Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4591results about "Machine gearing/transmission testing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acoustic vibration analyzing apparatus and acoustic vibration analyzing method, program for analyzing acoustic vibration, and recording medium, readable by computer, on which program for analyzing acoustic vibration is stored

ActiveUS7401000B2Easy to carryReduce in quantityVibration measurement in solidsVehicle testingAnalysis methodAcoustics

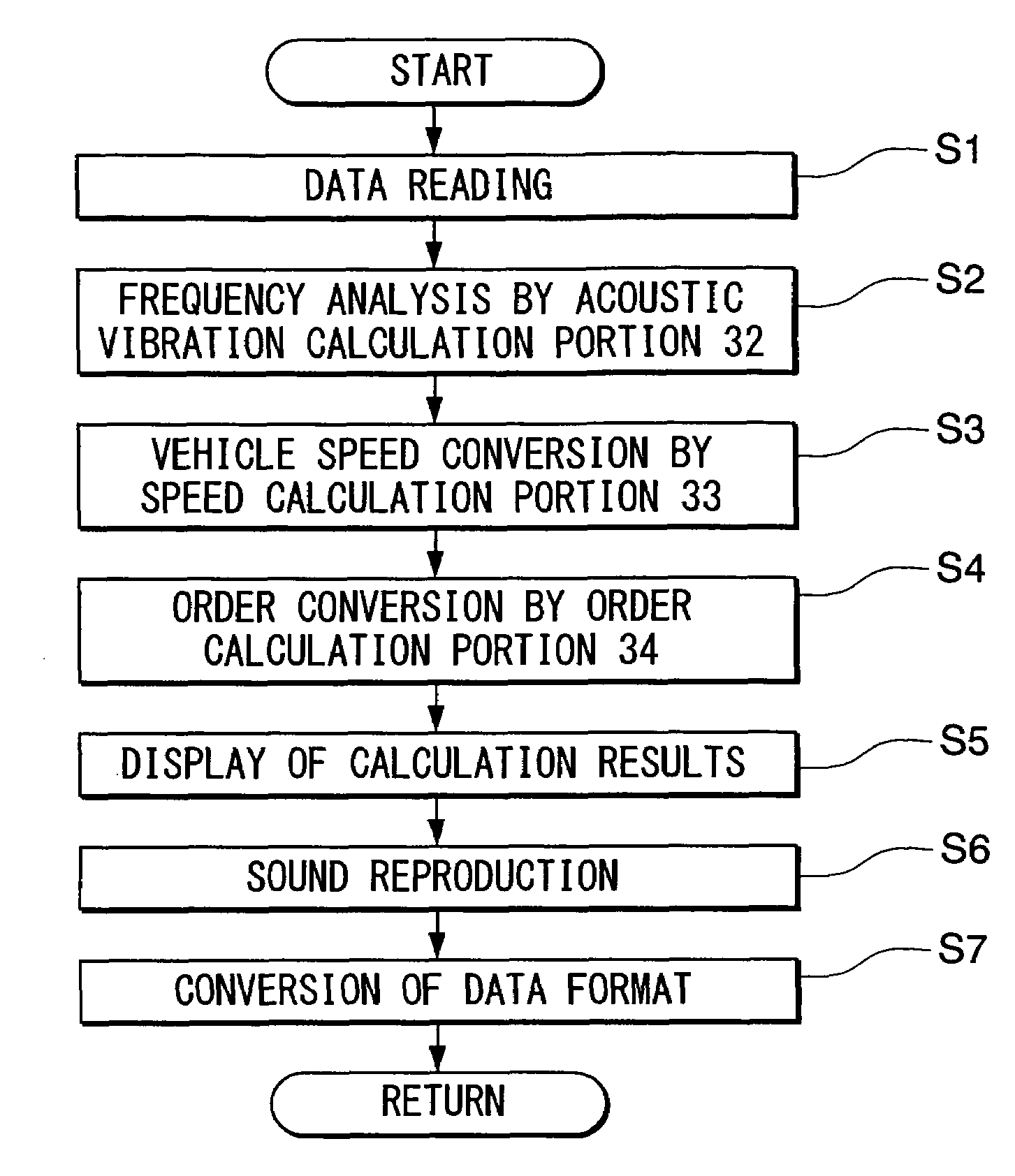

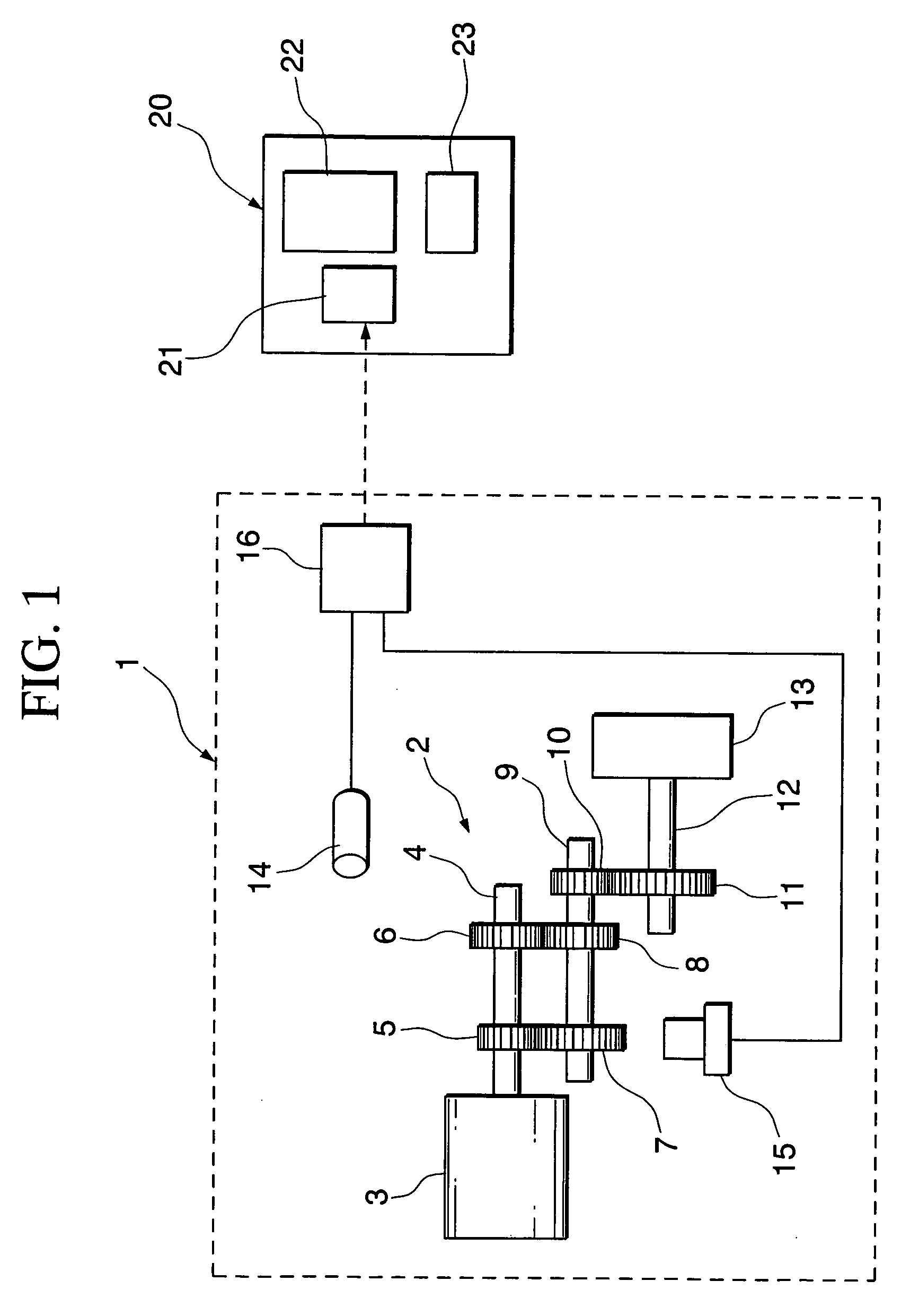

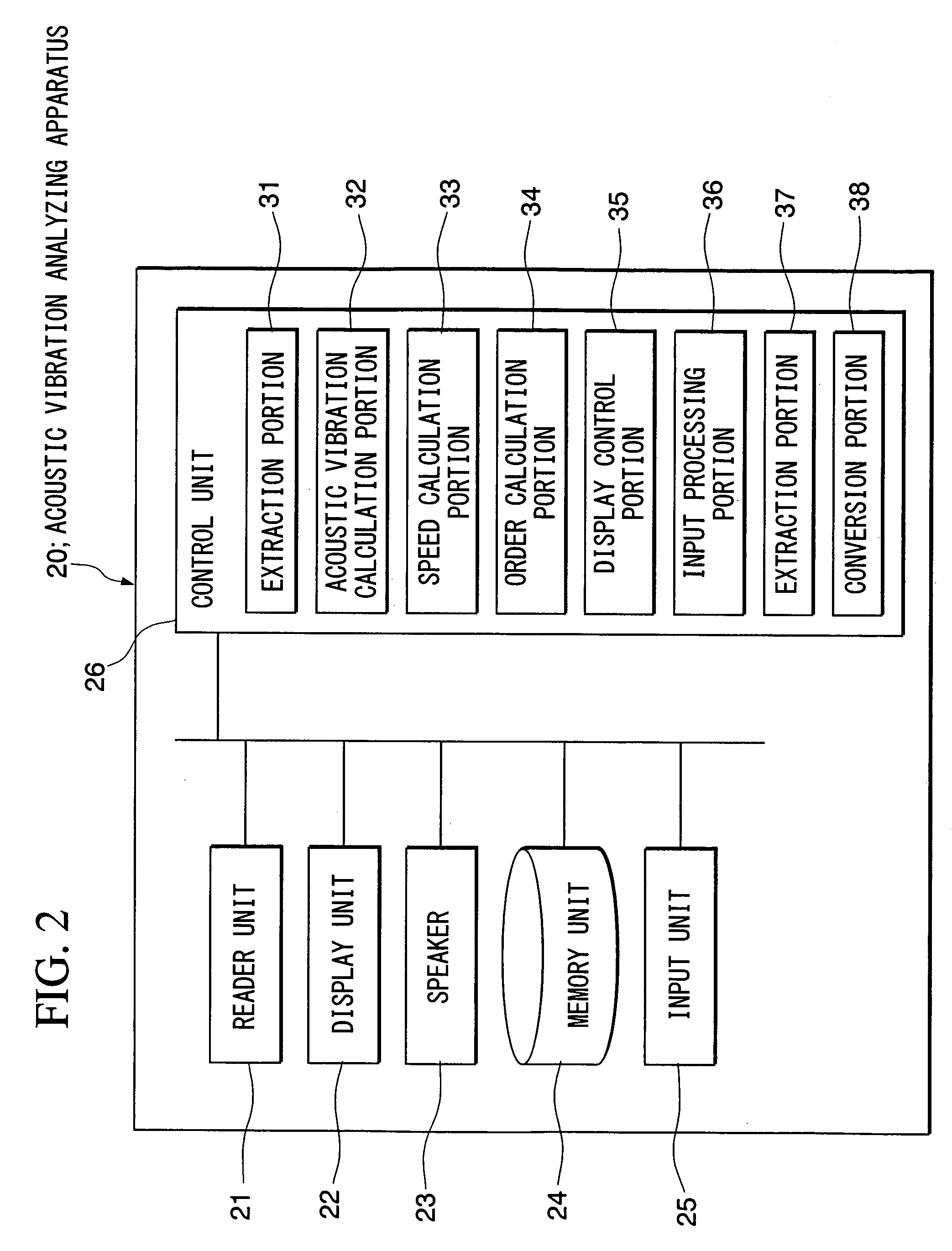

The present invention provides an acoustic vibration analyzing apparatus for carrying out acoustic vibration analysis by picking up data of sounds generated due to rotation of a plurality of gears and data of the number of revolutions of a gear selected from a plurality of gears when a transmission of a vehicle having the plurality of gears operates. The acoustic vibration analyzing apparatus comprises an acoustic vibration calculation portion for analyzing acoustic data in terms of frequency, an order calculation portion for calculating an order in compliance with the specifications of a plurality of gears, a speed calculation portion for calculating the speed of a vehicle, and a display unit for displaying acoustic pressure levels with the order and vehicle speed associated therewith.

Owner:HONDA MOTOR CO LTD

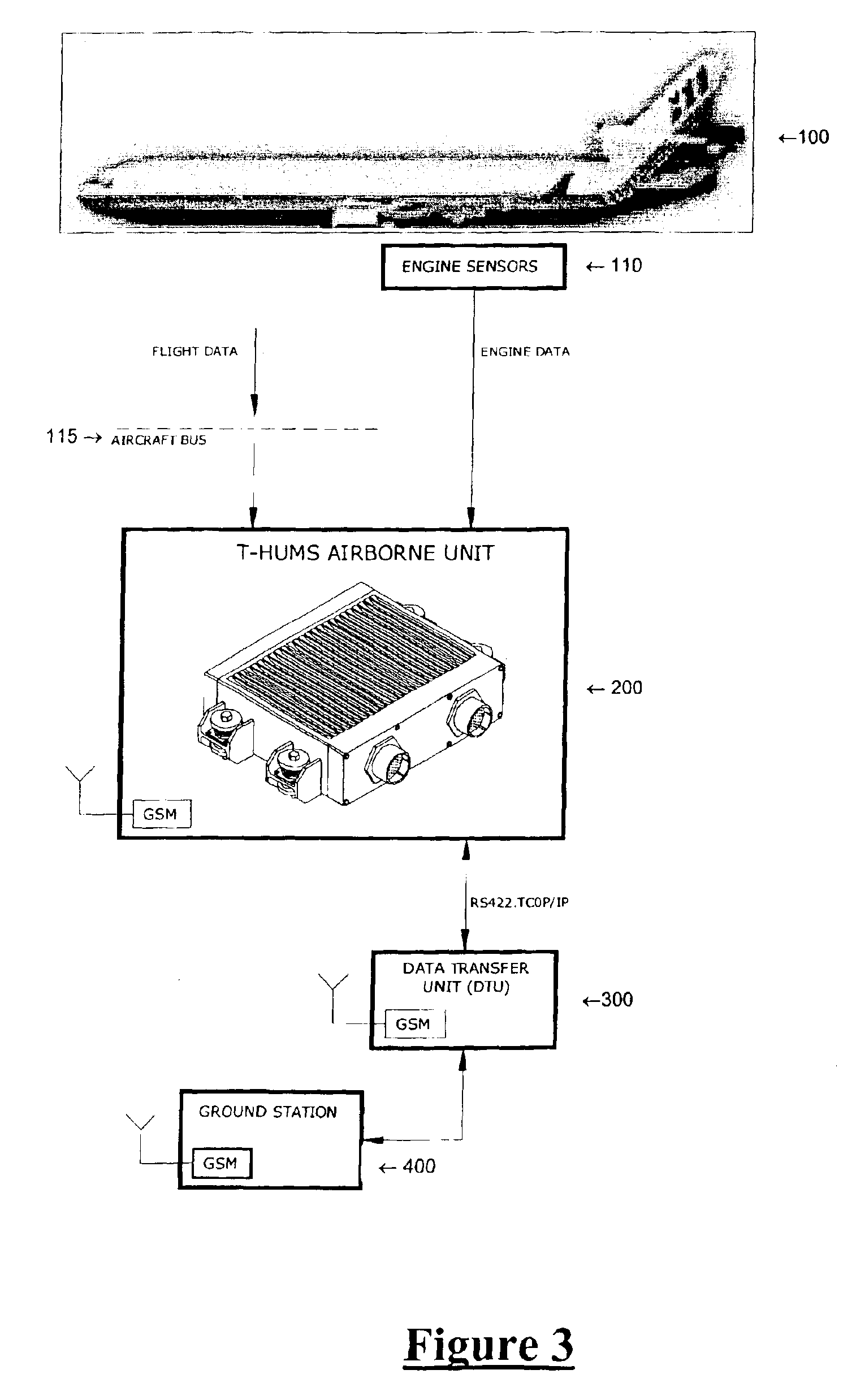

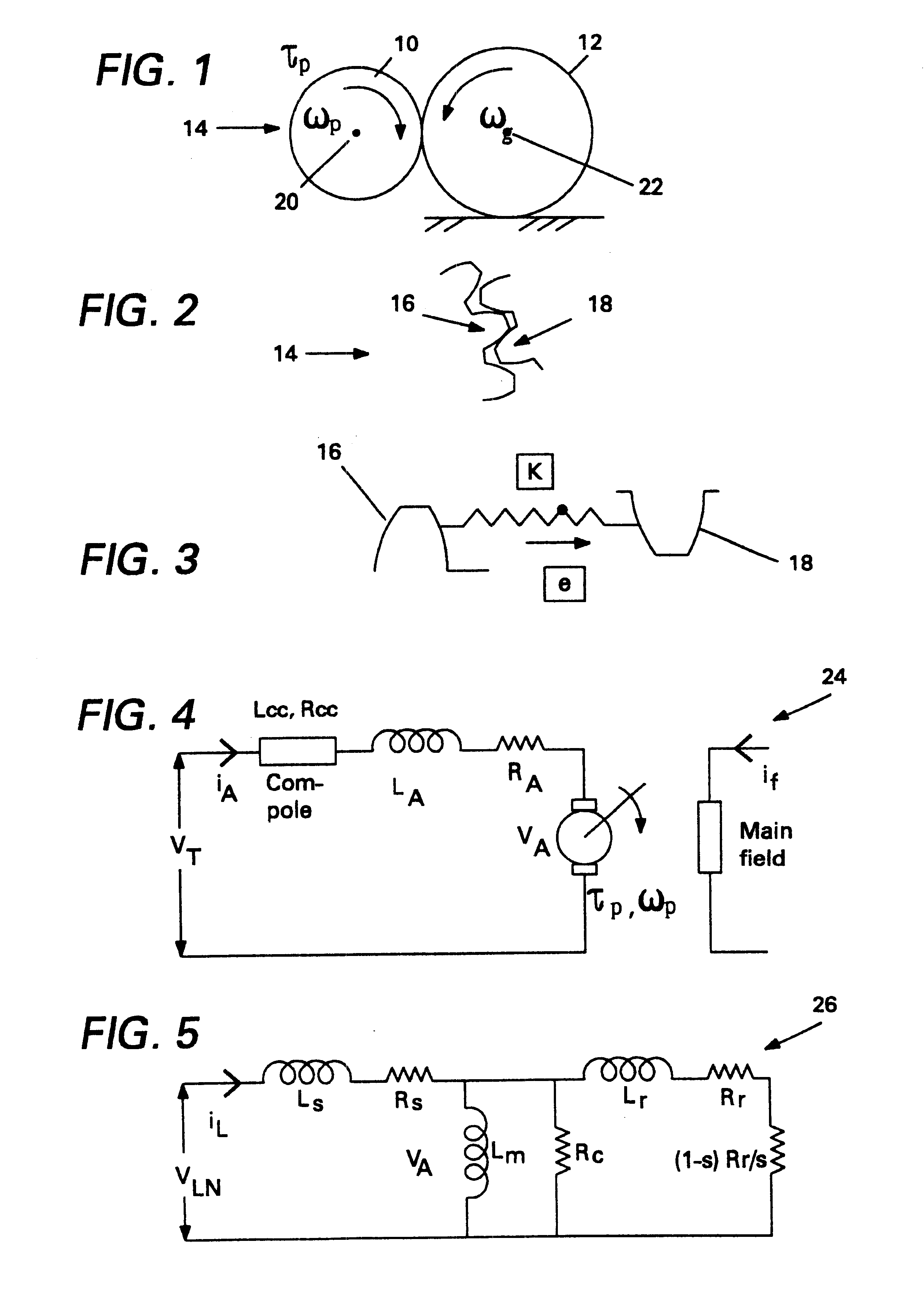

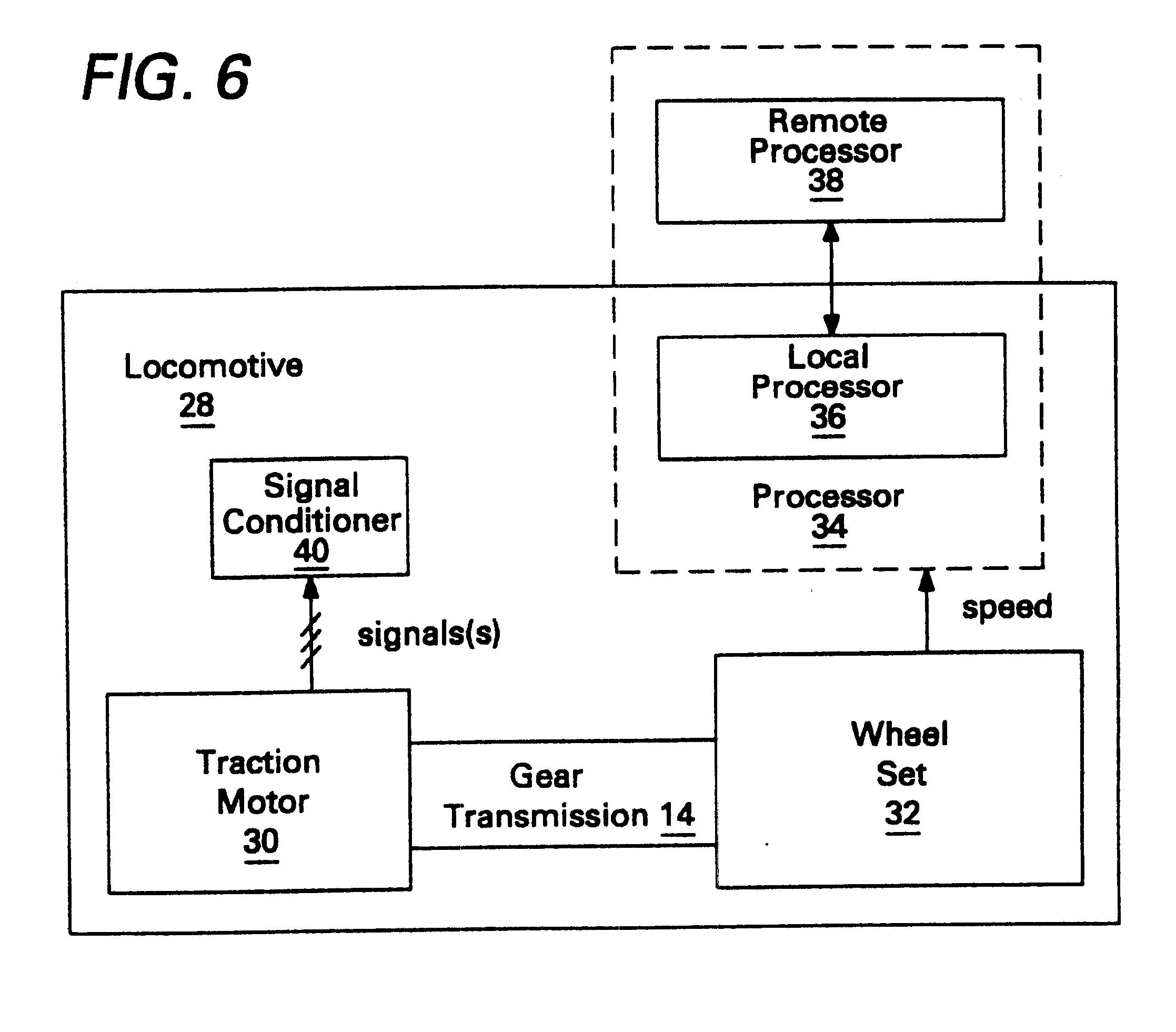

Method and system for diagnostics and prognostics of a mechanical system

InactiveUS20050096873A1Robust and efficient diagnosing and trendingImprove reliabilityVibration measurement in solidsMachine gearing/transmission testingFeature dataComputer science

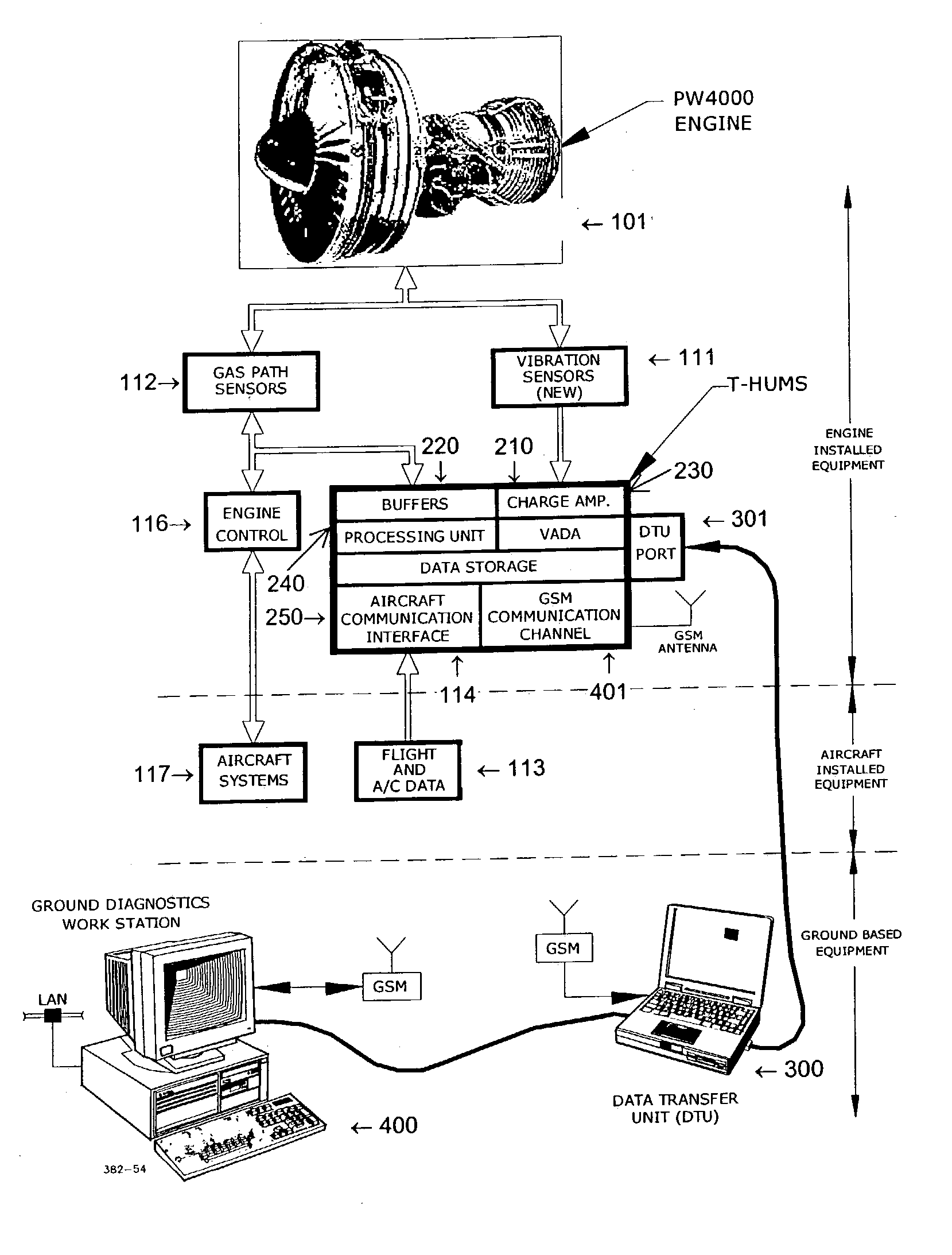

A vibrational analysis system diagnosis the health of a mechanical system by reference to vibration signature data from multiple domains. Features are extracted from signature data by reference to pointer locations. The features provide an indication of signature deviation from a baseline signature in the observed domain. Several features applicable to a desired fault are aggregated to provide an indication of the likelihood that the fault has manifested in the observed mechanical system. The system may also be used for trend analysis of the health of the mechanical system.

Owner:RSL ELECTRONICS

Method and system for diagnostics and prognostics of a mechanical system

InactiveUS7027953B2Robust and efficient diagnosing and trendingImprove reliabilityVibration measurement in solidsMachine gearing/transmission testingSystem diagnosisComputer science

A vibrational analysis system diagnosis the health of a mechanical system by reference to vibration signature data from multiple domains. Features are extracted from signature data by reference to pointer locations. The features provide an indication of signature deviation from a baseline signature in the observed domain. Several features applicable to a desired fault are aggregated to provide an indication of the likelihood that the fault has manifested in the observed mechanical system. The system may also be used for trend analysis of the health of the mechanical system.

