Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

8536results about "Gaseous heating fuel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

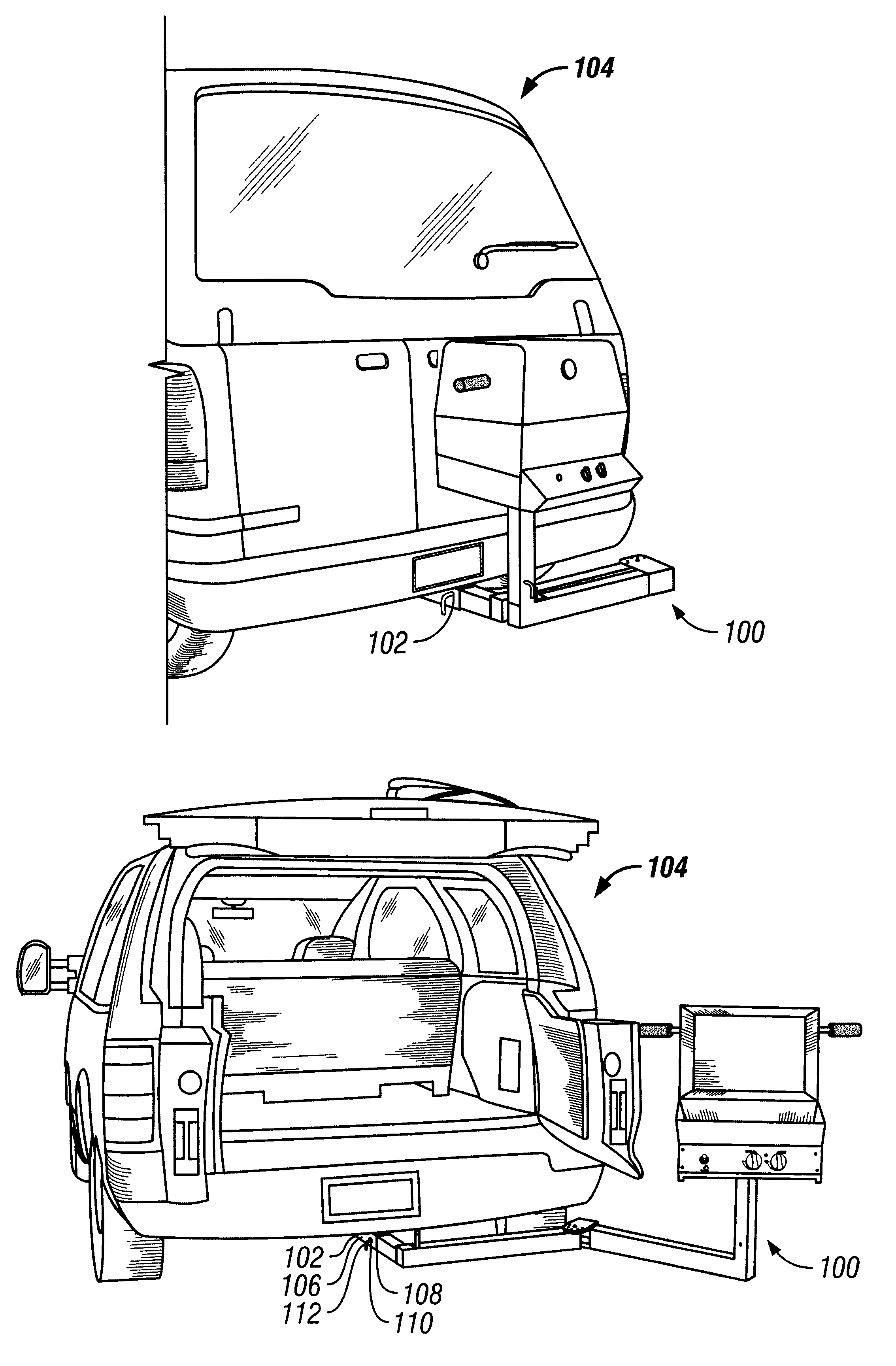

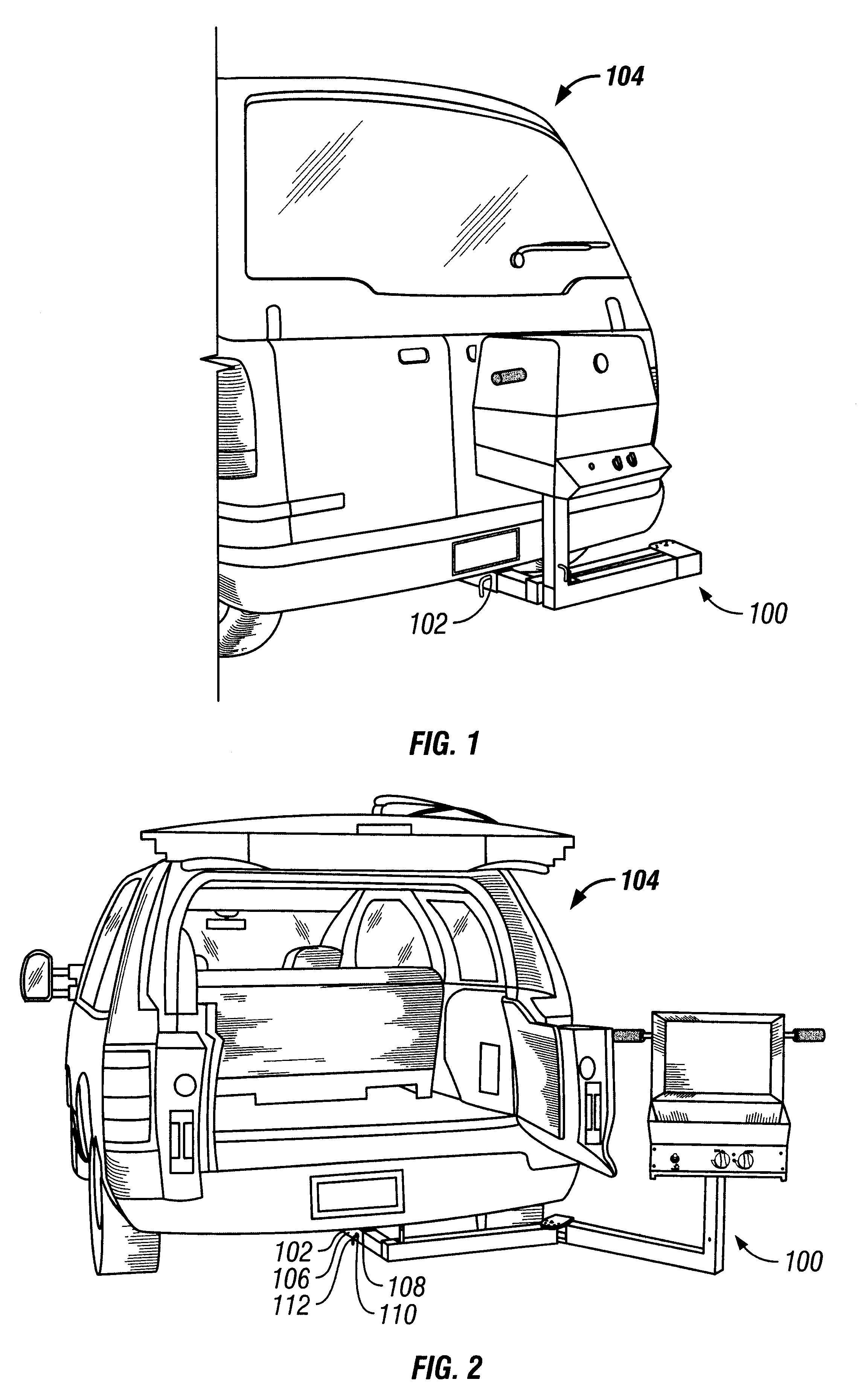

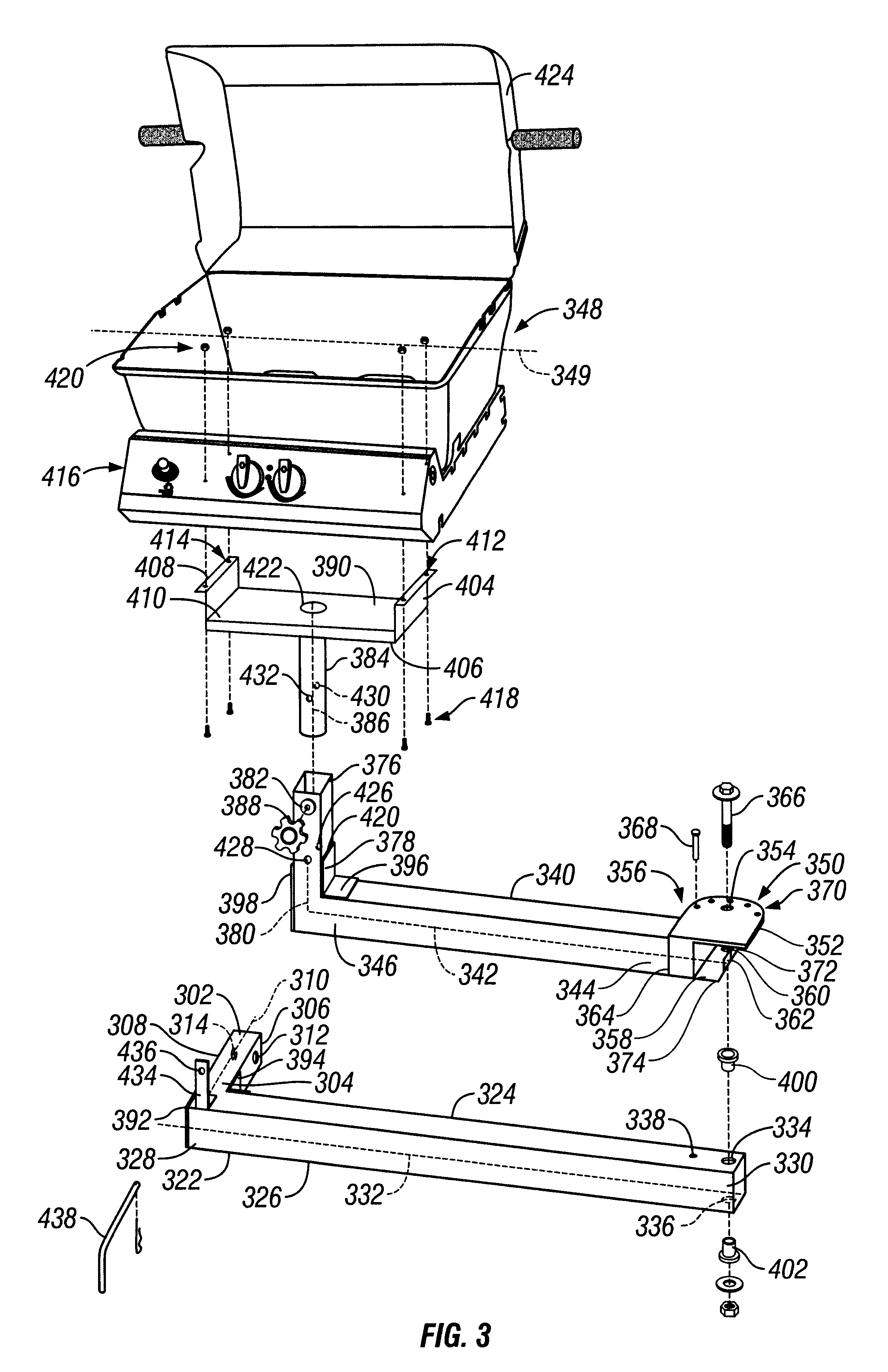

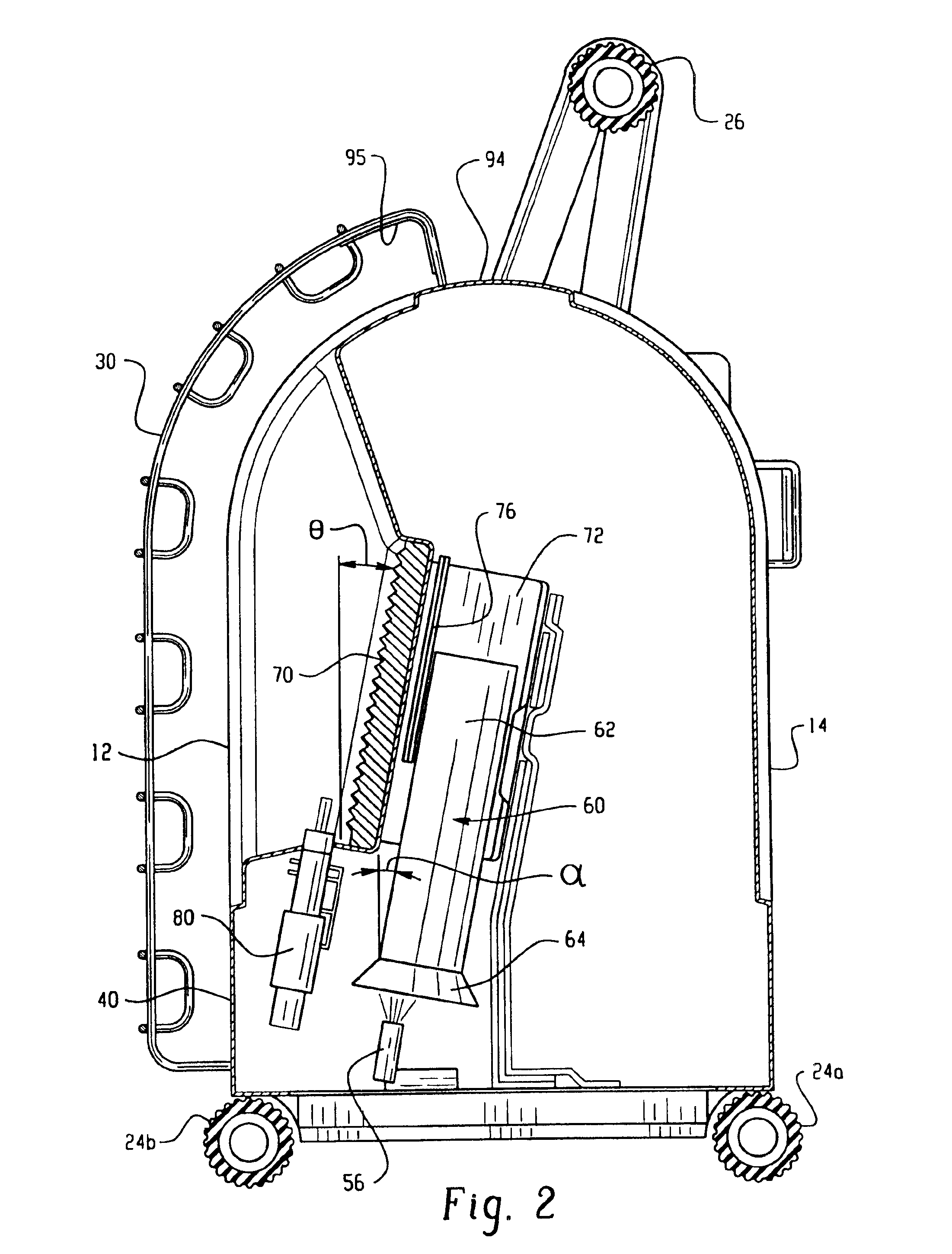

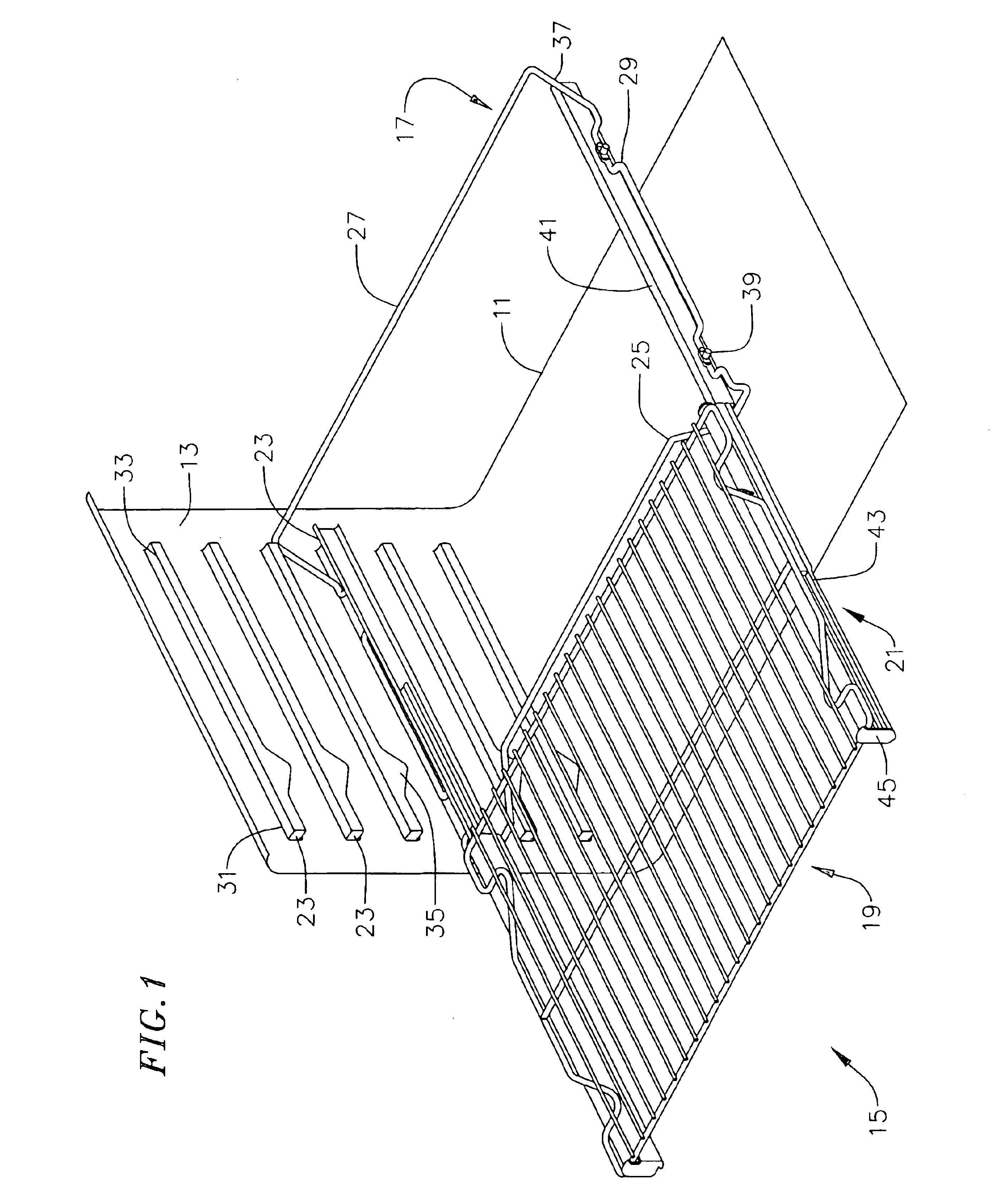

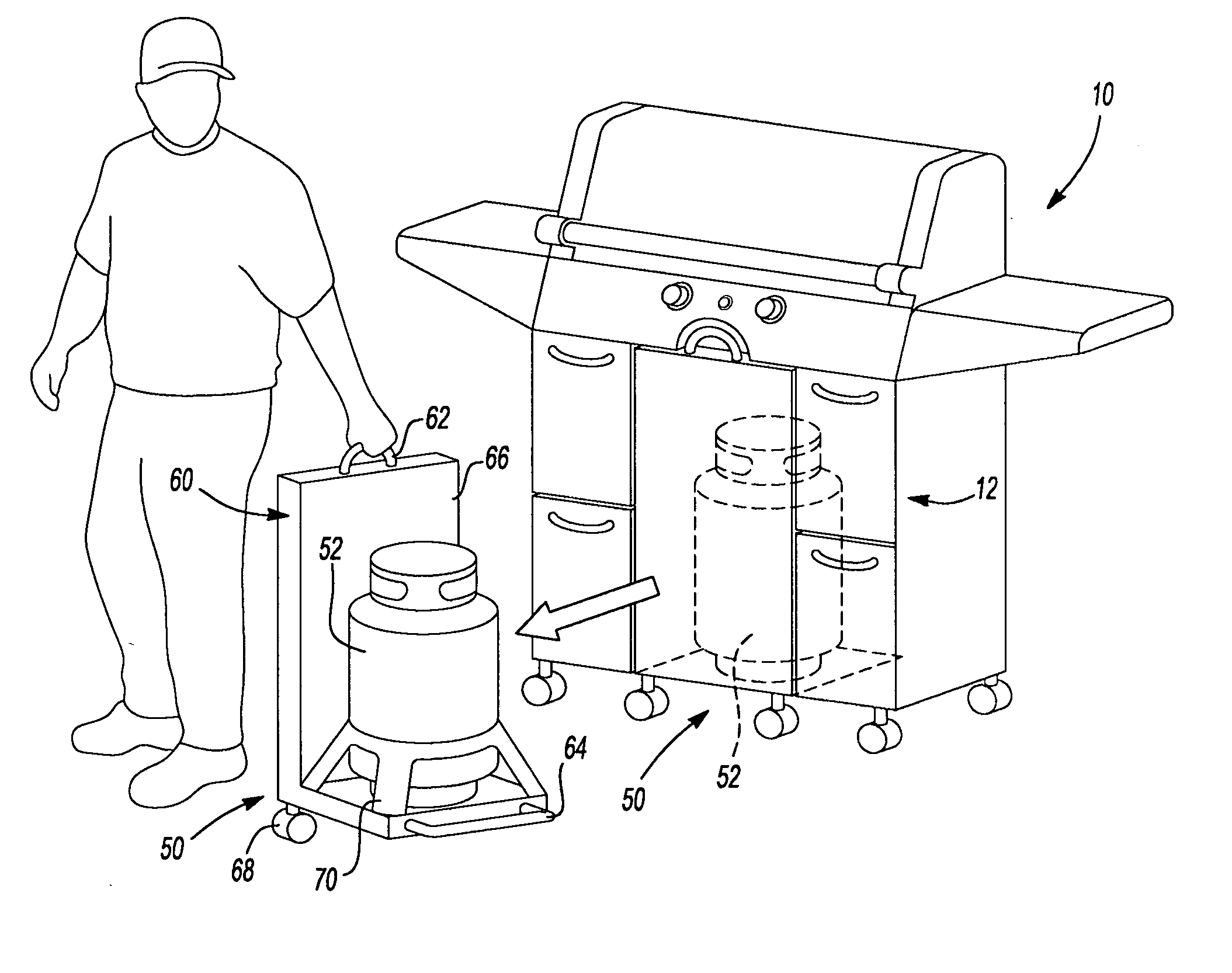

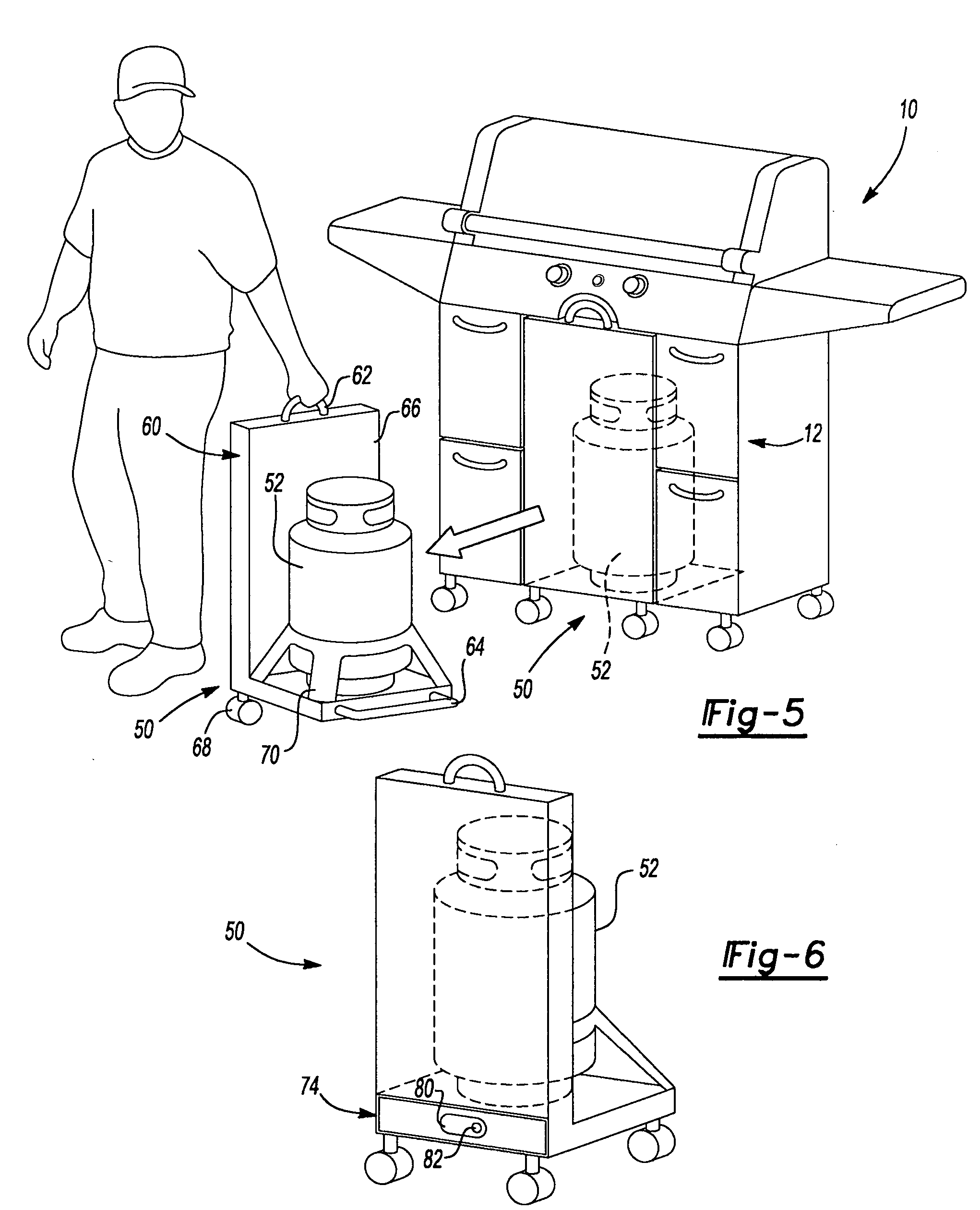

Swingable apparatus attachable to a vehicle for transporting a cooking device and permitting access to the vehicle

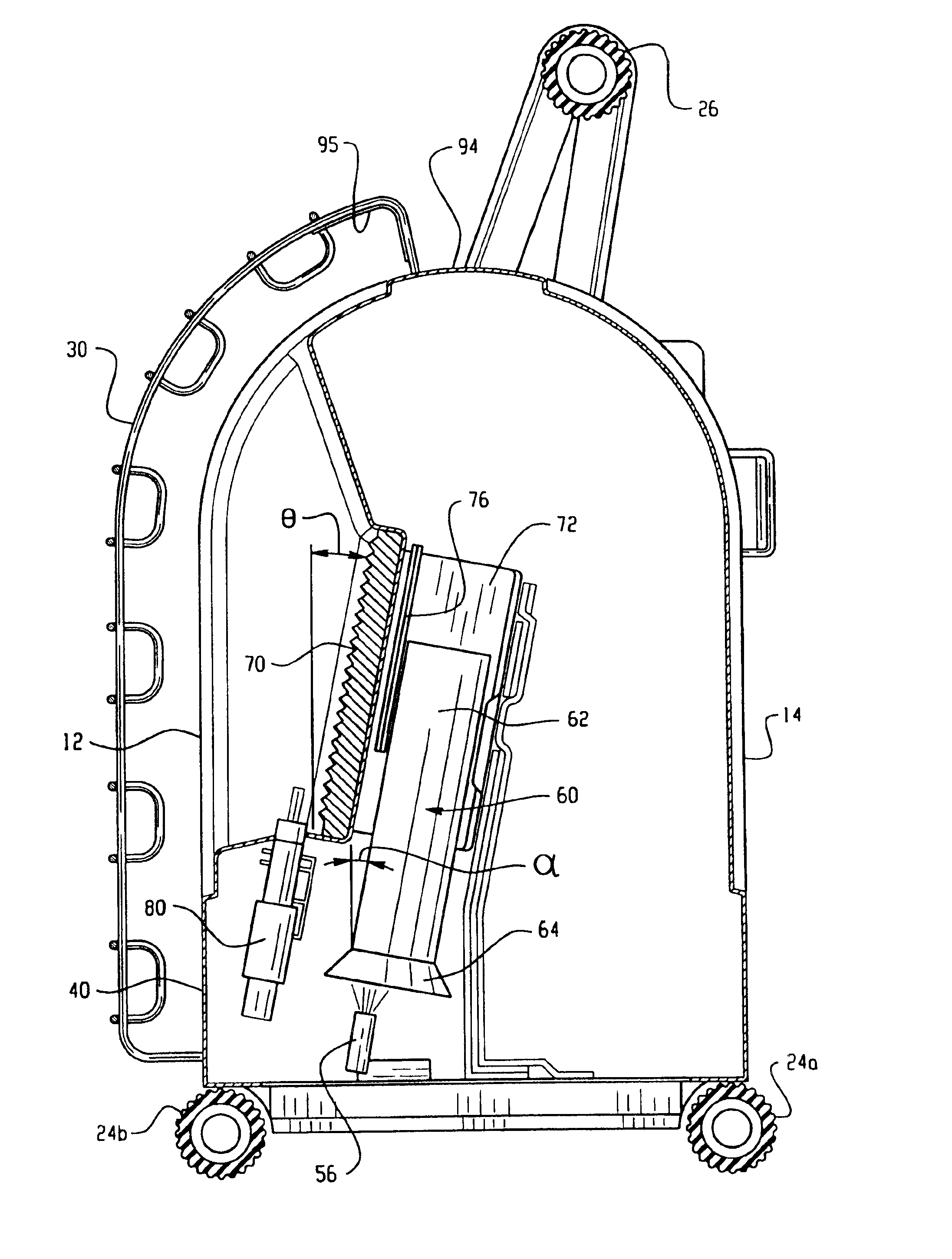

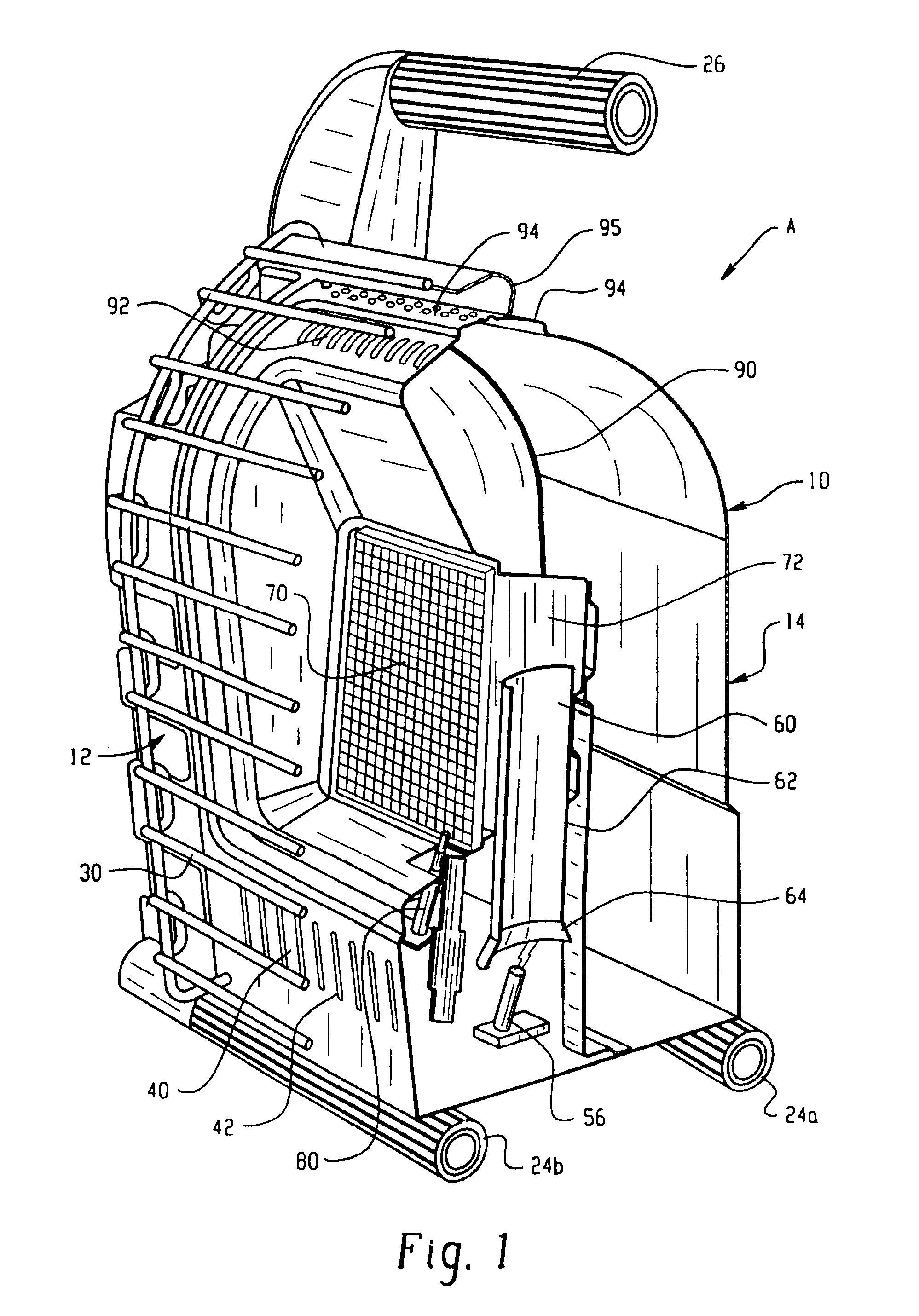

An apparatus that is selectively attachable to a vehicle, for transporting a cooking device and positioning the cooking device in a desired orientation for cooking that also permits access to the vehicle. The apparatus includes a hitch insertion member for insertion into a trailer hitch, a support arm attached to the hitch insertion member, a swing arm attached to the support arm with a locking hinge assembly, a pedestal attached to the swing arm, and a cooking device, for example a barbeque, that is attached to a column that is inserted into the pedestal and that can rotate in the pedestal. The locking hinge assembly has a plurality of locking holes for selective alignment with an angle securing hole in the support arm for locking the swing arm at a selected angle in relation to the support arm by placing an angle locking bar into the aligned holes.

