Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

409 results about "Auto industry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Automotive Manufacturing. The automotive industry includes the manufacturing of automobiles, parts and accessories and is driven primarily by competition and globalization, especially through a long history in Northeast Ohio. Key occupations in the automotive manufacturing industry have high levels of support from post-secondary training.

Heat curable, thermally expandable composition with high degree of expansion

Compositions containing at least one liquid epoxy resin, at least one solid epoxy resin, at least one propellant, at least one curing agent and at least one mica-containing filler produce expandable, thermally curable binder systems which may be used without the addition of hollow glass beads for the production of stiffening and reinforcing laminates and for the production of stiffening and reinforcing mouldings. Said laminates according to the invention are suitable for the stiffening and reinforcing of components, in particular in the automotive industry, such as car body frames, doors, boot lids, engine bonnets and / or roof parts. In addition, the mouldings that may be produced from said binders are suitable for the stiffening and reinforcing of hollow metal structures, in particular of hollow car body parts such as body frames, body supports and posts or doors in the automotive industry.

Owner:HENKEL KGAA

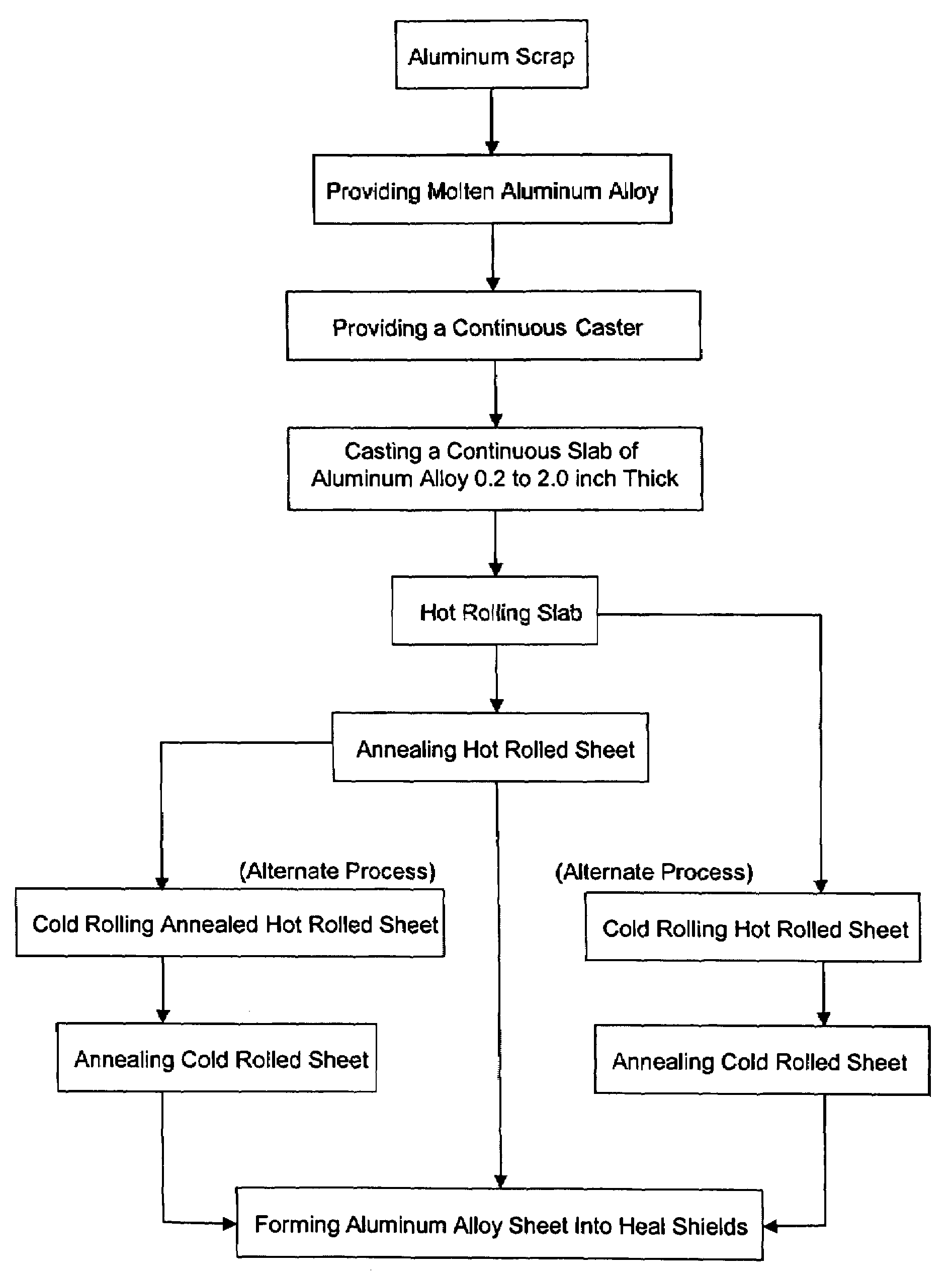

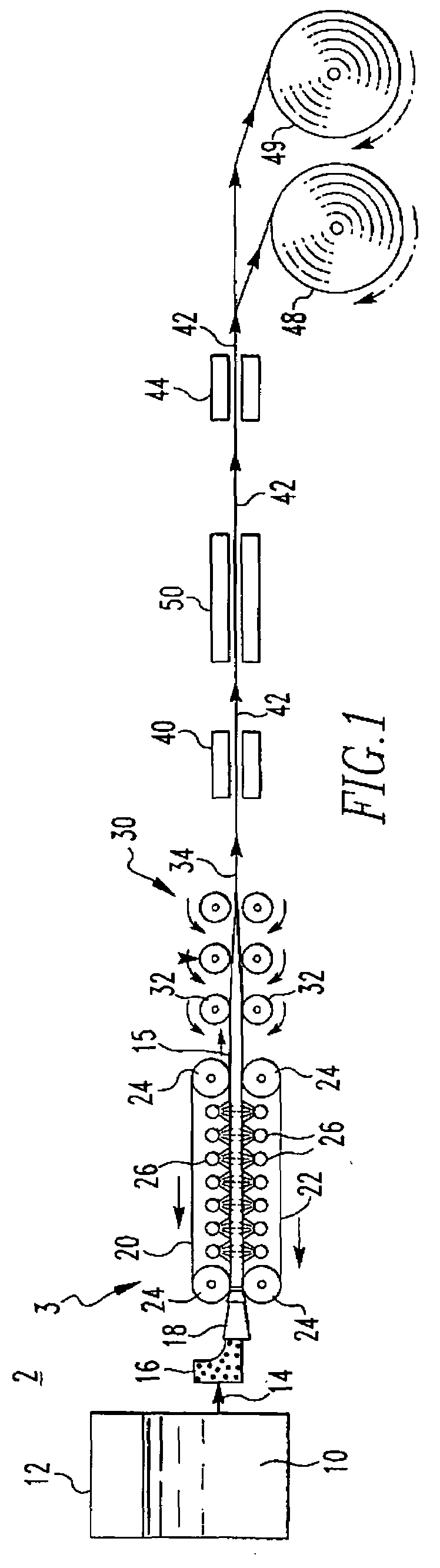

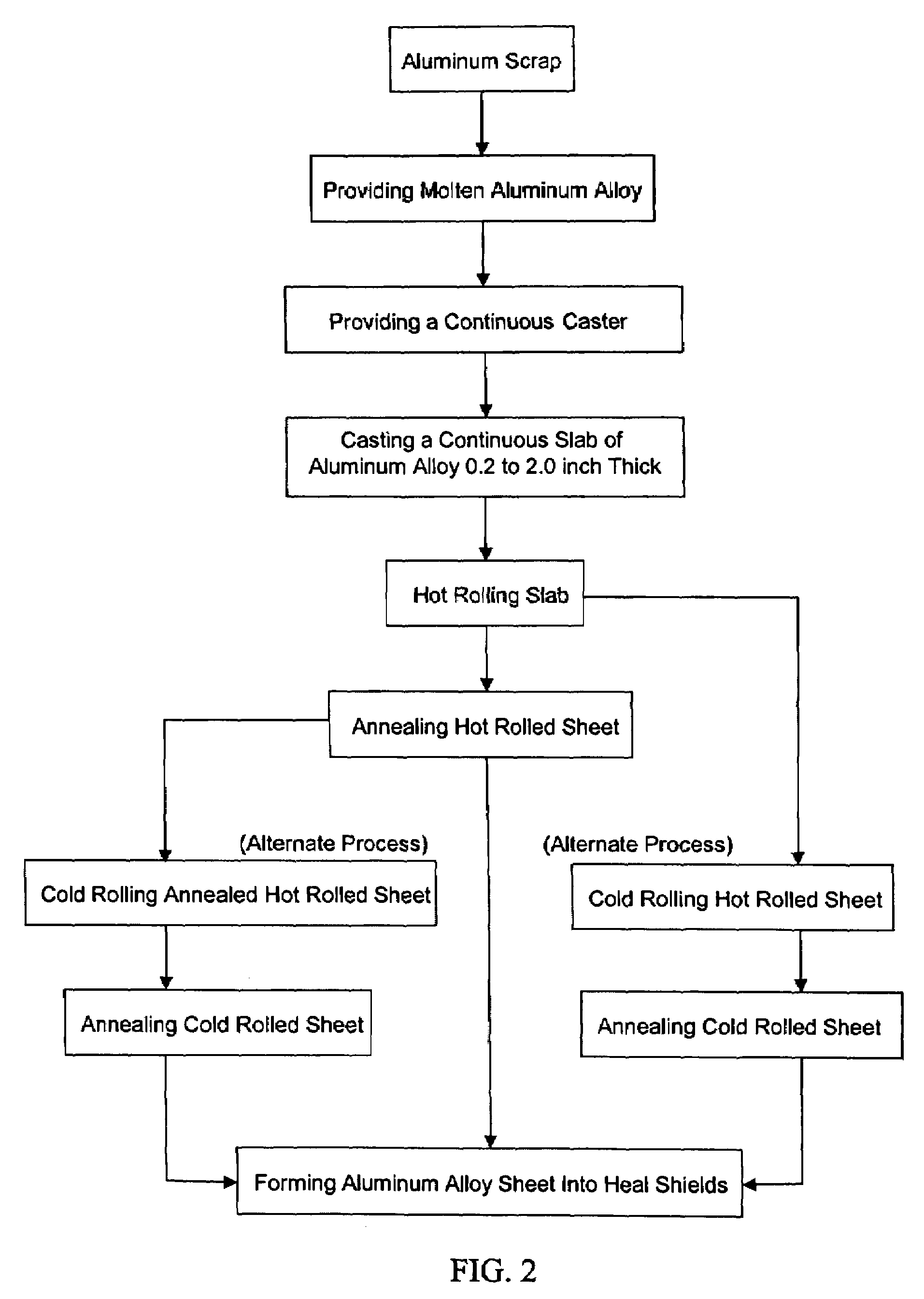

Aluminum automotive heat shields

Disclosed is a method for producing aluminum automotive heat shields or panels such as from scrap derived molten aluminum alloy using a continuous caster to cast the alloy into a slab. The method comprises providing a molten aluminum alloy consisting essentially of 0.1 to 0.7 wt. % Si, 0.2 to 0.9 wt. % Fe, 0.05 to 0.5 wt. % Cu, 0.05 to 1.3 wt. % Mn, 0.2 to 2.8 wt. % Mg, 0.3 wt. % max. Cr, 0.3 wt. % max. Zn, 0.2 wt. % max. Ti, the remainder aluminum, incidental elements and impurities and providing a continuous caster such as a belt caster, block caster or roll caster for continuously casting the molten aluminum alloy. The molten aluminum alloy is cast into a slab which is rolled into a sheet product and then annealed. Thereafter, the sheet product is formed into the automotive heat shield or panel with strength and formability as required by the automotive industry.

