Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

84results about How to "Improved shift quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

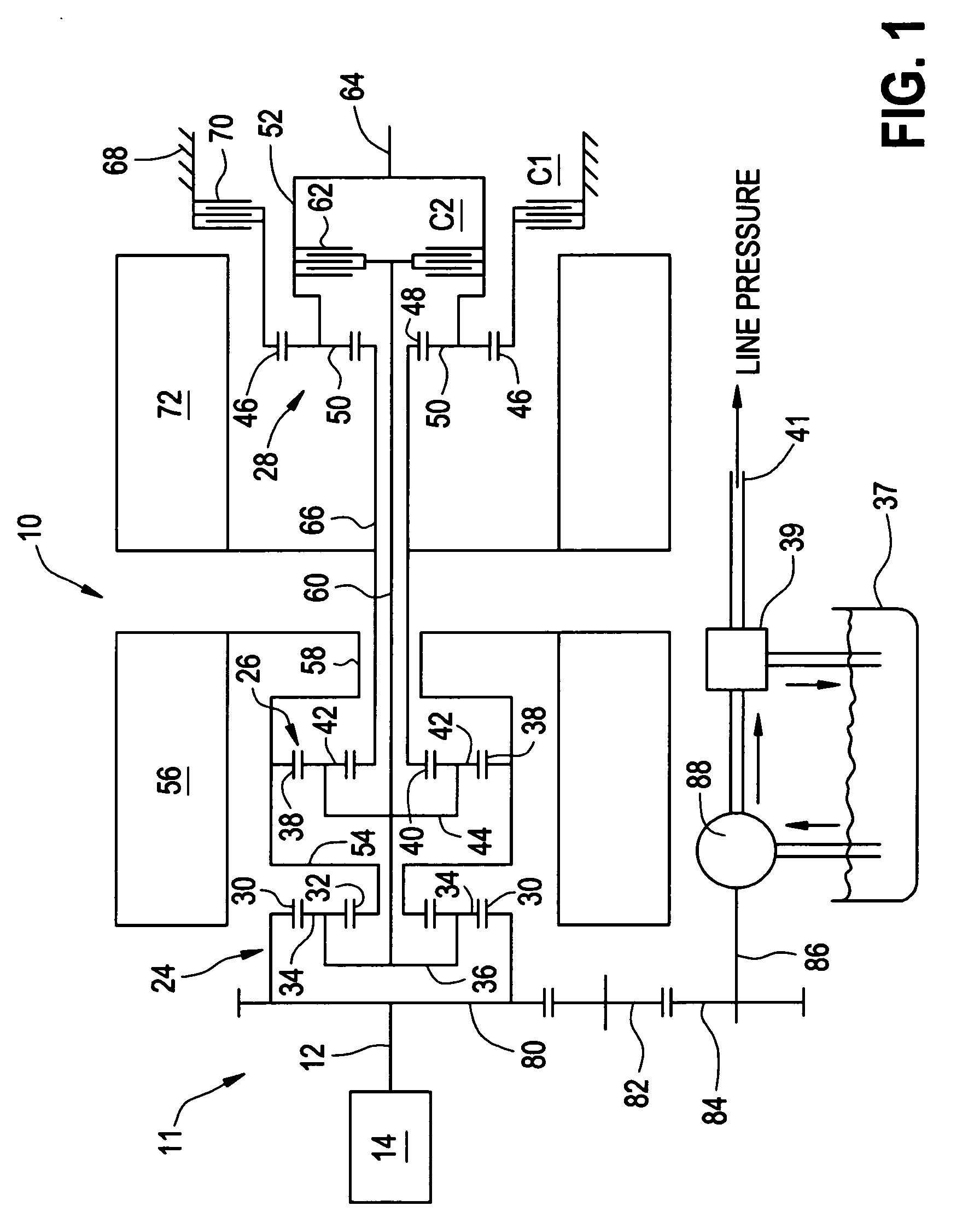

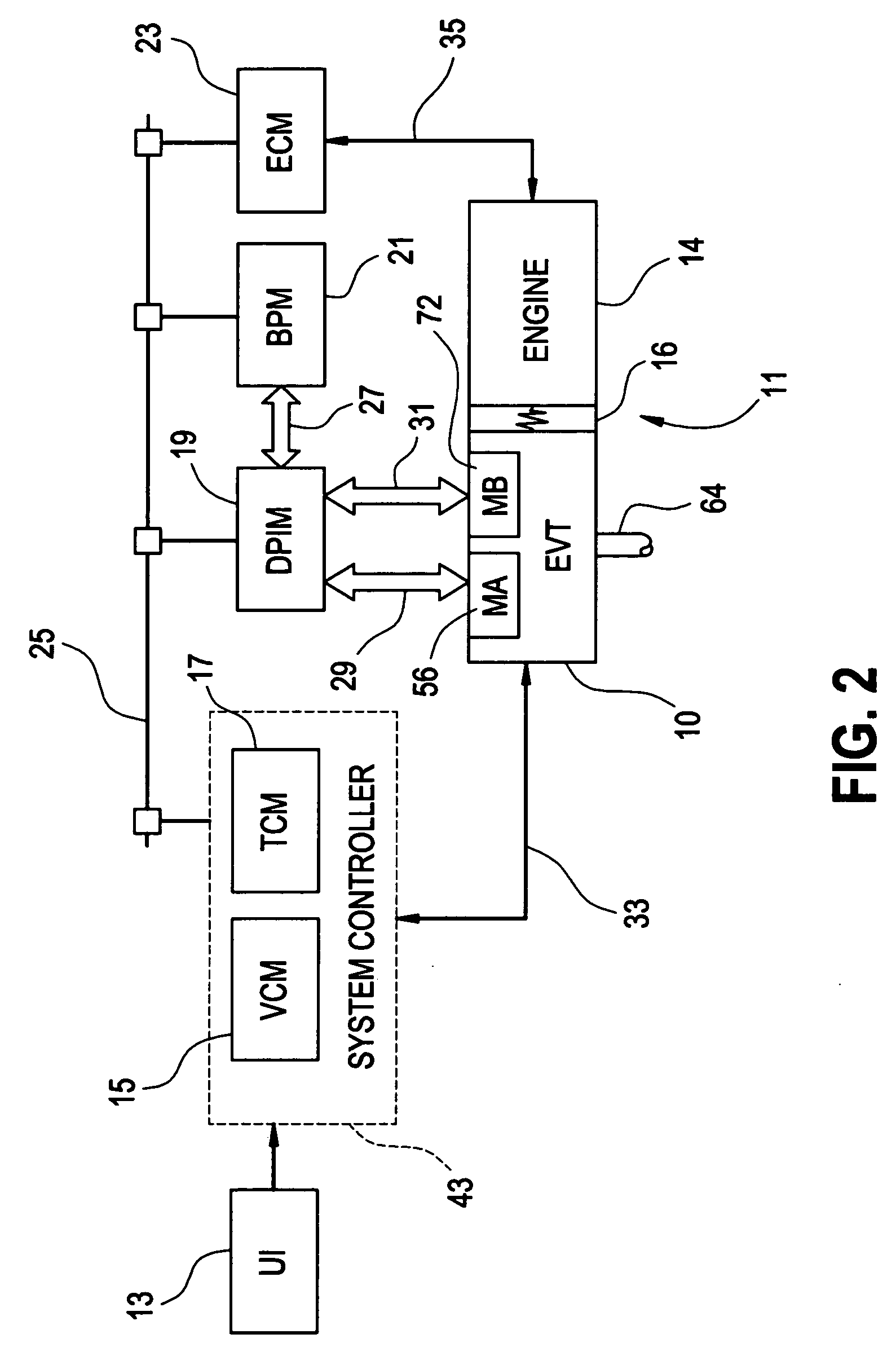

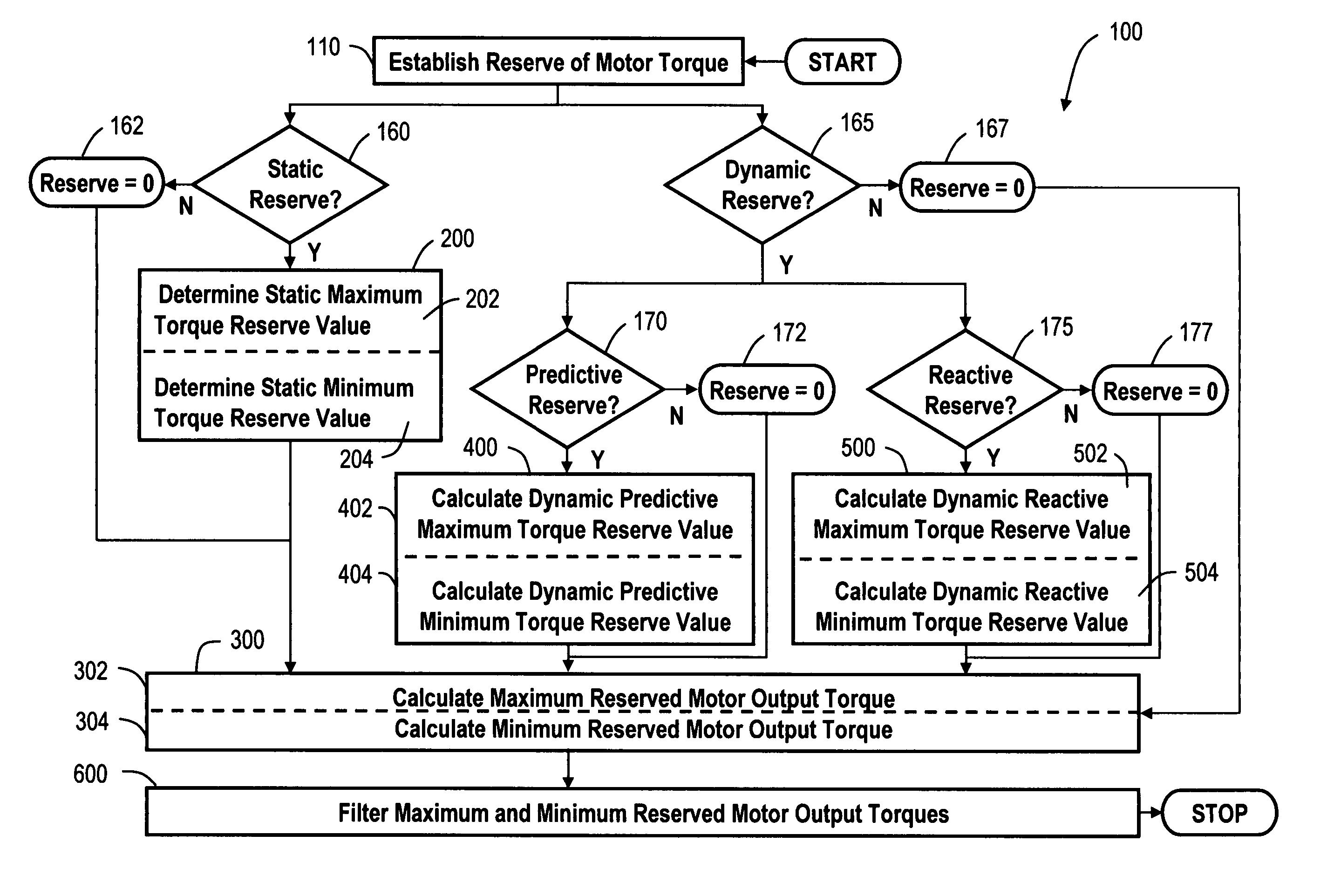

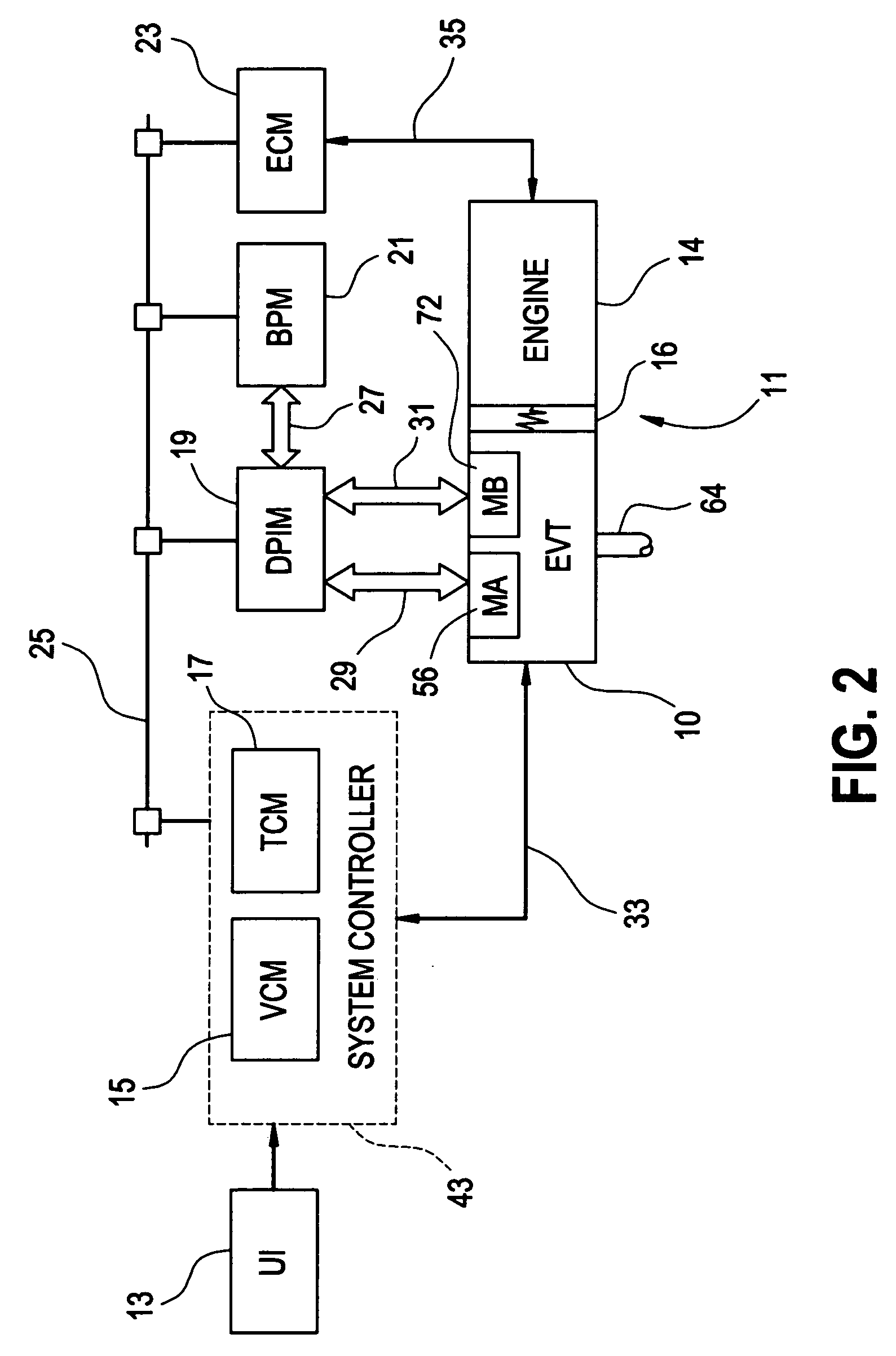

Method of providing electric motor torque reserve in a hybrid electric vehicle

ActiveUS20050255964A1Improve control robustnessImproved shift qualityHybrid vehiclesDigital data processing detailsDrivetrainBattery electric vehicle

A method of operating a vehicle powertrain system comprising an electric motor and transmission where the electric motor is operably and selectively coupled to the transmission and adapted to provide an output torque contribution thereto, and the electric motor has a predetermined maximum motor output torque and a predetermined minimum motor output torque which are used to determine a range of permissible control points for at least one transmission control parameter. The method includes establishing a motor torque reserve by performing at least one of decreasing the predetermined maximum motor output torque to a maximum reserved motor output torque and increasing the minimum motor output torque to a minimum reserved motor output torque, wherein the maximum reserved motor output torque and the minimum reserved motor output torque are used in place of the predetermined maximum motor output torque and the predetermined minimum motor output torque, respectively, to determine the range of permissible control points for the at least one transmission control parameter. The motor torque reserve may include a static motor torque reserve, a dynamic motor torque reserve, or a combination of both static and dynamic torque reserves. The dynamic torque reserve may include a predictive dynamic reserve, a reactive dynamic reserve, or a combination of a predictive reserve and a reactive reserve or reserves.

Owner:GM GLOBAL TECH OPERATIONS LLC

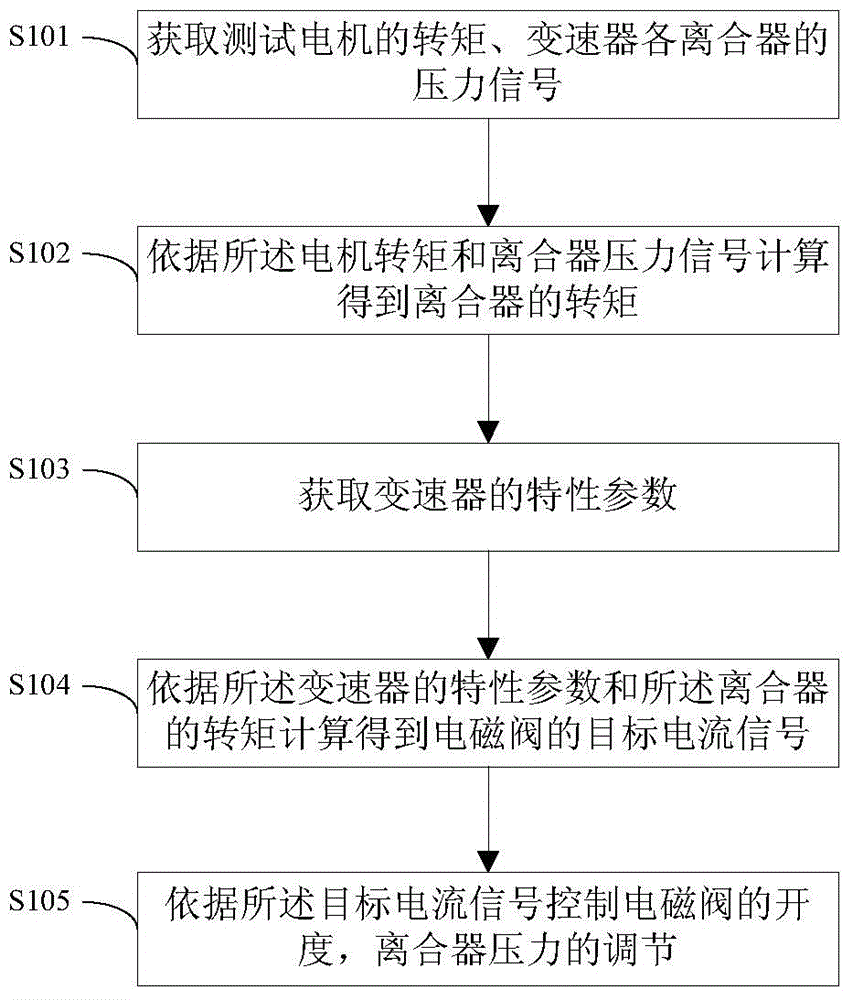

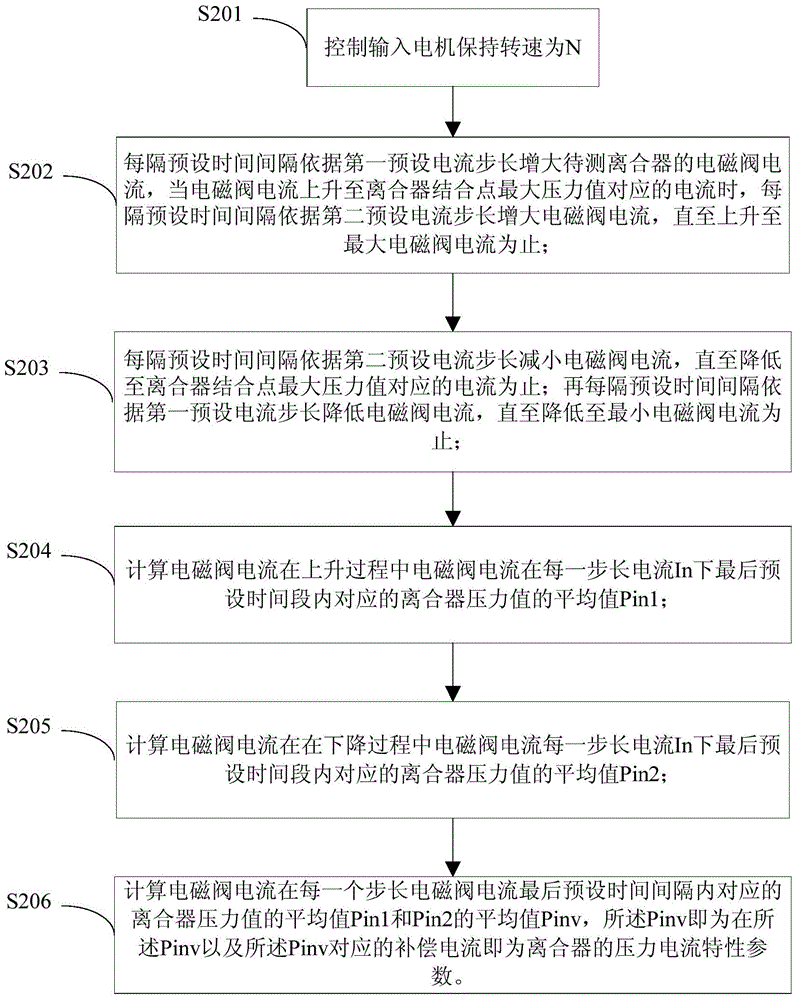

Testing method and system of speed changer

ActiveCN104316316AHigh control precisionImproved shift qualityMachine gearing/transmission testingQuality processSolenoid valve

The application discloses a testing method and system of a speed changer. The method is characterized in that an input torque of a testing motor and a speed changer structure parameter are obtained; a torque of a clutch is obtained by calculated according to the input torque of the testing motor and the speed changer structure parameter; a pressure signal of the clutch is obtained according to a pressure sensor at a pressure measuring port of the speed changer and a control current signal of the speed changer is obtained based on CAN communication, and a torque-pressure characteristic parameter, a pressure current characteristic parameter, and an oil charge characteristic parameter of the speed changer are obtained by calculation based on the signals; calculation is carried out to obtain a target current signal of a solenoid valve according to the characteristic parameters of the speed changer and the control torque of the clutch; and the opening degree of the solenoid valve is controlled based on the target current signal. Therefore, the clutch pressure is adjusted, thereby achieving an objective of reduction of a workload during the shifting quality improvement process.

Owner:SHENGRUI TRANSMISSION

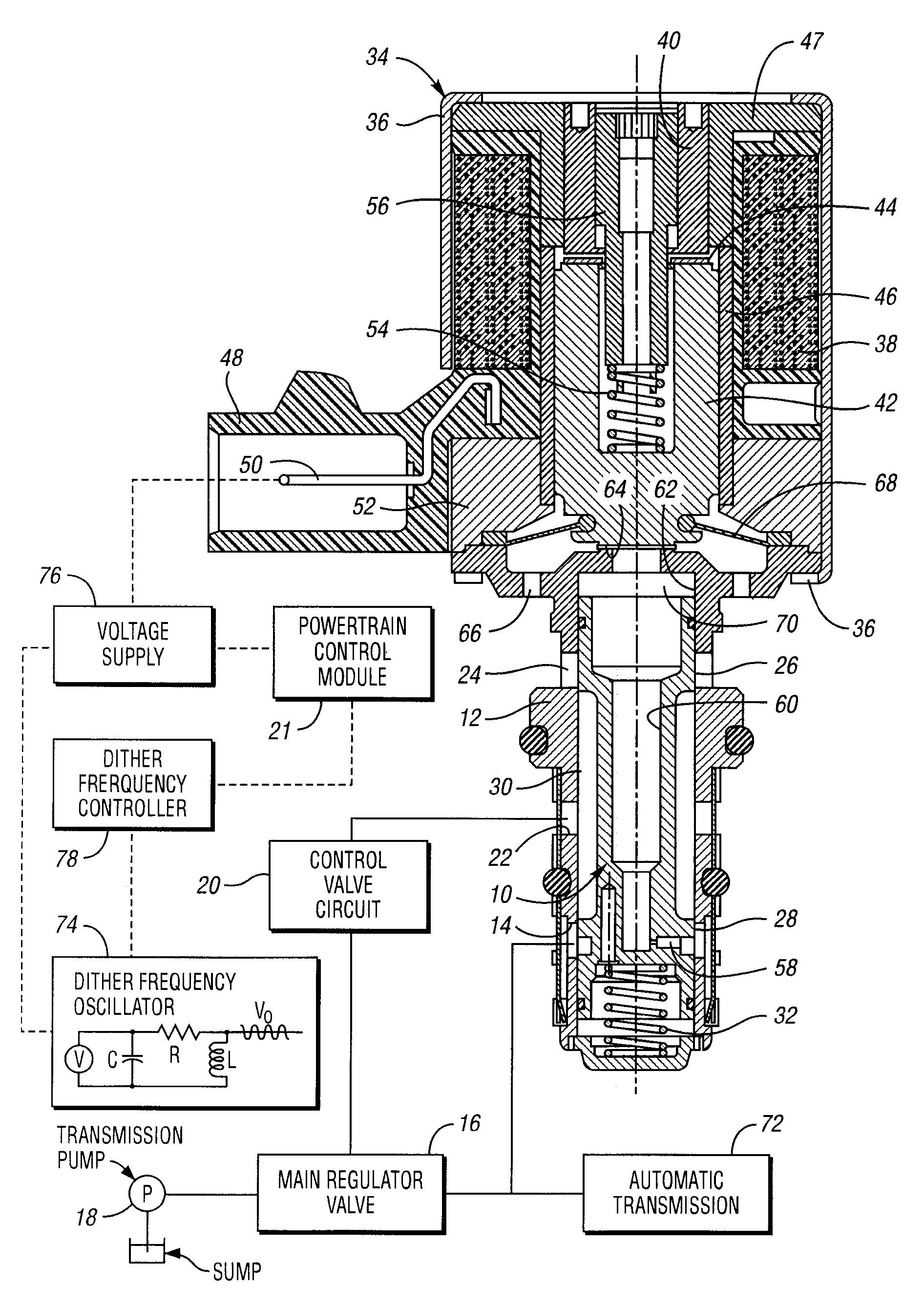

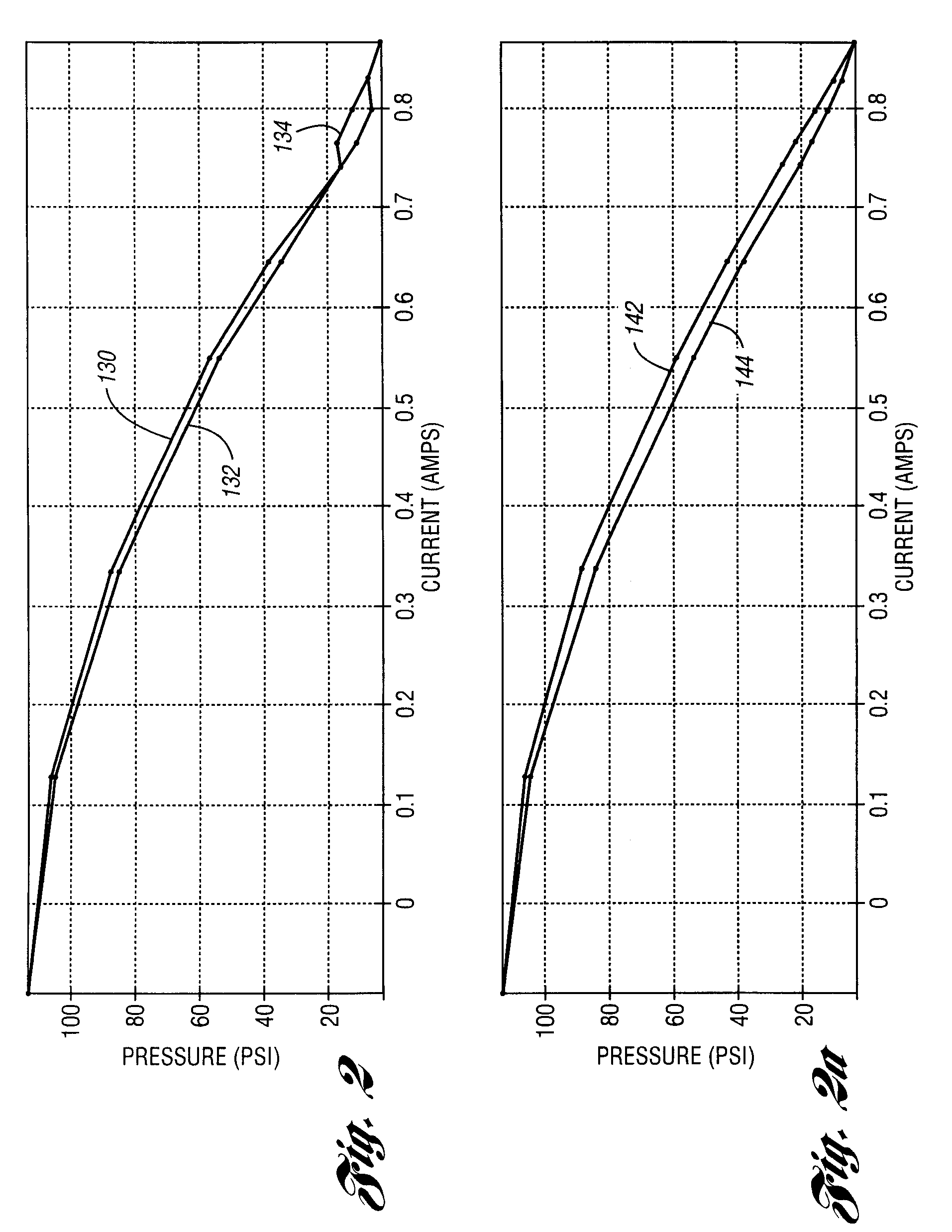

Control method and controller for a solenoid-operated electrohydraulic control valve

ActiveUS7192005B2Reduce valve sticking and an accompanying undesirable hysteresisReduced internal wearOperating means/releasing devices for valvesServomotor componentsInstabilityControl valves

A method and system for controlling a solenoid-operated pressure regulator valve to achieve high compliance with respect to a commanded current in accordance with a precalibrated transfer function. A dither frequency imposed on applied current is changed at precalibrated regulated pressure values to avoid dynamic instability.

