Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

13456 results about "Polylactic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

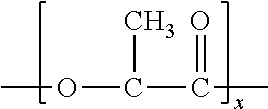

Polylactic acid or polylactide (PLA) is a thermoplastic aliphatic polyester derived from renewable resources. In 2010, PLA had the second highest consumption volume of any bioplastic of the world, although it is still not a commodity polymer. Its widespread application has been hindered by numerous physical and processing shortcomings.

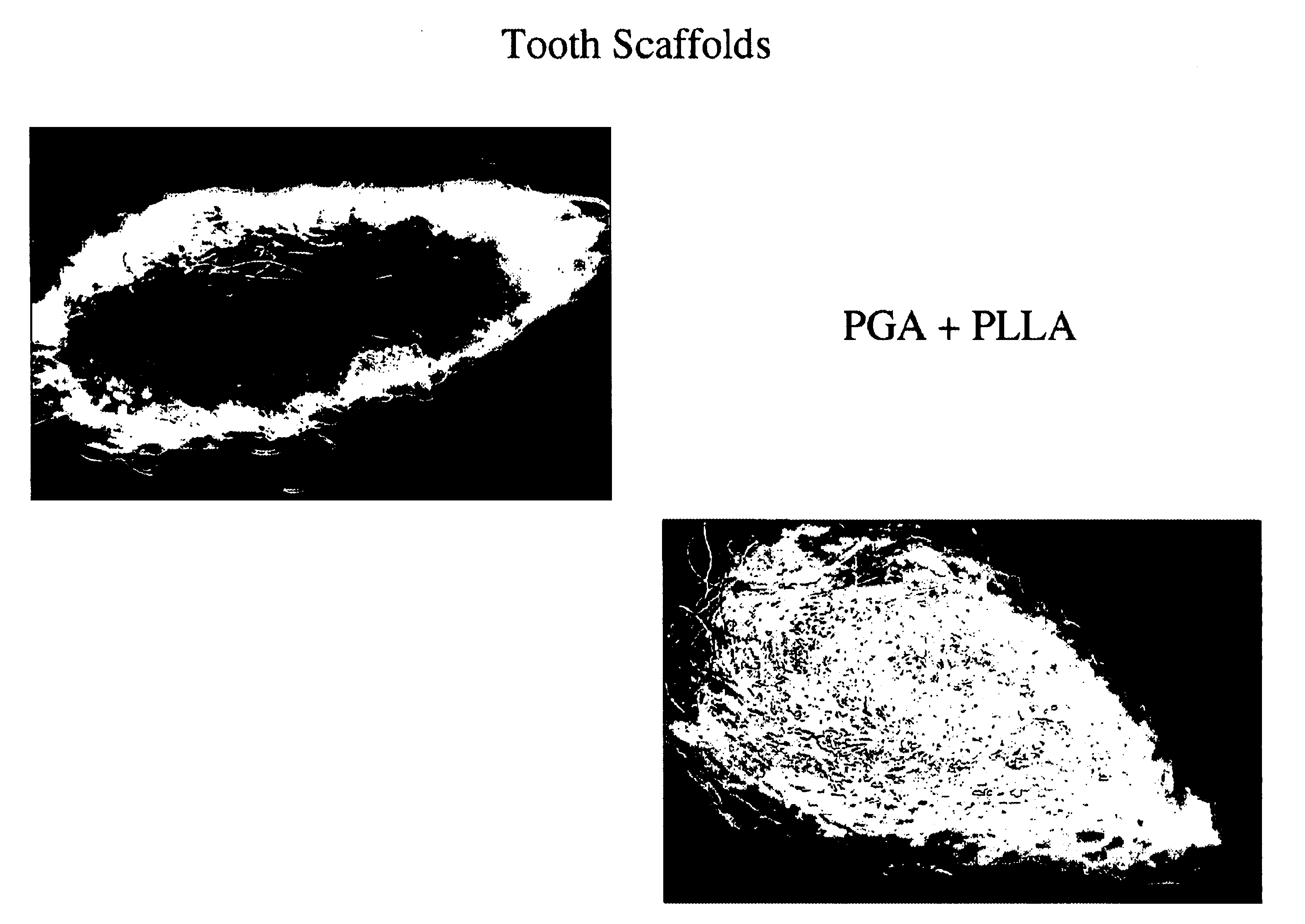

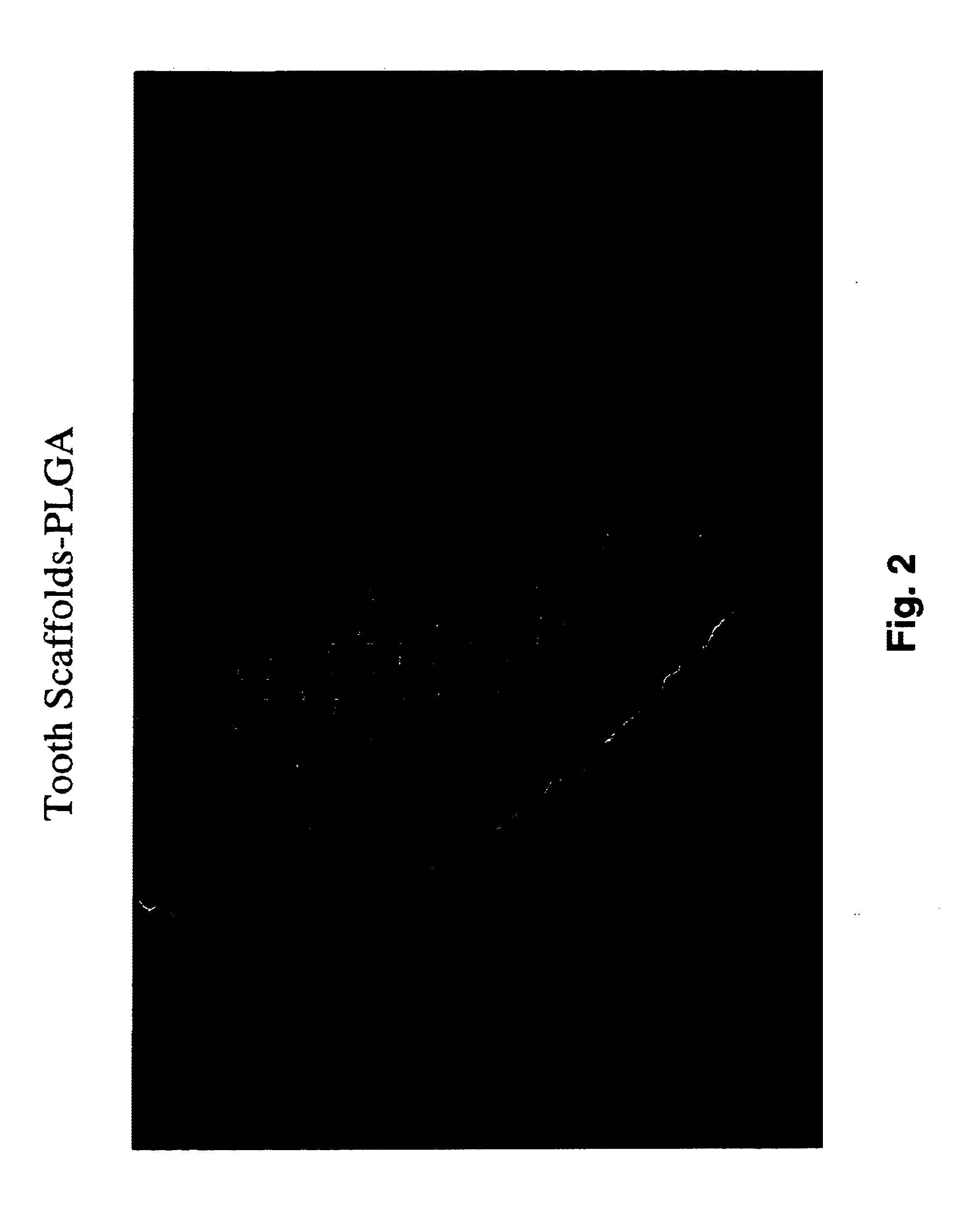

Methods and compositions for culturing a biological tooth

Tooth tissues include the pulp mesenchyme that forms the dentin and an epithelium that is responsible for enamel formation. Cells from these tissues were obtained from porcine third molars and were seeded onto a biodegradable scaffold composed of a polyglycolic acid—polylactic acid copolymer. Cell polymer constructs were then surgically implanted into the omentum of athymic nude rats so that the constructs would have a blood supply and these tissues were allowed to develop inside the rats. Infrequently, columnar epithelial cells were observed as a single layer on the outside of the dentin-like matrix similar to the actual arrangement of ameloblasts over dentin during early tooth development. Developing tooth tissues derived from such cell polymer constructs could eventually be surgically implanted into the gum of an edentulous recipient where the construct would receive a blood supply and develop to maturity, providing the recipient with a biological tooth replacement.