Owner:COMMONWELATH IND

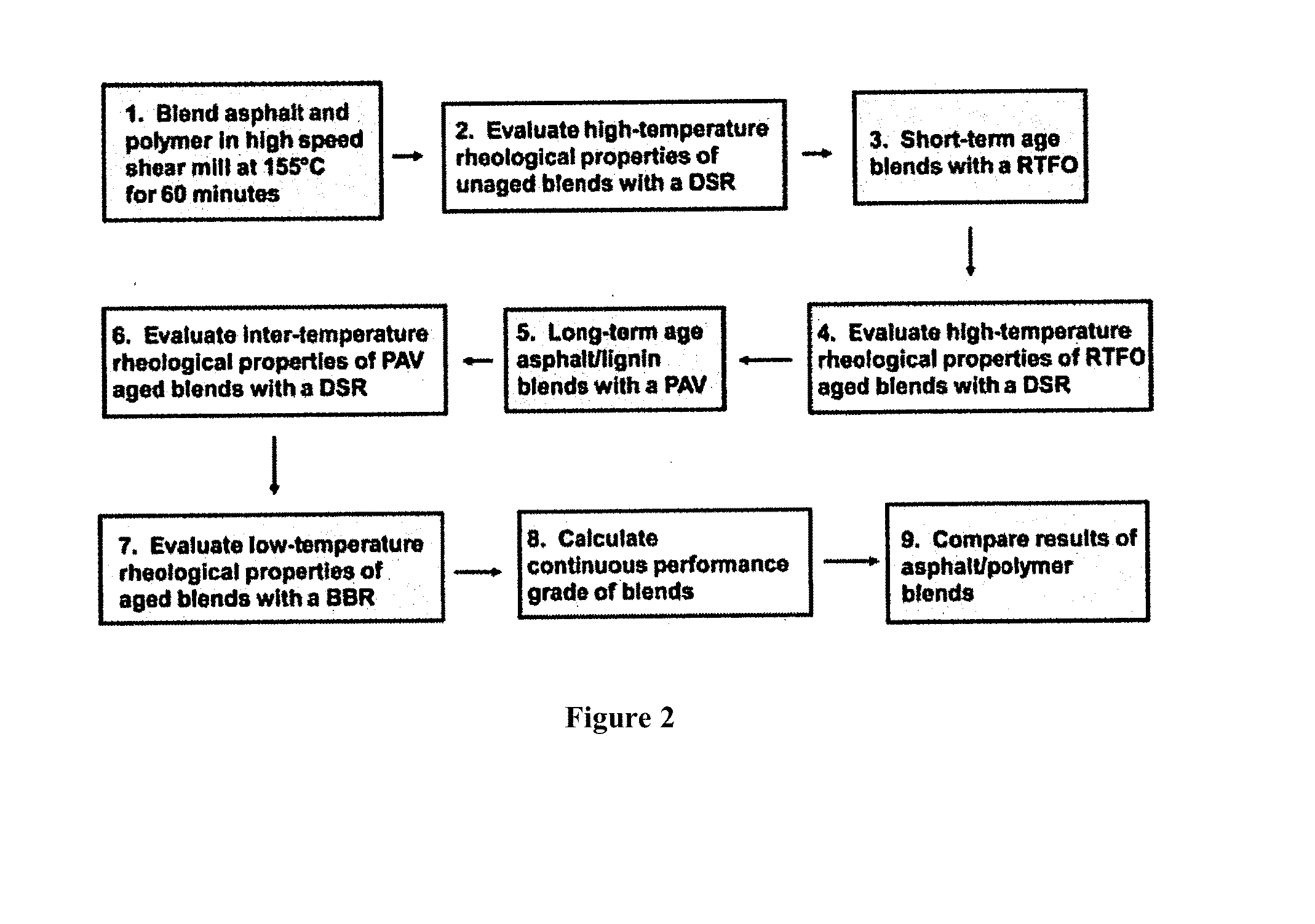

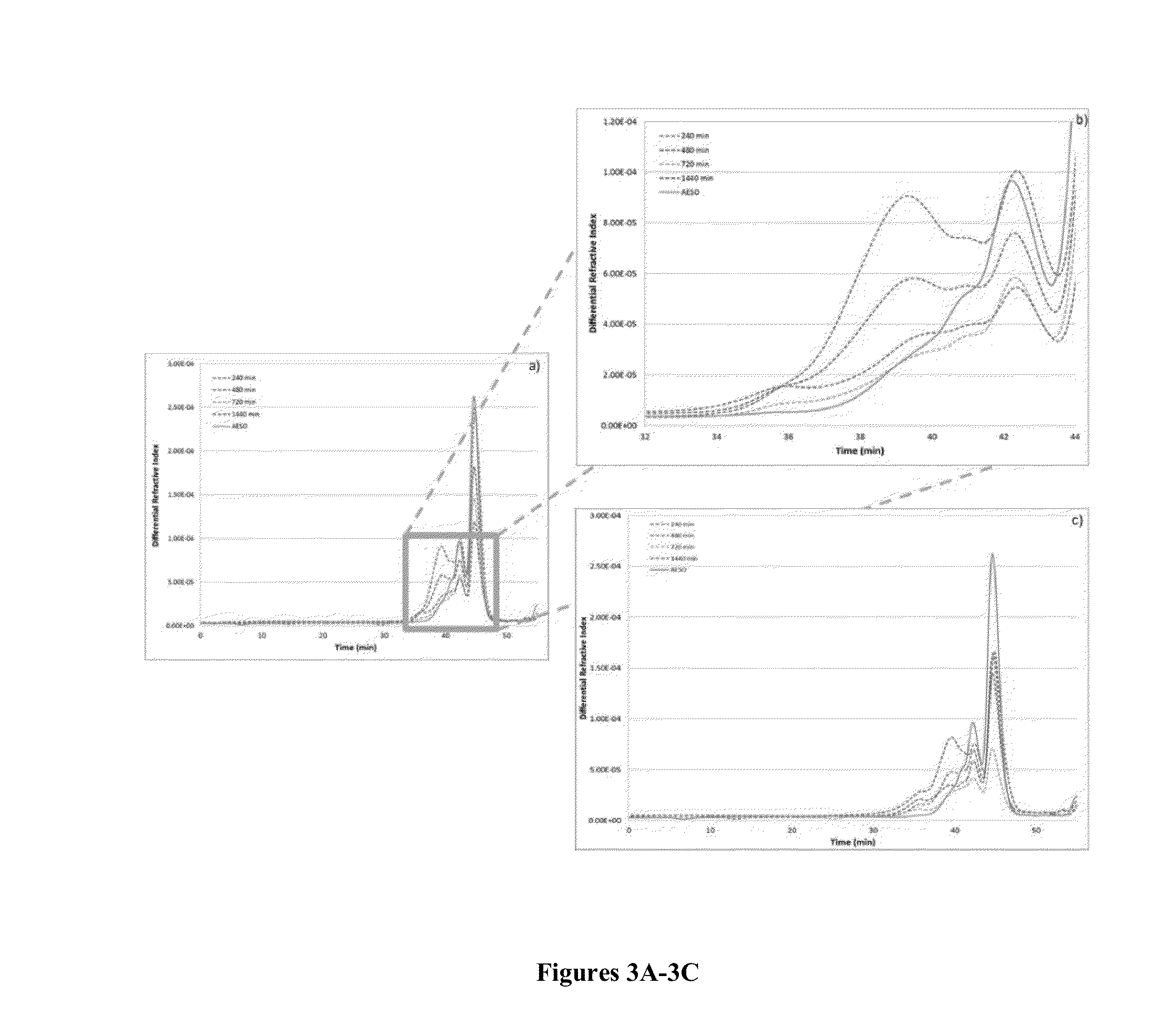

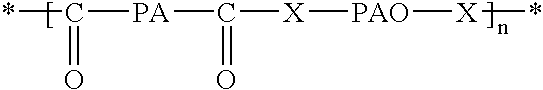

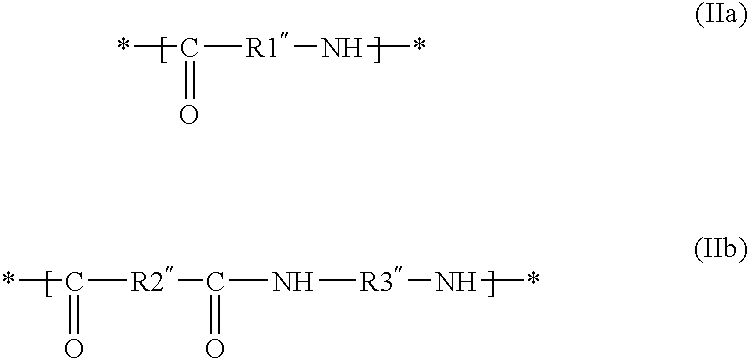

Thermoplastic elastomers via atom transfer radical polymerization of plant oil

The present invention relates to a block copolymer comprising at least one PA block and at least one PB block. The PA block represents a polymer block comprising one or more units of monomer A, and the PB block represents a polymer block comprising one or more units of monomer B. Monomer A is a vinyl, acrylic, diolefin, nitrile, dinitrile, or acrylonitrile monomer. Monomer B is a radically polymerizable plant oil monomer containing one or more triglycerides. The present invention also relates to a method of preparing a thermoplastic block copolymer by radical polymerizing a radically polymerizable monomer with a radically polymerizable plant oil monomer containing one or more triglycerides, in the presence of an initiator and a transition-metal catalyst system to form the thermoplastic block copolymer. The polymerized plant oil-based block copolymers are useful in a variety of applications, such as asphalt modifiers, rubber compositions, adhesives, tires, in the automobile industry, footwear, packaging, etc.

Owner:IOWA STATE UNIV RES FOUND

Crosslinked composition comprising a core/shell copolymer, method of obtaining same and uses thereof

InactiveUS20090306246A1Excellent surface appearanceEasy to processSolesSpecial tyresElastomerPolyolefin

The invention relates to is a crosslinked composition containing in parts by weight: 20 to 100 parts of at least one elastomer (I), 2 to 50 parts of at least one core / shell copolymer (II), and 0 to 100 parts of at least one thermoplastic polymer (III). The invention also relates to a method of producing one such crosslinked composition, which is characterized in that it consists in: mixing an elastomer and a core / shell copolymer optionally in the presence of: a grafted polyolefin, a plasticizer, fillers and / or additives, and a suitably-selected crosslinking system, and subsequently crosslinking said mixture at a suitable temperature. In a preferred embodiment of the invention, the mixture is crosslinked at a temperature of between 150 and 320° C. The invention method be carried out in an internal mixer, or, alternately, in a twin-screw extruder or a Buss®-type co-kneader. Depending on the case, the resulting mass is calendared or extruded, cooled and subsequently granulated. The granules thus obtained are then ready to be transformed, by means of heating, into sheets, plates, extrusions, tubes or other desired products. The invention further relates to the use of one such composition in the production of ducts, pipes, tubing, couplers or similar for conveying fluids, such as the fluid transfer conduits, pipes and other elements which are used in the automobile industry in braking, cooling, steering and air-conditioning systems. The inventive crosslinked composition can also be used in the production of belts, tires, electrical cable sheaths, and shoe soles.”

Owner:ARKEMA FRANCE SA

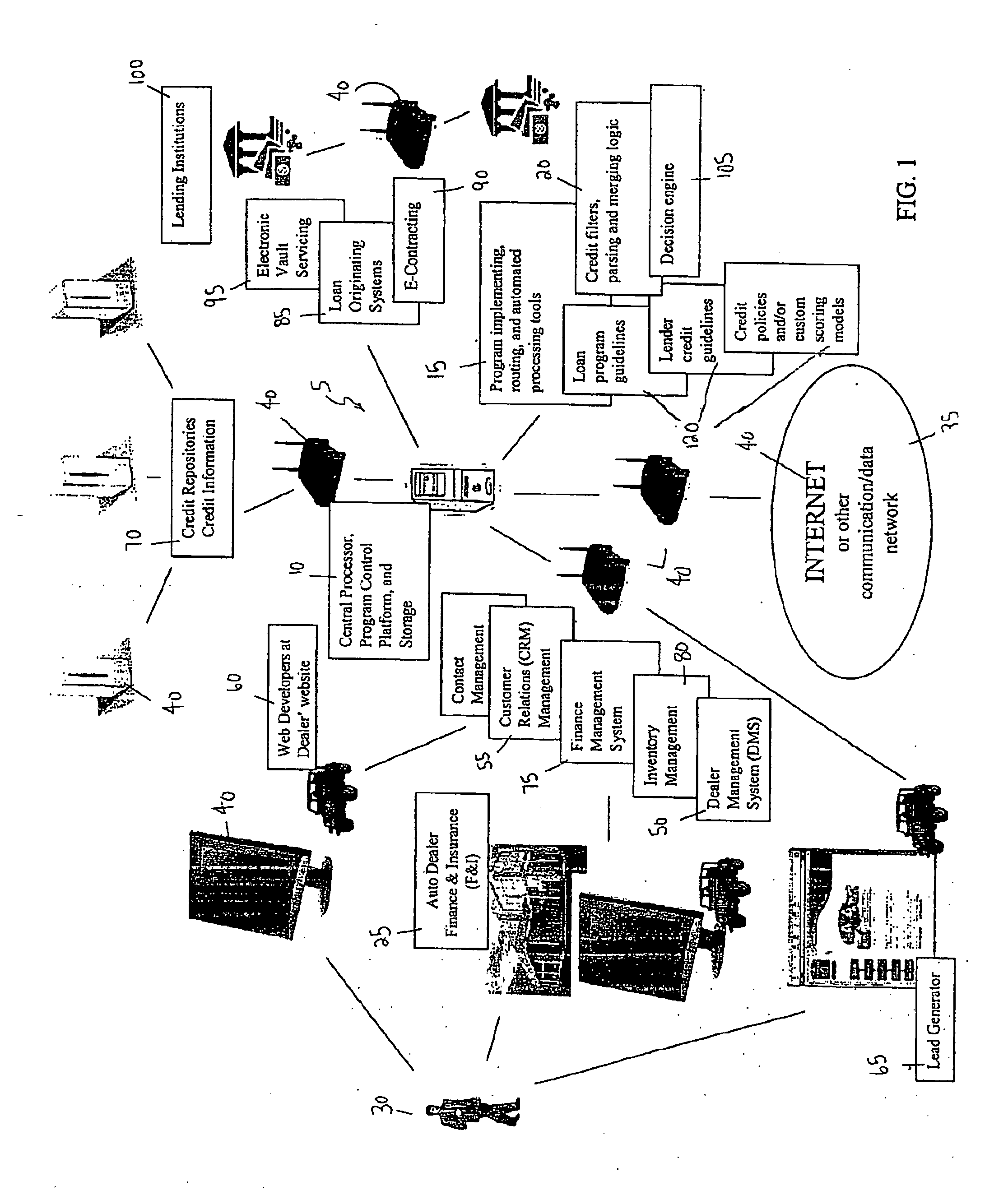

Computer implemented finance management routing system

ActiveUS20100023447A1Improve the buying experienceComplete banking machinesFinanceAuto industryManagement tool

Broadly, the present invention relates to data processing in general and more particularly to a finance management system or “system” (5) relating to the auto industry (25) that provides a gateway for vehicle purchase lead management tools to seamlessly integrate the auto sales process with the auto finance process, and enables sellers (25) to initiate, process, and decision loan transactions with financial institutions (100). The financial management system (5) described herein preferably includes, among other things, credit filters, (20), auto population of documents, and a decision engine (105) that retrieves or collects and combines or merges the borrower's credit file(s) (110) with an applicant's information (115), processes the information or data to a specific vehicle (145) and finance structure (160), matches the data against a lender's proprietary mix of loan programs, pricing, credit policies and / or custom scoring models (120) to determine if a borrower (30) has qualified for a loan, and makes a result presentation (155) of a finance level of acceptability available to the auto dealer (25).

Owner:DEALERCENTRIC SOLUTIONS

Identification method for potential customers of auto industry based on tri-training

ActiveCN108256052AAccurate marketing targetSave labor costRelational databasesCharacter and pattern recognitionAuto industryData modeling

The invention discloses an identification method for potential customers of an auto industry based on tri-training. The method comprises the following steps of data preprocessing and data modeling, wherein the data preprocessing comprises abnormal value processing, missing value processing, classification attribute processing, combination feature generation, feature selection and data normalization; the data modeling adopts a tri-training cooperative training algorithm in semi-supervised learning and selects a BP neural network as a base learner in the process of cooperative training. The historical selling data (customer data with category labels) of an automobile brand dealer and the collected potential customer data (customer data without labels) are utilized to construct a semi-supervised customer identification model, so that accurate marketing targets are provided for accurate marketing of the auto industry, the manpower cost and cost of funds are saved.

