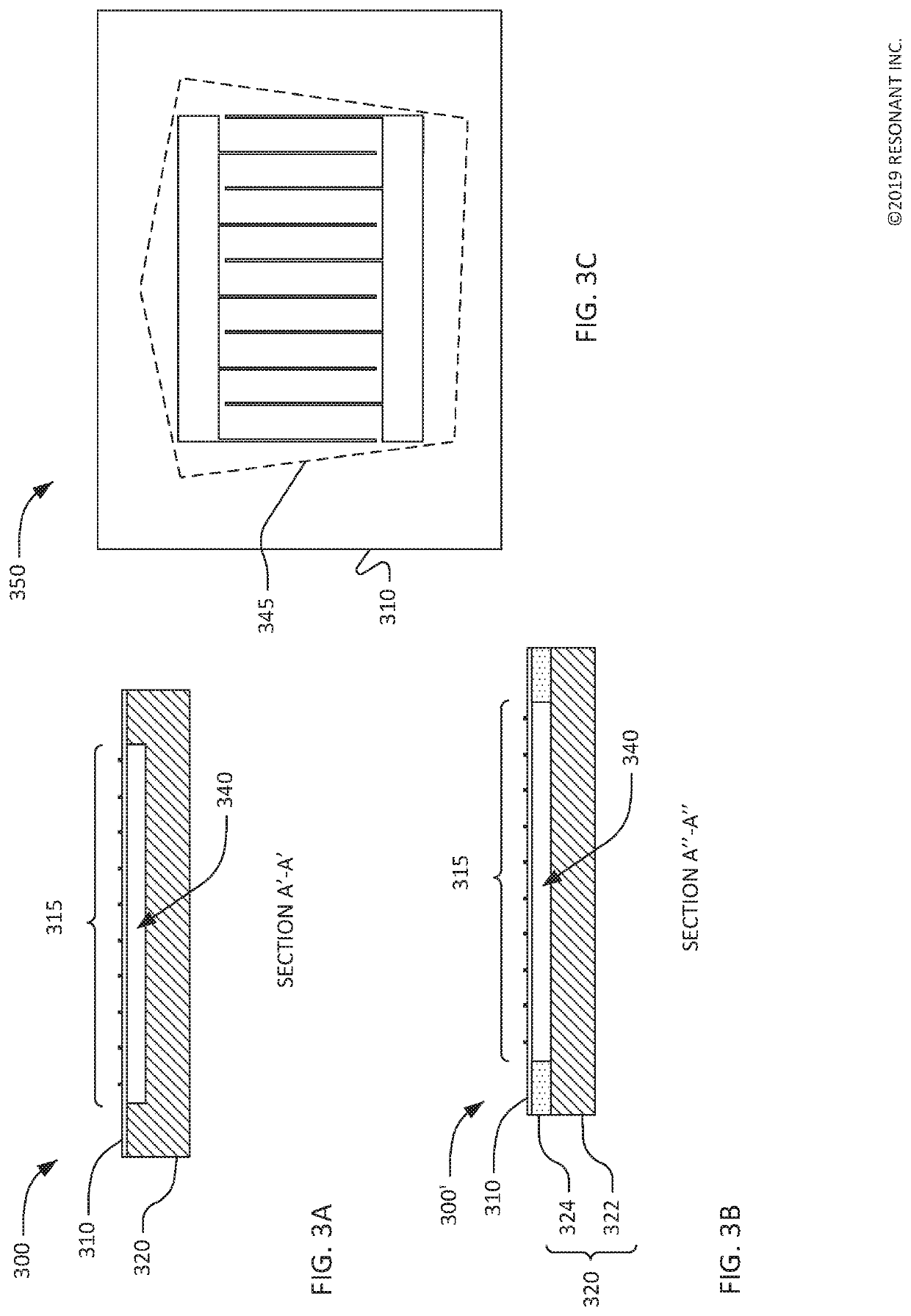

Solidly-mounted transversely-excited film bulk acoustic resonator

Resonator devices, filter devices, and methods of fabrication are disclosed. A resonator device includes a substrate and a single-crystal piezoelectric plate having parallel front and back surfaces. An acoustic Bragg reflector is sandwiched between a surface of the substrate and the back surface of the single-crystal piezoelectric plate. An interdigital transducer (IDT) is formed on the front surface. The IDT is configured to excite shear acoustic waves in the piezoelectric plate in response to a radio frequency signal applied to the IDT.

