Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1416results about How to "High concentricity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

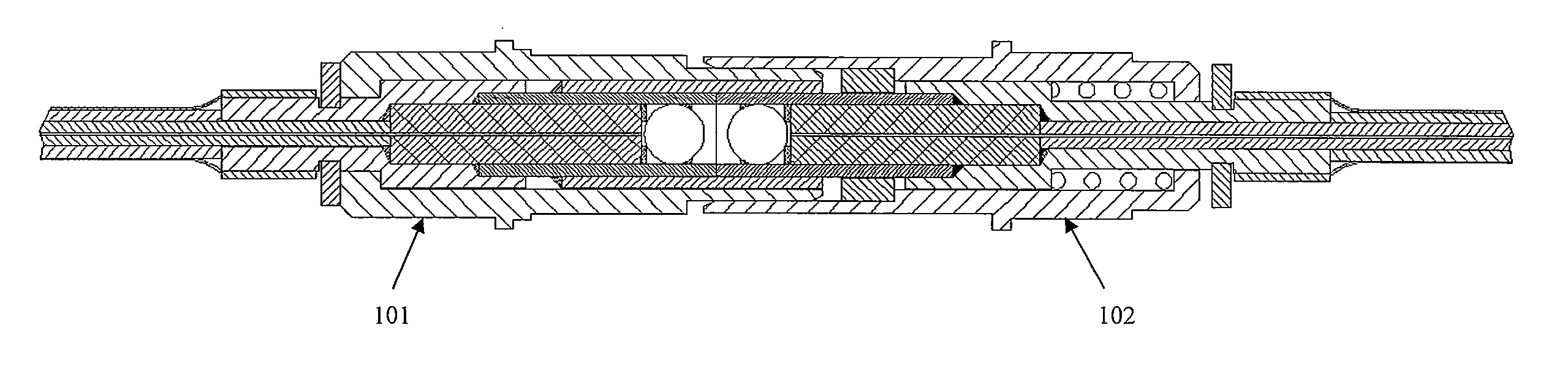

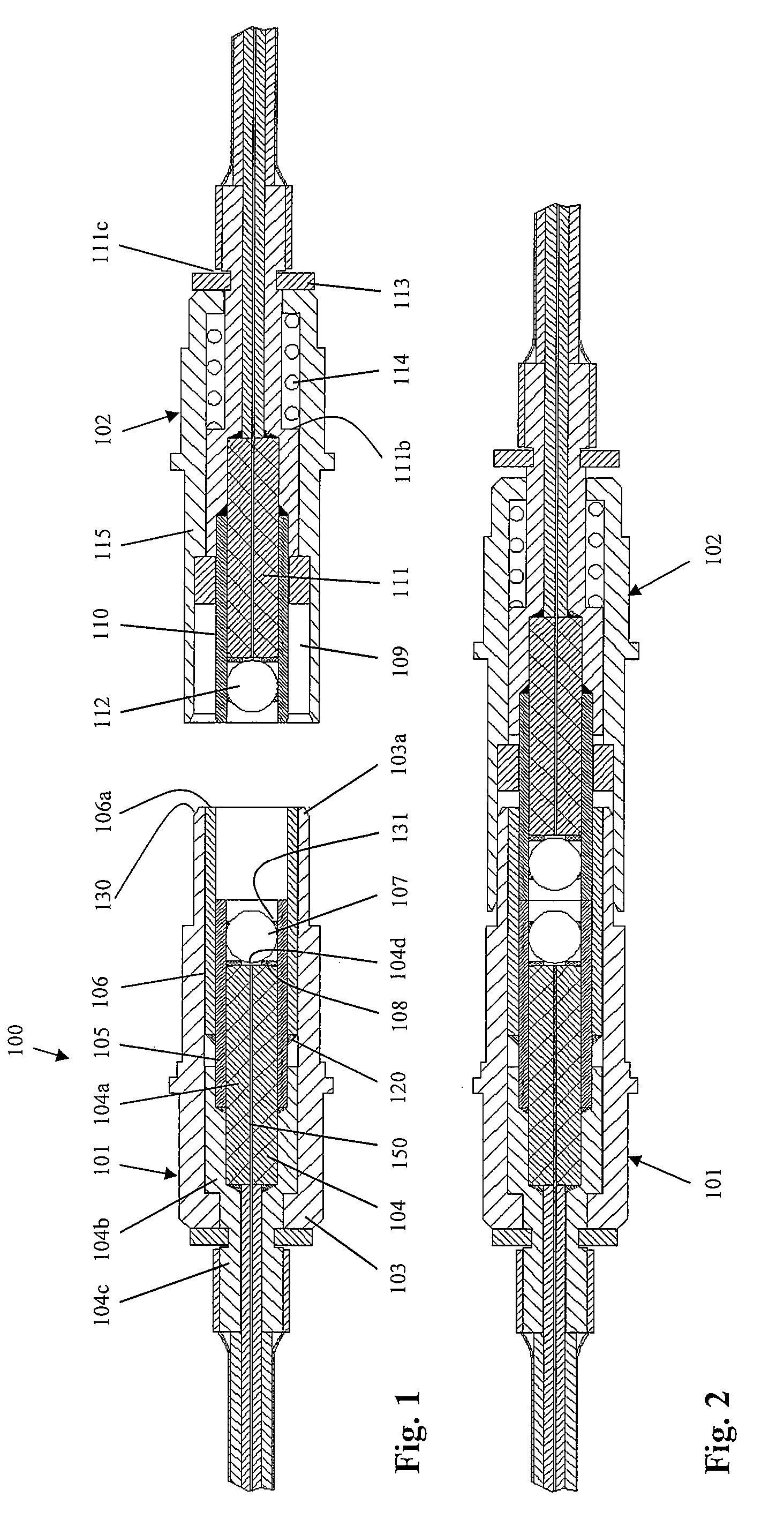

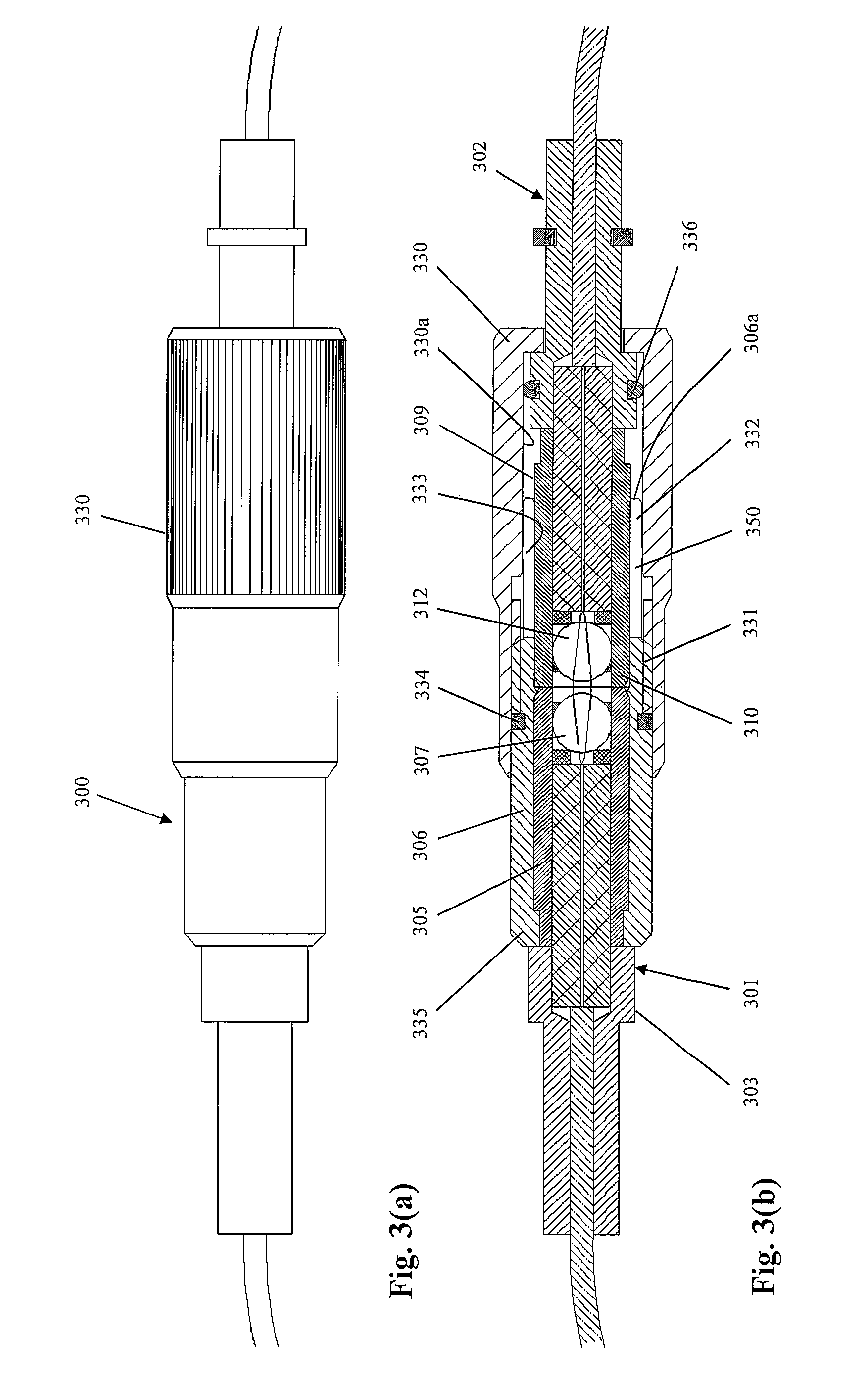

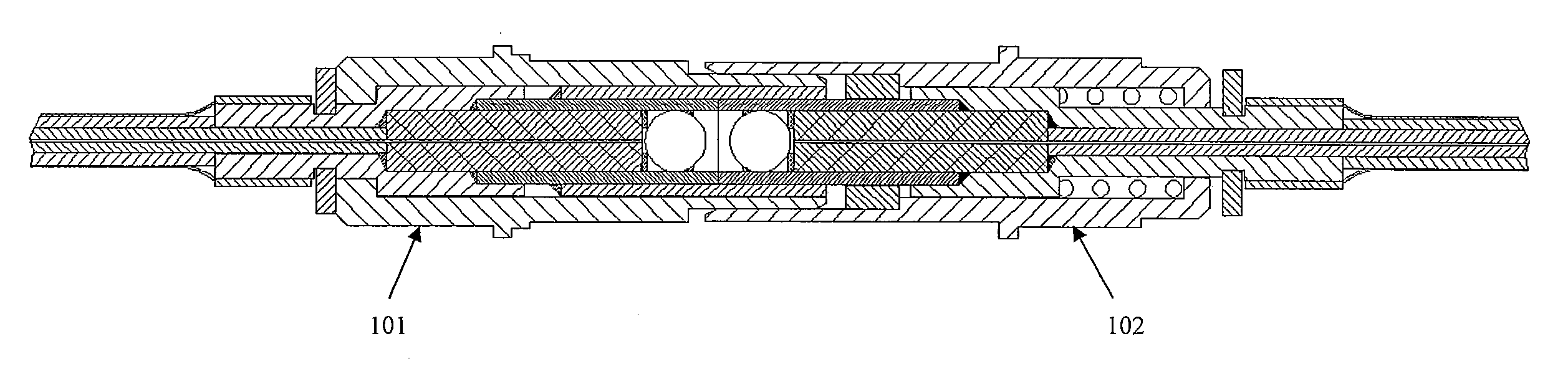

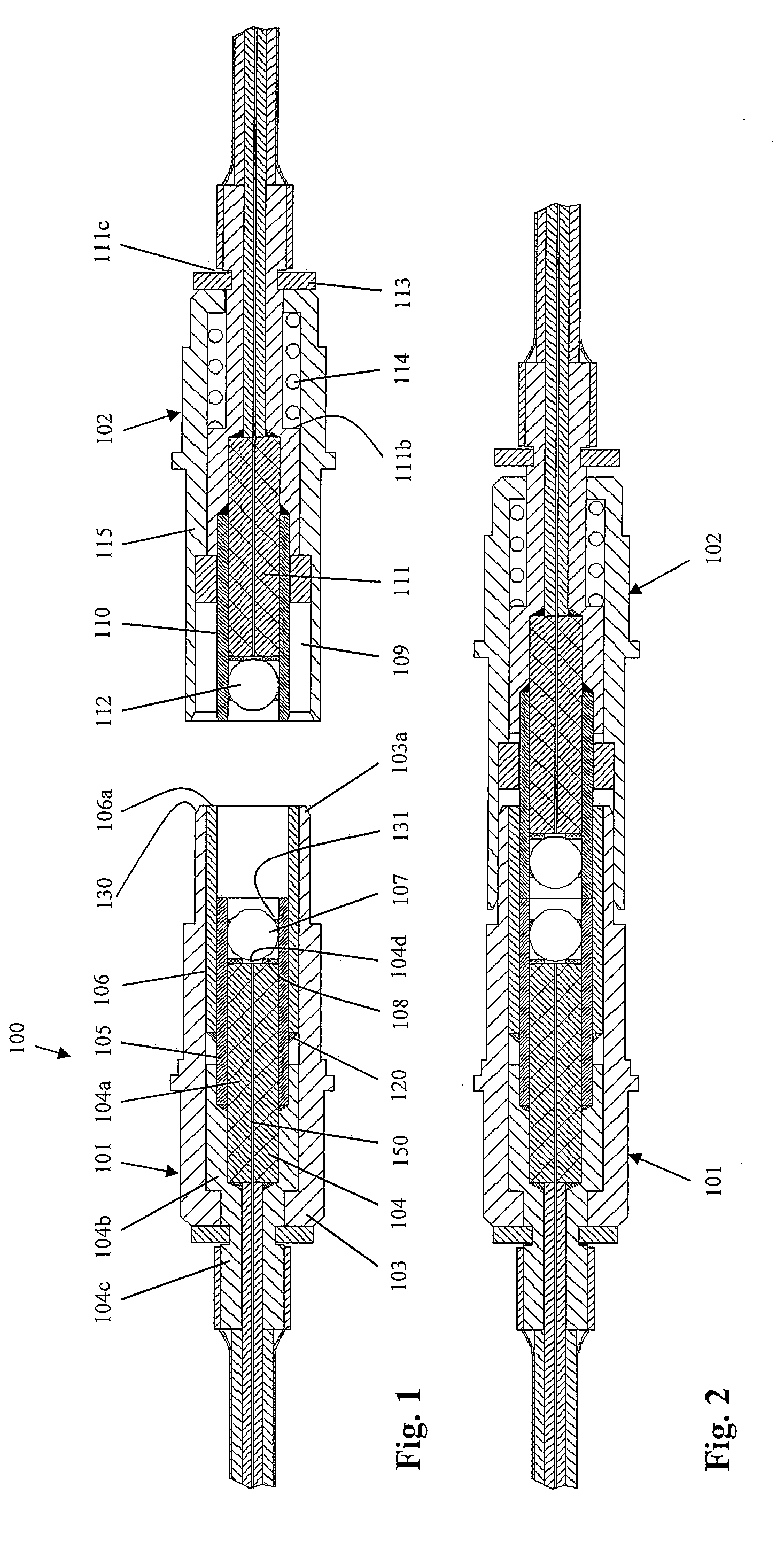

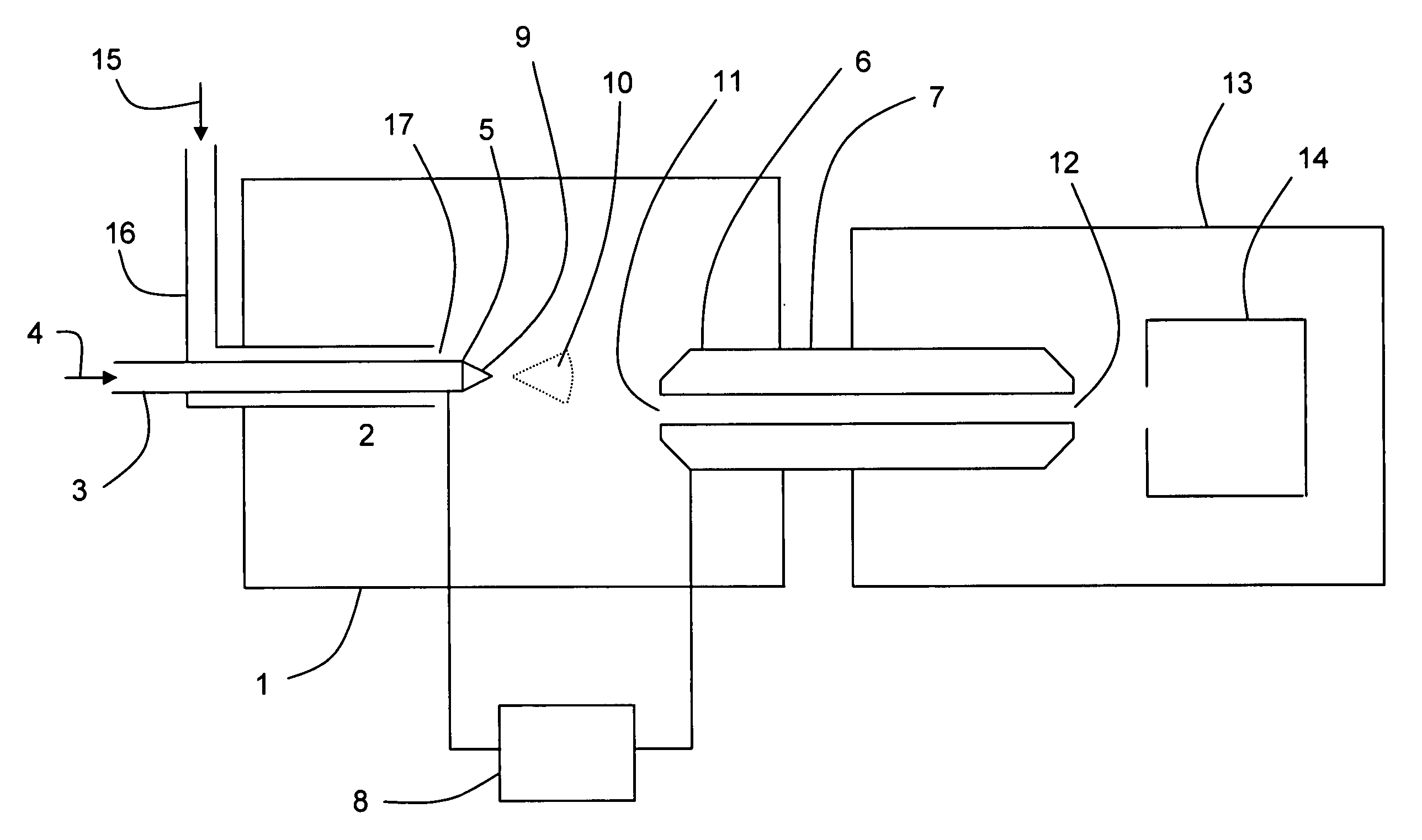

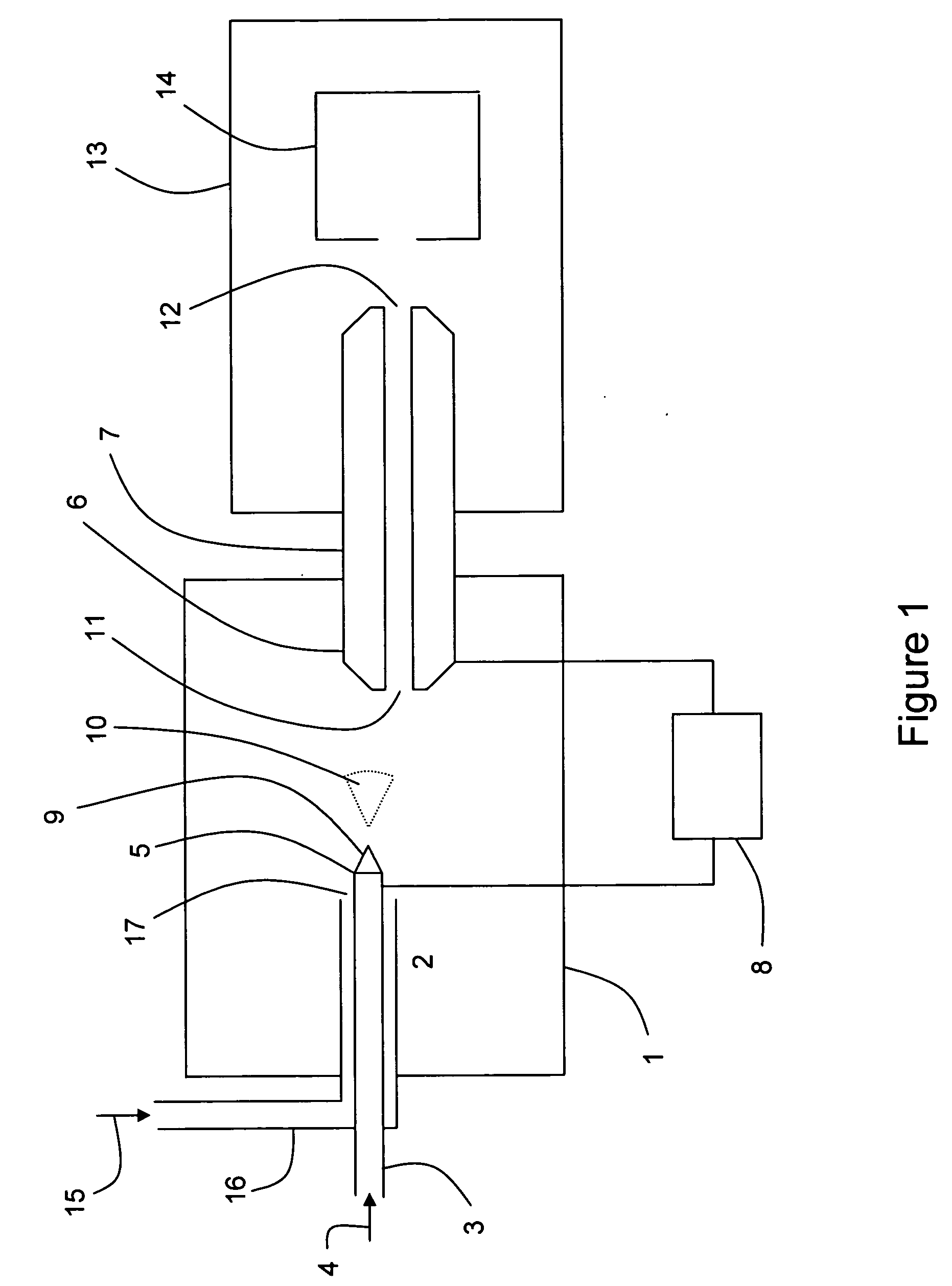

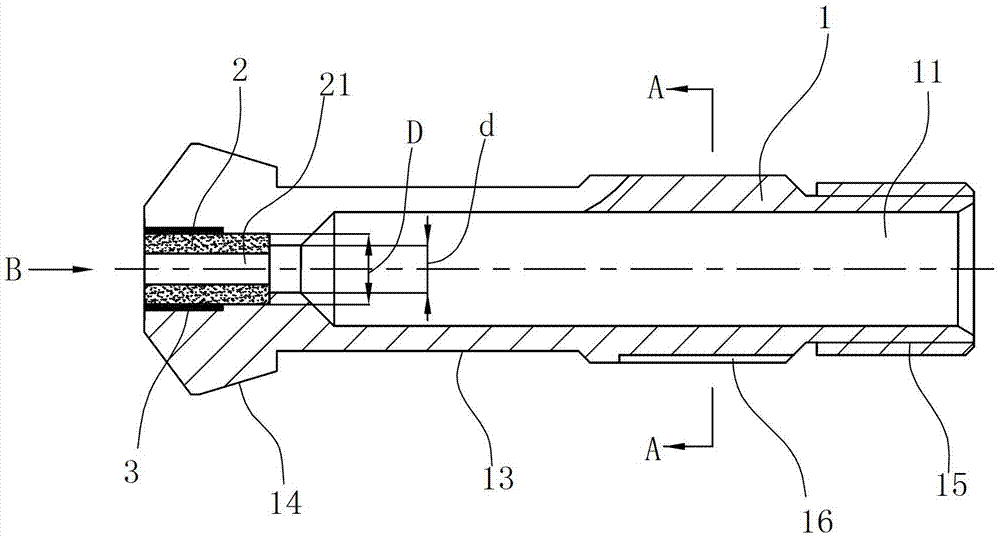

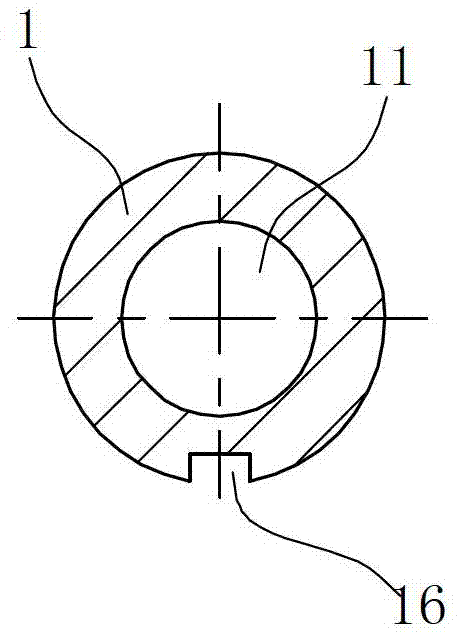

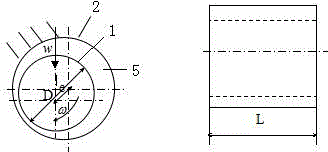

Single-channel expanded beam connector

A single-channel, expanded beam connector having a front and rear orientation and comprising: (a) a housing; (b) an outer sleeve at least partially contained by the housing; (c) a first inner sleeve disposed at least partially in the outer sleeve; (d) a ferrule disposed at least partially in the first inner sleeve; (e) a lens disposed at least partially in the first inner sleeve in front of the ferrule, wherein the lens and the ferrule have about the same outside first diameter which is just slightly less than that of the inside diameter of the first inner sleeve such that the ferrule and the lens are held in optical alignment in the first inner sleeve, and wherein the distal end of the outer sleeve extends beyond the inner sleeve to receive a second inner sleeve of a mating structure, the first and second inner sleeves having the same diameter which is just slightly less than the inside diameter of the outer sleeve such that the first and inner sleeves are aligned within the outer sleeve.

Owner:TYCO ELECTRONICS LOGISTICS AG (CH)

Single-channel expanded beam connector

ActiveUS20100104244A1Small sizeSmall dimensionCoupling light guidesBiomedical engineeringOptical alignment

A single-channel, expanded beam connector having a front and rear orientation and comprising: (a) a housing; (b) an outer sleeve at least partially contained by the housing; (c) a first inner sleeve disposed at least partially in the outer sleeve; (d) a ferrule disposed at least partially in the first inner sleeve; (e) a lens disposed at least partially in the first inner sleeve in front of the ferrule, wherein the lens and the ferrule have about the same outside first diameter which is just slightly less than that of the inside diameter of the first inner sleeve such that the ferrule and the lens are held in optical alignment in the first inner sleeve, and wherein the distal end of the outer sleeve extends beyond the inner sleeve to receive a second inner sleeve of a mating structure, the first and second inner sleeves having the same diameter which is just slightly less than the inside diameter of the outer sleeve such that the first and inner sleeves are aligned within the outer sleeve.

