Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1848results about How to "Improve interface compatibility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Graphene composite material and preparation method thereof

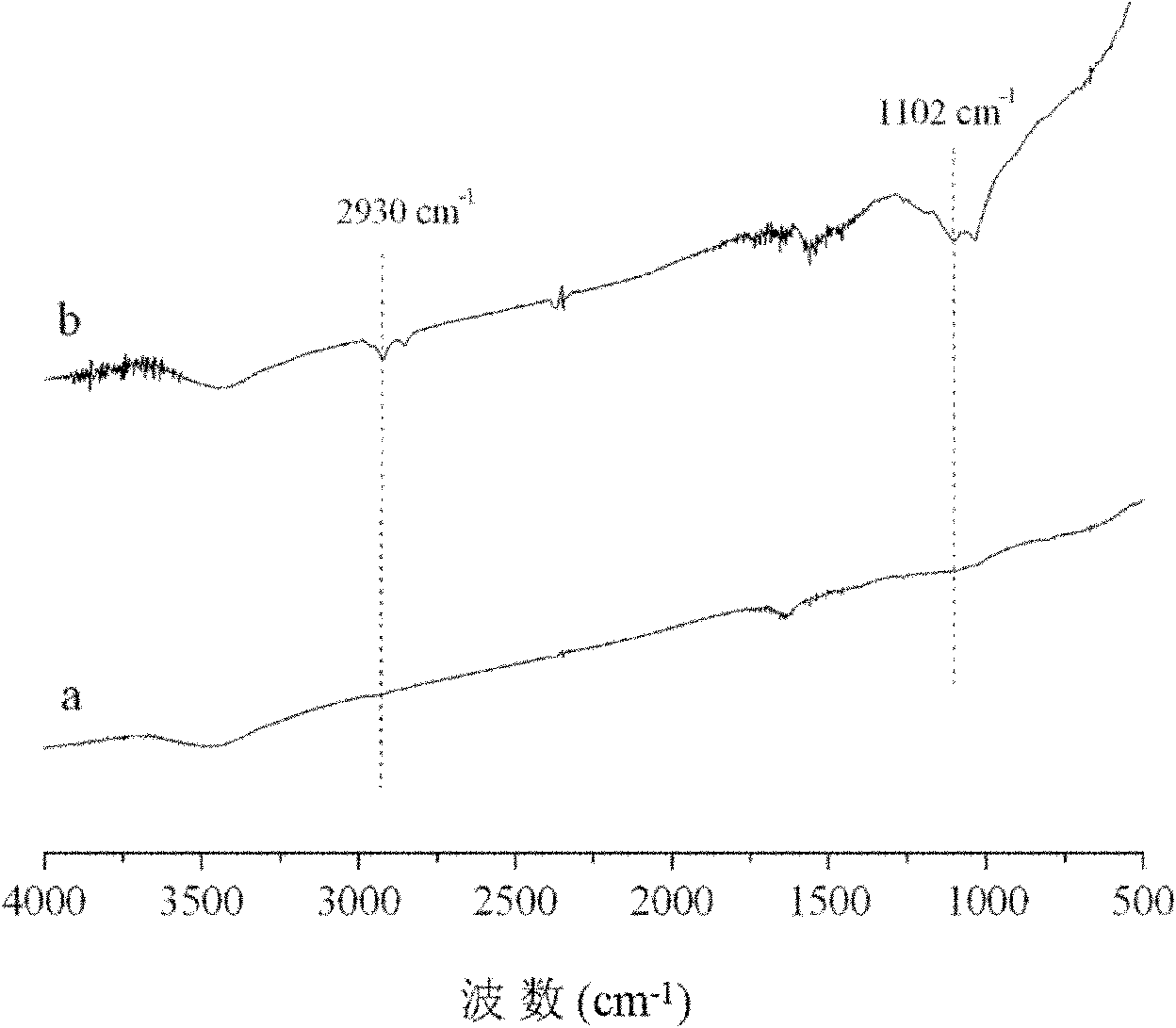

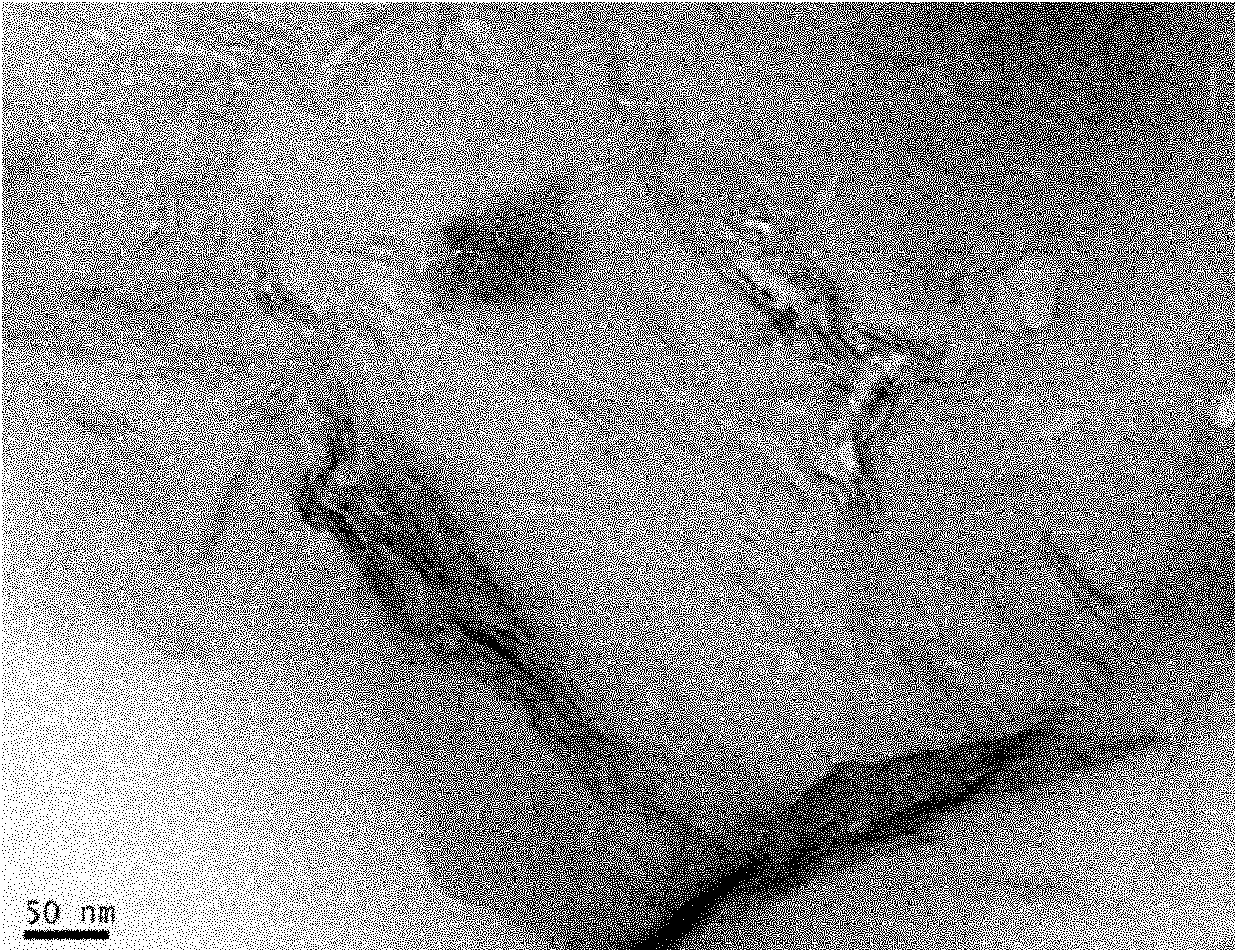

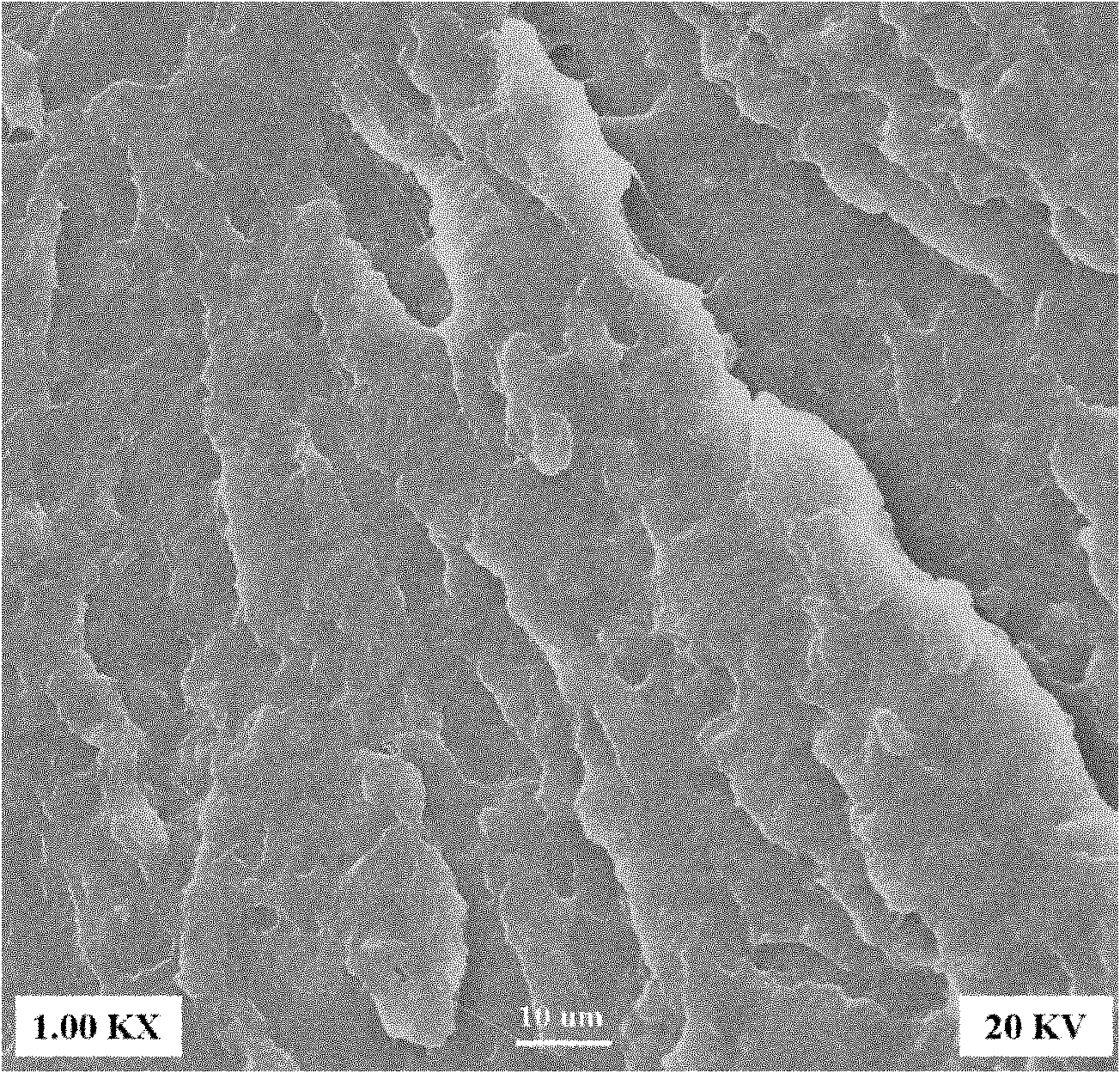

The embodiment of the invention discloses a graphene composite material and a preparation method thereof. In the method, graphene and organosilane are taken as reactants; the organosilane undergoes a hydrolysis reaction, and then undergoes a dehydration condensation reaction with hydroxyl on the graphene so as to obtain organosilane-modified graphene. Compared with the prior art, the organosilane-modified graphene expands the interlayer spacing of graphene, so that the organosilane-modified graphene is difficultly agglomerated when the organosilane-modified graphene is mixed with a polymer, the organosilane-modified graphene is uniformly dispersed in a polymer substrate, and a prepared graphene composite material has an enhanced effect. Moreover, the organosilane-modified graphene undergoes chemical bonding or intermolecular force with the polymer, so that the prepared graphene composite material has excellent interface compatibility. Proved by experiment results, the graphene composite material prepared in the invention has high mechanical property.

Owner:UNIV OF SCI & TECH OF CHINA

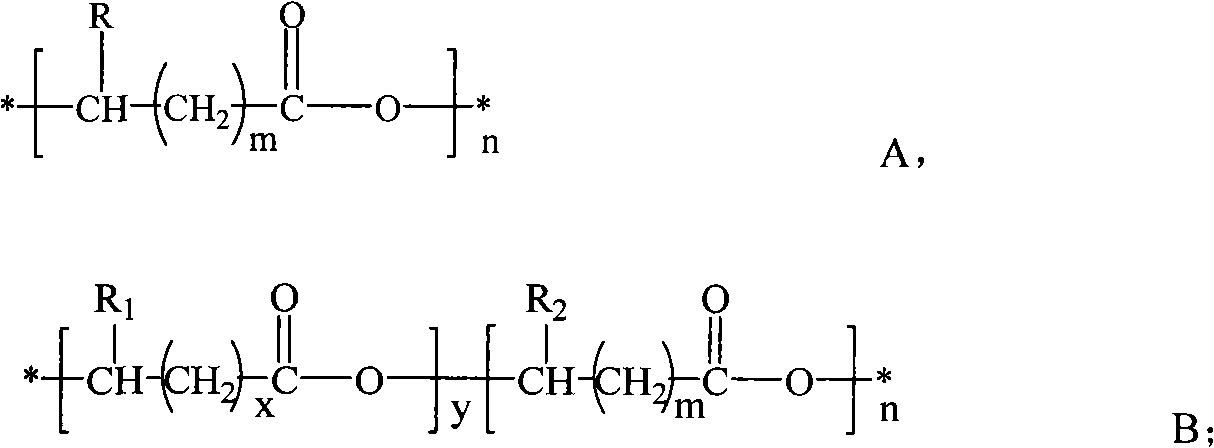

Fully-biodegradable PLA/PBAT composite film and making method thereof

The invention belongs to the technical field of high-molecular materials, and relates to a PLA / PBAT composite film and a making method thereof. The composite film is made by using the following components, by weight, 10-90 parts of polylactic acid, 10-90 parts of PBAT, 0.04-2.5 parts of a compatibilizer A, 0.04-2.5 parts of a compatibilizer B, 0-3 parts of a lubricant, 0-3 parts of an antioxidant and 1-50 parts of a filler. A blend provided by the invention has a very good flexibility, and the made film can be fully biodegraded, and can be widely used in the field of films.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Entire biodegradation PLA/PBAT composite material and preparing method therefor

The invention belongs to the technical field of polymer materials, and relates to an entire biodegradation PLA / PBAT composite material and a preparing method therefor. The composite material comprises, by weight, 10-90 parts of polylactic acid, 10-90 parts of poly(butylene adipate-co-butylene terephthalate)ester, 10-80 parts of thermoplastic starch, 0.01-1.5 parts of compatilizer A, 0.1-10 parts of compatilizer B, and 1-40 parts of filling materials. The preparing method and an operation process for the composite material are simple, product manufacturing cost is relatively low, the composite material has excellent mechanical properties, is of excellent flexibility, is entirely biodegradable, and can be widely used in the field of consumer products such as packaging materials and disposable tableware.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Bamboo powder filling biodegradable compound material and preparation method thereof

The invention relates to a bamboo powder filling biodegradable compound material and a preparation method thereof. The bamboo powder filling biodegradable compound material comprises the following raw materials in part by mass: 30 to 80 parts of biodegradable resin, 20 to 70 parts of bamboo powder, 1 to 19 parts of plasticizer, 0.6 to 6 parts of interface modifier and 4 to 12 parts of aids. The preparation method comprises the following steps of: uniformly mixing the biodegradable resin, bamboo powder, plasticizer, interface modifier and auxiliary agent by using a mixer according to formula proportion; performing melt blending and granulation of the obtained mixture by using a screw extruder to obtain particles; and processing the particles by using an injection molding machine, a sheet extrusion forming machine, a blow molding machine or a film blowing machine, and molding in molds of different shapes to obtain the bamboo powder filling biodegradable compound materials of different shapes. The method has the advantages of high production efficiency and low cost; and the powder filling biodegradable compound material prepared by the method has the advantages of high environmentally-friendly property and economy and excellent usability.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

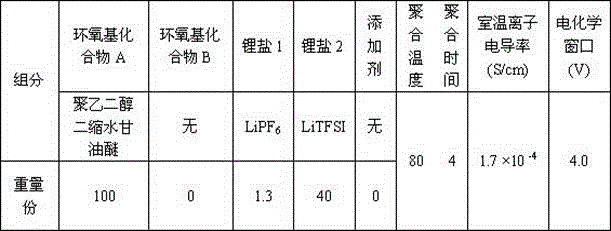

Preparation method of all-solid polymer electrolyte through in-situ ring opening polymerization of epoxy compound, and application of the all-solid polymer electrolyte in all-solid lithium battery

ActiveCN105914405AIncrease contactImprove interface compatibilityFinal product manufactureLi-accumulatorsEpoxySolid state electrolyte

