Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

497results about "Domestic slide fasteners" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

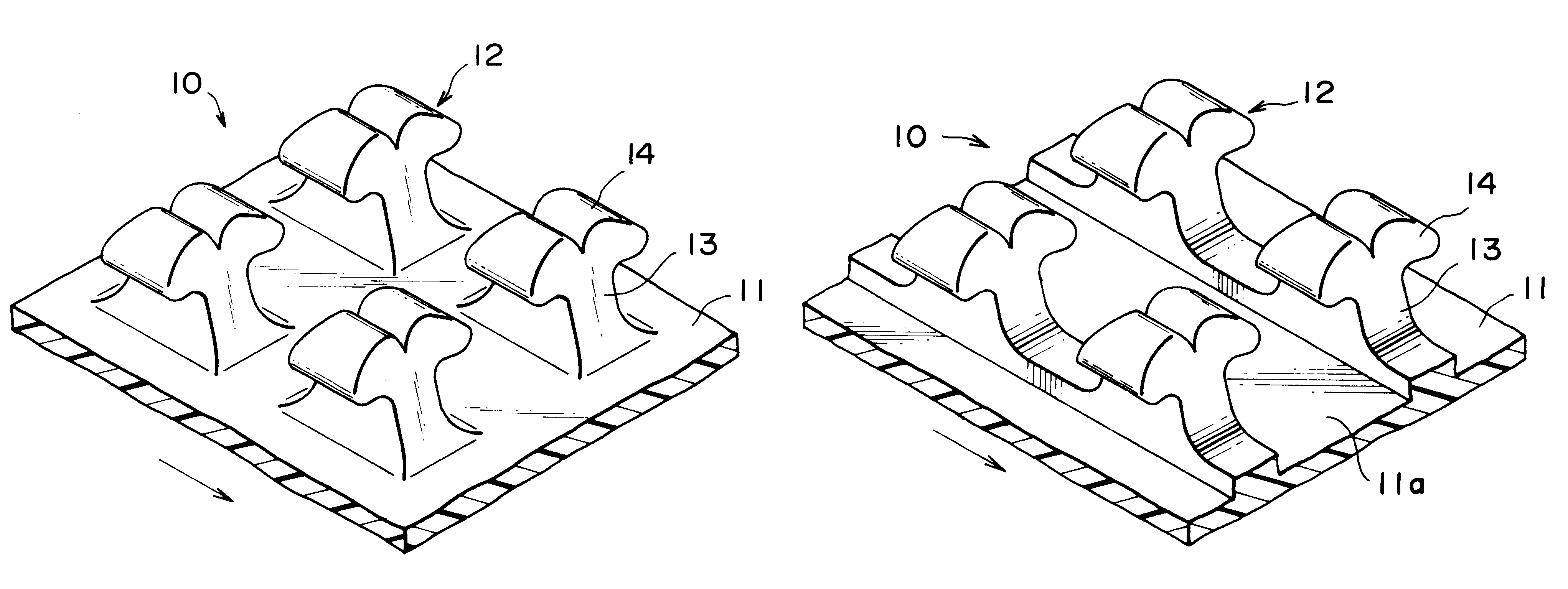

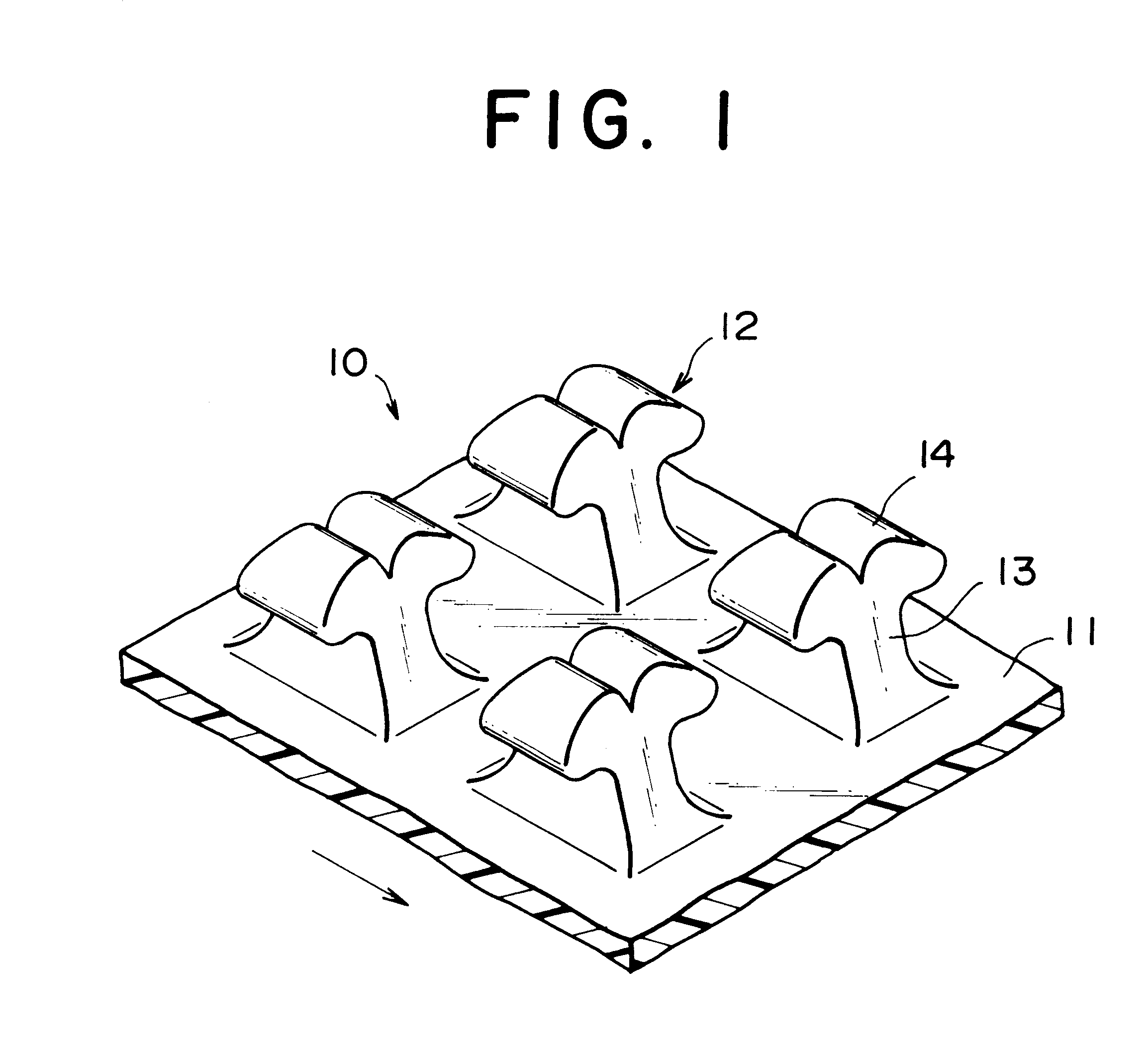

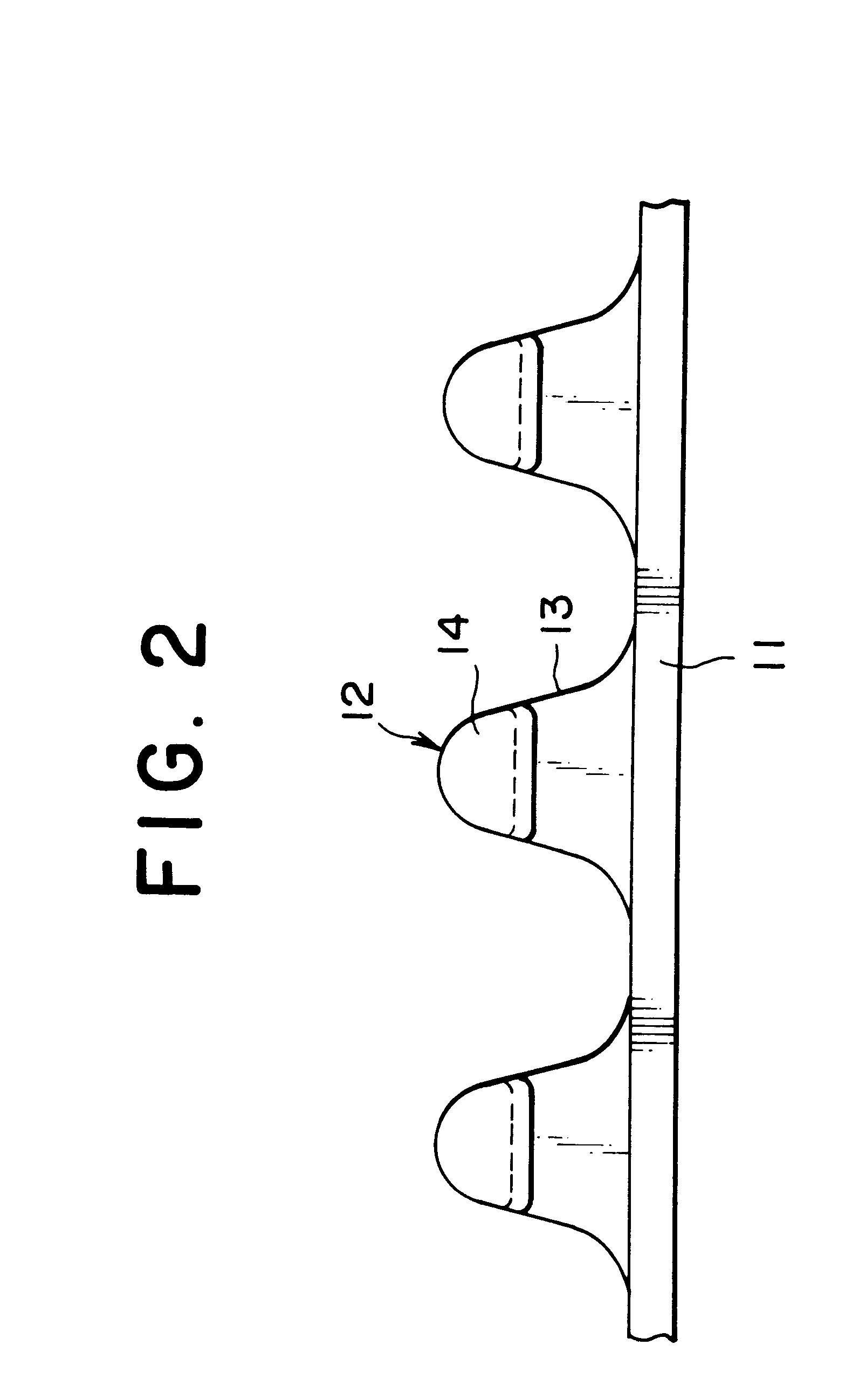

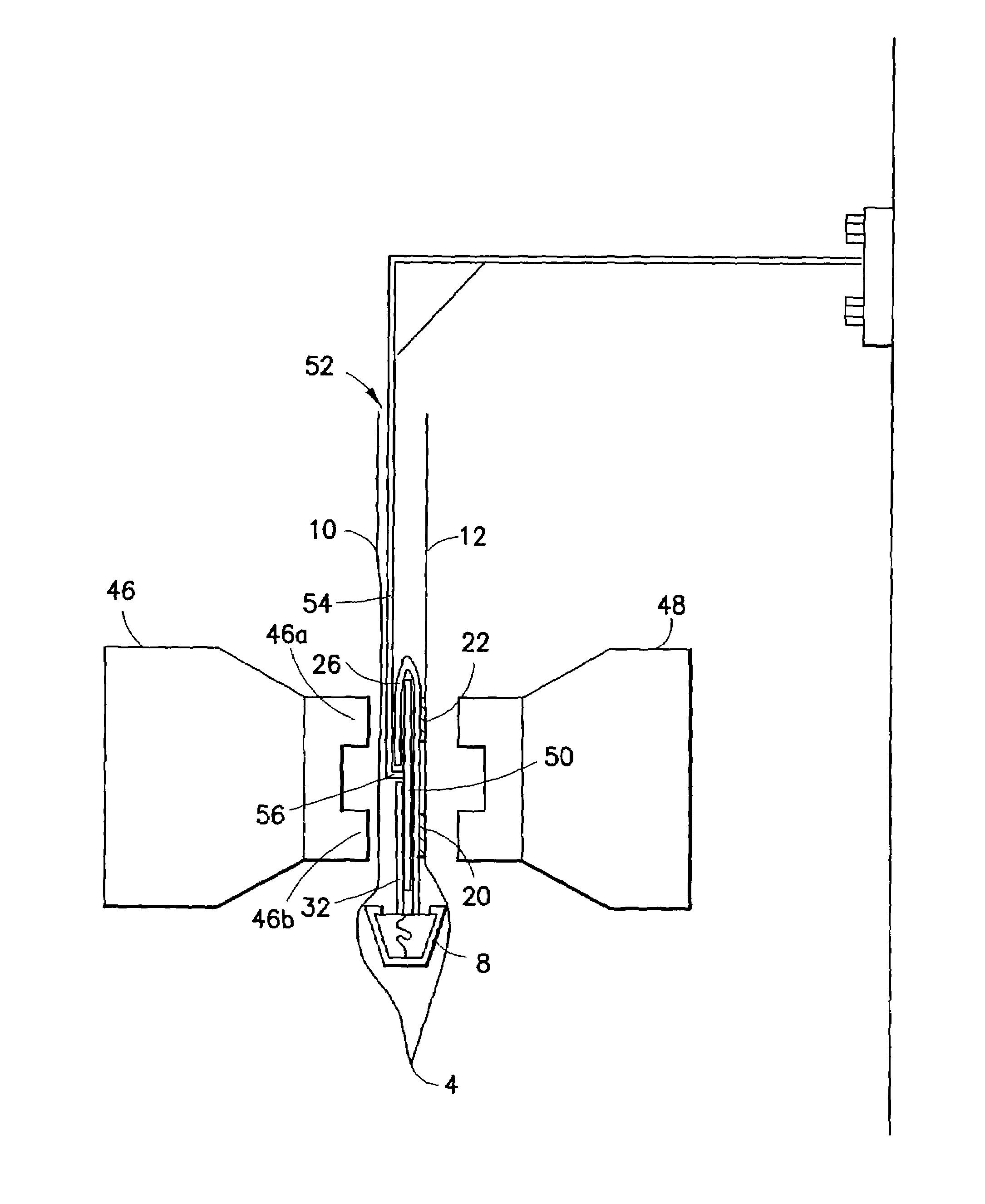

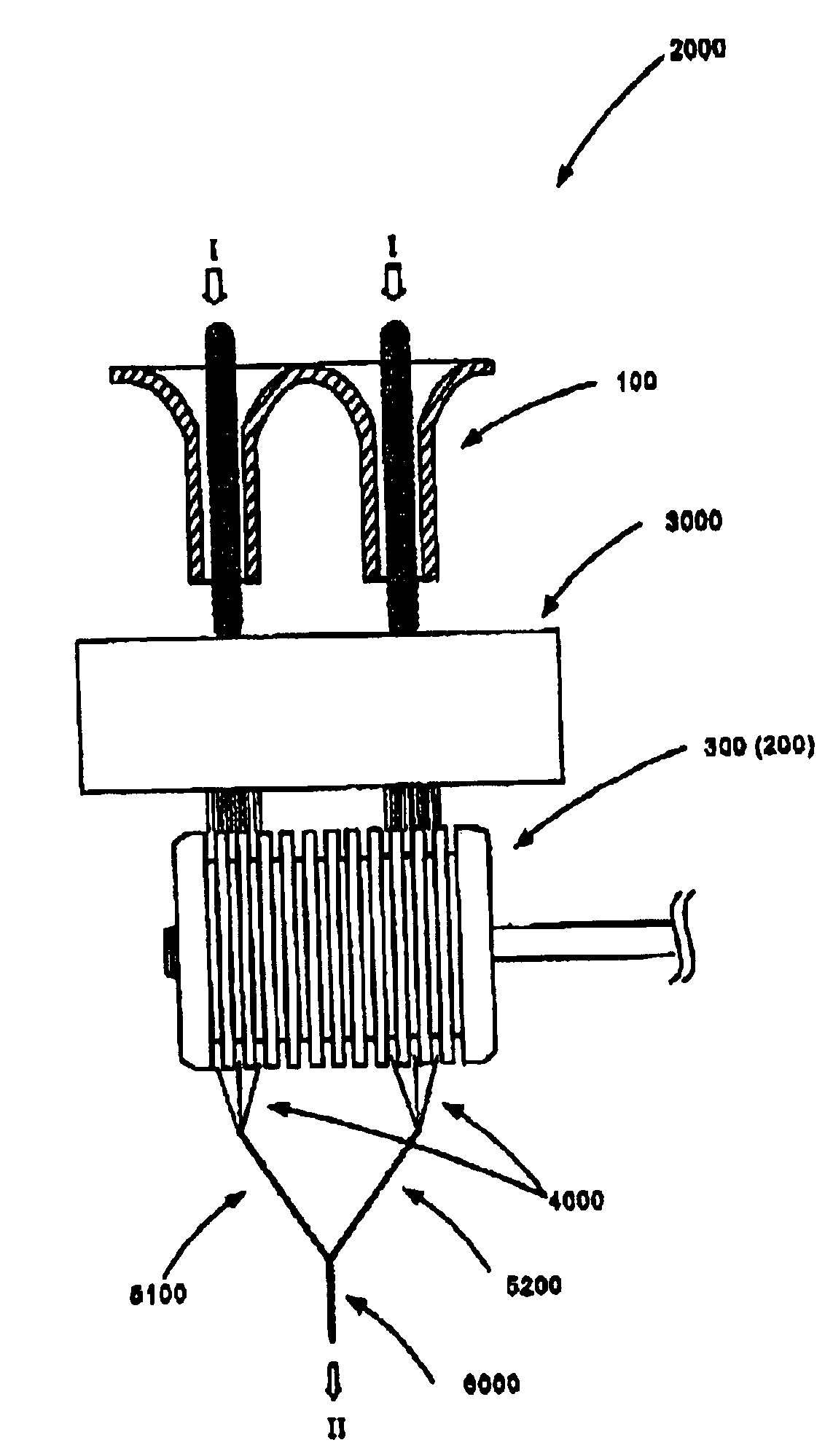

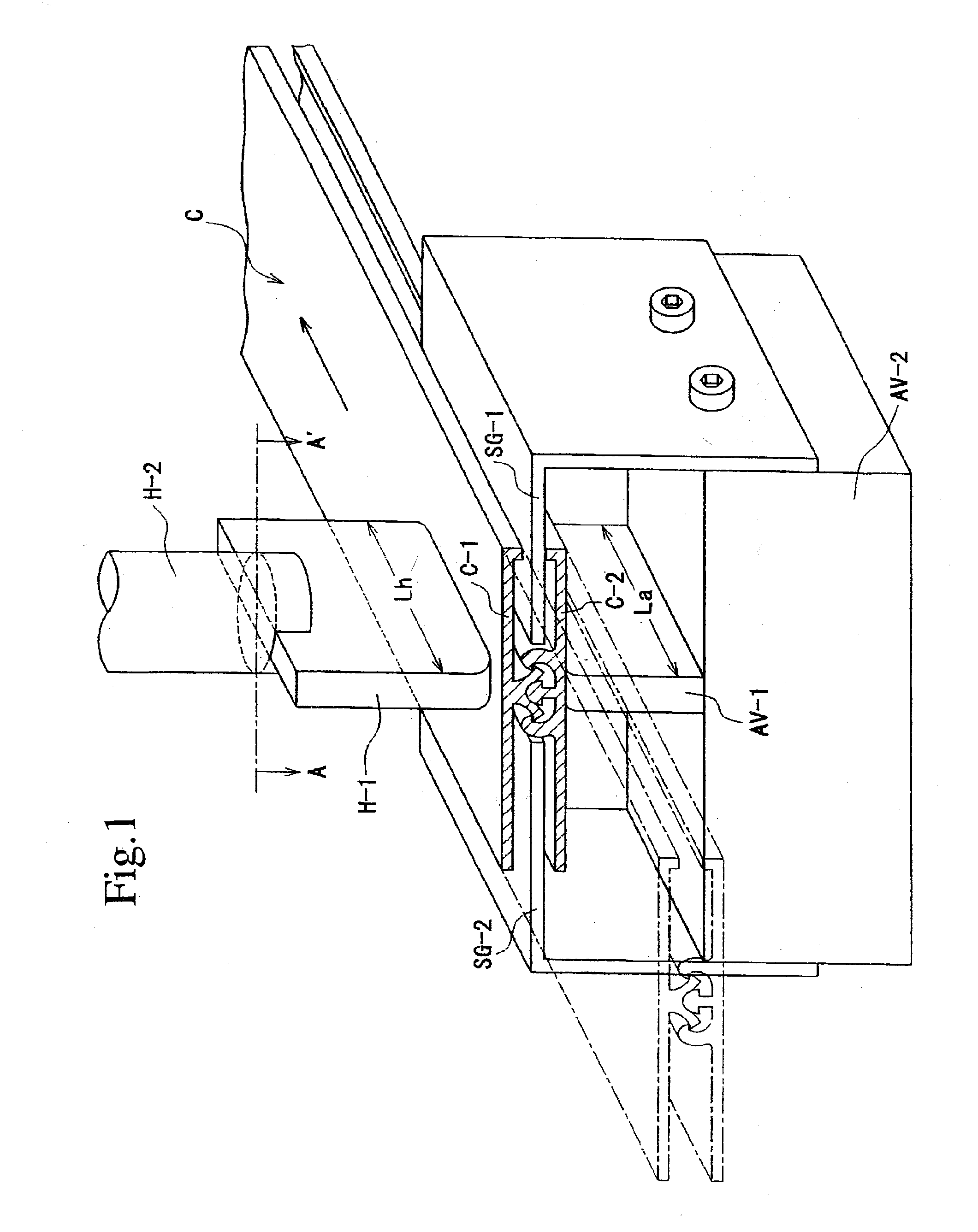

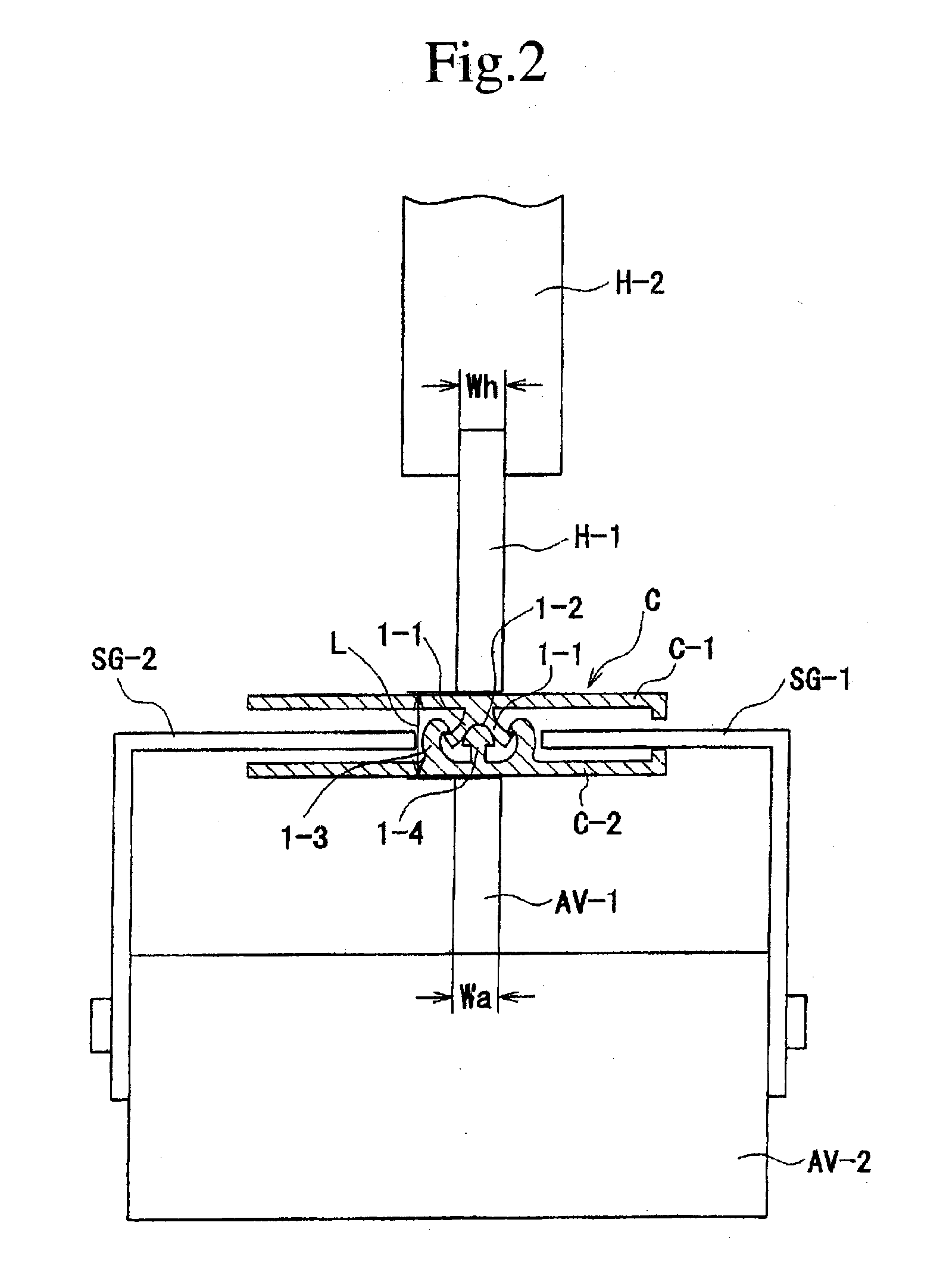

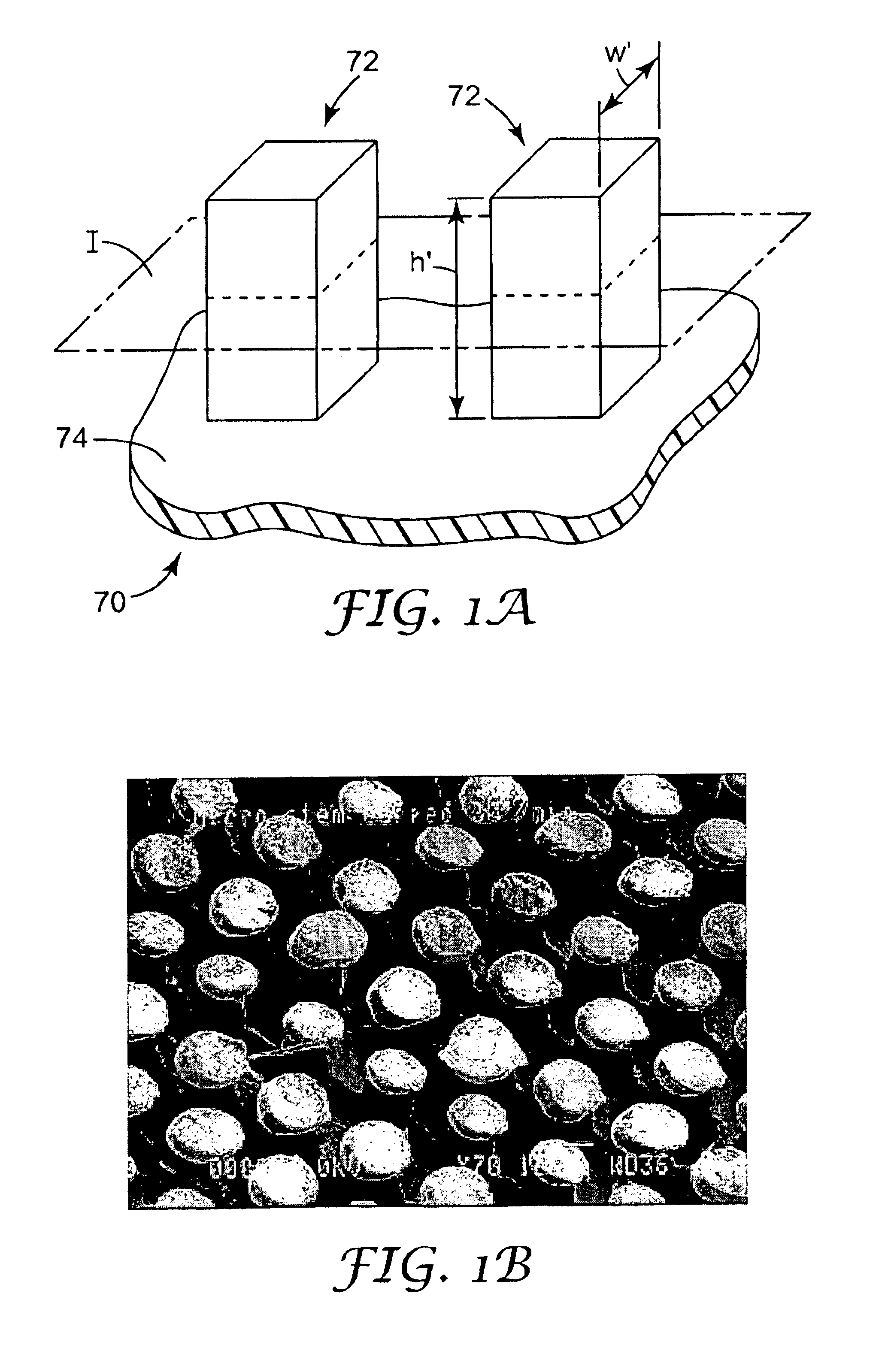

Molded surface fastener, and molding method and molding apparatus of the same

InactiveUS6209177B1Easy maintenanceEasy to manageSnap fastenersClothes buttonsProduction rateEngineering

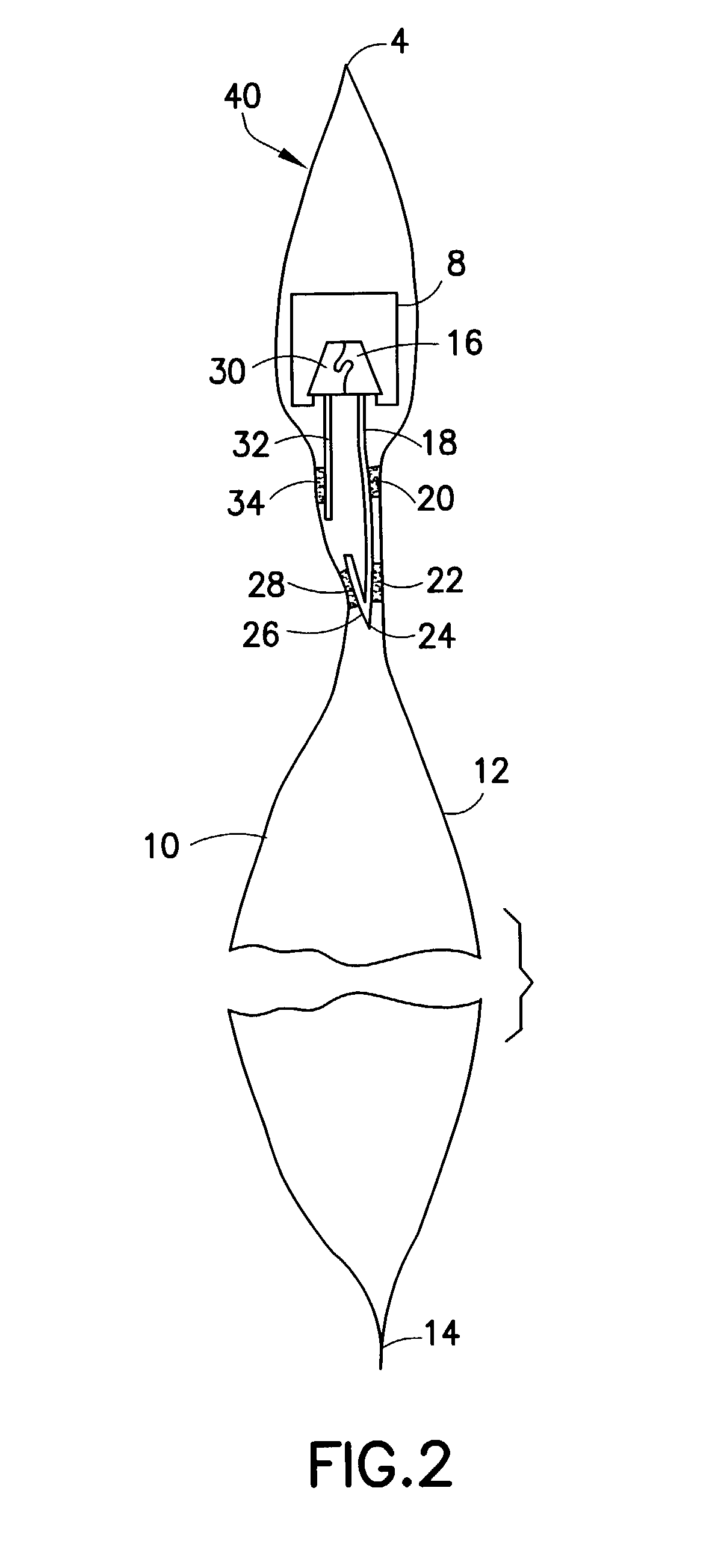

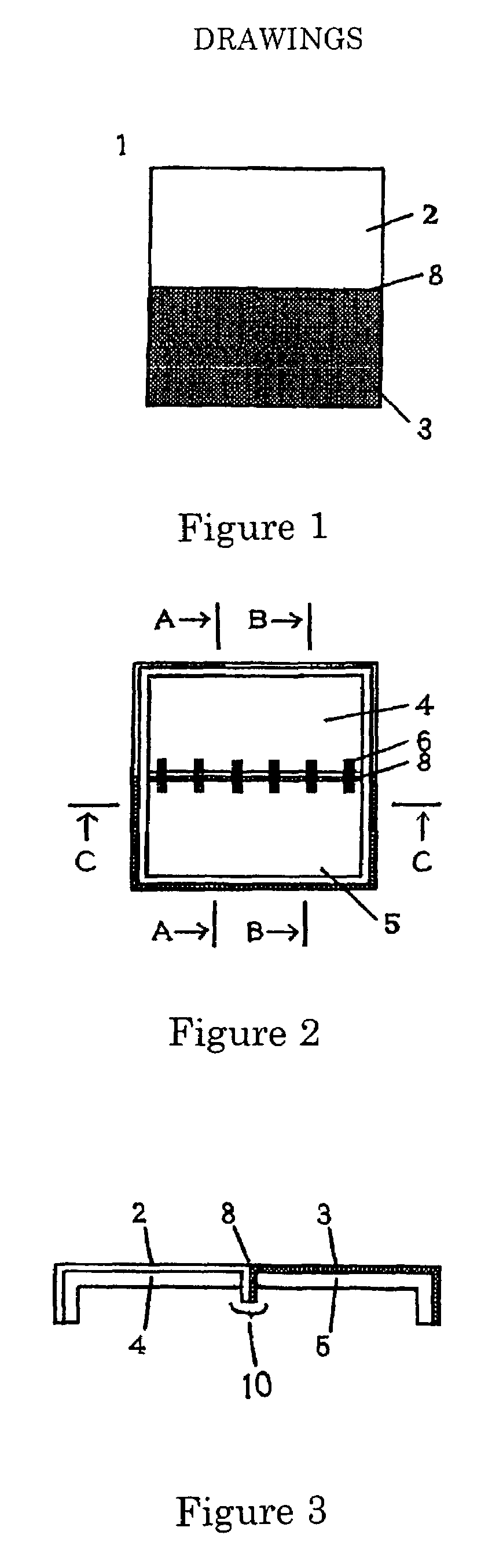

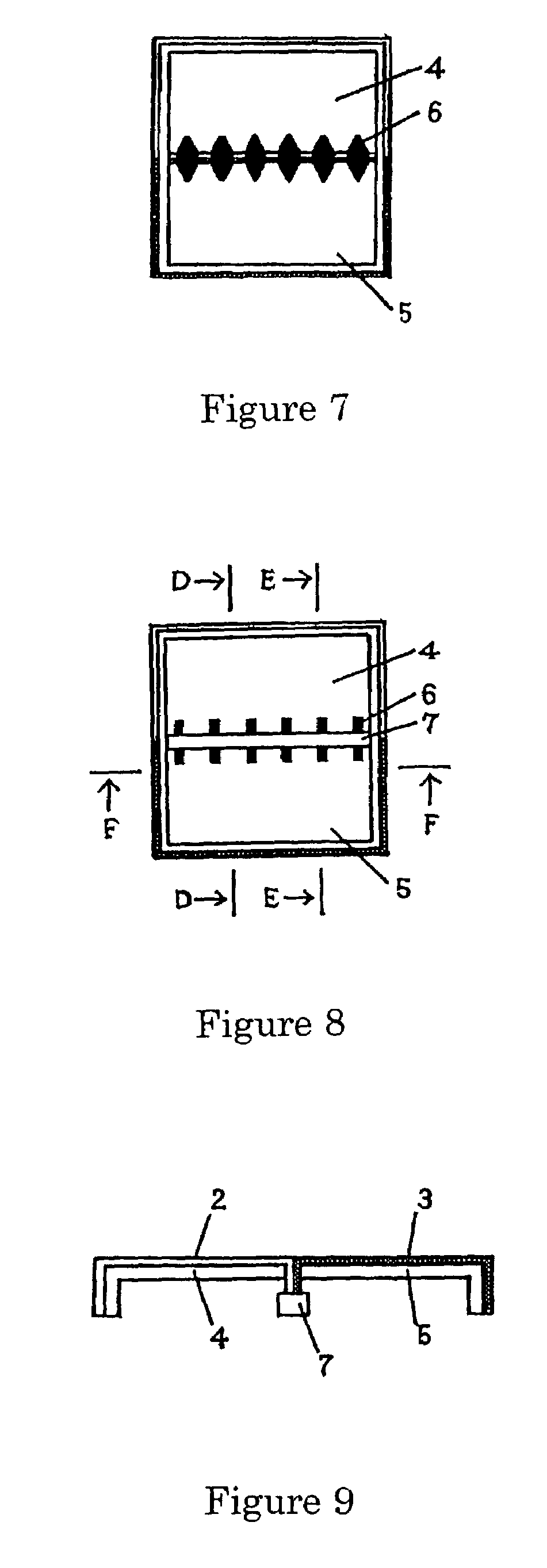

Molten resin material is continuously extruded from an extruding hole including a plurality of engaging-element-molding portions disposed with a constant pitch in a width direction of an extruding nozzle and a substrate-molding portion with which lower ends of the engaging-element-molding portions communicate. An ascending / descending member disposed at a front face of the extruding nozzle and made of a laterally long plank ascends and descends to vertically open and close the extruding hole of the extruding nozzle. As a result of such continuous molding, a surface fastener is continuously molded in which each of plurality engaging elements has stem and an engaging extruding head projecting at least toward one side from an end of the stem standing on a surface of a flat substrate. The engaging element thus molded has a thickness, in a direction perpendicular to a projecting direction of the engaging head, gradually increasing from a top portion of the engaging head to a base end of the stem. With such engaging elements that can be molded with a not conventional but new shape in various sizes, and its molding method and apparatus, maintenance and management are easy and productivity is high.

