Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

464 results about "Automotive industry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The automotive industry comprises a wide range of companies and organizations involved in the design, development, manufacturing, marketing, and selling of motor vehicles. It is one of the world's largest economic sectors by revenue. The automotive industry does not include industries dedicated to the maintenance of automobiles following delivery to the end-user, such as automobile repair shops and motor fuel filling stations.

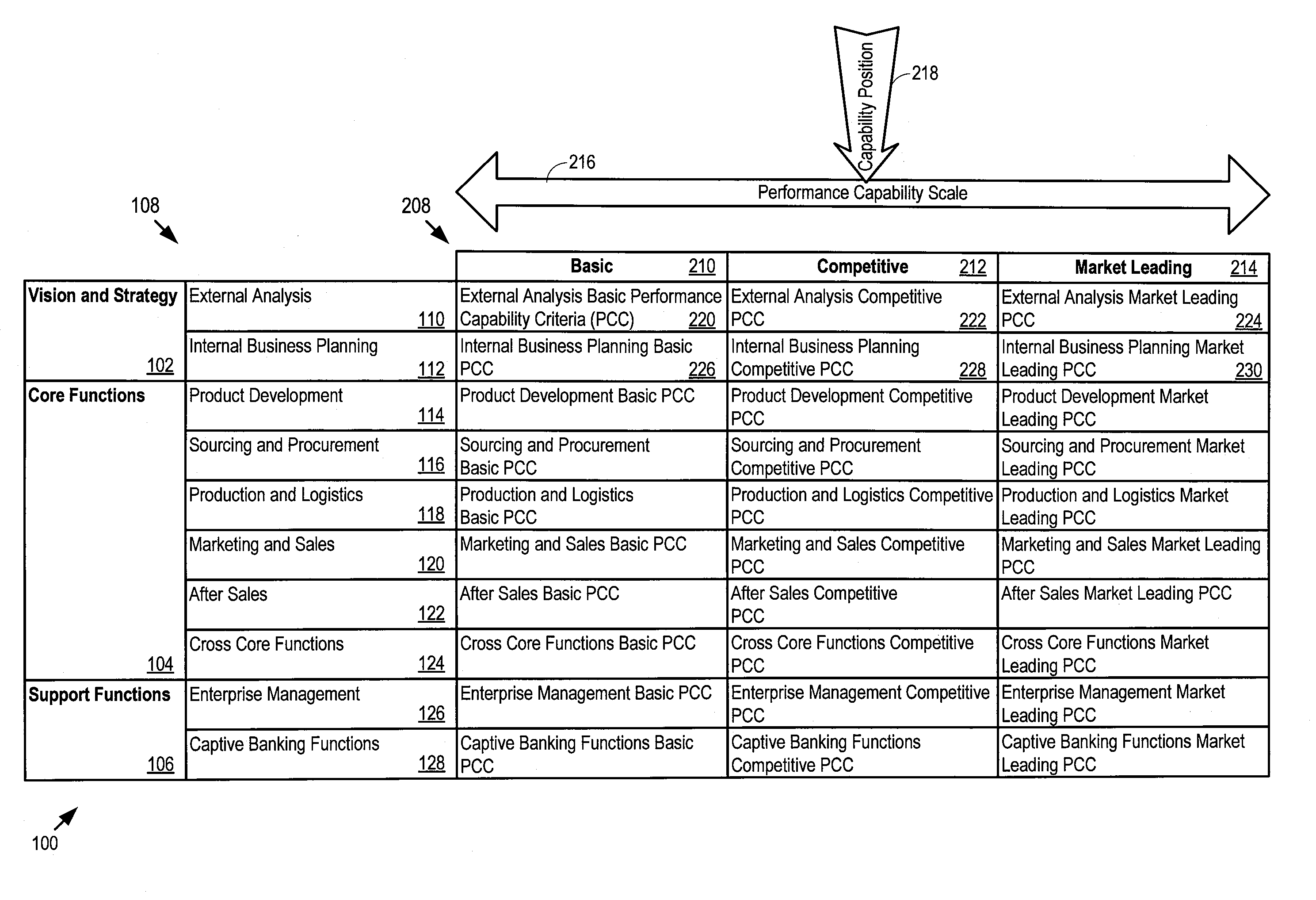

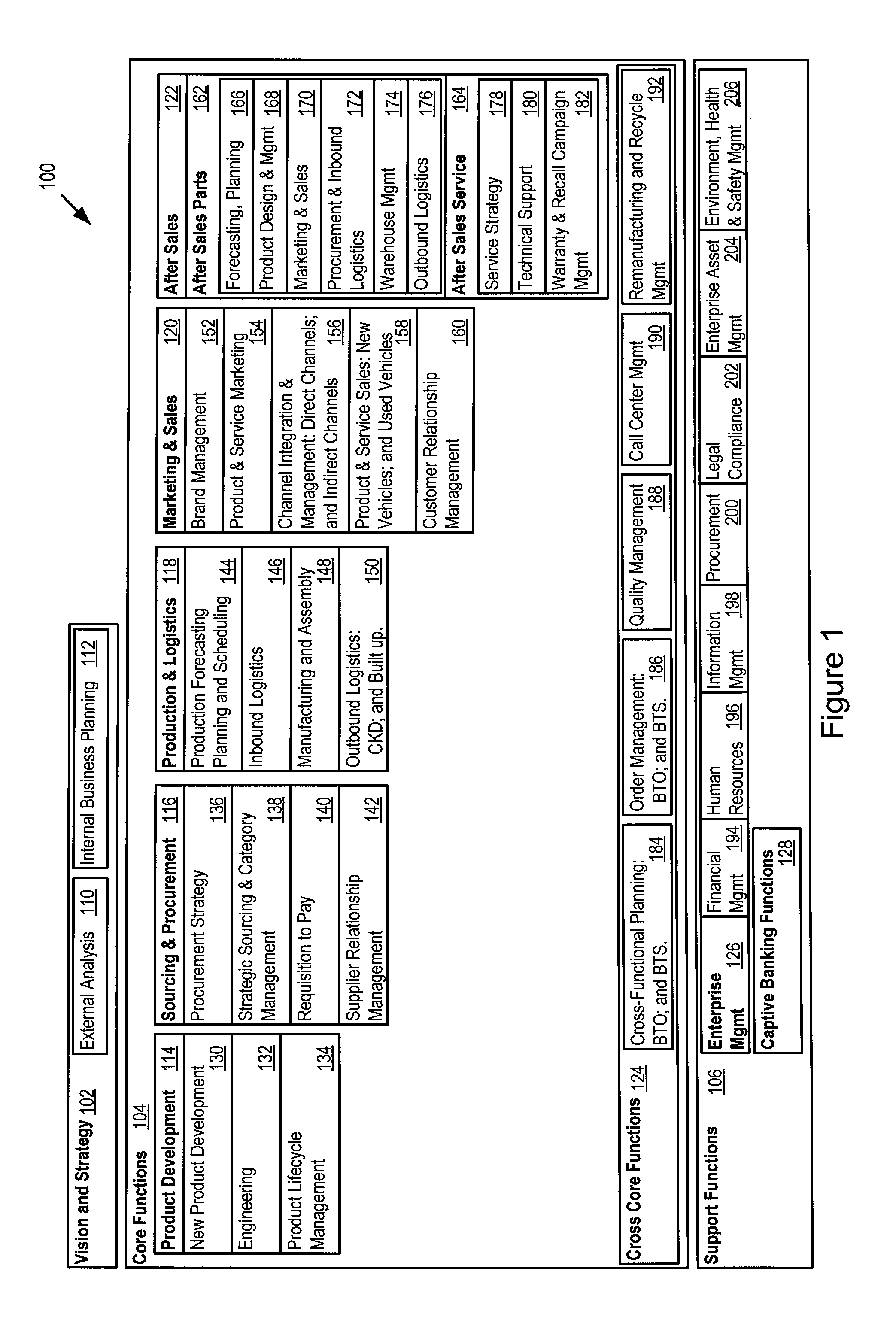

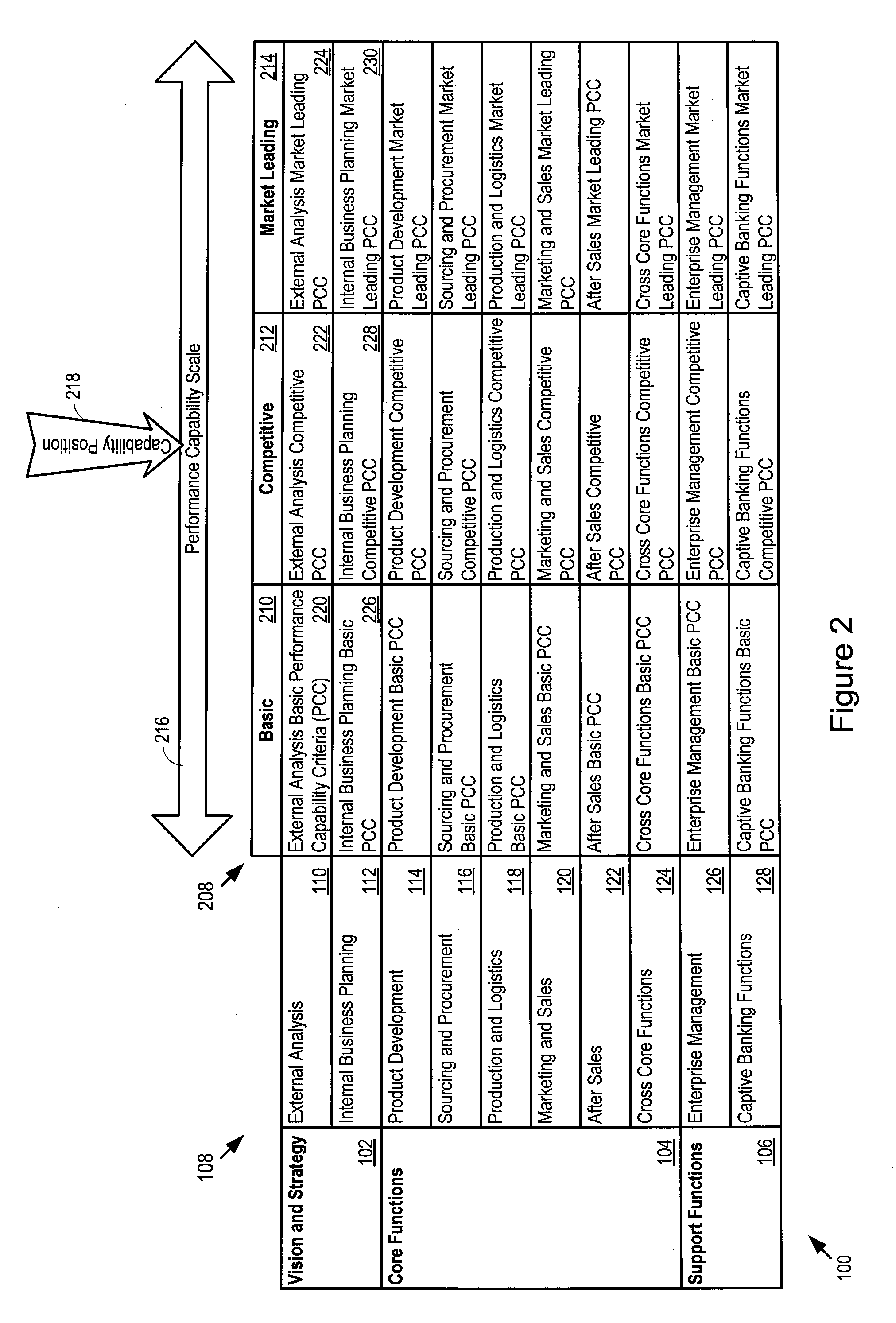

Automotive industry high performance capability assessment

A high performance capability assessment model helps an automotive industry business meet the challenges of the global marketplace. As a result, the automotive industry business can achieve the clarity, consistency, and well-defined execution of core processes that reduce inefficiencies and waste that result from unnecessary process complexity and exceptions. In addition, the high performance capability assessment model helps the automotive industry business to identify specific areas in which improvements may be made and understand how to make the improvements, and establishes levels of capability along the way to reaching an ultimate capability goal.

Owner:ACCENTURE GLOBAL SERVICES GMBH

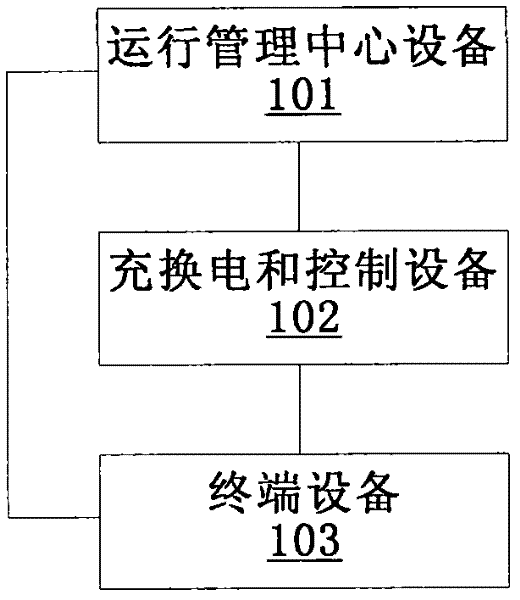

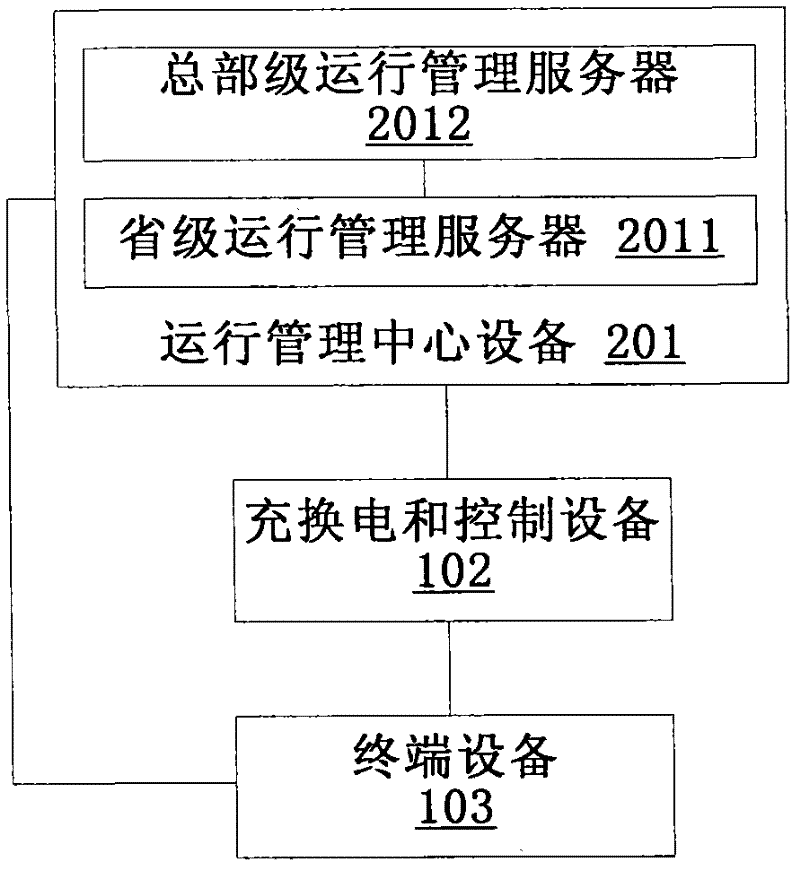

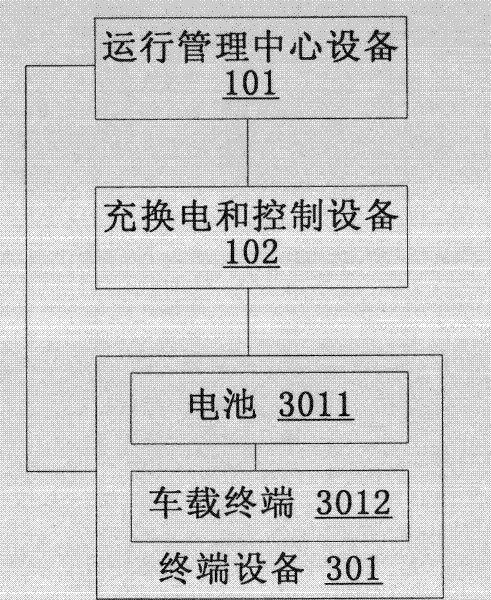

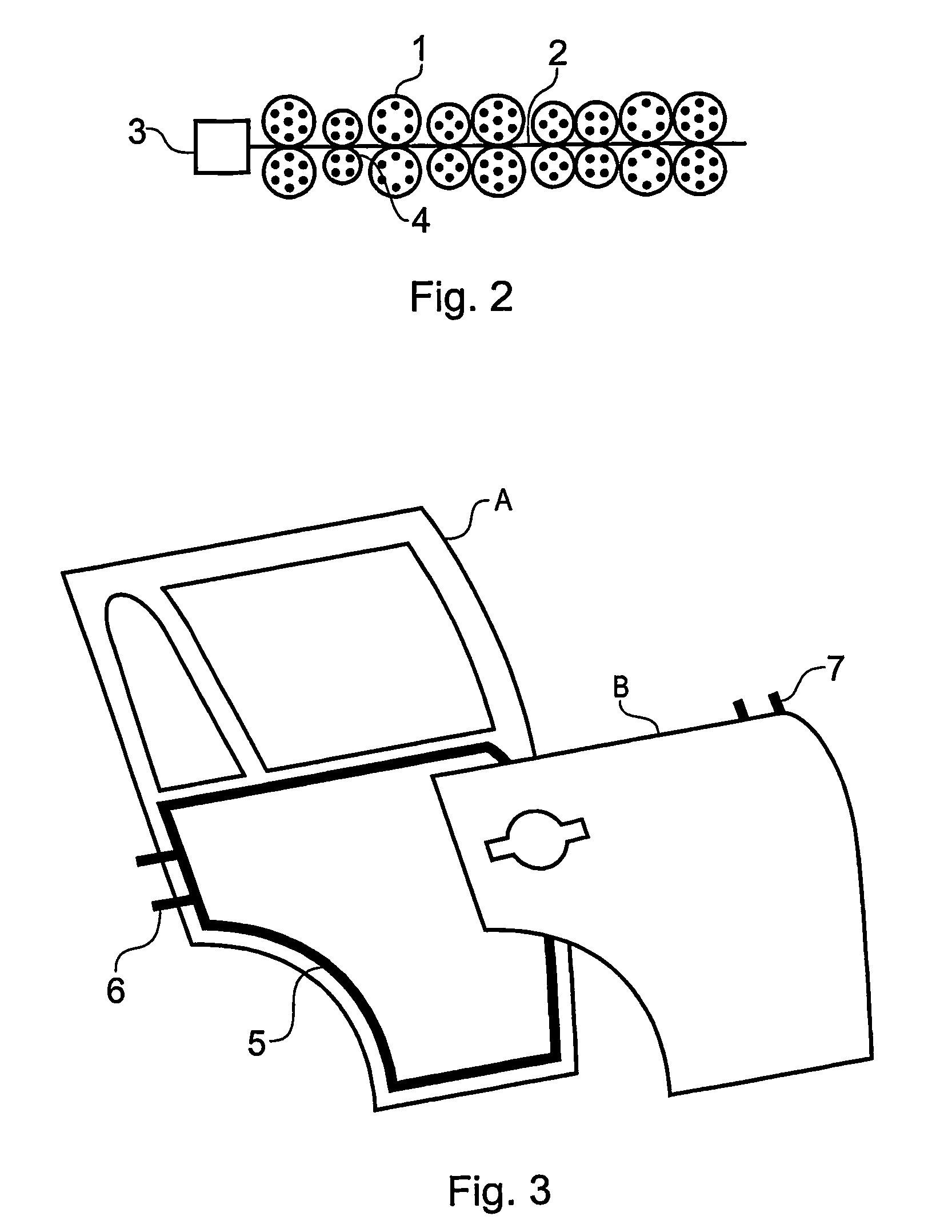

Charging and battery changing system and operating method thereof

ActiveCN102055790AImprove operating conditionsGet running status easilyBatteries circuit arrangementsElectric powerElectricityArea network

The invention discloses a charging and battery changing system and an operating method thereof, wherein the system comprises an operating management center device, a charging, battery converting and controlling device and a terminal device; the operating management center device is used for managing the charging and battery changing information in a managed area; the charging, battery converting and controlling device is connected with the operating management center device via a communication network and connected with the terminal device via a wireless local area network and a controller area network (CAN) bus, and is used for charging and changing a battery, controlling a charging and battery changing station and identifying the terminal device; and the terminal device is connected with the operating management center device via the communication network and is used for providing the operating state of the terminal device. According to the invention, the scattered and isolated terminal devices are connected with charging and battery changing devices via the network so that the operating management center device can conveniently acquire the operating state of each device, thus the charging and battery changing system can comprehensively monitor and manage each device; and furthermore, according to the invention, a basis can be provided for the development of the electric vehicle industry.