Owner:RSL ELECTRONICS

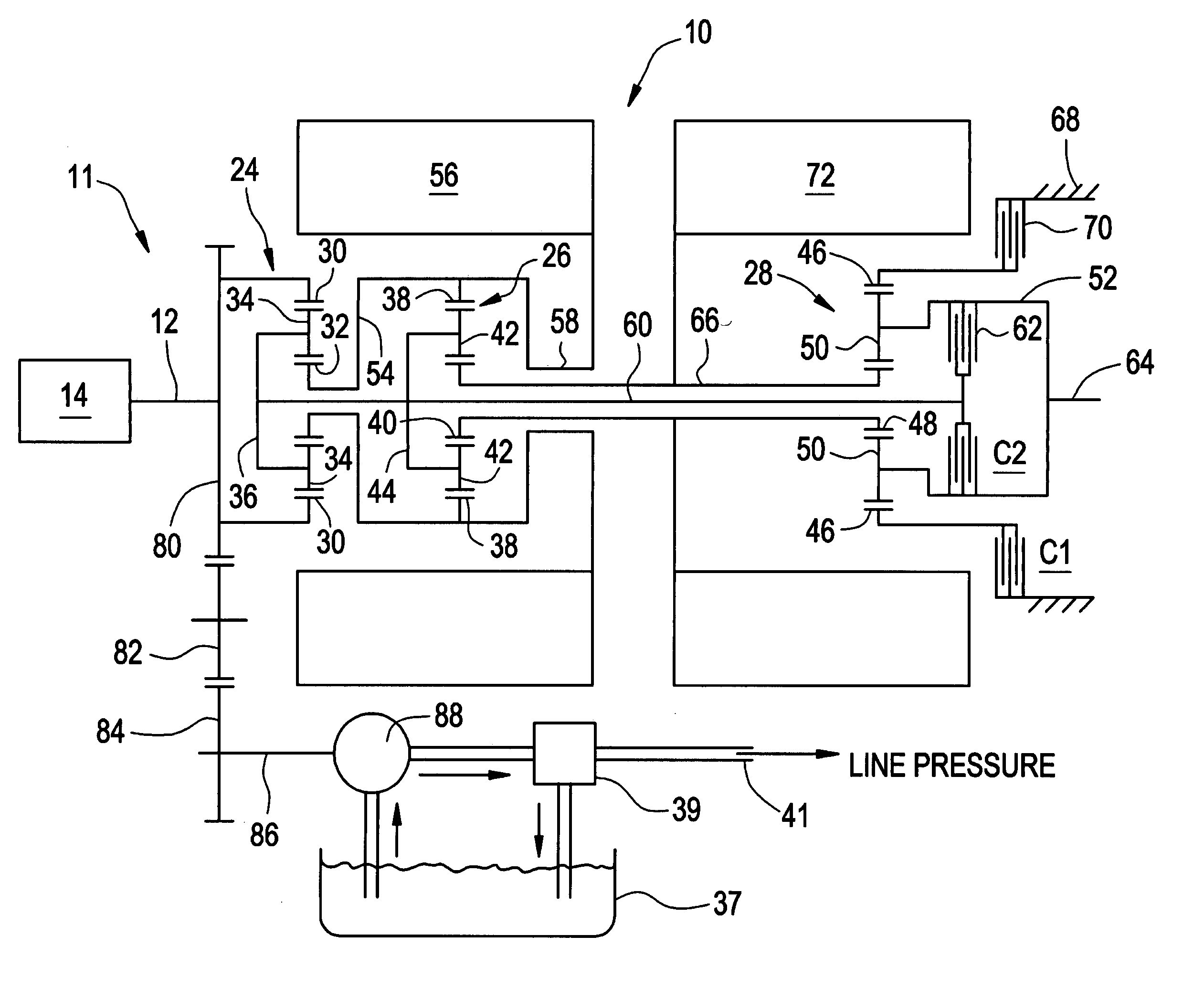

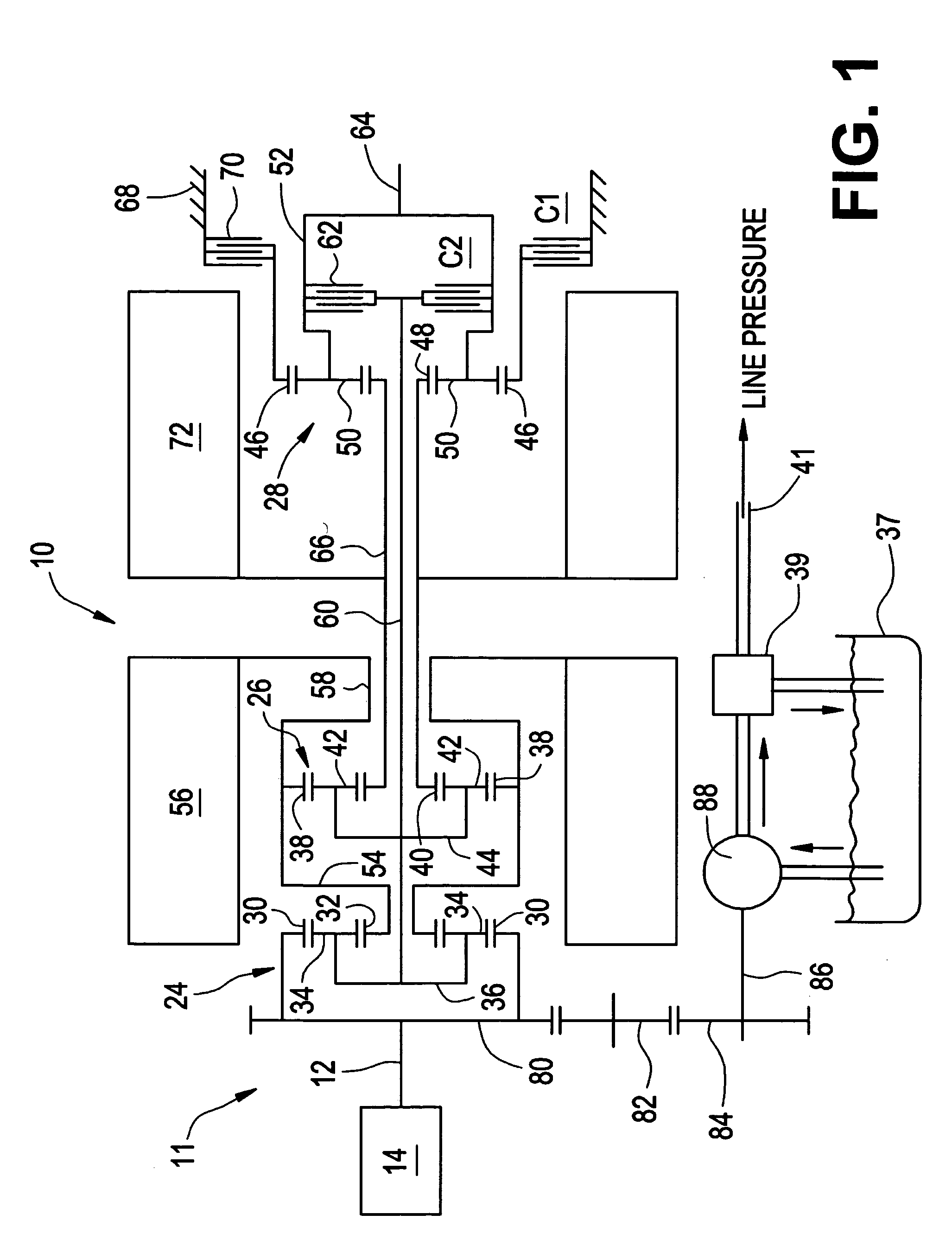

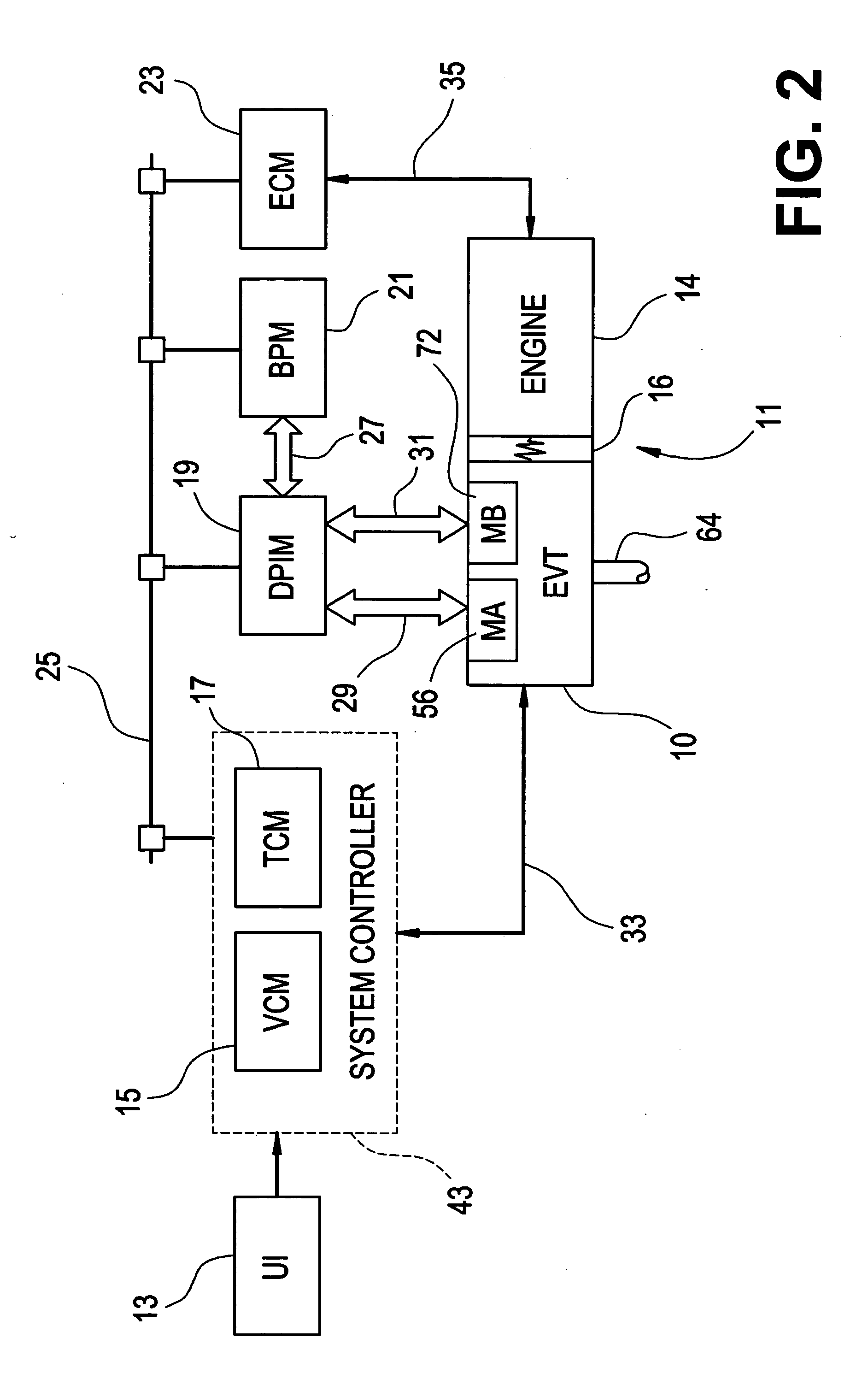

Diagnostic method for a torque control of an electrically variable transmission

ActiveUS20050252283A1Impaired speed controlImpaired torque controlVehicle testingRegistering/indicating working of vehiclesLoop controlLow speed

A condition of impaired speed and torque control of a parallel electrically variable transmission due to factors beyond nominal modeling and estimation errors is diagnosed under low speed operation. The transmission includes at least one electric machine and a motor torque controller for regulating the transmission input speed and output torque. The motor torque controller includes an open-loop control path based on predetermined torques and accelerations and a closed loop control path based on input speed error. The presence of a larger than expected closed-loop correction magnitude, combined with low output speed and one or more other conditions is used to diagnose a condition of potential torque error, in which case the transmission control is altered to prevent unwanted operation.

Owner:GM GLOBAL TECH OPERATIONS LLC

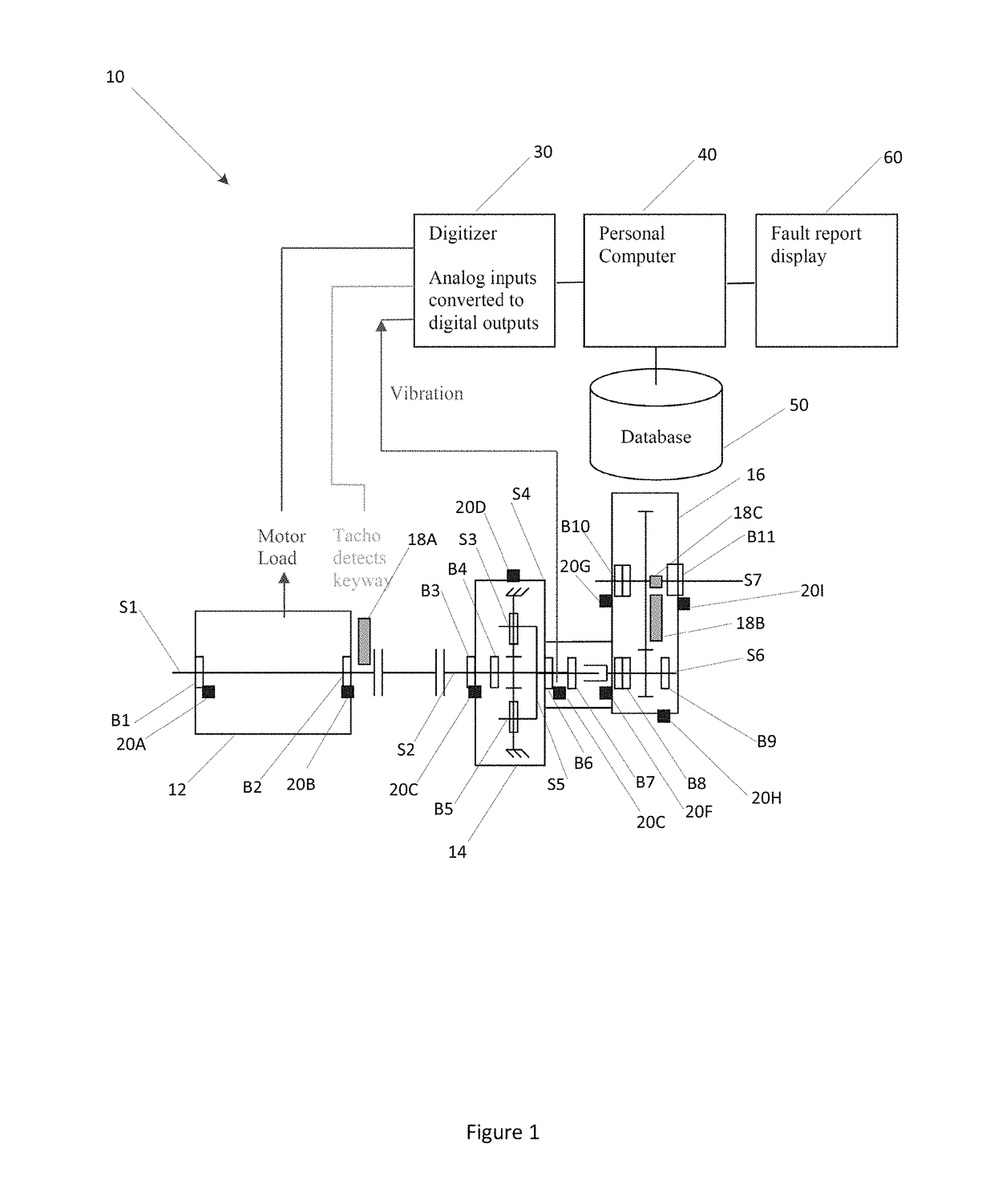

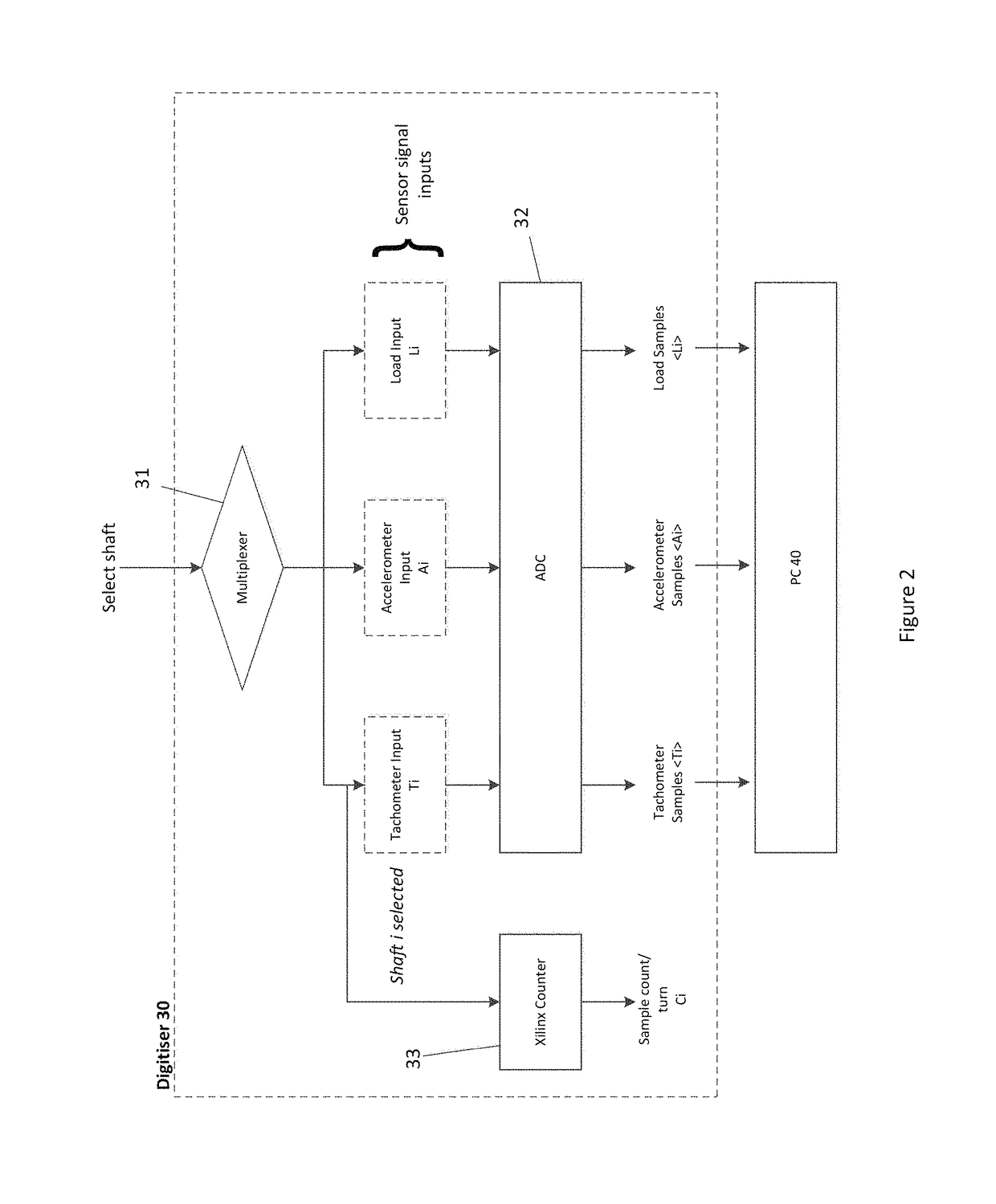

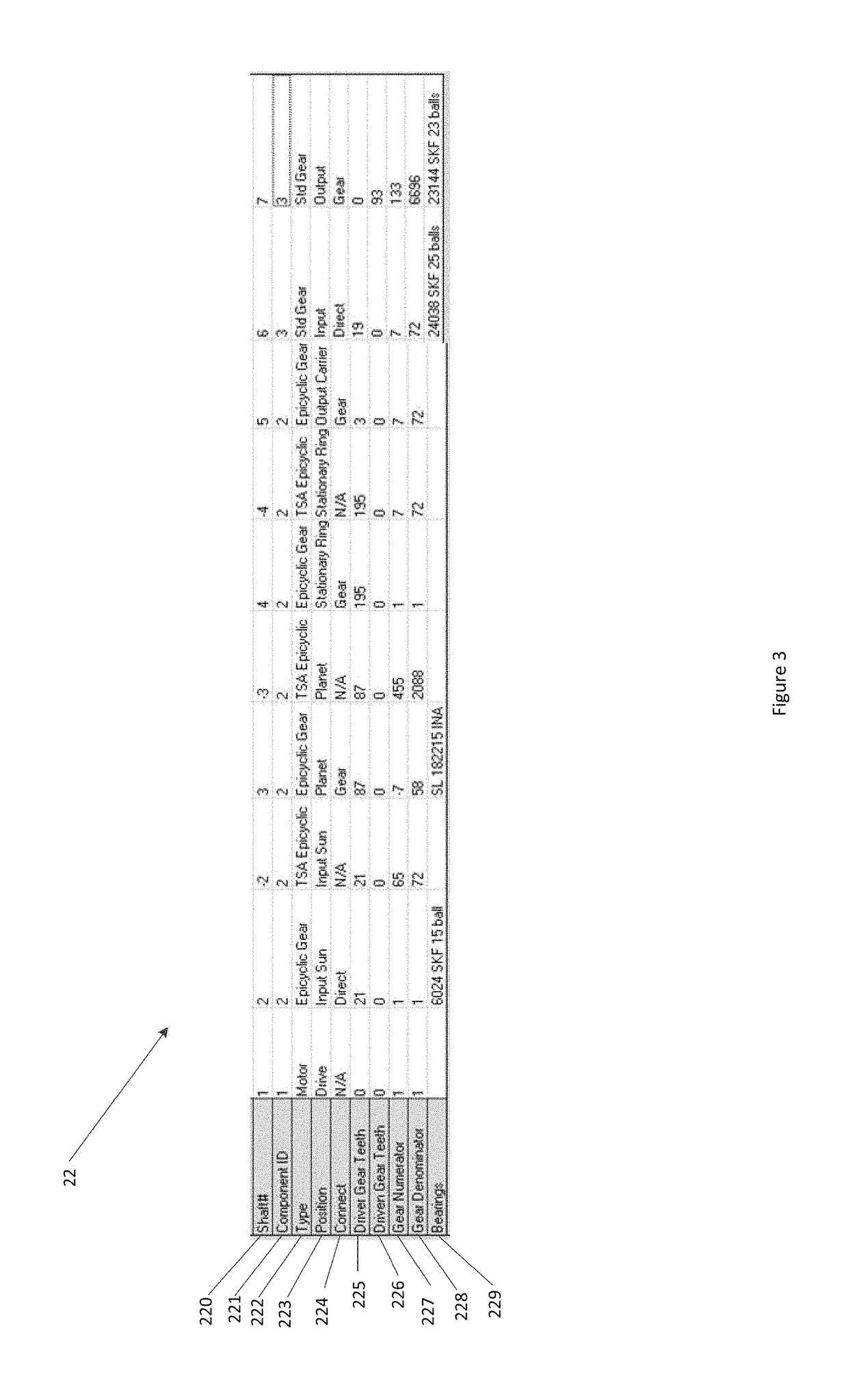

Vibration measurement and analysis

ActiveUS10168248B1Machine gearing/transmission testingMachine bearings testingVibration measurementEngineering

A method of measuring and analyzing vibrations of a mechanical system, e.g., for performing gear and bearing fault detection within a system having a reference shaft and a plurality of rotating components. The method may include the steps of tabulating gear ratios of the plurality of rotating components relative to the reference shaft in integer form, establishing a measurement specification and communicating the measurement specification to a digitizer, recording vibration data from the mechanical system during operation, and resampling the recorded vibration data using the tabulated gear ratios to obtain vibration data corresponding to the rotating components and a vibration signature for a component of interest at predetermined angular increments.

Owner:TENSOR SYST PTY LTD

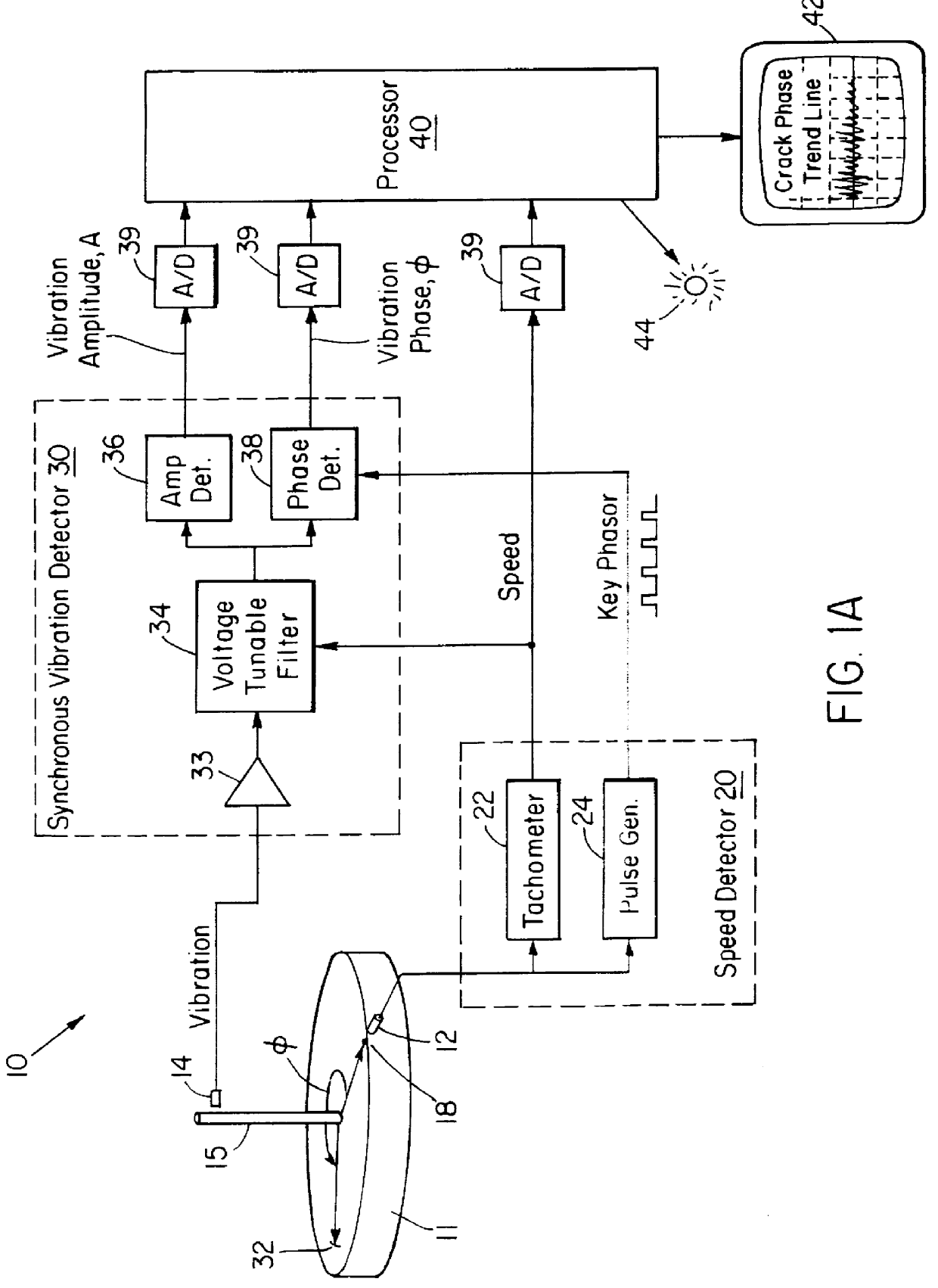

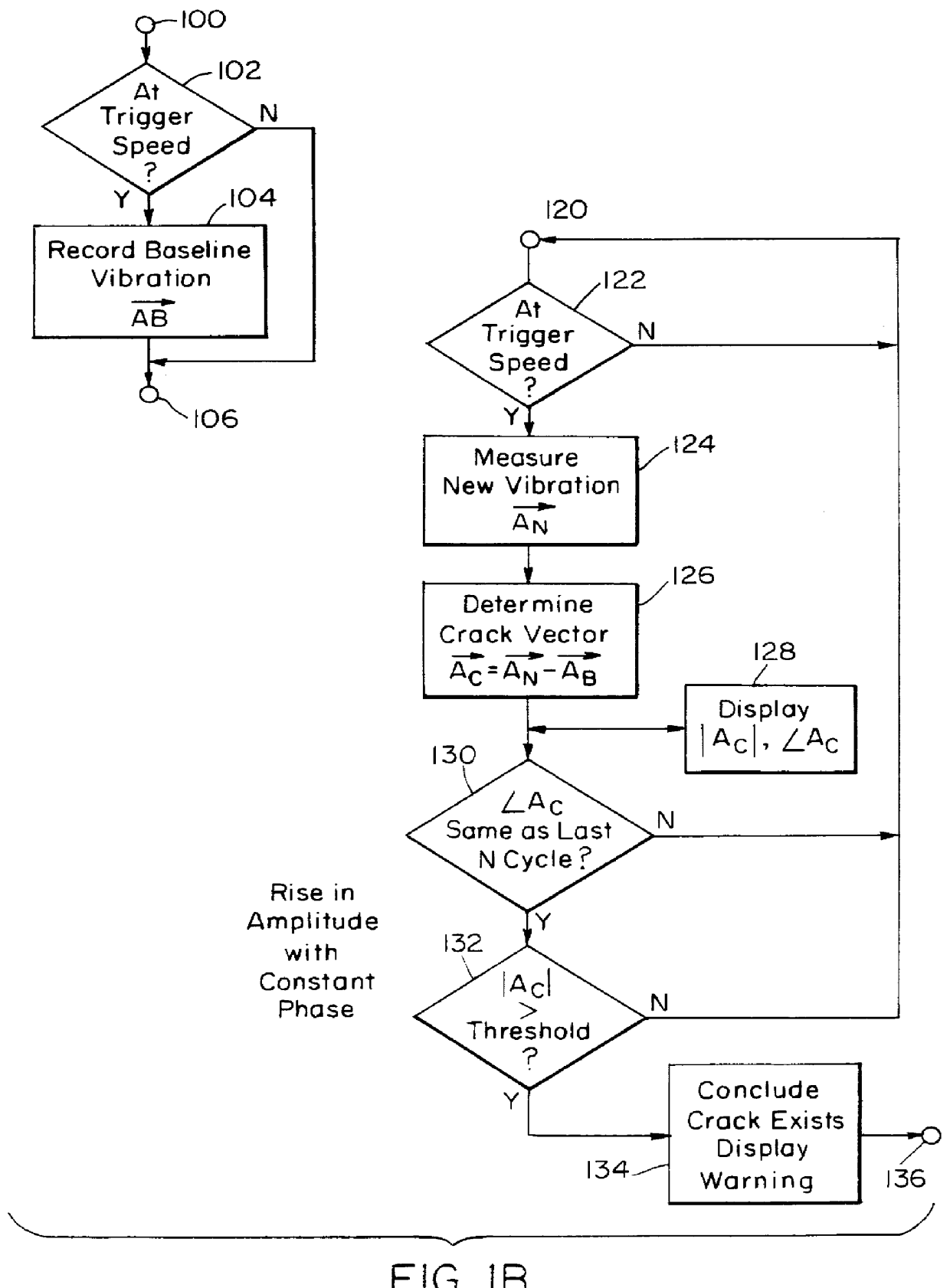

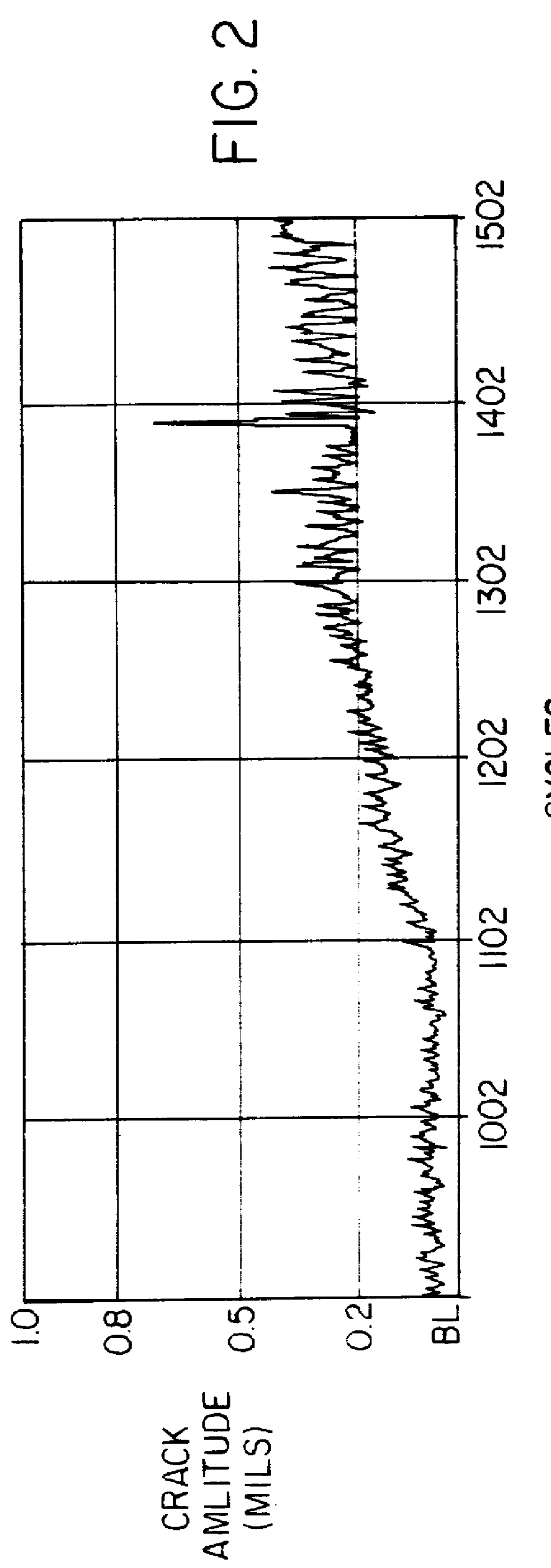

Detecting anomalies in rotating components

InactiveUS6098022AImprove accuracyHigh sensitivityMachine gearing/transmission testingFlow propertiesVibration measurementAcoustics

A method for detecting an anomaly, such as a crack, in a rotor includes measuring the rotational speed and vibration of the rotor. A vibration signal synchronous with the frequency of rotation is filtered from the vibration measurement. A background vibration vector is then subtracted from the synchronous vibration signal to produce a vibration difference signal. The phase and amplitude of the vibration difference signal are measured and evaluated to determine whether an anomaly has developed. An apparatus for performing this method includes vibration and speed sensors coupled to a filter for extracting a signal from the vibration measurement having a frequency synchronous with the rotation of the rotor. A processor is coupled to the filter and the speed sensor and is programmed to perform the processing steps, described above.