Owner:FORSYTH DENTAL INFARY FOR CHILDREN +2

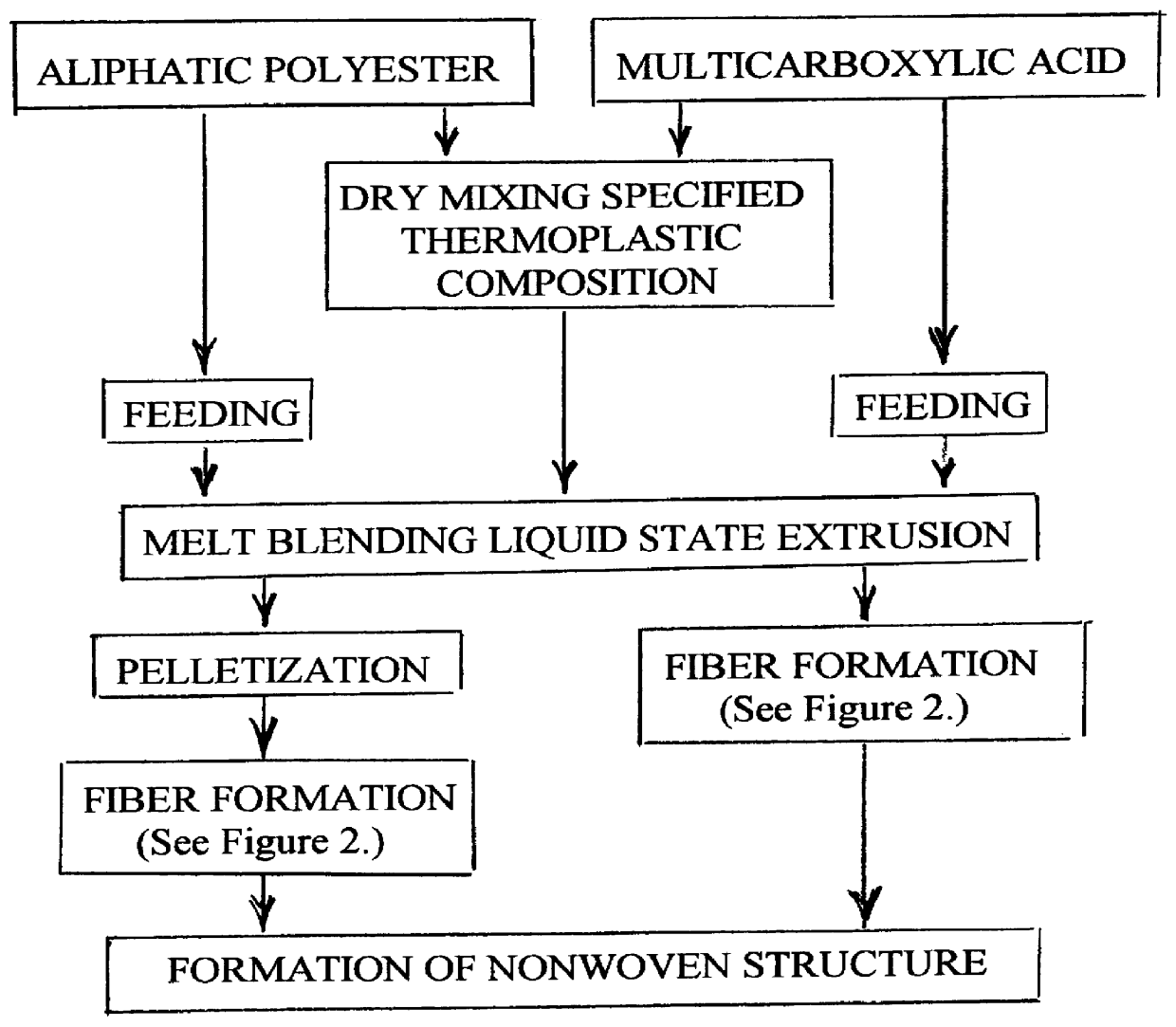

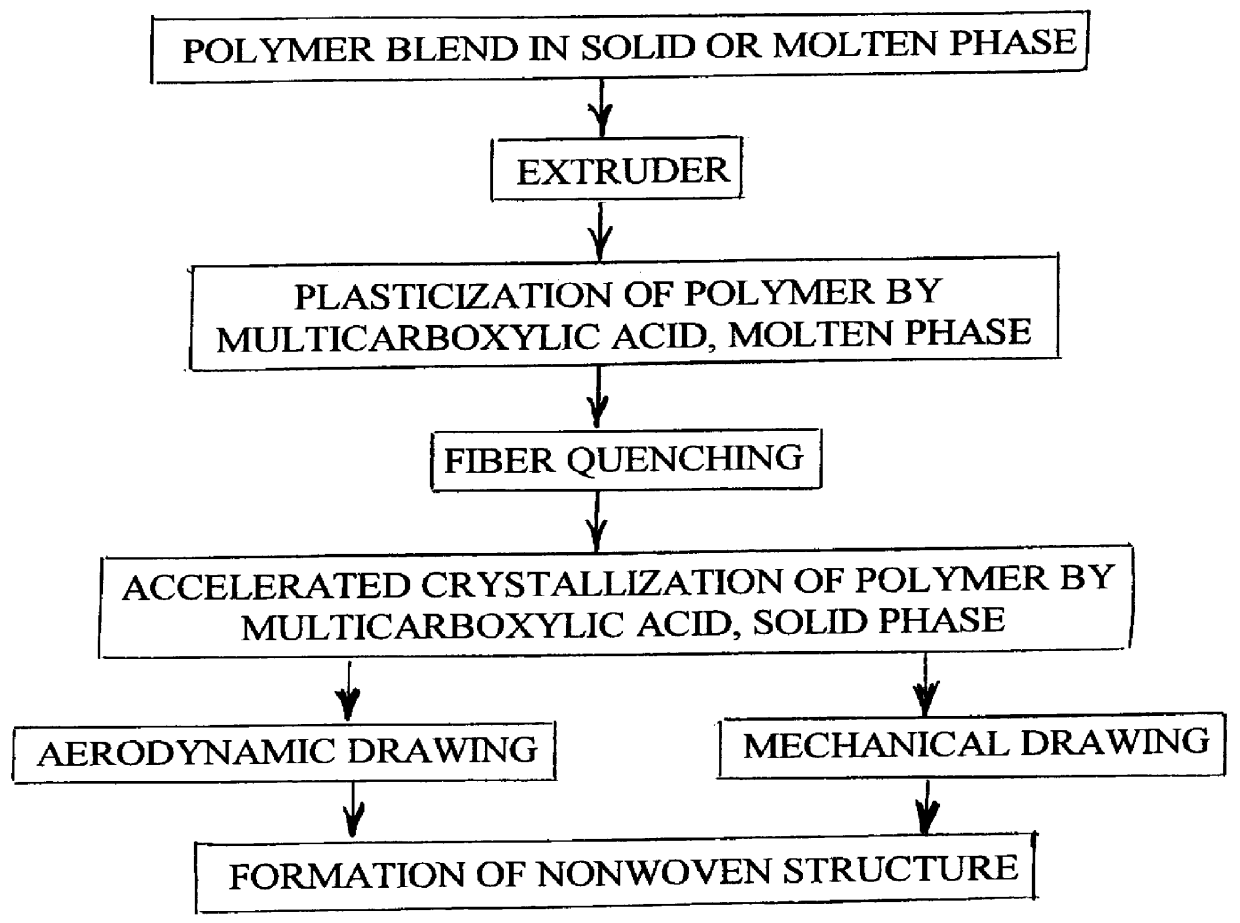

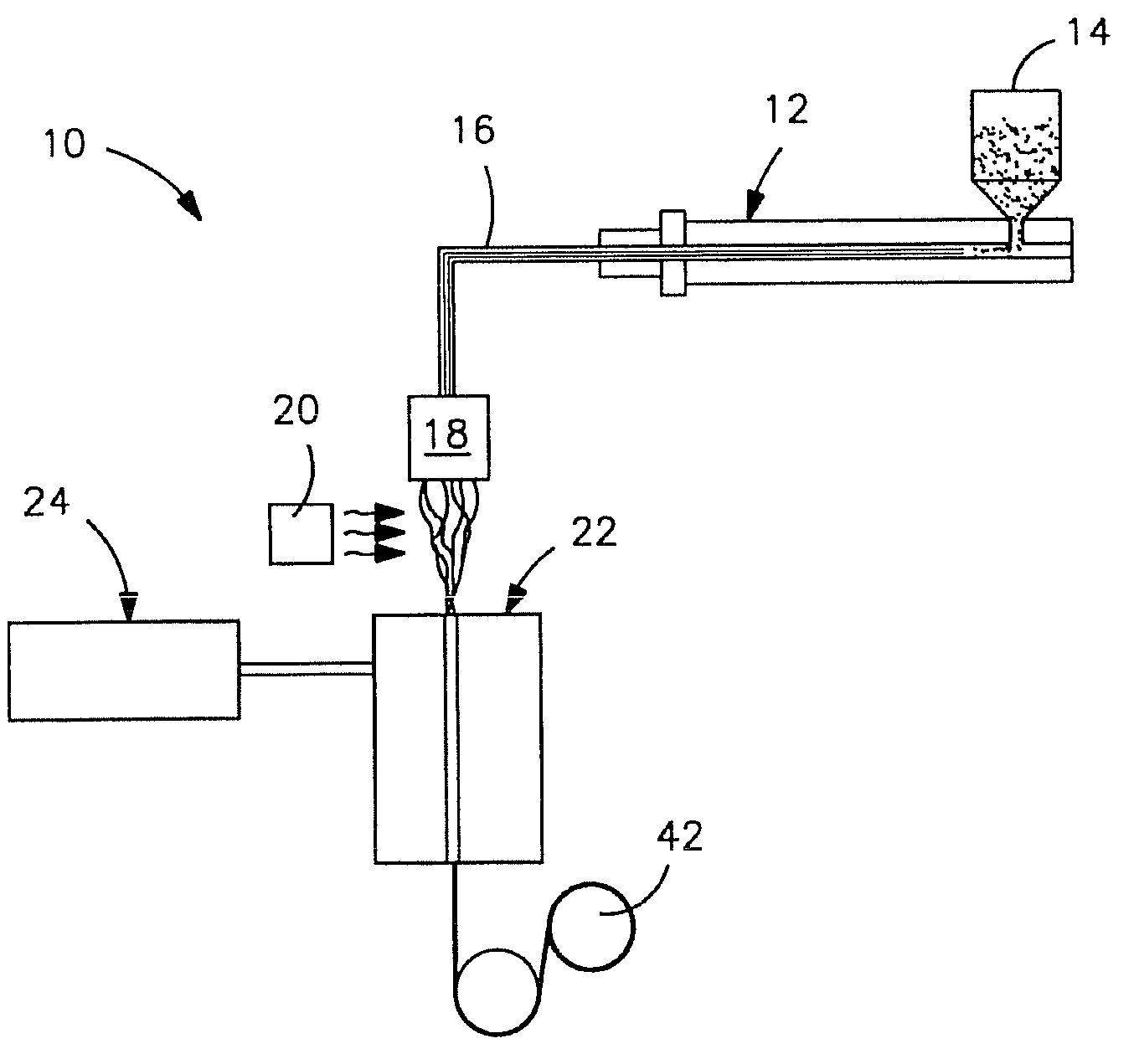

Synthetic fiber

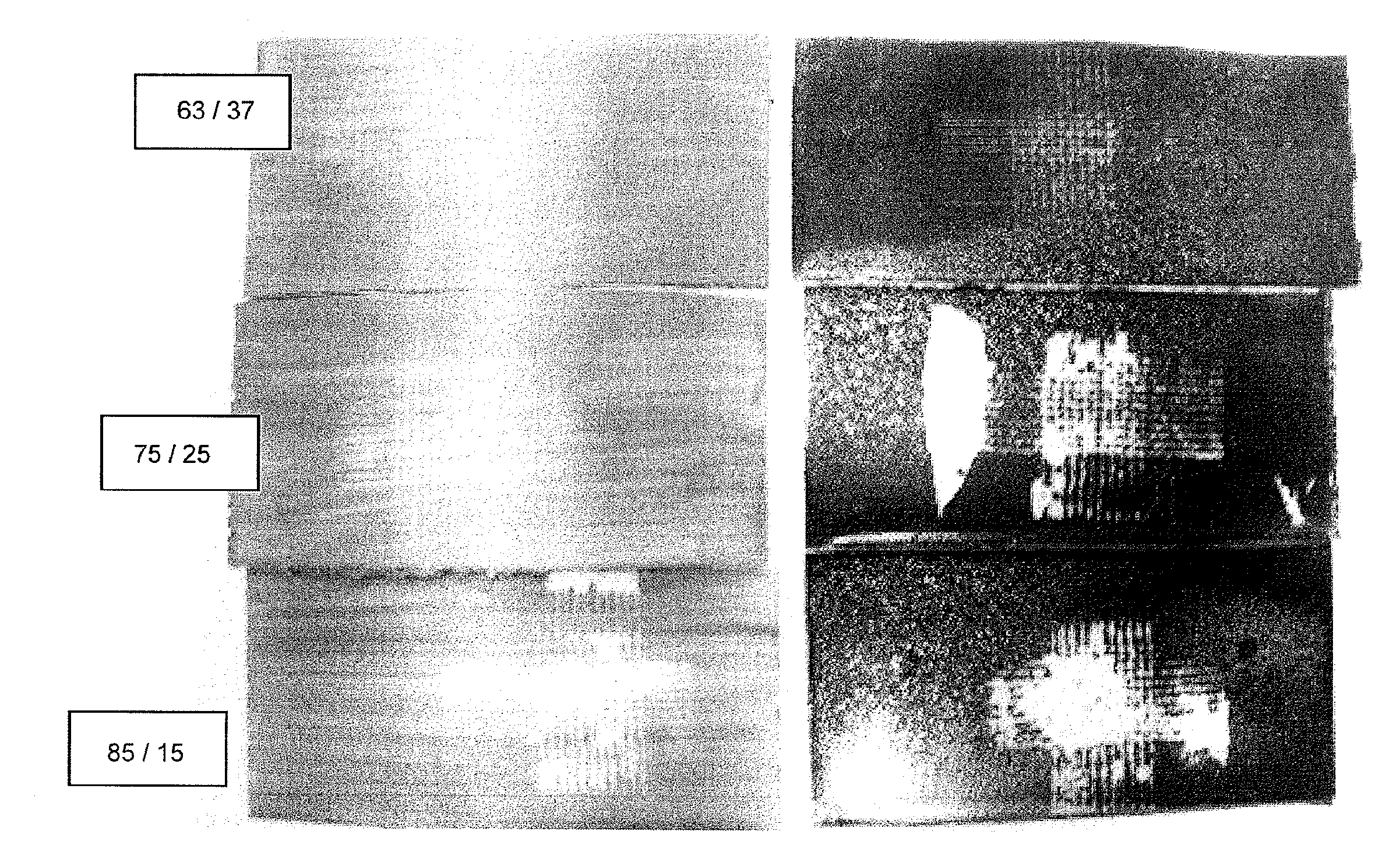

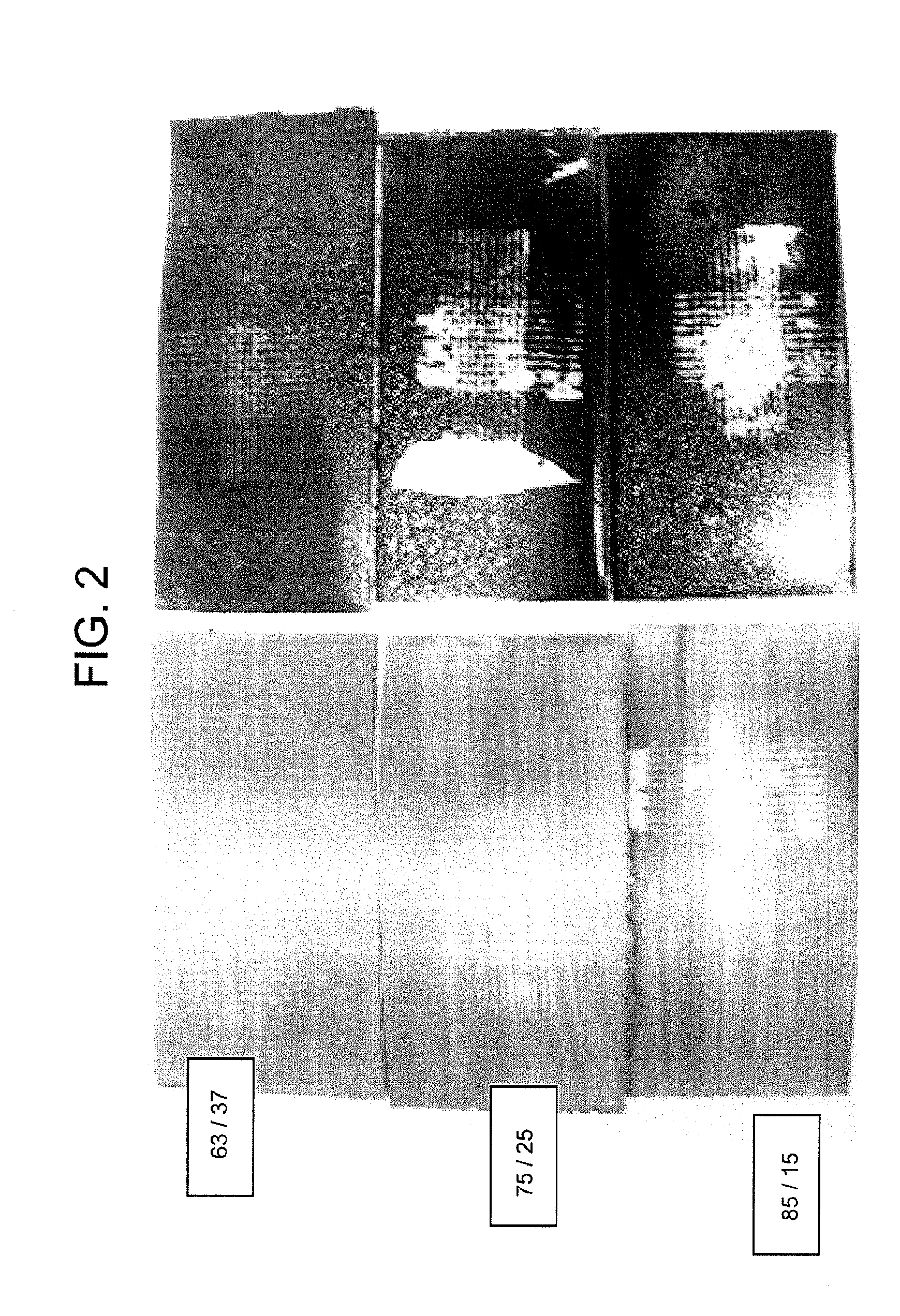

InactiveUS6135987AFormed easily and efficientlyCeramic shaping apparatusBaby linensPolyesterVitrification