Owner:STATE GRID CORP OF CHINA +1

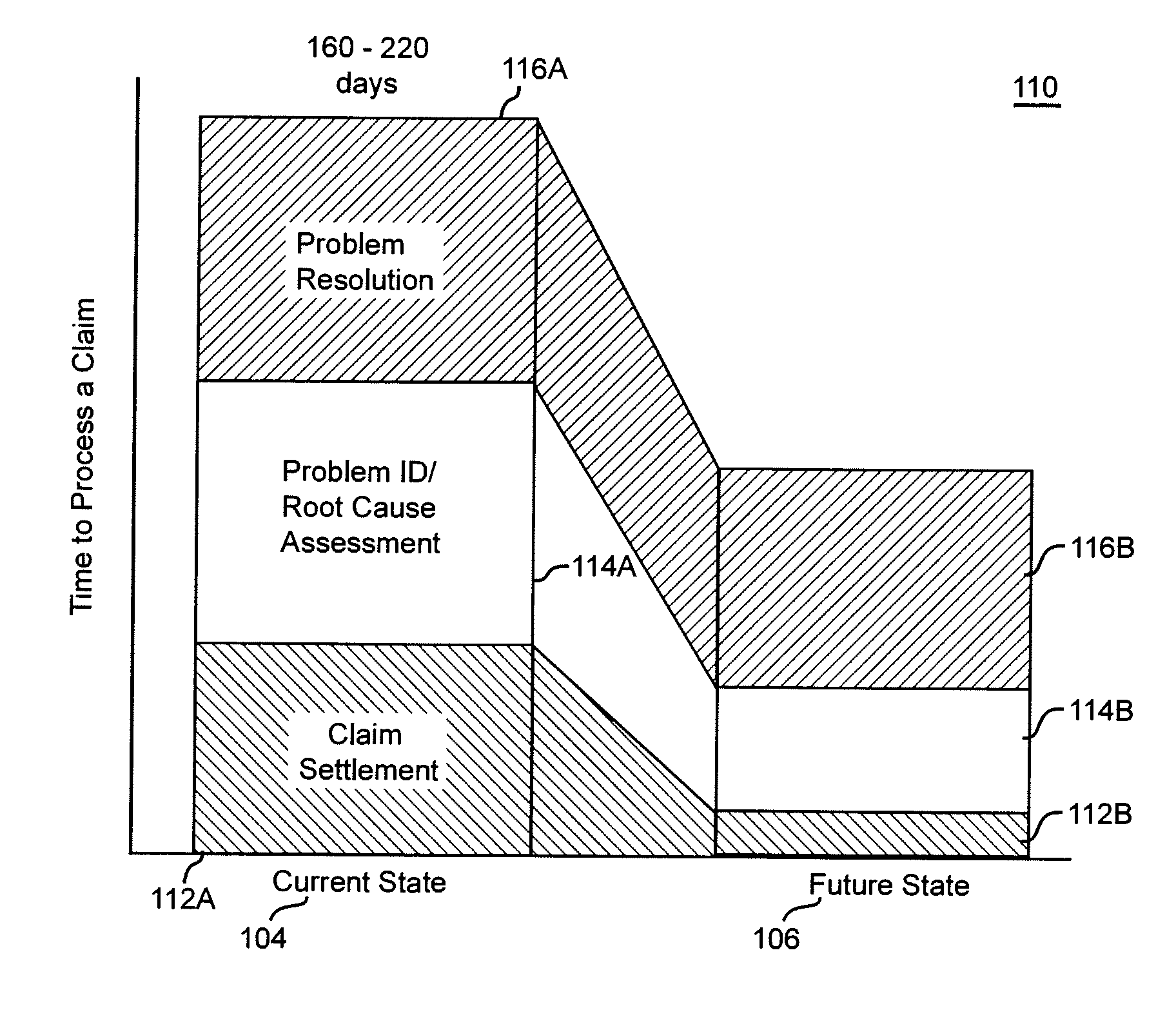

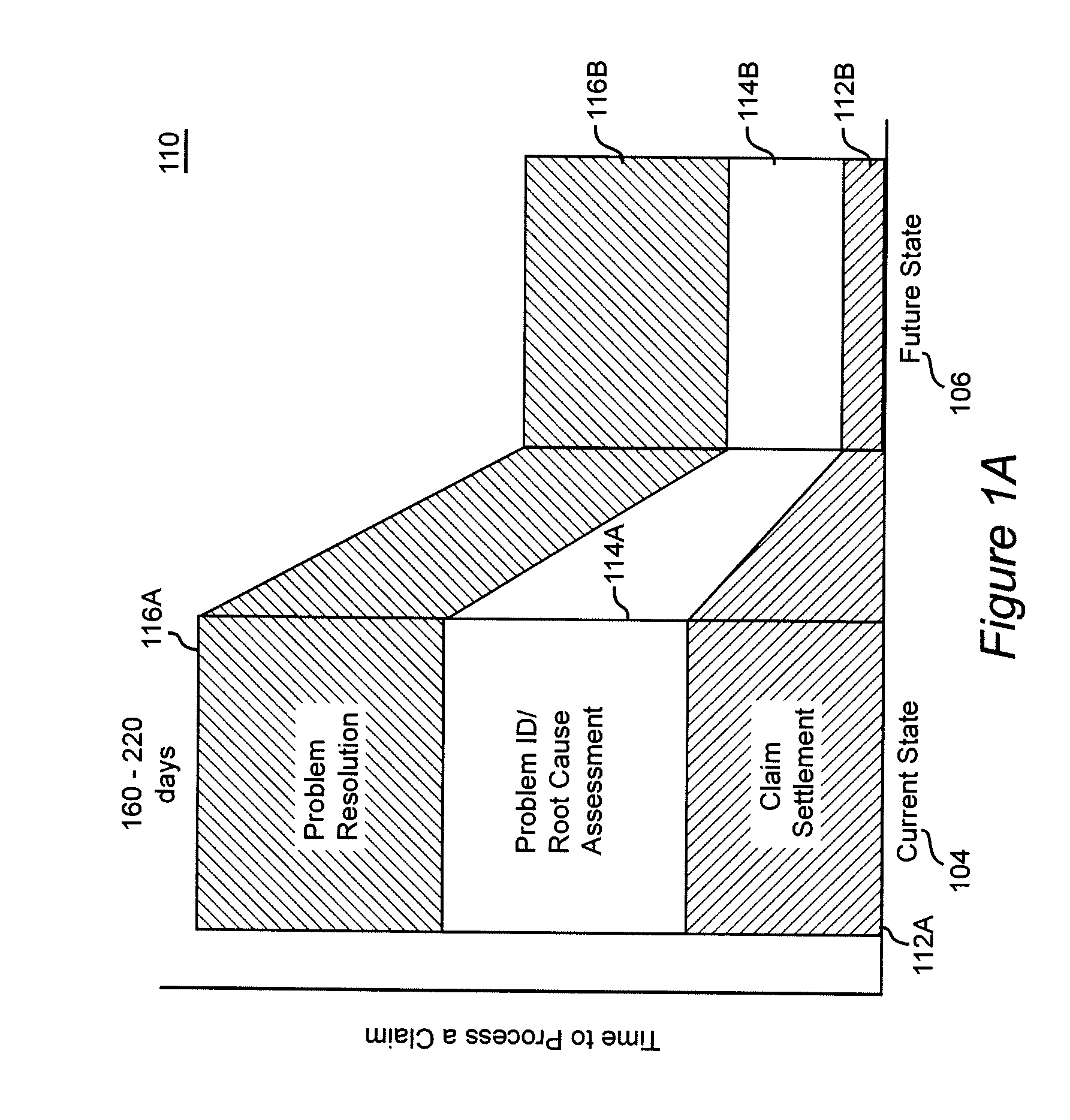

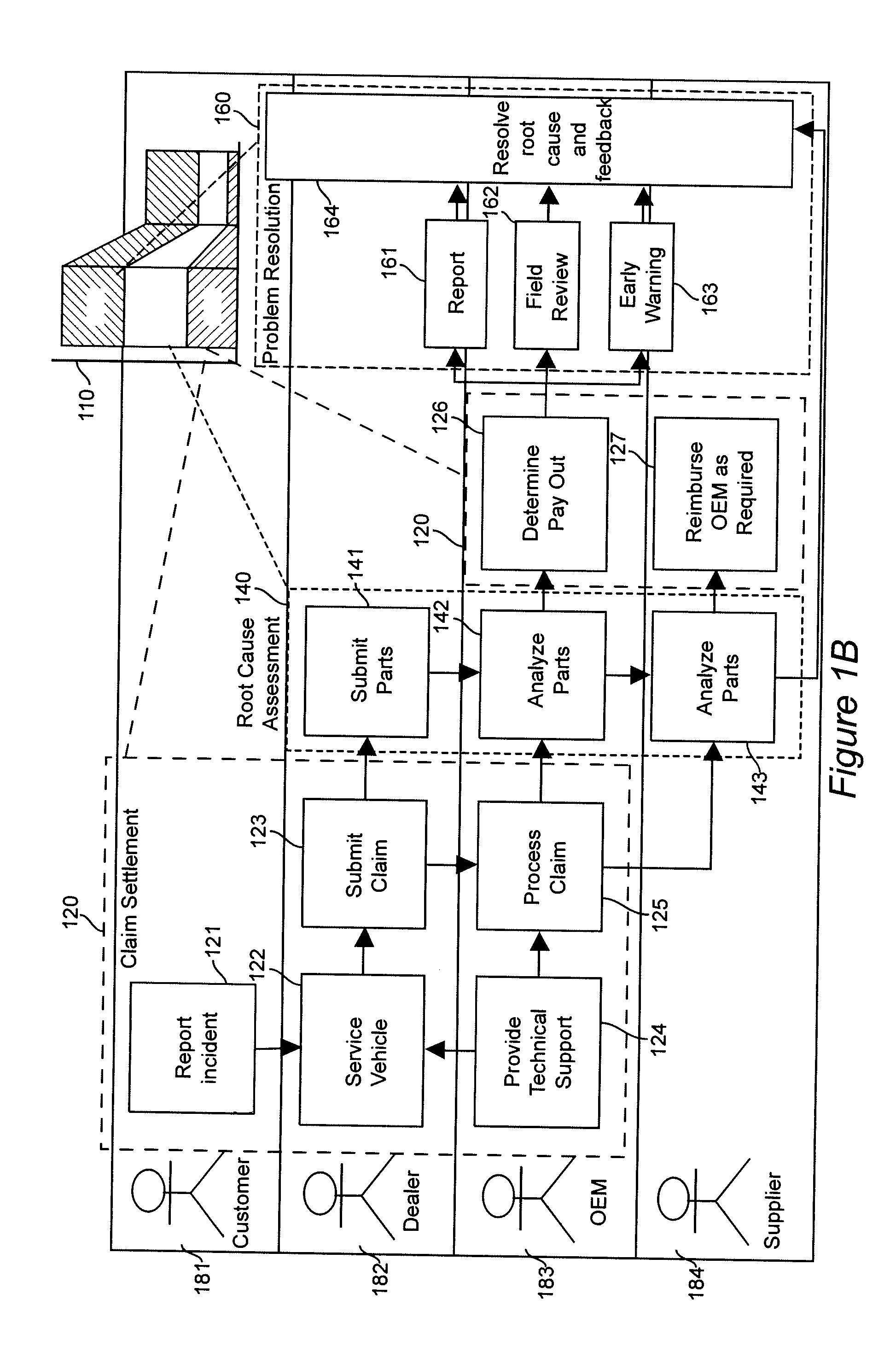

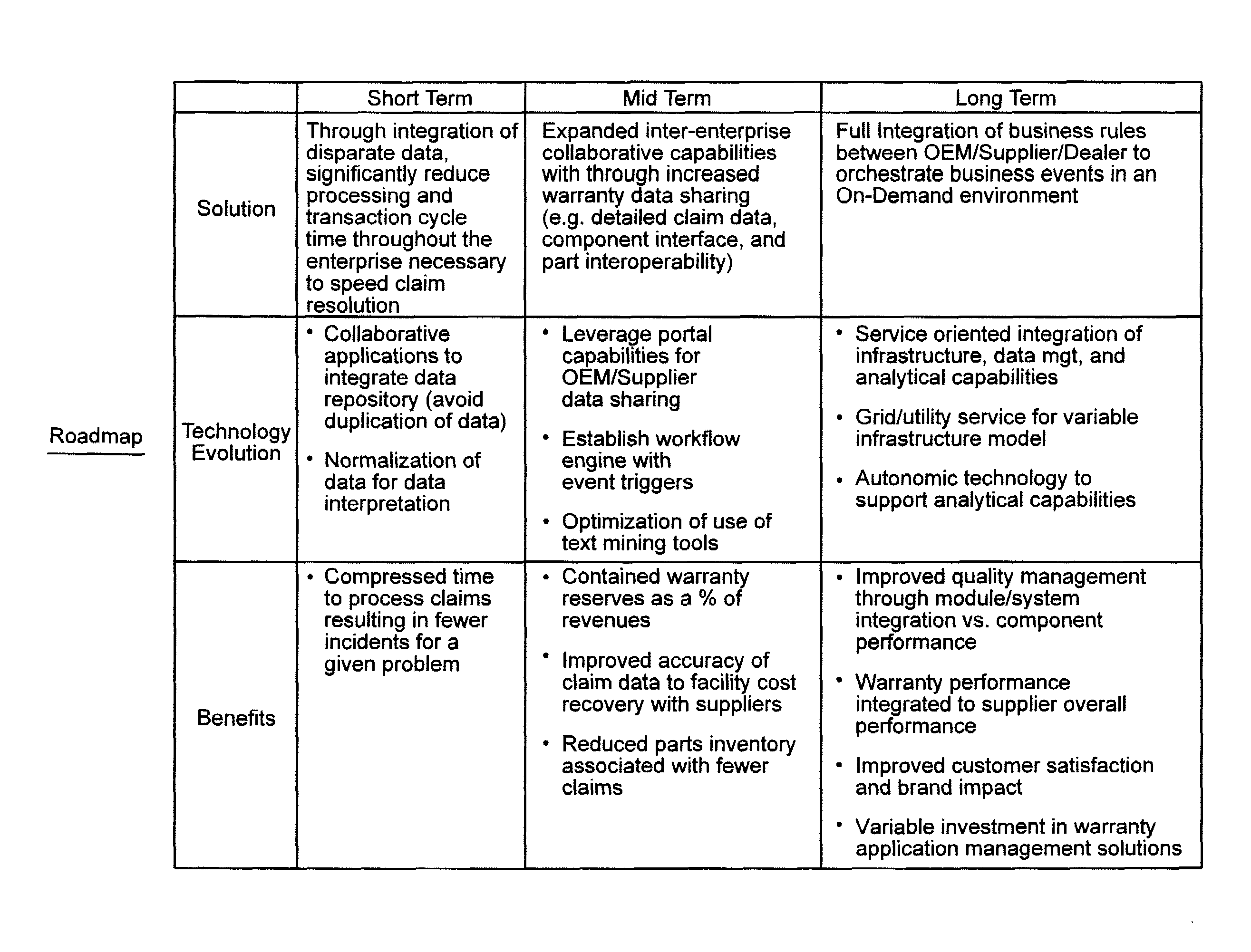

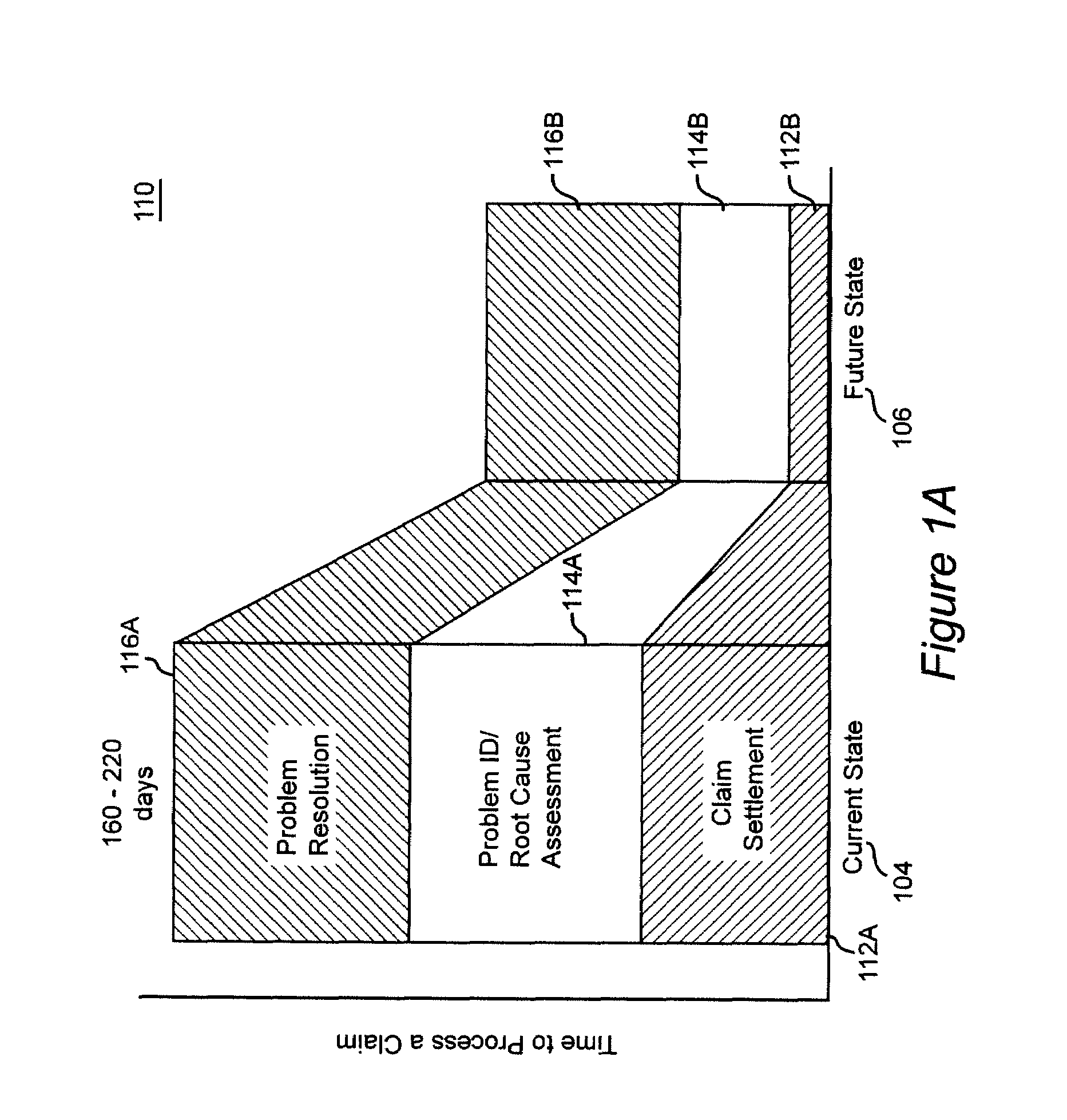

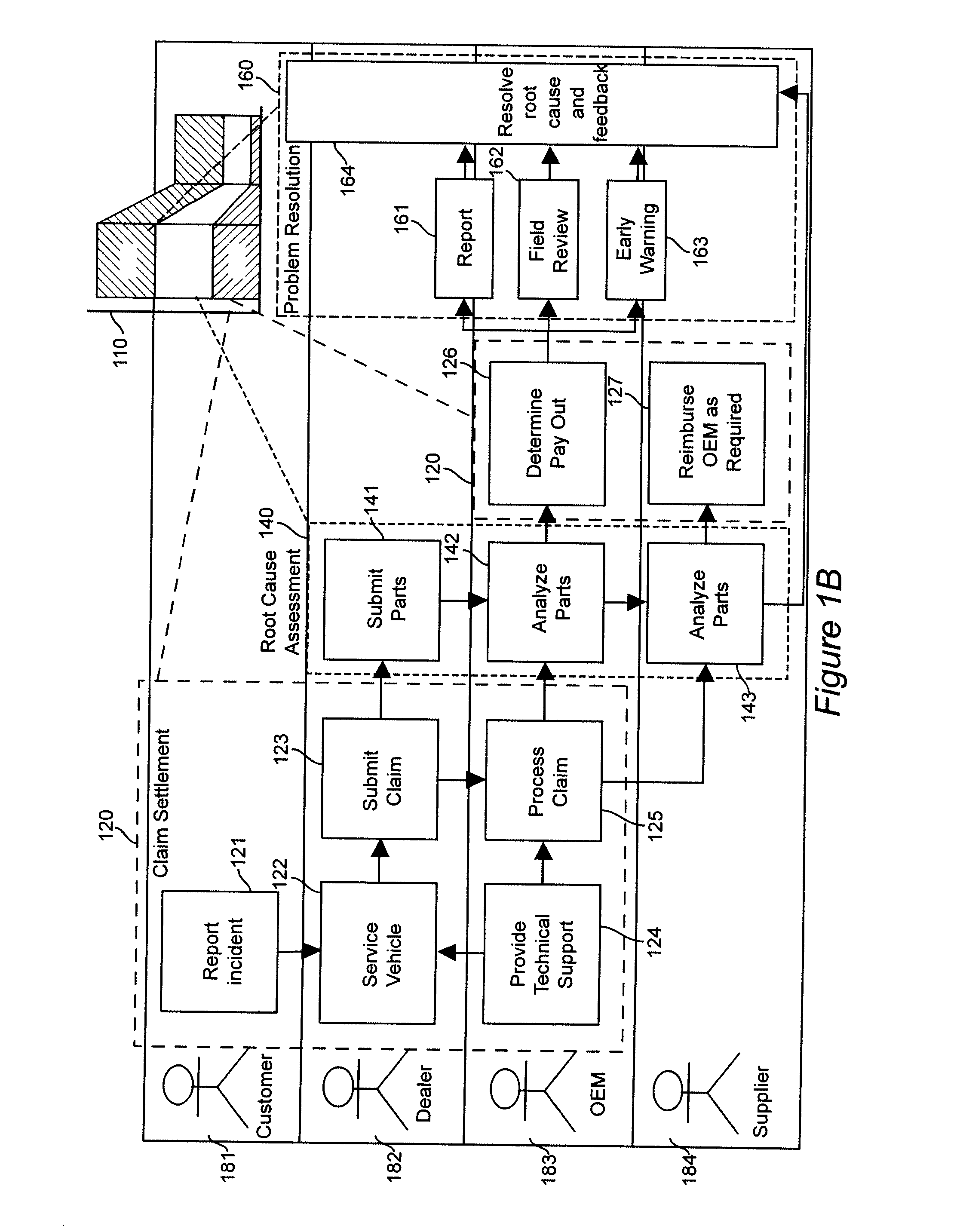

Method and system for using a component business model to transform warranty claims processing in the automotive industry

InactiveUS20070022410A1Optimize business processesResourcesSpecific program execution arrangementsAutomotive industryComponent business model

A method, system and service for using a component business model to transform a business process. The invention uses a component business model of a business to prioritize business changes affecting key performance indicators for the business process, defines an information technology architecture to support the business changes, and specifies a roadmap for implementing the supporting information technology architecture. In a particular application of the invention to the automobile manufacturing business, the business process is the warranty claims process, and a length of time to process a warranty claim is a key performance indicator.

Owner:IBM CORP

Heat curable, thermally expandable composition with high degree of expansion

Compositions containing at least one liquid epoxy resin, at least one solid epoxy resin, at least one propellant, at least one curing agent and at least one mica-containing filler produce expandable, thermally curable binder systems which may be used without the addition of hollow glass beads for the production of stiffening and reinforcing laminates and for the production of stiffening and reinforcing mouldings. Said laminates according to the invention are suitable for the stiffening and reinforcing of components, in particular in the automotive industry, such as car body frames, doors, boot lids, engine bonnets and / or roof parts. In addition, the mouldings that may be produced from said binders are suitable for the stiffening and reinforcing of hollow metal structures, in particular of hollow car body parts such as body frames, body supports and posts or doors in the automotive industry.

Owner:HENKEL KGAA

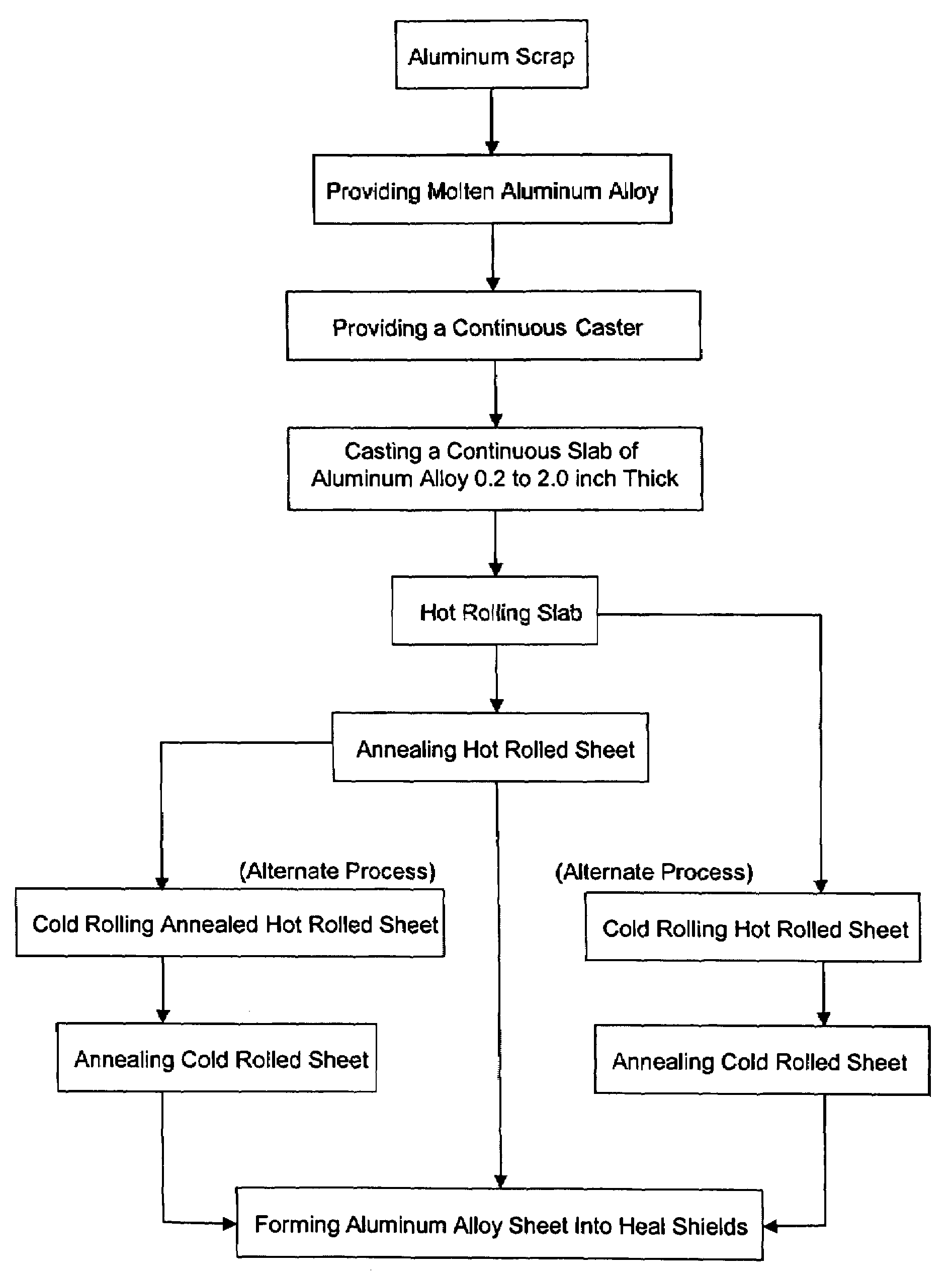

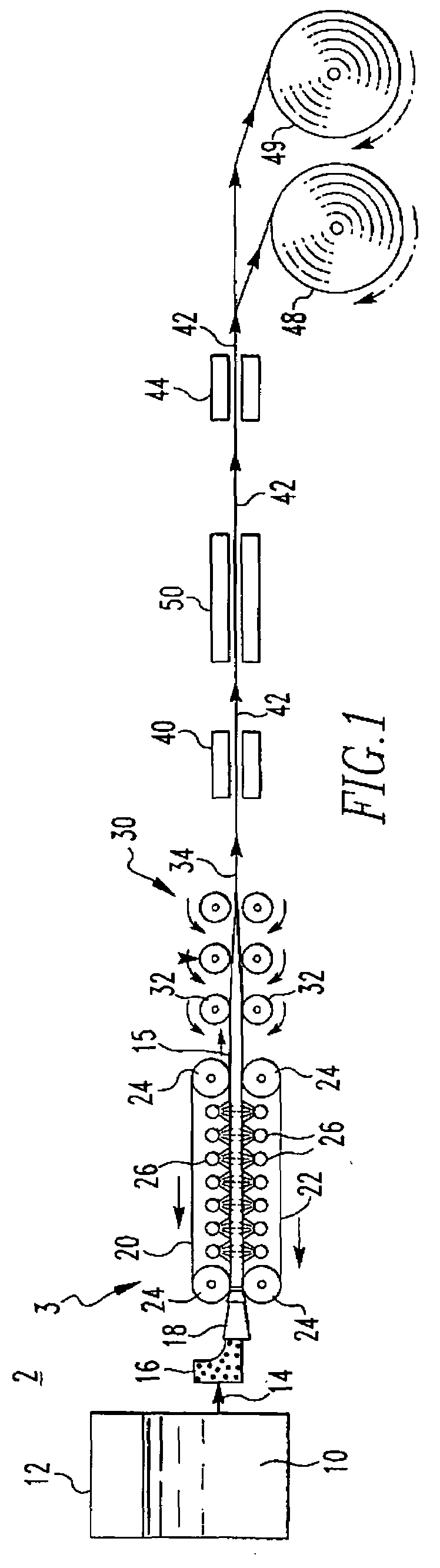

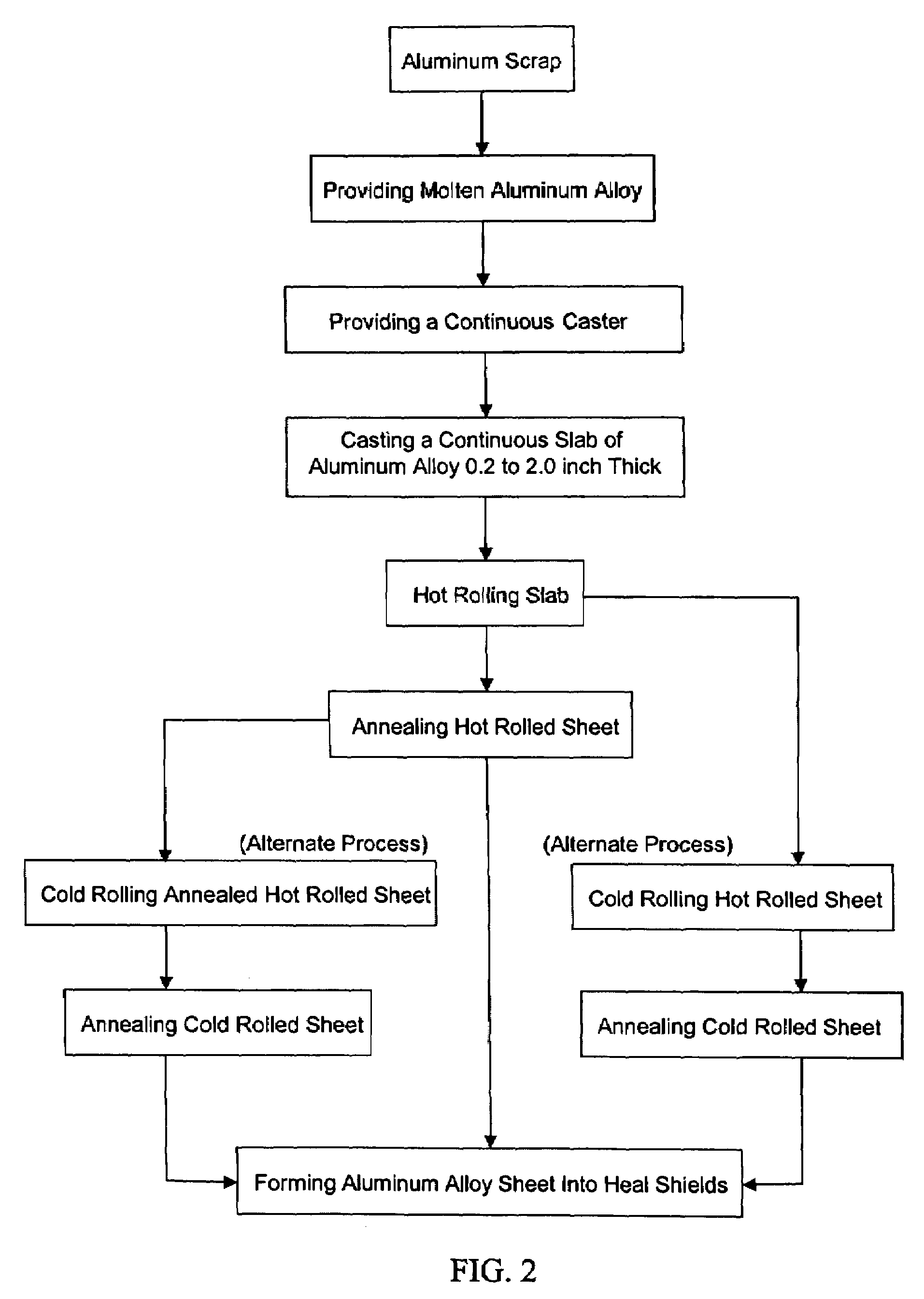

Aluminum automotive heat shields

Disclosed is a method for producing aluminum automotive heat shields or panels such as from scrap derived molten aluminum alloy using a continuous caster to cast the alloy into a slab. The method comprises providing a molten aluminum alloy consisting essentially of 0.1 to 0.7 wt. % Si, 0.2 to 0.9 wt. % Fe, 0.05 to 0.5 wt. % Cu, 0.05 to 1.3 wt. % Mn, 0.2 to 2.8 wt. % Mg, 0.3 wt. % max. Cr, 0.3 wt. % max. Zn, 0.2 wt. % max. Ti, the remainder aluminum, incidental elements and impurities and providing a continuous caster such as a belt caster, block caster or roll caster for continuously casting the molten aluminum alloy. The molten aluminum alloy is cast into a slab which is rolled into a sheet product and then annealed. Thereafter, the sheet product is formed into the automotive heat shield or panel with strength and formability as required by the automotive industry.

Owner:COMMONWELATH IND

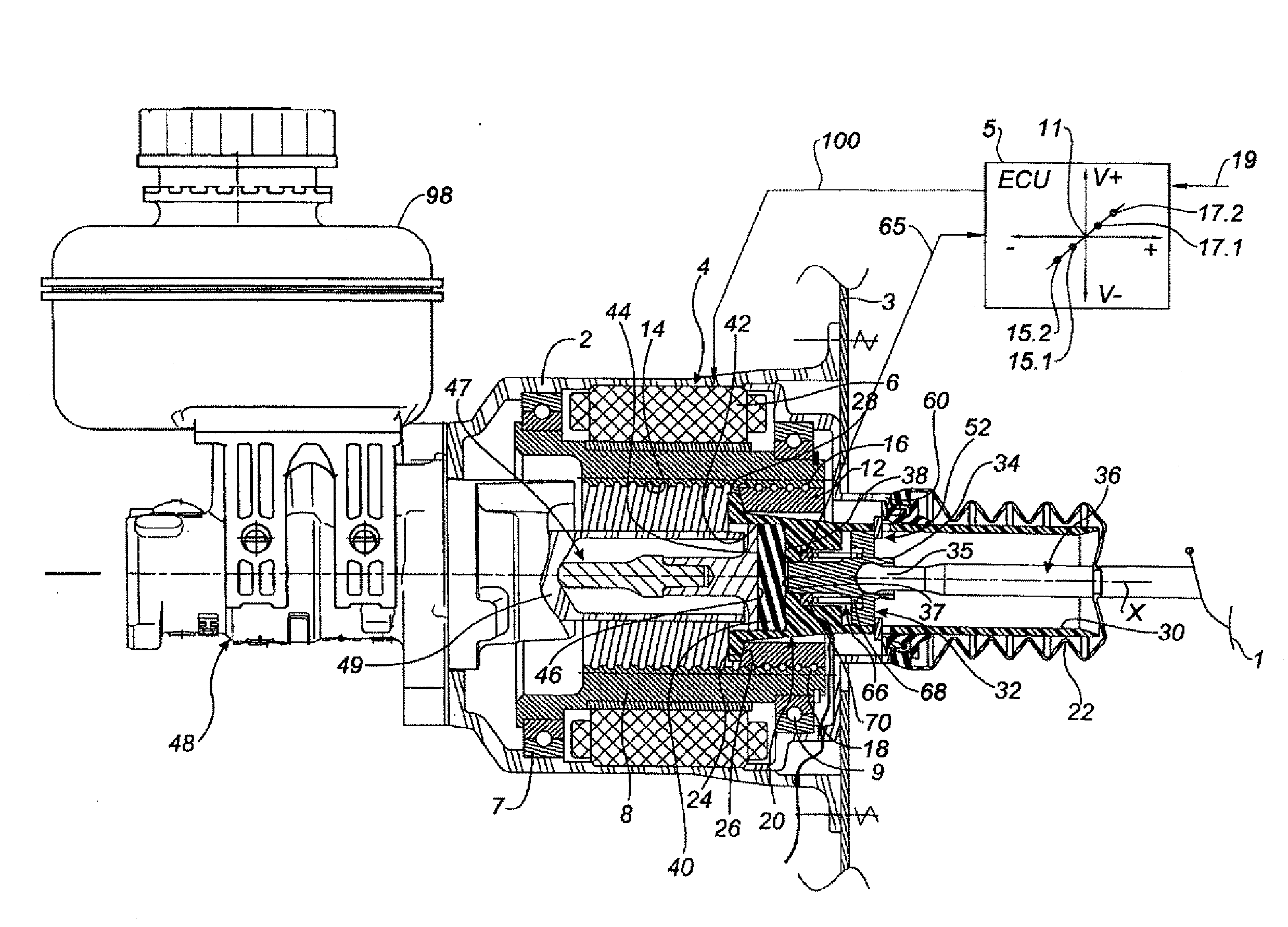

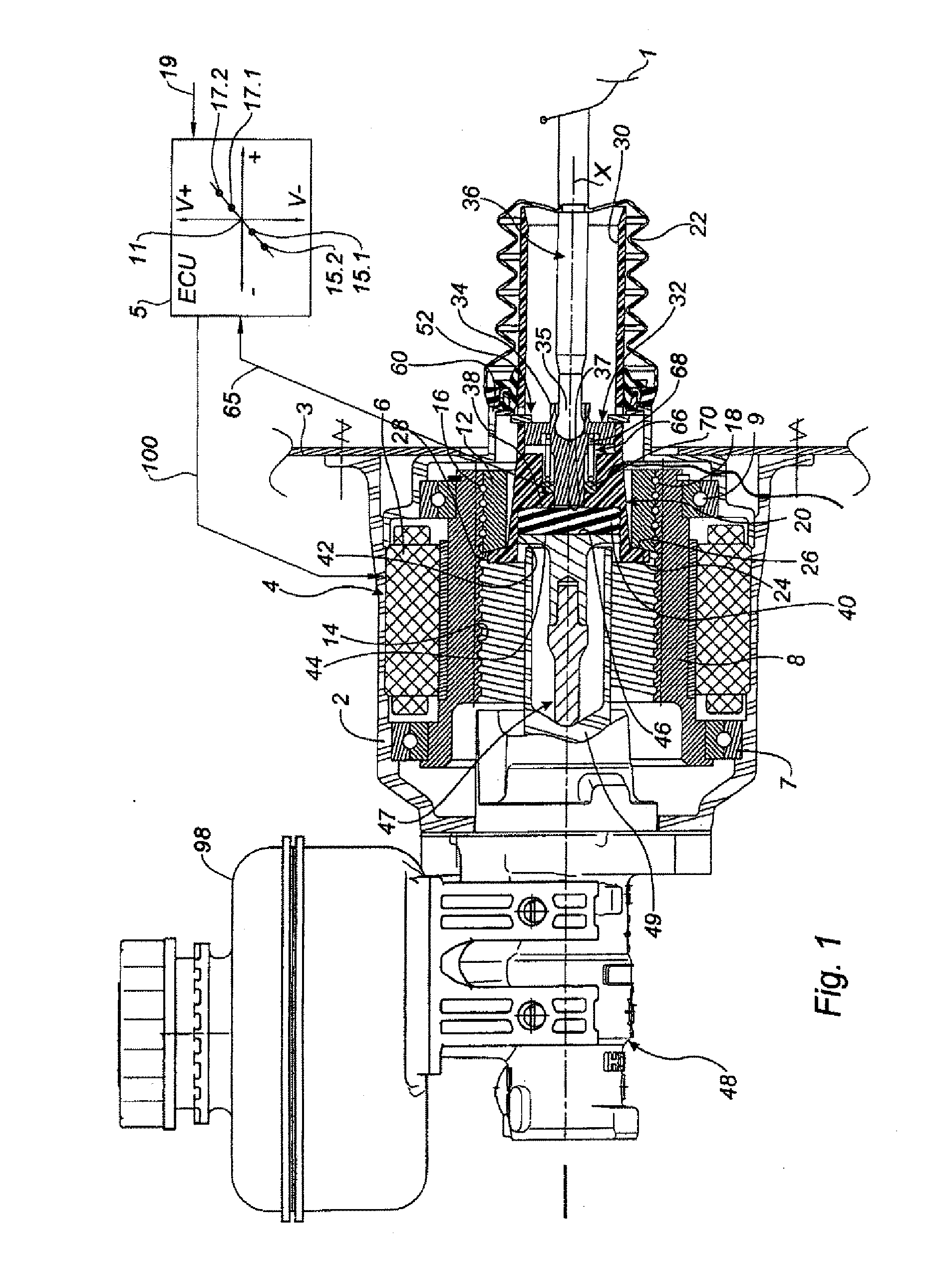

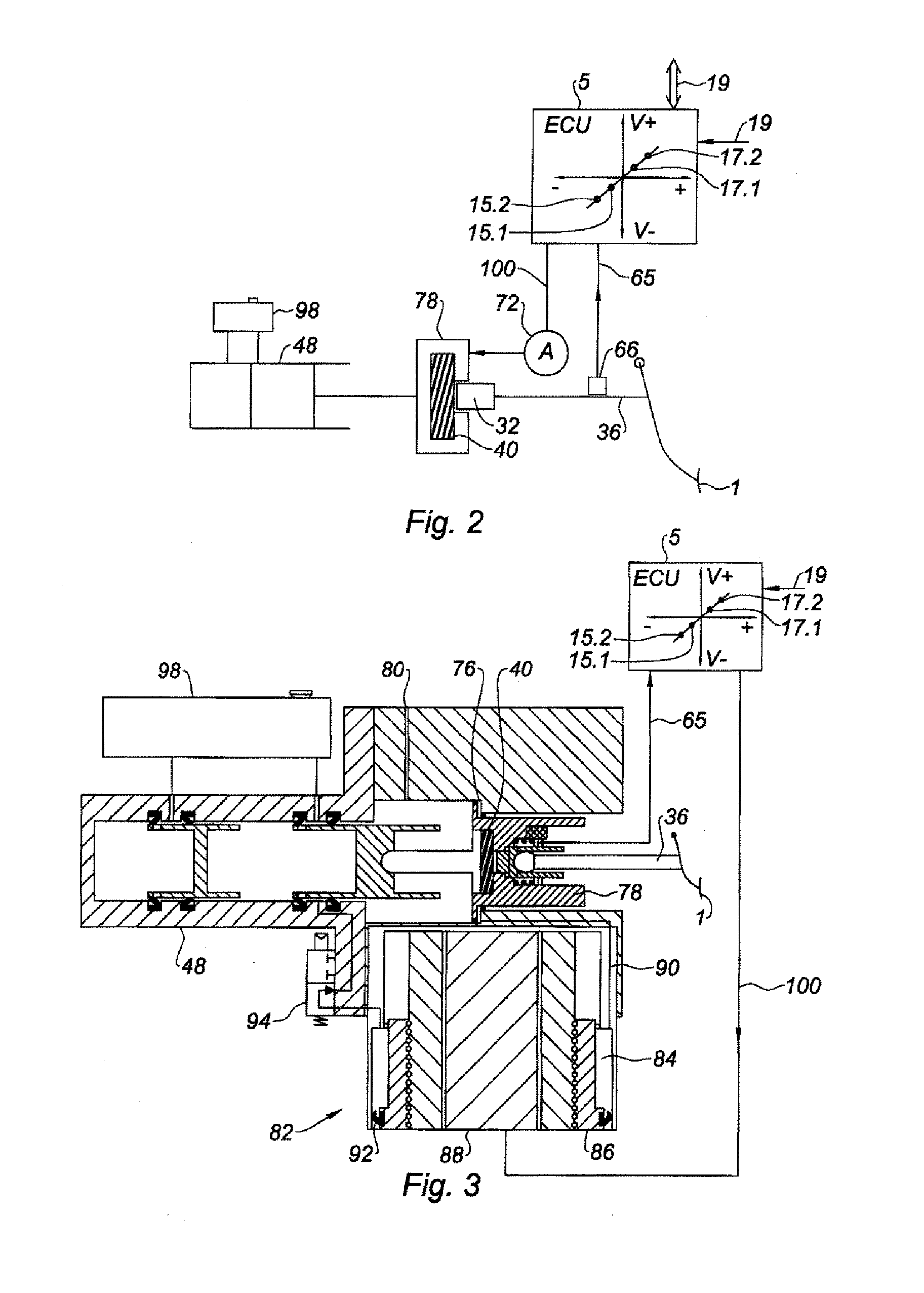

Adjustable brake booster

ActiveUS20110178687A1Analogue computers for trafficComputations using stochastic pulse trainsAutomotive industryEngineering

The present invention relates mainly to a brake booster that is adjustable, notably in terms of the value of the jump.Advantageously, according to the invention, the “target” value for equilibrium of operation of the booster actuator is altered. A target value of a signal delivered by a position sensor is defined either by programming the electronic control unit or by selecting a coefficient in a program as a function of the braking characteristic or characteristics that it is desired to implement. Once the setpoint value has been determined, the electronic control unit commands the actuator using a setpoint value so that the actuator permanently and dynamically works toward achieving the previously defined and / or selected target value. The setpoint may be calculated as a function of torque, force, position or some other parameter.The invention applies notably to the automotive industry.The invention applies mainly to the braking industry.