Owner:FORD GLOBAL TECH LLC

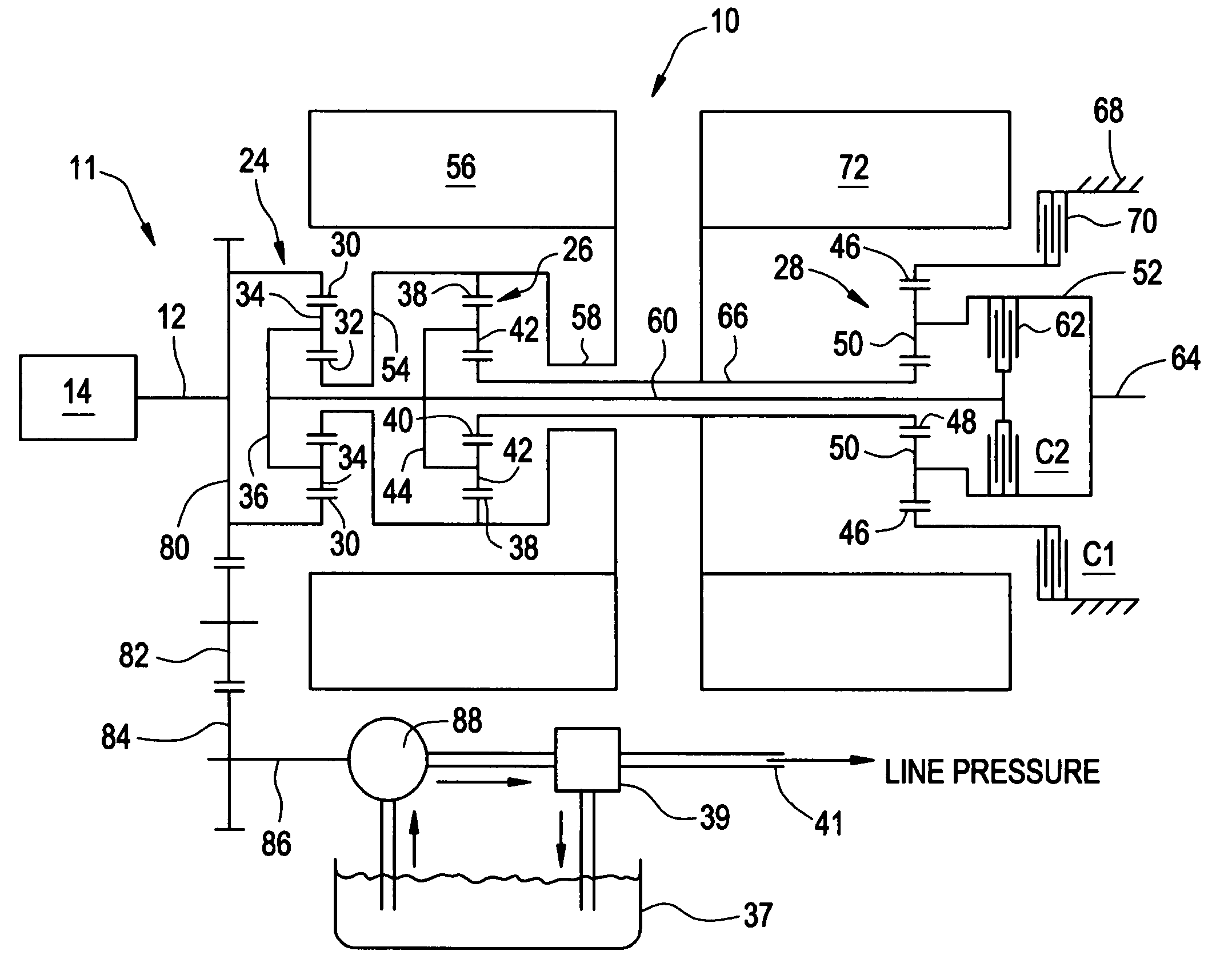

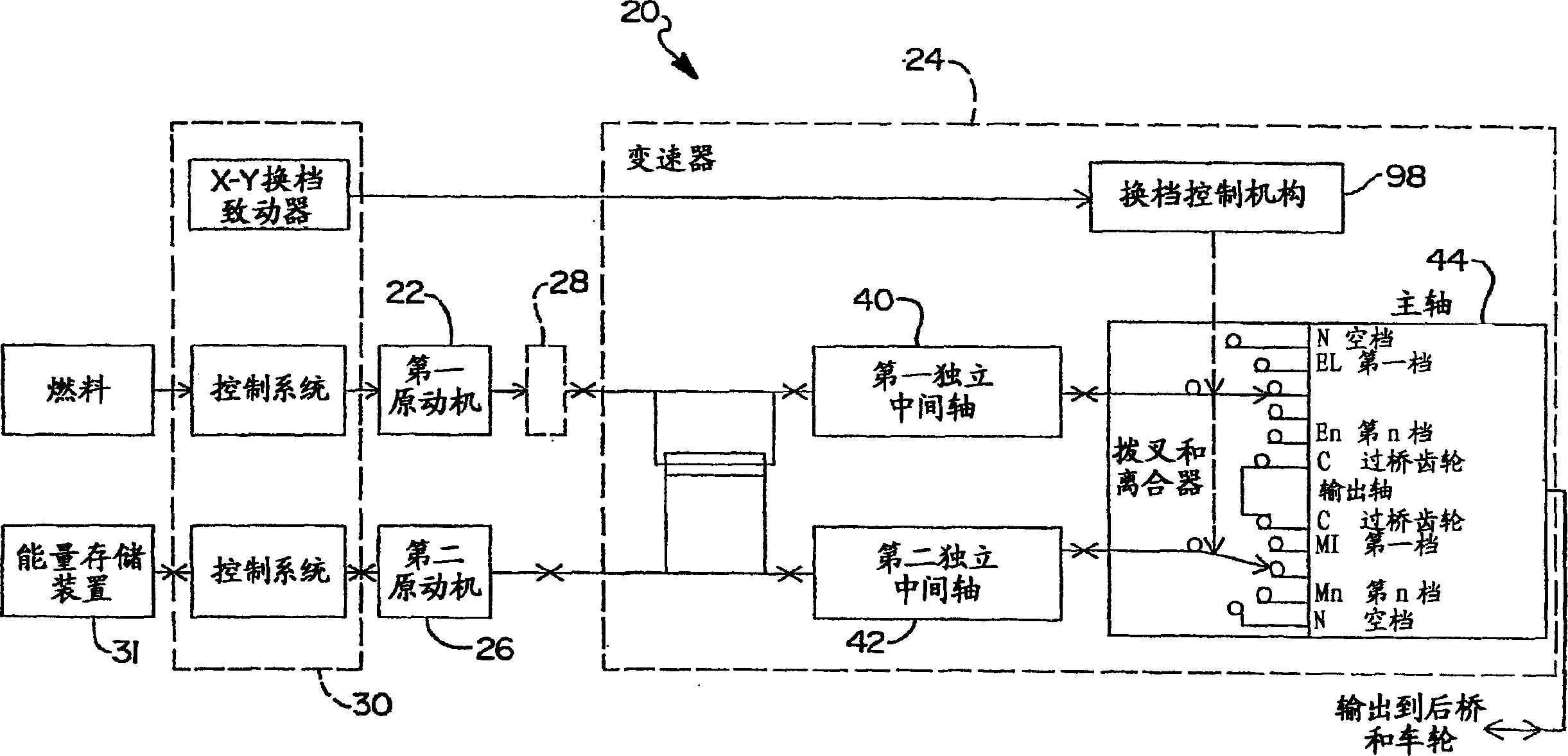

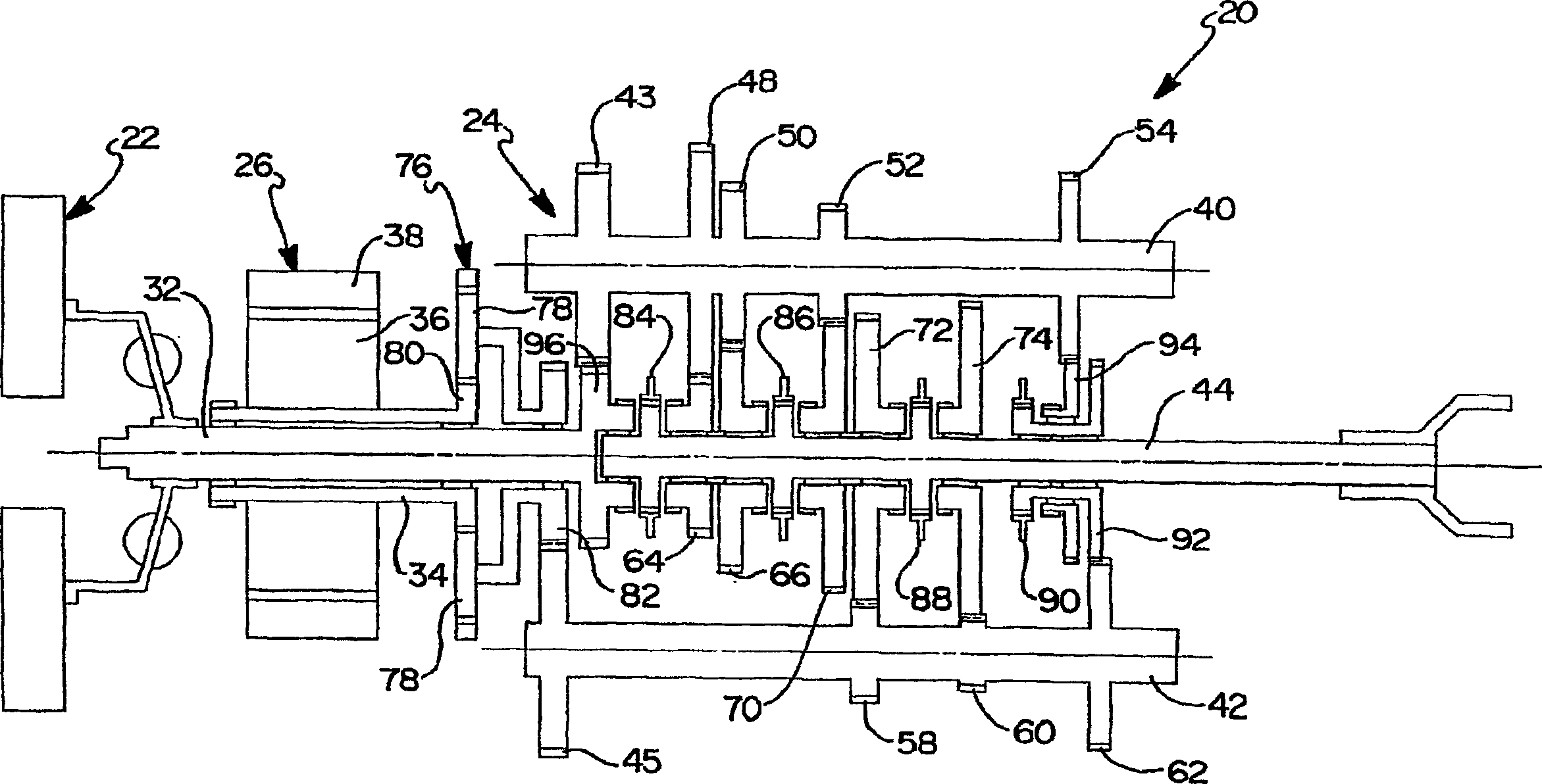

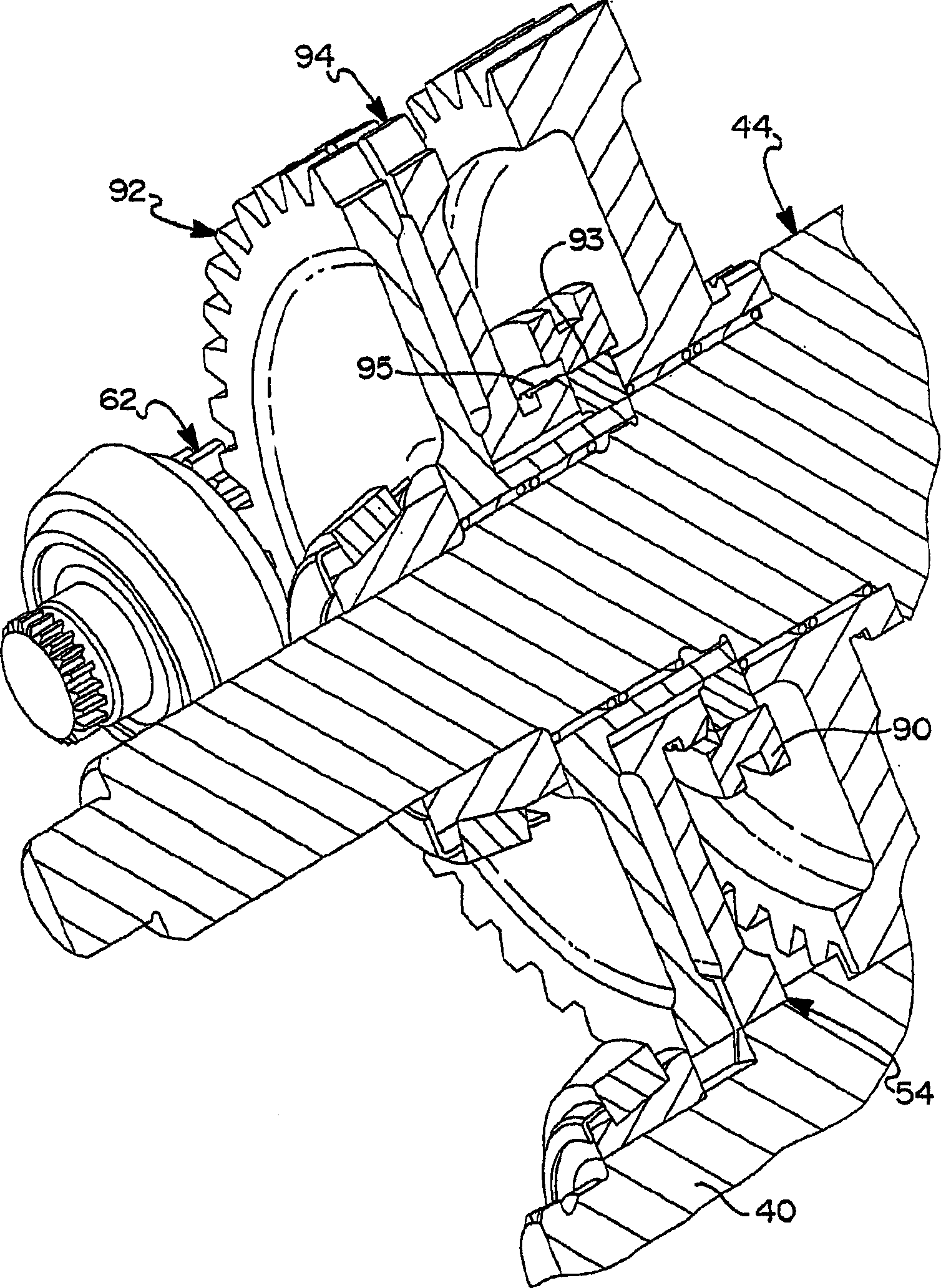

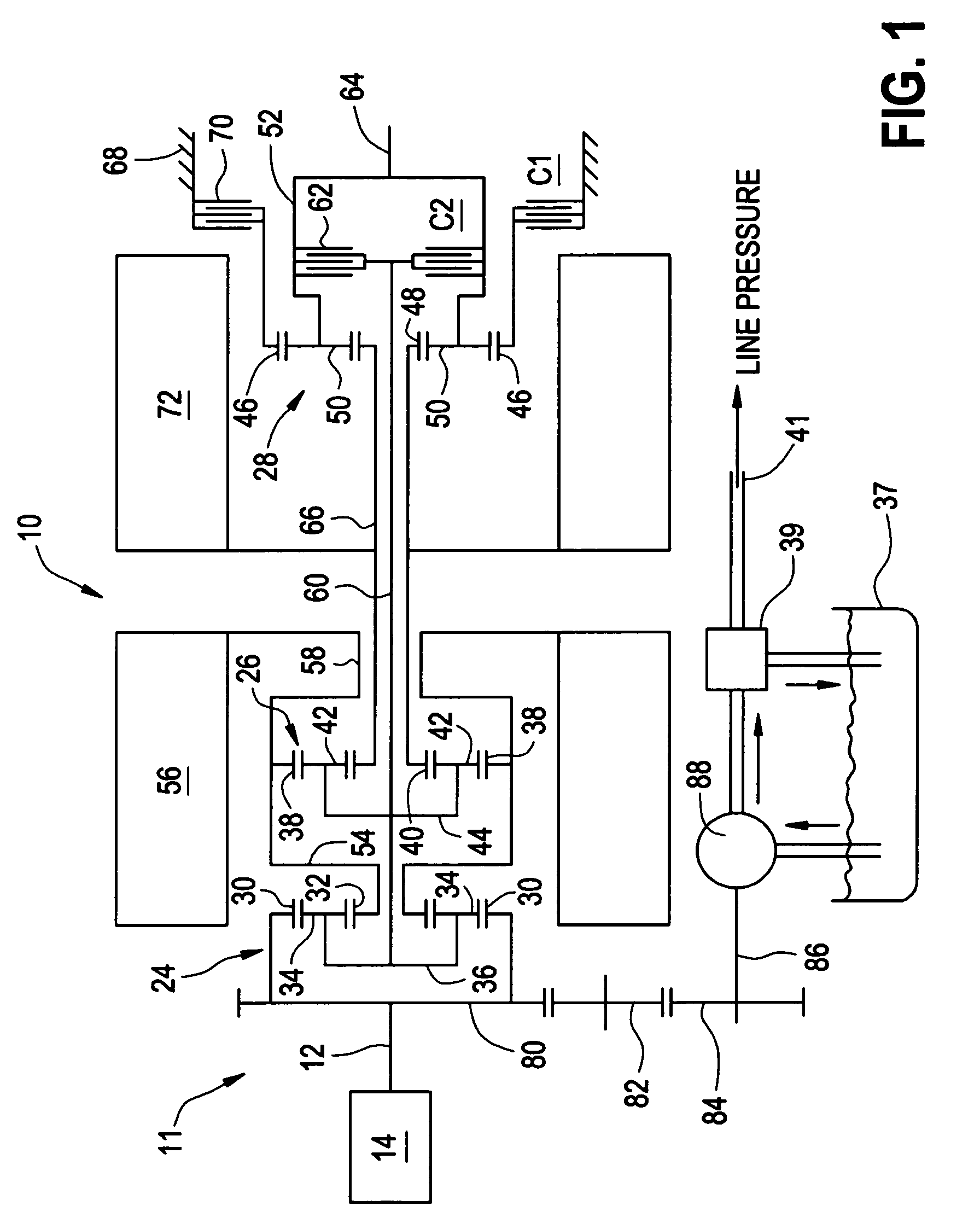

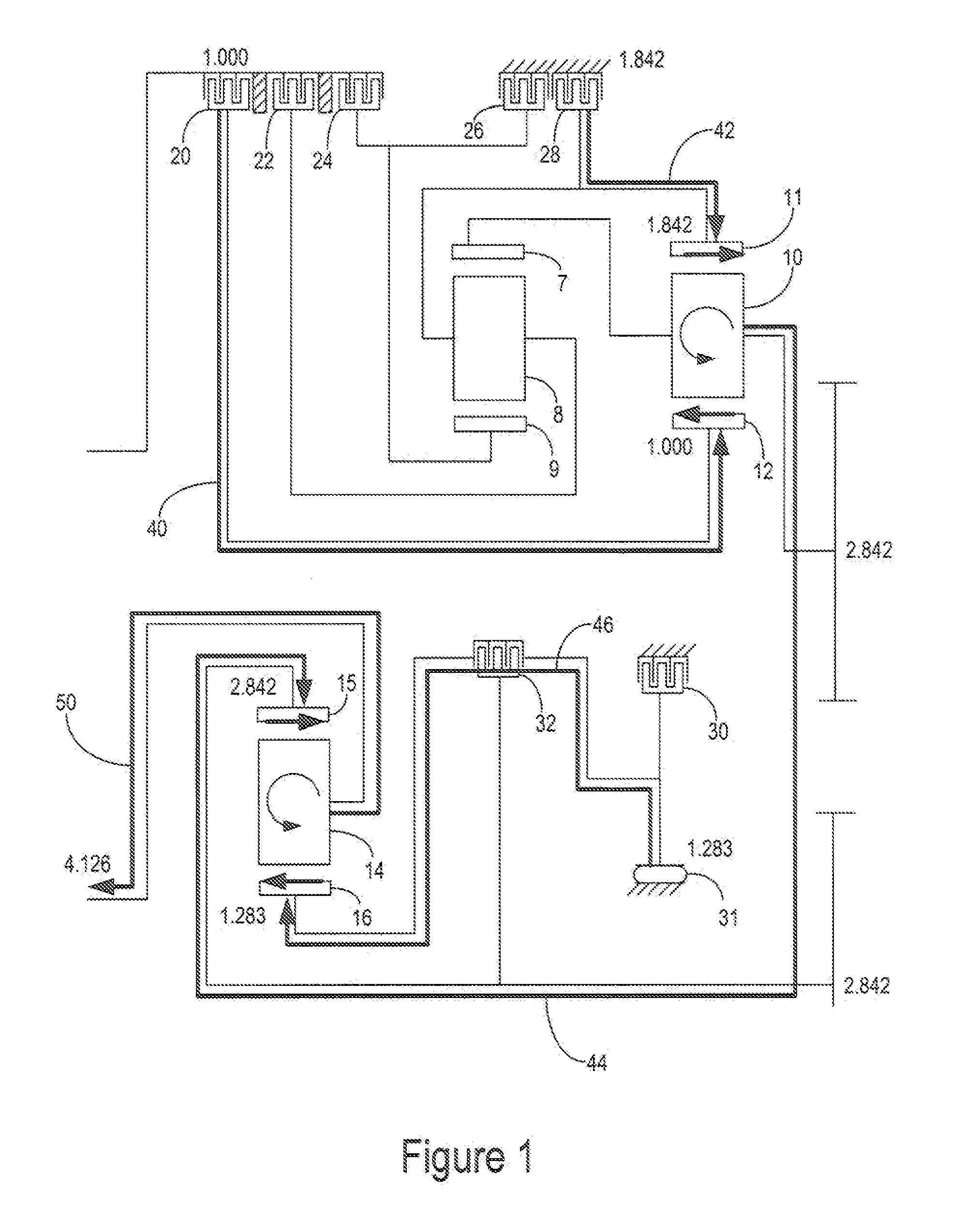

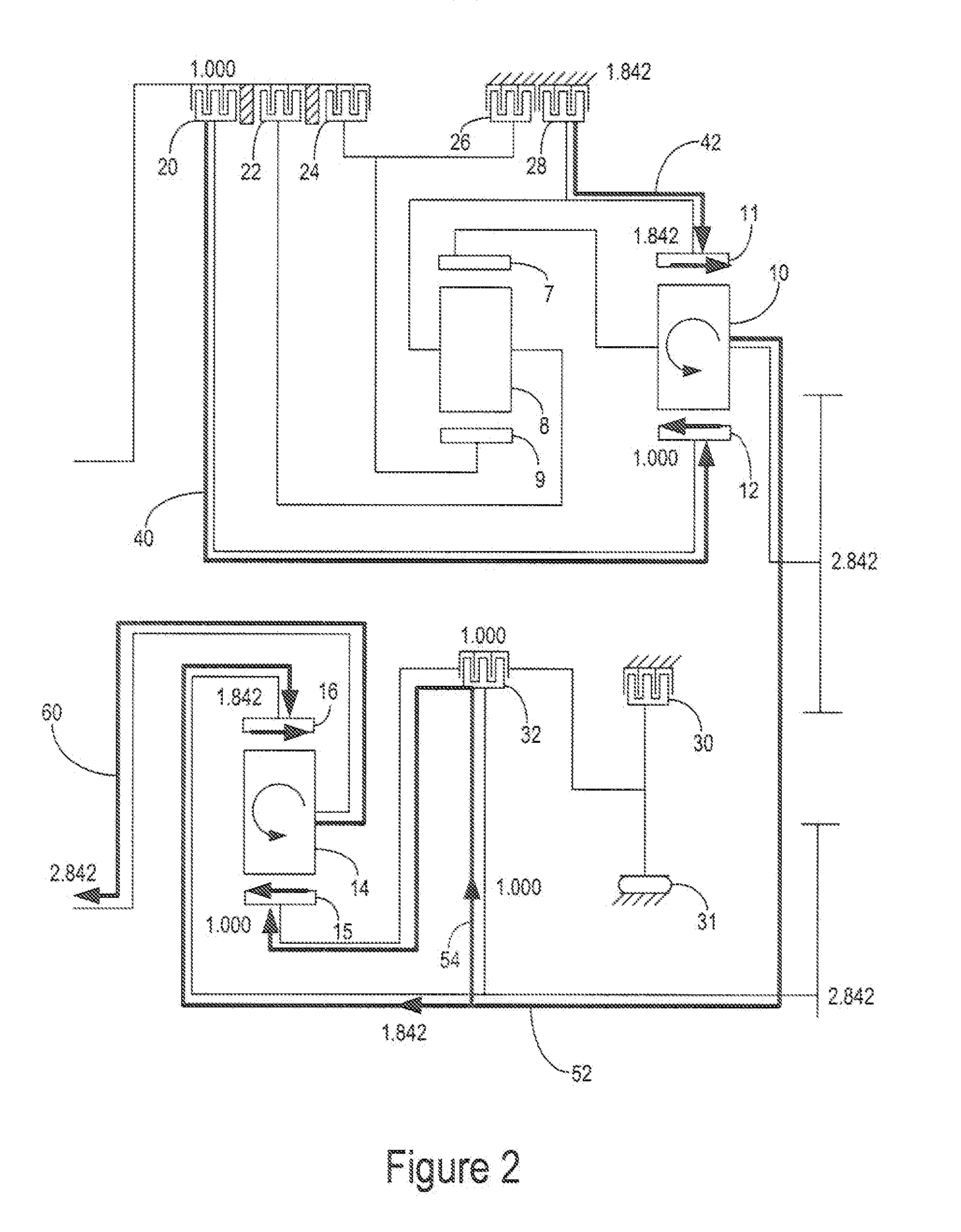

Hybrid powertrain system

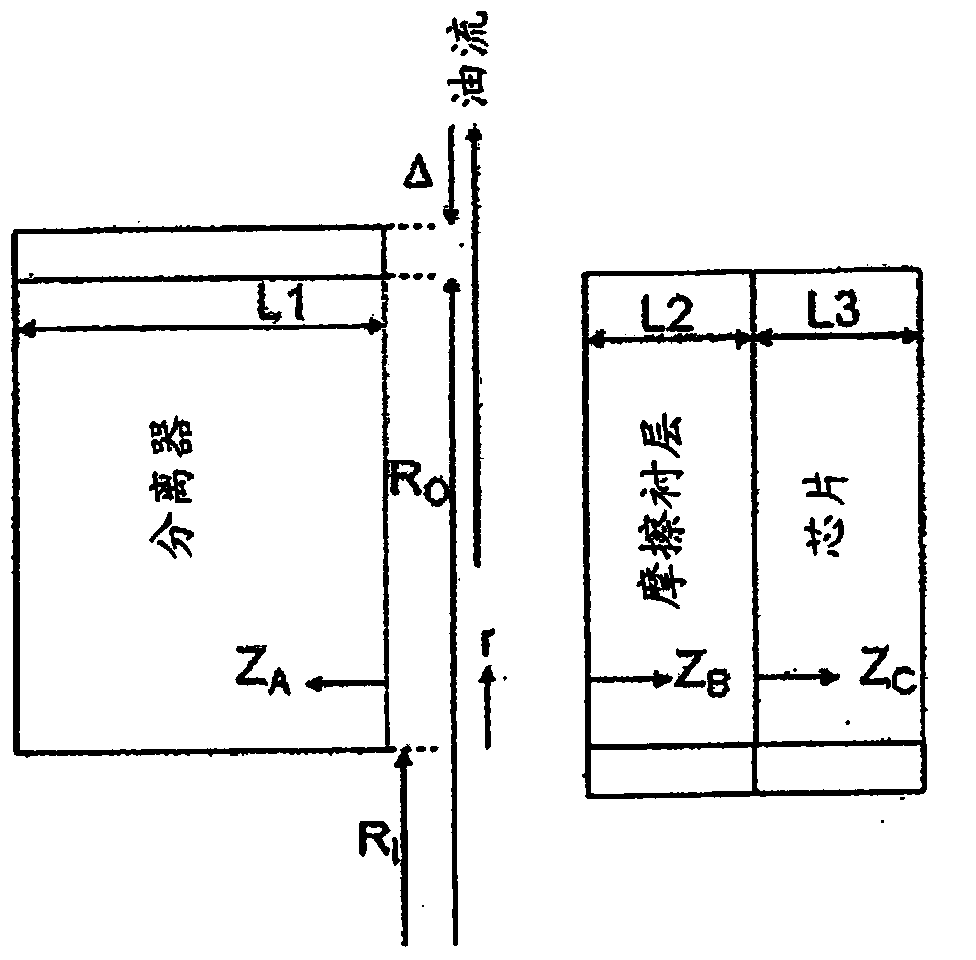

InactiveCN1656330AEnable automatic power shiftImproved shift qualityToothed gearingsGas pressure propulsion mountingControl theoryHybrid powertrain

Owner:EATON CORP

Method for determining wet clutch temperature

ActiveCN103459876AAvoid Overheating FailuresReduce Warranty CostsClutchesVaporizationThreshold temperature

A method (500) for determining clutch temperature. The method provides an accurate real-time clutch temperature that can be used to improve shift quality and protect against failure due to clutch overheating (510). A counter is incremented (506) every time the clutch exceeds a threshold temperature (504) to track cumulative high temperature conditions. Determining the clutch temperatures (502) includes taking account of heat generation, clutch cooling by transmission oil flow from a groove when the clutch is engaged, clutch cooling by open transmission oil flow when the clutch is disengaged, oil vaporization, and heat conduction.