Owner:SUNBEAN PROD INC

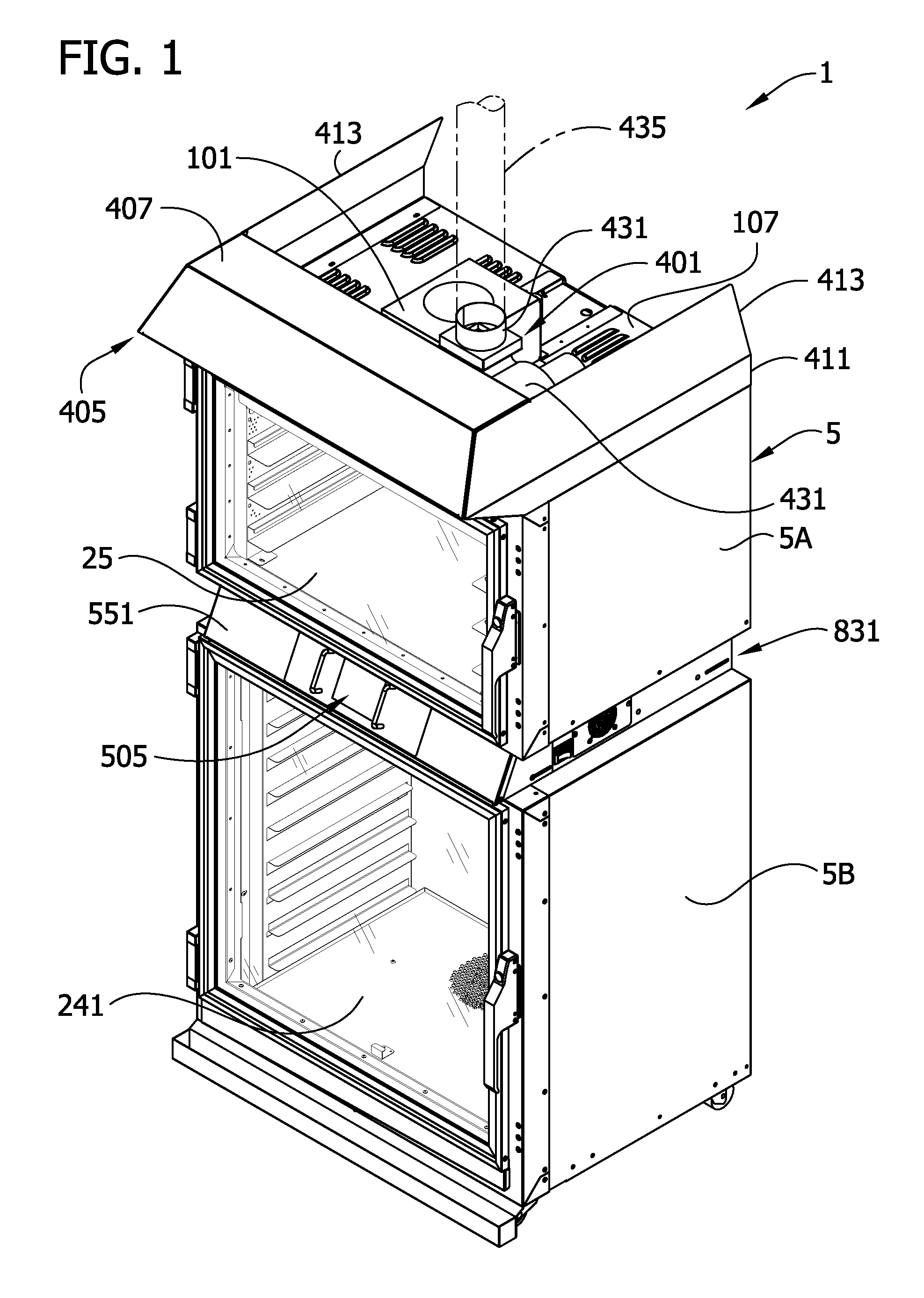

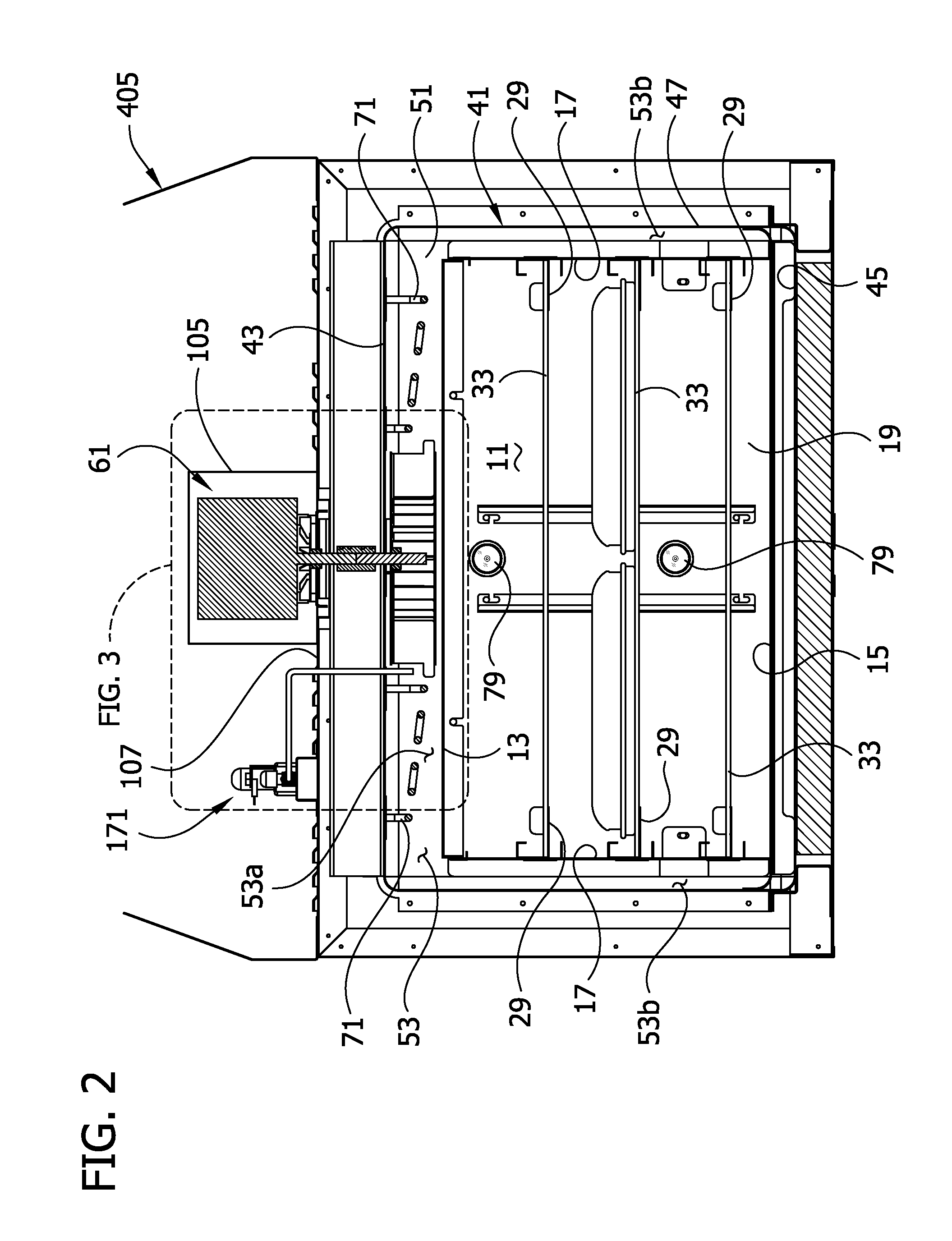

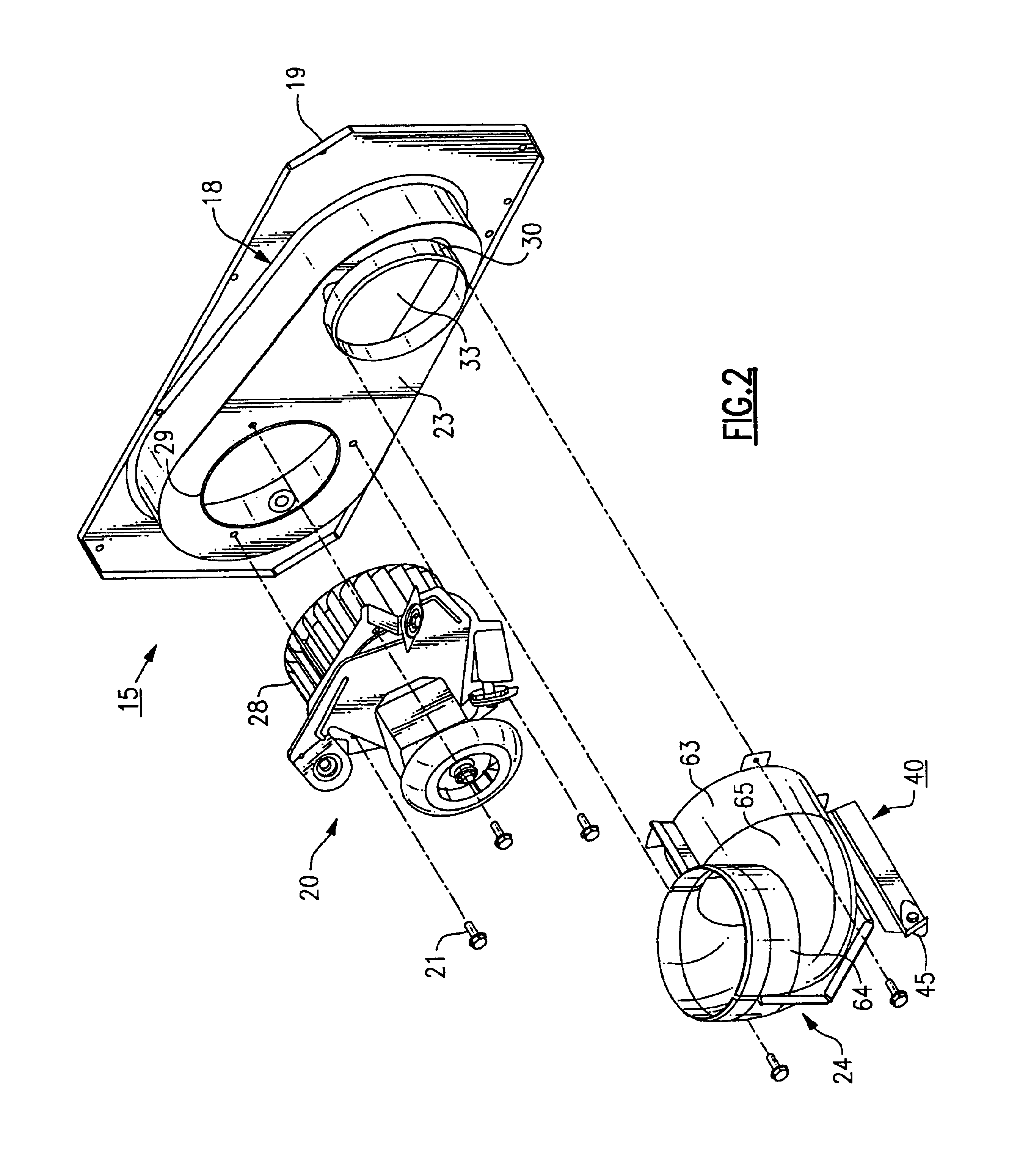

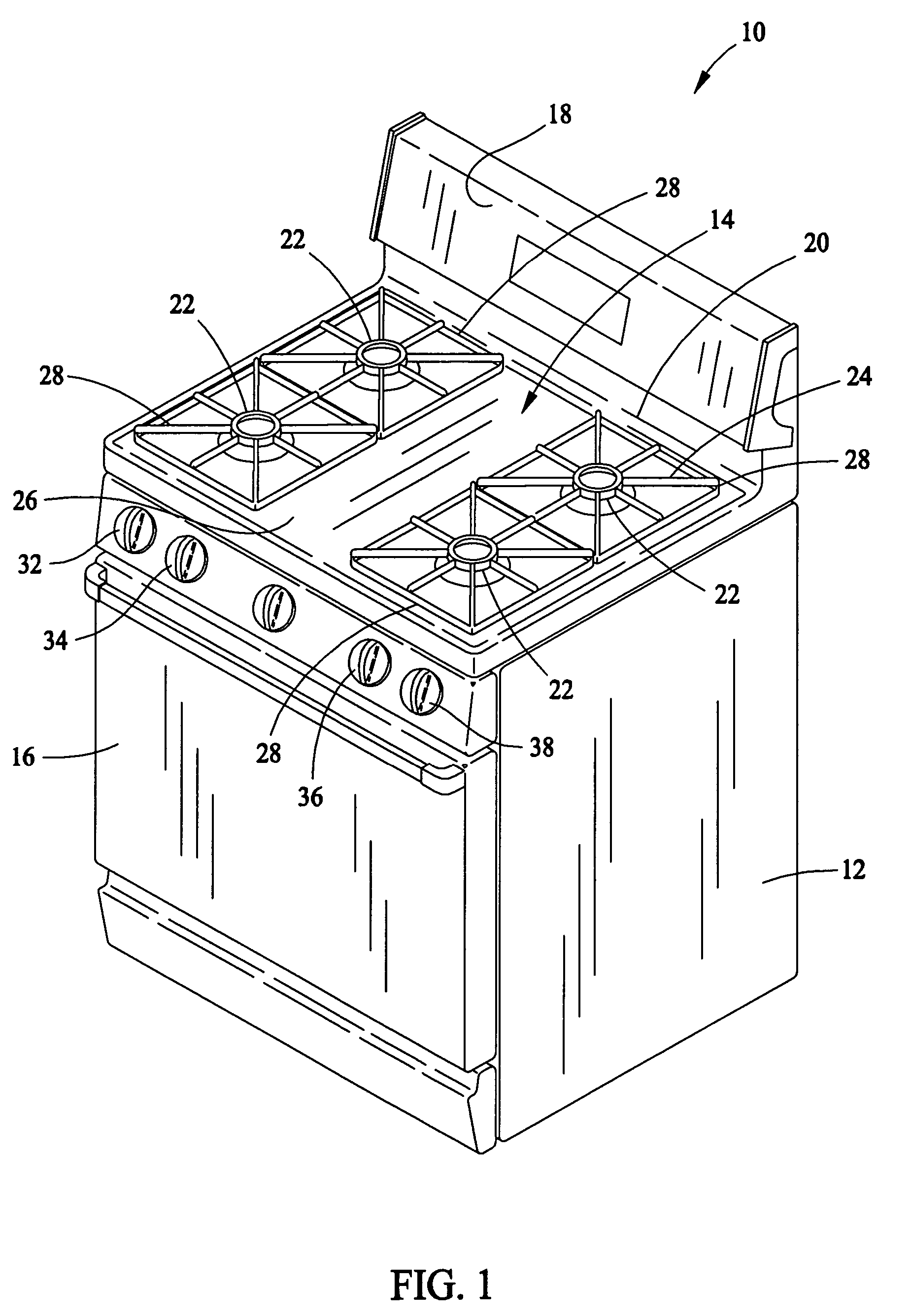

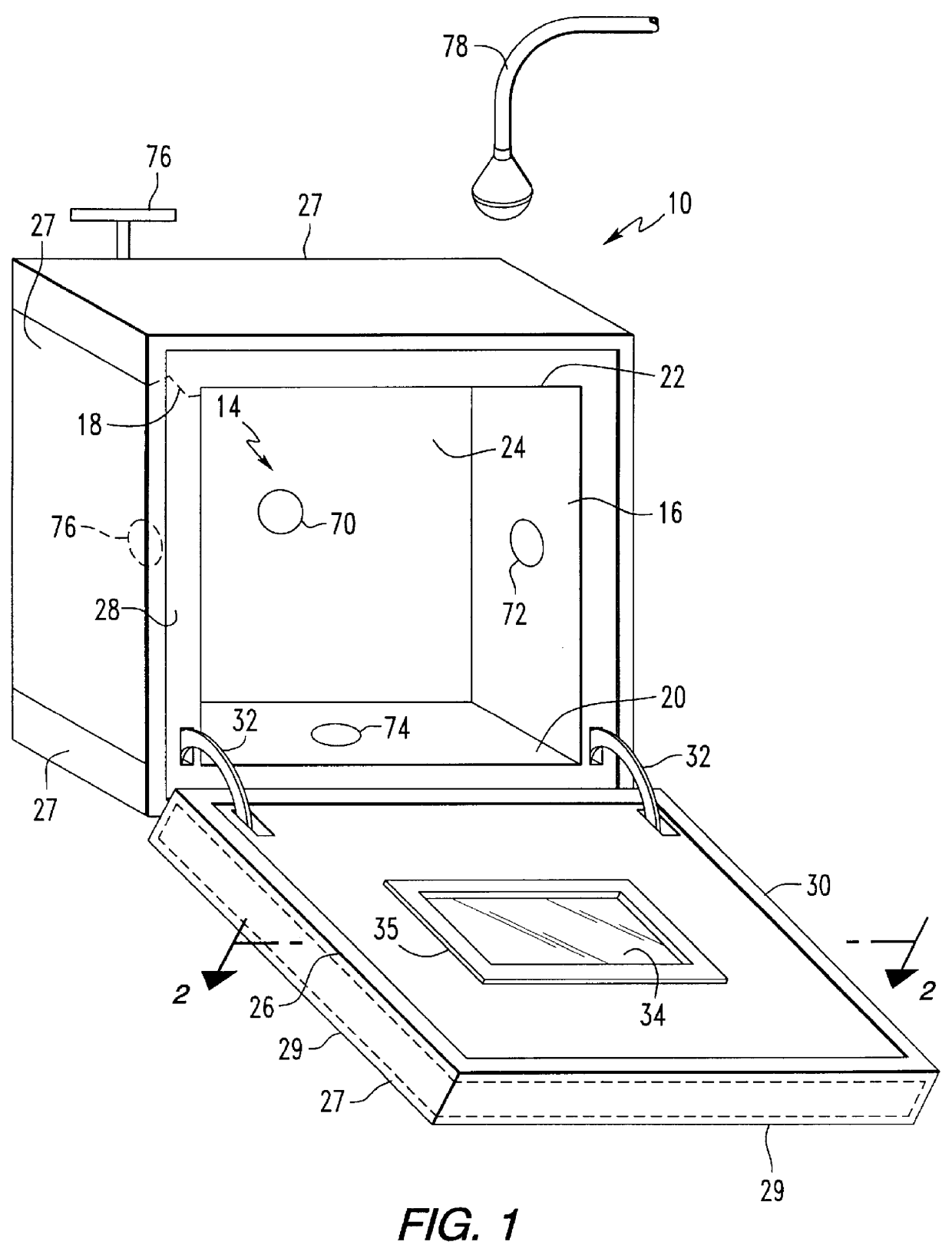

Speed cooking oven

InactiveUS6874495B2Prevent excessive grease build-upSolve the quick installationSelf-cleaning stoves/rangesMeat/fish preservationAir movementProcess engineering

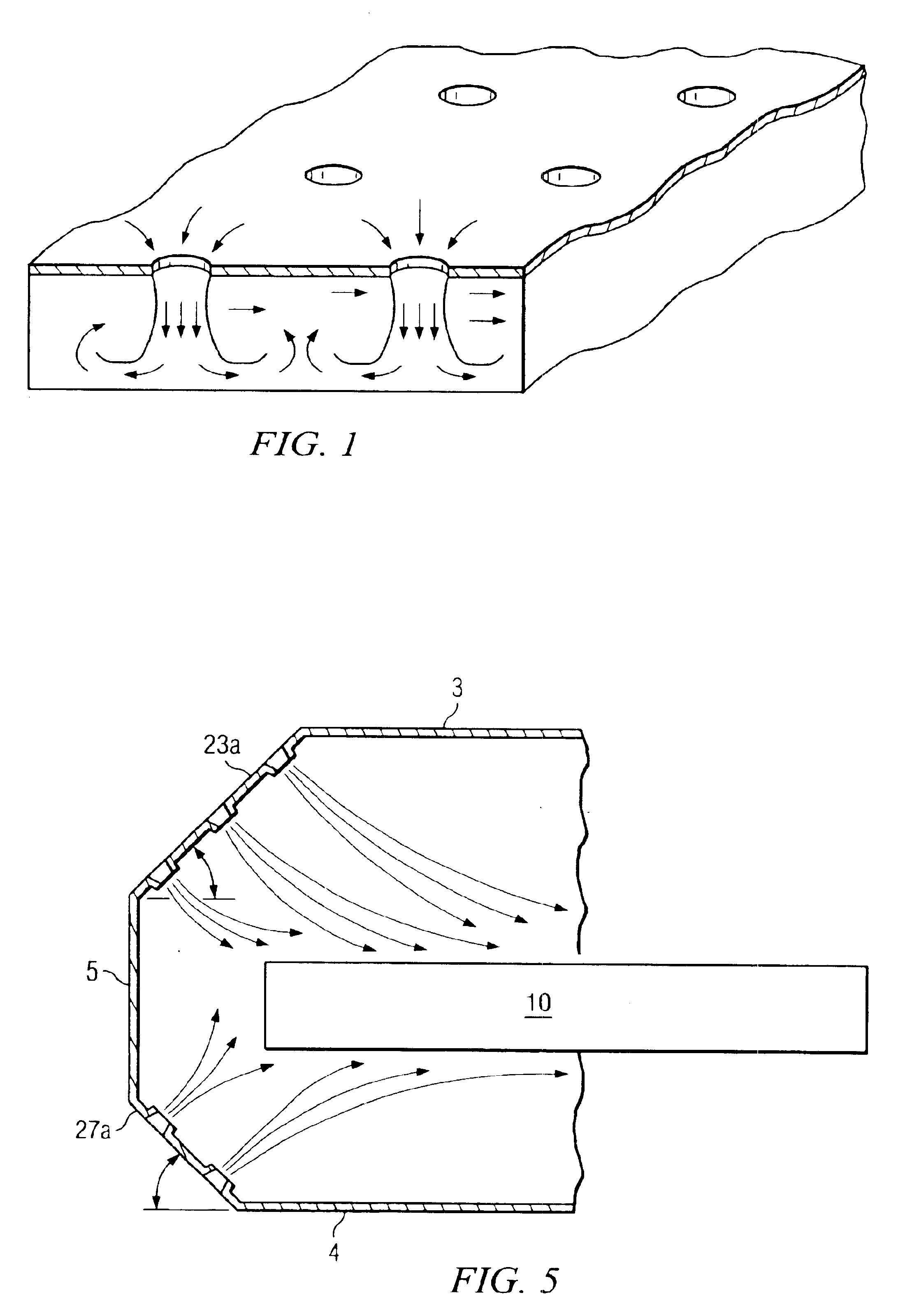

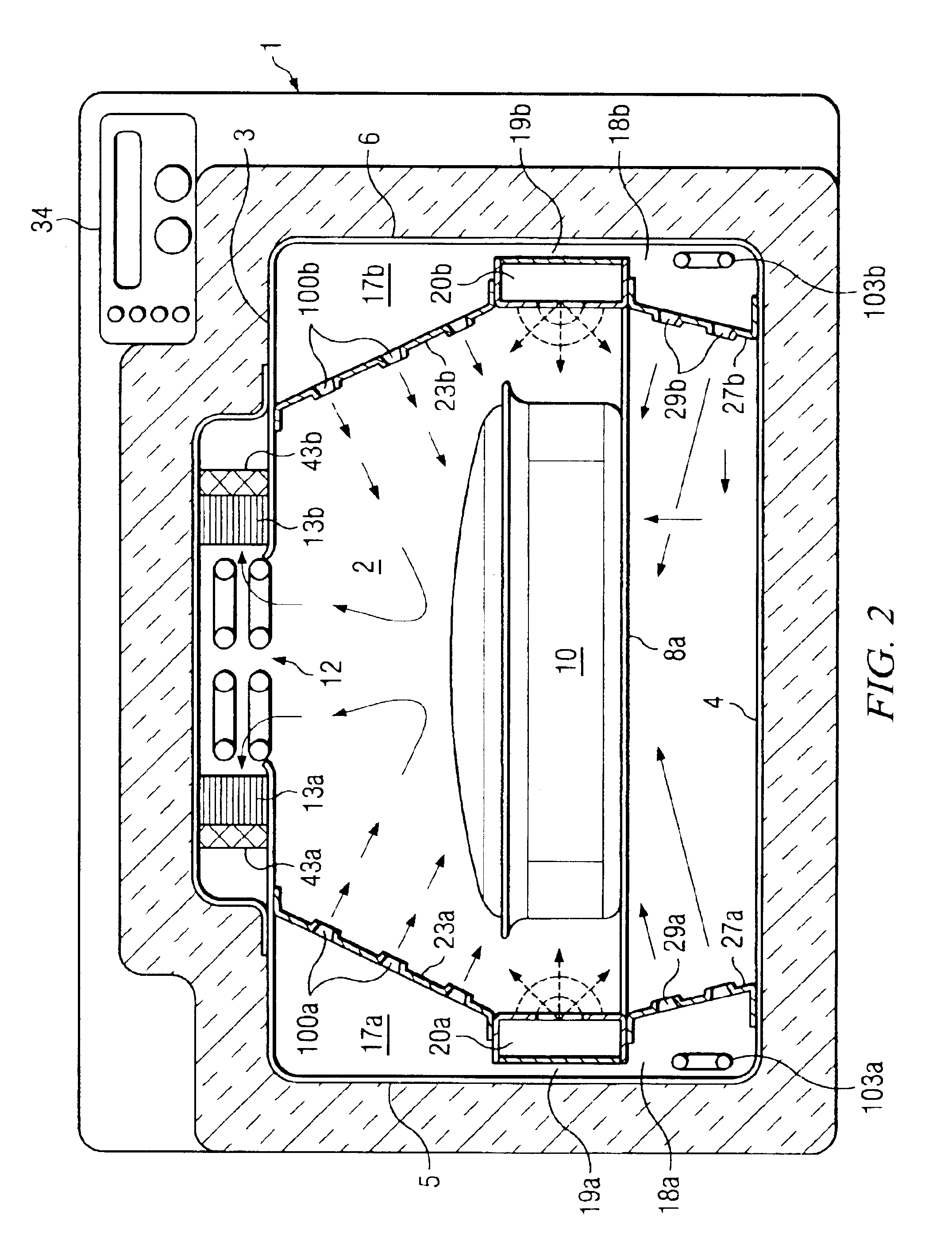

A speed cooking ovens is disclosed comprising a cooking cavity, thermal heating source, air movement and directing means, air flow control means, an air delivery means, and a vent assembly. The speed cooking oven may additionally utilize air flow control mechanisms and be practiced as a single rack speed cooking oven or a multi rack speed cooking oven. Hot gas is circulated to and from the oven cavity via air delivery means, such that turbulently mixed glancing, conflicting and colliding air flows mix at and about the surfaces of the food product. The turbulently mixed air flows are spatially averaged over the surface area of the food product producing high heat transfer and moisture removal rates, thereby optimizing speed cooking of the food product.

Owner:TURBOCHEF TECH INC

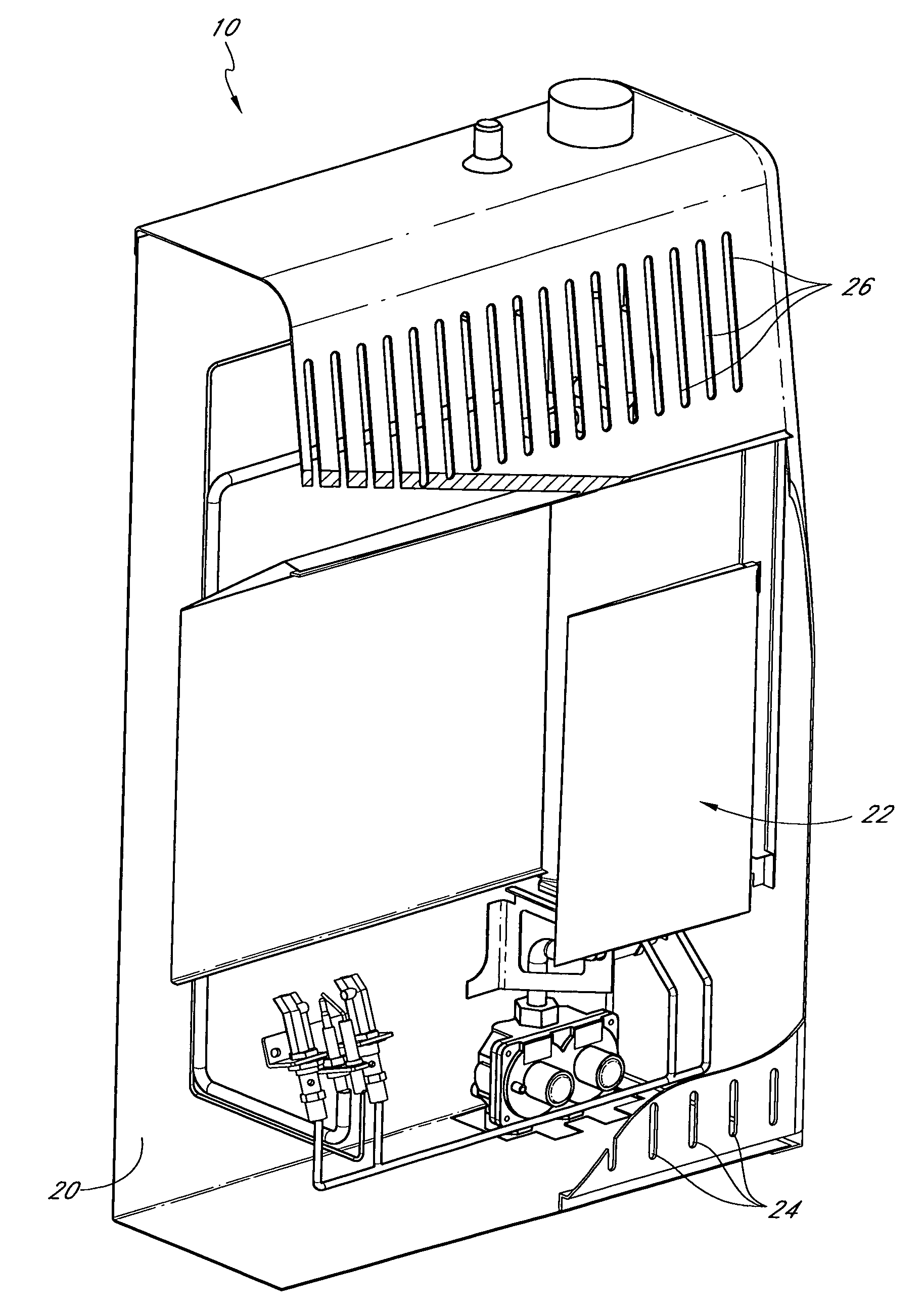

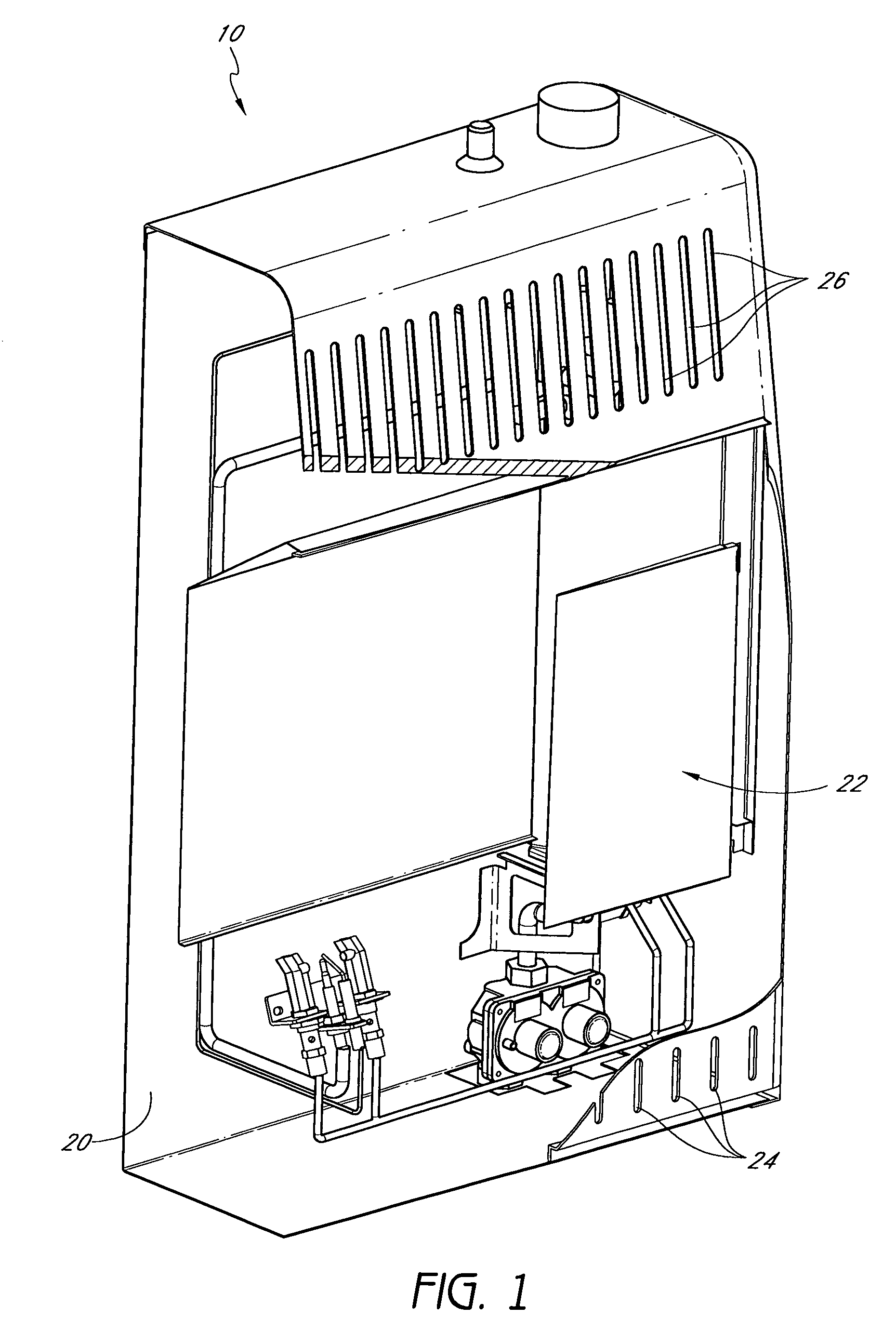

Gas fired portable unvented infrared heater

InactiveUS6884065B2Reduce the temperatureIncrease air velocityMechanical apparatusDomestic stoves or rangesFresh airEngineering

A portable heater adapted for use in a recreational enclosure or temporary work enclosure includes a housing having an air inlet on the lower front face. A gas supply is partially enclosed by the housing which provides propane to the mouth of a burner venturi located within the housing. Air is drawn through the air inlet and also enters the mouth of the burner venturi. The air and gas are mixed thoroughly as they travel upwardly through the burner venturi. A chimney effect increases fresh air flow velocity into the burner venturi and allows the heater to operate at a reduced fuel gas pressure. Upon exiting the burner venturi, the air / gas mixture is to a plenum and radiant surface where combustion takes place. Any conventional means may be provided to ignite the air / gas mixture in order to cause combustion. The combustion products deflect off a deflector, which is cooled on a rear face by air flow through the housing, which decreases the temperature of the combustion products before exiting an outlet. An oxygen depletion system (ODS) shuts off the portable heater when oxygen levels begin to drop and consequently carbon monoxide levels begin to rise.

Owner:ENERCO GROUP

Multiple fuel cooking unit

InactiveUS20170164783A1Maintain sufficiencyWide rangeDomestic stoves or rangesLiquid heating fuelElectrical resistance and conductanceAutomatic control

A cooking unit may operate using multiple types of fuel to cook food. One or more first heat source, such as gas burners, electrical resistive heaters, and / or other heating technology, may provide radiant heat to a cooking chamber. One or more second heat source, such as a firebox, may provide indirect heat to the cooking chamber, for example by producing smoke. User operable controls and / or an automated control unit may alter the rate at which a fuel and / or air is supplied to one or more heat source.

Owner:SMOKESTEAK LLC

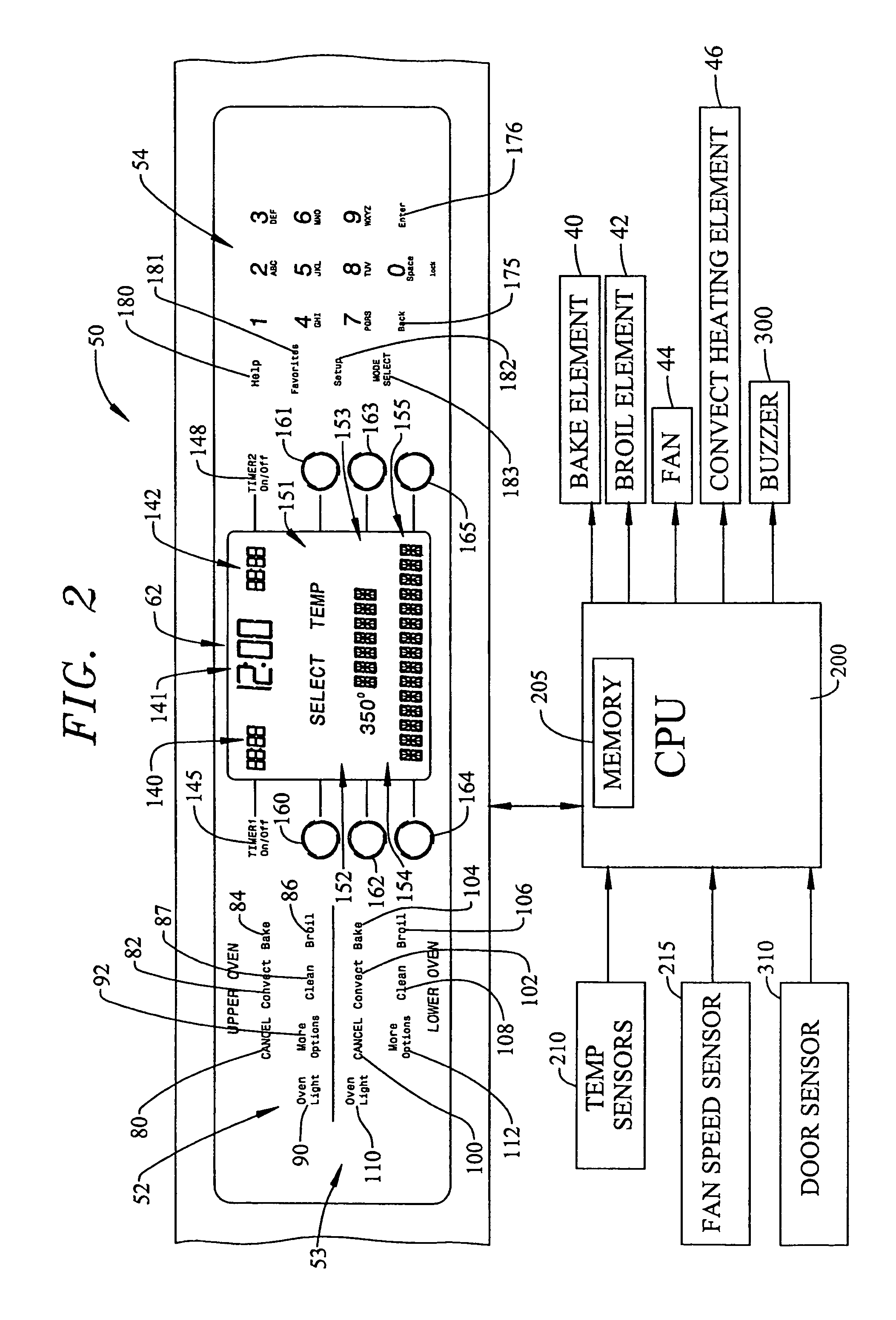

Convection oven

ActiveUS8378265B2Easy accessSelf-cleaning stoves/rangesElectrical heating fuelImpellerLiquid-crystal display

Owner:DUKE MANUFACTURING COMPANY

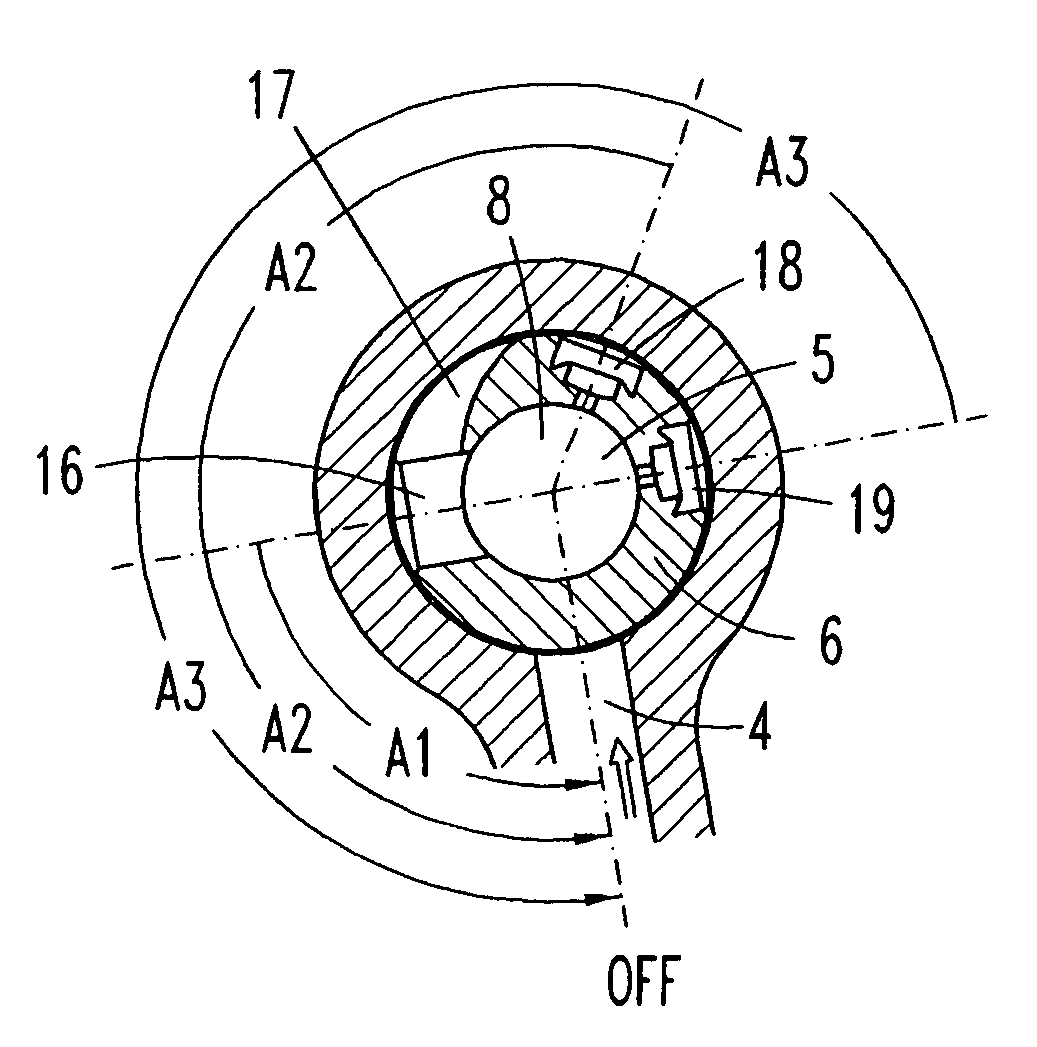

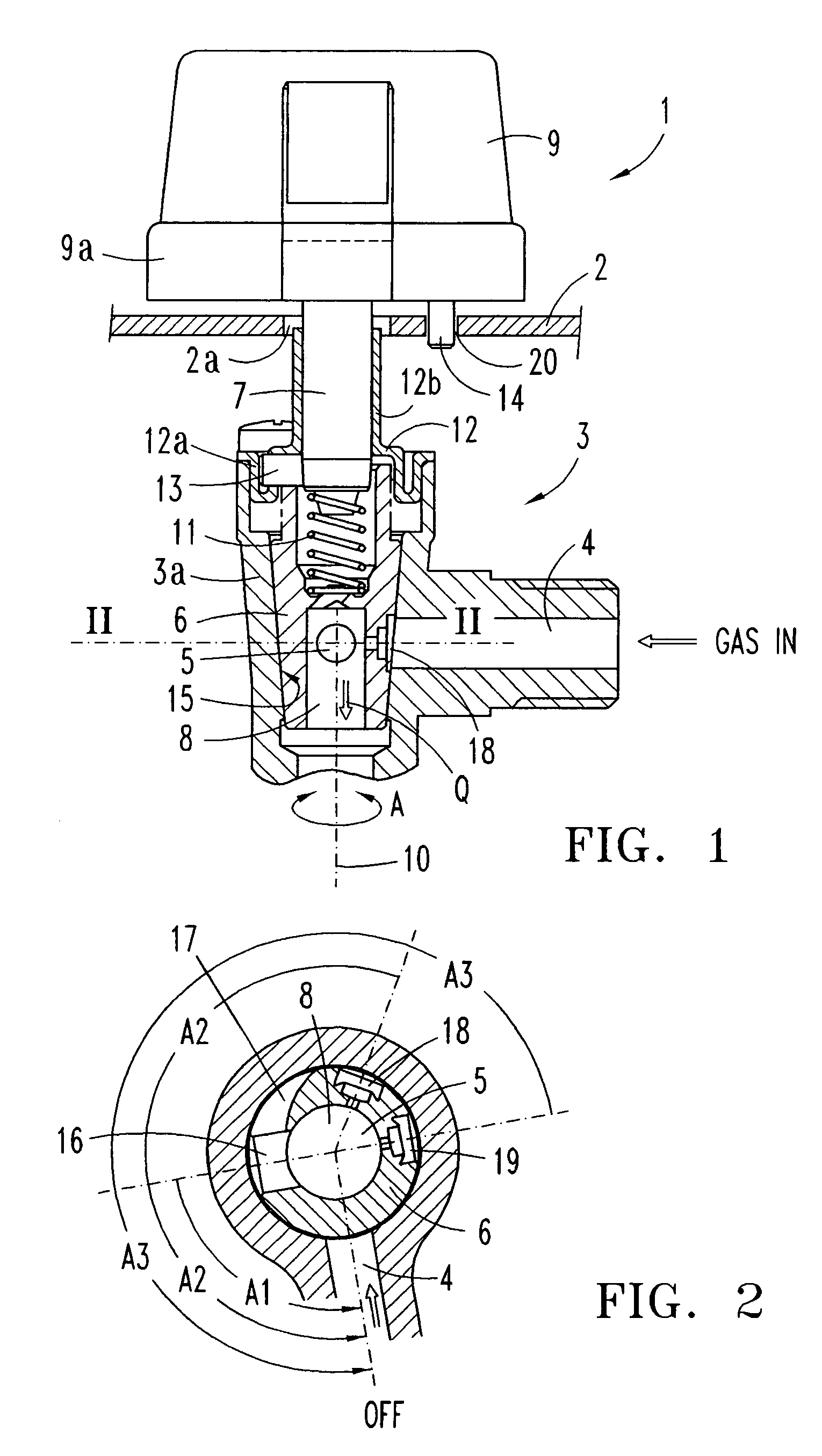

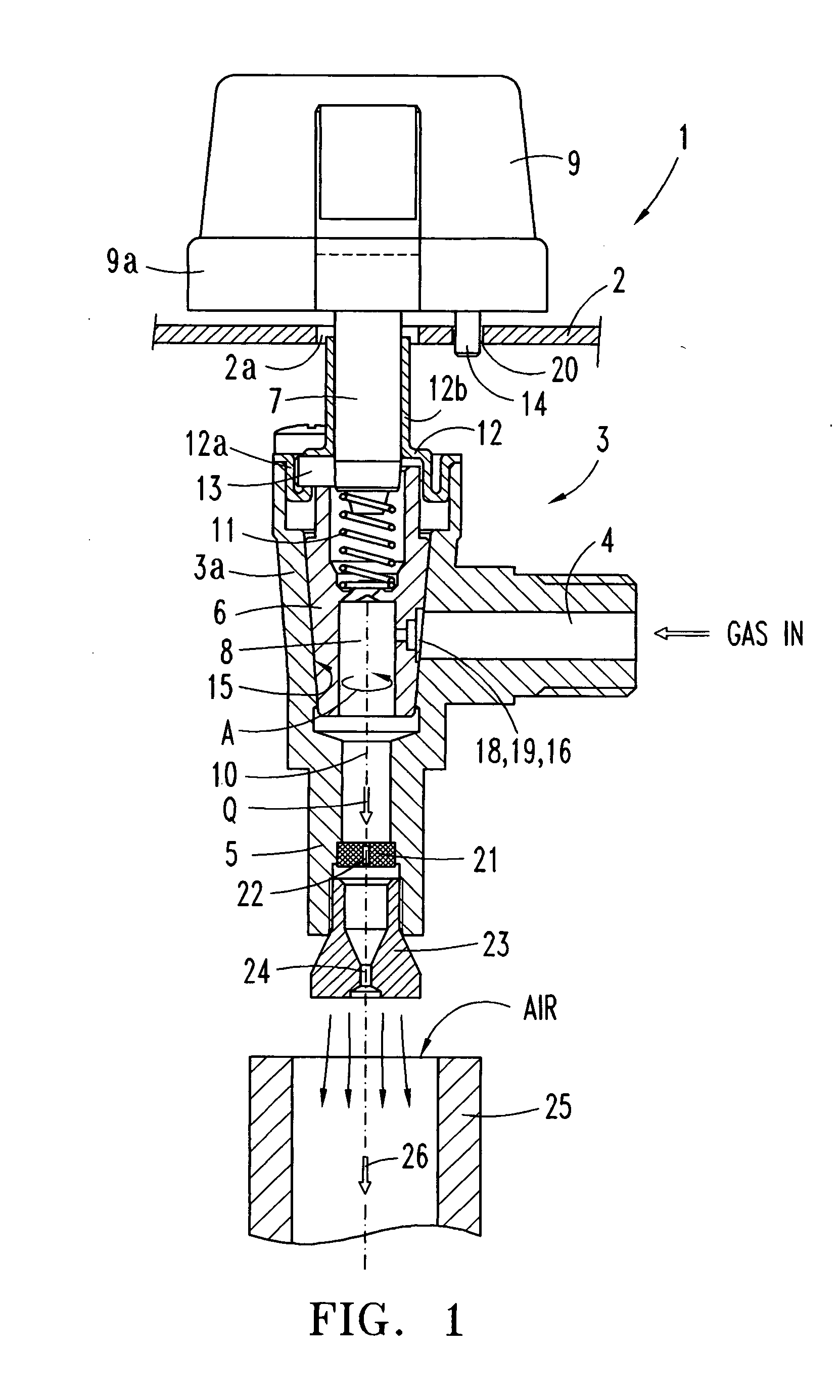

Rotary valve in a multi-gas cooker

The cooking appliance (1) having a control panel (2) is equipped with one or more gas flow (Q) regulating valves, wherein the rotary regulator organ (6) is provided with various peripheral through holes (16–19). The control knob (9) being interchangeable for fitting to the actuating shaft (7), is chosen from the two units available, one and the other permitting different angular limit positions (A2, A3) for the supply of a constant minimum gas flow Qmin, through one of two successive holes (18, 19) calibrated each one for a different type of gas NG or LPG, one or the other hole being superimposed to a valve inlet duct (4) at a different angular position A2, A3. An integral lug (14) on the control knob (9) running into a slide groove (20) in the control panel (2), establishes a first rotation stop A2.