Owner:成都达拓智通科技有限公司

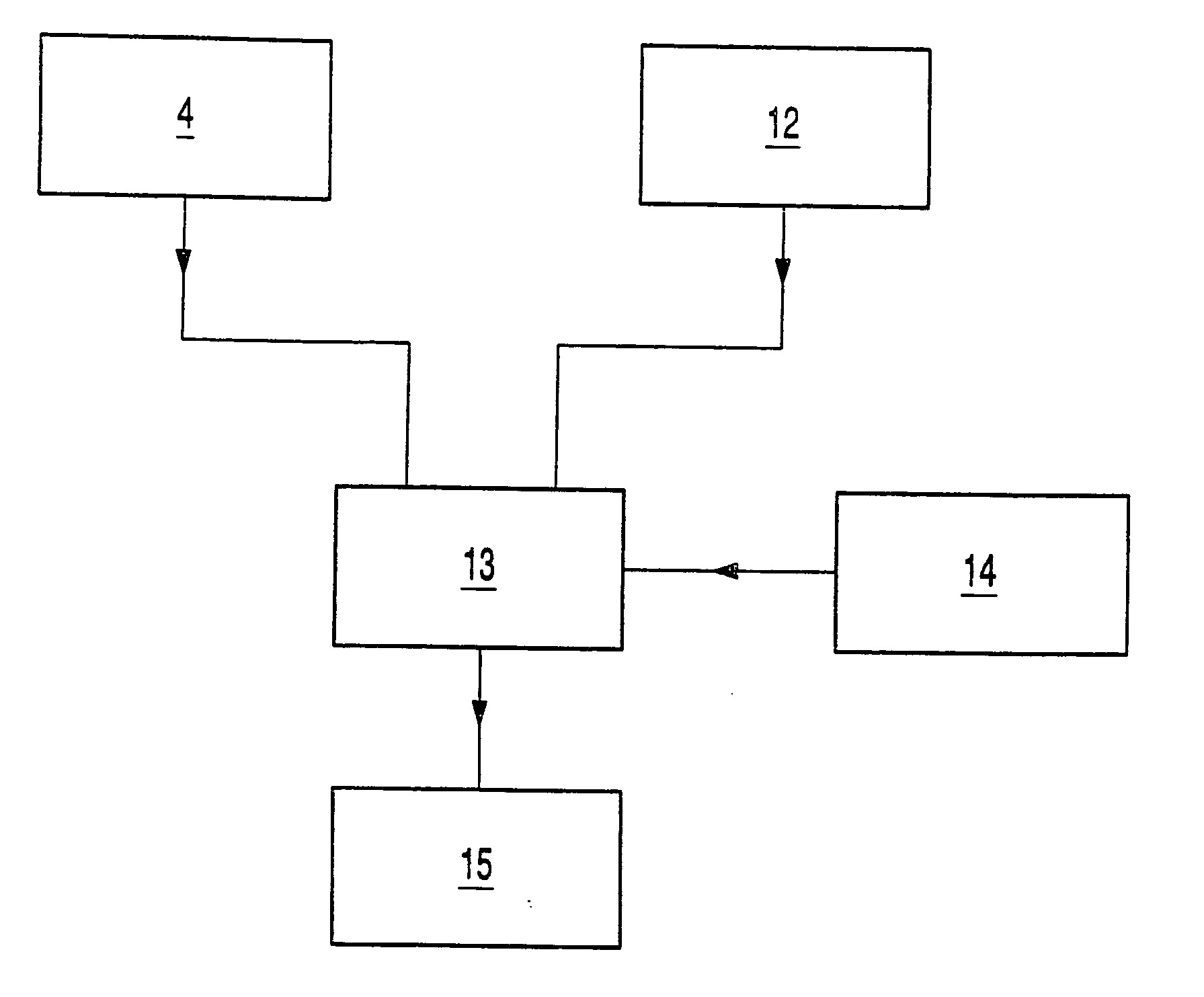

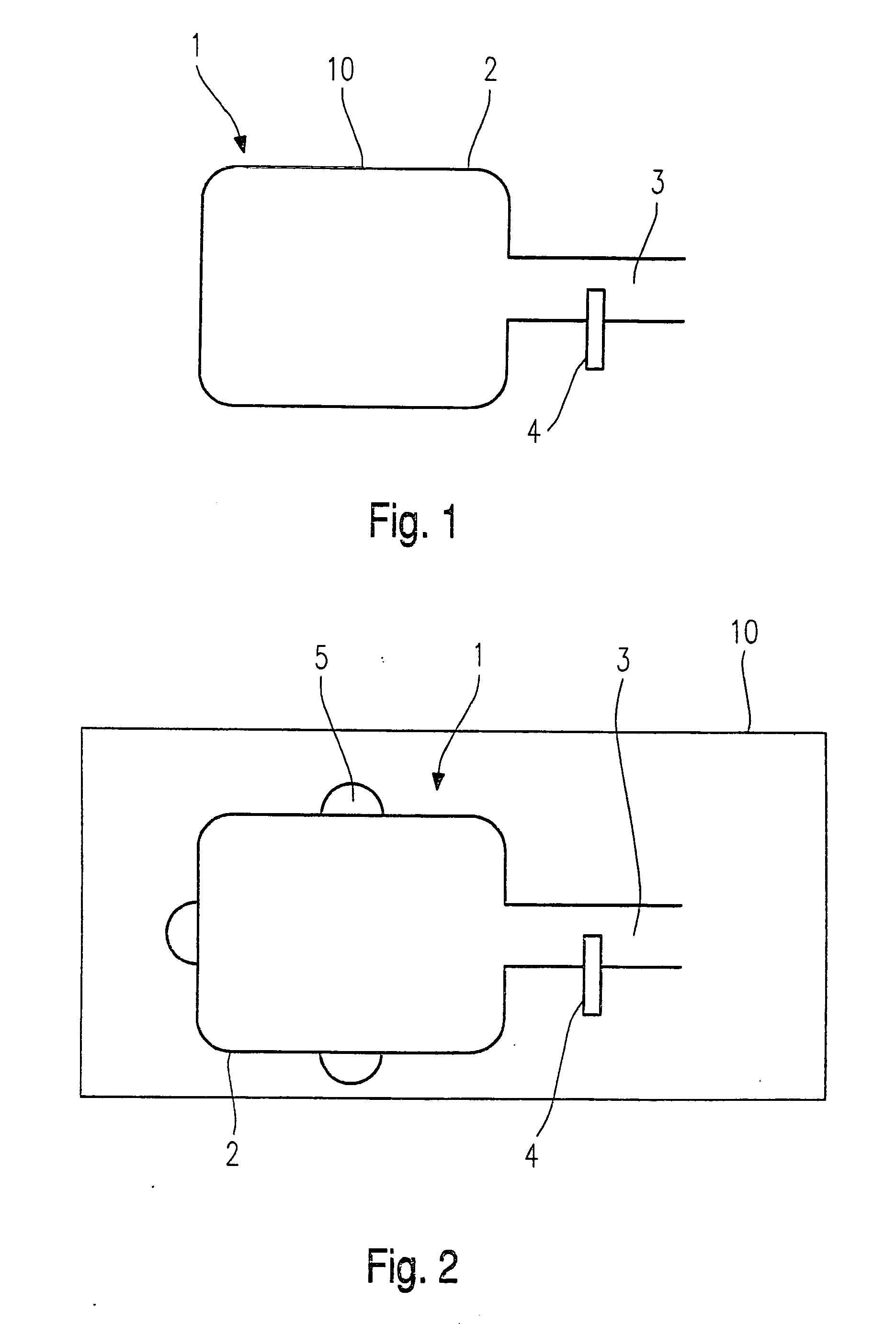

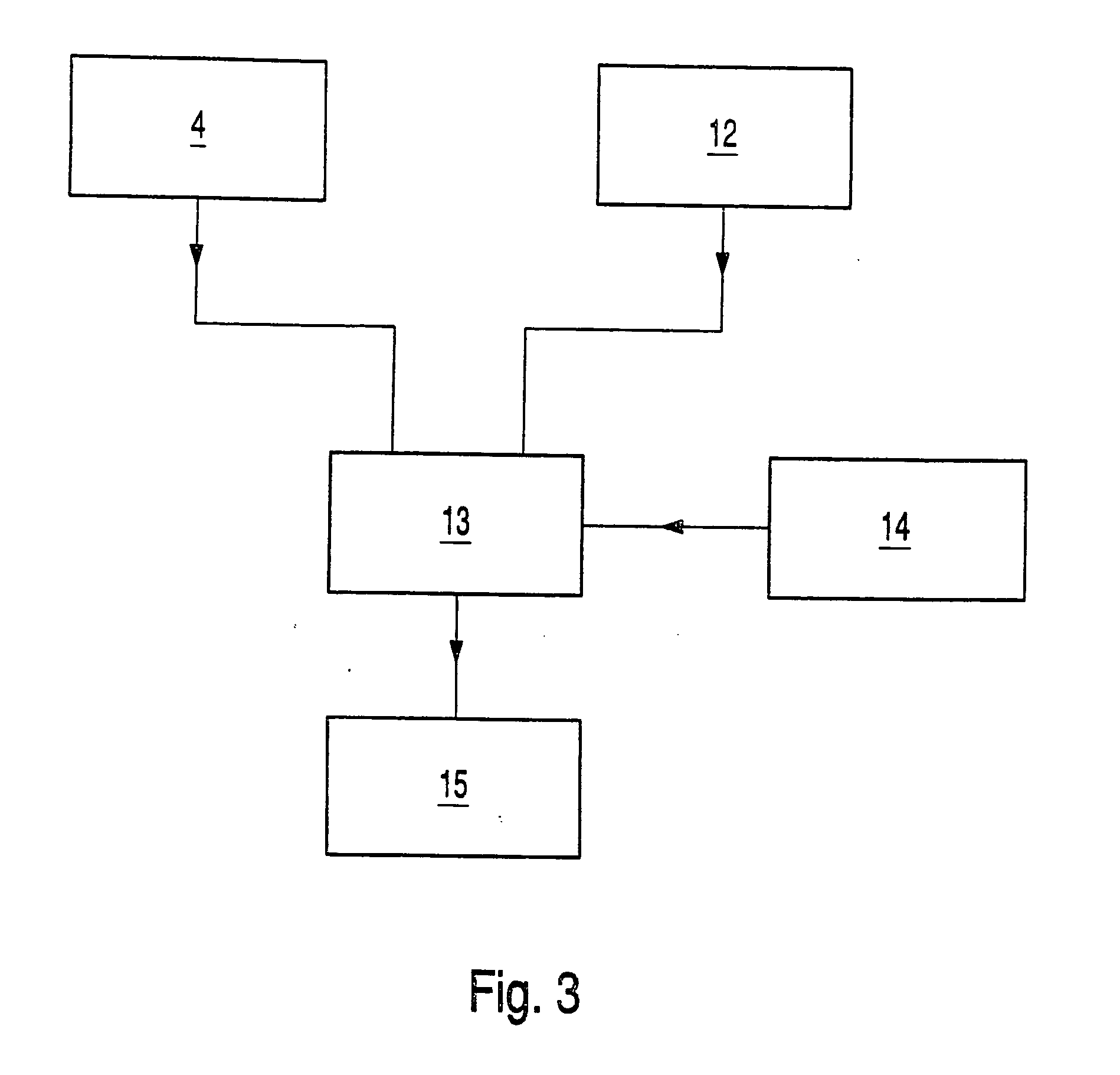

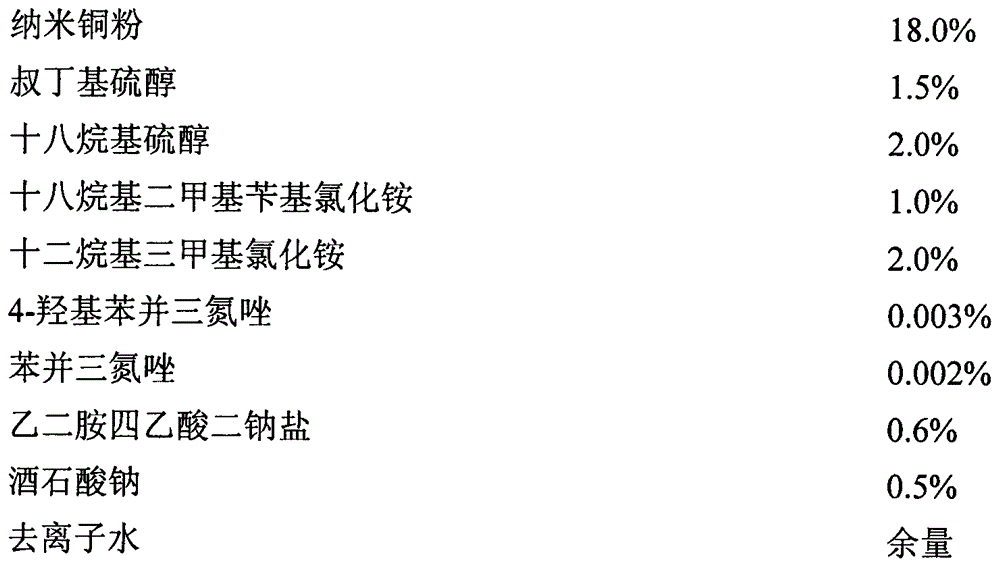

Device for detecting a deformation of a structural component

A device 1 for detecting a deformation of a component 10, in particular in the automotive industry, having a deformable hollow body arrangement assigned as a deformation indicator to component 10 and having at least one orifice area 3, and at least one sensor device 4; 12 situated in the particular orifice area 3 for measuring an air flow corresponding to the deformation of hollow body arrangement 2. In addition, the present invention relates to a method of detecting such a deformation of a component 10 and activating an appropriate safety application, the measured data being analyzed by an analyzer unit 13 after measurement of the deformation, and a suitable safety application optionally being activated if the measured data of the at least one sensor device 4; 12 indicates a deformation of hollow body arrangement 2 and thus of component 10.

Owner:ROBERT BOSCH GMBH

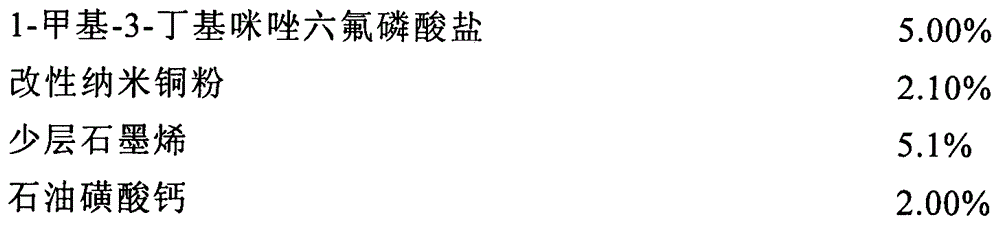

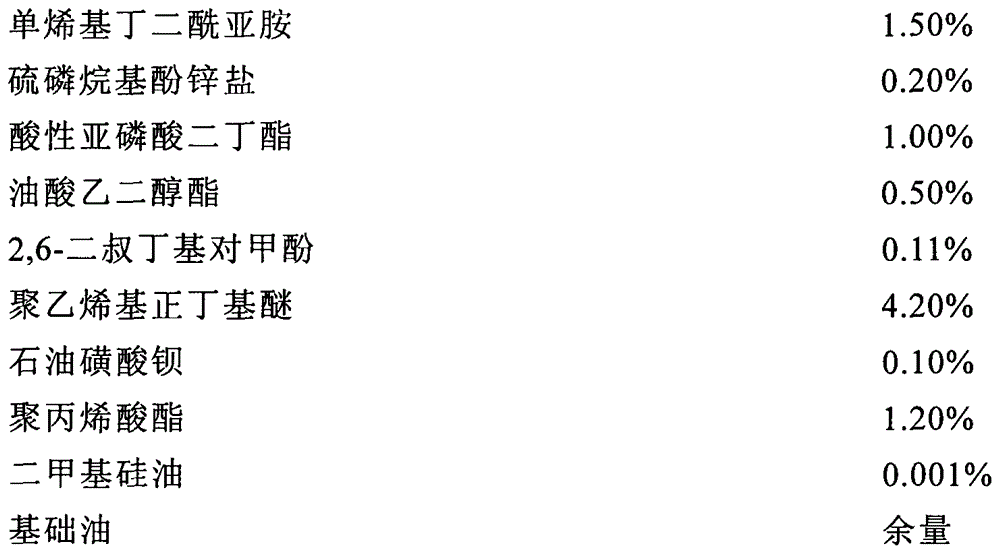

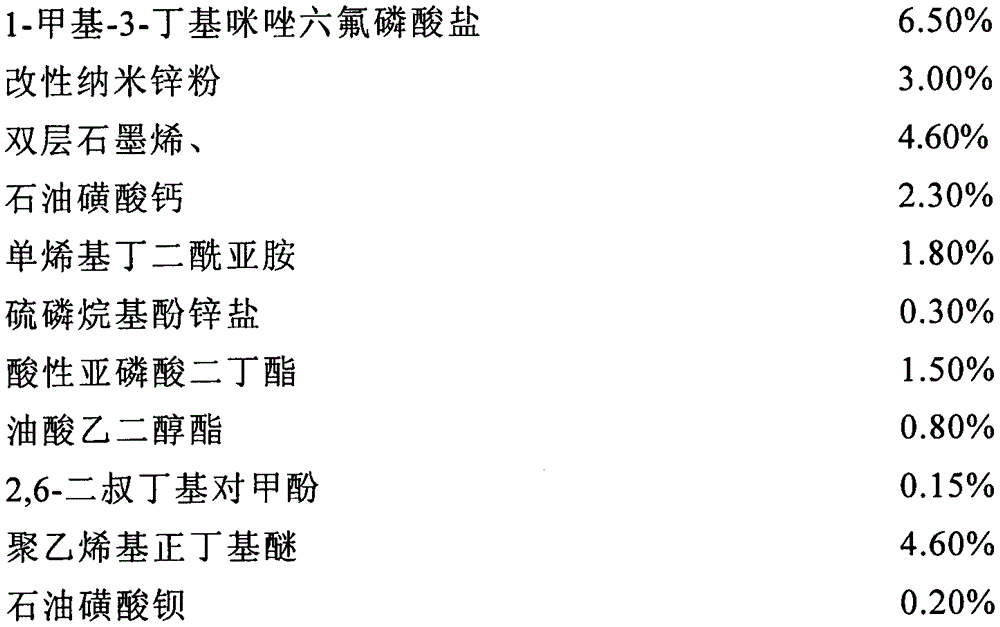

Preparation method for lubricating oil composition containing ionic liquid, modified nanometer copper powder and graphene

