Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

269results about How to "Easy to sew" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

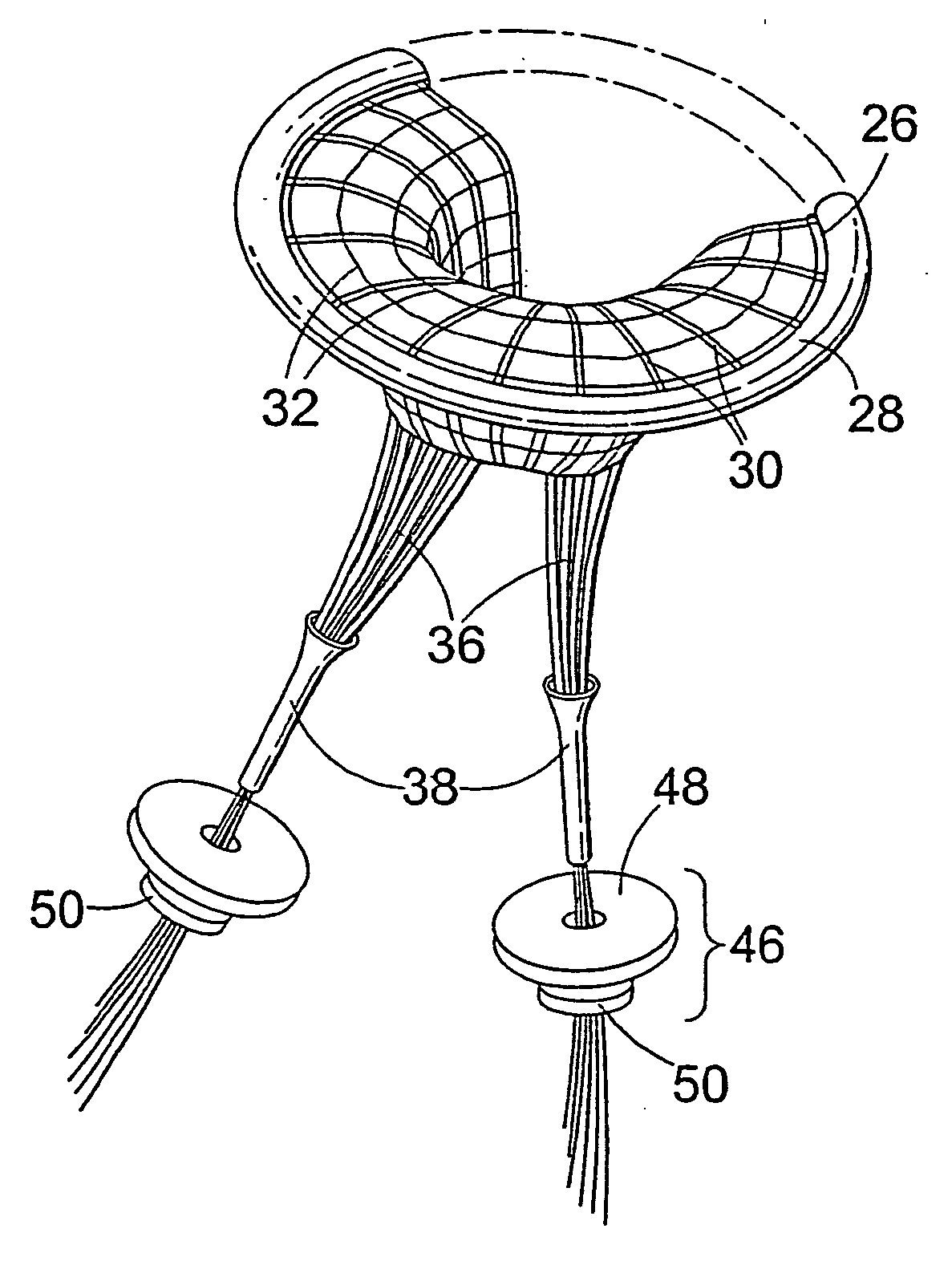

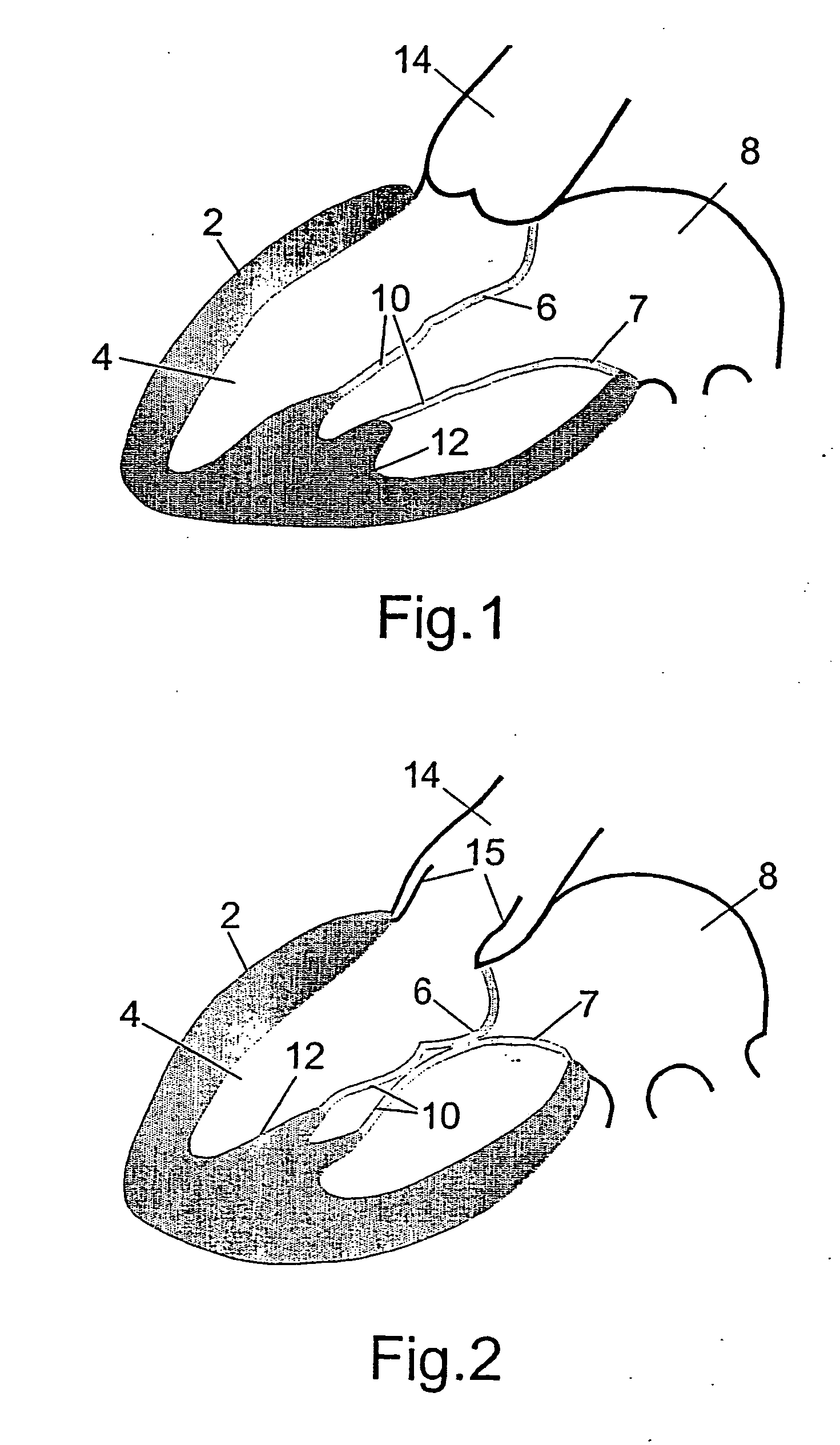

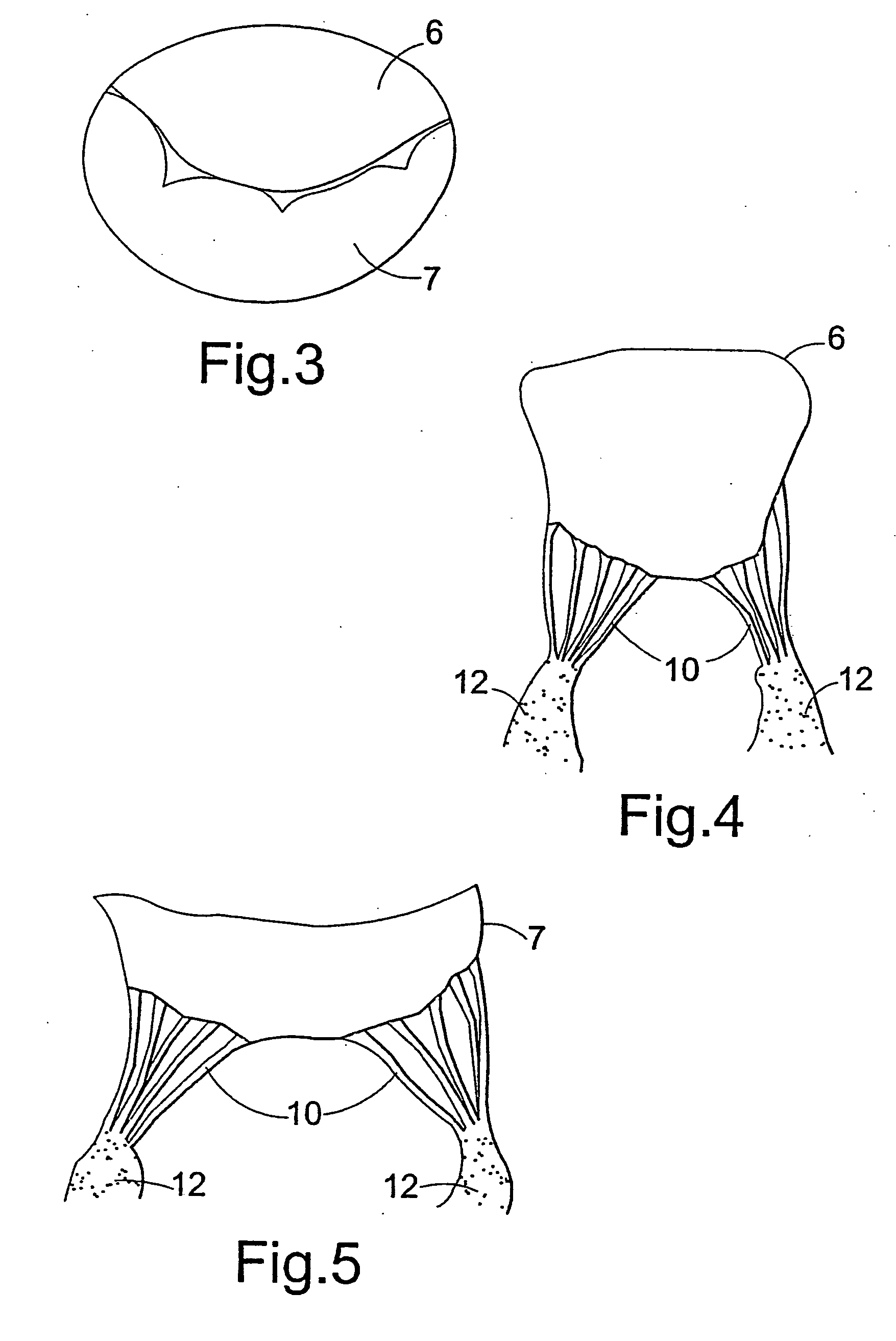

Mitral valve prosthesis

The present invention relates to a mitral valve prosthesis comprising flexible leaflet-like elements with curved coapting surfaces and means for maintaining continuity of the valve when inserted into the mitral annulus, which mimics the continuity between the papillary muscles, the chordae tendineae, the mitral valve leaflets and the mitral annulus of a natural valve. The present invention also relates to a method of fitting such a prosthesis to heart of a patient.

Owner:THE UNIV COURT OF THE UNIV OF GLASGOW

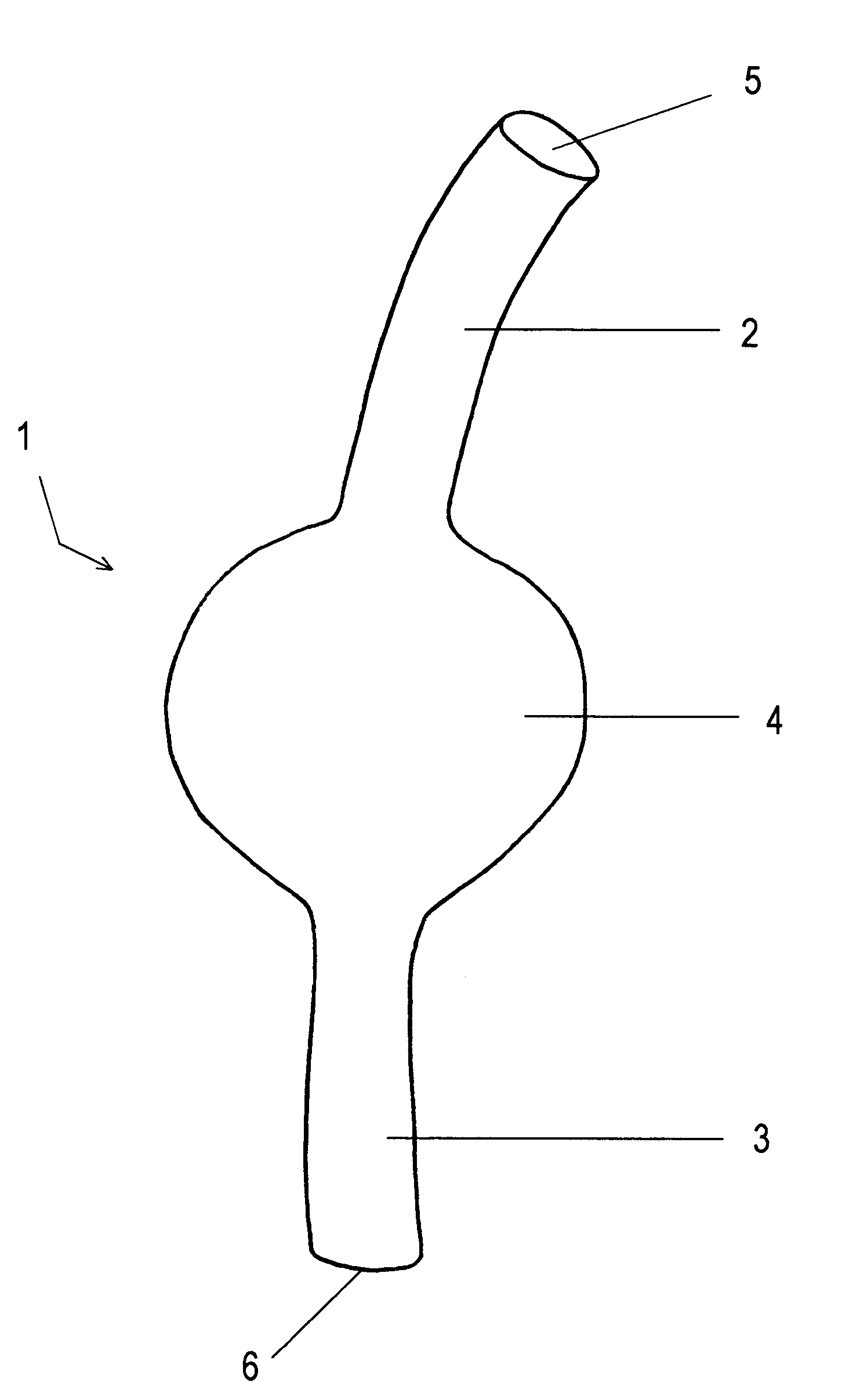

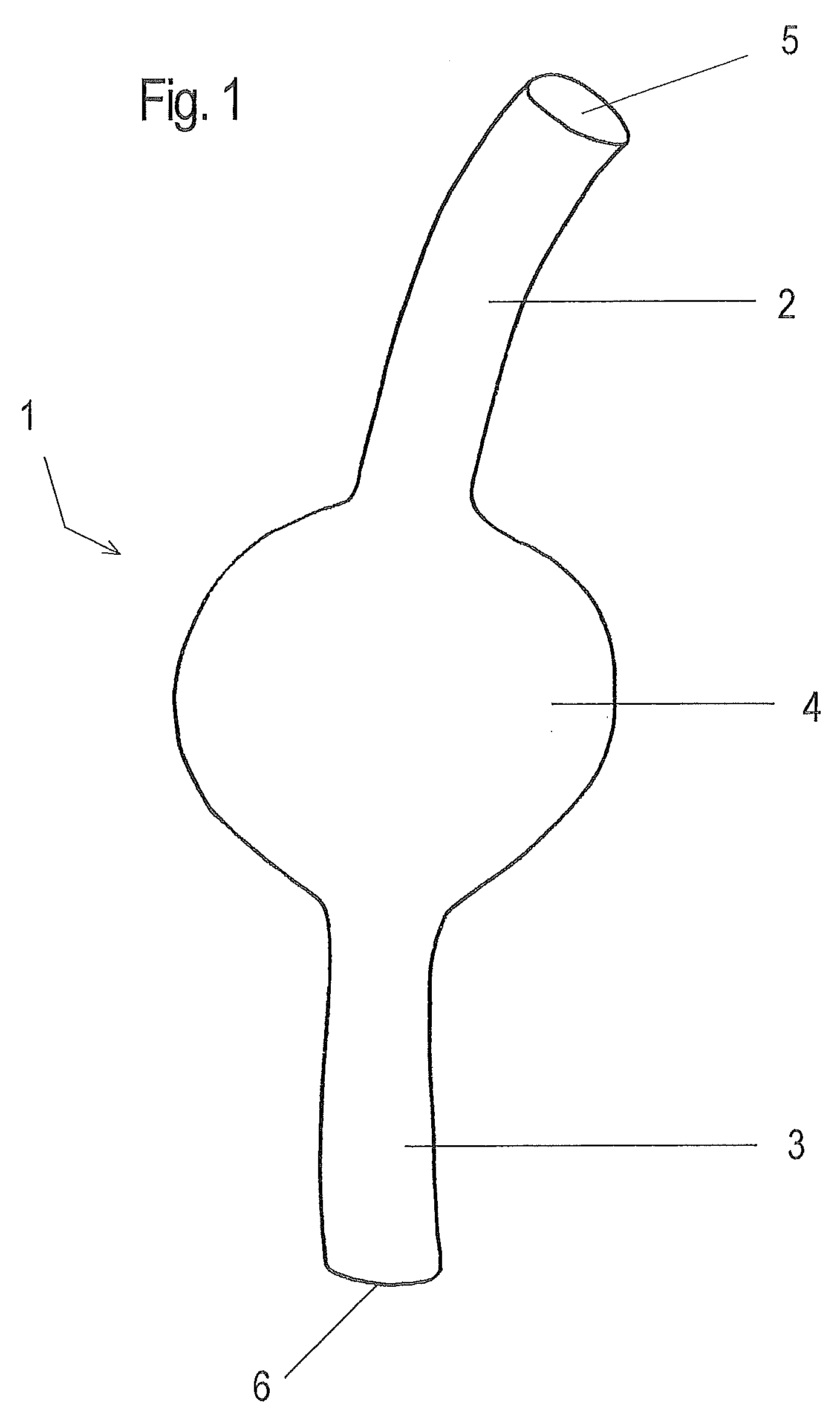

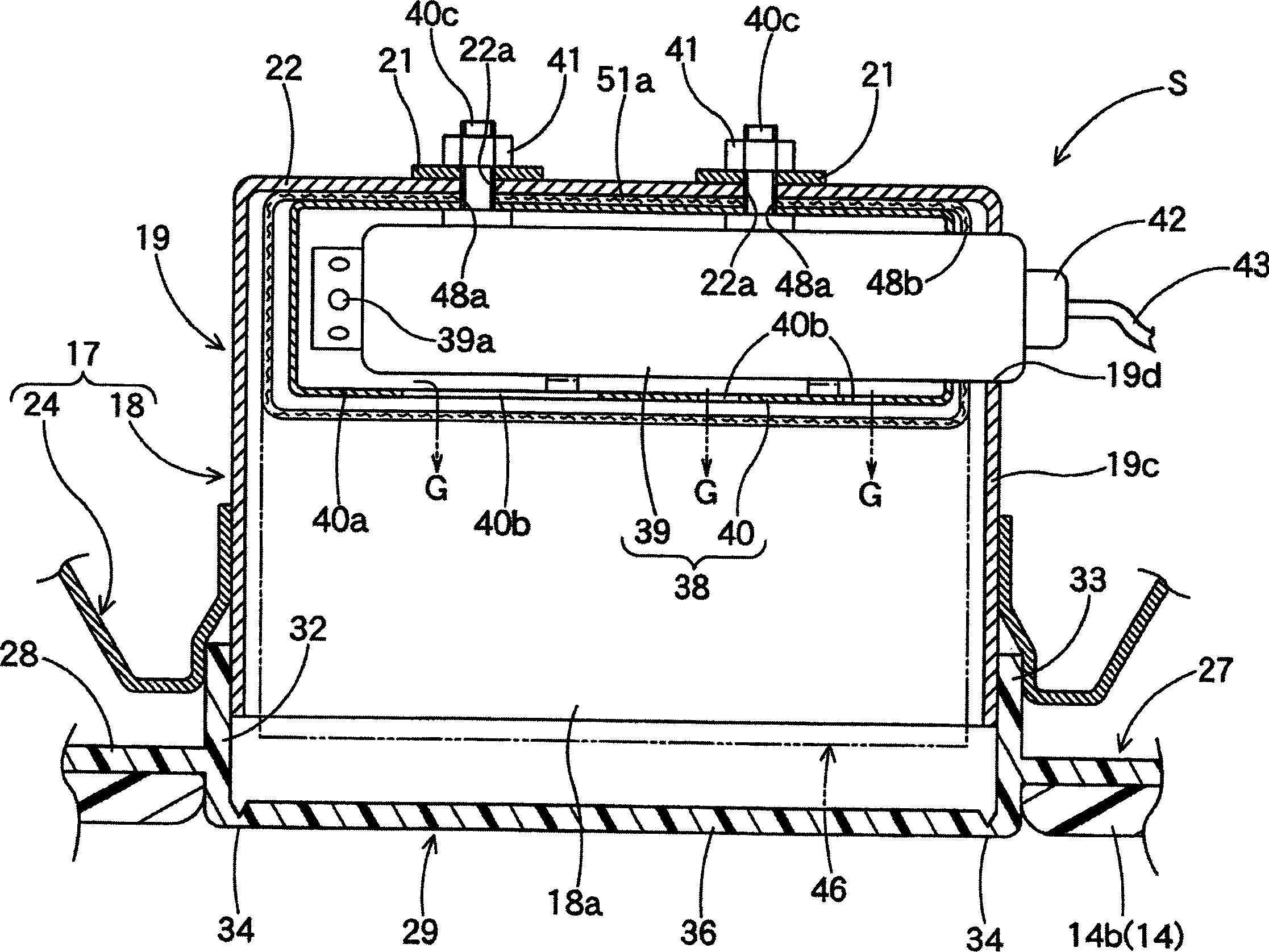

Medical implant

InactiveUS7513914B2Reduce obesityEasy to sewIntravenous devicesTubular organ implantsSmall intestineBiomedical engineering

