Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

119results about How to "Maintain sufficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

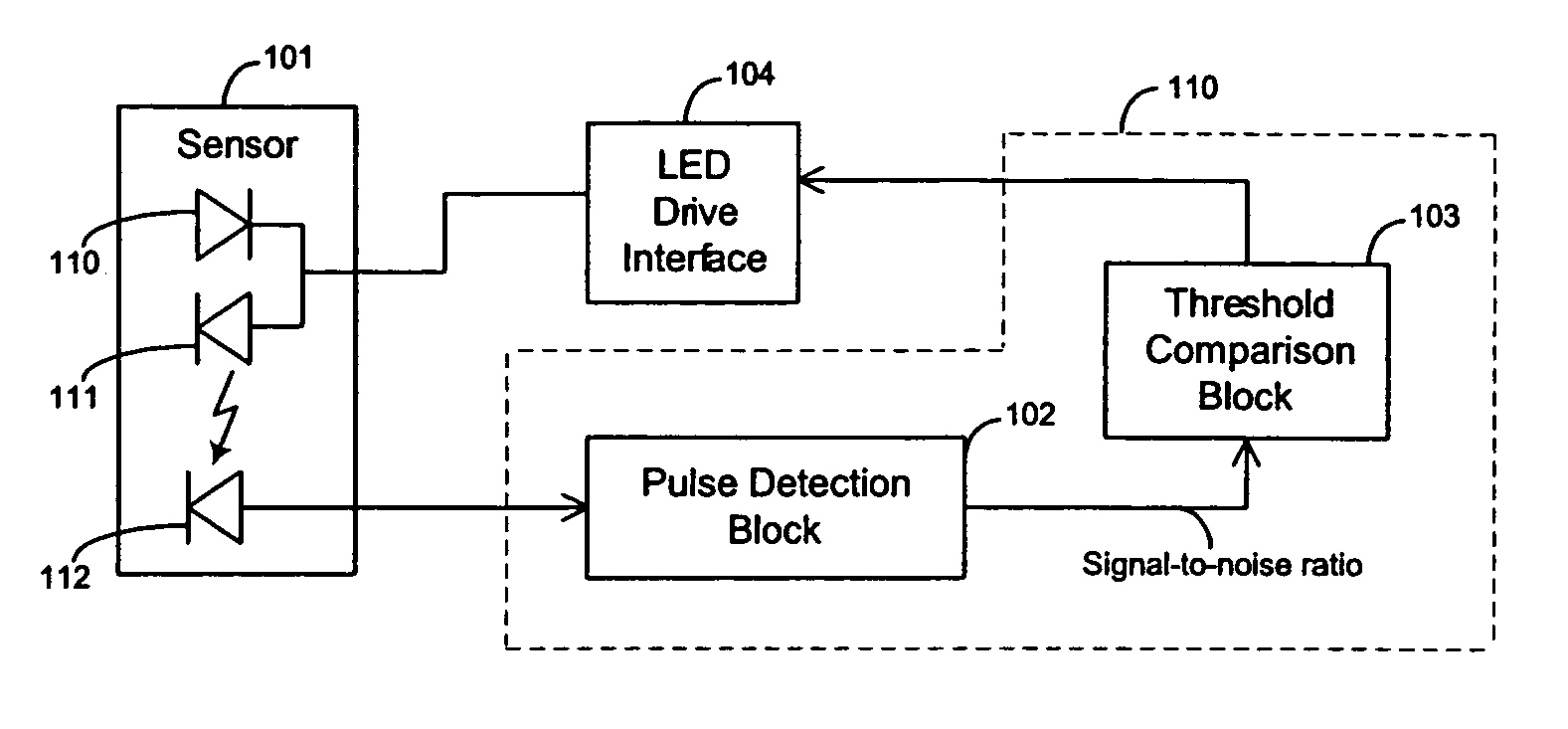

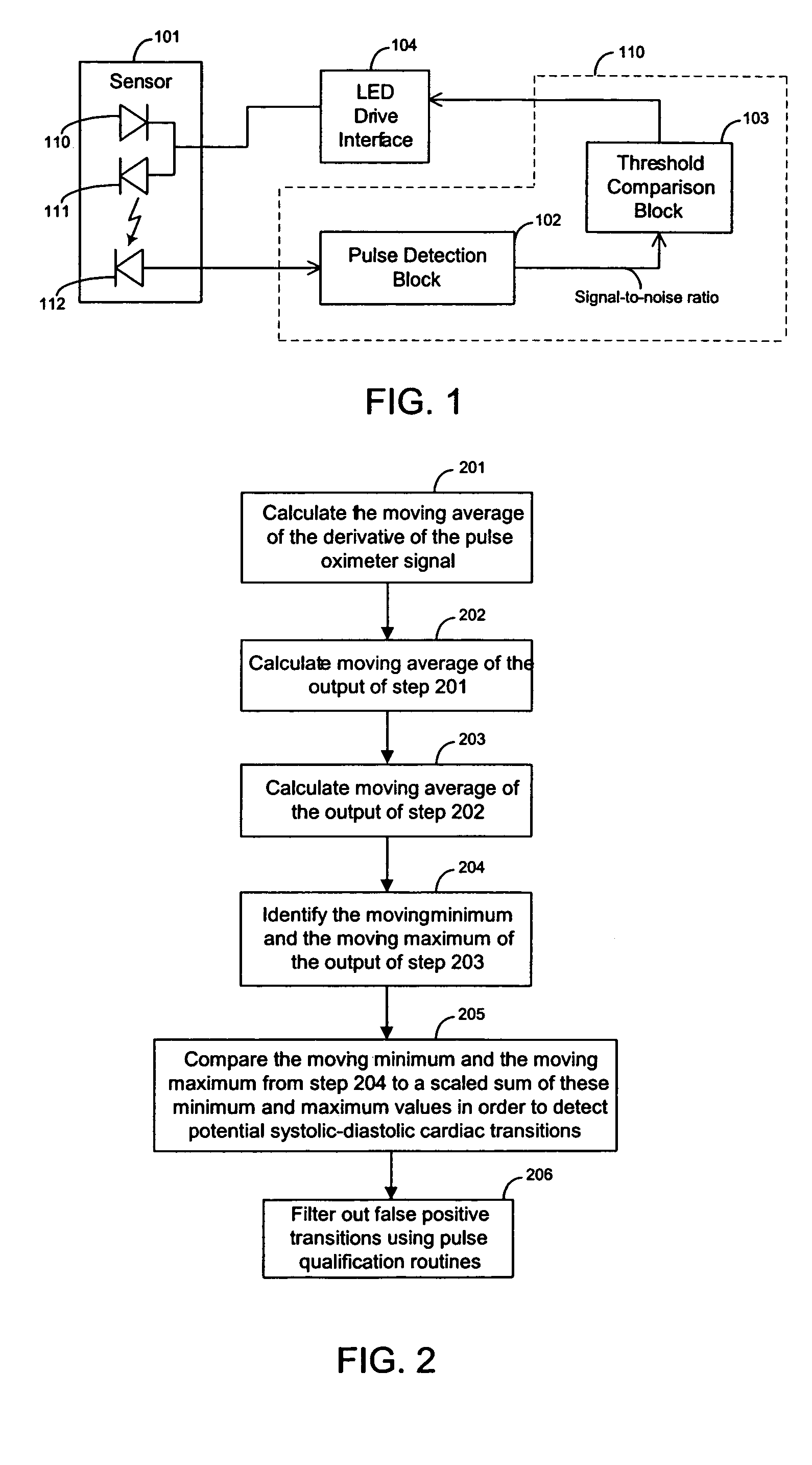

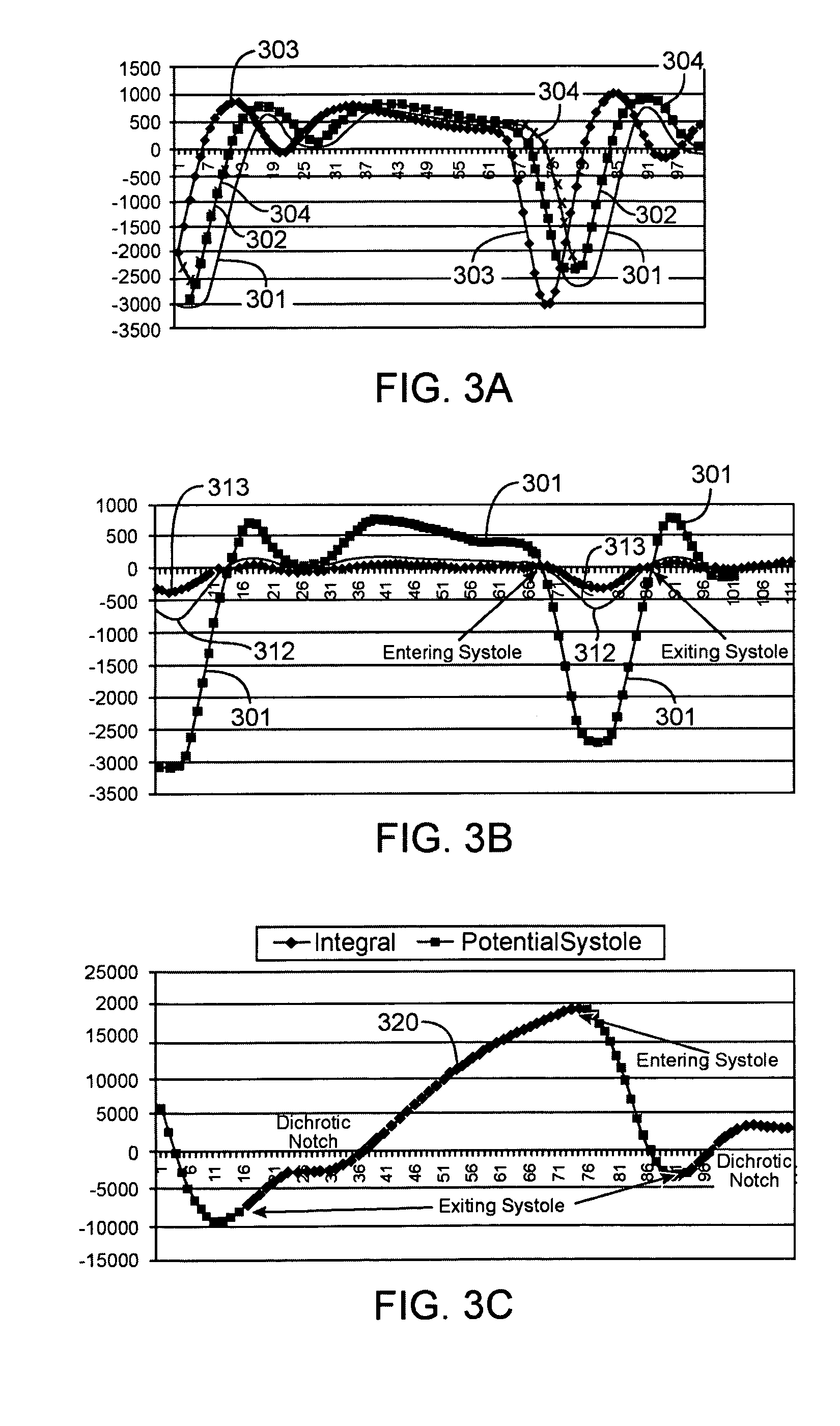

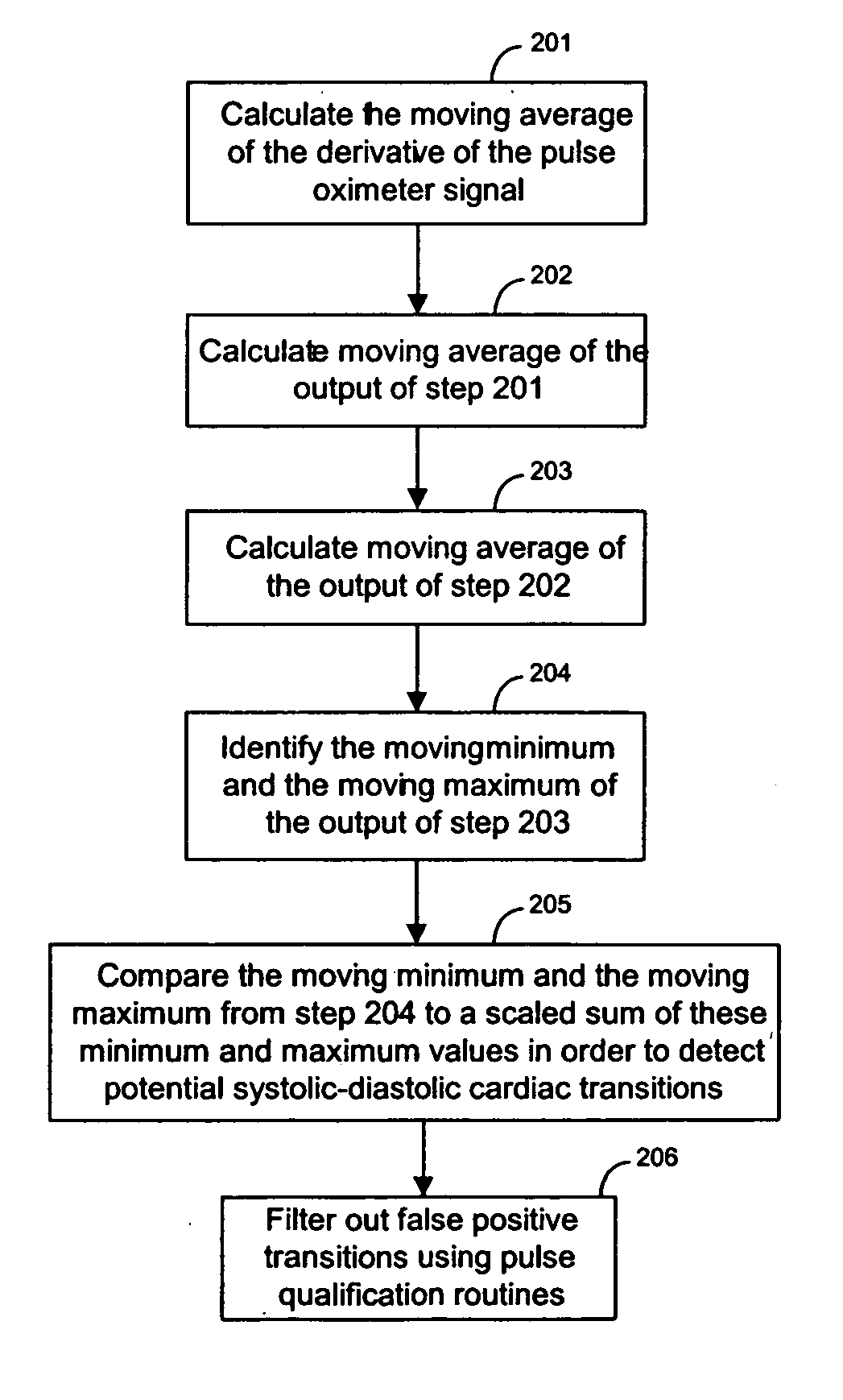

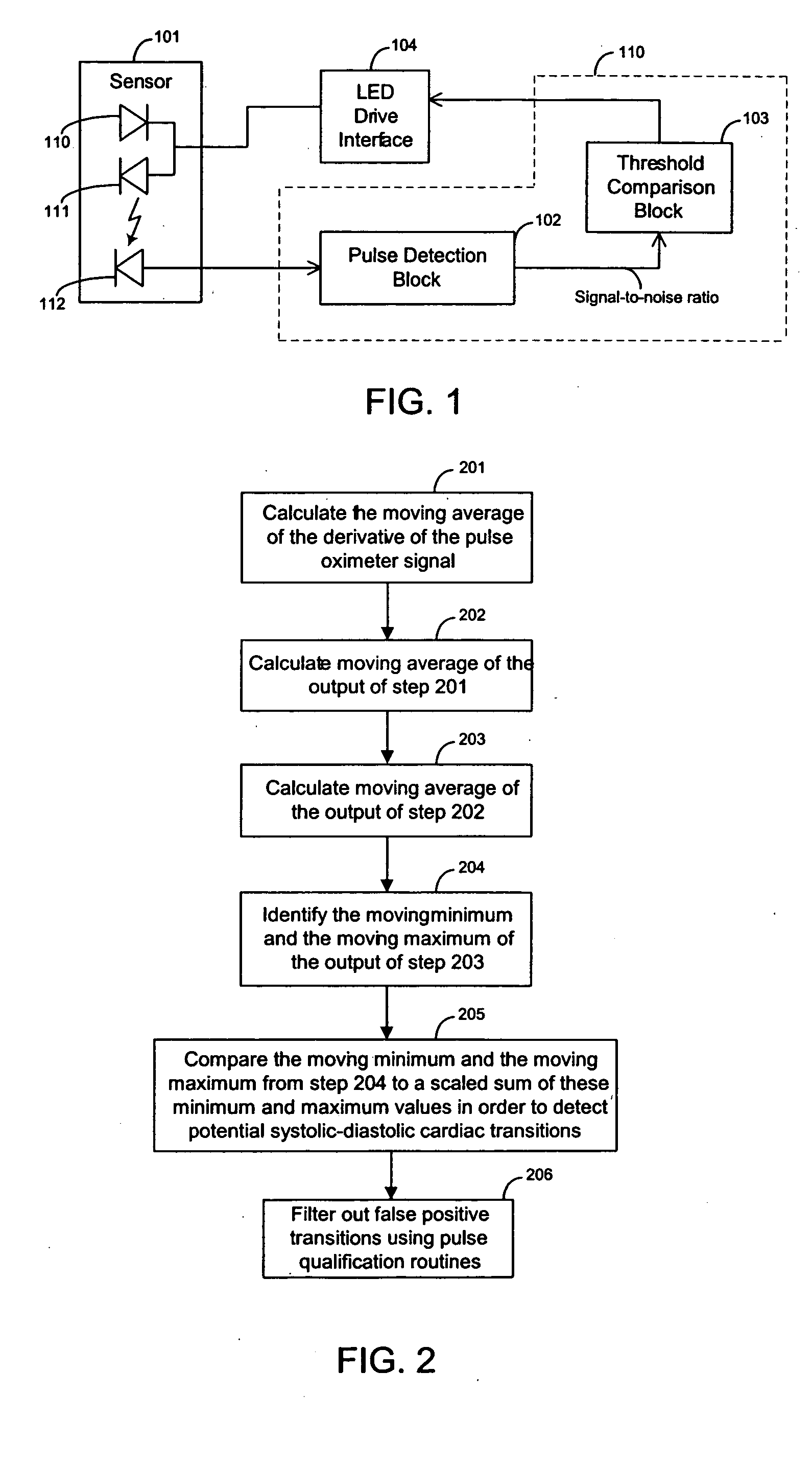

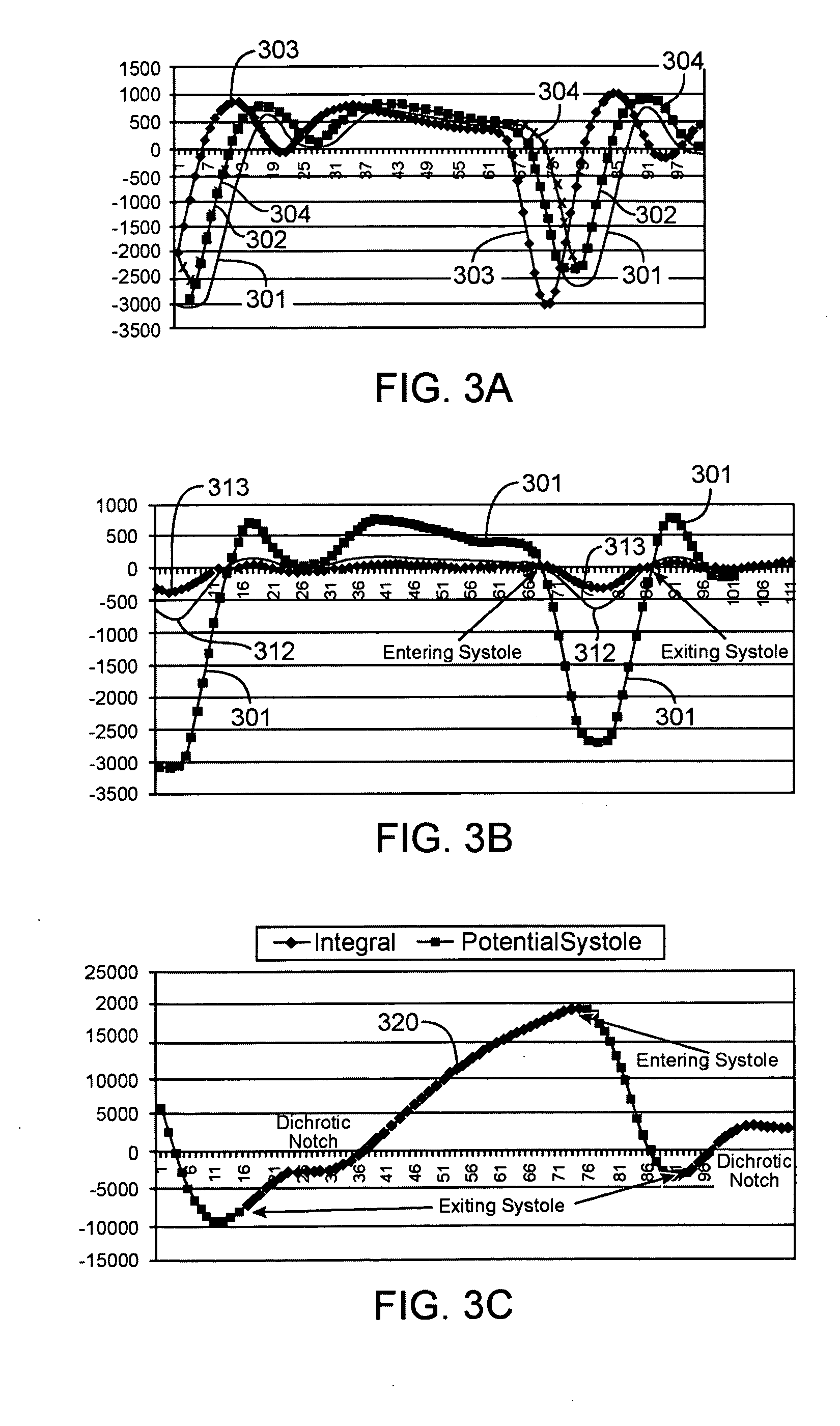

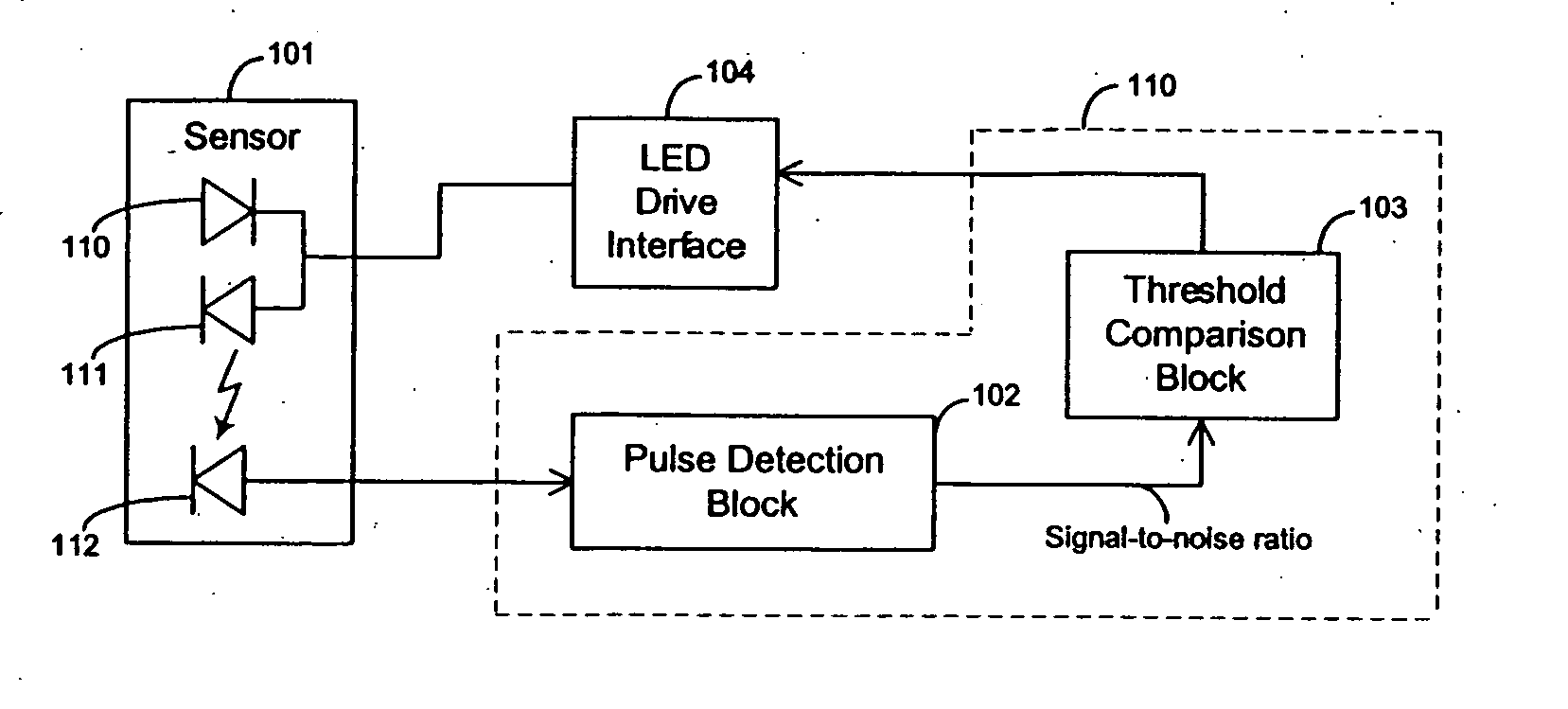

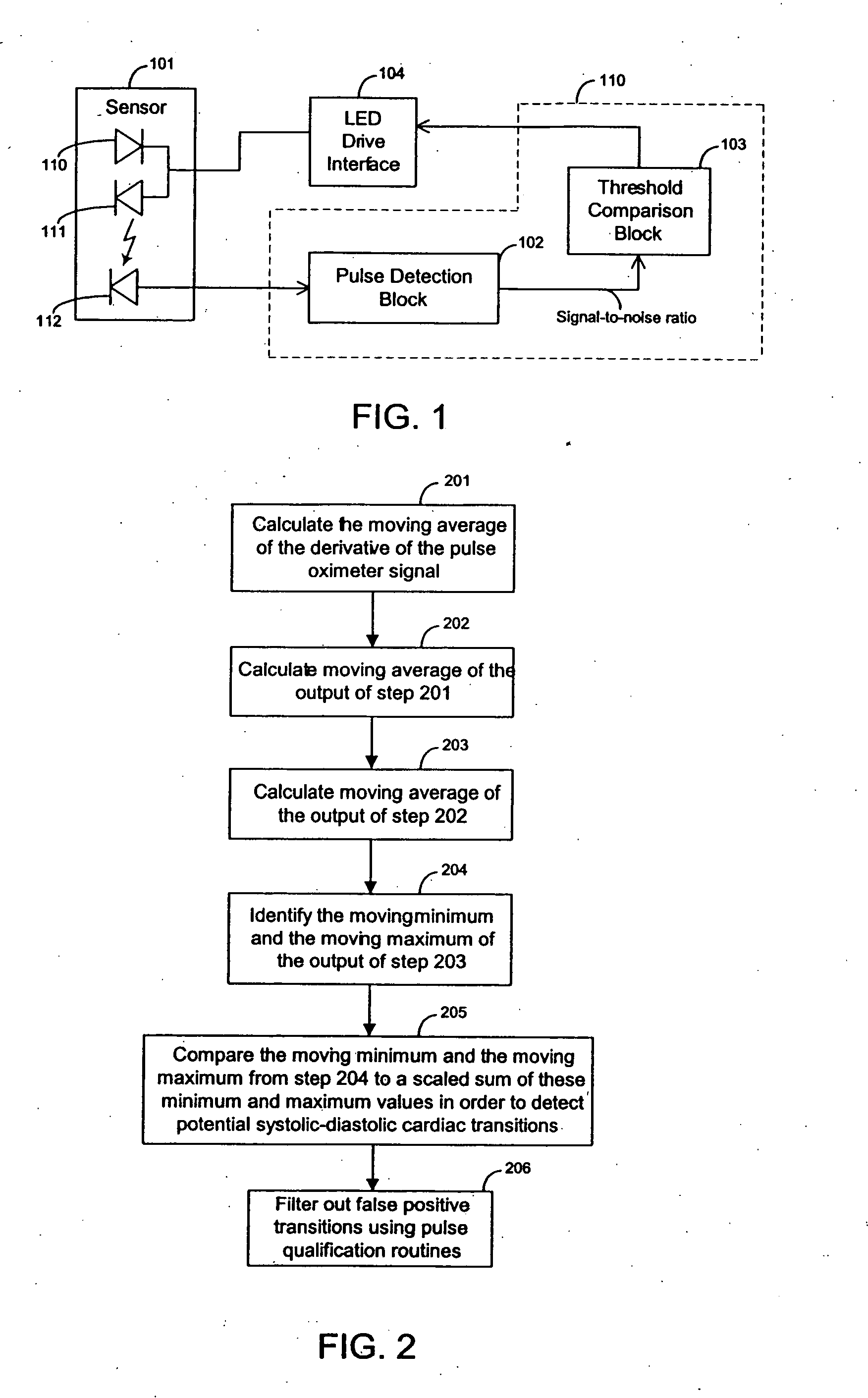

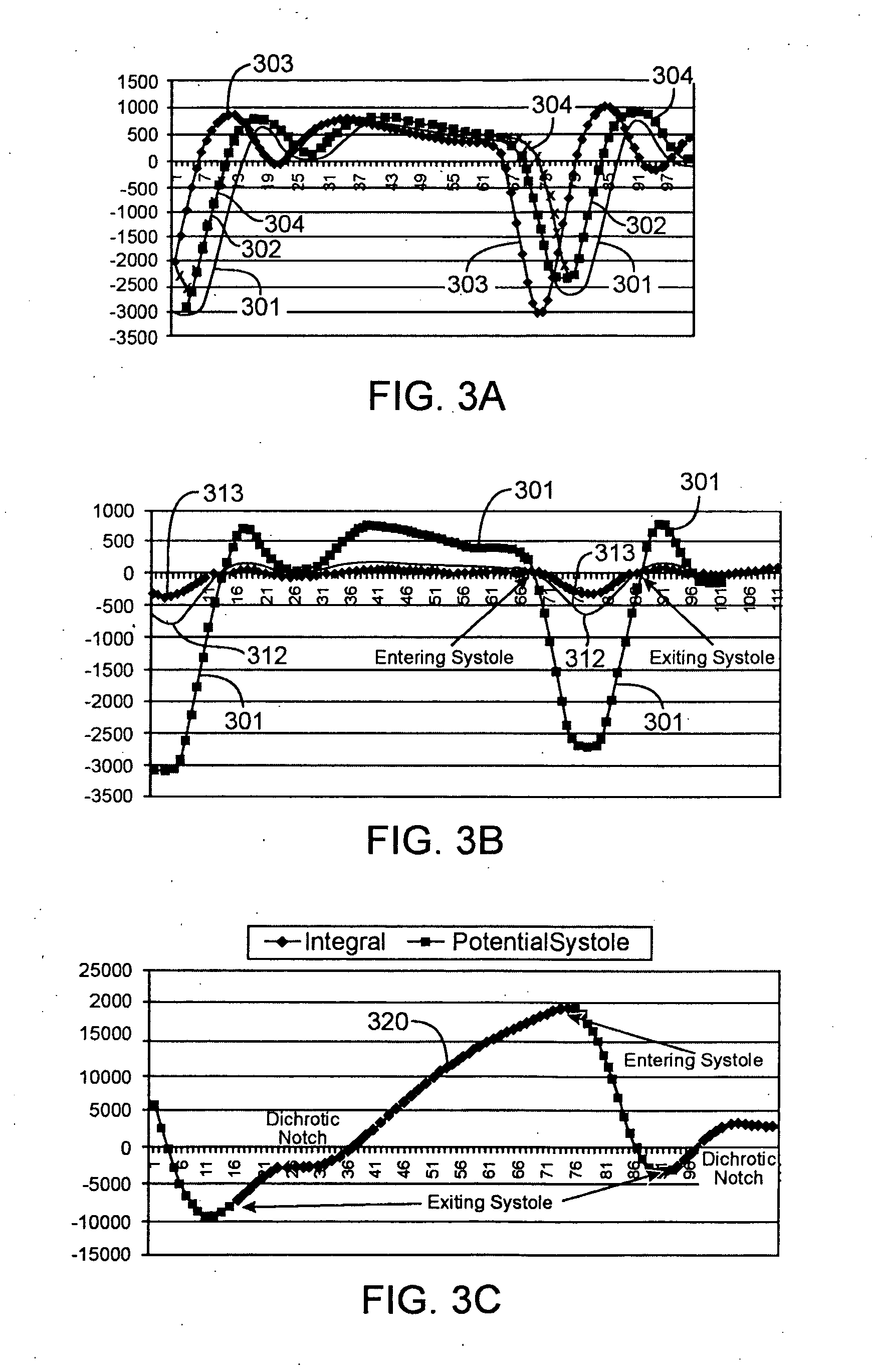

Techniques for detecting heart pulses and reducing power consumption in sensors

ActiveUS7162288B2Reduce power consumptionMaintain sufficiencySensorsMeasuring/recording heart/pulse rateDriving currentPower flow

Low power techniques for sensing cardiac pulses in a signal from a sensor are provided. A pulse detection block senses the sensor signal and determines its signal-to-noise ratio. After comparing the signal-to-noise ratio to a threshold, the drive current of light emitting elements in the sensor is dynamically adjusted to reduce power consumption while maintaining the signal-to-noise ratio at an adequate level. The signal component of the sensor signal can be measured by identifying systolic transitions. The systolic transitions are detected using a maximum and minimum derivative averaging scheme. The moving minimum and the moving maximum are compared to the scaled sum of the moving minimum and moving maximum to identify the systolic transitions. Once the signal component has been identified, the signal component is compared to a noise component to calculate the signal-to-noise ratio.