Owner:CHRYSLER GROUP LLC

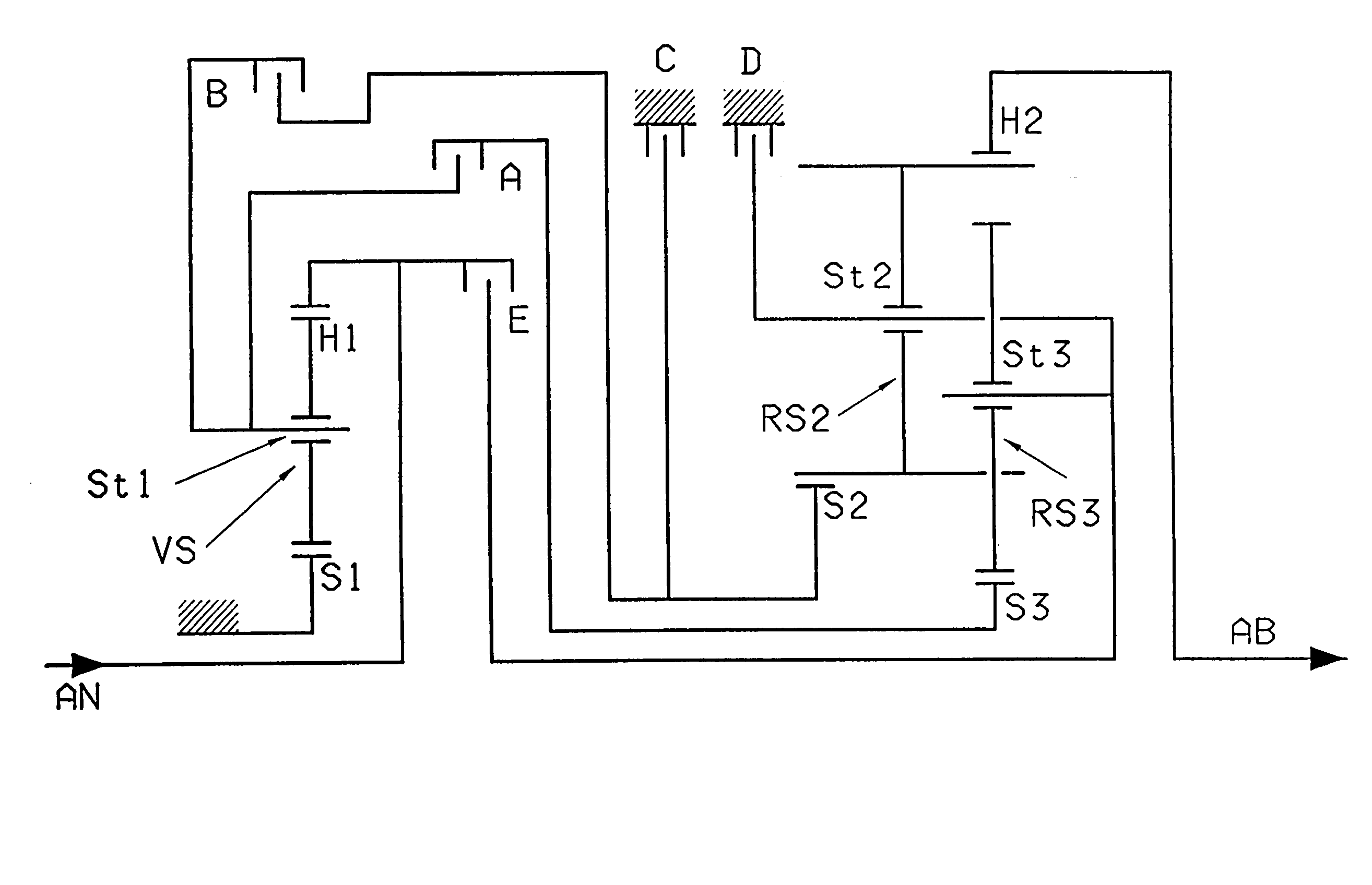

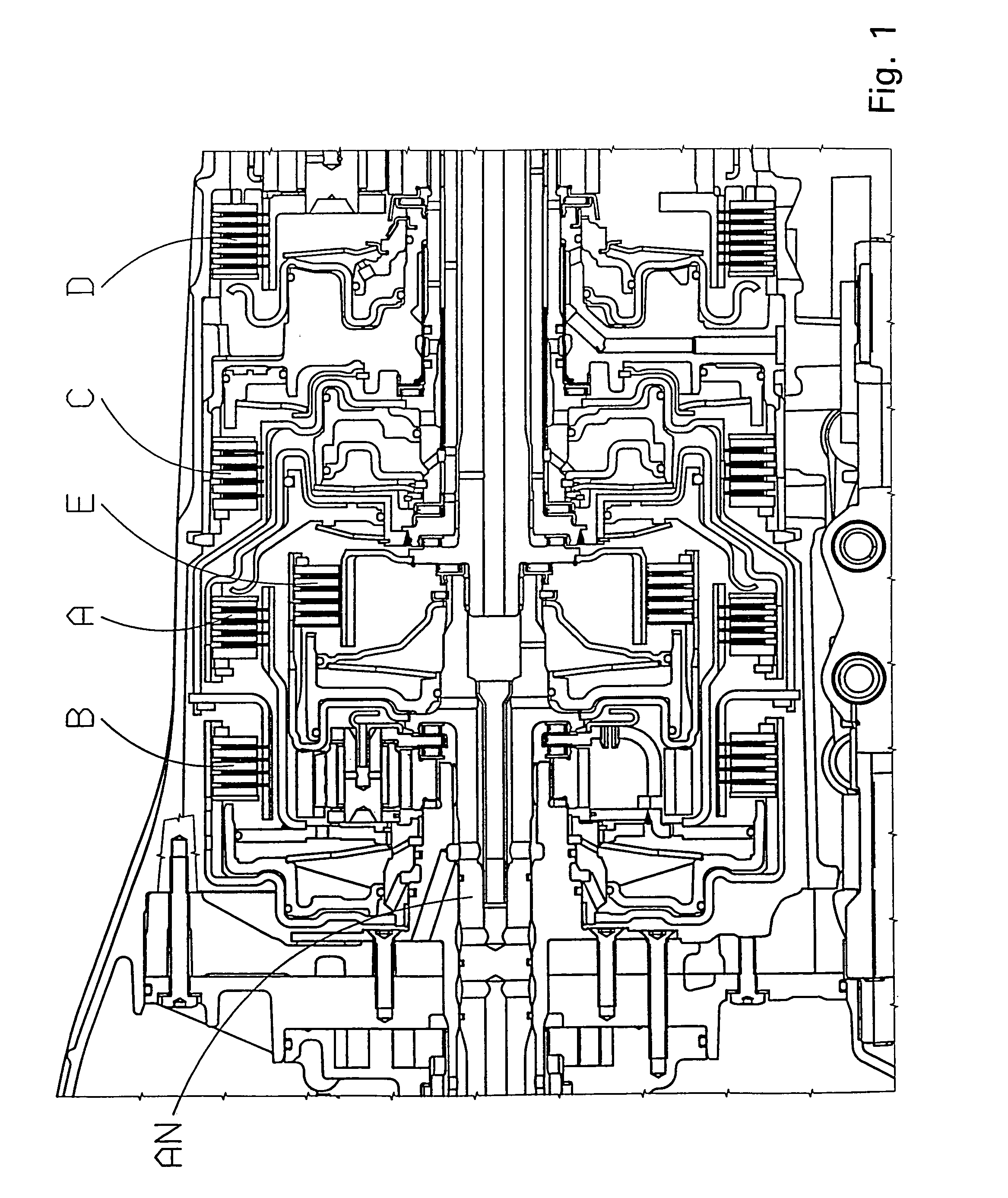

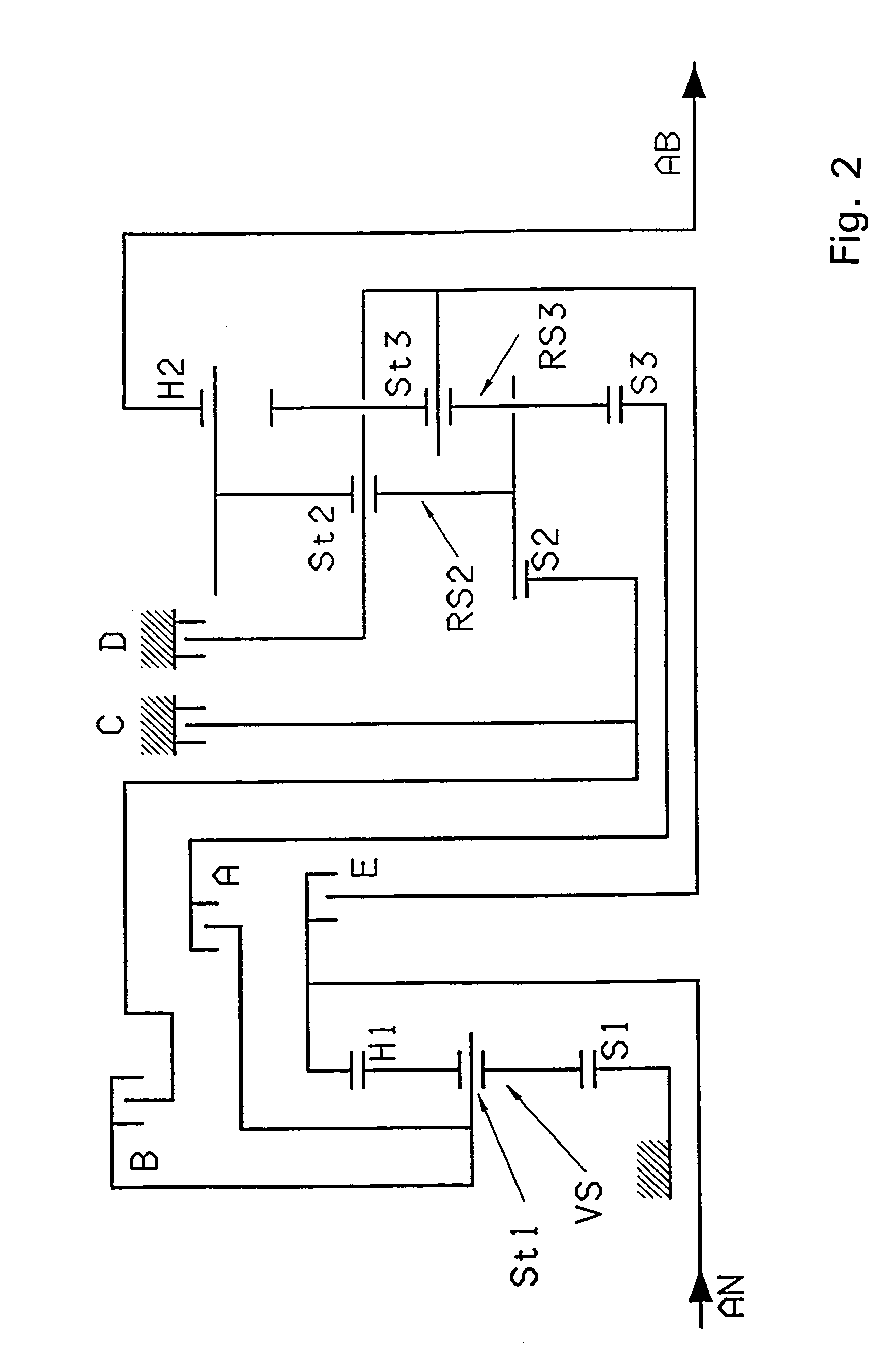

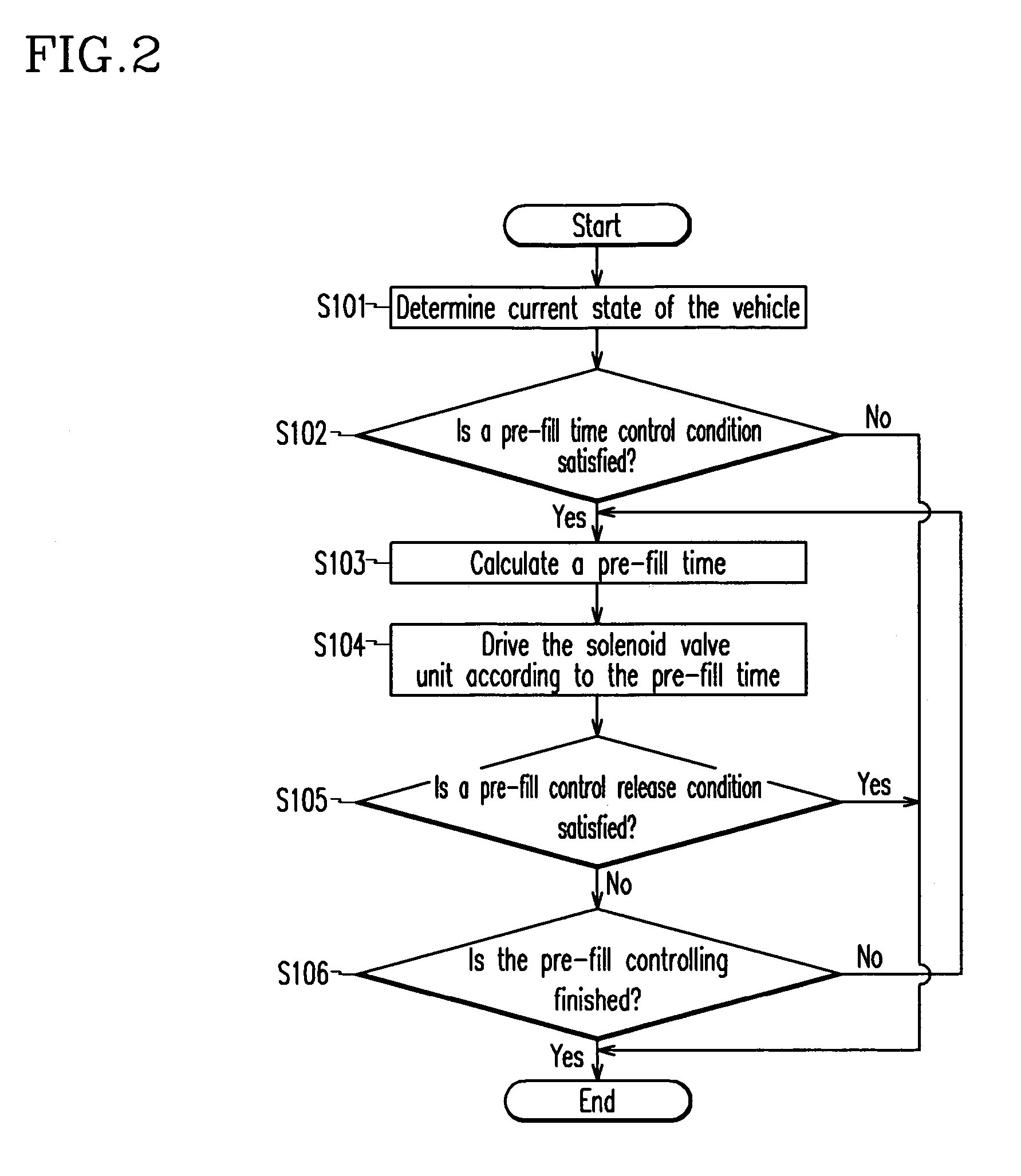

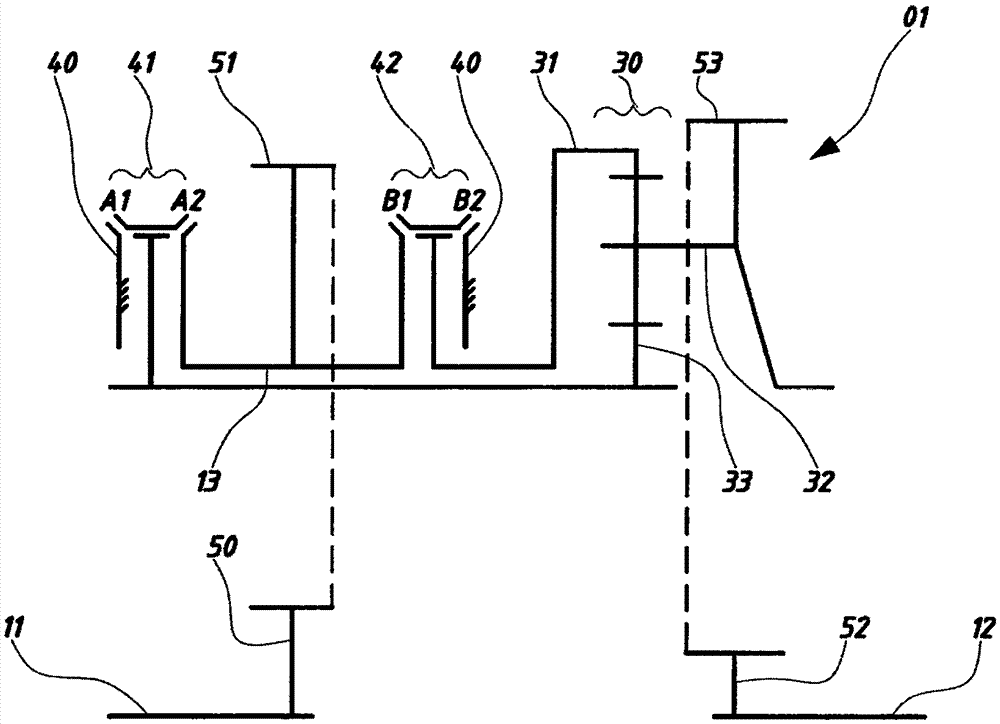

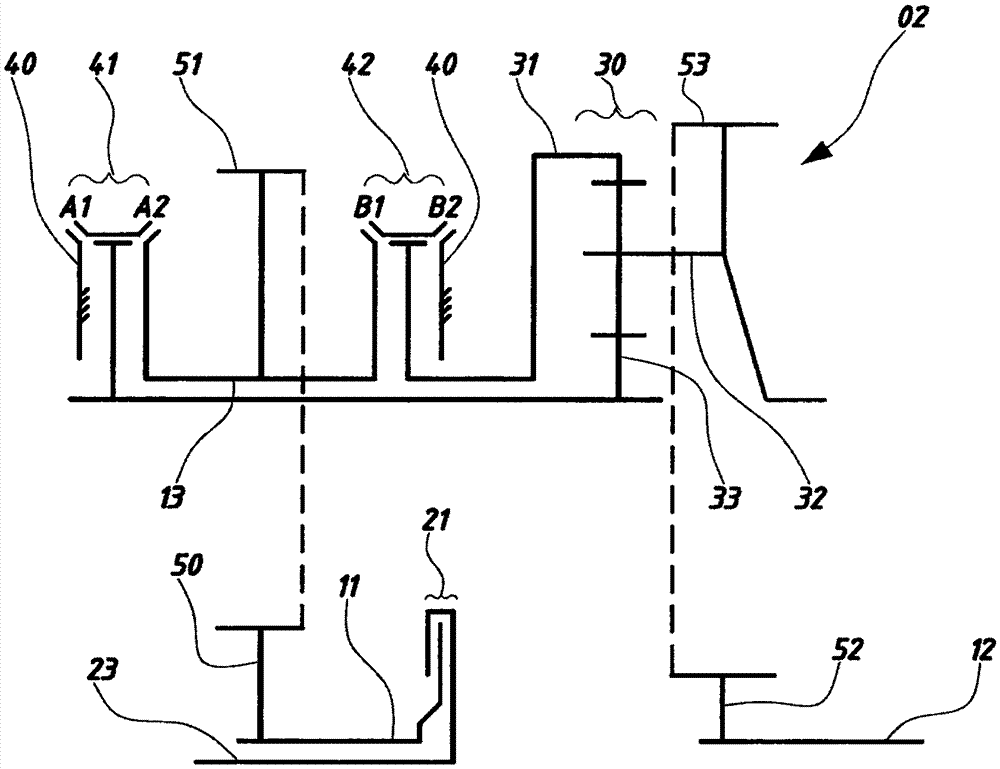

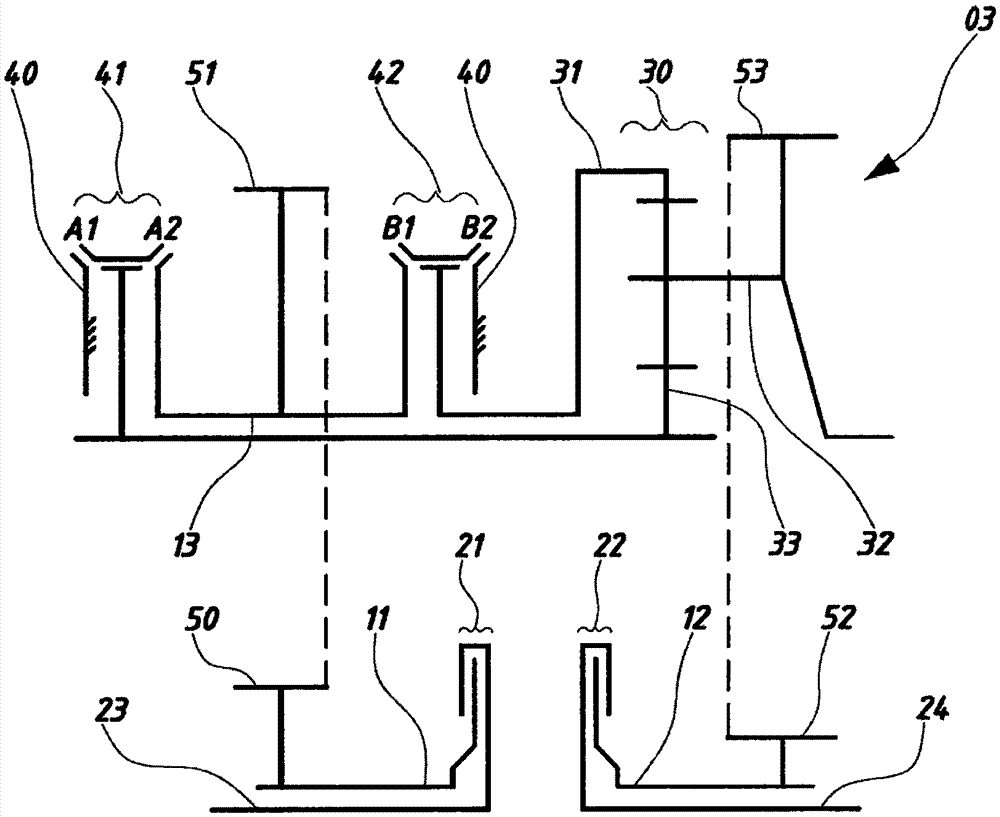

Multi-stage transmission

InactiveUS7125360B2Improved shift qualityToothed gearingsTransmission elementsCircular discDrive shaft

A multi-stage transmission comprising two planetary gear sets (RS2, RS3) and one planetary reduction gear set (VS), one first clutch (A) and one second clutch (B), one third clutch (E) and one first brake (C), one second brake (D), the external disc carrier of the clutch (B) being connected with one output element of the planetary reduction gear set (VS), the internal disc carrier of the clutch (B) leads to the internal disc carrier of the brake (C) which is connected with one element of the planetary gear set (RS2), the internal disc carrier of the clutch (A) being connected with one output element of the planetary reduction gear set (VS) and the external disc carrier of the clutch (A) with one element of the planetary gear set (RS3), the external disc carrier of the clutch (E) being connected with one input element of the planetary reduction gear set (VS) and with the drive shaft (AN), the internal disc carrier of the clutch (E) being connected respectively with one element of the planetary gear set (RS2) and of the planetary gear set (RS3), the brake (D) being connected with the planetary gear set (RS2) and the housing being connected with one supporting element of the planetary reduction gear set (VS) and the driven shaft (AB) with the planetary gear set (RS2).

Owner:ZF FRIEDRICHSHAFEN AG

Method of providing electric motor torque reserve in a hybrid electric vehicle

ActiveUS7090613B2Improve control robustnessImproved shift qualityHybrid vehiclesDigital data processing detailsDrivetrainElectric vehicle

A method of operating a vehicle powertrain system comprising an electric motor and transmission where the electric motor is operably and selectively coupled to the transmission and adapted to provide an output torque contribution thereto, and the electric motor has a predetermined maximum motor output torque and a predetermined minimum motor output torque which are used to determine a range of permissible control points for at least one transmission control parameter. The method includes establishing a motor torque reserve by performing at least one of decreasing the predetermined maximum motor output torque to a maximum reserved motor output torque and increasing the minimum motor output torque to a minimum reserved motor output torque, wherein the maximum reserved motor output torque and the minimum reserved motor output torque are used in place of the predetermined maximum motor output torque and the predetermined minimum motor output torque, respectively, to determine the range of permissible control points for the at least one transmission control parameter.

Owner:GM GLOBAL TECH OPERATIONS LLC

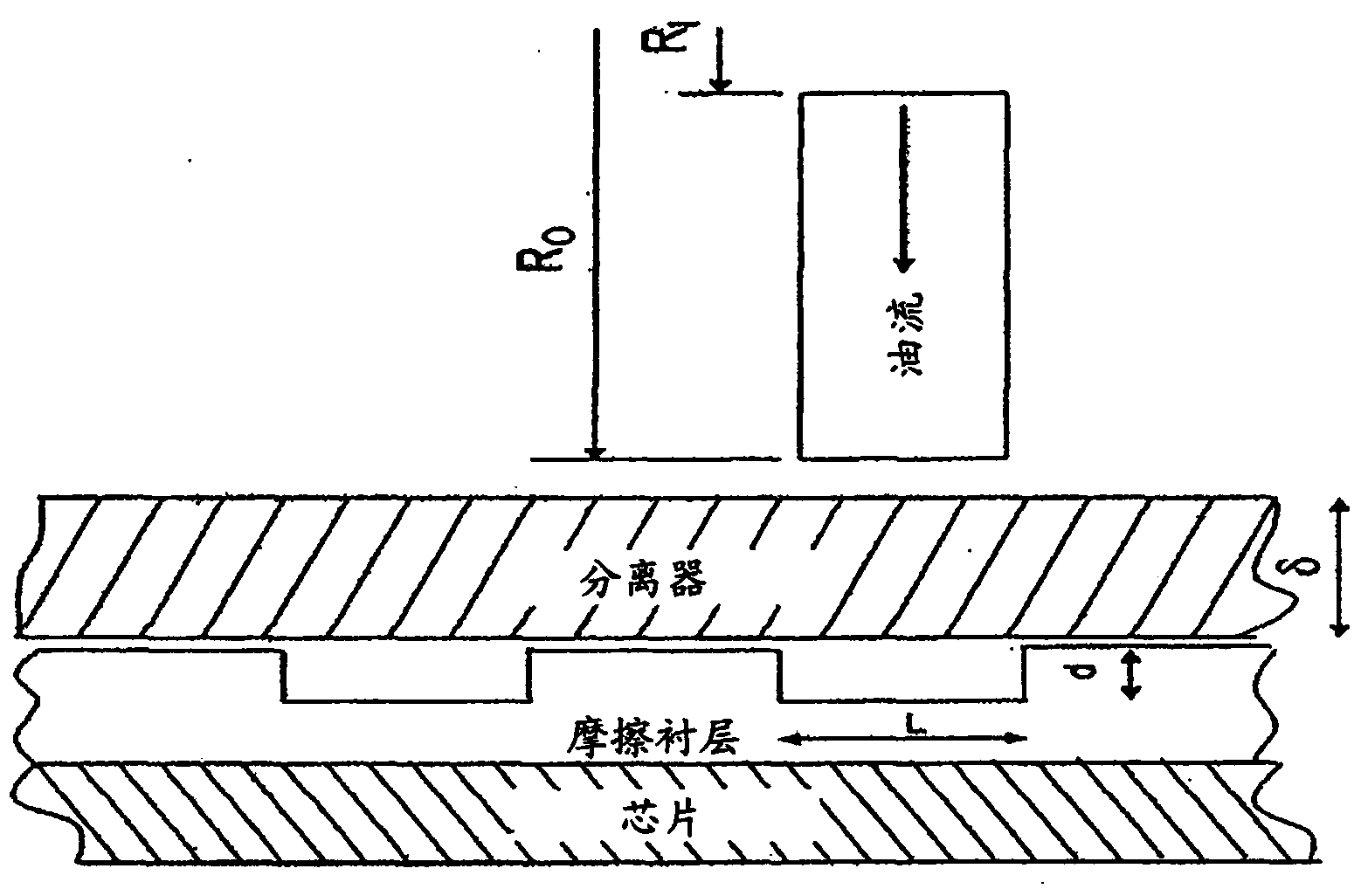

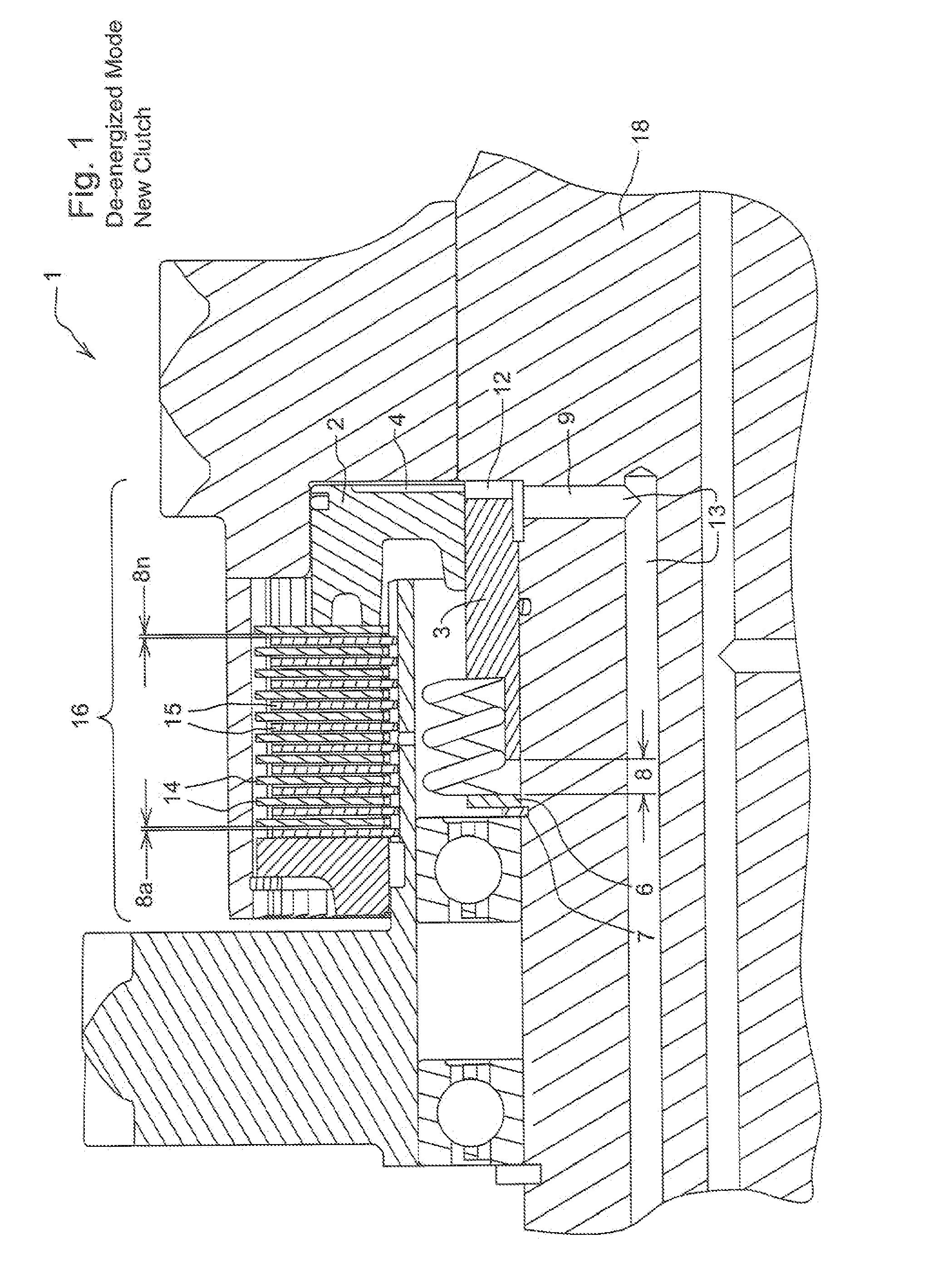

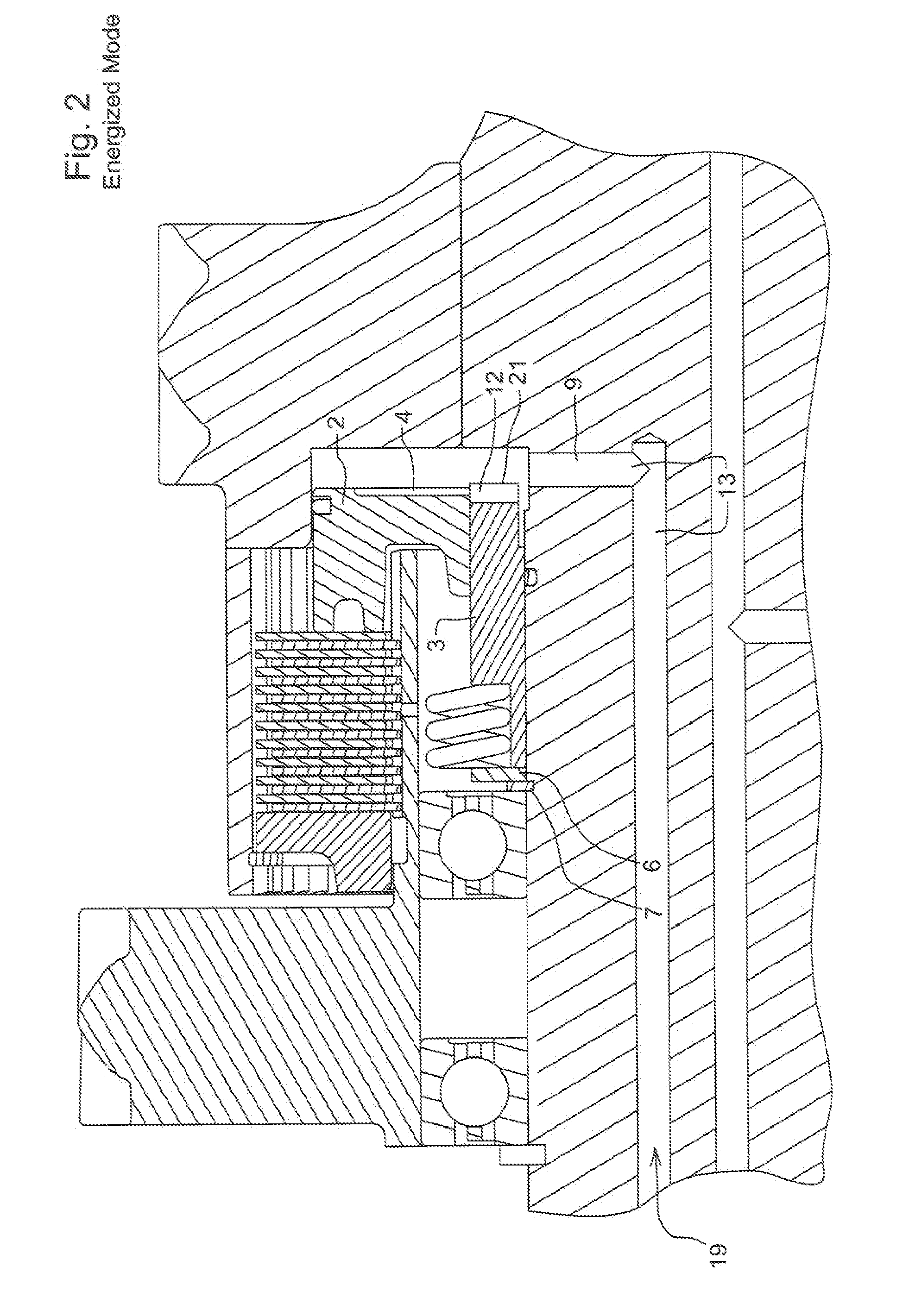

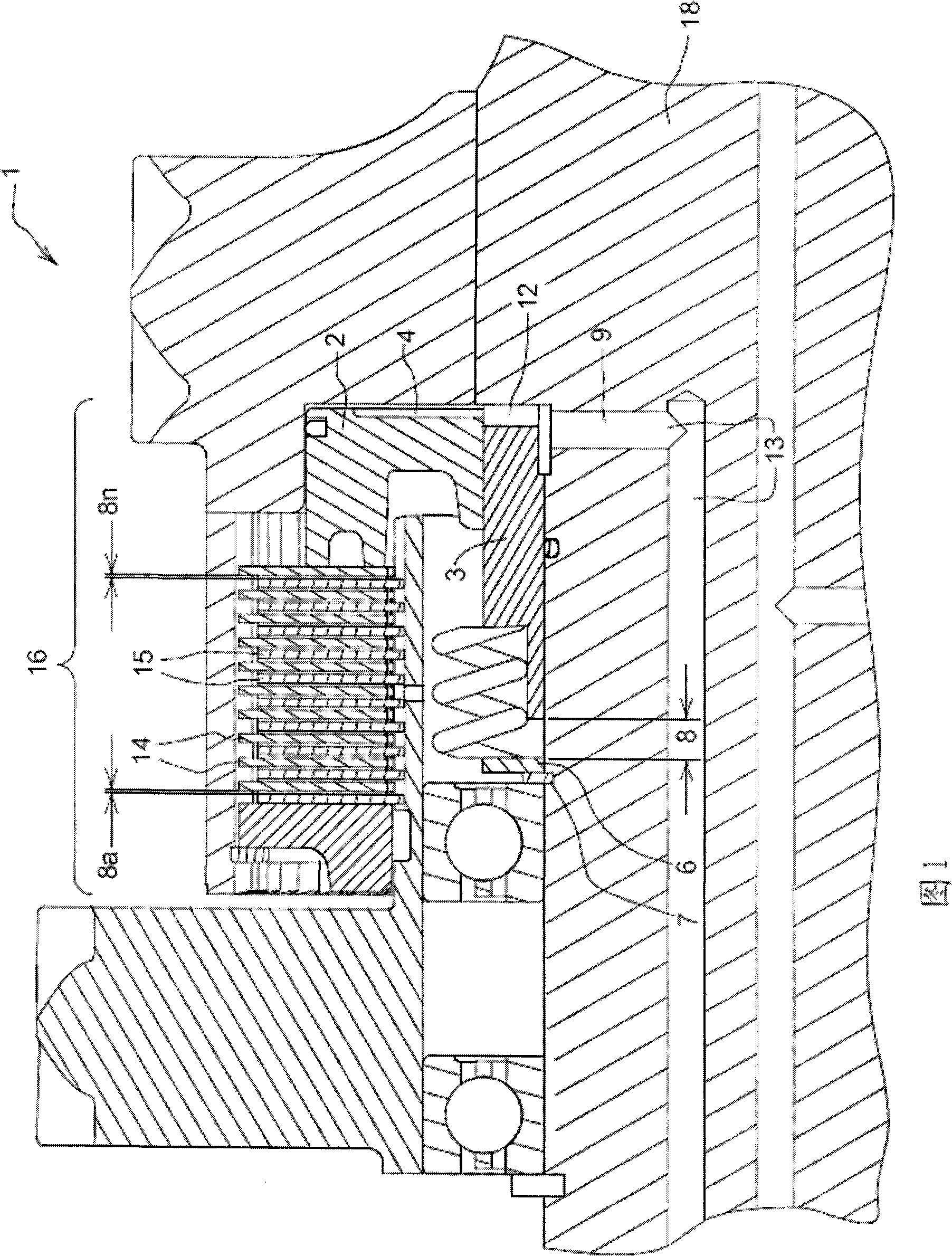

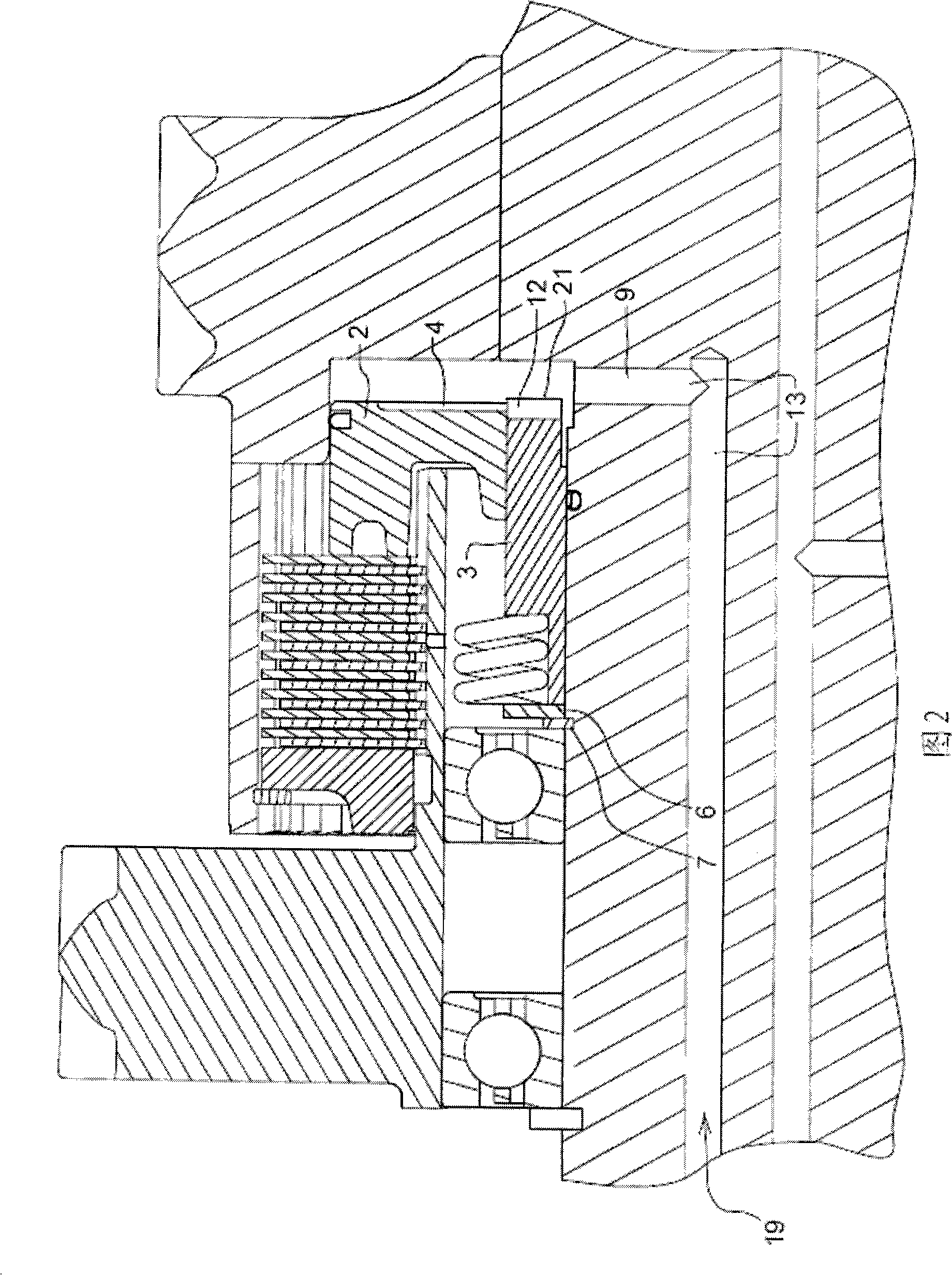

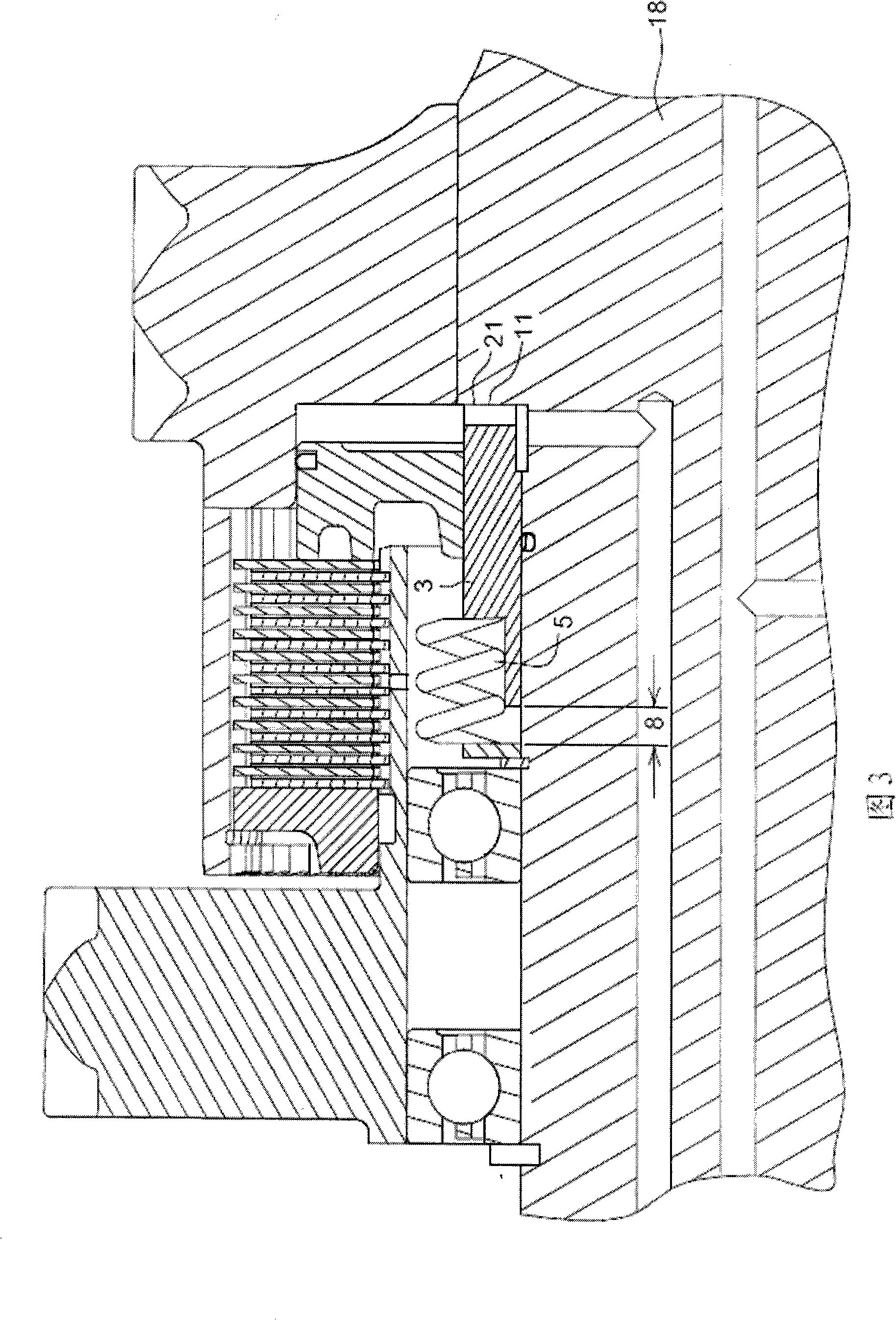

Powershift Transmission Clutch System With A Predetermined Running Clearance

InactiveUS20080296123A1Minimize windage lossReduce componentsFluid actuated clutchesAutomatic clutchesEngineeringPiston

A simplified and improved clutch piston, retractor system is provided for controlling the running clearance of clutch plate(s) to minimize windage loss and to improve transmission shift quality. This improved shift quality helps improve operator's comfort reduce shock loads on power transmission components, and reduce the energy input to the clutches when changing gears during the acceleration and deceleration of the vehicle. The clutch piston retractor system is self adjusting to accommodate wear to the clutch disks and optimize the shift quality, while compensating for the additional travel distance. Thus, the need to periodically recalibrate the entire system is eliminated.