Owner:TYCO ELECTRONICS LOGISTICS AG (CH)

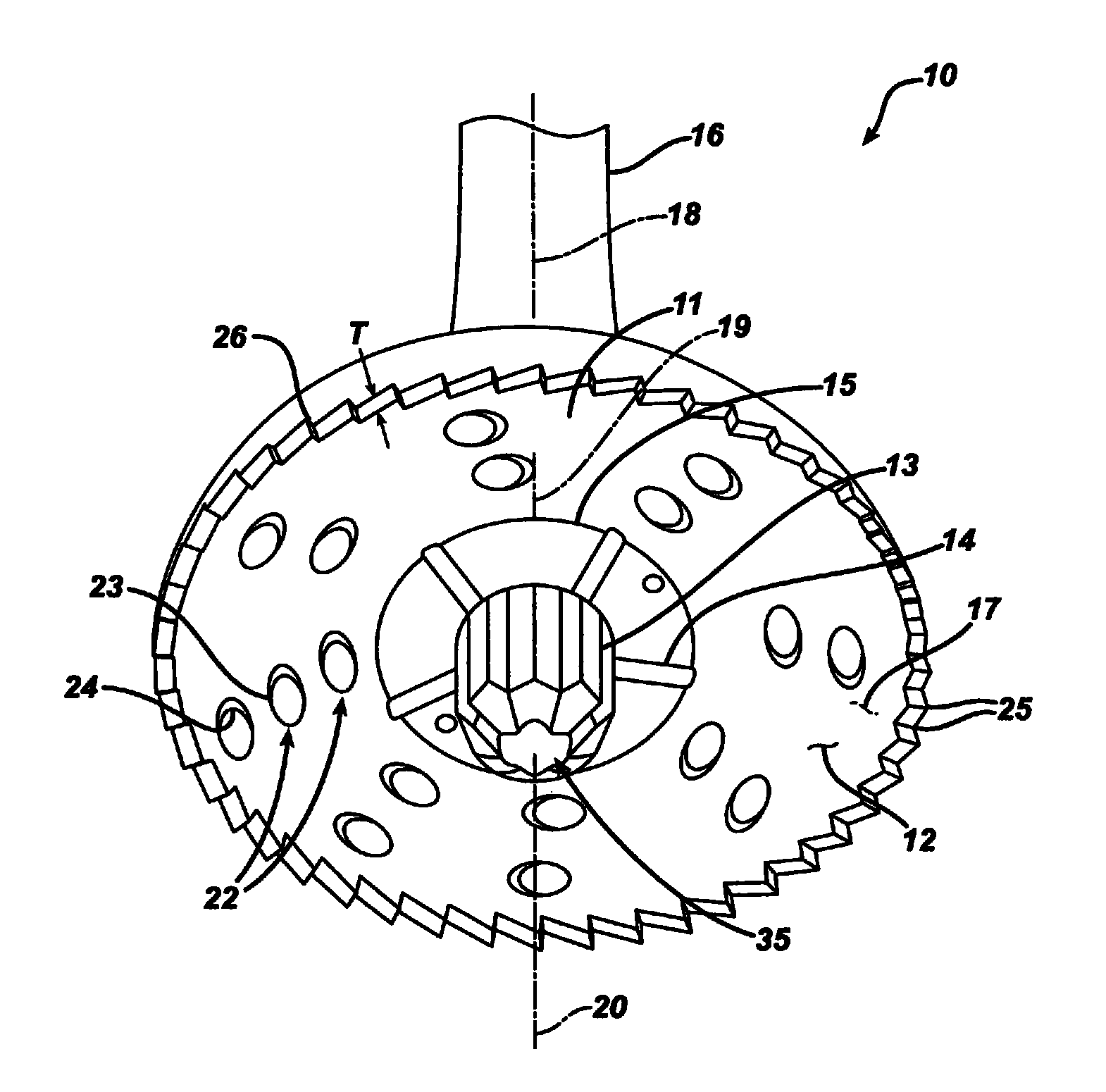

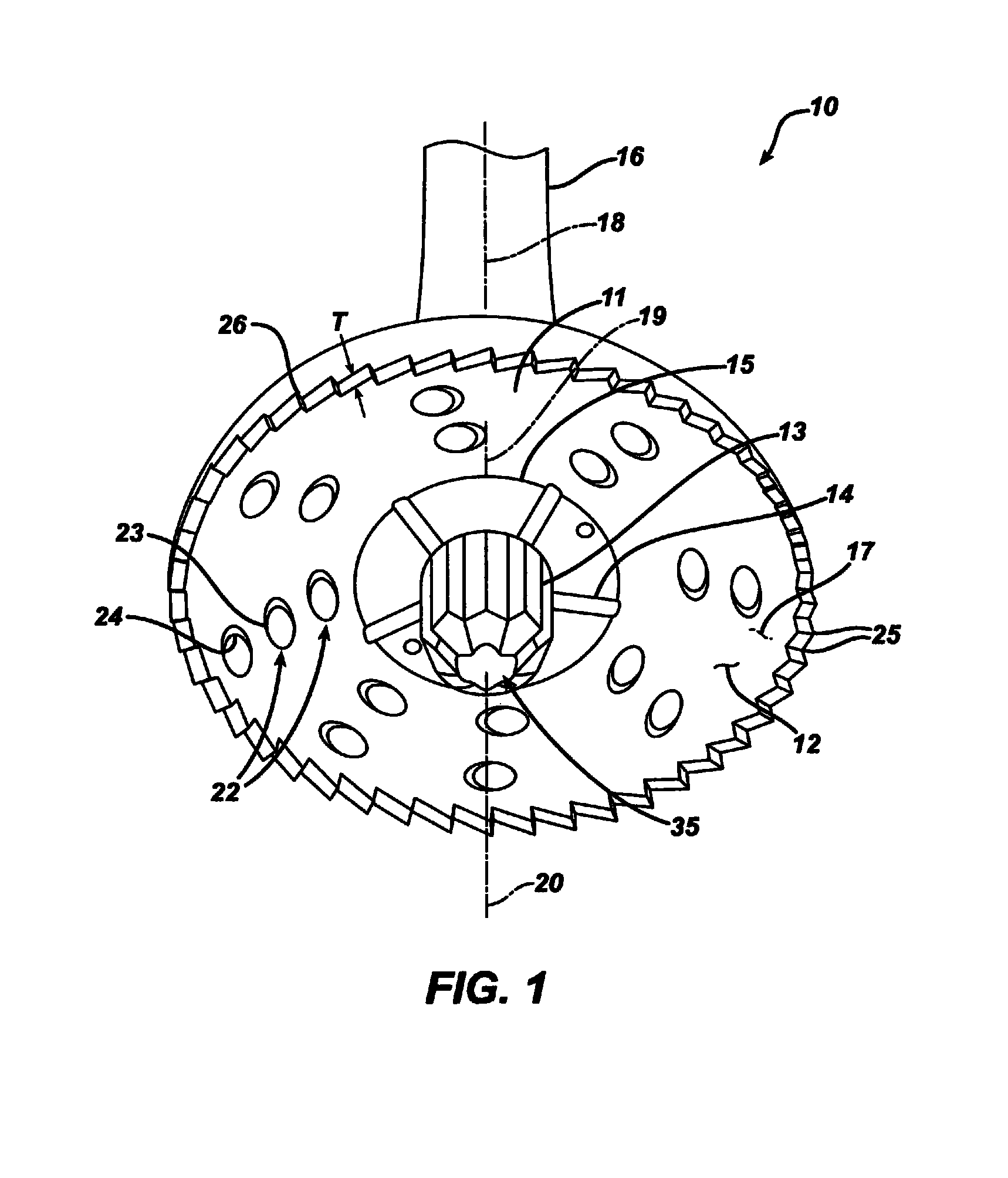

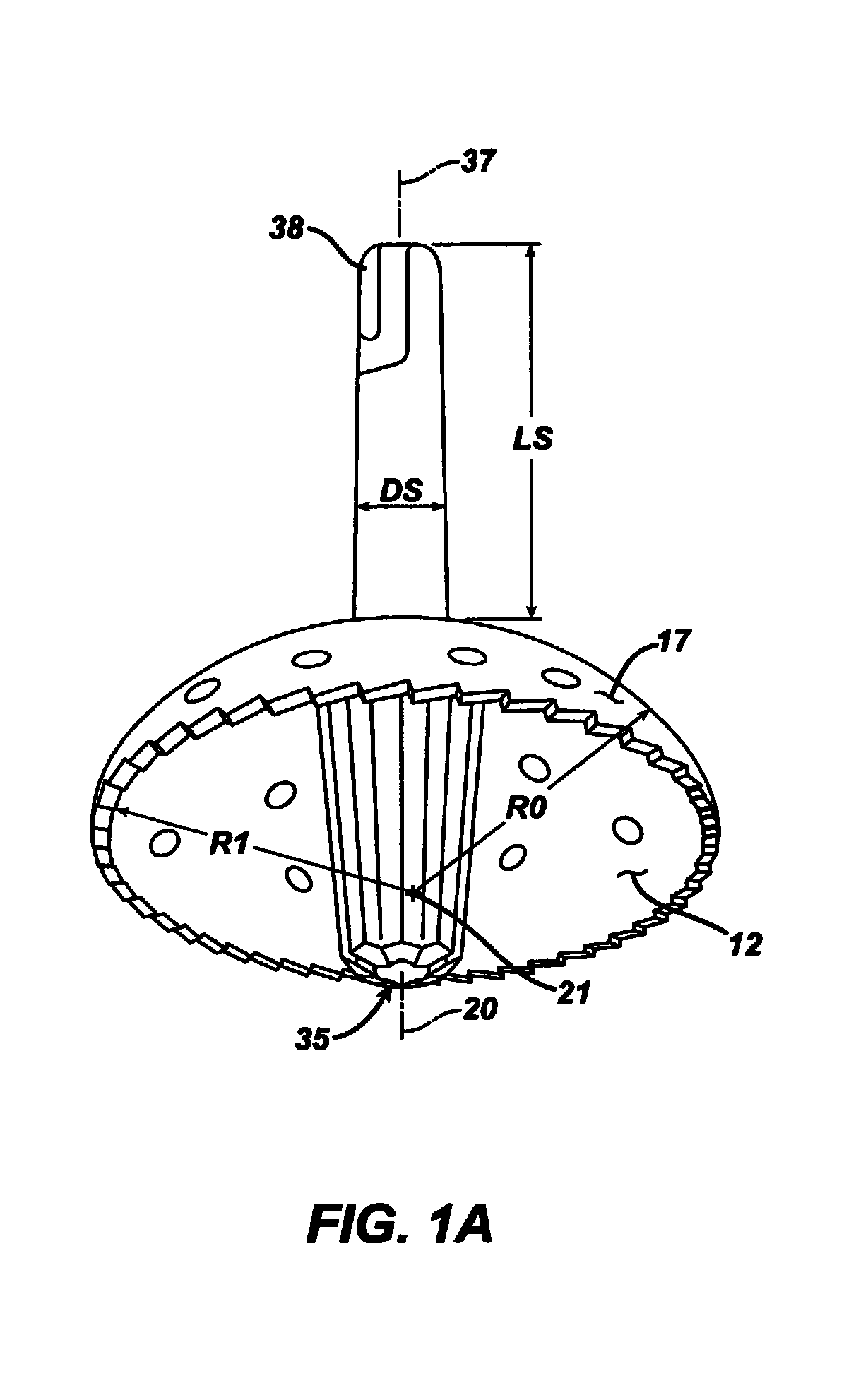

Arthroplasty instruments and associated method

ActiveUS8366713B2Shorten the timeReduce the amount requiredDiagnosticsSurgerySacroiliac jointBiomedical engineering

An instrument(10) for use in performing arthroplasty is provided. The instrument(10) includes a first portion(11) adapted to prepare a convex surface(64) on the head(5) of the long bone(4). The instrument (10) also includes a second portion (13) adapted to prepare an elongated cavity (62) or a third portion (14) adapted to prepare a central support surface (56) on the head (5) of the long bone (4), or both second portion (13) and the third portion (14). The third portion (14) and the second portion (13) are operably associated with the first portion(11).

Owner:DEPUY SYNTHES PROD INC

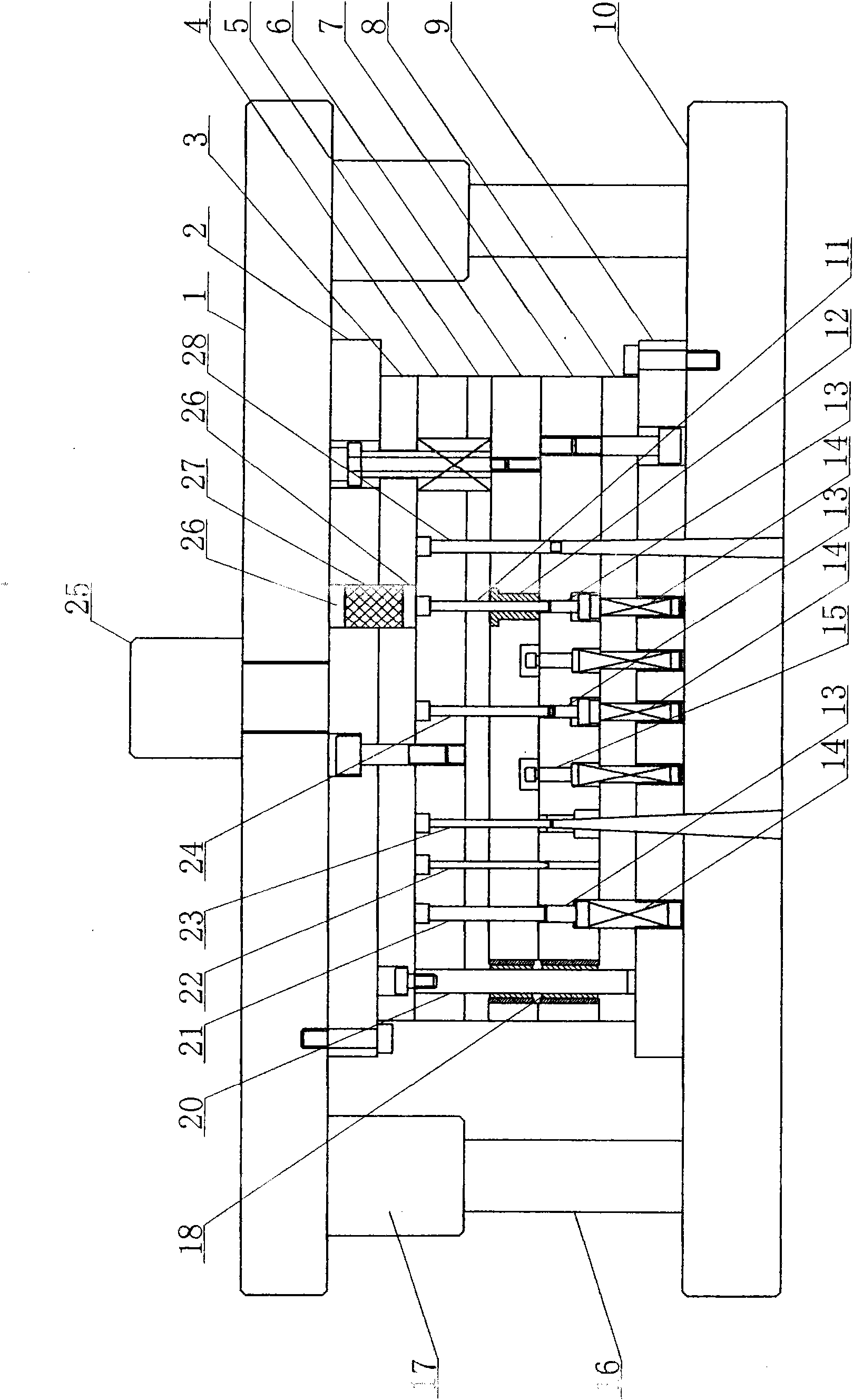

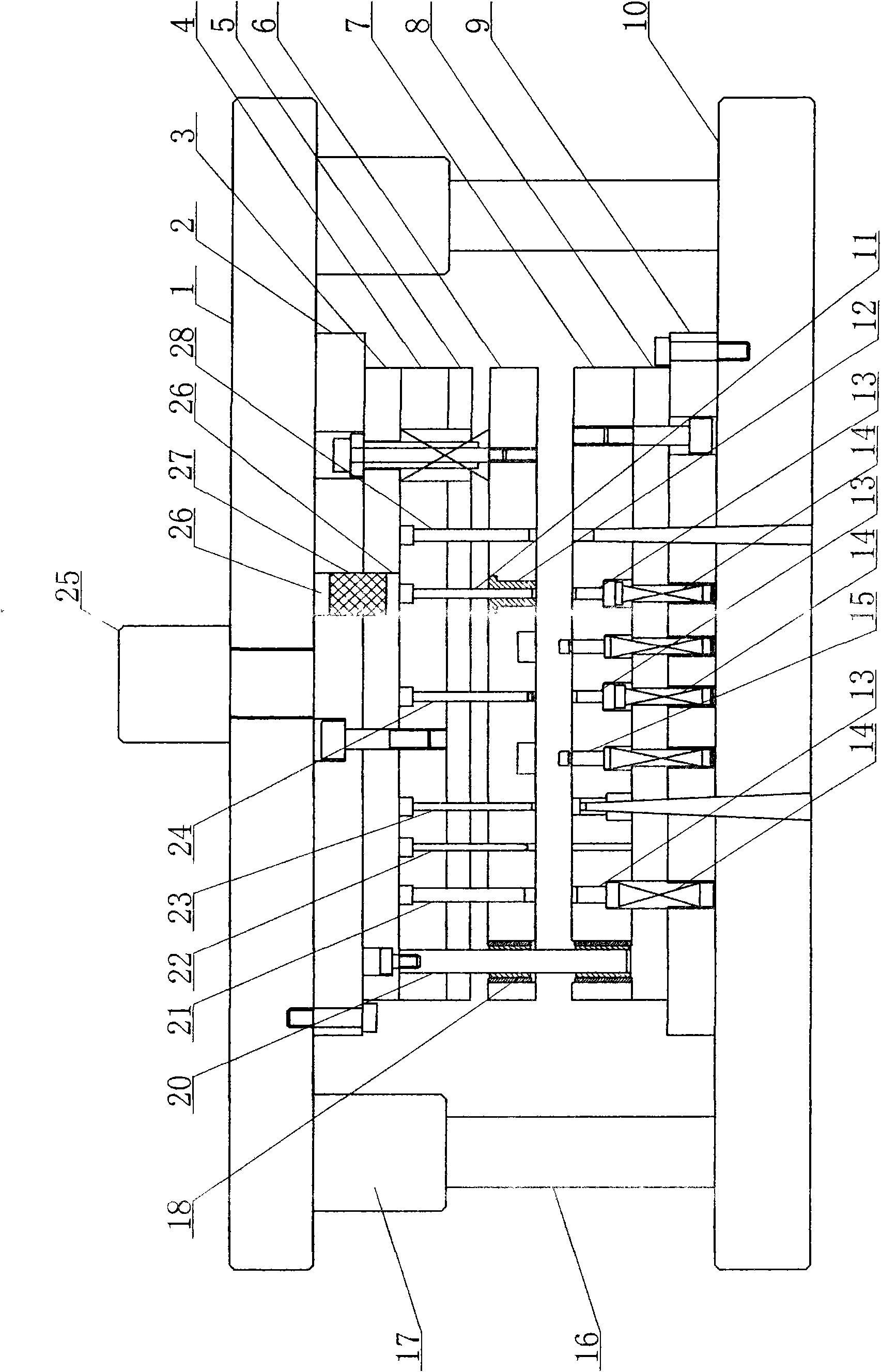

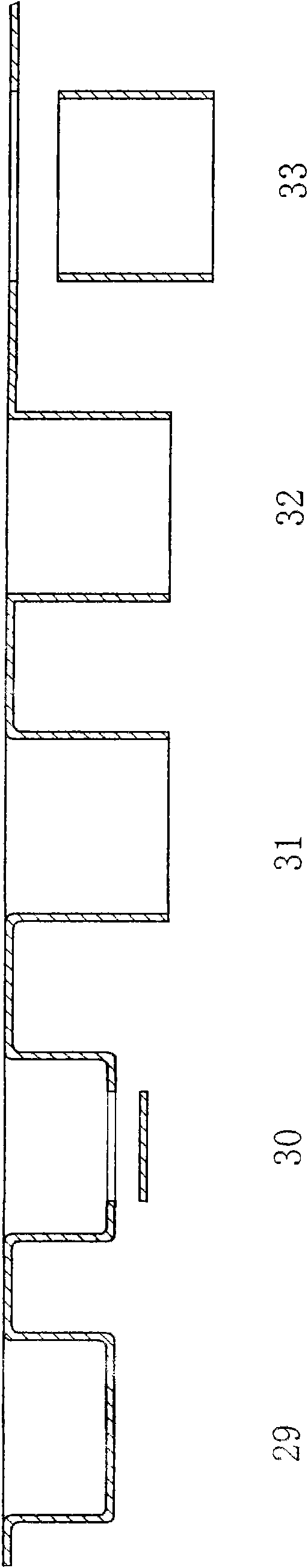

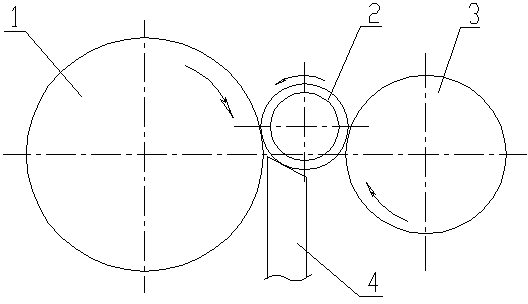

Method for producing thin-wall metal circular ring and grading stamping mould used therefor

ActiveCN101767164AIncrease productivityUniform wall thicknessShaping toolsPunchingElectronic industry

The invention discloses a method for producing a thin-wall metal circular ring, which comprises the steps of deep-drawing, punching, turning up, shaping and blanking plate materials or strip-shaped materials on a grading stamping mould. The grading stamping mould used for implementing the method mainly comprises an upper mould part and a lower mould part, wherein a deep-drawing male mould, a punching male mould, a turning-up male mould, a shaping male mould and a blanking male mould are arranged on the upper mould part sequentially; the male moulds all pass through a discharging plate; an annular convex part is arranged on the part, which surrounds the shaping male part, of the discharging plate; a deep-drawing female mould, a punching female mould, a turning-up female mould, a shaping female mould and a blanking female mould are arranged on the lower mould part sequentially; and spring-ejecting parts are arranged in the cavities of the deep-drawing female mould, the turning-up female mould and the shaping female mould. The method solves the technical problems of low processing precision and low production efficiency of the metal circular ring with two straight end faces. The method has a simple structure and is widely applied to the production manufacturing industry of the metal circular ring in electronic industry.