Owner:ROBERT BOSCH GMBH

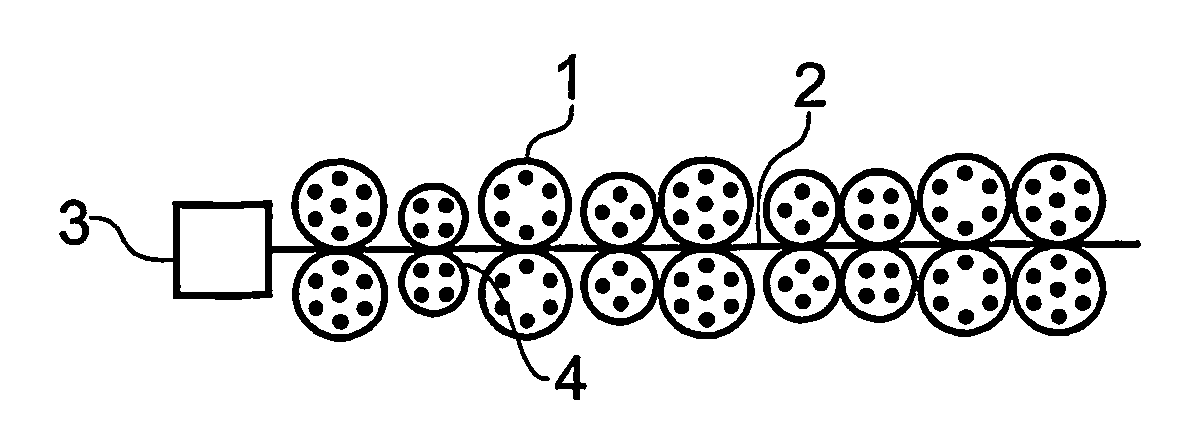

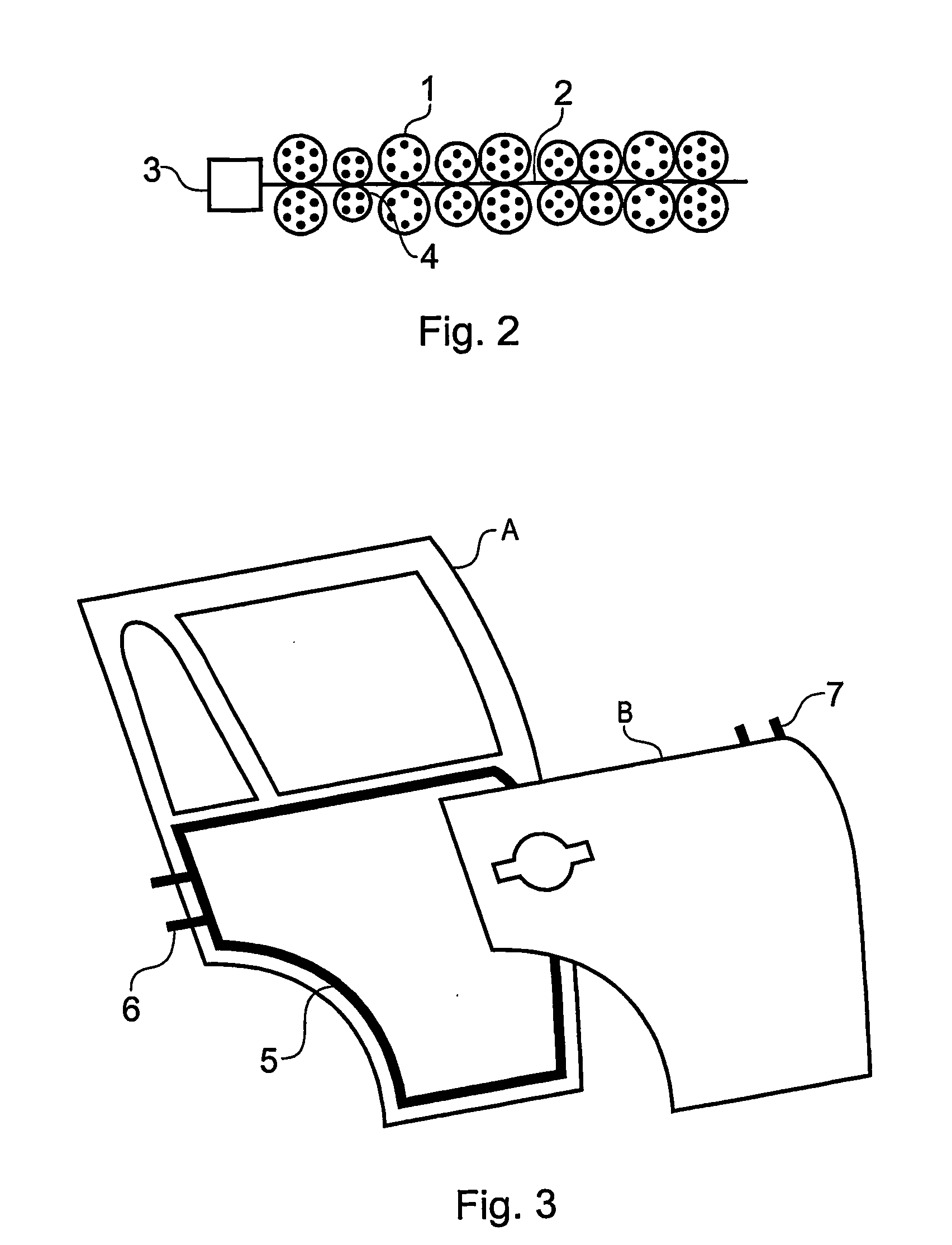

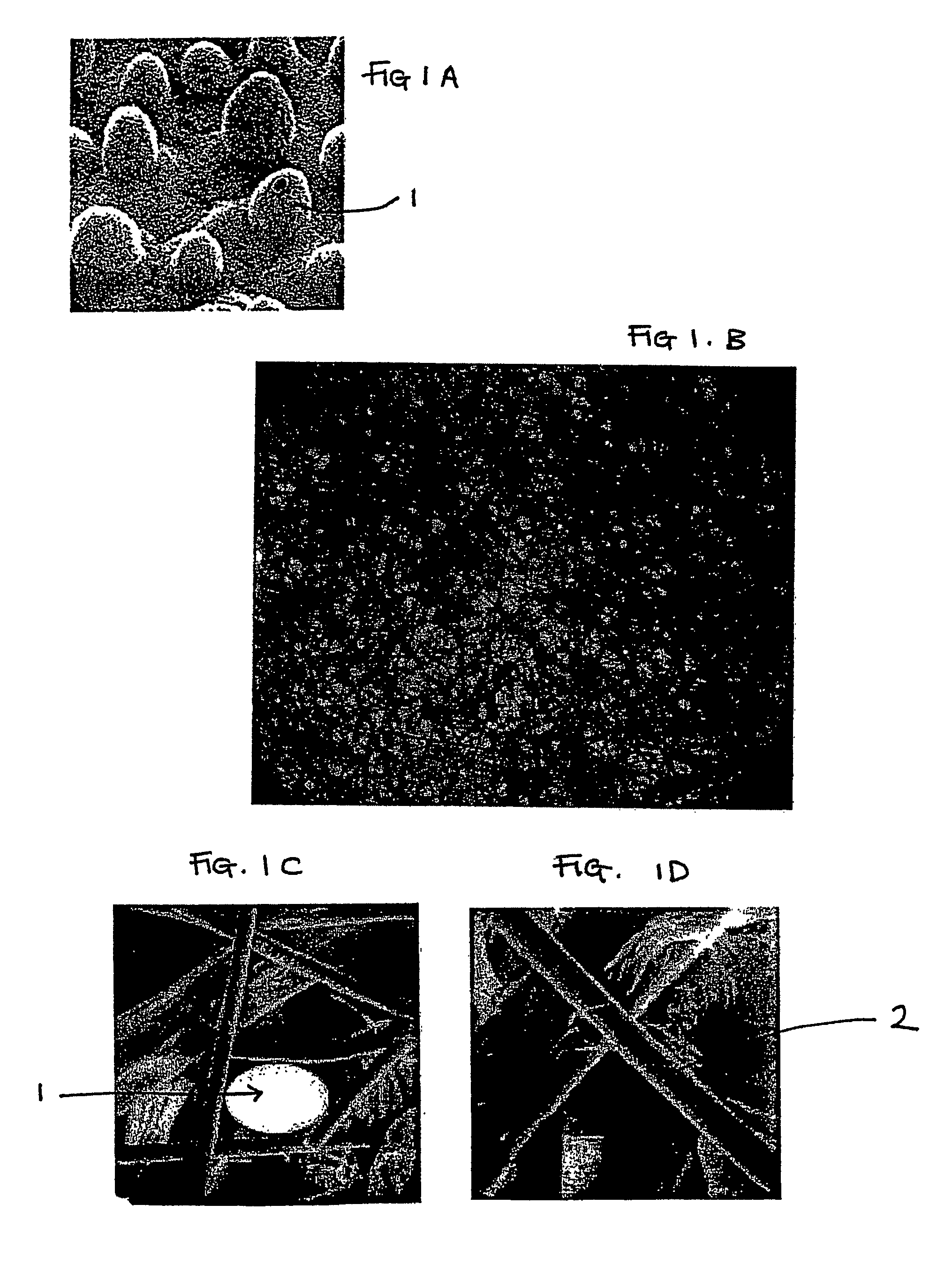

Method and apparatus for bonding and debonding adhesive interface surfaces

InactiveUS20060219350A1Shorten the timeEvenly distributedEngine sealsNanostructure manufactureThermal energyMicrosphere

The present invention relates to a system and a method of improving the debonding of two or more surfaces together. The invention utilises thermoexpanadable microspheres and thermal energy to debond interfaces in an adhesive system or as vehicle carriers. It also discloses a method of curing the adhesive system prior to the debonding step so that the same adhesive system may be used for both phases. It is especially useful in the automotive industry for end of vehicle life dismantling.

Owner:BAIN & COMPANY

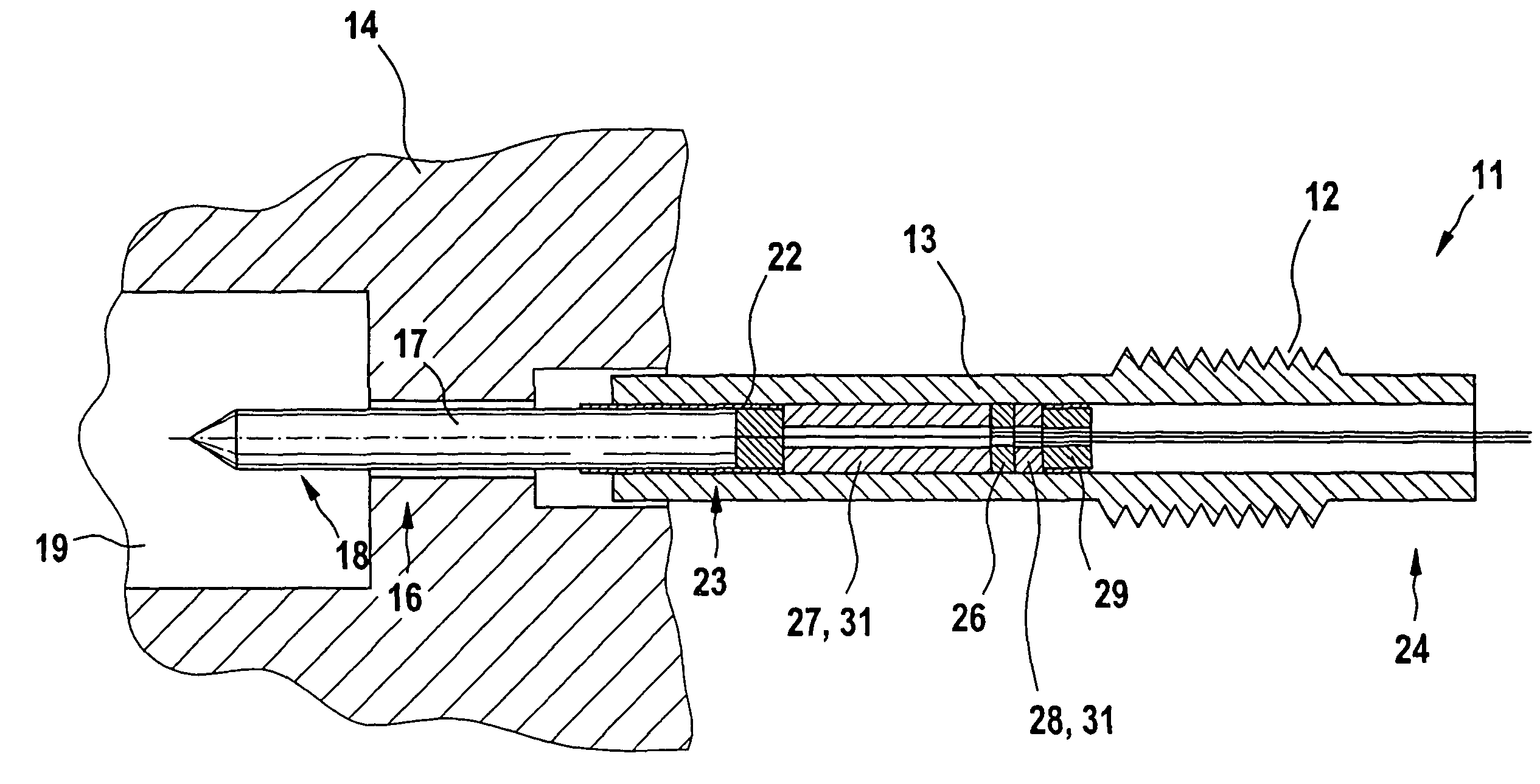

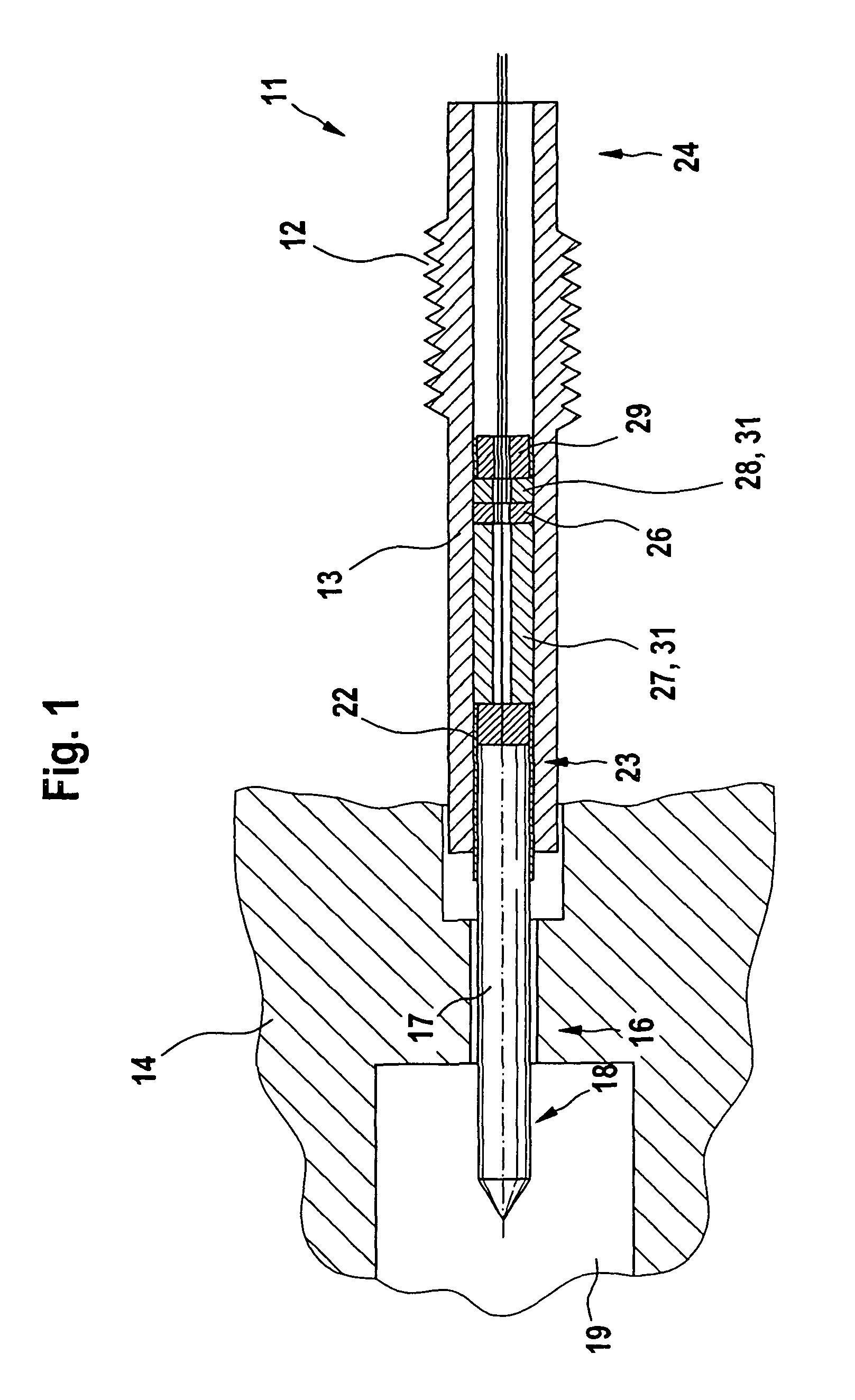

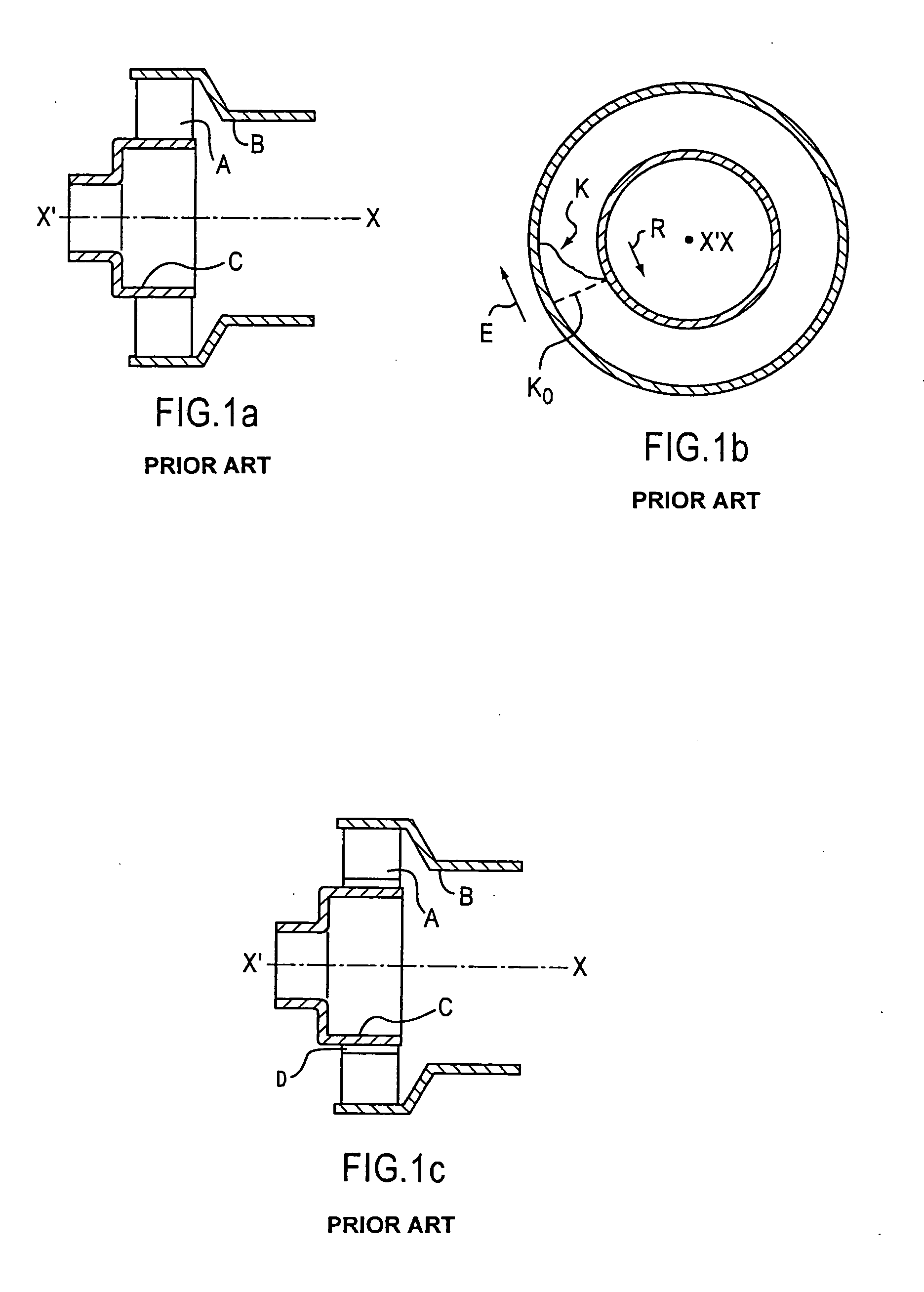

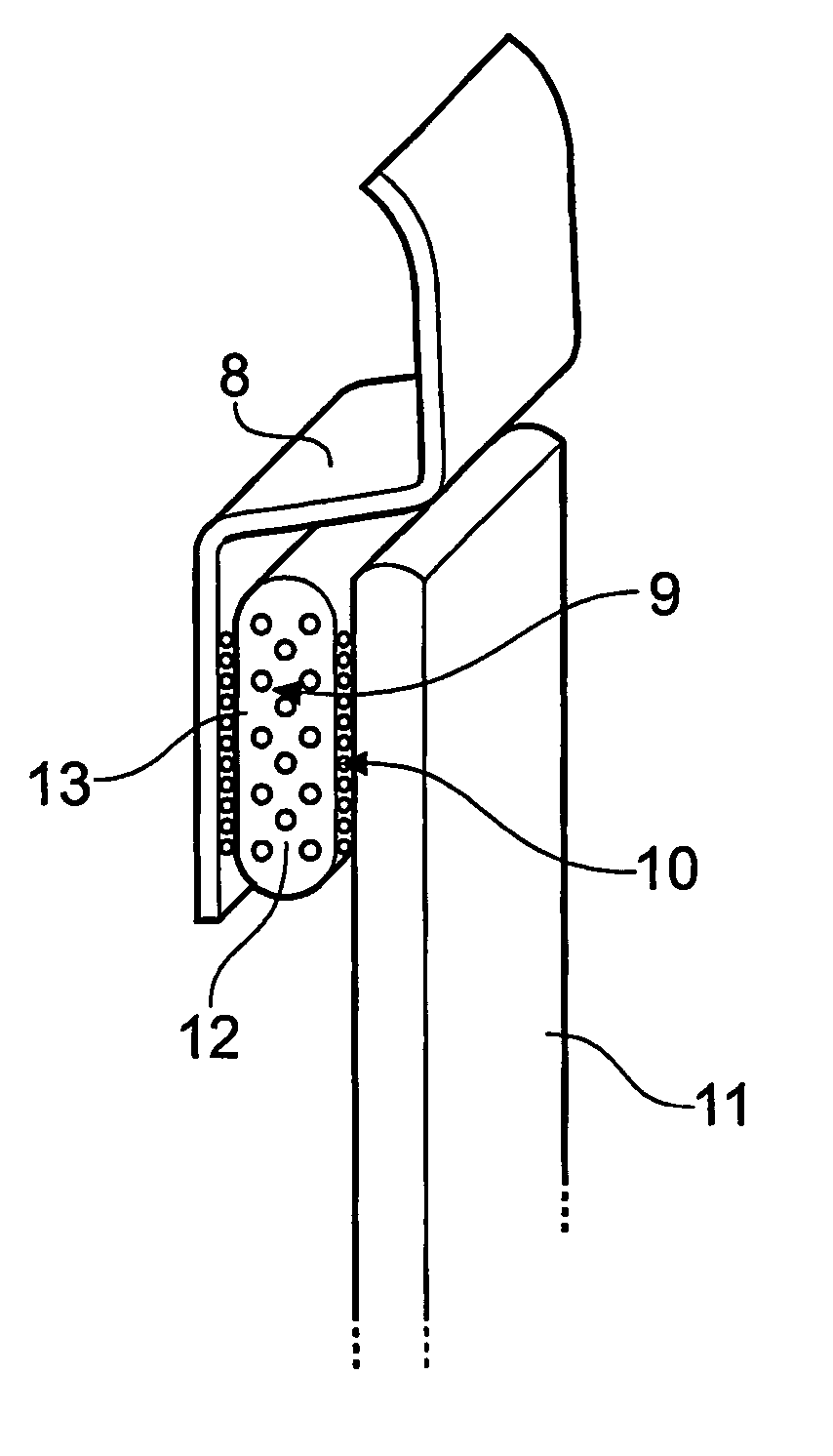

Device for detecting the combustion-chamber pressure in an internal combustion engine

InactiveUS7730771B2Reduce hysteresisReduce heat loadInternal-combustion engine testingIncandescent ignitionCombustion chamberFixation point

A device for detecting the combustion-chamber pressure in an internal combustion engine is configured in such a way that the combustion-chamber pressure is able to be detected in a reliable and reproducible manner. To this end, a heating pin exposed to the combustion-chamber pressure is fixed in place in a housing of the glow plug with the aid of a fixation member. A sensor is affixed in the housing of the glow plug via a fixation element set apart from this fixation member. This sensor detects the elastic longitudinal expansion of the housing caused by the combustion-chamber pressure between the end of the fixation member facing the sensor and the fixation point of the fixation element on the housing. This device is preferably utilized in the automotive industry.

Owner:ROBERT BOSCH GMBH

Aqueous electrolyte lithium sulfur batteries

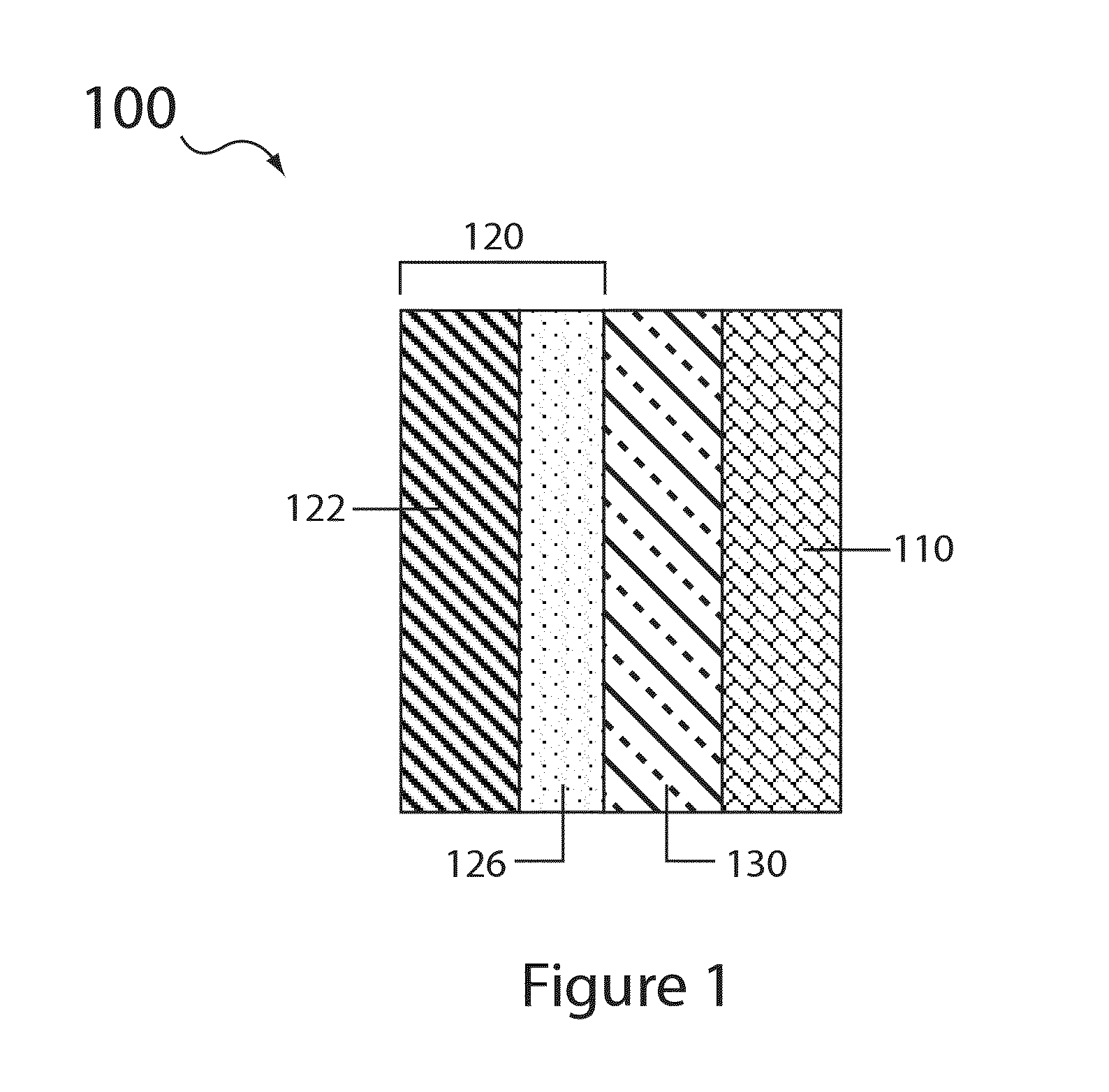

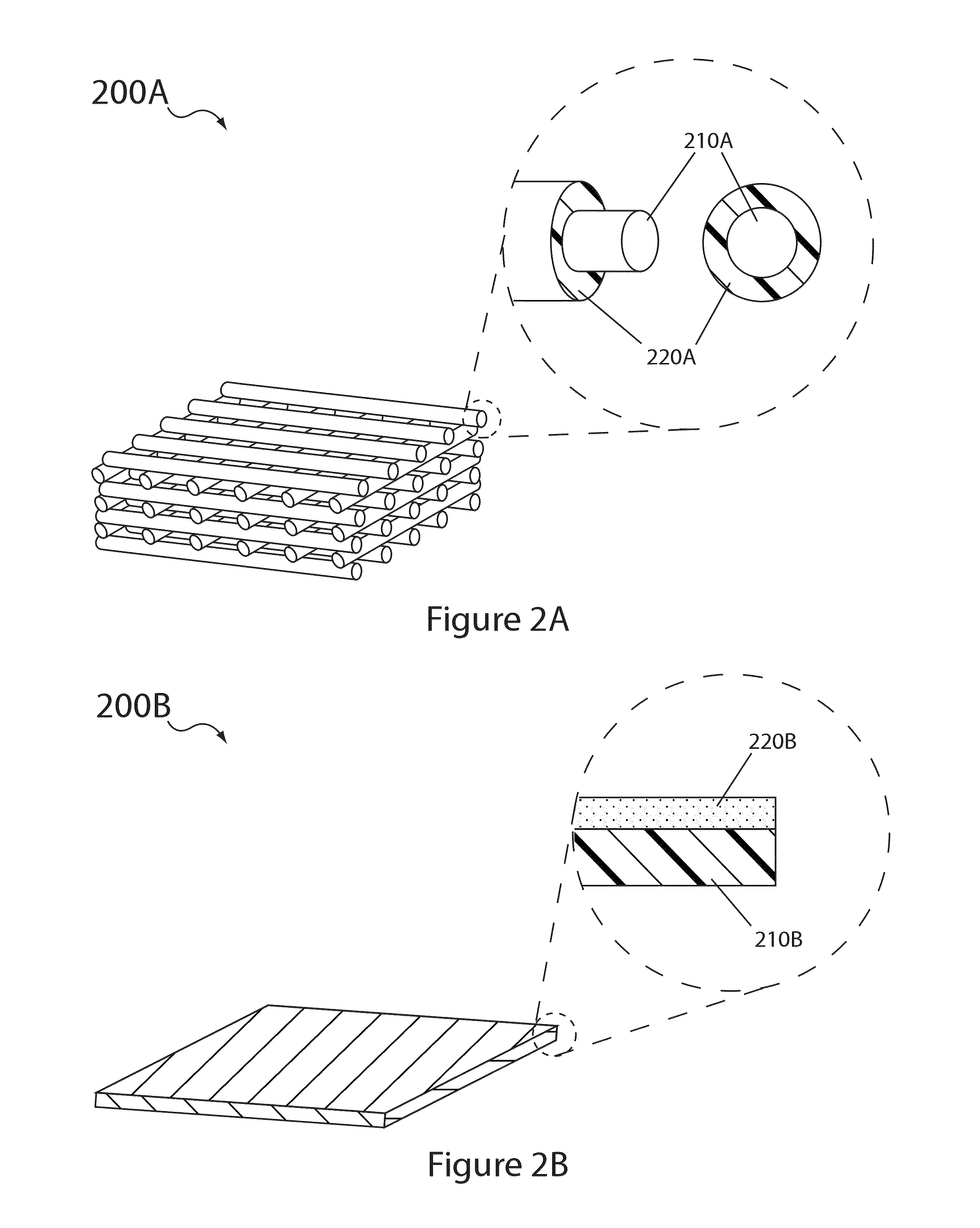

InactiveUS20130141050A1Maintain cell integrityMaintain securityBatteries circuit arrangementsFuel and secondary cellsLithium sulfurAqueous electrolyte

Provided are lithium sulfur battery cells that use water as an electrolyte solvent. In various embodiments the water solvent enhances one or more of the following cell attributes: energy density, power density and cycle life. Significant cost reduction can also be realized by using an aqueous electrolyte in combination with a sulfur cathode. For instance, in applications where cost per Watt-Hour (Wh) is paramount, such as grid storage and traction applications, the use of an aqueous electrolyte in combination with inexpensive sulfur as the cathode active material can be a key enabler for the utility and automotive industries, providing a cost effective and compact solution for load leveling, electric vehicles and renewable energy storage.

Owner:POLYPLUS BATTERY CO INC

Electrolyte compositions for aqueous electrolyte lithium sulfur batteries

ActiveUS8828574B2Improve solubilityImprove ionic conductivityElectrode carriers/collectorsSolid electrolyte cellsLithium sulfurAqueous electrolyte

Provided are lithium sulfur battery cells that use water as an electrolyte solvent. In various embodiments the water solvent enhances one or more of the following cell attributes: energy density, power density and cycle life. Significant cost reduction can also be realized by using an aqueous electrolyte in combination with a sulfur cathode. For instance, in applications where cost per Watt-Hour (Wh) is paramount, such as grid storage and traction applications, the use of an aqueous electrolyte in combination with inexpensive sulfur as the cathode active material can be a key enabler for the utility and automotive industries, providing a cost effective and compact solution for load leveling, electric vehicles and renewable energy storage.