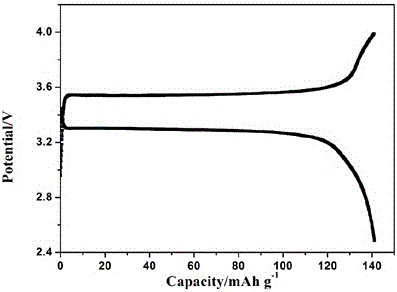

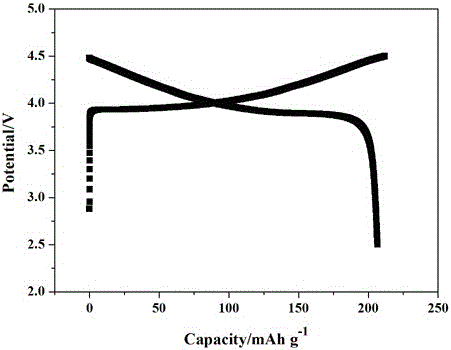

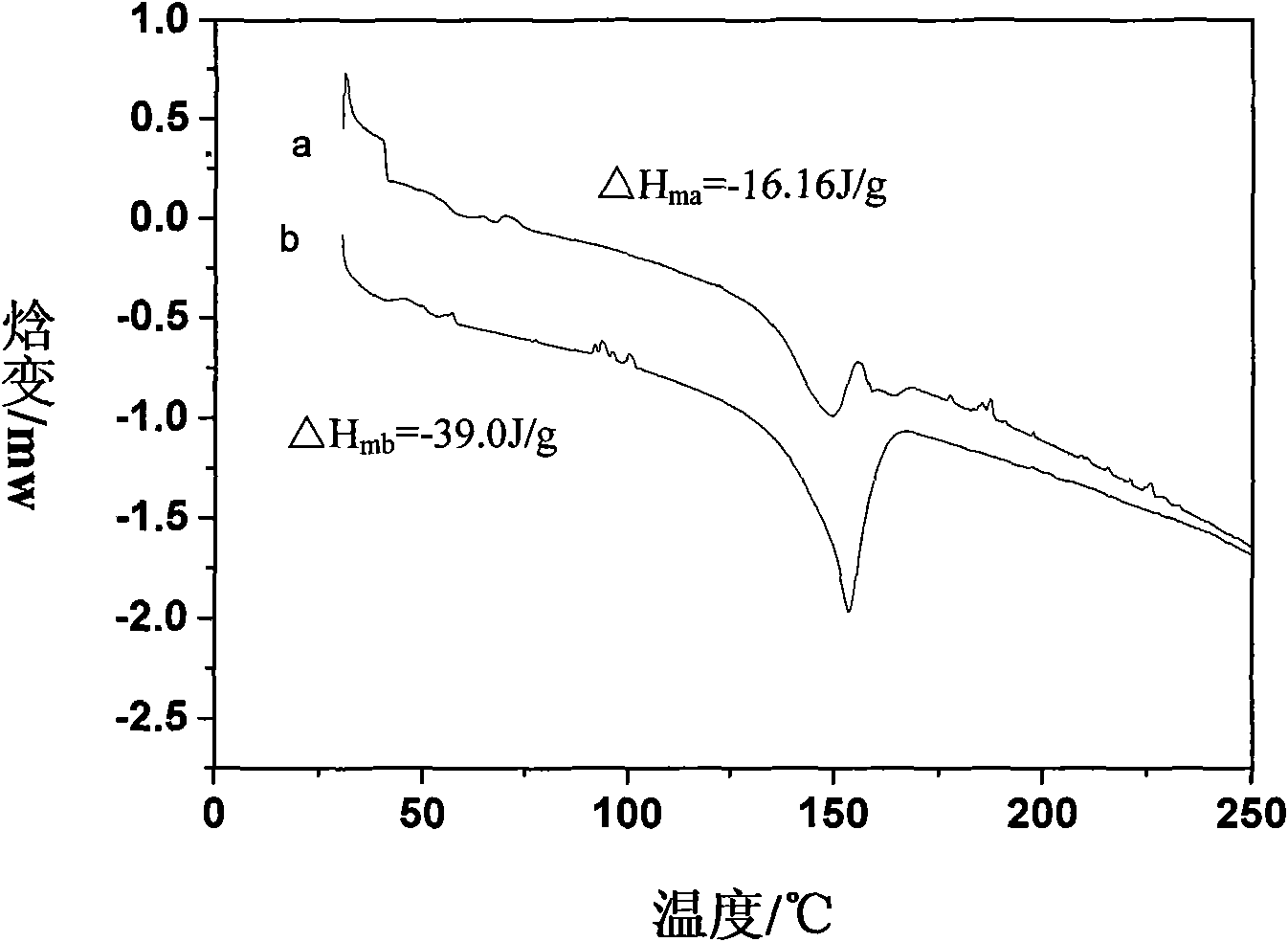

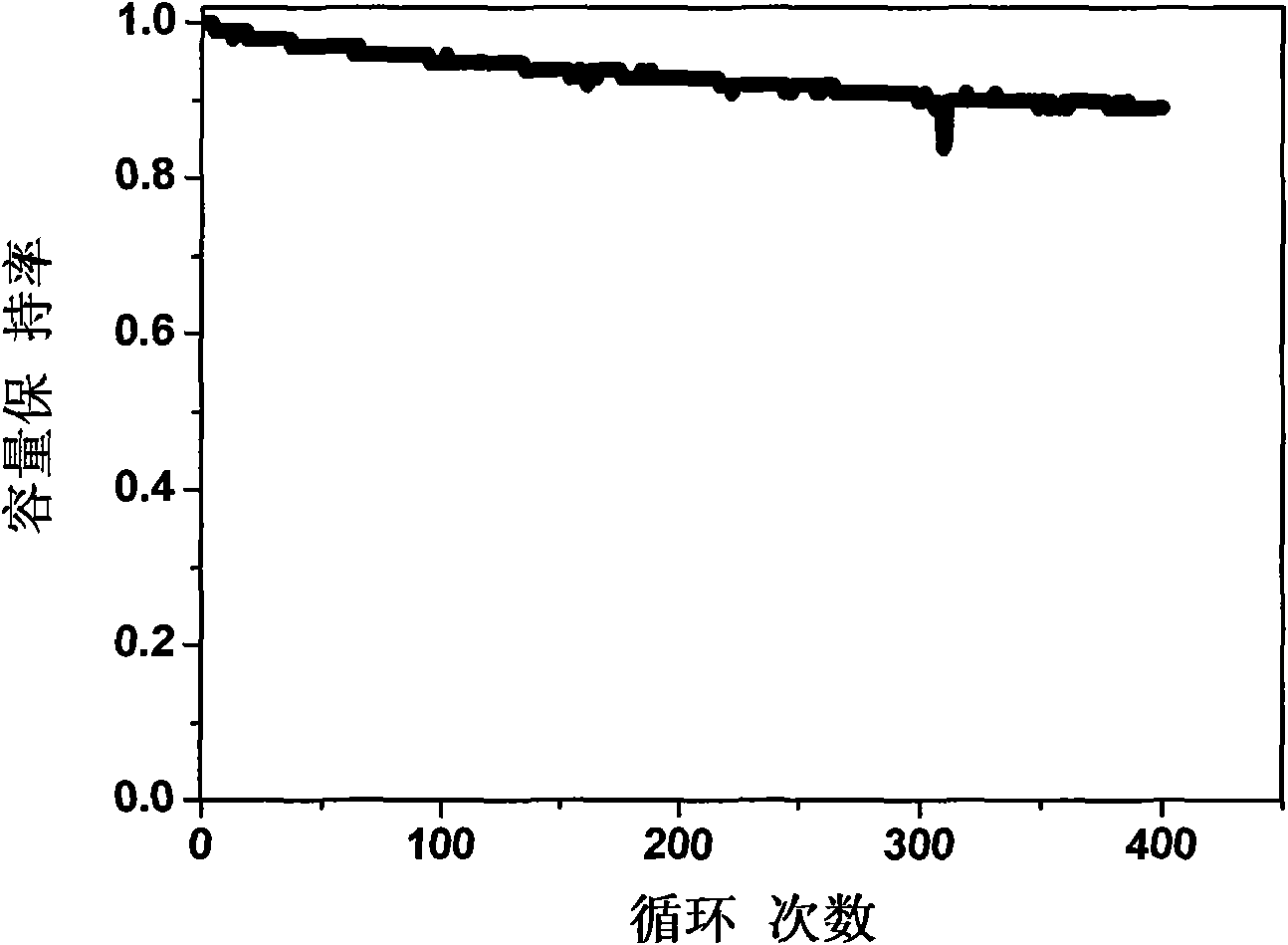

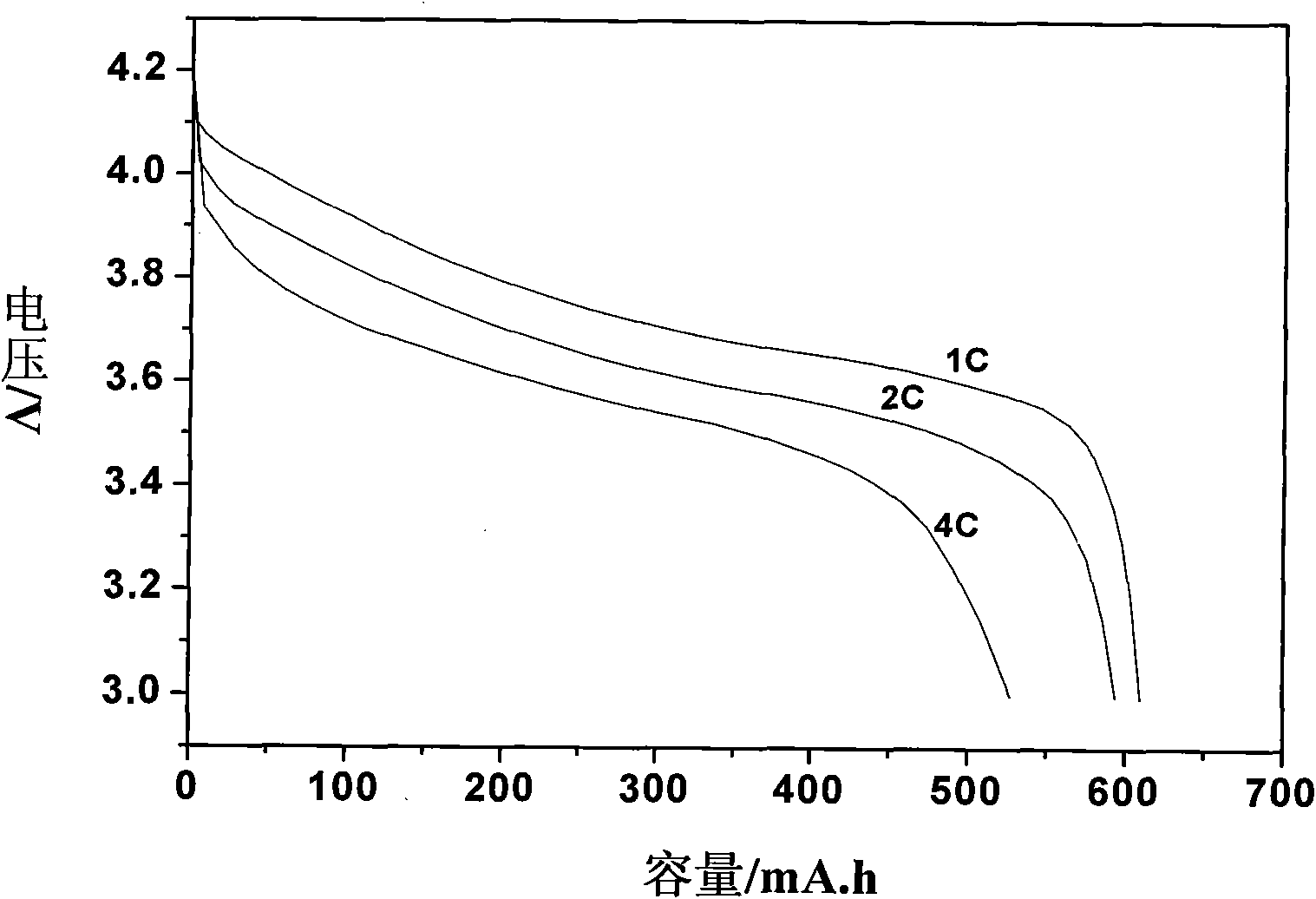

The invention discloses a preparation method of an all-solid polymer electrolyte through in-situ ring opening polymerization of an epoxy compound, and an application of the all-solid polymer electrolyte in an all-solid battery. The preparation method is characterized in that a liquid-state epoxy compound, a lithium salt, a battery additive and the like are employed as precursors and are injected into between a positive pole sheet and a negative pole sheet of the battery, and under a heating condition, in-situ polymerization solidification is carried out to form the all-solid polymer electrolyte, and furthermore, the all-solid battery is produced. The ionic conductivity at room temperature of the all-solid polymer electrolyte can reach from 1*10<-5> S / cm to 9*10<-3> S / cm and electric potential window is 3.5-5 V. The all-solid polymer electrolyte is prepared through the in-situ copolymerization method, so that the all-solid polymer electrolyte has excellent contact with electrodes, thereby greatly improving interface compatibility of the solid-state battery, reducing interface wetting and modification steps of the solid-state battery, reducing production cost of the solid-state battery and improving performances of the solid-state battery. The invention also discloses an all-solid polymer lithium battery assembled from the all-solid polymer electrolyte.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

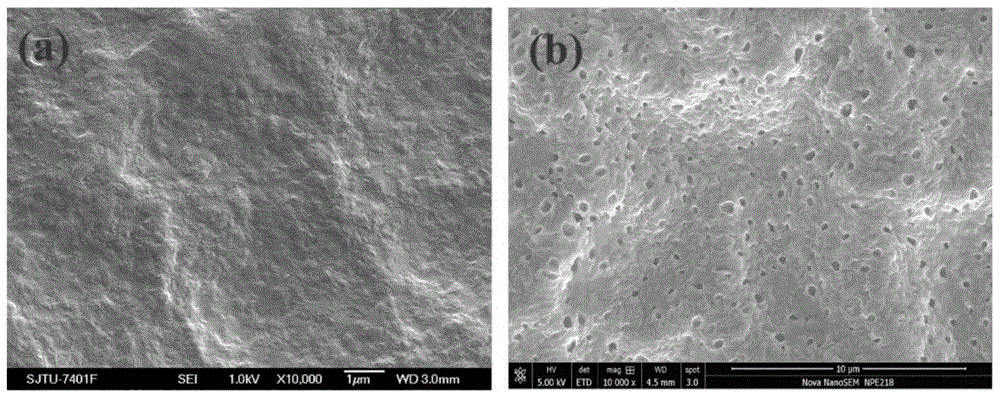

Polymer porous membrane, preparation method thereof, polymer electrolyte, polymer battery and preparation method of battery

ActiveCN102035043AImprove rate discharge performanceImprove cycle performanceFinal product manufactureSynthetic resin layered productsPolymer electrolytesPolymer science

The invention provides a polymer porous membrane, a preparation method of the polymer porous membrane, a polymer electrolyte, a polymer battery and a preparation method of the polymer battery. A carbon material is dispersed in the polymer porous membrane, so that the degree of crystallization of a polymer which constitutes the polymer porous membrane is lowered and the liquid absorption of the polymer porous membrane is increased; the liquid absorption rate, liquid holding capability and ionic conductivity of the polymer porous membrane are increased; interface impedance is reduced, battery magnification discharging performance and the circulating performance of the battery are enhanced; simultaneously, the battery prepared by the method has excellent high temperature circulation and storage performance and low expansion ratio at a high temperature and further meets the development requirement of the polymer battery. Simultaneously, the preparation method is simple and is easy to implement and the prepared battery has high performance.

Owner:SHANGHAI BYD

Water-resistant wood-plastic composite material and preparation method thereof

InactiveCN101613503AImprove interface compatibilityImprove composite effectPolyolefinPolymer substrate