Owner:WEIFANG YUYUAN ELECTRONICS CO LTD

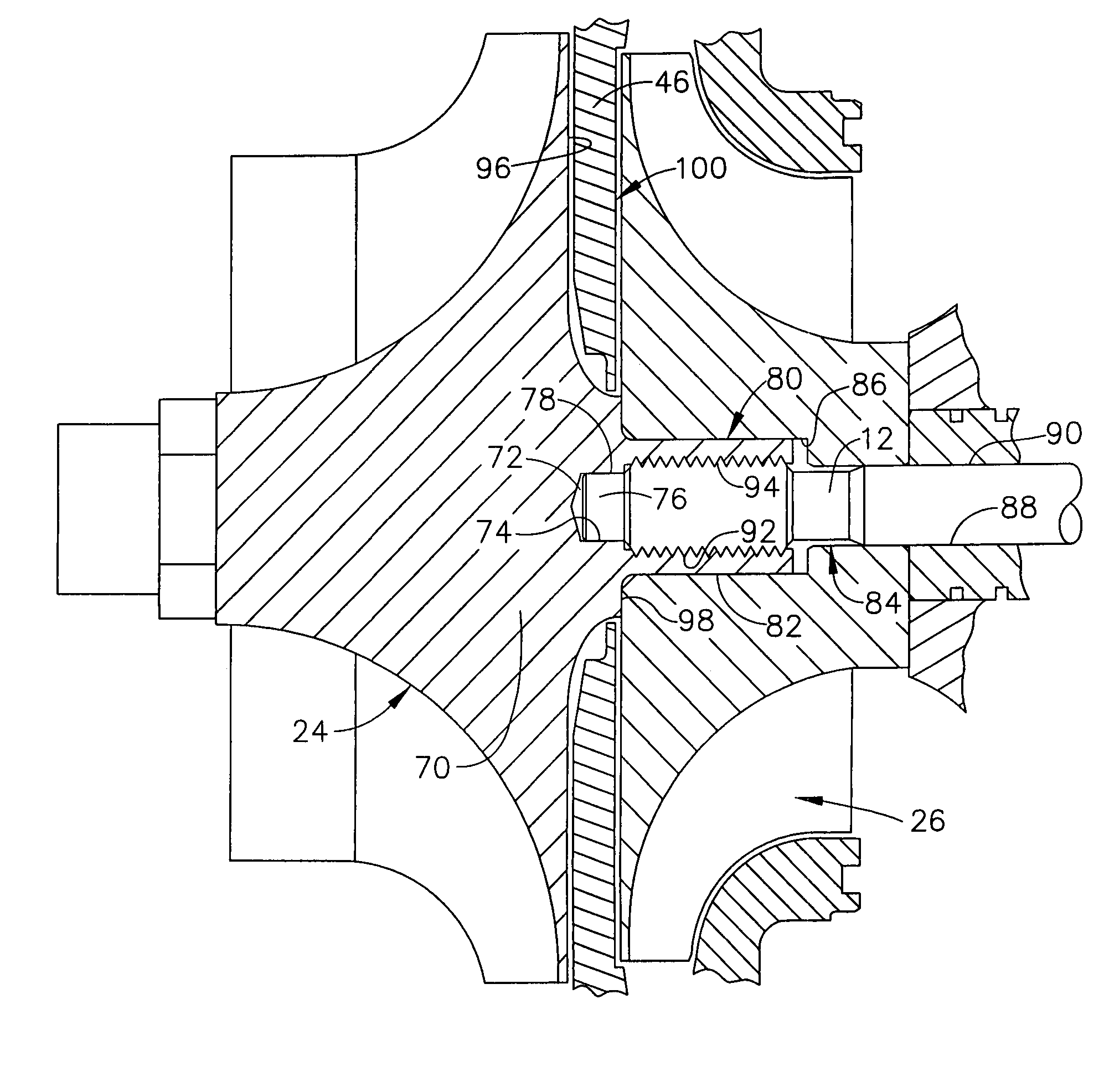

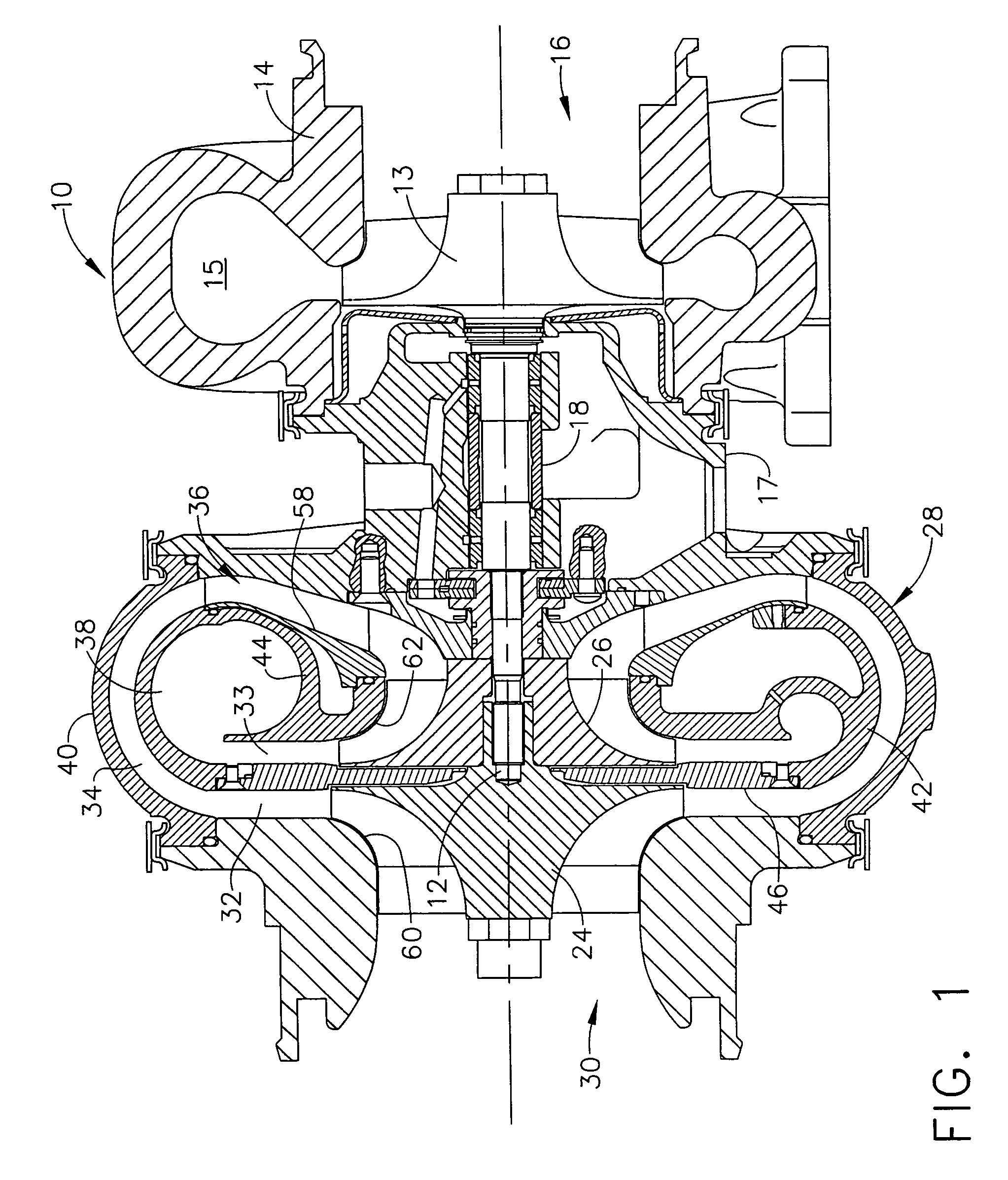

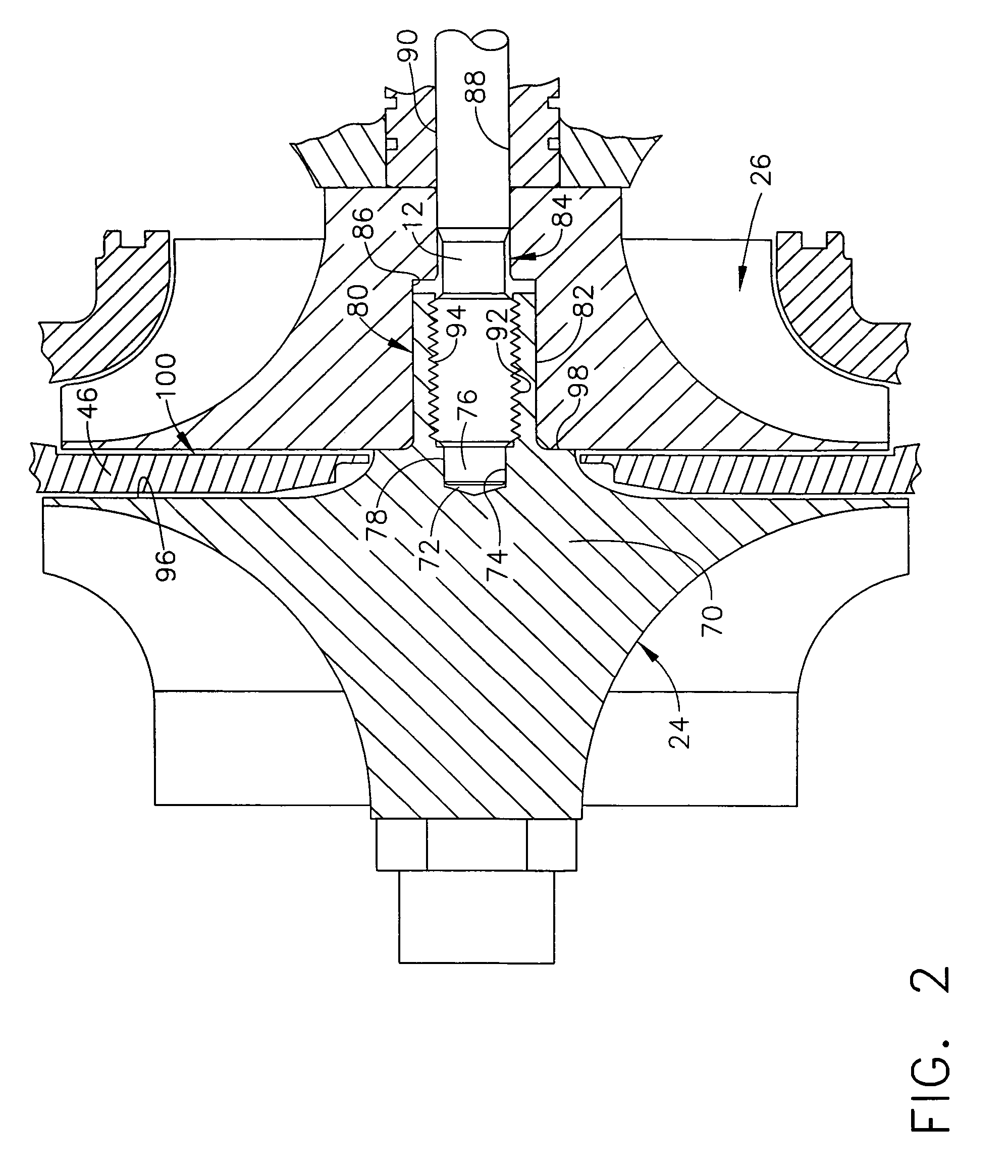

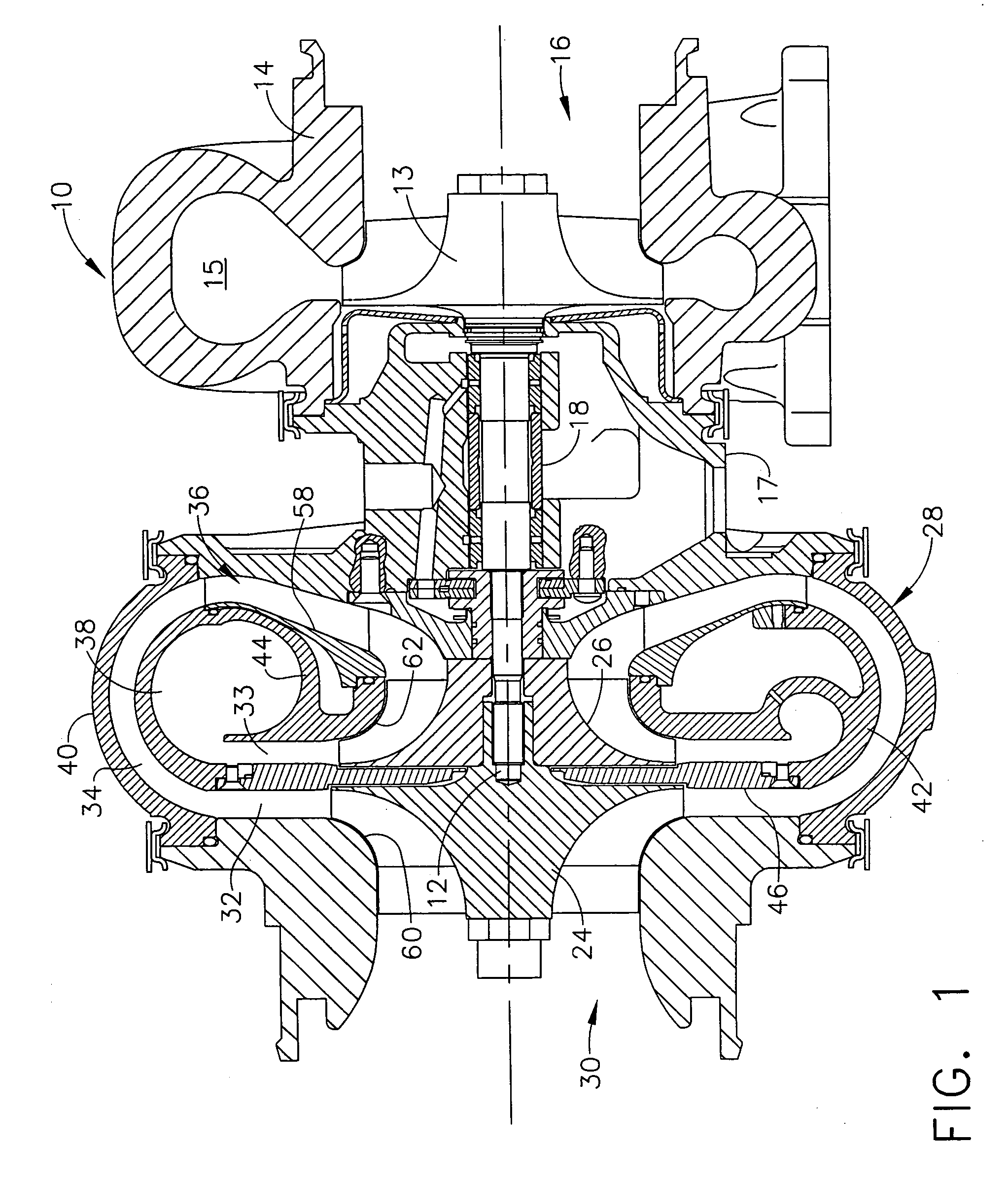

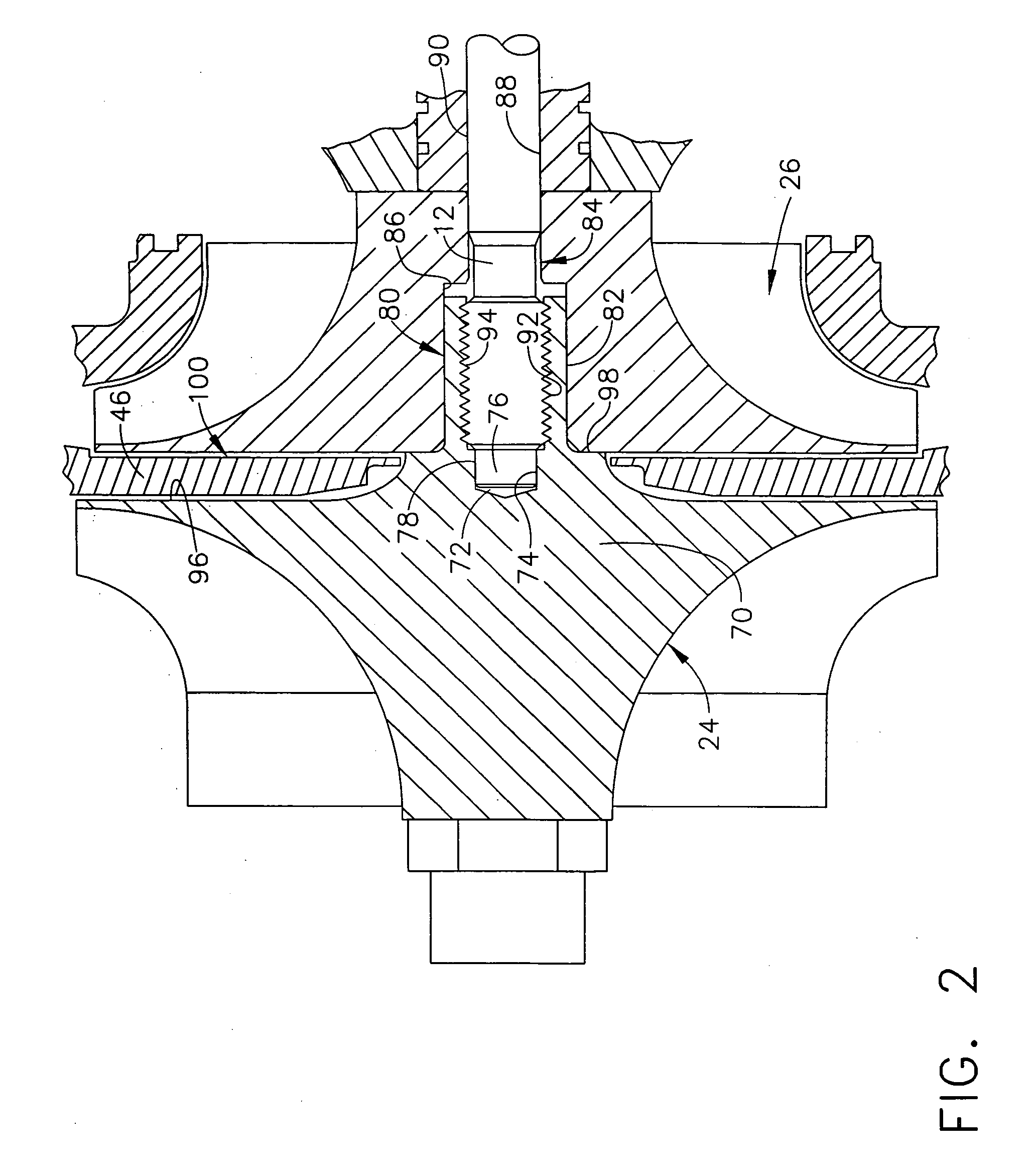

Turbocharger having two-stage compressor with boreless first-stage impeller

ActiveUS7568883B2High concentricityImprove manufacturabilityPump componentsMixer accessoriesImpellerPilot hole

A turbocharger with a two-stage compressor having first- and second-stage impellers mounted on a common shaft in a back-to-back configuration. The first-stage impeller has a boreless configuration, defining an unthreaded pilot hole receiving an unthreaded end of the shaft so as to establish a coaxial relationship between the impeller and the shaft. The first impeller further defines a hollow cylindrical pilot member that projects from the back of the impeller and is received in a portion of the bore through the second-stage impeller to position the impellers coaxially with each other. The shaft passes through the pilot member and is externally threaded for engaging threads on the inner surface of the pilot member to secure the impellers to the shaft. The bore of the second impeller has a second portion that engages an outer cylindrical surface of the shaft to establish a coaxial relationship between the shaft and impeller.

Owner:GARRETT TRANSPORATION I INC

Turbocharger having two-stage compressor with boreless first-stage impeller

ActiveUS20070122296A1High concentricityImprove manufacturabilityPump componentsMixer accessoriesImpellerPilot hole

A turbocharger with a two-stage compressor having first- and second-stage impellers mounted on a common shaft in a back-to-back configuration. The first-stage impeller has a boreless configuration, defining an unthreaded pilot hole receiving an unthreaded end of the shaft so as to establish a coaxial relationship between the impeller and the shaft. The first impeller further defines a hollow cylindrical pilot member that projects from the back of the impeller and is received in a portion of the bore through the second-stage impeller to position the impellers coaxially with each other. The shaft passes through the pilot member and is externally threaded for engaging threads on the inner surface of the pilot member to secure the impellers to the shaft. The bore of the second impeller has a second portion that engages an outer cylindrical surface of the shaft to establish a coaxial relationship between the shaft and impeller.

Owner:GARRETT TRANSPORATION I INC

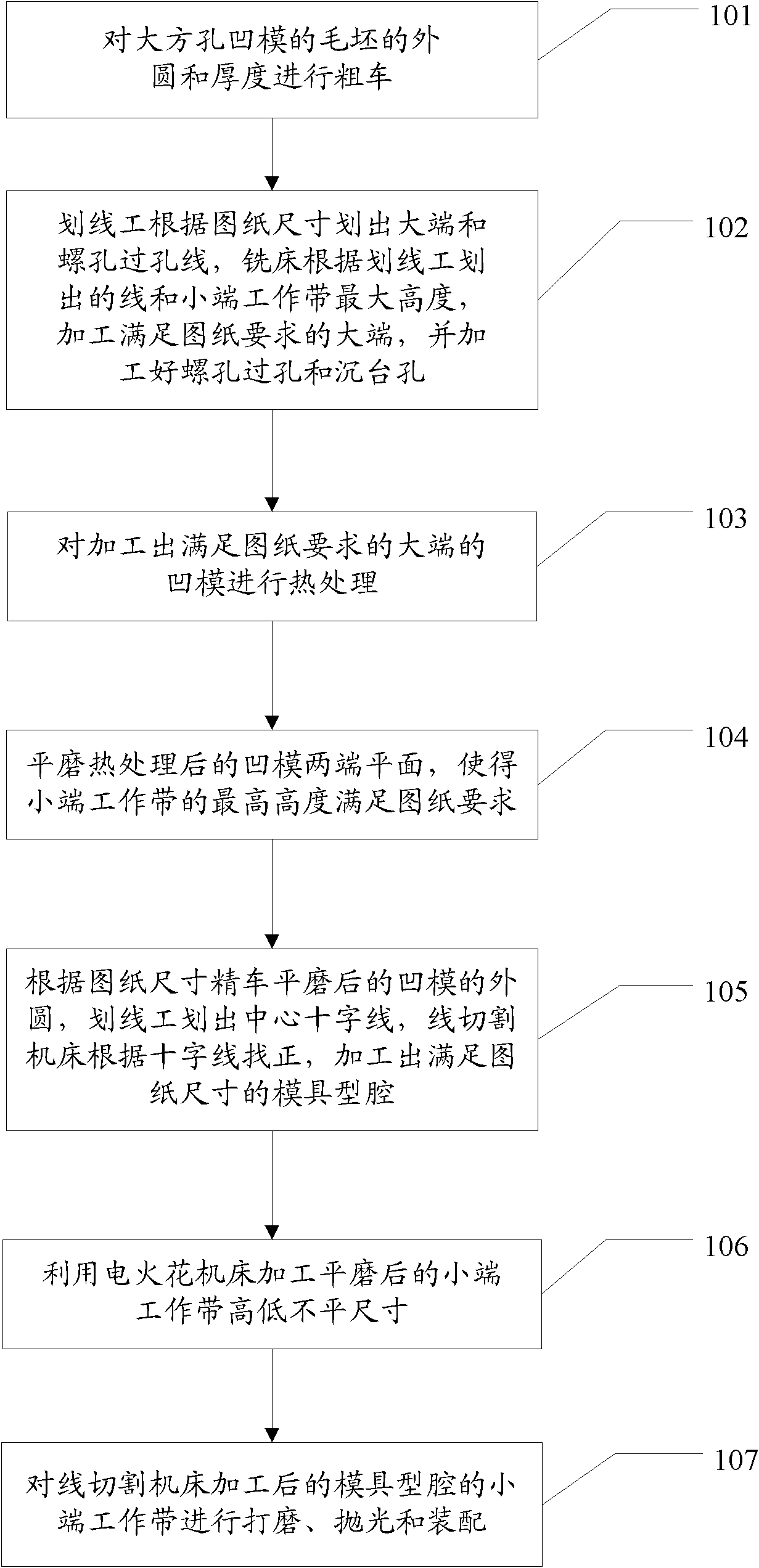

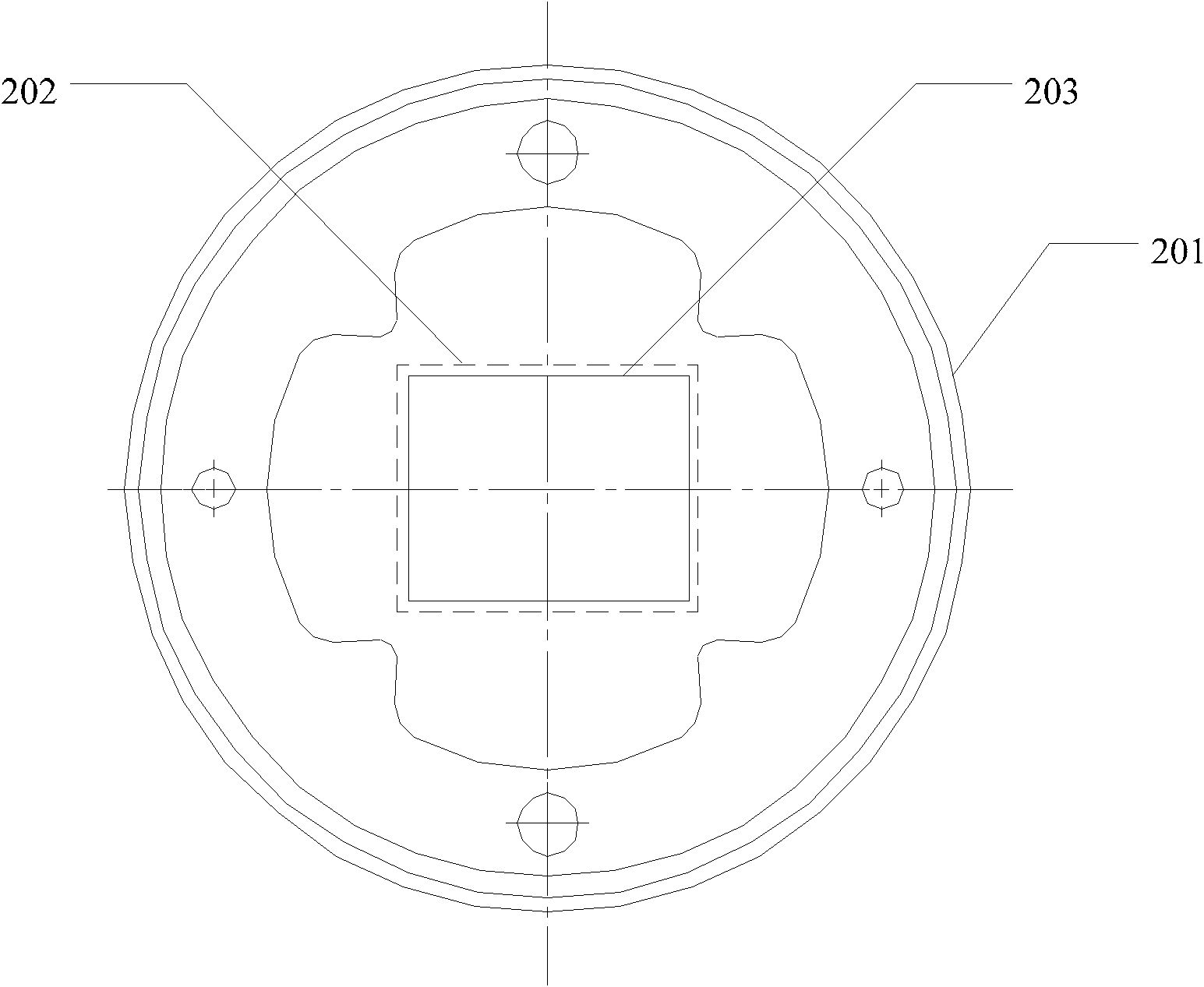

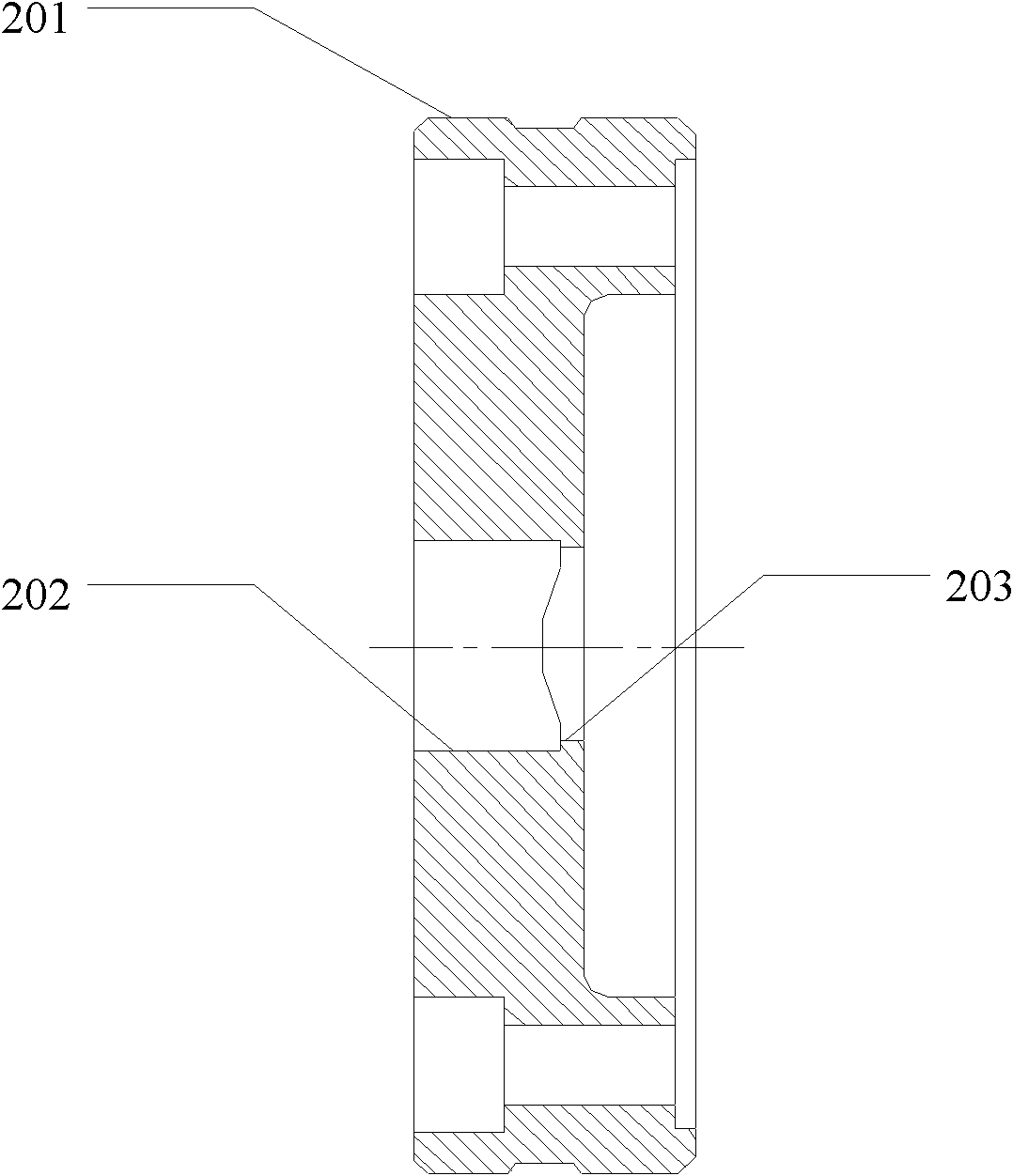

Method for processing female die with large square hole

ActiveCN102303221AHigh concentricityIncrease productivityMilling equipment detailsEngineeringMachine tool

The embodiment of the invention discloses a method for processing a female die with a large square hole. The method comprises the following steps of: roughly turning the excircle and thickness of a blank of the female die with the large square hole; processing the blank by using a milling machine, and thus obtaining a large end which meets requirements of a drawing; semi-finishing a small end by using a numerically controlled milling machine, and thus obtaining a small-end working tape which meets the requirements of the drawing; processing a screw through hole and a sunk table hole, and reserving an allowance for the size of a cavity of the small-end working tape; performing heat treatment on the female die, and flatly grinding planes at two ends of the female die to make the largest height of the small-end working tape meet the requirements of the drawing; performing finish turning on the excircle of the female die which is flatly ground; performing finish machining, and thus obtaining a mold cavity which meets the size of the drawing; processing an uneven part of the small-end working tape which is flatly ground by using an electric spark machine tool; and grinding, polishing and assembling the small-end working tape of the mold cavity which is subjected to finish machining by the numerically controlled milling machine. By adoption of the method provided by the embodiment of the invention, production efficiency can be improved, and production cost is reduced.

Owner:SOUTHWEST ALUMINUM GRP

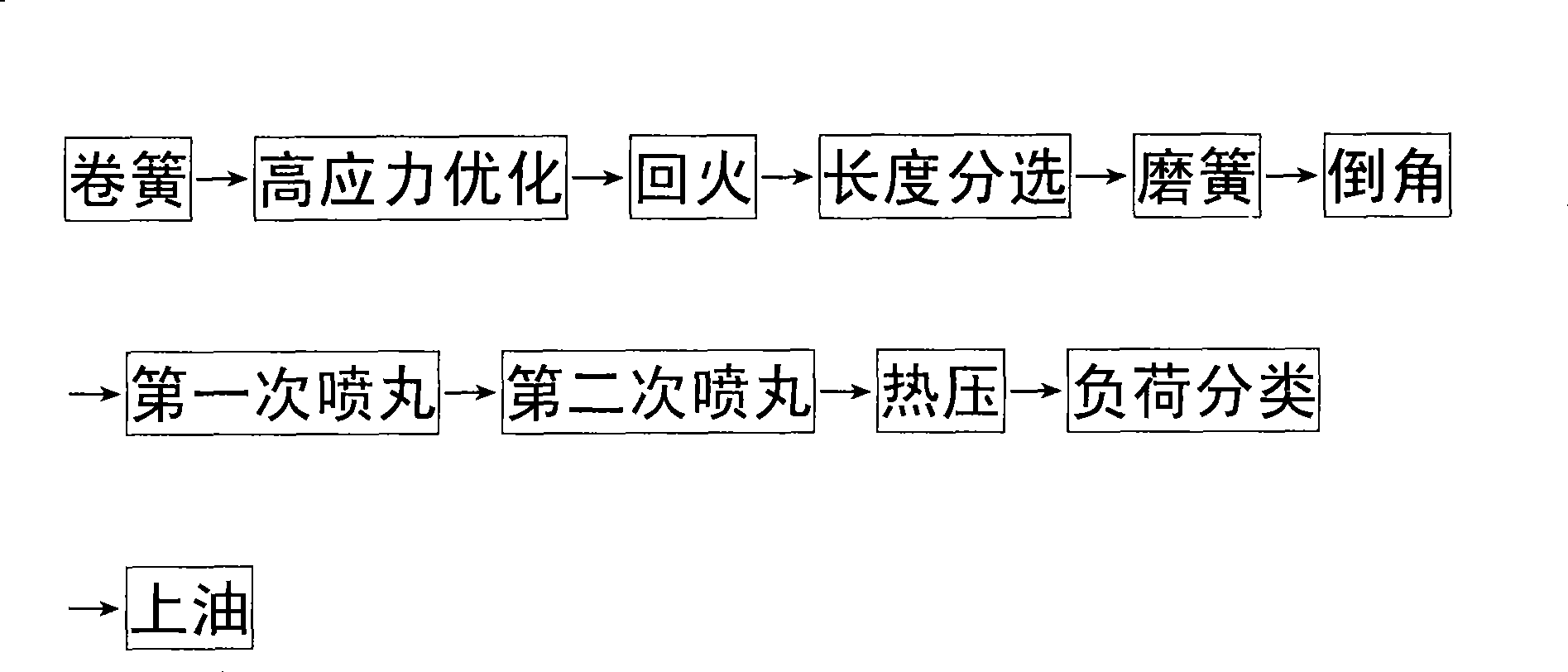

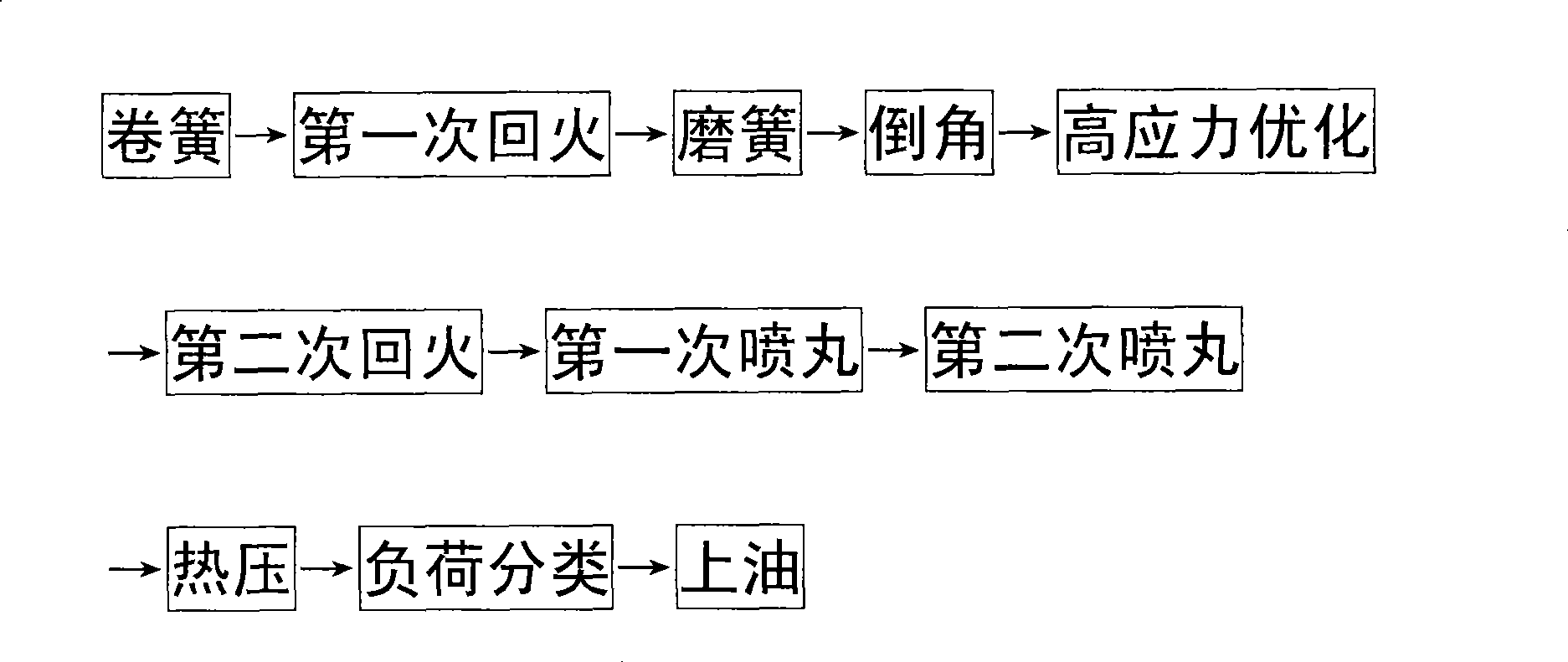

Process for manufacturing heavily stressed valve spring

The invention provides a manufacturing process used for a high-stress valve spring, which can improve the quality and product qualification ratio of the spring product, reduce the production cost of the spring and comprises the processes as follows: spring rolling: steel wire blanks are rolled and made into semi-finished springs; primary temper: the spring is tempered at low temperature so that the stress is removed; spring grinding: two end surfaces of the spring are grinded so as to achieve the required length; chamfering: the burrs of the grinded spring are removed; stress optimization: secondary temper: the spring is tempered again at low temperature so that the stress is removed; shot blasting which is used for prolonging the service life of the spring; hot-pressing; load classification: the spring with bad load is removed and the product with qualified load is used as the high-stress valve spring product; oiling: the high-stress valve spring is oiled; and is prepared for packaging. The process improves the quality and the qualification ratio of the spring product and reduces the production cost of the spring as the working procedure of length classification is saved and the stress optimization process is arranged after the process of spring grinding and chamfering in the traditional process.