Owner:TEST DEVICES

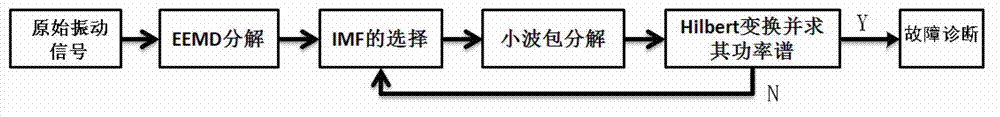

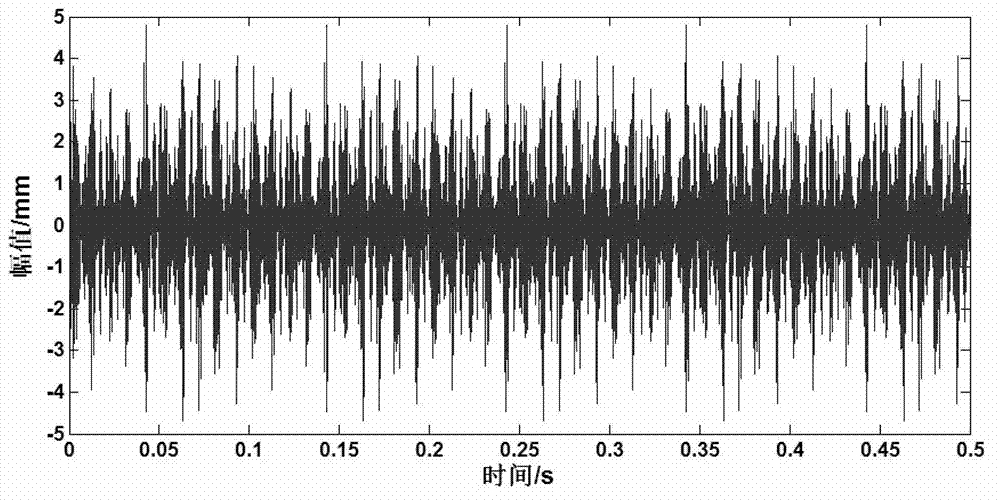

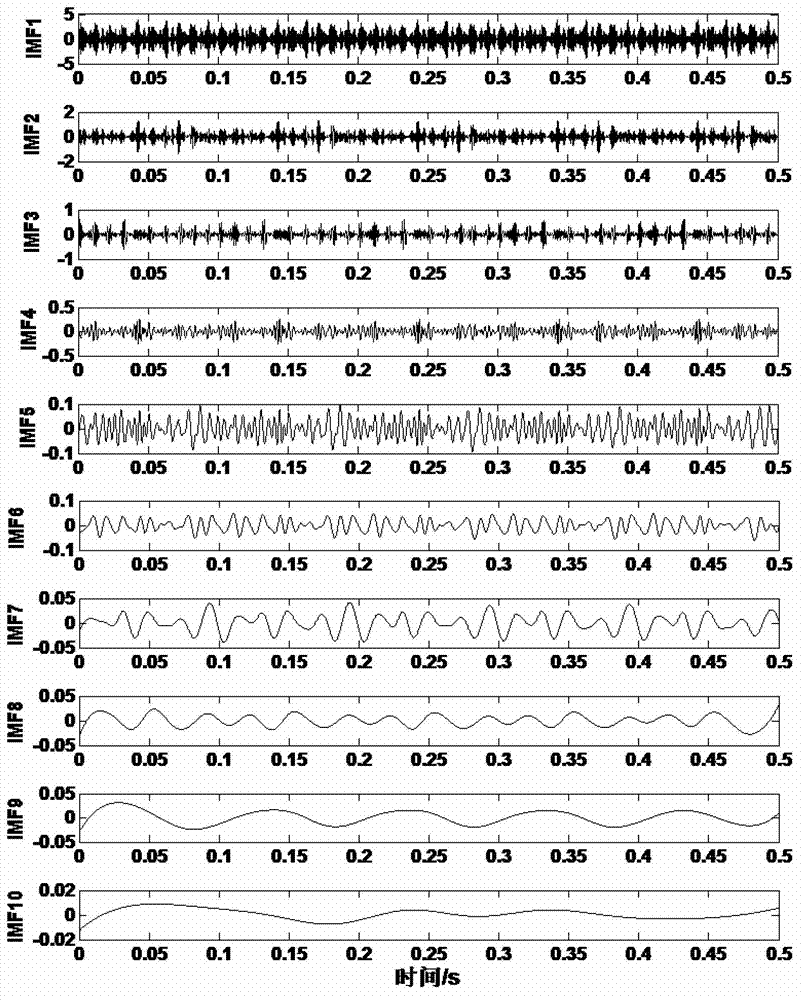

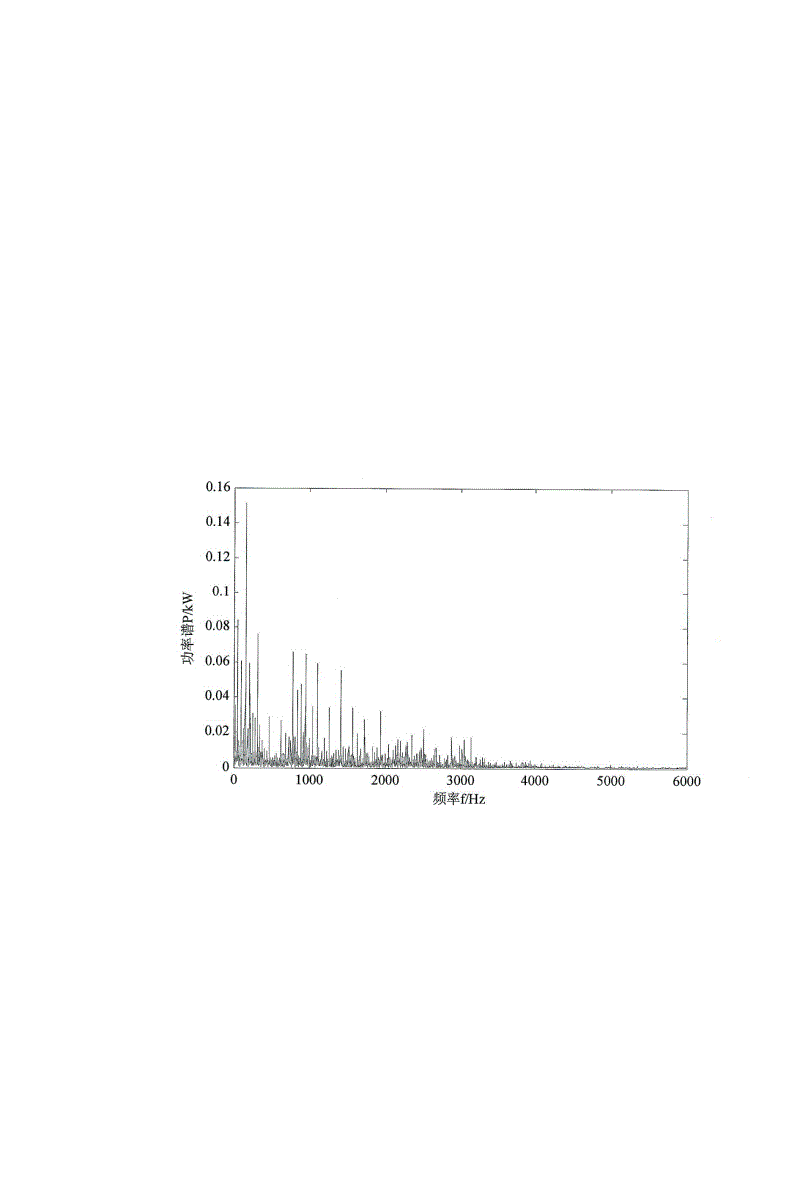

Extraction method for early failure sensitive characteristics based on ensemble empirical mode decomposition (EEMD) and wavelet packet transform

InactiveCN103091096AGuaranteed Adaptive Accurate PartitioningAdaptive Precise Partition PreciseMachine gearing/transmission testingMachine bearings testingNODALDecomposition

The invention relates to an extraction method for early failure sensitive characteristics based on ensemble empirical mode decomposition (EEMD) and wavelet packet transform. The extraction method for the early failure sensitive characteristics based on the EEMD and the wavelet packet transform includes the following steps: (1), collected original vibration signals of mechanical and electrical equipment are decomposed according to the EEMD, white noise is added, and intrinsic mode function (IMF) components are obtained through decomposition; (2), the sensitive IMF components closely related to failure are chosen, and other irrelative IMF components are ignored; (3), the sensitive IMF components chosen through step (2) are decomposed in an orthogonal wavelet packet mode, and a wavelet coefficient of each node is obtained; and (4), envelopes are extracted from the obtained wavelet packet coefficients by adoption of the Hilbert transform and the Fourier transform, power spectrums are calculated, the power spectrum corresponding to each wavelet packet coefficient is obtained and serves as the early failure sensitive characteristic , and the sensitive characteristics are automatically obtained. Self-adapting signals can be decomposed, the sensitive characteristics can be convenient to obtain automatically, diagnosis precision and speed are improved, and a mechanical and electrical system can be diagnosed quickly, accurately and stably. The extraction method for the early failure sensitive characteristics based on the EEMD and the wavelet packet transform can be applied to the field of mechanical and electrical equipment failure diagnosis.

Owner:BEIJING INFORMATION SCI & TECH UNIV

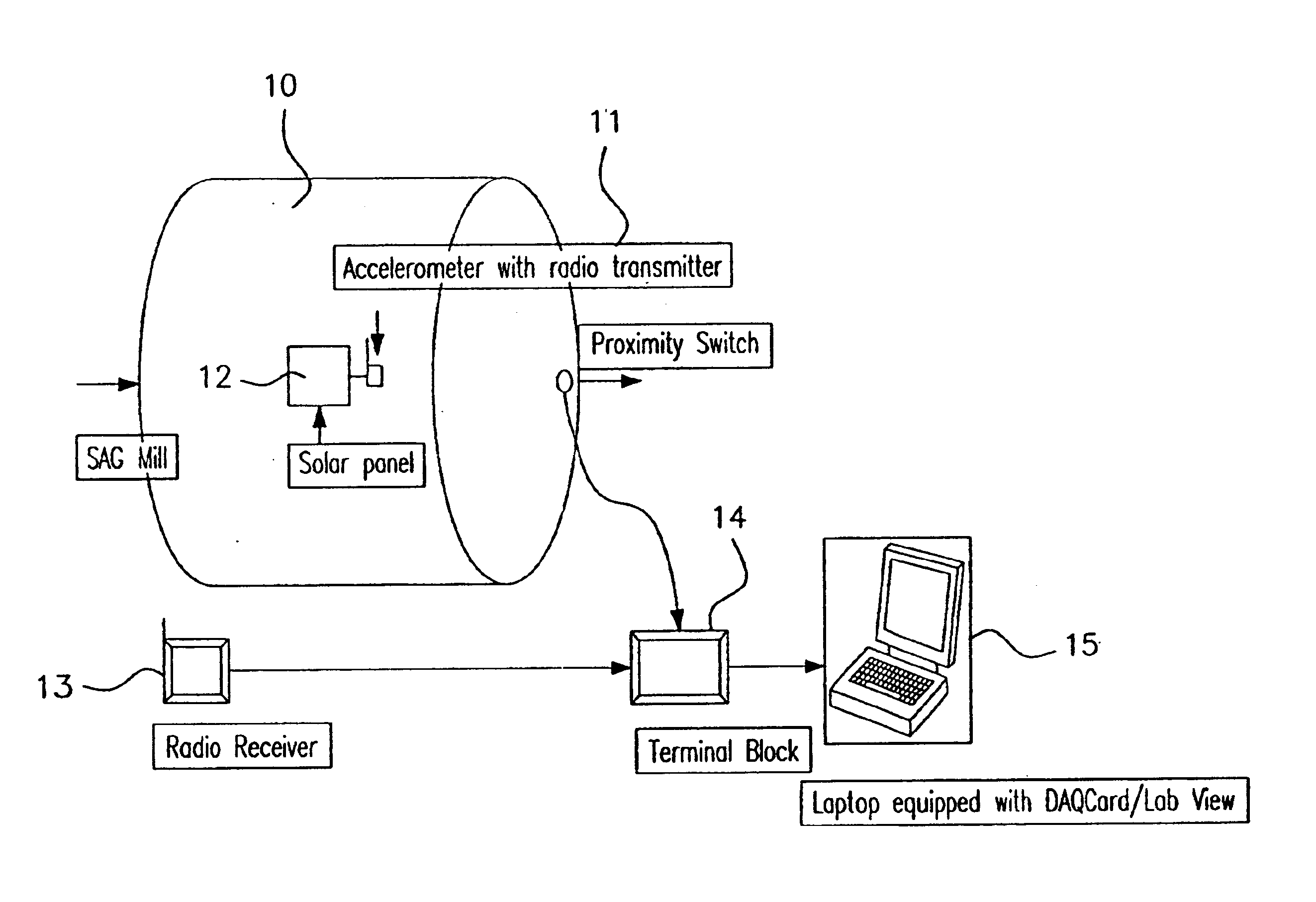

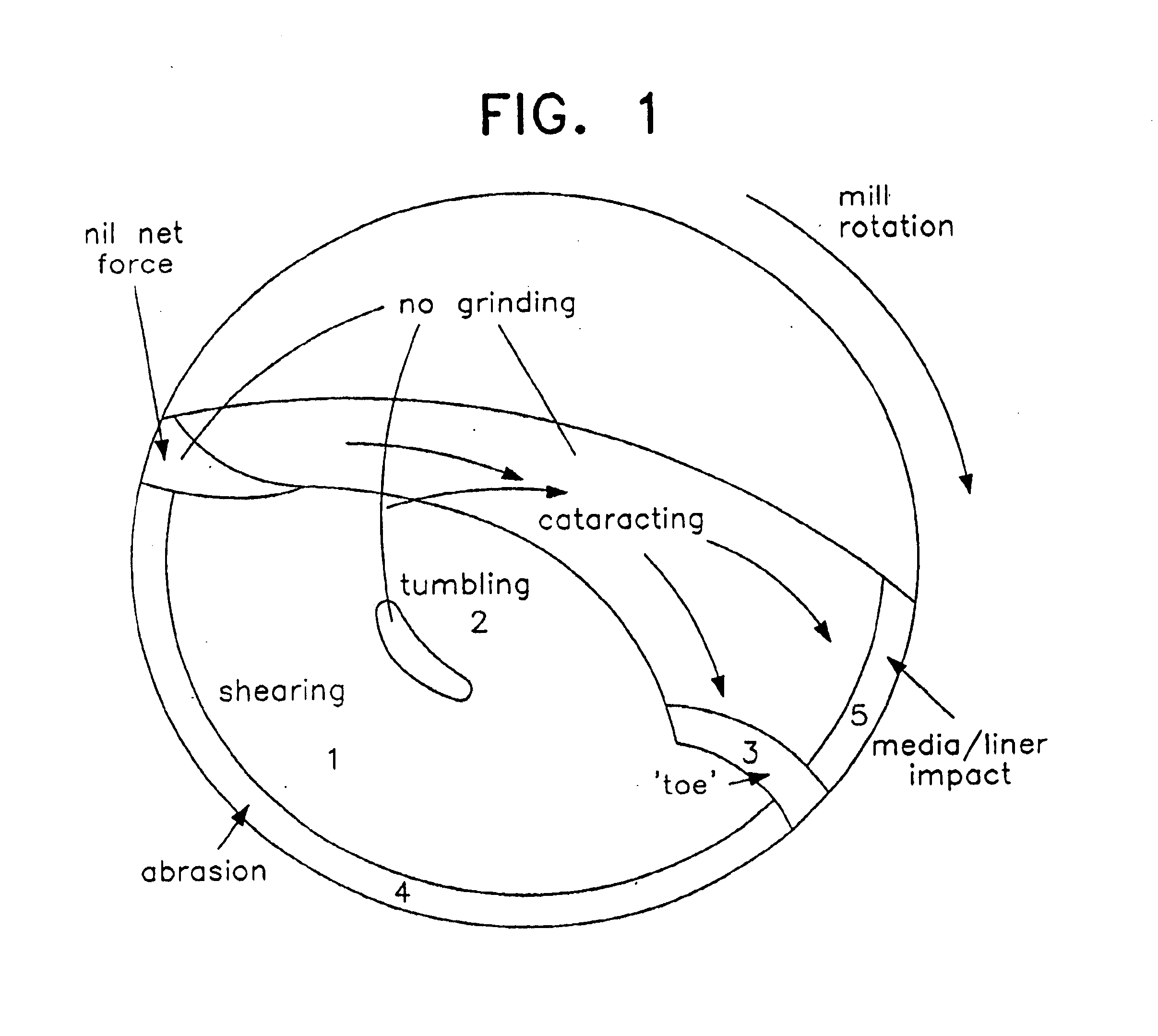

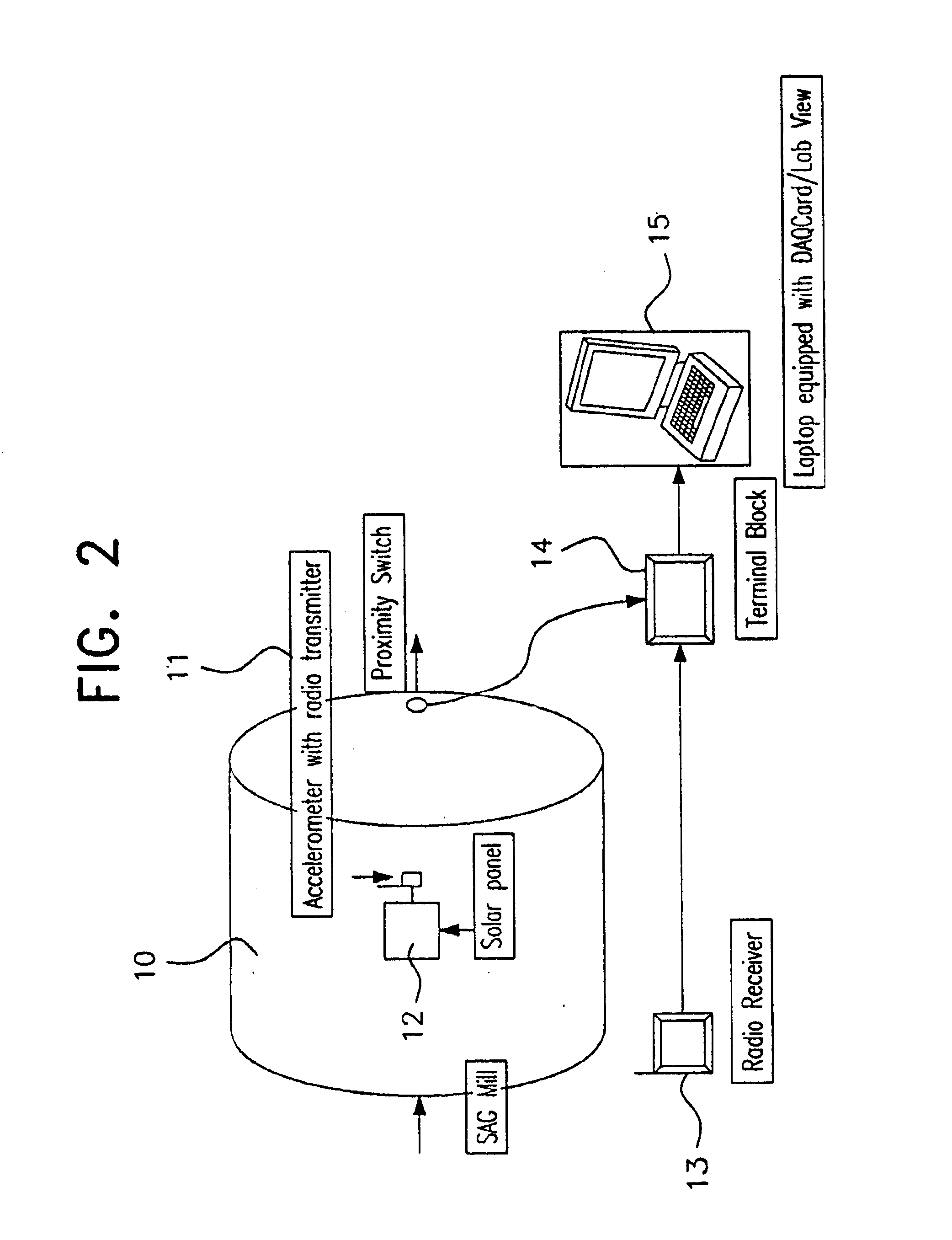

System for monitoring mechanical waves from a moving machine

InactiveUS6874364B1Minimise number/amplitude/frequencyMinimizes valueVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesParticulatesEngineering

A system for monitoring mechanical waves from a machine which in operation has moving particulate matter therein, the system including at least one sensor located on the machine at a location away from the central axis of the machine, the sensors being for sensing acoustic waves and including a transmitter for transmitting signals representing the sensed mechanical waves to a receiver at a location remote from the sensor(s), a data processor connected to the receiver for receiving signals from the receiver which signals represent the mechanical waves and processing the signals to produce output signals for display on a display means, wherein the output signals for display represent one or more parameters indicative of mechanical waves emitted from the machine over a predetermined period of time.

Owner:COMMONWEALTH SCI & IND RES ORG

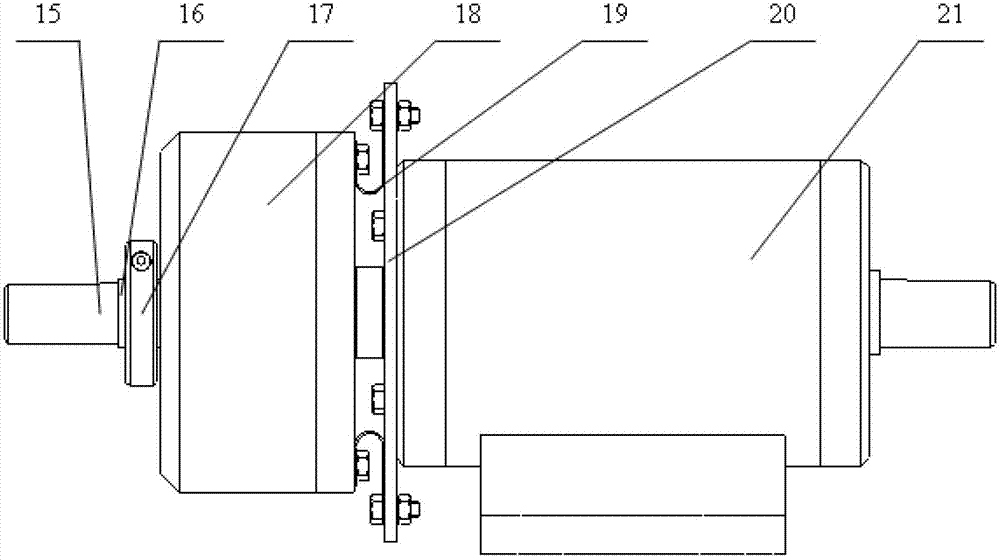

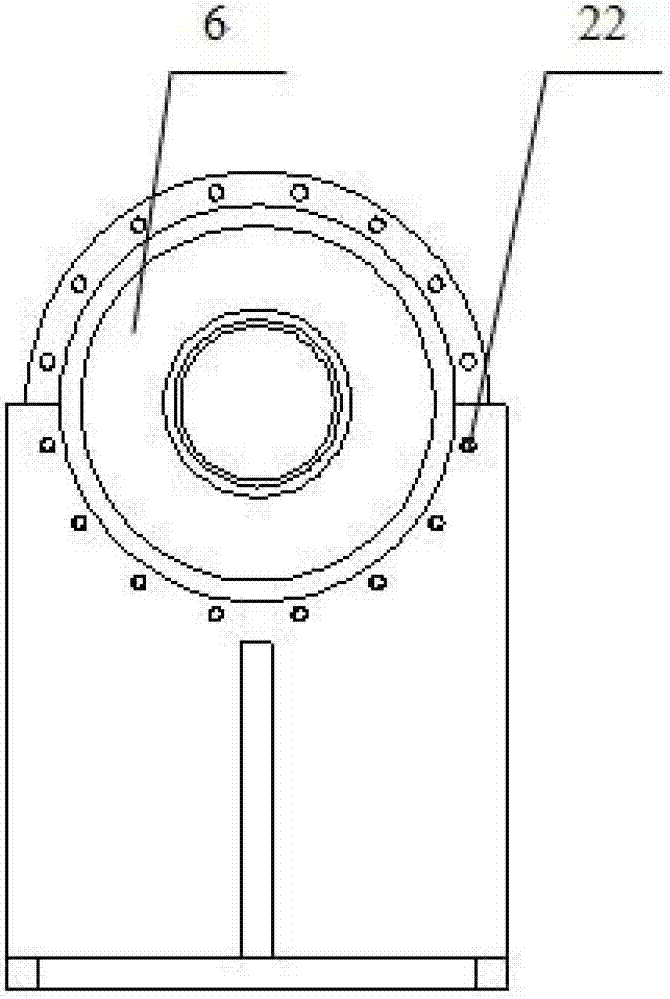

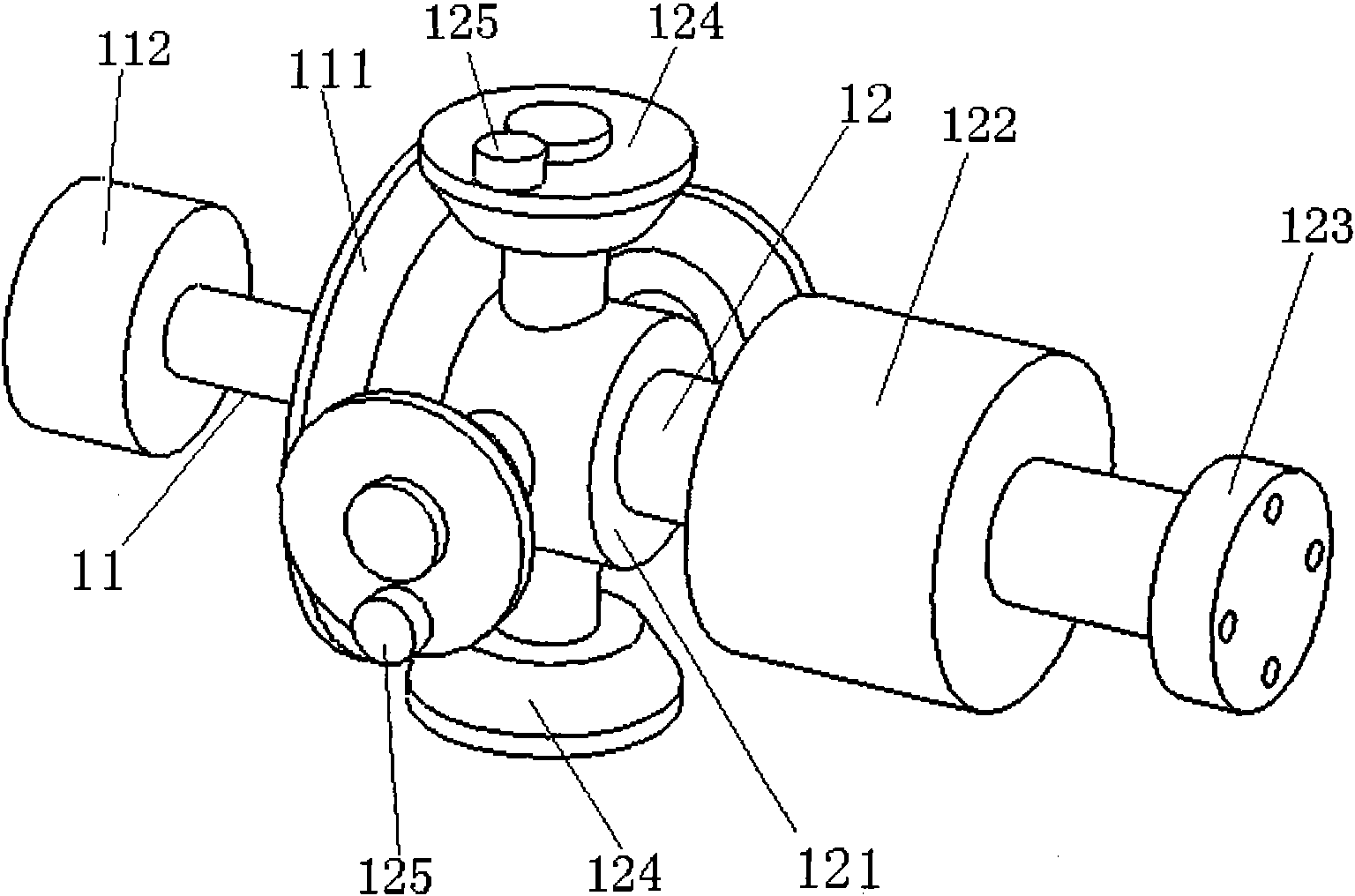

Comprehensive performance experiment platform for water-lubricated bearings and transmission systems

ActiveCN102269654AReal performance testPerformance testing is completeMachine gearing/transmission testingMachine bearings testingLow noiseDrive motor

The invention discloses a water lubricated bearing and transmission system comprehensive performance testing platform, which comprises a water lubricated bearing, a dynamic seal device, an elastic coupling, a gearbox, a water circulating system, a driving motor, an intermediate bearing, a bearing block, a loading and testing device and other parts. The loading device loads a test shaft in the circumferential direction, axial direction and radial direction so as to simulate complicated working conditions of the water lubricated bearing and the transmission system thereof; the testing system can detect various parameters of the water lubricated bearing, such as working speed, torque, temperature, frictional characteristics, water film pressure distribution, interface deformation distribution, shaft centerline orbit, noise and dynamic characteristics, and comprehensive performance of the dynamic seal, the elastic coupling and the transmission system on line; and the testing platform can be applied to research of scientific problems such as the loading bearing of a water lubricated friction pair, failure mechanism and evolution law, tribological performance and dynamic service behaviors, and provides a key scientific and technological basis for developing a pollution-free, low-noise, high-reliability, long-life, high-efficiency and energy-saving water lubricated bearing and a transmission system thereof.

Owner:CHONGQING UNIV

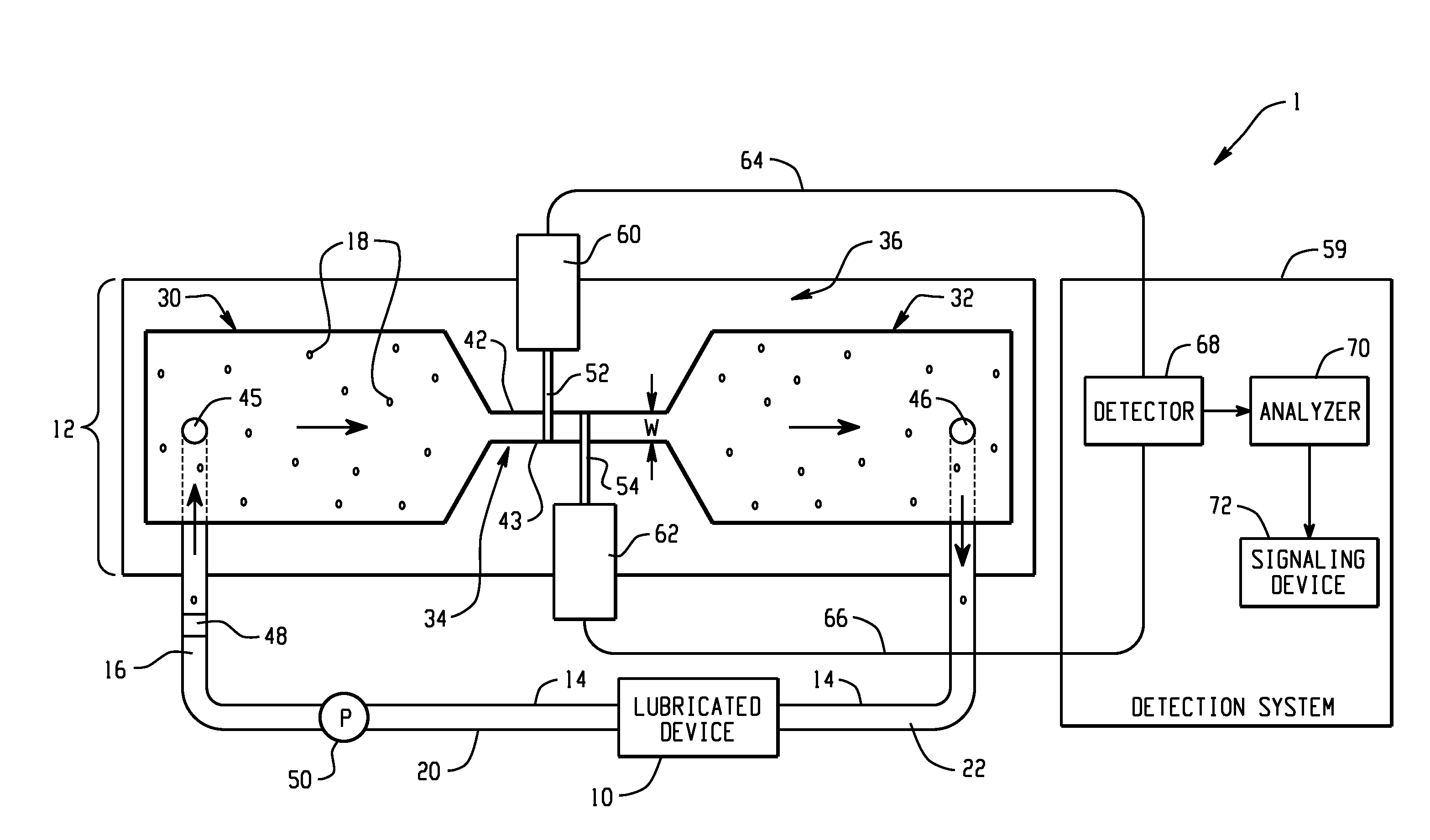

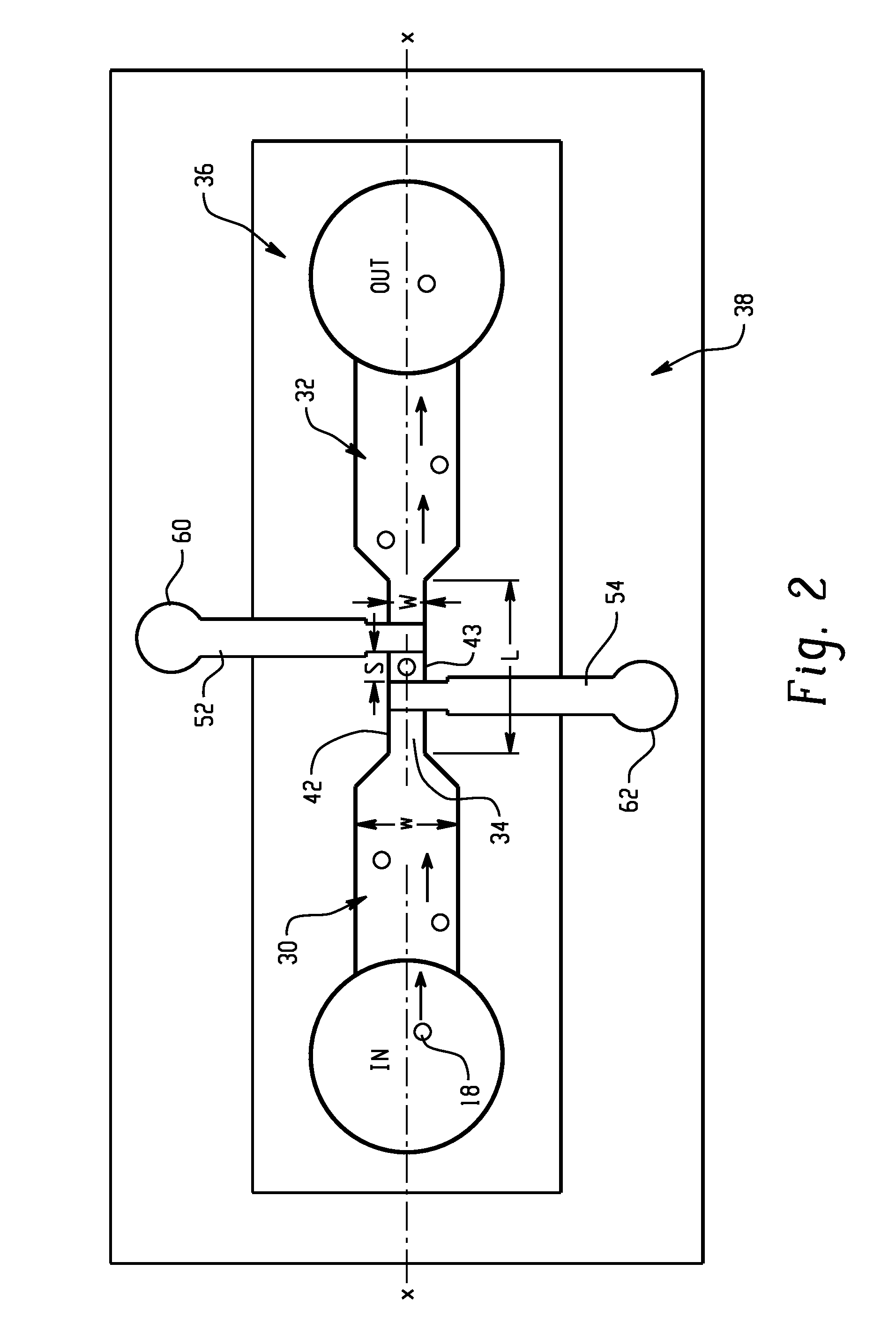

Metal wear detection apparatus and method employing microfluidic electronic device

ActiveUS20100109686A1Rapid responseMachine gearing/transmission testingResistance/reactance/impedenceCapacitanceWear particle

An apparatus and a method for detection of wear particles in a lubricant are disclosed. The apparatus includes a microfluidic device including a microchannel sized for a lubricant containing wear particles to pass therethrough and first and second electrodes extending into the microchannel. A detection system is coupled with the electrodes for detection of wear particles passing through the microchannel, based on a change in capacitance of the electrodes.

