Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3058 results about "Drivetrain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The drivetrain of a motor vehicle is the group of components that deliver power to the driving wheels. This excludes the engine or motor that generates the power. In contrast, the powertrain is considered to include both the engine or motor and the drivetrain.

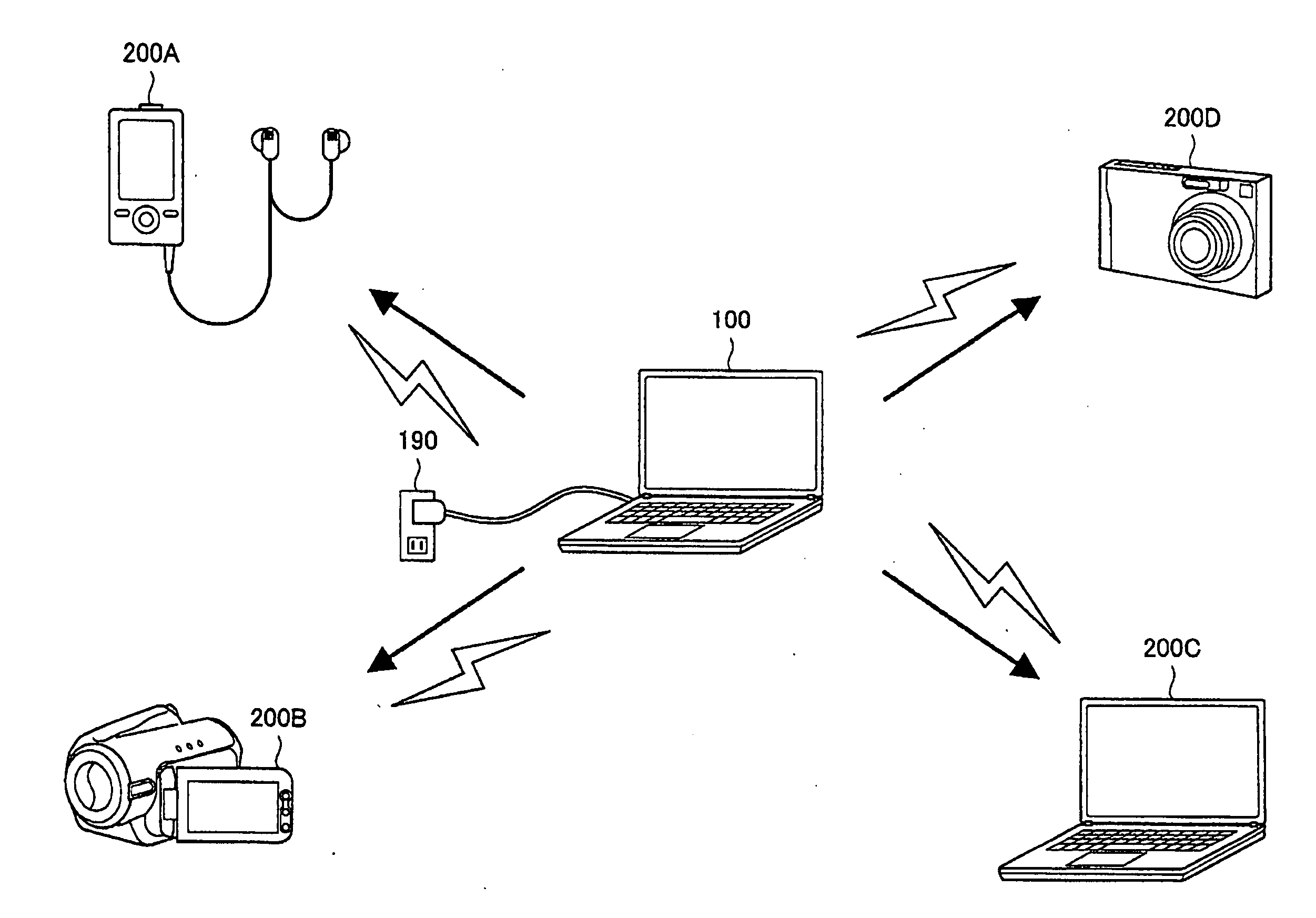

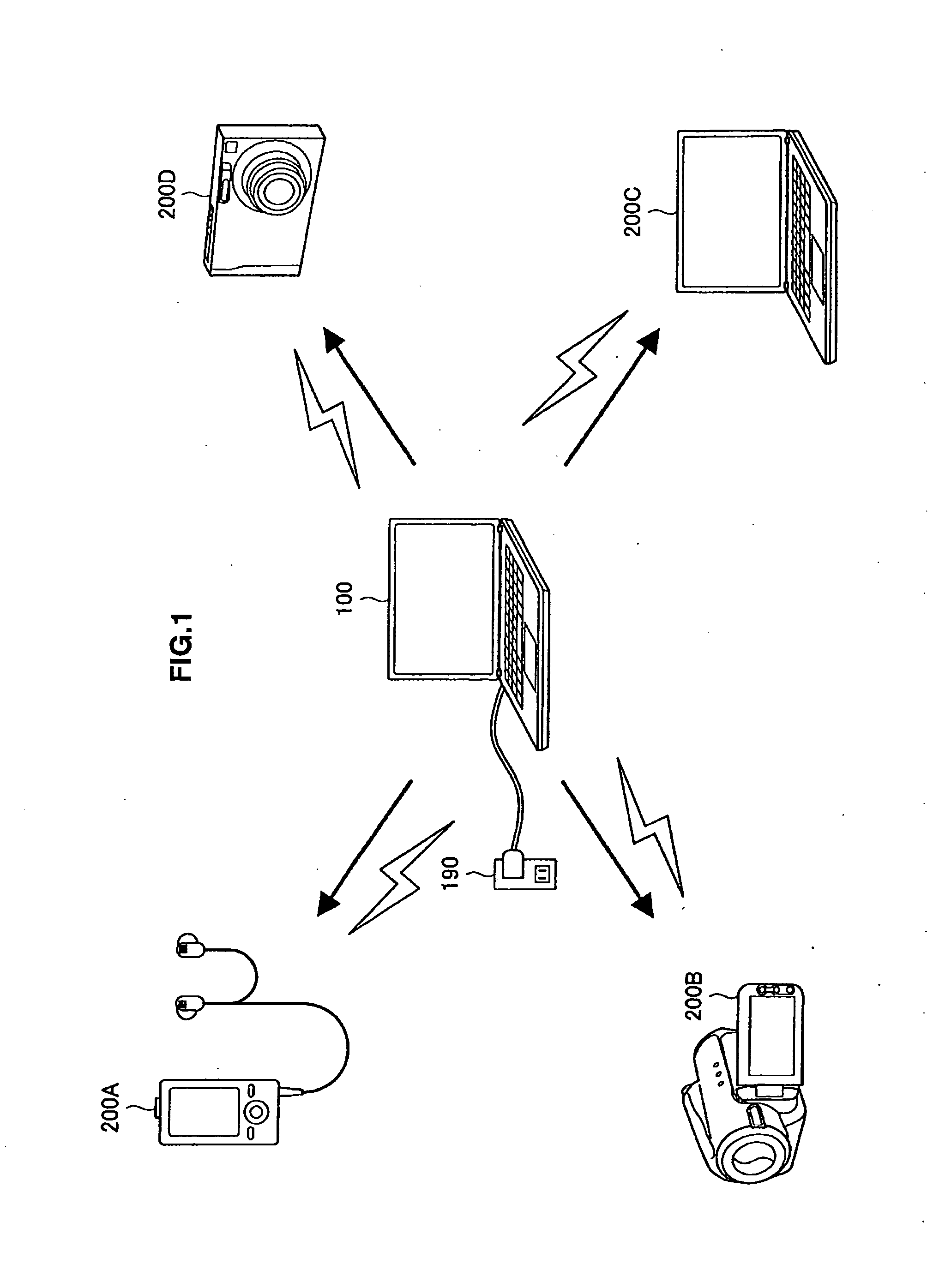

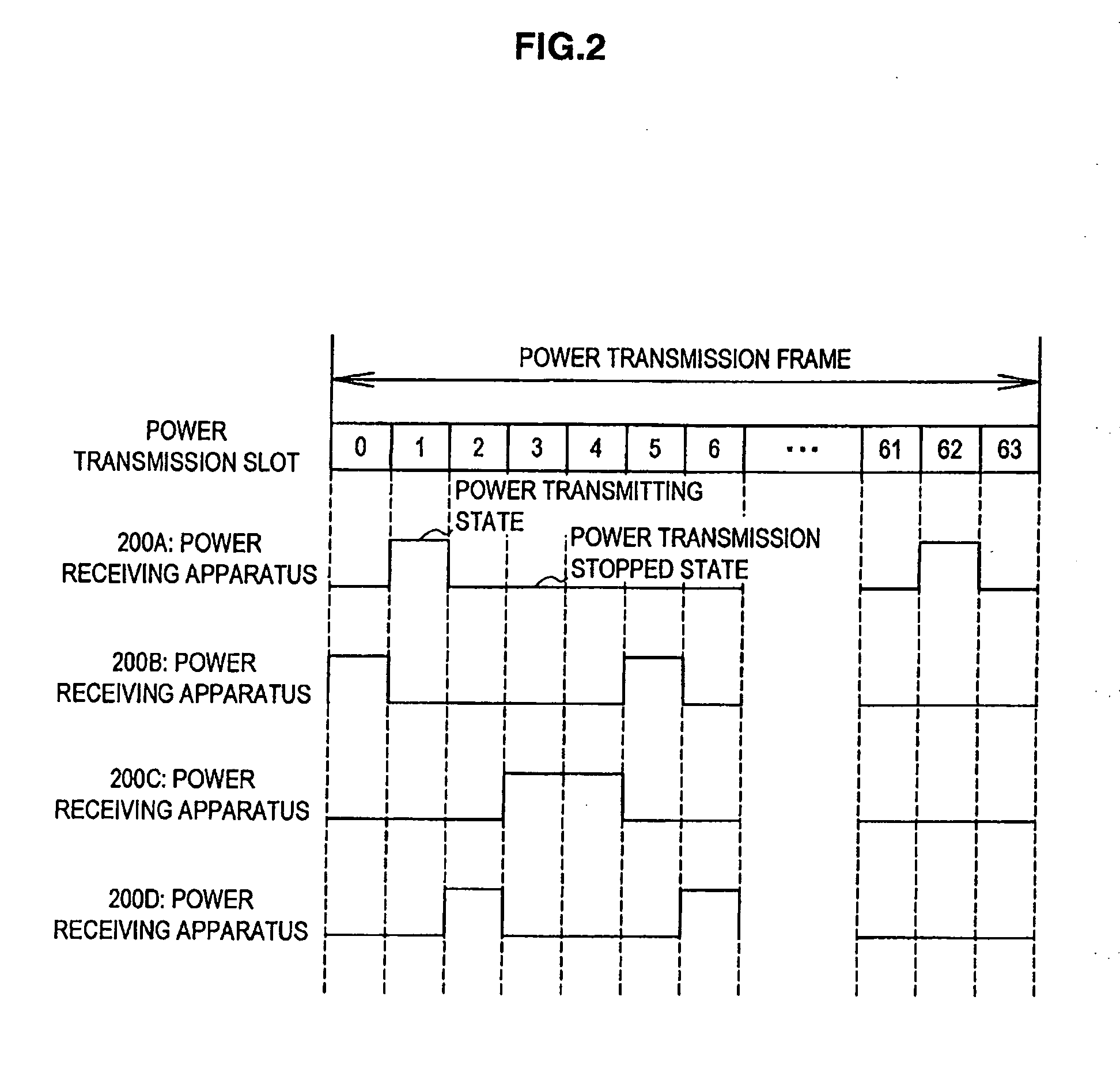

Power Transmitting Apparatus, Power Transmission Method, Program, and Power Transmission System

ActiveUS20090271048A1Good transmission powerImprove powerMechanical power/torque controlNear-field transmissionElectric power transmissionCommunication unit

There is provided a power transmitting apparatus including a power transmission side communication unit for communicating with one or more power receiving apparatus for receiving transmitted power; a power transmission unit for transmitting power to the one or more power receiving apparatus in a non-contact manner; an allocating unit for dividing transmission of power from the power transmission unit to the power receiving apparatus to a plurality of dividing periods for every predetermined period, and allocating the one or more power receiving apparatus to one of the dividing periods; and a power transmission control unit for selectively transmitting power to the one or more power receiving apparatus for every dividing period based on the allocation result in the allocating unit.

