Sewing machine

A technology for sewing machines and driving motors, which is applied to sewing machine components, sewing machine control devices, sewing equipment, etc. It can solve the problems of feeding teeth colliding with the needle plate, noise, and large changes in needle pitch, so as to avoid collisions of parts and simplify electrical wiring. control program, occupying a small volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

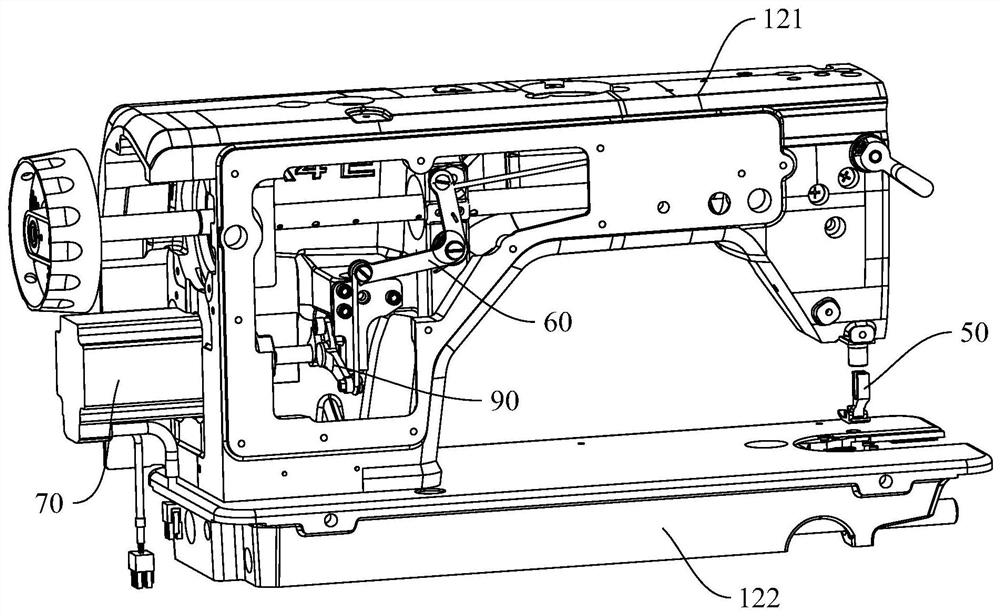

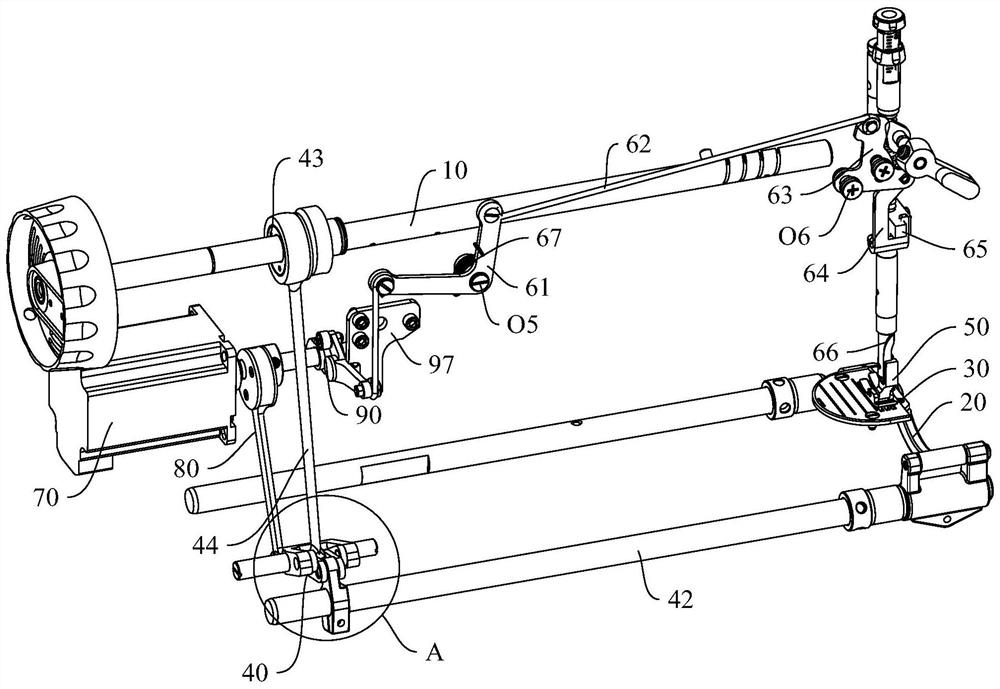

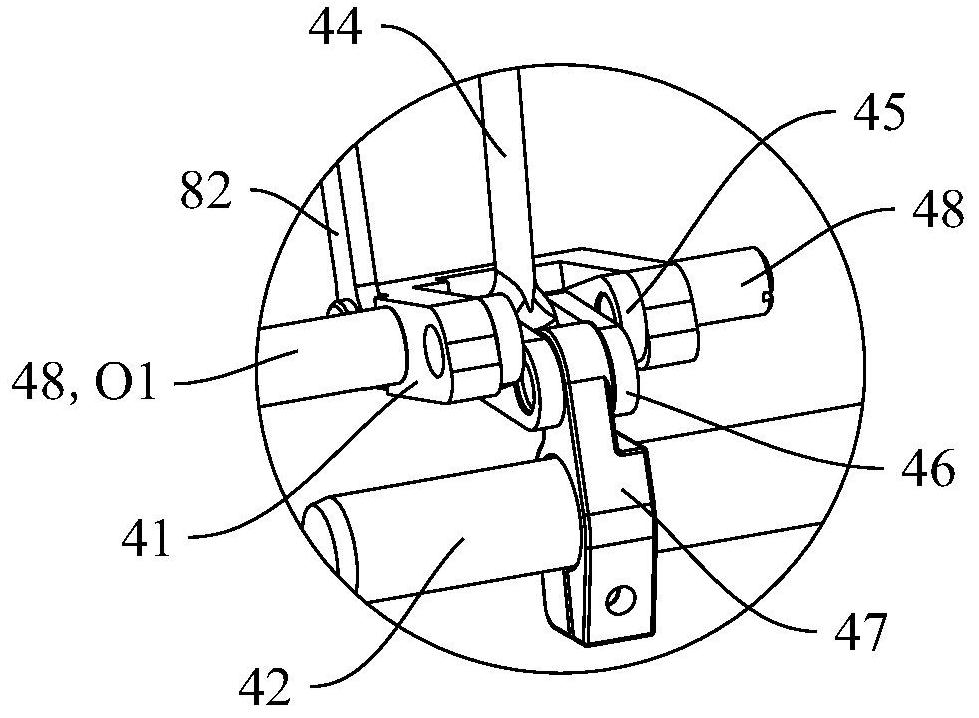

[0128] Such as figure 1 and figure 2 As shown, except that the sewing machine includes the main shaft 10 extending left and right, the sewing machine also includes a tooth frame 20, a feed dog 30 fixedly installed on the tooth frame 20, a feeding mechanism 40 connected between the main shaft 10 and the front end of the tooth frame 20, and a press. The pin 50, the presser foot lifting mechanism 60 connected to the presser foot 50, the drive motor 70, the needle pitch power transmission mechanism 80 connected between the output shaft of the drive motor 70 and the feeding swing seat 41, and the drive motor 70 The presser foot lifting transmission mechanism 90 between the output shaft and the presser foot lifting mechanism 60, the feeding mechanism 40 has a feeding swing seat 41 that can rotate around the first fixed swing fulcrum O1, and the angle of the feeding swing seat 41 determines the needle pitch of the sewing machine. The needle pitch power transmission mechanism 80 ena...

Embodiment 2