Owner:MURATA MFG CO LTD

Thin film bulk acoustic resonator and method of manufacturing the same

InactiveUS20050269904A1Eliminate reflectionsLow spuriousPiezoelectric/electrostriction/magnetostriction machinesImpedence networksThin-film bulk acoustic resonatorAcoustics

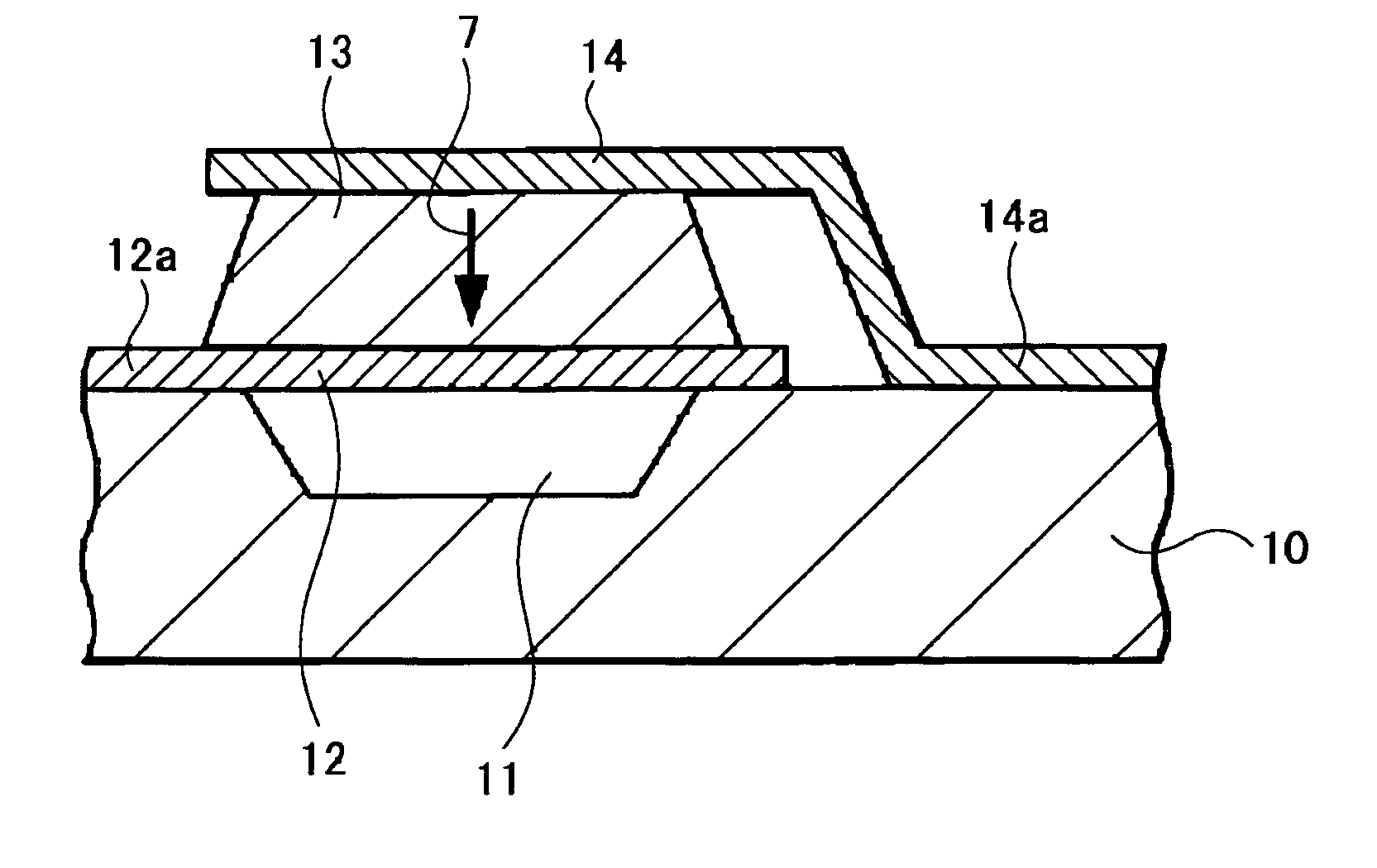

A thin film bulk acoustic resonator is provided in which the spurious caused by a lateral vibration mode is reduced. The thin film bulk acoustic resonator includes a laminated body having a first electrode 12, a piezoelectric layer 13 adjacently formed on an upper surface of the first electrode 12, and a second electrode 14 adjacently formed on an upper surface of the piezoelectric layer 13, and is made such that these first and second electrodes 12 and 14 have boundary surfaces contacting with air, in which the whole end surface of the piezoelectric layer 13 is made to exist inside the first electrode 12 and second electrode 14.

