Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2075results about "Pressers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

System for designing integrated circuits with enhanced manufacturability

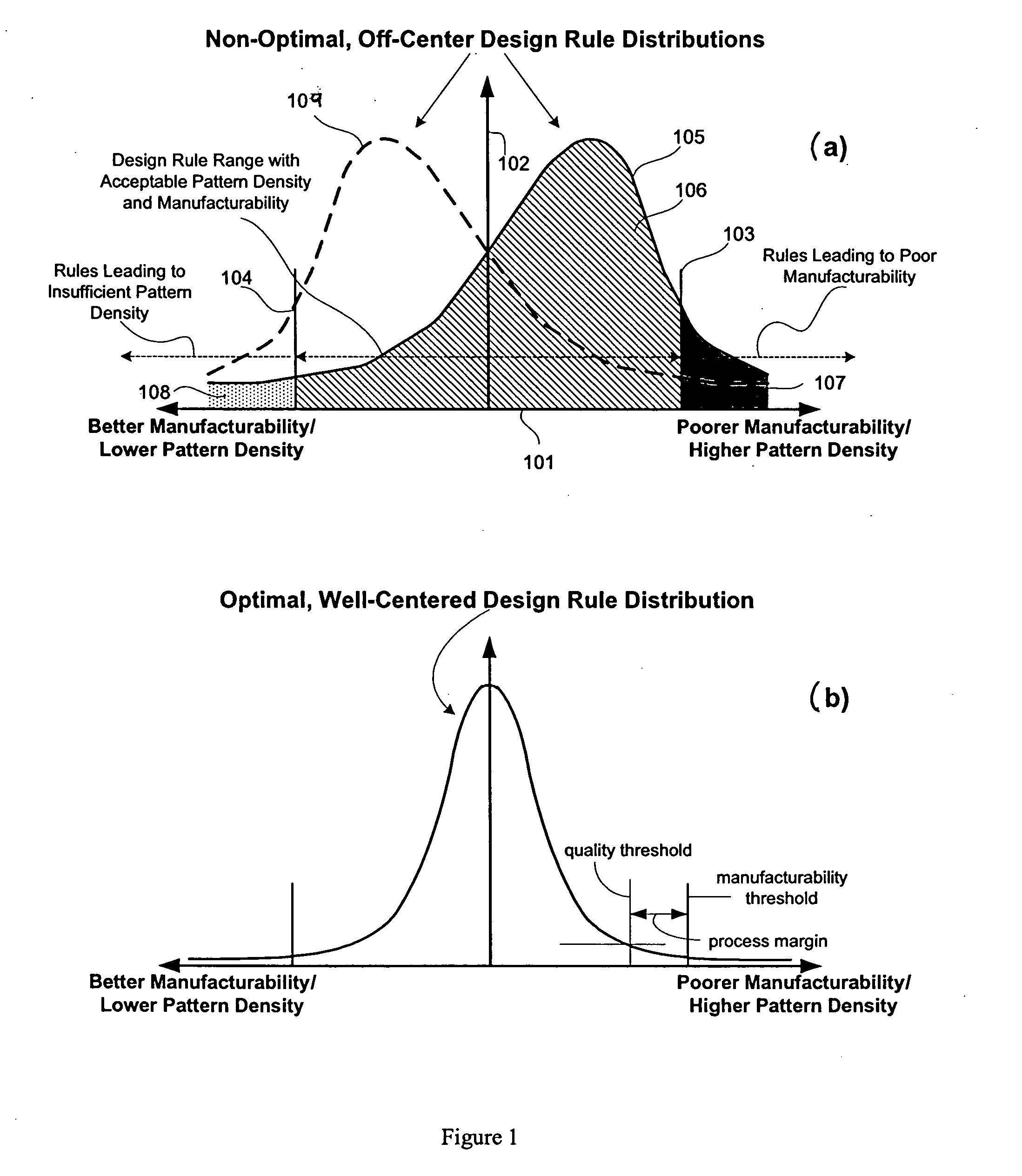

ActiveUS7523429B2Improve manufacturabilityLittle interferencePressersMattress sewingGranularityEngineering

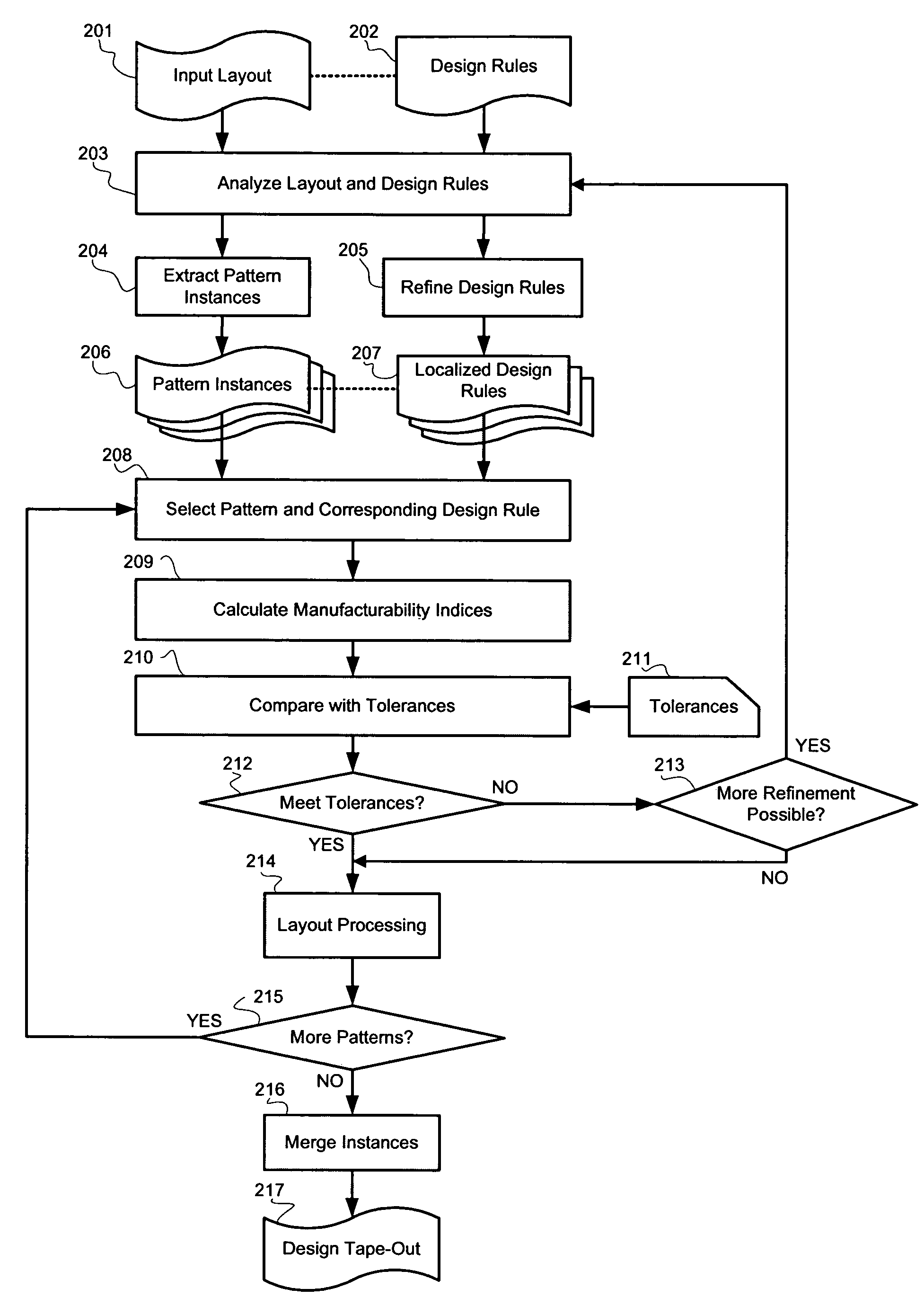

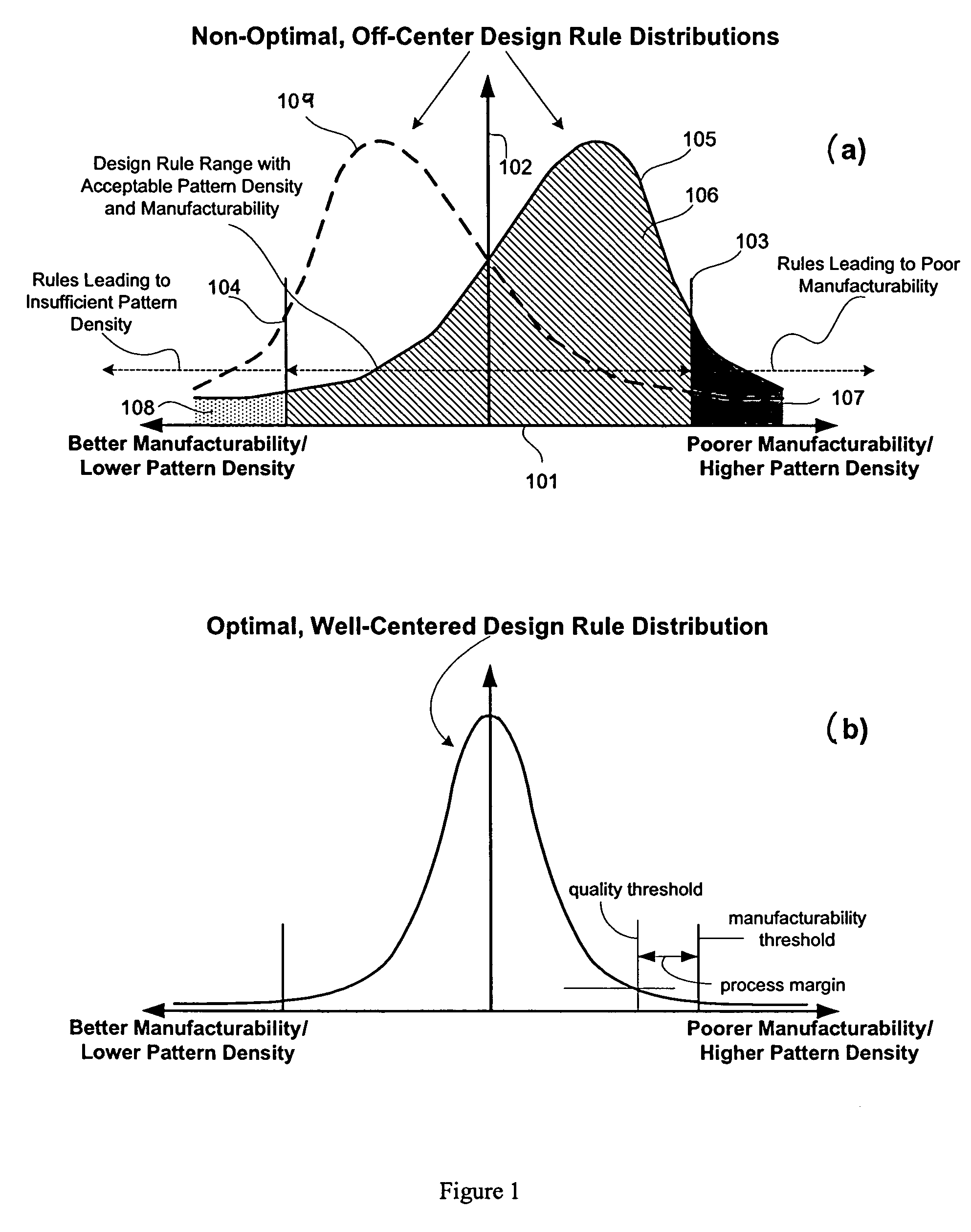

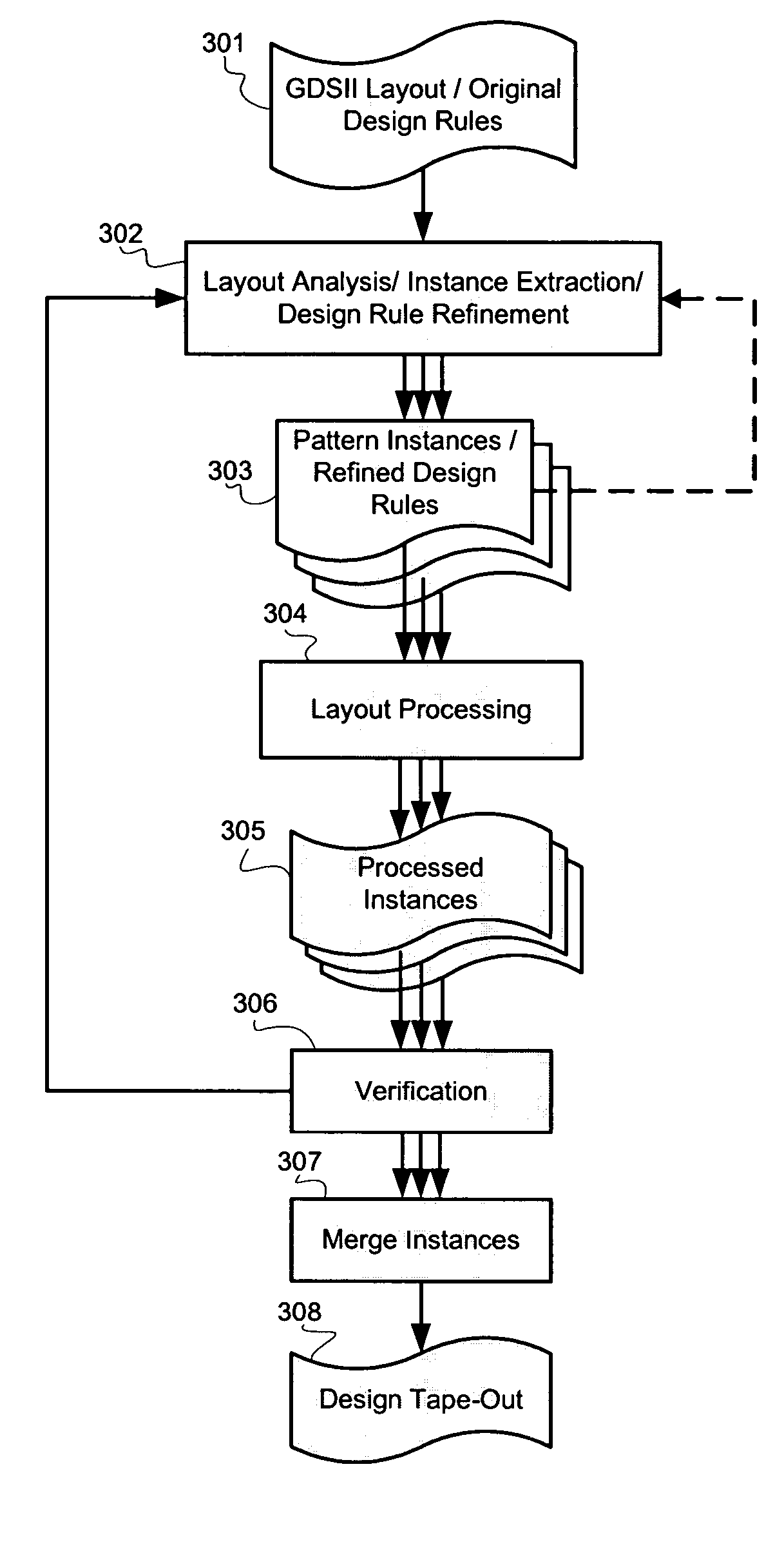

A system and method for integrated circuit design are disclosed to enhance manufacturability of circuit layouts through generation of hierarchical design rules which capture localized layout requirements. In contrast to conventional techniques which apply global design rules, the disclosed IC design system and method partition the original design layout into a desired level of granularity based on specified layout and integrated circuit properties. At that localized level, the design rules are adjusted appropriately to capture the critical aspects from a manufacturability standpoint. These adjusted design rules are then used to perform localized layout manipulation and mask data conversion.

Owner:APPLIED MATERIALS INC

System for designing integrated circuits with enhanced manufacturability

ActiveUS20050188338A1Improve manufacturabilityLittle interferencePressersMattress sewingData conversionIntegrated circuit

A system and method for integrated circuit design are disclosed to enhance manufacturability of circuit layouts through generation of hierarchical design rules which capture localized layout requirements. In contrast to conventional techniques which apply global design rules, the disclosed IC design system and method partition the original design layout into a desired level of granularity based on specified layout and integrated circuit properties. At that localized level, the design rules are adjusted appropriately to capture the critical aspects from a manufacturability standpoint. These adjusted design rules are then used to perform localized layout manipulation and mask data conversion.

Owner:APPLIED MATERIALS INC

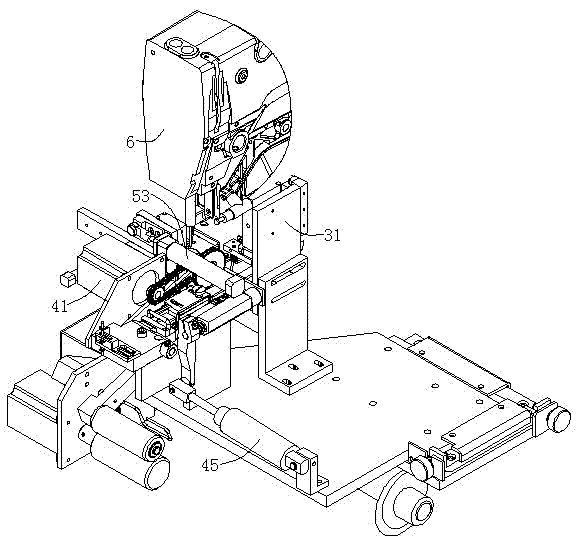

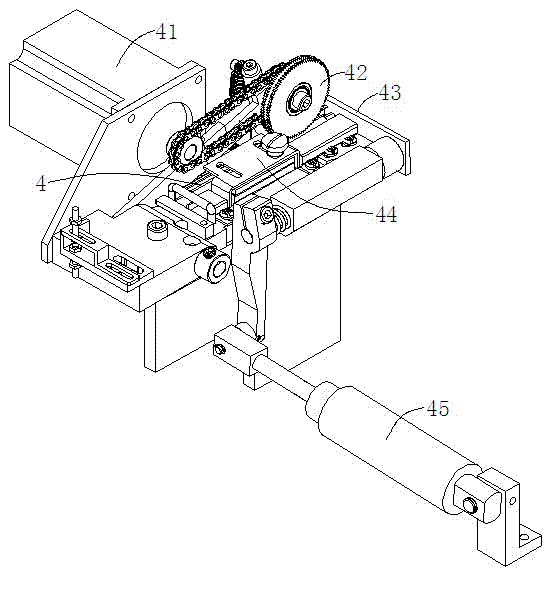

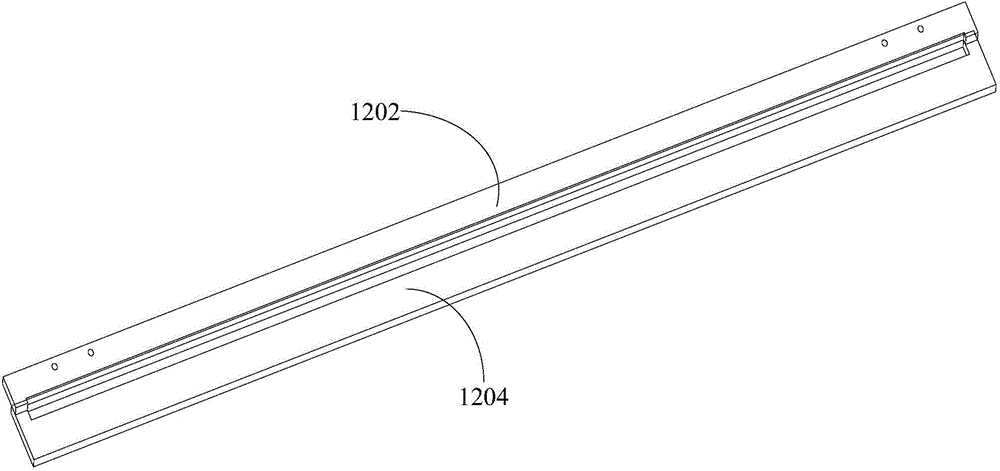

Ribbon loom

ActiveCN103696153ASimple structureImprove processing efficiencyWorkpiece carriersWork-feeding meansMechanical engineeringEngineering