[0155] The difference between the second embodiment of the sewing machine and the first embodiment of the sewing machine is that in the first embodiment of the sewing machine, the transmission eccentric wheel 81 and the transmission cam 91 are two independent parts, which are respectively fixed on the output shaft of the driving motor 70 by screws; In the second example, the transmission eccentric wheel 81 and the transmission cam 91 are combined into an integrated structure, such as Figure 18 and Figure 19 shown.

Embodiment 3

[0157] The difference between the third embodiment of the sewing machine and the first embodiment of the sewing machine lies in the specific structure of the power transmission mechanism 80 for adjusting the needle distance. In the third embodiment of the sewing machine, the structure of the fork-shaped transmission link 83 is adopted. Specifically, if Figure 20 to Figure 22 As shown, the stitch adjustment power transmission mechanism 80 in the third embodiment of the sewing machine includes a transmission eccentric 81, a fork-shaped transmission connecting rod 83, and a first connecting rod 84 with a second fixed swing fulcrum O2 at one end. The transmission eccentric 81 passes through The screw is fixed on the output shaft of the driving motor 70. The upper end of the fork-shaped transmission link 83 is a fork-shaped part with a first chute 831. The fork-shaped part is in rotation and sliding fit with the transmission eccentric wheel 81. The fork-shaped transmission link Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com