Top-intake burner of gas cooker

A gas cooker and burner technology, which is applied to gas fuel burners, burners, combustion methods, etc., can solve the problems of misalignment between the nozzle and the ejector tube, insufficient primary air intake, and unstable burner operation. Good draft effect, stable overall appearance and high concentricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

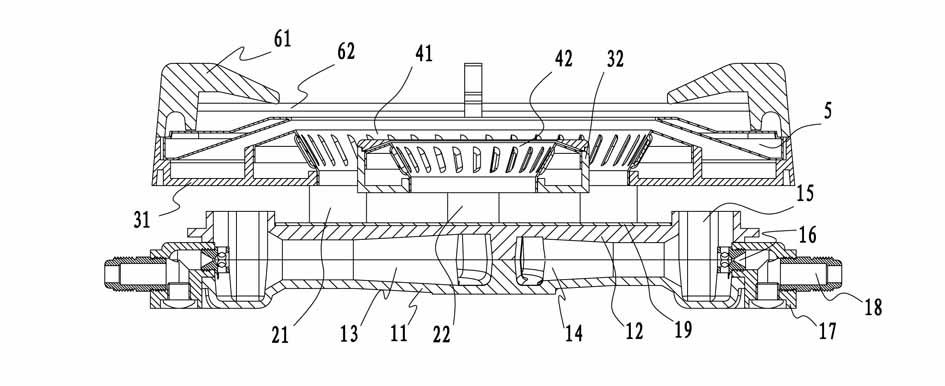

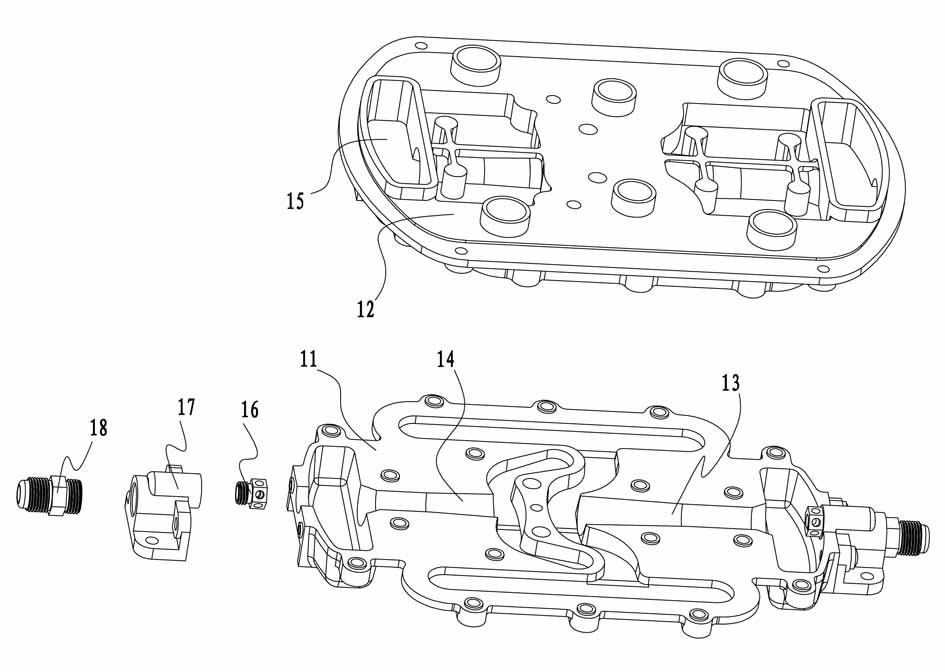

[0019] Example 1, such as figure 1 As shown in FIG. 1 , an upper air intake burner for a gas cooker includes a burner support, a fire distribution seat and a fire cover. Such as figure 2 As shown, the burner support includes a lower seat 11 and an upper cover 12, and the lower seat 11 and the upper cover 12 are fastened by screws, and an outer ring fire venturi ejector tube 13 and a central fire venturi ejector tube 13 propelled from the outside to the inside are formed inside. Fire Venturi ejector tube 14, outer ring fire Venturi ejector tube 13 and center fire Venturi ejector tube 14 are arranged in opposite directions, and there are two primary air intake holes 15 opening upwards on the edge of the burner support. The air inlet hole 15 is correspondingly communicated with the mouth of the outer ring fire Venturi injection pipe 13 and the central fire Venturi injection pipe 14, and the gas nozzle 16 is installed on the burner support through the nozzle seat 17. The gas noz...

Embodiment 2

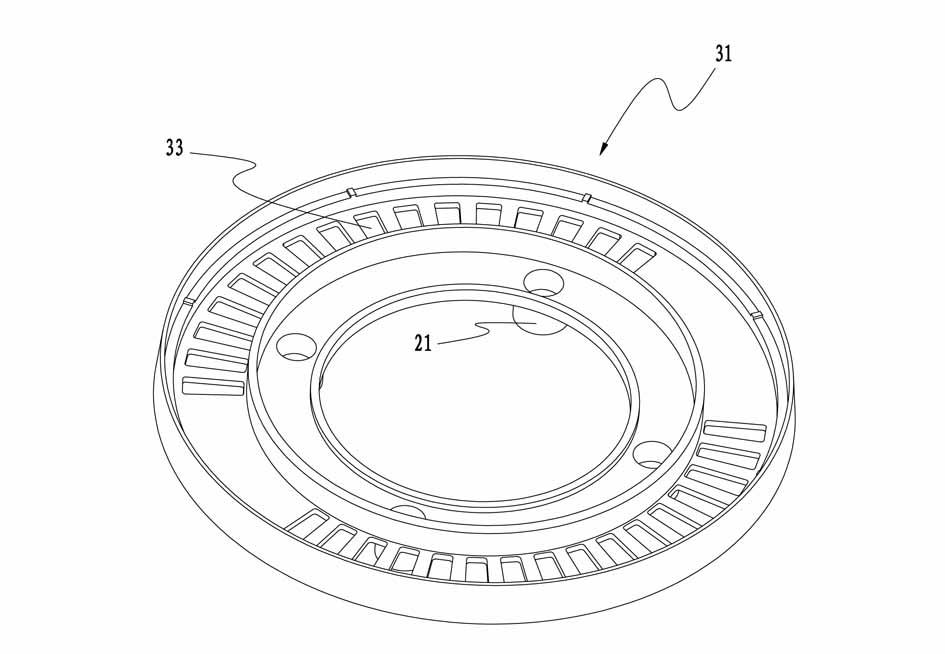

[0025] Example 2, such as Figure 4 The difference between the present embodiment shown and the previous example is that four Venturi ejector tubes and corresponding four gas nozzles 16 and four primary air intake holes 15 are distributed in the burner support, one of which is the center Fire Venturi ejector tube 14, the other three are outer ring fire Venturi ejector tubes 13. The central fire Venturi ejector tube 14 communicates with the central fire distribution chamber of the central fire seat 32 through two central fire air guide tubes 22, and the three outer ring fire Venturi ejector tubes 13 communicate with the outer ring distributor through three outer ring fire air guide tubes 21. The fire distribution cavity of the fire seat 32 adopts a multi-injection system, and the primary air is sufficient, which can realize full combustion of gas and increase the thermal load of the burner.

[0026] The burner of the present invention is embedded on the cooker panel through it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com