Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

165 results about "Solid immersion lens" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

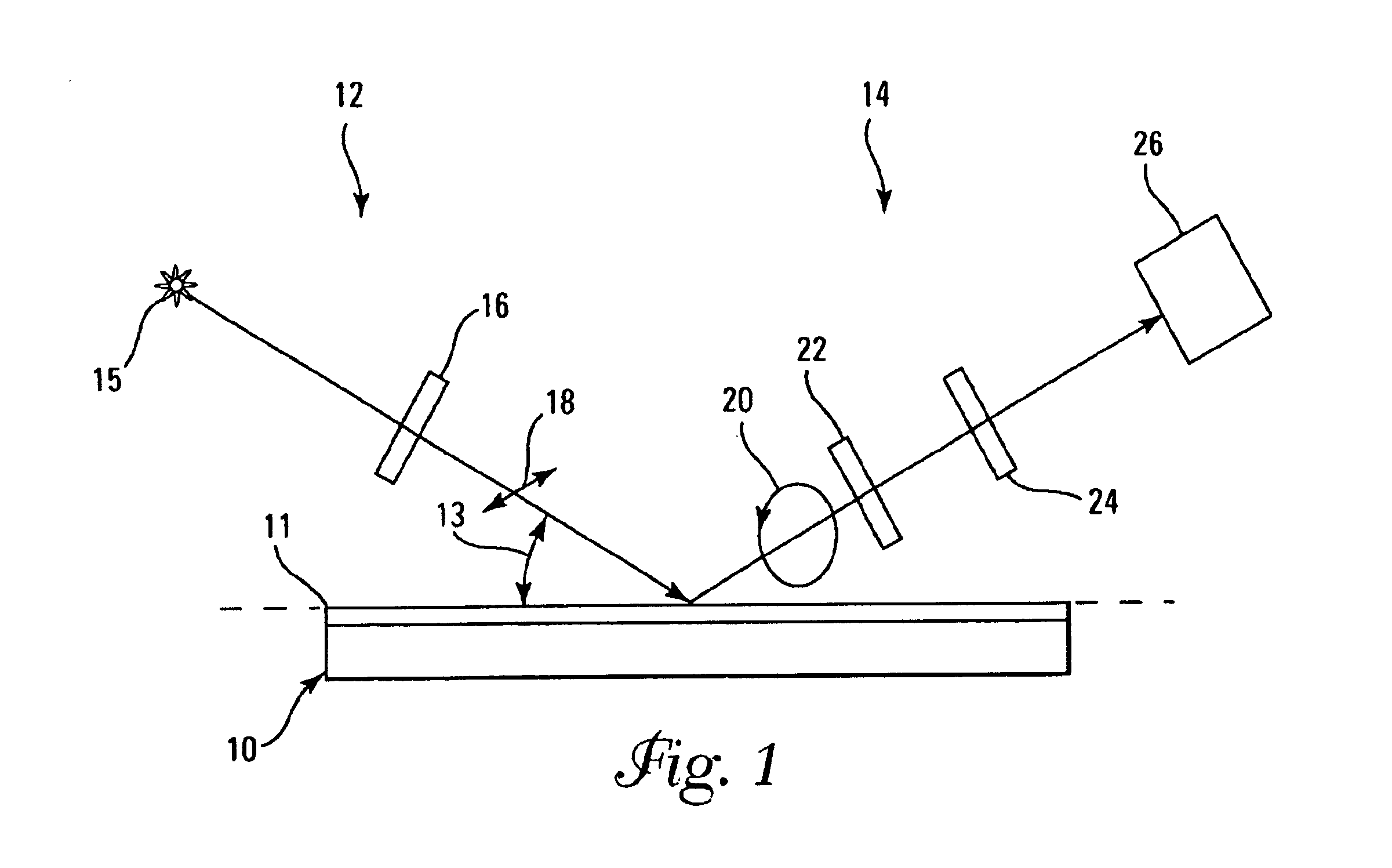

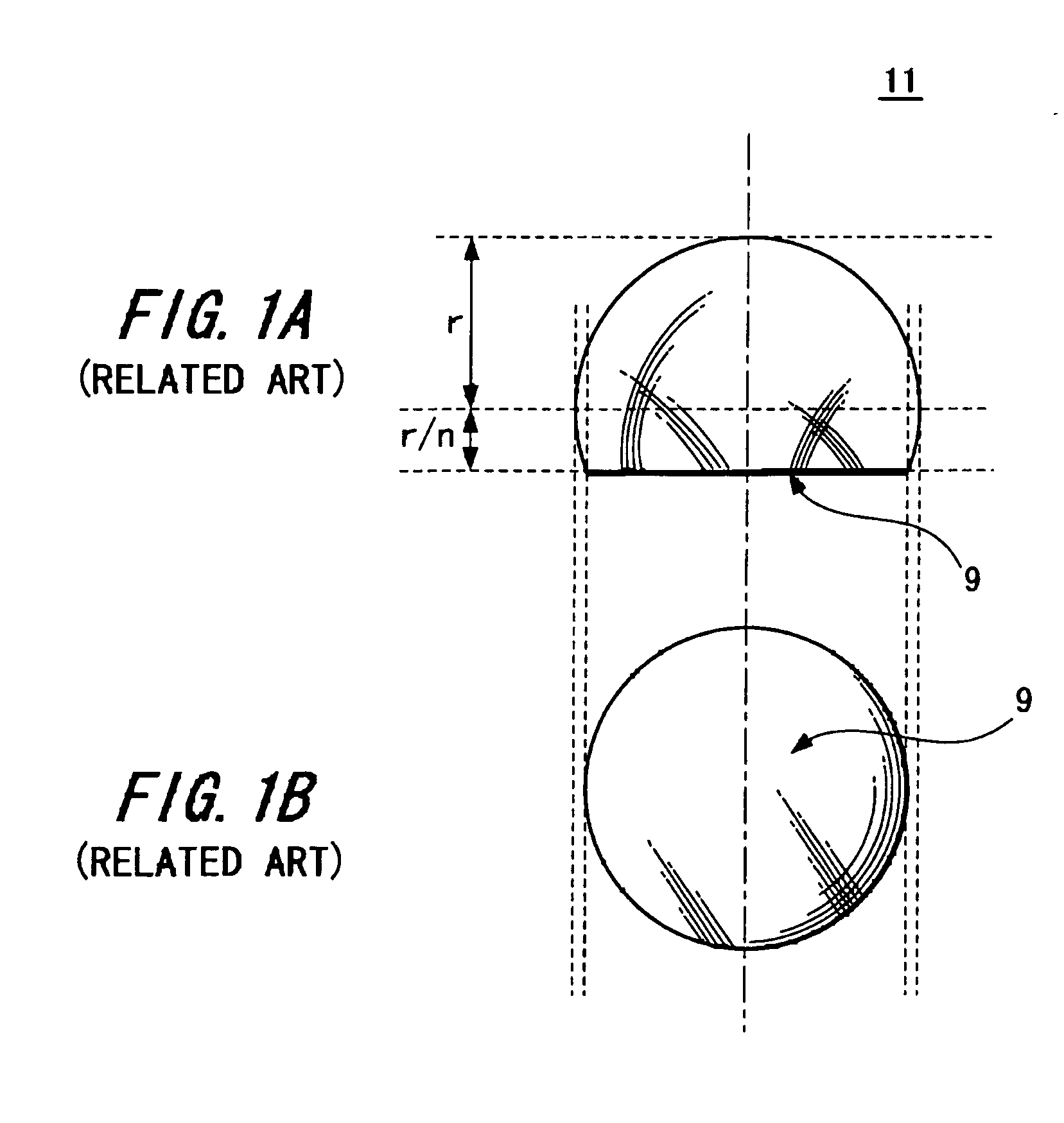

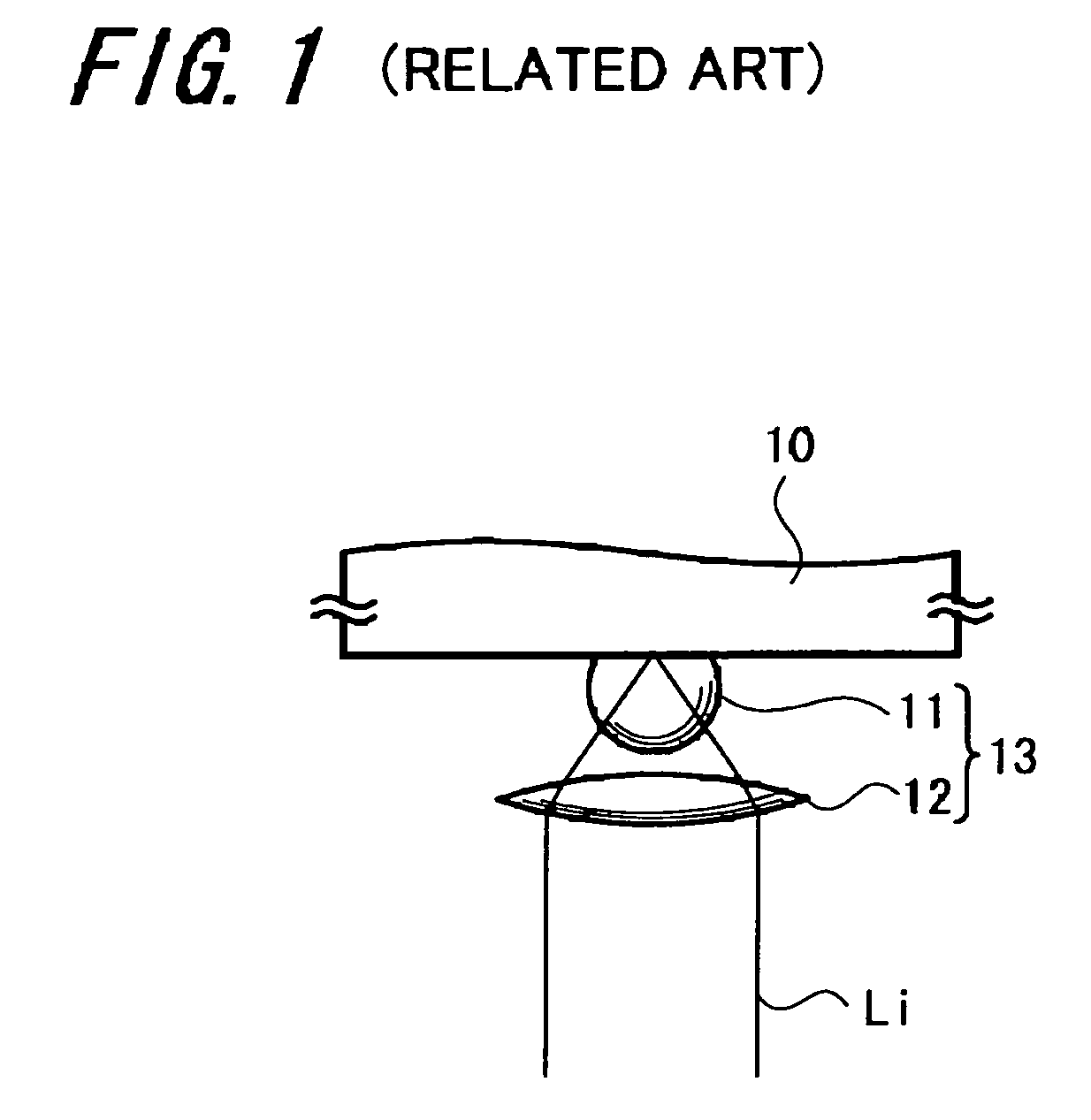

A solid immersion lens (SIL) has higher magnification and higher numerical aperture than common lenses by filling the object space with a high-refractive-index solid material. SIL was originally developed for enhancing the spatial resolution of optical microscopy. There are two types of SIL: Hemispherical SIL: Theoretically capable of increasing the numerical aperture of an optical system by n, the index of refraction of the material of the lens.