Owner:SONY CORP

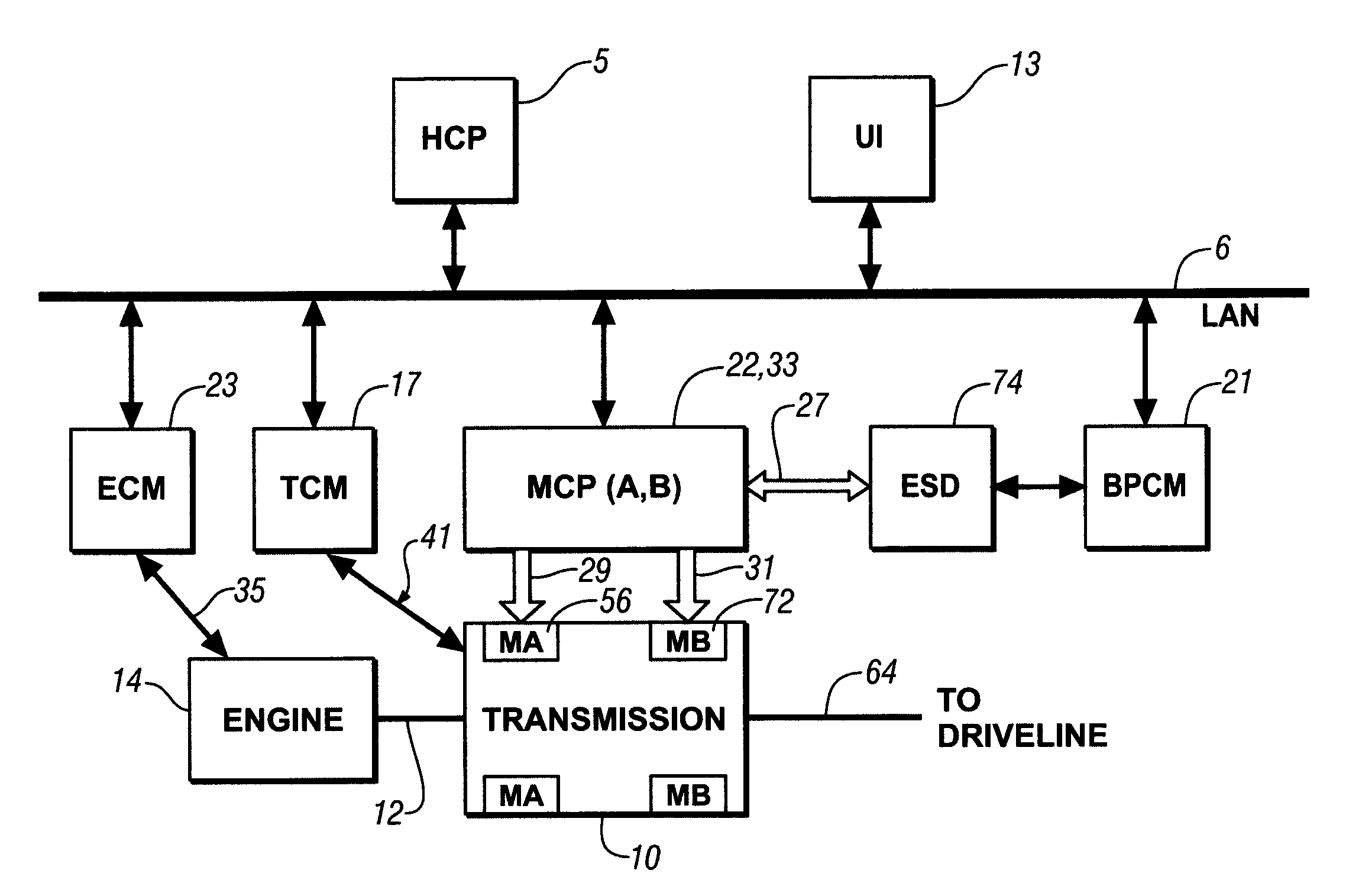

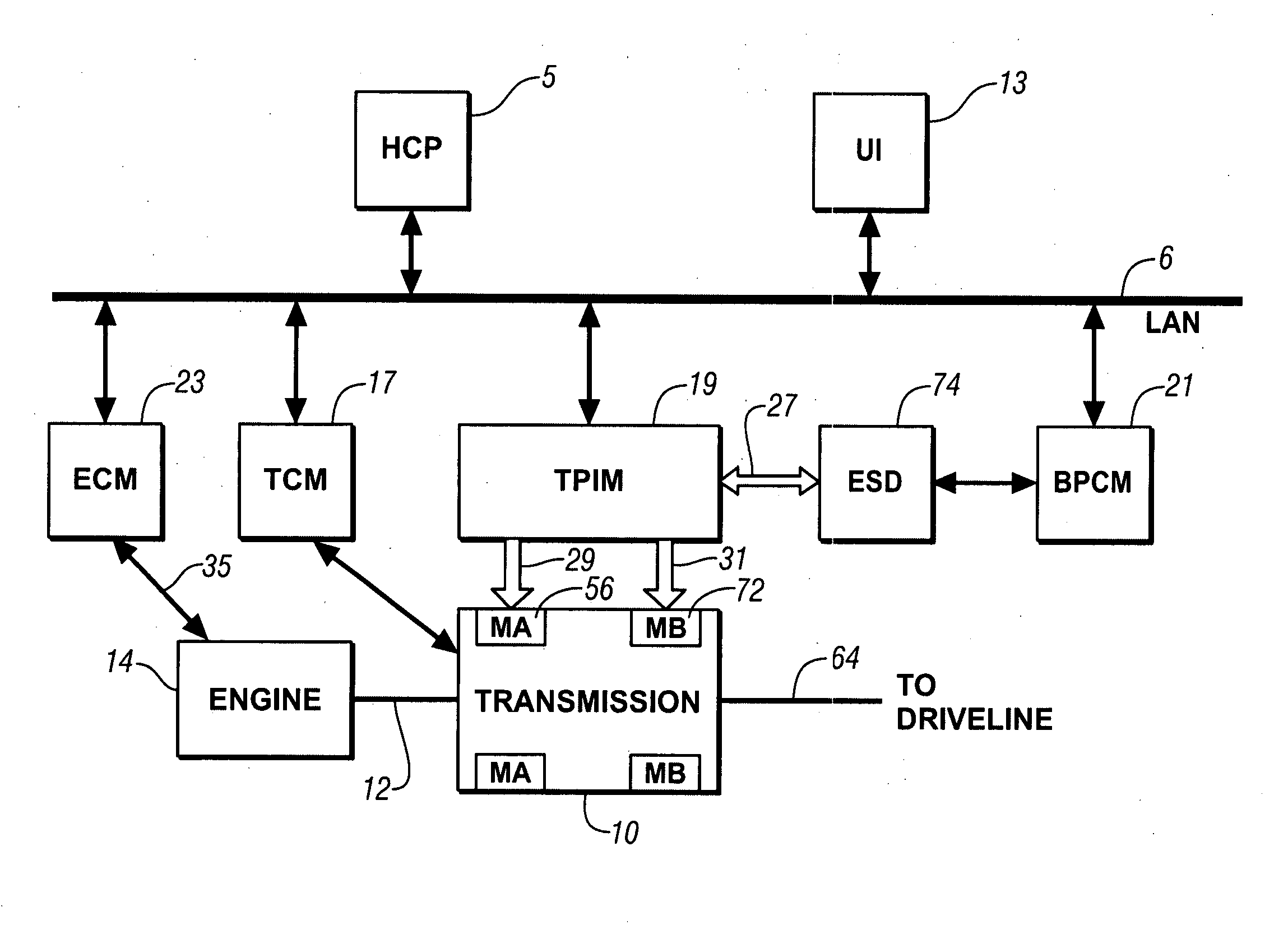

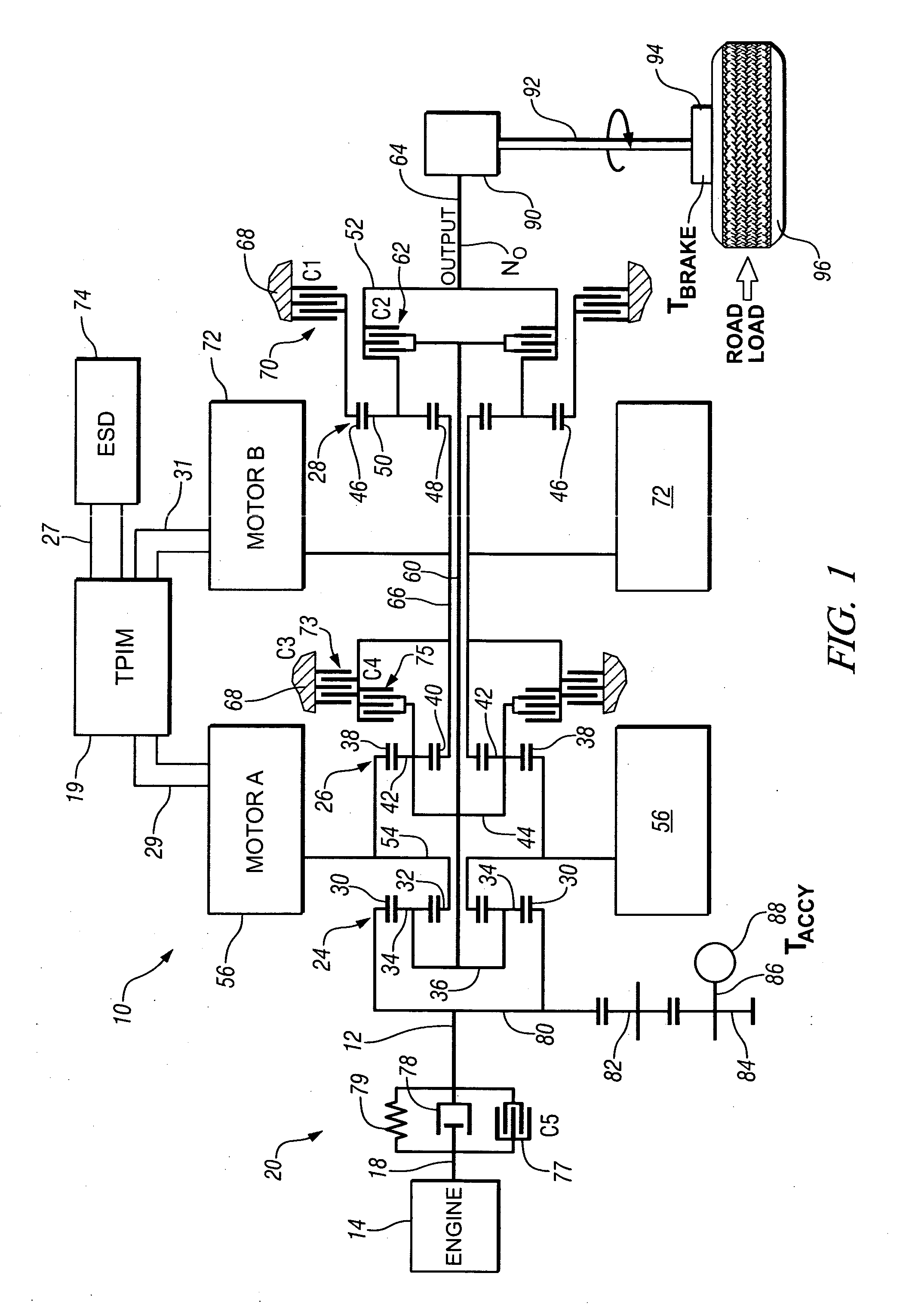

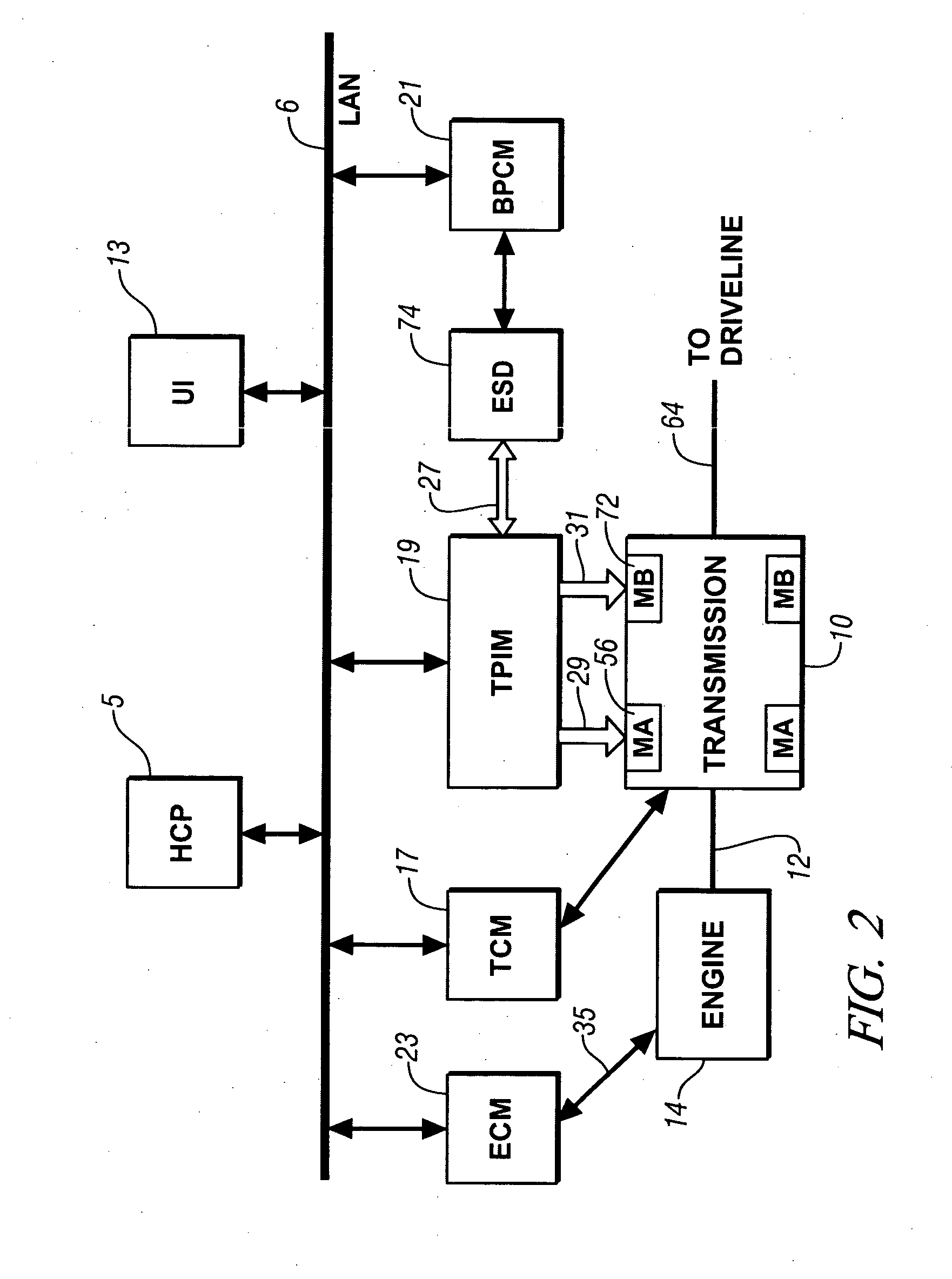

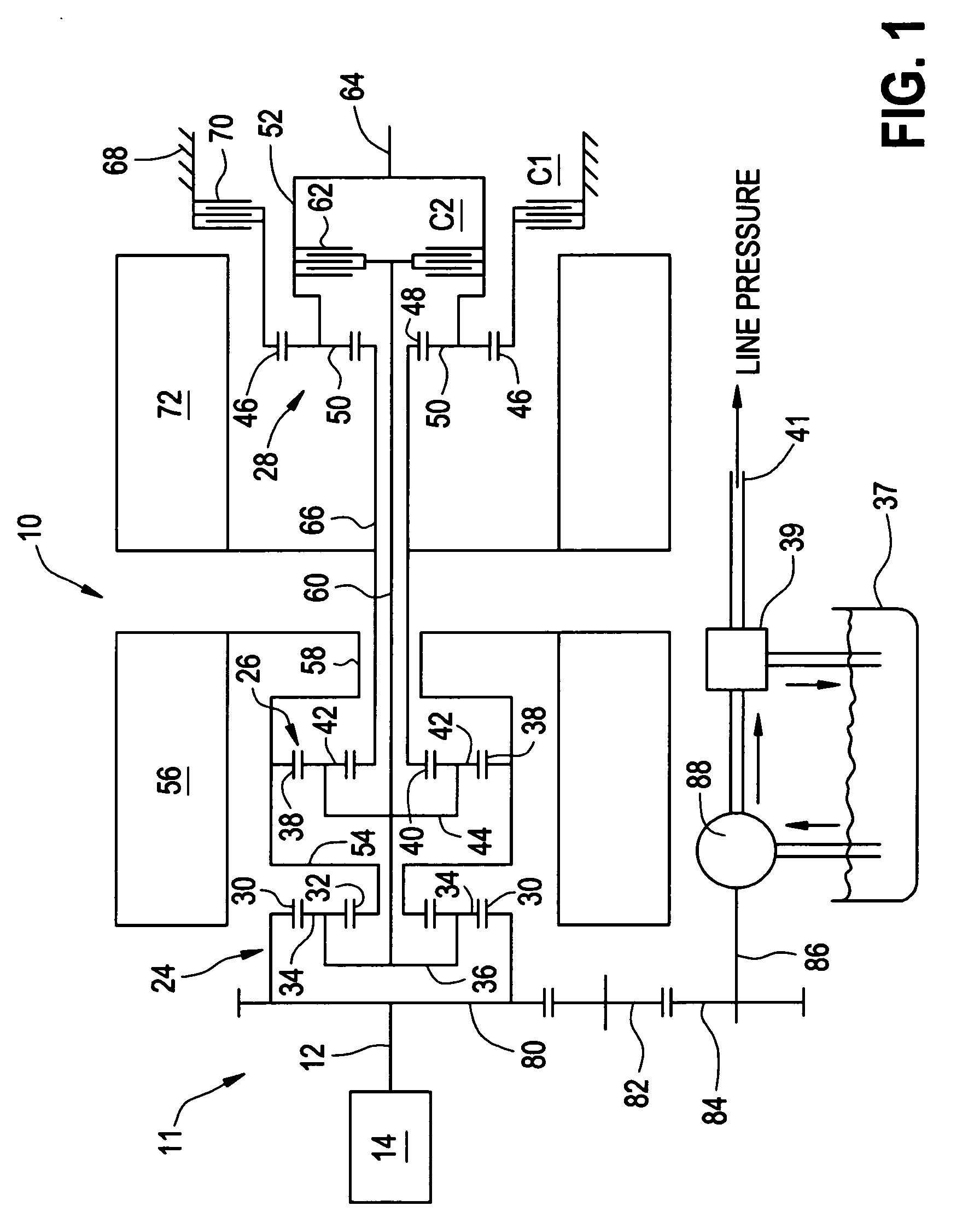

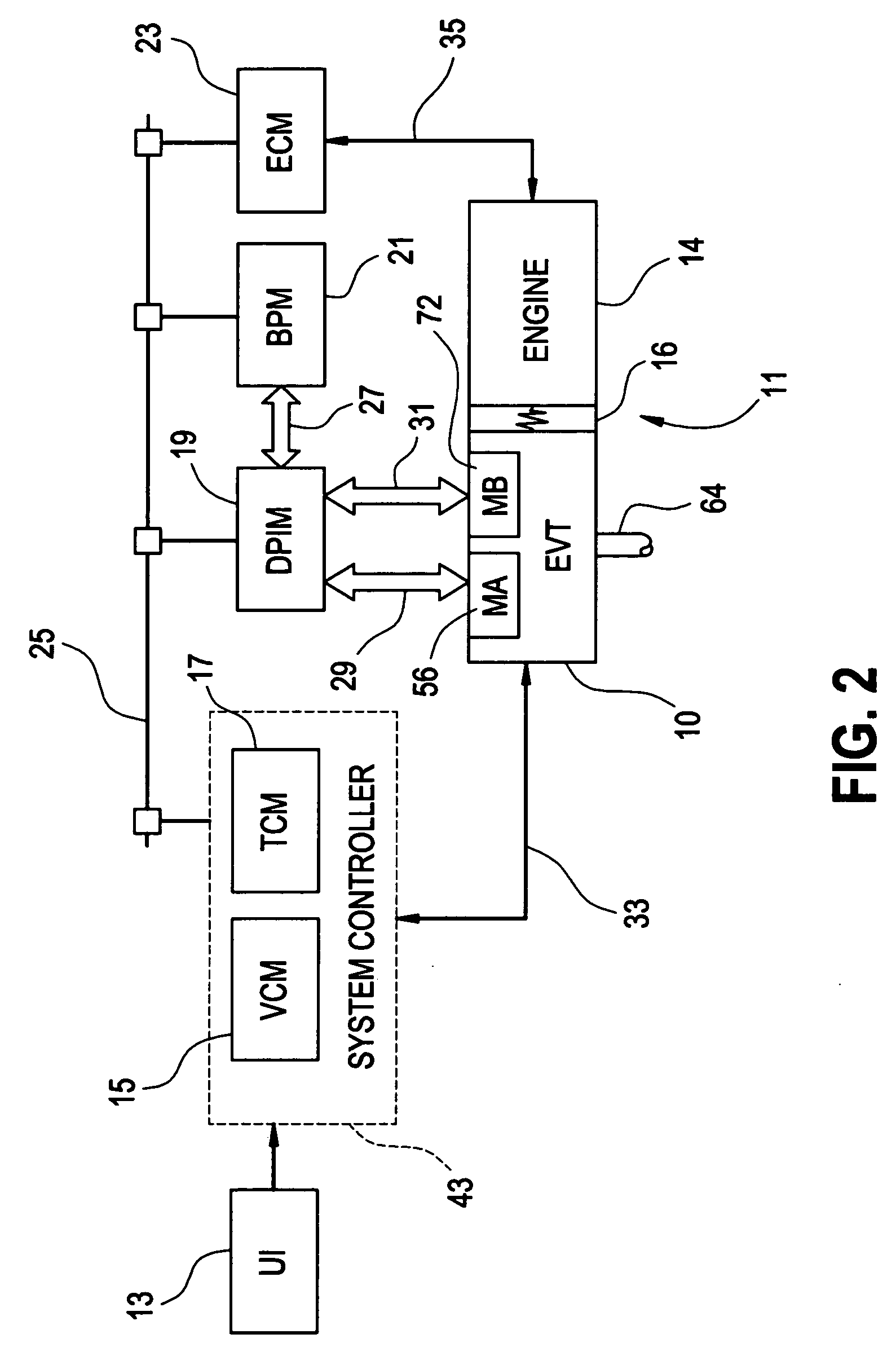

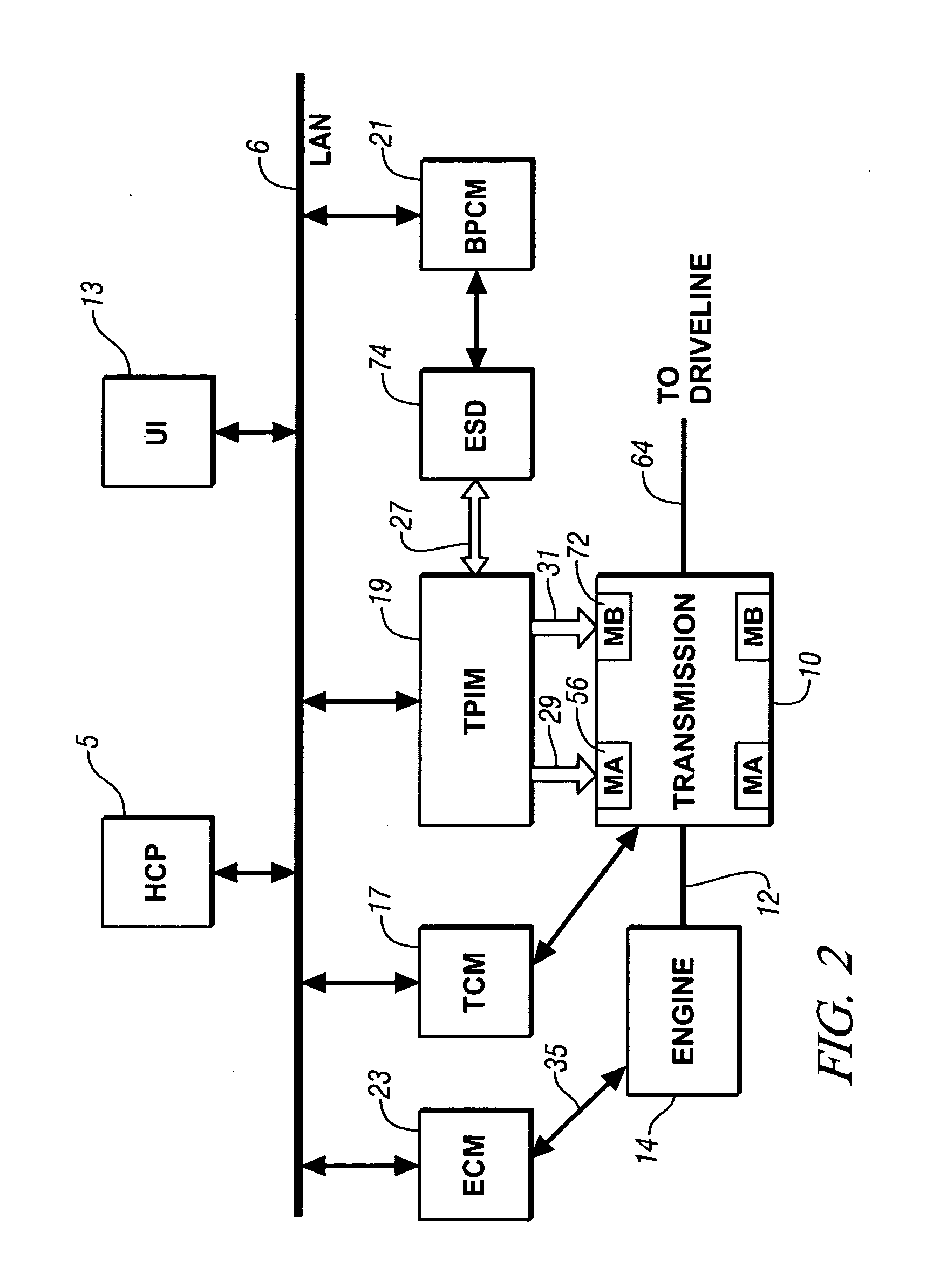

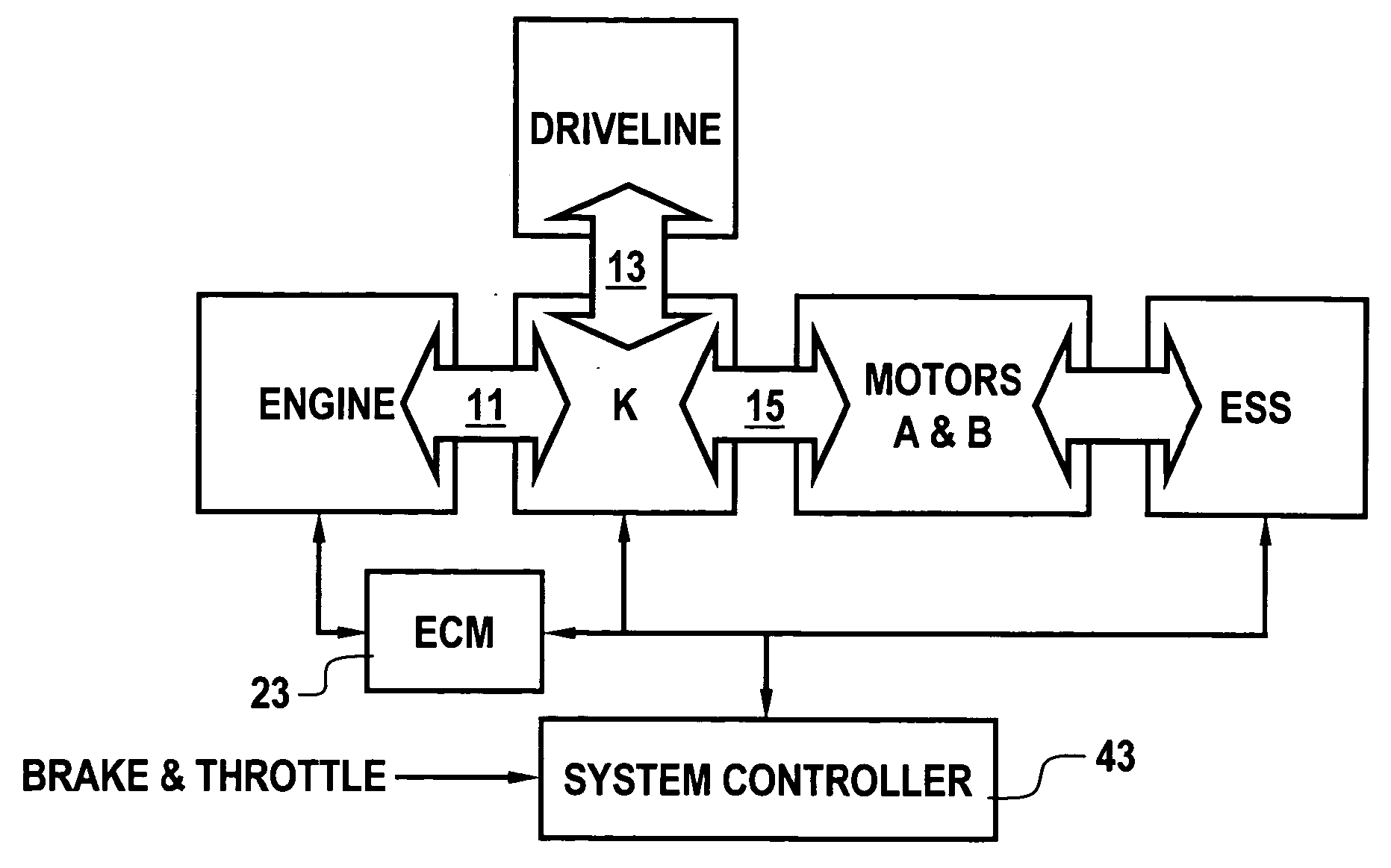

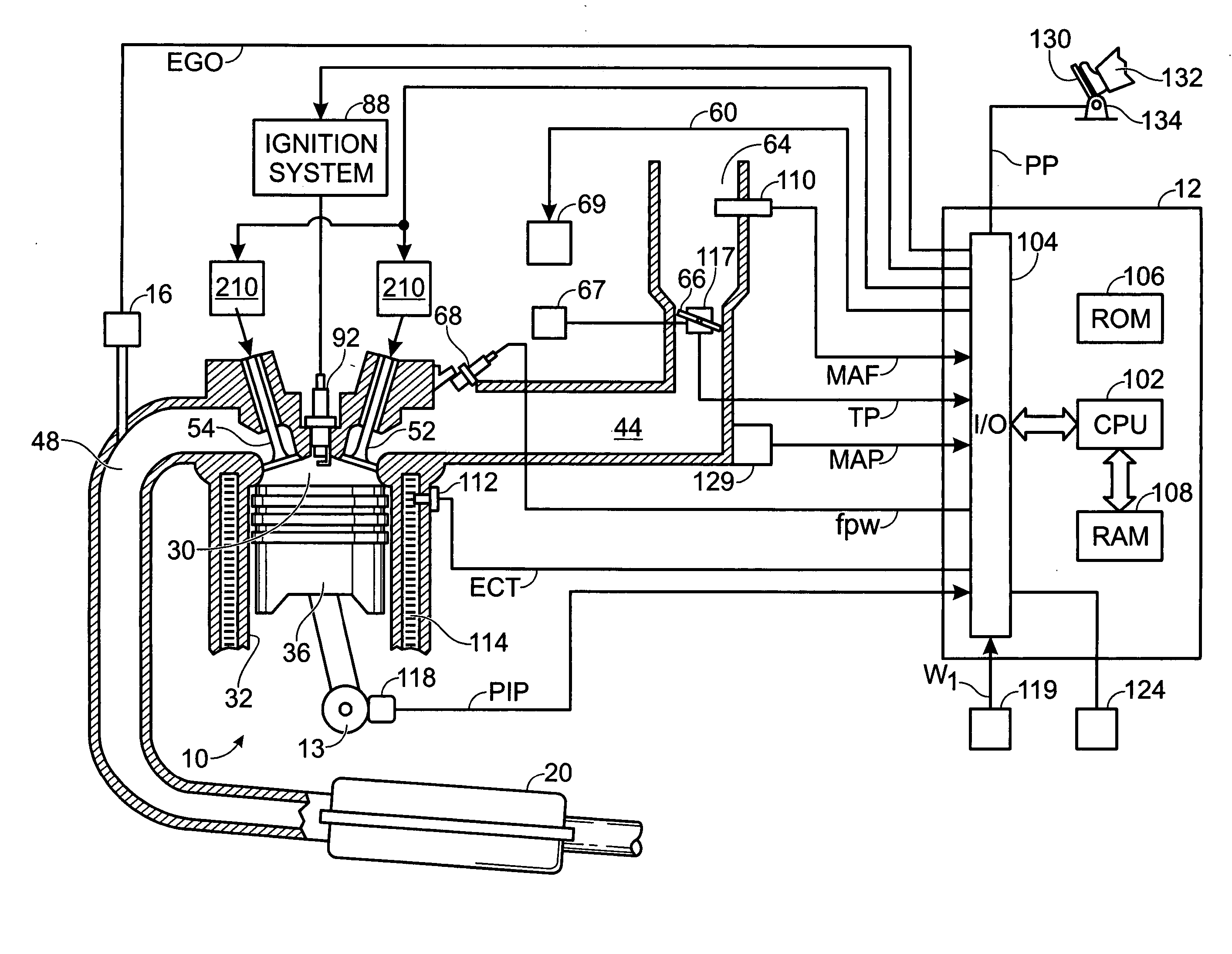

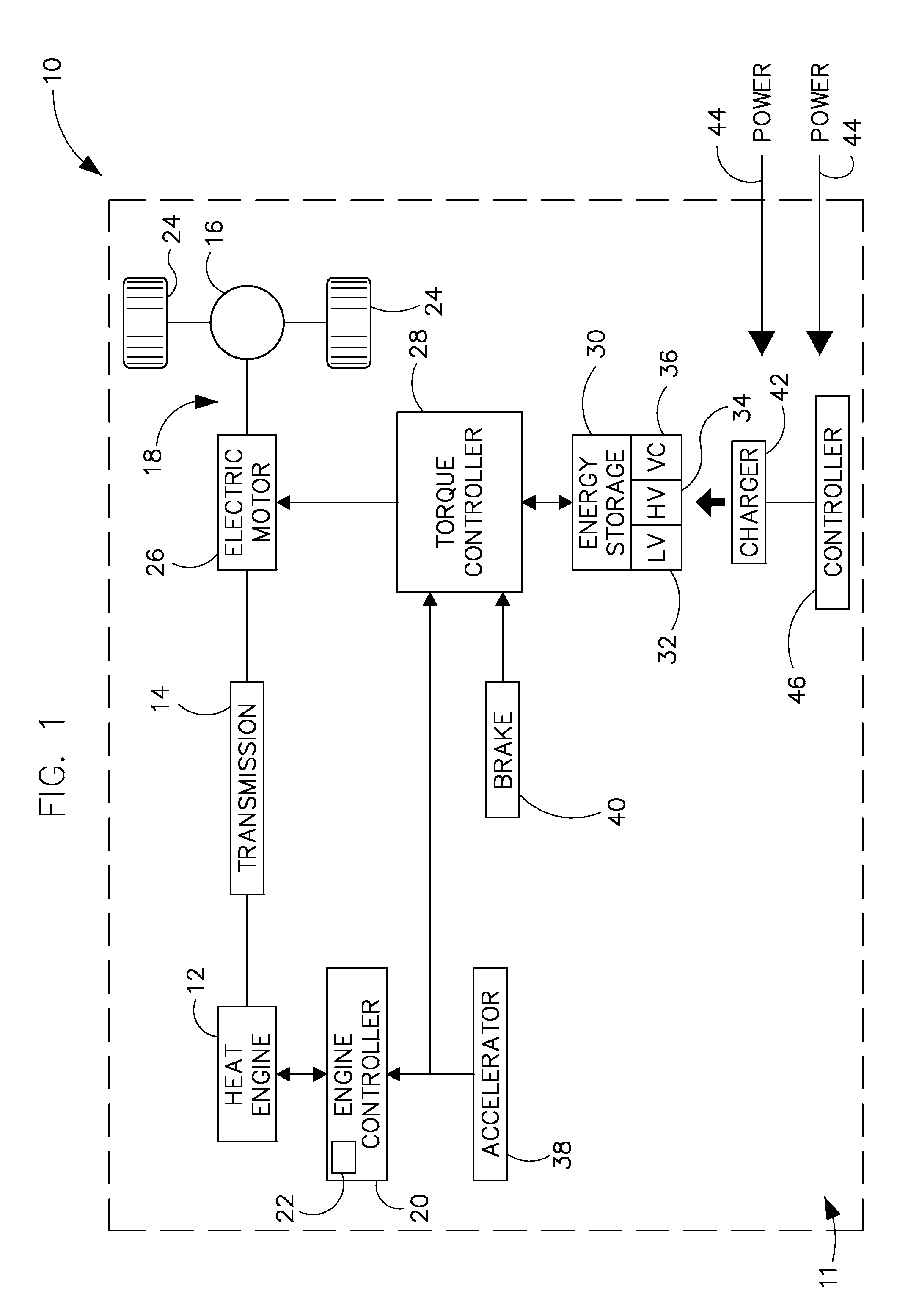

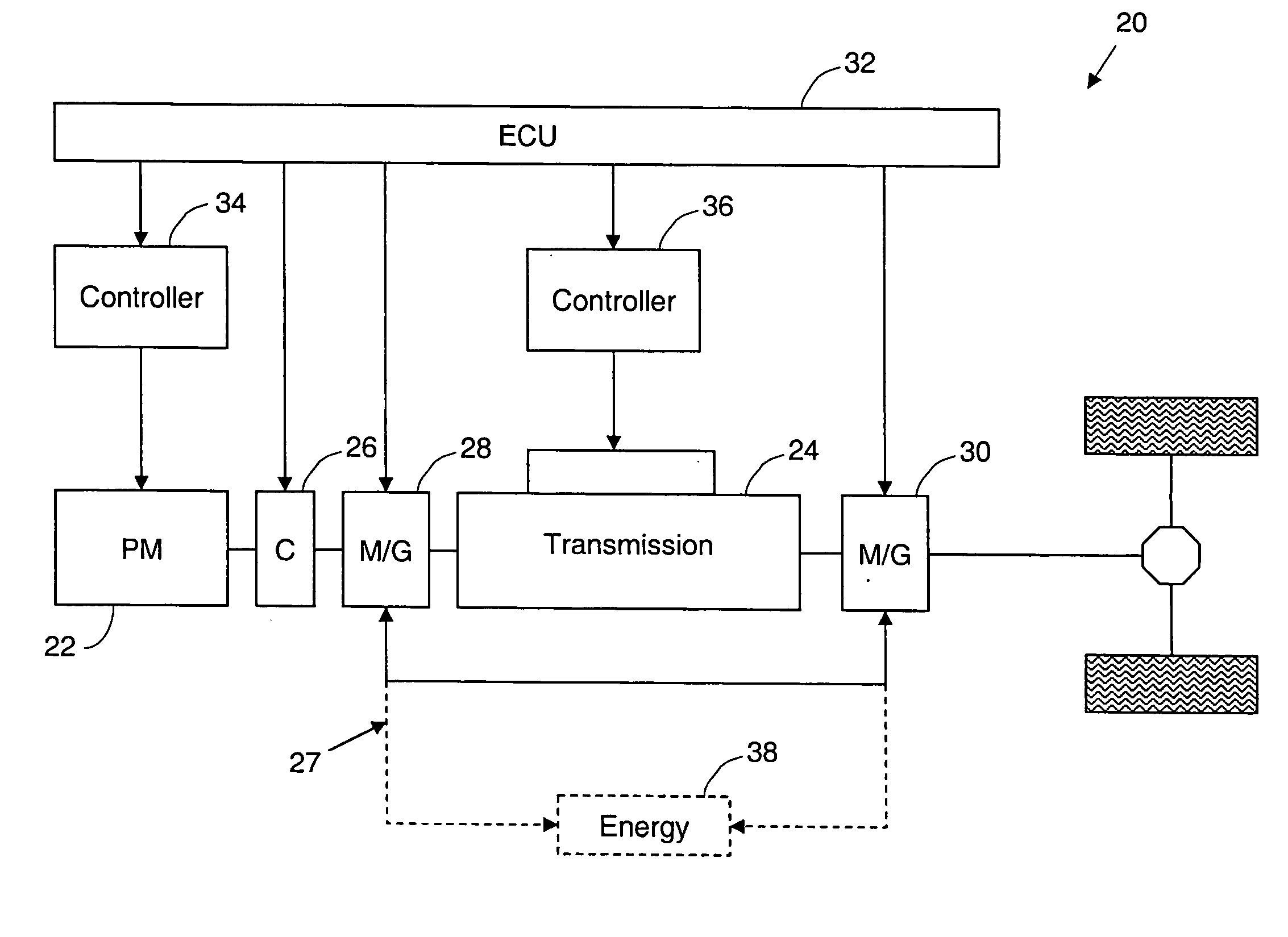

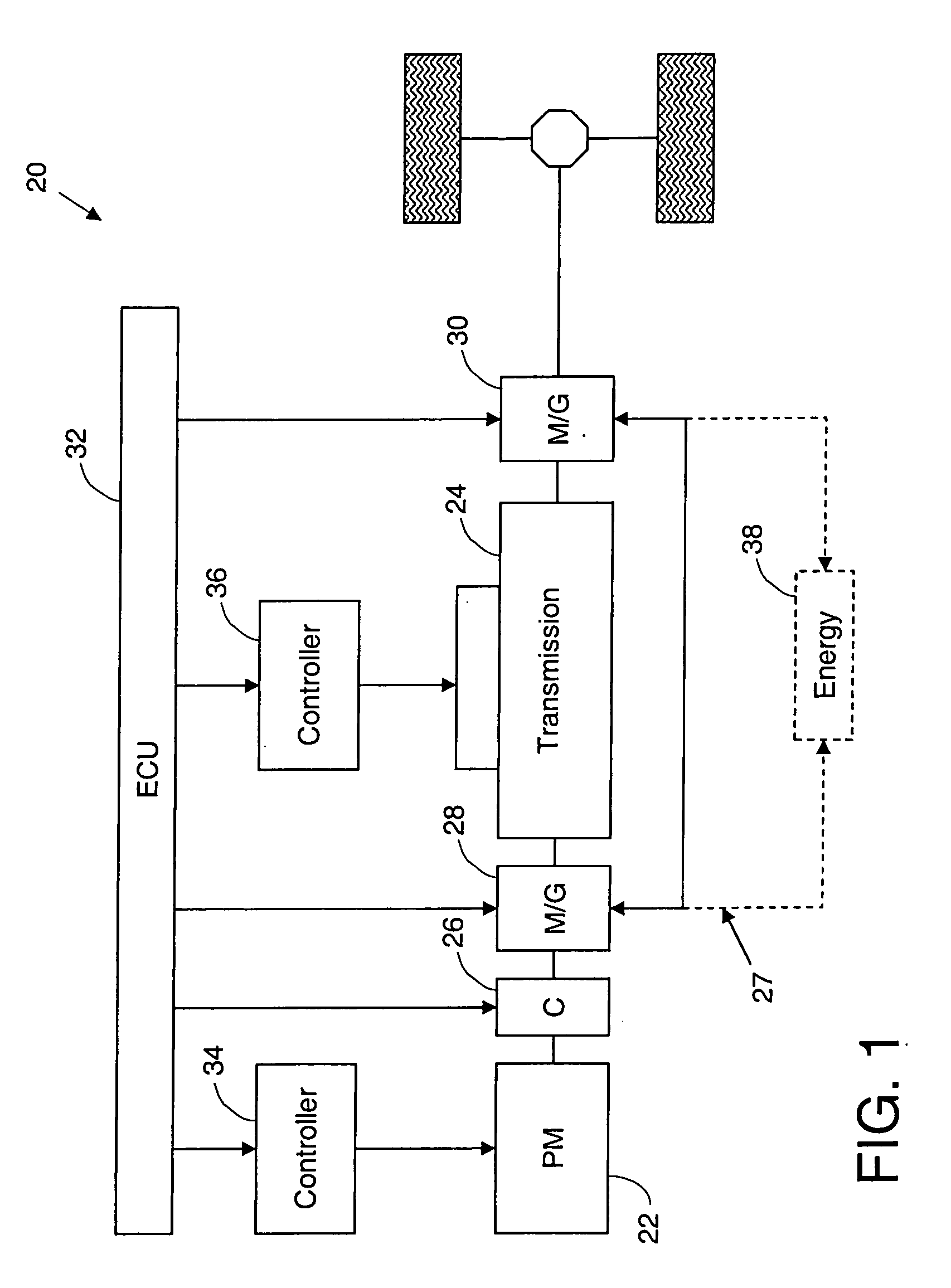

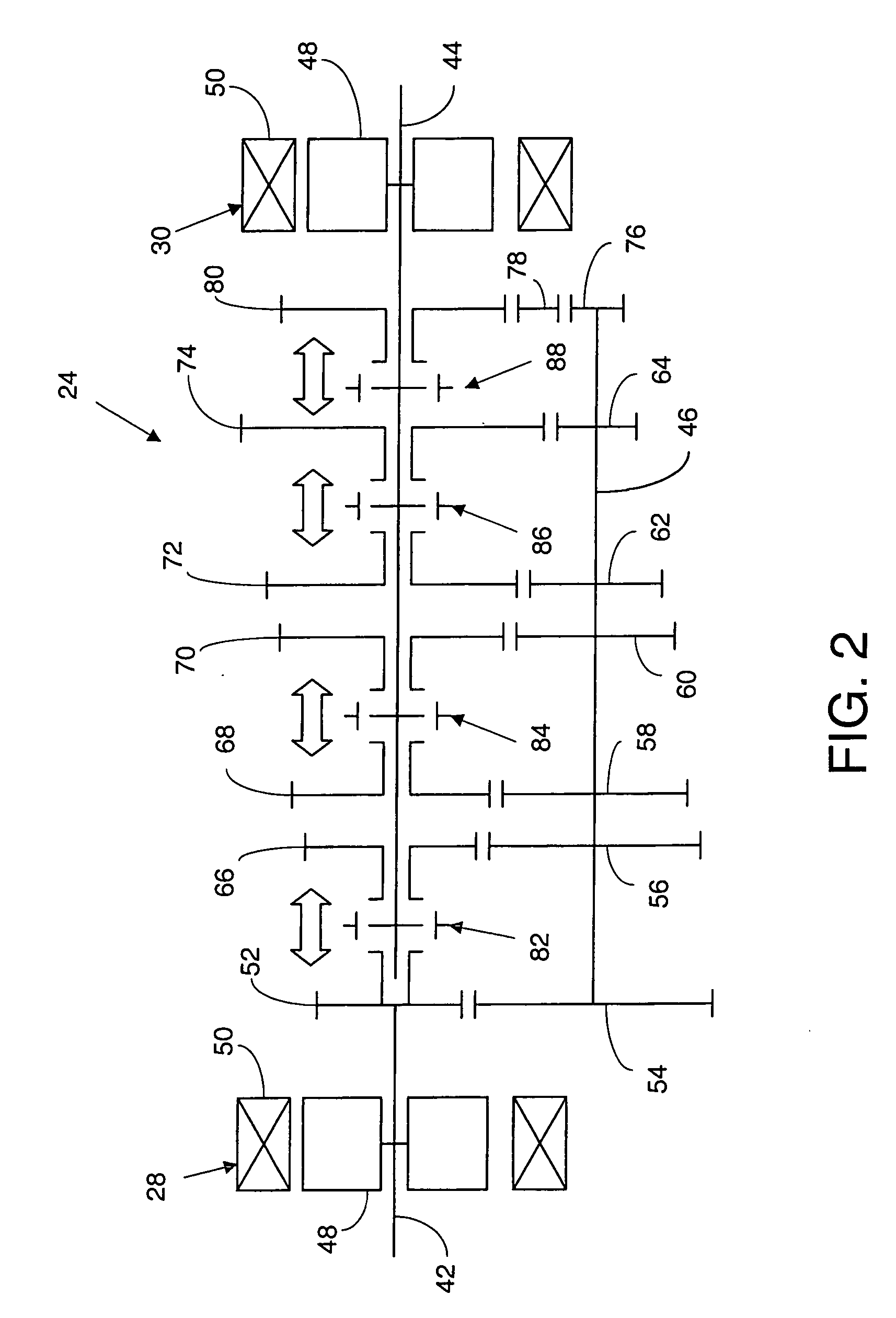

Control system architecture for a hybrid powertrain

InactiveUS20080064559A1Hybrid vehiclesElectric propulsion mountingDrivetrainInternal combustion engine

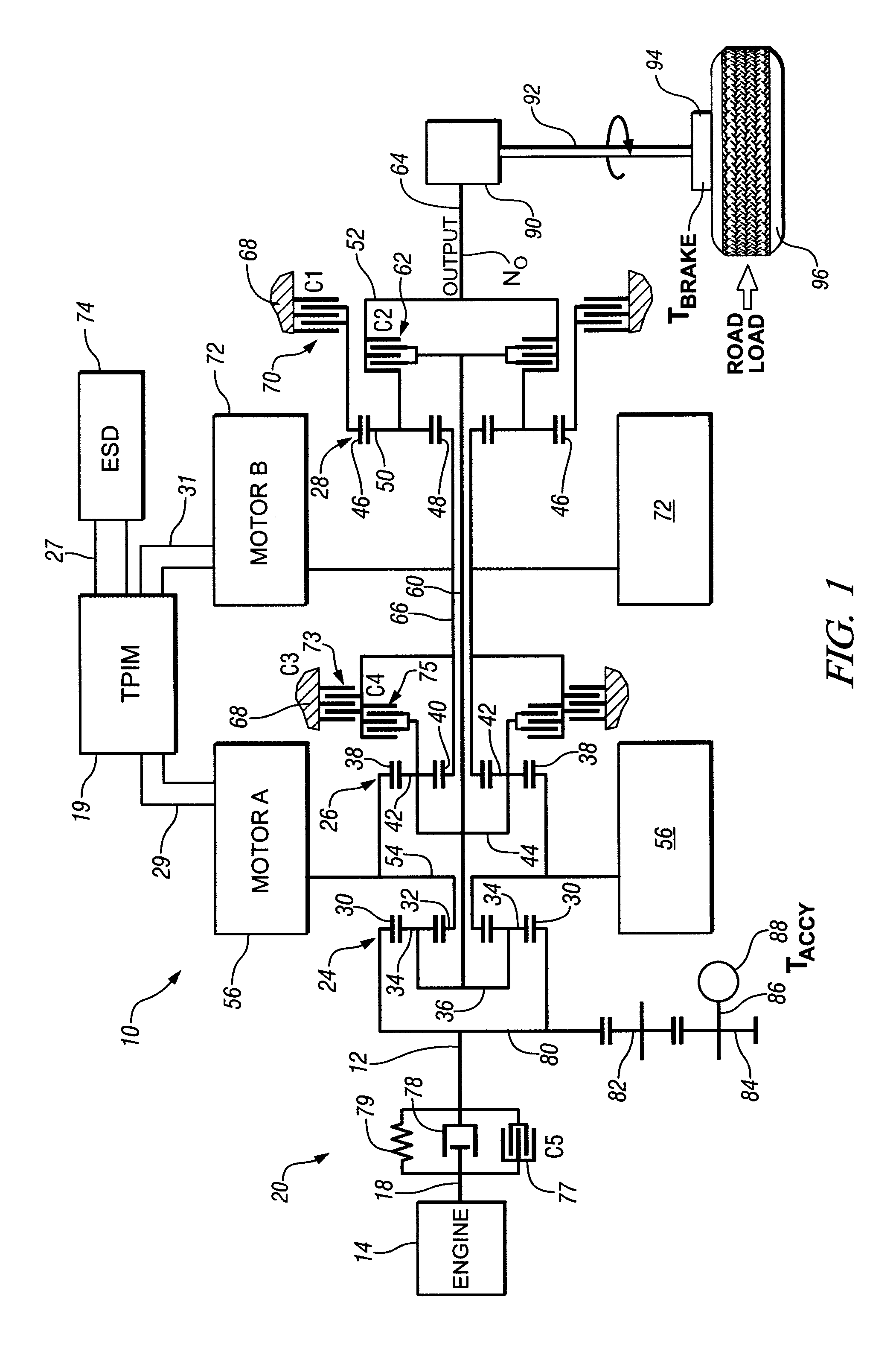

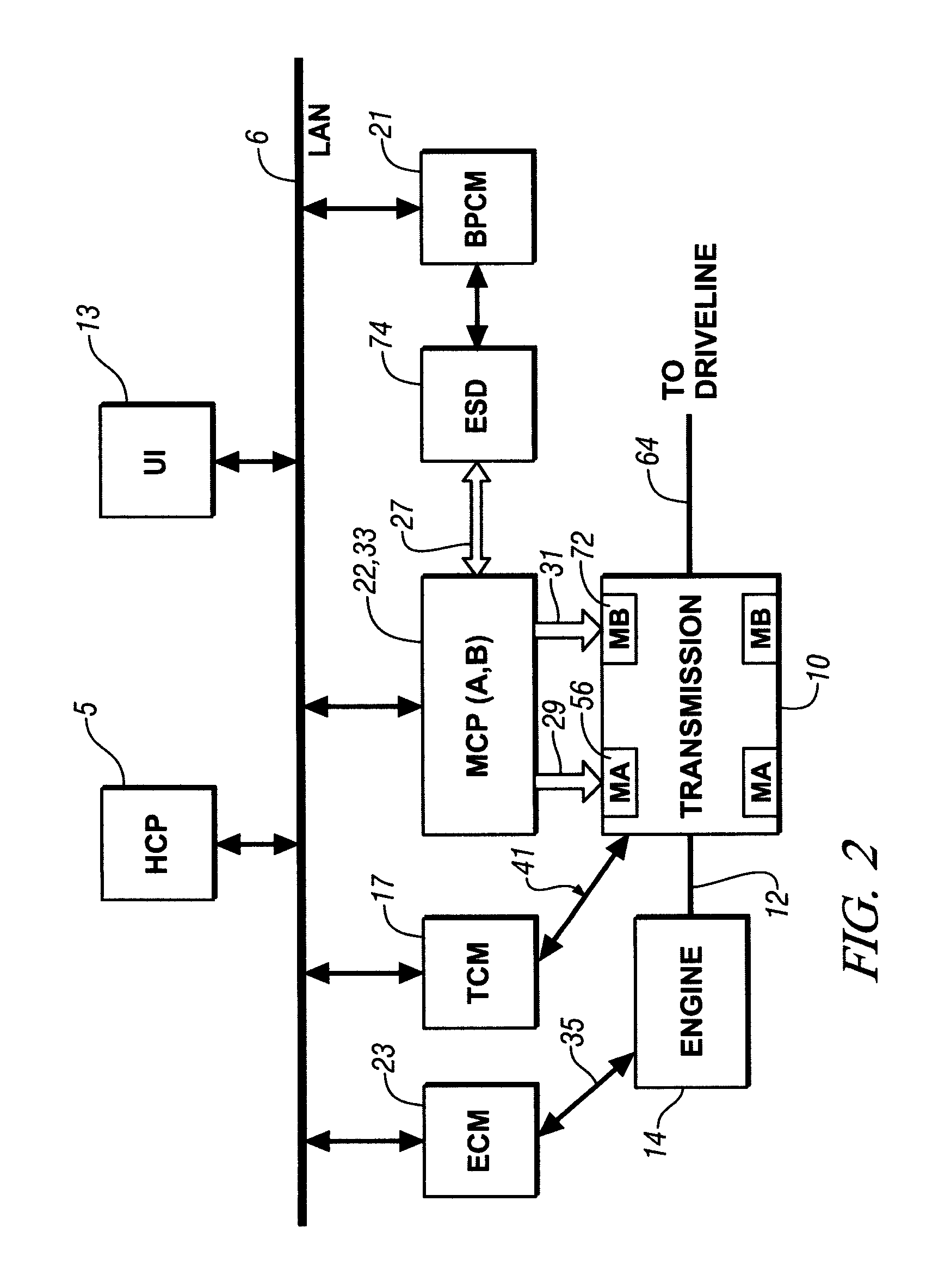

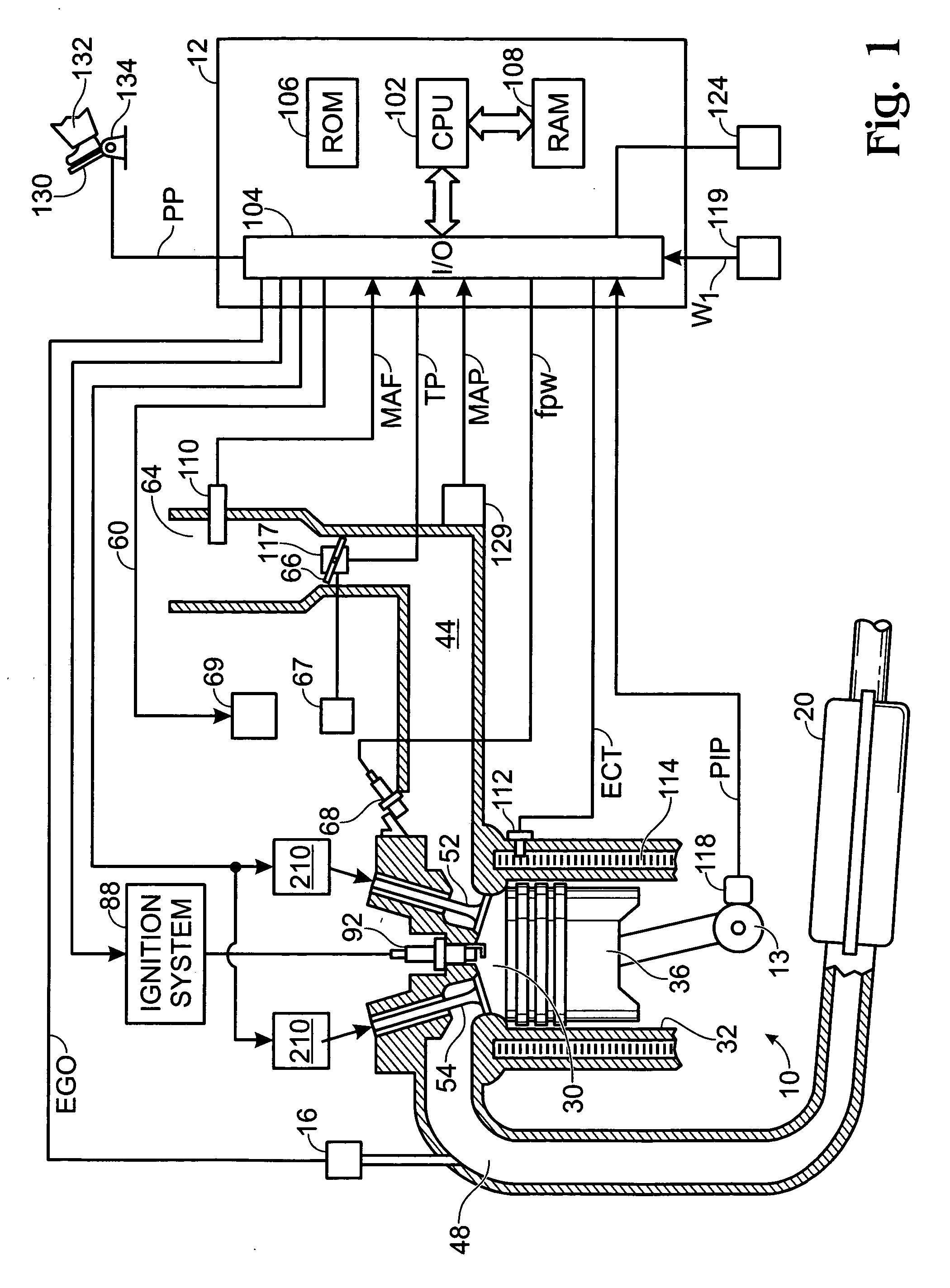

A control apparatus for a powertrain system comprising an engine and two electrical machines operably coupled to a two-mode compound-split electro-mechanical transmission is provided. It includes a system controller and two motor control processors. The system controller communicates with the motor control processors via two high speed communications buses and directly-linked serial peripheral interface buses. The motor control processors control flow of electrical power between the electrical machines and an electrical energy storage device. A second control device is operable to control the engine, preferably to control torque output. The internal combustion engine preferably has a crank position sensor which is signally connected to a dedicated input to the second control device and to a dedicated input to the system controller of the first control device.

Owner:ELECTRONICS DATA SYST CORP +1

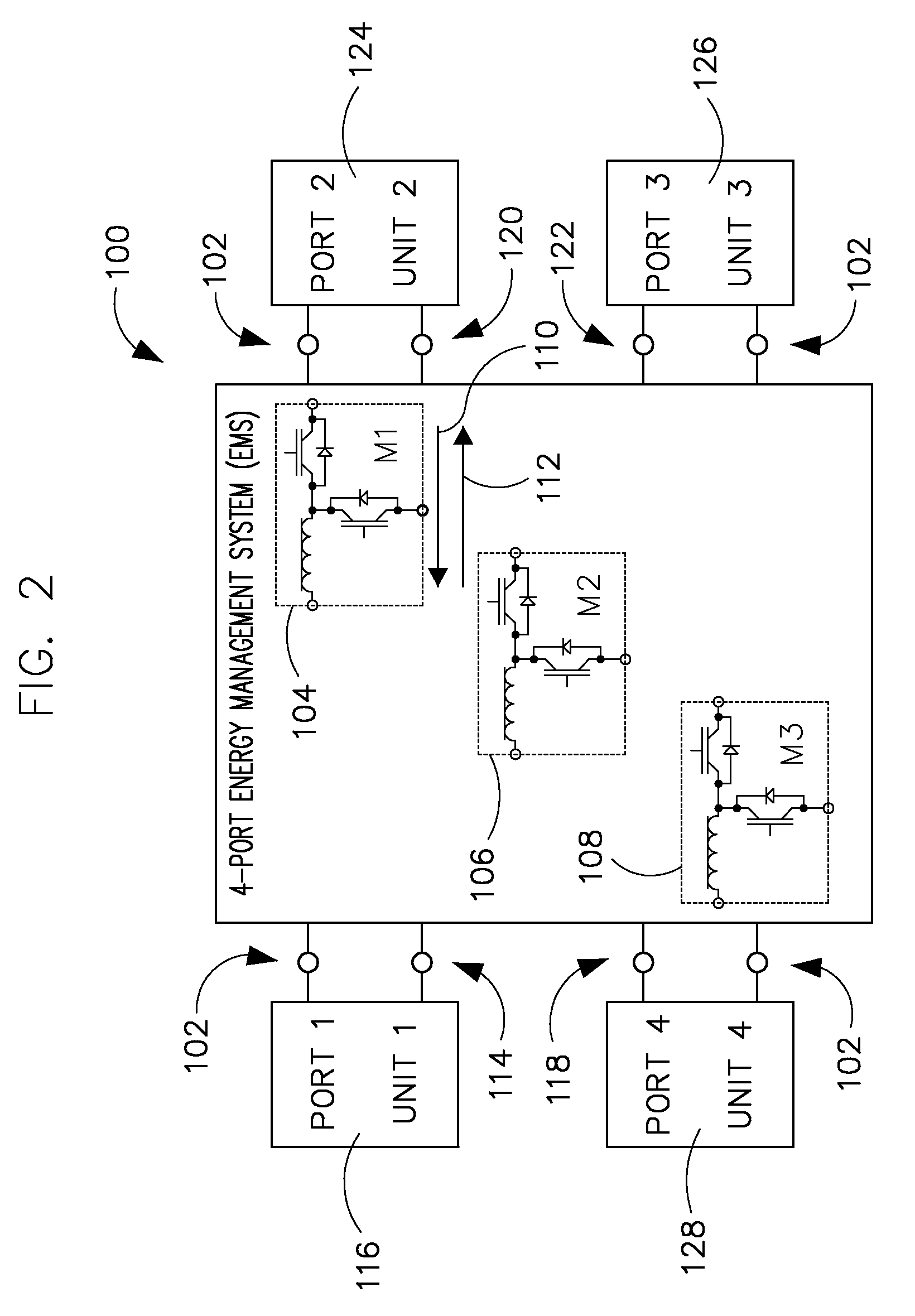

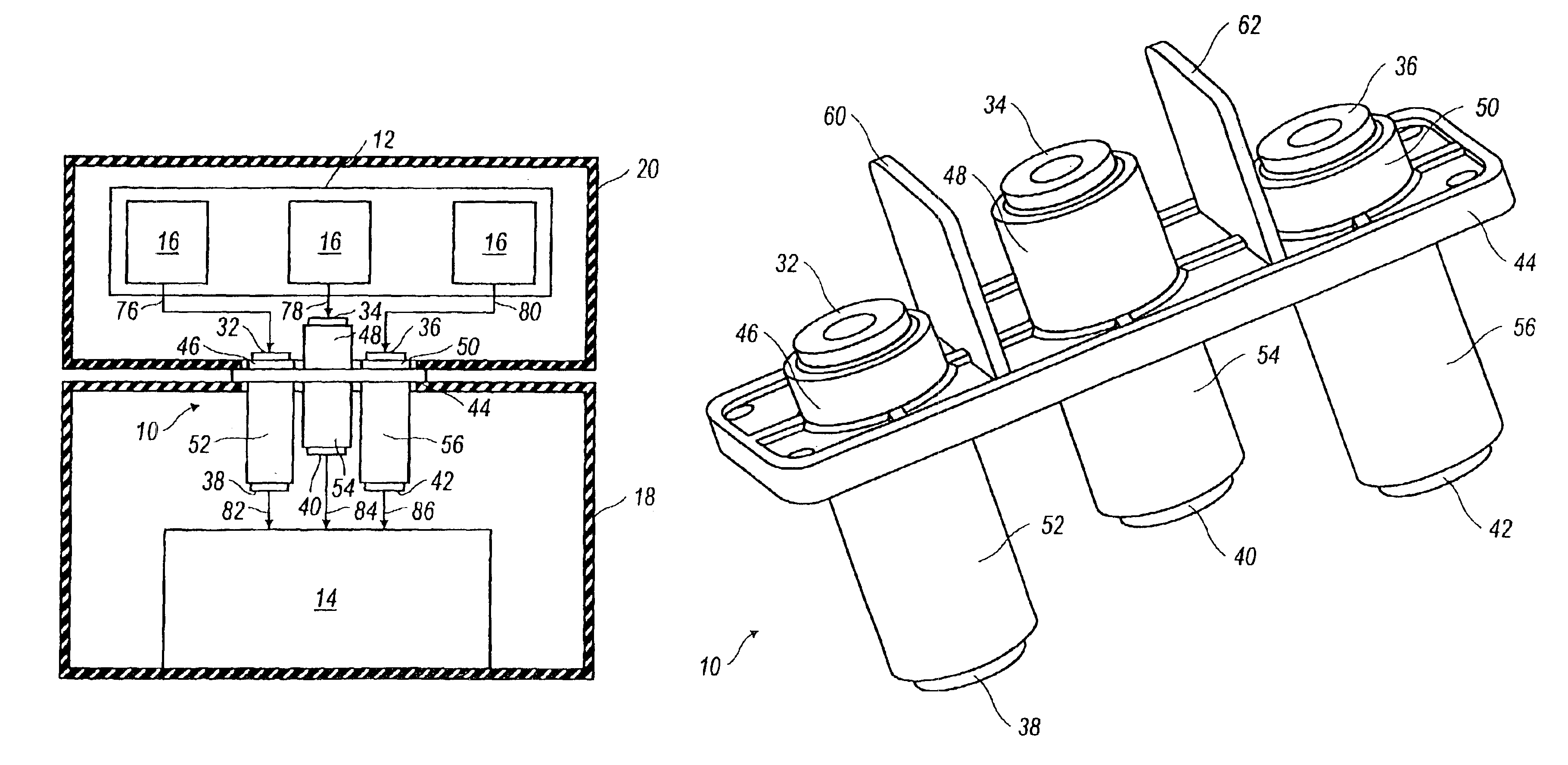

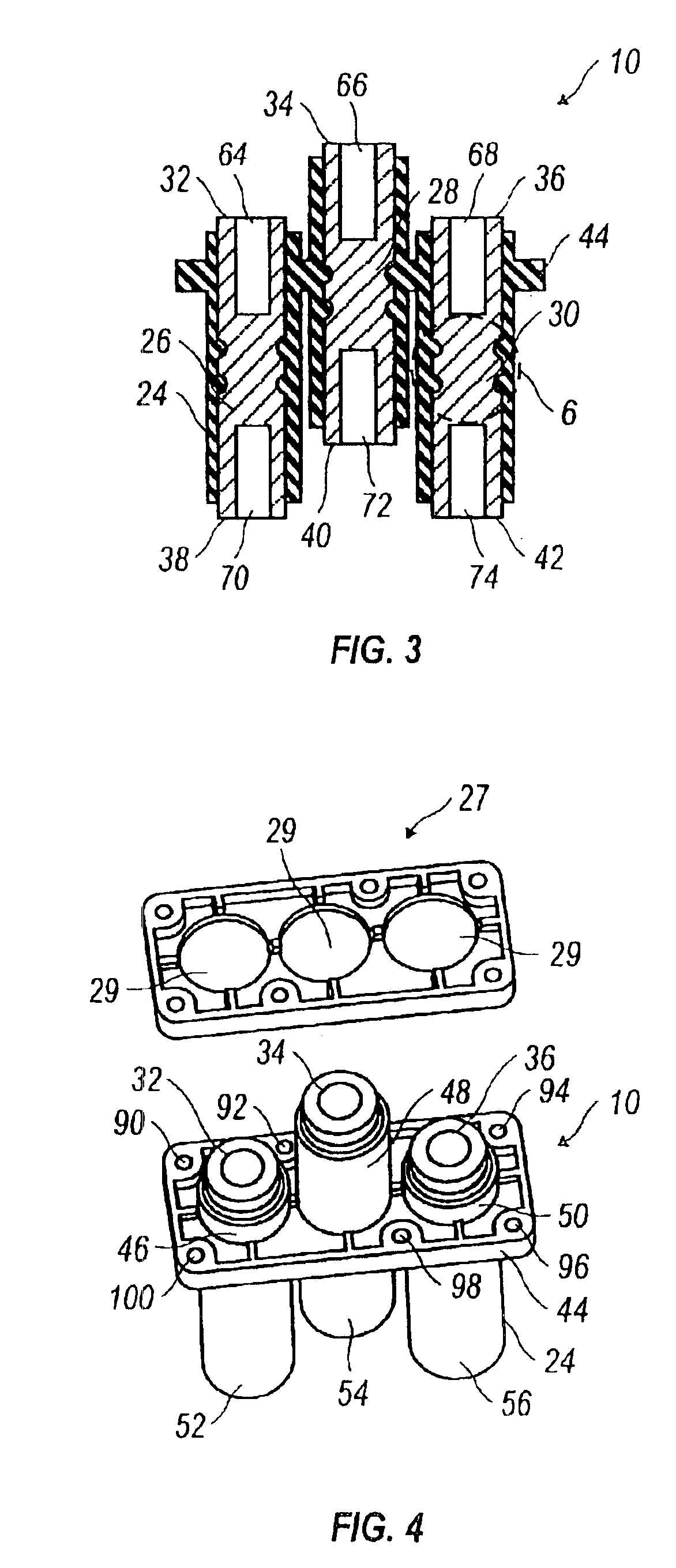

Method and apparatus for power electronics and control of plug-in hybrid propulsion with fast energy storage

InactiveUS20070068714A1Compact and inexpensiveInterconnection becomes expensivePlural diverse prime-mover propulsion mountingPower to auxillary motorsDrivetrainElectrical battery

A plug-in hybrid propulsion system includes a fast energy storage device that preserves battery life, where the energy storage elements of the hybrid drive train may be charged with externally supplied electricity as well as energy from the engine or regenerative braking. Electronic switches, passive electronics, an enclosure, controller circuitry, and / or control algorithms are used to manage the flow of power between a fuel powered engine, a battery, a fast energy storage system, traction motors, a charger, ancillary systems, an electrical distribution system, and / or a drive train.