Owner:YKK CORP

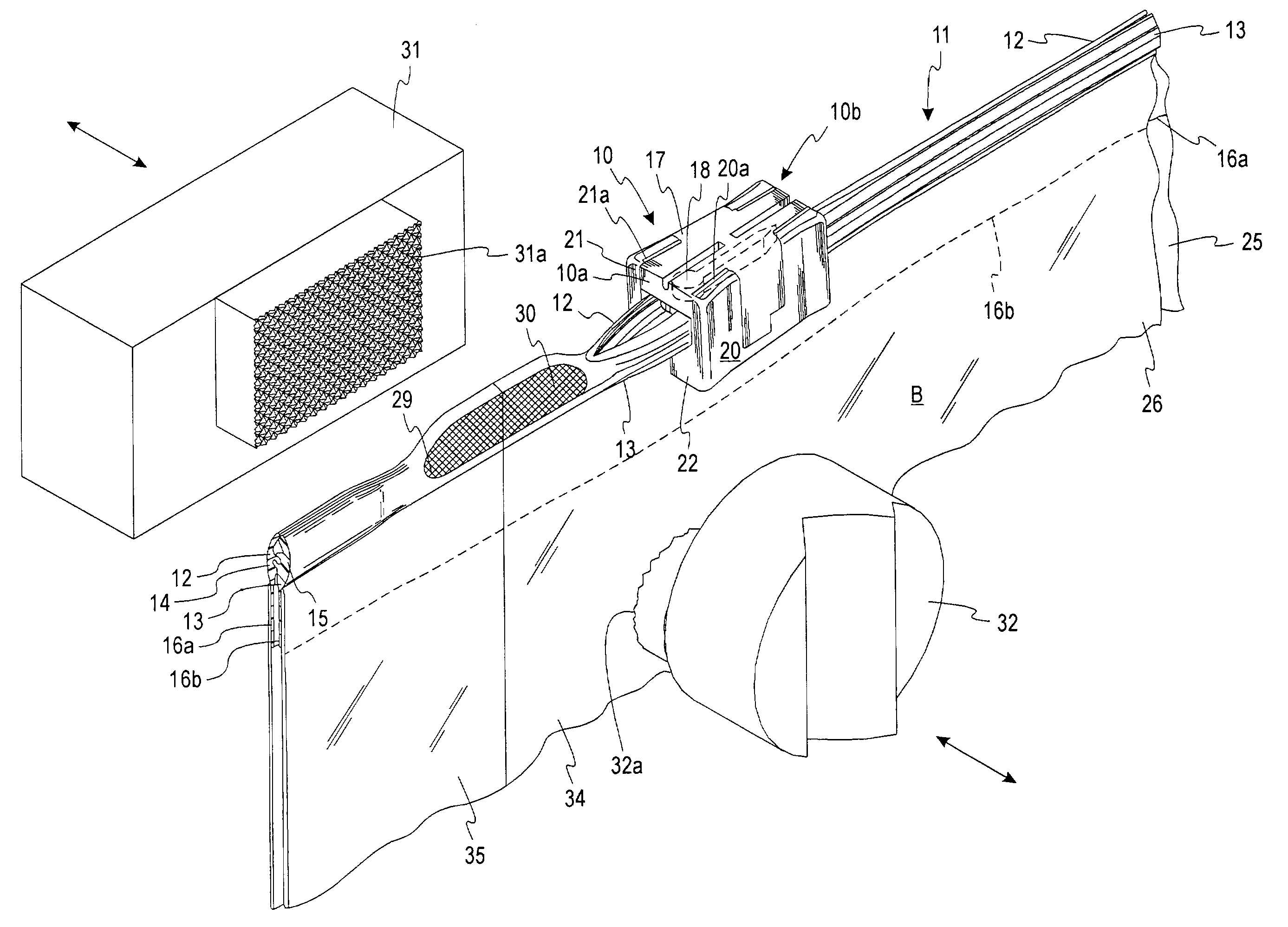

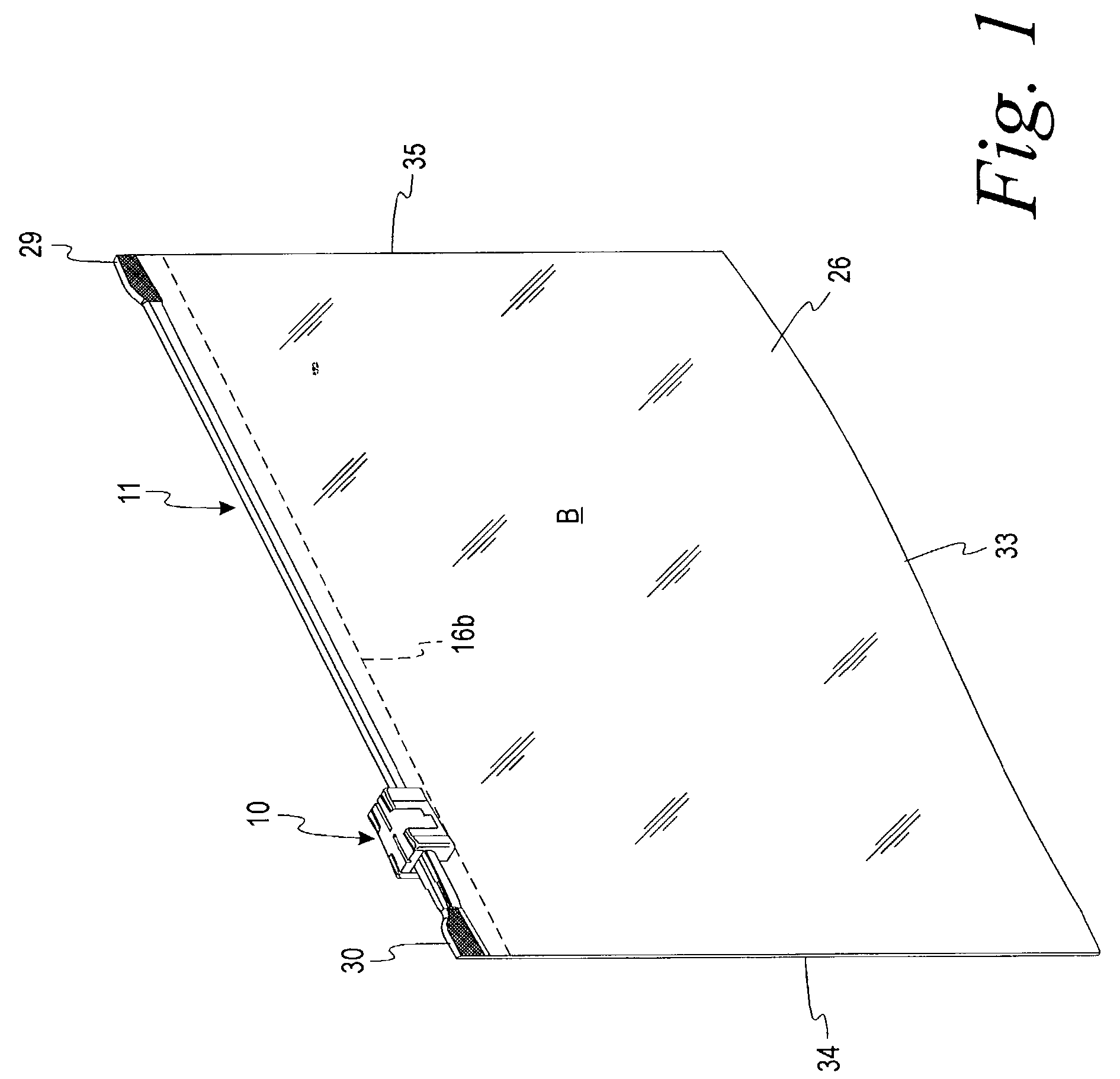

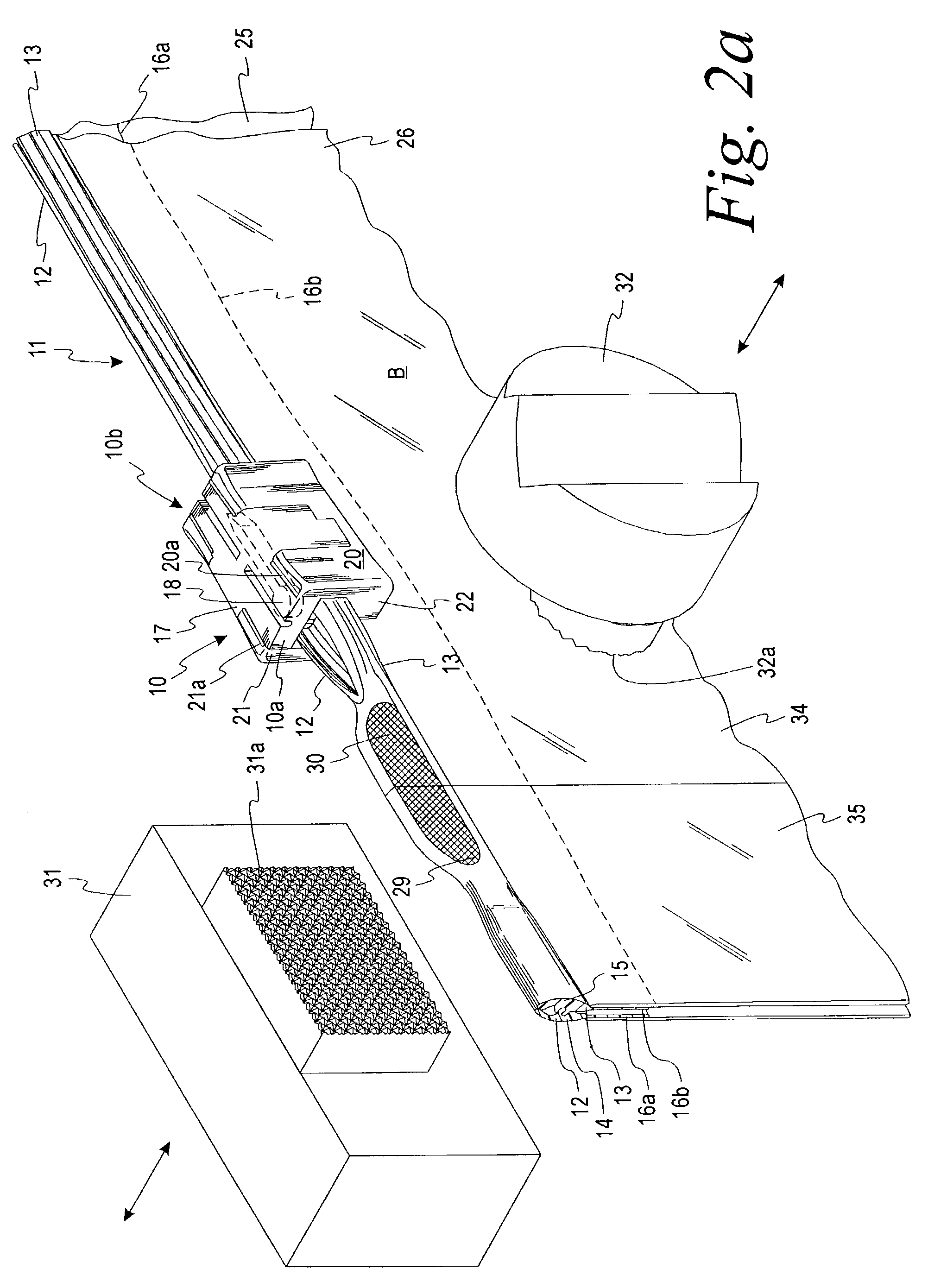

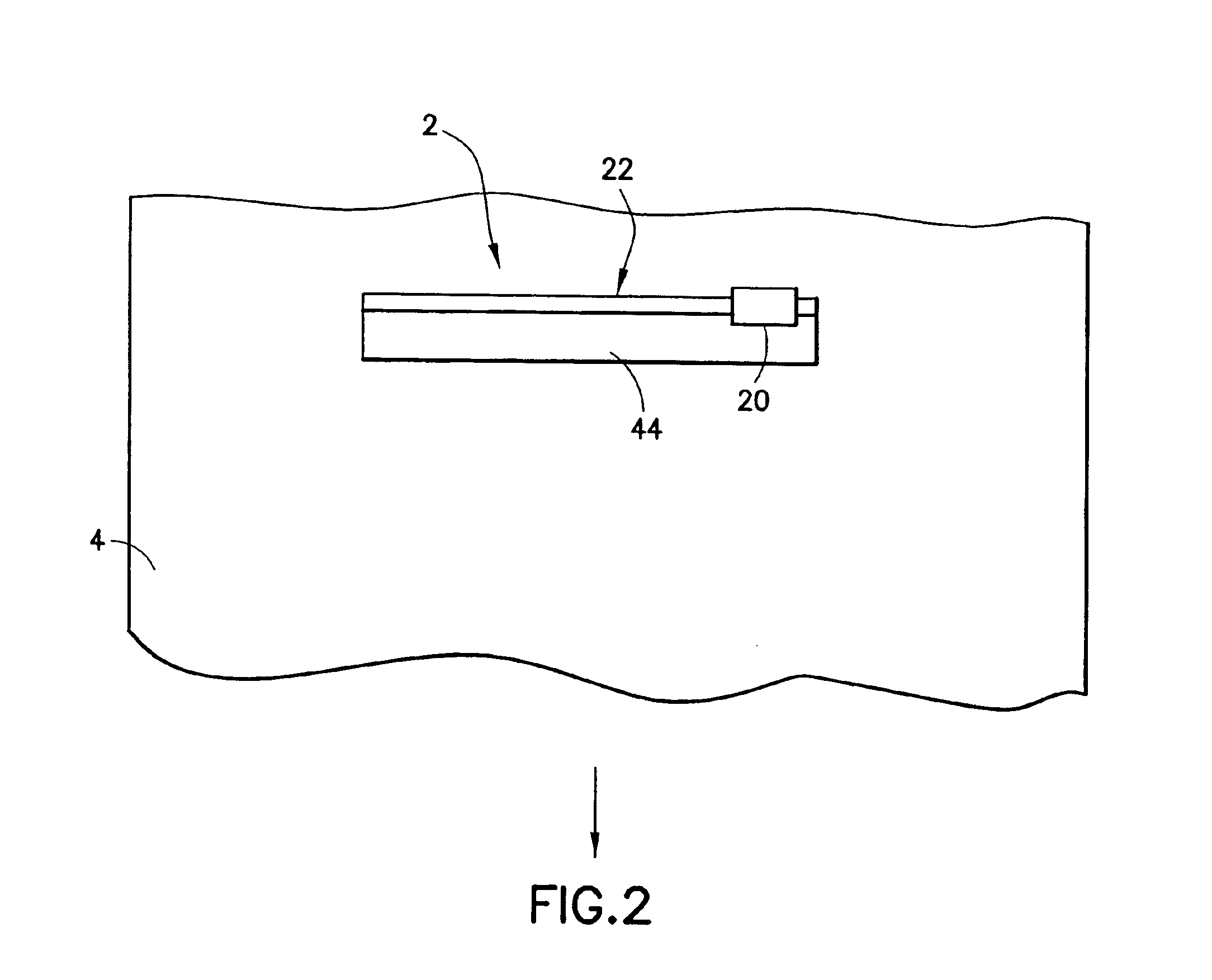

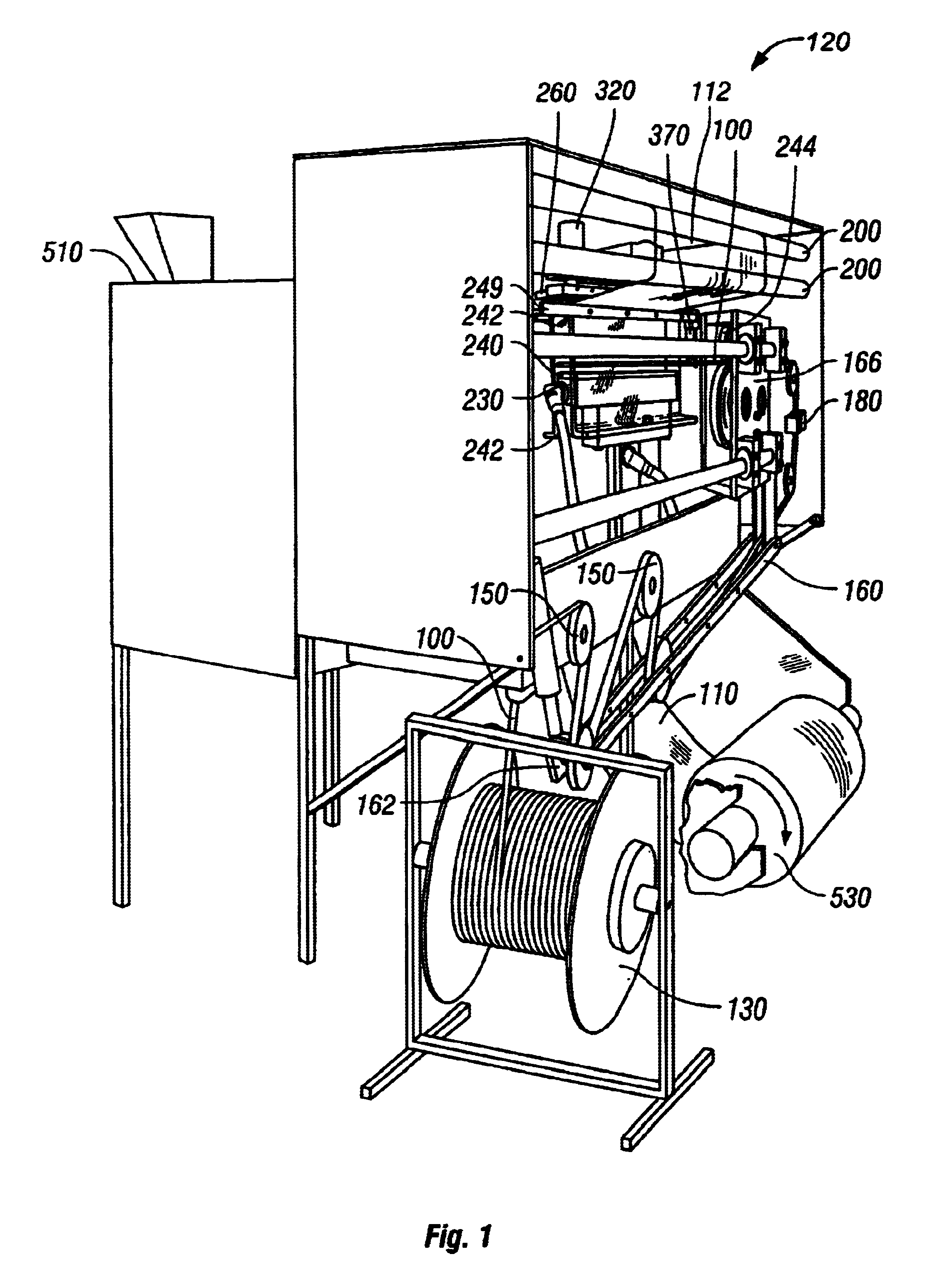

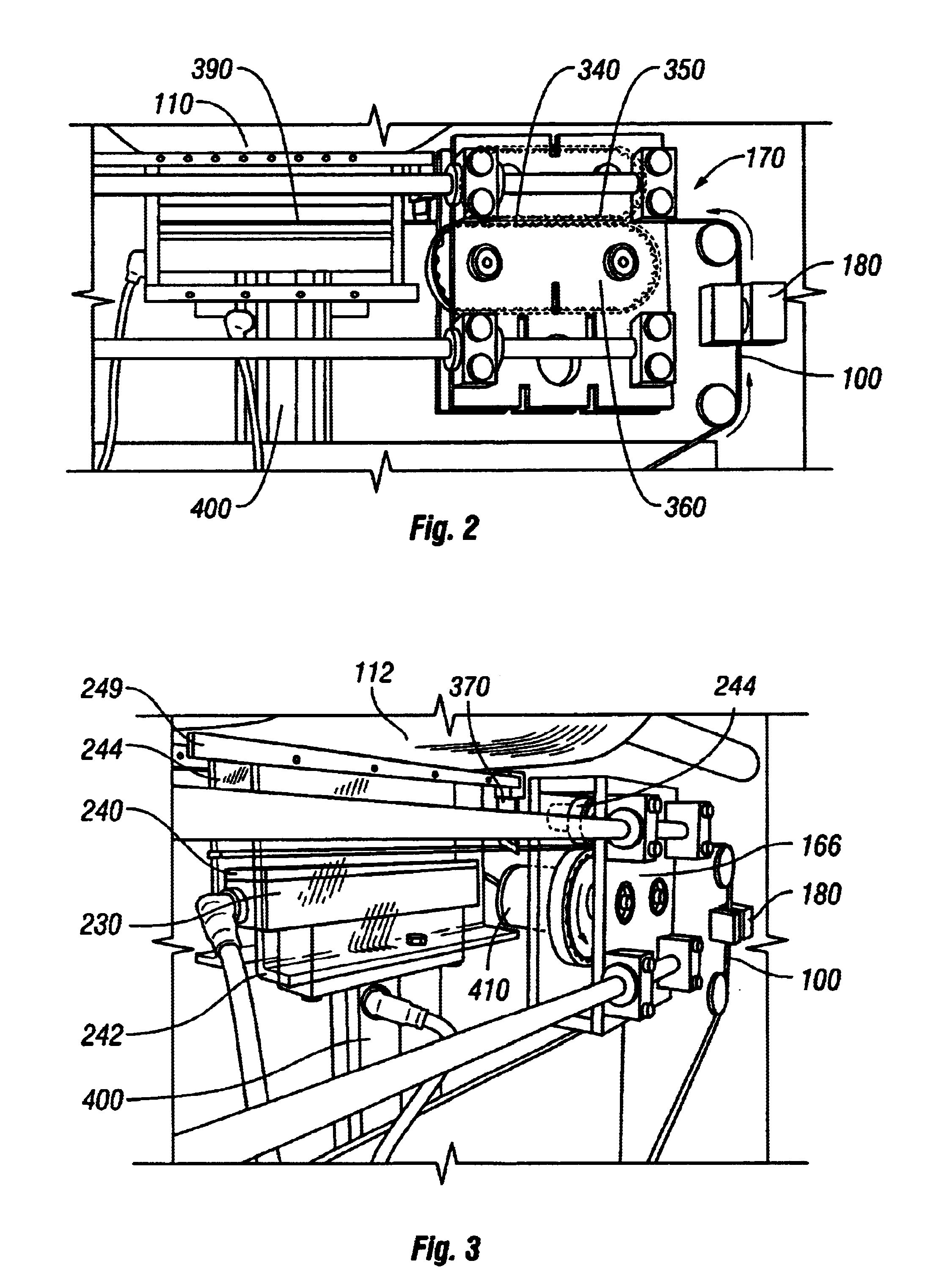

Method and apparatus for making reclosable plastic bags using a pre-applied slider-operated fastener

InactiveUS6871473B1Not adversely impactEasy to modifyEnvelopes/bags making machineryWire articlesThin membraneEngineering

A method and apparatus for making reclosable plastic bags is provided. In the method and apparatus, a fastener is attached to a moving flat web of plastic film, preferably in the direction of web movement and near the center of the web. A plurality of sliders are mounted to the fastener either before or after the fastener is attached to the flat web, but prior to conveying the web to a FFS machine. The flat web, with the slider-operated fastener already attached thereto, is then conveyed to a vertical or horizontal FFS machine where the flat web is formed into bags, and the bags are successively filled and sealed.

Owner:REYNOLDS PRESTO PRODS

Method and apparatus for guiding and sealing split-flange zipper tape to bag making film

A method and an apparatus for sealing a split-flange zipper tape in a center fold of a web of bag making film without sealing or tacking the two sides of the split zipper web together.

Owner:ILLINOIS TOOL WORKS INC

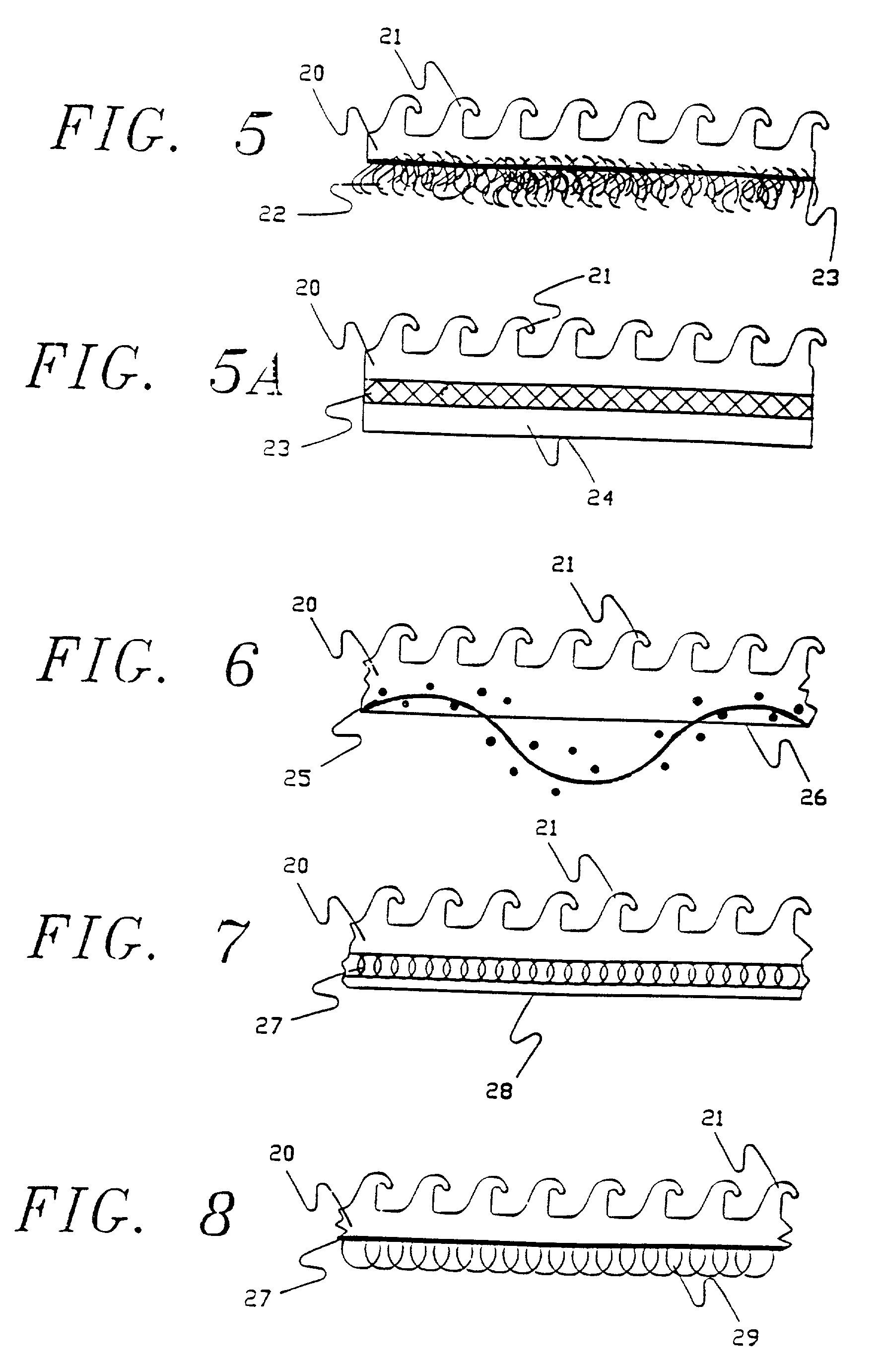

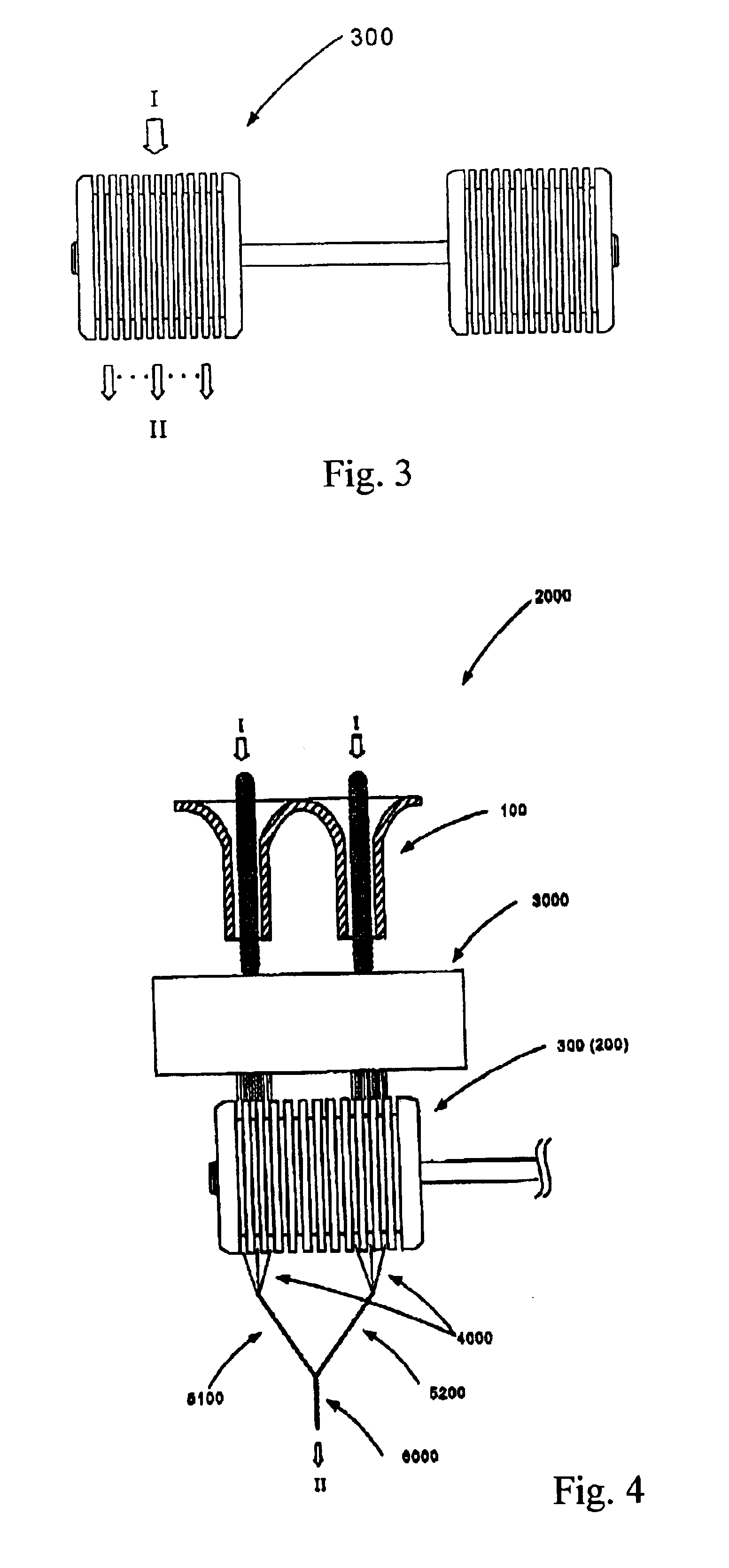

Molding fastener products having backings

An extruded hook fastener strip is created on a roll having hook forming cavities in its surface by extruding plastic material into the interface between the forming roll and a second strip carried by a backing roll. The second strip is firmly bonded to the fastener strip on that side opposite the formed hooks.