The invention discloses a preparation method for a lubricating oil composition containing ionic liquid, modified nanometer copper powder and graphene. The method comprises the following steps: compounding base oil, a detergent, a dispersant, a preservative, an extreme-pressure antiwear agent, an oiliness agent, an antioxidant, a viscosity index improver, an antirusting agent, a depressant, an antifoamer, the ionic liquid, the modified nanometer copper powder and the graphene so as to obtain the lubricating oil composition containing the ionic liquid, the modified nanometer copper powder and the graphene. The method in the invention has the advantages of simple and practicable production process, small equipment investment and low energy consumption, is pollution-free to the environment and is favorable for popularization and application. The lubricating oil composition prepared by using the method in the invention can be widely applied in the industrial fields of mechanical industry, automobile industry, precision instruments, electric power industry, metallurgy industry, die manufacturing and application industry, iron and steel industry, machine tool industry, etc., and has broad application prospects.

Owner:烟台广和润滑油有限公司

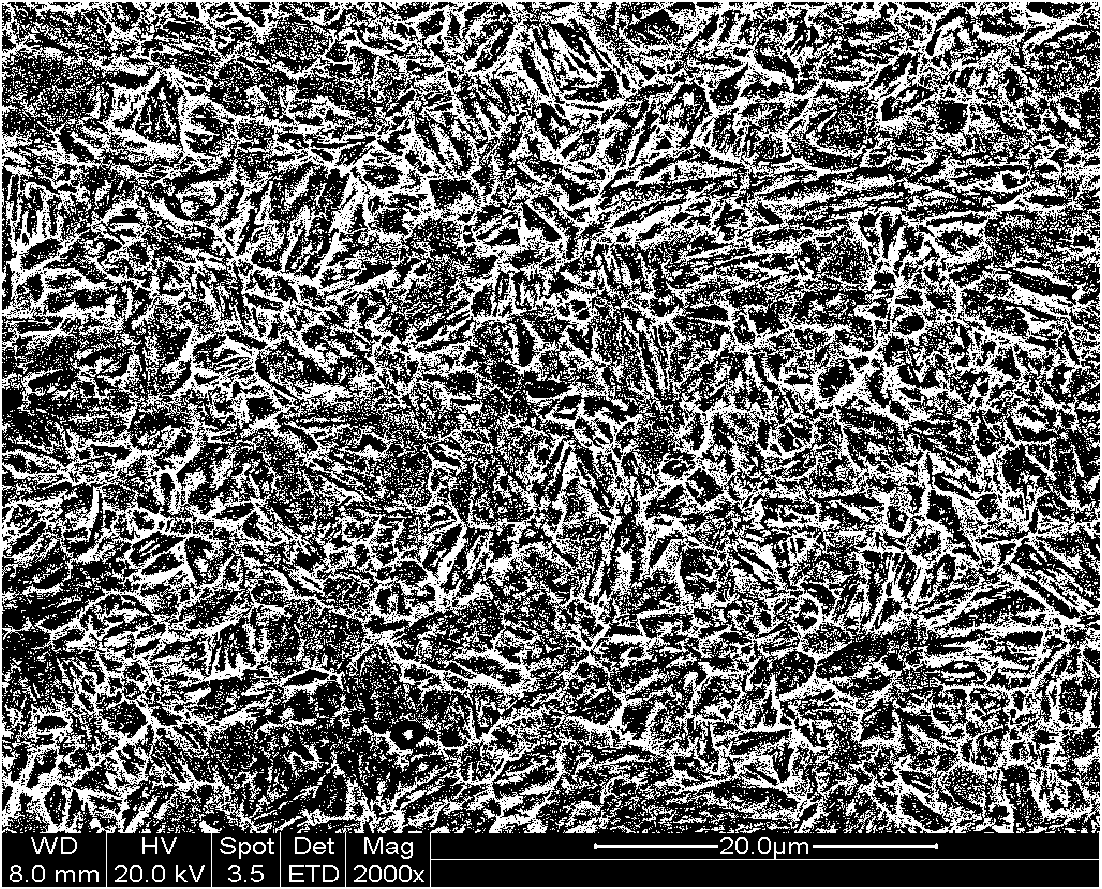

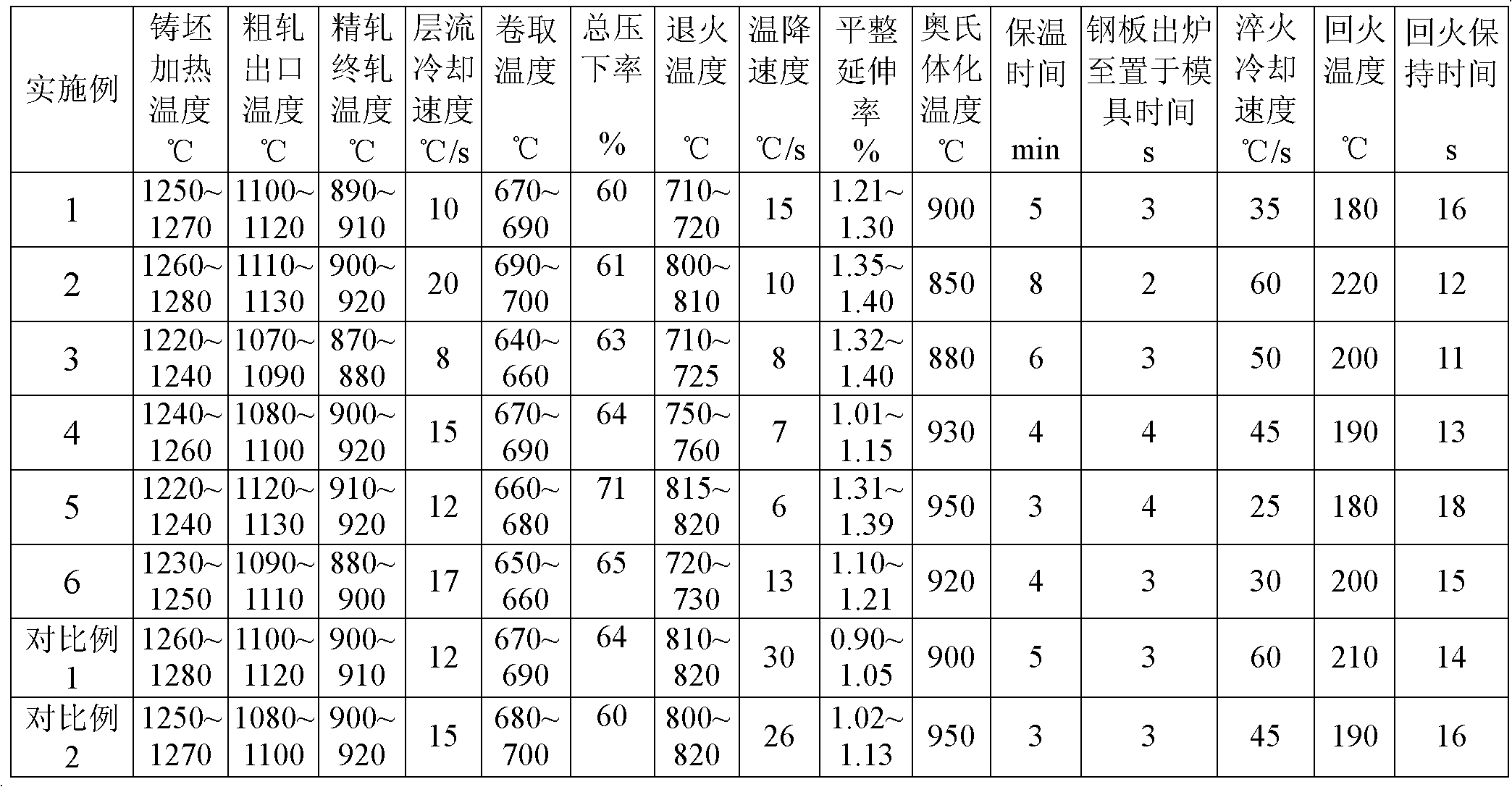

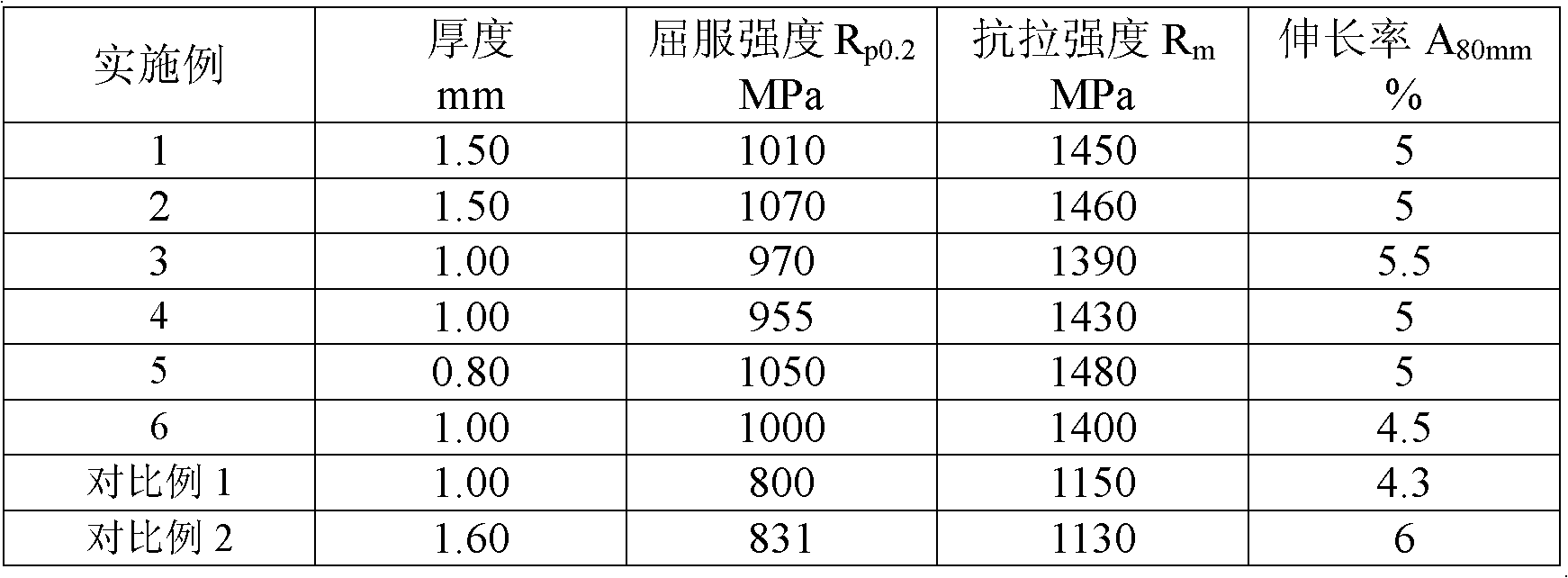

Steel with 1,300MPa-level tensile strength for automobile safety piece and production method thereof

The invention relates to steel with 1,300MPa-level tensile strength for an automobile safety piece and a production method thereof. The steel comprises the following components in percentage by weight: 0.12 to 0.22 percent of C, 0.10 to 0.40 percent of Si, 1.00 to 1.60 percent of Mn, 0.10 to 0.45 percent of Cr, 0.01 to 0.10 percent of Ti, 0.0005 to 0.005 percent of B, 0.01 to 0.06 percent of Als,less than or equal to 0.025 percent of P, less than or equal to 0.010 percent of S and less than or equal to 0.008 percent of N. The production method comprises the following steps of: smelting by using a converter; alloying; performing vacuum treatment and component fine turning; continuously casting; heating a casting blank to the temperature of between 1,220 and 1,280 DEG C; performing rough rolling; performing fine rolling; performing laminar flow cooling; reeling; performing acid-washing; performing cold rolling; annealing; smoothing; finishing; cutting; heating and austenitizing under the protective atmosphere of nitrogen; forming a mold; quenching; tempering; and taking a member out for later use. The steel has ultrahigh intensity, meets the requirements of an automobile industry on the intensity and the rigidity of the safety piece of a vehicle body, can be complicatedly deformed without resilience, has high dimensional accuracy of parts and can be industrially produced on common large production equipment.