Owner:ALBIZURI INIGO

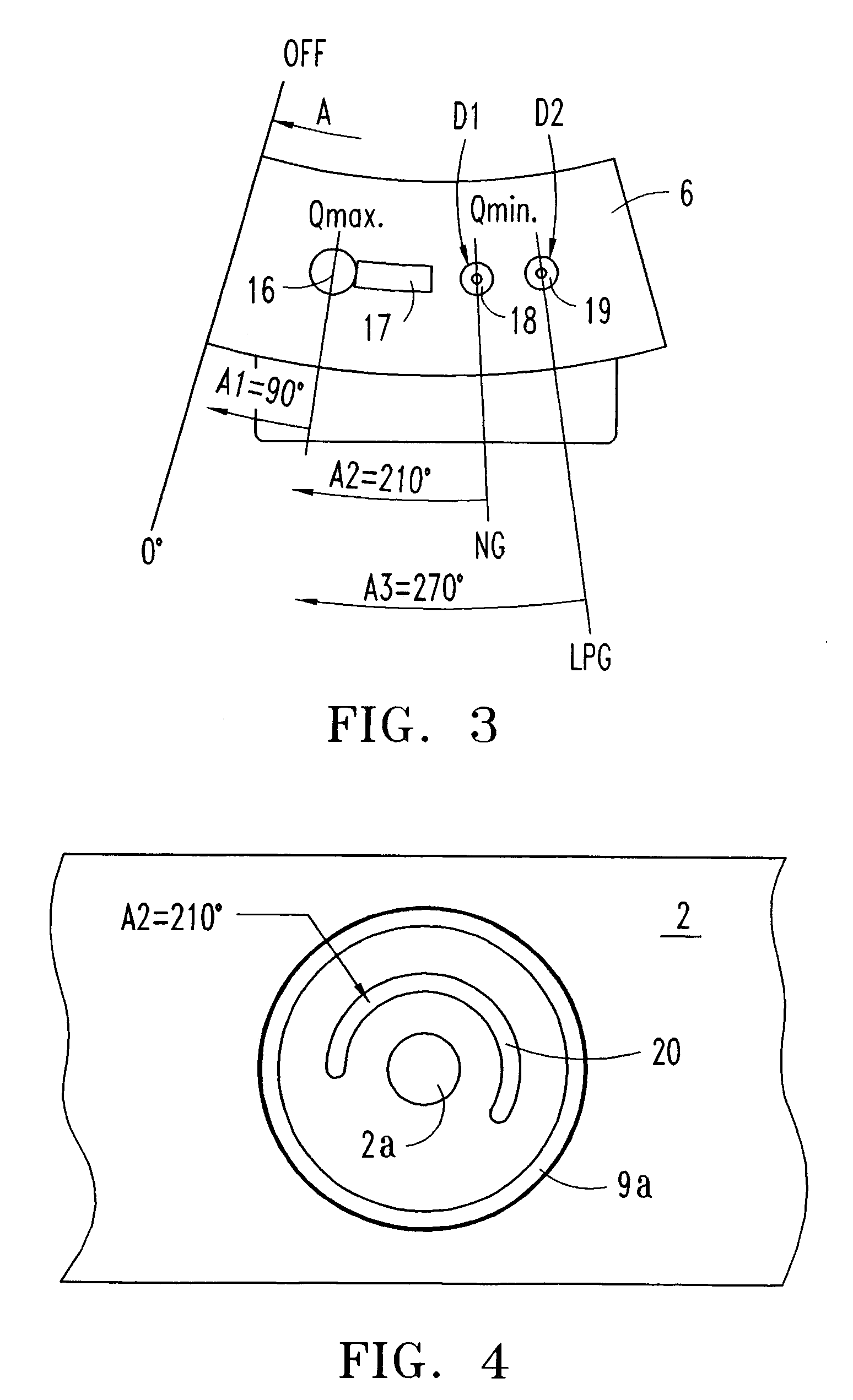

System and method for draft safeguard

A gas furnace responsive to a thermostat includes a thermal switch wired in series between the furnace power supply and the thermostat. A microprocessor connected to the thermal switch detects when the switch opens and closes, carrying out prearranged programs in response thereto. The thermal switch is mounted so that it opens when an over-pressure in the furnace draft system is detected, as evidenced by hot flue gasses passing over the thermal switch probe. The switch is allowed to cycle at least one time before the furnace is disabled. After a certain period of the time, the combustion cycle is reinitiated and the above steps are repeated if the thermal switch again resets.

Owner:CARRIER CORP

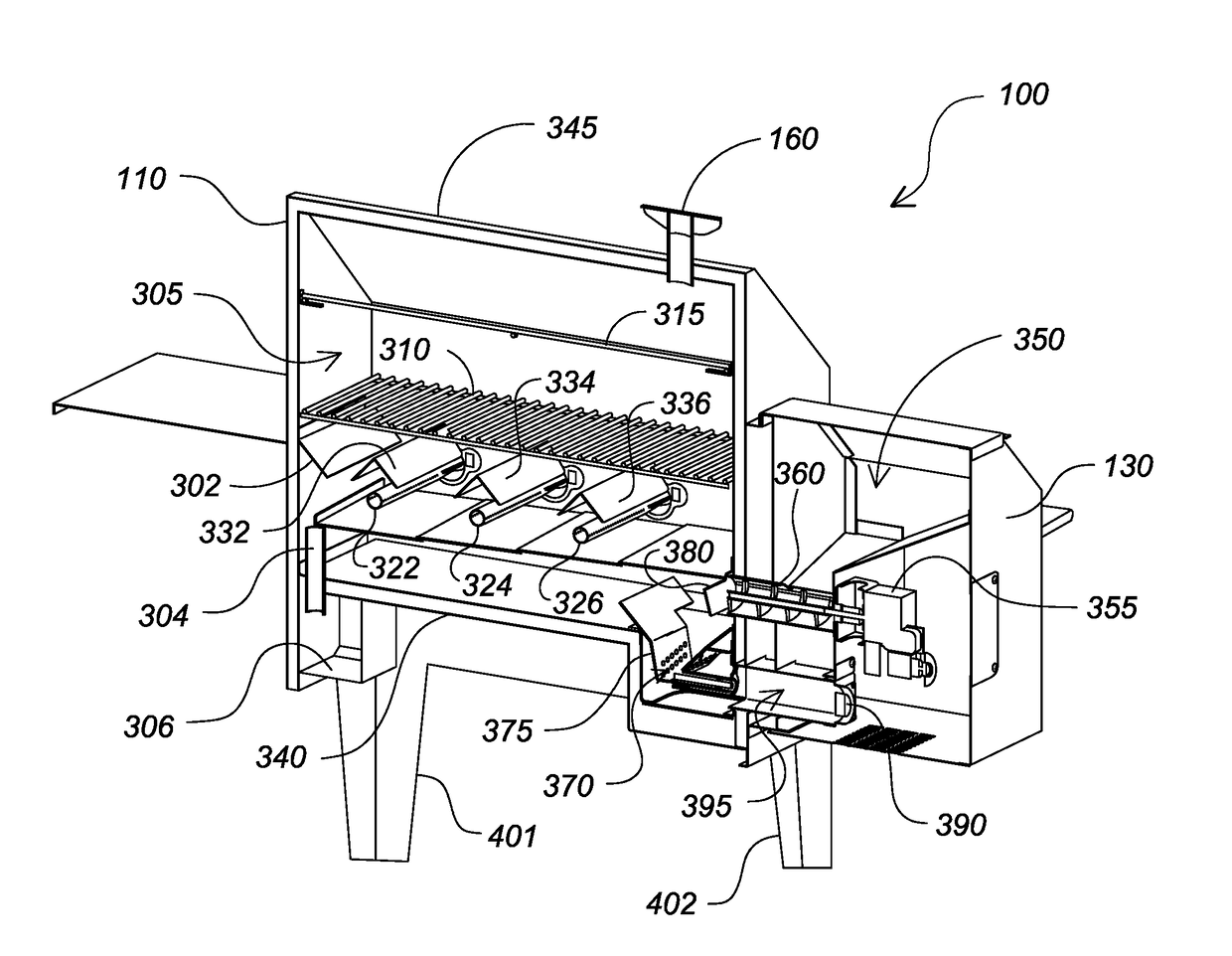

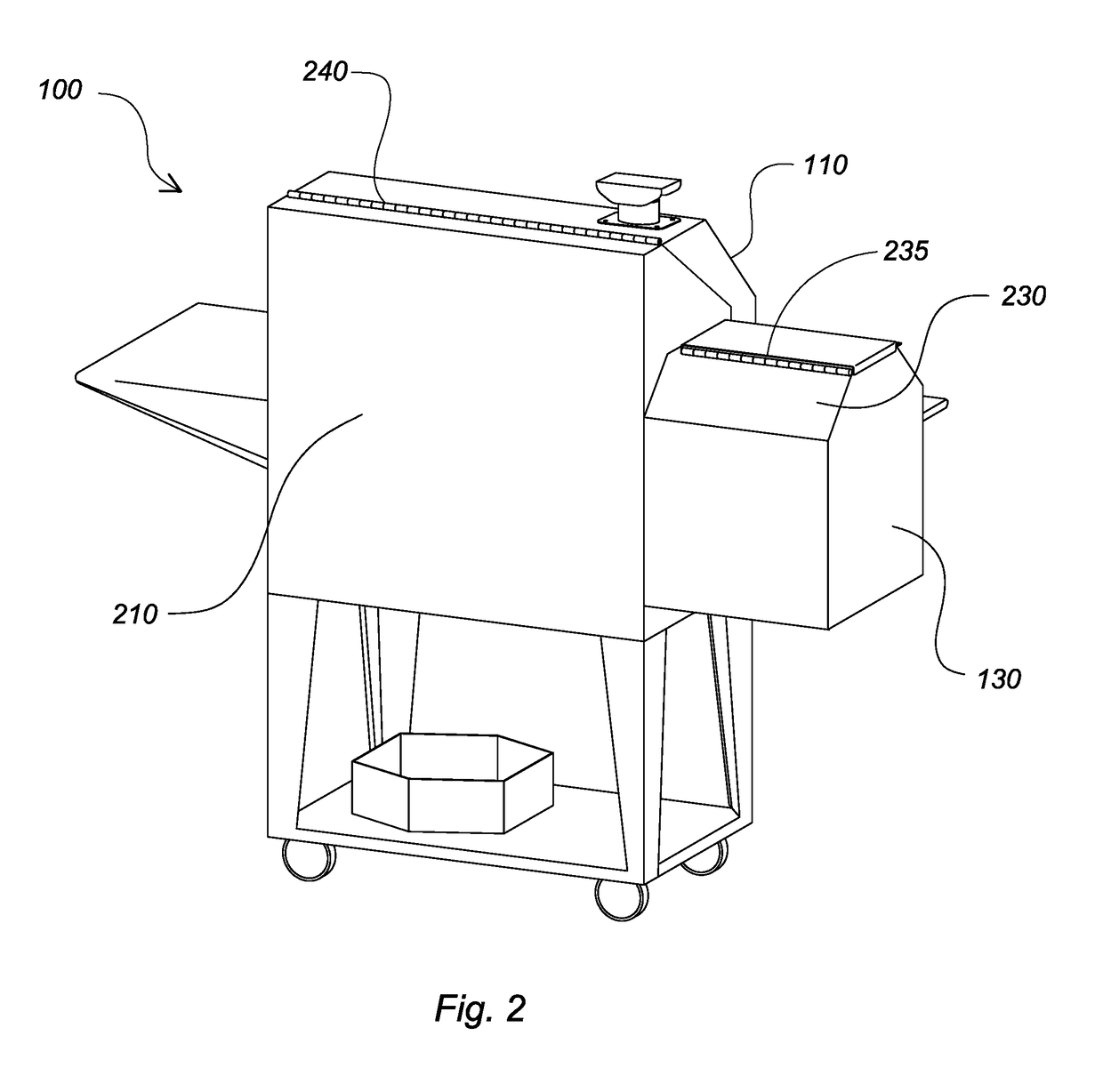

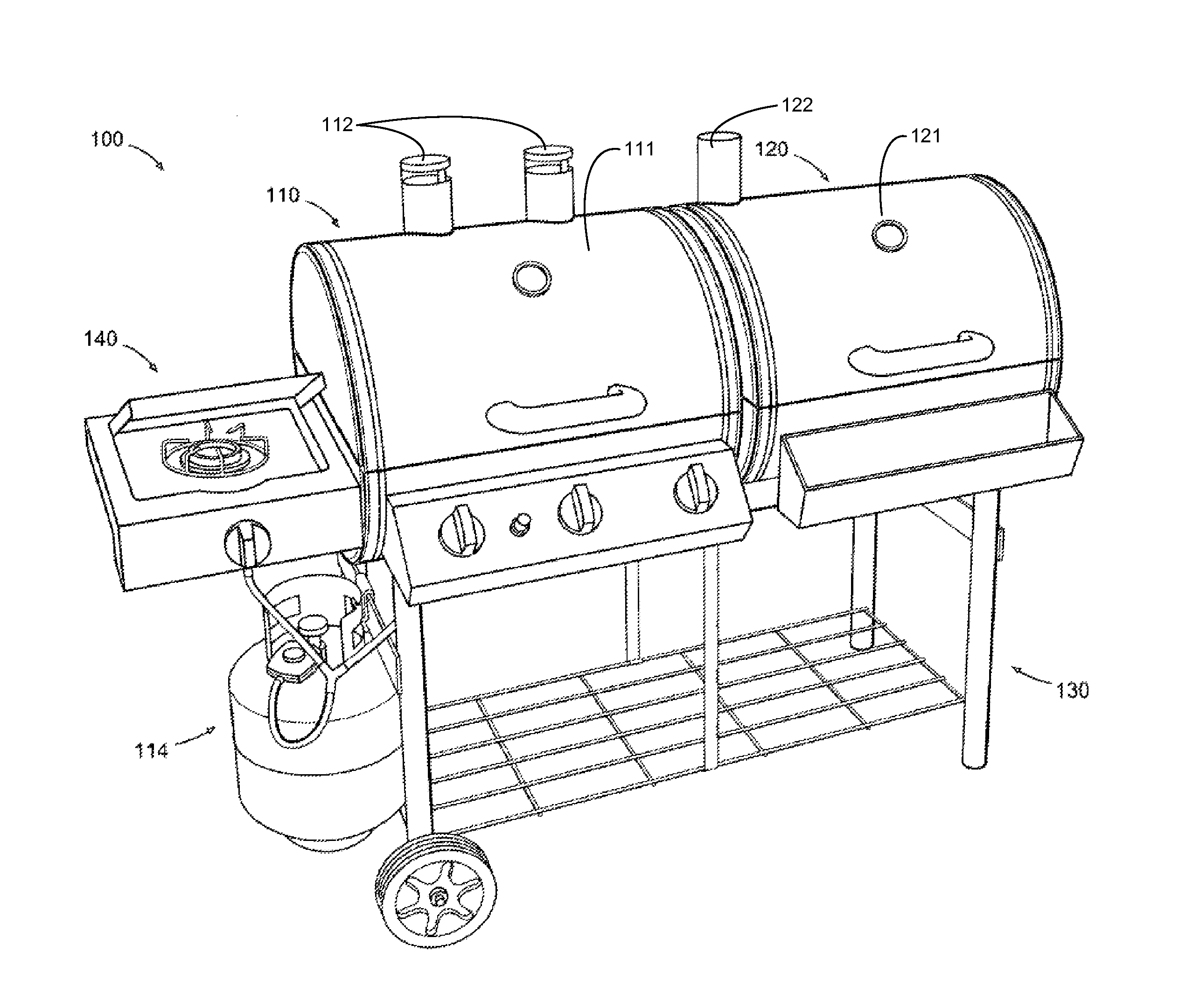

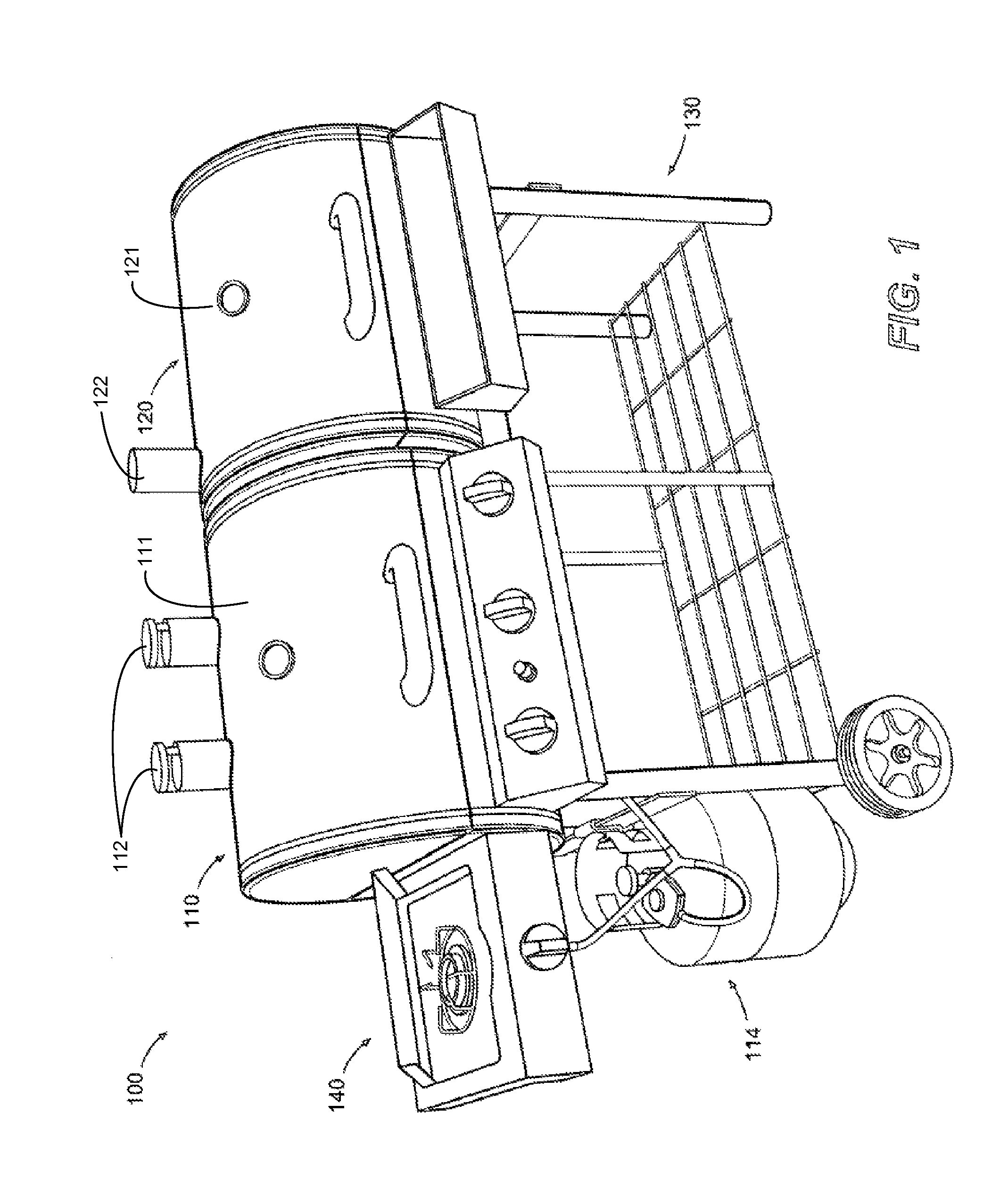

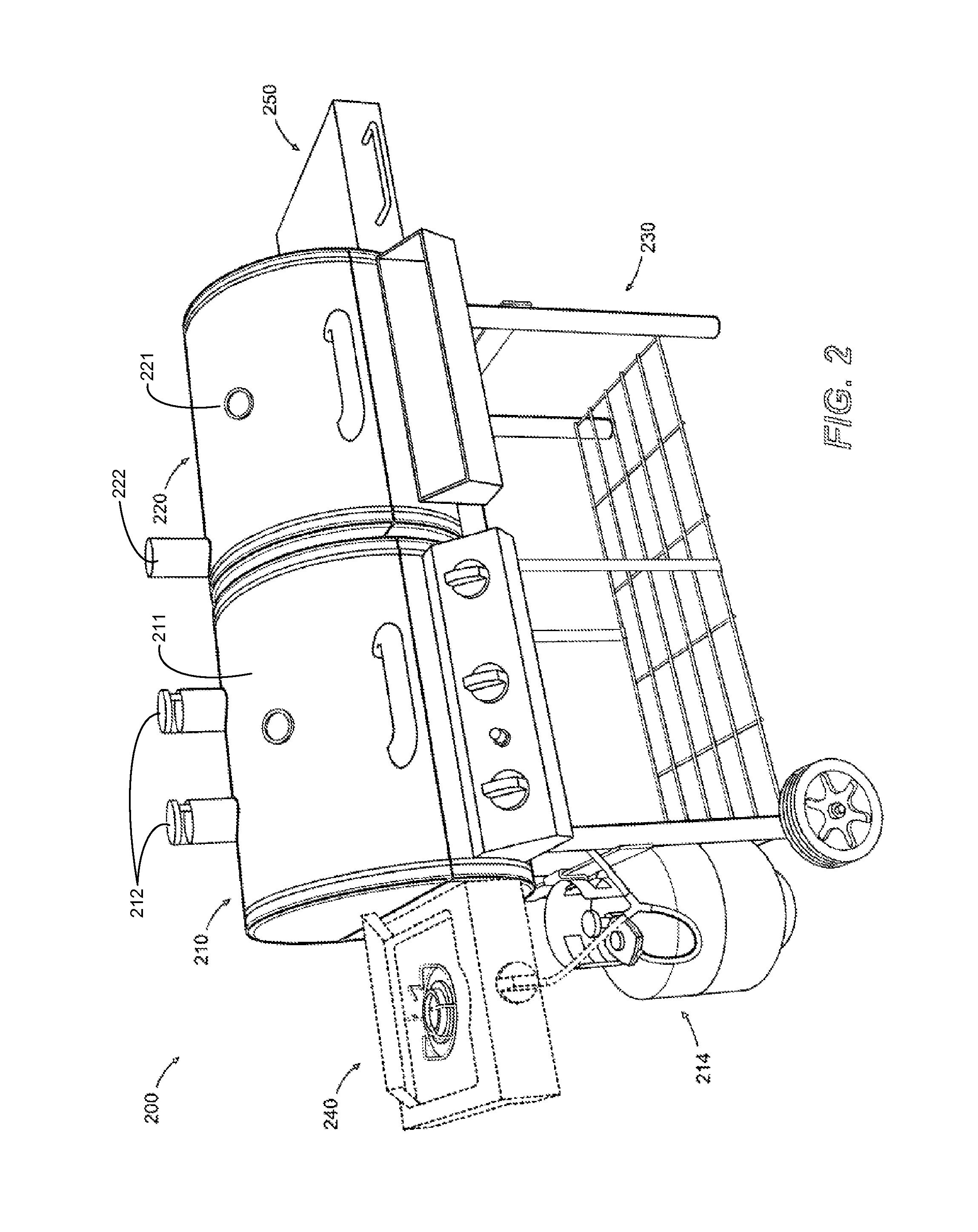

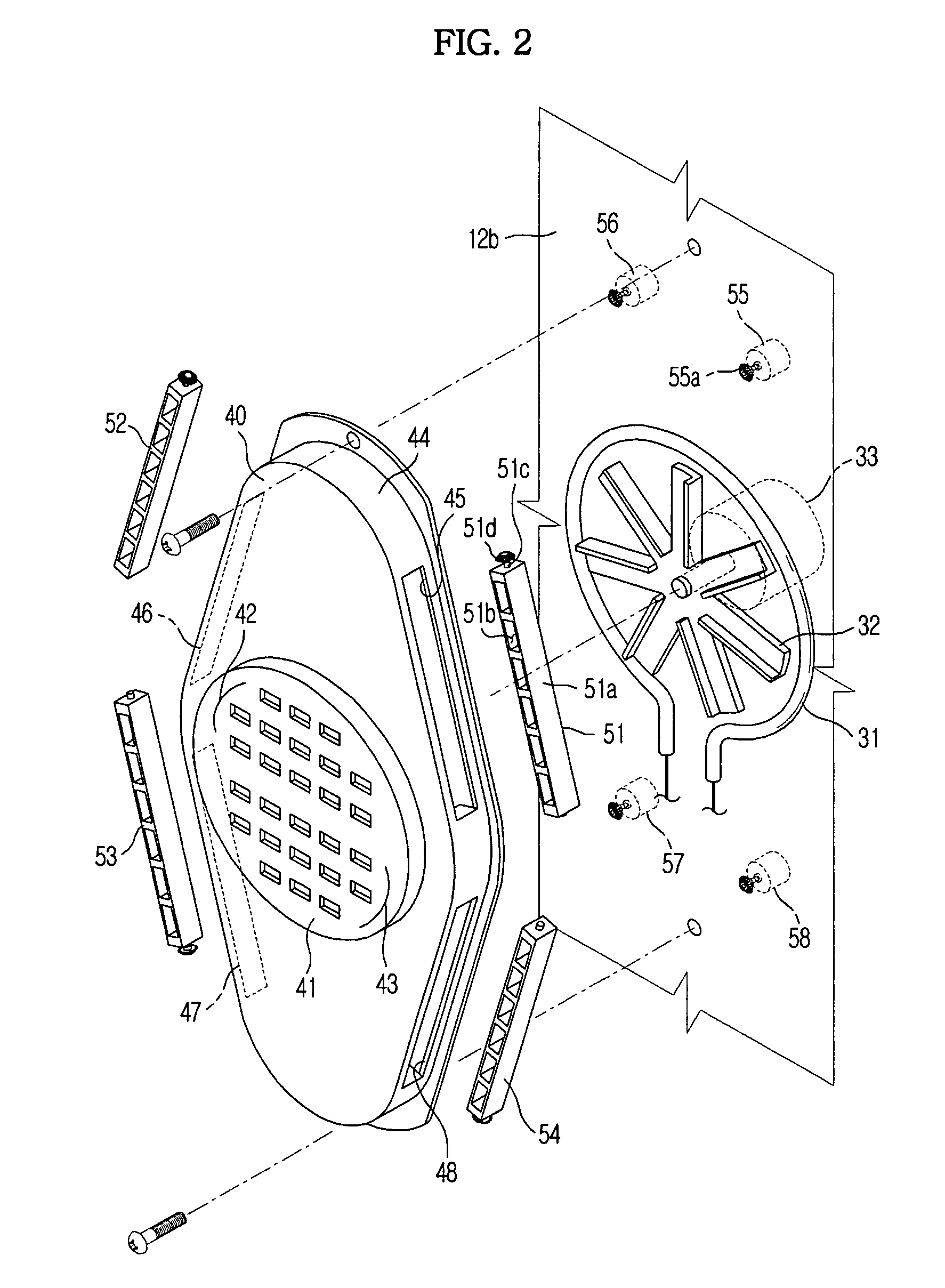

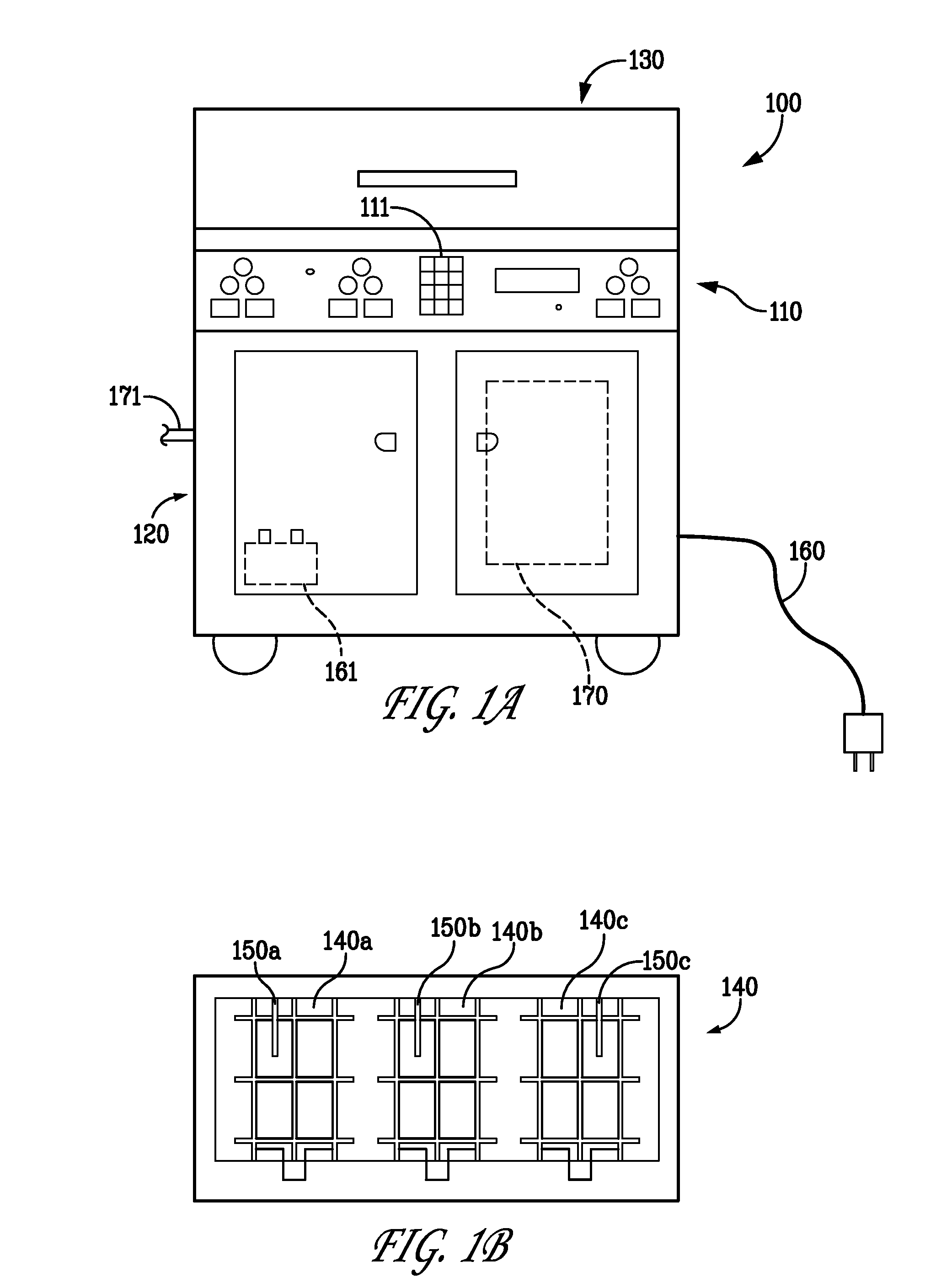

Simultaneous multiple cooking mode barbecue grill

ActiveUS8381712B1Effectively and conveniently prepareStoves/ranges foundationsDomestic stoves or rangesProcess engineering

A simultaneous multiple cooking mode barbecue grill that includes a first cooking mode unit configured to prepare food in a first cooking mode, a second cooking mode unit configured to prepare food in a second cooking mode, and a supporting structure that supports the first cooking mode unit and the second cooking mode unit so that the first and second cooking mode units can be moved securely and operated simultaneously to prepare food using multiple cooking modes.

Owner:A&J MFG

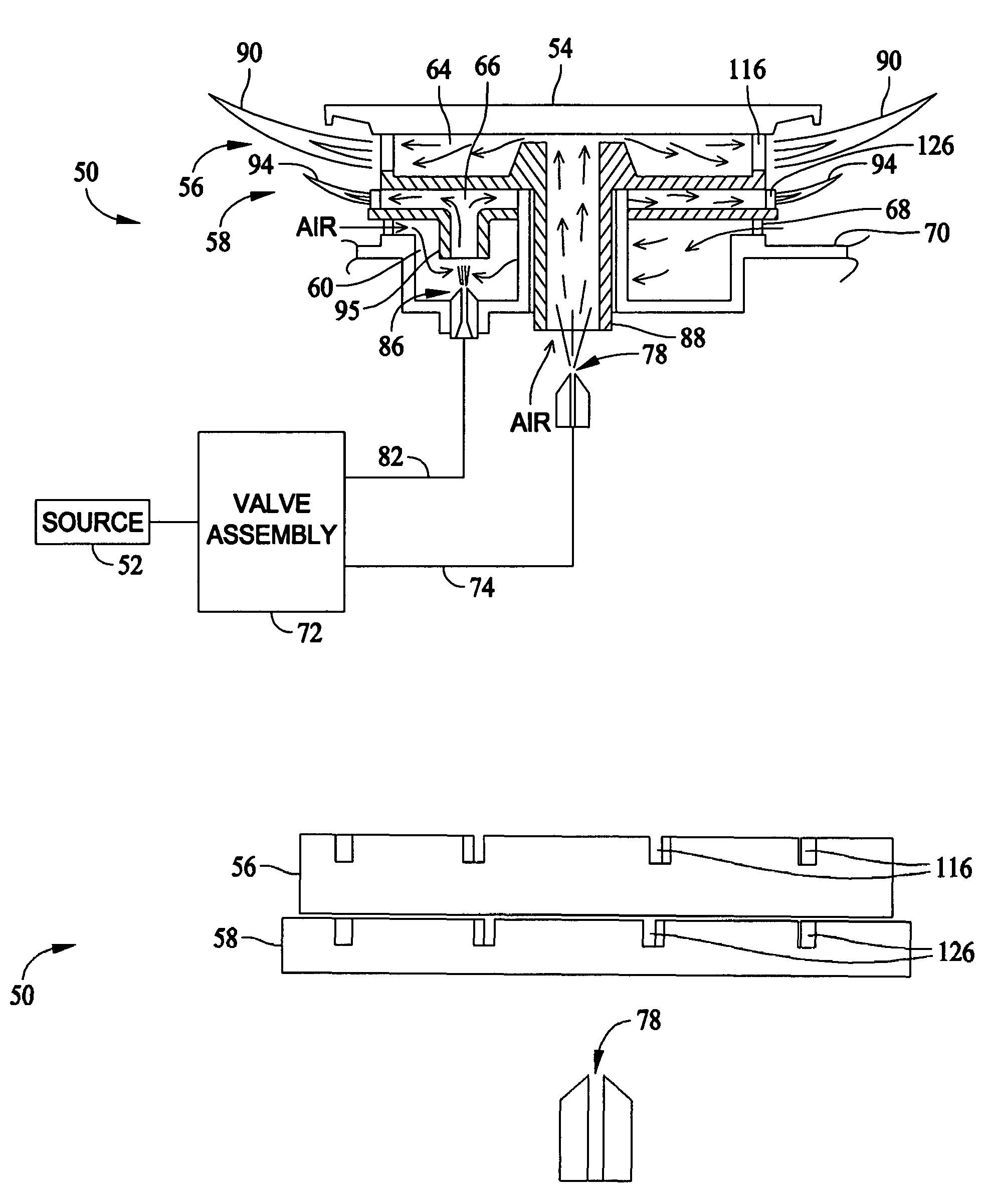

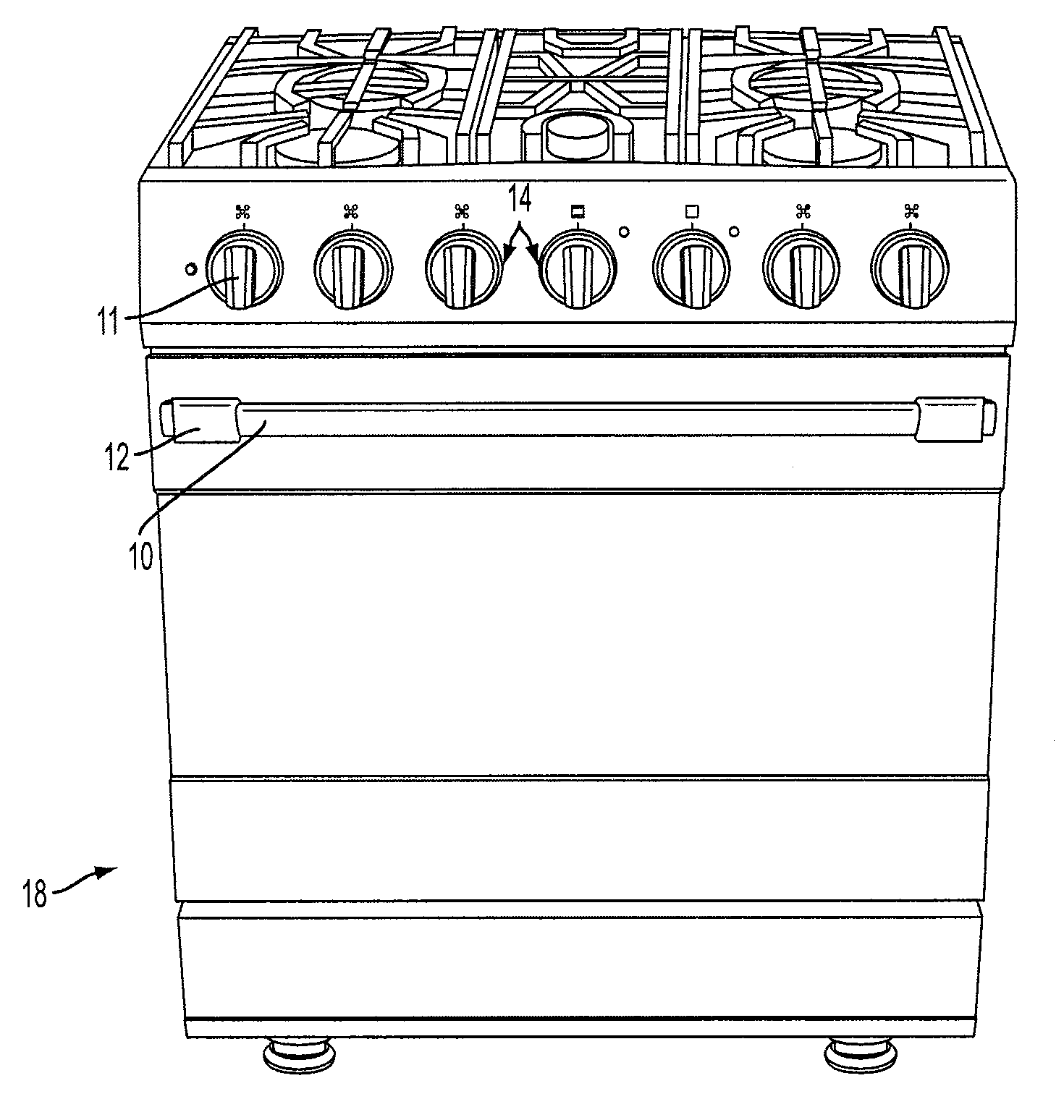

Dual stacked gas burner and a venturi for improving burner operation

ActiveUS7291009B2Amount of timeFacilitates simmeringDomestic stoves or rangesSpray nozzlesEngineeringThermal efficiency

A cooktop burner assembly is described. The cooktop burner assembly includes a main burner, and a simmer burner located below the main burner, where a diameter of the simmer burner is greater than a diameter of the main burner. The closer placement of the main burner to a cooking vessel placed on top of the cooktop burner assembly as compared to the placement of the simmer burner from the cooking vessel increases thermal efficiency. Moreover, the farther placement of the simmer burner from the cooking vessel facilitates simmering of items in the cooking vessel and the larger diameter of the simmer burner reduces a possibility of overheating the main burner and the cooking vessel.