Owner:POLYPLUS BATTERY CO INC

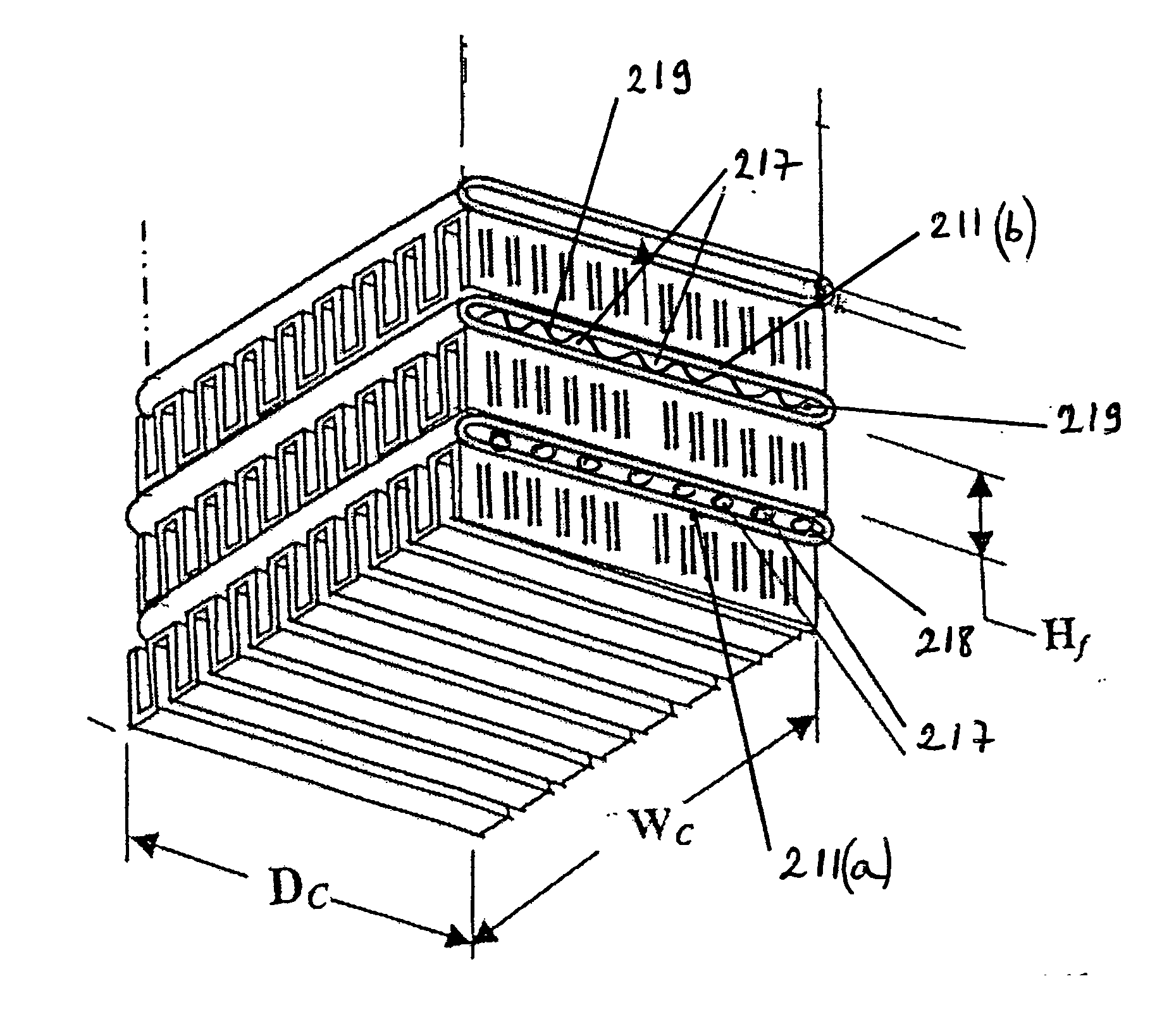

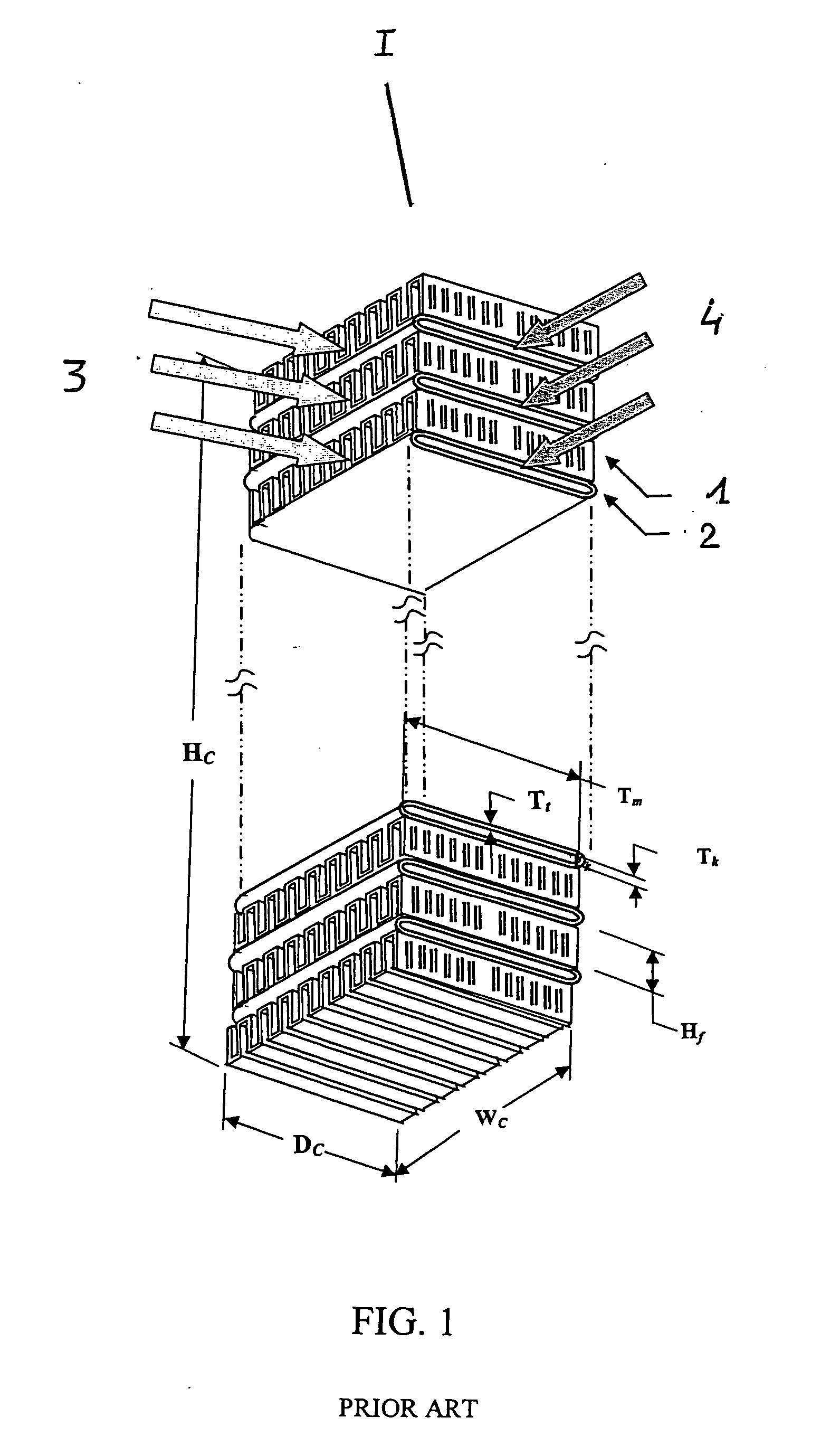

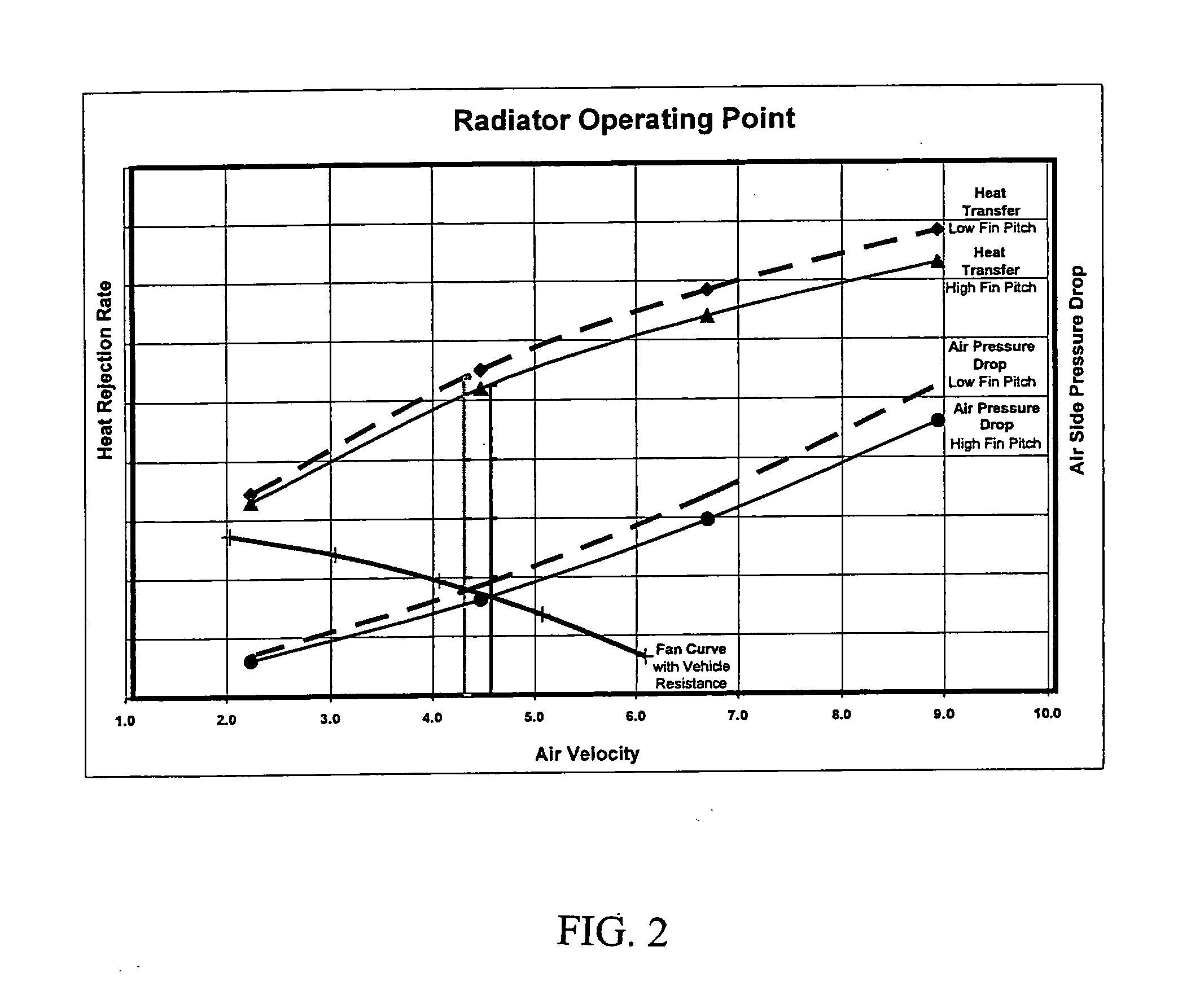

Aluminum heat exchanger and method of making thereof

InactiveUS20050045314A1Few side pressure dropMaximum performanceHeat exhanger finsStationary conduit assembliesAutomotive industryEngineering

The present invention relates to an aluminum heat exchanger. More particularly, the present invention relates to an aluminum heat exchanger useful for motorized power systems similar to those utilized in the automotive industry for engine heat exchange, including, in particular, radiators. In a preferred method, the flat tubes of the heat exchanger are formed from flat sheet braze material and at least one portion is formed approximately normal to the wide portion (major axis) and parallel to the minor axis of the tube.

Owner:VALEO INC

Method and system for using a component business model to transform warranty claims processing in the automotive industry

ActiveUS20080215400A1Optimize business processesResourcesMarket data gatheringCar manufacturingComponent business model

A method, system and service for using a component business model to transform a business process. The invention uses a component business model of a business to prioritize business changes affecting key performance indicators for the business process, defines an information technology architecture to support the business changes, and specifies a roadmap for implementing the supporting information technology architecture. In a particular application of the invention to the automobile manufacturing business, the business process is the warranty claims process, and a length of time to process a warranty claim is a key performance indicator.

Owner:IBM CORP

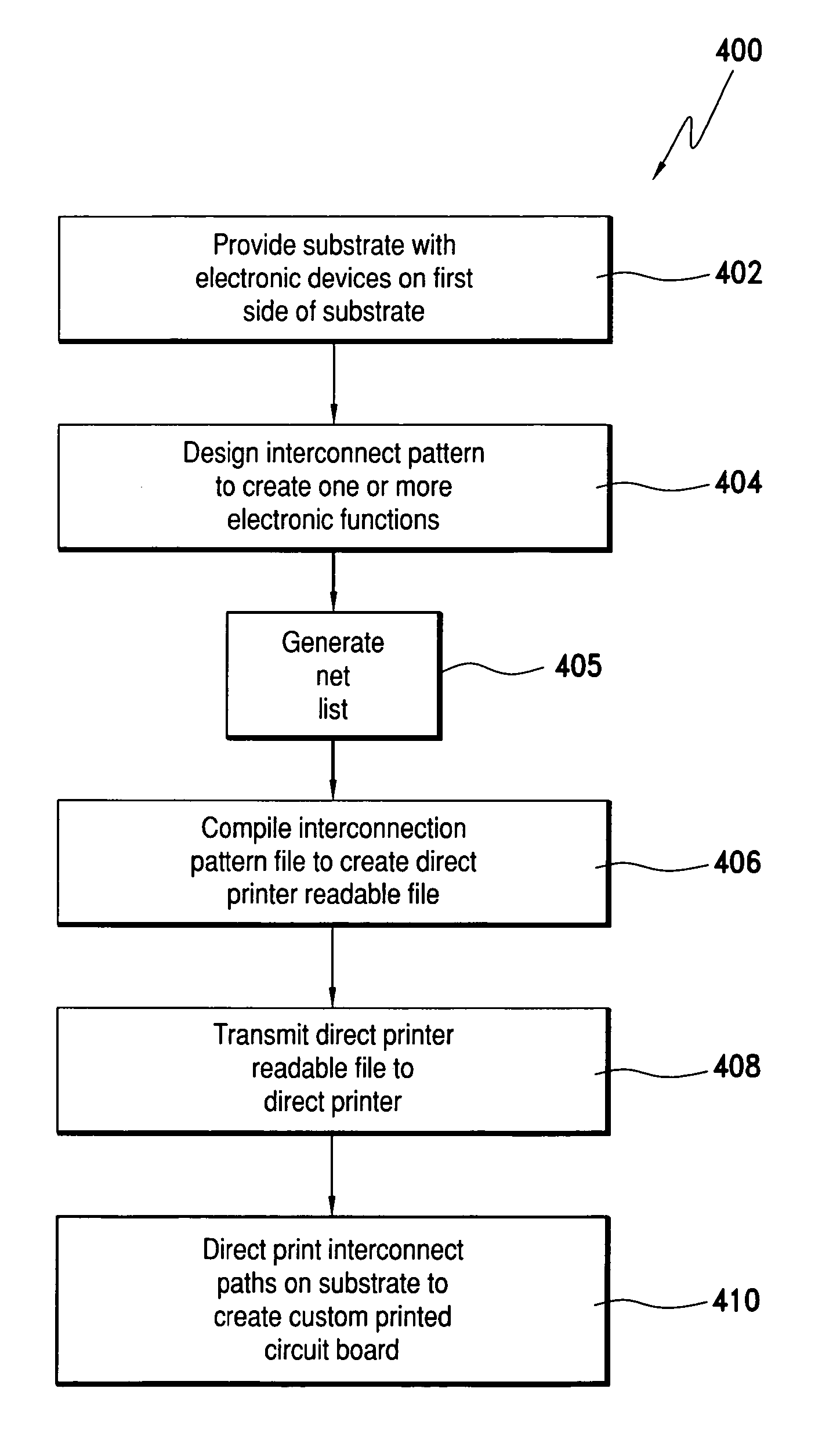

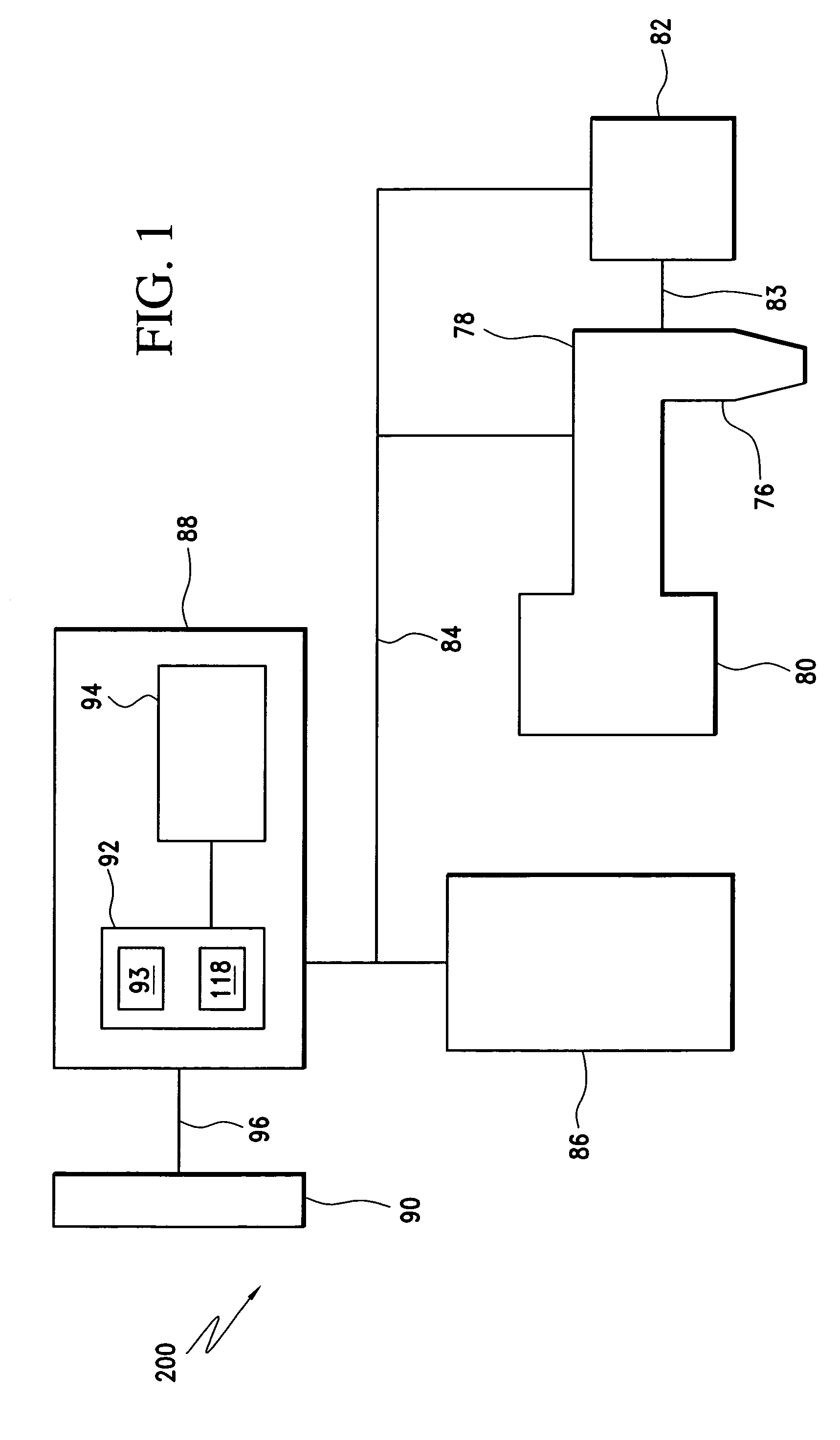

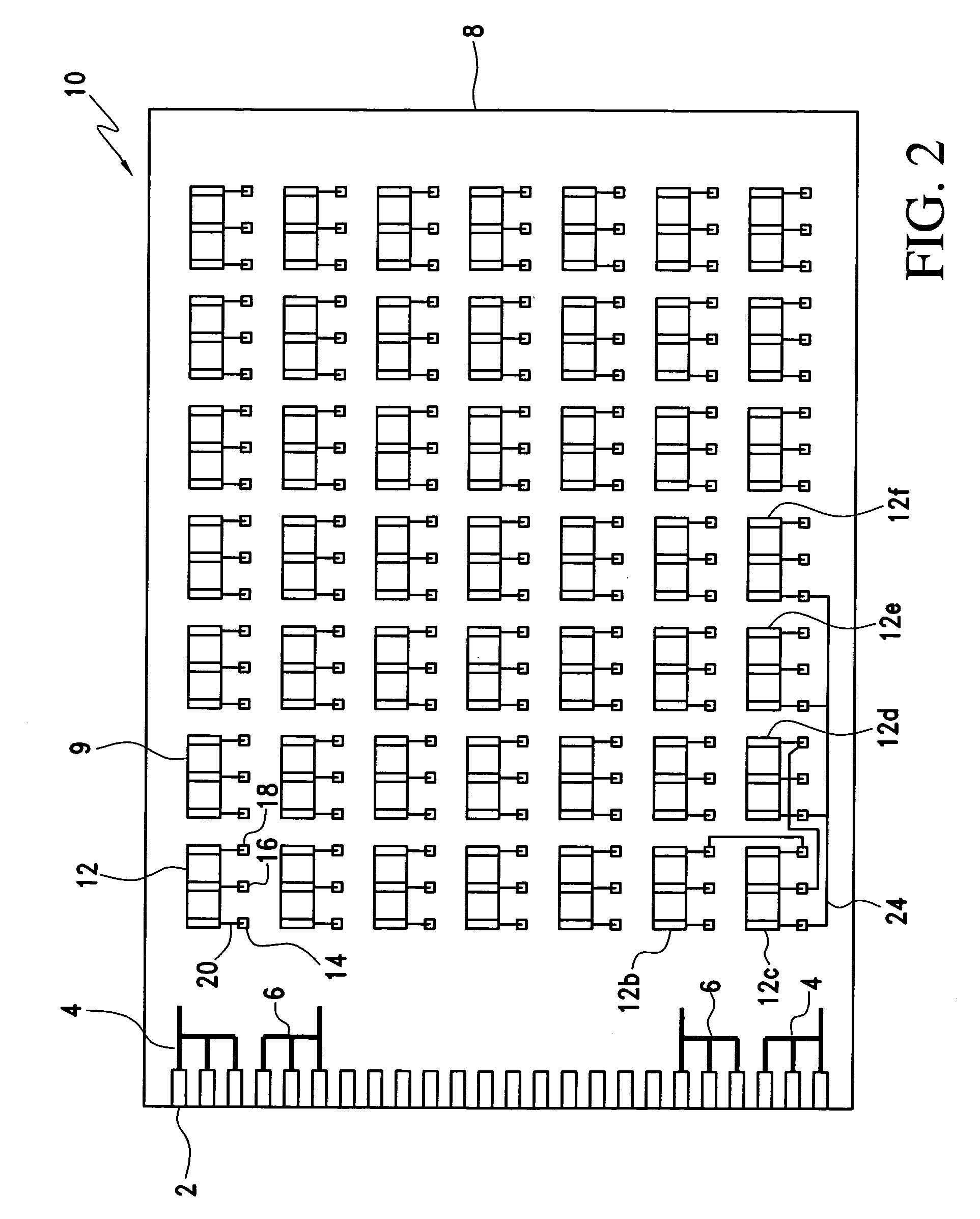

System and process for manufacturing custom electronics by combining traditional electronics with printable electronics

InactiveUS7533361B2Easily and inexpensively modifyPrinted circuit assemblingSemiconductor/solid-state device detailsDisplay deviceAutomotive industry

A system and process for manufacturing custom printed circuit boards on pre-provided substrates, wherein the substrate is pre-provided with standard integrated circuits. The standard integrated circuits are pre-provided on the substrate in a conventional manner, such as by standard integrated circuit technologies, in many different packing technologies. The user designs the custom printed circuit board using a design tool to perform one or more specific electronic functions, based on the pre-provided electronic devices, and / or custom designed and direct printed electronic devices. The electronic devices includes transistors, resistors, capacitors, among other types of devices. The system and process allows users to customize standard “generic” circuit boards with some known electronic functions for their own particular application. Examples of such uses include displays, the automotive industry and many others.

Owner:CABOT CORP

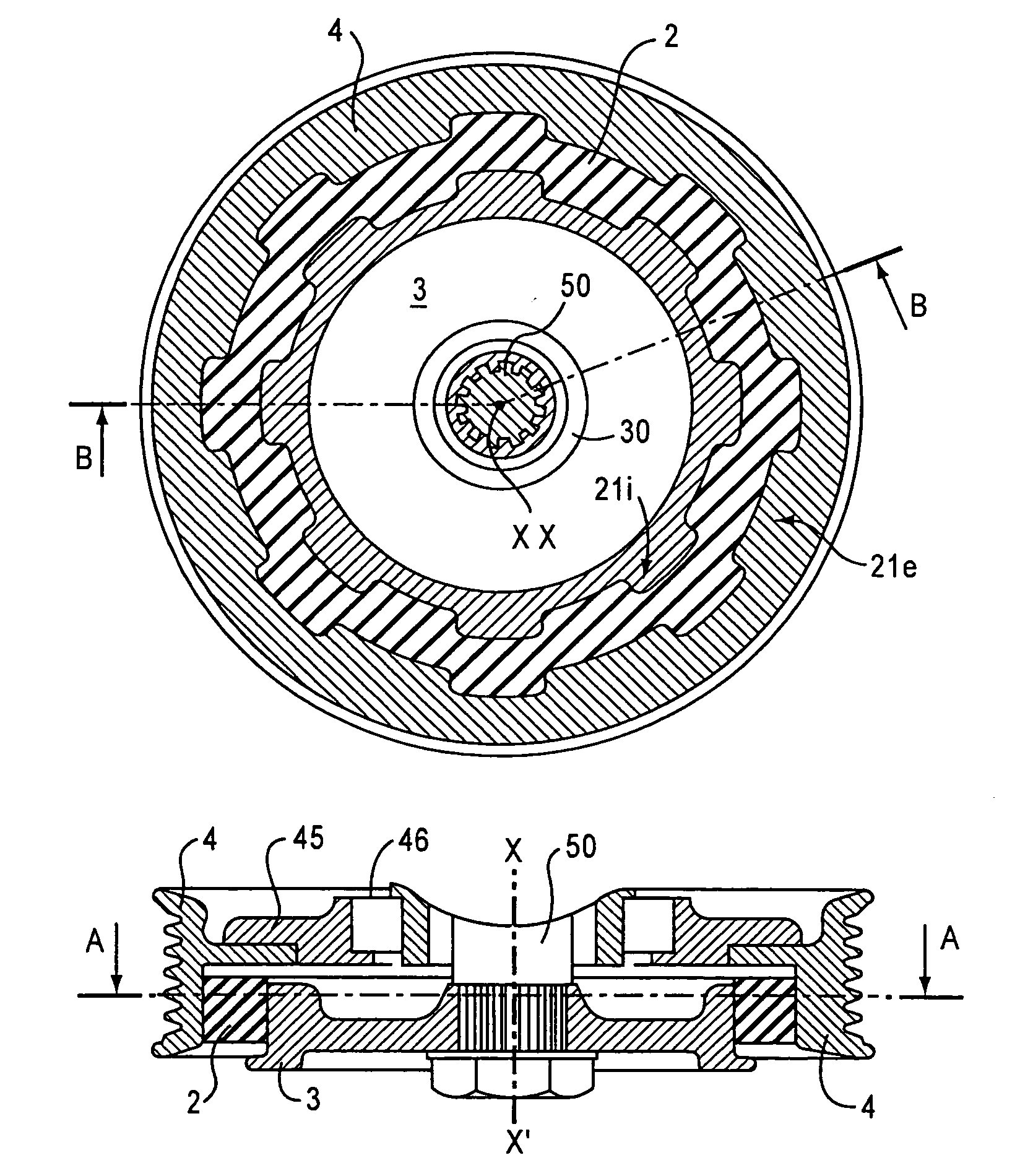

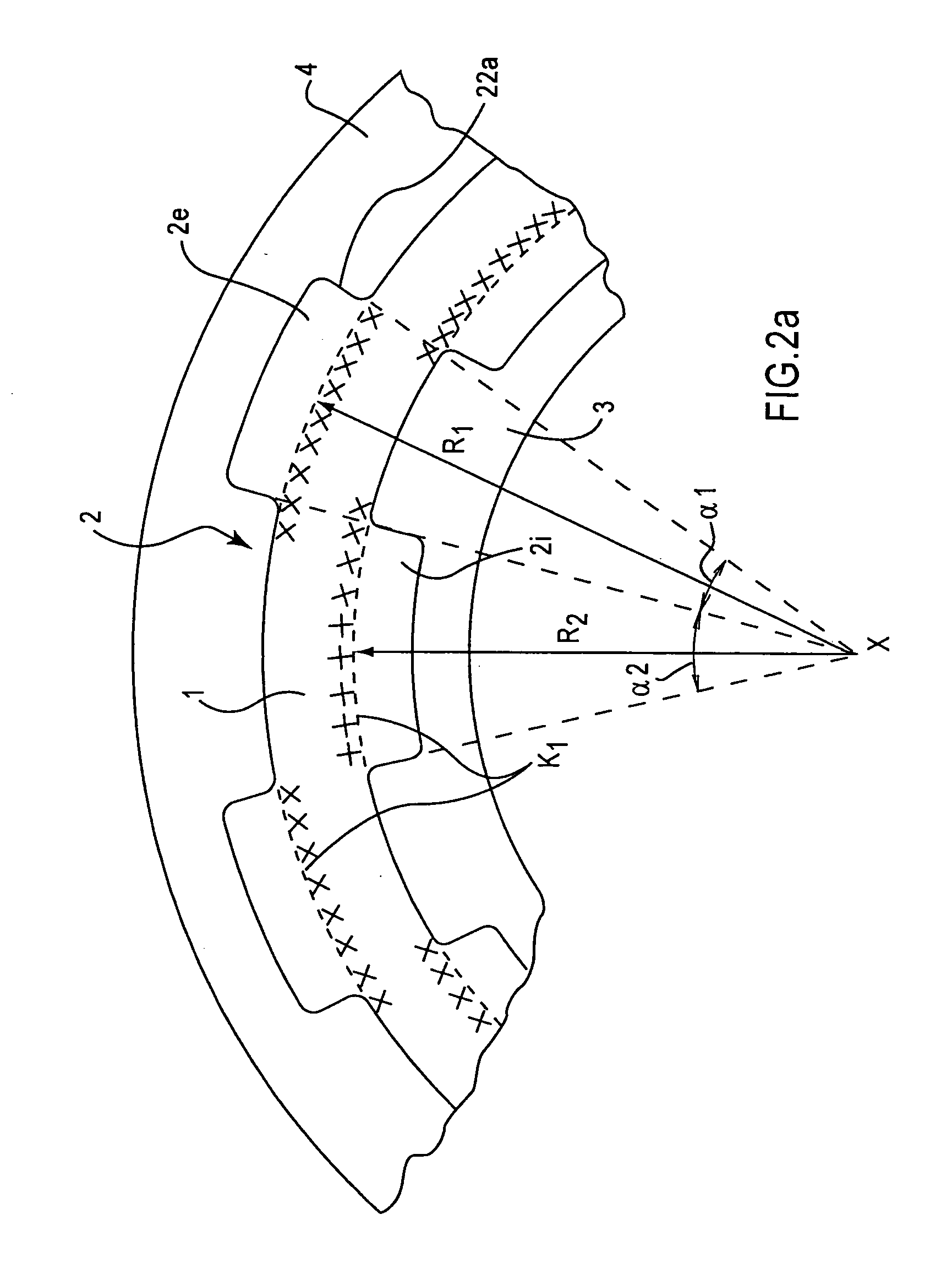

Decoupling element of deformable material in a power transmission system

ActiveUS7244185B2Increasing angular offsetConstant stiffnessYielding couplingSlip couplingElectric power transmissionCoupling

The invention seeks to improve the transfer function of drive devices such as pulleys and other coupling means, and it proposes creating zones of shear in the inserted deformable material forming a decoupling element. In an embodiment, the decoupling element is made in the form of a ring (2) presenting at least one meshing face (21e, 21i) complementary to a corresponding meshing face (31, 41) formed on the facing support (3, 4), the meshing projections (2e, 2i, 3e, 4i) engaging in one another to take up power transmission torque by working in shear by being blocked against each other during rotation. The invention is applicable to all drive devices including a filtering, damping, or absorbing element, e.g. for use in the automotive industry.