Owner:SHANGHAI SPRING CORP

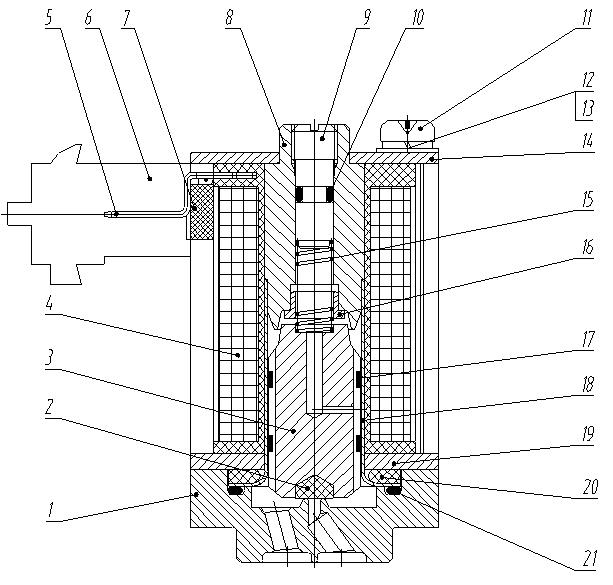

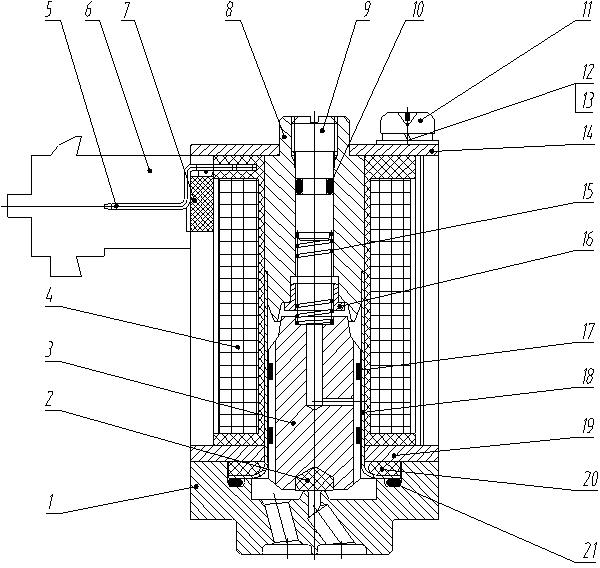

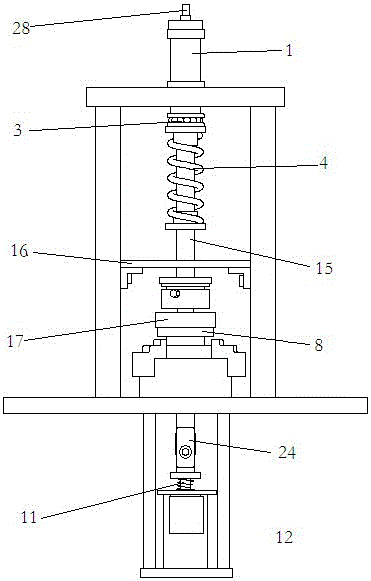

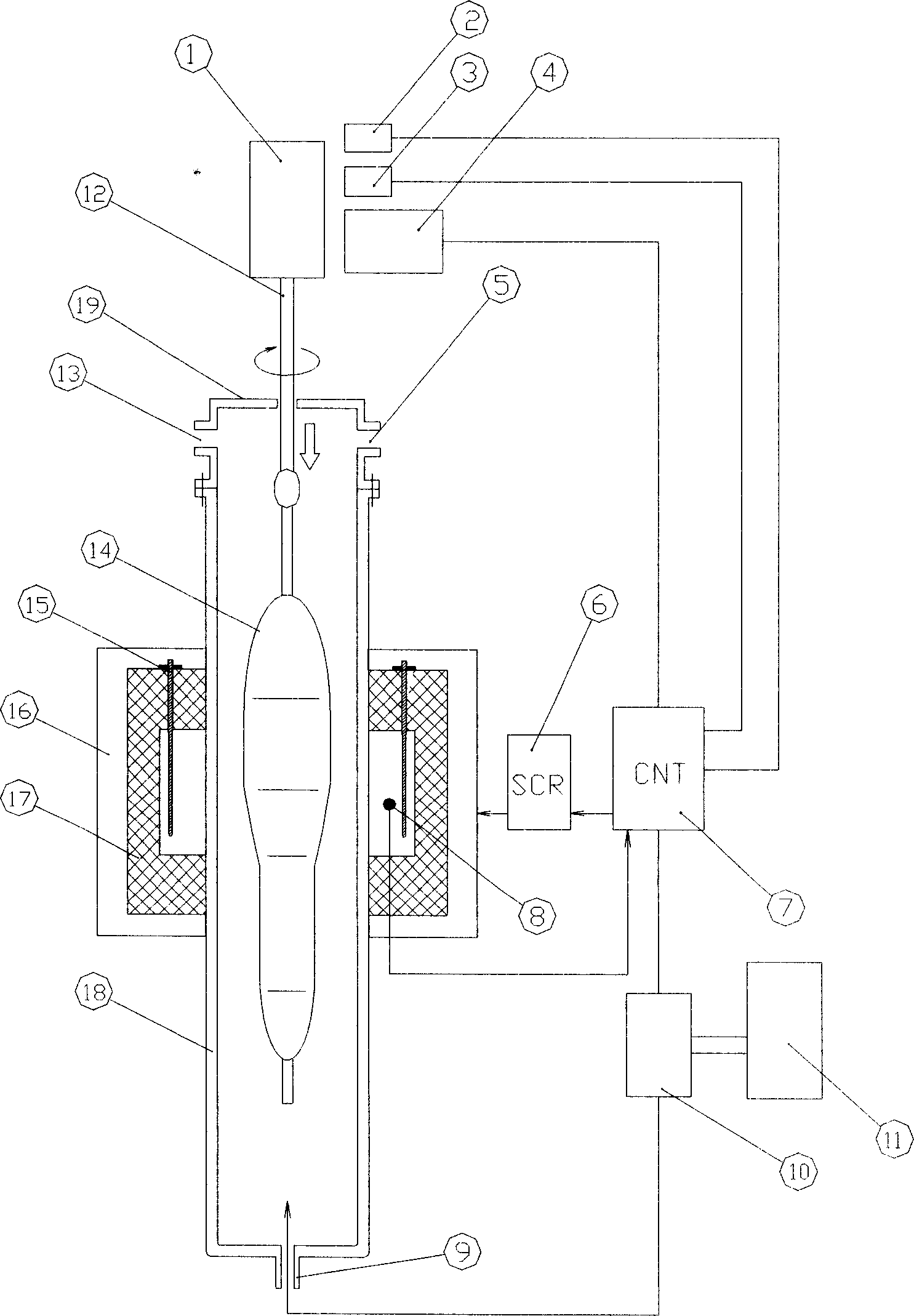

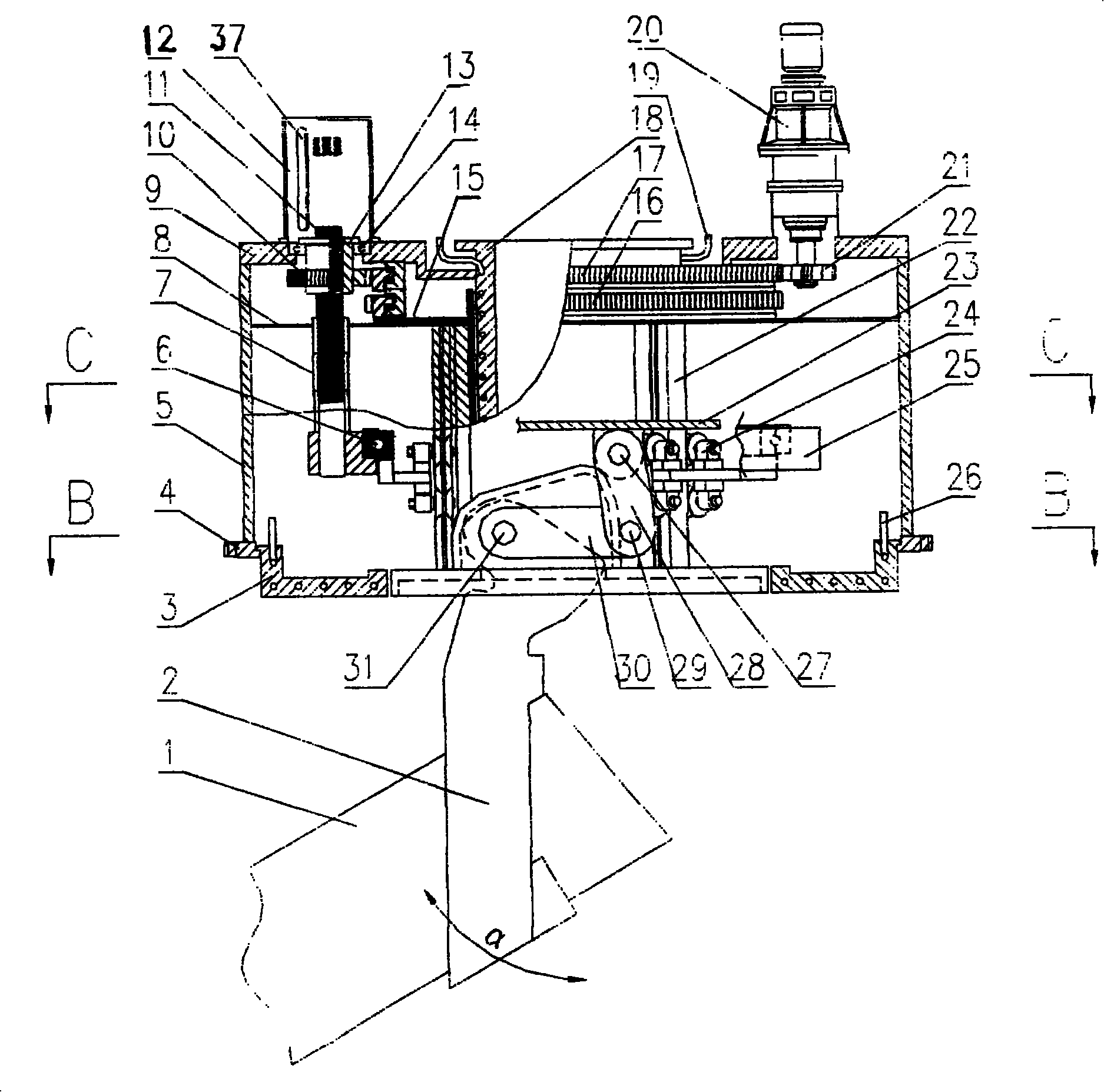

Proportional electromagnetic valve for electrically controlled high-pressure common-rail fuel injection system of diesel engine

InactiveCN102506217AMeet the use requirementsControl on and offOperating means/releasing devices for valvesFuel injection apparatusDriving currentCommon rail

The invention discloses a proportional electromagnetic valve for an electrically controlled high-pressure common-rail fuel injection system of a diesel engine and relates to an electromagnetic valve. A position at which a fixed iron core (8) and a movable iron core (3) of the electromagnetic valve attract each other is a conical polar plane. The fixed iron core (8), the movable iron core (3), a guide pipe (18), a spiral spring (15), an electromagnetic coil (4), a square iron core (19), a shell (14) and a valve body (1) jointly form the electromagnetic valve in an assembling way. When driving current is input into the electromagnetic coil, a magnetic field is generated through a magnetic path in the valve, electromagnetic force with magnitude which is in proportion with the magnitude of the driving current and is not related to a stroke is generated relative to the movable iron core, the movable iron core is enabled to overcome spring force to move, the movable iron core stops moving at a balance point of the two kinds of force and therefore is kept at a stable position, and the movable iron core can proportionally and continuously move according to the magnitude of the driving current to control the opening of the valve. Under complex working conditions under which the diesel engine works, the electromagnetic valve not only can stably control the on / off of a fuel path, but also can accurately and proportionally control the flow of the fuel path according to the driving current.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY +1

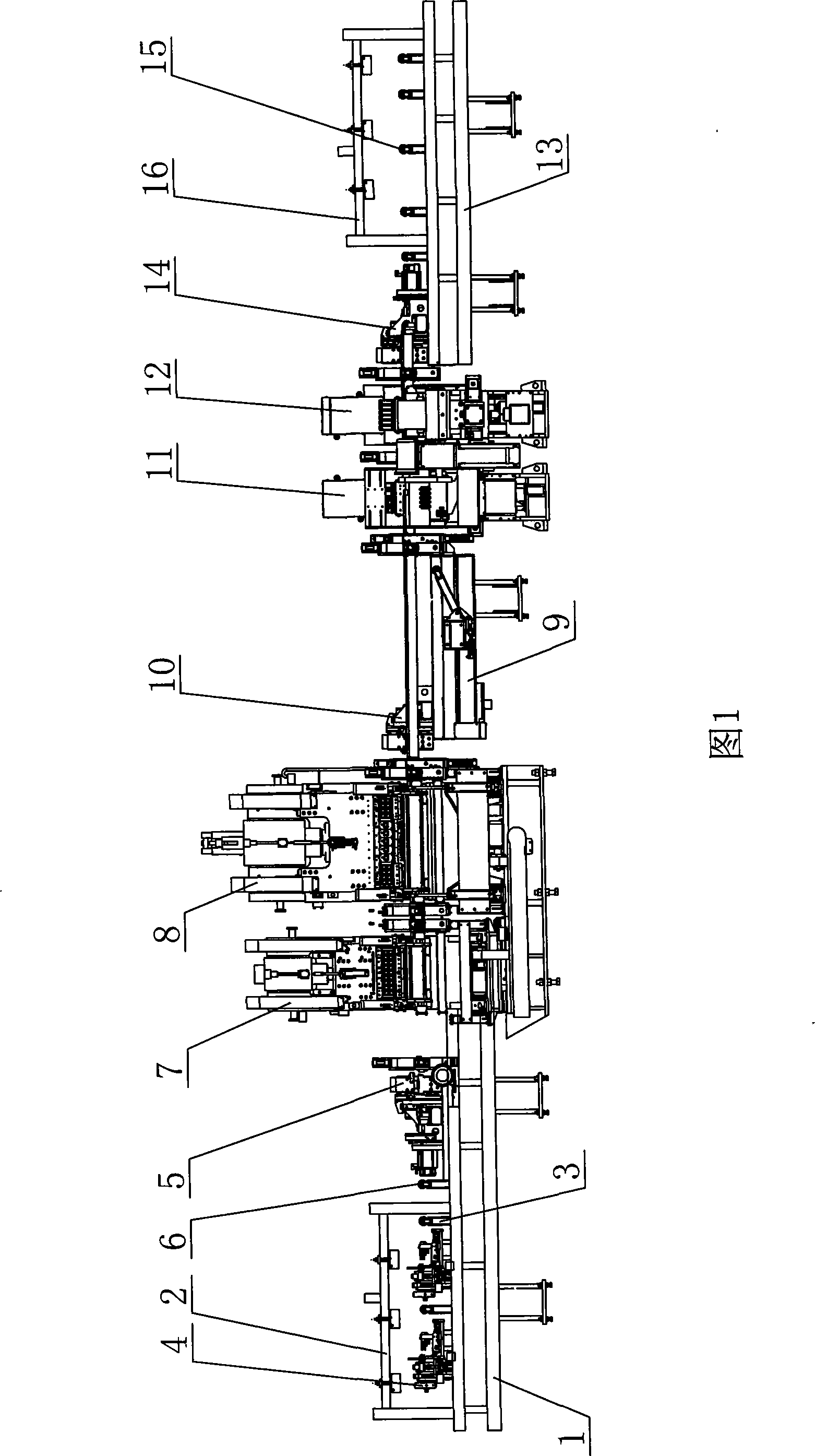

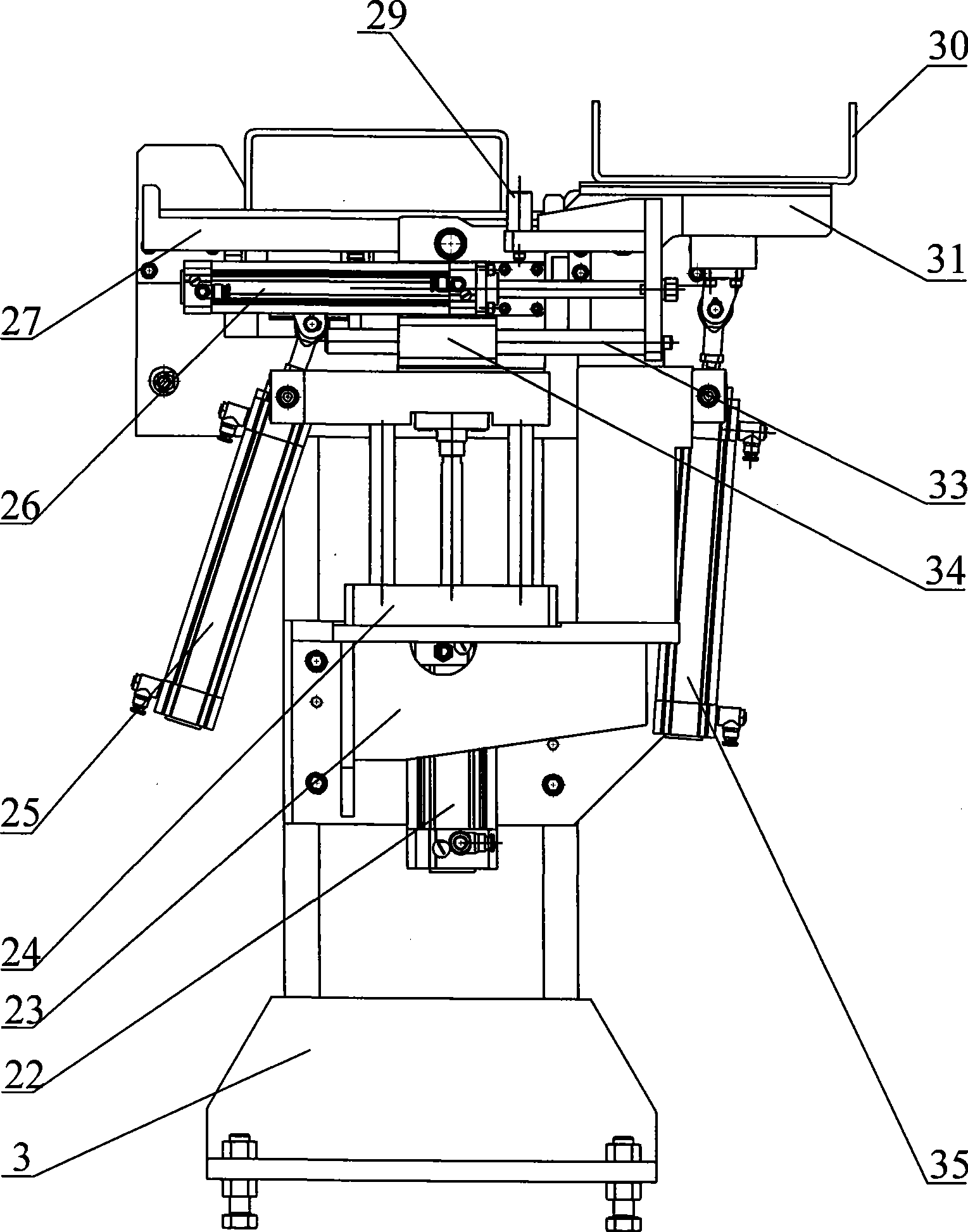

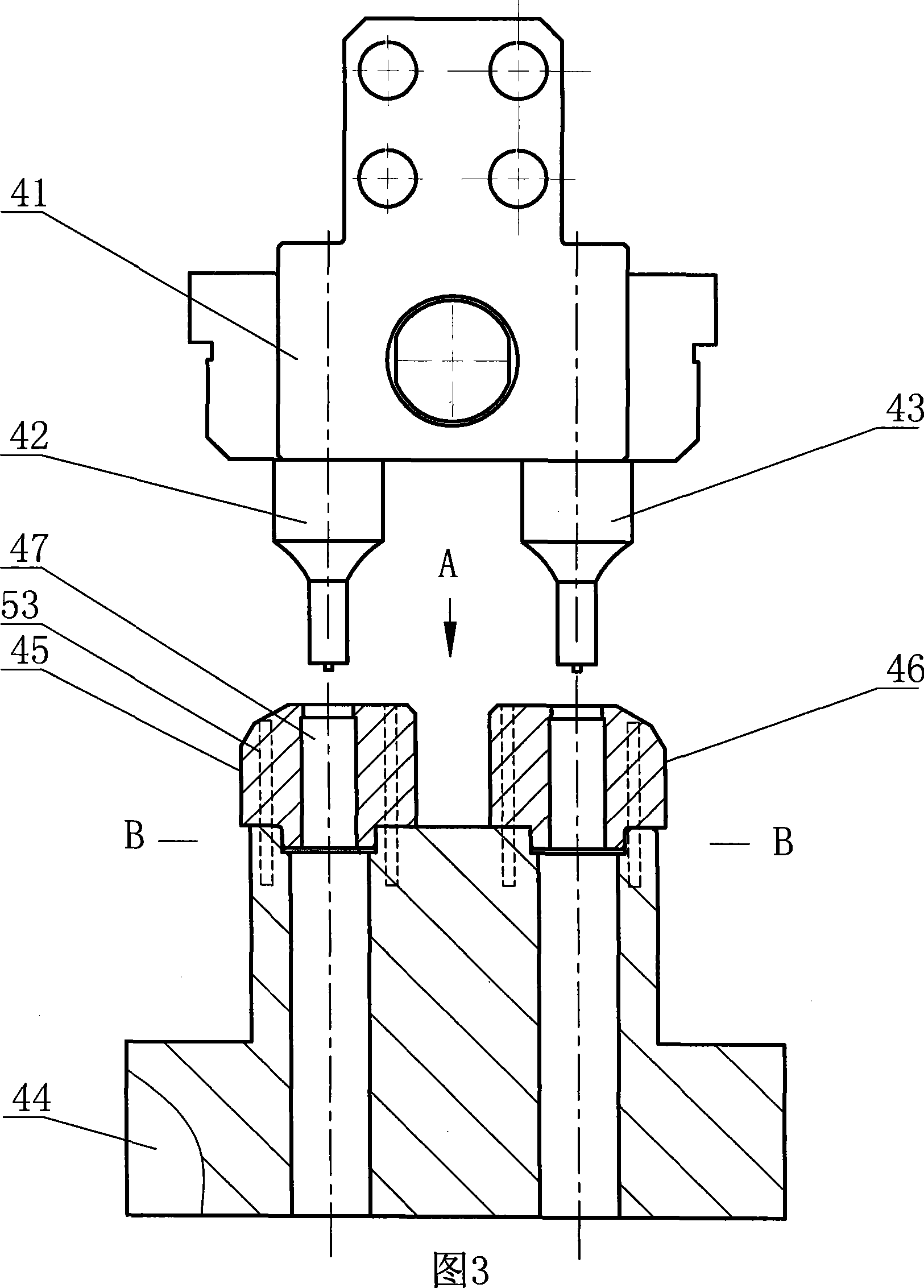

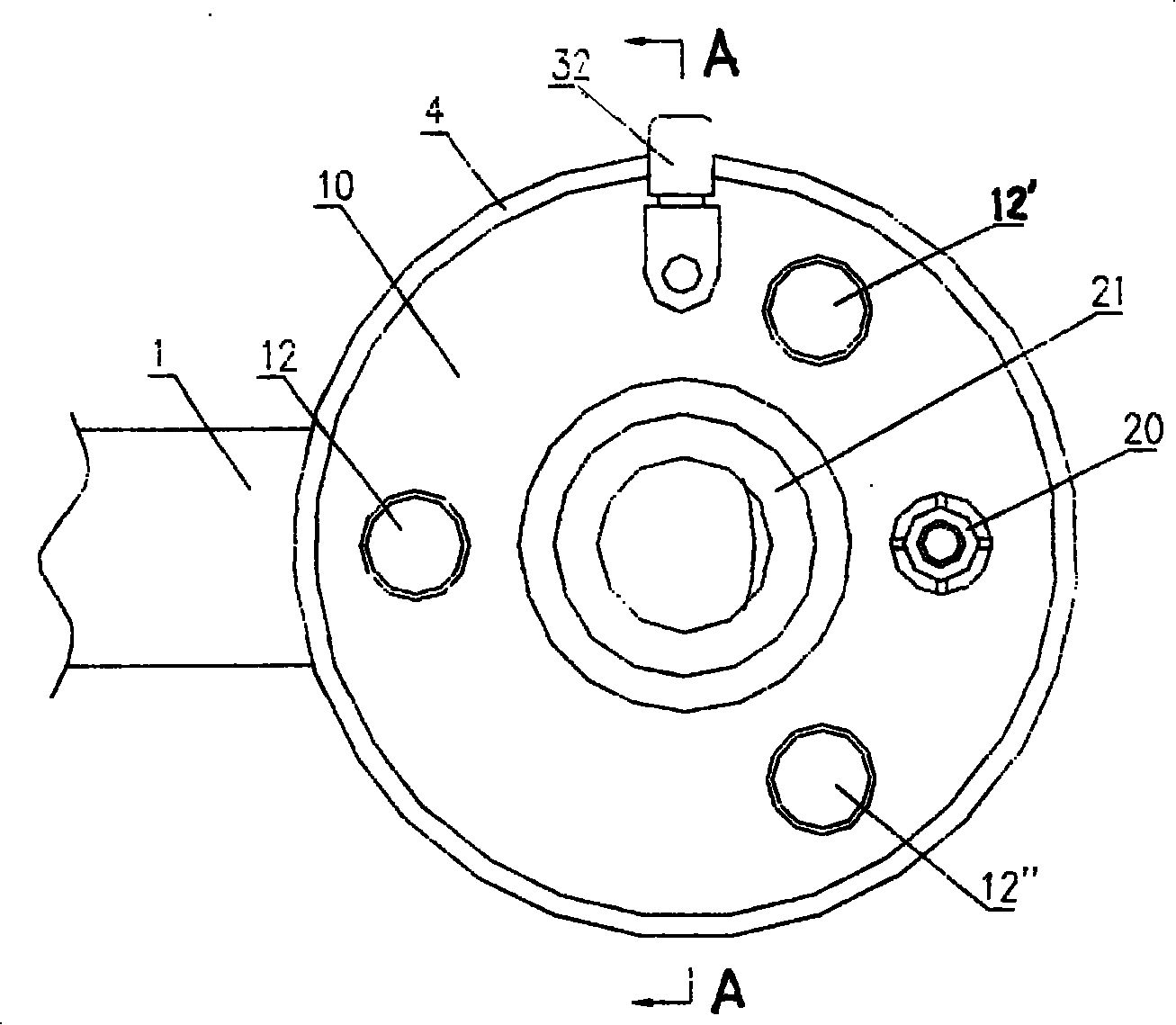

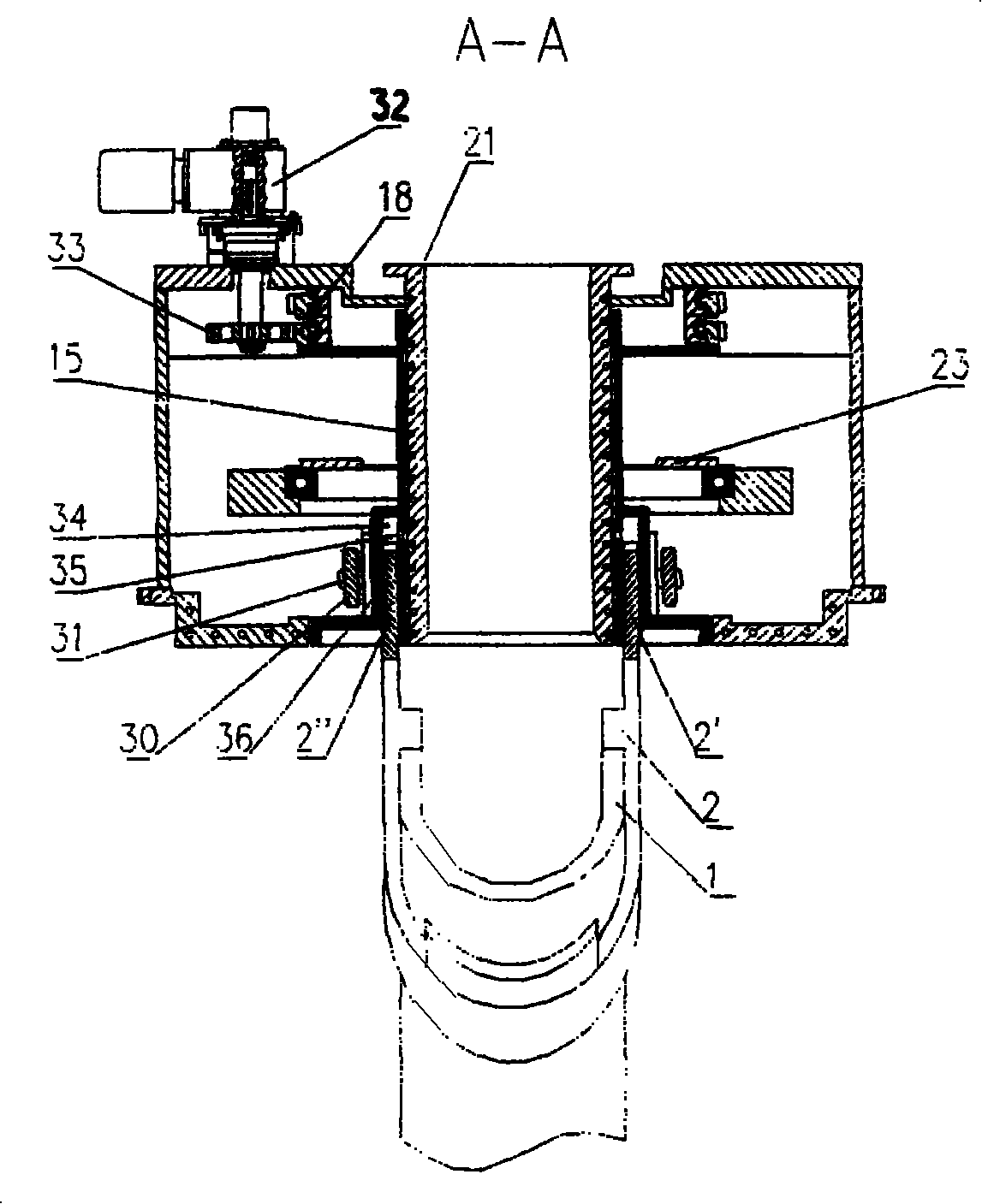

U shaped beam three-face punching technique and production device using the technique

InactiveCN101386046AThe punching position is accurateReduce manufacturing costShaping toolsPerforating toolsShaped beamPunching

The invention discloses a three-side-punch process of a U-shaped beam and a production device used in the process. The process comprises the following steps: the U-shaped beams are placed on a feeding platform, a feed picking device is adopted to successively pick up the spare U-shaped beams and hoist the beams to a support roller of the feeding end; a first feeding clamping device is adopted to clamp the U-shaped webs and feed the webs to working platforms of a ventral small punching machine which can move along the X / Y axis and a ventral large punching machine which can move along the Y axis; the ventral small punching machine which can move along the X / Y axis and the ventral large punching machine which can move along the Y axis punch the beams; a second feeding clamping device clamps the U-shaped beams and continuously feed the beams to the working platform of a left wing punching machine and a right wing punching machine; the left wing punching machine and the right wing punching machine punch the beams; the U-shaped beams are hoisted to a discharging platform after being fully punched. The invention has the advantages of simple process, high production efficiency, low cost and reasonable process arrangement; and the produced U-shaped beams have precise punching location.