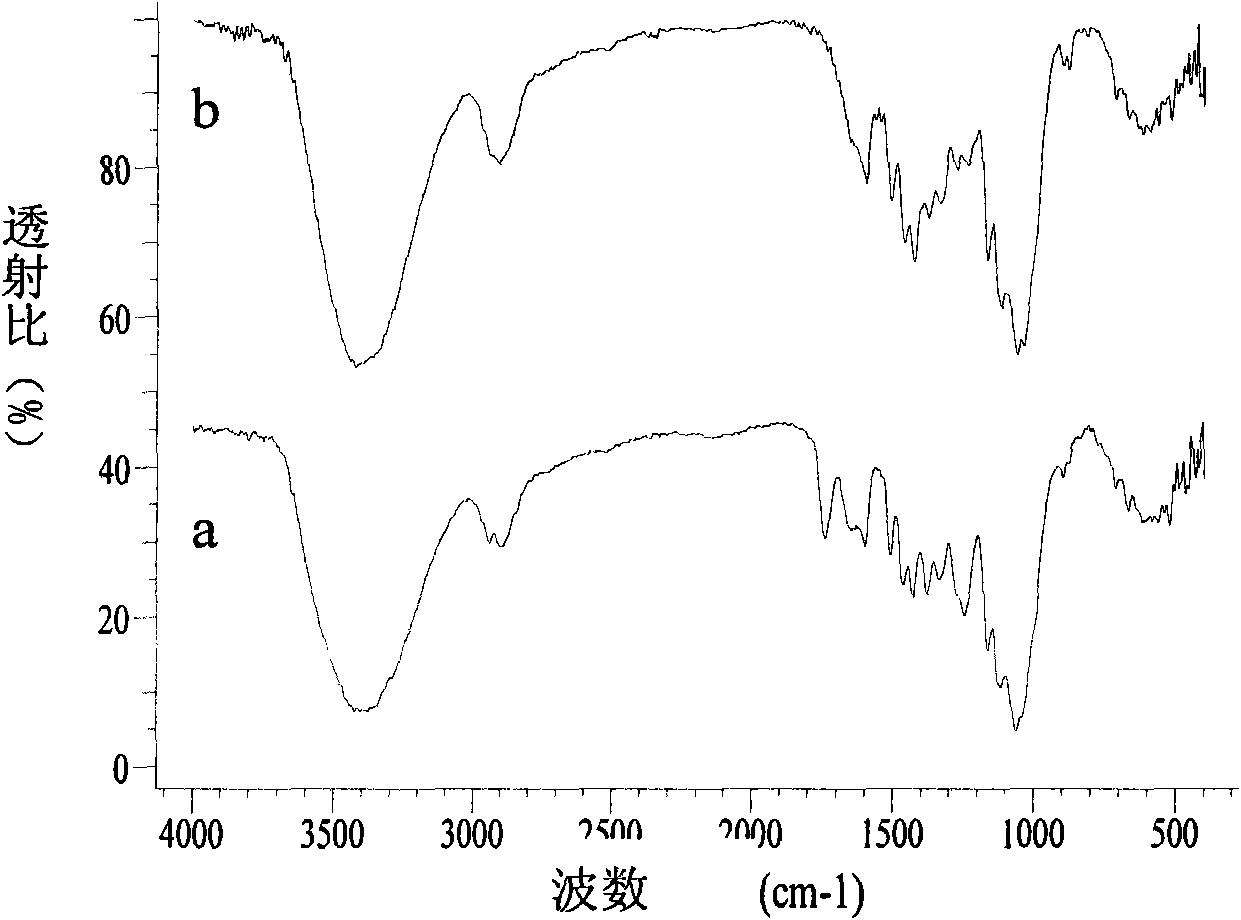

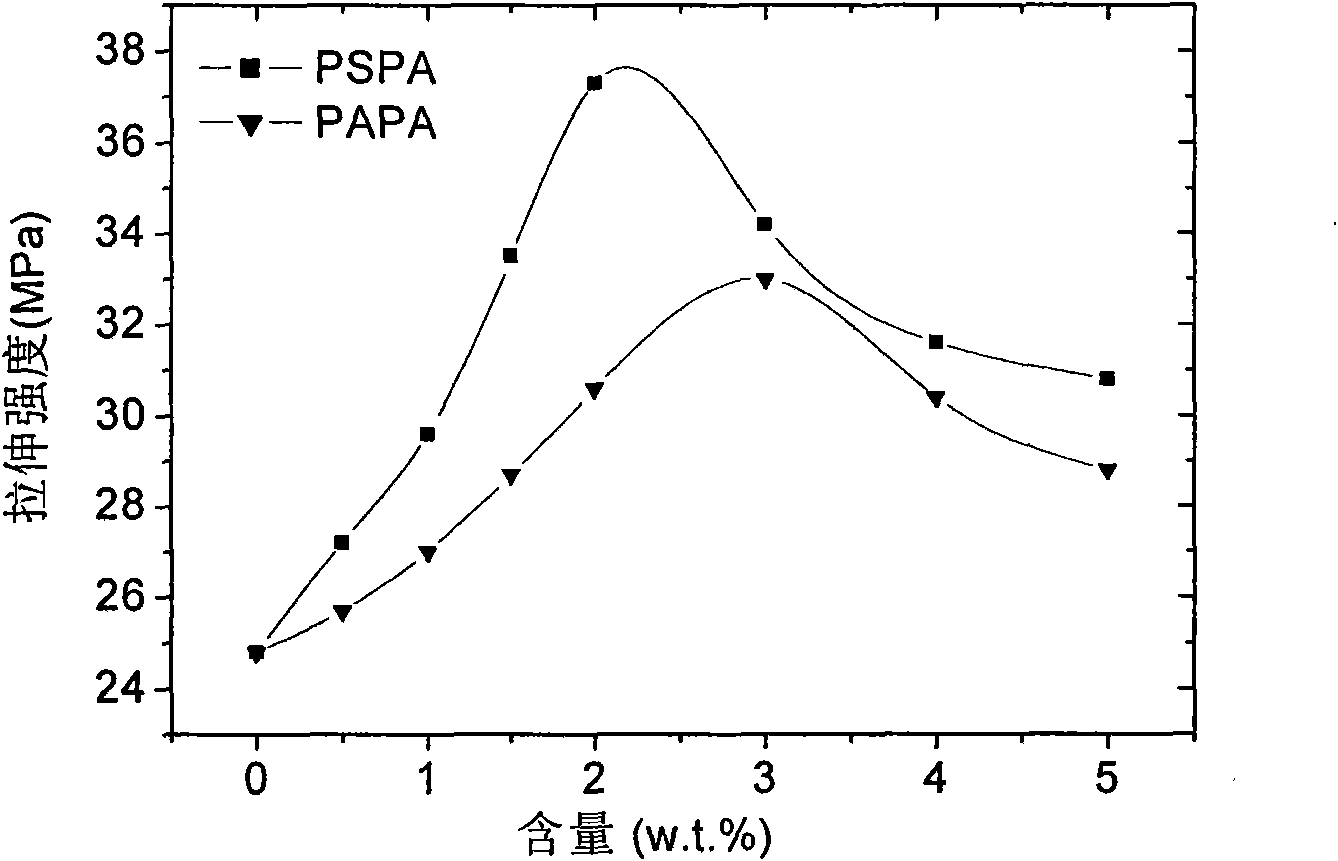

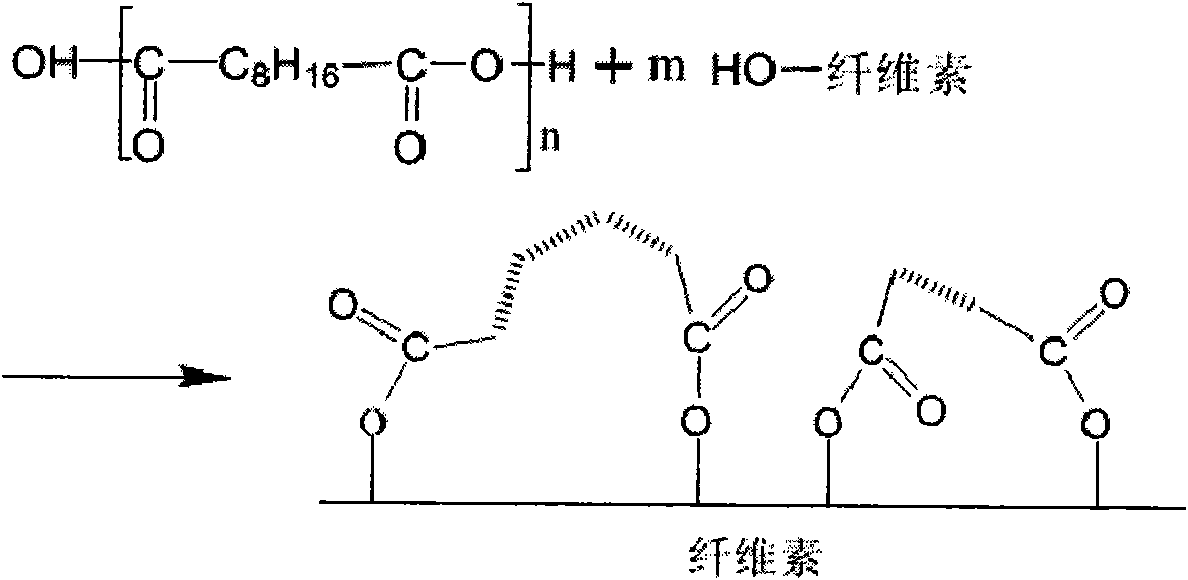

The invention discloses a water-resistant wood-plastic composite material, which is prepared from the following raw materials in percentage by weight: 1-65% modified wood powder, 25-98% of polyolefin matrix and 1-10% compatilizer; wherein, the compatilizer is one of polysebacic polyanhydride (PSPA) and polyazelaic polyanhydride (PAPA) or both the two. The invention also discloses a preparation method of the water-resistant wood-plastic composite material. The method is as follows: PSPA and / or PAPA are / is utilized to carry out segmented surface grafting on the wood powder to improve the interface compatibility between the wood powder and polyethylene, and the wood powder is pretreated by alkali liquor to removing unstable substances, such as semi-cellulose and esters with small molecules, in the wood powder, thus enhancing the composite effect and the mechanical property of lignocellulose to the polyolefin matrix and obtaining the wood-plastic composite material with excellent mechanical property, low water absorption capacity and good dimensional stability; in addition, the operation of the preparation method is simple, and the method is applicable to industrial production.

Owner:ZHEJIANG UNIV +1

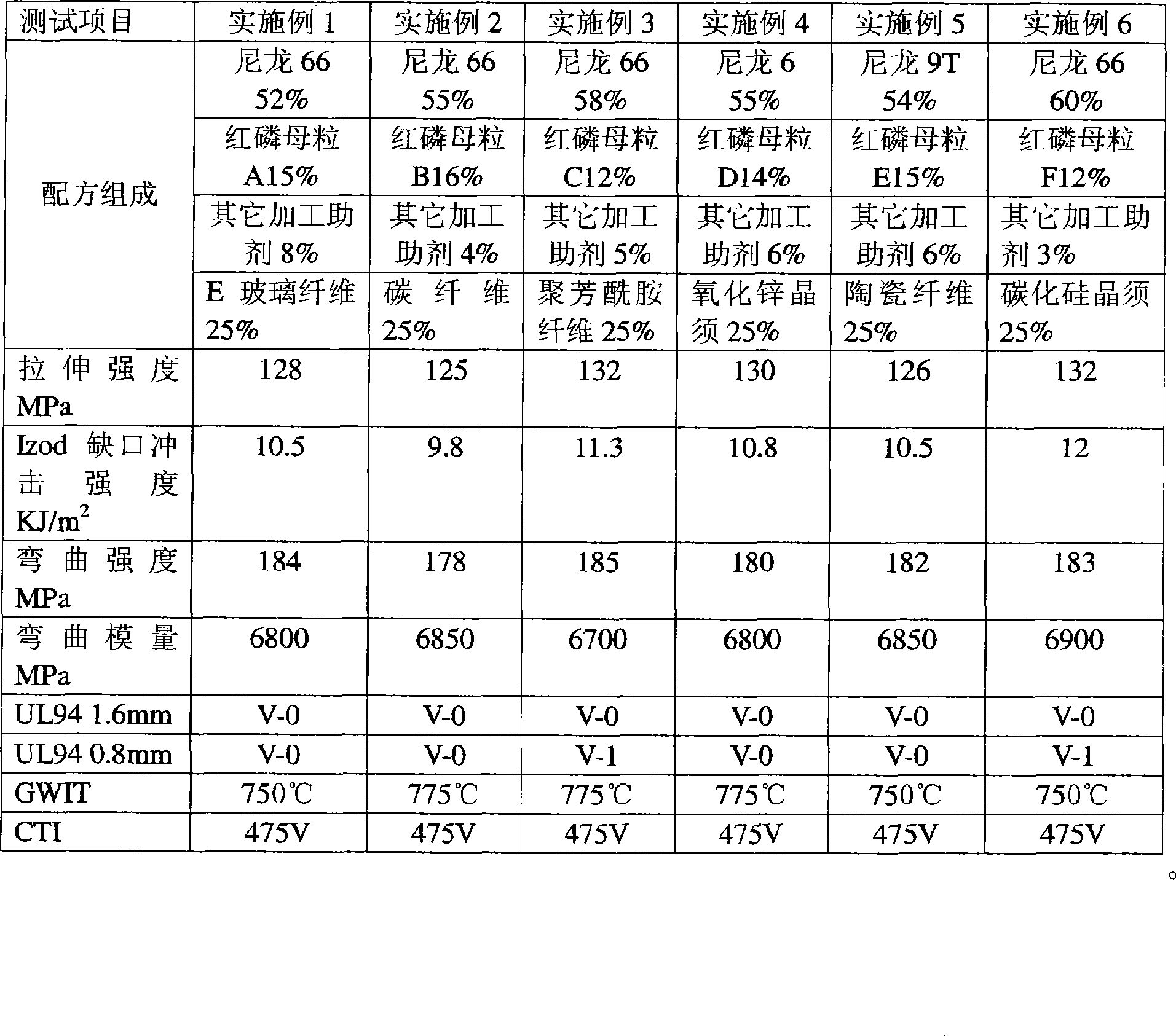

Red phosphorus flame-retardant enhanced thermoplastic polyamide composition

The invention discloses a red phosphorus flame retardation reinforced thermoplastic polyamide compound. The red phosphorus flame retardation reinforced thermoplastic polyamide compound comprises the following components by weight percentage: (1) 30 to 90 percent of thermoplastic polyamide resin; (2) 1 to 30 percent of red phosphorus which receives micro-encapsulation cladding treatment; (3) 10 to 50 percent of fiber reinforced material; and (4) 0 to 25 percent of additive. The red phosphorus flame retardation reinforced thermoplastic polyamide compound comprises an inorganic-organic composite cladding system; in addition, a thermosetting cladding system and a thermoplastic cladding system are used together in the organic cladding system; and the thermoplastic polymer introduced into the cladding system has good functions of interface compatibility and lubrication so as to prevent the clad red phosphorus from being damaged by the high temperature and strong shearing action in a screw extruder. The compound can serve as the thermoplastic red phosphorus flame retardation polyamide with industrial application value and can be successfully applied to the trades of electrical engineering, electronics, electric appliances, and the like.

Owner:KINGFA SCI & TECH CO LTD +1

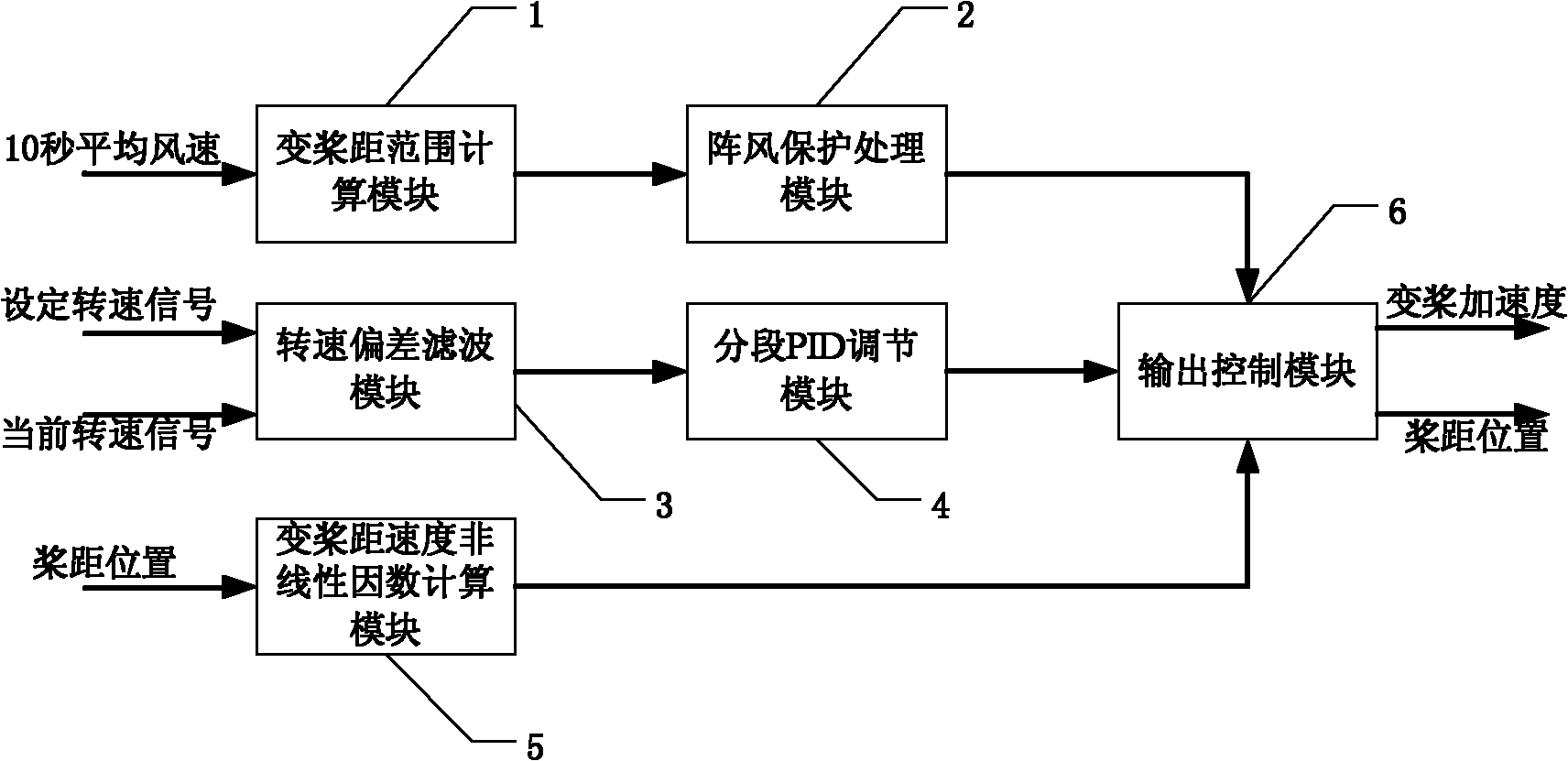

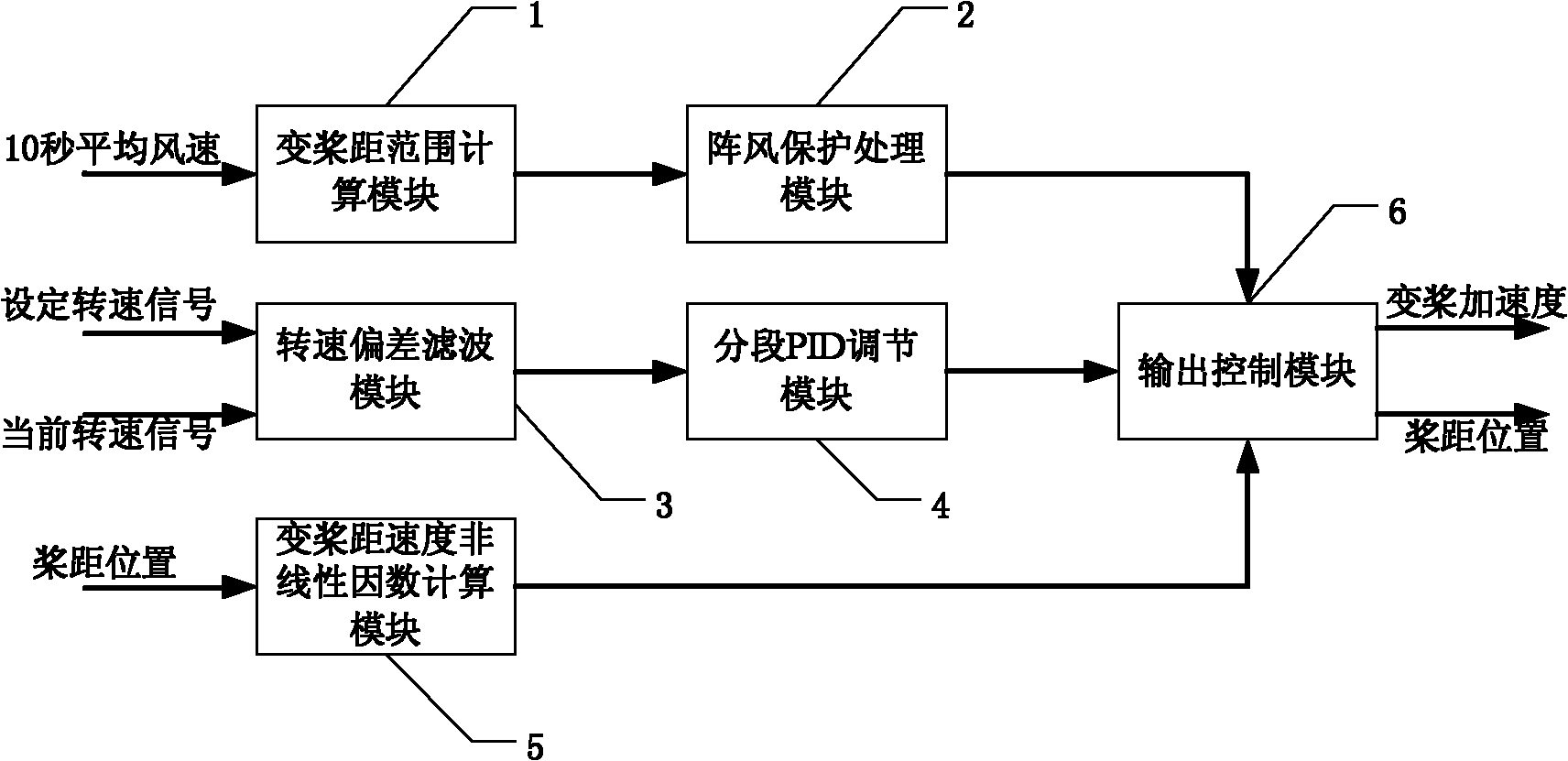

Fan control system adopting variable-structure PID (Proportion Integration Differentiation) variable-propeller control

ActiveCN101900080AStable speedStable speed control effectWind motor controlMachines/enginesProportion integration differentiationControl system

The invention discloses a fan control system adopting variable-structure PID variable-propeller control, which comprises a variable-propeller-pitch range computing module, a gust protection processing module, a rotating speed deviation filtering module, a segmented PID regulating module, a variable-propeller-pitch speed nonlinear factor computing module and an output control module. In the invention, the rotating speed of a generator is accurately controlled through the PID regulation for rotating speed deviation, and the fan control system has stable and reliable performance, can effectively improve the output power of a fan and has the advantages of excellent performance, safety and stability.