Owner:TYCO HEALTHCARE GRP LP

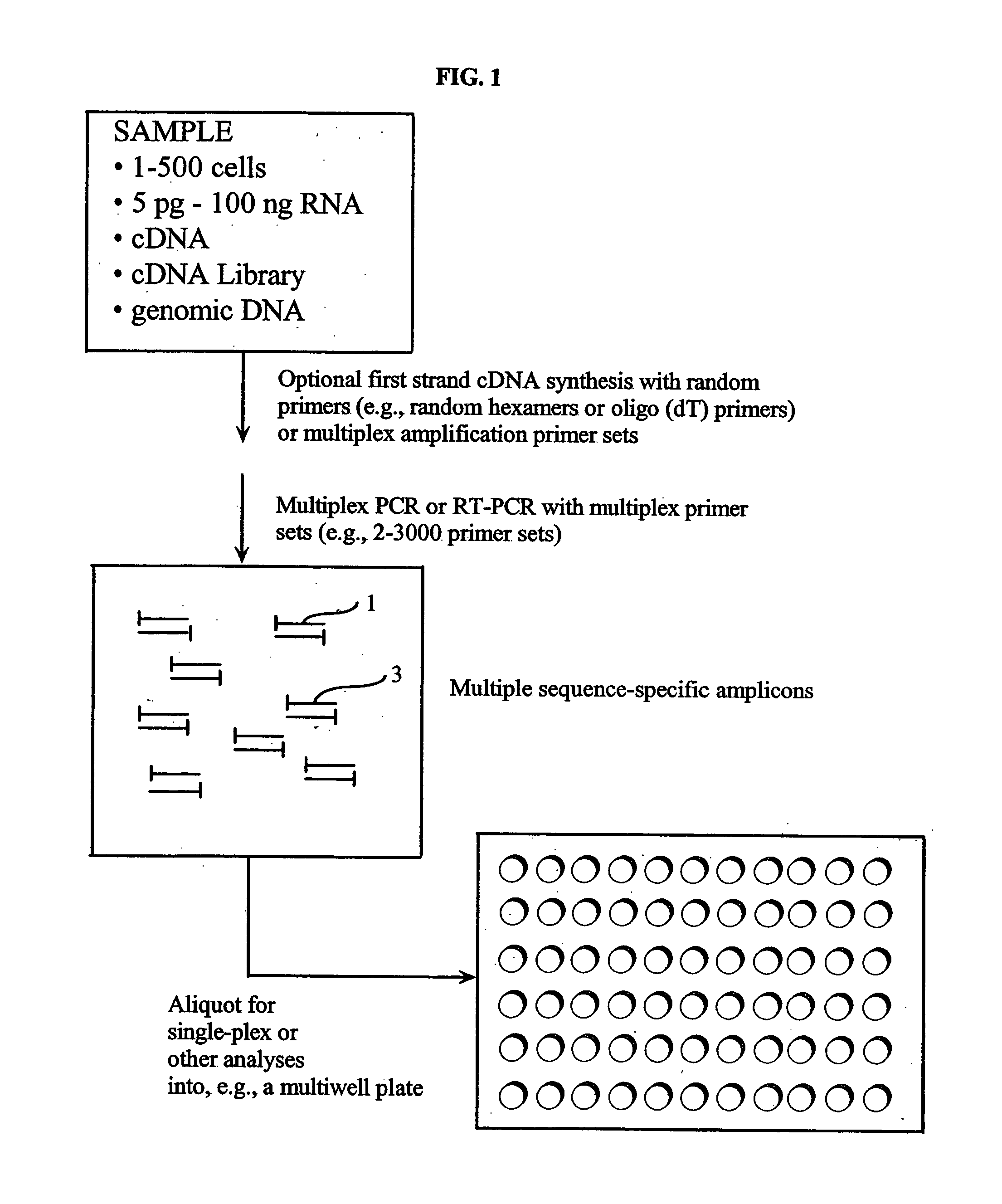

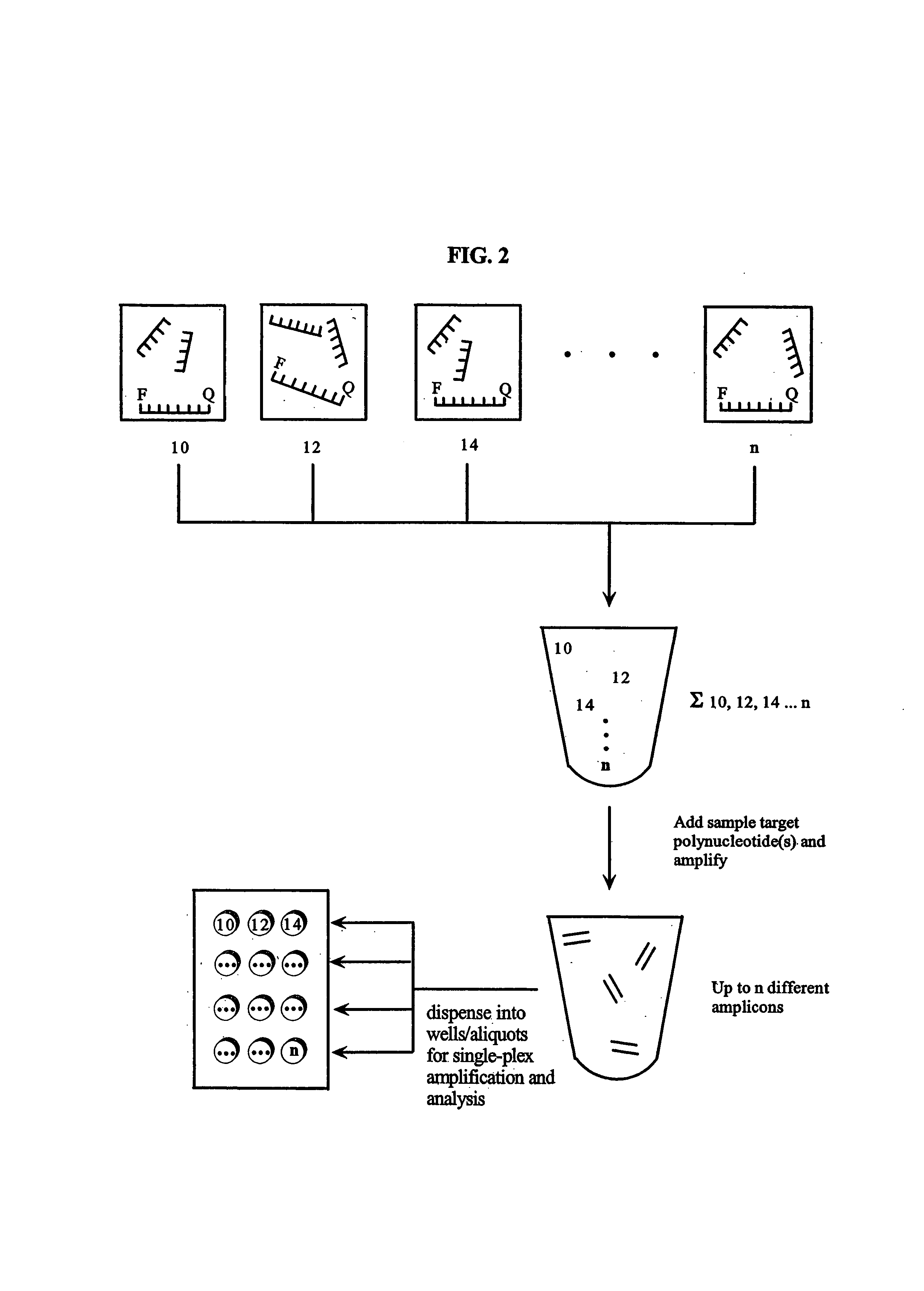

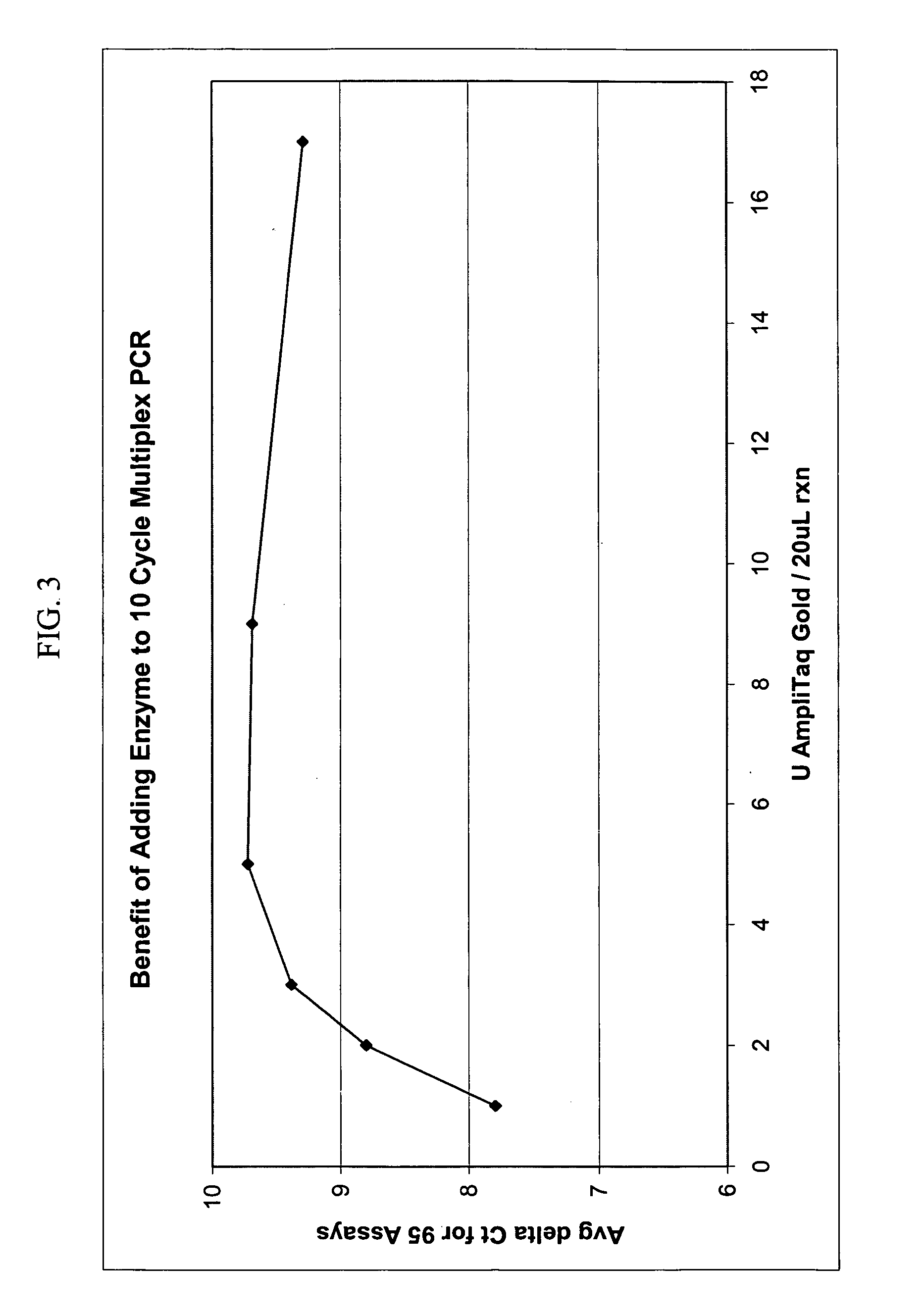

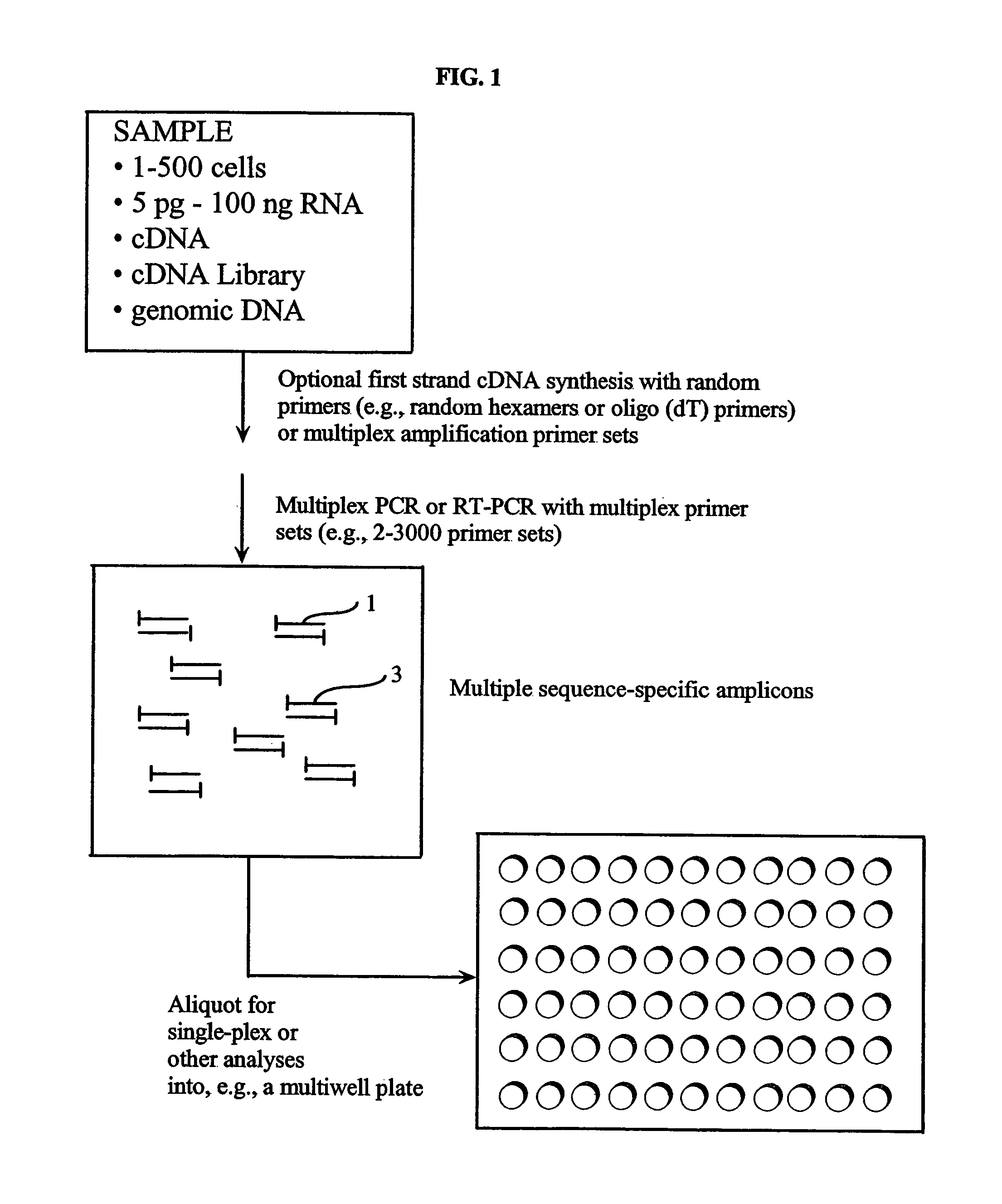

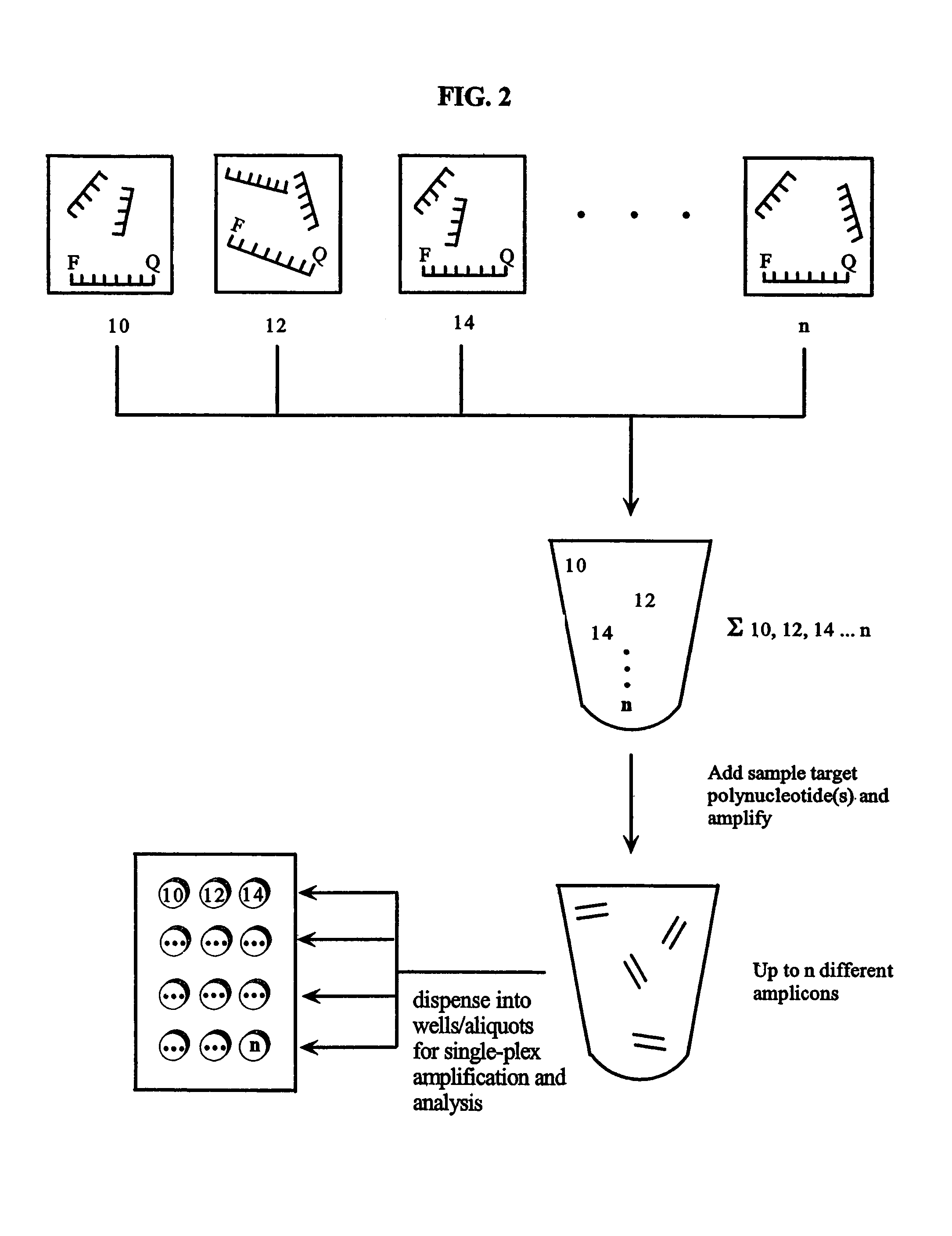

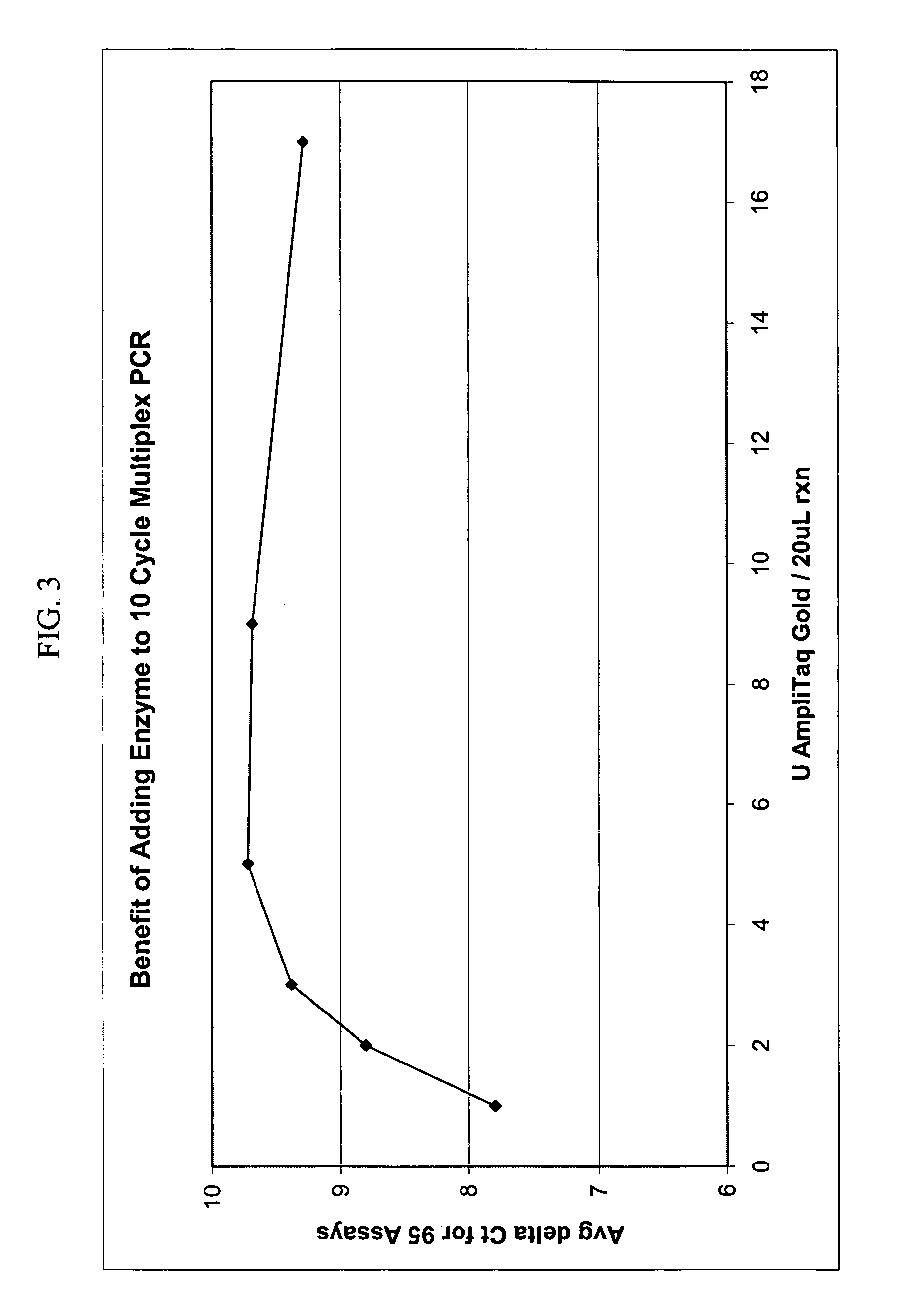

Multiplex amplification of polynucleotides

ActiveUS20040175733A1Improve efficiencyIncrease concentrationSugar derivativesMicrobiological testing/measurementPolynucleotideBiology

The present invention provides methods, reagents and kits for carrying out a variety of assays suitable for analyzing polynucleotides or samples that include an amplification step performed in a multiplex fashion. Also provided are methods for analyzing and improving the efficiency of amplification and for carrying out gene expression analysis.

Owner:APPL BIOSYSTEMS INC

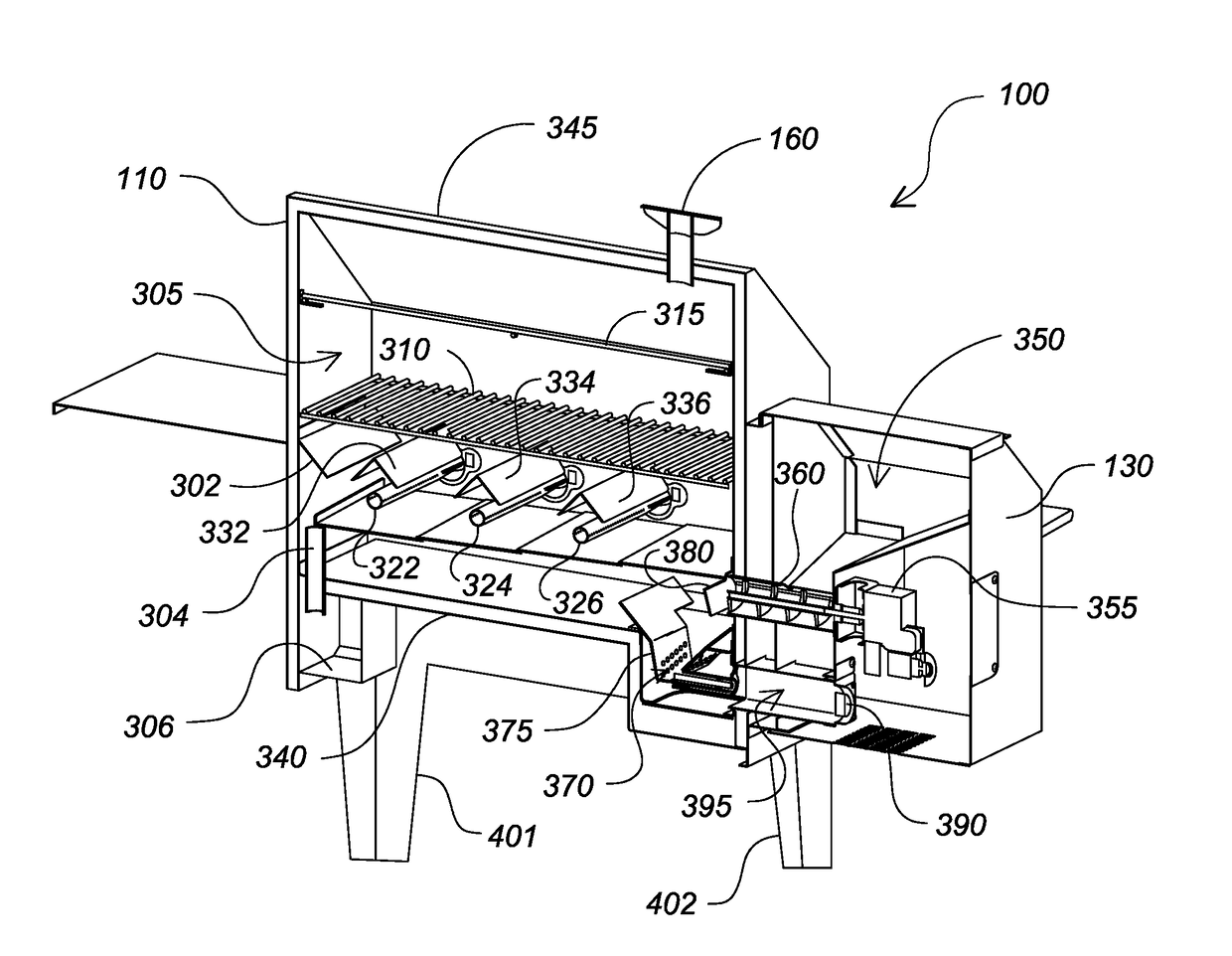

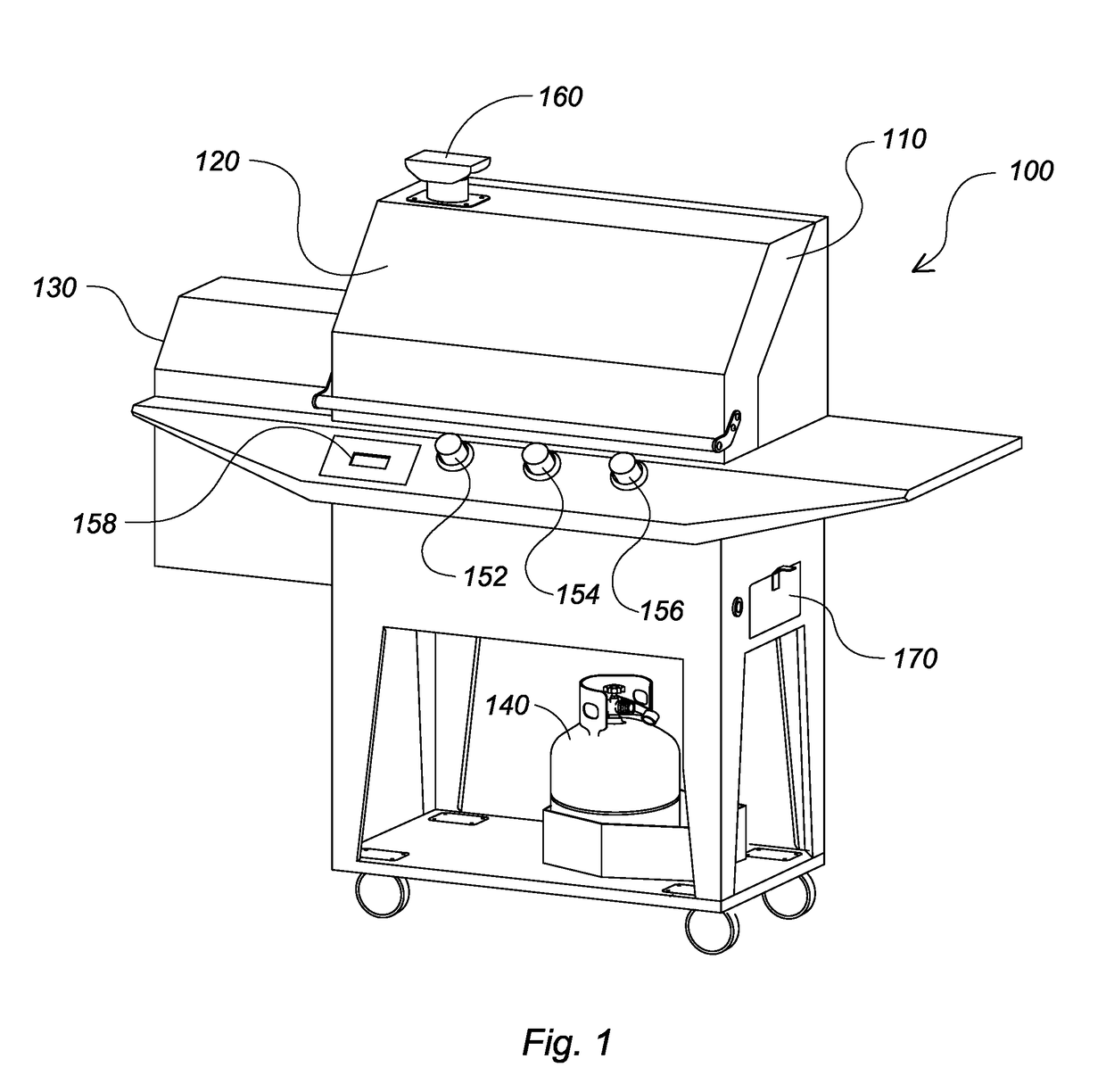

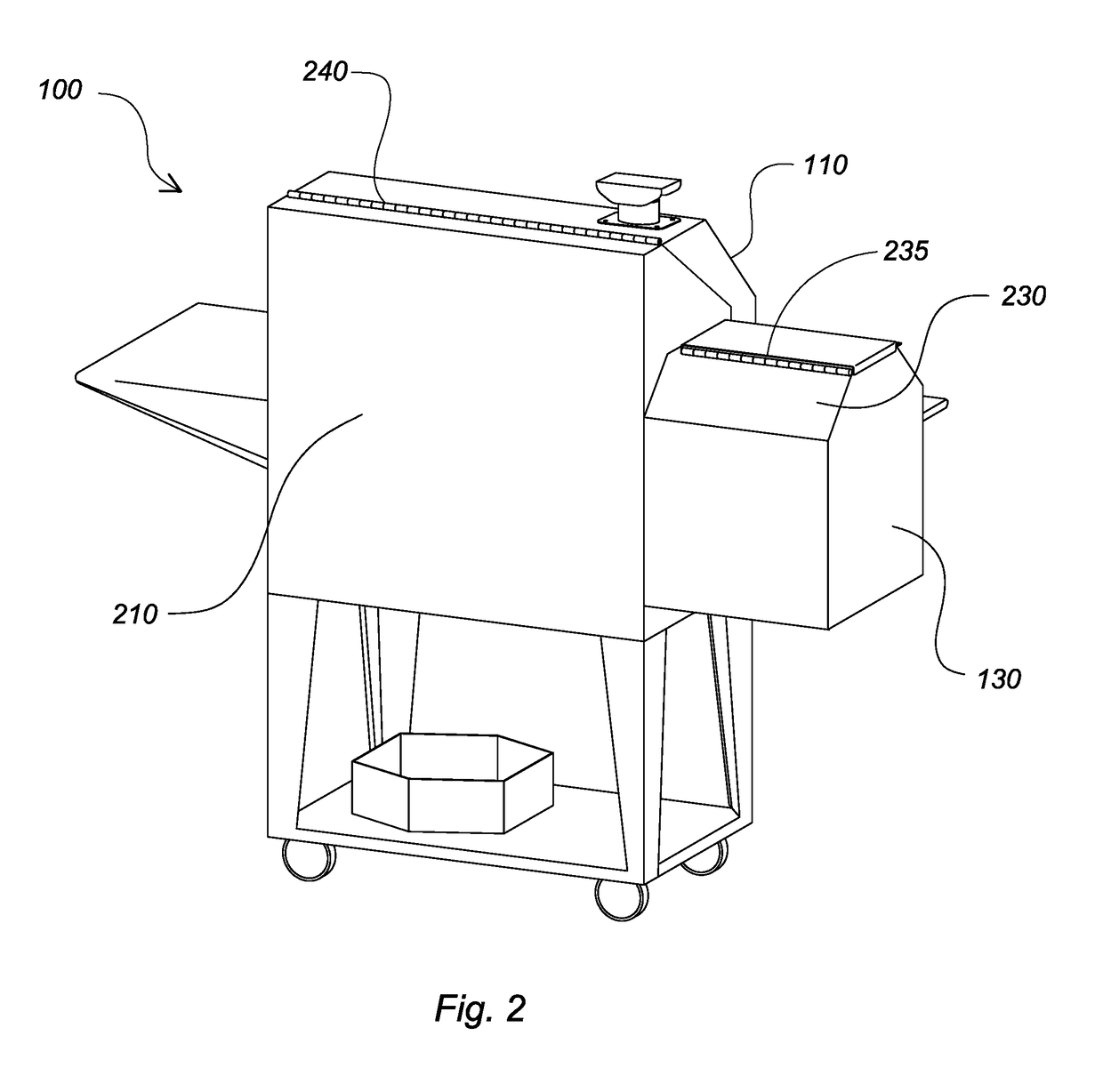

Multiple fuel cooking unit

InactiveUS20170164783A1Maintain sufficiencyWide rangeDomestic stoves or rangesLiquid heating fuelElectrical resistance and conductanceAutomatic control

A cooking unit may operate using multiple types of fuel to cook food. One or more first heat source, such as gas burners, electrical resistive heaters, and / or other heating technology, may provide radiant heat to a cooking chamber. One or more second heat source, such as a firebox, may provide indirect heat to the cooking chamber, for example by producing smoke. User operable controls and / or an automated control unit may alter the rate at which a fuel and / or air is supplied to one or more heat source.

Owner:SMOKESTEAK LLC

Techniques for detecting heart pulses and reducing power consumption in sensors

ActiveUS20050187446A1Reduce power consumptionAdequately maintainSensorsMeasuring/recording heart/pulse rateSignal-to-noise ratio (imaging)Noise component

Low power techniques for sensing cardiac pulses in a signal from a sensor are provided. A pulse detection block senses the sensor signal and determines its signal-to-noise ratio. After comparing the signal-to-noise ratio to a threshold, the drive current of light emitting elements in the sensor is dynamically adjusted to reduce power consumption while maintaining the signal-to-noise ratio at an adequate level. The signal component of the sensor signal can be measured by identifying systolic transitions. The systolic transitions are detected using a maximum and minimum derivative averaging scheme. The moving minimum and the moving maximum are compared to the scaled sum of the moving minimum and moving maximum to identify the systolic transitions. Once the signal component has been identified, the signal component is compared to a noise component to calculate the signal-to-noise ratio.

Owner:TYCO HEALTHCARE GRP LP

Multiplex amplification of polynucleotides

ActiveUS8323897B2Increase concentrationExpansion quantitySugar derivativesMicrobiological testing/measurementPolynucleotideBiology

The present invention provides methods, reagents and kits for carrying out a variety of assays suitable for analyzing polynucleotides or samples that include an amplification step performed in a multiplex fashion. Also provided are methods for analyzing and improving the efficiency of amplification and for carrying out gene expression analysis.

Owner:APPL BIOSYSTEMS INC

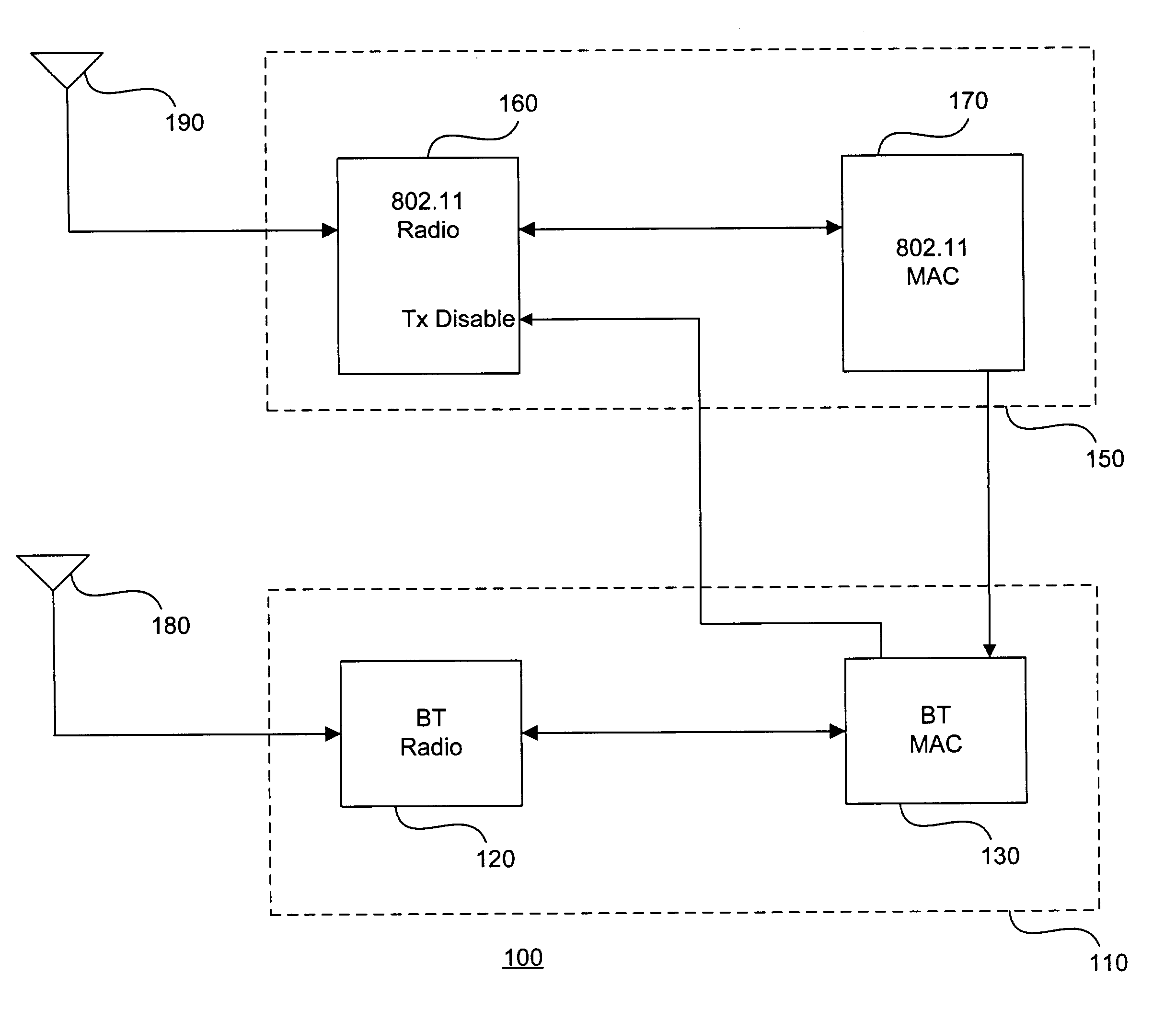

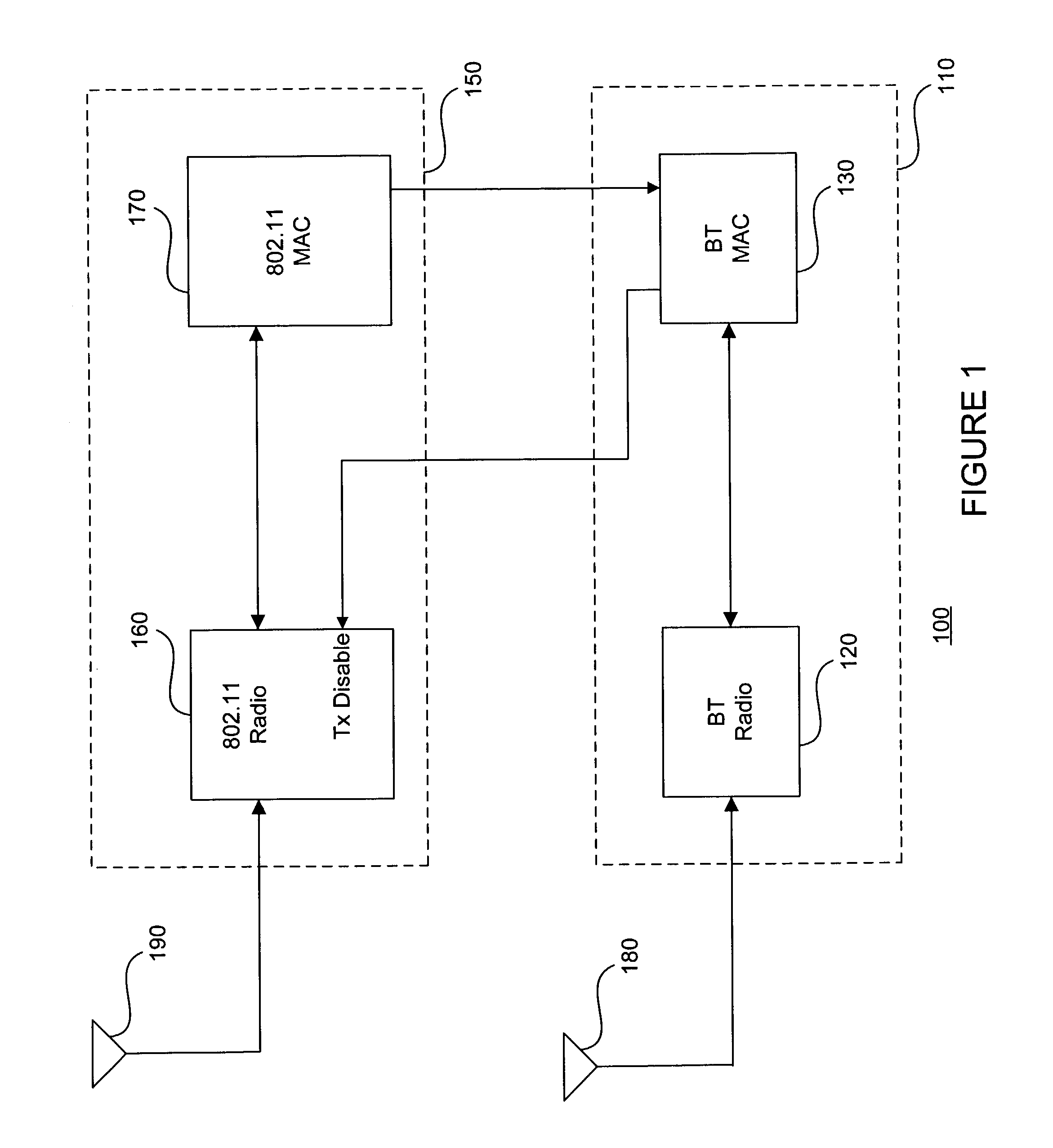

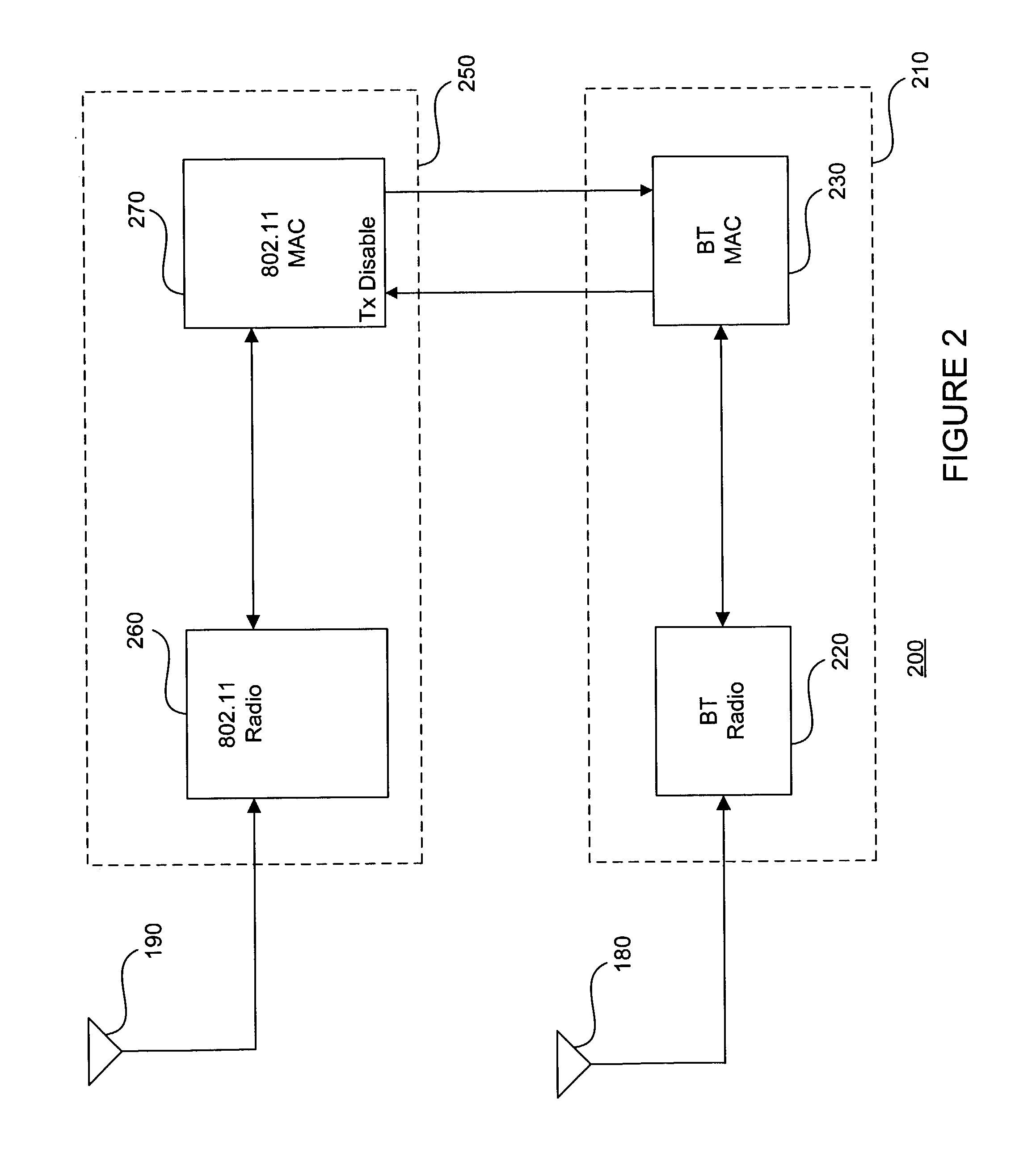

Method and apparatus for a dual-mode radio in a wireless communication system

InactiveUS7643463B1Reduce reception errorsMaintain sufficiencyTime-division multiplexSubstation equipmentThree levelCommunications system

The present invention is a novel method and apparatus for a dual-mode radio (DMR) in a wireless communication system. The present invention allows Bluetooth™ protocol and 802.11 protocol devices to co-exist. The present inventive method classifies Bluetooth™ protocol and 802.11 protocol events according to importance. In the basic dual-mode radio method, the present invention assigns two levels of importance or priority Bluetooth™ events: “high” and “low”. In the enhanced dual-mode radio method, the present invention assigns three levels of importance or priority to Bluetooth™ events: “high”, “low” and “promotable”. The present inventive apparatus provides a means for disabling 802.11 transmissions when high-priority Bluetooth™ events are detected.