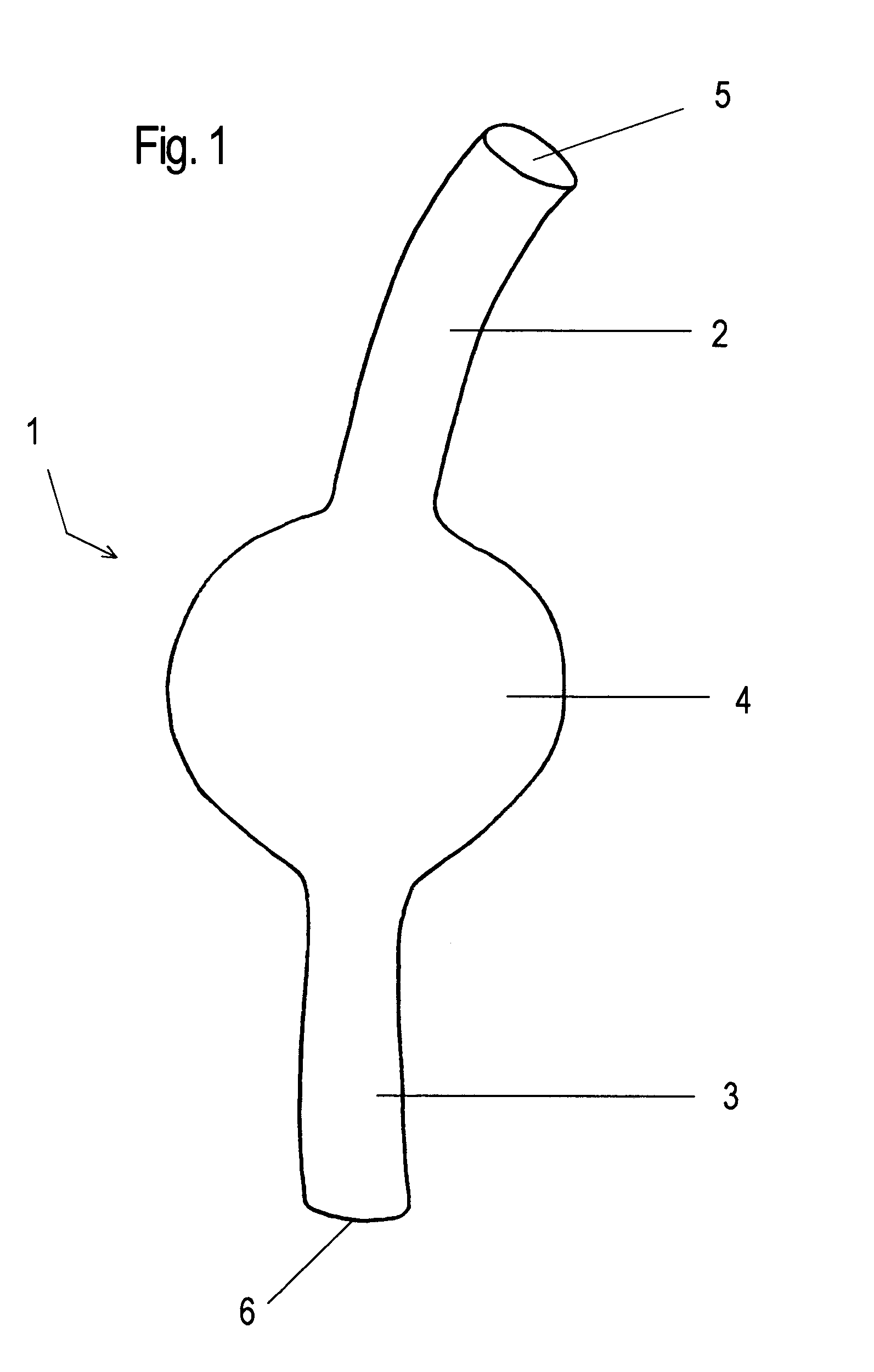

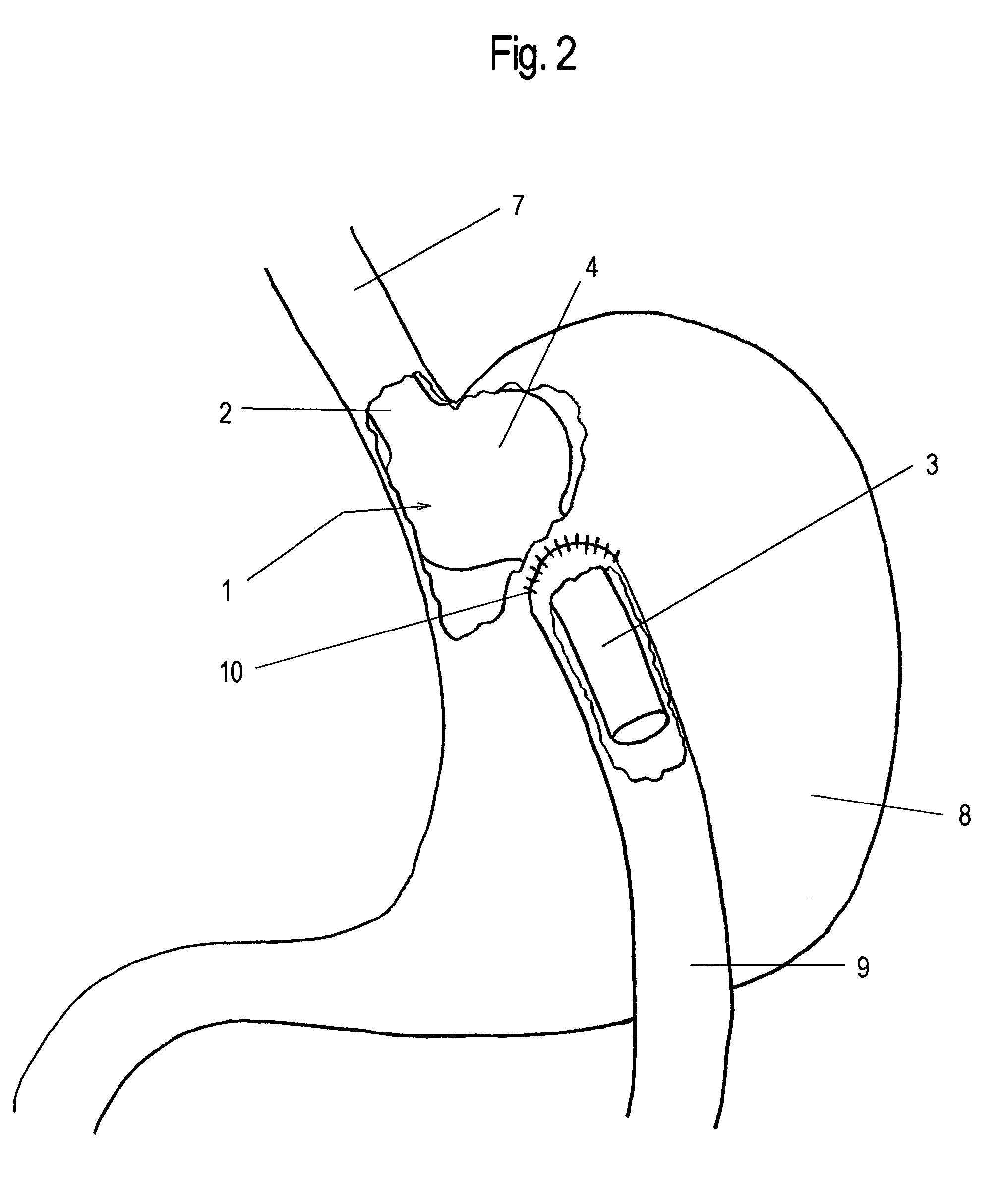

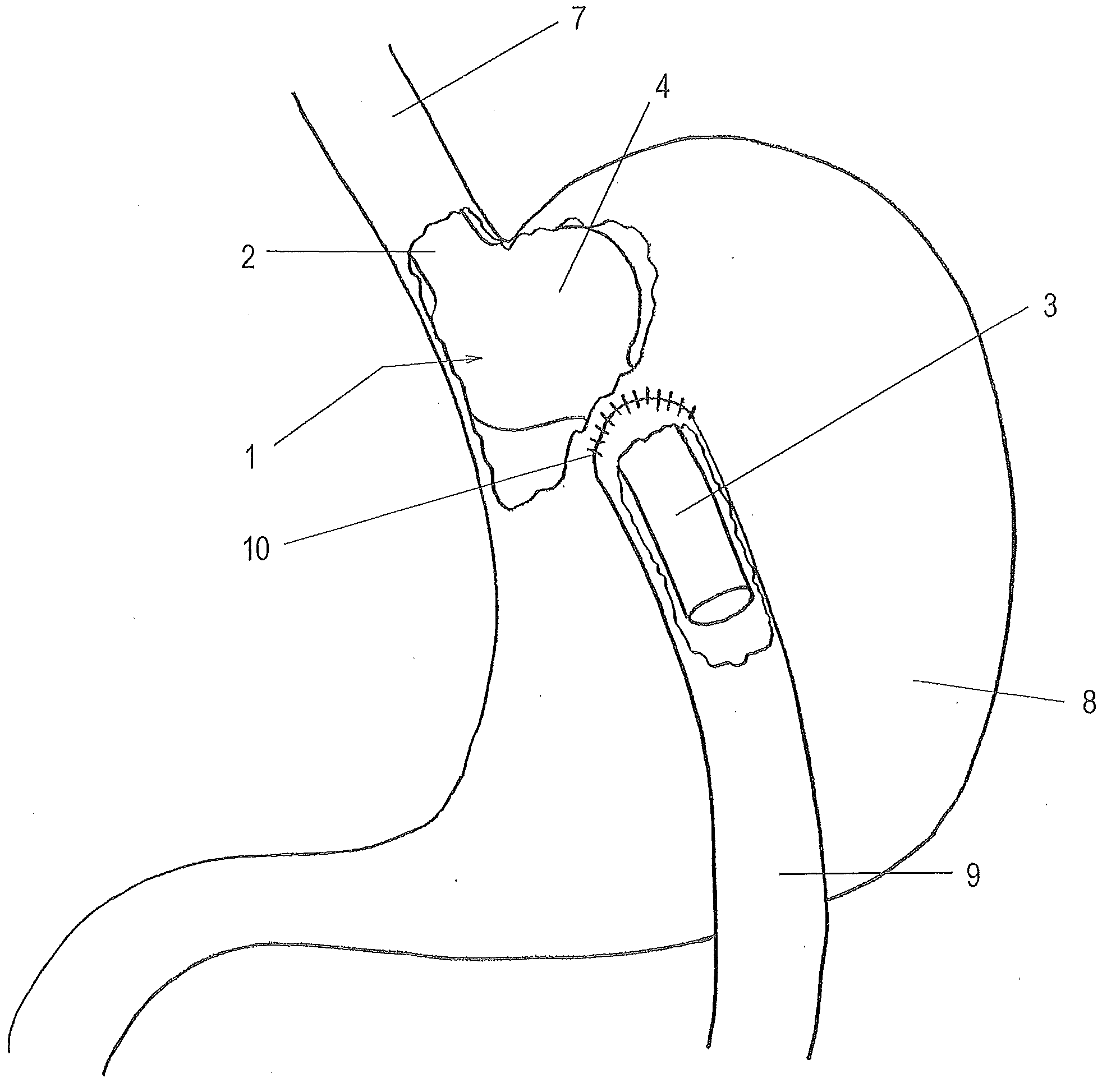

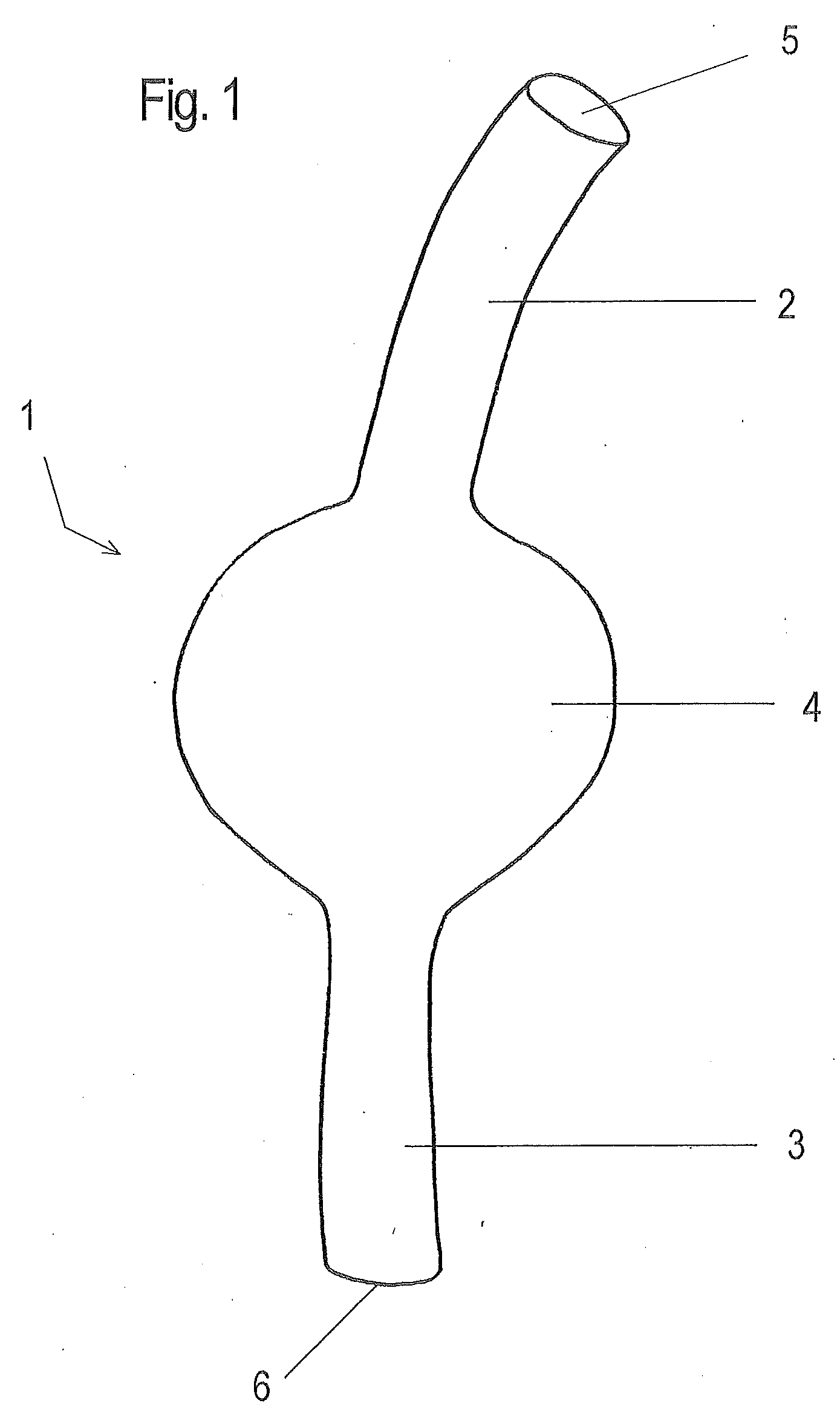

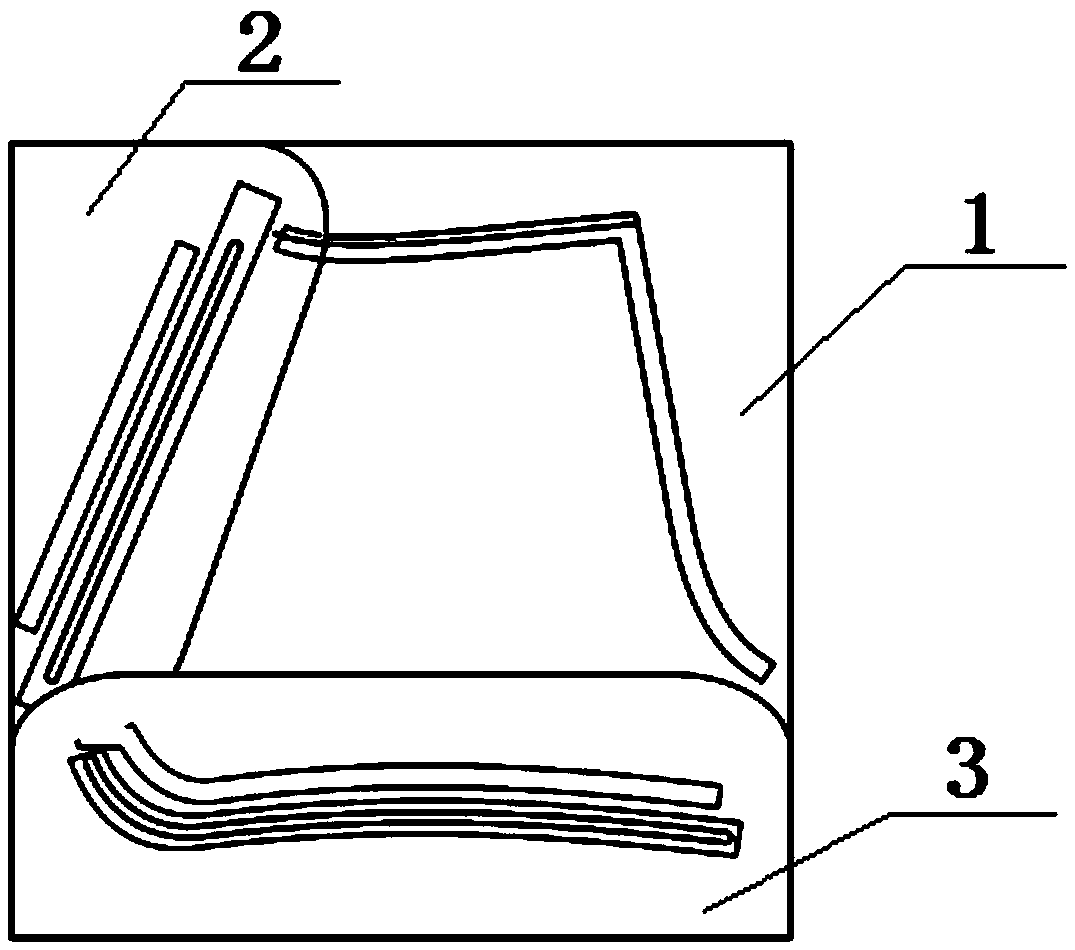

A medical implant is disclosed, said implant having a flexible hollow body (1) which can be implanted inside the stomach (8) of a patient and which has a first tube-like end section (2) and a second tube-like end section (3), wherein the first tube-like end section (2) is dimensioned such that it can be fitted into the esophagus (7) of the patient, and the second tube-like end section (3) is dimensioned such that it can be connected to the small intestine loop (9) of the patent in a sealing manner.