Owner:THE UNIVERSITY OF AKRON

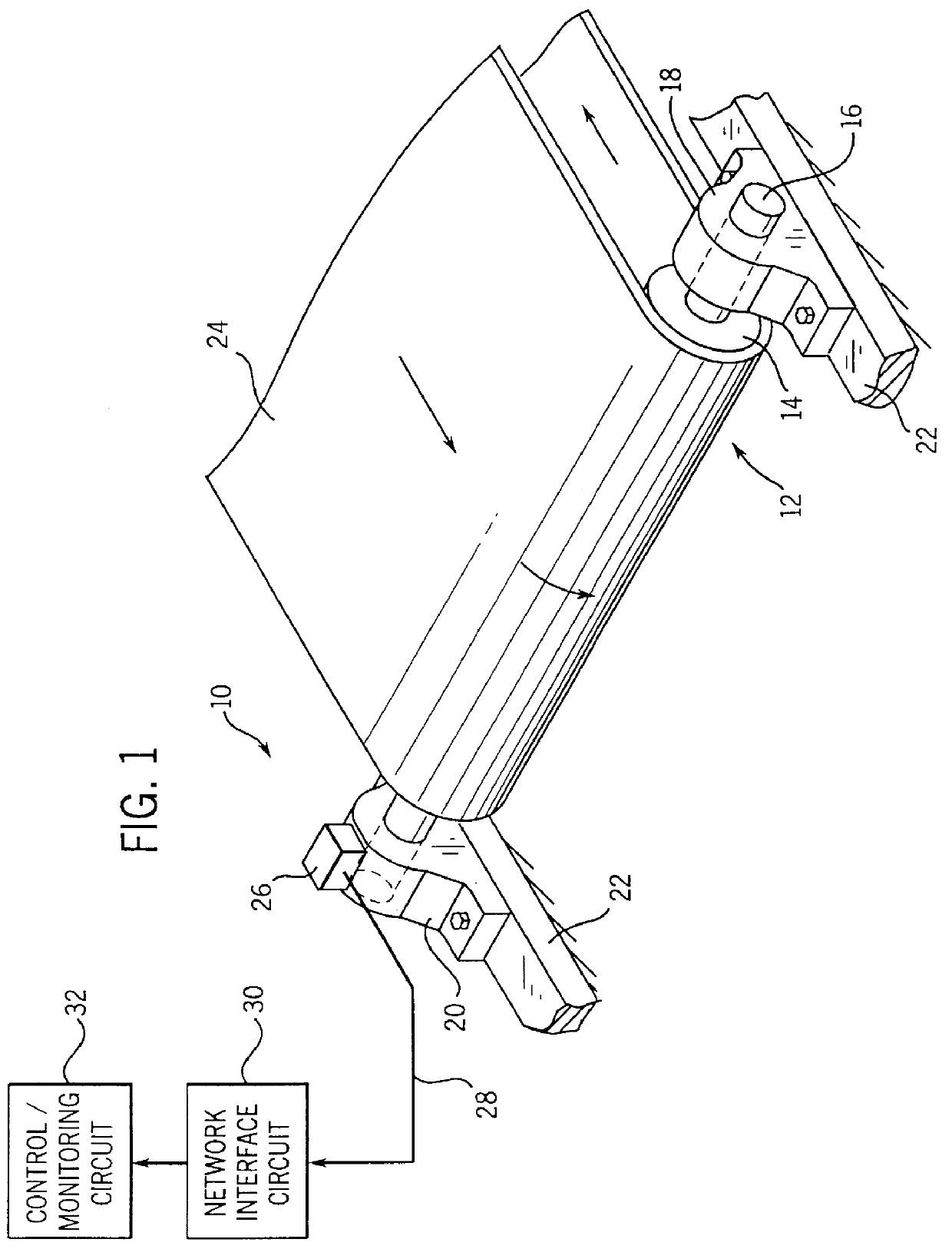

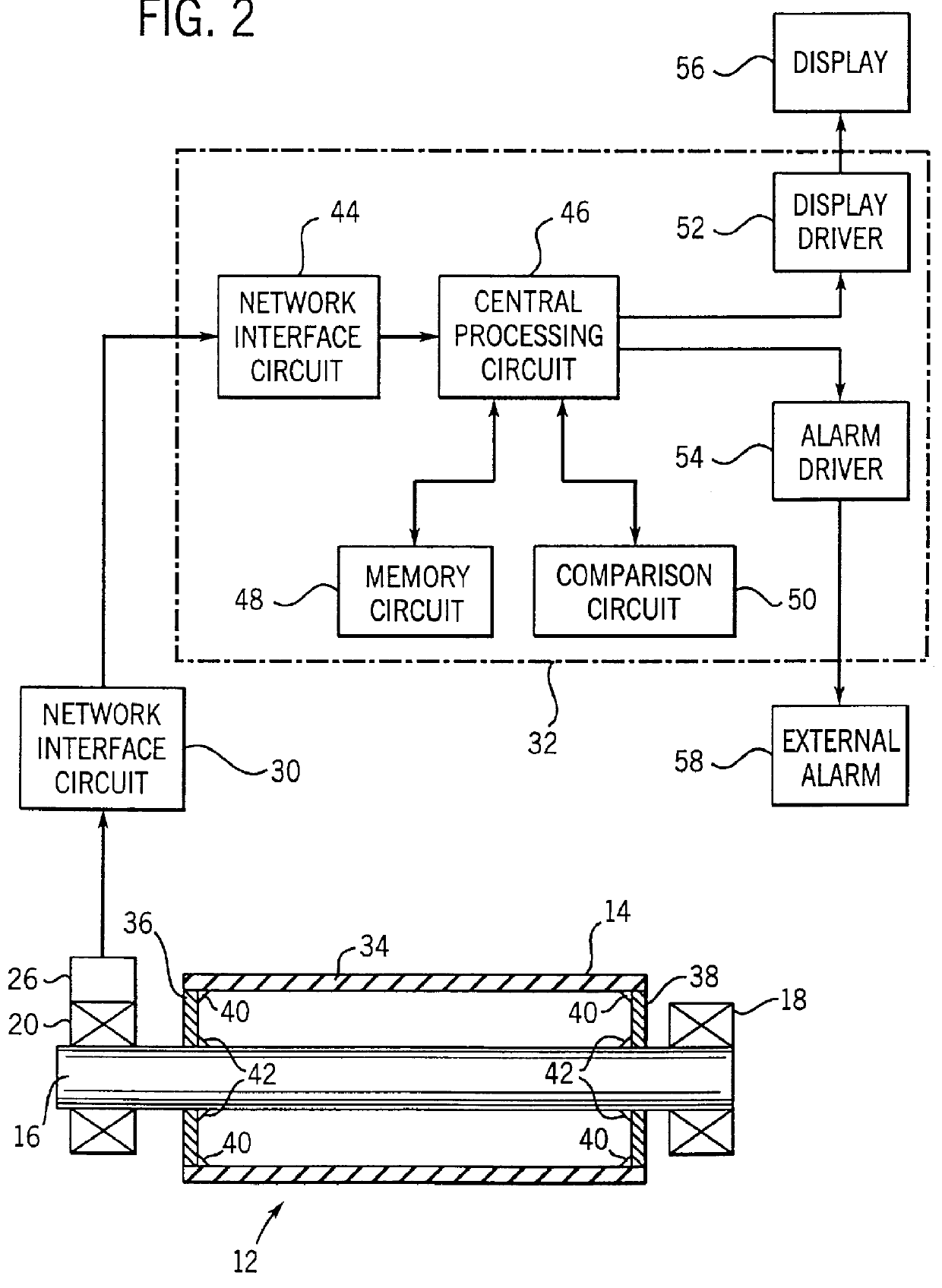

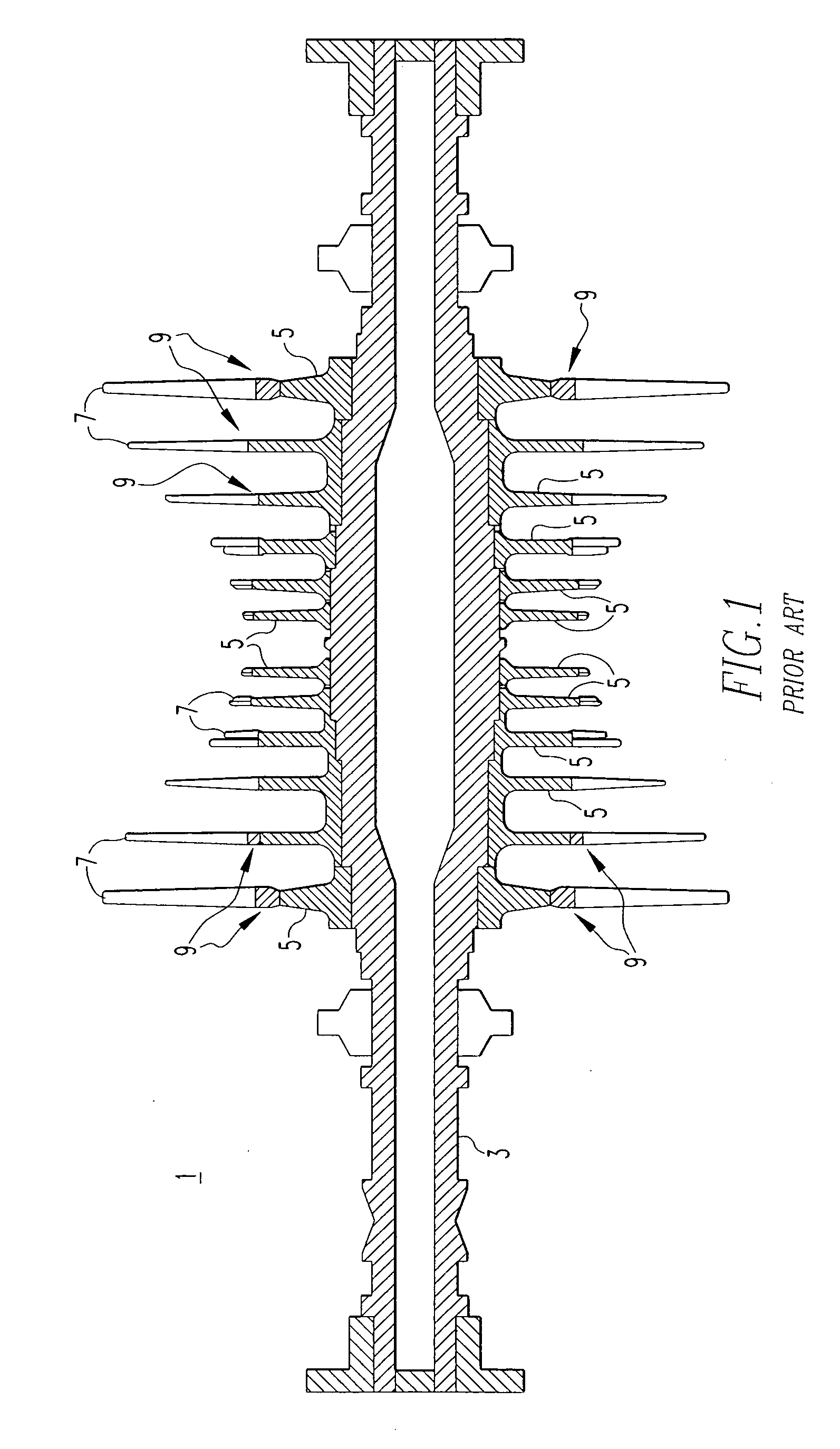

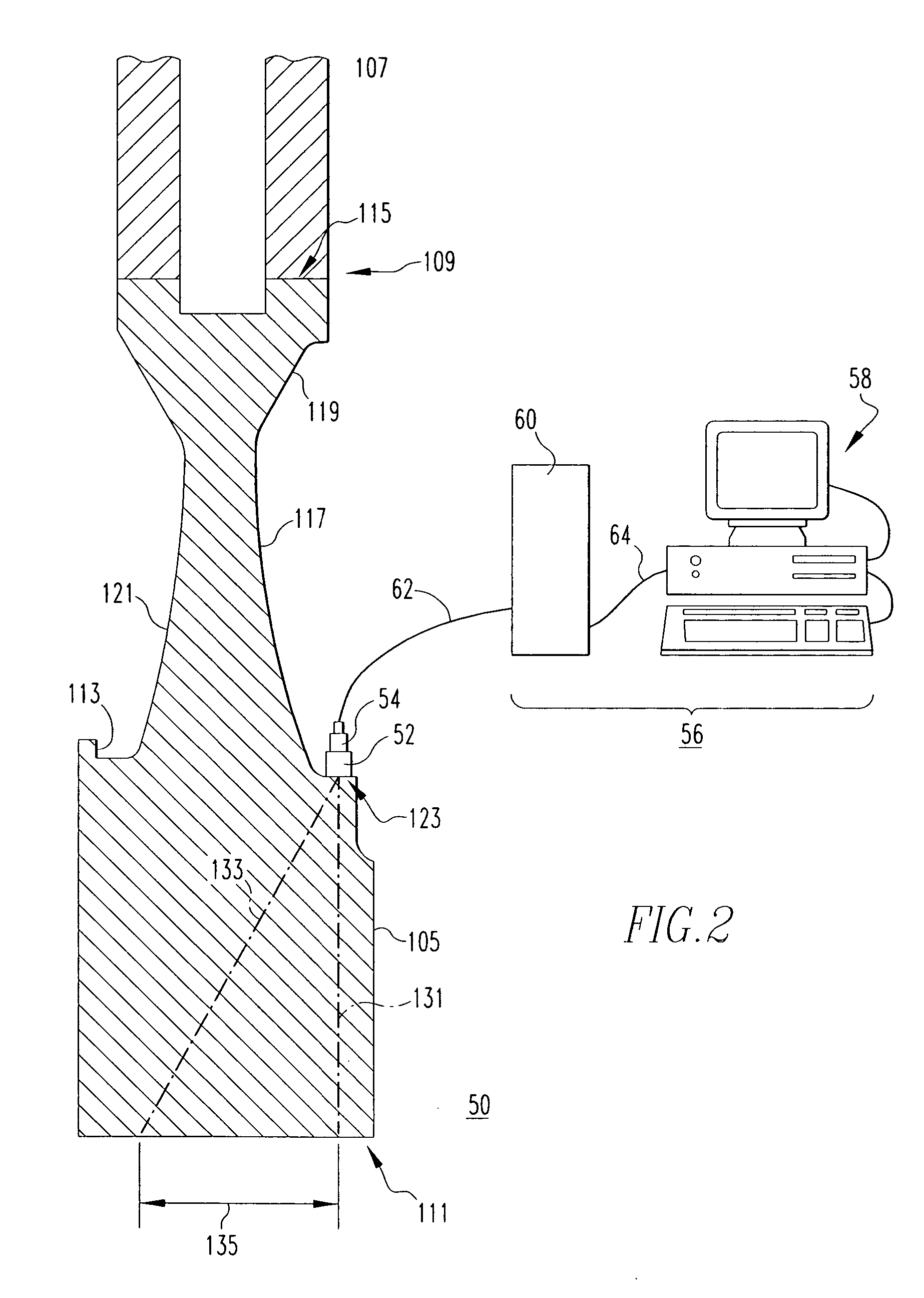

Method and apparatus for identifying defects in a rotating machine system

InactiveUS6116089AVibration measurement in solidsMaterial analysis using sonic/ultrasonic/infrasonic wavesAccelerometerEngineering

A system for detecting defects in a rotating machine system includes a sensor such as an accelerometer coupled to the machine system for detecting vibrations of a rotating element. Output of the accelerometer is transmitted, preferably via a network data link to a monitoring / control circuit. The monitoring / control circuit analyzes the vibration data to develop a normal vibration profile for the machine system during a normal operating phase. The normal vibration profile is stored in a memory circuit for later reference. During subsequent operation of the machine system, the monitoring / control circuit cyclically analyzes vibration data to develop actual vibration profiles. The actual vibration profiles are compared to the normal vibration profile and, where variations between the profiles exceed preset tolerances, the circuit provides an indication of a malfunction or defect in the machine system. The technique is particularly well suited to conveyor systems such as drum pulleys and the like in which cracks, breaks and other defects can result in unexpected failure and maintenance.

Owner:BALDOR ELECTRIC COMPANY

Method and system for predicting disk drive failures

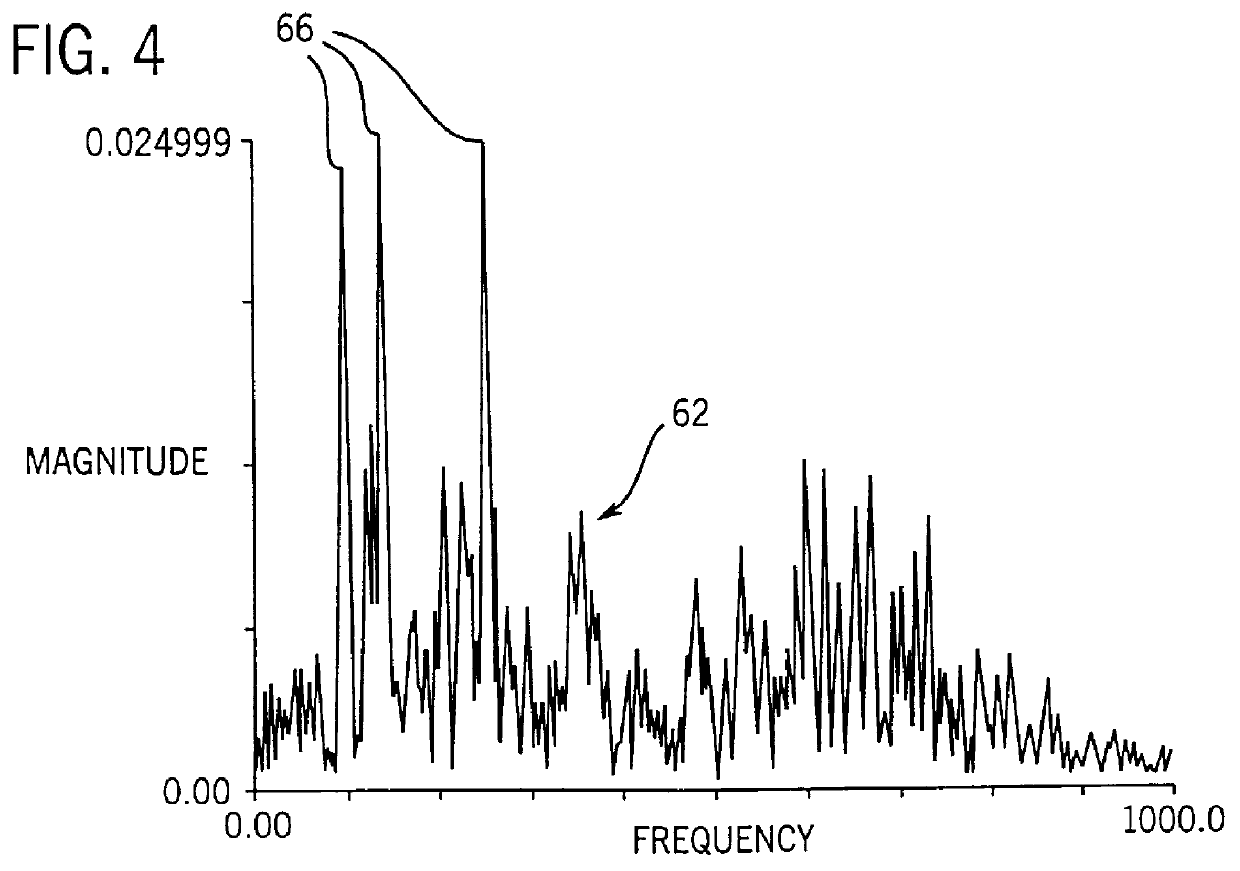

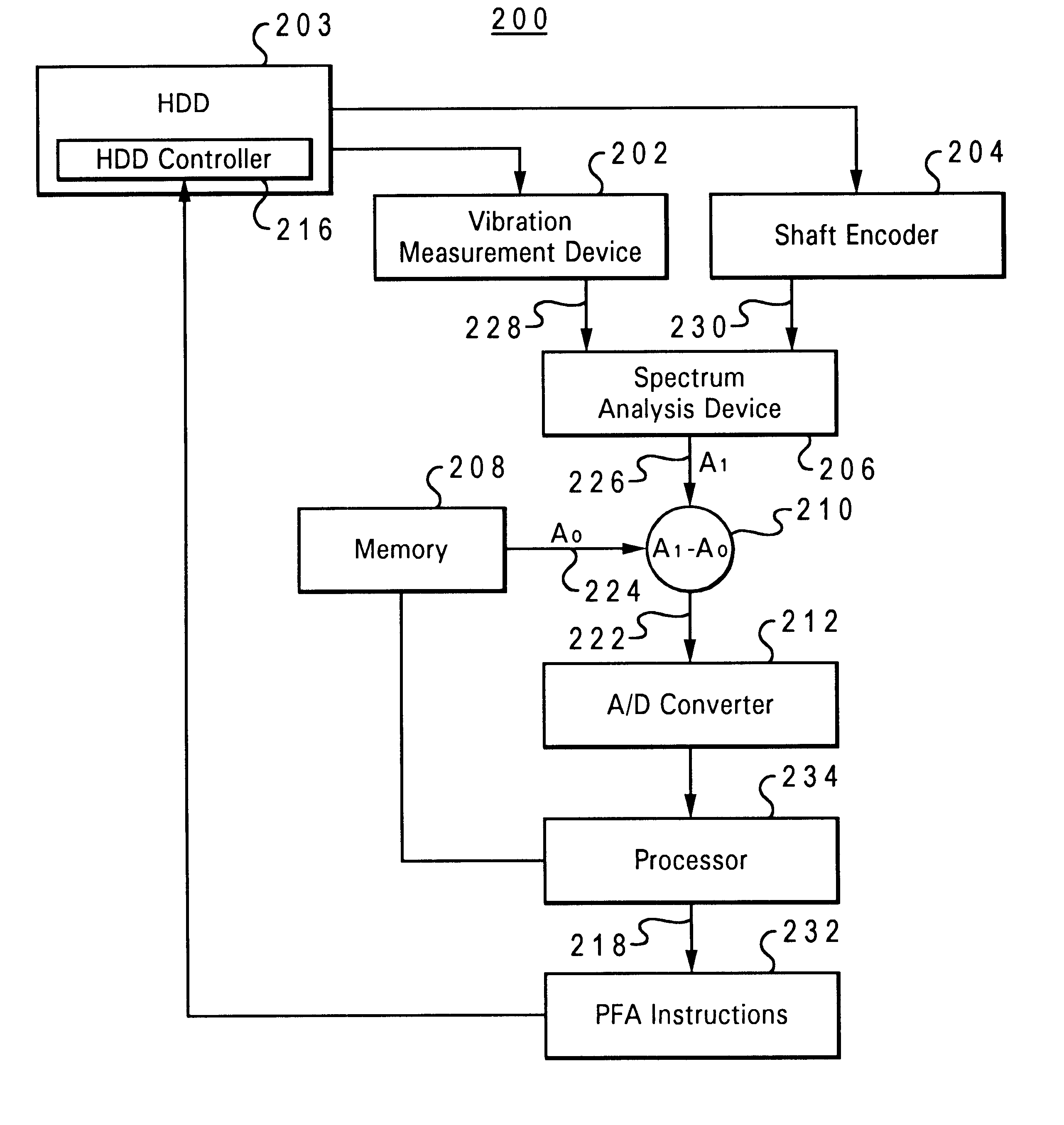

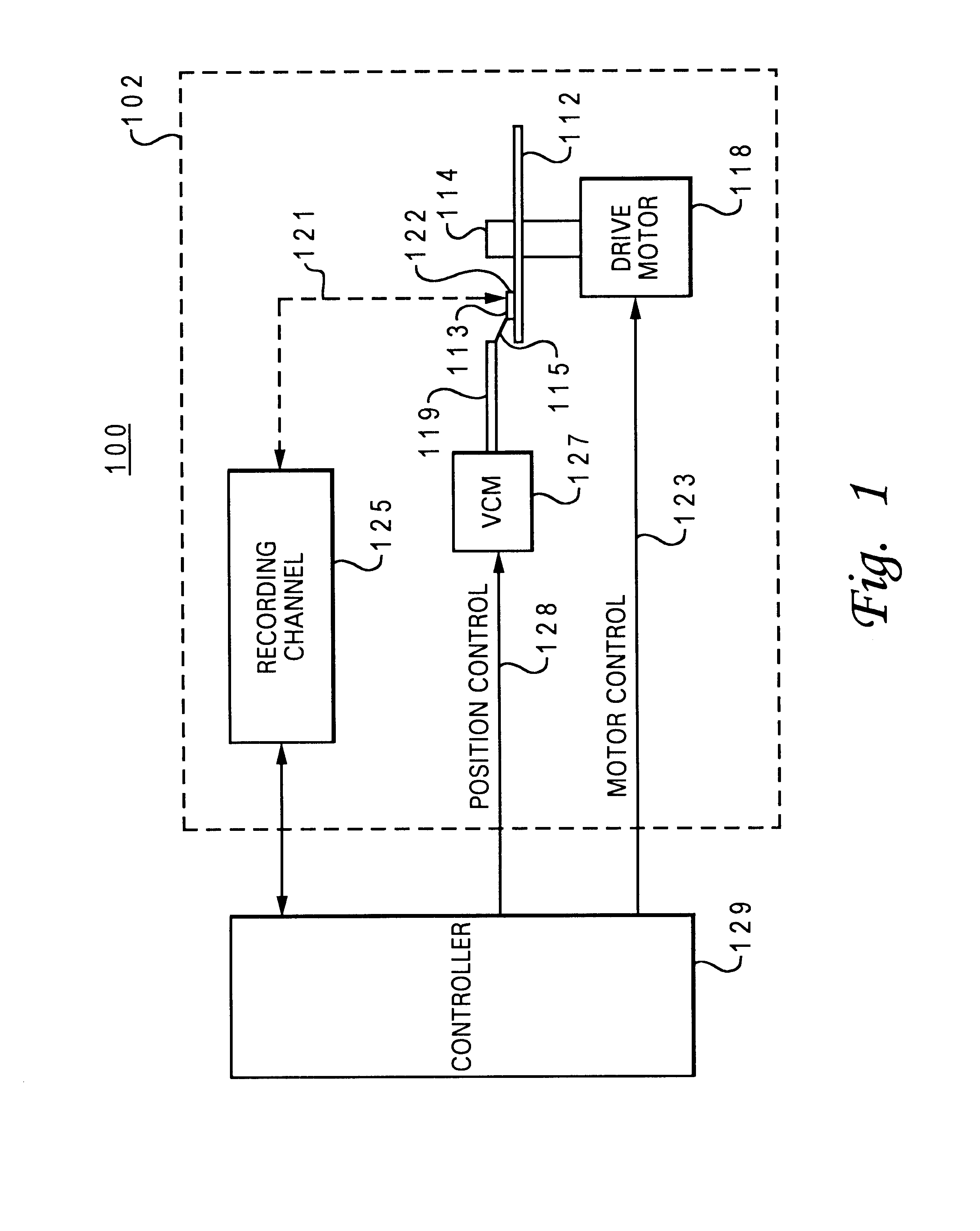

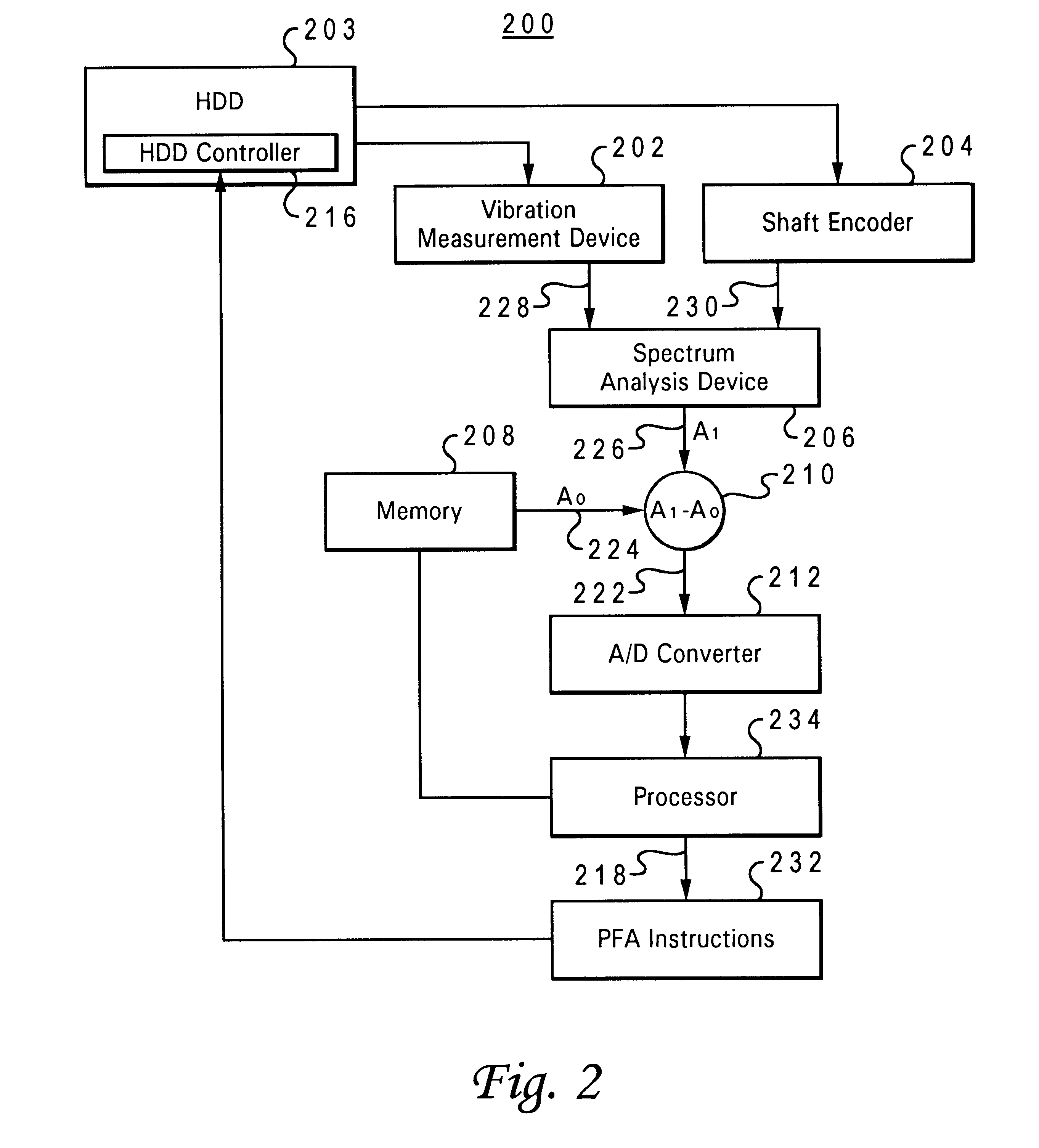

InactiveUS6415189B1Not easy to failAvoid data lossVibration measurement in solidsMaterial analysis using sonic/ultrasonic/infrasonic wavesData processing systemHard disc drive

A method and system within a data processing system for predicting failure of a hard disk drive having a fluid bearing during runtime operation of said hard disk drive, wherein said fluid bearing has an established signature dynamic fluid response. First, a runtime vibration level of the fluid bearing is measured. This runtime vibration level is then translated into a runtime dynamic fluid response which provides an indication of the operating condition of the fluid bearing. The runtime dynamic fluid response is compared with the baseline dynamic fluid response in real-time during operation of the hard disk drive. Finally, in response to a predetermined departure of the runtime dynamic fluid response from the baseline dynamic fluid response, a protective response is initiated, such that data loss within the data storage system due to fluid bearing failure is prevented.