Owner:QUALCOMM INC

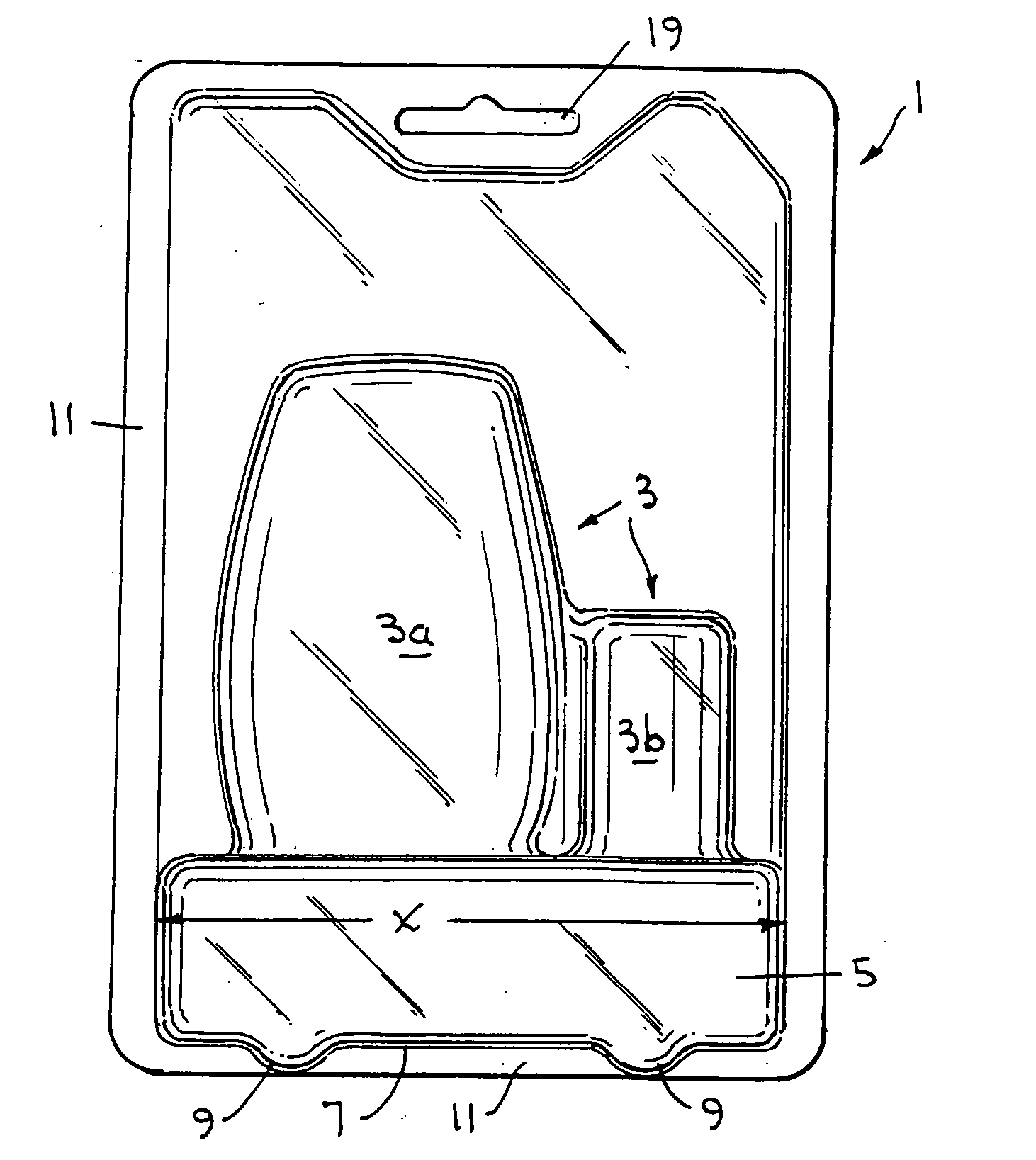

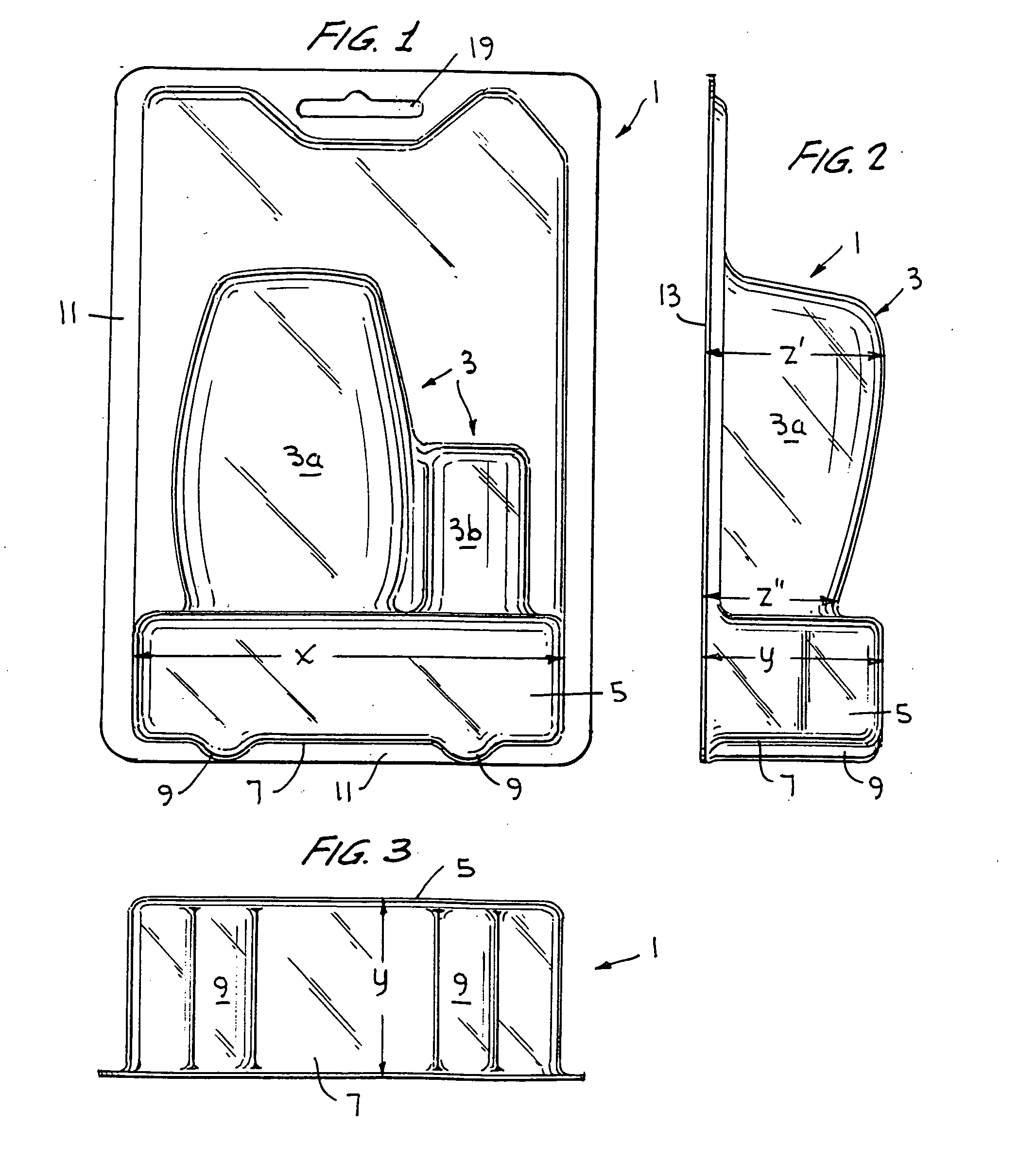

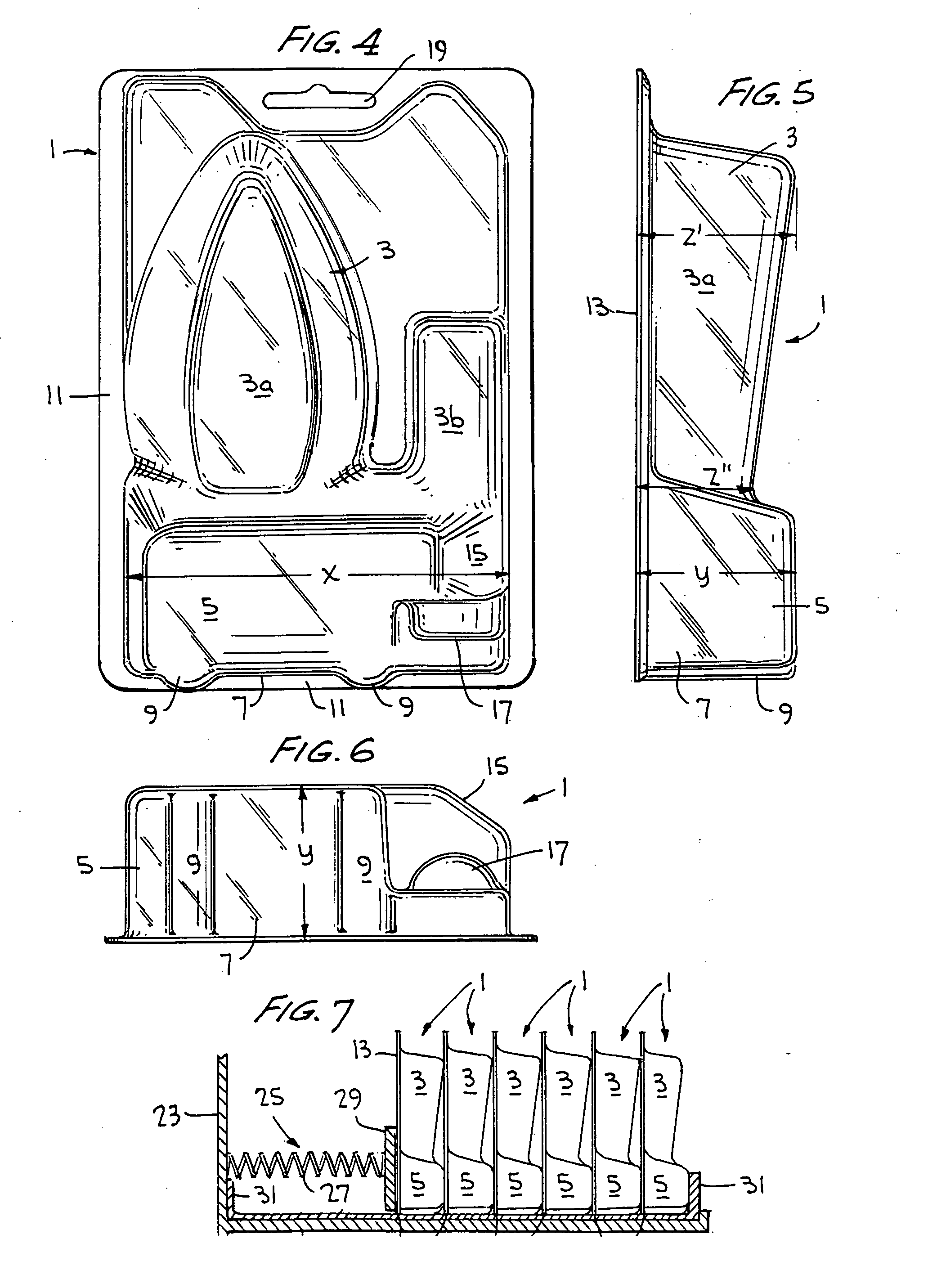

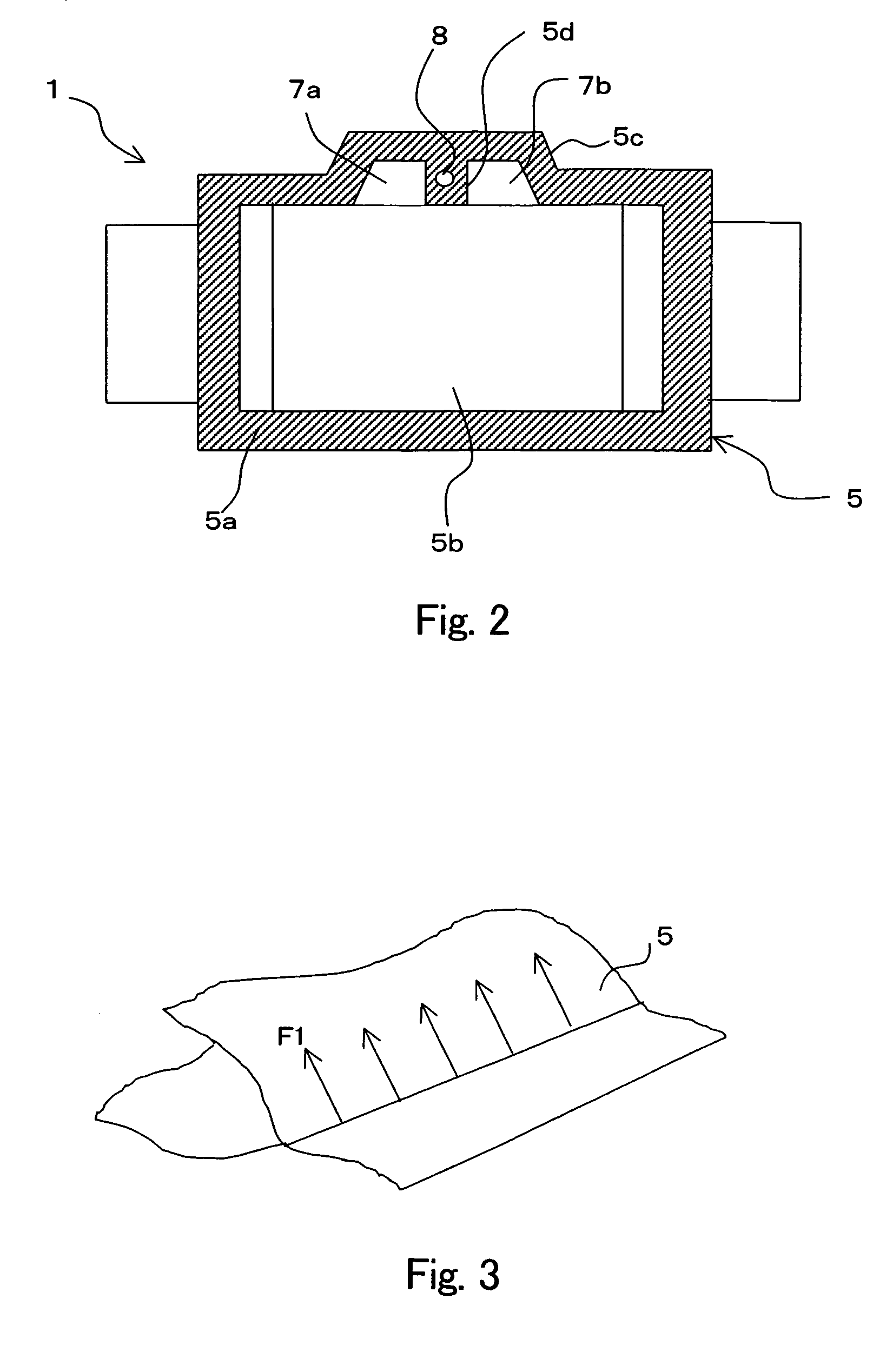

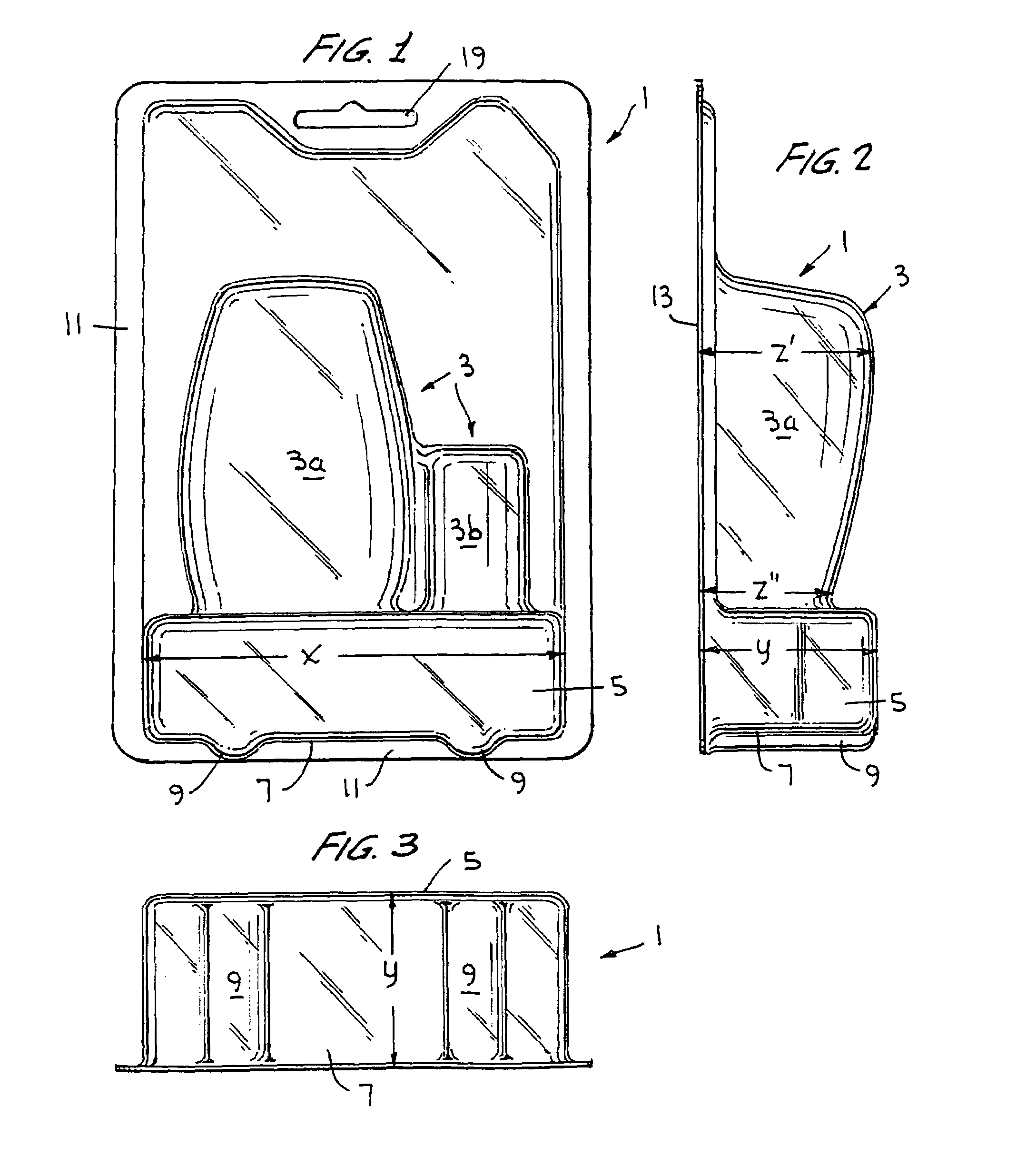

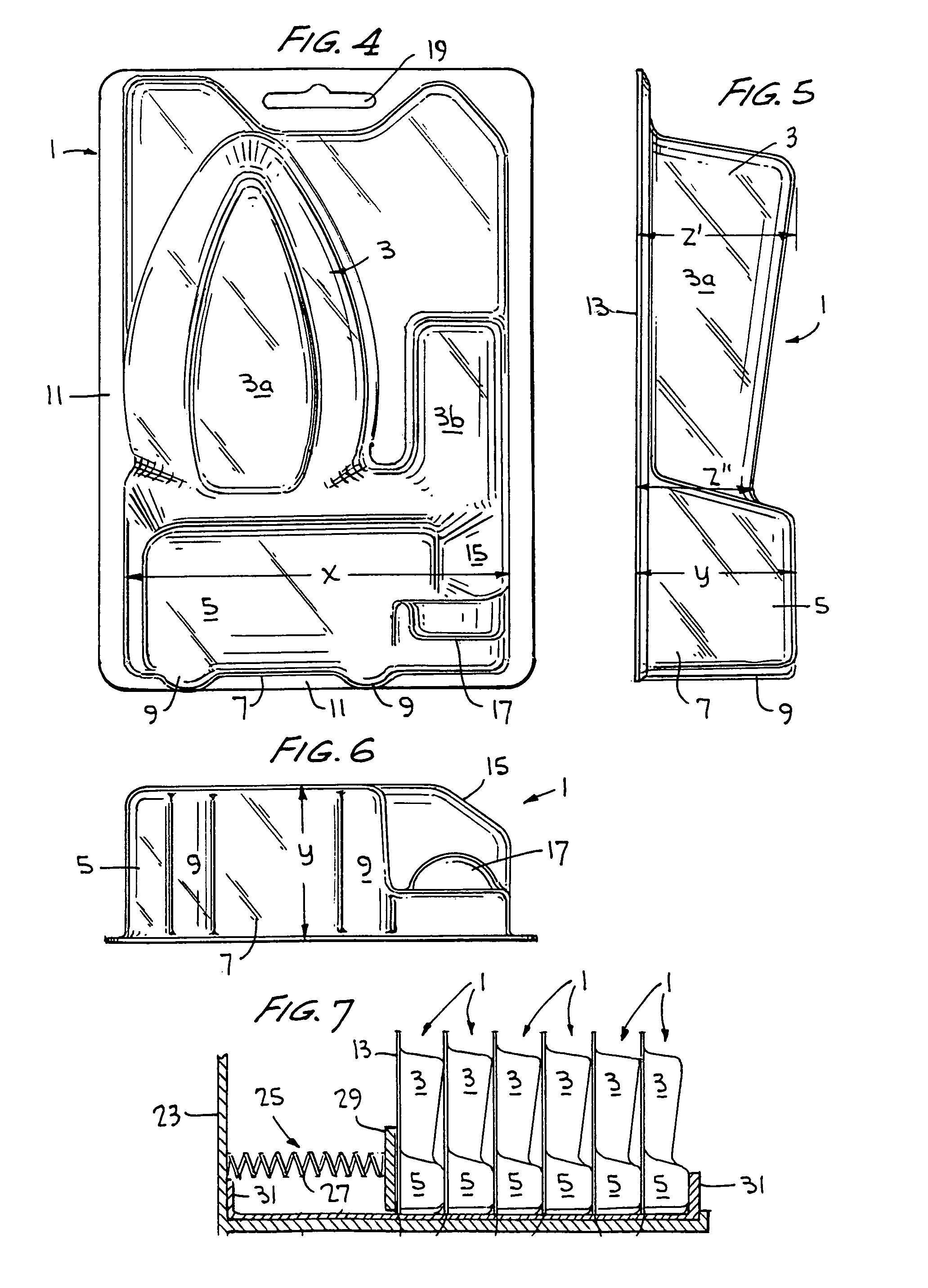

Display package with stabilizing and indexing means

ActiveUS20050092644A1Provide stabilityImprove package stabilityRacksOther accessoriesEngineeringBlister pack

A blister pack and package including such blister pack is described which provides for package stability and self-indexing in relation to adjacently aligned packages. The blister pack is configured to include at least one compartment for enclosing an article, and an outward projecting portion or foot in the bottom portion of the blister pack. The foot is configured to have a width, depth and height sufficient to allow the package to be freestanding and self-indexing. The package is especially suited for use in a merchandise point-of-sale display including a pressure applicator for maintaining displayed packages in a forwardmost position in the display when one or more packages are removed from the display. The foot provides for a predetermined stable spacing during packaging and while in storage and on display, and provides for self-indexing, i.e. maintenance of proper spacing, when a pressure applicator moves the aligned packages forward in a display.

Owner:SC JOHNSON & SON INC

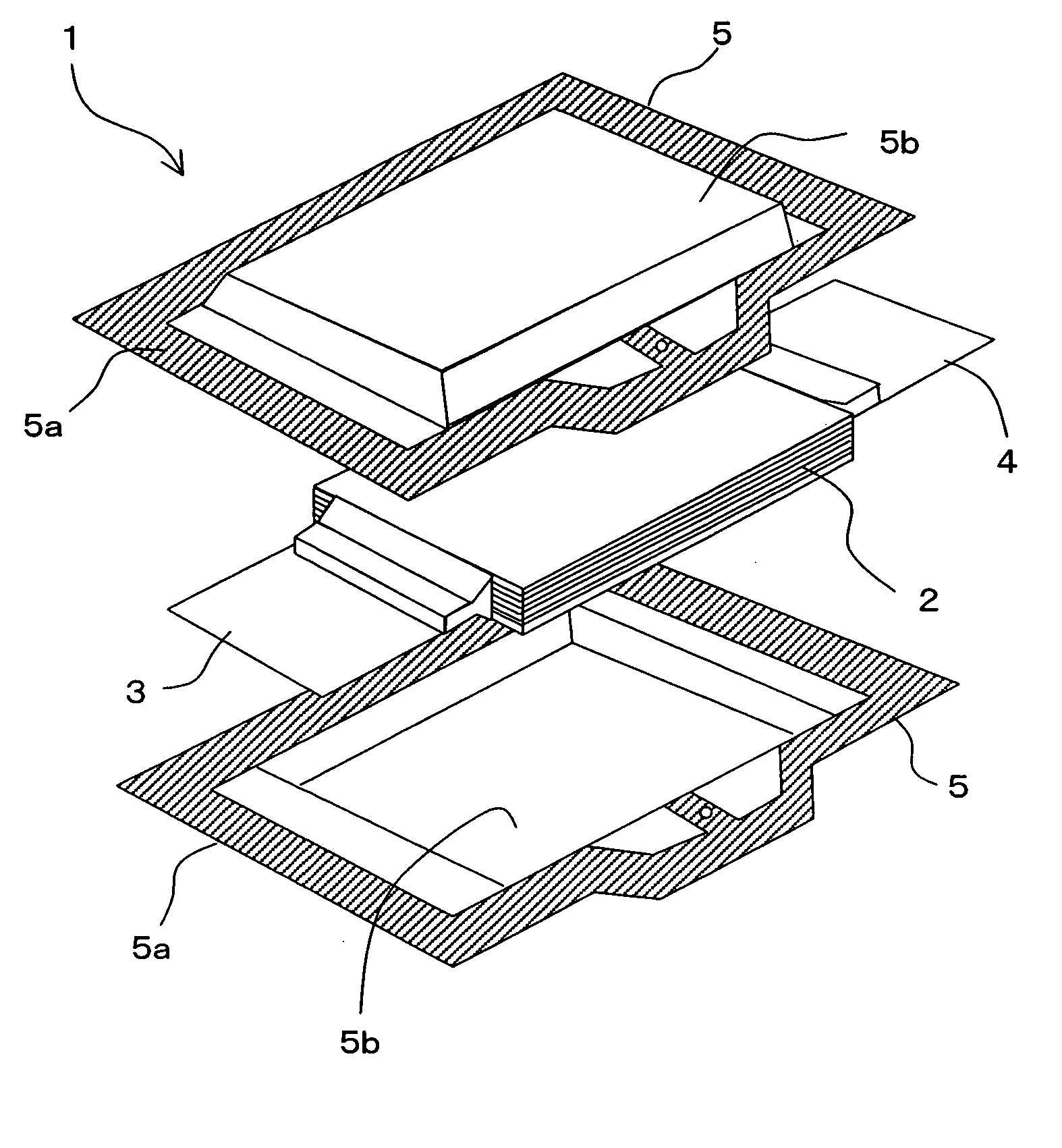

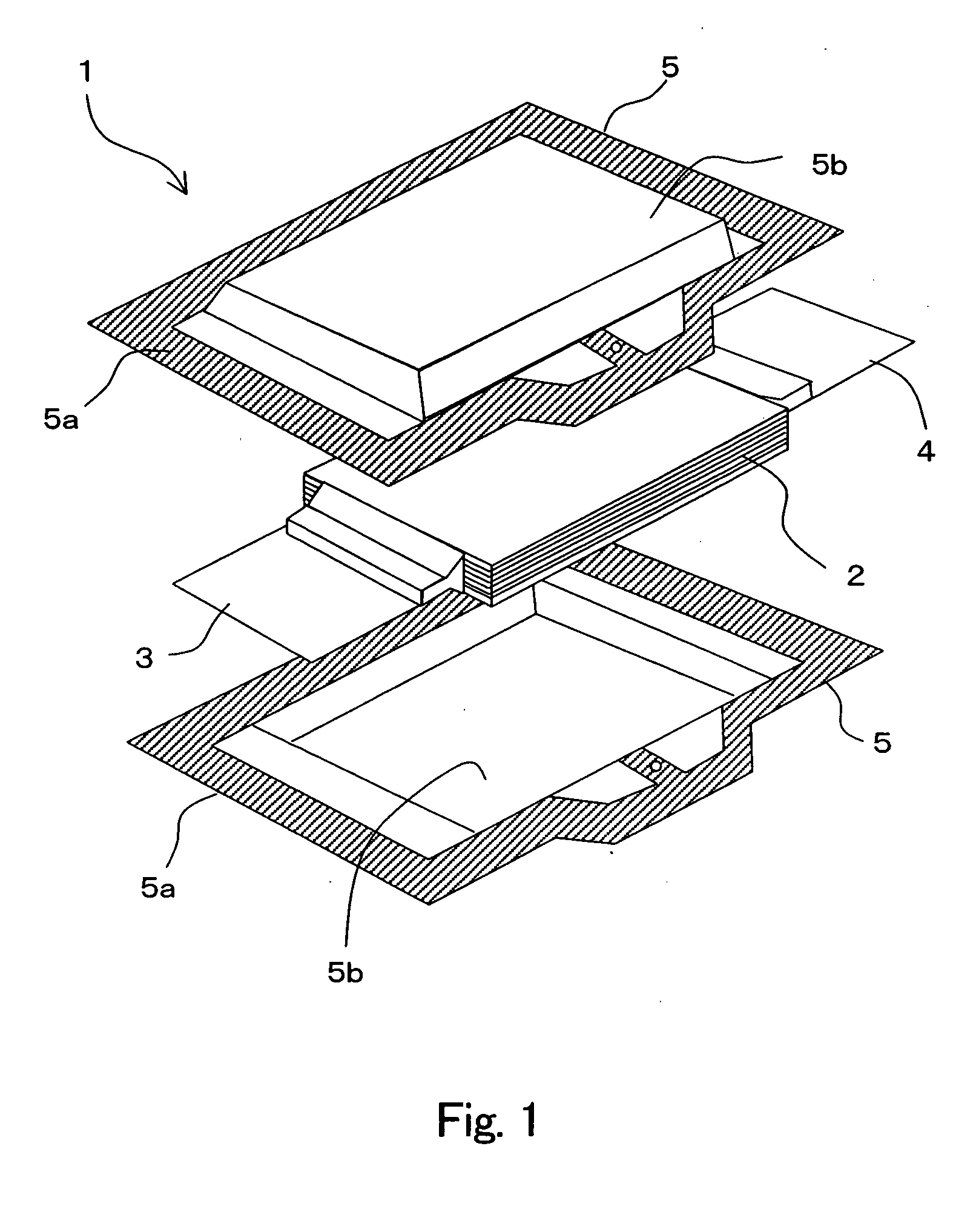

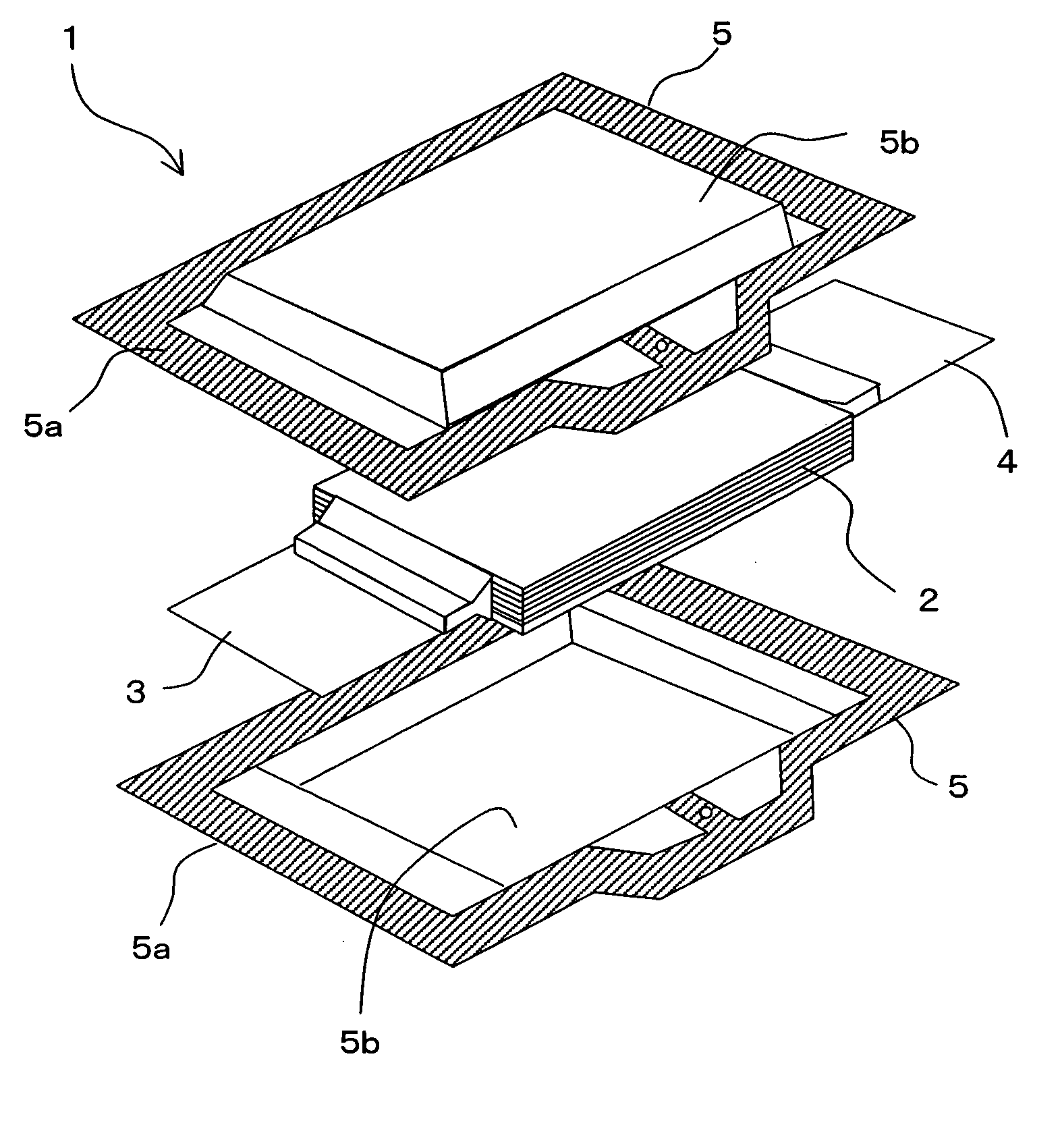

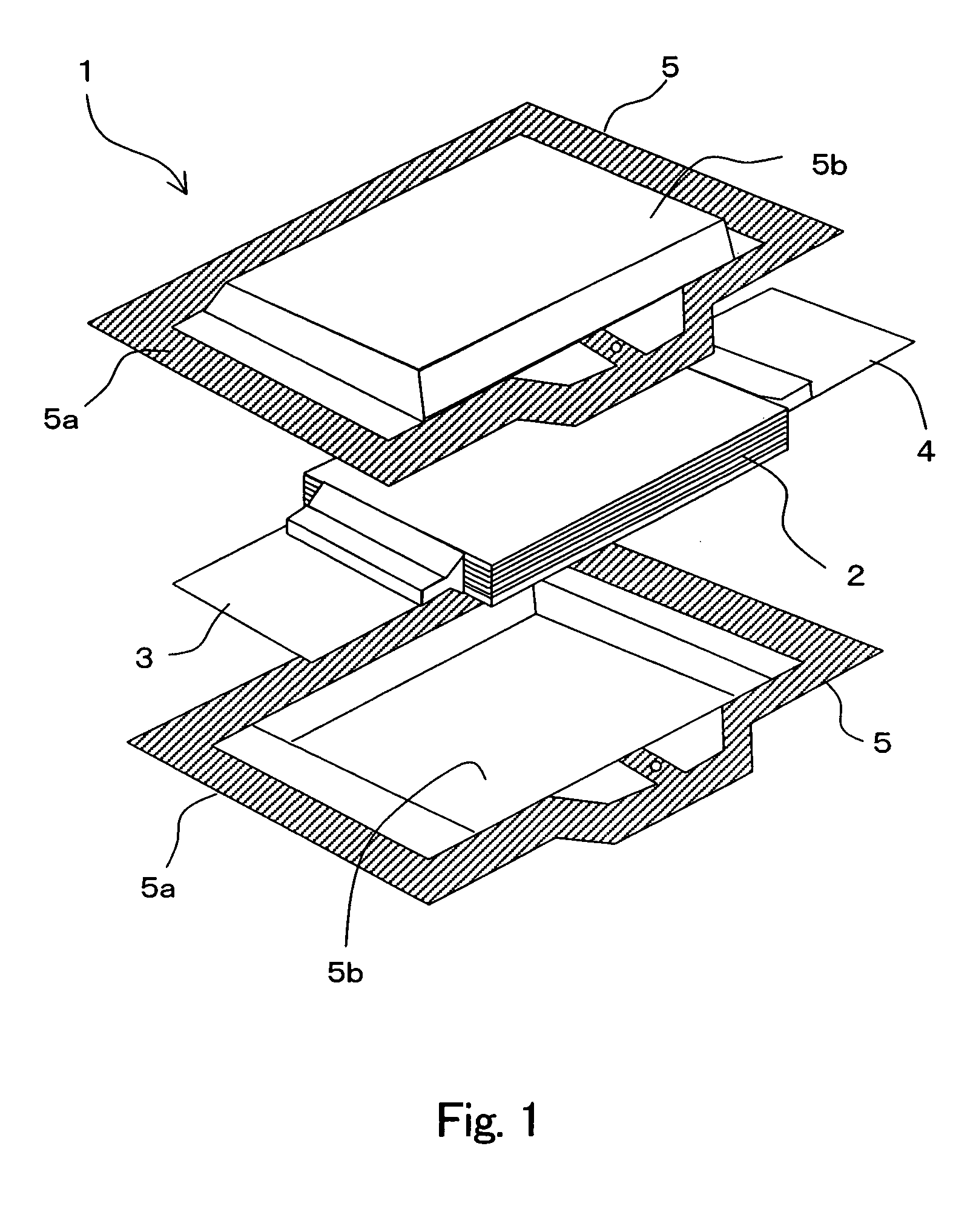

Film-covered electric device having pressure release opening

ActiveUS20050158622A1Reduce sealEasy to set upClosuresFixed capacitor housing/encapsulationStress concentrationElectrical devices

A film-covered electric device has an electric device element and casing films. The casing films include a sealing area formed by thermally fusing the facing surfaces of the casing films together around the periphery of the electric device element, an electric device element receiving part encapsulating the electric device element inside the sealing area, and unfused portions formed in the shape of cove communicating with the electric device element receiving part. The casing films further include a stress concentrating portion touching the unfused portions for concentrating thereon the peeling stress of the casing films generated at the sealing area by the expansion of the electric device element receiving part, and a pressure releasing part is formed in the stress concentrating portion.