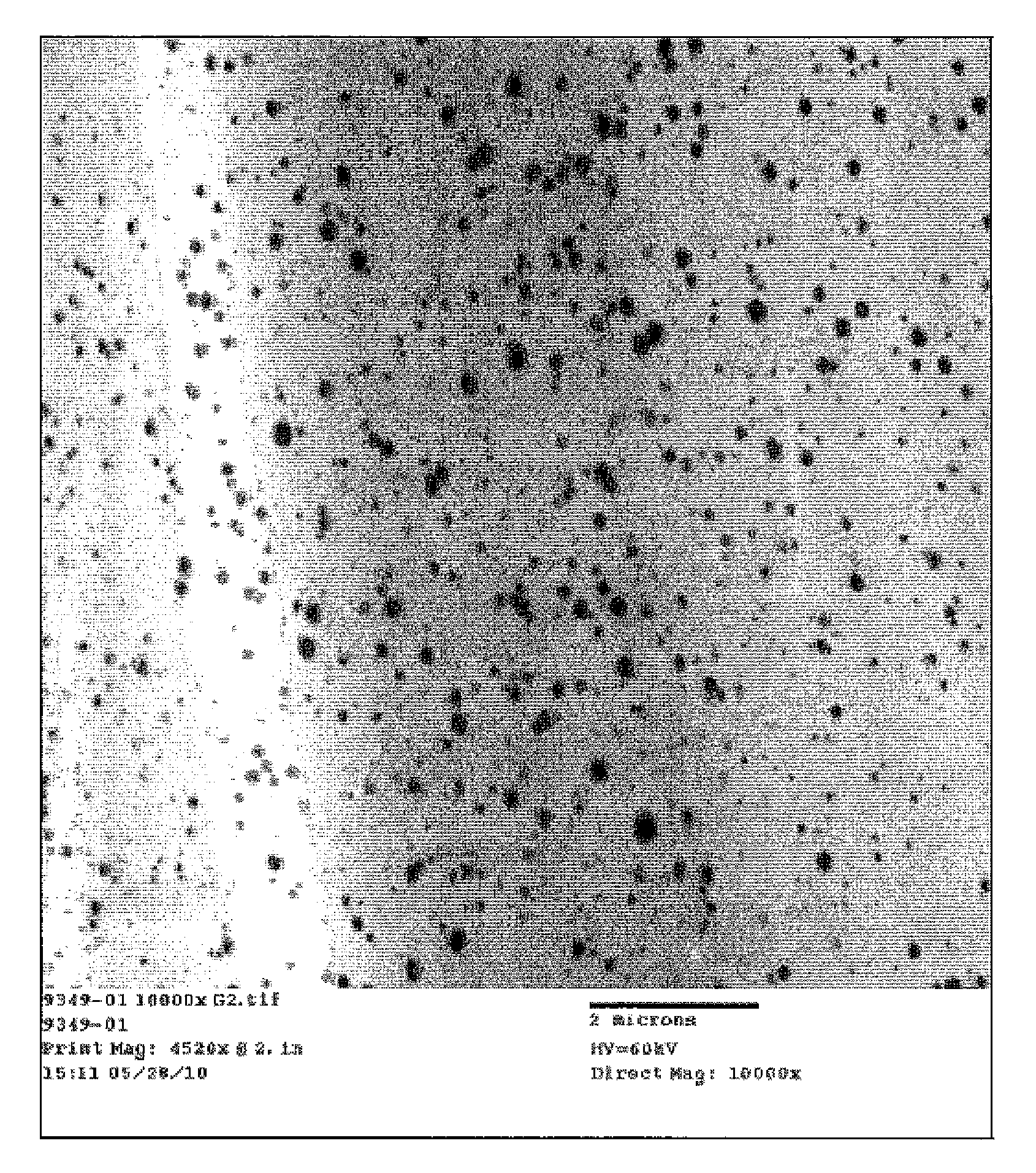

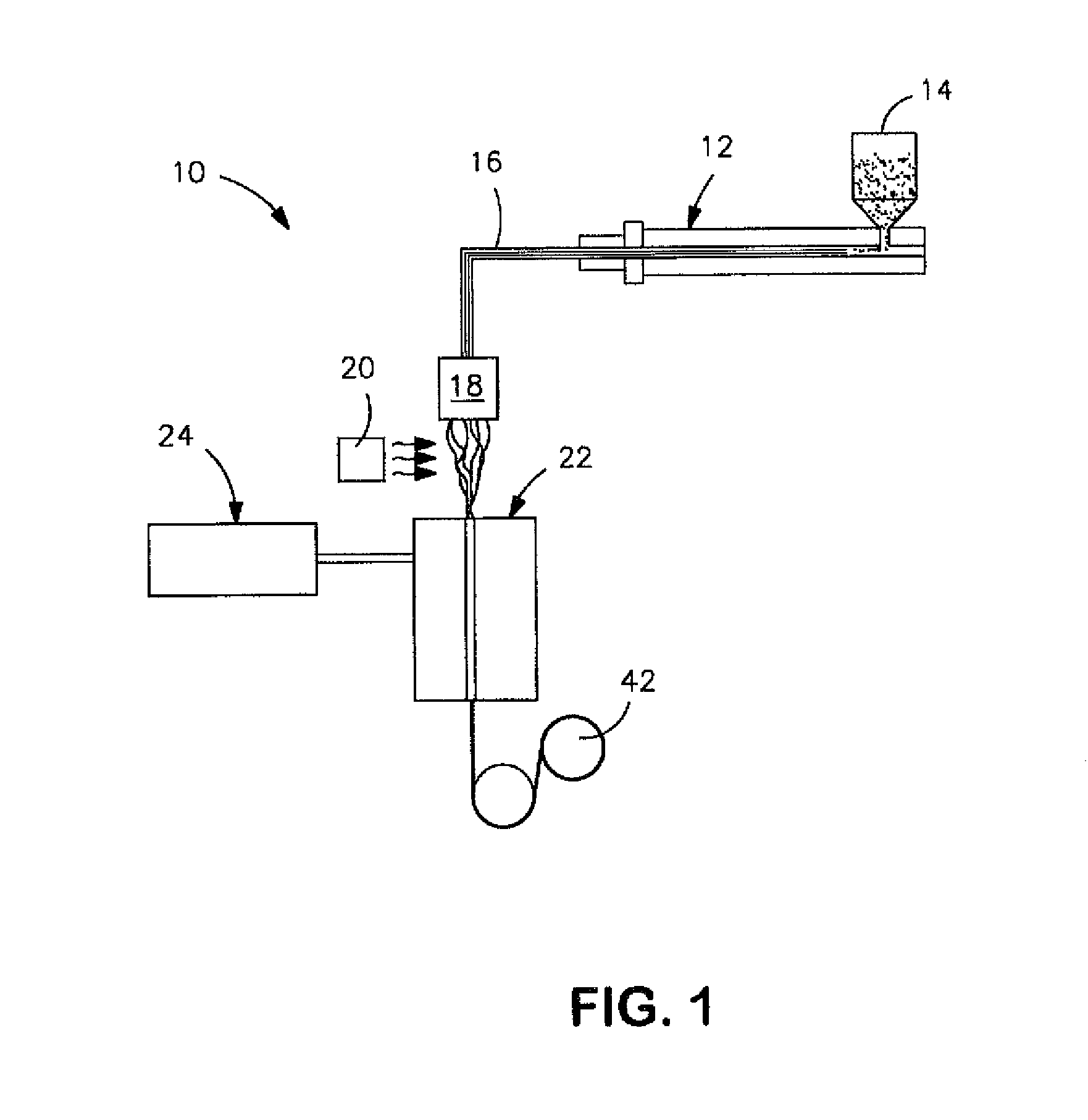

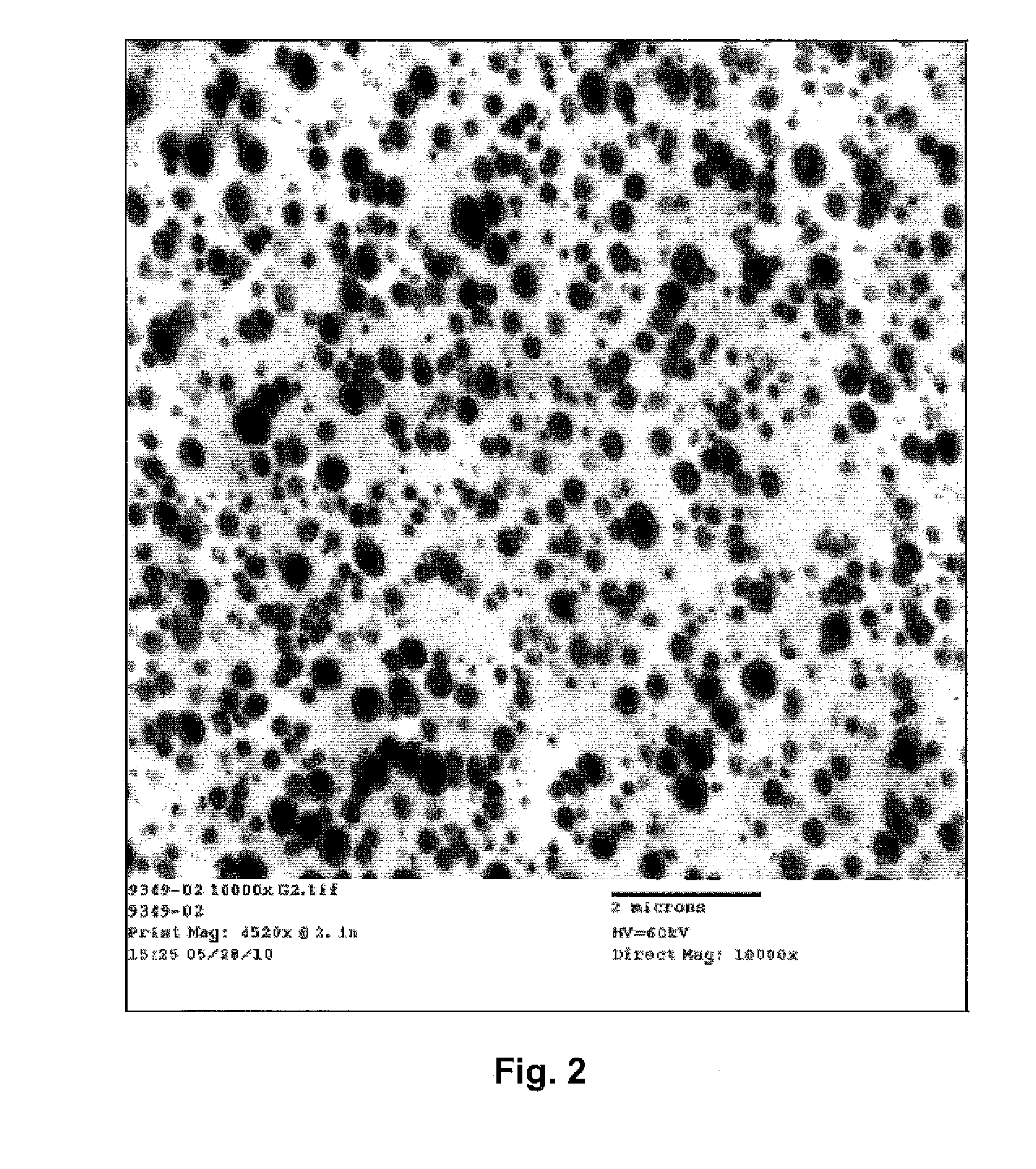

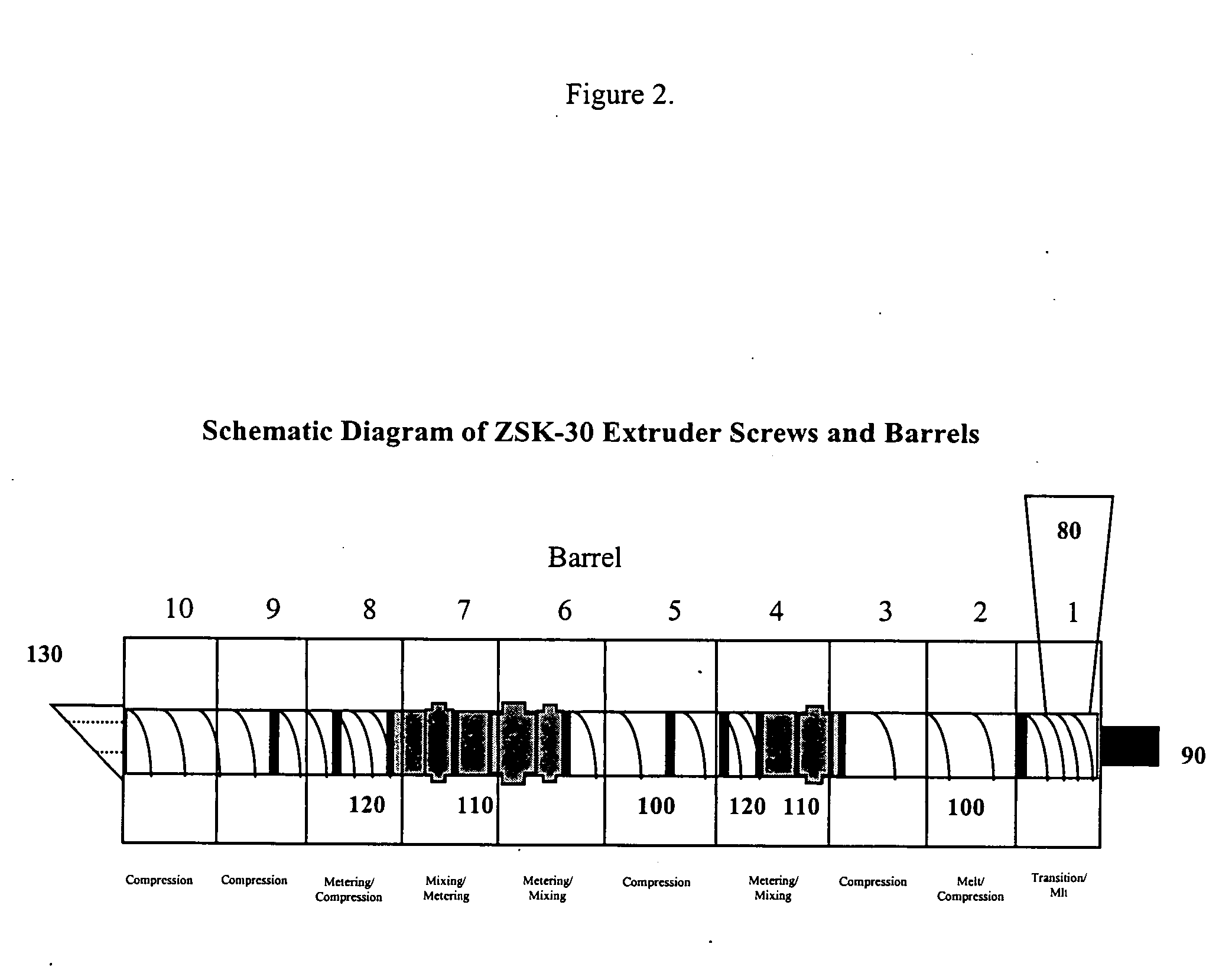

A process is disclosed for forming a synthetic fiber including providing a first component of an aliphatic polyester polymer a second component of a multicarboxylic acid, mixing the first component aliphatic polyester polymer and the second component multicarboxylic acid to form an unreacted specified thermoplastic composition, and melt blending the unreacted specified thermoplastic composition in an extruder or a mixer. The second component multicarboxylic acid lubricates the extruder and provides a nucleating agent for crystallizing the specified thermoplastic composition to form a mean crystal size less than about 120 Angstroms. Fiber composed of the specified thermoplastic composition has a mean crystal size less than about 120 Angstroms. The fiber has a glass transition temperature (Tg) less than about 55 DEG C. In one aspect, a first component of polylactic acid and a second component of adipic acid provide synthetic fibers in a nonwoven structure used in a biodegradable and compostable disposable absorbent product for the absorption and removal of body fluids.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Porous biomaterials and methods for their manufacture

InactiveUS6376573B1High strengthOvercome disadvantagesImpression capsBone implantUltimate tensile strengthPorous ceramics

An improved porous ceramic biomaterial is disclosed in which a polymer such as polylactic acid is polymerized in situ to fill the micropores substantially without filling the macropores. The polymer reinforcement helps improve the strength of the implant while preserving its ability to support ingrowth of bone to help integrate the implant into its surgical environment.