Owner:NOVINEON HEALTHCARE TECH PARTNERS

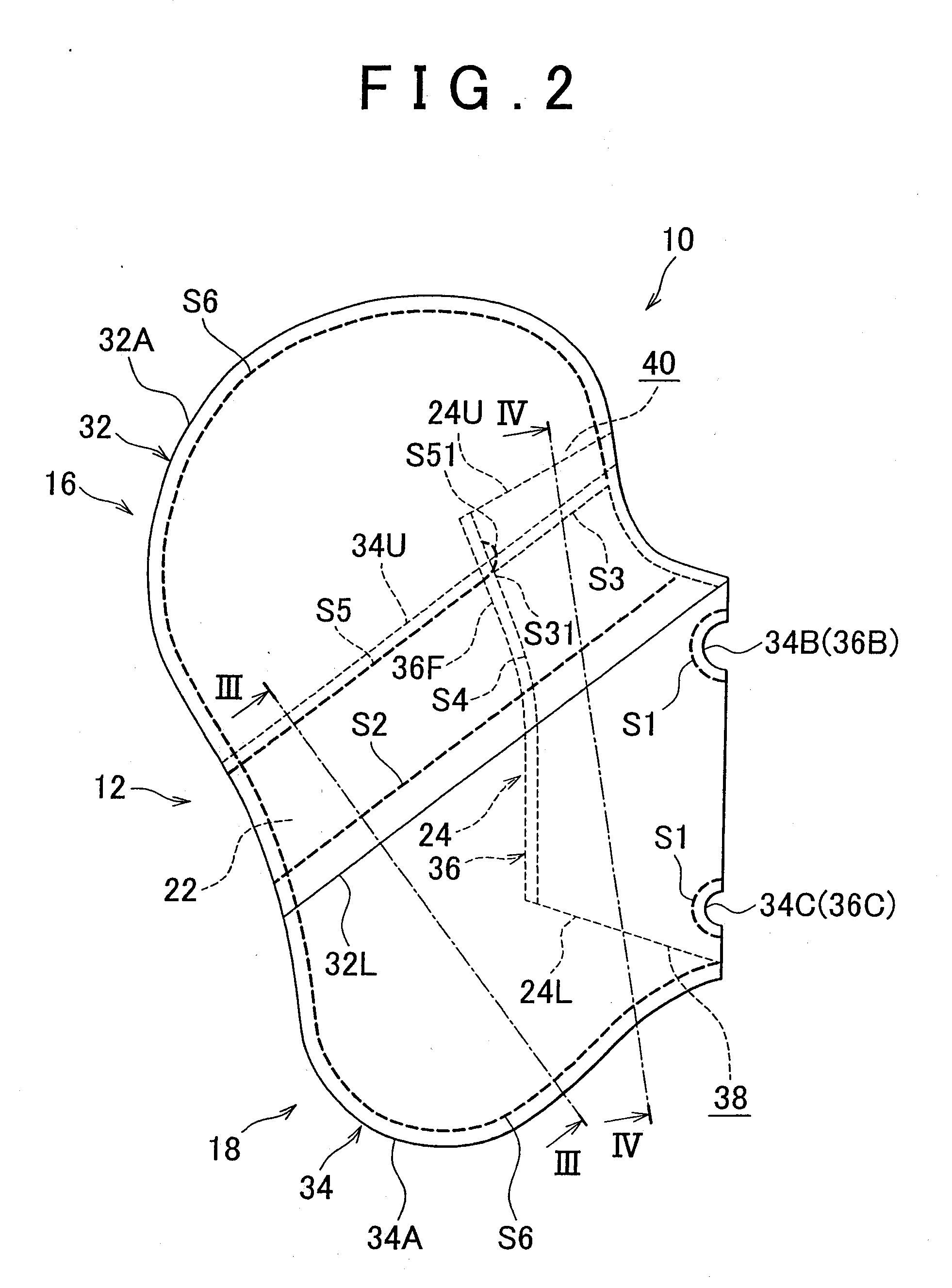

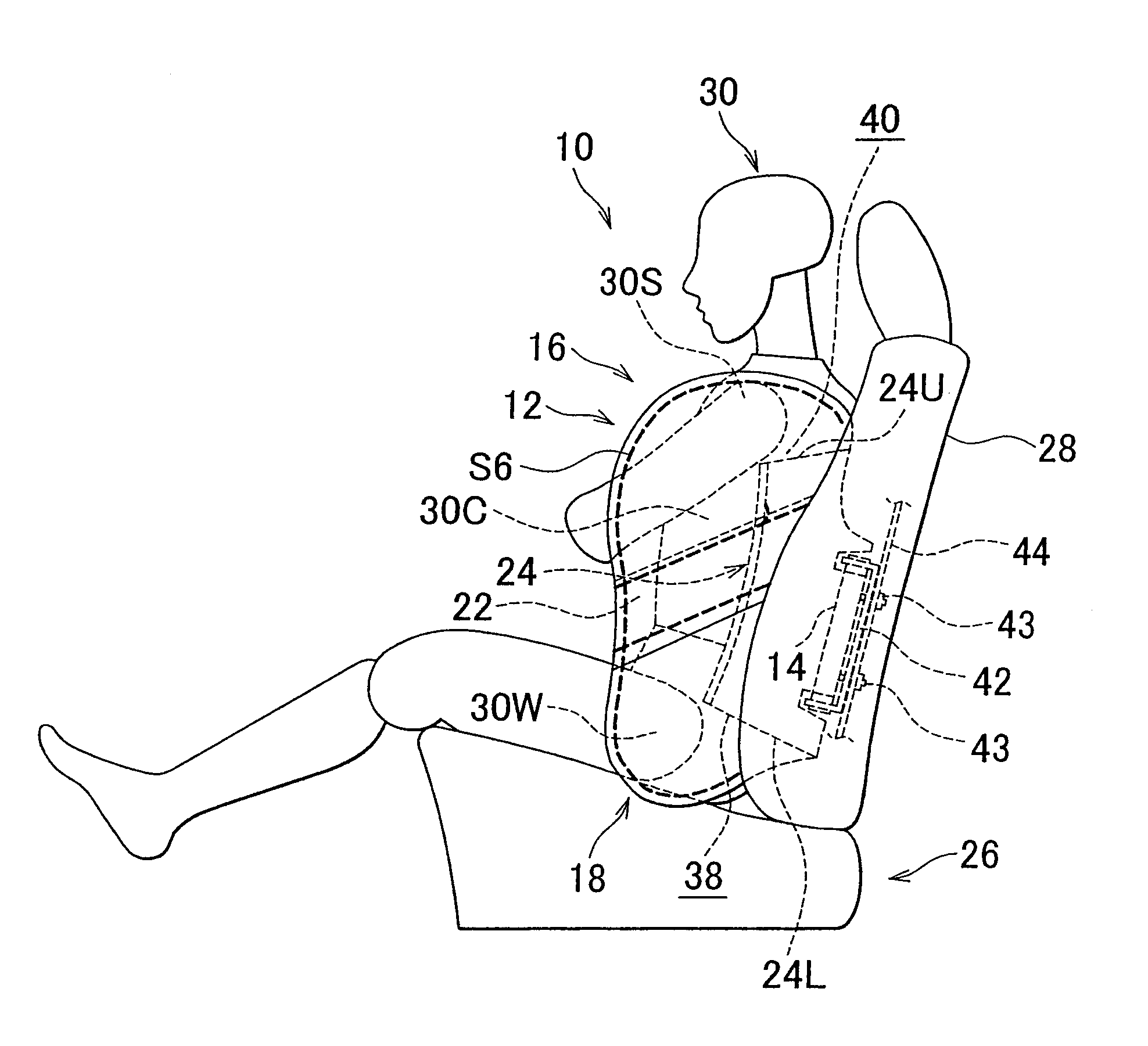

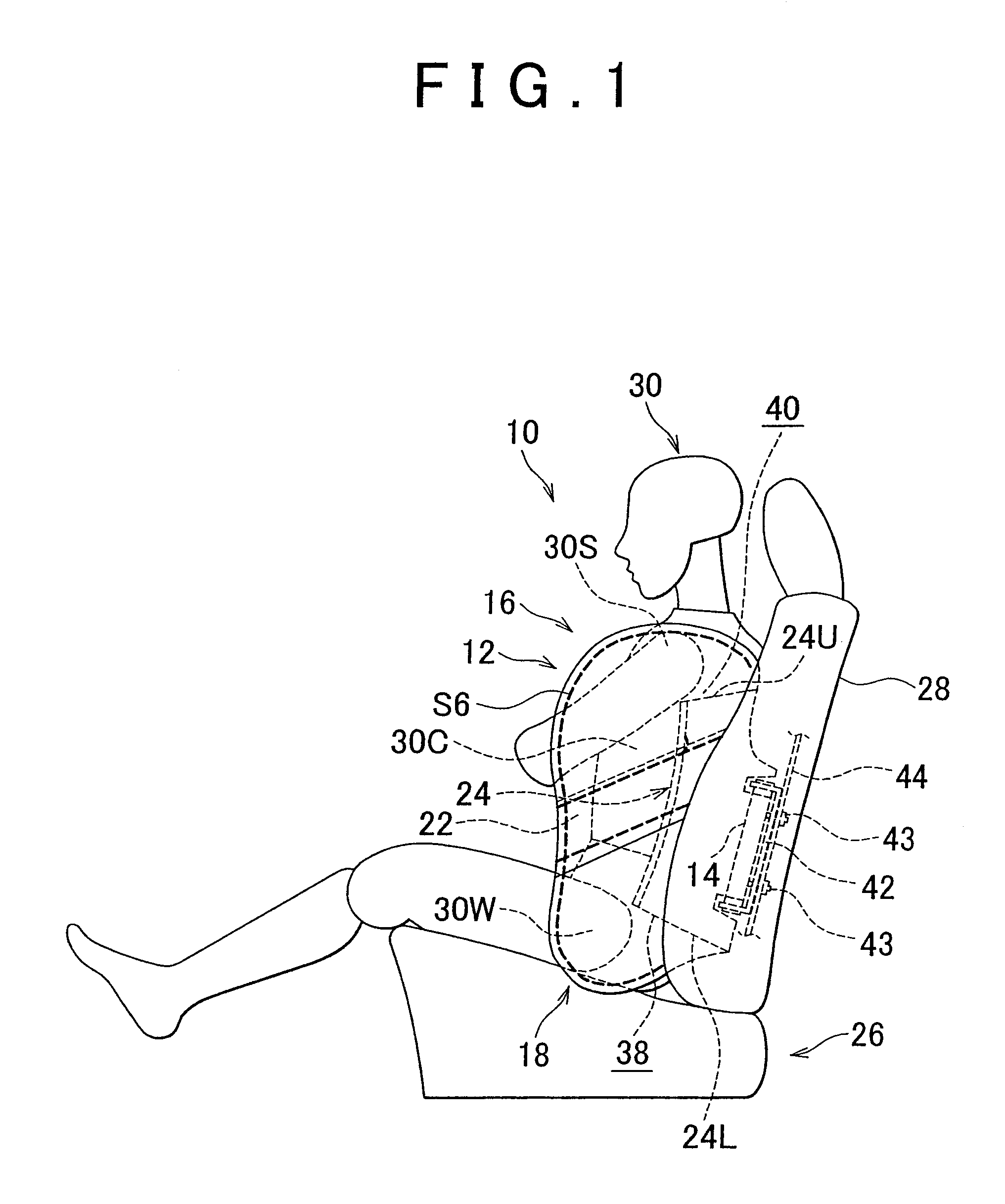

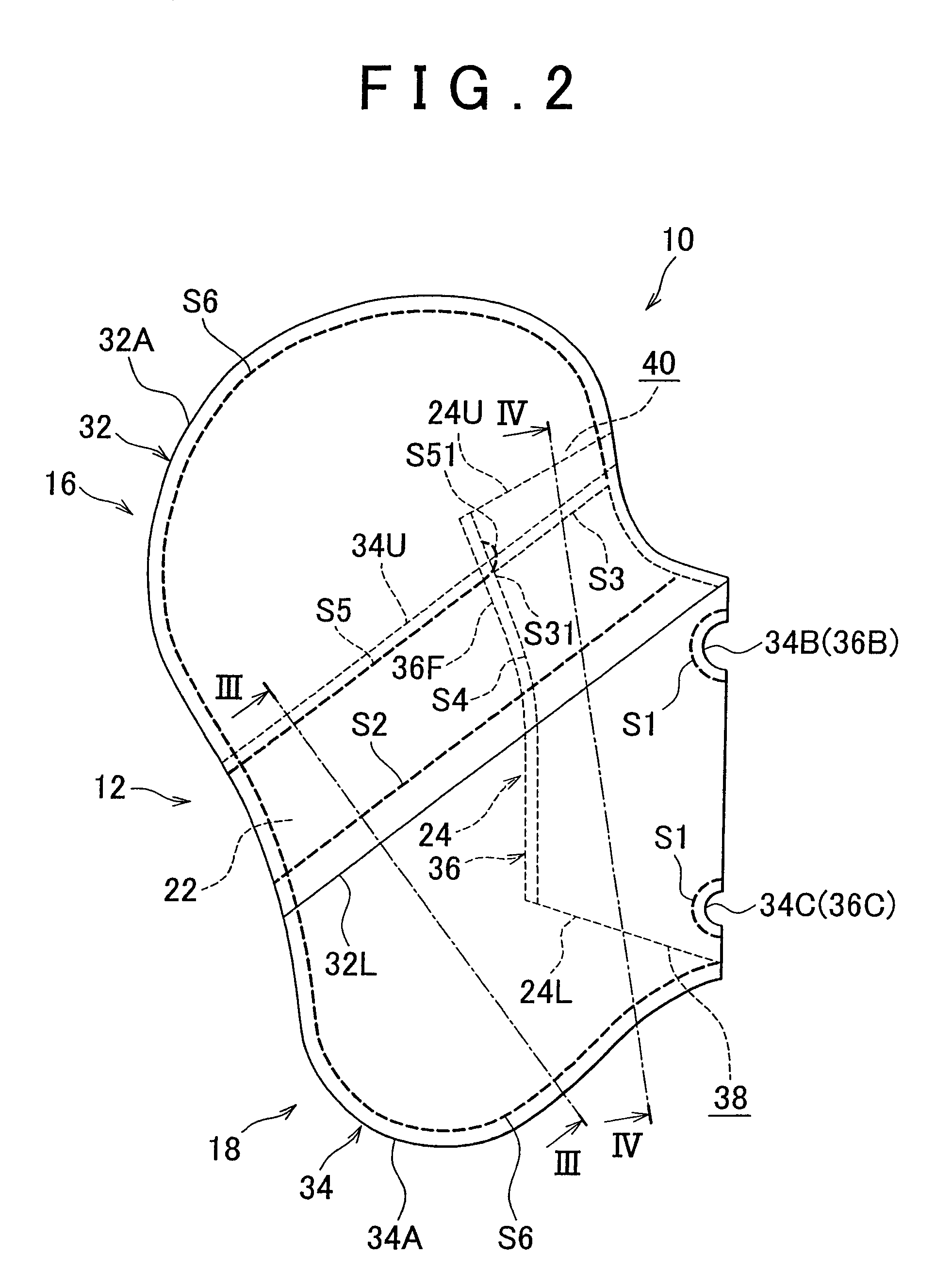

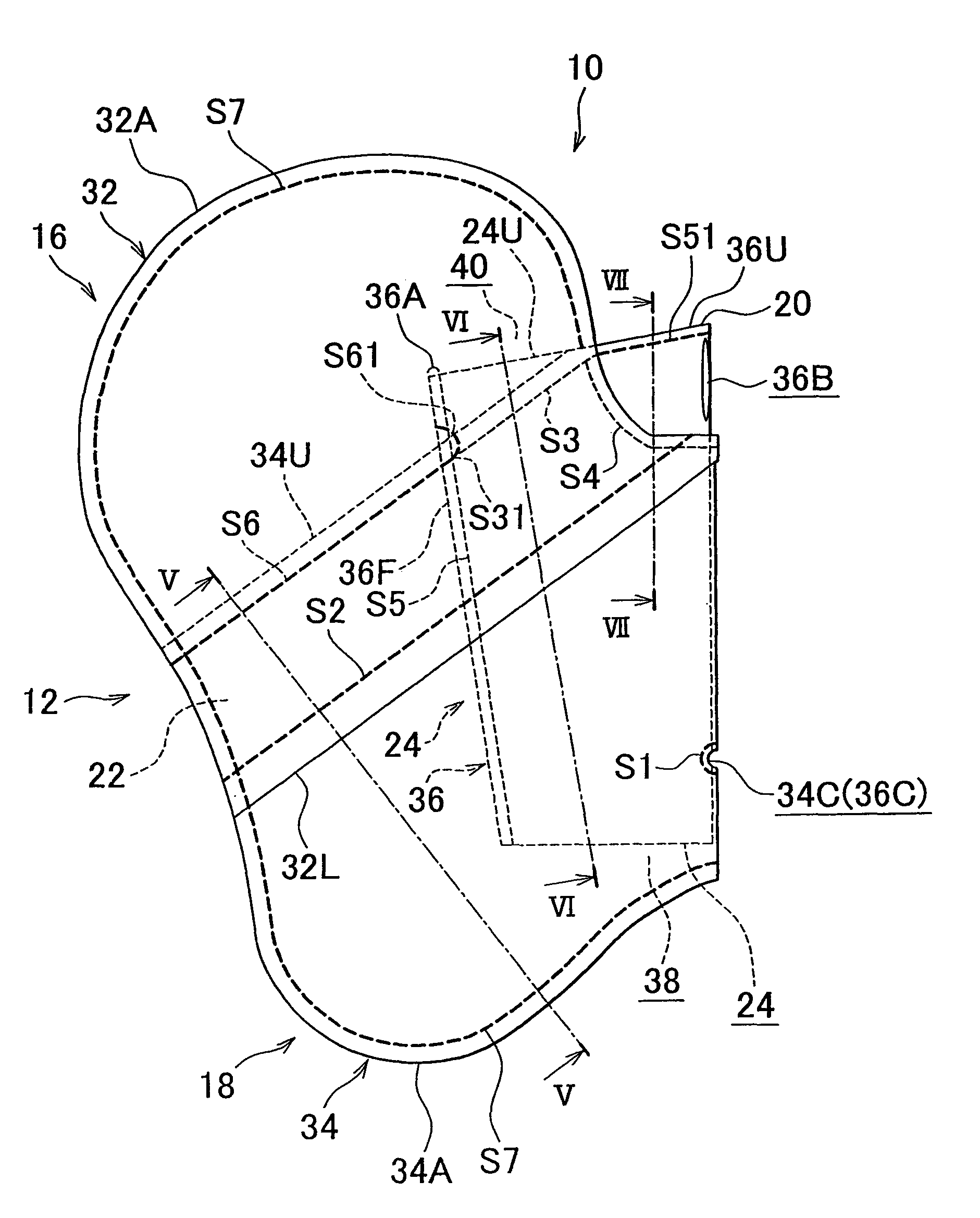

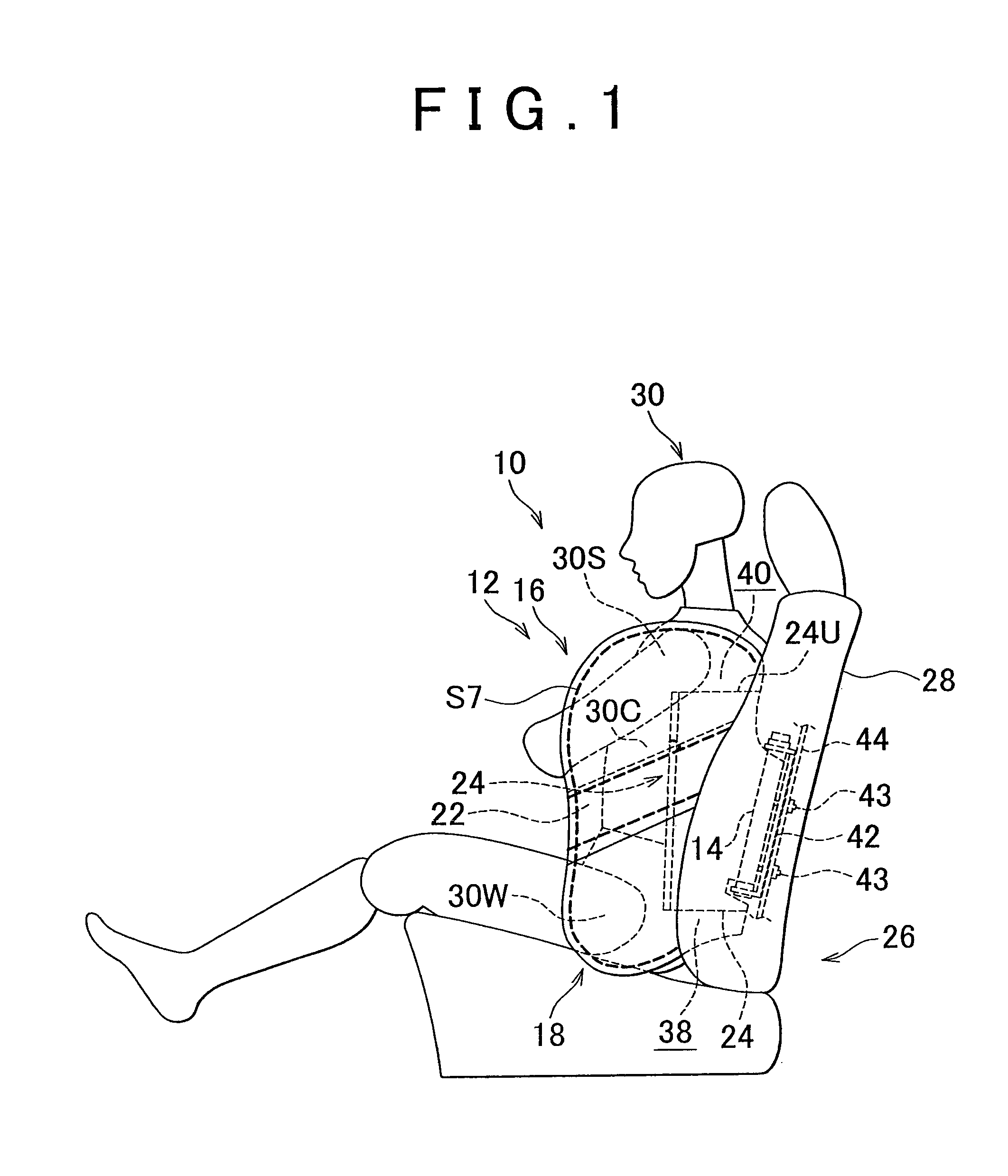

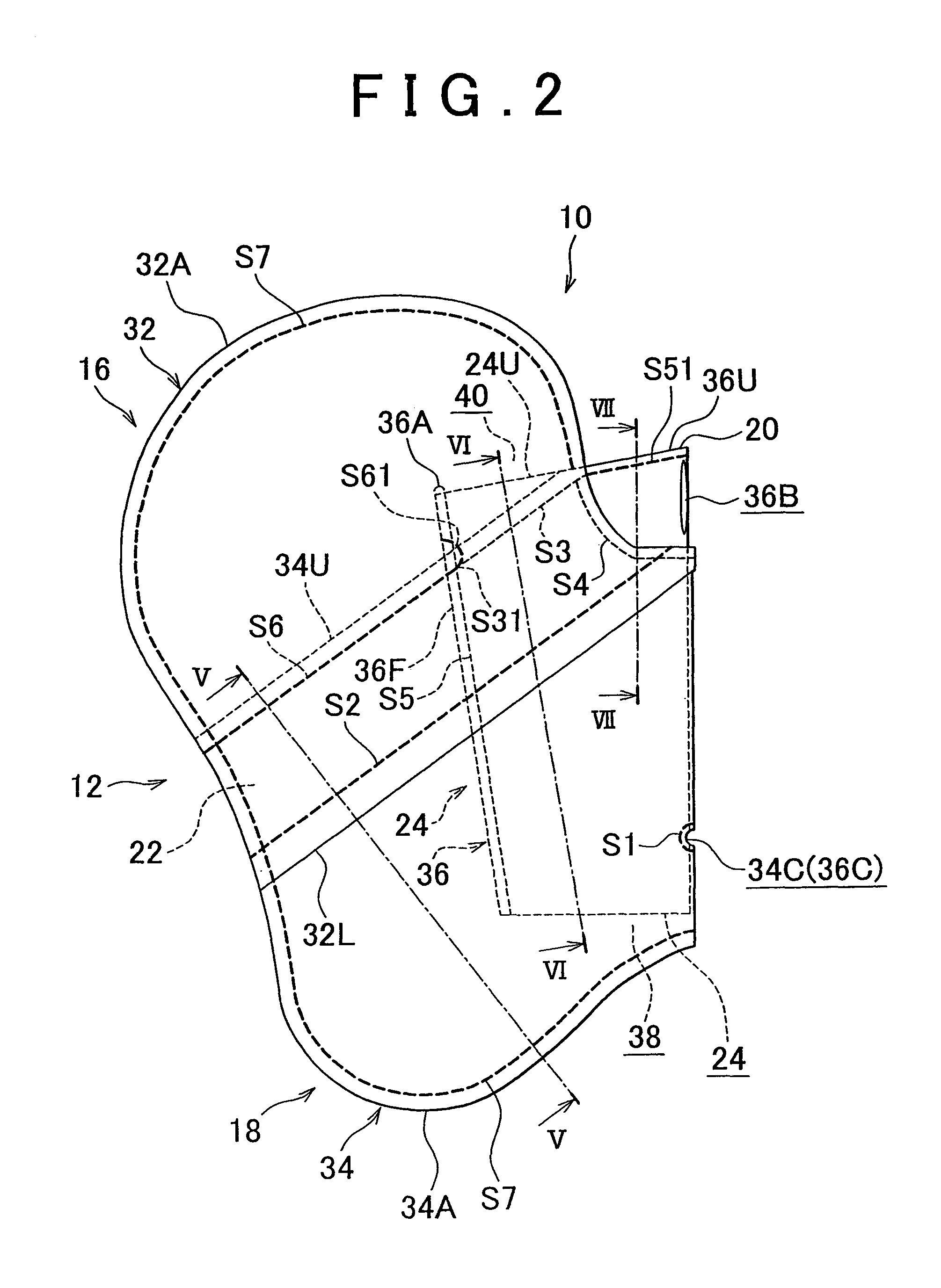

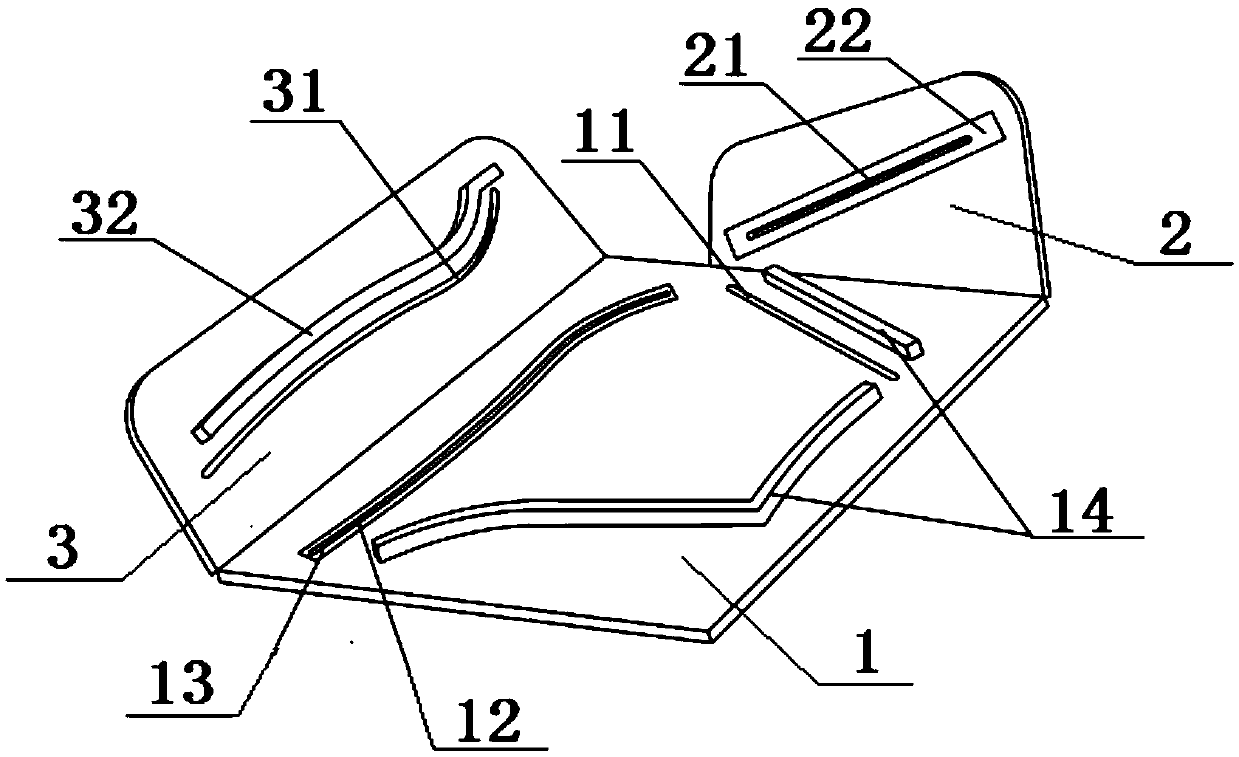

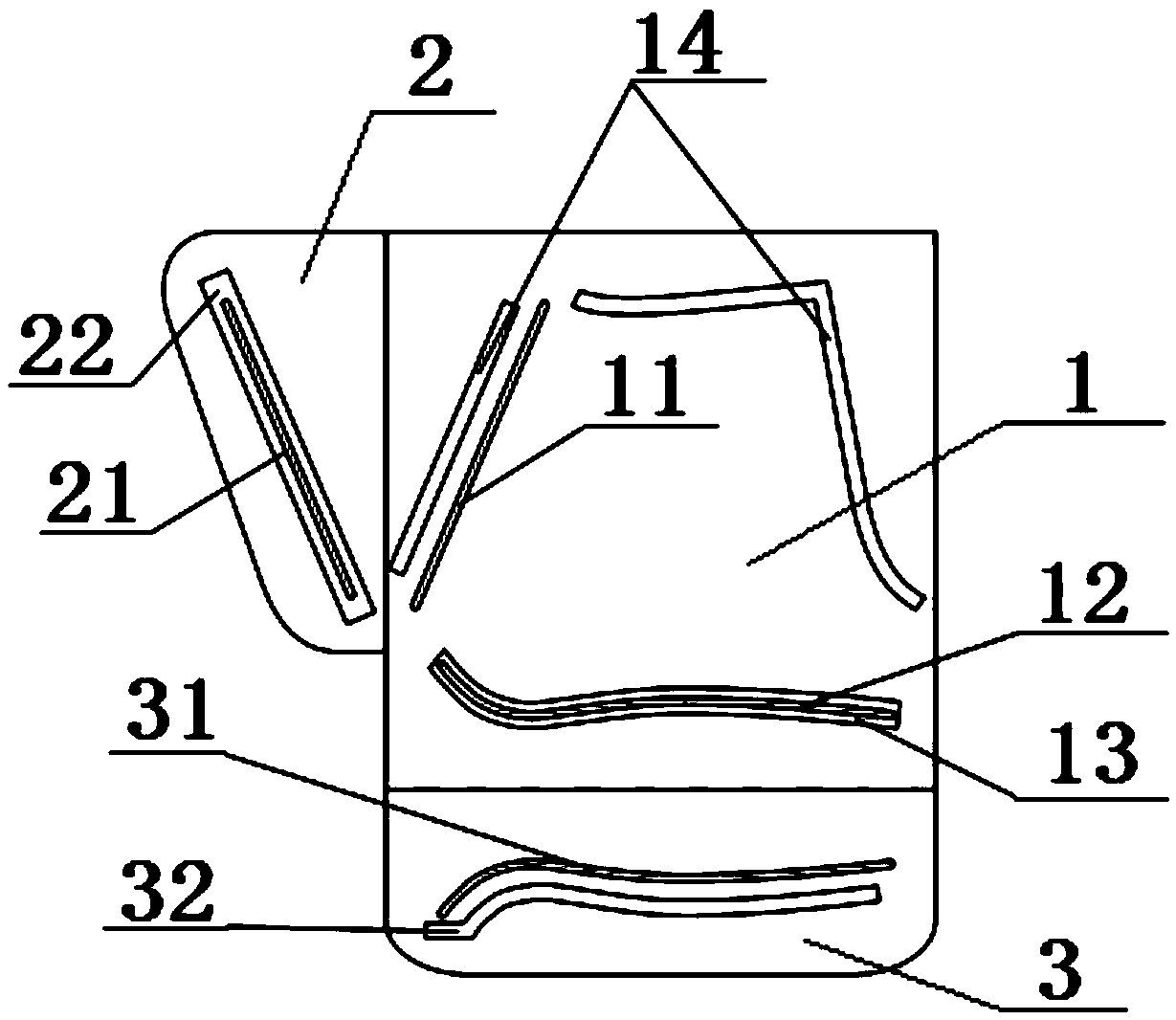

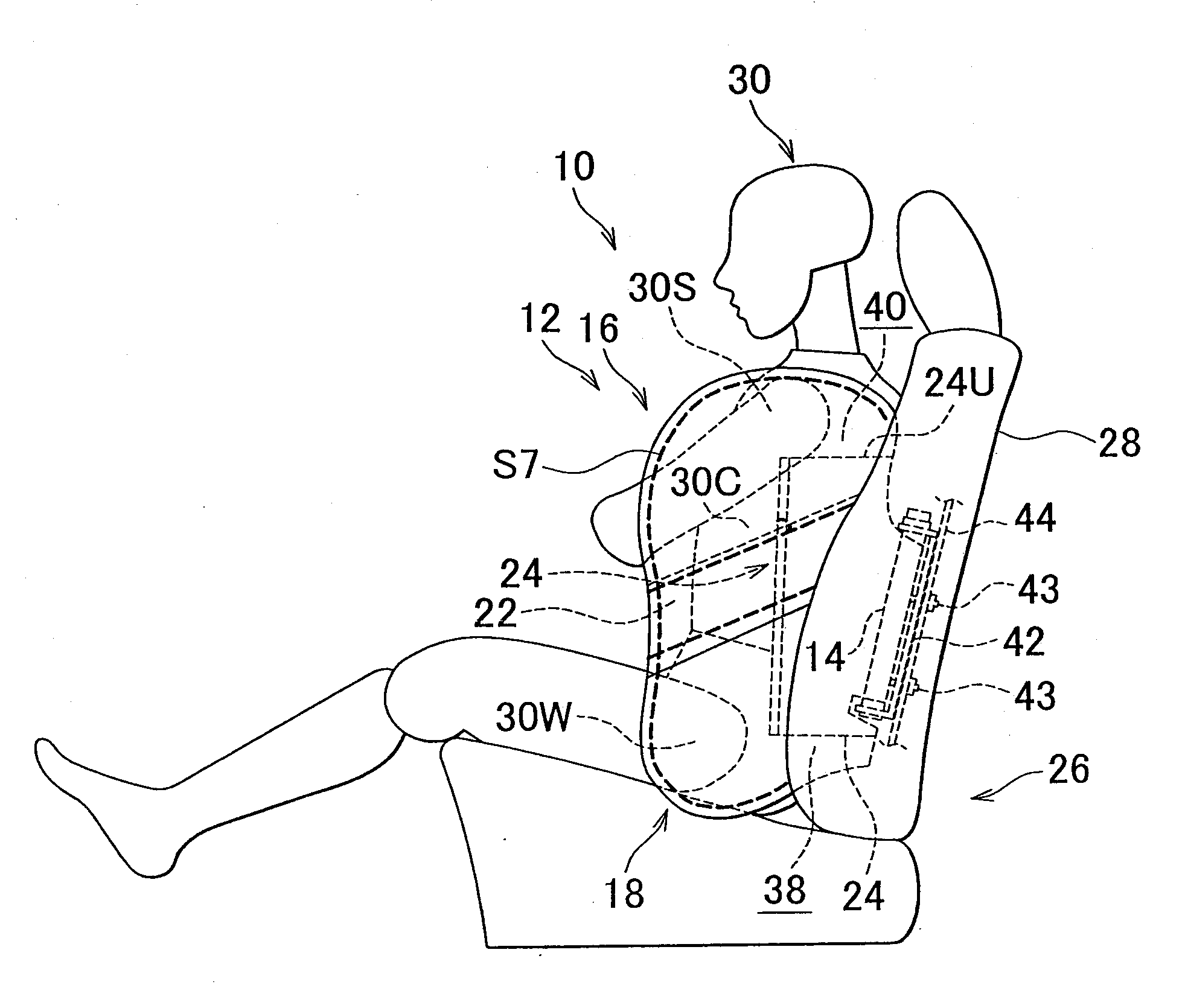

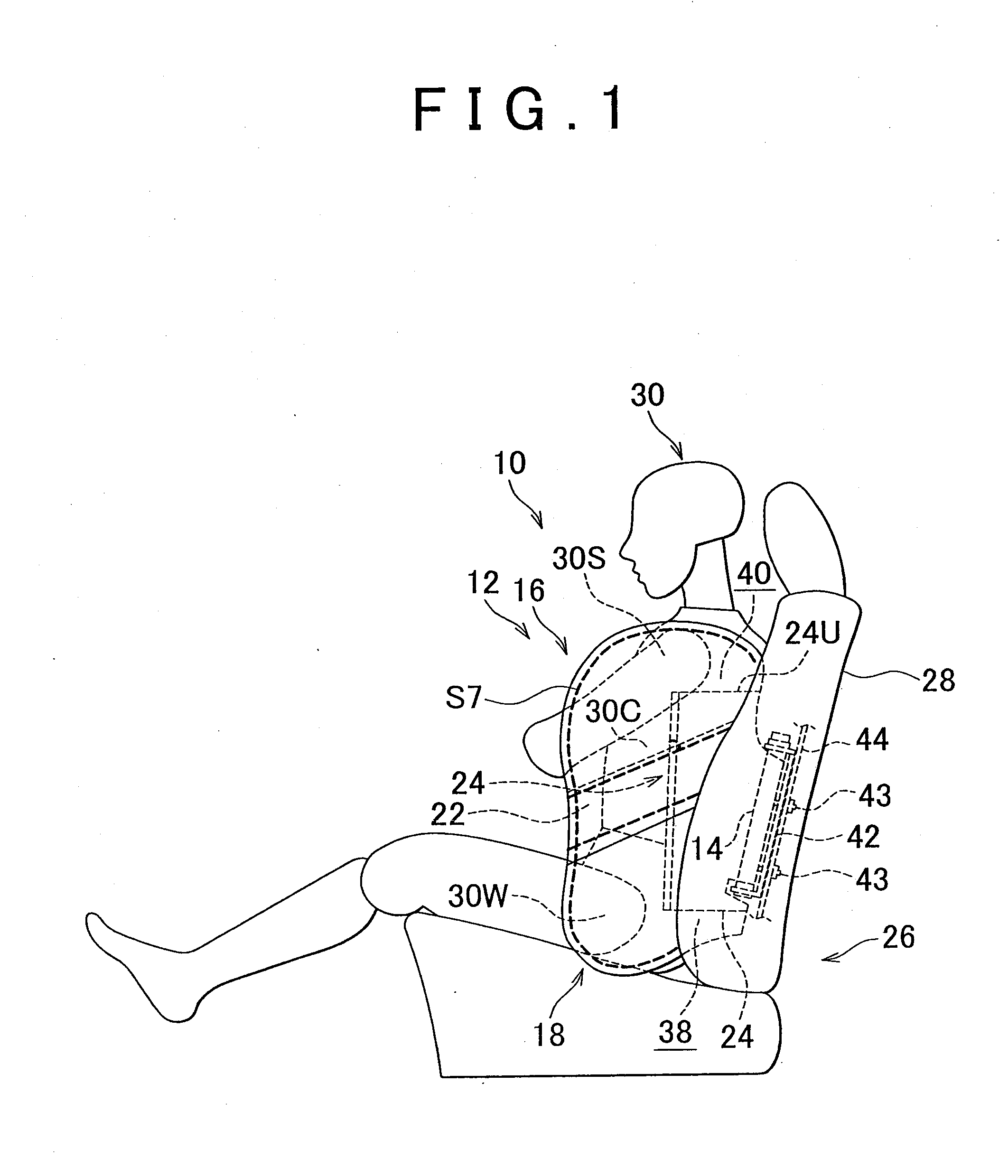

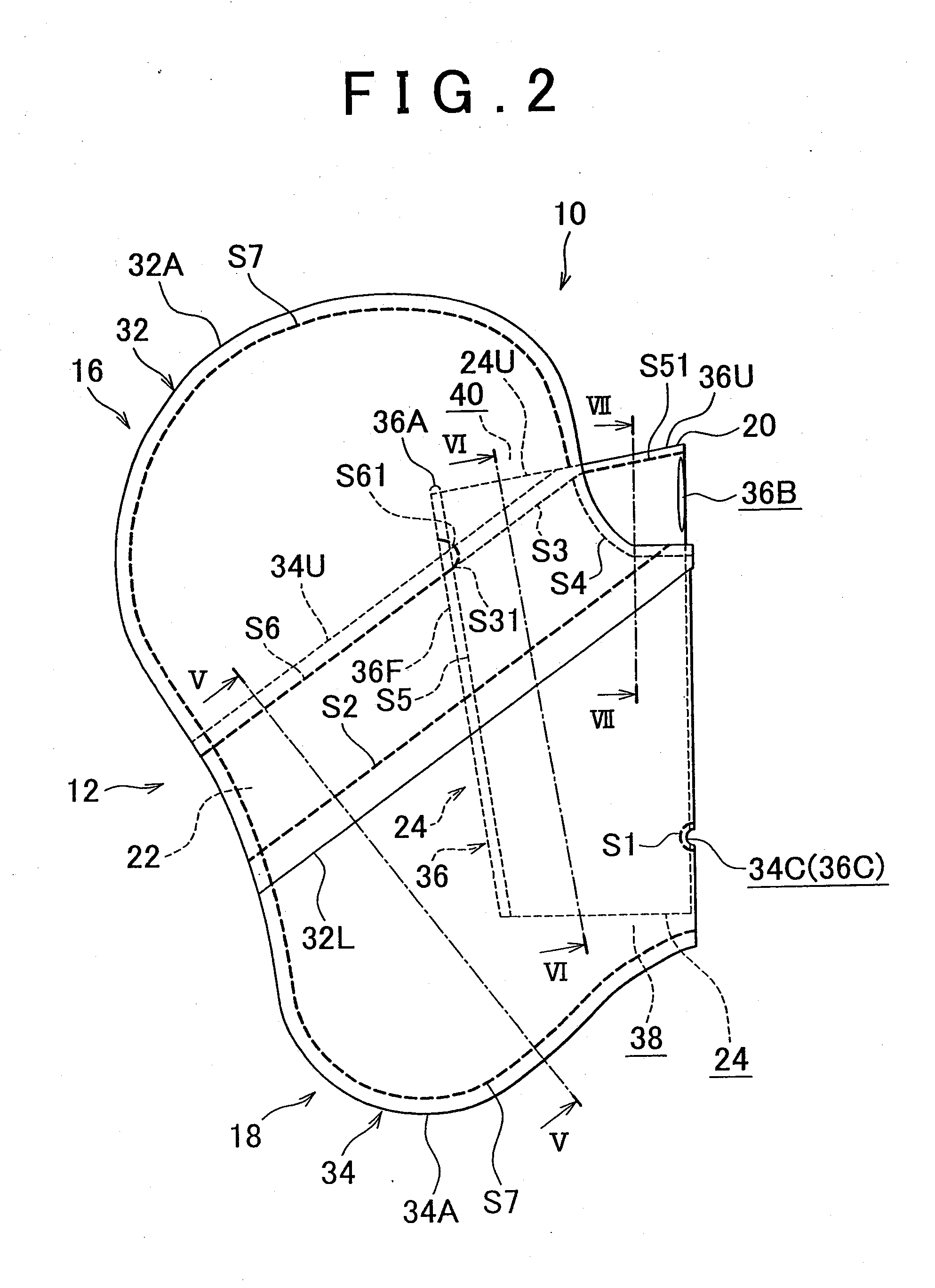

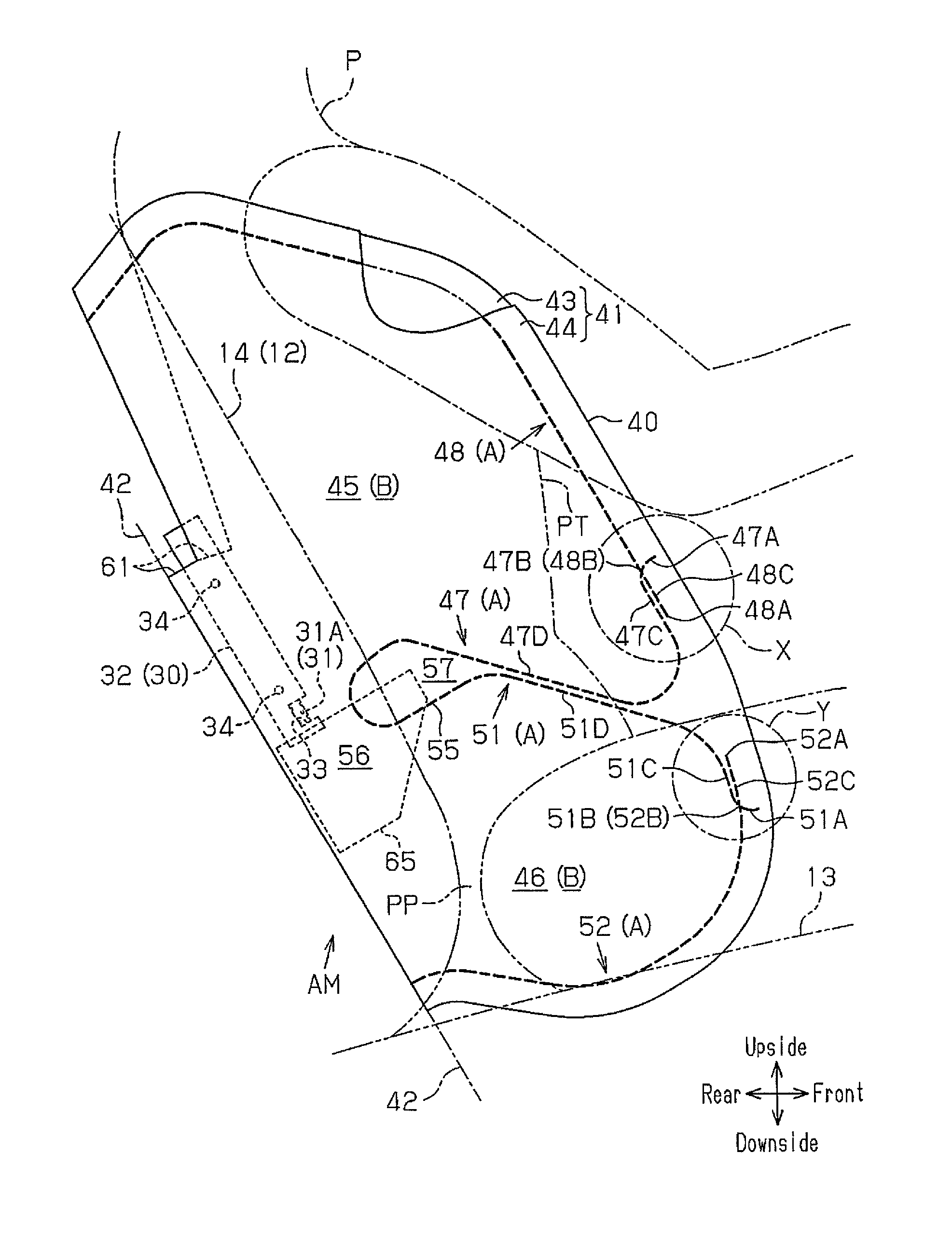

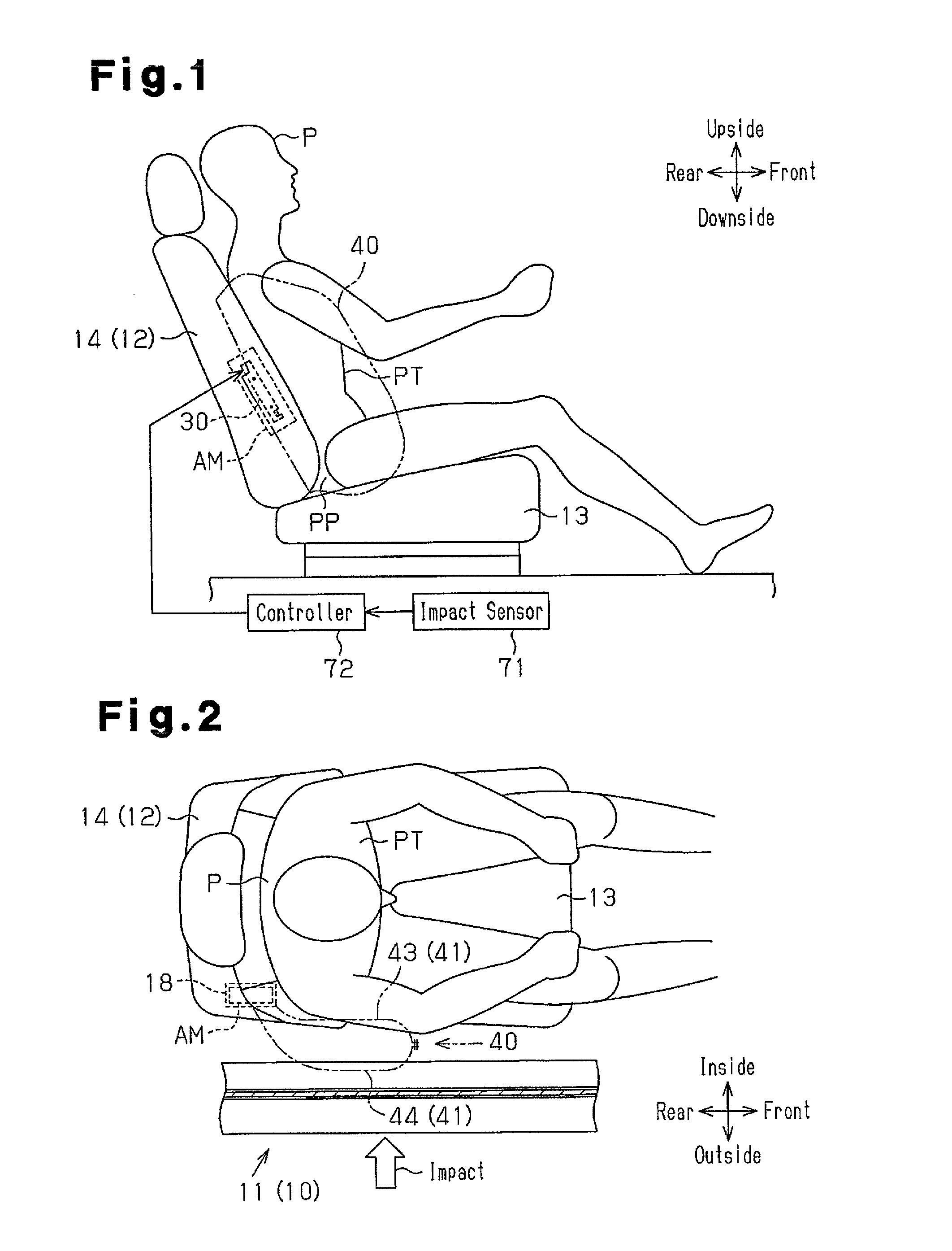

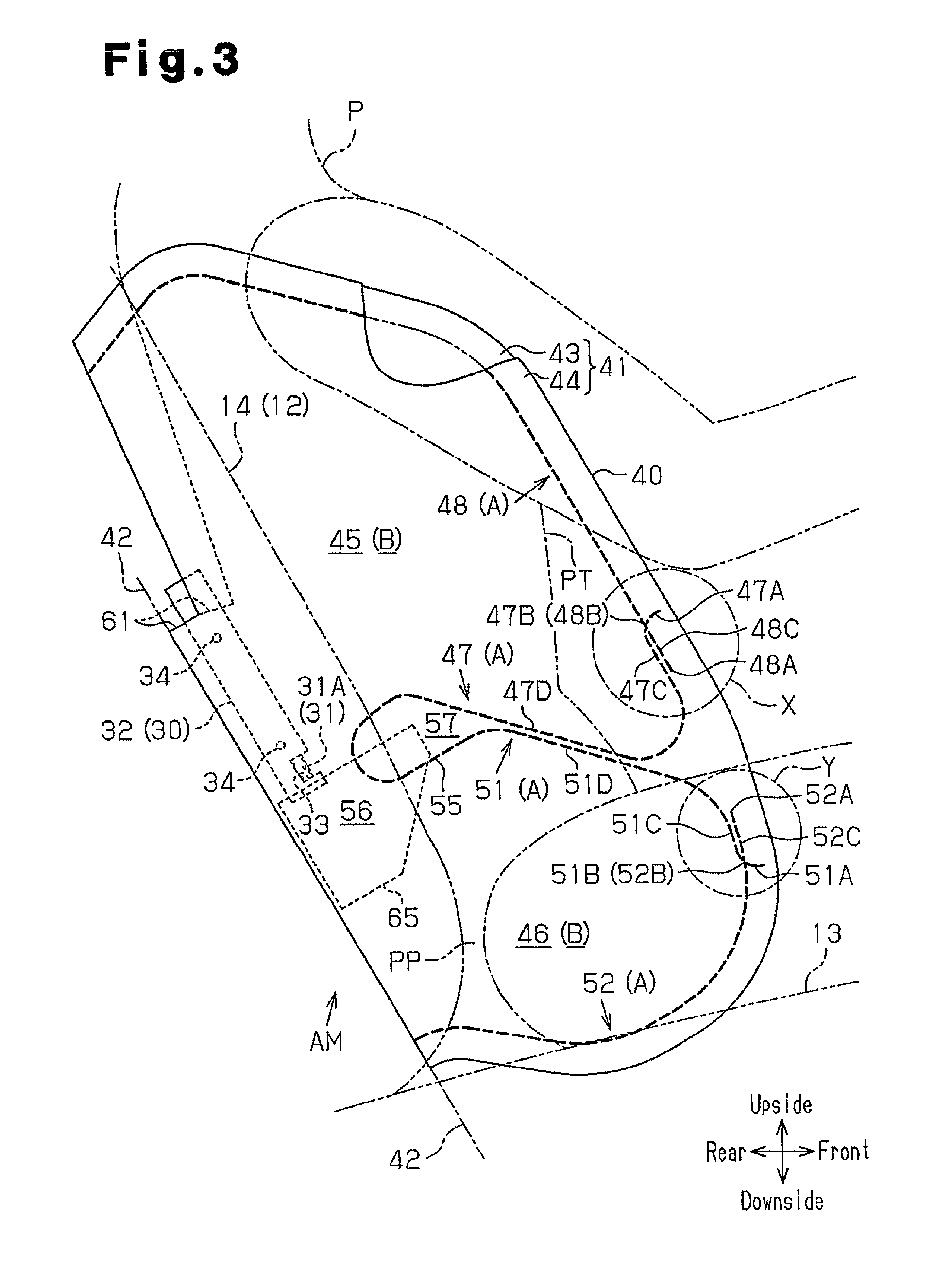

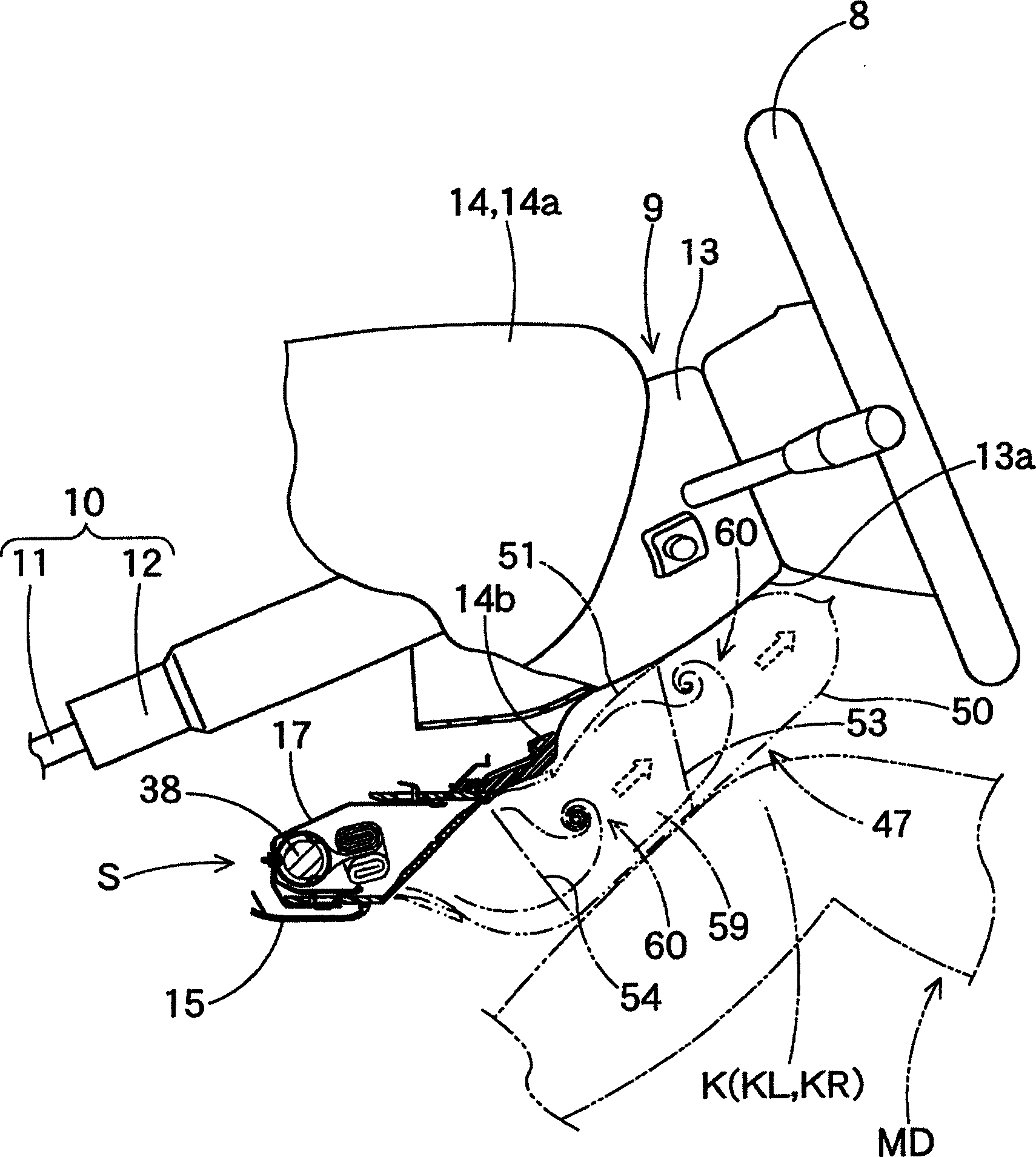

Side airbag system and method of manufacturing side airbag

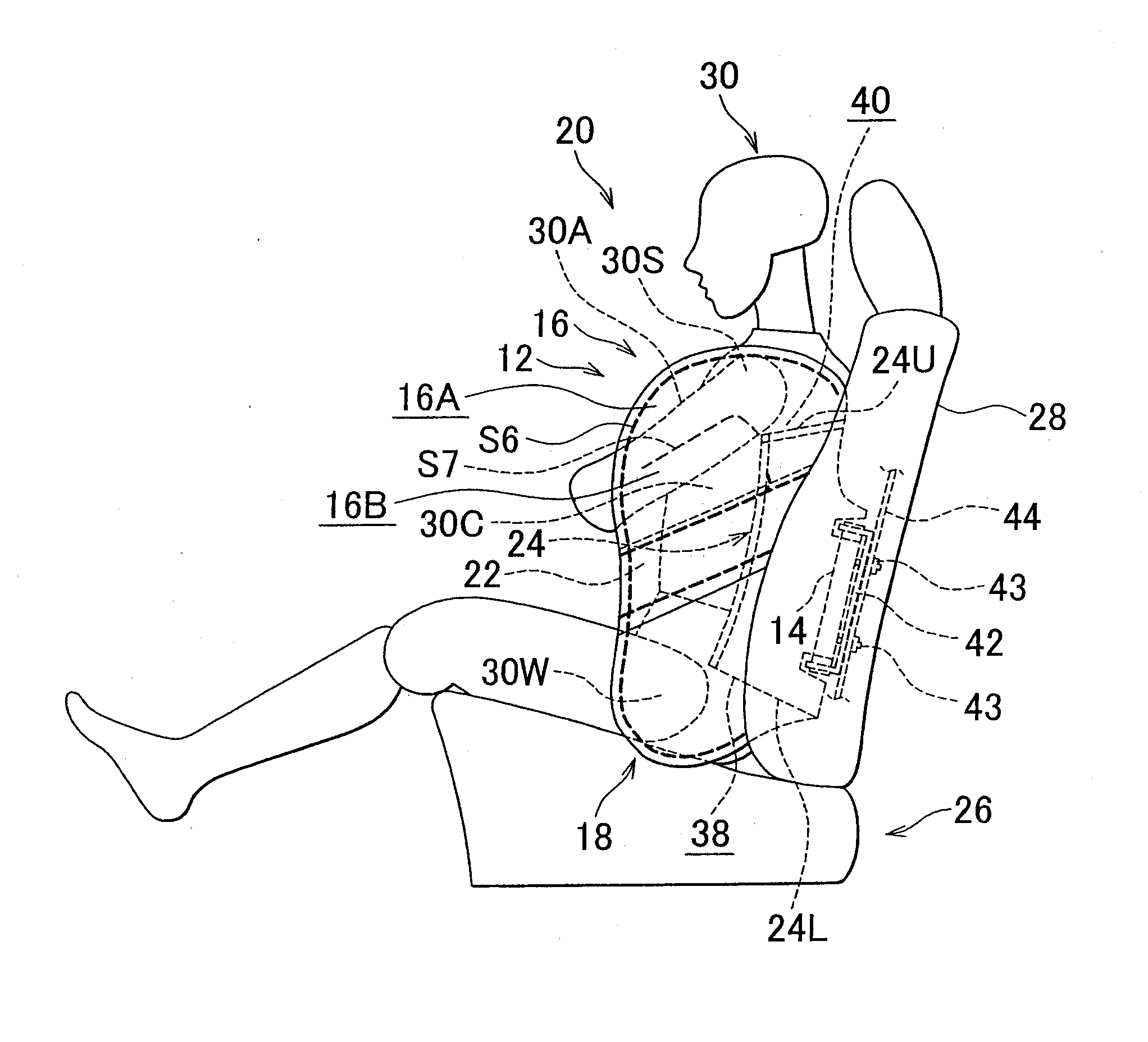

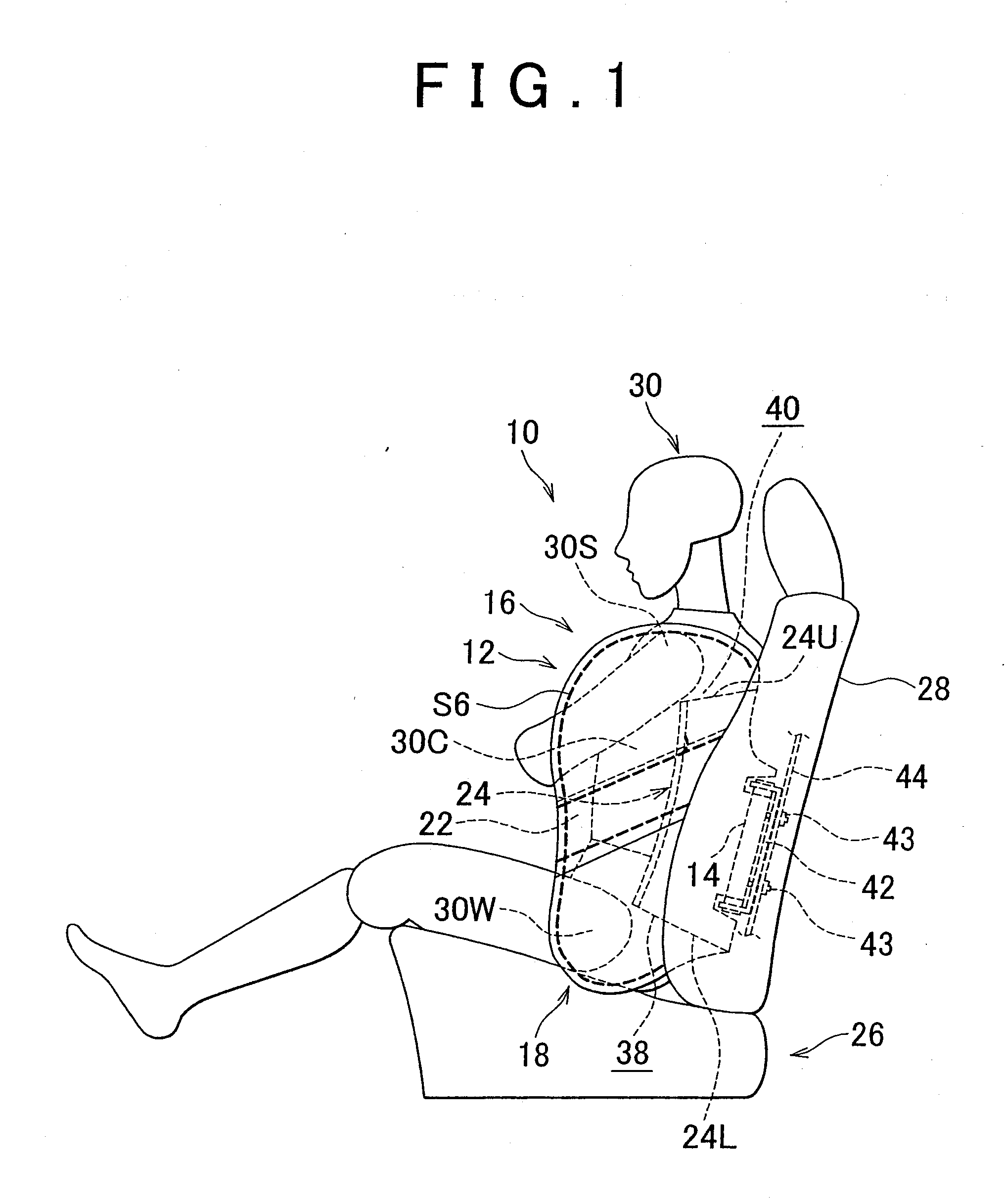

In a side airbag system (10), a tether portion (22), which serves as a partition between an upper bag portion (16) and a lower bag portion (18), is formed of upper regions (34U) of a piece of lower base fabric (34), and is formed by sewing the upper regions (34U) of the lower base fabric (34), folded toward a vehicle front side along a fold axis, together. In addition, a tube (24) that distributes inflation gas between the upper bag portion (16) and the lower bag portion (18) extends through the tether portion (22) to the lower bag portion (18) and to the upper bag portion (16). The tube (24) is formed into a cylindrical shape in such a manner that a piece of tube base fabric (36) is sewed to the upper regions (34U) of the lower base fabric (34) and folded toward a vehicle front side along the fold axis and then front ends (36F) of the folded tube base fabric are sewed together in a tube longitudinal direction.

Owner:TOYOTA JIDOSHA KK

Medical Implant

InactiveUS20090138094A1Reduce obesityEasy to sewTubular organ implantsNon-surgical orthopedic devicesSmall intestineBiomedical engineering

A medical implant is disclosed, said implant having a flexible hollow body (1) which can be implanted inside the stomach (8) of a patient and which has a first tube-like end section (2) and a second tube-like end section (3), wherein the first tube-like end section (2) is dimensioned such that it can be fitted into the esophagus (7) of the patient, and the second tube-like end section (3) is dimensioned such that it can be connected to the small intestine loop (9) of the patent in a sealing manner.

Owner:NOVINEON HEALTHCARE TECH PARTNERS

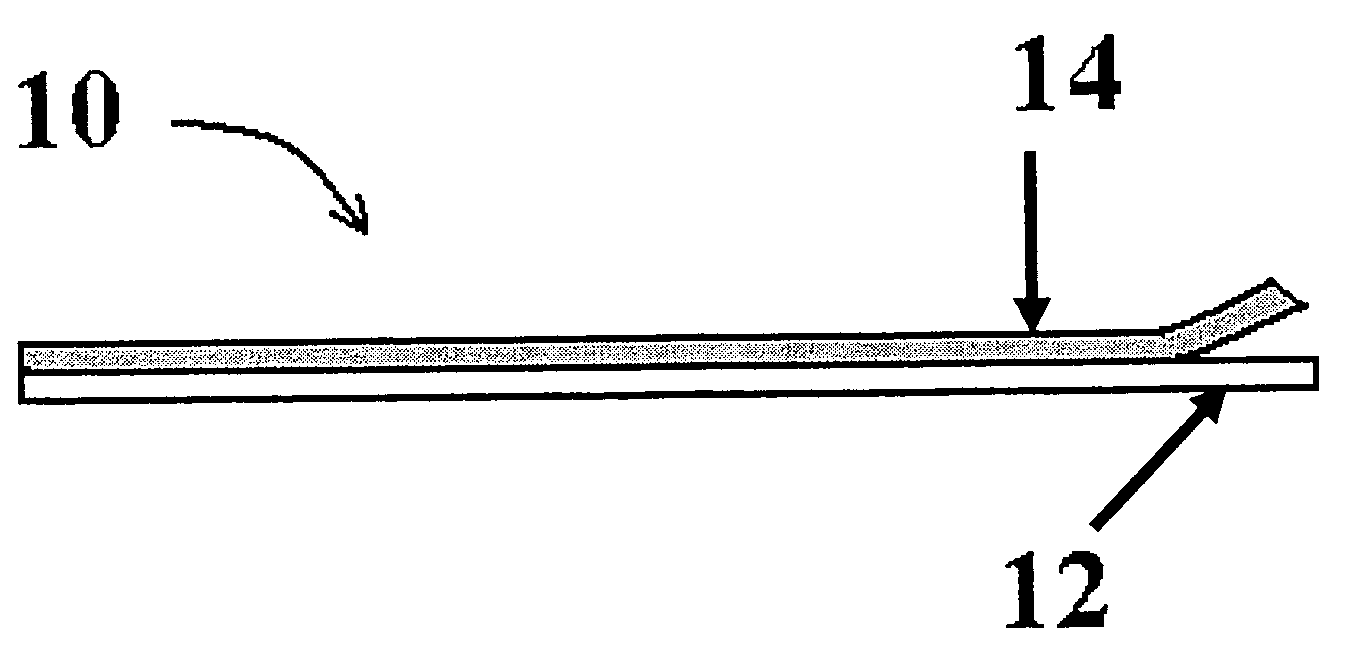

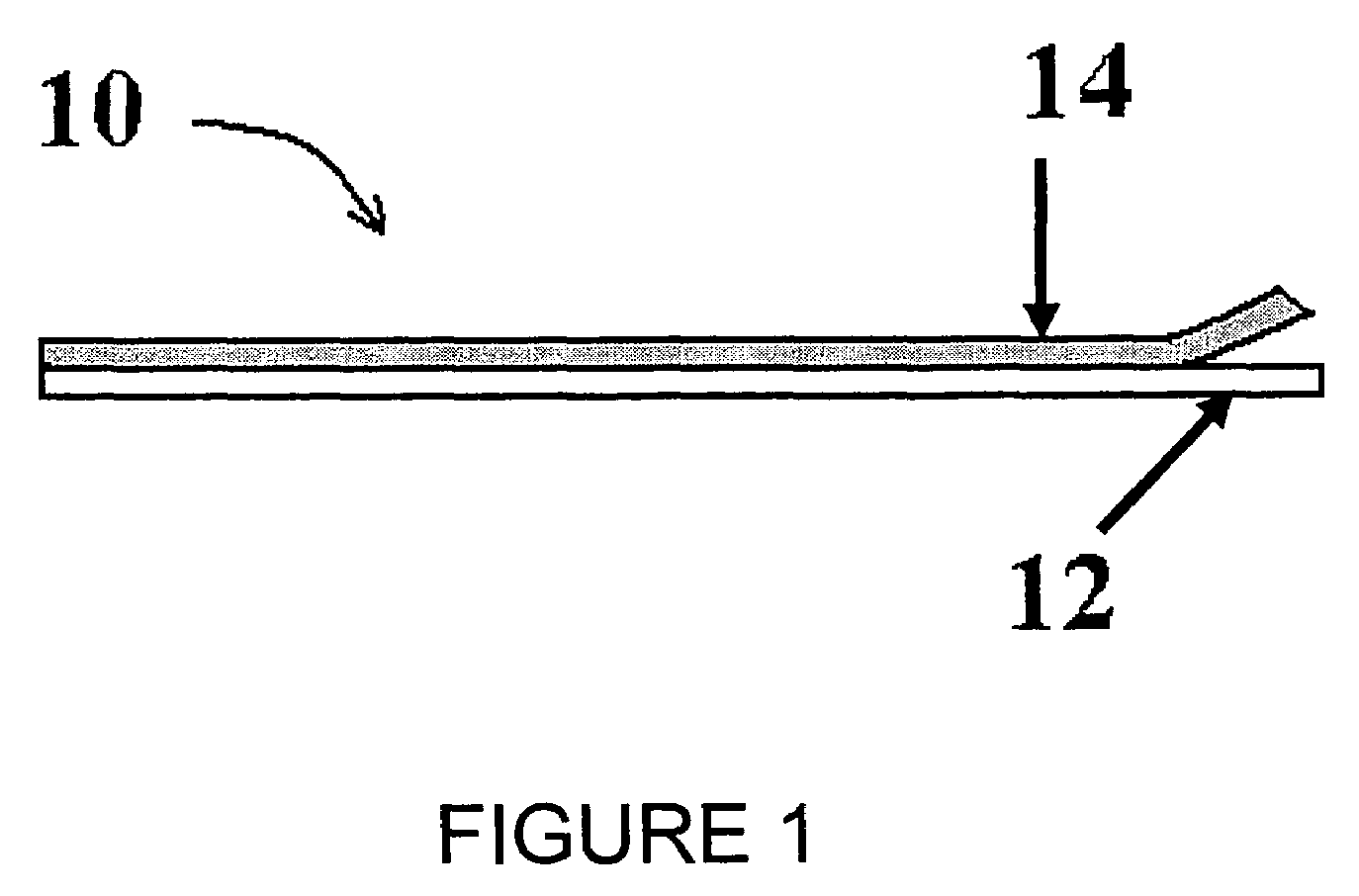

Heat-reflective nonwoven liner material

InactiveUS20060135019A1Cost efficientEasy to sewSynthetic resin layered productsWoven fabricsThermoplasticEngineering

A heat reflective garment interlining laminate is provided that includes a continuous filament layer and a metallized thermoplastic film. The laminate is characteristically low-cost and suitable for such apparel applications as sports clothing, military clothing, camping gear, hunting / fishing clothing, and the like.

Owner:AVINTIV SPECIALTY MATERIALS INC

Method for processing a digital image and image representation format

InactiveUS7480418B2Easy to analyzeEasily be manipulatedGeometric image transformationCharacter and pattern recognitionZeroth orderDigital image

Owner:NOKIA TECH OY

Side airbag system and method of manufacturing side airbag

ActiveUS8419060B2Easy to sewIncrease productivityLeather sewingPedestrian/occupant safety arrangementLateral airbagEngineering

In a side airbag system (10), a tether portion (22), which serves as a partition between an upper bag portion (16) and a lower bag portion (18), is formed of upper regions (34U) of a piece of lower base fabric (34), and is formed by sewing the upper regions (34U) of the lower base fabric (34), folded toward a vehicle front side along a fold axis, together. In addition, a tube (24) that distributes inflation gas between the upper bag portion (16) and the lower bag portion (18) extends through the tether portion (22) to the lower bag portion (18) and to the upper bag portion (16). The tube (24) is formed into a cylindrical shape in such a manner that a piece of tube base fabric (36) is sewed to the upper regions (34U) of the lower base fabric (34) and folded toward a vehicle front side along the fold axis and then front ends (36F) of the folded tube base fabric are sewed together in a tube longitudinal direction.