Owner:SHANGHAI ELECTRICGROUP CORP

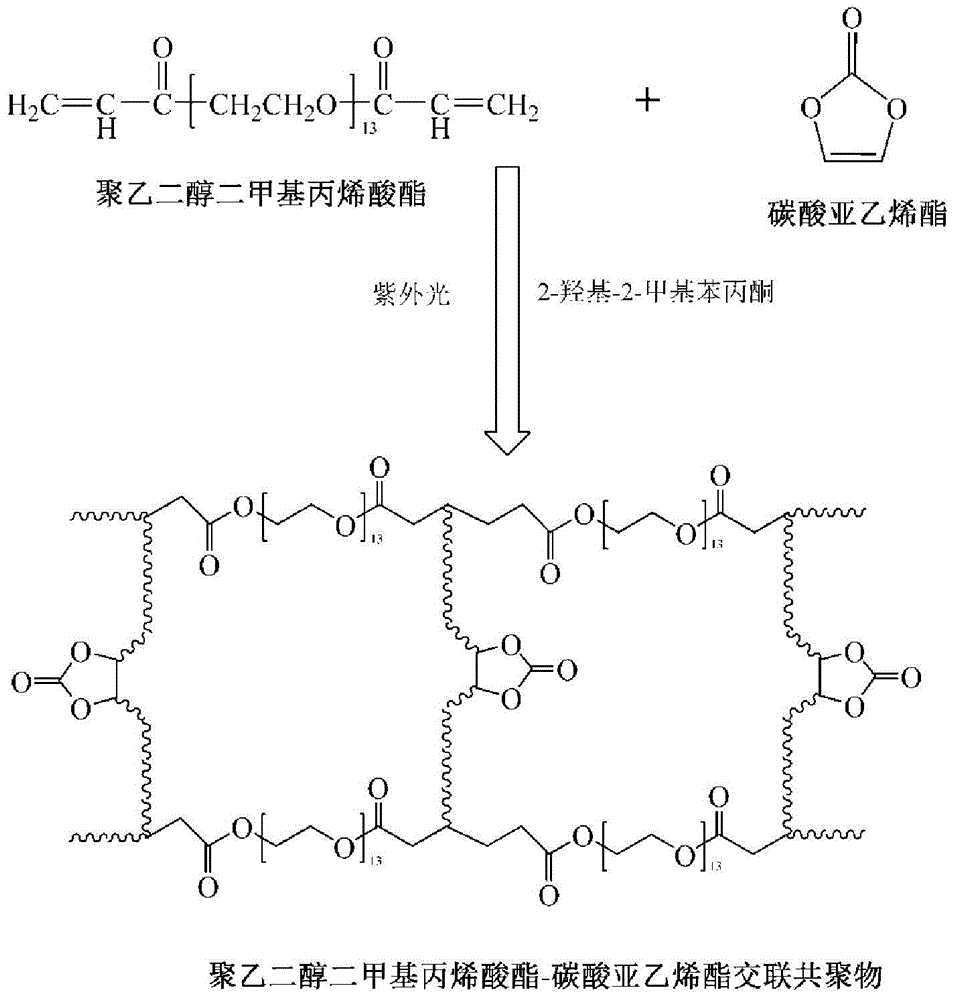

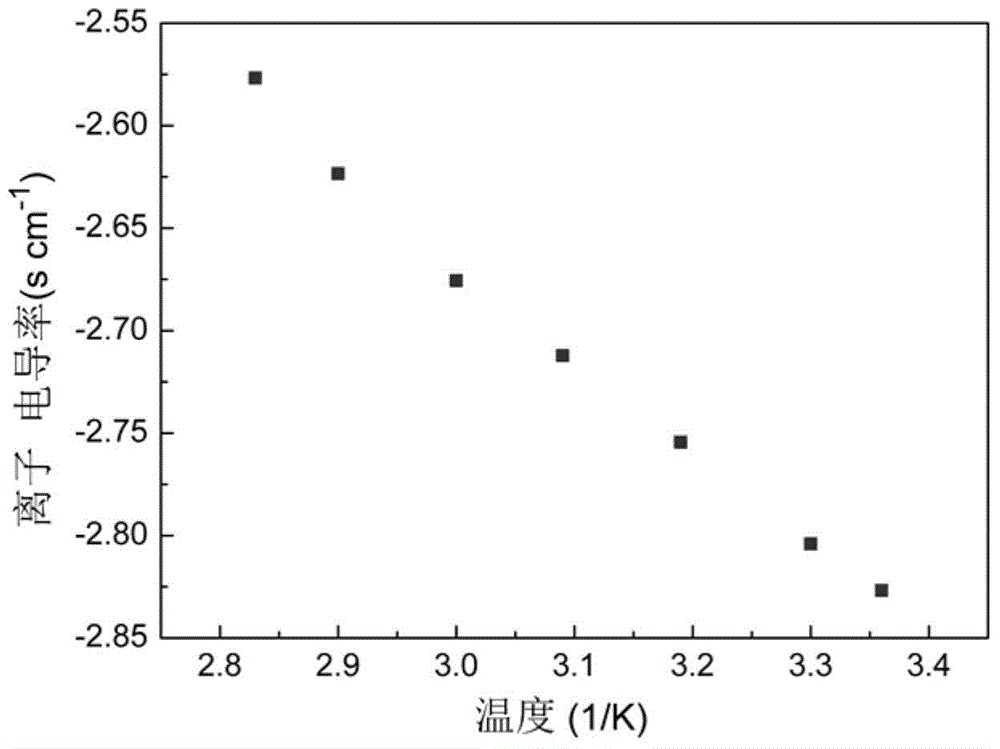

Preparation method of semi-interpenetrating network polymer gel electrolyte membrane

The invention provides a preparation method of a semi-interpenetrating network polymer gel electrolyte membrane. The method comprises the following steps: (A) adding a linear polymer and a solvent to a sample bottle, stirring and dissolving the linear polymer and the solvent, adding polyethylene glycol dimethyl acrylic ester, vinylene carbonate and a photoinitiator, and mixing the polyethylene glycol dimethyl acrylic ester, the vinylene carbonate and the photoinitiator evenly to form a solution; (B) coating a glass plate with the solution, covering a layer of glass plate to form a sandwich structure, and curing the sandwich structure to obtain an ultraviolet-cured semi-interpenetrating network polymer membrane; and (C) immersing the ultraviolet-cured semi-interpenetrating network polymer membrane into liquid electrolyte. According to the gel electrolyte provided by the invention, the balance between the ionic conductivity and the mechanical property is relatively well realized; the ionic conductivity at room temperature can be up to 1.49*10<-3>S cm<-1>; the mechanical property is good; the heat stability is good; the electrolyte can be prevented from leaking; the interface stability is good; and a lithium iron phosphate / metal lithium battery assembled by the gel polymer electrolyte membrane has excellent cycle performance and rate performance.

Owner:SHANGHAI JIAO TONG UNIV

Composite wear-resisting shoe sole

A composite wear-resisting shoe sole is prepared from, by weight, 60-100 parts of natural rubber, 10-50 parts of styrene butadiene rubber, 5-20 parts of polar rubber, 10-60 parts of modified white carbon black, 1-10 parts of zinc oxide, 1-4 parts of accelerant, 0.1-0.5 part of antioxidant, 2.5-4.5 parts of active agent, 5-20 parts of filler and 1-10 parts of sulfur .The filler is tetrapod-like zinc oxide whiskers .According to the composite wear-resisting shoe sole, the natural rubber and a small amount of polar rubber are jointly used as main rubber materials, the white carbon black subjected to toluene diisocyanate graft modification is added to serve as a reinforcing material, the tetrapod-like zinc oxide whiskers of a highly regular structure are used as a filling frame, the accelerant, the composite antioxidant and the active agent are added in sequence, and the composite wear-resisting shoe sole with high slippery resistance and tear strength and a remarkably improved frictional coefficient is prepared.

Owner:宁波市富罗迷鞋业有限公司

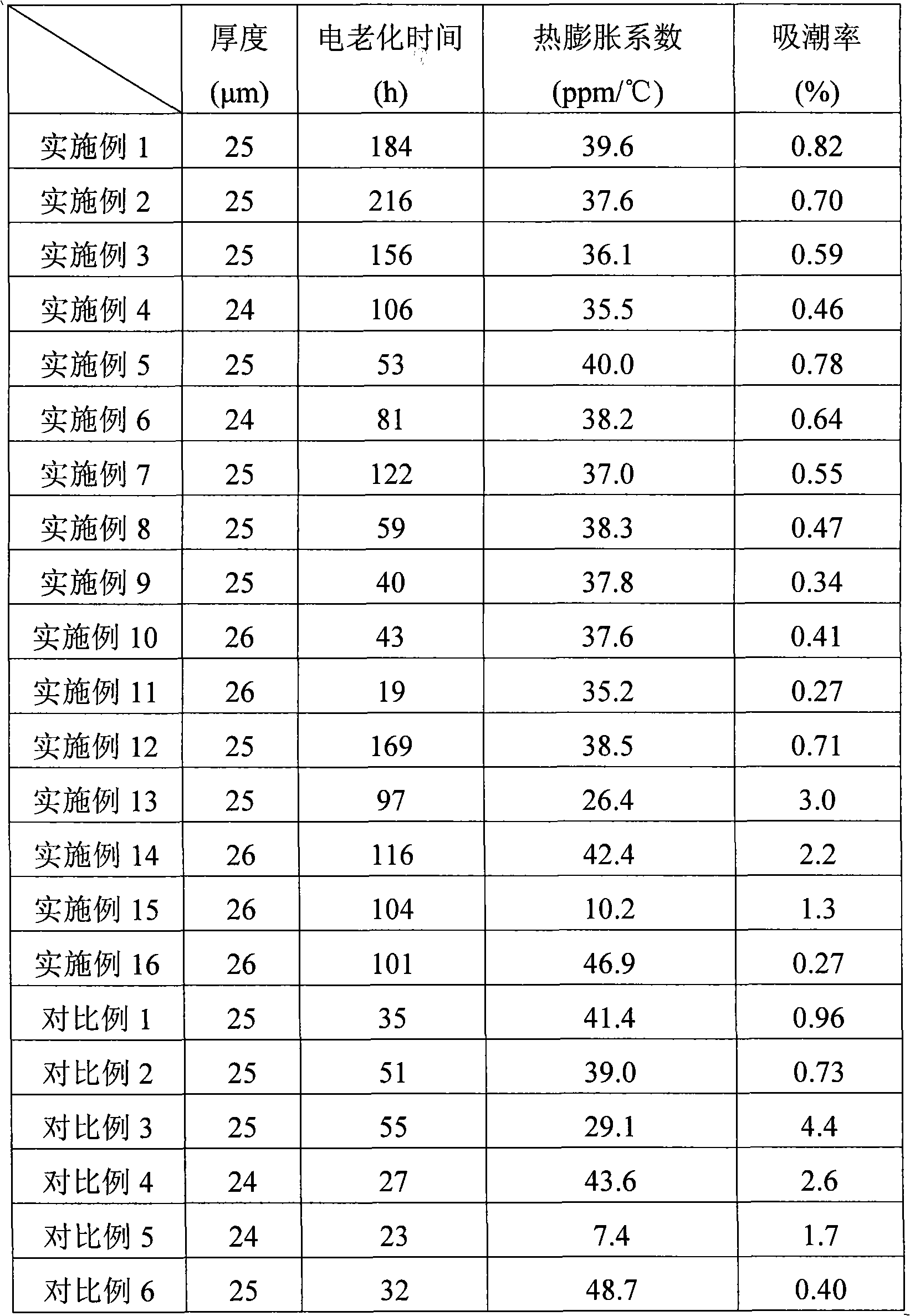

Spherical silica/polyimides composite membrane, preparation thereof and applications

ActiveCN101289542ACorona resistantImprove corona resistanceInsulating bodiesAdhesiveThermal coefficient

The invention discloses a spherical silicon dioxide / polyimide composite film and a method for making the same as well as an application. The method for making the spherical silicon dioxide / polyimide composite film comprises the following steps that: 1) spherical silicon dioxide particles are scattered into an organic solvent evenly to obtain the spherical silicon dioxide particle suspension liquid; 2) a surface treatment agent, a molecular weight modifying agent, an auxiliary adhesive, a flatting agent and aromatic series diamine are dissolved inside the spherical silicon dioxide particle suspension liquid; organic dicarboxylic anhydride is added to be stirred in order to obtain a spherical silicon dioxide / polyamide acid mixing resin solution; 3) the mixing resin solution is coated on the surface of a flat substrate and is heated up to make the solvent volatilize and complete the imide reaction to obtain the spherical silicon dioxide / polyimide composite film. The spherical silicon dioxide / polyimide composite film has good mechanical property, good corona resistance, low thermal coefficient of expansion and low moisture absorption ratio, and has important application value in an insulating system of a frequency conversion speed motor.

Owner:INST OF CHEM CHINESE ACAD OF SCI

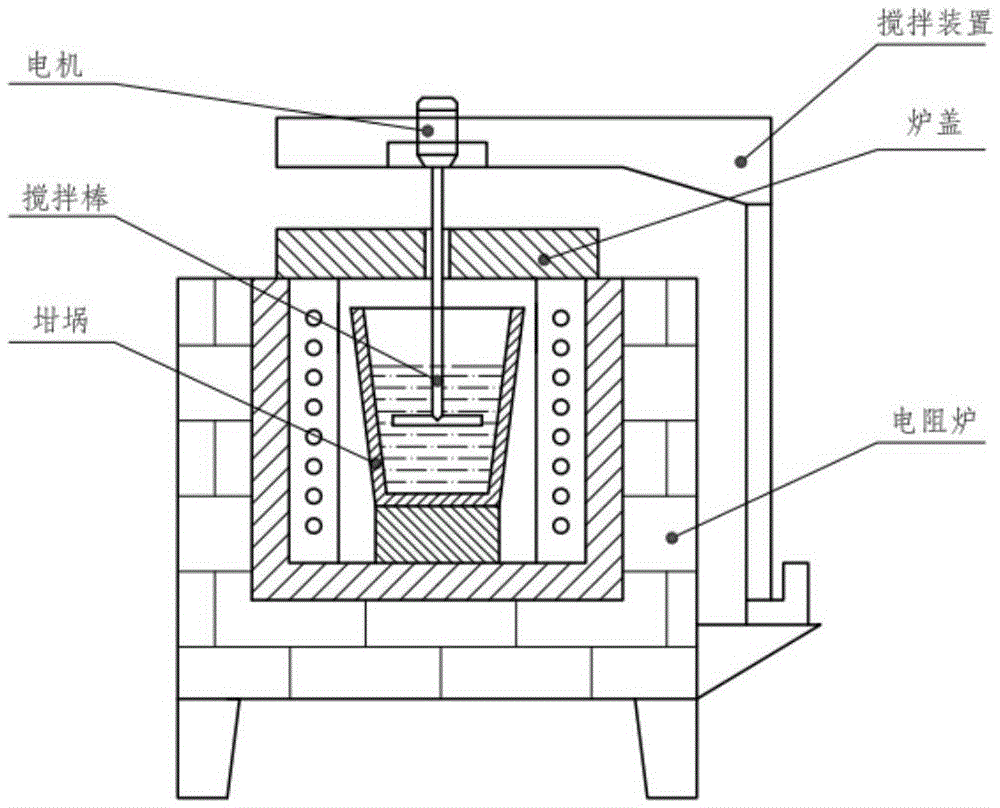

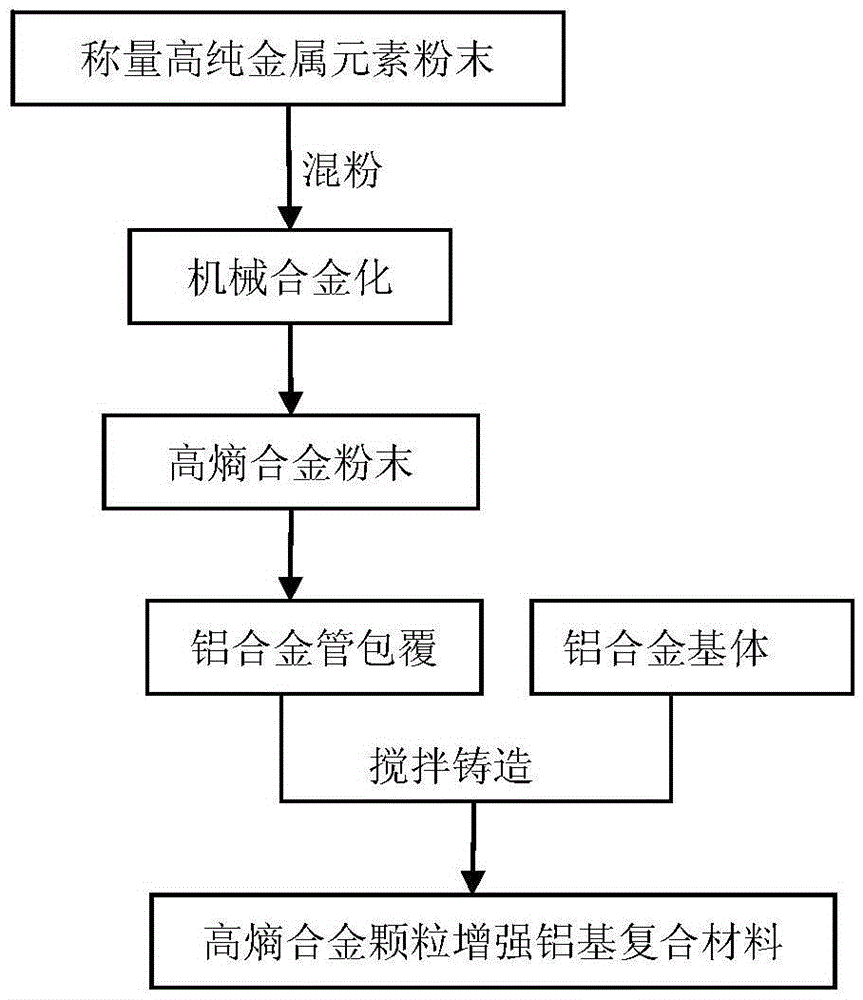

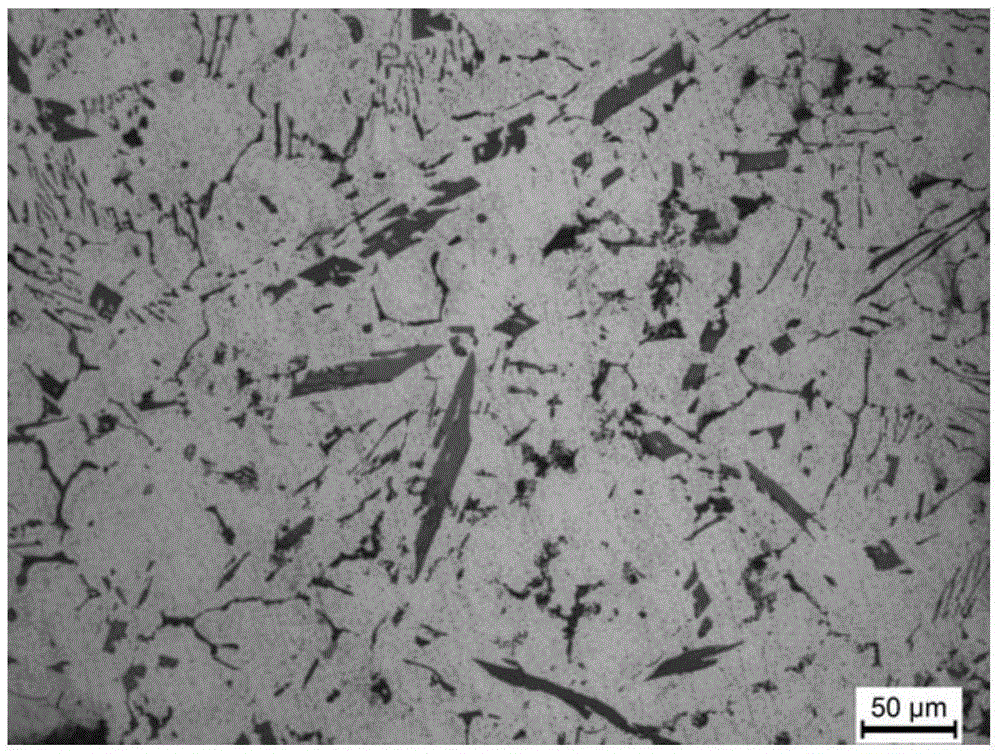

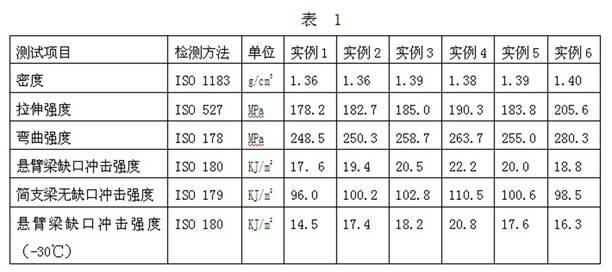

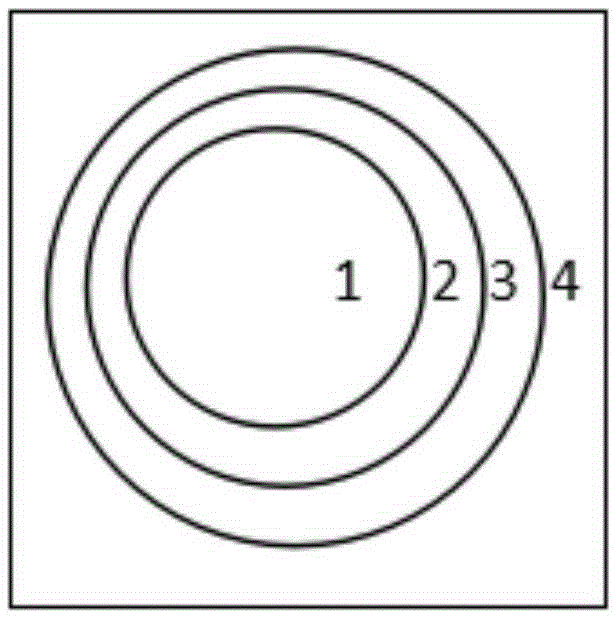

High-entropy alloy particle reinforced aluminum base composite material and stirring casting preparation process thereof

The invention discloses a high-entropy alloy particle reinforced aluminum base composite material and a stirring casting preparation process thereof. The preparation process adopts mechanical alloying to prepare high-entropy alloy powder and screen to obtain high-entropy alloy particles; the high-entropy alloy particles are sealed by adopting an aluminum alloy pipe having the same material with a basal body; the aluminum alloy pipe weighed in a segmented manner is added in the molten basal body; the high-entropy alloy particles are dispersed by a stirring mode; and the high-entropy alloy particle reinforced aluminum base composite material is prepared by a casting process. The high-entropy alloy particles are 0.1-35%; aluminum alloys are 65-99.9%; and the sum of the two is 1. The high-entropy alloy particles in the structure of the prepared composite material are uniformly dispersed; the high-entropy alloy and aluminum alloy interface bonding compatibility is excellent; the strength and the toughness are excellent; the preparation process is simple; the powder has no need to be treated; the cost is low; the stability is good; and the composite material is suitable for large-batch production and standard production, and is excellent in promotion and application prospect.