Owner:NINGBO SUPREME ELECTRONIC MASCH INC

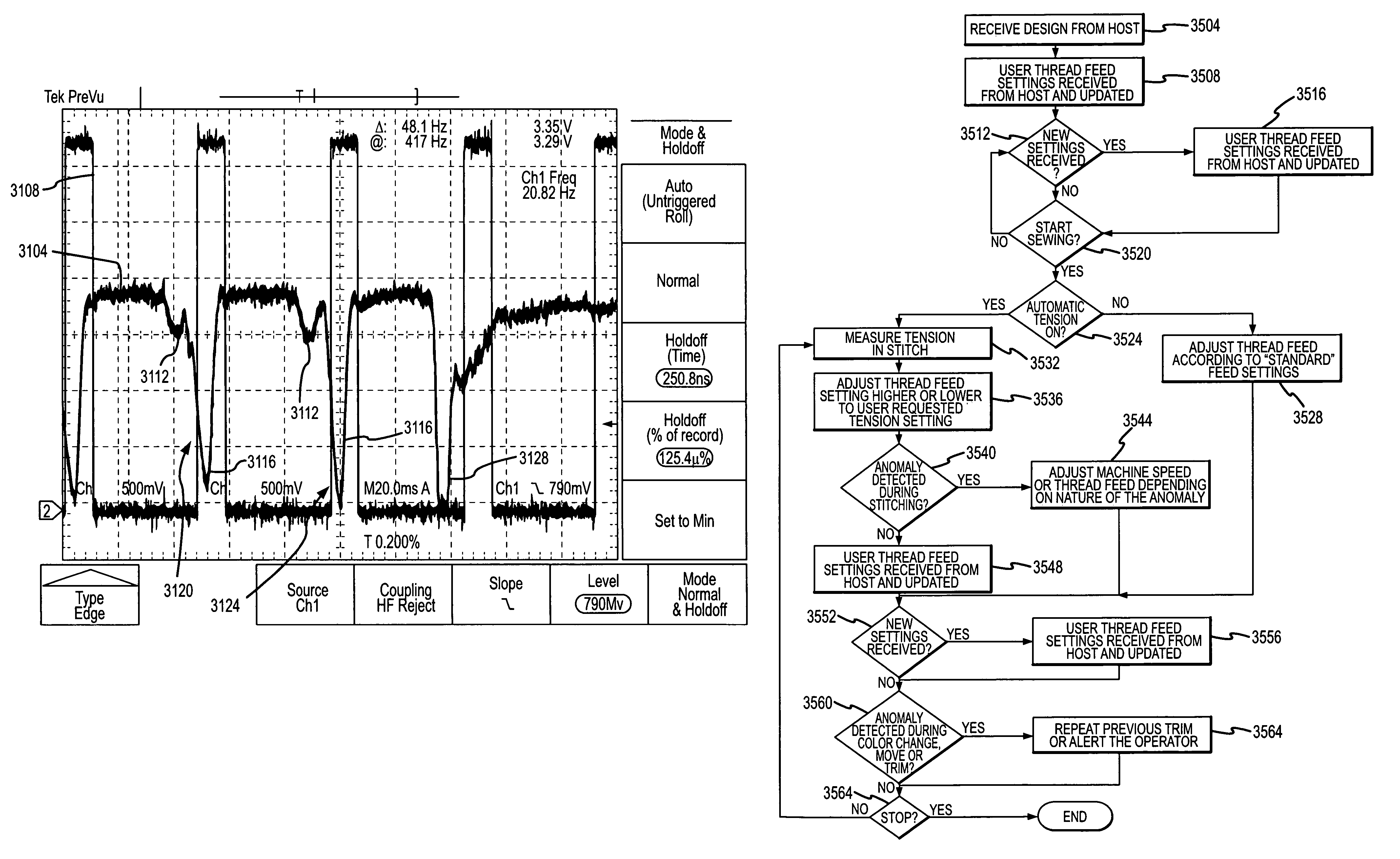

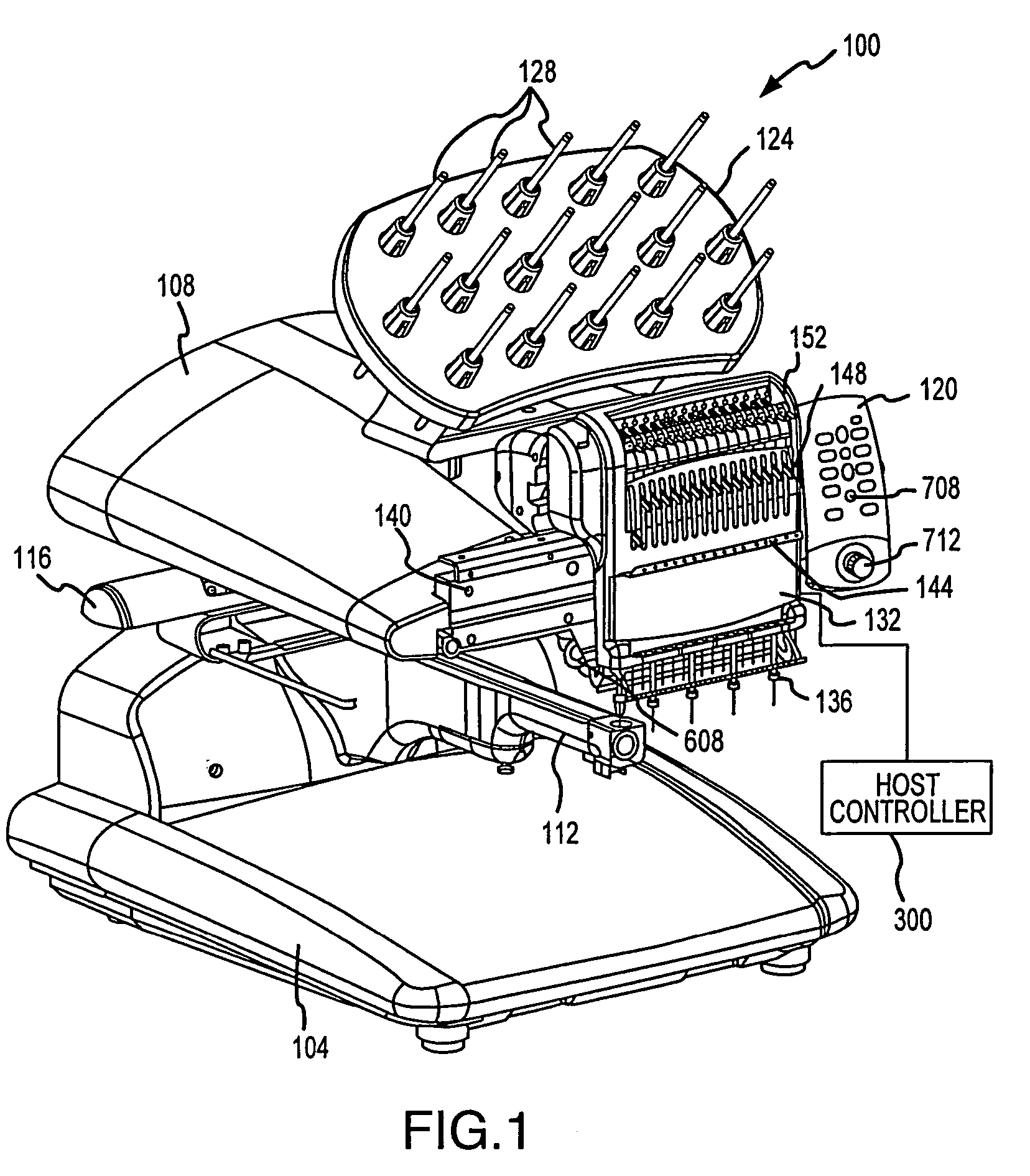

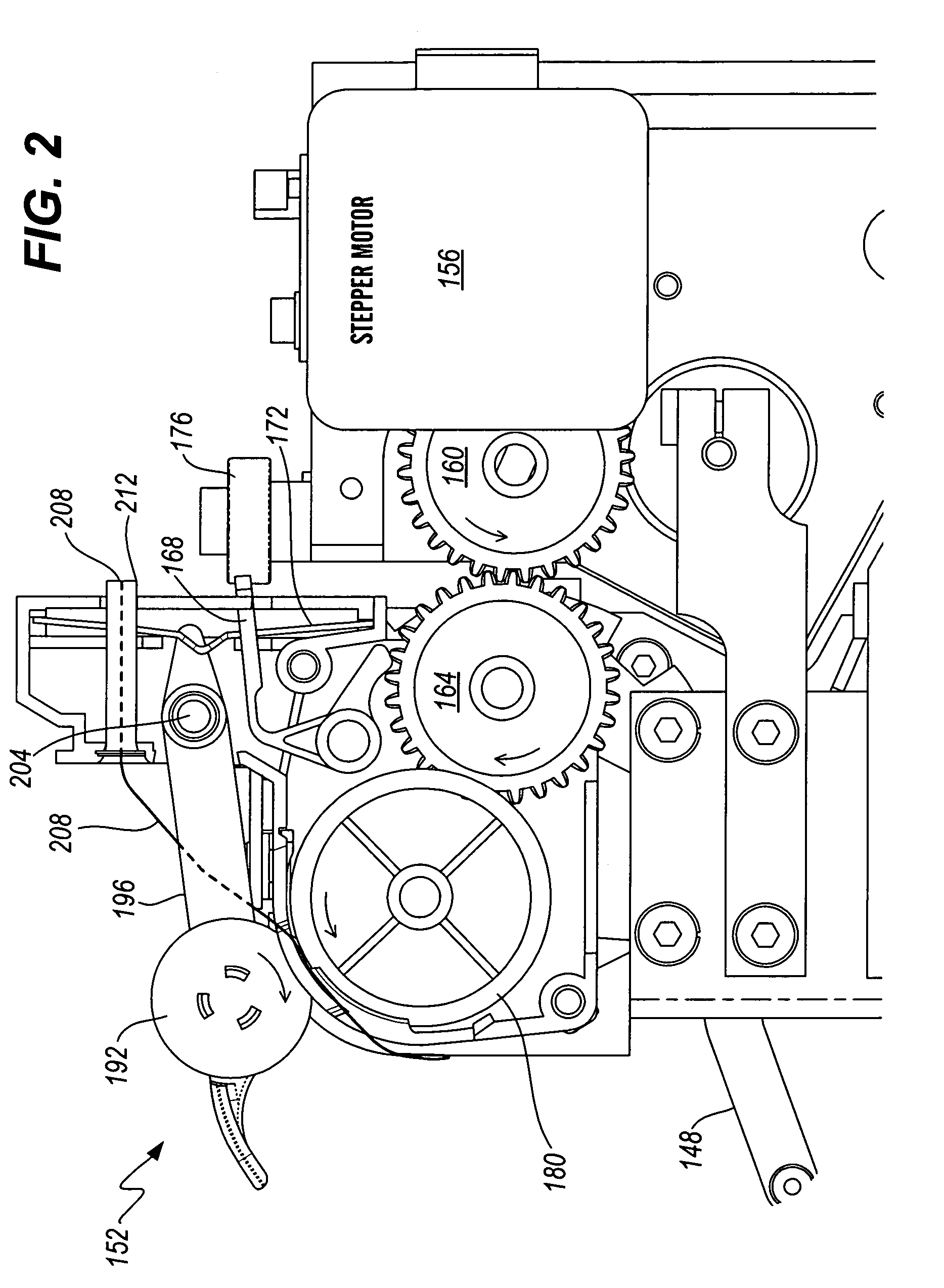

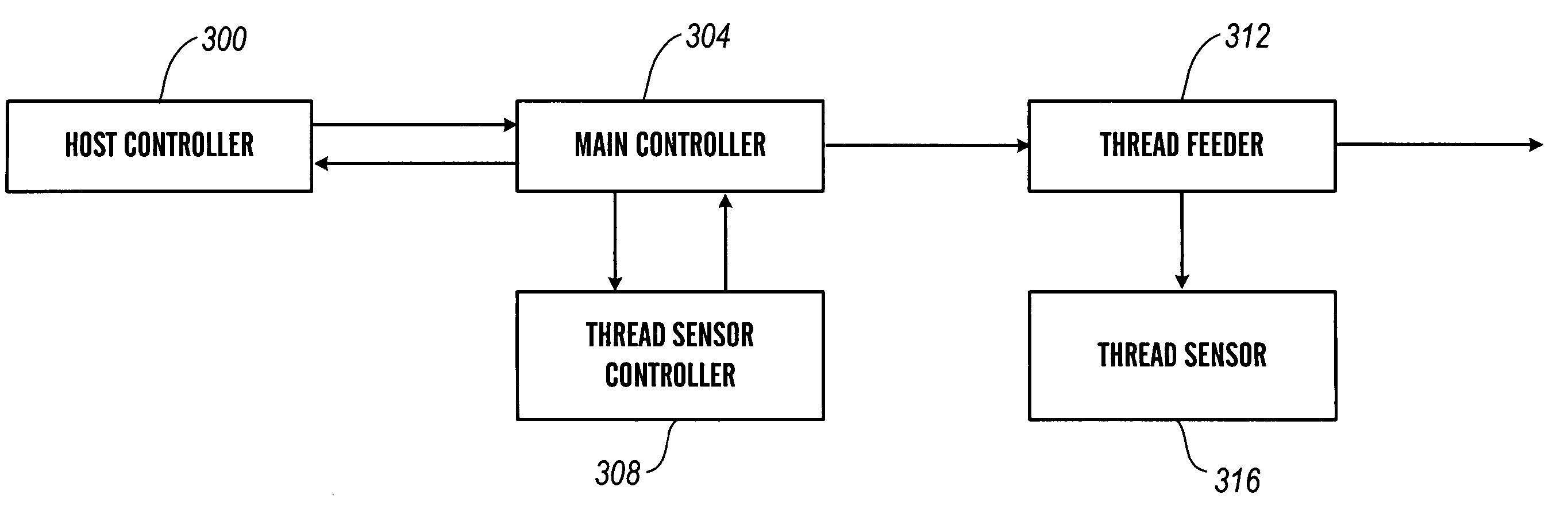

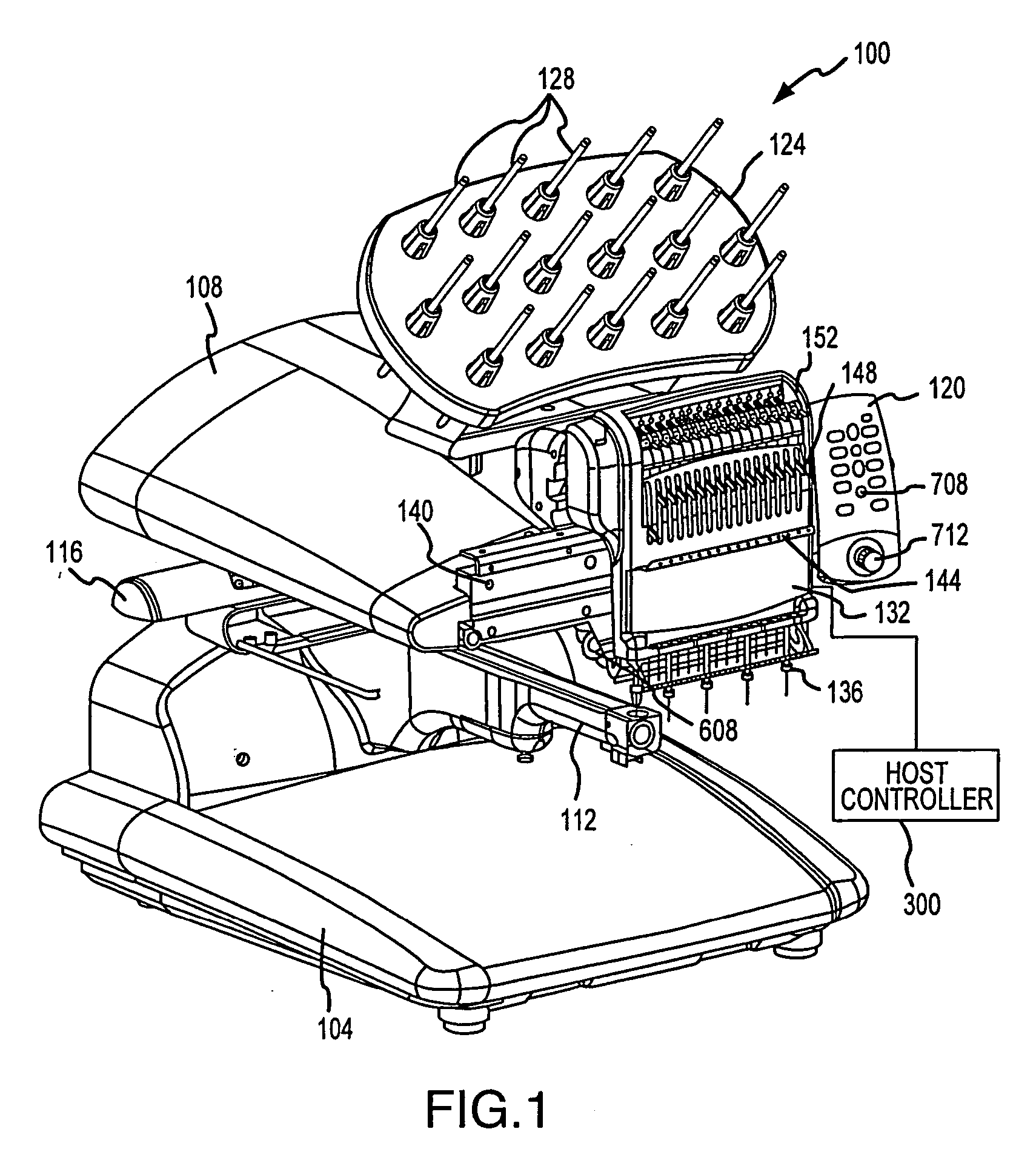

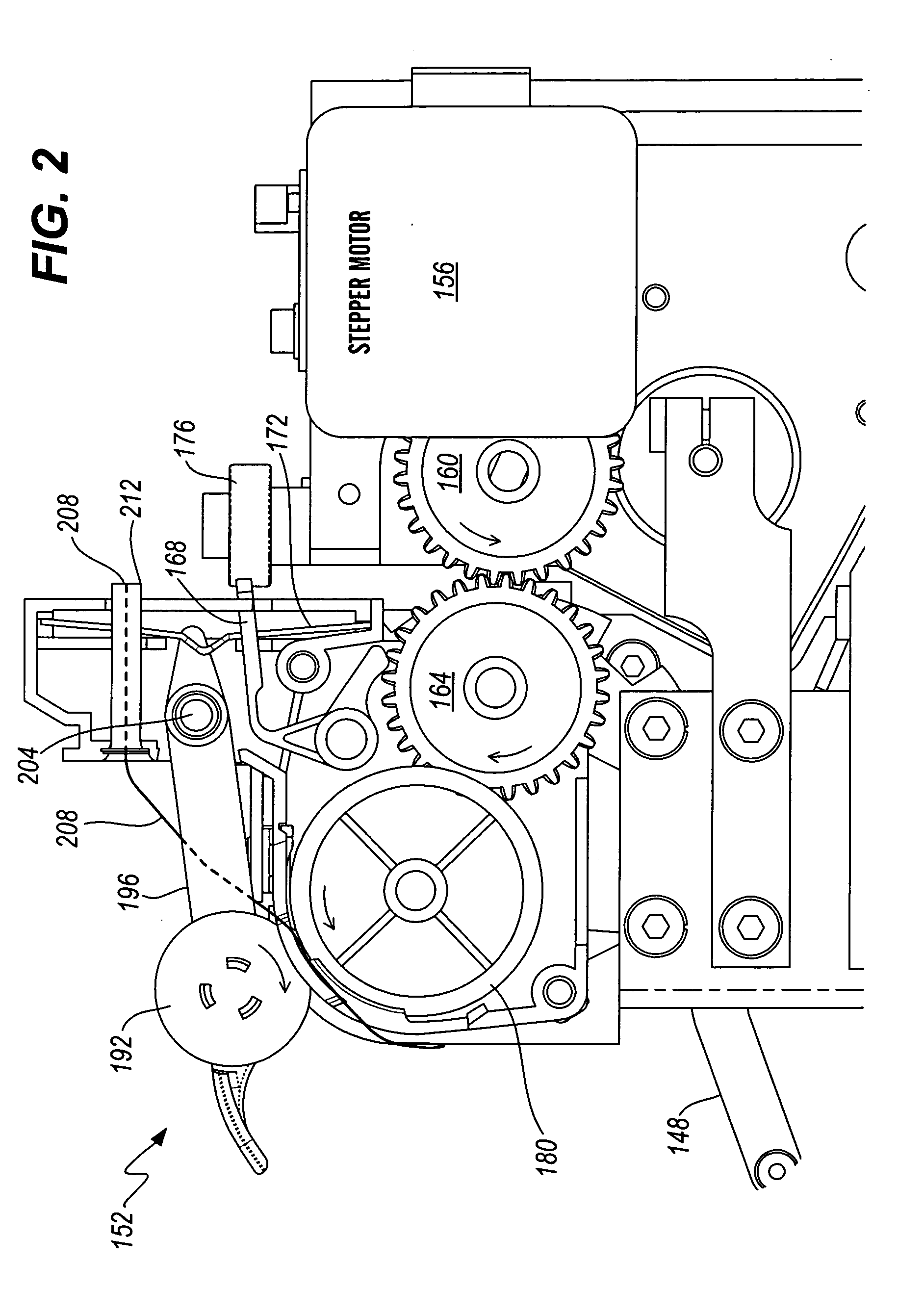

Computerized stitching including embroidering

InactiveUS7308333B2Easy to controlProgramme-controlled sewing machinesPressersAnomaly detectionRemedial action

A stitching apparatus with thread tension control is provided. Tension in a thread is monitored during stitching apparatus operations, and remedial action is taken in response to the detection of an anomaly in the thread tension profile. The remedial action can include altering a feed rate of the thread in order to adjust the thread tension, and / or repeating a previous operation. Anomaly detection can be performed with respect to stitching or sewing operations, and also with respect to trim operations performed in connection with moving between elements and / or thread color changes.

Owner:MELCO INT

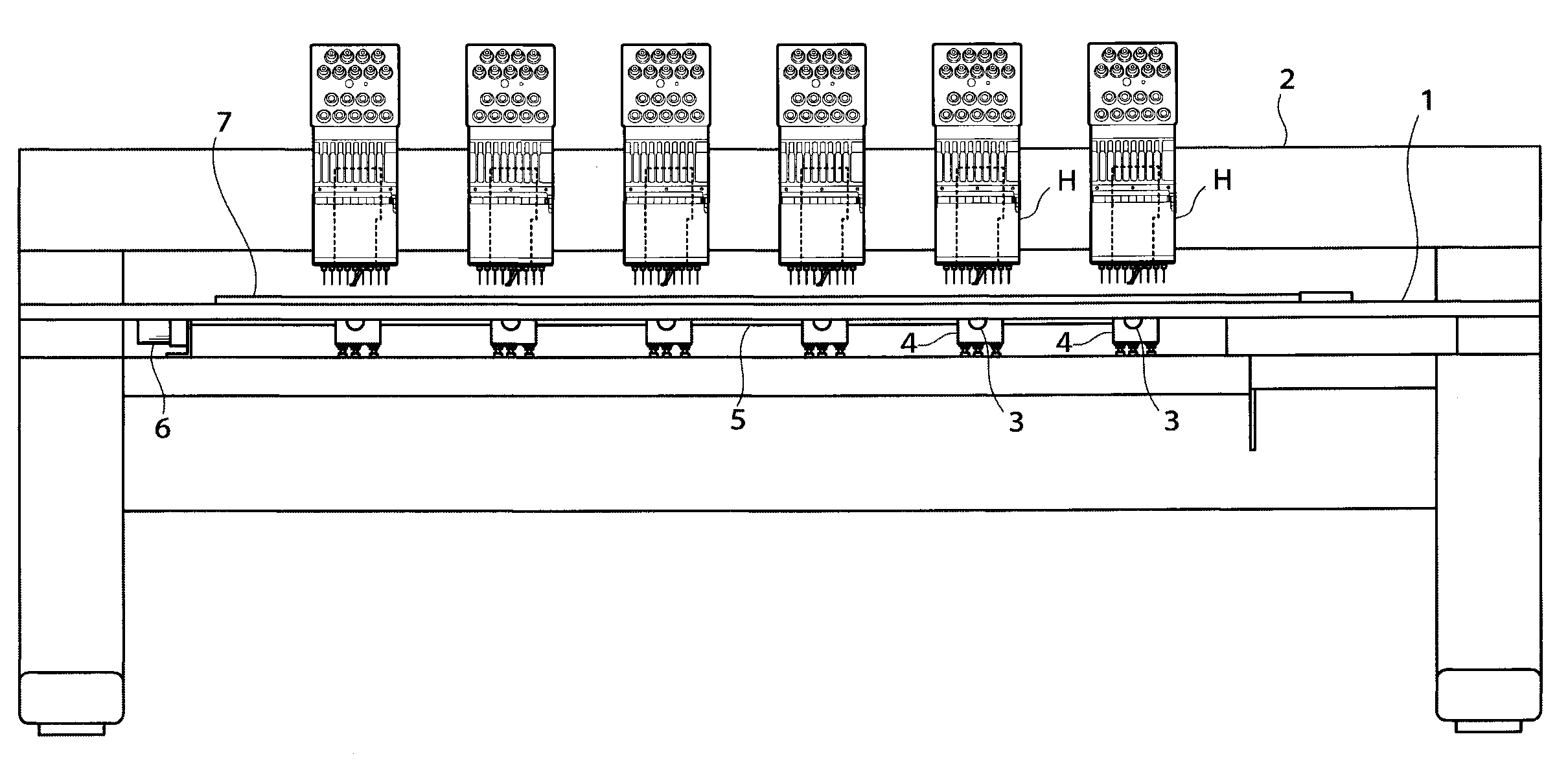

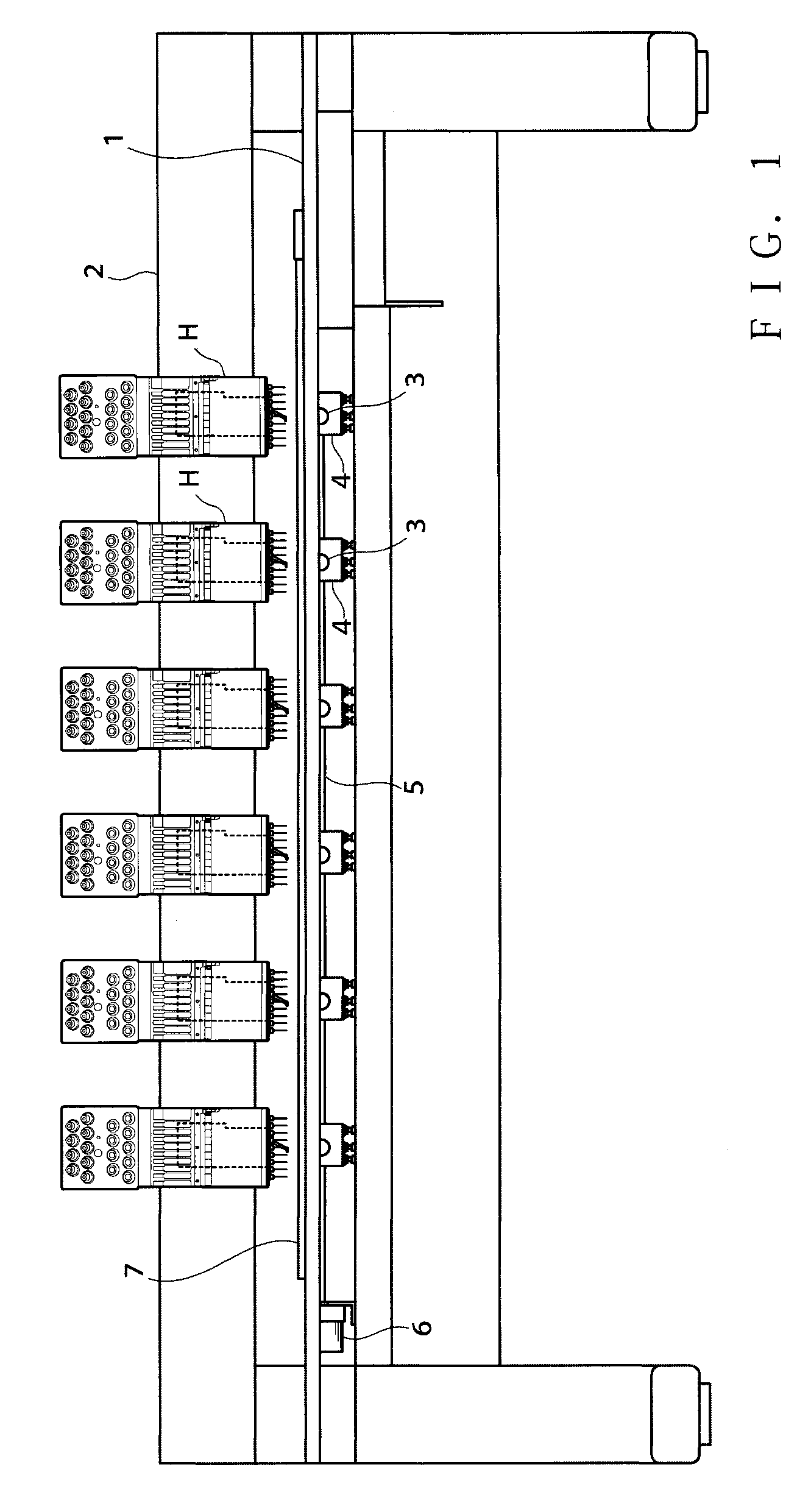

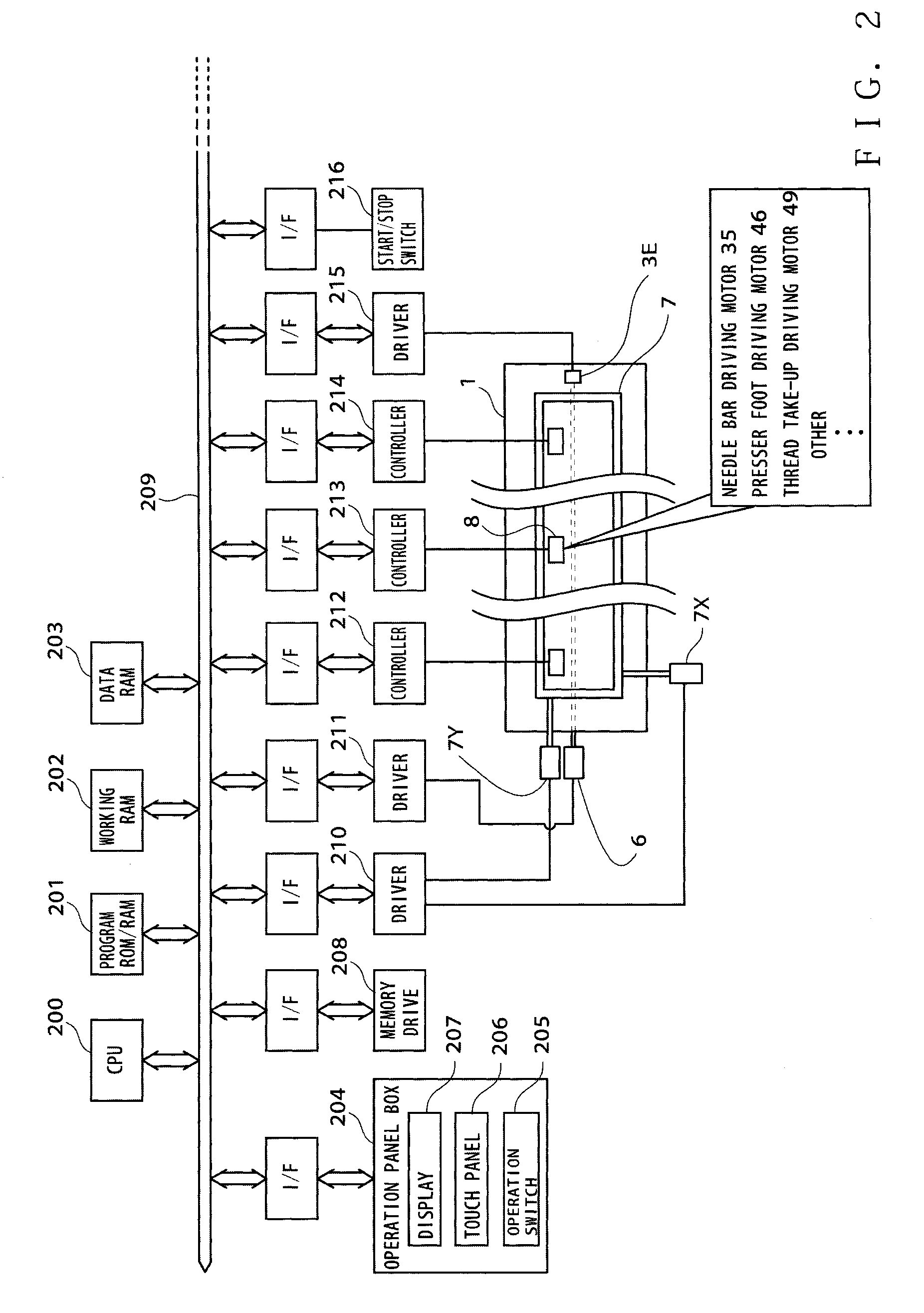

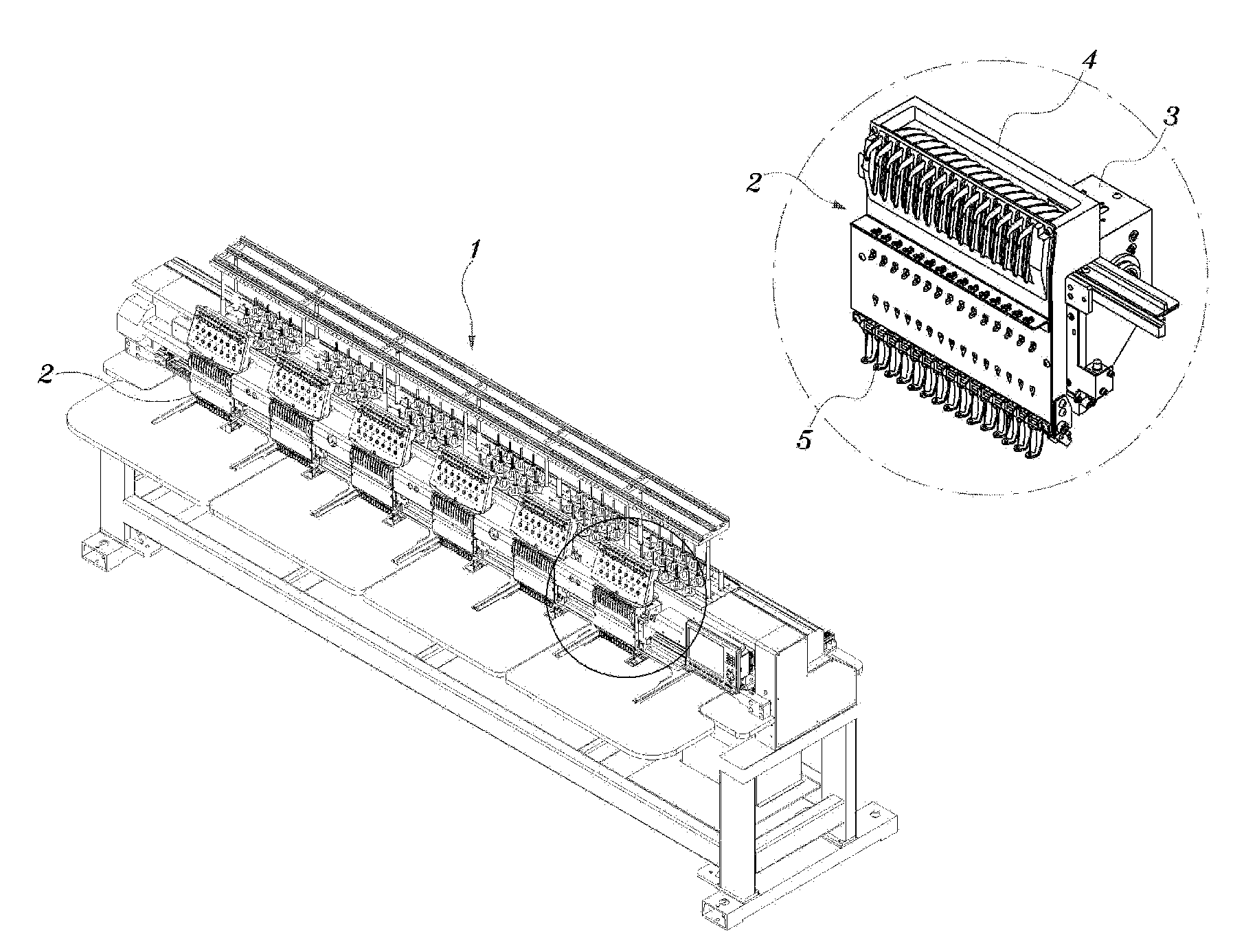

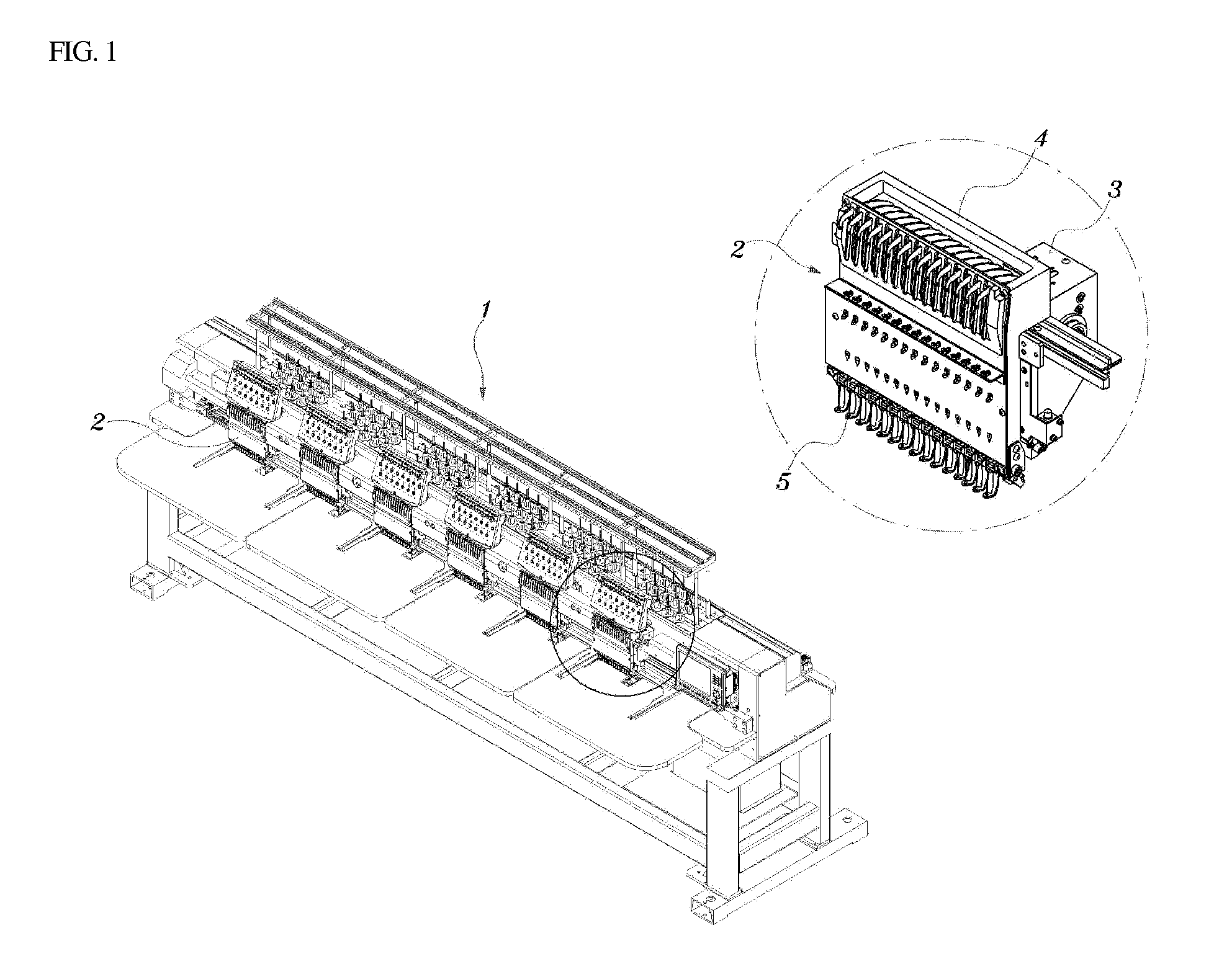

Multi-head embroidery sewing machine

InactiveUS20070261621A1Avoid unevennessEasy to switchPressersSewing-machine control devicesMechanical componentsEngineering

Individual motors in a sewing machine of the invention are provided, for each of a plurality of machine heads, for individually driving respective mechanical components, such as a needle bar driving mechanism, thread take-up lever and presser foot mechanism. A plurality of rotary hooks are driven by a common motor. Even in a case where embroidering workpieces set on the individual machine heads differ in material between the heads and upper threads used for the machine heads differ in characteristic between the heads, the sewing machine can make, in a concurrent, parallel fashion, embroidery products of different texture suited for the respective materials, characteristics, etc., by setting independent stitch formation per machine head.