Owner:AFS TRINITY POWER CORP

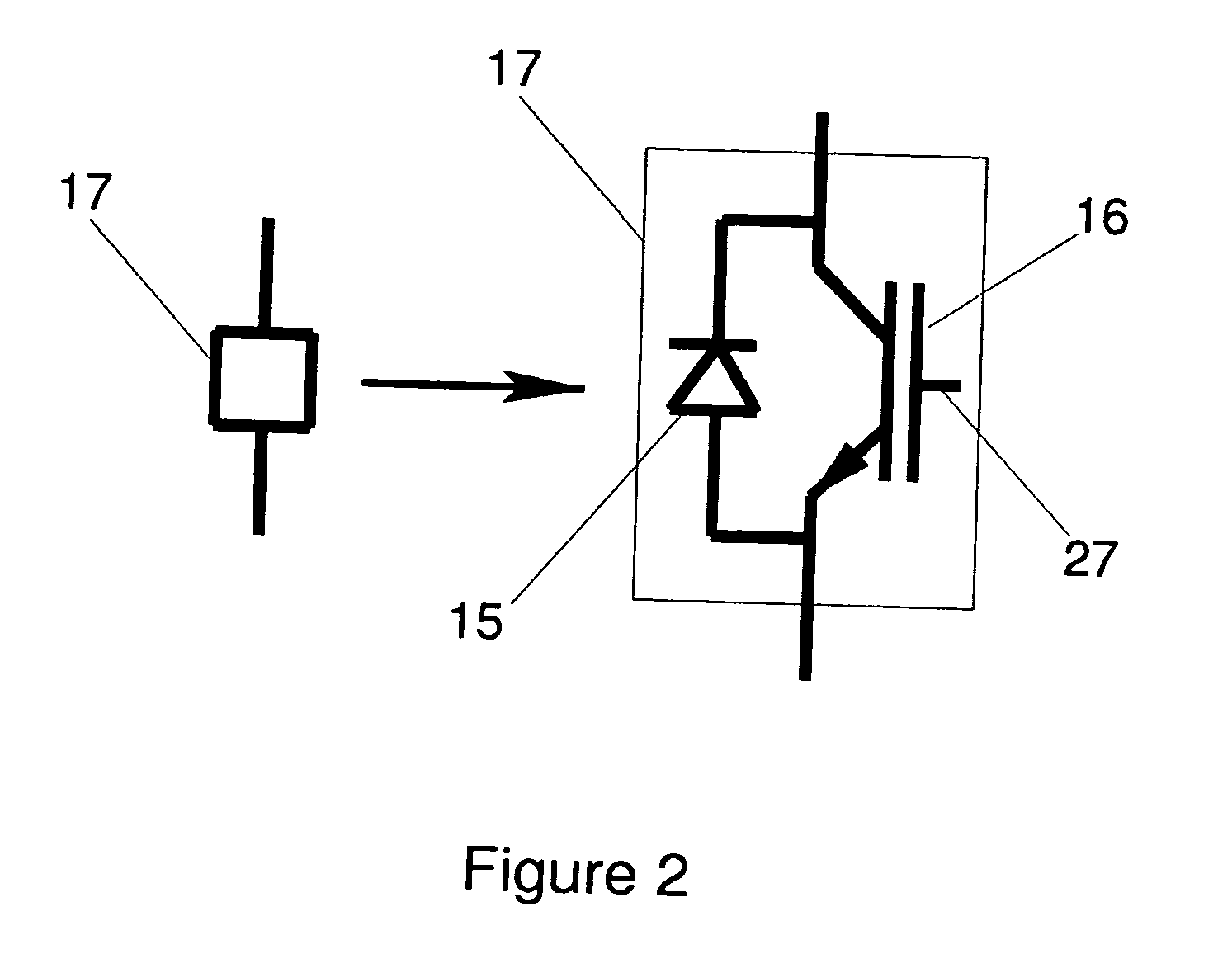

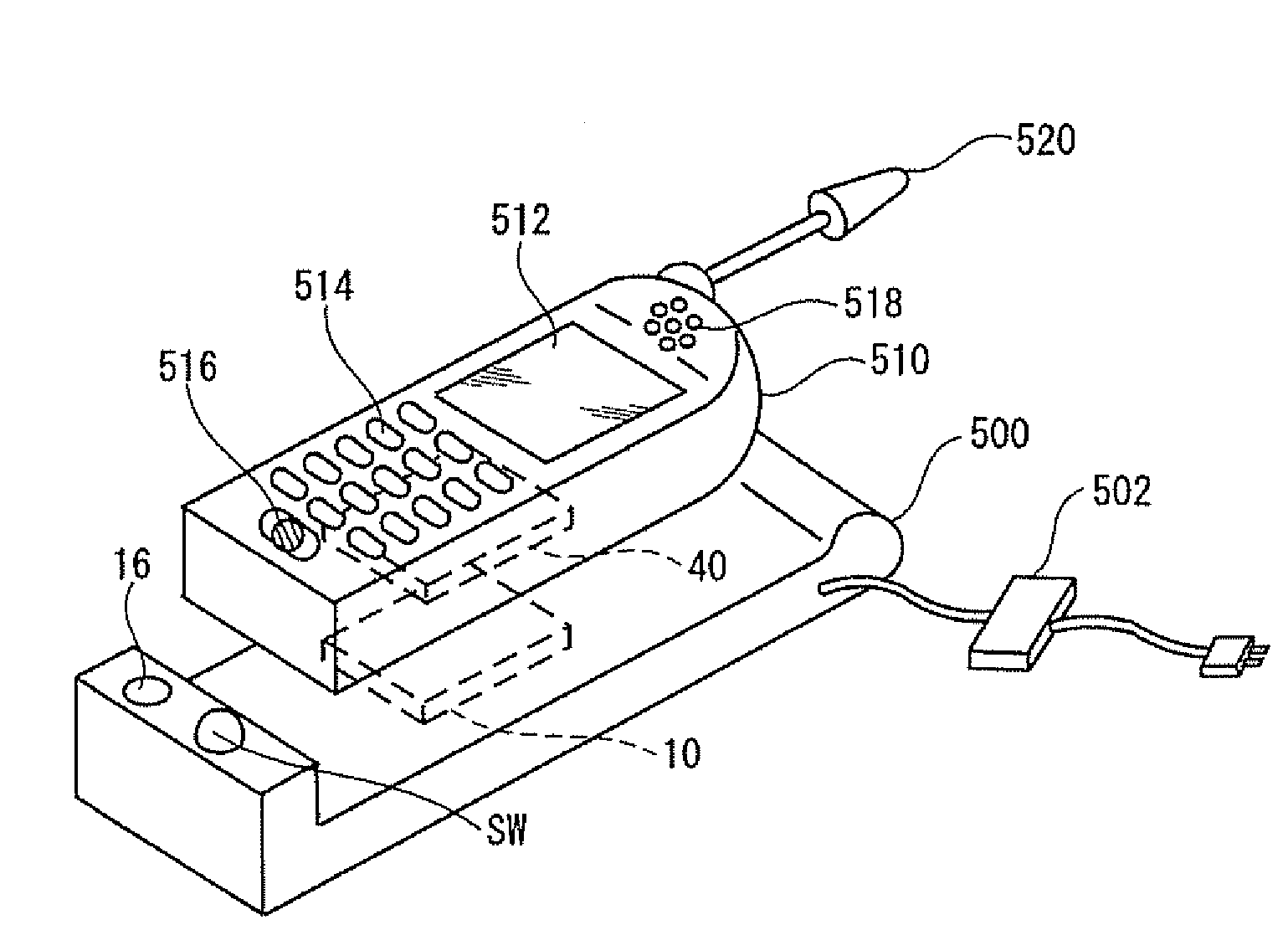

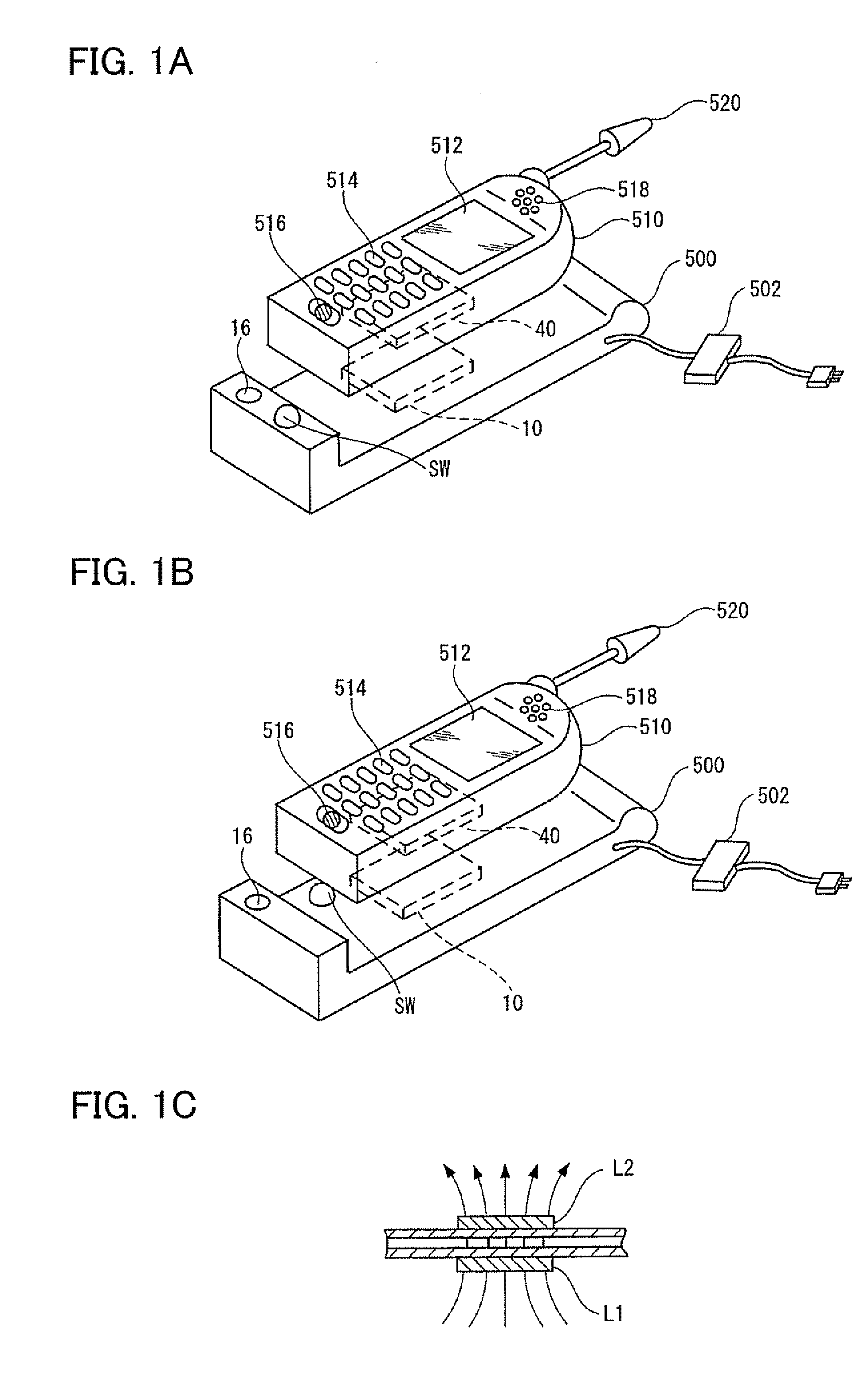

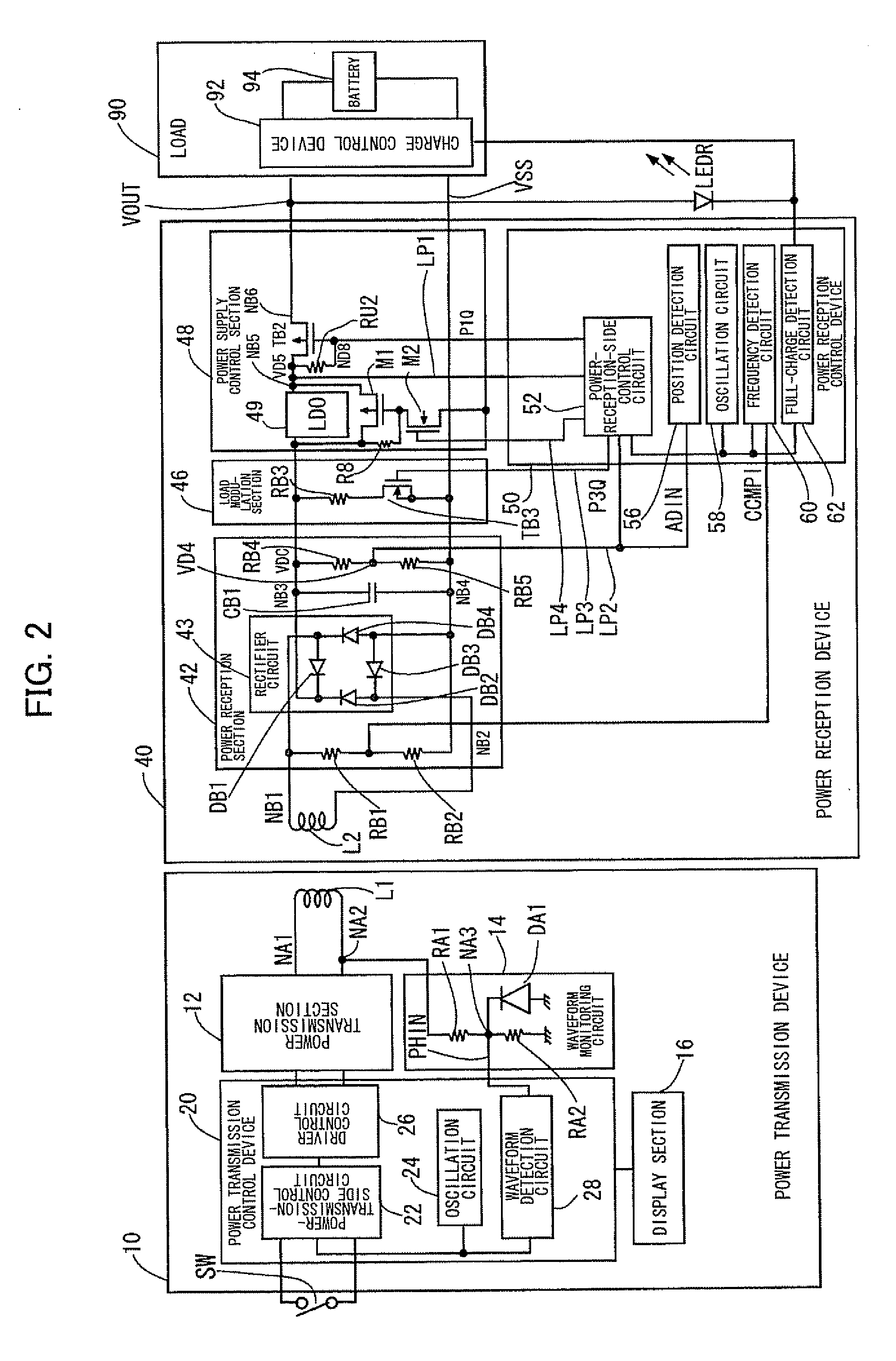

Power transmission control device, power transmission device, non-contact power transmission system, and electronic instrument

ActiveUS20090001932A1Low costSmall sizeCircuit authenticationNear-field transmissionElectric power transmissionDrivetrain

A power-transmission-side control circuit causes a power transmission device to perform temporary power transmission when a switch provided in a power-transmission-side instrument has been turned ON, and performs ID authentication based on ID authentication information. The power-transmission-side control circuit detects the presence or absence of a foreign object during normal power transmission by monitoring a change in induced voltage in a primary coil, causes the power transmission device to stop temporary power transmission when the ID authentication information from the power reception device has not been received within a given period of time, causes the power transmission device to stop temporary power transmission when the ID authentication has failed, and causes the power transmission device to stop normal power transmission when removal, a metal foreign object, a takeover state, or a full-charge state has been detected after normal power transmission has started.

Owner:SEIKO EPSON CORP

Driveline lash estimation and clunk management using multivariable active driveline damping

ActiveUS20070225888A1Minimize impactHybrid vehiclesDigital data processing detailsDrivetrainEngineering

Driveline lash and clunk are controlled in a powertrain system having multiple torque-generative and torque control devices using a multivariable feedback control approach to provide active driveline damping. Control parameters used by a state estimator are different, depending on whether the driveline lash is taken up or is currently slack. When the estimated driveline axle torque is not substantially zero, the nominal parameters for transmission mode or gear are used in the state estimator. When the estimated axle torque is substantially zero, the parameters are switched to neutral parameters, the lash estimator indicates neutral lash state, and angle of lash is tracked until it accumulates an expected amount of lash in the driveline. During a lash transition time, active damping controls the driveline component speeds so that the effect of lash take-up is minimized. After lash take-up occurs, desired axle torque is used by the system.

Owner:GM GLOBAL TECH OPERATIONS LLC

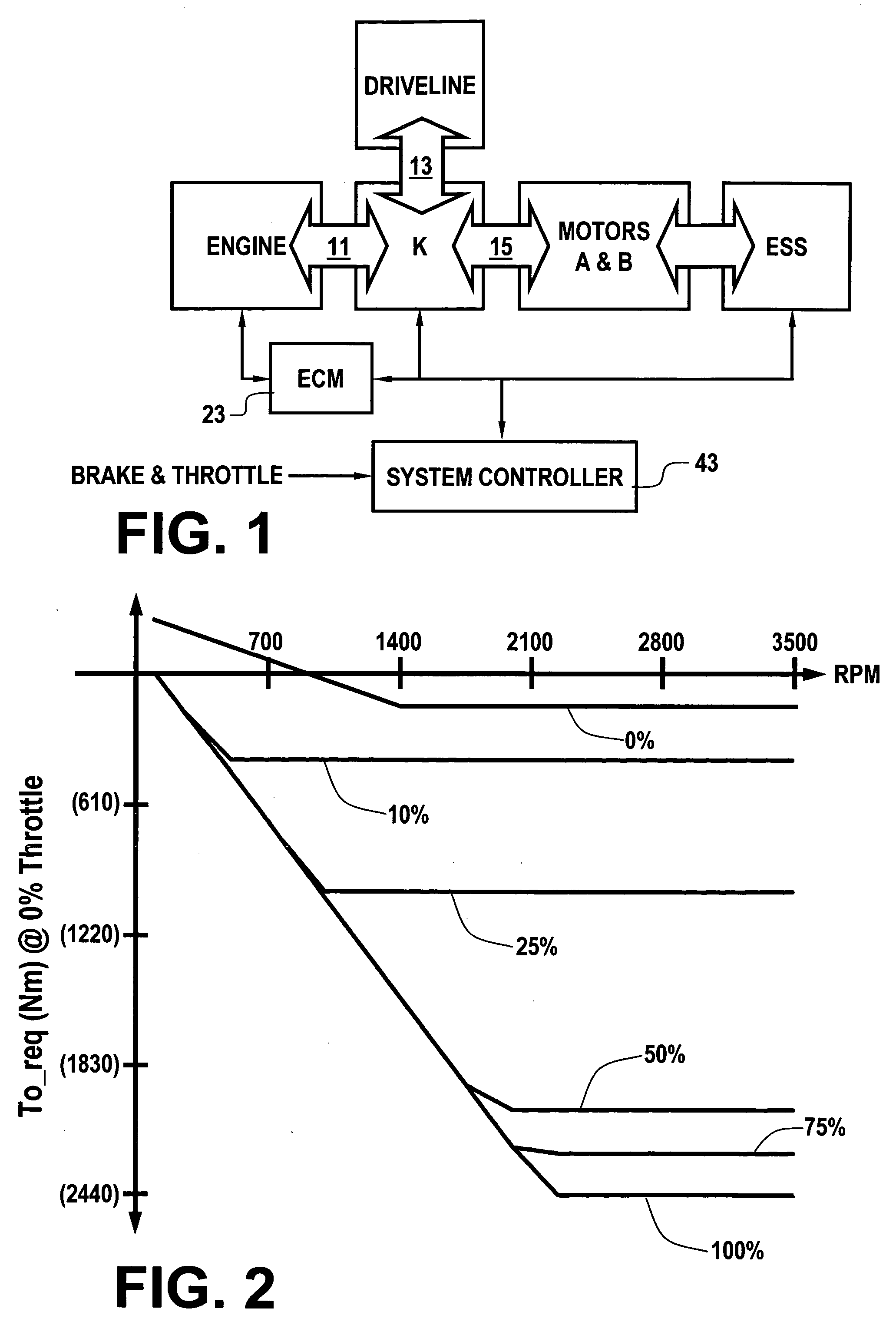

Method of providing electric motor torque reserve in a hybrid electric vehicle

ActiveUS20050255964A1Improve control robustnessImproved shift qualityHybrid vehiclesDigital data processing detailsDrivetrainBattery electric vehicle

A method of operating a vehicle powertrain system comprising an electric motor and transmission where the electric motor is operably and selectively coupled to the transmission and adapted to provide an output torque contribution thereto, and the electric motor has a predetermined maximum motor output torque and a predetermined minimum motor output torque which are used to determine a range of permissible control points for at least one transmission control parameter. The method includes establishing a motor torque reserve by performing at least one of decreasing the predetermined maximum motor output torque to a maximum reserved motor output torque and increasing the minimum motor output torque to a minimum reserved motor output torque, wherein the maximum reserved motor output torque and the minimum reserved motor output torque are used in place of the predetermined maximum motor output torque and the predetermined minimum motor output torque, respectively, to determine the range of permissible control points for the at least one transmission control parameter. The motor torque reserve may include a static motor torque reserve, a dynamic motor torque reserve, or a combination of both static and dynamic torque reserves. The dynamic torque reserve may include a predictive dynamic reserve, a reactive dynamic reserve, or a combination of a predictive reserve and a reactive reserve or reserves.

Owner:GM GLOBAL TECH OPERATIONS LLC

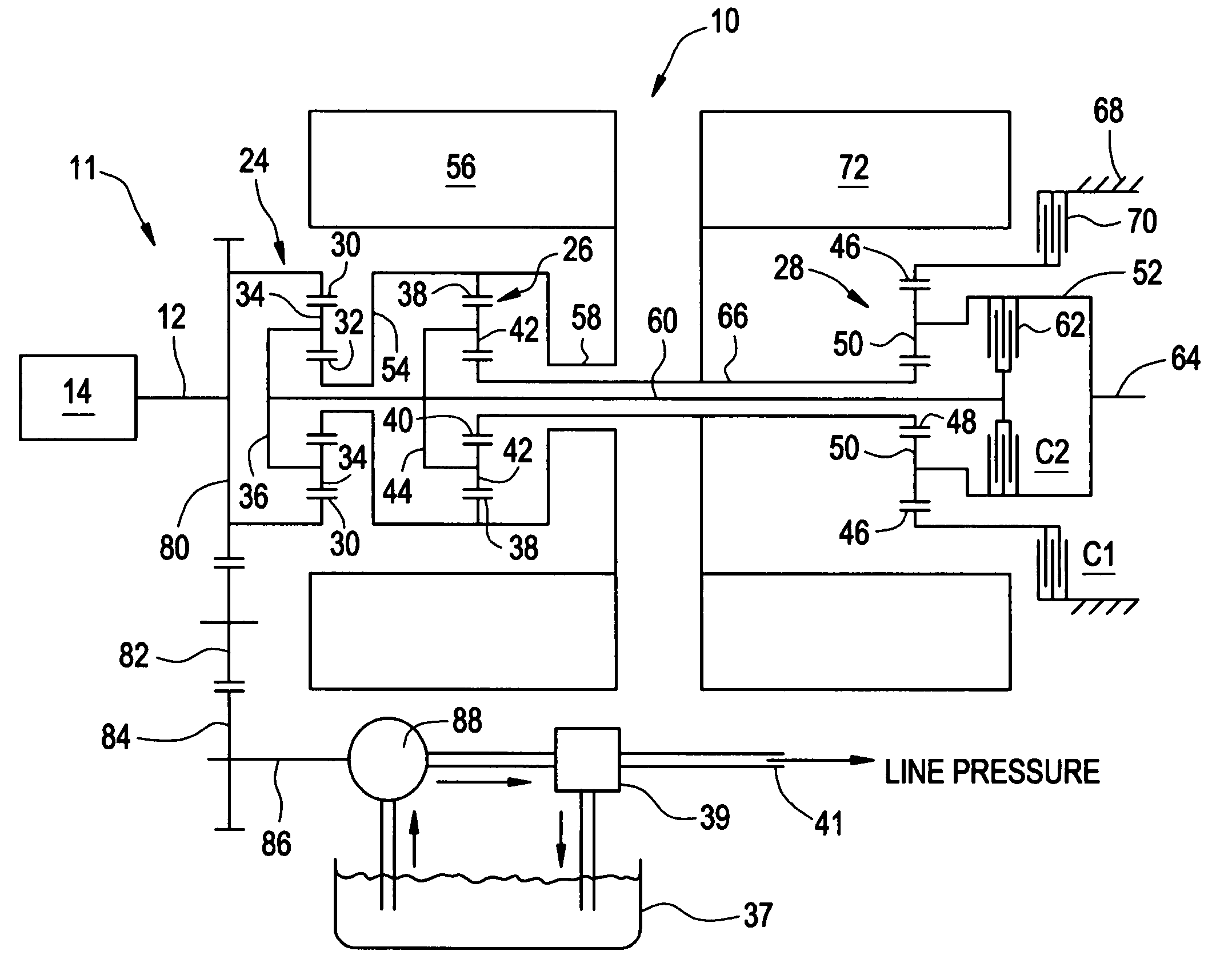

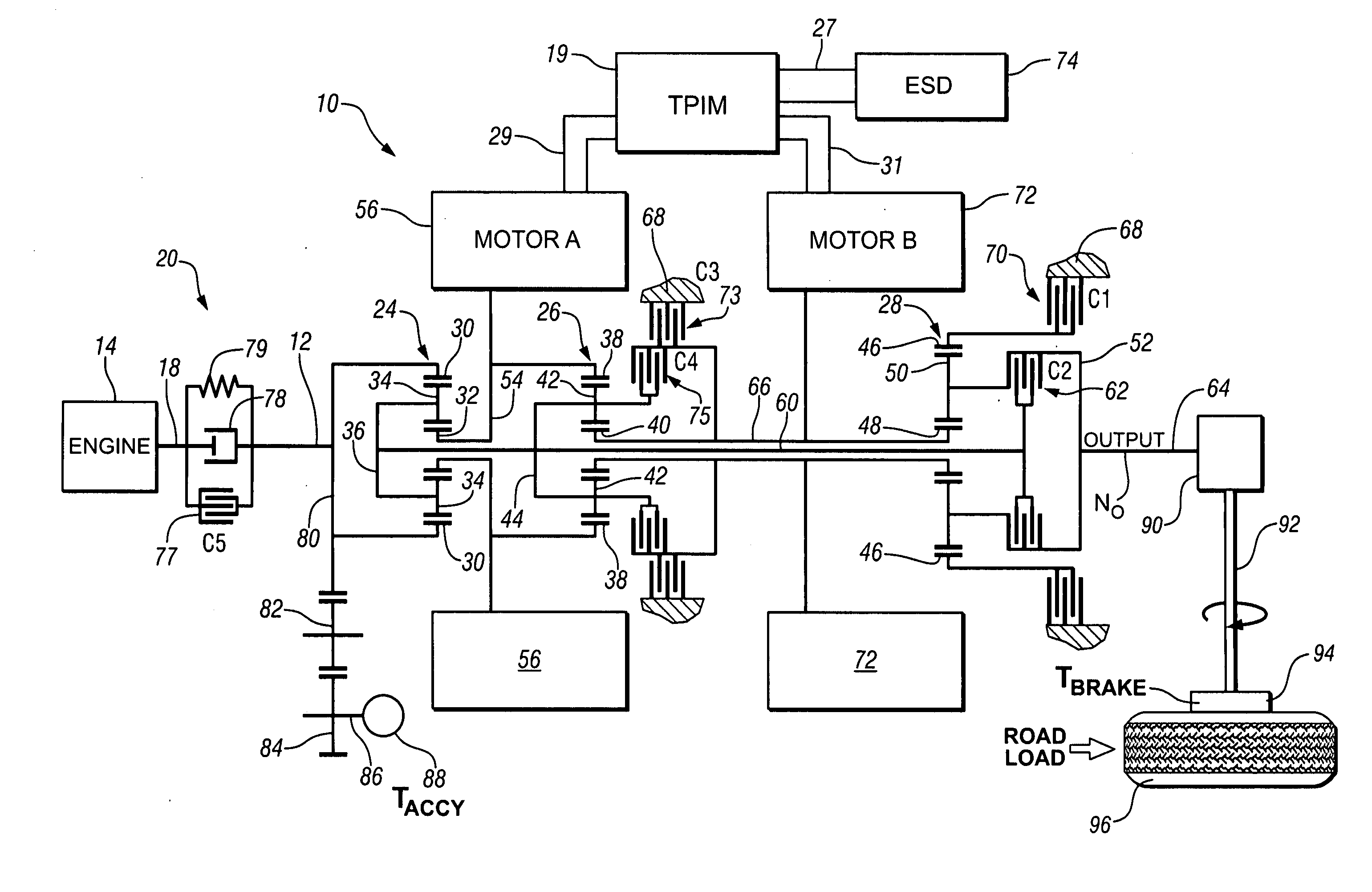

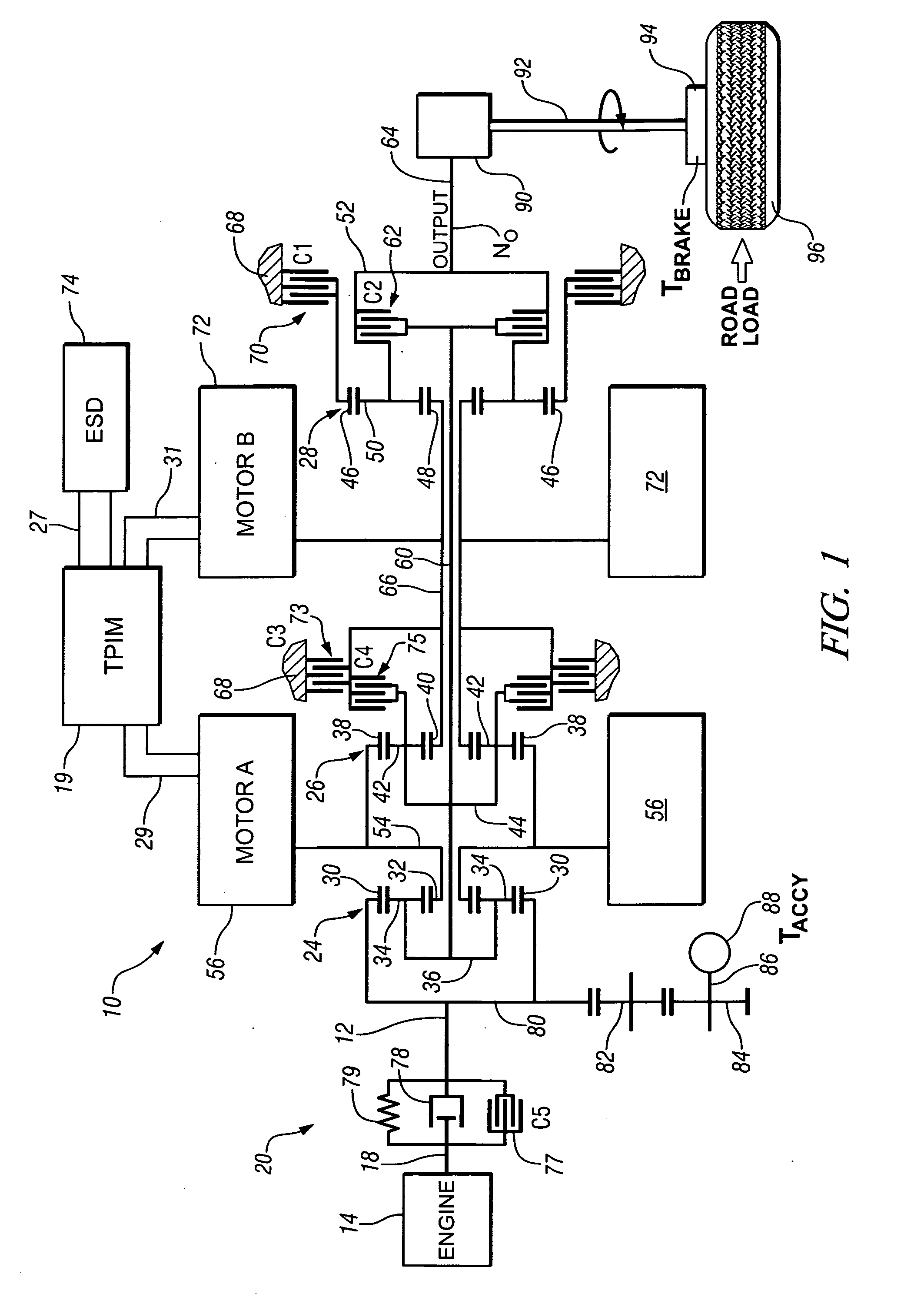

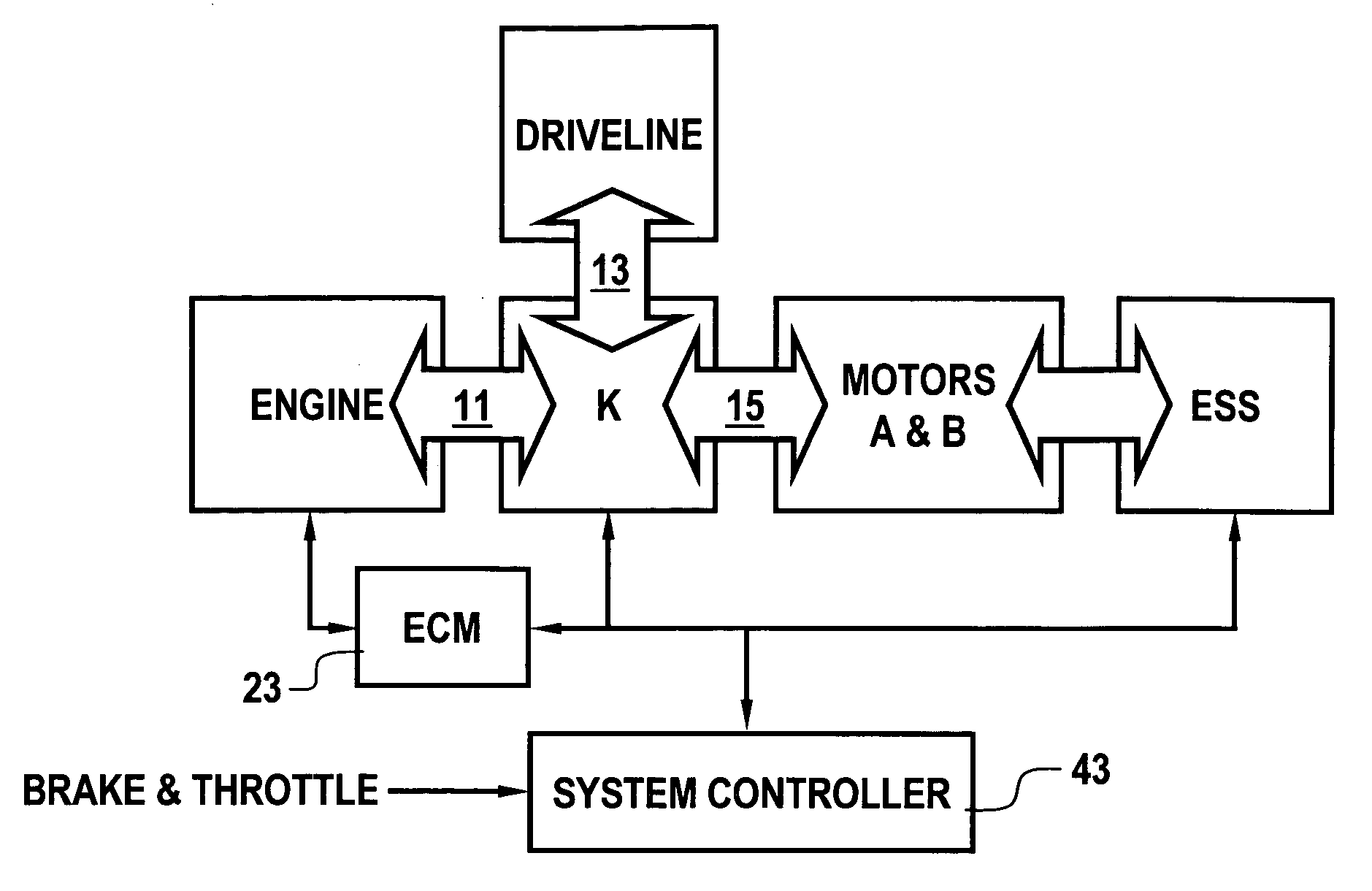

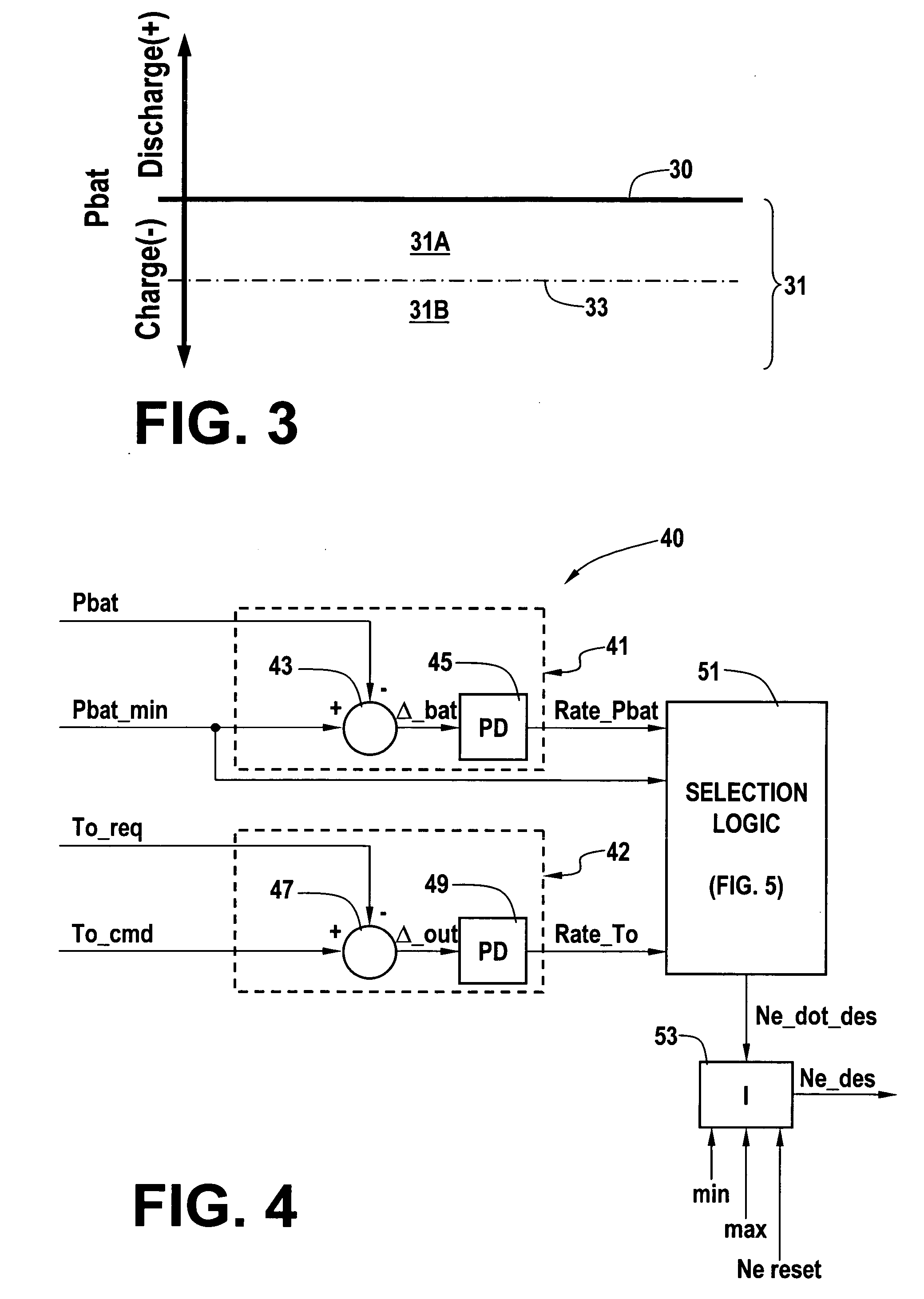

Method and apparatus for multivariate active driveline damping

A multivariate control method and system to control torque output from a powertrain system to a driveline is provided, to reduce driveline oscillations. The powertrain preferably comprises hybrid powertrain having a plurality of torque-generative devices connected to a transmission. Desired powertrain and driveline operating states are determined, as are a plurality of operating state errors. Each torque-generative device is controlled, based upon the operating state errors, and operating mode of the transmission. A damping torque command, additive to a commanded torque, is determined for one or more of the torque-generative devices based upon the determined transmission operating mode. Determined operating states include operator input, and powertrain / driveline including driveline torque; transmission input torque, rotational speed of the torque-generative devices; road load; and, accessory load.

