Aluminum automotive heat shields

a technology of automotive heat shields and alloys, applied in the field of aluminum alloy vehicular heat shields or panels, can solve the problems of fracture, low cost, and inability to continue casting, and achieve the effect of low cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

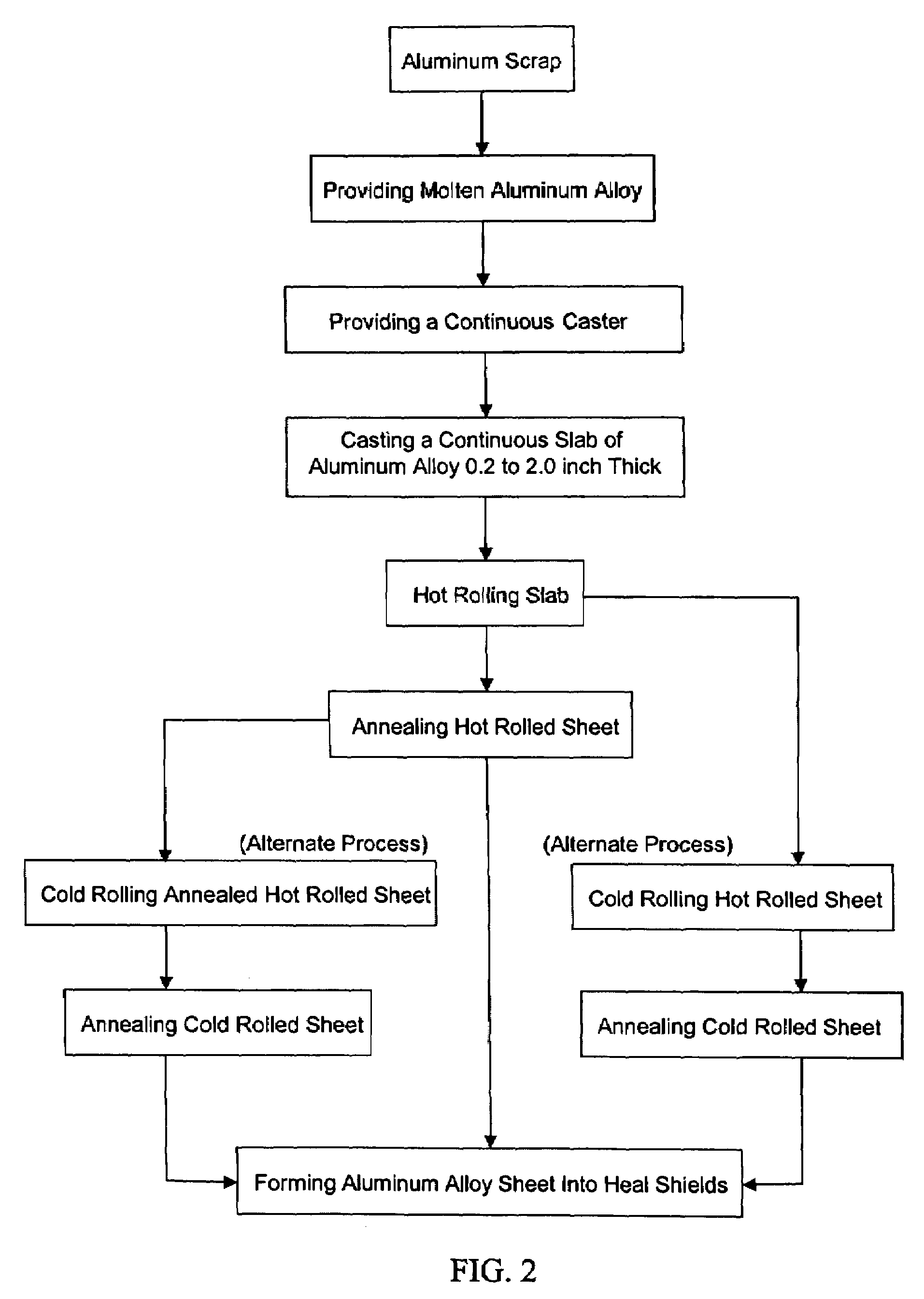

[0063]Aluminum scrap was melted to provide an aluminum base alloy containing 0.23 wt. % Si, 0.54 wt. % Fe, 0.16 wt. % Cu, 1.0 wt. % of Mn, 0.91 wt. % Mg, 0.03 wt. % Cr, 0.05 wt. % Zn, 0.013 wt. % Ti, and incidental elements and impurities. The melt was fed to a twin belt caster at a temperature of 1280° F. and solidified to produce a 0.875 inch thick slab existing the caster at a temperature of 1020° F. The slab was directly fed into a three stand hot rolling mills and rolled to a gauge of 0.90 inch. The temperature of introducing the slab to the hot rolling mill was at about 950° F. and the temperature of exiting the mill was at about 475° F. The hot rolled sheet was wound into a coil. The coil was cold rolled to a final gauge of 0.035 inch and annealed in an anneal furnace at 850° F. for four hours. The annealed coil was tension leveled and slit into the required width. The material had properties in the rolling direction before forming into automotive heat shields of: ultimate te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com