Owner:HAIER US APPLIANCE SOLUTIONS INC

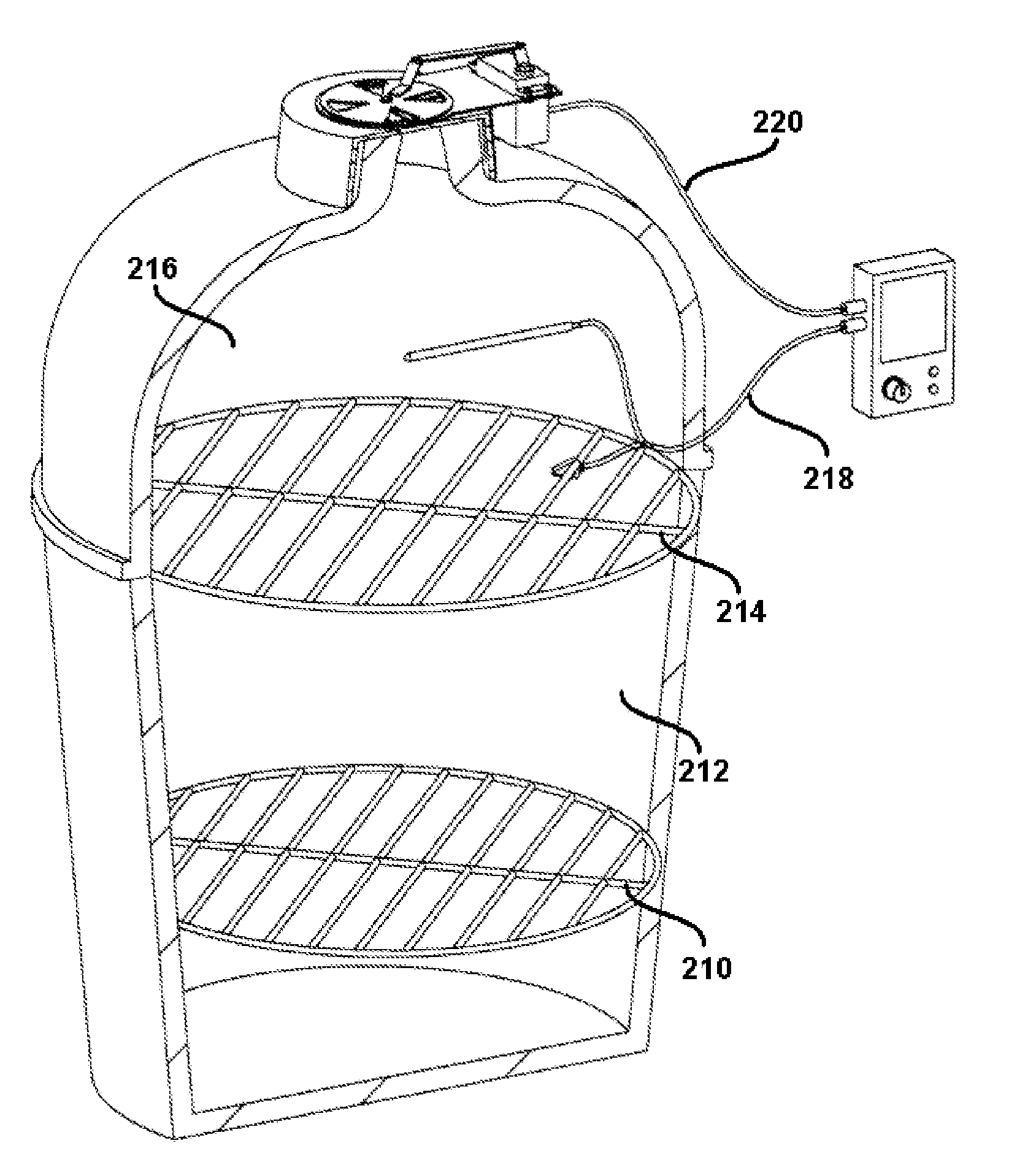

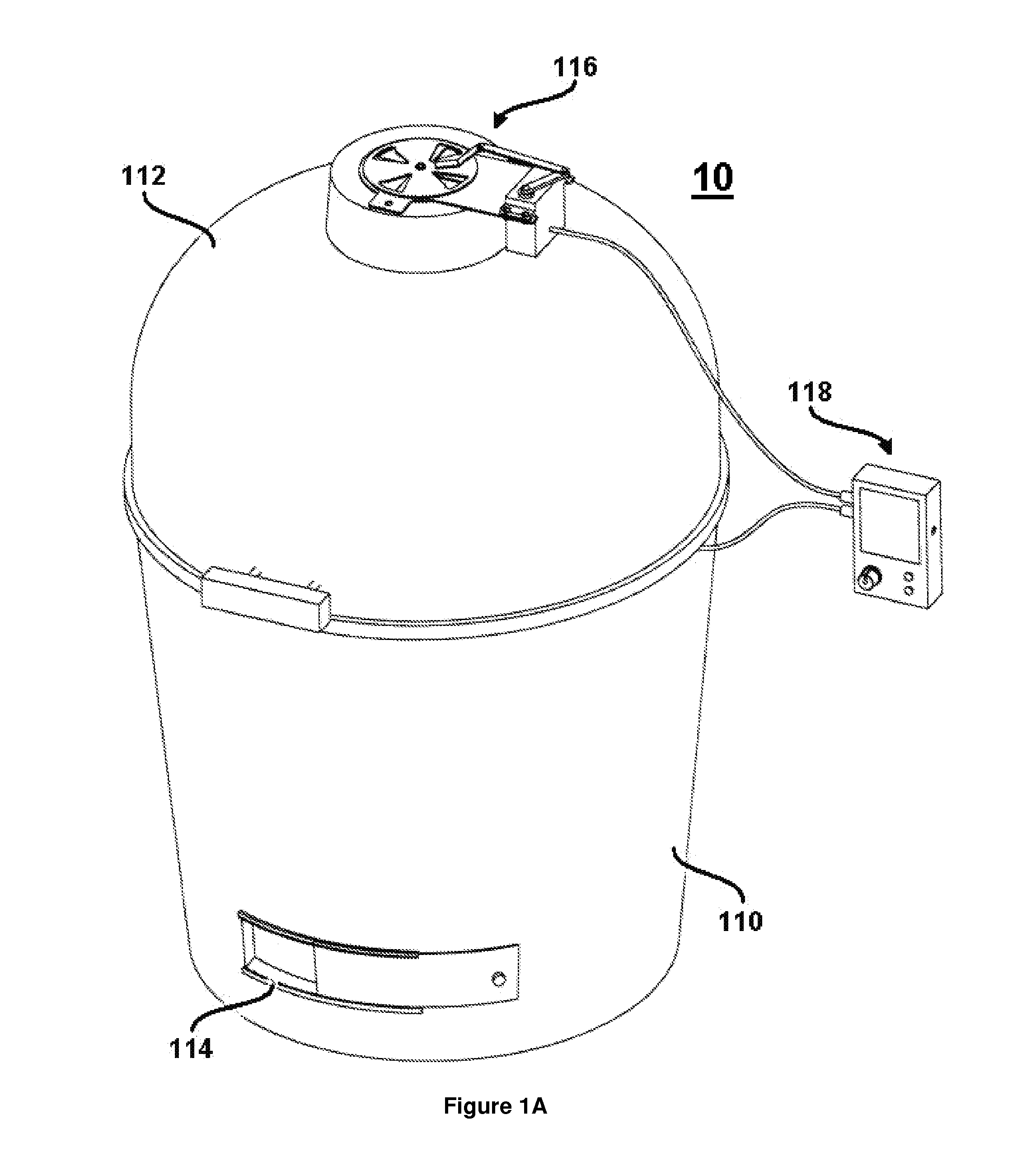

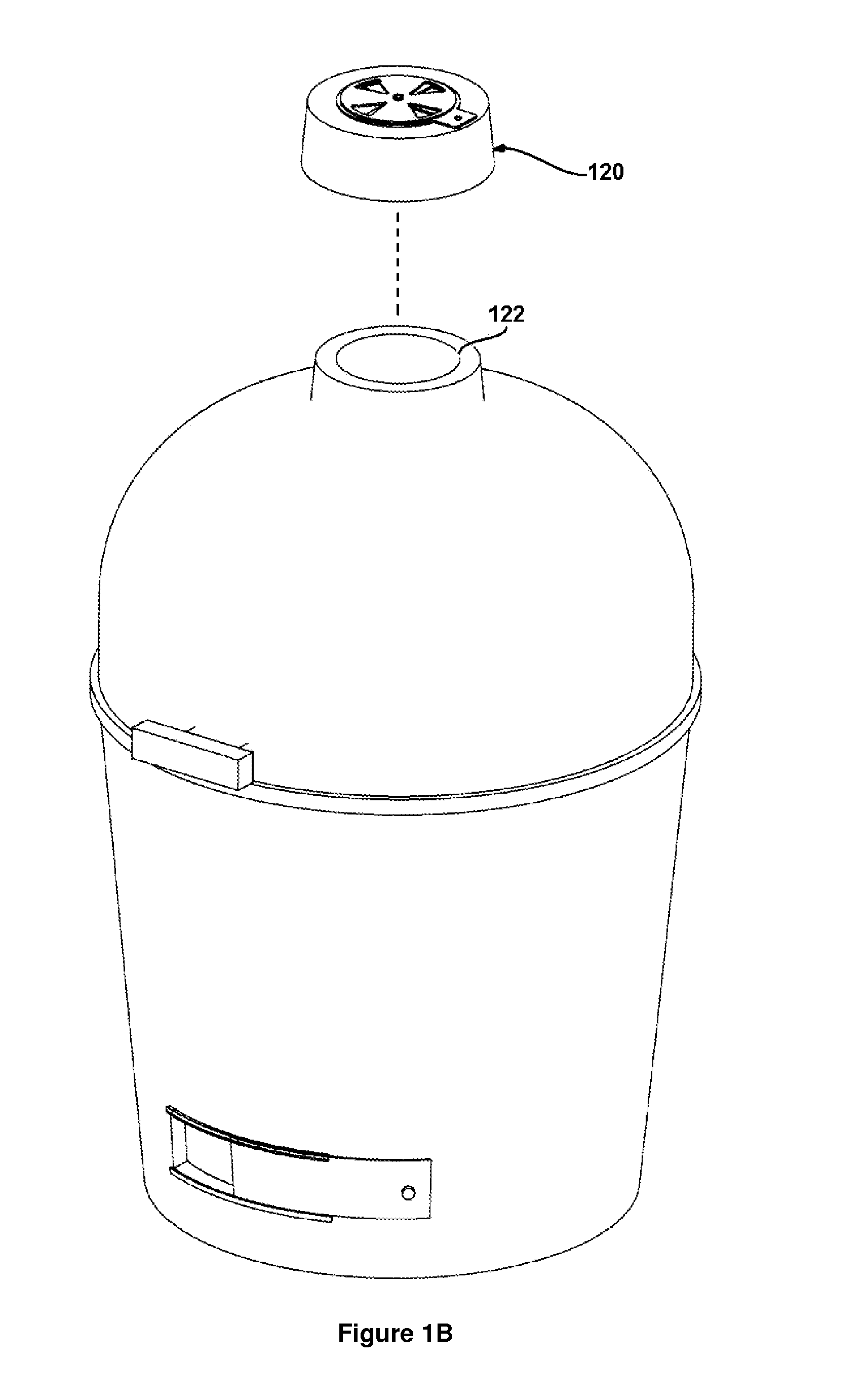

Automated Temperature Control System for Solid-Fueled Grills or Ovens

ActiveUS20130061765A1Precise temperature controlEliminate needTemperature control without auxillary powerLighting and heating apparatusTemperature controlRemote control

An automated temperature control system for a barbecue grill or other structure comprises an automated damper assembly coupled to a vent of said grill, which damper assembly opens and closes selectively to adjust the flow passage area of the grill's vent. The system further comprises an operating area temperature probe for communicating the temperature of the operating area of the grill to the automated damper assembly, such that the automated damper assembly may maintain a user-specified target operating temperature by way of affecting combustion rates within the grill. A remote control may also be provided to allow the user to input a desired temperature for the system to obtain and / or to change temperature information for the grill or other structure.

Owner:IOT CONTROLS LLC

Dual fuel heater

ActiveUS7607426B2Fuel supply regulationDomestic stoves or rangesCombustion chamberNuclear engineering

In certain embodiments, a dual fuel heater has a pressure regulating device for selectively coupling with a first source or a second source operating at different pressures. The dual fuel heater can also include first and second fuel lines, a fluid flow controller, a combustion chamber and first and second oxygen depletion sensor nozzles. The fluid flow controller is configured to selectively permit flow of fuel to either the first fuel line or to the second fuel line. In some embodiments, the first fuel line is connected to the first oxygen depletion sensor nozzle and the second fuel line is connected to the second oxygen depletion nozzle.

Owner:PROCOM HEATING

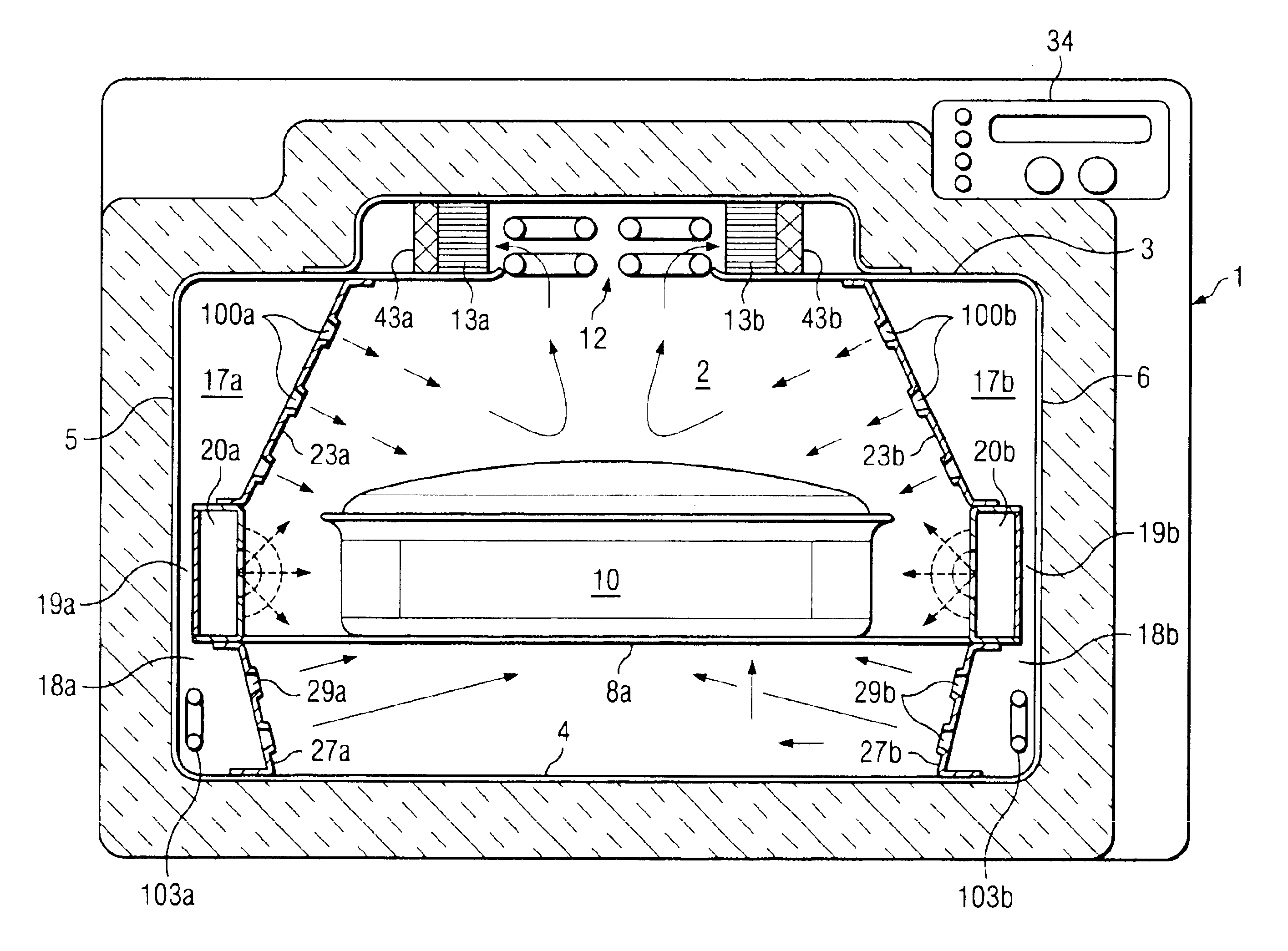

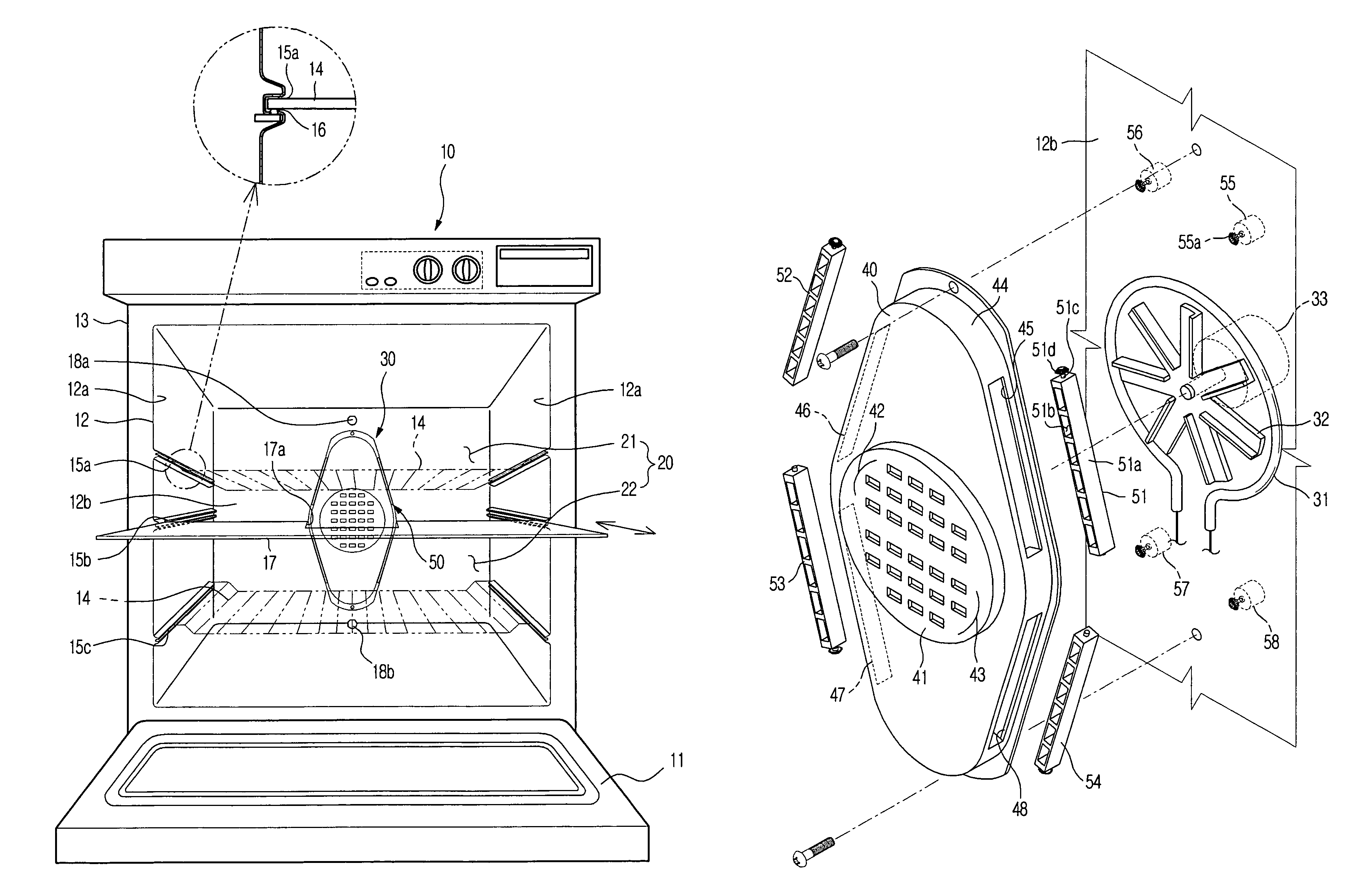

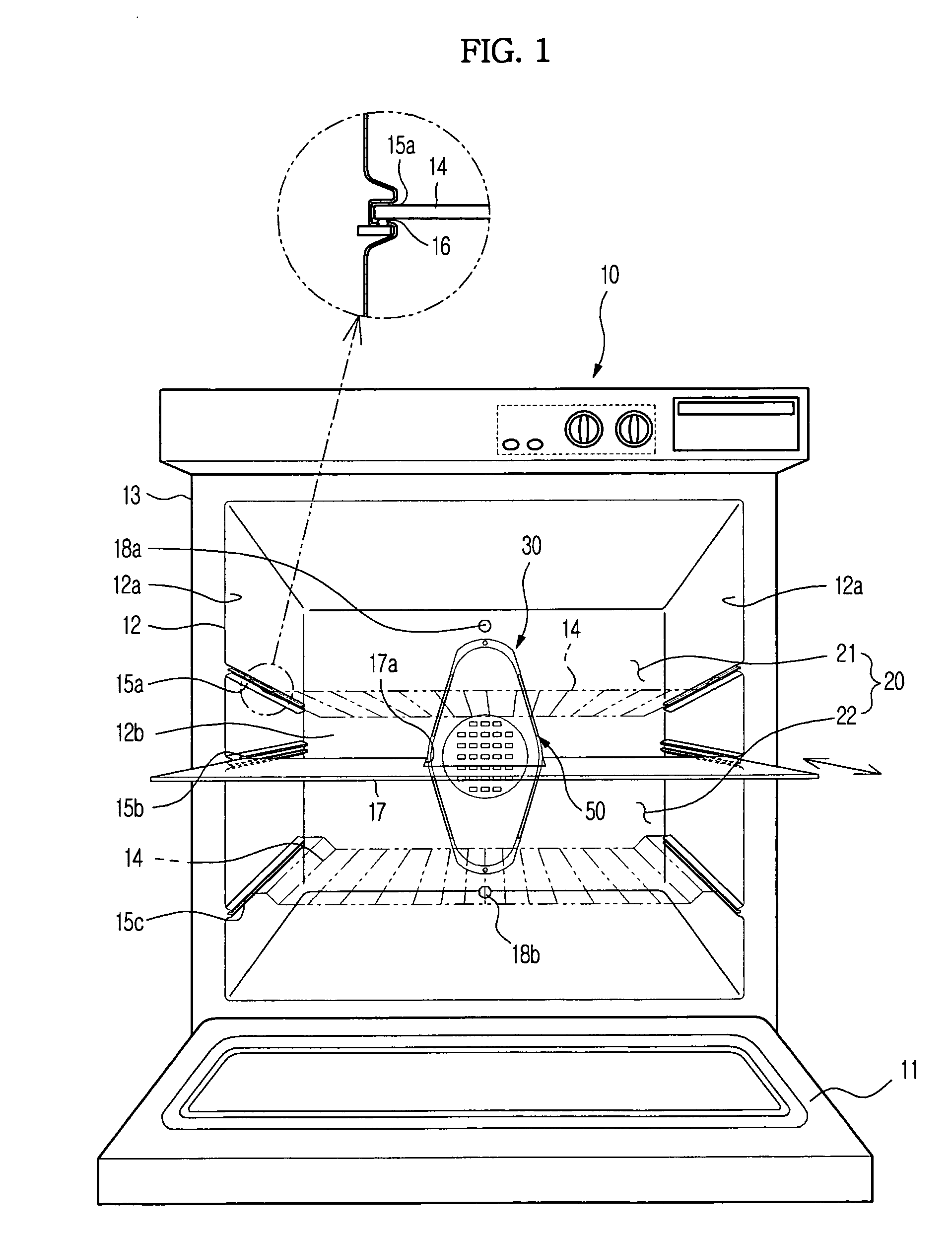

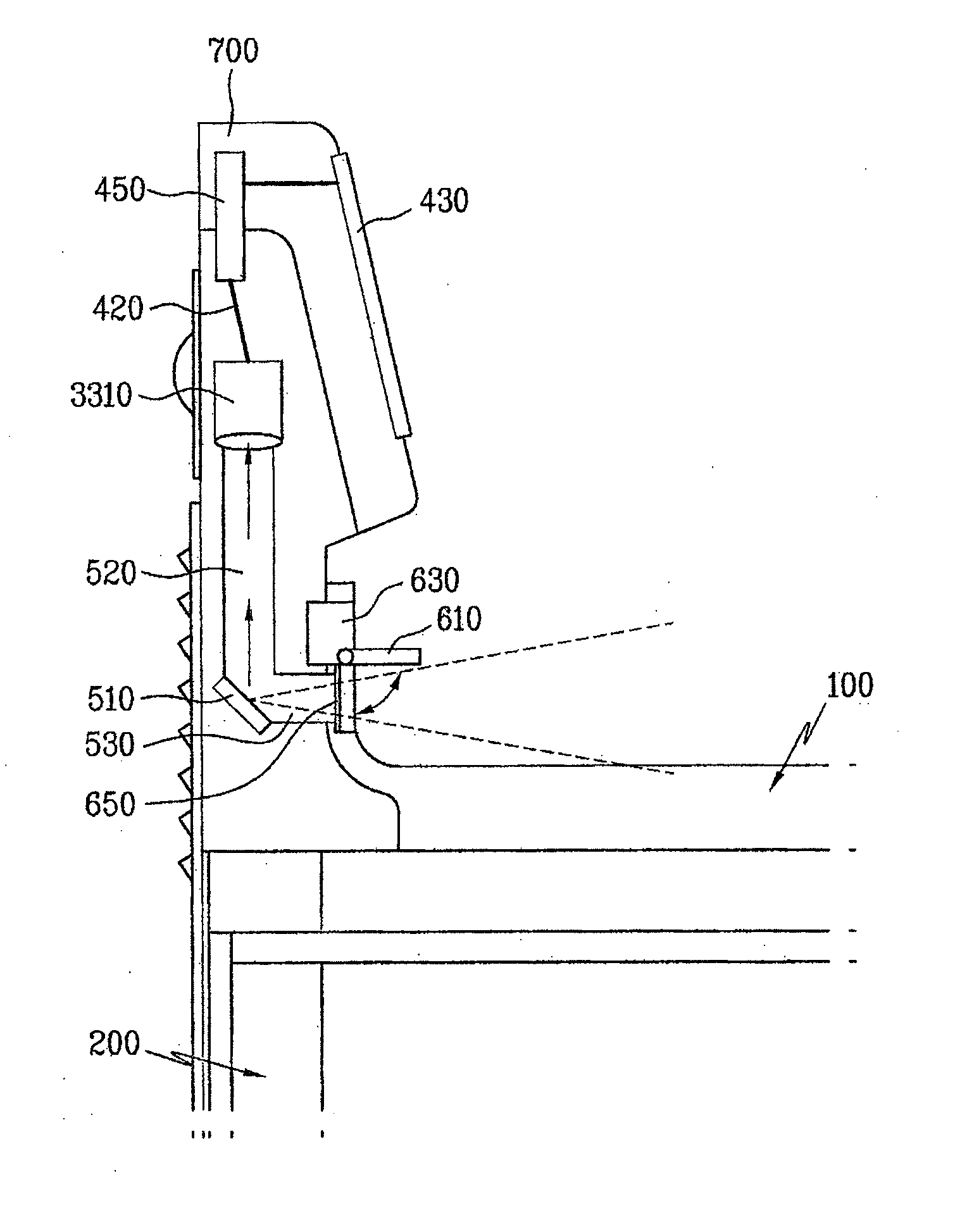

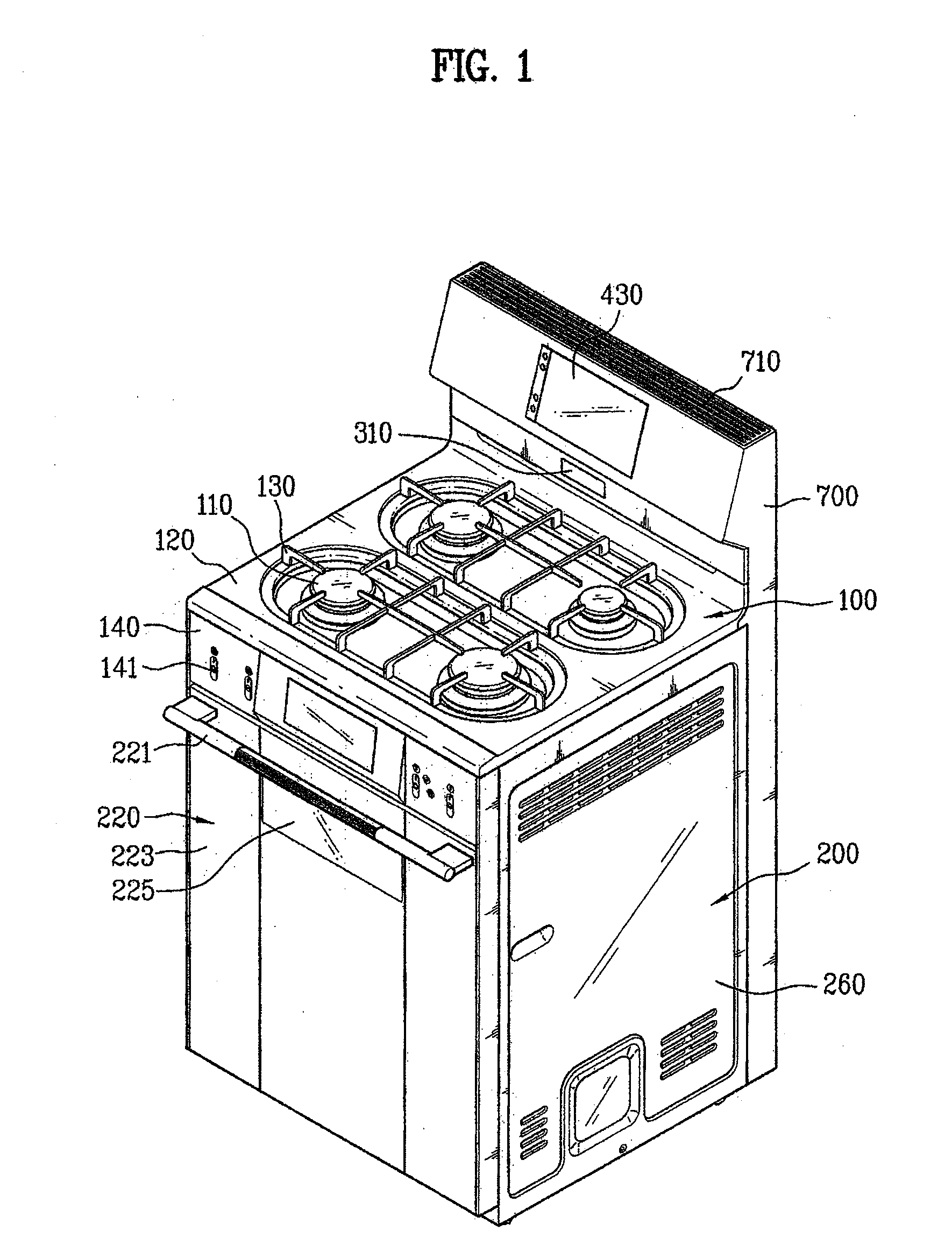

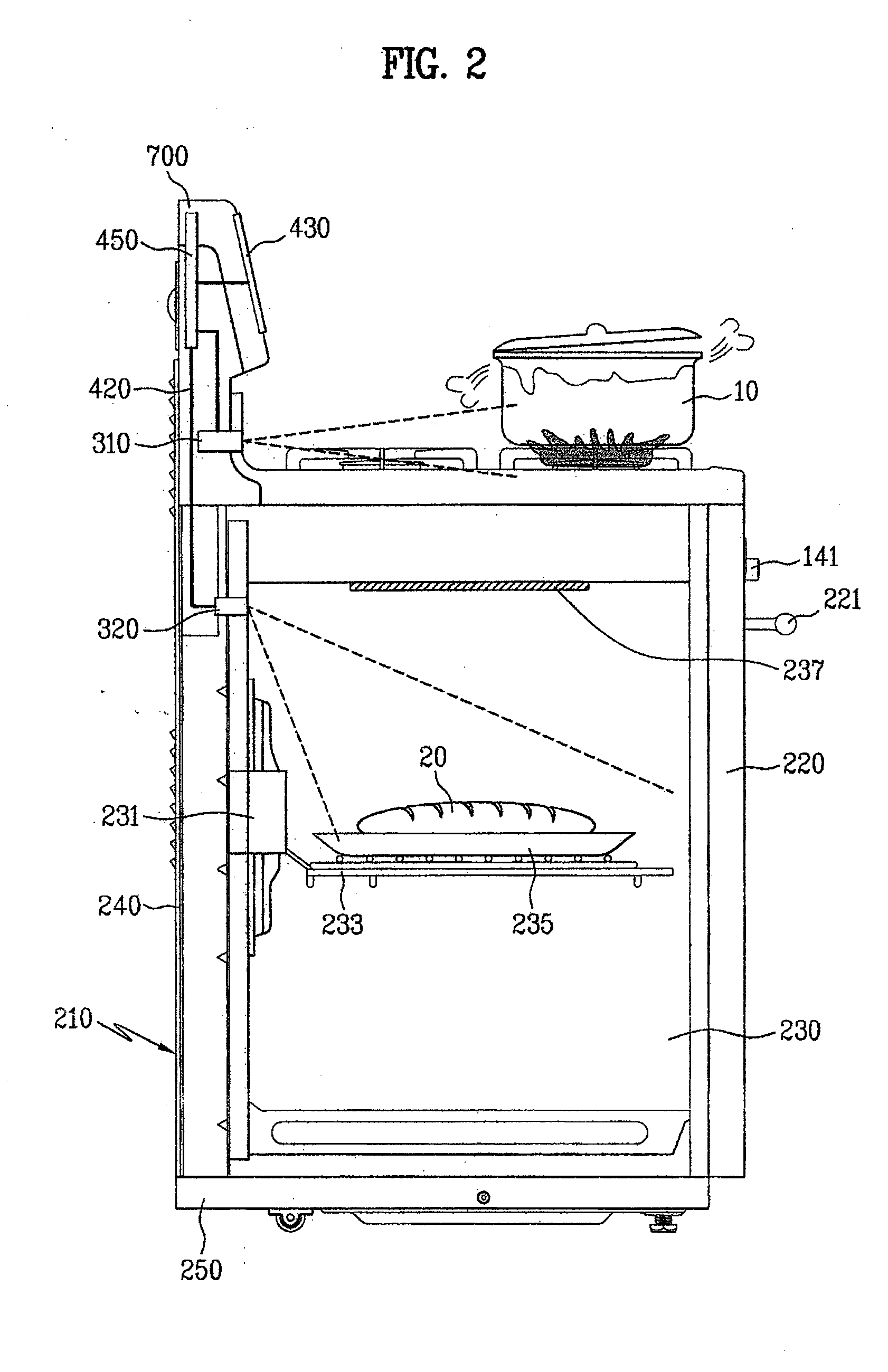

Cooking apparatus and method for controlling the same

InactiveUS7766003B2Uniform temperature distributionAvoid dischargeSelf-cleaning stoves/rangesElectrical heating fuelProcess engineering

A cooking apparatus to change the direction of hot air to be fed into a cooking chamber. The cooking apparatus includes a cooking chamber, a hot-air feeder to feed hot air into the cooking chamber, and an air-direction regulator to change a direction of the hot air fed from the hot-air feeder.