Owner:NEC CORP

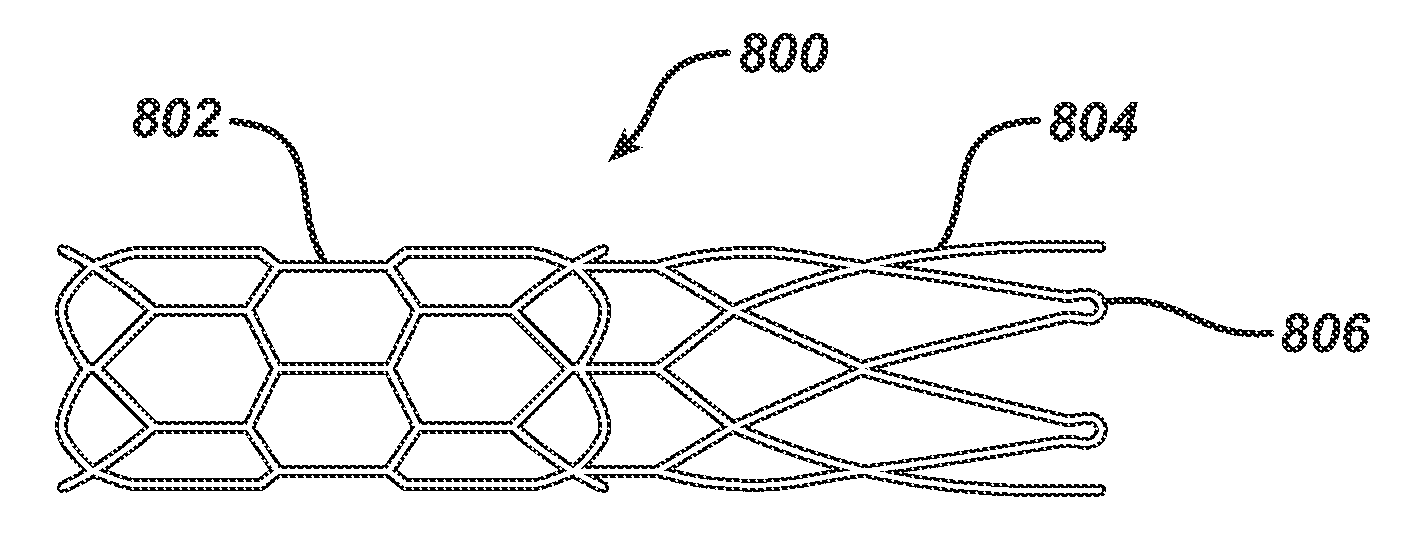

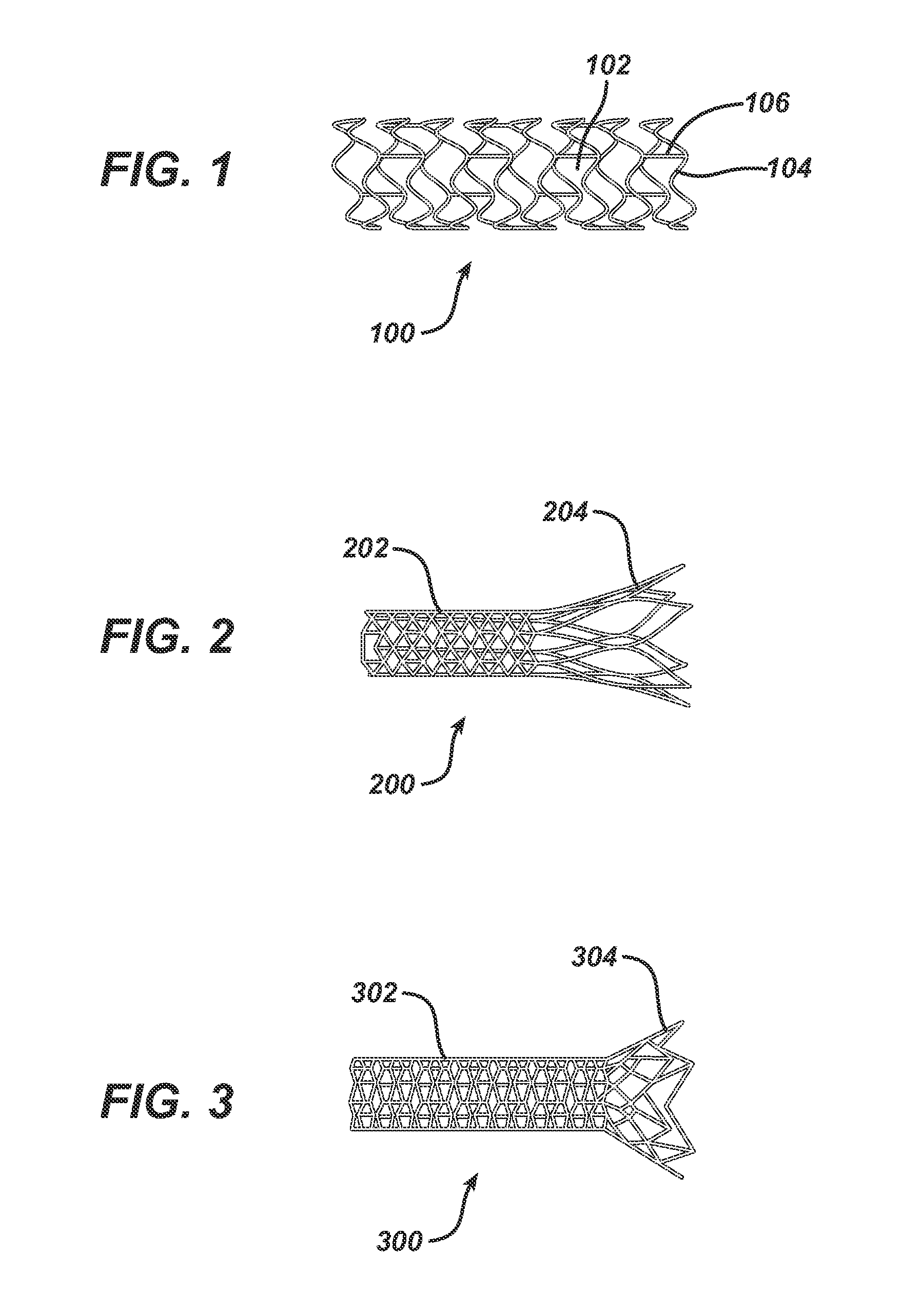

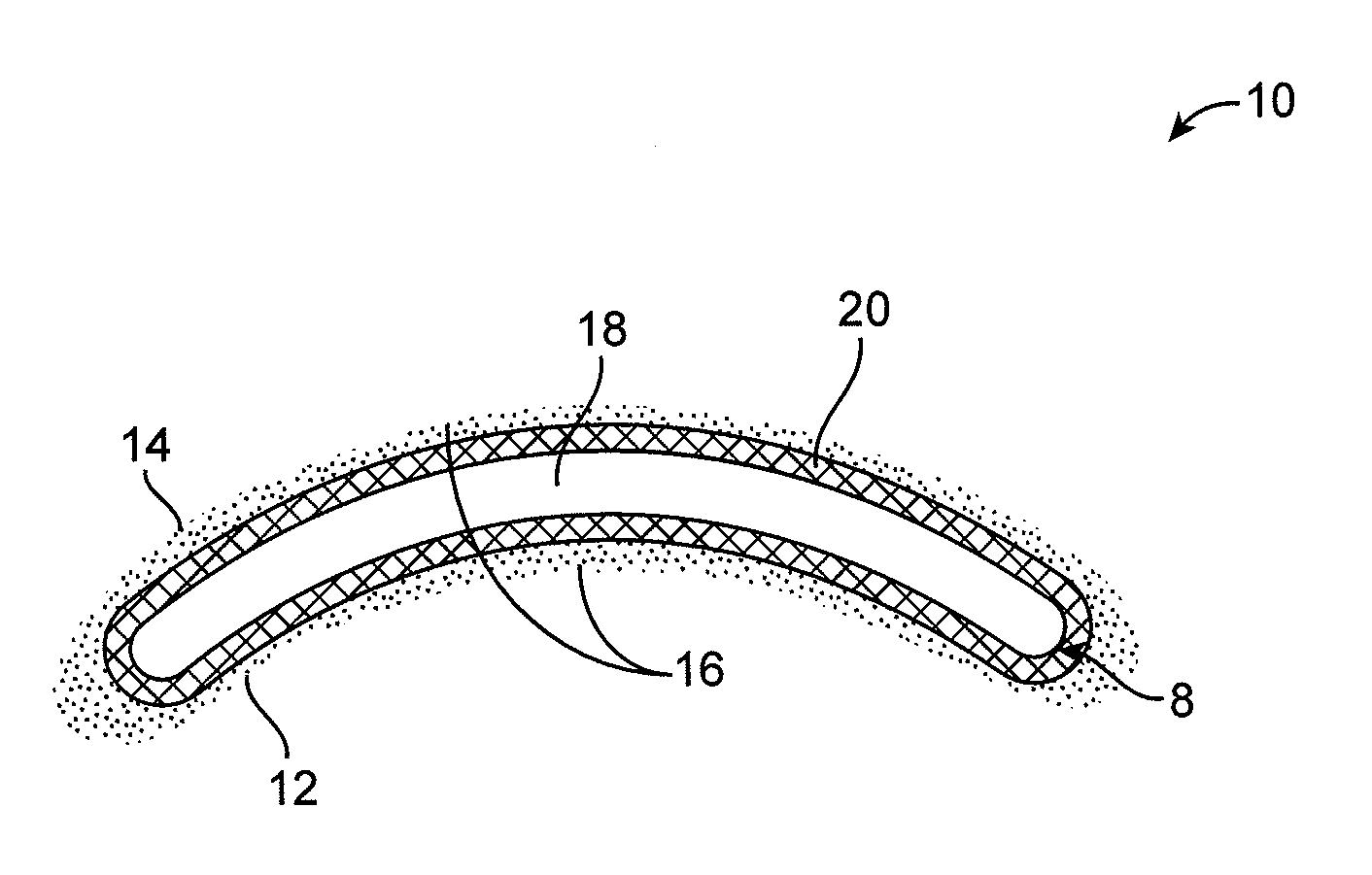

Bioabsorbable Spacers and Spacer Delivery Systems for Use in the Ear, Nose and Throat

A spacer for delivery into the natural or man-made openings to the frontal, maxillary, sphenoid, anterior or posterior ethmoid sinuses, or other cells or cavities, anatomical regions such as nostrils, nasal cavities, nasal meatus, and other passageways such as the Eustachian tubes, naso-lachrymal ducts or airway is described. The bioabsorbable polymeric spacers maintain the opening and / or are useful for delivering drugs or other substances to the natural or man-made openings.

Owner:ACCLARENT INC

Cu-Mn Alloy Sputtering Target and Semiconductor Wiring

InactiveUS20100013096A1Functional deteriorationStrong oxidizing powerCellsSemiconductor/solid-state device detailsSelf-diffusionDeposition process

Proposed is a Cu—Mn alloy sputtering target, wherein the Mn content is 0.05 to 20 wt %, the total amount of Be, B, Mg, Al, Si, Ca, Ba, La, and Ce is 500 wtppm or less, and the remainder is Cu and unavoidable impurities. Specifically, provided are a copper alloy wiring for semiconductor application, a sputtering target for forming this wiring, and a manufacturing method of a copper alloy wiring for semiconductor application. The copper alloy wiring itself for semiconductor application is equipped with a self-diffusion suppression function for effectively preventing the contamination around the wiring caused by the diffusion of active Cu, improving electromigration (EM) resistance, corrosion resistance and the like, enabling and facilitating the arbitrary formation of a barrier layer, and simplifying the deposition process of the copper alloy wiring for semiconductor application.

Owner:JX NIPPON MINING& METALS CORP

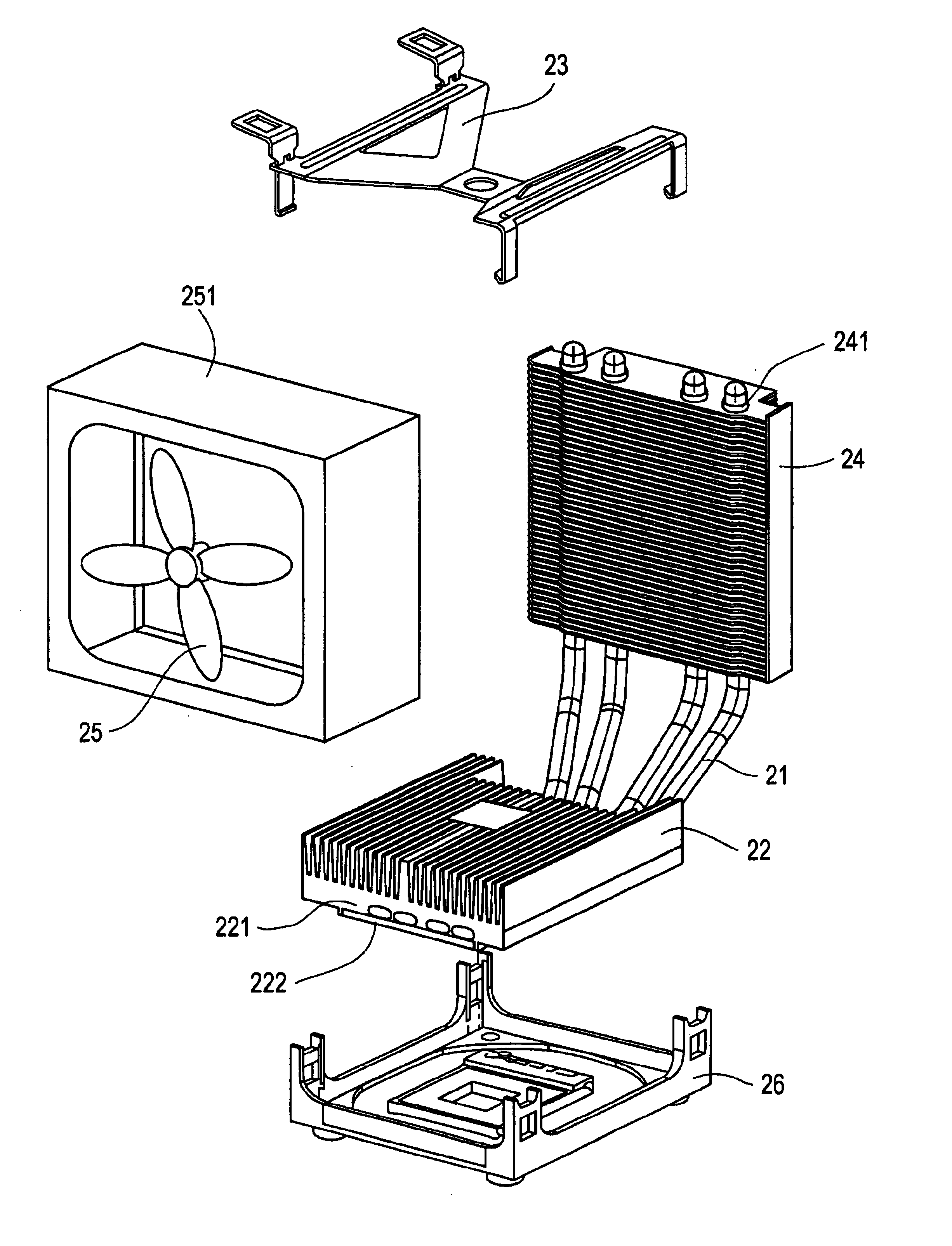

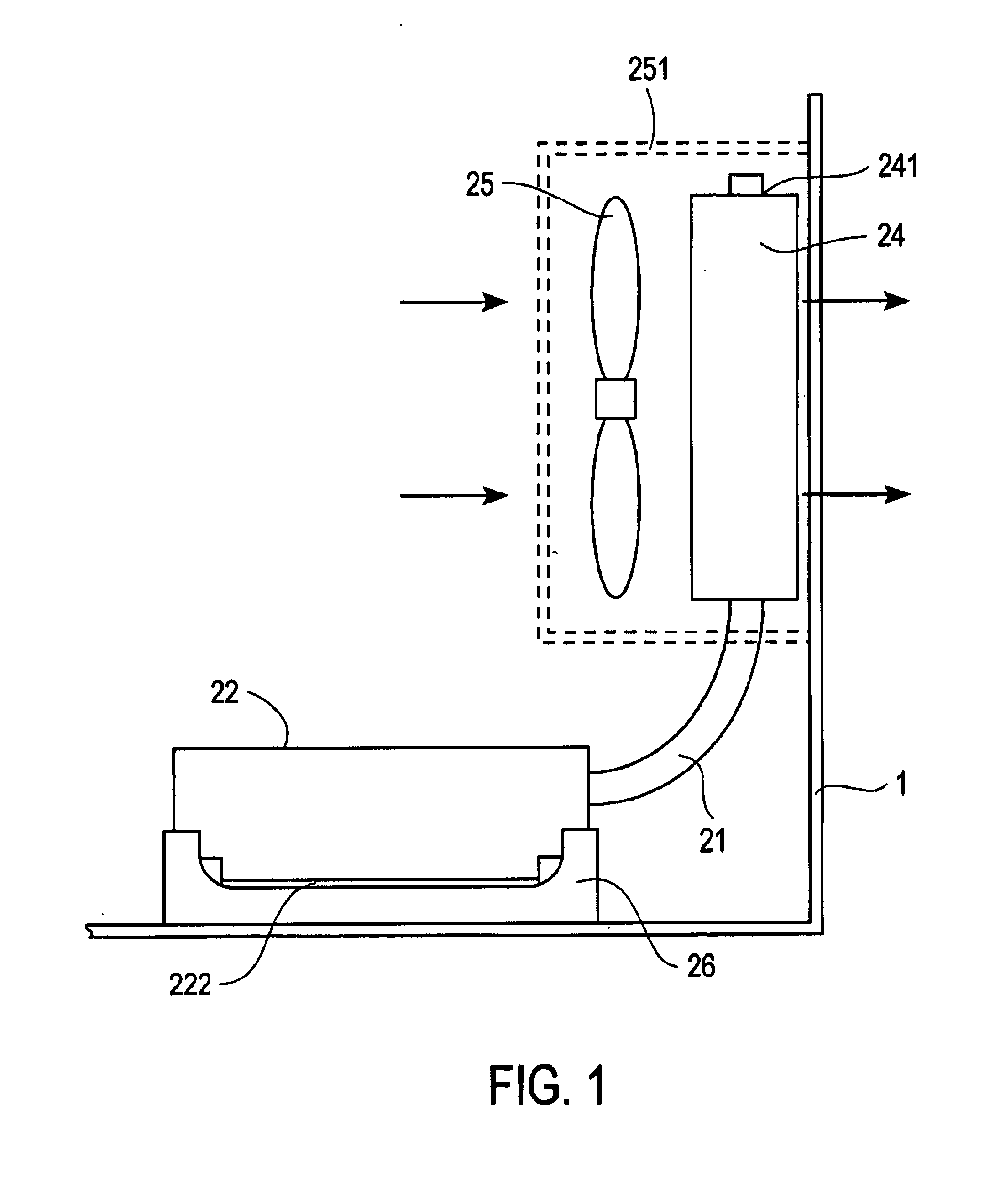

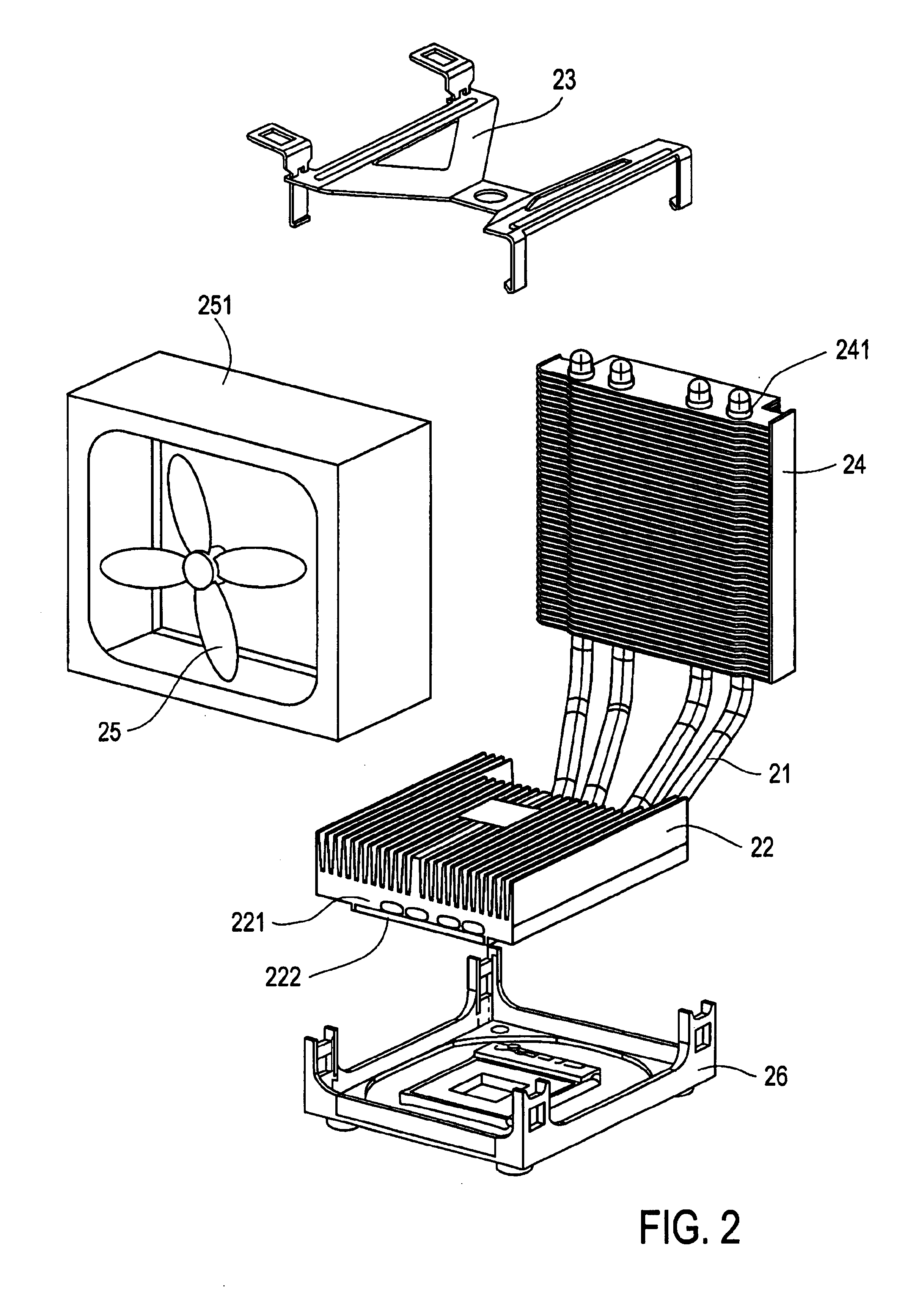

CPU cooling using a heat pipe assembly

ActiveUS6940717B2Less space useAbility of to maintainDigital data processing detailsSemiconductor/solid-state device detailsNuclear engineeringPersonal computer

A CPU cooling apparatus comprises a fin, a heat sink, and a heat pipe thermally coupling the fin and the heat sink. When installed in a personal computer, the fin thermally couples with a CPU to receive heat generated by the CPU. The heat pipe conducts the heat to a heat sink, which is cooled by an exhaust fan that directs a flow of air outside the computer.

Owner:SHUTTLE COMP GRP INC +1

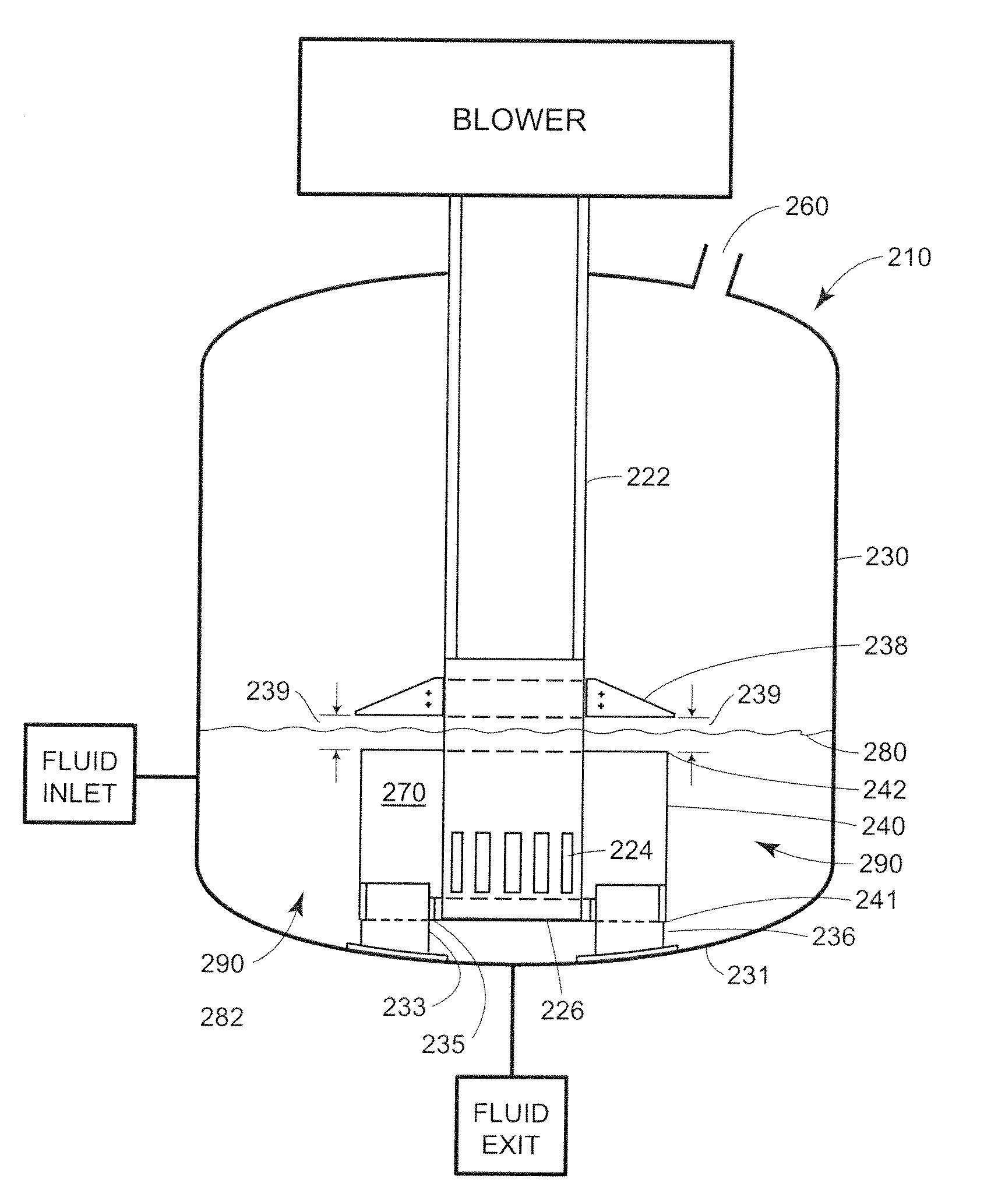

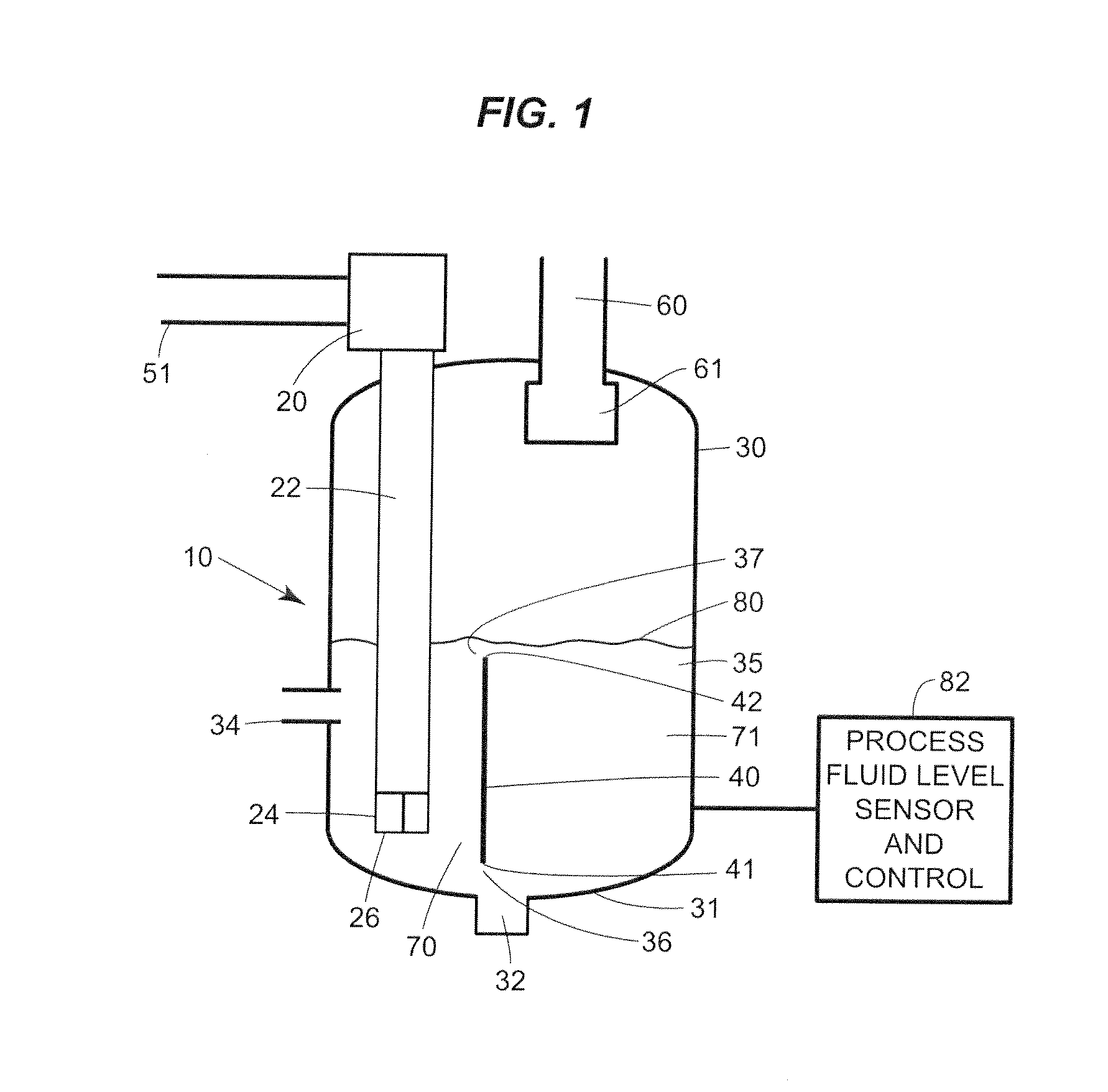

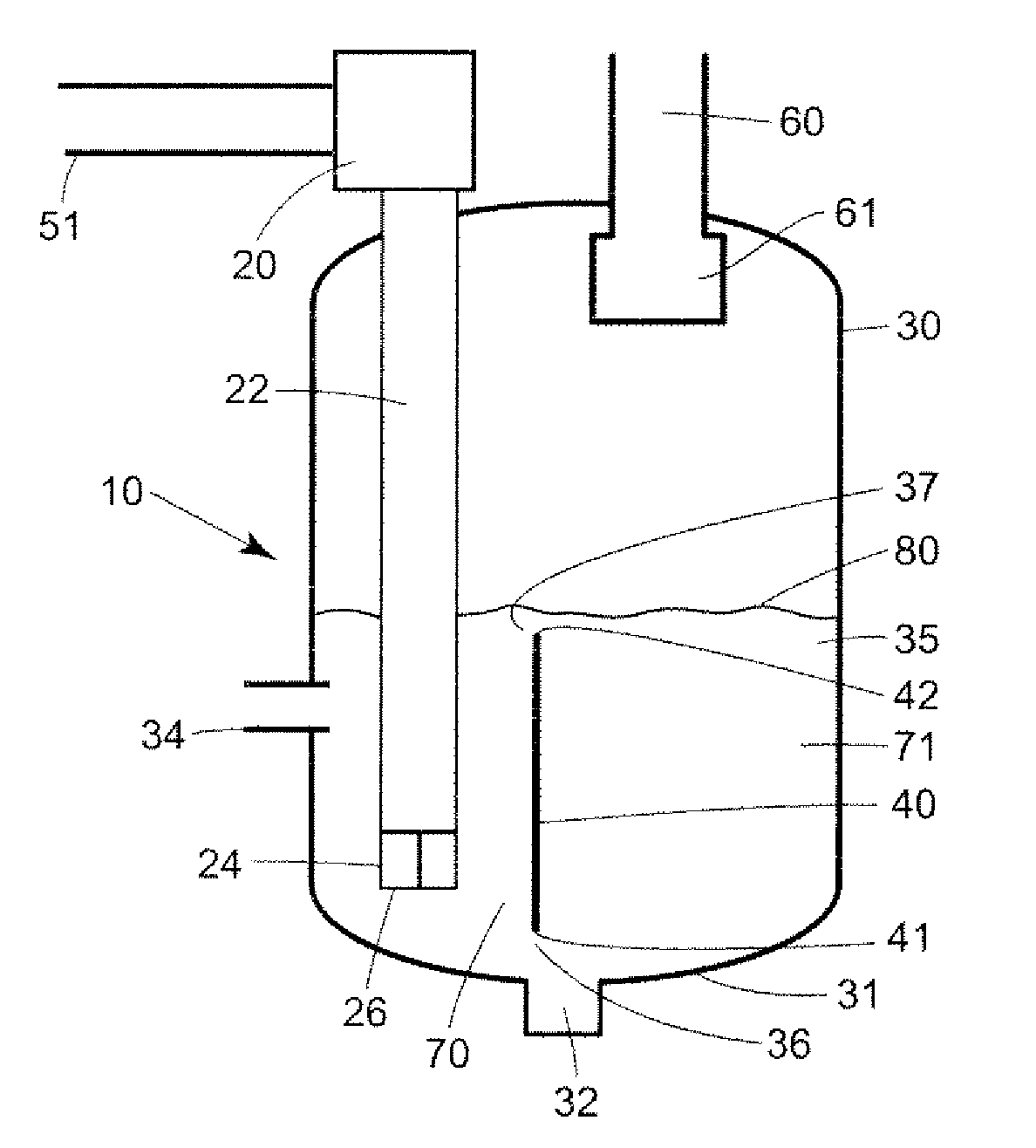

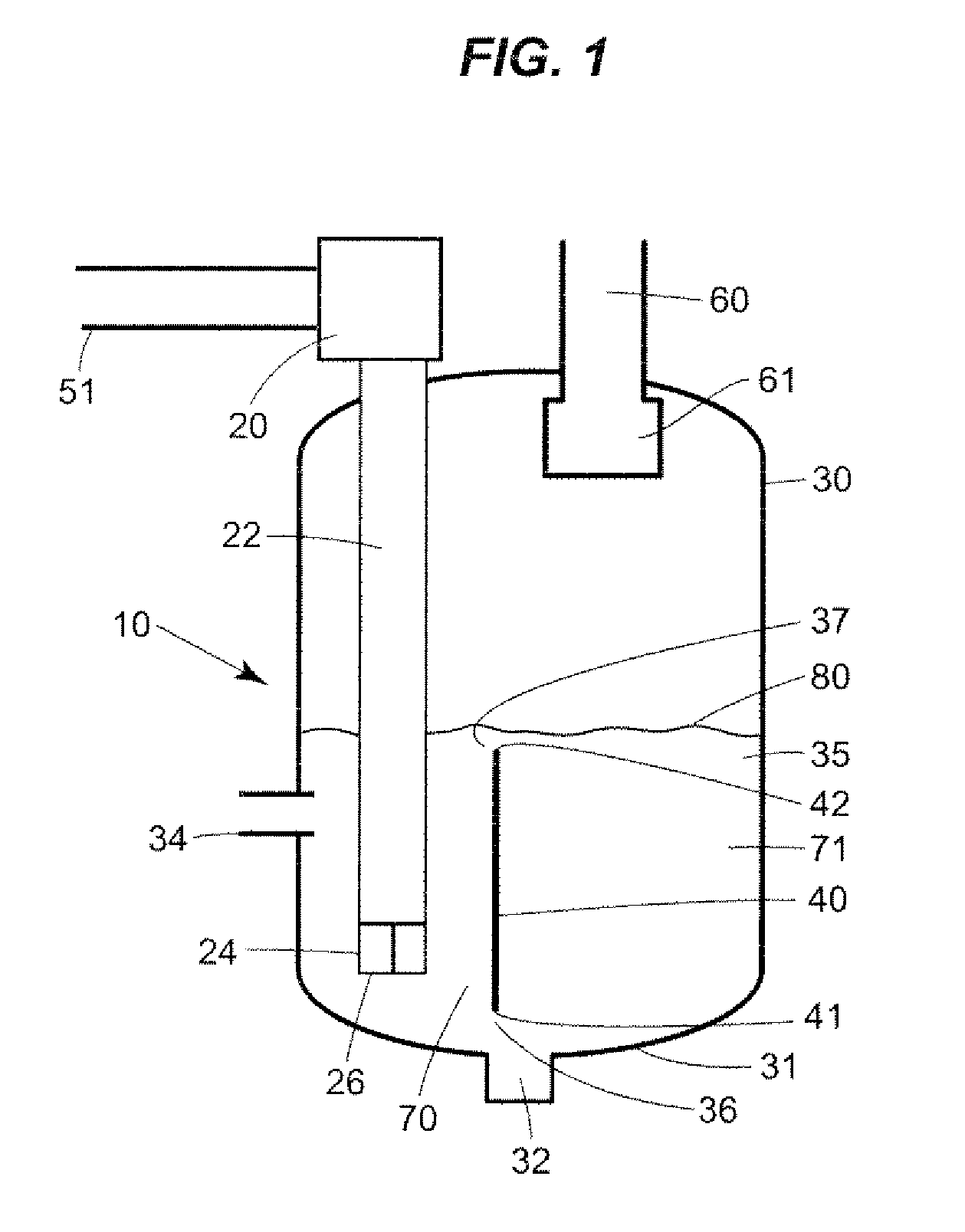

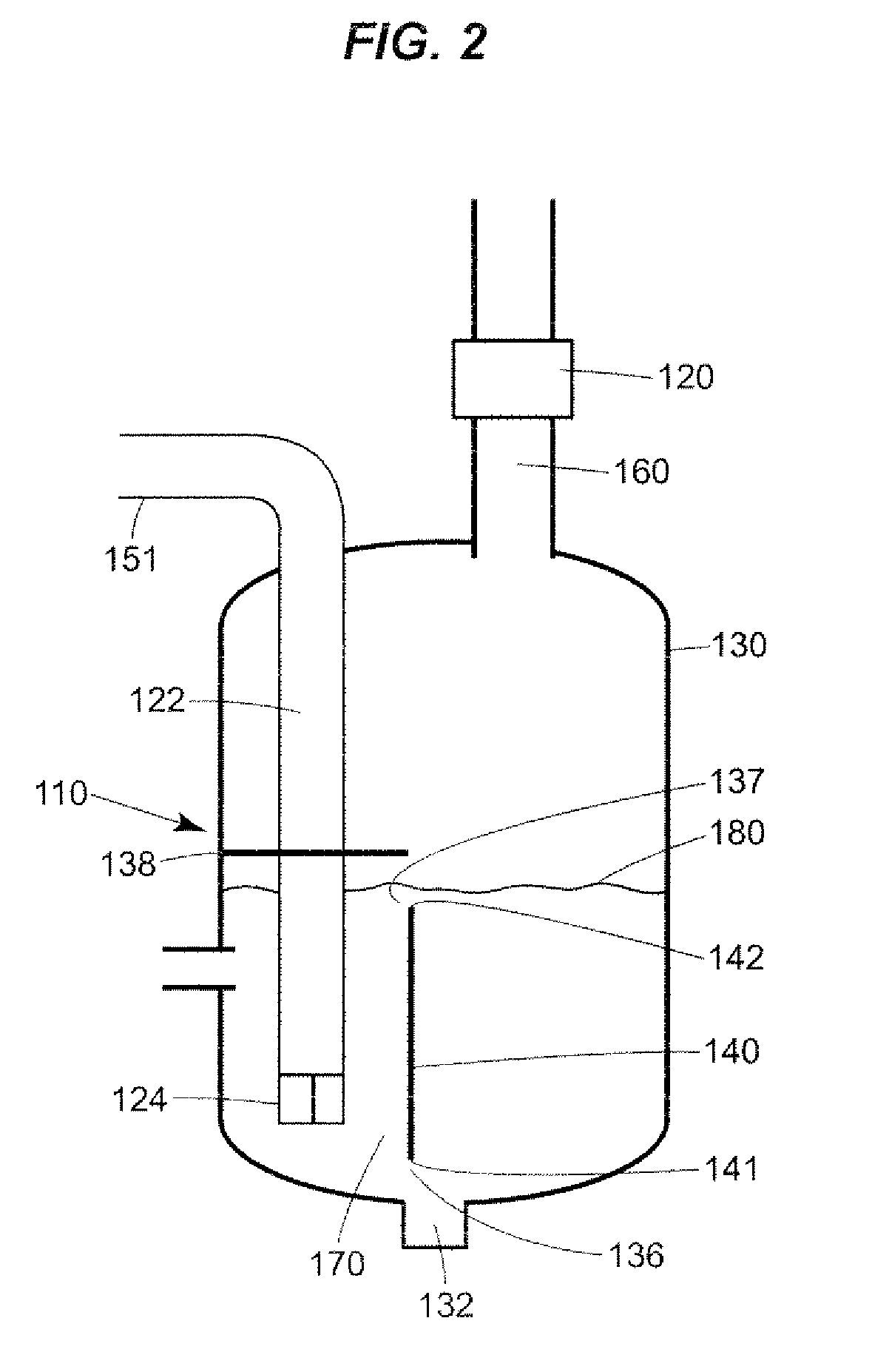

Cooling tower

InactiveUS8136797B2Enhanced mixing processReduce cloggingCarburetting airLiquid degasificationHigh rateCooling tower

Owner:HEARTLAND TECH PARTNERS

Non-Aqueous Electrolyte and Non-Aqueous Electrolyte Battery Comprising the Same

InactiveUS20080153005A1Improve battery performanceNon-combustibility of the non-aqueous electrolyte can be highly improvedOrganic electrolyte cellsSolid electrolyte cellsHalogenAlkoxy group

This invention relates to a non-aqueous electrolyte exhibiting a non-combustibility even under a condition having a higher oxygen concentration, and more particularly to a non-aqueous electrolyte characterized by comprising a non-aqueous solvent containing a cyclic phosphazene compound represented by the following general formula (I):(NPR12)n (I)[wherein R1s are independently a halogen element or a monovalent substituent; and n is 3-4] and a fluorophosphate compound represented by the following general formula (II):[wherein R2s are independently a halogen element, an alkoxy group or an aryloxy group, and at least one of the two R2s is the alkoxy group or the aryloxy group], and a support salt.