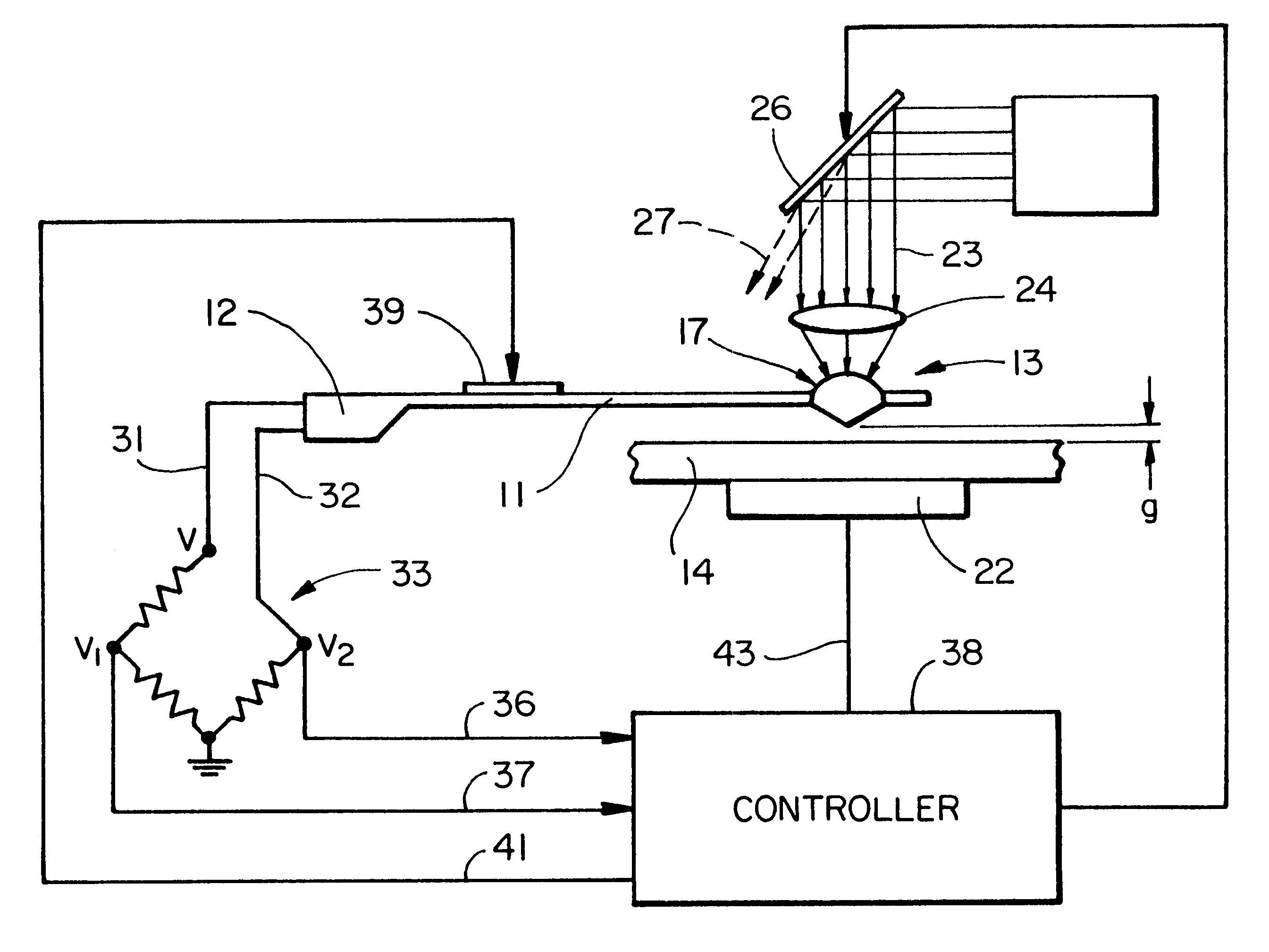

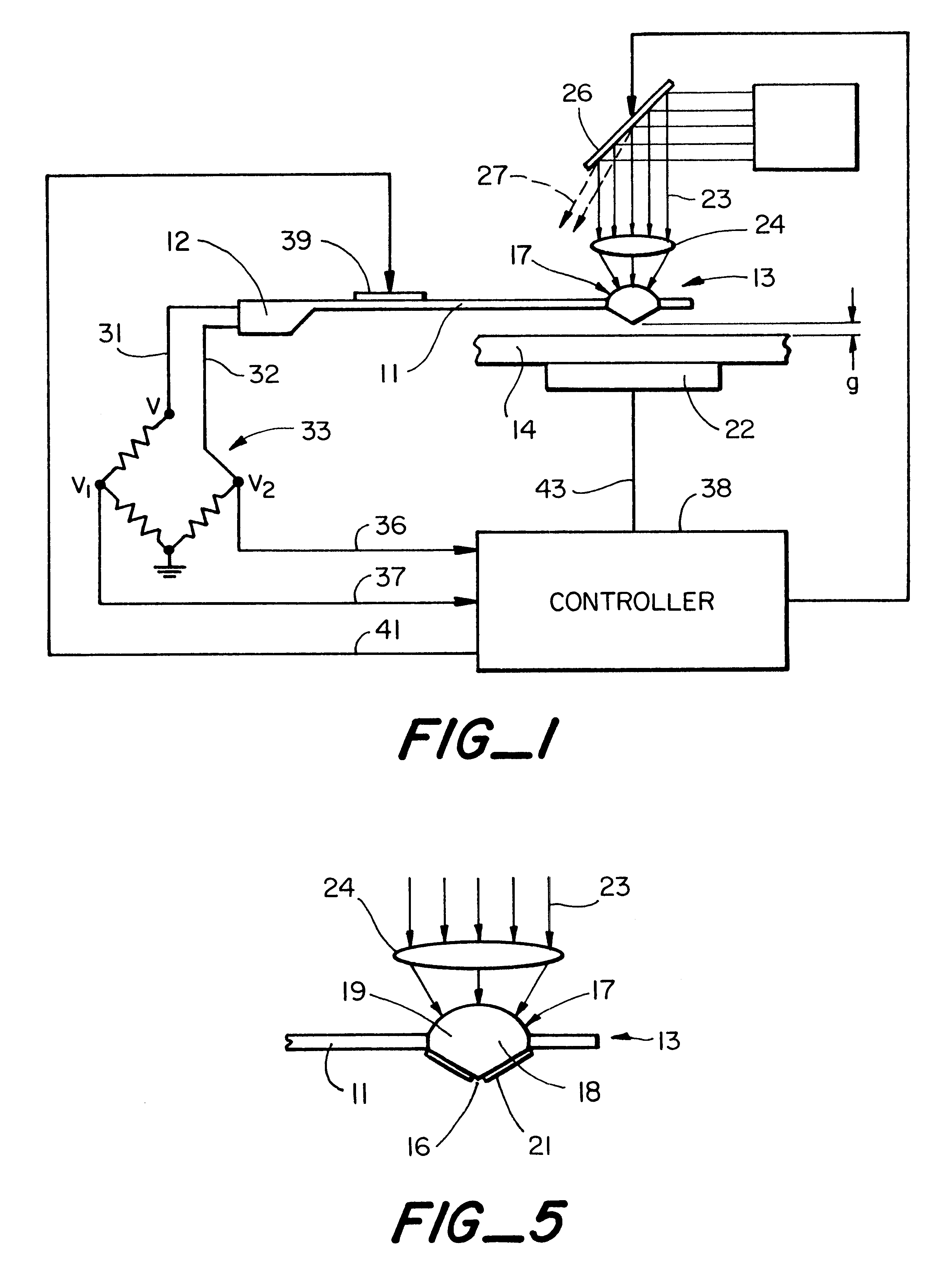

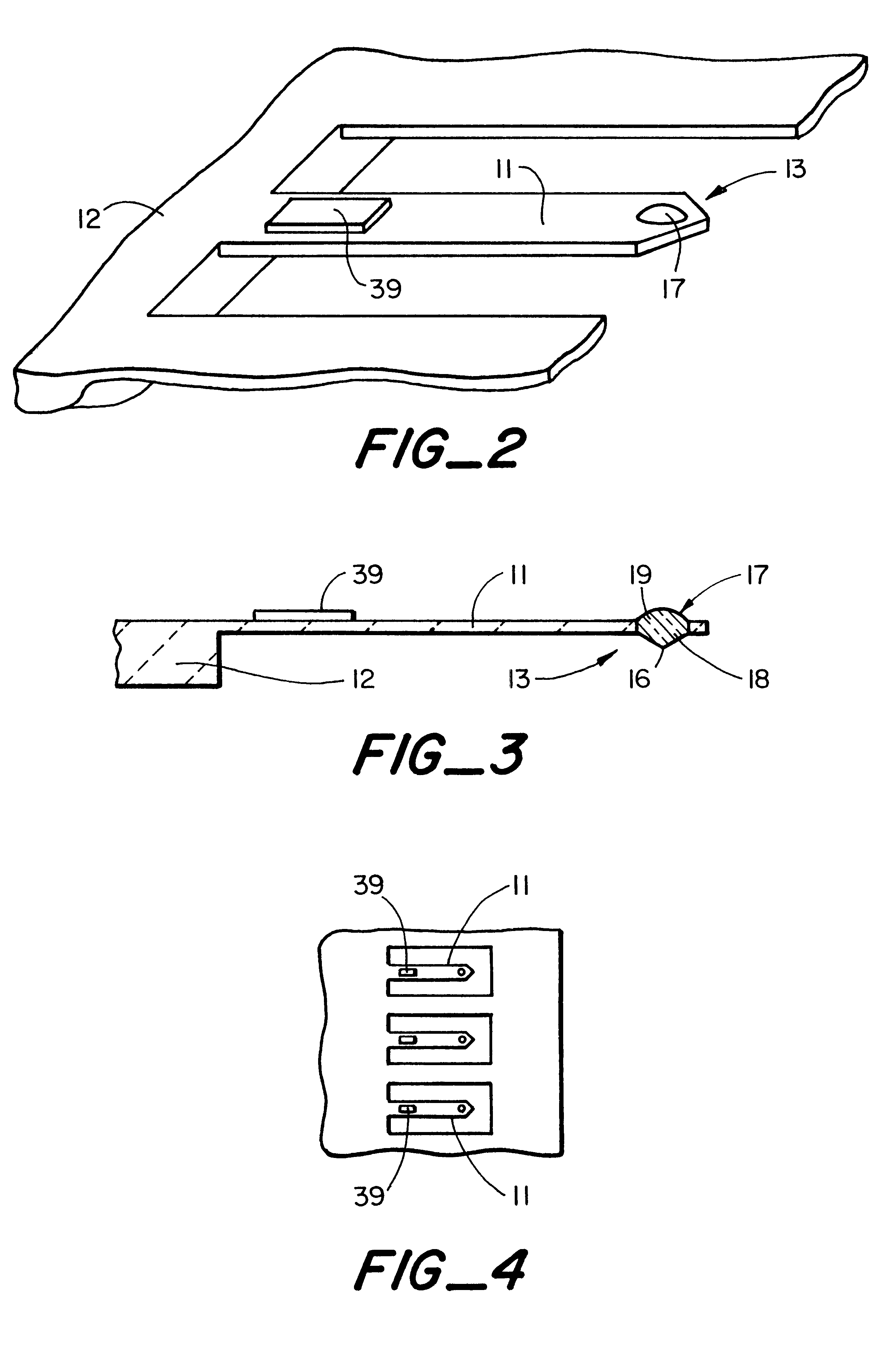

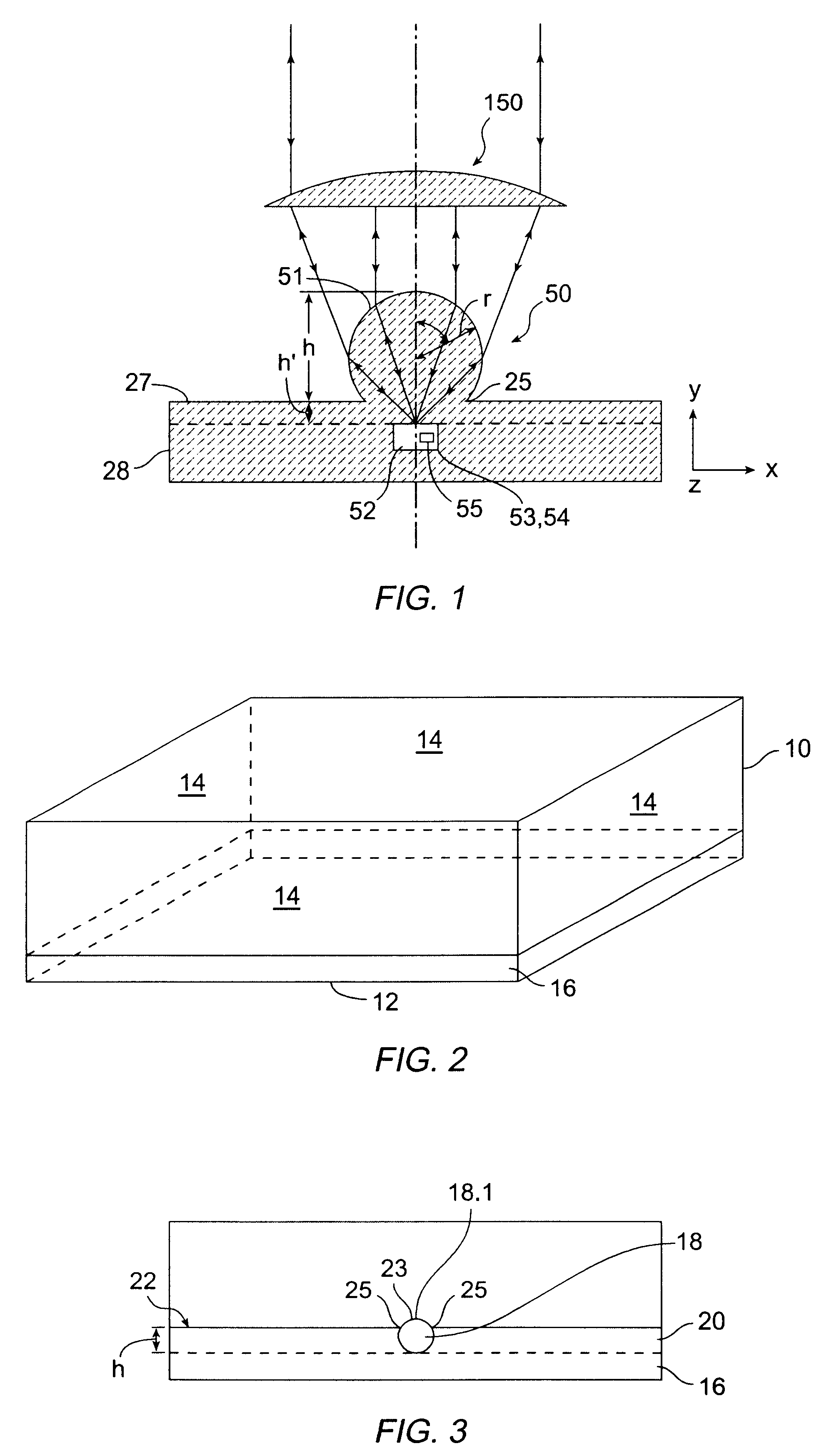

Near field optical scanning system employing microfabricated solid immersion lens

A solid immersion lens integrated on a flexible support such as a cantilever or membrane is described, together with a method of forming the integrated structure.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