Owner:TOKAI IND SEWING MACH CO LTD

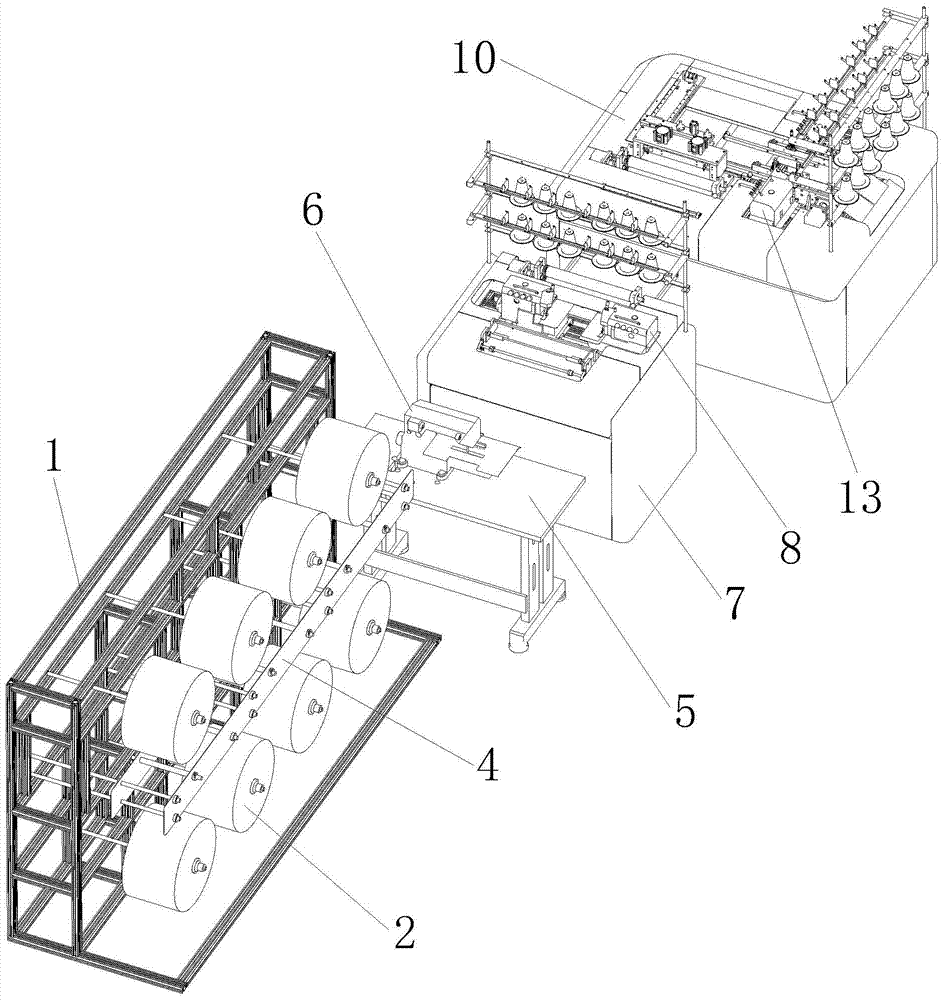

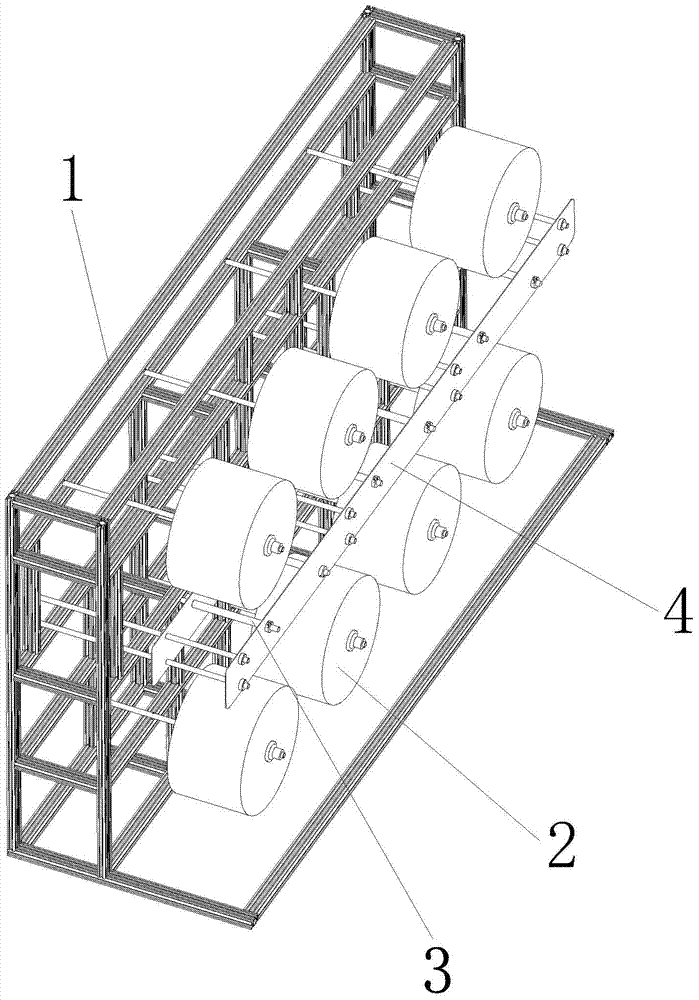

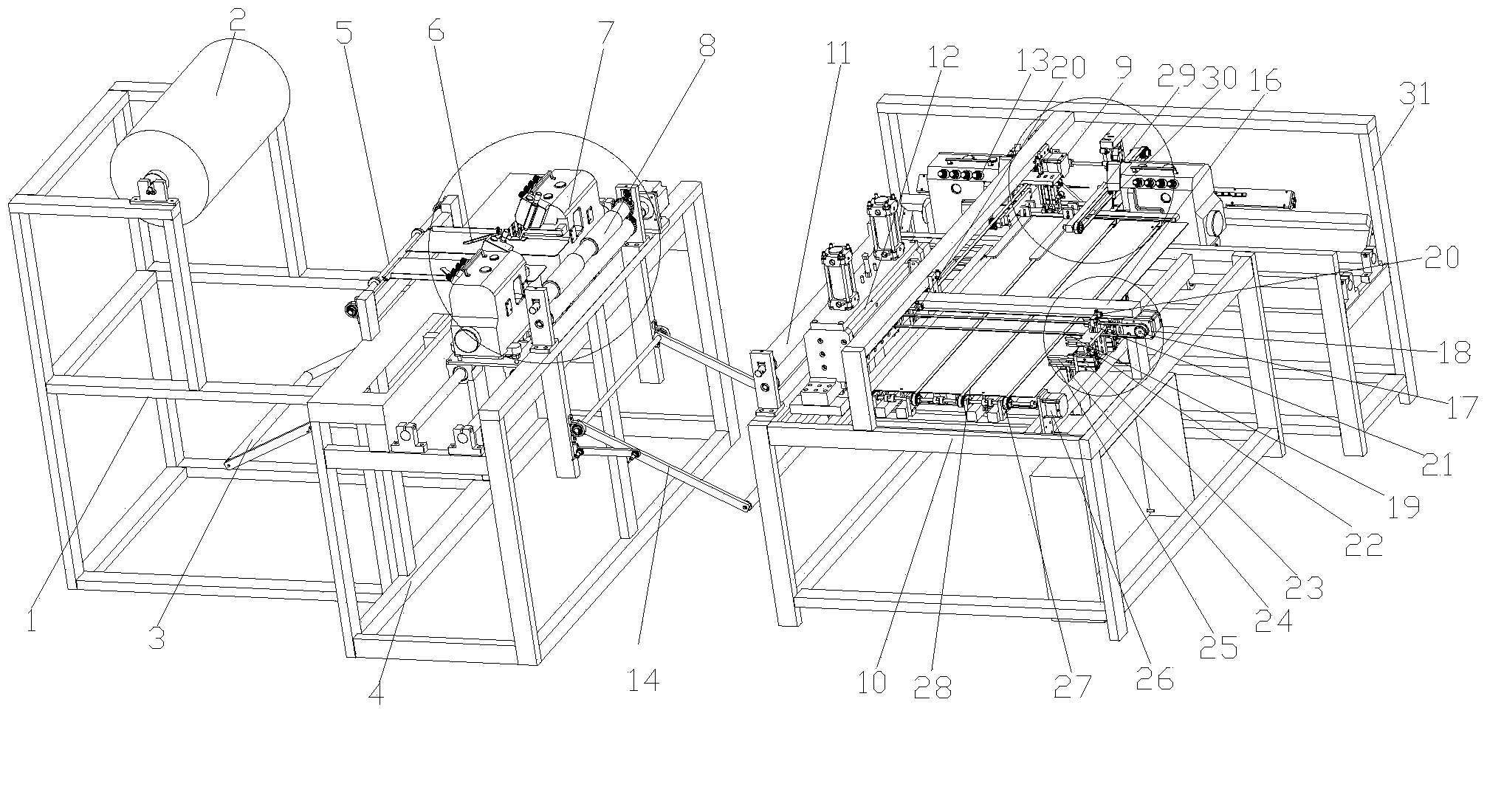

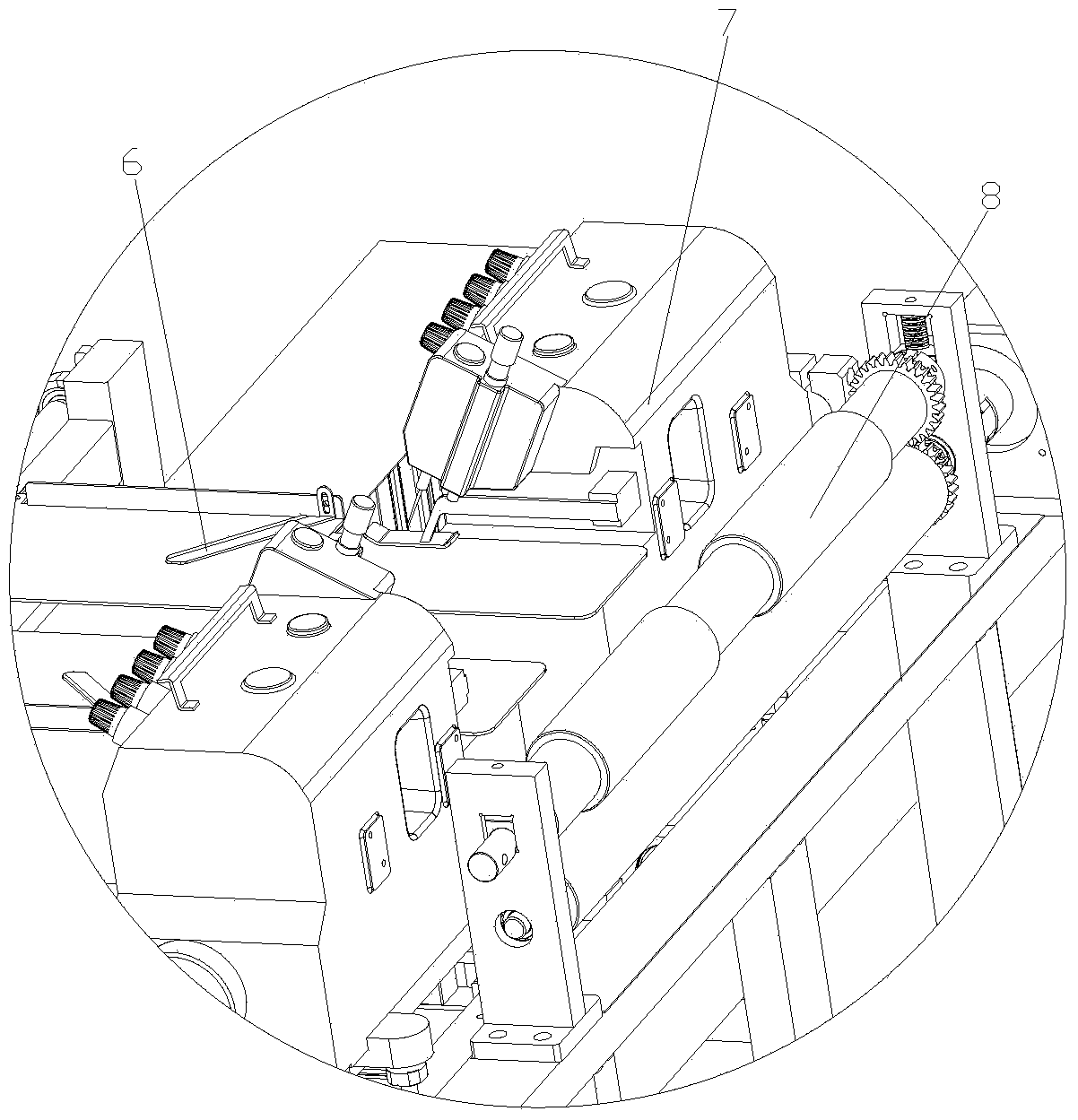

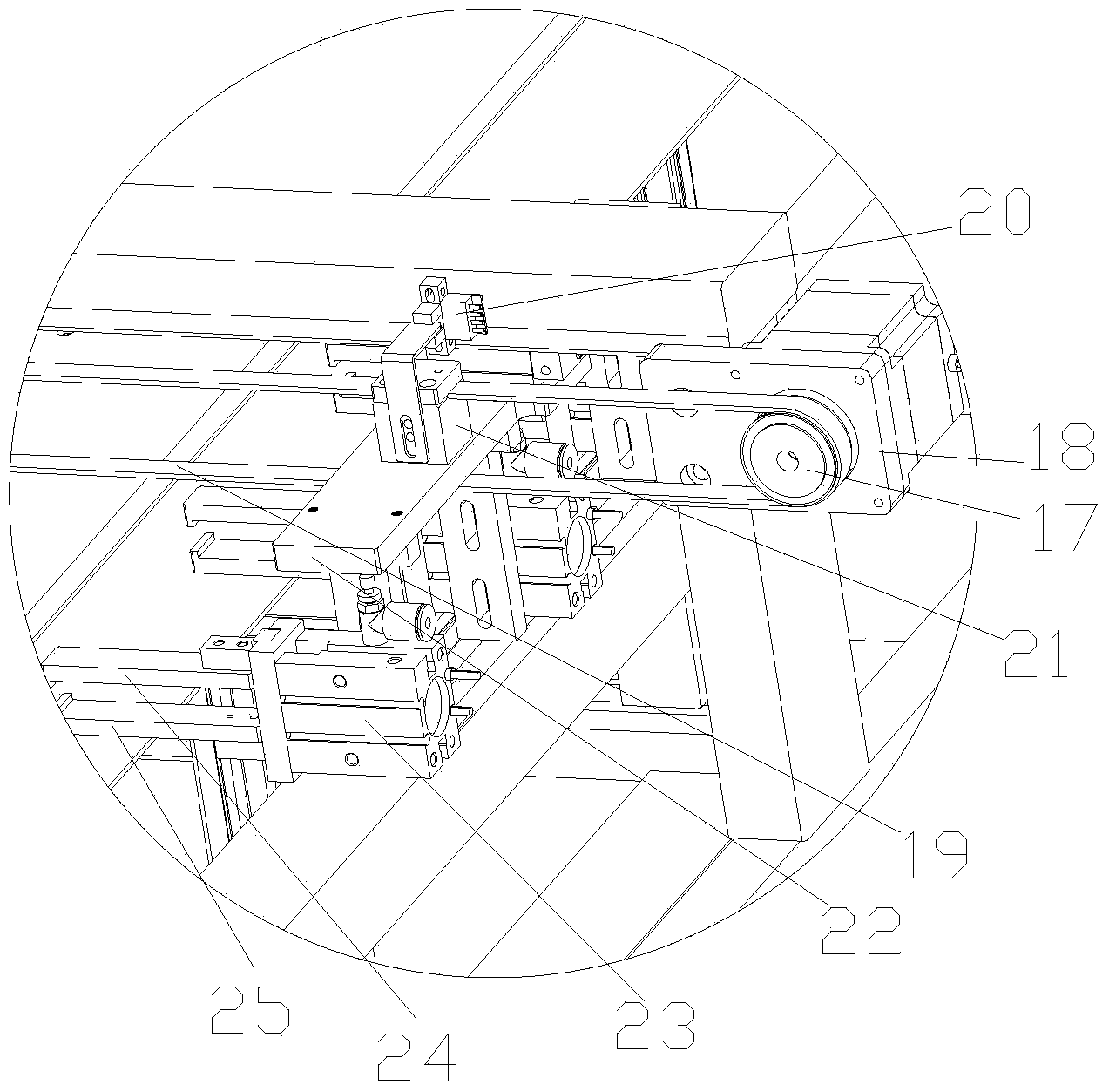

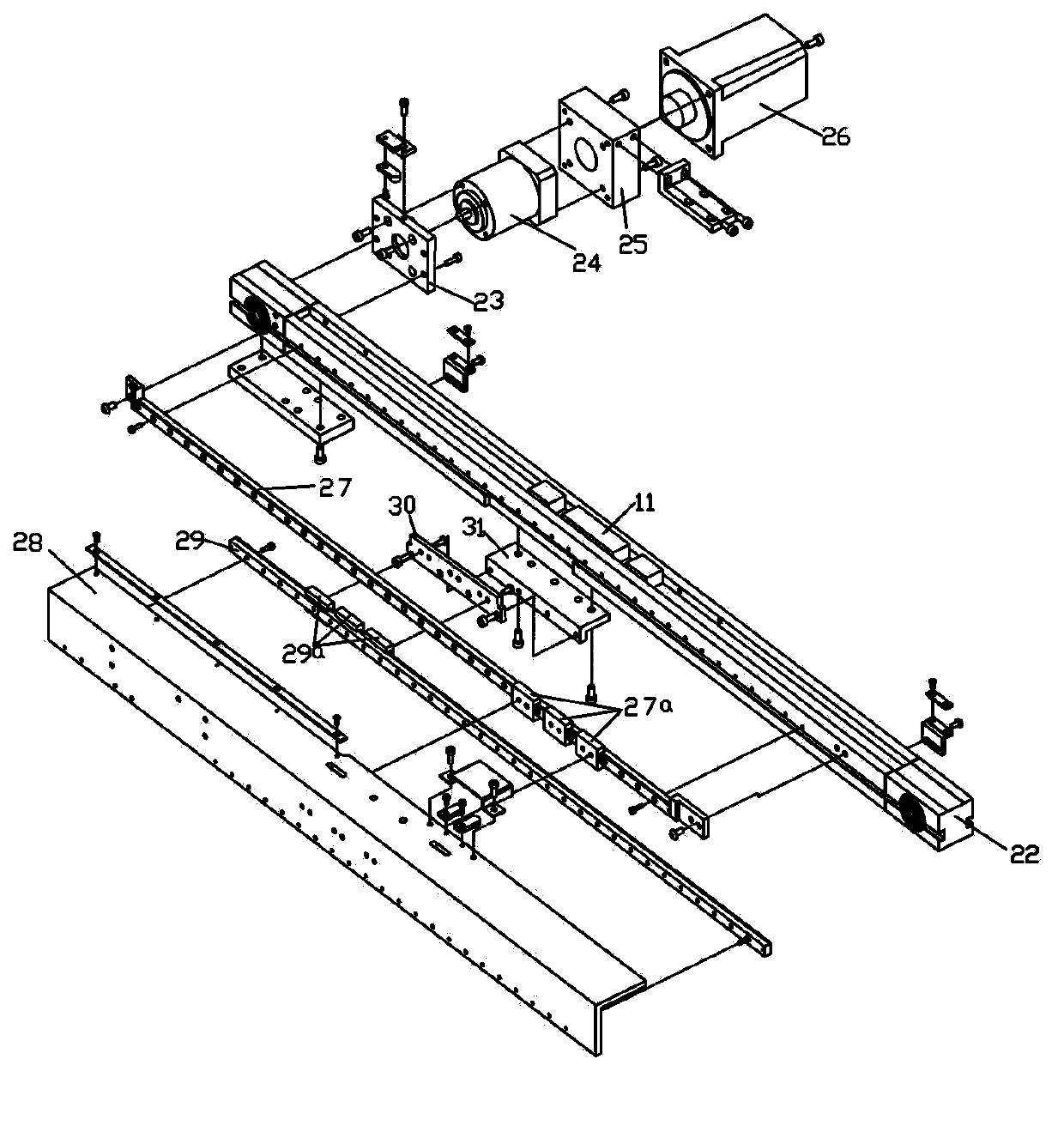

Towel machine

ActiveCN103498291AReduce manufacturing costIncrease productivityWorkpiece carriersWork-feeding meansIndustrial engineering

The invention discloses a towel machine. The towel machine comprises a feeding device, a first processing device and a second processing device. The feeding device, the first processing device and the second processing device are oppositely and fixedly placed in sequence. The feeding device is used for feeding cloth to the first processing device; the first processing device is used for binding off the two edges of the cloth fed by the feeding device for the first time; the second processing device is used for cutting off the cloth fed by the first processing device and then binding off the two edges of the cloth for the second time. According to the towel machine, original manual operation is replaced by mechanical automatic operation for towel production, so that labor intensity is greatly reduced for workers, the production mode that a single worker operates multiple machines can be realized in production, production efficiency of the product is improved, production cost is lowered, effective production management is facilitated, and the production value of the product is maximized.

Owner:SUZHOU TRANSPARENT TECH CO LTD

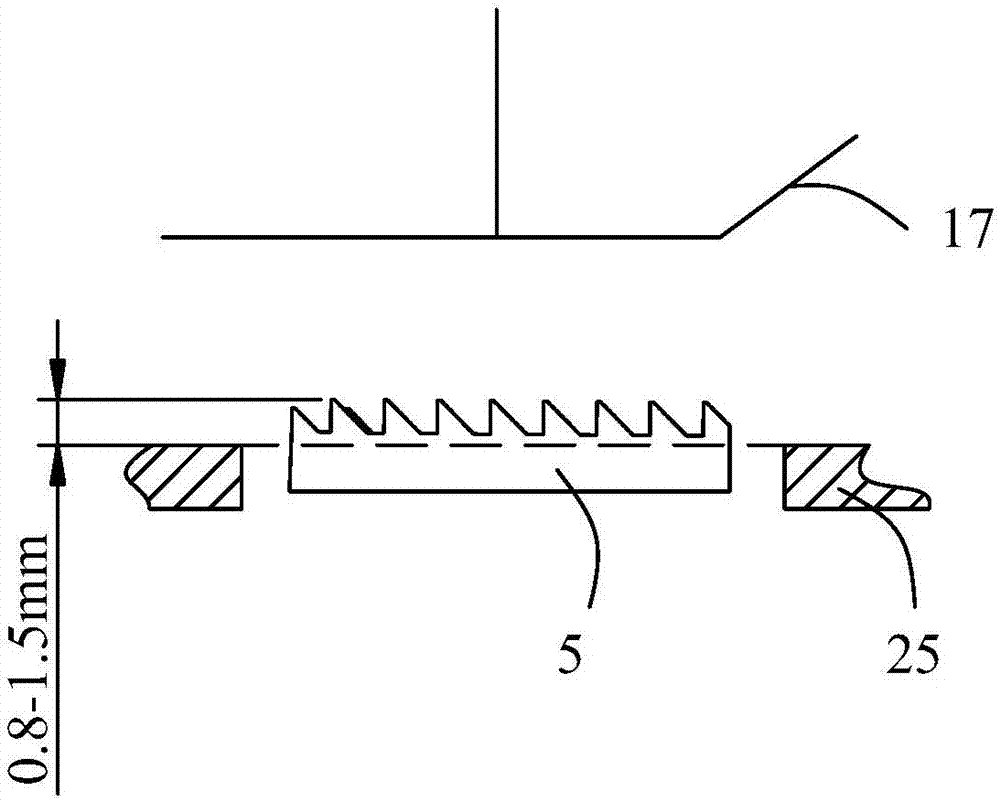

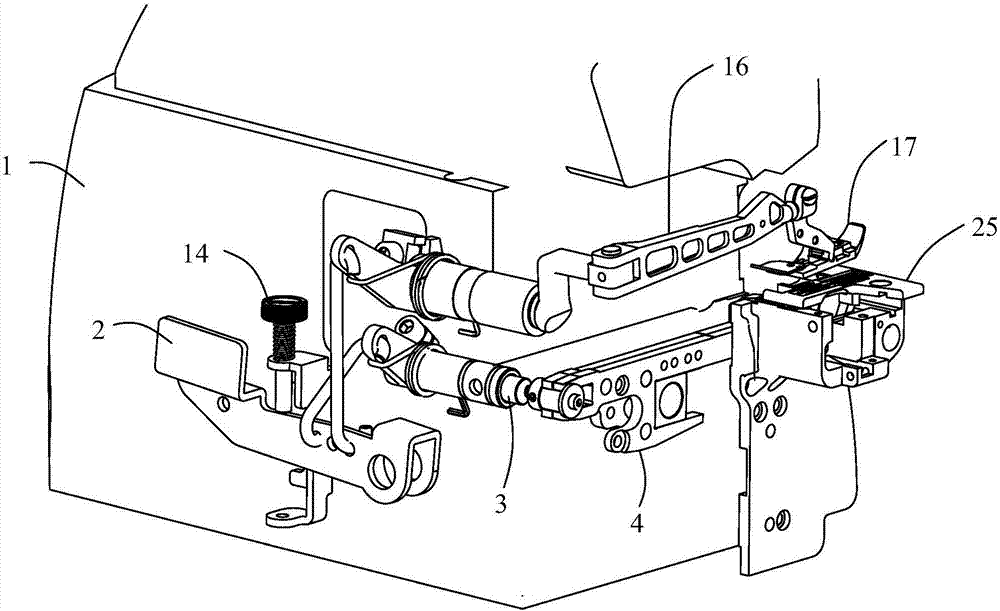

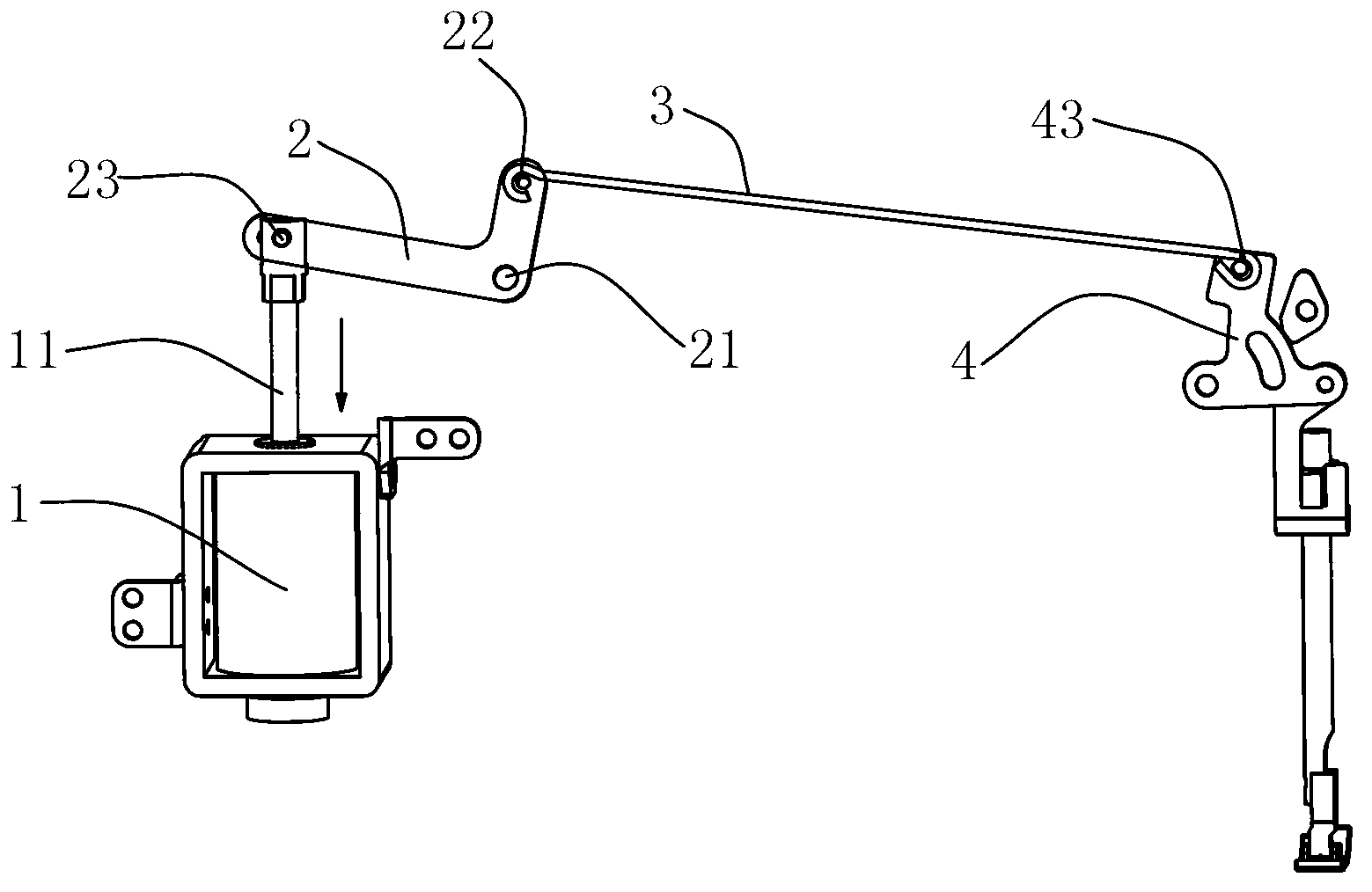

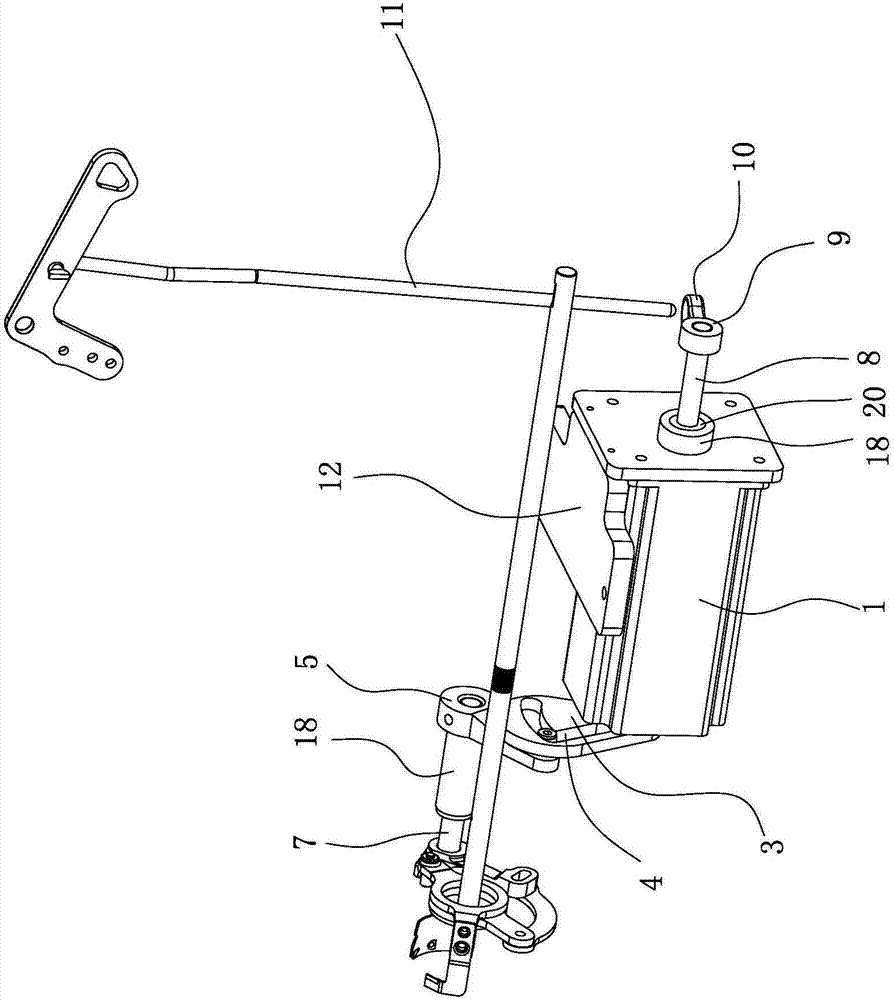

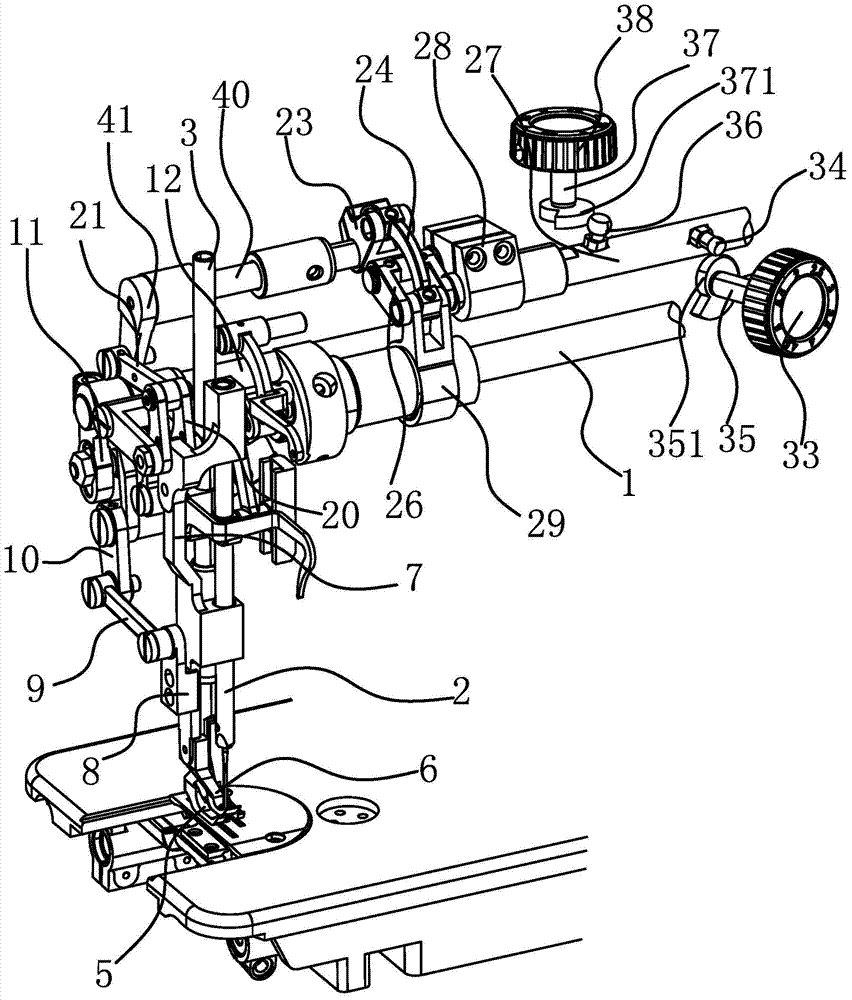

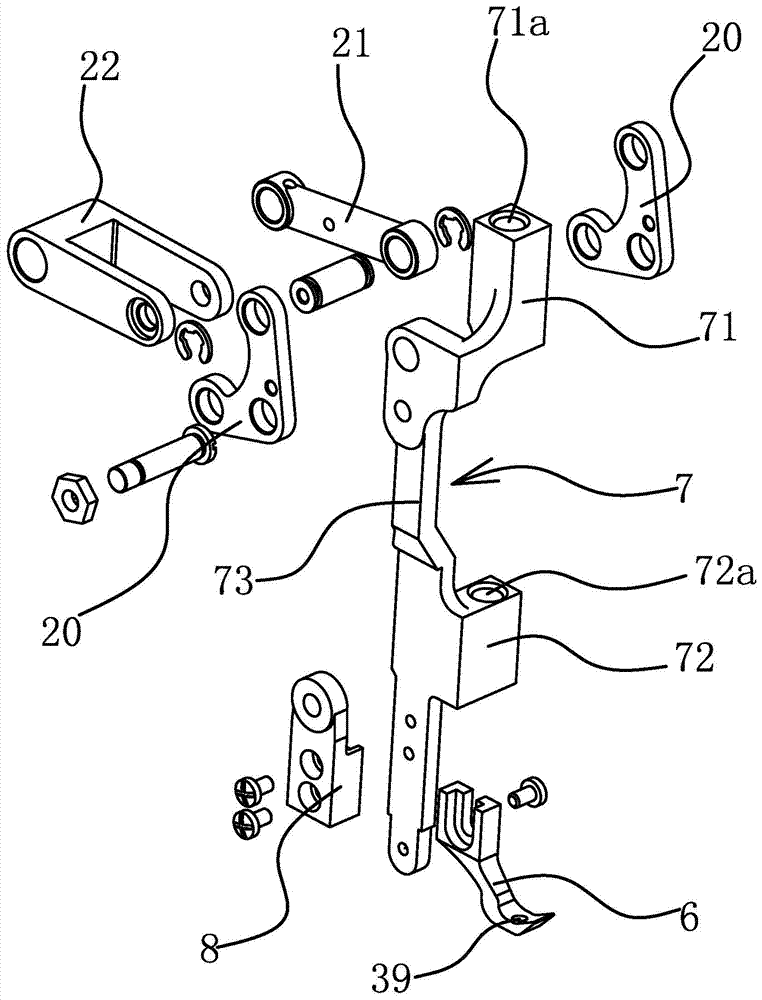

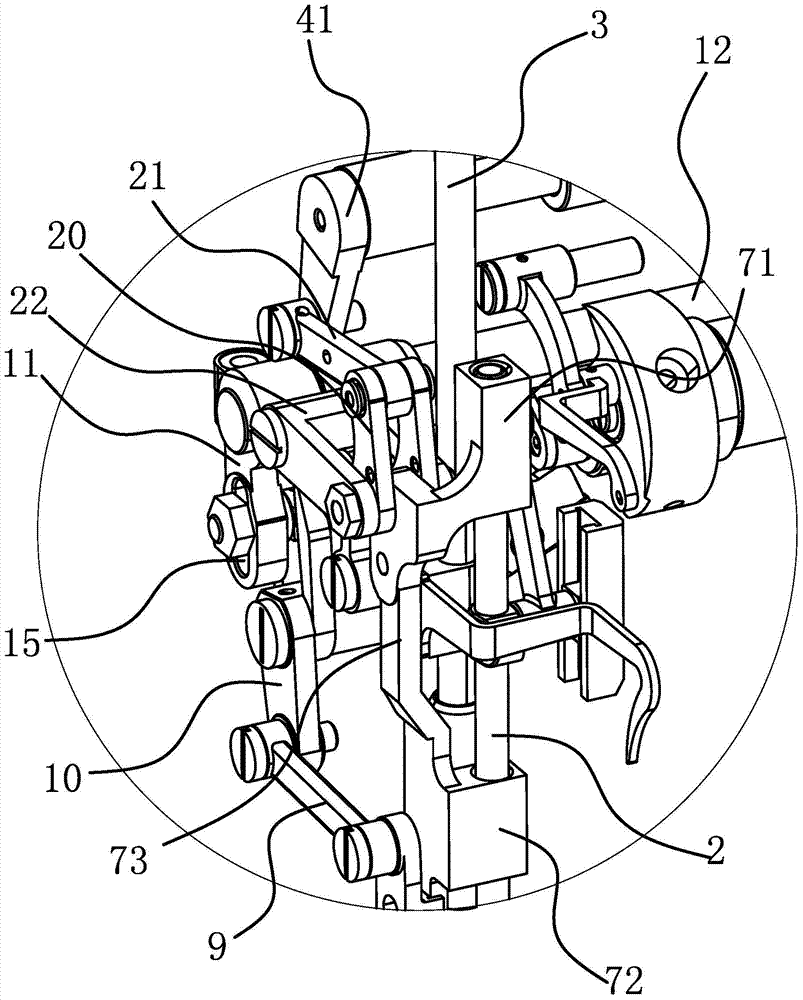

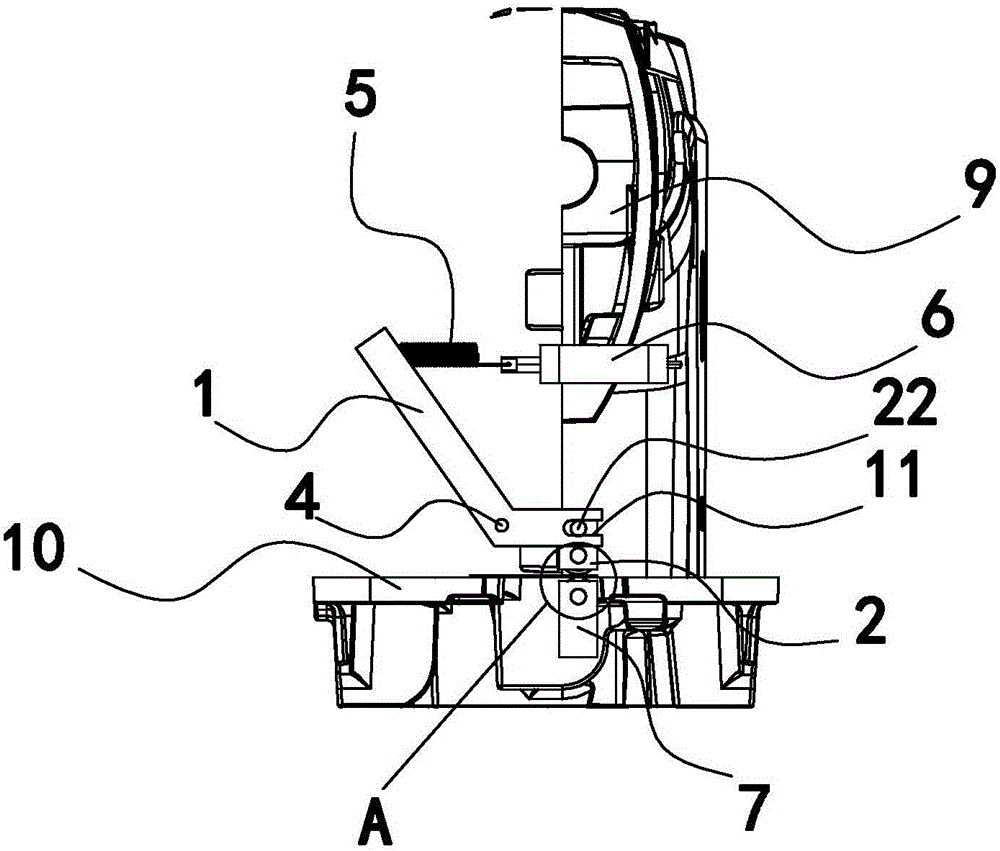

Feeding mechanism downward movement structure controlled by presser foot lifting mechanism and sewing machine

ActiveCN106988030AGuaranteed effective heightEasy to feedWork-feeding meansPressersDental ArticulatorsEffective height

The invention provides a feeding mechanism downward movement structure controlled by a presser foot lifting mechanism and a sewing machine. The feeding mechanism downward movement structure includes a presser foot lifting wrench, an eccentric shaft rotatably installed in a machine housing, a dental articulator having a second swinging supporting point, and a feeding tooth installed at one end of the dental articulator; a sliding groove is formed in the dental articulator, the eccentric shaft has a shaft body part and a shaft eccentric part eccentrically arranged on the shaft body part, the presser foot lifting wrench is connected with the shaft body part of the eccentric shaft through a first transmission mechanism, and the shaft eccentric part of the eccentric shaft can be rotatably installed in the sliding groove of the dental articulator and cooperated with the sliding groove in a sliding mode; when a presser foot is lifted, the presser foot lifting wrench swings around a first swinging supporting point and swings around the second swinging supporting point through a first transmission mechanism and an eccentric shaft driven dental articulator, so that the end, provided with the feeding tooth, of the dental articulator moves downward to the upper surface of a needle plate, the effective height between the presser foot and the needle plate after the presser foot is lifted is ensured, and therefore a to-be-sewed material is easily delivered between the presser foot and the needle plate before sewing is started.

