Comprehensive performance resting experiment table for precision speed reduction device

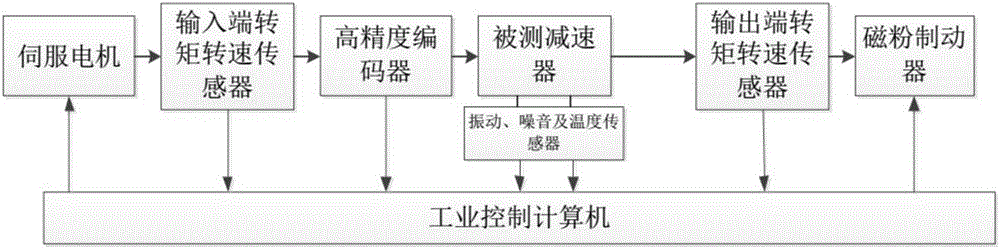

A comprehensive performance testing, precision reducer technology, applied in the testing of machine/structural components, machine gear/transmission mechanism testing, mechanical component testing, etc. Stiffness and transmission efficiency, inability to test the transmission efficiency of the reducer, etc., to meet the requirements of high-precision performance testing and testing, improve testing efficiency, and improve testing stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

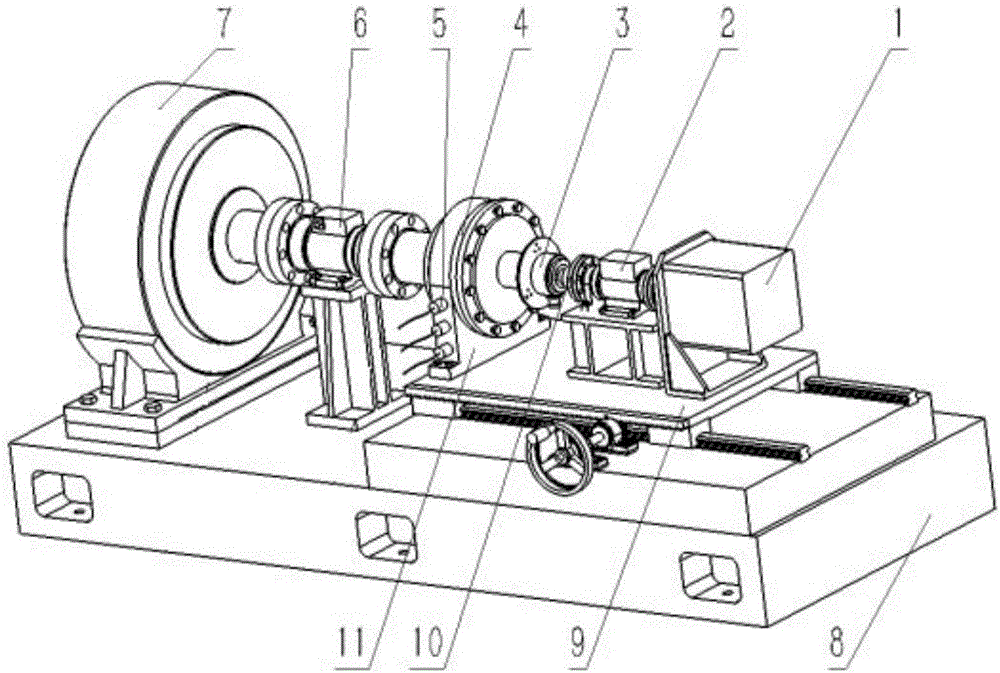

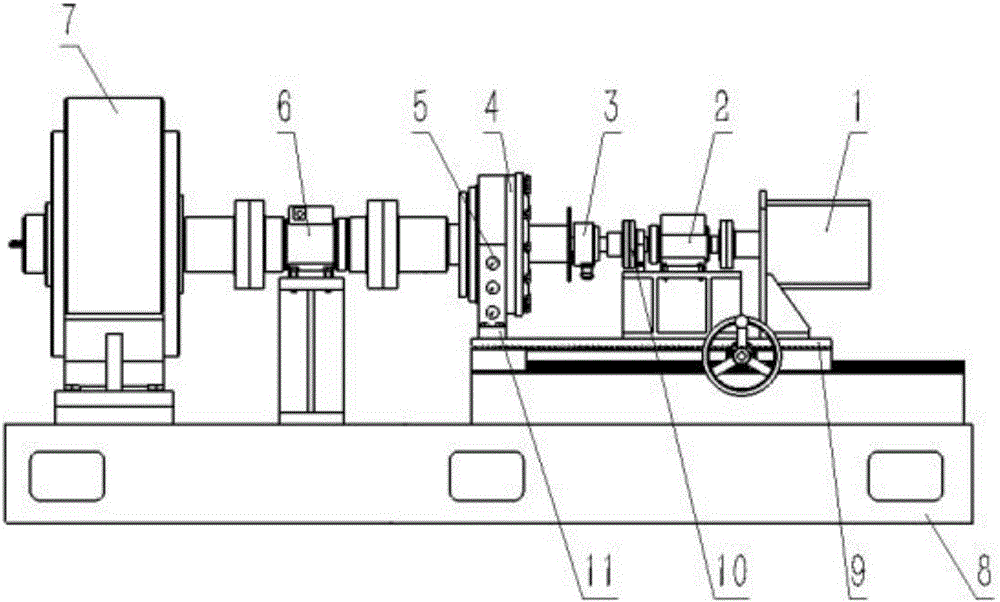

[0029] Such as figure 1 , figure 2 , image 3 As shown, the precision reducer comprehensive performance test bench provided by the present invention consists of a servo motor 1, an input torque speed sensor 2, a high-precision encoder 3, a measured reducer 4, a vibration noise and temperature sensor 5, an output terminal The torque speed sensor 6, the main parts of the magnetic powder brake 7 and the base 8, the horizontal slide table 9, the coupling 10, the reducer mounting seat 11 and other connected and fixed auxiliary parts are characterized in that: the servo motor 1 is input The end torque torque sensor 2 is connected to the input shaft of the tested reducer 4, the high-precision encoder 3 is installed on the input shaft of the tested reducer 4, and the high-precision encoder 3 is used to read the input of the tested reducer 4 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com