Owner:武汉钢铁有限公司

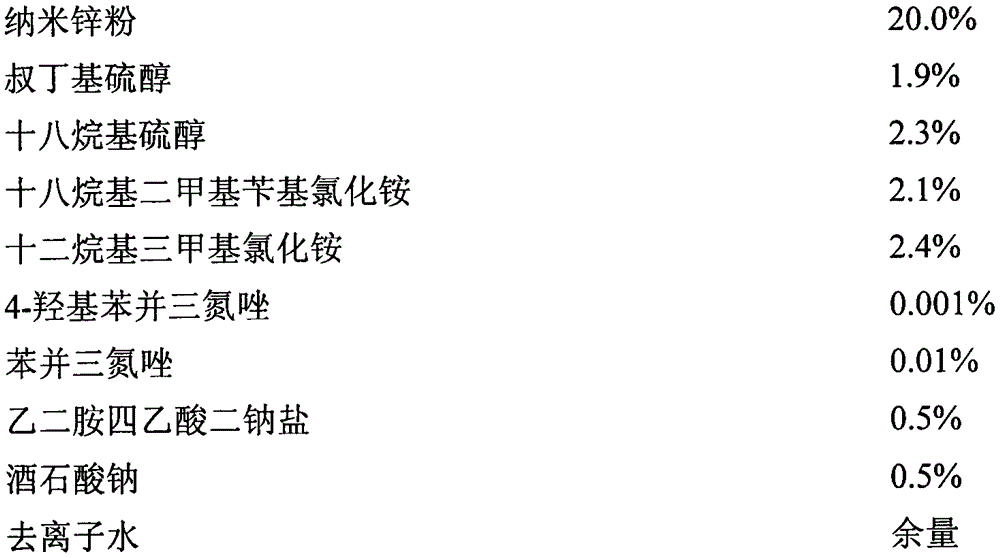

Preparation method of lubricating oil composition containing ionic liquid, modified nano-zinc powder and graphene

The invention discloses a preparation method of a lubricating oil composition containing ionic liquid, modified nano-zinc powder and graphene. According to the method, base oil, a cleaning agent, a dispersing agent, a preservative, an extreme pressure anti-wear agent, an oiliness agent, an antioxidant, a viscosity index improver, an anti-rust agent, a pour point depressant, an antifoaming agent, ionic liquid, modified nano-zinc powder and graphene are adopted for compounding to obtain the lubricating oil composition. The method has the advantages of simple and easy production process, low equipment investment, low energy consumption and no environmental pollution, and is conductive to popularization and application. The lubricating oil composition product containing the ionic liquid, modified nano-zinc powder and graphene can be widely applied in the industrial fields of mechanical industry, automobile industry, precision instruments, power industry, metallurgical industry, mold manufacturing and application industry, steel and iron industry, machine tool industry and the like, and has broad application prospects.

Owner:大庆招远圣通机械设备有限公司

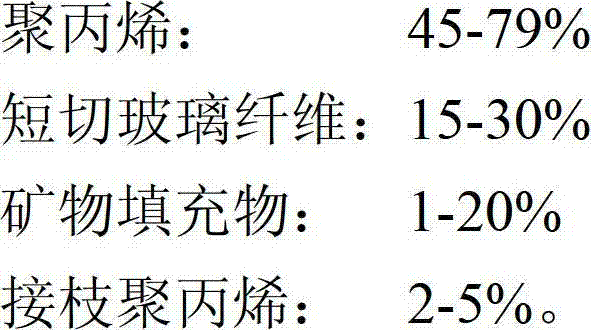

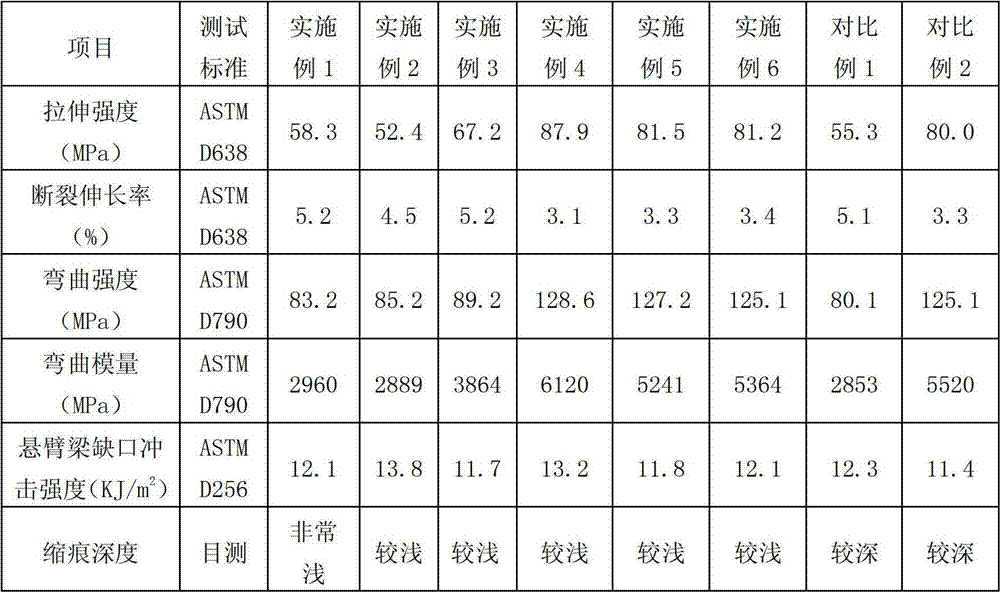

Glass fiber-reinforced polypropylene material with shallow shrinkage mark and low warpage as well as preparation method and application thereof

The invention discloses a glass fiber-reinforced polypropylene material with shallow shrinkage mark and low warpage as well as a preparation method and an application of the glass fiber-reinforced polypropylene material. The polypropylene material is prepared by using the following raw materials including 45-79% of polypropylene, 15-30% of chopped glass fiber, 1-20% of mineral fillers and 2-5% of grafted polypropylene, wherein the polypropylene includes high crystalline polypropylene as well as homopolymerized polypropylene and / or copolymerized polypropylene; the mineral fillers are one or more of barium sulfate, calcium carbonate or mica.The preparation method for preparing the glass fiber-reinforced polypropylene material provided by the invention uses the high crystalline polypropylene, the added chopped glass fiber and the mineral fillers for composite reinforcement and can effectively increase the cooling and curing rates of the material during the injection moulding process. The prepared product has the characteristics of shallow shrinkage mark, low warpage and high surface gloss, has the advantages of high flexural strength and modulus, good processability and low cost, can be used in household appliances and automotive industries, and can replace engineering plastic, and meet the requirements of high dimensional stability, high wrap and high mechanical properties of the parts.

Owner:KINGFA SCI & TECH CO LTD +1

Hot continuous rolling plate strip steel for 510MPa automotive frame and production technology thereof

InactiveCN103451535ARealize reduced productionImprove performanceTemperature control deviceAuto industryStrip steel

The invention belongs to the technical field of steel rolling, and particularly relates to a low cost hot continuous rolling plate strip steel for a 510MPa automotive frame and a production technology thereof. The hot continuous rolling plate strip steel for the automotive frame comprises the following components by weight percent: 0.13-0.18% of C, 0.30-0.50% of Si, 0.75-1.15% of Mn, 0.02-0.06% of Alt, less than or equal to 0.025% of P, less than or equal to 0.008% of S, 0.008-0.025% of Ti, less than or equal to 0.006% of N, the balance of Fe, and inevitable impurities. According to the production technology, by slightly adjusting the content of C and Si, lowering the content of Mn, only adding a small quantity of cheap Ti, and adding no other precious alloy elements, the production cost is remarkably lowered, the production quantity of the type of steel is reduced, the energy is saved, the consumption is lowered, the cost is lowered, and an automotive frame steel with excellent comprehensive properties is obtained, so that the production technology can provide products with high cost performance for the auto industry.

Owner:JIGANG GRP

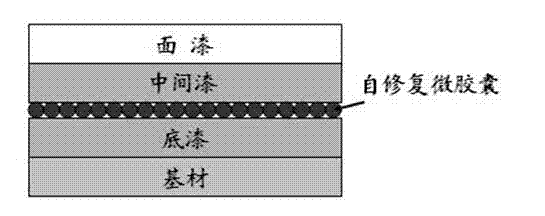

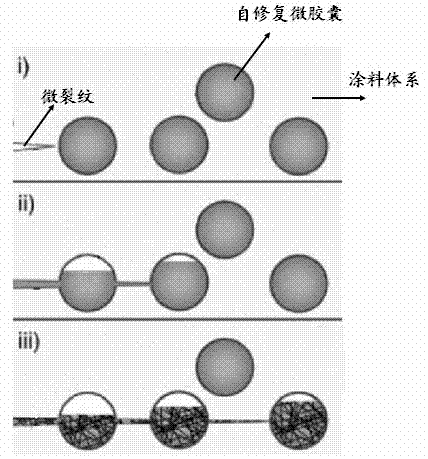

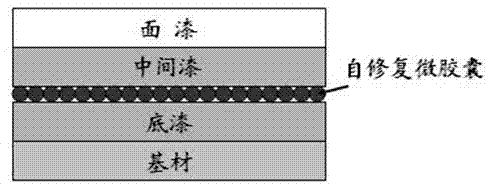

Automobile anticorrosive coating with self-recovery function and application thereof

InactiveCN102390147AWide variety of sourcesIntegrity guaranteedSynthetic resin layered productsAnti-corrosive paintsAuto industryCrazing

The invention provides an automobile anticorrosive coating with a self-recovery function and application thereof and belongs to the field of automobile anticorrosive materials. In the automobile anticorrosive coating, self-recovery microcapsules are uniformly dispersed between an intermediate coat and a primer of an automobile coating so as to form the anticorrosive coating, of which the structure is similar to a sandwidge structure. Microcracks can be easily formed in the automobile coating due to influence of factors such as physical impact, temperature change, aging and the like on the automobile coating during long-time use; the self-recovery microcapsules embedded in the coating are damaged by an outer force; released core materials can directly generate crosslinking polymerization reaction with oxygen in the air without catalyst so as to recover the microcracks to prevent further corrosion on the metallic surface; and the automobile anticorrosive coating can be widely applied to self-recovery of automobile industrial anticorrosive coatings.

Owner:SOUTH CHINA UNIV OF TECH

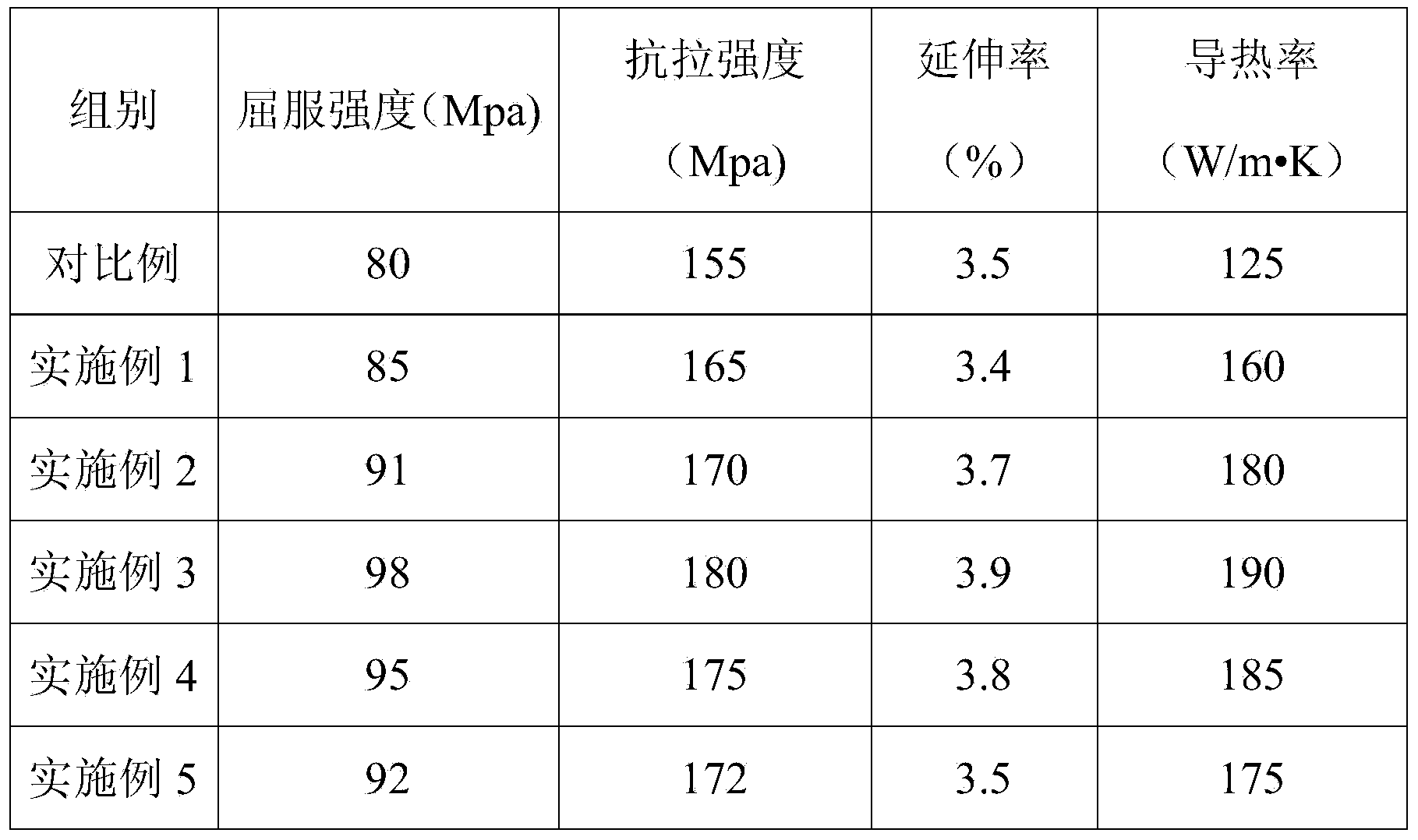

High-thermal-conductivity die casting aluminum alloy and preparation method thereof

The invention relates to a high-thermal-conductivity die casting aluminum alloy and a preparation method thereof. The high-thermal-conductivity die casting aluminum alloy comprises the following ingredients according to weight percent: 10.50wt%-13.50wt% of Si, 0.10wt%-0.50wt% of Co, 0.20wt%-0.40wt% of Fe, 0.01wt%-0.05wt% of Ti, 0.01wt%-0.05wt% of B, less than or equal to 0.2% of other impurities, and the balance of aluminum. In the preparation process of the die casting aluminum alloy, the cobaltous oxide is used as an alterant, the addition of elements of B and Ti is combined, so that the die casting aluminum alloy of which the thermal conductivity reaches 190 W / (m.K)is prepared. On the basis of an existing cast aluminum alloy ZL102, the thermal conductivity of the high-thermal-conductivity die casting aluminum alloy is remarkably improved, moreover the excellent die casting property is achieved, and the application requirements of IT and automobile industries are greatly met.

Owner:SUZHOU KAI YOU ELECTRONICS SCI & TECH LTD

Low-temperature-resistance polypropylene composition and preparation method thereof

The invention discloses a low-temperature-resistance polypropylene composition, which comprises the following components in percentage by weight: 40 to 75 percent of polypropylene resin, 15 to 45 percent of toughening system and 10 to 30 percent of mineral filler. The polypropylene resin is a propylene polymer of which the comonomers include ethylene, 1-butene and 1-hexylene, and the content of the comonomers is 5 to 20 percent. The toughening system comprises an elastomer and a toughening synergistic agent. The preparation method comprises the following steps: (1) adding a mineral filler anda polypropylene resin into a high-temperature mixer according to a certain ratio, pre-mixing at 170 to 250 DEG C, granulating, and cooling to obtain coarse material; and (2) uniformly mixing the coarse material with the left polypropylene resin, the elastomer and the toughening synergistic agent, adding the mixture to a double-screw extruder, melting and mixing at 180 to 230 DEG C, granulating, cooling, drying and packaging. The invention has the advantage that the low-temperature-resistance polypropylene composition can meet the safety and appearance use requirements of automobile industry and has high low-temperature impact resistance.