Owner:SAMSUNG ELECTRONICS CO LTD

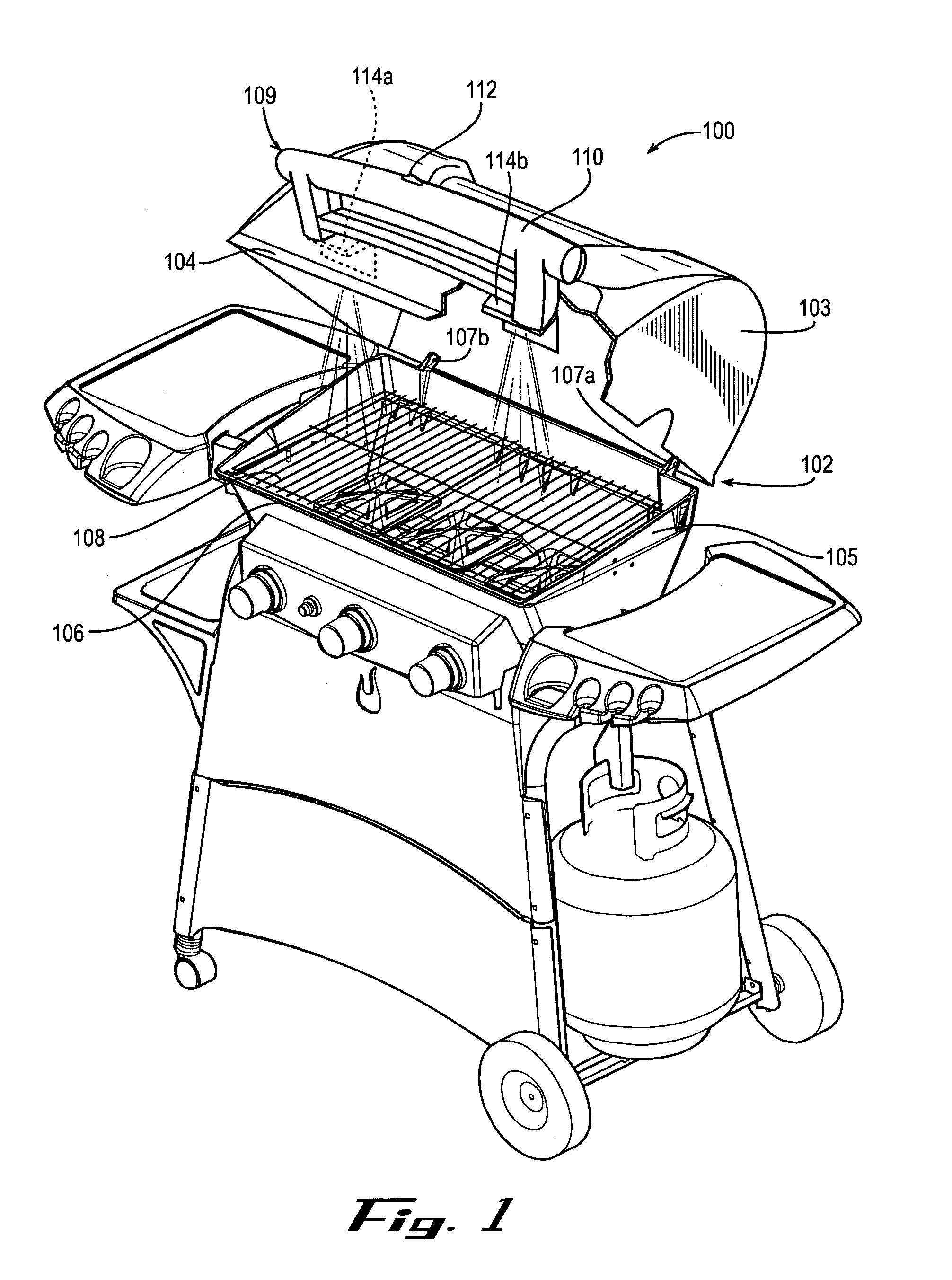

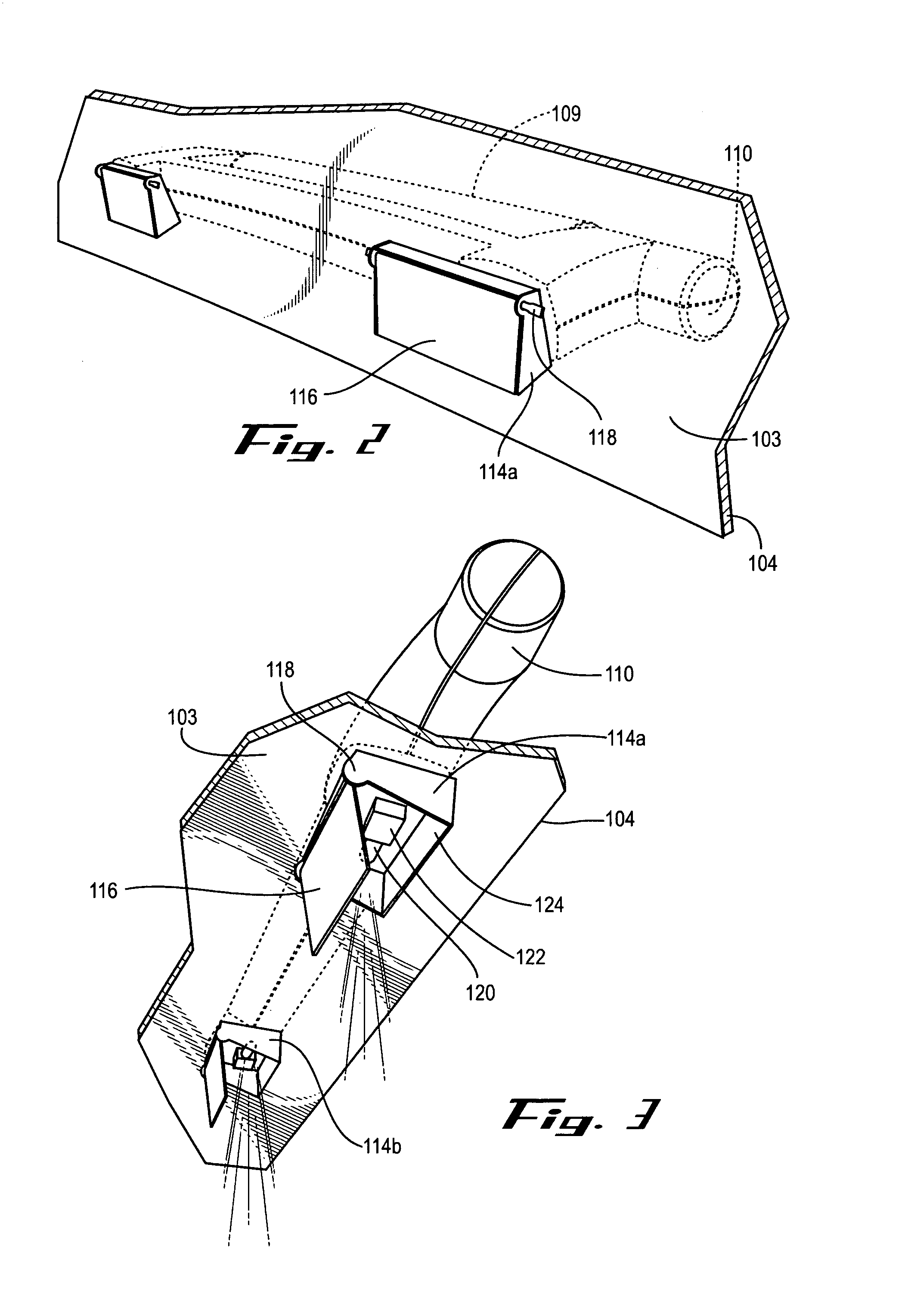

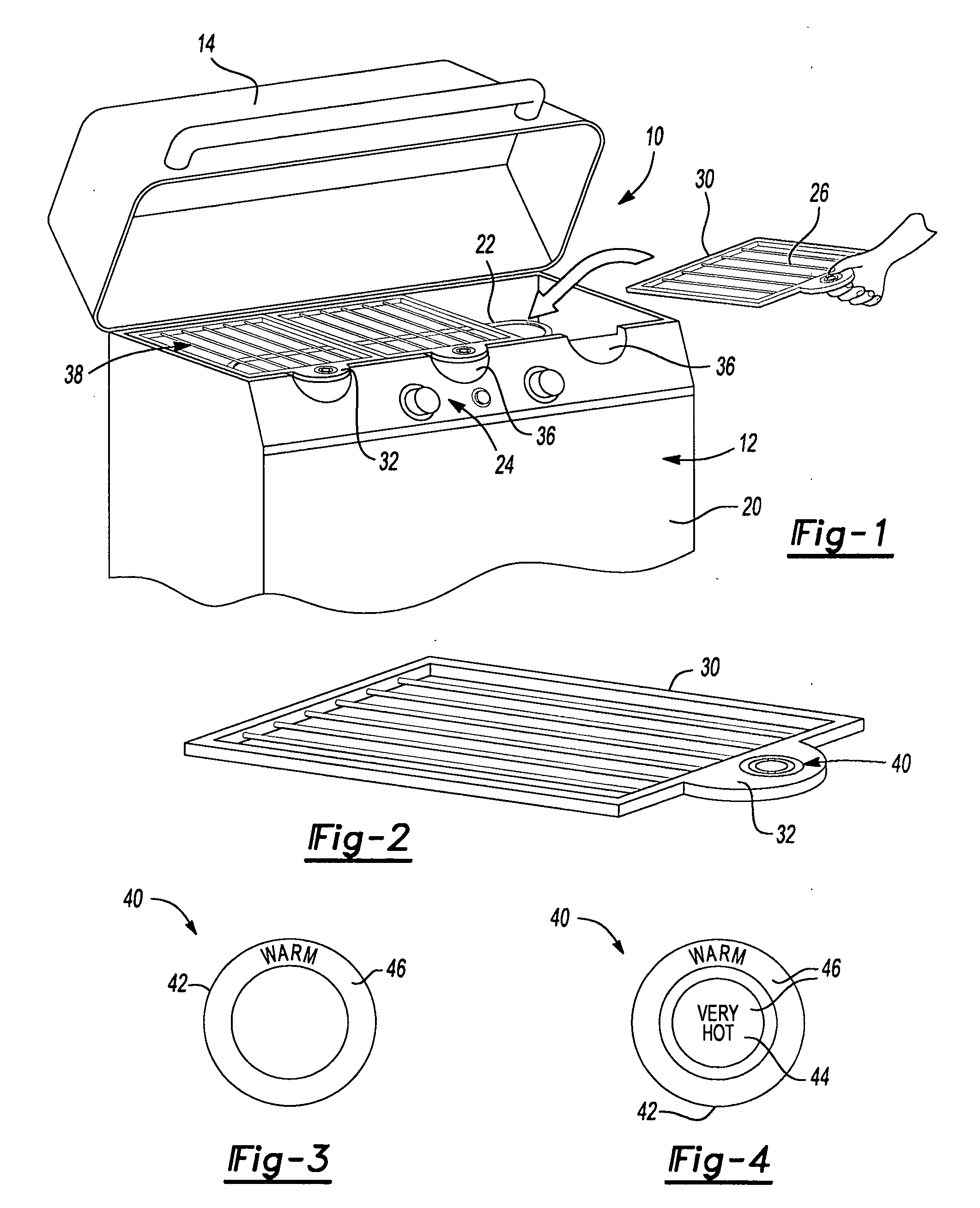

Handle and light assembly for barbecue grills

A handle and light assembly for use on a barbecue grill. The assembly is inclusive of handle and at least one source of illumination for illuminating a cooking surface inside a hollow cooking chamber of the barbecue grill. The handle may function both as a means for opening a lid to access the cooking surface and also as a compartment for retaining the energy used to power the source of illumination. The lid includes at least one channel for the appropriate wiring to extend from the energy compartment to the illumination source. Accordingly, the handle may be located on the outside of the grill lid, and the source of illumination may be located inside the hollow cooking chamber.

Owner:W C BRADLEY CO

Photocatalytically-activated self-cleaning appliances

InactiveUS6054227ASelf-cleaning stoves/rangesLiquid surface applicatorsCoated surfaceSufficient time

An appliance is rendered self-cleaning of accumulated organic contaminants on one or more surfaces of the appliance, by coating such surfaces of the appliance with a photocatalytically-activated self-cleaning coating. Upon exposing such coated surfaces to radiation of the appropriate wavelength, for a sufficient interval of time, at least a portion of the organic contaminants present on the photocatalytically-activated self-cleaning coating are removed. The coated surface is thereby cleaned without the need of manual effort or high temperatures. The radiation is generally actinic radiation, and more particularly includes ultraviolet radiation.

Owner:PPG IND OHIO INC

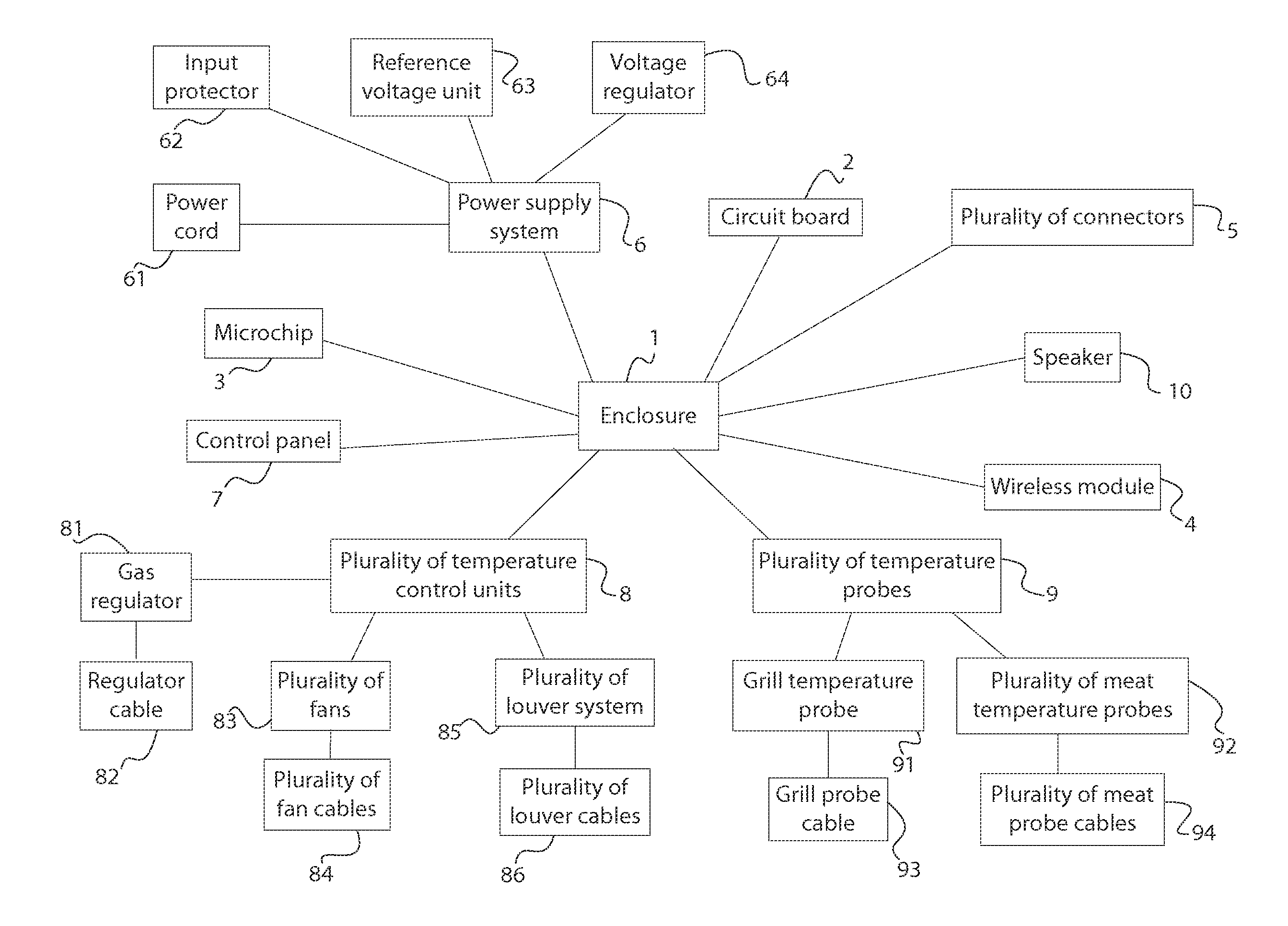

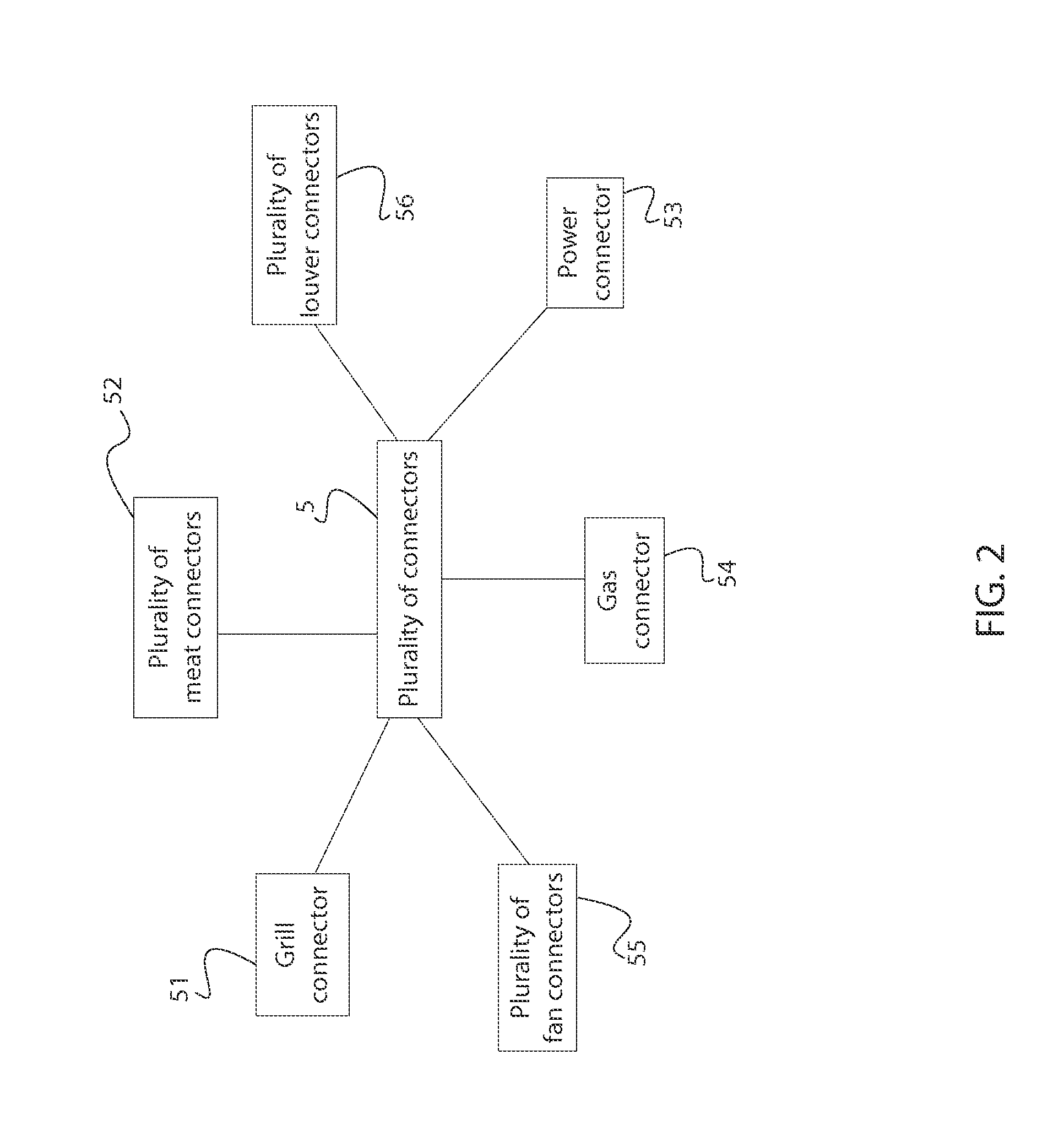

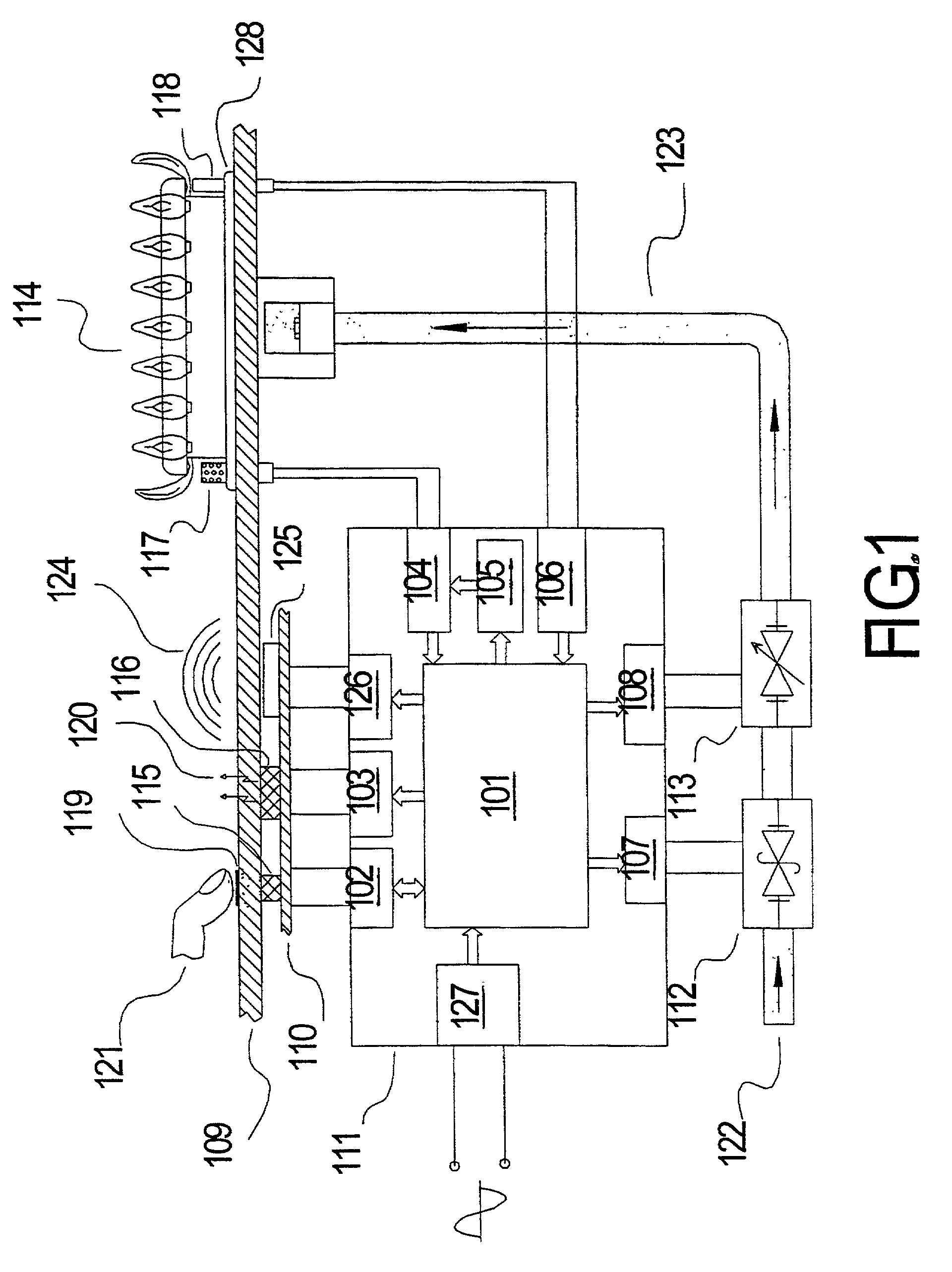

Device to remotely control an outdoor grill or an indoor oven with a web-enabled computing device

InactiveUS20130265159A1Programme controlElectric signal transmission systemsGraphicsTemperature control

A grill controller device, which remotely controls any type or grill or oven, comprises a circuit board, a plurality of connector, a power supply system, a control panel, a plurality of temperature control units, a plurality of temperature probes, and a speaker. The grill controller device is wirelessly connected with a graphic user interface so an user can wirelessly operate the grill controller device through the graphic user interface. The grill controller device externally attaches to existing grills and ovens. The plurality of temperature control units adjusts a grill temperature and a plurality of meat temperatures according to the user. A plurality of alerts is controlled by control software and the plurality of alerts comprises different functionality relative to different components. The user is able to control total functionality of the existing grills and ovens through the grill controller device while saving time.

Owner:MICHAEL DURIAN

Electronic gas cooktop control with simmer system and method thereof

InactiveUS7255100B2Reduce heating powerHigh outputFuel supply regulationDomestic stoves or rangesControl systemElectromagnetic interference

An electronically activated gas cooktop control system, responsive to a touch-sensitive user interface, and capable of providing a predetermined range of cooking and simmer levels of BTU output, has two complementary heating modes of operation A first heating mode of operation is provided to produce a wide selection of simmer levels of BTU output, by electronically sequencing a solenoid-operated modulating gas valve “on” and “off”, at a predetermined level of flame. A second cooking mode of operation is provided by electronically modulating the level of flame, through use of a pulse-width-modulation (PWM) output signal to produce a wide selection of cooking levels of BTU output. An igniter system capable of insuring proper ignition of gas without generating harmful electromagnetic interference is also provided.

Owner:COMPUVALVE +1

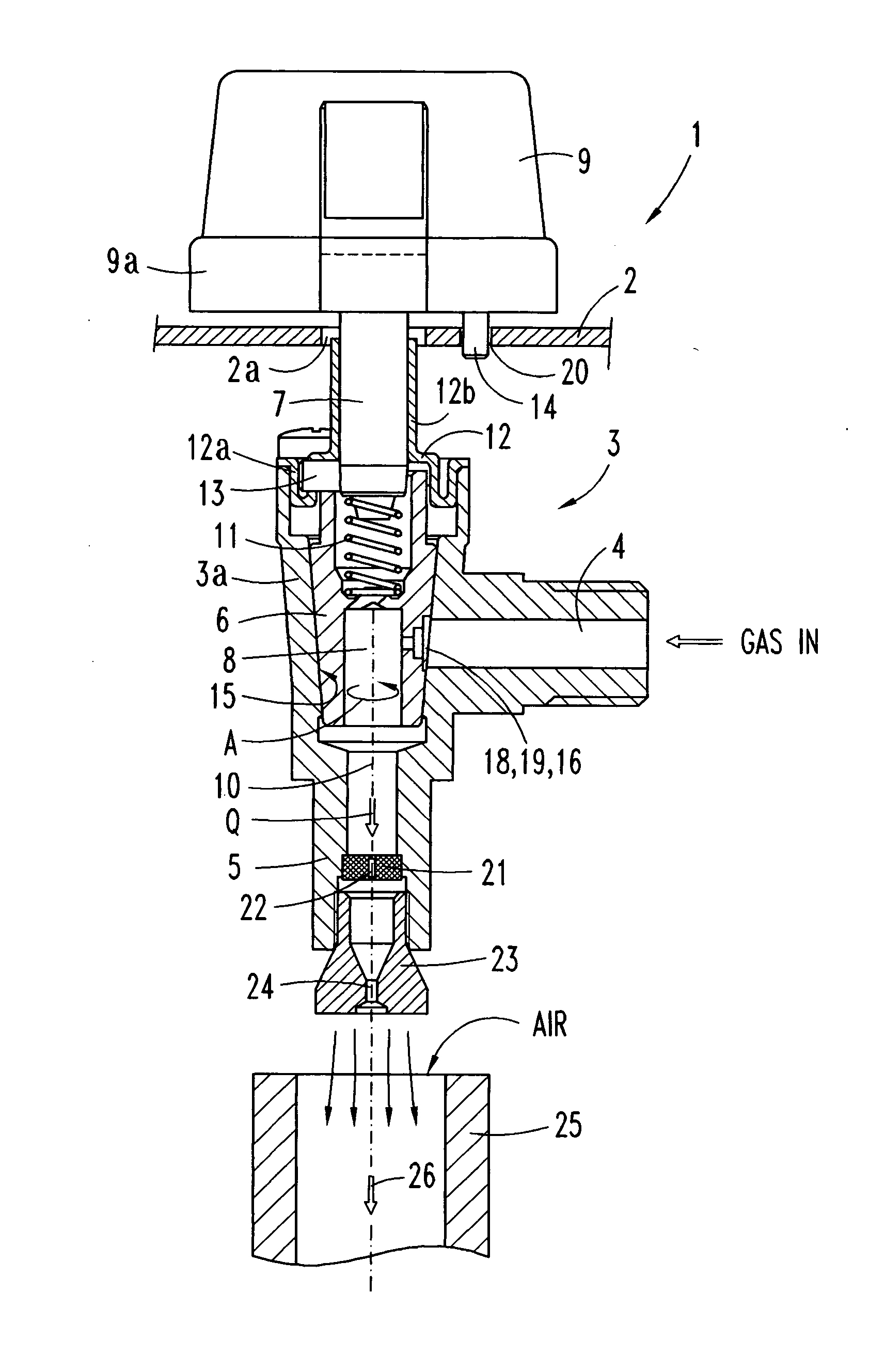

Multi-gas cooker, with a rotary valve provided with interchangeable regulating means

The cooking appliance (1) having a control panel (2) is equipped with one or more gas flow (Q) regulating valves, wherein the rotary regulating plug (6) is provided with various peripheral through holes (16-19). The control knob (9) being interchangeable for fitting to the actuating shaft (7), is chosen from the two units available, one and the other permitting different angular limit positions of the regulating plug (6) for the supply of a constant minimum gas flow Qmin, adjusted each one for a different type of gas N gas or LP gas. The outlet conduit (5) of the valve is equipped with a further injector nozzle (21,23) for adjusting a constant gas flow Qmax to be fed into the conduit (25) of the correspondent burner, when the cooking appliance is supplied with a LP gas.

Owner:COPRECITEC

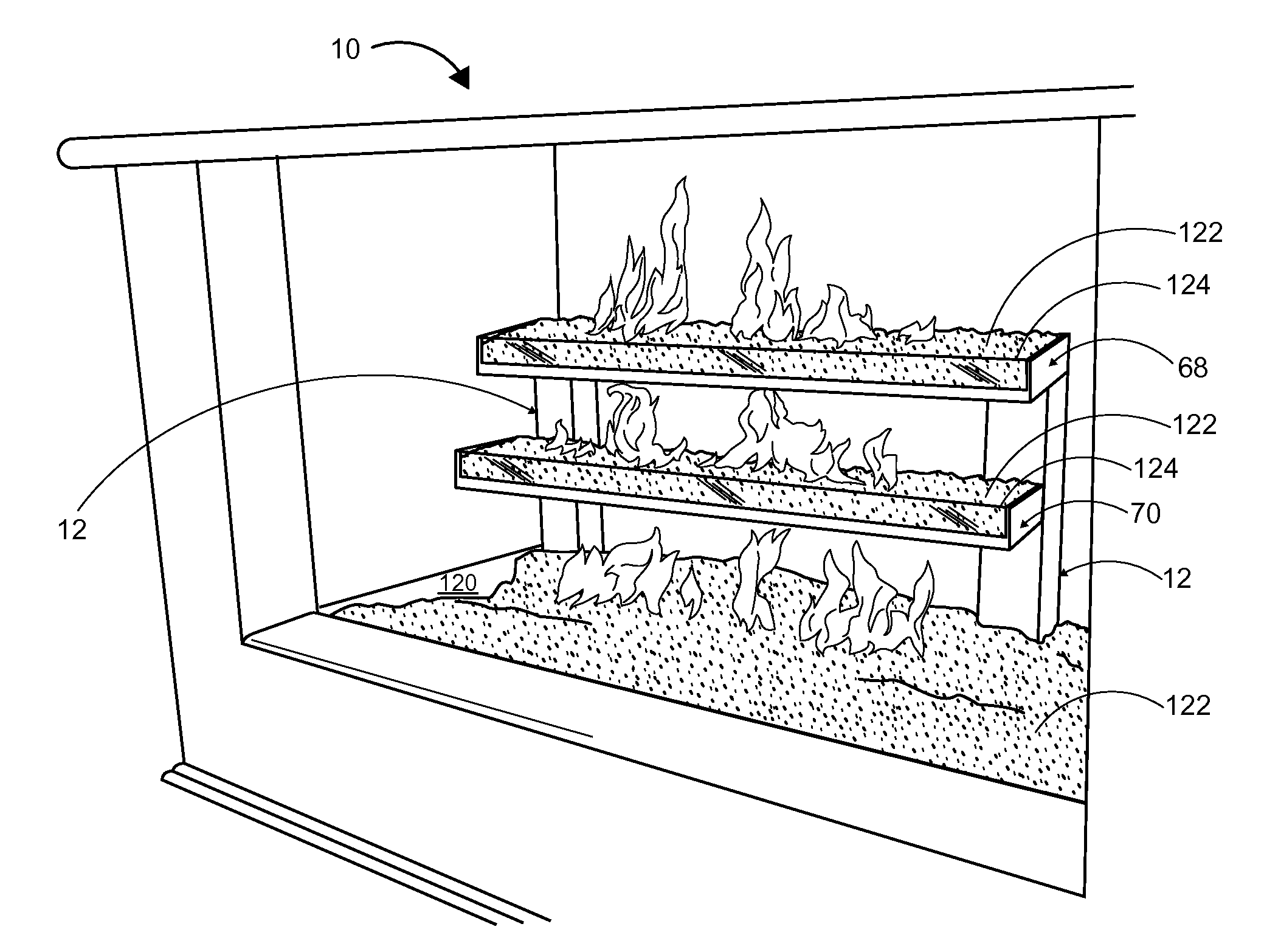

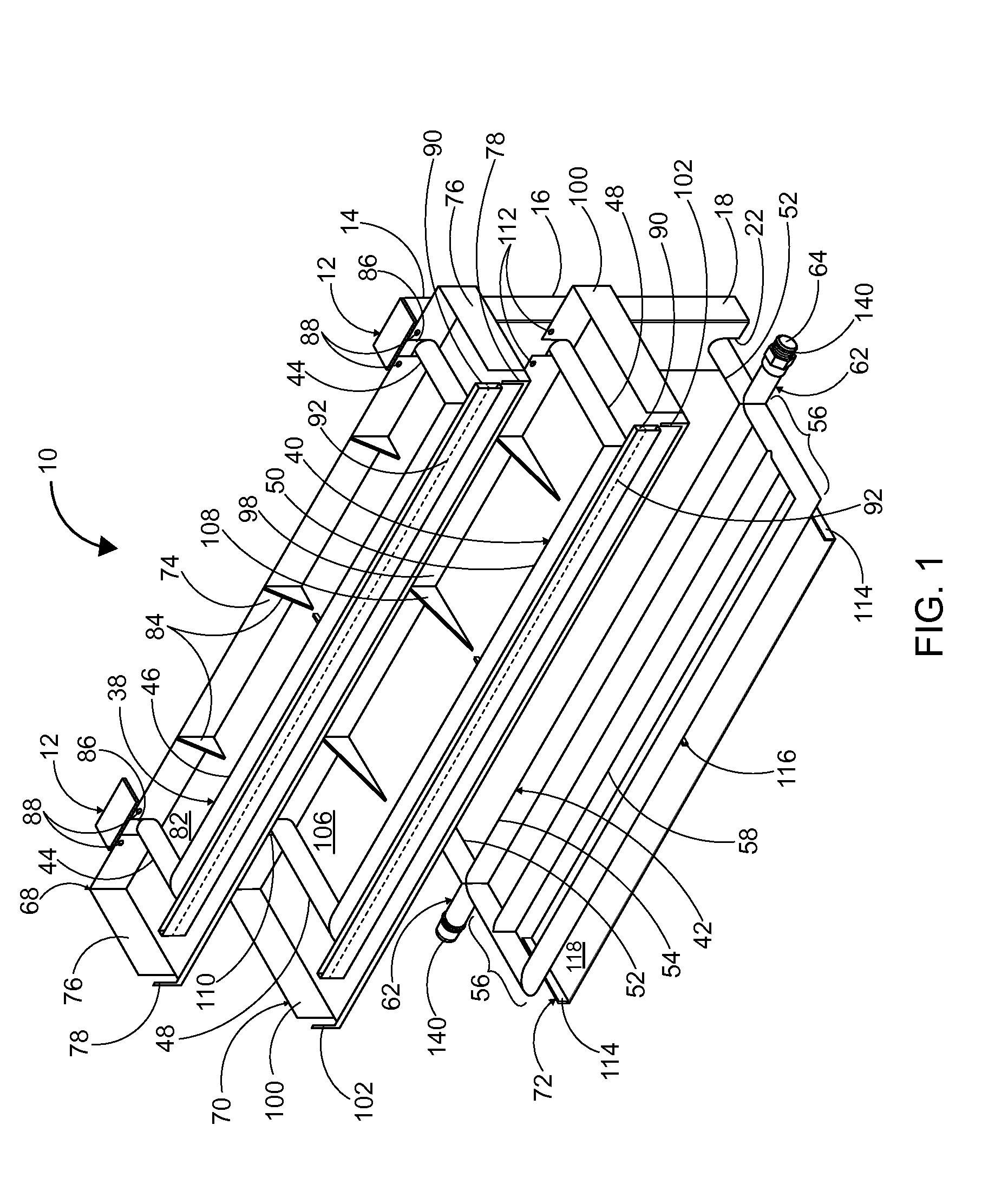

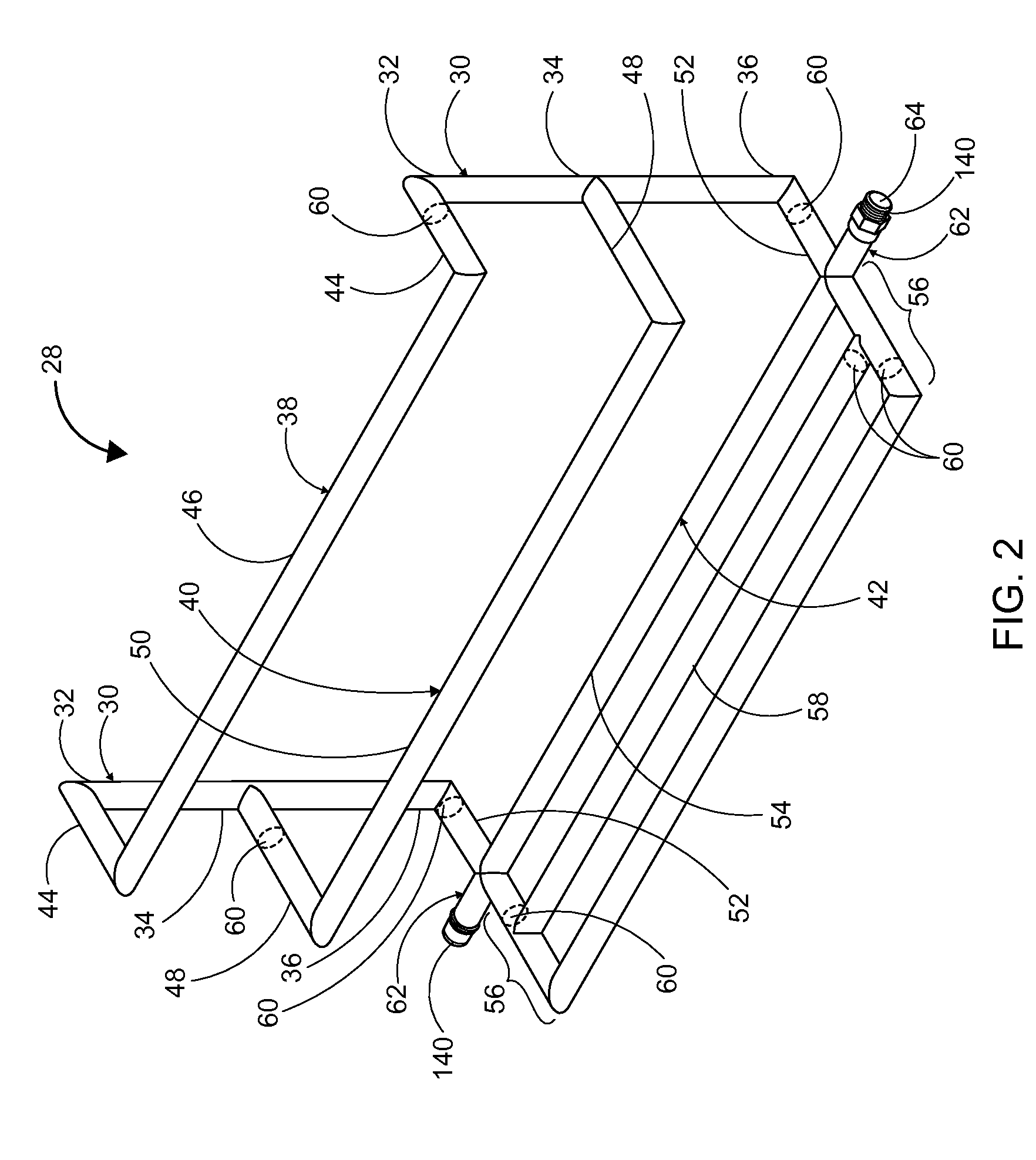

Multi-Level Floating Flames Gas Fireplace

InactiveUS20140116418A1Easy to installReduce noiseDomestic stoves or rangesLiquid heating fuelCombustorSuppressor

A multi-level floating flame gas fireplace comprises a pair of supporting members, a burner assembly and a plurality of trays. The burner assembly includes a pair of tube members spaced parallel in vertical orientation and is secured between inner portions of each supporting member, a plurality of burners evenly spaced and extended forwardly between the pair of tube members. A plurality of orifices and at least one sound suppressor are provided in the burners to provide even flow or distribution of gas and to reduce noise. Each tray is positioned below each burner and attached between the supporting members. The trays are filled up with a glass media like fire glasses and the burners are covered with the fire glasses. Thus, the structure of the fireplace becomes invisible and when the burners are turned on, the fireplace showcases layers of the floating flames suspended in a stepped back manner.