Owner:GUANGDONG XINGFA ALUMINUM +1

Nylon engineering plastics for high-speed transit railway track and manufacture method thereof

The invention relates to nylon engineering plastics and a manufacture method thereof, in particular to nylon engineering plastics for high-speed transit railway tracks and a manufacture method thereof. The nylon engineering plastics comprise the following components in percentage by weight: 35 to 60 percent of nylon resin, 20 to 35 percent of glass fibre, 0 to 10 percent of inorganic mineral, 16 to 30 percent of compatilizer, 0.3 to 0.5 percent of light stabilizer, 0.1 to 0.3 percent of coupling agent, 0.1 to 0.5 percent of antioxygen and 0.4 to 1 percent of lubricant, wherein the compatilizer is one kind of or a mixture of two kinds of Maleic anhydride grafted EPDM (Ethylene Propylene Diene Monomer) rubber and maleic anhydride grafted POE (Polyolefin Elastomer), and the melt flow rate of the compatilizer is 0.5 to 1.5g / 10min. The manufacture method comprises the steps of: adding the compatilizer into an extruder in a lateral feeding addition method under the condition that the melt temperature is 220 to 280 DEG C and the mixing time is 1-5min; and controlling the rotate speed of a screw between 300 and 450rpm. According to the invention, the tensile strength, the impact toughness and the size stability can all meet the requirements for the operation of high-speed trains with running speed more than 300km / h.

Owner:NANJING JULONG SCI&TECH CO LTD

Method for preparing polyvinylidene fluoride (PVDF) porous nanofiber membrane with high ion migration number

InactiveCN102268783AHigh lithium ion transfer numberHigh liquid absorptionFilament/thread formingCell component detailsPolyvinylidene fluorideCarbon nanotube

The invention relates to a method for preparing a polyvinylidene fluoride (PVDF) porous nanofiber membrane with a high ion migration number. The method is characterized by comprising the following steps of: 1, adding a single-walled carbon nanotube and lithium salts into an organic solvent to form a mixed solution; adding polyvinylidene fluoride, heating, stirring and dissolving, cooling to the room temperature, adding polyvinyl pyrrolidone, stirring and dissolving to obtain a spinning solution; and 2, performing electrostatic spinning on the obtained spinning solution to obtain a fiber membrane; impregnating the obtained fiber membrane in ethanol for 1-2 hours to obtain the PVDF porous nanofiber membrane with the high ion migration number. The PVDF porous nanofiber membrane prepared with the method is used as a lithium ion battery isolation membrane, and maintains good mechanical strength at the same time of maintaining high lithium ion migration number, high liquid absorption rate and good electrochemical stability in a range of from 20 to 70 DEG C.

Owner:DONGHUA UNIV

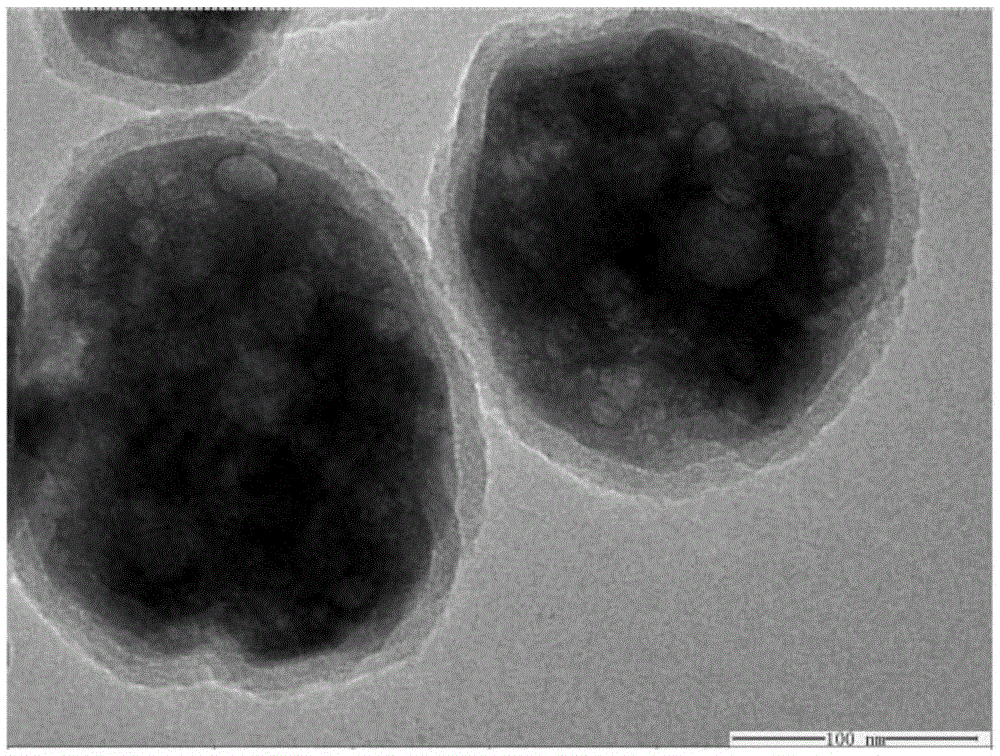

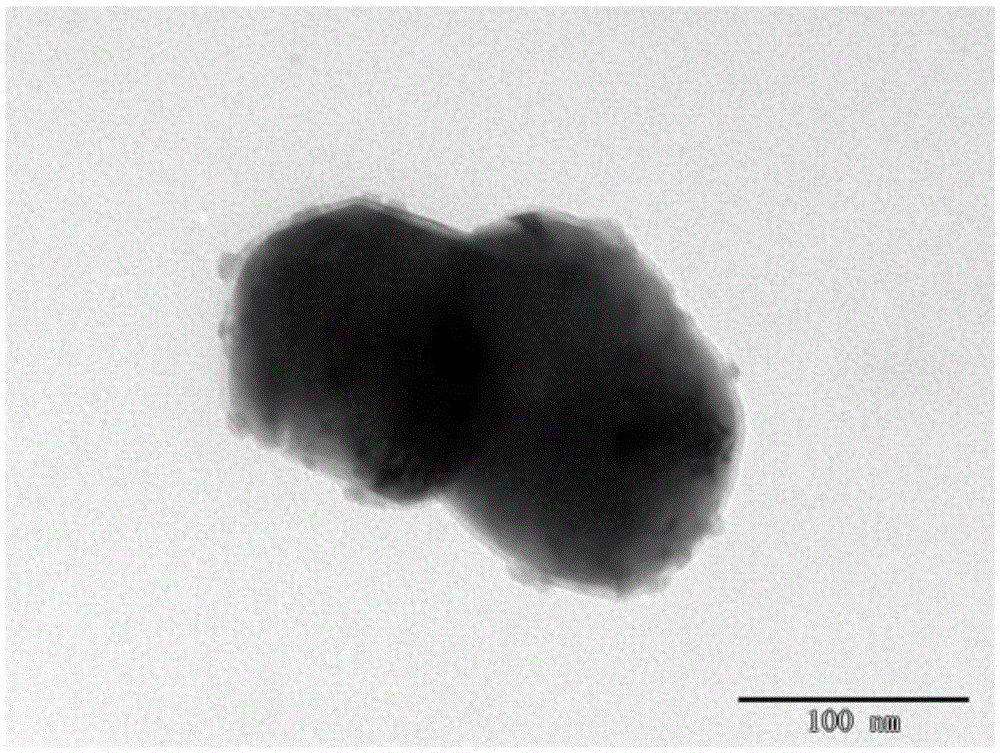

Polymer-based dielectric energy storage composite film material with core-shell structure and preparation method

The invention provides a polymer-based dielectric energy storage composite film material with a core-shell structure and a preparation method. The composite film material is prepared from, by mass, 10%-50% of nanometer filler with a core-shell structure, 50%-90% of polymer matrix and 0-10% of combination layer, and the nanometer filler with the core-shell structure is evenly dispersed in the polymer matrix. According to the preparation method, inorganic nanometer particles with the core-shell structure are prepared by adopting a wet chemistry method, the composite film is prepared through a flow casting method, and the prepared composite film has good dielectric property, high breakdown field strength and high energy storage density. By adjusting the thickness of the surface shell of the inorganic nanometer filler with the core-shell structure, the dielectric constant of the composite film can reach about 30, the dielectric loss is kept to below 5 percent, the breakdown field strength can reach 350 kV / mm, and the energy storage density ranges from 5 kJ / L to 10 kJ / L.

Owner:UNIV OF SCI & TECH BEIJING

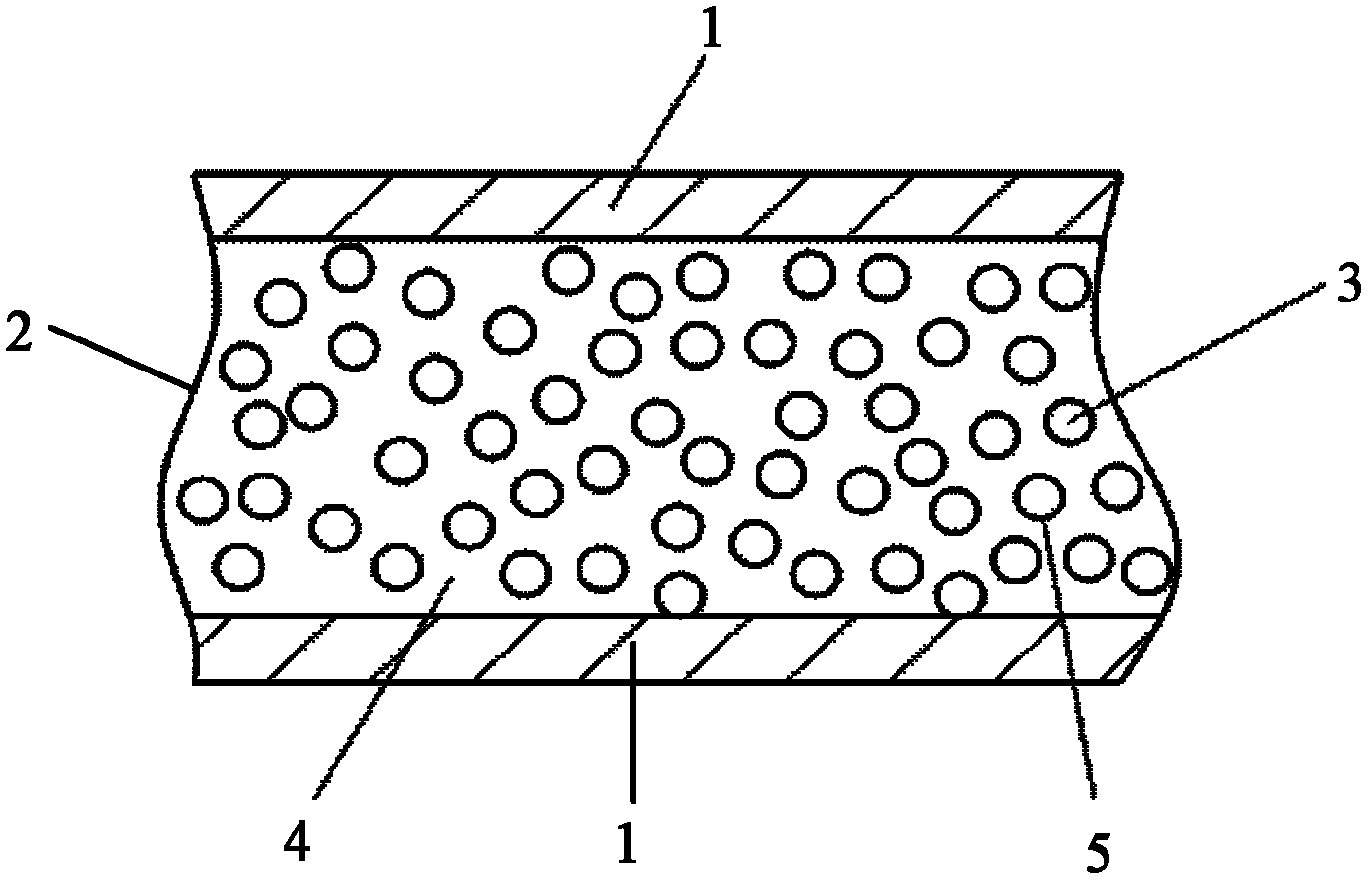

Composite heat-insulating wallboard and preparation method thereof

InactiveCN102505798AImprove interface compatibilityImprove physical and mechanical propertiesClimate change adaptationCeramic shaping apparatusCalcium silicateEmulsion

The invention discloses a composite heat-insulating wallboard and a preparation method thereof and relates to a heat-insulating wallboard. The heat-insulating wallboard is provided with two layers of calcium silicate plates, wherein a heat-insulating core material is clamped between the two layers of calcium silicate plates and is prepared from cement, coal ash, gypsum, expandable polystyrene (EPS), Maleamic Acid-Isobutyl Polyhedral Oligomeric Silsesquioxane (POSS), emulsion powder, a water reducing agent, a foaming agent and an early strength agent. Dry POSS powder is dissolved in normal hexane and then the solution is sprayed onto the surface of EPS particles to obtain substance A; the cement, the coal ash, the gypsum and the emulsion powder are drily stirred, water is added into the mixture, the mixture is stirred into paste, the substance A is added into the paste to form a slurry B; the foaming agent solution is stirred through a stirrer to form foam C; the slurry B and the foam C are mixed to obtain a heat-insulating core material slurry; the surfaces of the calcium silicate plates are brushed and washed, the calcium silicate plates are placed on the two sides of a fixed mold, the heat-insulating core material slurry is poured into the middle of the two calcium silicate plates, and the mold is vibrated to mold the slurry; and the mold is de-molded, and after watering to maintain, the wallboard is obtained.