Owner:WESTERN DIGITAL TECH INC

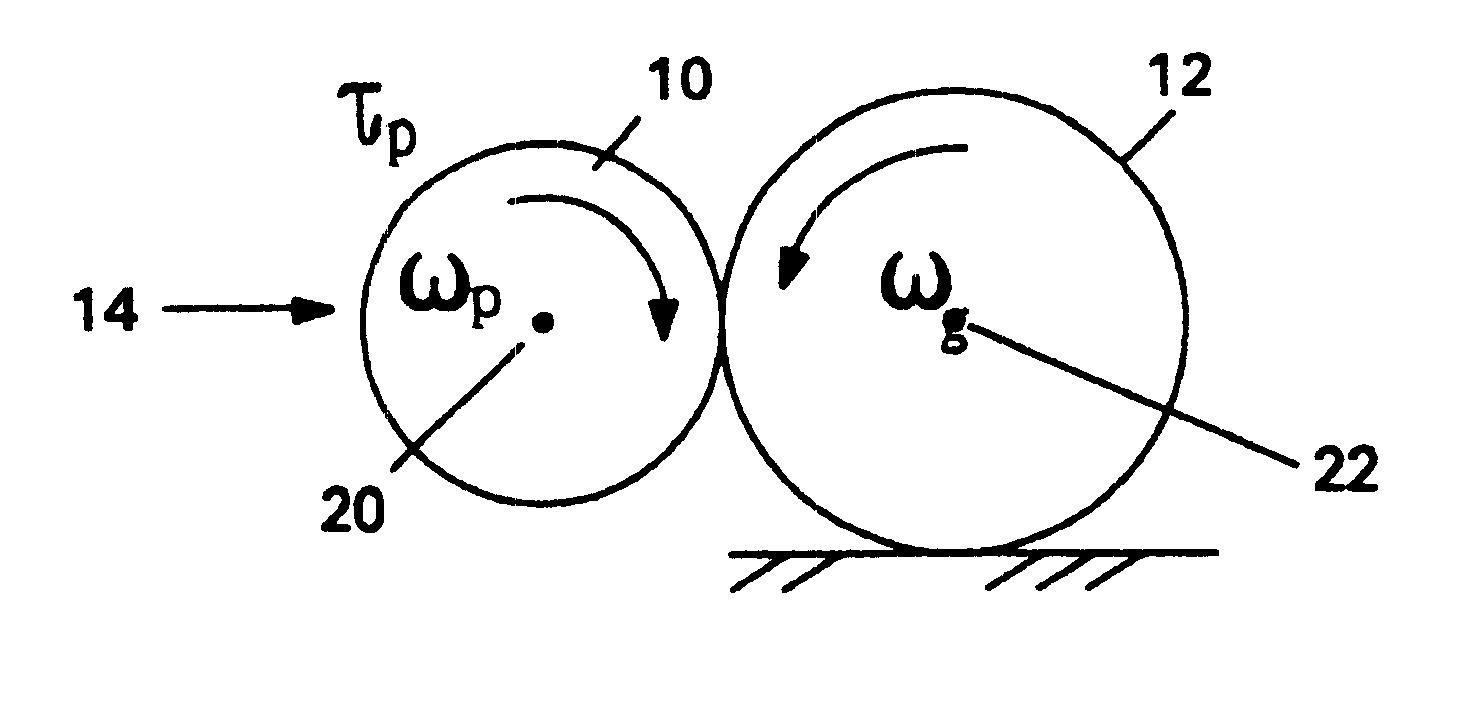

Gear transmission condition monitoring method and apparatus

InactiveUS6507789B1Plug gaugesMachine gearing/transmission testingFrequency spectrumTime frequency spectrum

A gear transmission monitoring method includes: forming a good operating condition baseline matrix by, for each of a plurality of different gear mesh frequencies, obtaining a good operating condition signal indicative of gear transmission conditions over a segment of time and transforming the obtained good operating condition signal into a good operating condition time-frequency spectrum; and then obtaining a gear mesh frequency and a test signal over a segment of time, transforming the obtained test signal into a test time-frequency spectrum, and using the gear mesh frequency and the good operating condition baseline matrix to examine the test time-frequency spectrum to monitor gear transmission conditions.

Owner:GE GLOBAL SOURCING LLC

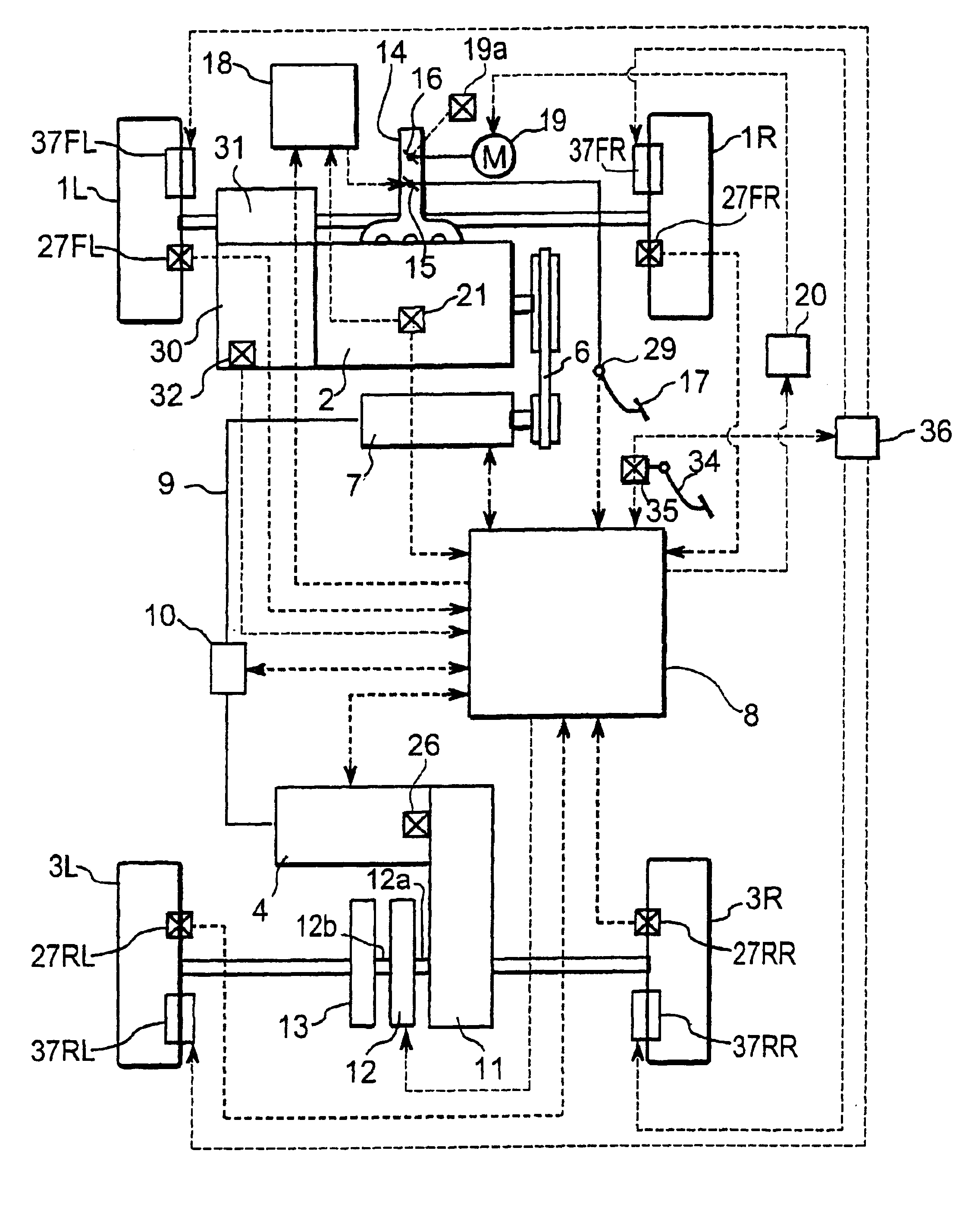

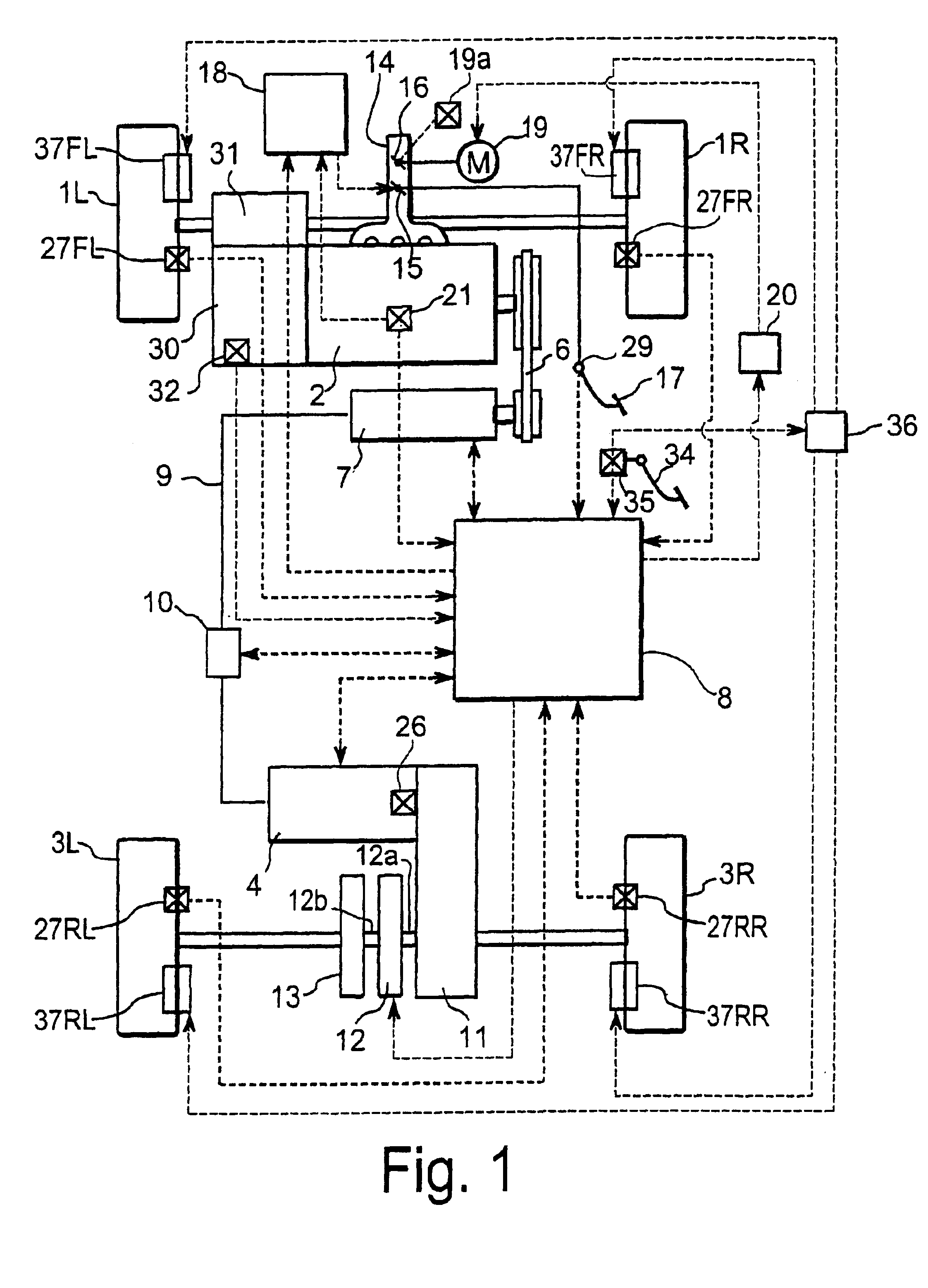

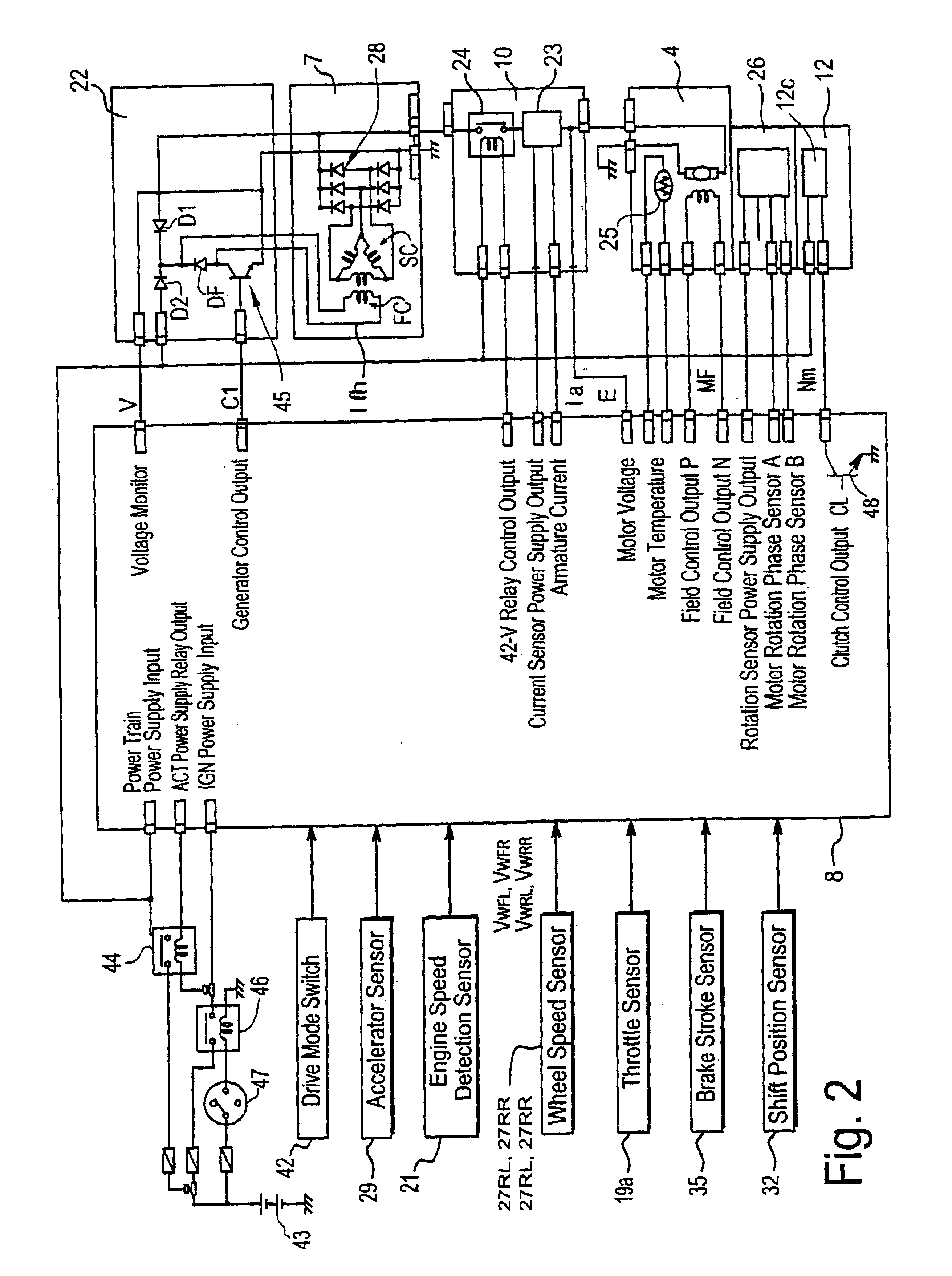

Vehicle driving force control apparatus

ActiveUS7004018B2Tendency to deteriorateInhibit bad effectsMachine gearing/transmission testingPlural diverse prime-mover propulsion mountingEngineeringInternal combustion engine

A vehicle driving force control apparatus controls a control torque command of an electric motor based on a power supplying condition of an electric power source. The power source supplies electric power to the electric motor that drives at least one wheel of the vehicle. An electric power supplying status detecting section determines an electric power supplying capacity of the electric power source based on the power supplying condition of the power source, while an electric motor torque control section controls the control torque command of the electric motor based on the power supplying condition determined by the electric power supplying status detecting section. Preferably, an internal combustion engine that drives at least one other wheel also drives a generator that acts as the power source of the electric motor. The vehicle driving force control apparatus is especially useful in a four-wheel drive vehicle.

Owner:NISSAN MOTOR CO LTD

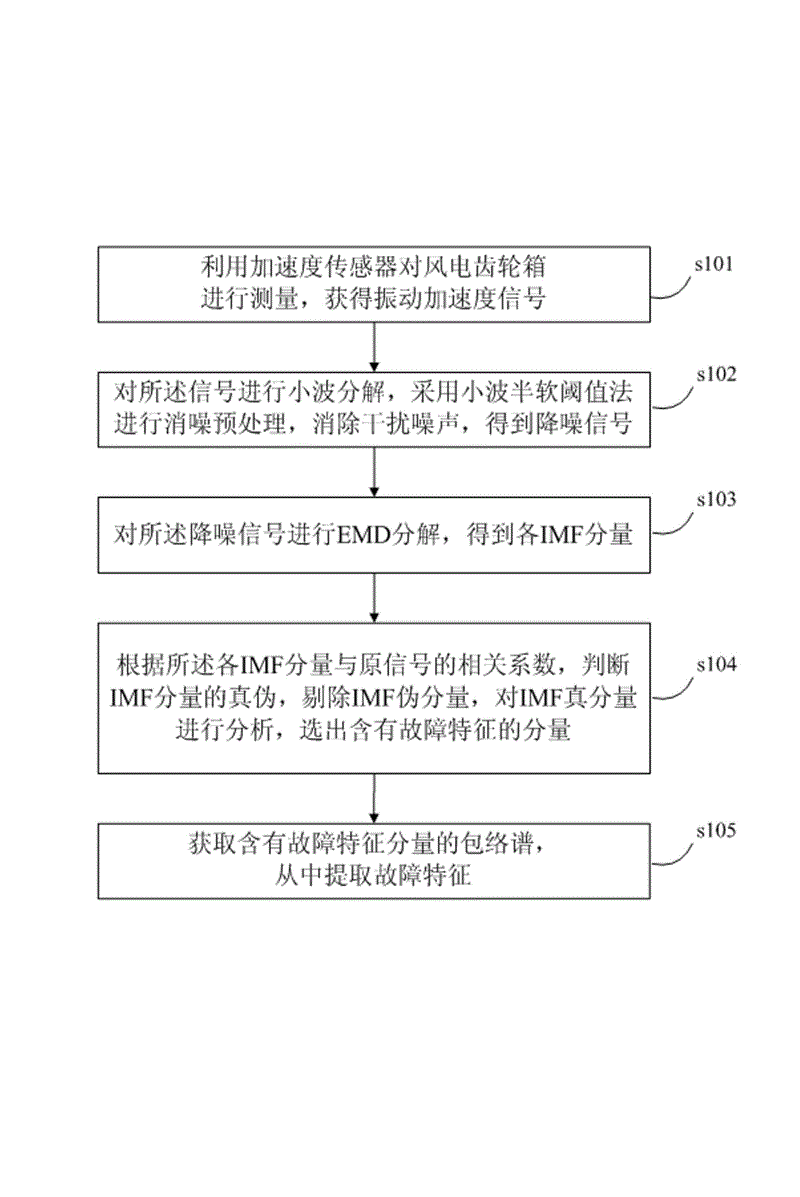

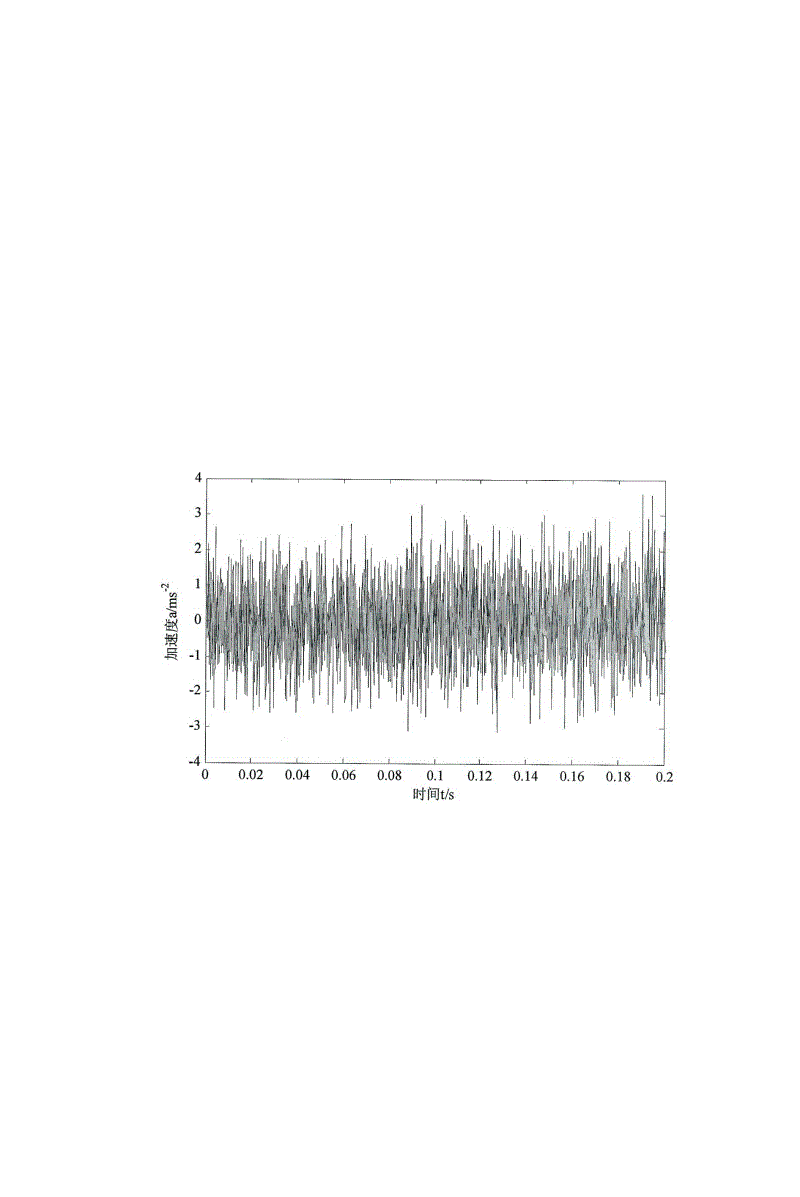

Wind-power gear box fault diagnosis method based on wavelet medium-soft threshold and electronic-magnetic diaphragm (EMD)

InactiveCN102620928AResolution statusTroubleshooting Troubleshooting IssuesMachine gearing/transmission testingElectricityVibration acceleration

The invention discloses a wind-power gear box fault diagnosis method based on wavelet medium-soft threshold and electronic-magnetic diaphragm (EMD), which includes: A. measuring a wind-power gear box by utilizing an acceleration sensor to obtain vibration accelerator signals; B. performing wavelet analysis on the signals, performing de-noising preprocessing through a wavelet medium-soft threshold method to eliminate interfering noise and obtain de-noising signals; C. performing EMD analysis on the de-noising signals to obtain each intrinsic mode function (IMF) component; D. judging true and false of the IMF components according to the related coefficients between the IMF components and original signals, rejecting false IMF components, and analyzing true IMF components to obtain components containing fault characteristics; and E. obtaining envelope spectrums containing fault characteristic components to draw fault characteristics. The wind-power gear box fault diagnosis method combines wavelet medium-soft threshold de-noising and the EMD and is effective in fault characteristic information drawing.

Owner:YANSHAN UNIV

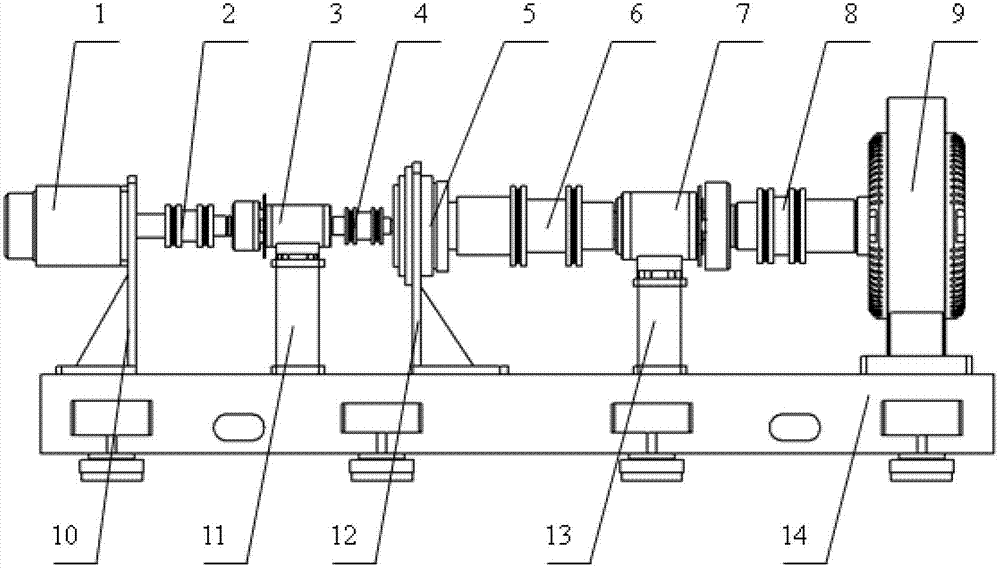

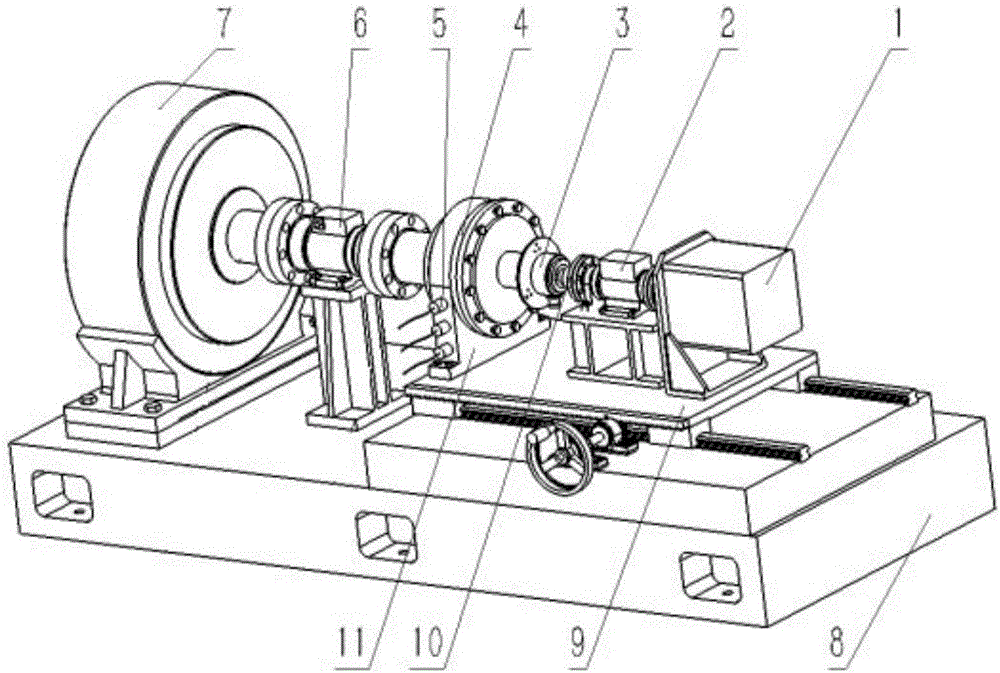

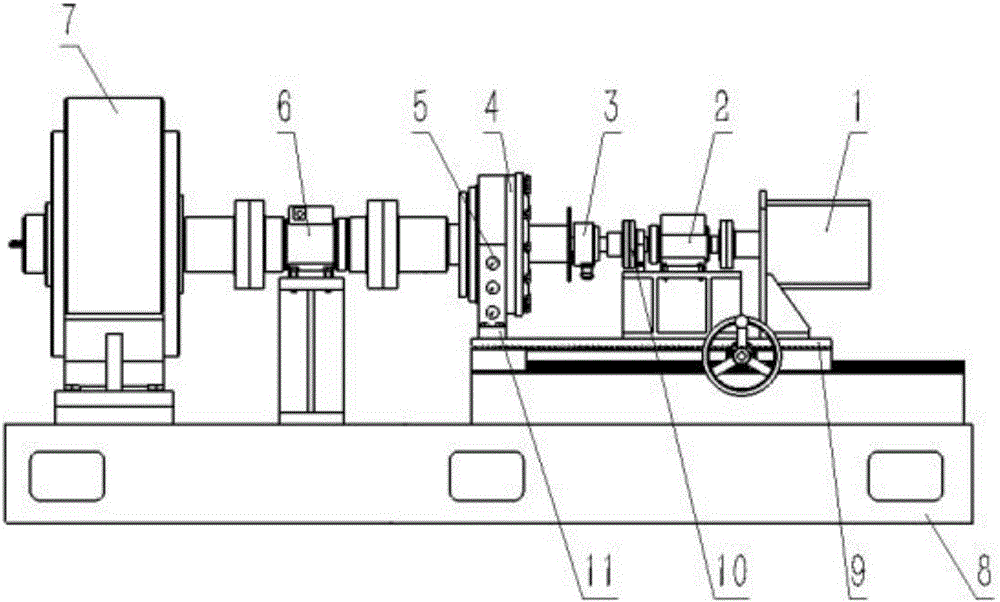

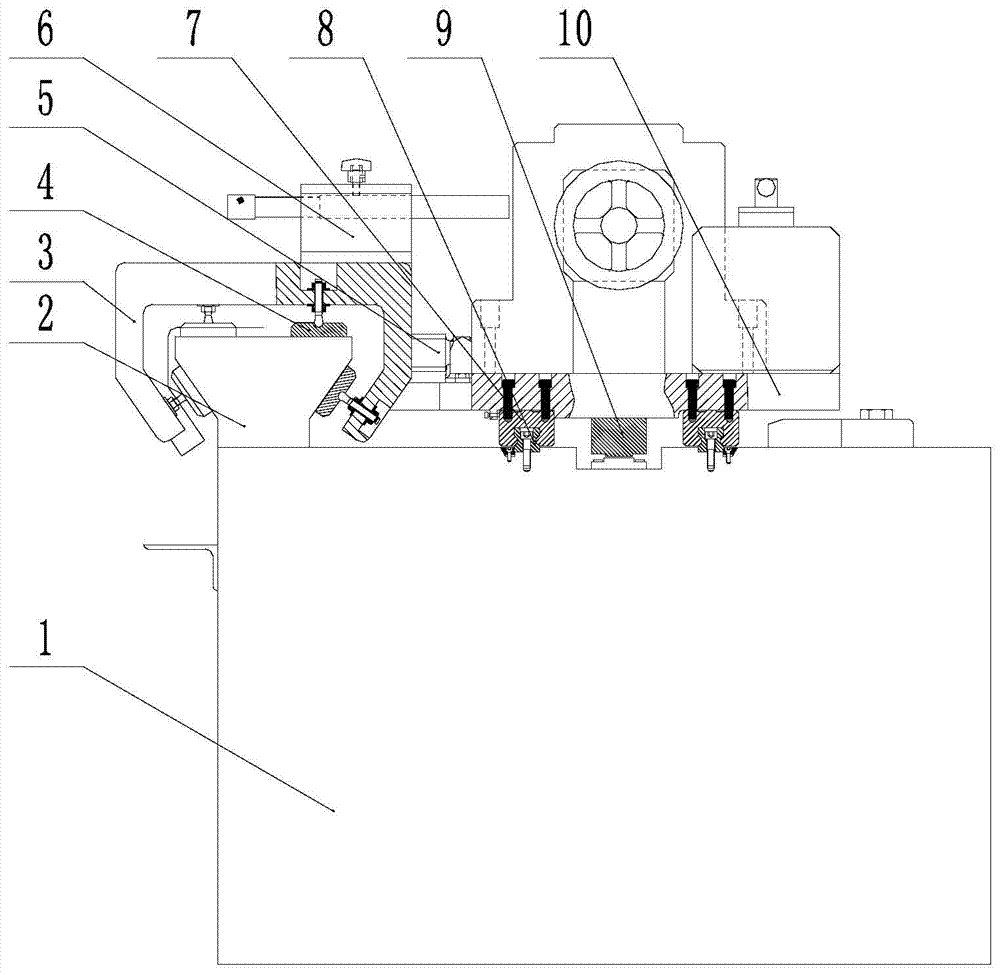

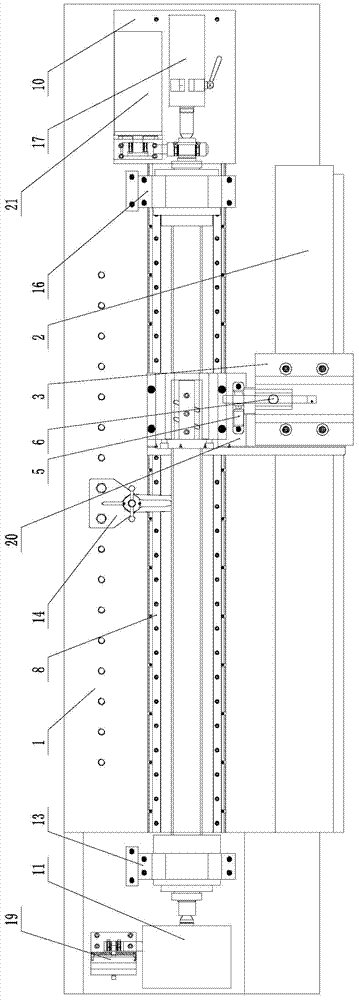

Robot reducer transmission performance comprehensive testing device

InactiveCN103091102AImprove general performanceCompact structureMachine gearing/transmission testingTest efficiencyElectric machine

The invention discloses a robot reducer transmission performance comprehensive testing device. The robot reducer transmission performance comprehensive testing device comprises a base (14), wherein a drive motor (1), a first coupling (2), a reducer input end torque angular displacement sensor (3), a second coupling (4), a to-be-tested reducer (5), a third coupling (6), a reducer output end torque angular displacement sensor (7), a fourth coupling (8) and a brake (9) are arranged on the base (14), share the same axis on the level direction, and are connected in sequence, and the drive motor (1), the reducer input end torque angular displacement sensor (3), the to-be-tested reducer (5) and the reducer output end torque angular displacement sensor (7) are respectively arranged on the base (14) through a motor support (10), a first support (11), a to-be-tested reducer support (12) and a second support (13). The robot reducer transmission performance comprehensive testing device meets the requirements of transmission performance tests such as high precision composite roller movable teeth transmission reducer ratio, return difference and efficiency, and thus testing efficiency and testing accuracy are high.