Owner:DEERE & CO

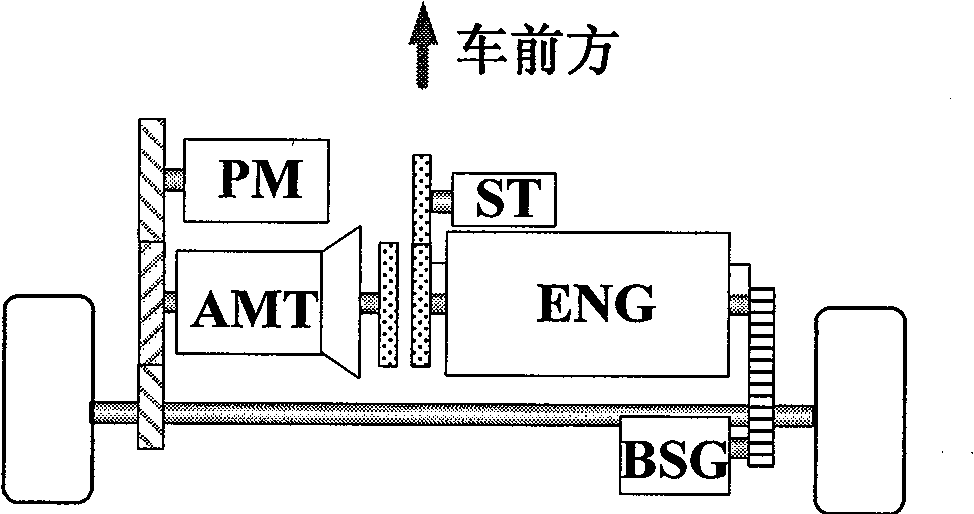

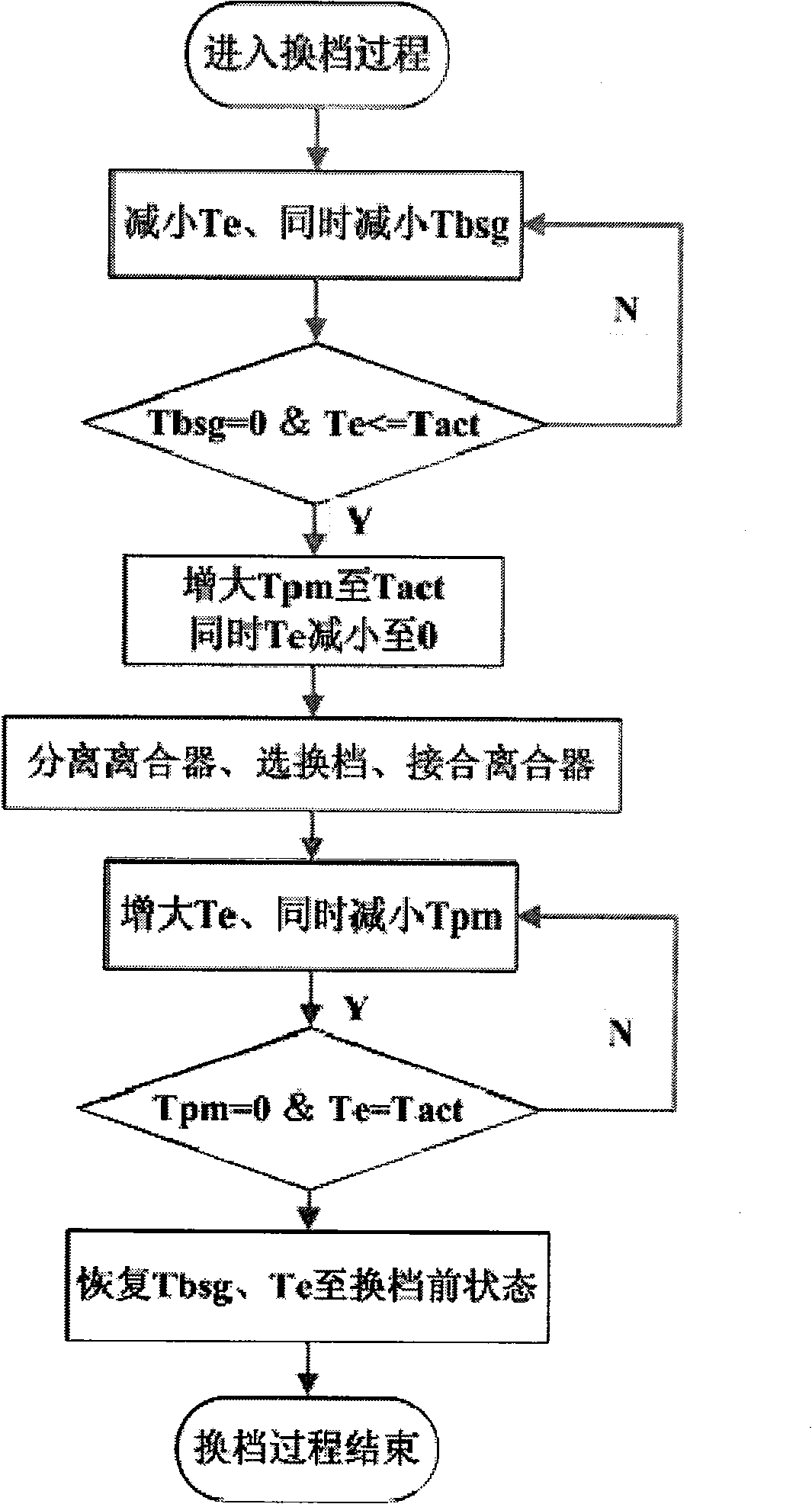

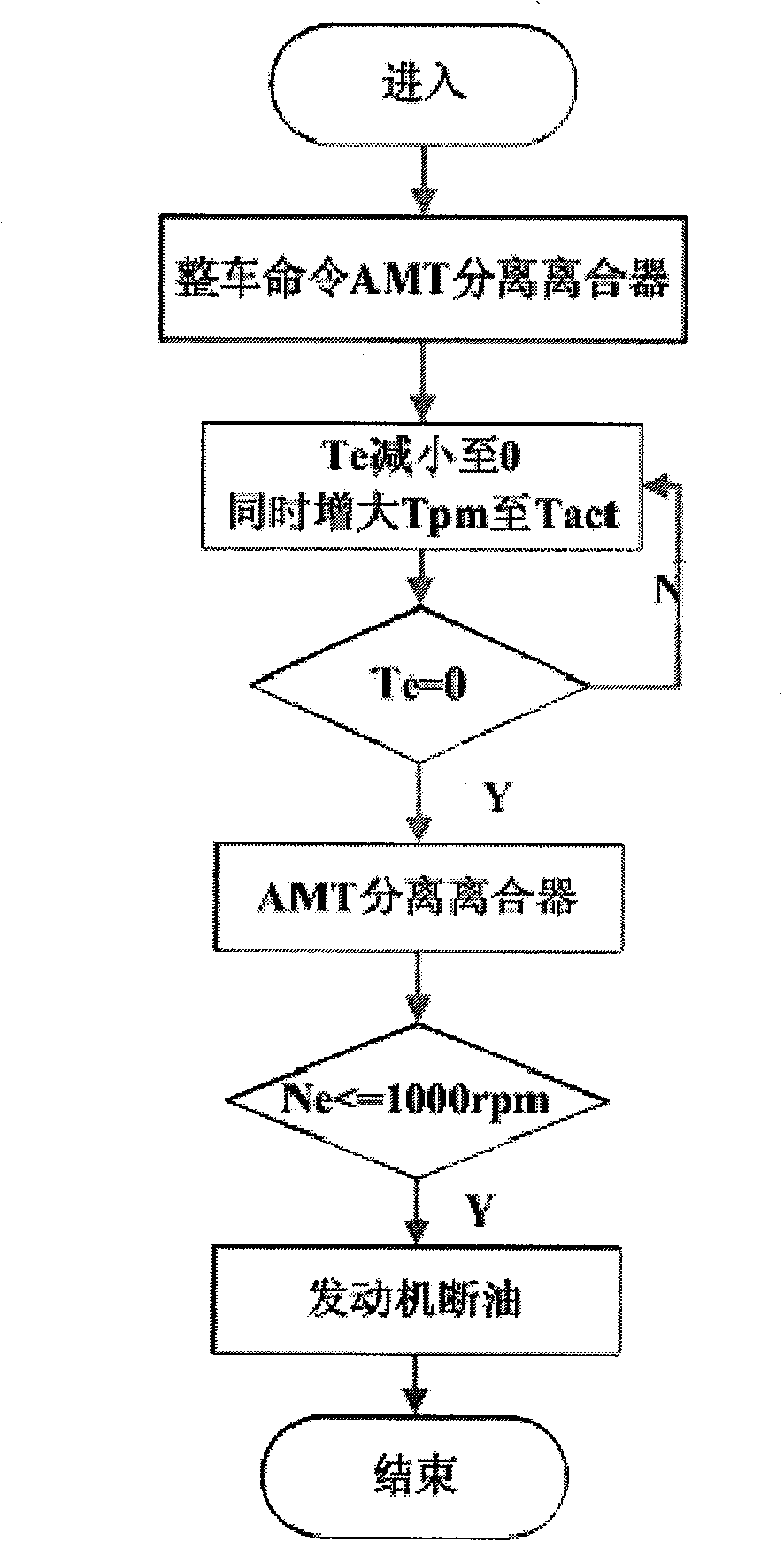

Method for controlling gear shift without power interruption of hybrid car

InactiveCN101987571AImproved shift smoothnessImproved shift qualityHybrid vehiclesGas pressure propulsion mountingVariatorMotor drive

The invention relates to a method for controlling gear shift without power interruption of a hybrid car, which is characterized by comprising the following concrete control steps of a gear shift process, a transition process from pure motor driving to engine driving, a transition process from the engine driving to the pure motor driving; and an BSG motor is connected with a crank pulley of a motor, and a driven main motor is connected with an output shaft of a transmission. By means of a fast response characteristic of a motor system, output torque of the whole power transmission system is adjusted and compensated during the gear shift so as to realize the gear shift process without power interruption. In the method of the invention, the defect of power interruption during the gear shift of the traditional AMT system can be made up preferably, dynamic property of the whole car is improved, and smoothness of the whole car is enhanced.

Owner:FAW GROUP

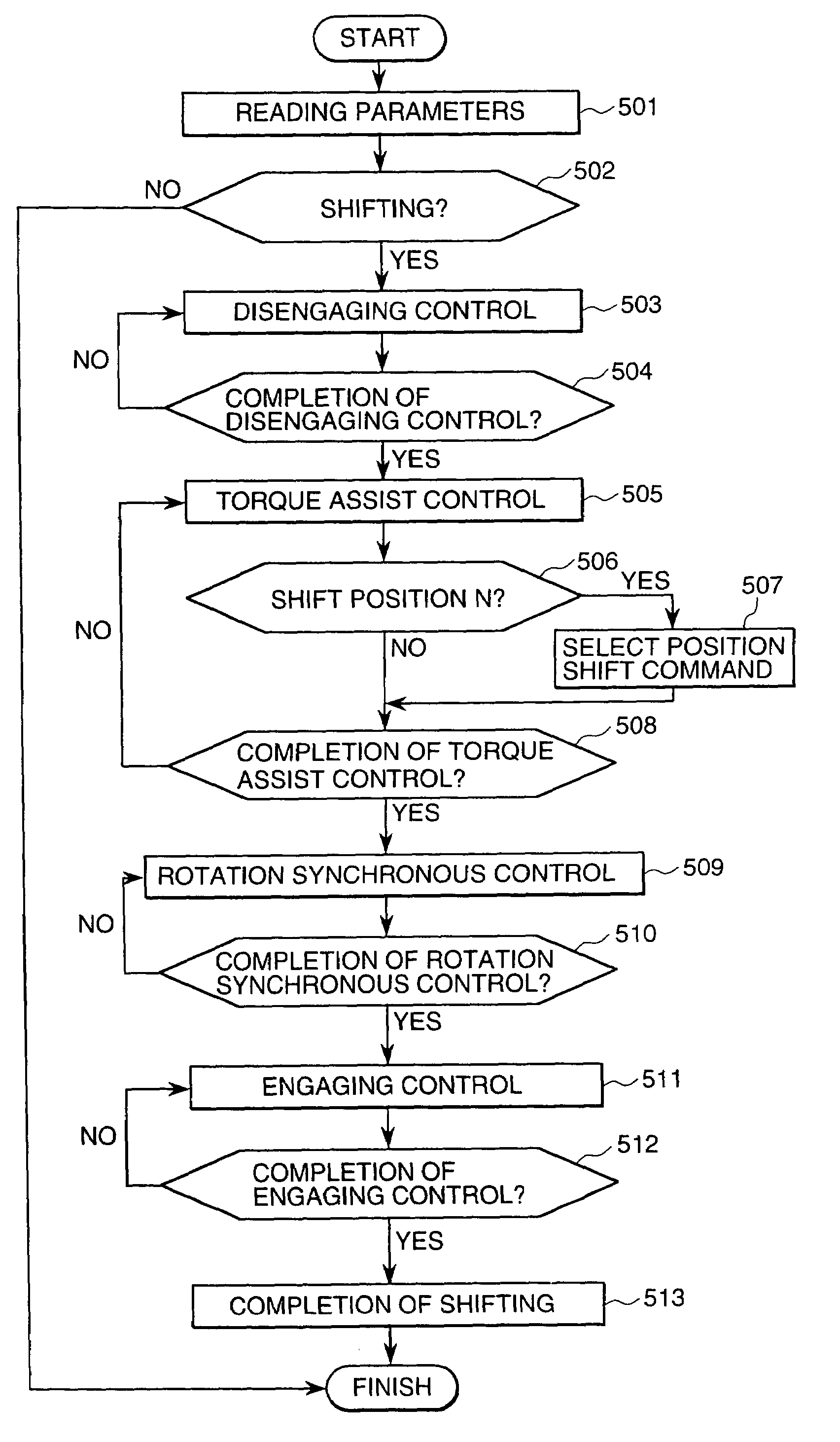

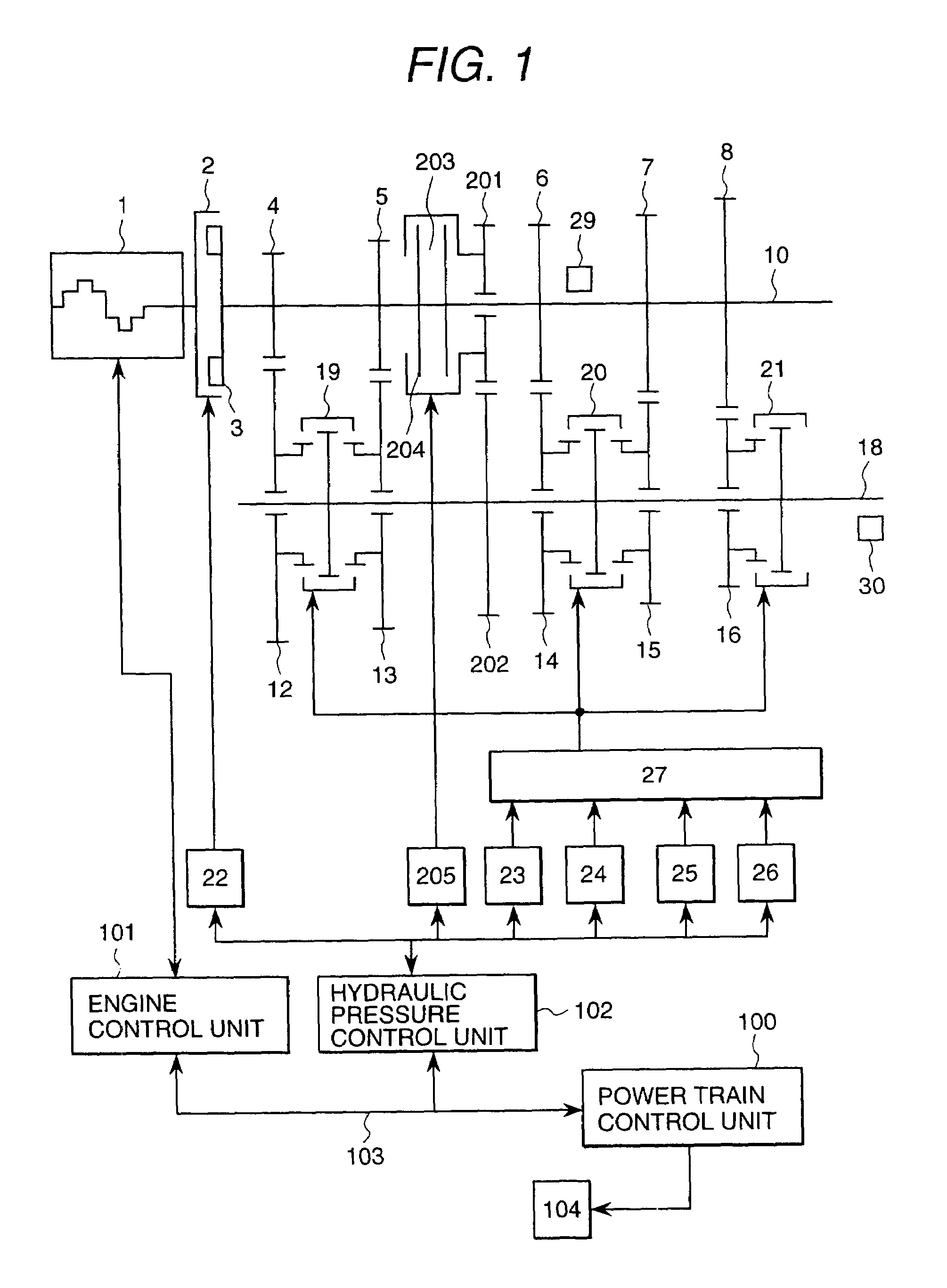

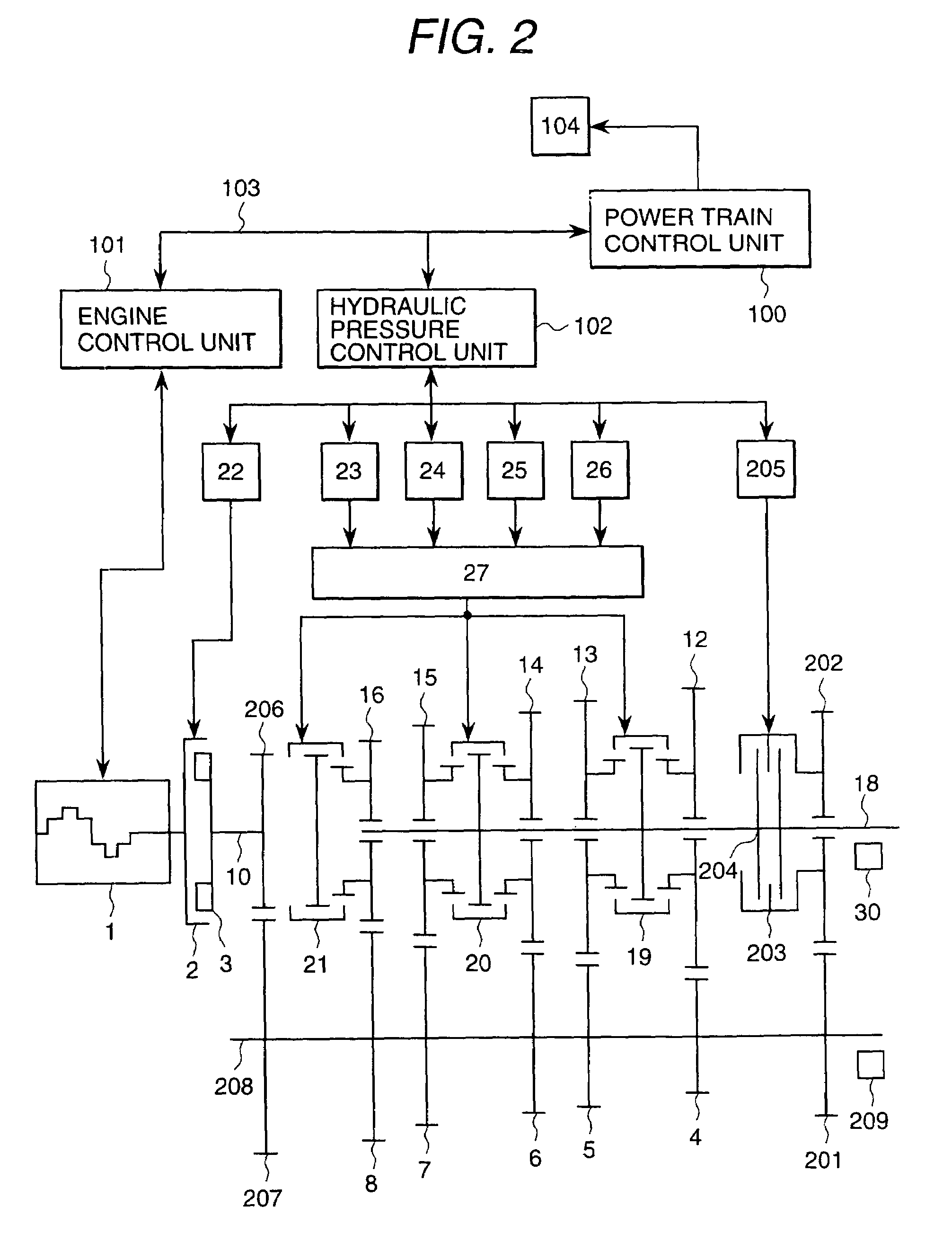

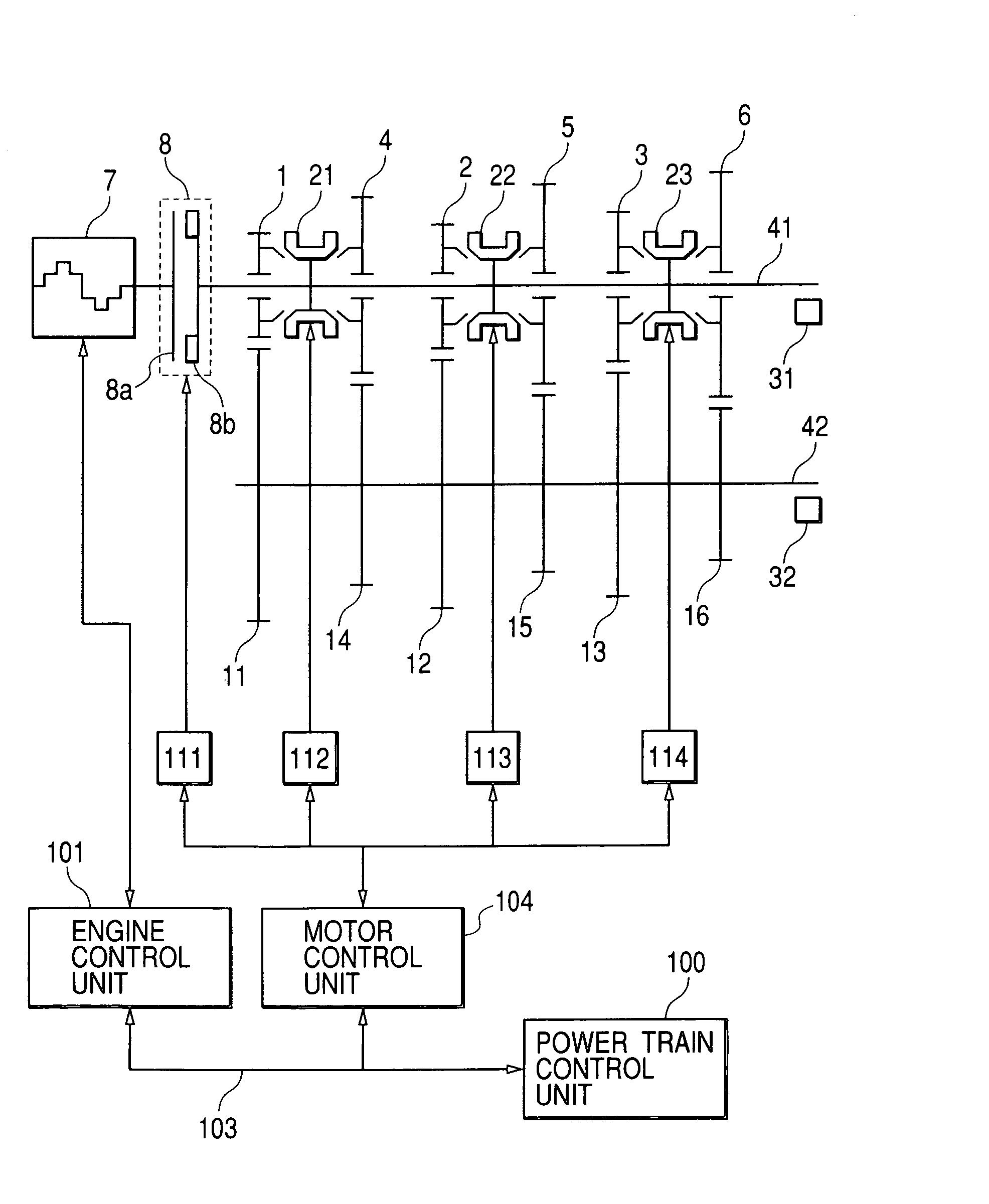

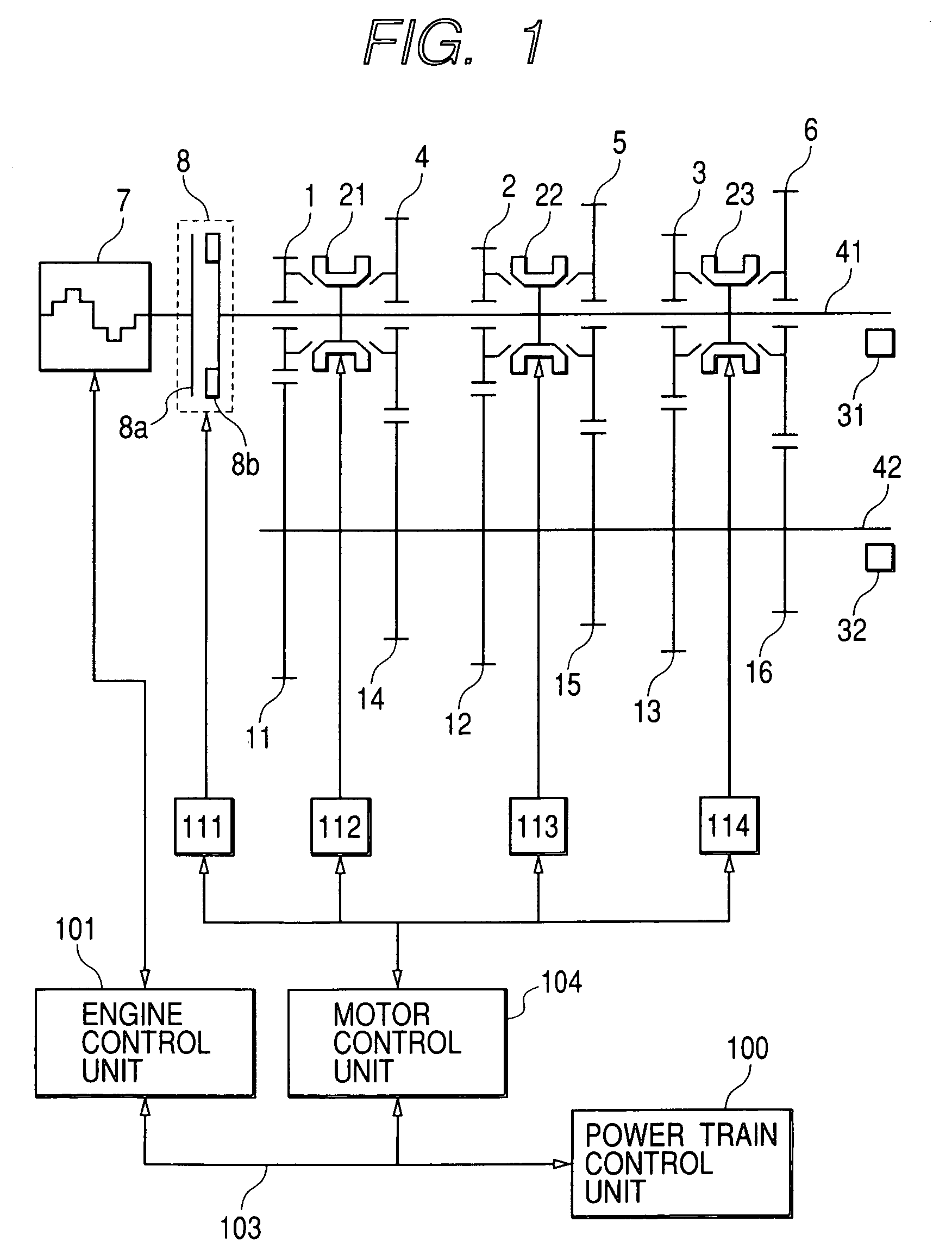

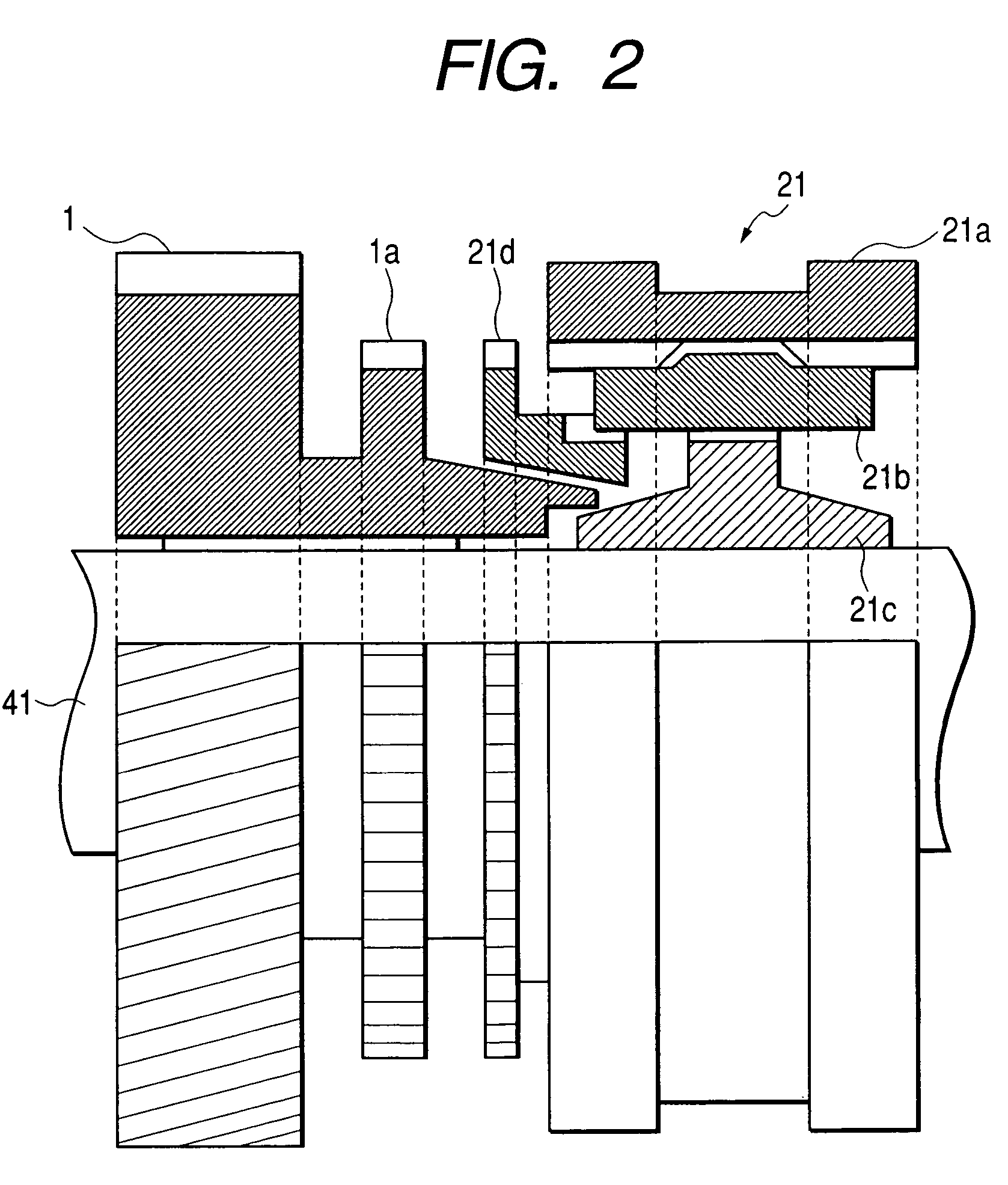

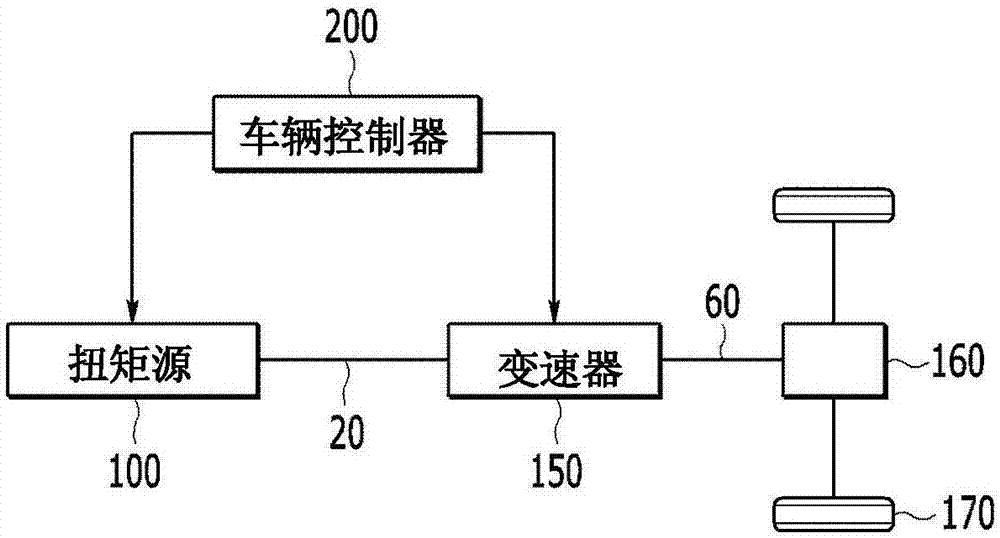

Method of controlling a vehicle, apparatus for controlling the same, transmission and apparatus for controlling the same

InactiveUS7211028B2Improved shift qualityAvoid timeDigital data processing detailsGearing controlShift timeControl unit

Power train control unit 100 controls friction clutch 203 when shifting from one cogwheel row to the other cogwheel row, sets the target synchronous rotation speed based on the output rotation speed of a transmission and parameters indicative of the state of engine 1 or the transmission, and sets the command value to the friction clutch so that the input rotation speed can be synchronized with the target synchronous rotation speed. Control unit 100 sets the target shifting required time based on parameters indicative of the state of engine 1 or the transmission, and corrects the command value to the friction clutch so that the required shift time can approach the above target shift required time.