Owner:SONY CORP

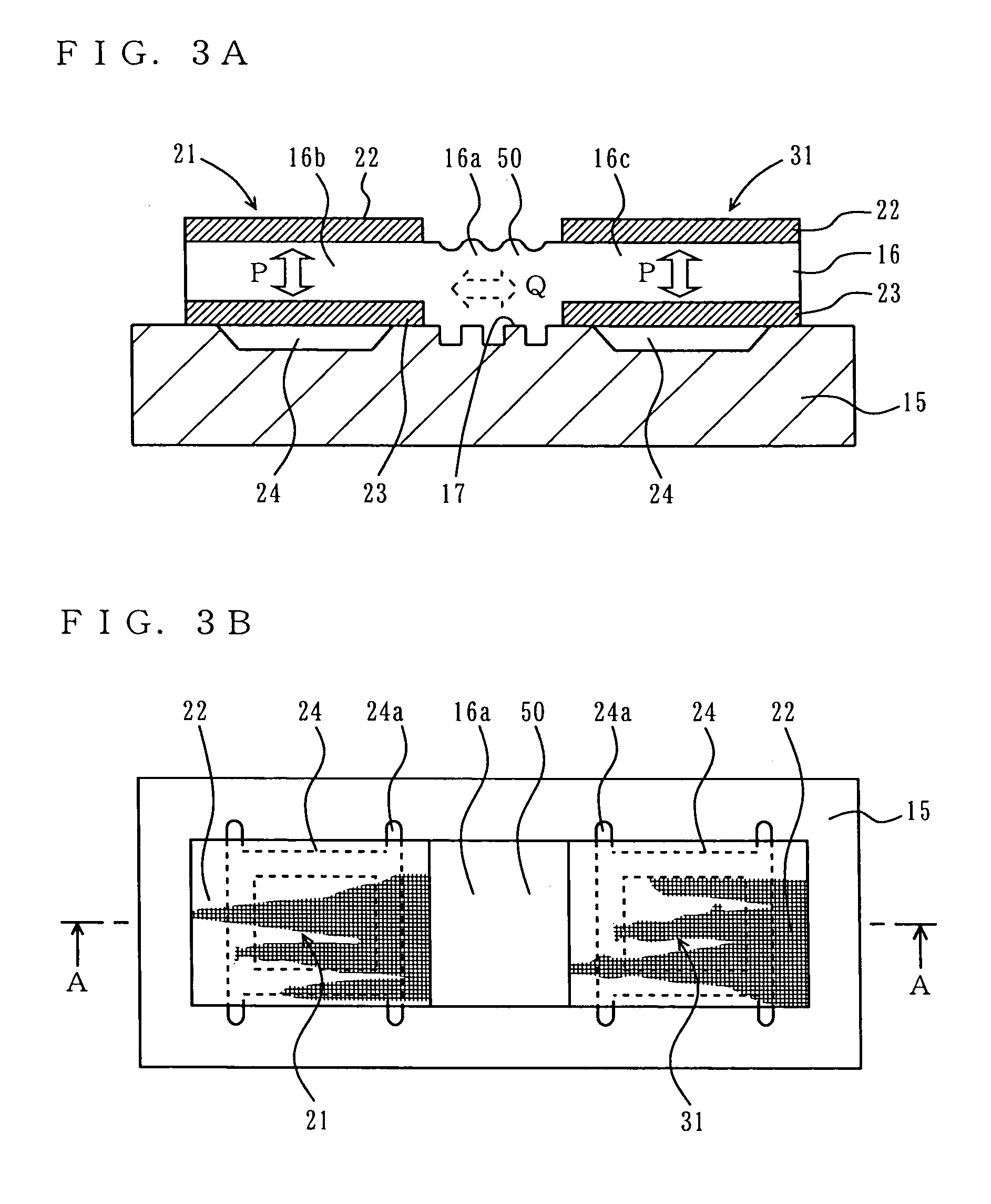

Film bulk acoustic wave resonator, its fabrication method and film bulk acoustic wave resonator filter using the resonator