Owner:WENZHOU UNIVERSITY

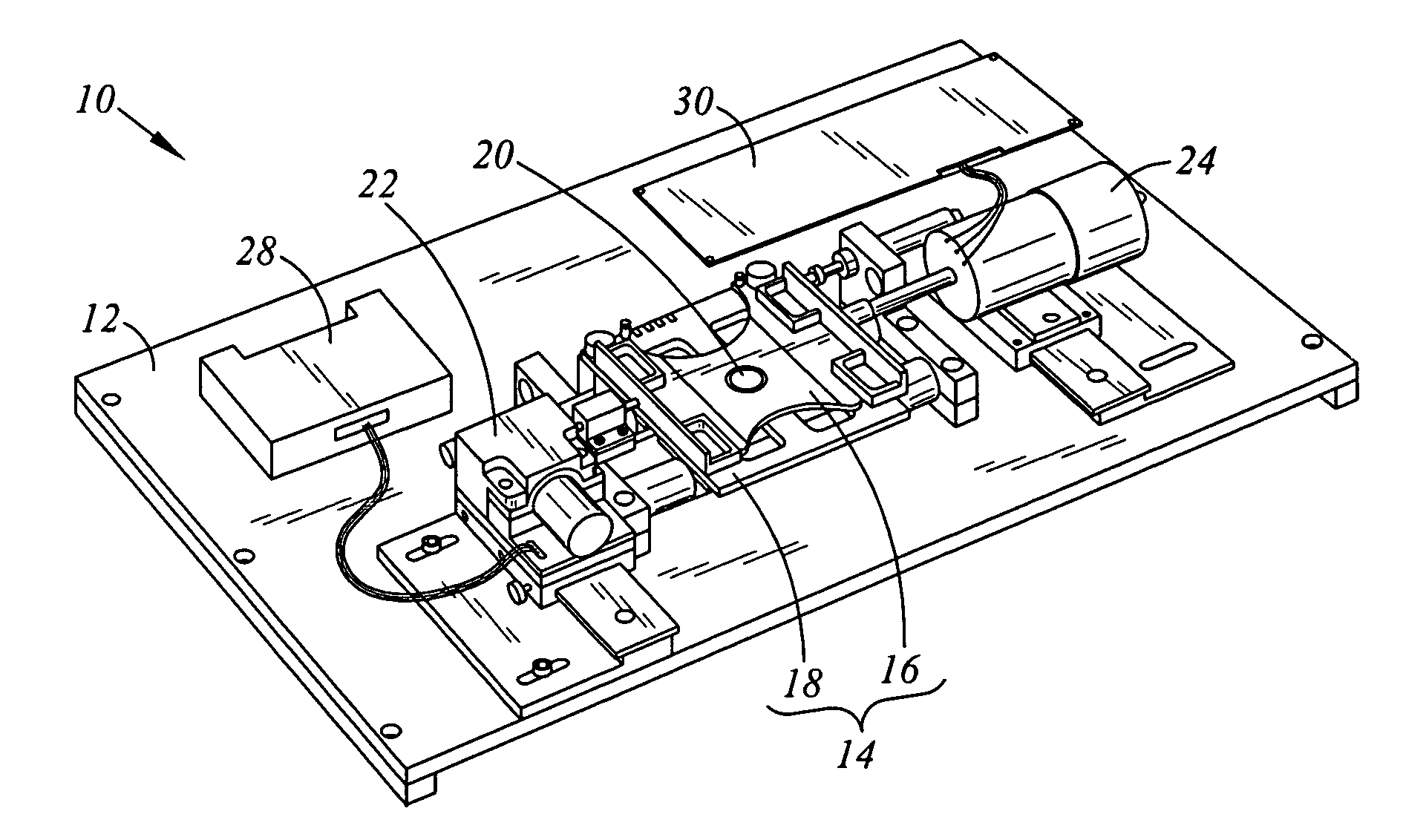

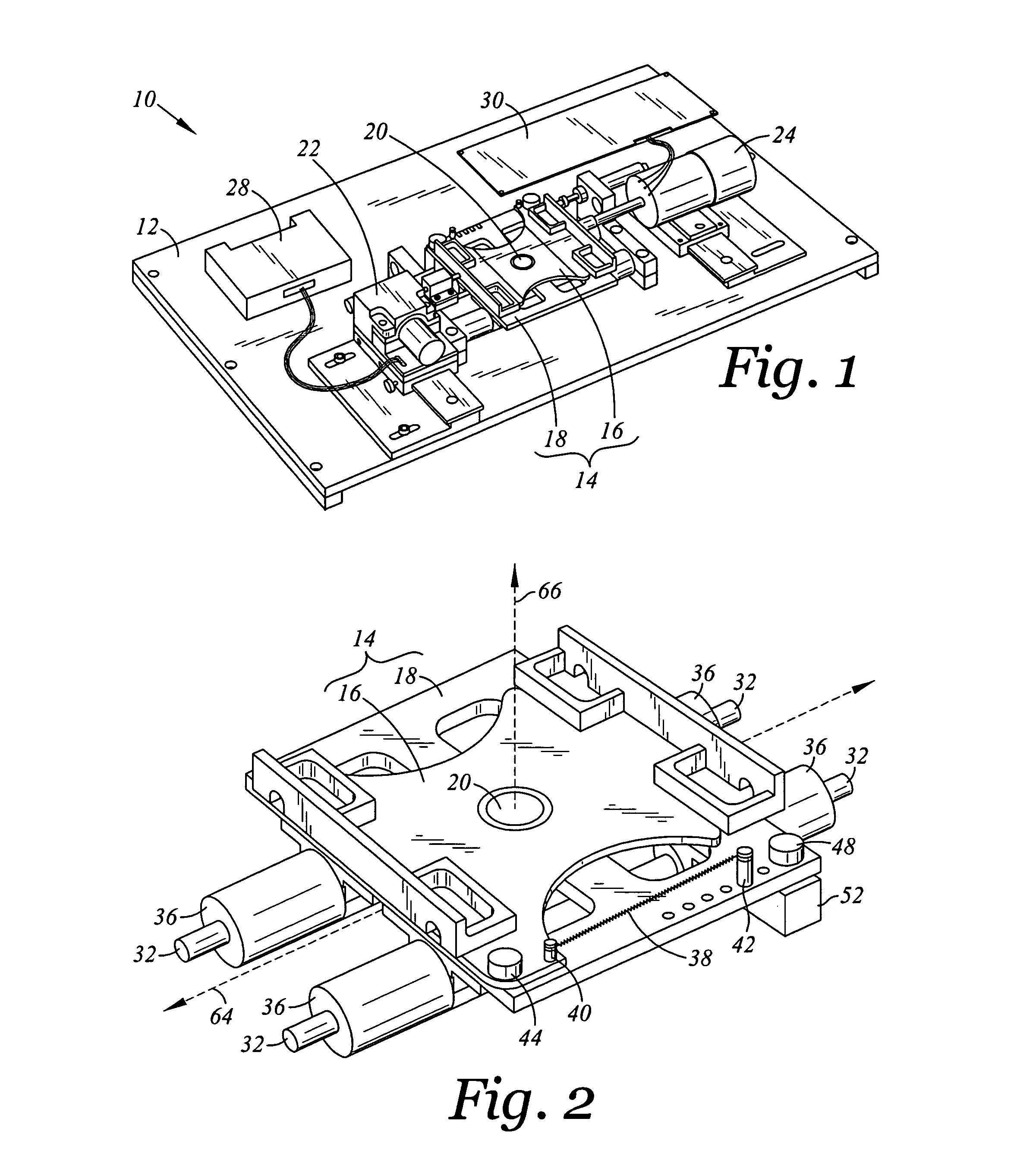

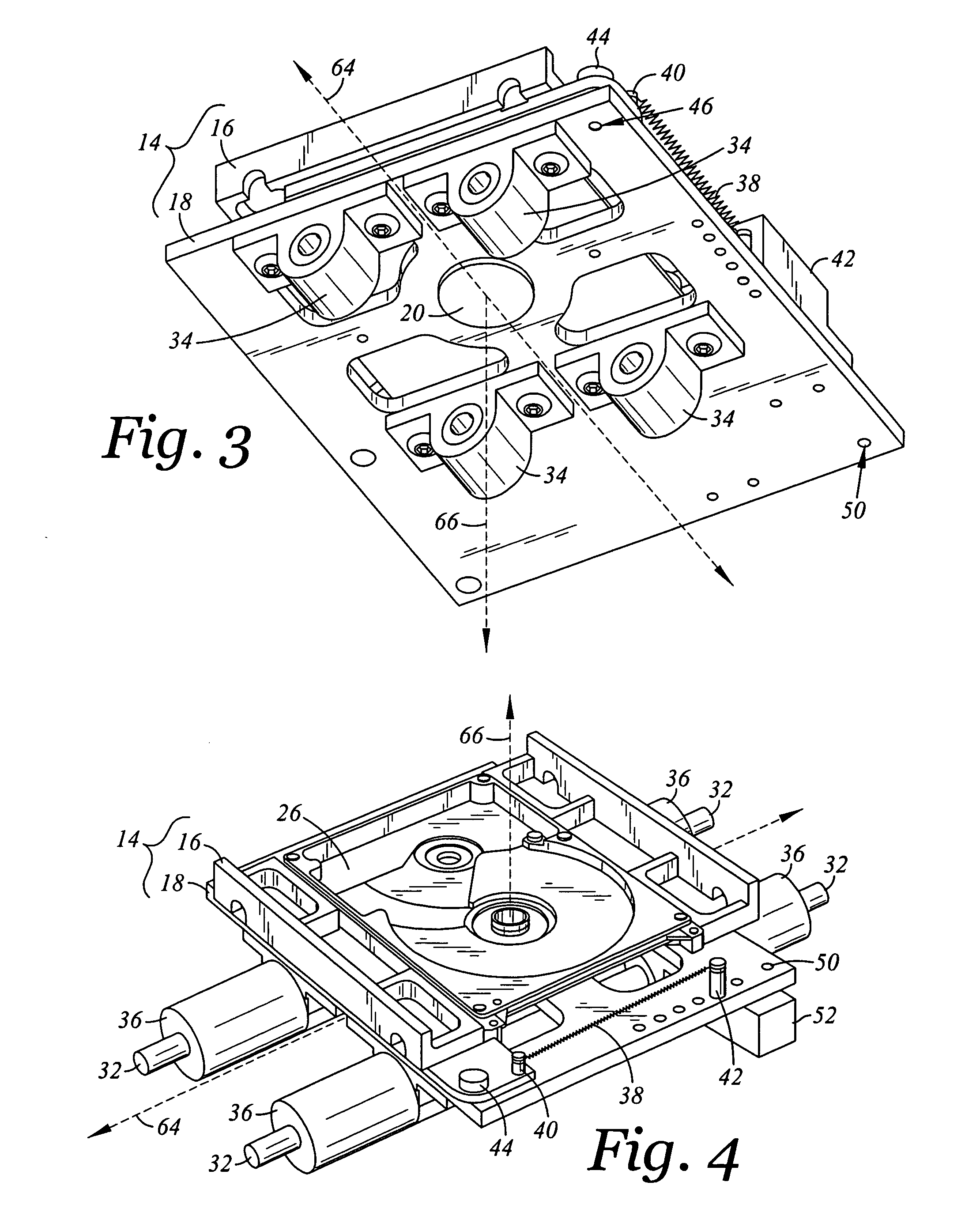

Data storage testing apparatus for delivering linear or rotational acceleration

InactiveUS7013731B1Vibration measurement in solidsMaterial analysis using sonic/ultrasonic/infrasonic wavesLinear motionActuator

A testing apparatus for use with a data storage component that includes a base platform and a retaining element coupled to the base platform. The retaining element is sized and configured to retain the data storage component. The retaining element is linearly movable relative to the base platform during a linear acceleration mode without substantial rotational movement. The retaining element is rotationally movable relative to the base platform without substantial linear movement during a rotational acceleration mode. The testing apparatus further includes an actuator disposable in mechanical communication with the retaining element for moving the retaining element relative to the base platform.

Owner:WESTERN DIGITAL TECH INC

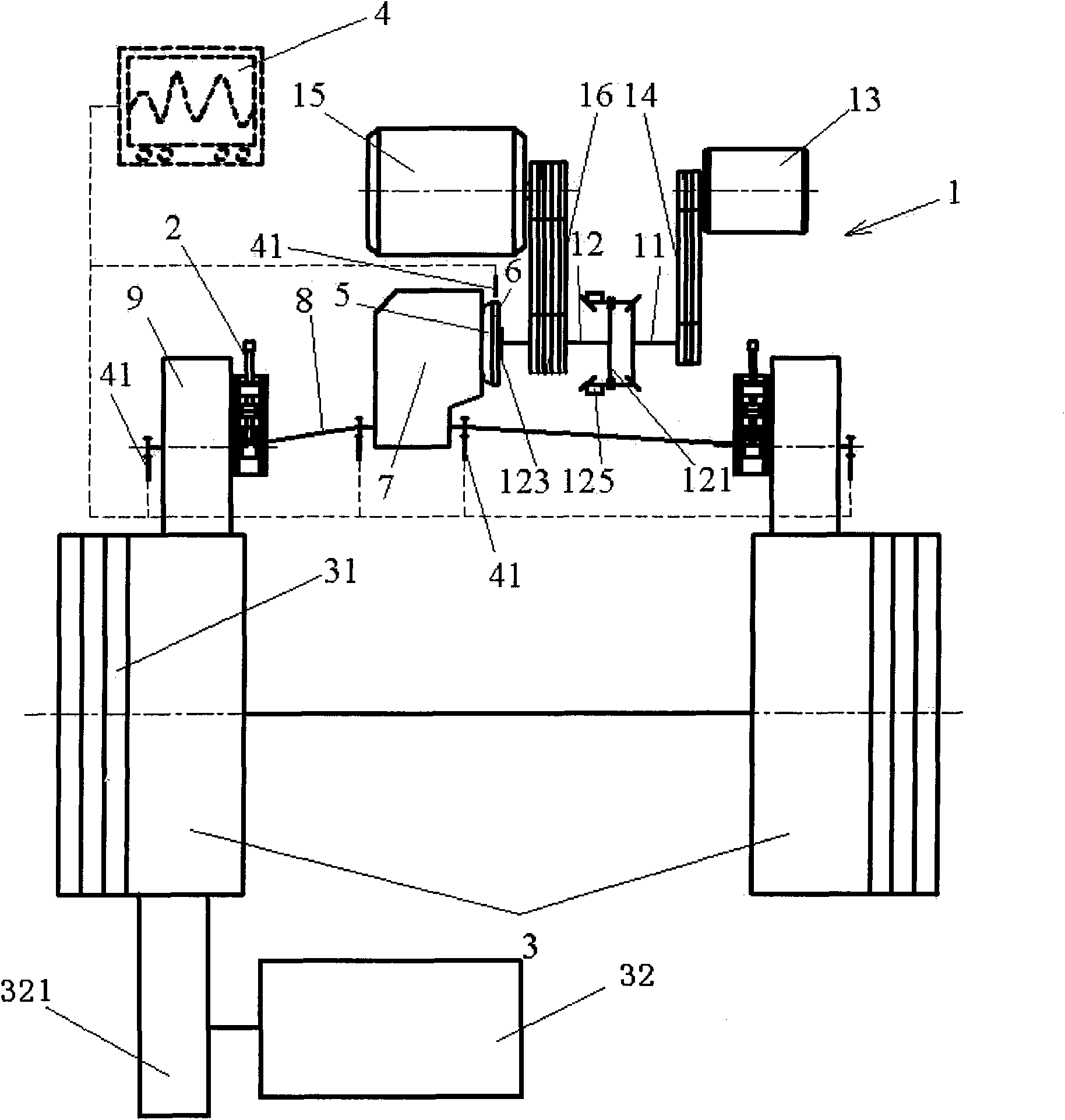

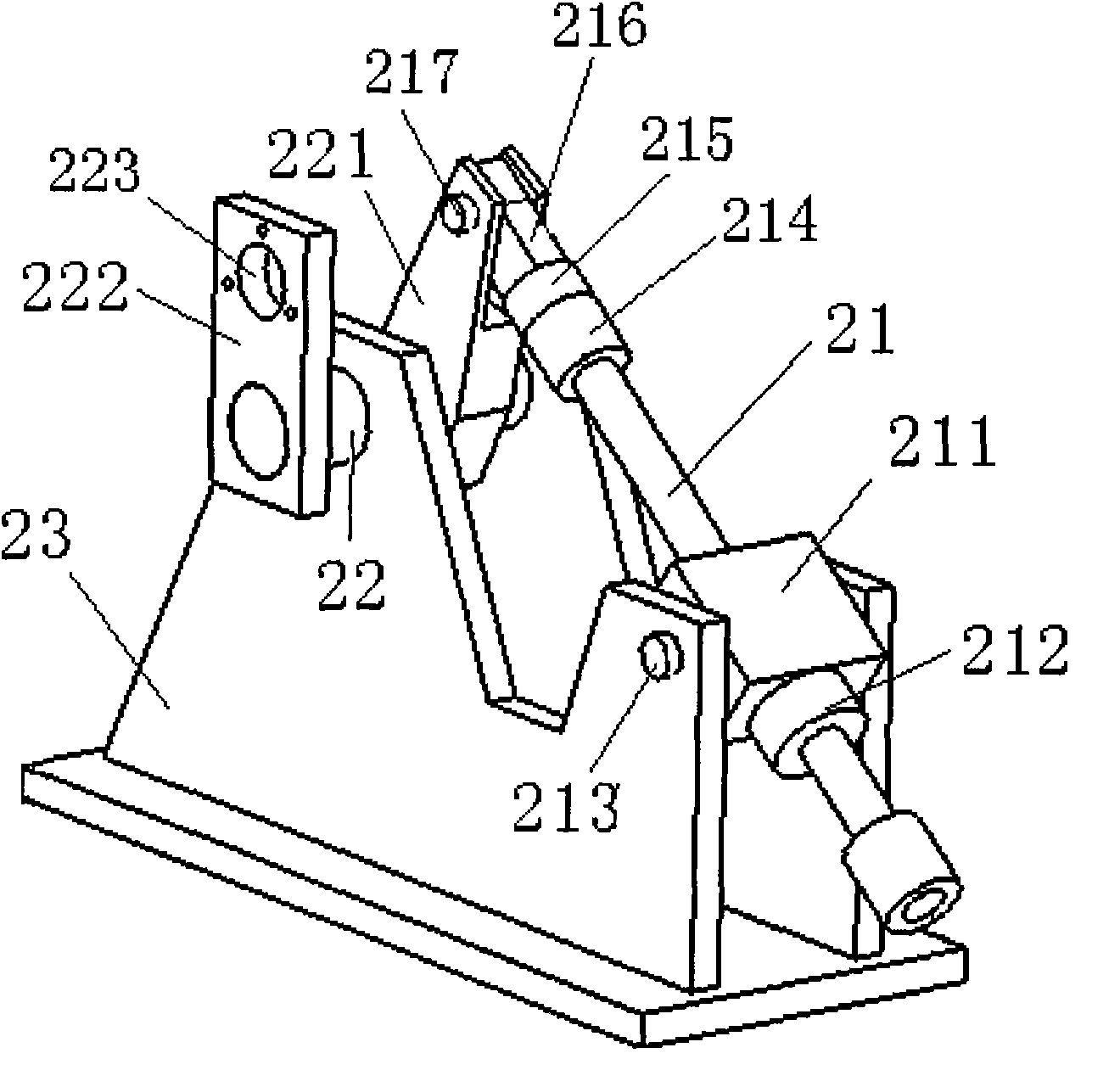

Torsional vibration excitation device and test bed of vehicle drive system

InactiveCN101865778AChange frequencyLarge amount of adjustmentVehicle testingMachine gearing/transmission testingElectric machineryDrive motor

The invention relates to a torsional vibration excitation device and a test bed of a vehicle drive system, comprising a torsional vibration excitation device, a wheel loading device, an inertia flywheel and a testing system. The torsional vibration excitation device is used for providing a torsional vibration excitation torque for the torsional vibration research of the drive system and providing power for the drive system. The wheel loading device is used for supporting wheels and simulating a carload acting on the wheels, pressing the wheels towards the inertia flywheel through a mechanical loading mode and locking the positions of the wheels. The testing system is used for collecting pull and pressure signals as well as rotate speed signals output by a sensor and analyzing the pull and pressure signals as well as the rotate speed signals. The torsional vibration excitation device comprises a driving motor, a driving gear shaft, an excitation gear shaft and an excitation motor, wherein the driving motor drives the driving gear shaft to rotate through the belt of the driving motor, the excitation motor drives the excitation gear shaft to rotate through the belt of the excitation motor, and the excitation gear shaft is coaxial with the driving gear shaft.

Owner:CHONGQING UNIV

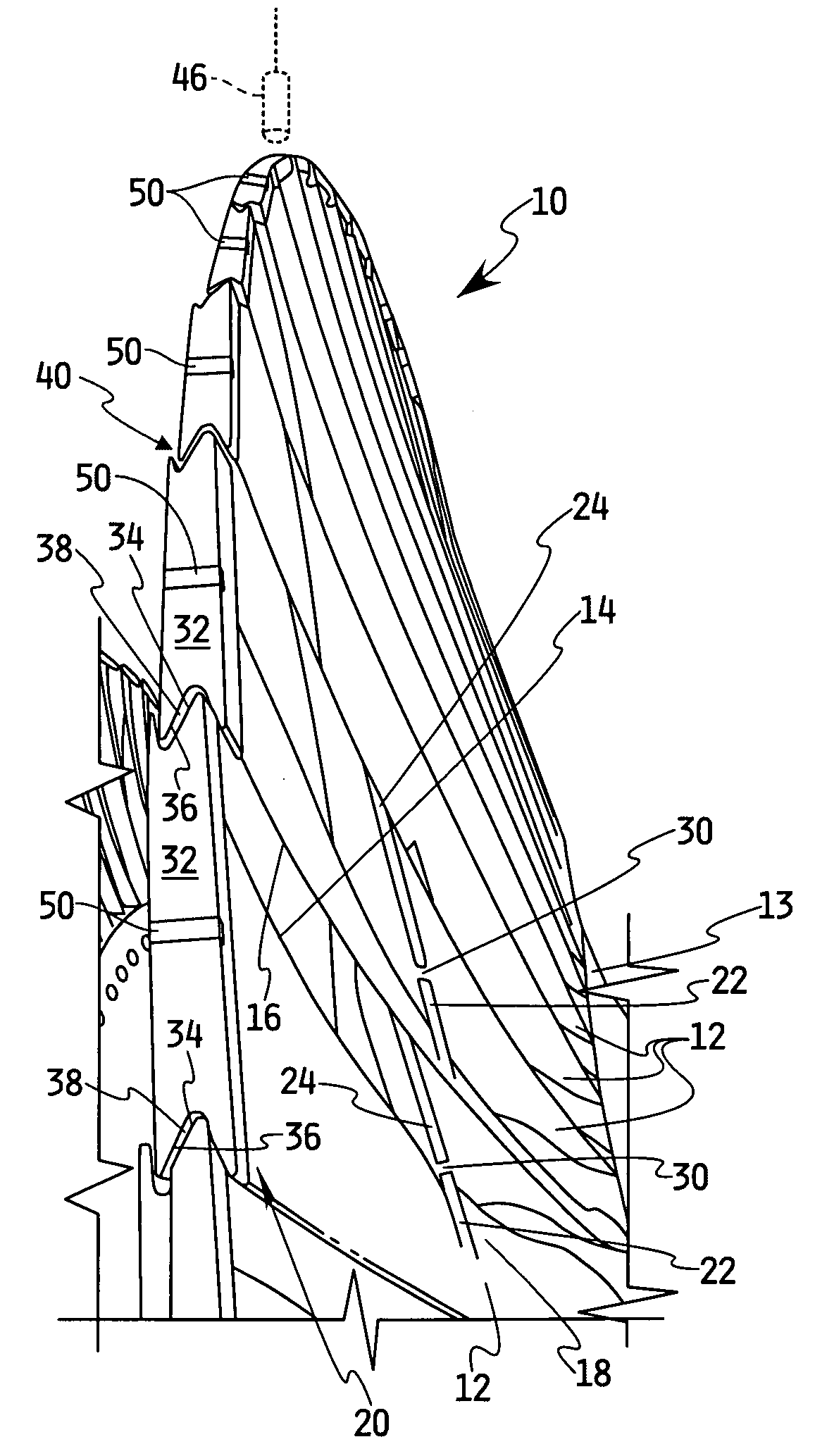

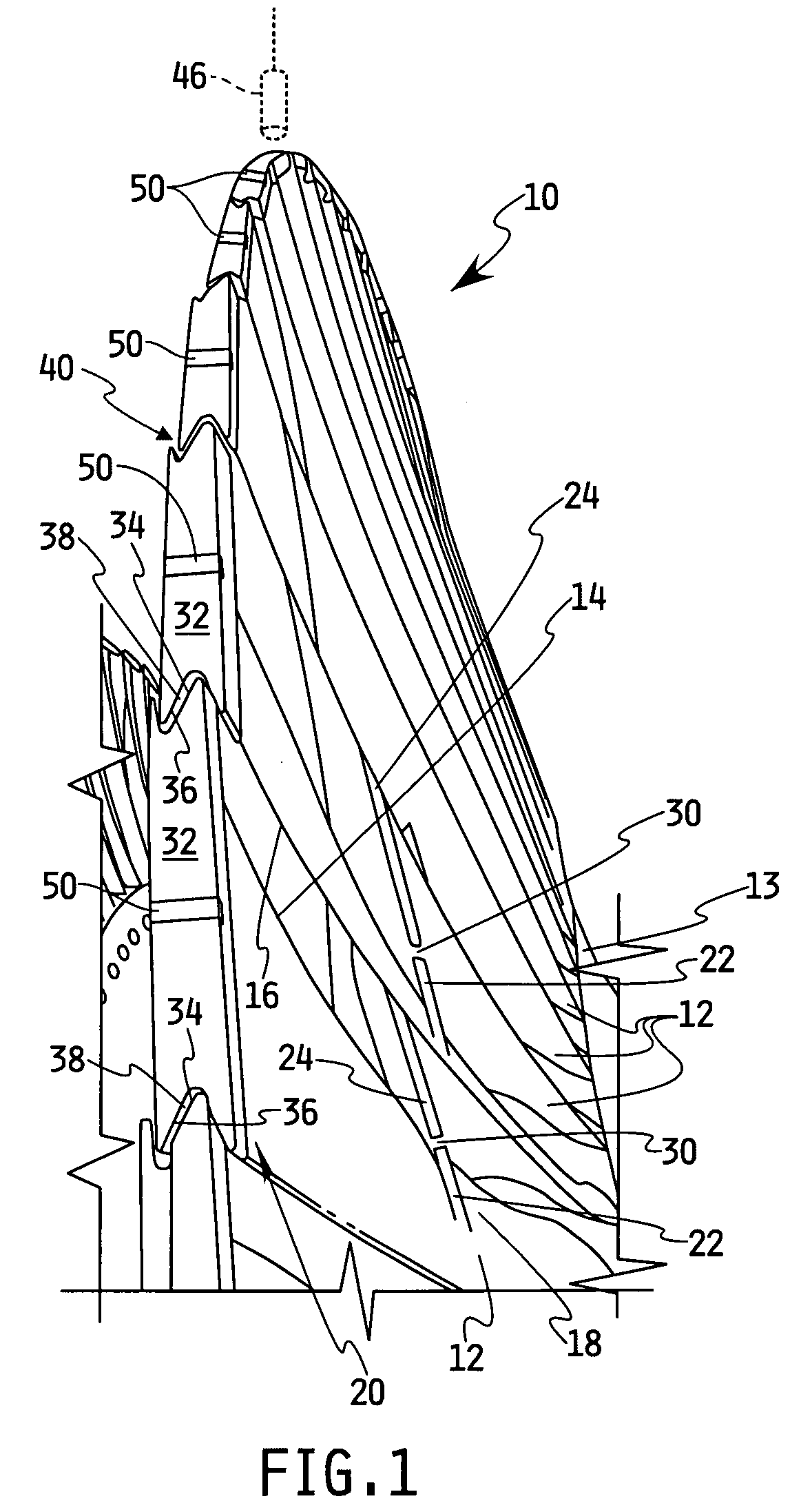

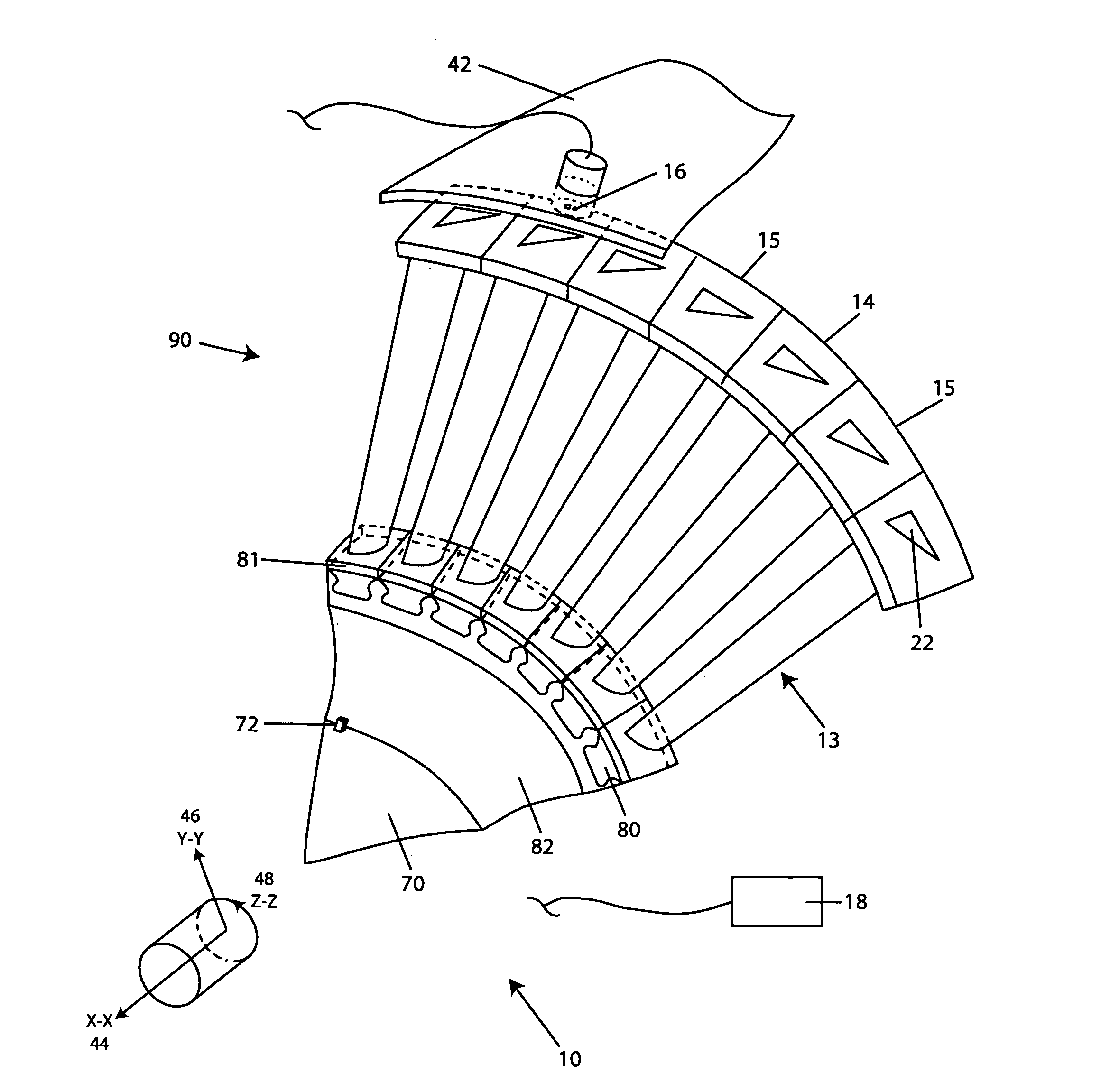

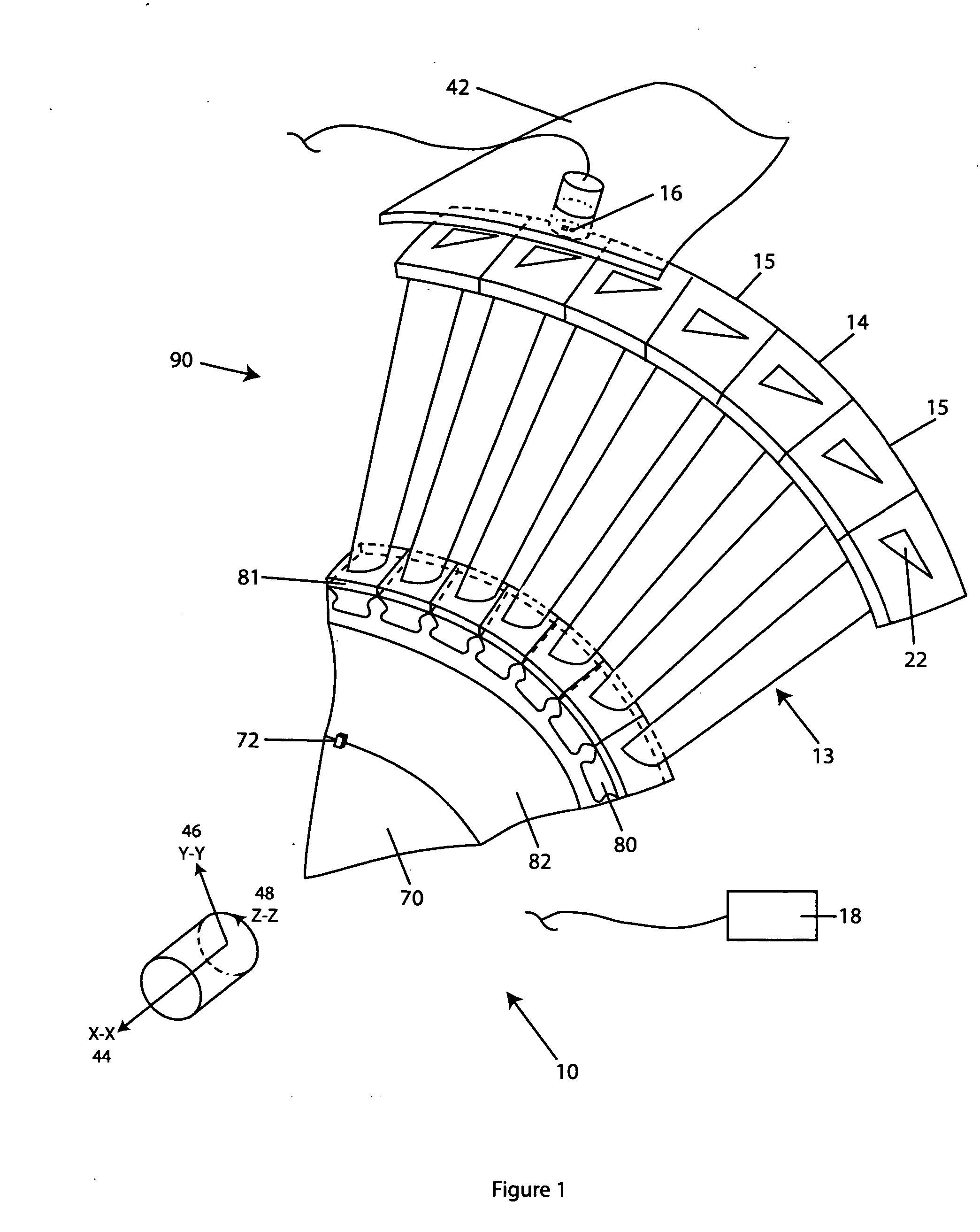

Blade shroud vibration monitor

ActiveUS20080206057A1Vibration measurement in solidsMaterial analysis using sonic/ultrasonic/infrasonic wavesEngineeringKnife blades

A method for predicting a blade structure failure within a coupled blade structure including a plurality of blades supported for rotation on a rotor and a shroud structure coupling the blades. The method includes the steps of determining displacements of a plurality of predetermined circumferential locations on the shroud structure during rotation of the blade row, where the displacements are provided as a function of time relative to the periodic rotation of the shroud structure for time intervals that are integer multiples of rotor rotation. A signal characteristic related to vibrational mode and a nodal diameter of the shroud structure is derived based on the displacements of the circumferential locations on the shroud structure.