Owner:BRIDGESTONE CORP

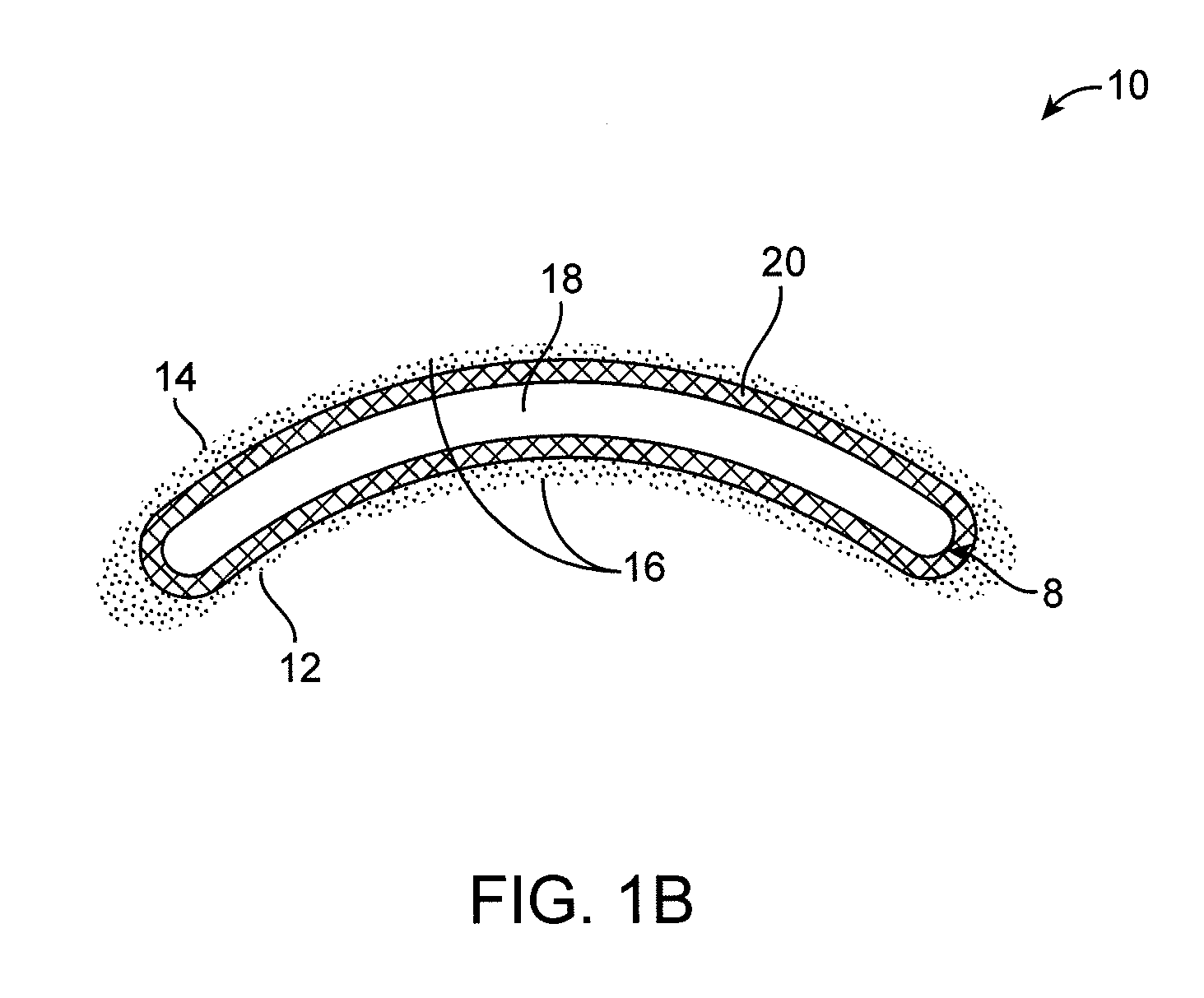

Contact lens with a hydrophilic layer

ActiveUS20150234204A1Adequate on eye movementStay healthySpectales/gogglesOptical articlesRigid gas permeable lensHydrophilic polymers

Embodiments of the technology relate to a contact lens having a core that is coated by a hydrogel layer, and to methods of making such a lens. The coated lens can include a rigid gas permeable contact lens. The coated lens can also include a hybrid silicone and rigid gas permeable contact lens. In one aspect, embodiments provide for a coated contact lens comprising a lens core with a water equilibrium constant of less than about 2% comprising an outer surface; and a hydrogel layer covalently attached to at least a portion of the outer surface, the hydrogel layer adapted to contact an ophthalmic surface, wherein the hydrogel layer comprises a hydrophilic polymer population of one or more species.

Owner:TANGIBLE SCI LLC

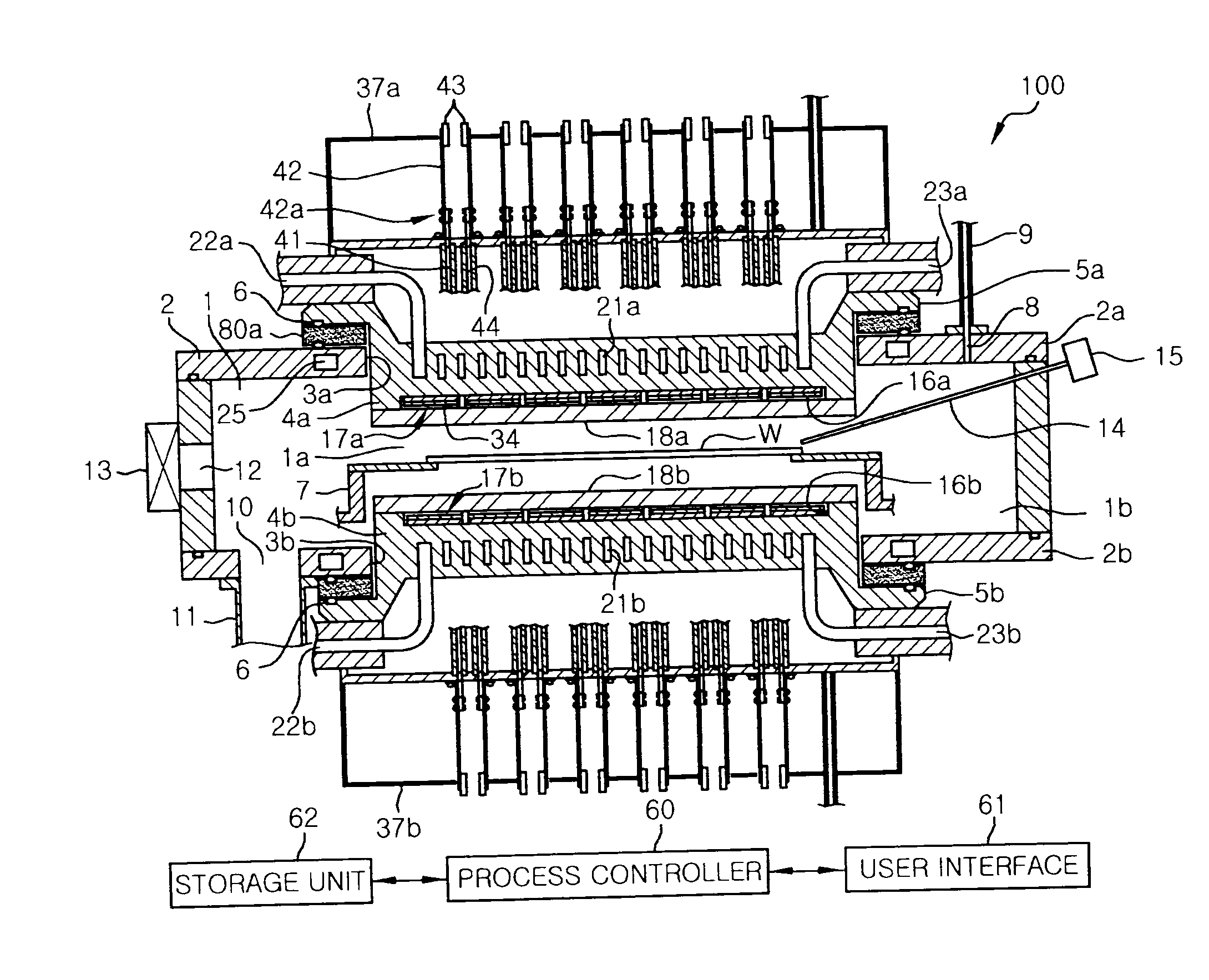

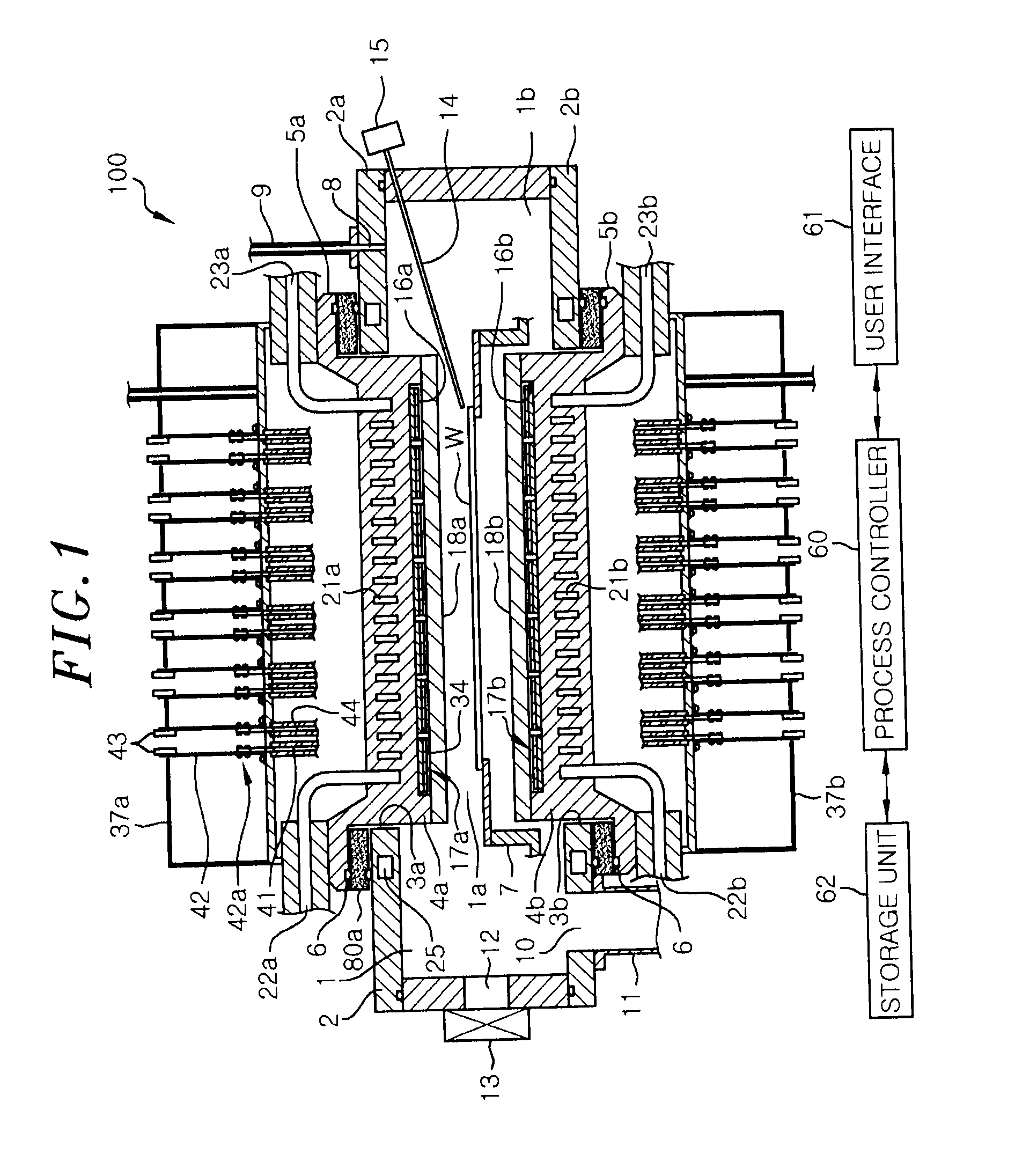

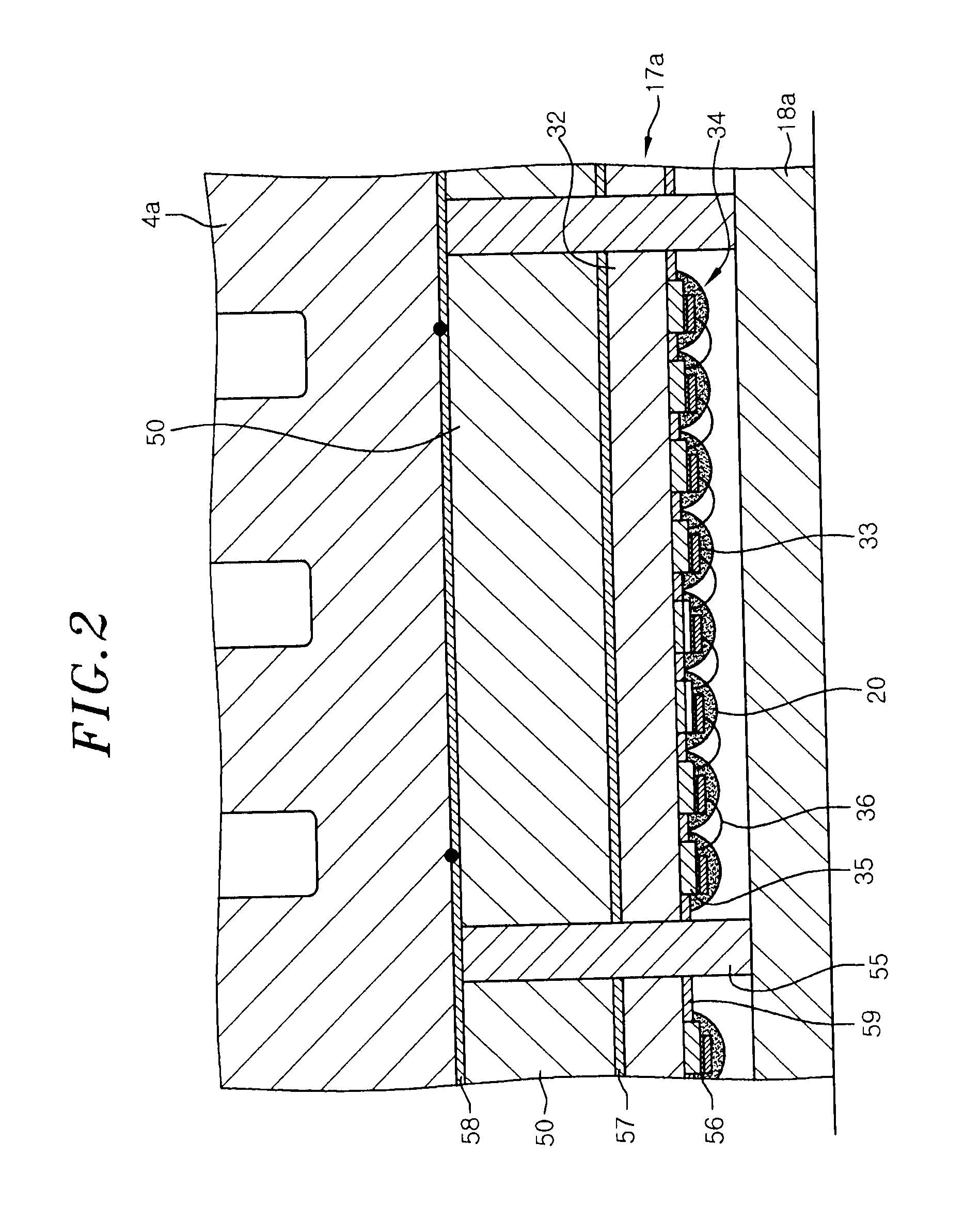

Annealing apparatus

ActiveUS20110033175A1Improve cooling effectReduce maintenanceDomestic stoves or rangesDrying solid materials with heatSilver pasteLed array

An annealing apparatus includes heating sources 17a and 17b provided to face a wafer W, the heating sources 17a and 17b having LEDs 33 emitting lights to the wafer; light-transmitting members 18a and 18b for transmitting the lights emitted from the LEDs 33; and cooling members 4a and 4b made of aluminum and provided to directly contact with the heating sources 17a and 17b, respectively. The heating sources 17a and 17b include a plurality of LED arrays having supporters 32 made of AlN, each having one surface on which the LEDs 33 are adhered by using a silver paste 56; and other surface on which thermal diffusion members 50 made of copper are adhered by using a solder 57. The LED arrays 34 are fixed to the cooling member 4a(4b) by using screws via a silicon grease.

Owner:TOKYO ELECTRON LTD

Techniques for detecting heart pulses and reducing power consumption in sensors

ActiveUS20070208240A1Reduce power consumptionMaintain sufficiencySensorsMeasuring/recording heart/pulse rateDriving currentSignal-to-noise ratio (imaging)

Owner:COVIDIEN LP

Film-covered electric device having pressure release opening

ActiveUS7267906B2Reduce sealEasy to set upLayered productsFixed capacitor housing/encapsulationStress concentrationElectrical devices

A film-covered electric device has an electric device element and casing films. The casing films include a sealing area formed by thermally fusing the facing surfaces of the casing films together around the periphery of the electric device element, an electric device element receiving part encapsulating the electric device element inside the sealing area, and unfused portions formed in the shape of cove communicating with the electric device element receiving part. The casing films further include a stress concentrating portion touching the unfused portions for concentrating thereon the peeling stress of the casing films generated at the sealing area by the expansion of the electric device element receiving part, and a pressure releasing part is formed in the stress concentrating portion.

Owner:NEC CORP

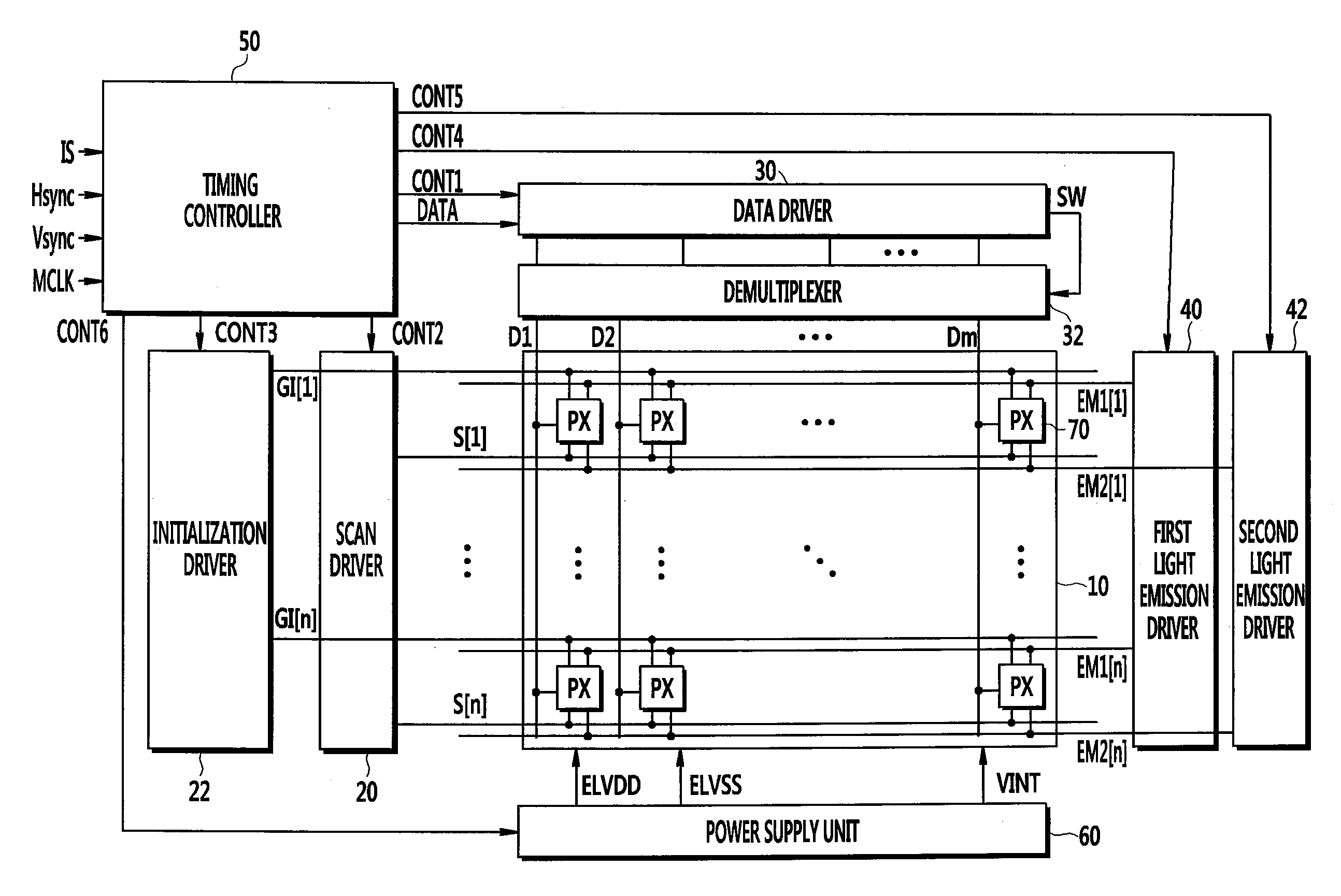

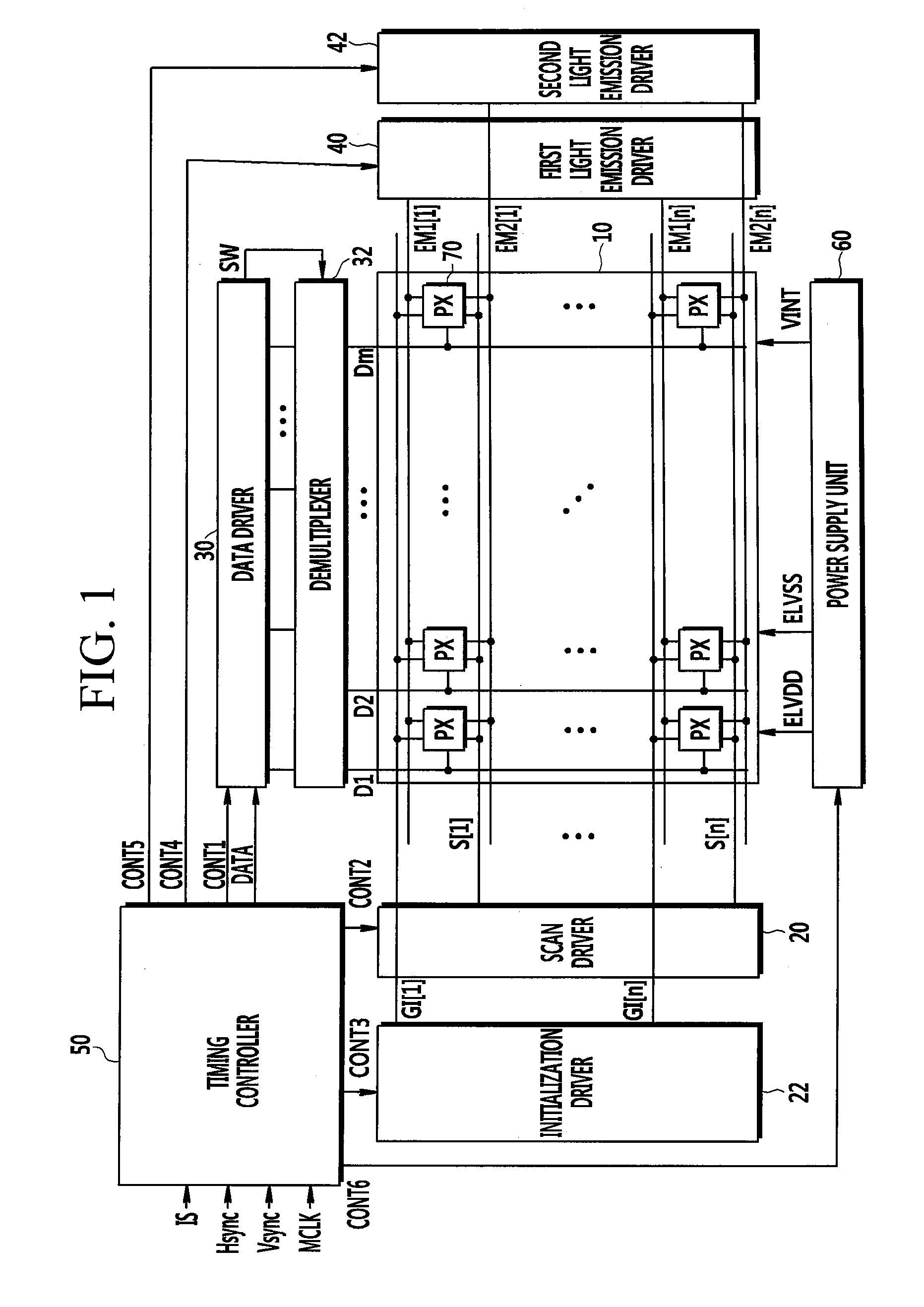

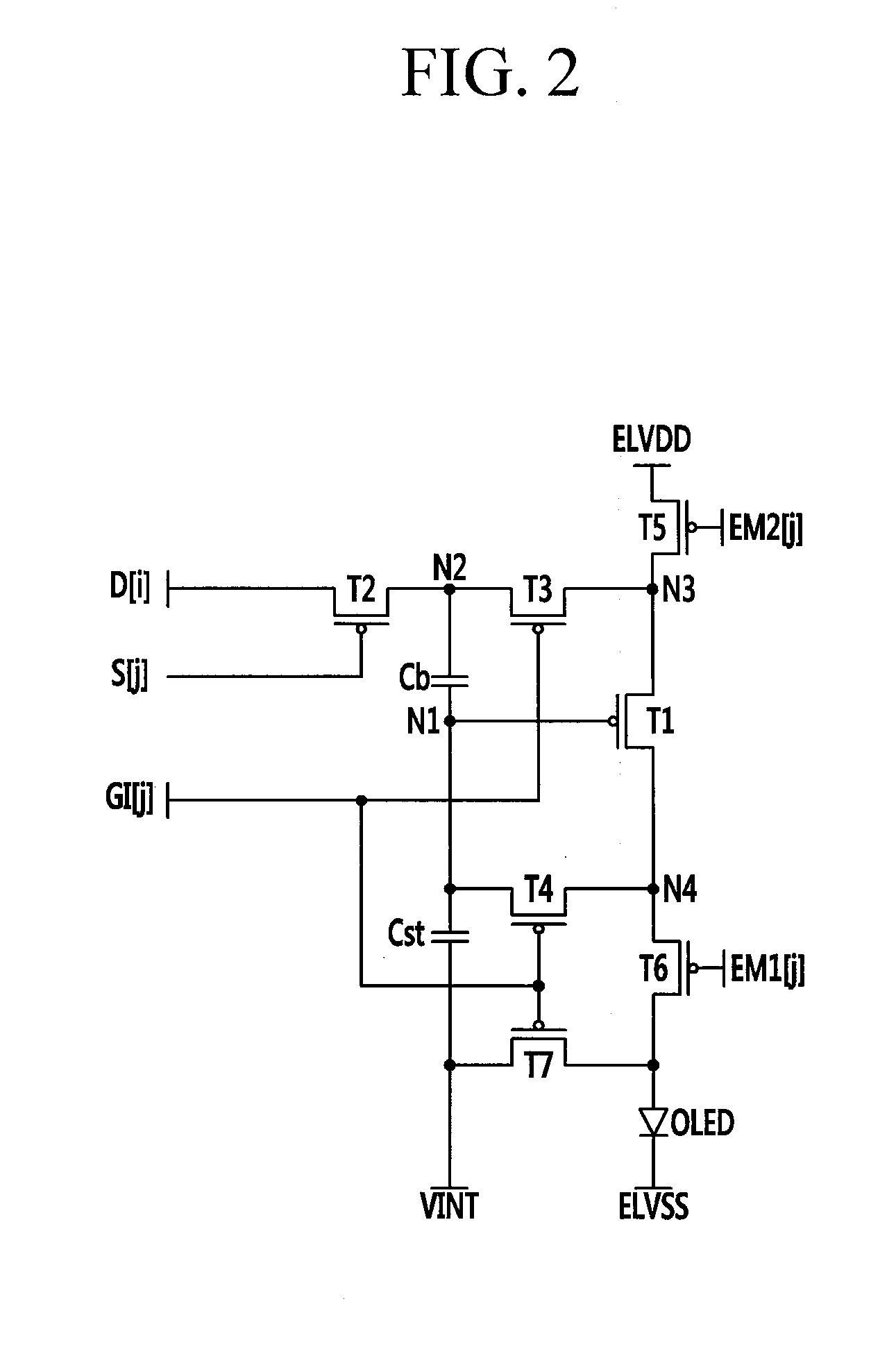

Pixel, display device comprising the same and driving method thereof

ActiveUS20160203794A1Improve display qualityIncrease contrastCathode-ray tube indicatorsInput/output processes for data processingData signalDisplay device

A display device includes: a display unit including a plurality of pixels, each of the pixels including: an OLED; and a driving transistor to supply current to an anode of the OLED according to a voltage applied to a gate of the driving transistor and a power supply voltage; a scan driver to supply scan signals to the pixels; an initialization driver to supply initializing signals to the pixels; a data driver to supply data signals to the pixels; light emission drivers to supply first and second light emission signals to the pixels; and a power supply to supply the power supply voltage and an initialization voltage to the pixels, wherein the initialization voltage is supplied to the anode during a first period, and the power supply voltage corresponding to a threshold voltage of the driving transistor is supplied to the gate during a first sub-period of the first period.