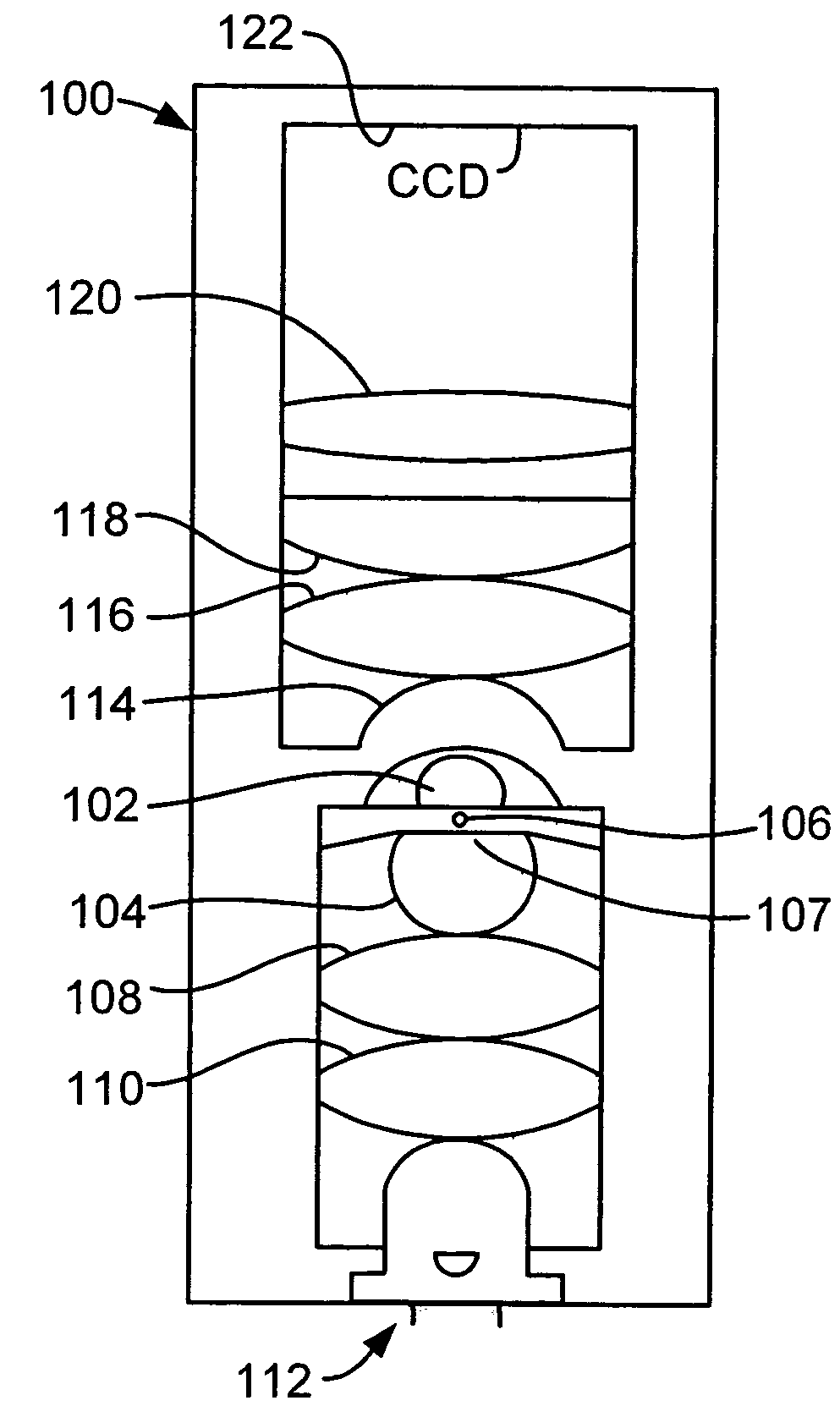

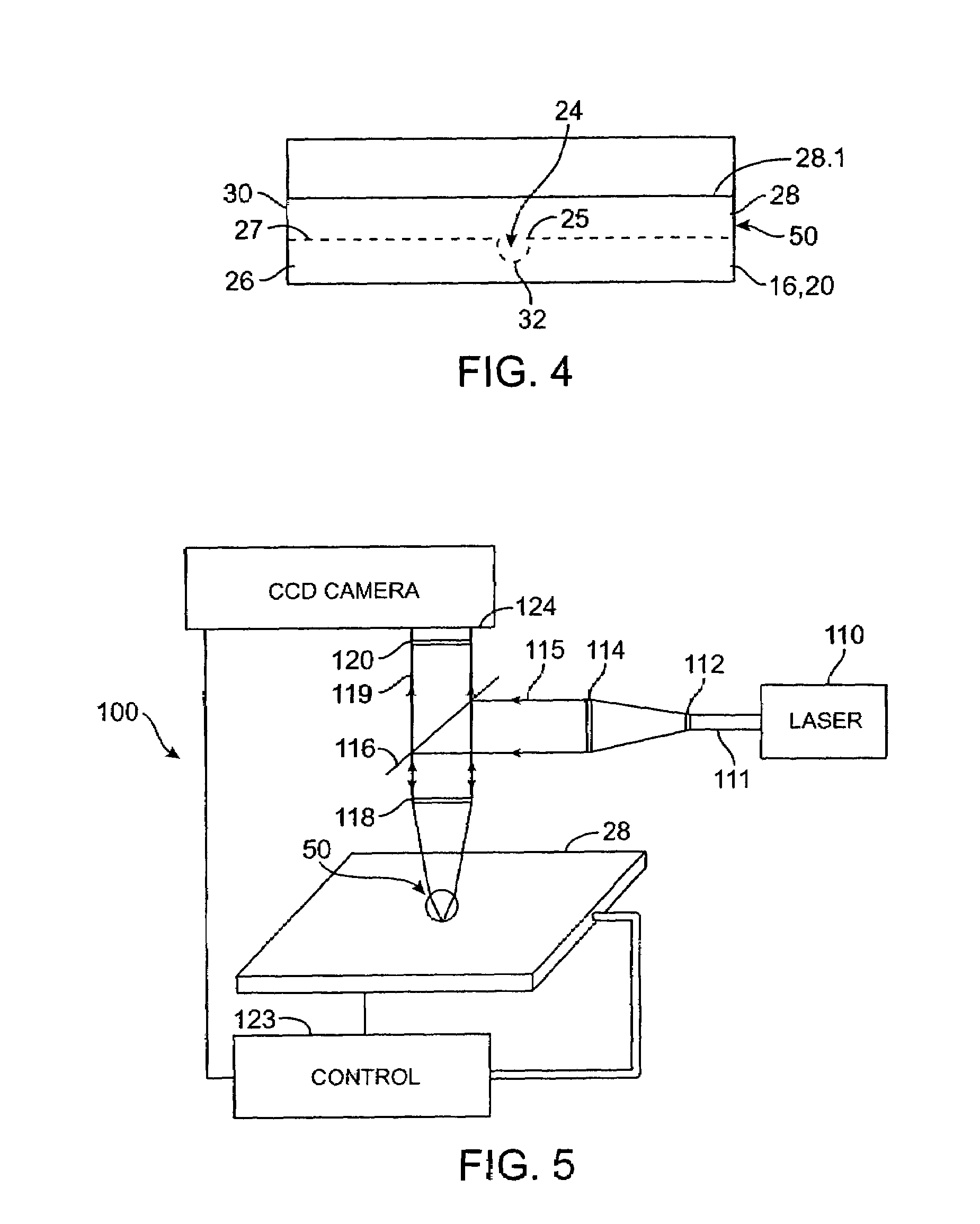

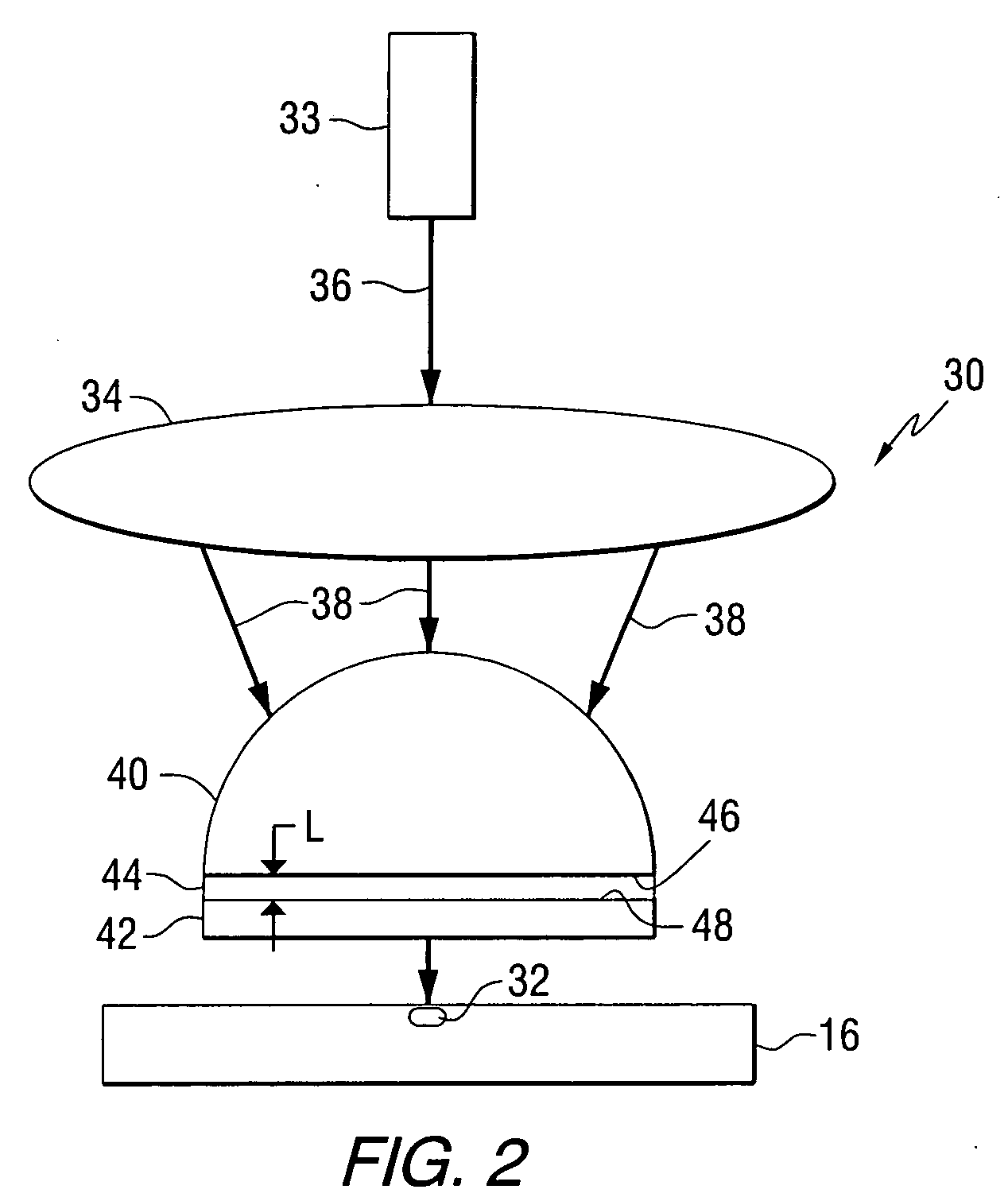

Solid immersion lens structures and methods for producing solid immersion lens structures

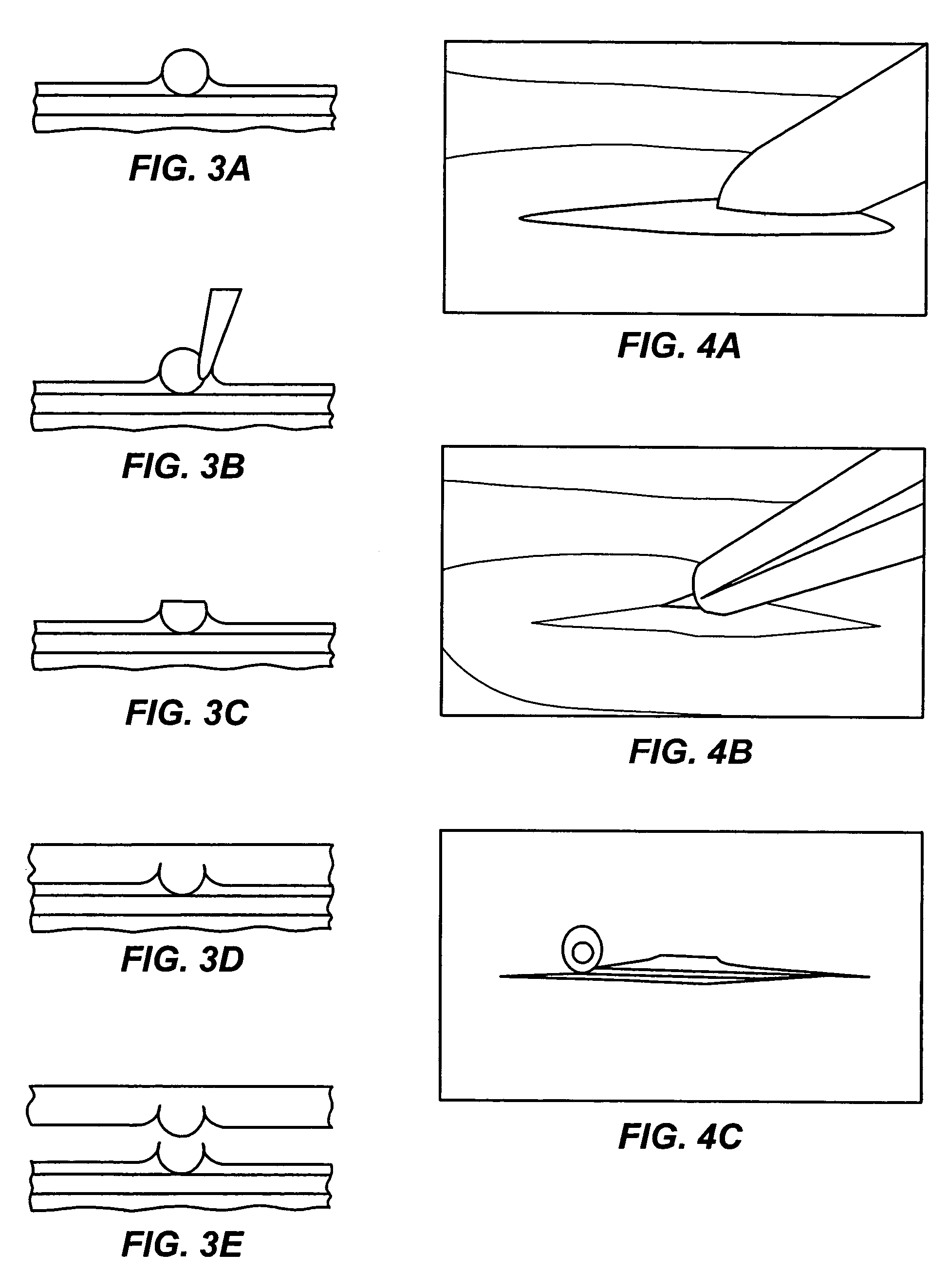

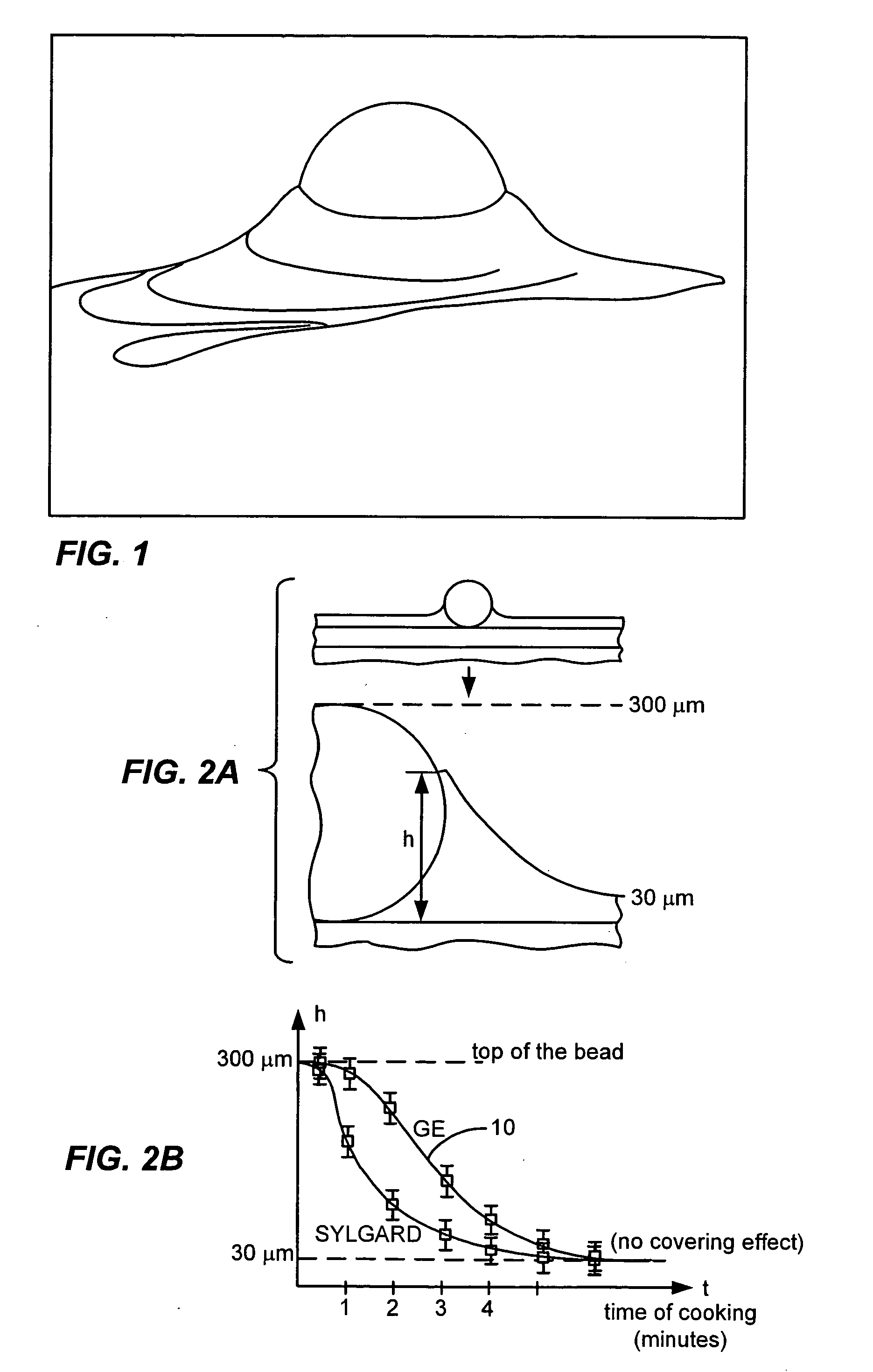

A solid immersion lens structure is a translucent pliant elastomer cast to a desired shape and smoothness. A method for construction of a solid immersion lens structure includes providing a mold defining a lens shaped cavity in which a solid immersion lens is cast, casting a translucent liquid elastomeric material into the lens cavity, permitting the elastomeric material to set to form the solid immersion lens portion and removing the solid immersion lens portion from the mold. A specific material for use as the solid immersion lens is a translucent silicone elastomer of a refractive index greater than n=1.4, such as General Electric RTV 615.