Owner:VELCRO IND BV

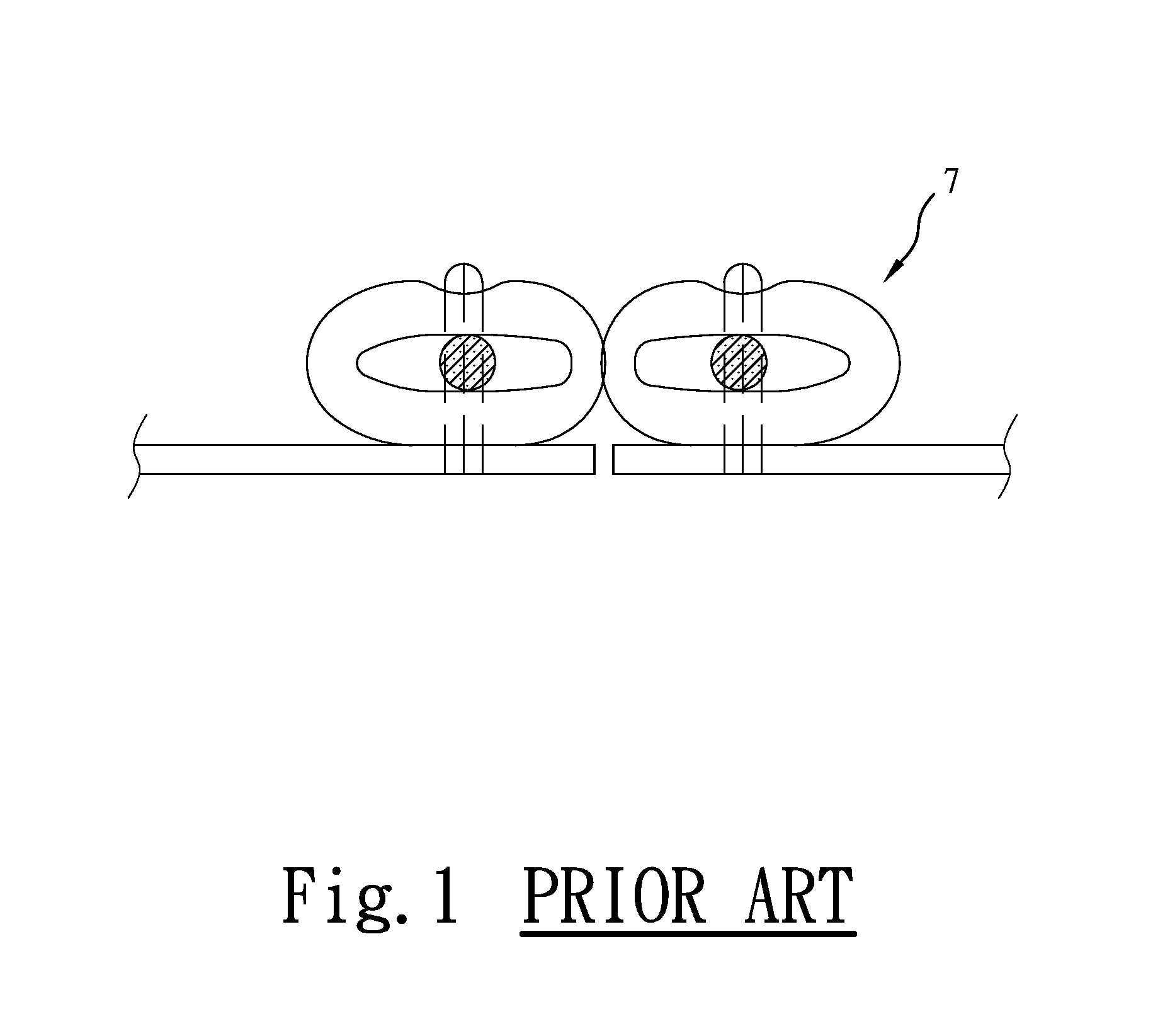

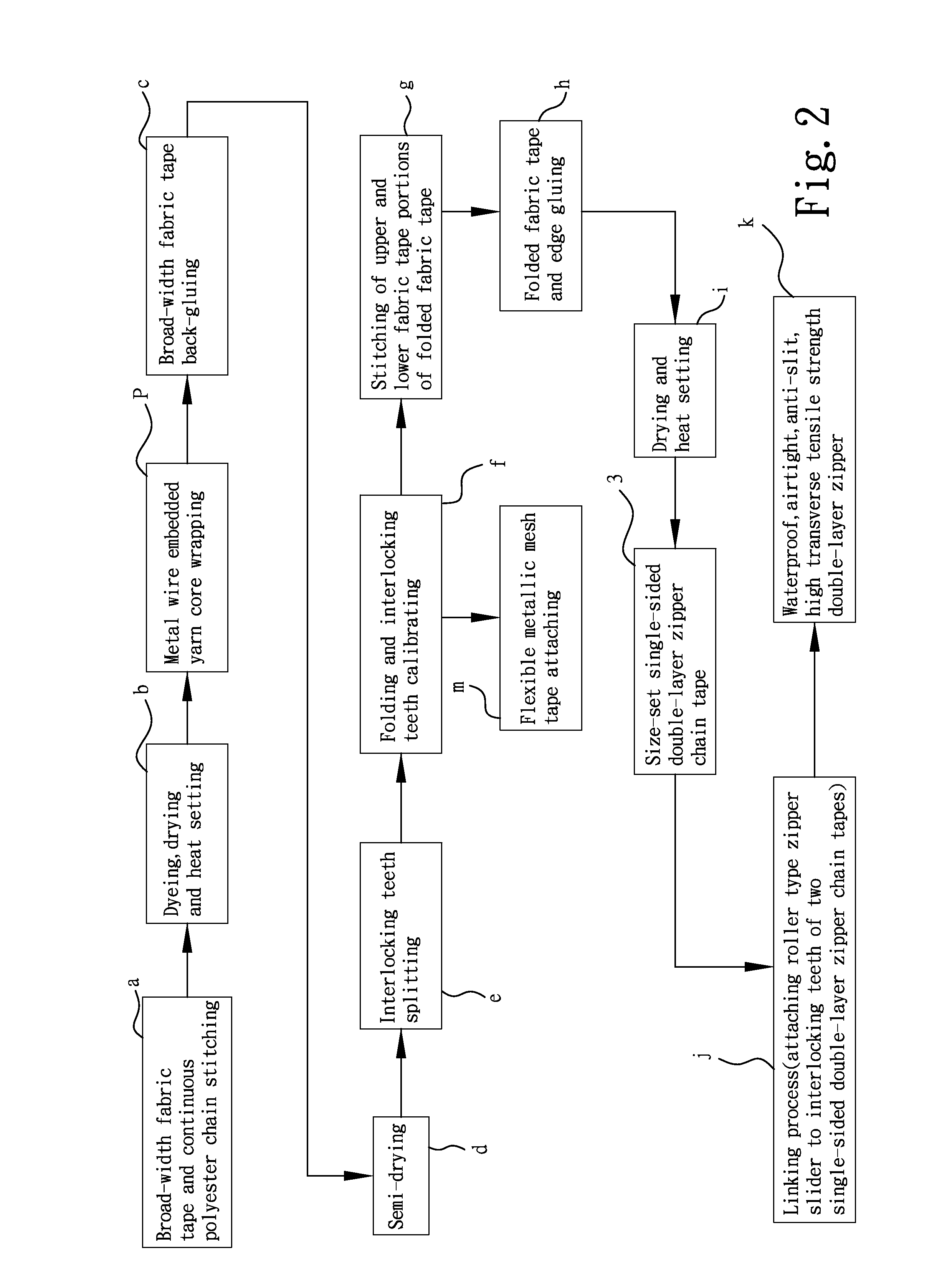

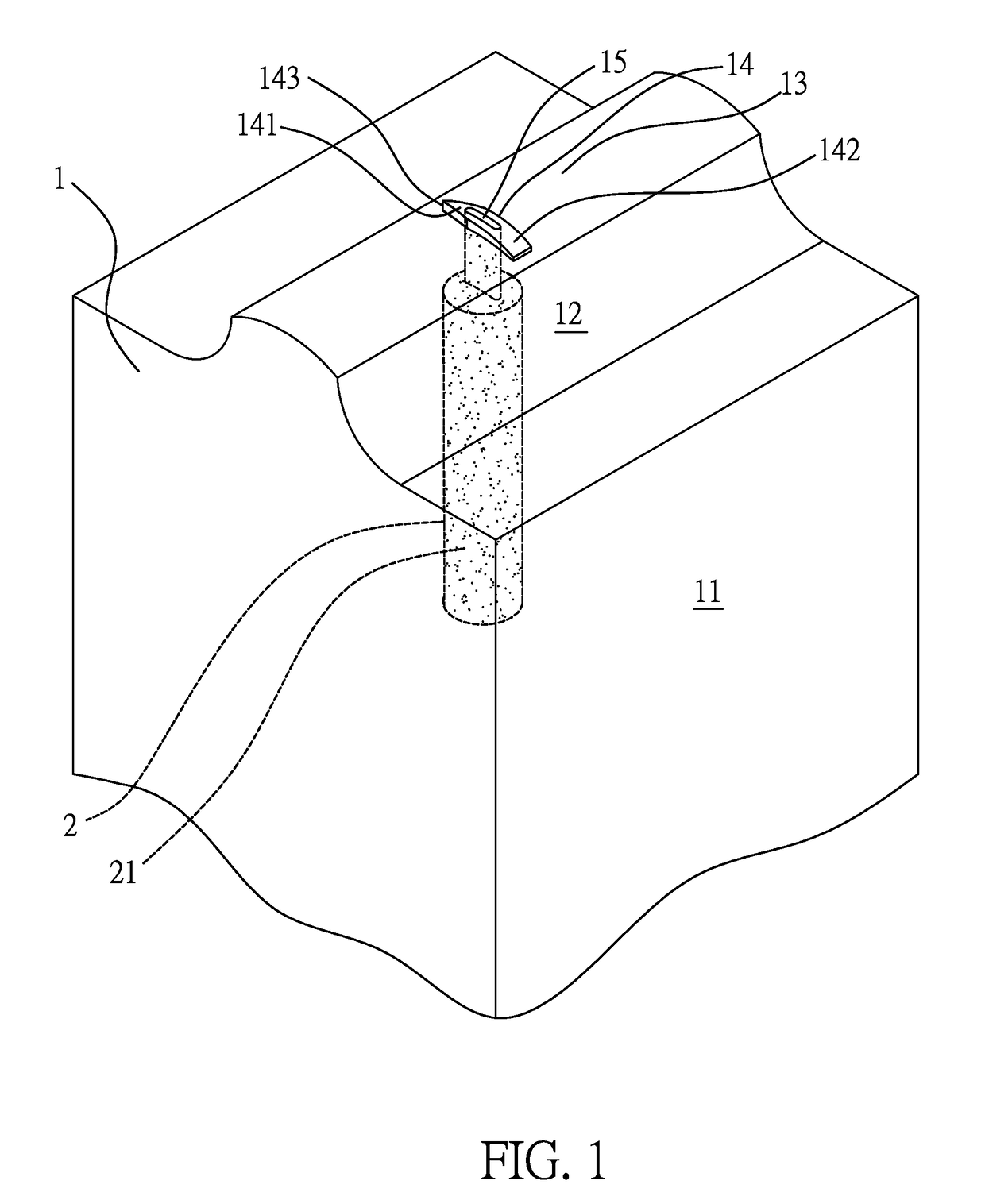

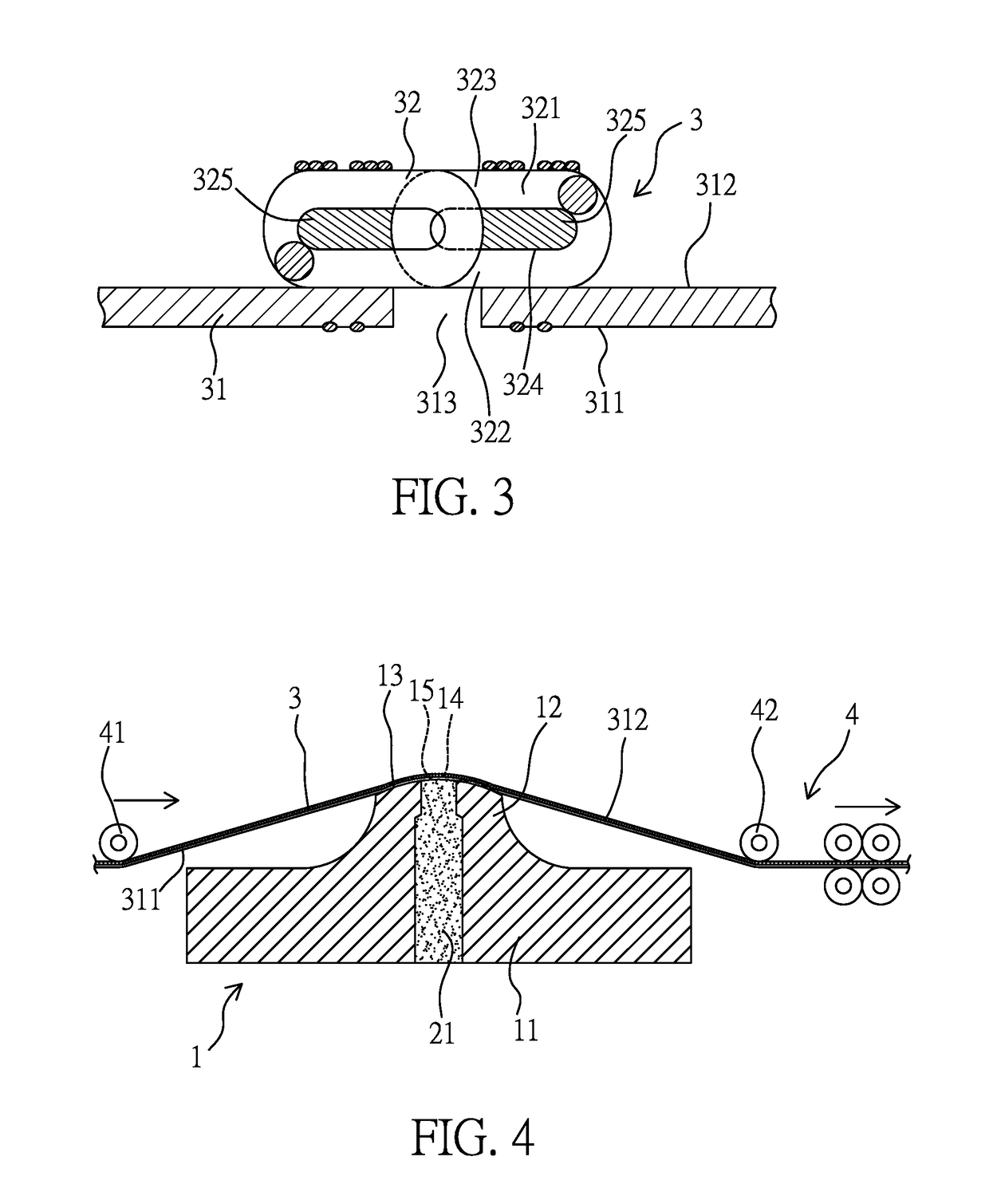

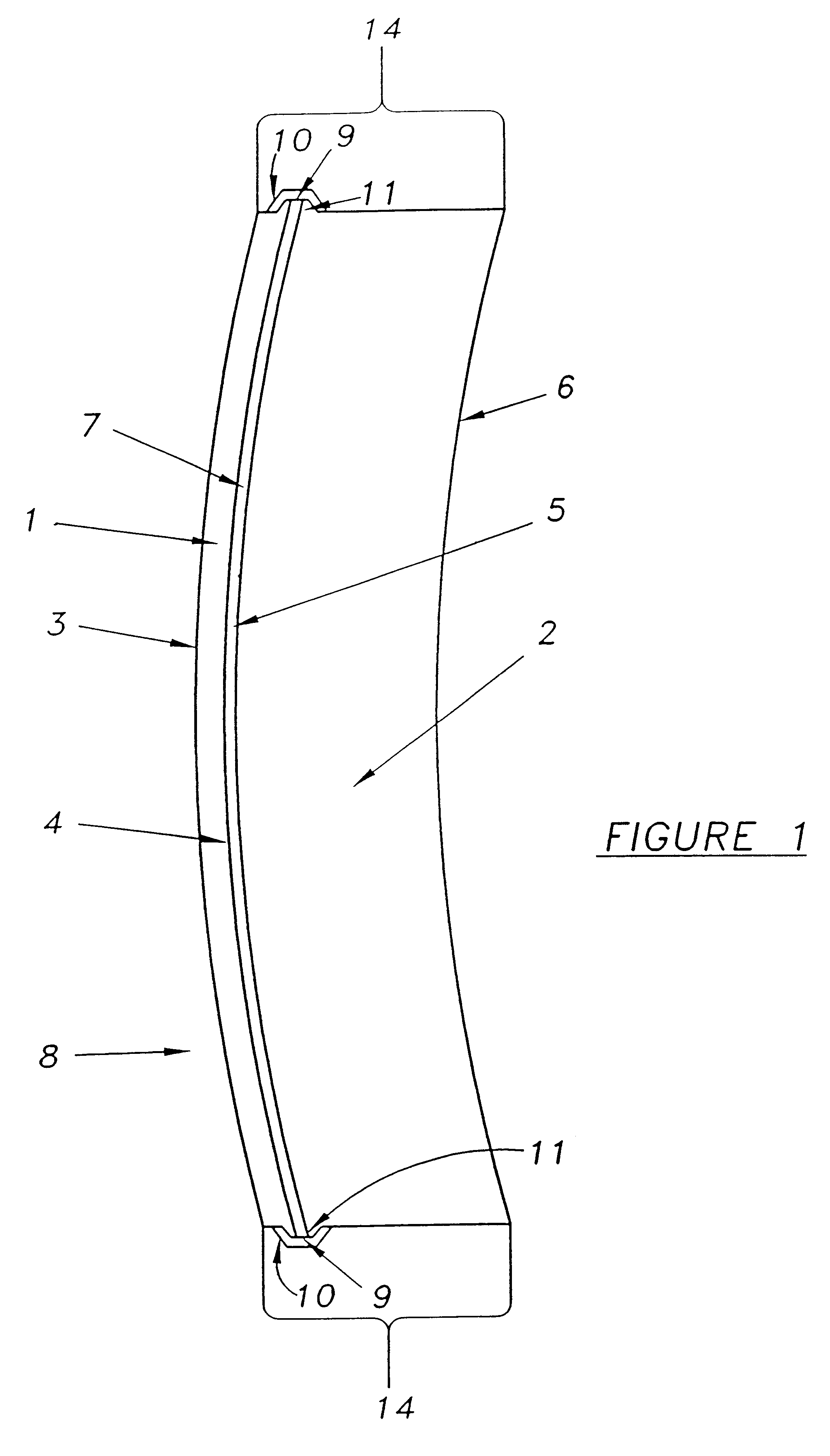

Waterproof, Anti-Split, High Transverse Tensile Strength Double-Layer Zipper and its Fabrication Method

ActiveUS20140359978A1Good for stable movementHigh strengthSnap fastenersWire articlesPolyesterHigh intensity

A waterproof, airtight, anti-slit, high transverse tensile strength double-layer zipper made by: stitching a continuous polyester chain to a middle part of a broad-width fabric tape and then separating the continuous polyester chain into left and right series of interlocking teeth after zipper chain tape dyeing and drying and gluing processes, and then folding up the zipper chain tape and stitching up the open side of the folded zipper chain tape so as to obtain a single-sided double-layer zipper chain tape, and then using a zipper slider to couple two single-sided double-layer zipper chain tapes, thereby obtaining a waterproof, airtight, anti-slit, high transverse tensile strength double-layer zipper. Alternatively, the continuous polyester chain can be stitched to the broad-width fabric tape near its one lateral side for making a high-strength double-layer zipper with less fabric consumption.

Owner:WANG LIEN CHOU

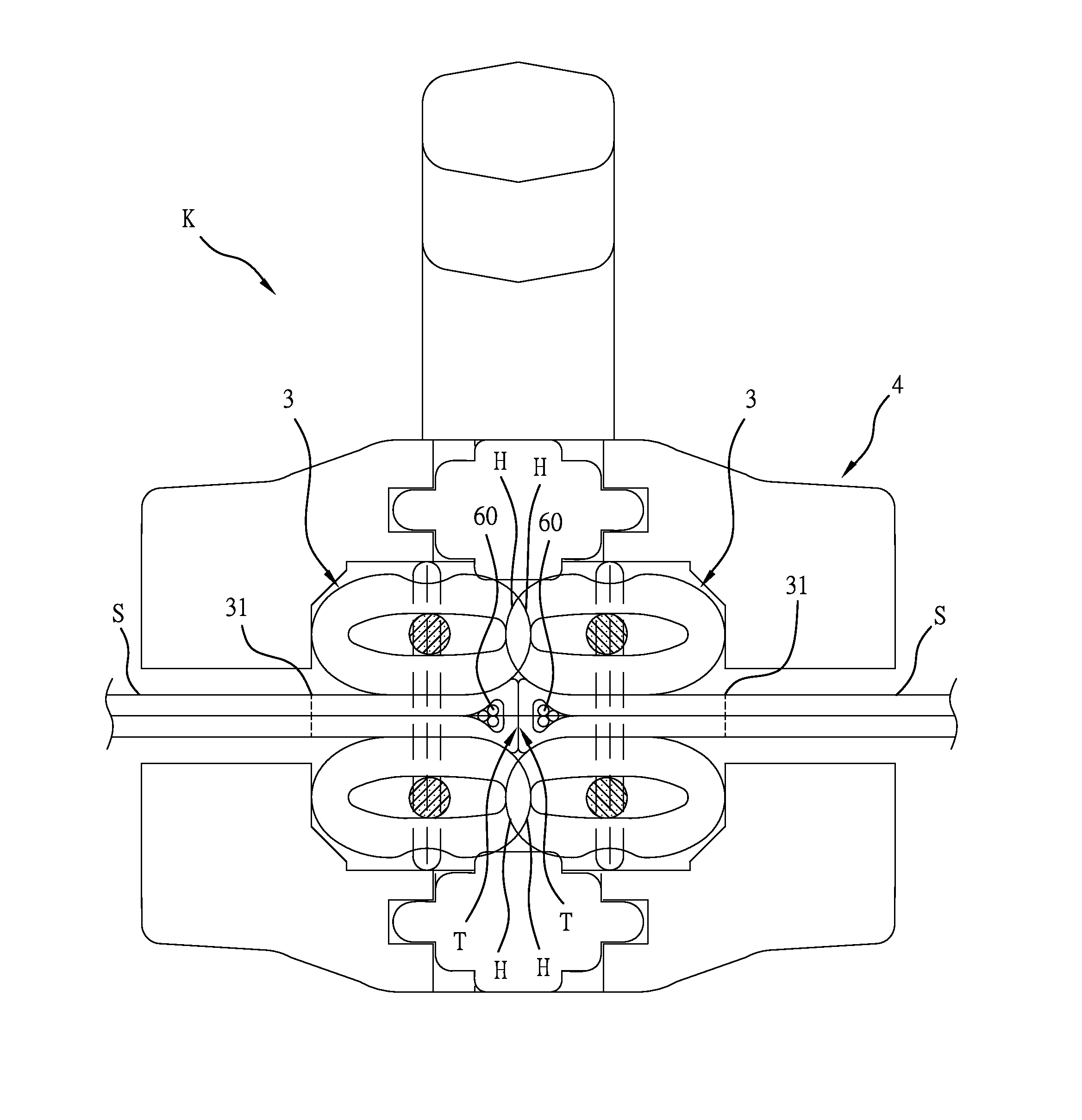

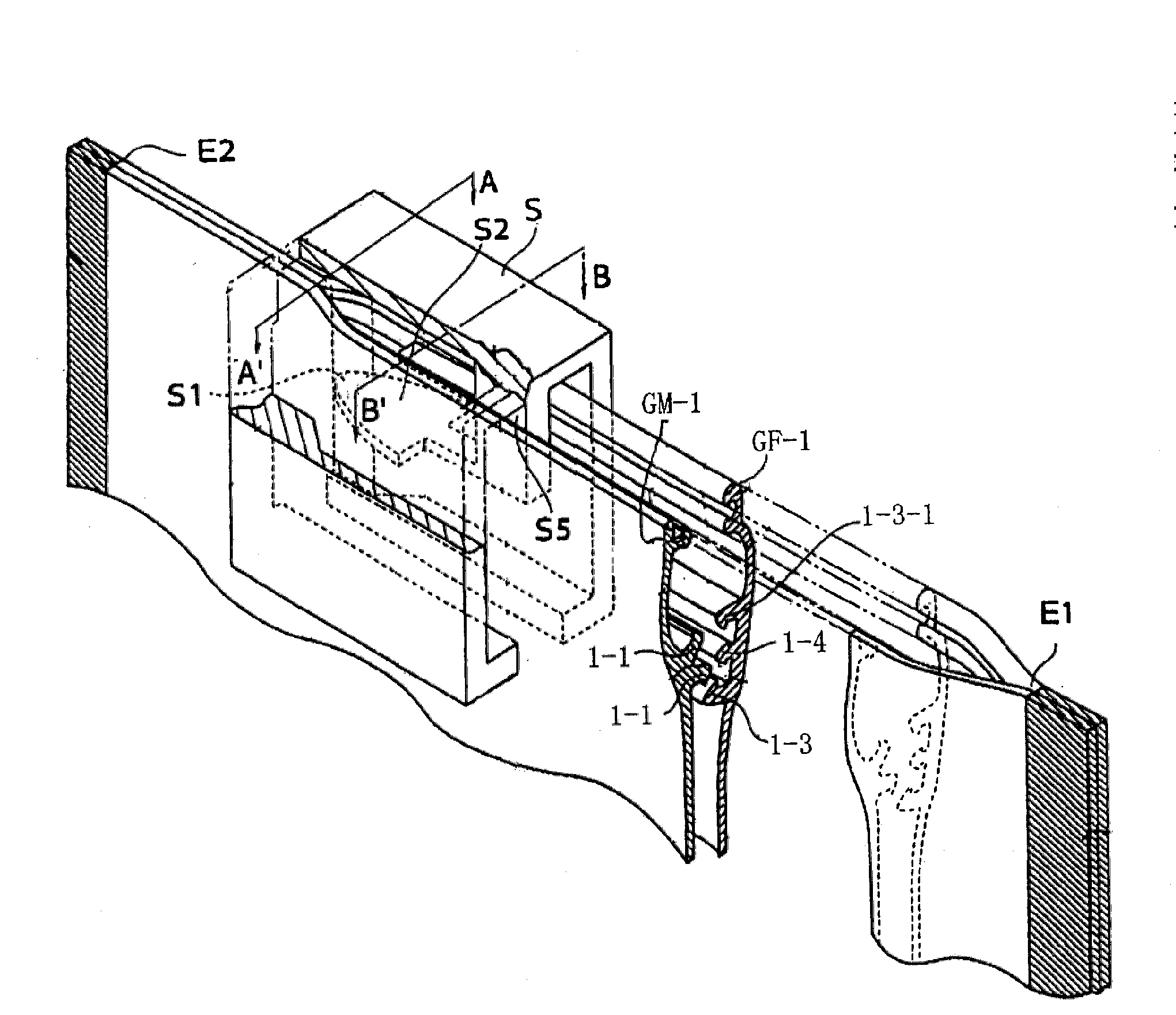

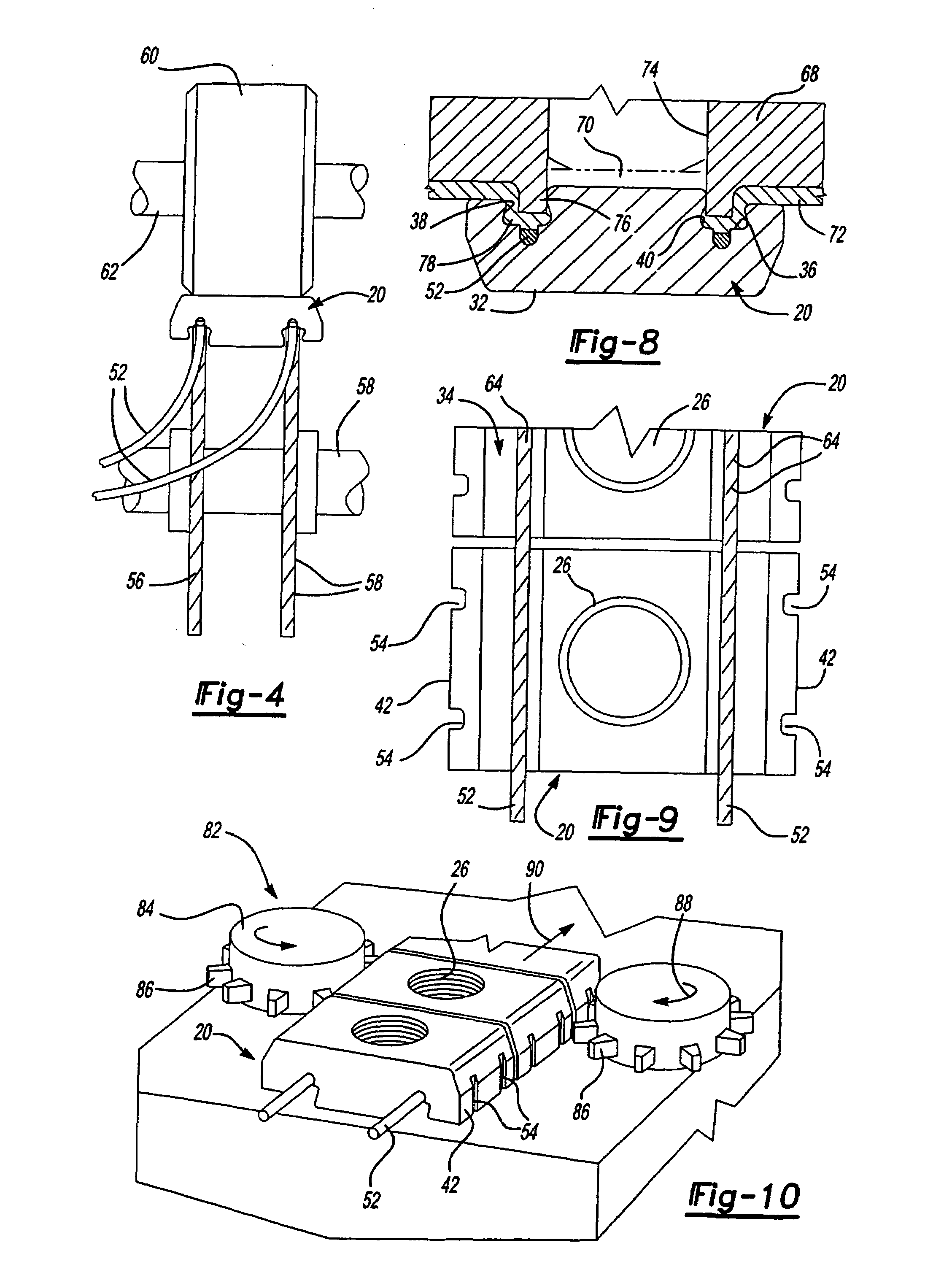

Thermal plastic elastomer injection mold, water impervious slide fastener manufactured utilizing the same and finished product having the water impervious slide fastener

A thermal plastic elastomer injection mold comprises: a mold base, formed with a platform having a top surface thereof formed with an arc-shaped surface adhered with a pair of support-tapes of a slide fastener and formed with an elongated arc-shaped ridge having a wedge-shaped tip thereby being able to be stably moved into a gap between the pair of support-tapes and a surface of the arc-shaped ridge is formed with a thermal plastic elastomer injection port connected to at least one extruder; and a thermal plastic elastomer, extruded out from the at least one extruder and passing the thermal plastic elastomer injection port so as to be injected into the gap and slits inside two rows of coupling elements disposed at inner edges of the pair of support-tapes, wherein the slide fastener is formed with a water impervious structure after the thermal plastic elastomer inside the gap is cut.