Owner:GM GLOBAL TECH OPERATIONS LLC

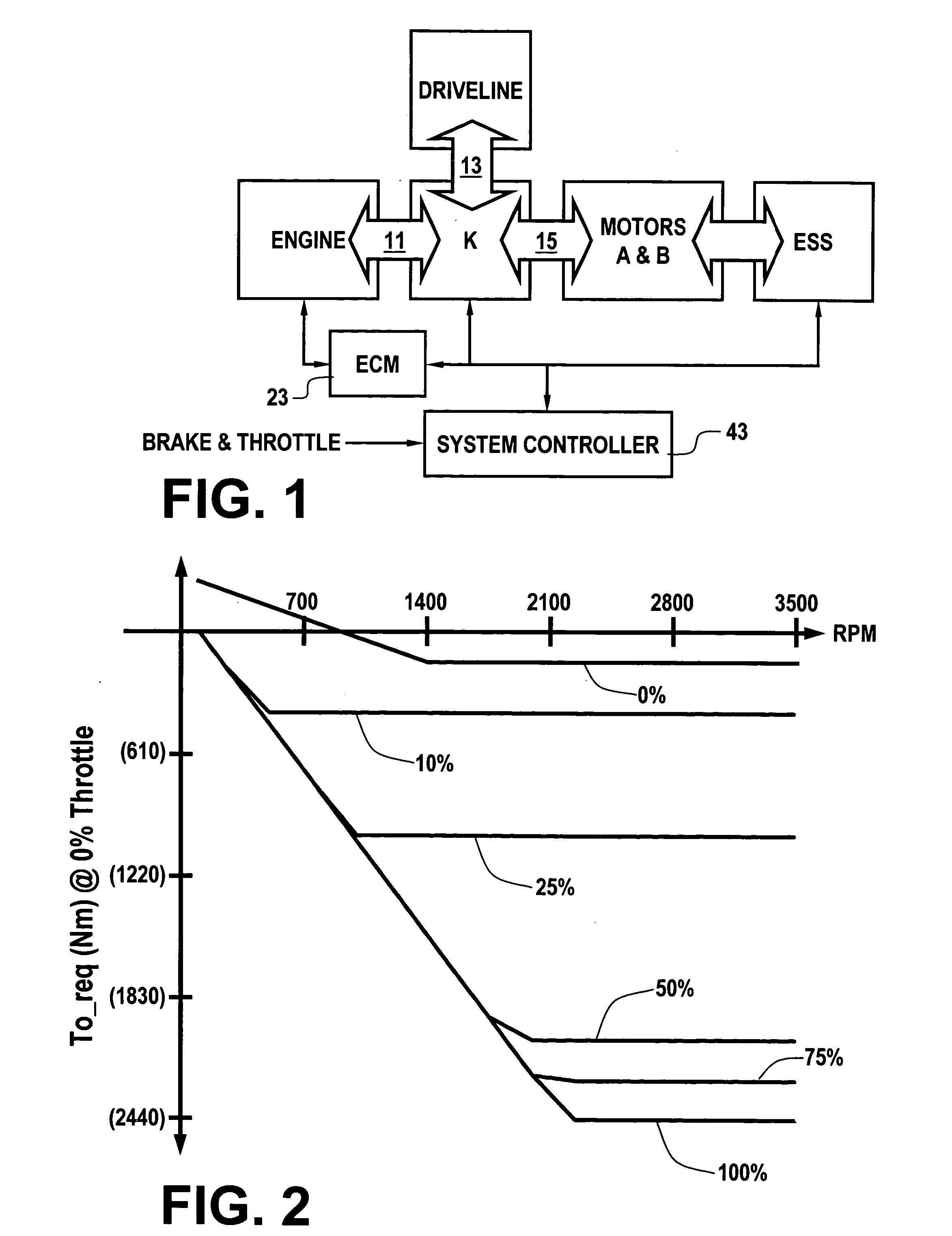

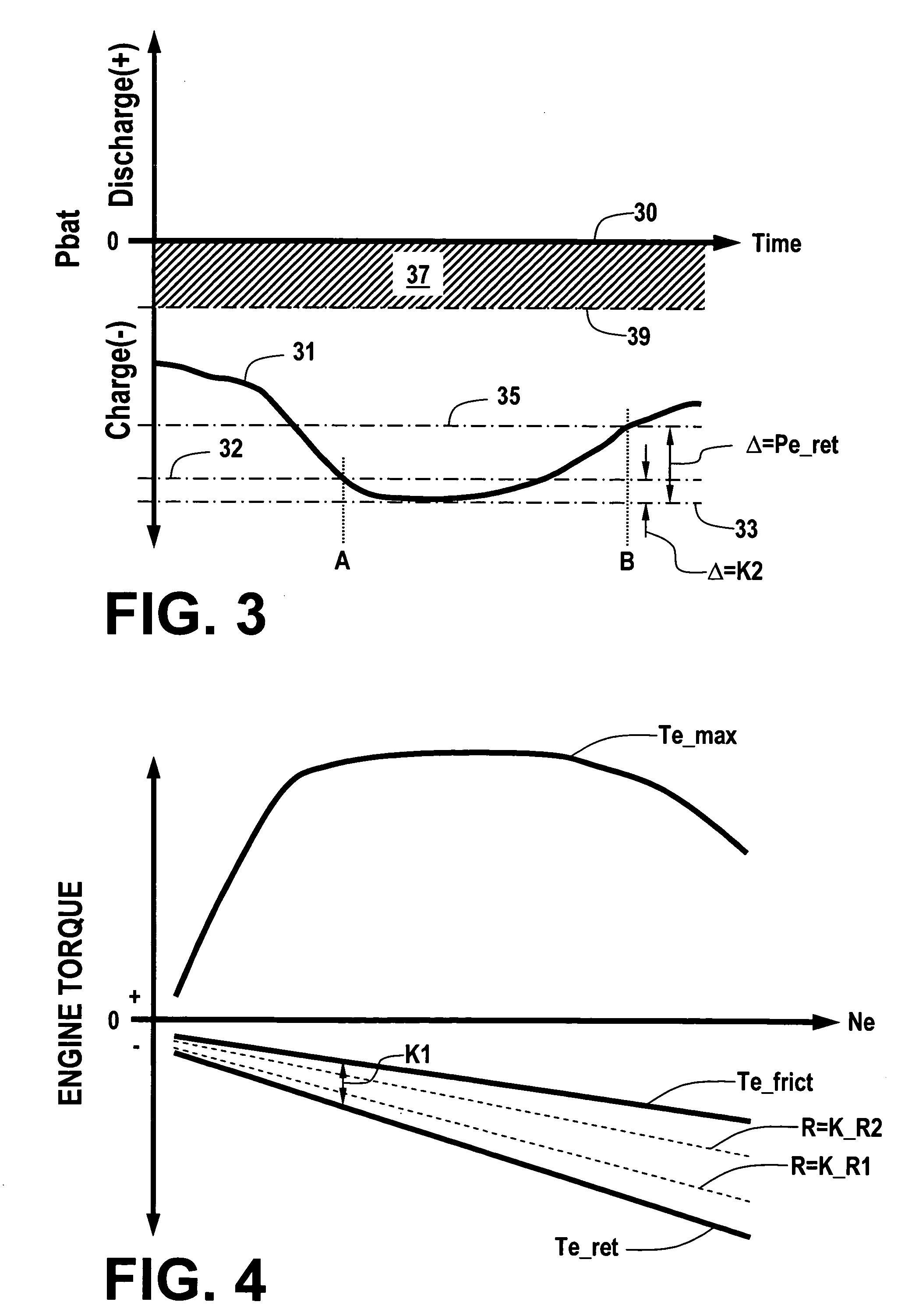

Coordinated regenerative and engine retard braking for a hybrid vehicle

ActiveUS20050255965A1Increases the engine retard braking contributionReduce contributionHybrid vehiclesBraking element arrangementsPower flowGear wheel

A hybrid vehicle includes a powertrain having a retarded diesel engine, an electric machine and energy storage system. The engine and motor are operatively coupled through one or more planetary gearsets and selective coupling paths in accordance with application and release of various torque transfer devices to a drivetrain via an output. Regenerative and retarded engine braking are coordinated to provide priority to energy return to an energy storage system in accordance with predetermined power flow limits. Power flow in excess of the limits are handled by increased engine retard braking contributions via engine speed increases.

Owner:ALLISON TRANSMISSION INC

Engine retard operation scheduling and management in a hybrid vehicle

ActiveUS20050255966A1Hybrid vehiclesBraking element arrangementsOperation schedulingElectric machine

A hybrid vehicle includes a powertrain having a retarded diesel engine, an electric machine and energy storage system. The engine and motor are operatively coupled through one or more planetary gearsets and selective coupling paths in accordance with application and release of various torque transfer devices to a drivetrain via an output. Regenerative and retarded engine braking are coordinated to provide priority to energy return to an energy storage system in accordance with predetermined power flow limits.

Owner:GM GLOBAL TECH OPERATIONS LLC

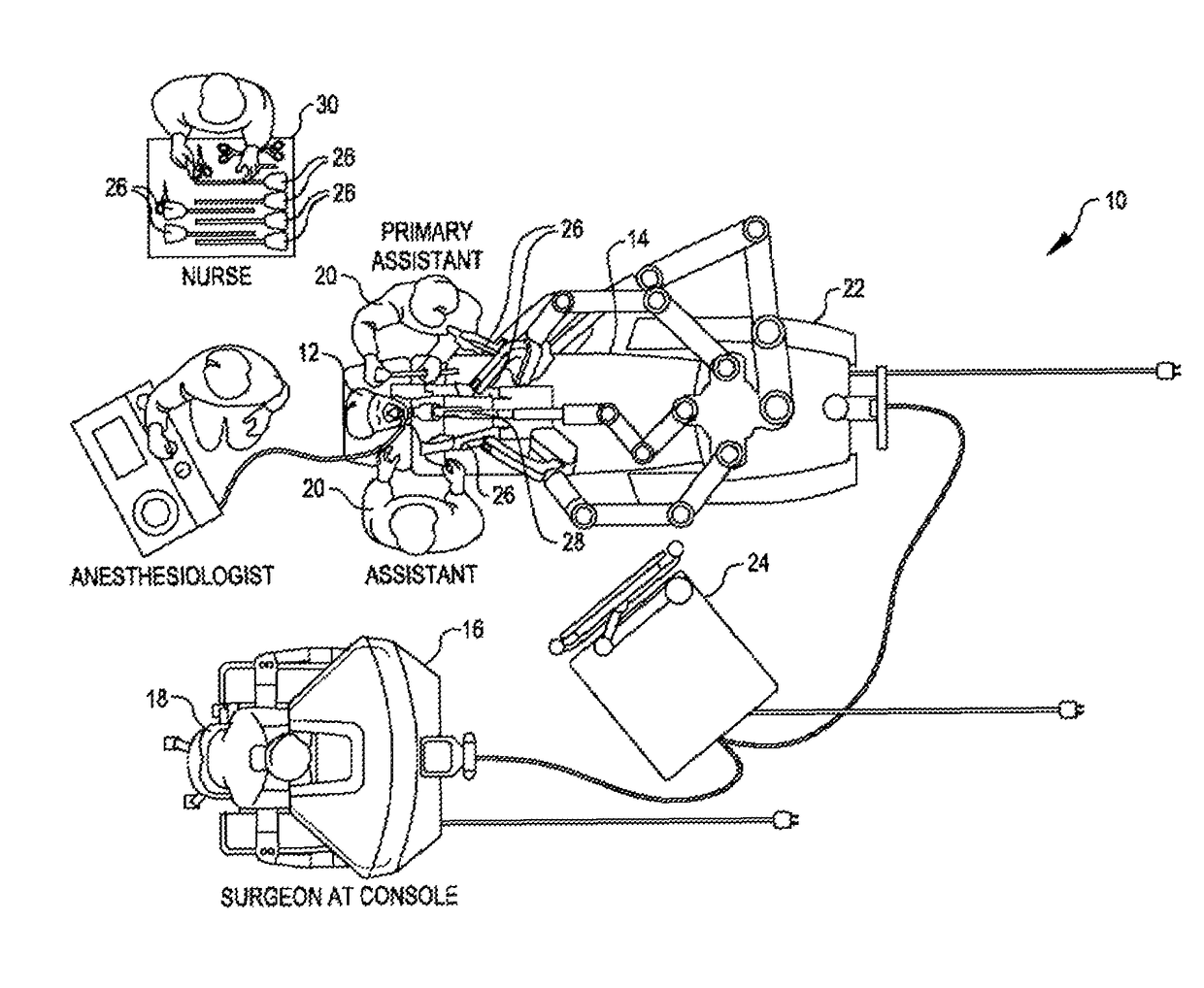

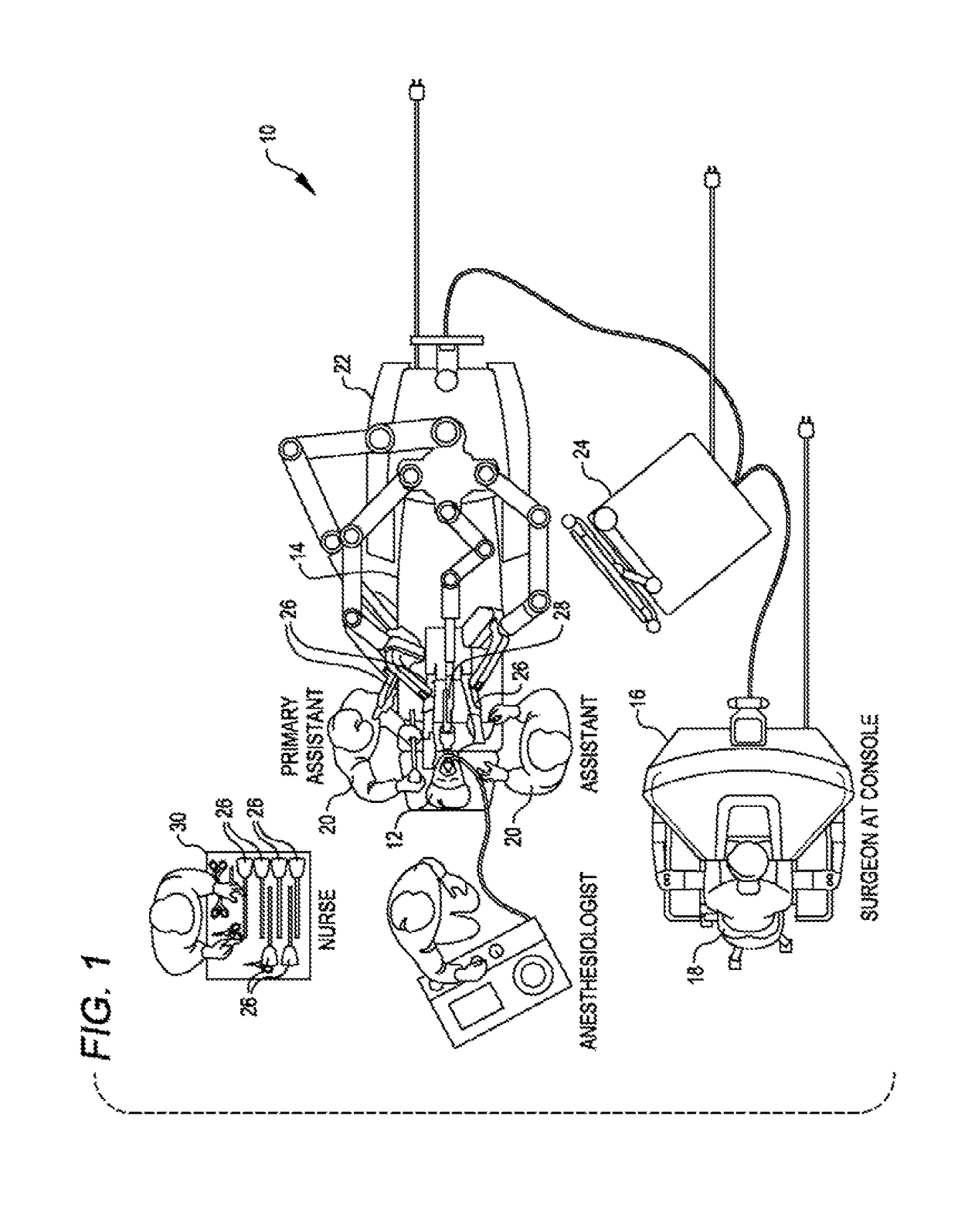

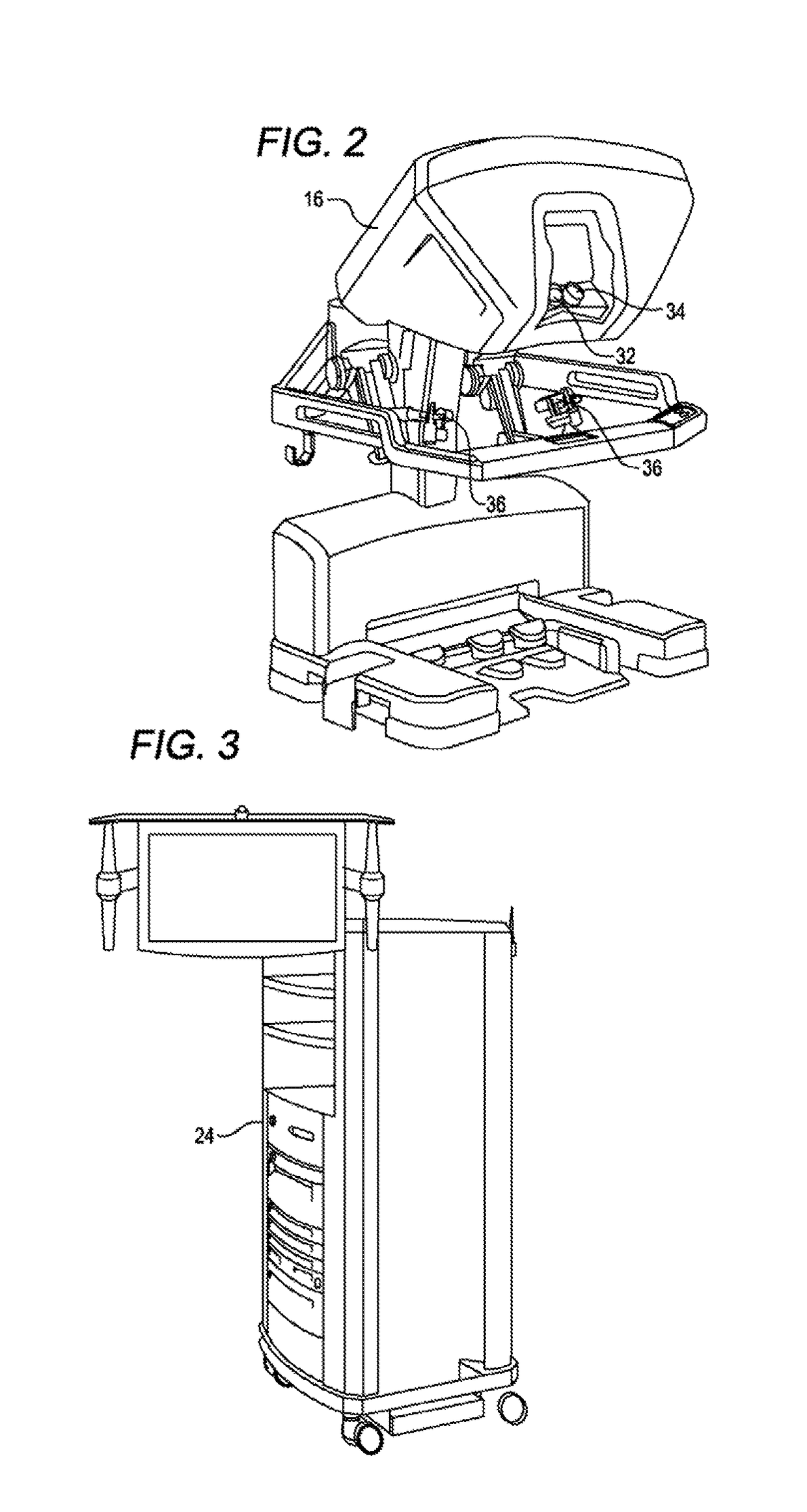

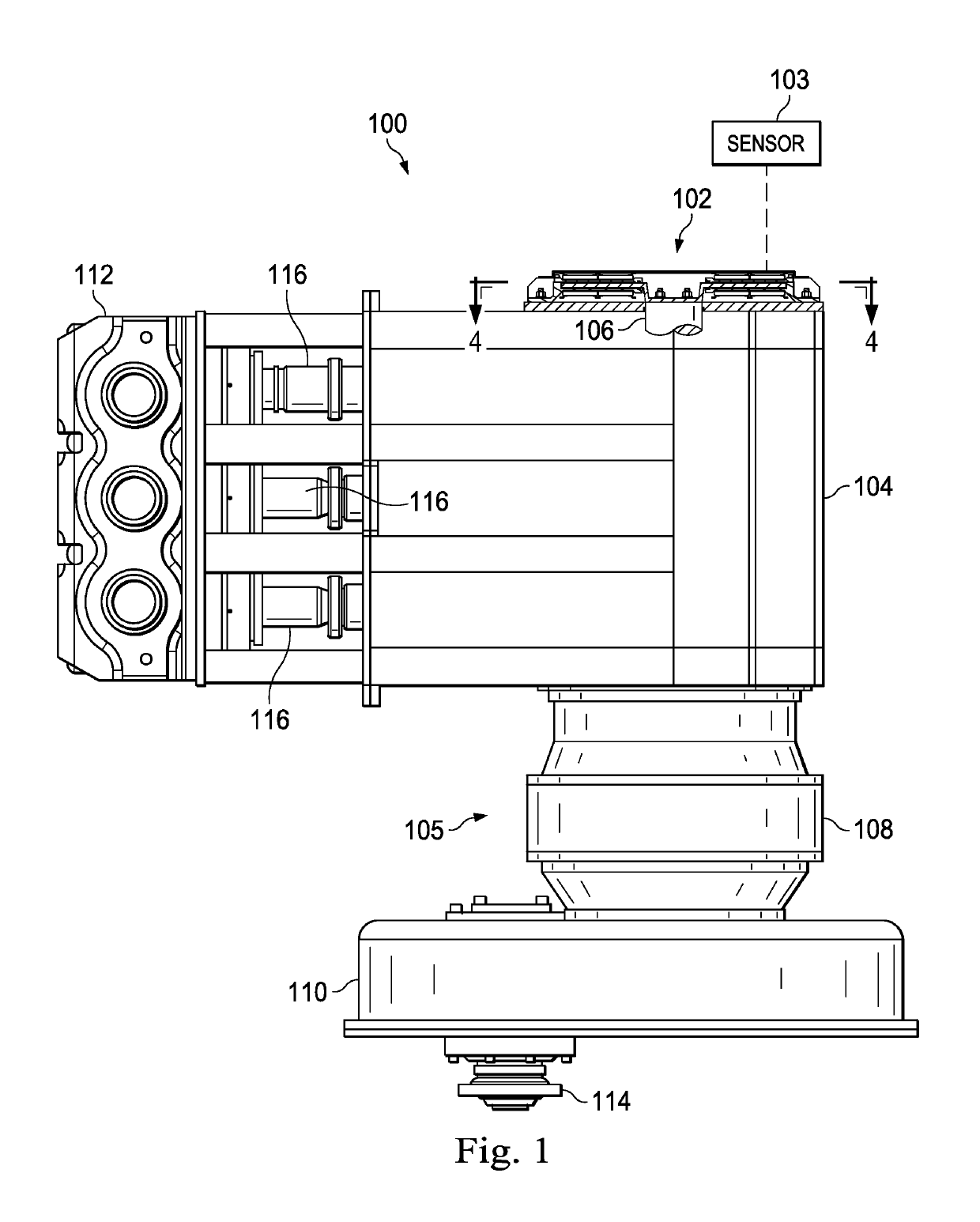

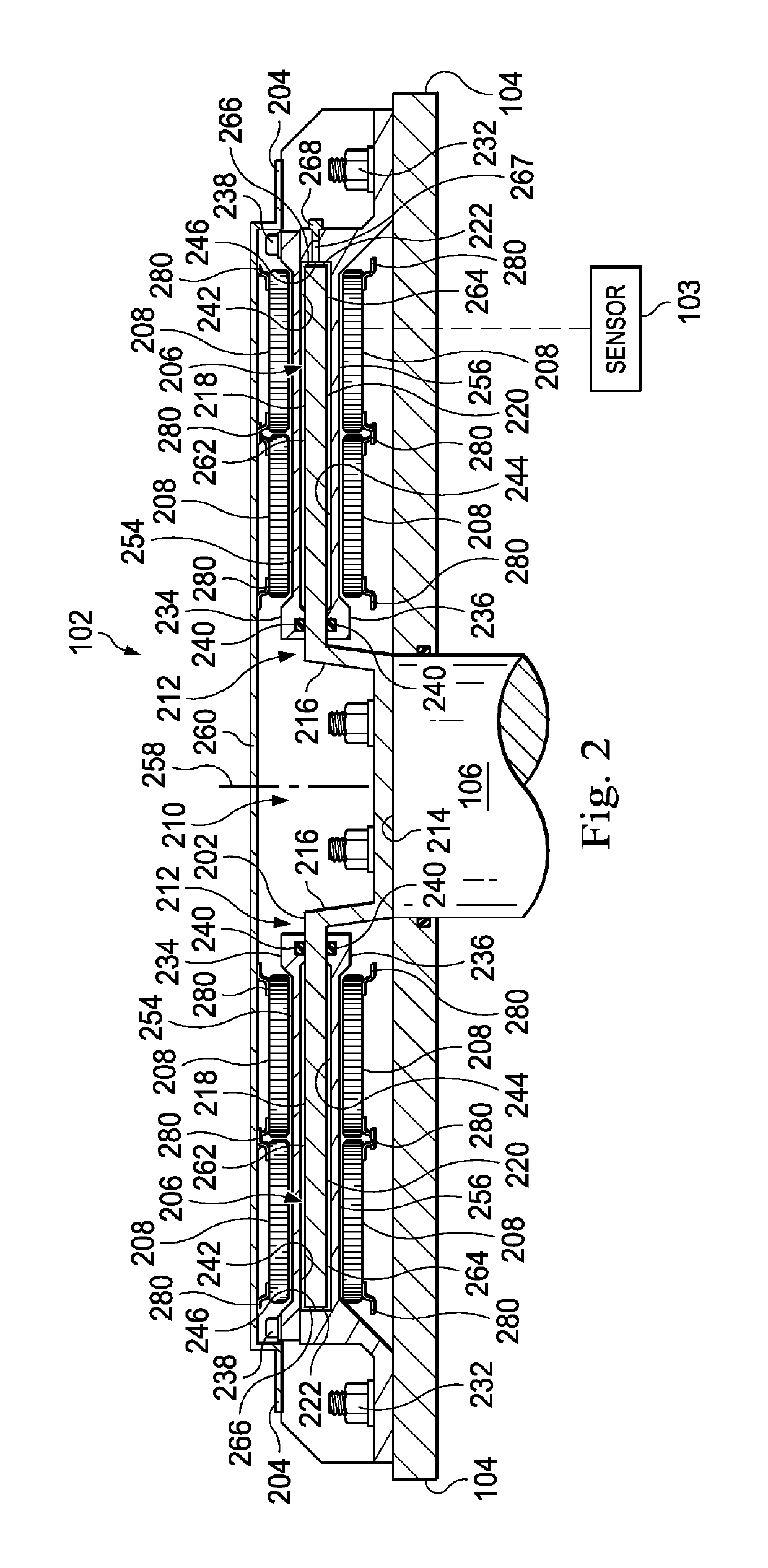

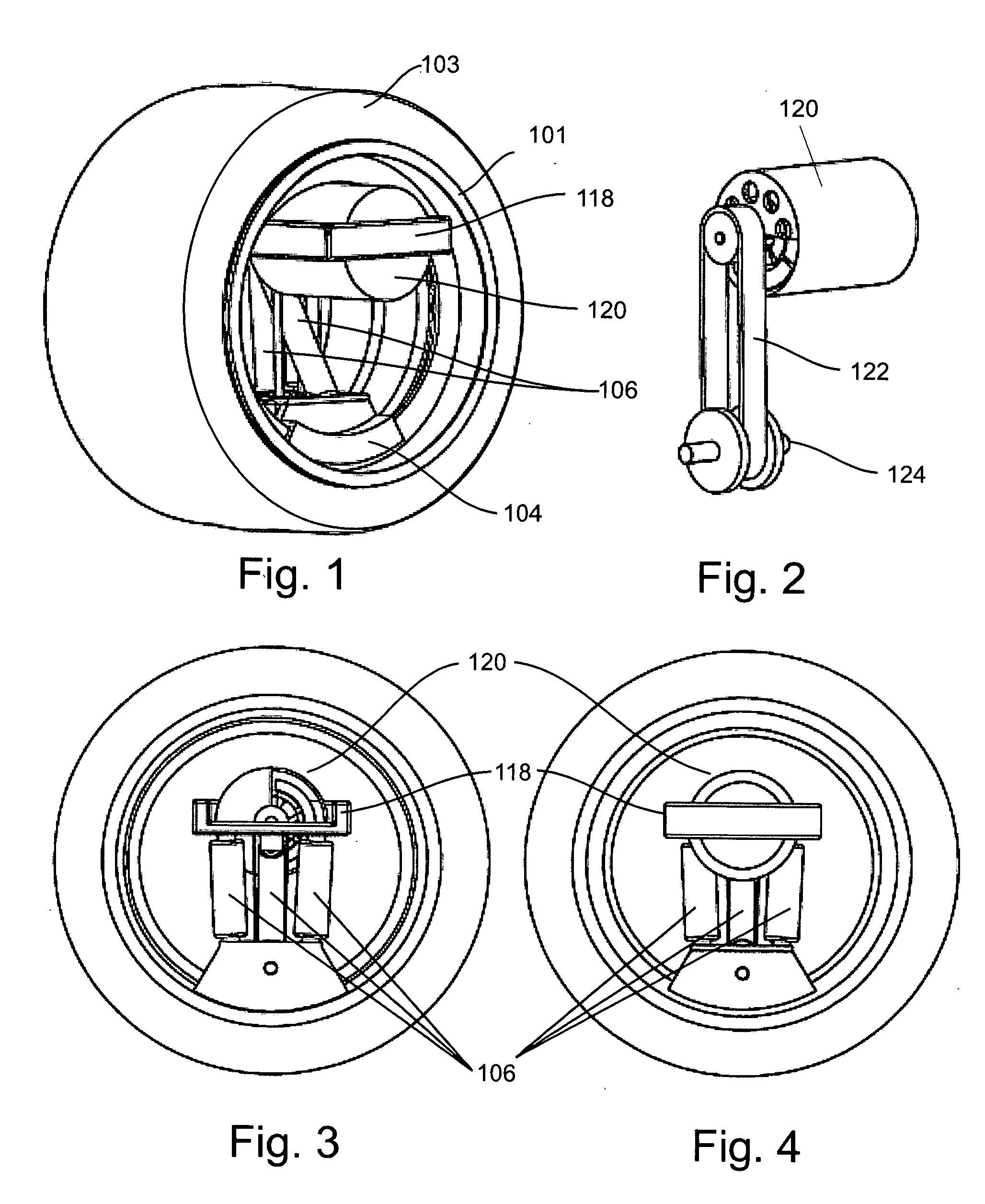

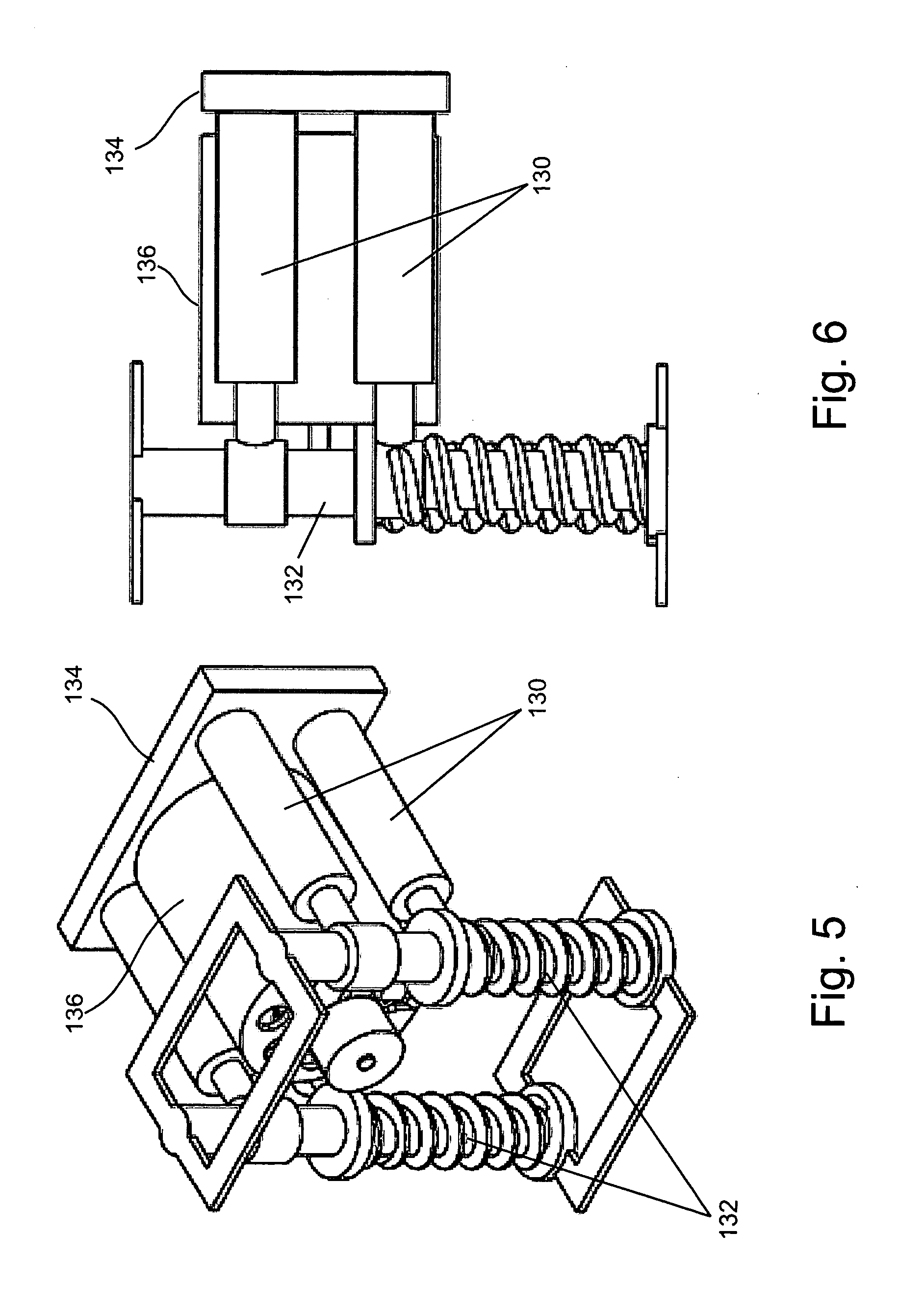

Control input accuracy for teleoperated surgical instrument

A surgical system having a patient side cart having at least one telesurgically operated instrument, the at least one telesurgically operated instrument comprising a surgical end effector having a plurality of effector components. A transmission is coupled to a motor. The drive train includes at least a first effector drive train and a second effector drivetrain. A controller comprises at least one processor for controlling the transmission. The controller is performs a method by locking an output gear of the second effector drivetrain rotating a camshaft to shift coupling of the motor from the first effector drivetrain to the second effector drivetrain; determining that the output gear is aligned by driving the locked output gear using a first torque; determining that the output gear is properly braked by driving the locked output gear using a second torque; disengaging the lock from the output gear; and driving the second effector drivetrain using the motor.