Owner:CALIFORNIA INST OF TECH

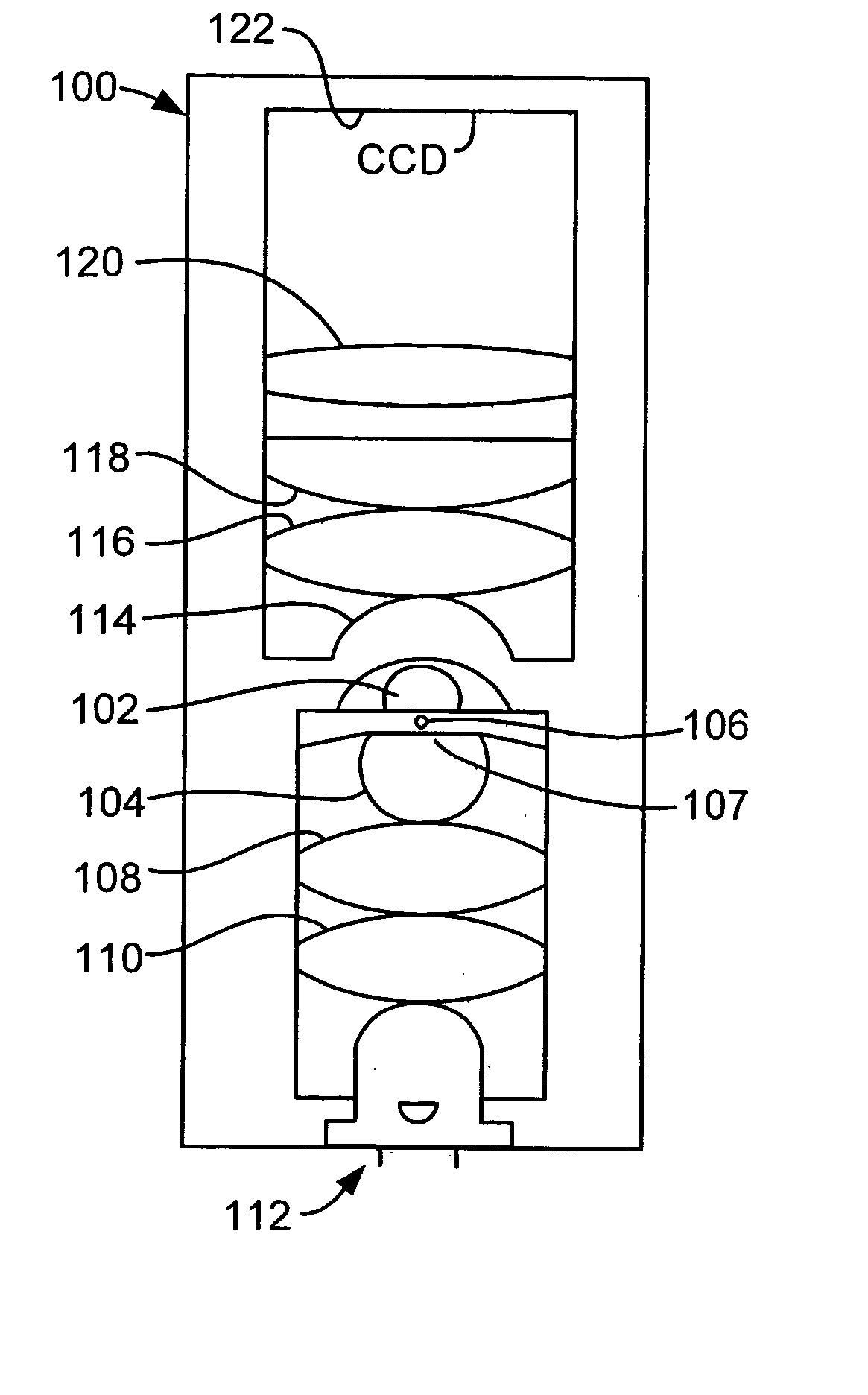

Microfabricated rubber microscope using soft solid immersion lenses

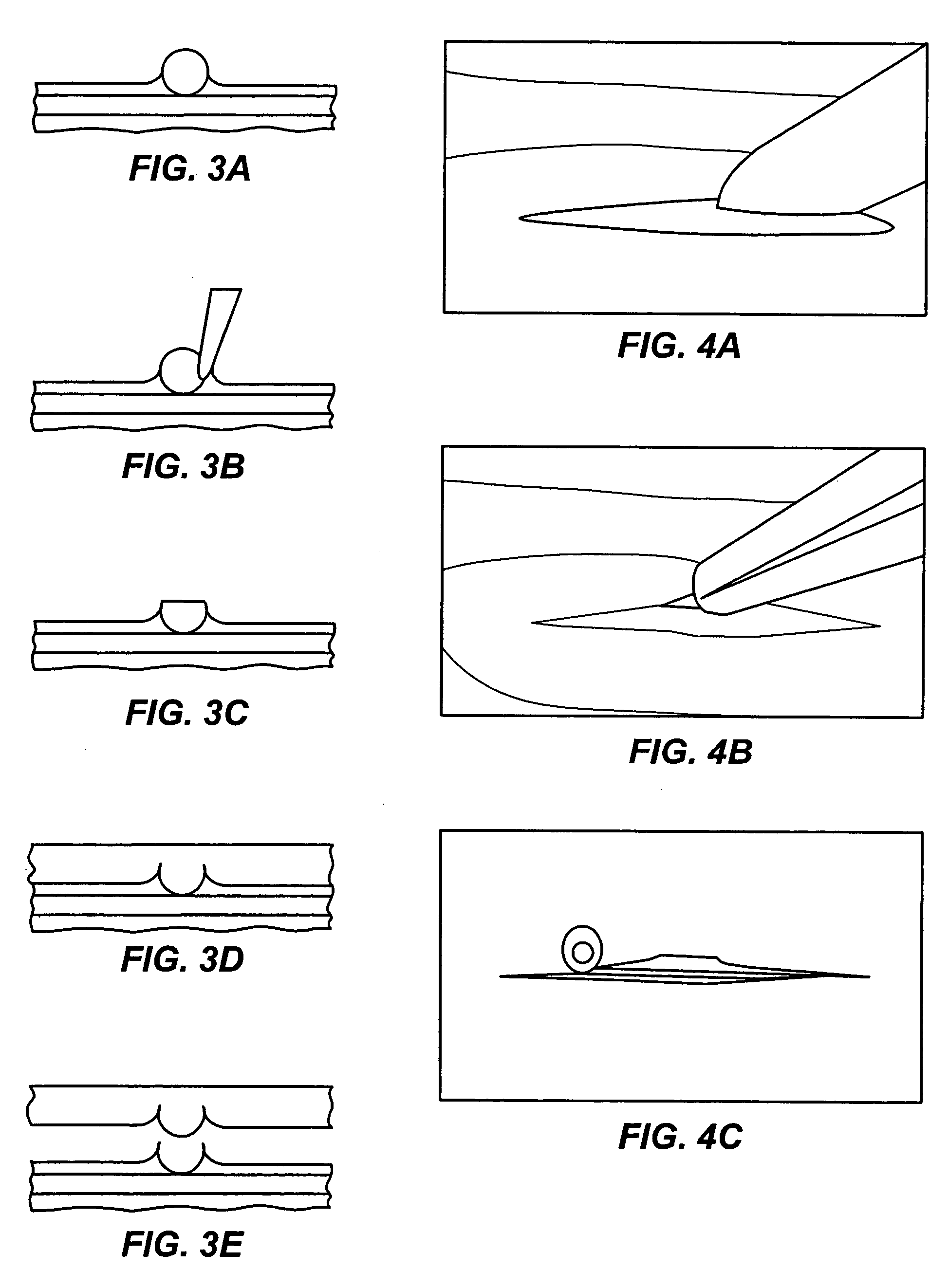

Soft lithography with surface tension control is used to microfabricate extremely efficient solid immersion lenses (SILs) out of rubber elastomeric material for use in microscope type applications. In order to counteract the surface tension of the mold material in a negative mold that causes creep on a positive mold, material such as RTV is partially cured before use in order to allow the reticulation of polymer chains to change the viscosity of the uncured material in a controllable manner. In a specific embodiment, the techniques of soft lithography with surface tension control are used to make molded SILs out of the elastomer polydimethylsiloxane. The lenses achieve an NA in the range of 1.25. The principle of compound lens design is used to make the first compound solid immersion lens, which is corrected for higher light gathering ability and has a calculated NA=1.32. An important application of these lenses is integrated optics for microfluidic devices, specifically in a handheld rubber microscope for microfluidic flow cytometry.

Owner:CALIFORNIA INST OF TECH

Low profile clamp for use with apparatus for thermal control in the analysis of electronic devices

InactiveUS20090146359A1Eliminate reflection lossReduce frictionPositioning apparatusMetal-working holdersElectronSilicon

A heat spreader comprising a sheet of transparent diamond with an aperture therein that accommodates a solid-immersion lens (SIL). The heat spreader may be mounted within a clamp which allows the heat spreader to move freely across the Device Under Test (DUT) whilst maintaining a very high degree of planarity and contact between the diamond and the silicon substrate of the DUT. The DUT is secured to its electrical interface with a low profile clamp, the DUT may be held within the clamp by a mechanism that applies a pressure to the sides of the DUT package.

Owner:PRESTO ENG

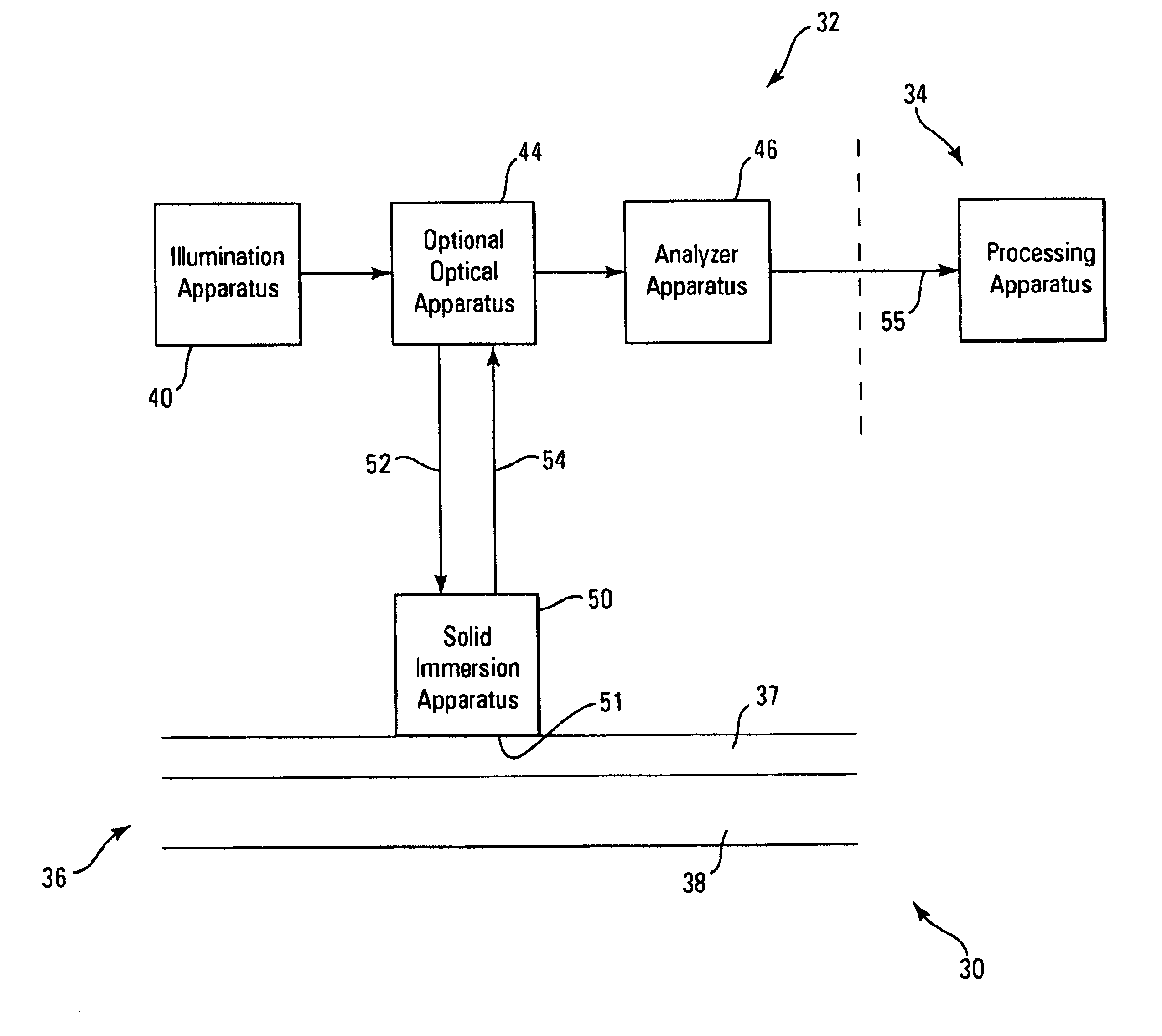

Ellipsometry methods and apparatus using solid immersion tunneling

InactiveUS6934024B2Accurate measurementFacilitates optical tunnelingPolarisation-affecting propertiesLight polarisation measurementRefractive indexPrism

A solid immersion tunneling ellipsometer and methods relating thereto may include a solid immersion apparatus (e.g., a prism or an objective lens in combination with a solid immersion lens) that facilitates optical tunneling and provide information that can be used in the determination of one or more characteristics (e.g., thickness, index of refraction, etc.) of samples (e.g., thin films, ultrathin films, etc.).

Owner:RGT UNIV OF MINNESOTA

Thin Plenoptic Cameras Using Solid Immersion Lenses

InactiveUS20130128030A1Small pixel sizeImprove concentrationTelevision system detailsColor television detailsCamera lensRadiance

Methods and apparatus for capturing and rendering high-quality photographs using relatively small, thin plenoptic cameras. Plenoptic camera technology, in particular focused plenoptic camera technology including but not limited to super-resolution techniques, and other technologies such as solid immersion lens (SIL) technology may be leveraged to provide thin form factor, megapixel resolution cameras suitable for use in mobile devices and other applications. In addition, at least some embodiments of these cameras may also capture radiance, allowing the imaging capabilities provided by plenoptic camera technology to be realized through appropriate rendering techniques. Hemispherical SIL technology, along with multiple main lenses and a mask on the photosensor, may be employed in some thin plenoptic cameras. Other thin cameras may include a layer between hemispherical SILs and the photosensor that effectively implements superhemispherical SIL technology in the camera.