Owner:JACK SEWING MASCH CO LTD

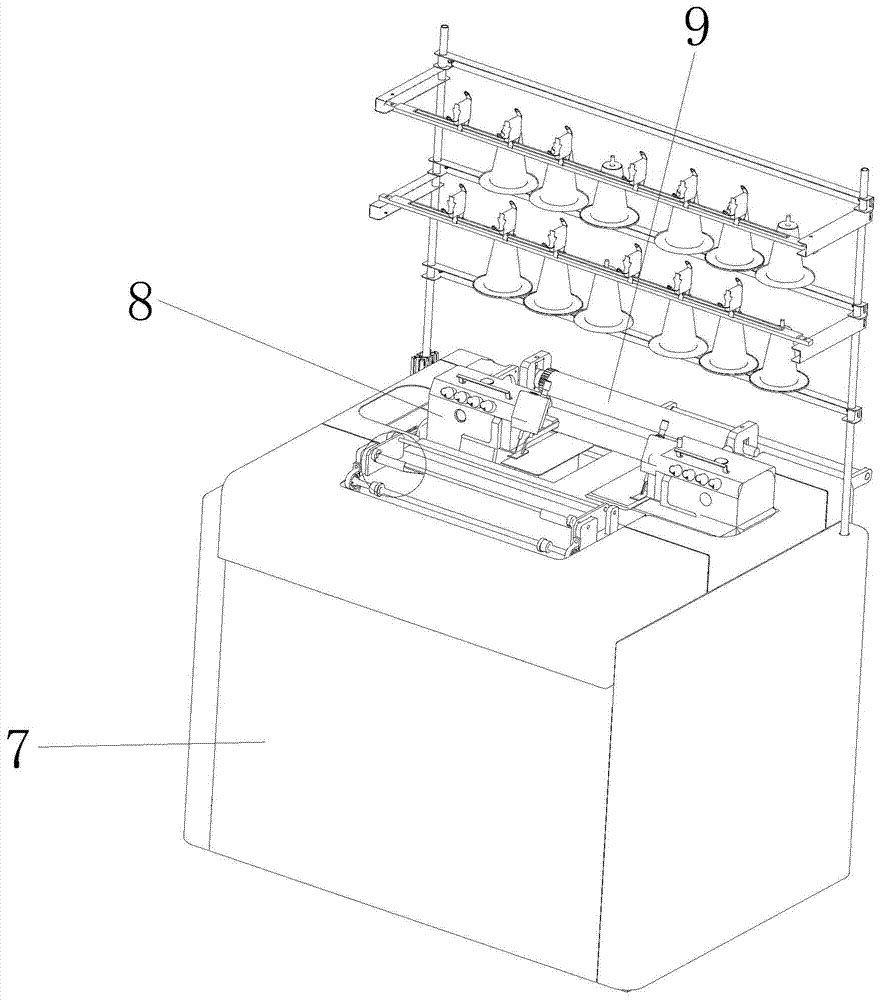

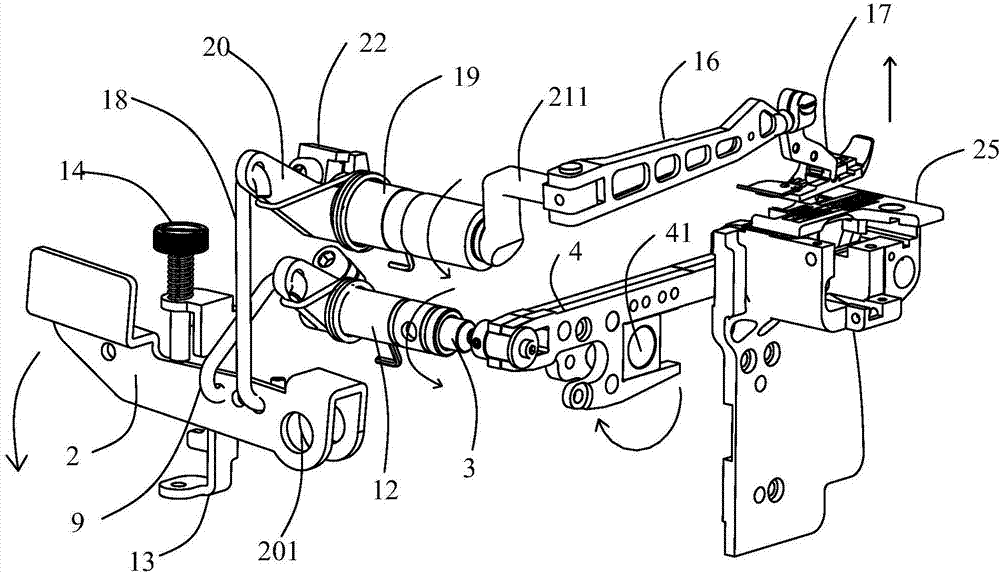

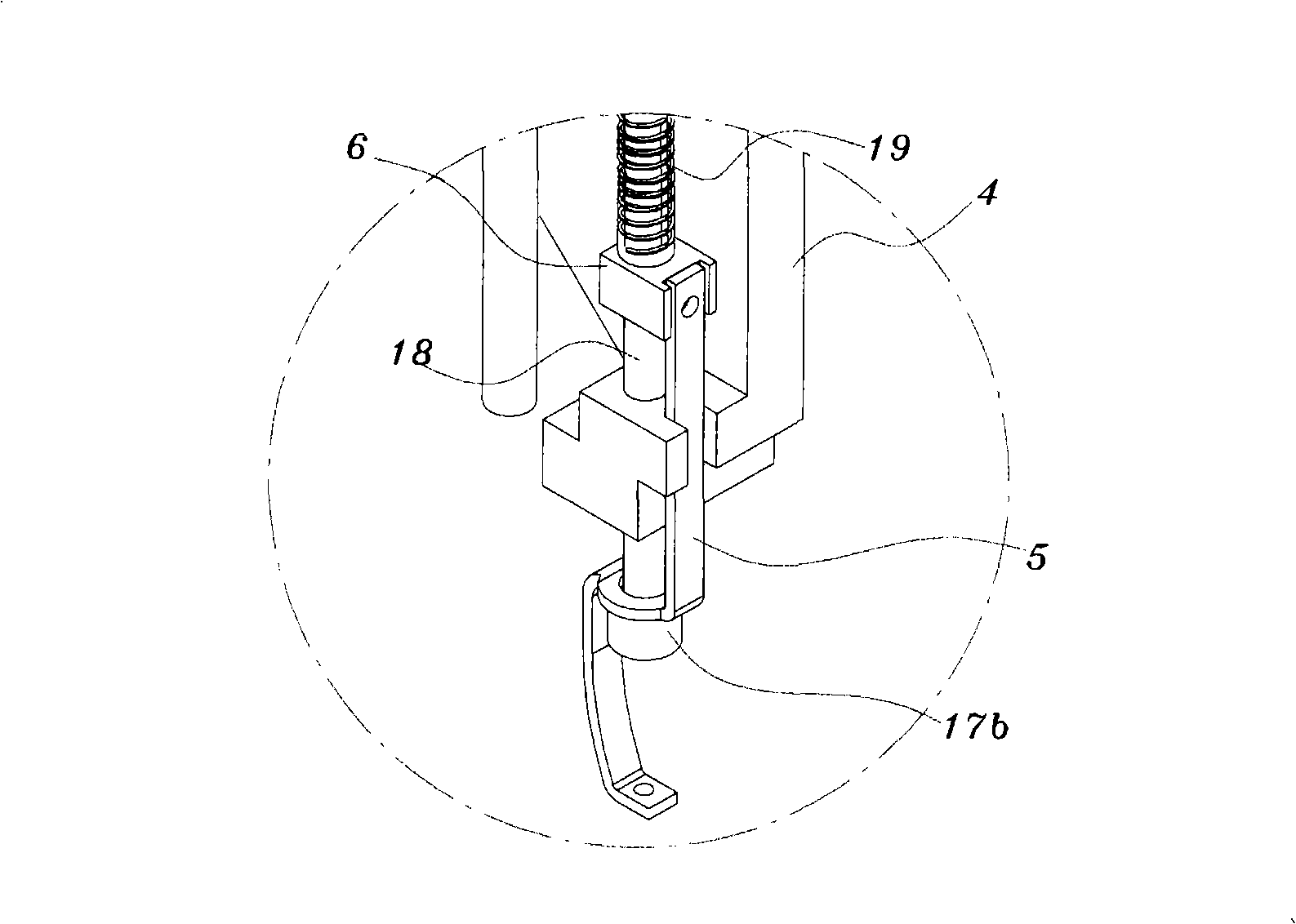

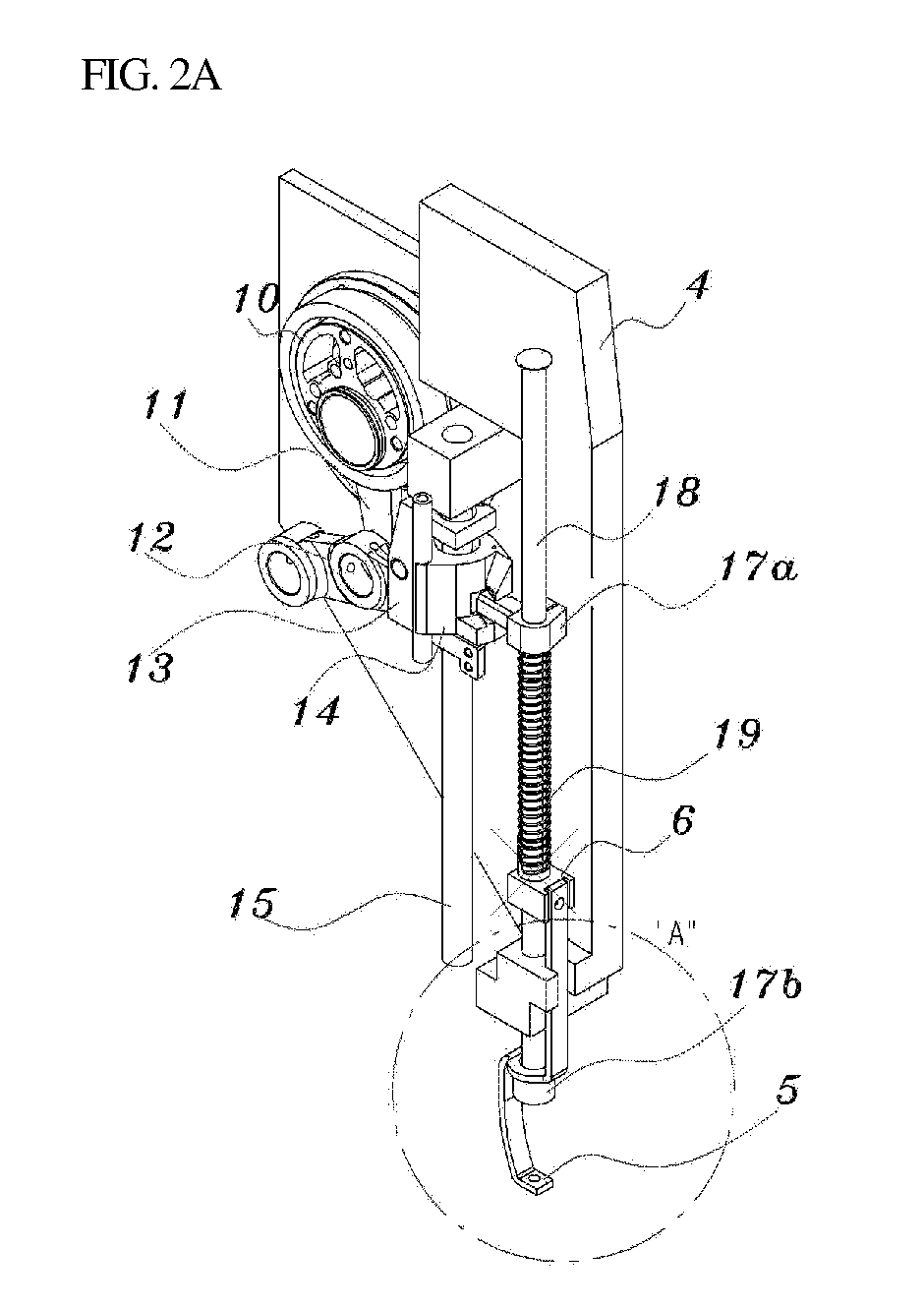

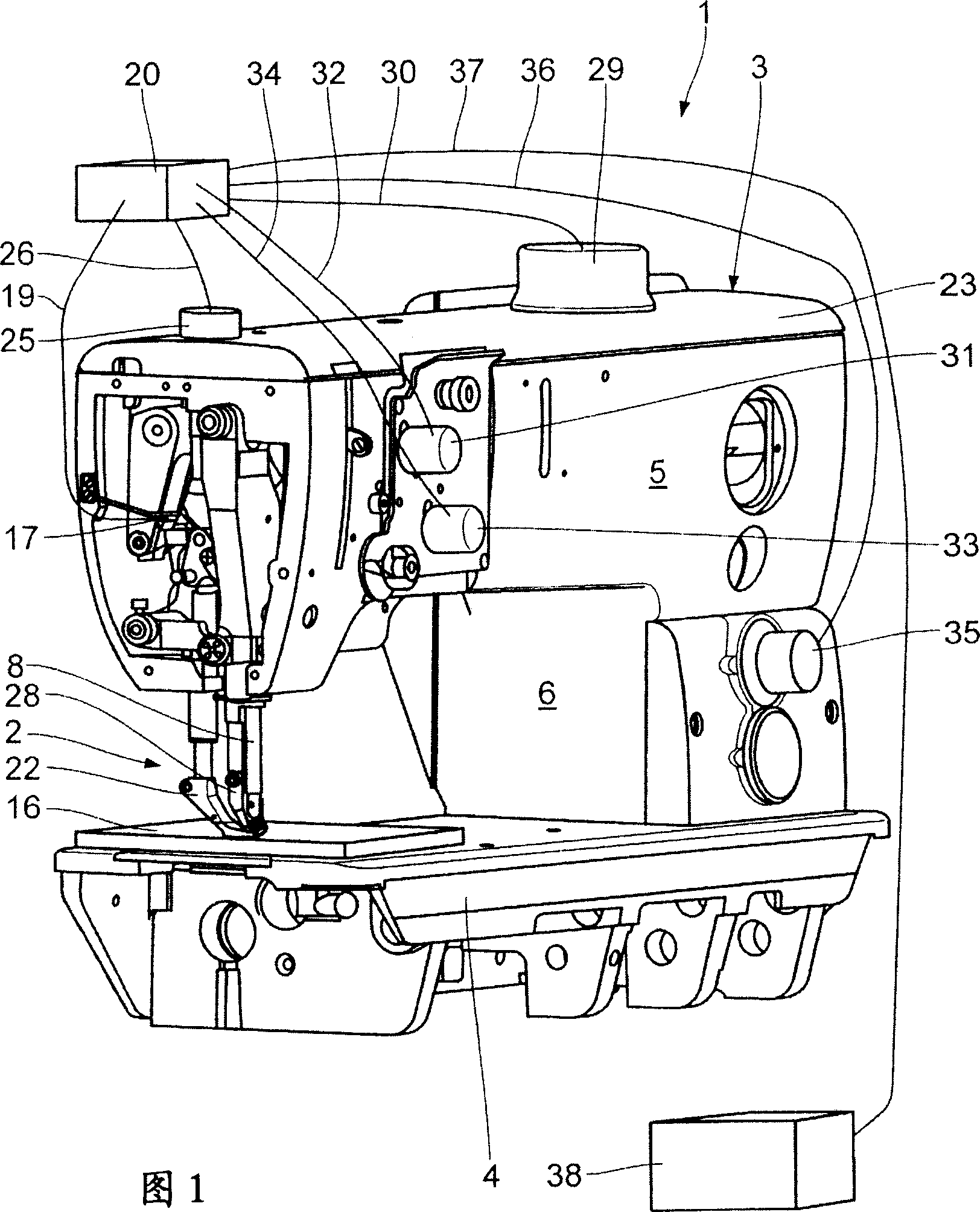

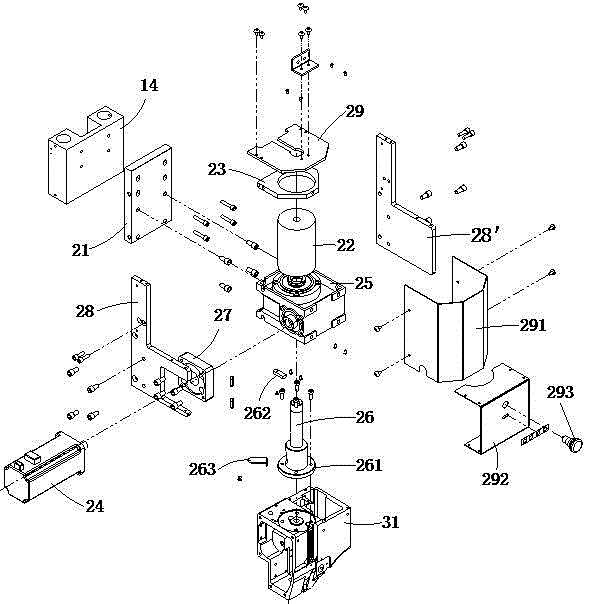

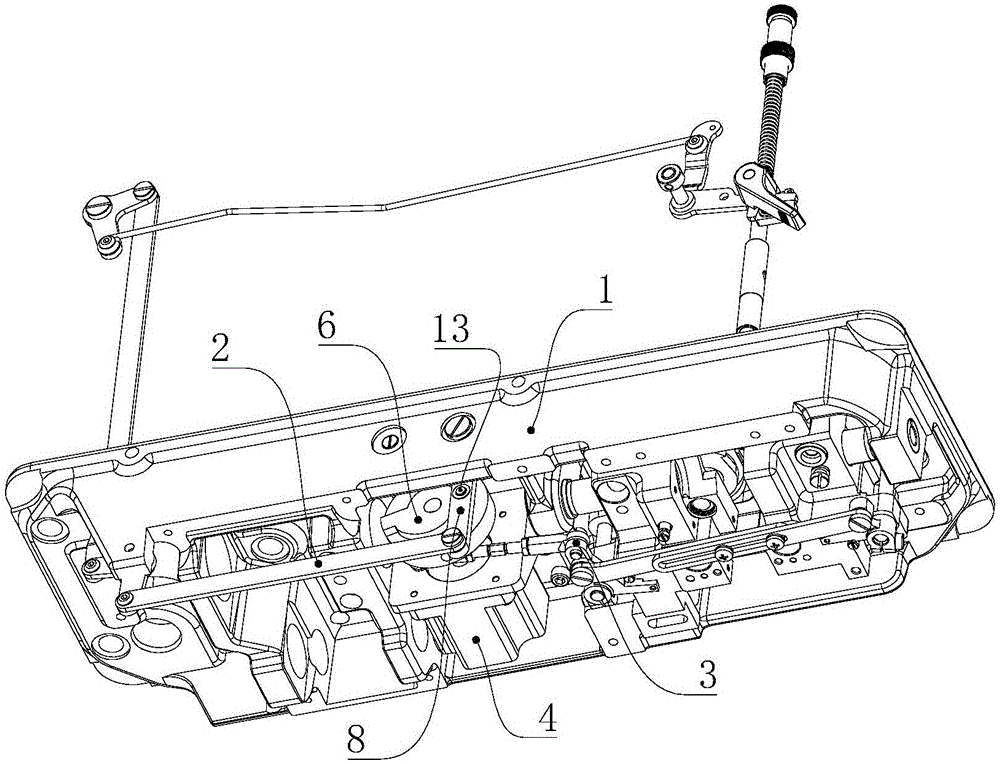

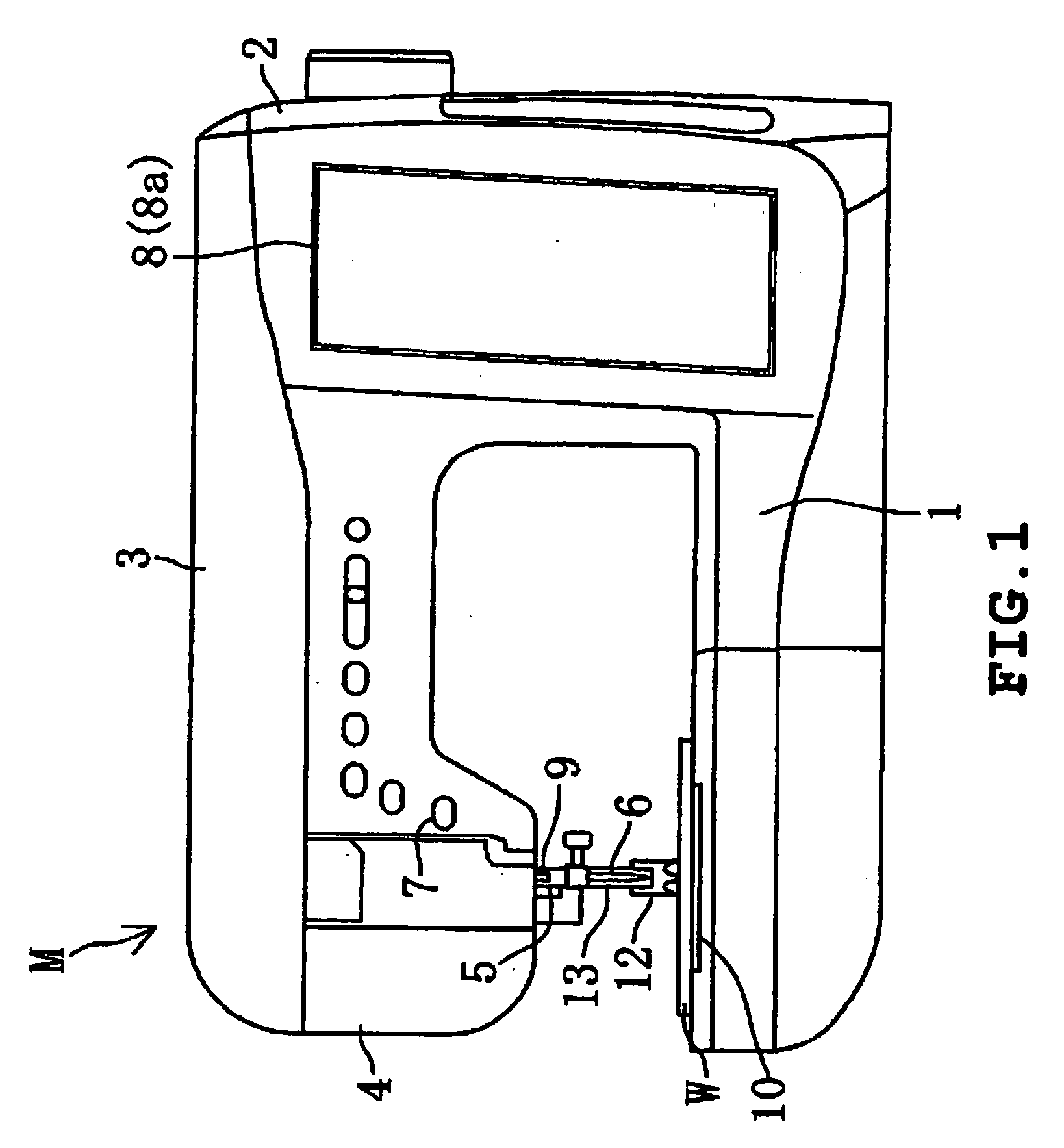

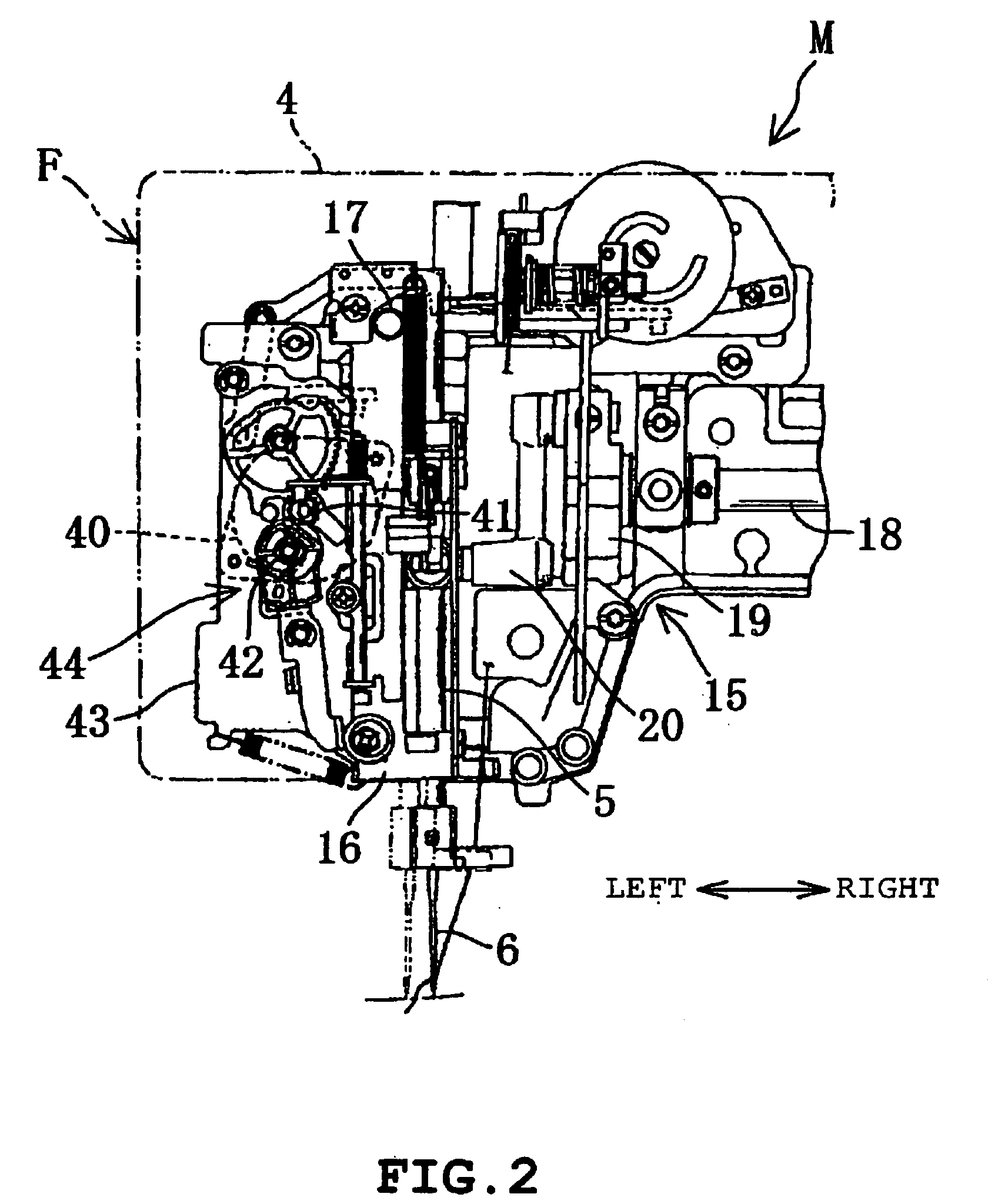

Embroidery machine

InactiveCN101260601AChange itineraryProgramme-controlled sewing machinesPressersEngineeringPRESSURE FEET

An embroidery machine includes a sewing arm having an upper shaft for providing a driving force, a needle bar support case, which is assembled to a front portion of the sewing arm so as to be laterally movable, a needle bar provided in a needle bar support case, the needle bar having a needle at a lower end thereof and vertically carrying the needle using a rotation driving force of the upper shaft, and a presser foot, which is provided in the needle bar support case so as to be vertically movable, characterized in that each of the needle bar and the presser foot is operated by an individual drive mechanism. The presser foot is separately driven by its own drive source, independent of the drive source of the needle bar.

Owner:SUSR PRECISION CO LTD

Embroidery Machine

An embroidery machine includes a sewing arm having an upper shaft for providing a driving force, a needle bar support case, which is assembled to a front portion of the sewing arm so as to be laterally movable, a needle bar provided in a needle bar support case, the needle bar having a needle at a lower end thereof and vertically carrying the needle using a rotation driving force of the upper shaft, and a presser foot, which is provided in the needle bar support case so as to be vertically movable, characterized in that each of the needle bar and the presser foot is operated by an individual drive mechanism. The presser foot is separately driven by its own drive source, independent of the drive source of the needle bar.

Owner:SUSR PRECISION CO LTD

Computerized stitching including embroidering

InactiveUS20060064195A1Easy to controlProgramme-controlled sewing machinesPressersAnomaly detectionRemedial action

A stitching apparatus with thread tension control is provided. Tension in a thread is monitored during stitching apparatus operations, and remedial action is taken in response to the detection of an anomaly in the thread tension profile. The remedial action can include altering a feed rate of the thread in order to adjust the thread tension, and / or repeating a previous operation. Anomaly detection can be performed with respect to stitching or sewing operations, and also with respect to trim operations performed in connection with moving between elements and / or thread color changes.