Owner:SAMSUNG DISPLAY CO LTD

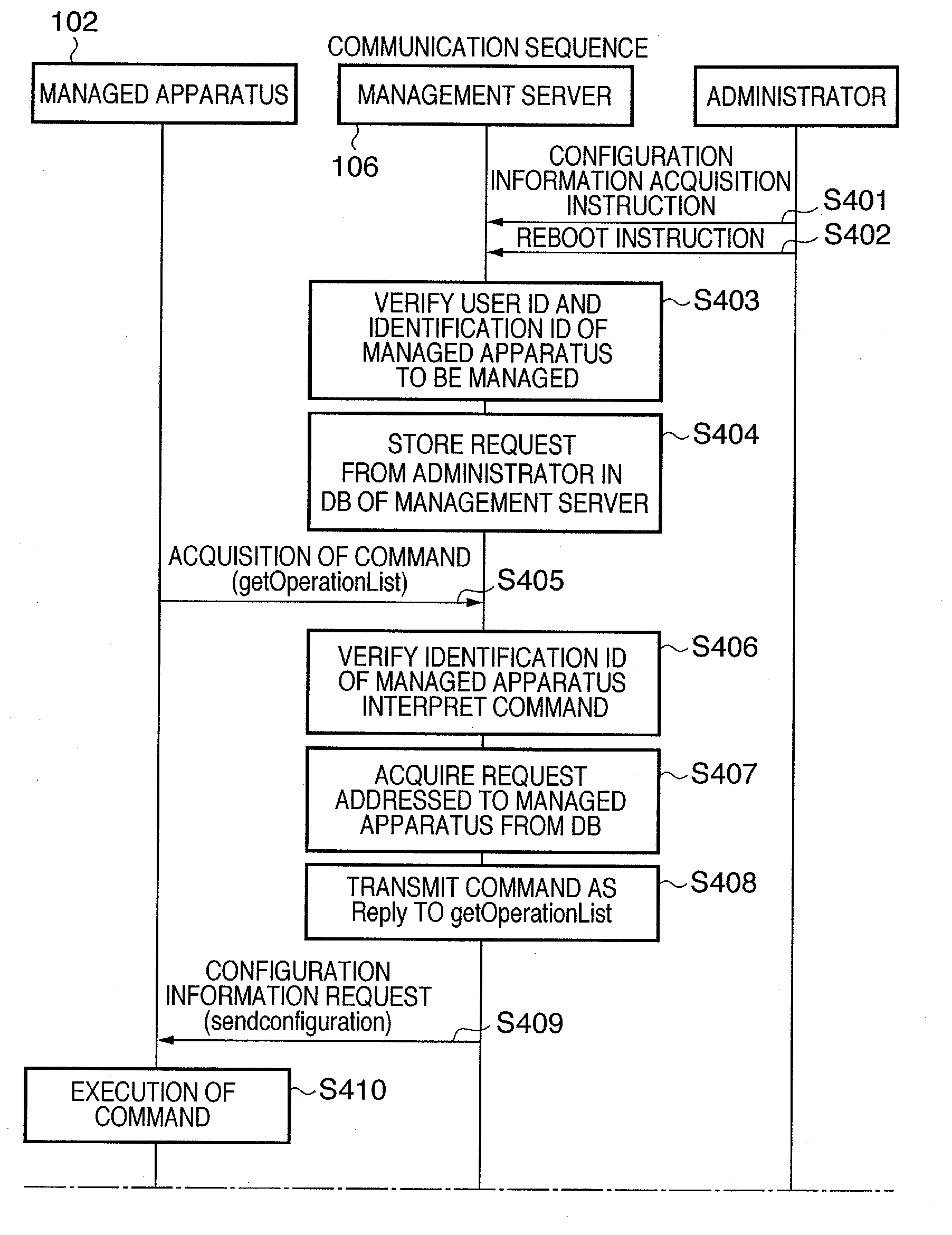

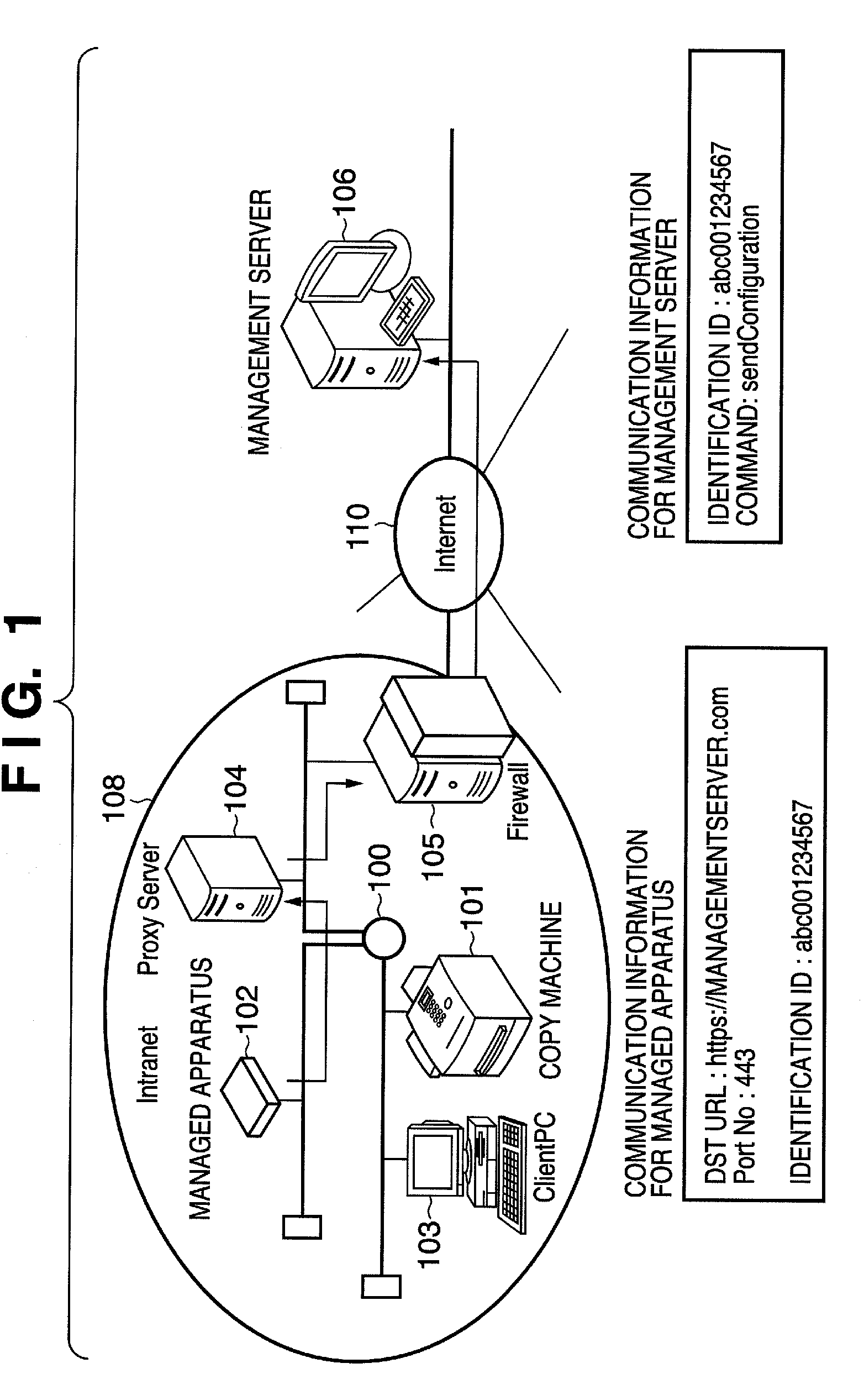

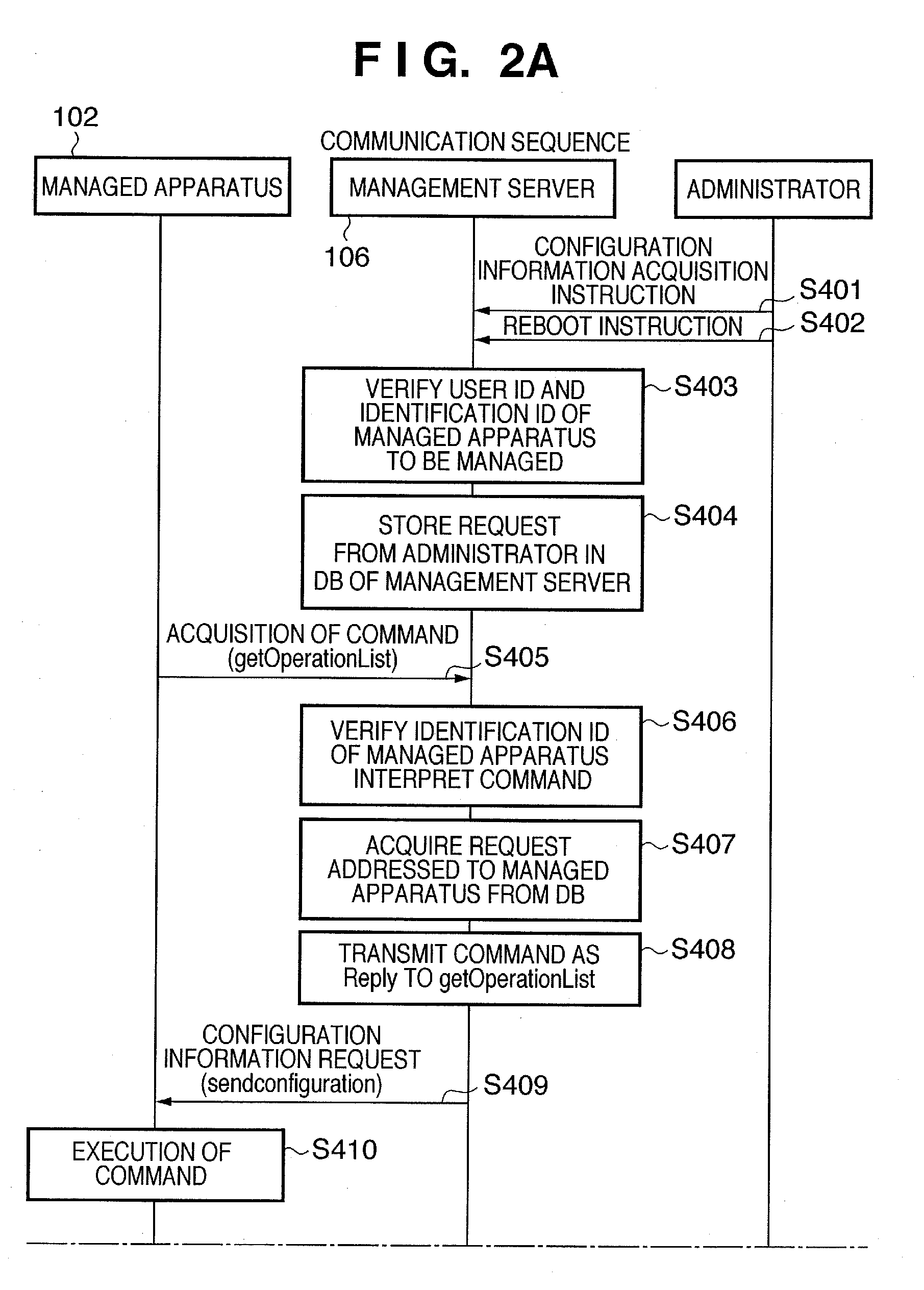

Management apparatus, control method, and storage medium

InactiveUS20070294228A1Maintain sufficiencyReduce in quantityMultiple digital computer combinationsProgram controlOperating systemWeb environment

Owner:CANON KK

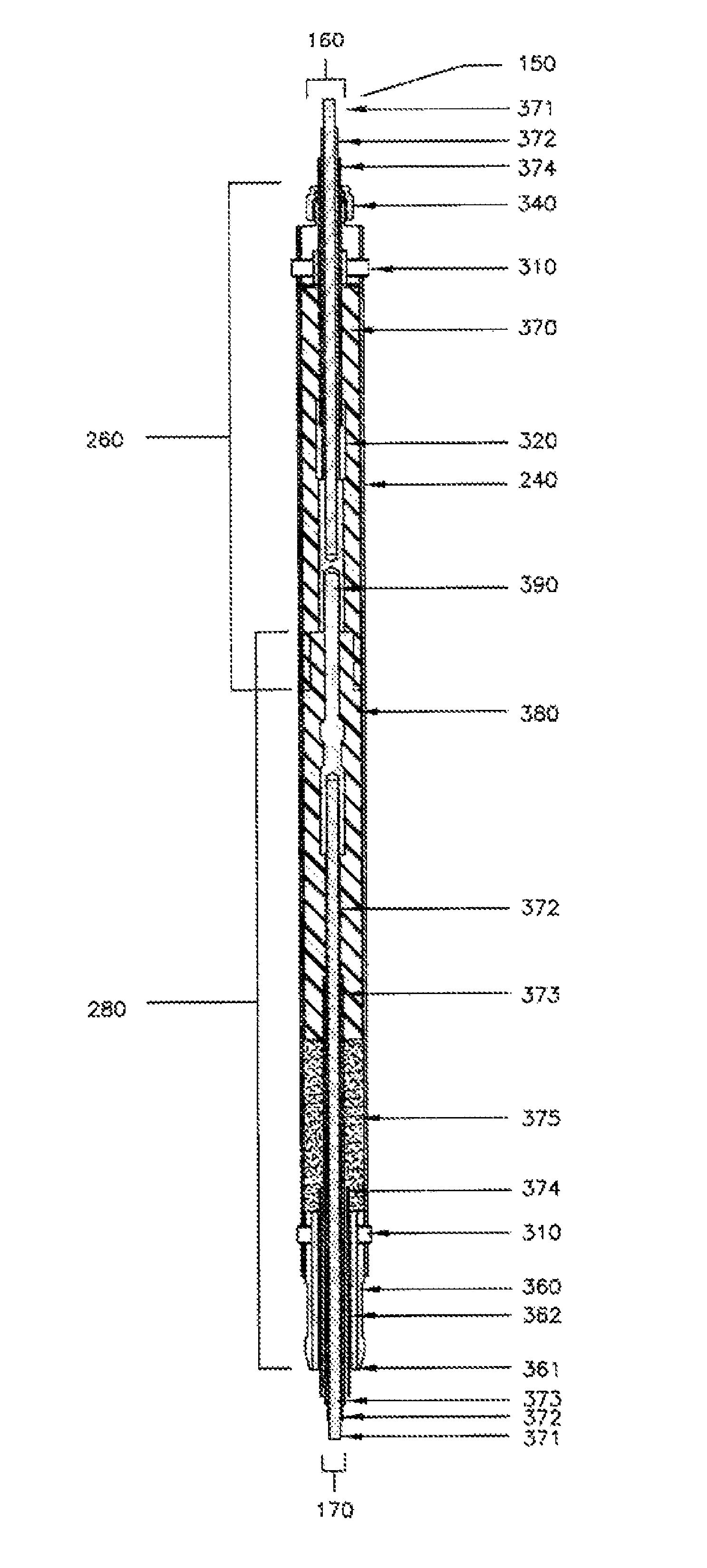

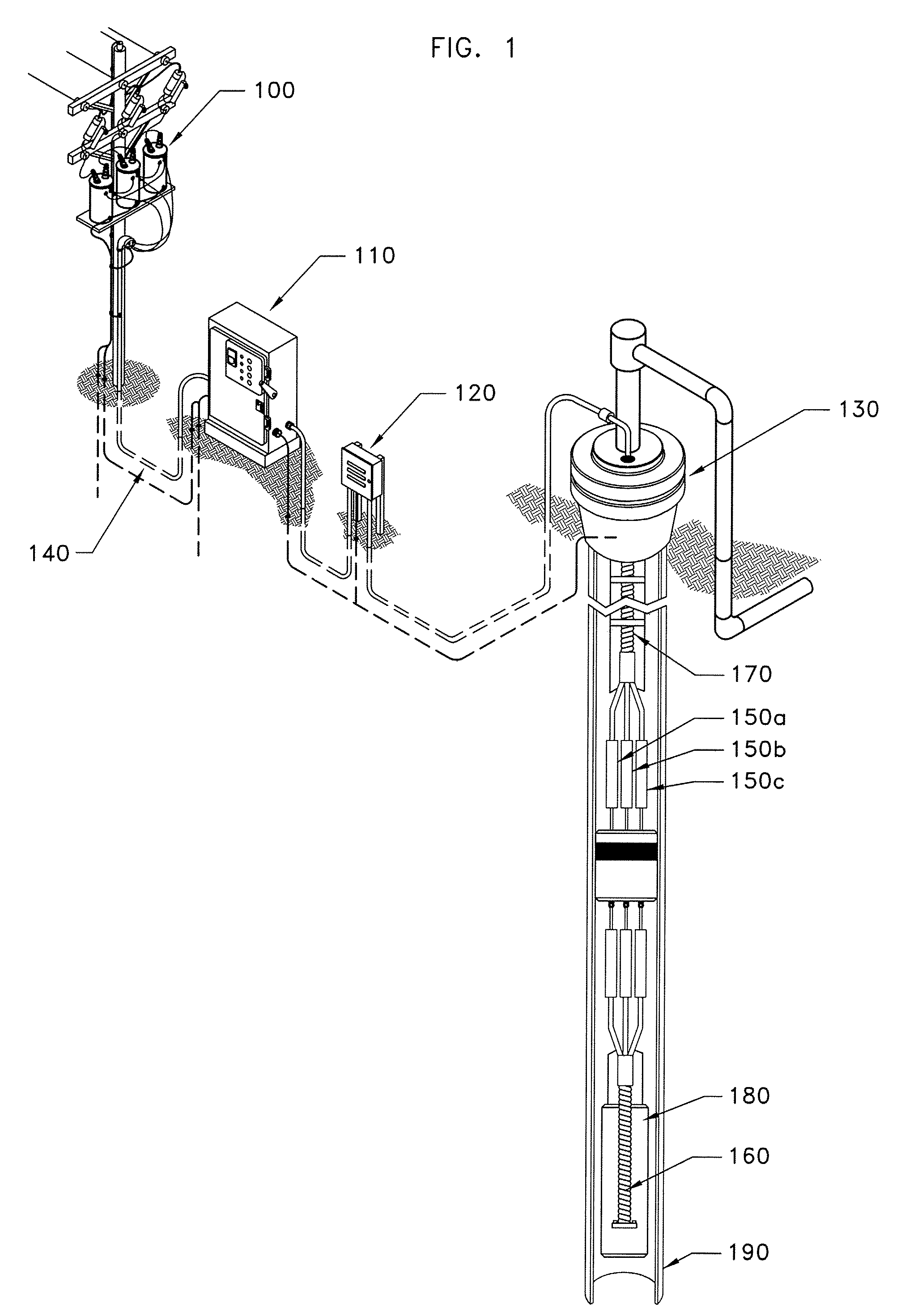

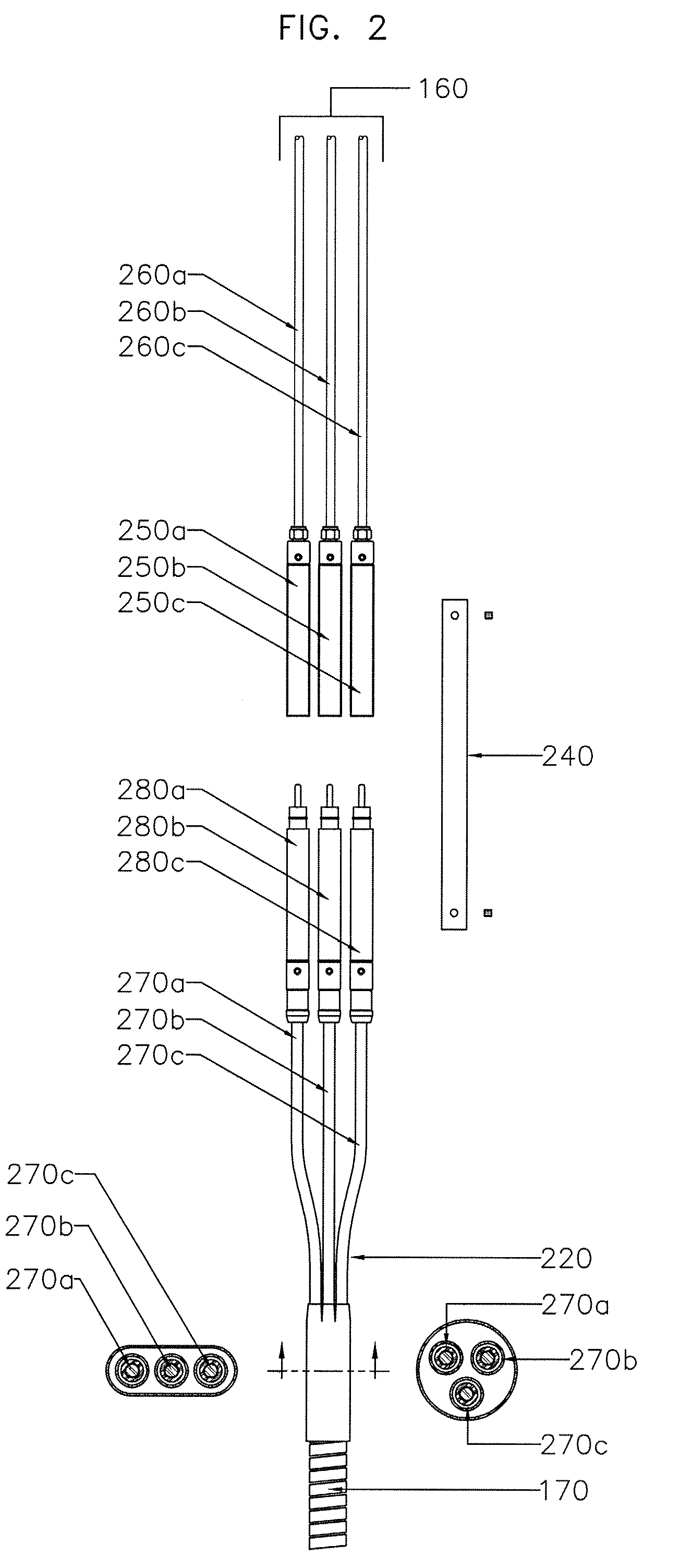

Down hole electrical connector and method for combating rapid decompression

ActiveUS8297345B2Maintain sufficiencyDrilling rodsSecuring/insulating coupling contact membersElectricityPower cable

Embodiments of the present invention provide an effective seal and connector that maintain a removable mechanical and electrical connection between any two down hole power cables, despite cable movement and well pressure. The connector preferably includes a fluid seal comprised an encasing material that surrounds and / or adheres to protective tubing encapsulating an electrical cable's conductor wires. The encasing material may also surround and / or adhere to the conductive wire's insulation to prevent its outward expansion during well pressure events. The connector's fluid seal also comprises a relatively rigid connection between the connector's protective outer sleeve and the protective tubing encapsulating the conductor wire.

Owner:QUICK CONNECTORS

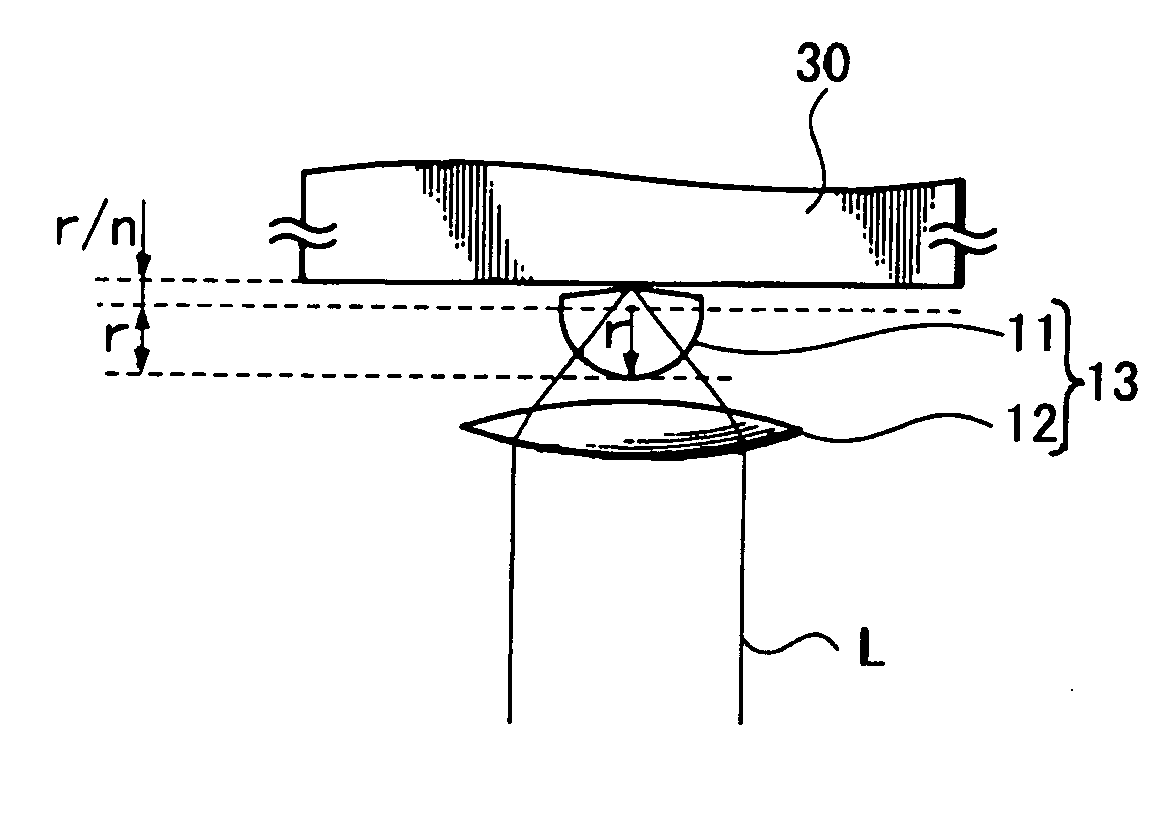

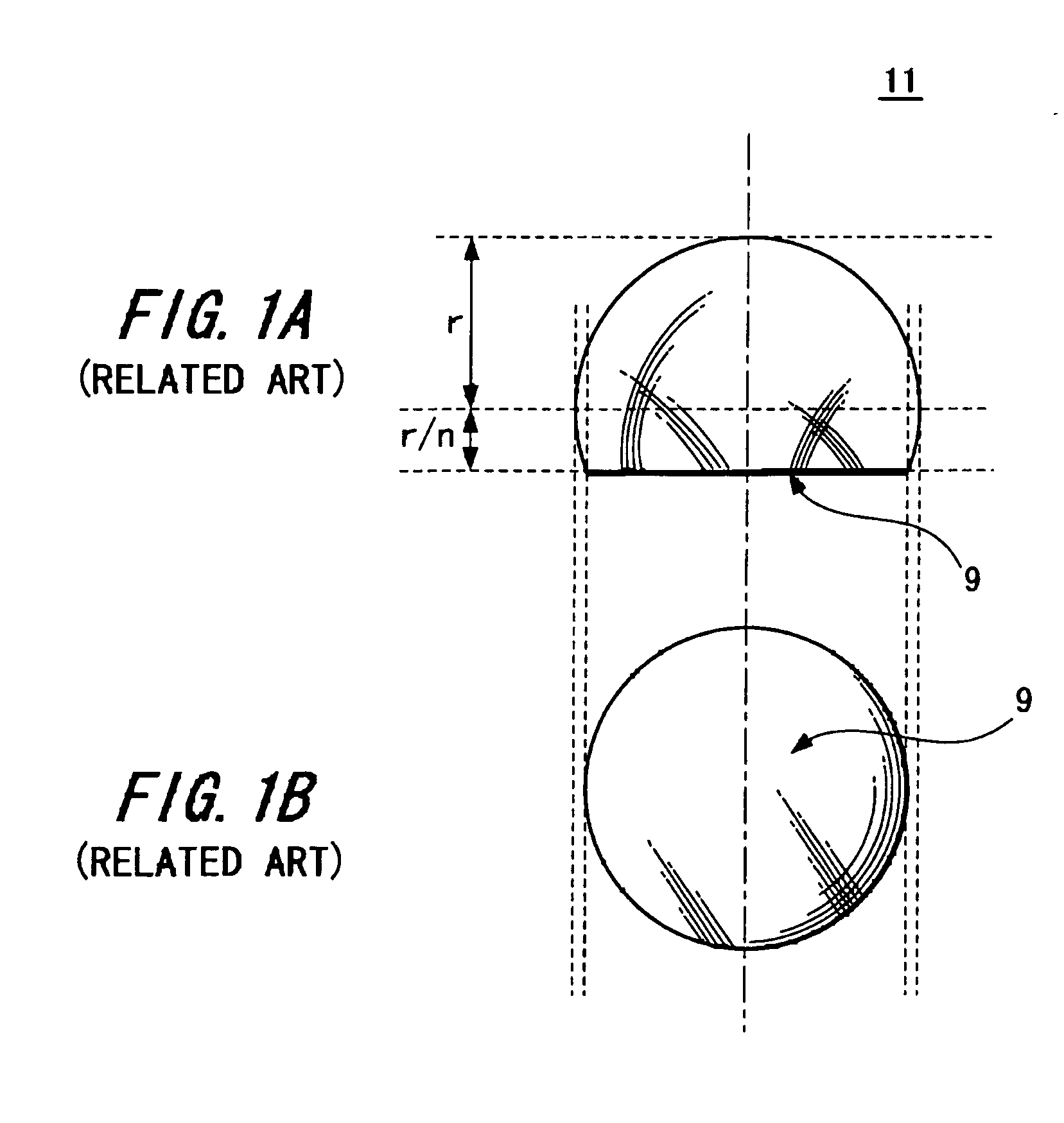

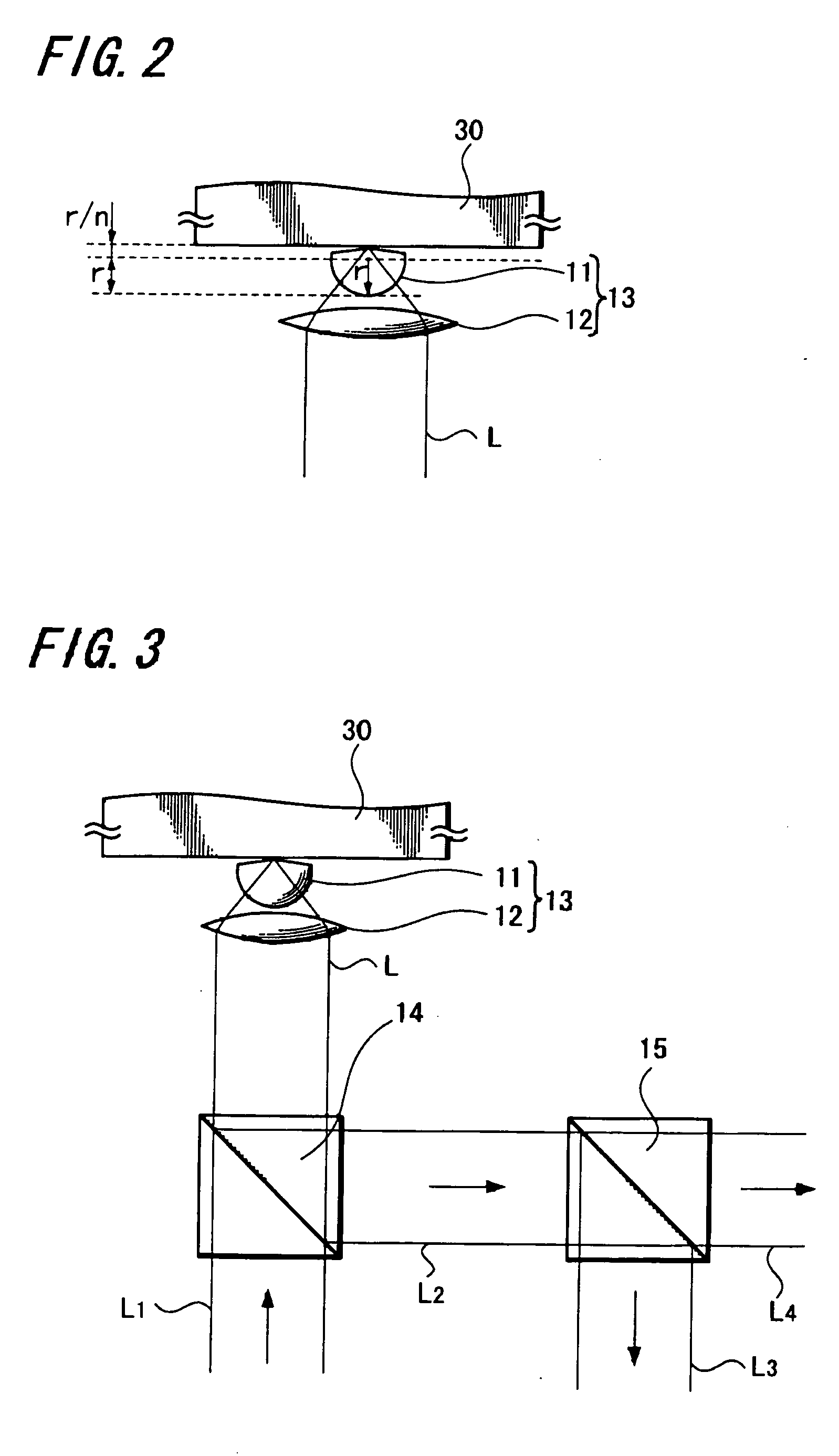

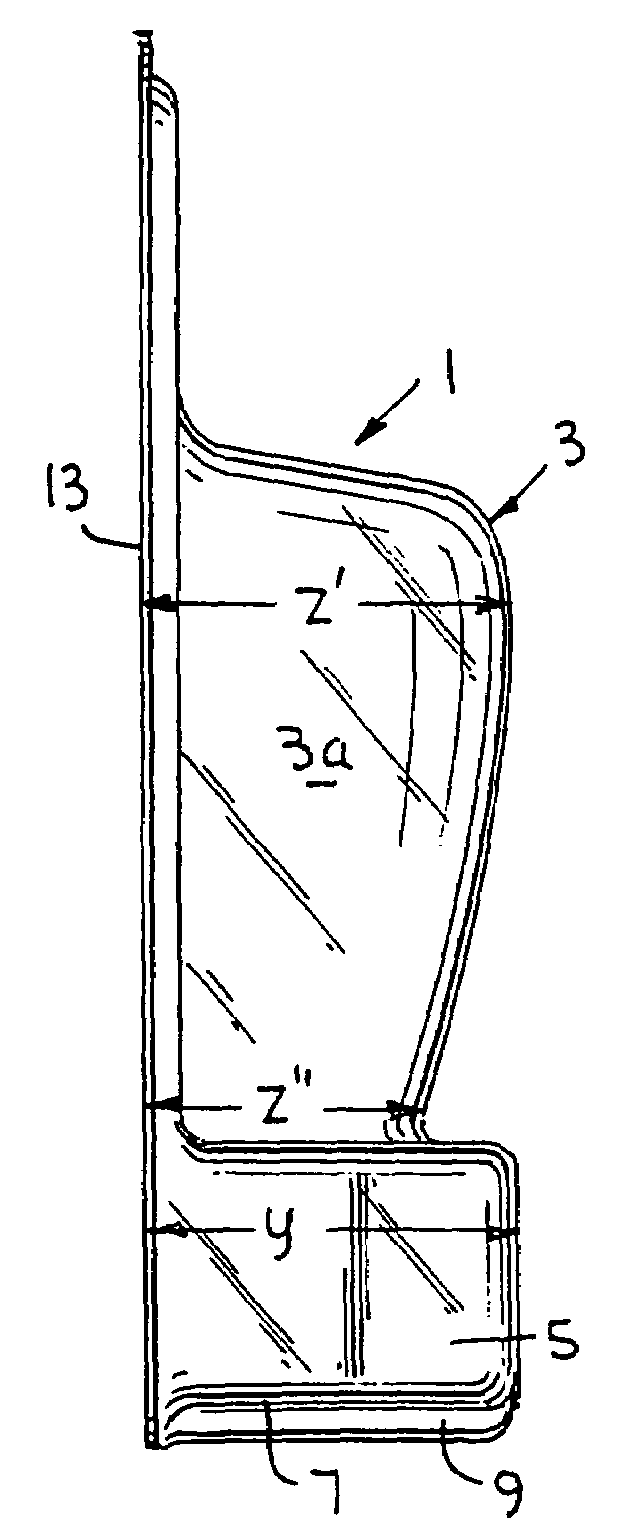

Solid immersion lens, condensing lens, optical pickup device, optical recording and reproducing apparatus and method of forming solid immersion lens

InactiveUS20050232120A1Large numerical apertureEasy to getCombination recordingRecord information storageOptical pickupAngle of incidence

A solid immersion lens 11 has an inclined portion 4 formed on at least a part thereof from the tip end portion of the objective side to a spherical portion and an inclination angle θ is expressed as θ≧i where θi represents the angle of incidence of light incident on the solid immersion lens 11. There are provided a solid immersion lens capable of increasing a tilt margin between a lens and an optical recording medium and so on and which can decrease a diameter of a lens and a method for forming a solid immersion lens.