Owner:KINGFA SCI & TECH CO LTD +2

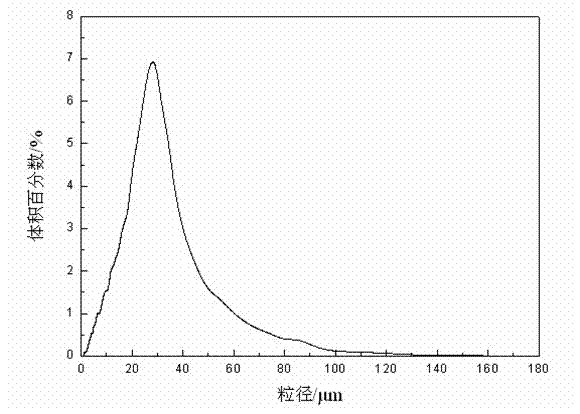

Self-repairing microcapsule used for metal anticorrosion coating and preparation method thereof

InactiveCN102391710AImprove mechanical propertiesWide variety of sourcesAnti-corrosive paintsMicroballoon preparationAuto industryCrazing

The invention discloses a self-repairing microcapsule used for a metal anticorrosion coating and a preparation method thereof, which belong to the technical field of self-repairing materials. The wall material of the self-repairing microcapsule is urea resin, the core material of the self-repairing microcapsule is natural plant oil, and the self-repairing microcapsule is prepared with a one-step in-situ polymerization method. The natural plant oil has the advantages of wide source and low cost and is easy to obtain. The metal anticorrosion coating is coated on the surface of metal to form an anticorrosion coating. Microcracks appear in the long-term use process, the self-repairing microcapsule embedded in the coating is broken by external force, and released natural plant oil and oxygen in the air can directly generate crosslinking polymerization reaction without catalysts to repair the microcracks to prevent the surface of the metal from being further corroded. The self-repairing microcapsule synthetized by the core material substance has the advantages of good mechanical performance, simple preparation technology and low cost and can be widely applied to the self repairing of metal anticorrosion coatings, such as automobile industry, ship industry and the like.

Owner:SOUTH CHINA UNIV OF TECH

Electrostatic Composition Based On A Polyamide Matrix

InactiveUS20070203282A1Improve balanceImprove temperature stabilitySpecial tyresPolyamide coatingsChemistryElectrically conductive

The invention relates to a composition based on a polyamide matrix comprising electrically conductive charges and antistatic agents. This composition makes it possible to obtain plastic articles, for example, body parts used in the automobile industry that are well-suited for painting by means of an electrostatic paint deposition process.

Owner:RHODIA ENG PLASTICS

Easily-degradable environment-friendly plastic

The invention relates to an easily-degradable environment-friendly plastic. The plastic comprises the following components by weight: 40 to 70 parts of ABS, 3 to 8 parts of an interface coupling agent, 3 to 10 parts of a toughening agent, 0.5 to 1.0 parts of a dispersion lubricant, 5 to 10 parts of starch and 10 to 15 parts of polyethylene. The easily degradable environment-friendly plastic provided by the invention has excellent degradability and environment friendliness and can be widely used in the automobile industry for manufacturing of auto parts, the household appliance industry and the architectural ornament industry and used for production of daily necessities like safety helmets, motorcycle gear plates, heelpieces, snow sports goods, toys, clocks, shells of loudspeaker boxes, suitcases, buttons and cosmetic boxes and advertising articles like nameplates and accessories.

Owner:广东美特家家居用品有限公司

Automobile interior trim part material and preparation method thereof

The invention discloses an automobile interior trim part material which is characterized by being prepared from raw materials in percentage by weight: 70-90 percent of polypropylene, 5-25 percent of talcum powder, 0.1-7 percent of scratch resistant agent, 0.1-1 percent of processing aid, 0.05-0.8 percent of stabilizing agent, 0.1-2 percent of antioxidant, 0.05-0.8 percent of acid absorbent and 0.1-7 percent of toner; the scratch resistant agent is a nanometer-modified polysiloxane polymer elastomer having the molecular weight within 60-1000,000 range; and a nanometer modified agent is polyhedral oligomeric silsesquioxane. The automobile interior trim part material disclosed by the invention has the advantages of excellent scratch resistant performance, low cost and excellent heat stabilizing performance, impact resistant performance, strength, tenacity and other combination properties and well meets the requirement of an automobile industry on the good scratch resistant performance and the good combination properties. The preparation method of the automobile interior trim part material disclosed by the invention can be used for industrial scale production. The special polypropylene material used in the invention can be used for interior trim parts such as an automobile instrument panel, a central console box, an upright post, a tailboard lining, a seat, an inner side wall of an automobile door and the like.

Owner:CHONGQING UNIV OF ARTS & SCI

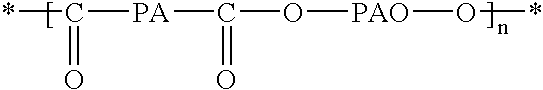

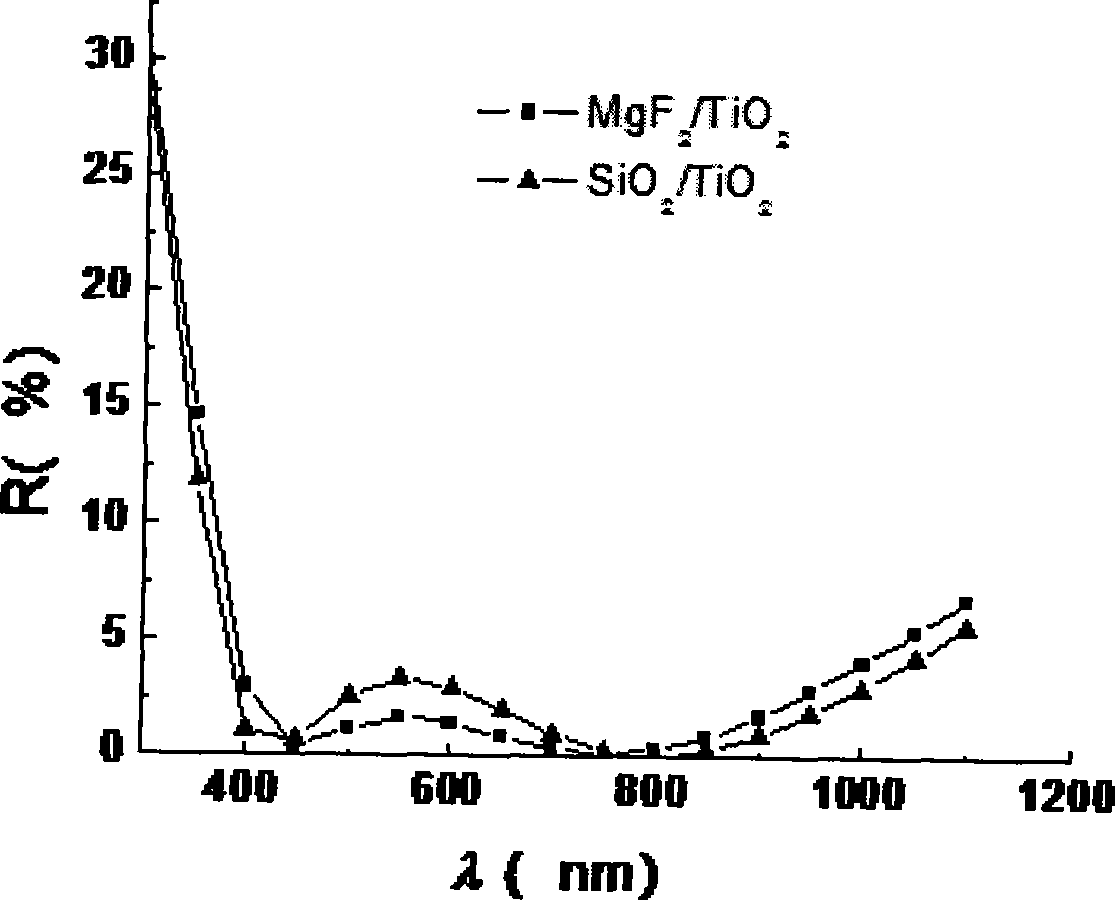

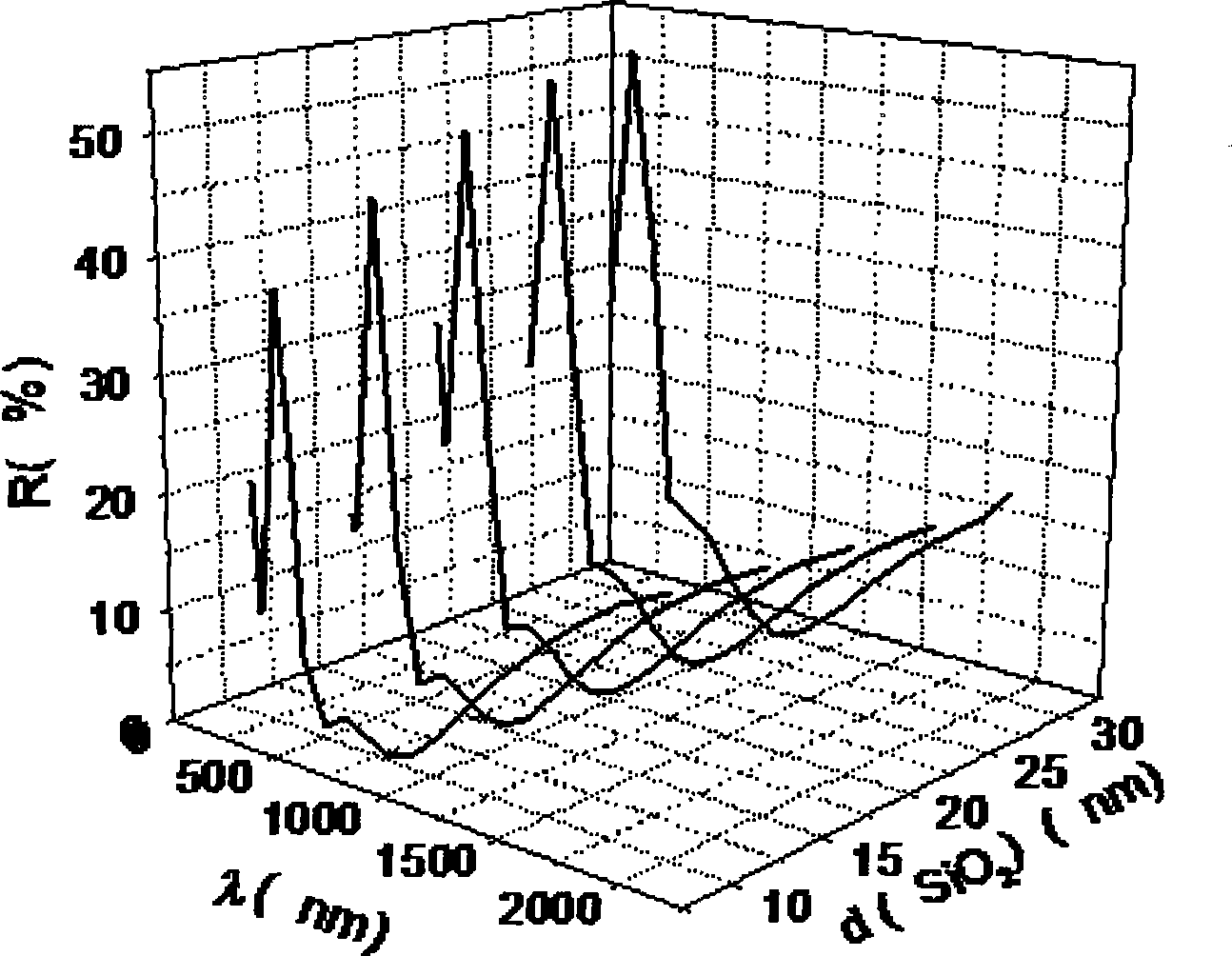

Nano-material anti-reflection film with low refractive index

InactiveCN101431110ABest Film ParametersSmall weighted average reflectancePhotovoltaic energy generationSemiconductor devicesAuto industryBuilt environment

The invention relates to a low refractive index nano-material anti-reflecting film, and low refractive index nano-material is introduced to the design of the anti-reflecting film to obtain good effect; the design result of the low refractive index nano-material anti-reflecting film has the advantages of convenient technology, wide realization and application prospect, and the like; and the low refractive index nano-material anti-reflecting film provides preparation parameters for the preparation of space silicon solar anti-reflecting film, and can be applied to the fields of solar energy industry, communication, building environment protection energy saving, IT industry, auto industry, military affairs, aerospace engineering, and the like.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

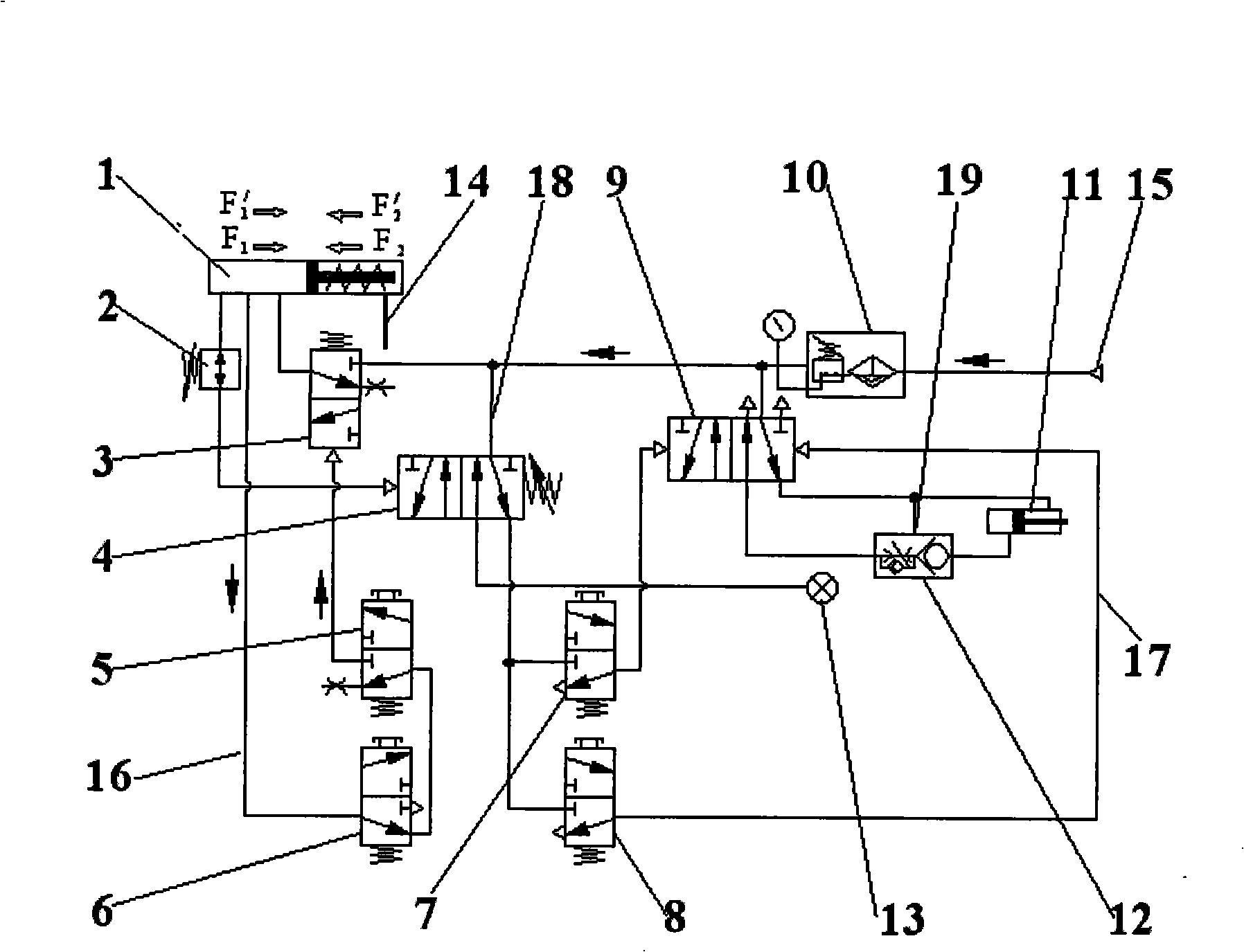

Industrial production sling safety system and security protection method

ActiveCN101269781ASimple structureReasonable structureServomotor componentsSafety gearControl systemProtection system