Owner:TOYOTA JIDOSHA KK

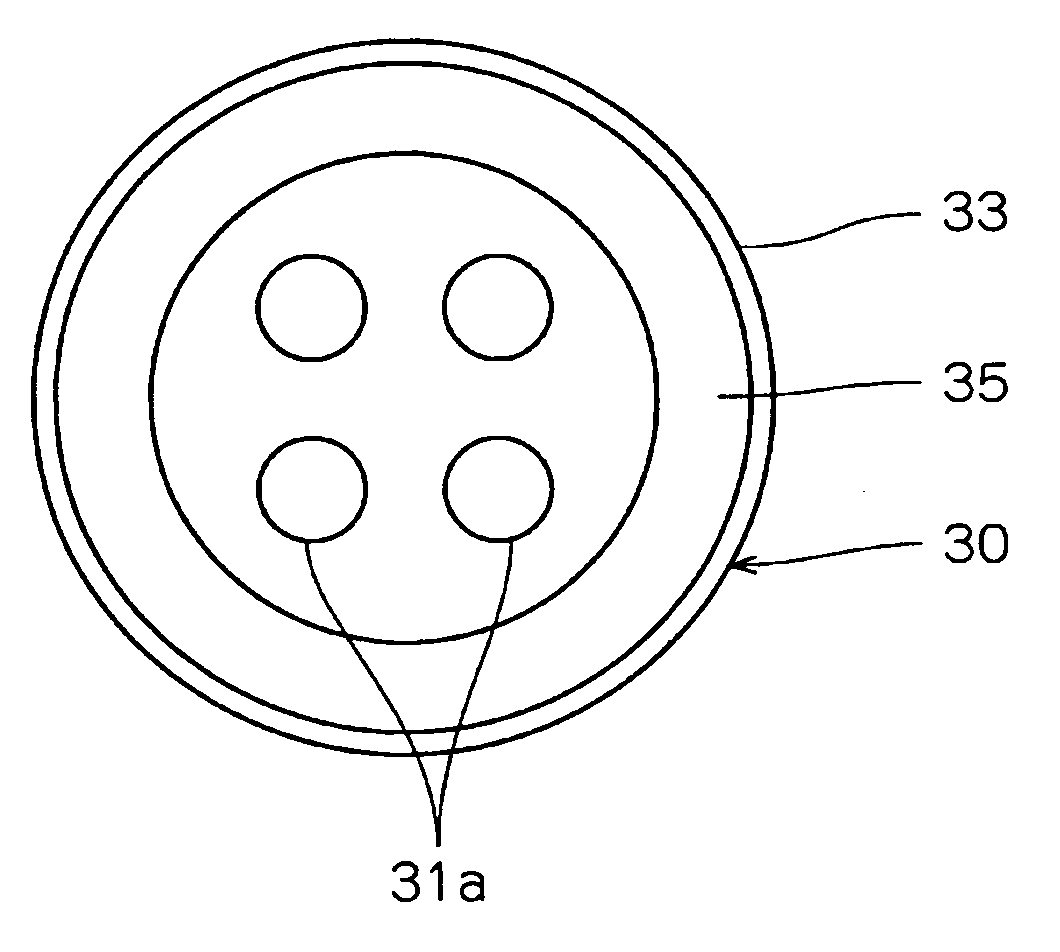

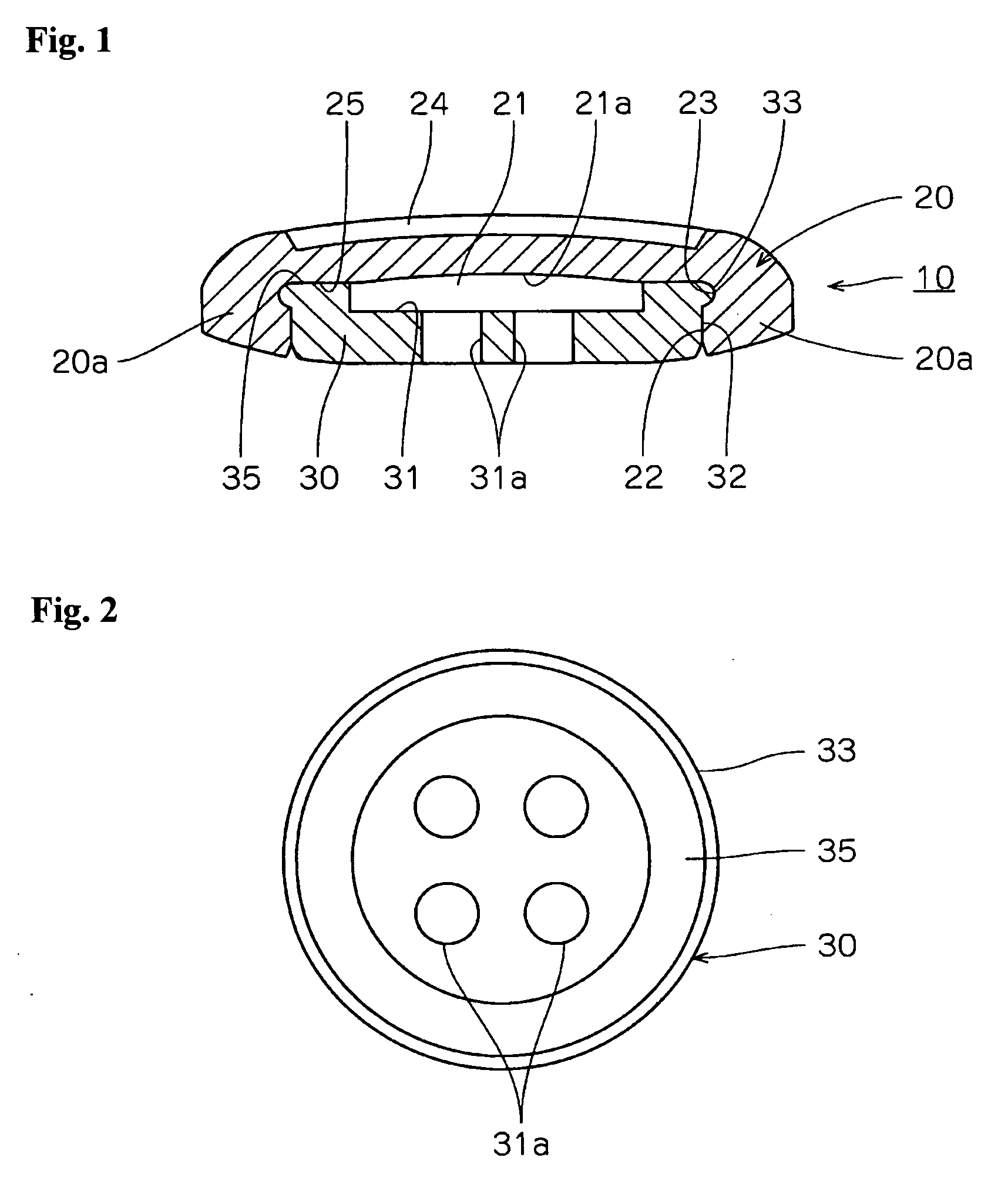

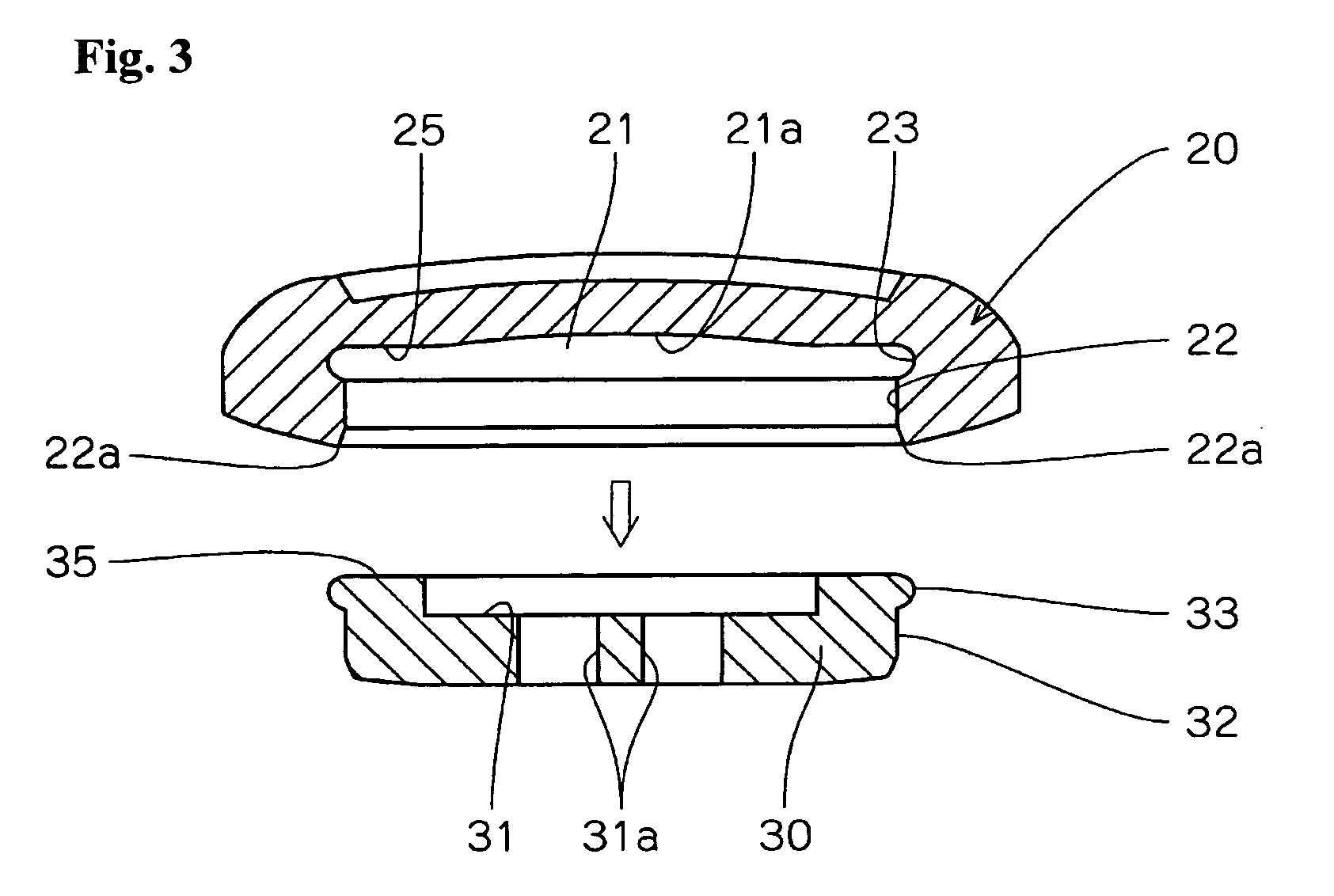

Separable ornamented button

InactiveUS20080244873A1Increase the areaEasy to sewSnap fastenersClothes buttonsMechanical engineering

The invention is a simple structure ornamented button with design changeability according to the user taste, position and opportunity and also uneasy detaching characteristic in spite of easy attaching. The separable ornamented button 10 comprises two parts engaged with each other into one body, one being a top ornamented part 20 and the other a bottom part 30 provided with string holes 31a. The top part 20 comprises an ornamented center portion 24 and a periphery portion 20a forming a receiving concave 21 at the backside thereof having a rocking groove 23 at an inside sidewall 22 while the bottom part 30 comprises a center flat portion 31 provided with string holes 31a and a periphery ring sleeve 32 having a protrusion 33 at an outside sidewall. When the ornamented top part 20 is engaged with the bottom part 30, the periphery ring sleeve wall 32 of the bottom part 30 getting a tight contact to a periphery wall 22 of the receiving concave 21 and the rocking groove or protrusion 33 of the ring sleeve 32 of the bottom part 30 being engaged with the corresponding protrusion and groove 23 of the receiving concave 21 of the top part 20, resulting in difficult detaching property and good looking design when sewed.

Owner:YAMASHITA KOJIRO +1

Heat-reflective nonwoven liner material

InactiveUS7452833B2High retention rateCost efficientSynthetic resin layered productsWoven fabricsInterliningThermoplastic

A heat reflective garment interlining laminate is provided that includes a continuous filament layer and a metallized thermoplastic film. The laminate is characteristically low-cost and suitable for such apparel applications as sports clothing, military clothing, camping gear, hunting / fishing clothing, and the like.

Owner:AVINTIV SPECIALTY MATERIALS INC

Medical implant

InactiveUS8182543B2Reduce obesityEasy to sewTubular organ implantsNon-surgical orthopedic devicesSmall intestineBiomedical engineering

A medical implant is disclosed, said implant having a flexible hollow body (1) which can be implanted inside the stomach (8) of a patient and which has a first tube-like end section (2) and a second tube-like end section (3), wherein the first tube-like end section (2) is dimensioned such that it can be fitted into the esophagus (7) of the patient, and the second tube-like end section (3) is dimensioned such that it can be connected to the small intestine loop (9) of the patent in a sealing manner.

Owner:NOVINEON HEALTHCARE TECH PARTNERS

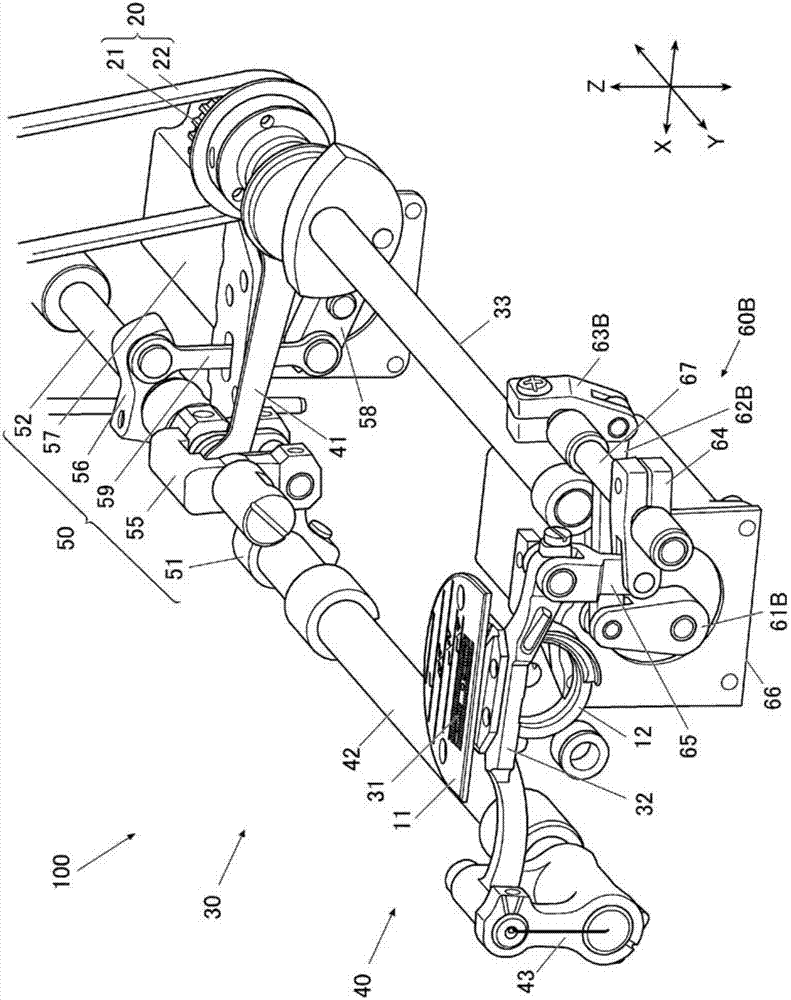

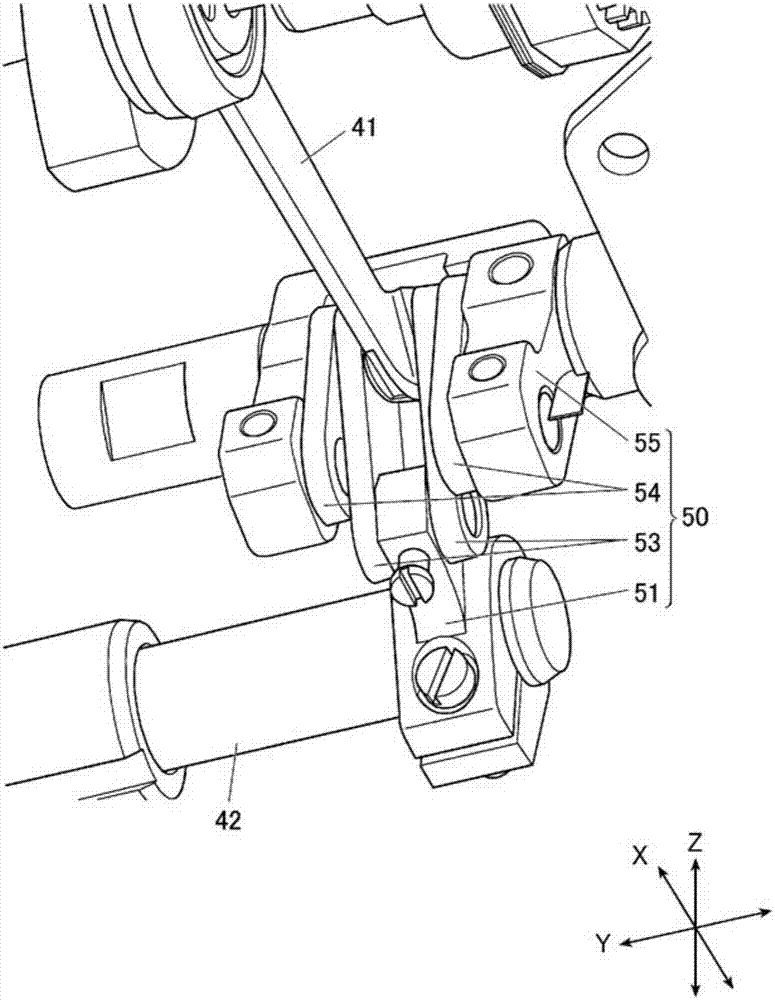

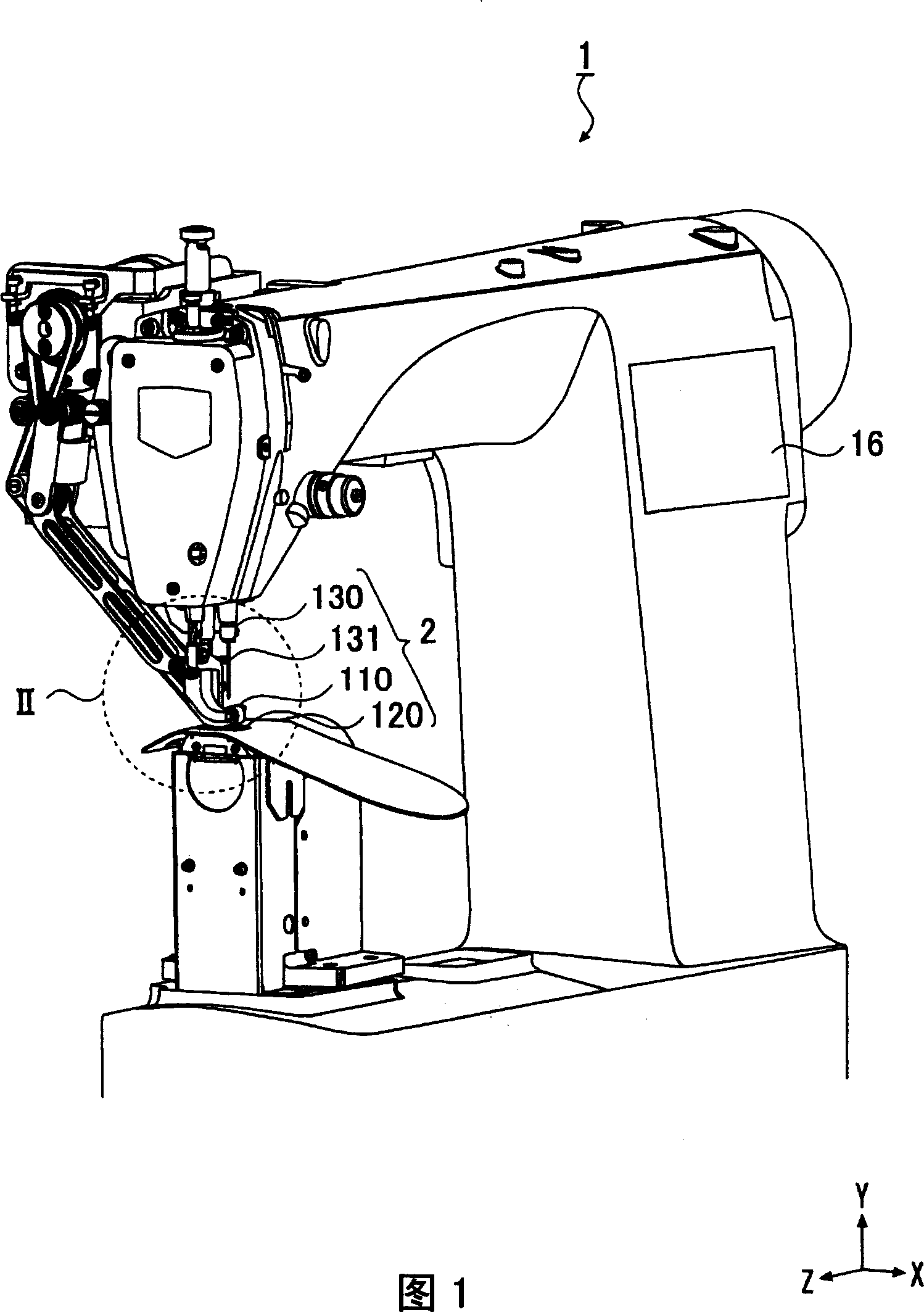

Sewing machine

Parameters, such as the amount of up-and-down sending after a to-be-sewed objects detect a step which becomes thick, press pin pressure and thread tension, can be changed. A sewing machine includes: a cloth press pin (71), which presses a sewed object from above; a press pin height detection unit (76), which detects the height of the cloth press pin (71); and a control device (90), which plays a control role if the press pin height detection unit (76) detects that the cloth press pin (71) jumps on the step thicked by the sewed object so as to change parameters associated with sewing. For instance, if the press pin height detection unit (76) detects that the cloth press pin (71) jumps on the step, the control device (90) controls an up-and-down feeding motor (66) applying upward and downward reciprocating movement to feeding teeth (31) to raise the feeding teeth (31) in a feeding interval.