Owner:ADOBE INC

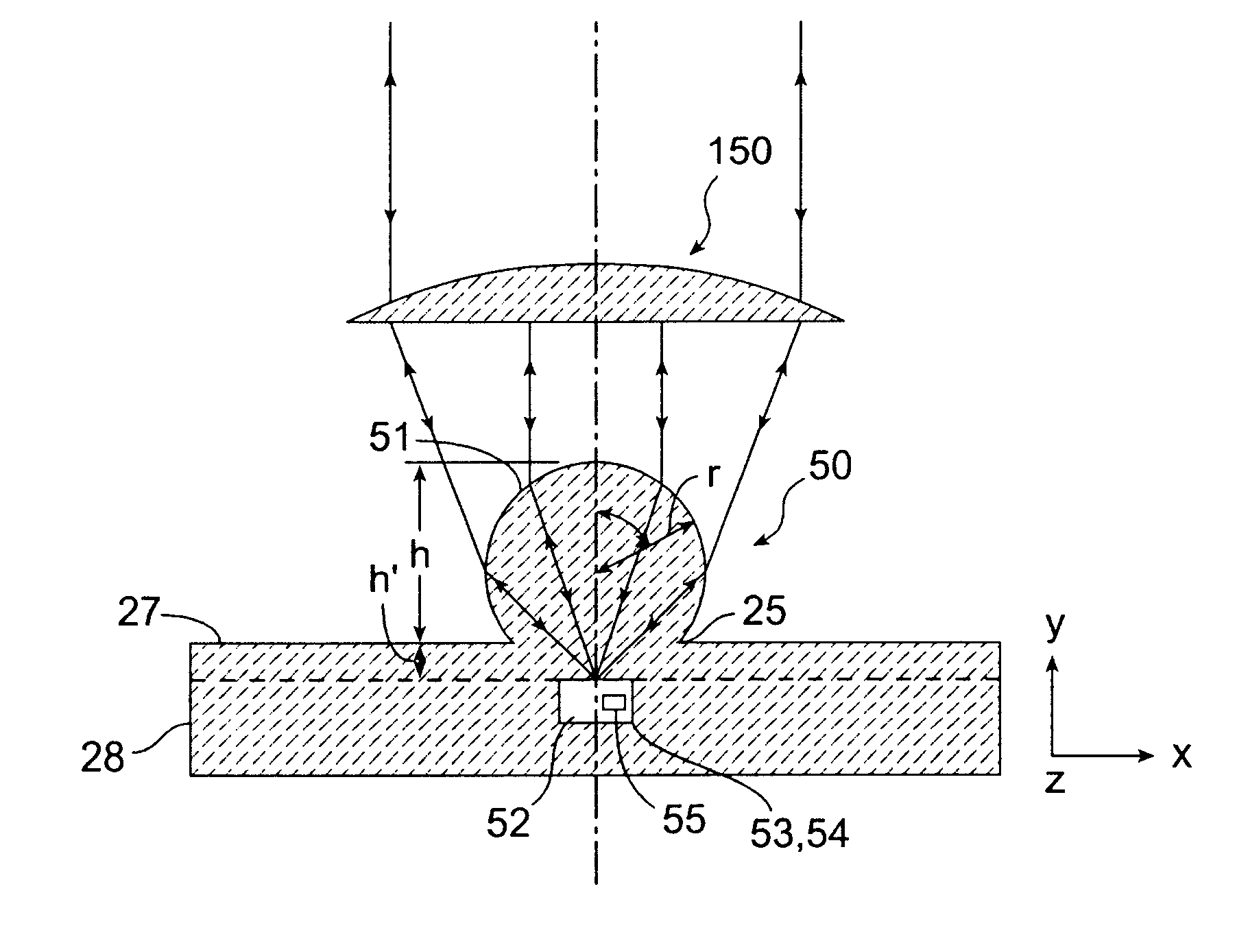

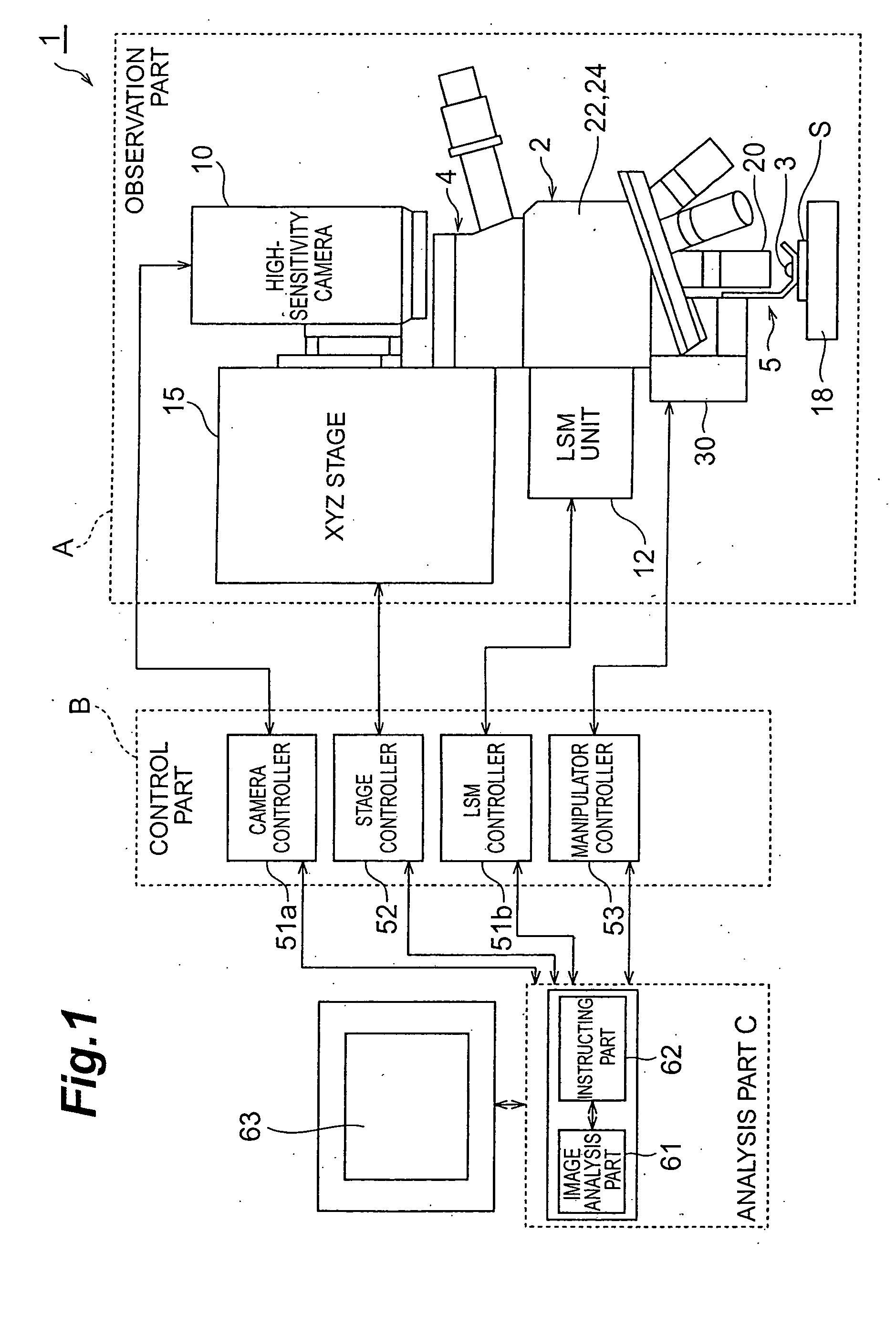

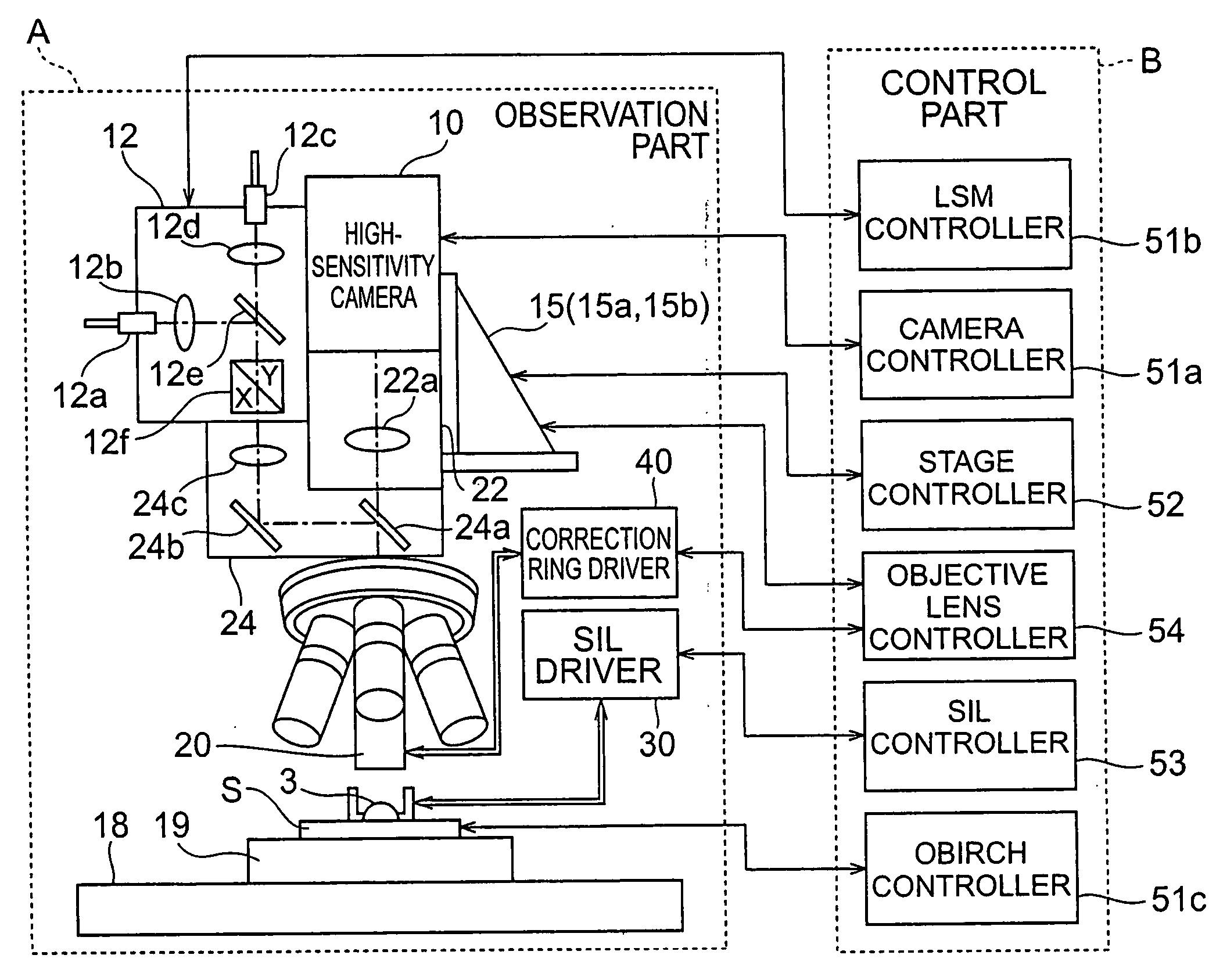

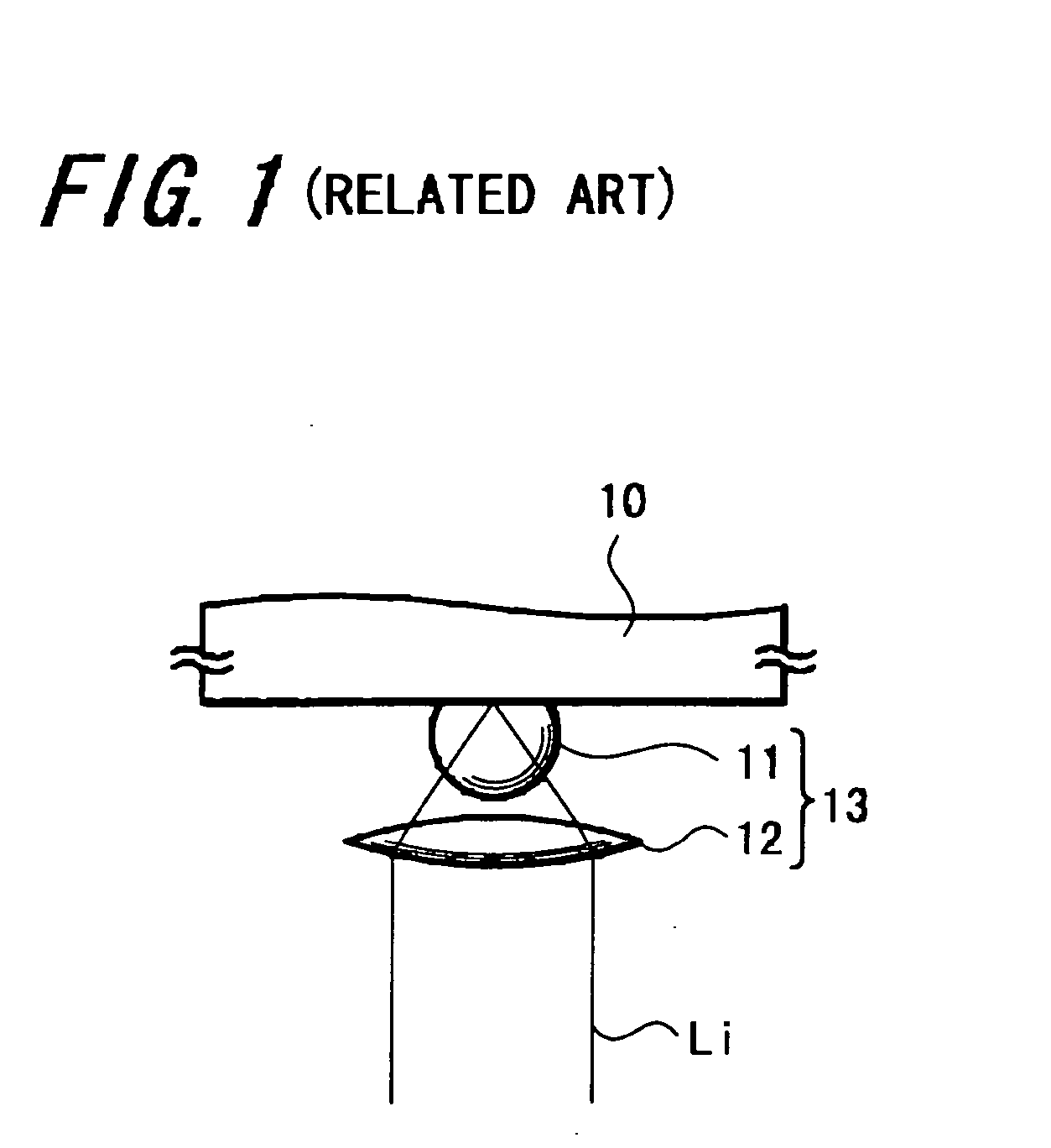

Microscope and sample observation method

For a semiconductor device S as an inspected object, there are provided an image acquisition part 1, an optical system 2 including an objective lens 20, and a solid immersion lens (SIL) 3 movable between an insertion position including an optical axis from the semiconductor device S to the objective lens 20 and a standby position off the optical axis. Then observation is carried out in two control modes consisting of a first mode in which the SIL 3 is located at the standby position and in which focusing and aberration correction are carried out based on a refractive index no and a thickness to of a substrate of the semiconductor device S, and a second mode in which the SIL 3 is located at the insertion position and in which focusing and aberration correction are carried out based on the refractive index no and thickness t0 of the substrate, and a refractive index n1, a thickness d1, and a radius of curvature R1 of SIL 3. This provides a microscope and a sample observation method capable of readily performing observation of the sample necessary for an analysis of microstructure or the like of the semiconductor device.

Owner:HAMAMATSU PHOTONICS KK

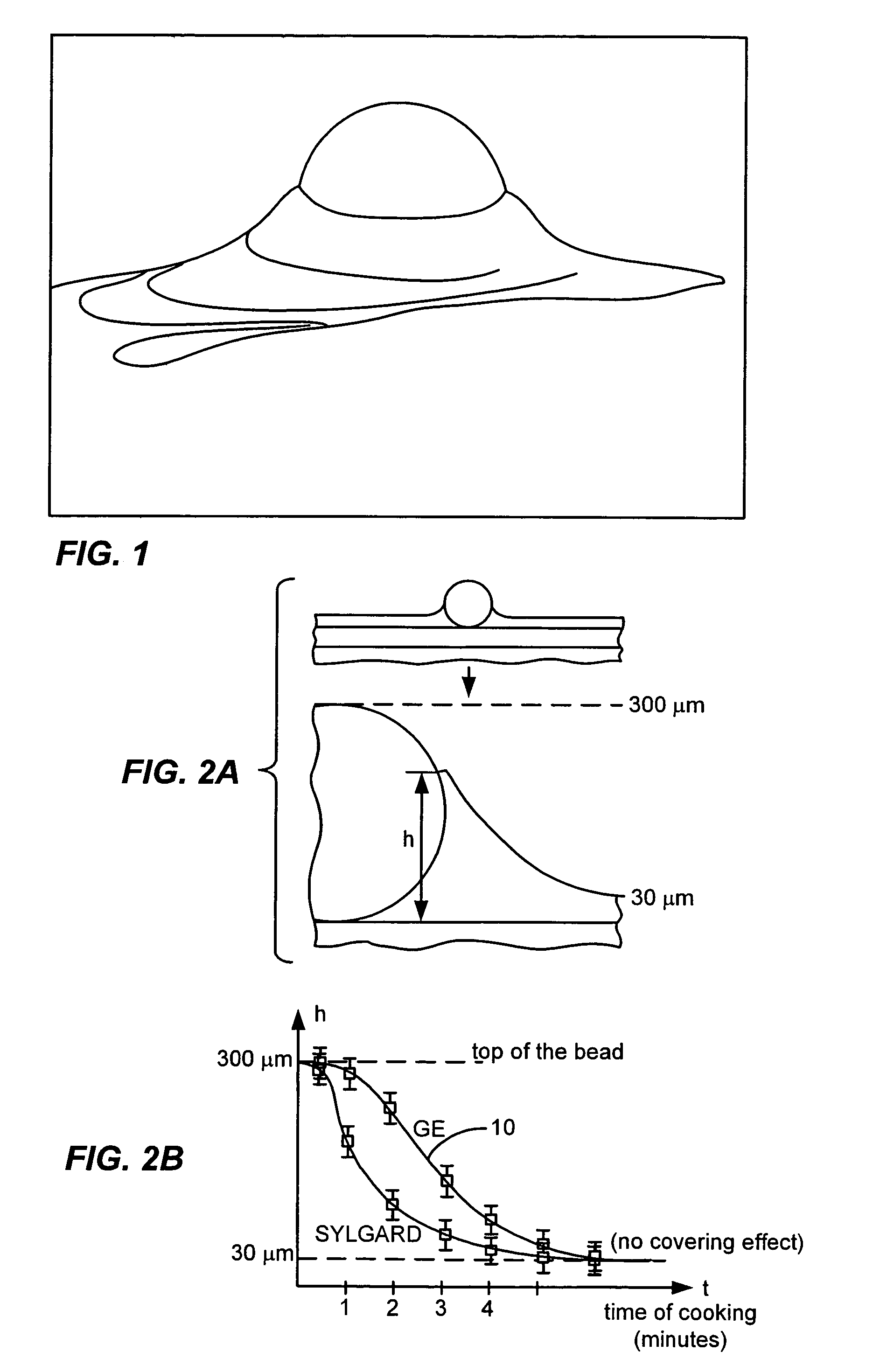

Microfabricated rubber microscope using soft solid immersion lenses

Soft lithography with surface tension control is used to microfabricate extremely efficient solid immersion lenses (SILs) out of rubber elastomeric material for use in microscope type applications. In order to counteract the surface tension of the mold material in a negative mold that causes creep on a positive mold, material such as RTV is partially cured before use in order to allow the reticulation of polymer chains to change the viscosity of the uncured material in a controllable manner. In a specific embodiment, the techniques of soft lithography with surface tension control are used to make molded SILs out of the elastomer polydimethylsiloxane. The lenses achieve an NA in the range of 1.25. The principle of compound lens design is used to make the first compound solid immersion lens, which is corrected for higher light gathering ability and has a calculated NA=1.32. An important application of these lenses is integrated optics for microfluidic devices, specifically in a handheld rubber microscope for microfluidic flow cytometry.

Owner:CALIFORNIA INST OF TECH

Methods for achieving high resolution microfluoroscopy

A microfluoroscope has a source of soft x-rays and a solid immersion lens including a plano surface. There is means for placing a sample in close proximity to the plano surface so that an x-ray absorption shadowgraph of the sample is projected onto the plano surface by the source of soft x-rays. A scintillator on the solid immersion lens plano surface produces fluorescent light from soft x-rays passing through the sample. An optical microscope is used for viewing through the solid immersion lens the fluorescent light from the scintillator corresponding to the x-ray absorption shadowgraph of the sample. A microfluoroscope is also disclosed which includes a source of soft x-rays, a fluorescent screen placed at a plane to receive x-rays and means for placing a sample in close proximity to the plane so that an x-ray absorption shadowgraph of the sample is projected onto the fluorescent screen. A nanochannel mask placed between the fluorescent screen and the sample for limiting x-rays reaching the fluorescent screen to a periodic matrix of nanochanneled beams. A computer system combines all the discrete images at each raster position into a composite image representing the x-ray absorption shadowgraph of the entire sample.