Owner:JINAN CASTING FORGING MACHINERY INST

Electroplating preparation method for copper cladded aluminum wire or copper cladded magnesium alloy wire

InactiveCN101187046AAvoid it happening againImprove bindingSingle bars/rods/wires/strips conductorsSuperimposed coating processCopper platingZinc

The invention discloses a process for preparing copper cladding aluminum or copper cladding wire of aluminum magnesium alloy, which utilizes a continuous striking-wire copper plating pipeline of being in series connection with a plurality of lengthening electric plating aluminum-magnesium parts plating groove, sets out line uninterruptedly between adjacent plating grooves, and arranges a transiting water ditch between front groove and rear groove which can avoid wire to contact with air to generate oxide coating when changing the grooves. A problem of burning wire can be resolved by adjusting main plating current to about 300 A before having to shutdown in short time. Simultaneously, the invention employs technique of thickening dip galvanized coating and wiping off zinc cover of the zinc dipping by pickling to overcome the main difficulty of utilizing electric plating method to produce copper cladding aluminum wire or copper cladding wire of aluminum magnesium alloy. Compared with coating method, the invention has the advantages of great binding force between metals, high concentricity of copper layer and core wire, low production cost on producing high tensile strength and high stretch rate production, low reject rate, low product specific gravity and the like, and is a good method for producing copper cladding aluminum wire and copper cladding wire of aluminum magnesium alloy by the electroplating method.

Owner:仲庆

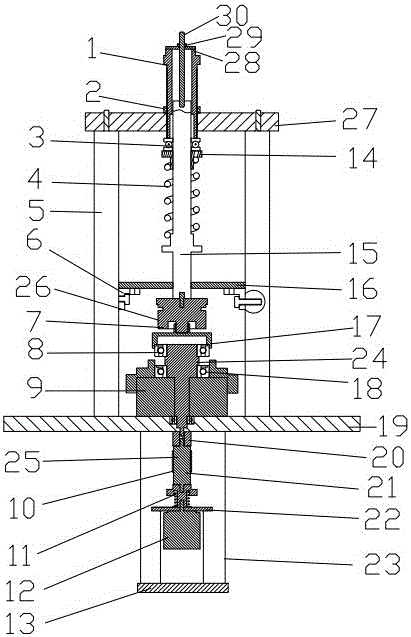

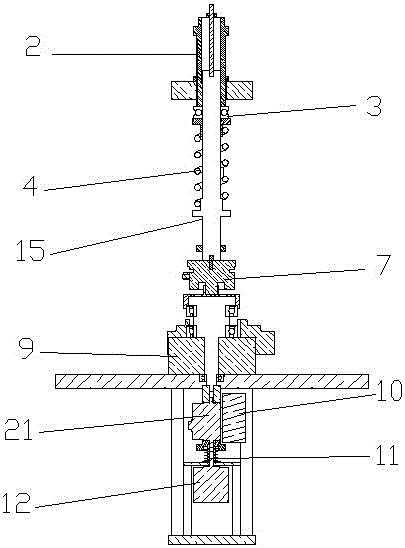

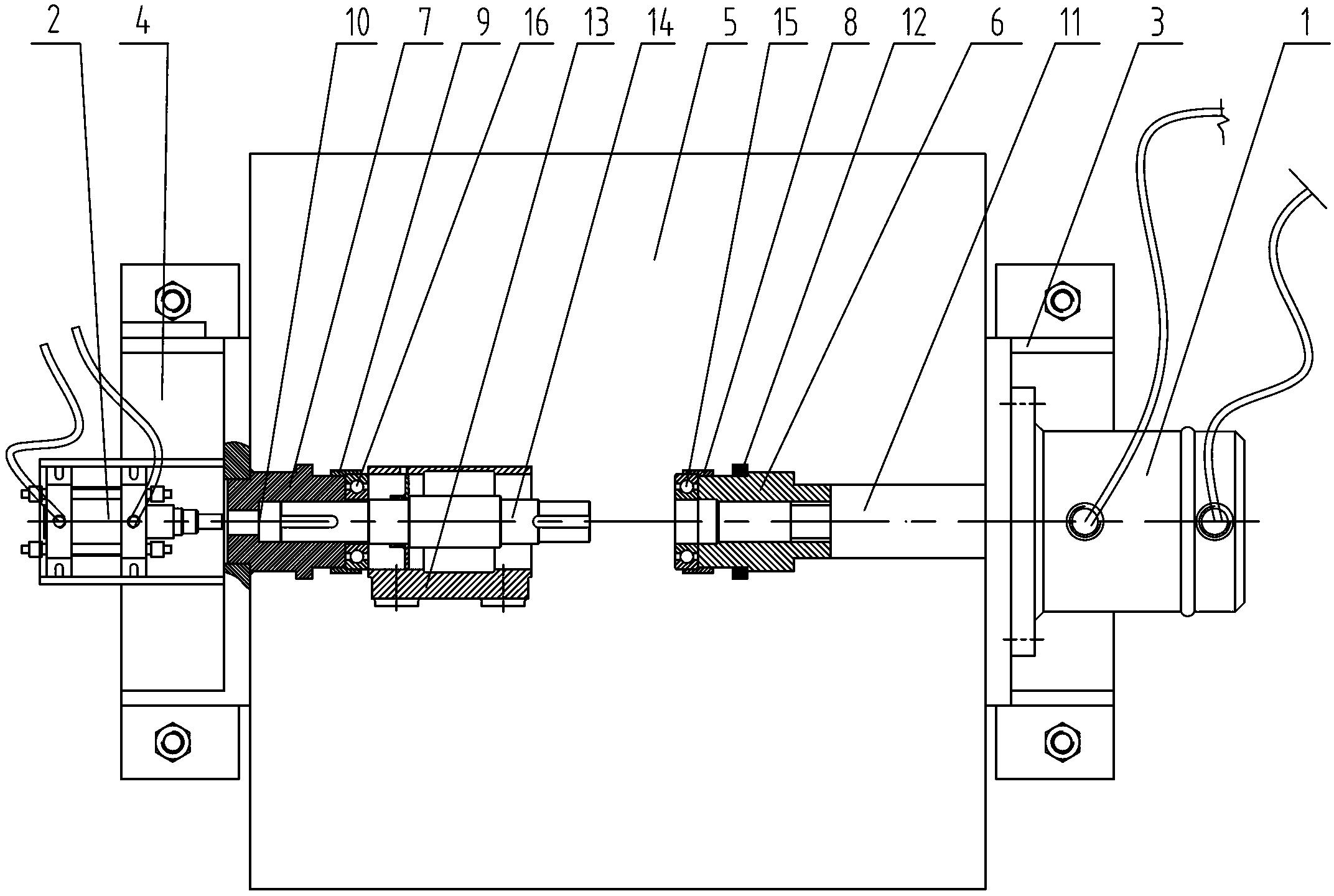

Bearing rotation torque test device

Provided is a bearing rotation torque test device. The center shaft of an axial loading member is connected with a thrust bearing and a spring spacer. A micro-load rod matches a pressure sensor connected with an axial loading sleeve. A measuring member is formed through clearance fit between the inner holes of two identical upper and lower detection bearings and a test shaft. The lower end of the test shaft is connected with an elastic coupler. The outer diameter of the upper detection bearing matches the axial loading sleeve mounted on the pressure sensor, and the outer diameter of the lower detection bearing matches a three-claw chuck mounted on a test bench. The shaft of a stepper motor is additionally equipped with a torque overload device, so damage to a torque sensor by detection overload is avoided. The thrust bearing, the spring spacer and the elastic coupler are provided with an aligning function, so the concentricity of the device is guaranteed. After loading, the three-claw chuck is released. The bearings are undirected, and are completely unaffected by tilting load and other pressures. The test values are more accurate. The trouble of detection tool replacement for test of bearings of different specifications is reduced. The problem that inaccurate values, poor repeatability and poor practicability are caused by loading deformation of the detection bearings is solved completely.

Owner:CIXING GROUP

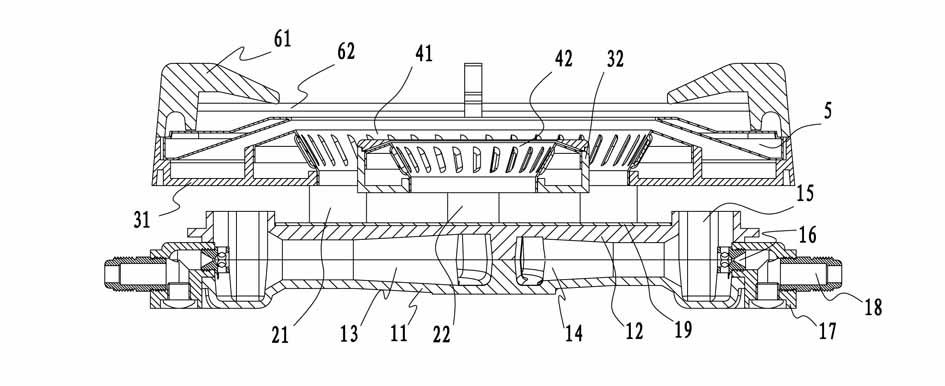

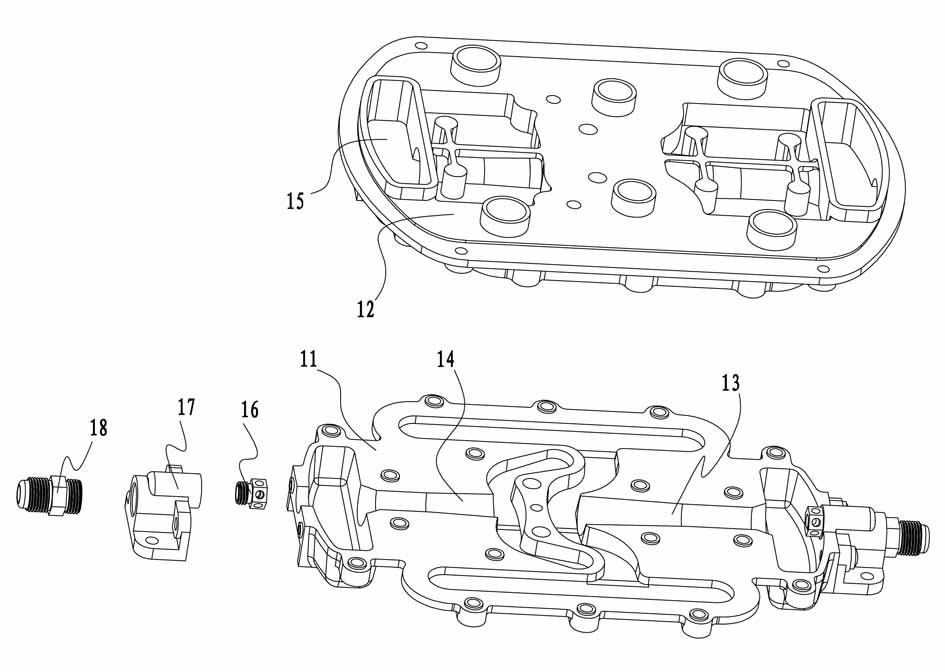

Top-intake burner of gas cooker

InactiveCN102661606AImprove combustion performanceImprove combustion thermal efficiencyDomestic stoves or rangesStoves/ranges topsFuel gasGas stoves

The invention relates to a top-intake burner of a gas cooker. The top-intake burner comprises a burner support, a fire distribution seat and fire caps. The top-intake burner is characterized in that the burner support is combined by an lower support and an upper cover, at least two Venturi ejector pipes are formed, the openings of the Venturi ejector pipes are correspondingly communicated with primary air inlets with an upward opening, a single gas nozzle is mounted in the primary air correspondingly and is disposed right against the center of one of the the Venturi ejector pipes, the other end of the gas nozzle is communicated with a gas inlet pipe, one Venturi ejector pipe is communicated with a fire distribution chamber of the fire distribution seat through one gas guide pipe or multiple gas guide pipes, and an air passage is reserved between the upper cover of the burner support and the fire distribution seat. The top-intake burner is reasonable in structural design, efficient and energy saving, is capable of realizing precision supply of primary and secondary air and complete and stable burning of the gas, and is especially suitable for embedded household gas stoves.

Owner:HUNAN XUNDA JI TUAN YOU XIAN GONG SI +1

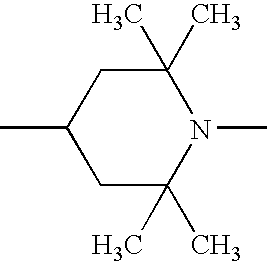

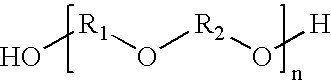

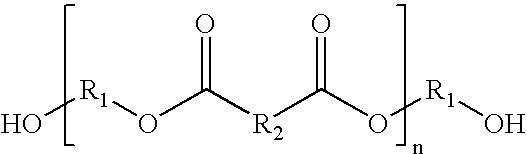

Urethane elastomers with improved color stability

InactiveUS20040018895A1Improved color stabilityQuality improvementSpecial tyresGolf ballsElastomerPolyol

A golf ball including a center, a cover, and, optionally, at least one intermediate layer disposed between the center and the cover, wherein the cover is formed from a polyurethane composition, or a reaction product thereof, including at least one polyol; at least one polyisocyanate; at least one curing agent; and at least one color stabilizer; wherein the color stabilizer is present in an amount sufficient to provide a DeltaC* of less than about 22 upon exposure to UV light over a timeframe of 1 hour.

Owner:ACUSHNET CO

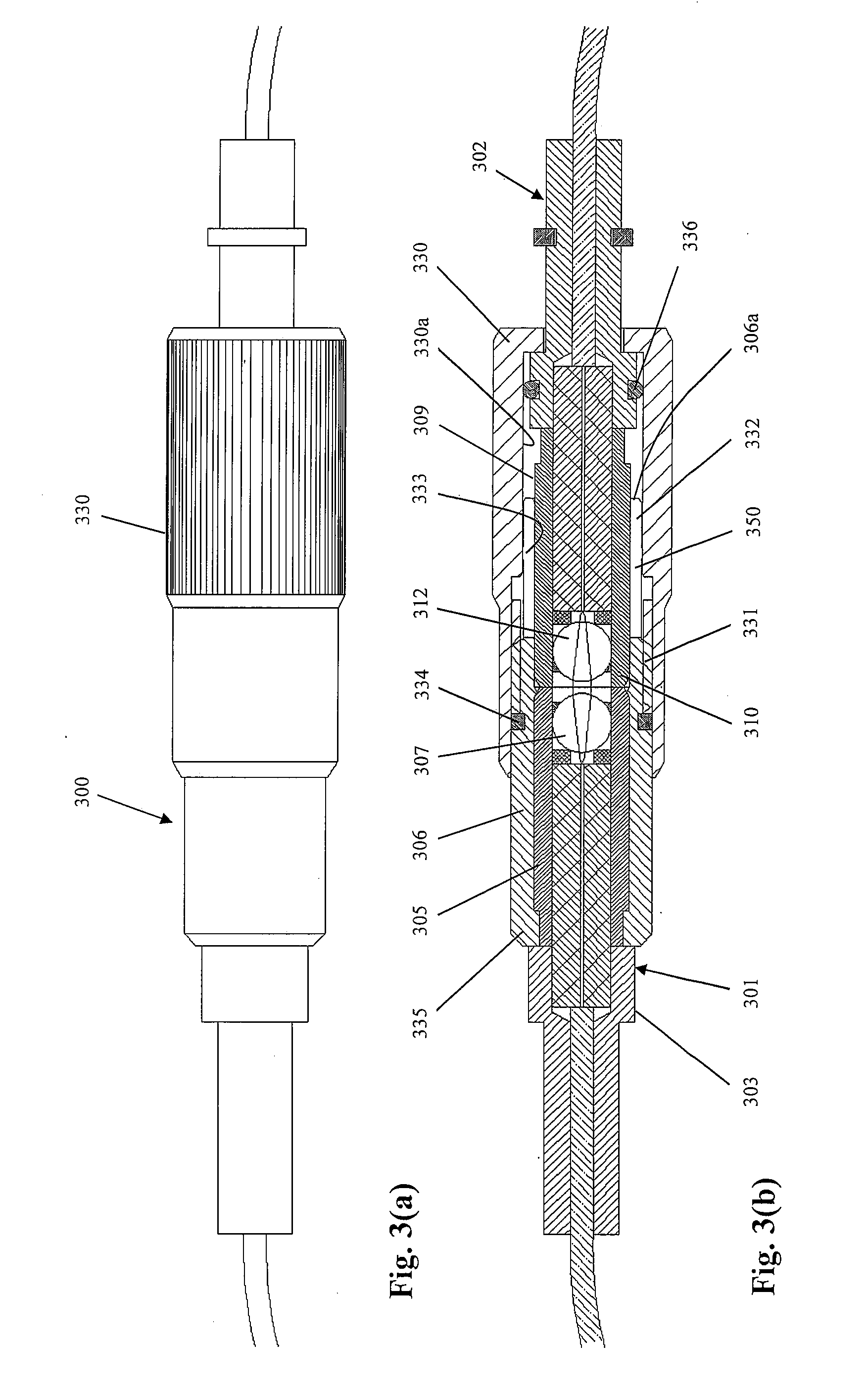

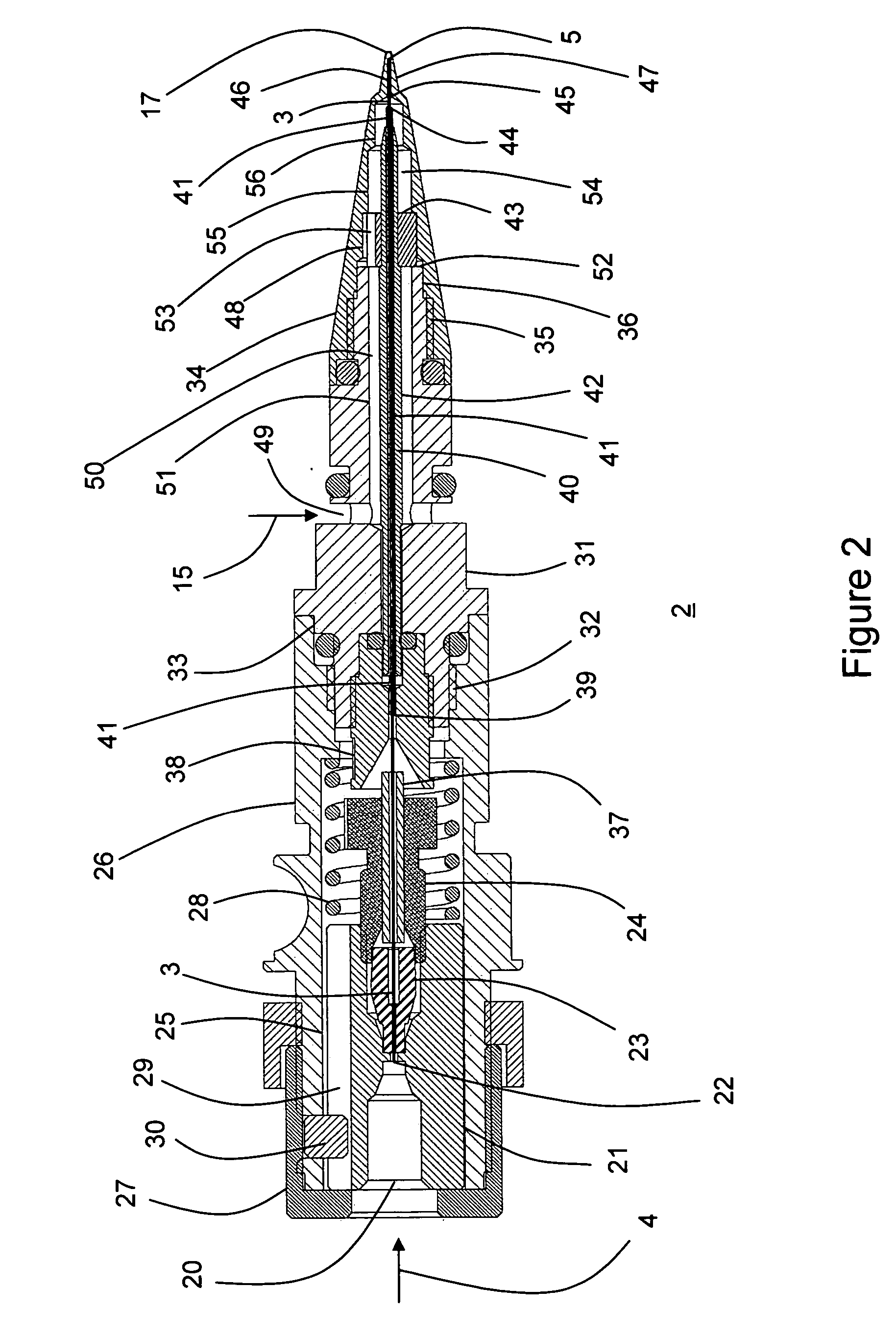

Charged droplet spray probe

ActiveUS20050258361A1Easily and inexpensively re-configuredAccurate and precise coaxial alignmentSludge treatmentSamples introduction/extractionOperational stabilityMechanics

An improved sample introduction probe is disclosed for the production of ions from liquid sample solutions in an electrospray ion source. Nebulization of a liquid sample emerging from the end of an inner flow tube is pneumatically assisted by gas flowing from the end of an outer gas flow tube essentially coaxial with the inner sample flow tube. The disclosed probe provides for adjustment of the relative axial positions of the ends of the liquid and gas flow tubes without degrading the precise concentricity between the inner and outer tubes. Additionally, the terminal portion of the outer gas flow tube may be fabricated either from a conductive or dielectric material, thereby allowing the pneumatic nebulization and electrospray processes to be optimized separately and independently. Hence, the disclosed invention provides a pneumatically-assisted electrospray probe with improved mechanical and operational stability, reliability, reproducibility, and ease of use compared to prior art probes.

Owner:PERKINELMER U S LLC

Bearing outer ring grinding process

ActiveCN103419100AGood concentricityReduced outer diameter grinding processRevolution surface grinding machinesEngineeringControllability

The invention relates to a bearing outer ring grinding process and solves the problems that appearance is influenced due to the fact that processing prints are unavoidably left on an outer ring of a bearing and the outer ring needs to be ground for many times during processing of a grooved way of the bearing when the circular center of the groove way of the bearing deviates from the circular center of the outer diameter of the bearing in the prior art of processing of the outer ring. The bearing outer ring grinding process is characterized by including the following steps: grinding the outer ring of the bearing for three times, directly grinding the outer ring to be in a final size, and adopting ceramic support for grinding of the grooved way of the outer ring of the bearing. The grooved way and the outer diameter are good in concentricity, process turnover is reduced, production efficiency of the outer ring is improved, grinding time and processing cost are reduced, wall thickness difference is high in controllability, and roundness accuracy of the grooved way of the outer ring is greatly improved.