Owner:JUKI CORP

Sewing fixture for sewing suit front part with flap pocket adding with welt to front facing

InactiveCN105350189AShort working hoursEasy to operateWork-feeding meansClothes making applicancesWaste productEngineering

Owner:盛楠

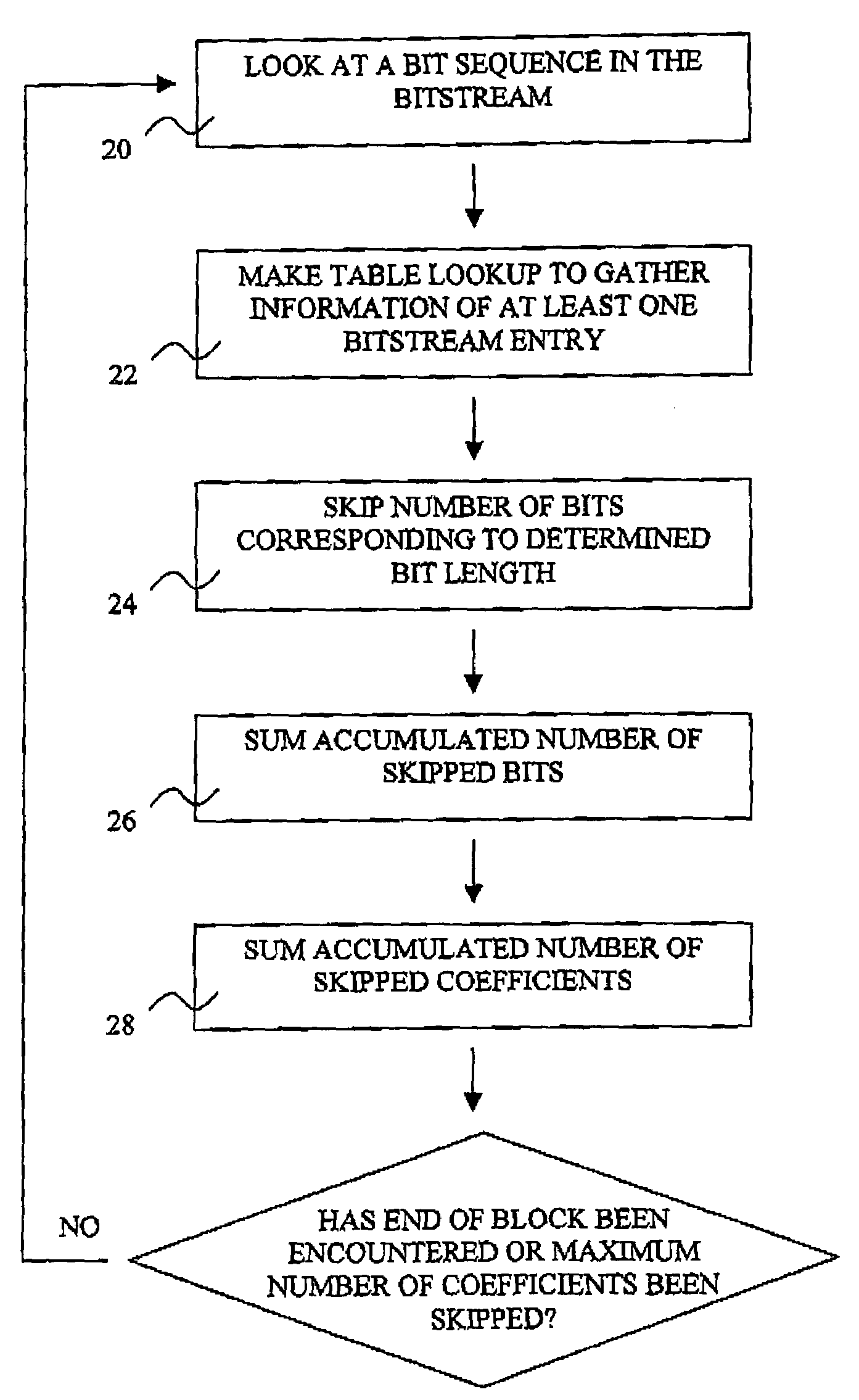

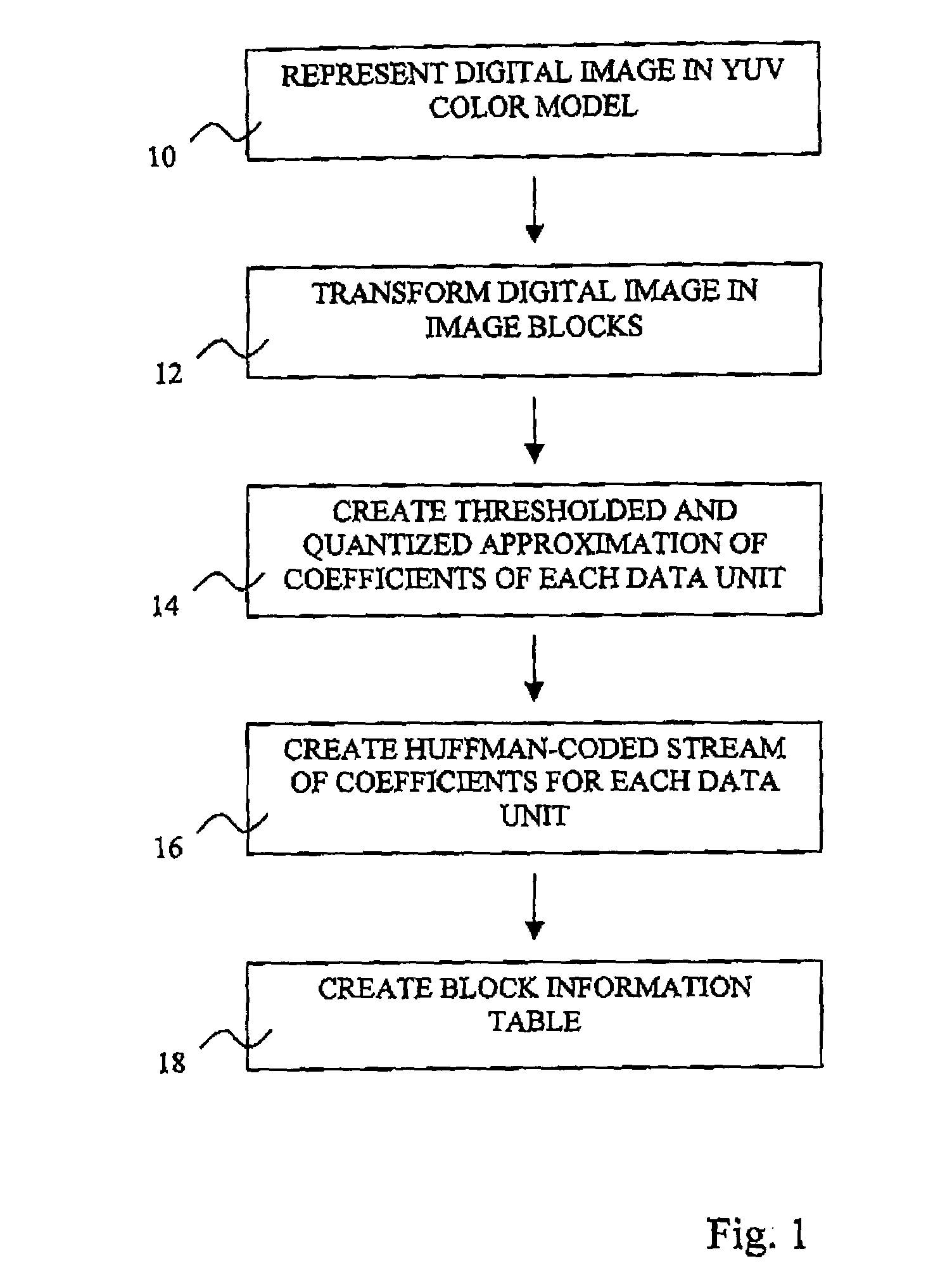

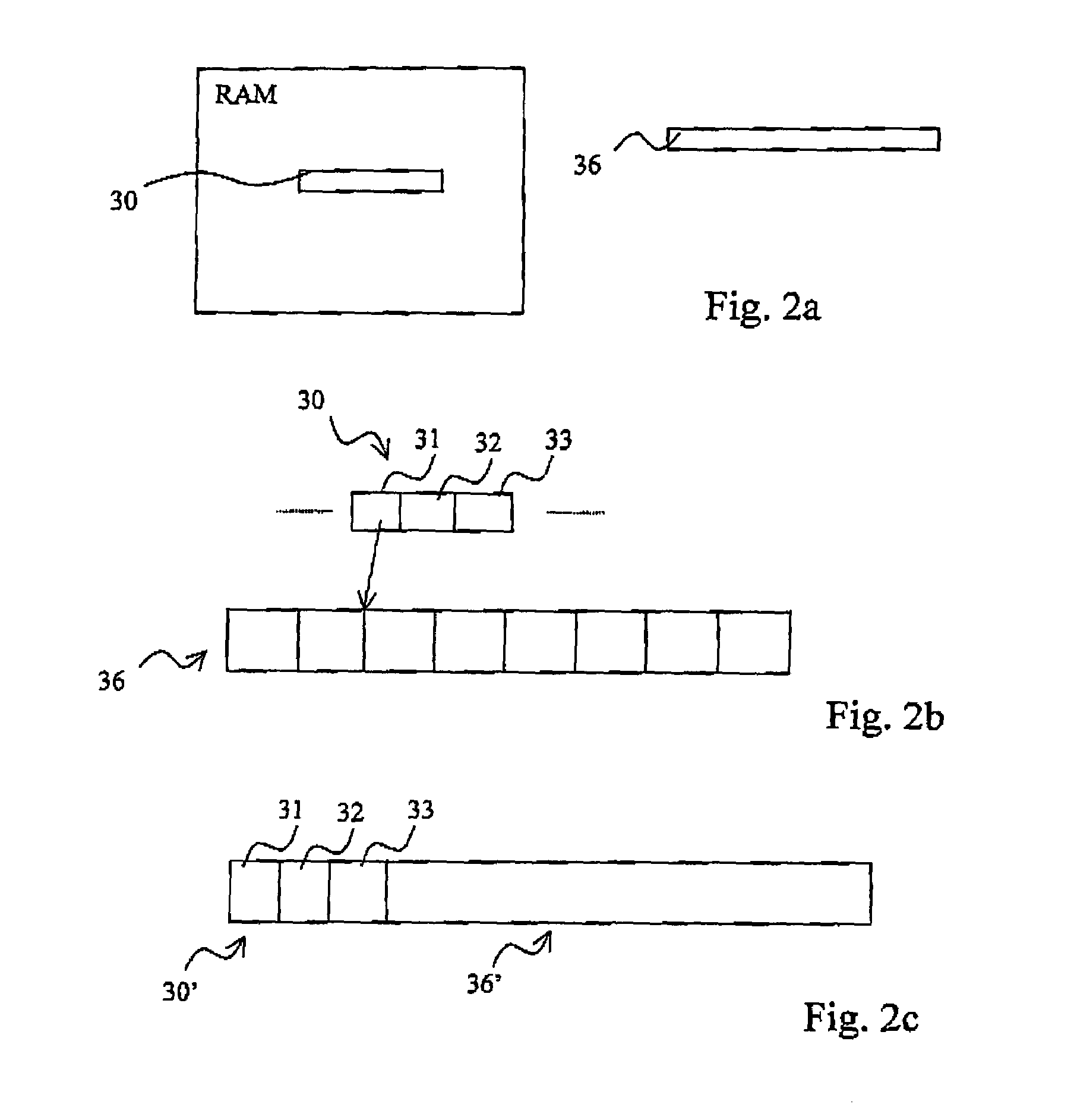

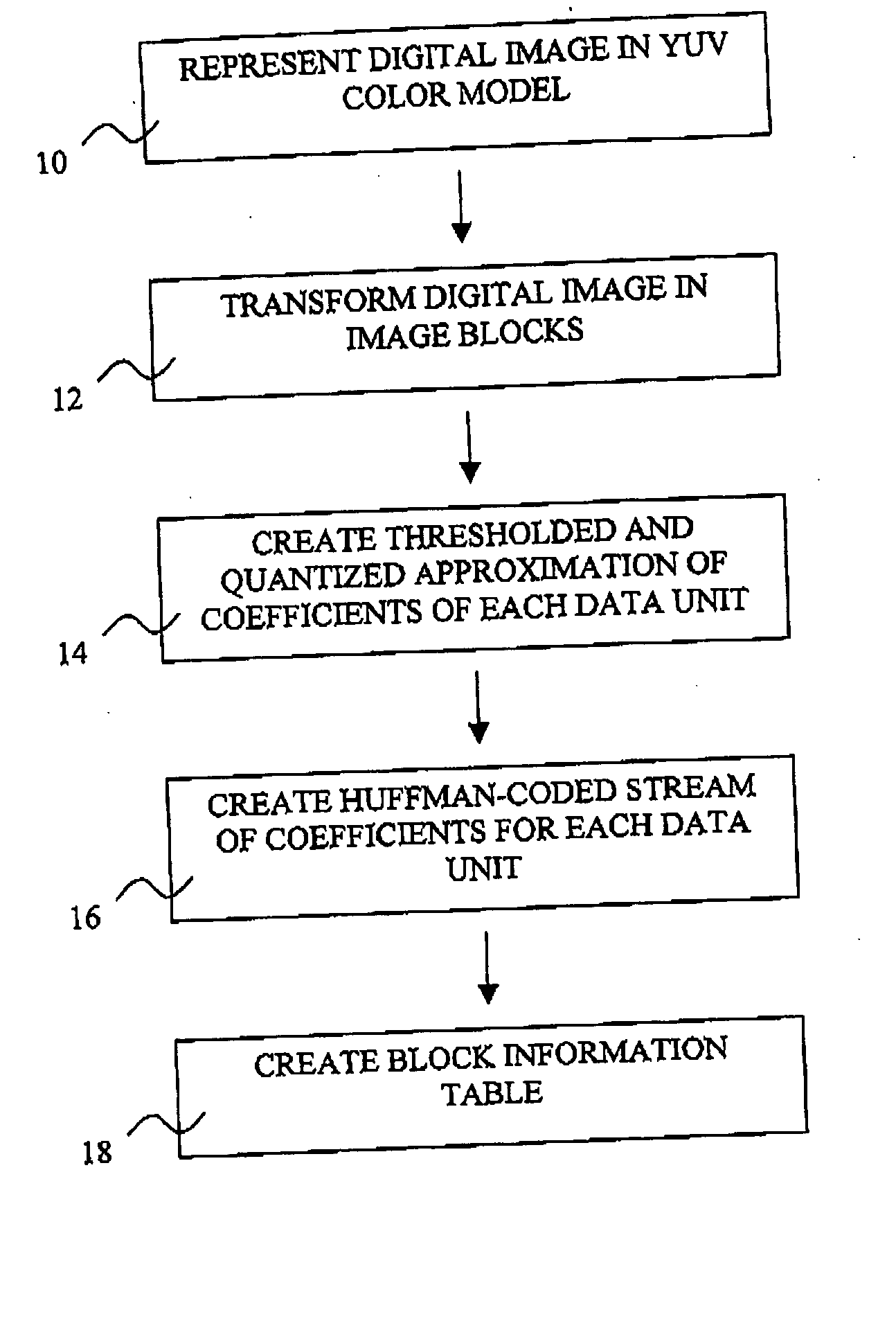

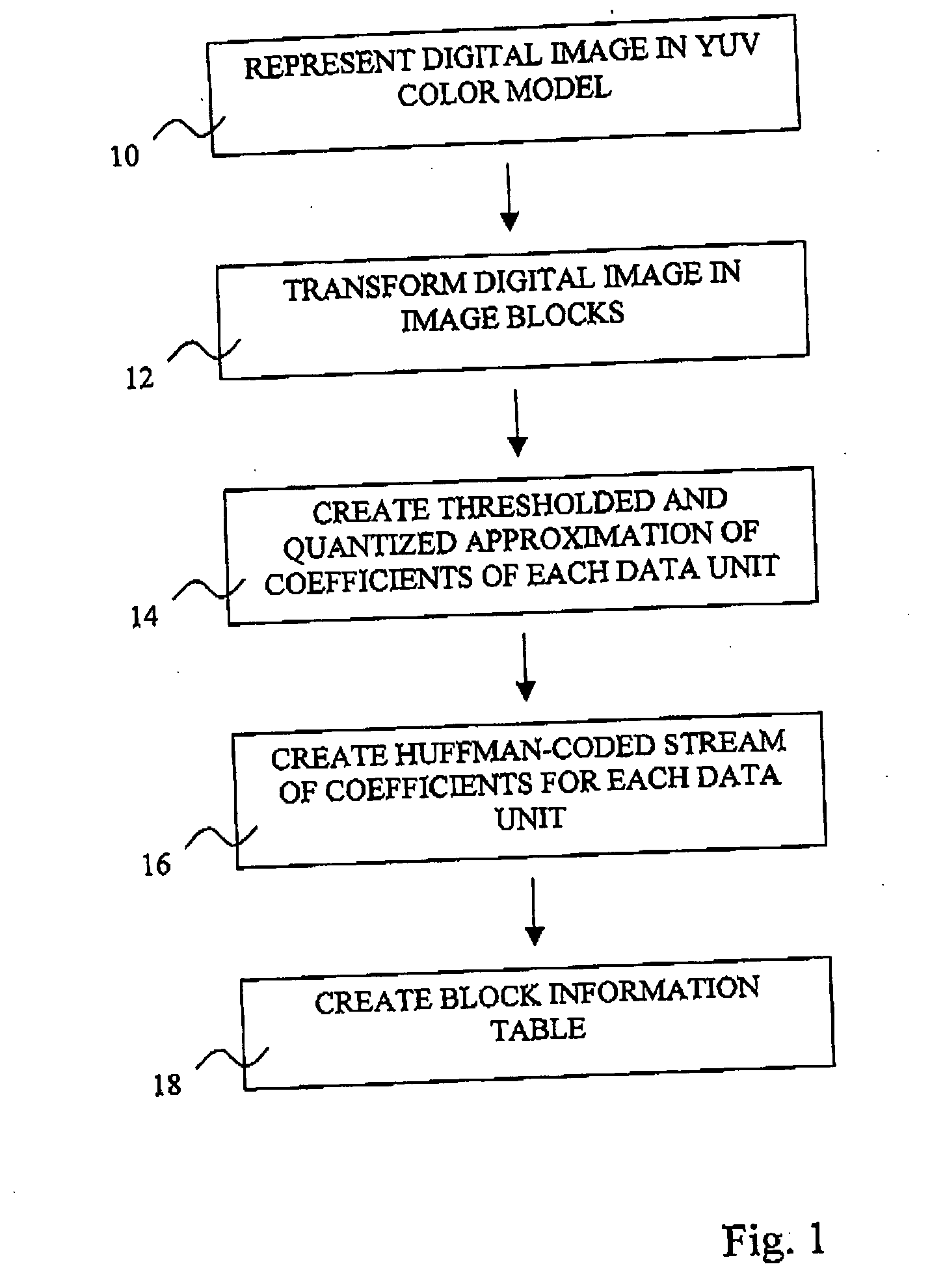

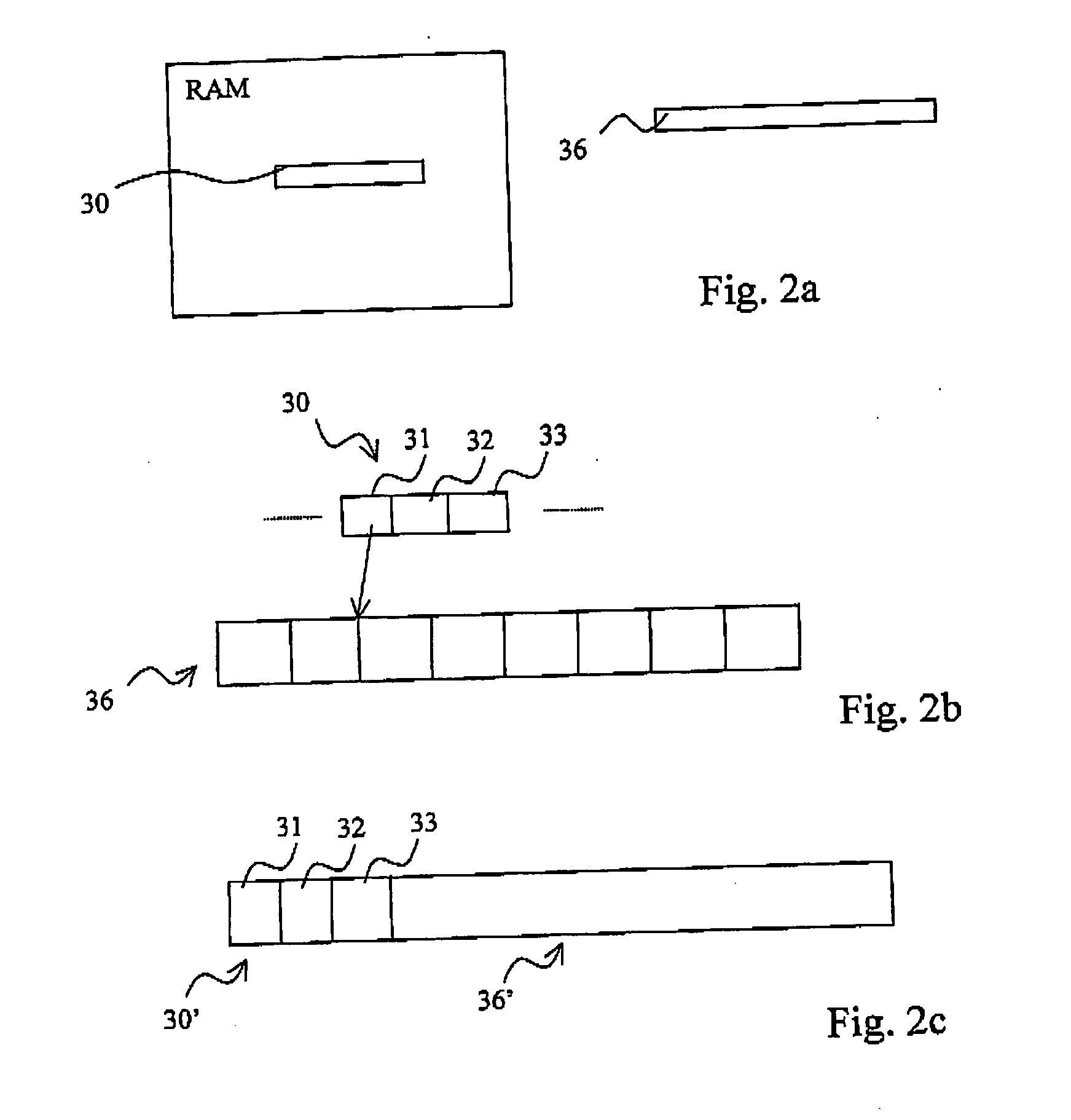

Method for processing a digital image and image representation format

InactiveUS20050152608A1Easy to compressSmall memory capacityGeometric image transformationImage codingZeroth orderDigital image

An image representation format for representing a digital image comprises: image information stored as a bitstream representing sequential image blocks, each block comprising one or more components, each component comprising one or more data units and each data unit being represented as a Huffman-coded stream of coefficients of basis functions, wherein a zeroth order coefficient is represented as a difference to the previous zeroth order coefficient of the corresponding component, and a block information table, which comprises: indicators to the first coefficient of a specified order of each image block in said bitstream, information indicating the number of bits in the bitstream between adjacent coefficients of said specified order of the image block, and the zeroth order coefficient of at least the first data unit of each components said zeroth order coefficient being represented in a non-differential form.

Owner:NOKIA TECHNOLOGLES OY

Side air bag apparatus and manufacturing method of a side air bag

ActiveUS8356835B2Easy to sewQuality improvementPedestrian/occupant safety arrangementEngineeringMechanical engineering

A protruding portion that is exposed from the outer peripheries of upper base cloths and a lower base cloth and provided with an insertion hole for inserting an inflator is provided on a portion of a tube base cloth. The inflator is inserted into the side air bag through the insertion hole. The peripheral edge portion of the insertion hole is fixed to the inflator by a clamp. The upper base cloths are not sewn to together in an area where the outer peripheries of the upper base cloths overlap with the tube base cloth, and the lower base cloth is not sewn to itself in an area where the outer periphery of the lower base cloth overlaps with the tube base cloth.

Owner:TOYOTA JIDOSHA KK

Basalt fiber coating film filter material

InactiveCN102228764AImprove breathabilitySoft touchSynthetic resin layered productsFiltration separationWater basedCooking & baking

The invention relates to a basalt fiber coating film filter material which is formed by hot-pressing and coating basalt fiber bulk yarn base cloth and a PTFE (Polytetrafluoroethylene) film at a high temperature after the basalt fiber bulk yarn base cloth is subjected to dewaxing, the dipping treatment with a surface treatment solution, and baking, wherein the surface treatment solution is a water-based mixed solution which is prepared from the following components in percentage by weight: 5%-40% of tetrafluorine emulsion, 0.3%-5% of waterproofing agent, 0.05%-5% of coupling agent and the balance of water. The basalt fiber coating film filter material can be used for a long term at a high temperature of 300 DEG C, and can achieve the filtering efficiency of 99.995% for 1-micron or smaller dust.

Owner:SINOMA SCI & TECH

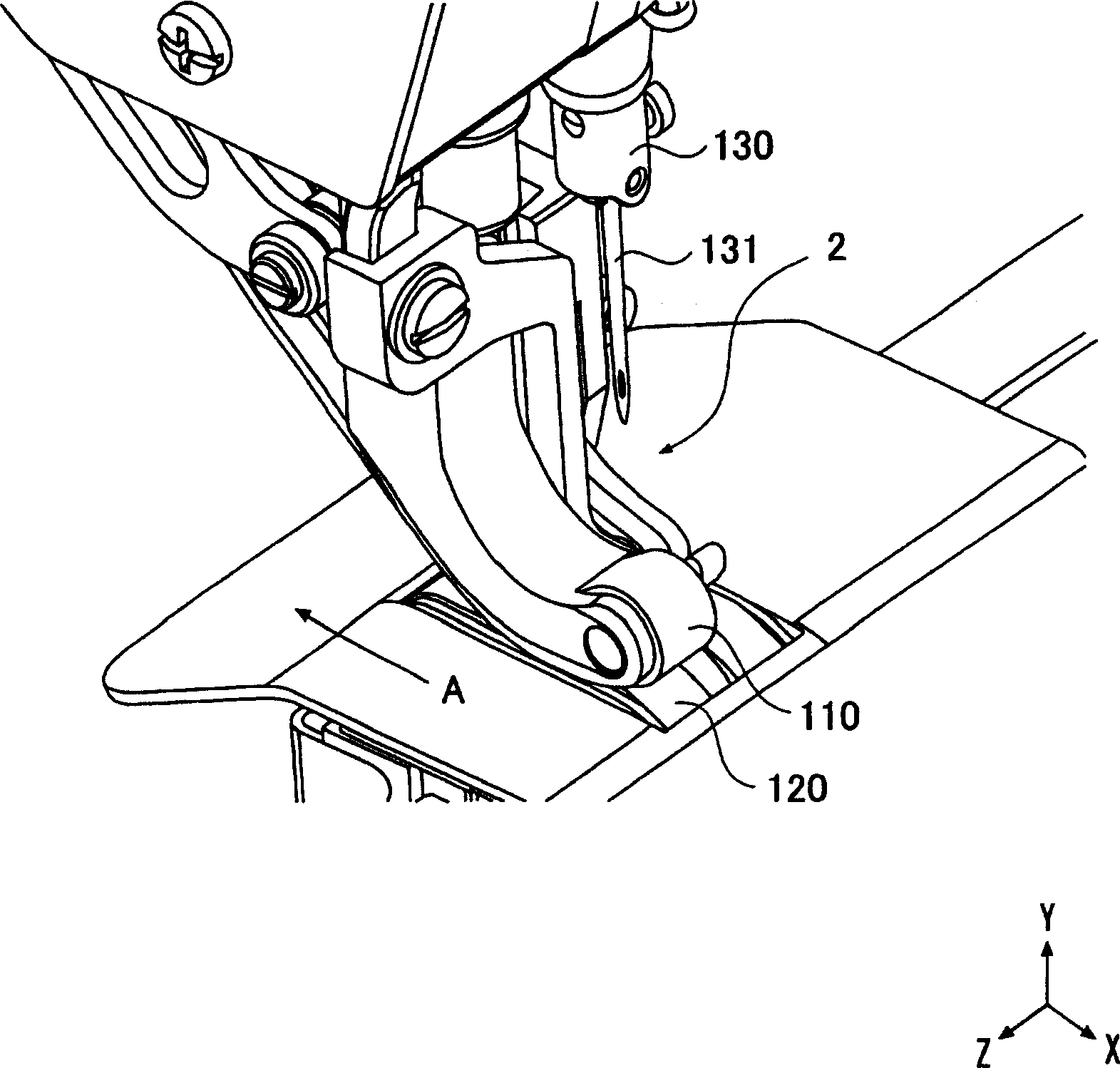

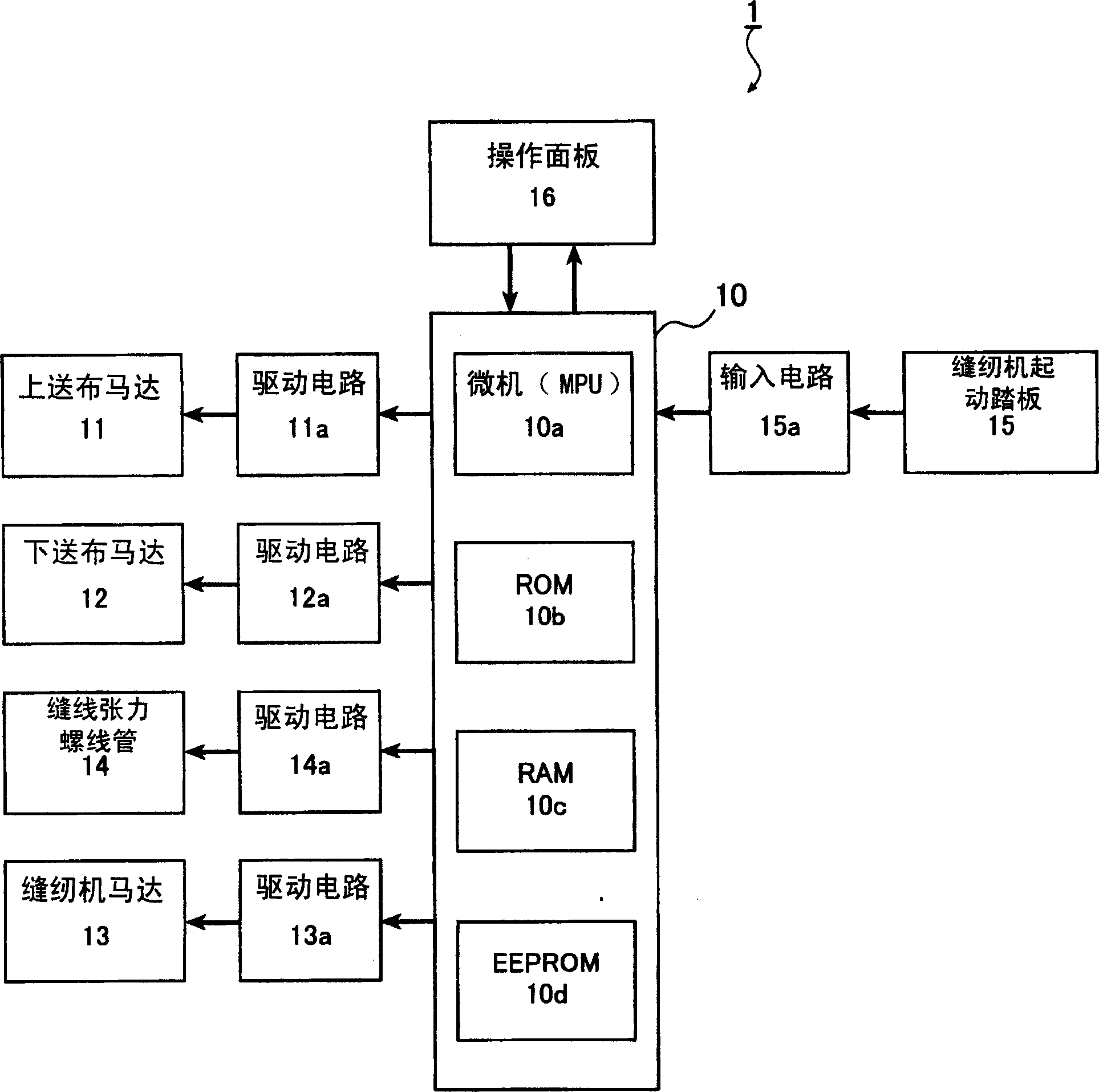

Sewing machine

InactiveCN1693566AEasy to sewSewing ExecutionProgramme-controlled sewing machinesWork-feeding meansEngineeringSewing machine

The invention makes it easy to select stored sewing patterns in a differential feed sewing machine. In the differential feed sewing machine 1 in which a selecting means (a control section 10) selects desired sewing pattern data from a plurality of sewing pattern data stored a storing means (a ROM 10b) to make a sewing means (a sewing driving section 2) perform the action of contracting sewing according to the selected sewing pattern data, the sewing pattern data has sewing data for operating the sewing means, image data for displaying a displaying figure according to the sewing pattern data, and pattern specifying data for specifying the sewing pattern data, so that the desired sewing pattern data is specified and selected according to the pattern specifying data inputted by the input means (an operation panel 16).