Owner:BIOMET MFG CORP

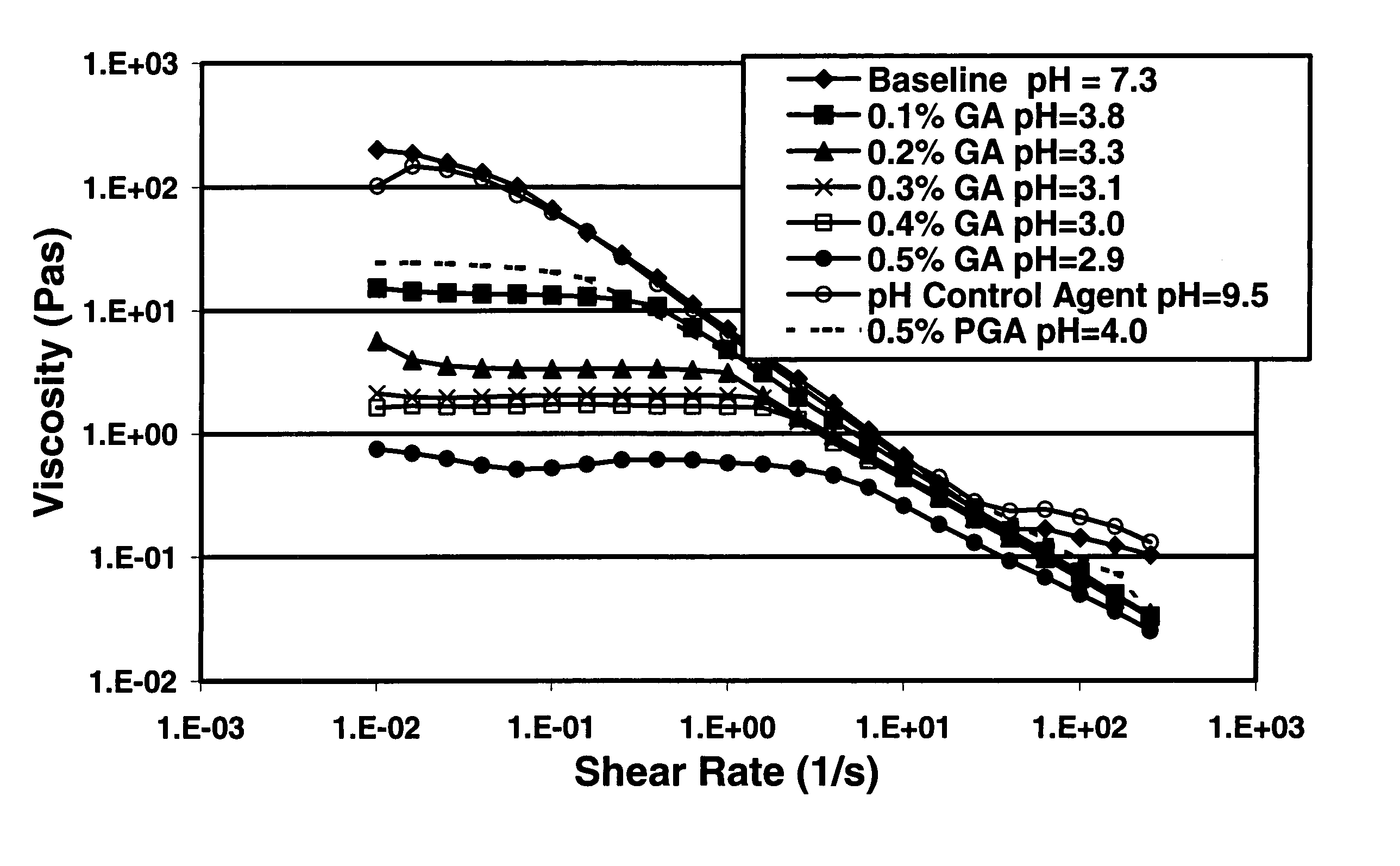

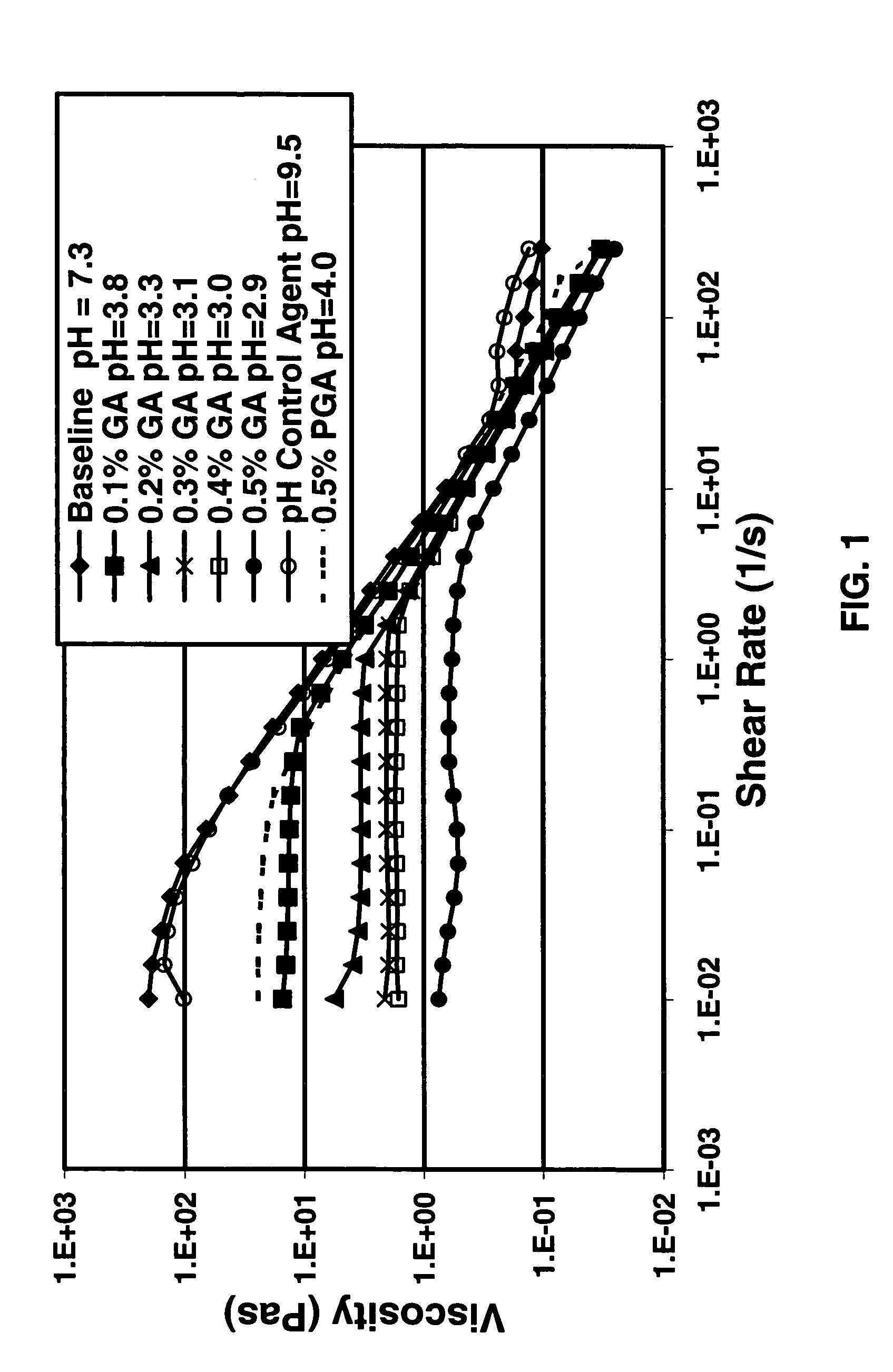

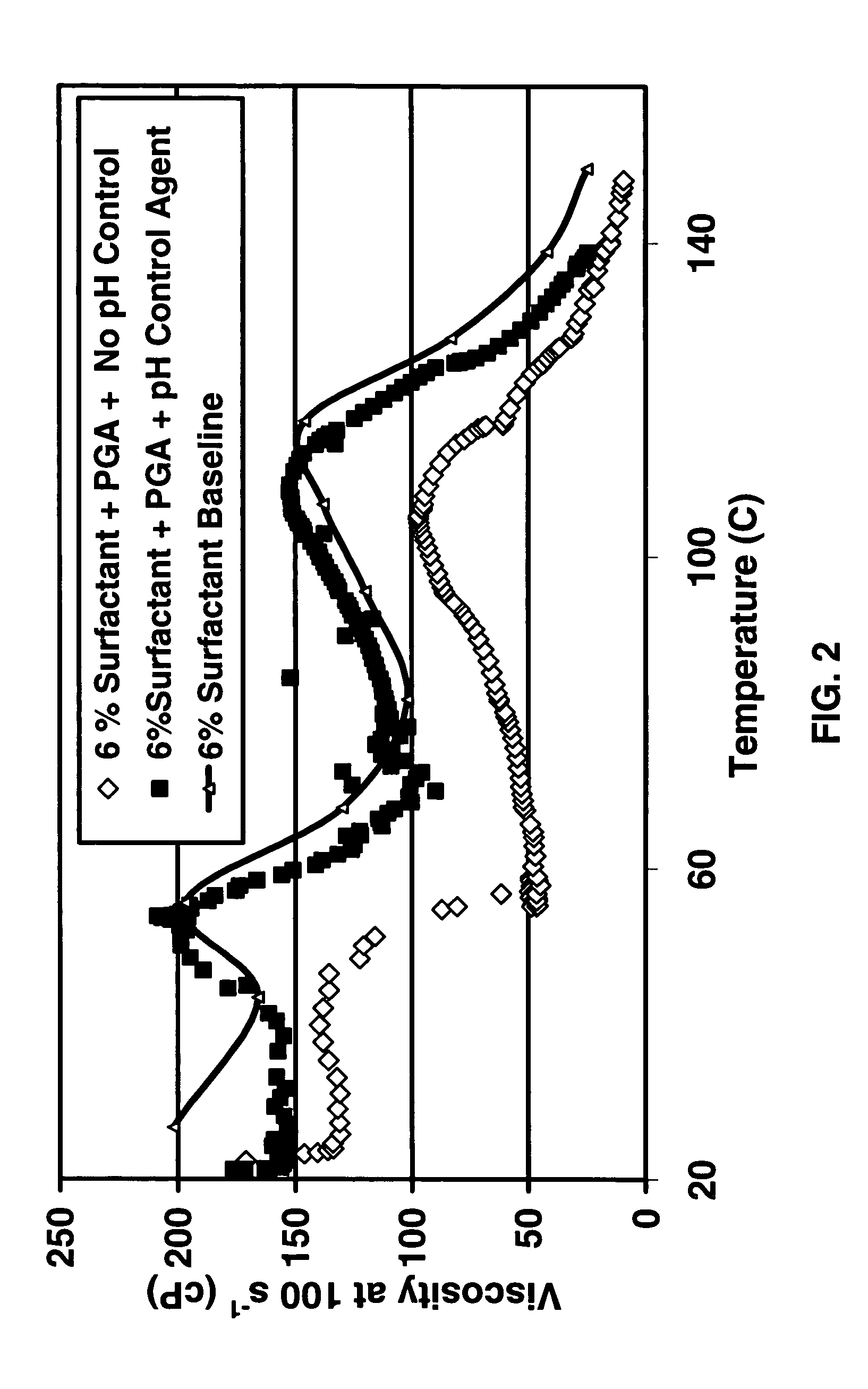

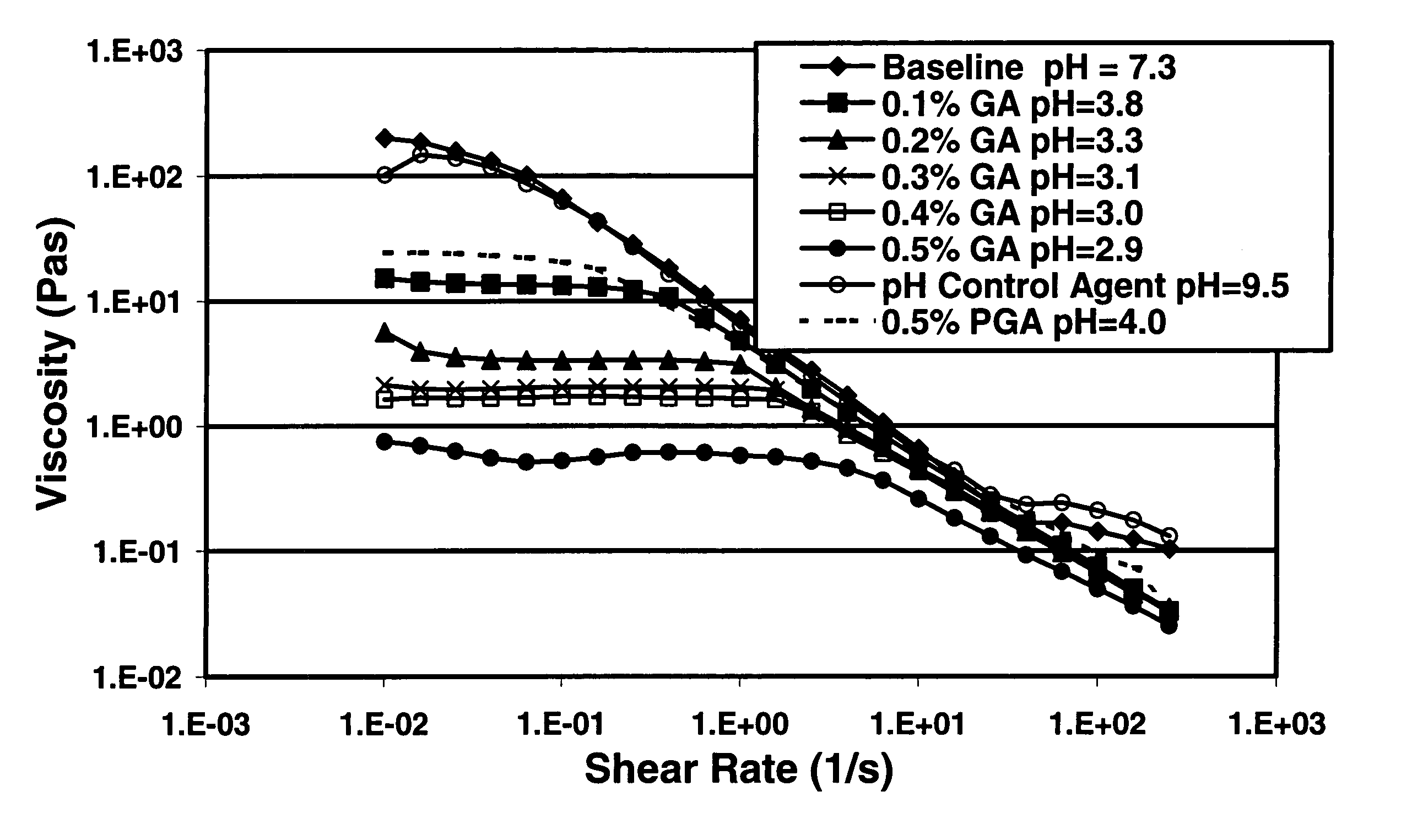

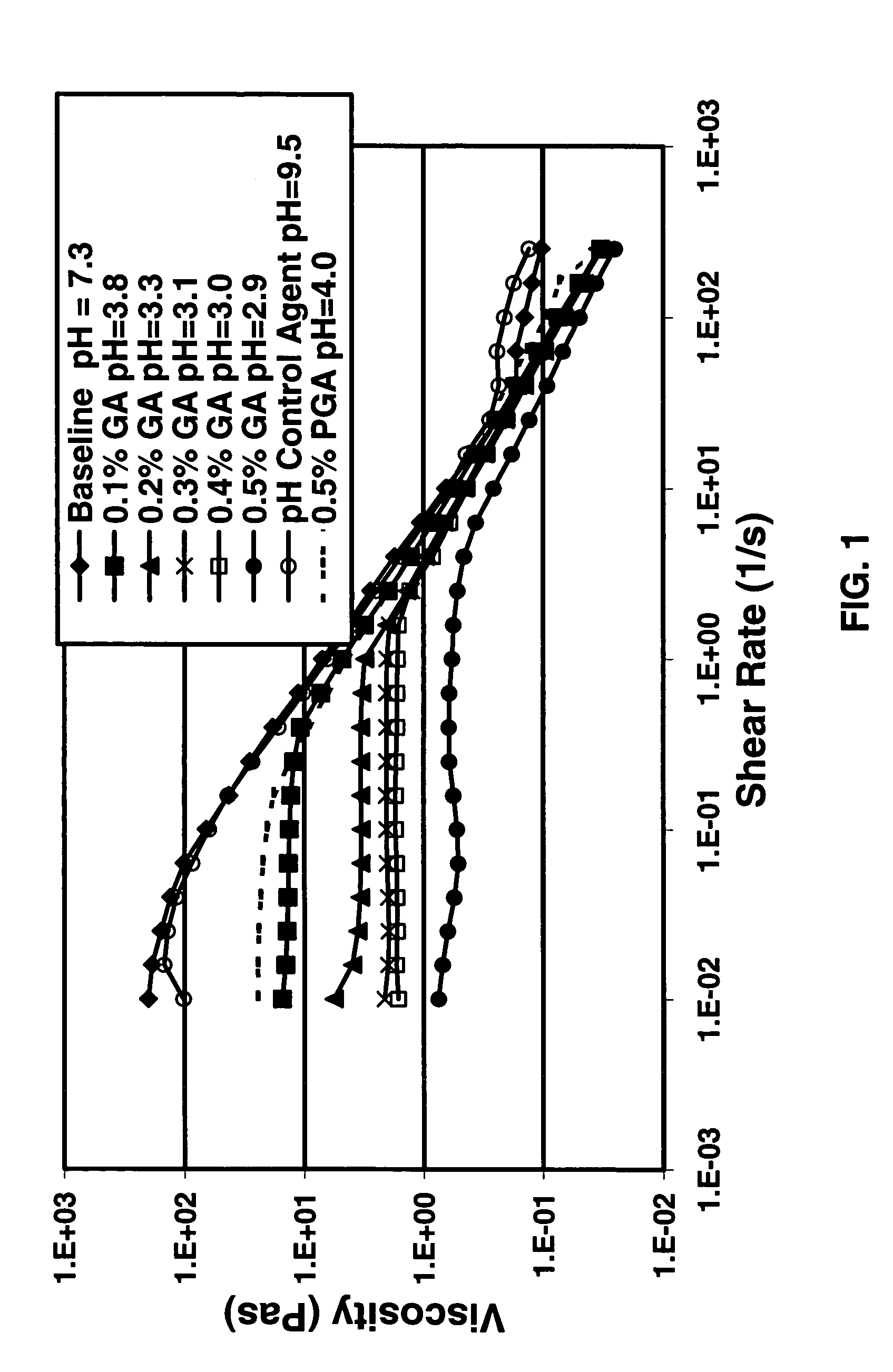

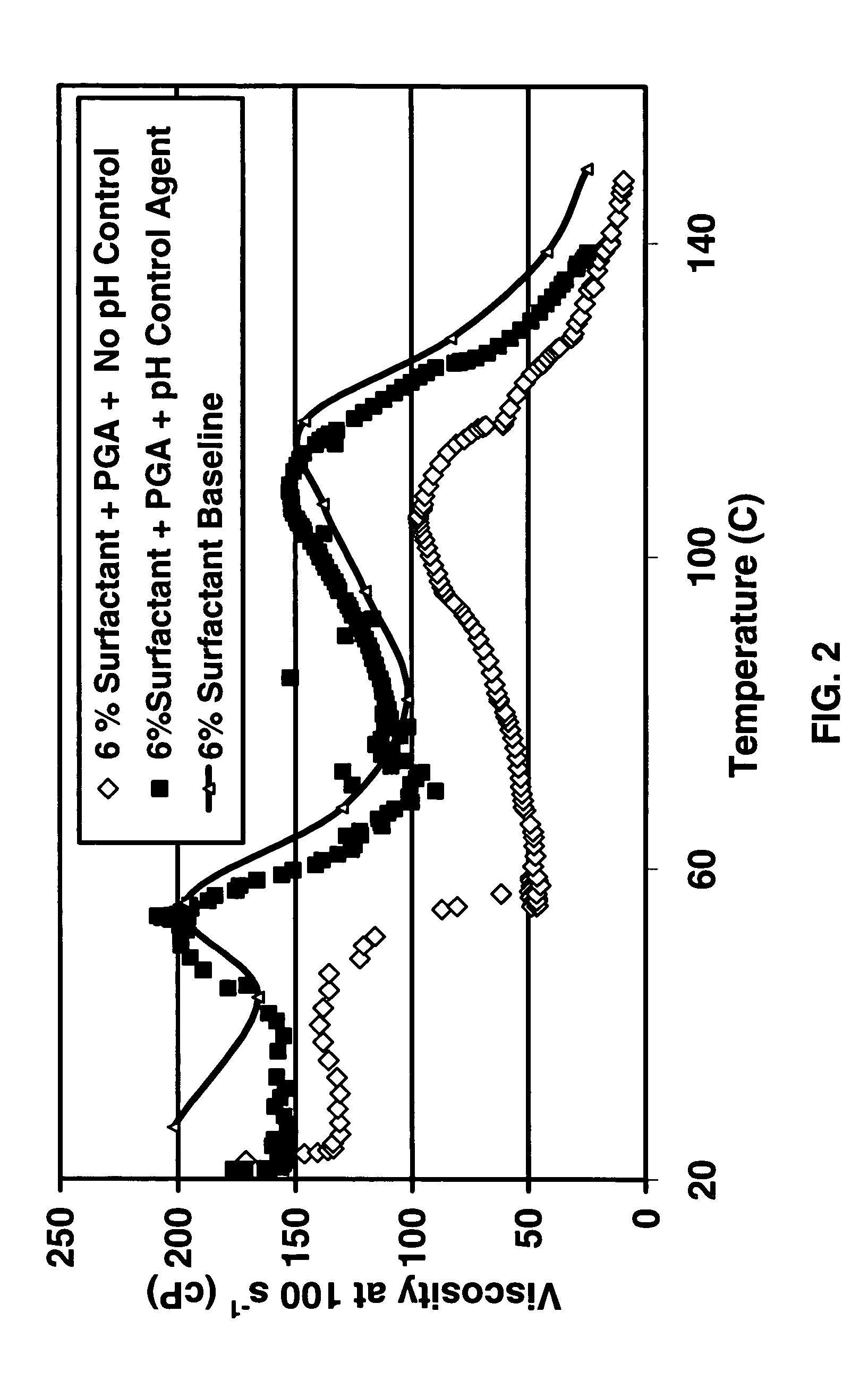

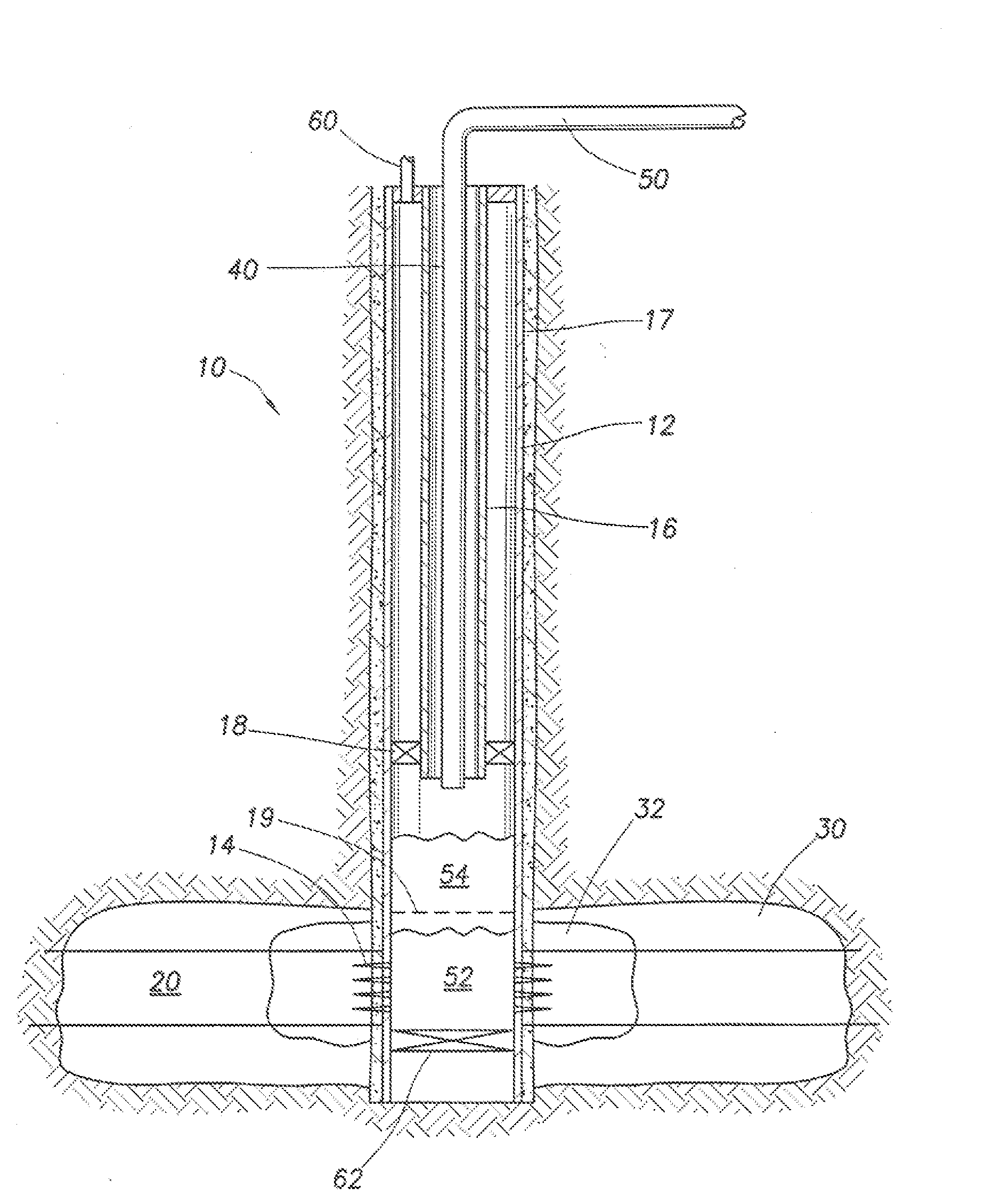

Degradable additive for viscoelastic surfactant based fluid systems

A method is given for treating a subterranean formation penetrated by a wellbore with a viscosified fluid. The fluid contains a solid hydrolysable polyacid that upon dissolution and hydrolysis releases an acid that is a breaker for the viscosifying system. Suitable solid hydrolysable polyacids include polylactic acid and polyglycolic acid. The fluid also contains a pH control agent, present in an amount sufficient to neutralize any acid present in the solid hydrolysable polyacid before the injection and to neutralize any acid generated by the solid hydrolysable polyacid during the injection, so that the acid breaker is not available to break the fluid during the injection. In one embodiment the viscosifier is a viscoelastic surfactant fluid system and the solid hydrolysable polyacid is of a size selected to be a fluid loss additive, for example in fracturing or gravel packing. In another embodiment, the solid hydrolysable polyacid is used in particles sufficiently small that they enter the pores of the formation. In either case, the viscosifier is broken after the solid releases more acid than can be neutralized by the pH control agent.

Owner:SCHLUMBERGER TECH CORP

Degradable additive for viscoelastic surfactant based fluid systems

A method is given for treating a subterranean formation penetrated by a wellbore with a viscosified fluid. The fluid contains a solid hydrolysable polyacid that upon dissolution and hydrolysis releases an acid that is a breaker for the viscosifying system. Suitable solid hydrolysable polyacids include polylactic acid and polyglycolic acid. The fluid also contains a pH control agent, present in an amount sufficient to neutralize any acid present in the solid hydrolysable polyacid before the injection and to neutralize any acid generated by the solid hydrolysable polyacid during the injection, so that the acid breaker is not available to break the fluid during the injection. In one embodiment the viscosifier is a viscoelastic surfactant fluid system and the solid hydrolysable polyacid is of a size selected to be a fluid loss additive, for example in fracturing or gravel packing. In another embodiment, the solid hydrolysable polyacid is used in particles sufficiently small that they enter the pores of the formation. In either case, the viscosifier is broken after the solid releases more acid than can be neutralized by the pH control agent.