InactiveUS20090127978A1ConnectionGuaranteed StrengthPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesThin-film bulk acoustic resonatorResonator filter

The film bulk acoustic wave resonator includes a laminate structure composed of a piezoelectric layer, and first and second electrode layers interposing at least part of the piezoelectric layer, in which the first metal electrode is dispersively formed on an electrode plane facing the second metal electrode, and a gap is formed in a substrate correspondingly to the laminate-structured resonance part. Except for an area of a wire electrode electrically connected to the first electrode layer and an area of a wire electrode electrically connected to the second electrode layer, the piezoelectric layer, first electrode layer and second electrode layer do not come in contact with the insulating substrate but are supported on a hollow. Also, a prop is formed in the gap to support the laminate structure.

Owner:HITACHI MEDIA ELECTORONICS CO LTD

Acoustic resonator

ActiveUS20050146401A1High quality factorEasily undergoImpedence networksThin-film bulk acoustic resonatorAcoustics

A tuneable film bulk acoustic resonator (FBAR) device. The FBAR device includes a bottom electrode, a top electrode and a piezoelectric layer in between the bottom electrode and the top electrode. The piezoelectric layer has a first overlap with the bottom electrode, where the first overlap is defined by a projection of the piezoelectric layer onto the bottom electrode in a direction substantially perpendicular to a plane of the bottom electrode. The FBAR device also includes a first dielectric layer in between the piezoelectric layer and the bottom electrode and a mechanism for reversibly varying an internal impedance of the device, so as to tune a resonant frequency of the FBAR device.

Owner:INTERUNIVERSATAIR MICRO ELEKTRONICA CENT IMECVZW BELGIUM

Transversely-excited film bulk acoustic resonator

Owner:MURATA MFG CO LTD

Transversely excited film bulk acoustic resonator using rotated z-cut lithium niobate

Acoustic resonator devices, filters, and methods are disclosed. An acoustic resonator includes a substrate and a lithium niobate (LN) plate having parallel front and back surfaces, the back surface attached to a surface of the substrate except for a portion of the LN plate forming a diaphragm that spans a cavity in the substrate. An interdigital transducer (IDT) is formed on the front surface of the LN plate such that interleaved fingers of the IDT are disposed on the diaphragm. The IDT is configured to excite a primary acoustic mode in the diaphragm in response to a radio frequency signal applied to the IDT. A direction of acoustic energy flow of the primary acoustic mode is substantially orthogonal to the surfaces of the diaphragm. The Euler angles of the LN plate are 0°, β, 90°, where β is greater than or equal to −15° and less than 0°.

Owner:MURATA MFG CO LTD

Transversely-excited film bulk acoustic resonators with molybdenum conductors

There is disclosed acoustic resonators and filter devices. An acoustic resonator includes a substrate having a surface and a single-crystal piezoelectric plate having front and back surfaces, the back surface attached to the surface of the substrate except for a portion of the piezoelectric plate forming a diaphragm that spans a cavity in the substrate. An interdigital transducer (IDT) is formed on the front surface of the single-crystal piezoelectric plate such that interleaved fingers of the IDT are disposed on the diaphragm. The interleaved fingers of the IDT are substantially molybdenum. The piezoelectric plate and the IDT are configured such that a radio frequency signal applied to the IDT excites a primary shear acoustic mode in the diaphragm. A thickness of the interleaved fingers of the IDT is between 0.25 times and 2.5 times a thickness of the piezoelectric plate.

Owner:MURATA MFG CO LTD

Thin film bulk acoustic resonator, method for producing the same, filter, composite electronic component device, and communication device

InactiveUS7230511B2Simple processImprove filter characteristicsImpedence networksThin-film bulk acoustic resonatorAcoustic wave

A thin film bulk acoustic resonator includes a piezoelectric film, and a pair of electrodes between which the piezoelectric film is interposed. The piezoelectric film includes an outer region extending outwards from at least a portion of the periphery of a resonator portion composed of the pair of electrodes and the piezoelectric film. The outer region includes, in at least a portion thereof, an acoustic damping region for damping acoustic waves.

Owner:PANASONIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com