Owner:MELCO INT

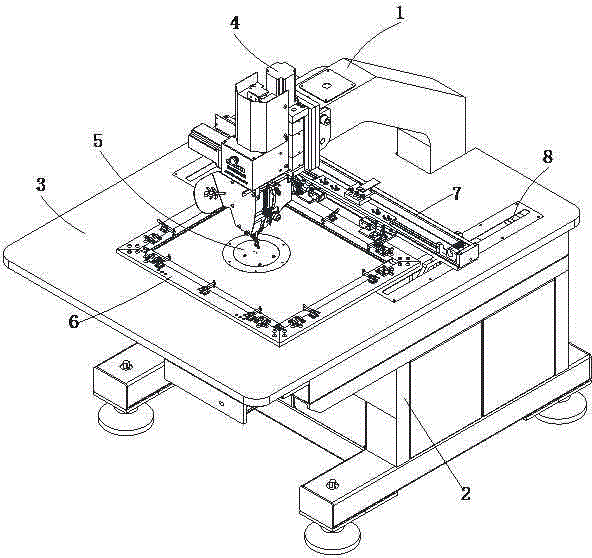

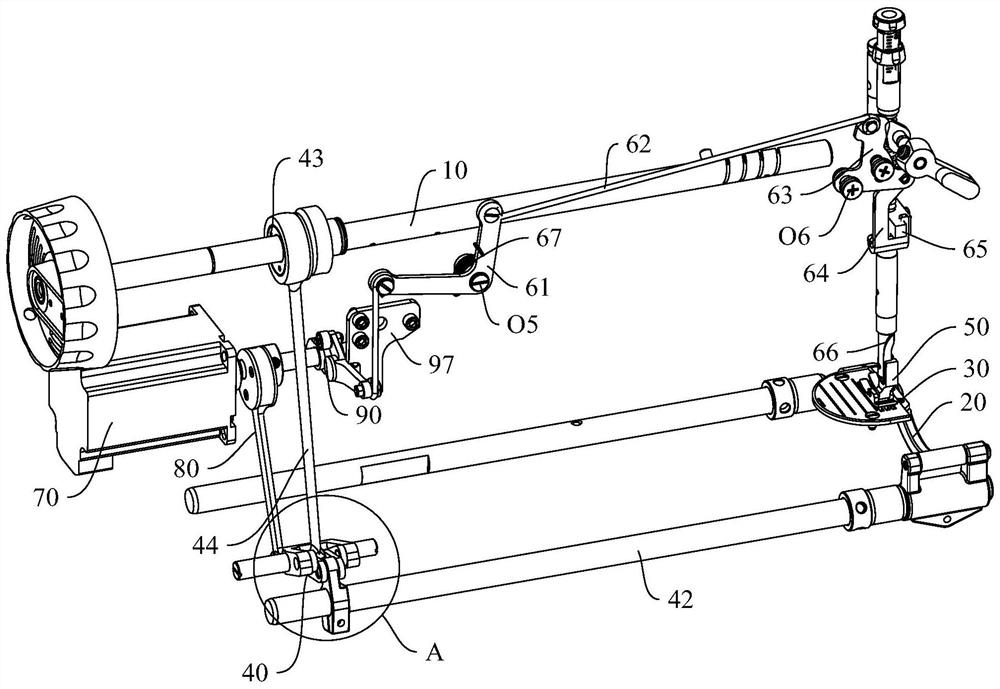

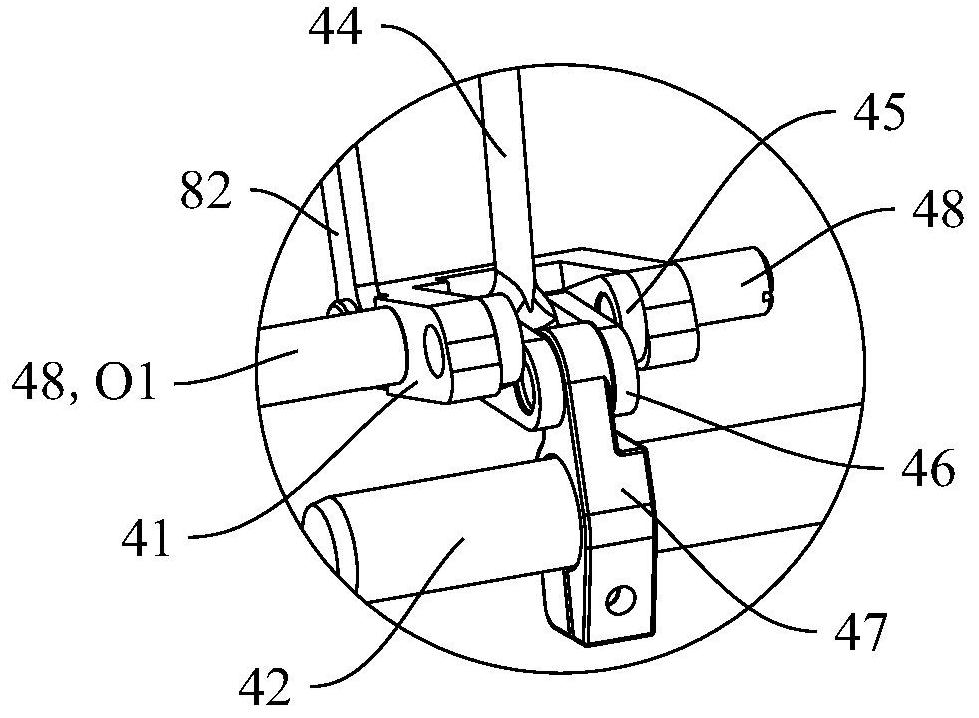

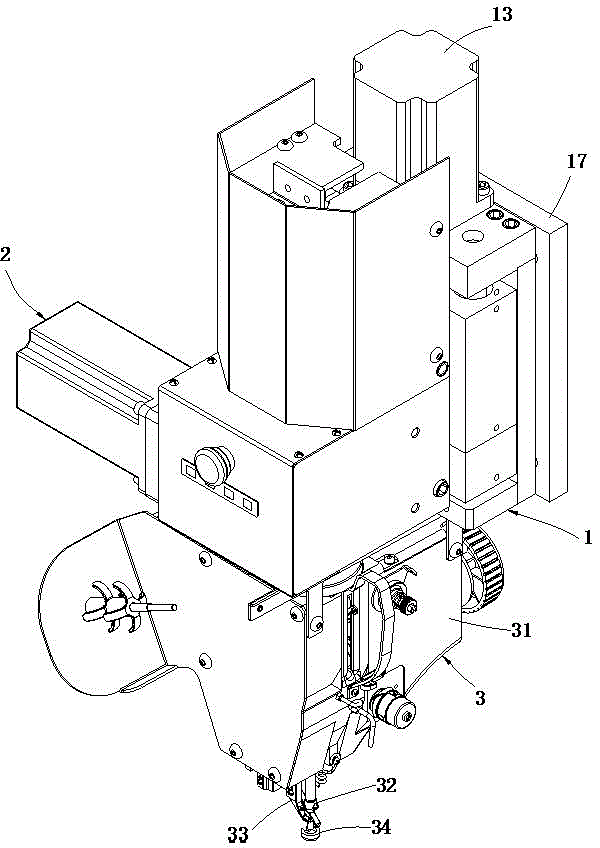

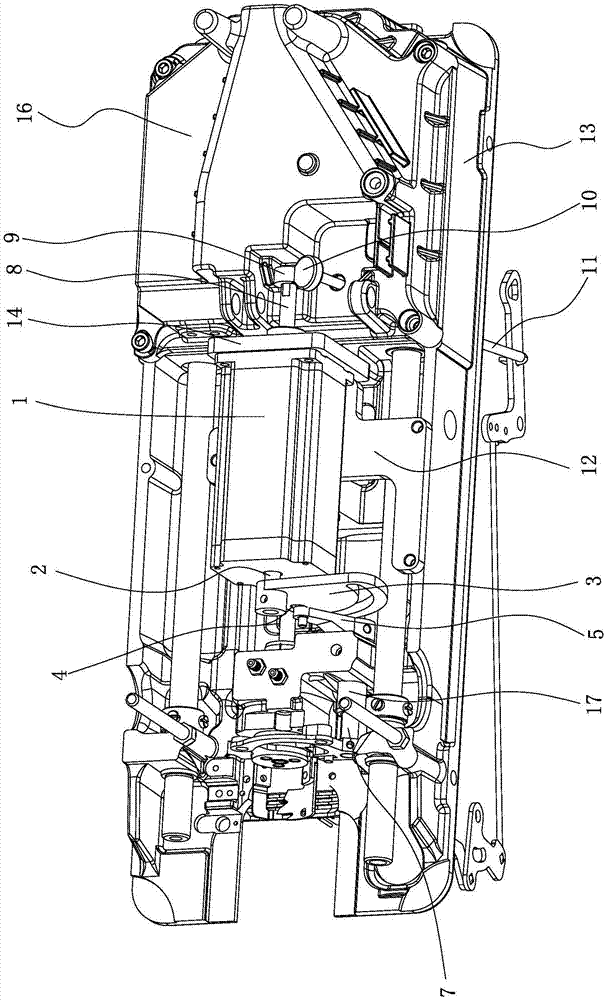

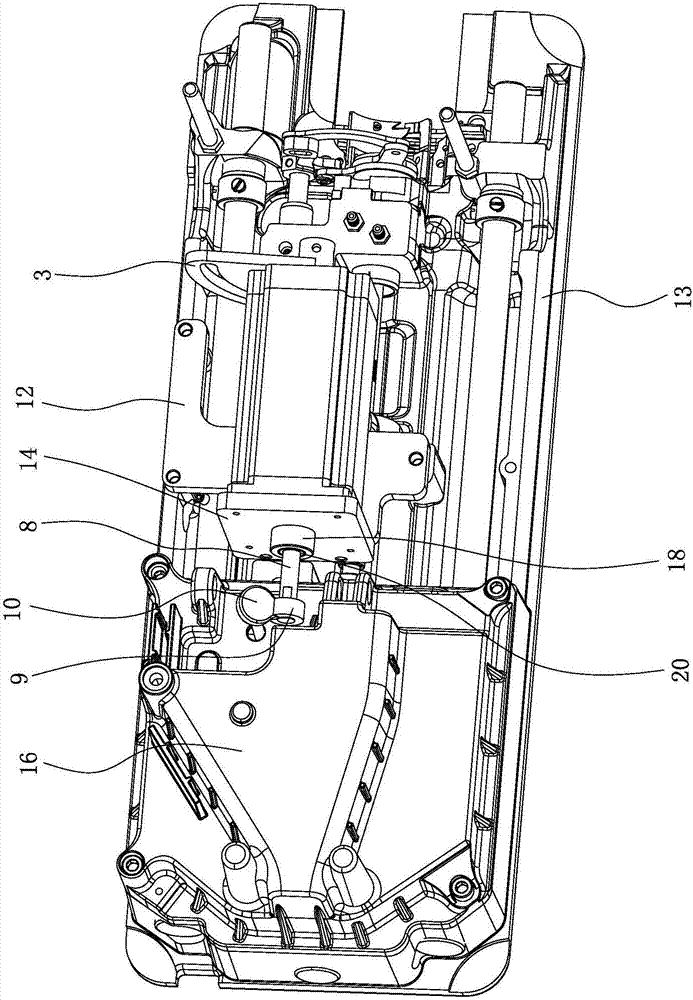

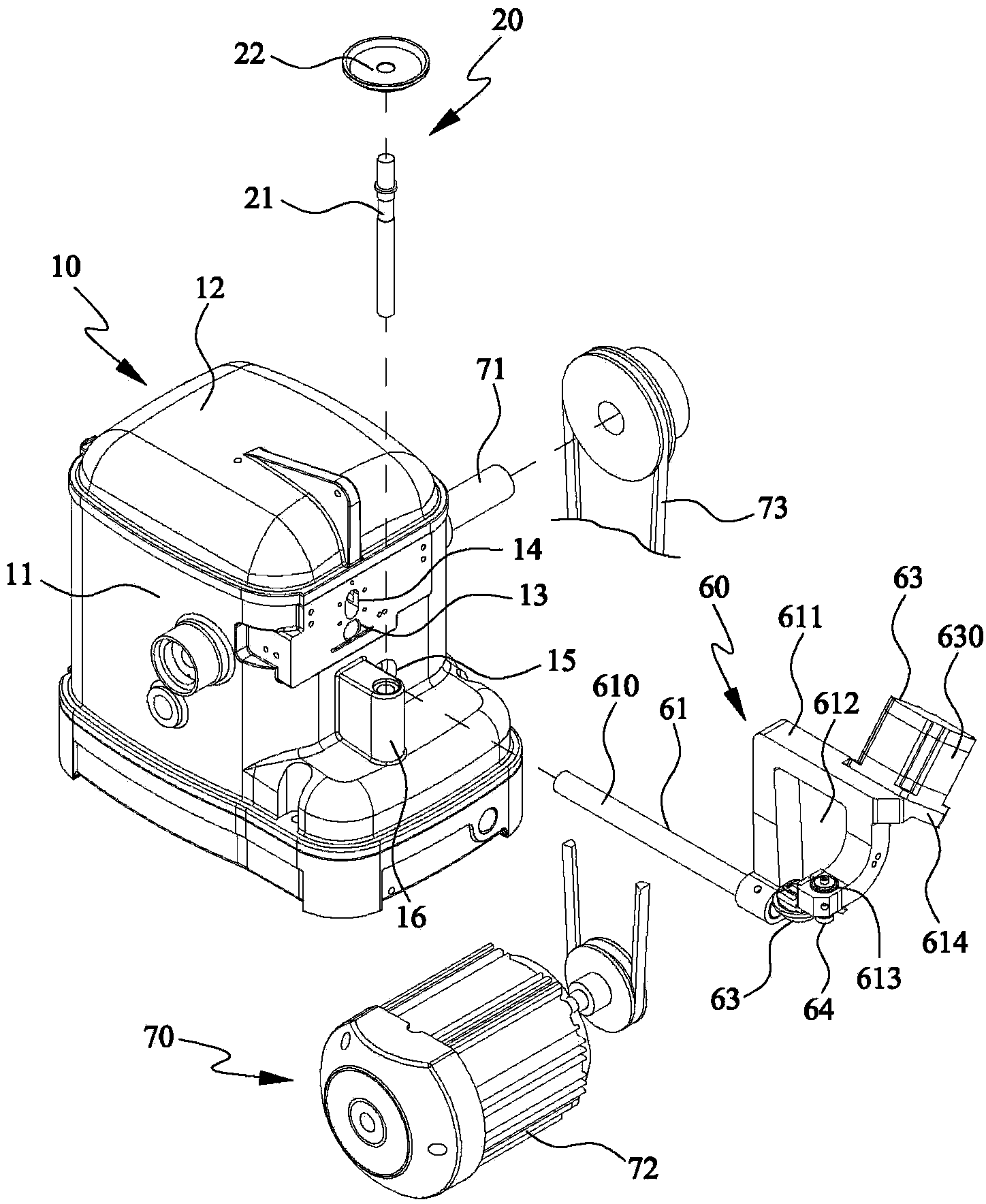

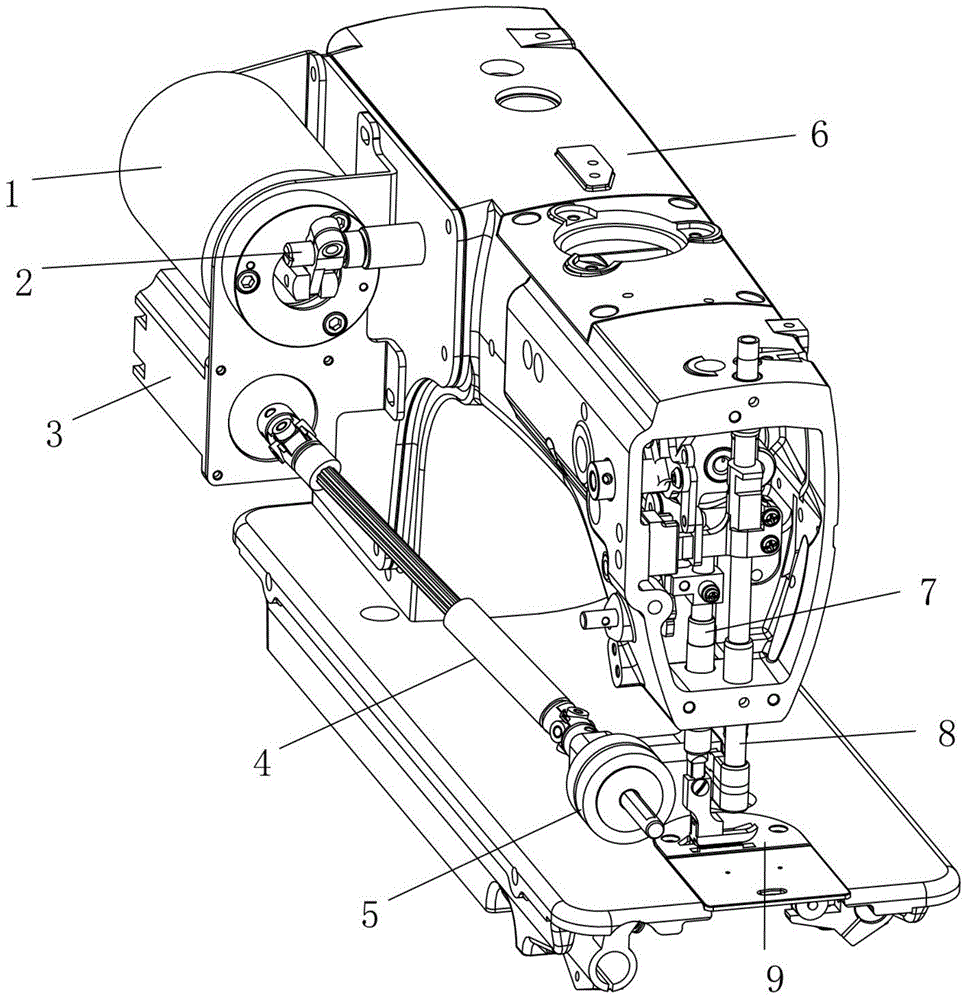

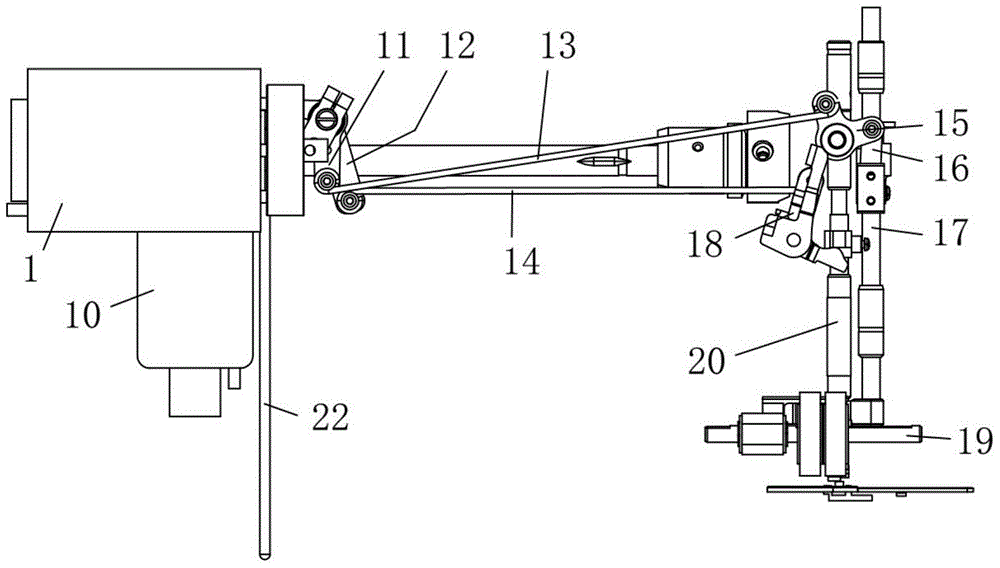

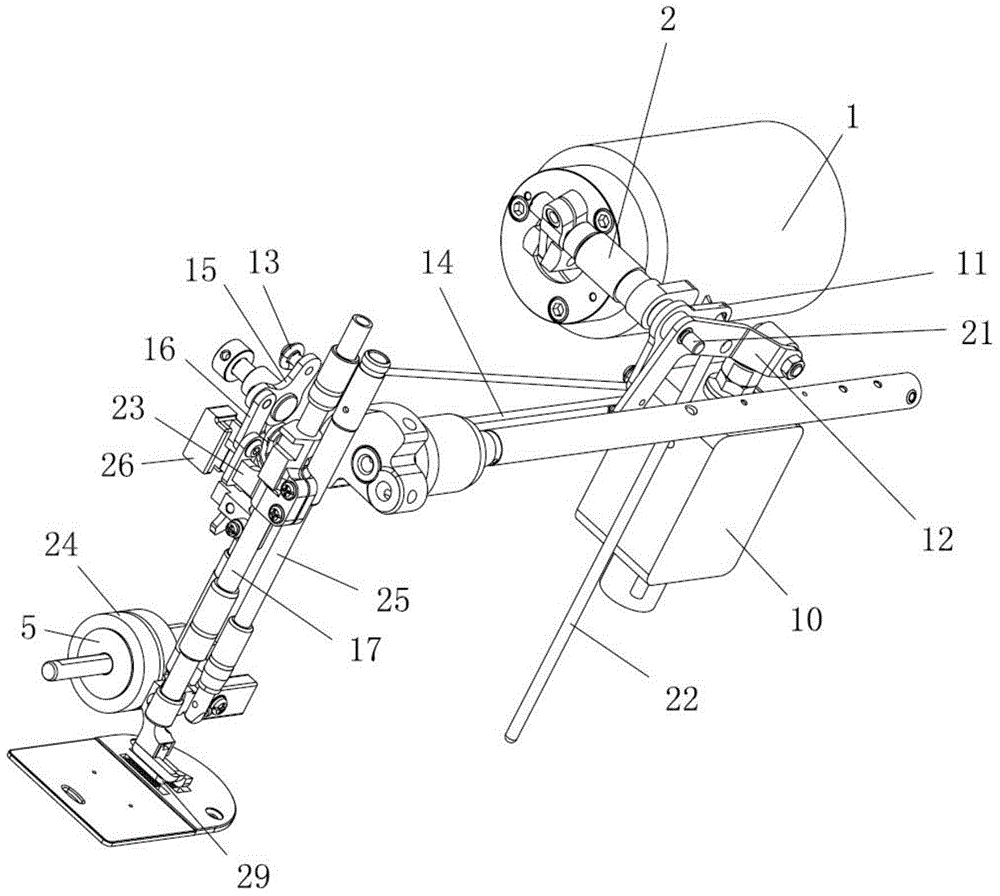

Outrigger rotating type independently-driven automatic sewing equipment

ActiveCN103981638AMeet processing needsPowerfulPressersNeedle barsFailure rateAutomatic test equipment

The invention relates to outrigger rotating type independently-driven automatic sewing equipment. The equipment comprises an upper machine head and a lower machine head which are independently driven respectively, wherein the upper machine head comprises a machine head lifting assembly, a machine head rotating assembly and a machine head assembly, the machine head rotating assembly is fixedly arranged on the machine head lifting assembly, the machine head assembly is fixedly arranged at the lower part of the machine head rotating assembly, and the upper machine head can rise / fall and can also adaptively rotate synchronously with the lower machine head; the lower machine head comprises a bottom line rotating assembly and a bottom shuttling system, the bottom shuttling system is arranged at the upper part of the bottom line rotating assembly, and the bottom line rotating assembly drives the bottom shuttling system to rotate in 360 degrees in any direction; each of the upper and lower machine heads is further provided with a servo-control system, and the servo-control systems control the steering of a bottom line rotating shaft and control the bottom line rotating shaft and machine head rotating shafts to correspond to each other and be in the same rotating speed. The equipment has the advantages that various machining needs can be met, the scope of application is greatly enlarged, and the function is powerful; the stability is high, the failure rate is low, and the maintenance is simple and convenient.

Owner:浙江锦上智控科技有限公司

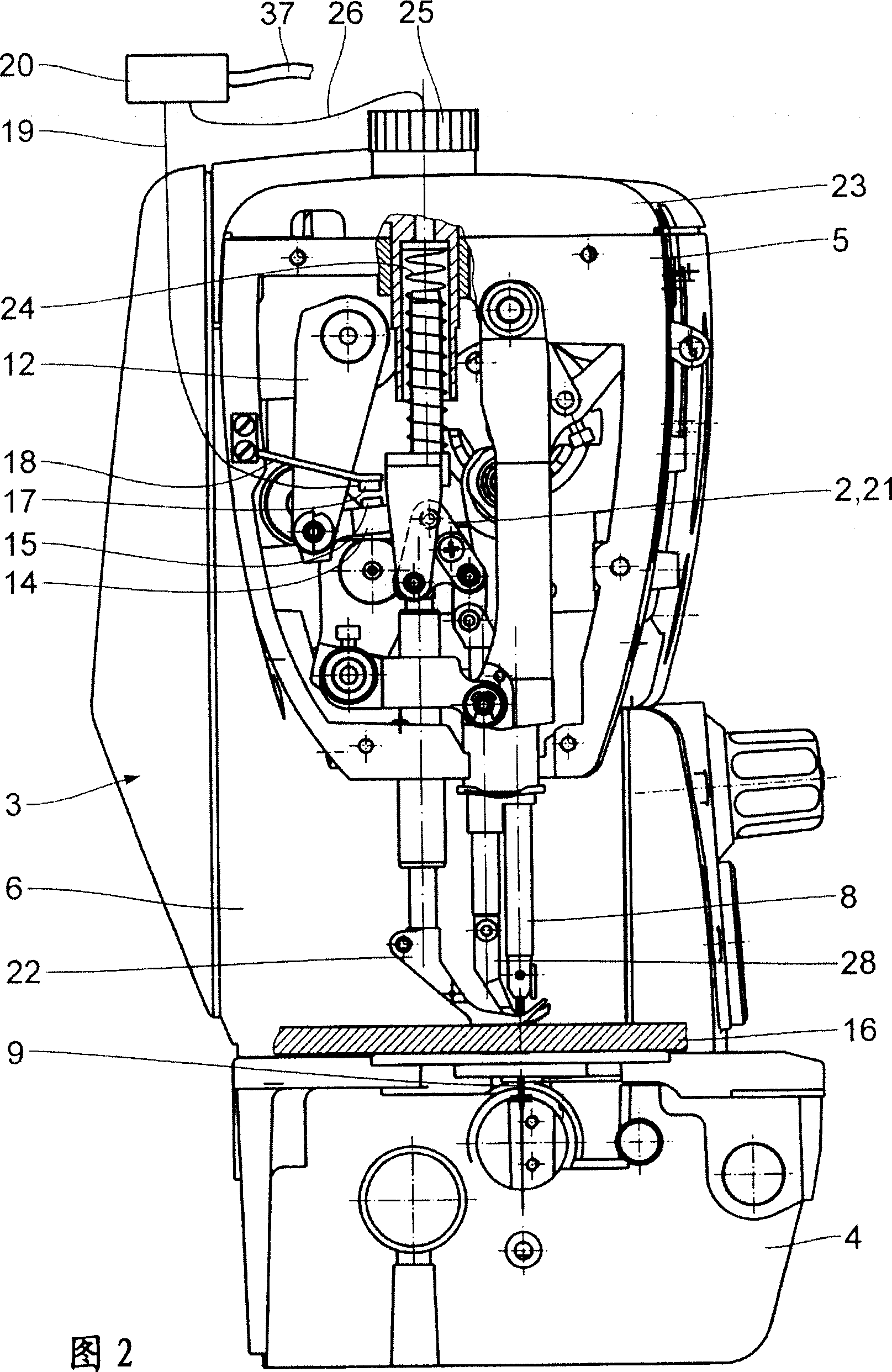

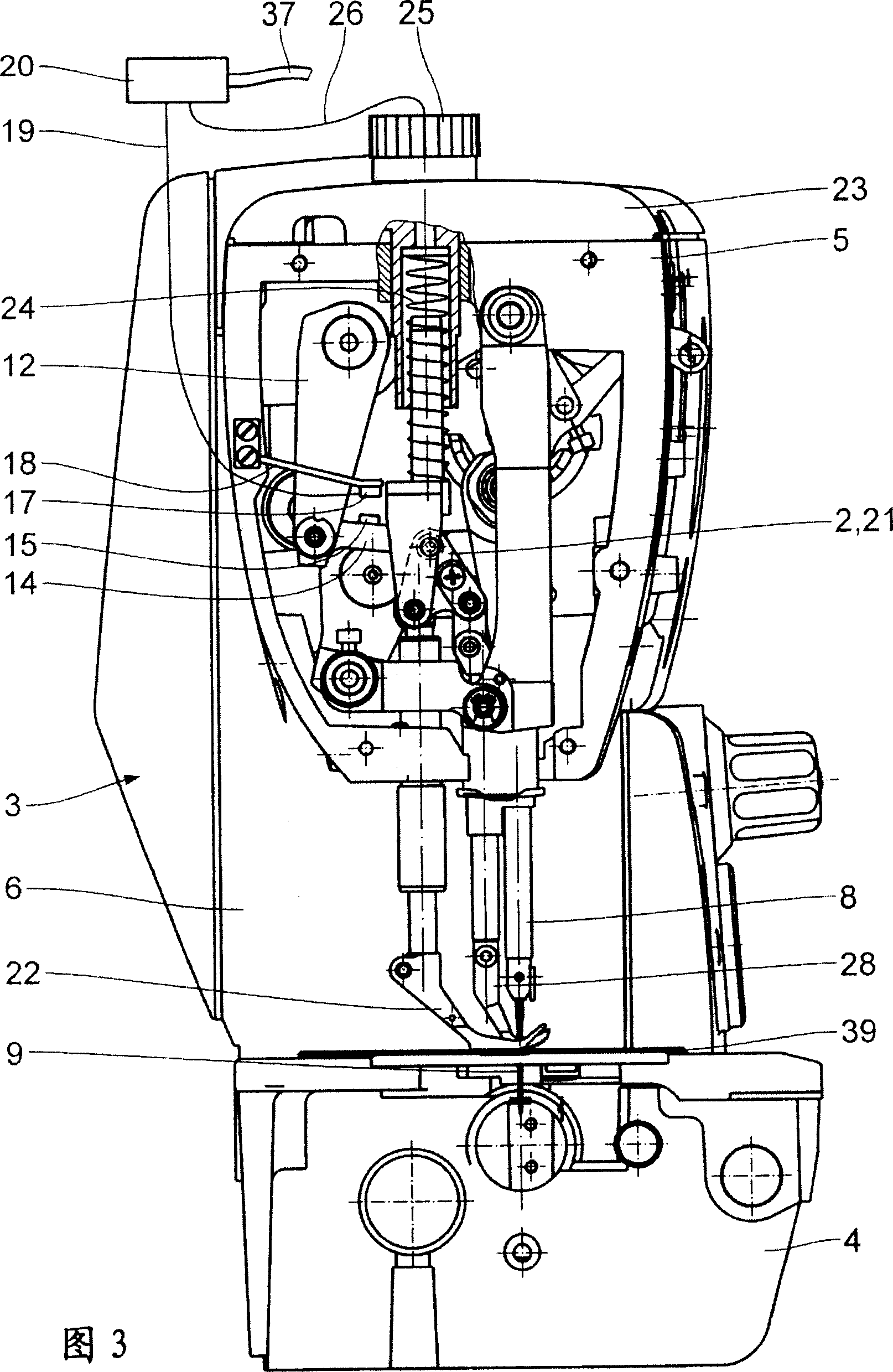

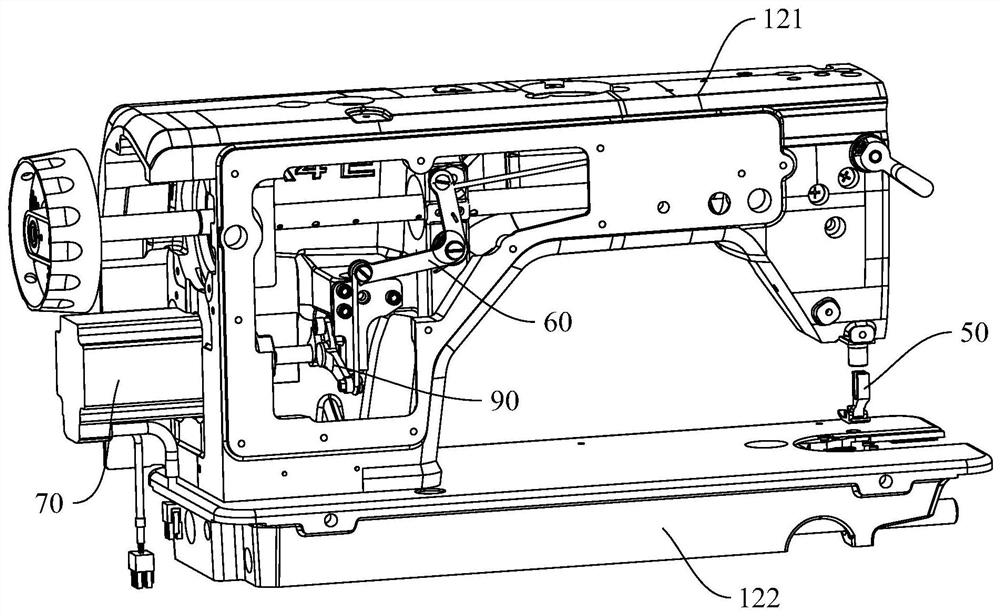

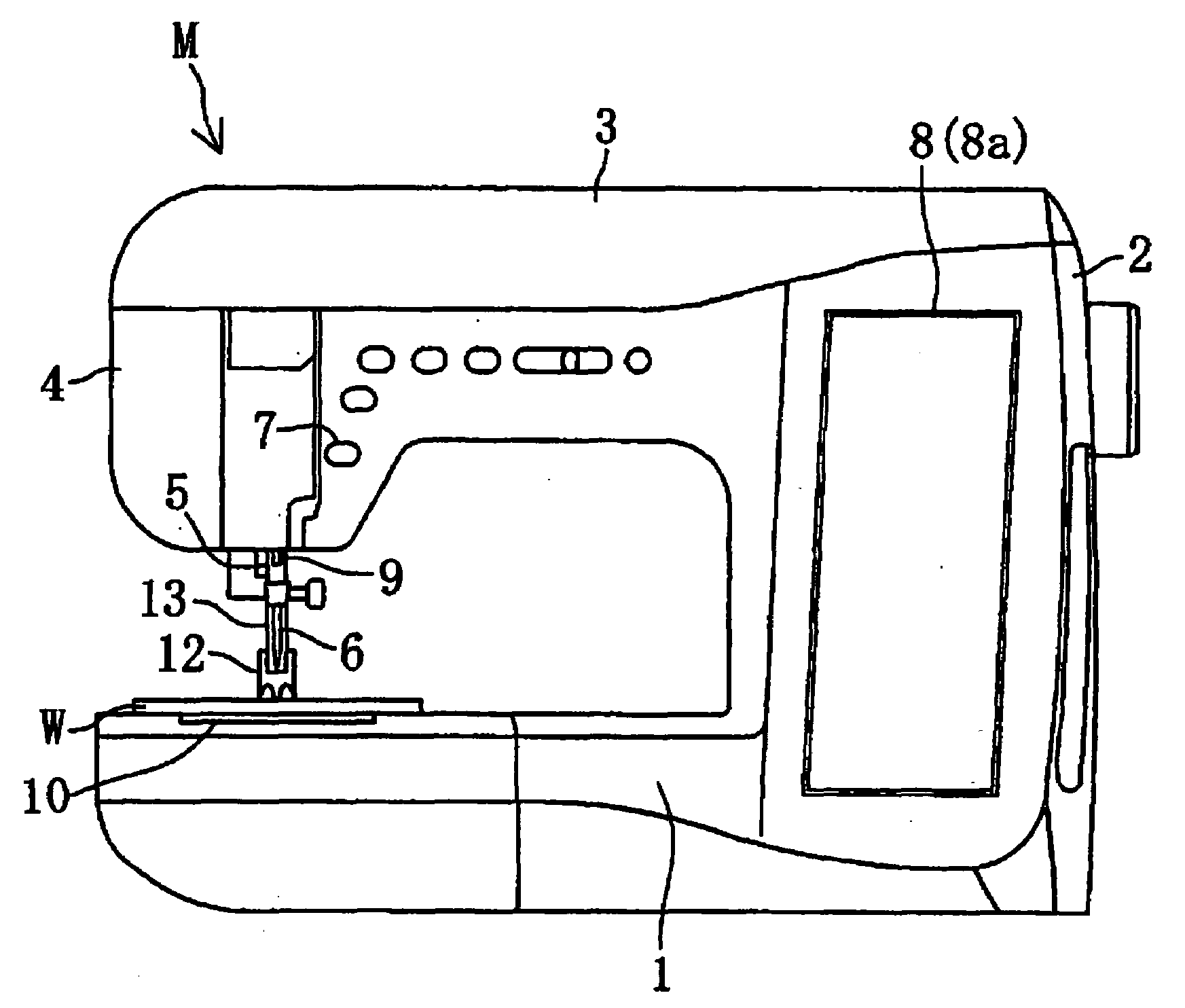

Sewing machine

InactiveCN1891887AReduce setup timeAvoid misadjustmentProgramme-controlled sewing machinesWork-feeding meansControl systemEngineering

The invention provided a sewing machine, improved to automatically switch the sewing machine to the thickness of cloth. This sewing machine includes: a housing having a base plate; a top arm; and a strut for integrating the base plate with the top arm. A metallic presser presses a cloth piece near a stitch forming position. The metallic presser driven by a movable rod is capable of moving between the lift position for releasing the cloth piece and the pressing position for the cloth piece to be pressed. When the metallic presser moves between these positions, the distance of at least one movable rod part from a reference structure fixed to the housing stably changes. The position sensor detects the position of the metallic presser in the pressing position. A control system makes signal connection thereto. The system sets an adjustment variable for the sewing machine depending upon the output value of the position sensor. As a result, the obtained sewing machine automatically performs switching to the thickness of variable cloth piece.