Owner:HITACHI LTD

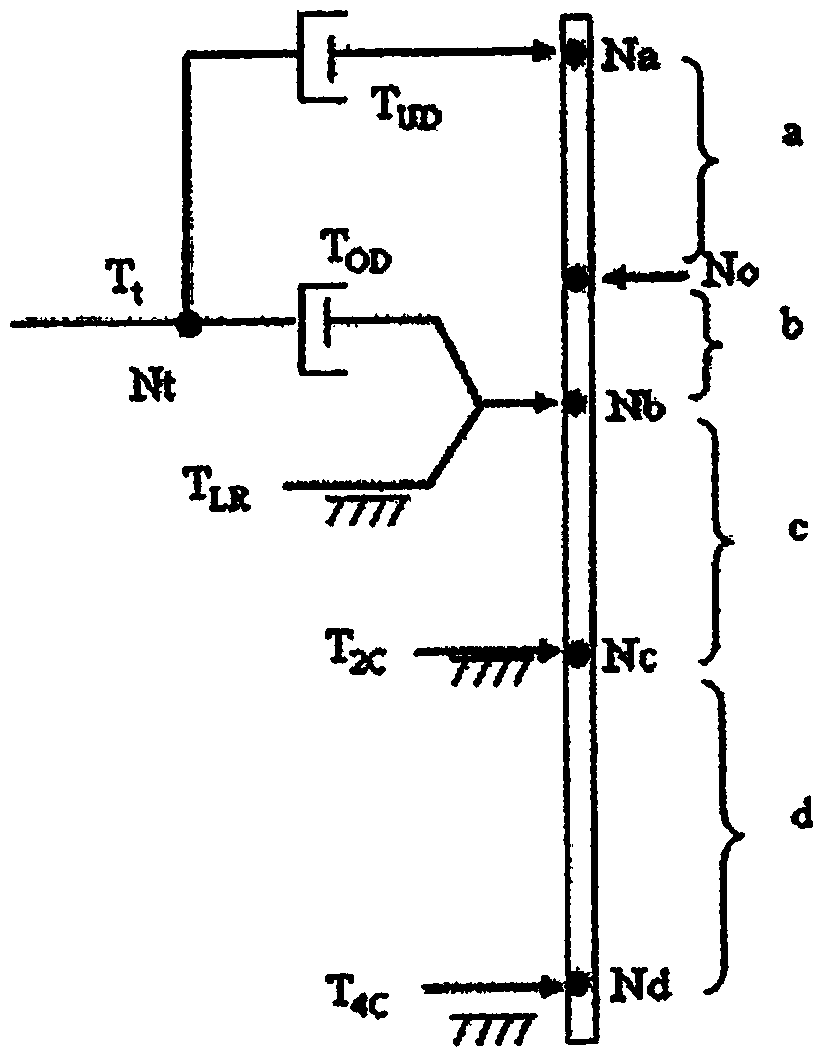

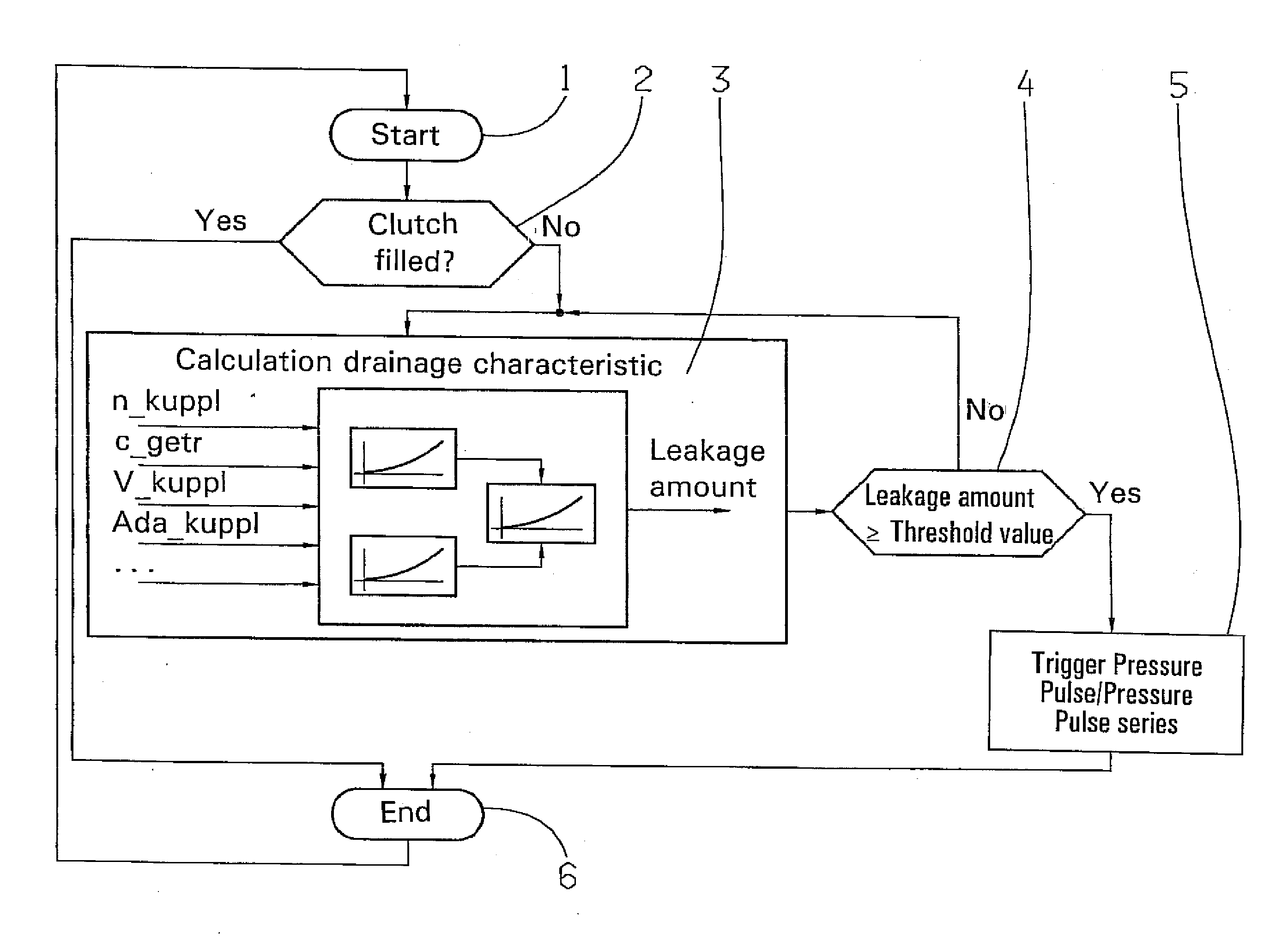

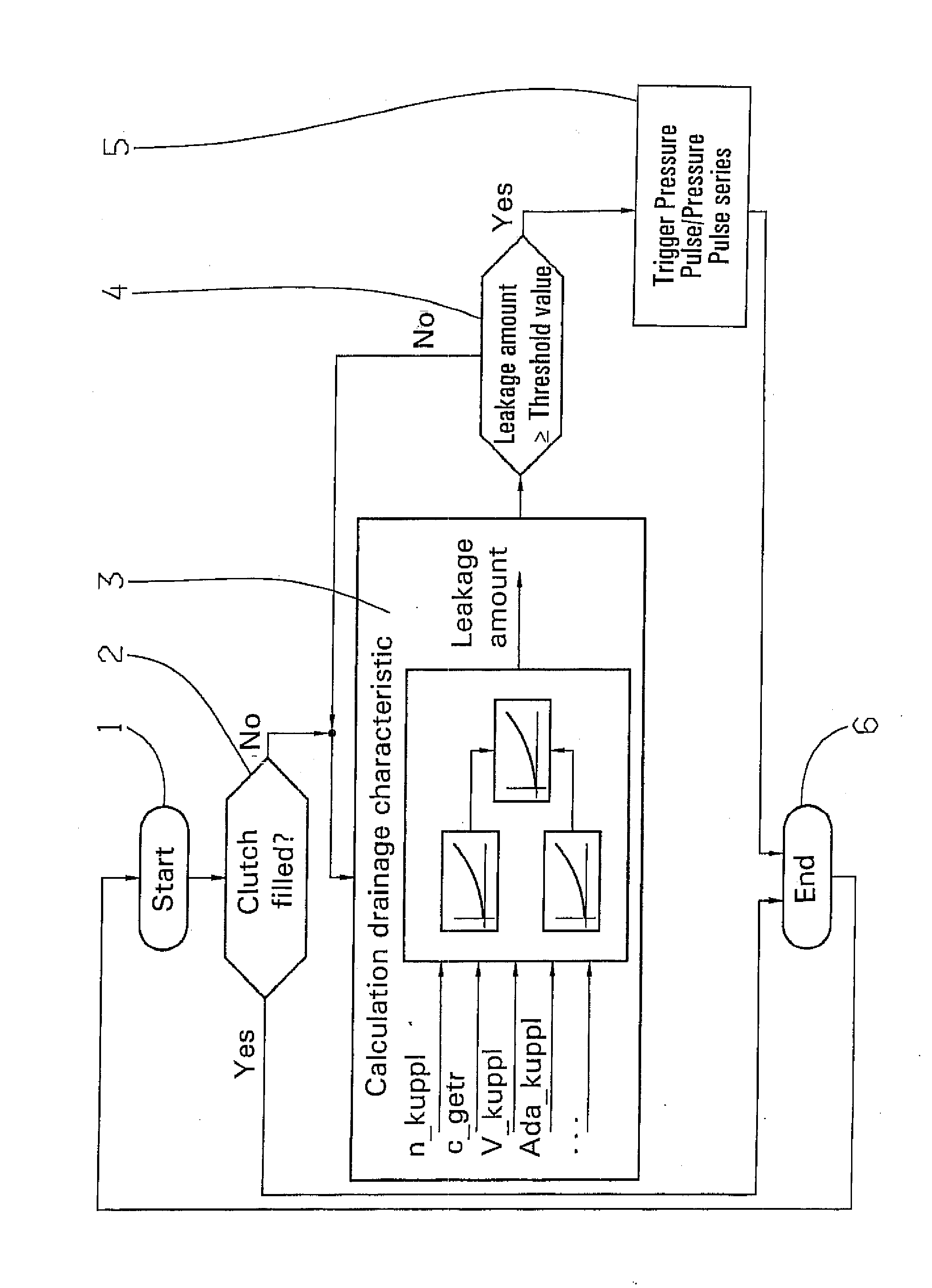

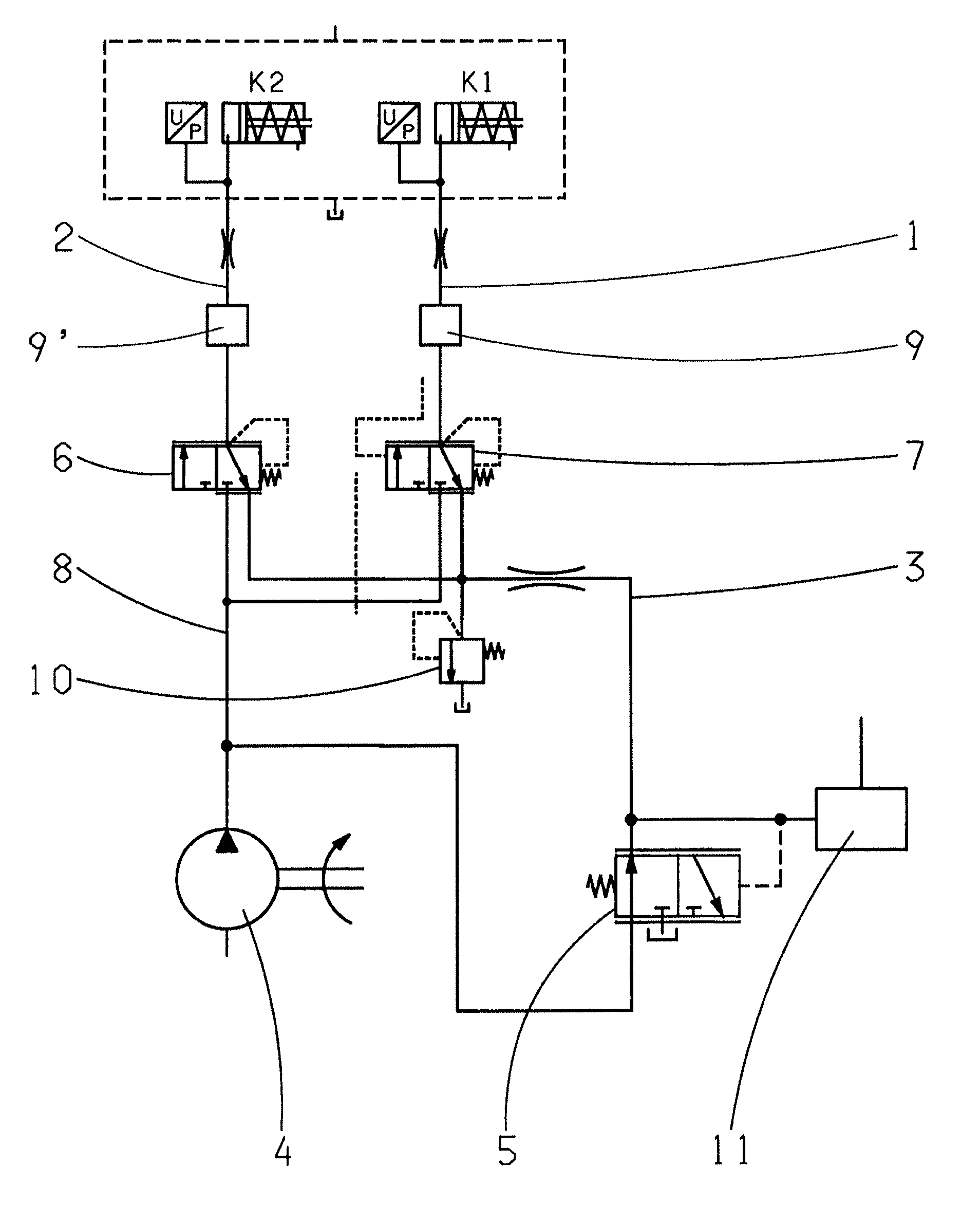

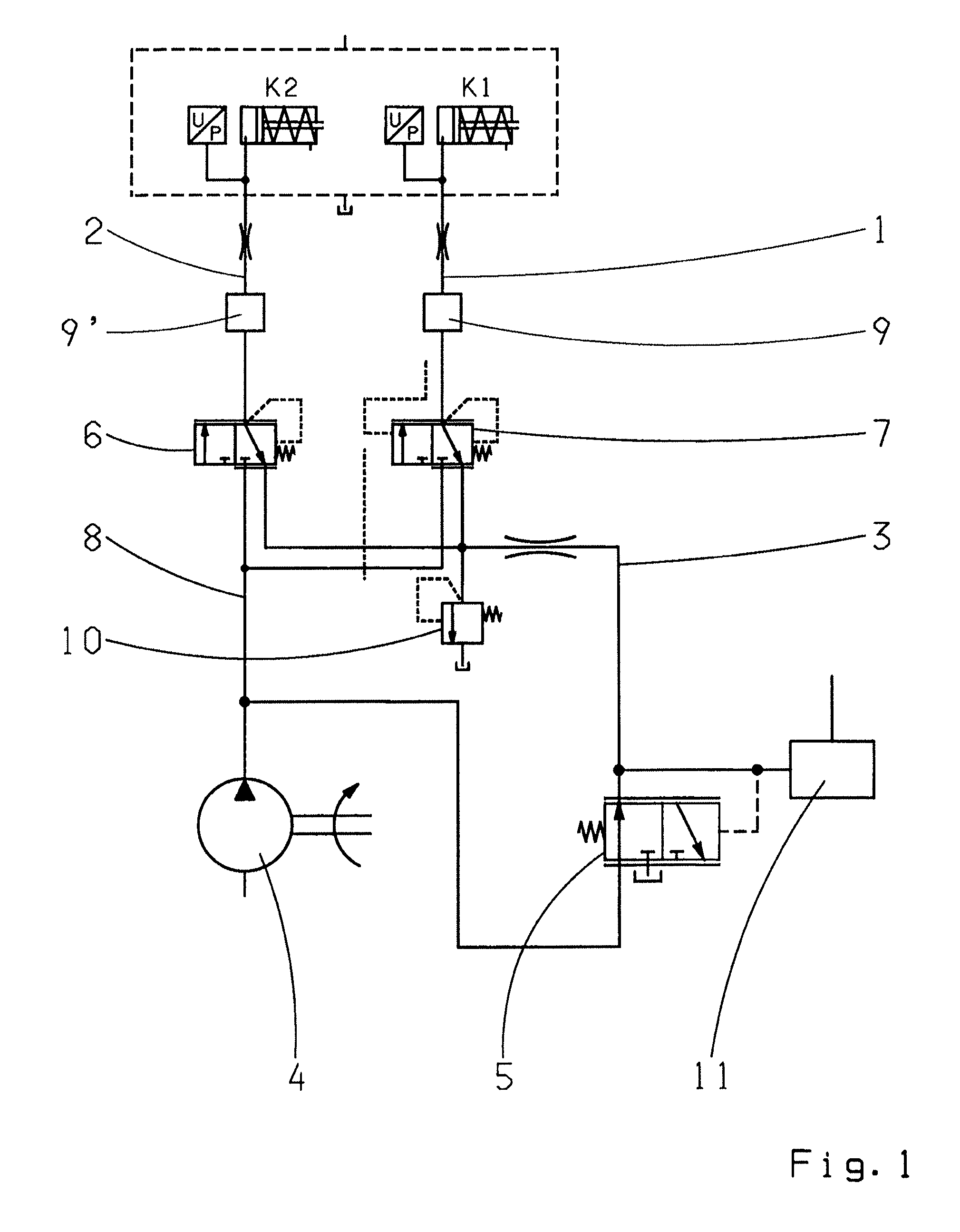

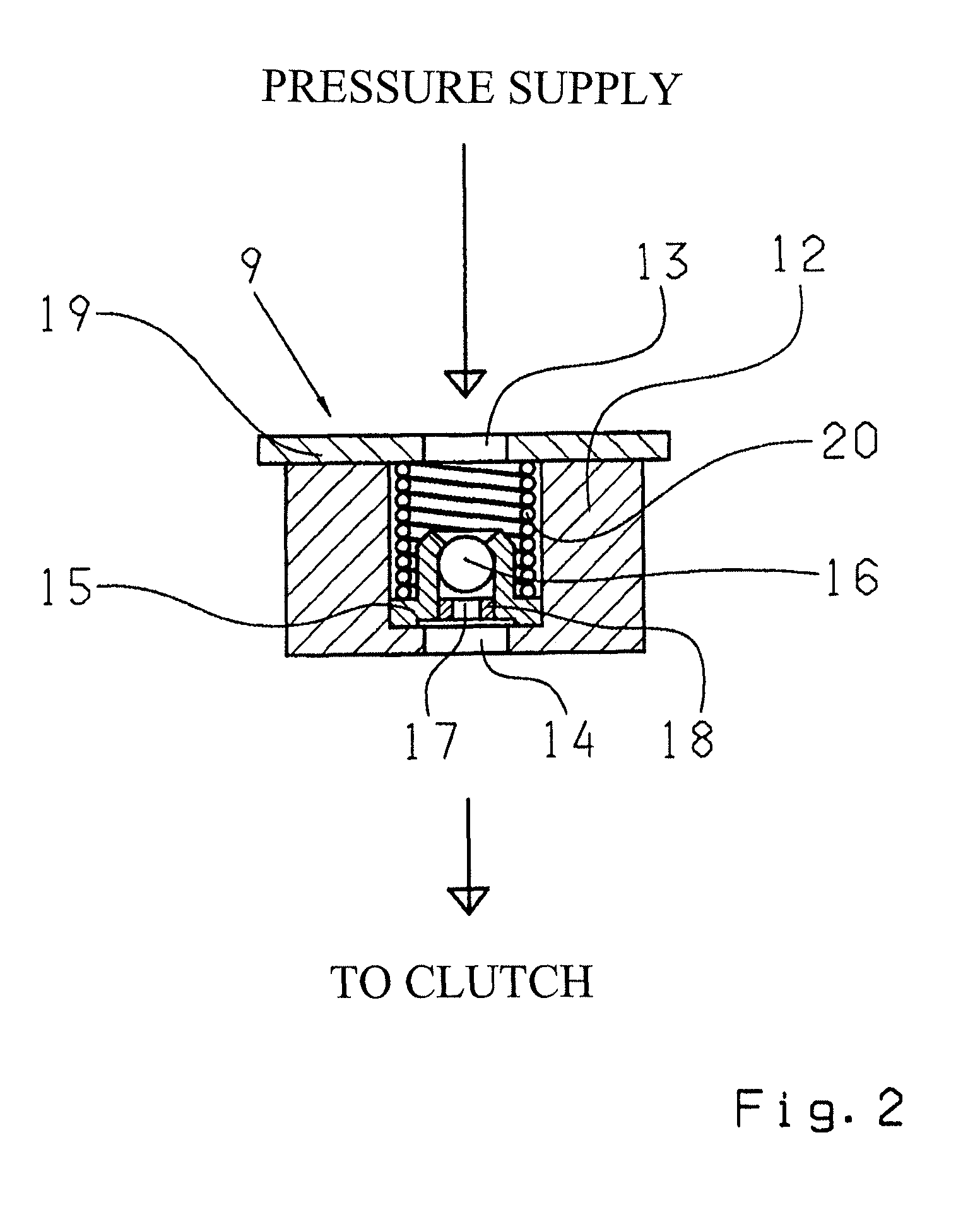

Process for pressure actuation of a shifting element

InactiveUS20080217134A1Improved shift qualityExact fitDigital data processing detailsFluid actuated clutchesAutomatic transmissionEngineering

The invention concerns a process for pressure actuation of a rotating shifting element of an automatic transmission or automated manual transmission, in which the shifting element is configured with a piston that interacts with a torque transfer element and a pressure medium supply, by way of which the piston can be actuated with pressure medium in order to be displaced into a positioned defined for an activated state of the shifting element, and in which a pressure pulse can be induced in the pressure medium supply in a de-activated state of the shifting element. It is proposed that the pressure medium pulse be triggered when the pressure medium amount drained from the de-activated shifting element has reached a predefined value.

Owner:ZF FRIEDRICHSHAFEN AG

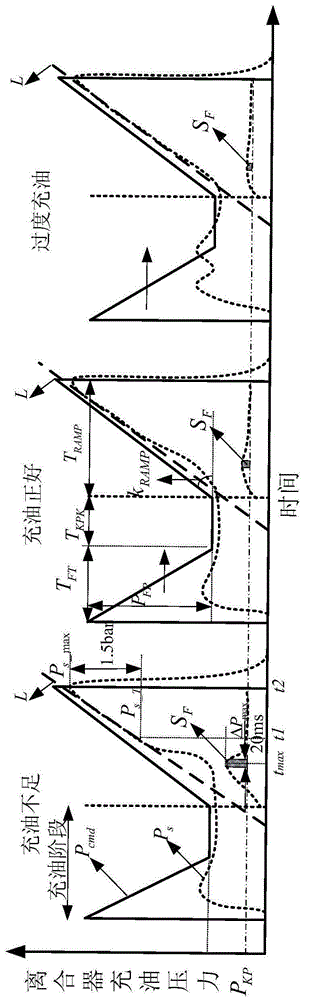

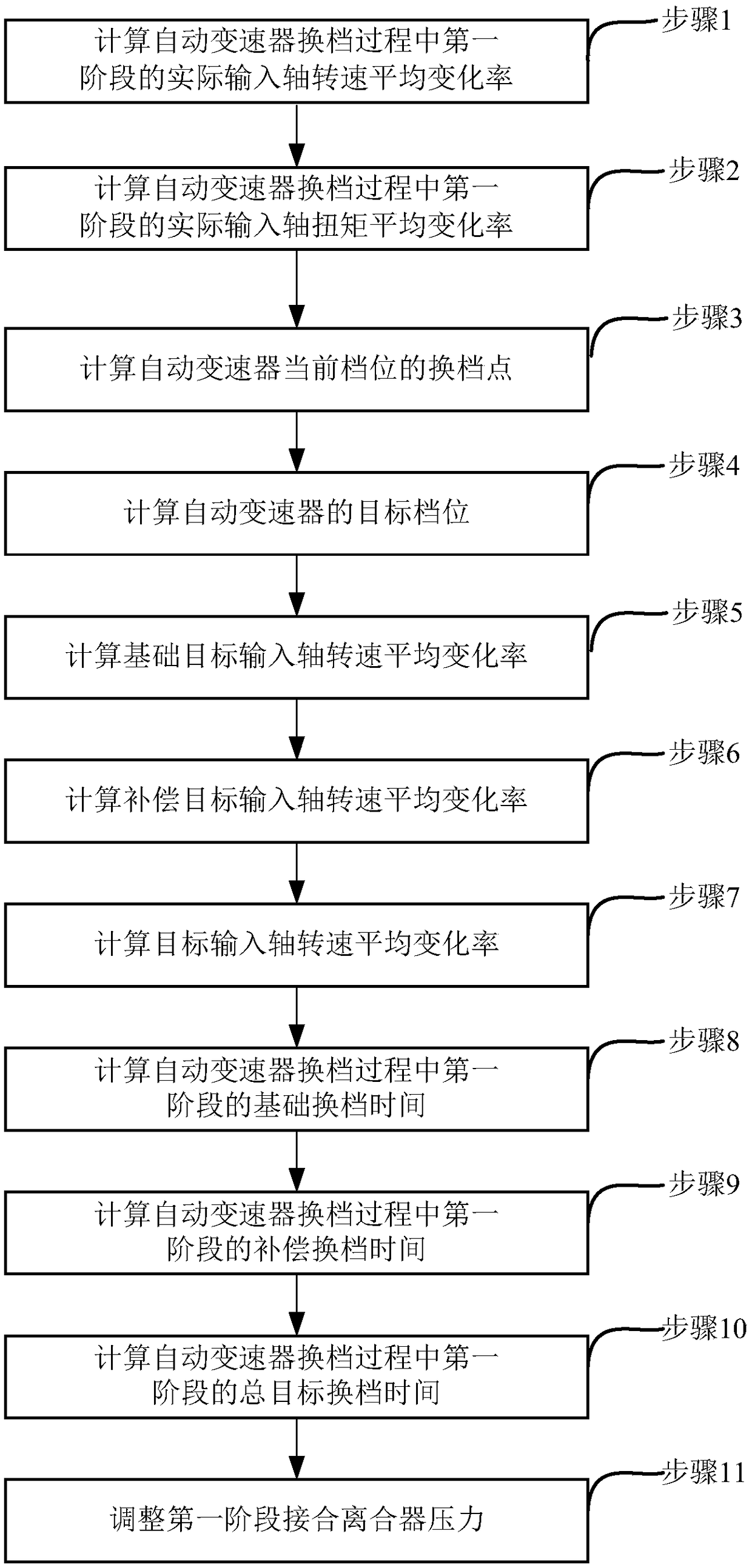

Self-adaptation control method for torque of automatic transmission clutch

ActiveCN109163087AThe rate of change of speed is reducedShift Time GuaranteedGearing controlAutomatic transmissionOptimal control

The invention provides a self-adaptation control method for torque of an automatic transmission clutch. The self-adaptation control method can ensure the optimal control over the torque of the clutchduring the gear shifting process; as for the power upshifting process, the oil filling phase, the torque phase, the speed phase and the locking stage are sequentially performed, according to the inputshaft rotating speed change rate, the gear shifting time, the current gear position and the target gear position in the oil filling phase and the torque phase in the gear shifting process, the engaged clutch pressure correction amount is dynamically adjusted, and therefore on the basis of guaranteeing the gear shifting time, the input shaft rotating speed change rate is reduced, the gear shiftingshock is reduced, and the gear shifting quality is improved.

Owner:FAW JIEFANG AUTOMOTIVE CO

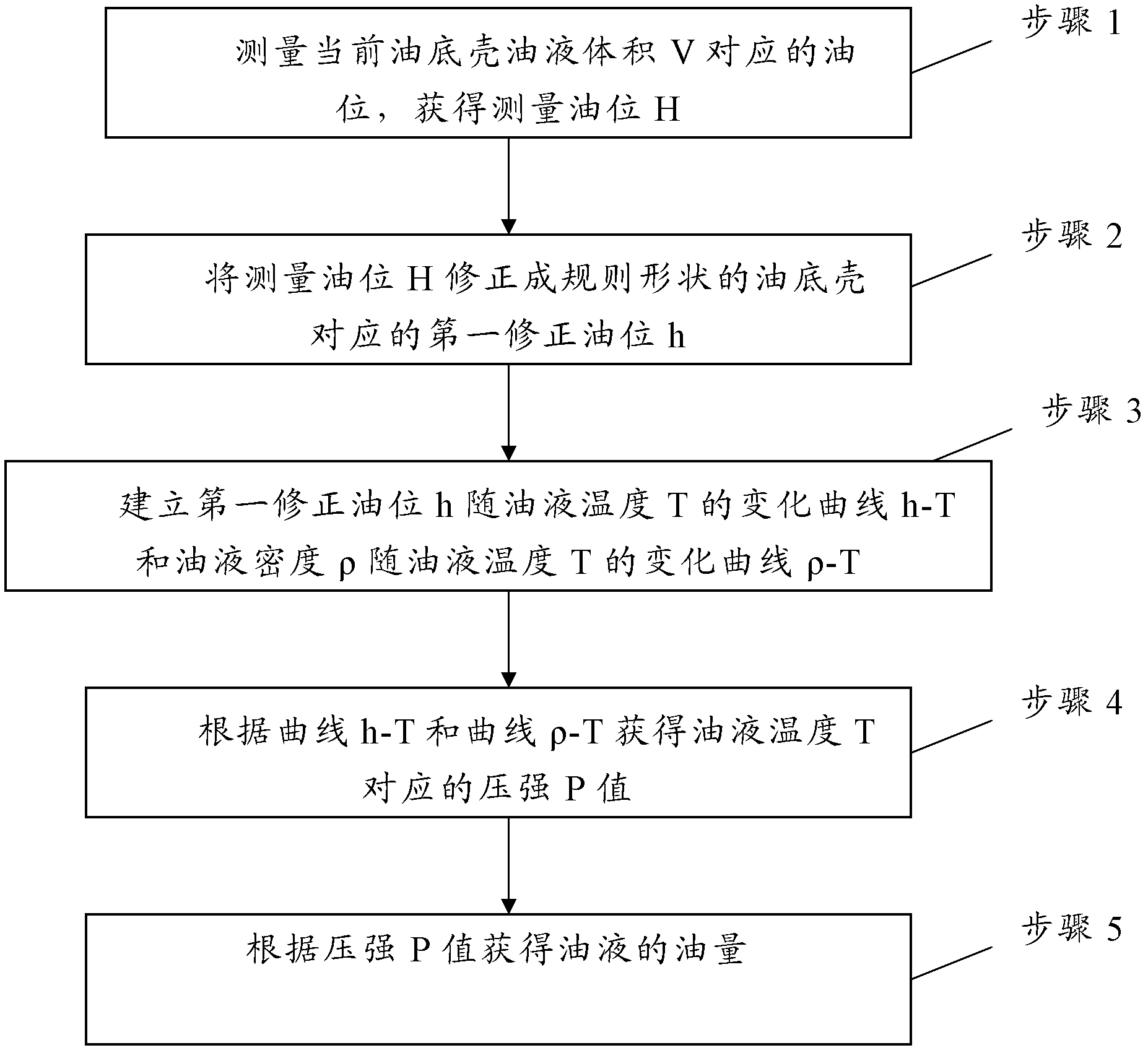

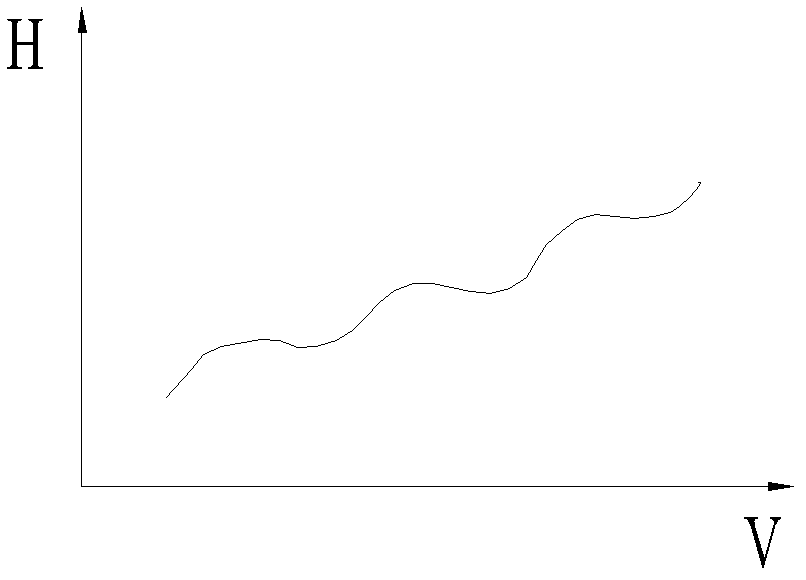

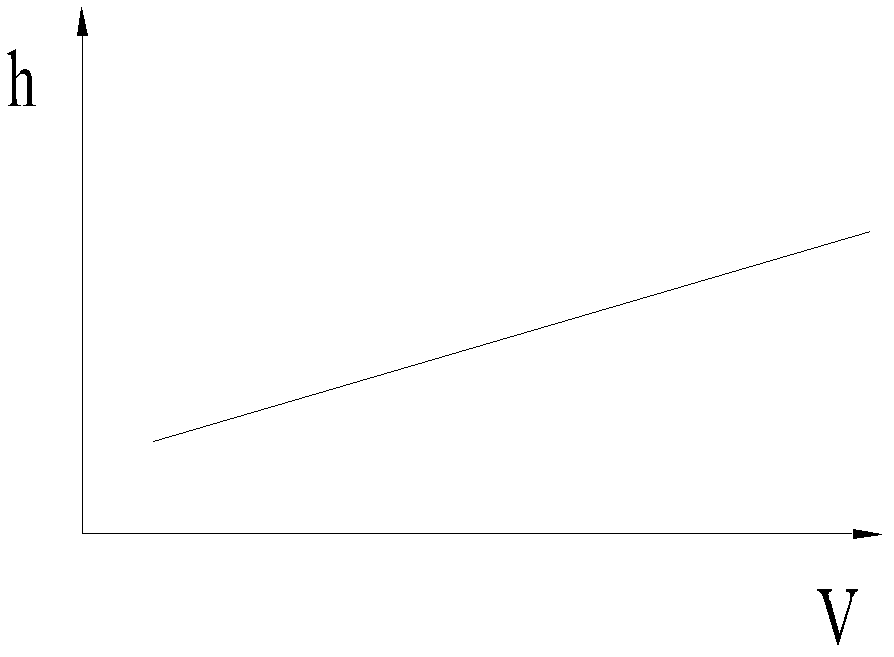

Oil mass measuring method, oil mass measuring device and oil pressure calibration method

InactiveCN102644736AExtended service lifeImproved shift qualityGear lubrication/coolingGearing controlAutomatic transmissionOil temperature

An embodiment of the invention discloses an oil mass measuring method, an oil mass measuring device and an oil pressure calibration method, relates to the technical field of automatic transmissions, and aims at solving the technical problem that in the prior art, an oil level is greatly influenced by temperature and shape variation of an oil pan so that the real oil mass of transmission oil cannot be measured accurately. The oil mass measuring method comprises measuring an oil level corresponding to current volume V of oil pan oil, and obtaining a measurement oil level H; correcting the measurement oil level H to a first correction oil level h corresponding to the oil pan in a regular shape; establishing a changing curve h-T of the first correction oil level h along with the oil temperature T and a changing curve rho-T of the oil density rho along with the oil temperature T; obtaining a pressure P value corresponding to the oil temperature T according to the curve h-T and the curve rho-T; and obtaining the oil mass of oil according to the pressure P value. The oil mass measuring method, the oil mass measuring device and the oil pressure calibration method are used for measuring the oil mass of a gearbox of the automatic transmissions.