Owner:CHOU CHAO MU +1

Ultrasonic end stops on zipper closure bags and methods for making same

ActiveUS7267856B2Reduce thicknessEnvelopes/bags making machineryWrappersHigh densityCyclic olefin copolymer

Ultrasonic end stops and methods of making ultrasonic end stops are provided The present invention relates to plastic reclosable fasteners with sliders for opening and closing the reclosable fasteners on plastic bags and the like and particularly to the use of protruding end stop structures on reclosable fasteners to prevent travel of sliders past the fastener ends The end stop structures include at least one of high density polyethylene, medium density polyethylene, polypropylene, a cyclic olefin copolymer, a high density material, or a high modulus material and may optionally include low density polyethylene or linear low density polyethylene

Owner:REYNOLDS CONSUMER PROD INC

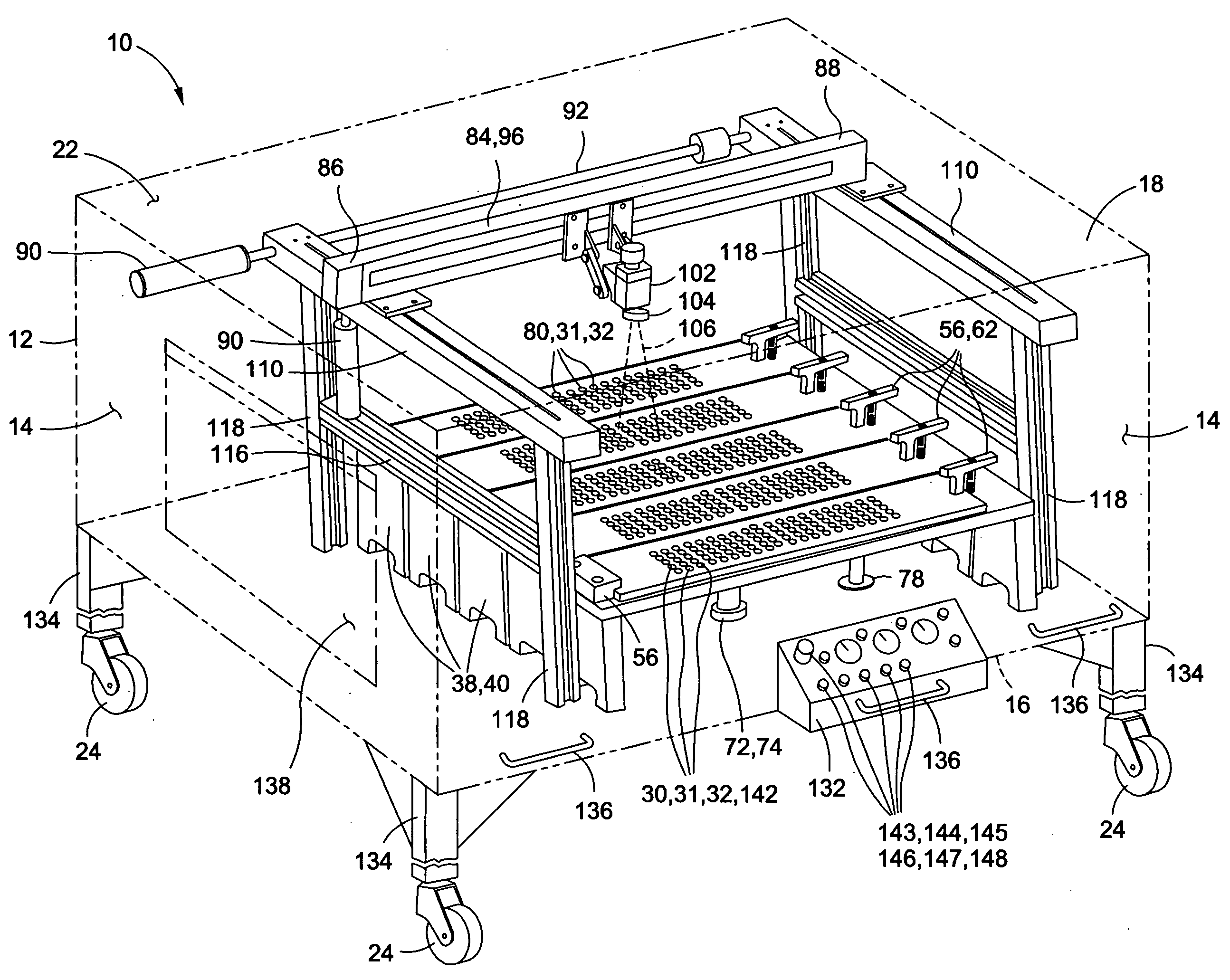

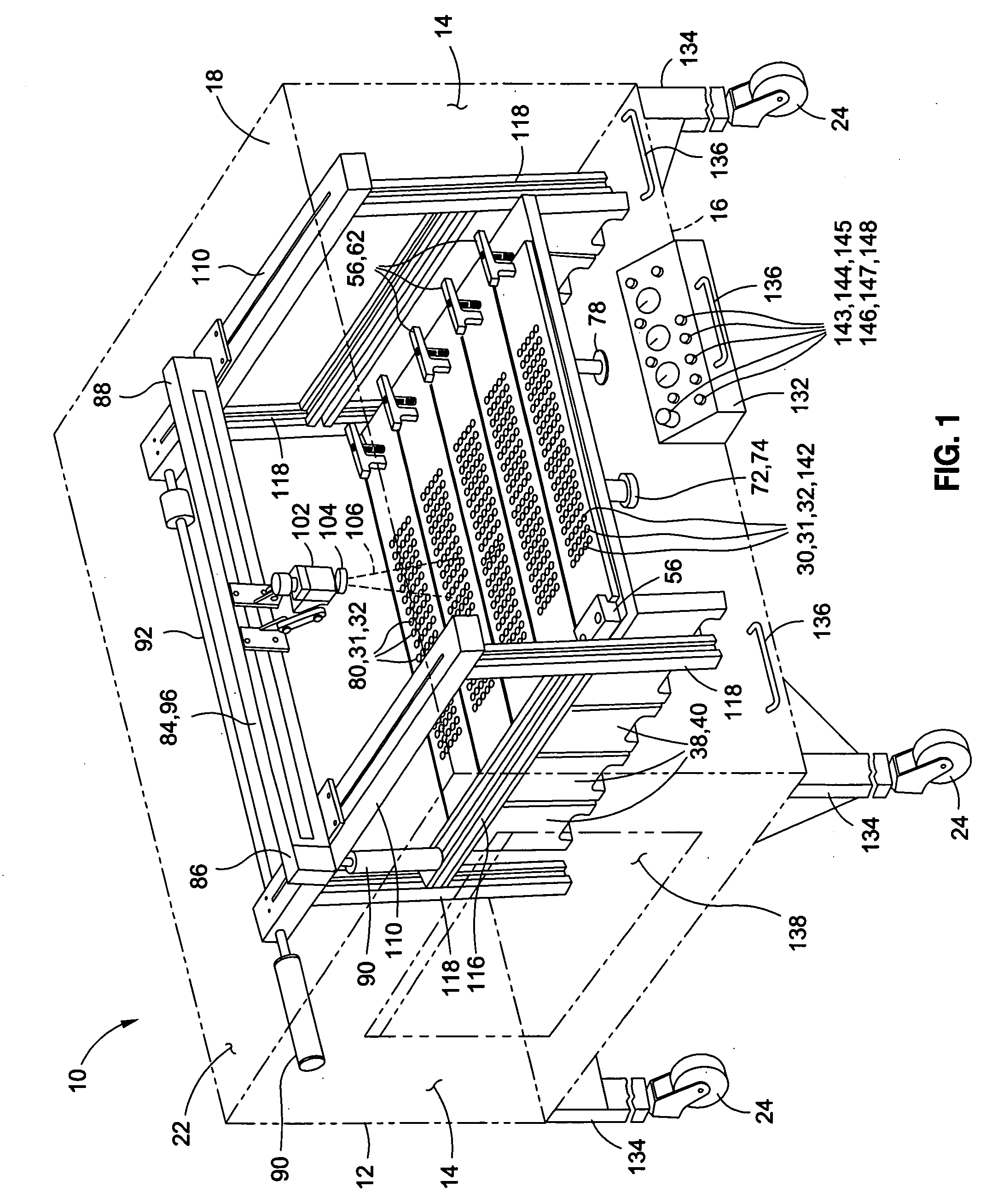

Controlled environment fastener head painting device and method

ActiveUS20100173090A1Small sizeEasy to controlWire articlesSlide fastenersEngineeringMechanical engineering

A painting apparatus for applying a coating material to a member surface of a member comprises a housing, at least one slide rail, a rack assembly, a cross beam and a spraying device. The slide rail may be mountable within the housing and may have a plurality of rack positions. The rack assembly is mountable within the housing at one of the rack positions. The rack assembly is configured to support the member such that the member surface is exposed. The cross beam may be coupled to the slide rail. The cross beam is movable along the slide rail and is positionable at the rack positions. The spraying device is mountable on the cross beam and is configured to move along the cross beam while spraying the coating material onto the member surface.

Owner:THE BOEING CO

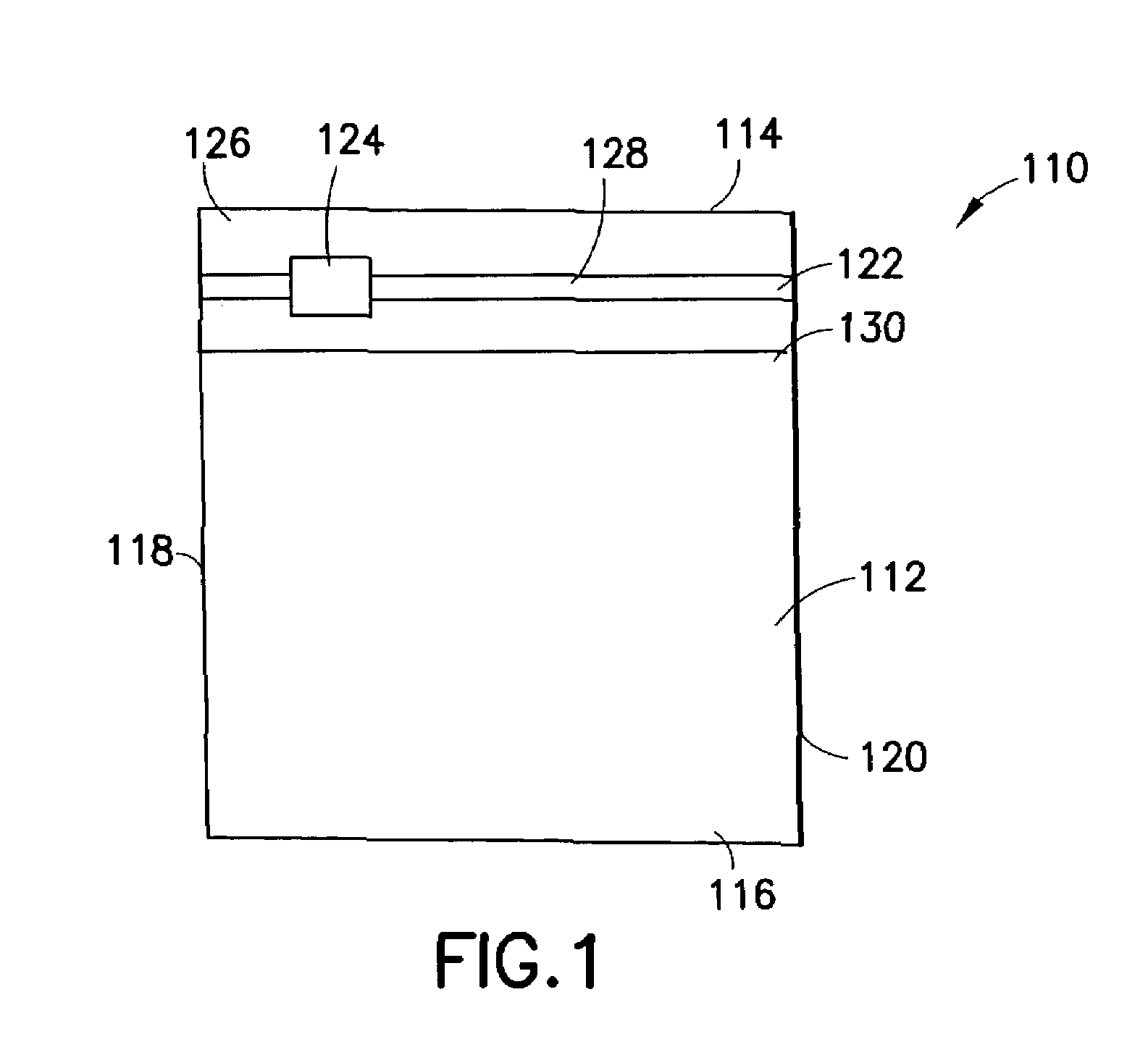

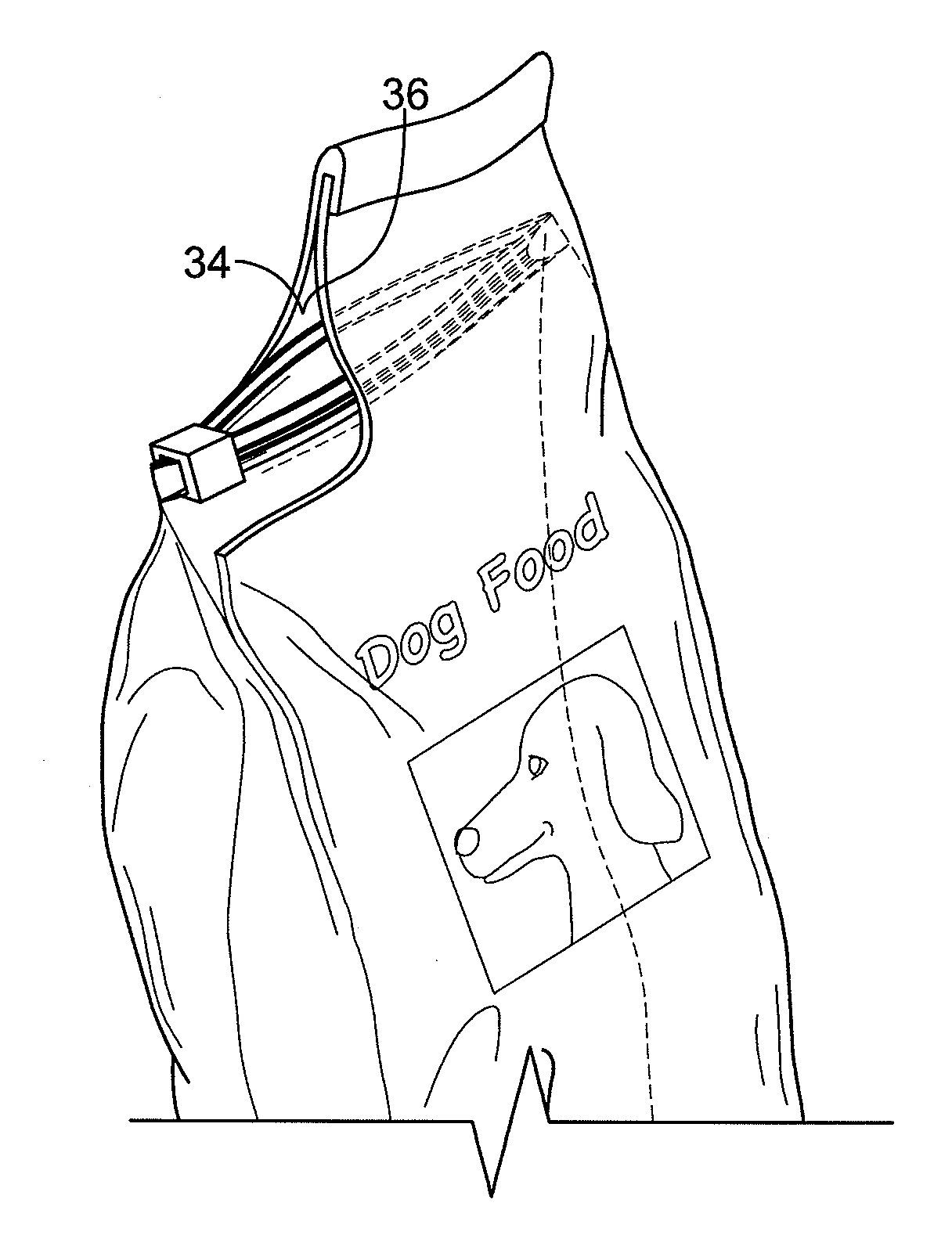

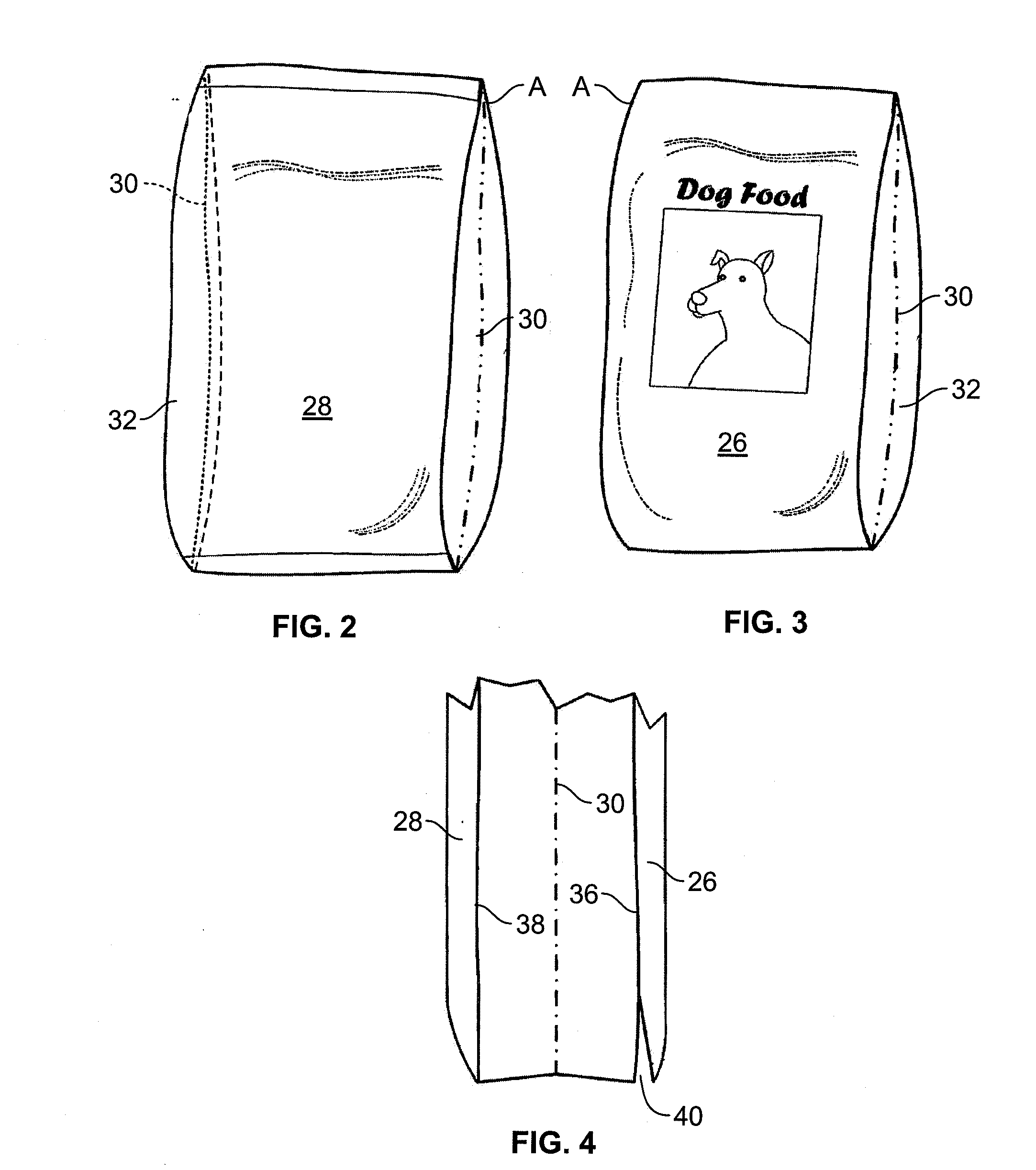

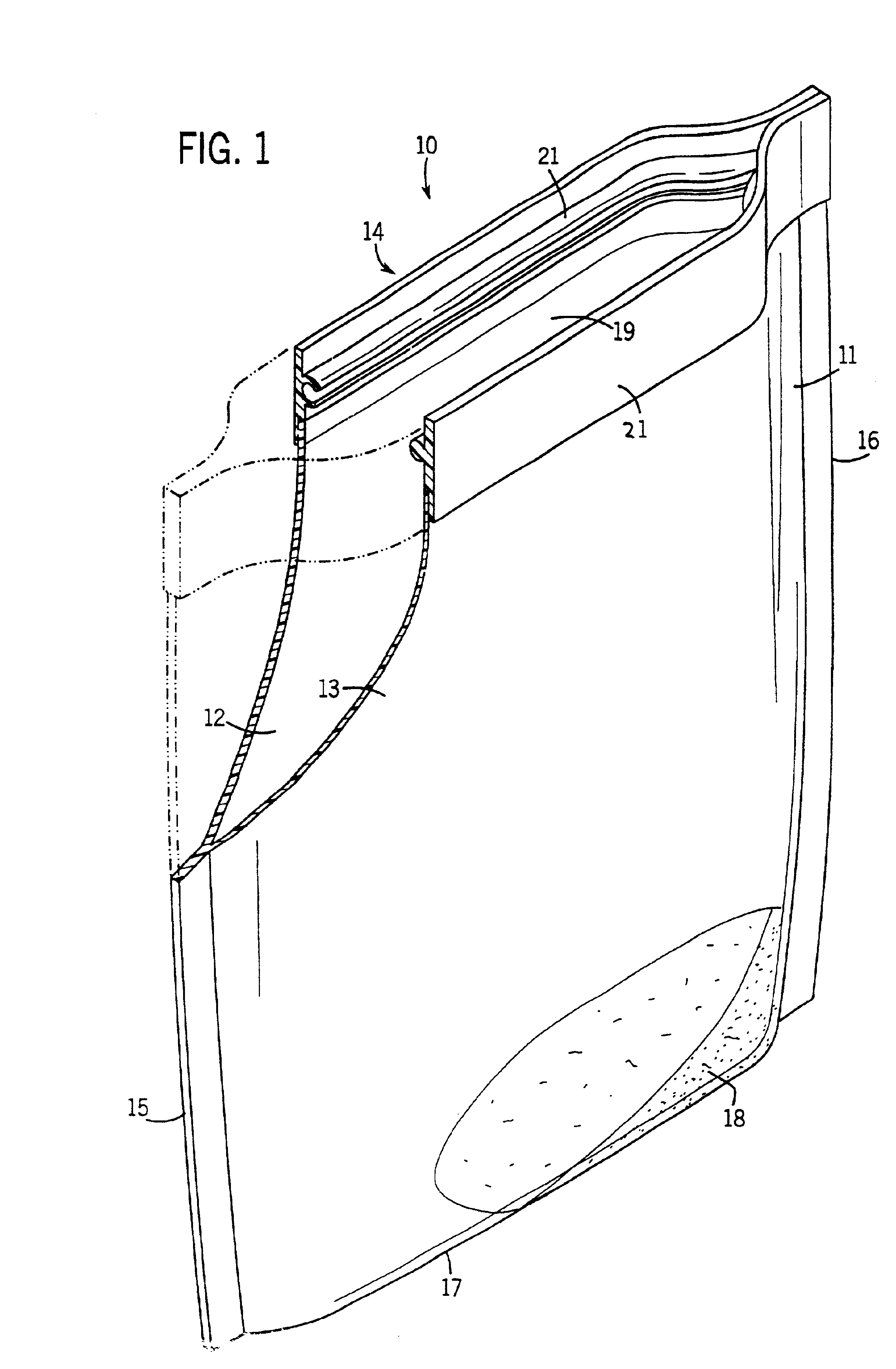

Fill-through-the-top package and method and apparatus for making the same

A fill-through-the-top reclosable package includes first and second opposing body panels joined to each other along a pair of sides and a bottom bridging the pair of sides. The package is provided with a reclosable fastener extending alone a package top disposed opposite the bottom. The fastener includes first and second opposing tracks. The first track includes a male profile, while the second track includes a female profile adapted to releasably interlock with the male profile. To provide tamper evidence, the first and second tracks may be joined to each other along an area of weakness. When making the package, the first track is first attached to the first panel, the package, the first track is first attached to the first panel, the package is filled with a product via a fill opening between the second track and the second panel, and then the second track is attached to the second panel.

Owner:REYNOLDS PRESTO PRODS

Plastic zipper improved in durability

Owner:HIPACK

Reclosable packaging having zipper with sculpted slider end stops

Owner:ILLINOIS TOOL WORKS INC

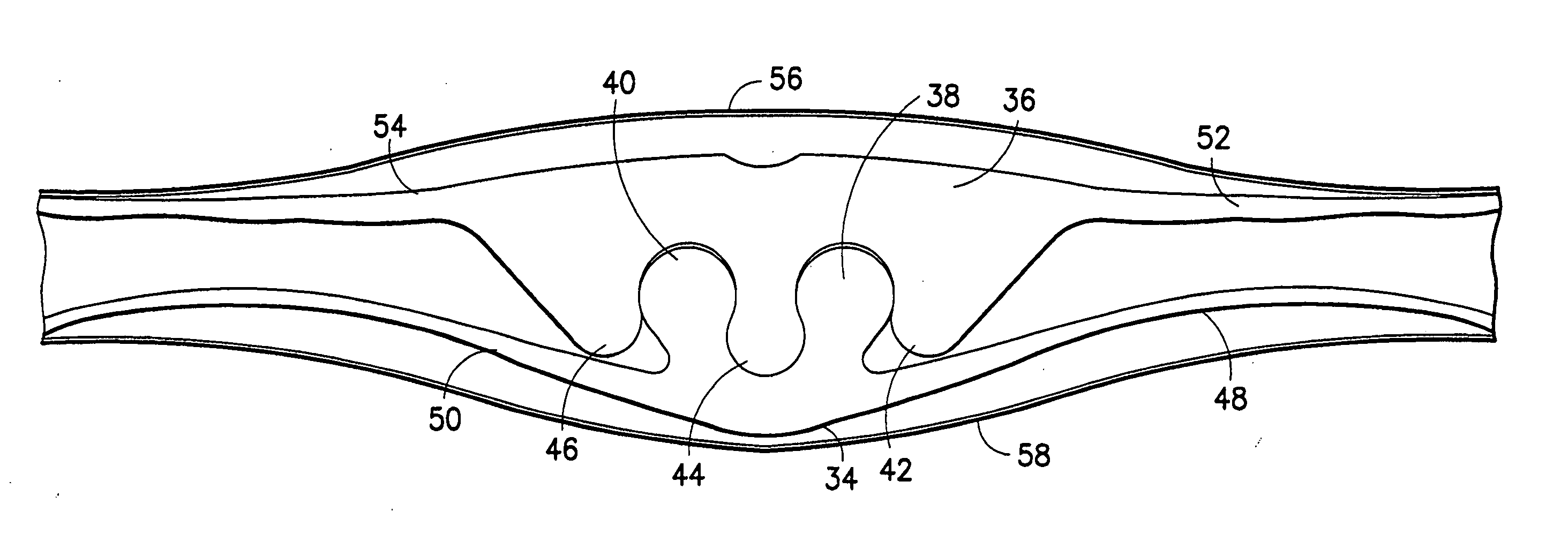

Interlocking closure device

InactiveUS6953542B2Improve leak-proof effectDesired audible and/or tactile effectsSnap fastenersMechanical working/deformationThermoplasticCold formed

A closure device for a thermoplastic bag which includes two opposing, longitudinally extending interlockable male and female fastening strips having respective male and female closure elements or profiles that are deformed to interdigitate and produce an audible clicking sound and or tactile effect that is perceptible to the touch as the closure device is opened and closed. Interdigitation of the two profiles is achieved by cold forming the profiles while interlocked. The shape of the cold form is a stepped deflection of both profiles so that their shapes are generally congruent. The stepped deflections provide a change in the occlusion and peel force of the interlocking closure device thereby resulting in an audible clicking or popping sound as the closure device is opened and closed and a tactile effect that is perceptible to the touch as the closure device is closed.

Owner:WATER KINETICS LTD

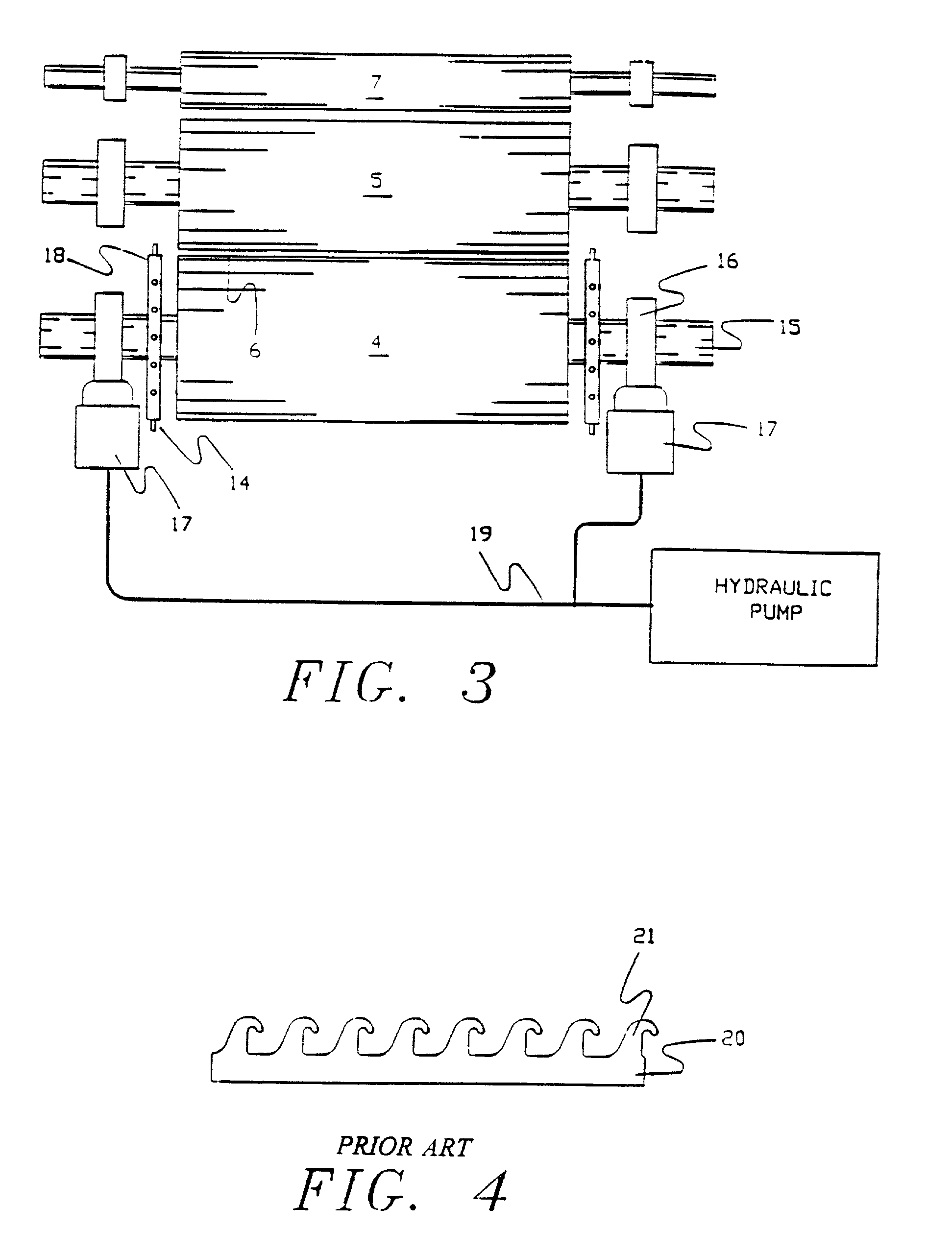

Leakproof zipper end crush for reclosable bag and related method of manufacture

ActiveUS20060029299A1Sufficient wave energySmall overall deformationEnvelopes/bags making machinerySlide fastenersEngineering

A reclosable bag that can be hermetically sealed. The bag comprises a pair of zipper strips that are joined in respective zones without substantial deformation of the longitudinal profiled closure elements. These zones of zipper strip joinder assist in providing a leakproof transition from the openable section of the zipper to the corner seals, where the longitudinal profiled closure elements are either substantially deformed (e.g., crushed) or absent. The method of manufacture involves the steps of ultrasonically welding a wide area and then thermally crushing a narrower area overlapping the wide welded area to form leakproof zipper joints. This method can be applied to string (flangeless) zippers as well as flanged zippers.

Owner:ILLINOIS TOOL WORKS INC

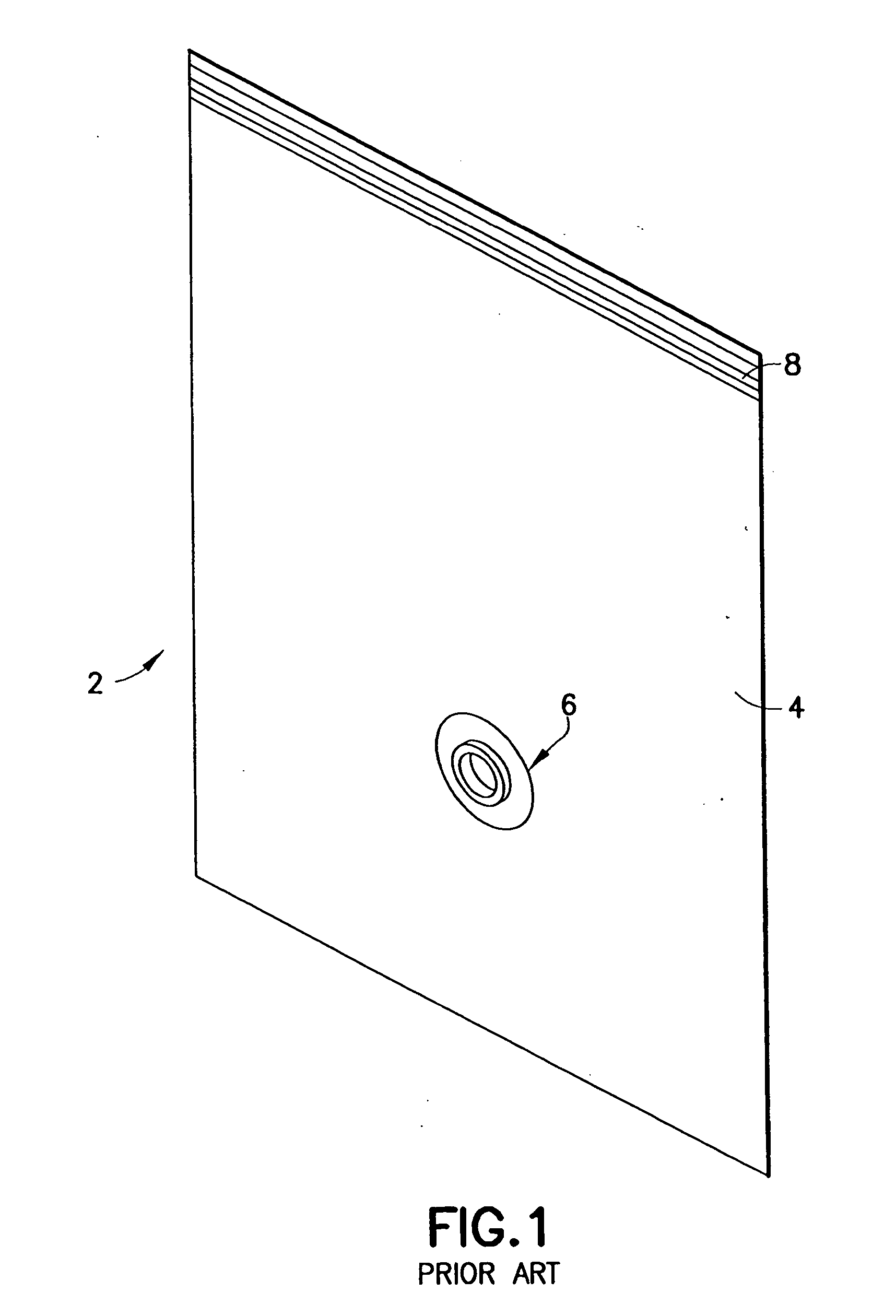

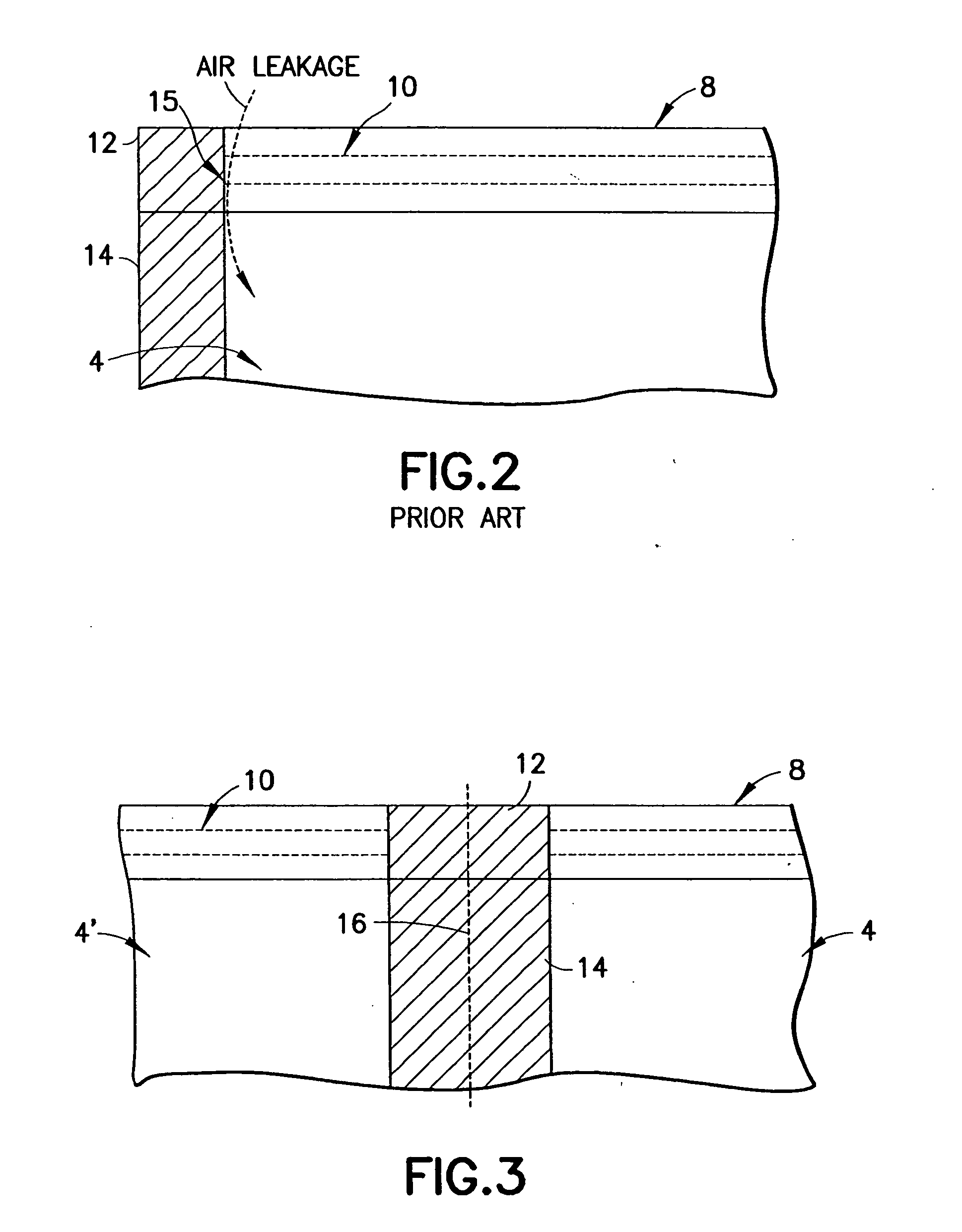

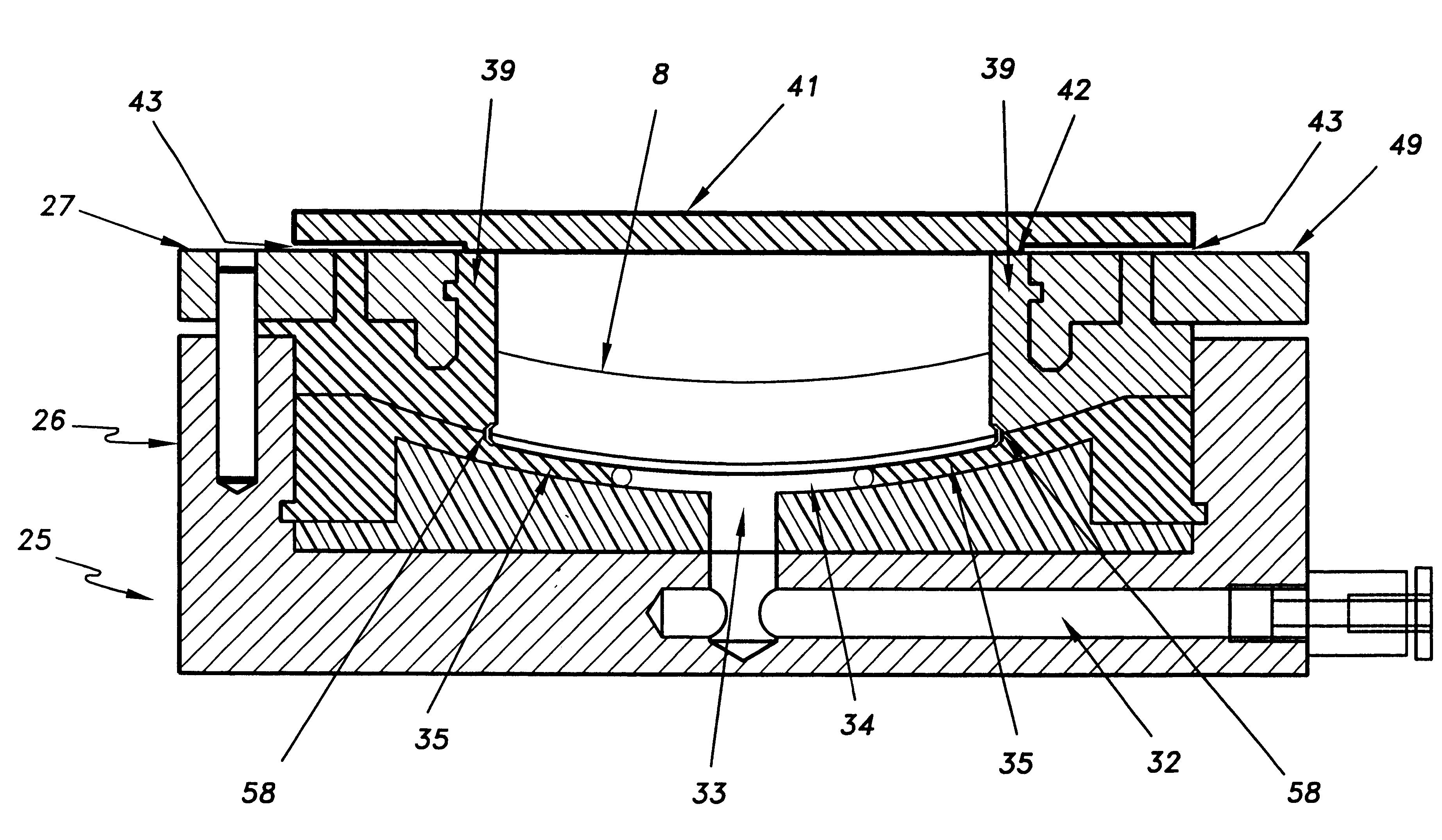

Method for forming a molded edge seal

A method for sealing the circumferential edge region of a laminated electrochromic device is disclosed. The method involves inserting a device to be sealed into a mold having a cavity aligned with the portion of the edge region to be sealed, and injecting a sealant into the cavity. Devices containing molded edge seals are also disclosed.