Owner:THOMAS RAZMIK

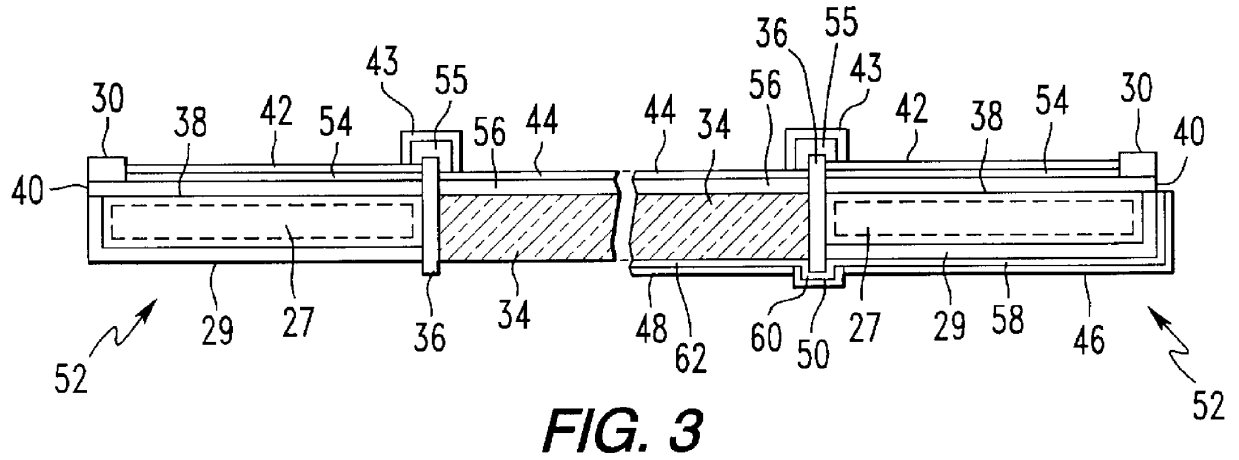

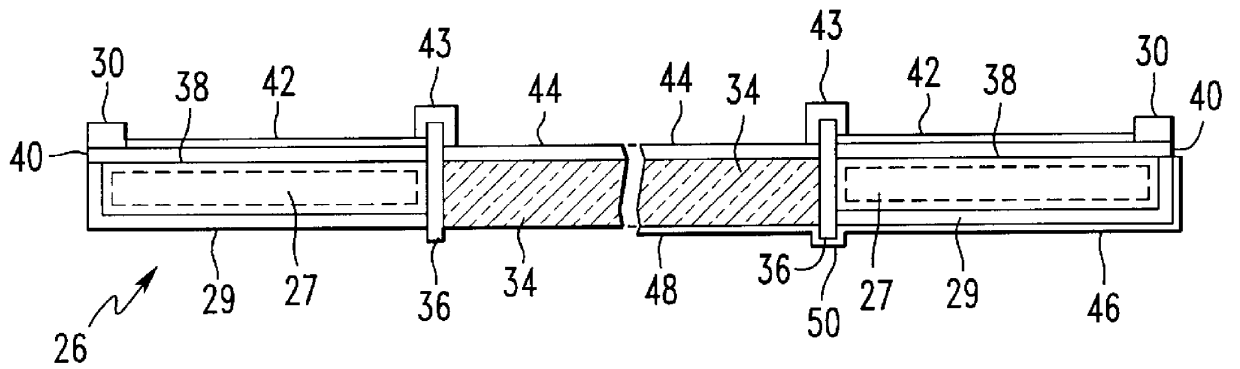

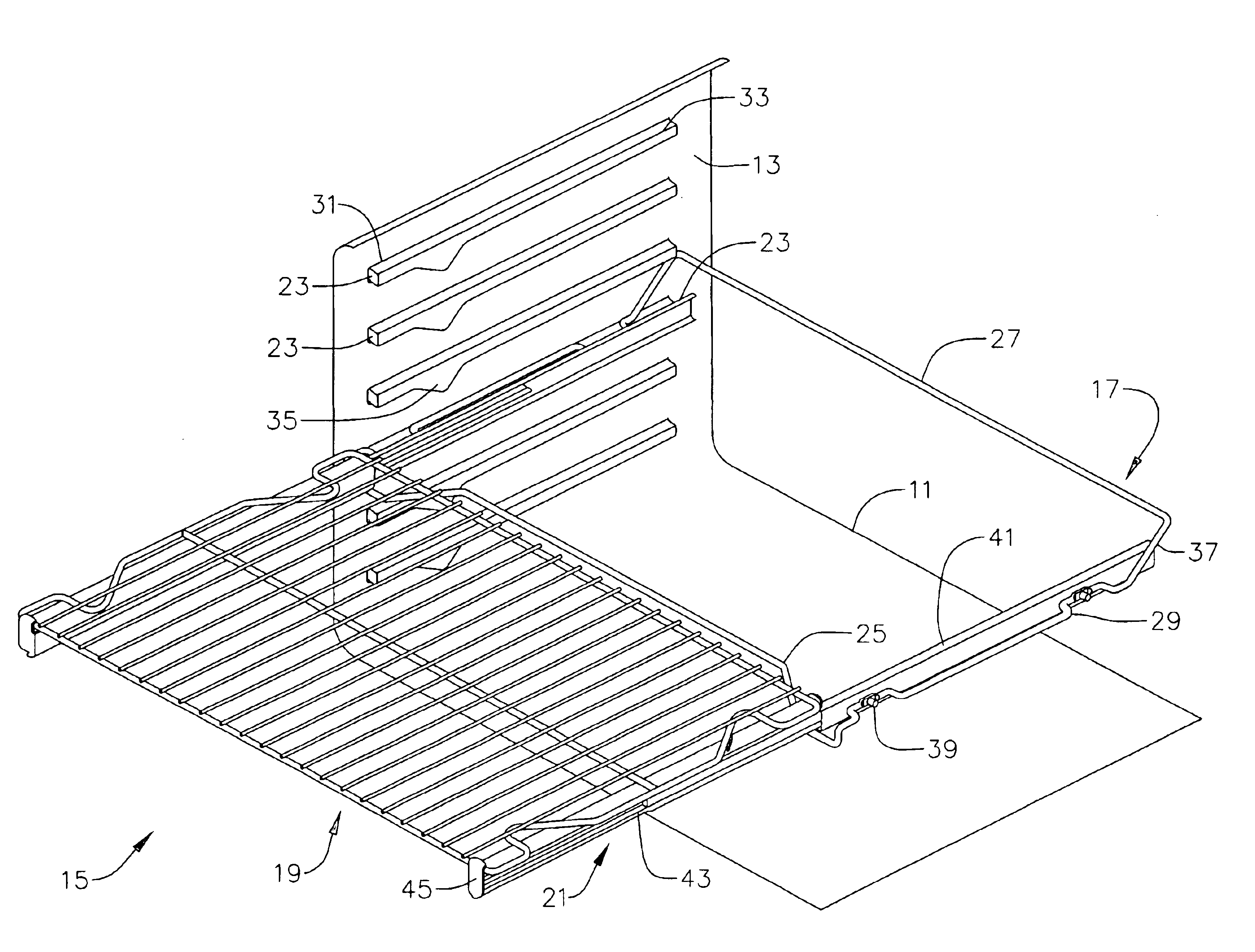

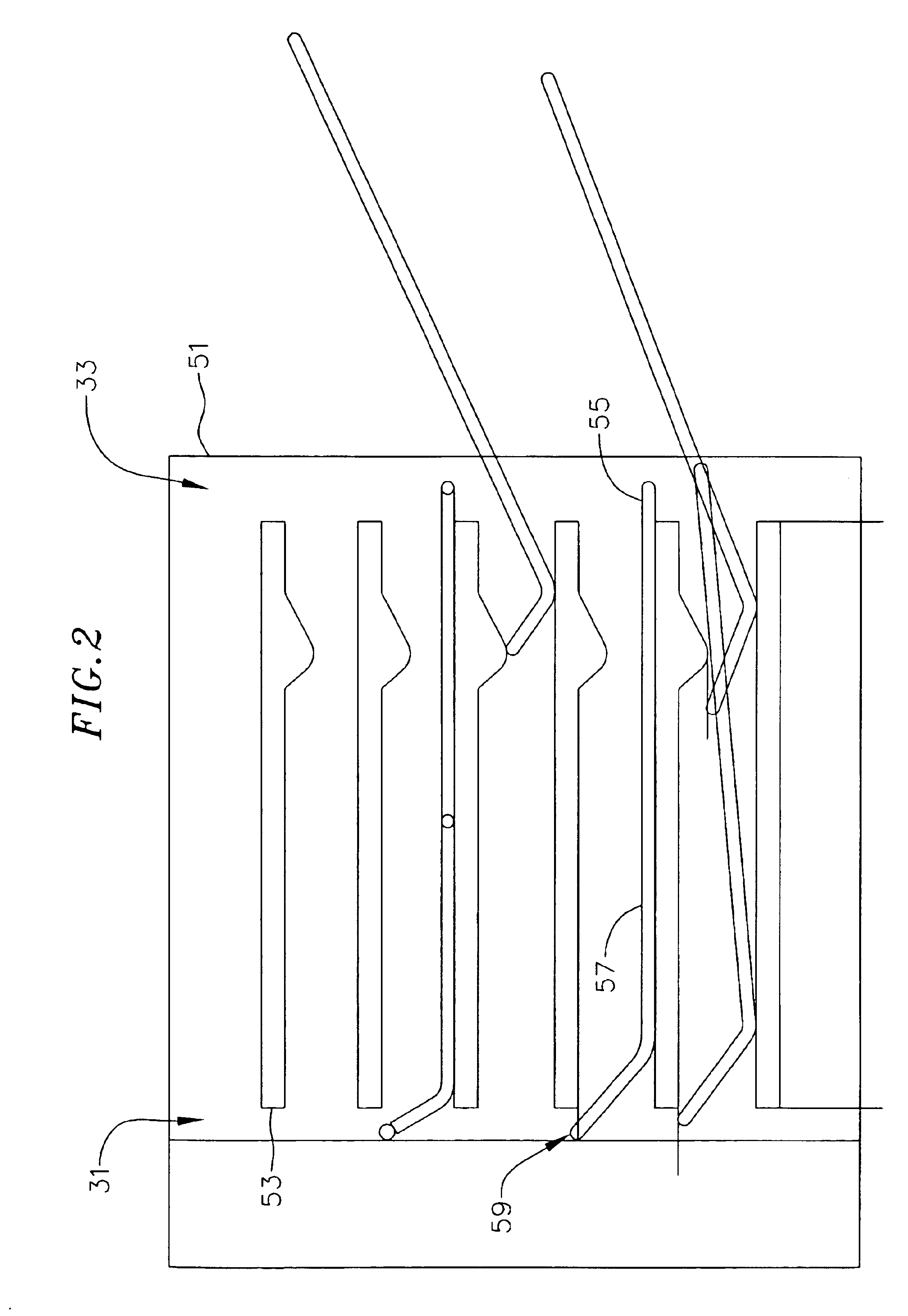

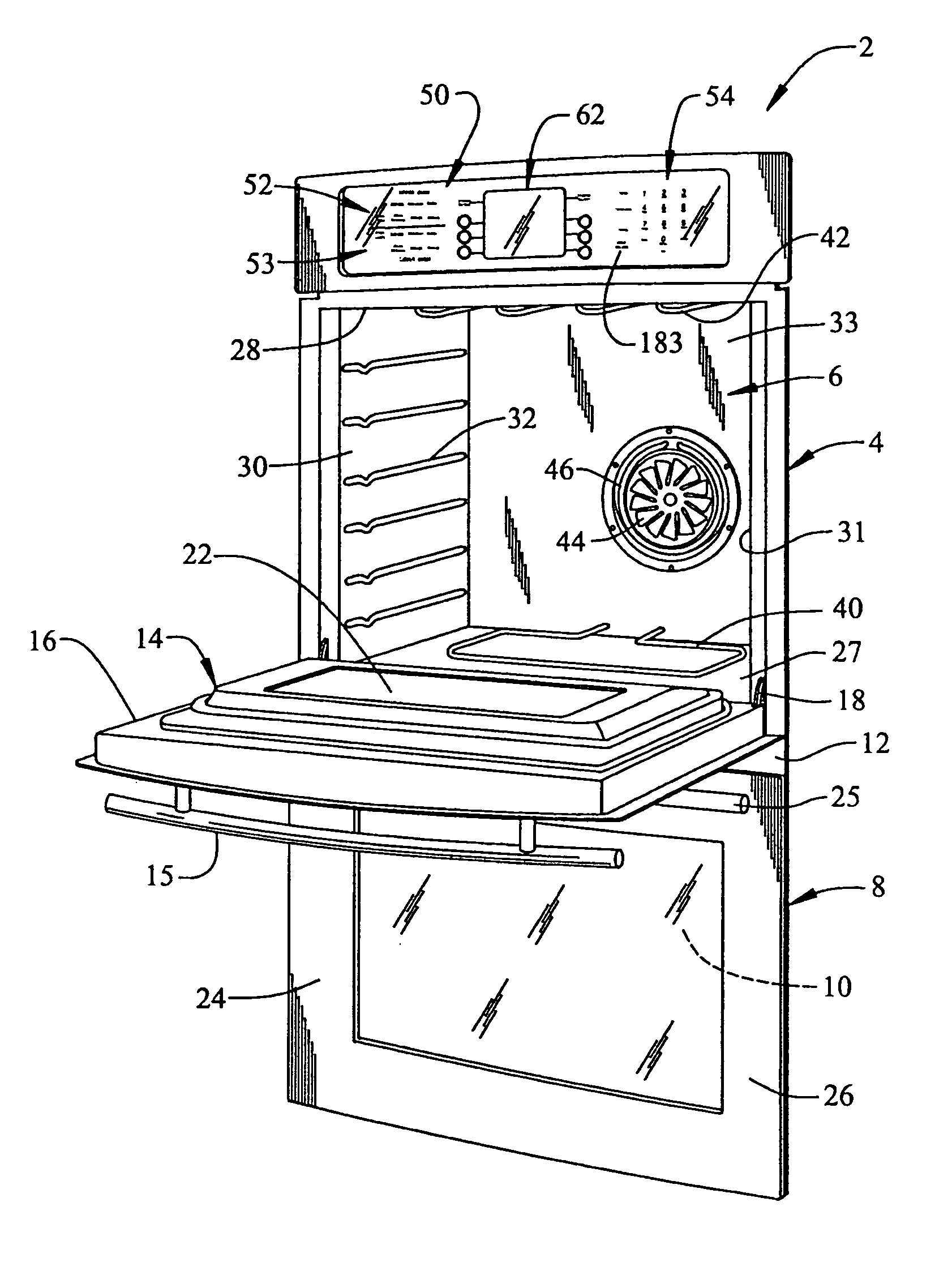

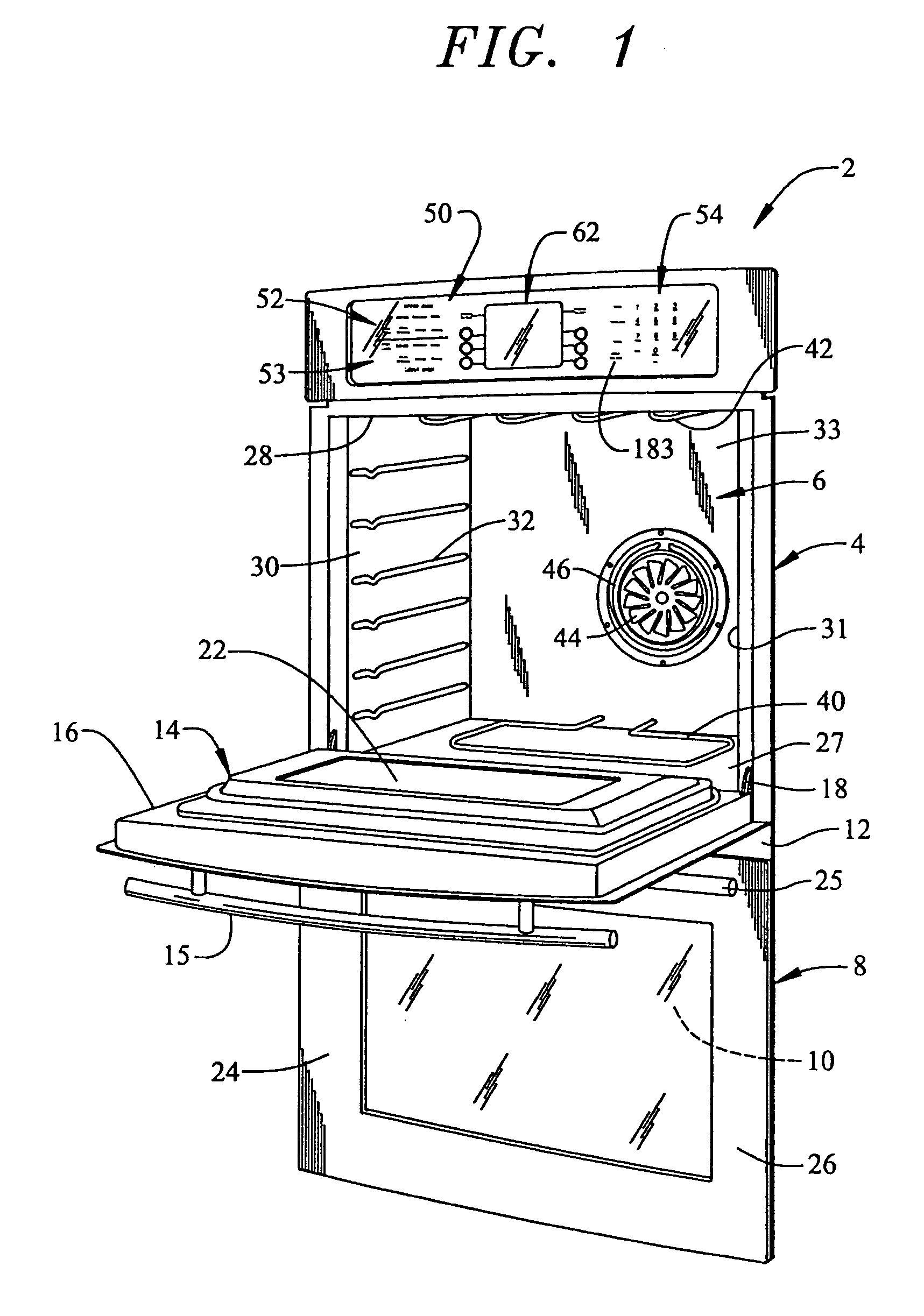

Oven assembly with slides

InactiveUS6938617B2Avoid relative motionSelf-cleaning stoves/rangesStoves/ranges shelves or racksEngineeringMechanical engineering

An oven rack assembly including full extension slides. Full extension slides are mounted to an oven rack and oven rack frames or wire racks providing full extension of an oven rack from an oven enclosure. The rack frame is mounted to oven walls or the slides are coupled to wire racks along oven slide walls.

Owner:STANDARD PURISHIJIYAN

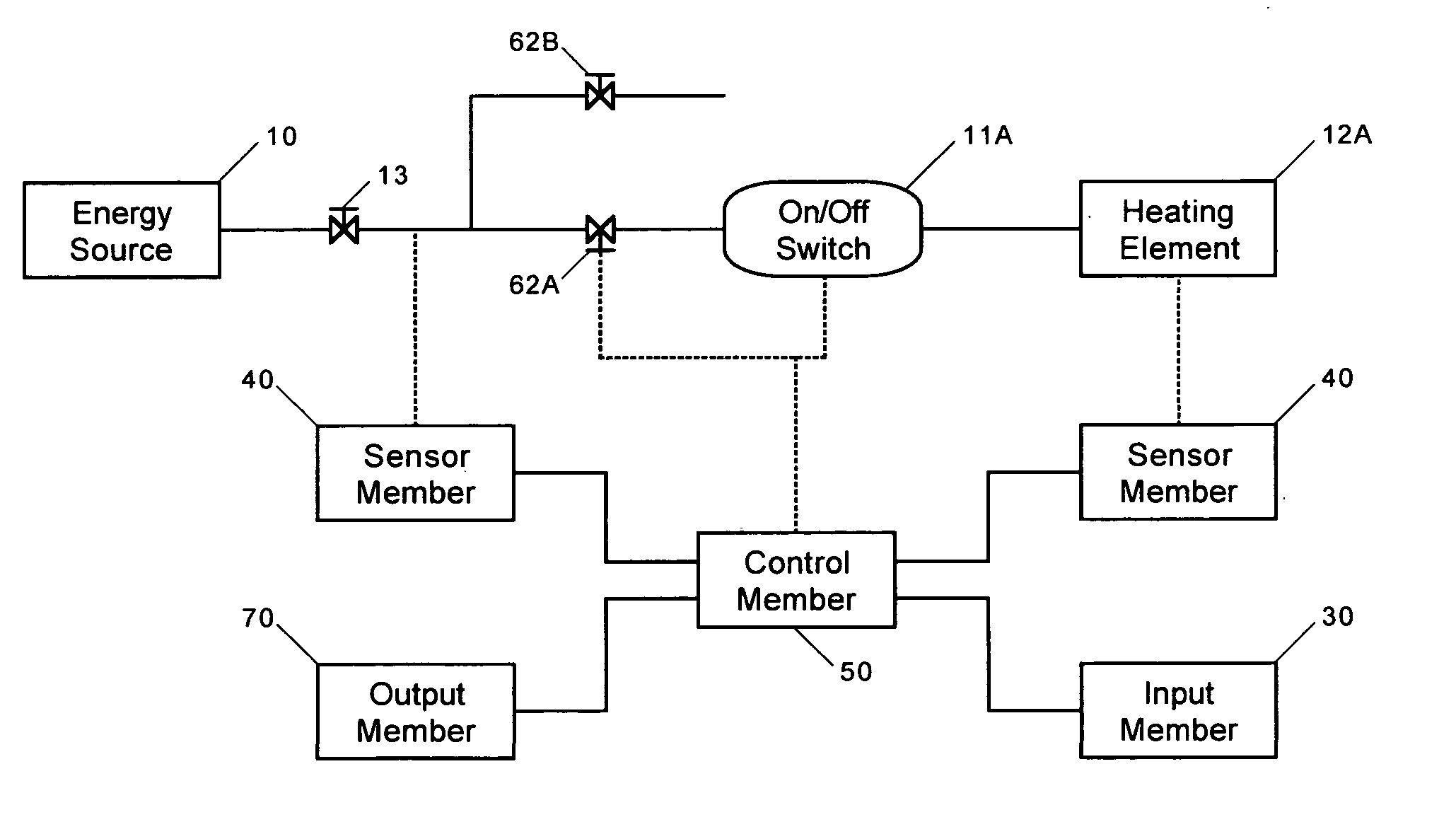

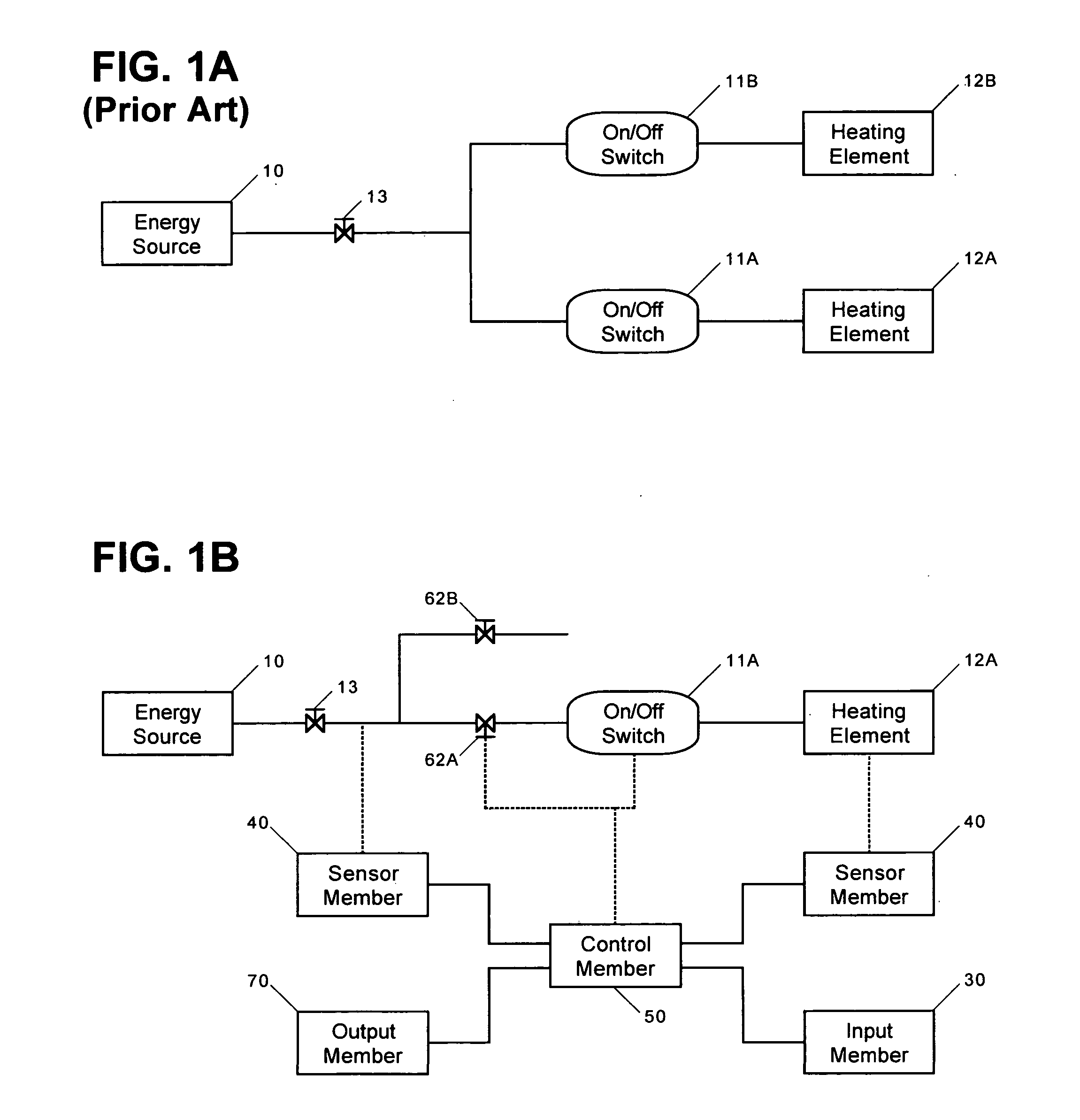

Grill safety systems and methods

InactiveUS20050229918A1Avoid accidentsFuel supply regulationDomestic stoves or rangesElectricityCombustor

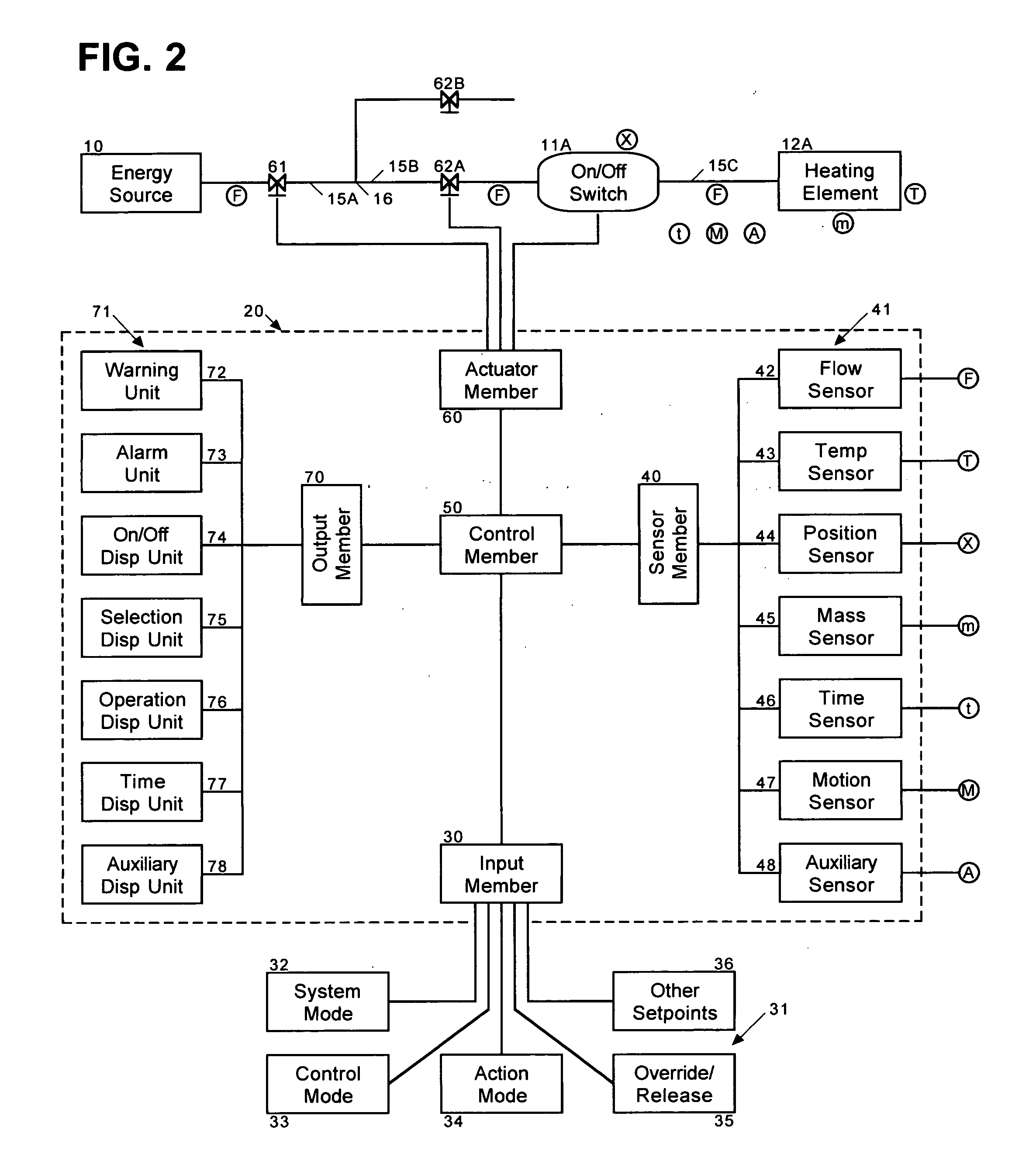

The present invention relates to grill assemblies for generating heat from various sources. In particular, the present invention relates to grill assemblies including various control members to detect unintended heating and terminating such. The present invention also relates to various methods of detecting the unintended heating by the heating elements and stopping such operations. The present invention also relates to various processes for providing various control members and grill assemblies including such control members. Such control members may be incorporated into grill assemblies for generating heat from various sources, e.g., burning gas, flowing electricity, irradiating electromagnetic waves thereby, and so on. In addition, the control members of this invention may be implemented into various stationary and / or portable grills and ovens for cooking food, various fireplaces or burners for heating interior, and the like.

Owner:SHIM YOUNGTACK

Programmable cooking appliance

ActiveUS9057526B2Preventing the food item from burningReduce power levelDomestic stoves or rangesLighting and heating apparatusControl systemProcess engineering

A control system for a cooking appliance can operate in first or second modes of operation. In the first mode, a consumer is required to input both a temperature parameter and a time parameter before initiating a cooking operation. Once the cooking operation has completed, the control system operates the cooking appliance in a low temperature mode for a predetermined period. In this manner, a cooked food item is maintained at a reduced temperature so that the food item does not burn. In the second mode, the consumer can choose to bypass the required time input parameter so as to operate the cooking appliance based solely on the temperature parameter.

Owner:MAYTAG

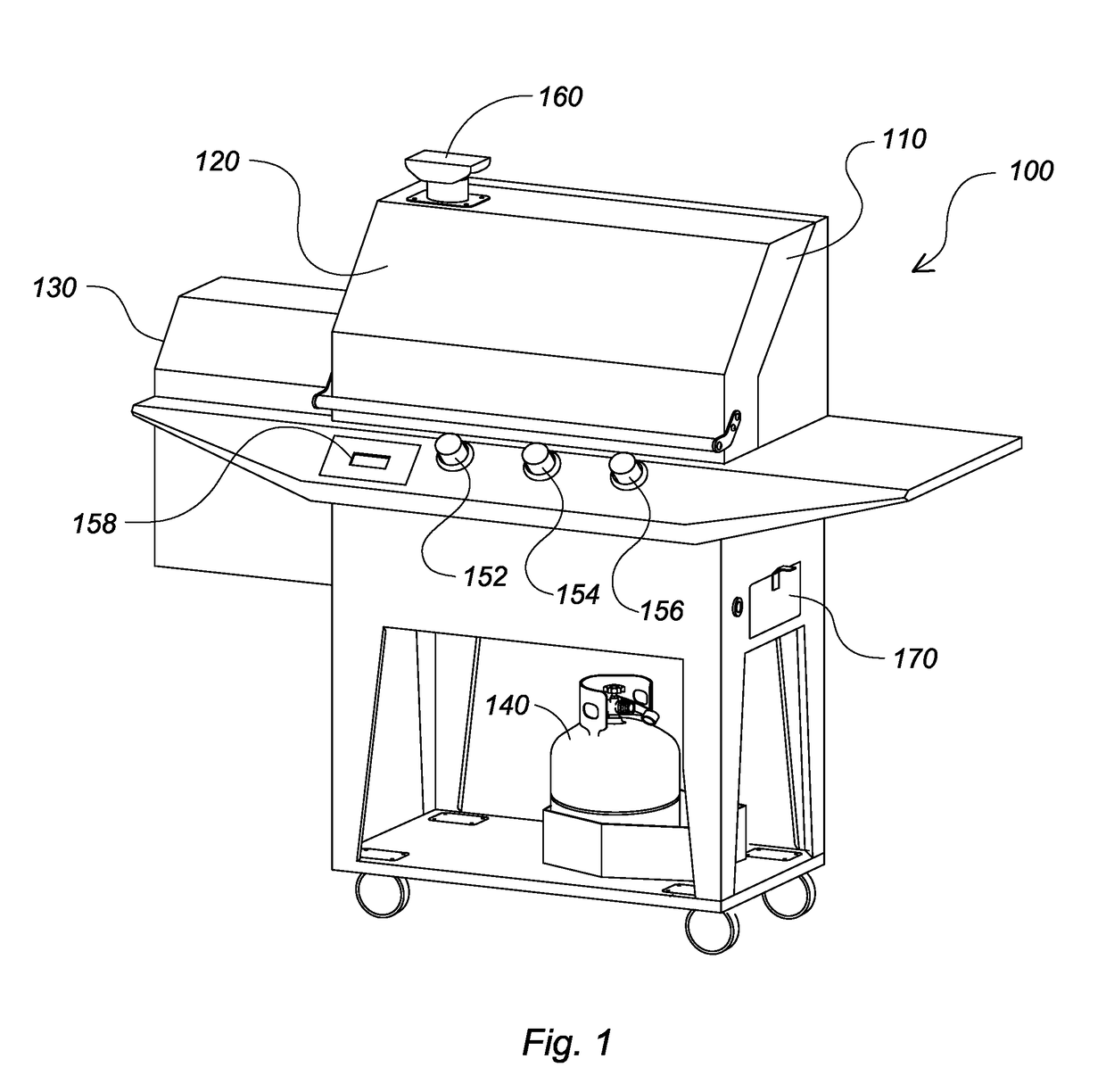

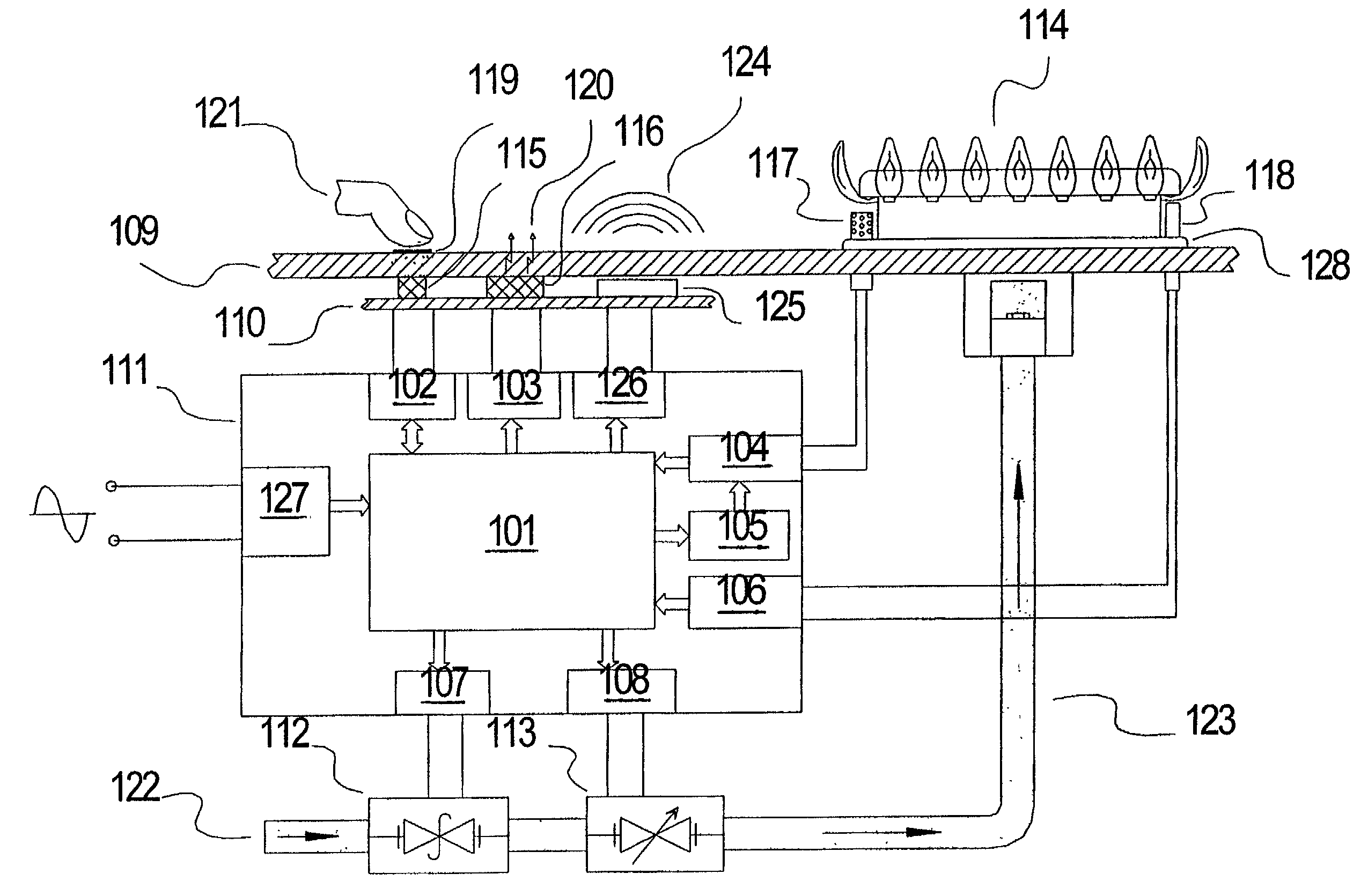

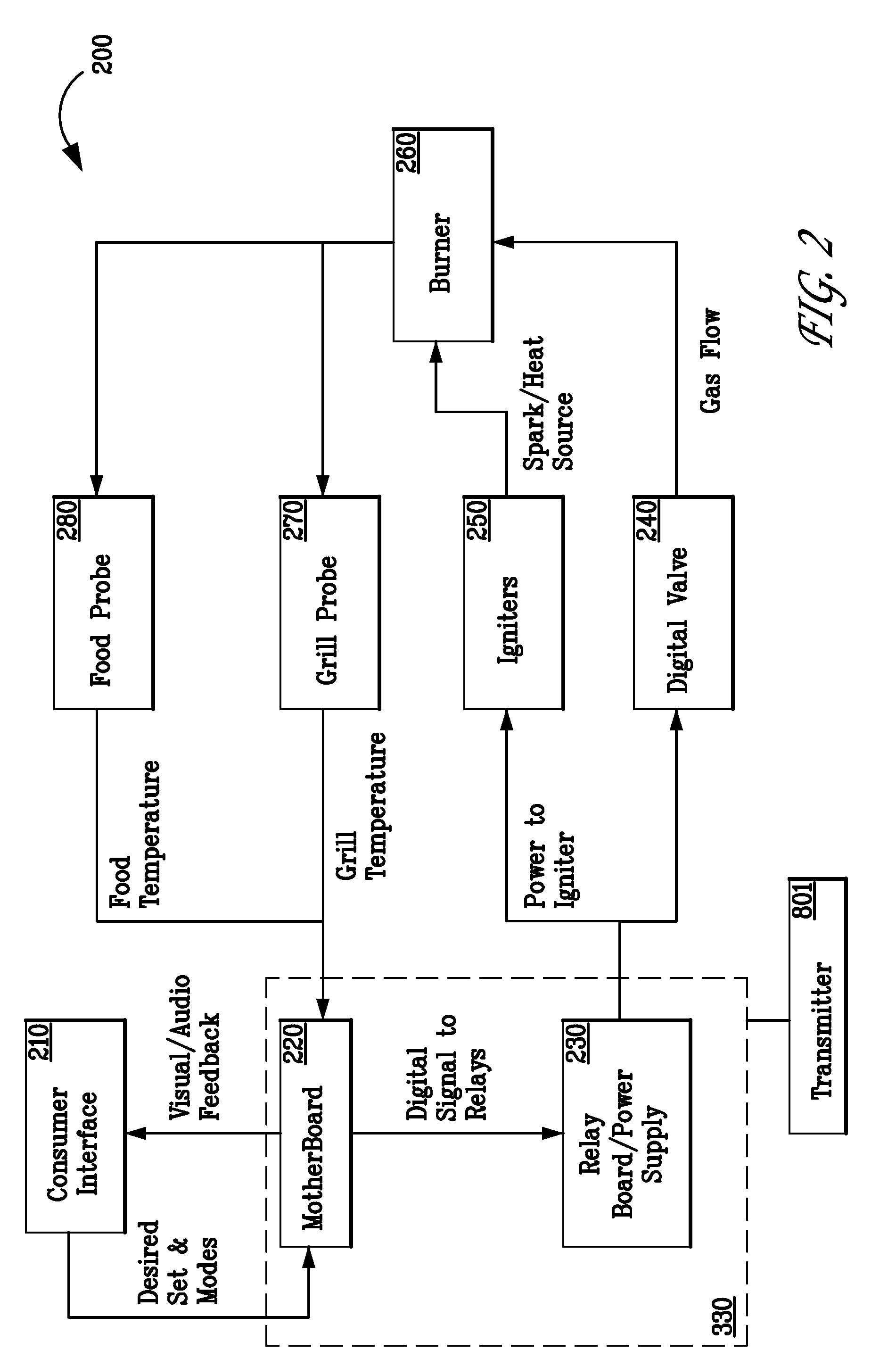

Gas grill

ActiveUS20100132692A1Overcome disadvantagesMaintain working temperatureFuel supply regulationBoiling over preventionAutomatic controlControl system

A control system for a gas grill is disclosed. The gas grill has a cooking surface. The control system includes at least two fuel flow valves located between a fuel source and at least one grill burner, a user interface unit configured to receive grill operation settings, at least one temperature sensor disposed adjacent to the cooking surface and configured to detect at least a grill operating temperature and a control unit configured to, receive the grill operation settings from the user interface unit, receive the grill operating temperature from the at least one temperature sensor, and automatically control the at least one fuel flow valve for modulating the amount of fuel delivered to the at least one grill burner to maintain the grill operating temperature at a predetermined temperature based on the operation settings and the grill operating temperature.