Owner:GREAT WALL MOTOR CO LTD

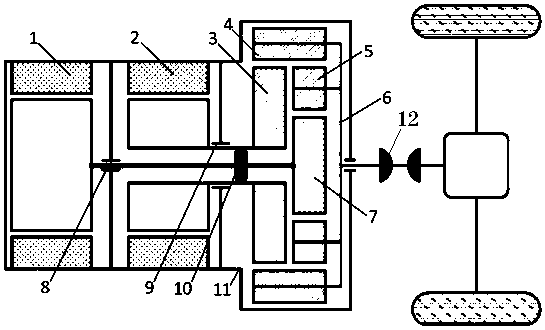

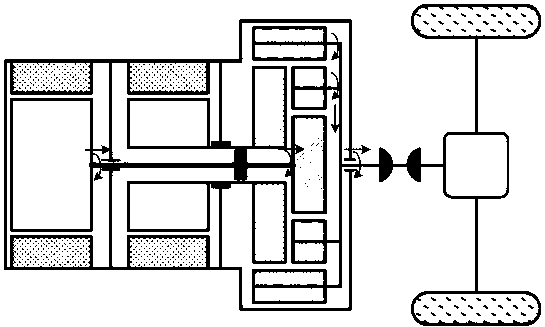

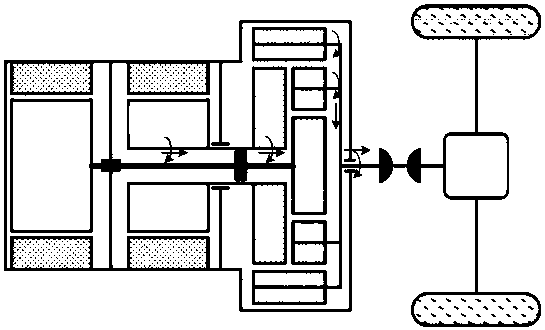

Novel double-motor coupling power mechanism and control method thereof

PendingCN108528188AImproved shift qualityEasy to controlSpeed controllerElectric propulsion mountingElectric machineClutch

The invention provides a novel double-motor coupling power mechanism and a control method thereof. The novel double-motor coupling power mechanism comprises a main driving motor and an auxiliary driving motor, wherein the main driving motor is provided with a first output shaft; the first output shaft is fixedly connected with a first sun gear; a first planet gear set is arranged on the outside ofthe first sun gear; a second planet gear set is arranged on the outside of the first planet gear set; the auxiliary driving motor is provided with a second output shaft which sleeves the outside of the first output shaft; the second output shaft is fixedly connected with a second sun gear; the second sun gear is engaged with the second planet gear set; a clutch is arranged between the first output shaft and the second output shaft; and brakes are separately arranged on the outside of the first output shaft and the outside of the second output shaft. By the two brakes and the clutch, power ofa power system does not interrupt in a gear shifting process, impact does not exist during gear shifting, the power system has good gear shifting quality, only one of the brakes and the clutch requires to be controlled to switch over different modes, and thus, the power system is controlled simply.

Owner:FUZHOU UNIV

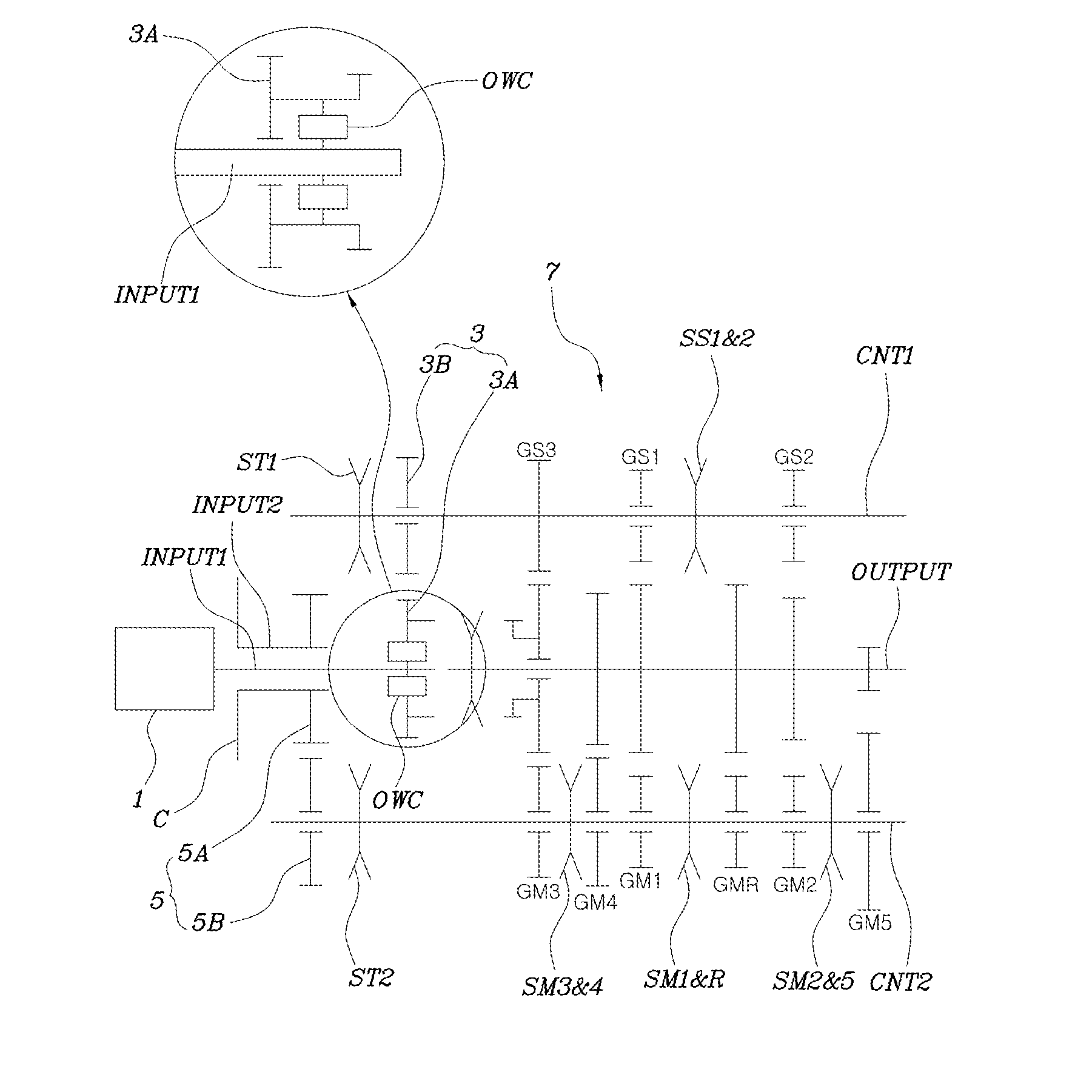

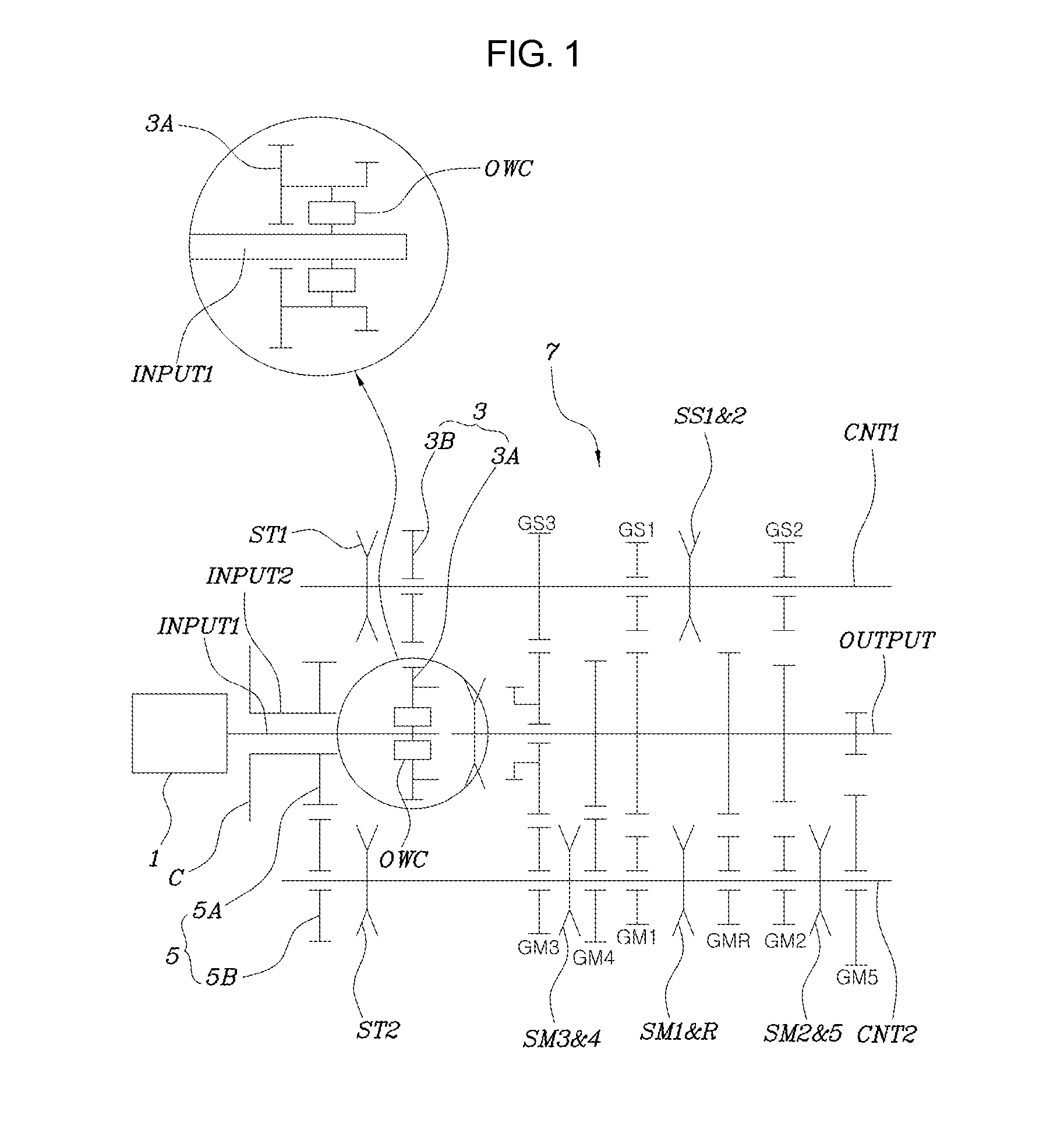

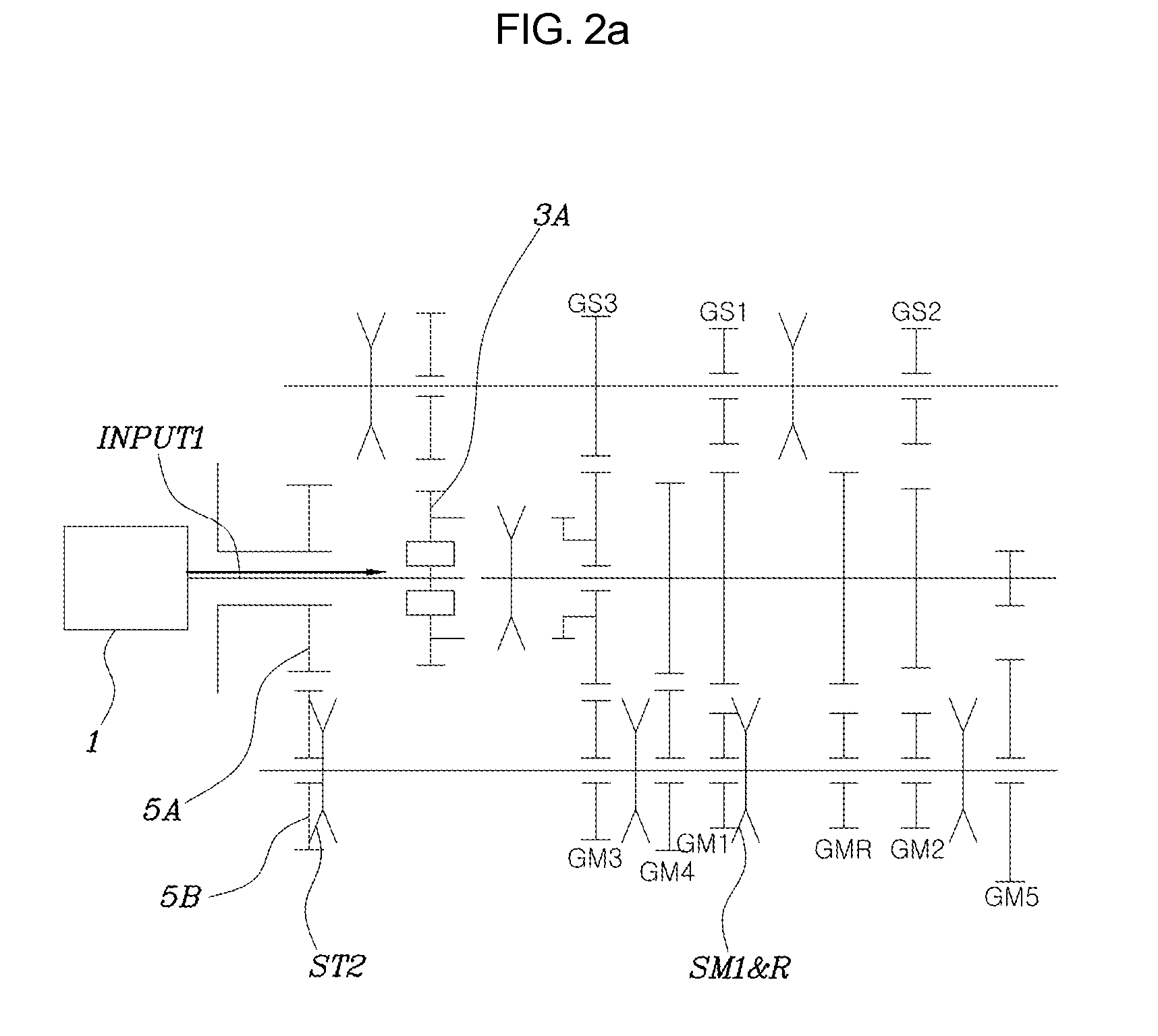

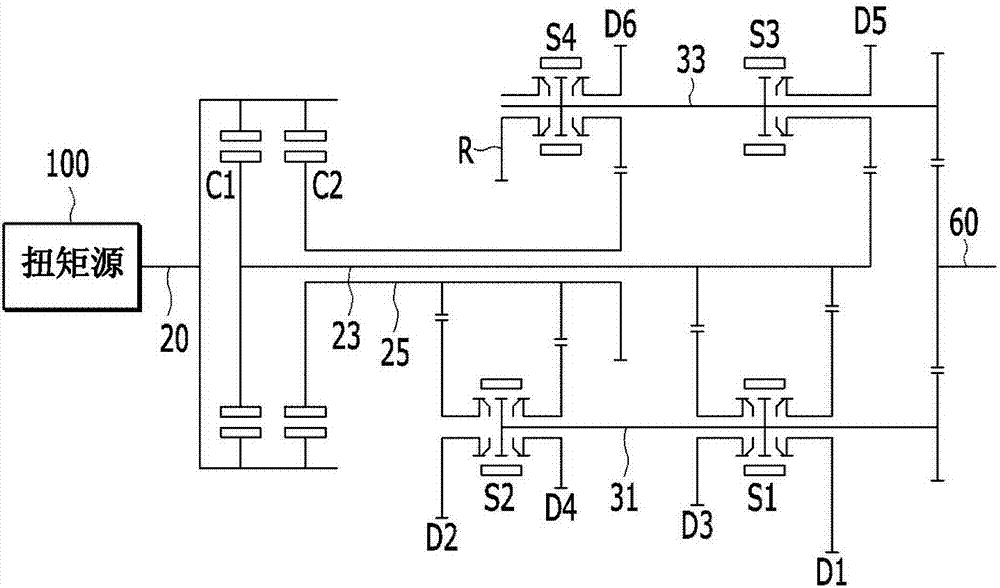

Transmission for vehicle

A transmission for a vehicle may include a first input shaft continuously receiving rotational power from a power source; a second input shaft selectively receiving the rotational power of the power source through a clutch; a first counter shaft and a second counter shaft connected to the first input shaft and the second input shaft through a transfer gear pair, respectively; a controlling device selecting the transfer gear pair to transfer the rotational power from the first input shaft and the second input shaft to the first counter shaft and the second counter shaft; a one-way clutch allowing the rotational power provided to the first input shaft to be transferred only from the first input shaft toward the first counter shaft.

Owner:HYUNDAI MOTOR CO LTD

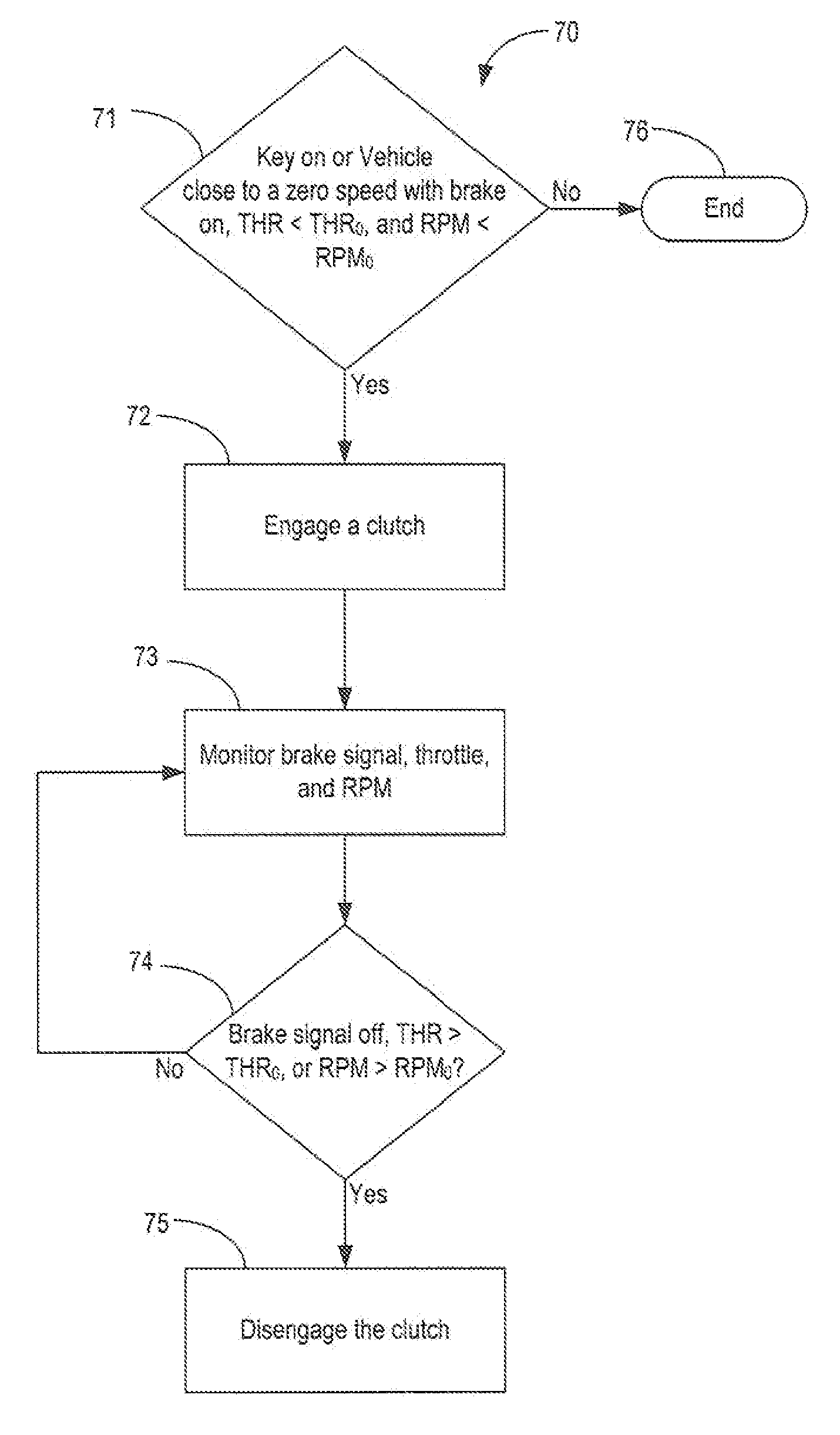

Methods and systems for drive-to-neutral and neutral-to-drive transmission garage shift quality improvement

InactiveUS20080269014A1Reduce torqueMinimizing reactionGearing controlEngine controllersGear ratioVehicle suspension system

The present disclosure improves both the D-N and N-D garage shift by reducing torque applied to the powertrain mount system and vehicle suspension systems during garage shifts. Since less energy in stored in the mount system and suspension system, the reaction bump during garage shifts will be reduced without compromising vehicle performance. For the N-D garage shift, such as after key-on when a shift lever is positioned in drive, a vehicle shifts to second gear (or some other higher gear) which provides reduced torque applied to the powertrain mount system and vehicle suspension system. For the D-N garage shift, as a vehicle slows down to a zero speed with the brake on, the vehicle is shifted into a higher gear. As the vehicle starts to launch, the vehicle is immediately shifted back to first gear, launching the vehicle with its first gear ratio.

Owner:FCA US

Pressure medium supply device of a hydraulically actuated shifting element

InactiveUS8662272B2Simple andPrevent drainageMechanical actuated clutchesFluid actuated clutchesEngineeringMechanical engineering

Owner:ZF FRIEDRICHSHAFEN AG

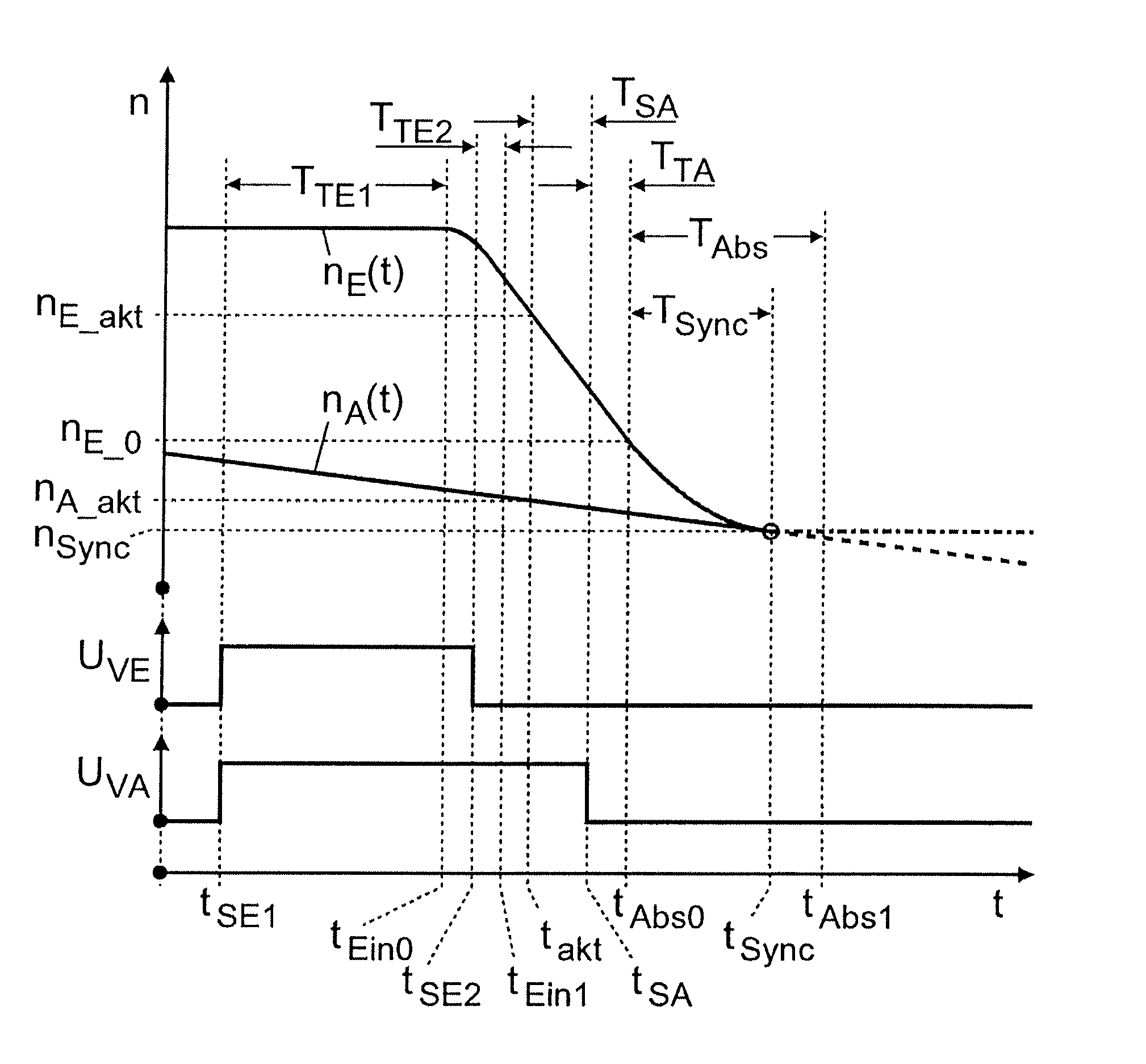

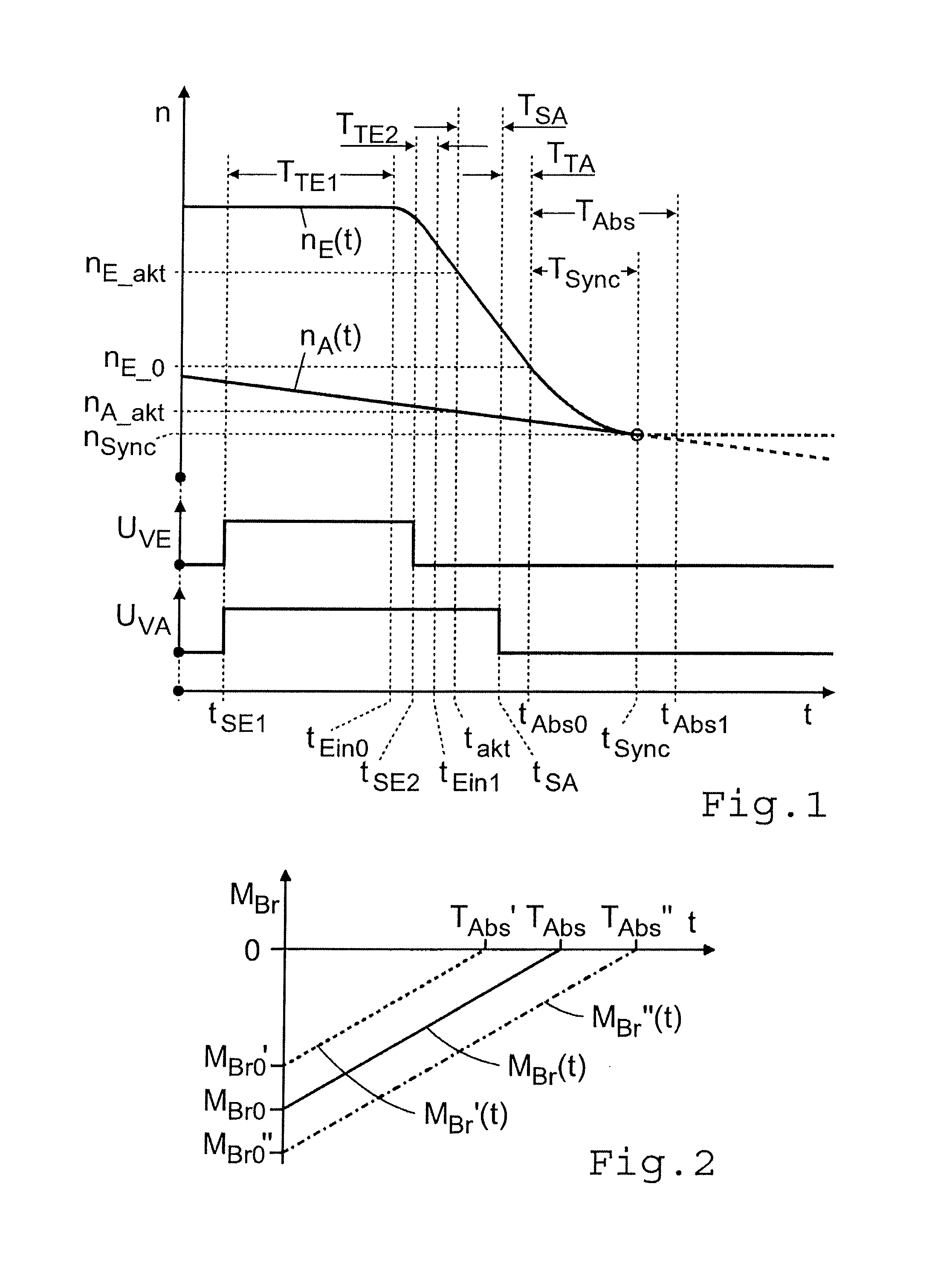

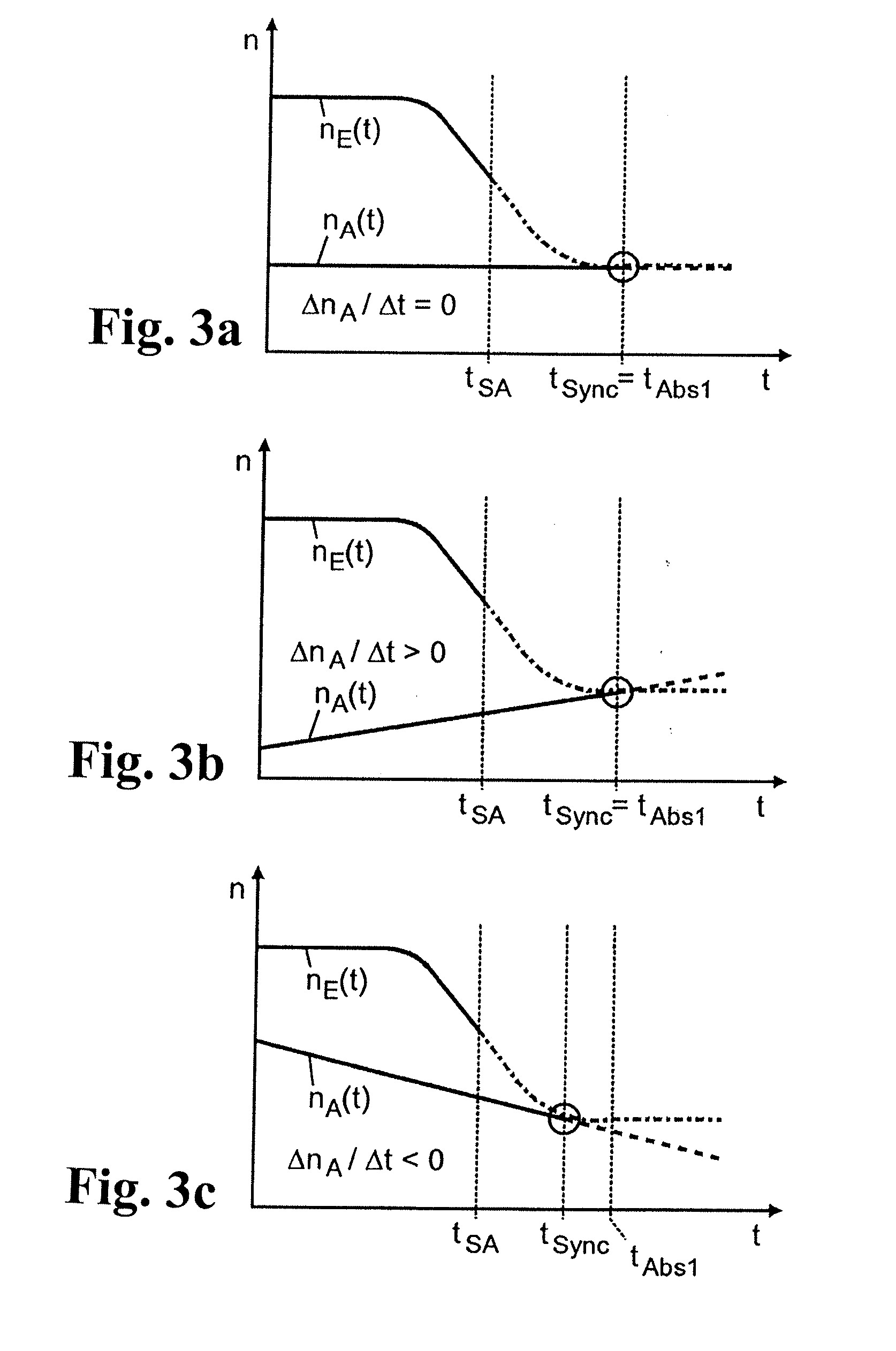

Method for controlling a transmission brake

ActiveUS20120330519A1Improved shift qualityProperty is limitedDigital data processing detailsToothed gearingsDead timeTransmission brake

A method of controlling a transmission brake that is actuated by inlet and outlet valves. For determining when to transmit a disengagement signal for opening the outlet valve, the current input and output speeds are determined and the respective gradients of these speeds are calculated. Variation of the input speed, during the disengagement of the brake, is determined as a function of the input gradient, the optimum time for reaching the synchronous speed, during brake disengagement, is determined from the input speed variation as a function of the output gradient, and the time interval until transmission of the disengagement signal is determined as a function of the current input and output speeds and their gradients, by a back-calculation from the time when the synchronous speed is reached, taking a disengagement dead time of the brake, between transmitting the disengagement signal and start of disengagement, into account.

Owner:ZF FRIEDRICHSHAFEN AG

Powershift transmission clutch system with a predetermined running clearance

The present invention relates to a powershift transmission clutch system with a predetermined running clearance. A simplified and improved clutch piston, retractor system is provided for controlling the running clearance of clutch plate(s) to minimize windage loss and to improve transmission shift quality. This improved shift quality helps improve operator's comfort reduce shock loads on power transmission components, and reduce the energy input to the clutches when changing gears during the acceleration and deceleration of the vehicle. The clutch piston retractor system is self adjusting to accommodate wear to the clutch disks and optimize the shift quality, while compensating for the additional travel distance. Thus, the need to periodically recalibrate the entire system is eliminated.