Owner:PPG IND OHIO INC

Woven Polymeric Bag with Pinch-Bottom Seal and Method of Making the Same

InactiveUS20110255807A1Facilitates chemical bondingImprove adhesionBox making operationsPaper-makingMechanical engineeringPolymer

Owner:AMS ASSOC

Laminated hook fastener

InactiveUS20010001283A1High strengthSubstantial modificationSnap fastenersVehicle seatsPlastic materialsEngineering

Owner:VELCRO IND BV

Method for laminating closure member to film web

InactiveUS6860952B2Quick connectionQuick attachEnvelopes/bags making machinerySlide fastenersEngineeringExtrusion

Methods for forming a thermoplastic film with an attached closure strip are disclosed. The film can be used to produce zippered reclosable plastic bags. The methods include providing a thermoplastic film web having a sealing surface and a closure strip having a binding surface, both being in a non-melted condition. The film web and the closure strip are aligned in non-overlapping relationship and a heated thermoplastic binder layer is positioned on the film web sealing surface and on the closure strip binding surface quickly after extrusion. The hot binder layer transfers enough heat to the closure strip and to the film web to melt the closure strip binding surface and the film web sealing surface. Pressure is applied to seal the closure strip to the film web. An apparatus for practicing the method and a reclosable bag formed from the thermoplastic film with attached closure strips are also disclosed.

Owner:SC JOHNSON & SON INC

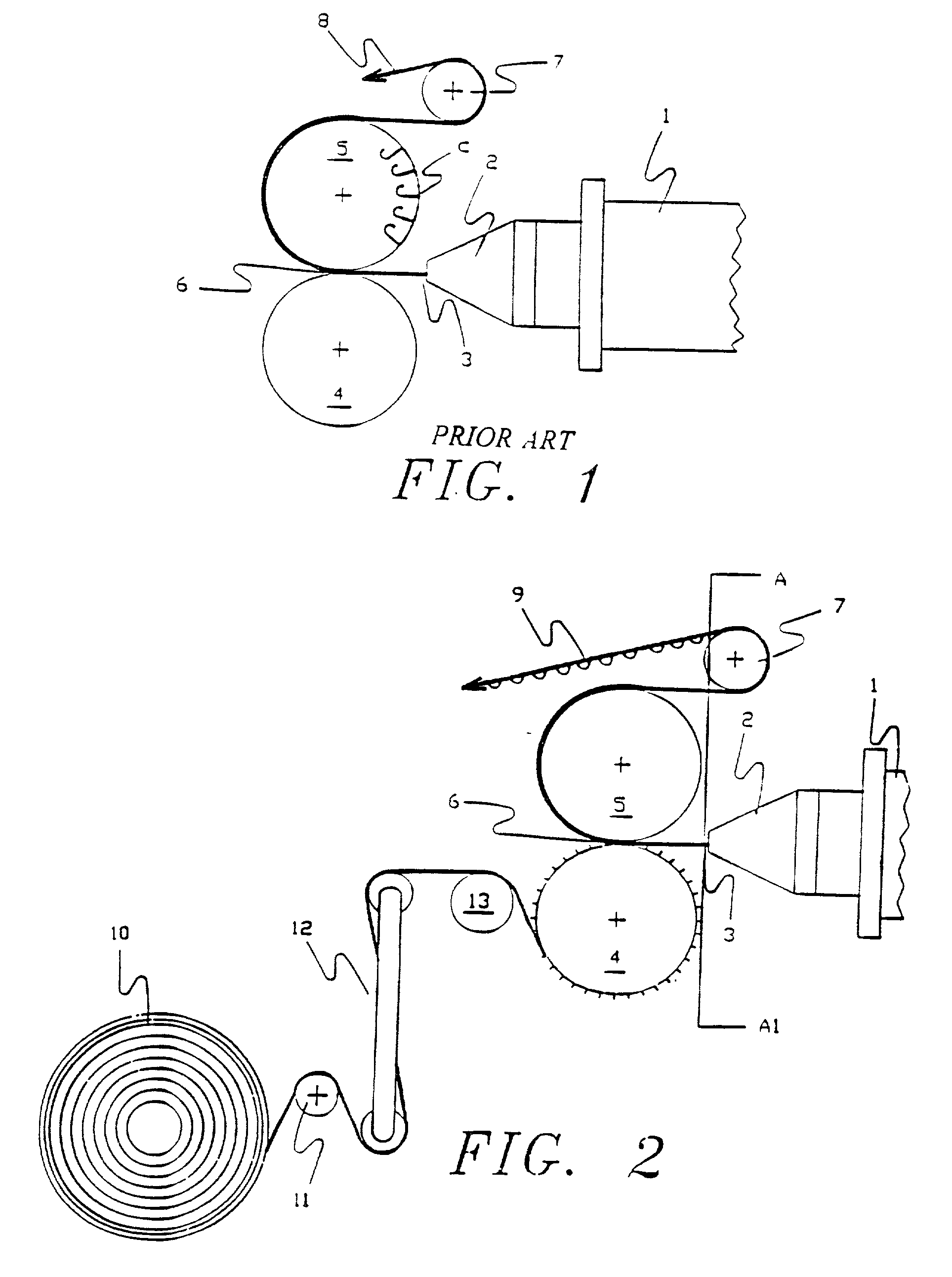

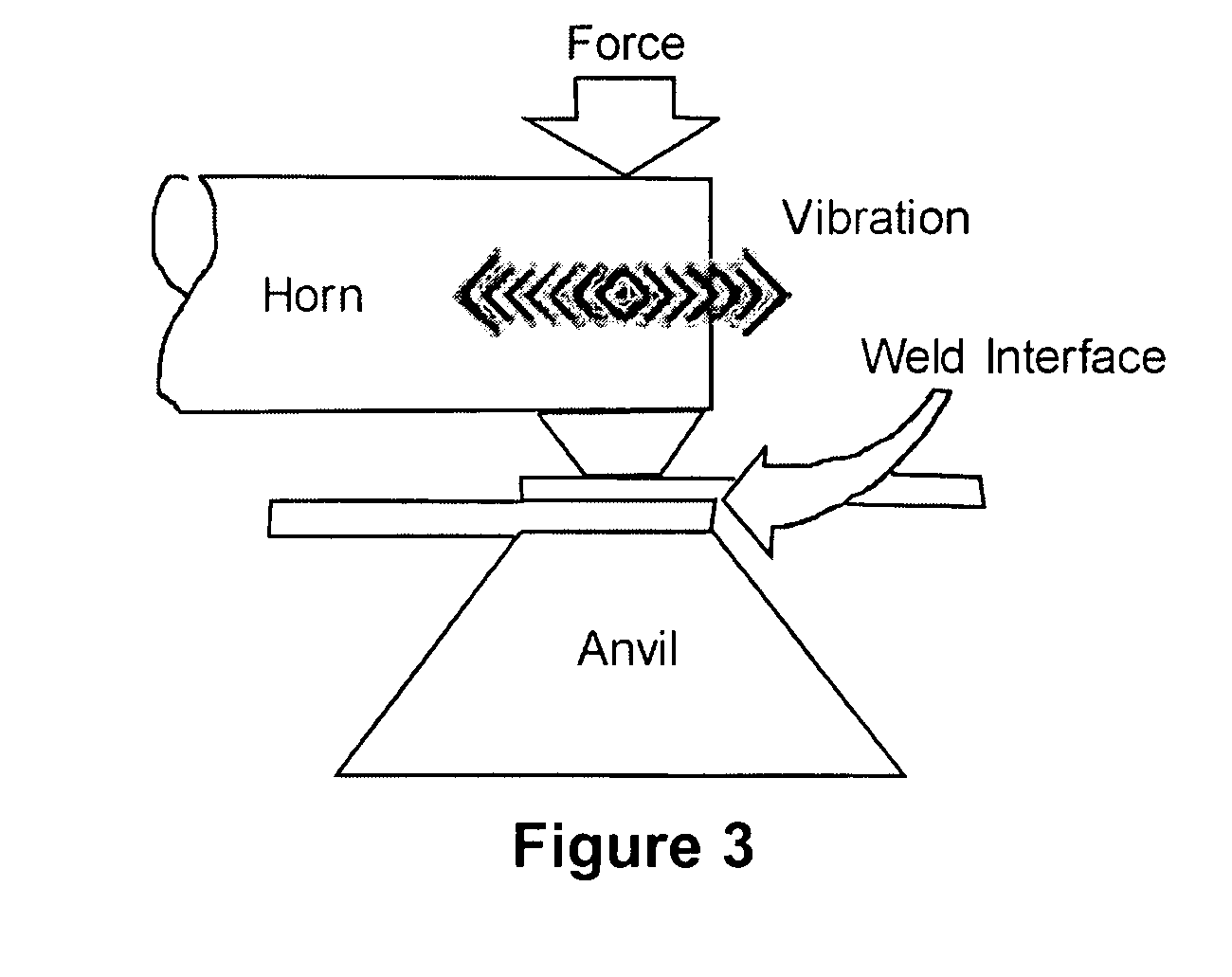

Ultrasonic apparatus with non-rotating horn and rotating anvil for welding plastic parts

InactiveUS7025841B2Cushions the deflection of the horn awayEnvelopes/bags making machineryLamination ancillary operationsUltrasound deviceRotational axis

A method and an apparatus for ultrasonically welding plastic parts together. The ultrasonic welding apparatus includes: an air cylinder having a piston rod; an ultrasonic horn substantially rigidly coupled to an end of the piston rod and having a distal end; a rotary anvil having an axis of rotation generally perpendicular to an axis of the piston rod and comprising a periphery; a transducer for converting electric potential differences into ultrasound wave energy, the horn being acoustically coupled to the transducer; and drive means for causing the anvil to rotate. The distal end of the horn confronts the periphery of the anvil throughout rotation of the anvil. On one application, interlocked zipper strips are passed through a gap between the distal end of the horn and the periphery of the anvil. The anvil periphery has a plateau that presses the zipper against the distal end of the horn. The transducer is energized in synchronism with the plateau being opposed to the distal end of the horn.

Owner:ILLINOIS TOOL WORKS INC

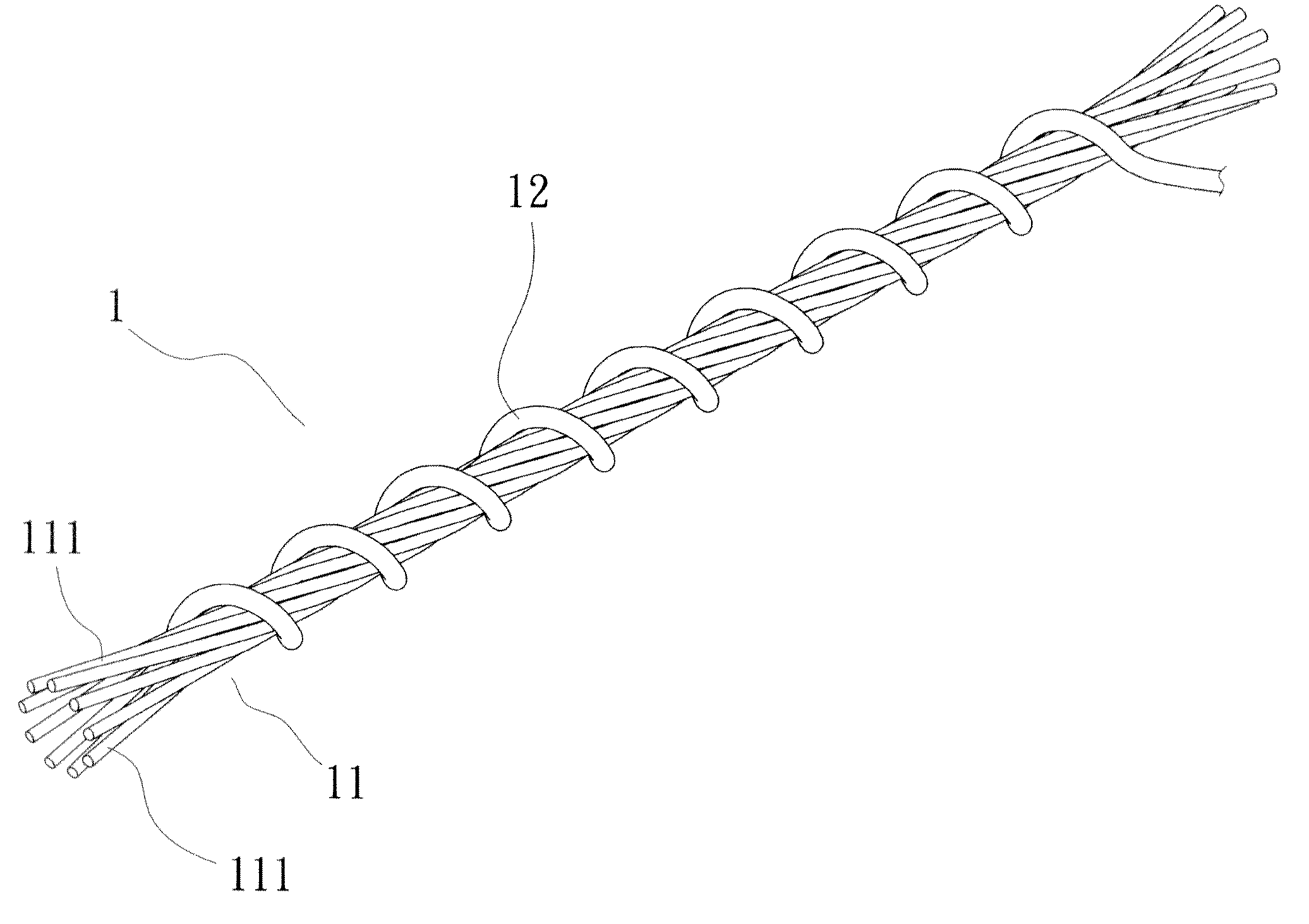

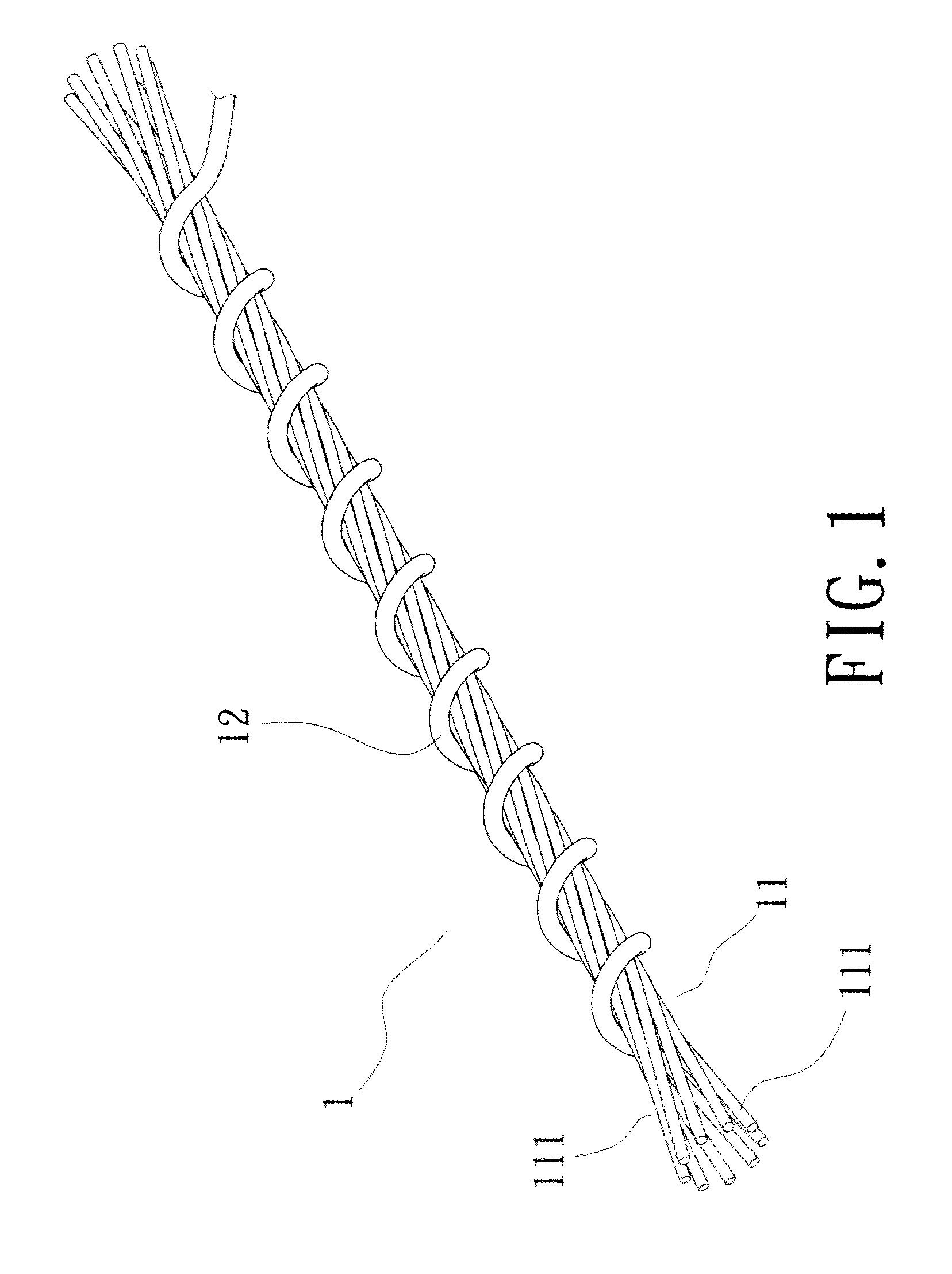

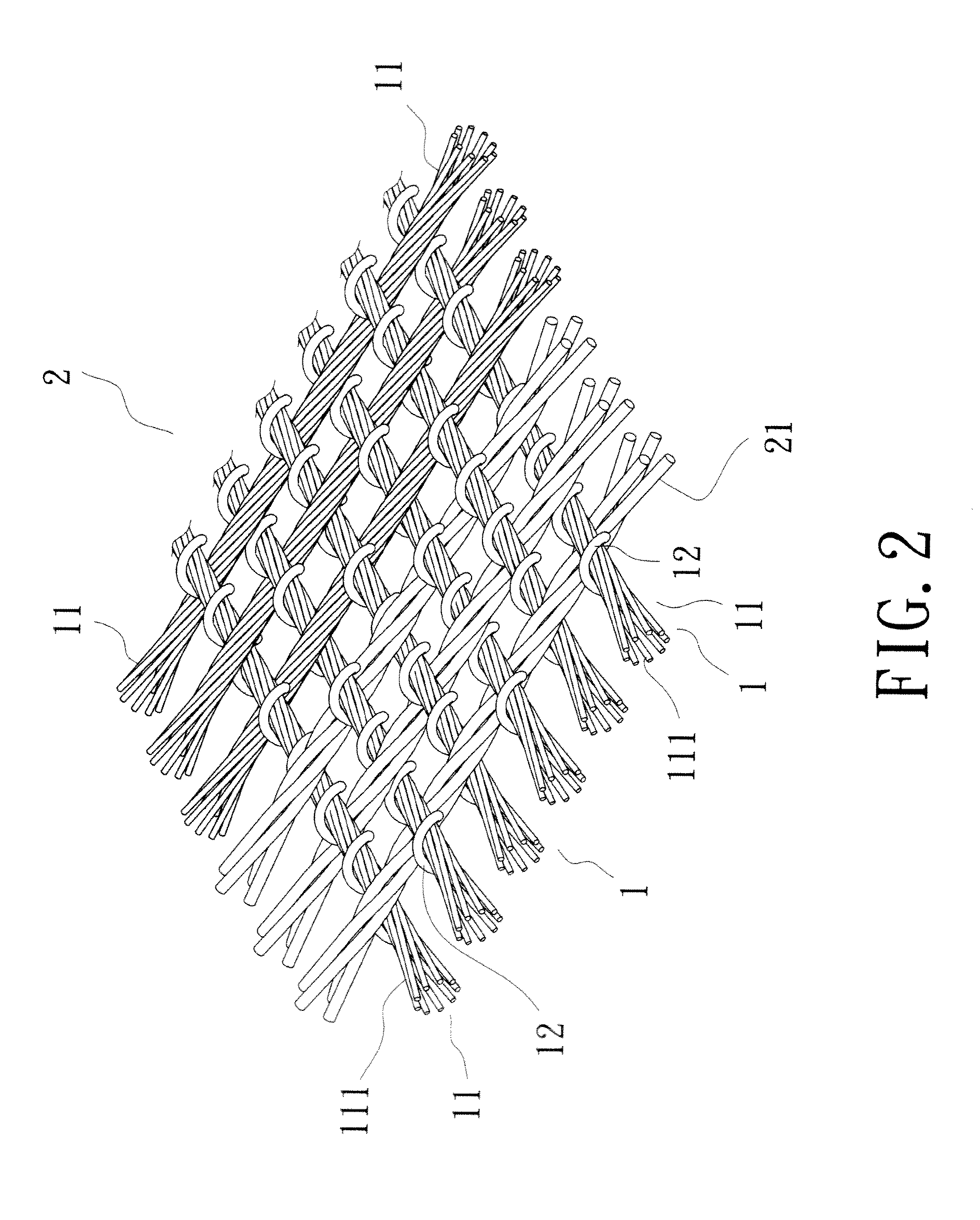

Conductive yarn and cloth containing the same

InactiveUS20110047957A1High energy consumptionEnergy lossCurtain accessoriesBed linenFiberElectricity

A conductive yarn and a cloth containing the same are revealed. A plurality of fibers is wound with a heating element in a spiral form so as to form a yarn with electrical conductivity and flexibility. The conductive yarn is used as a thread in a first direction while regular yarns with conductive metal wires arranged at the two sides thereof are used as threads in a second direction. Thus the threads are woven into a cloth that generates heat while being conducted with electricity. Thereby the cloth can be made into mattress, curtains, textile wall coverings, oversleeves, knee braces, waist supports, foot pads, seat cushions, and carpets etc so as to replace various heating equipment.