Owner:HIRSCH GREGORY

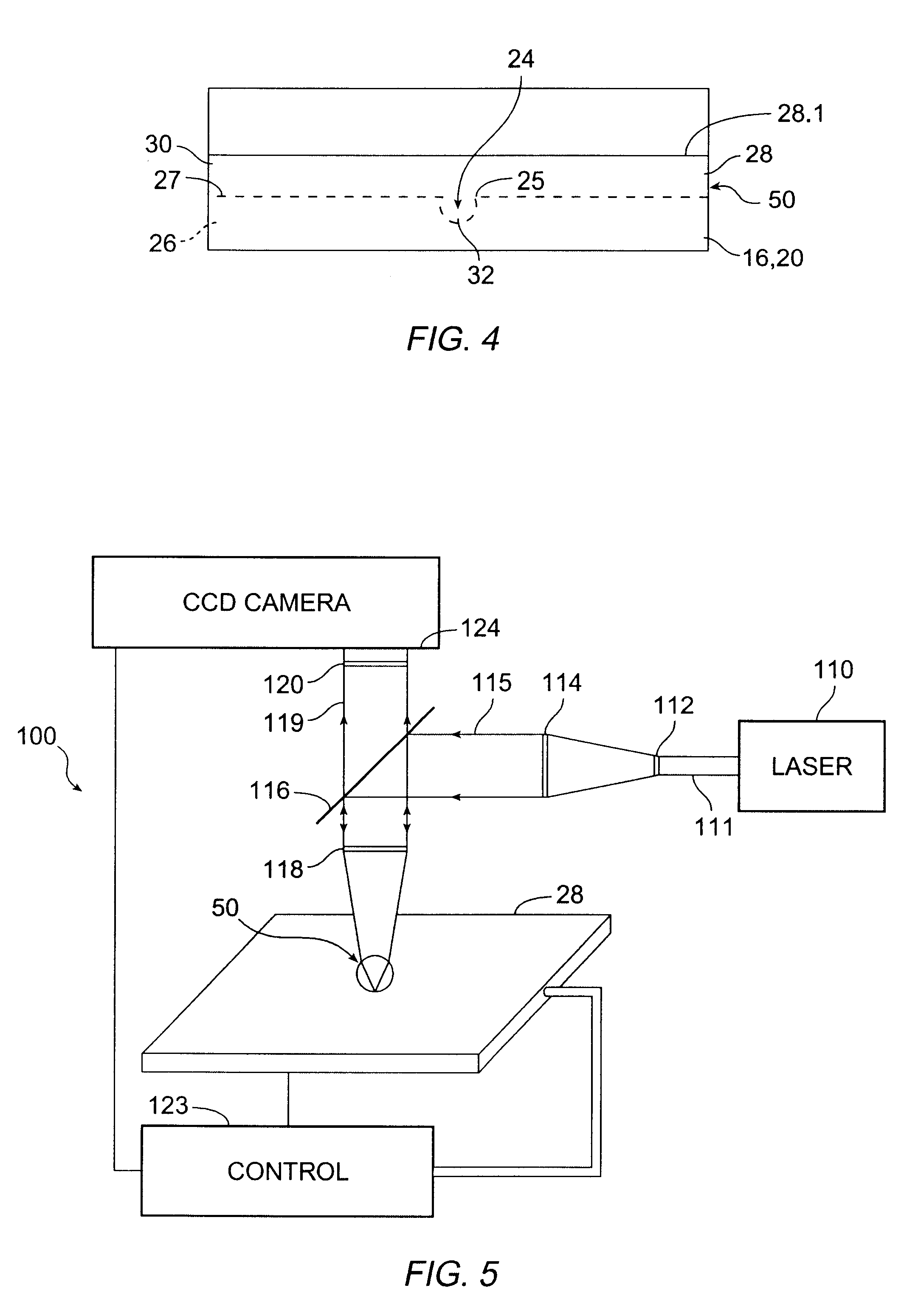

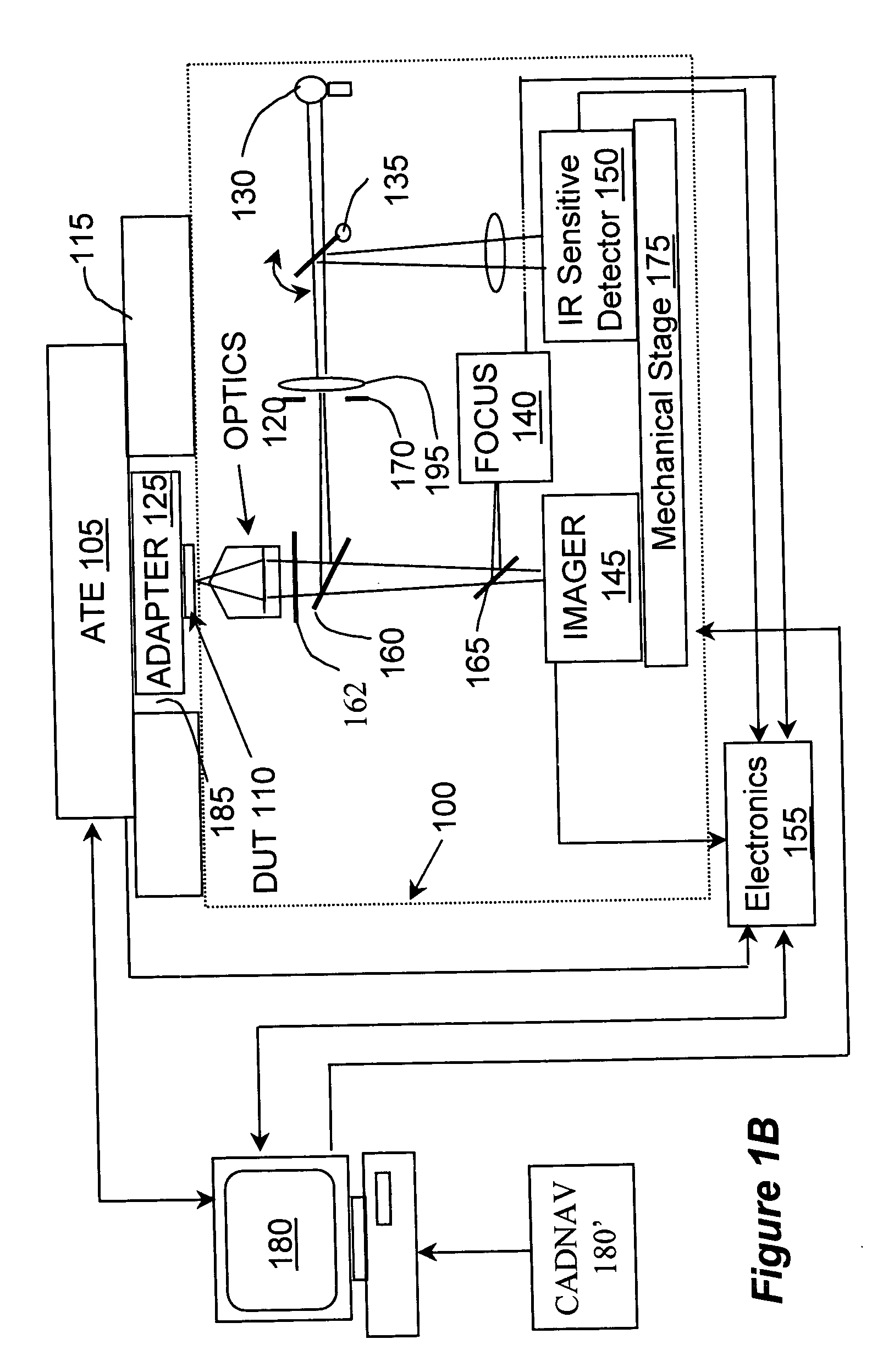

Inspection system utilizing solid immersion lenses

ActiveUS20120092655A1Easy to sewLarge field of viewOptically investigating flaws/contaminationMicroscopesThermal isolationCamera lens

An inspection system including a lens. In one instance, the lens is a solid immersion lens. The inspection system includes a component or components for providing a self aligning solid immersion lens arrangement in order to allow at most a small distance between the solid immersion lens and a device under test and components or components for constraining a force exerted on the device under test. The inspection system may include a “purge” port, or a thermal isolation configuration or an anti-contamination component. The inspection system may include software and hardware to prevent crashing of the lens. The inspection system may also include a method for ensuring that various objective lenses can be replaced while maintaining the intended spacing between lenses.

Owner:INFRARED LAB

Microfabricated lenses, methods of manufacture thereof, and applications therefor

InactiveUS6841096B2Improved light collection/focusing propertyGood optical performanceOptical articlesLaboratory glasswaresSolid immersion lensOptics

Microfabricated lenses, e.g., solid immersion lens (SIL) structures, are provided along with techniques for constructing these lens structures, as well as selected applications of such lens structures.

Owner:CALIFORNIA INST OF TECH

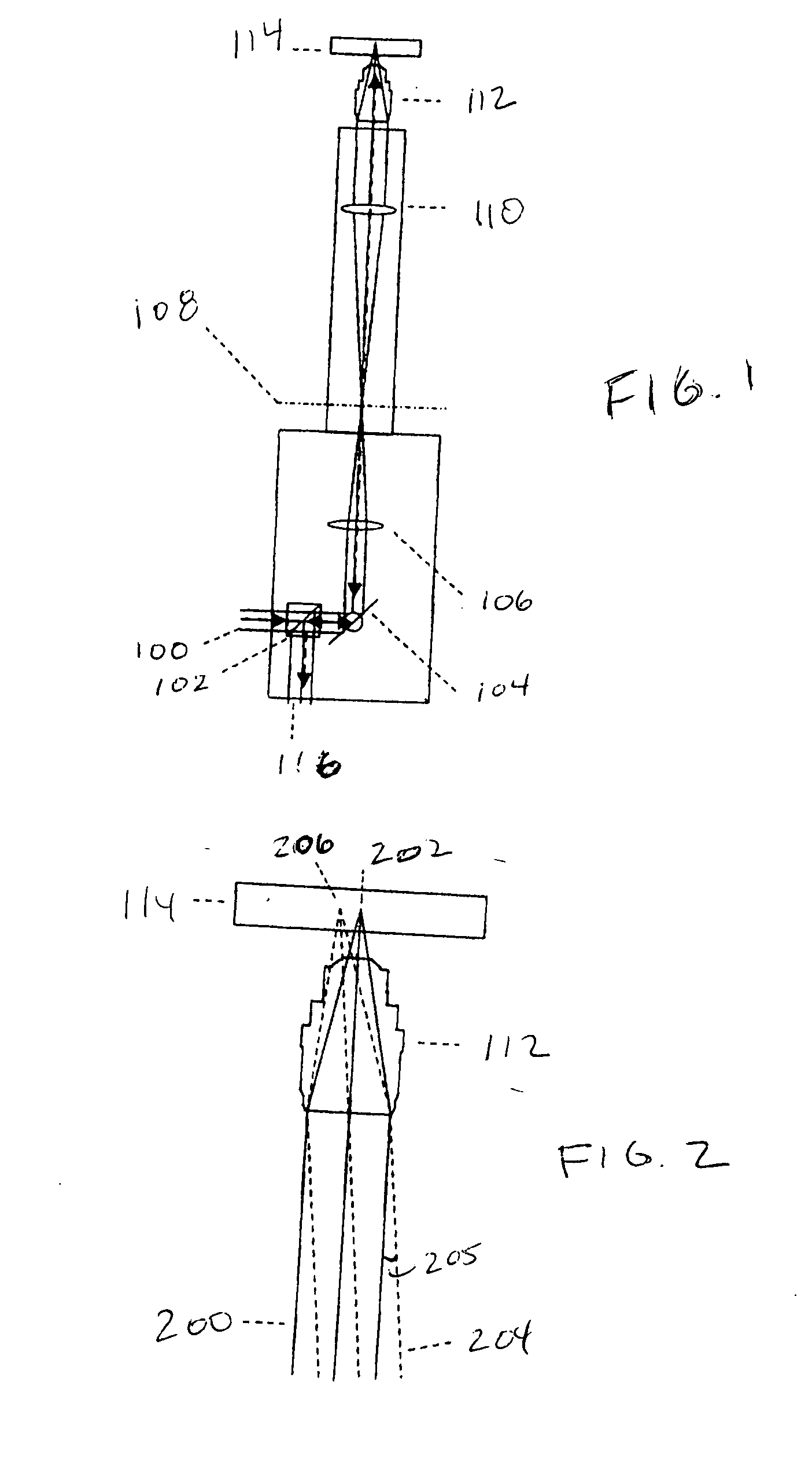

Optics landing system and method therefor

InactiveUS20050030051A1Avoid damageAccurate control and placementCombination recordingMaterial analysis by optical meansProximity sensorEngineering

A landing system is provided for accurate placing of collection optics in a microscope. In one example, a solid immersion lens (SIL) is used for light collection, and the landing system is operated to place the SIL in contact with an IC. A proximity sensor is used for determining the SIL's position with respect to the IC. The arrangement is attached to a z-motion stage. During the placement procedure, the navigation is performed in steps and at each step the compression of the SIL is measured relative to its uncompressed state. When a measured compression exceeds a preset threshold, a SIL landing is recognized. In one example, after a landing is recognized, a further compression is imparted to the SIL in order to place the SIL in a focusing distance to the objective lens.

Owner:CREDENCE INC +1

Solid immersion lens, condensing lens, optical pickup device, optical recording and reproducing apparatus and method of forming solid immersion lens

InactiveUS20050232120A1Large numerical apertureEasy to getCombination recordingRecord information storageOptical pickupAngle of incidence

A solid immersion lens 11 has an inclined portion 4 formed on at least a part thereof from the tip end portion of the objective side to a spherical portion and an inclination angle θ is expressed as θ≧i where θi represents the angle of incidence of light incident on the solid immersion lens 11. There are provided a solid immersion lens capable of increasing a tilt margin between a lens and an optical recording medium and so on and which can decrease a diameter of a lens and a method for forming a solid immersion lens.

Owner:SONY CORP

Solid immersion lens holder

InactiveUS20050094293A1Facilitate communicationAccurate observationMicroscopesMountingsCamera lensSolid immersion lens

An arrangement, equipped with a holder 9, which supports a solid immersion lens 3 in the gravity direction with the bottom surface of solid immersion lens 3 being protruded downward through an opening 9b, is provided. With this arrangement, when solid immersion lens 3 is set on an observed object, solid immersion lens 3 is put in a state in which it is raised by the observed object and is made free with respect to holder 9. Also in this state, an excessive pressure will not be applied to the observed object and yet solid immersion lens 3 is put in close contact in conformance with the observed object and temperature drifts at the holder 9 side or the observed object side are cut off from the counterpart side and thus the influences of such temperature drifts are eliminated. A solid immersion lens holder, with which the damaging of the observed object can be eliminated and which enables high-precision observation, is thus provided.

Owner:HAMAMATSU PHOTONICS KK

Optical information recording-reproduction apparatus

InactiveUS20080198728A1High speed approachStable servo-controlOptical head protectionOptical flying-type headsDriver circuitLight beam

An optical information recording-reproduction apparatus comprises: a light source; an objective lens and a SIL (solid immersion lens) for focusing a light beam from the light source on an optical recording medium; an aperture element for collecting a part of the light beam reflected by an optical recording medium, corresponding to the effective aperture number of the objective lens and SIL of less than 1; a detecting element for detecting the part of the light beam from the aperture element corresponding to the effective aperture number of less than 1; a speed-generating circuit for reducing the speed of approach of the SIL to the recording medium in accordance with the level of the signal detected by the detecting element; and a driver circuit for driving the objective lens and the SIL in accordance with output from the speed-generating circuit.

Owner:CANON KK

Optics landing system and method therefor

InactiveUS7123035B2Accurate control and placementAvoid damageMaterial analysis by optical meansMicroscopesProximity sensorEngineering

A landing system is provided for accurate placing of collection optics in a microscope. In one example, a solid immersion lens (SIL) is used for light collection, and the landing system is operated to place the SIL in contact with an IC. A proximity sensor is used for determining the SIL's position with respect to the IC. The arrangement is attached to a z-motion stage. During the placement procedure, the navigation is performed in steps and at each step the compression of the SIL is measured relative to its uncompressed state. When a measured compression exceeds a preset threshold, a SIL landing is recognized. In one example, after a landing is recognized, a further compression is imparted to the SIL in order to place the SIL in a focusing distance to the objective lens.

Owner:CREDENCE INC +1

Microfabricated lenses, method of manufacture thereof, and applications therefor

InactiveUS7038856B2Improved light collection/focusing propertyGood optical performanceOptical articlesLaboratory glasswaresSolid immersion lensOptics

Owner:CALIFORNIA INST OF TECH

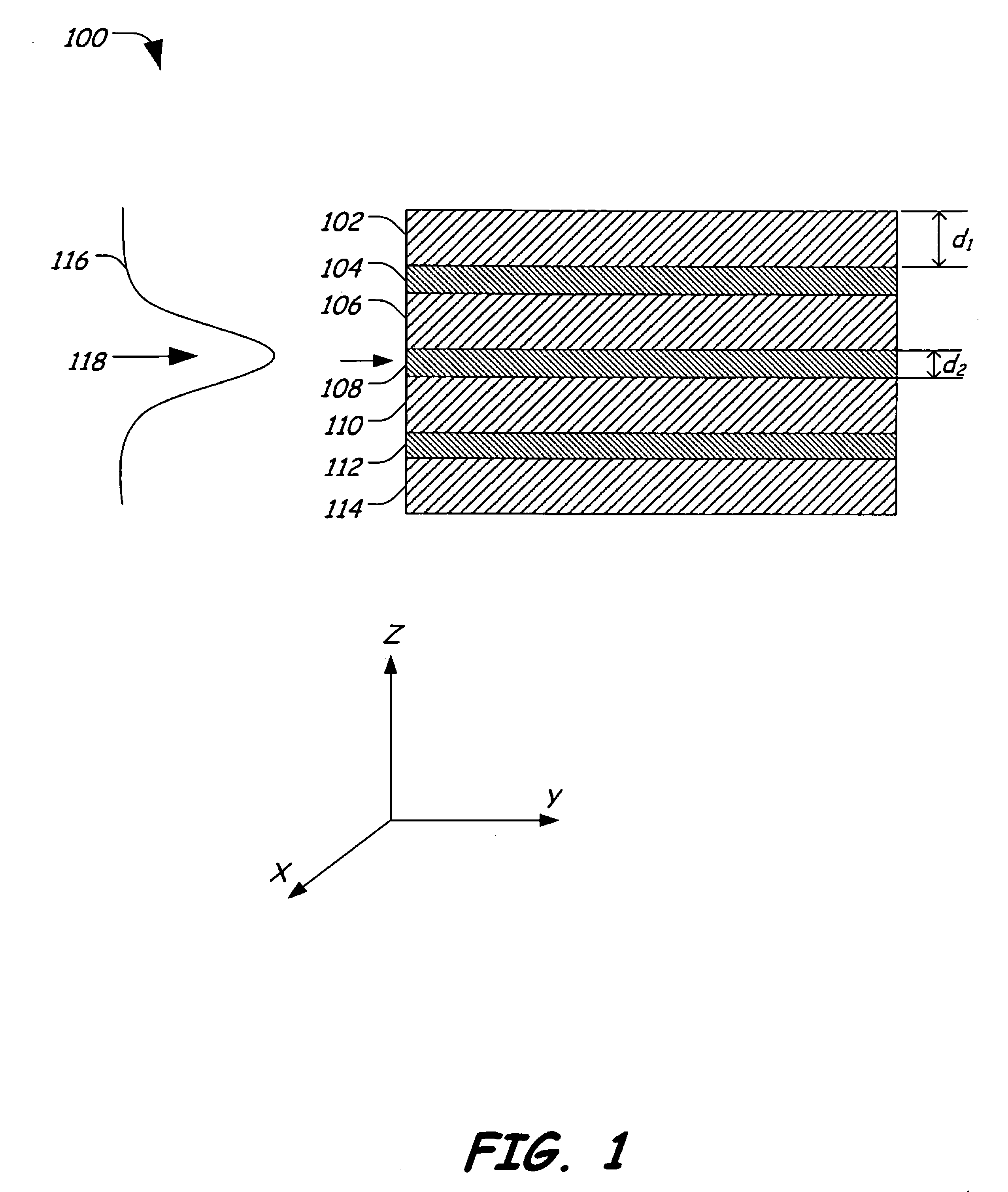

Solid immersion focusing apparatus for high-density heat assisted recording

In a particular embodiment, a solid immersion lens includes meta-material slabs formed from multiple layers of at least two different compositions. Each meta-material slab has a first effective index of refraction. The meta-material slabs are adapted to propagate an evanescent wave in a direction parallel to an axis to form a cone-shaped wave along the axis. The solid immersion lens further includes a core sandwiched between the meta-material slabs along the axis and having a second index of refraction that is less than the first effective index of refraction. The core directs surface plasmons that are excited by the cone-shaped wave to a focused area coincident with the axis.