Owner:JUKI CORP

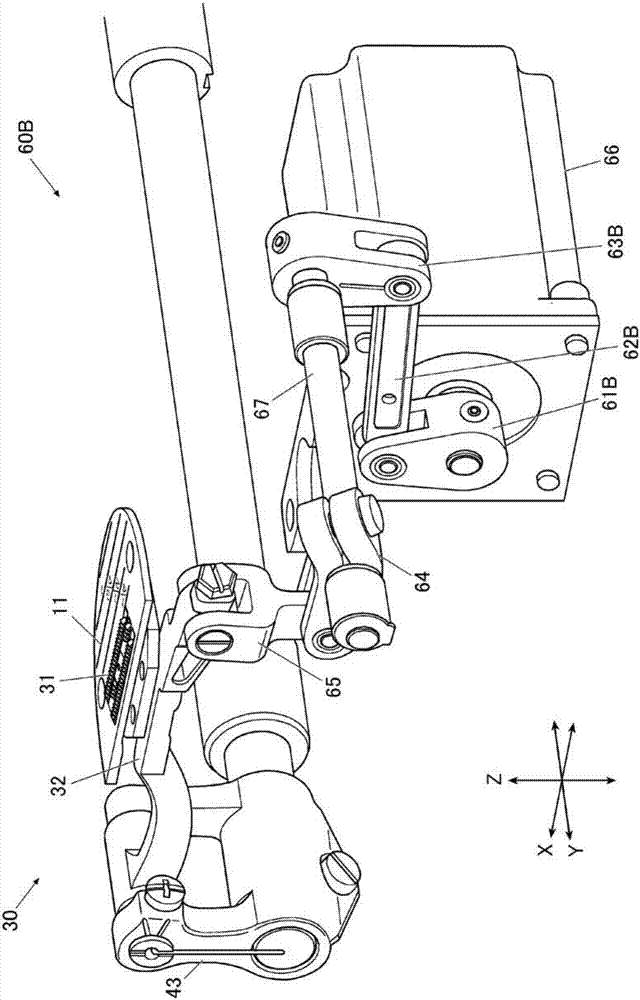

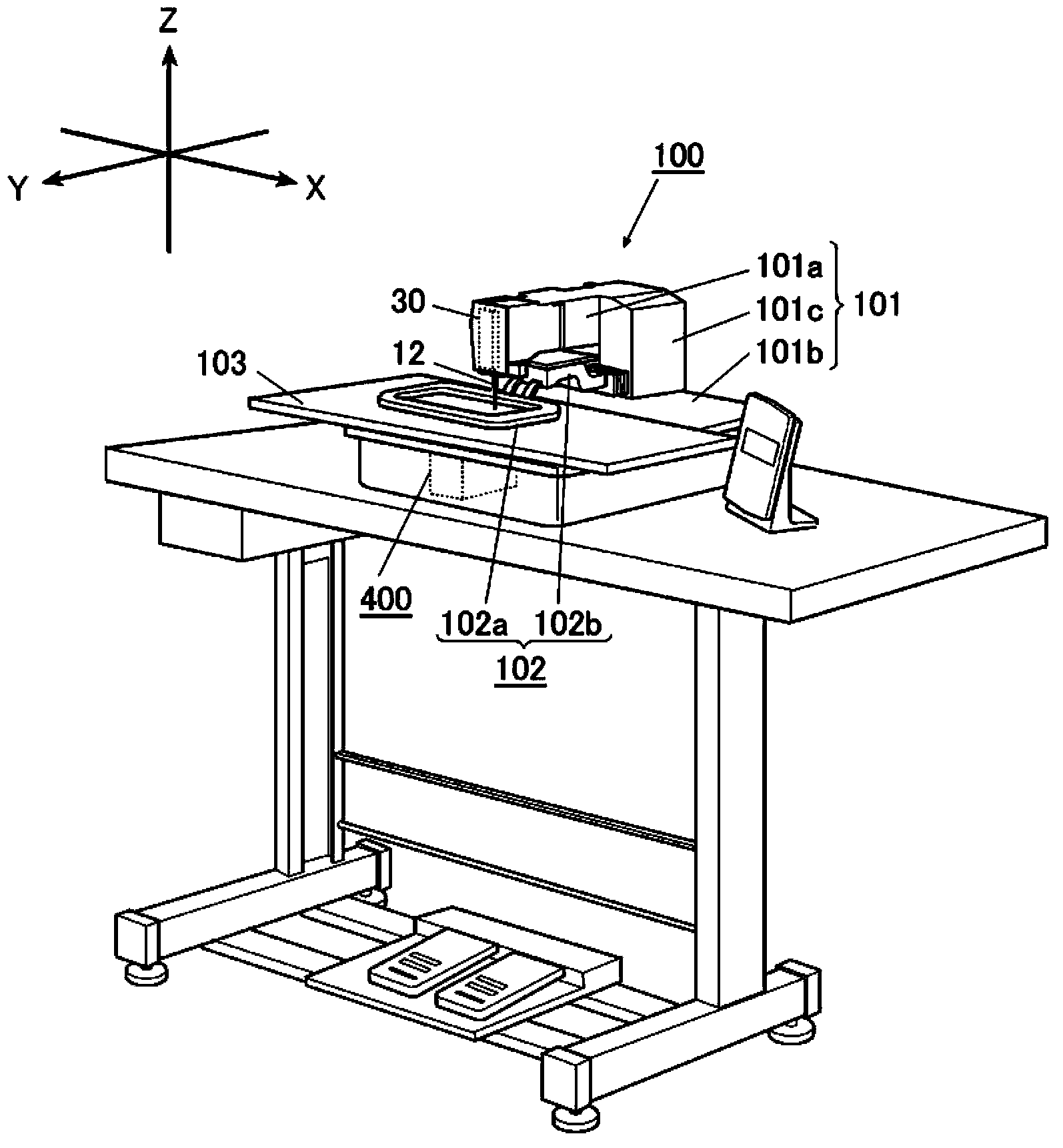

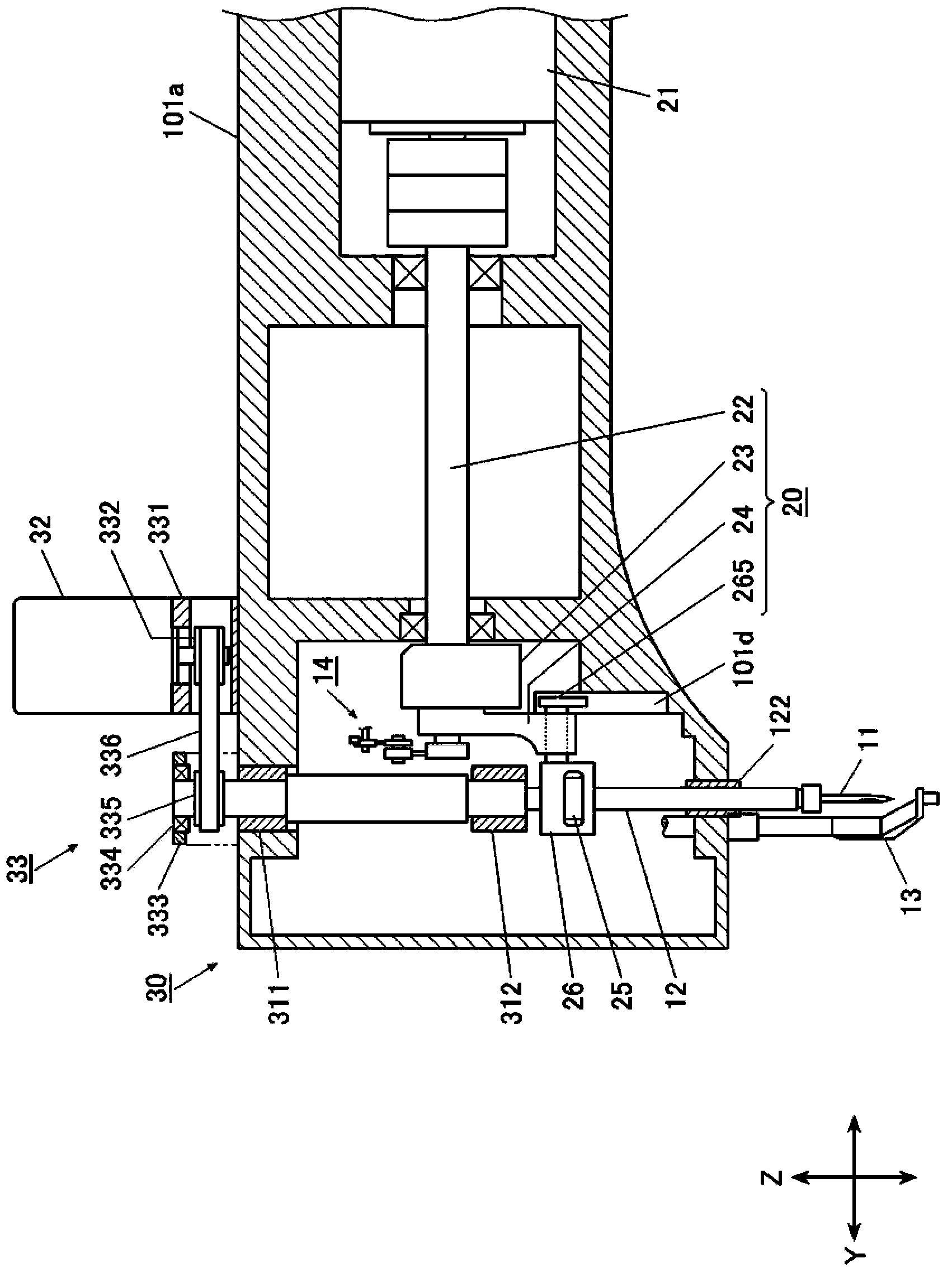

Sewing machine

ActiveCN103374797AGood followabilityAchieve lightweightNeedle barsBiomedical engineeringSewing machine

The invention provides a sewing machine that can realize high-speed needle rotation, wherein the sewing machine comprises a needle rod (12) that holds a needle (11); a needle rod rotation platform (31) that can move up and down to support the needle rod, and is supported on the sewing machine frame by rotating together with the needle rod around a centre line (C); a needle up-and-down move mechanism (20) that is connected with the needle rob and moves the needle rod up and down; a needle rotating motor (32) as a power for driving the needle rod rotate; and a scale (14) that pulls a thread. The needle rod rotation platform (31) can support part of the needle rod by moving up and down. The needle up-and-down move mechanism (20) is connected to the needle rod when the needle up-and-down move mechanism doesn't coincide with part of the needle rod supported by the needle rod rotation platform.

Owner:JUKI CORP

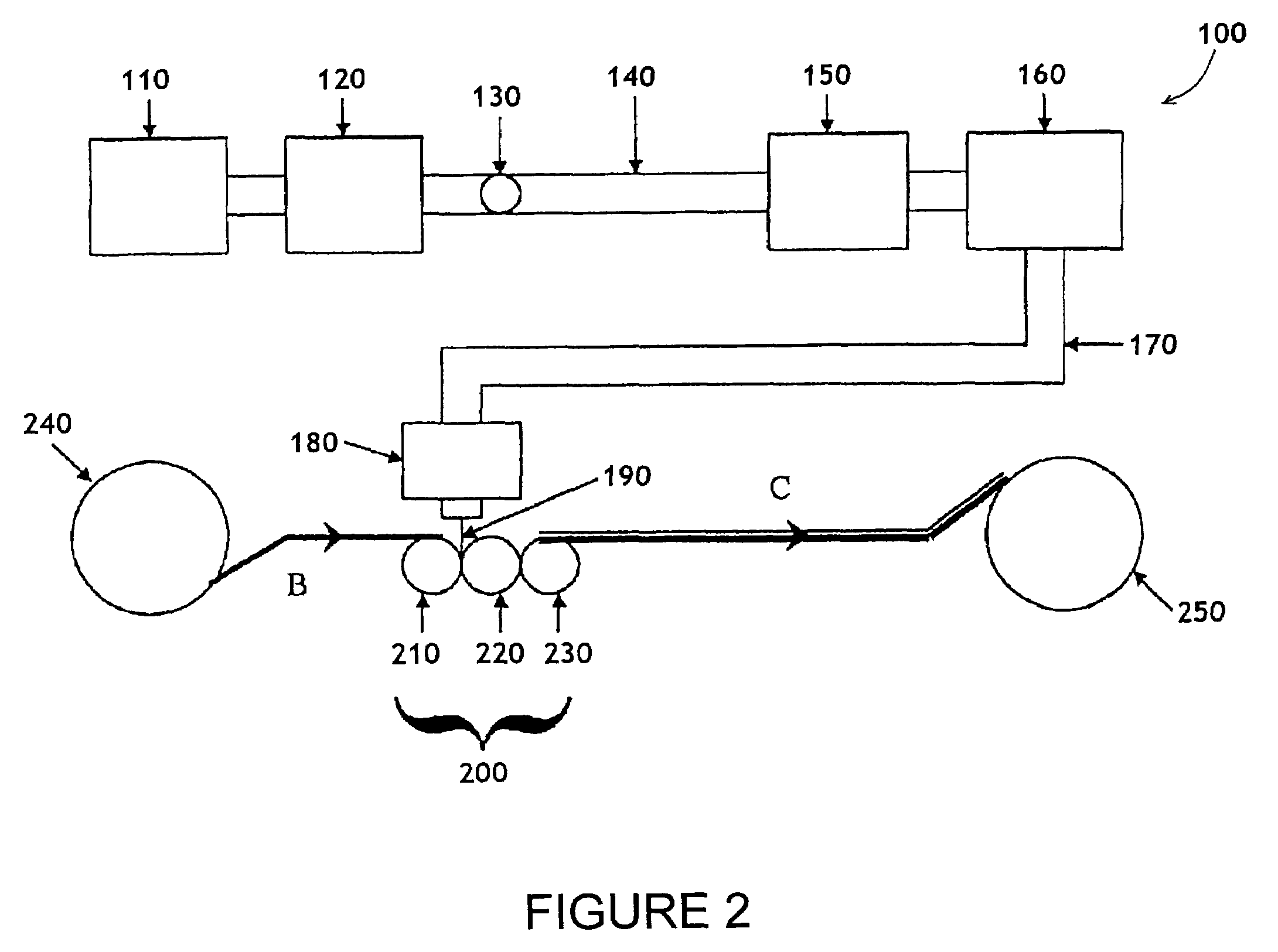

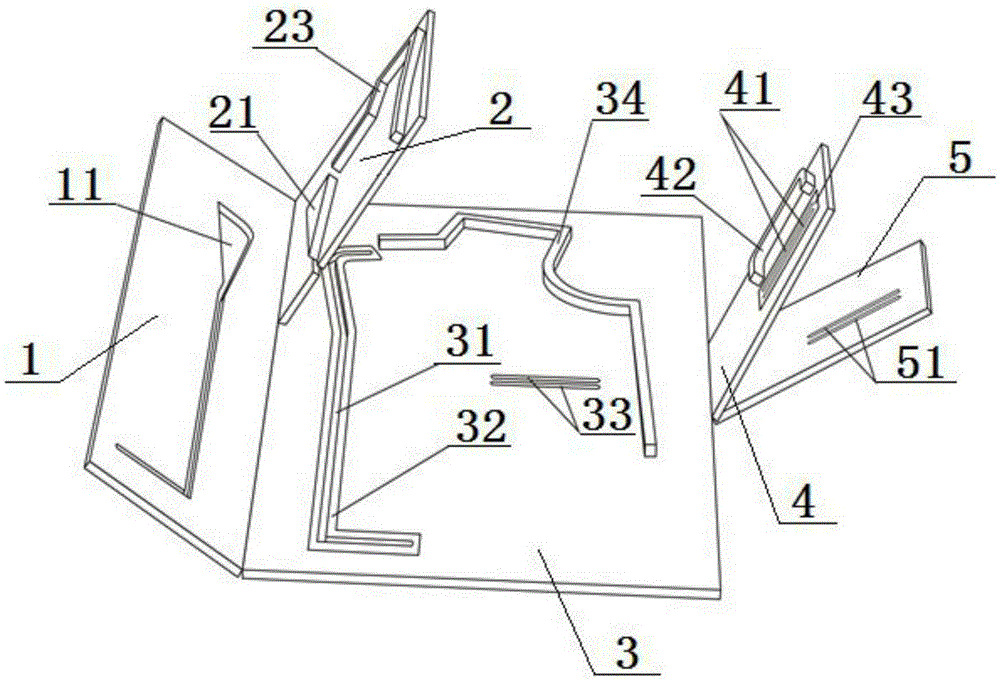

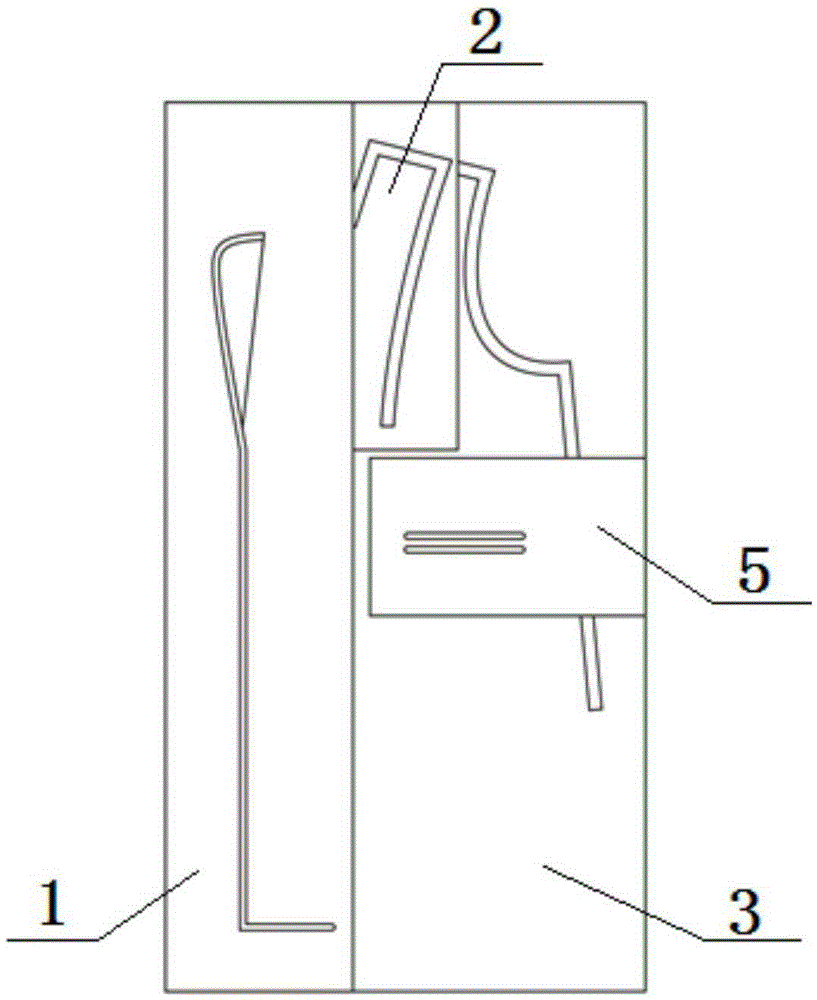

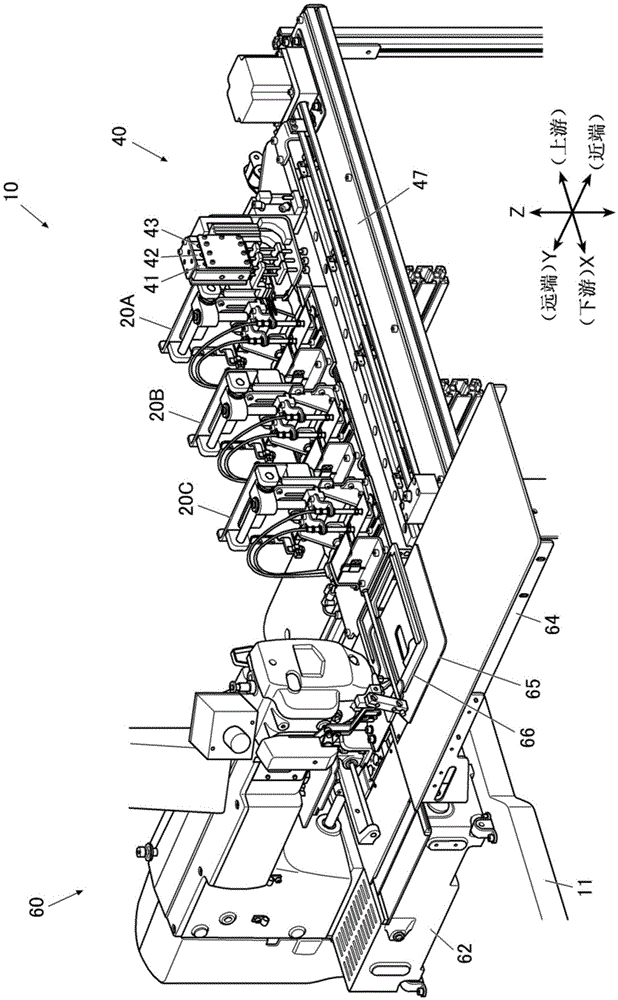

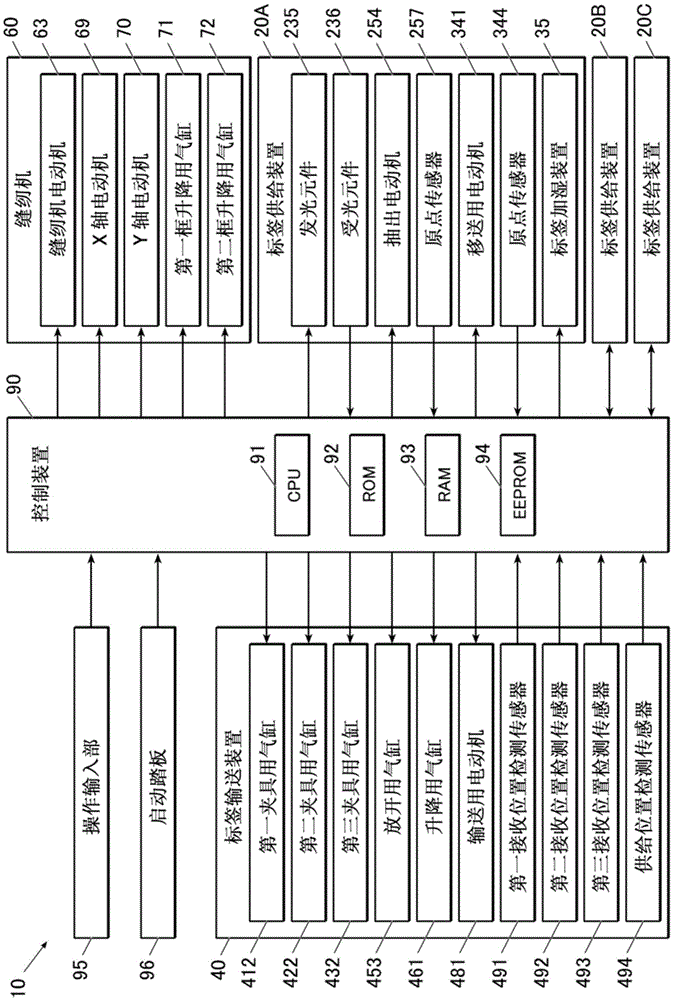

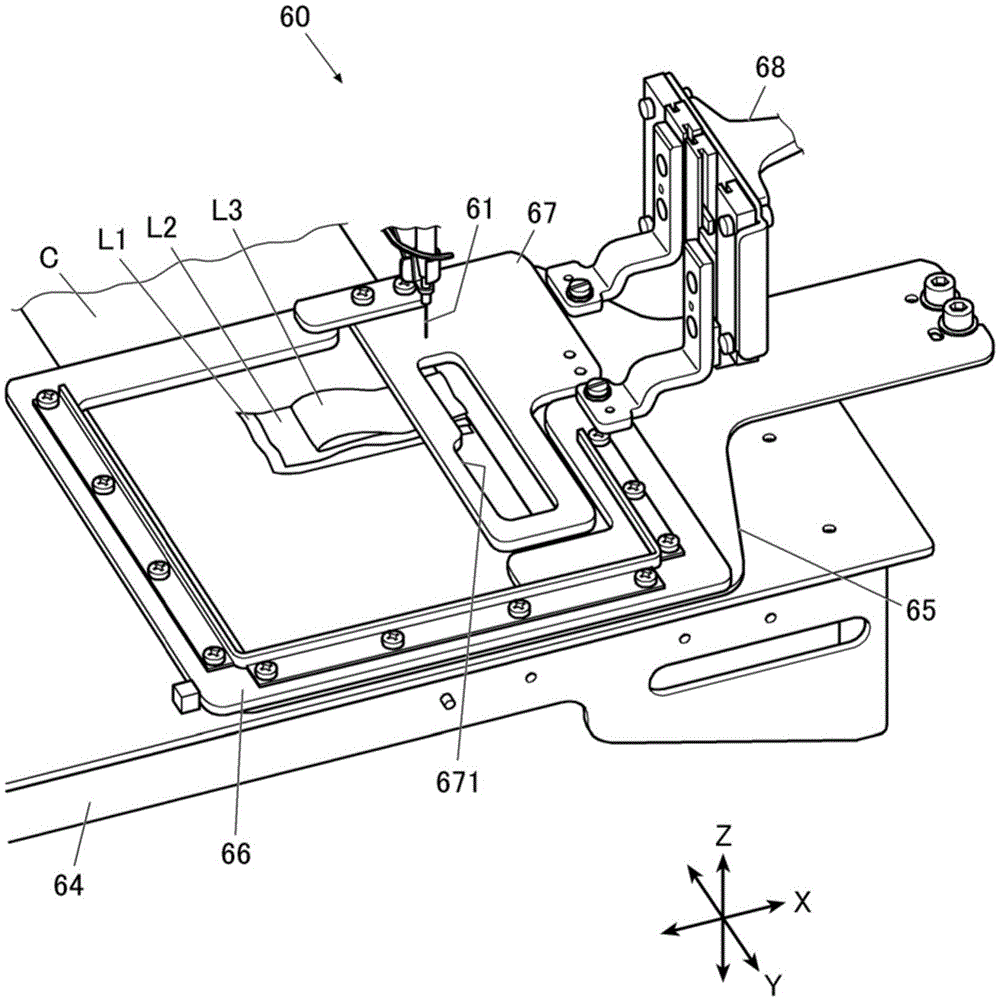

Label sewing device

InactiveCN105803687AImprove rigiditySuppression of poor sewingWork-feeding meansCurve shapeCotton material

The invention provides a label sewing device which prevents bending of a label when a sewing machine supplies the label through a simple structure. The device comprises a label supply device (20) and a label conveying device (40), and a sewing machine (60). The label supply device (20) supplies a label (L) which is to be sewn on a cloth (C). The label conveying device (40) conveys the label which is supplied by the label supply device. The sewing machine (60) sews the label which is conveyed by the label conveying device to the cloth. The label conveying device is provided with upper fixture components (411-431) and a lower fixture component (44). The fixture components make one end of the label clamp the label along a direction orthogonal to a conveying direction in an extending state. The upper fixture components and the lower fixture component have fixture surfaces (441) which contact with each other by surfaces. The shape of the respective fixture surface of the upper fixture components and the lower fixture component, observed from the extending direction of the label, is a curve shape or a fold line shape.