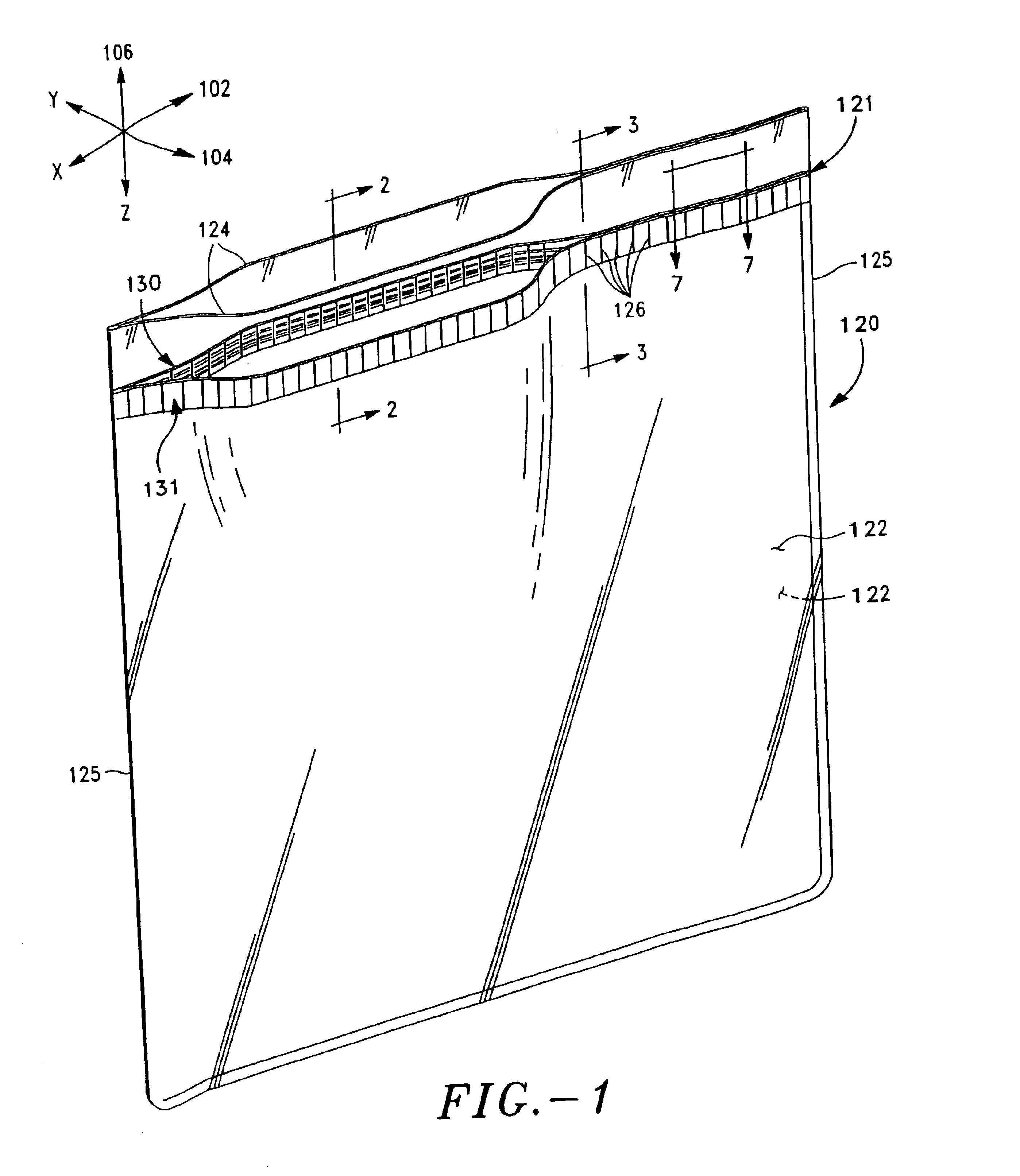

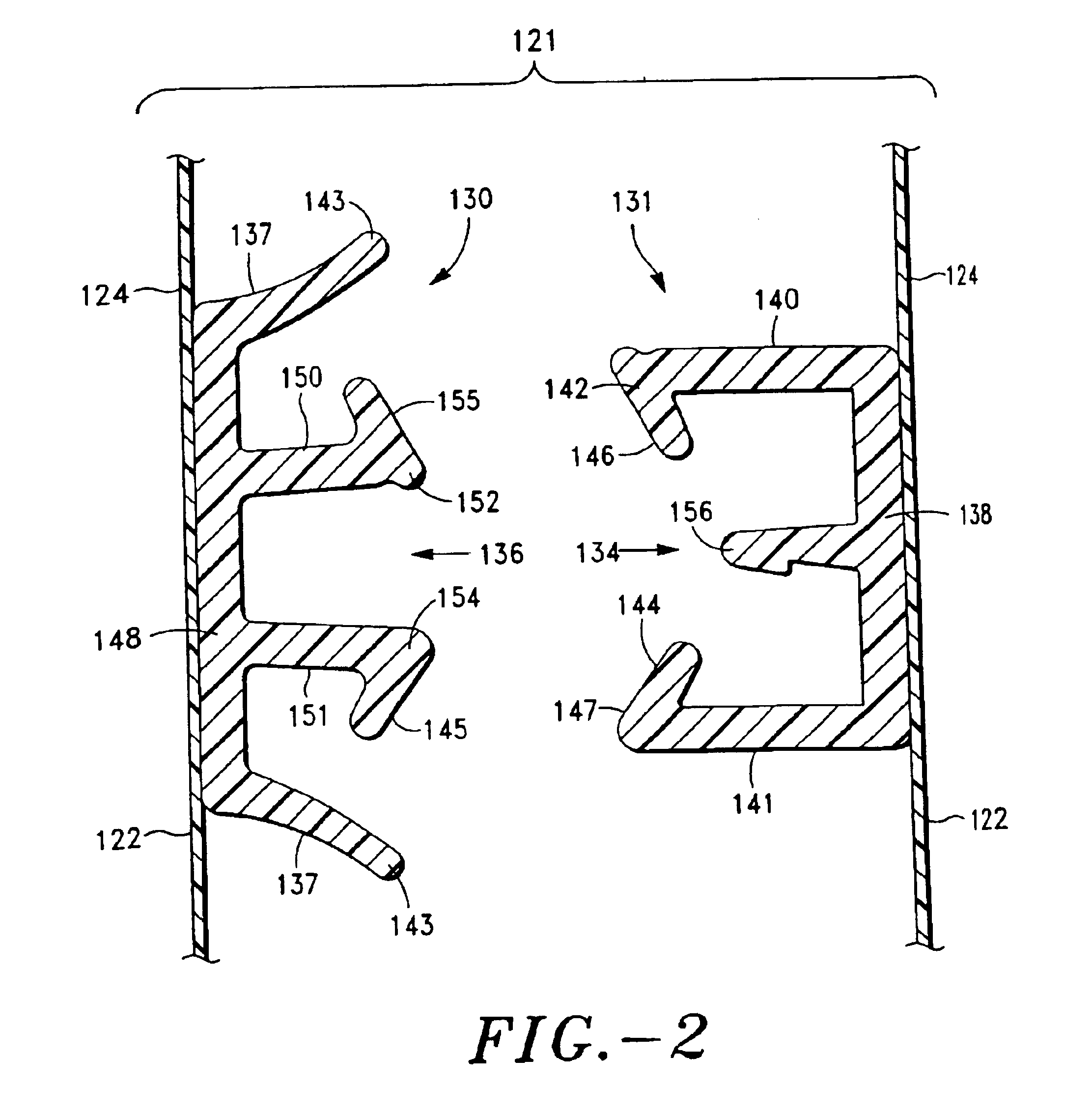

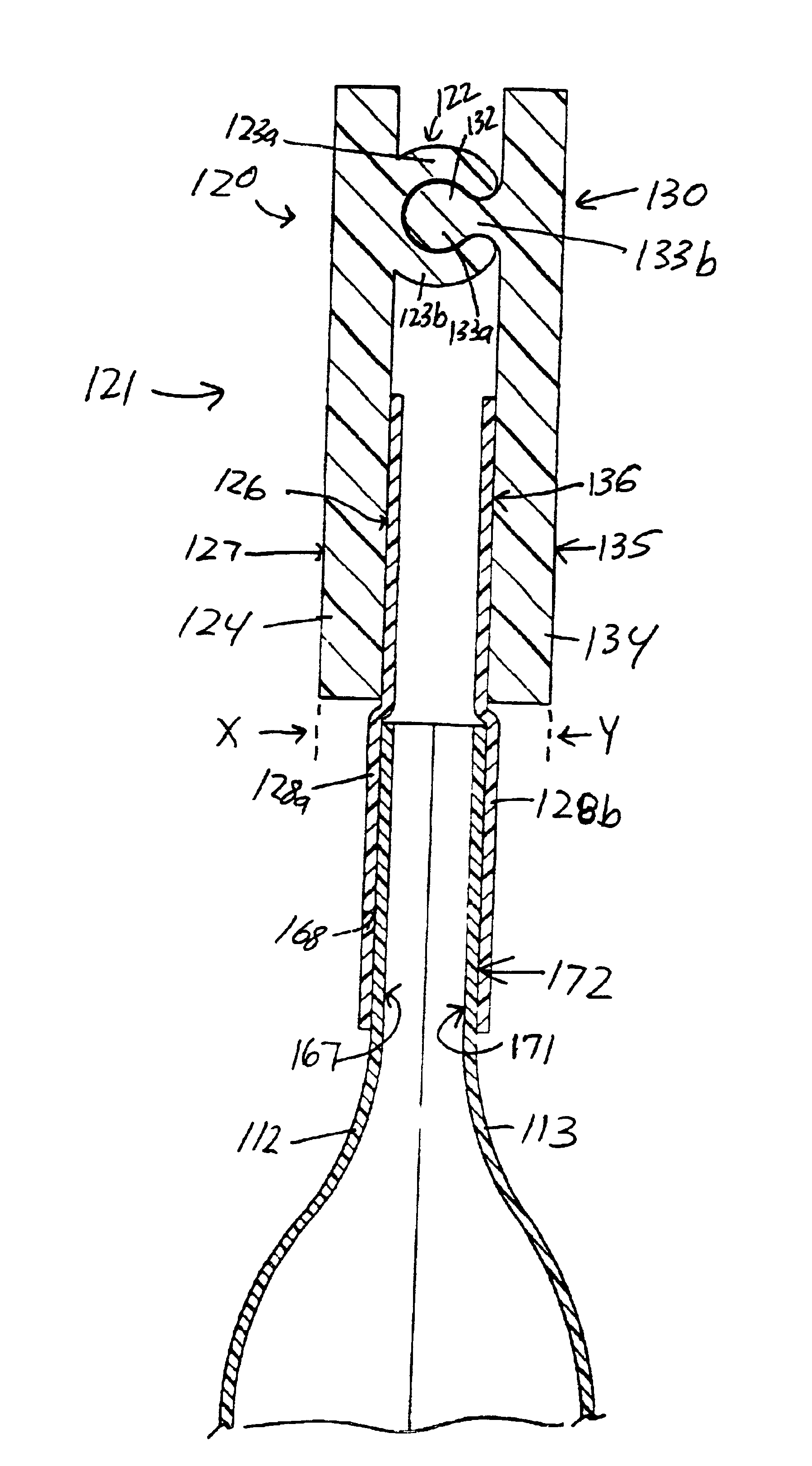

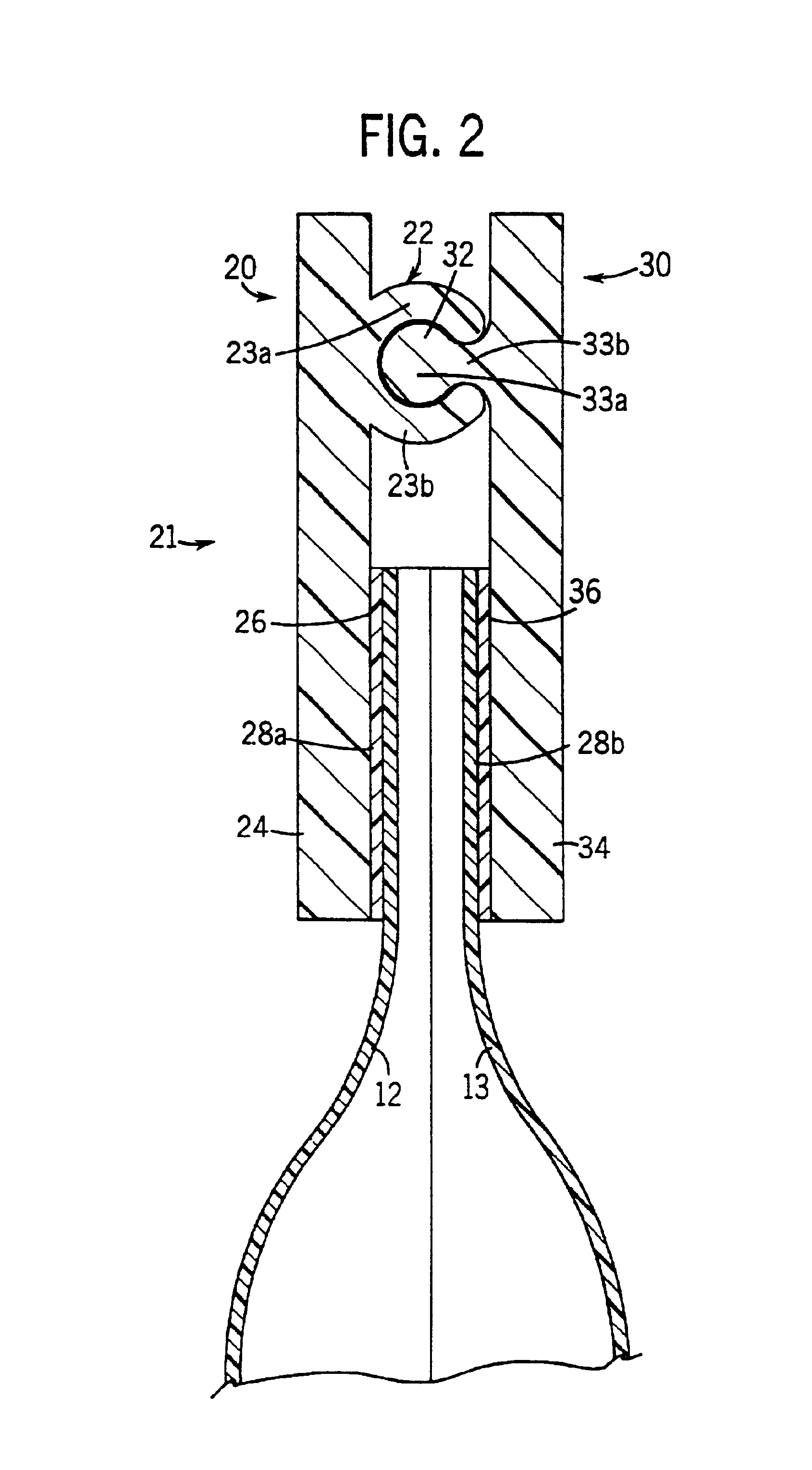

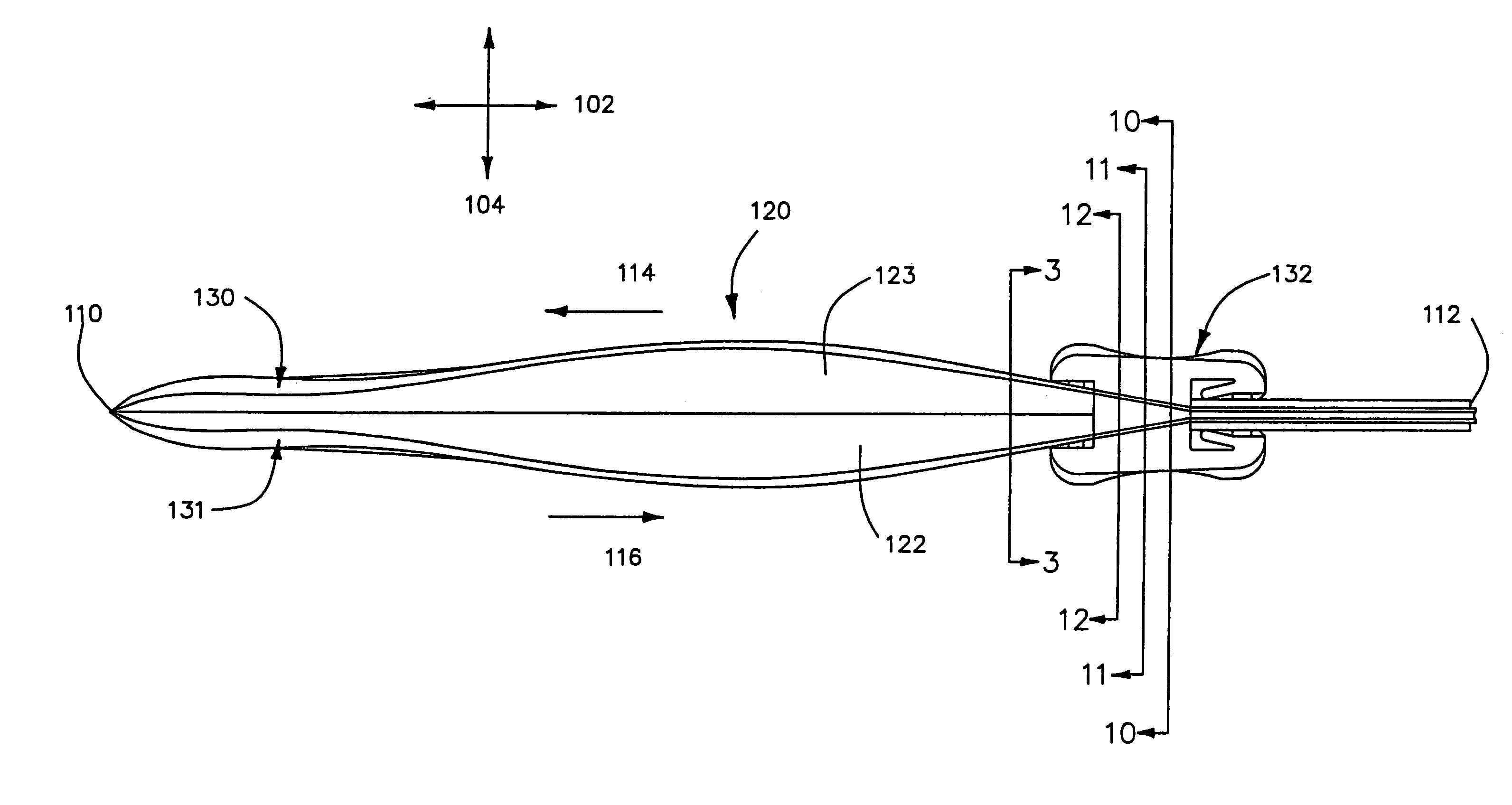

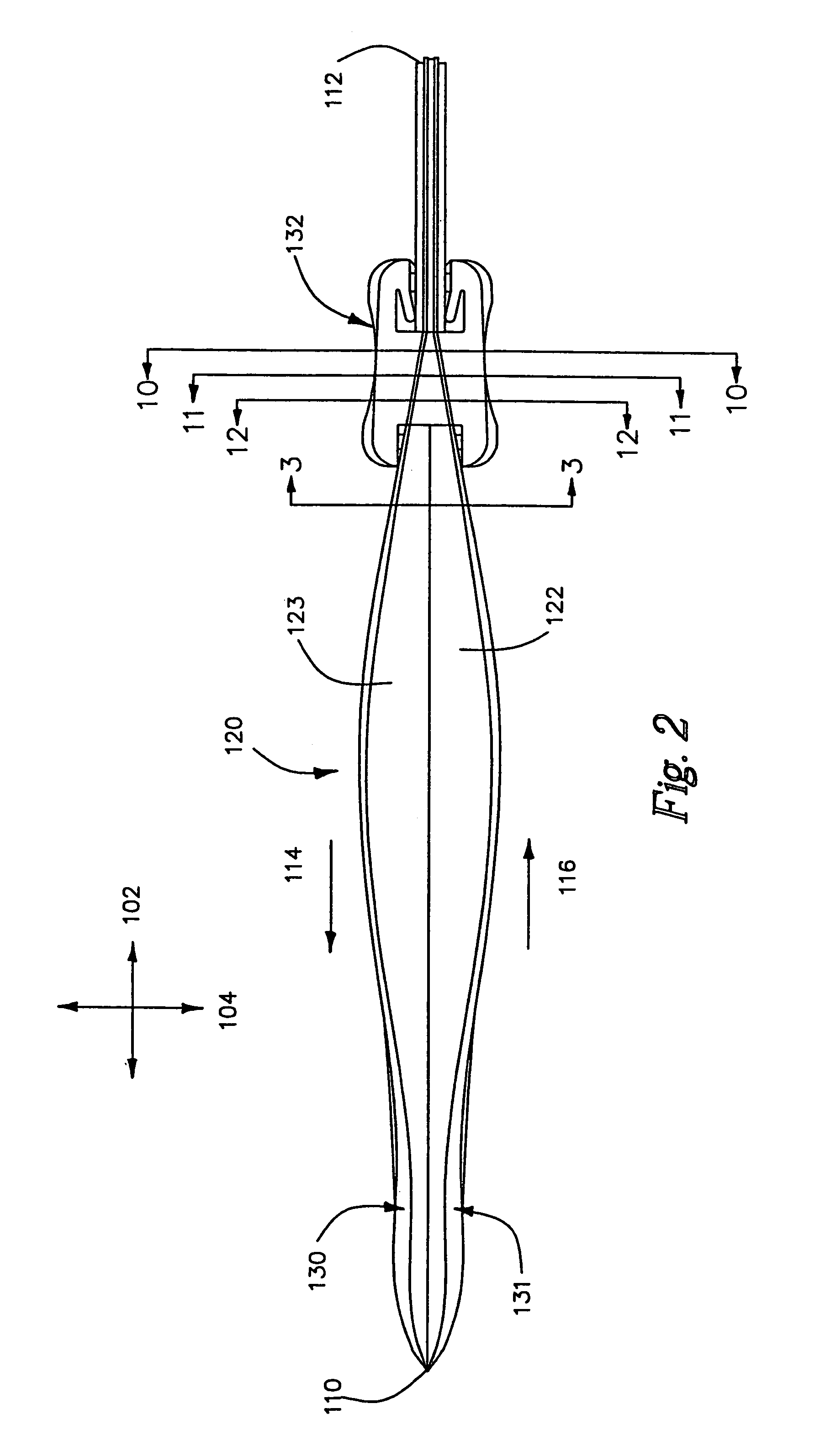

Closure device

InactiveUS7134192B1Facilitating occlusion and deocclusionGood adhesionSnap fastenersEnvelopes/bags making machineryMechanical engineeringEngineering

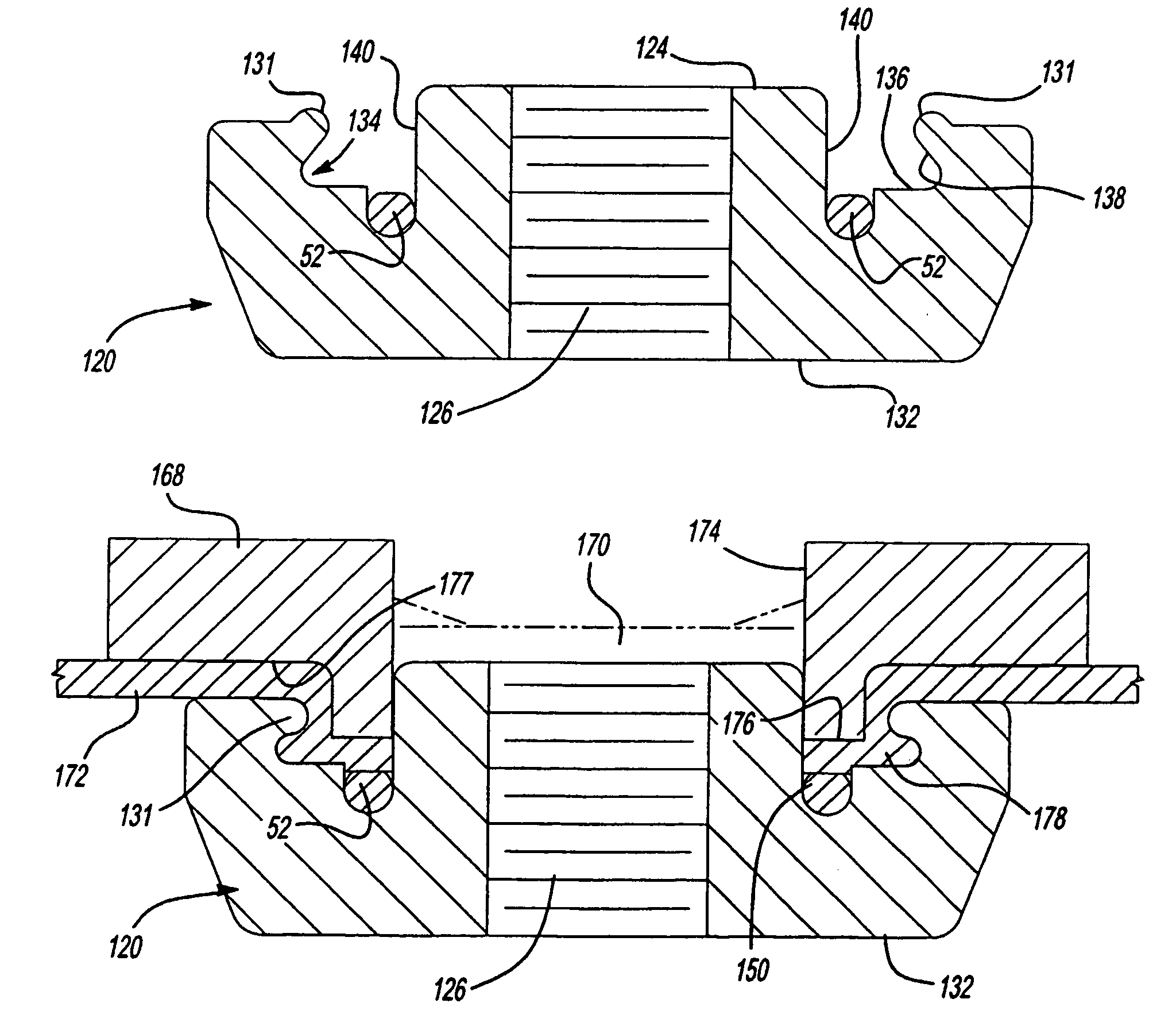

The closure device (121) includes interlocking fastening strips (130, 131) and a slider (132) slidably disposed on the fastening strips for facilitating the occlusion and deocclusion of the fastening strips (130, 131) when moved towards first and second ends thereof. A slider (132) is provided for facilitating the attachment of the slider (132) onto the fastening strips (130, 131) in the horizontal X axis (102). The slider (132) provides resistance against the removal of the slider (132) from the fastening strips (130, 131) in the horizontal X axis (102) and the vertical Z axis (106).

Owner:THE GLAD PROD CO

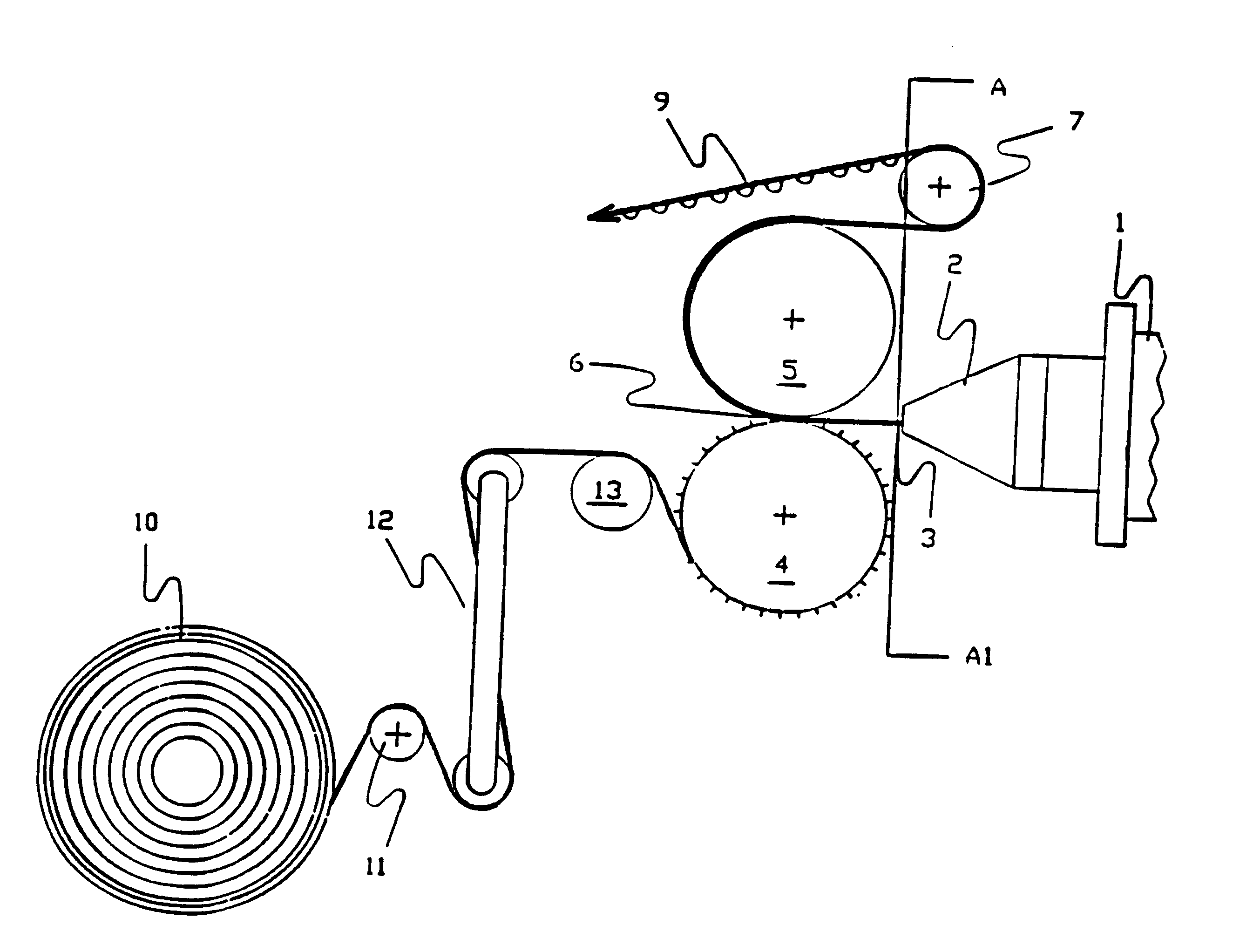

Manufacturing method and apparatus for torque-free singles ring spun yarns

InactiveUS6860095B2Simple methodImprove versatilityDomestic slide fastenersContinuous wound-up machinesEngineeringE-textiles

An internal torque balancing method of short fiber yarns related to the art of textile and the manufacturing apparatus thereof. The present invention proposes a completely new mechanical processing method of single torque-free yarns, and applies it into the process of ring spinning. Said method accomplishes a machine and a possibility of processing single torque-free yarns within one processing step by simple improvement on the existing ring spinning machine. Said technique is applicable to the production of all types of short fiber materials, and can overcome the maximum bundle yarn count of Ne limit of the torque-free yarns processed by the existing physical balancing technique. Meanwhile, said technique can process the yarns with low twist, which is unable to be processed normally by the conventional ring spinning machine. The torque-free singles ring spinning machine has good mechanical behavior, good handle, and evenness without residual torque.

Owner:THE HONG KONG POLYTECHNIC UNIV

Method for producing a hermetic plastic zipper and a hermetic plastic zipper

ActiveUS20110103717A1Easily peelableUniform strengthSnap fastenersEnvelopes/bags making machineryEngineeringUltimate tensile strength

Owner:KASSAI

Multilayer molded articles

InactiveUS7014907B2High strengthGood lookingWood working apparatusSuperstructure subunitsShell moldingEngineering

Disclosed is a multilayer molded article comprising a thermoplastic resin substrate and at least two kinds of skin materials laminated on a surface of the substrate, the at least two kinds of skin materials including a pair of skin materials adjacent to each other wherein the pair of skin materials are folded toward the substrate to have folded edges which separate the substrate at least partly to define two portions, wherein the separated portions of the substrate are combined together via a plurality of ribs of the thermoplastic resin molded integrally with the substrate, the ribs enclosing therein a part of the folded edges of the pair of skin materials.

Owner:SUMITOMO CHEM CO LTD

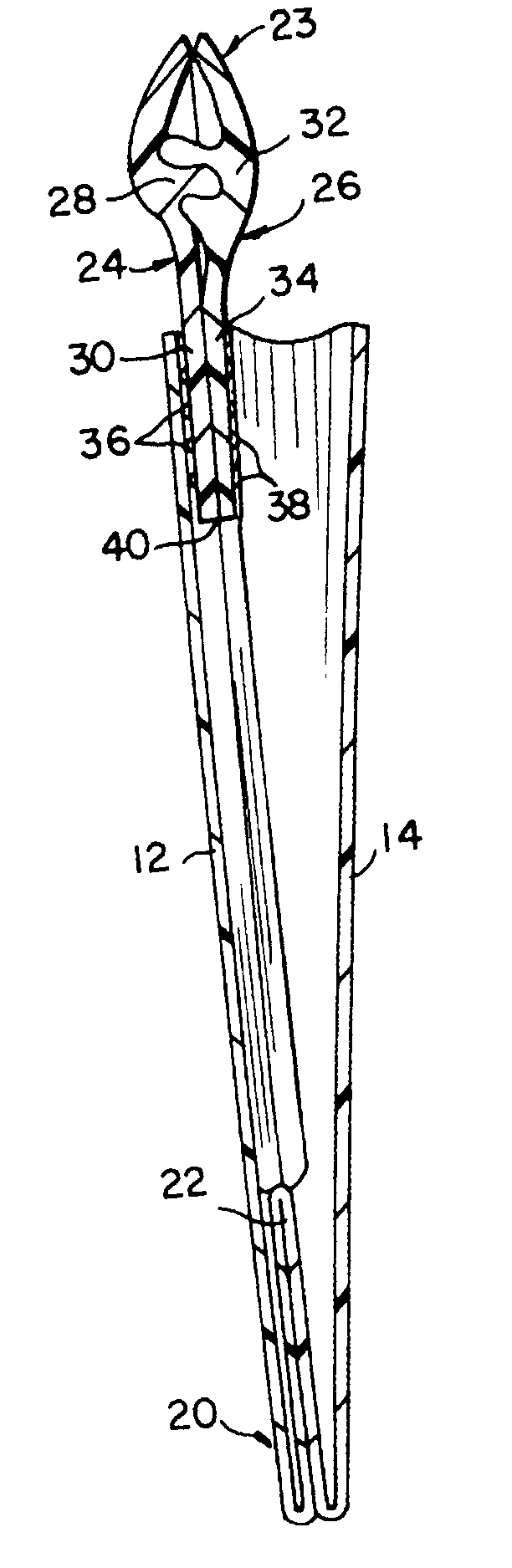

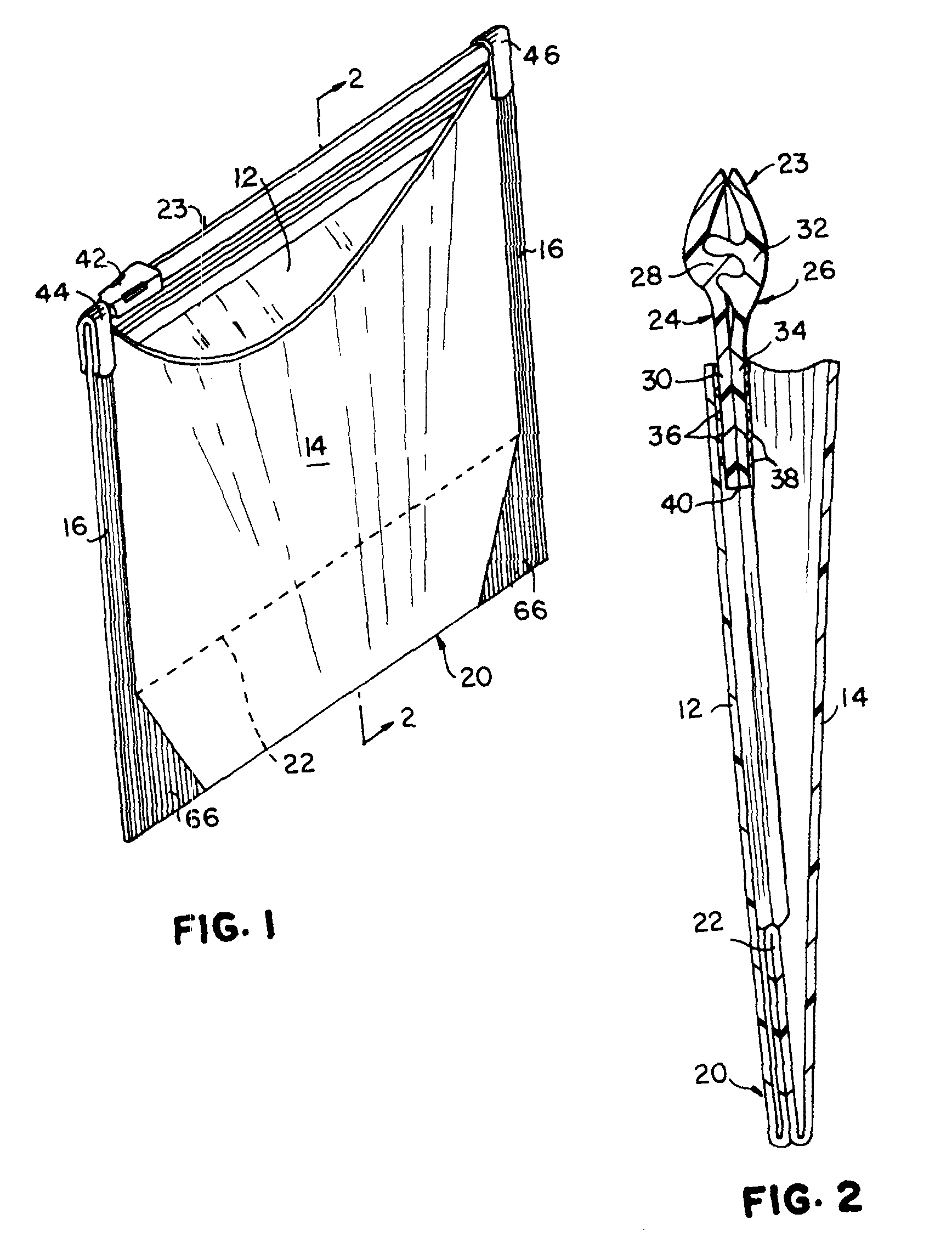

Self-attaching fastener systems

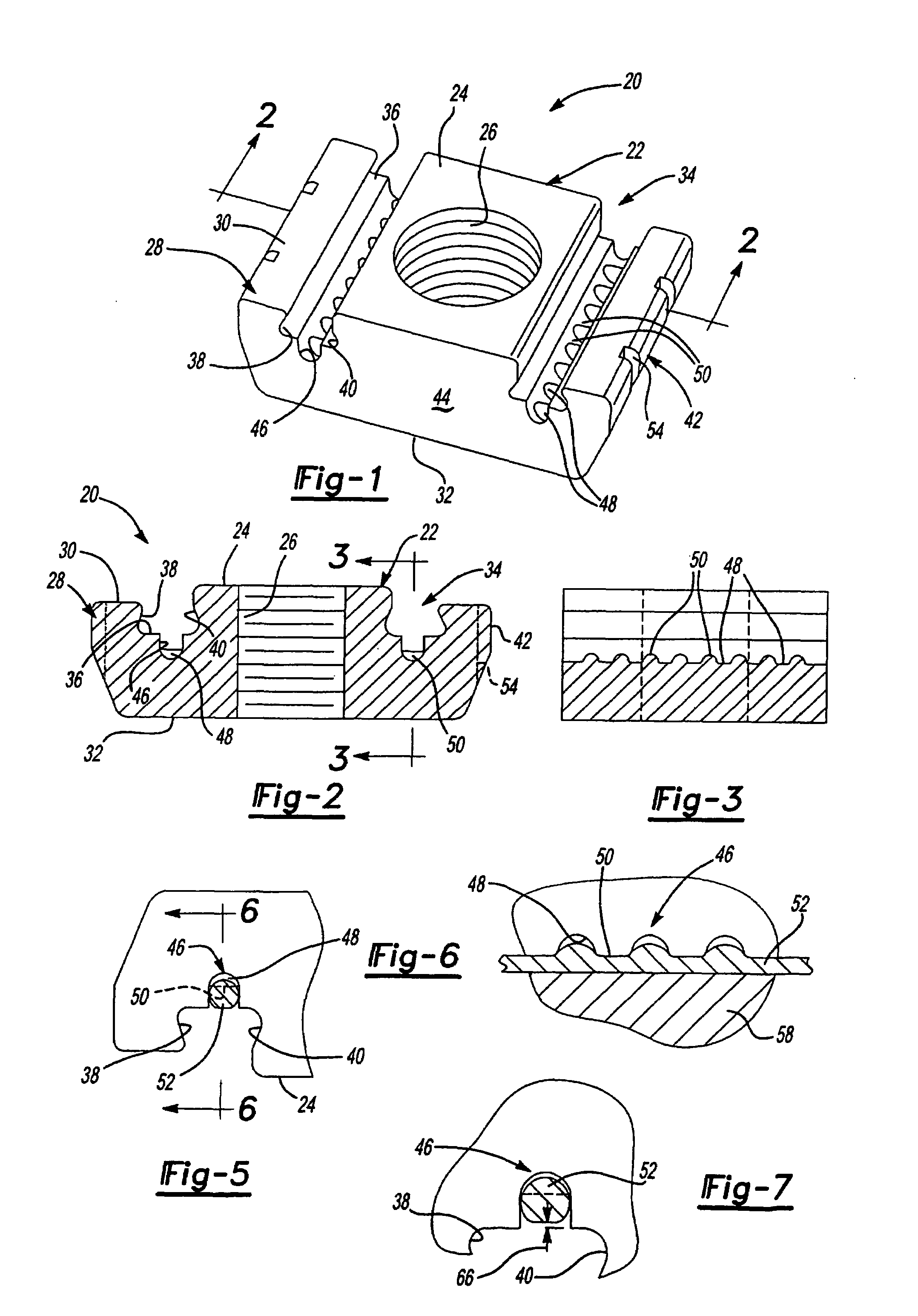

Methods of forming and feeding self-attaching fasteners are disclosed wherein the strip includes a plurality of spaced abutment surfaces, preferably notches, which may be used both during the manufacturing process and feeding of a strip of fasteners to an installation head. Where the fasteners are interconnected in a strip, by frangible wires, the wires are located in the bottom wall of the panel receiving grooves in the flange portions on opposed sides of the projecting pilot portion. A self-attaching fastener having deformable inclined lip portions which extend upwardly and toward the pilot portion from the flange portions which are deformed during installation to provide further securement for the panel when deformed in the grooves.