Owner:DURKOPP ADLER AG

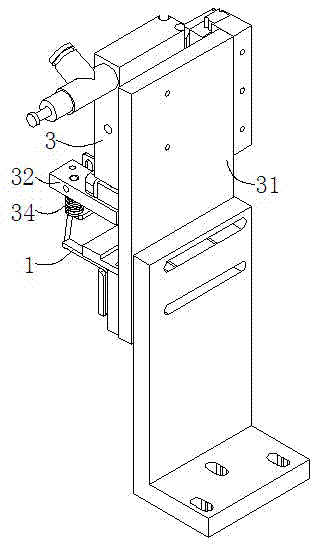

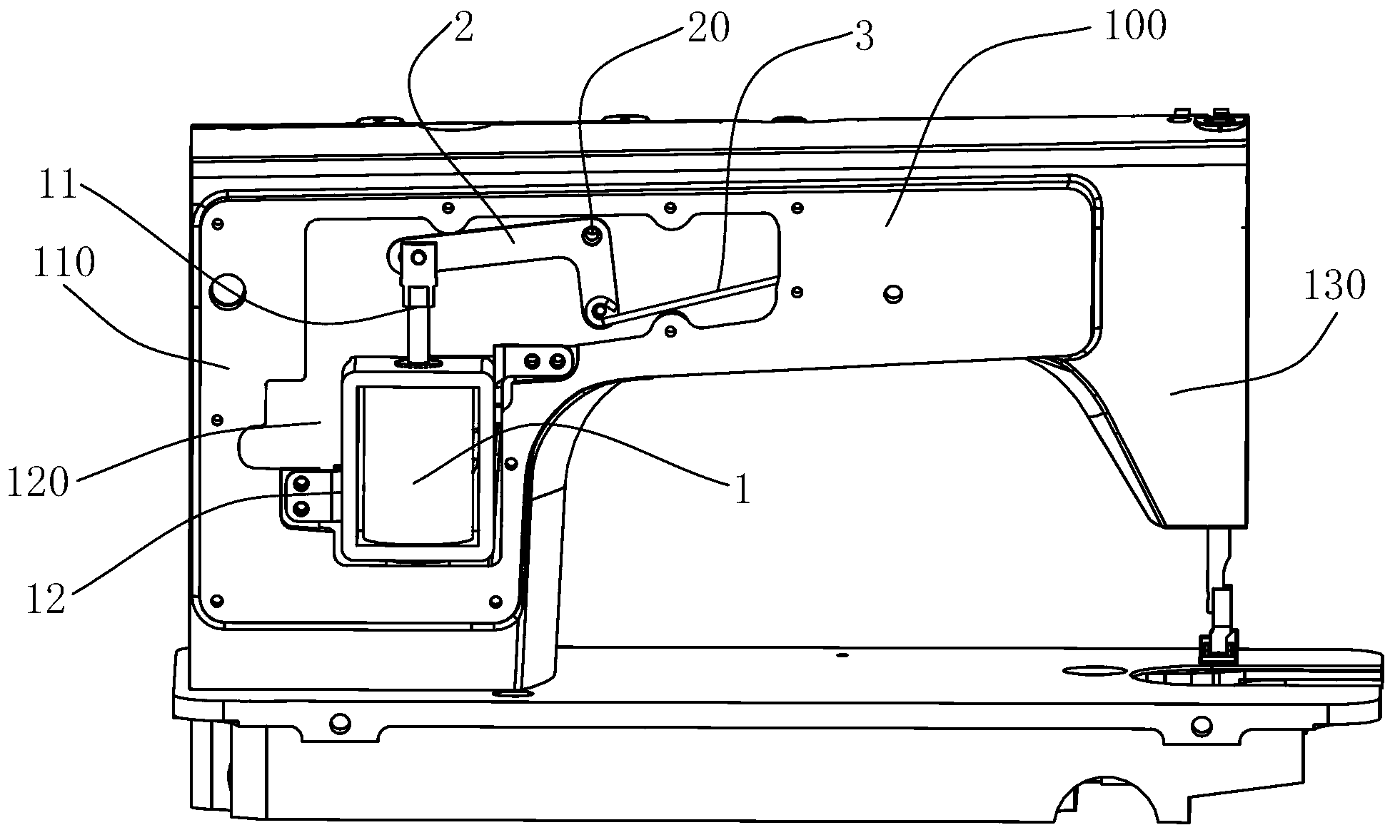

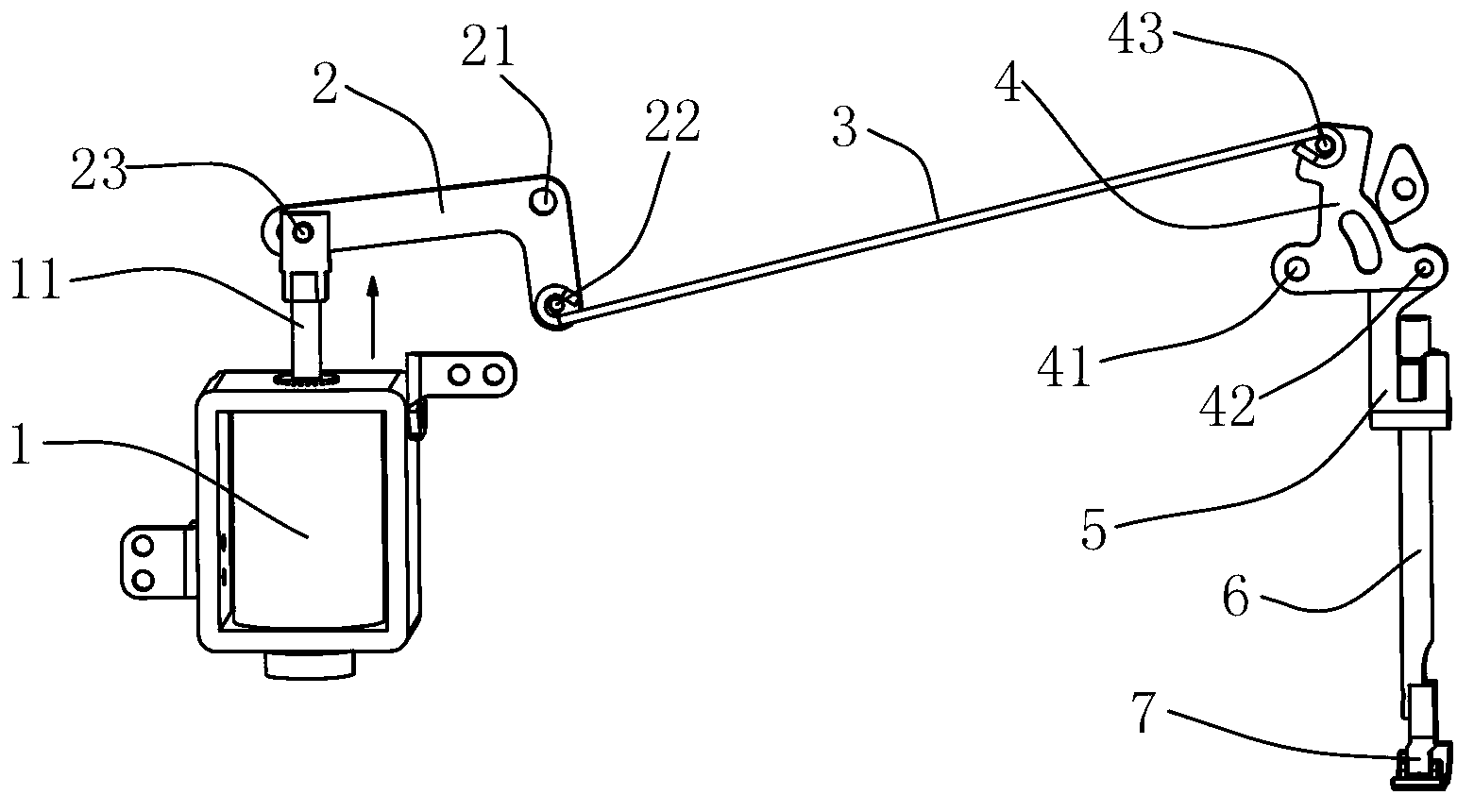

Built-in type automatic pressure foot lifting mechanism of sewing machine

The invention discloses a built-in type automatic pressure foot lifting mechanism of a sewing machine. The built-in type automatic pressure foot lifting mechanism comprises a housing, a linear driver, a back lever, a front lever and a pull rod, wherein the housing comprises an upright column part; a cavity is formed in the upright column part; the linear driver is fixedly mounted in the cavity and comprises a drag rod which is capable of linearly moving in a reciprocating manner; a back pin hole of the back lever is hinged with one end part of the drag rod, a first front pin hole of the back lever is rotationally connected onto the housing through a pin shaft, and the distance from the back pin hole to the first front pin hole is greater than the distance from a second front pin hole to the first front pin hole; the front lever comprises three pin holes, the first pin hole is rotationally connected onto the housing through a pin shaft, and the second pin hole is hinged with a pressure foot lifting plate; and the back end of the pull rod is hinged with the second front pin hole of the back lever, and the front end of the pull rod is hinged with the third pin hole of the front lever. According to the built-in type automatic pressure foot lifting mechanism, the linear driver is arranged in the housing, so the structure of the whole mechanism is more compact, the appearance of the mechanism is more attractive, and vibration and noise produced when the automatic pressure foot lifting device works are also reduced.

Owner:JACK SEWING MASCH CO LTD

Towel machine with high product quality

ActiveCN103757827AReduce labor intensityReduce manufacturing costWork-feeding meansPressersUltimate tensile strengthAutomation

The invention discloses a towel machine with high product quality. The towel machine comprises a feeding device, a serging device, a manufacturing device and a hot melting device. The feeding device is fixedly connected with the serging device. The manufacturing device and the serging device are arranged in a relatively fixed mode. The hot melting device is arranged on the side face of the manufacturing device. Cloth is fed into the serging device by the feeding device. Primary double-side serging is carried out on the cloth fed by the feeding device by the serging device. Secondary double-side serging is carried out on the cloth by the manufacturing device after the cloth discharged out of the serging device is cut off. The hot melting device carries out hot melting on the cloth discharged out of the manufacturing device. According to the towel machine with the high product quality, mechanical automation replaces the original manual operation to produce towels, the labor intensity of workers is lowered, product production efficiency is stably improved, production cost is lowered, production can be effectively managed, and practical high production requirements are met.

Owner:SUZHOU TRANSPARENT TECH CO LTD

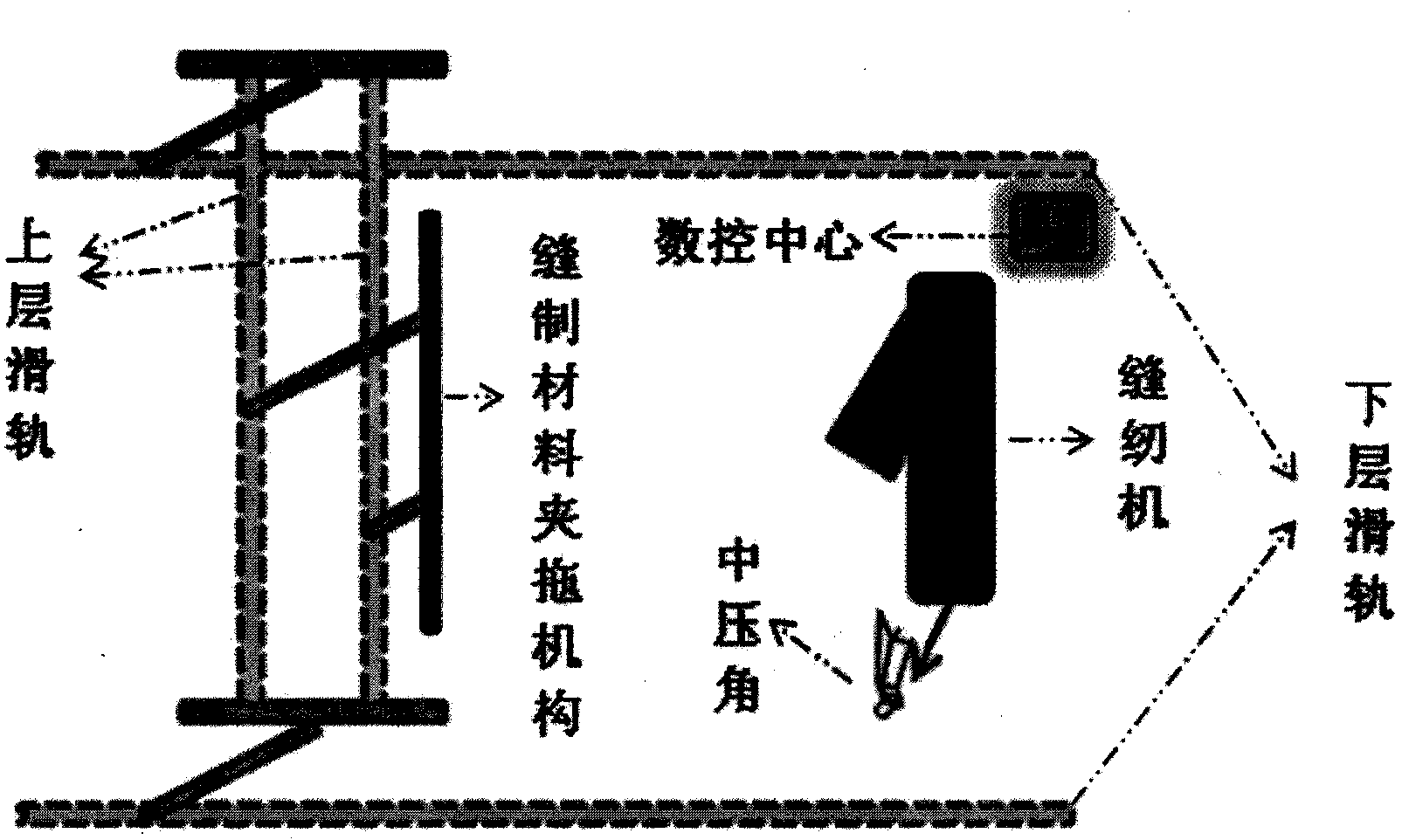

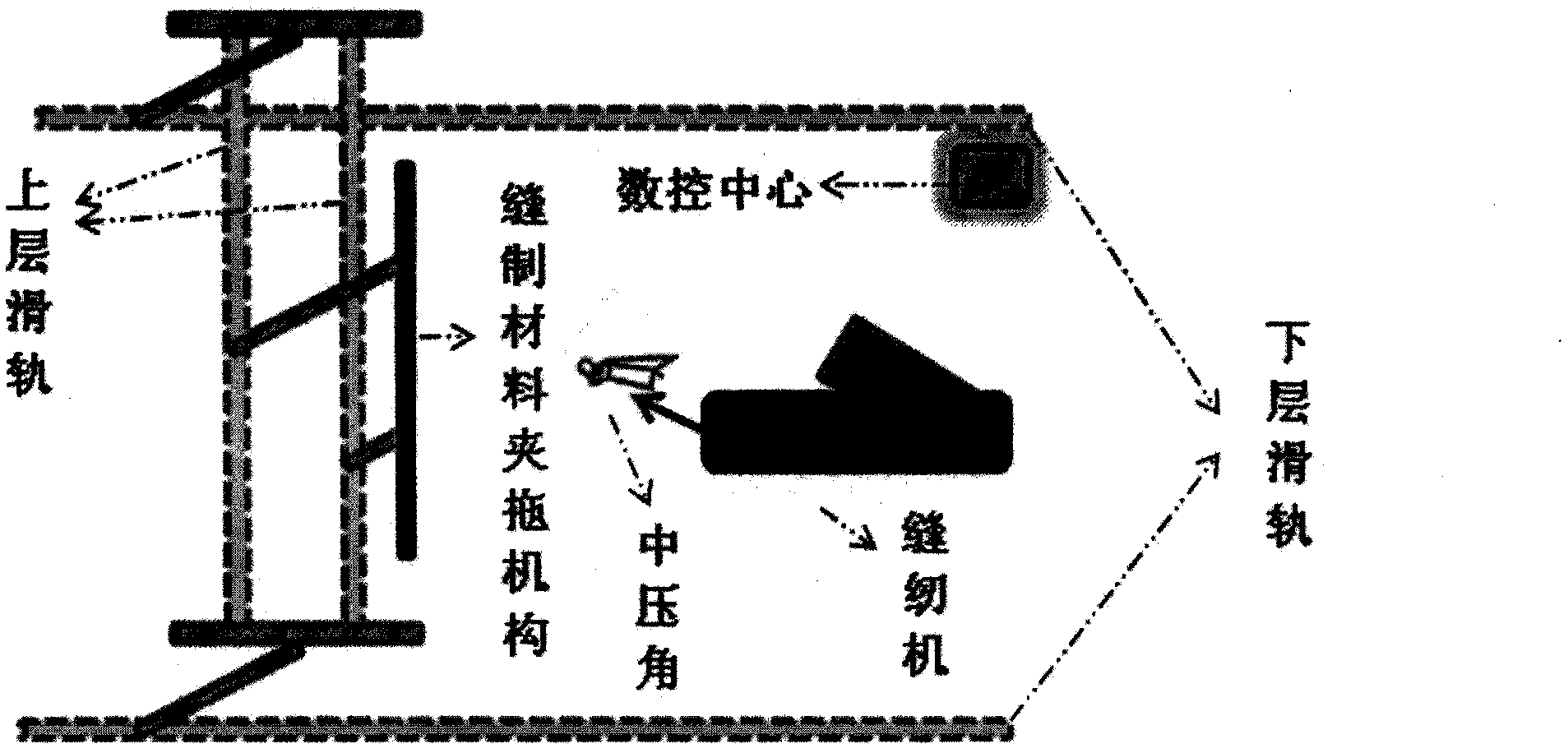

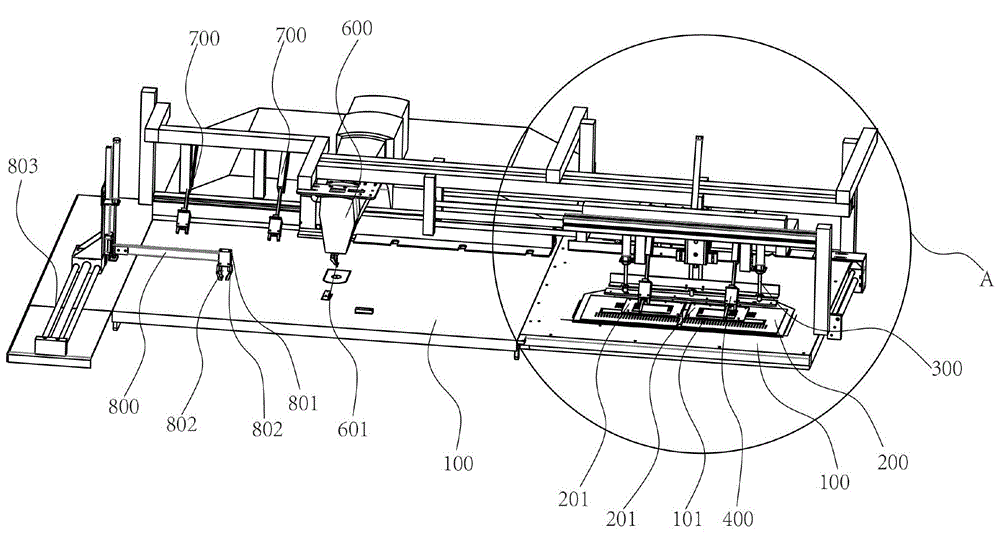

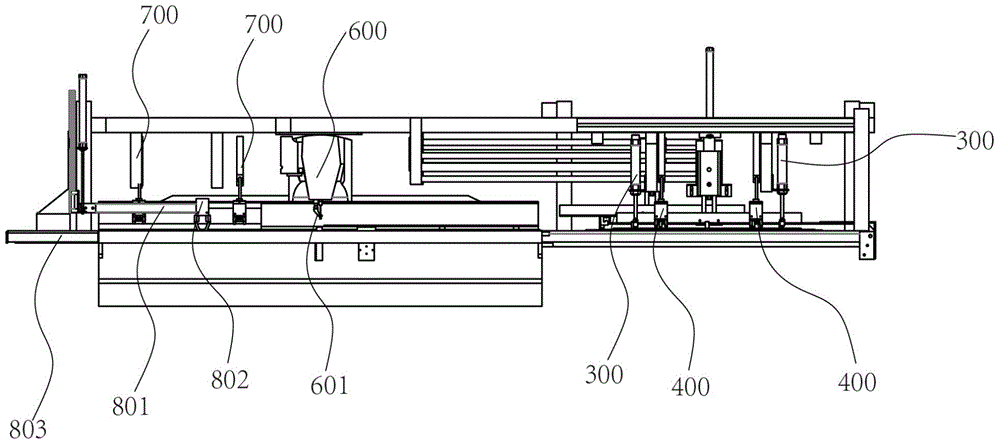

Numerical-control sewing processing equipment

InactiveCN104233647AGuaranteed operational safetyGuaranteed independenceWork-feeding meansSewing-machine control devicesNumerical controlMultiple layer

Owner:王艳玲

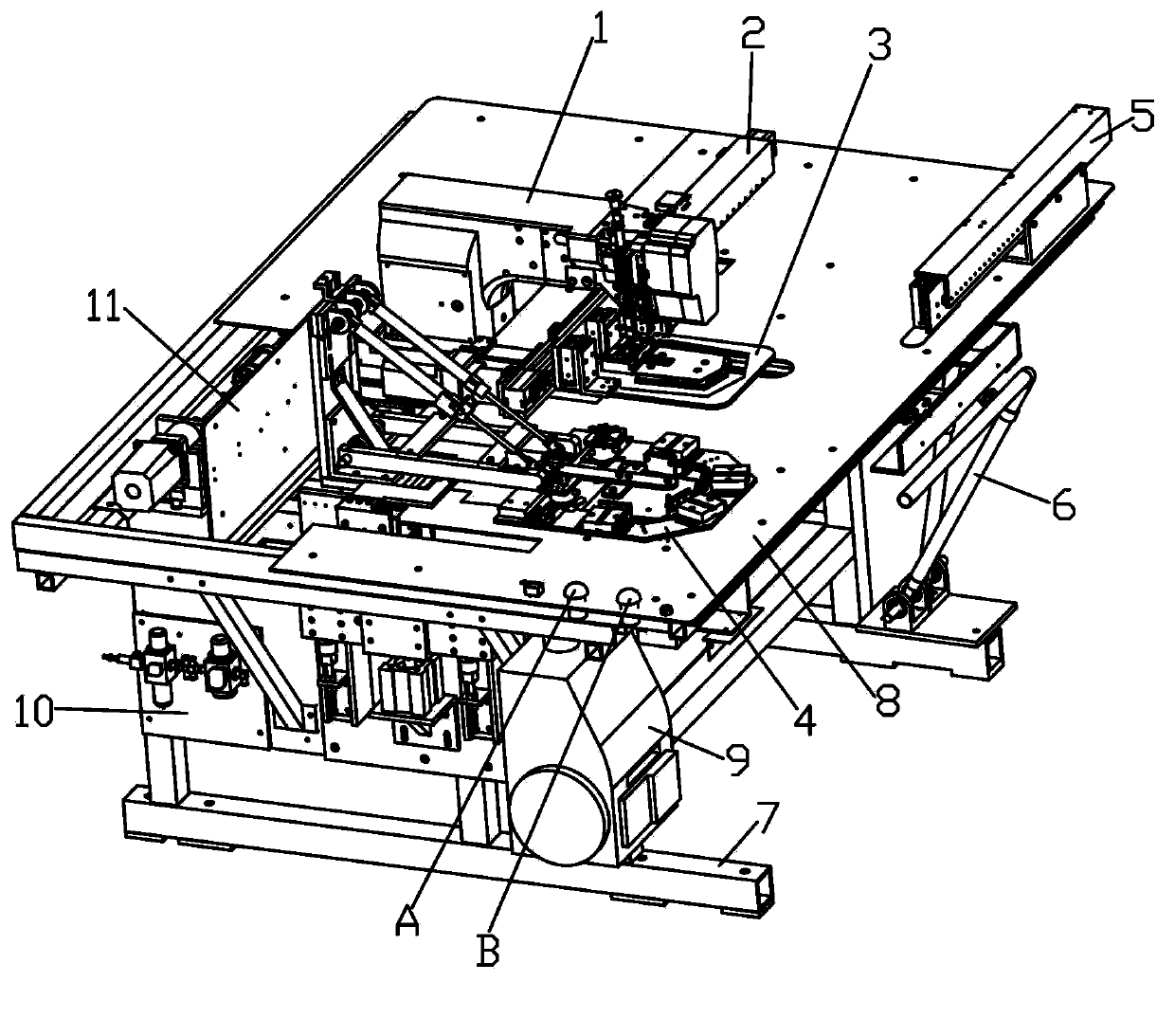

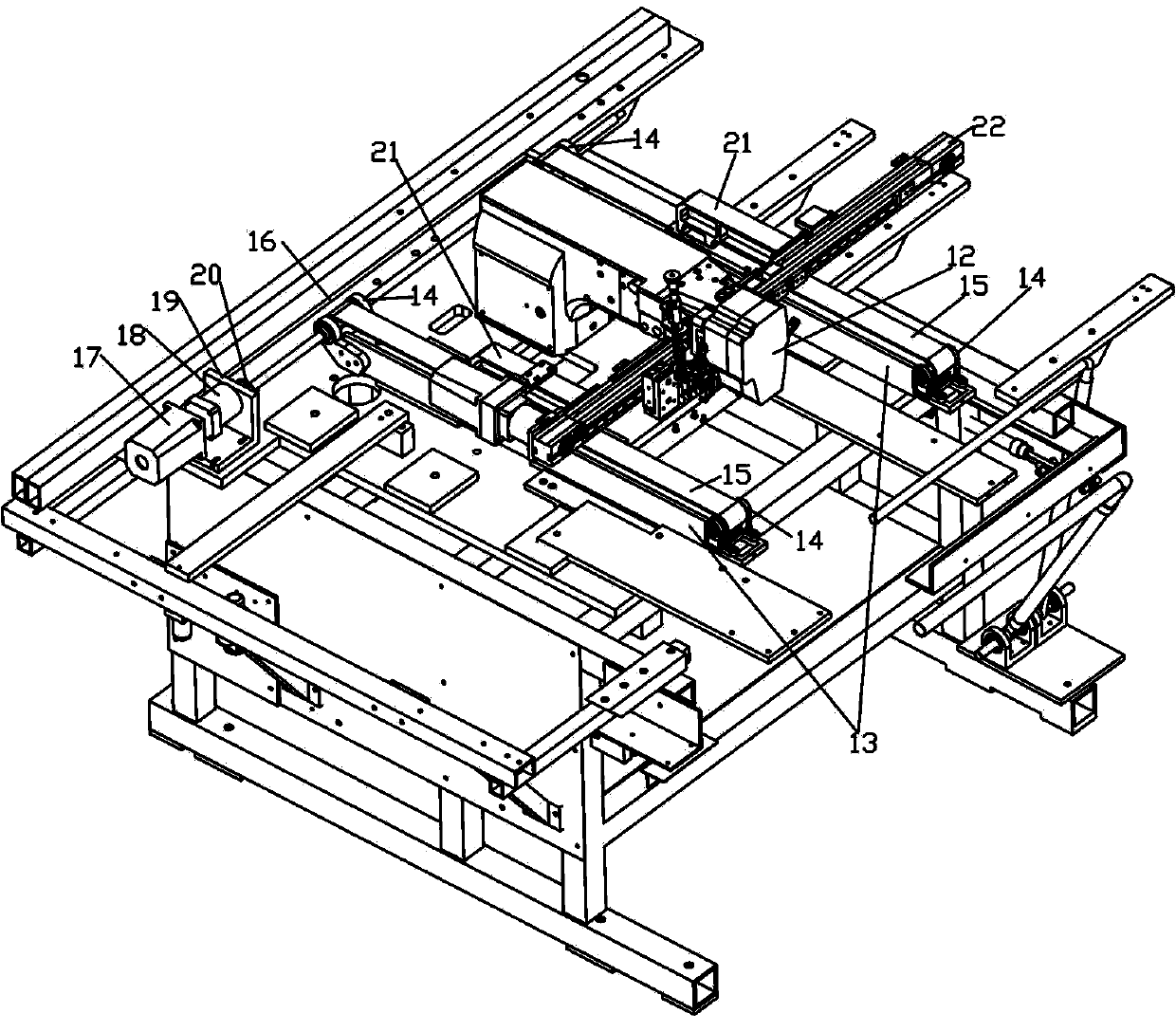

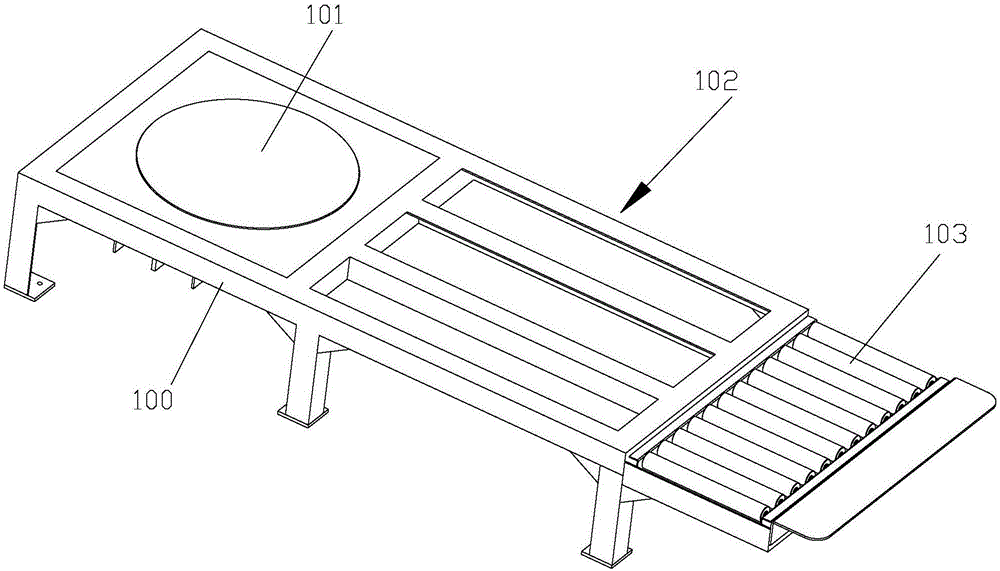

Automatic seam abutting device for cutting pieces and seam abutting method of automatic seam abutting device