Owner:XIAMEN UNIV +1

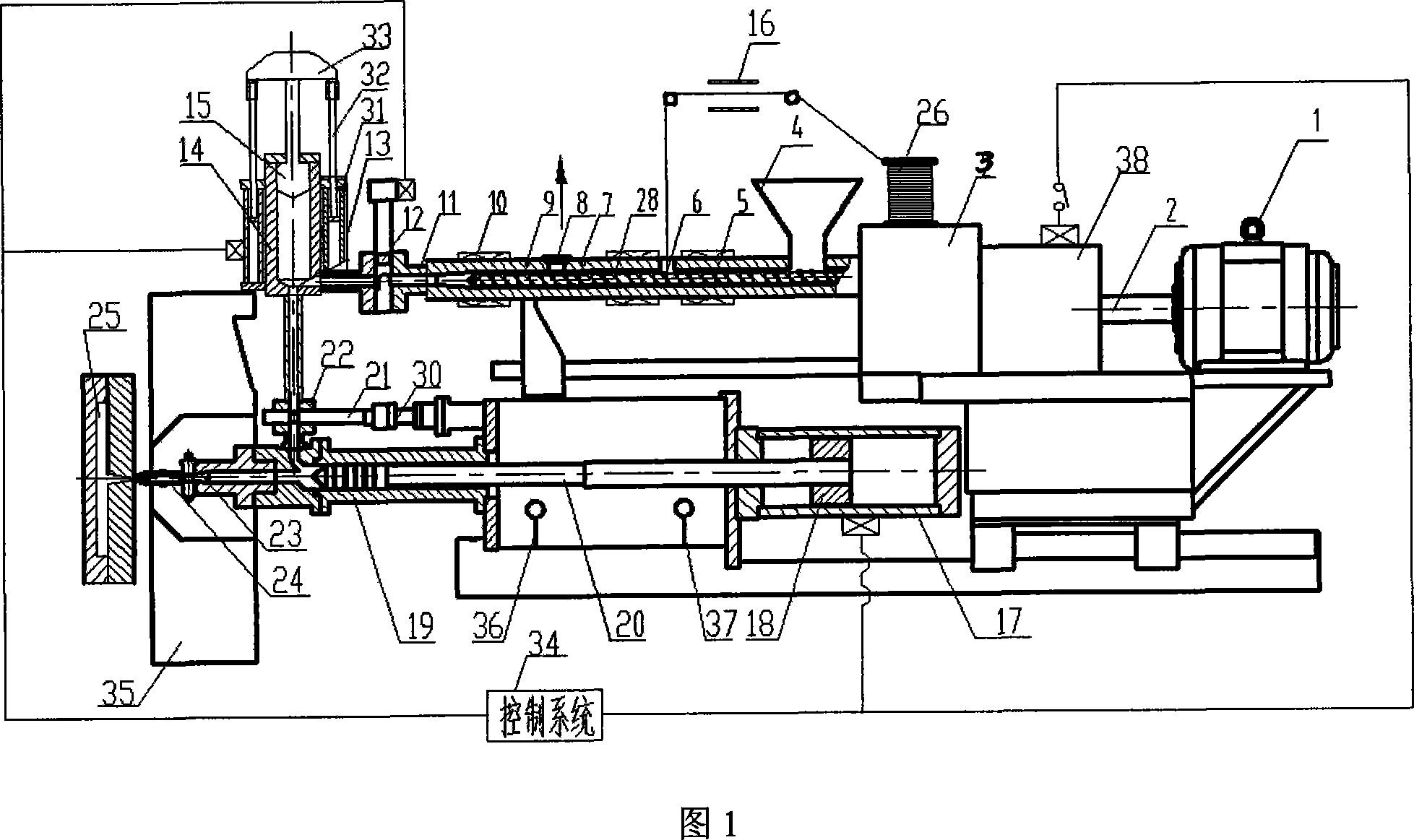

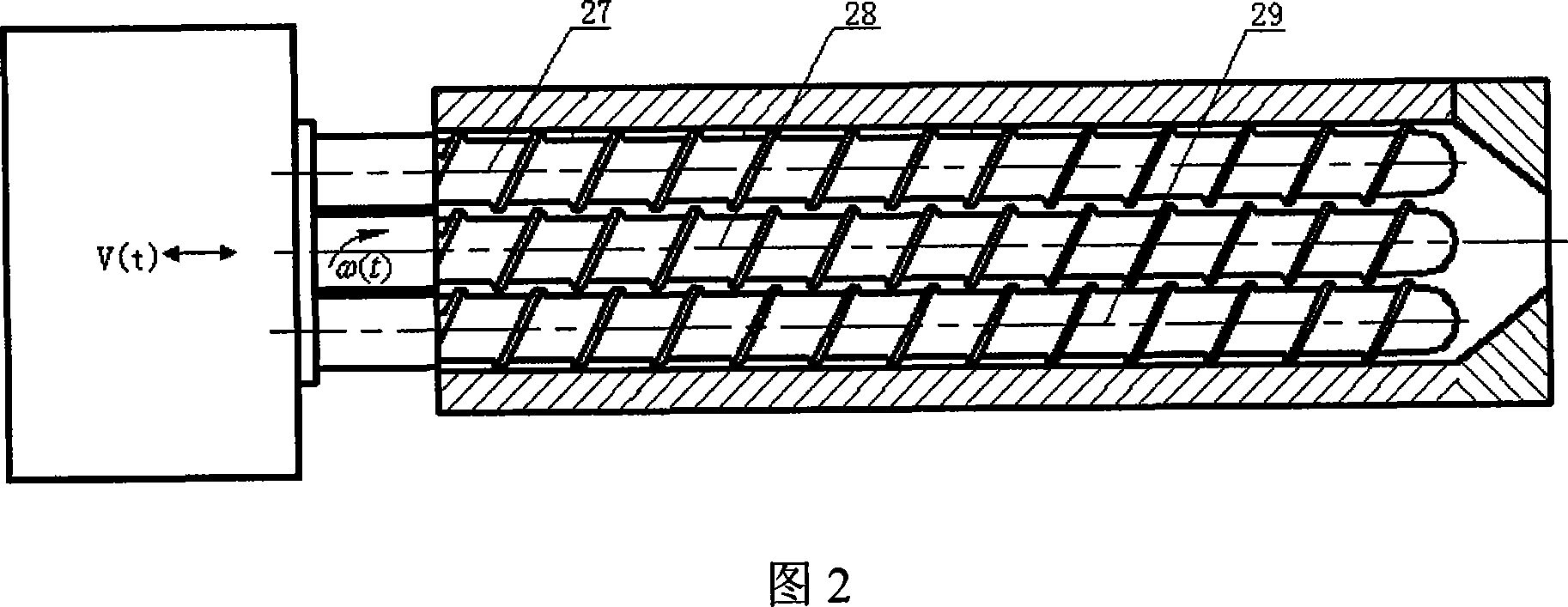

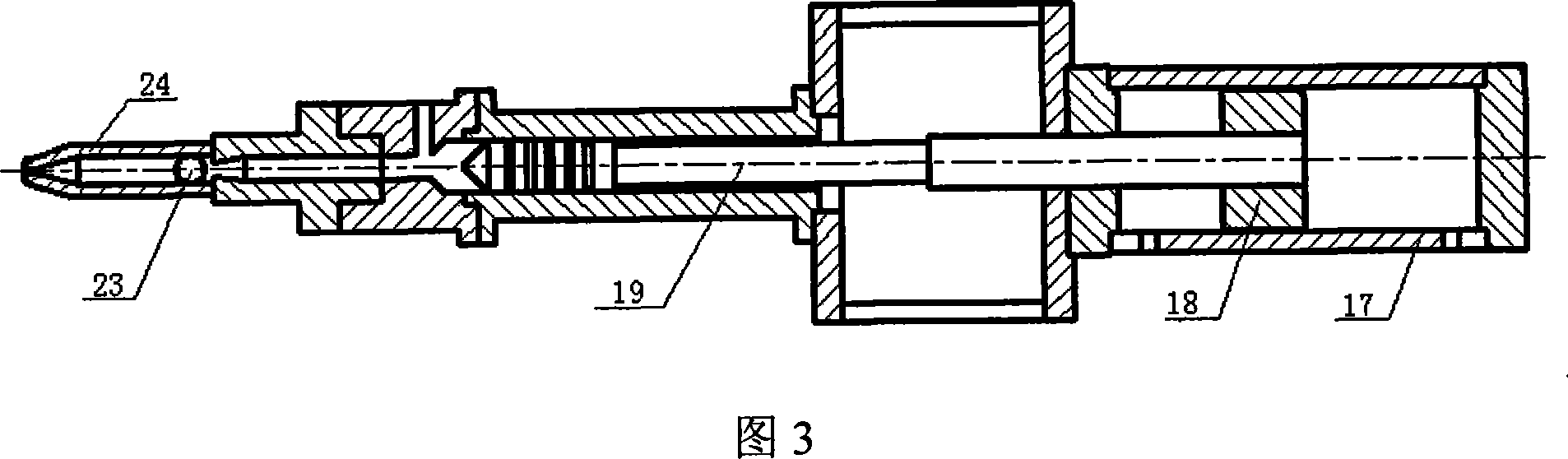

Pulse type shock processing on-line compound injection molding method and its equipment

InactiveCN101077611AIncrease fill ratioImprove interface compatibilityEngineeringFiber-reinforced composite

The present invention discloses pulse type shock reinforced in-line mixing and injecting forming method and apparatus. Pulse type shock is introduced into the whole in-line mixing and injecting forming process of producing fiber reinforced composite polymer material. The apparatus includes one plasticizing extruder with three screws arranged in one line and including one main screw capable of generating periodical axial pulse shock, one buffering storing device, and one pulse type shock pressure reinforcing plunger injecting device. The present invention can lower melt viscosity, raise mixing and homogenizing effect, raise the compatibility between fiber and polymer, lower the processing power consumption and raise product quality.

Owner:SOUTH CHINA UNIV OF TECH

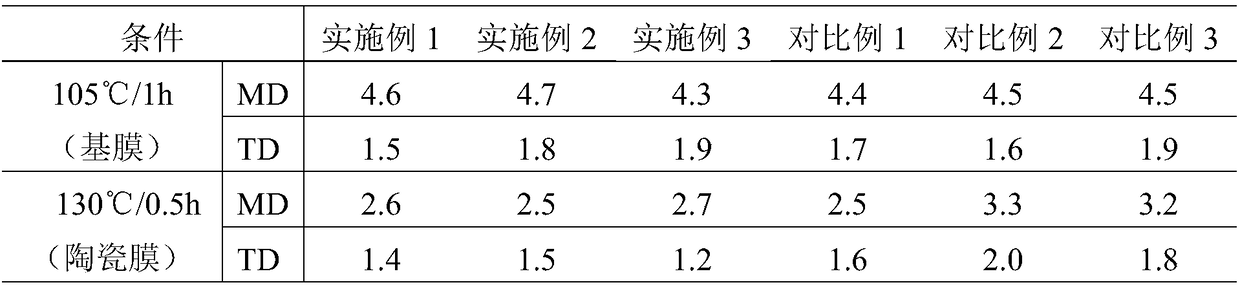

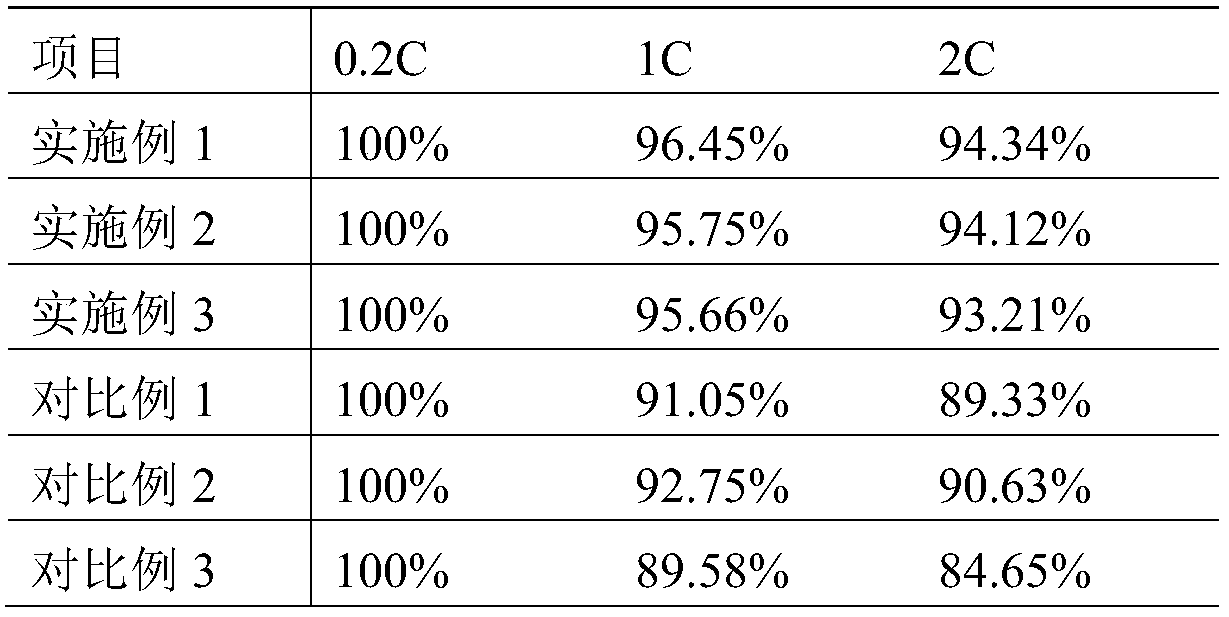

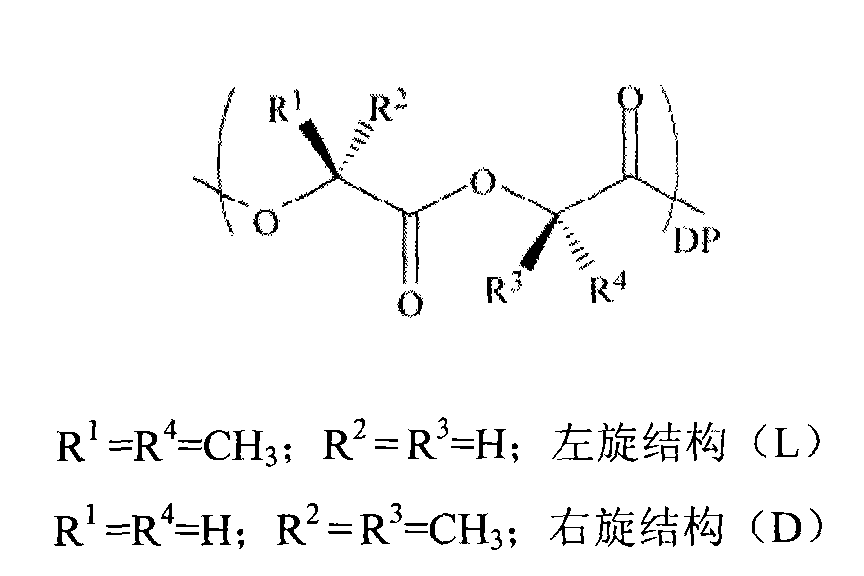

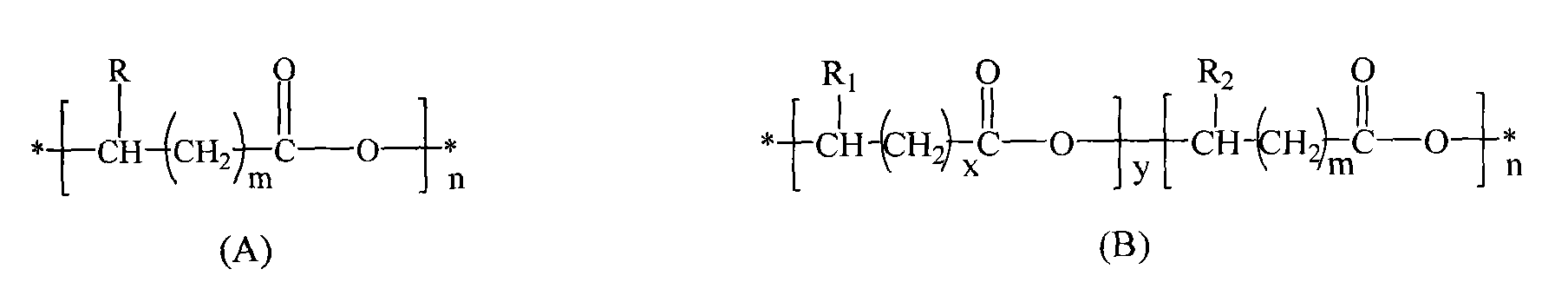

Conductive ceramic composite diaphragm and solid-state battery

ActiveCN108878751AImprove thermal stabilityHigh strengthLi-accumulatorsCell component detailsSolid state electrolyteCeramic composite

The invention relates to a conductive ceramic composite diaphragm and a solid-state battery. The conductive ceramic composite diaphragm comprises a porous base membrane and a conductive ceramic composite coating layer which is coated on one side or two sides of the porous base membrane, wherein the conductive ceramic composite coating layer comprises the following components based on the total weight thereof: 5-80wt% of an organic polymer, 10-85wt% of a nano inorganic solid electrolyte, 1-20wt% of high-molecular grafted modified ceramic, 1-12wt% of a binder and 0.1-0.5wt% of a wetting agent.

Owner:NINGDE ZHUOGAO NEW MATERIAL TECH CO LTD

Bamboo powder filled biomass-based resin composite material and preparation method thereof

ActiveCN101602882AImprove interfacial compatibility and bond strengthImprove overall performanceBiomassResin composite

The invention discloses a bamboo powder filled biomass-based resin composite material comprising the following components in part by weight: 20-60 parts of bamboo powder, 40-80 parts of biomass-based resin, 0.8-5 parts of resin acceptor, 0.2-0.6 part of antioxidant and 0.1-0.7 part of ultraviolet absorbent. The invention also discloses a preparation method of the composite material. Compared with the prior art, the invention has the advantages that waste bamboo powder is used as raw material, the hydrophilic and oleophobic bamboo powder is coupled with the oleophylic and lyophobic biomass-based resin by the resin acceptor, and thus the compatibility and the cohesional strength of interfaces of the bamboo powder and the biomass-based resin are improved. The composite material can be widely applied to the fields of automobile interior parts, traffic road blocks, food bags, preservative films, disposable tablecloth, disposable lunch boxes, flowerpots, knives and forks, and the like.

Owner:SHENZHEN HONGCAI NEW MATERIAL TECH

Glass fiber infiltrating agent composition as well as preparation method and application thereof

The invention provides a glass fiber infiltrating agent composition. The glass fiber infiltrating agent composition comprises a carbon nano material, a dispersant, a polymer emulsion, a coupling agent and a solvent in a mass ratio of (0.05-3):(0.025-4):(0.15-5):(0.05-1.25):(8-49). The infiltrating agent composition has good stability, the deposition of the carbon nano material on fiber surfaces is realized by coating the infiltrating agent composition on glass fiber surfaces, the performance of the glass fibers and the carbon nano material can not be damaged, and the mechanical property and thermal conductivity of the glass fibers and a composite material thereof can be effectively improved at the same time.