Owner:SCHLUMBERGER TECH CORP

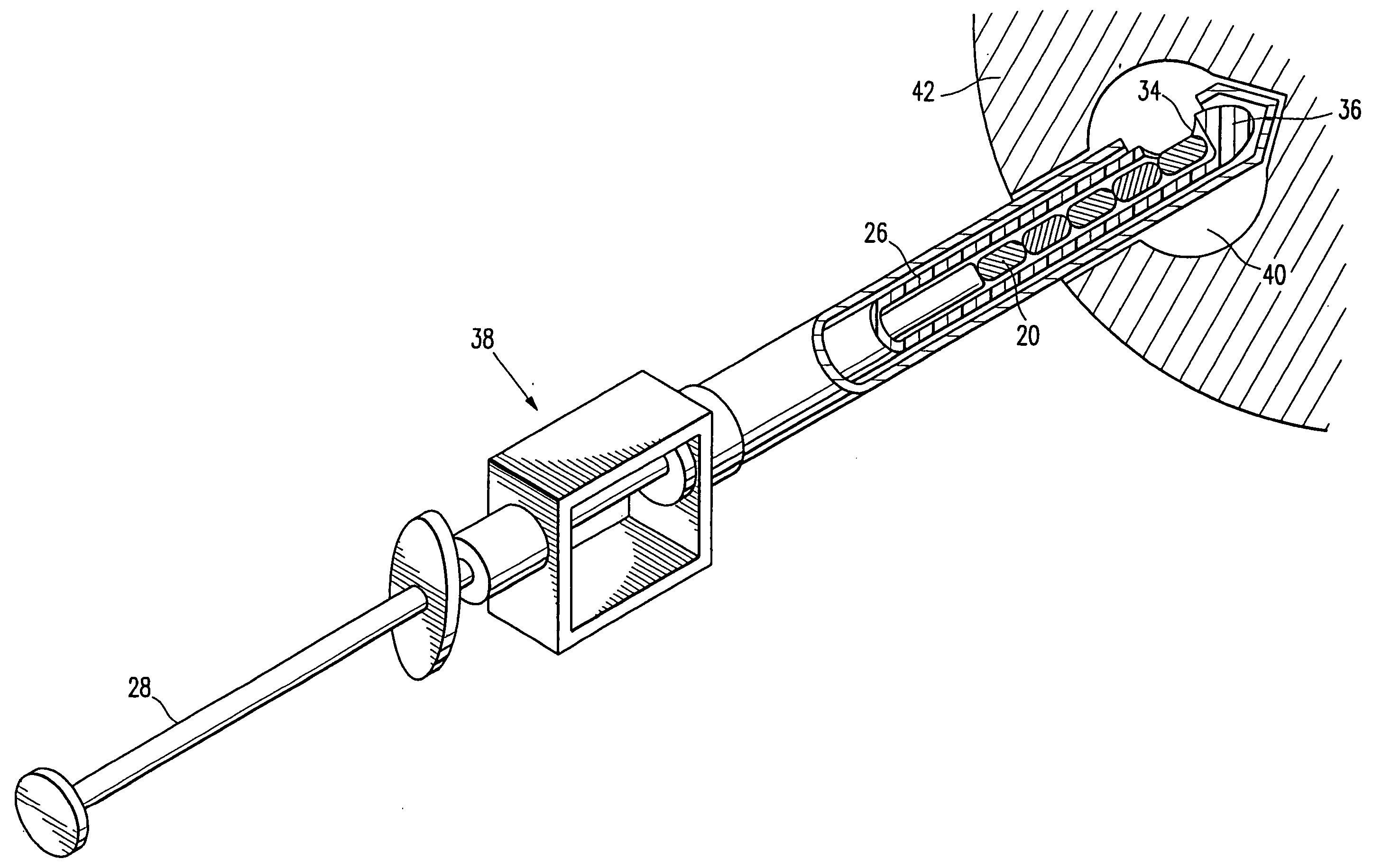

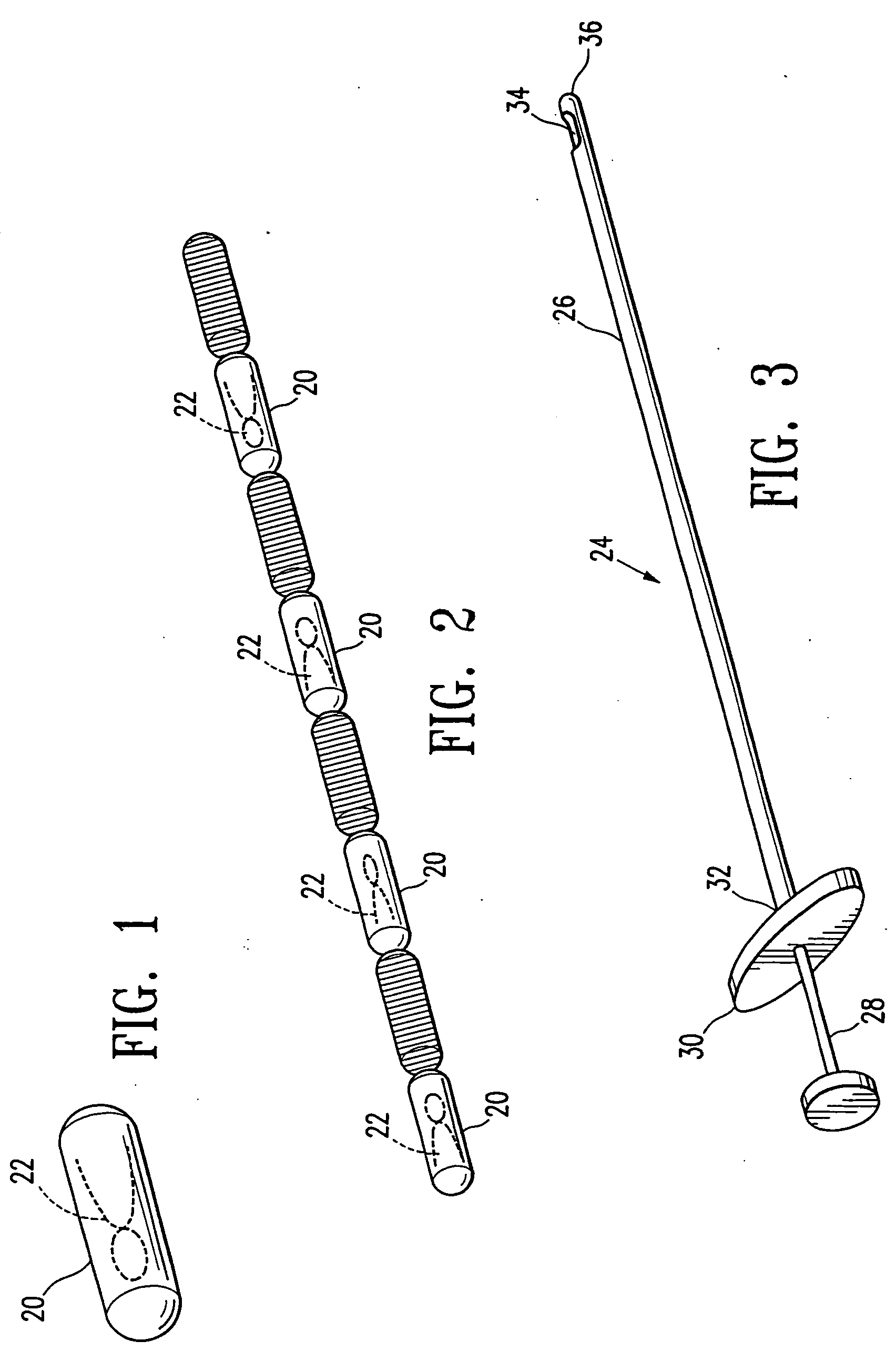

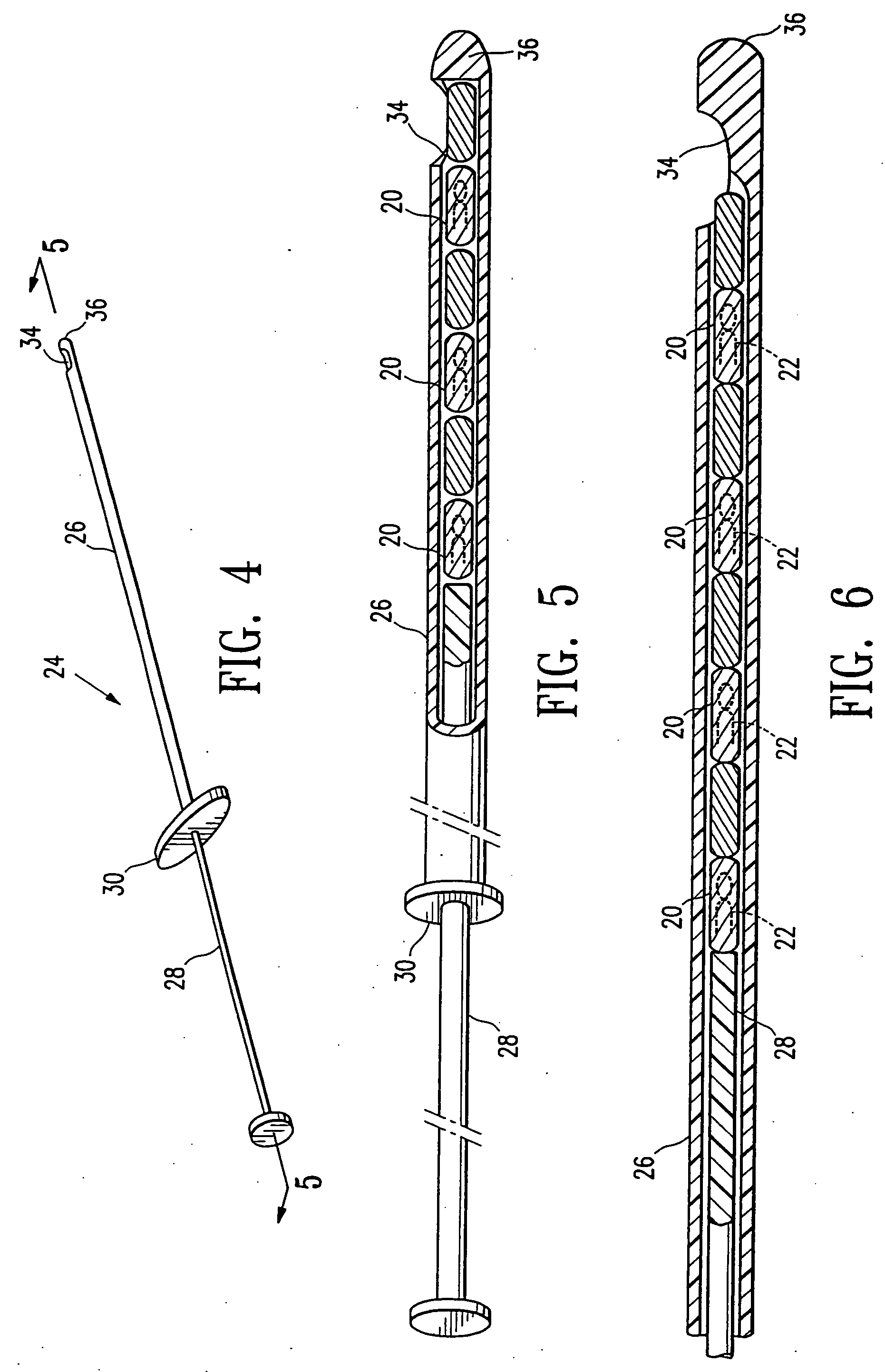

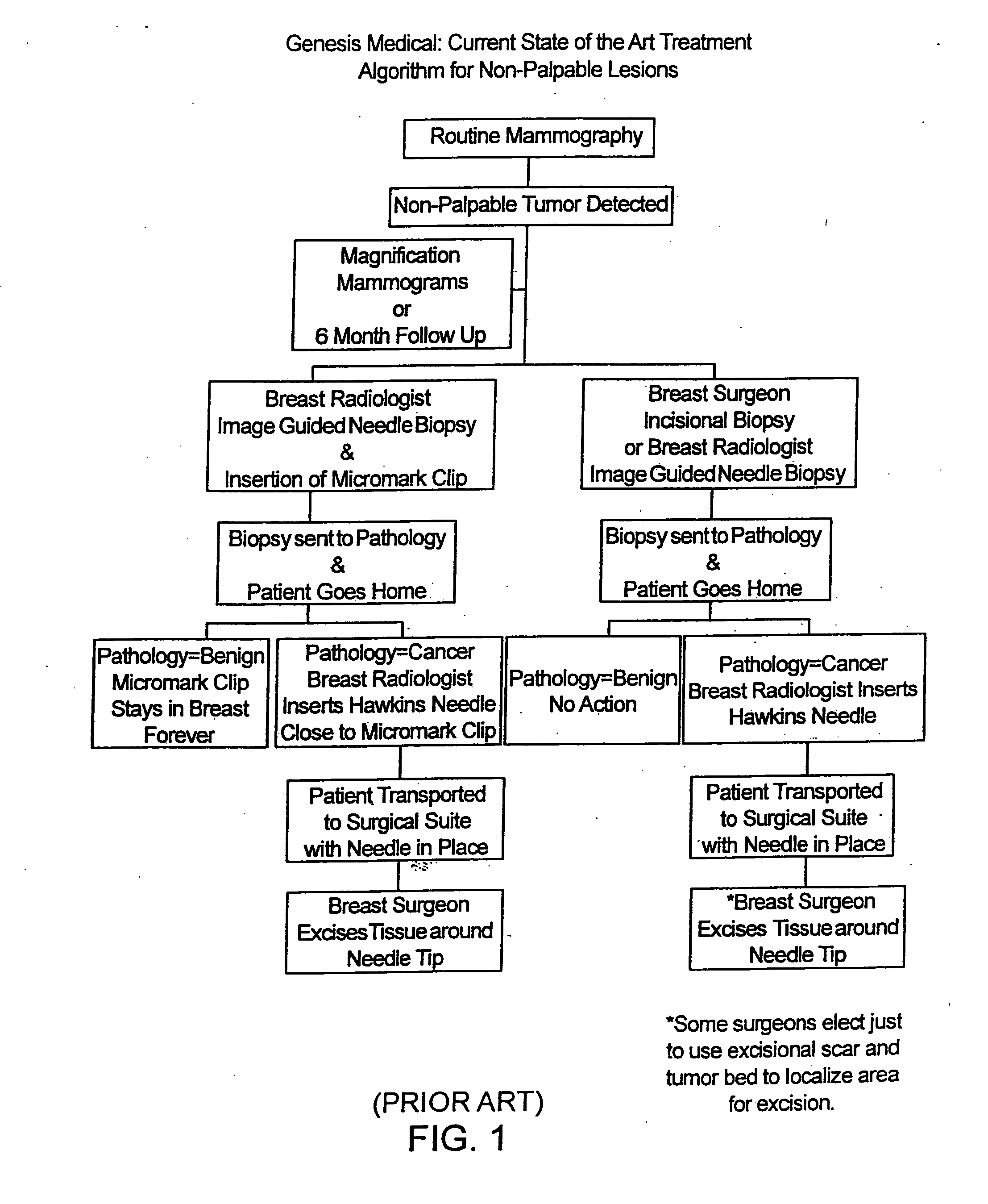

Imageable biopsy site marker

InactiveUS20060122503A1Accurately excise and remove a quantityMark accuratelyLuminescence/biological staining preparationOrgan movement/changes detectionRadiologyPiston

A biopsy site marker having at least one small marker body or pellet of bioresorbable material such as gelatin, collagen, polylactic acid, polyglycolic acid which has a radiopaque object, preferably with a non-biological configuration. The at least one bioresorbable body or pellet with a radiopaque object is deposited into the biopsy site, by an delivery device that includes an elongated tubular body with a piston slidable within the tubular body. One end of the tube is placed into the biopsy site. At least one but preferably several marker bodies or pellets are deposited sequentially into the biopsy site through the tube. At least the bioresorbable materials of the detectable markers remain present in sufficient quantity to permit detection and location of the biopsy site at a first time point (e.g., 2 weeks) after introduction but clear from the biopsy site or otherwise do not interfere with imaging of tissues adjacent the biopsy site at a second time point (e.g., 5-7 months) after introduction.