Owner:JUKI CORP

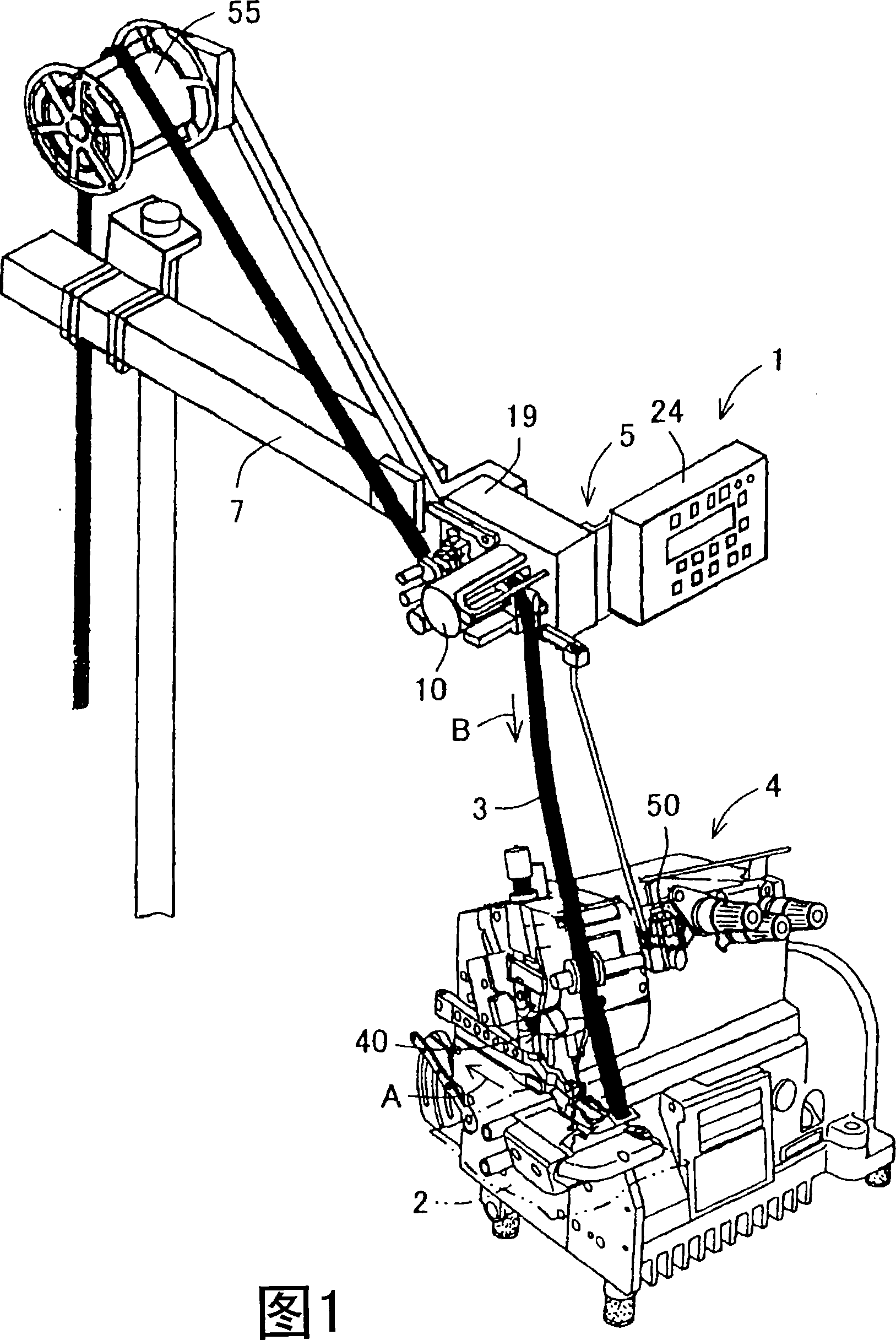

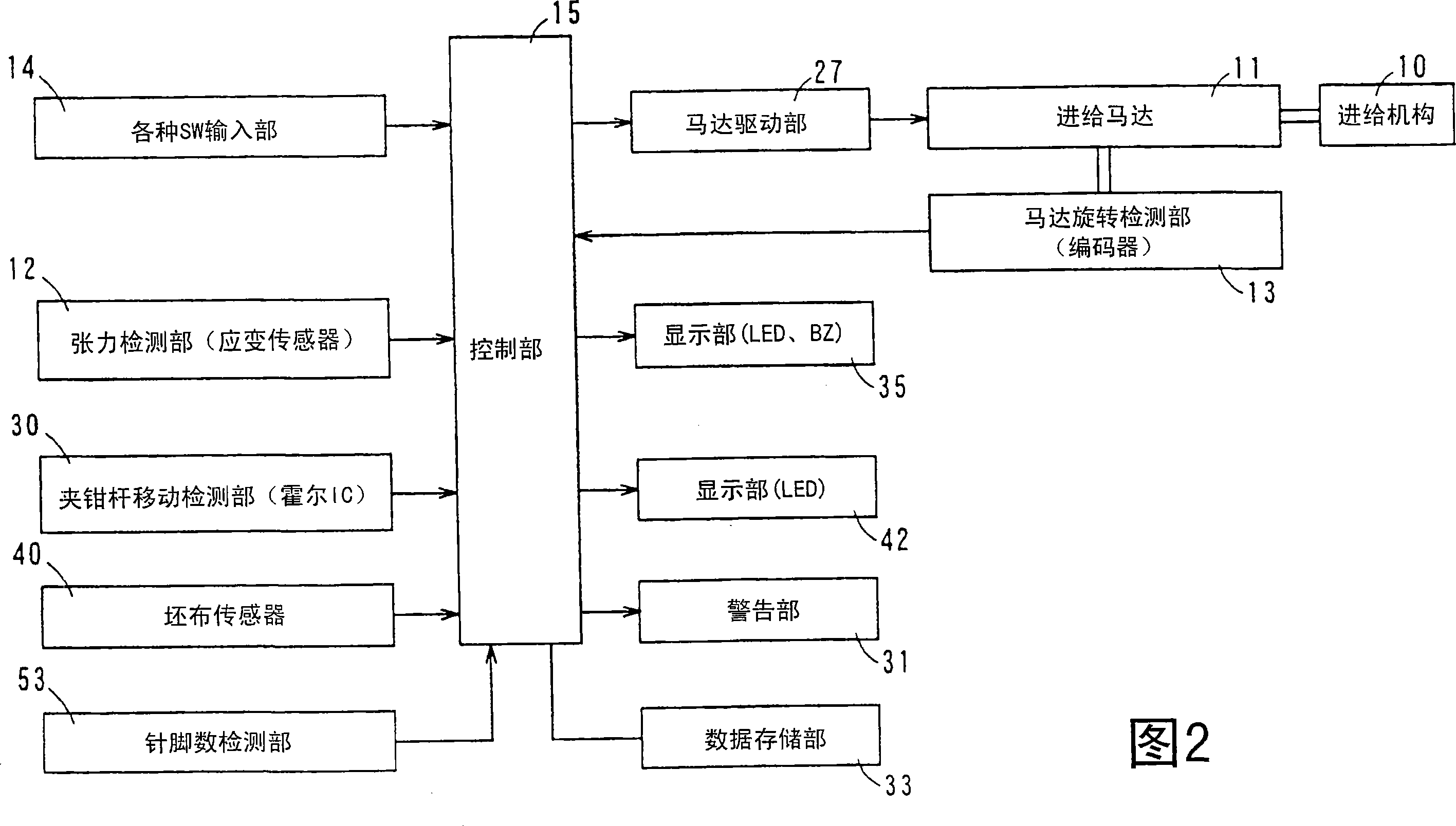

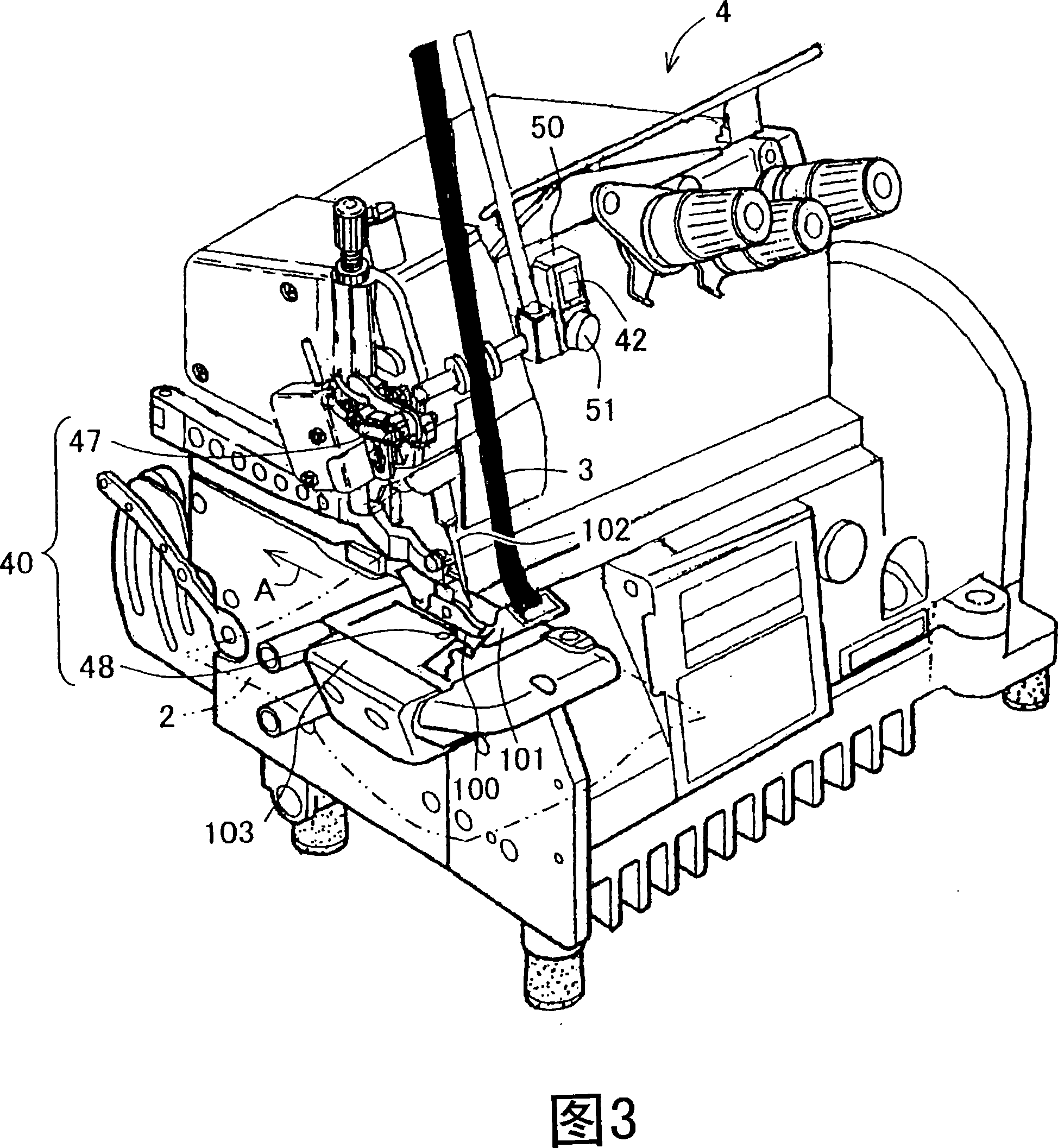

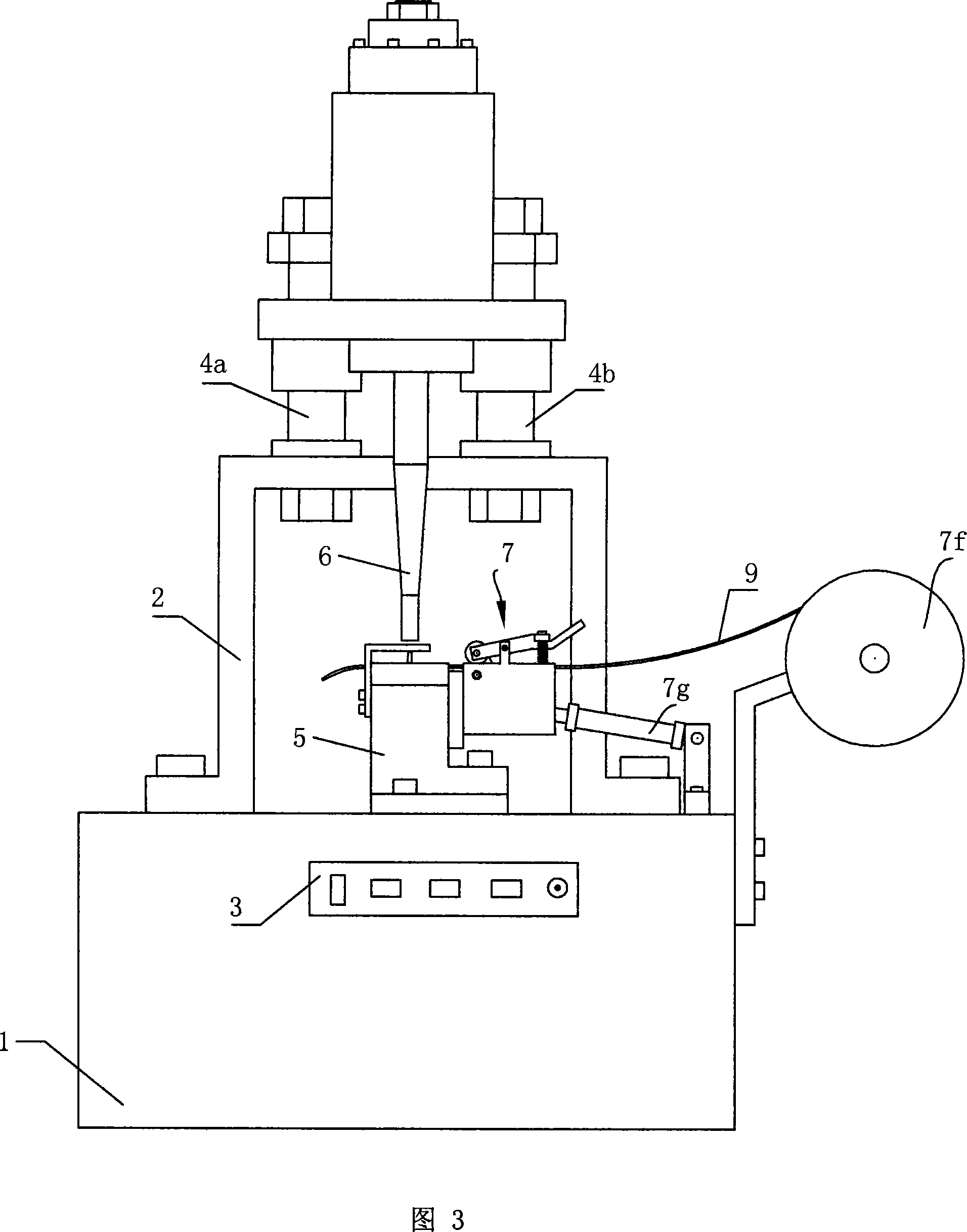

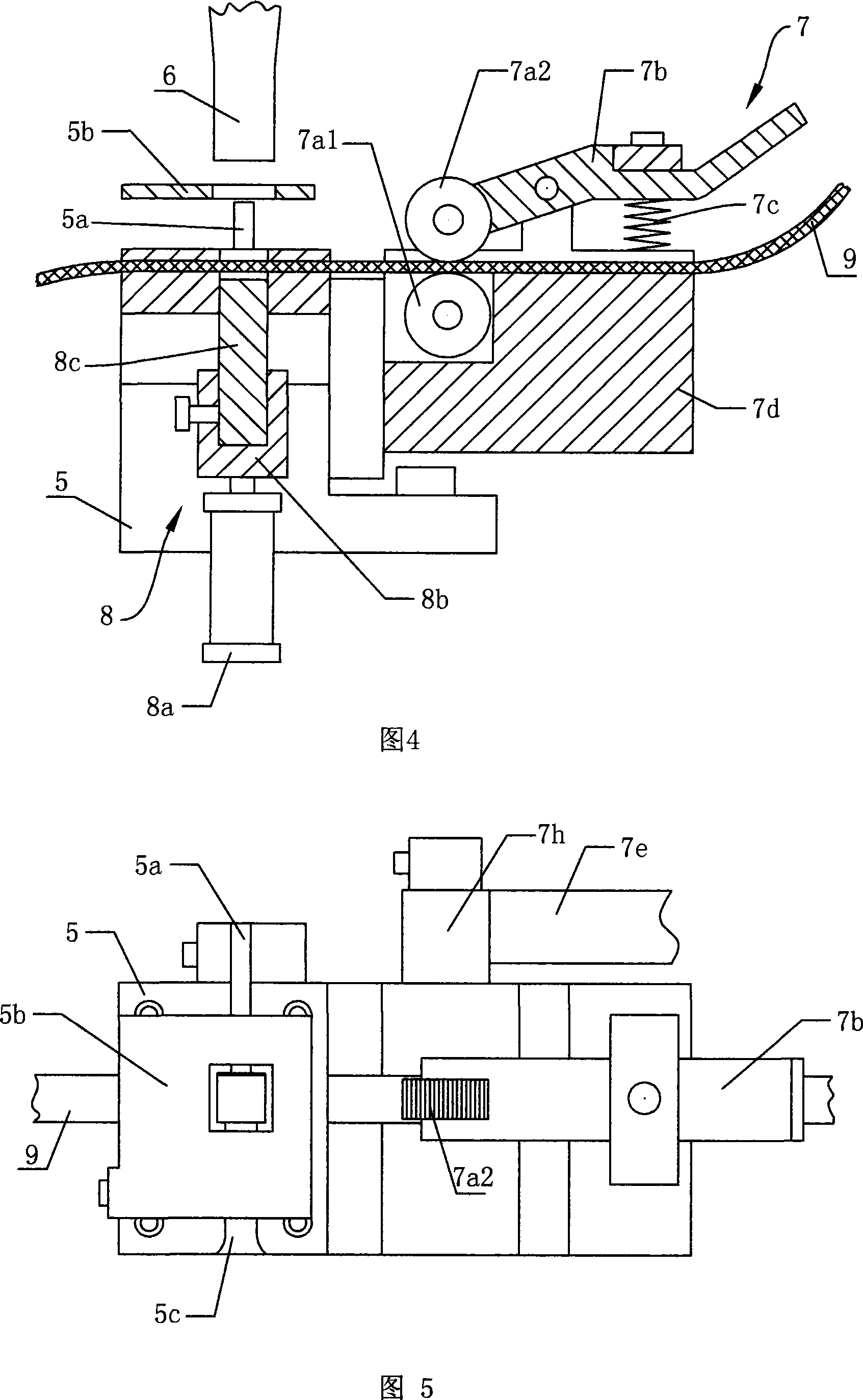

Belt sewing method and device

ActiveCN101070667AEliminate bad conditionsEasy to changeProgramme-controlled sewing machinesWork-feeding meansDrive shaftEngineering

This invention relates to a method and device of ribbon splicing, which can eliminate bad condition controlled by the tension induced by stitch number to splice a ribbon to the blank, no need of detection of action amount of sewing machine. The length dimension of ribbon(3) is set corresponding with tension, when the ribbon(3) is spliced to the blank (2), the feed level and tension of the ribbon(3) are detected. During feeding the ribbon(3) of preset length, the corresponding tension is applied on the ribbon(3). Thus, the tension is controlled by feed level of the ribbon(3) of the sewing machine (4), not by the action amount of the sewing machine (4) of rotational velocity of driving shaft, stitch number.

Owner:YAMATO SEWING MASCH MFG CO LTD

Side air bag apparatus and manufacturing method of a side air bag

ActiveUS20120049494A1Easy to sewQuality improvementLeather sewingPedestrian/occupant safety arrangementEngineeringMechanical engineering

A protruding portion that is exposed from the outer peripheries of upper base cloths and a lower base cloth and provided with an insertion hole for inserting an inflator is provided on a portion of a tube base cloth. The inflator is inserted into the side air bag through the insertion hole. The peripheral edge portion of the insertion hole is fixed to the inflator by a clamp. The upper base cloths are not sewn to together in an area where the outer peripheries of the upper base cloths overlap with the tube base cloth, and the lower base cloth is not sewn to itself in an area where the outer periphery of the lower base cloth overlaps with the tube base cloth.

Owner:TOYOTA JIDOSHA KK

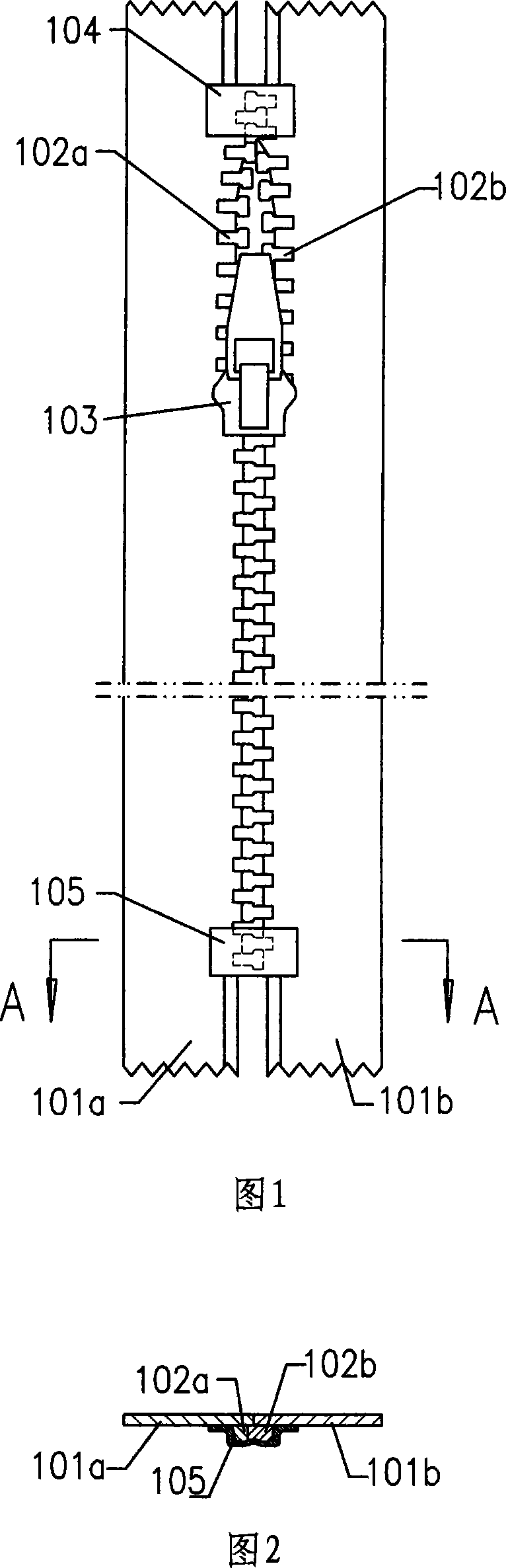

Method for processing nylon zipper and zipper stopper and zipper stopper welder

InactiveCN101069592AEasy to lay flatConsistent and fast feedingSlide fastenersDomestic slide fastenersEngineeringPlastic film

The present invention discloses a nylon zipper. It includes the following several portions: two zipper strips, two tooth chains which are respectively fixed on the opposite edges of the described two zipper strips, lower stop fastener fixed in the lower end portion of the described two tooth chains and upper stop fastener fixed in the upper end portion of the described two tooth chains. The described upper stop fastener and lower stop fastener are made up by using plastic sheet respectively, the described plastic sheets are respectively welded on the projected surfaces of said two tooth chains. Besides, said invention also provides a zipper stop fastener welding machine and a processing method of said zipper stop fastener.

Owner:钟砚宝

Airbag apparatus

ActiveUS8550495B2Prevent leakageAvoid wear and tearPedestrian/occupant safety arrangementEngineeringMechanical engineering

An airbag apparatus having an airbag, which is formed into a bag shape by sewing a base fabric, is disclosed. The airbag includes a seam having a first seam section and a second seam section, which is formed after the first seam section is formed. The second seam section has an extremity and an overlapped portion, which is a section between the extremity and an intersected portion. The first seam section has an end part, which includes an overlapping portion. The overlapping portion is located at a position inside of the overlapped portion of the second seam section and extends along the overlapped portion. The overlapping portion includes an intersecting portion, which intersects the intersected portion of the second seam section. The end part of the first seam section further includes an extension, which extends from the intersecting portion to a position that is outside of the second seam section.

Owner:TOYODA GOSEI CO LTD

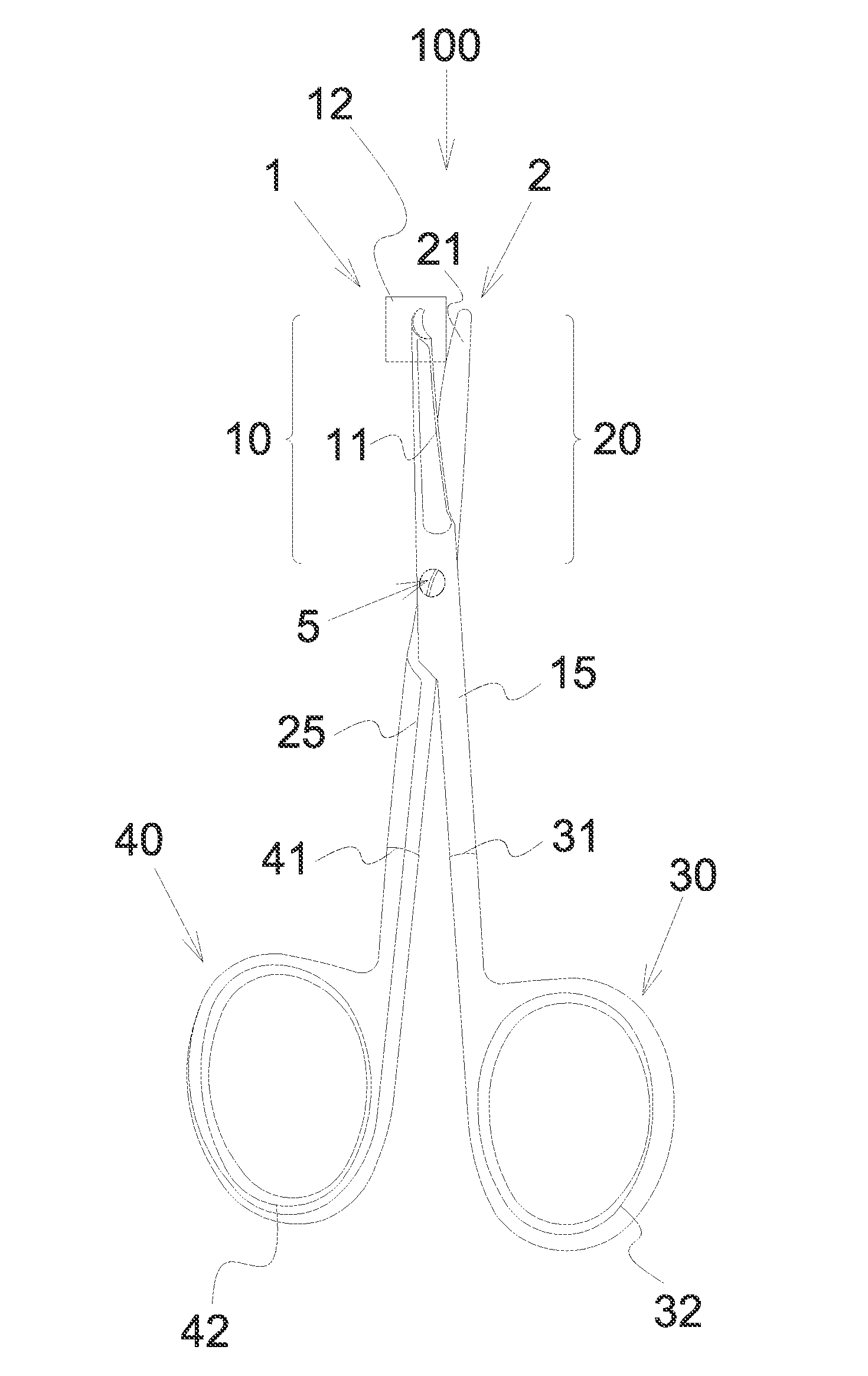

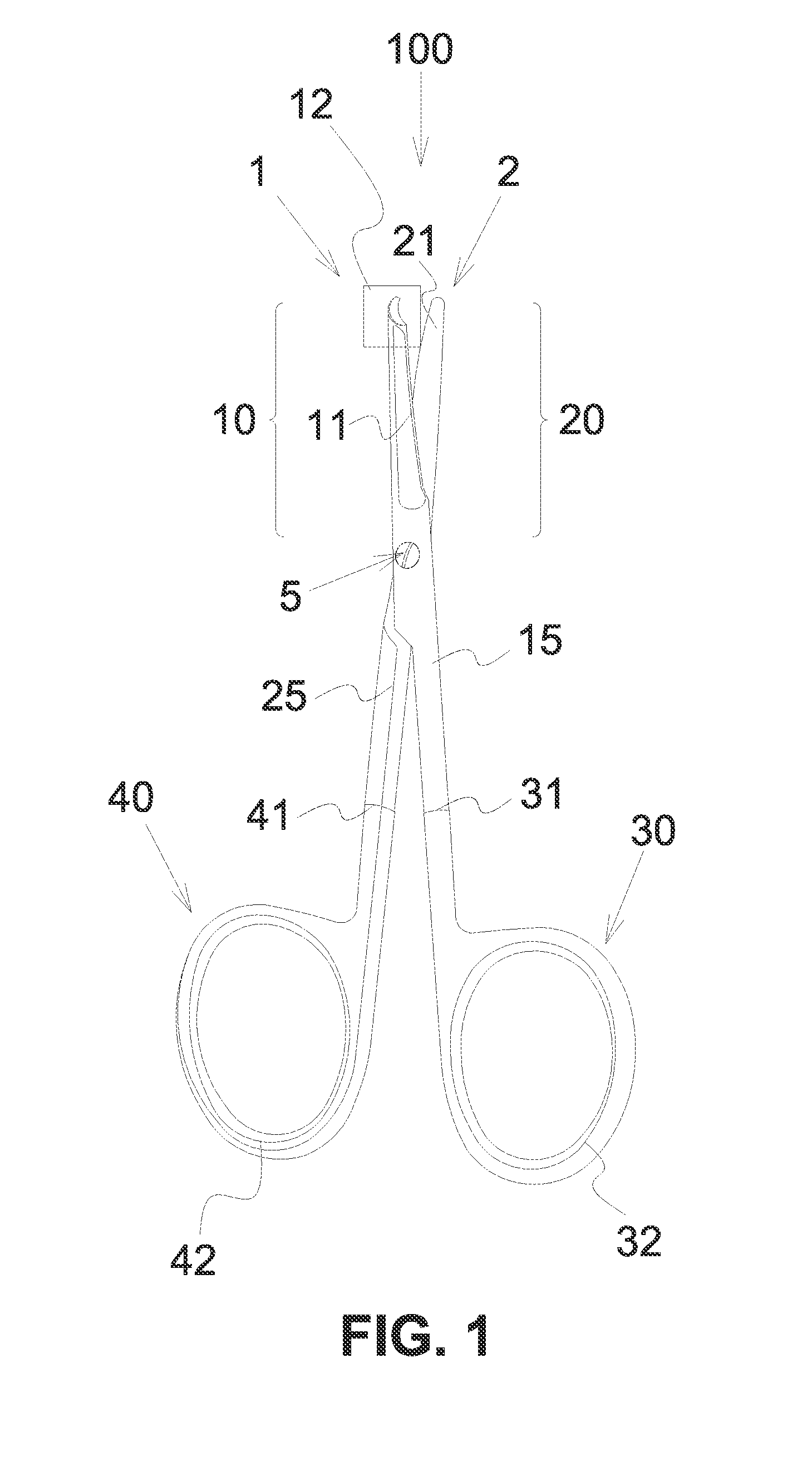

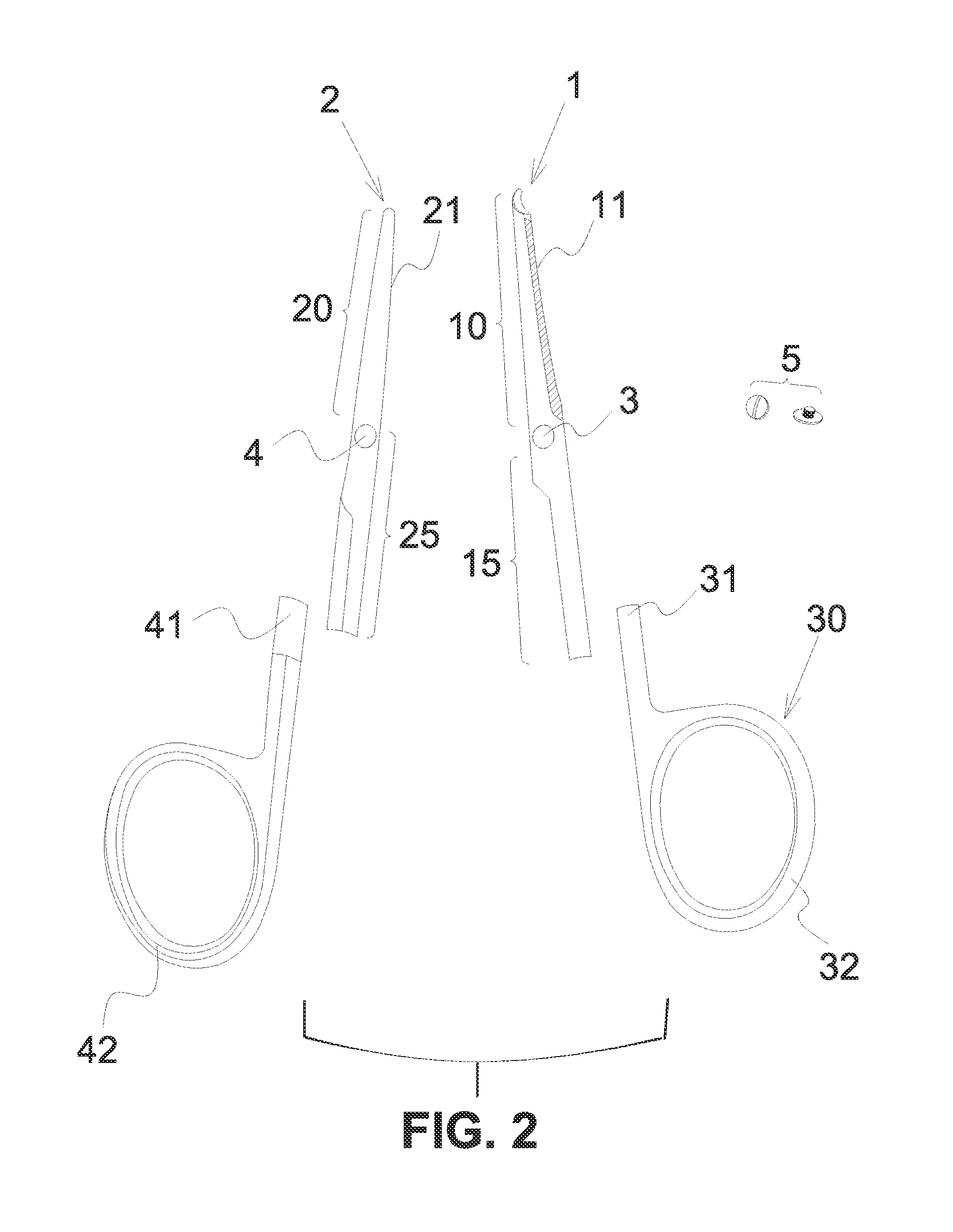

Seam Ripper Scissors

InactiveUS20140101944A1Difficult to handleEasy to operateSeam-ripping devicesMetal working apparatusEngineeringConcave surface

The apparatus of the present invention is a hand operated seam ripping or cutting instrument. It comprises a pair of metal blades pivoted so that the sharpened edges slide toward or away from each other when the handles opposite to the pivot are brought close to or separate from each other. The unique ripping section, which has an appearance of a craved hook, residing at the free end of one of the blades, is provided with a concave surface which is preferably sharp enough to rip a sewed seam but dull enough to prevent from inadvertently cutting the fabric and a tip that is preferably somewhat thin but rounded or smooth to avoid accidental snags in fabric or poke on the user's