Owner:SIEMENS ENERGY INC

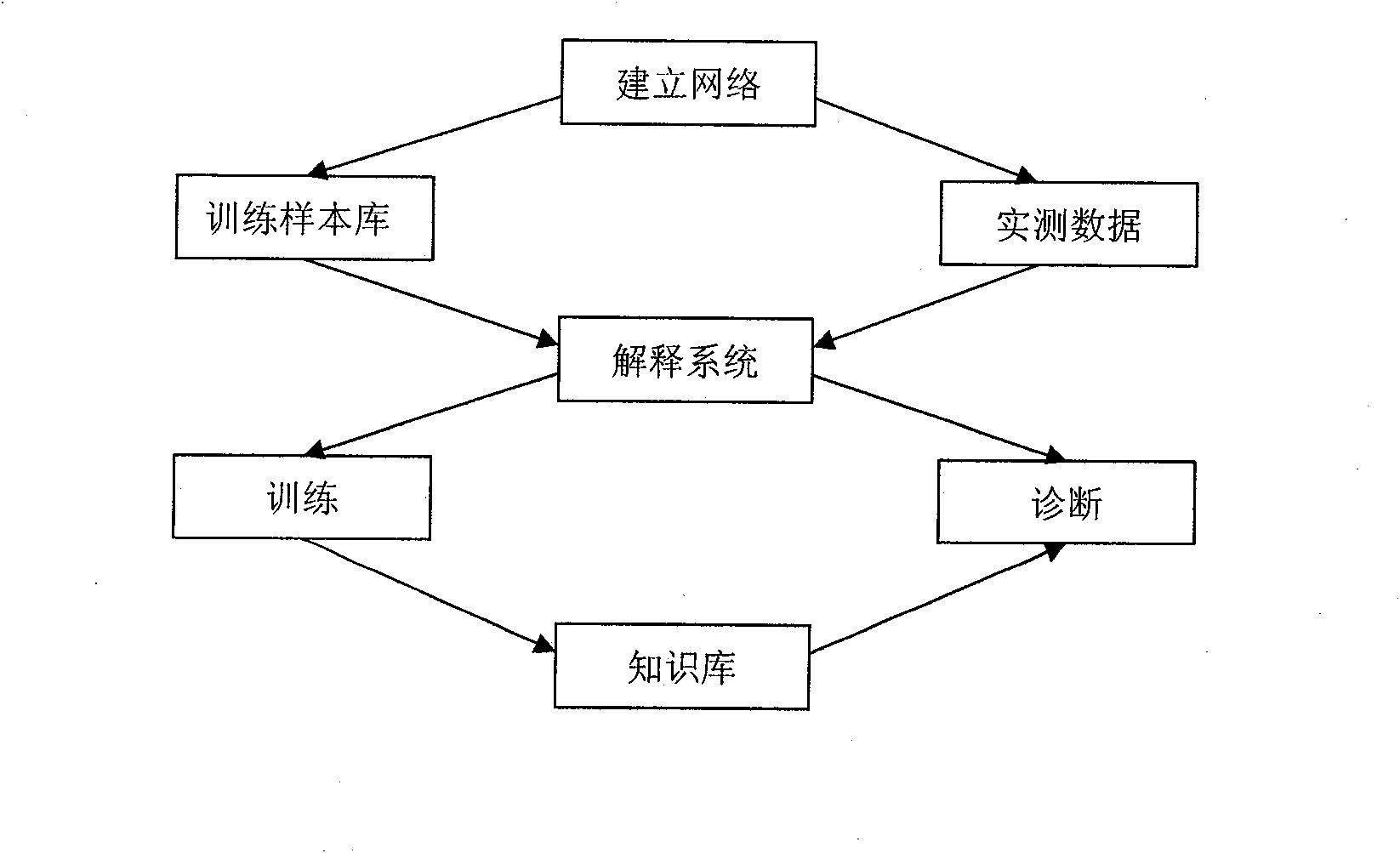

Intelligent gearbox fault diagnosis method based on mixed inference and neural network

InactiveCN101634605AFully automatedRealize intelligenceMachine gearing/transmission testingInference methodsInformation processingNerve network

The invention relates to an intelligent gearbox fault diagnosis method based on mixed inference and neural network, mainly comprising the following steps: enriching a knowledge base of an intelligent diagnosis system; storing expert knowledge into a computer; combining the neural network to recognize patterns; analyzing a main abnormal phenomenon of a gearbox; systematically researching generation mechanisms of vibration and noise of a gear; analyzing a mathematical model of gear vibration; analyzing the vibration mechanisms of various fault types by fully using on-site fault data; enriching time domain and frequency domain characteristics of various faults; and ensuring a characteristic extraction method of gear fault signals. A data analysis method mainly comprises the steps: band-pass filter frequency analysis, double-meaning analysis, envelope demodulation analysis and demodulation analysis based on EMD. The intelligent gearbox fault diagnosis method based on mixed inference and neural network solves the problems of the traditional serial information processing in the fields of pattern recognition, artificial intelligence, and the like so that a pattern recognition network is completely realized by the computer; and the intelligent gearbox fault diagnosis method based on mixed inference and neural network is convenient to realize the automation and the intelligence of the fault diagnosis and can provide a basis for a diagnosis decision in time.

Owner:BEIJING UNIV OF TECH

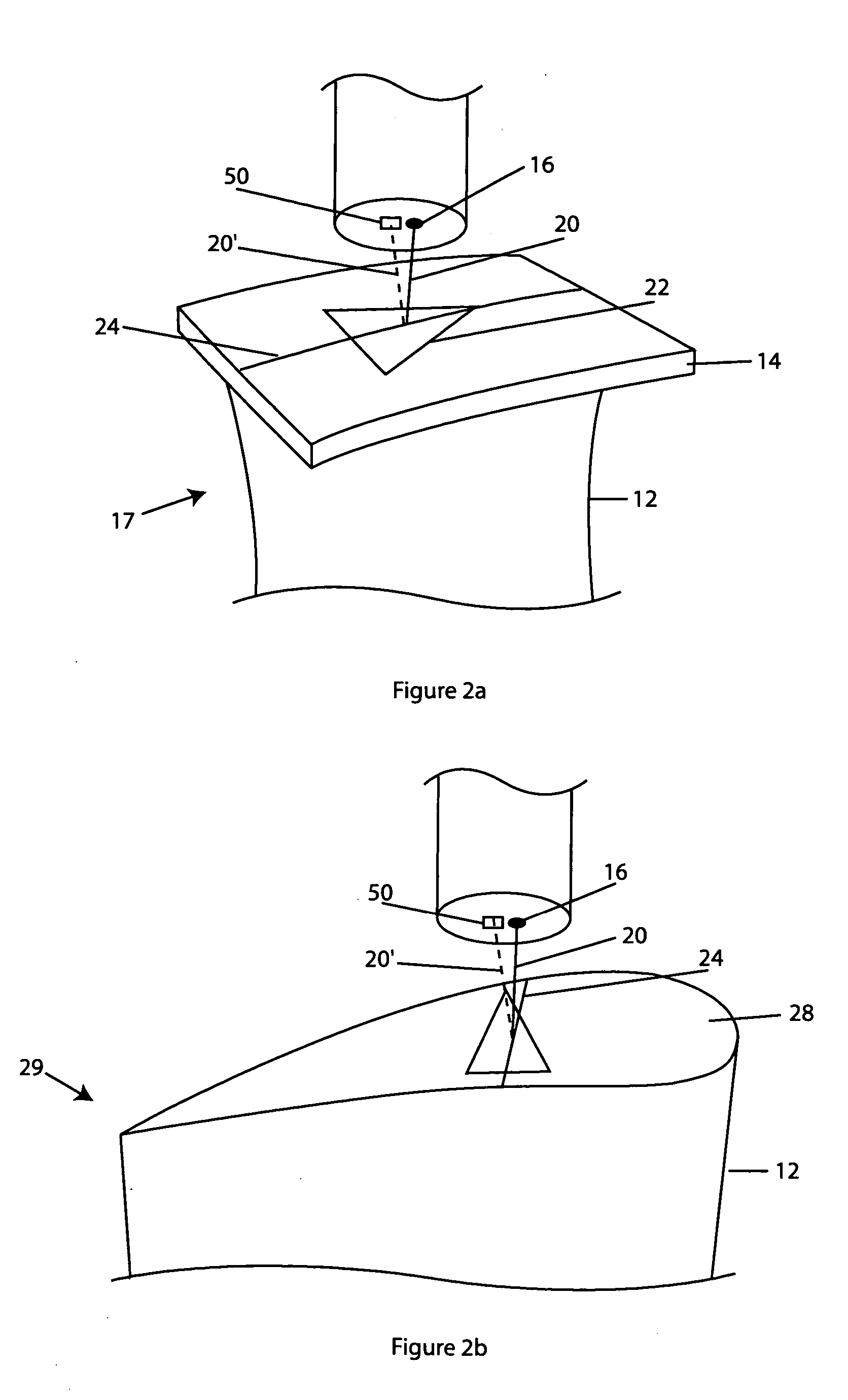

Turbine blade for monitoring blade vibration

ActiveUS20060000283A1Vibration measurement in solidsMaterial analysis using sonic/ultrasonic/infrasonic wavesTurbine bladeEngineering

The claimed invention provides a blade vibration measuring system comprising a blade, a transmitter, a target with non parallel edges located on the blade shroud and a receiver. The present invention also provides a blade adapted for measuring blade vibration. Furthermore, the claimed invention provides a method for monitoring blade vibration.

Owner:SIEMENS ENERGY INC

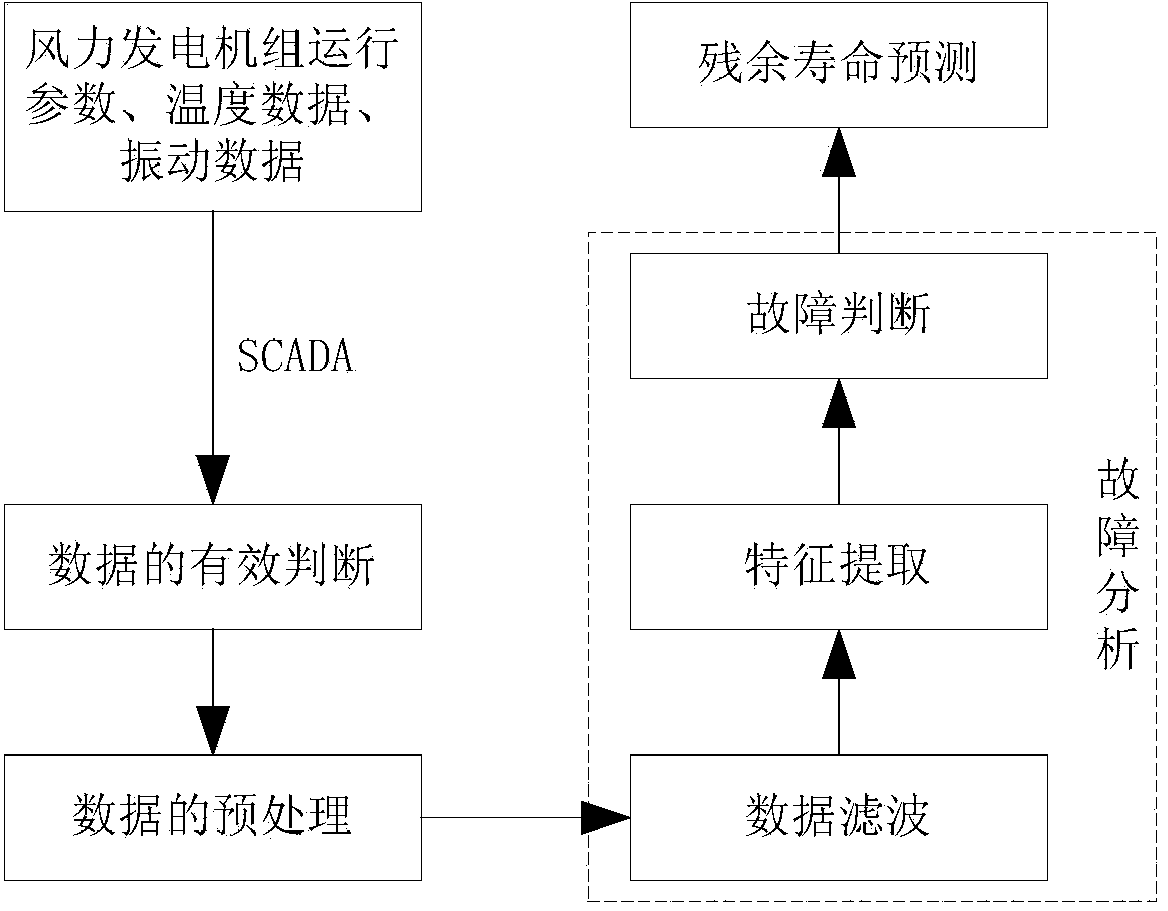

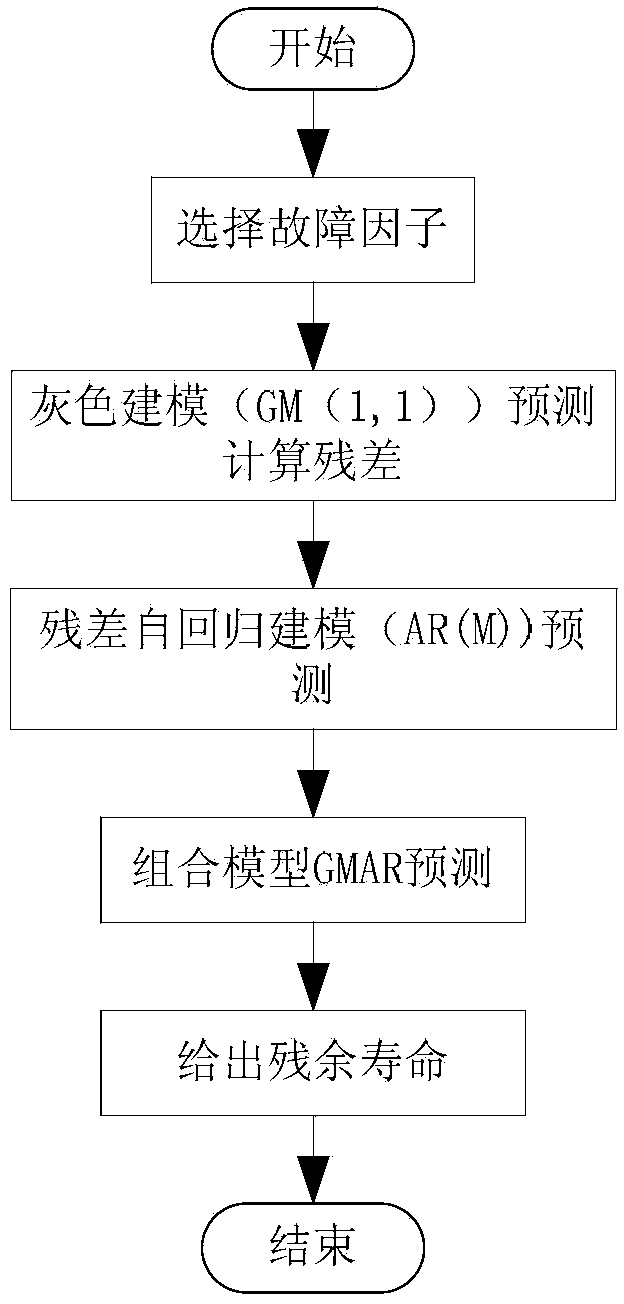

Wind turbine set gearbox remote online state monitoring and life assessment method

InactiveCN103645052AEnable real-time estimationImprove reliabilityMachine gearing/transmission testingElectricityTime domain

The invention provides a wind turbine set gearbox remote online state monitoring and life assessment method. The method comprises the following steps: (1) a remote center computer collects a real-time operation parameter, temperature data and vibration data of each wind turbine through SCADA; (2) through analyzing the characteristic values of signal time domain and frequency domain, whether a vibration sensor has a fault or not is diagnosed; (3) the data is subjected to normalization process, a difference between data is reduced, and the diagnosis precision is raised; (4) when the fault of a wind generator set gearbox is diagnosed, different filtering modes are employed for different algorithms to extract the corresponding characteristic; (5) the collected data is subjected to characteristic extraction; (6) the fault diagnosis is carried out to provide the fact that whether the fault exists or not and the degree of the fault; (7) the residual life of the failed gearbox is estimated through a gray theory model, and an autoregression model is established for the residual error of the predication result to raise the predication precision. According to the method, the real-time estimation of the residual life is realized, and a basis is provided for the planned maintenance of the wind turbine set.

Owner:BEIHANG UNIV +1

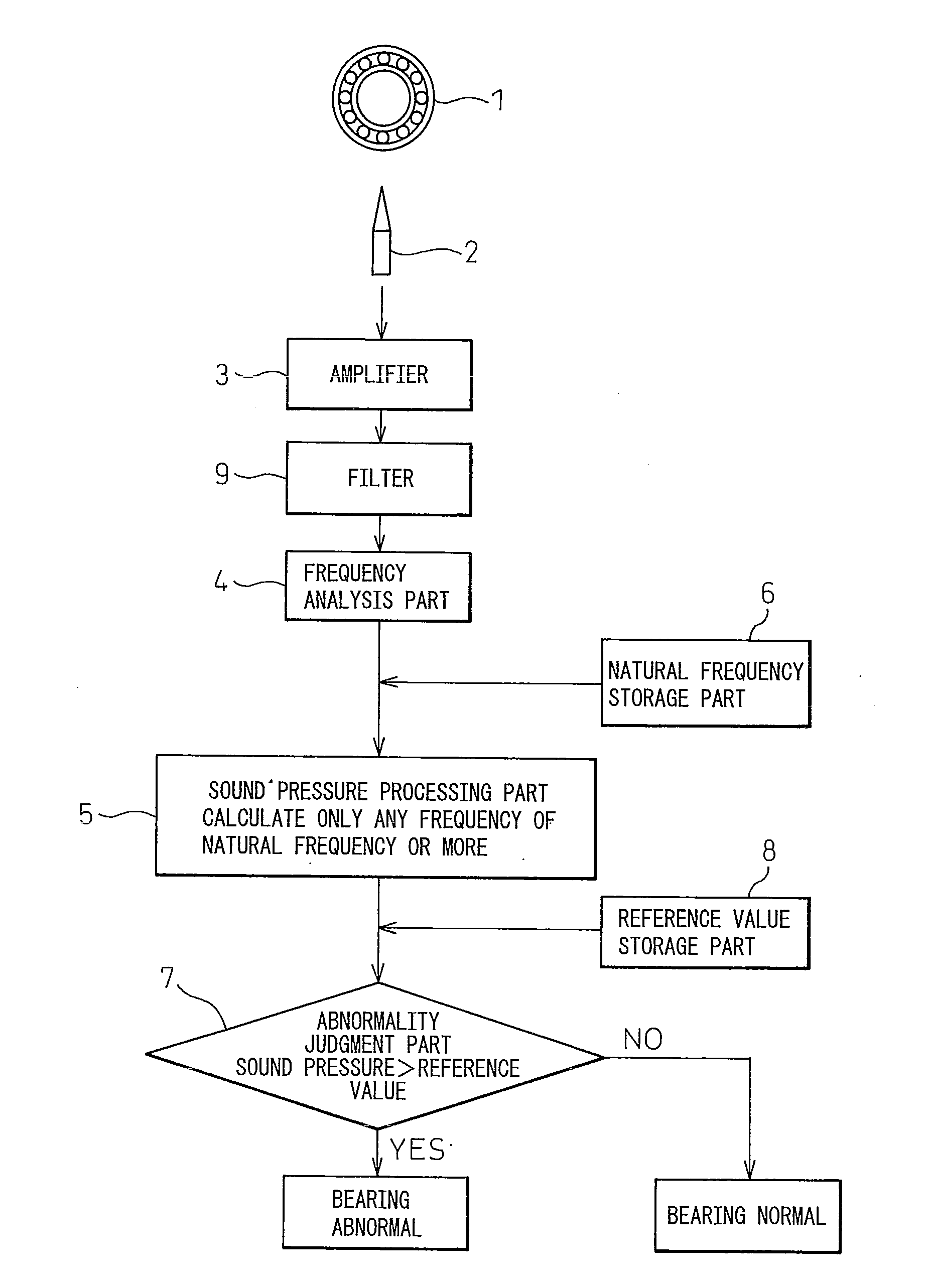

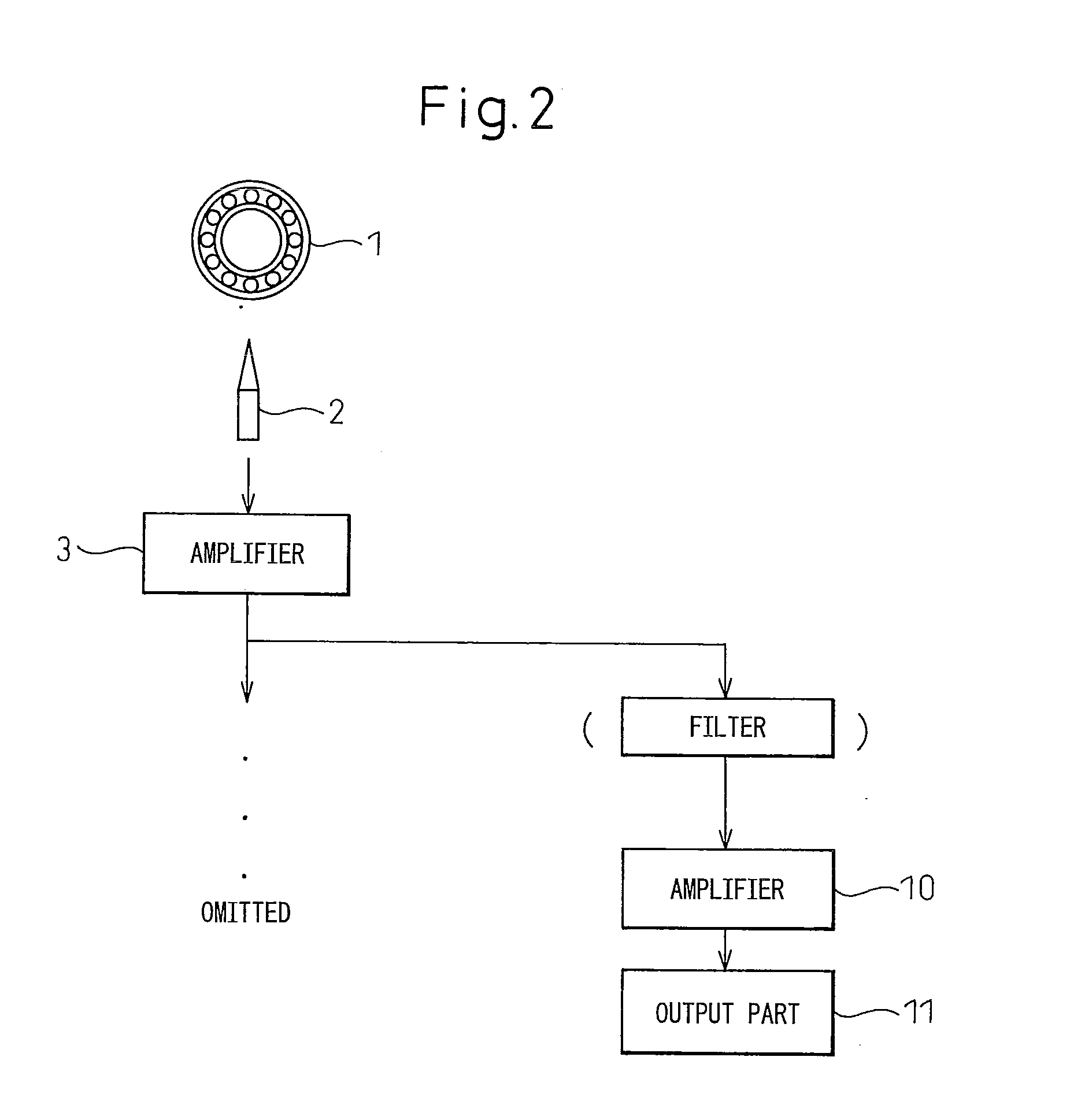

Method and system for abnormality diagnosis of very low speed rotating machine

InactiveUS20100116060A1Inexpensive and high accurate diagnosisVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesFrequency spectrumMechanical Abnormality

The present invention provides a high accuracy, inexpensive diagnosis method and system diagnosing an abnormality of a 10 rpm or less very low speed roller bearing using an acoustic signal, that is, detects an acoustic signal emitted from a roller bearing of a 10 rpm or less ultralow speed rotating machine using a sensor having a sound pickup performance of 10 kHz or less, uses frequency analysis to find the spectrum distribution, processes this to obtain the frequency analysis waveform, compares the spectral average value or effective value of a frequency of the natural frequency of the bearing or more of this with a reference value, and judges that the bearing is abnormal when this spectral average value or effective value exceeds the reference value.

Owner:NIPPON STEEL CORP

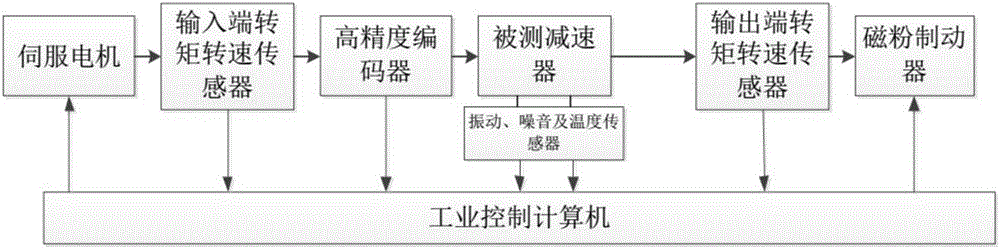

Comprehensive performance resting experiment table for precision speed reduction device

InactiveCN106441883AMeet the test requirementsMeet the testing requirementsMachine gearing/transmission testingCouplingReduction drive

The invention discloses a comprehensive performance resting experiment table for a precision speed reduction device. The comprehensive performance resting experiment table comprises main components, such as a servo motor, an input end torque and rotational speed sensor, a high precision encoder, a measured speed reducer, a vibration noise and temperature sensor, an output torque and rotational speed sensor, a magnetic powder brake, and auxiliary components for connecting and fixing, such as a base, a horizontal sliding table, a coupling and a speed reducing mounting base; the comprehensive performance resting experiment table adopts the mode that the magnetic powder brake provides input end load, the input end of the servo motor is loaded, and angle, rotate speed, temperature, vibration and noise testing devices are added in the middle, so as to test the comprehensive performances of the precision speed reduction device. The comprehensive performance resting experiment table can accomplish testing of performances, such as transmission efficiency, torsional rigidity, vibration, noise and temperature rise, on one experiment table, and can test the comprehensive performances of different models of precision speed reduction devices. The comprehensive performance resting experiment table has the advantages of simple structure, high testing precision and high automation degree, and can meet the testing and detection requirements on the comprehensive performances of the precision speed reduction device.