ActiveCN104593956AGuaranteed continuous operationLower skill requirementsWork-feeding meansPressersEngineeringMechanical engineering

The invention discloses an automatic seam abutting device for cutting pieces and a seam abutting method of the automatic seam abutting device. The automatic seam abutting device comprises a machine table, a control device, an air sucking device, a stamper device, a positioning device, a feeding device and a sewing device, wherein the air sucking device is provided with a plurality of air sucking holes, and the air sucking holes are formed in a table surface of the machine table; the stamper device is provided with at least one pressing arm and a stamper driving device for driving the pressing arm to move; the positioning device is provided with at least one positioning arm and a positioning driving device for driving the positioning arm to move; the air sucking device, the stamper device, the positioning device, the feeding device and the sewing device are connected to the machine table, and the air sucking device, the stamper driving device, the positioning driving device, the feeding device and the sewing device are electrically connected to the control device. The automatic seam abutting device for the cutting pieces involved by the invention is suitable for the seam abutting technology of most collars, the requirements for the skills of workers are greatly lowered, and the production efficiency is improved.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD +1

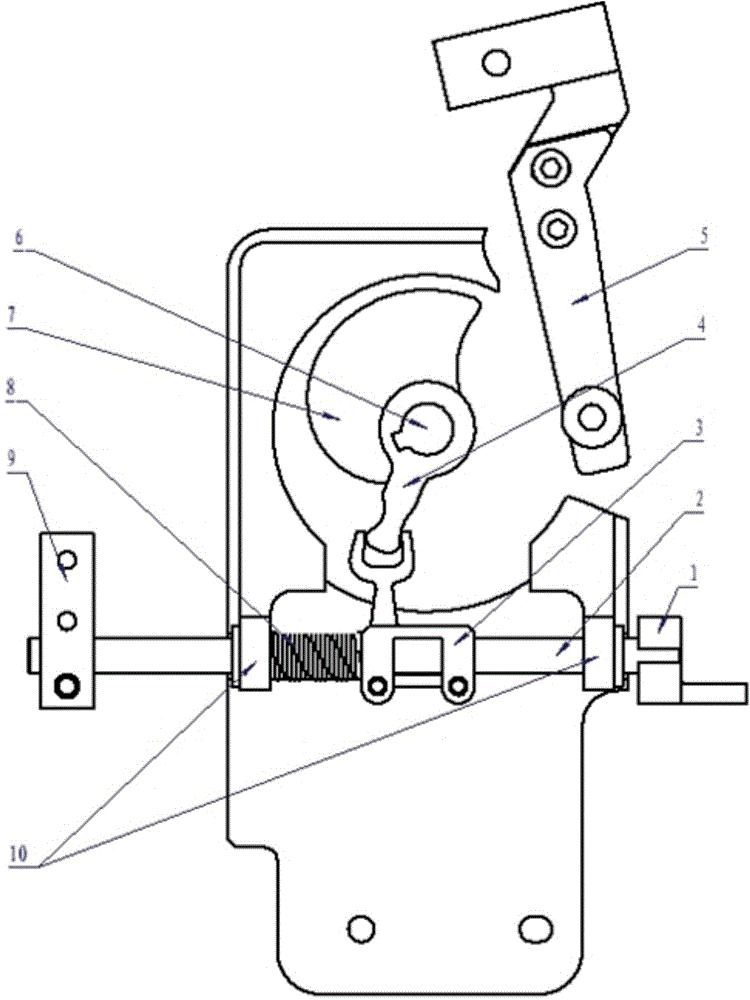

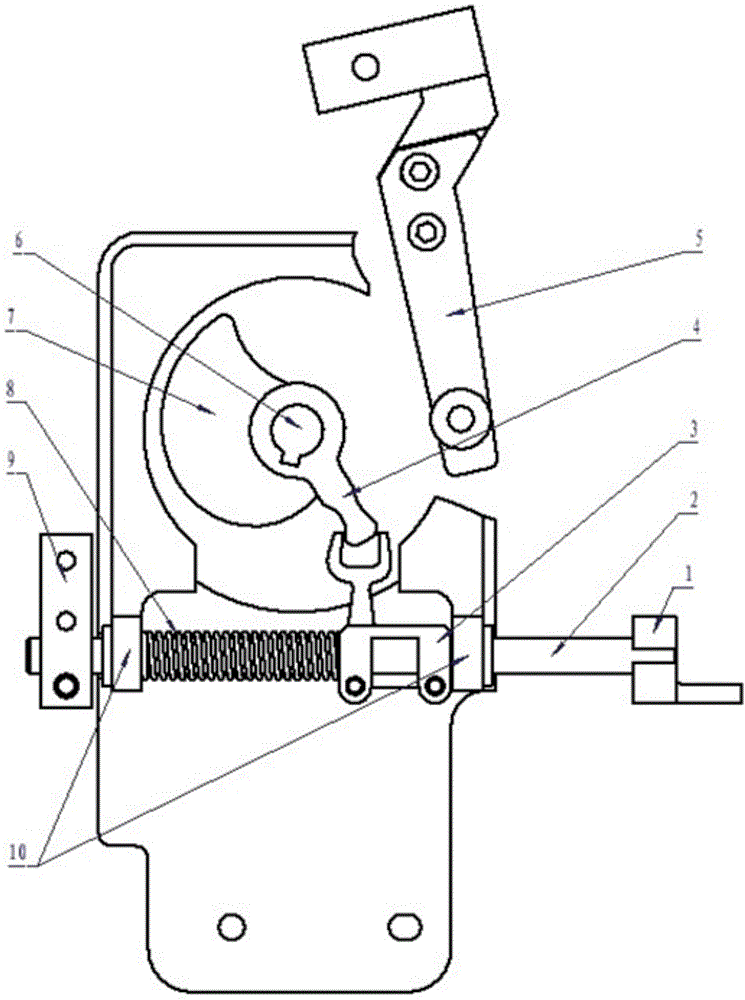

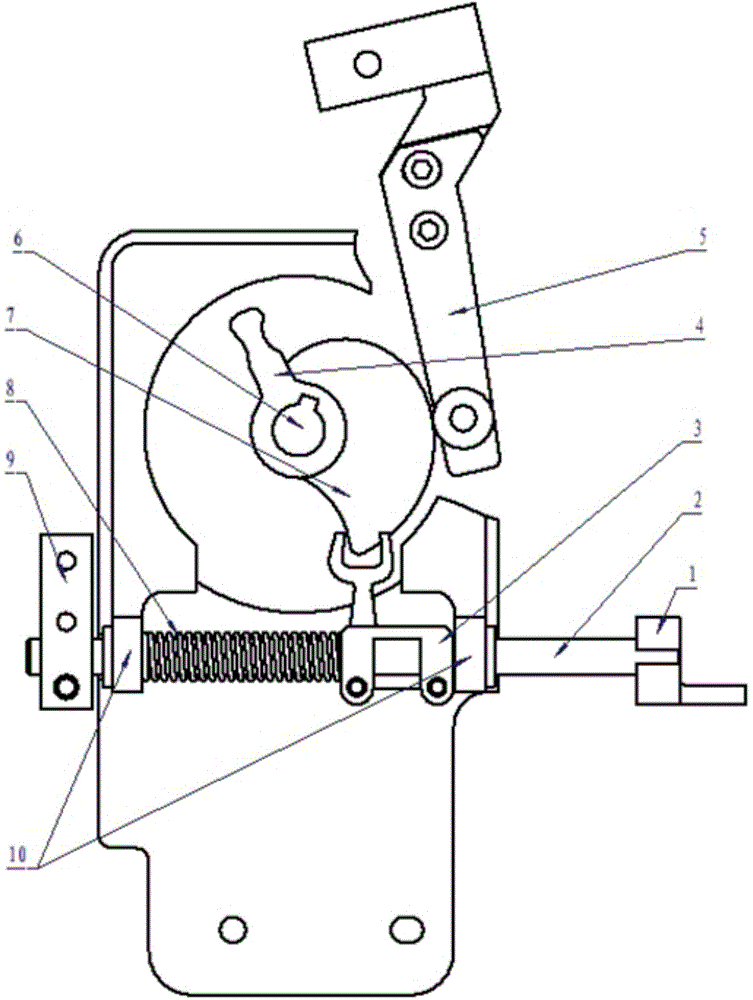

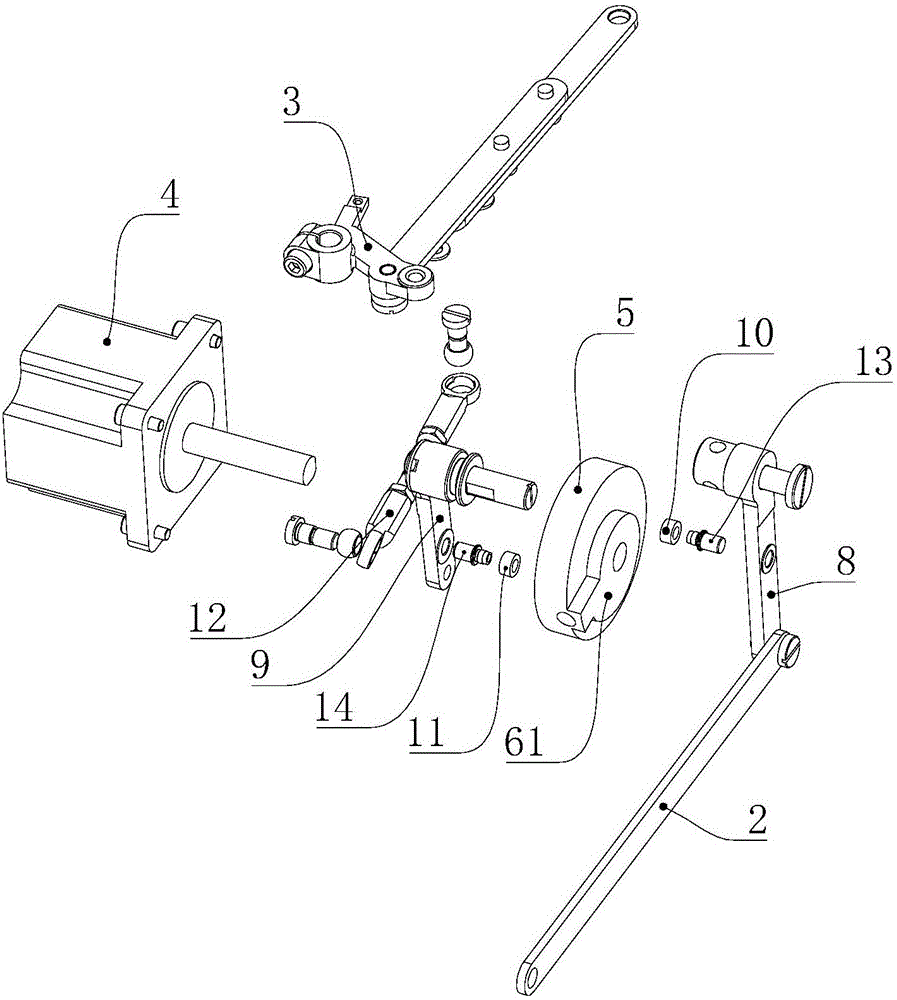

Thread trimming and presser foot raising driving device of sewing machine

ActiveCN104878529AFew partsLow costNeedle severing devicesSewing-machine control devicesEngineeringCam

The invention provides a thread trimming and presser foot raising driving device of a sewing machine. The technical problems that thread trimming, thread loosening and presser foot raising are implemented by two existing thread trimming and presser foot raising driving devices, the cost is high, occupied space is large, noises are large, mounting time is long, and mounting is not facilitated are solved. The thread trimming and presser foot raising driving device of the sewing machine comprises a stepping motor, a shifting fork mechanism and a cam, wherein the shifting fork mechanism comprises a shifting rod, a fork rod, a sliding rod and at least two fixing rings; one end of the shifting rod and the cam are fixed on a spindle of the stepping motor; the other end of the shifting fork can extend in the fork rod and drives the fork rod to move; the fork rod is fixed on the sliding rod; the sliding rod is positioned in the two fixing rings and can slide in the fixing rings; and a movement trace of the cam and a free end of a presser foot raising connecting rod of the sewing machine are intersected. A lower thread trimming device and a thread slacking device are driven to perform thread trimming, thread clamping and thread slacking through the shifting fork mechanism, and presser foot raising is implemented through the cam.

Owner:STRONG H MACHINERY TECH

Sewing machine

ActiveCN111648053AAvoid collisionCompact structureWork-feeding meansPressersElectric machineryEngineering

The invention provides a sewing machine. The sewing machine comprises a main shaft, a material feeding mechanism, a presser foot lifting mechanism, a driving motor, a needle pitch adjusting power transmission mechanism and a presser foot lifting transmission mechanism, wherein the material feeding mechanism is provided with a material feeding swinging seat; the needle pitch adjusting power transmission mechanism enables power transmission to continuously exist between the driving motor and the material feeding swinging seat; a collision avoidance structure is arranged in the presser foot lifting transmission mechanism; a corner of an output shaft of the driving motor is provided with a needle pitch active adjusting area and a presser foot lifting area; when the output shaft of the drivingmotor operates within the needle pitch active adjusting area, the sewing machine is provided with effective needle pitch; the collision avoidance structure enables no power transmission to exist between the driving motor and a presser foot lifting mechanism; when the output shaft of the driving motor operates within the presser foot lifting area, the presser foot lifting transmission mechanism enables power transmission to exist between the driving motor and the presser foot lifting mechanism; and the absolute value of a needle pitch corresponding to an angle of the material feeding swinging seat is not larger than a maximum absolute value of the effective needle pitch. According to the sewing machine, timely response, suspended seam and very good needle pitch adjusting stability of the needle pitch adjusting mechanism are realized.

Owner:JACK SEWING MASCH CO LTD

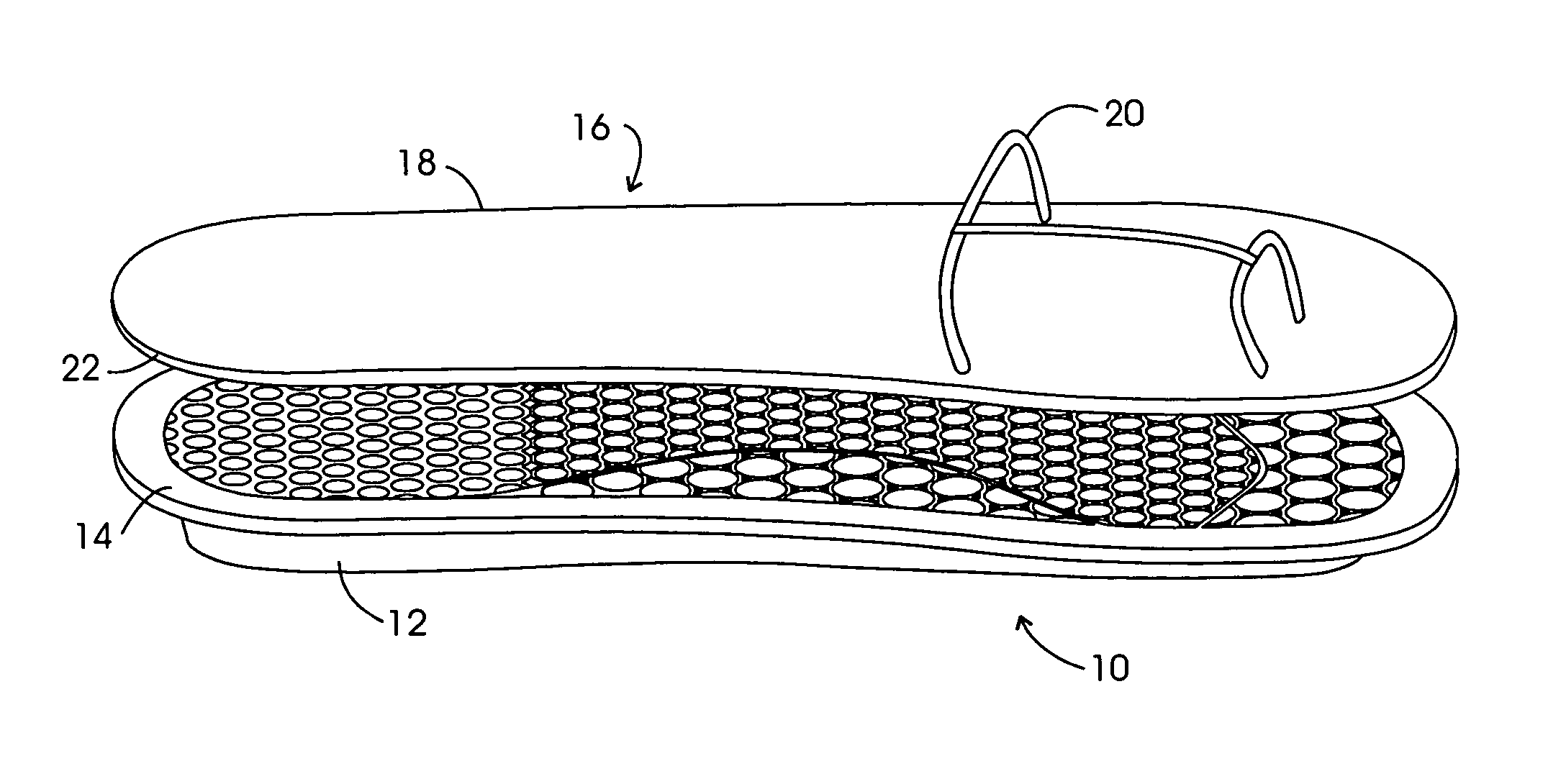

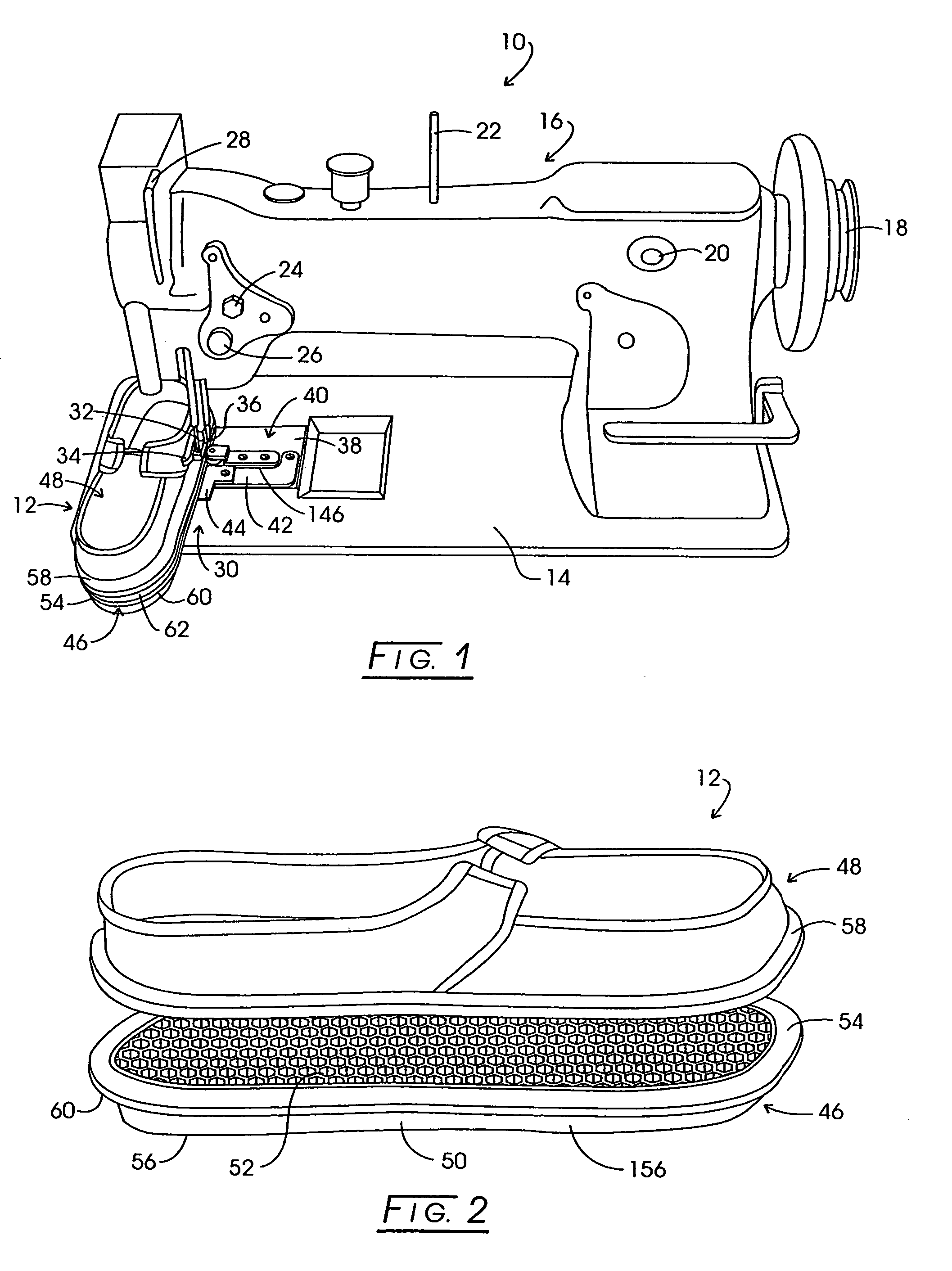

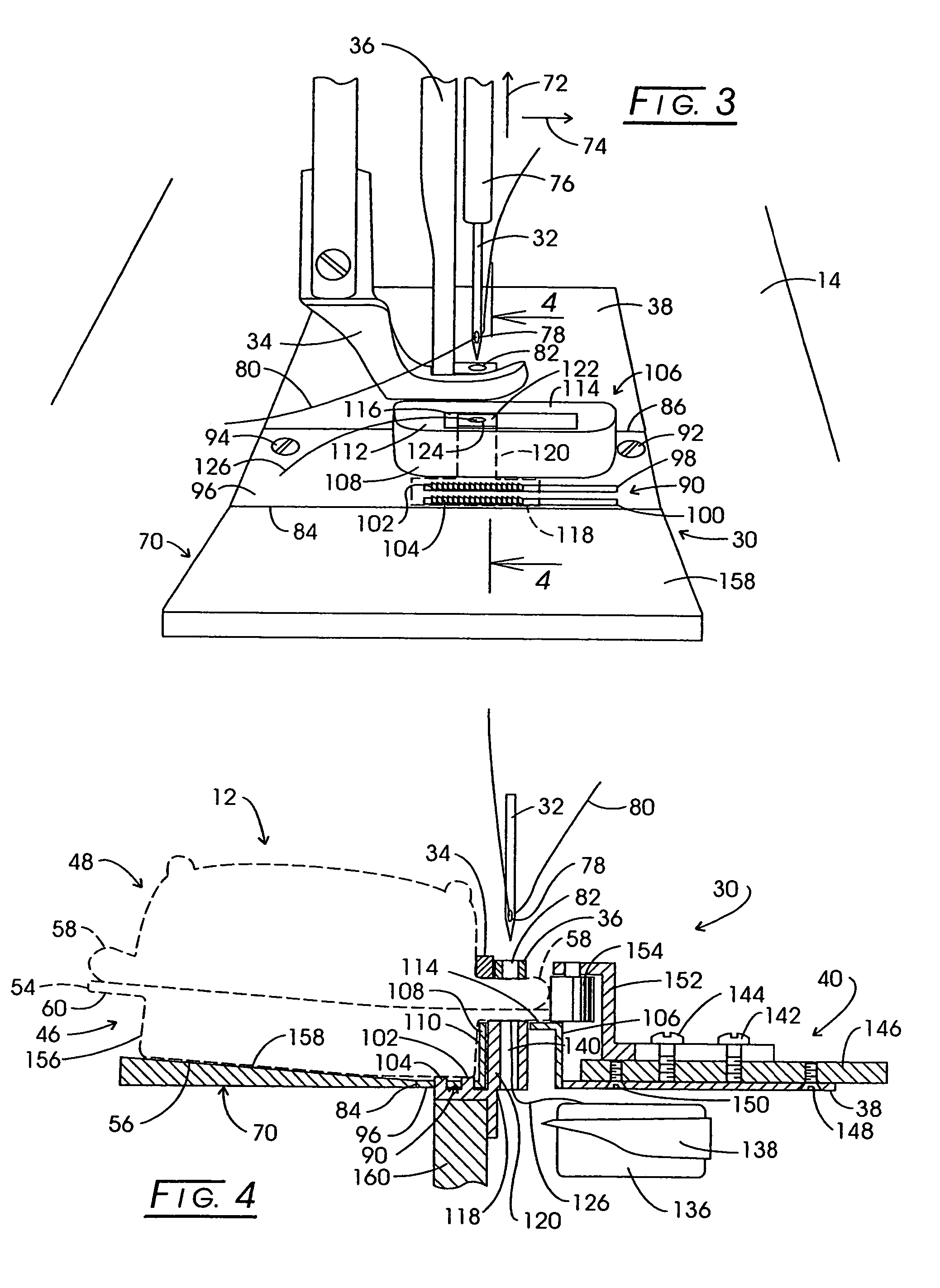

Elastomeric sole for use with converted flatbed sewing machine

The present invention addresses an elastomeric sole having a sidewall with a height less that 0.625 inch, forming a cavity and a horizontally disposed rim extending from the top surface of the sidewall. The sole includes at least two upstanding regions extending upwardly from the cavity lower surface, each region formed from elastomer and having a different effective modulus of elasticity. The invention also includes the combination of an elastomeric sole and an upper and a method for sewing an elastomeric sole to an upper by means of a converted sewing machine.