Owner:INTUITIVE SURGICAL OPERATIONS INC

Pump drivetrain damper system and control systems and methods for same

ActiveUS10316832B2Reduce vibrationLiquid resistance brakesPositive displacement pump componentsControl signalDrivetrain

Owner:SPM OIL & GAS INC

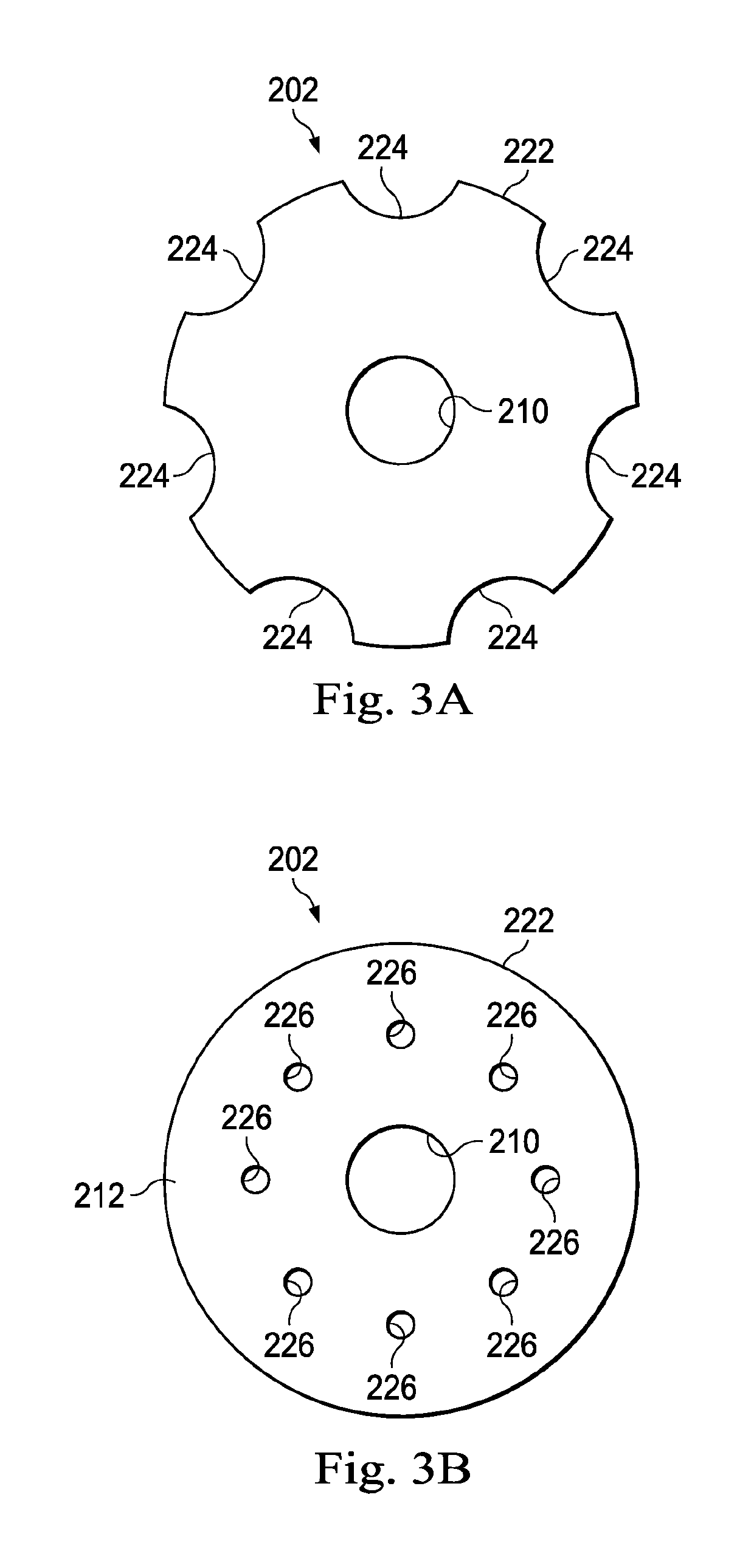

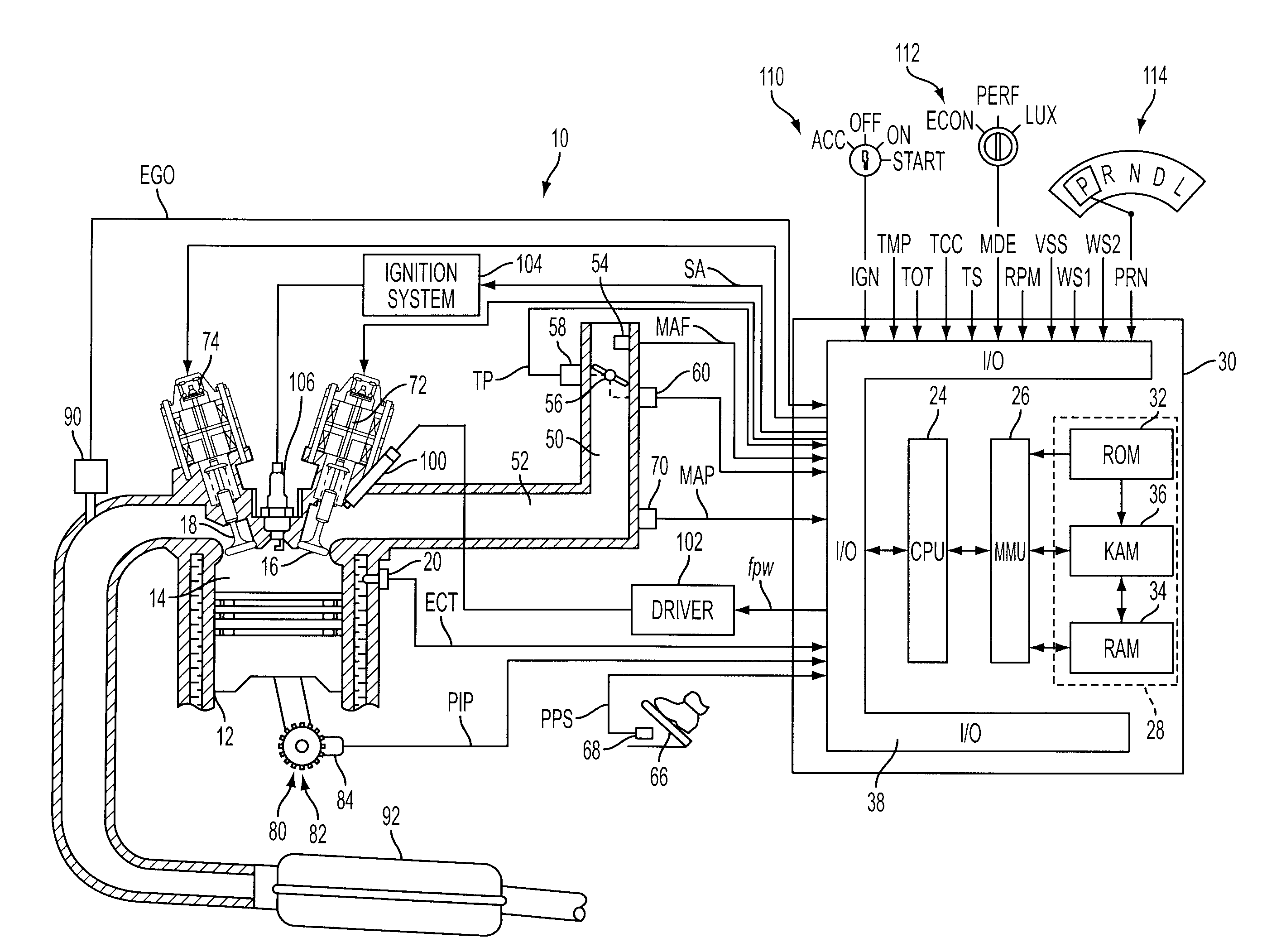

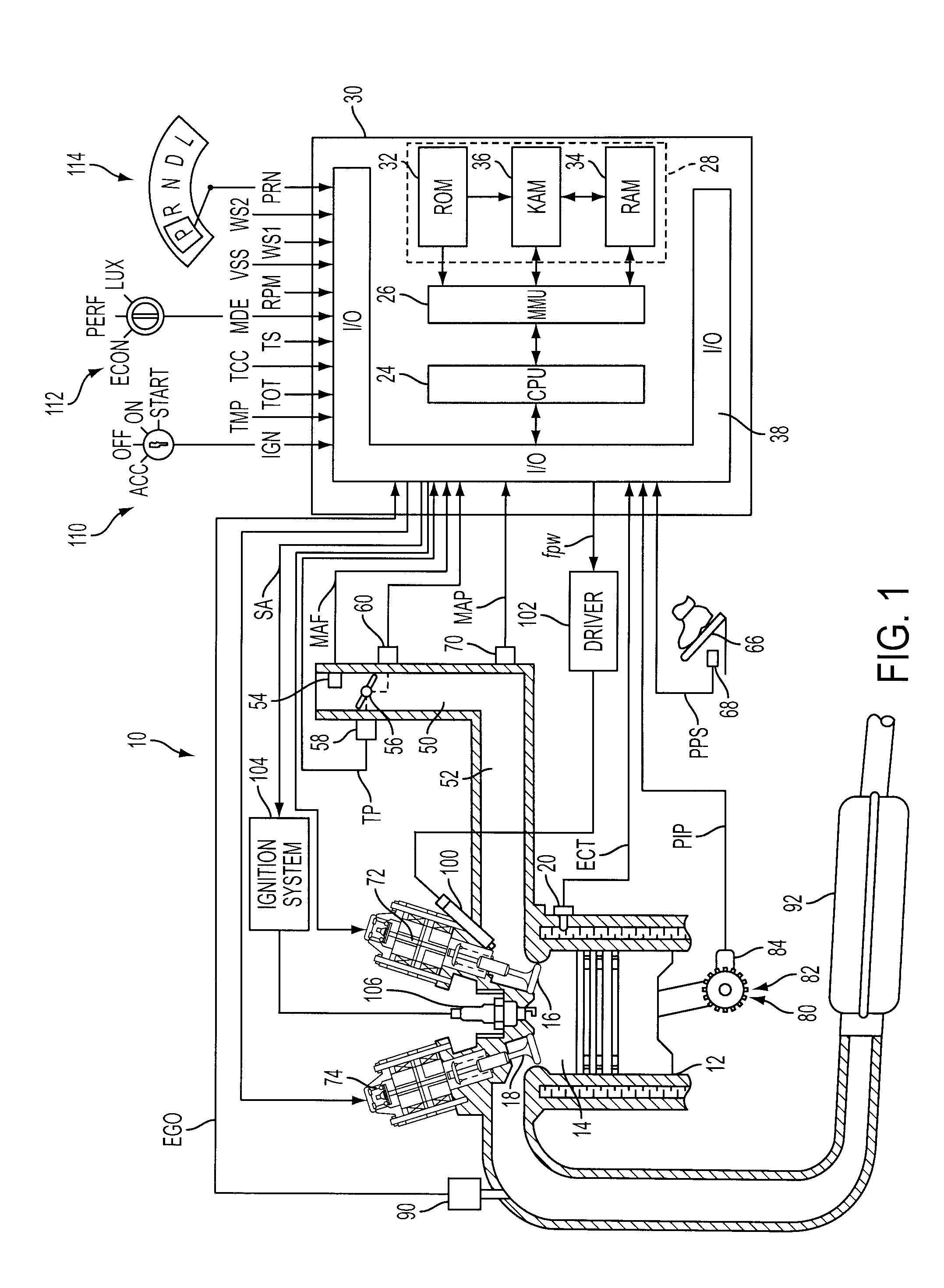

Variable Displacement Engine Operation With NVH Management

InactiveUS20080154468A1Reduce and eliminate torque reactionNo backlashAnalogue computers for vehiclesDigital data processing detailsClose couplingDrivetrain

A system and method for controlling an internal combustion engine operable with a first cylinder firing frequency and a second cylinder firing frequency to reduce or eliminate transmission of torsional vibrations associated with the second cylinder firing frequency to reduce or eliminate constraints on reduced displacement mode operation using a closely coupled drive train component rotating in an opposite direction relative to rotating components of the engine. A close coupling device allows the inertia of the counter-rotating elements to reduce or eliminate the torque reaction of the drivetrain associated with acceleration and deceleration of the engine crankshaft in response to the second cylinder firing frequency in the reduced displacement mode.

Owner:FORD GLOBAL TECH LLC

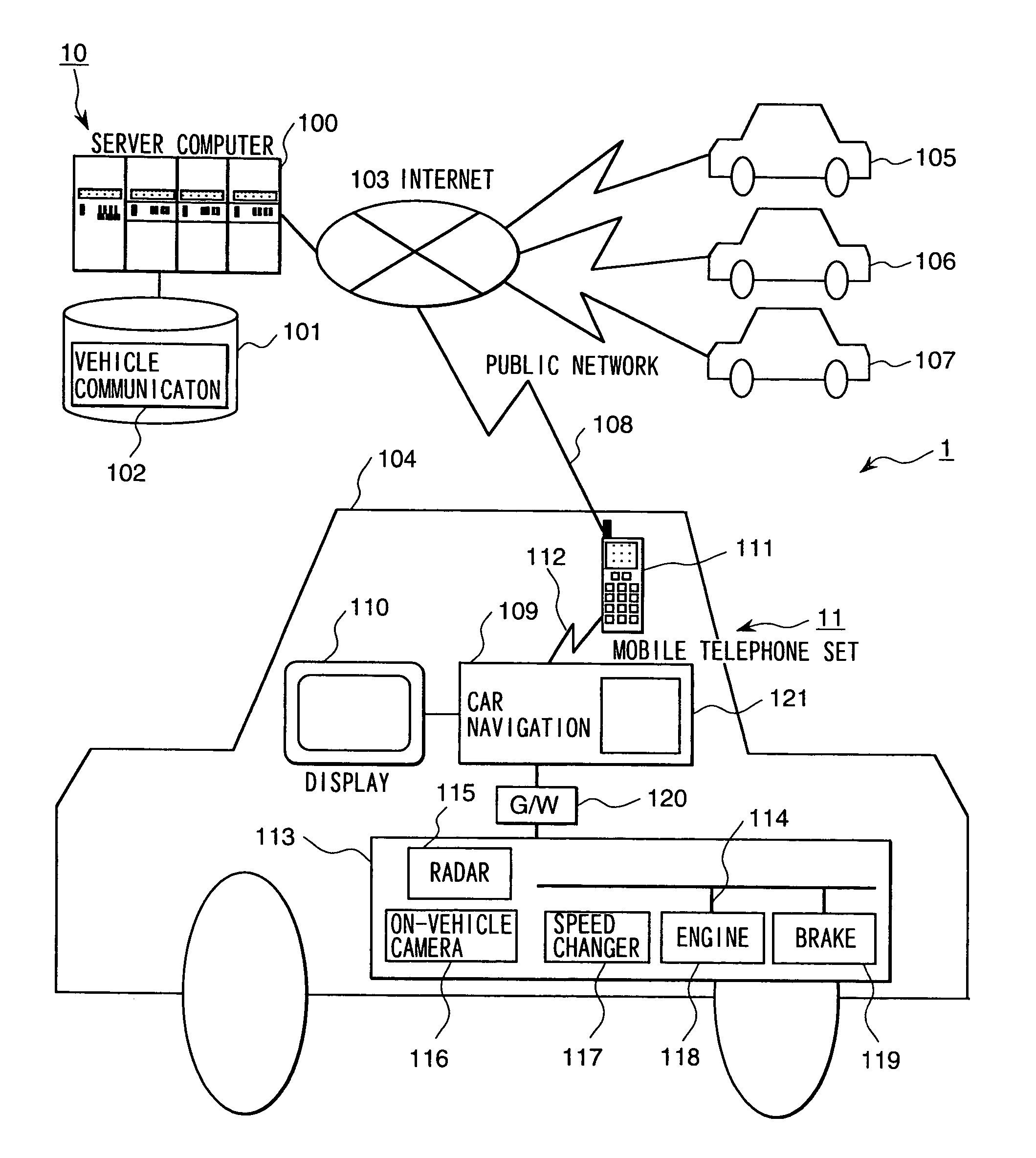

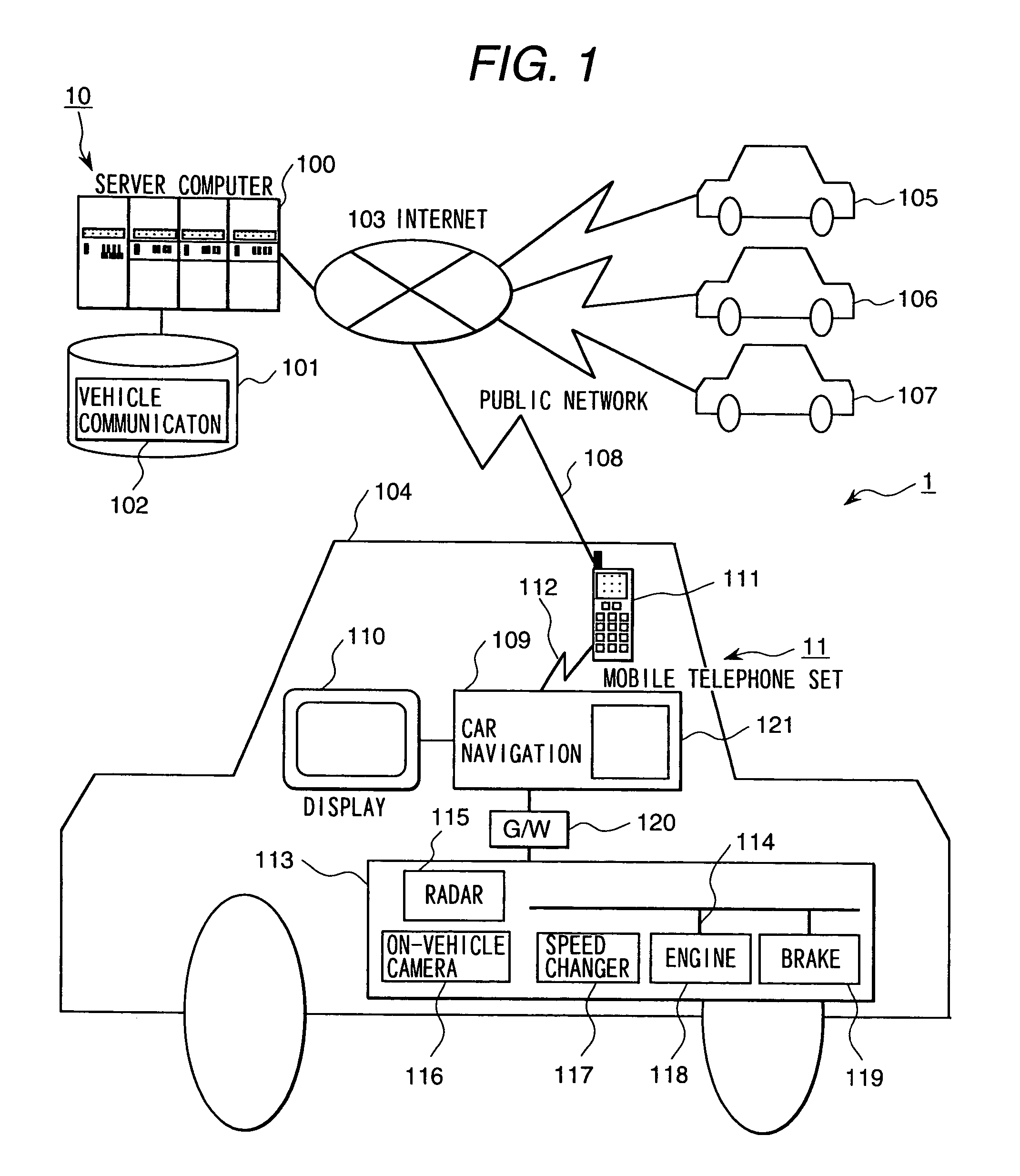

On-vehicle breakdown-warning report system

InactiveUS6972669B2Easy selectionShorten the timeVehicle testingRegistering/indicating working of vehiclesDrivetrainCommunication device

An on-vehicle breakdown-warning report system is disclosed. an occurrence of break-down is detected and judged based on a signal in an electronic control system installed on a control apparatus for an engine ignition system, a charging system, an engine fuel system, a engine cooling system, a power transmission system, and an oil lubricating system of an automobile or a diagnosis display system; and a diagnostic data is sent to an information terminal device of a diagnosis and maintenance agency or a service company having a diagnosis and maintenance agency as a contents information by using an on-vehicle mobile communication apparatus, and an action for an emergency measures and a maintenance schedule is asked.

Owner:HITACHI LTD

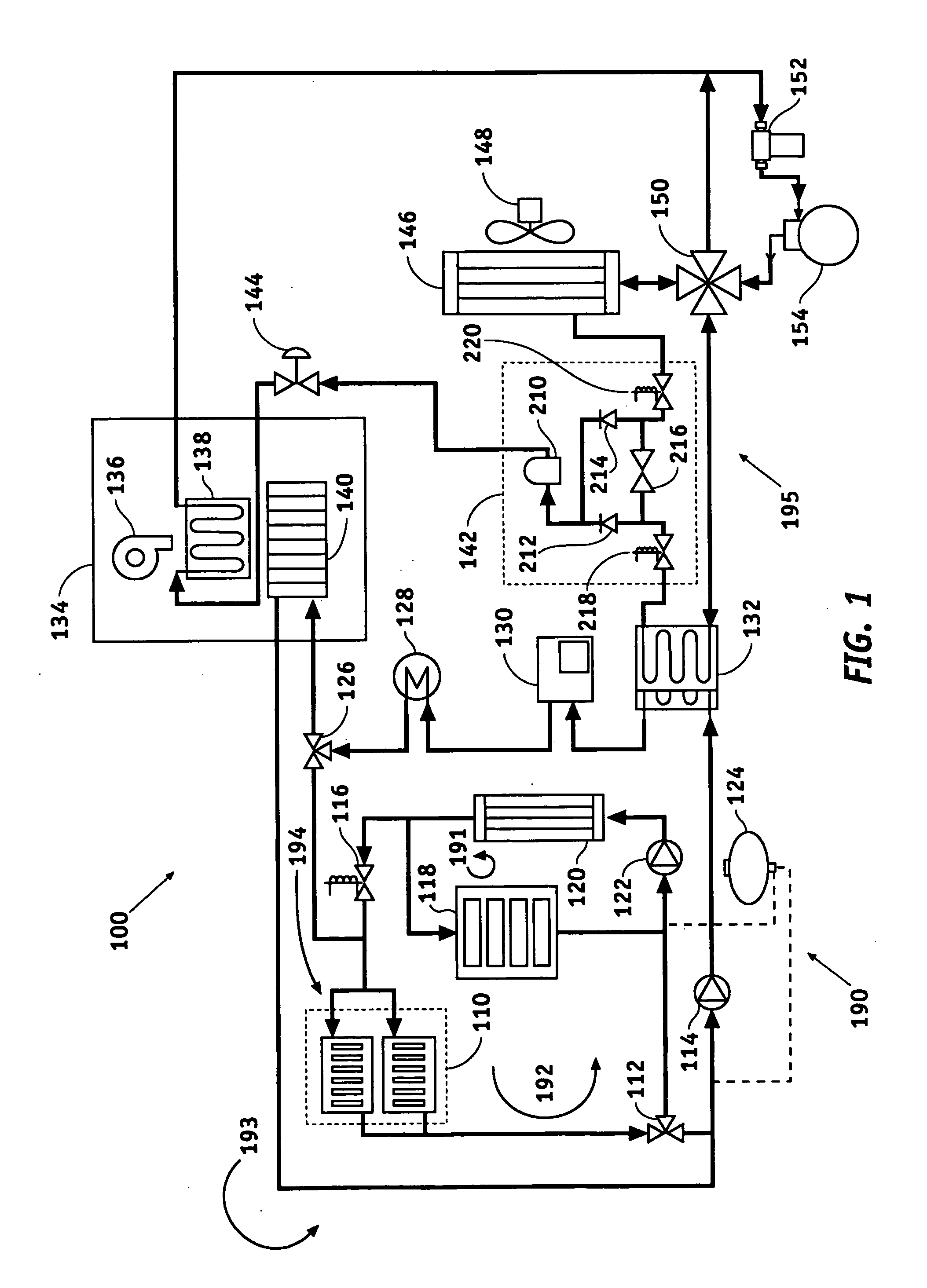

Full function vehicle HVAC/PTC thermal system

The integrated automotive HVAC / PTC system of the present invention includes a bi-fluidic heat exchanger between an air conditioning subsystem and a heating subsystem which enables heat extracted during dehumidification of the ventilation air to be transferred into dehumidified ventilation air. The HVAC / PTC system includes reconfigurable coolant loops and reconfigurable refrigerant loops, some of which act in concert and some of which may be isolated. Power train components, including the power supply, may be grouped by heat transfer requirements and may be cooled or heated as needed. Power train cooling is accomplished with coolant in the heating subsystem chilled by the air conditioning system.

Owner:GM GLOBAL TECH OPERATIONS LLC

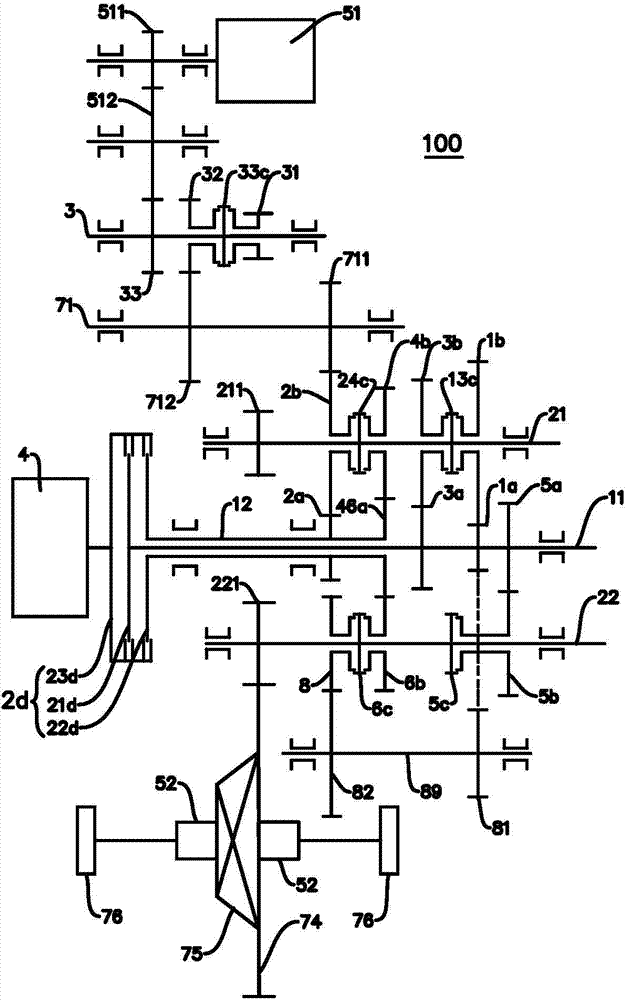

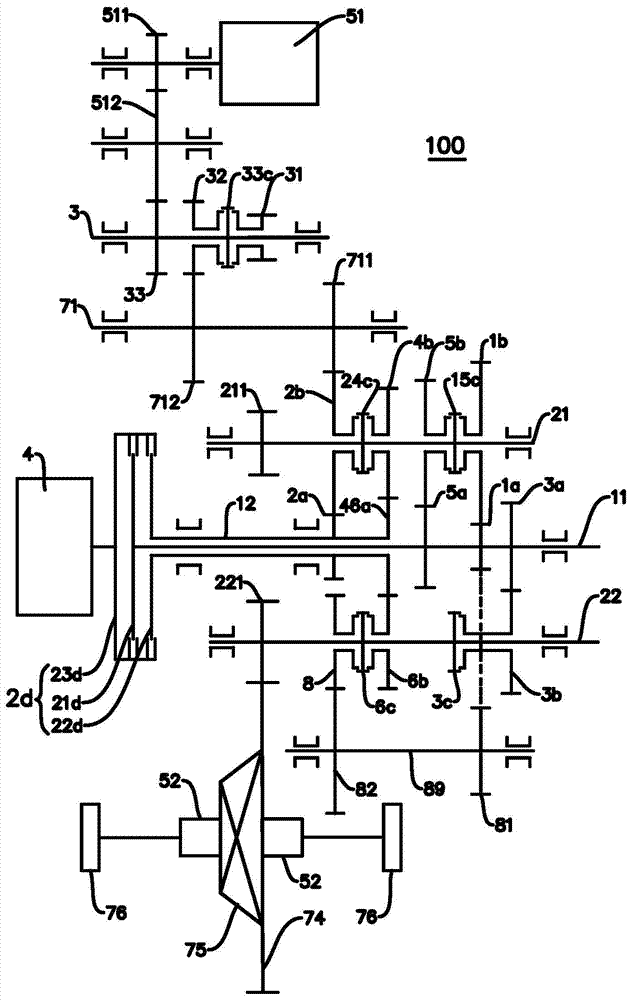

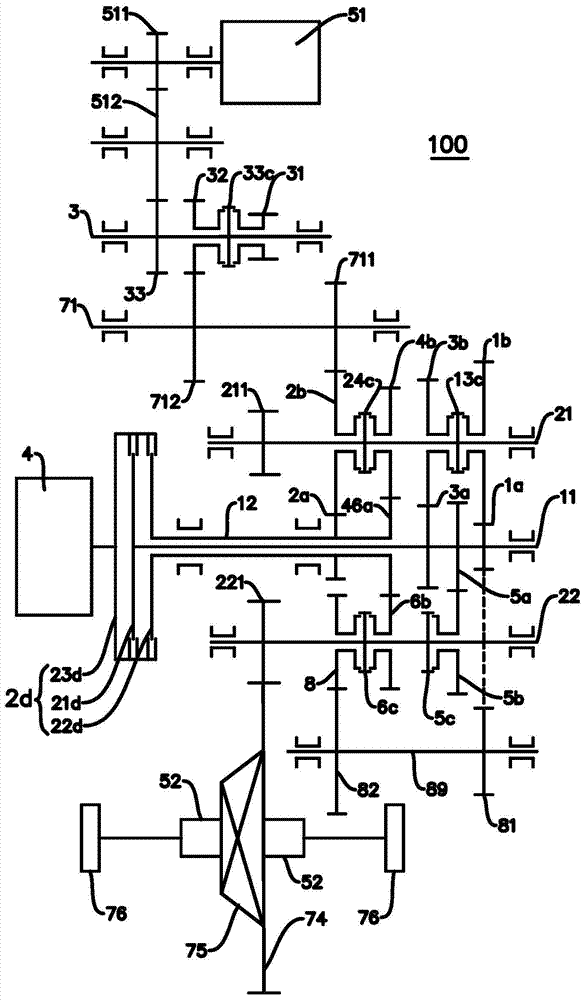

Speed changer, power transmission system and vehicle

ActiveCN104773063ARich transmission modeRealize parking chargingHybrid vehiclesElectric propulsion mountingVariatorDrivetrain

The invention discloses a speed changer, a power transmission system and a vehicle. The speed changer comprises a plurality of input shafts, a plurality of output shafts, a reverse gear shaft and a motor power shaft, wherein the input shafts and the output shafts are transmitted through gears; a reverse gear output gear sleeves on one of the output shafts in an idling mode, and a reverse gear synchronizer is further arranged on the output shaft; the reverse gear shaft is linked with one of the input shafts, and is also linked with the reverse gear output gear; a first gear and a second gear of the motor power shaft sleeve on the motor power shaft in an idling mode; a motor power shaft synchronizer is further arranged on the motor power shaft; the second gear of the motor power shaft is arranged to be linked with one of gear driven gears. According to the speed changer for the vehicle disclosed by the embodiment of the invention, transmission modes are enriched, and various working conditions such as parking charging and charging for an engine while driving can be realized.

Owner:BYD CO LTD

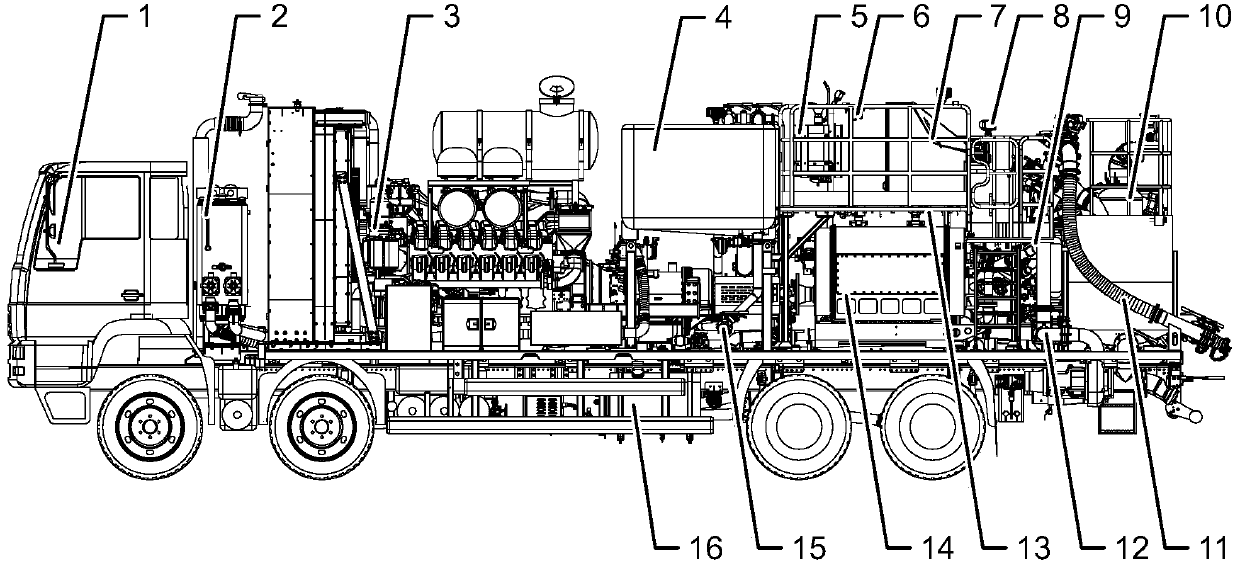

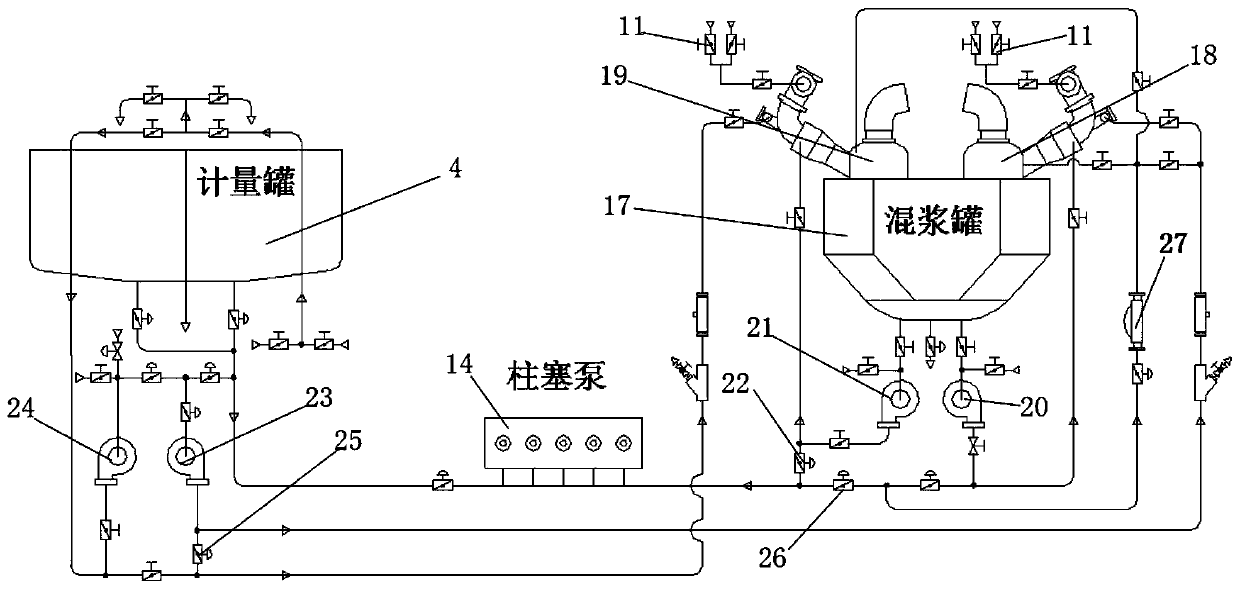

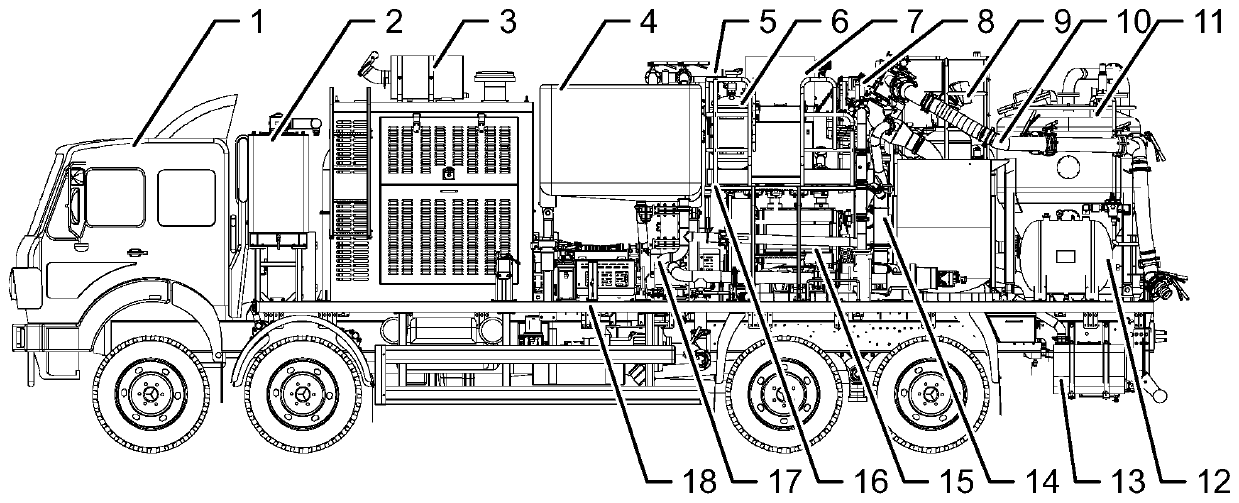

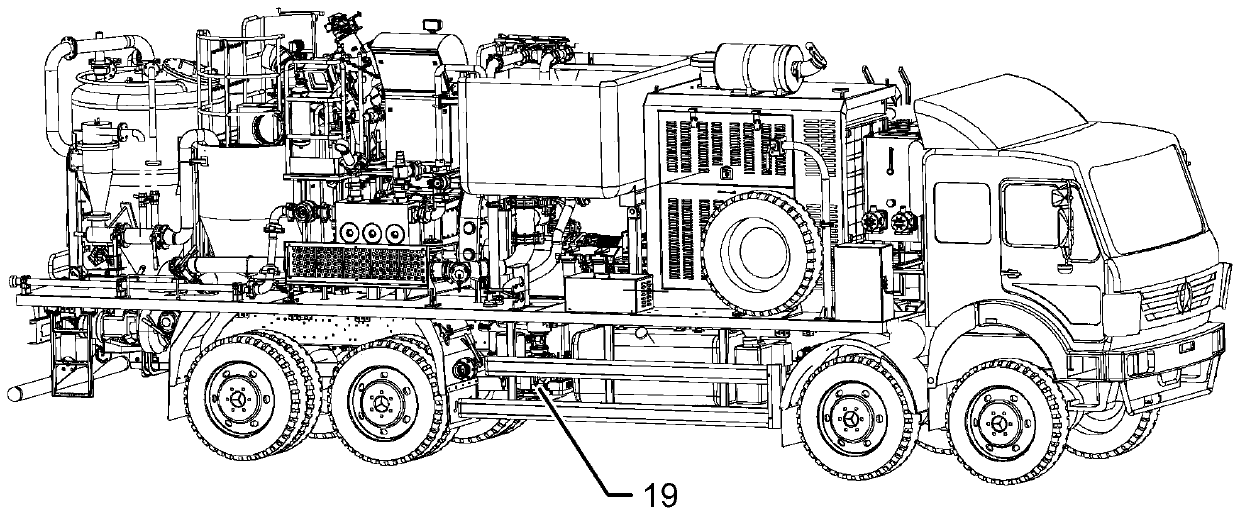

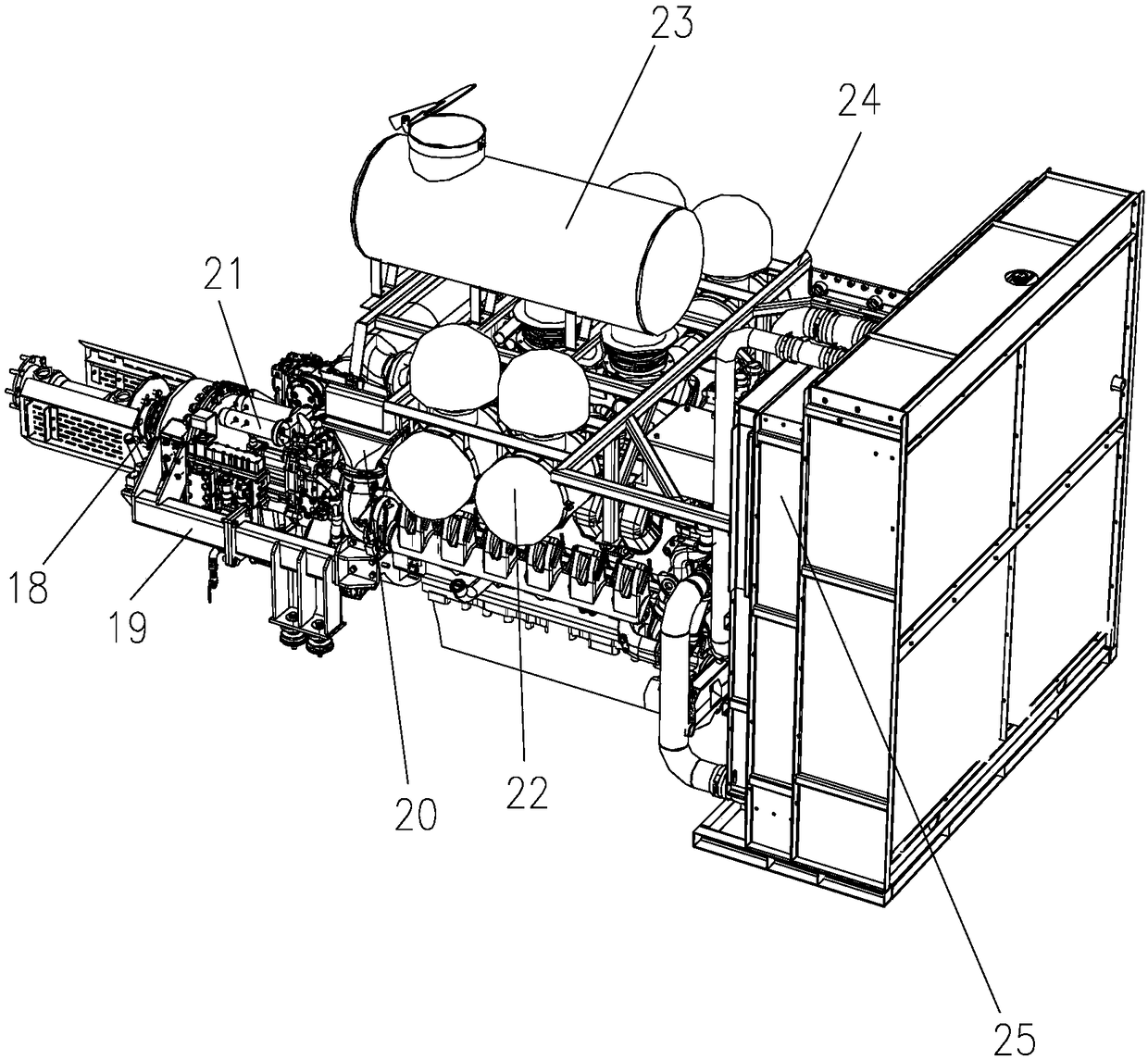

Novel ultra-large-displacement ultrahigh-pressure well cementing equipment

PendingCN111173476AIncrease pressureIncrease displacementItem transportation vehiclesSealing/packingUltra high pressureDrivetrain

The invention discloses novel ultra-large-displacement ultrahigh-pressure well cementing equipment. The novel ultra-large-displacement ultrahigh-pressure well cementing equipment comprises a loading carrier. A hydraulic system, a power transmission system, a metering tank, an electrical system, an air path system, a control system, an operating platform, a plunger pump, a clean water manifold, a mud manifold, a high-pressure manifold, a mixing system and an ash feeding manifold are mounted on the loading carrier, wherein the plunger pump is a five-cylinder plunger pump. The five-cylinder plunger pump is adopted to increase the pressure and displacement of the well cementing equipment, and the requirements of high pressure and large displacement are met; slurry mixing is carried out by double mixing devices, the mixing efficiency is improved, the stability of the slurry mixing density is improved, and the requirement of long-time uninterrupted operation is guaranteed; a mixing system pipeline is optimized, multiple sets of mixing systems are integrated on one slurry mixing tank, and the stability of the equipment is improved; and the clean water manifold is optimized, so that watersupply requirements of the multiple mixing devices can also be met at the same time by using one injection pump, and the requirement of large displacement is met.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

Novel well cementation truck

PendingCN111075391AEasy to operateFlexible and Efficient MobileItem transportation vehiclesSealing/packingDrivetrainWell cementing

The invention discloses a novel well cementation truck, which comprises a loading body, an electrical system, a plunger pump, a clear water manifold, a mud manifold and a high-pressure manifold, wherein the loading body is provided with a cross beam; the cross beam is provided with a hydraulic system, a power transmission system, a metering tank, an operating platform and a mixing system in sequence; the operating platform is provided with a gas path system and an operating system in sequence; the electrical system supplies power to the well cementation truck; the plunger pump, the clear watermanifold, the mud manifold and the high-pressure manifold are all arranged below the operating platform; the clear water manifold supplies water to the plunger pump and the mixing system; the mud manifold provides mud for the plunger pump; the plunger pump injects the mud into a well through the high-pressure manifold; and the well cementation truck also integrates with a steady pressure ash can,an air compressor and an air bottle. The novel well cementation truck has the beneficial effects that a spatial layout is optimized, and the steady pressure ash can, the air compressor and the air bottle are integrated in one well cementation truck. An ash feeding manifold is optimized, so that the steady pressure ash can supplies ashes, and ash supply equipment can be externally connected for supplying ashes. The large-volume air bottle is adopted, and therefore, air can be supplied to other equipment while the requirements of the well cementation truck are met.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