Owner:HAIER US APPLIANCE SOLUTIONS INC

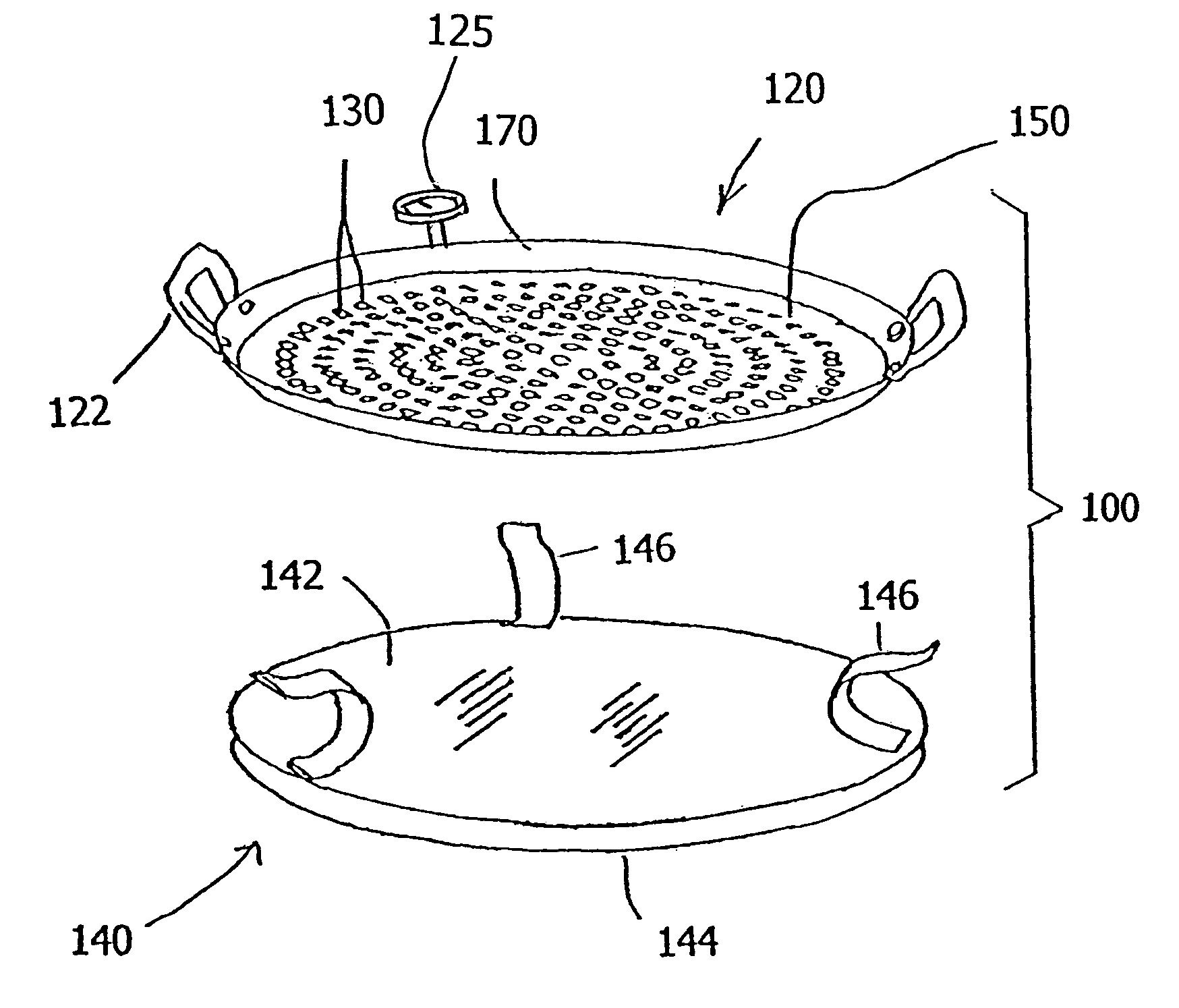

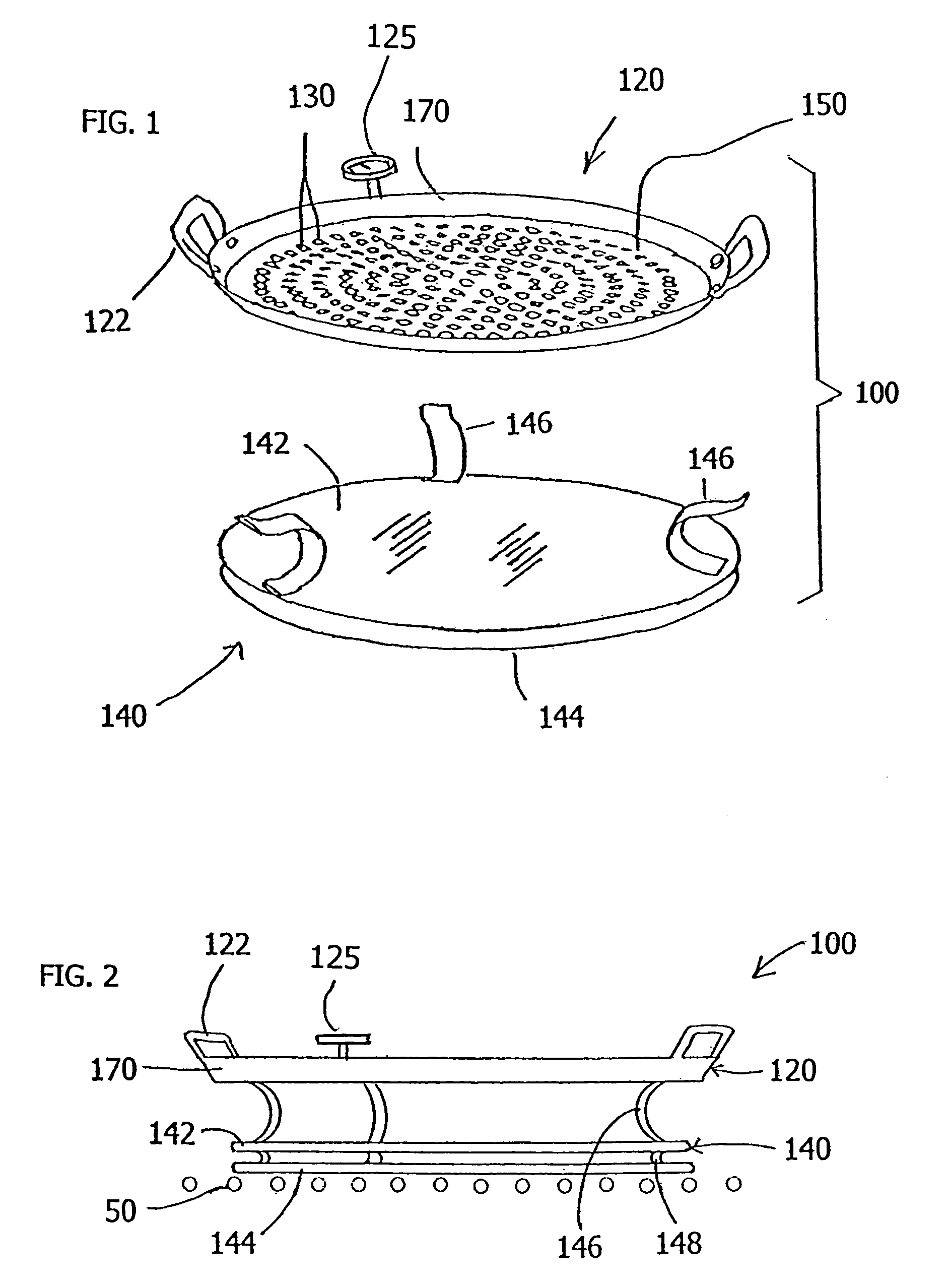

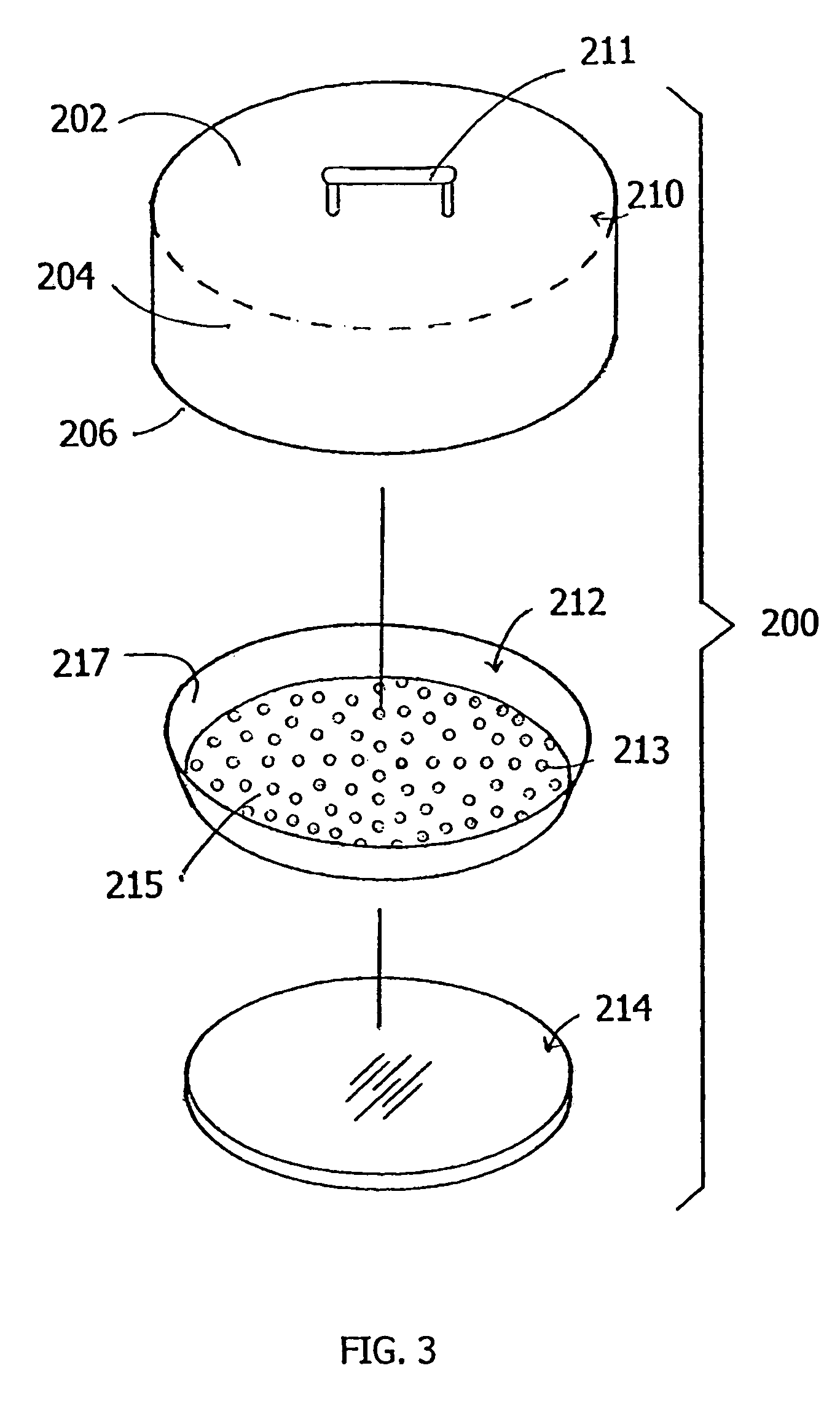

Kit, apparatus and method for use in cooking over an intense heat source

InactiveUS7219663B2Firm supportModerates being transferredDomestic stoves or rangesLiquid heating fuelEngineeringHeat shield

A portable cooking kit, apparatus and method is usable for moderating heat from an intense heat source, such as an outdoor grill or 1. The apparatus includes a food support member, including a perforated panel surrounded by a rim. The food support member rests on top of a heat shield made from a heat-tolerant material. During use, the heat shield is stably suspended over direct, intense heat from a heat source. The food to be cooked is placed on the food support member, and the food support member may then be placed on top of the heat shield. By buffering the direct heat from the heat source, the heat shield allows food placed on the food support member to cook, but protects the underside of the food from becoming scorched. Optionally, a dome-shaped cover may be used to cover both the food support member and the heat shield.

Owner:ISLANDER INNOVATIONS

Grill

A grill, such as a gas-fired grill, can employ a light assembly for illuminating a cooking area and / or a fuel gage that can be more readily and accurately read to determine an amount of fuel in a fuel tank. The light assembly includes a light source, which is mounted to an upper one of two discrete lids. The light source can be selectively illuminated via a switch. The switch may be coupled to a handle that is employed to open and close the second lid. The handle can be coupled to a side of the lid so as to position the switch in a location that can be relatively cool. The fuel gage can employ a pivoting platform, the motion of which may be employed to determine an amount of fuel in the fuel tank.

Owner:BLACK & DECKER INC

Cooking apparatus and control method of the same

InactiveUS20070246453A1Transmitted directlyAvoid damageDomestic stoves or rangesElectrical heating fuelComputer vision

Owner:LG ELECTRONICS INC

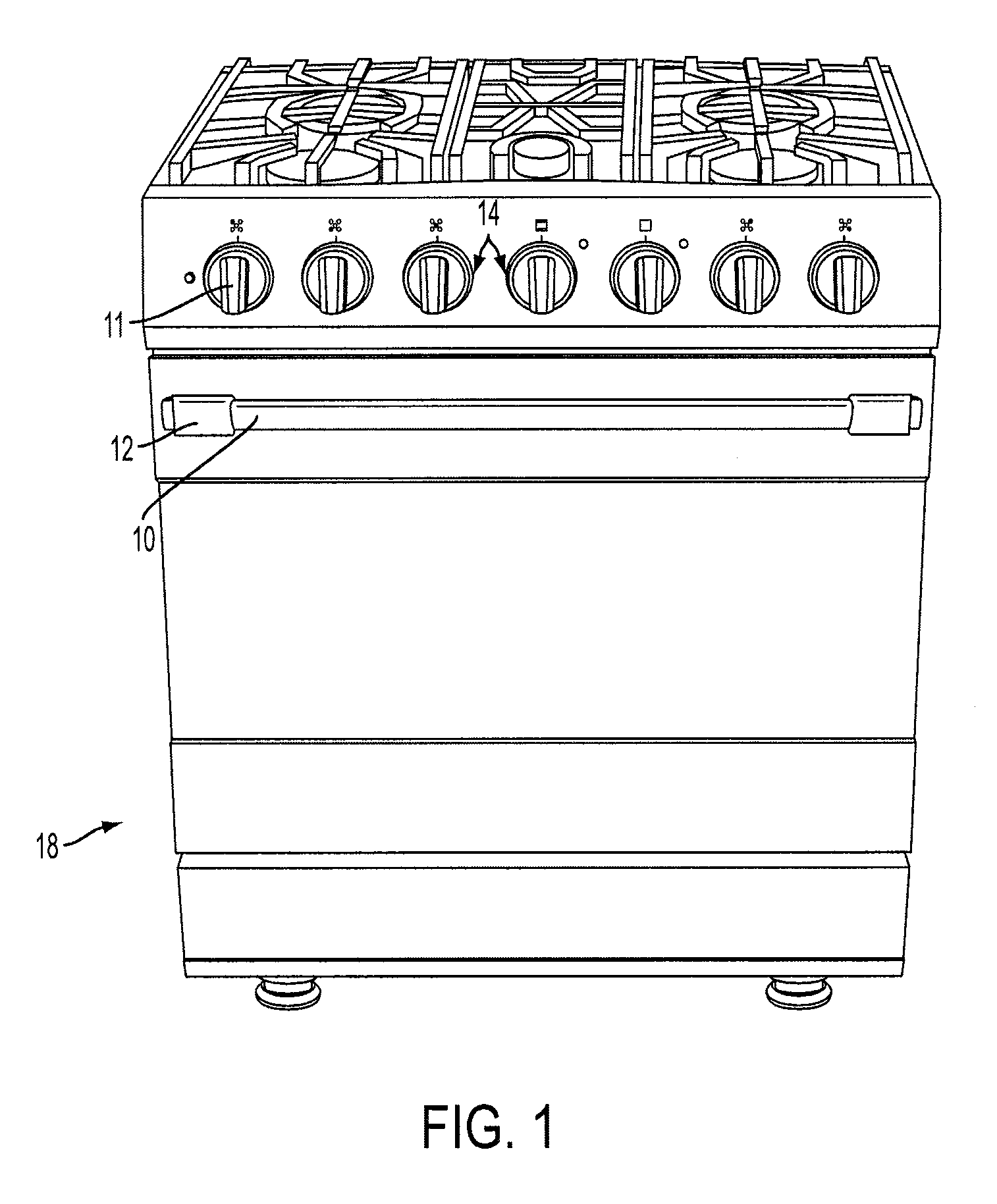

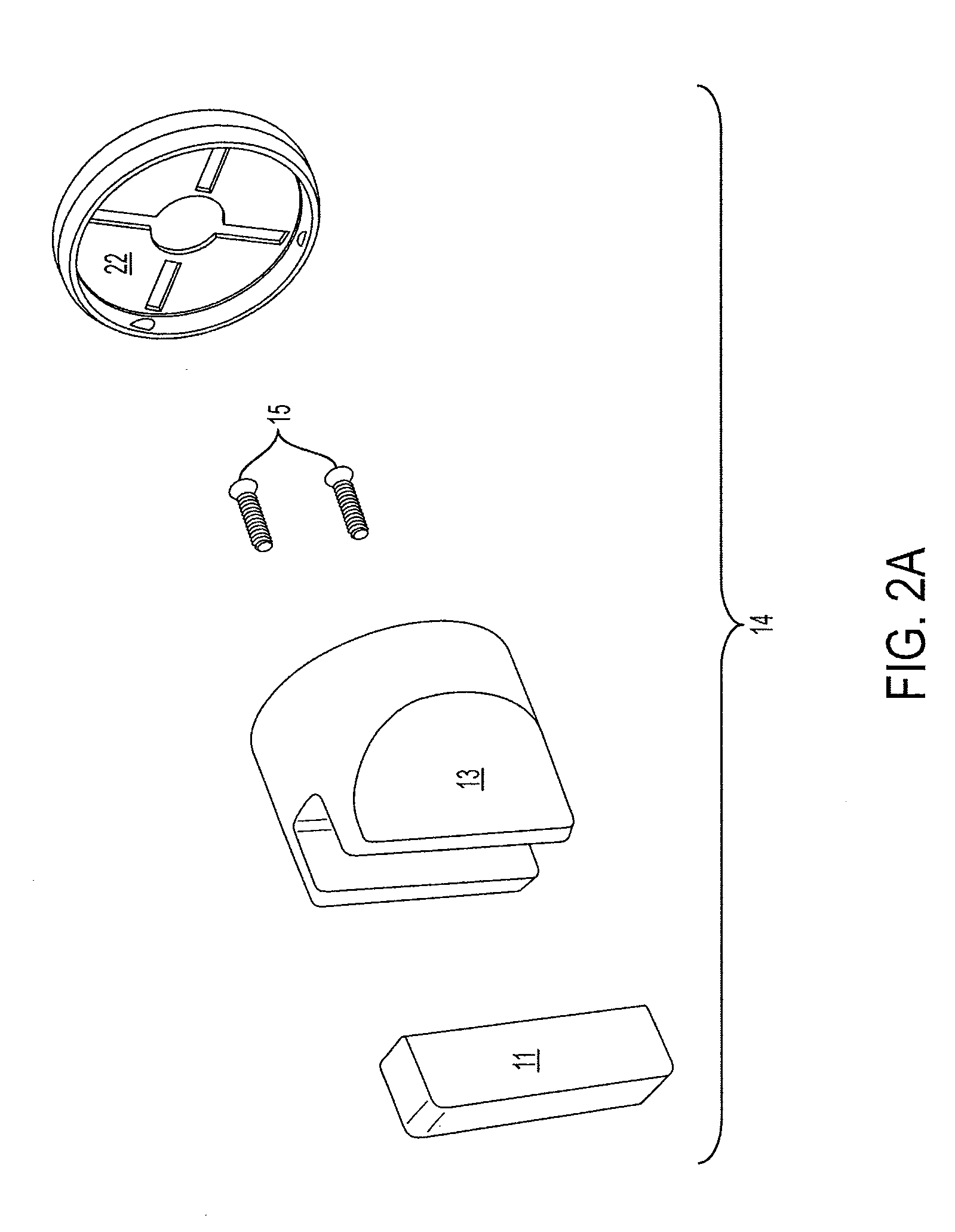

Interchangeable Appliance Insert Components and System

InactiveUS20120272784A1Mechanical apparatusDomestic stoves or rangesEngineeringMechanical engineering

A selectable and interchangeable accessory insert system for an appliance is disclosed. The appliance includes at least a handle or a knob. The handle includes at least a base portion and a first insert, with the first insert being separable from the base portion. The base portion being sized to receive a second insert after the first insert is separated therefrom. In an appliance with multiple knobs or handles, each knob or handle can include exchangeable inserts to allow the inserts to be exchanged to have similar appearances or features.

Owner:VIKING RANGE

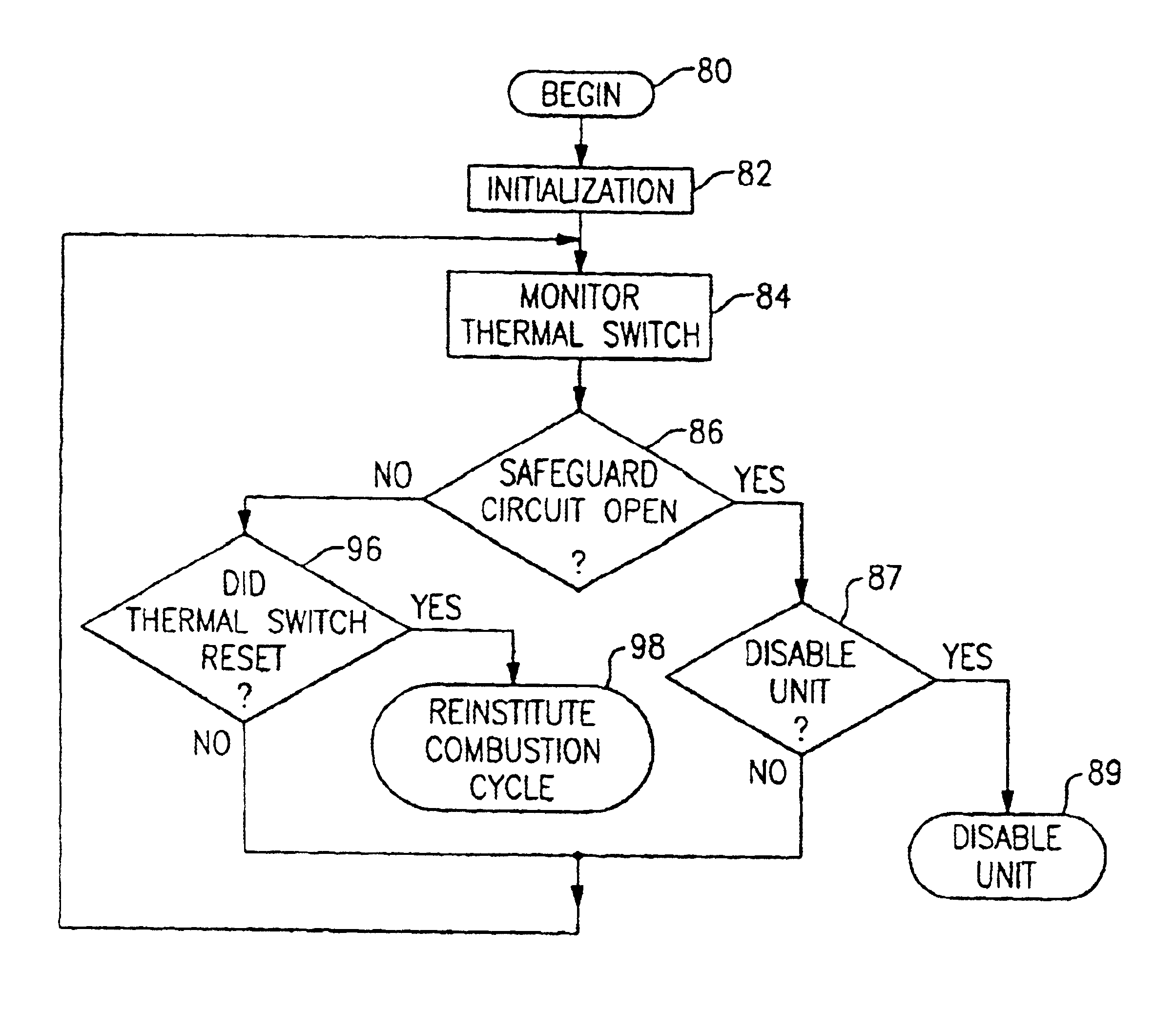

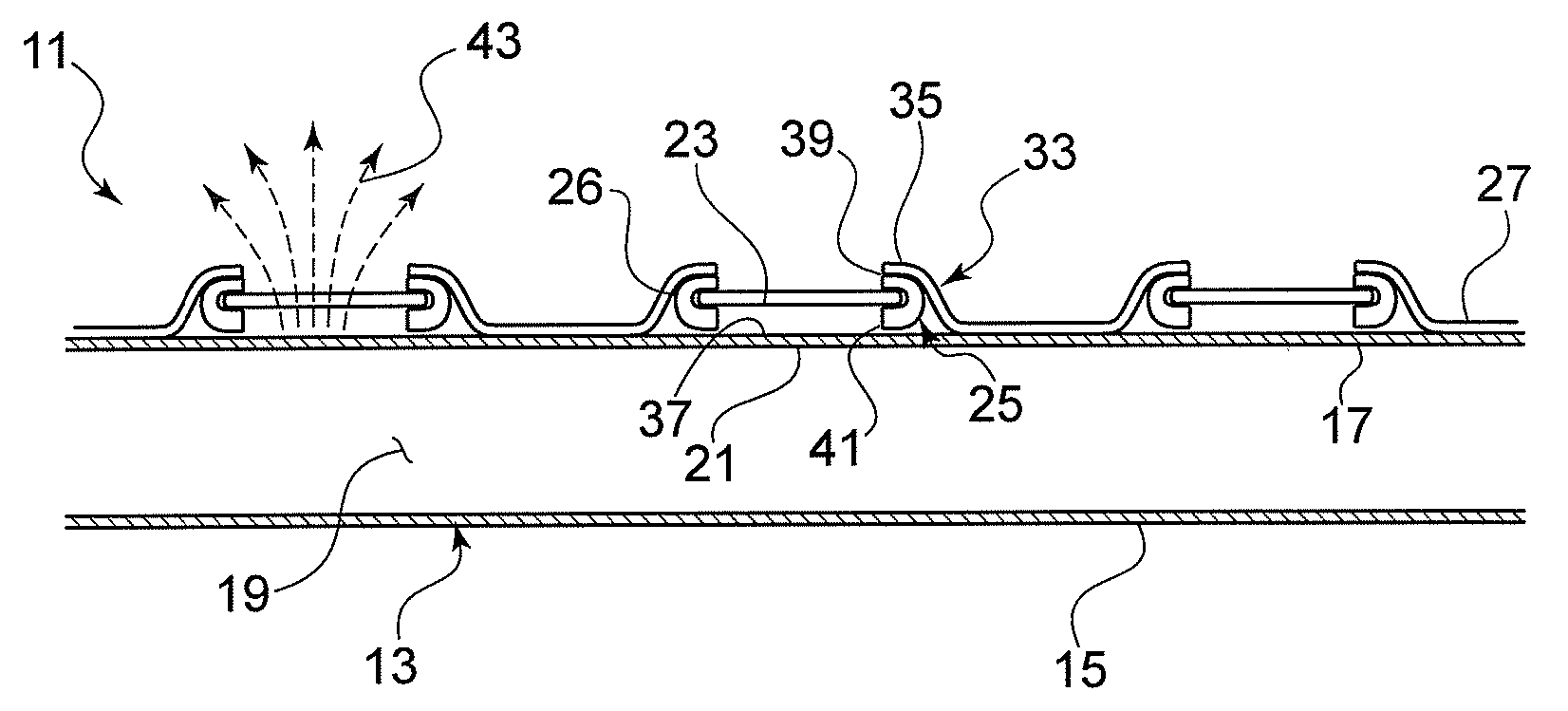

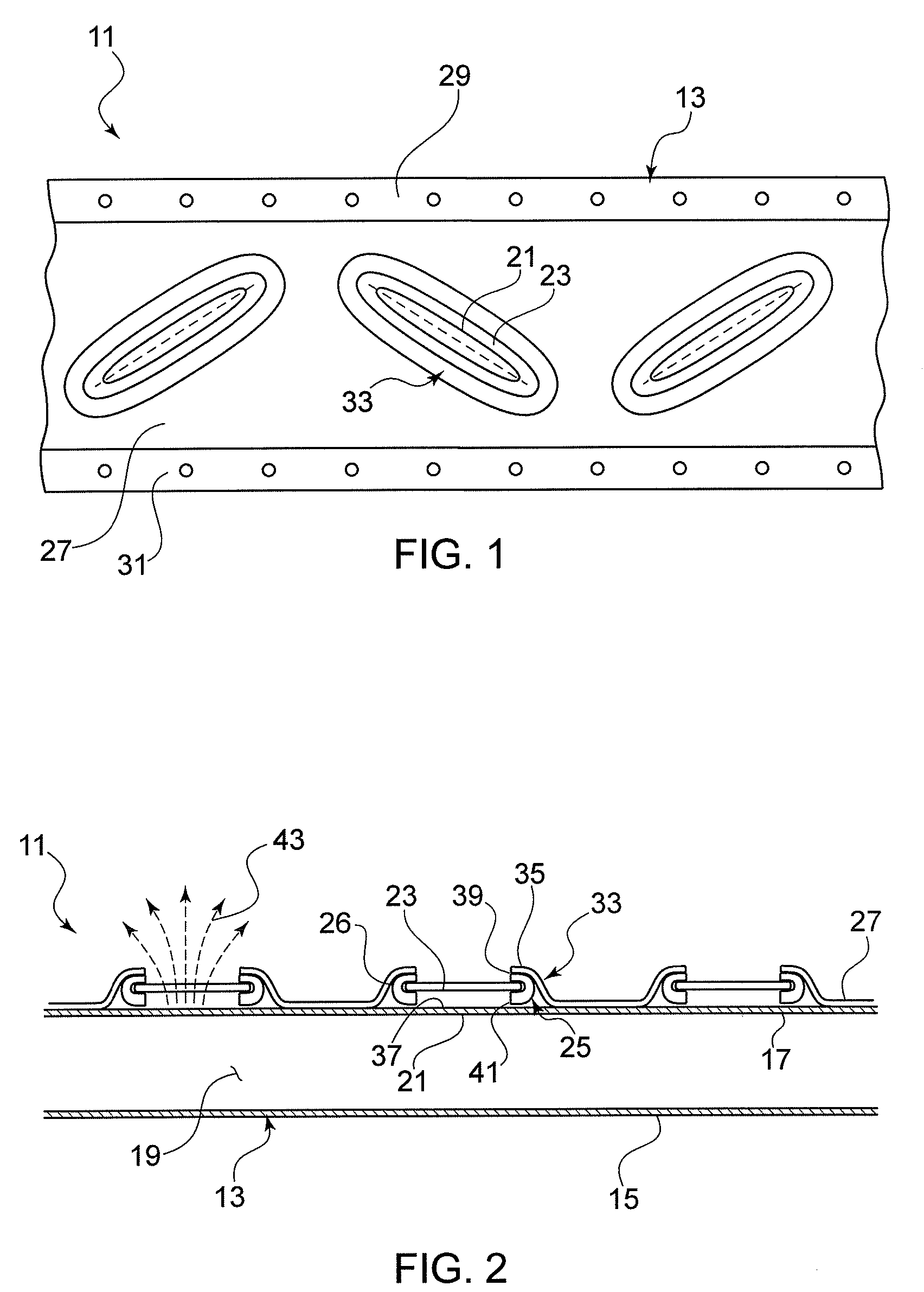

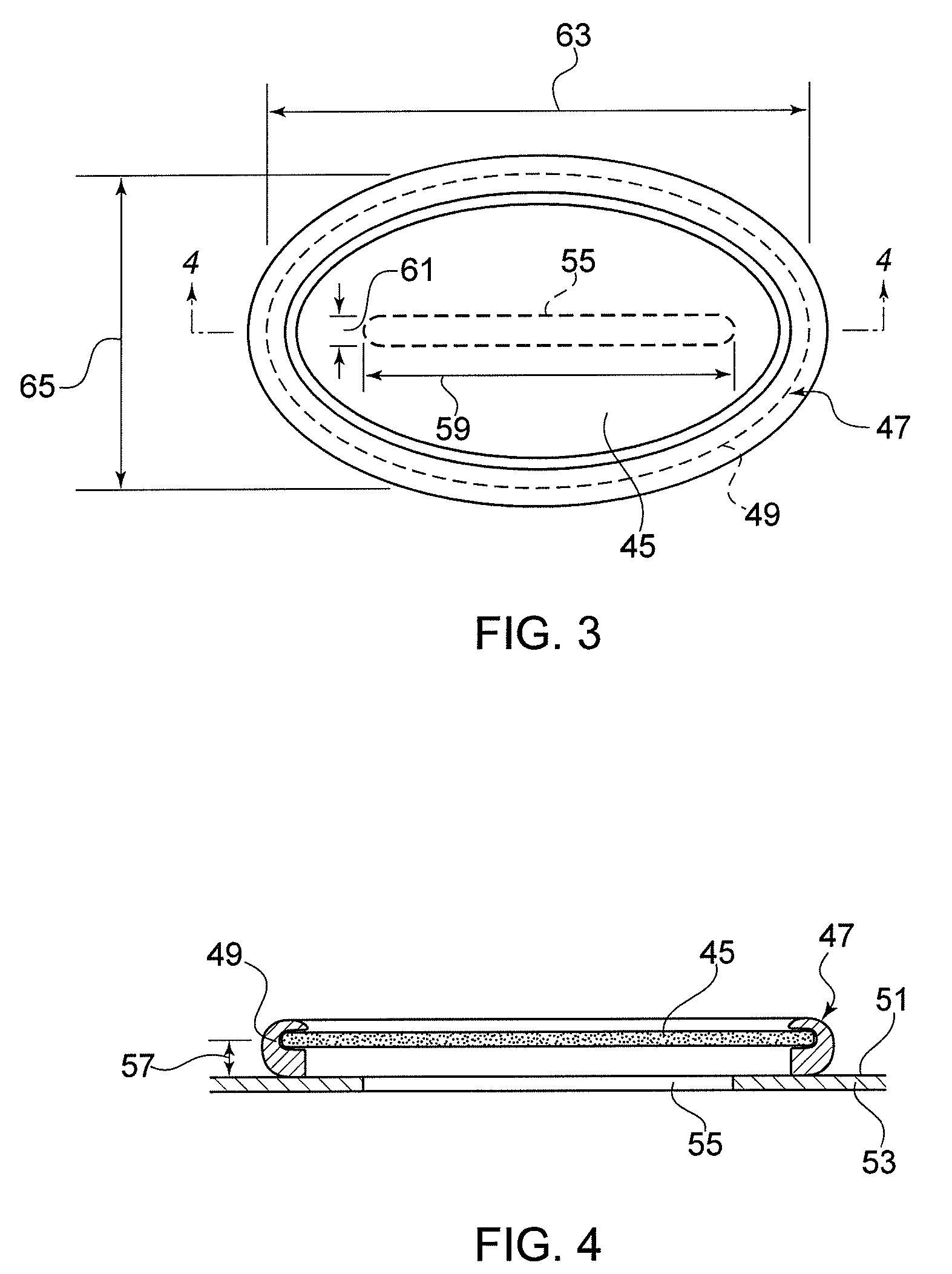

Primary Heat Exchanger Design for Condensing Gas Furnace

ActiveUS20110174301A1Domestic stoves or rangesEnergy efficient heating/coolingProcess engineeringHeat exchanger

A compact furnace heat exchanger for a gas furnace is disclosed. The compact furnace heat exchanger may include a first pass having an inlet end, a second pass in fluid communication with the first pass through a first return bend, and a third pass having an outlet end and in fluid communication with the second pass through a second return bend. The third pass may further include a plurality of irregularities for optimizing performance of the compact furnace heat exchanger and the associated gas furnace.

