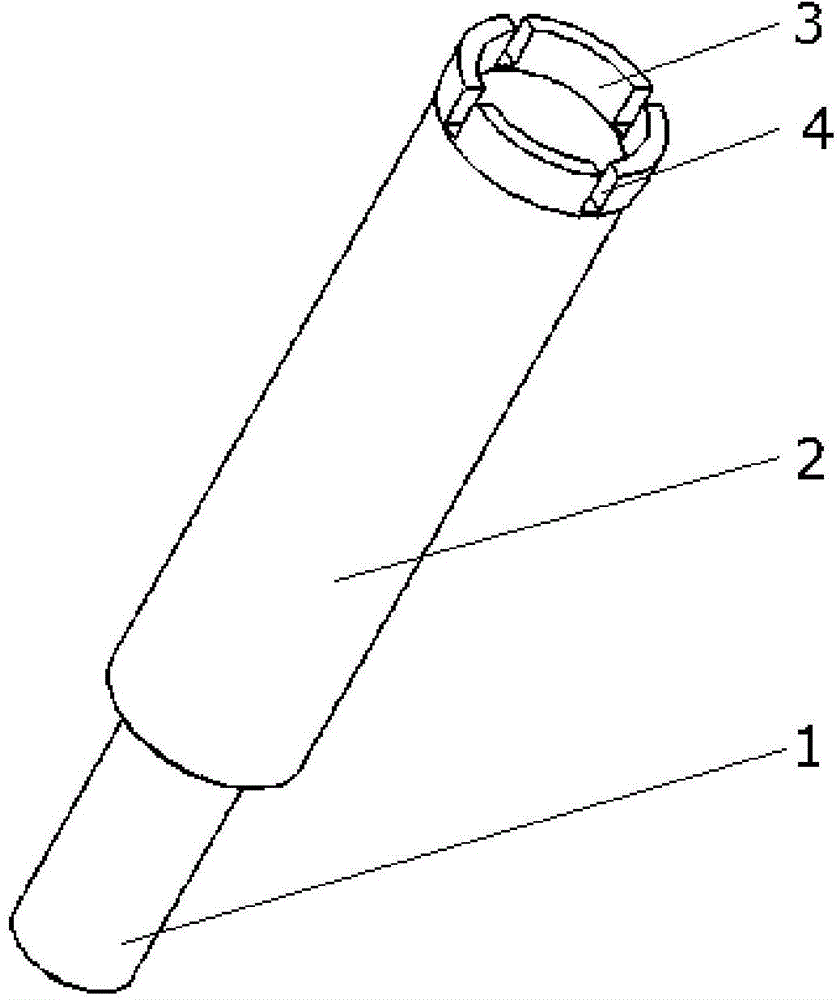

Diamond trepanning drill bit for sapphire crystal bar taking and preparing method of diamond trepanning drill bit

A diamond cutter head and diamond technology, applied in the direction of drill bits, drilling equipment, earthwork drilling and mining, etc., can solve the problems of poor concentricity between the diamond casing drill bit and the drill pipe, improve chip removal effect, increase the life of the drill bit, reduce the The effect of rings and missing teeth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

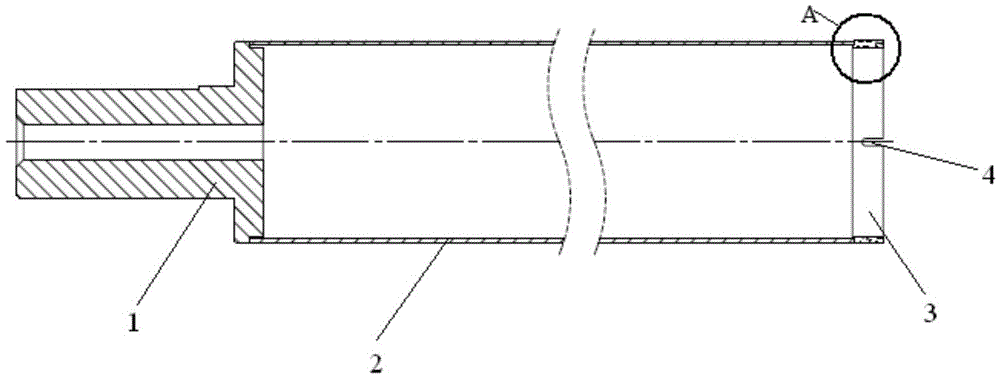

[0039] The present invention also provides a kind of preparation method of above-mentioned diamond casing bit, is used for preparing above-mentioned diamond casing bit, and this preparation method comprises:

[0040] The rough machining preparation step of the diamond cutter head is to prepare the diamond cutter head blank; the welding step is to weld the drill pipe and the joint together, and the diamond cutter head blank and the drill pipe are laser welded together to form the diamond sleeve drill bit blank; the finishing preparation Step 1: Carry out grinding and sharpening treatment and finished product inspection on the diamond cutter head blank of the diamond nesting drill bit blank, so as to obtain the diamond nesting drill bit.

[0041] In the welding step, an annular welding step is processed along the axial direction of the diamond cutter head blank on the end face of the diamond cutter head blank connected to the drill pipe, and the annular welding step is packed int...

Embodiment 1

[0053] (1) take working layer metal powder by weight: 12 parts of iron powders, 33 parts of cobalt powders, 50 parts of copper powders, 5 parts of tin powders and the diamond that accounts for 55% of working layer gross weight ratio carry out compounding; Add glycerin and alcohol when the layer metal powder and diamond are mixed, the amount of glycerin and alcohol added is 1% and 1.5% of the sum of the working layer metal powder and diamond mass respectively, and the mixing time is 4 hours. The cutter head transition layer contains iron, cobalt and copper powder, and takes by weight 52 parts of iron powder, 40 parts of copper powder and 8 parts of cobalt powder compound; when the transition layer metal powder is mixed, alcohol is added, and the amount of alcohol added is the transition layer 1.5% of the mass of metal powder, the mixing time is 2.5 hours. After the working layer powder (including diamond) and the transition layer powder are mixed, add glue and granulate respect...

Embodiment 2

[0059] (1) take working layer metal powder by weight: 34 parts of iron powders, 22 parts of cobalt powders, 42 parts of copper powders, 2 parts of tin powders and the diamond that accounts for 35% of working layer gross weight ratio carry out compounding; Glycerin and alcohol should be added when the layer metal powder and diamond are mixed. The amount of glycerin and alcohol added is 1% and 1.5% of the sum of the working layer metal powder and diamond mass respectively, and the mixing time is 5 hours. The cutter head transition layer contains iron-cobalt copper powder, and takes by weight 52 parts of iron powder, 40 parts of copper powder and 8 parts of cobalt powder for compounding; when the transition layer metal powder is mixed, alcohol is added, and the addition of alcohol is transition 1.5% of the mass of the layer metal powder, and the mixing time is 2 hours. After the working layer powder (including diamond) and the transition layer powder are mixed, add glue and granu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com