Owner:HUTCHINSON SA

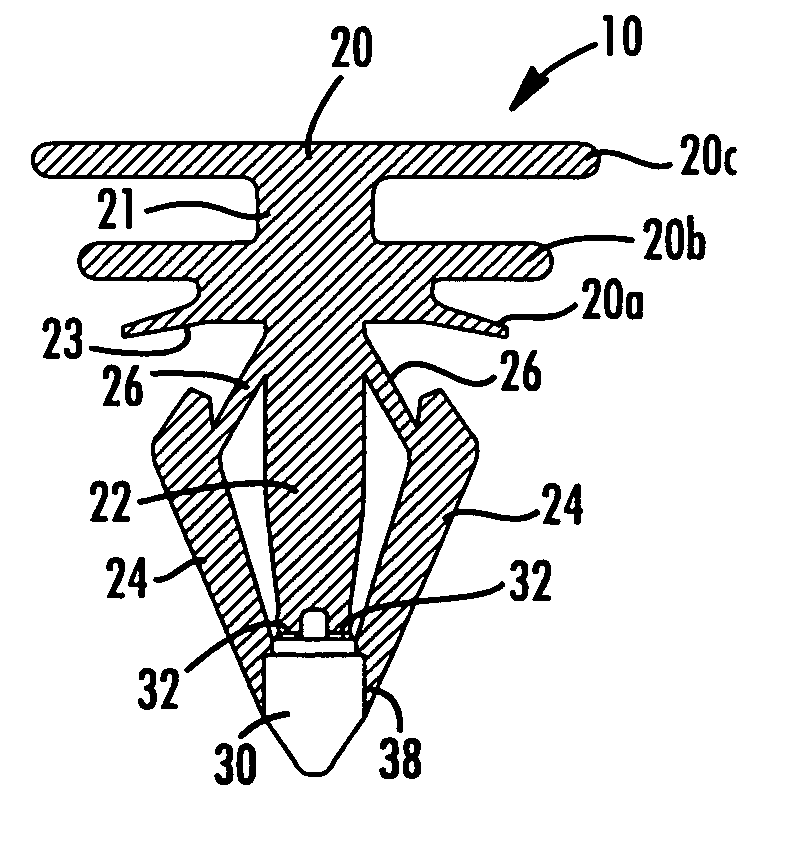

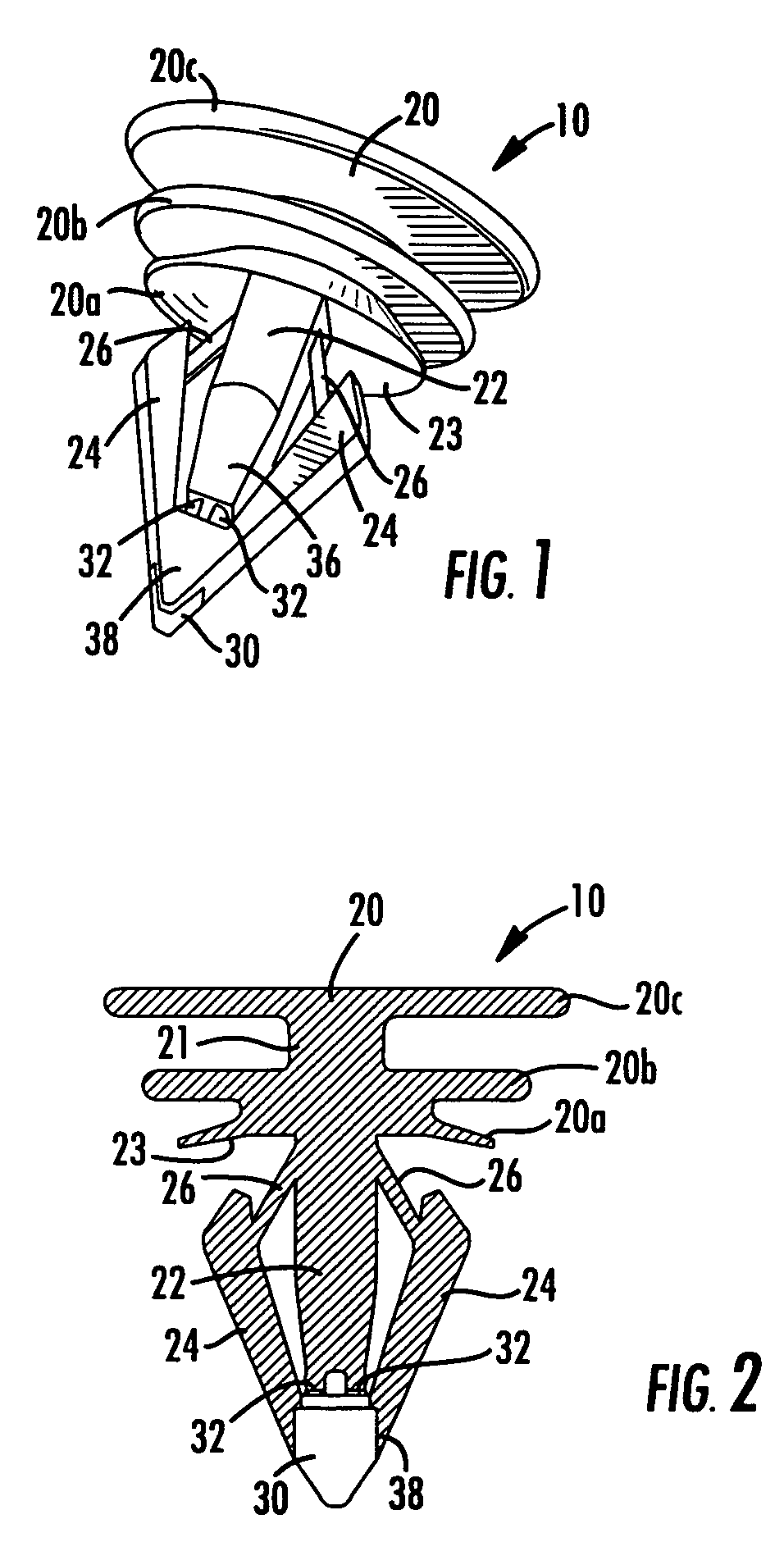

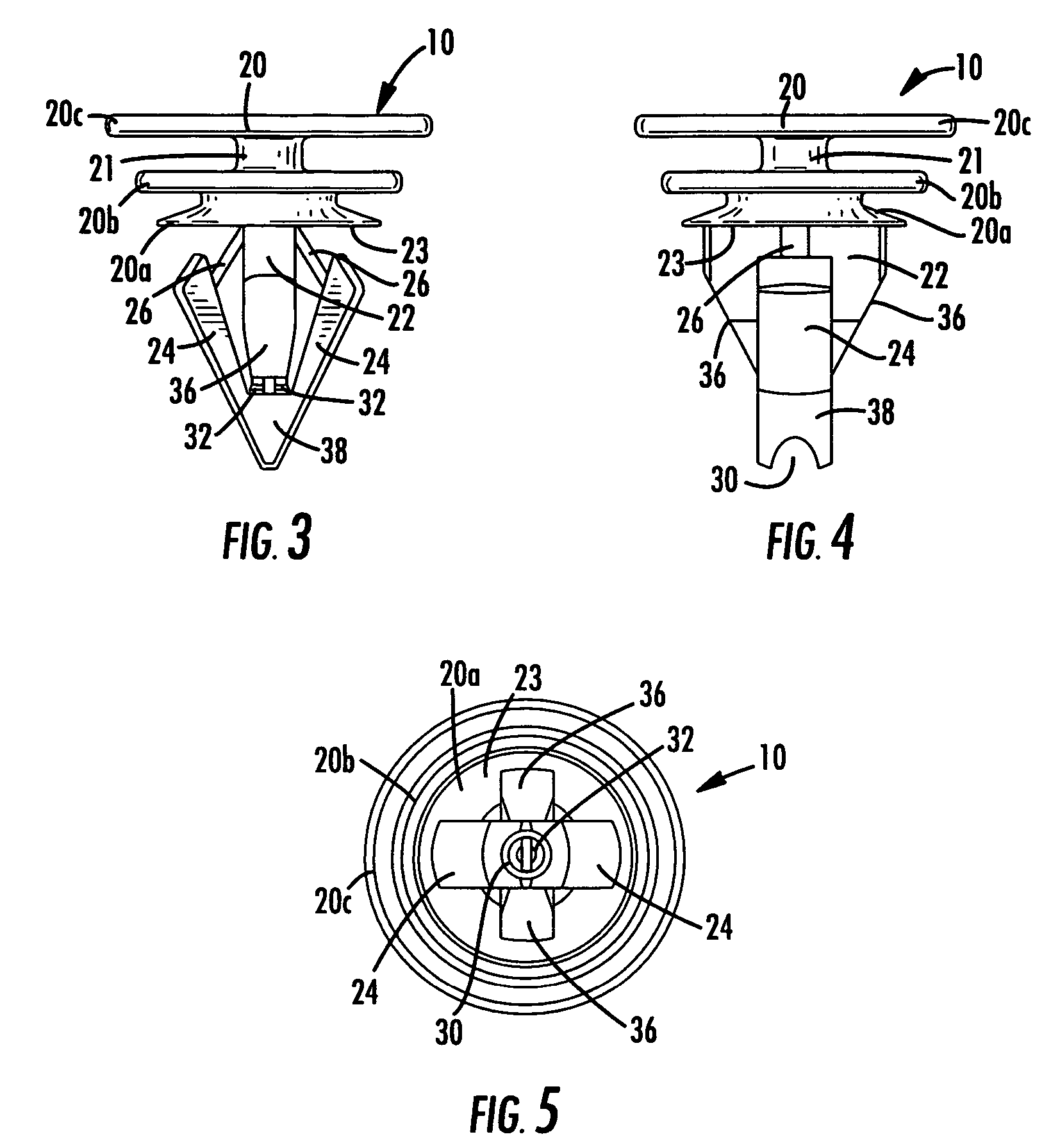

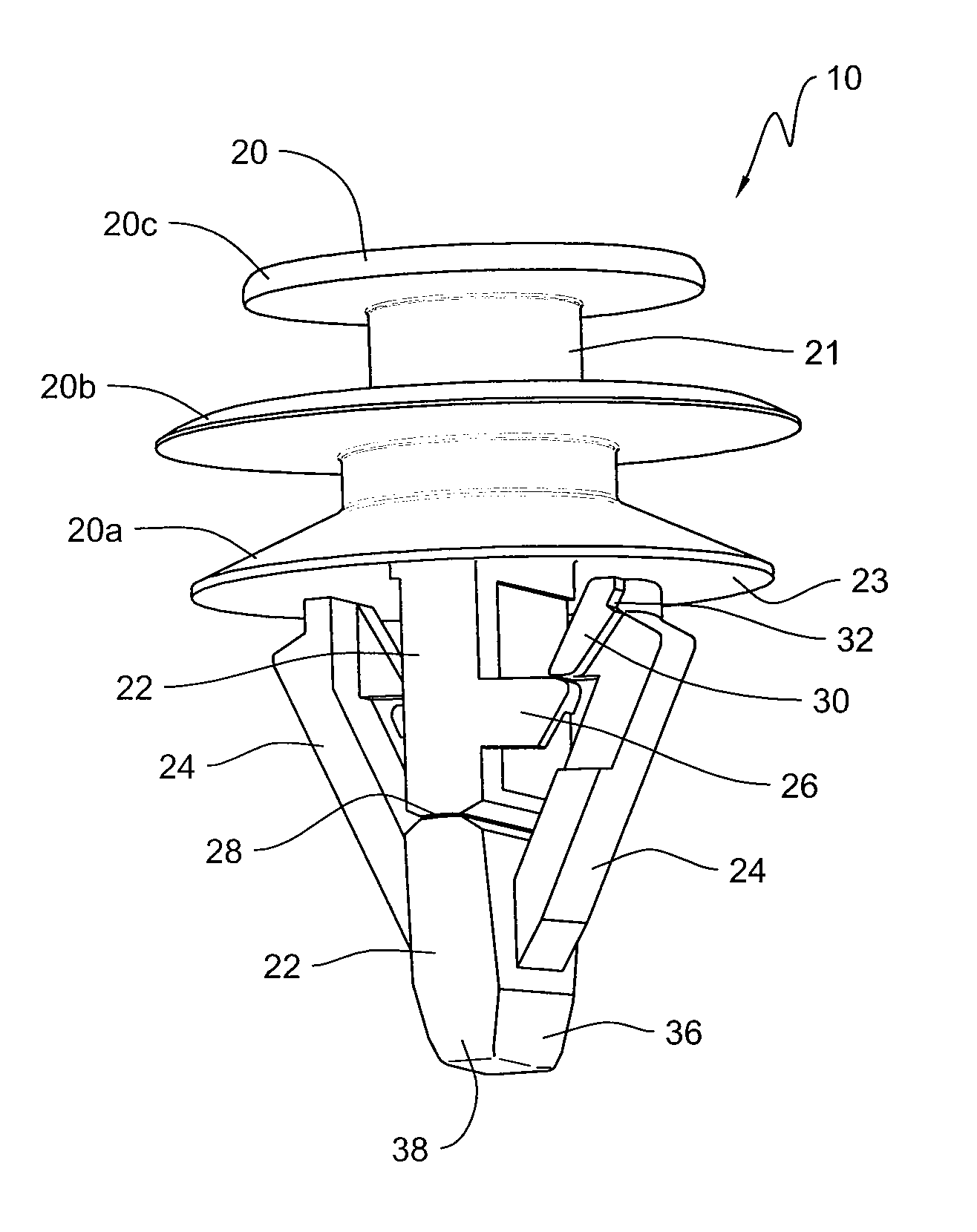

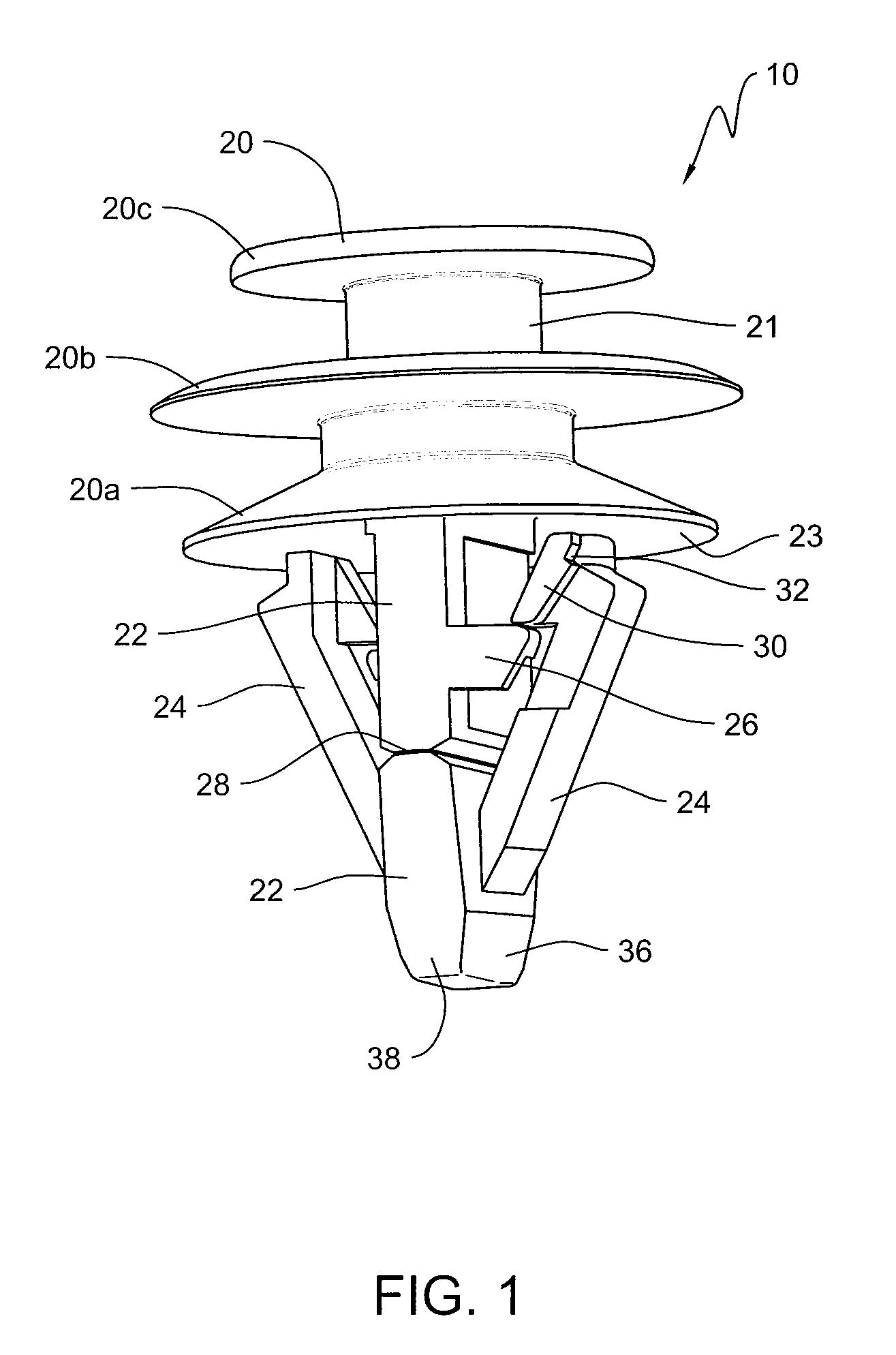

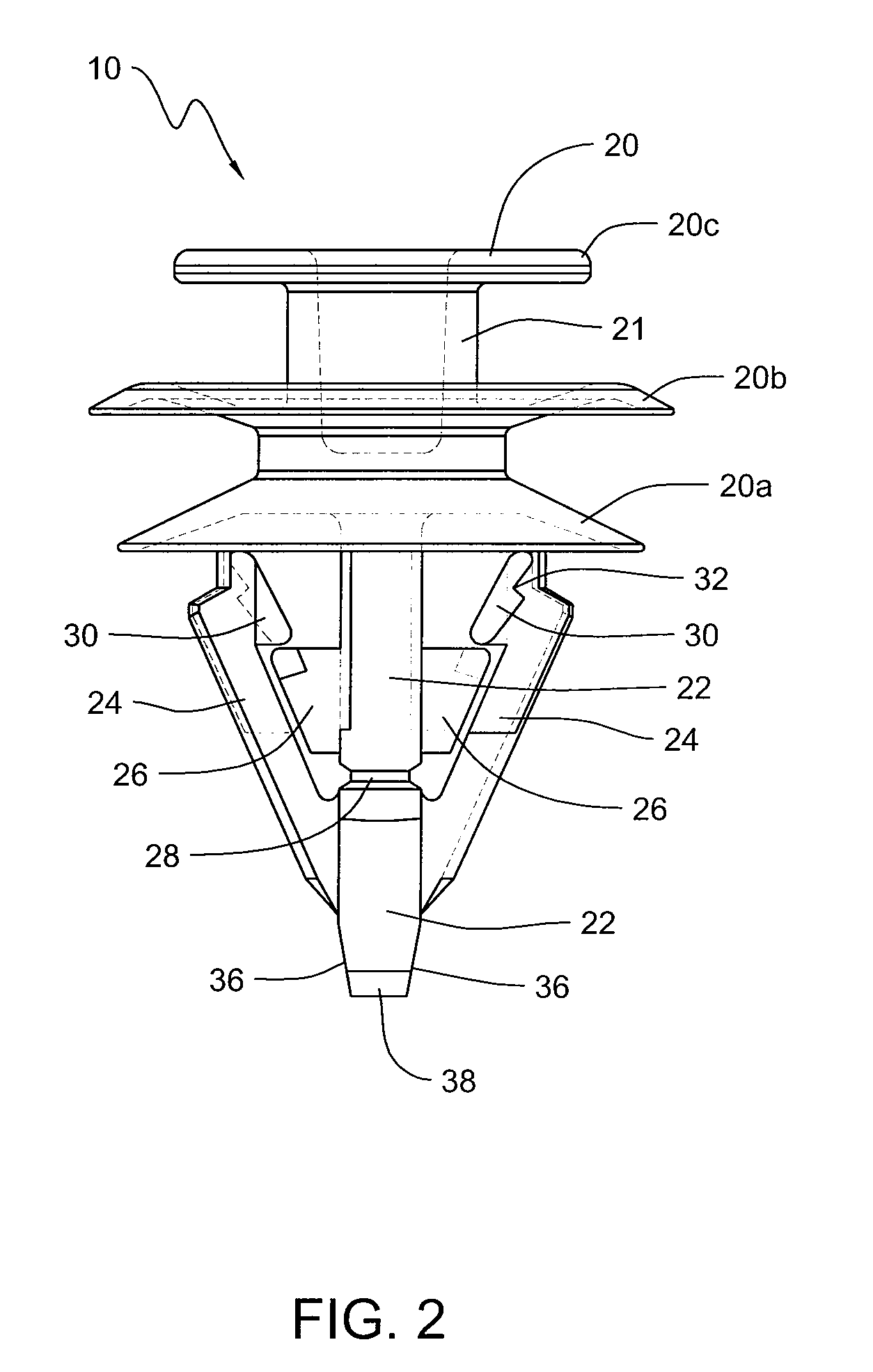

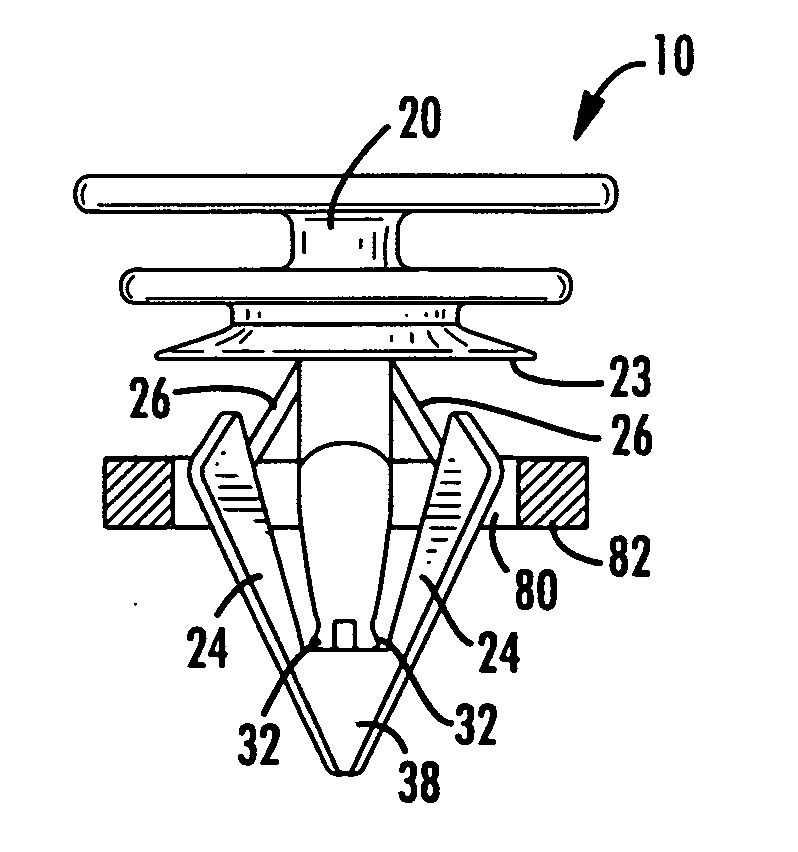

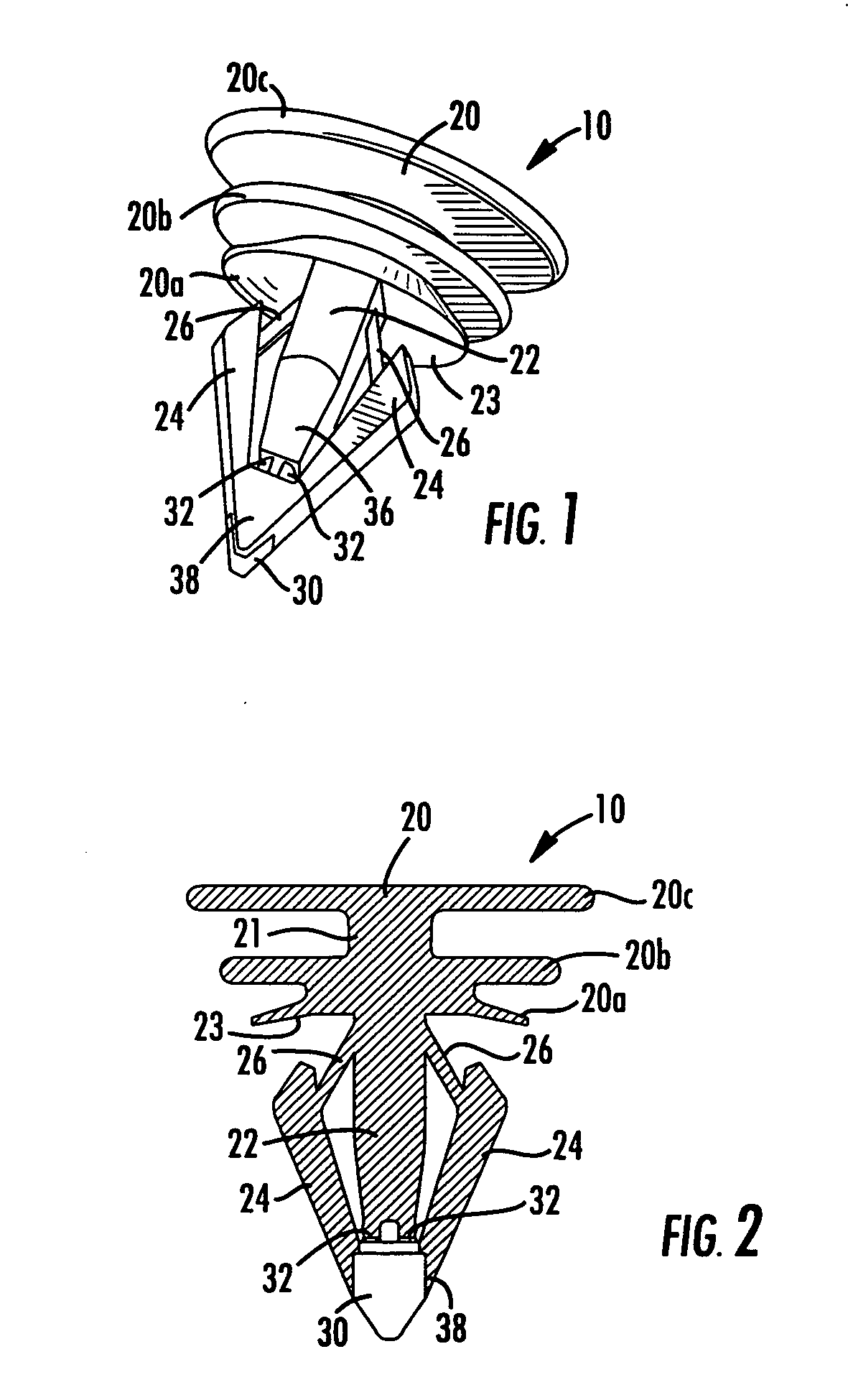

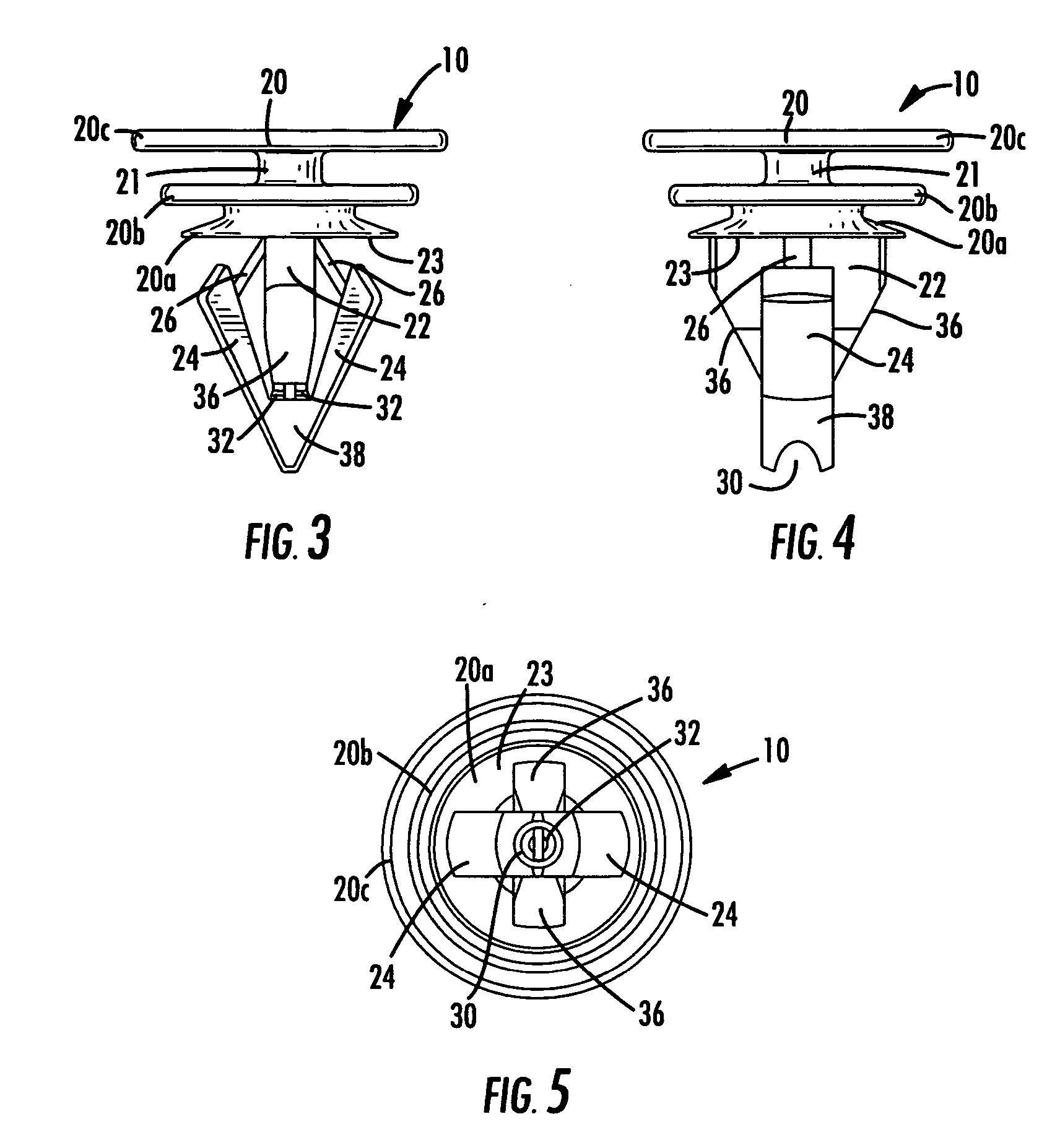

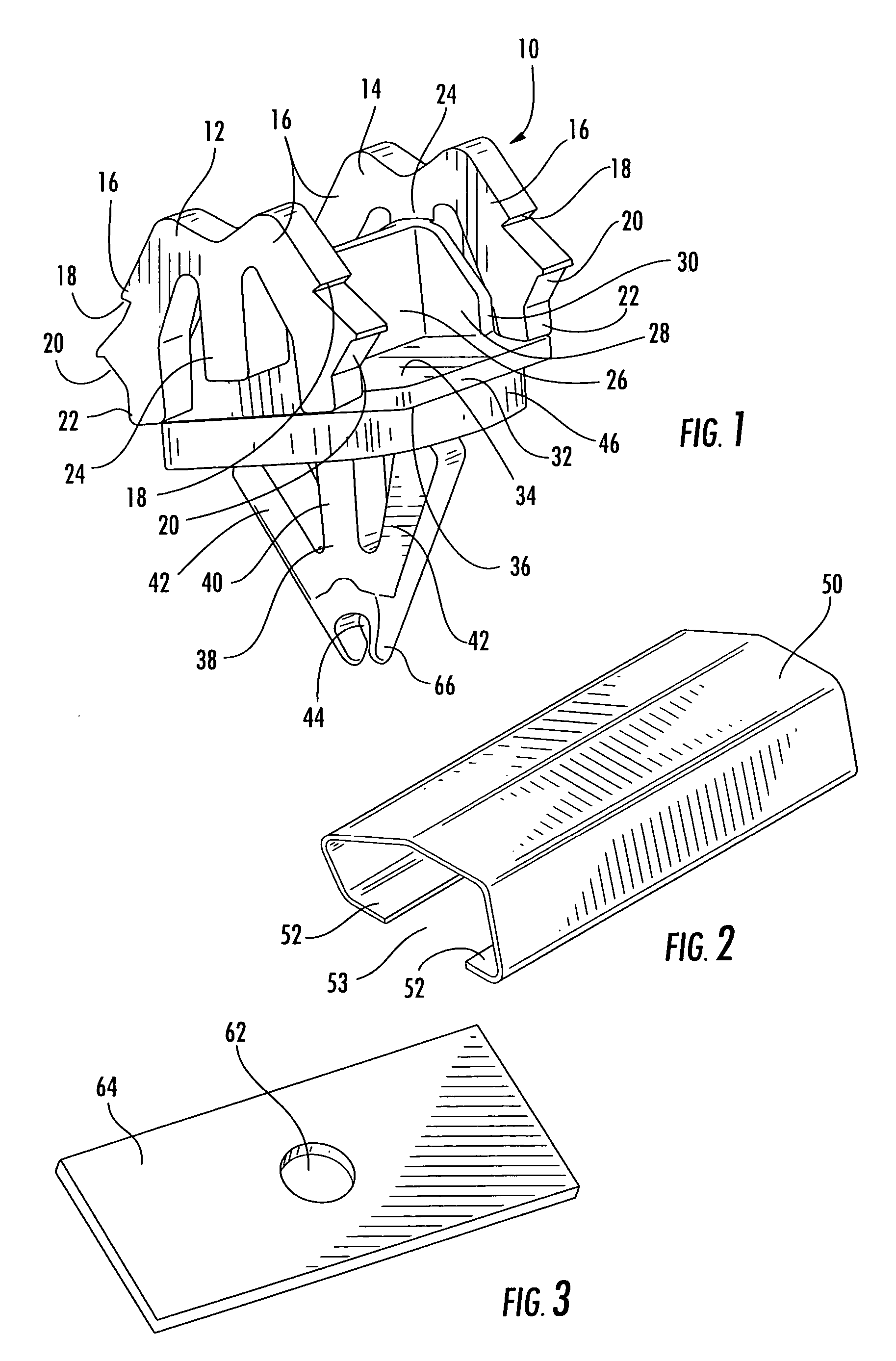

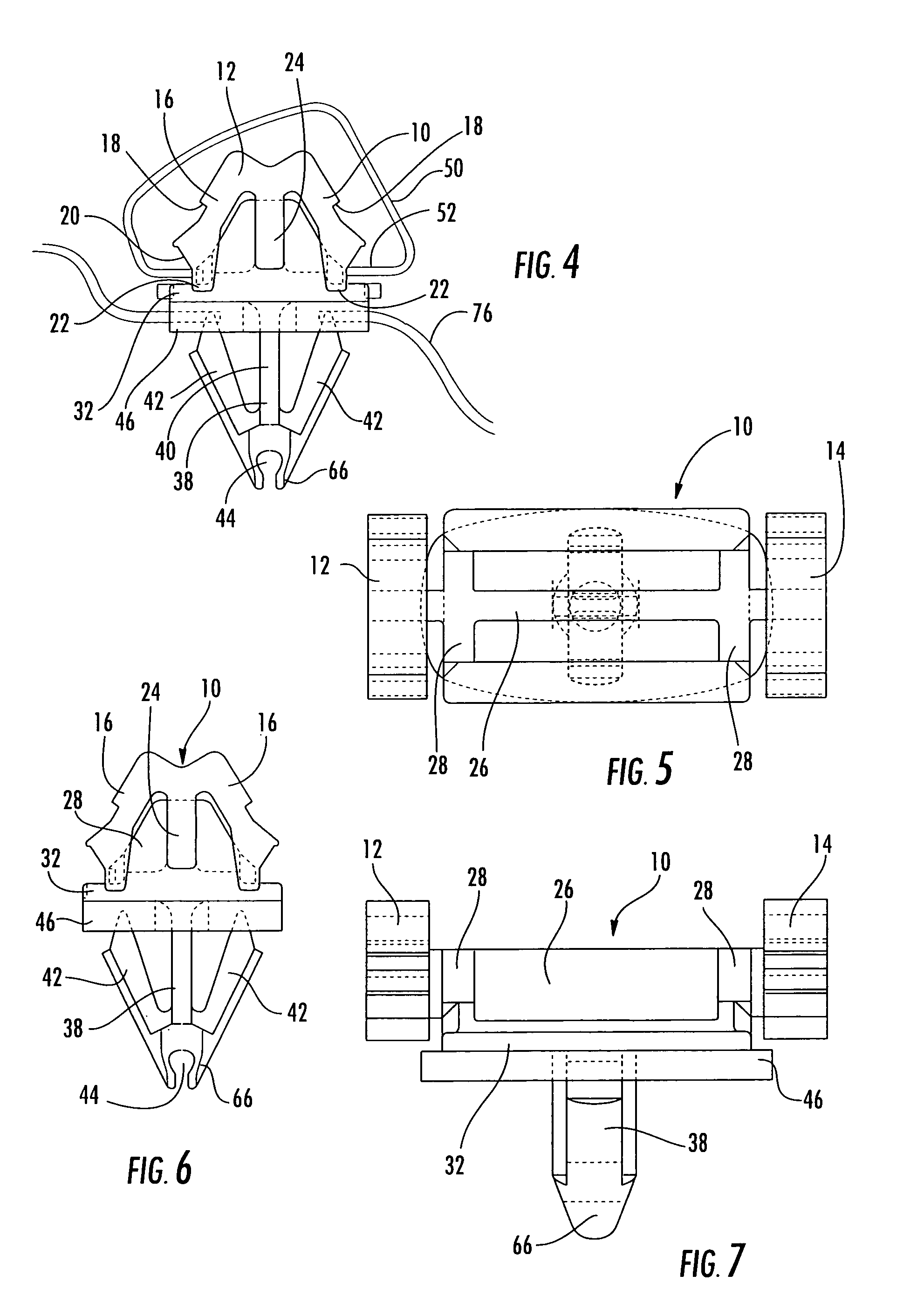

Serviceable w-base fastener

A w-base fastener that may be used in many applications, including numerous applications throughout the automotive industry, combines the functionality of a w-base fastener with the serviceability of other fasteners. The w-base fastener of the invention provides the ability to service the w-base fastener without damaging the panel or hole in which the fastener is inserted. This is accomplished by incorporating a secondary connection into the w-base fastener. This secondary connection permits the fastener to be easily extracted by providing a technique for pulling the legs of the w-base fastener inward prior to extraction of the fastener from the hole.