The invention discloses an industrial production lifting tool safety protection system, which comprises a pneumatic balancer (1), a clamping cylinder (11) and a main air supply (15), wherein, the pneumatic balancer is used for the elevation and the subsidence of a lifting tool; the clamping cylinder is used for tightly holding a workpiece; the main air supply is used for the drive and the control; the safety protection system is provided with a lifting tool elevation-subsidence control air circuit (16), a workpiece clamping air circuit (17), an elevation-subsidence and clamping interlocking air circuit (18) and an air-break protection air circuit (19), and each of the air circuits is communicated with the main air supply (15) by the same air circuit. The invention also relates to a safety protection method adopted by the industrial production lifting tool safety protection system. By adopting the technical proposal, a production lifting tool used in industrial production especially automobile industrial production realizes mutually correlative multiple safety protection, the safety protection system has the advantages of simple and reasonable structure and convenient and reliable operation, and the safety performance of the system is guaranteed and accidents of incorrect manipulation, air break, air leakage, etc. are stopped to happen.

Owner:CHERY AUTOMOBILE CO LTD

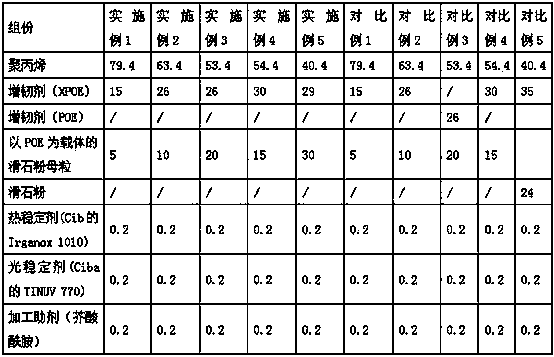

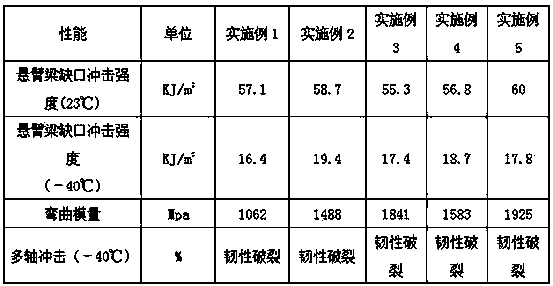

Ultra-low temperature toughened polypropylene composition

The invention discloses an ultra-low temperature toughened polypropylene composition. The ultra-low temperature toughened polypropylene composition comprises the following components: 40-80% of polypropylene, 15-30% of a toughening agent and 5-30% of a filling reinforcing agent. According to the invention, elastic bodies with low density, low melt index and low glass transition temperature are selected and used to be in crosslinking with dicumyl peroxide (DCP) to obtain XPOE used as the toughening agent. The prepared polypropylene composition has good low temperature impact toughness, particularly, the multi-shaft low temperature impact strength, and also has good rigidity. An automobile upholstery prepared by using the ultra-low temperature toughened polypropylene composition can meet the automobile industrial safety and appearance use requirements, and can pass an ultra-low temperature (-40 DEG C) multi-shaft impact test.

Owner:TIANJIN KINGFA NEW MATERIAL +1

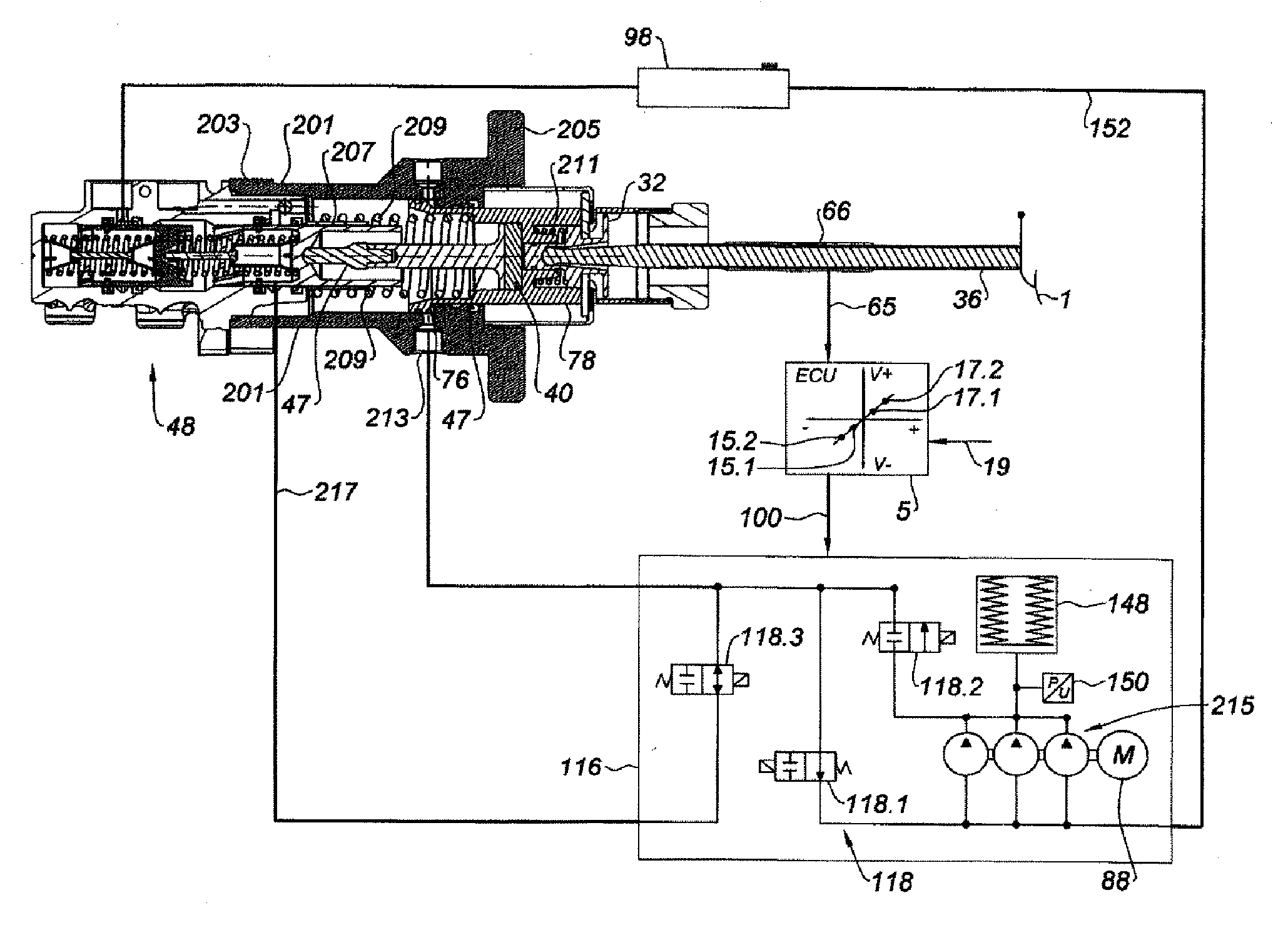

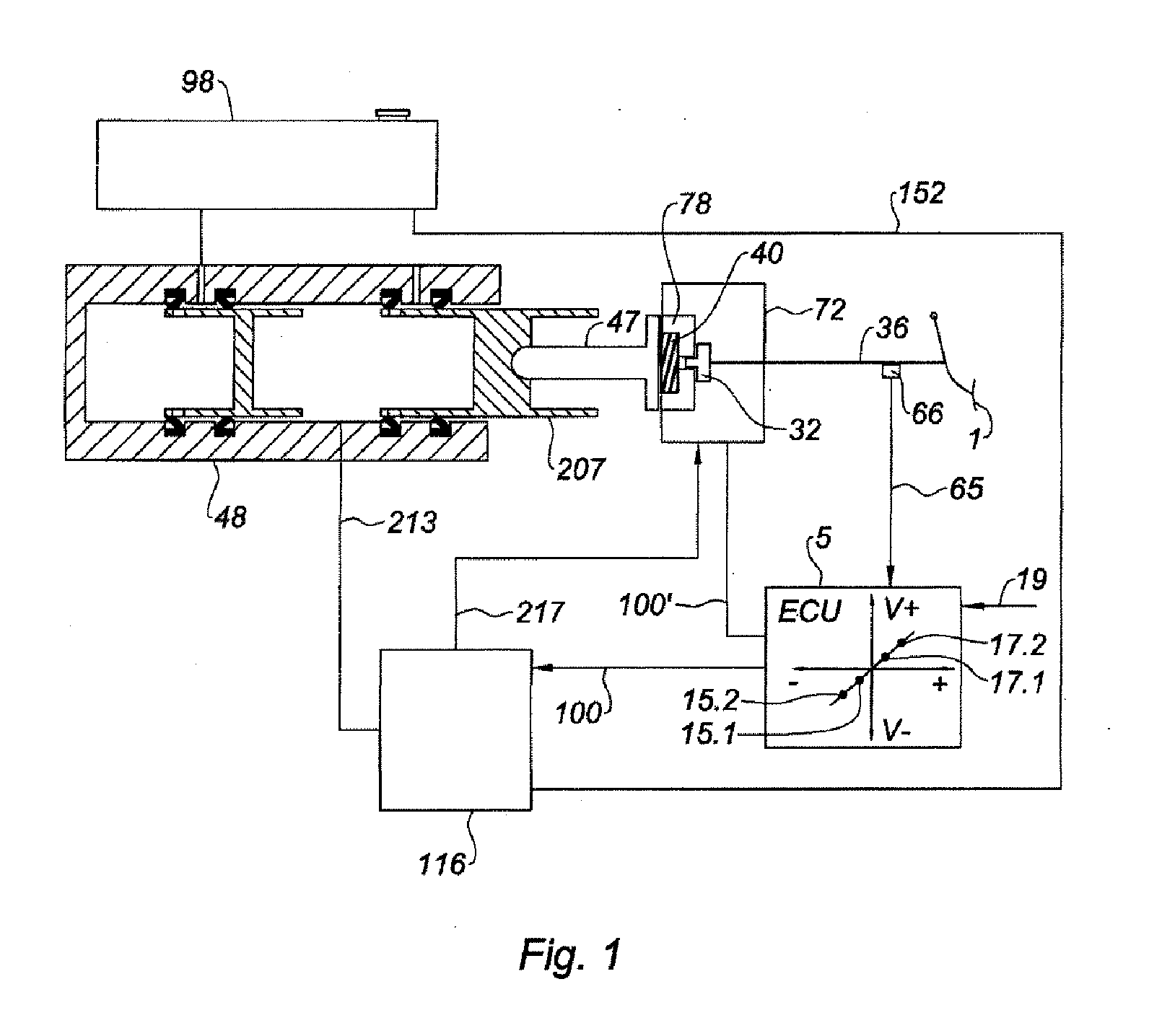

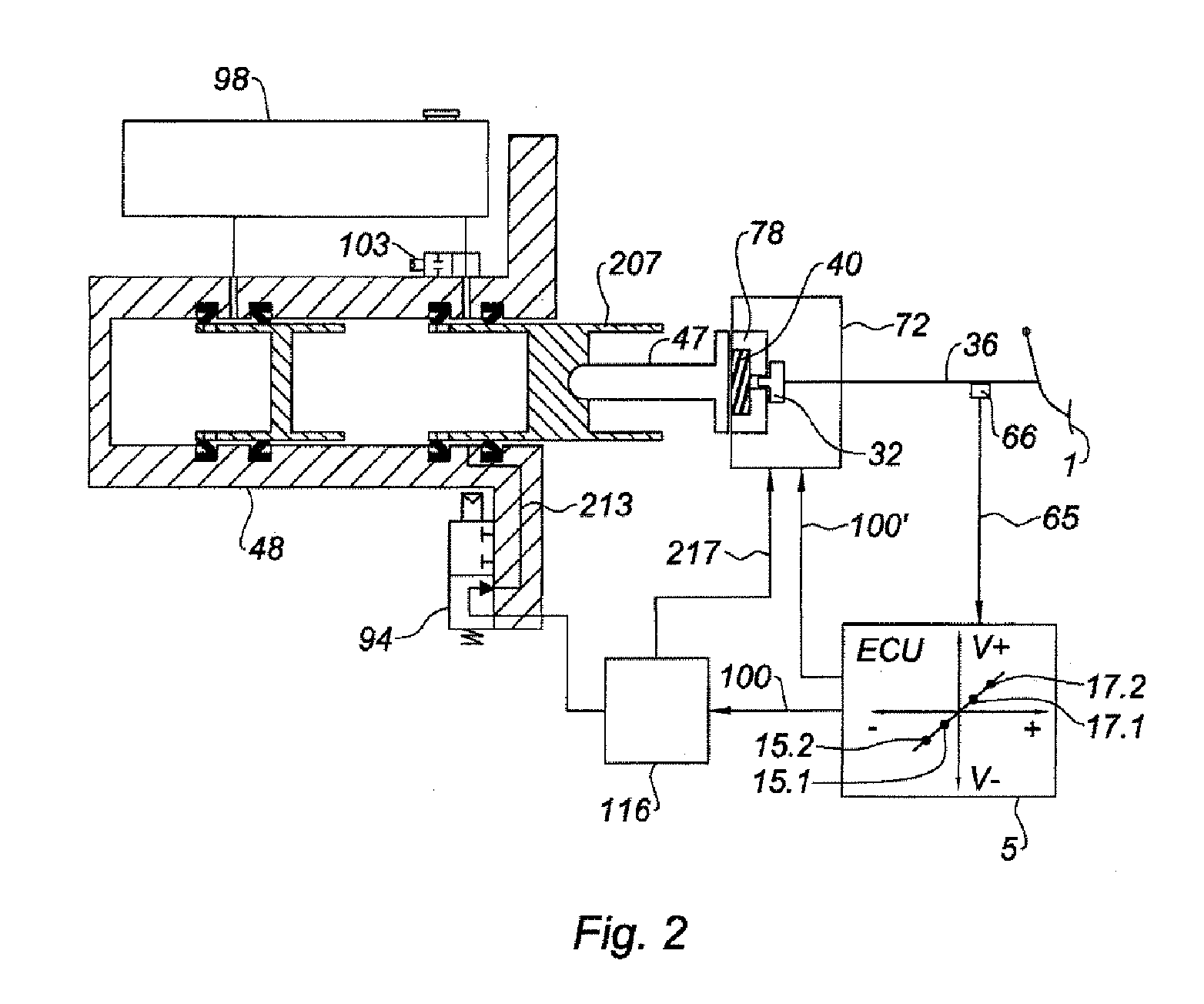

Master Cylinder Comprising Means For Injecting Brake Fluid Into Said Master Cylinder, And Braking System Comprising Such A Master Cylinder