Owner:杭州人本轴承有限公司 +1

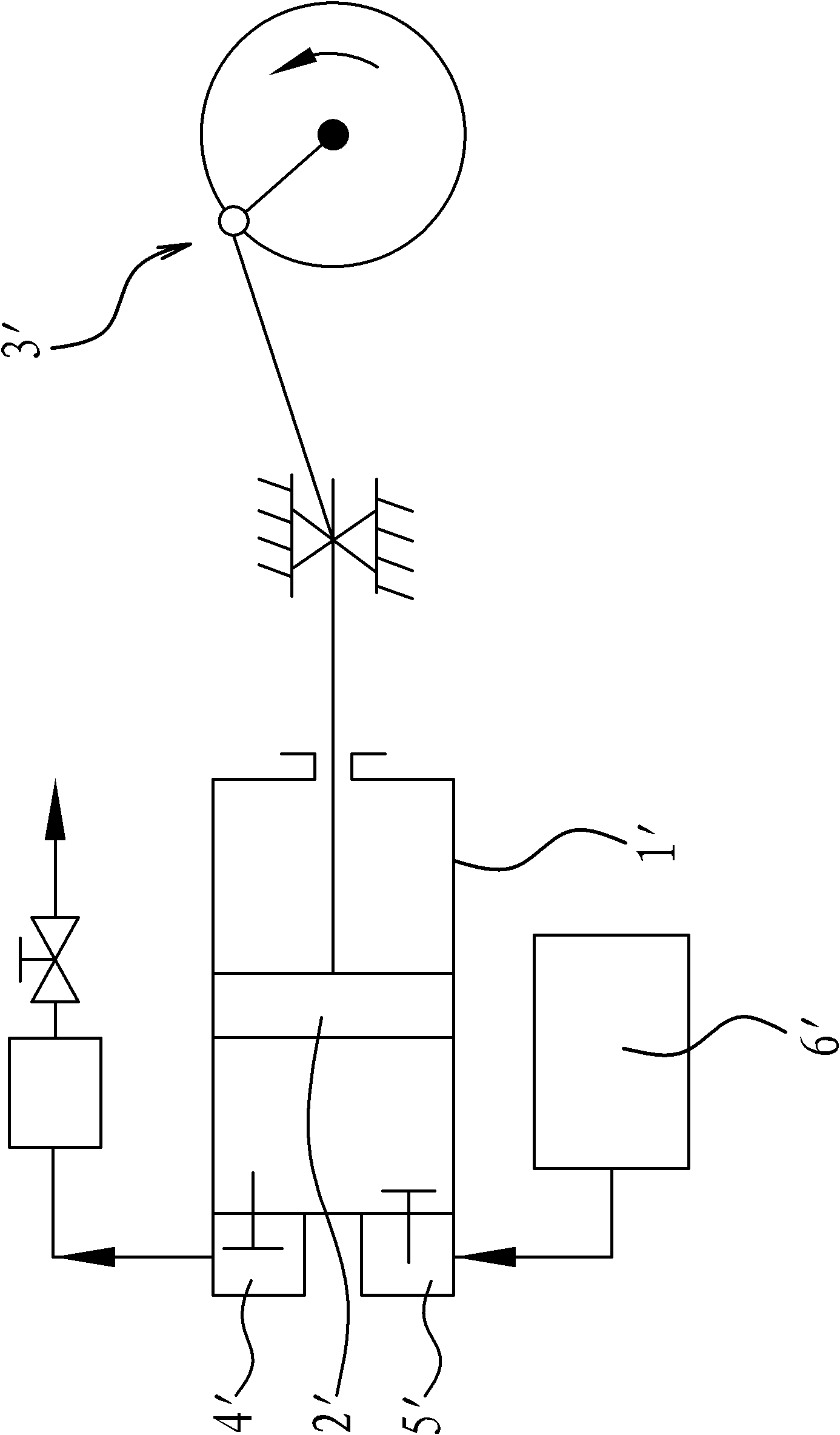

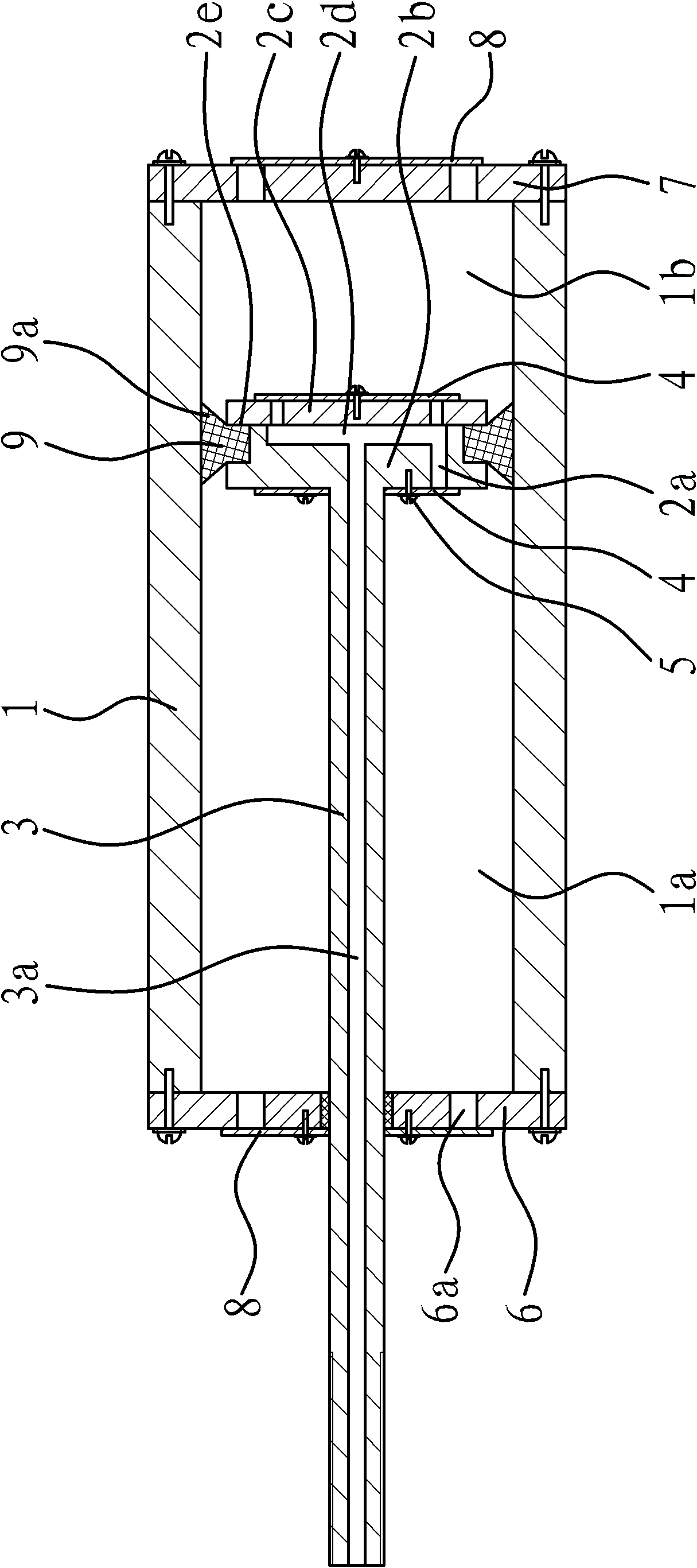

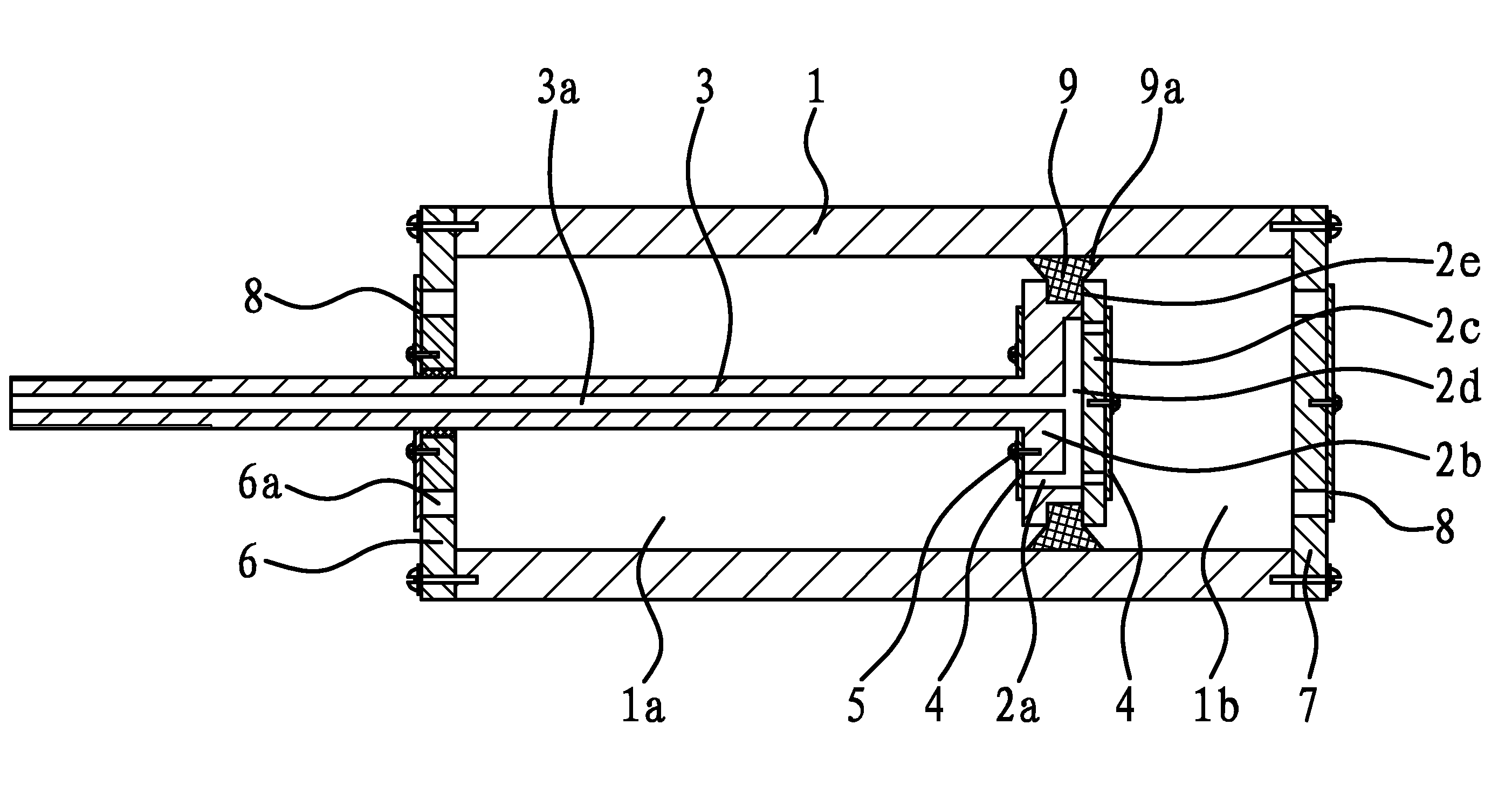

Piston-type reciprocating double-action single-cylinder pumping device of vacuum pump

ActiveCN101806295AEven by forceReduce wearPumpsPositive-displacement liquid enginesLow noiseEngineering

The invention provides a piston-type reciprocating double-action single-cylinder pumping device of a vacuum pump, which belongs to the field of vacuum pumps, and solves the problems of low working efficiency, uneven stress, high noise and the like of a traditional single-action vacuum pump. The piston-type reciprocating double-action single-cylinder pumping device of the vacuum pump comprises a cylinder body, a piston and a piston rod fixedly connected with the piston; the piston can move relative to the cylinder body; a sealing part which can prevent two cavities separated by the piston frombeing communicated is arranged between the piston and the cylinder body; the outer end of the piston rod extends out of the cylinder body, and a pumping channel is arranged in the piston rod; the piston is provided with a hollow structure which is connected with the pumping channel; both sides of the piston are fixedly provided with one-way valves 1 capable of preventing the air in the two cavities from entering the cavity of the piston, and both ends of the cylinder body are fixedly provided with one-way valves 2 capable of preventing outside air from entering the corresponding cavity. The piston-type reciprocating double-action single-cylinder pumping device of the vacuum pump adopts a double-action pumping method, doubles the working efficiency, and has uniform stress on all moving parts, little wear and low noise.

Owner:NANTONG CITY WEISHI VACUUM EQUIP

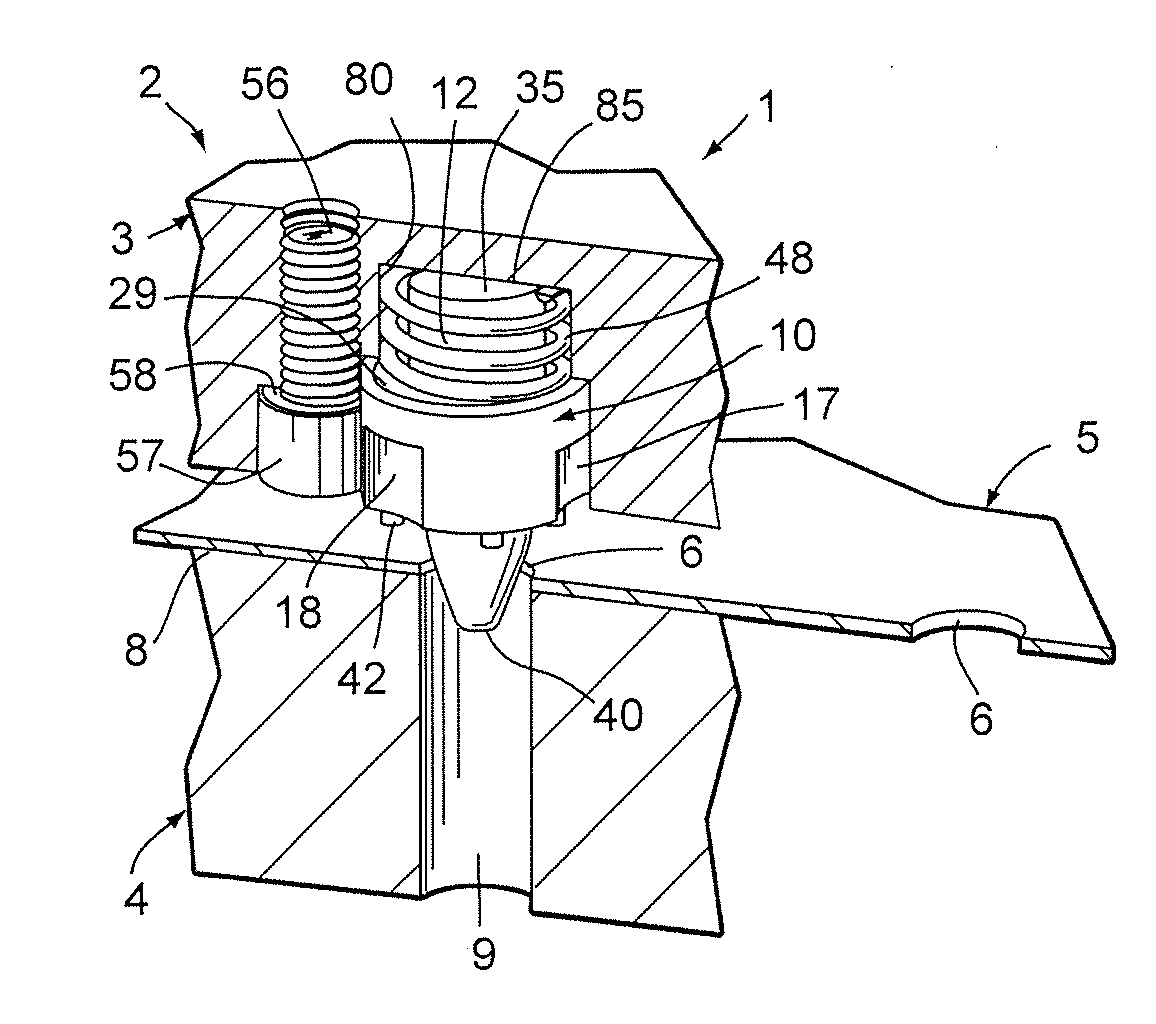

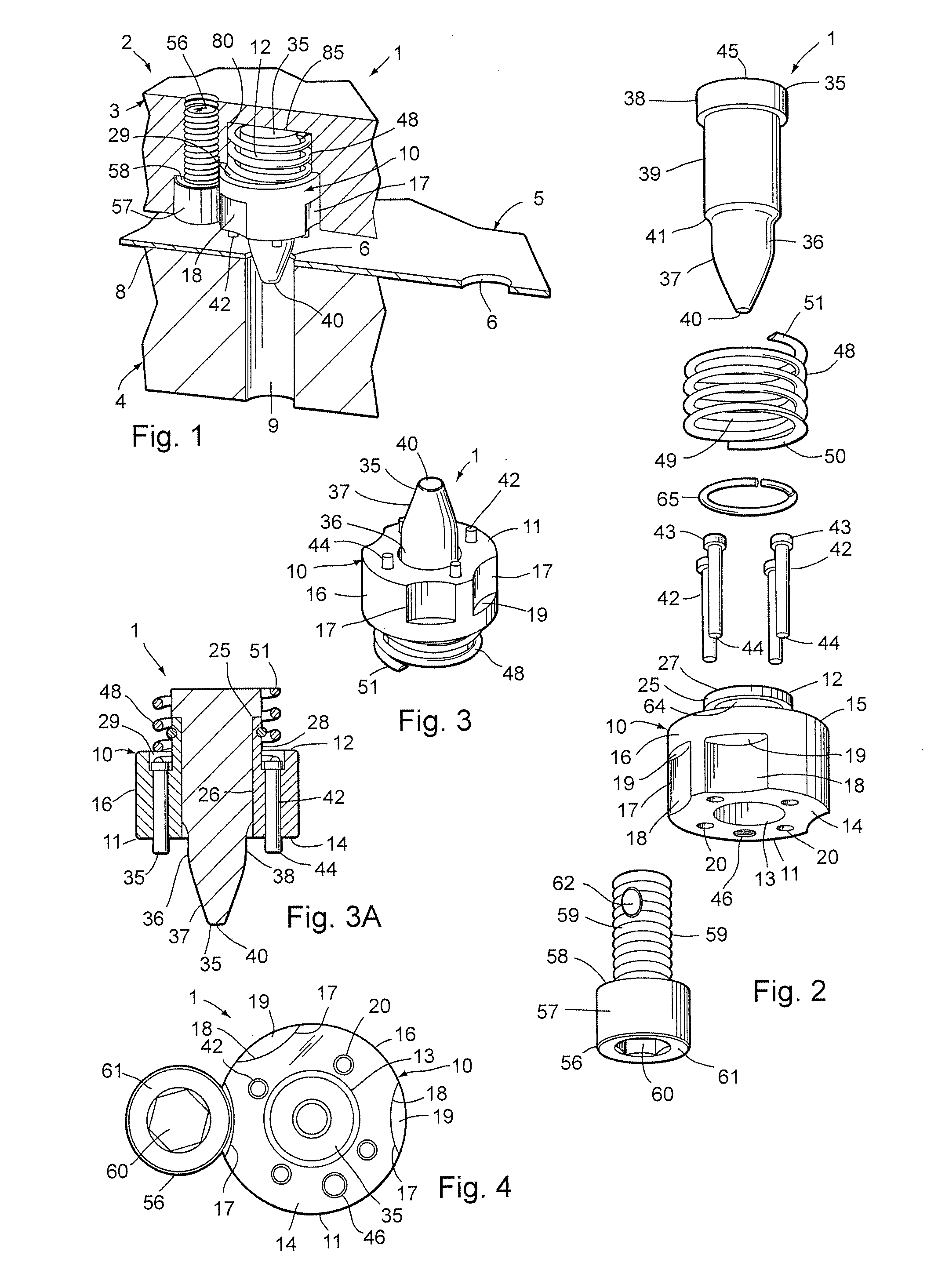

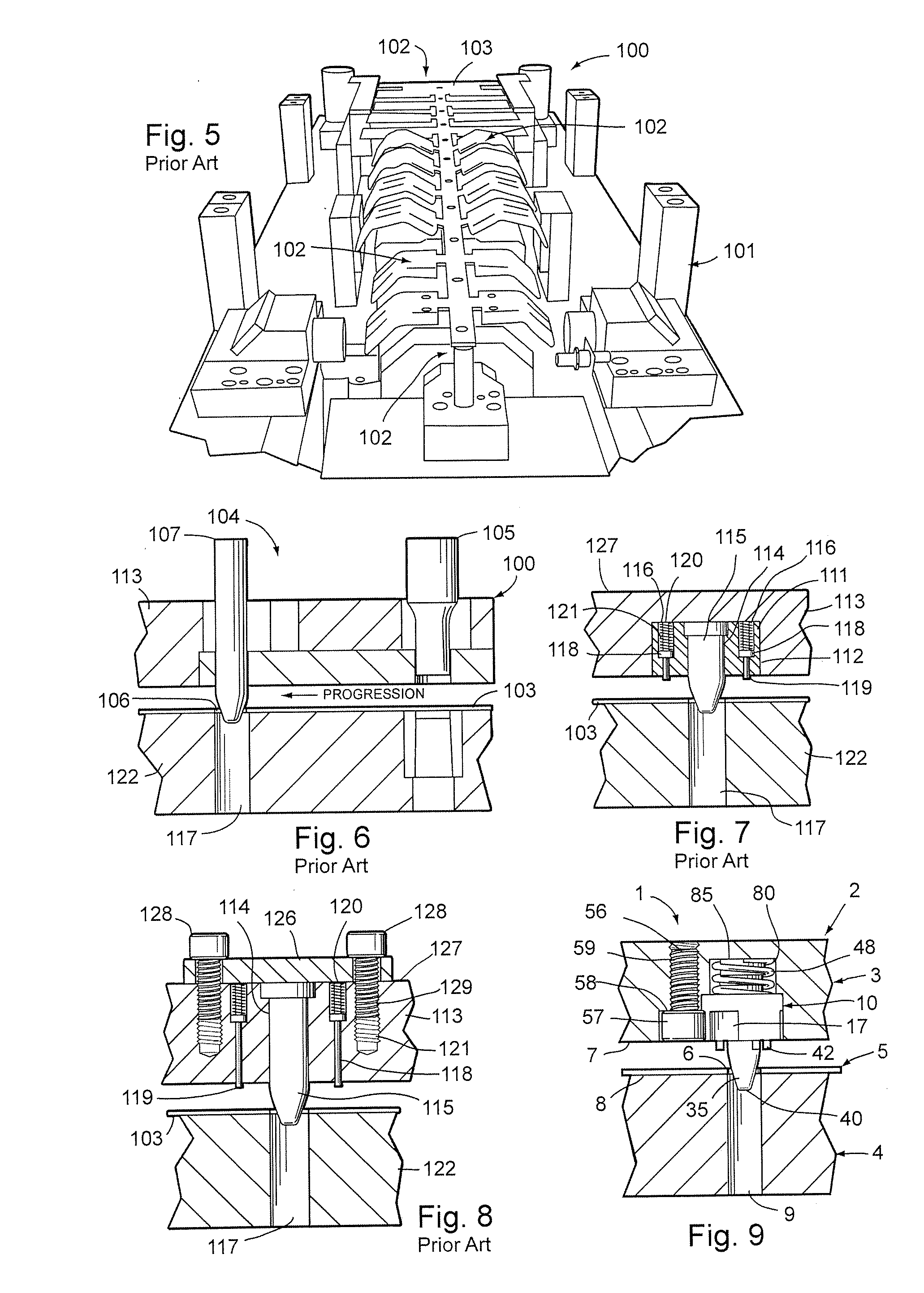

Modular pilot assembly with self-contained stripper and method for metal forming dies

ActiveUS20130167612A1Easily instalFacilitate useShaping toolsMetal-working feeding devicesEngineeringMetal forming

A pilot assembly and method has a cylindrical pilot sleeve with an apertured outer end in which a separate pilot pin is received, a grooved inner end, and a central portion with at least one inwardly curved sidewall relief, as well as internally mounted reciprocating ejector pins with outer ends that protrude through holes in the outer body end to strip stock from the pilot pin. A spring has its outer end mounted in the sleeve groove, and an inner end captured in a die pocket in a pretensed condition. A mounting screw has an enlarged head that has at least a portion thereof fit into the pilot sidewall relief, and a threaded shank that anchors the pilot sleeve in the die.

Owner:STANDARD LIFTERS INC

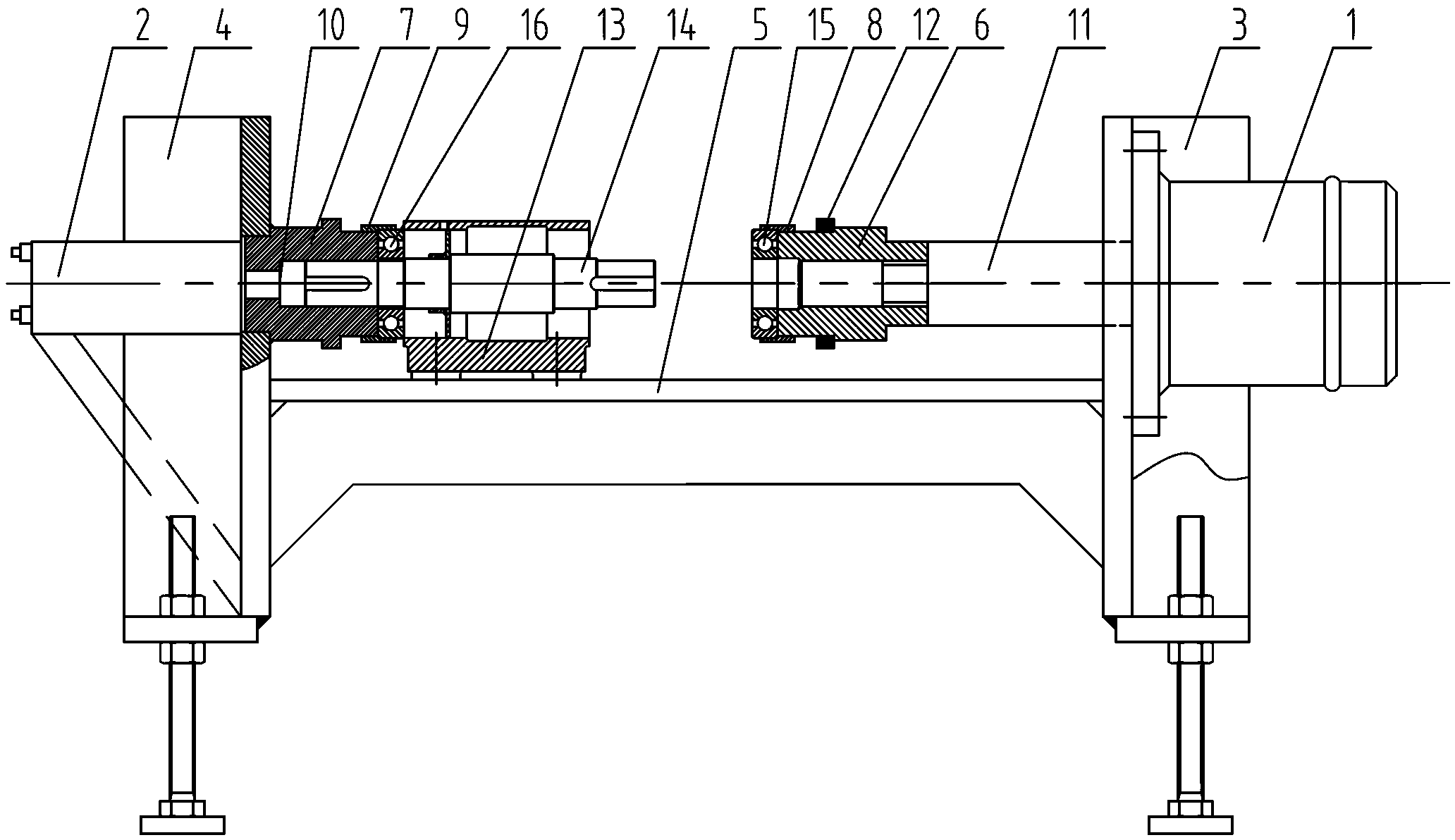

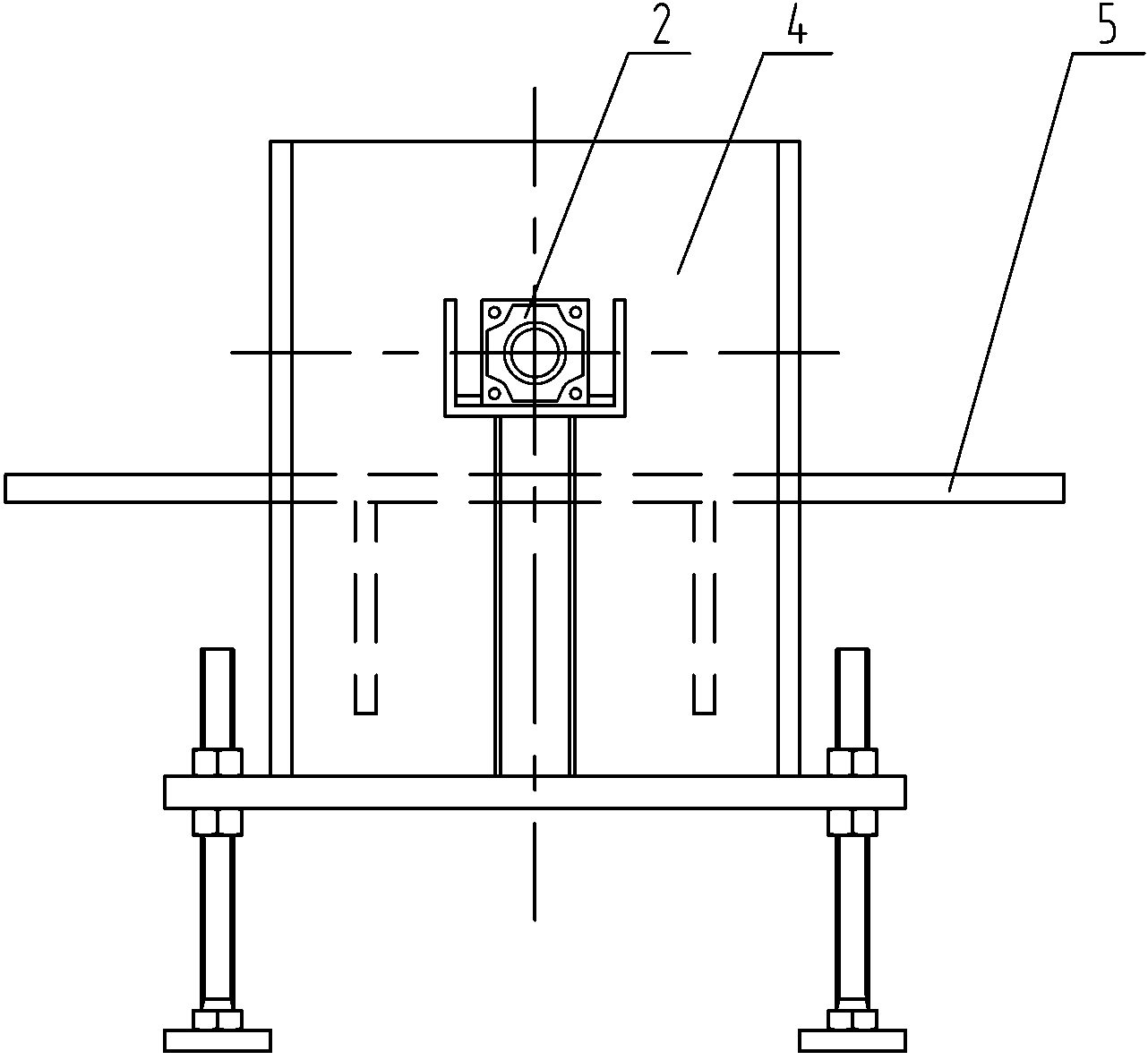

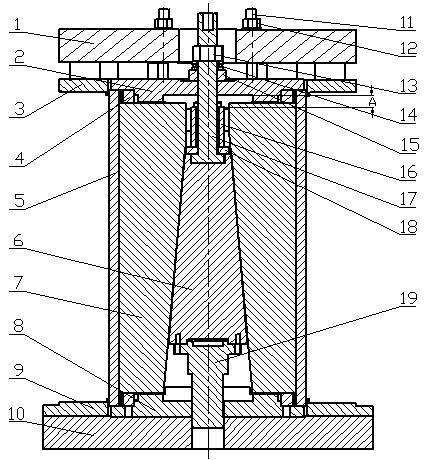

Pressing fit machine for rolling bearing pedestal

ActiveCN103182641AHigh concentricityHigh precisionMetal working apparatusHydraulic cylinderMechanical engineering

The invention provides a pressing fit machine for a rolling bearing pedestal. A support platform consists of a left support base, a right support base and a pressing fit table, and the heights of the left support base and the right support base can be respectively adjusted, so that the levelness of the pressing fit table can be guaranteed; and the right support base is fixedly provided with a hydraulic cylinder, a piston rod of the hydraulic cylinder horizontally and leftwards extends, the front end of the piston rod is fixedly provided with a piston rod connecting piece, the left end of the piston rod connecting piece is provided with a first bearing installing part, and the left support base is a main shaft installing part. When the pressing fit machine is used, a left-side bearing and a main shaft workpiece are directly arranged on a main shaft fixed guide sleeve, the left-side bearing and the main shaft workpiece are coaxial with each other, and the pressing fit machine can be better positioned, is free from adjustment, and can be used only by adjusting the coaxial relationship between a right-end bearing and the main shaft, so that one adjustment can be reduced, and the assembly efficiency and precision can be improved. Meanwhile, the bearing in the device is directly clamped into a bearing guide lantern ring, so that the pressing fit machine can be conveniently and quickly used.