Owner:CHONGQING POLYCOMP INT

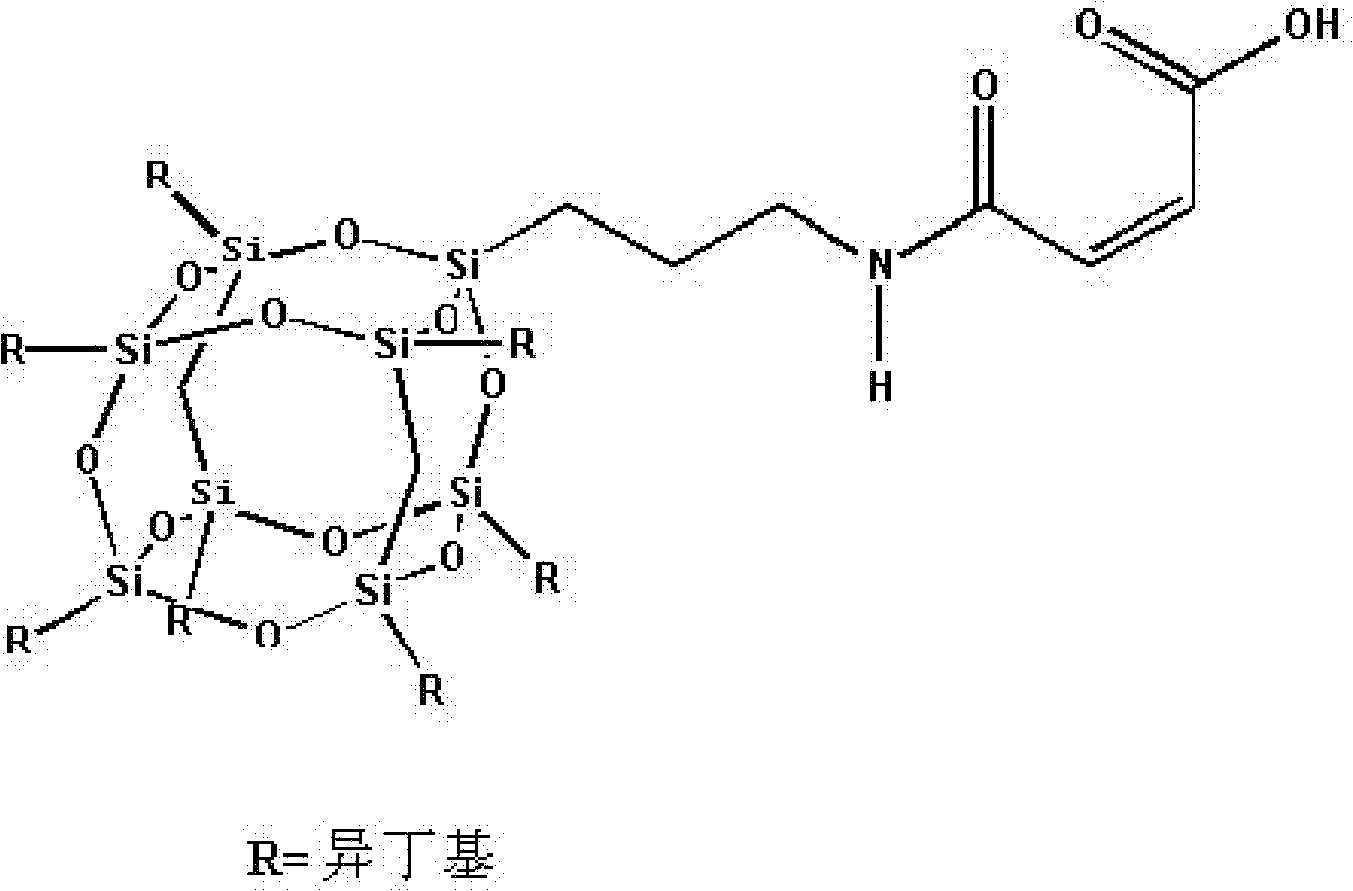

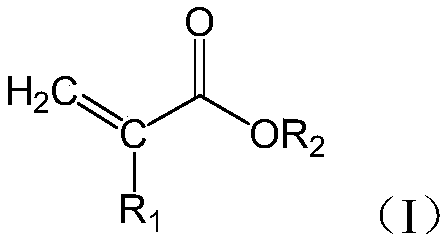

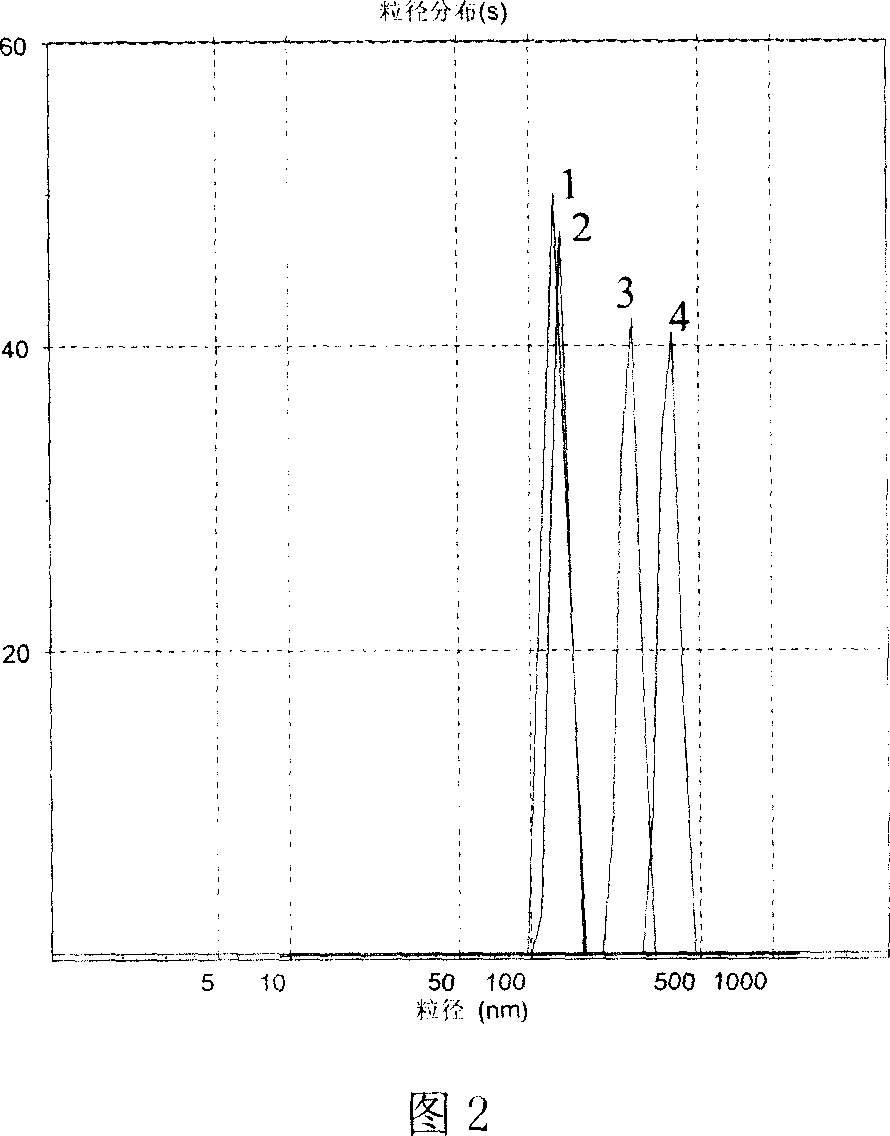

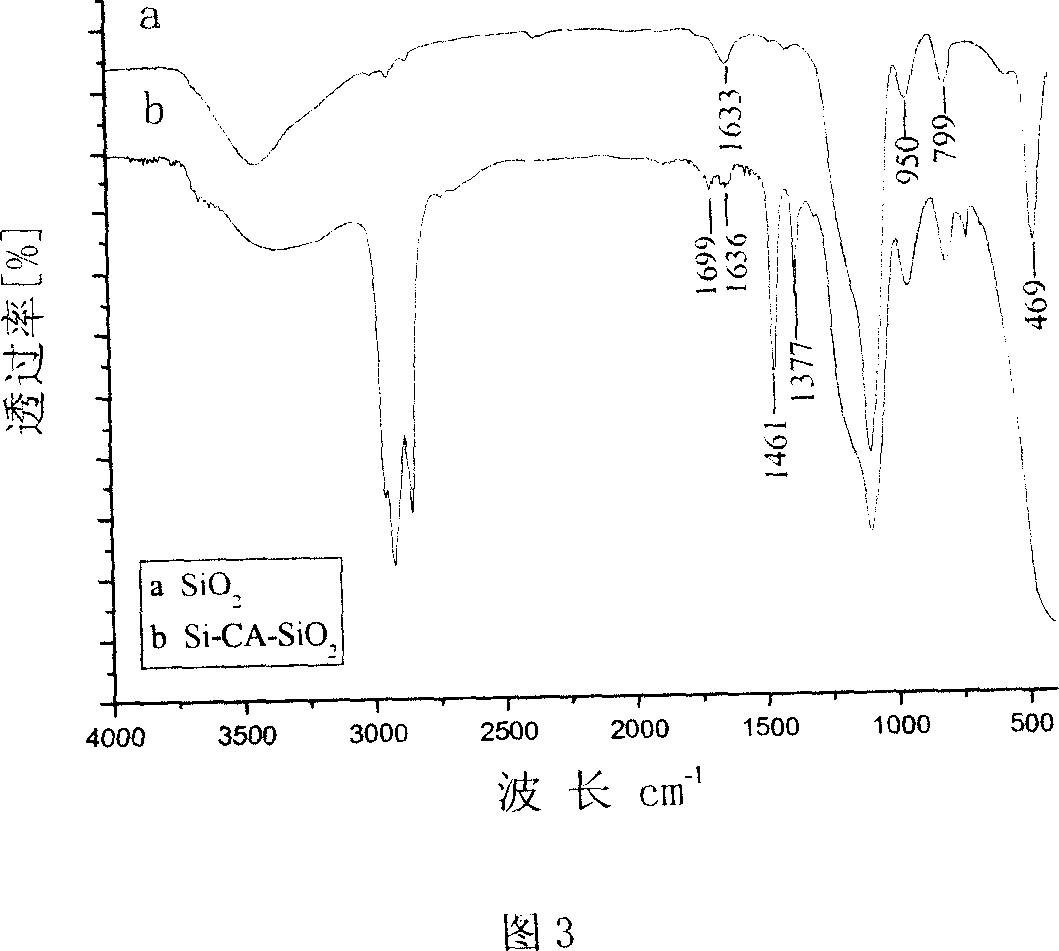

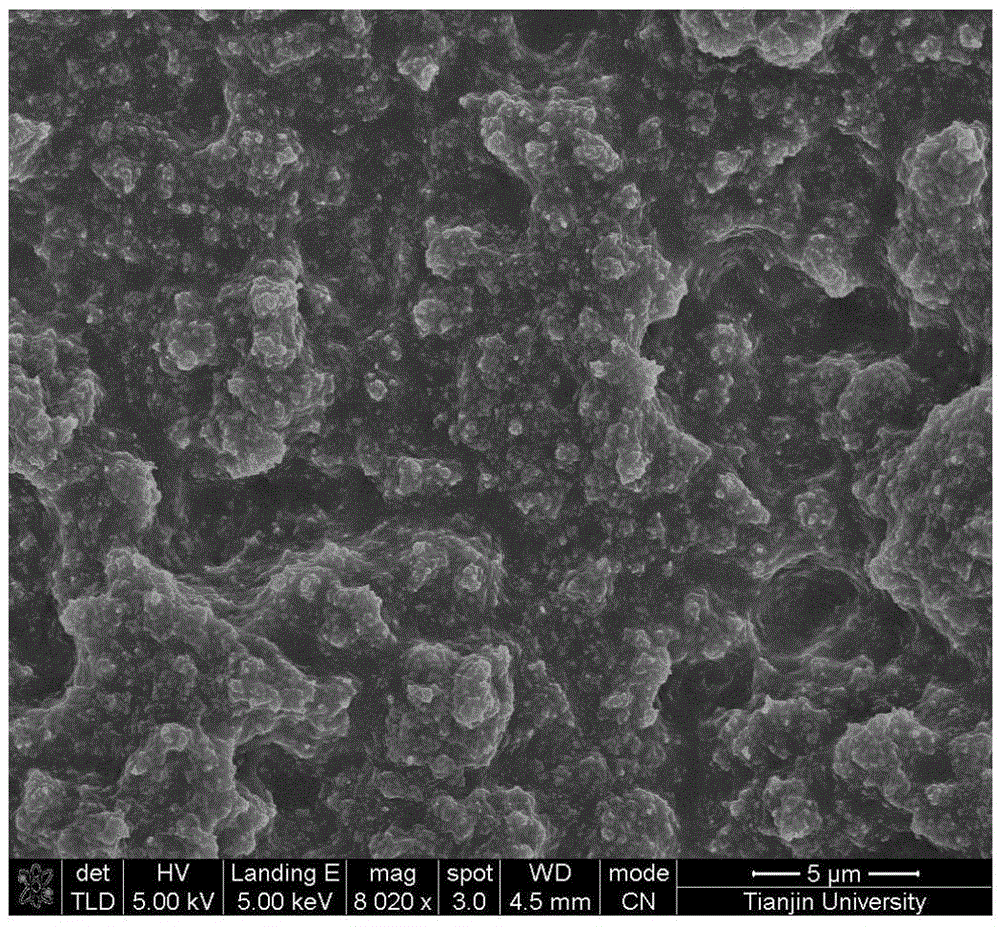

Poly acrylate composite emulsion for pressure' sensitive adhesive and its preparing and using method

InactiveCN1944479AImprove interface compatibilityUniform particle sizeFilm/foil adhesivesEster polymer adhesivesEmulsionAcrylic acid

The present invention is composite polyacrylate emulsion for pressure sensitive adhesive and its preparation process and application, and relates to polyacrylate based adhesive. The composite emulsion is one core-shell structure with silane cross-linking agent surface modified nanometer silica as the core and the copolymer of acrylate and acrylic acid as the shell, and has solid content of 30-40 %, viscosity of 1-6 mPa.s, composite emulsion particle size of 250-700 nm and particle size dispersing index of 0.005-0.15. The composite polyacrylate emulsion is prepared through preparing nanometer silica alcohol sol, surface modification of nanometer silica and preparing nanometer silica-polyacrylate composite emulsion. The composite polyacrylate emulsion coating is dried to obtain the pressure sensitive adhesive with high initial adhering performance and cohesive property.

Owner:HEBEI UNIV OF TECH

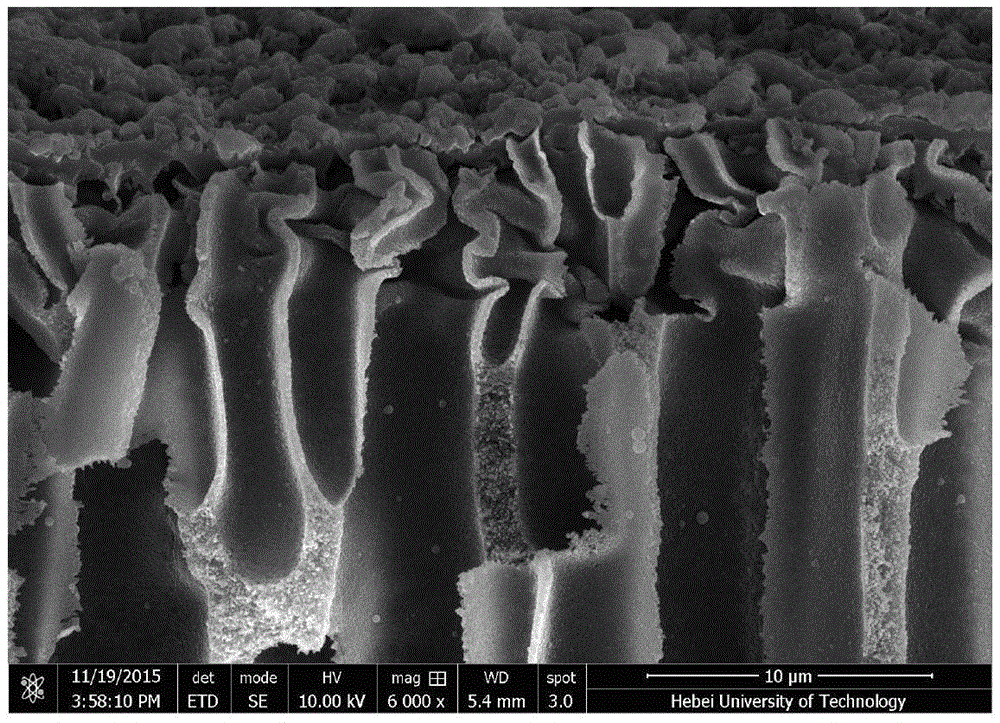

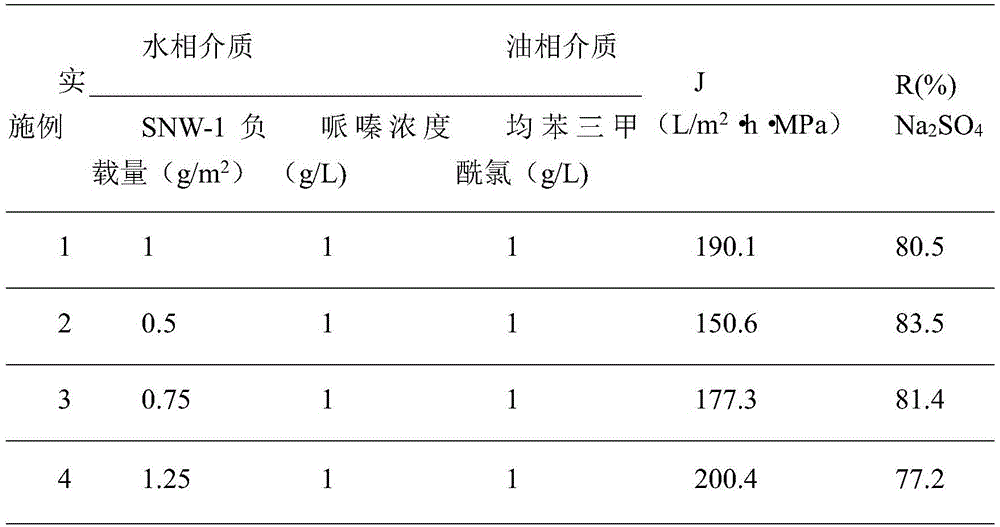

Polyamide/COFs hybridized nanofiltration composite membrane and preparation method thereof

ActiveCN105642133AImprove interface compatibilityHigh retention rateSemi-permeable membranesPolymer sciencePolyamide

The invention provides a polyamide / COFs hybridized nanofiltration composite membrane. The composite membrane comprises a composite layer and a loaded porous frame material. The composite layer is a layer of polyamide compound formed by conducting polymerization reaction on piperazine and trimesoyl chloride, and the thickness is 100-500 nm. The porous frame material is SNW-1 obtained when melamine and terephthalaldehyde react, and is a compound layer with the loading amount of 0.5-3 g / m<2>. A covalent organic framework is effectively hybridized in a separation layer of the composite membrane, and more water channels are provided for the nanofiltration membrane. By means of the method, various types of COFs can be introduced onto a polyether sulfone base membrane, the water flux can reach 200 L / m<2>.h.MPa and increased by 2 times, the sodium sulfate retention rate of the nanofiltration membrane is still kept at 80% or above, and the high water flux and the high retention rate are achieved.

Owner:HEBEI UNIV OF TECH

Method for preparing wood-plastic composite by blending heat-treated plant fiber with plastic

The invention relates to a method for preparing a wood-plastic composite, in particular to a method for preparing a wood-plastic composite by blending heat-treated plant fibers with plastics. The method comprises the following steps of: crushing the plant fiber, screening the crushed plant fiber by a sieve of 20-120 meshes to prepare the plant fiber powders; carrying out heat treatment on the crushed plant fiber under an oxygen deficient condition, wherein the heat treatment time is 0.5-24h, the temperature is 140-350 DEG C and the preferably selected temperature range is 180-250 DEG C; uniformly mixing the plastic, a lubricant, a plasticizer, a stabilizer, a compatibilizer and the plant fiber modified by heat treatment to prepare the mixture under the high-speed mixing condition with the rotation speed of 800-1000r / min; and extruding the mixture out of a twin-screw extruder after reaction; and granulating and obtaining granules or directly extruding and obtaining the product by a die. The heat-treated plant fiber powder reduces the amount of hydroxy groups, the hydrophilicity and the water absorption of the final product and improves the dimension stability.

Owner:FUJIAN NORMAL UNIV

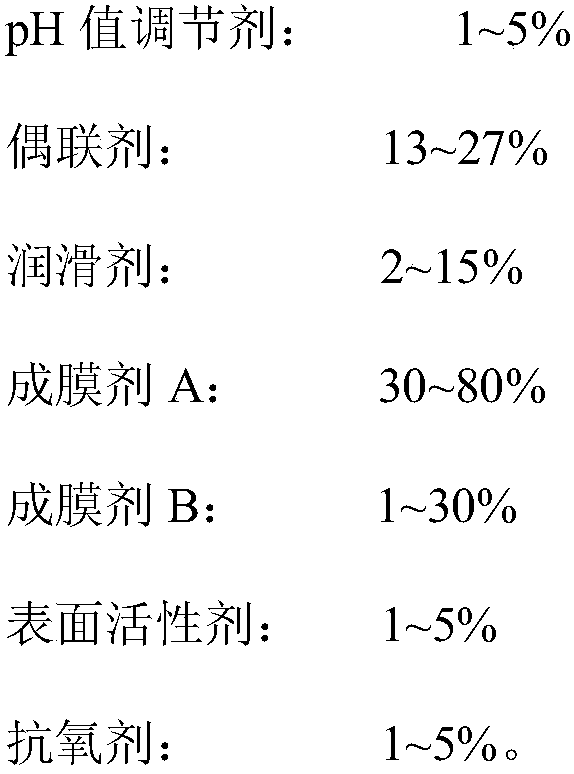

High-dipping-property alkali-free glass fiber impregnating agent for LFT reinforced polypropylene as well as application thereof

ActiveCN108996923AIncrease productivityImprove interface compatibilityAlkali freeMicrocrystalline wax

The invention relates to a high-dipping-property alkali-free glass fiber impregnating agent for LFT reinforced polypropylene as well as the application thereof. The impregnating agent comprises a pH value regulator, a silane coupling agent, a film-forming agent A, a film-forming agent B, a lubricating agent, a surfactant, an antioxidant and deionized water, wherein the film-forming agent A is a maleic anhydride grafted and modified polypropylene wax emulsion; the film-forming agent B is a maleic anhydride grafted and modified polyethylene emulsion; the lubricating agent is the combination of aPEG lubricating agent and a mineral oil lubricating agent; the surfactant is the combination of microcrystalline wax emulsion and cationic polyacrylamide emulsion; and the antixodiant hypophosphite is hypophosphite. The invention also provides the application of the impregnating agent to production of alkali-free glass fiber for the LFT reinforced polypropylene. The glass fiber produced by the impregnating agent has a high interface bonding property, can be rapidly fused with polypropylene resin at high temperature, is high in dipping speed, has good processing property, high wear resistanceand little filoplume, and has a high dipping property, so that the production efficiency can be improved and the production cost can be reduced.

