Water-cooled motor controller for high power density electric vehicle

A high power density, electric vehicle technology, applied to the circuit layout, cooling/ventilation/heating transformation of the support structure, etc., can solve the problem that the volume and weight of the motor controller are difficult to meet the development requirements of light weight and high integration of electric vehicles , The internal power module generates a lot of heat and affects the service life of the controller, etc., to achieve the effect of easy optimization control, reasonable internal structure layout, and good electromagnetic compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The water-cooled motor controller for a high power density electric vehicle of the present invention will be described in detail below in combination with the embodiments and the accompanying drawings.

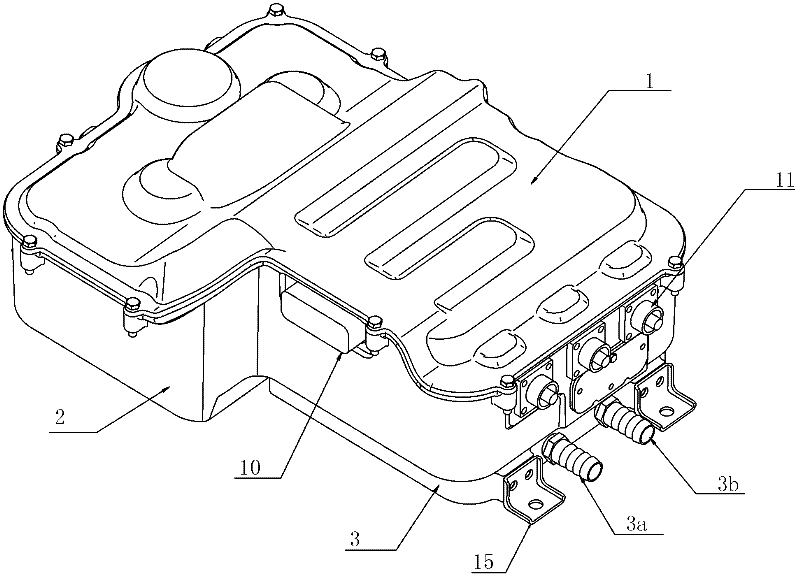

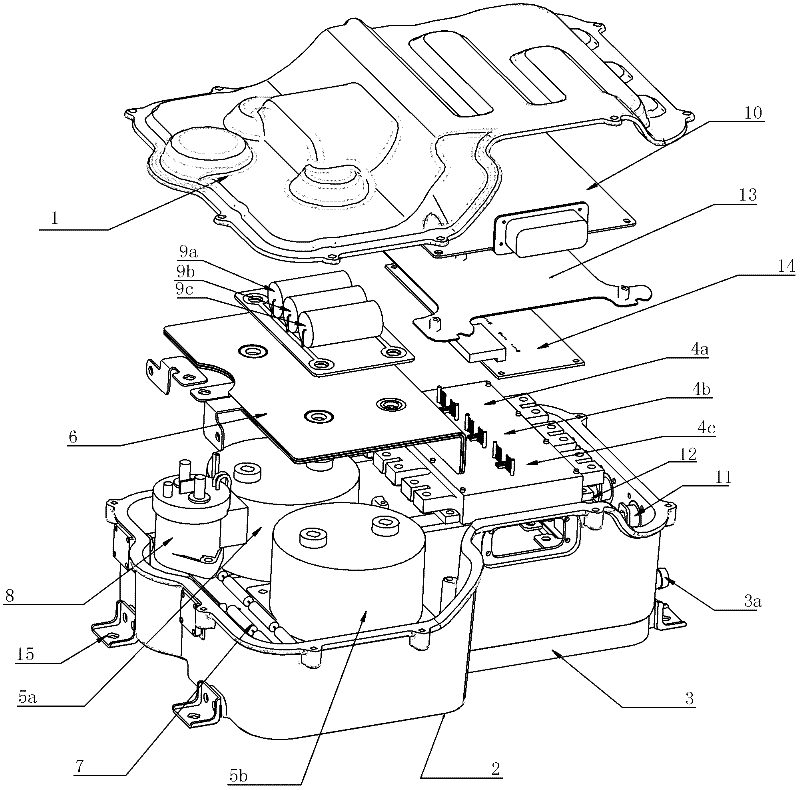

[0038] Such as figure 1 , figure 2 , image 3 As shown, the water-cooled motor controller for high power density electric vehicles of the present invention includes an upper cover 1 and a casing 2 that are processed and formed at one time by die casting, and an opening is formed at the bottom of one side of the casing 2. A water-cooling radiator 3 is provided at the opening of the housing 2; a power module 4, a DC bus support capacitor 5, a pre-power-on resistor 7, a main relay 8 and a current sensor 12 are respectively arranged in the housing 2, wherein the power module 4 is set on the upper surface of the water-cooled radiator 3 and consists of three first half-bridges 4a, second half-bridges 4b and third half-bridges 4c with built-in freewheeling diodes, and each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com