Owner:MOULTRIE HYARLIEN

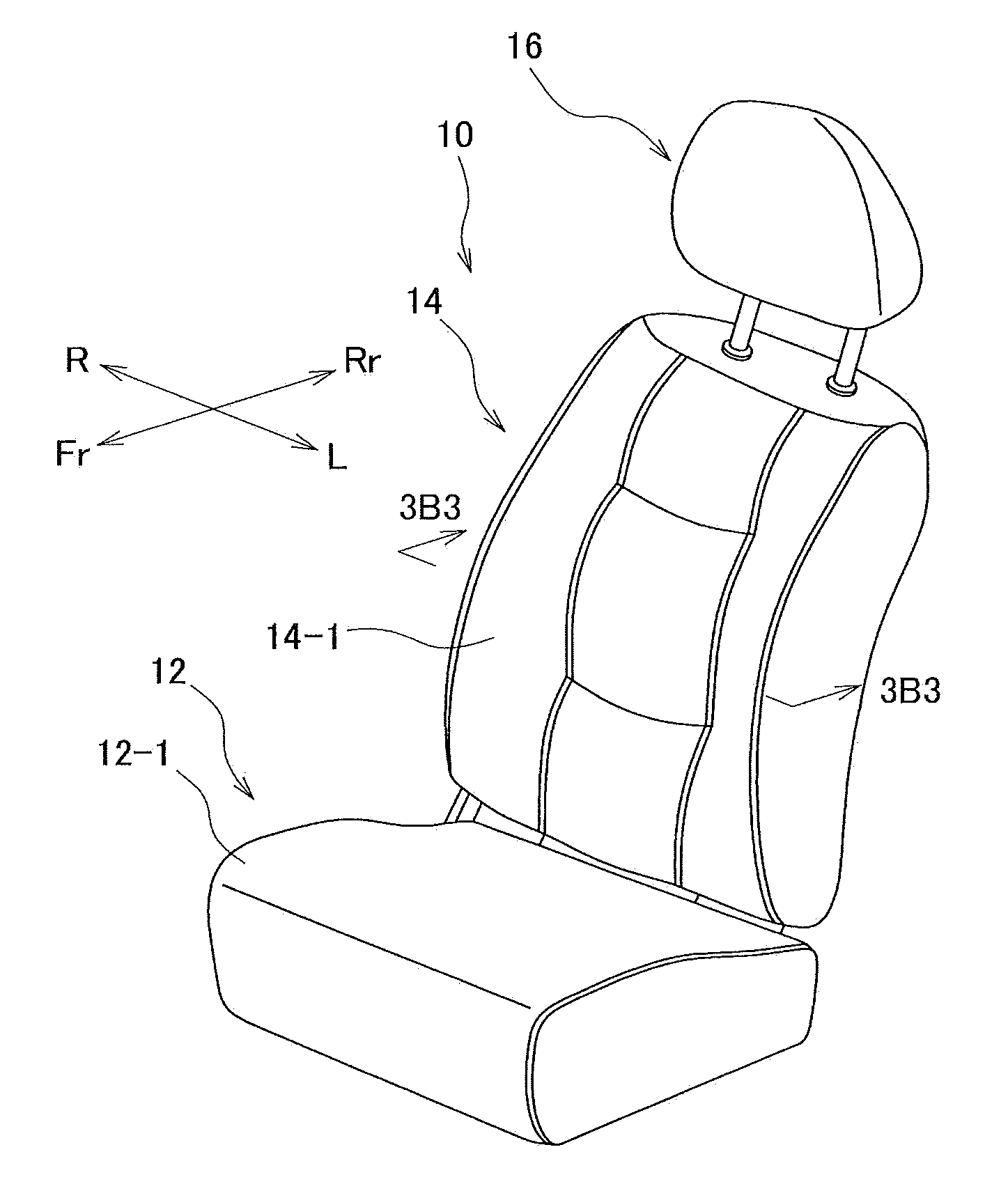

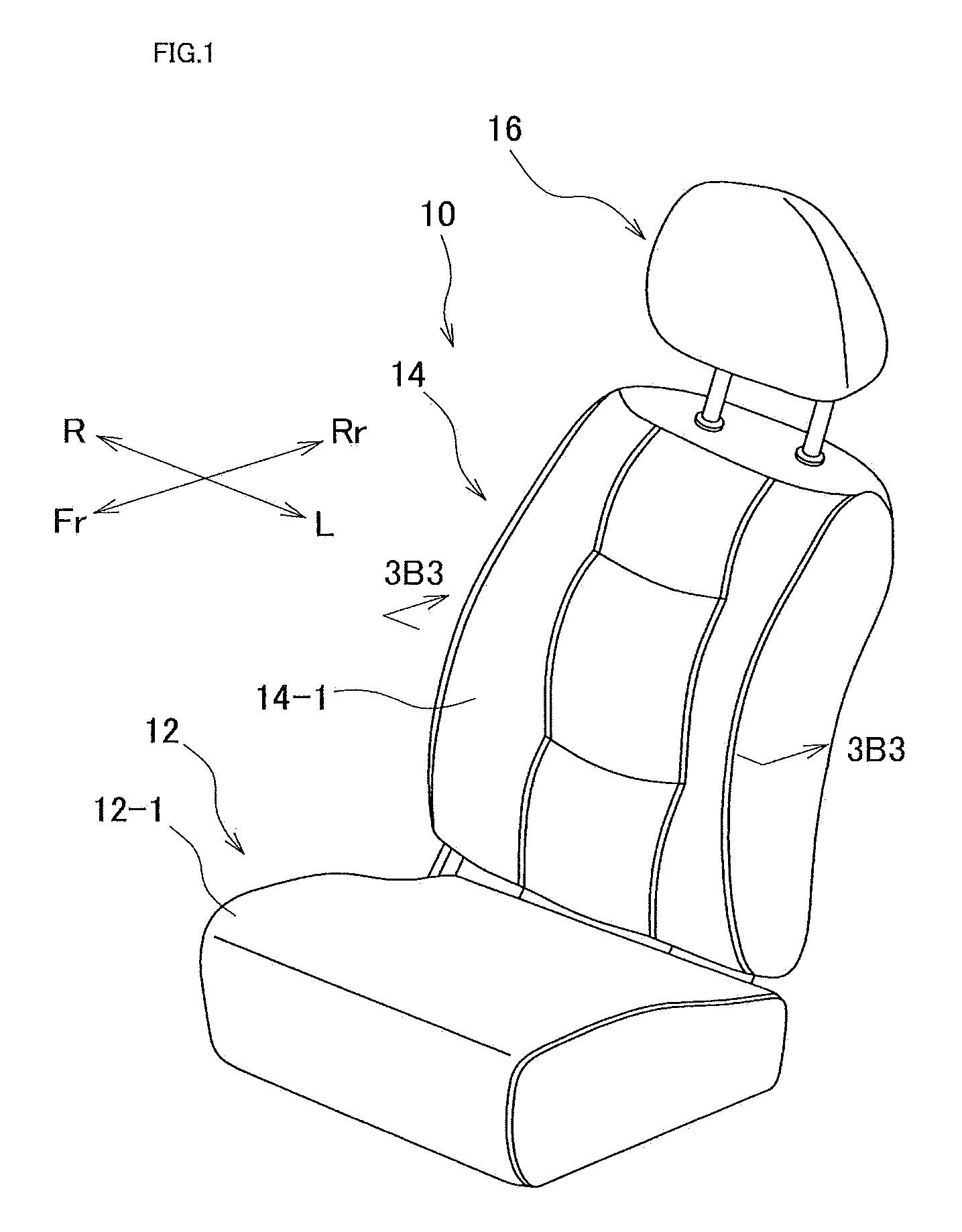

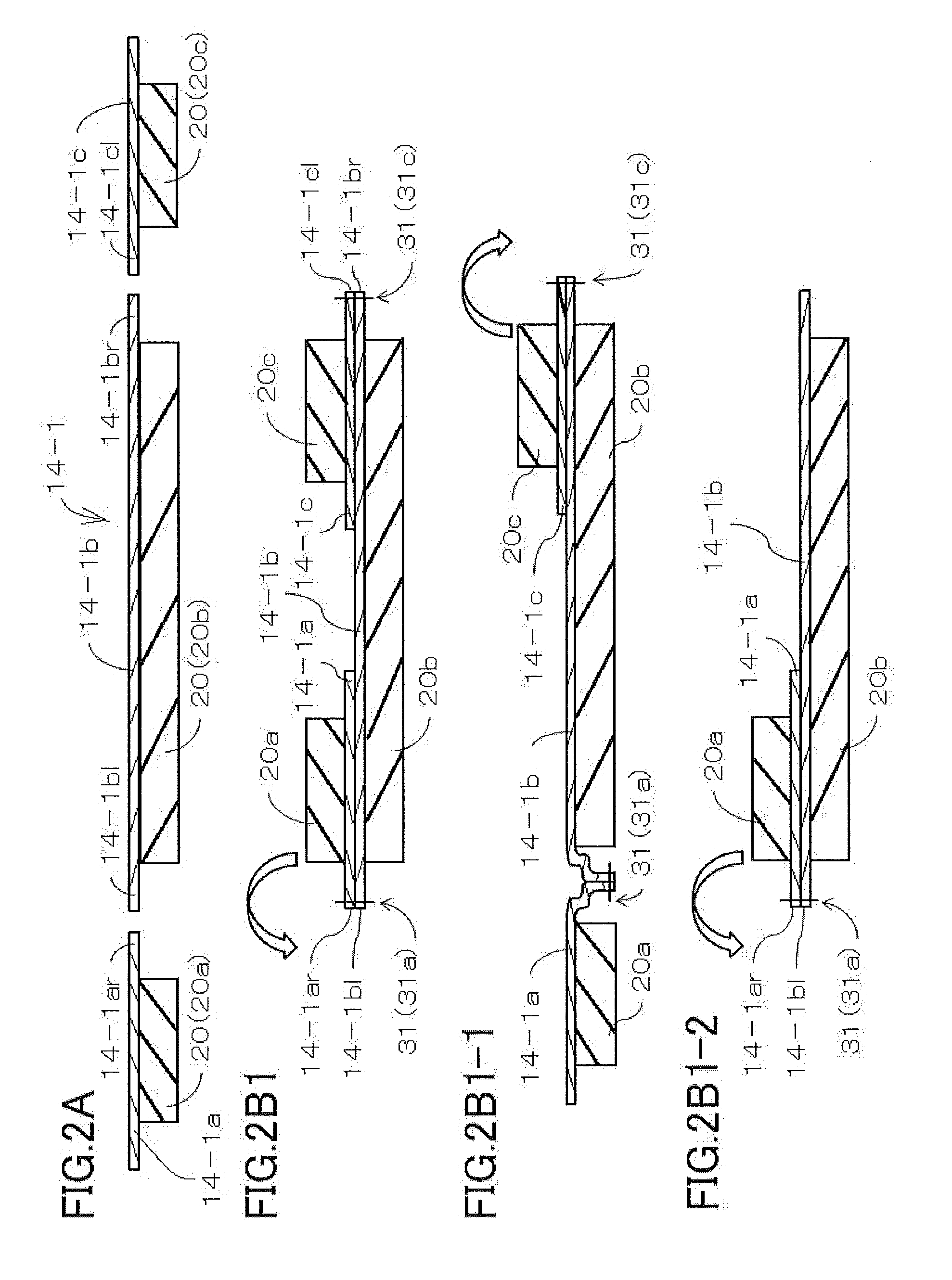

Surface structure of wadded seat and method of manufacturing surface structure of wadded seat

ActiveUS20160339819A1Easy to sewImpairment of out appearanceUpholstery manufactureSeat coveringsEngineeringMechanical engineering

A surface structure of wadded seat, with a trim cover having a plurality of trim cover pieces backed with wadding members and sewed together at ends, further includes: first sewed portions, each formed by sewing two adjacent trim cover pieces at one end of each trim cover piece, while serving as seam allowance, the portions not backed with the wadding members; second sewed portions, each formed first by forming a continuous trim cover piece, then by laying a long wadding member on the backs of the wadding members, and finally by sewing, at both ends of the continuous trim cover piece, the wadding members on the backs of the trim cover pieces and the long wadding member; and third sewed portions, each formed by sewing, at both ends of each first sewed portion, the long wadding member to the end of each trim cover piece.

Owner:TACHI S CO LTD

Airbag for protecting knee

InactiveCN1796188AReduce production man-hoursLow costPedestrian/occupant safety arrangementEngineeringAirbag

The present invention relates to an air bag for protecting knee portion of passenger. Said air bag can be folded, and can be received in the front side of knee portion of the passenger taken seat. Said air bag includes said air bag main body and tie band, and said air bag main body contains air channel and air flowing hole. Said invention also provides the concrete structure of said air bag main body and its application method.

Owner:TOYODA GOSEI CO LTD

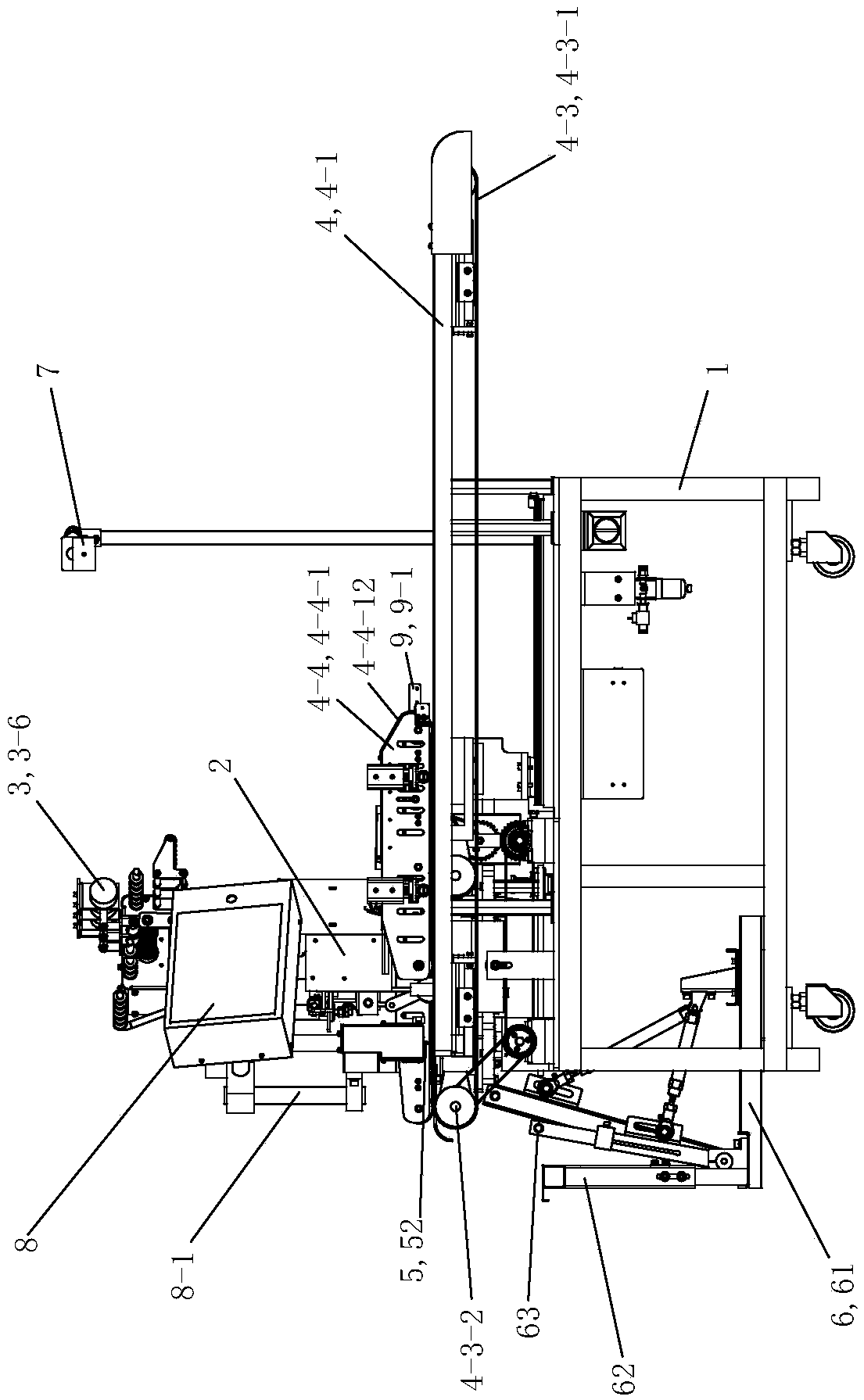

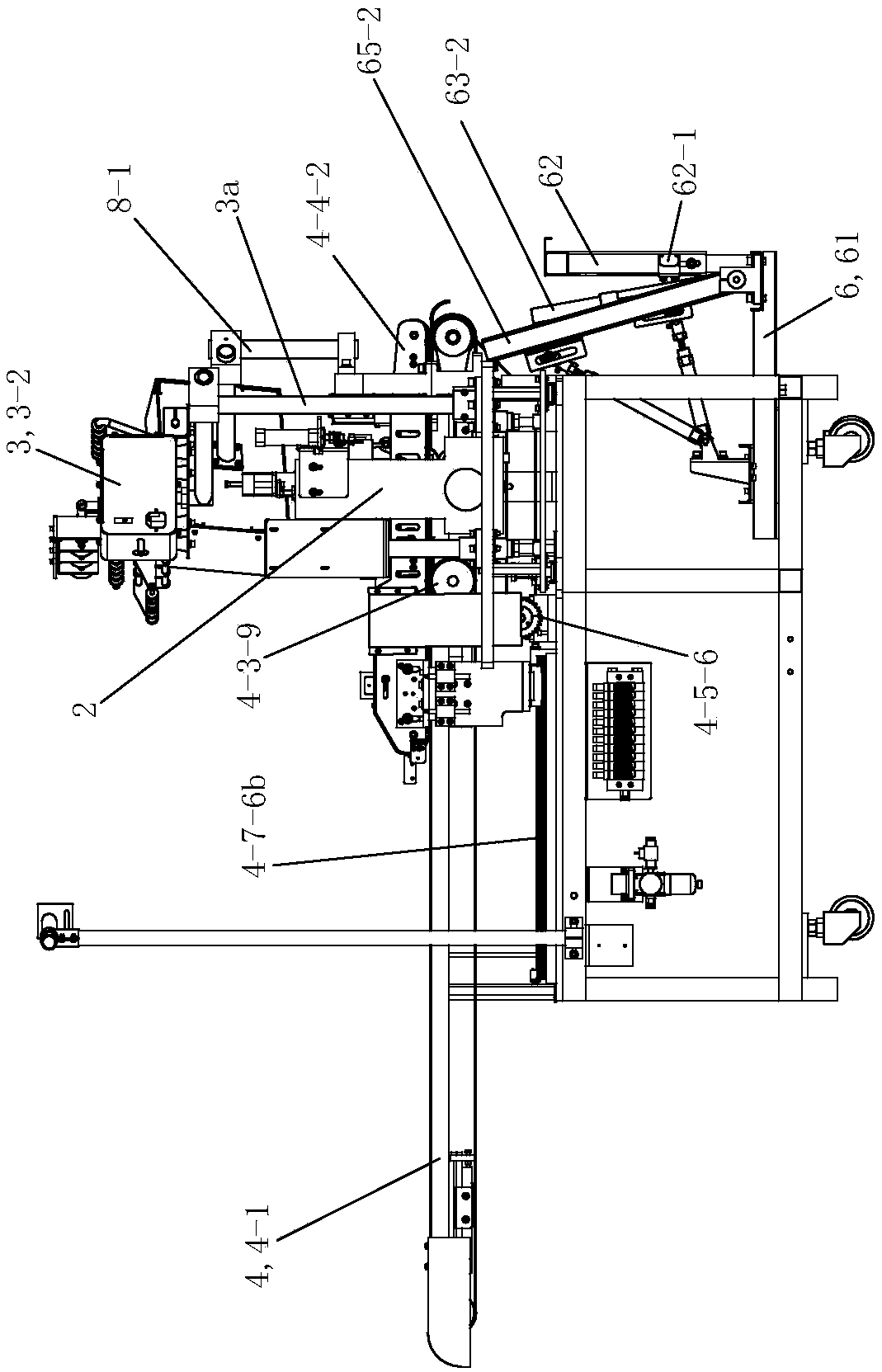

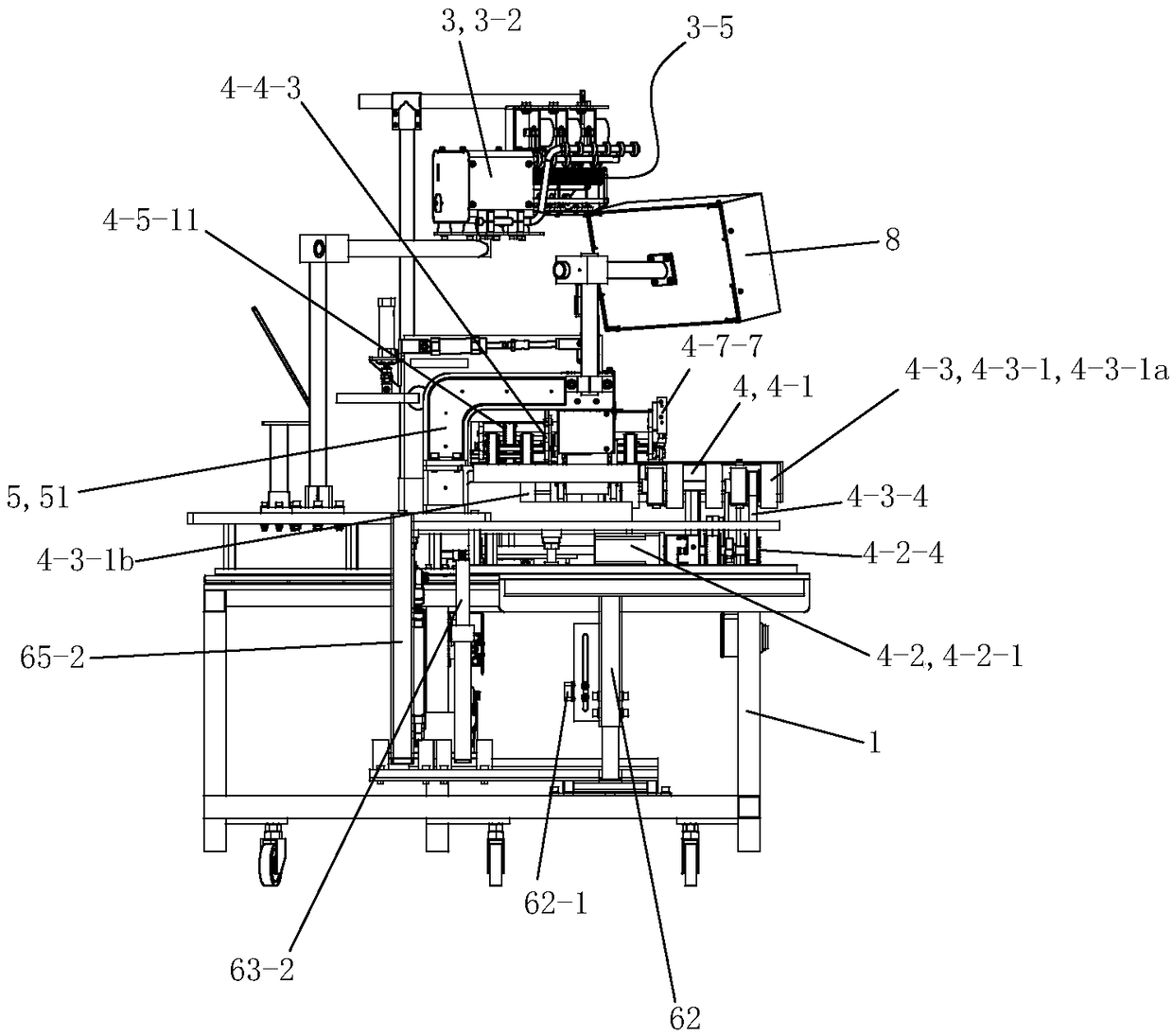

Full-automatic multi-decoration strip sewing equipment

PendingCN108642733ASimple structureEasy to useWorkpiece carriersWork-feeding meansHuman–computer interactionControl equipment

The invention discloses a full-automatic multi-decoration strip sewing equipment, which comprises a frame, a multi-needle sewing machine and a control panel, wherein the control panel is provided witha man-machine interaction interface for displaying the equipment state and controlling the equipment. The multi-needle sewing machine is fixedly arranged on the left part of the frame. The equipmentis characterized by also comprising a decorative strip feeding device, a feeding device and a shearing device. A pull cylinder is arranged on the multi-needle sewing machine. The decorative strip feeding device is arranged on the frame and above the multi-needle sewing machine. The decorative strip feeding device is used for making the decorative strip to be sewed to be in a relaxed state to enterthe pulling cylinder of the needle sewing machine to roll the edge. The feeding device is arranged on the frame, and the feeding direction of the feeding device is arranged along the left and right direction. The feeding device is used for feeding the cloth to needle sewing machine to be sewed with the decorative strips with rolled edges, and feeding the cloth sewn with the decorative strips outof the multi-needle sewing machine. The shearing device is used for cutting off the corresponding decorative strips after the sewing is finished.

Owner:CHANGZHOU ZHIGU ELECTROMECHANICAL TECH CO LTD

Tanning process for making fur-bearing animal specimen

InactiveCN103757148AGood extensibilityEasy to sewLeather manufacturingTanning treatmentExtensibilityWarm water

The invention discloses a tanning process for making a fur-bearing animal specimen. The tanning process comprises the steps of removing meat from a fresh hide which is just peeled off from an animal carcass, shaving and cleaning the hide and then draining off excessive moisture, dipping in a degreasing solution for degreasing, washing with warm water and throwing away moisture on the hide, dipping in an acidizing fluid for pickling, evenly shaving the hide and dipping the hide in a neutralizing solution for neutralization, putting in a tanning agent for tanning for 12-24 hours, regulating alkali 1 hour later after the hide is put in, regulating alkali by one gram at a time and total three times at an interval of 2 hours, and stabilizing the final pH within the range from 3.5 to 4.0 and finishing tanning. The hide plate tanned by the tanning process is light, soft, white and good in extensibility; the fur is loose and soft, and bright; the hair of the animal is permanently fixed on the leather which is high in tensile strength; and the animal specimen is easier to fur and sew, and also is resistant to corrosion, mothproof, shrinkage-proof, deformation-proof, and environment-friendly.

Owner:YANTAI HAOYU SPECIMENS CO LTD

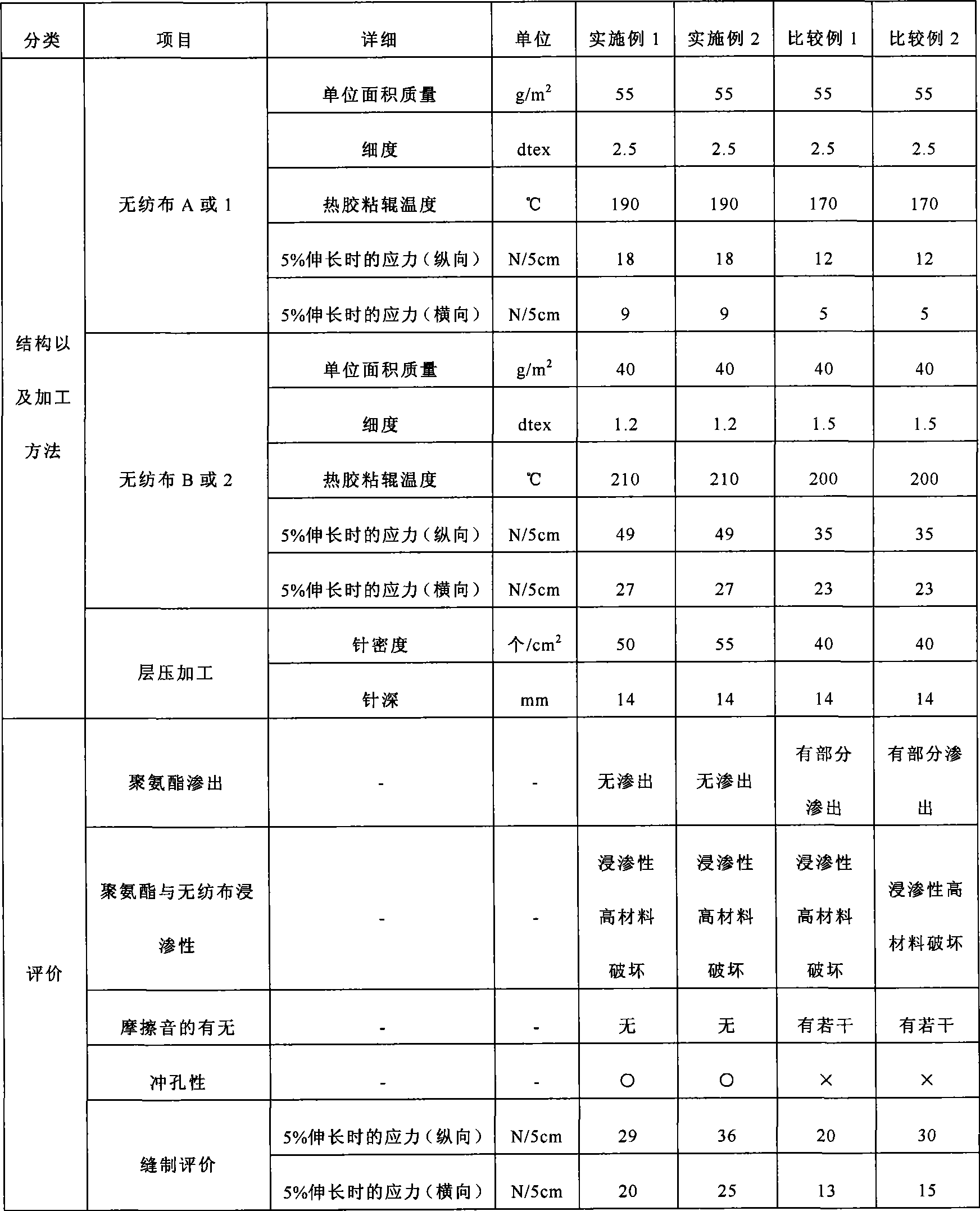

Urethane foam reinforcing material

InactiveCN101473082AReduce exudationImprove punching effectLayered productsWoven fabricsProduction rateVolumetric Mass Density

The present invention provides a urethane foam reinforcing material, which can suppress abrasion sound generated with a metal spring, high productivity, excellent handleability, and can be applied to even a urethane foam mold having large unevenness. A urethane foam reinforcing material is characterized in that a nonwoven cloth (A) having a single yarn fineness of 1.0-3.0dtex, and a nonwoven cloth (B) having a single yarn fineness of 0.5-2.5dtex are laminated by needle punch process at a needle density of 35-70 needles / cm, by permitting needles to enter from a direction of the nonvwoven cloth (A).

Owner:TOYOBO CO LTD

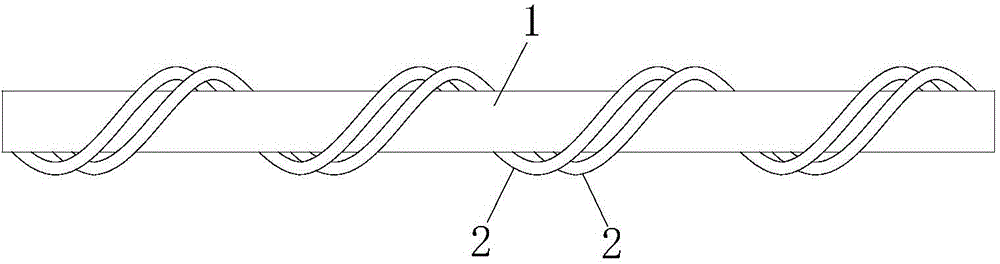

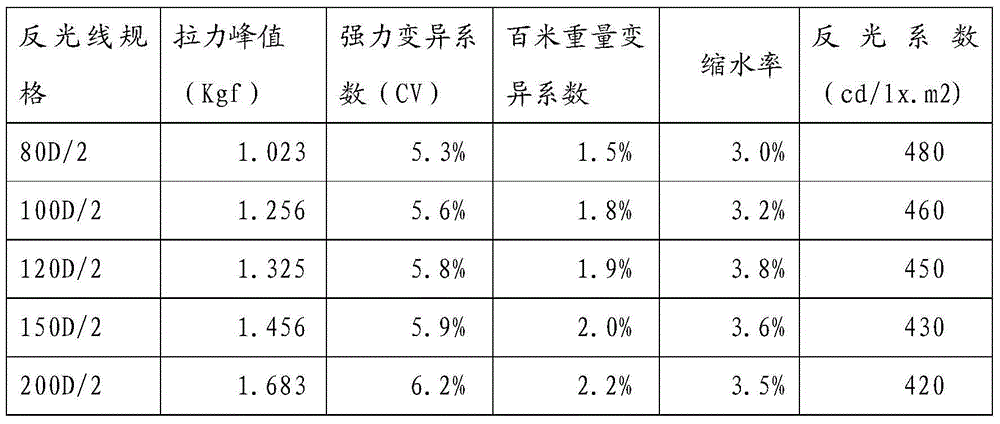

Water-soluble reflective thread and production process thereof

The invention discloses water-soluble reflective thread. The water-soluble reflective thread is formed by compositing a yarn core and at least one wrapped yarn. The wrapped yarn is wound on the outer surface of the yarn core in a spiral mode. The yarn core is a reflective silk, and the wrapped yarn is water-soluble yarn. A water-soluble reflective thread production process includes the following steps that (1) the water-soluble yarn is twisted; (2) the reflective silk is selected, wherein the surface of a PET film is coated with glass beads and are cut into different specifications, and reflective silks are obtained; (3) at least one water-solute yarn treated through the step 1 is wound on the reflective silk obtained through the step 2 in a spiral mode, and reflective yarn is obtained; (4) the reflective yarn is branched and coiled to be of the fixed length, and the water-soluble reflective thread is obtained. According to the water-soluble reflective thread and the production process, the water-soluble yarn is matched with the reflective silk, the sewability of the water-soluble reflective thread is enhanced, no twisting happens, no thread breakage occurs in the using process, and sewing is facilitated; meanwhile, after the thread is used, textile is washed, the water-soluble yarn part can dissolve and disappear, and the reflective effect is improved.

Owner:DONGGUAN COCOU TEXTILE MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com