Overlying tool for large motor stator iron core

A technology of laminating tooling and stator cores, which is applied in the manufacture of stator/rotor bodies, etc., can solve the problems of large outer diameter, large gap between the shaft and the inner diameter of the punch, and cannot meet the size requirements, so as to improve the concentricity and reduce the size. gap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

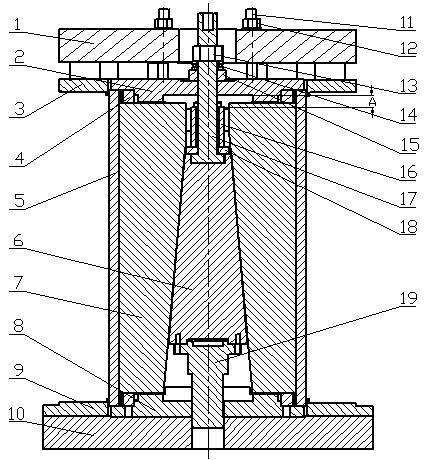

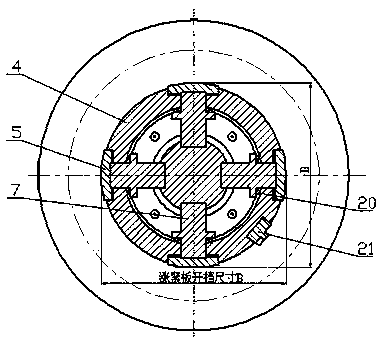

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0020] The present invention is a large-scale motor lamination tooling. The cylindrical body 4 is line-cut to process 4 rectangular holes equally divided on the circumference, and the groove shape is correspondingly cut out. The outer diameter of the cylindrical body is 20mm smaller than the inner diameter of the stator punch, 4 One end surface of one wedge-shaped plate 7 is processed into a 5-degree inclined surface, and four 5-degree inclined-plane grooves are processed on the upper circumference of the mandrel 6. The wedge-shaped plate 7 is slidingly matched with the inclined surface of the mandrel 5, and the four wedge-shaped plates 7 are embedded in the cylinder. In the rectangular hole; the surface corresponding to the wedge-shaped block slope is connected with the tension plate 5, and the radius of the outer arc surface of each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com