Full-automatic pillowcase machine

A fully automatic, pillowcase technology, applied in mechanical cleaning, cloth pressing mechanism, cloth feeding mechanism, etc., can solve the problems of low production efficiency, poor standardization, human error, etc., and achieve high production efficiency and reasonable overall structure layout. , the effect of strong practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

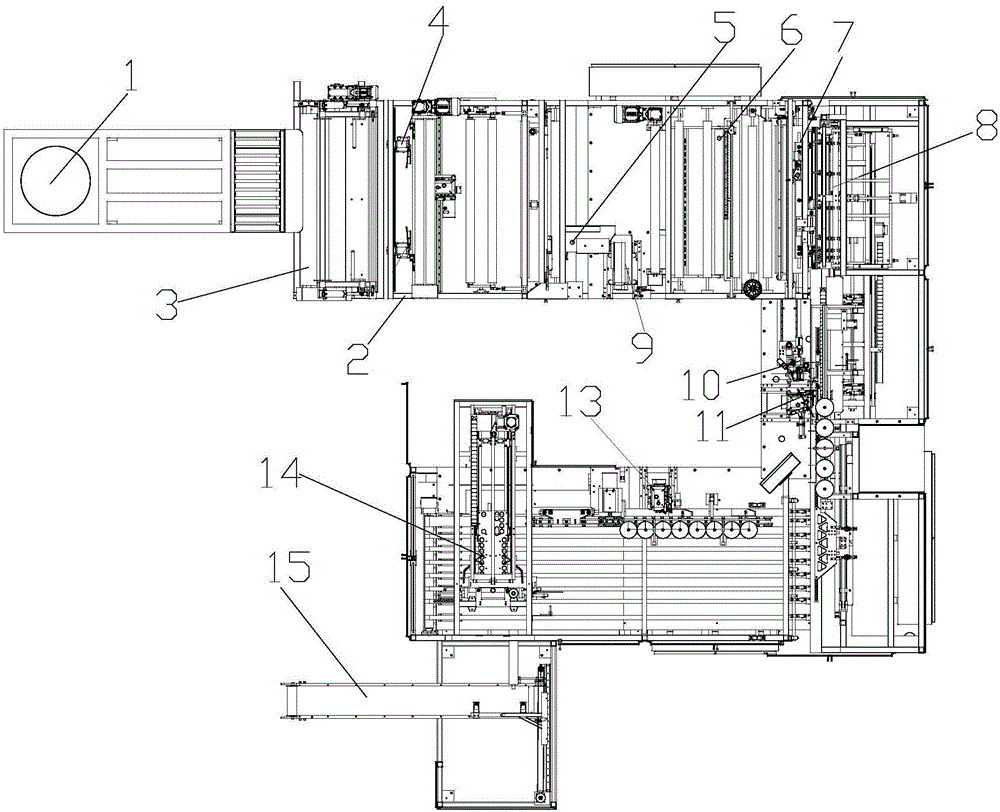

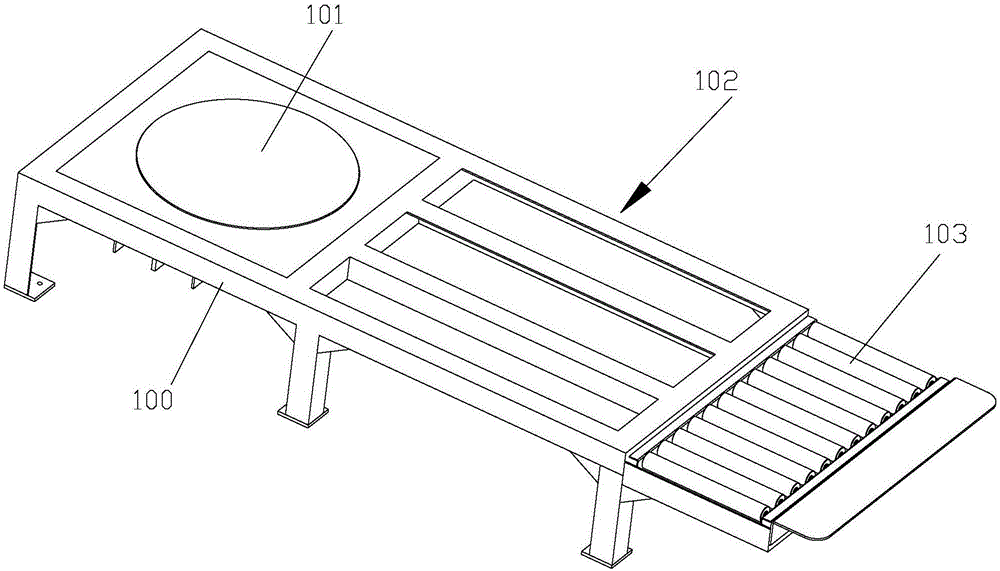

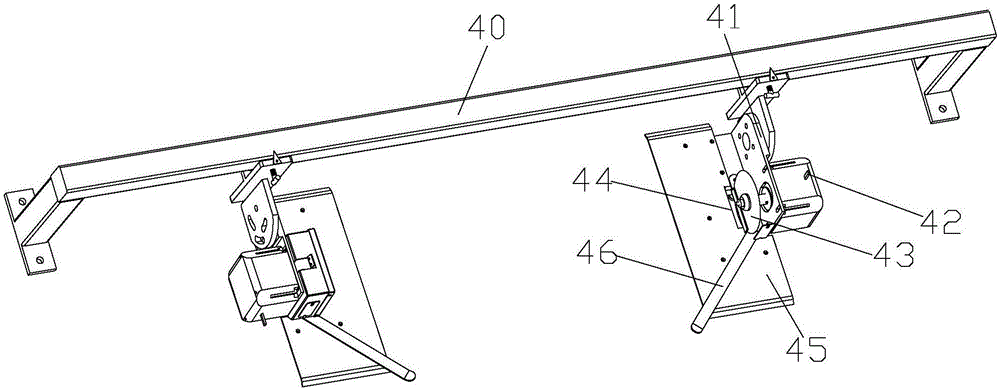

[0037] as attached figure 1 A full-automatic pillow case machine according to the present invention shown includes a feeding buffer 1, a frame 2, a feeding assembly 3, a trimming device 4, a hemming device 5, a sewing machine 9, a cloth buffer mechanism 6, a deviation correction Device 7, fixed-length cloth breaking mechanism 8, label feeding device 10, first over-edge device 11, second over-edge device 13, bag turning device 14 and material receiving device 15; the loading buffer zone 1 is located on the frame 2 One side; the feeding assembly 3, trimming device 4, hemming device 5, cloth buffer mechanism 6, deviation correcting device 7 and fixed-length cloth breaking mechanism 8 are sequentially distributed on the frame 2; the fixed-length cloth breaking mechanism The lower end of 8 is provided with the label sending device 10 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com