Owner:ILLINOIS TOOL WORKS INC

Al-Si-Cu-Mg cast aluminum alloy and preparation method thereof

InactiveCN104073699AImprove performanceAccurate element content control valuePressure castingAutomotive industry

The invention relates to metal smelting technology and particularly relates to a Al-Si-Cu-Mg cast aluminum alloy and a preparation method thereof. The cast aluminum alloy comprises 89.5-90.5wt% of aluminum (Al) and the balance of 6.5-7.5wt% of silicon (Si) and 0.02-0.04wt% of modificator strontium (Sr), wherein according to the alloy, the content of copper (Cu) is 1.5-2.5wt%, the content of magnesium (Mg) is 0.35-0.65wt% and 0.05-0.25wt% of zirconium (Zr) and 0.1-0. 5wt% of cadmium (Cd) are both added into the alloy. The preparation method comprises the steps of smelting, refining, carrying out modification treatment, adding 0.04wt% of Sr, standing for 40-60 minutes, carrying out low pressure casting by using an electromagnetic pump and carrying out T6 heat treatment on castings to obtain the corresponding castings. Since more accurate element content control values and reliable operation process parameters are provided by the scheme, the high-performance cast aluminum alloy, especially suitable for the automotive industry can be prepared based on the optimized configuration of trace elements in AlSi7Cu2Mg.

Owner:QUZHOU COLLEGE OF TECH

Aqueous electrolyte lithium sulfur batteries

InactiveUS8828575B2Improve solubilityImprove ionic conductivityBatteries circuit arrangementsFuel and secondary cellsLithium sulfurAqueous electrolyte

Provided are lithium sulfur battery cells that use water as an electrolyte solvent. In various embodiments the water solvent enhances one or more of the following cell attributes: energy density, power density and cycle life. Significant cost reduction can also be realized by using an aqueous electrolyte in combination with a sulfur cathode. For instance, in applications where cost per Watt-Hour (Wh) is paramount, such as grid storage and traction applications, the use of an aqueous electrolyte in combination with inexpensive sulfur as the cathode active material can be a key enabler for the utility and automotive industries, providing a cost effective and compact solution for load leveling, electric vehicles and renewable energy storage.

Owner:POLYPLUS BATTERY CO INC

Method and apparatus for bonding and debonding adhesive interface surfaces

InactiveUS7901532B2Strong and rapid powerEngine sealsNanostructure manufactureThermal energyMicrosphere

Owner:BAIN PETER STEWART

Breakaway W-base fastener

A w-base fastener that may be used in many applications, including numerous applications throughout the automotive industry, combines the functionality of a w-base fastener with the serviceability of other fasteners. The w-base fastener of the invention provides the ability to service the w-base fastener without damaging the panel or hole in which the fastener is inserted. This is accomplished by incorporating a break joint configured to break at a predetermined load. This break joint permits the fastener to be easily extracted when it breaks under the predetermined load. As the two sections of the fastener are separated, hooks on the fastener body engage tabs on the legs and pull the legs of the w-base fastener inward to prevent interference between the legs and the panel as the fastener is extracted from the hole.

Owner:ILLINOIS TOOL WORKS INC

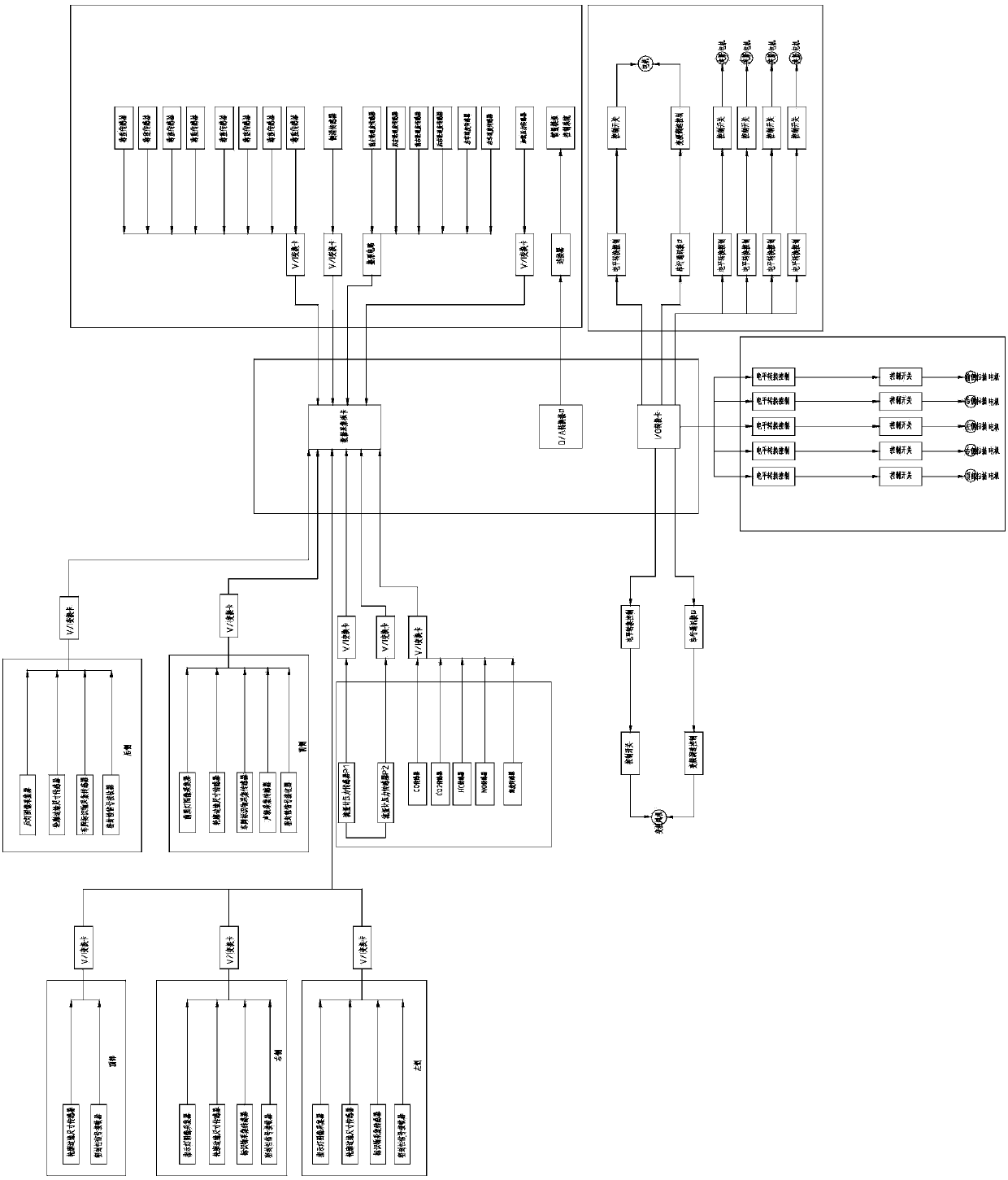

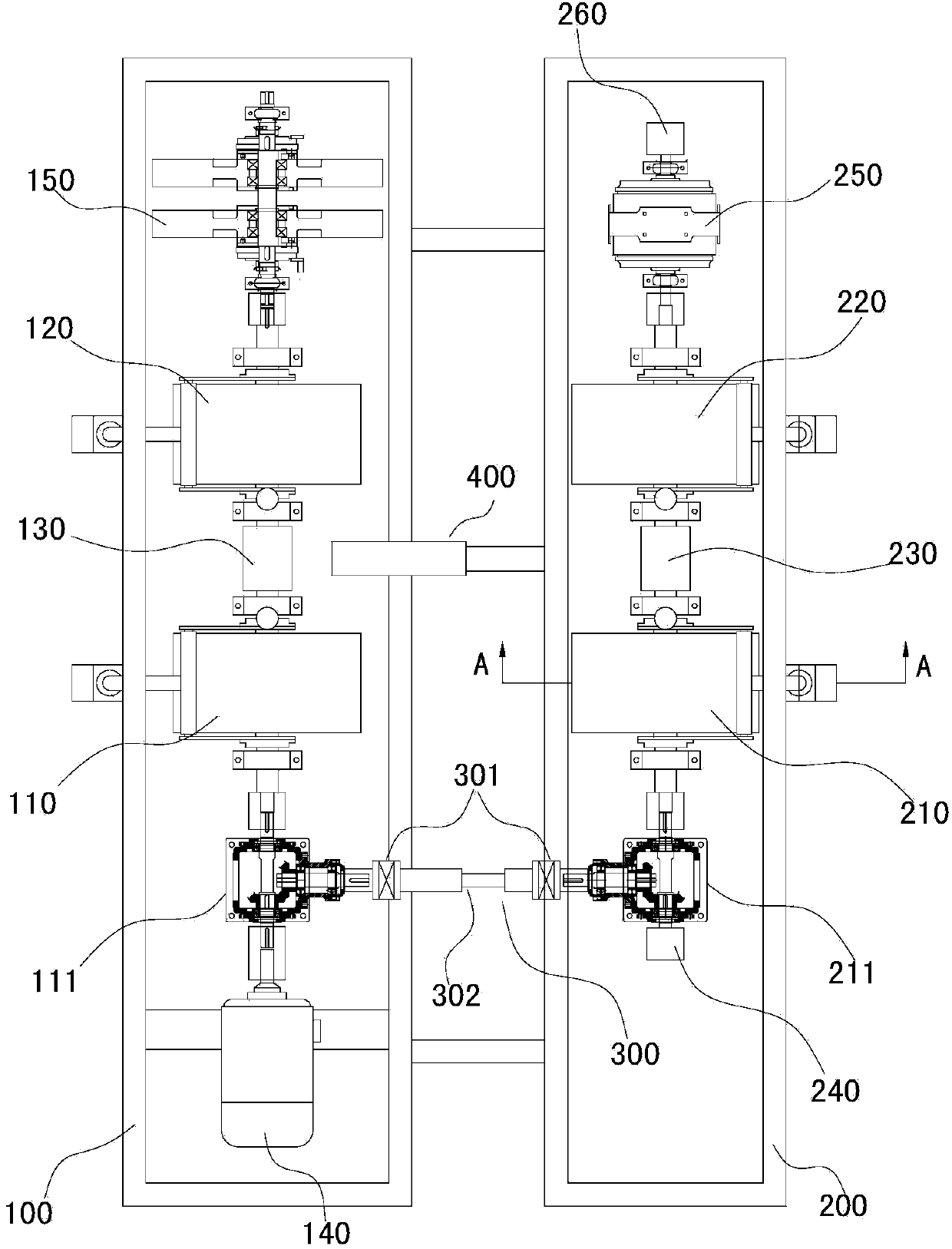

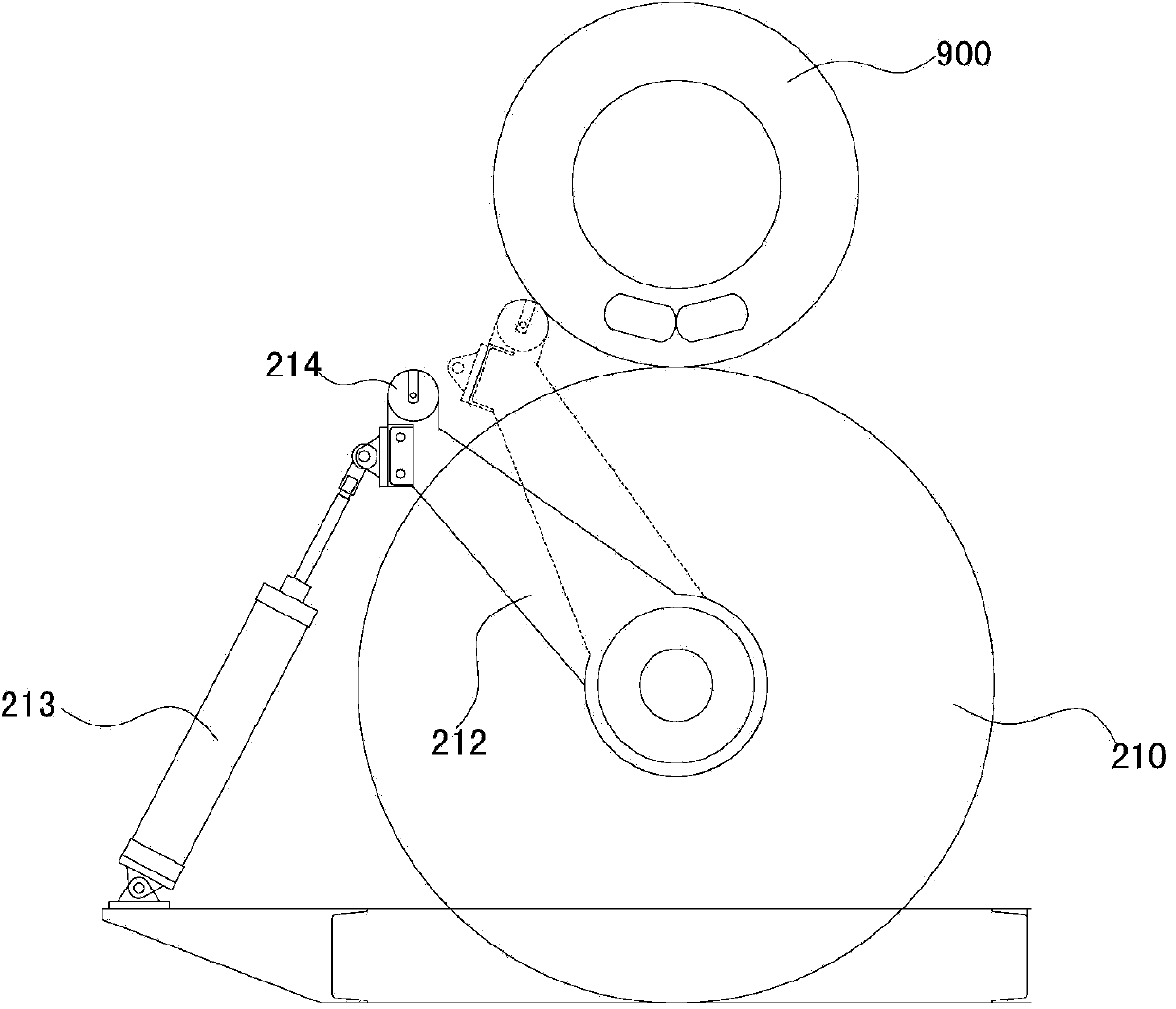

Dynamic intelligent detecting platform and method for motor vehicle external characteristics

The invention provides a dynamic intelligent detecting platform and method for motor vehicle external characteristics. A motor vehicle is made to simulate various speed and load changes in actual driving through the detecting platform, all external characteristic indexes such as axle loads, side sliding, high-speed and low-speed braking, power, oil consumption, waste gas exhaust, sealing performance, headlamps, steering lamps, a fog lamp, a marker and contours are fast completed at a time under different road surface butt joint and half-to-half separation conditions, and a chart curve is formed and uploaded to a network to become public data sources for social share. Because the inner source factors of an automobile are not taken into consideration, measurement of an ABS, an EBD, an ESP and a cruise control system becomes possible, a uniform standard for evaluating the motor vehicle external characteristics is enacted and provided for the automobile industry chain, external characteristic detection is provided for the links of research and development, delivery inspection, automobile using detection and maintenance, and a historical breakthrough is made in site, time, mode and management. A standard is provided for the Internet of things, public safety and energy conservation and environmental protection of automobiles worldwide.

Owner:庞抗美

Serviceable w-base fastener

A w-base fastener that may be used in many applications, including numerous applications throughout the automotive industry, combines the functionality of a w-base fastener with the serviceability of other fasteners. The w-base fastener of the invention provides the ability to service the w-base fastener without damaging the panel or hole in which the fastener is inserted. This is accomplished by incorporating a secondary connection into the w-base fastener. This secondary connection permits the fastener to be easily extracted by providing a technique for pulling the legs of the w-base fastener inward prior to extraction of the fastener from the hole.

Owner:ILLINOIS TOOL WORKS INC

Flexible high thermomechanical stress-resistant and fireproof halogen-free thermoplastic compositions

ActiveUS7897673B2No excessive viscosity increaseImprove performanceFireproof paintsPlastic/resin/waxes insulatorsThermoplasticPhosphate

The invention concerns flexible high thermomechanical stress-resistant and fire retardant halogen-free thermoplastic compositions, comprising a polyamide block-graft copolymer consisting of a trunk and on average at least one polyamide graft, wherein the grafts are bound to the trunk by the residues of an unsaturated monomer (X) having a function capable of reacting with a polyamide at the amine-terminal, the unsaturated monomer residues (X) being bound on the trunk by grafting or copolymerization from the double bond thereof. The invention is characterized in that the compositions comprise a mixture: 50 to 70 wt. % of polyamide block copolymer, 25 to 35 wt. % of a flame-retardant agent selected among ammonium phosphates, phosphinates, pyrophosphates, and polyphosphates, about 2 wt. % of zeolite, or hydrotalcitemolecular sieves. Said compositions are particularly useful for making electric cables, electric components, for molding electrotechnical housings, or for making coating layers or thermal protection sleeves for fluid transfer lines in the automotive industry.

Owner:ARKEMA FRANCE SA

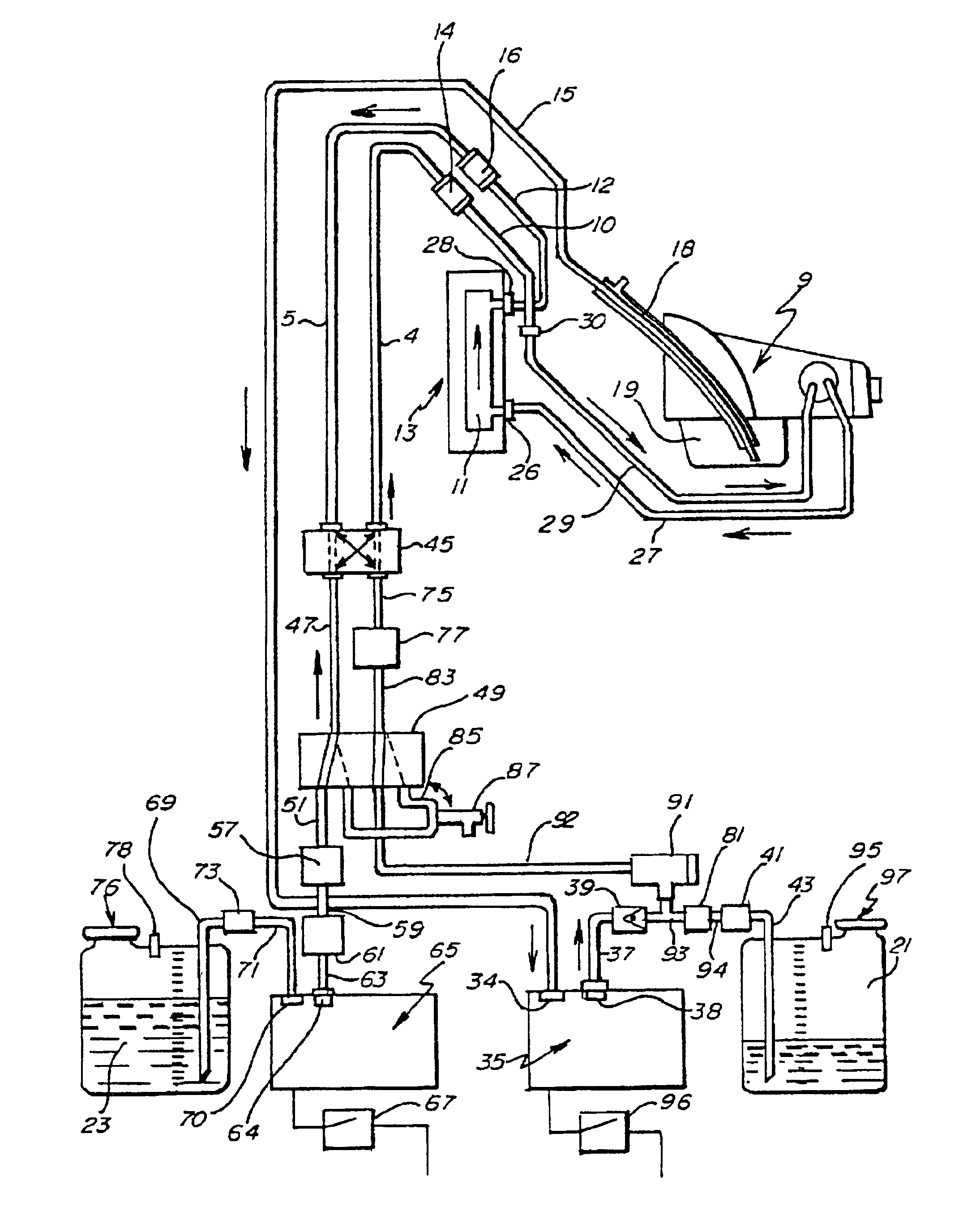

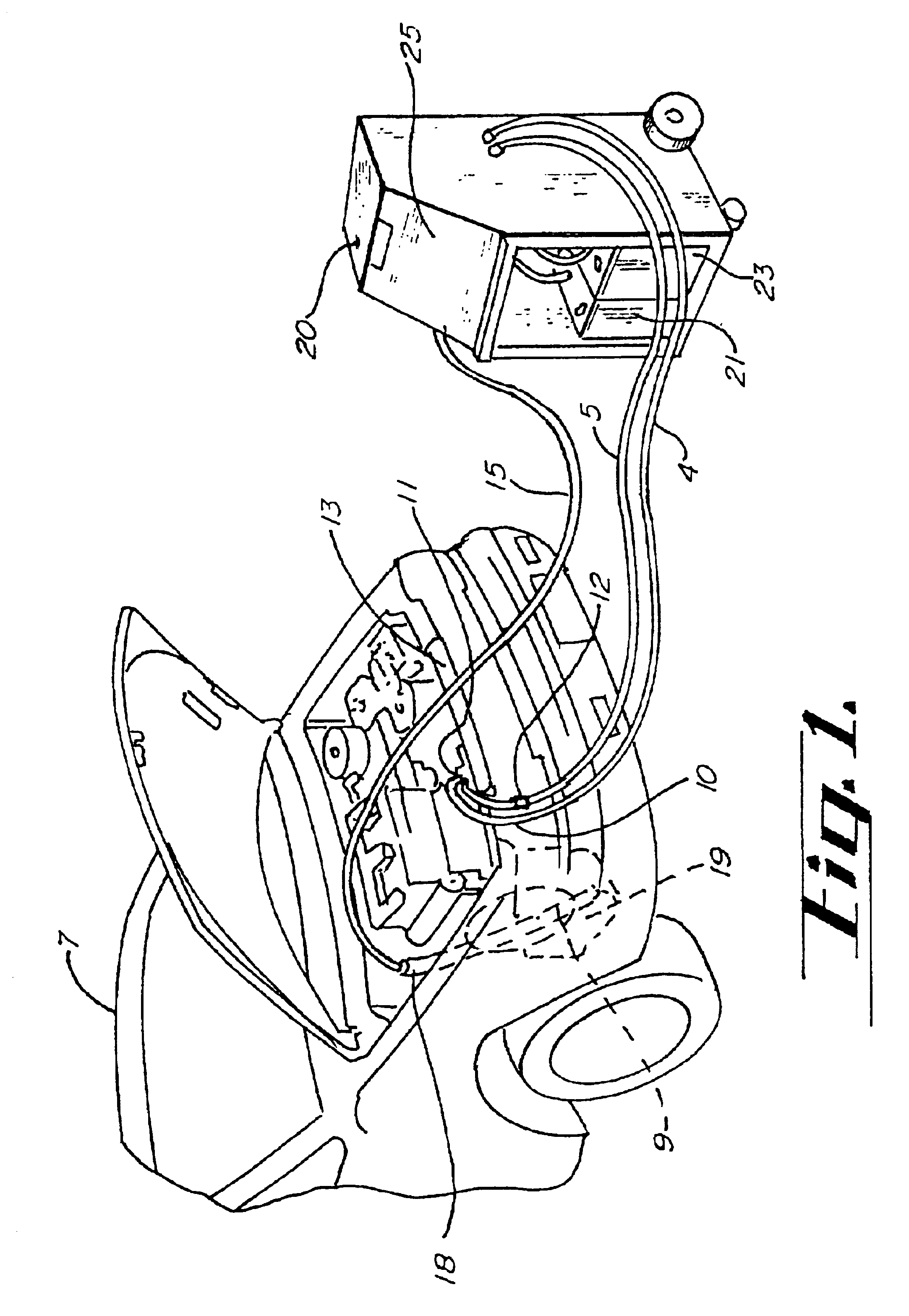

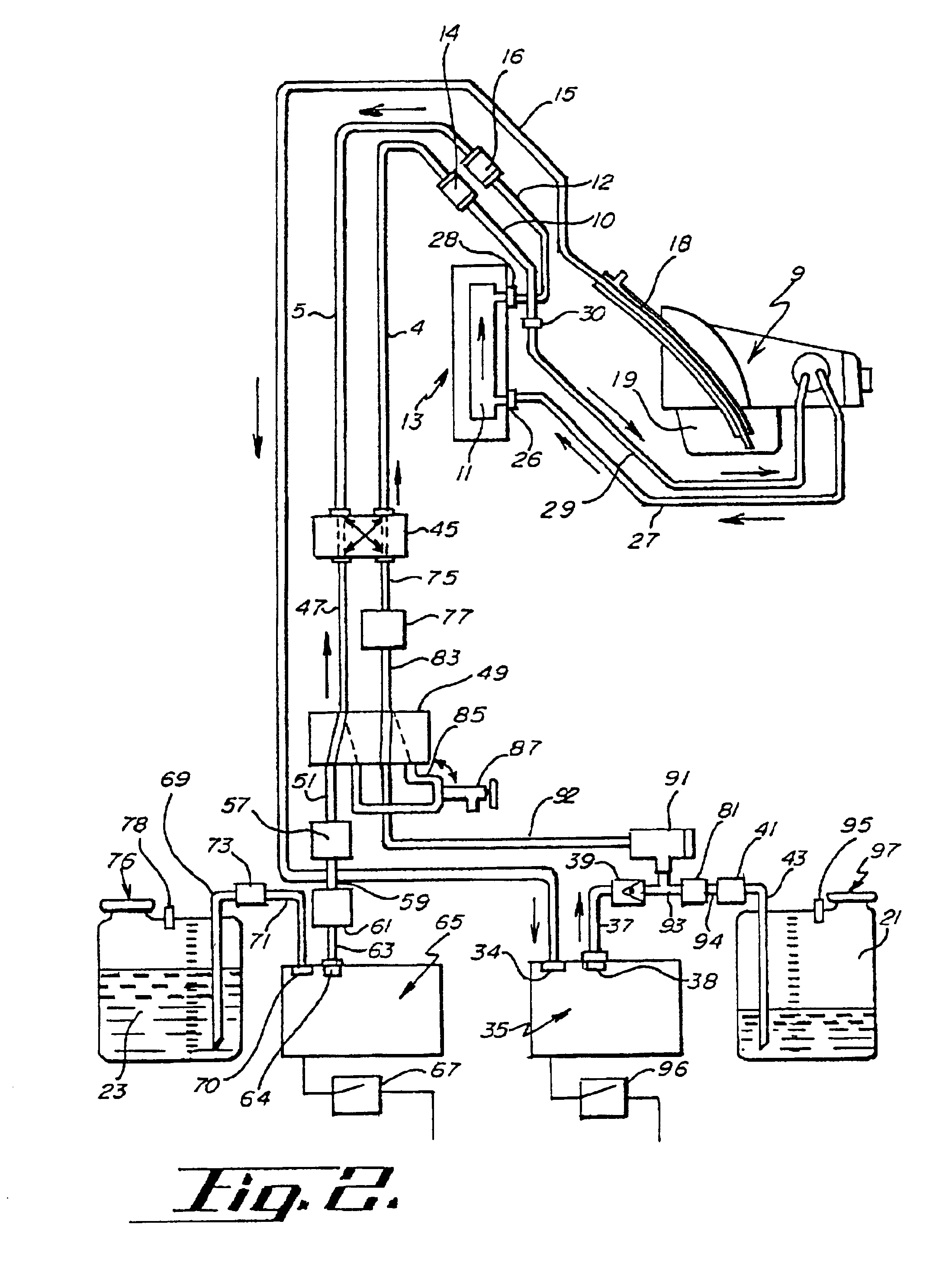

Complete fluid exchange system for automatic transmissions

InactiveUS6779633B2Highly effectiveEasy to operateCrankshaftsLiquid fillingAutomatic transmissionAutomotive industry

An improved system for changing the fluid of vehicular automatic transmissions and the like, which has the capability to provide a complete fluid exchange faster and with less usage of fresh fluid in a manner that is easier to operate. This is accomplished by the system's unique capability to extract used fluid and replace it with fresh fluid at a faster, balanced rate than before possible in prior art. This is accomplished by decreasing or removing restriction from the exhausting of the used fluid and introducing fresh fluid at more than one locus. The unique, novel capability of the invention to use a dual use pan access tube to combine a static change with a dynamic change, and to introduce fresh fluid into the transmission from two different loci instead of one as in all prior art, allows the fluid exchange to be completed in a shorter time with less use of fluid. These improvements increase the commercial utility and value of complete fluid changing in automatic transmissions and should extend its commercial viability as a routine maintenance procedure in the vehicular or automotive industry.

Owner:VIKEN JAMES P

Process for producing twin crystal inducement plastic steel material with high carbon content

InactiveCN101429590AHigh elongationImprove propertiesTemperature control deviceFurnace typesCrystal twinningHigh carbon

The invention belongs to the field of preparing a steel material and in particular relates to a method for preparing a twin crystal induced plastic steel material with high carbon content. The twin crystal induced plastic steel material comprises the following compositions in the range: 0.2 to 0.49weight percent or 0.55 to 1.5weight percent of C, 10 to 22weight percent or 23.1 to 35weight percent of Mn, less than 1weight percent of Al, less than 1weight percent of Si, less than 0.008 percent of S, less than 0.02 percent of P and the balance being Fe and inevitable impurities. The preparation method comprises the following steps: a plate blank prepared through smelting is subjected to a hot rolling process to obtain a hot rolled sheet in a use state; or the plate blank is subjected to hot rolling and cold rolling to obtain a cold rolled sheet; the sheet is subjected to heat treatment in order that the tensile strength is between 750 and 1,200 MPa, the yield strength is between 230 and 615 MPa, the extension rate is between 45 and 70 percent; and no tough brittle turning point exists at a temperature of more than 100 DEG C. The steel material with high strength and high plasticity has excellent comprehensive mechanical performance, machining performance and forming performance, can be used for a steel rail of a railroad, automobile manufacture, engineering machinery, an oil and gas transportation pipeline, a liquefied natural gas transportation ship, war industry and other industries and has important value and great application space for an automobile industry and a war industry with rapid development.

Owner:UNIV OF SCI & TECH BEIJING

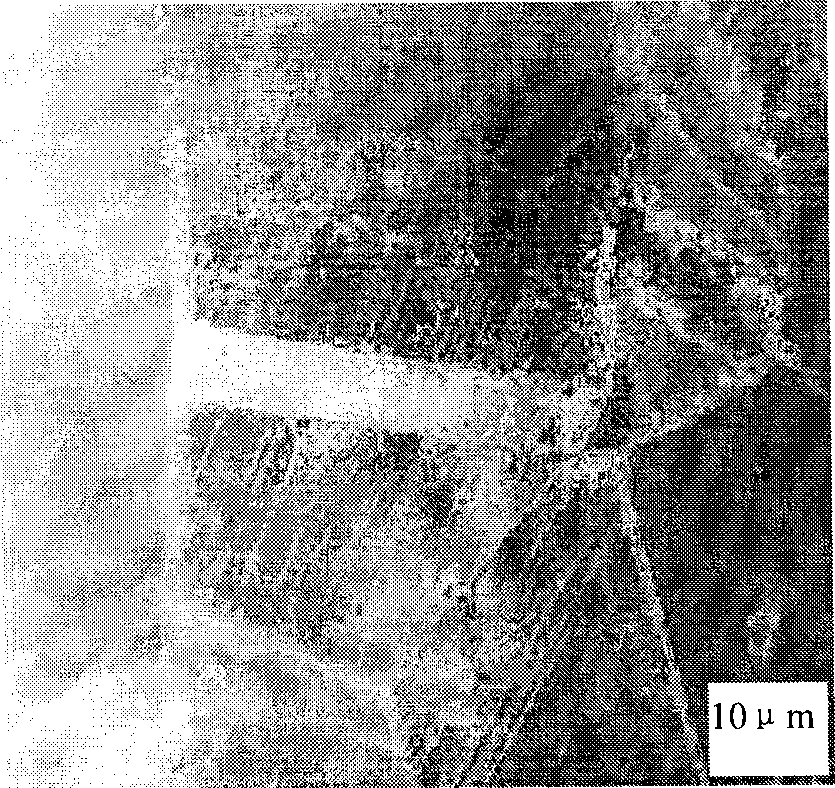

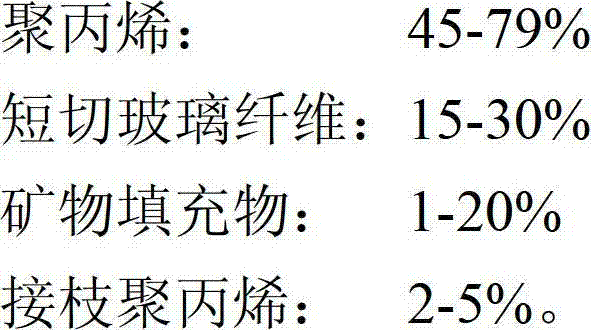

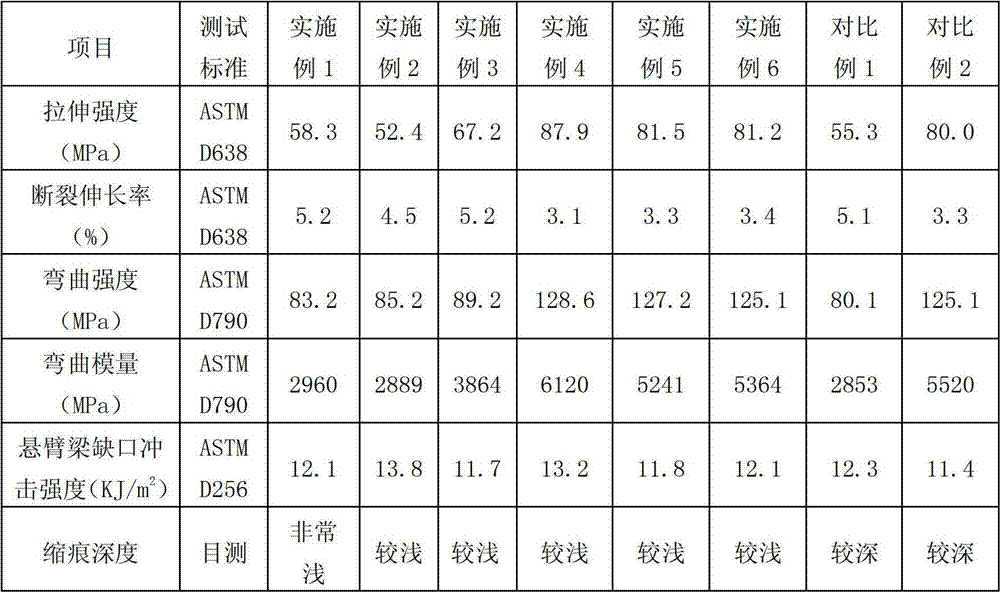

Glass fiber-reinforced polypropylene material with shallow shrinkage mark and low warpage as well as preparation method and application thereof

The invention discloses a glass fiber-reinforced polypropylene material with shallow shrinkage mark and low warpage as well as a preparation method and an application of the glass fiber-reinforced polypropylene material. The polypropylene material is prepared by using the following raw materials including 45-79% of polypropylene, 15-30% of chopped glass fiber, 1-20% of mineral fillers and 2-5% of grafted polypropylene, wherein the polypropylene includes high crystalline polypropylene as well as homopolymerized polypropylene and / or copolymerized polypropylene; the mineral fillers are one or more of barium sulfate, calcium carbonate or mica.The preparation method for preparing the glass fiber-reinforced polypropylene material provided by the invention uses the high crystalline polypropylene, the added chopped glass fiber and the mineral fillers for composite reinforcement and can effectively increase the cooling and curing rates of the material during the injection moulding process. The prepared product has the characteristics of shallow shrinkage mark, low warpage and high surface gloss, has the advantages of high flexural strength and modulus, good processability and low cost, can be used in household appliances and automotive industries, and can replace engineering plastic, and meet the requirements of high dimensional stability, high wrap and high mechanical properties of the parts.