Owner:SENORX

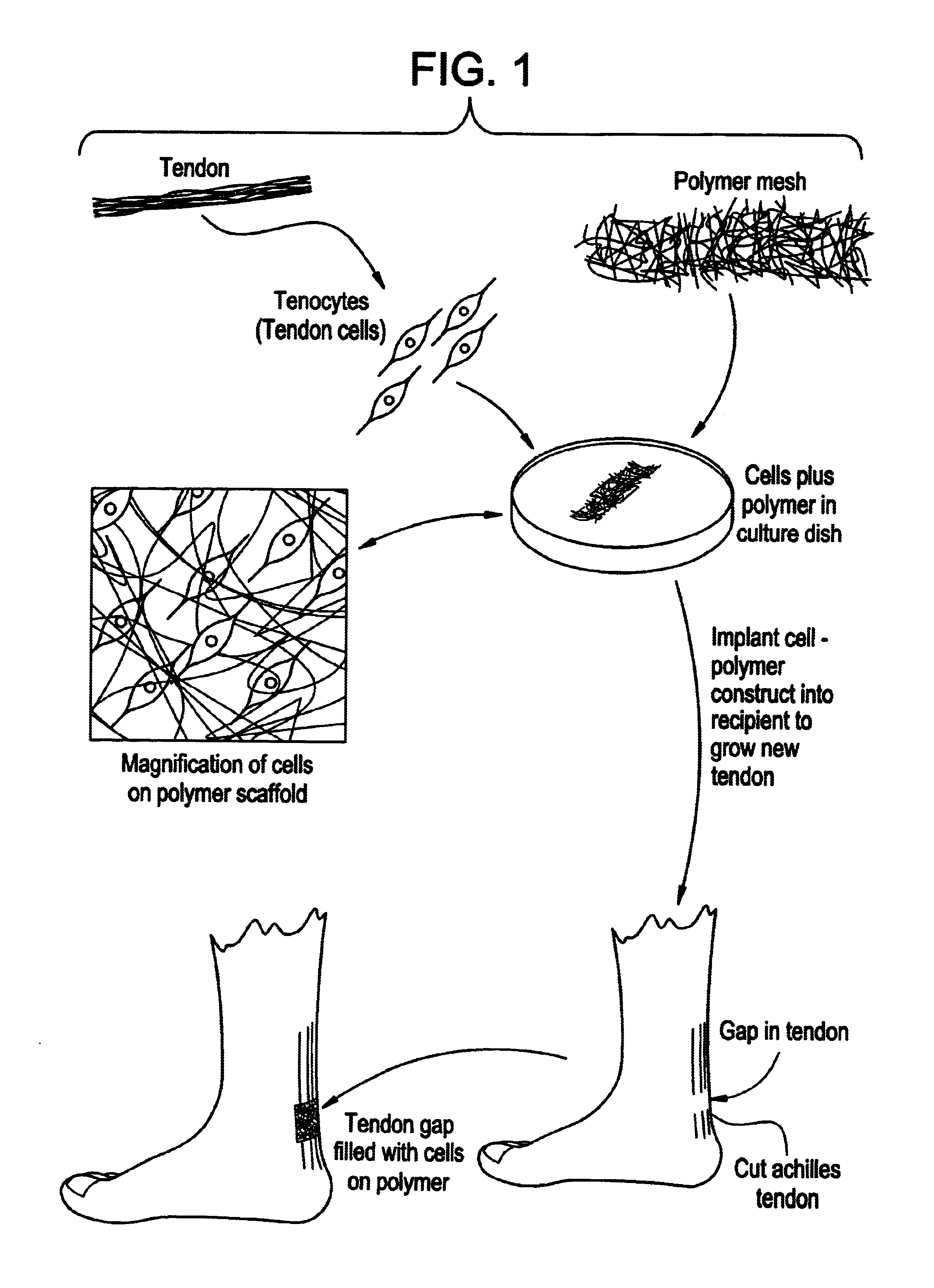

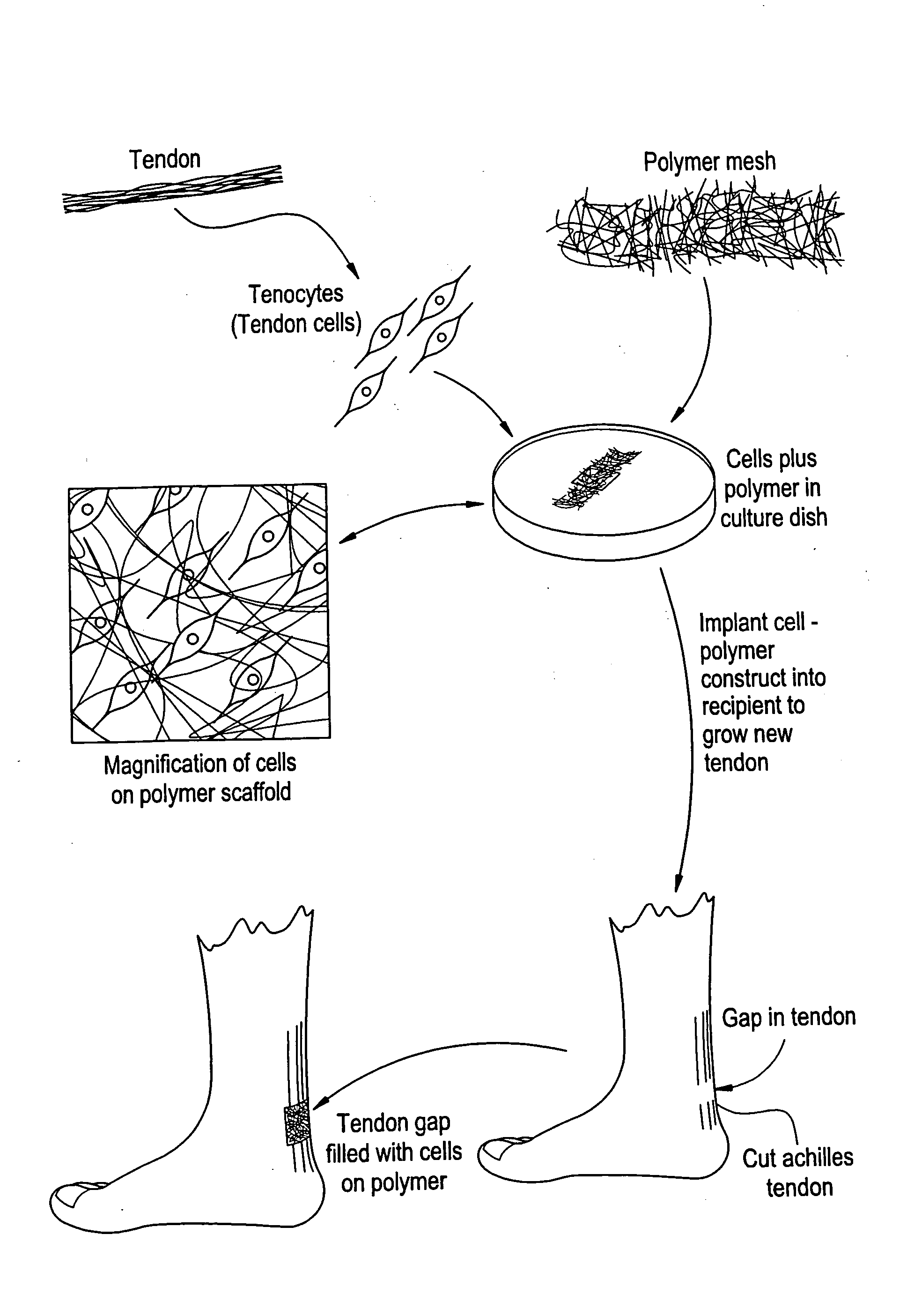

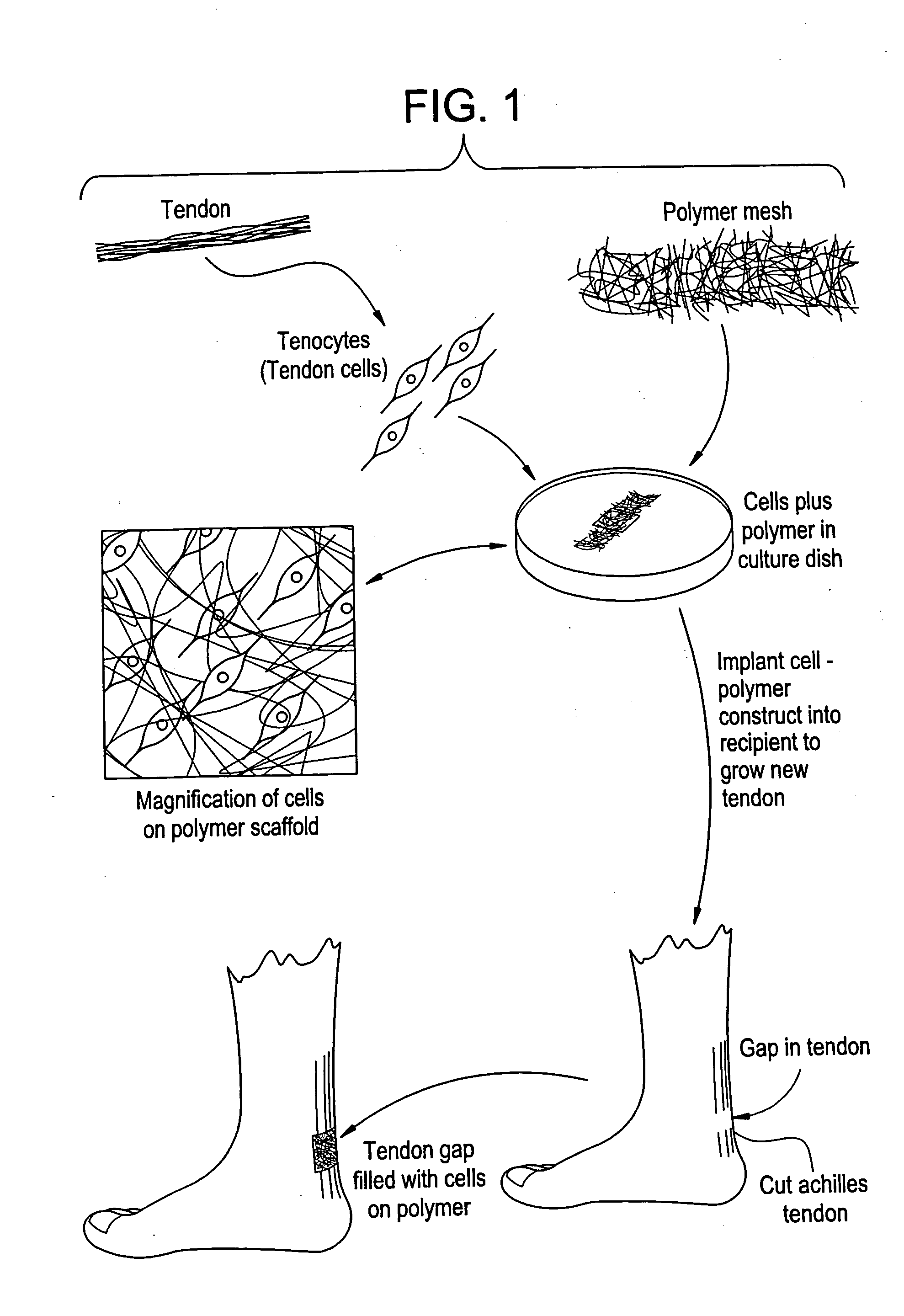

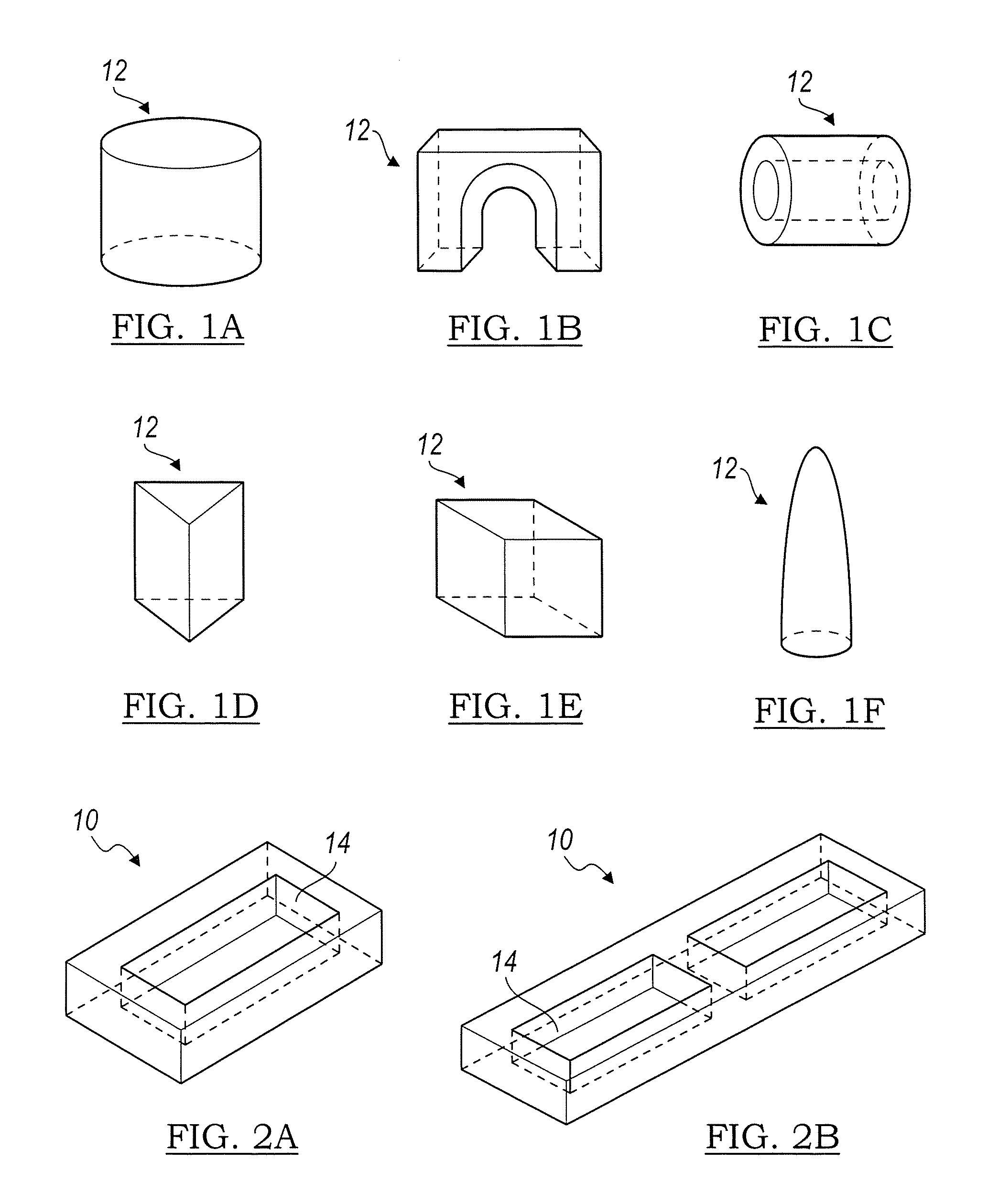

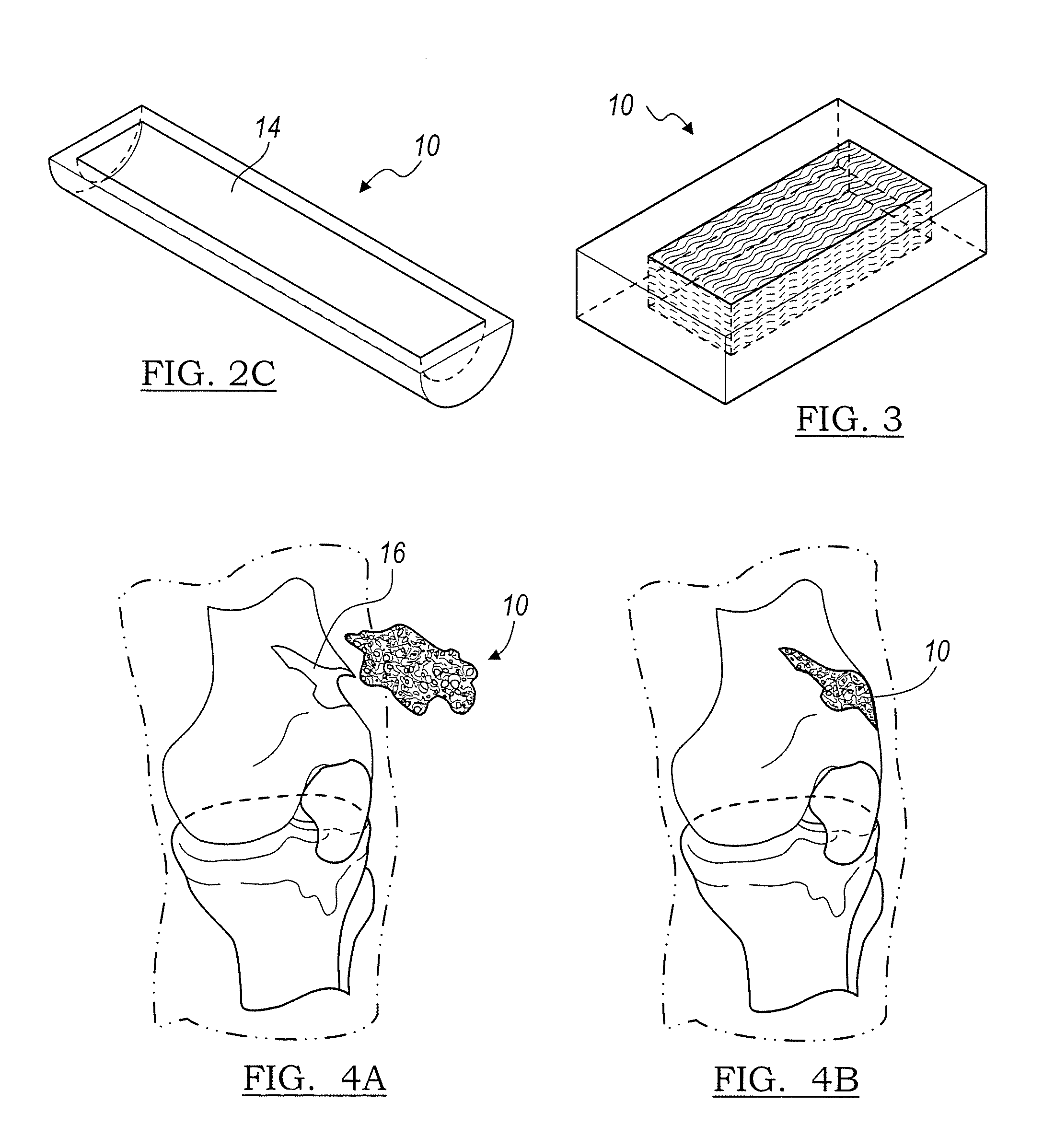

Tissue engineered tendons and ligaments

InactiveUS6840962B1Moderate strengthReduce inflammationLigamentsMusclesEnzymatic digestionLigament structure

Connective tissue, including neo-tendons and ligaments, has been constructed using biodegradable synthetic scaffolds seeded with tenocytes. The scaffolds are preferably formed from biodegradable fibers formed of a polymer such as polyglycolic acid-polylactic acid copolymers, and seeded with cells isolated from autologous tendon or ligament by means of enzymatic digestion or direct seeding into tissue culture dishes from explants. The cell polymer constructs are then surgically transplanted to replace missing segments of functioning tendon or ligament.