Owner:SONY CORP

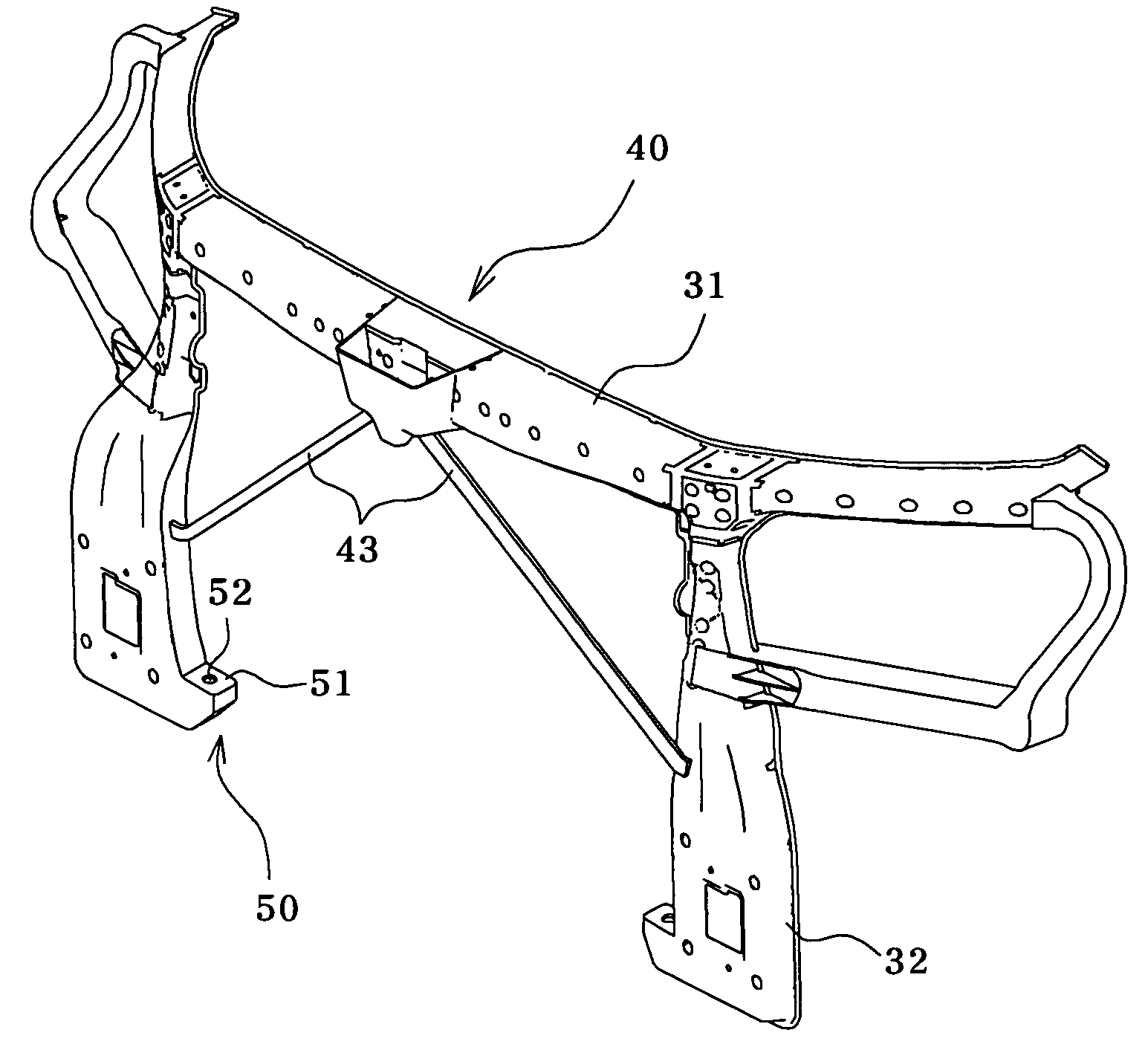

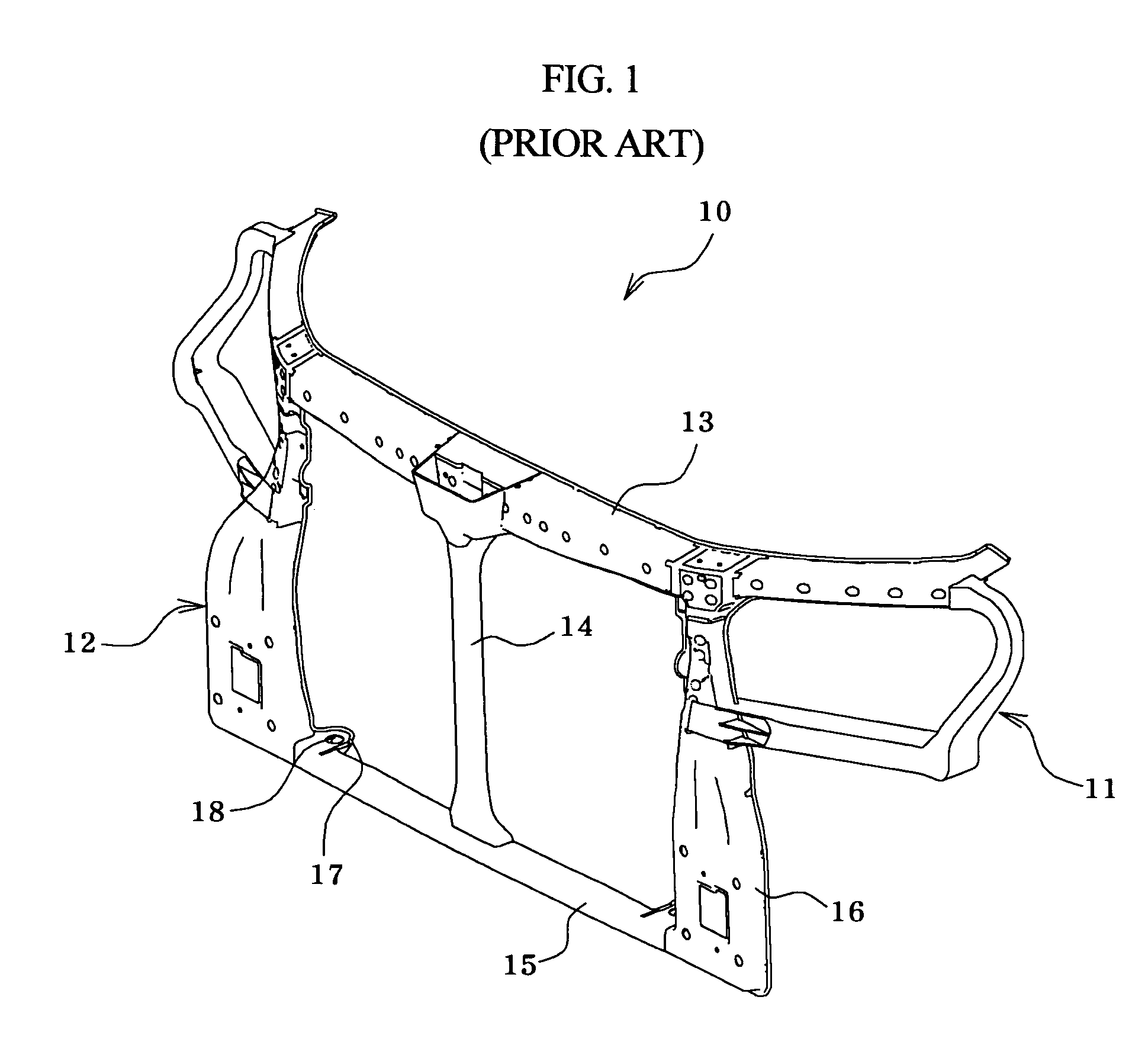

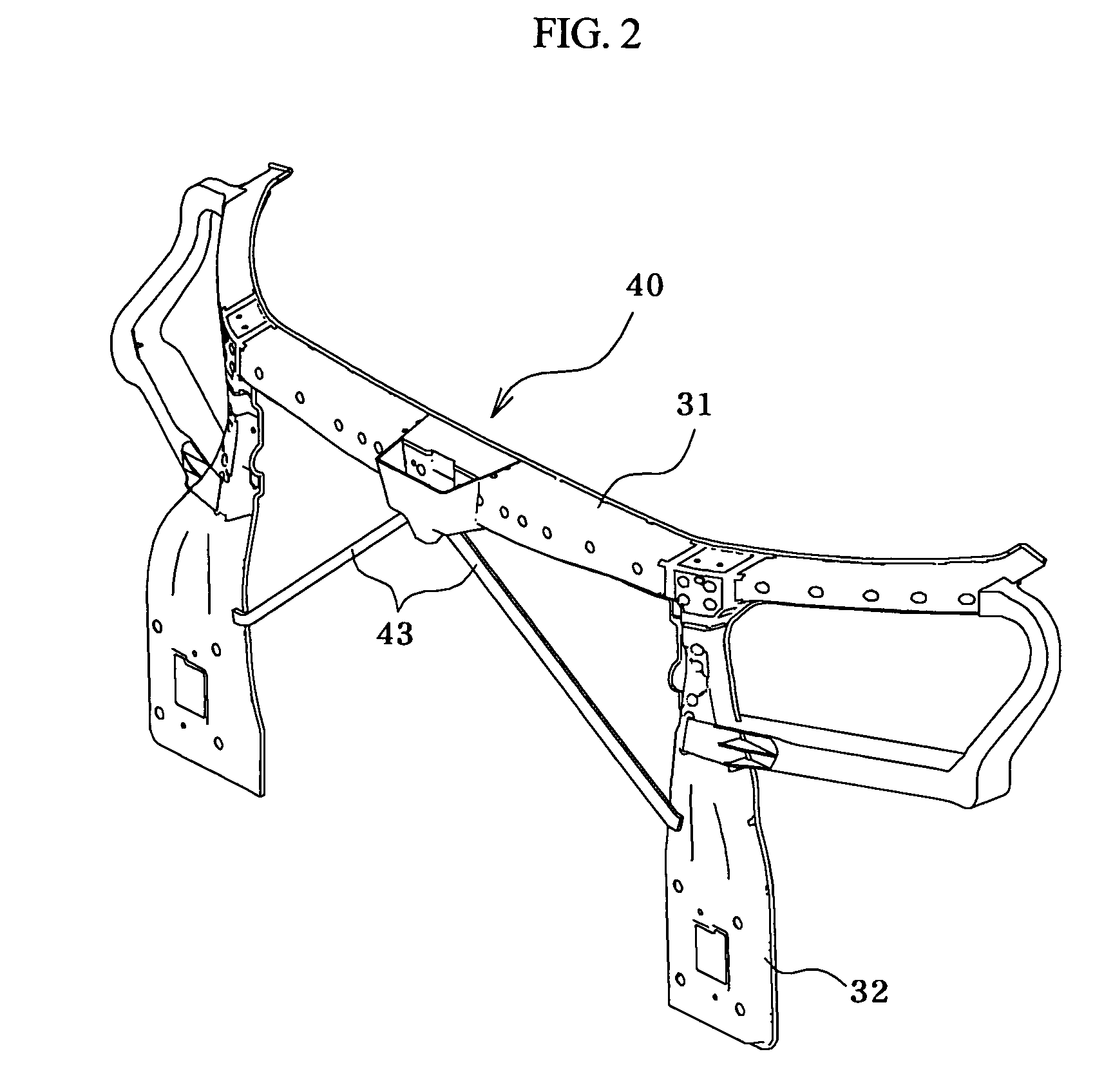

Structure of carrier

Owner:HYUNDAI MOBIS CO LTD

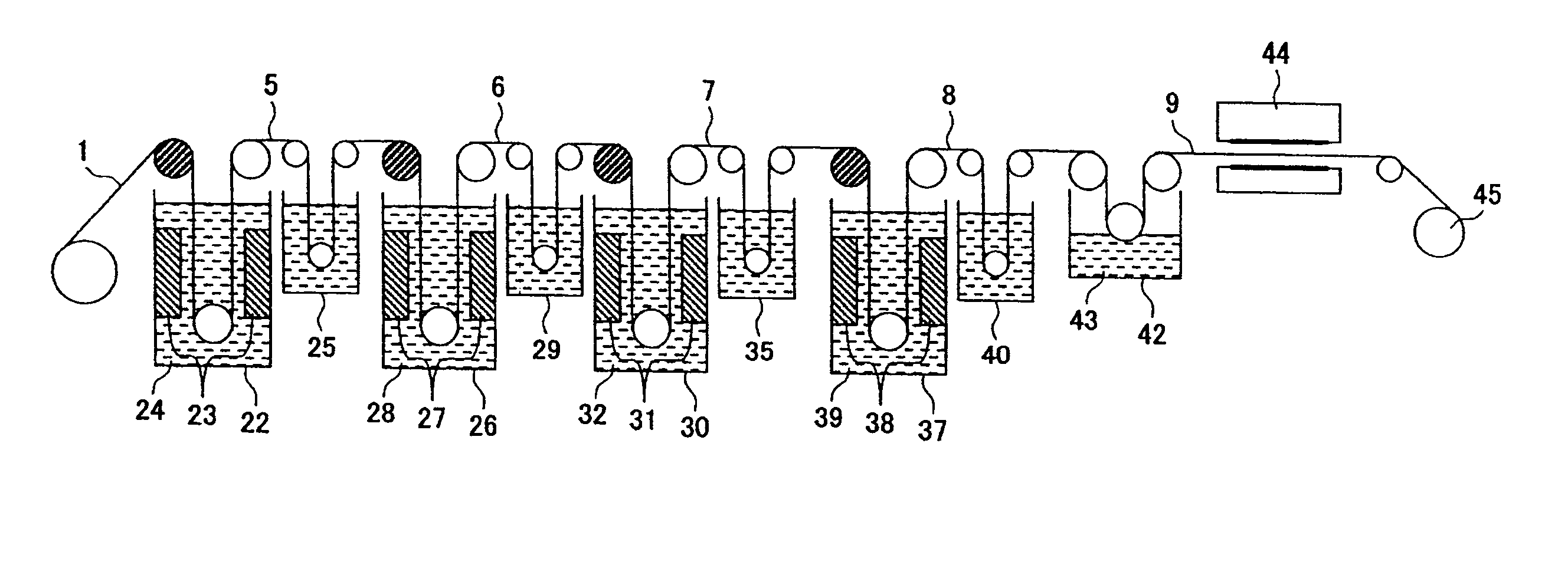

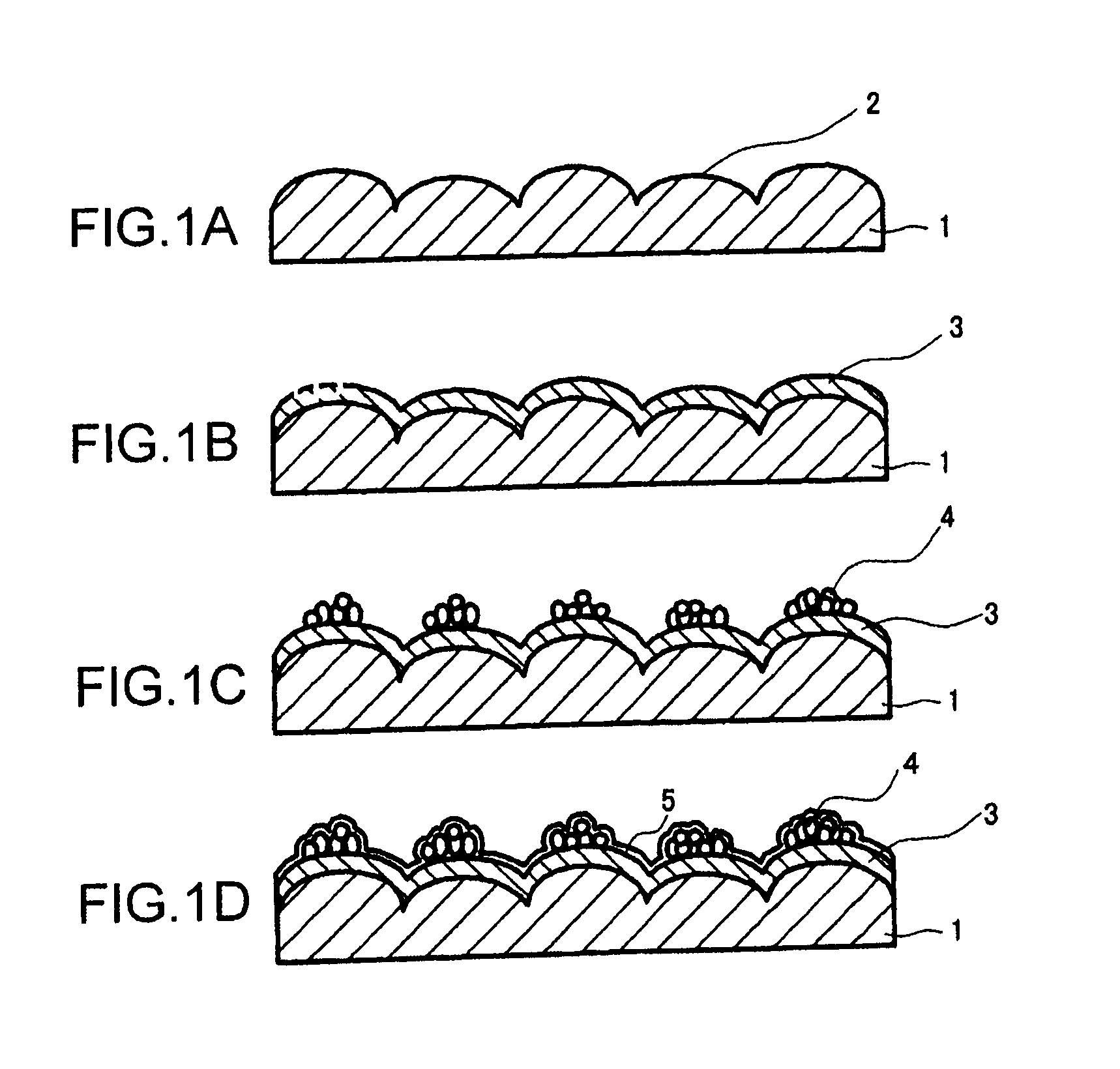

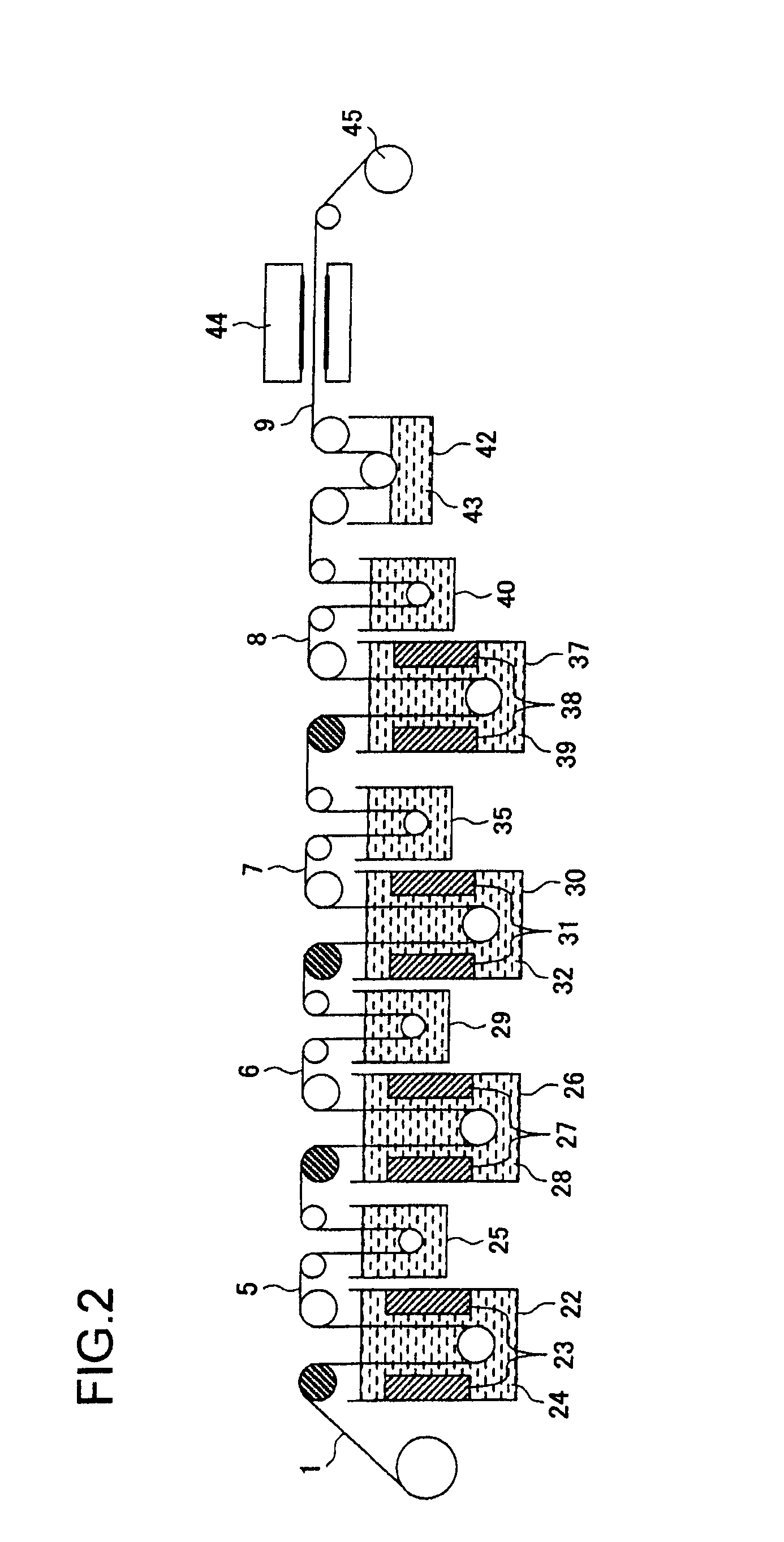

Copper foil with resistance layer, method of production of the same and laminated board

InactiveUS20120111613A1Suitable elasticitySuitable plasticityChromatisationPrinted circuit aspectsElectrical resistance and conductanceAlloy

A copper foil with a resistance layer is provided, wherein the variation value is small when it is made into a resistance element, the adhesion with the resin substrate to be laminated with is able to be sufficiently maintained, which has an excellent characteristics as a resistance element for a rigid and a flexible substrate. A copper foil with a resistance layer of the present invention comprises a copper foil on one surface of which a metal layer or alloy layer is formed from which a resistance element is to be formed, the surface of the metal layer or alloy layer being subjected to a roughening treatment with nickel particles. A method of production of a copper foil with a resistance layer of the present invention comprises: forming a resistance layer of phosphorus-containing nickel on a matte surface of an electrodeposited copper foil having crystals comprised of columnar crystal grains wherein a foundation of the matte surface is within a range of 2.5 to 6.5 μm in terms of Rz value prescribed in JIS-B-0601; and performing roughening treatment to a surface of the resistance layer with nickel particles wherein a roughness is within a range of 4.5 to 8.5 μm in terms of Rz value prescribed in JIS-B-0601. The alloy layer is for example formed from phosphorus-containing nickel.

Owner:FURUKAWA ELECTRIC CO LTD

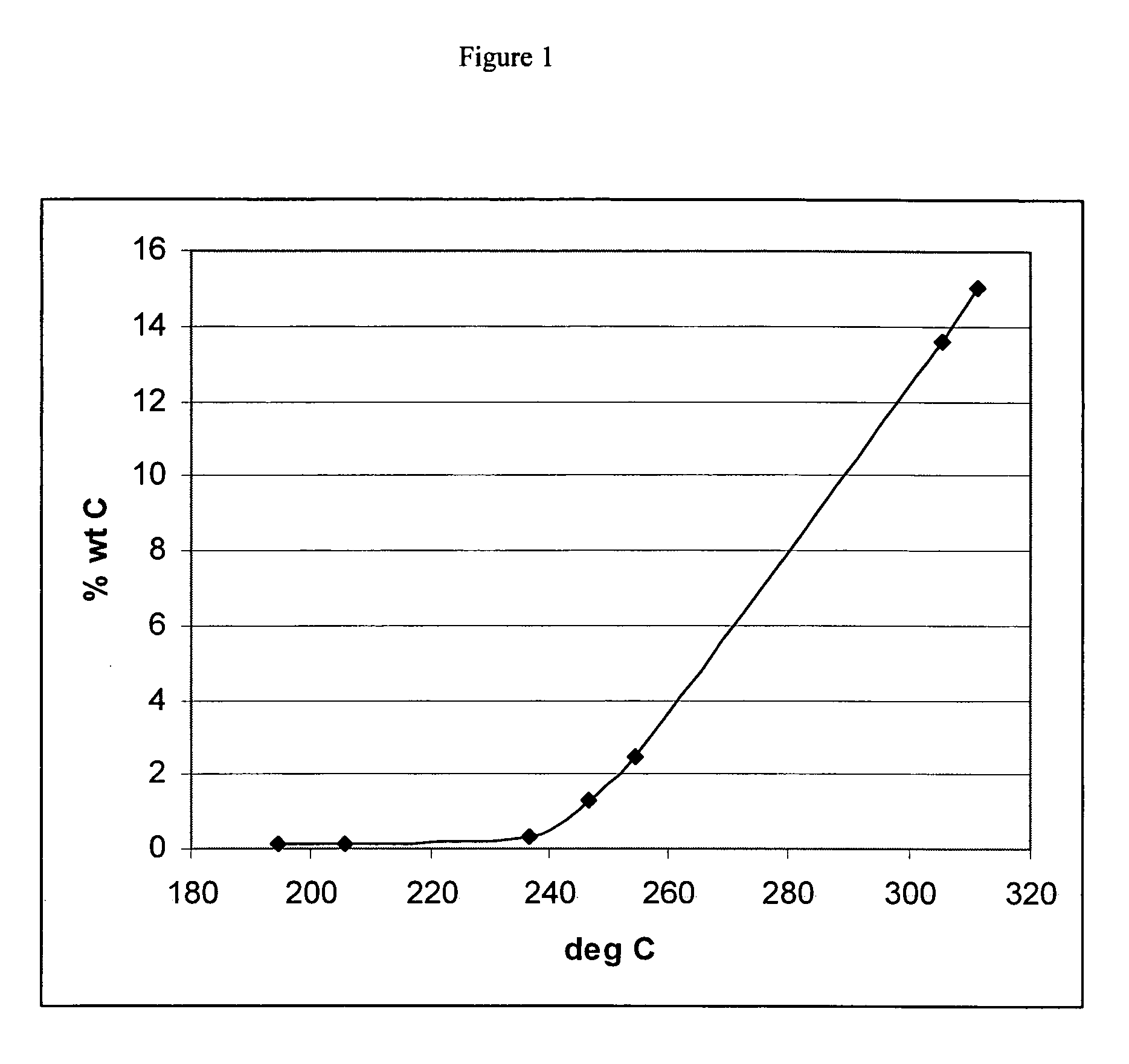

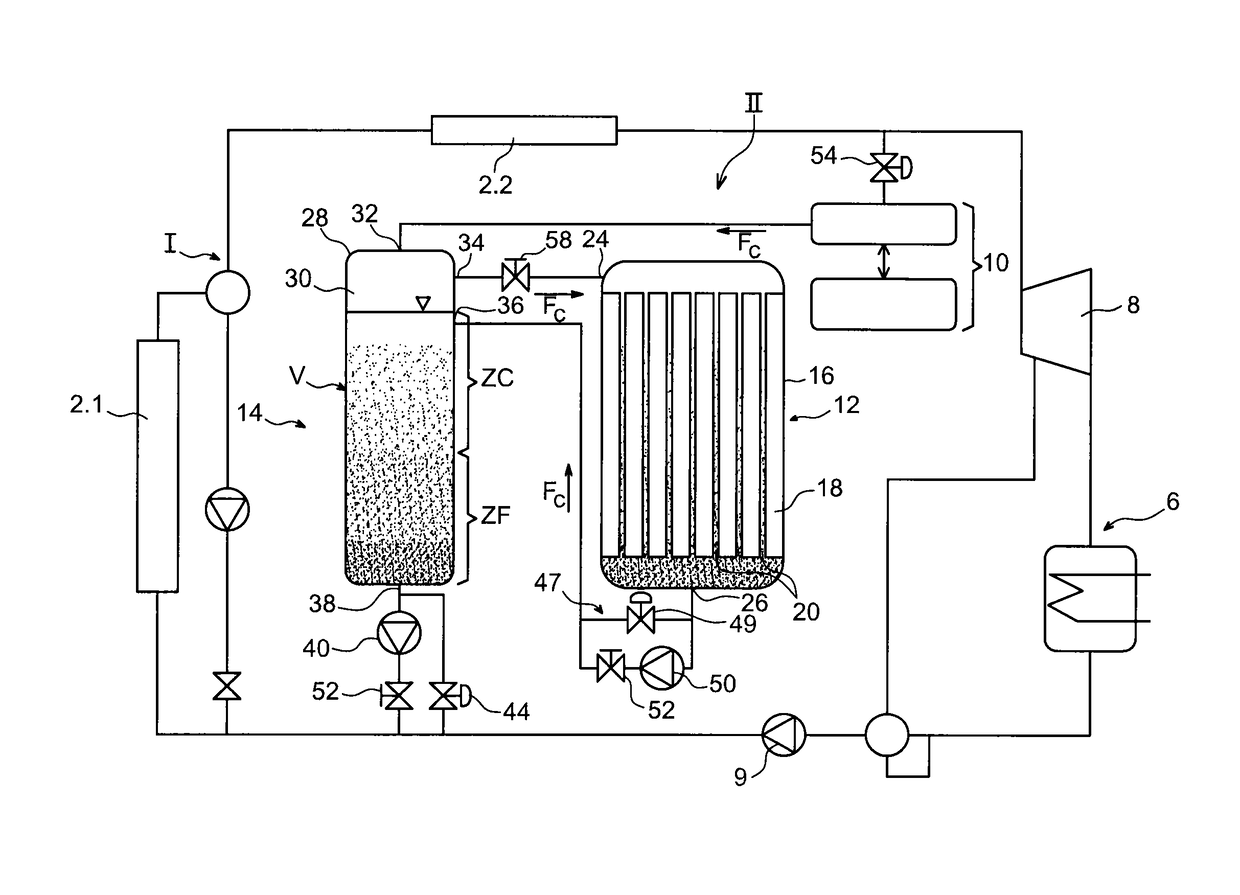

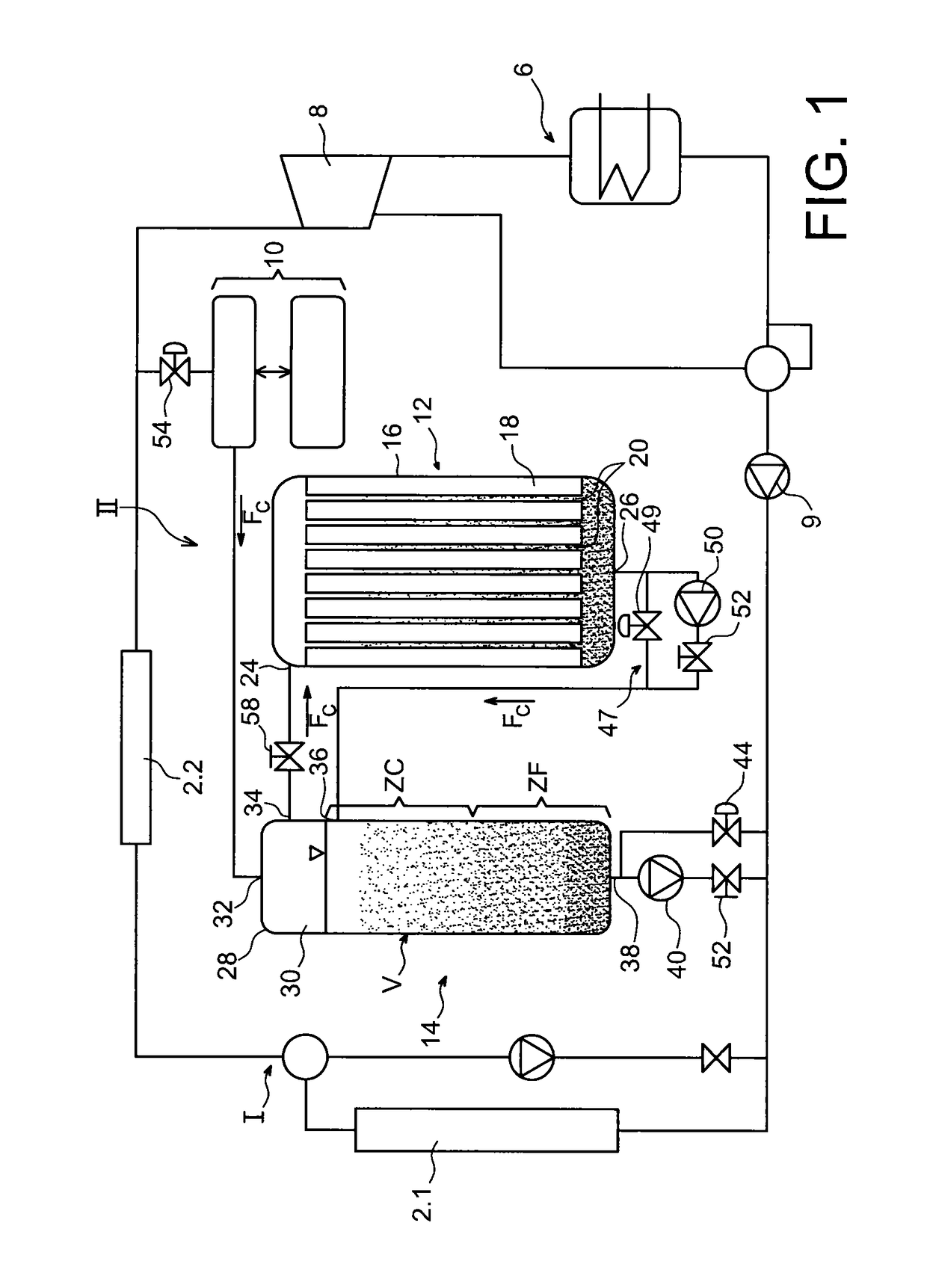

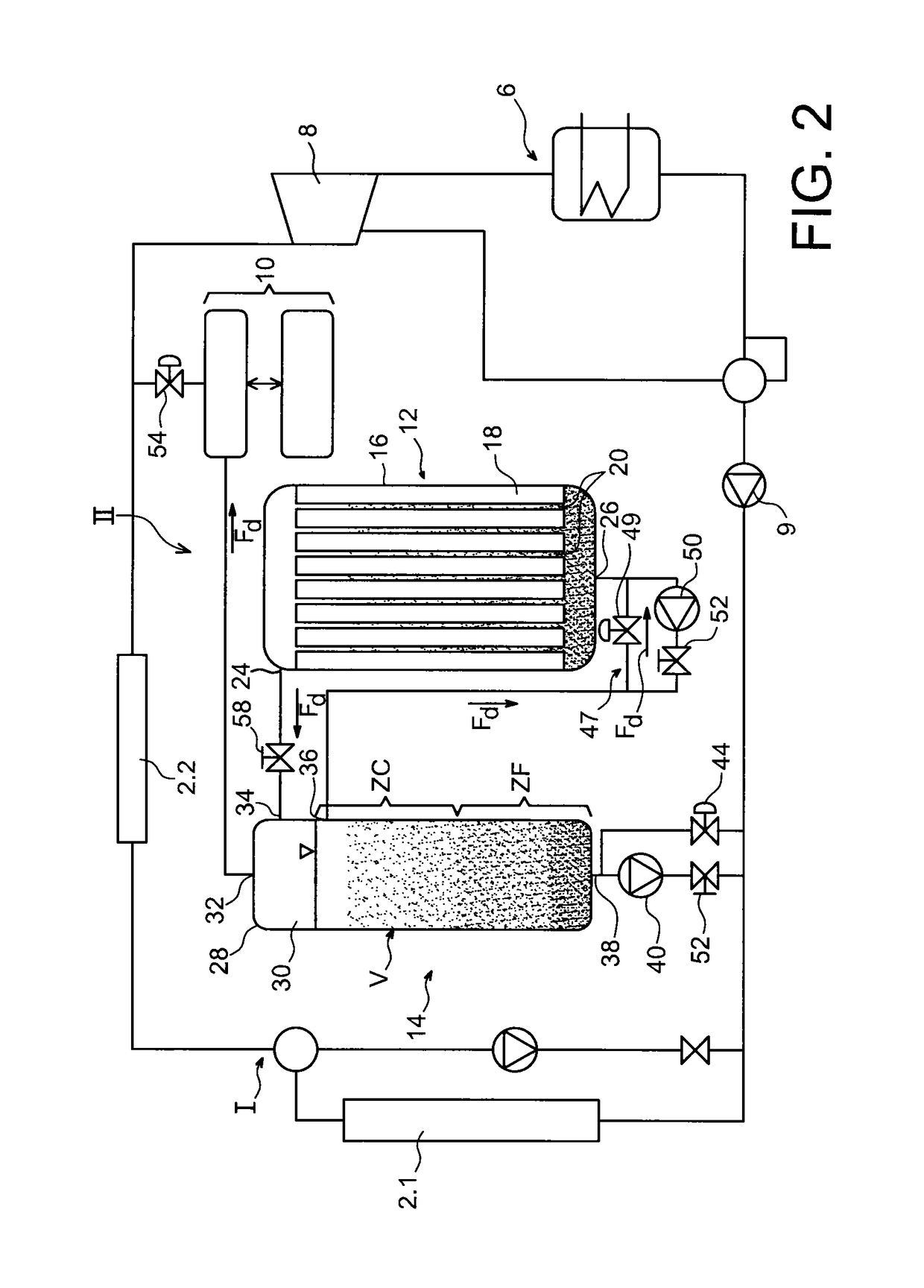

Oligomerisation of Olefins

ActiveUS20090221862A1Not to damageImprove cooling effectHydrocarbons from unsaturated hydrocarbon additionHydrocarbonsPhosphoric acidAlkene

Olefin feeds with high olefin content and / or containing a substance that generates water when contacting the catalyst, are oligomerised over solid phosphoric acid catalyst in tubular reactors by introducing the olefin feed into the reactor and maintaining the reacting mixture under conditions whereby the peak temperature is controlled to be below 265° C. and preferably a single liquid or dense phase is maintained and the average temperature throughout the reactor is maintained in the range 190° C. to 260° C.

Owner:EXXONMOBIL CHEM PAT INC

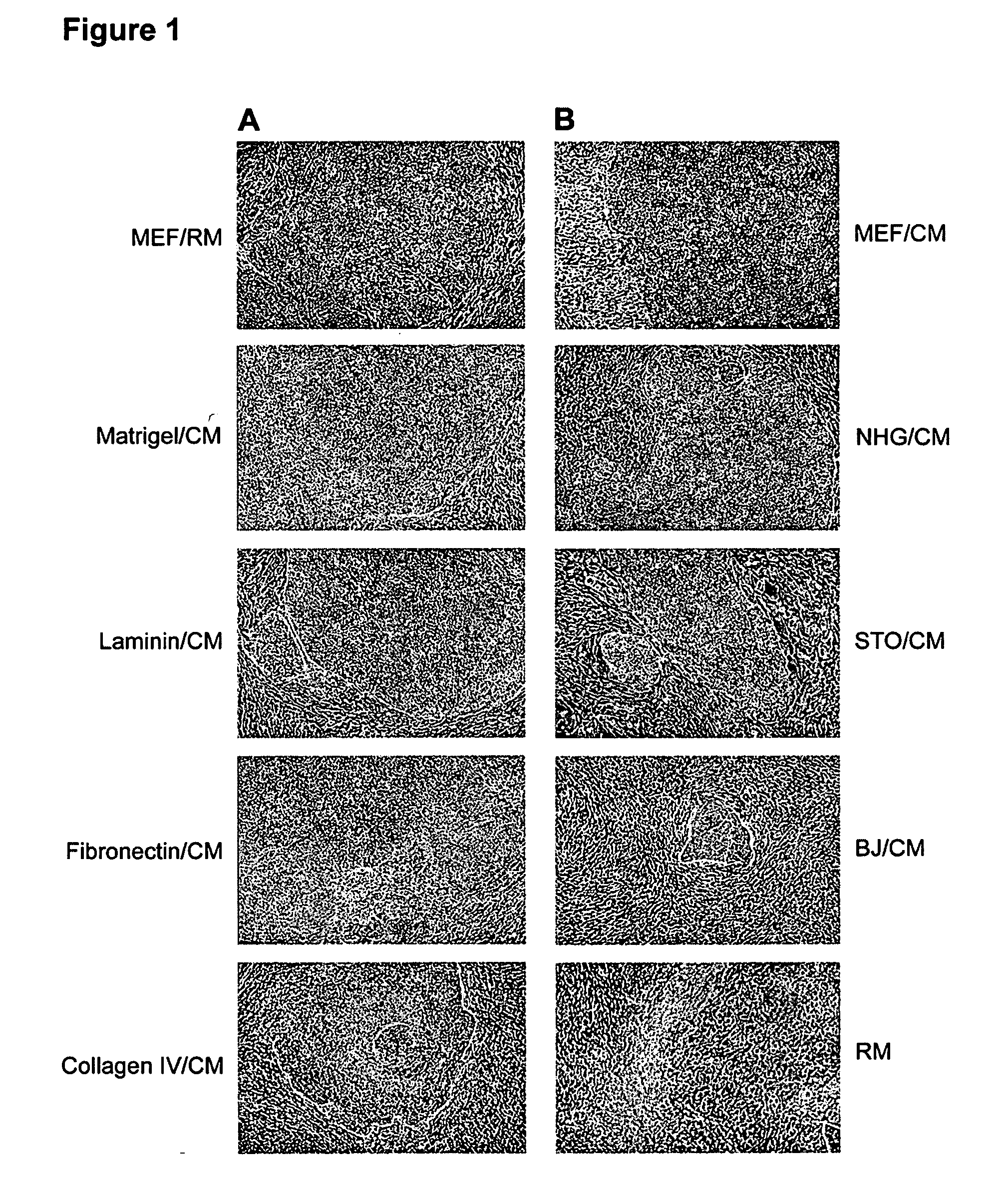

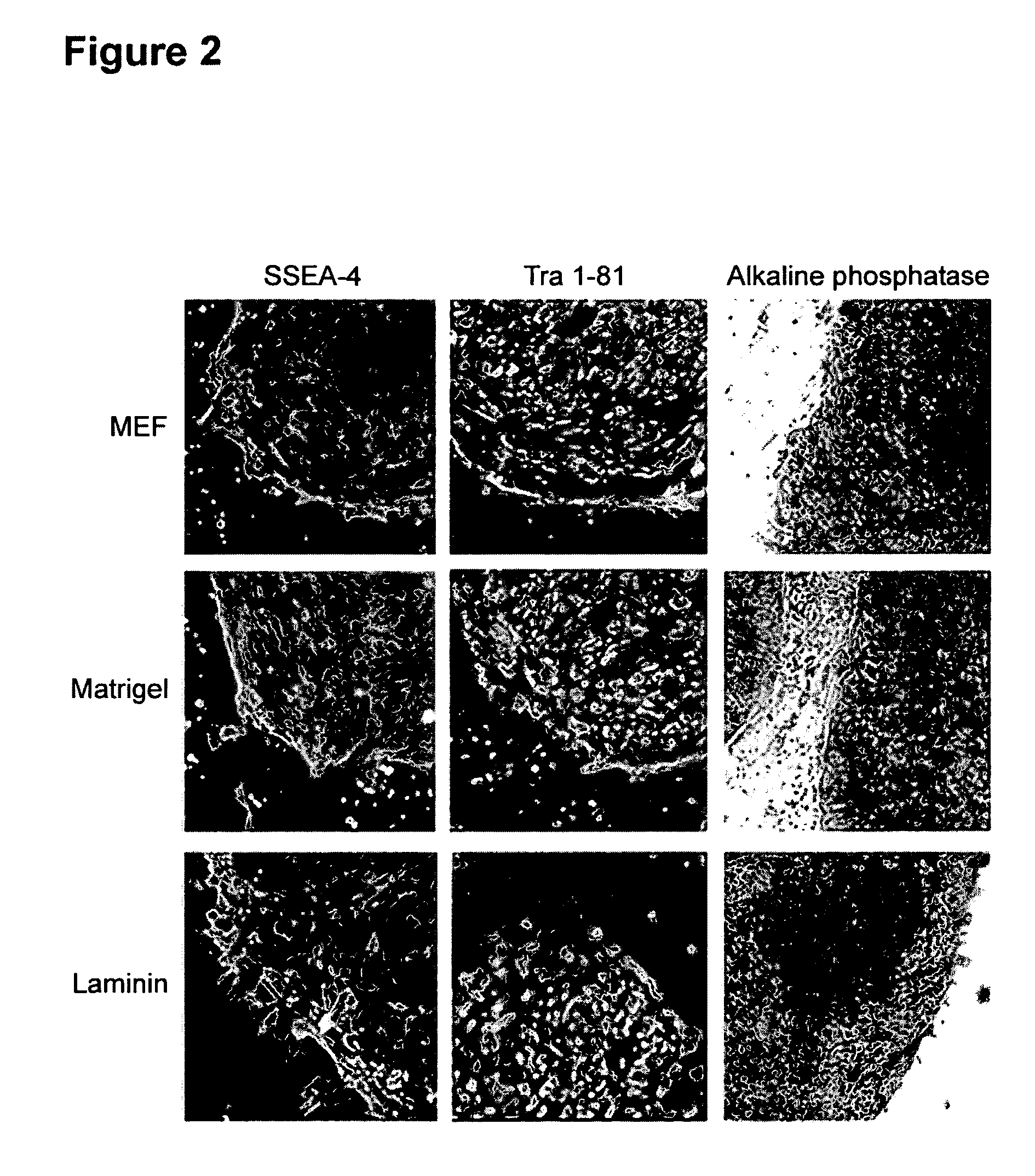

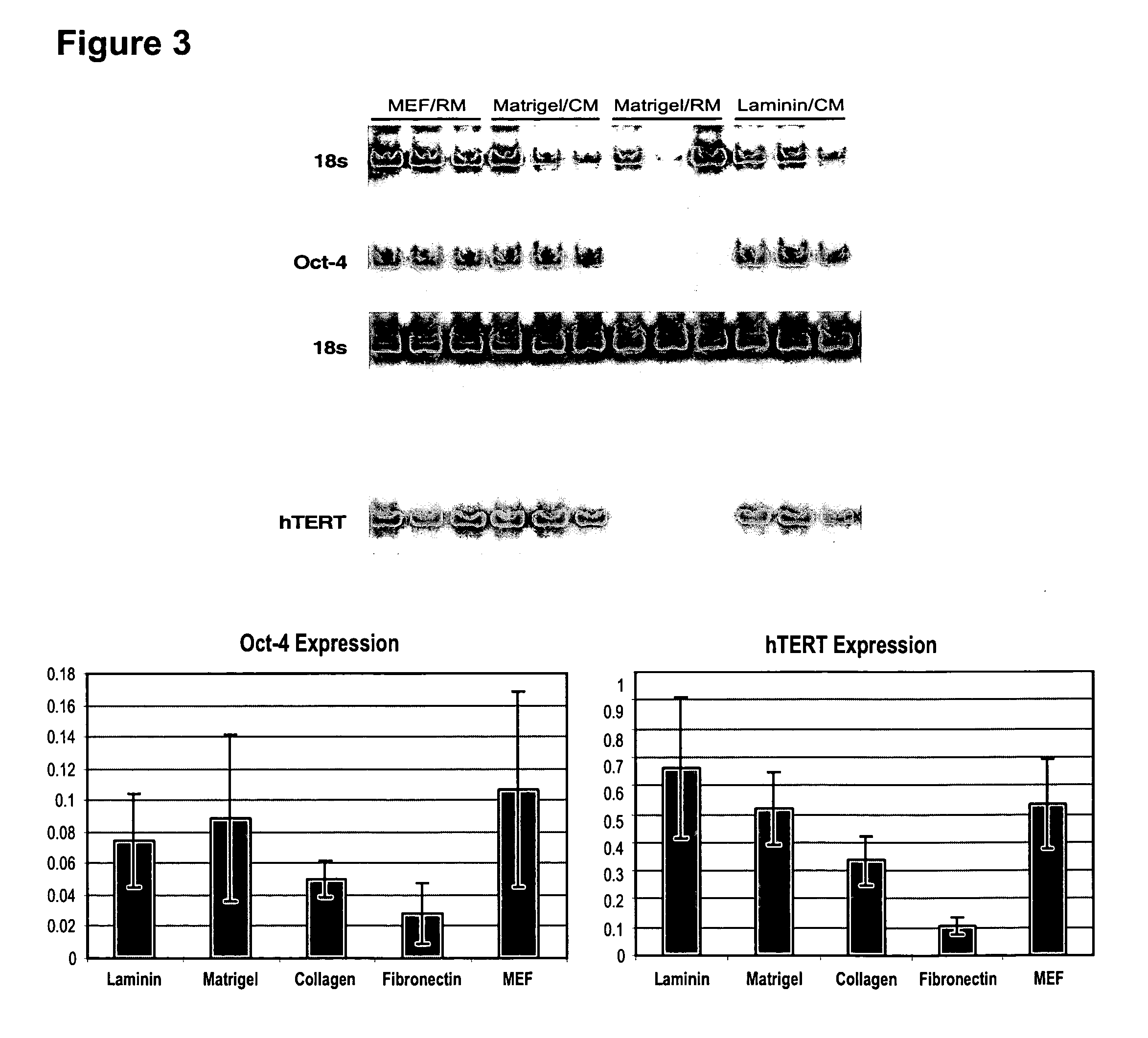

Using fibroblast growth factor to establish a line of embryonic stem cells

InactiveUS20050153444A1Rapid productionSimple systemHepatocytesGastrointestinal cellsGerm layerPluripotential stem cell

This disclosure provides an improved system for culturing human pluripotent stem cells. Traditionally, pluripotent stem cells are cultured on a layer of feeder cells (such as mouse embryonic fibroblasts) to prevent them from differentiating. In the system described here, the role of feeder cells is replaced by components added to the culture environment that support rapid proliferation without differentiation. Effective features are a suitable support structure for the cells, and an effective medium that can be added fresh to the culture without being preconditioned by another cell type. Culturing human embryonic stem cells in fresh medium according to this invention causes the cells to expand surprisingly rapidly, while retaining the ability to differentiate into cells representing all three embryonic germ layers. This new culture system allows for bulk proliferation of pPS cells for commercial production of important products for use in drug screening and human therapy.