Owner:CENT SOUTH UNIV

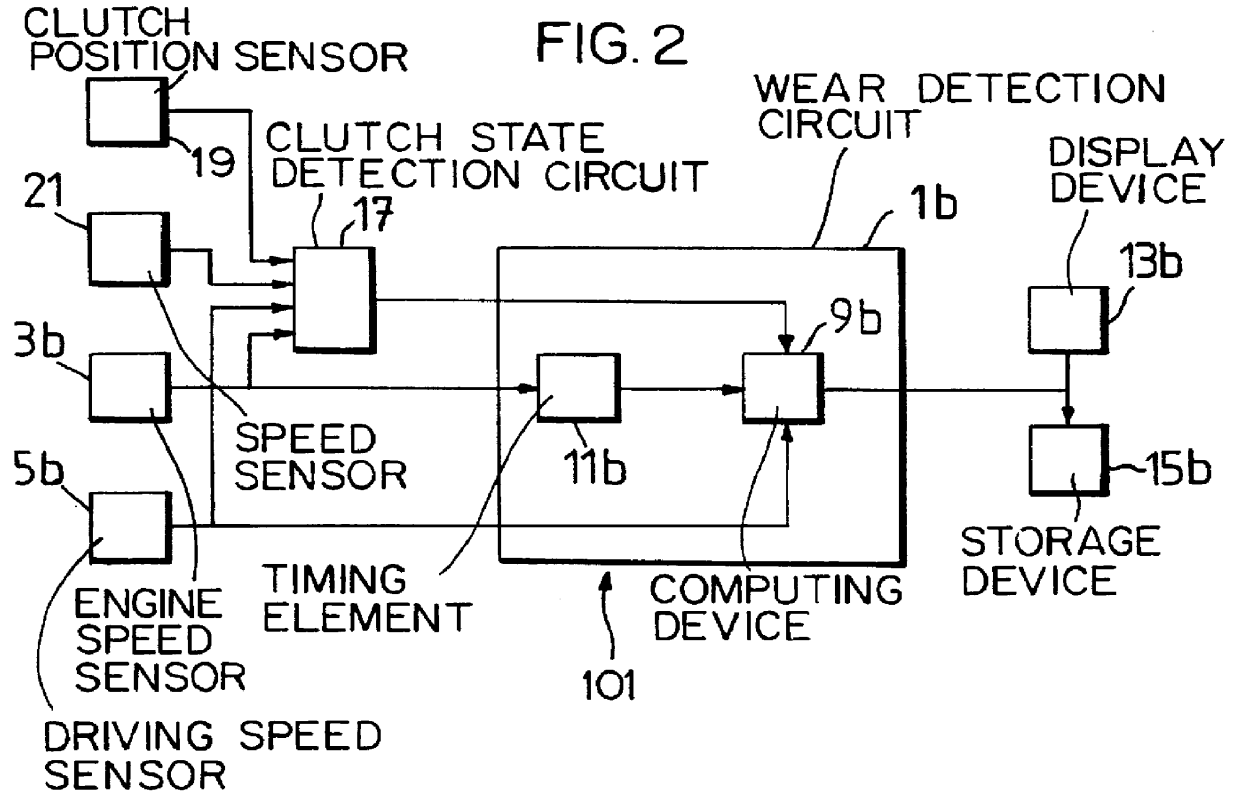

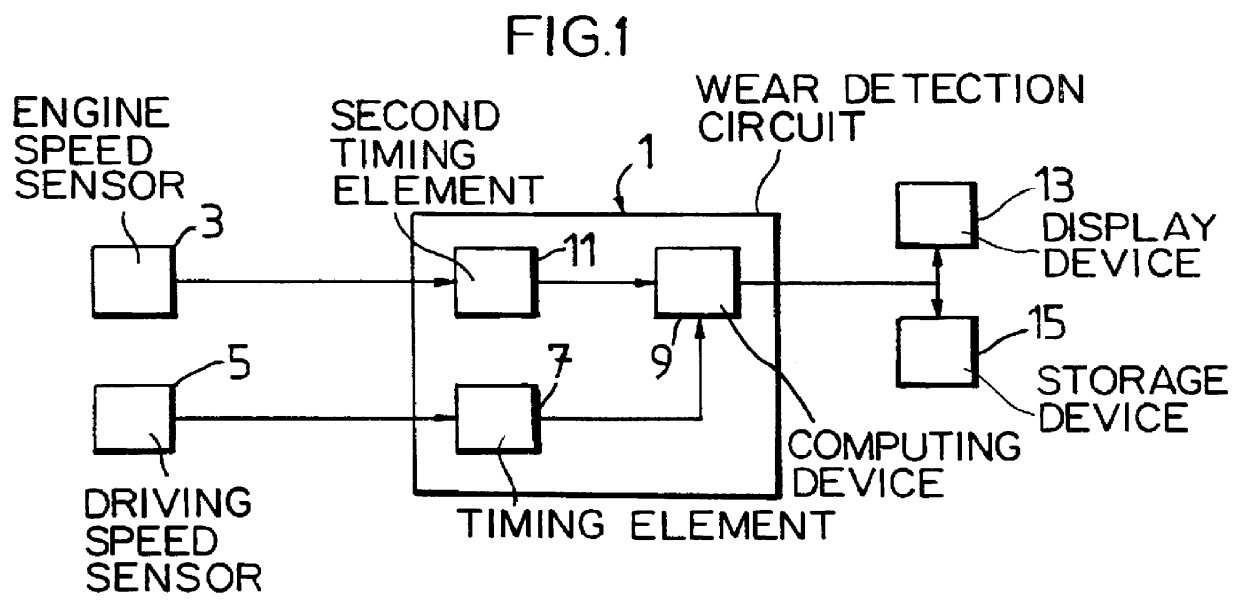

Arrangement for monitoring the wear status of a friction clutch

An arrangement for monitoring the wear status of a friction clutch in the drivetrain of a motor vehicle driven by an internal combustion engine includes a wear detection circuit that responds to speed information representing the instantaneous input speed of the friction clutch supplied by a first speed sensor and to information supplied by a movement sensor representing the beginning of a starting process. The wear detection circuit supplies, as a measurement for the loading of the friction clutch during a starting process, load information which is a predetermined monotonic function of a value of the first speed information following the beginning of movement after a predetermined time interval. The monotonic function could also be of a mean value from a plurality of values of the first speed information succeeding one another at predetermined time intervals following the beginning of movement.

Owner:ZF FRIEDRICHSHAFEN AG

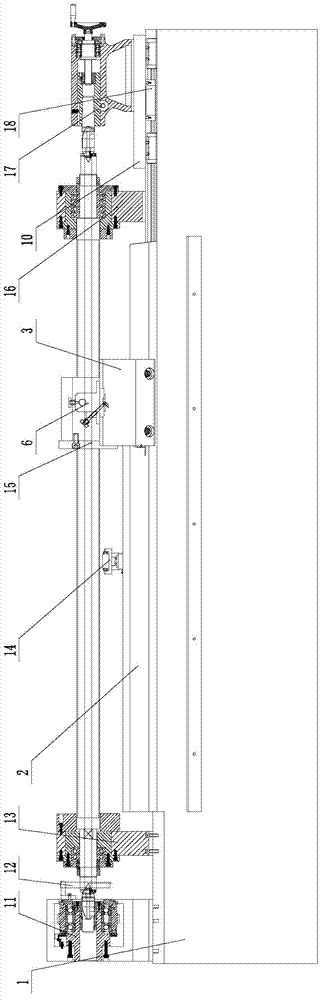

High-speed screw and screw pair comprehensive examination test bed

InactiveCN103543010ATake advantage of stabilityImprove economyMachine gearing/transmission testingDynamic stiffnessFriction torque

The invention discloses a high-speed screw and screw pair comprehensive examination test bed comprising a granite base, a floating guide rail and linear guide rails. The floating guide rail and the linear guide rails are arranged on the granite base parallelly. A linear guide rail holding plate is arranged on the linear guide rails, and the lower side of the linear guide rails is connected with a linear motor arranged on the granite base. A floating guide rail holding plate used for mounting a probe system is arranged on the floating guide rail and is connected with the linear guide rail holding plate through a connecting mechanism. By the aid of the test bed, a function of testing the features such as geometric accuracy, positioning accuracy, backlash, driving speed and acceleration, natural frequency, vibration mode, damping, and static and dynamic stiffness, friction torque and fatigue in the high-speed screw and screw pair and a function of testing stability in the high-speed screw and screw pair can be realized, and the rapid and accurate evaluation on most performance parameters of a precision ball screw can be given.

Owner:XI AN JIAOTONG UNIV

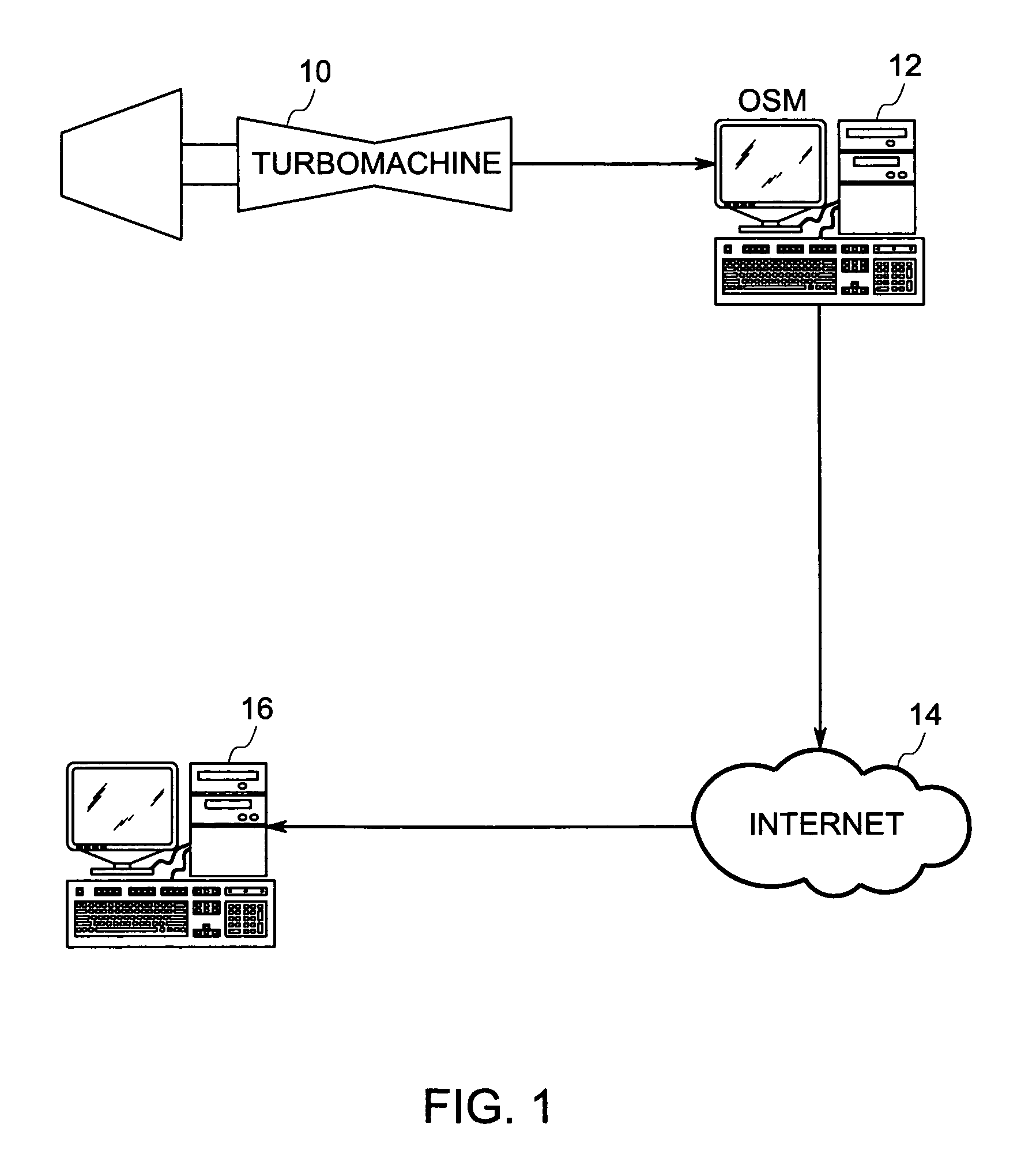

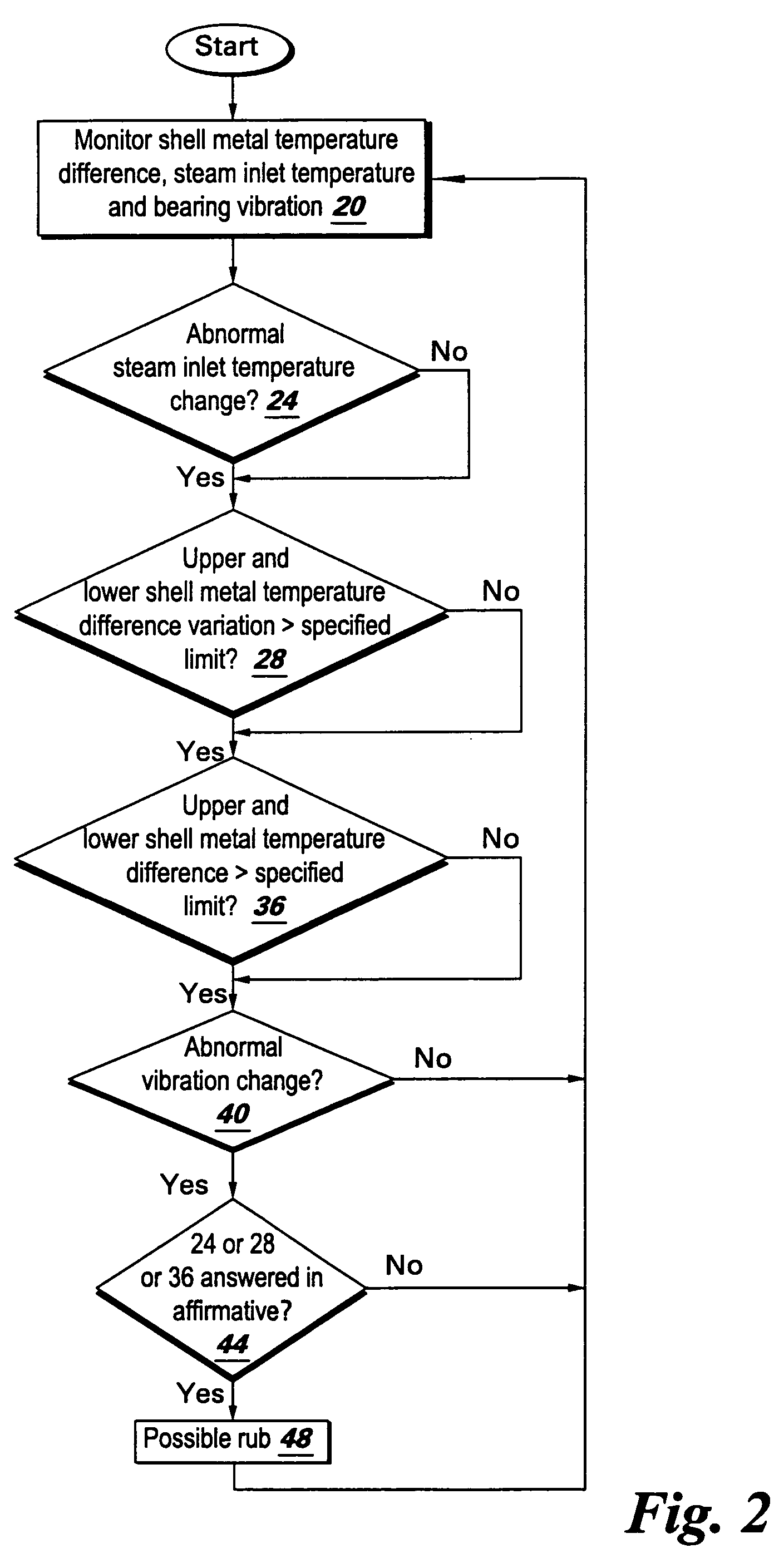

Method and apparatus for detecting rub in a turbomachine

ActiveUS7409319B2Vibration measurement in solidsMaterial analysis using sonic/ultrasonic/infrasonic wavesEmbedded system

An embodiment of the disclosed method and apparatus relates to a system for detecting a rub in a turbomachine. The system includes a turbomachine; sensors monitoring turbomachine conditions; and an on site monitor in communication with the sensors, and loaded with instructions to implement a method for detecting a rub in the turbomachine.

Owner:GENERAL ELECTRIC CO

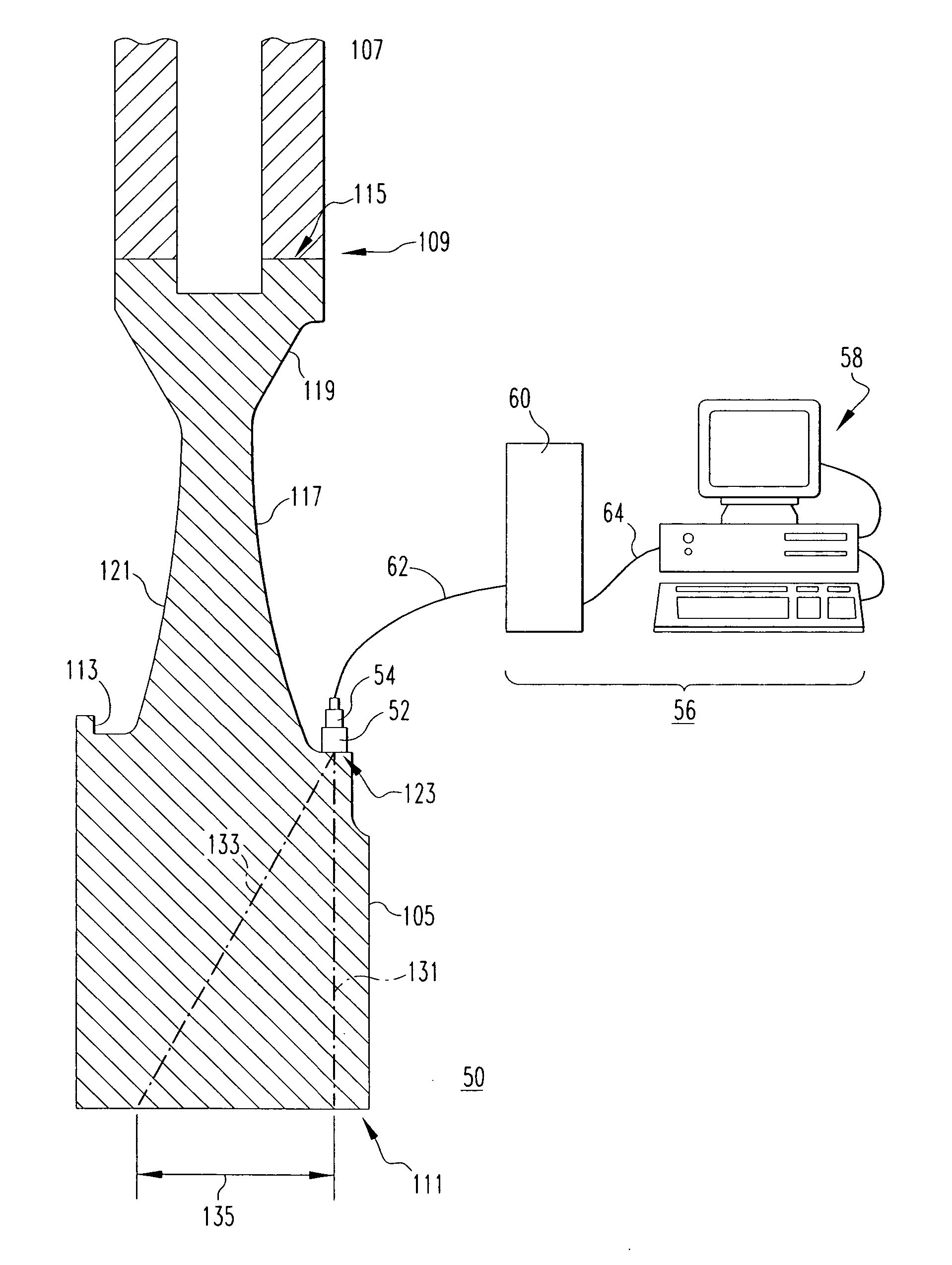

Phased array ultrasonic testing system and methods of examination and modeling employing the same

ActiveUS20060283250A1Vibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesCircular discSonification

A phased array ultrasonic testing system is for examining turbine disc bores and blade attachments for discontinuities, such as stress corrosion cracking. The system is particularly suited to perform an accurate and efficient inspection of components despite their having a relatively complex geometry, such as axial entry blade attachments and bores of associated discs. The system includes a control system with a computer and a controller for programming, emitting, and steering an ultrasonic beam via at least one two-dimensional phased array probe, thereby precisely inspecting the area of interest while simultaneously accommodating the aforementioned complex geometry of the disc or blade attachment. Computer control of the beam permits the number of inspection locations and the number of different probe wedges to be reduced providing for an efficient, timely inspection. Methods of profiling and examining turbine components of known and unknown geometries, are also disclosed.

Owner:SIEMENS ENERGY INC

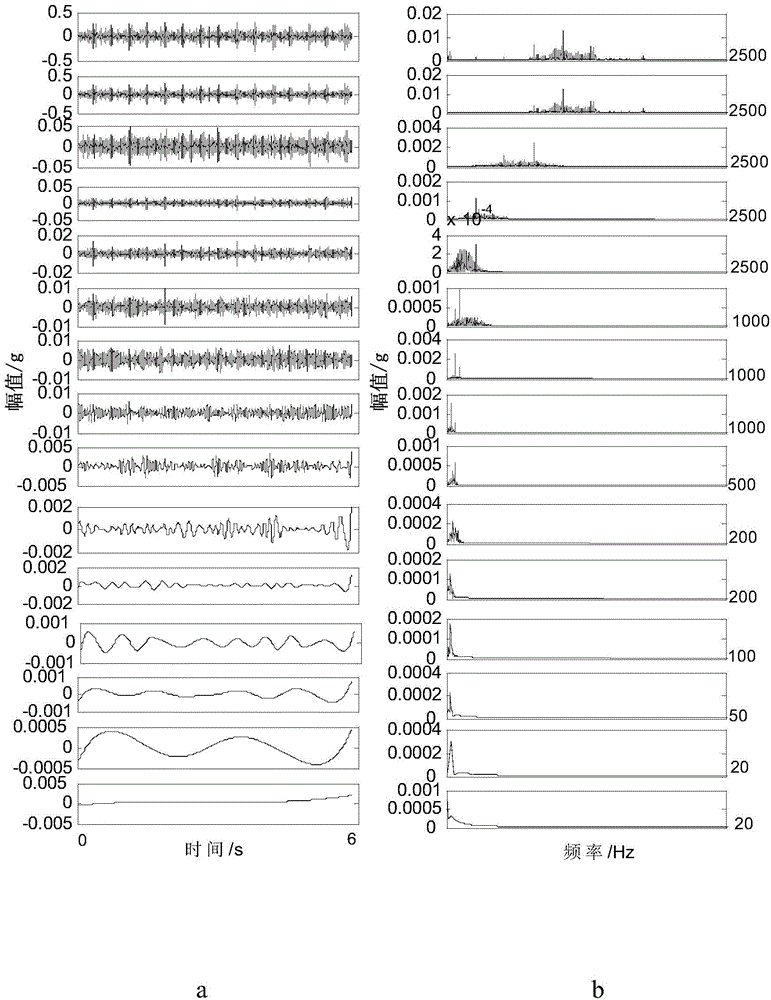

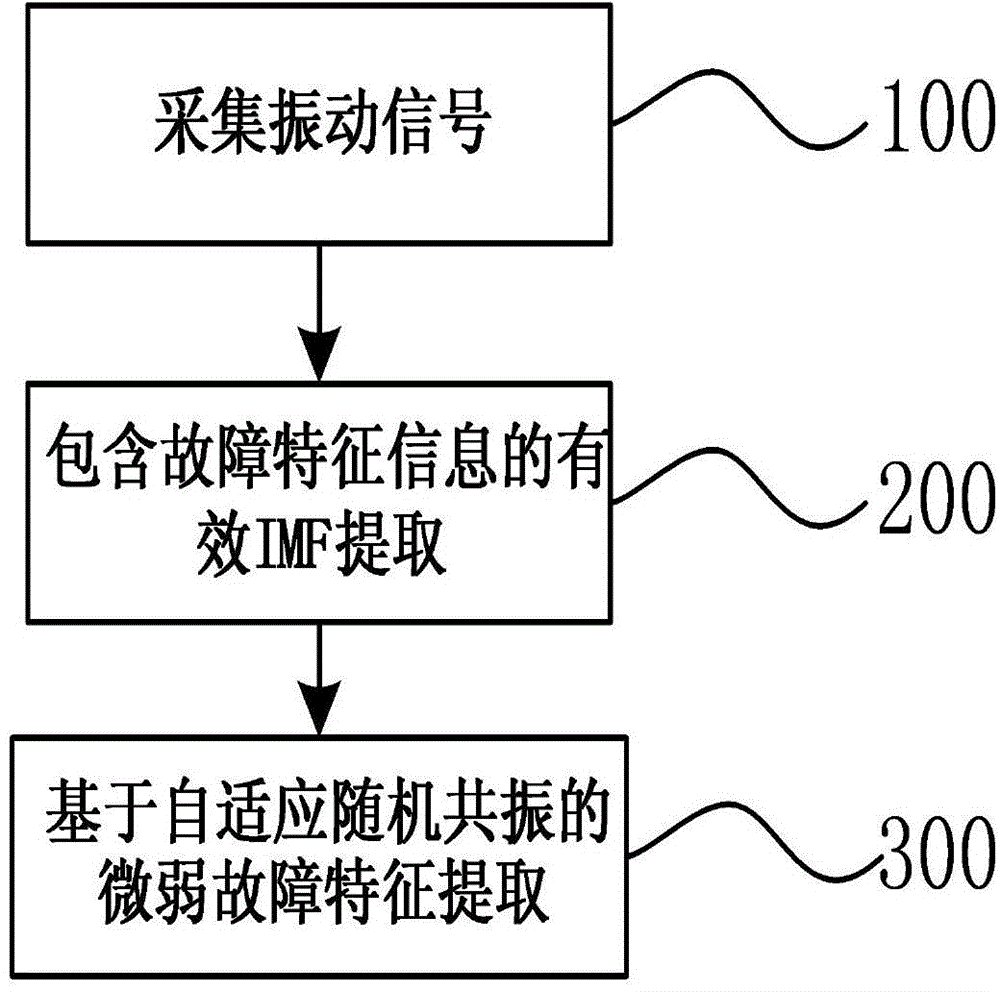

Method for extracting weak fault characteristic information of planetary gear

ActiveCN104483127AEliminate manufacturing errorsEliminate installation errorsMachine gearing/transmission testingFeature extractionSelf adaptive

The invention discloses a method for extracting weak fault characteristic information of a planetary gear based on improved ensemble average empirical mode decomposition and adaptive stochastic resonance. The method comprises vibration signal acquisition, fault characteristic information effective IMF extraction and weak fault characteristic extraction based on adaptive stochastic resonance. The method can extract the weak fault characteristic information generated due to faults of the planetary gear, and can realize planetary gear fault diagnosis according to the extracted weak fault characteristic information; and the method is an effective planetary gear weak fault characteristic information extraction method.

Owner:SHANDONG ZHONGHENG OPTOELECTRONIC TECH CO LTD

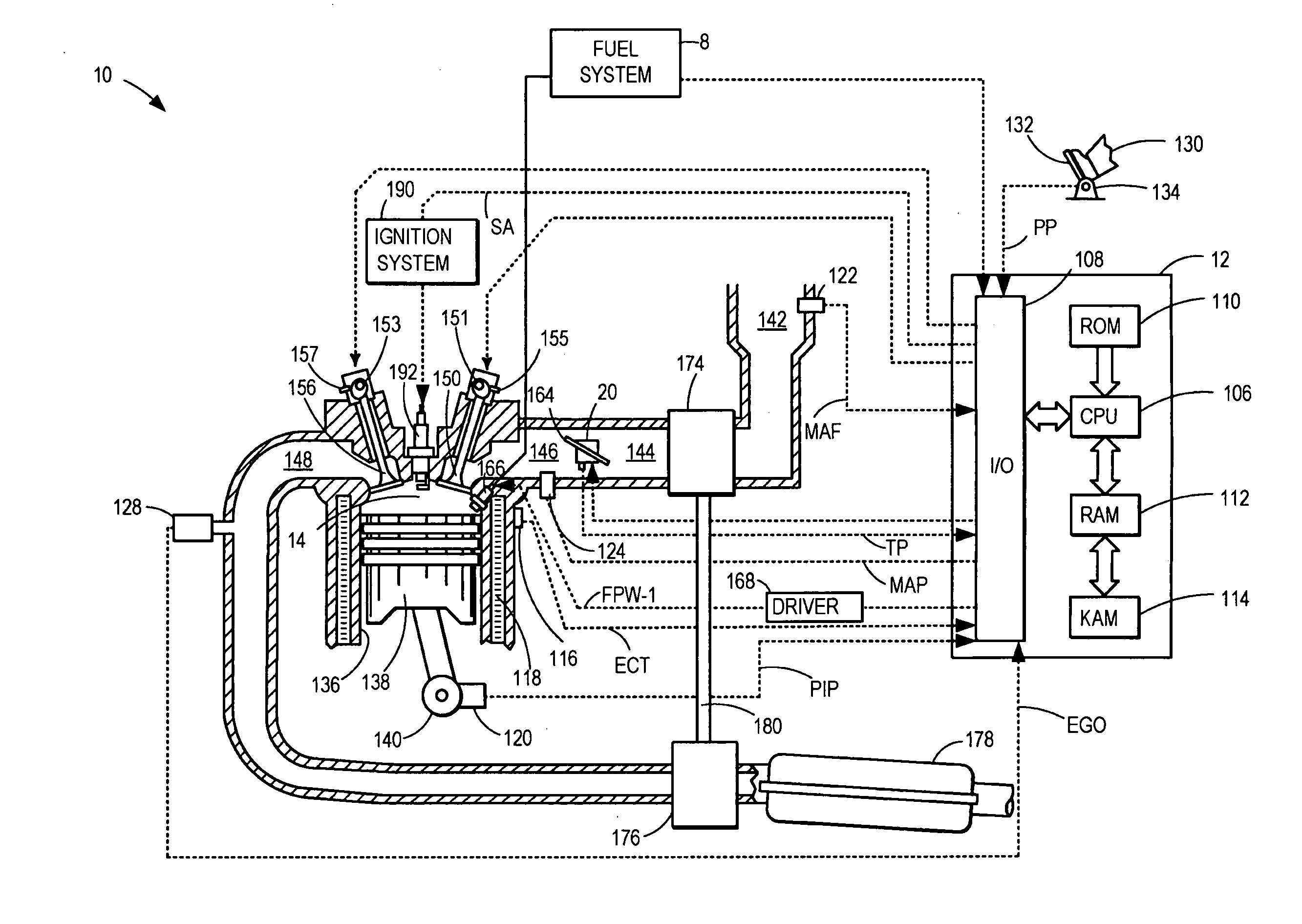

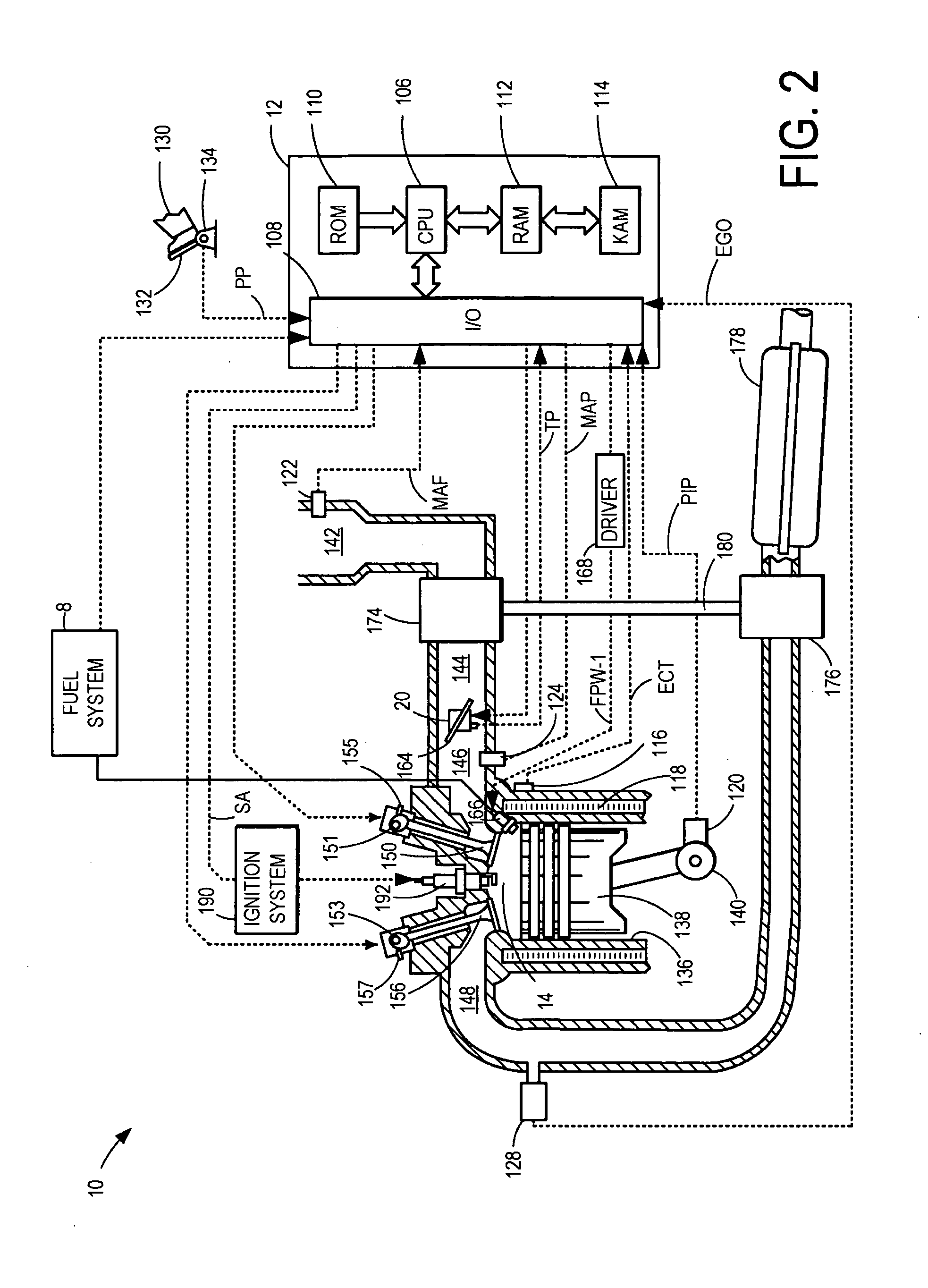

Variable displacement engine diagnostics

ActiveUS20100175463A1Improve fuel economyInternal-combustion engine testingElectrical controlEngineeringCylinder Valve

Methods and systems are provided for monitoring cylinder valve deactivation of a cylinder valve of an engine. One example method comprises, indicating degradation of cylinder valve deactivation in response to manifold pressure at or around a characteristic frequency.

Owner:FORD GLOBAL TECH LLC

Popular searches

Vibration measurement in fluid Linear/angular speed measurement Machines/engines Level indicators Special data processing applications Indication of measured values Subsonic/sonic/ultrasonic wave measurement Digital computer details Fluid pressure measurement by mechanical elements Container/cavity capacity measurement

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com