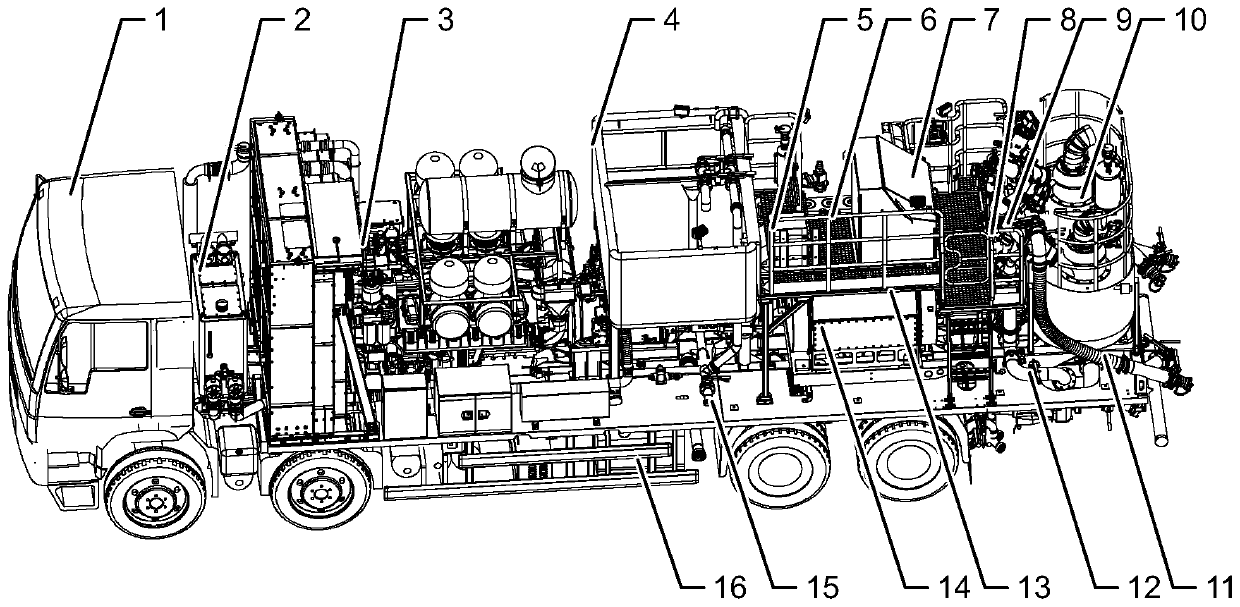

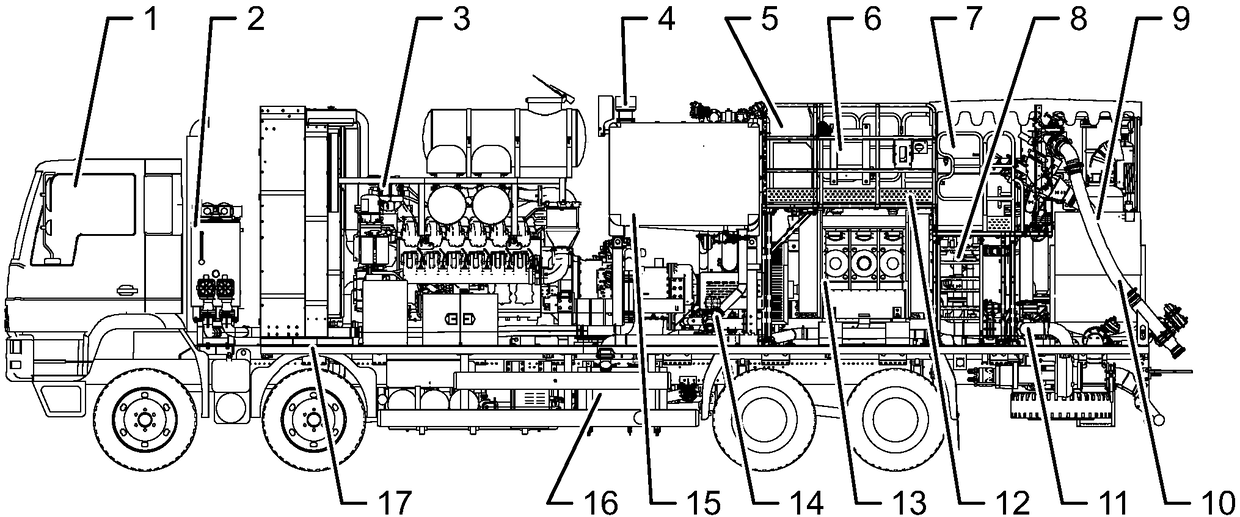

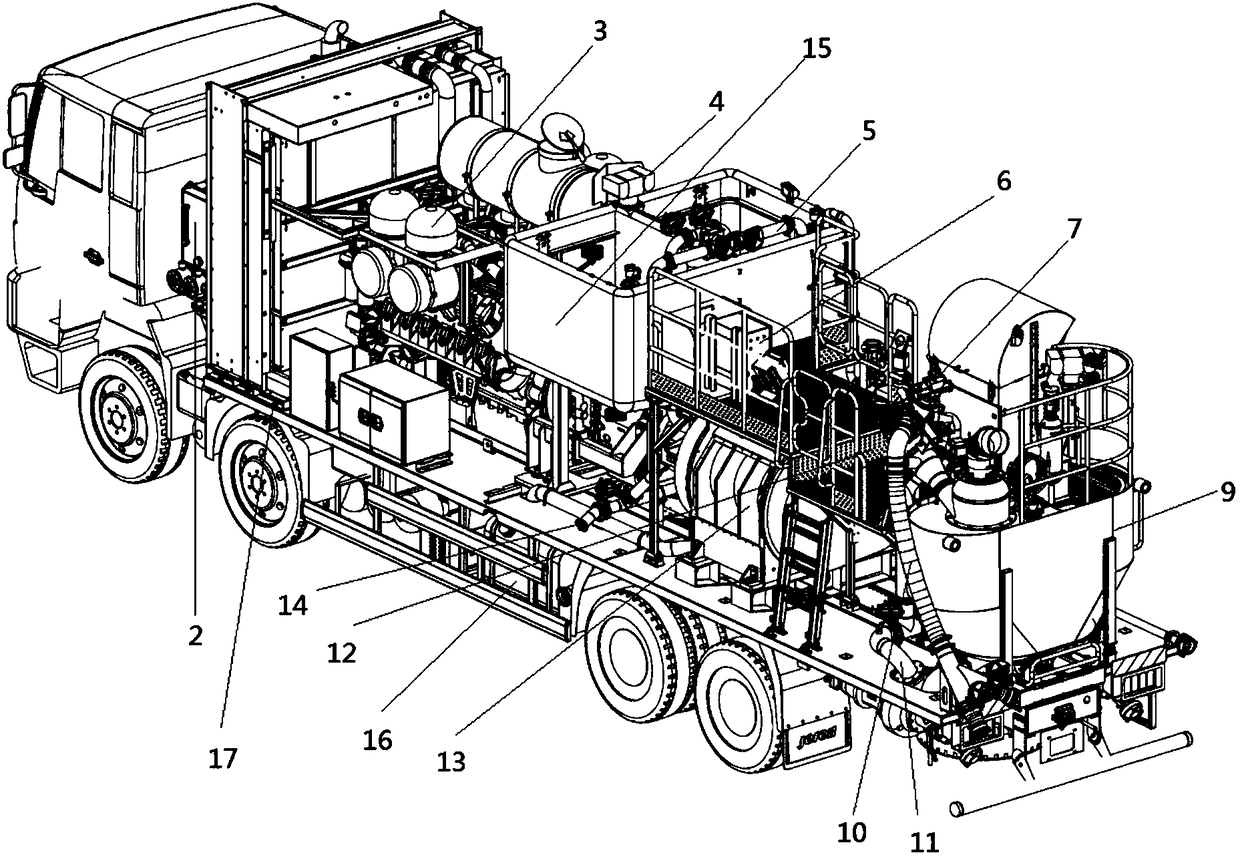

Novel ultra-high-power cementing equipment integrated with remote control

PendingCN108561098AQuick arrangementSave work spacePositive displacement pump componentsPumpsUltra high pressureDrivetrain

The present invention relates to the technical field of petroleum equipment, in particular to novel ultra-high-power cementing equipment integrated with remote control. The novel ultra-high-power cementing equipment integrated with remote control comprises a loading system and a secondary beam, wherein the secondary beam is connected with a hydraulic system, a power transmission system, a meteringtank, an electrical system, a gas circuit system, a control system and a mixing system from front to rear in sequence, the lower portion of the gas circuit system is provided with a plunger pump, theplunger pump is connected with a high-pressure discharge system; a control platform is arranged at the lower part of the electrical system; the control system is positioned above the control platform; and the control system is connected with the remote control system. The novel ultra-high-power cementing equipment integrated with remote control meets the requirements of high pressure, large displacement, long time and continuous uninterrupted operation during the ultra-deep cementing operation and the ultra-high pressure gas well operation; and the occupied area is small, the pipeline connection is simple, and the maintenance frequency is low.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

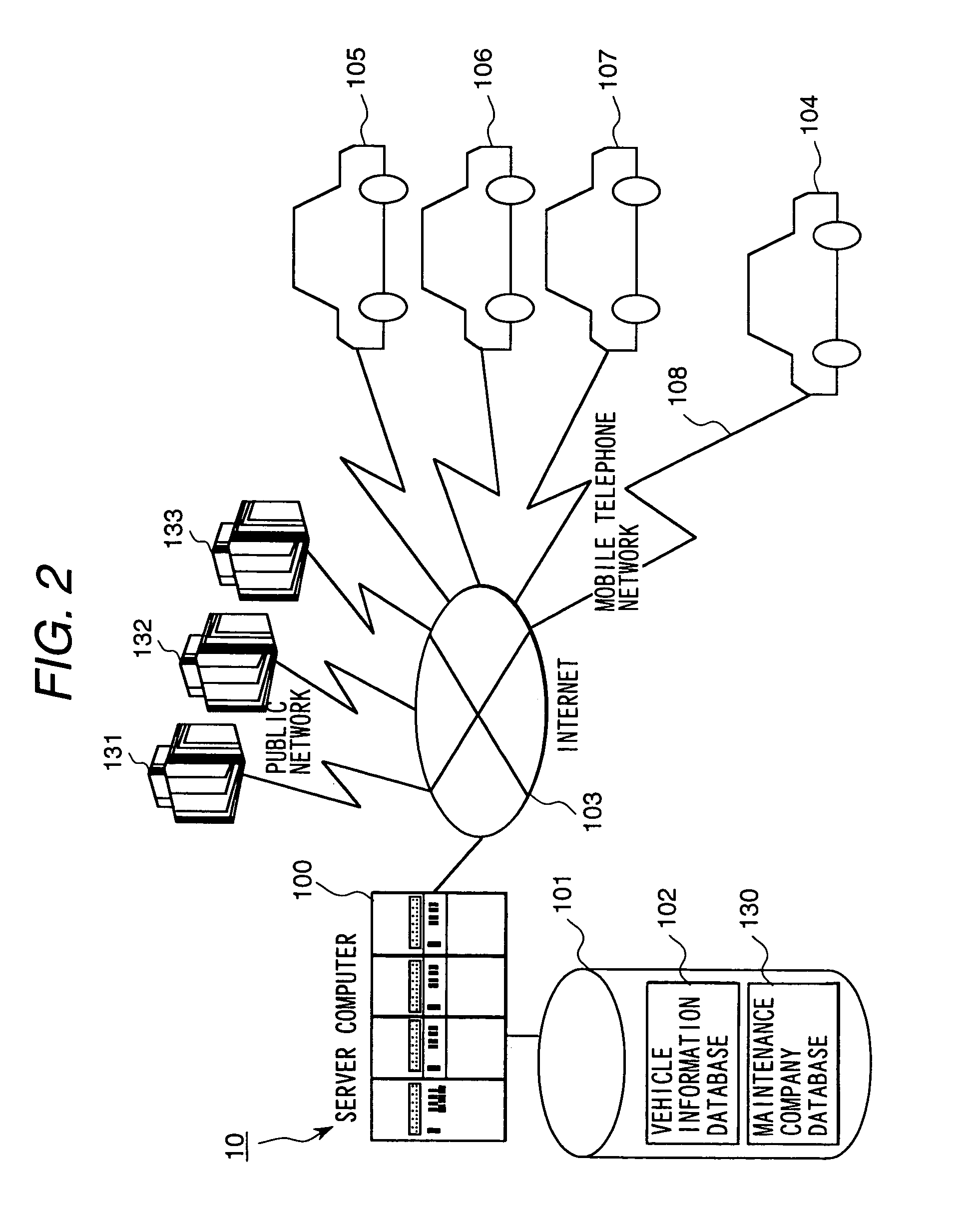

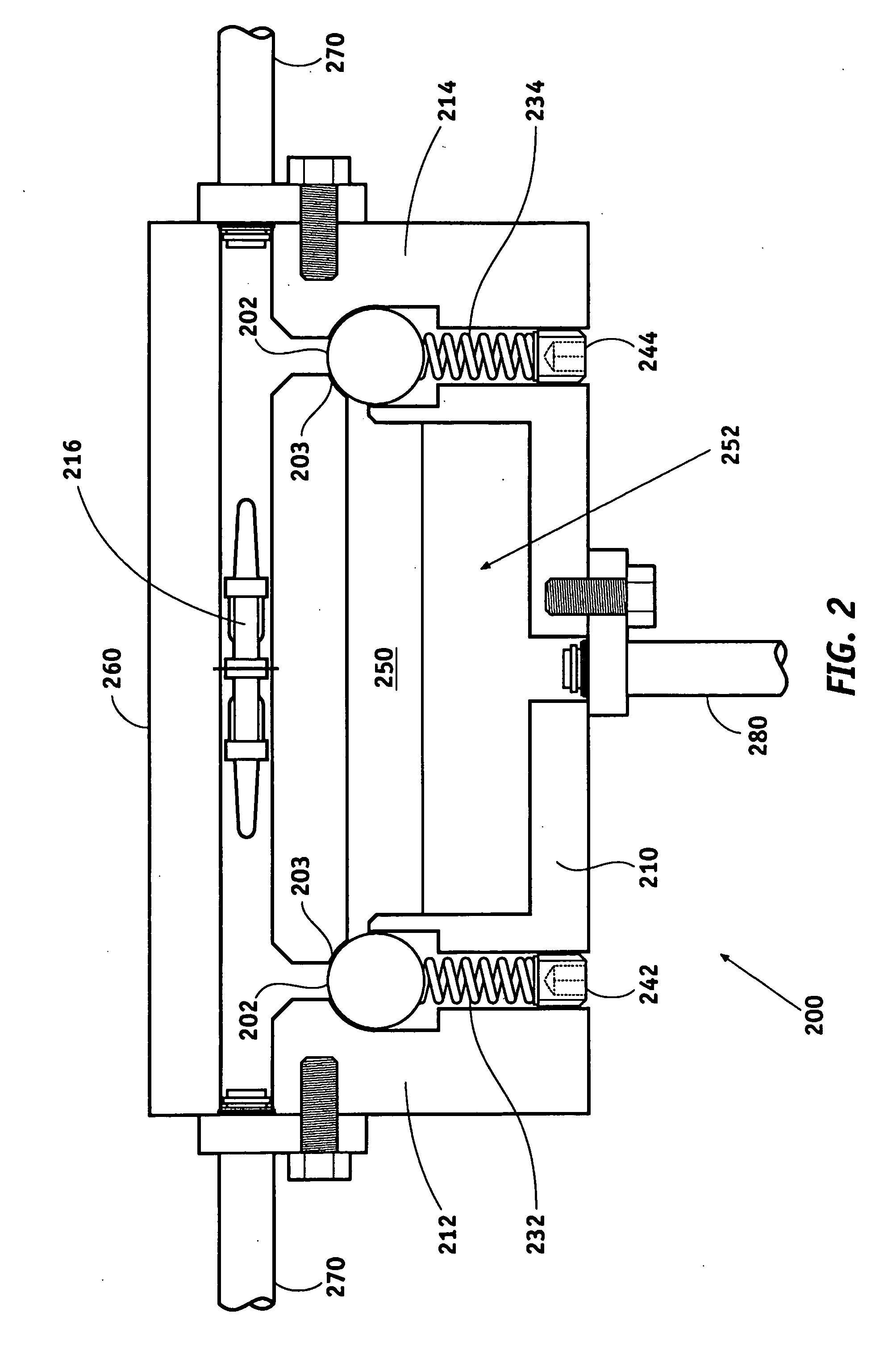

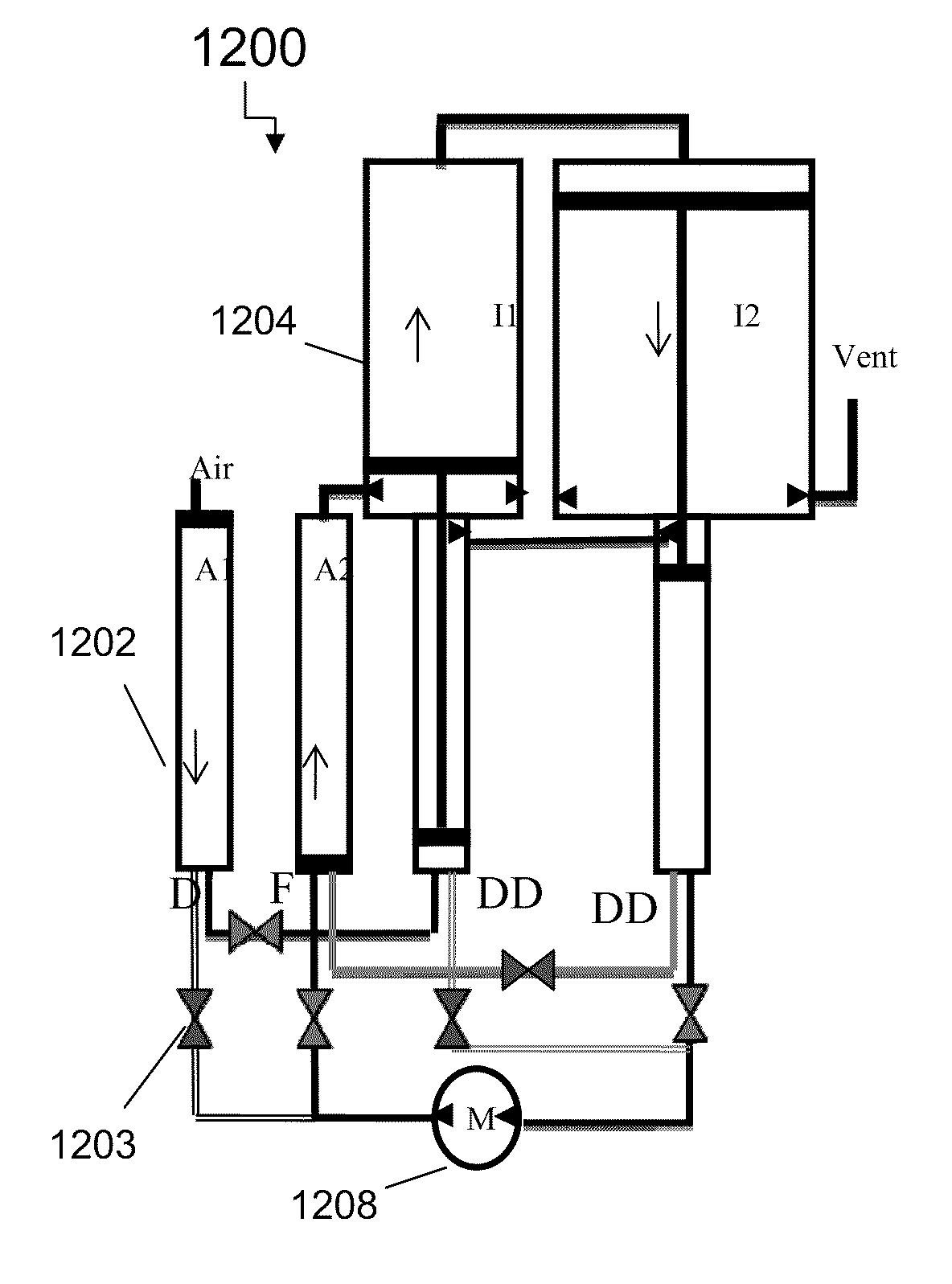

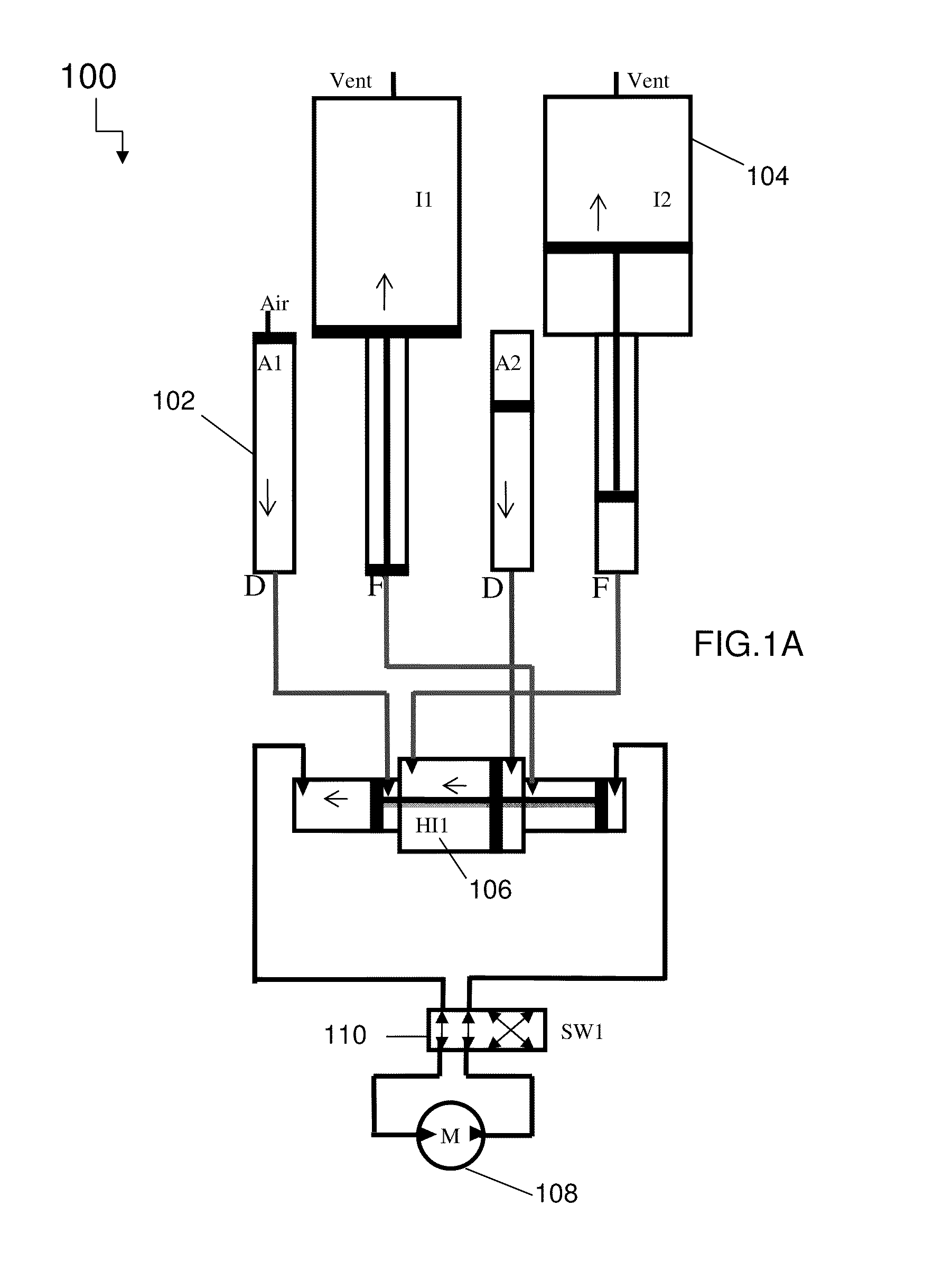

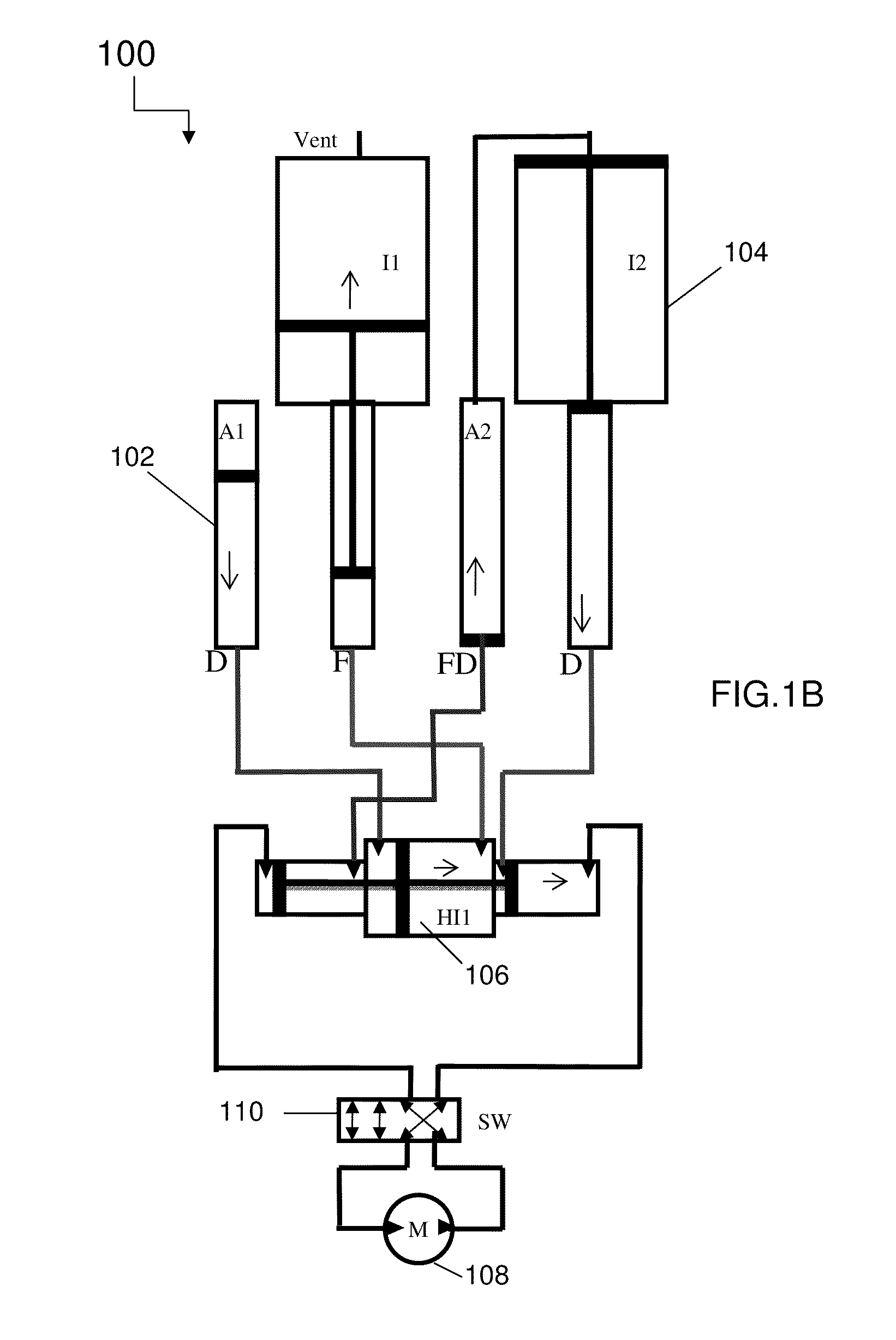

Systems and Methods for Improving Drivetrain Efficiency for Compressed Gas Energy Storage and Recovery Systems

InactiveUS20100307156A1Easy to testLow costElectrical storage systemGas turbine plantsHydraulic motorDrivetrain

The invention relates to power generation and energy storage and recovery. In particular, the invention relates to compressed gas energy storage and recovery systems using staged pneumatic conversion systems for providing narrow pressure ranges to a hydraulic motor.

Owner:SUSTAINX

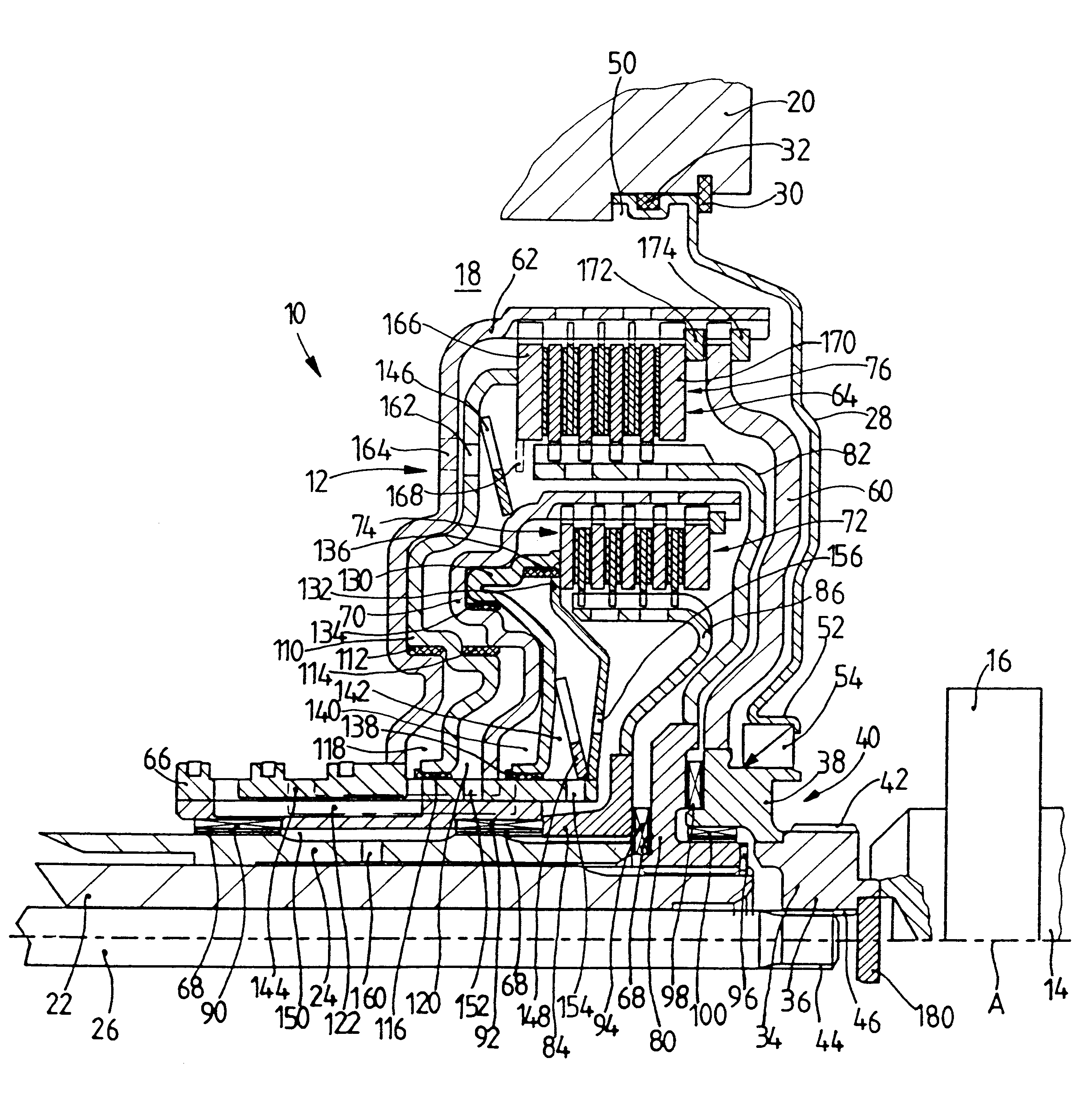

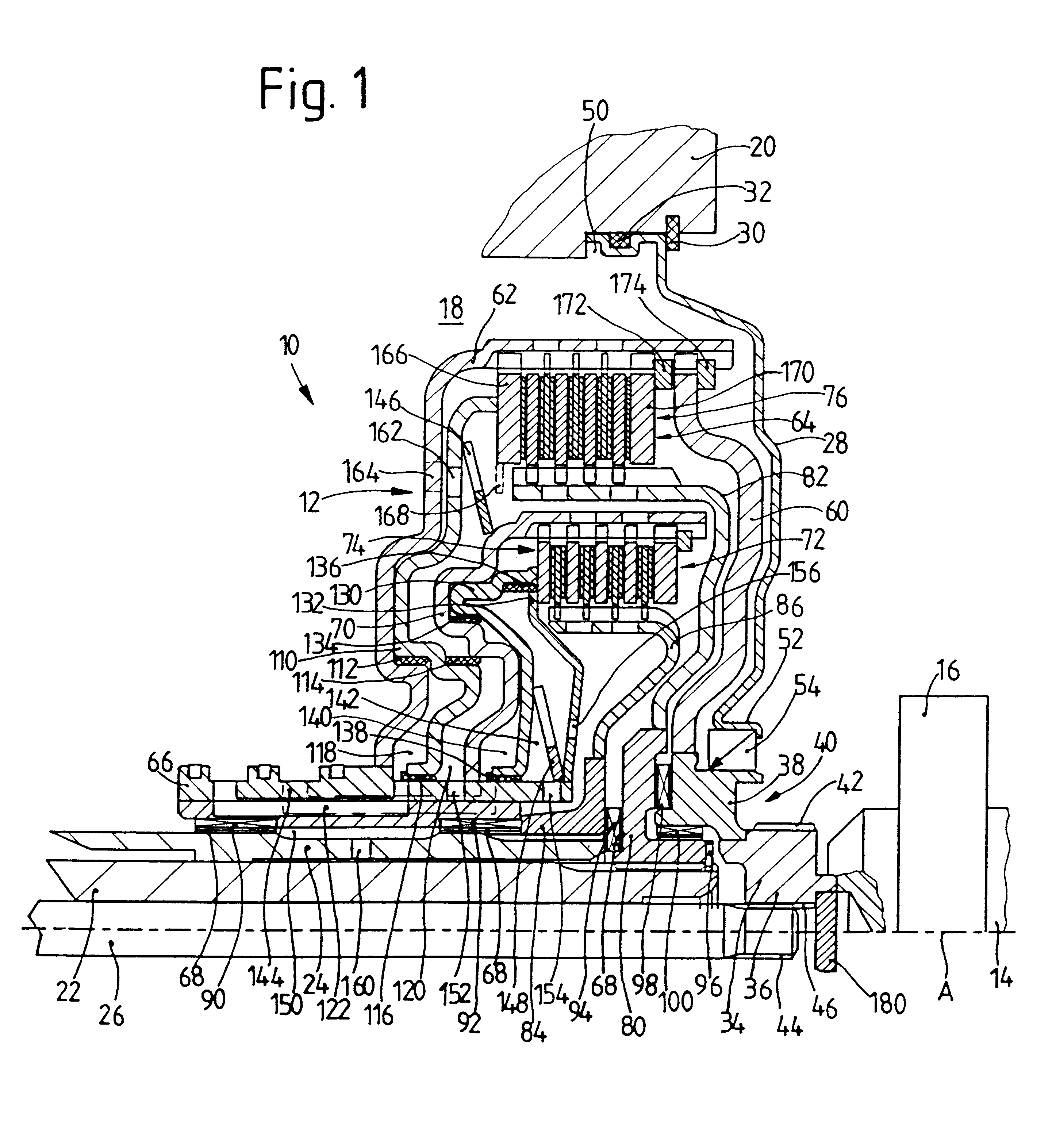

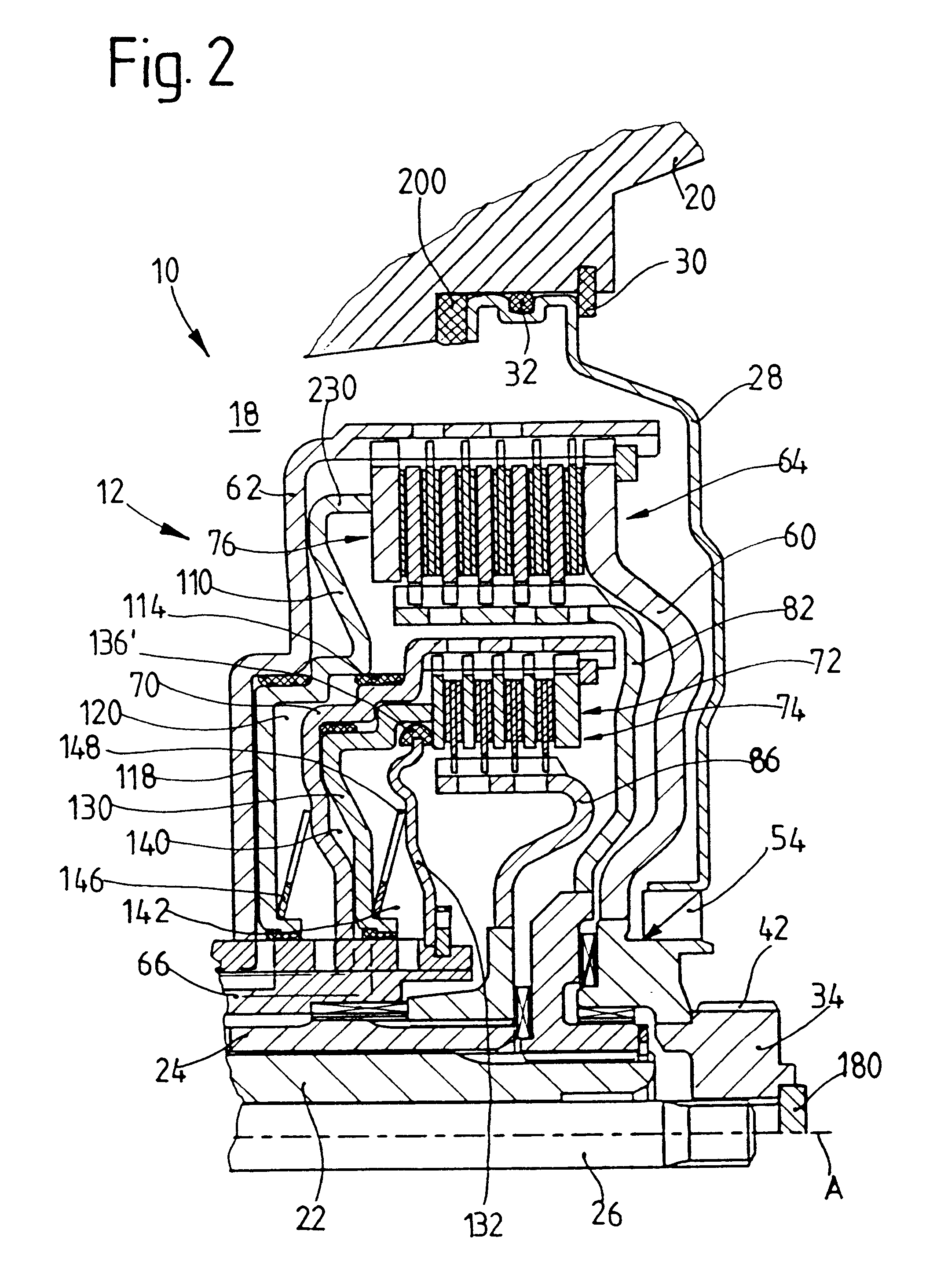

Multiple-clutch device

InactiveUS6523657B1Large massLarge heat capacityRoad transportFluid actuated clutchesMobile vehicleDrivetrain

The invention is directed to a multiple-clutch device, such as a double-clutch device, for arranging in a drivetrain of a motor vehicle between a drive unit and a transmission, wherein the clutch device has a first clutch arrangement associated with a first transmission input shaft of the transmission and a second clutch arrangement associated with a second transmission input shaft of the transmission for transmitting torque between the drive unit and the transmission. According to one aspect of the invention, it is suggested that plates in a plate stack of a clutch arrangement constructed as a plate clutch arrangement which have at least one friction facing can be brought into frictional engagement with plates having no friction facing, wherein at least one of the plates not having a friction facing is thicker in axial direction than friction facing carrying elements of adjacent plates having at least one friction facing. Alternatively or in addition, it is suggested that at least one plate which has at least one friction facing of sintered material and at least one plate which has at least one friction facing made of another friction facing material are provided in the plate stack, wherein the other friction facing material has a progressive frictional coefficient curve (dlambd / dDELTAN) in relation to a slip speed (DELTAN).