Owner:DEERE & CO

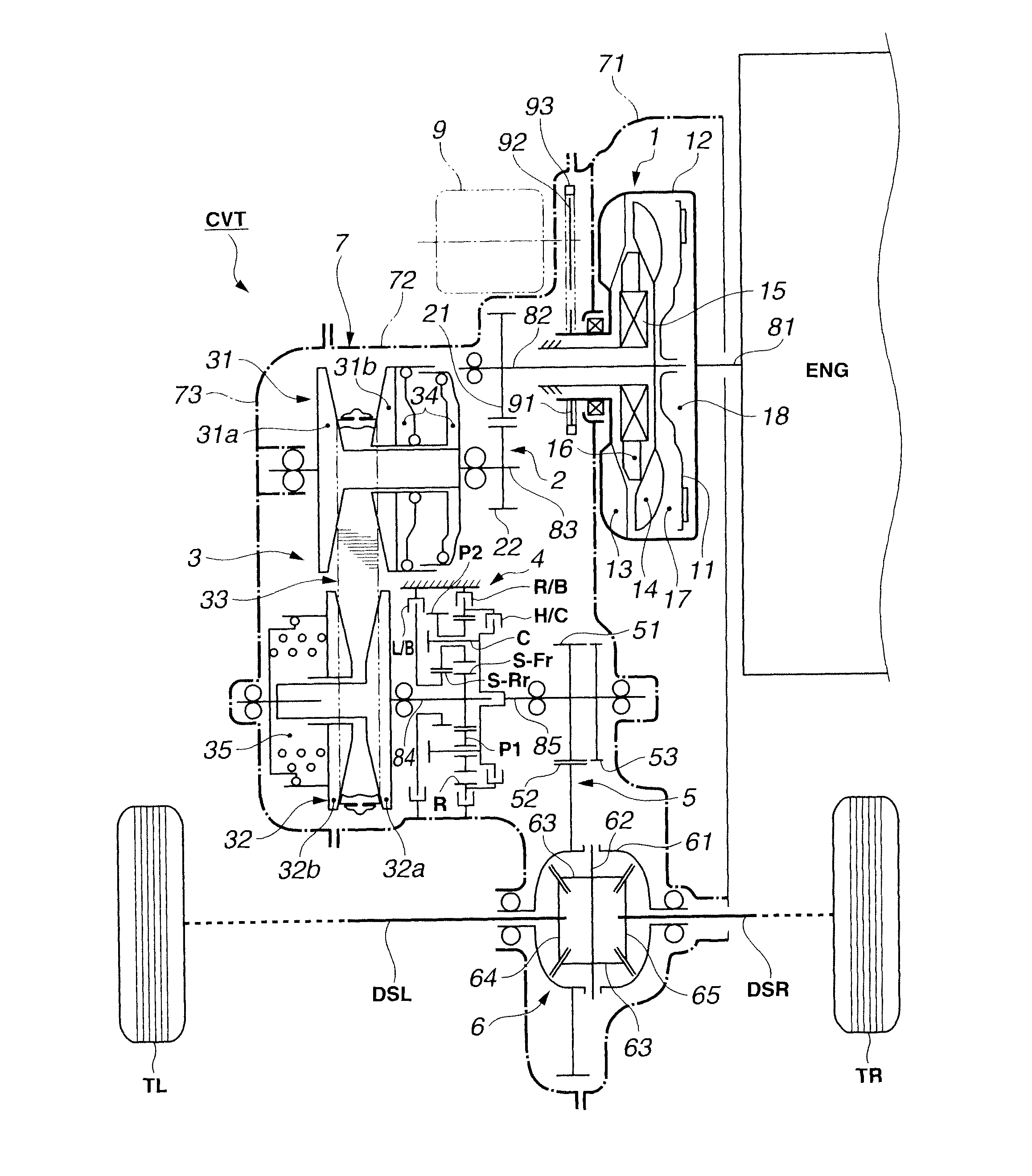

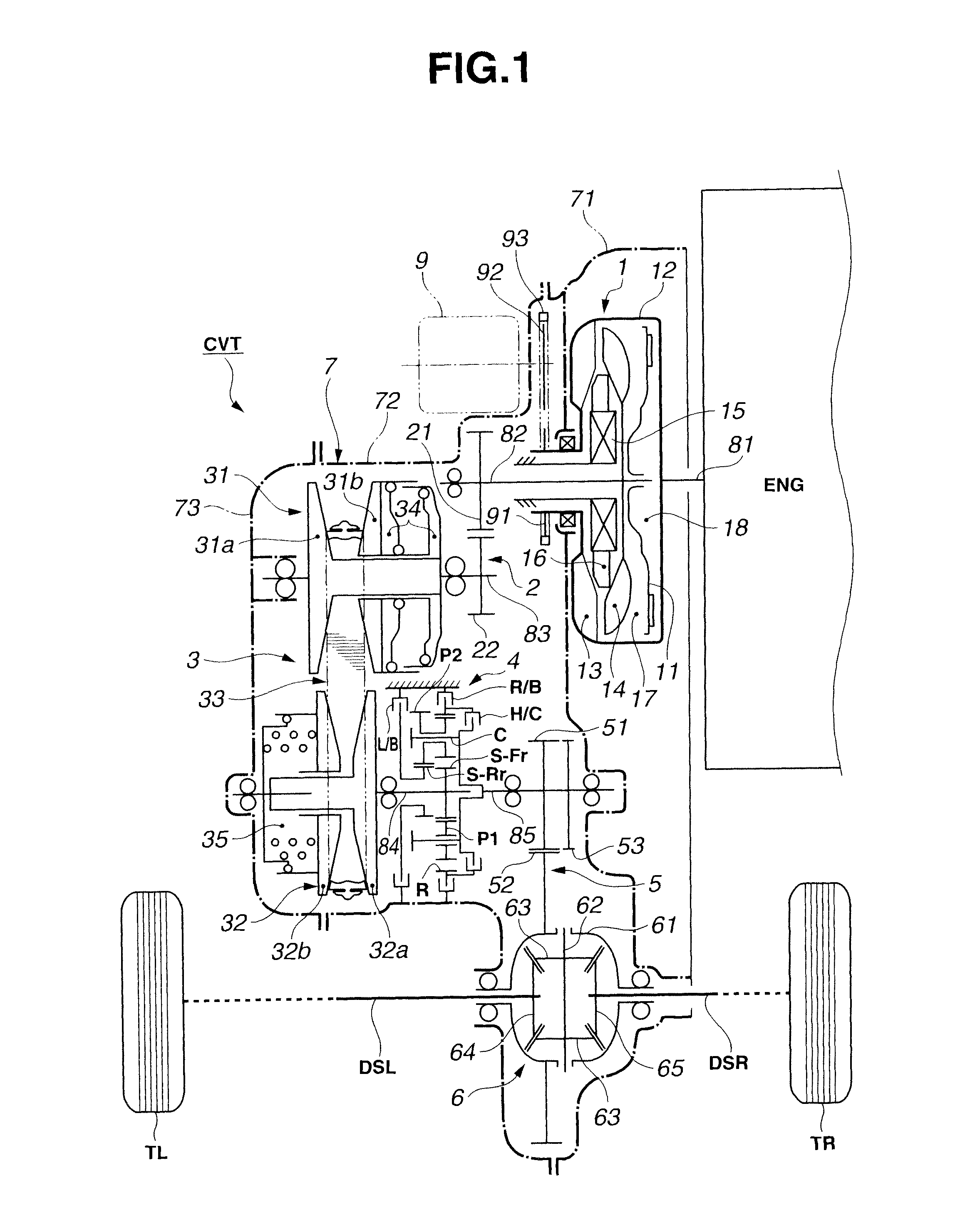

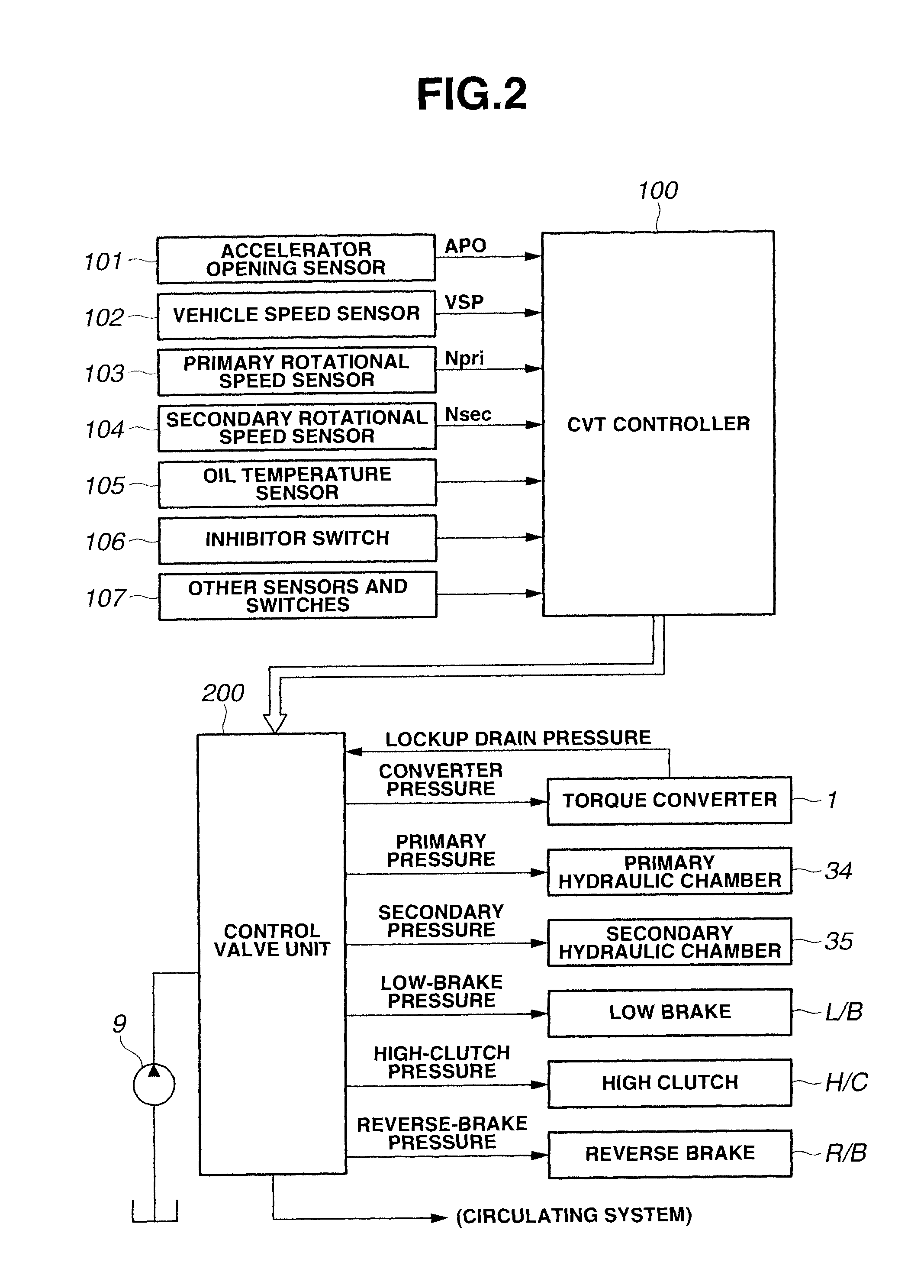

Continuously-variable transmission for vehicle

ActiveUS8620539B2Improved shift qualityIncrease widthDigital data processing detailsGearingEngineeringElectrical and Electronics engineering

Owner:JATCO LTD +1

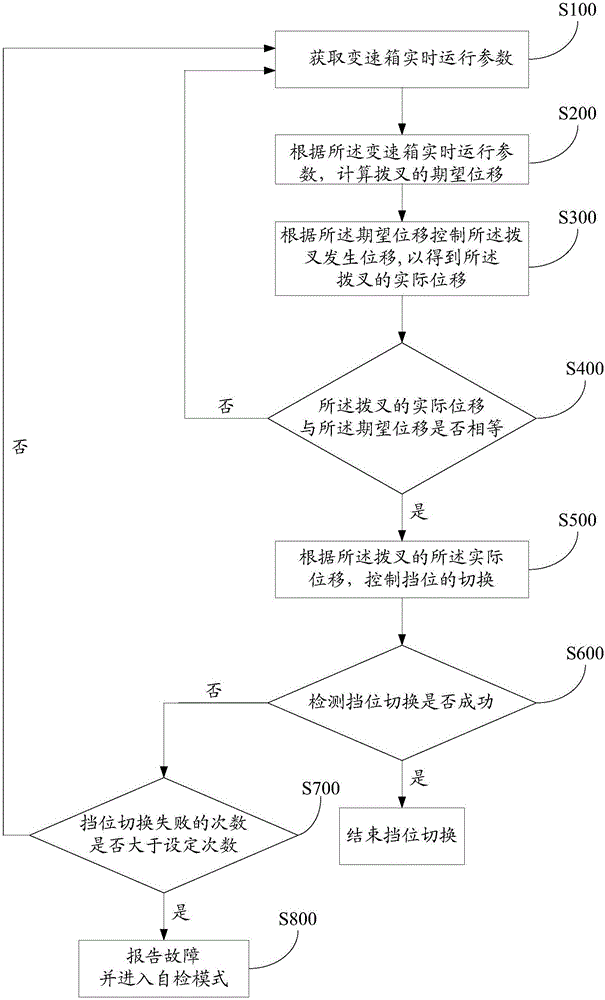

Gear switching control method for automatic transmission of wet dual clutch

InactiveCN107524794AHigh precisionImprove comfort and reliabilityGearing controlLoop controlClosed loop

The invention discloses a gear switching control method for an automatic transmission of a wet dual clutch. Control on a shifting fork is changed into closed-loop control from the traditional open-loop control by optimization of a gear engagement and separation control strategy, feedback is carried out when error exists between the measured actual displacement of the shifting fork and the expected displacement, and then the displacement of the shifting fork is controlled effectively. Compared with the prior art, the gear switching control method for the automatic transmission of the wet dual clutch has the advantages that the precision of control on the position of the shifting fork can be improved, furthermore, reliability and comfort of gear shifting can be improved, impact and noises during gear shifting are reduced, the gear shifting quality is improved, and the problem that vibration and noises are caused by the reason that the shifting fork cannot be engaged or is engaged too fast is avoided.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

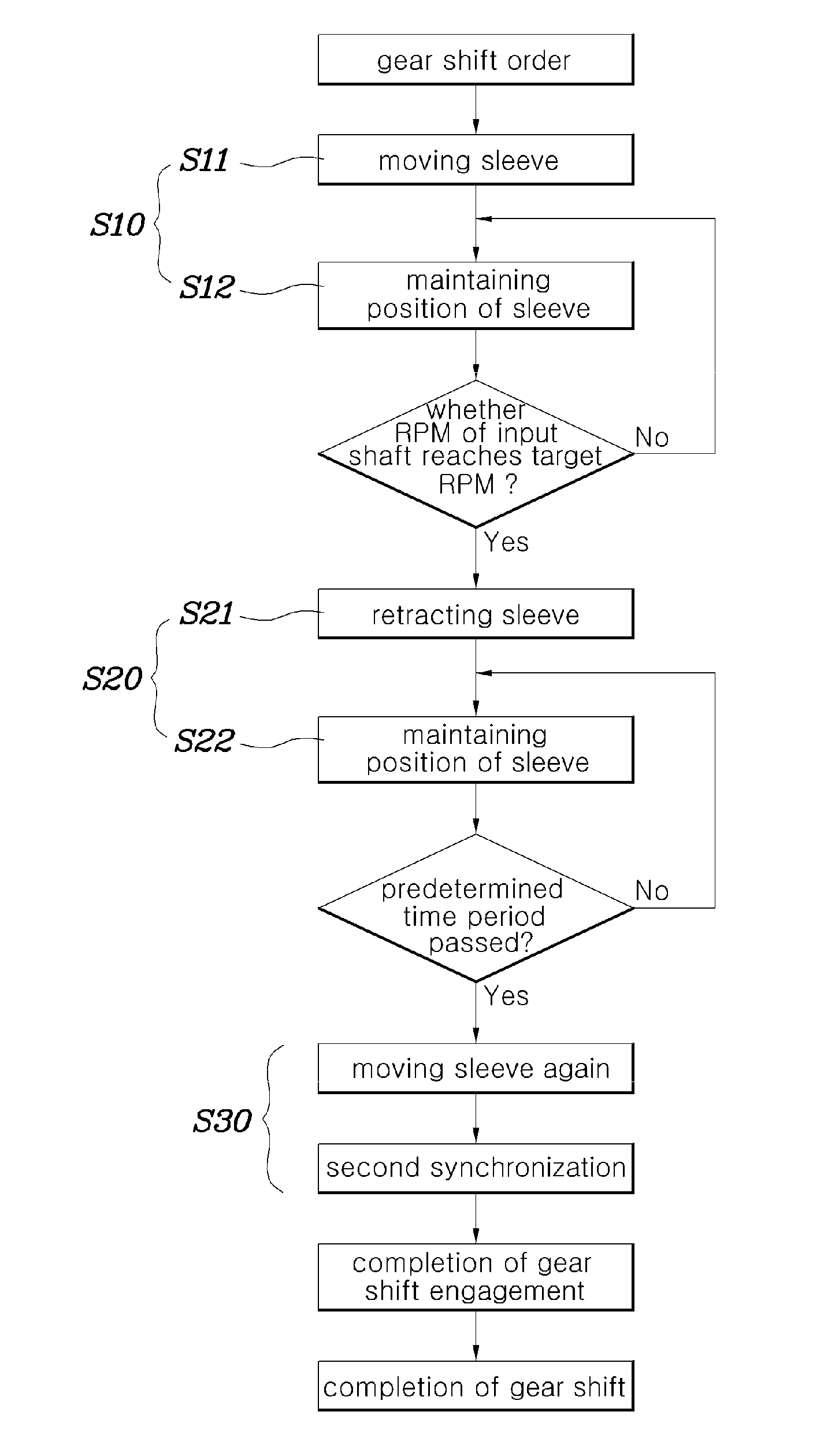

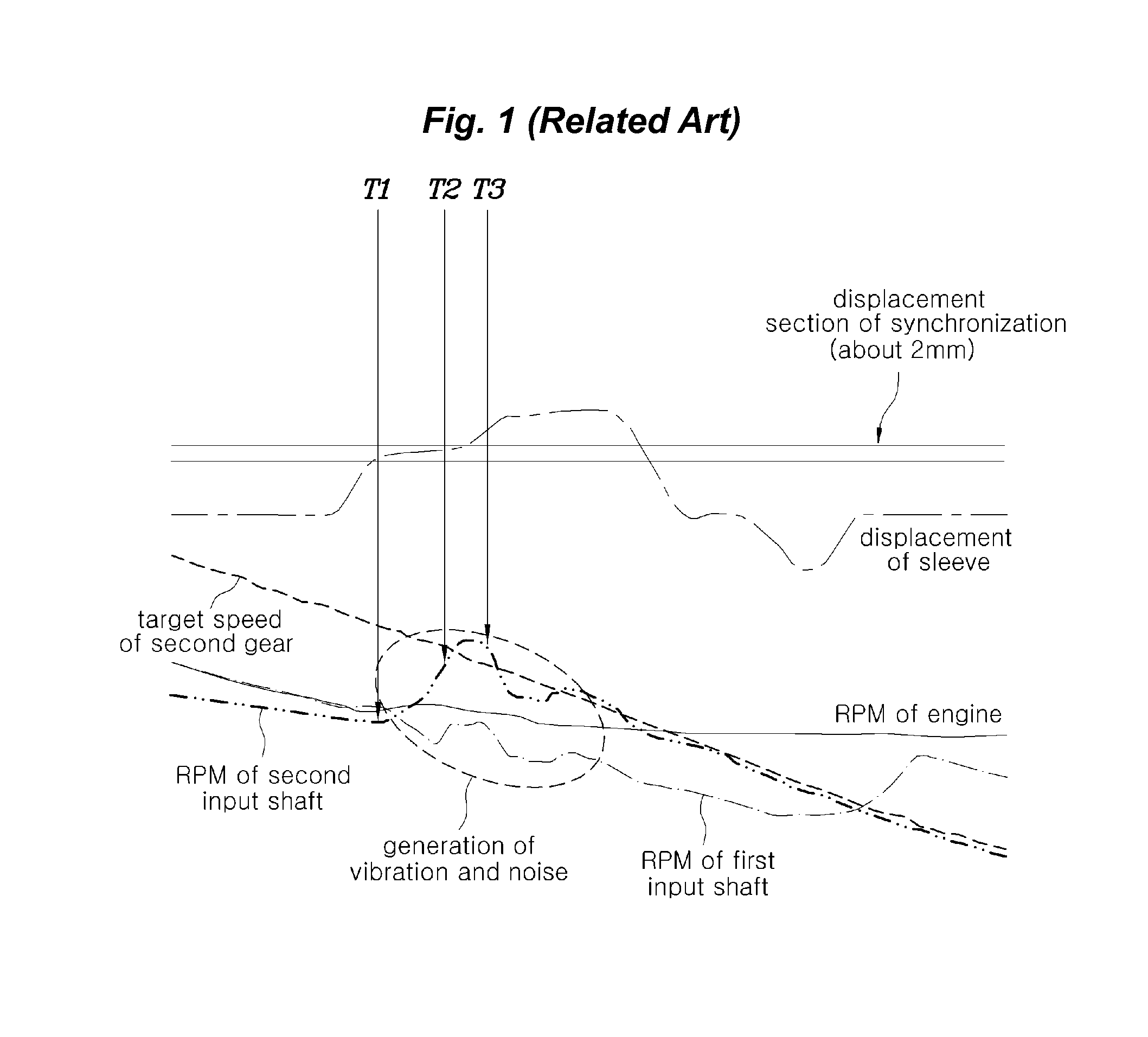

Control method and control apparatus of automatic transmission

InactiveUS7013746B2Small differenceImproved shift qualityGearing controlEngine controllersAutomatic transmissionControl theory

When shifting the gear position into a target gear position from a current gear position, some gear position different from said current gear position is used as one distributing gear position. The control unit controls the pressing load of a synchromesh of one distributing gear position to make at least part of the rotation torque from the drive power source transfer by the friction. Thereby it makes at least part of the rotation torque transferred by a synchromesh of the current gear position decrease. And then it moves the synchromesh of said current gear position to a disengaging position not meshed with said idle gear. Thereafter another gear position different from said target gear position and said one distributing gear position is used as another distributing gear position. So that it controls the pressing load of the synchromesh of another distributing gear to make the transfer torque increase gradually by the friction, and simultaneously makes the pressing load of the synchromesh of one distributing gear position decrease gradually. Besides such a distribution of transfer torque, it makes the speed of said input shaft synchronize with the speed corresponding to said target gear position by controlling the speed of said input shaft, and then moves the synchromesh of the target gear position to the meshing position.

Owner:HITACHI LTD +1

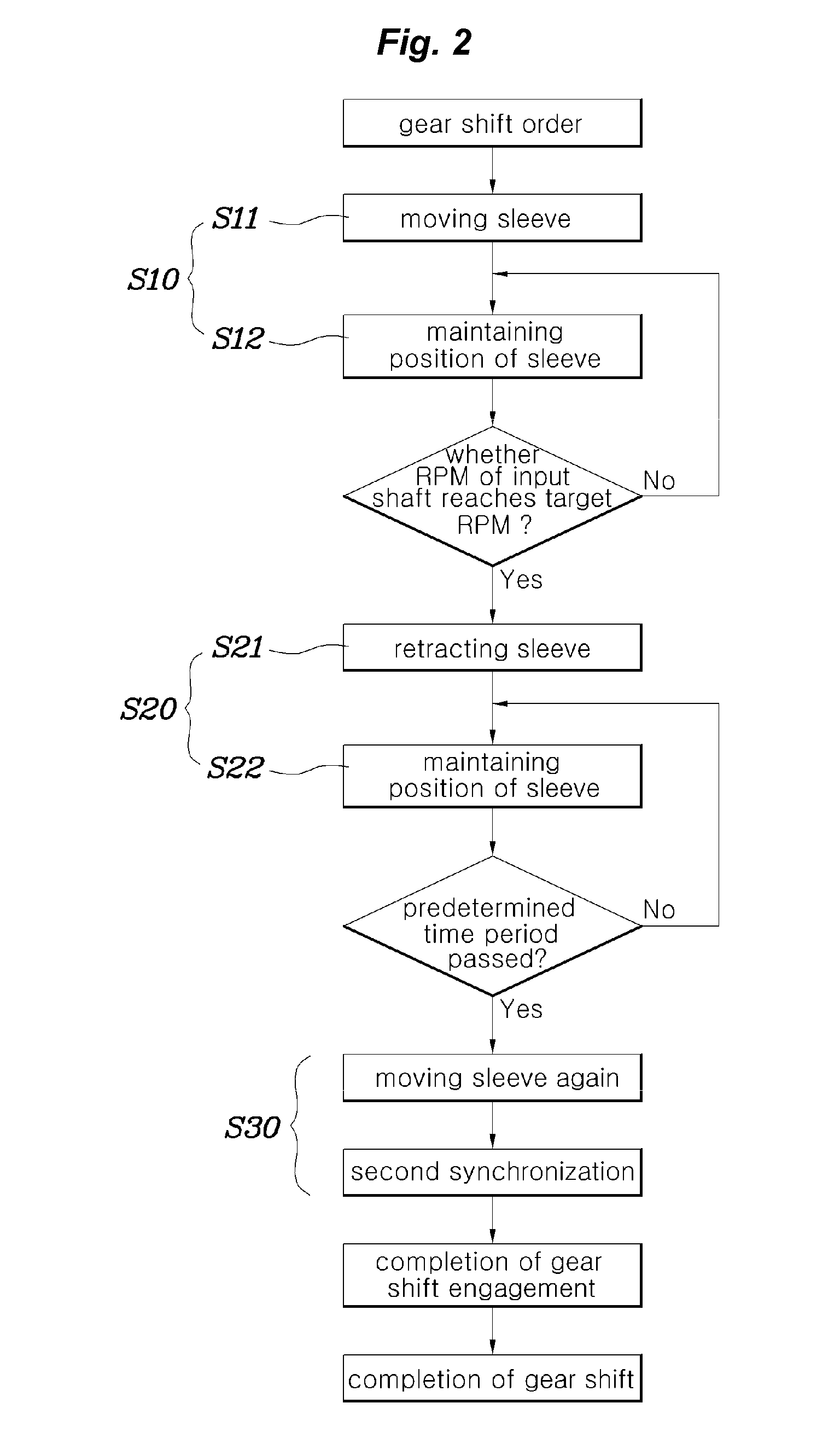

Method of controlling transmission of vehicle

InactiveUS20120312652A1Improved shift qualityImprove quietnessGearing controlEngine controllersReduction driveEngineering

Owner:HYUNDAI MOTOR CO LTD

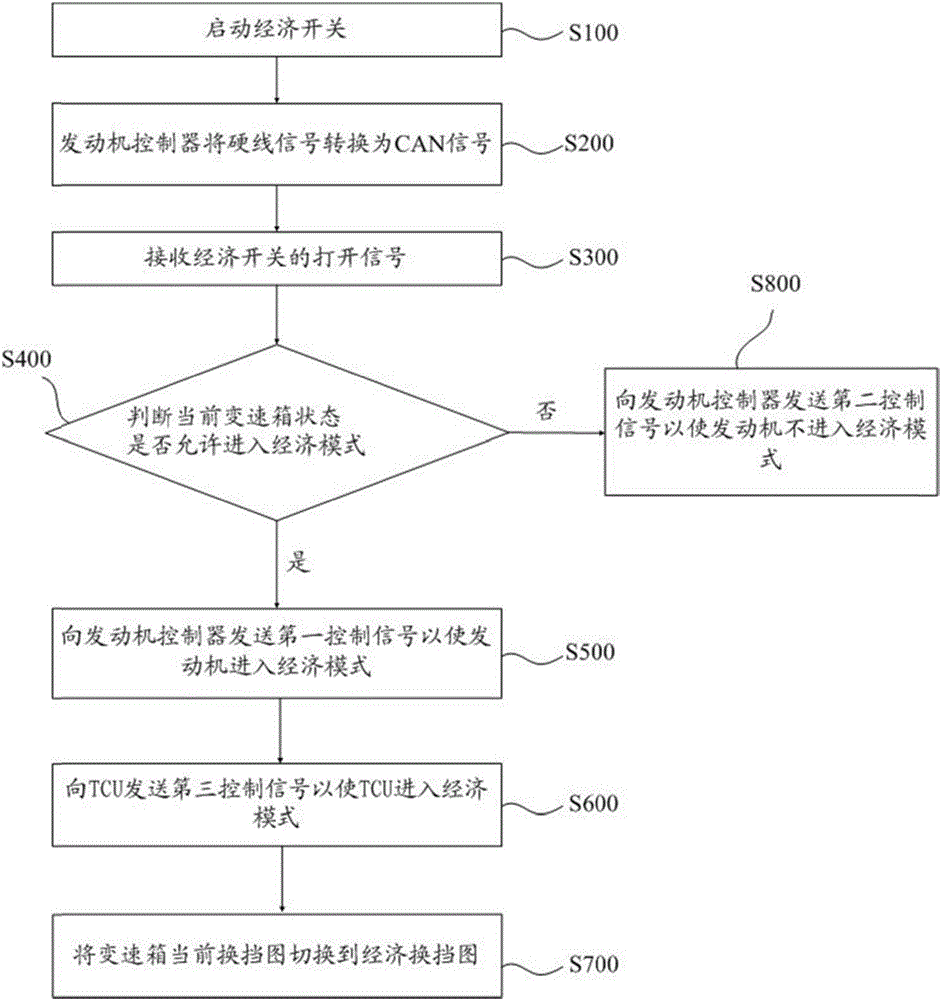

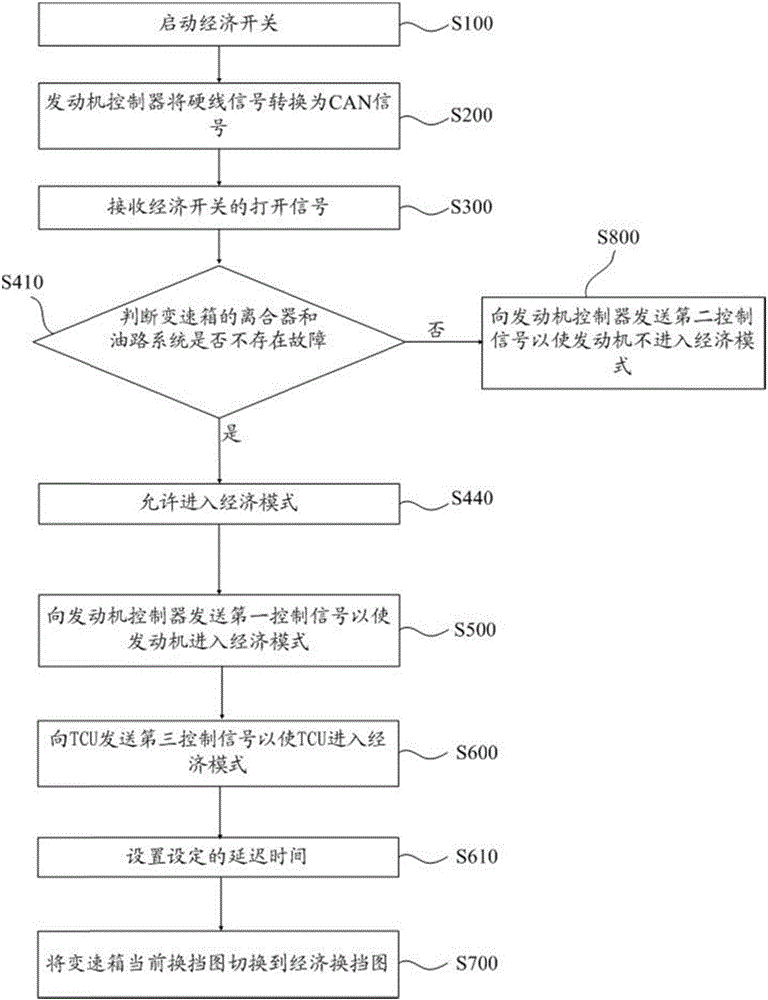

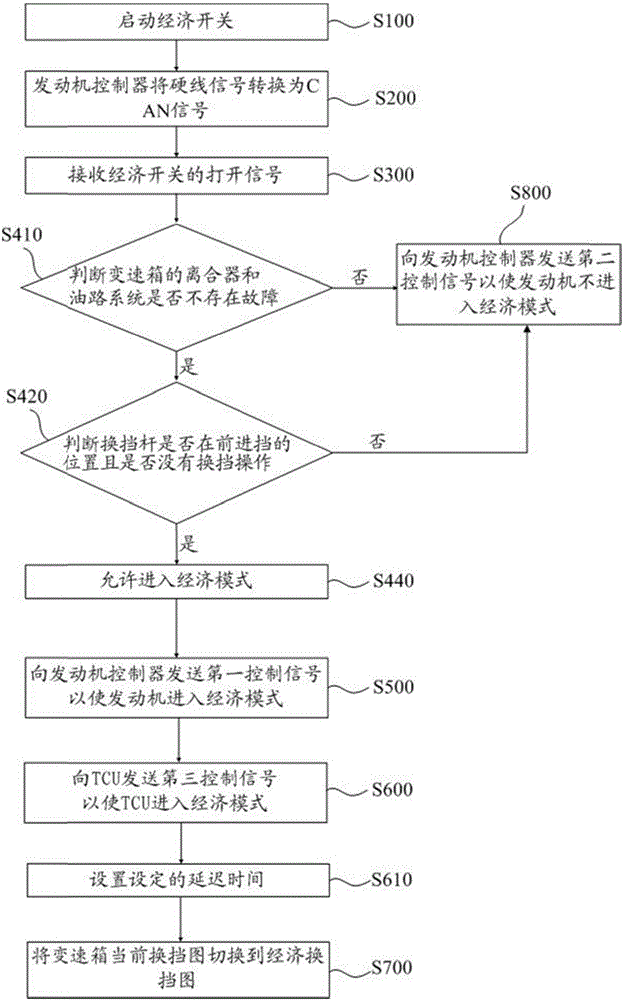

Control method of wet type dual-clutch transmission

ActiveCN106224535AImprove economyAvoid the problem of frequently switching shift mapsGearing controlControl signalClutch

The invention discloses a control method of a wet type dual-clutch transmission. The method comprises the steps of receiving an opening signal of an economy switch; judging whether the current transmission state is allowed to enter the economic mode or not; if yes, sending a first control signal to an engine controller so as to enable an engine to be in the economic mode; switching a current gear shifting figure of the transmission to an economic gear shifting figure; according to the control method of the wet type dual-clutch transmission, after the engine enters in the economic mode, the current gear shifting figure of the transmission is switched into the economic gear shifting figure, and therefore the transmission enters in the economic mode after the engine enters in the economic mode, the transmission and the engine achieve economic mode cooperation, and the fuel economy is further improved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Method and apparatus for controlling fluid supply to a clutch pack of an automatic transmission