Owner:KINGFA SCI & TECH CO LTD +1

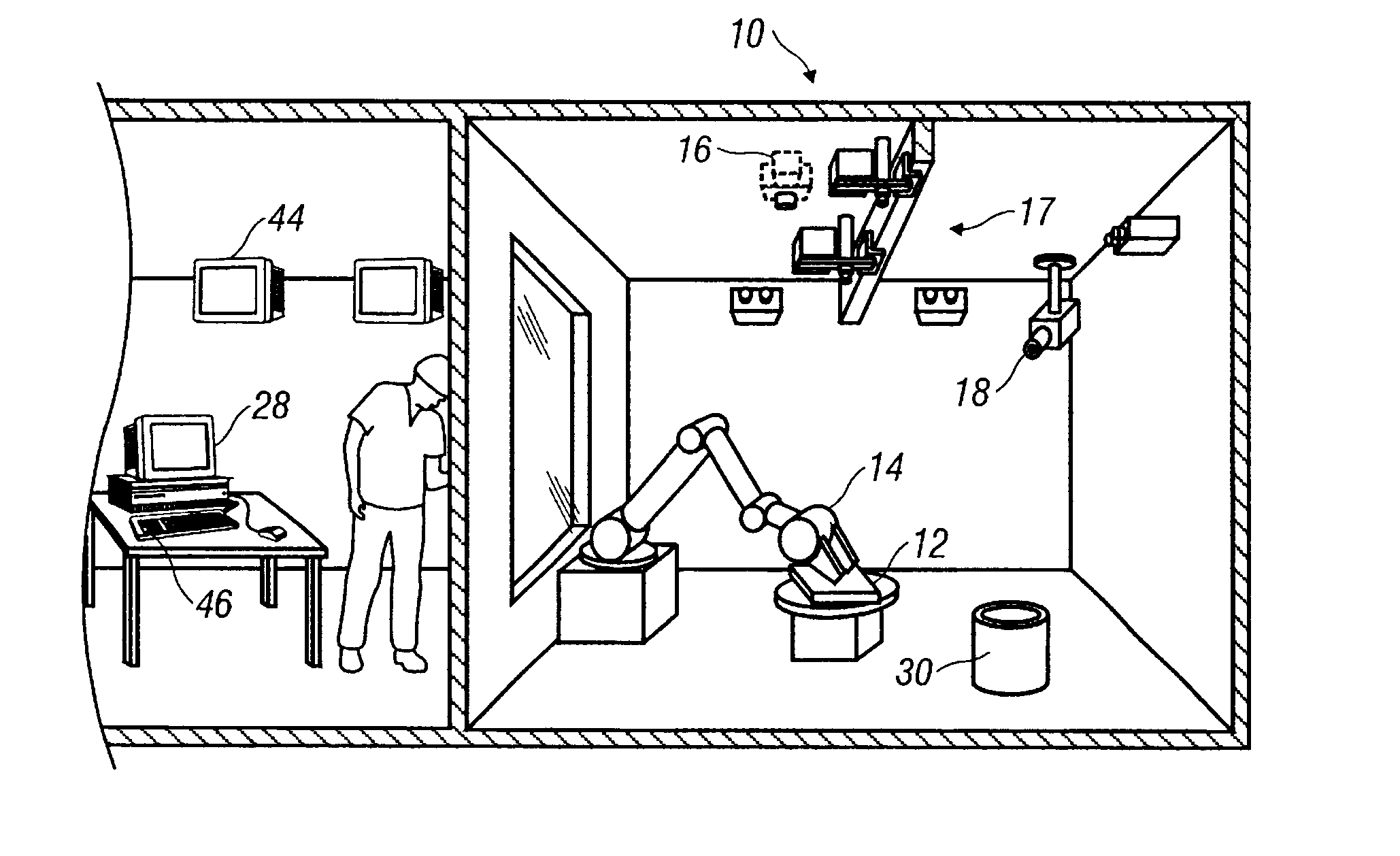

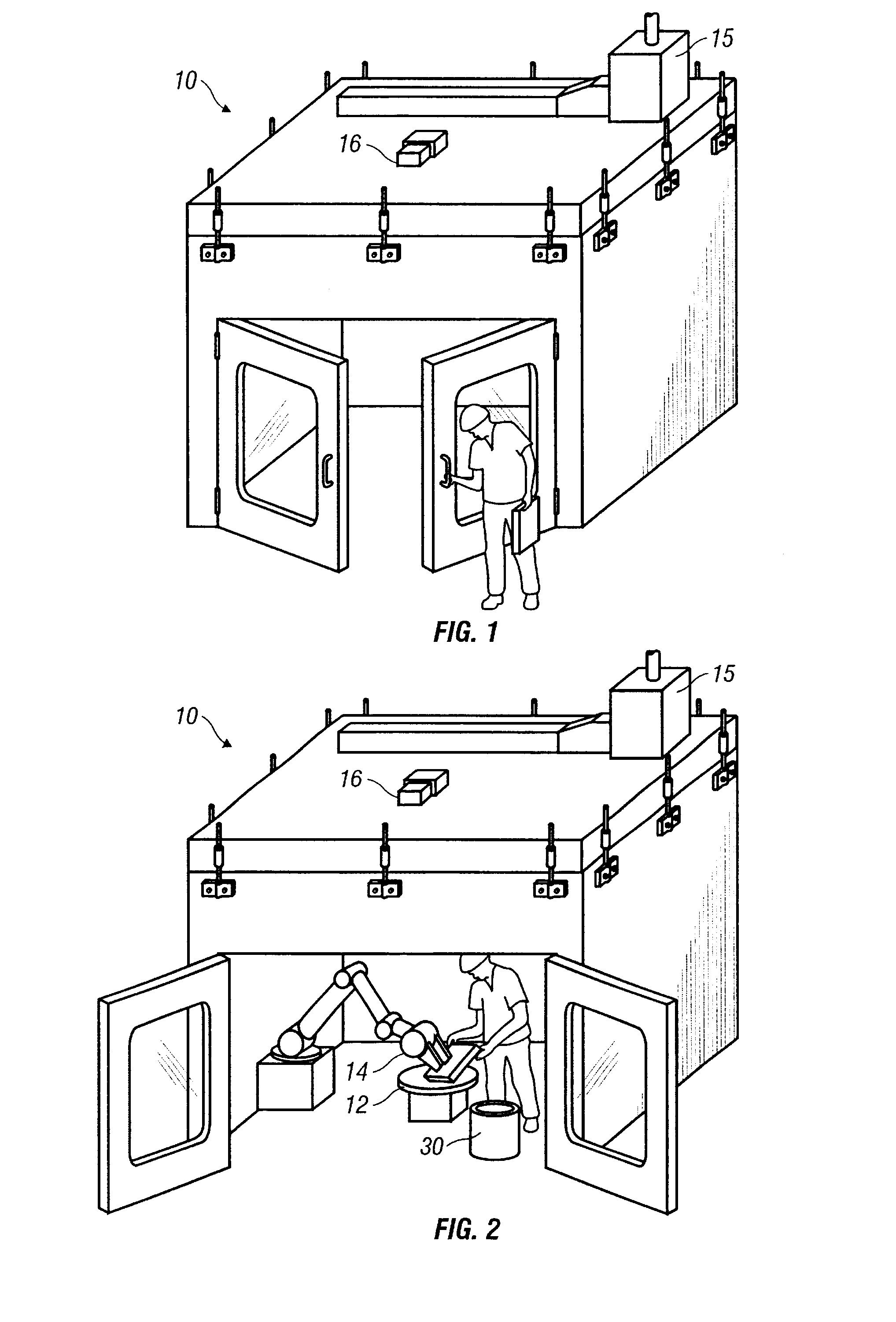

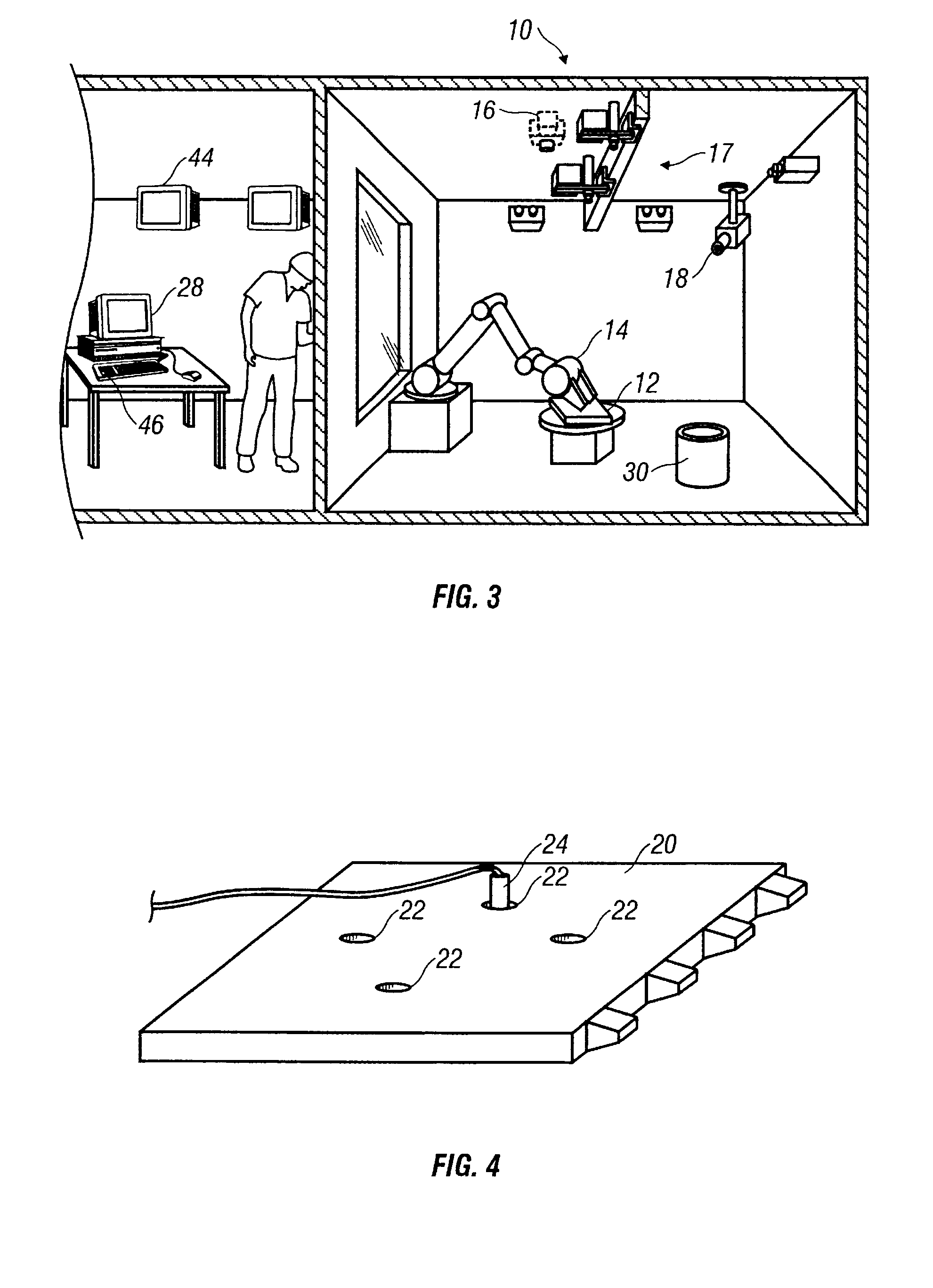

Automated spray form cell

InactiveUS6640878B2High sensitivityAccurate distributionMolten spray coatingCasting safety devicesStress inducedAutomotive industry

Owner:FORD MOTOR CO

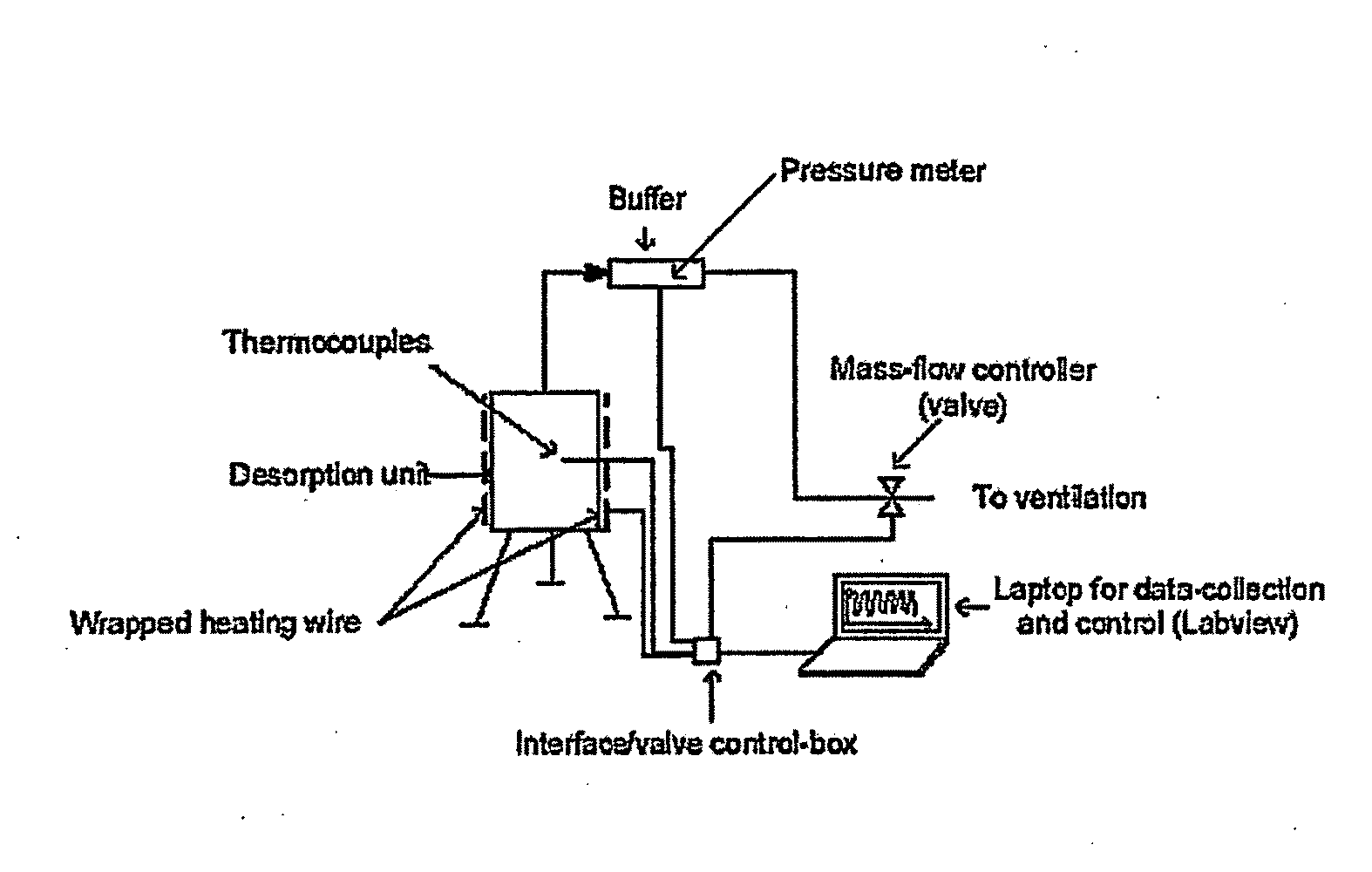

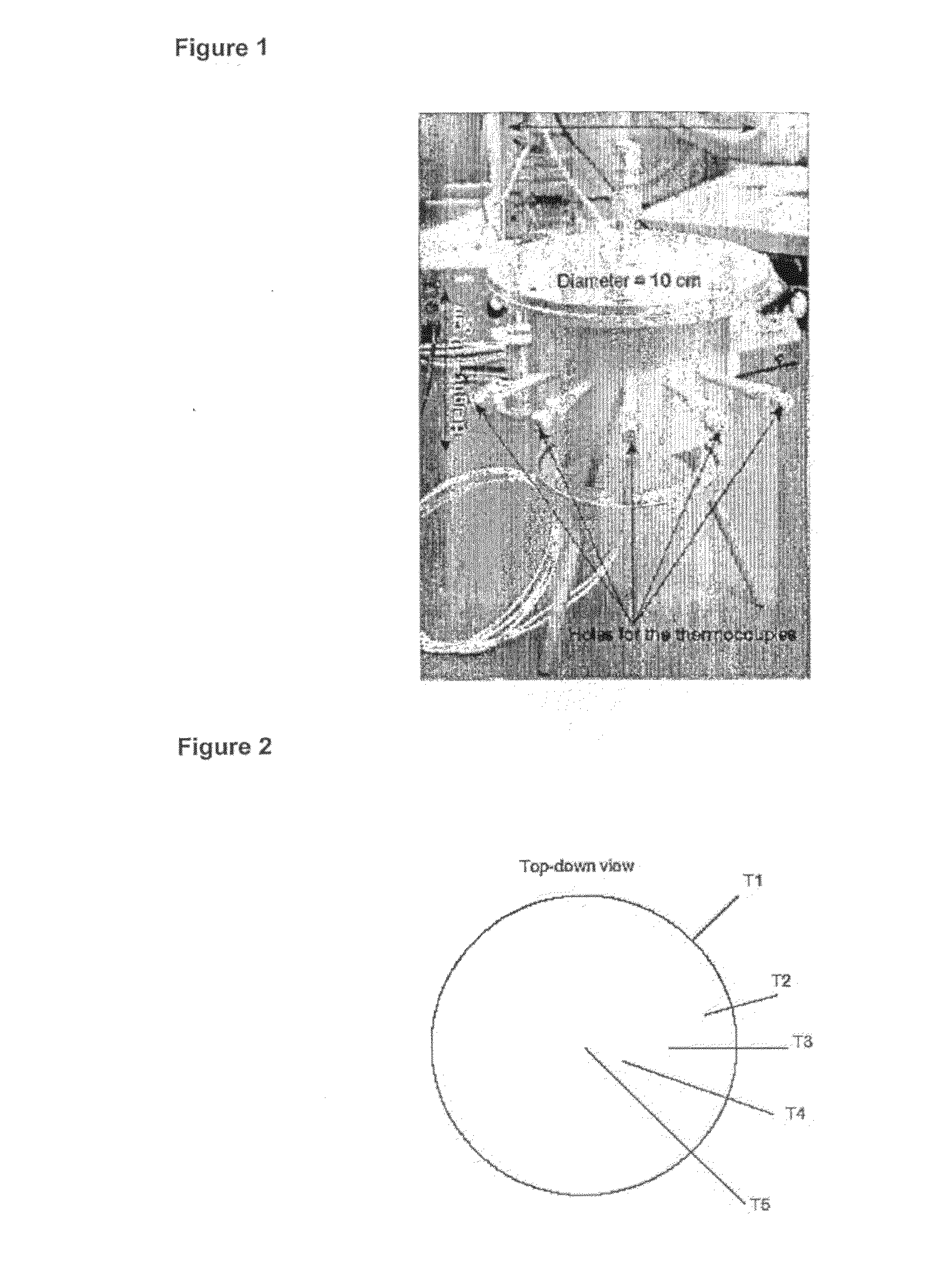

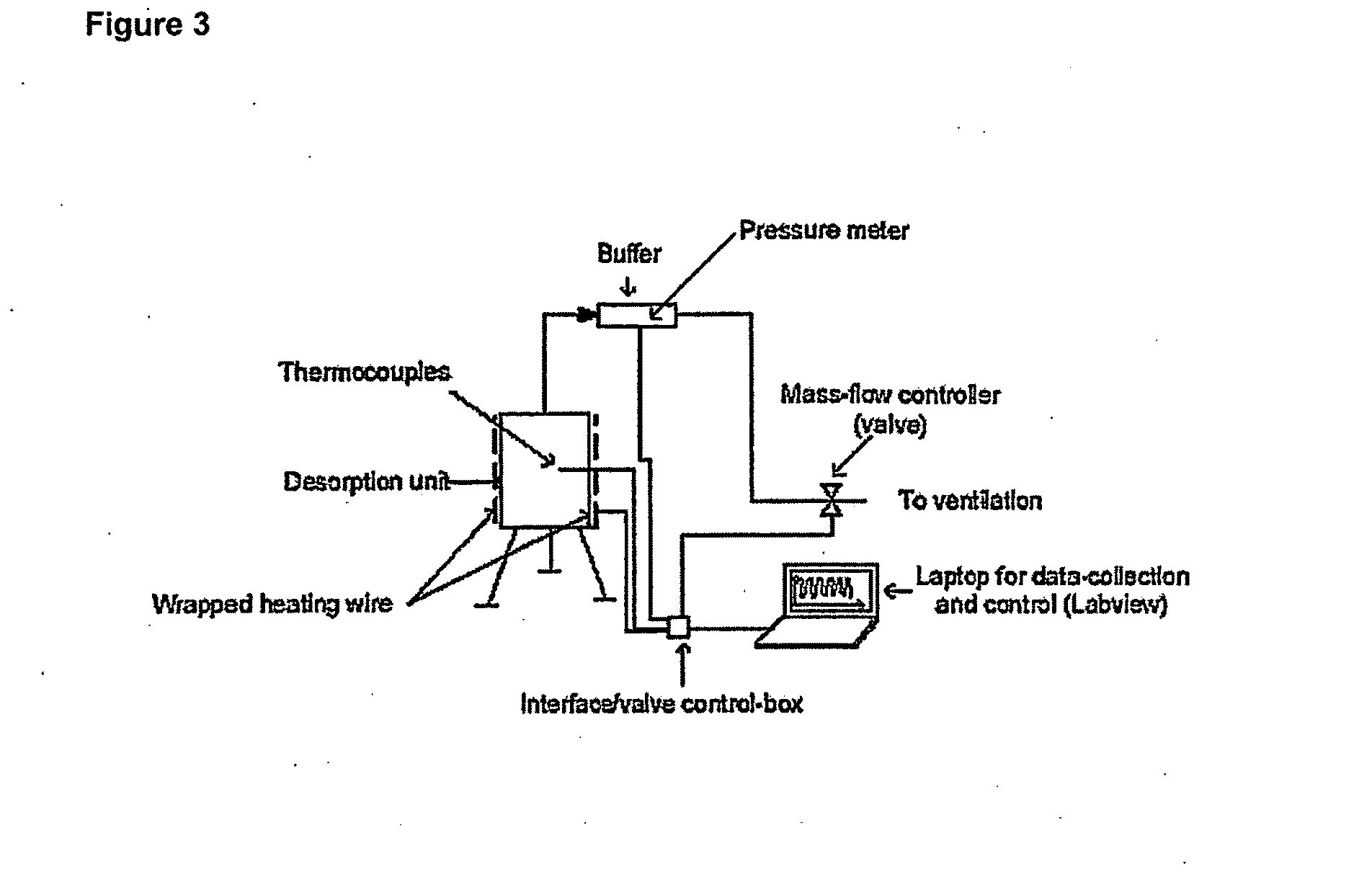

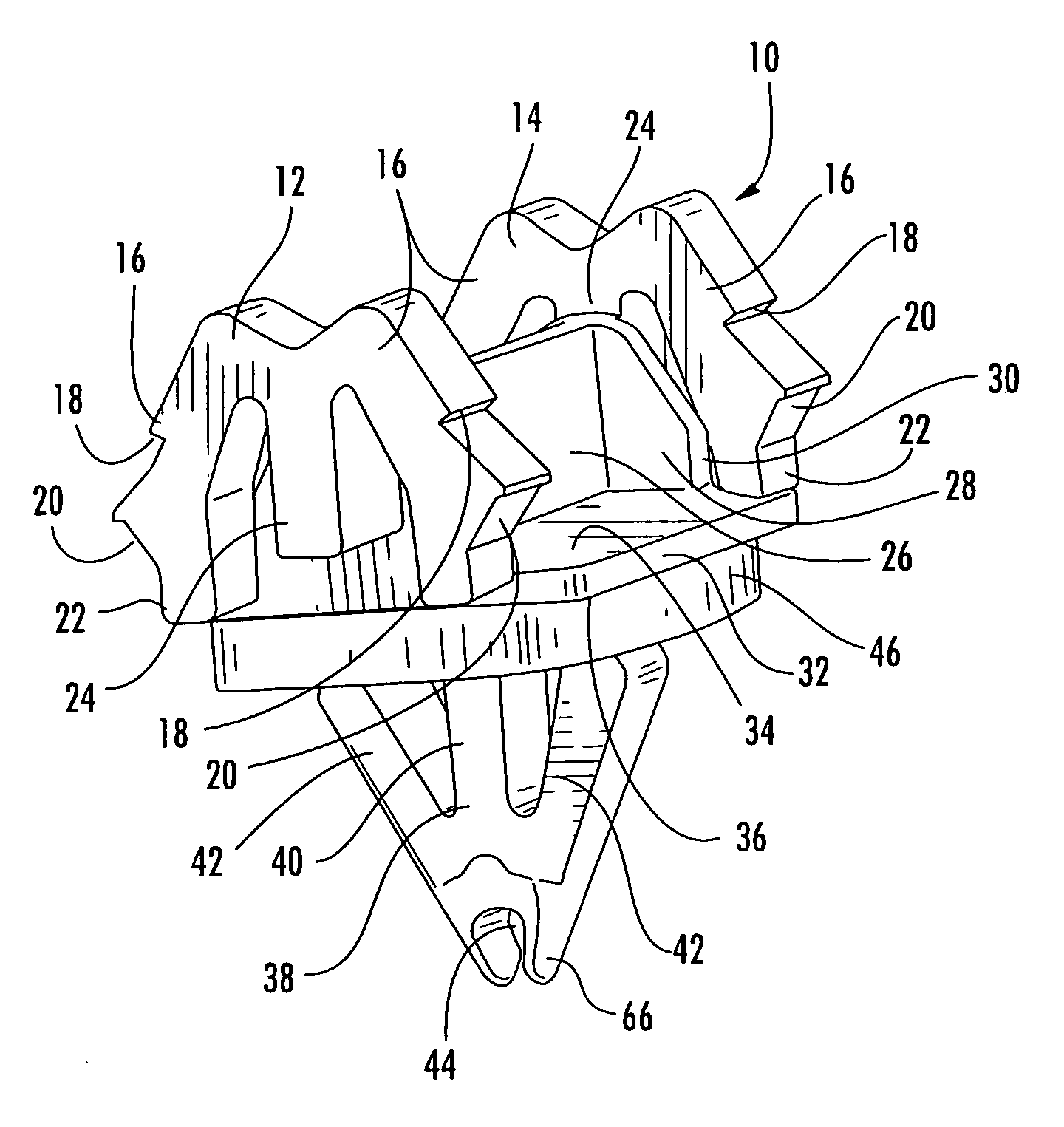

Solid ammonia storage and delivery material

InactiveUS20090280047A1Cobalt ammonia complexesNitrogen compoundsAlkaline earth metalAmmonia storage

A solid ammonia storage and delivery material A solid ammonia storage material comprising: an ammonia absorbing salt, wherein the ammonia absorbing salt is an ionic salt of the general formula: Ma(NH3)nXz, wherein M is one or more cations selected from alkaline earth metals, and / or one or more transition metals, such as Mn, Fe, Co, Ni, Cu, and / or Zn, X is one or more anions, a is the number of cations per salt molecule, z is the number of anions per salt molecule, and ri is the coordination number of 2 to 12, wherein M is Mg provides a safe, light-weight and cheap compact storage for ammonia to be used in the automotive industry.

Owner:AMMINEX EMISSIONS TECH

W-base retainer

A w-base retainer that may be used in many applications, including numerous applications throughout the automotive industry, includes two-stage double-snap-over w-base features with opposite w-base features for assembling moldings to a sheet metal or substrate panel. The w-base retainer will improve the ease of assembly of parts, provide a proper fit, and provide a functional retention of moldings to structural panels. The w-base retainer may be used on, for example, automotive body side moldings, including, for example, doors, pillars, green house moldings and other moldings.

Owner:ILLINOIS TOOL WORKS INC

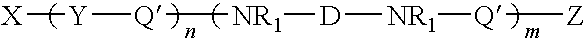

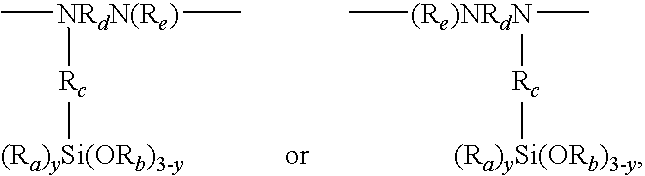

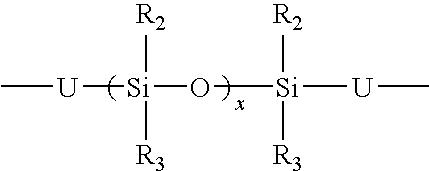

Organosilicon-polyurea base polymer, elastomer prepared therefrom, preparation thereof and use of the same

InactiveUS20090099291A1High molecular weightControlled molecular weightMixingPigment pastesElastomerPolymer science

An organosilicon-polyurea base polymer capable of self-crosslinking under humid condition, an elastomer prepared therefrom, preparation thereof and use of the same. By using an amino-polysiloxane, a polyisocyanate, and multiple active amino-containing silane as main materials, an organosilicon-polyurea base polymer is prepared by virtue of the copolymerization thereof. The organosilicon-polyurea base polymer has excellent high- and low-temperature resistance, and solvent resistance, and relatively better mechanical properties, and is also curable at room temperature. A crosslinked network structure of intra- and inter-molecules is formed in the base polymer through inter-crosslinking of siloxane groups at terminals and side chains of the molecular chains, thereby producing adhesives, sealants, coatings and buffer layers, in particular sealants used in automotive industry.