Owner:山东开泰工业科技有限公司

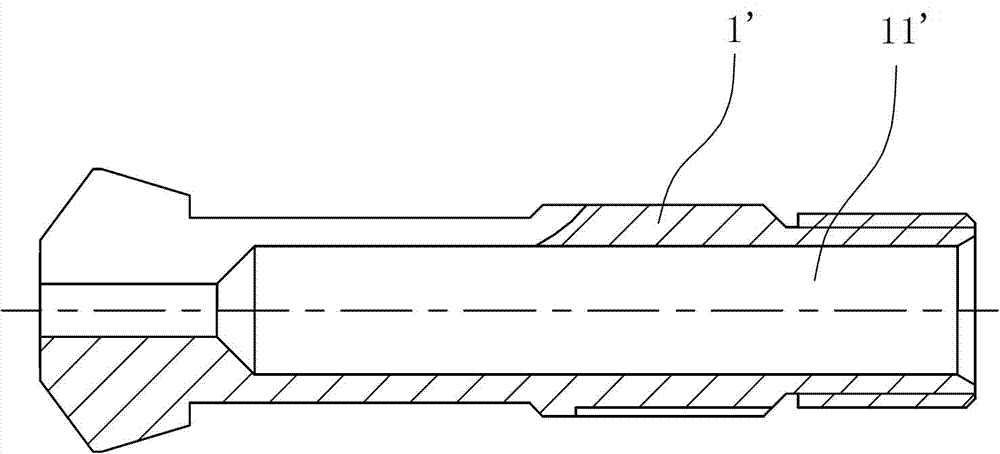

Clamp head and processing process of clamp head

InactiveCN103072029AImprove wear resistanceExtended service lifePositioning apparatusMetal-working holdersAlloyMachining process

The invention relates to a clamp head, which comprises a clamp head body, wherein the clamp head body is provided with an inner hole in the axial direction. The clamp head is characterized in that the part of the inner hole positioned at the front end of the clamp head body is also fixed and embedded with a hard alloy sleeve pipe, and the hard alloy sleeve pipe is provided with a pipe hole for a workpiece to penetrate in a rotating way. The clamp head has the advantages that the hard alloy sleeve pipe is fixedly arranged in the inner hole of the clamp head, the abrasion of the inner hole of the clamp head in the processing process is reduced, and the abrasion performance of the clamp head is improved; the head part of the clamp head adopts the uniform equant structure, so the head part of the clamp head has a certain elasticity, and tight locking caused by tight workpiece clamping is prevented; and the clamp head adopts the novel processing process, the uniformity of the clamp head material can be ensured, the deformation of the clamp head is reduced, the concentricity and the roughness of the clamp head are improved, in addition, the cost of the whole process flow is low, the realization is easy, and the quality of the clamp head obtained through processing is good, so the workpiece processed through the fixation of the clamp head is enabled to have higher precision and better quality.

Owner:ZHEJIANG BUSINESS TECH INST

Sintering device of loose body optical fiber prefabricated rod

A sintering apparatus for prefabricatnig the loosen optical fibre rod is composed of sintering quartz pipe with gas inlet and cover, heating unit with casing, insulating material and heater, moving controller, position sensor, gas supplying unit, temp sensor with heating driver, and controller.

Owner:JIANGSU FASTEN PHOTONICS

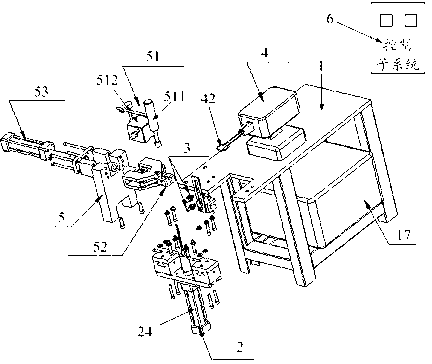

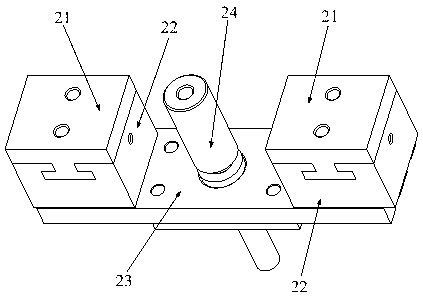

Drill welding system and drill welding method

ActiveCN103028832AClear structureReasonable settingWelding/cutting auxillary devicesAuxillary welding devicesRadial positionUltimate tensile strength

The invention discloses a drill welding system, the drill welding system comprises a cutter bar moving device, a welding and heating device, a tool bit adjusting device and a controlling subsystem, the cutter bar moving device is used for placing and moving the cutter bar placed a tool bit and welding materials on the top portion; the welding and heating device is used for heating the welding materials to melt to an end portion of the cutter bar; the tool bit adjusting device is used for adjusting the axial position and radial position of the tool bit and the cutter bar, thereby guaranteeing the concentricity and compactness of the cutter bar and the tool bit; the cutter bar moving device, the welding and heating device and the tool bit adjusting device are respectively connected with the controlling subsystem, the cutter bar moving device used for a controlling positioning pre-added drill returns to seat after sequentially passing the welding and heating device and the tool bit adjusting device. The invention further provides a drill welding method. The drill welding system and drill welding method has the advantages of improving accuracy as well as speed of welding, greatly improving the quality of welding and productivity and lowering the labor intensity of workers. The drill also has high concentricity and firm connection.

Owner:SHANGHAI KUNJEK HANDTOOLS & HARDWARE

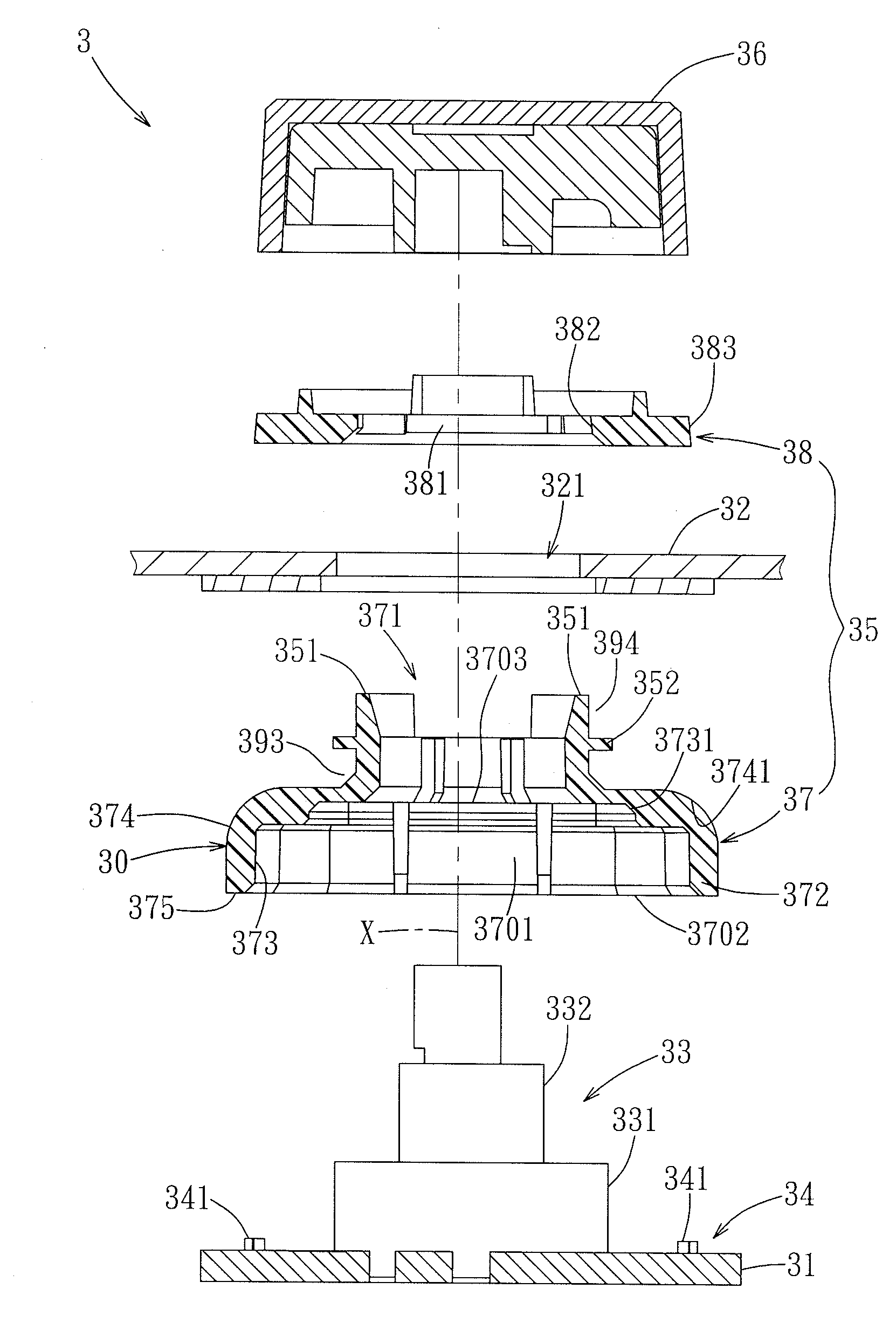

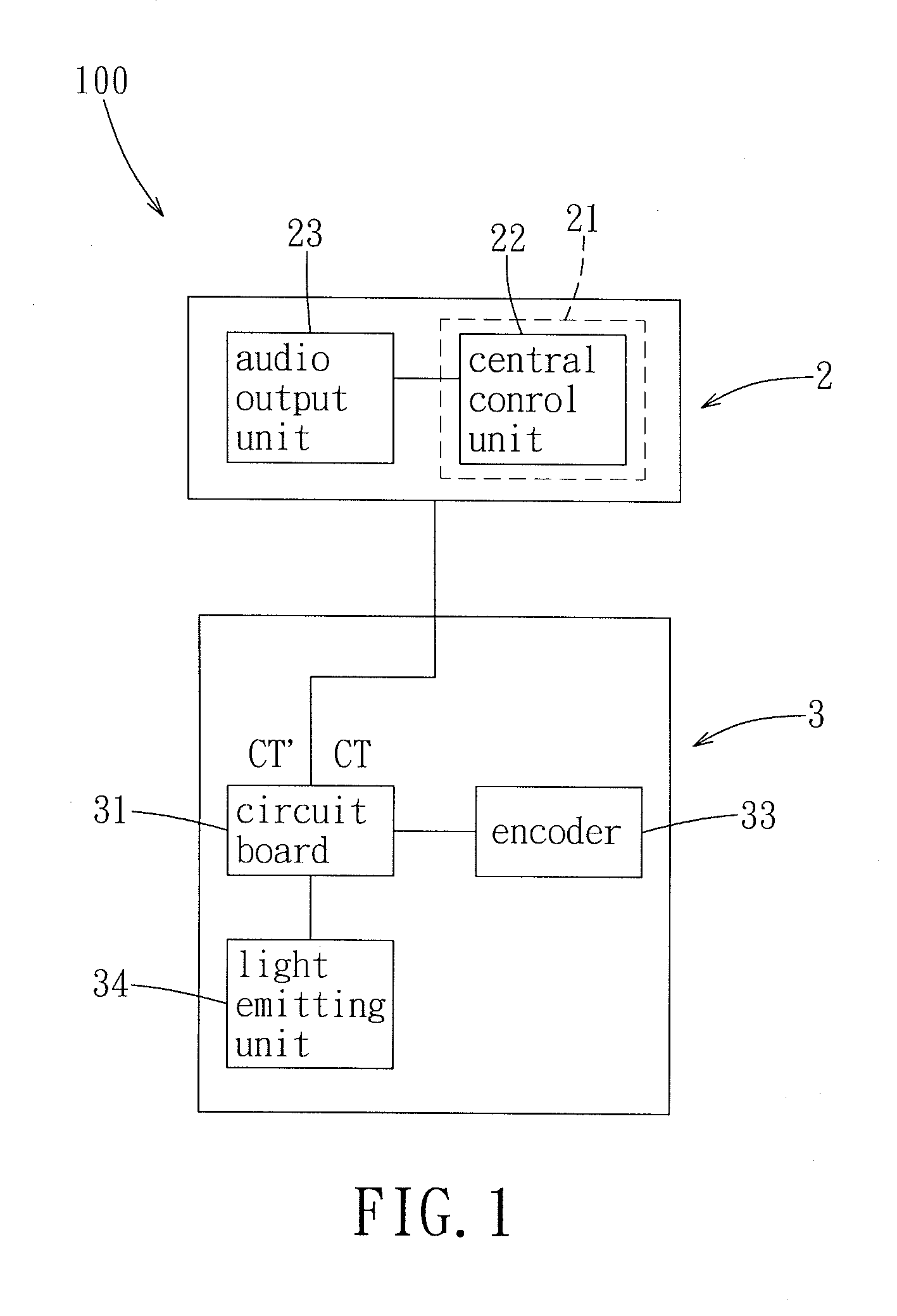

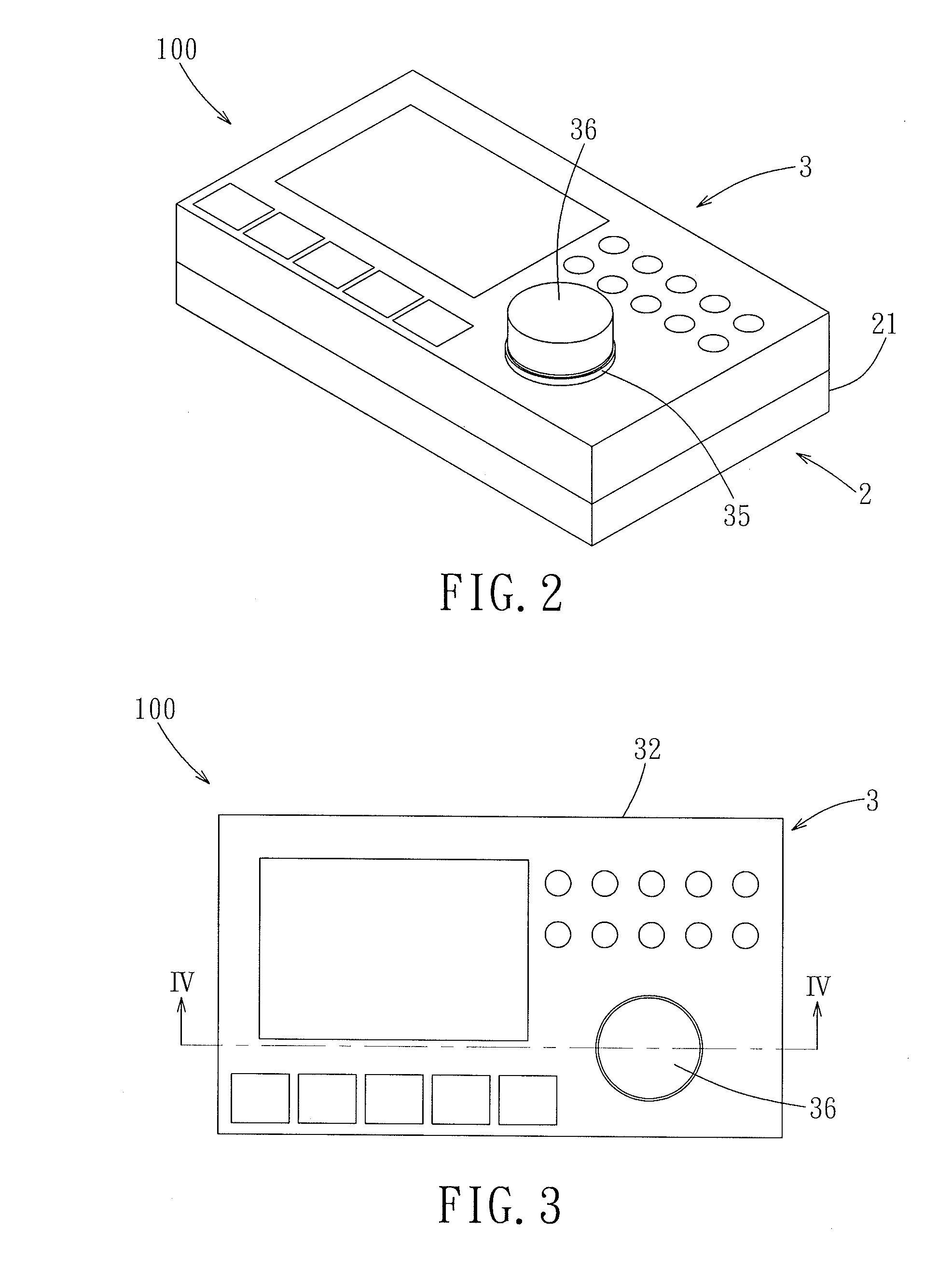

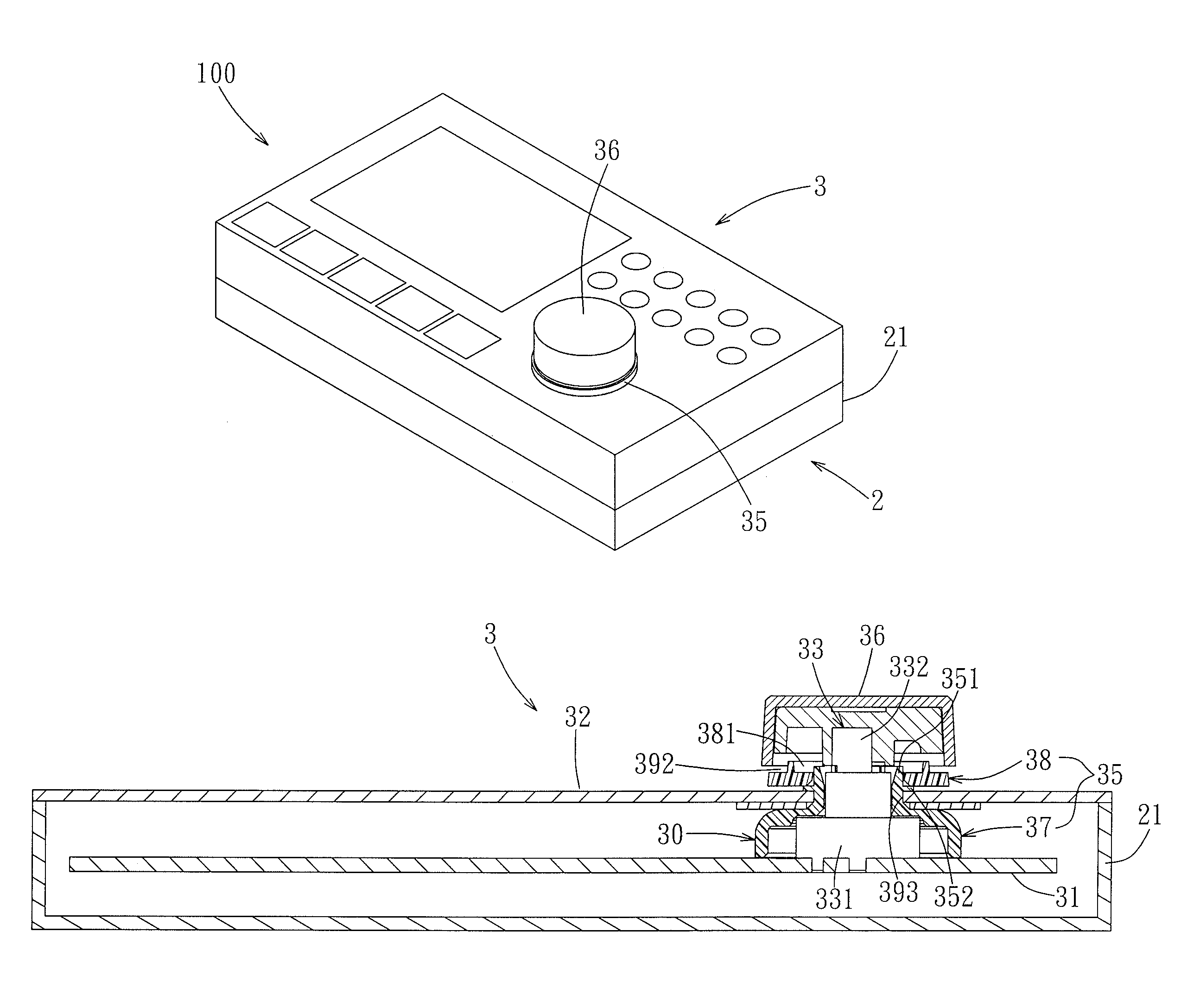

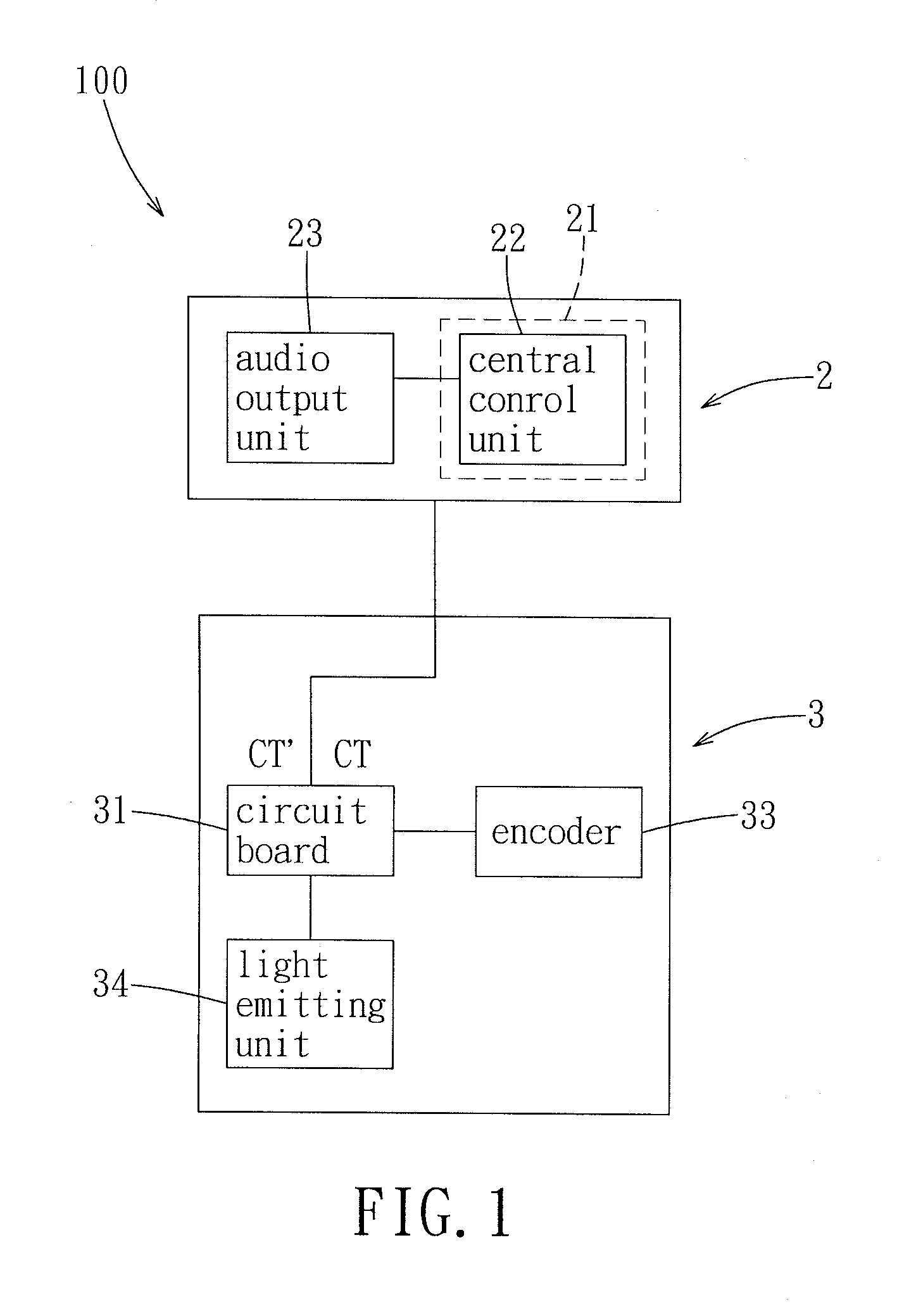

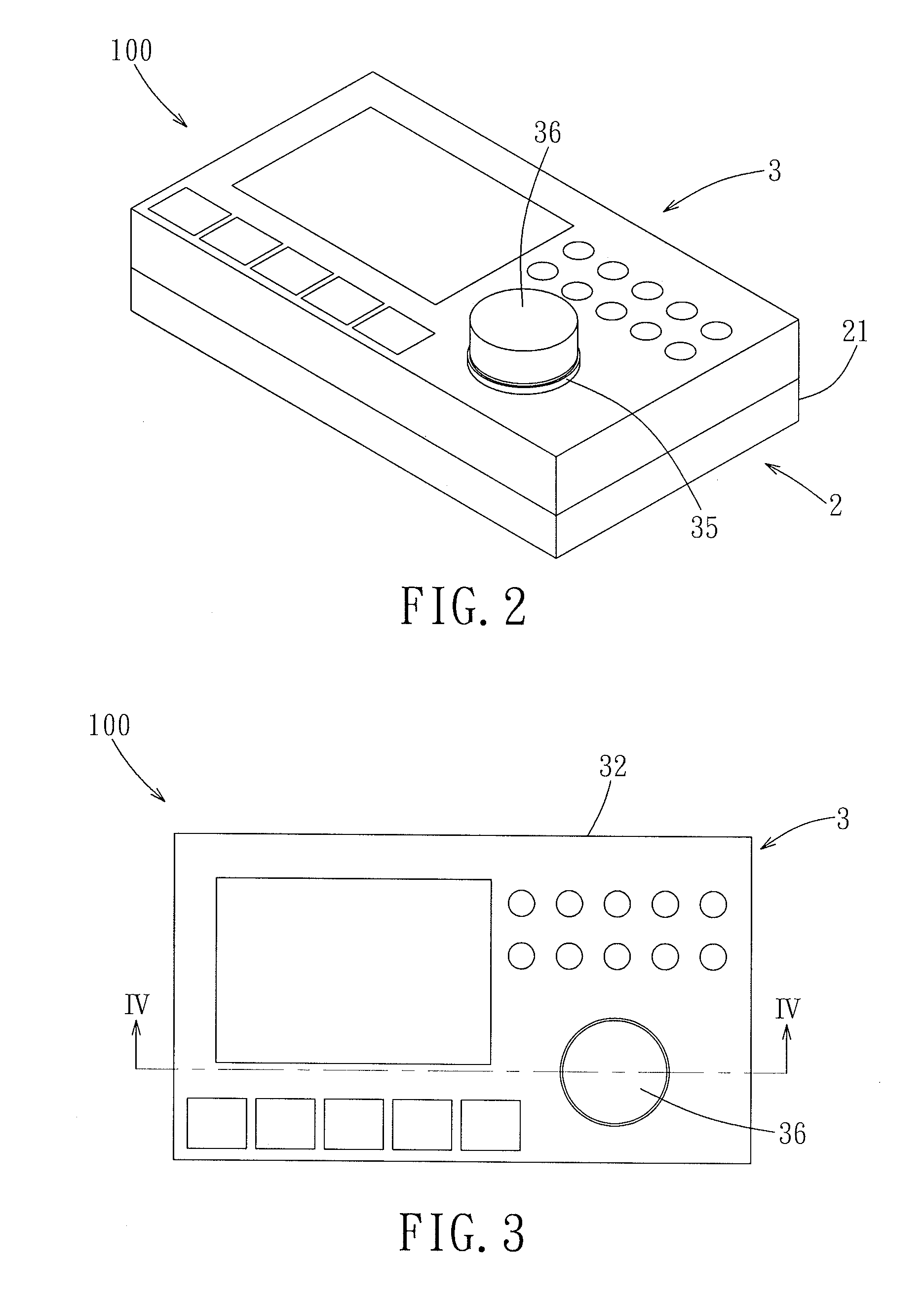

Light-emitting knob mechanism and an audio system incorporating the same

ActiveUS20130163226A1High light transmittanceHigh concentricityControlling membersMechanical apparatusLight guideEngineering

A knob mechanism includes an encoder and a light guide unit. The light guide unit includes a lower member tightly sleeved on the encoder, protruding out of a housing, and having an opening and an optical channel, and an upper ring sleeved on the lower member, and having a light incident surface connected to the optical channel and a light transmitting surface spaced apart from the light incident surface. A rotary rod of the encoder protrudes out of the lower member through the opening. A knob is engaged to the rotary rod and is operable to rotate the same about an axis. Light irradiating the lower member propagates through the optical channel, into the light incident surface, and then out from the light transmitting surface in radial directions.