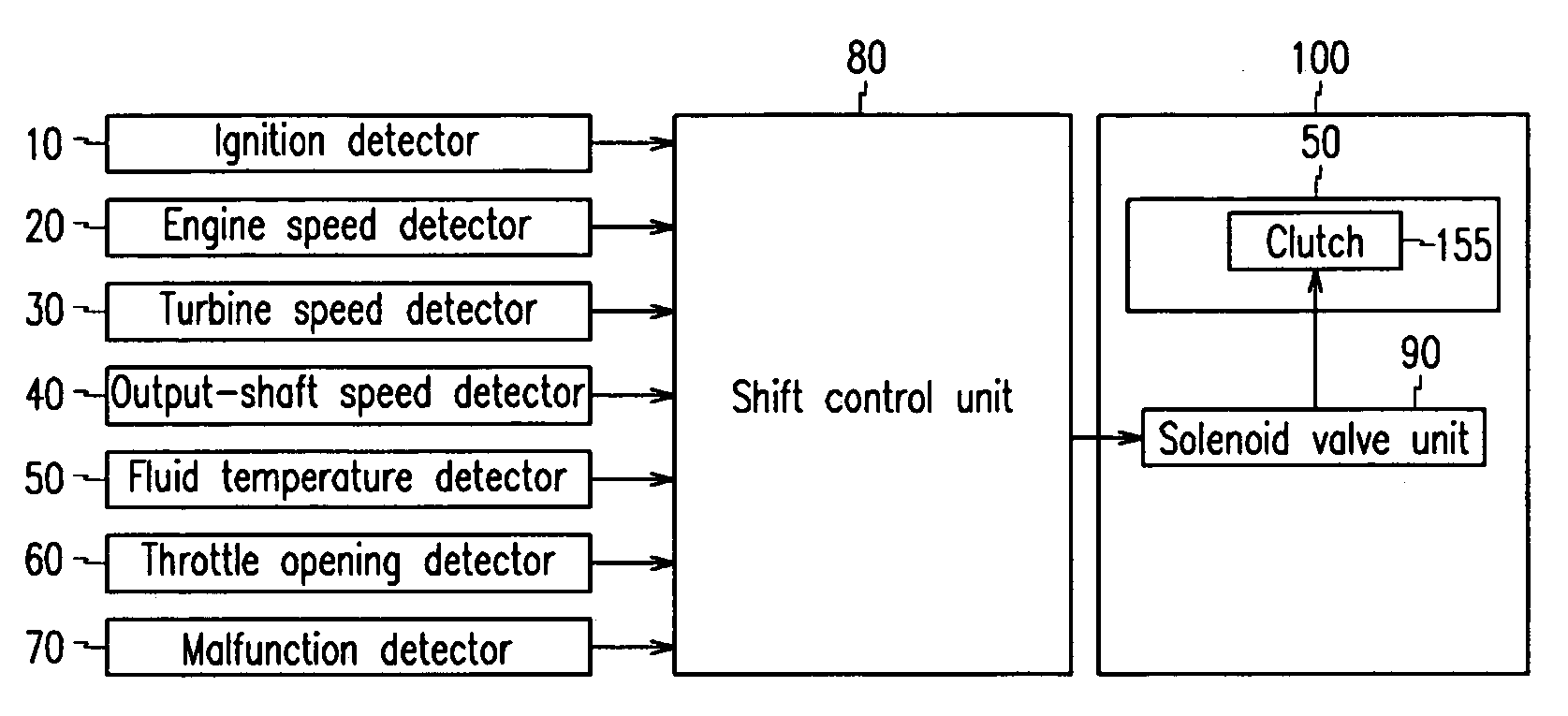

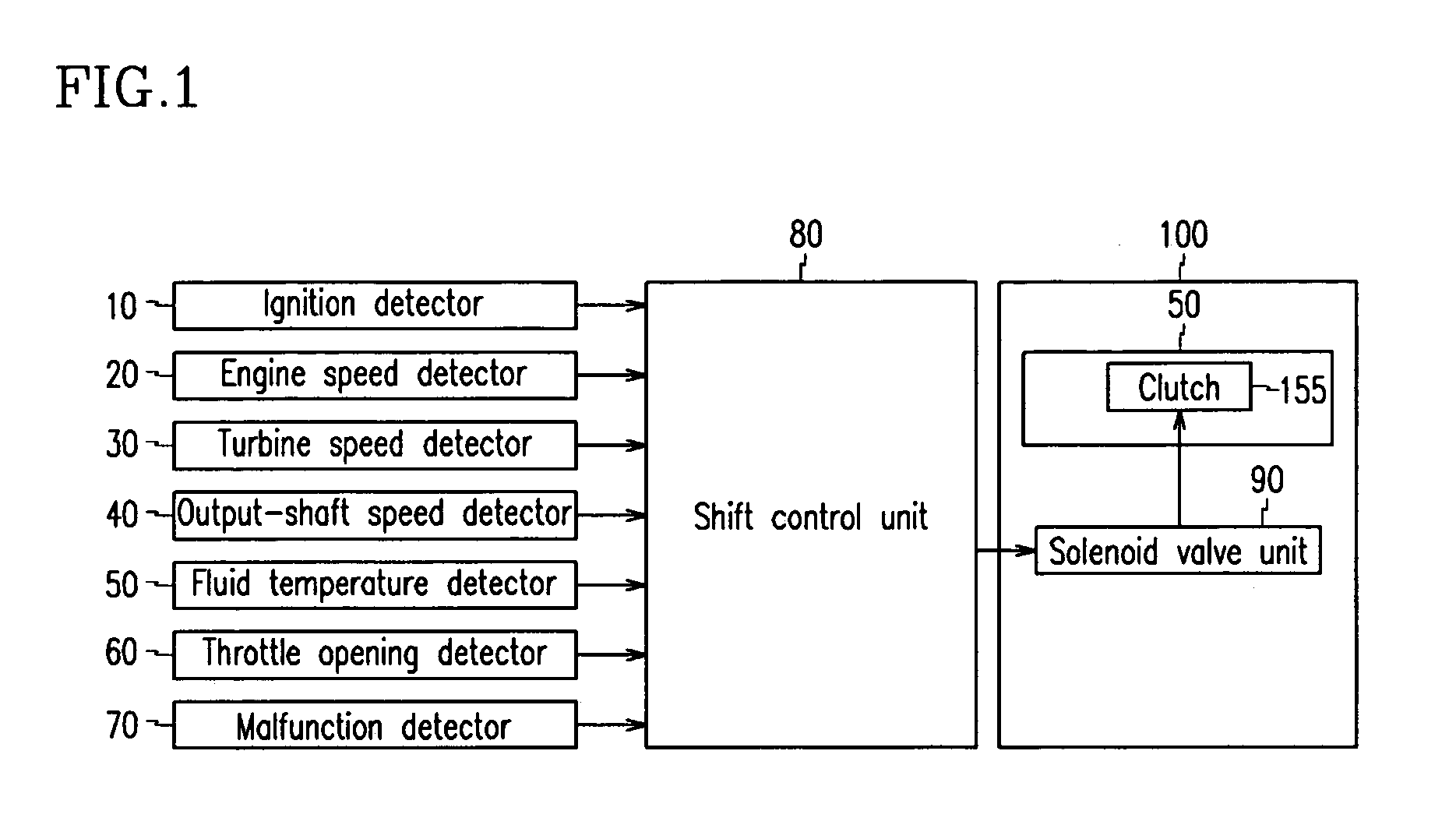

InactiveUS7181327B2Improve shift qualityShift-shock is reducedDigital data processing detailsGearing controlEngineeringFluid supply

When an engine is restarted after a predetermined period of being stopped oil is supplied to a clutch pack for a 2–3 and / or 3–4 shift while a transmission is engaged in the first speed for the first time since starting. The amount of oil drained during the predetermined period of being stopped is complemented in advance such that shift quality of a first 2–3 and / or 3–4 shift is enhanced.

Owner:HYUNDAI MOTOR CO LTD

Three-speed transmission provided with two input shafts

InactiveCN106931143AClose gear ratioWide range of gear ratiosToothed gearingsGearing detailsSingle stageElectric machine

The invention provides a three-speed transmission provided with two input shafts. The three-speed transmission provided with the two input shafts is mainly used for electric automobiles. The transmission can provide three advancing gears, and the problem that an electric automobile only with a single-stage reduction ratio cannot take the driving force and the speed into consideration is solved. The three-speed transmission provided with the two input shafts comprises a planetary gear row, gear selecting assemblies, the first input shaft, the second input shaft and the like. The two input shafts are connected with two sets of motors correspondingly. Through the two gear selecting assemblies, a sun gear or a gear ring of the planetary gear row is used as an input component, and a planetary carrier is used as an output component so that three different gear ratios can be obtained. The three-speed transmission provided with the two input shafts has the advantages of being compact in structure, low in weight, high in transmission efficiency, reliable in transmission and the like and is particularly suitable for the electric automobiles.

Owner:重庆红岭动力技术有限公司

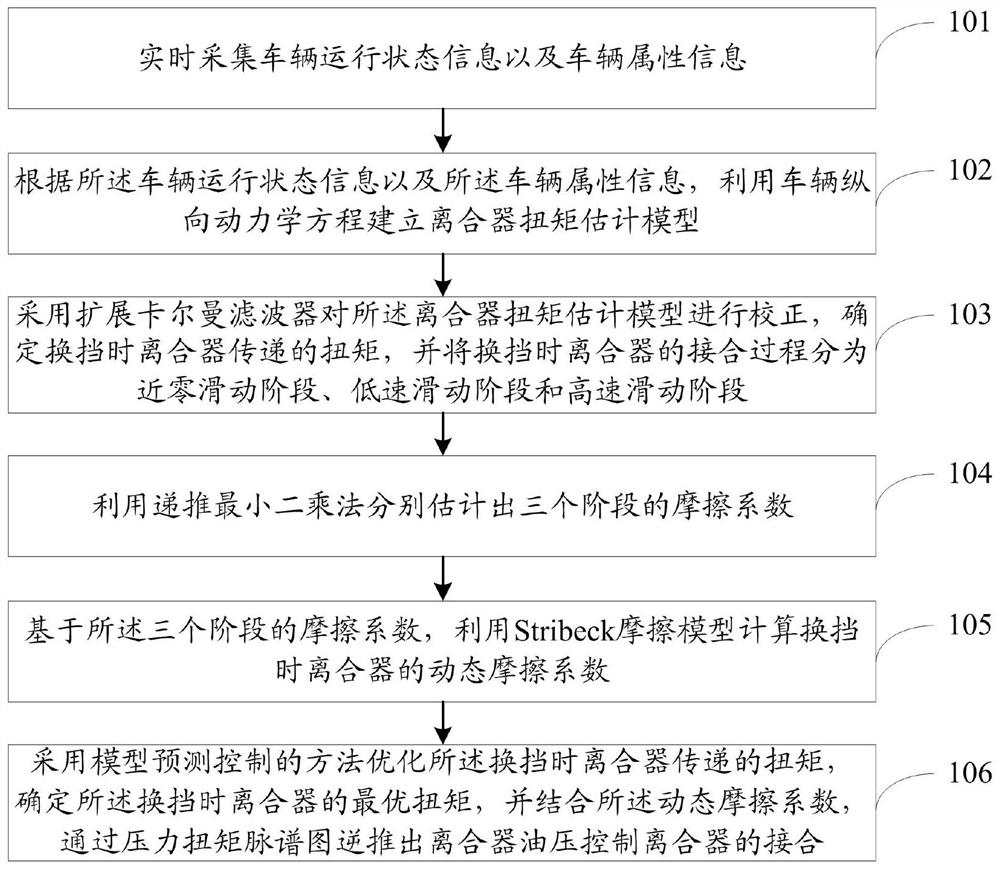

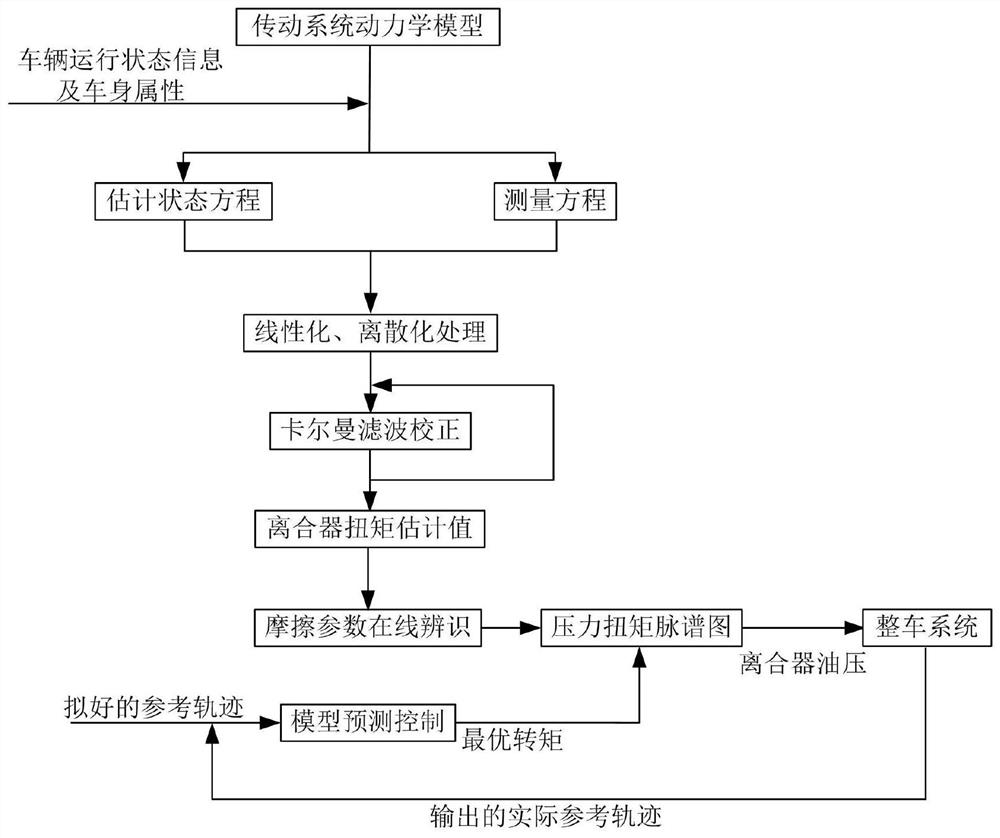

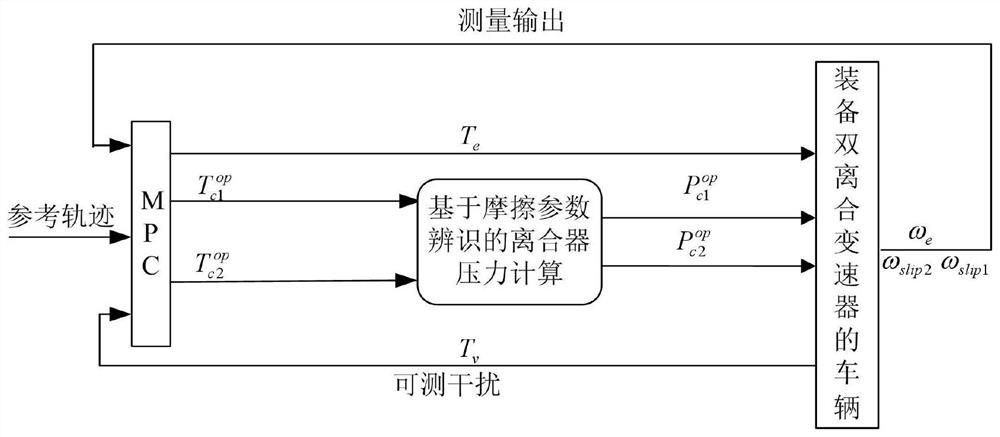

Wet-type double-clutch gear shifting control method and system

ActiveCN112417592AExtended service lifeImproved shift qualityGeometric CADSustainable transportationLeast squaresOil pressure

The invention relates to a wet-type double-clutch gear shifting control method and system. The control method comprises the steps of collecting vehicle running state information and vehicle attributeinformation in real time; establishing a clutch torque estimation model by using a vehicle longitudinal kinetic equation; correcting the clutch torque estimation model by adopting an extended Kalman filter, determining the torque transmitted by the clutch during gear shifting, and dividing the engagement process of the clutch during gear shifting into three stages; respectively estimating frictioncoefficients of the three stages by using a recursive least square method; calculating the dynamic friction coefficient of the clutch during gear shifting by using a Seebeck friction model; optimizing the torque transmitted by the clutch during gear shifting by adopting a model prediction control method, determining the optimal torque of the clutch during gear shifting, and controlling the engagement of the clutch by reversely deducing the clutch oil pressure through a pressure torque pulse spectrogram in combination with the dynamic friction coefficient. The gear shifting quality of the clutch can be rapidly improved through the control method without changing the structure of the transmission.

Owner:NINGXIA UNIVERSITY

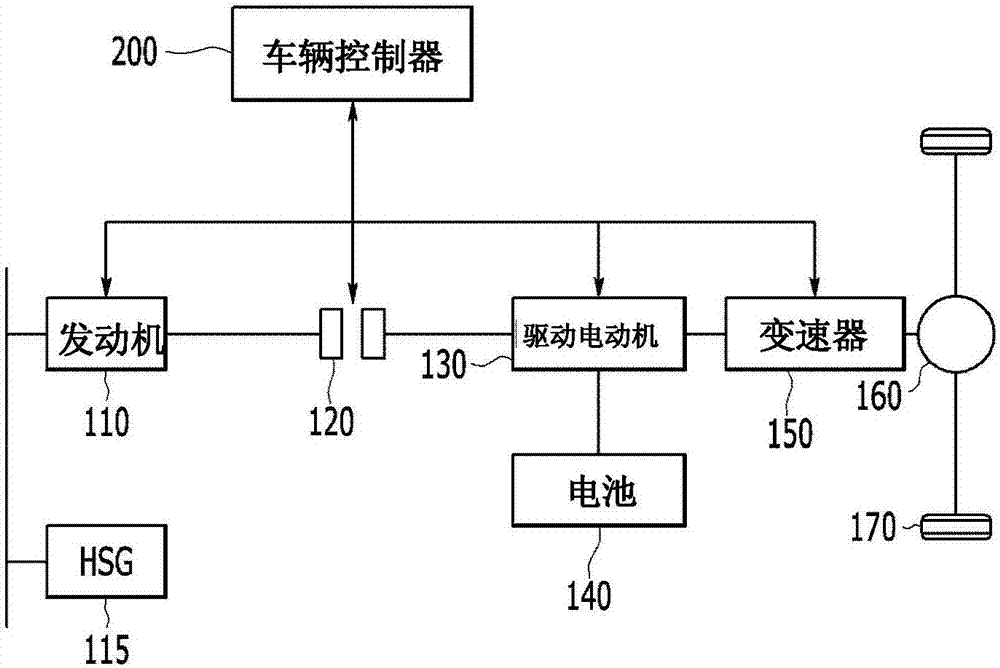

Shift control apparatus and method of vehicle

ActiveCN107387748AShorten shift timeImproved shift qualityHybrid vehiclesGearing controlVehicle controlClutch

The present disclosure relates to a shift control apparatus of a vehicle and its method. In particular, the shift control apparatus includes: a transmission including a first clutch and a second clutch; a torque source to generate power for driving a vehicle; a data detector to detect a vehicle state data; and a vehicle controller to connect a current stage synchronizer to a next stage driving gear if the vehicle state data satisfy a shift condition, release the first clutch to be connected to the driving gear of a current stage, perform a speed control of a torque source while maintaining the second clutch connected to the driving gear of the next stage in a slip state, and release the second clutch and connect the first clutch if the vehicle stage data satisfy a speed control completion condition to complete a shift to a target stage.

Owner:HYUNDAI MOTOR CO LTD

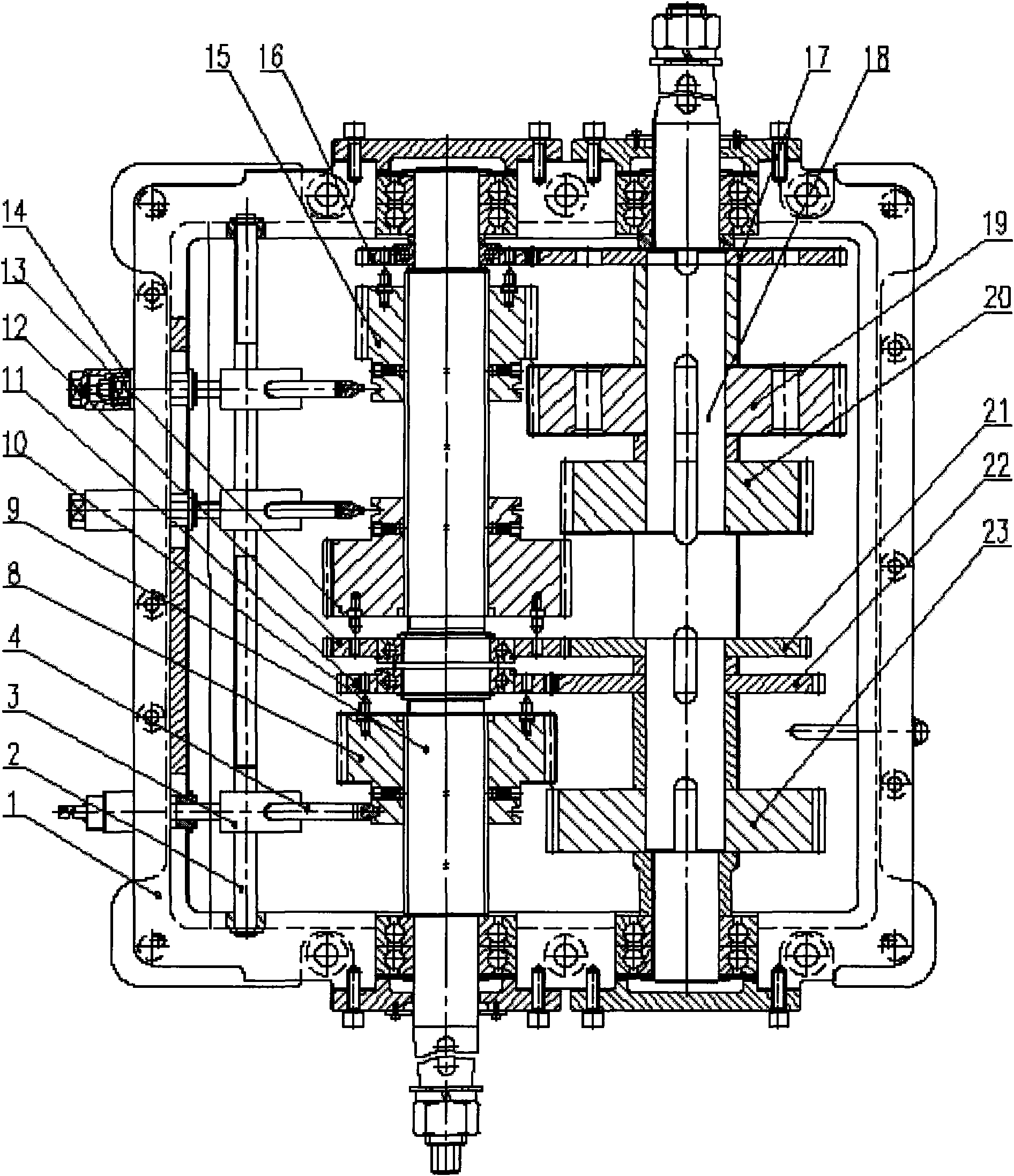

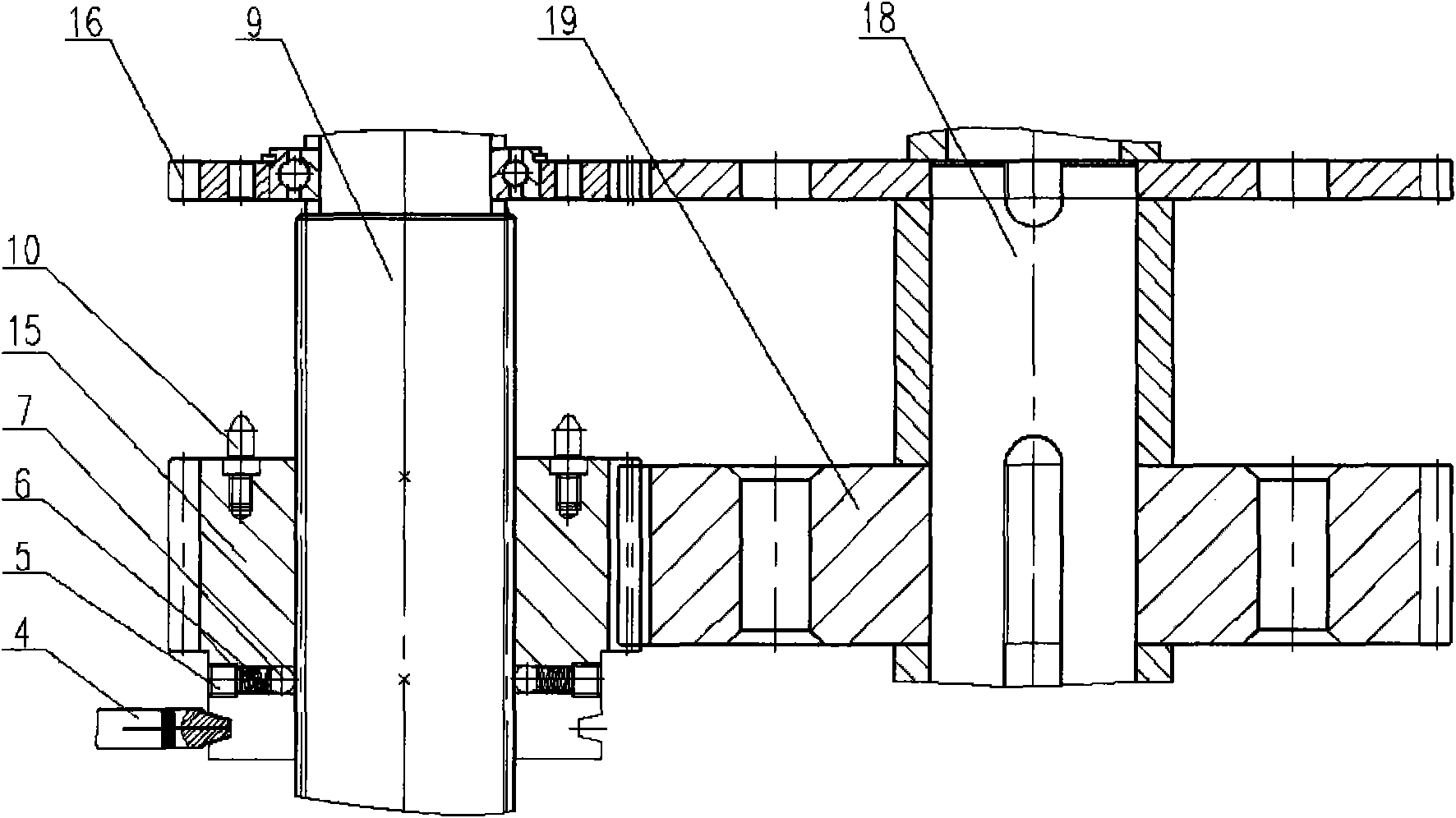

Stroke frequency regulating apparatus of oil pumping machine

The invention relates to a stroke frequency regulating apparatus of an oil pumping machine, which belongs to the technical field of oil exploitation and extraction equipment and is characterized in that three synchronizing pinions (16), (12) and (11) and three variable speed pinions (15), (13) and (8) are arranged on an input shaft (9); three synchronizing gearwheels (17), (21) and (22) and three variable speed gearwheels (19), (20) and (23) are arranged on an output shaft (18); three pairs of synchronizing gears keep engaged all the time; and when a shifting handle (14) is screwed and a fork head (4) of a shifting fork is pressed, the fork head can be clamped in fork pockets on the three variable speed pinions (15), (13) and (8) on the input shaft (9), so that the variable speed pinions can be toggled to move axially and realize shift operation. The regulating apparatus has simple and compact structure and convenient manufacture and can fully adapt to shift demands under various conditions, and when the stroke frequency regulating apparatus is arranged on the oil pumping machine, the shift quality can be improved, and the shift time can be reduced.

Owner:YANGTZE UNIVERSITY

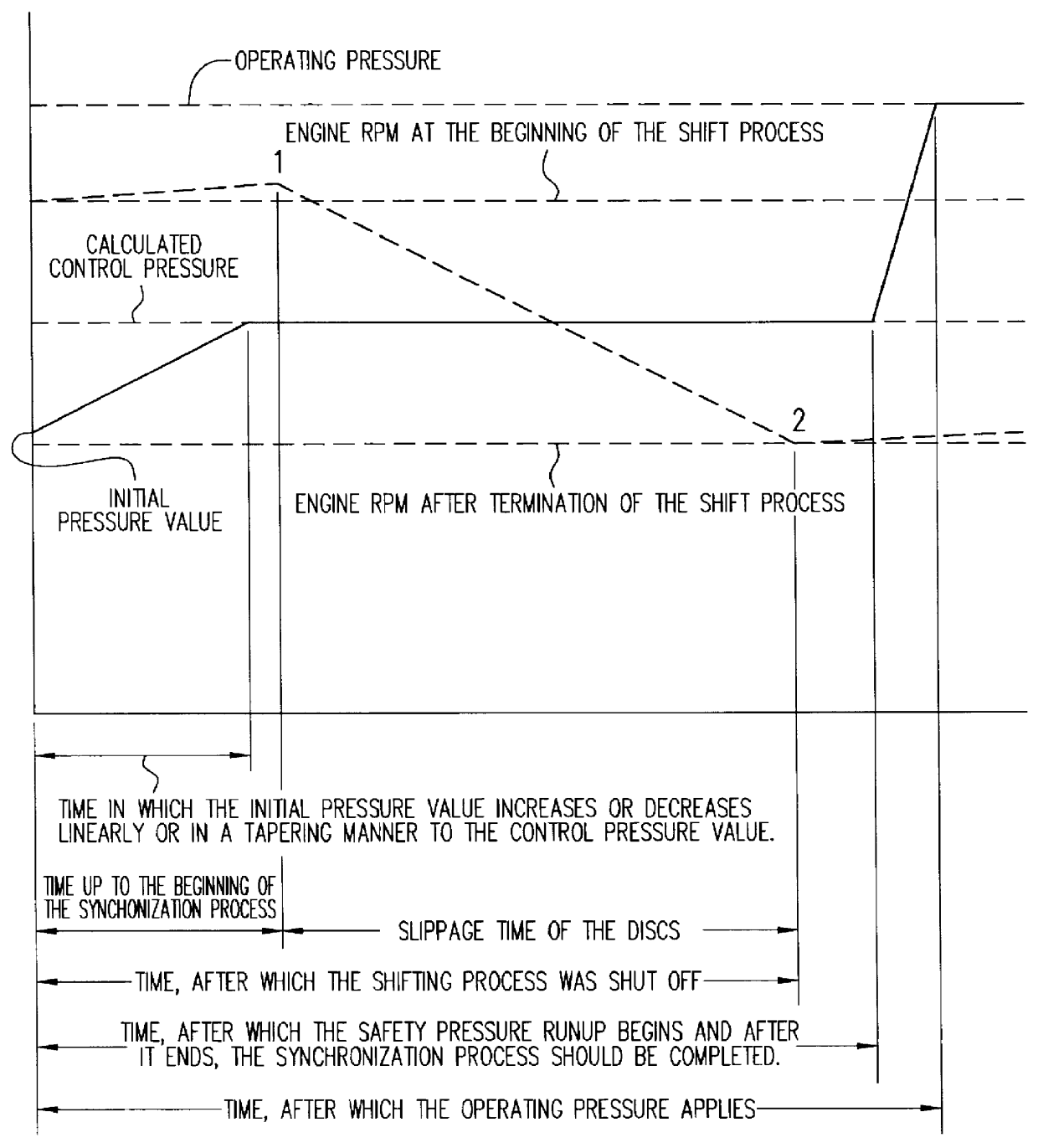

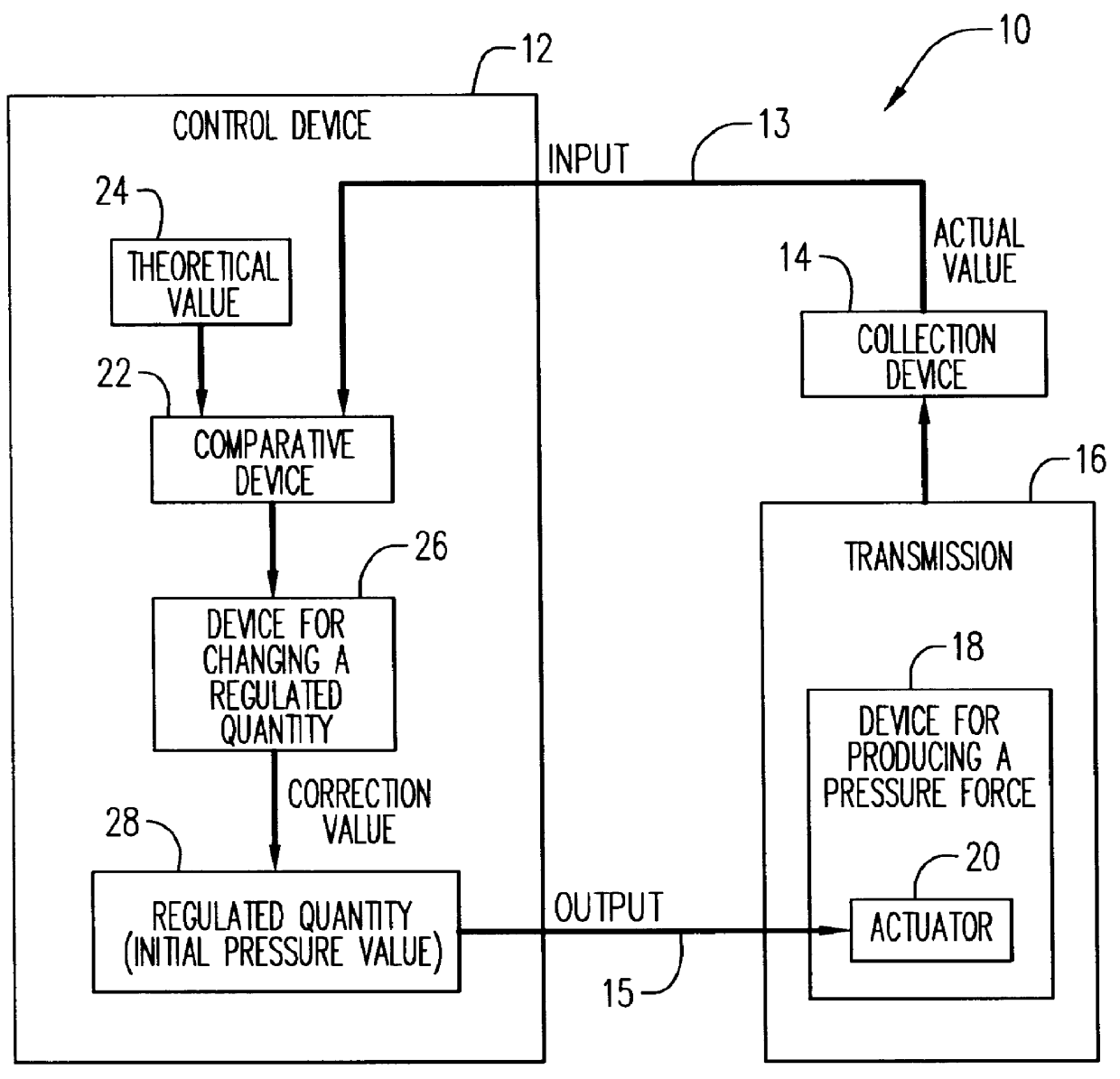

Method of operating a vehicle transmission

InactiveUS6095948AQuality improvementSmall loadGearing controlEngine controllersDirect effectsEngineering

PCT No. PCT / EP96 / 03777 Sec. 371 Date Oct. 21, 1998 Sec. 102(e) Date Oct. 21, 1998 PCT Filed Aug. 2, 1996 PCT Pub. No. WO97 / 08479 PCT Pub. Date Mar. 6, 1997A process is provided for operating a vehicle transmission with preferably electrohydraulically actuatable friction elements for shifting between different transmission steps, in a vehicle with at least one drive engine in which an actual value of at least one of the quantities characterizing the shift process is determined for each shift process, which actual value is compared with a theoretical value that can be established and stored. When the actual value deviates from the theoretical value, a regulated quantity for at least direct influencing is changed by a correction value that can be established. For each shift process, the time duration for the output of a gear shift signal up to the beginning of the synchronization process and / or the change of the drive rpm during this time period is determined as a first and / or second actual value of the quantity characterizing the process. When the time period up to the beginning of the synchronization process deviates from the pre-given theoretical time period or if the drive rpm change given in advance is not achieved after a shift process, the initial pressure value is changed by the correction value in order to introduce the necessary pressure force of the coupling components that can be coupled together in a force-interlocking manner.

Owner:VOITH TURBO GMBH & CO KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com