Owner:SEAGATE TECH LLC

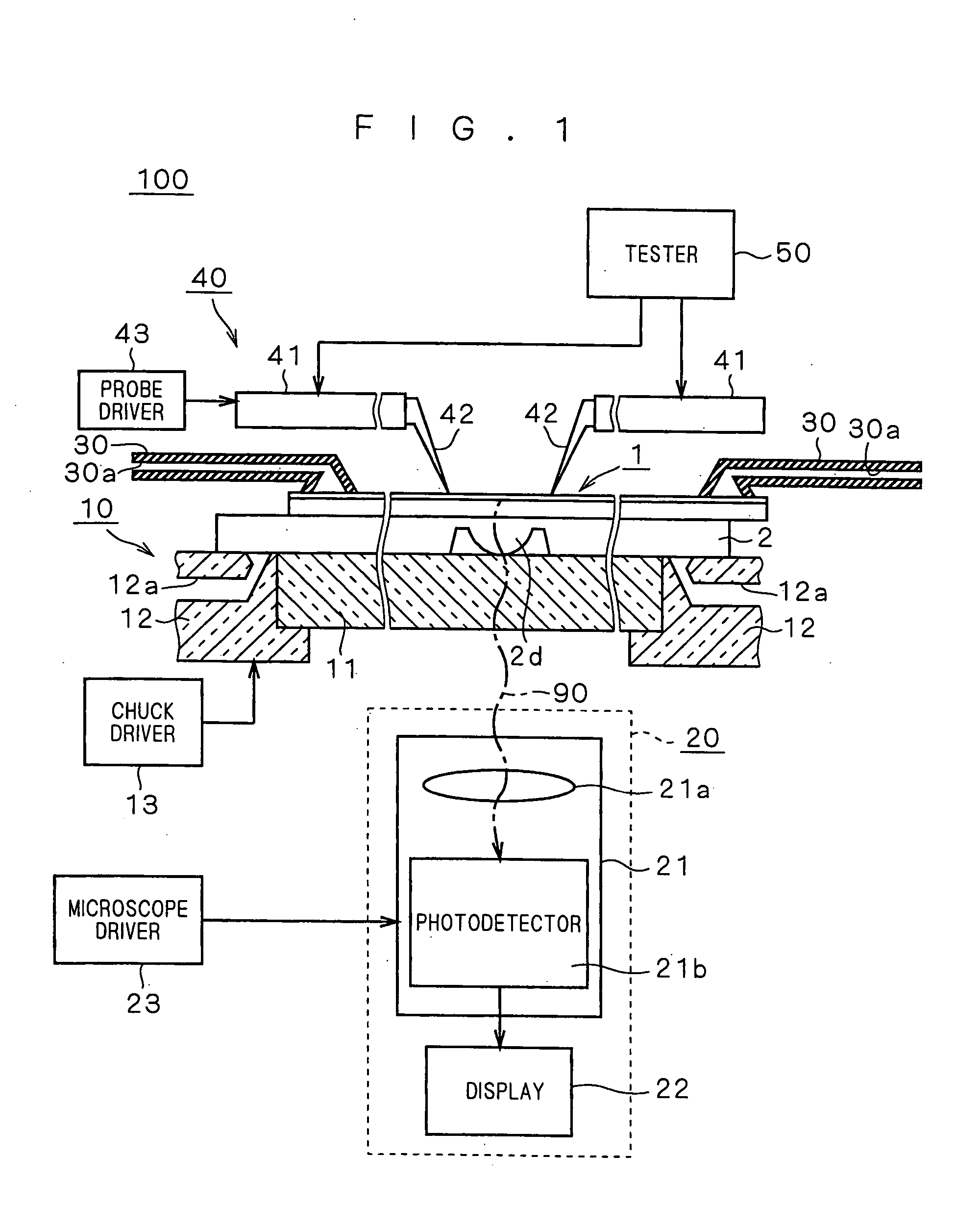

Failure analyzer

InactiveUS20040212380A1Easy to carryEasy to installSemiconductor/solid-state device testing/measurementIrradiation devicesFault analysisSolid immersion lens

A sample (1) is mounted on a stage (11) with an analysis plate (2) interposed therebetween. A recess (2c) is provided in a main surface (2b) of the analysis plate (2), and a protrusion (2d) functioning as a solid immersion lens is provided on a bottom surface (2ca) of the recess (2c). The protrusion (2d) does not protrude from the main surface (2b) of the analysis plate (2). Because of provision of the analysis plate (2) which includes a solid immersion lens and is separate from the sample (1), an analysis range can be changed. Further, since the protrusion (2d) does not protrude from the main surface (2b) of the analysis plate (2), the sample (1) can be stably mounted on the stage (11) with the analysis plate (2) interposed therebetween.

Owner:RENESAS TECH CORP

System for confined optical power delivery and enhanced optical transmission efficiency

InactiveUS20060182393A1Lesser refractive indexRecord information storageRecording/reproducing/erasing methodsCouplingOptical power

A system for confined optical power delivery and enhanced optical transmission efficiency includes a waveguide defining an aperture, a focusing element, and a coupling layer positioned between the waveguide and the focusing element. The waveguide may be, for example, in the form of a ridge waveguide. The focusing element is formed of a material having a refractive index that is greater than a refractive index of the coupling layer. The focusing element may be, for example, a solid immersion lens or a solid immersion mirror.

Owner:SEAGATE TECH LLC

Solid immersion focusing apparatus for high-density heat assisted recording

In a particular embodiment, a solid immersion lens includes meta-material slabs formed from multiple layers of at least two different compositions. Each meta-material slab has a first effective index of refraction. The meta-material slabs are adapted to propagate an evanescent wave in a direction parallel to an axis to form a cone-shaped wave along the axis. The solid immersion lens further includes a core sandwiched between the meta-material slabs along the axis and having a second index of refraction that is less than the first effective index of refraction. The core directs surface plasmons that are excited by the cone-shaped wave to a focused area coincident with the axis.

Owner:SEAGATE TECH LLC

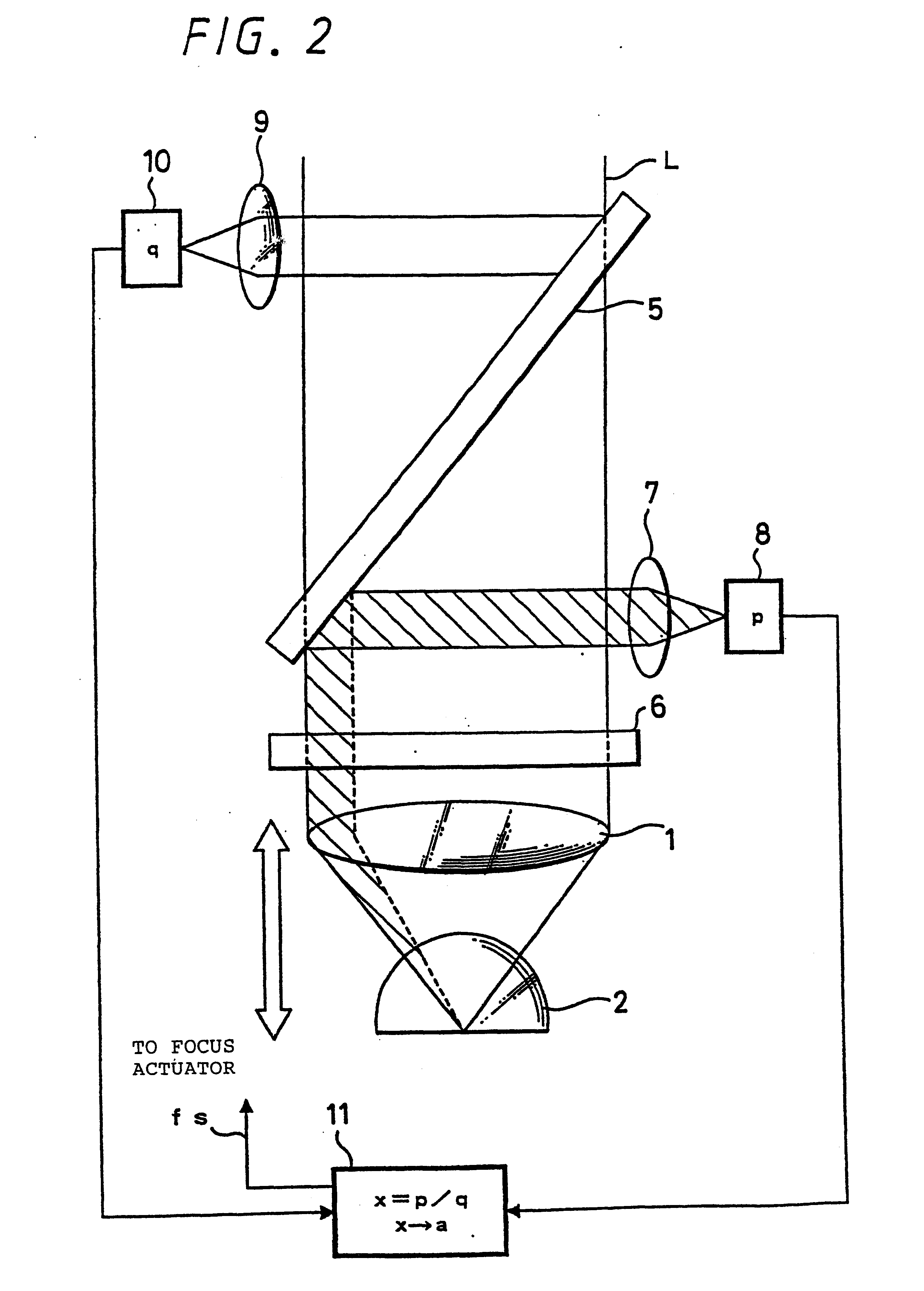

Focus control method and focus controller

InactiveUS6845066B1High response rateAccurate focus controlDisposition/mounting of recording headsNanoinformaticsActuatorNumerical aperture

The present invention aims to perform high-accuracy focus control in an optical disk drive, even if a solid immersion lens (SIL) or a solid immersion mirror (SIM) is set between an objective lens and the optical disk in order to increase a numerical aperture, by accurately detecting a change of the distance between an SIL or SIM and an optical disk.The present invention comprises light detection means (8) for detecting the light incoming to an SIL (2) or an SIM from an objective lens (1) at an incidence angle at which a numerical aperture is larger than 1 and reflected from a plane of the SIL (2) or SIM facing an optical disk, light detection means 10 for detecting the light incoming to the objective lens (1), comparison means (11) for finding a ratio between light amounts of the light detected by light detection means (8) and (10), and control means (11) for controlling operations of a focus actuator in accordance with the ratio.