Owner:SEWING INNOVATIONS & MACHINE COMPANY

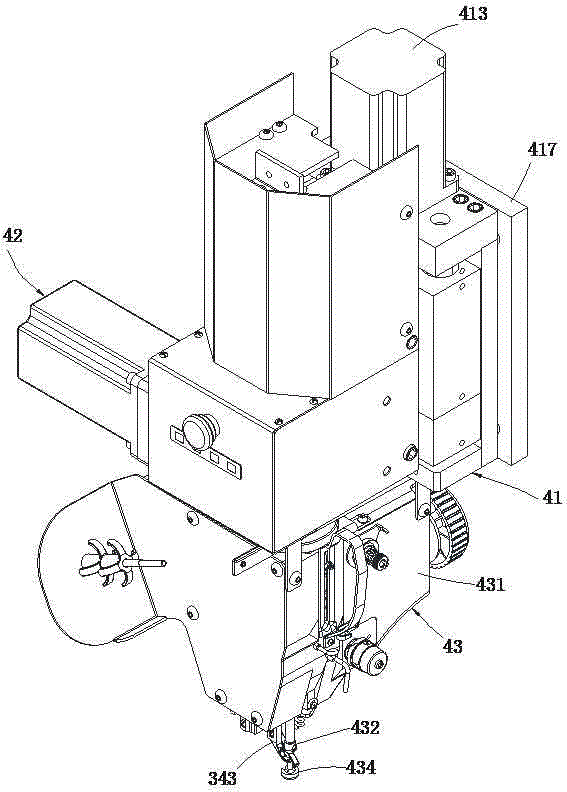

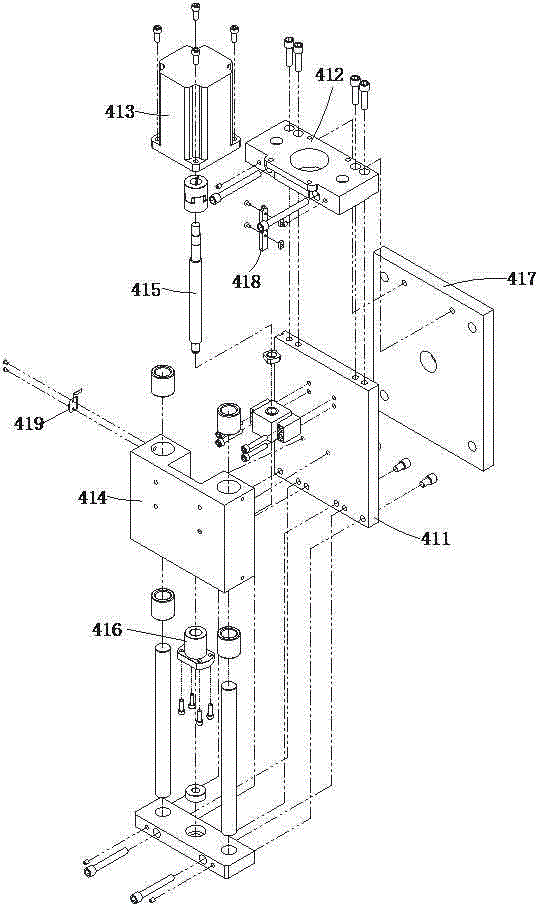

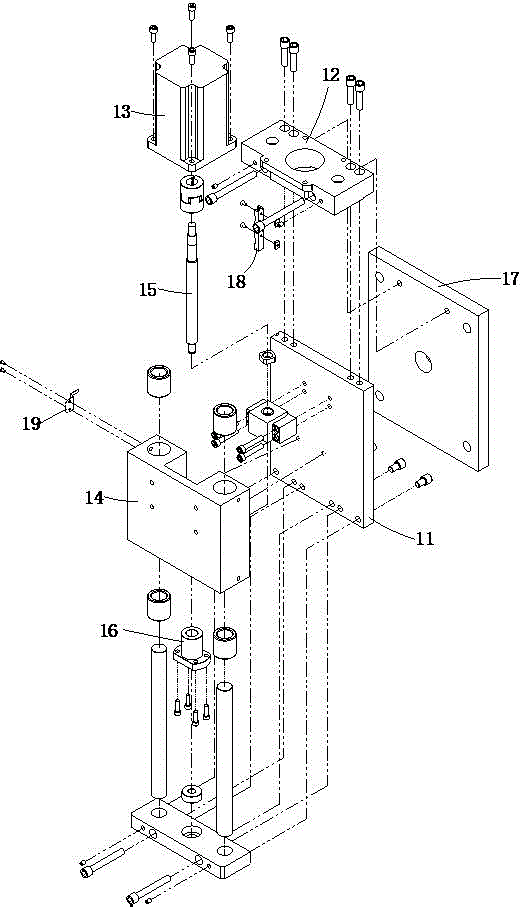

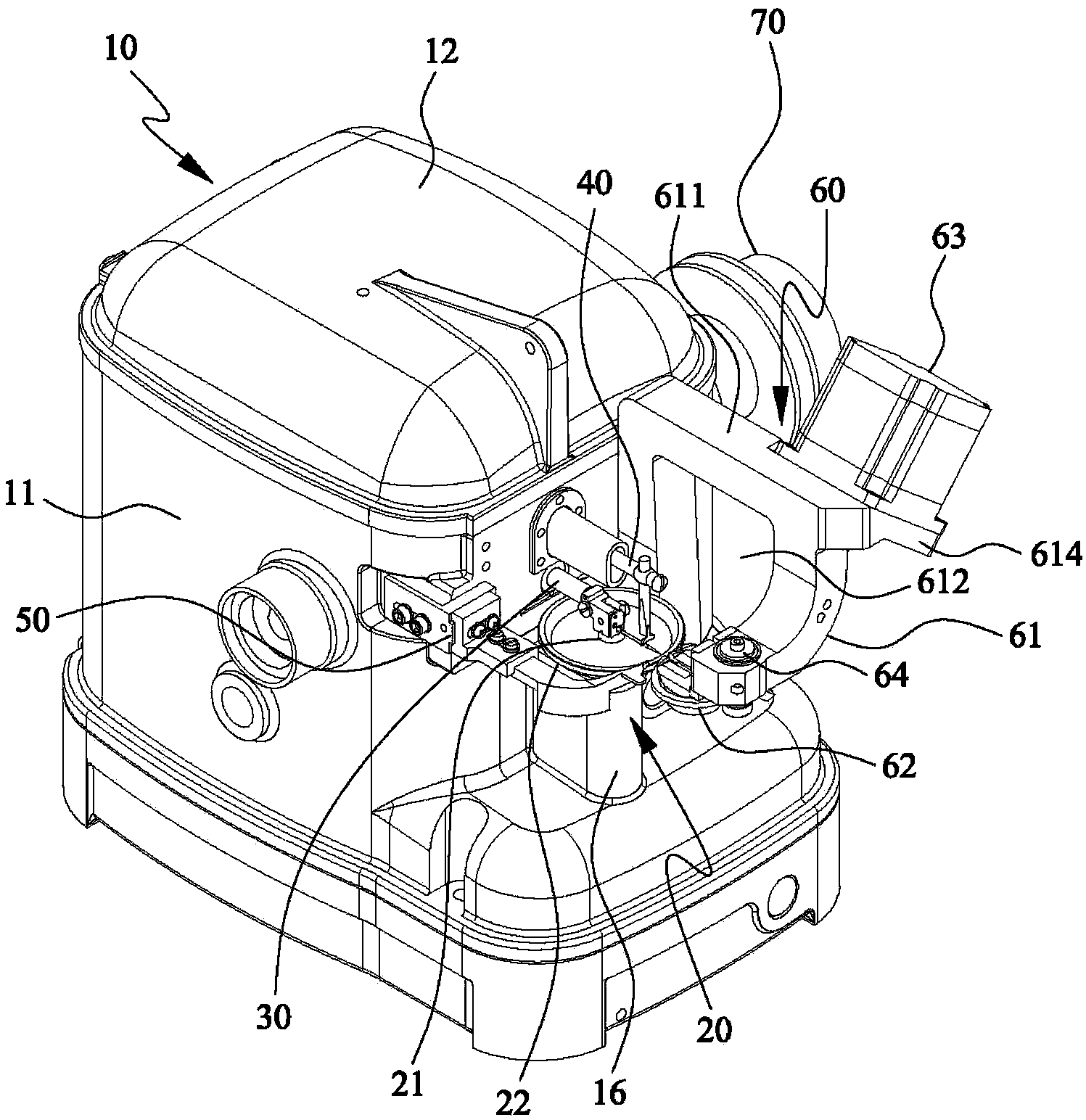

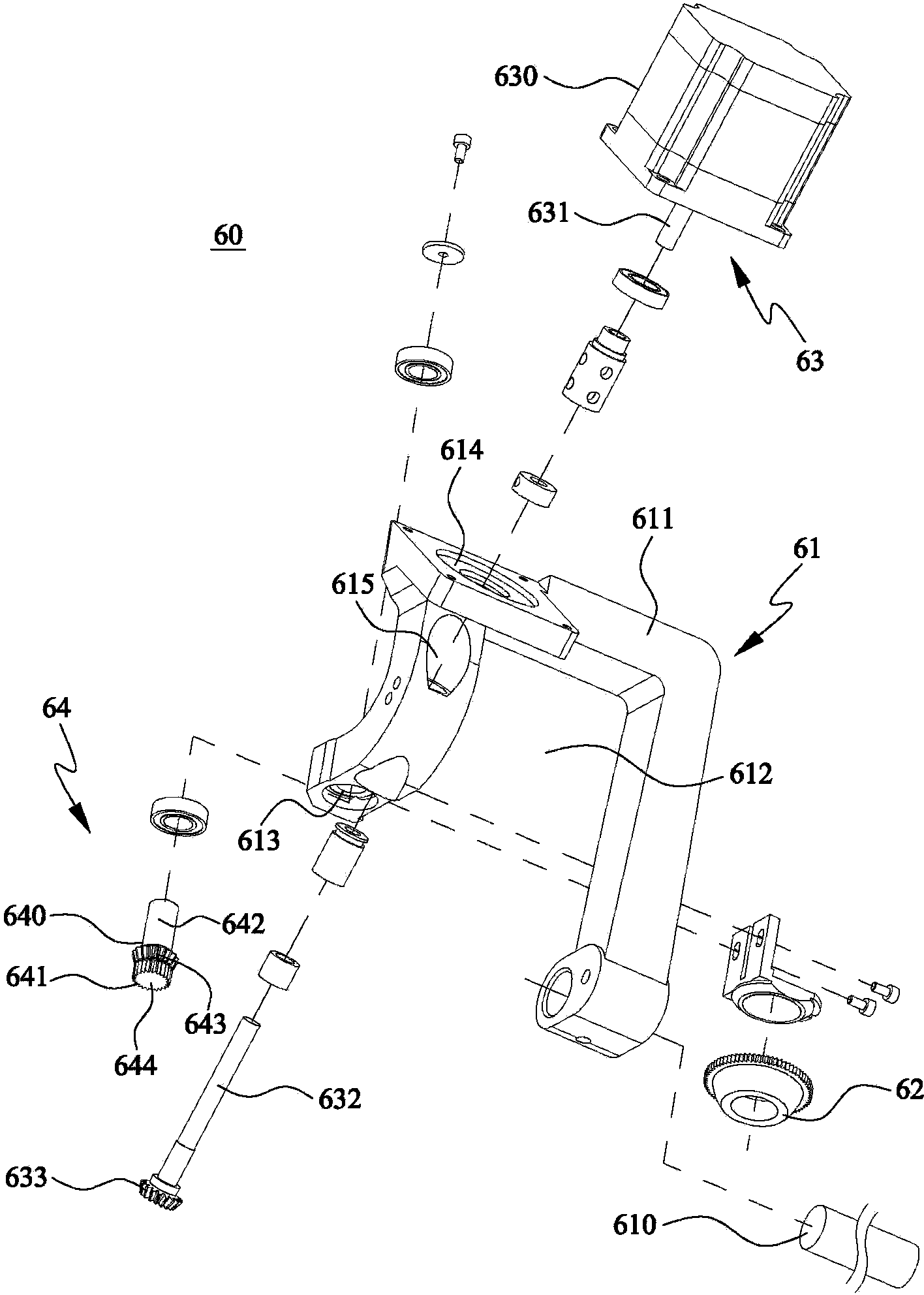

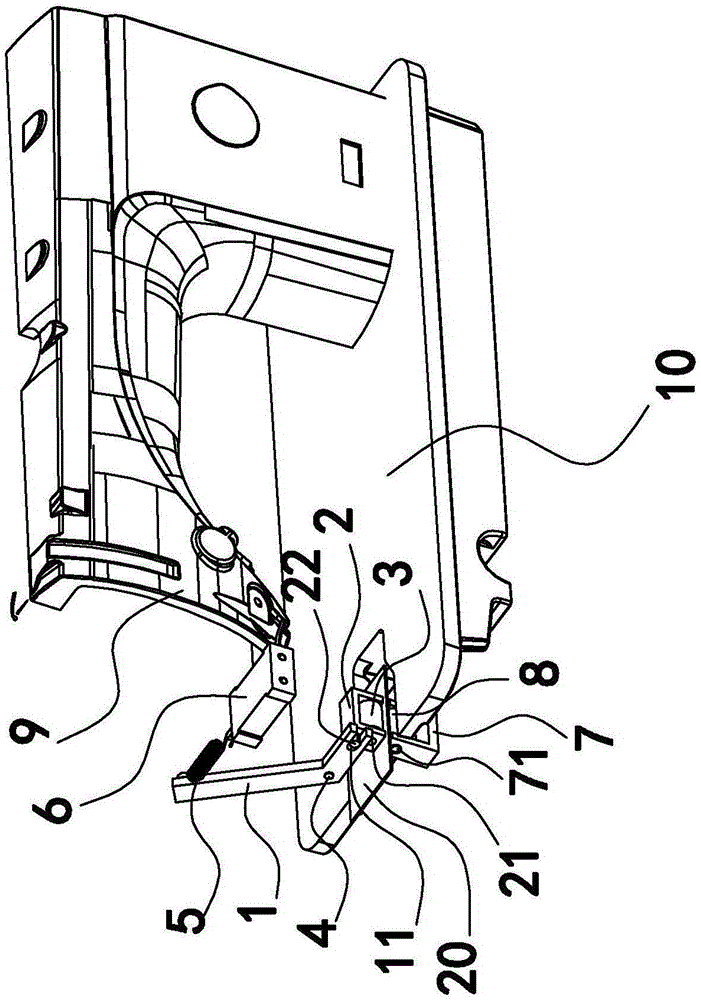

Upper machine head of independently-driven rotary type automatic sewing device

ActiveCN103981649AReduce volumeHigh degree of integrationPressersSewing-machine control devicesFailure rateMachining

The invention relates to an upper machine head of an independently-driven rotary type automatic sewing device. The upper machine head comprises a machine head lifting assembly, a machine head rotating assembly and a machine head assembly, wherein the machine head rotating assembly is fixedly arranged on the machine head lifting assembly; the machine head assembly is fixedly arranged at the lower part of the machine head rotating assembly; the machine head rotating assembly comprises a conductive slip ring, a slip ring fixing seat, a machine head installation plate, a machine head rotating motor, a gearbox and a rotating shaft, the upper end of the rotating shaft is connected with the conductive slip ring for driving the conductive slip ring to rotate, and the rotating shaft can drive the machine head assembly to rotate clockwise or anticlockwise by 360 degrees; the machine head lifting assembly can drive the machine head assembly to move up and down through the machine head rotating assembly. The upper machine head disclosed by the invention can be lifted and can be rotated as well, various machining needs can be met, and the application range is greatly enlarged; the size is small, the integration degree is high, the upper machine head can be matched with a lower machine head for realizing synchronous high-speed rotating, the stability is high, the failure rate is low, and the maintenance is simple and convenient.

Owner:浙江锦上智控科技有限公司

Driving device for automatic thread trimming and automatic presser foot lifting

ActiveCN106012323ACompact structureSame rotation speedNeedle severing devicesPressersMotor driveEngineering

The invention belongs to the technical field of sewing machines, and particularly discloses a driving device for automatic thread trimming and automatic presser foot lifting. The driving device is simple in structure and capable of guaranteeing stable operation of a sewing machine. The driving device comprises a presser foot lifting transmission rod, a thread trimming transmission rod, a stepping motor, a cam body arranged on the stepping motor, a pressure foot lifting connecting rod and a thread trimming connecting rod. The cam body is provided with a pressure foot lifting driving cam surface and a thread trimming driving cam surface, both of which comprise a base circle surface and a lift curved surface. The other end of the pressure foot lifting connecting rod is hinged to one end of the pressure foot lifting transmission rod, and the pressure foot lifting connecting rod is provided with a first driven pin. The thread trimming transmission rod is hinged to the other end of the thread trimming connecting rod, and the thread trimming connecting rod is provided with a second driven pin. When the stepping motor drives the cam body to rotate clockwise by a certain angle, one driven pin enters the lift curved surfaces from the base circle surfaces, and the other driven pin slides on the base circle surfaces; when the stepping motor drives the cam body to rotate anticlockwise, one driven pin slides on the base circle surfaces, and the other driven pin enters the lift curved surfaces from the base circle surfaces.

Owner:ZHEJIANG DUMA SEWING MACHINE

Sewing machine

ActiveUS20080078313A1Amount of movement is limitedProgramme-controlled sewing machinesPressersEngineeringSewing needle

A sewing machine capable of sewing while a workpiece cloth is moved by a manual operation includes a needlebar having a lower end to which a sewing needle is attached, a needlebar driving mechanism vertically driving the needlebar via a main shaft, a presser foot pressing the workpiece cloth, an imaging device imaging at least an area of the workpiece cloth near to the sewing needle, a movement amount operating device obtaining by operation a movement amount of the workpiece cloth based on image data supplied from the imaging device, a setting device setting a stitch pitch on the workpiece cloth, a comparing device comparing the obtained movement amount of the workpiece cloth and the set stitch pitch, a cloth movement limiter limiting movement of the workpiece cloth by the manual operation, and a control device controlling the cloth movement limiter according to a result of comparison.

Owner:BROTHER KOGYO KK

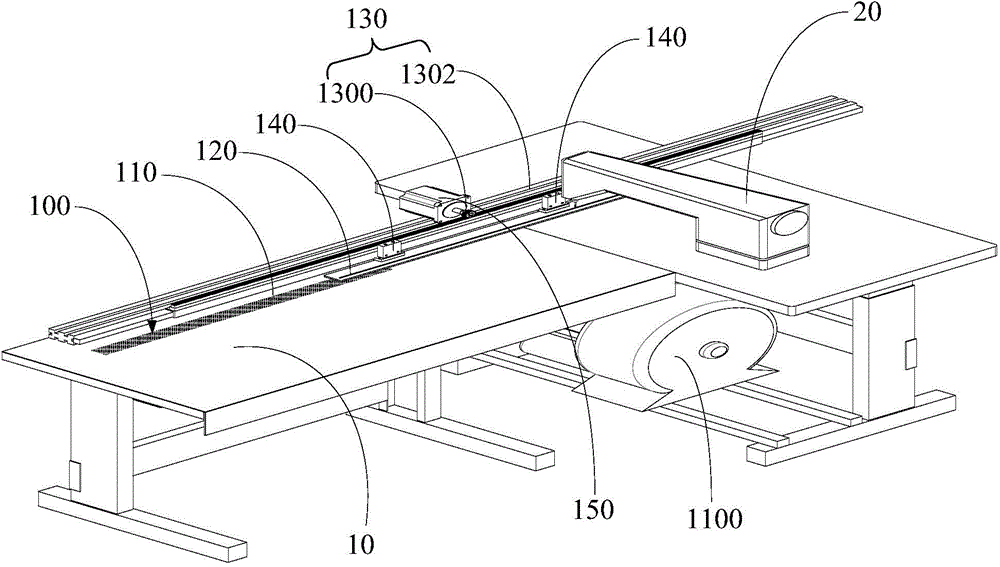

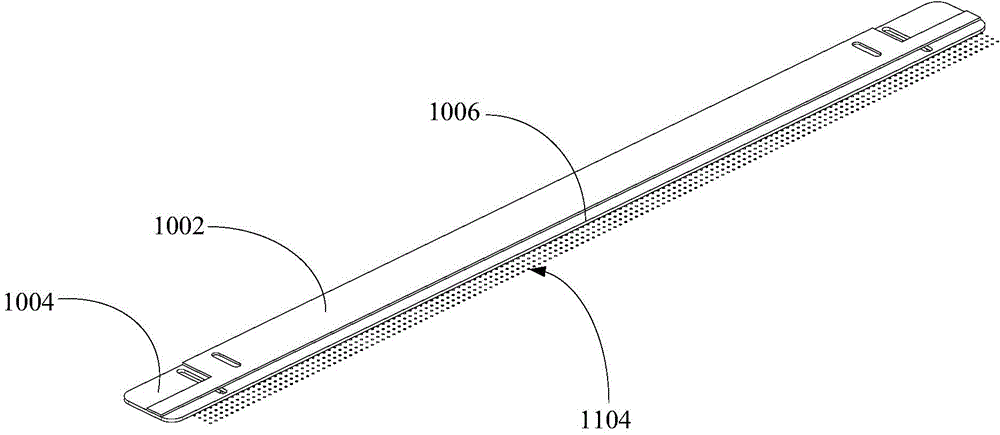

Sewing feeding device and method and sewing device

ActiveCN103603144ANo manual operationSave human effortProgramme-controlled sewing machinesPressersEngineeringSewing machine

The invention discloses a sewing feeding device and method and a sewing device. The sewing feeding device comprises a bench, a bypass mechanism, a suction mechanism, a compressing mechanism, a transmission mechanism and a drive mechanism, wherein the mechanisms are disposed on the bench. The bypass mechanism is adjacent to the suction mechanism. The compressing mechanism is slidably connected to the transmission mechanism; a projection of the compressing mechanism on the bench at least partly overlaps with the bypass mechanism or an extension of the bypass mechanism. The drive mechanism is connected with the compressing mechanism. After placed, a cut panel is automatically fed below a needle of a sewing machine and sewed, with no need for manual operations; labor is reduced, and labor cost is reduced. Through the application of the sewing device, production efficiency can be improved.

Owner:四方维控股有限公司

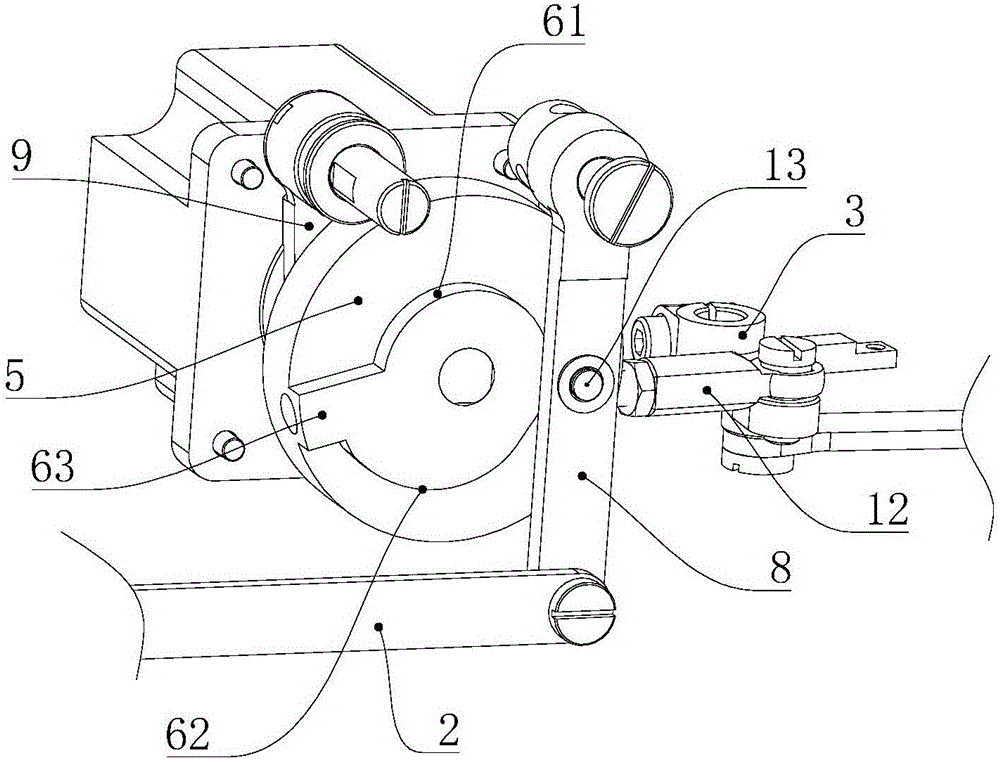

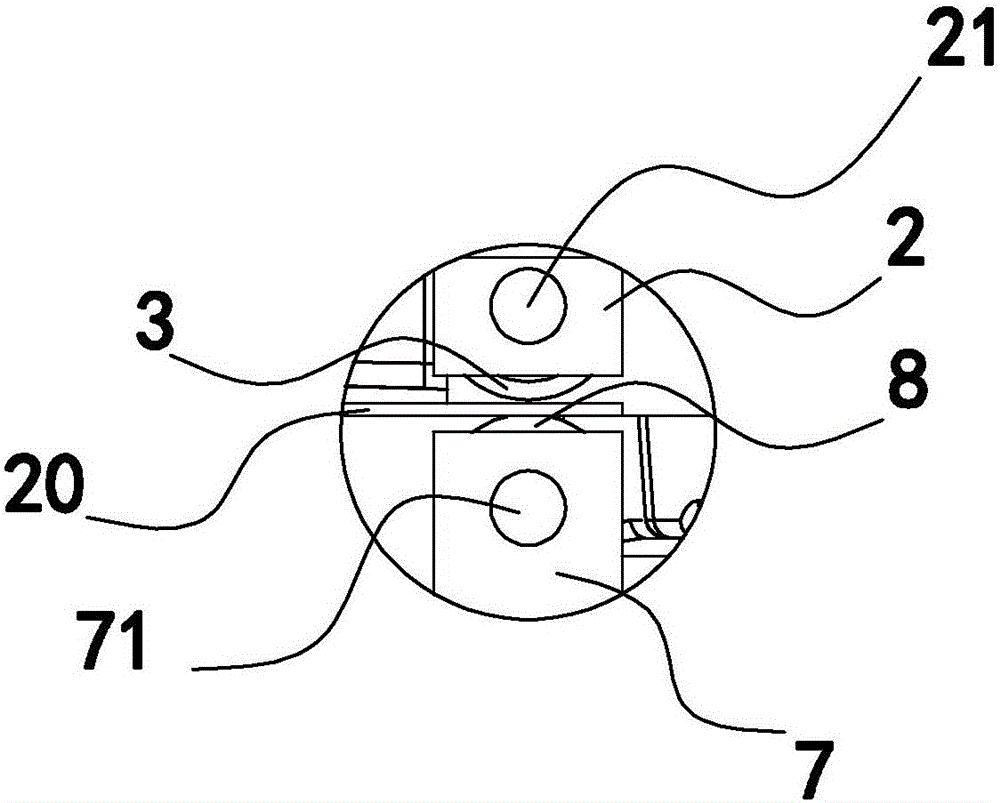

Thread cutting and presser foot lifting device of sewing machine and sewing machine

ActiveCN106948096ASimple structureSmall footprintNeedle severing devicesPressersElectric machineryEngineering

The invention belongs to the technical field of sewing machines and relates to a thread cutting and presser foot lifting device of a sewing machine and the sewing machine. The thread cutting and presser foot lifting device of the sewing machine comprises a double-end motor, a thread cutting cam assembly and a presser foot lifting crank assembly, wherein the thread cutting cam assembly comprises a thread cutting cam arranged on a motor shaft at one end of the double-end motor; a movement groove is formed in the thread cutting cam; one end of a thread cutting crank is connected with the thread cutting cam through a connecting pin; the connecting pin is arranged in the movement groove of the thread cutting cam; the other end of the thread cutting crank is connected with a thread cutting shaft; the thread cutting shaft is connected with a thread cutting mechanism; the presser foot lifting crank assembly comprises a presser foot lifting crank arranged on a motor shaft at the other end of the double-end motor; an abutting part is arranged on the presser foot lifting crank; the abutting part abuts against an ejection rod of a presser foot lifting mechanism. According to the thread cutting and presser foot lifting device of the sewing machine, one driving source is used for controlling movement of the thread cutting mechanism and the presser foot lifting mechanism; the driving source is reduced so that the structure is simpler and an occupied space is simple; the thread cutting and presser foot lifting device is convenient to mount and the cost is reduced.

Owner:JACK SEWING MASCH CO LTD

Cloth feeding mechanism for sewing machine

The invention provides a cloth feeding mechanism for a sewing machine, and belongs to the technical field of sewing machines. The problems of complexity in an upward-downward comprehensive cloth feeding structure and high manufacturing cost of the prior art are solved. The cloth feeding mechanism for the sewing machine comprises a main shaft, a needle bar, a pressure bar and a cloth feeding tooth driving shaft for driving a cloth feeding tooth to move, wherein an outer presser foot is fixedly connected to the lower end of the pressure bar. The cloth feeding mechanism also comprises an inner presser foot and a presser foot connecting rod, wherein the inner presser foot is fixedly connected to the lower end of the presser foot connecting rod; the needle bar is connected to the presser foot connecting rod, and can slide up and down on the presser foot connecting rod; the needle bar is radially fixed relative to the presser foot connecting rod; a forward-backward swinging mechanism capable of driving the presser foot connecting rod to swing forwards and backwards when the main shaft rotates is arranged between the presser foot connecting rod and the main shaft; an upward-downward movement mechanism capable of driving the presser foot connecting rod to move upwards and downwards when the main shaft rotates is also arranged between the presser foot connecting rod and the main shaft. The cloth feeding mechanism has the advantages of simple structure, low manufacturing cost and the like.

Owner:ZHEJIANG SHANGGONG GEM SEWING TECH CO LTD

Upper drawing machine

ActiveCN104233635ASimplify mechanical transmission partsEasy to useLeather sewingWork-feeding meansEngineeringMoving frame

The invention relates to an upper drawing machine which comprises a body, a main feeding mechanism, a needle rod mechanism, a crochet transmission mechanism, a stopping mechanism, a feeding moving mechanism, a first driving mechanism and a control unit. The main feeding mechanism is arranged inside the body and is provided with a feeding shaft, and the feeding shaft is connected with the first driving mechanism and is provided with a feeding wheel; the feeding moving mechanism is provided with a moving frame, a presser foot wheel and a second driving mechanism, and the presser foot wheel is arranged on the moving frame and is linked with the second driving mechanism. Besides, signals of the first driving mechanism can be transmitted to the second driving mechanism by the control unit, so that relative rotation speeds of the two wheels can be controlled, and differential movement of the two wheels can be changed. The upper drawing machine has the advantages that the feeding wheel and the presser foot wheel of the upper drawing machine can be respectively provided with independent driving sources, accordingly, mechanical transmission components can be effectively simplified, users can directly and quickly adjust the rotation speeds via the control unit without optional adjusting tools, and the service convenience can be greatly improved.

Owner:CHEE SIANG IND CO LTD

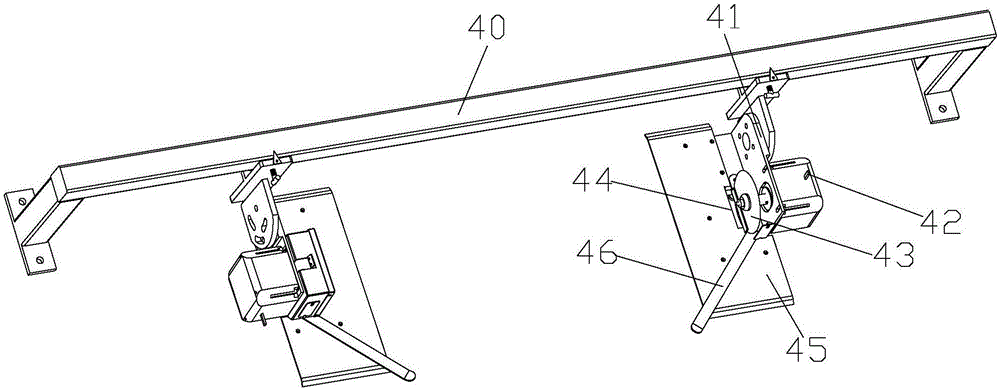

Automatic free-ironing pocket patching machine

InactiveCN103966770AImprove adjustabilityEasy to replaceWork-feeding meansPressersAutomationElectrical and Electronics engineering

The invention discloses an automatic free-ironing pocket patching machine. The automatic free-ironing pocket patching machine comprises a main sewing mechanism, a material-receiving transmission mechanism, a pressing mechanism, an automatic edging mechanism, a towing mechanism and a discharging mechanism, wherein the material-receiving transmission mechanism is positioned on the side surface of the main sewing mechanism; the pressing mechanism is positioned below the material-receiving transmission mechanism; the automatic edging mechanism is positioned on the side surface of the pressing mechanism; the towing mechanism is positioned on the other side surface of the pressing mechanism; the discharging mechanism is positioned below the towing mechanism; the towing mechanism and the discharging mechanism form a material-collecting mechanism. The automatic free-ironing pocket patching machine achieves automation of feeding, free ironing, edging, sewing, discharging and other working processes, and is low in cost and high in efficiency.

Owner:SHANGHAI GUIYI SEWING EQUIP MFG

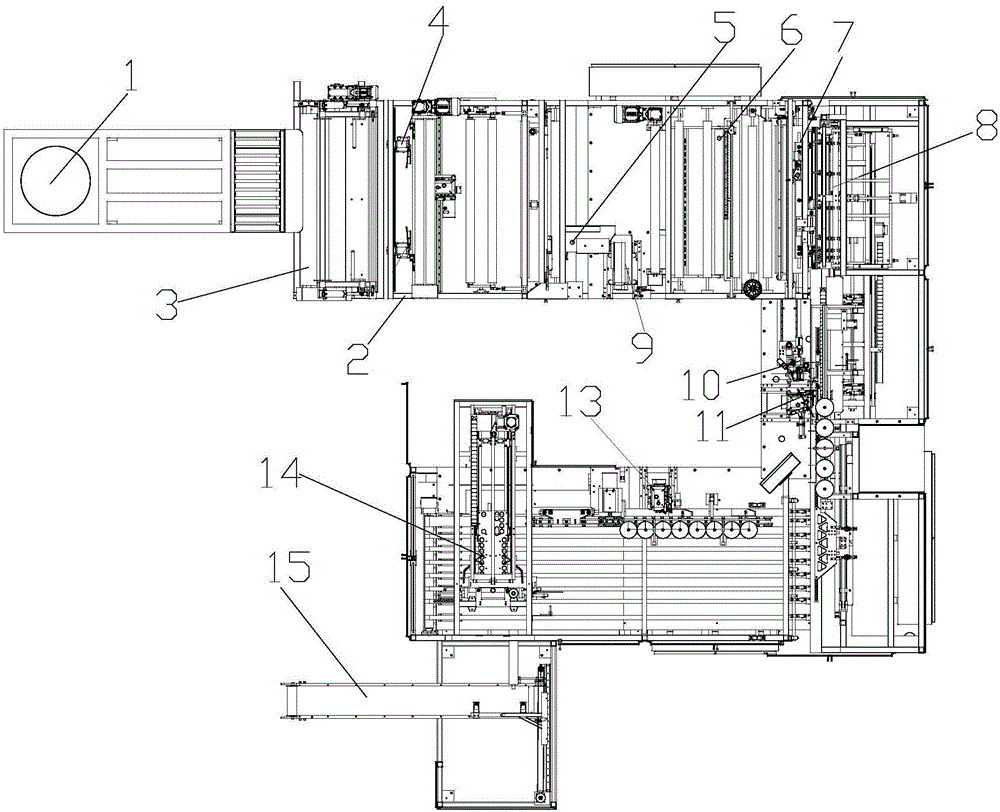

Full-automatic pillowcase machine

ActiveCN107435189AReasonable structure layoutMeet production and processing needsMechanical cleaningPressure cleaningEngineeringAssembly line

The invention relates to a full-automatic pillowcase machine. The machine comprises a feeding buffer area, a machine frame, a feeding component, a trimming device, an edge folding device, a sewing machine, a cloth slow storing mechanism, a correction device, a fixed-length cloth cutting-off mechanism, a label feeding device, a first binding-off device, a second binding-off device, a bag turning device and a collecting device, wherein the feeding component, the trimming device, the edge folding device, the sewing machine, the cloth slow storing mechanism, the correction device, the fixed-length cloth cutting-off mechanism, the label feeding device, the first binding-off device, the second binding-off device, the bag turning device and the receiving device are arranged on the machine frame; the feeding buffer area is located on one side of the machine frame; the feeding component, the trimming device, the edge folding device, the cloth slow storing mechanism, the correction device and the fixed-length cloth cutting-off mechanism are sequentially distributed on the machine frame; the label feeding device and the first binding-off device which are longitudinal distributed are arranged at the lower end of the fixed-length cloth cutting-off mechanism; the second binding-off device and the bag turning device are transversely distributed are arranged on one side of the lower end of the first binding-off device; the collecting device is arranged at the lower end of the bag turning device. The full-automatic pillowcase machine is reasonable in overall structural layout, assembly line processing of pillowcases can be automatically completed, the production efficiency is high, and the machine meets actual production and processing requirements.

Owner:SUZHOU TRANSPARENT TECH CO LTD

Cloth thickness detection device of sewing machine

ActiveCN105862265ASimple structureLow costMeasurement devicesPressersElectronic controllerEngineering

The invention provides a cloth thickness detection device of a sewing machine, belongs to the technical field of sewing, and solves the problems of high requirements on installation environment and poor detection accuracy by a traditional cloth thickness detection device. The cloth thickness detection device of the sewing machine comprises a rotary arm, a sensor device and an upper pinch roller installation seat, wherein the upper pinch roller installation seat is provided with an upper pinch roller; the upper pinch roller is rotatably installed on the upper pinch roller installation seat through a first rotation shaft, the lower end surface of the upper pinch roller extends out of the lower end surface of the upper pinch roller installation seat; the middle of the rotary arm is installed on the head of the sewing machine through a hinge pin, and the rotary arm swings around the hinge pin; the upper pinch roller installation seat is connected with the lower end of the rotary arm through a transmission structure; the transmission structure can drive the rotary arm to swing around the hinge pin; the sensor device is connected with the upper end of the rotary arm, can detect the information of the amplitude of swing of the rotary arm and sends the information of the amplitude of swing to a sewing machine electronic controller. The cloth thickness detection device of the sewing machine has the advantages of simple structure, convenience in installation and high detection accuracy.

Owner:ZHEJIANG ZOBOW MECHANICAL & ELECTRICAL TECH

Sewing machine based on automatic template split synchronizing wheel apparatus

ActiveCN104963105AOutstanding and Beneficial Technical EffectsLifting height can be controlled at willWork-feeding meansSewing-machine control devicesElectromagnetSewing machine

The invention belongs to the technical field of sewing machines, and particularly relates to a sewing machine based on an automatic template split synchronizing wheel apparatus. The sewing machine comprises a sewing machine body, the sewing machine body is provided with a drag wheel lifting and pressing mechanism and a lifting and pressing foot mechanism. A housing rear cover plate of the sewing machine body is provided with a lifting and pressing drag wheel electromagnet, a lifting and pressing foot electromagnet is disposed in the housing, and the lifting and pressing drag wheel electromagnet and the lifting and pressing foot electromagnet are used for respectively controlling the drag wheel lifting and pressing mechanism and the lifting and pressing foot mechanism to act. At the same time, a knee-operated lifting push rod is used for individually controlling the drag wheel lifting and pressing mechanism to act, so that the lifting height of a drag wheel can be adjusted at will, a cloth-dragging wheel can be lifted from a presser when a corner is sewed, and the presser can always pressed the cloth, the cloth can be normally sewed, the sewing performance can be raised, and the sewing effect can be ensured.

Owner:CHINA PRECIOUS SCI & TECH GRP CORP LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com