Owner:ASTERIAS BIOTHERAPEUTICS INC

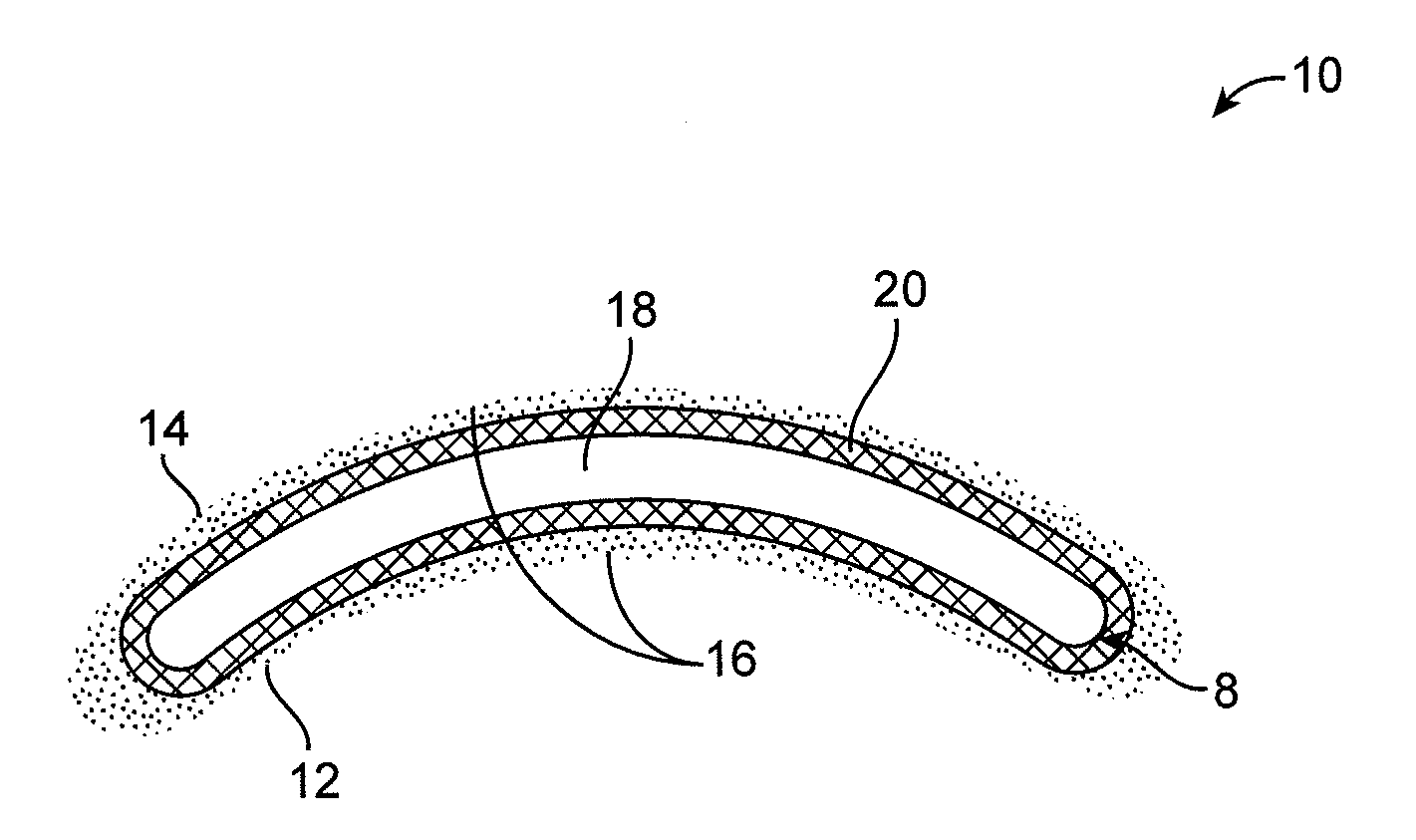

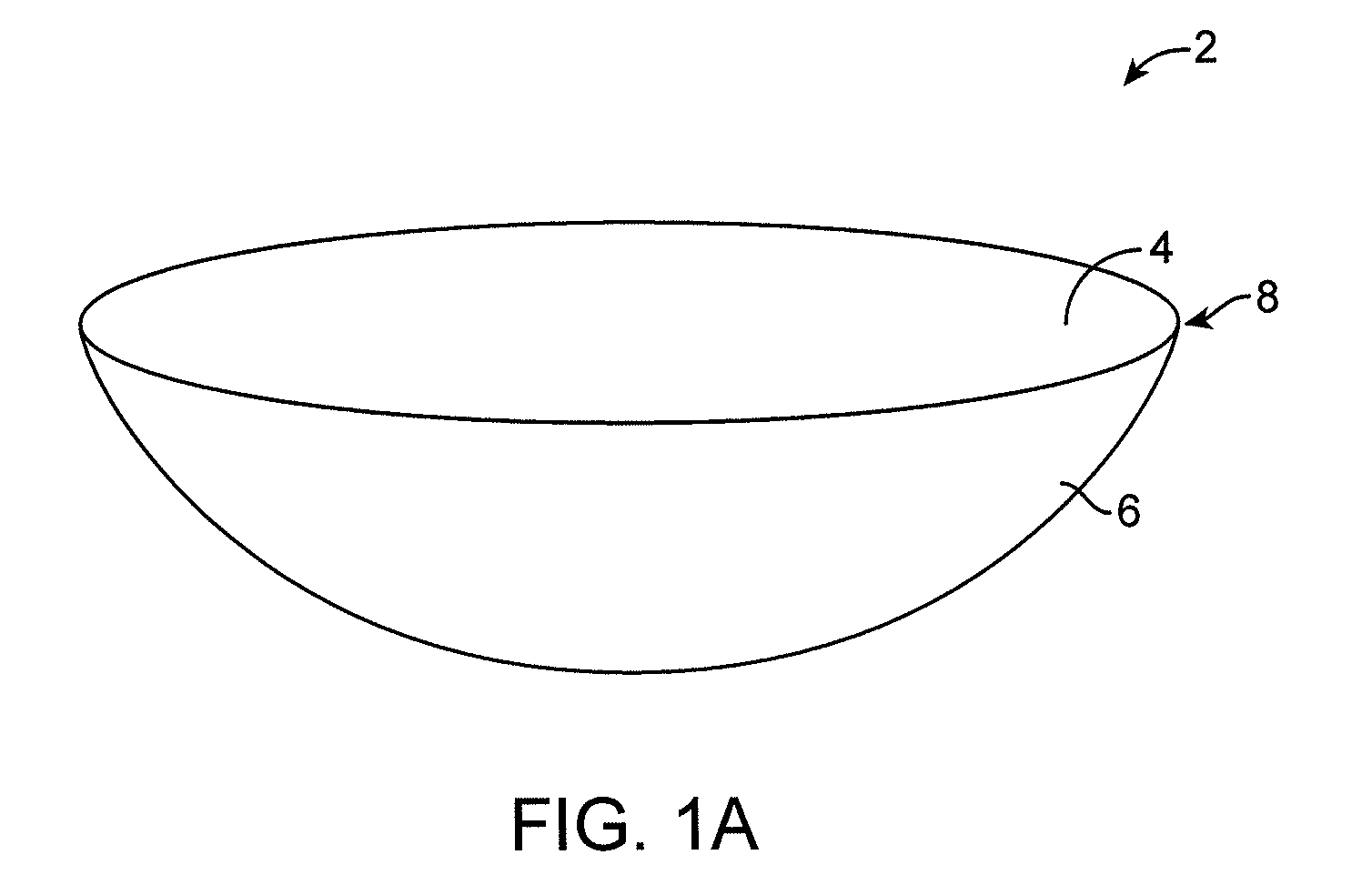

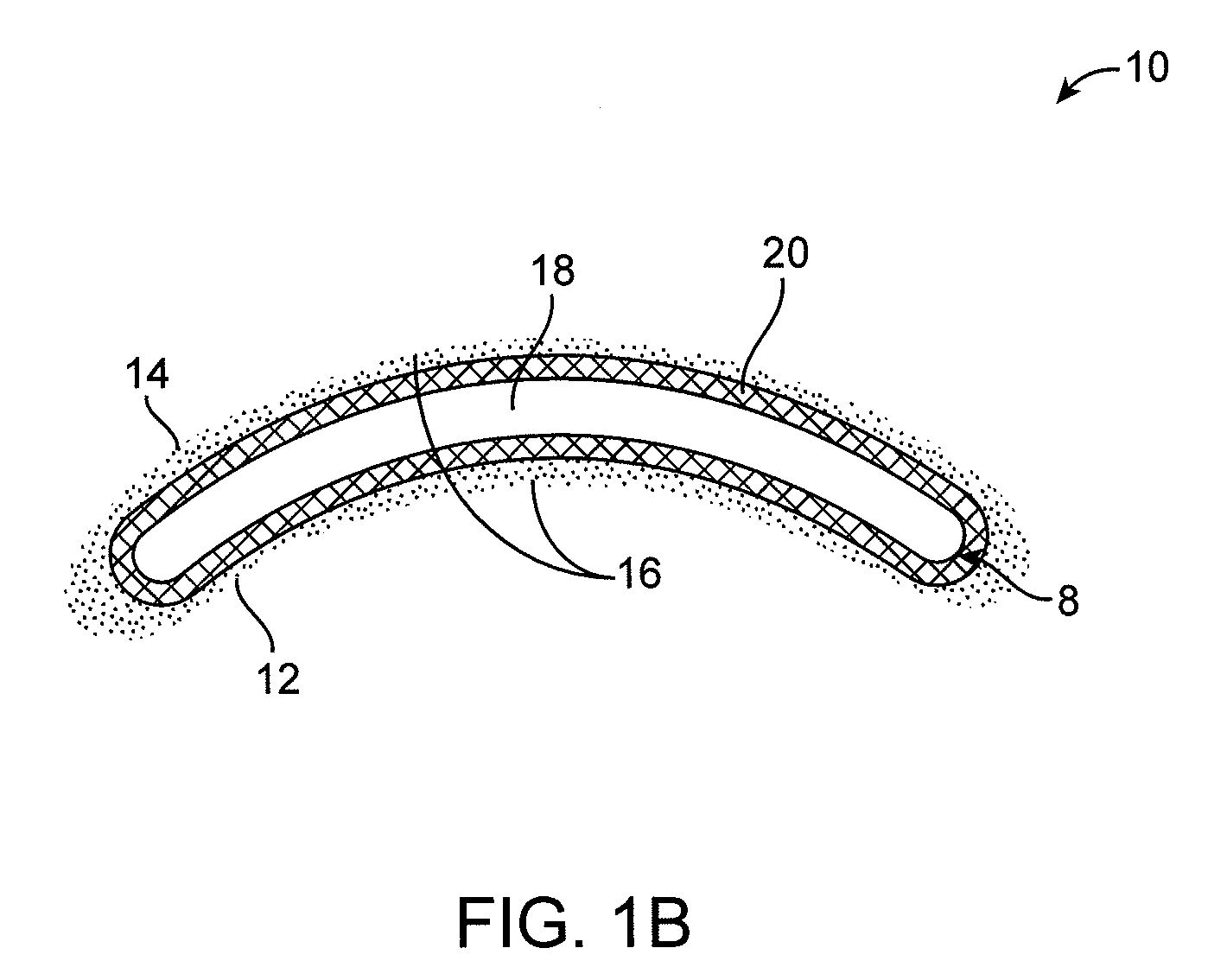

Contact lens with a hydrophilic layer

ActiveUS9310627B2Maintain the health of the ophthalmic surface and wearer comfortMaintain sufficiencySpectales/gogglesOptical articlesRigid gas permeable lensHydrophilic polymers

Embodiments of the technology relate to a contact lens having a core that is coated by a hydrogel layer, and to methods of making such a lens. The coated lens can include a rigid gas permeable contact lens. The coated lens can also include a hybrid silicone and rigid gas permeable contact lens. In one aspect, embodiments provide for a coated contact lens comprising a lens core with a water equilibrium constant of less than about 2% comprising an outer surface; and a hydrogel layer covalently attached to at least a portion of the outer surface, the hydrogel layer adapted to contact an ophthalmic surface, wherein the hydrogel layer comprises a hydrophilic polymer population of one or more species.

Owner:TANGIBLE SCI LLC

Steam heat storage system

ActiveUS9683788B2Improve reliabilityImprove efficiencySolar heating energyFrom solar energySolar fieldSolar plant

A solar plant including a solar field for production of steam, a turbine using steam, and an excess steam storage and draw off system. The system includes a latent heat thermal storage module and a liquid displacement thermal storage module including a liquid volume and a steam blanket. The modules are connected together so that the steam produced passes through the steam blanket before passing through the latent heat module, condensing, to be injected in the liquid volume, the lower part of the liquid volume being connected to the solar field and to an outlet of the turbine to let in or return cold liquid. The liquid volume acts as a liquid displacement reservoir.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Display package with stabilizing and indexing means

ActiveUS7410056B2Provide stabilityImprove package stabilityRacksOther accessoriesDisplay deviceEngineering

A blister pack and package including such blister pack is described which provides for package stability and self-indexing in relation to adjacently aligned packages. The blister pack is configured to include at least one compartment for enclosing an article, and an outward projecting portion or foot in the bottom portion of the blister pack. The foot is configured to have a width, depth and height sufficient to allow the package to be freestanding and self-indexing. The package is especially suited for use in a merchandise point-of-sale display including a pressure applicator for maintaining displayed packages in a forwardmost position in the display when one or more packages are removed from the display. The foot provides for a predetermined stable spacing during packaging and while in storage and on display, and provides for self-indexing, i.e. maintenance of proper spacing, when a pressure applicator moves the aligned packages forward in a display.

Owner:SC JOHNSON & SON INC

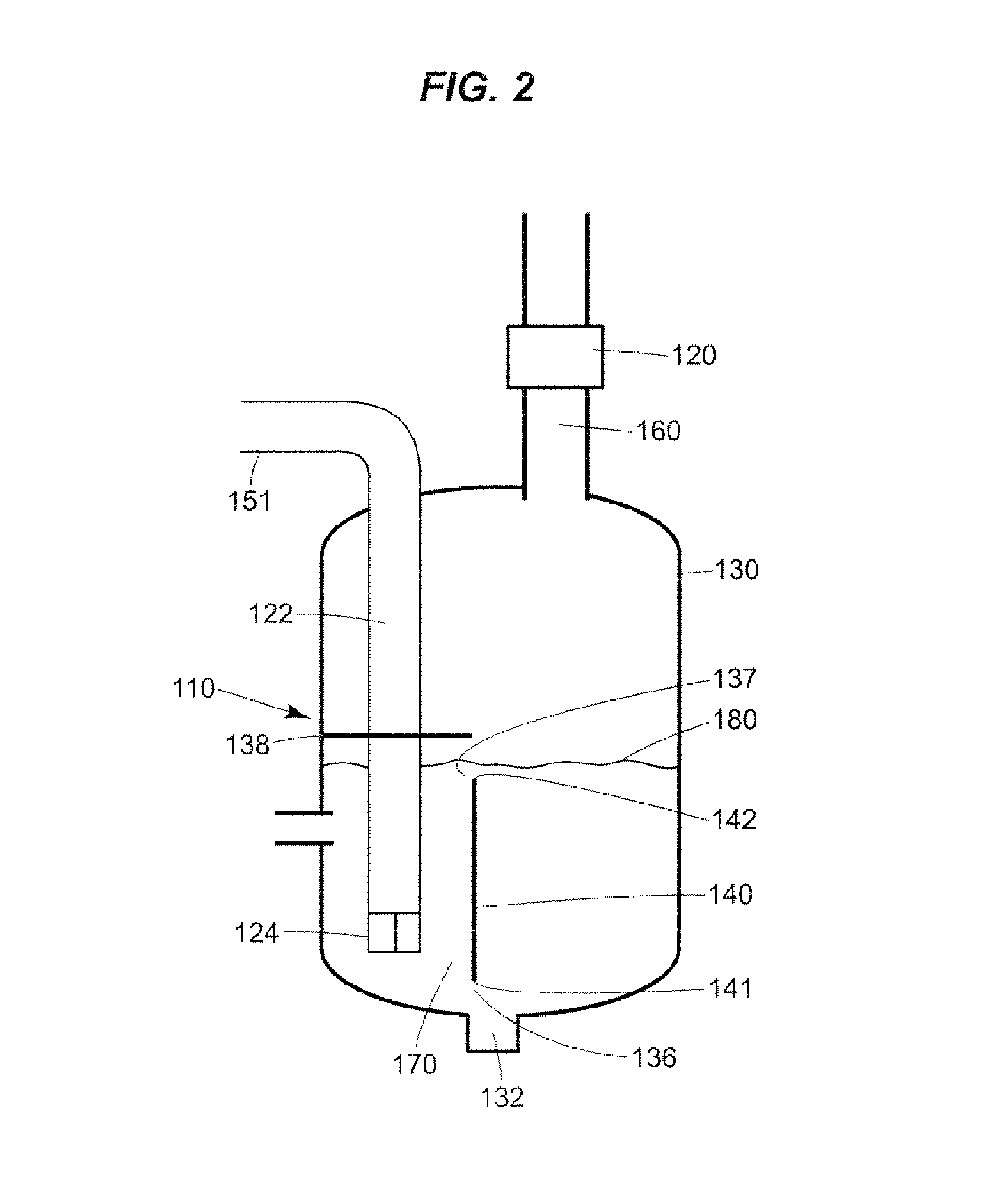

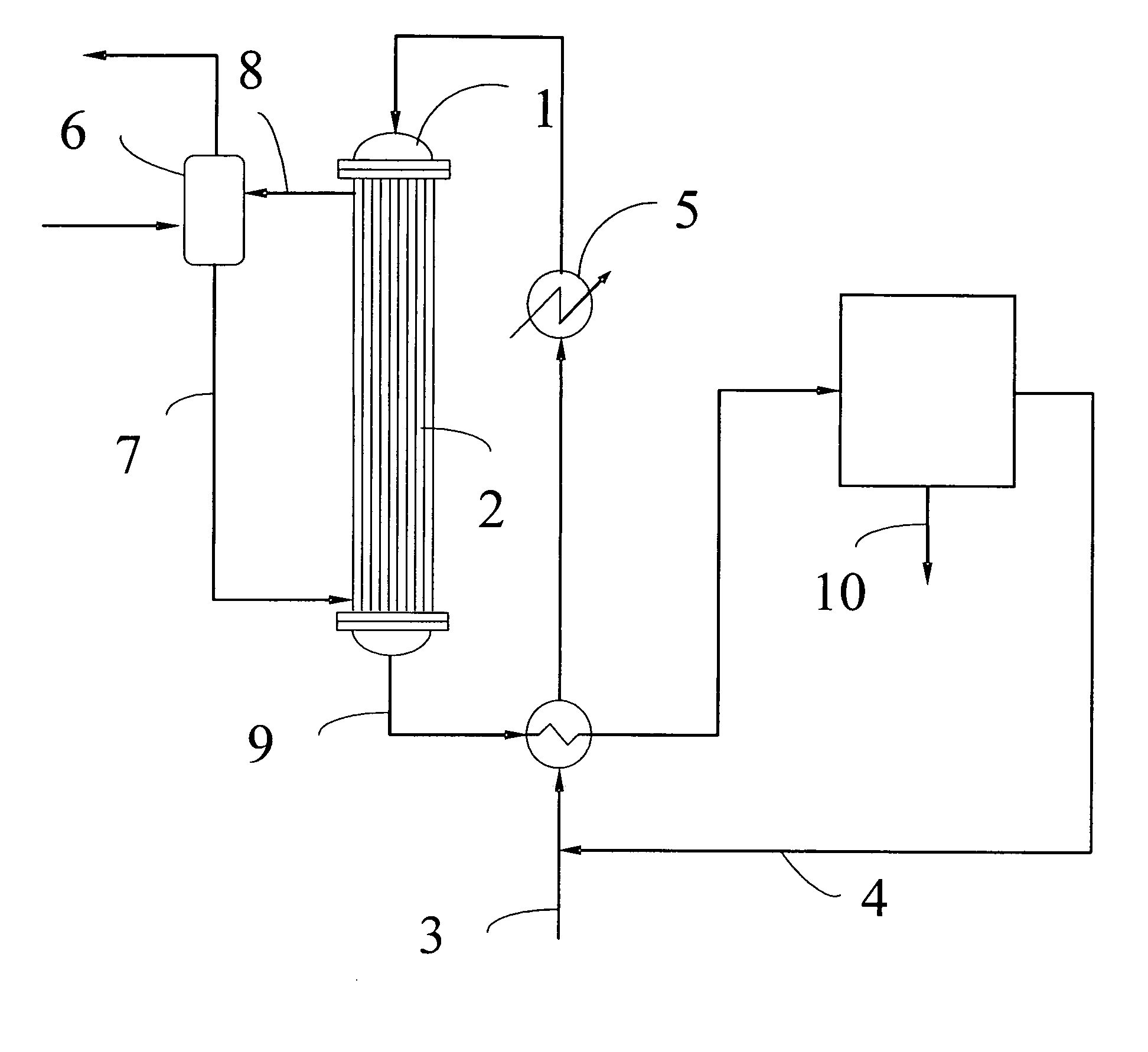

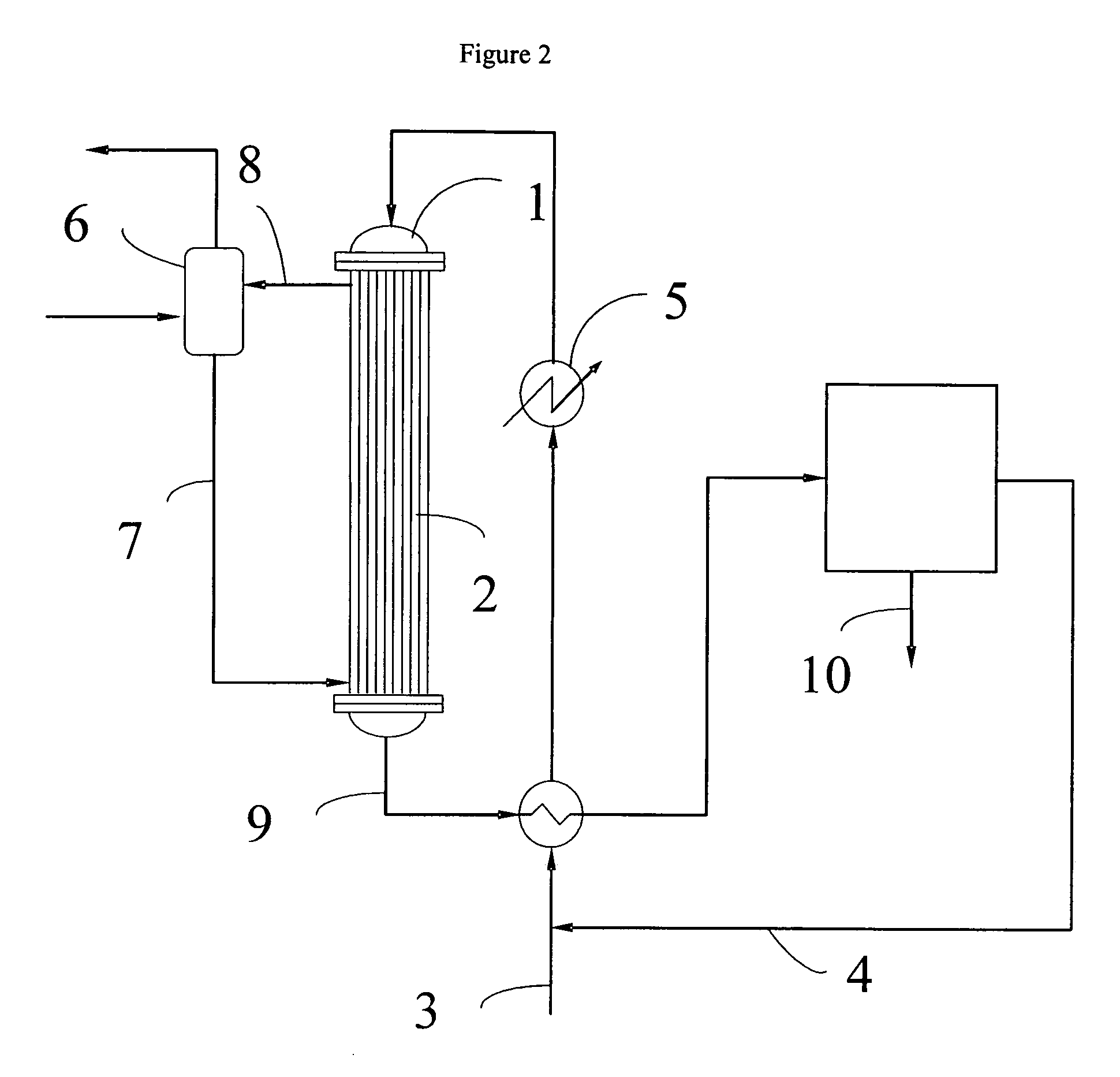

Cooling tower

InactiveUS20080173031A1Enhanced mixing processReduce cloggingCarburetting airLiquid degasificationHigh rateCooling tower

A cooling tower includes an evaporator vessel, a gas delivery tube partially disposed within the evaporator vessel to deliver a gas into the evaporator vessel and a water inlet that provides water to the evaporator vessel at a rate sufficient to maintain a controlled constant level of water within the evaporator vessel. A weir is disposed within the evaporator vessel adjacent the gas delivery tube to form a first fluid circulation path between a first weir end and a wall of the evaporator vessel and a second fluid circulation path, between a second weir end and an upper end of the evaporator vessel. During operation, gas introduced through the tube mixes with the water and the combined gas and fluid flow at a high rate with a high degree of turbulence along the first and second circulation paths defined around the weir, thereby promoting vigorous mixing and intimate contact between the gas and the water. This turbulent flow develops a significant amount of interfacial surface area between the gas and the water which leads to a more efficient and complete evaporation.

Owner:HEARTLAND TECH PARTNERS

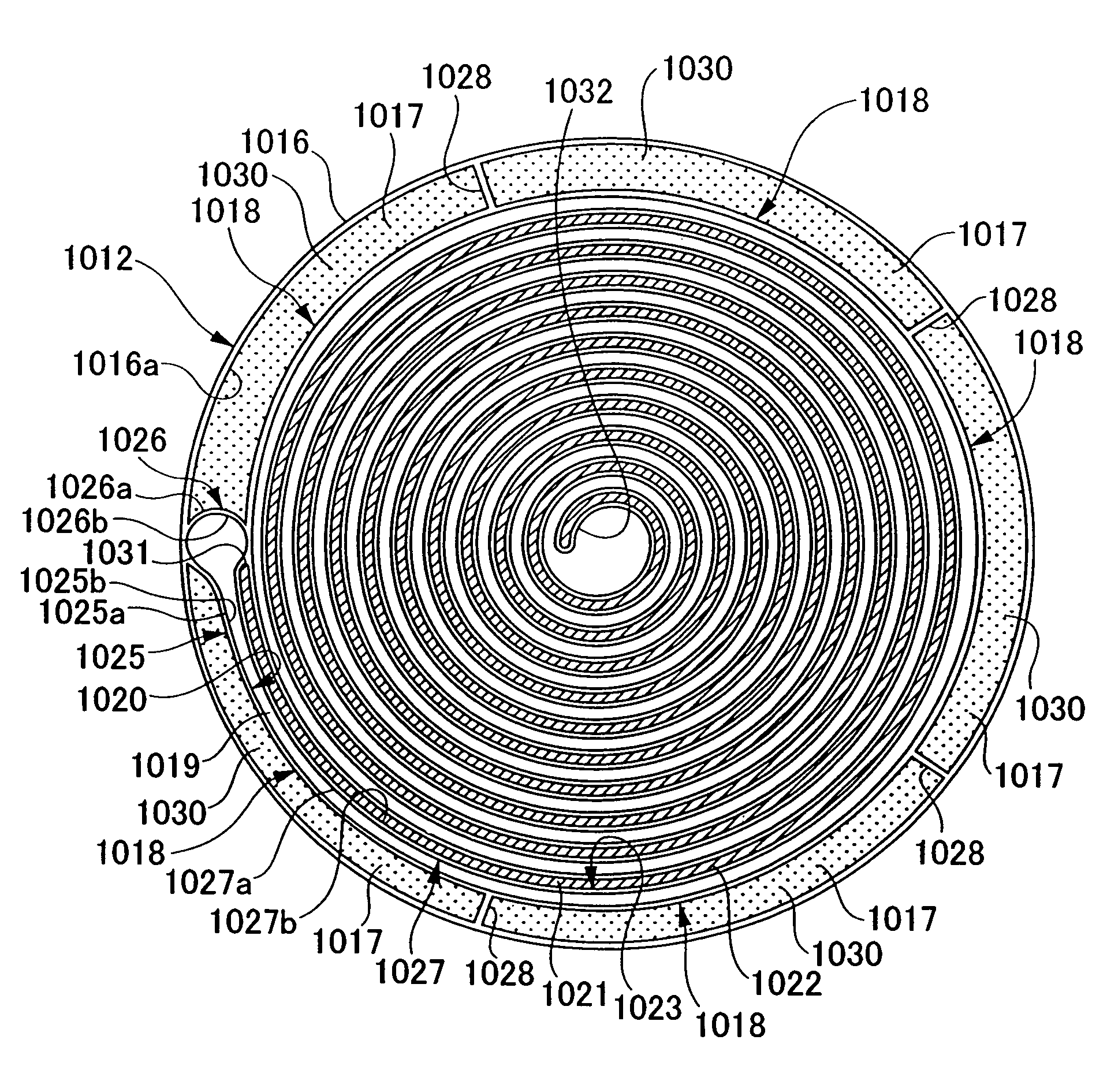

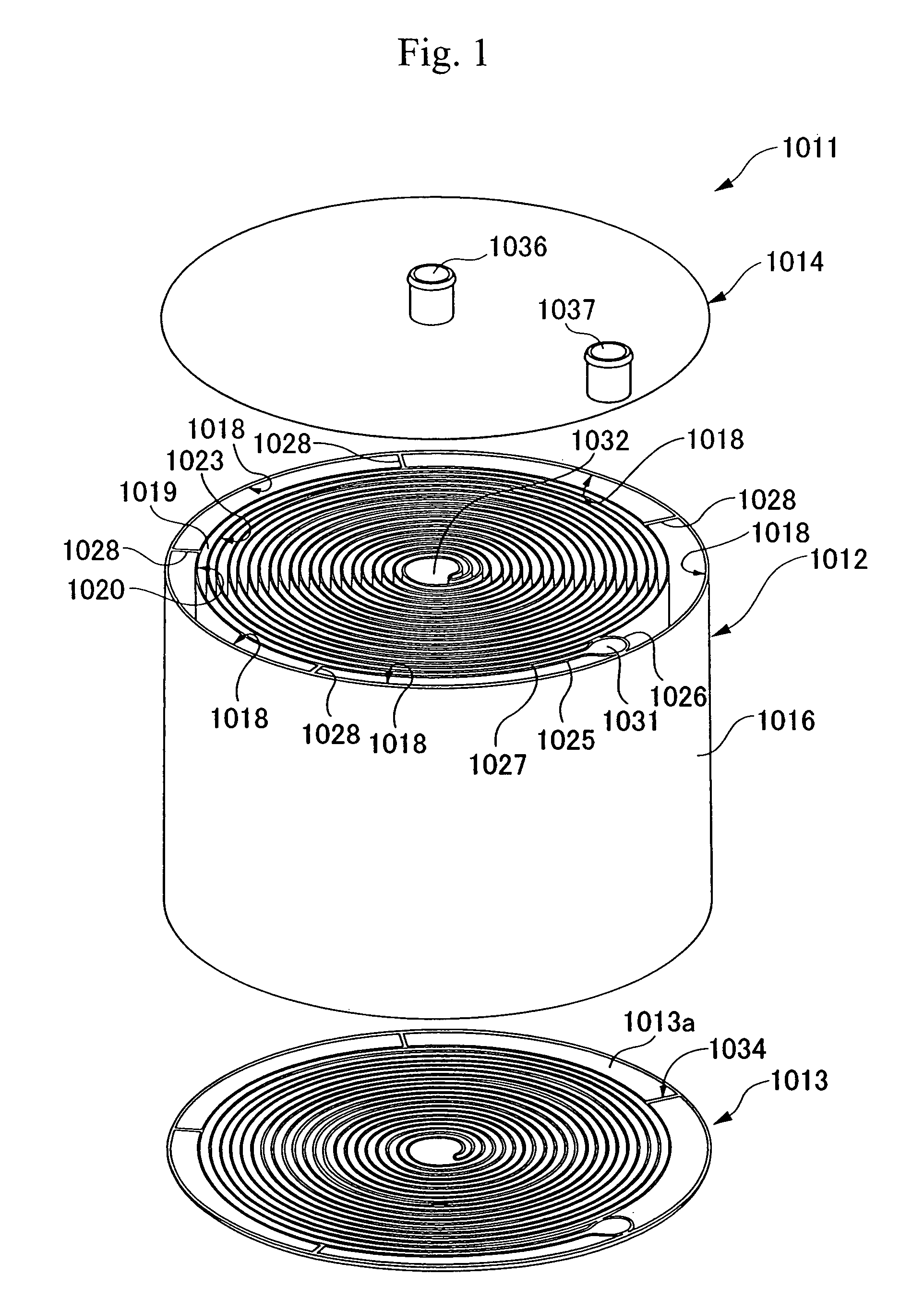

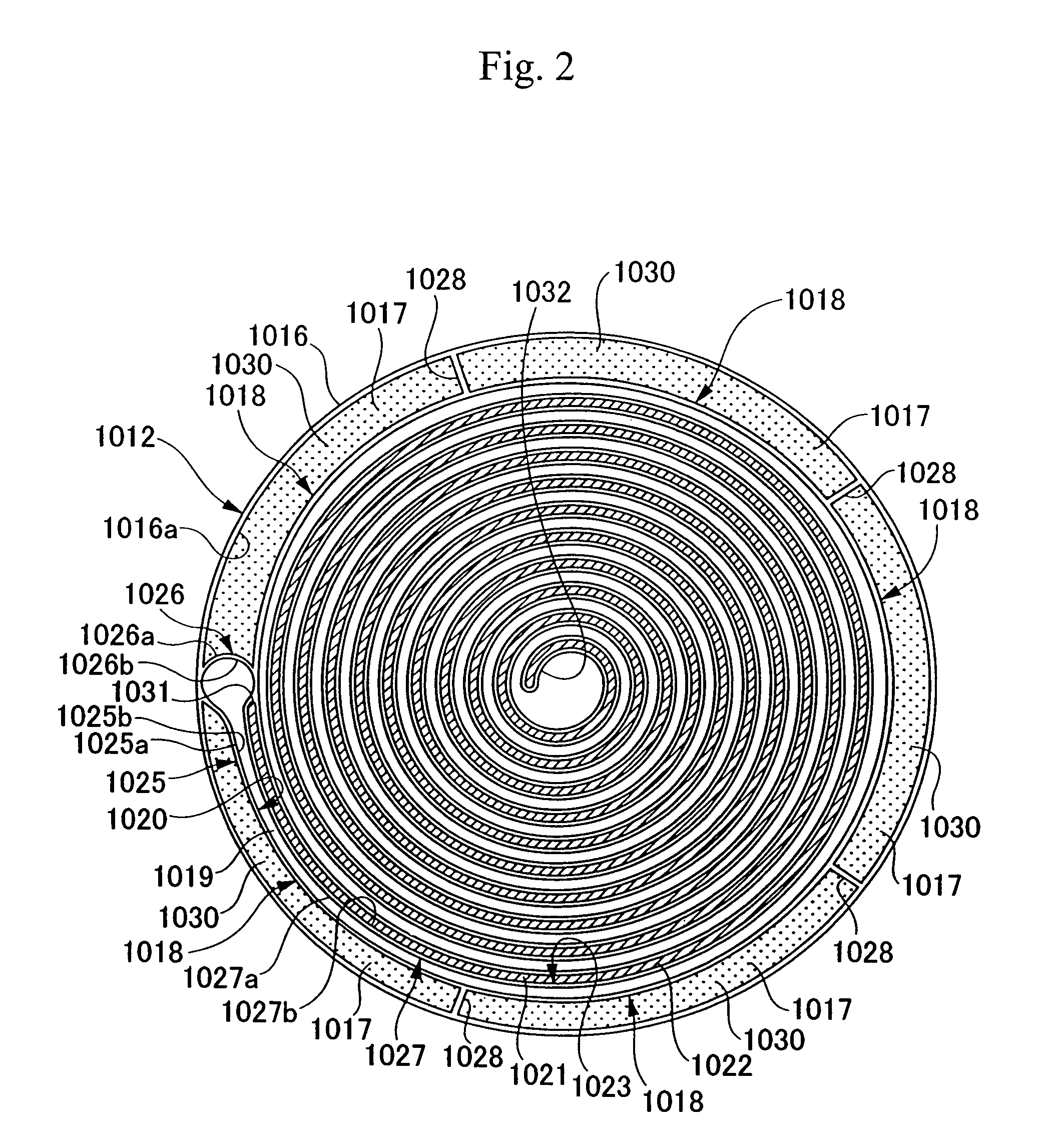

Heat storage unit and manufacturing method therefor

InactiveUS7156155B2Reduce heating capacityReduce heatHeat storage plantsRegenerative heat exchangersVolume variationHeat storage material

As a heat storage unit wherein, the volume variation of a heat storage material can be absorbed without an accompanying decrease in heat capacity, decrease in heat transfer coefficient, and oxidation and deterioration of the heat storage material due to oxygen in the air, so that the heat storage capacity can be adequately maintained and high performance can be attained, and moreover, the number of parts and the cost can be reduced, there is provided on the outside of a main member having; a fluid passage formation section which forms a fluid passage for circulating a fluid introduced from an inlet, on the inside of an outer wall section, and a heat storage material filling space formation section which forms a heat storage material filling space for filling with a heat storage material for which the volume varies corresponding to the heat storage condition, adjacent to the fluid passage, a passage switching section which selectively switches a flow-in destination of a fluid introduced from the inlet by the position of a travelling member which travels due to the volume variation of the heat storage material, to the fluid passage or to a bypass passage which bypasses the fluid passage to discharge the fluid.

Owner:HONDA MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com