Owner:CARRIER CORP

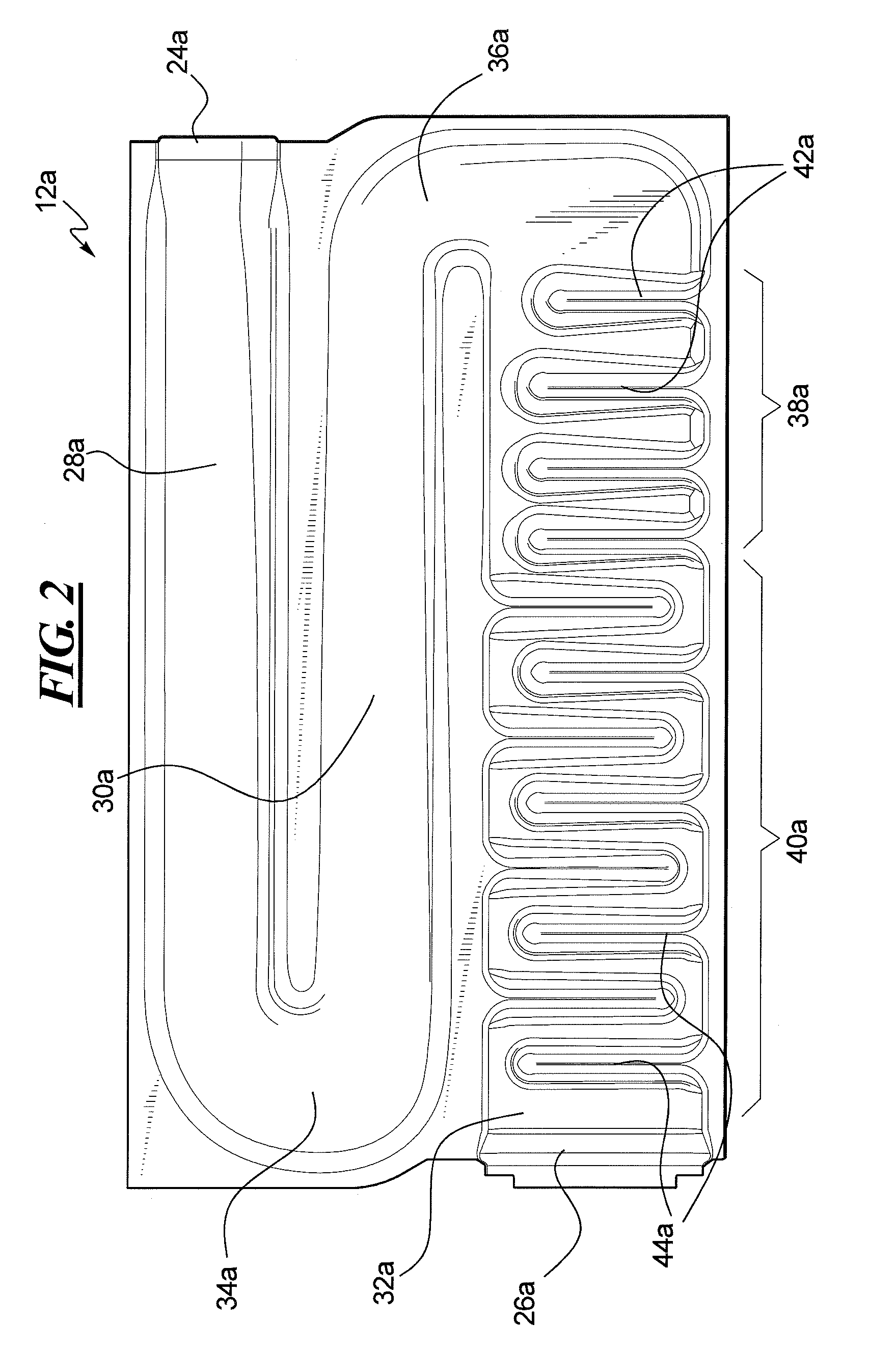

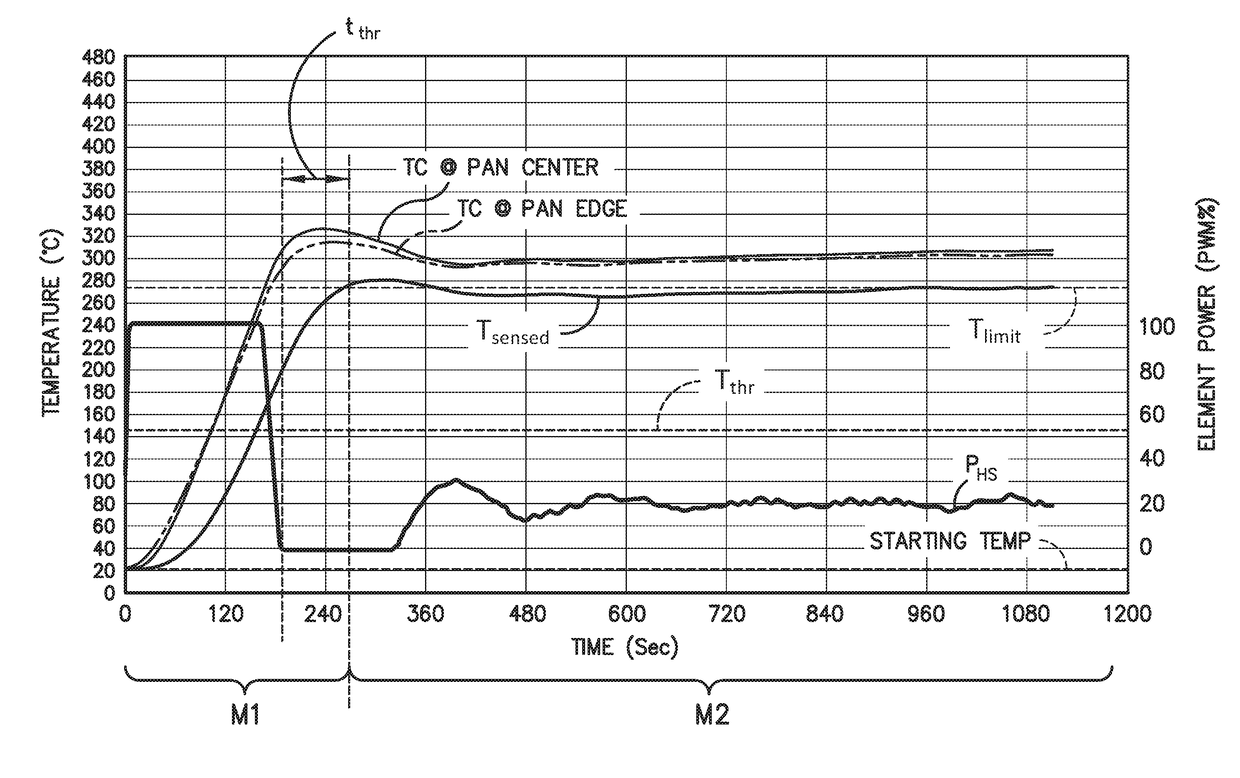

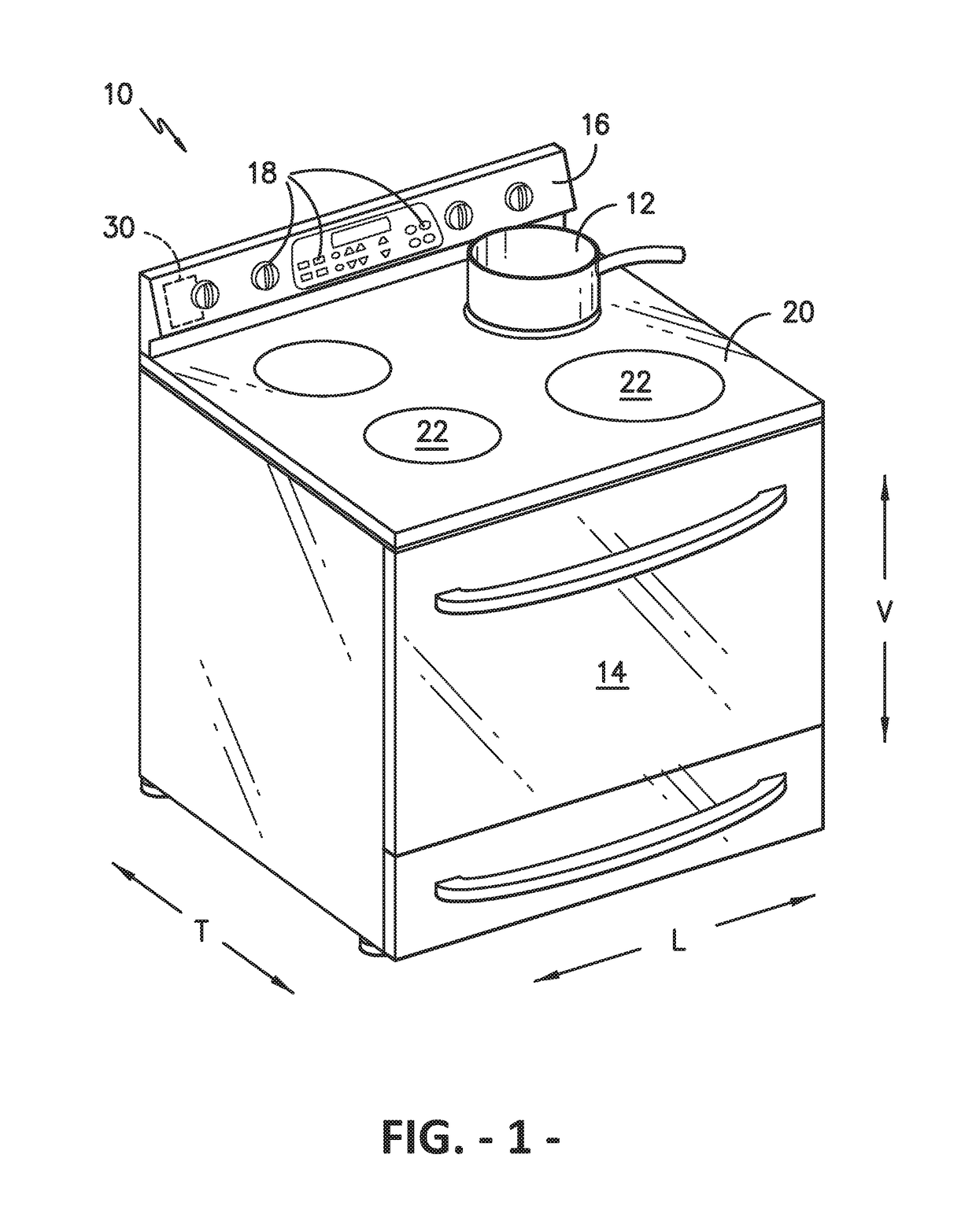

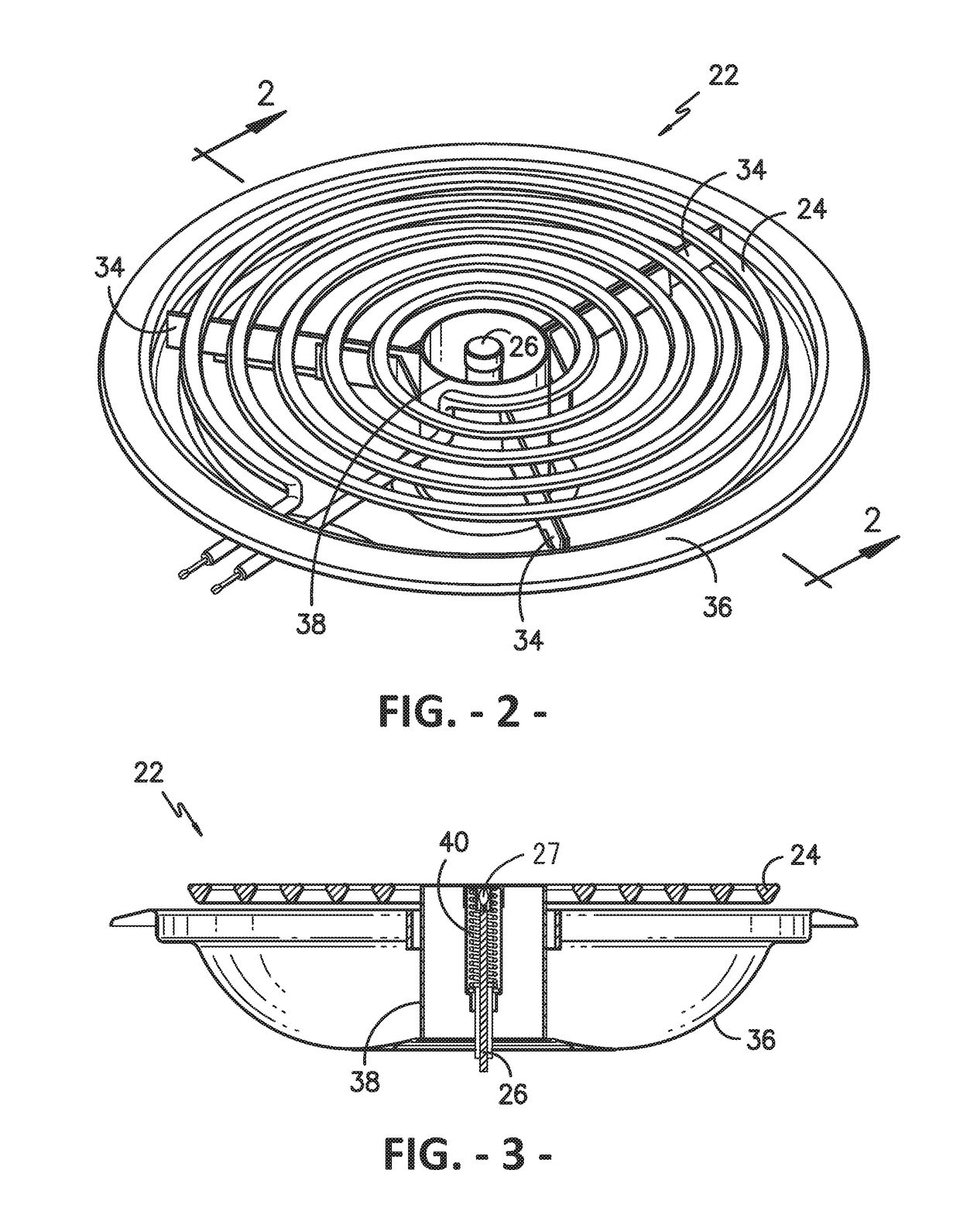

Cooking appliance and method for limiting cooking utensil temperatures using dual control modes

ActiveUS9909764B2Domestic stoves or rangesLighting and heating apparatusProcess engineeringElectric power

Cooking appliances and methods for operating cooking appliances are provided. In one exemplary embodiment, a method for operating a cooking appliance is provided. The method includes providing power to the heating source according to a first control mode; determining whether to transition from the first control mode to a second control mode and, if so, then providing power to the heating source according to the second control mode. The method further includes determining whether to transition to the first control mode and, if so, then returning to providing power to the heating source according to the first control mode. The cooking appliances and methods include features for limiting cooking utensil temperatures using dual control modes.

Owner:HAIER US APPLIANCE SOLUTIONS INC

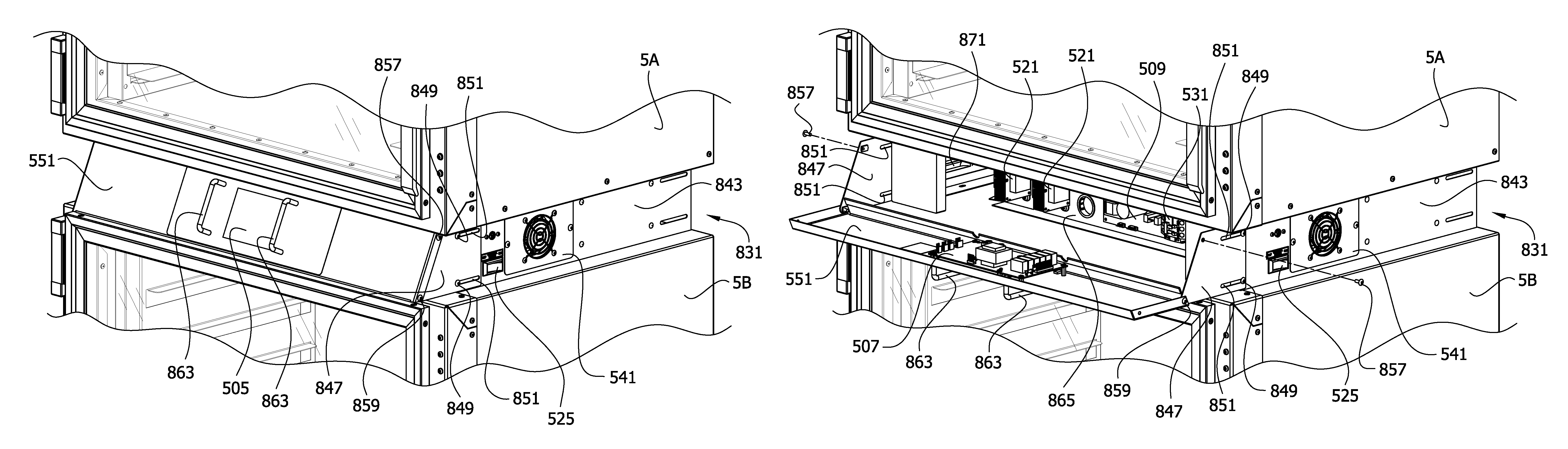

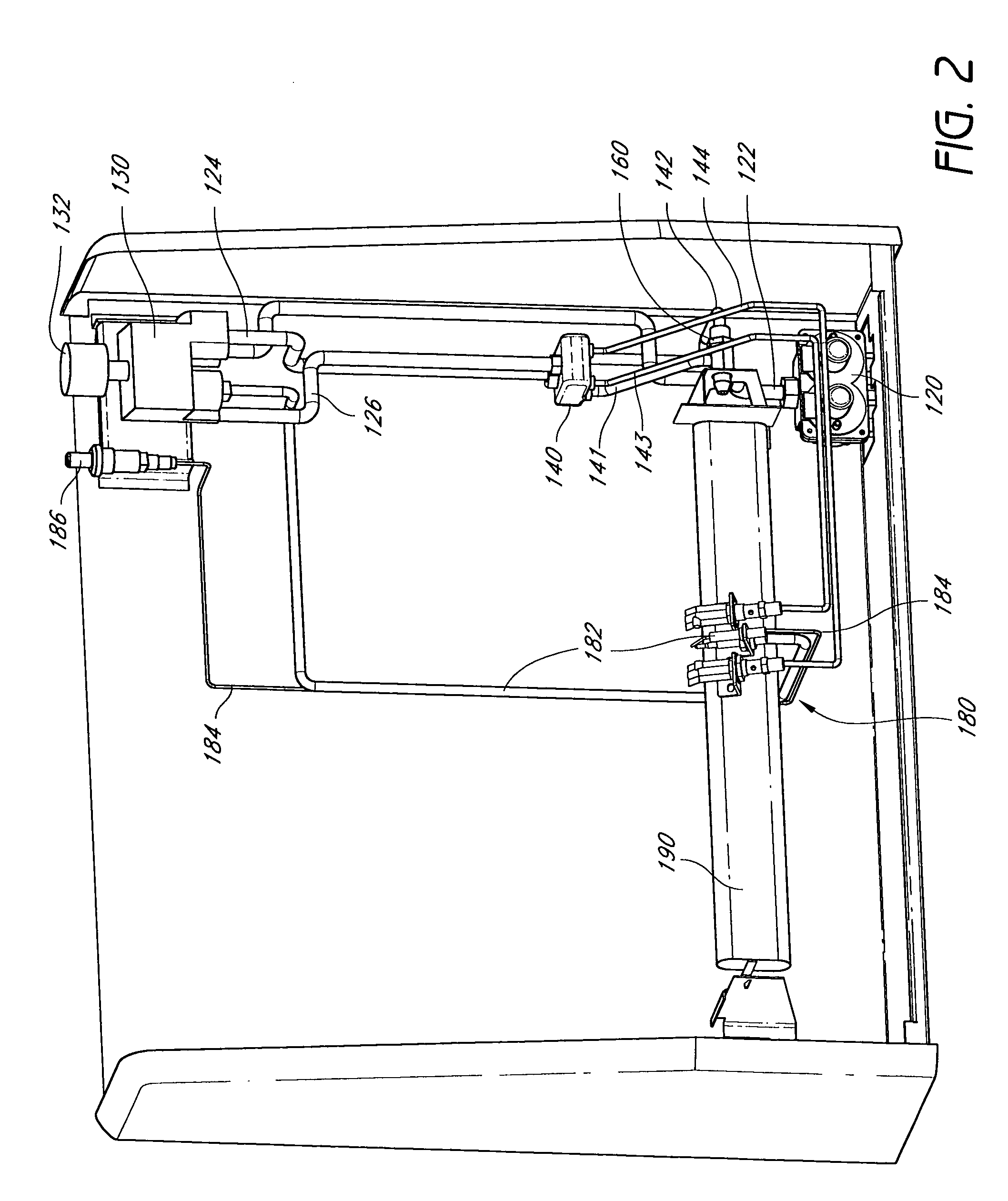

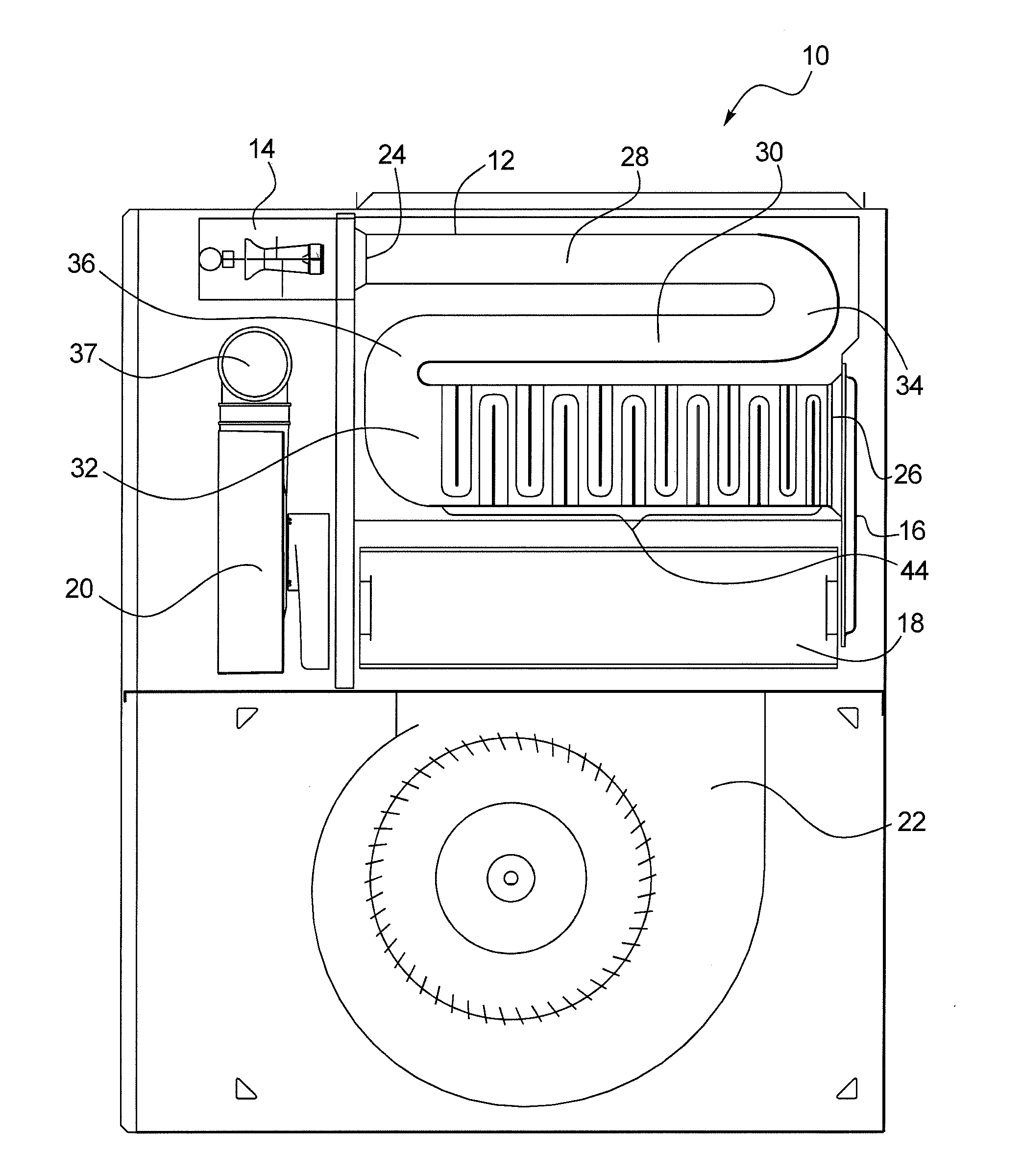

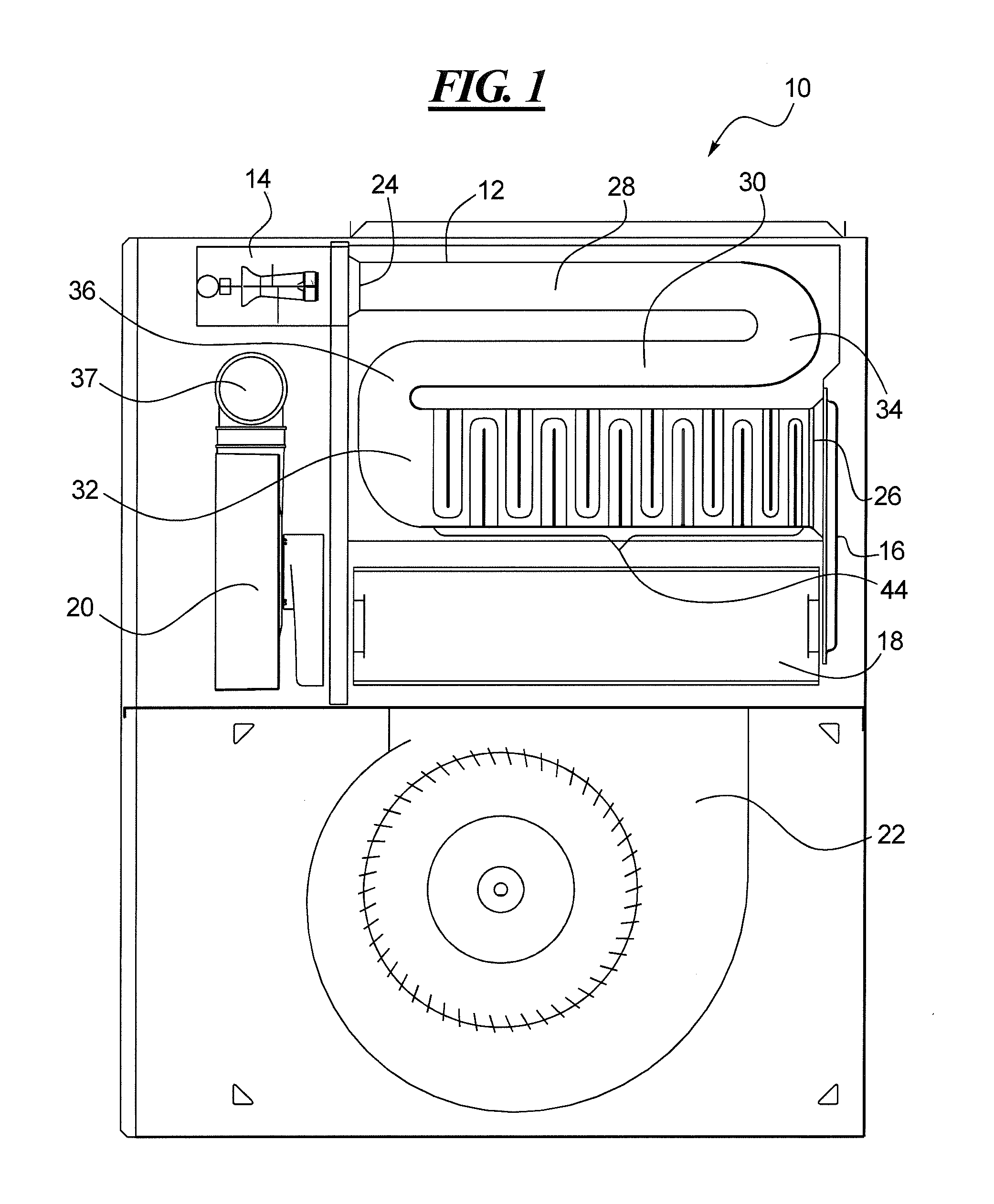

Combination speed cooking oven

ActiveUS20080296284A1Low costIncrease speedSelf-cleaning stoves/rangesAir-treating devicesProcess engineeringFood products

A combination cooking oven is disclosed comprising a cooking cavity, a controller, thermal heating source, blower assembly, air directing means, deflecting means and a vent assembly wherein speed cooking or slower cooking of food products may be accomplished within the same appliance by movement of a gas baffle.

Owner:TURBOCHEF TECH INC

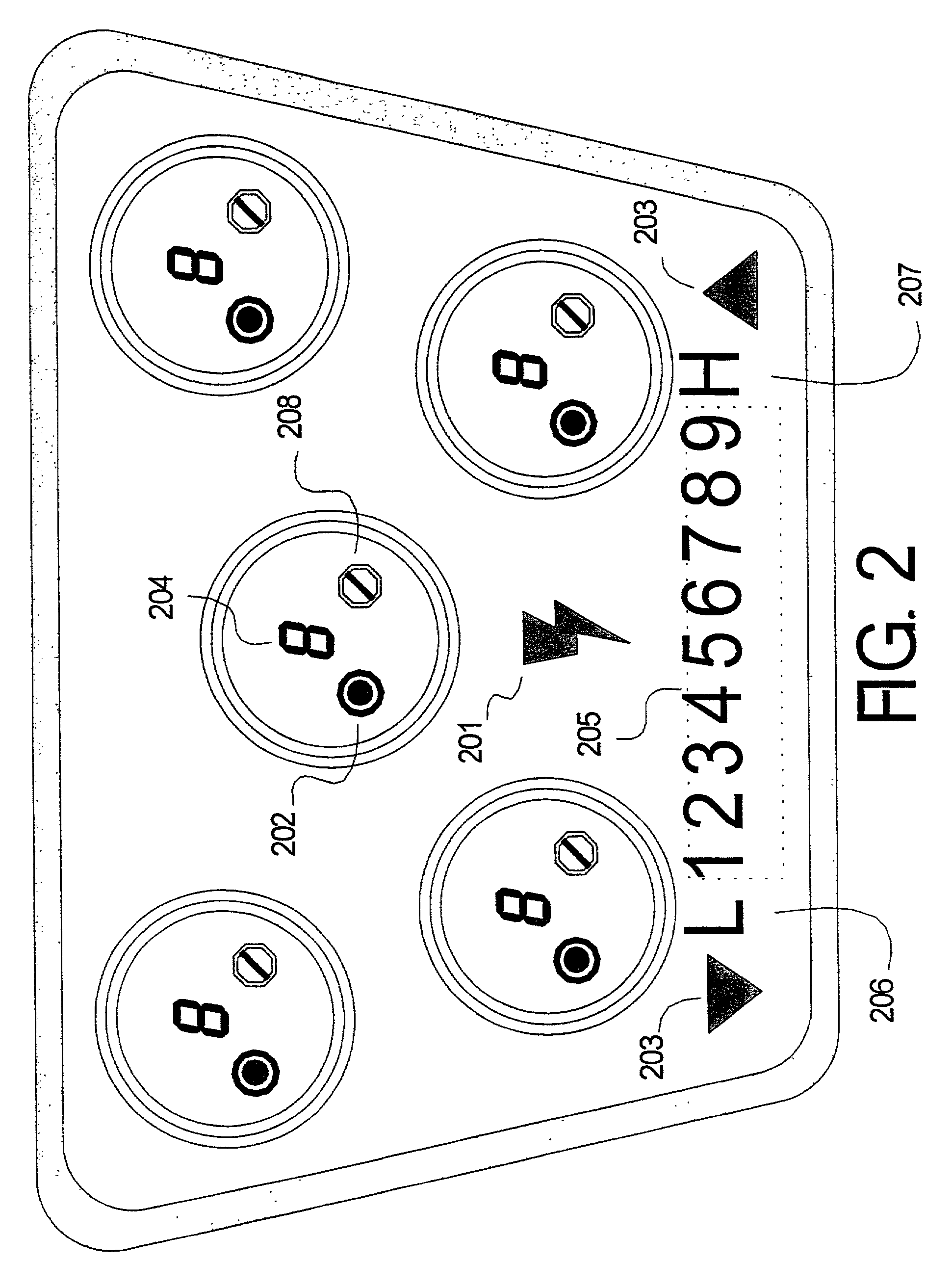

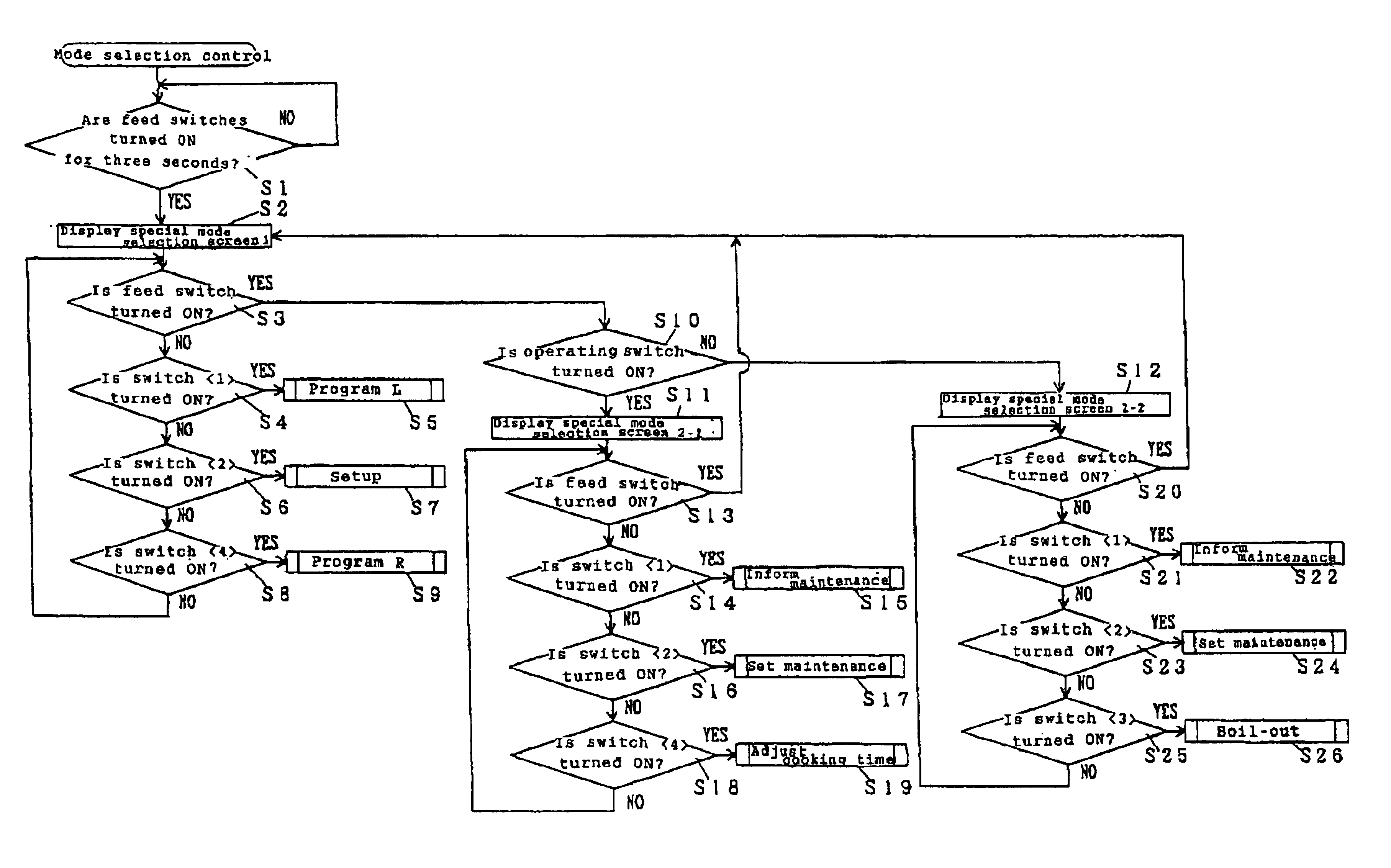

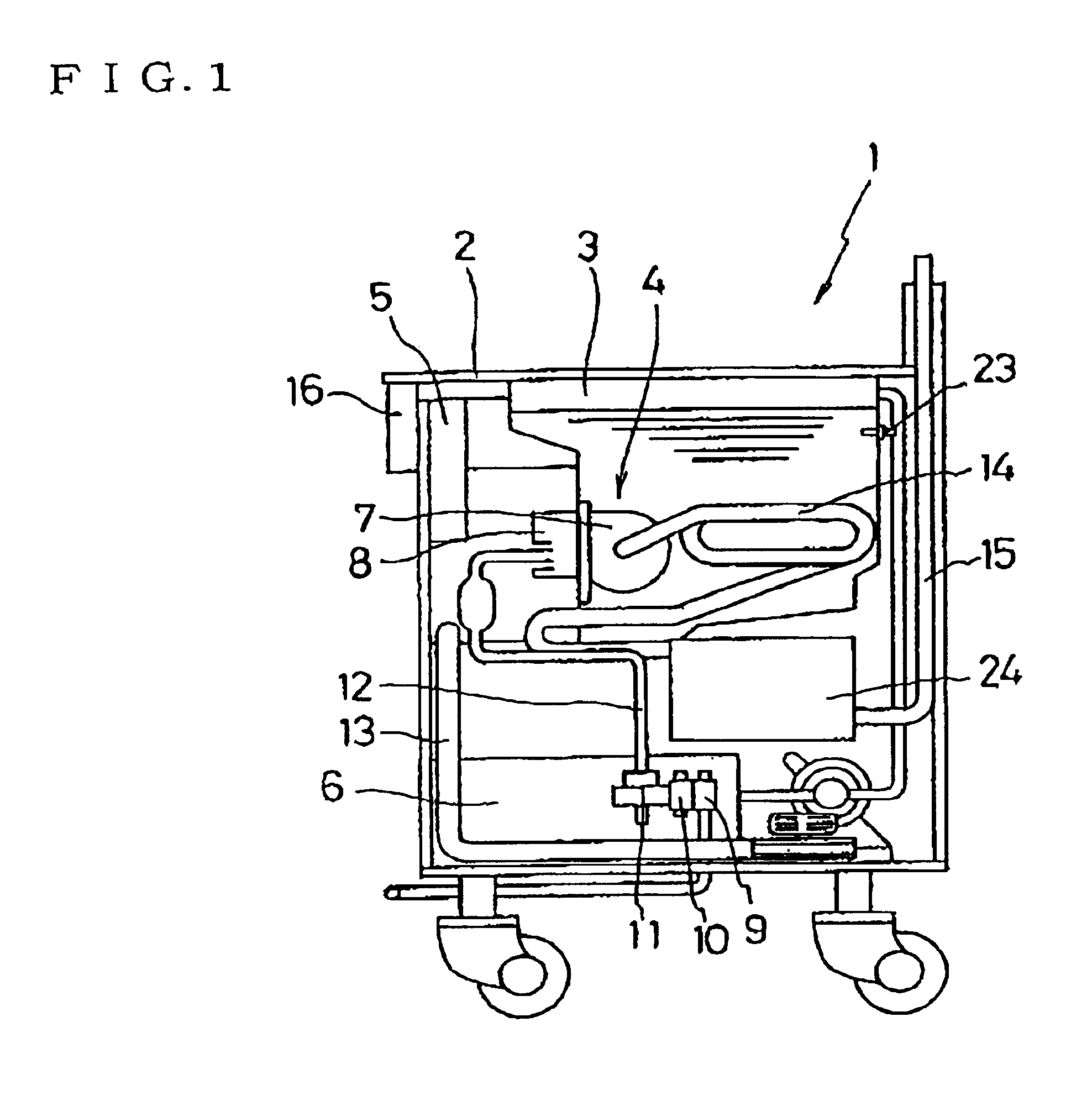

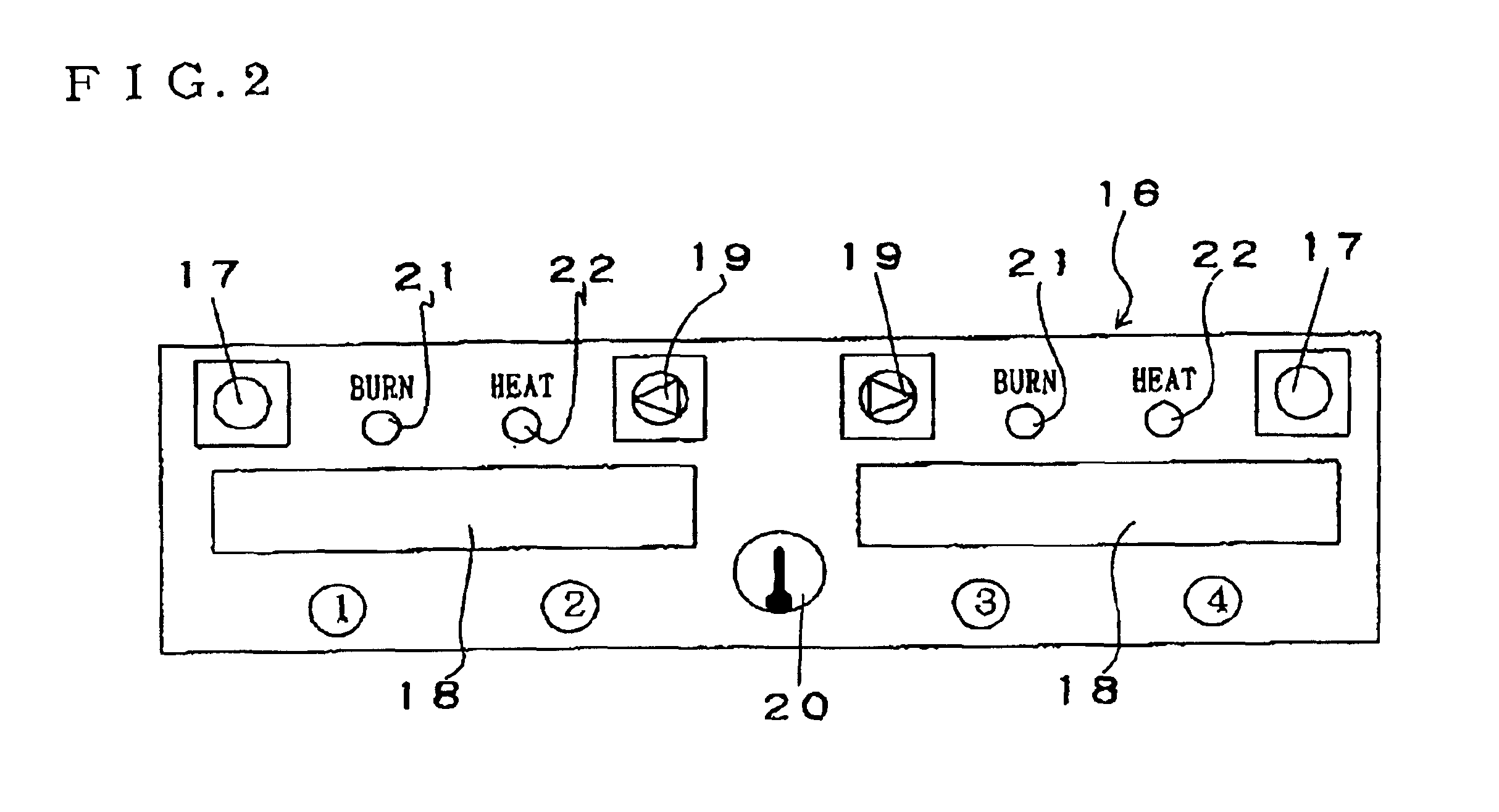

Cooking utensil

InactiveUS6841762B2Easily and reliably selecting such operation modePossible to selectDomestic stoves or rangesBoiling over preventionDisplay deviceOperation mode

When left and right feed switches are pressed simultaneously for three seconds at the step S1, a special mode selection screen 1 is changed such that the name of each operating mode is displayed at a display portion corresponding to the position of each of switches <1> to <4>. Thus, pressing any of the corresponding switches <1> to <4> under each display makes it possible to select each operating mode. In this way, an operation mode can be easily and reliably selected.

Owner:PALOMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com