Owner:SONY CORP

Solid immersion lens holder

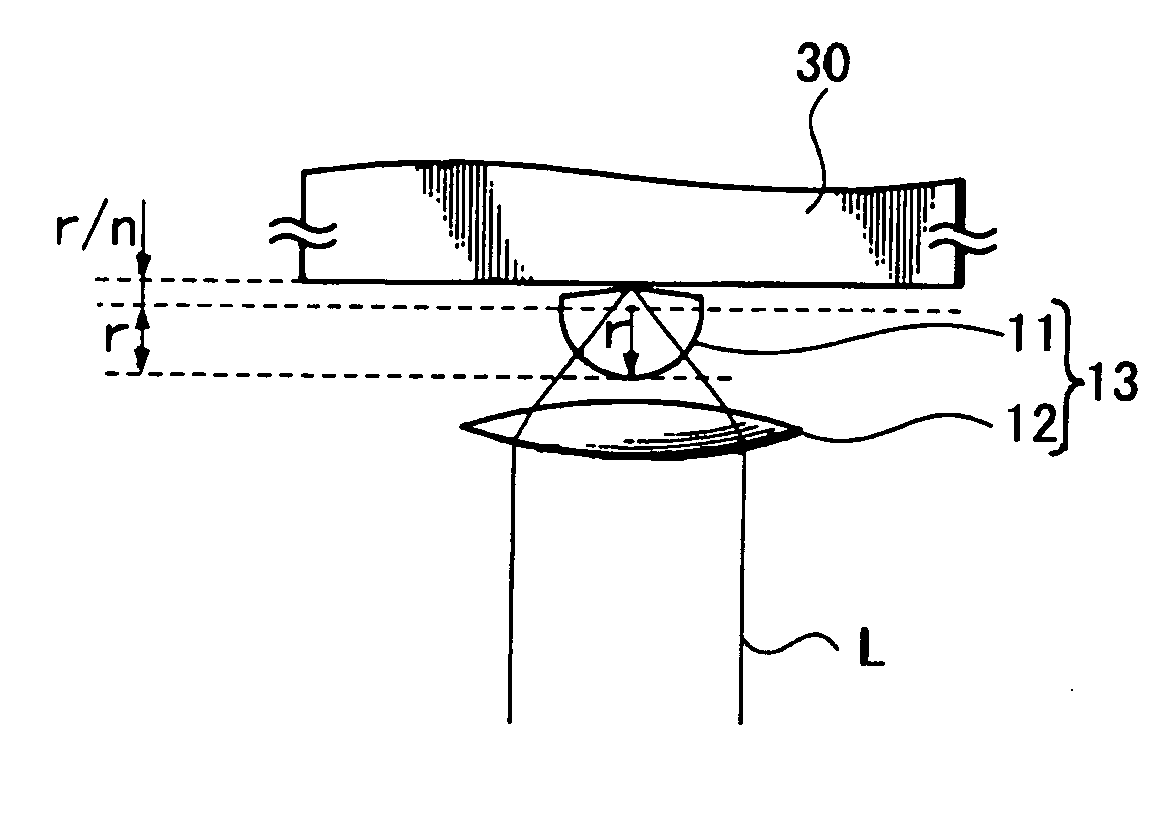

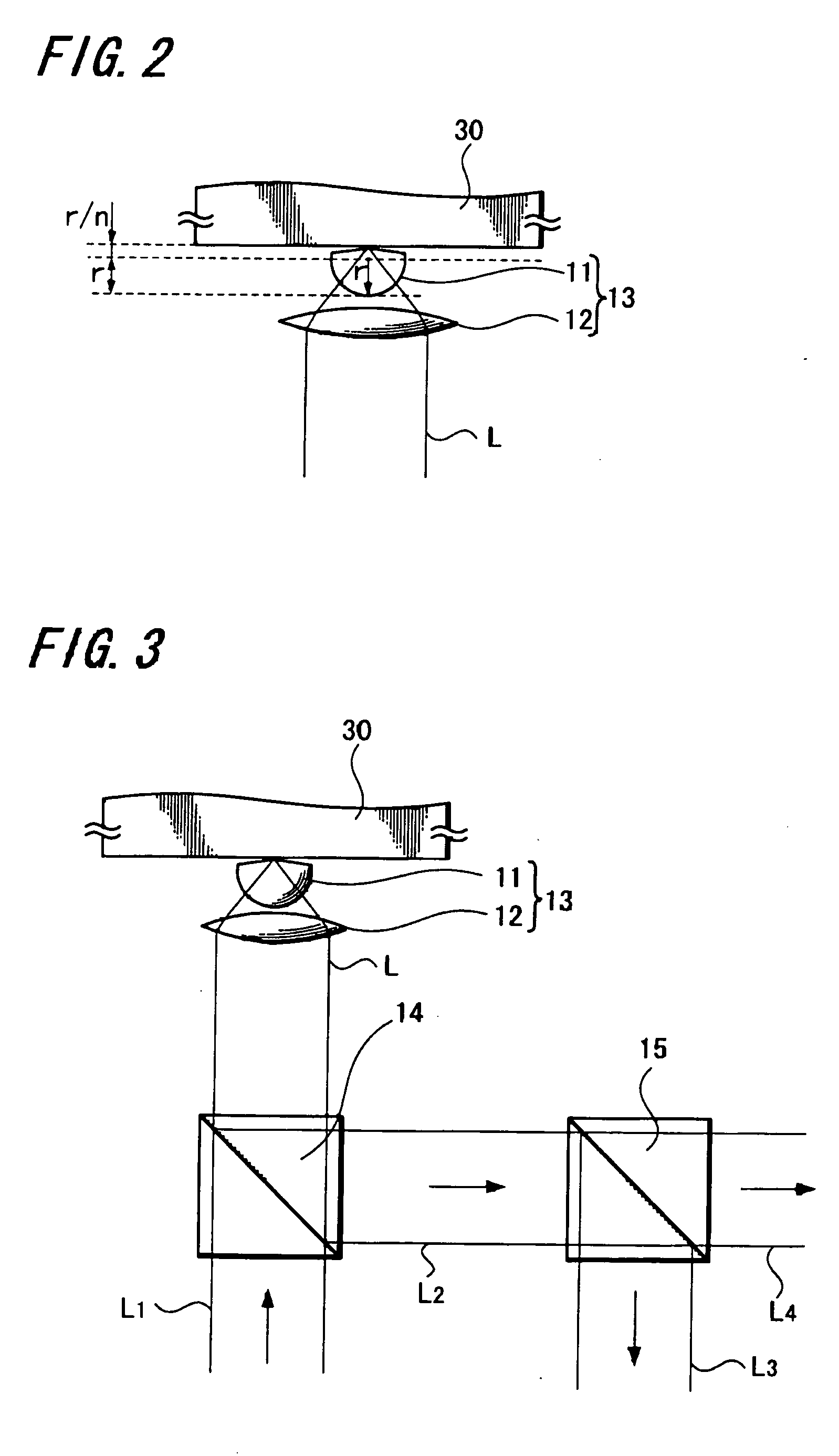

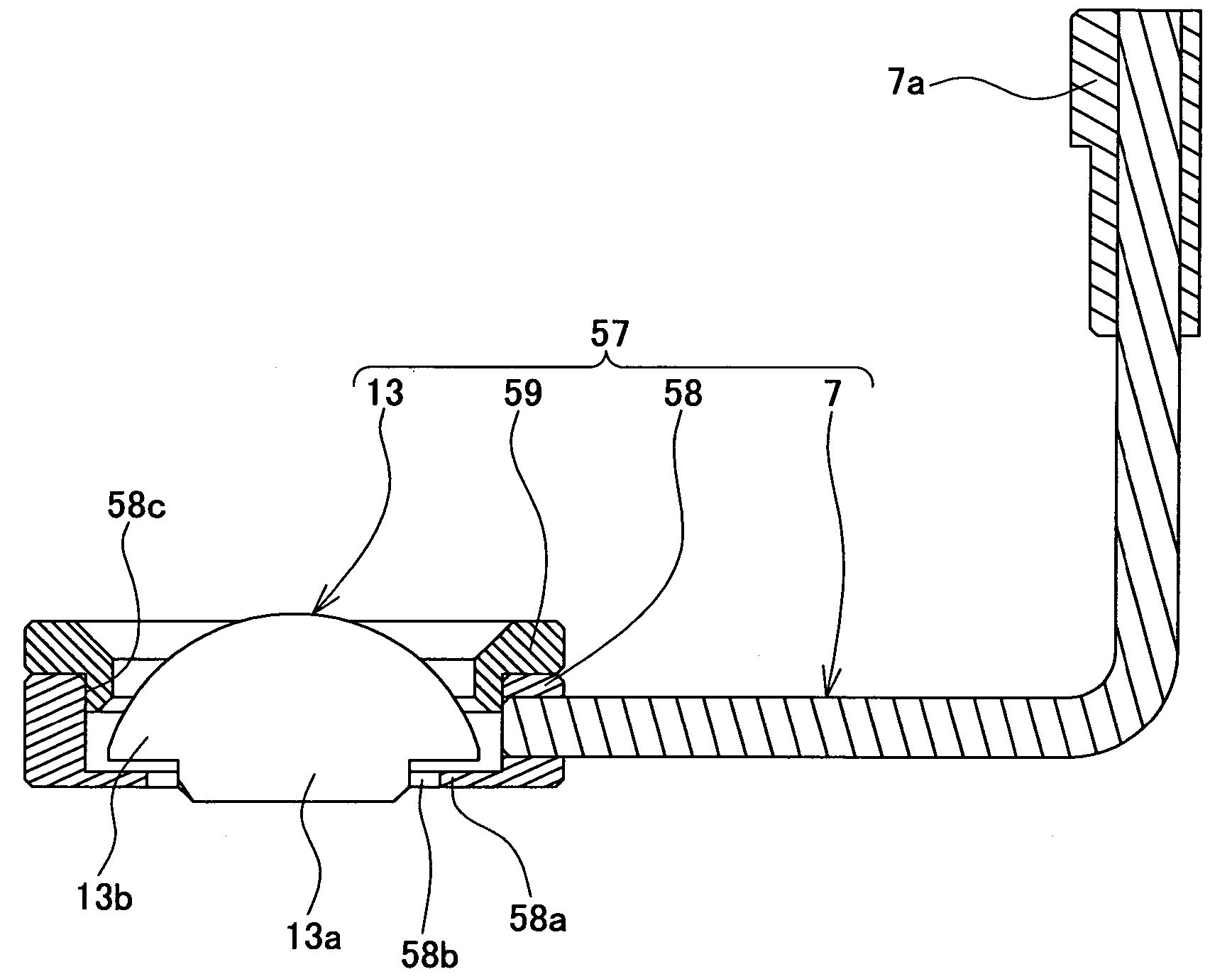

ActiveUS20060182001A1Record information storageOptical beam guiding meansOptical axisOptoelectronics

A solid immersion lens holder 8A is provided with a base part 50 attached to an objective lens 21, and a lens holding part 60 provided with the base part 50, extending in a direction of optical axis L of the objective lens 21, and arranged to hold a solid immersion lens 6 at an end portion thereof. The lens holding part holds the solid immersion lens so that light emerging from the solid immersion lens to the base part side travels through a region outside the lens holding part and toward the base part, and the base part has a light passing portion 53 which transmits the light toward the objective lens. Since the lens holding part extends in the direction of the optical axis L of the objective lens, even in a case where an observation object 11 is observed as located on a bottom surface of recess 13, the lens holding part will be prevented from contacting a side wall 13a of the recess. As a result, it becomes feasible to observe the observation object up to a region closer to the vicinity of peripheral part 11a of the observation object. This provides a solid immersion lens holder allowing observation up to a region closer to a peripheral part of an observation object even in a case where the observation object is set in a recess of a sample.

Owner:HAMAMATSU PHOTONICS KK

Solid immersion lens, focusing lens using solid immersion lens, optical pickup apparatus, optical recording reproducing apparatus and method of manufacturing solid immersion lens

InactiveUS20060077788A1More stablyIncrease bonding areaRecord information storageOptical beam guiding meansOptical pickupOptical recording

A convex portion is provided on the objective side of a solid immersion lens so as to protrude toward an optical recording medium and a difference-in-level portion or a concave portion is provided at least on a part of this convex portion. Then, there are provided a solid immersion lens for satisfactorily holding the bonding state of a lens holding member, a focusing lens using this solid immersion lens, an optical pickup apparatus, an optical recording and reproducing apparatus and a method of forming a solid immersion lens.

Owner:SONY CORP

Scanning optical system

ActiveUS20050073675A1Increase speedExtended service lifeRadiation pyrometryBeam/ray focussing/reflecting arrangementsPhoton emissionHigh resolution imaging

A scanned optical system for use in optical probing applications provides a large Field of View (FOV) for objective lenses having high Numerical Aperture (NA), such as Solid Immersion Lenses (SIL's). This enables high resolution imaging of semiconductor devices for such applications as laser probing, TIVA / LIVA, OBIRCH, and photon emission timing analysis. A hybrid scanning optics configuration is disclosed to provide high resolution imaging over a small area along with low resolution imaging over a large area.

Owner:DCG SYST

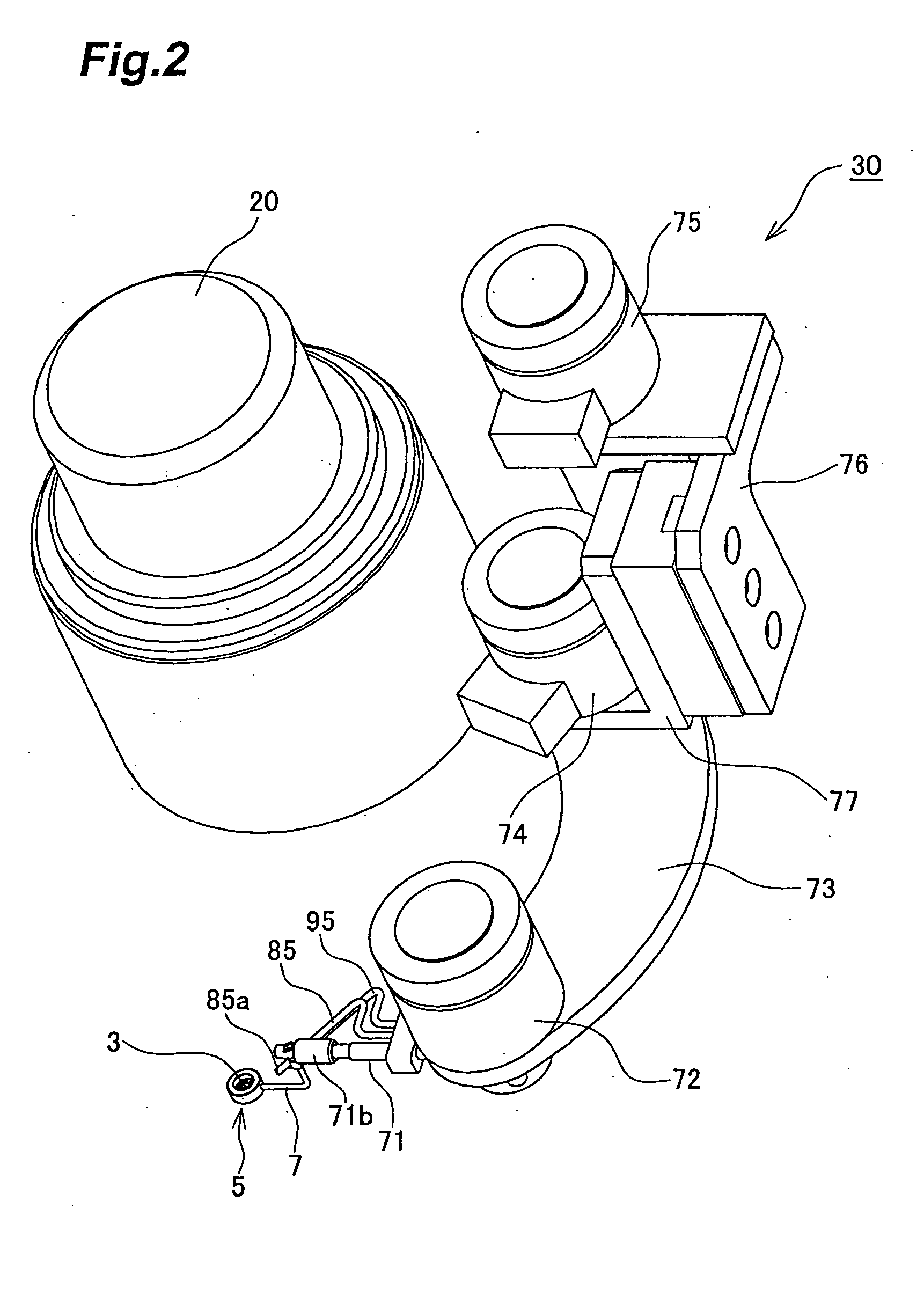

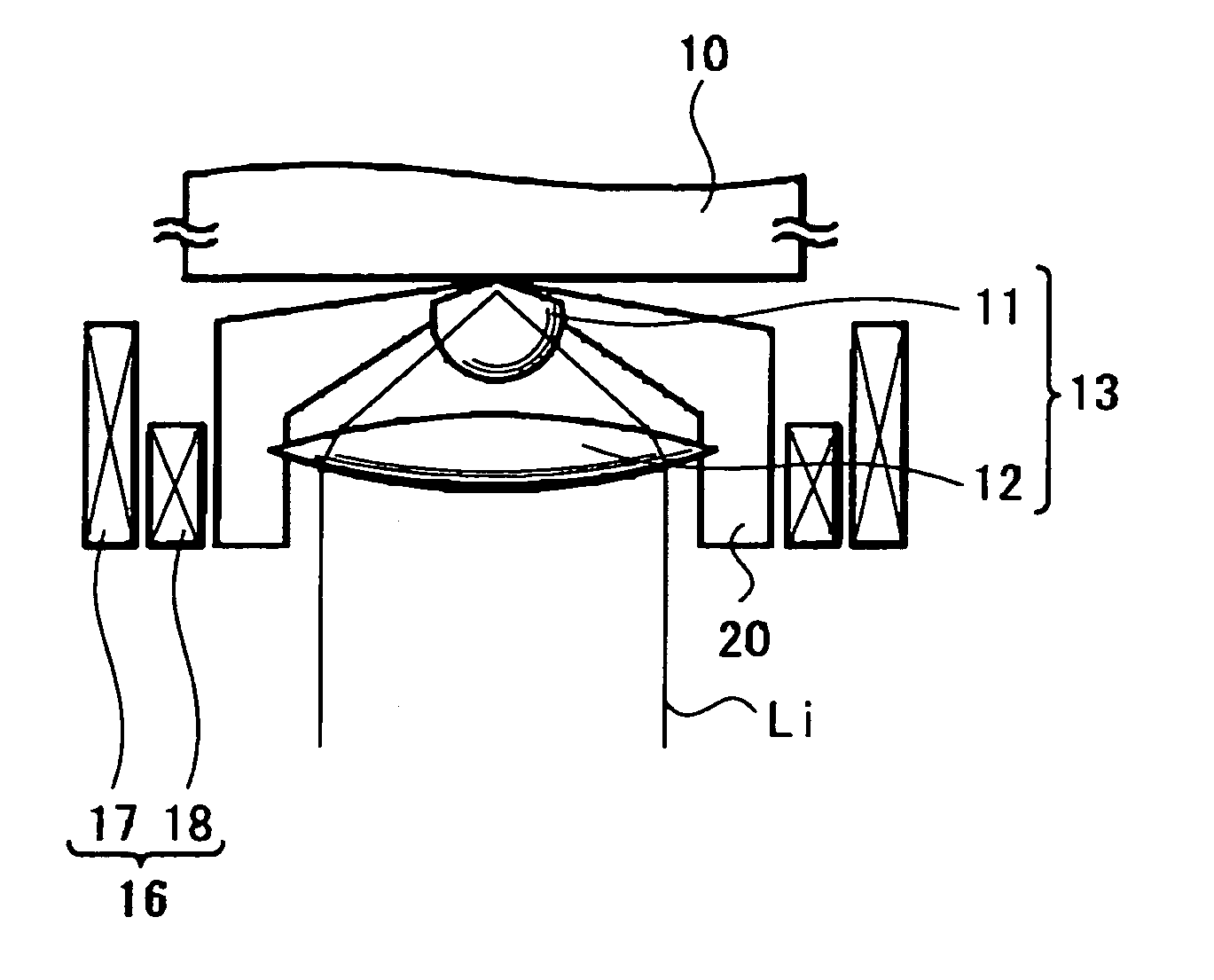

Solid immersion lens moving device and microscope using the same

InactiveUS20050094258A1High resolutionEasy to getMaterial analysis by optical meansMicroscopesSolid immersion lensMicroscope

A solid immersion lens moving device is provided with a first arm member 71, to which is connected a solid immersion lens holder 5 that supports a solid immersion lens 3; a first arm member rotation source 72, which rotates this first arm member 71 within an X-Y plane that is substantially parallel to an observed object; a second arm member 73, holding this first arm member rotation source 72; and a second arm member rotation source 74, having a rotation axis at a position that is non-coaxial to the rotation axis of first arm member rotation source 72 and rotating second arm member 73 within the X-Y plane. By enabling the movement of solid immersion lens 3 to a desired position within the X-Y plane by the rotation of the two arm members 71 and 73, the need to make the component parts long in the orthogonal X and Y directions is eliminated and a simple arrangement that occupies a small area is provided. A solid immersion lens moving device, with which low cost is realized while realizing compactness of the device, and a microscope equipped with the same are thereby realized.

Owner:HAMAMATSU PHOTONICS KK

Optical pickup device and recording and/or reproducing apparatus

InactiveUS20060274610A1Accurate detectionEasy to controlCombination recordingNanoinformaticsOptical pickupSolid immersion lens

An optical pickup device includes an objective lens (2), with a numerical aperture (NA) being not less than 1, having a solid immersion lens (1) which is made up by a spherical portion (1a) and a flat portion (1b) parallel to a surface (101a) of an optical disc (101). The component of the reflected light from the optical disc in the polarized state perpendicular to the polarized state of the reflected light which prevails when the distance between the surface of the optical disc and the flat portion of the solid immersion lens is zero is detected. The so detected light intensity is associated with the distance between the optical disc surface and the solid immersion lens to accurately detect the minute gap between the optical disc and the solid immersion lens.

Owner:SONY CORP

Method of formation of nanowires and method of manufacture of associated optical component

InactiveUS20120021554A1Easy to controlImprove the problemPolycrystalline material growthMaterial analysis using wave/particle radiationNanowireLight beam

A method of formation of nanowires at a surface of a substrate attached to a solid immersion lens. The method includes formation of a catalyst element at the surface of the substrate and growth of nanowires from the catalyst element formed at the surface of the substrate. The catalyst element is a metal nanoparticle and the formation of the catalyst element at the surface of the substrate deposits the metal nanoparticle using a light beam focused by the solid immersion lens at the surface of the substrate.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Microscope and sample observation method

ActiveUS20060176548A1Easy to implementMaterial analysis by optical meansMicroscopesDevice materialOptical axis

For a semiconductor device S as an inspected object, there are provided an image acquisition part 1, an optical system 2 including an objective lens 20, and a solid immersion lens (SIL) 3 movable between an insertion position including an optical axis from the semiconductor device S to the objective lens 20 and a standby position off the optical axis. Then observation is carried out in two control modes consisting of a first mode in which the SIL 3 is located at the standby position and in which focusing and aberration correction are carried out based on a refractive index n0 and a thickness t0 of a substrate of the semiconductor device S, and a second mode in which the SIL 3 is located at the insertion position and in which focusing and aberration correction are carried out based on the refractive index n0 and thickness t0 of the substrate, and a refractive index n1, a thickness d1, and a radius of curvature R1 of SIL 3. This provides a microscope and a sample observation method capable of readily performing observation of the sample necessary for an analysis of microstructure or the like of the semiconductor device.

Owner:HAMAMATSU PHOTONICS KK

Lens holding member, focusing lens using lens holding member, optical pickup apparatus and optical recording and reproducing apparatus

InactiveUS20060077789A1Increase tilt marginReduce thicknessRecord information storageOptical beam guiding meansOptical pickupOptical recording

In a lens holding member for holding a solid immersion lens, when a difference-in-level portion and / or slant face is constructed at least on a part of the objective side surface, a tilt margin which can be applied to a near field optical recording and reproduction solid immersion lens can be maintained. In a focusing lens using such lens holding member, the optical pickup apparatus and the optical recording and reproducing apparatus, stable transportation between the lens and the optical recording medium can be improved.

Owner:SONY CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com