Owner:PENN AUTOMOTIVE INC

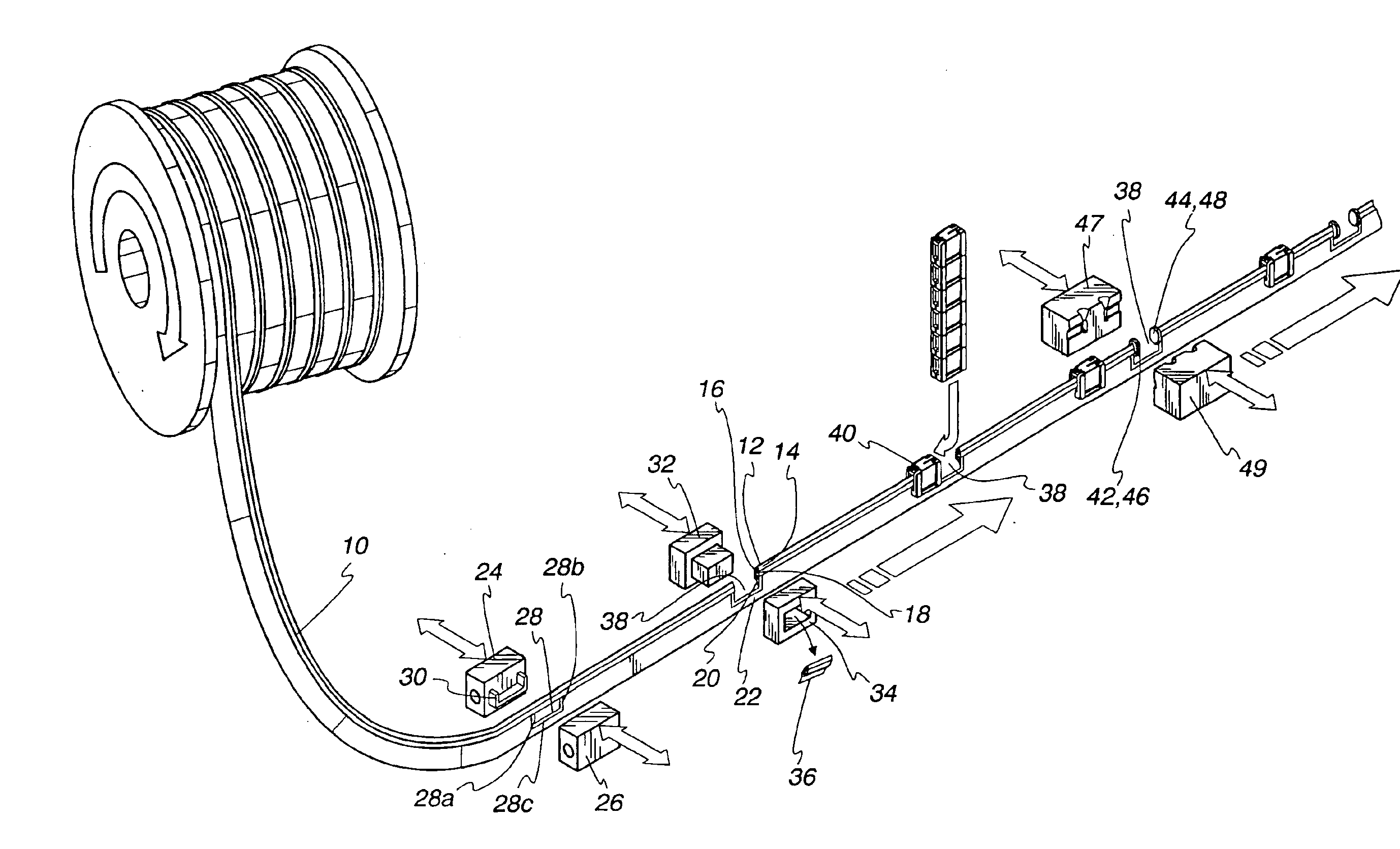

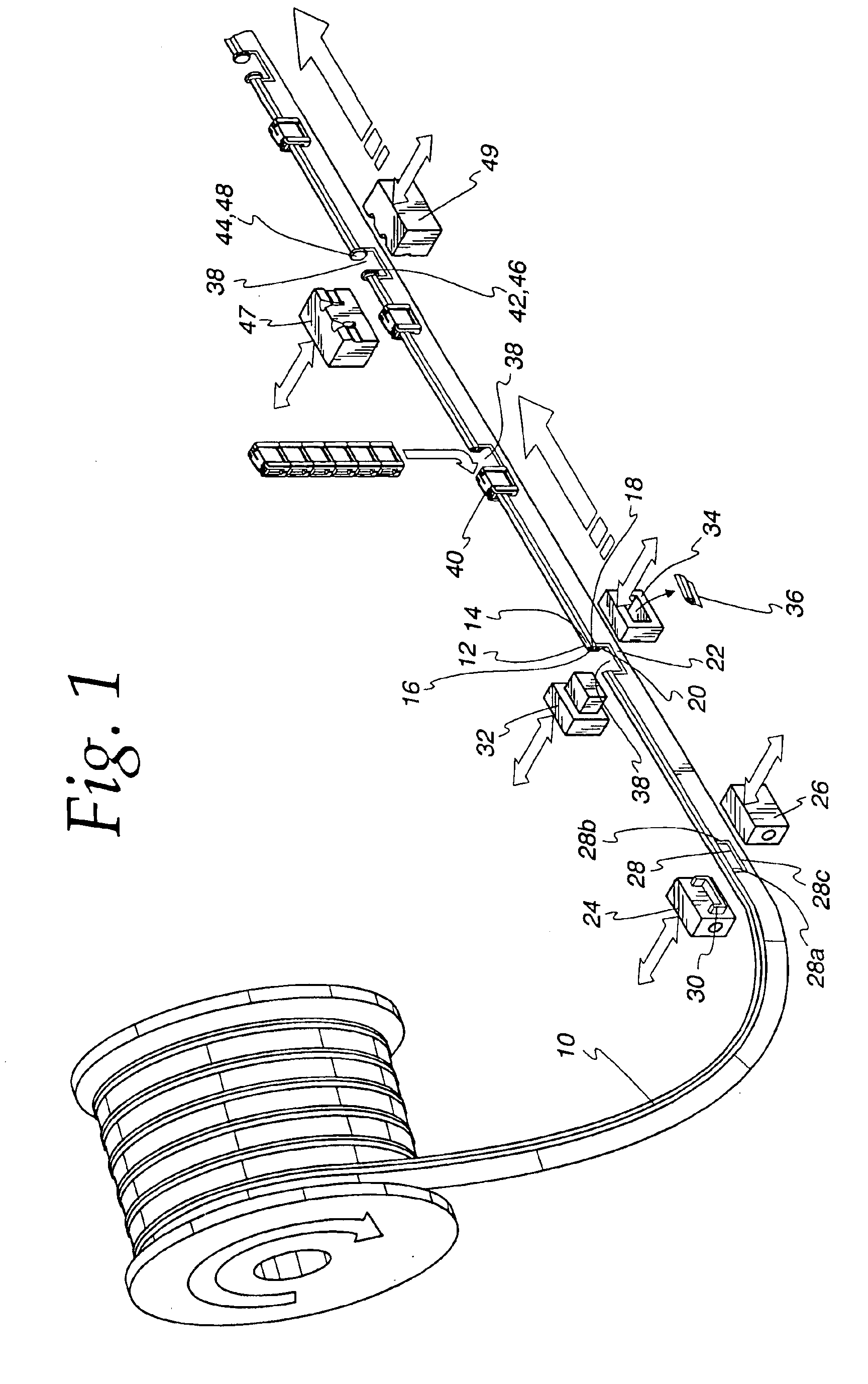

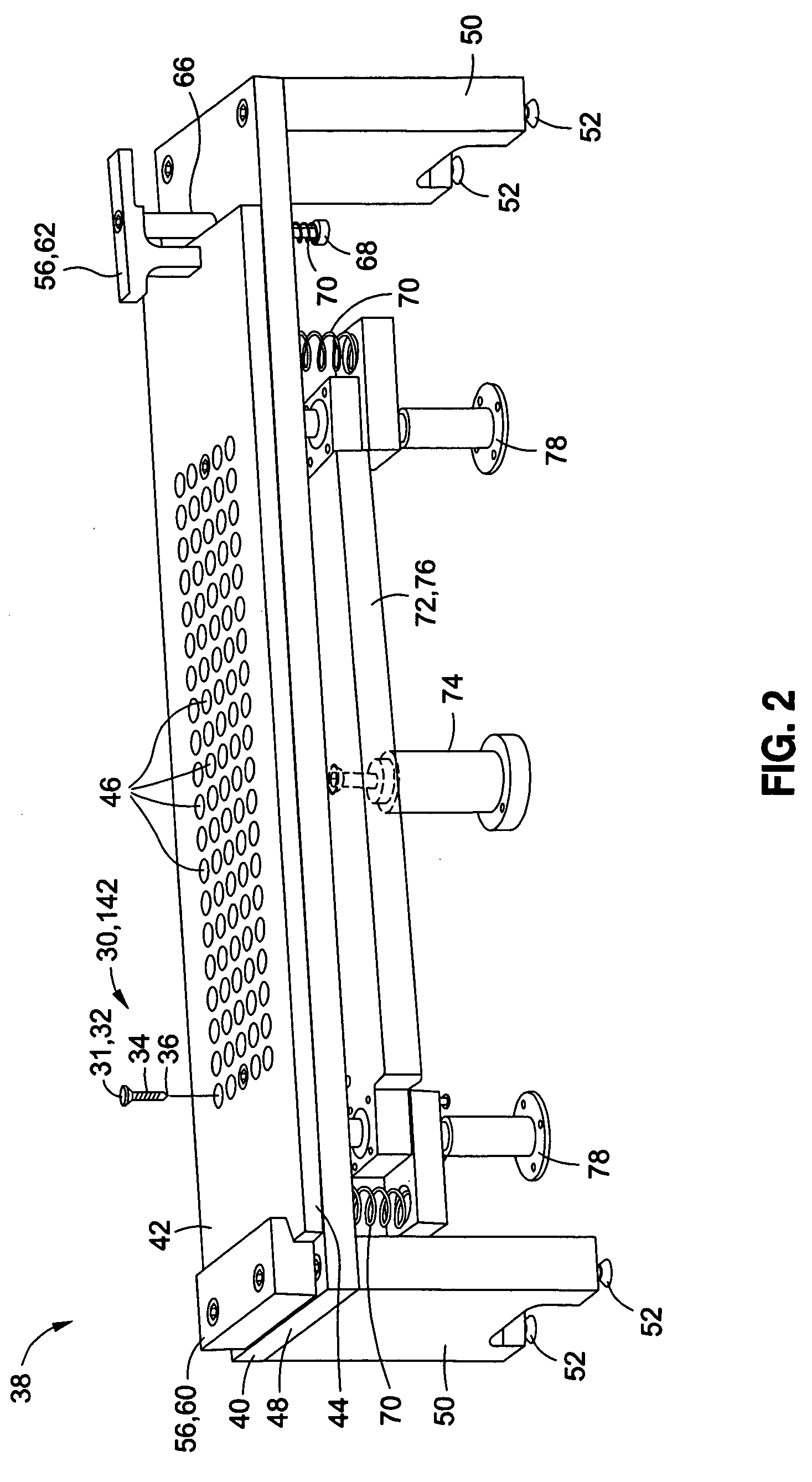

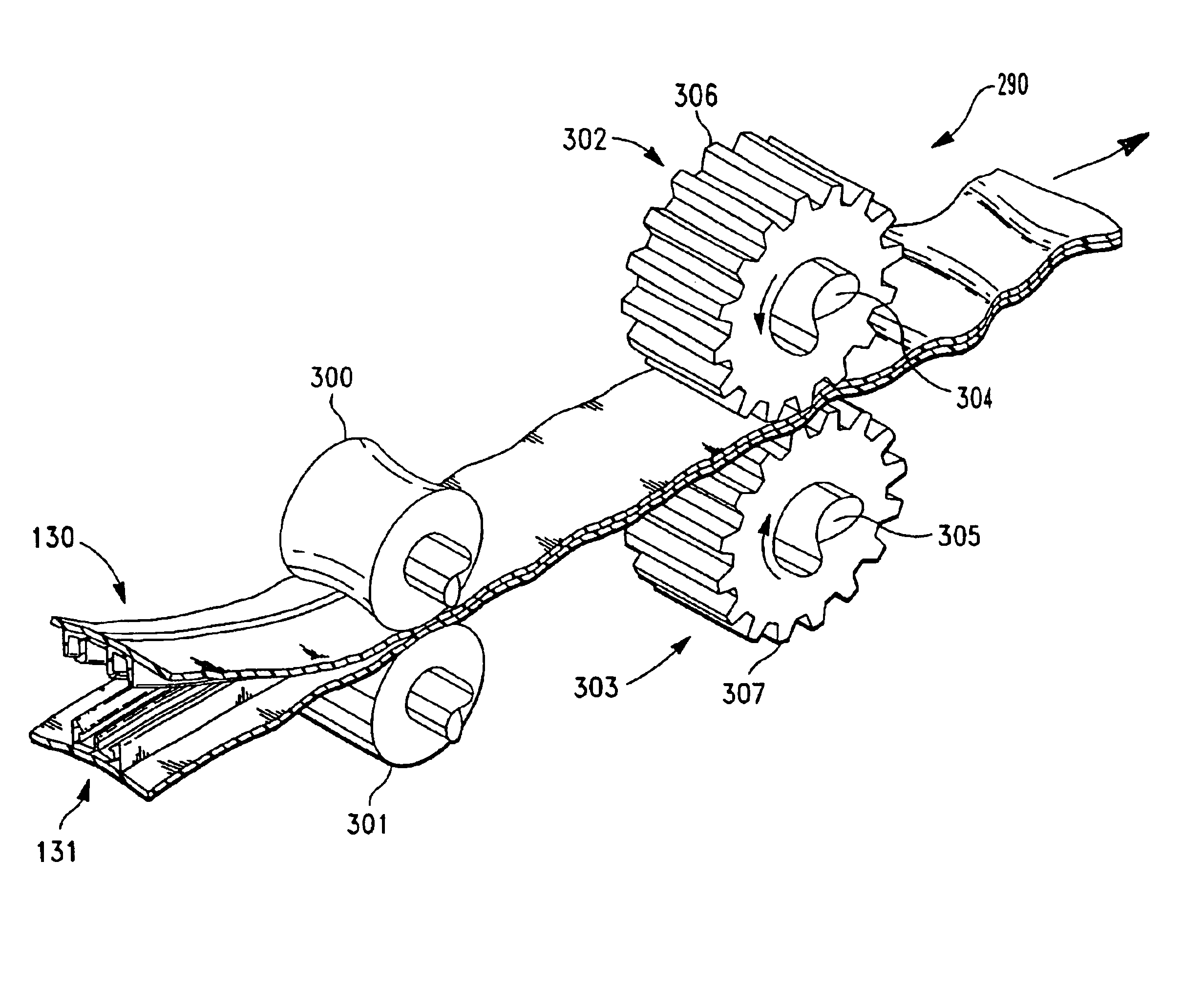

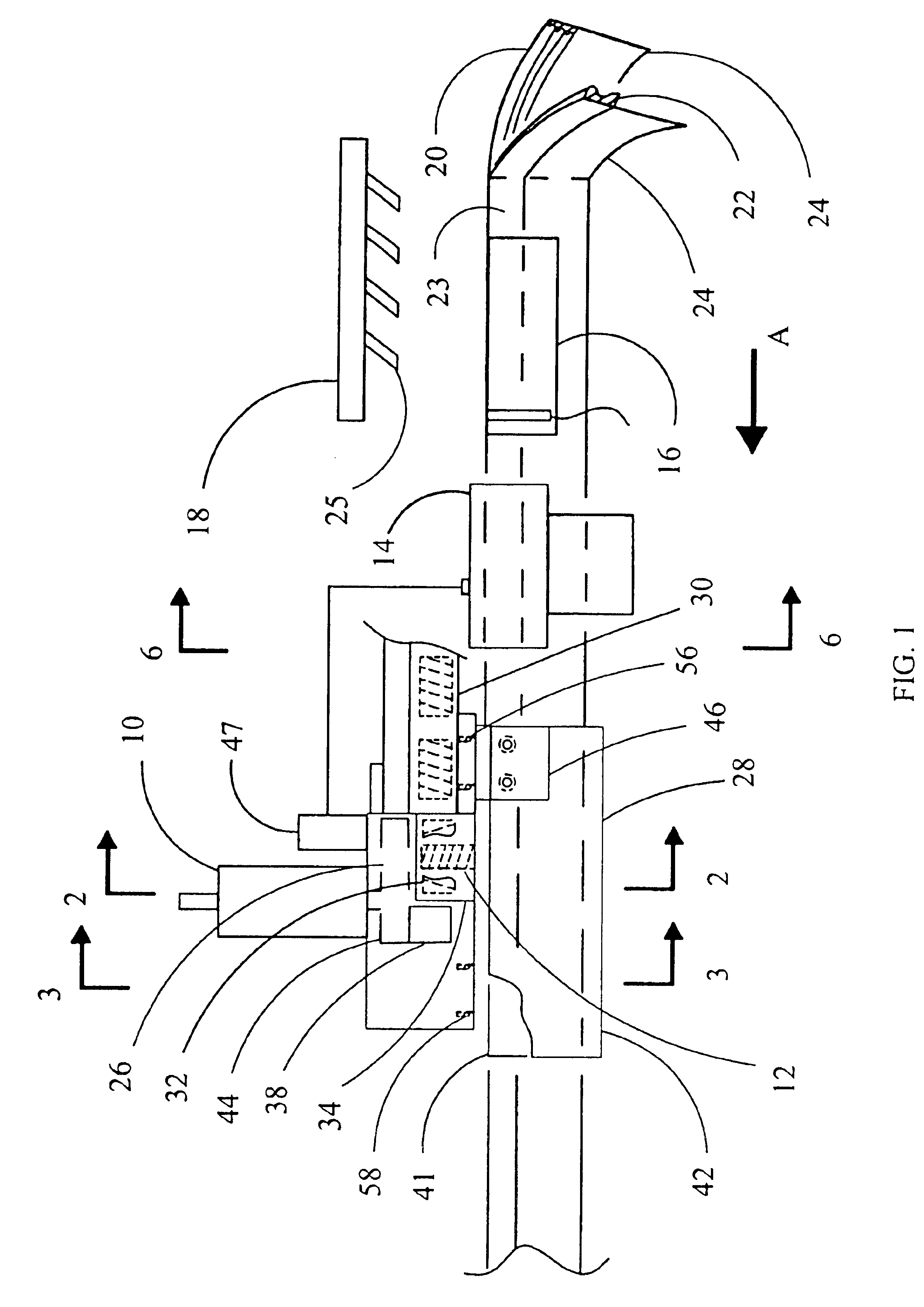

Apparatus for attaching sliders onto zipper bags and film

InactiveUS6842973B2Reduce the force requiredLess forceSlide fastenersMetal-working apparatusEngineeringMechanical engineering

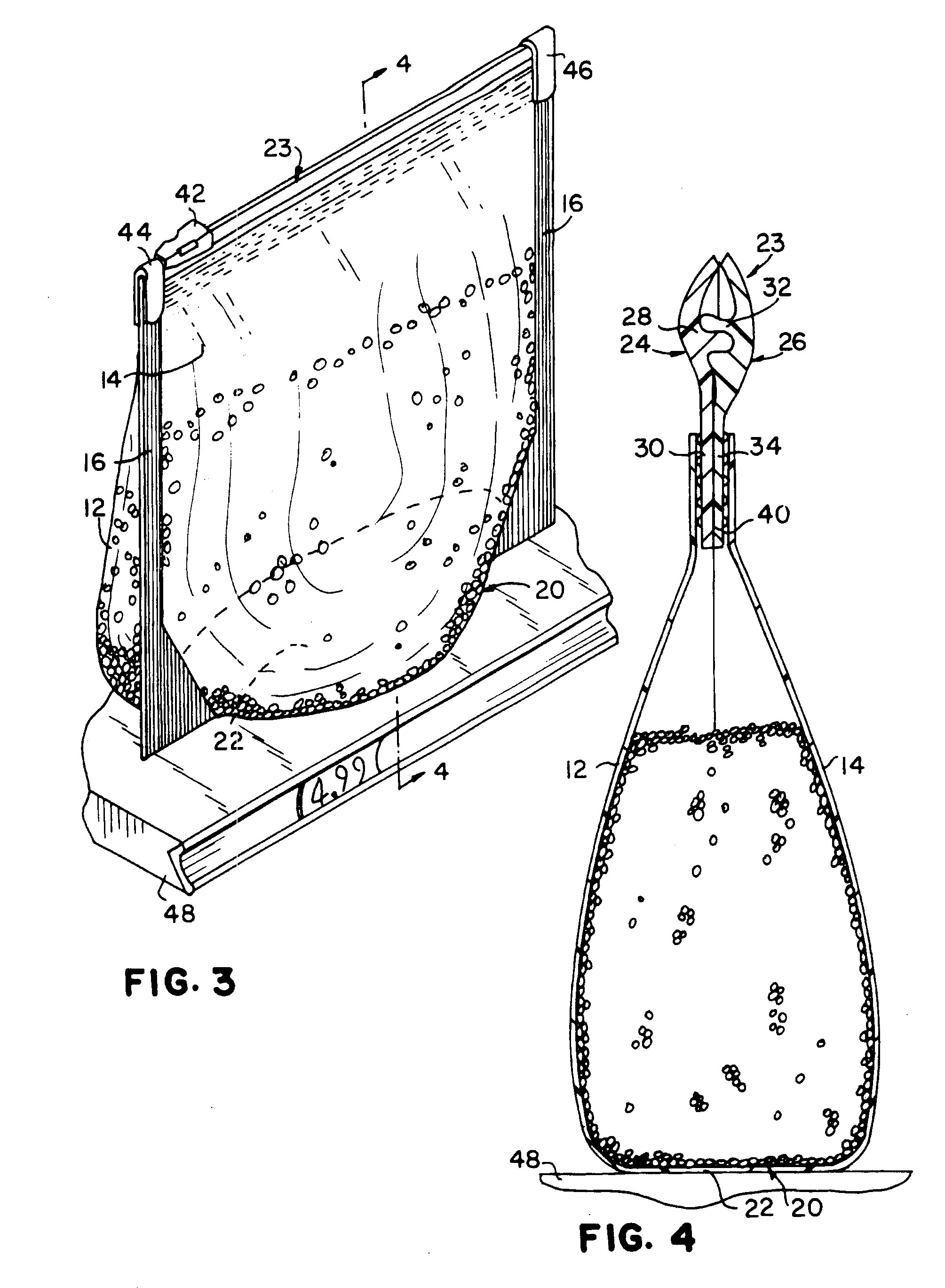

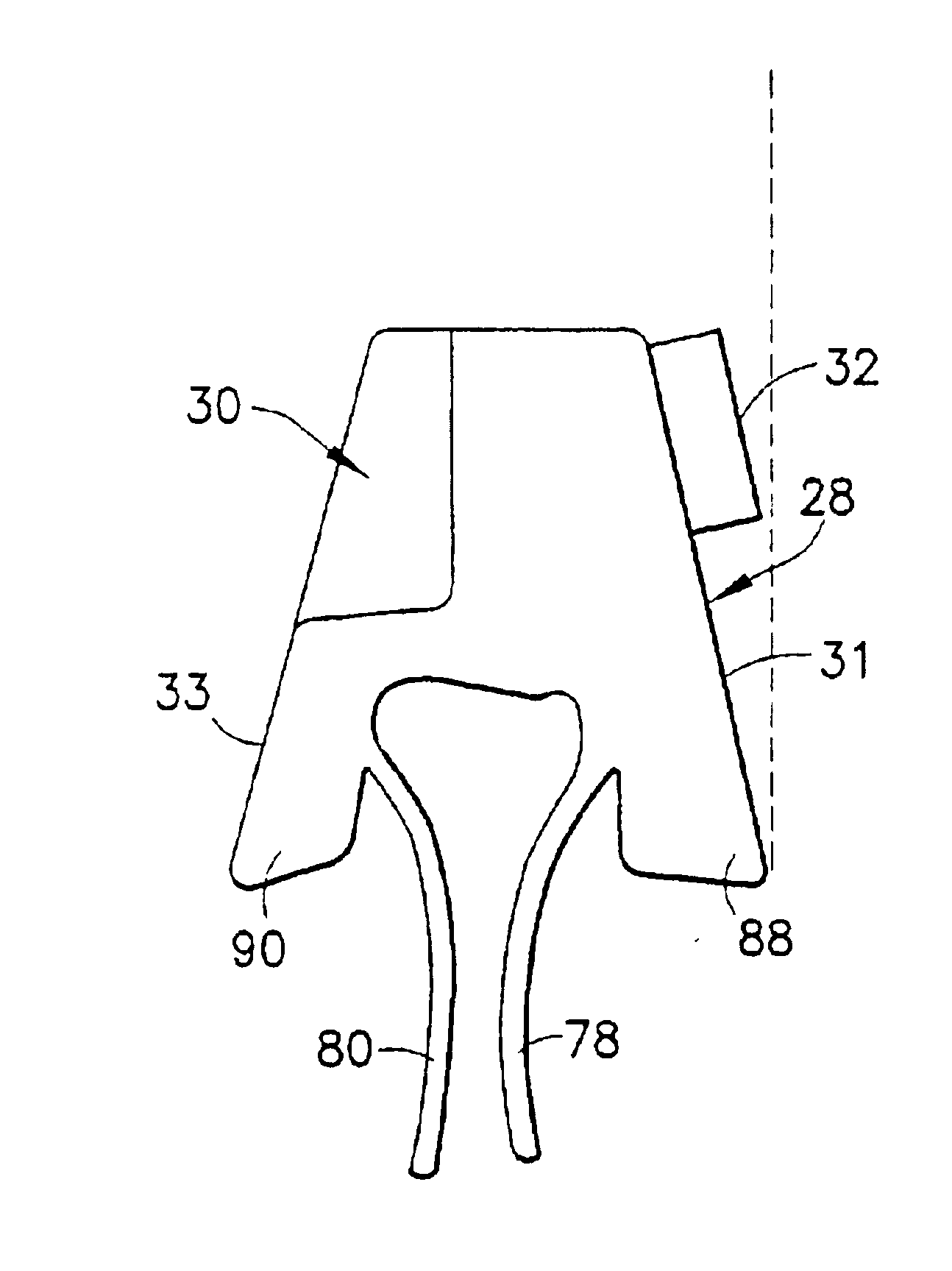

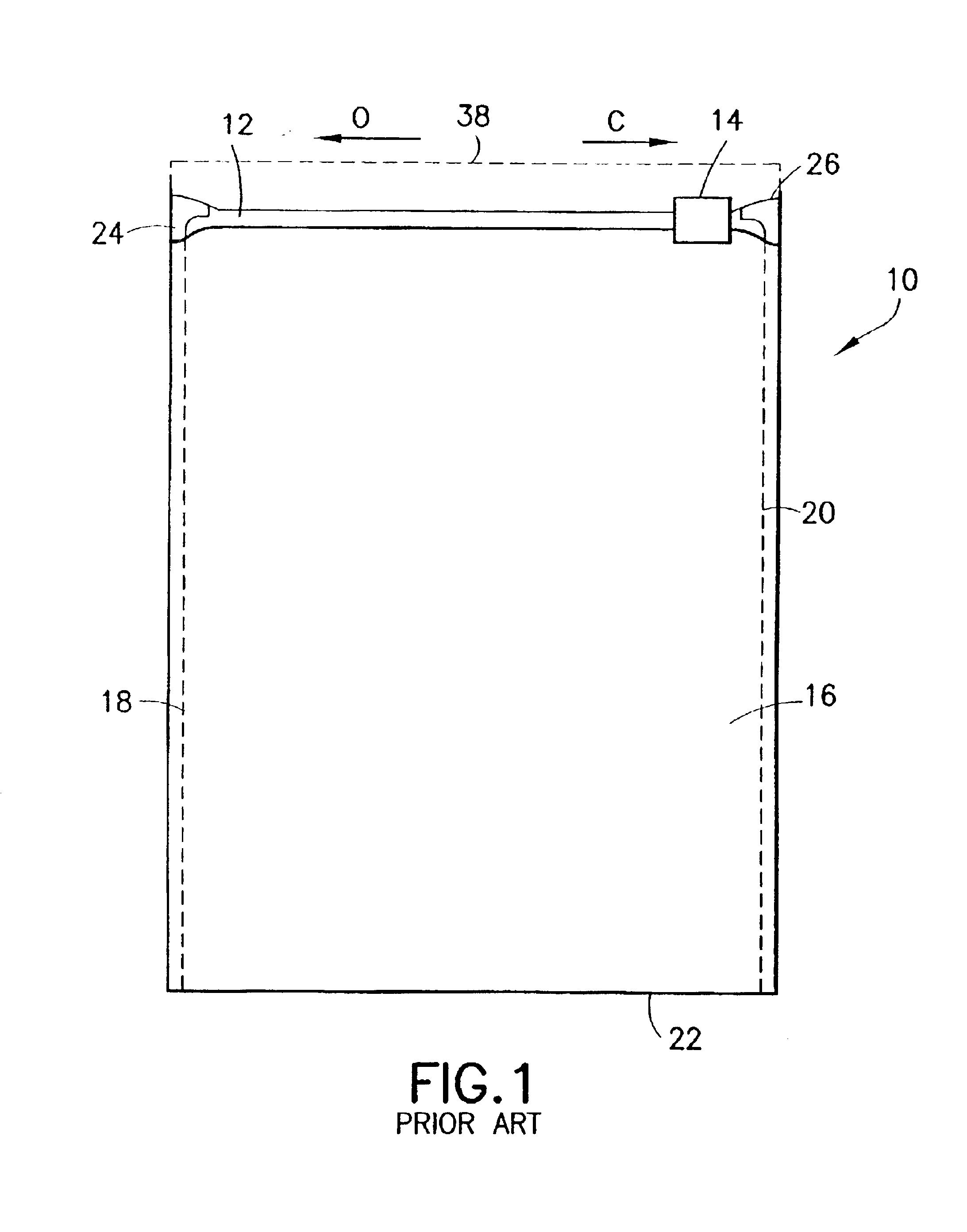

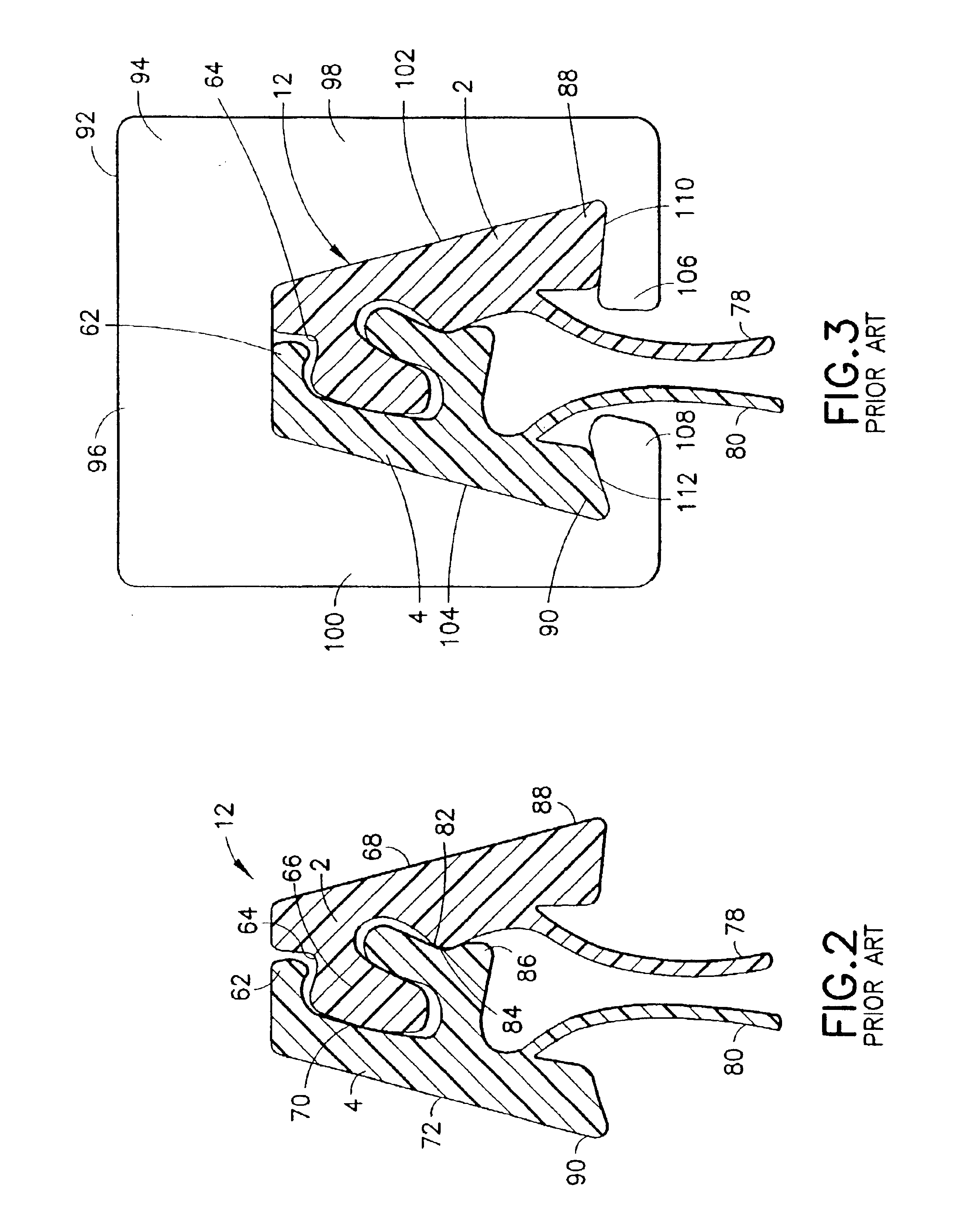

A keeper (12), a clamp (14), a heater strip (16) and a heated air diffuser (18) are provided for a slider insertion apparatus (10) which inserts sliders (28) on the interlocked profiles (20, 22) of a zipper (23). The heater strip (16) and / or the diffuser (18) heat the zipper (23) to a predetermined temperature prior to slider insertion. The keeper (12) aligns the slider (32) within the insertion area (34) with the activator with pusher (26) of the slider insertion apparatus (10). By changing the mounting of the zipper guide (28) and by actuating the clamp (14) during slider insertion, the zipper (32) indexes to the slider insertion apparatus (10) in alternate directions.