Owner:ZF FRIEDRICHSHAFEN AG +1

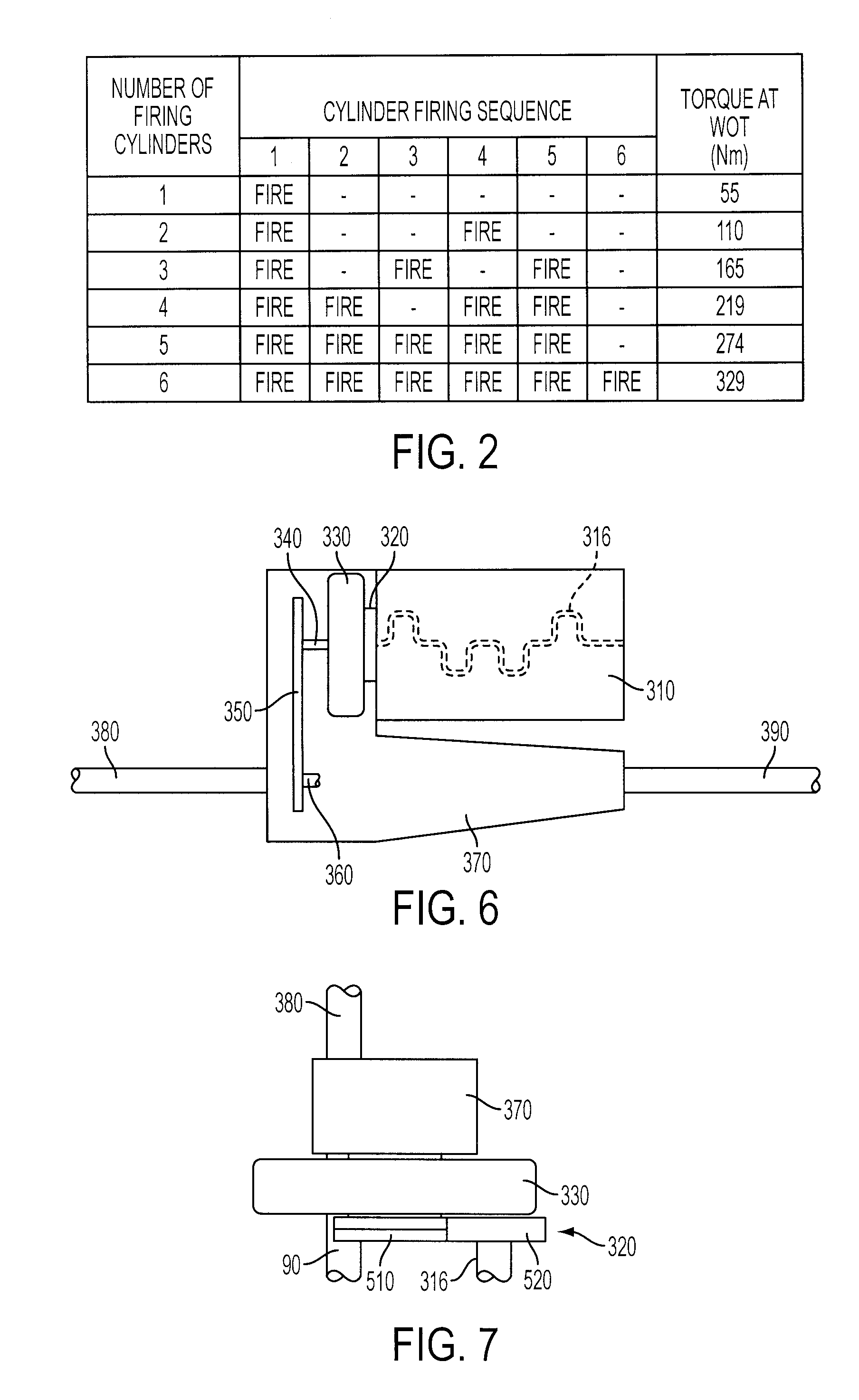

Cylinder deactivation method to minimize drivetrain torsional disturbances

ActiveUS20050131618A1Reduce engine vibrationImprove fuel economyAnalogue computers for vehiclesElectrical controlDriver/operatorDrivetrain

Owner:FORD GLOBAL TECH LLC

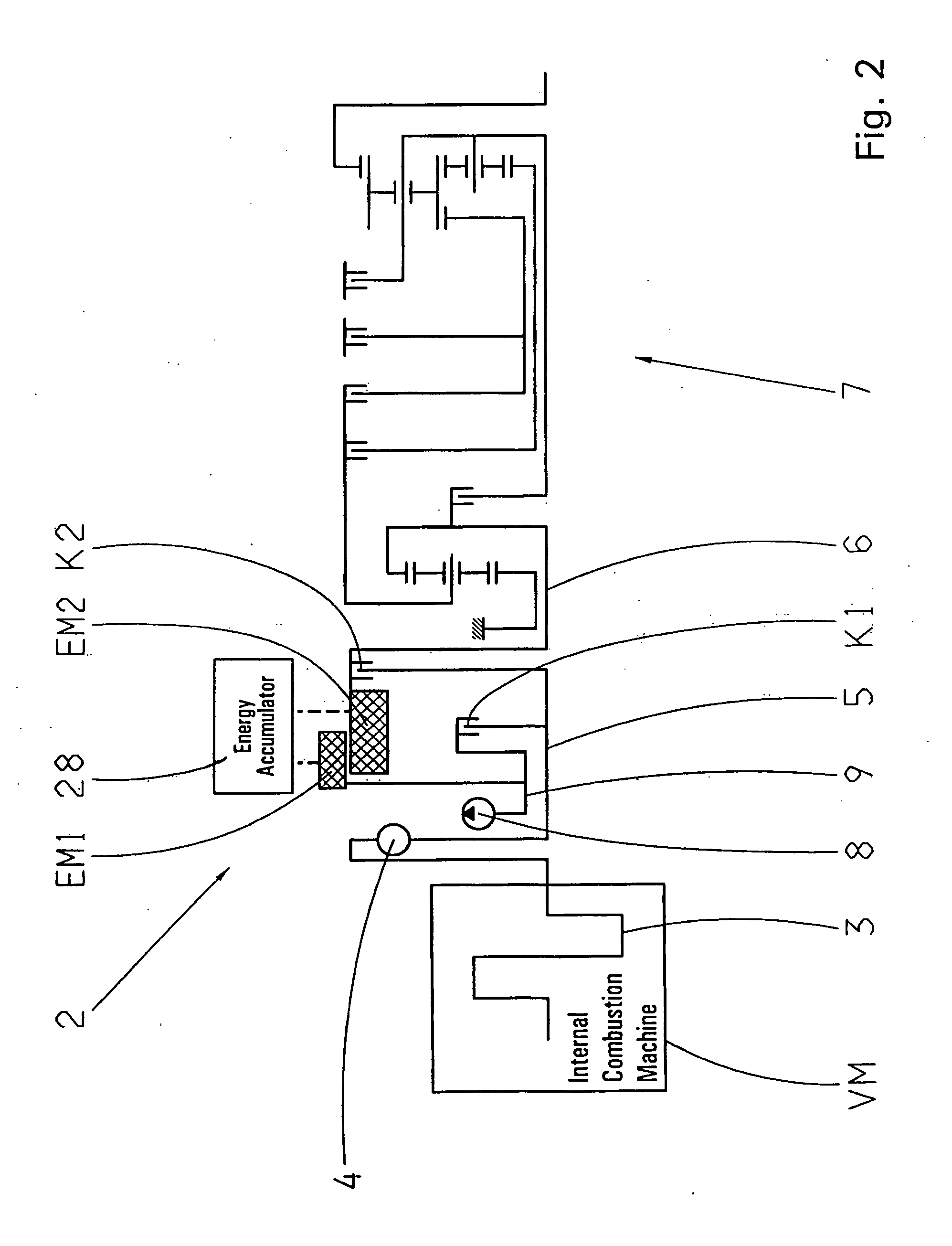

Device and method for steering and regulating components of a hybrid driveline of a vehicle

InactiveUS20060048516A1Reciprocating combination enginesElectric propulsion mountingDriver/operatorState of charge

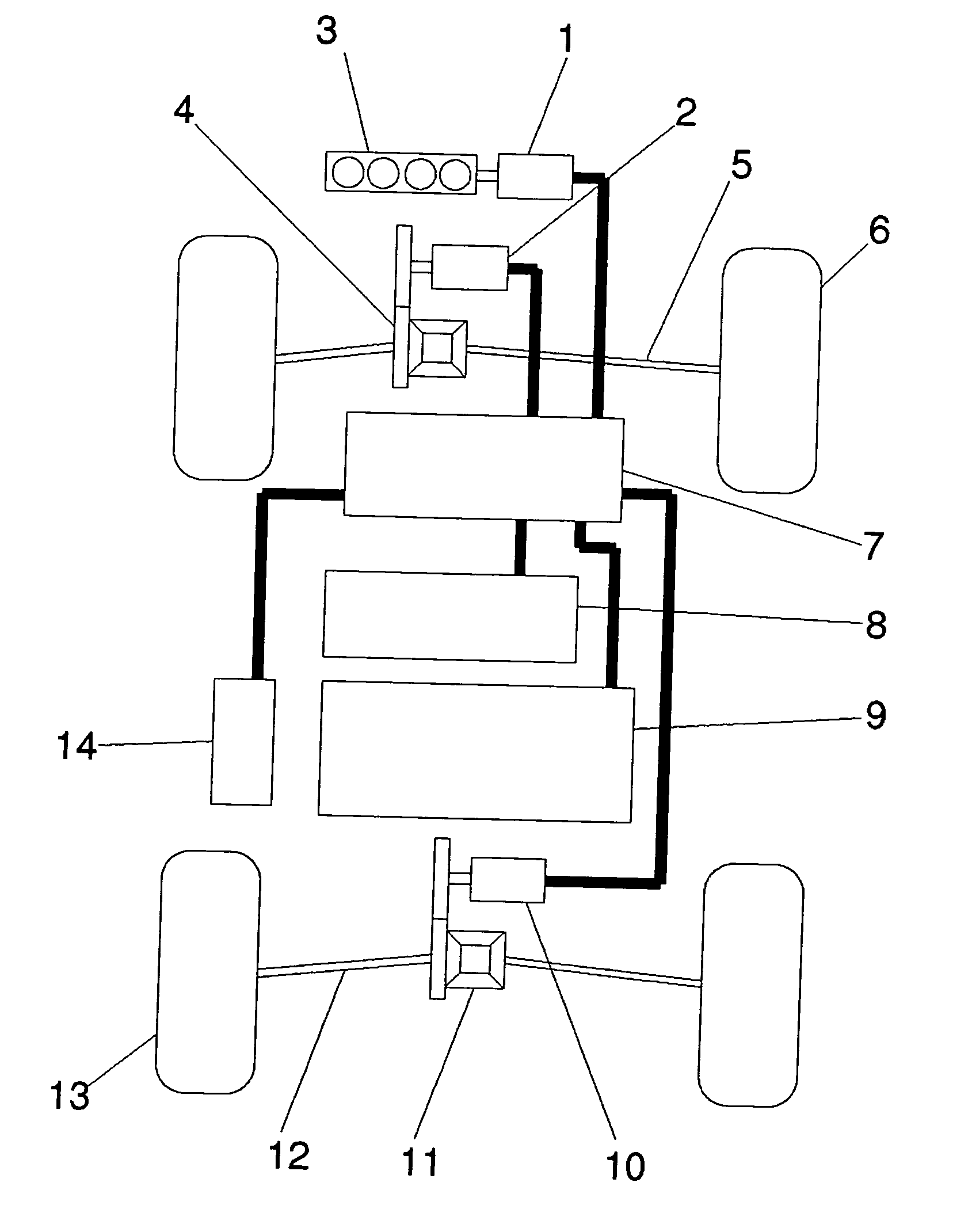

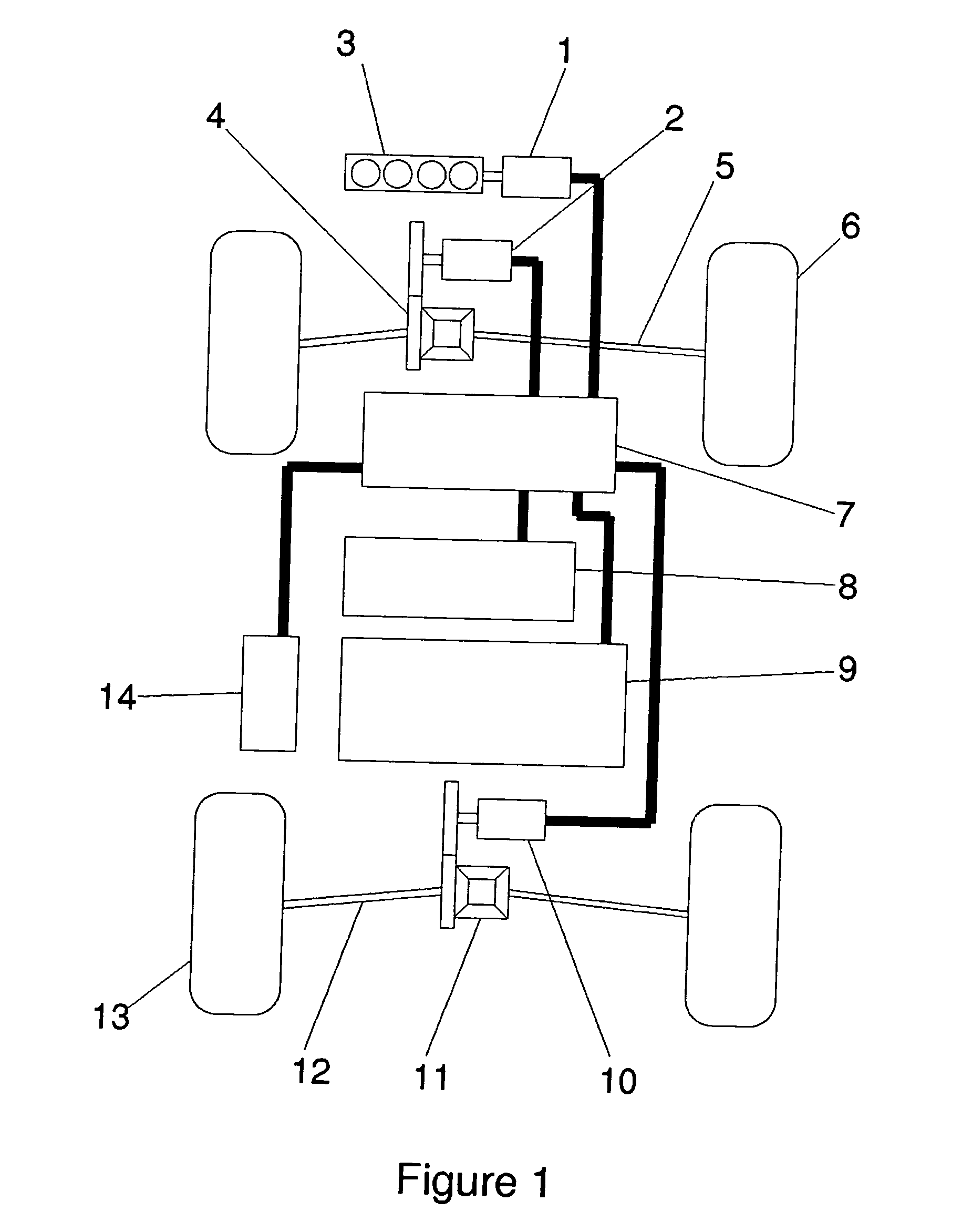

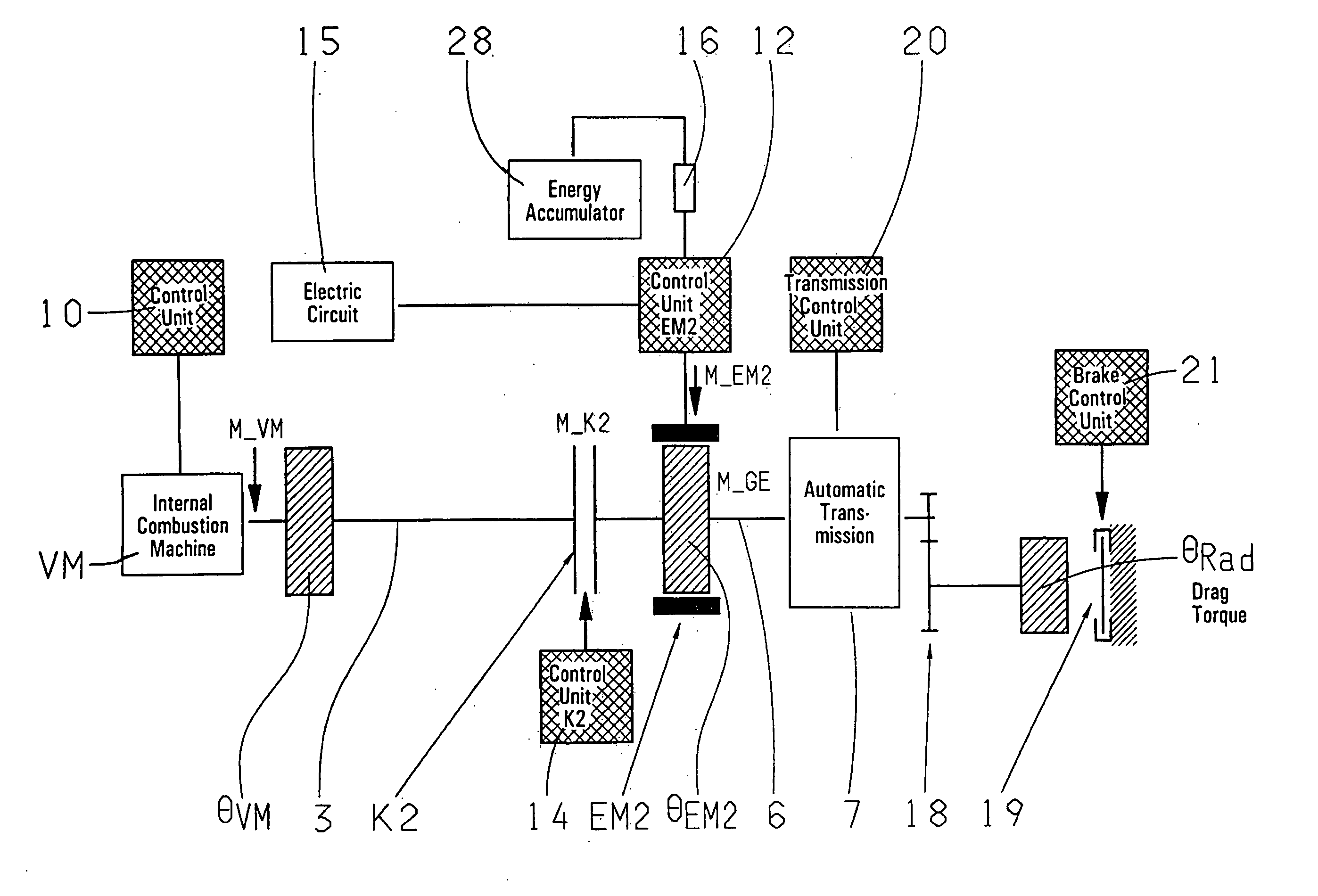

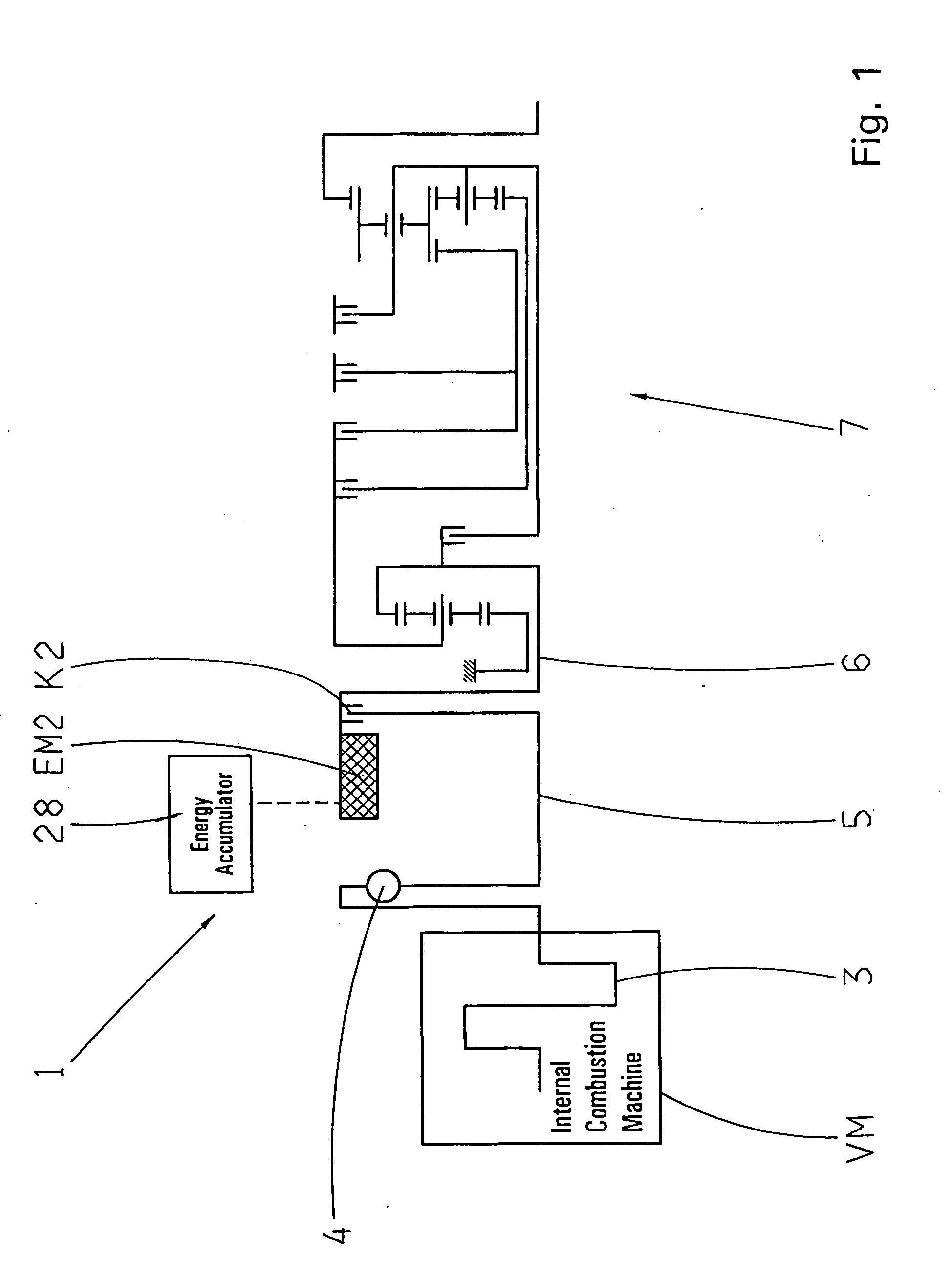

A method and a device for steering and regulating components of a hybrid driveline (1, 2). For the mode of operation sparing in fuel and poor in emission of a motor vehicle having one such driveline, it is provided that the input torque desired by the driver be distributed among the drive torques of one internal combustion machine (VM) and of at least one electric machine (EM1, EM2) and such a driving mode be selected so that the state of charge of an electric energy accumulator (28) is optimally adapted to the actual rather dynamic or rather economic mode of operation of the driver.

Owner:ZF FRIEDRICHSHAFEN AG

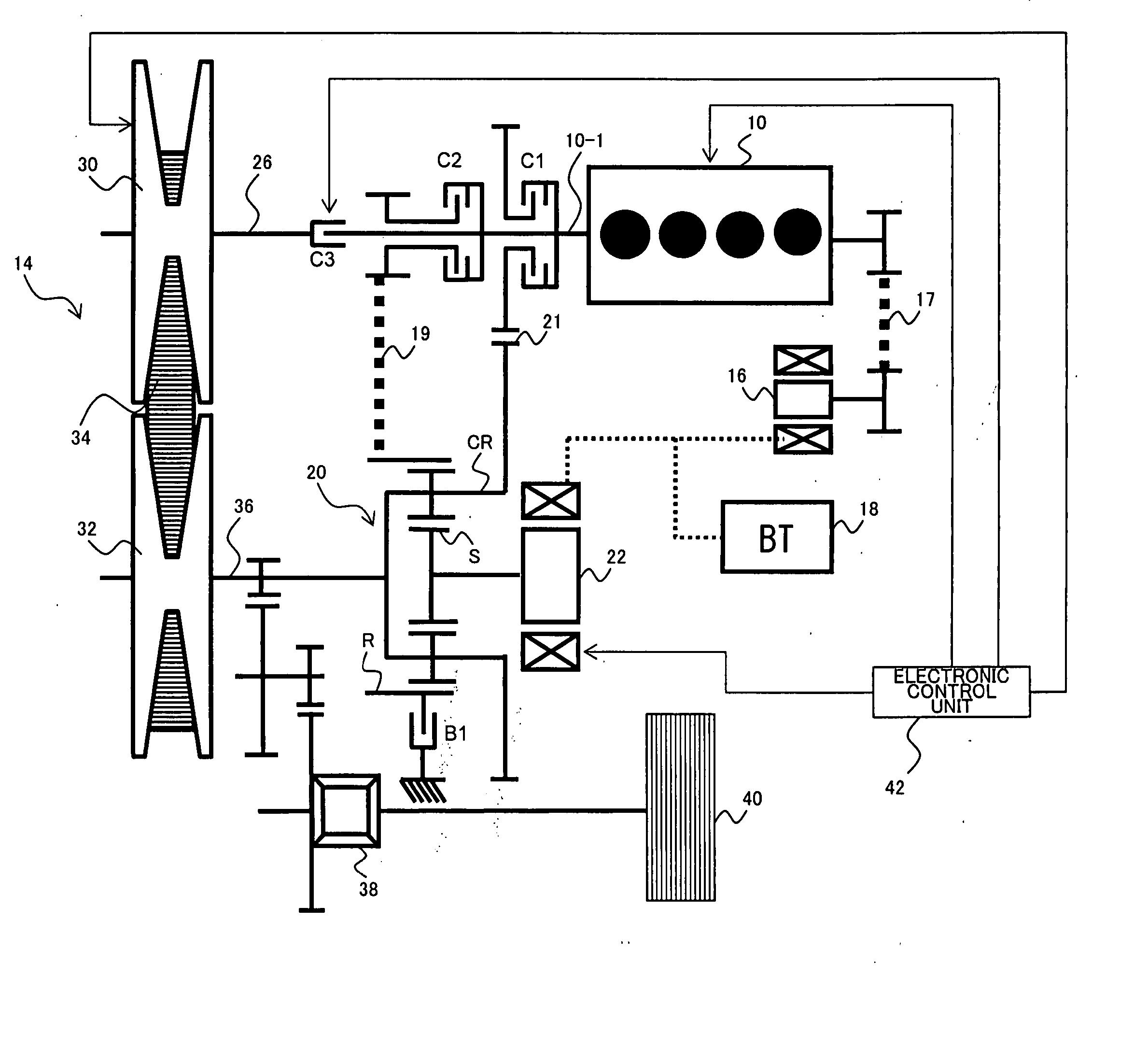

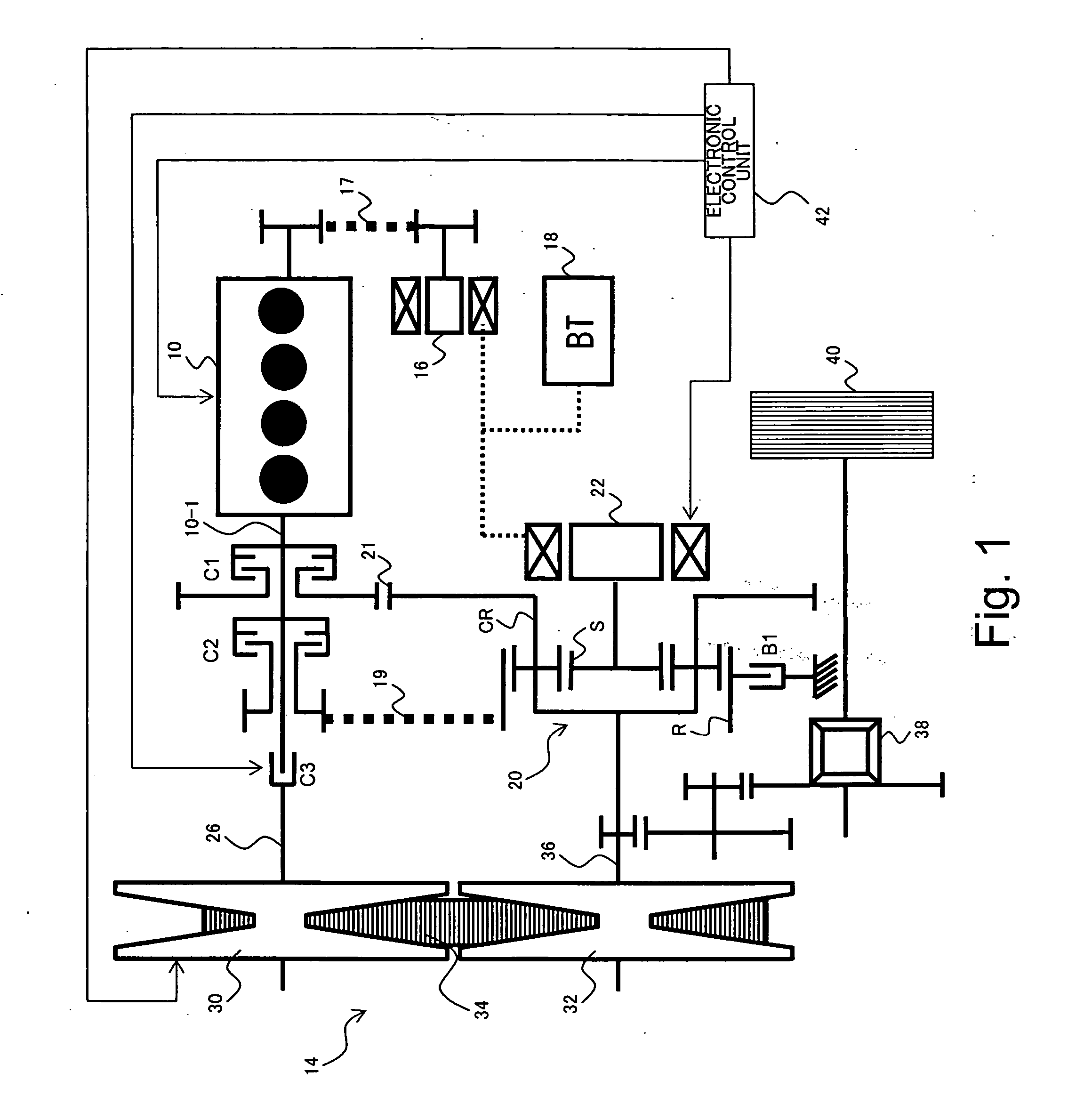

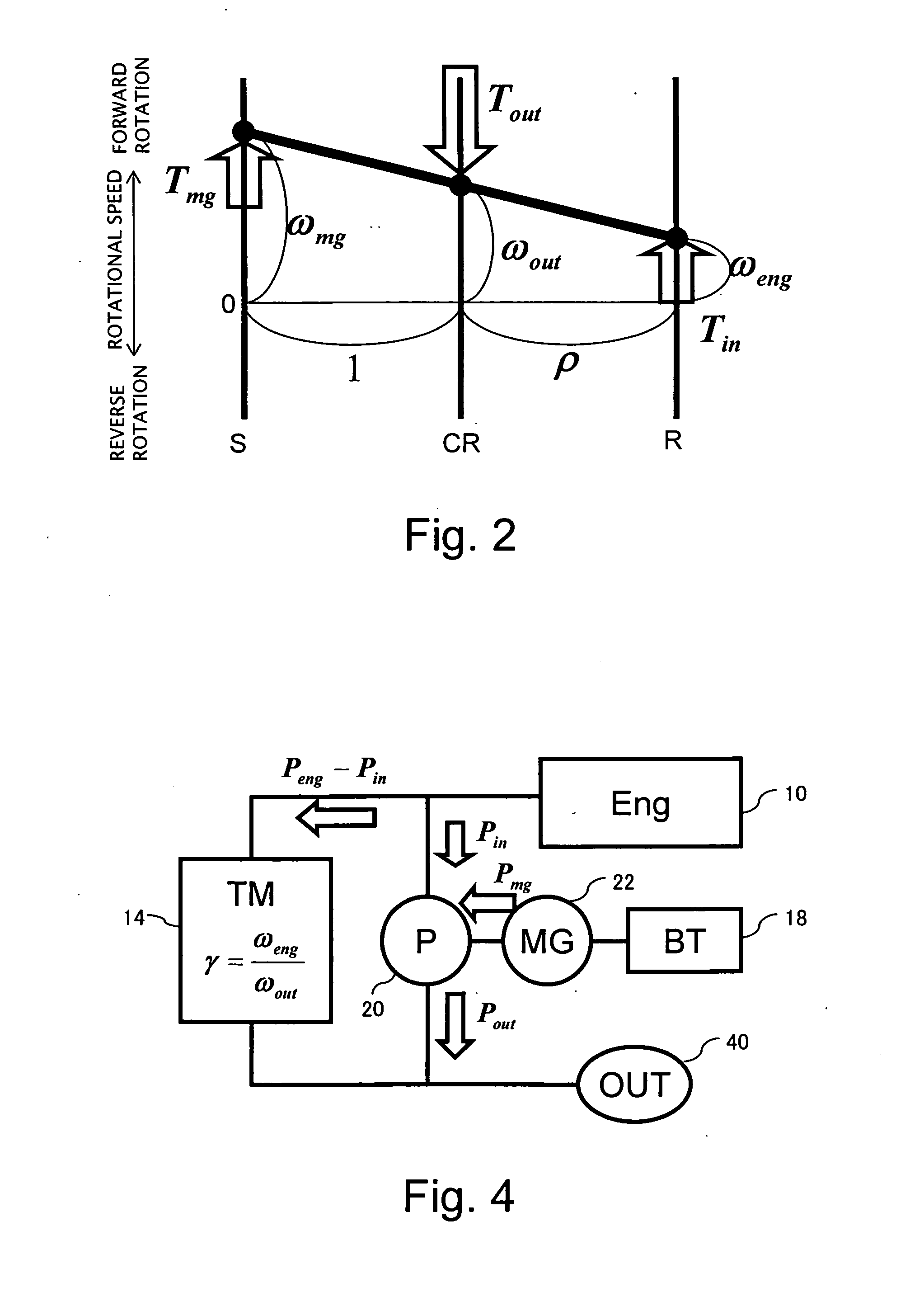

Power transmission system

InactiveUS20060247086A1High power transmission efficiencyReduce capacityHybrid vehiclesElectric propulsion mountingDrive wheelDrivetrain

In a power transmission system for transmitting power of an engine to a load, a planetary gear mechanism provided in parallel to a speed variator combines torque conveyed from the engine with torque conveyed from a motor generator in a state such that their torque ratio equals a predetermined ratio, and transmits the combined torque to a driven wheel. When performing power transmission between the engine and the driven wheel via both the speed variator and the planetary gear mechanism, power distribution between the power conveyed to the speed variator and the power conveyed to the planetary gear mechanism can be actively controlled by adjusting the torque of the motor generator. As a result, the speed variator capacity can be reduced while enhancing power transmission efficiency.

Owner:TOYOTA CENT RES & DEV LAB INC

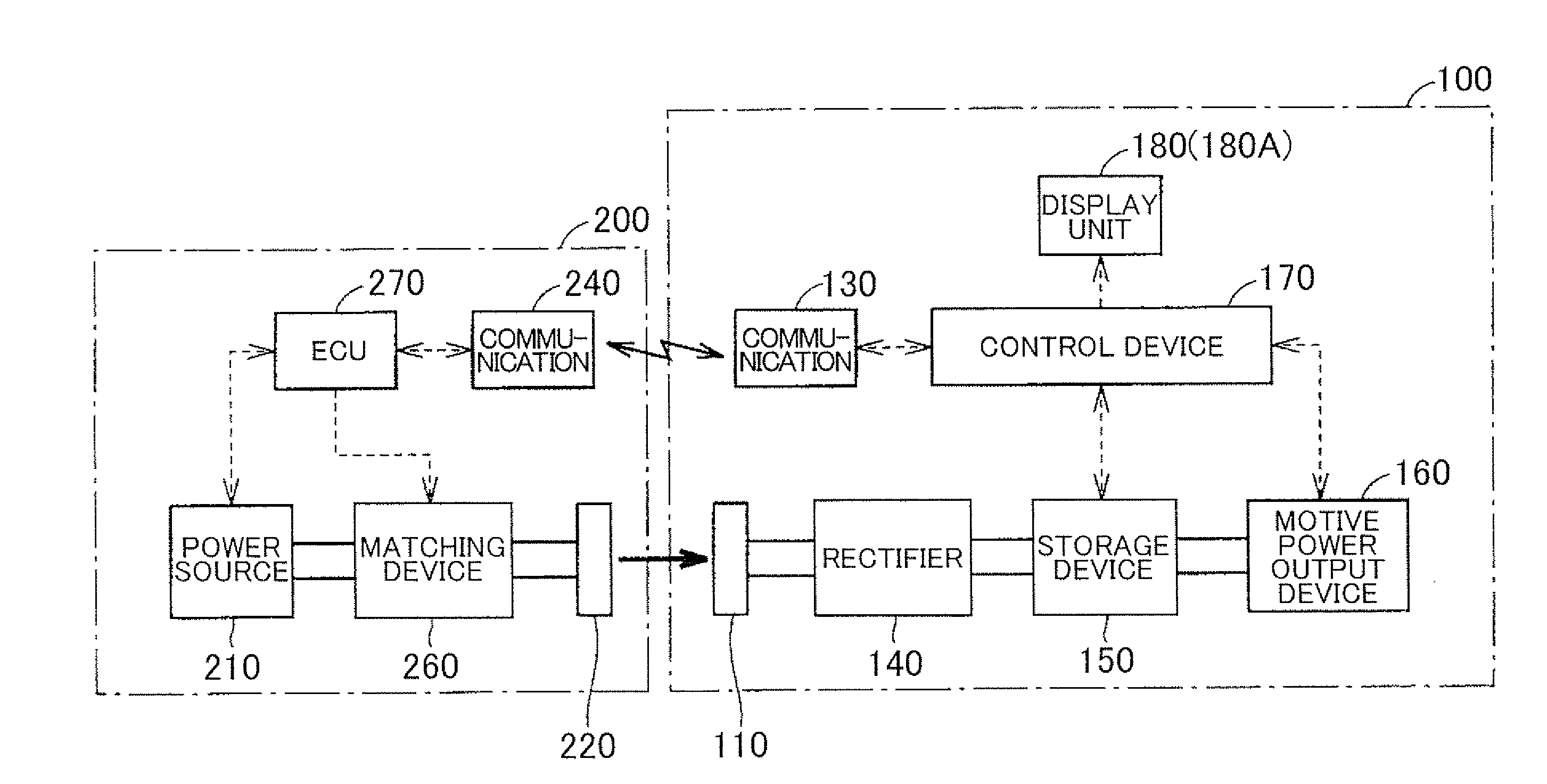

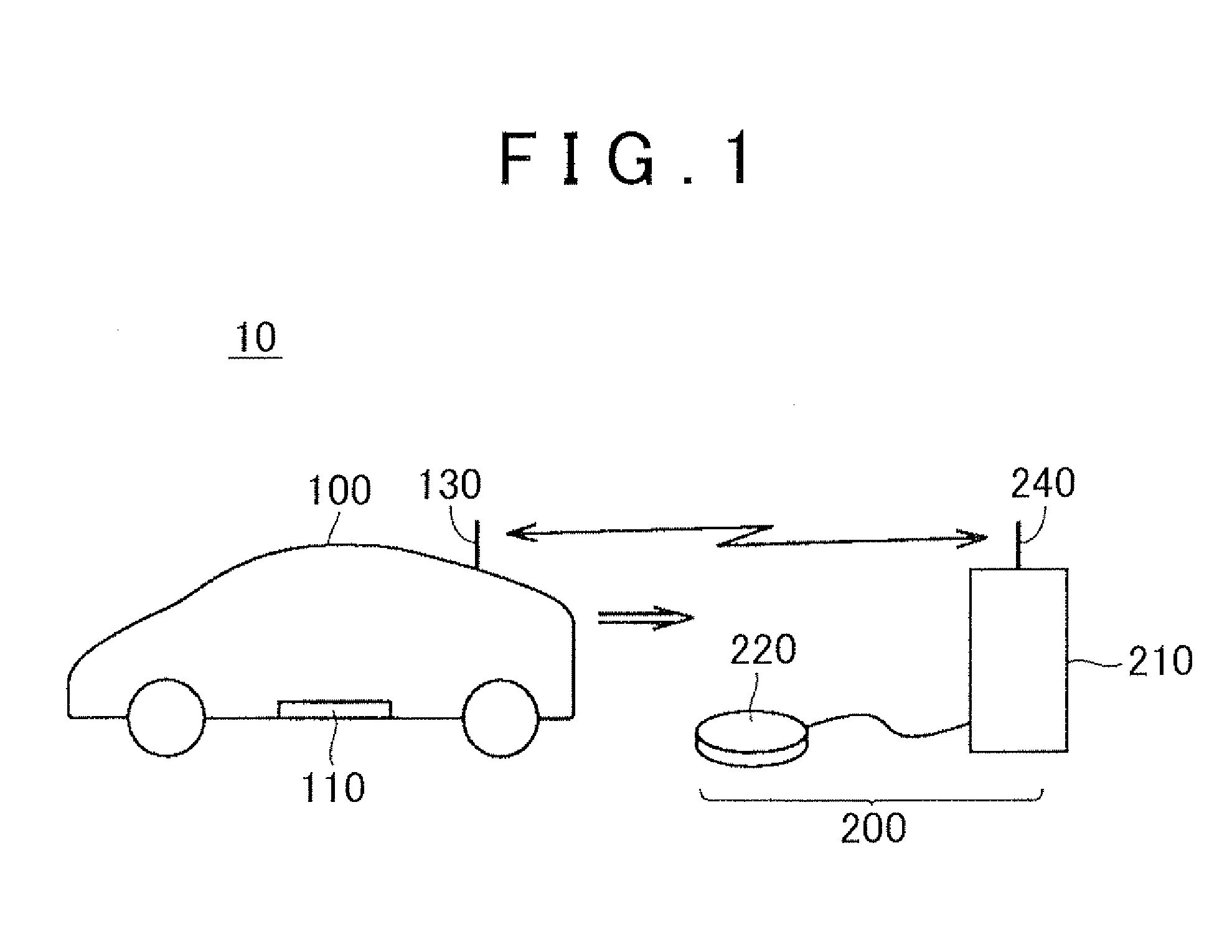

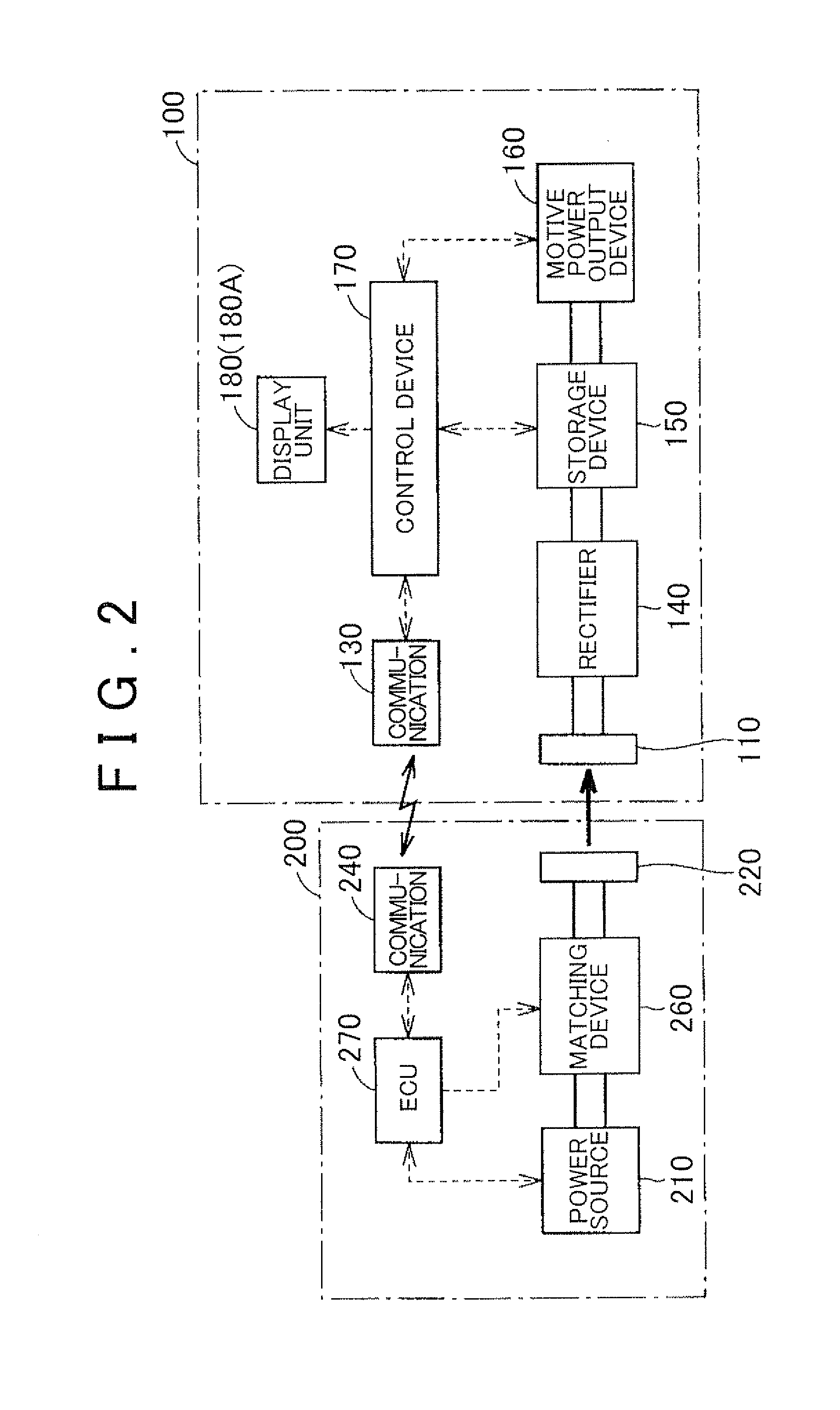

Power transmission system, vehicle and power supply facility

InactiveUS20130127409A1Easy to knowCircuit monitoring/indicationCharging stationsGraphicsElectric power transmission

Power is transmitted from a power supply facility to a vehicle in a contact-less manner. A control device detects a distance between a power transmission unit of the power supply facility and a power receiving unit of the vehicle. A display unit displays a graphic in a display pattern which varies in accordance with the distance detected by the detection unit.