Owner:WISTRON NEWEB

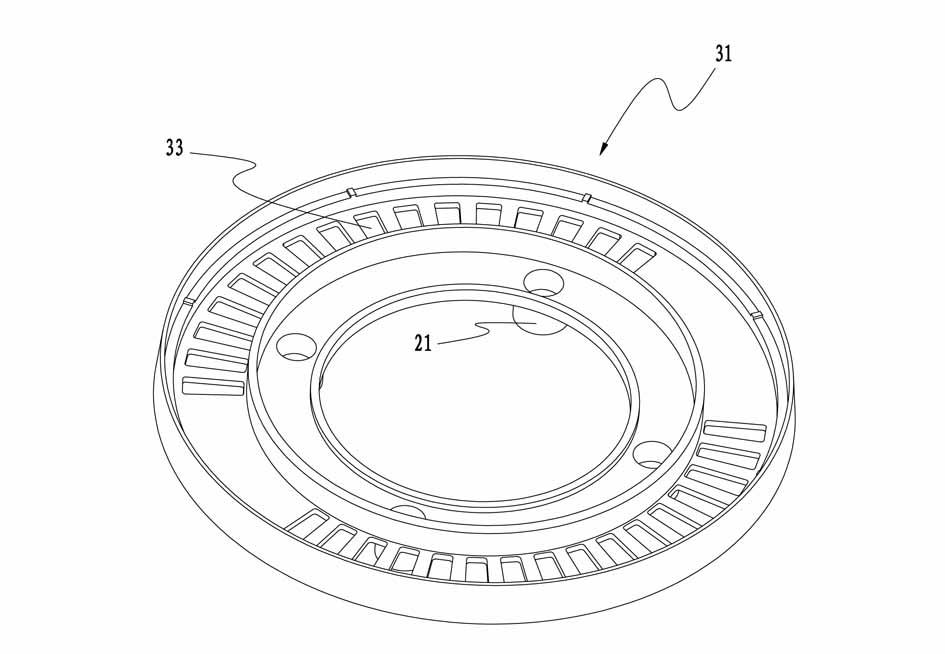

Blast furnace bellless furnace top distributor

ActiveCN101173321AExtended service lifeFully lubricatedBell-and-hopper arrangementBlast furnace detailsEngineeringShaft furnace

The invention discloses a bell-less top distributing gear of furnace, belonging to technical field of metallurgical industry. The invention adopts sealed cooling, a water-cooling venturi tube with pipe laying and a water-cooling chassis. A motor drives a chute to rotate and tilt; wherein, the motor drives the nut of the ball screw assembly to rotate and then drives the lead screw and the lifting rotary frame connected with the lead screw to move up and down in order to achieve chute to tilt for Alpha angle. The invention has the advantages of high coaxiality, high transmitting precision, long service life of the critical component, easy manufacture, light weight and low cost. The tilting Alpha angle of the chute and the stationarity of the tilting movement of the chute can be checked during the producing process of the furnace by the invention. The invention can be used in charging operation of furnace roof and also is suitable for shaft furnace or smelting reduction furnace which need to feed from the roof to the closed space and distribute regularly.

Owner:CISDI ENG CO LTD

Concentric centripetal sliding bearing formed by using interface slippage

ActiveCN104791381AImprove carrying capacityImprove support rigidityBearingsCoated surfaceUltimate tensile strength

The invention provides a concentric centripetal sliding bearing formed by using interface slippage. The sliding bearing comprises a shaft and a bearing hole which are concentric, wherein a gap is formed between the shaft and the bearing hole, and the gap is filled with fluid to form a lubrication region; the lubrication region is divided into a sub region I and a sub region II, the static contact surface of the sub region Iis coated with a coating, so that the interface shear strength between the fluid and the coating is too low to enable the fluid to generate slippage on the surface of the coating, and fluid does not generate slippage on the rest static contact surface of the bearing and the whole movable contact surface of the bearing. The bearing disclosed by the invention has definite bearing capacity, is low in friction coefficient, is good in abrasion resistance, is high in support precision, is simple to realize, is low in cost, and has an important use value.

Owner:怀宁吉利来精密机械科技有限公司

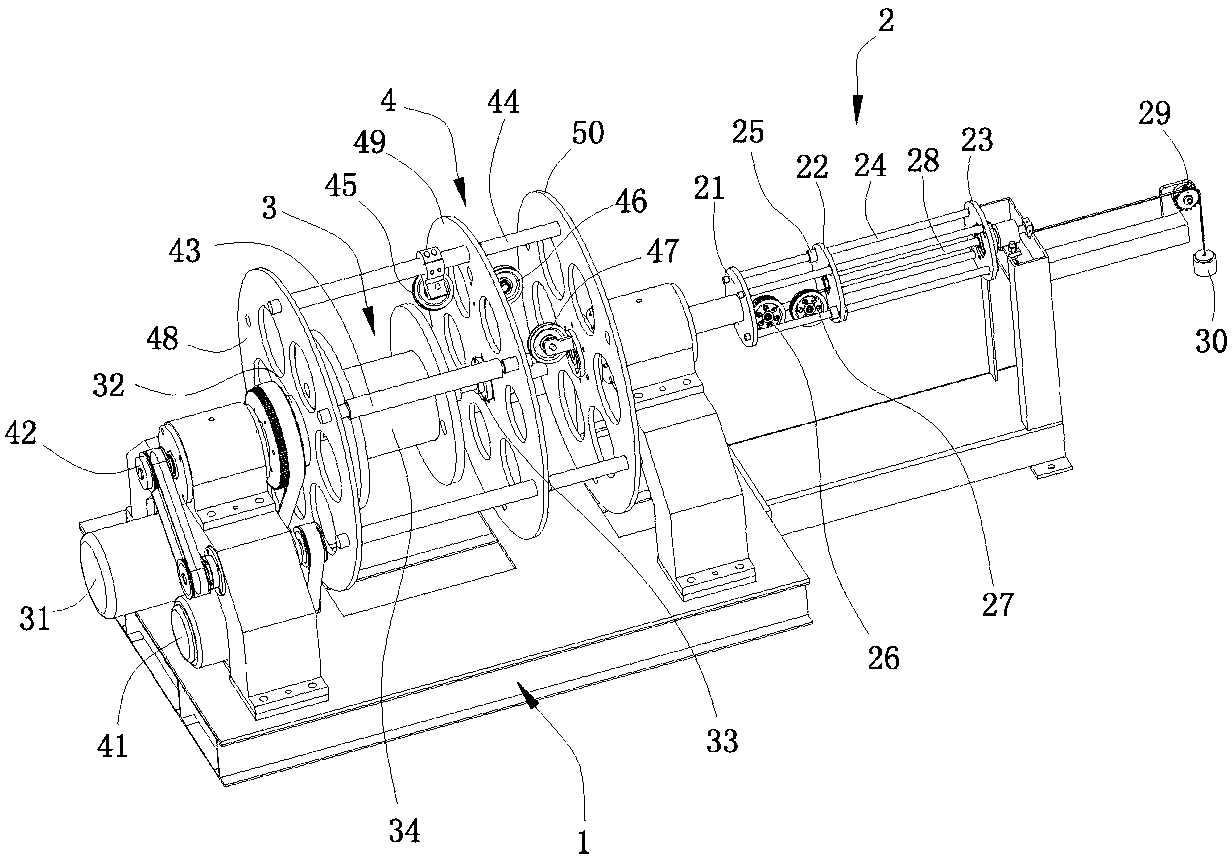

Active back-twist constant-force pay-off machine and production method thereof

ActiveCN103106982AReasonable structural designIngenious structural designCable/conductor manufactureConstant forceUltimate tensile strength

The invention discloses an active back-twist constant-force pay-off machine which comprises a machine frame, a back-twist pay-off device and a rotating tension device, wherein the back-twist pay-off device comprises a pay-off mechanism and a back-twist mechanism. The invention further discloses a production method of the active back-twist constant-force pay-off machine. The active back-twist constant-force pay-off machine is reasonable and ingenious in structural design and capable of quickly feeding a cable core to a stranding machine in a balanced mode with predetermined constant tension; at the same time, the rotating tension device and the stranding machine move in the same direction at the same rotation speed, and therefore the cable core can be effectively prevented from being damaged due to twist; in addition, regulating accuracy of the tension is high, the tension of the cable core can be automatically detected and adjusted in the whole production process, and therefore the tension of the cable core can always remain constant, and constant-tension cable feeding in a true sense is realized; and the active back-twist constant-force pay-off machine is convenient to operate, greatly lowers labor intensity, guarantees the quality of products, and is beneficial to improvement of the competitiveness of an enterprise. The production method of the active back-twist constant-force pay-off machine is simple in process, low in cost, easy to implement, and through the production method, the active back-twist constant-force pay-off machine can be produced rapidly.

Owner:DONGGUAN JINGTIE MACHINERY

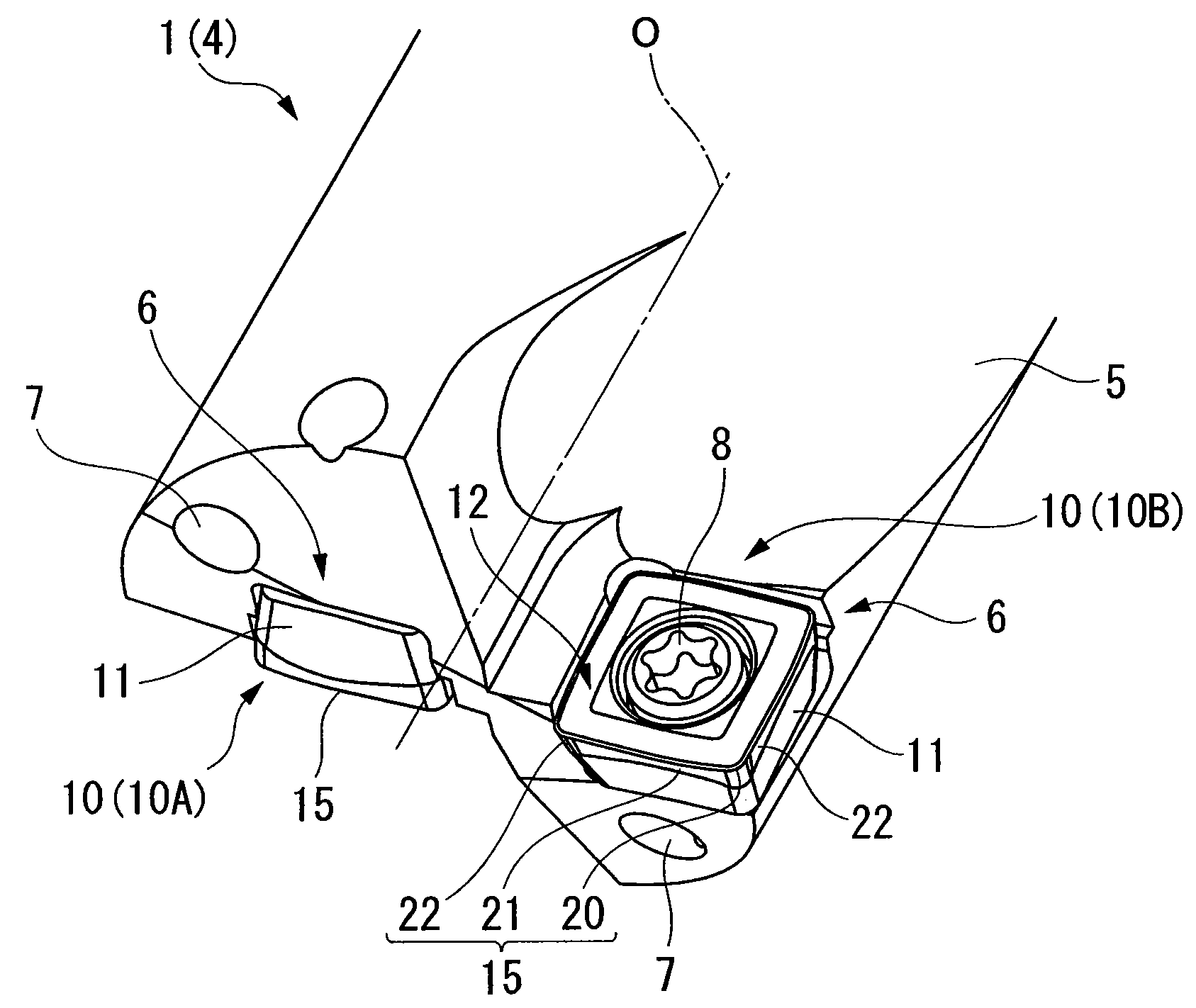

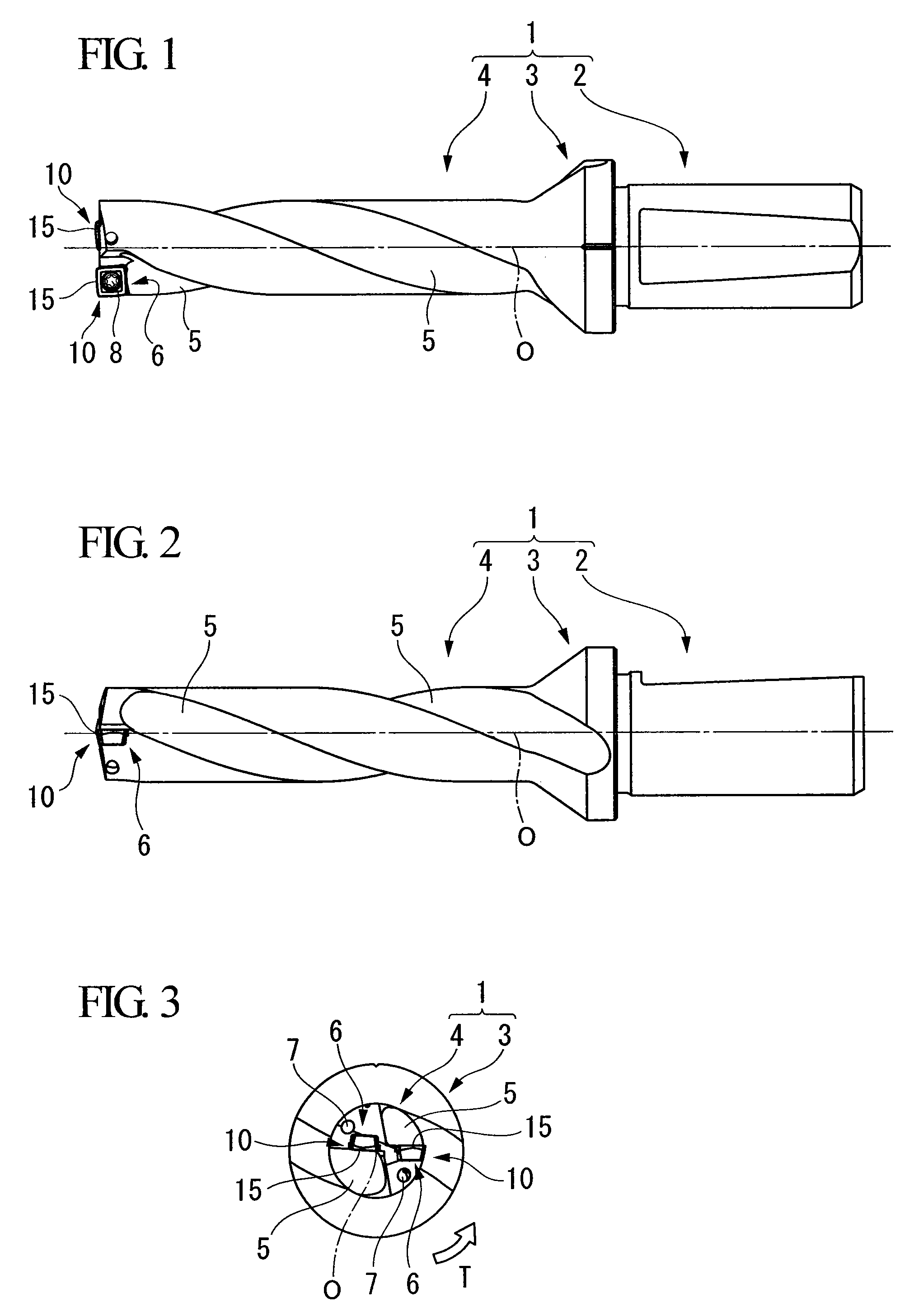

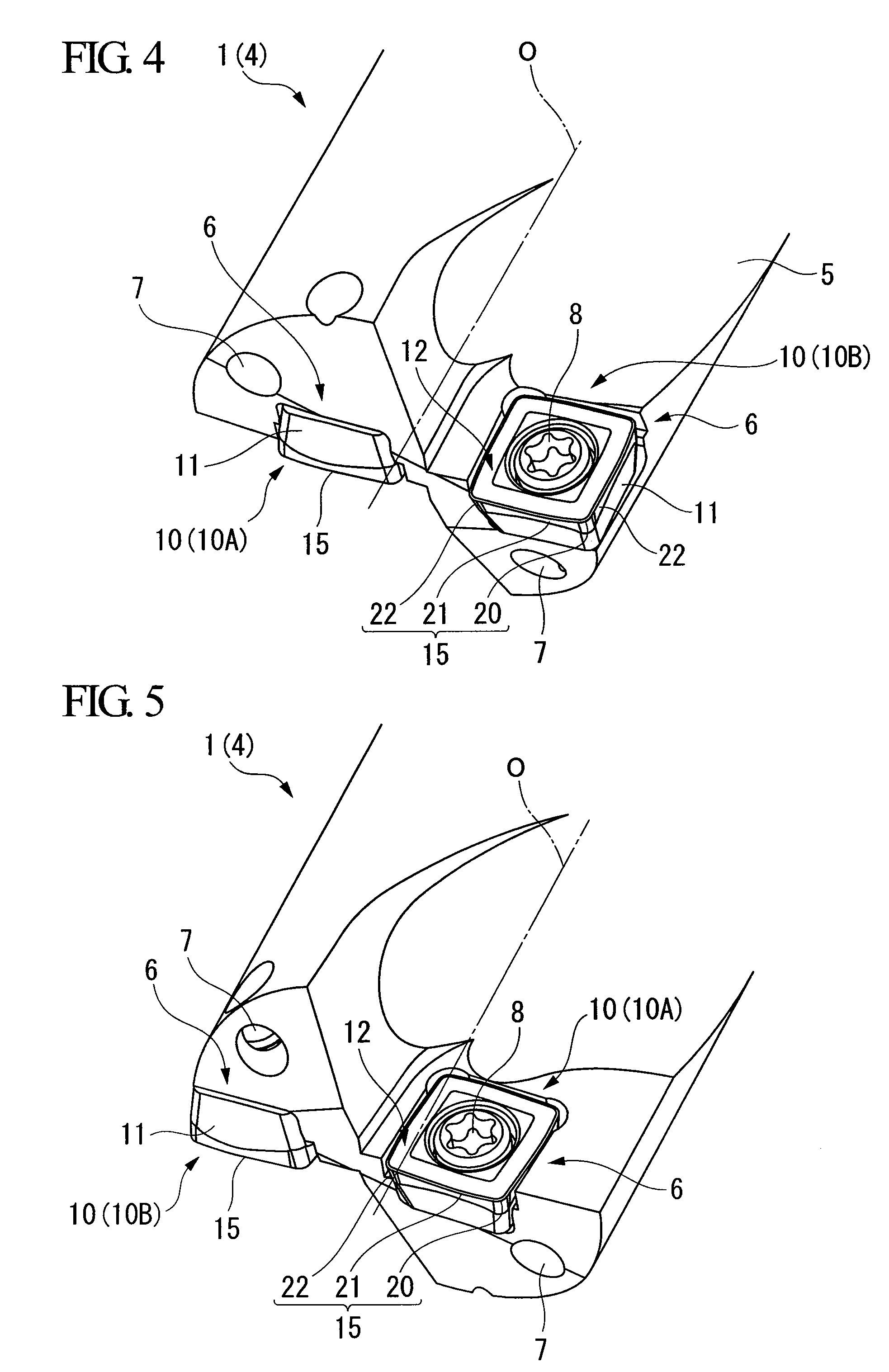

Insert for drill and indexable insert drill

ActiveUS20090245949A1Improve surface qualityHigh concentricityTransportation and packagingCutting insertsCurve shapeEngineering

An insert for a drill in which one of the cutting edges respectively formed at four side ridge portions of a rake face of a square flat plate-shaped insert body is made to protrude toward the tip of the drill body of the indexable insert drill while being detachably attached is provided. Each of the cutting edges has a corner cutting edge located at a corner of the rake face, and a major cutting edge and a wiper edge which extend substantially toward one peripheral direction of the rake face from a corner cutting edge. The major cutting edge has a first major cutting edge portion which has a convexly curved shape and extends from the corner cutting edge, and a second major cutting edge portion which smoothly touches the first major cutting edge portion and extends linearly, as seen from a direction facing the rake face. The wiper edge has a straight shape intersecting the second major cutting edge portion at an obtuse angle.

Owner:MITSUBISHI MATERIALS CORP

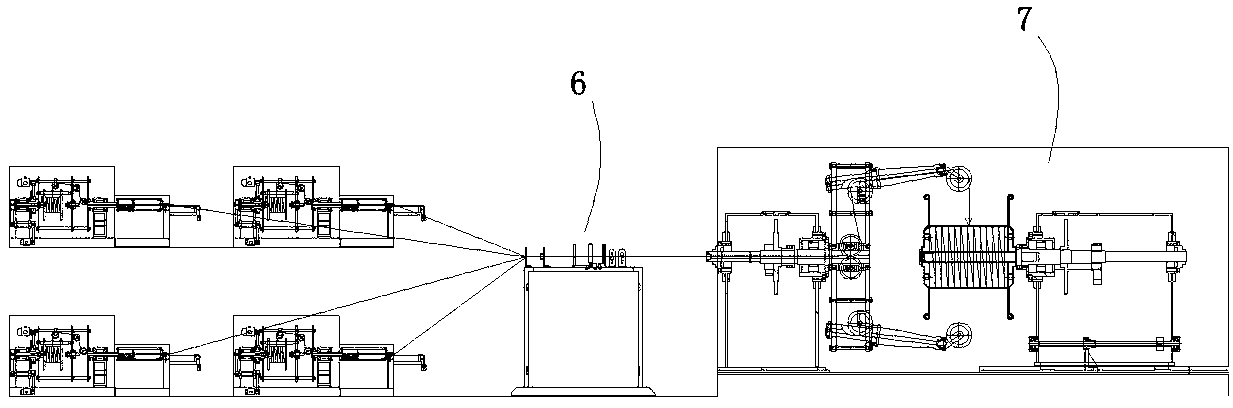

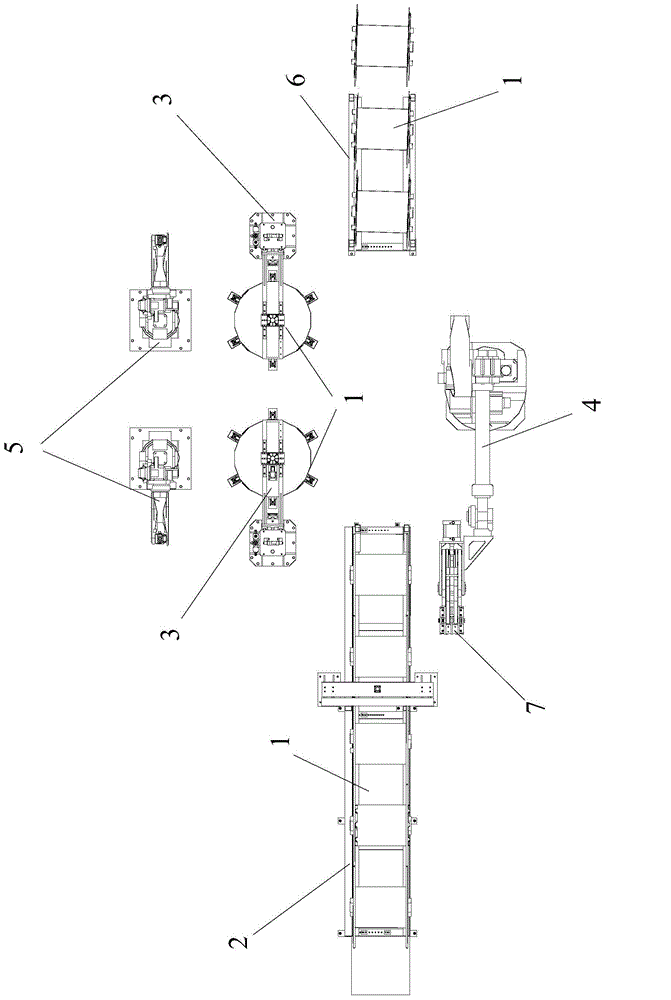

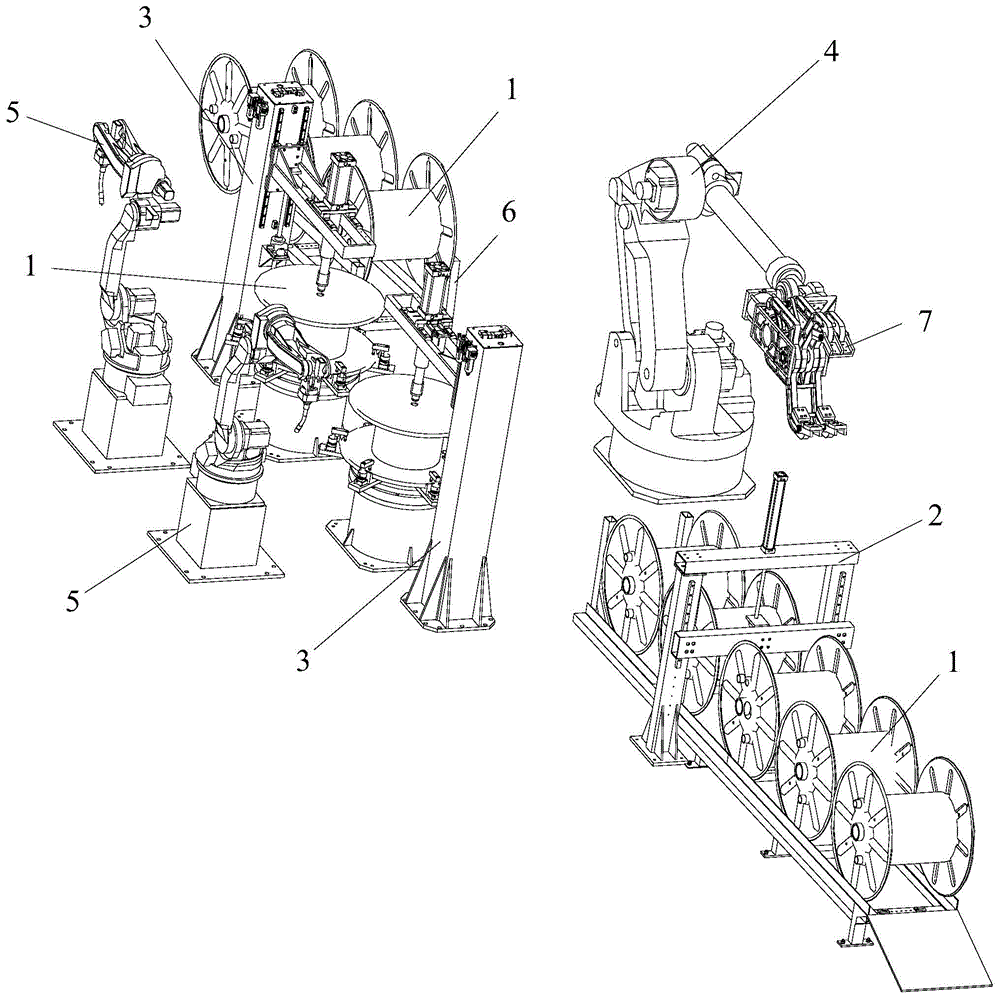

Automatic welding production line and automatic welding method for wire coils

ActiveCN104625454AHigh precisionHigh speedWelding/cutting auxillary devicesAuxillary welding devicesProduction lineEngineering

The invention provides an automatic welding production line for wire coils. The production line comprises a feeding and conveying mechanism, a pressing and positioning mechanism, a transferring manipulator, a welding manipulator, a discharging and conveying mechanism and a control mechanism in signal connection with the feeding and conveying mechanism, the pressing and positioning mechanism, the transferring manipulator and the welding manipulator. The production line is simple in structure, high in welding speed and high in welding quality stability, the phenomenon that welding of welded junctions is not uniform because of manual welding can be effectively avoided, and therefore welding efficiency, welding precision and welding quality of the wire coils can be improved. The invention further provides an automatic welding method for the wire coils. The method includes a feeding procedure, a transferring and positioning procedure, a welding procedure and a discharging procedure which are all performed in sequence, wherein in the transferring and positioning procedure, the transferring manipulator is controlled to clamp, move and overturn the wire coils, meanwhile, the pressing and positioning mechanism is used for pressing, positioning and rotating the wire coils, and the welding procedure starts. The method can be used for solving the problem that the automation degree in the current welding industry is low.

Owner:佛山市慧智智能装备有限公司

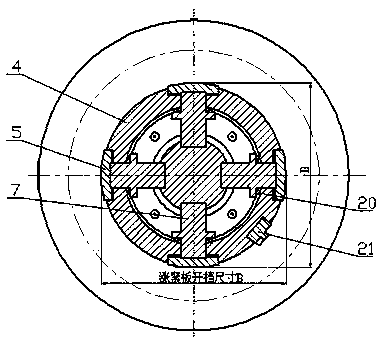

Overlying tool for large motor stator iron core

ActiveCN105515299AReduce gapHigh concentricityManufacturing stator/rotor bodiesEngineeringMechanical engineering

The invention relates to the technical field of motor stator laminations, in particular to an overlying tool for a large motor stator iron core. A vertical wedge-shaped expander structure is adopted in the overlying tool design. Four equant rectangular holes are formed in a cylinder, groove shapes are correspondingly formed through cutting, one end face of each of four wedge-shaped plates is machined into a 5-degree slope, four grooves with 5-degree slopes are machined in a spindle in an equant mode, and the wedge-shaped plates are in slide fit with the slopes of the spindle and embedded in the rectangular holes of the cylinder; a pull rod is connected to the top of the spindle, and the spindle can move up and down under the action of an adjusting nut to drive four tensioning plates to synchronously stretch or retract in the circumferential direction so that laminations can be positioned centrally and break away.

Owner:CHANGZHOU SHENLI MOTOR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com