Owner:JUSHI GRP CO

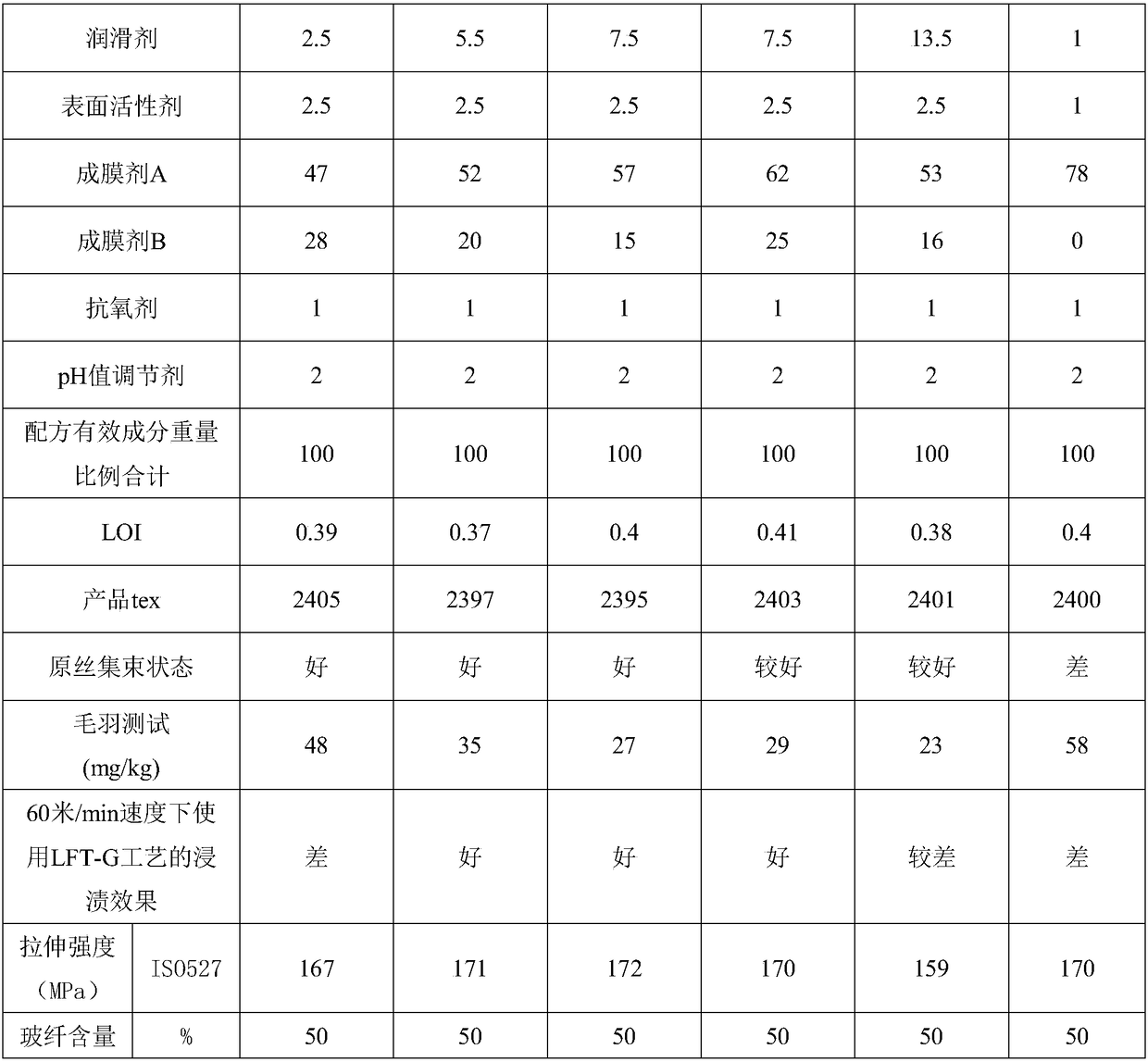

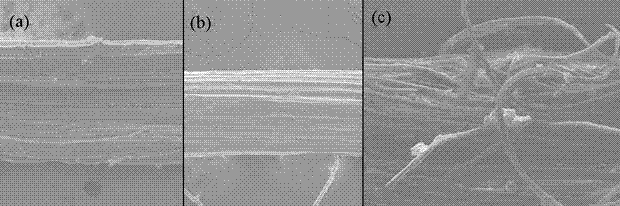

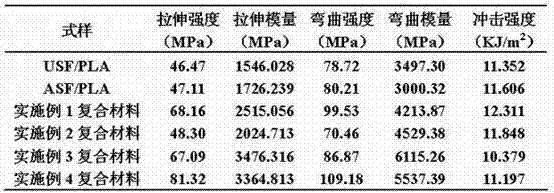

Bamboo fiber reinforced degradable PLA material and preparation method thereof

The invention discloses a bamboo fiber reinforced degradable PLA material and a preparation method thereof. Raw materials for preparing the bamboo fiber reinforced degradable PLA material comprise, by weight, 30-70 parts of polylactic acid resin, 15-40 parts of bamboo fibers, 0.5-2 parts of a coupling agent, 10-30 parts of inorganic powder, 0.5-5 parts of a compatilizer, 0.1-0.5 parts of an antioxidant, 0.5-3 parts of a dispersant and 3-5 parts of a lubricant. The bamboo fiber reinforced degradable PLA material is prepared through blending the bamboo fibers and other assistants with the polylactic acid resin, so the strength of the PLA material is effectively improved, thereby the PLA material can be widely applied in fields of automobile parts, decoration finishing, electric appliance products and packaging; and the material also has the advantages of degradability, environmental protection, and good environmental and social benefits.

Owner:FUZHOU FUSU SCI & TECH RES INST CO LTD

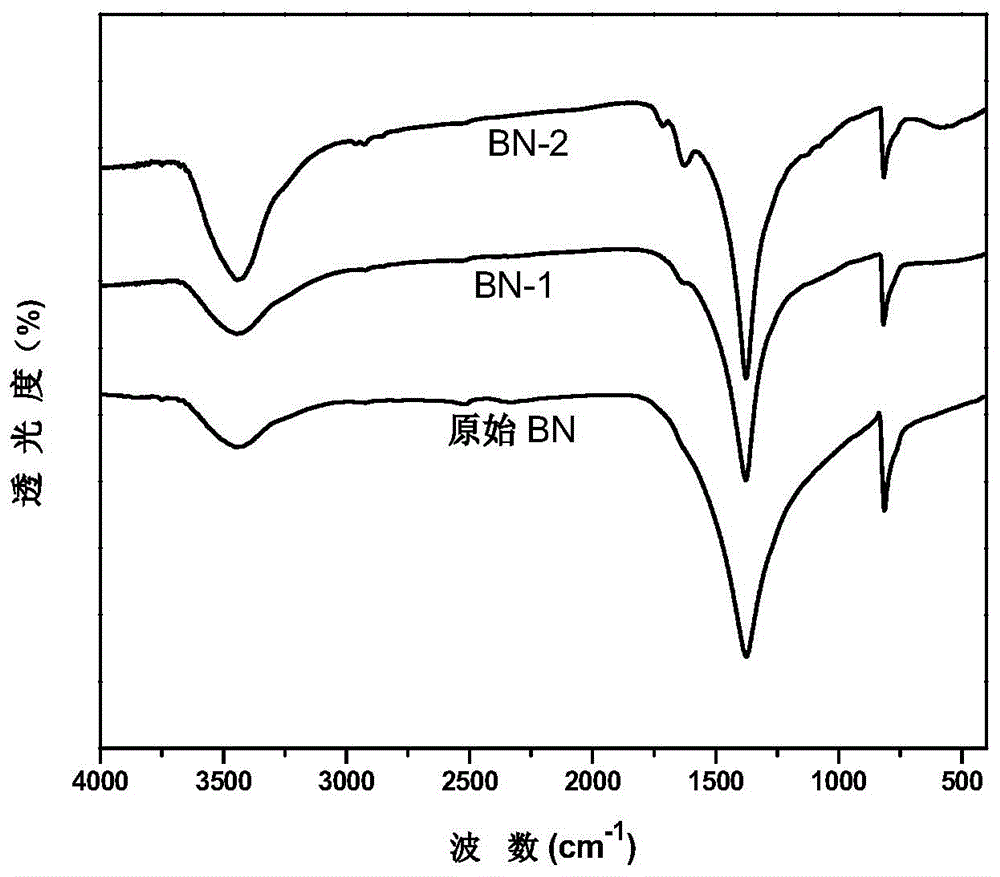

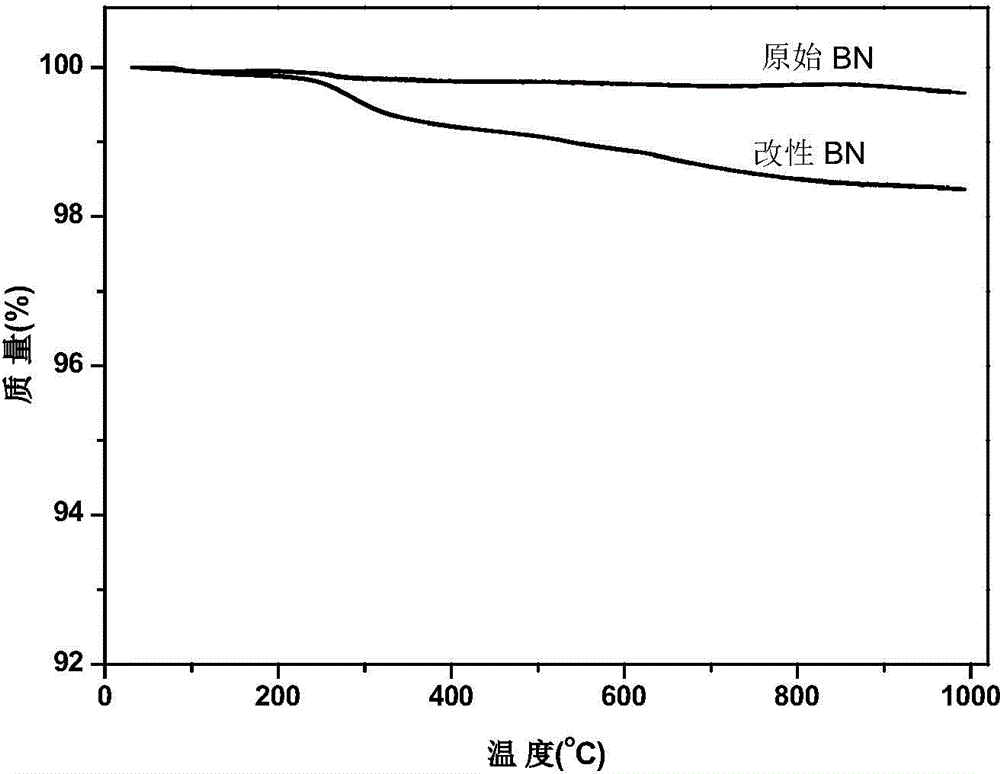

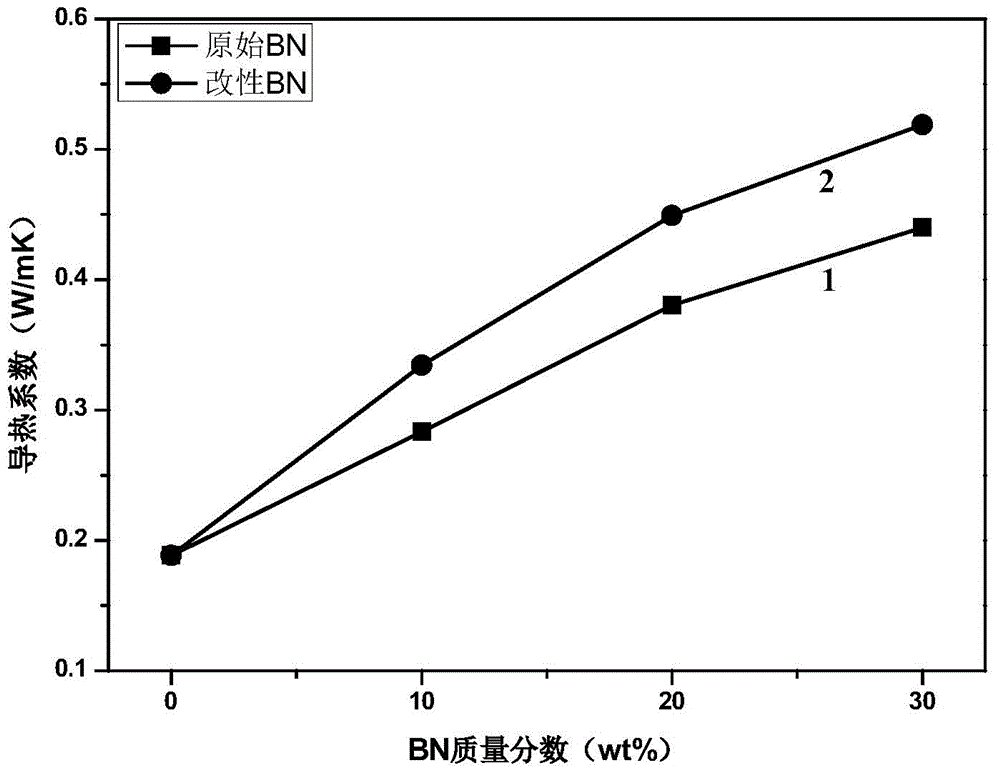

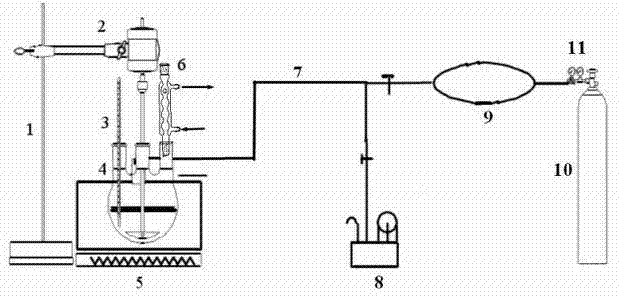

Preparation method of high-heat-conduction hexagonal boron nitride/polyimide composite material

The invention relates to a preparation method of a high-heat-conduction hexagonal boron nitride / polyimide composite material. The method comprises the following steps: step 1: mixing h-BN with mixed acid, facilitating reaction in a water bath, washing a product to be neutral, and drying the product; step 2: adding a solvent, ultrasonically dispersing, then adding binary isocyanate, and stirring and refluxing for 24h; step 3: adding aromatic diamine, and continuously stirring and refluxing for 24h; step 4: placing amination hexagonal boron nitride into a reactor, adding the solvent, and then stirring and ultrasonically dispersing; adding aromatic amine, adding aromatic dianhydride equimolar to aromatic amine, preparing a polyamide acid solution, smearing the polyamide acid solution onto a glass plate, carrying out the thermal imidization, and preparing a hexagonal boron nitride / polyimide composite film. By adopting the preparation method, the interaction force of the hexagonal boron nitride and polyimide is improved, a purpose of improving the dispersibility of a filler and compatibility of a base body can be realized, simplicity and feasibility can be realized, and the requirement on equipment is low.

Owner:HEBEI UNIV OF TECH

Preparation method for lactide grafted plant fiber reinforced poly lactic acid composite material

The invention discloses a preparation method for a lactide grafted plant fiber reinforced poly lactic acid composite material. The preparation method comprises: carrying out an alkali liquid soaking treatment on plant fibers, and drying; mixing the resulting plant fibers and a lactide monomer; carrying out a graft reaction under an anhydrous and anaerobic condition under a catalysis effect of stannous octanoate to obtain lactide grafted plant fibers; drying; mixing the dried lactide grafted plant fibers and ungrafted plant fibers; and carrying out blending, hot pressing molding and cooling shaping on the mixed fibers and completely-molten poly lactic acid to obtain the composite material. According to the present invention, lactide ring opening polymerization is adopted to carry out a graft treatment on plant fibers to change surface polarity of the fibers so as to improve interface compatibility between the plant fibers and the poly lactic acid matrix, and improve the whole performance of the composite material; compared with pure poly lactic acid and untreated plant fiber reinforced poly lactic acid composite materials, the composite material prepared by the preparation method of the present invention has the following characteristics that: interface properties between the plant fibers and the poly lactic acid matrix, and mechanical properties are significantly improved.

Owner:SOUTH CHINA UNIV OF TECH

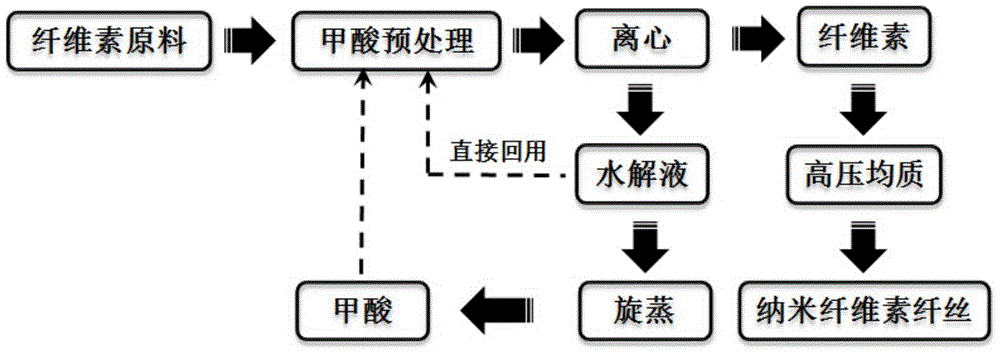

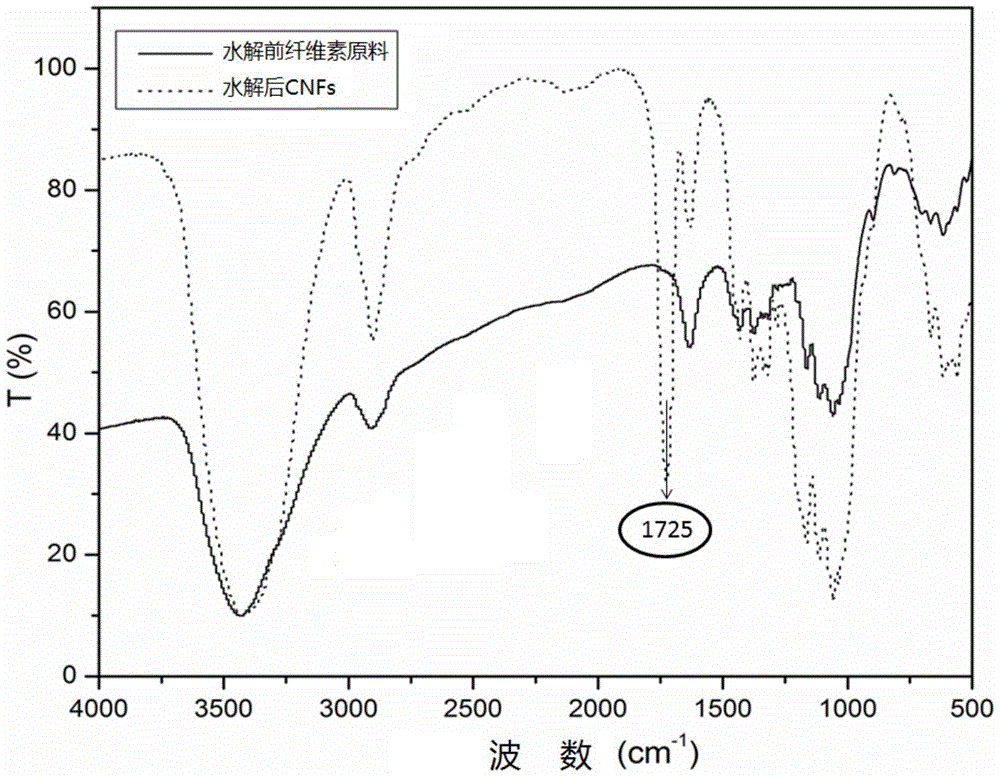

Method combining formic acid preprocessing and high-pressure homogenization to prepare nano-crystalline cellulose fibrils

The invention relates to a green, economical and sustainable method for preparing nano-crystalline cellulose fibrils. The method includes the steps of firstly, cellulose raw material is added into a formic acid solution, and heating and stirring are performed for hydrolysis to obtain preprocessed cellulose; secondly, the preprocessed cellulose is separated from hydrolysate through centrifugal settling, the settled cellulose is centrifugally washed with water, and the washed cellulose is diluted into a cellulose suspension with certain concentration; thirdly, the separated hydrolysate can be directly recycled at least once, the recycled hydrolysate can recycle formic acid through reduced-pressure distillation, and the recycled formic acid can be recycled; fourthly, the cellulose suspension obtained in the second step is homogenized for certain times under certain pressure through a high-pressure homogenizing machine to obtain the colloidal nano-crystalline cellulose fibrils. The method has the advantages that no catalysts are used, and the method is relatively mild in reaction condition, easy in reaction control, simple to operate and environmental friendly.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Method for preparing aqueous graphene/epoxy resin nanocomposite material

ActiveCN104231547AExcellent interfacial compatibility and binding forceImprove bindingGraphite oxideFirming agent

The invention discloses a method for preparing an aqueous graphene / epoxy resin nanocomposite material. The method comprises the following specific steps: carrying out functional modification and dispersion on graphene oxide obtained through a Hummers method, so as to obtain a high-concentration aqueous graphene dispersion solution; adding epoxy resin into the aqueous graphene dispersion solution, uniformly stirring, then, dewatering under the vacuum condition, adding a curing agent and mixing; carrying out high-temperature curing, thereby obtaining the graphene / epoxy resin nanocomposite material. According to the method, the operating process is simple, convenient and controllable, so that large-batch preparation and synthesis are facilitated; through obtaining the highly-stable aqueous graphene dispersion solution, graphene and epoxy resin can have excellent interface compatibility and adhesion; the matrix adhesion, corrosion resistance and impact resistance of epoxy resin are effectively improved; compared with the conventional aqueous epoxy resin materials, the aqueous graphene / epoxy resin nanocomposite material prepared by the method has the advantages that the hardness is improved by 1.5 times, and the impact resistance is improved by 12 times.

Owner:QINGDAO REALEADER ADVANCED MATERIALS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com