Owner:MASSACHUSETTS INST OF TECH +1

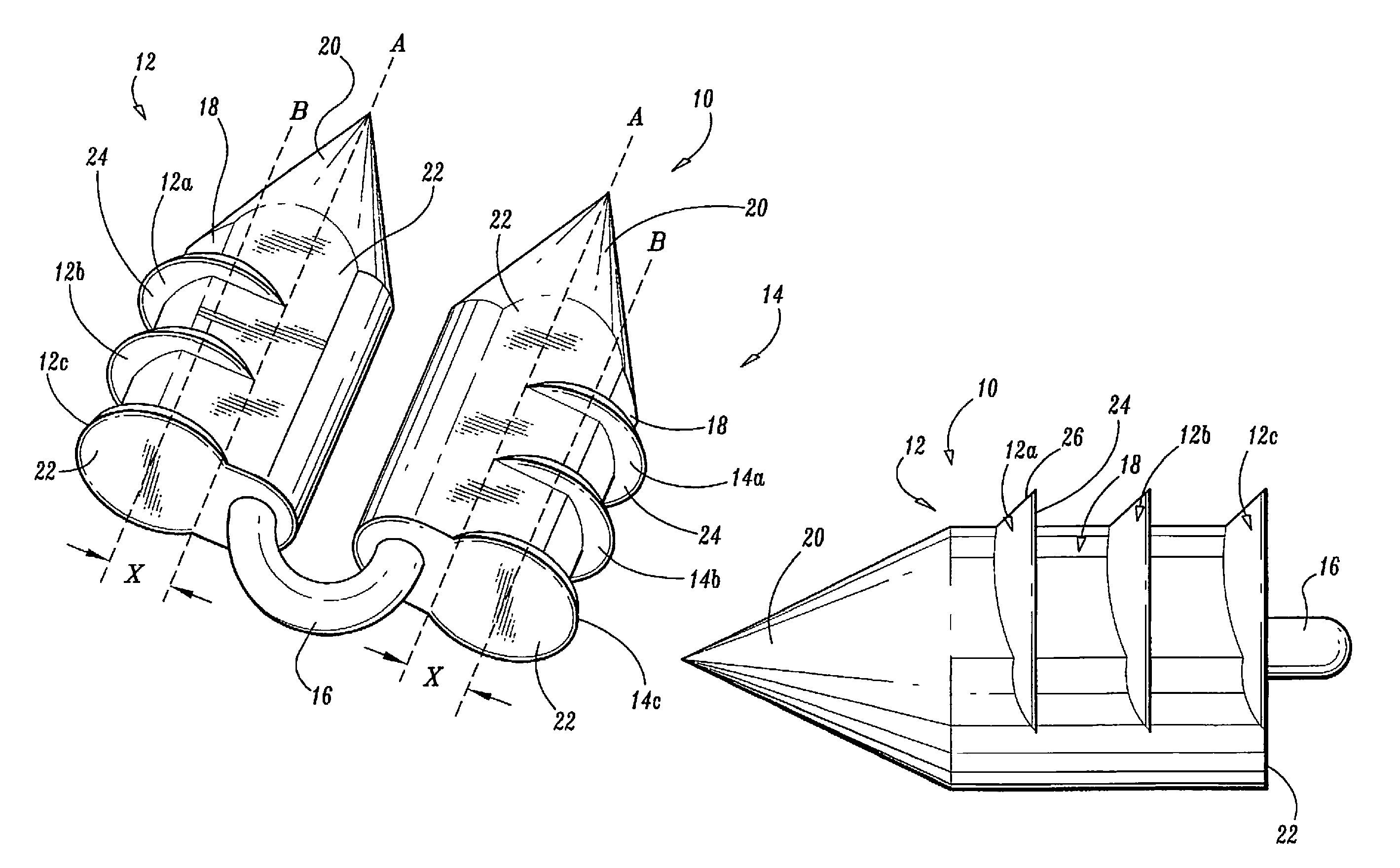

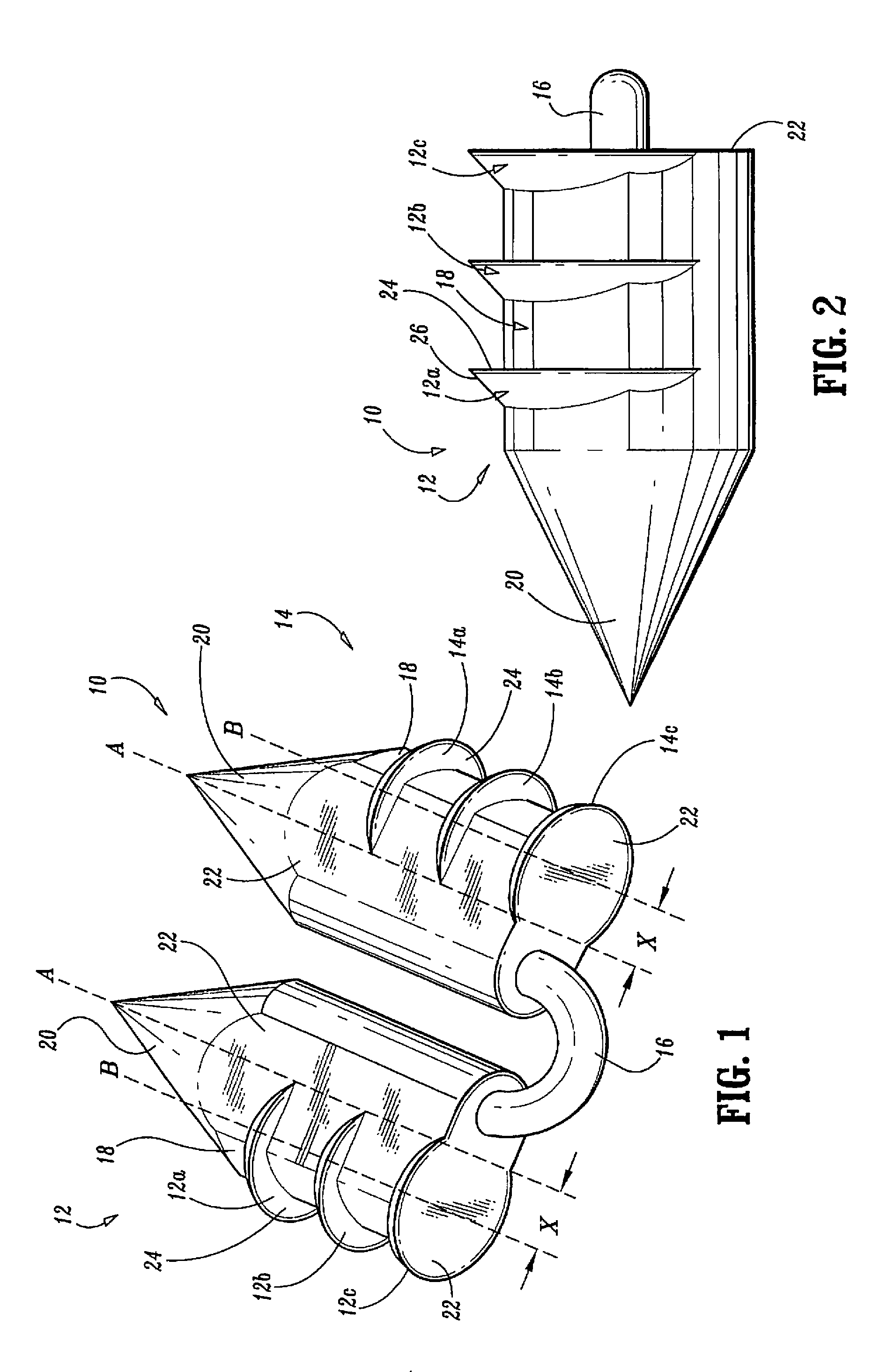

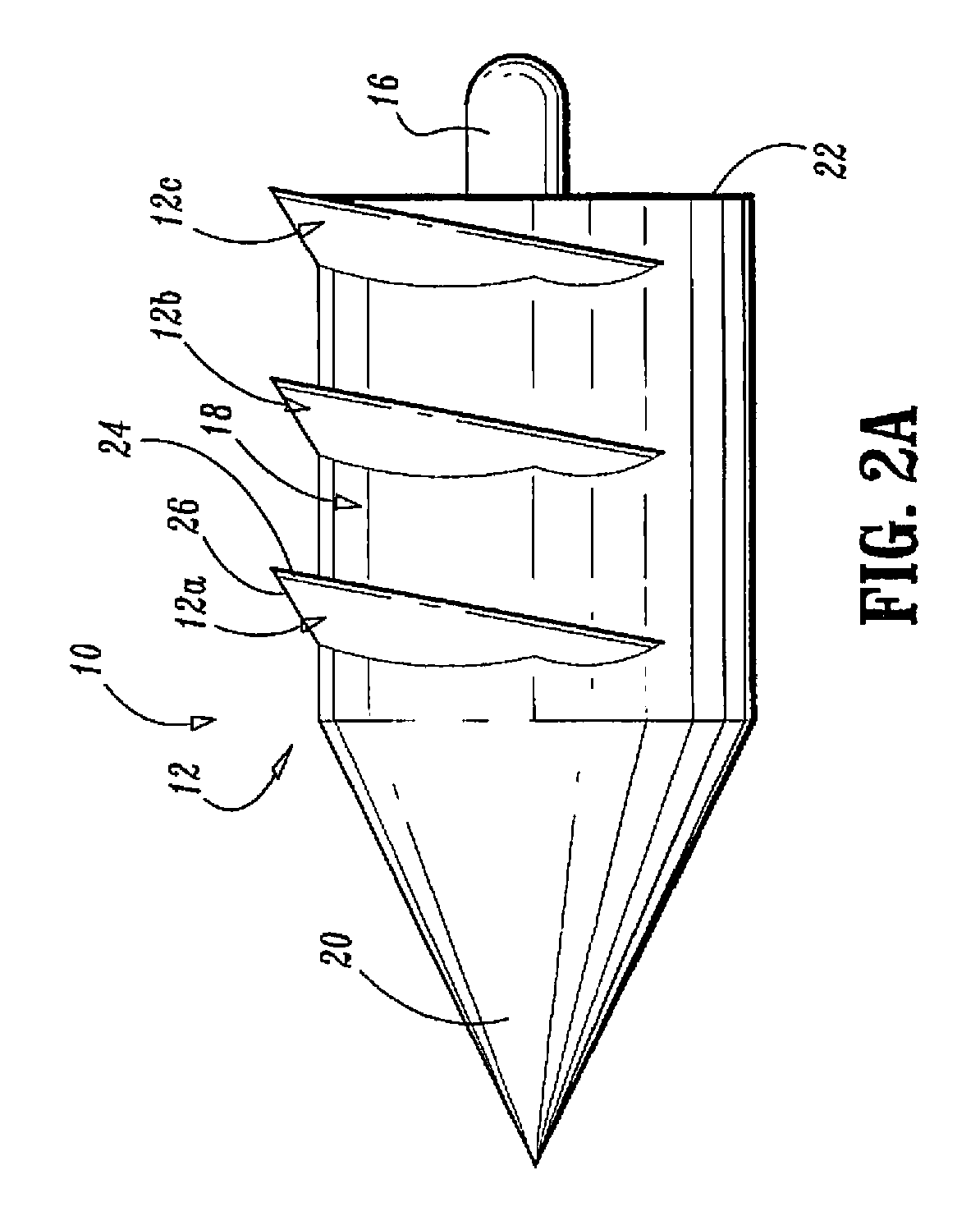

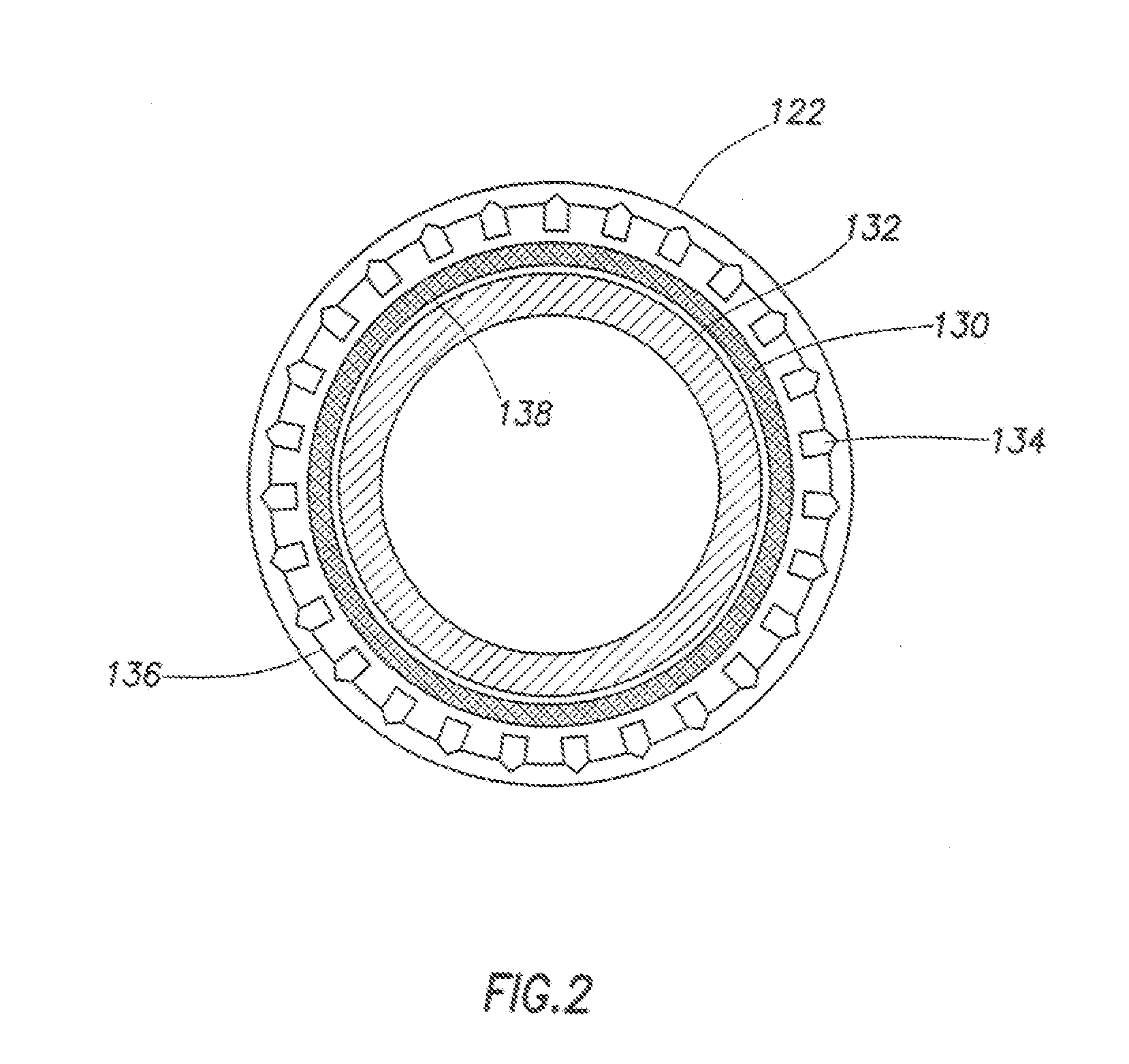

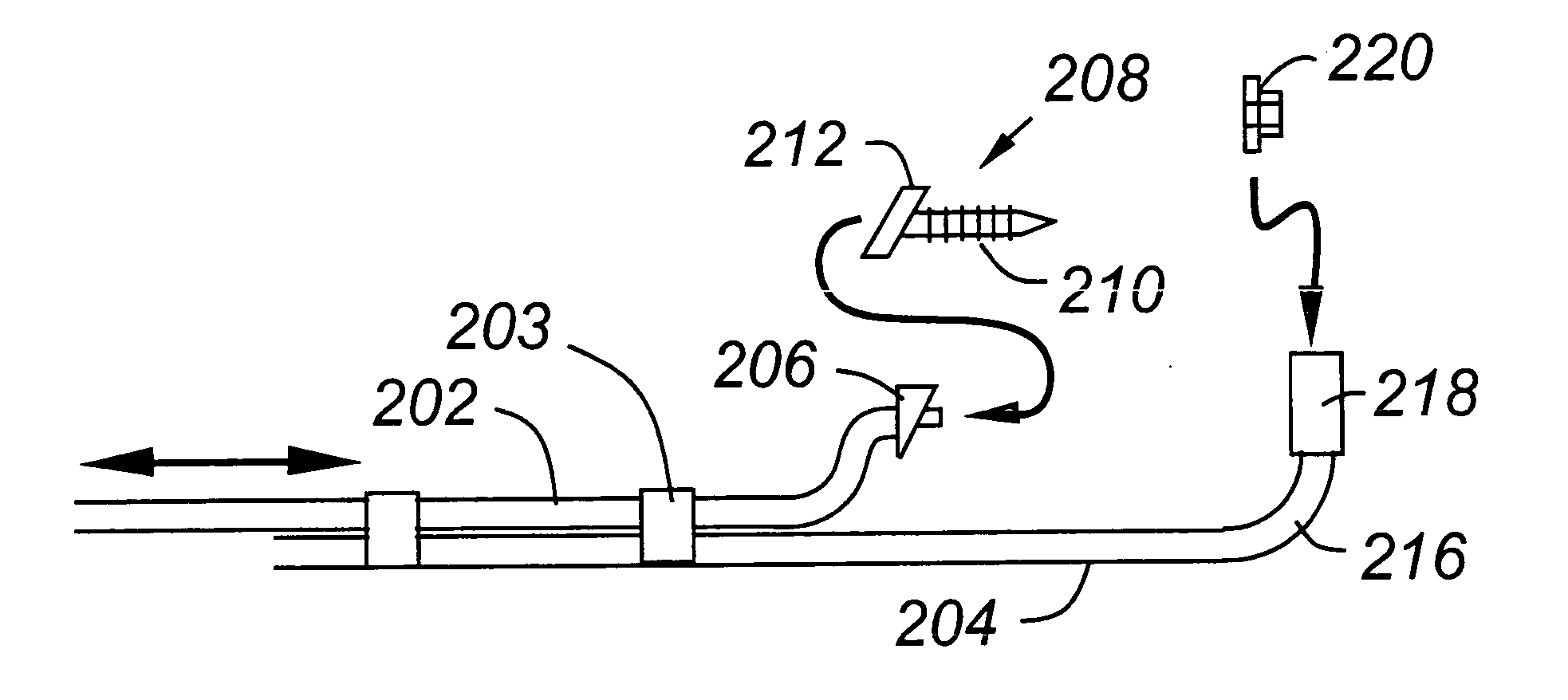

Absorbable fastener and applying apparatus

InactiveUS8034076B2Minimize formationReducing fastener-associated long-term discomfort to the patientSuture equipmentsStaplesAbsorbent materialBody tissue

A surgical fastener apparatus, for securing a surgical mesh material to body tissue including a pair of anchors each having a retaining structure formed on an outer surface thereof; and a suture tether interconnecting the pair of anchors to one another. The pair of anchors have a substantially cylindrical body having a conically tapered distal end and a planar proximal end. The retaining structure includes a series of semi-circular angled projections having a planar proximal surface and a tapered distal end, wherein a center of each of the angled projections is spaced a distance from a longitudinal central axis of the body portion. The surgical fastener is made from a bioabsorbable material which reabsorbs into said body tissue at an appropriate rate, such as for example, polyglycolic acid and polylactic acid.

Owner:COVIDIEN LP

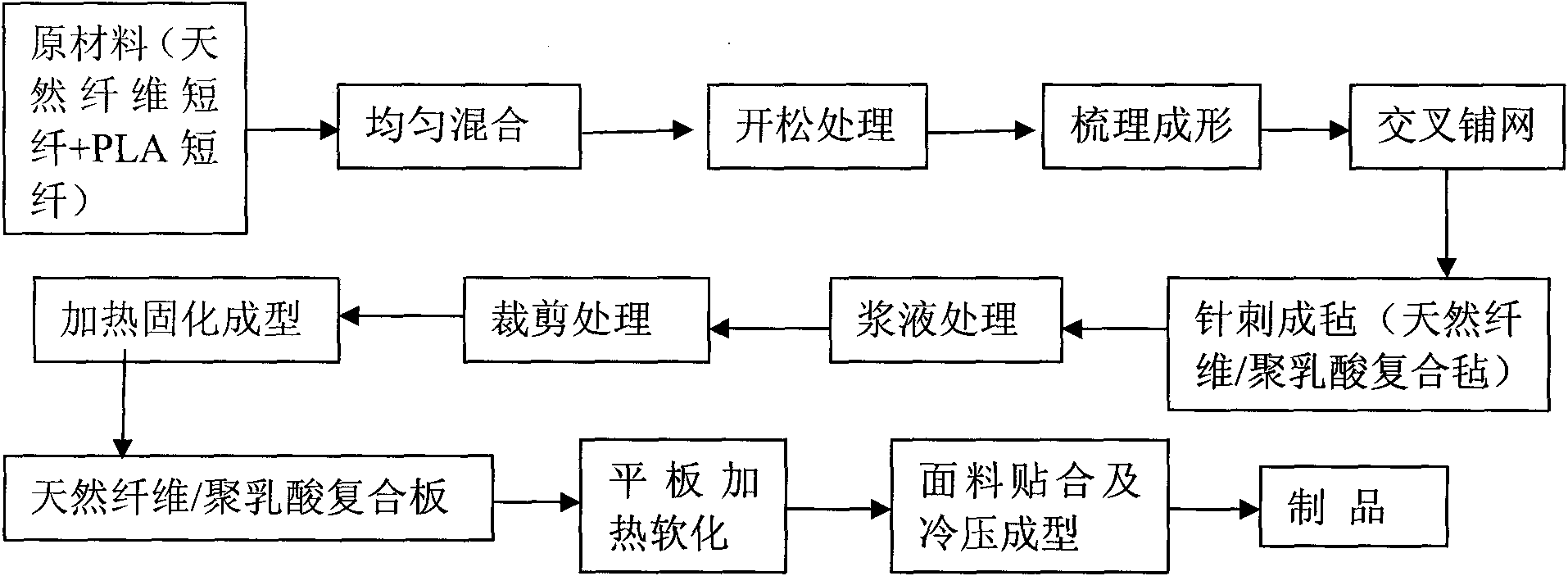

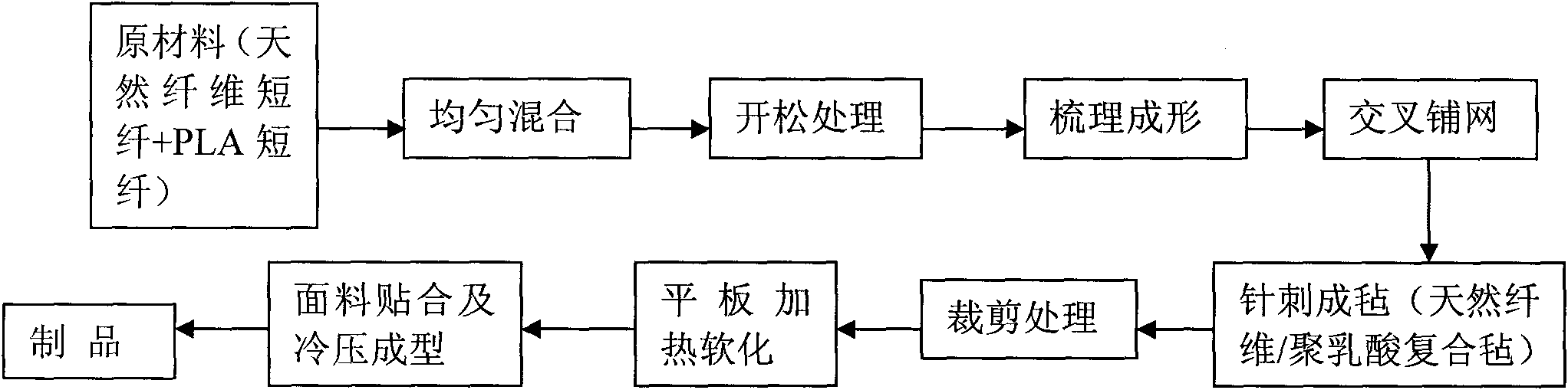

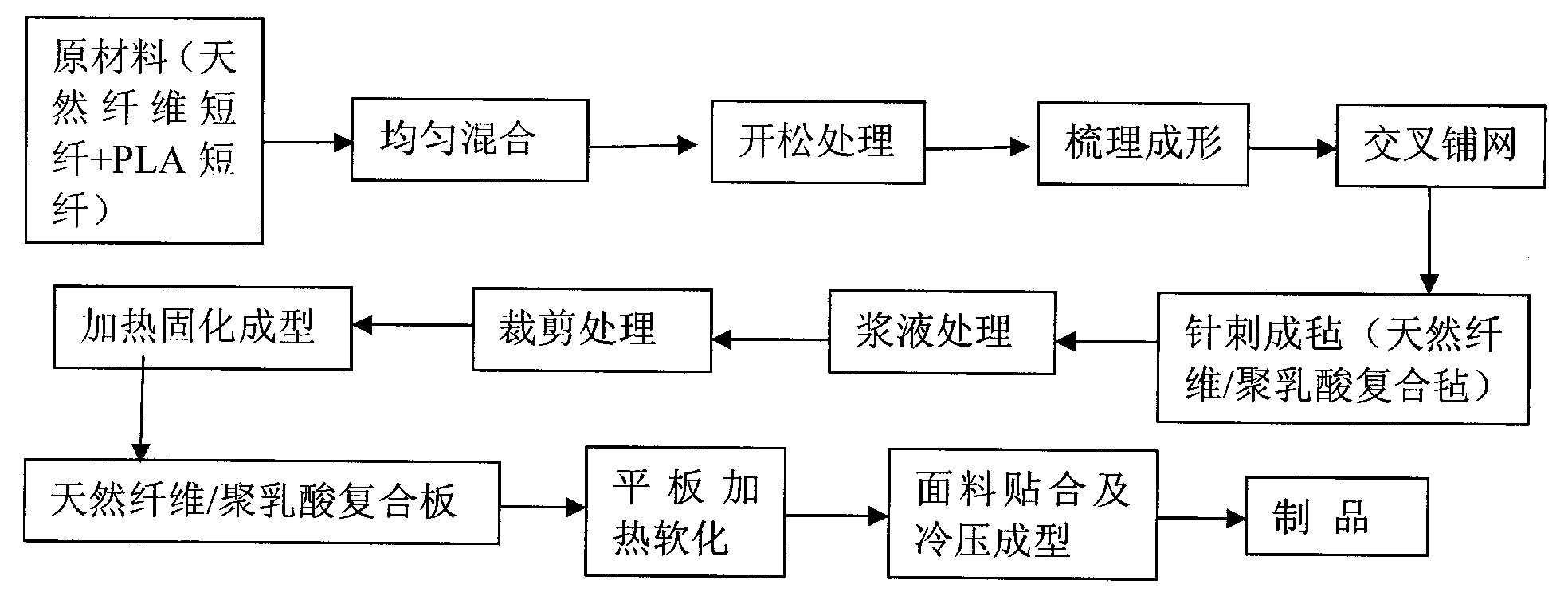

Composite material for automobile interior part and production method thereof

ActiveCN101812773ANo pollution in the processReduce lossVehicle componentsNon-woven fabricsMetallurgySlurry

The invention discloses a formula of a composite material for an automobile interior part. The formula consists of the following materials in percentage by weight: 40 to 60 percent of polylactic acid fiber and 40 to 60 percent of natural fiber. The production method of the invention comprises the following steps: uniformly mixing the raw materials; putting the mixture into an opener for opening, combing and shaping the obtained product, feeding the product into a lapping machine for cross lapping and feeding the cross-lapped product into a needling machine for needling to form a felt; immersing the fiber felt into a processing slurry; drying the immersed coiled material through hot blast and cutting the dried material into pieces of required size; placing the cut material into a mould for curing and shaping by heating; demoulding the material to form a composite plate; and softening the composite plate by flat panel heating, covering the plate with a surface decorative layer and performing cold molding on the plate through a product mould to manufacture the finished product finally; or softening the cut fiber felt by the flat panel heating directly, covering the plate with the surface decorative layer and performing the cold molding to manufacture the finished product finally. The composite material for the automobile interior part of the invention has the advantages of no toxicity, no pollution, simple processing technique, small energy consumption and high environment protection performance.