Owner:ILLINOIS TOOL WORKS INC

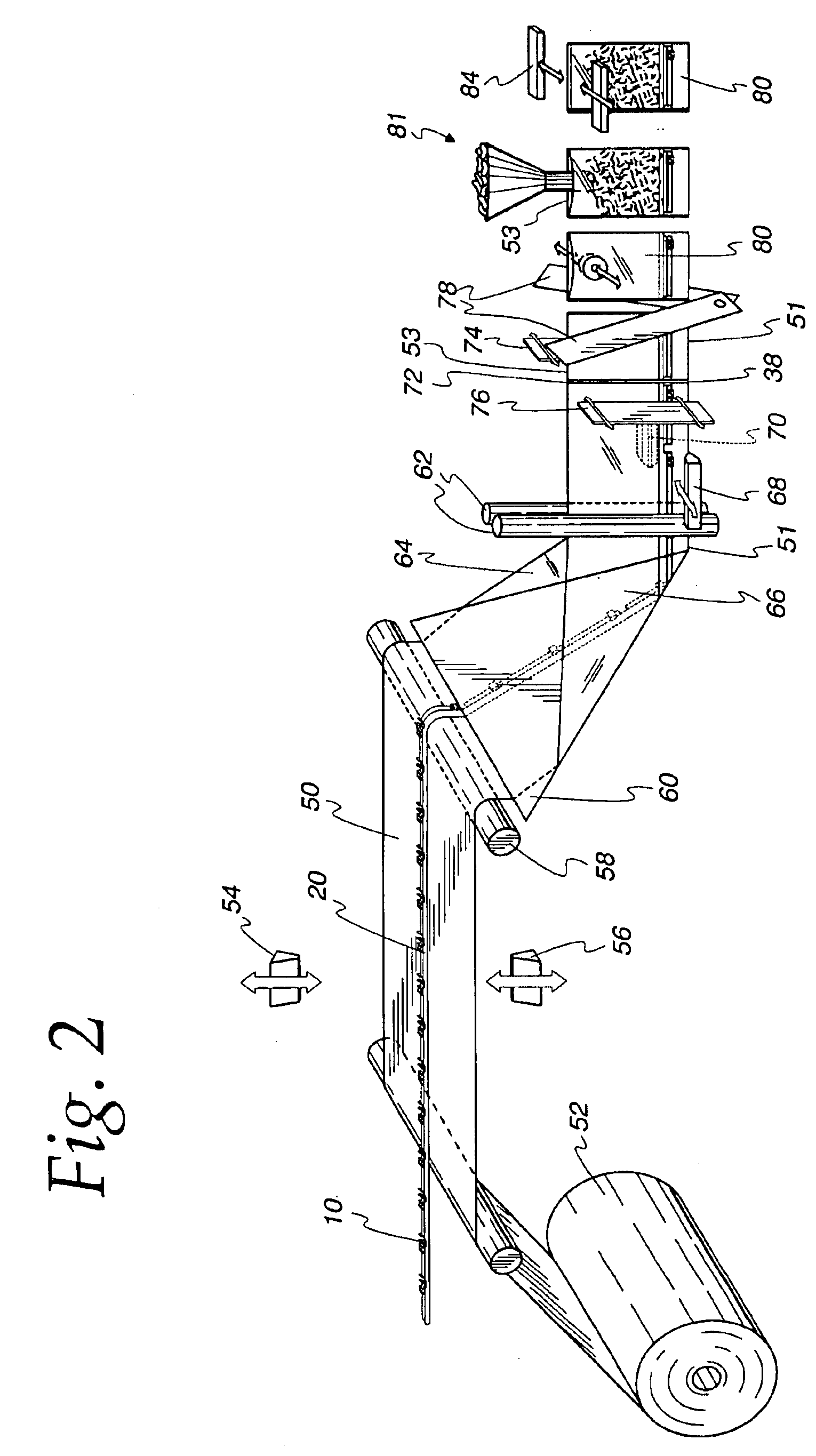

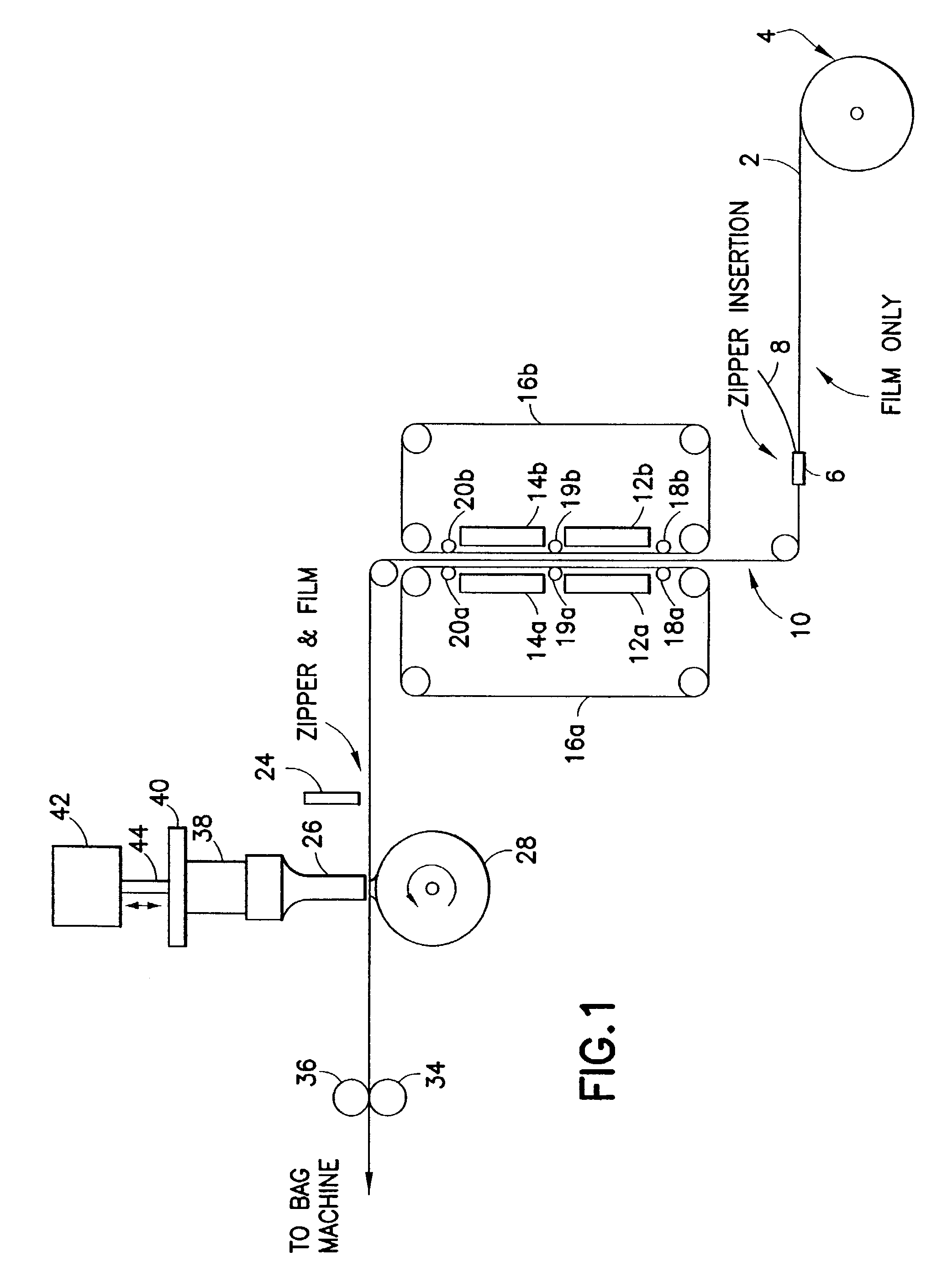

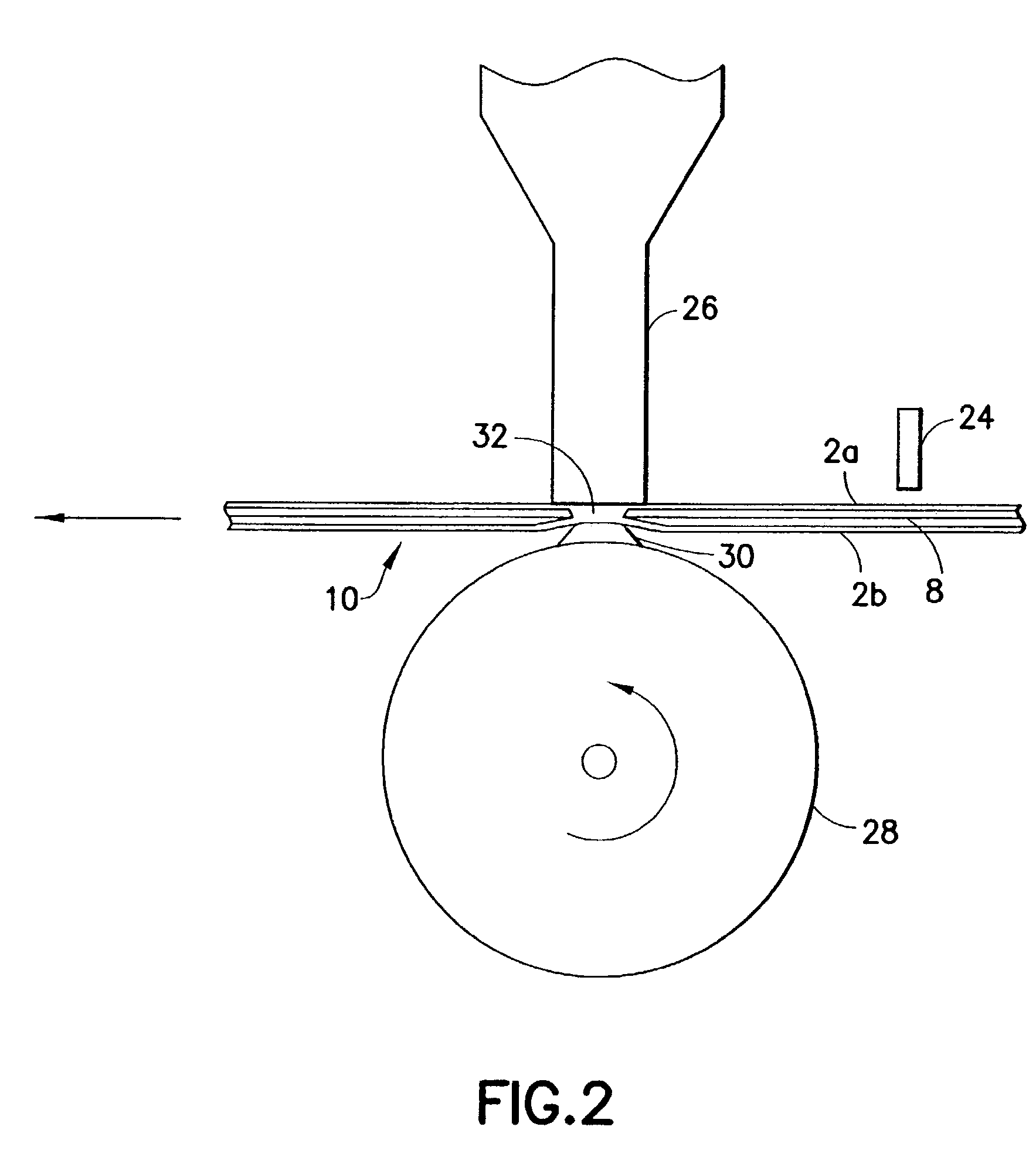

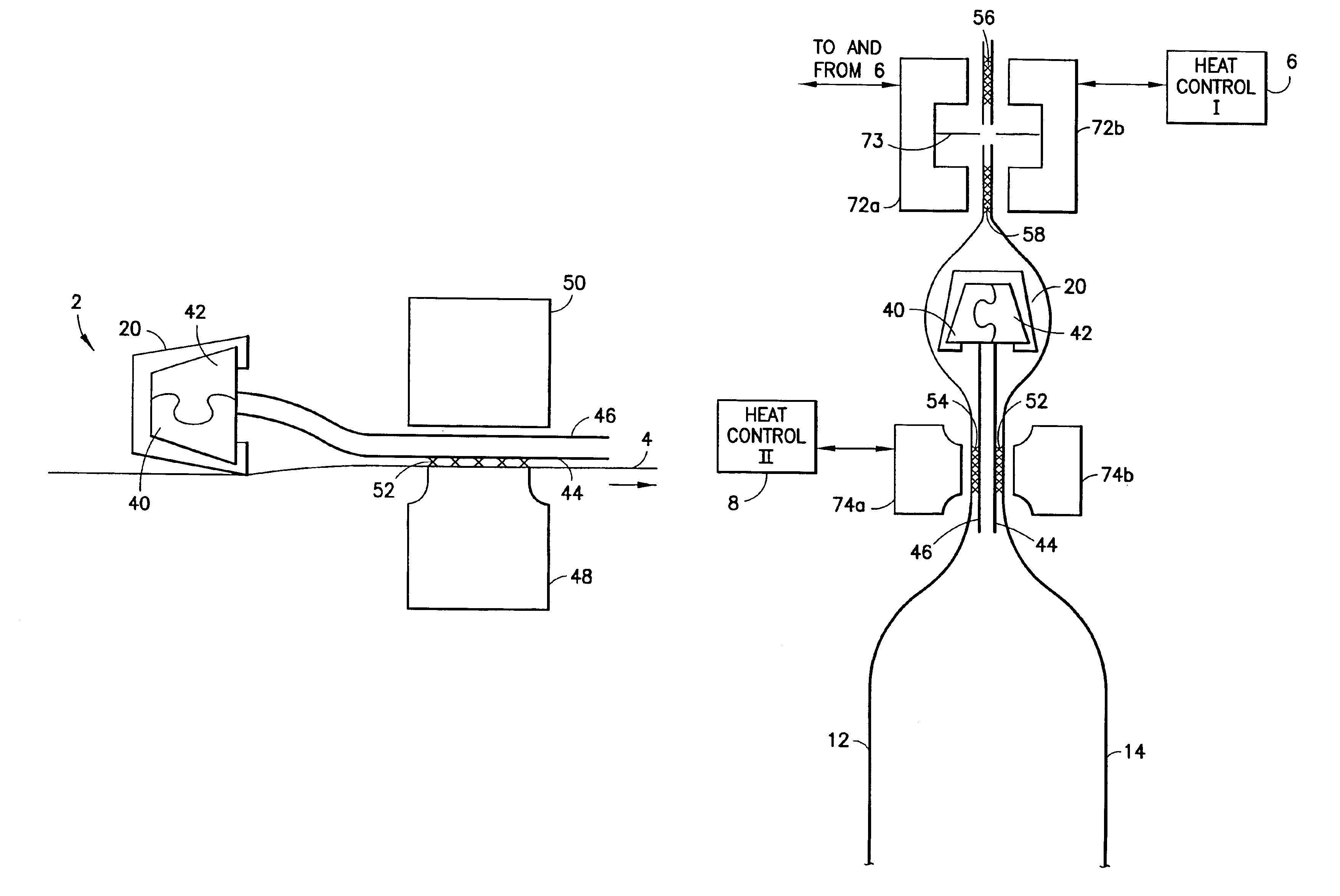

Method and apparatus for sealing zippers to bag making film

An automated reclosable packaging manufacturing equipment for applying zipper tape to bag making film, especially as part of a form-fill-seal process, and a method of joining a zipper flange of a zipper assembly to bag making film without “seal-through” of the zipper flanges. The method comprises the steps of: (a) pressing a web of bag making film and first and second zipper flanges of a zipper assembly together along the length of the latter, with the first zipper flange sandwiched between and in contact with the web of bag making film and the second zipper flange; and (b) during step (a), causing heat to be conducted through the web of bag making film into the first zipper flange. The amount of heat conducted through the web of bag making film must be sufficient to seal the web of bag making film to the first zipper flange without sealing the first zipper flange to the second zipper flange.

Owner:ILLINOIS TOOL WORKS INC

Adaptive continuous acoustic welding system for incompatible materials

InactiveUS20070257086A1Cooking-vessel materialsLamination ancillary operationsMaterial typeUltrasonic welding

A system and method are provided which enable the joining of two materials via ultrasonic welding, including materials normally considered incompatible in traditional ultrasonic welding techniques. The system permits ultrasonic welding of a first material to a second material, the second material including material types normally considered incompatible with the first material and includes an abrader for altering the surface of the material / s to be joined. A first pressure device is operative to vary the position of the abrader and thereby vary the abrasion applied to the materials. An ultrasonic source provides acoustic energy to a weld interface between the materials. A second pressure device is operative to vary the force applied to the interface between the materials while a sensor senses the weld interface temperature. A controller dynamically adjusts the acoustic energy of the ultrasonic source, the second pressure device, and at least one of the first pressure device and a temperature varying device during junction formation. The temperature varying device is operative to modify the temperature of the material / s being welded before abrasion and / or proximate the weld interface location. In this manner, the system enables a smooth, continuous junction to form at a predetermined rate.

Owner:SWCE

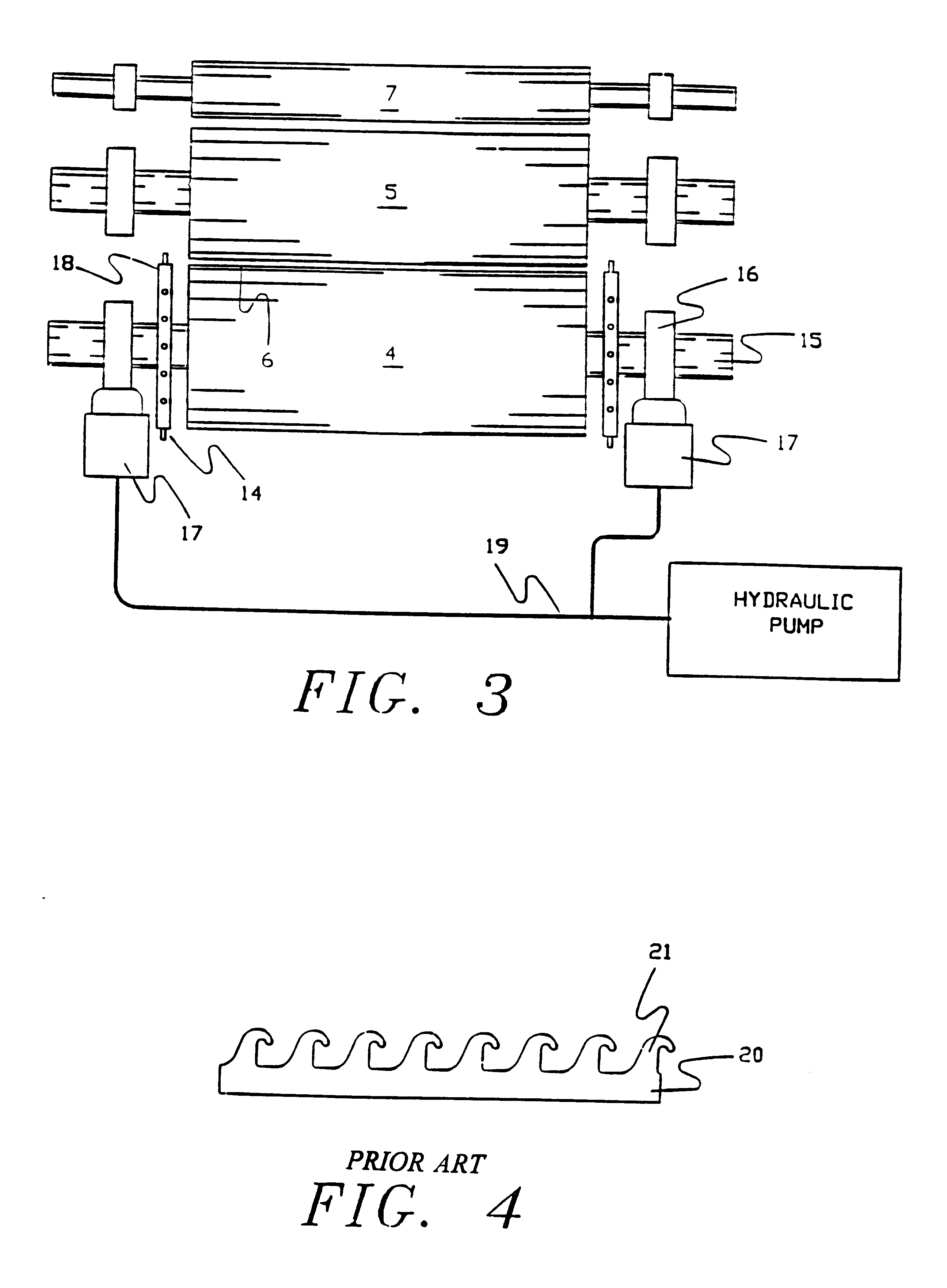

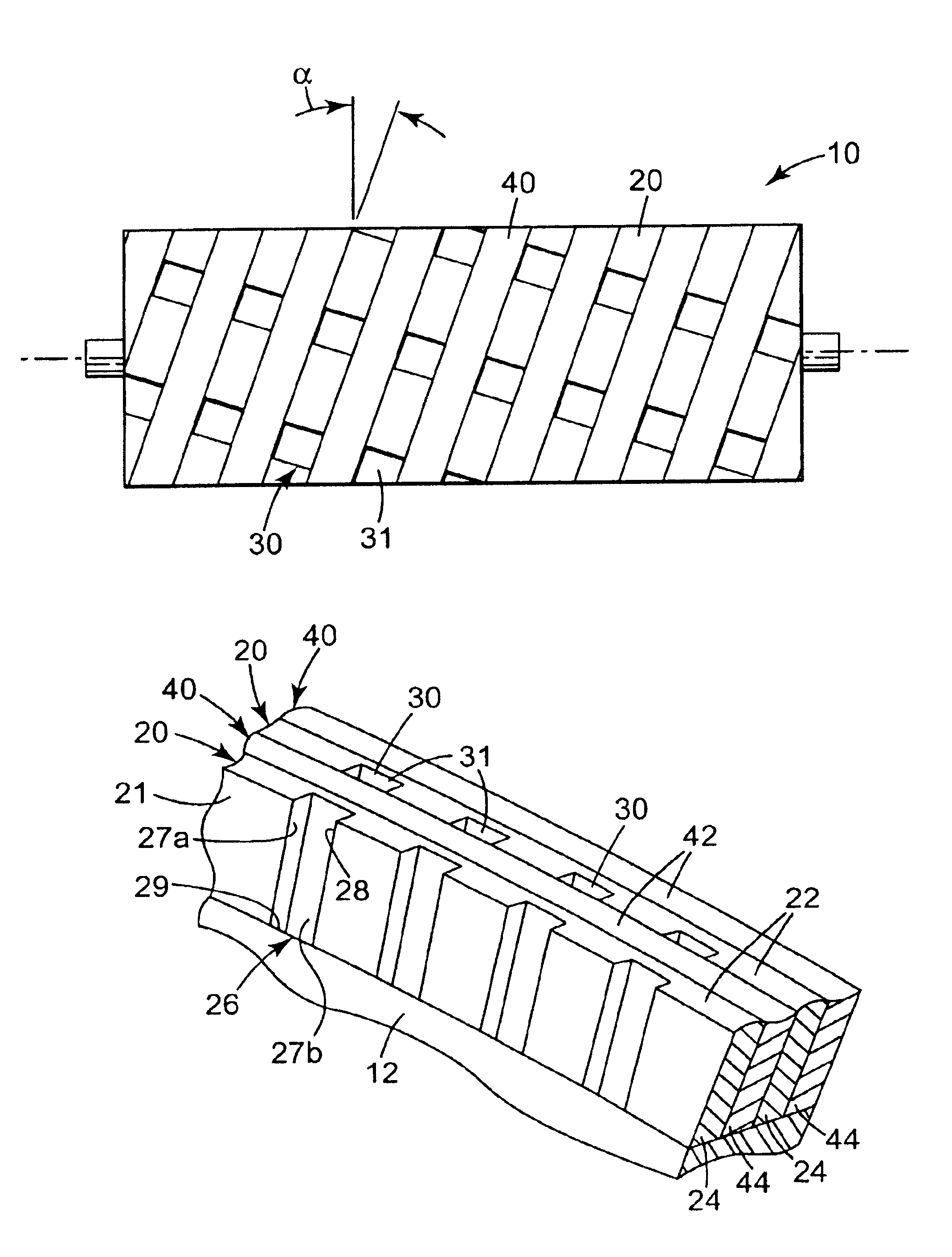

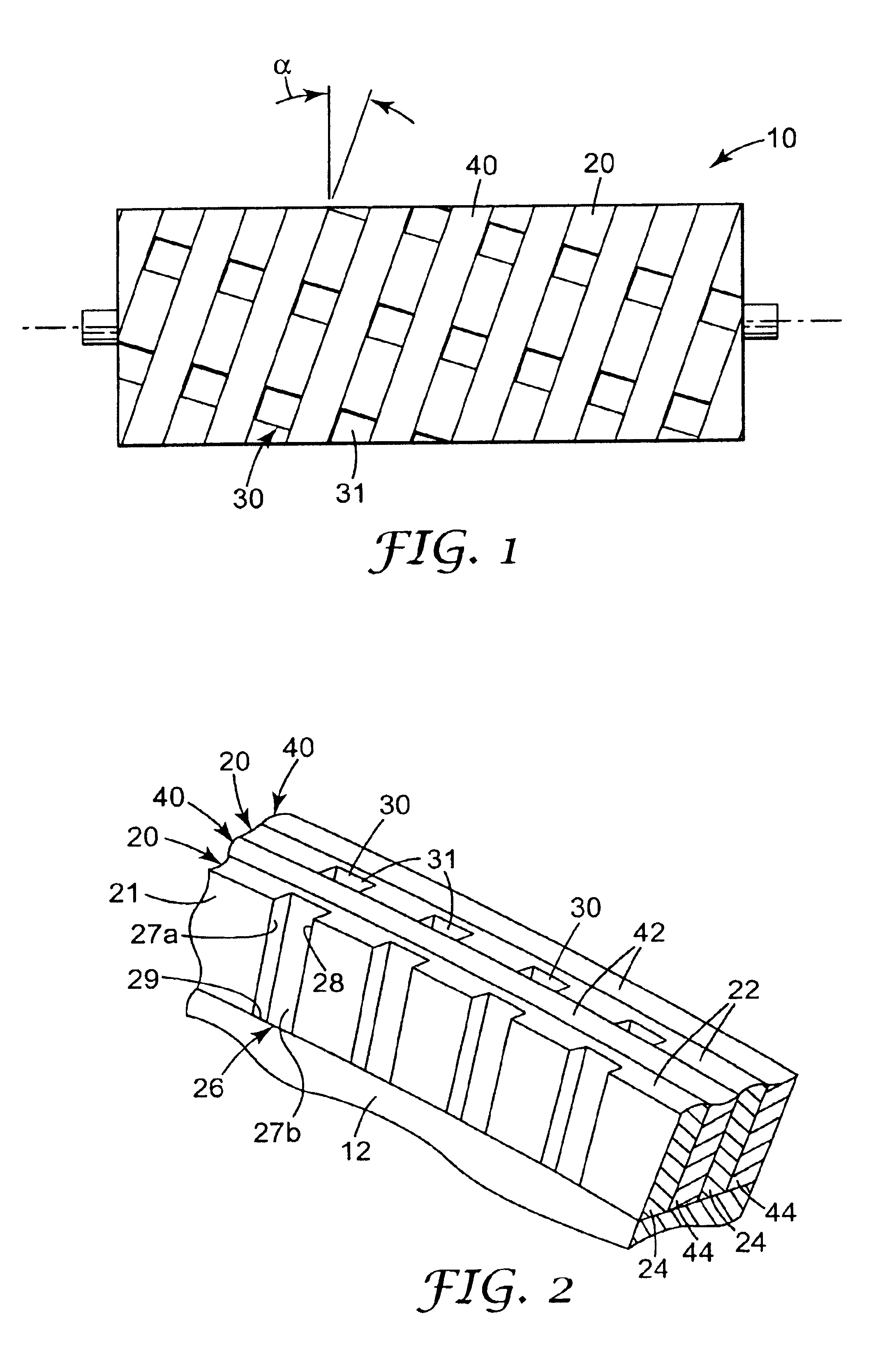

Wire wound tooling

InactiveUS6902389B2Small thermal massImprove uniformityConfectioneryPress rollersHelical coilEngineering

Tool rolls and methods of using the tool rolls to manufacture articles with one or more structured surfaces are disclosed. The tool rolls include an outer surface that, when used in connection with materials of the proper viscosity or formability, can form a structured surface on an article. Because the tools are manufactured in roll-form, they can be advantageously used in continuous manufacturing processes. Alternatively, discrete articles may be processed using the tool rolls. The tool rolls are constructed of a cylindrical base roll and are wrapped with one or more continuous wires in a helical pattern. The wires are used, in essence, to form a structured surface on the tool roll that is the negative of the structured surface to be formed on the articles processed using the tool roll. One of the wires wound around the base roll may include depressions formed therein that, when wound in helical coils about the base roll, form cavities on the outer surface of the tool roll. Alternatively, the helical pattern of one or more wound wires may be used to form a continuous helical structured surface, e.g., a helical groove or grooves.

Owner:3M INNOVATIVE PROPERTIES CO

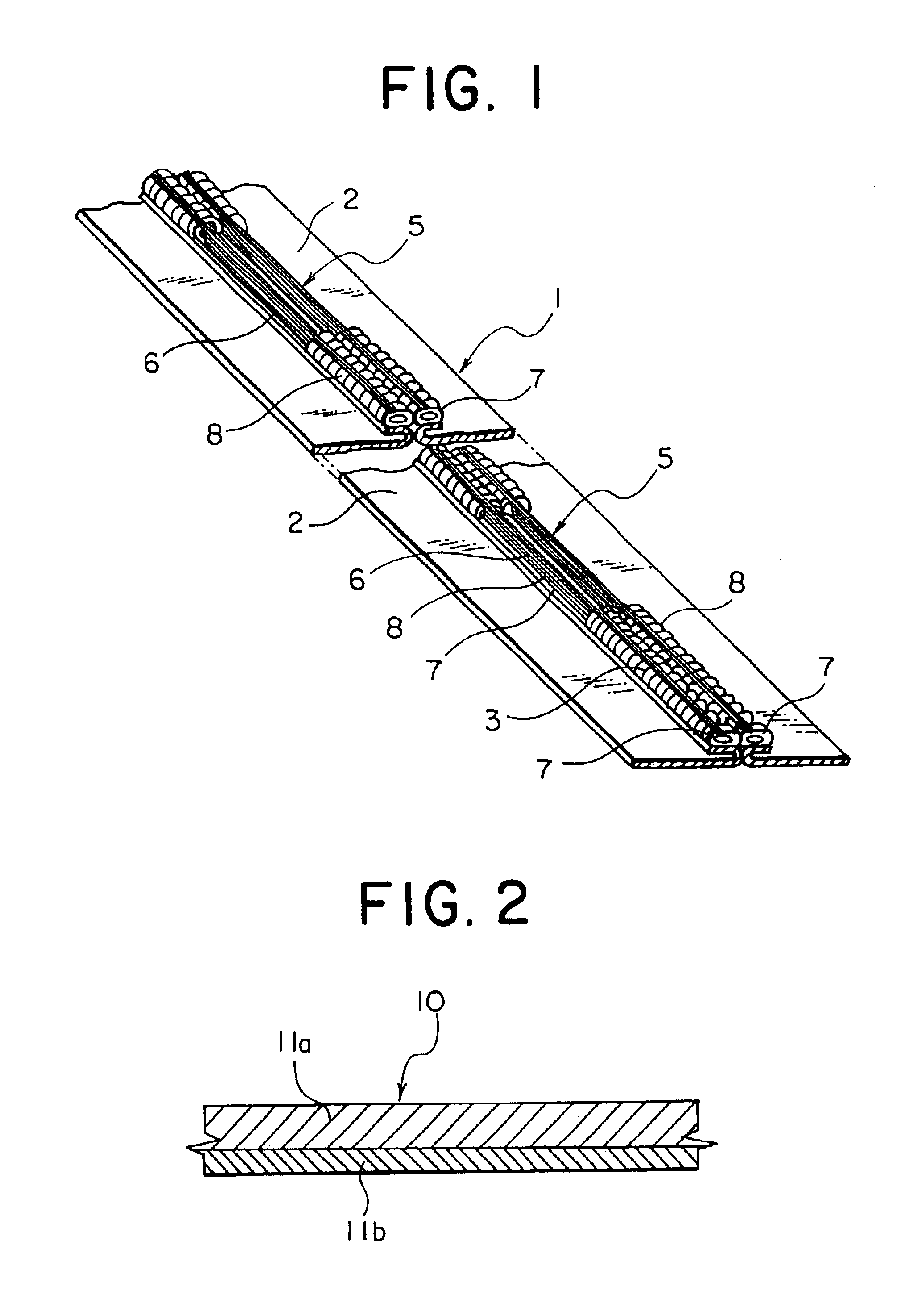

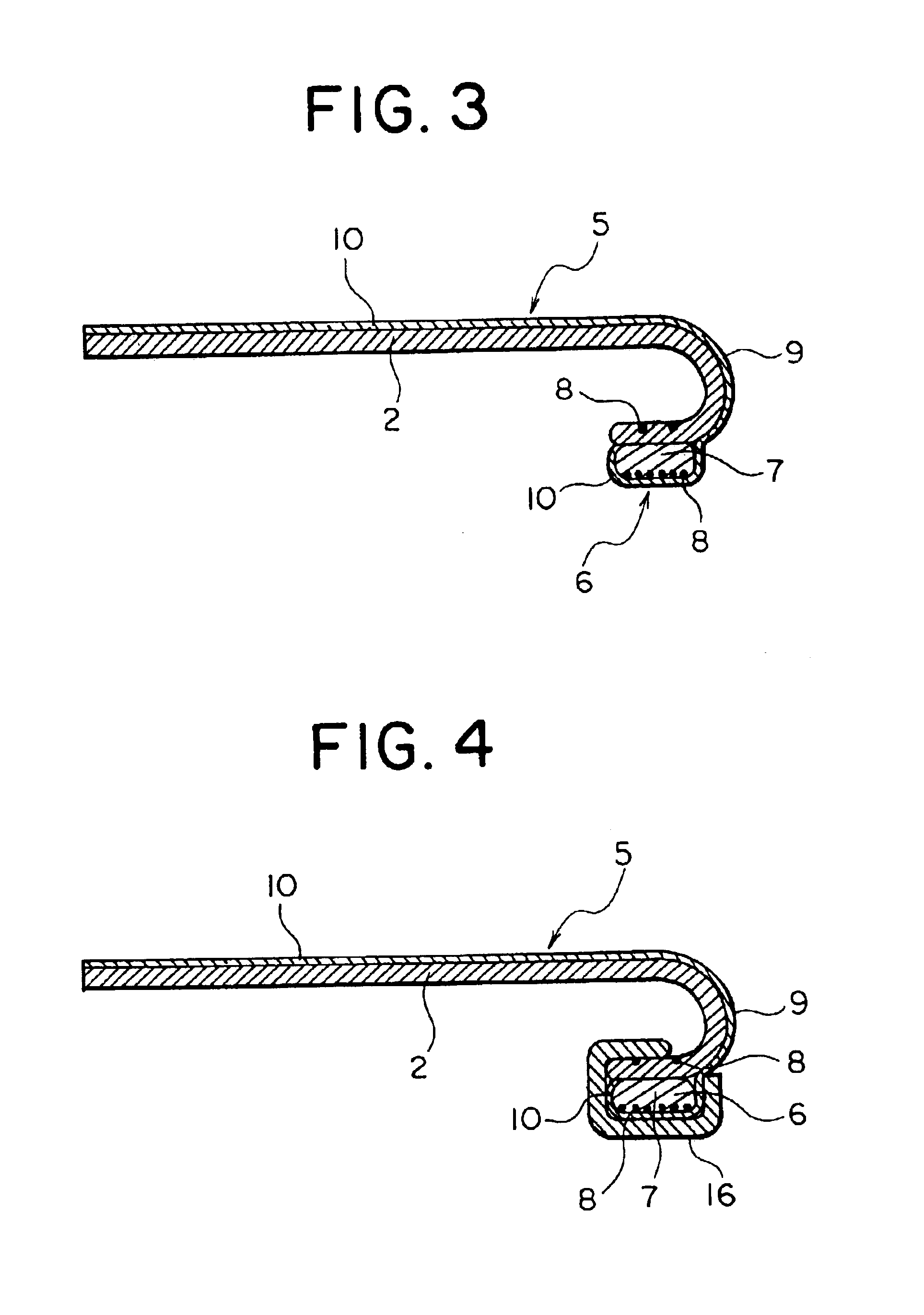

Concealed type slide fastener with separable bottom end stop

InactiveUS6851162B2Increased durabilityProcess stabilitySnap fastenersSlide fastenersUltrasonic weldingThermoplastic elastomer

A reinforcement tape is stuck to an outer front surface of a fastener tape and a fastener element removed portion at a space portion, in which fastener elements are removed and to which the separable bottom end stop of the concealed type slide fastener, for example, a insert pin or the like is attached, by ultrasonic welding. The reinforcement tape may be, for example, a tape whose front surface is made of a thermoplastic elastomer film while its rear surface is made of hot melt adhesive agent. At the same time of the above sticking, an edge portion is formed into a U shape and its surface is reinforced and then, the insert pin or the like is attached to this portion. The fastener tape itself does not come into contact with a diamond of a slider, even if outer face of the U-shaped edge portion comes into sliding contact with the diamond, so the fastener tape is protected from being worn or damaged.

Owner:YKK CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com