Owner:HENKEL KGAA

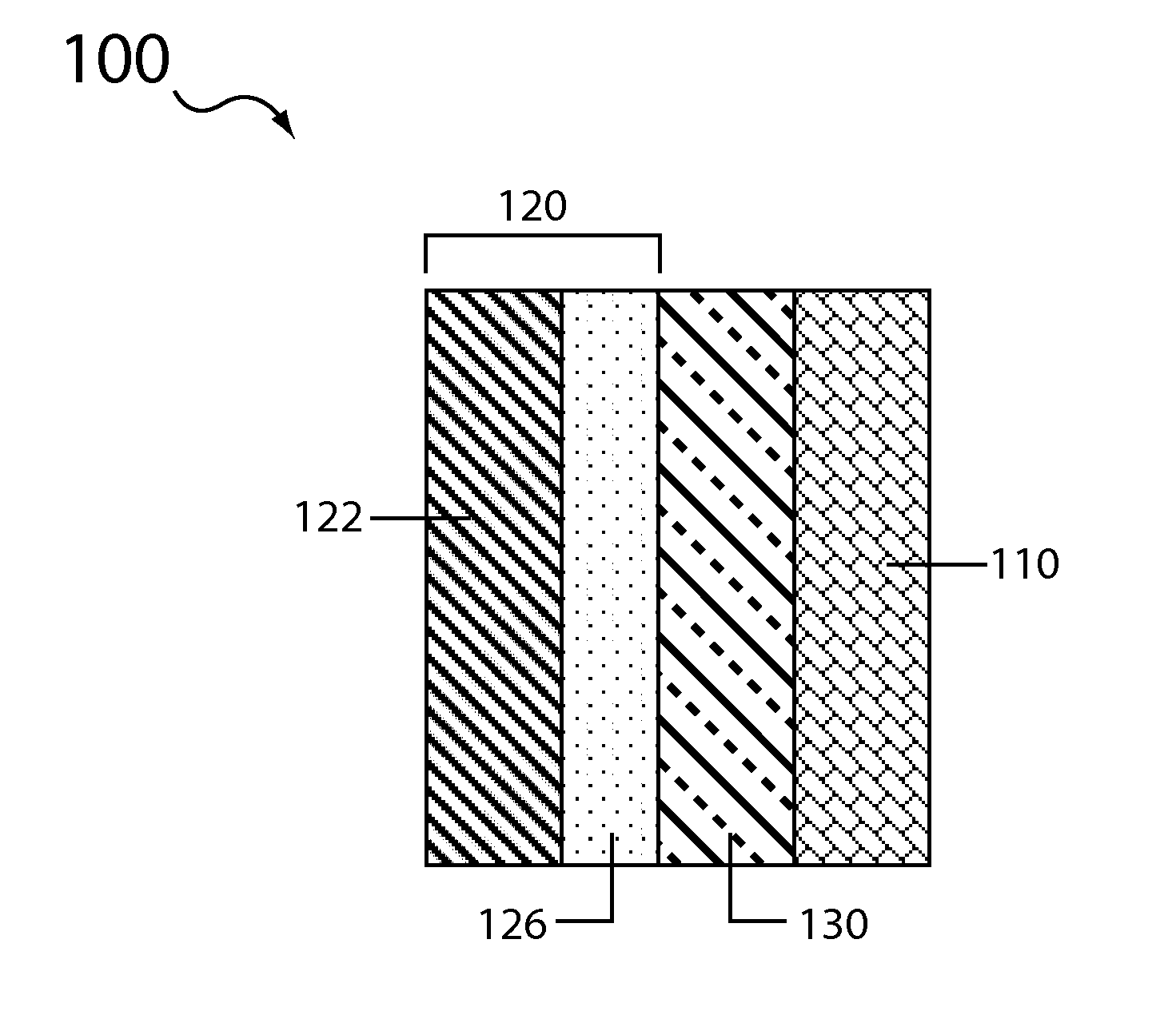

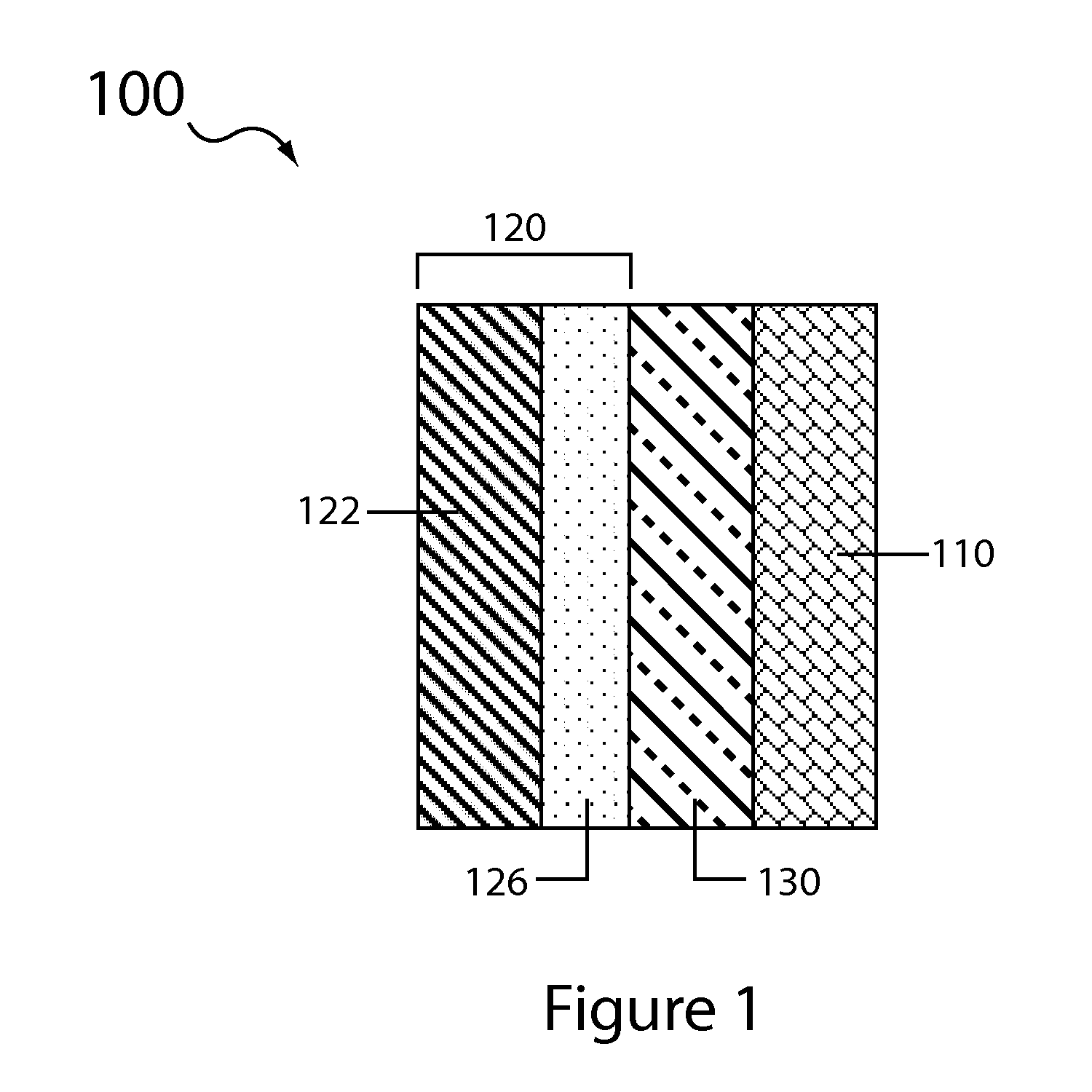

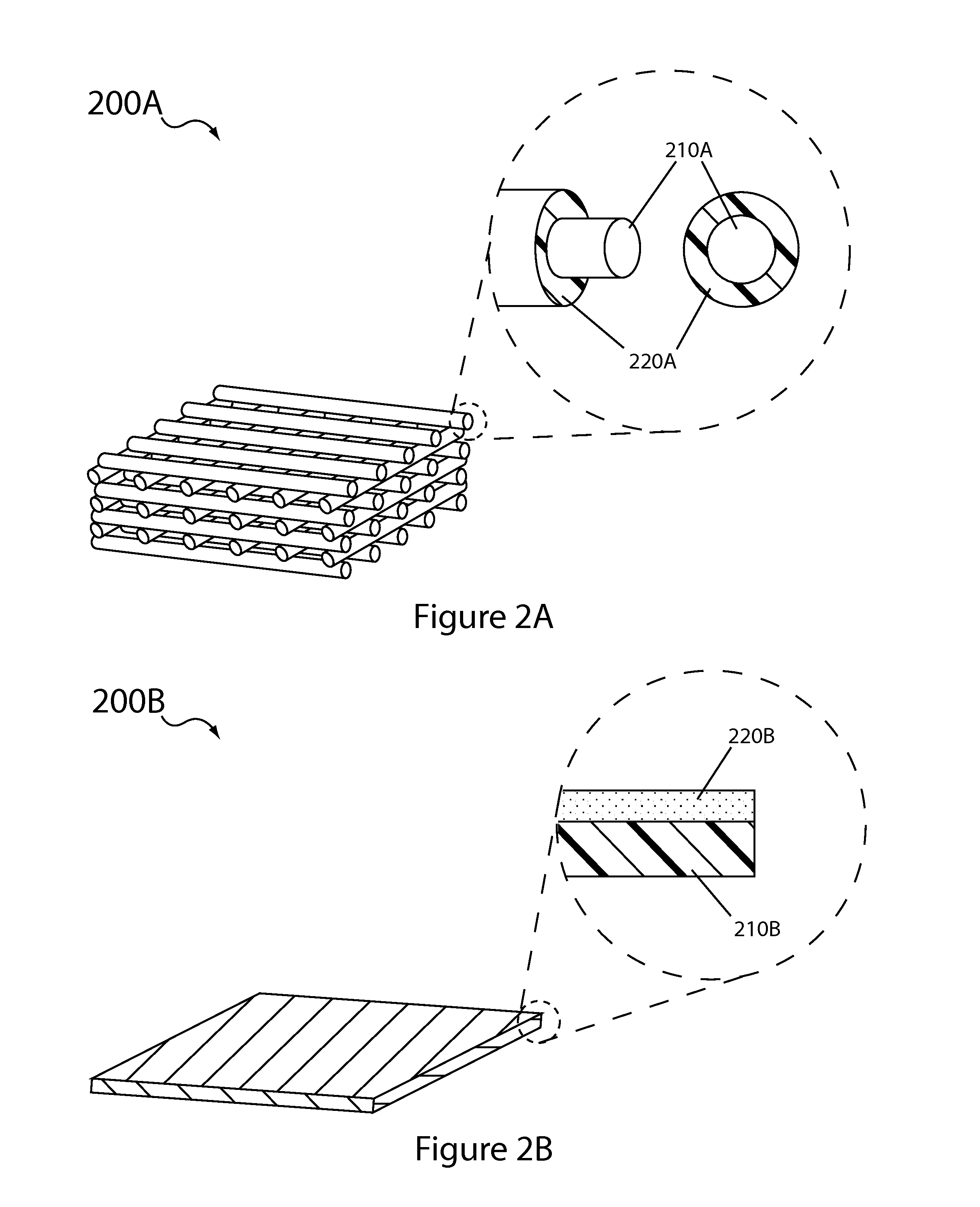

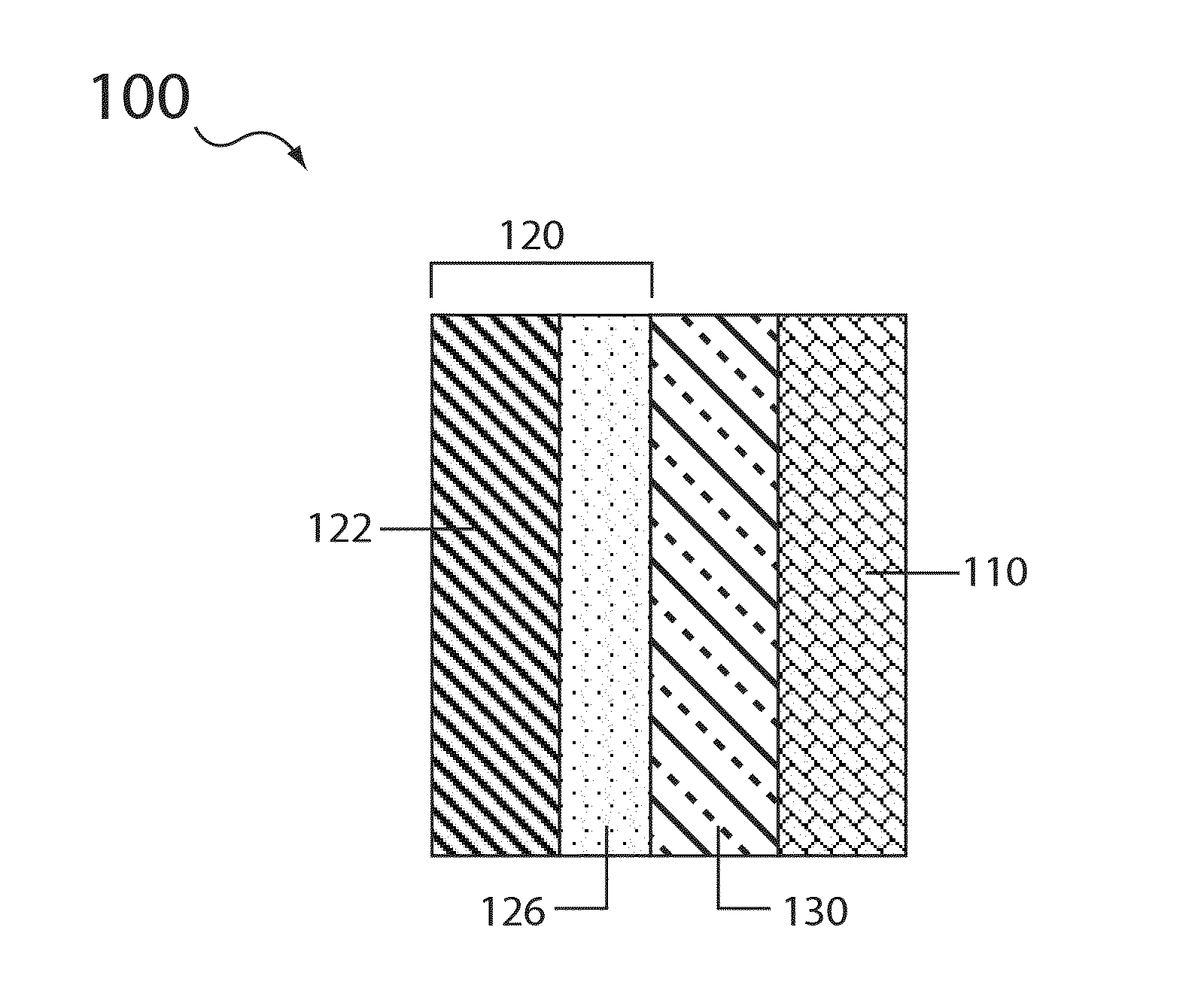

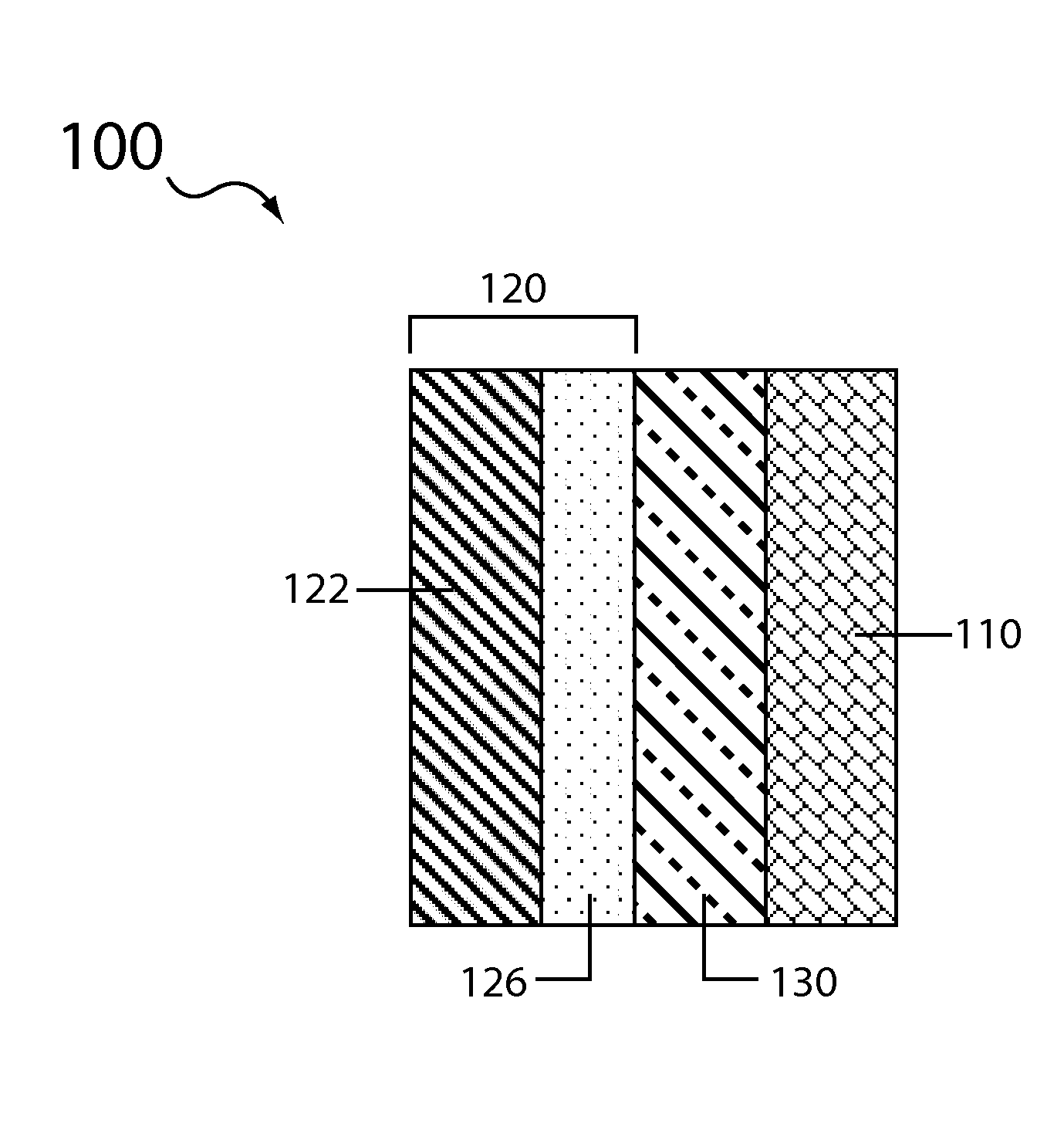

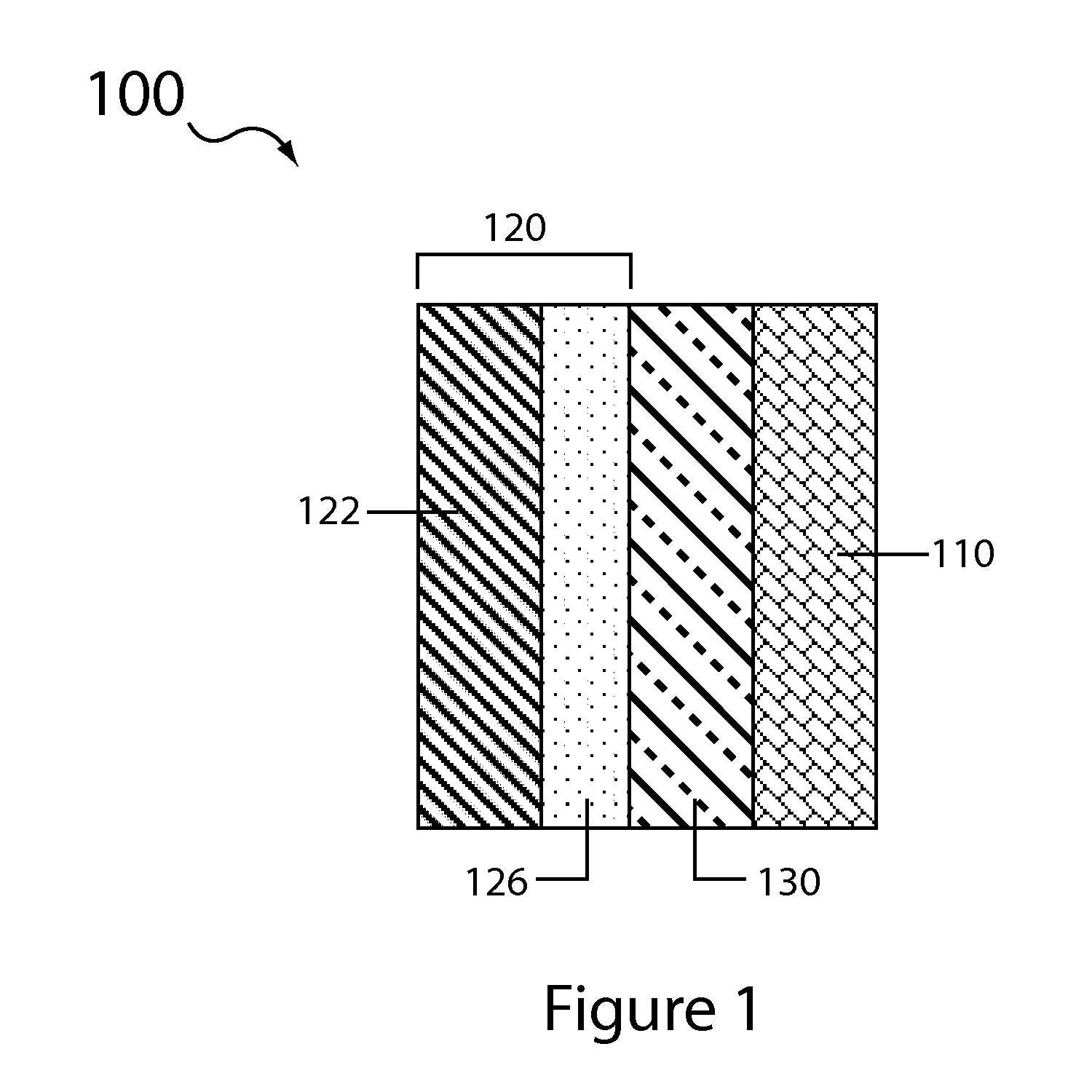

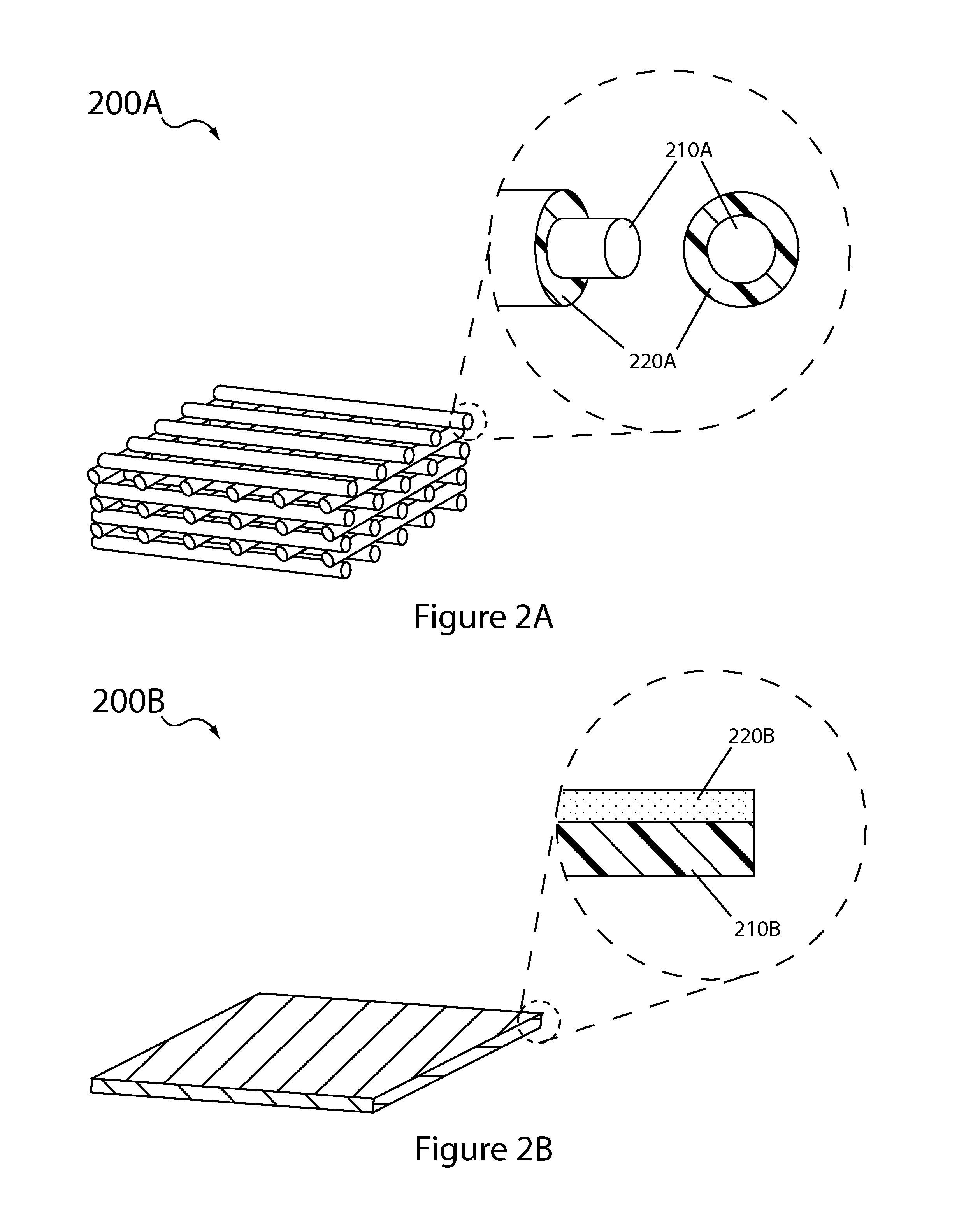

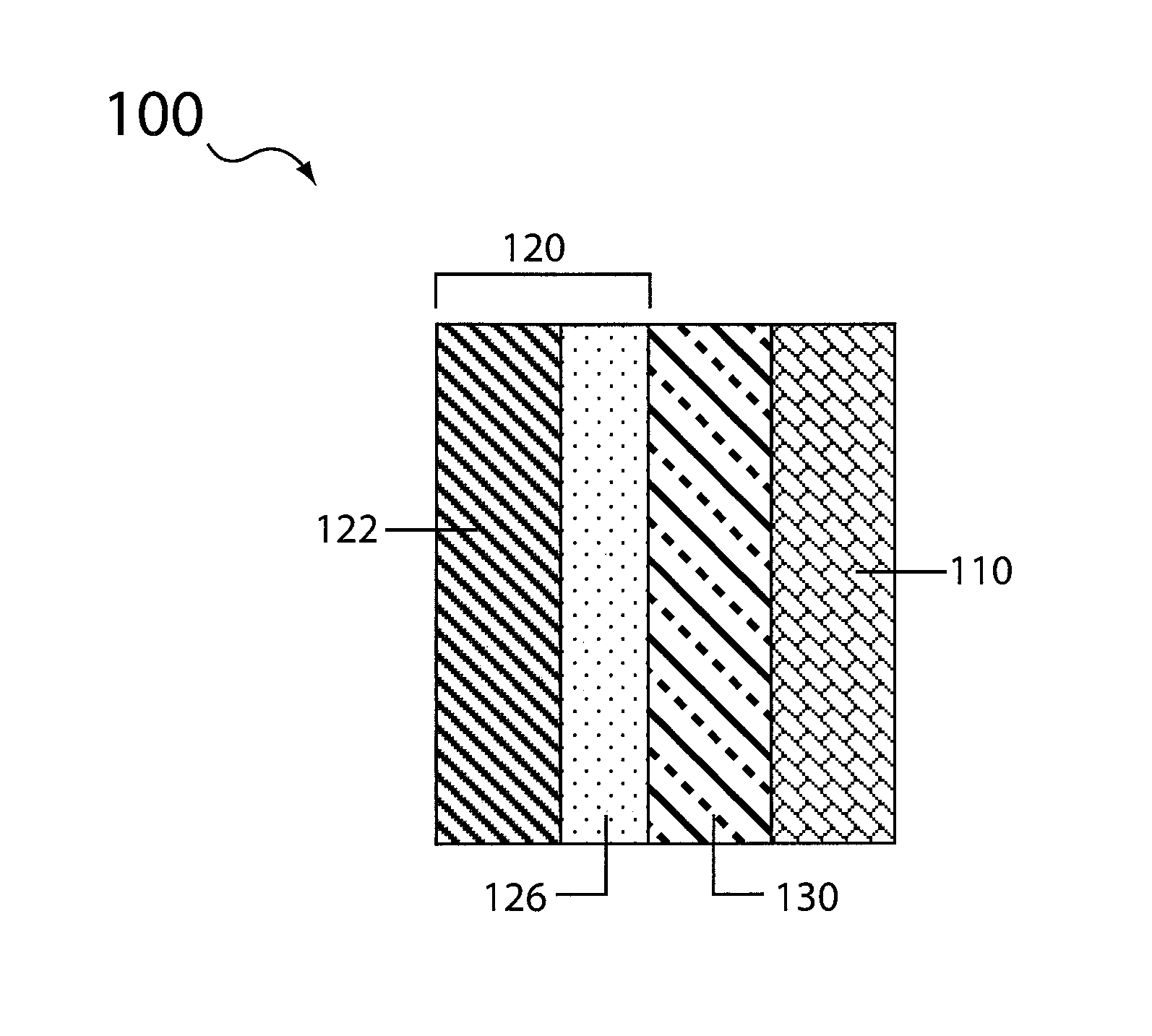

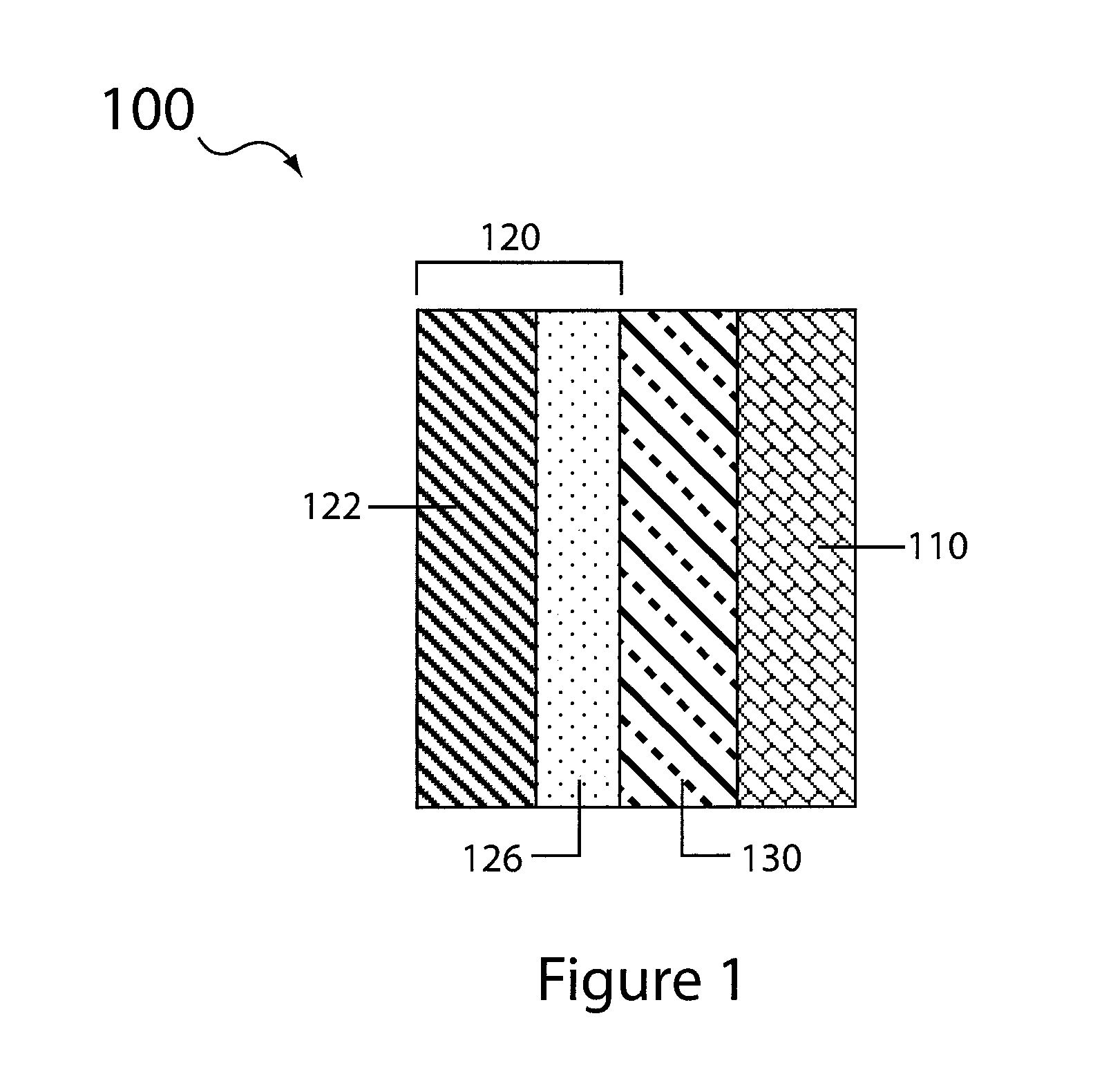

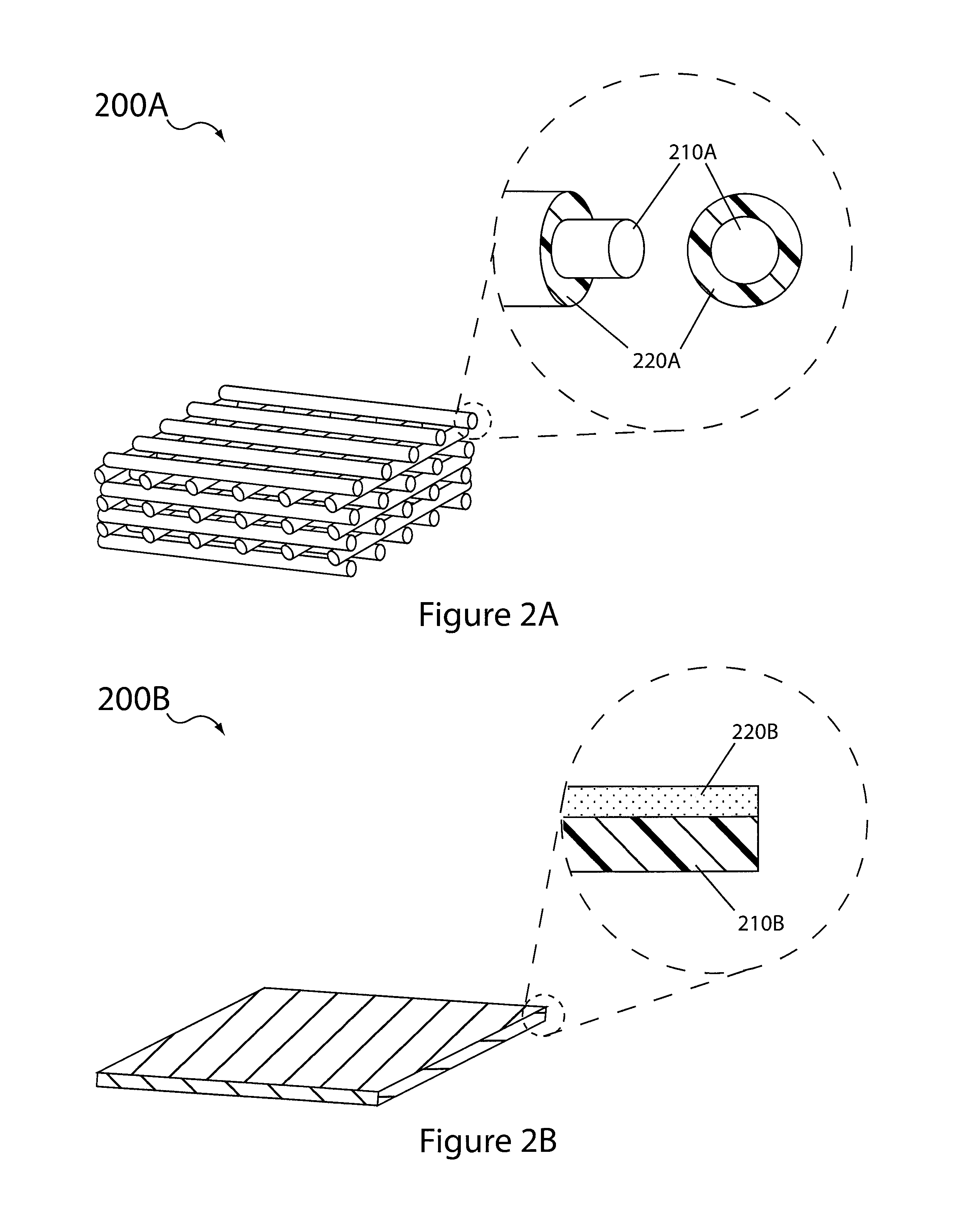

Electrode structures for aqueous electrolyte lithium sulfur batteries

InactiveUS8828573B2Improve solubilityImprove ionic conductivityAlkaline accumulatorsElectrode carriers/collectorsLithium sulfurAqueous electrolyte

Provided are lithium sulfur battery cells that use water as an electrolyte solvent. In various embodiments the water solvent enhances one or more of the following cell attributes: energy density, power density and cycle life. Significant cost reduction can also be realized by using an aqueous electrolyte in combination with a sulfur cathode. For instance, in applications where cost per Watt-Hour (Wh) is paramount, such as grid storage and traction applications, the use of an aqueous electrolyte in combination with inexpensive sulfur as the cathode active material can be a key enabler for the utility and automotive industries, providing a cost effective and compact solution for load leveling, electric vehicles and renewable energy storage.

Owner:POLYPLUS BATTERY CO INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com