ActiveUS20110120122A1Easy to produceHighly robustRotary clutchesTelemotorsMaster cylinderControl theory

The present invention relates mainly to a braking system comprising a master cylinder comprising means of connection to a hydraulic braking circuit and means of connecting at least one chamber of the master cylinder to means of injecting brake fluid into said chamber.The main subject of the invention is a master cylinder (48) comprising at least one variable-volume chamber and one moving piston (207), the movement of which causes the volume of said chamber to vary, and means of connecting said chamber to a hydraulic braking circuit, characterized in that it further comprises means (217) of connection to a source (116) of pressurized brake fluid.The invention applies notably to the motor industry.The invention applies mainly to the braking industry.

Owner:ROBERT BOSCH GMBH

High-strength and high-toughness die-casting aluminum alloy for automobile structural part and preparation method and application of high-strength and high-toughness die-casting aluminum alloy for automobile structural part

InactiveCN112176231ALow costLower yield strengthNon-rotating vibration suppressionSuperstructuresAuto industryVehicle frame

The invention discloses a high-strength and high-toughness die-casting aluminum alloy for an automobile structural part and a preparation method and application of the high-strength and high-toughnessdie-casting aluminum alloy for the automobile structural part. The high-strength and high-toughness die-casting aluminum alloy for the automobile structural part comprises the components of, 8.0%-12.0% of Si, 0.4%-1.2% of Mn, 0.1%-0.6% of Mg, 0.01%-0.2% of Sr, 0.005%-0.25% of Fe, 0.005%-0.2% of Sc and the balance Al and inevitable trace impurities, the content of a single element in the trace impurities is smaller than or equal to 0.1%, and the total amount of the trace impurities is smaller than or equal to 0.3%. The high-strength and high-toughness die-casting aluminum alloy is applied to the automobile stress structural part, the automobile stress structural part comprises an auxiliary frame and a shock absorber support, compared with a traditional aluminum alloy die-casting material and a mainstream Silafot36 aluminum alloy, the high-strength and high-toughness die-casting aluminum alloy has more excellent mechanical properties at a lower cost, is excellent in yield strength, tensile strength and elongation, is beneficial to the automobile industry to obtain higher performance at a lower cost, and is beneficial to the light weight of an automobile.

Owner:苏州有色金属研究院有限公司

Preparation method of ultrathin modified hydrotalcite and application thereof to rubber gas barrier thin film material

ActiveCN106674572AExtended Diffusion PathImprove interface compatibilityConjugated diene hydrocarbon coatingsHydrotalciteComposite filmHeat stability

The invention discloses a preparation method of ultrathin modified hydrotalcite and an application thereof to a rubber gas barrier thin film material. Firstly, coprecipitation is used for preparing ultrathin hydrotalcite with a high length diameter ratio, surface modification is carried out, spin coating method technology is used, the ultrathin modified hydrotalcite and rubber are compounded in order to form a film, and finally the gas barrier thin film material is prepared by compounding the ultrathin modified hydrotalcite and the rubber. The ultrathin hydrotalcite with a nanometer sheet shaped structure has high length diameter ratio, and can be used as a filler for substantially prolonging diffusion path of oxygen molecules in a thin film material; surface modification of hydrotalcite can improve interfacial compatibility between hydrotalcite and rubber, and reduce free volume, so that the composite thin film materials has excellent gas barrier performance, good heat stability and mechanical performance. The method has wide source, low cost, and simple preparation, and accords with environmental protection requirements; and the method has wide application prospects in the fields of automobile industry, outdoor packaging and aerospace industry.

Owner:BEIJING UNIV OF CHEM TECH

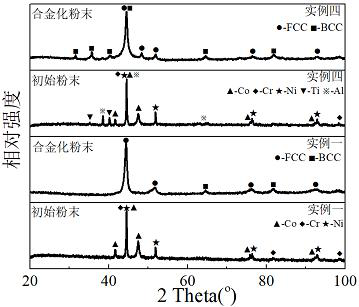

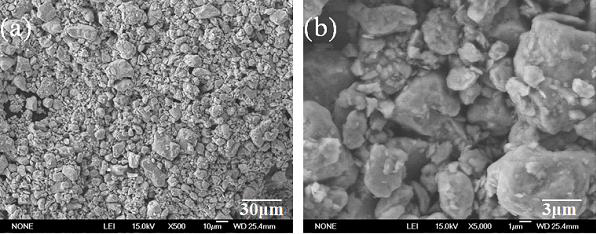

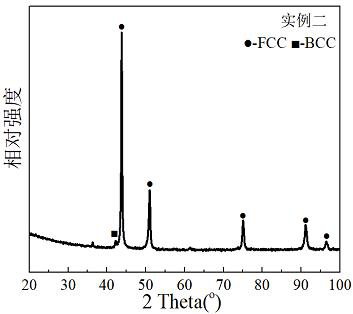

Medium-entropy alloy with high strength and high wear resistance and preparation method thereof

The invention relates to a medium-entropy alloy with high strength and high wear resistance. The medium-entropy alloy comprises the following components of (Co<1.1> CrNi<0.9>) <100-x> (Al<0.4>Ti<0.6>) <x>, x is a molar ratio, the value range of x is 0-20, the alloy is prepared from the following components of, in percentage by atom through a mechanical alloying process and spark plasma sintering, 29.3-36.7 at.% of Co, 26.7-33.3 at.% of Cr, 24.0-30.0 at.% of Ni, 0-8.0 at.% of Al and 0-12.0 at.% of Ti. Meanwhile, the invention further discloses a preparation method of the medium-entropy alloy. The prepared medium-entropy alloy has excellent strength, plasticity and wear resistance, and has important application prospects in the fields of aerospace and automobile industry high-temperature mechanical transmission moving parts.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Super-transparent acrylate pressure-sensitive adhesive emulsion capable of being coated at high speed as well as preparation method and application thereof

ActiveCN106519106AEnsure mechanical stabilityHigh light transmittanceEster polymer adhesivesPressure sensitive film/foil adhesivesAuto industryPolymer science

The invention discloses super-transparent acrylate pressure-sensitive adhesive emulsion capable of being coated at a high speed. The super-transparent acrylate pressure-sensitive adhesive emulsion is prepared from the following raw materials in parts by weight: 60 to 90 parts of an acrylate soft monomer, 3 to 25 parts of an acrylate hard monomer, 0 to 10 parts of a functional monomer, 2 to 10 parts of a high-refractive-index monomer, 0 to 0.05 part of a molecular weight regulator, 0.1 to 0.8 part of a reactive anionic emulsifier, 0.1 to 0.5 part of a reactive non-ionic emulsifier, 0.02 to 0.1 part of a defoaming agent, 0 to 0.08 part of a base material wetting agent, 0.2 to 1.0 part of an initiator and water; the pH (Potential of Hydrogen) value of the pressure-sensitive adhesive emulsion is 7.5 to 8, and the solid content is 40 percent to 55 percent. The pressure-sensitive adhesive emulsion disclosed by the invention can be coated at the high speed (150m / min to 300m / min), and an adhesive surface has no defects including bubbles and the like; the stripping force is not lower than 2.0N / 10mm, and the light transmittance can reach 90 percent or more; the super-transparent acrylate pressure-sensitive adhesive emulsion can be widely applied to protective adhesive films in the fields of manufacturing decoration, electronics, electrical appliances, automobile industries and the like.

Owner:余姚市维特胶粘制品有限公司

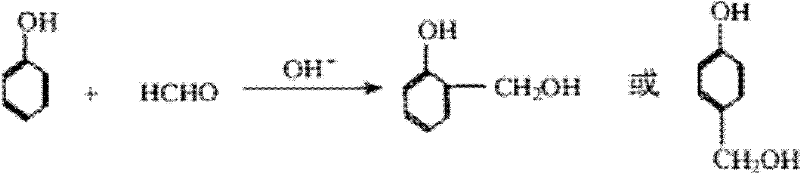

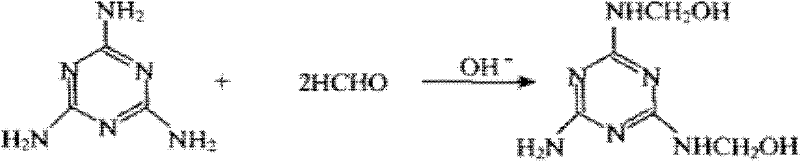

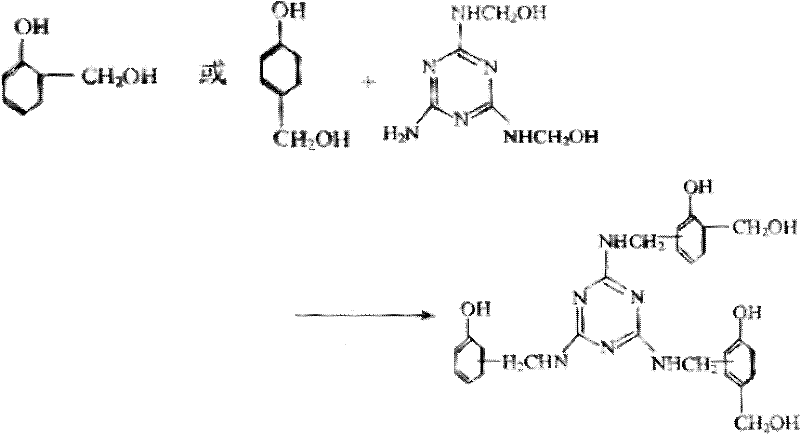

Preparation method of phenolic resin for auto-industry filter paper

The invention discloses a preparation method of a phenolic resin for auto-industry filter paper, which comprises the following steps: 1) aldehyde and phenol are subjected to a polycondensation reaction according to a molar ratio of 1.2 to 2.5:1 when the pH value is 7.5 to 9.0; 2) to a polycondensation product in the first step, an amine substance accounting for 20 to 60% of the mass of phenol is added, and the resultant product is stirred for 0.5 to 2hr at a temperature of 75 to 80 DEG C; 3) a product in the second step is subjected to vacuum distillation until the content of water is less than 7.5wt%; and an organic solvent is added for dilution, and a phosphate material is added, and then uniform mixing and cooling are carried out. The phenolic resin synthesized by the method provided by the invention can be used for auto-industry filter paper, and the flame retardancy of the industrial filter paper is improved.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

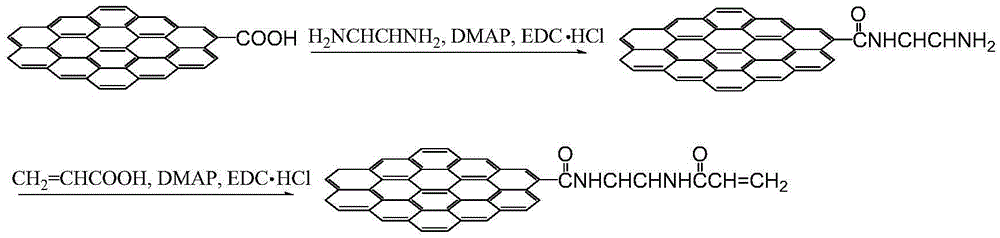

UV-resistant graphene quantum dot composite p-aramid fiber preparation method

ActiveCN105543997AGood dispersionShieldingArtifical filament manufactureMonocomponent polyamides artificial filamentBenzotriazoleUltraviolet

The invention discloses a UV-resistant graphene quantum dot composite p-aramid fiber preparation method. The preparation method comprises 1, graphene quantum dot vinylation functionalization, 2, grafting of reactive benzotriazole to the graphene quantum dots, 3, p-aramid modification through the reactive benzotriazole-grafted graphene quantum dots and 4, preparation of p-aramid fibers modified through the reactive benzotriazole-grafted graphene quantum dots. The p-aramid fiber has UV screening and absorption capabilities, has excellent UV resistance, improves a service life of the aramid fibers in air and can be used for an aerospace industry, national defense, an automobile industry, body armor, a communication cable and a sports car.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

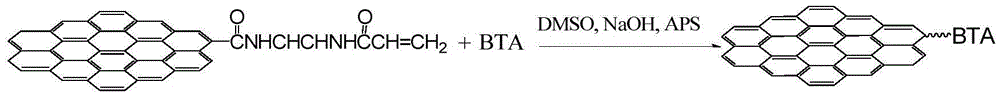

H bridge driving device of automobile electric boosting steering motor

InactiveCN101335493AImprove driving efficiencyAdapt to security requirementsEmergency protective circuit arrangementsEnergy industryElectric power steeringResistor

The invention discloses an H-bridge drive device of an electric power steering motor of an auto. The device comprises an H-bridge drive module, an H-bridge module, an undervoltage protection module, a motor armature current feedback module, an MOS tube on-bridge drain current monitoring and protecting module and an MOS tube down-bridge drain-electrode current monitoring and protecting module; each arm of the H-bridge module adopts the structure of the parallel connection of three N-channel MOS tubes; the drain electrodes of the three N-channel MOS tubes are connected together, the source electrodes are connected together, and the grid electrodes are connected together after being respectively connected with a resistor in series; the device reduces the power loss of the MOS tubes, enhances the drive efficiency of the H bridge and the reliability of the system, and can effectively avoid the influences of the emergency switching of the motor, the abrupt increase of the pulse current of the MOS tubes, and the abrupt change of armature current of the motor due to the special working conditions such as emergency large turning of an electric power steering system on the steering system, thus having high integration degree, good reliability, convenient use and being applicable to the requirement of safety, energy-saving and environment protection of the auto industry.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com