Owner:TOYOTA JIDOSHA KK

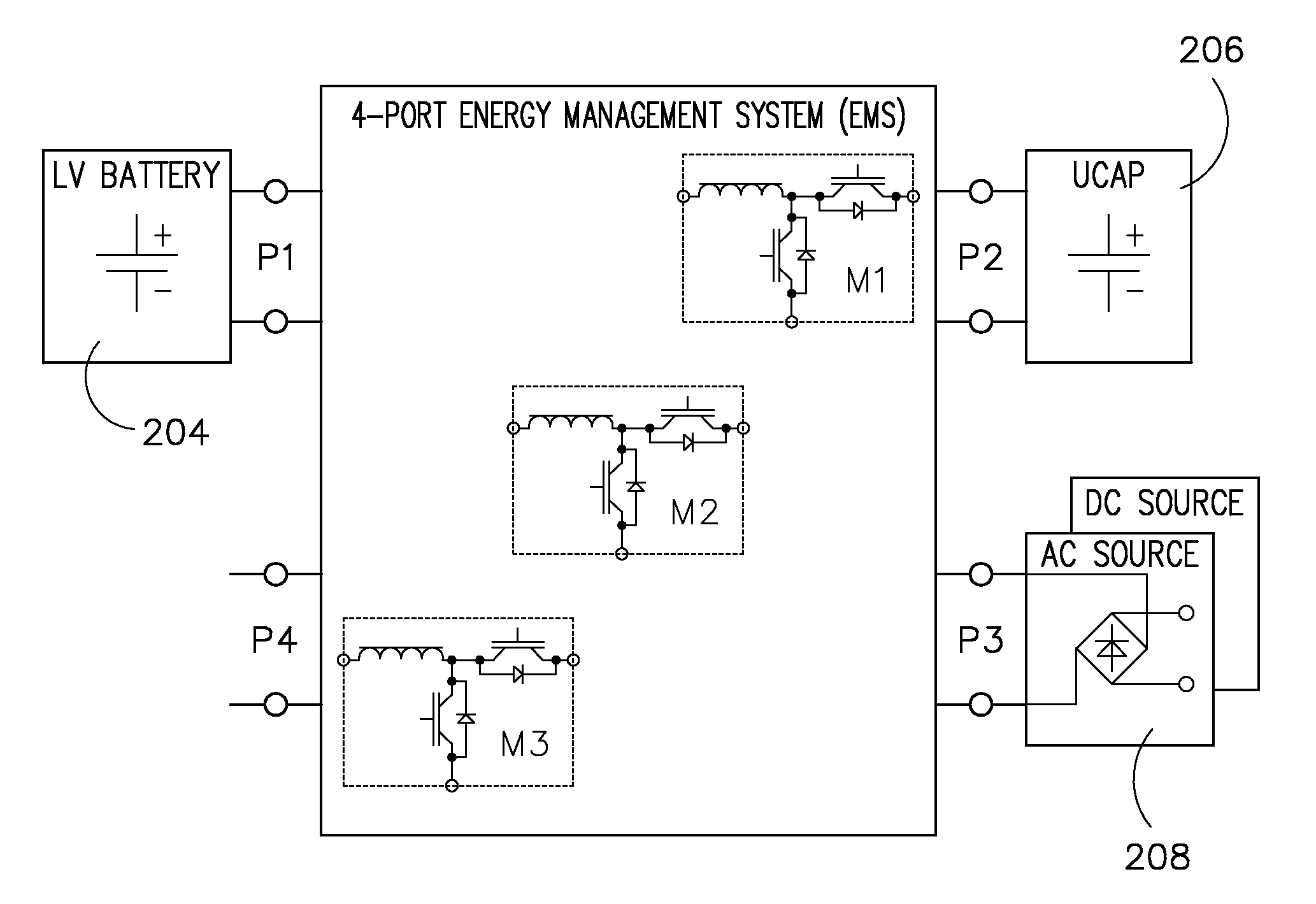

Apparatus and method for charging an electric vehicle

An energy management system (ESMS) includes energy storage devices coupled to a vehicle drivetrain and configured to store DC energy, a power electronic conversion system having energy ports, the power electronic conversion system comprising a DC electrical converters, each DC electrical converter configured to step up and to step down a DC voltage, wherein each of the energy ports is coupleable to each of the energy storage devices and each of the energy ports is coupleable to an electrical charging system. The EV includes a controller configured to determine a voltage of each energy port having either an energy storage device or a DC electrical charging system coupled thereto, and electrically connect a first energy port to a second energy port such that at least one of the DC electrical converters either steps up or steps down an input DC voltage based on the determined voltage of each energy port.

Owner:GENERAL ELECTRIC CO

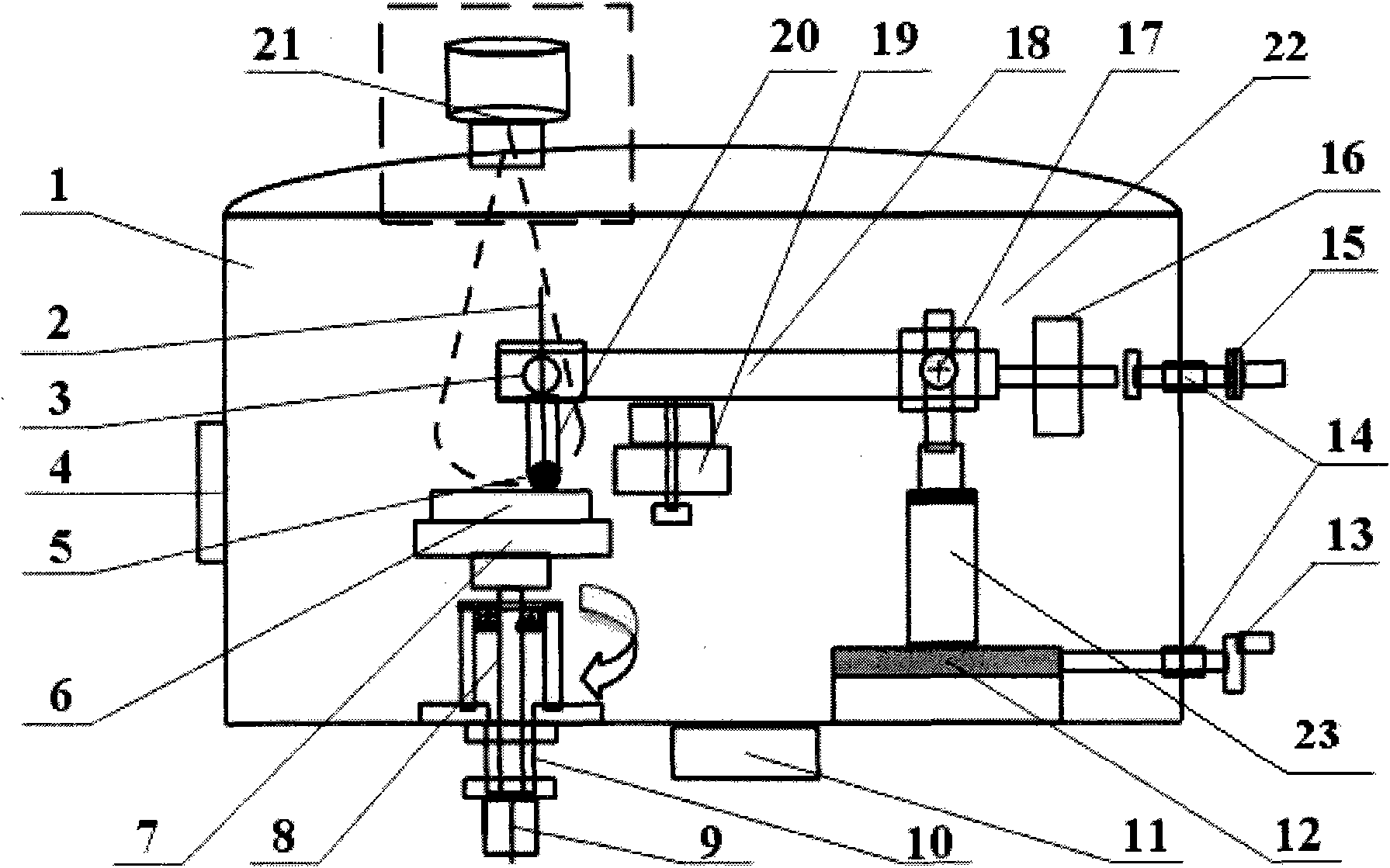

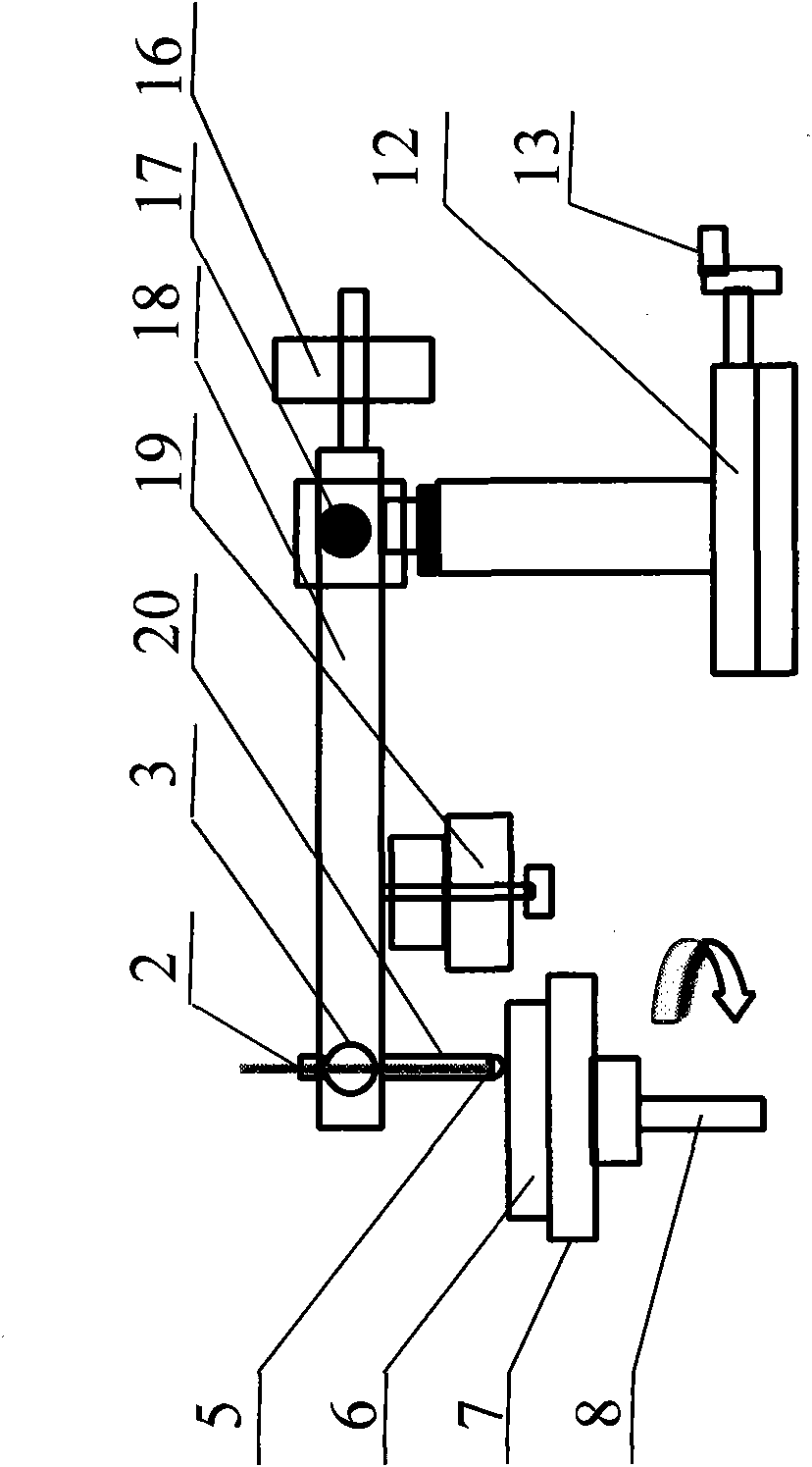

Multifunctional vacuum friction and wear testing machine

ActiveCN102759489APrecise position adjustmentAvoid time costInvestigating abrasion/wear resistanceDrivetrainEngineering

The invention provides a multifunctional vacuum friction and wear testing machine, which not only can simulate special environmental atmospheres such as vacuum, radiation and corrosion, but also can conduct tribology tests in a relatively wide speed and load range by using various contact manners (ball-disc and pin-disc). The multifunctional vacuum friction and wear testing machine mainly comprises a vacuum system, a friction and wear system, a power transmission system, a control system, and the like, wherein the friction and wear system comprises a lever structure (22) used for fixing a test sample fixture (20) and capable of freely rotating in a horizontal direction and a vertical direction; the lever structure (22) comprises a cantilever beam (18) and a vertical arm (23) which are arranged in a perpendicular manner; the cantilever beam (18) is connected with the vertical arm (23) through a two degree of freedom bearing structure (17); positions of the cantilever beam (18) and the vertical arm (23) can be adjusted in the horizontal direction and the vertical direction through the control of a manipulator (15) and a hand wheel structure (13), so that the test sample fixture (20) can accurately move within two degrees of freedom; and a temperature sensor (2) and a pressure sensor (3) are mounted on the test sample fixture (20), so as to detect / monitor friction coefficients and temperature variations during the tribology tests.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

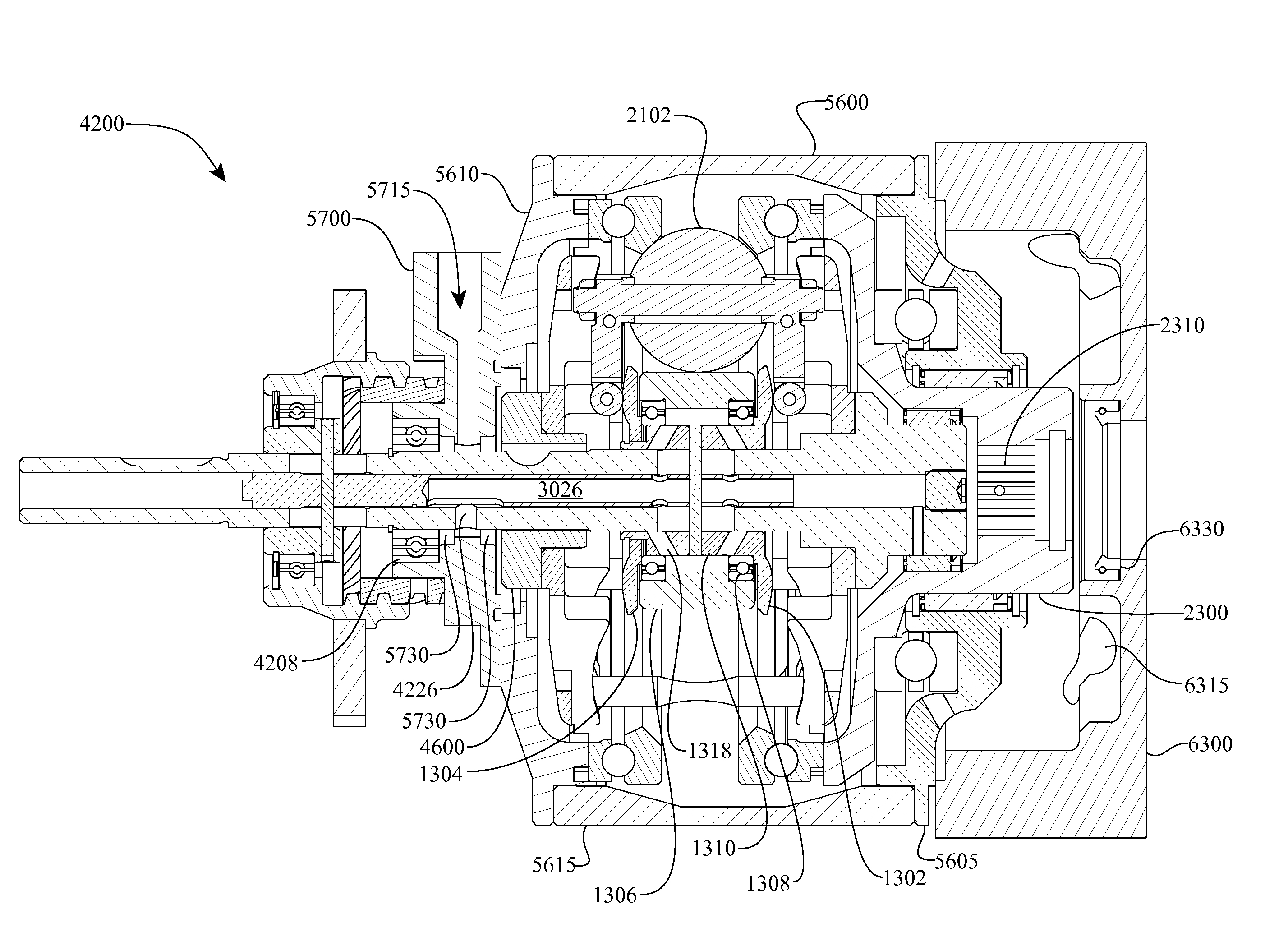

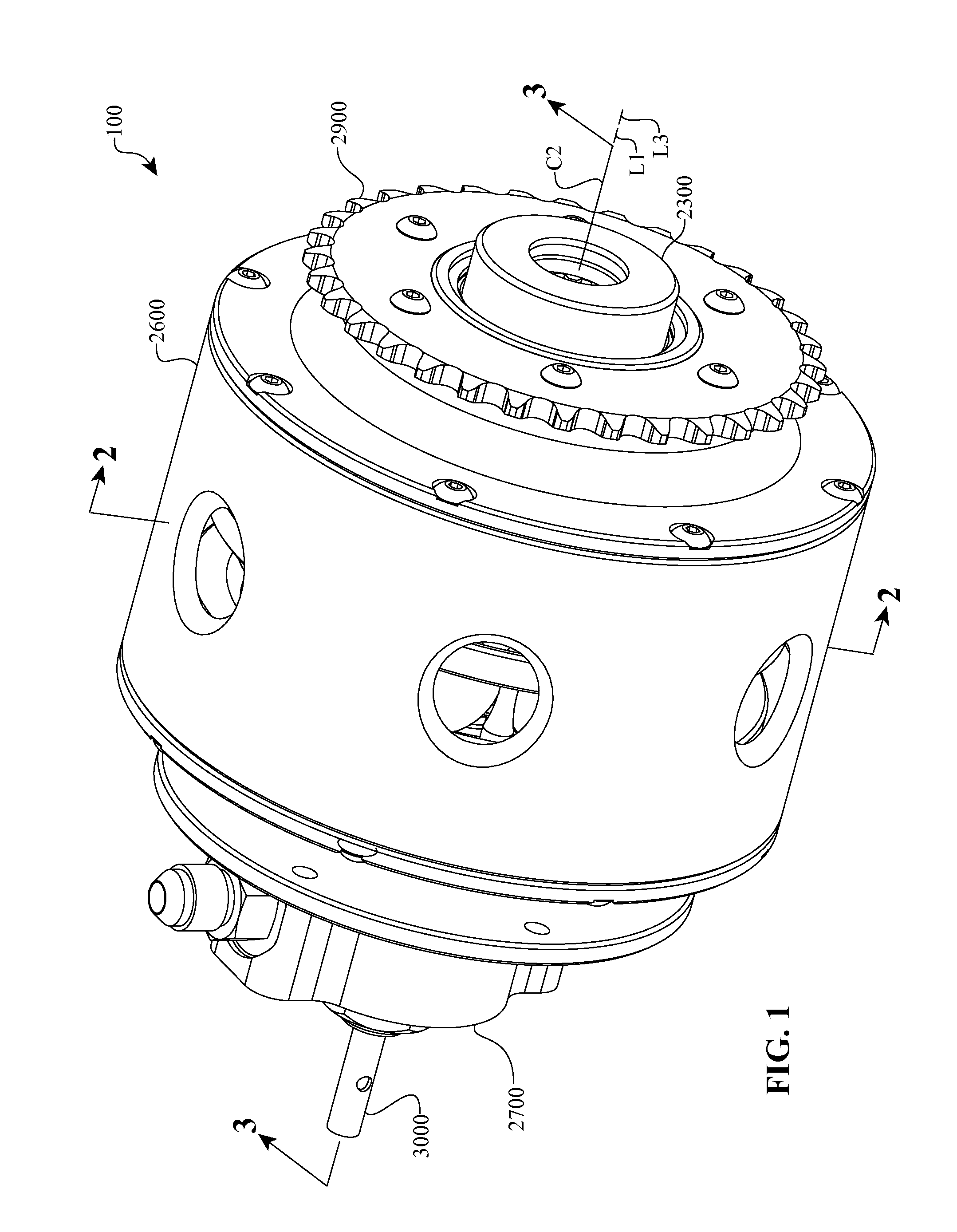

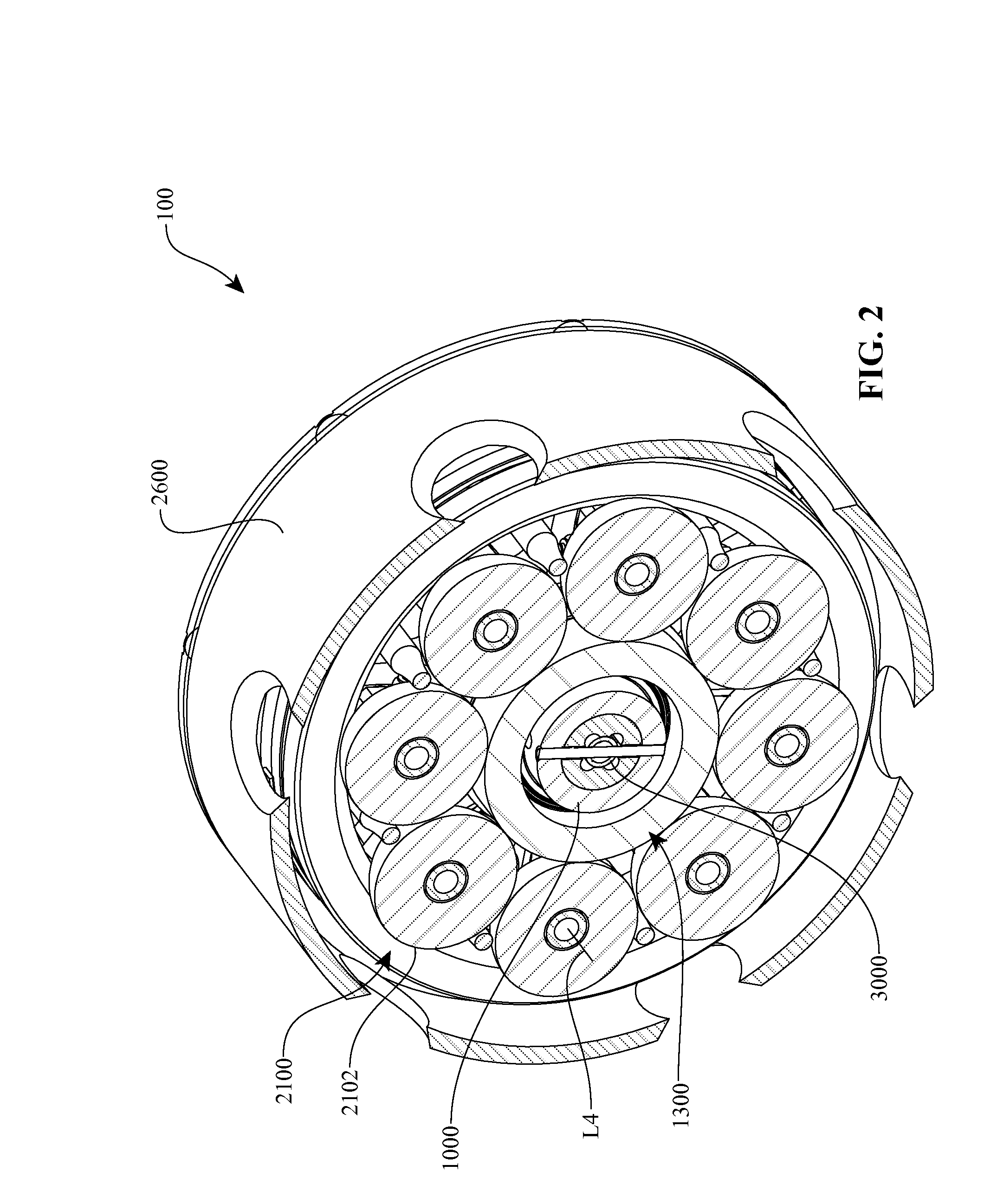

Continuously and/or infinitely variable transmissions and methods therefor

Inventive embodiments are directed to components, subassemblies, systems, and / or methods for continuously or infinitely variable transmissions (C / IVT). In one embodiment, a main axle is adapted to receive a shift rod that cooperates with a shift rod nut to actuate a ratio change in a C / IVT. In another embodiment, a lubricant manifold is adapted to cooperate with the main axle of the C / IVT to supply lubricant to the interior of the C / IVT. Embodiments of a drivetrain housing and housing cover plate are adapted to house components of a C / IVT and, in some embodiments, to cooperate with other components of the C / IVT to support operation and / or functionality of the C / IVT. Shift control interfaces for a C / IVT are disclosed that include, for example, a shift actuation subassembly having a translatable and rotatable shift pin collar. Mechanisms that facilitate shifting of the C / IVT are disclosed that include a shift rod and shift cam adapted to supply lubricant to the interior of the transmission.

Owner:FALLBROOK INTPROP COMPANY

Hybrid powertrain system including smooth shifting automated transmission

InactiveUS20050164827A1Easy transferElectric propulsion mountingGas pressure propulsion mountingDrivetrainHybrid powertrain

A powertrain system is provided that includes a prime mover and a change-gear transmission having an input, at least two gear ratios, and an output. The powertrain system also includes a power shunt configured to route power applied to the transmission by one of the input and the output to the other one of the input and the output. A transmission system and a method for facilitating shifting of a transmission system are also provided.

Owner:EATON CORP

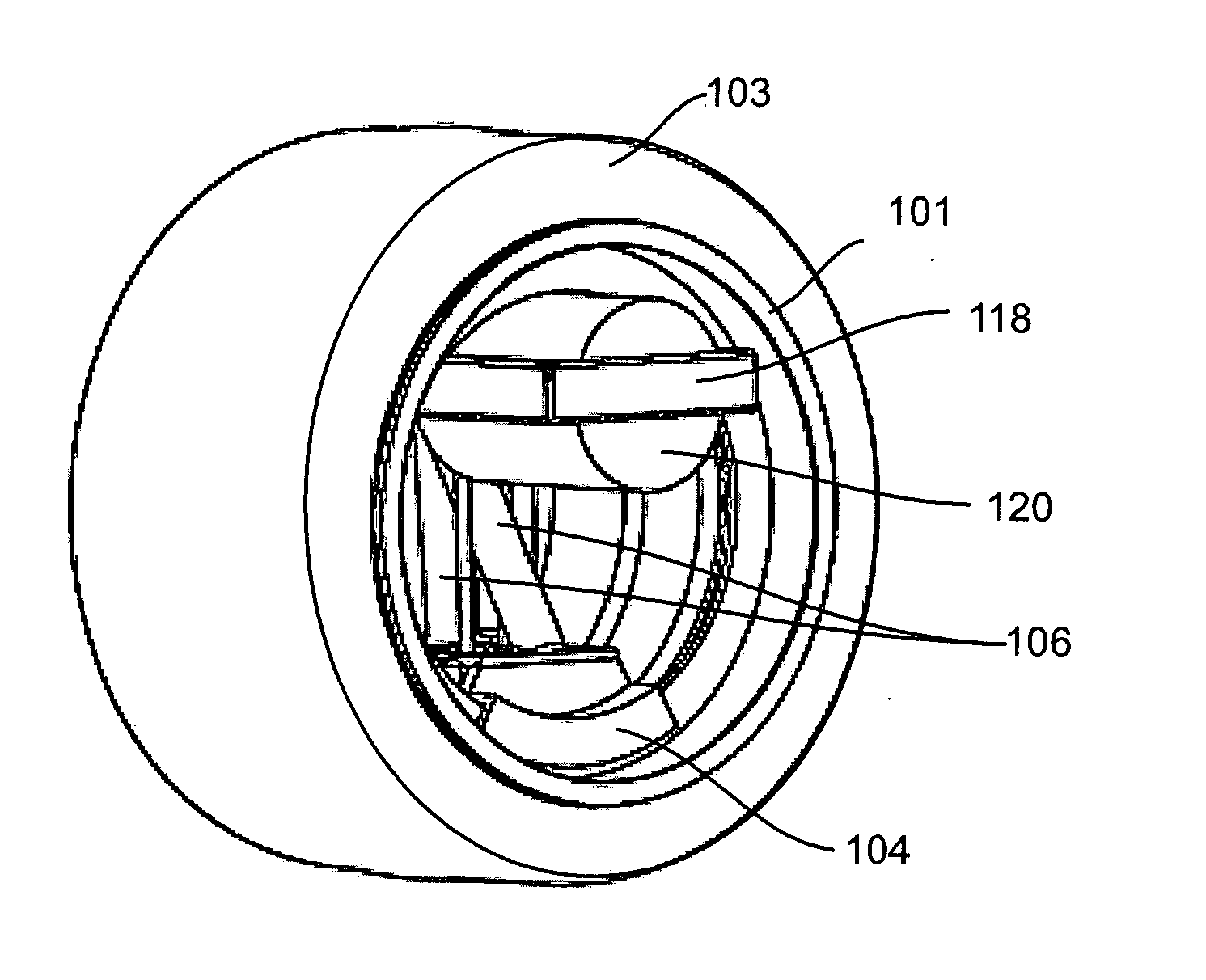

Wheel-embedded suspension

InactiveUS20060012144A1Simple designEasy and faster and cheapElectric devicesSteering linkagesDrive shaftDrivetrain

An in-the-wheel suspension system including a drive mechanism for coupling the rotational motion of a wheel rim to the drive shaft of an electric motor and for supporting the wheel rim with respect to the vehicle chassis using one or more springs and dampers. In a hubless version, a spring member supports extend between a frame member attached to the chassis and a bearing member that engages with the rim. In a version used with a wheel hub, the hub is supported by an axle and the spring member supports the axle in movable relation to the frame member. A pivoting support arm that is attached to the axel and pivots about a pivot point attached to the frame member at a location spaced from the wheel axis may be used to support the hub. A Peaucellier linkage may be used to support the axle for movement along a straight line vertical path, the linkage being attached to the frame member at two fixed pivot points. The wheel suspension units perform all the traditional drivetrain functions independently and can be attached to the chassis in a manner that allows for easy removal.

Owner:MASSACHUSETTS INST OF TECH

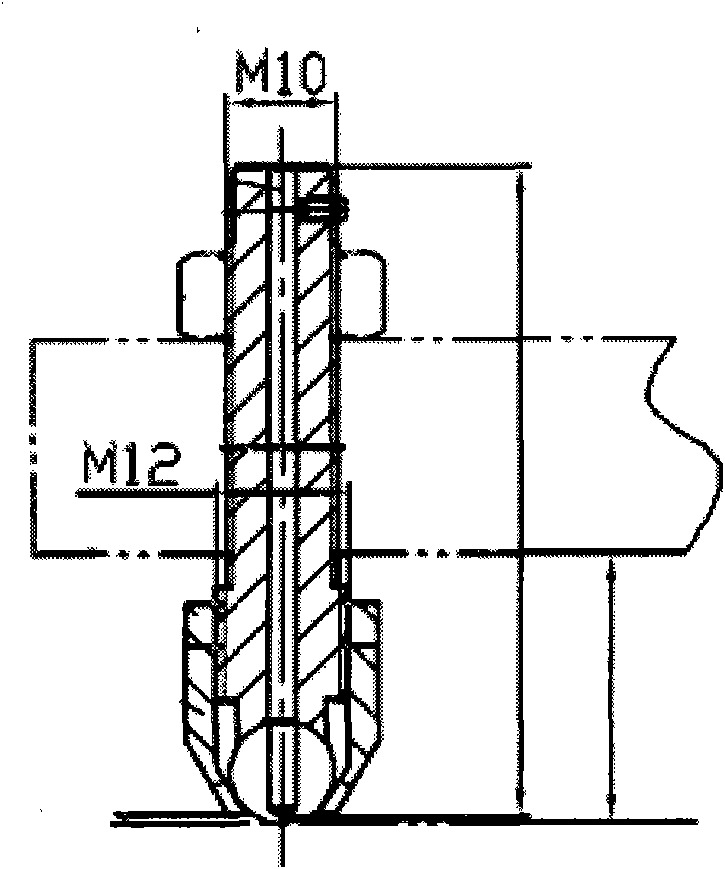

Three-phase connector for electric vehicle drivetrain

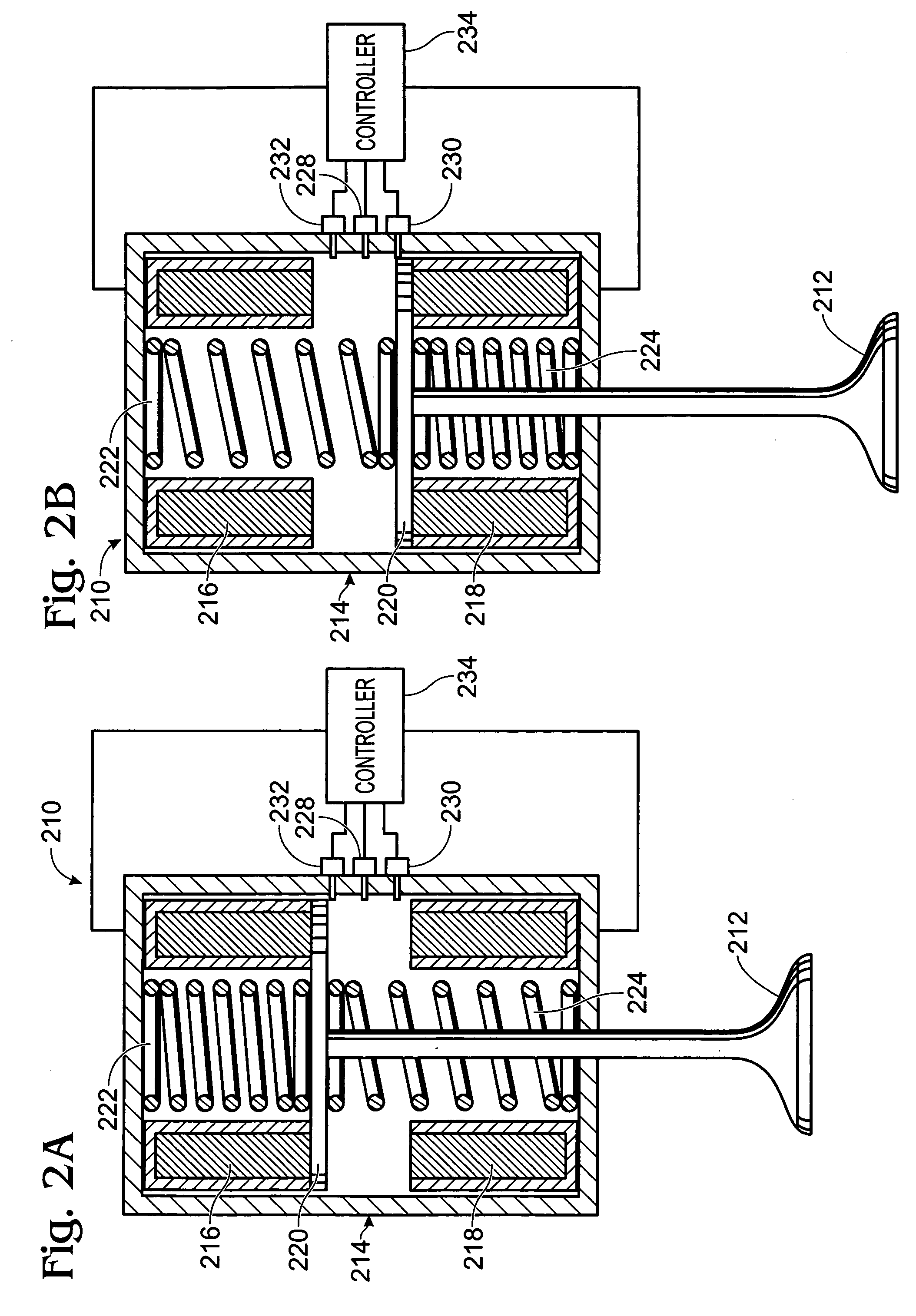

InactiveUS6890218B2Accurate isolationLow costElectric discharge tubesCoupling contact membersDrivetrainEngineering

A three-phase connector carries all three phases in one connector and keeps the phases properly isolated from each other and the motor case. The three-phase connector has metal connector components that are spaced from one another and supported in a nylon over molding covering each of the connector components, except for upper and lower exposed ends of the connector components, which are each drilled and tapped to receive bolts. First and second connector components extend above and below a flange of the three-phase connector with their respective exposed upper and lower ends offset in different planes than the exposed upper and lower ends of the third connector component.

Owner:SIEMENS VDO AUTOMOTIVE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com