Owner:CHERY COMML VEHICLE ANHUI

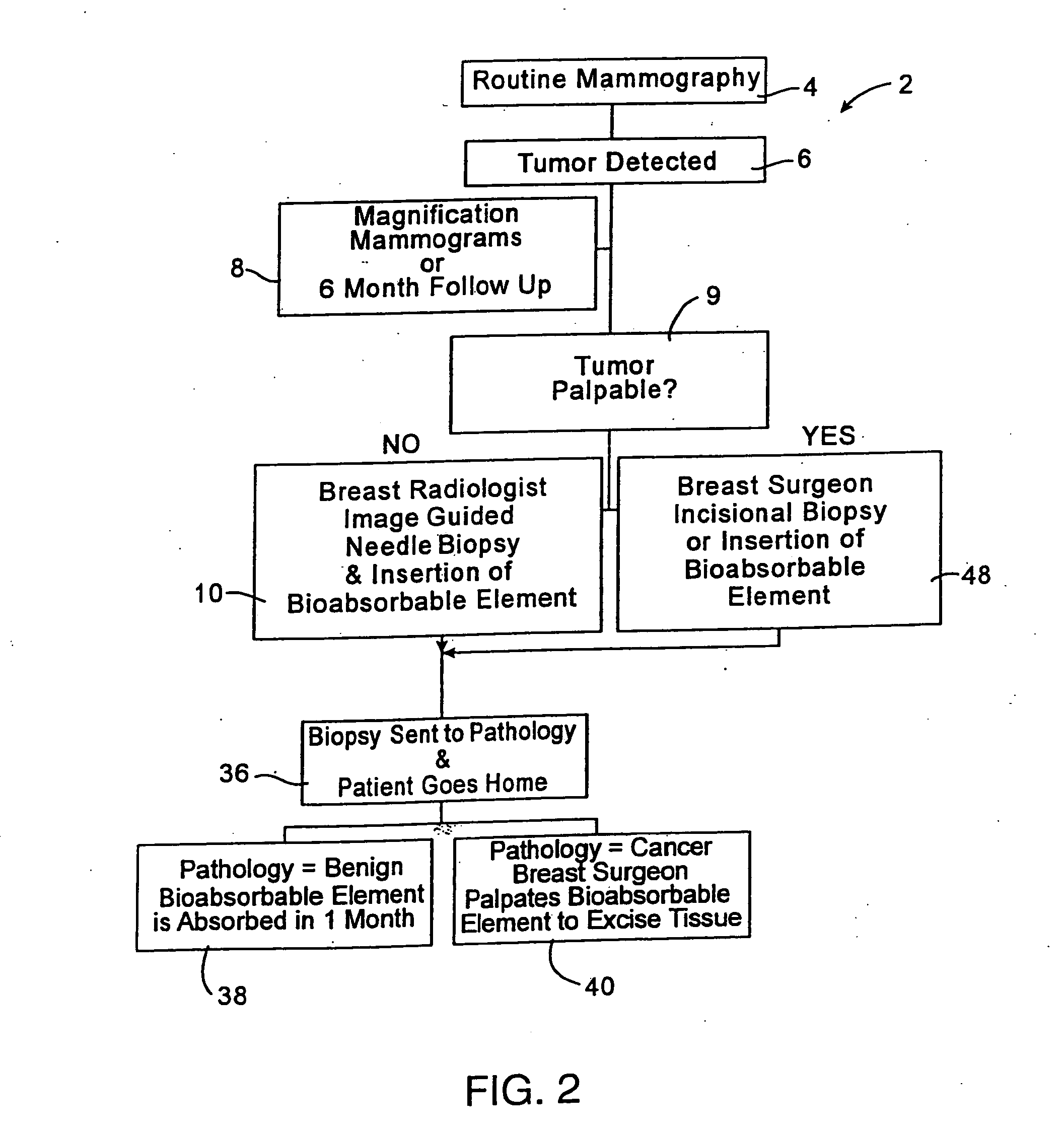

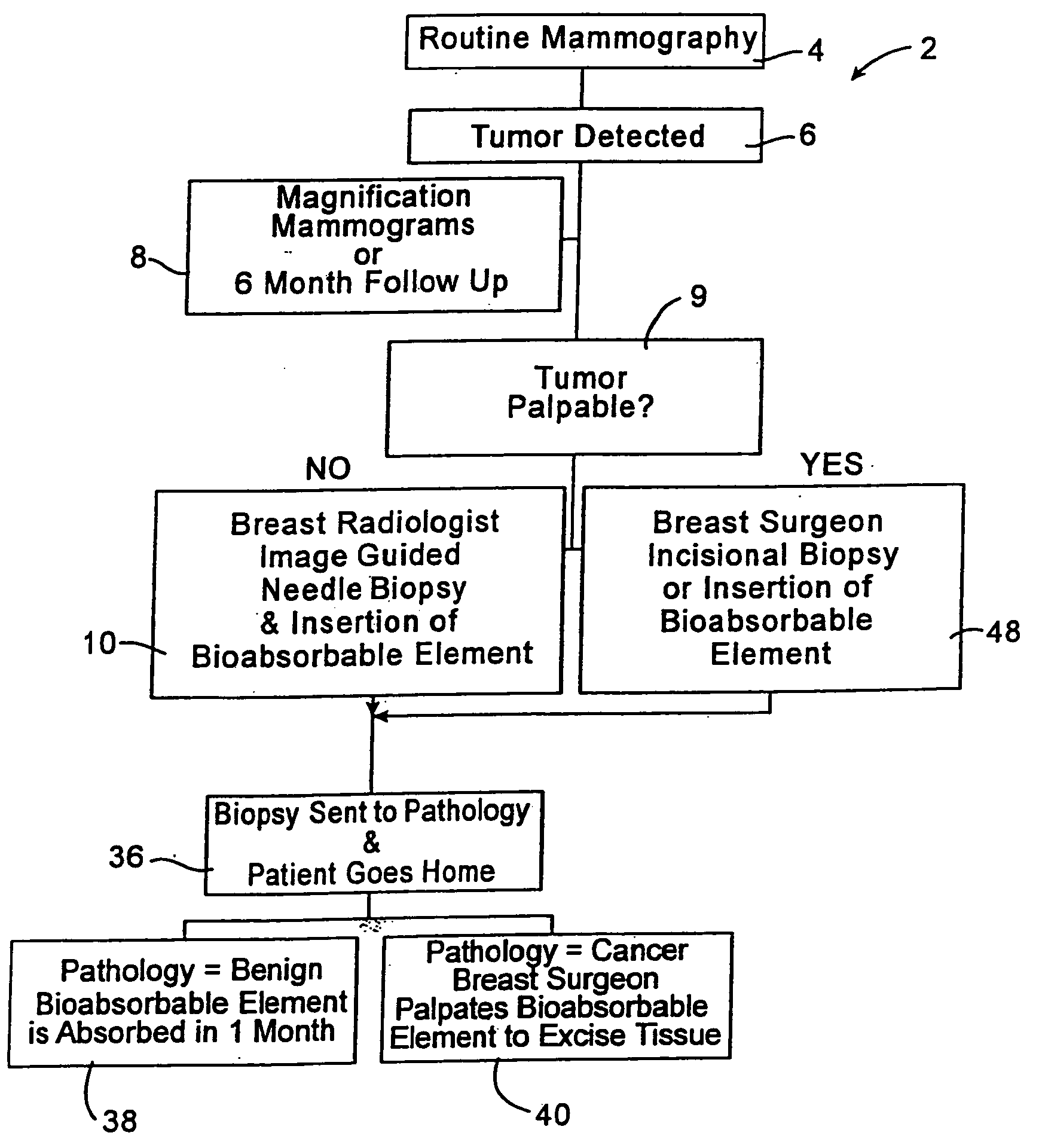

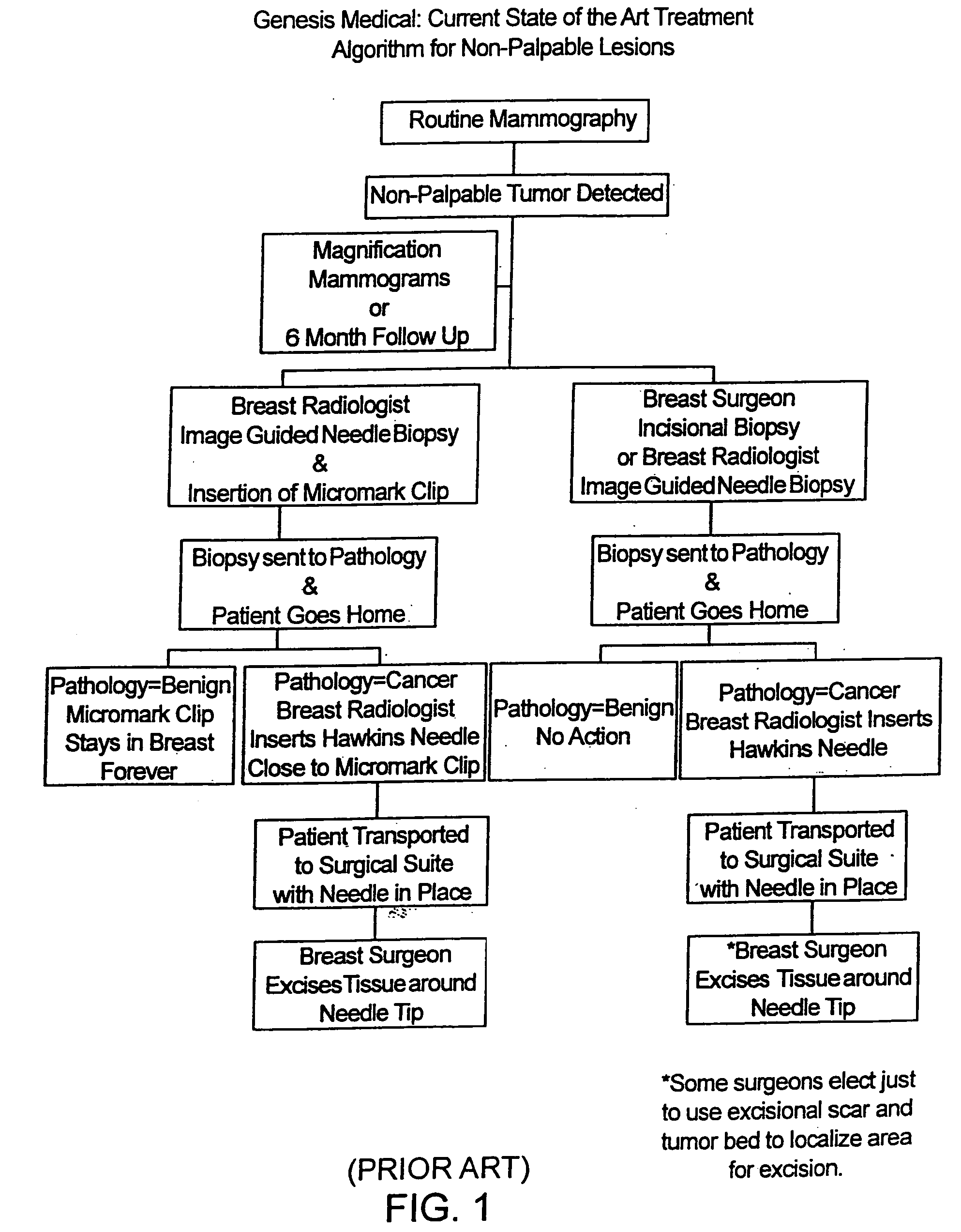

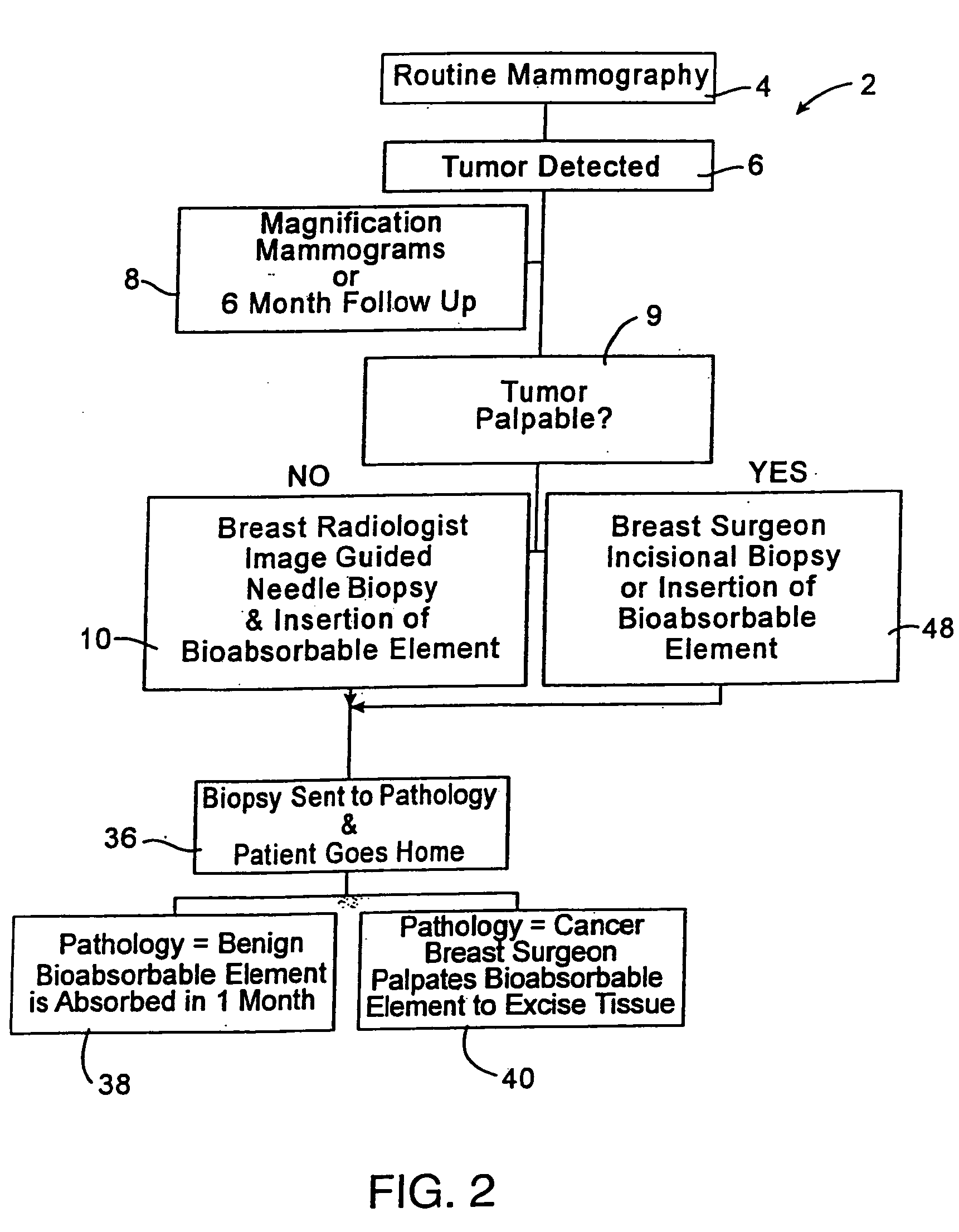

Biopsy localization method and device

Methods for localizing a biopsy site are disclosed. The method includes taking a tissue sample from a biopsy site and positioning a detectable, bioabsorbable element at the biopsy site at the time that the tissue sample was taken. The tissue sample is then tested. The biopsy site is then relocated by finding the bioabsorbable element. The bioabsorbable element may be made of collagen, gelatin, cellulose, polylactic acid, and / or polyglycolic acid. The detectable bioabsorbable element may be relocated using ultrasound or mammography. The bioabsorbable element may also swell upon contact with body fluid.

Owner:DEVICOR MEDICAL PROD

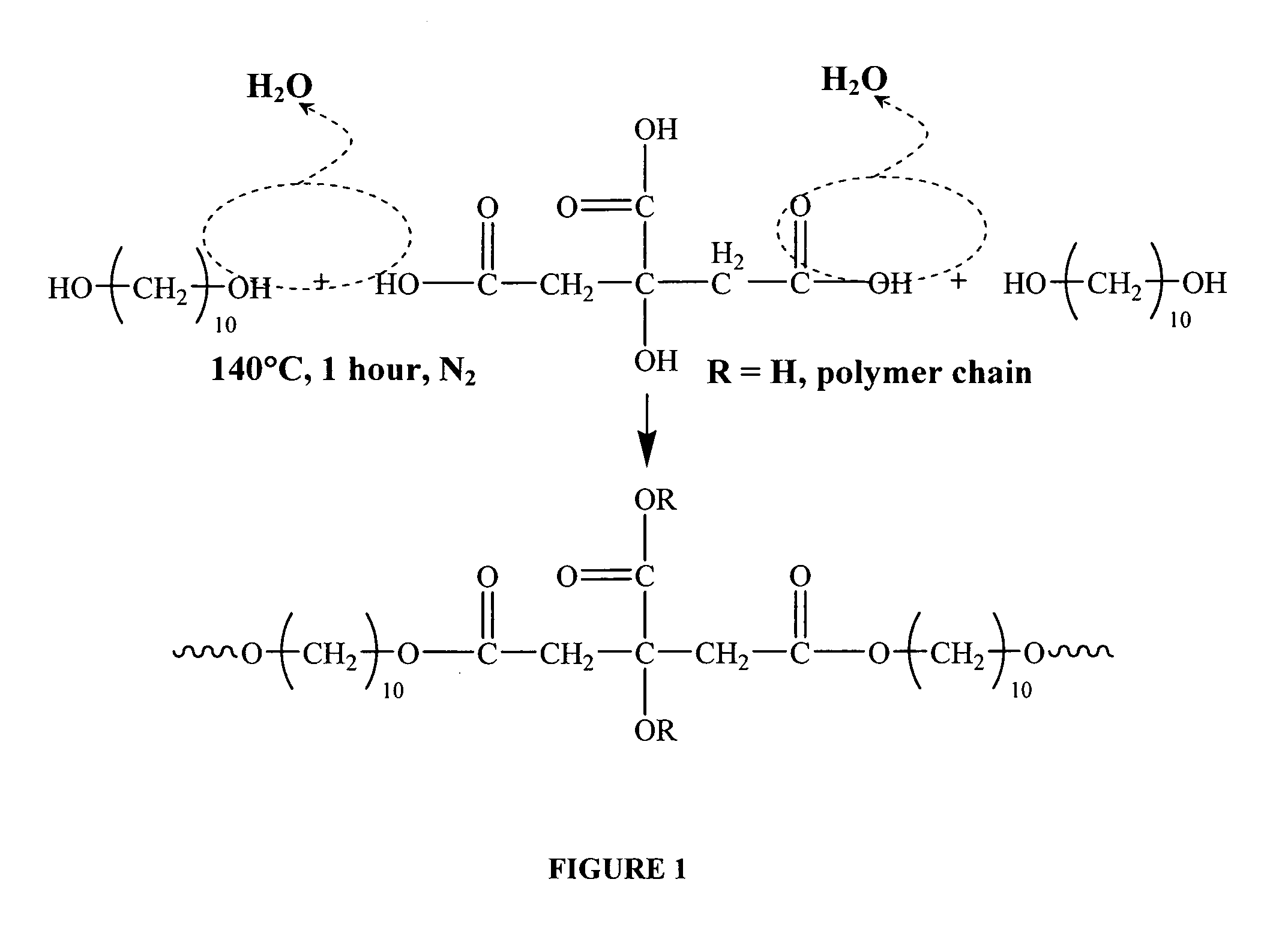

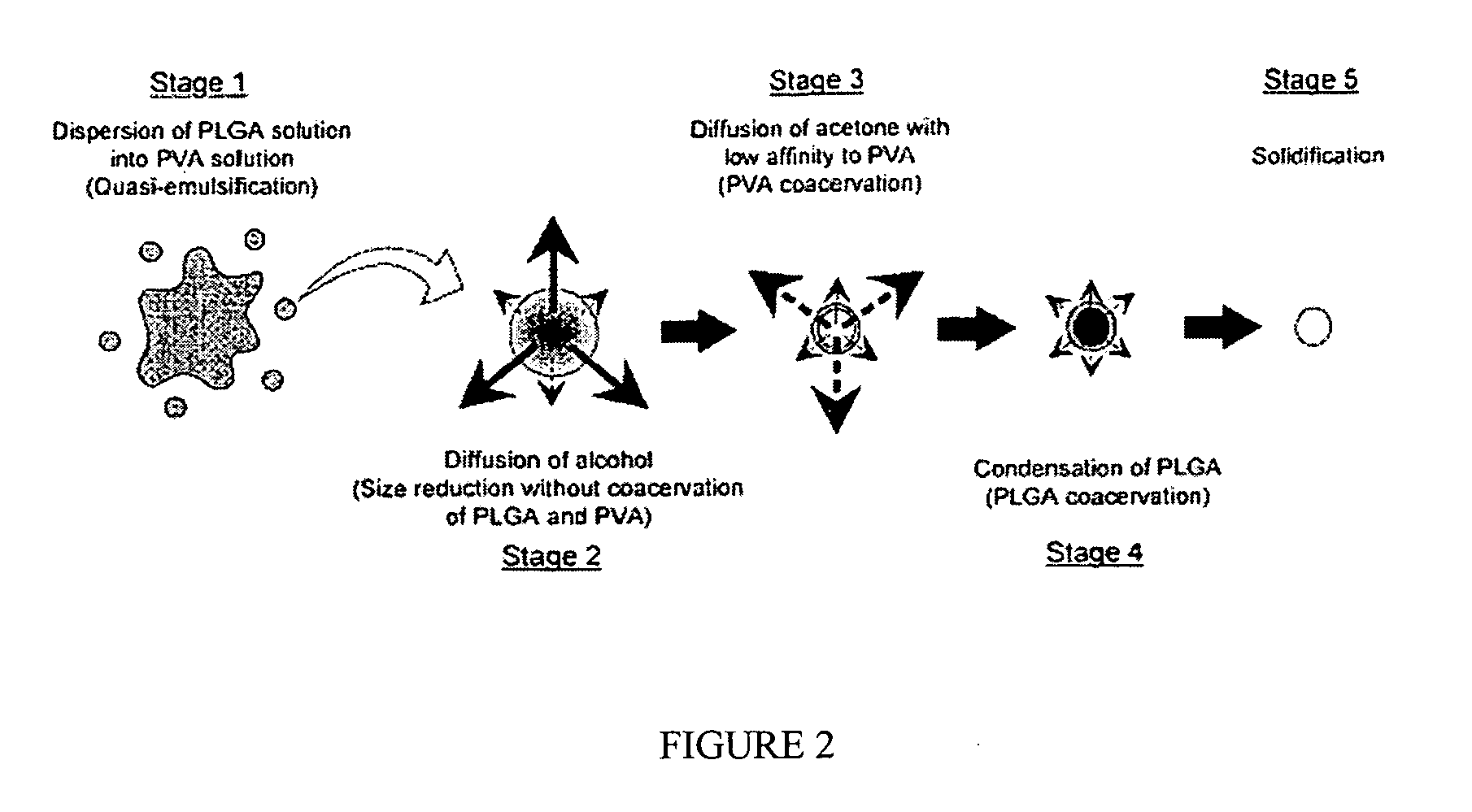

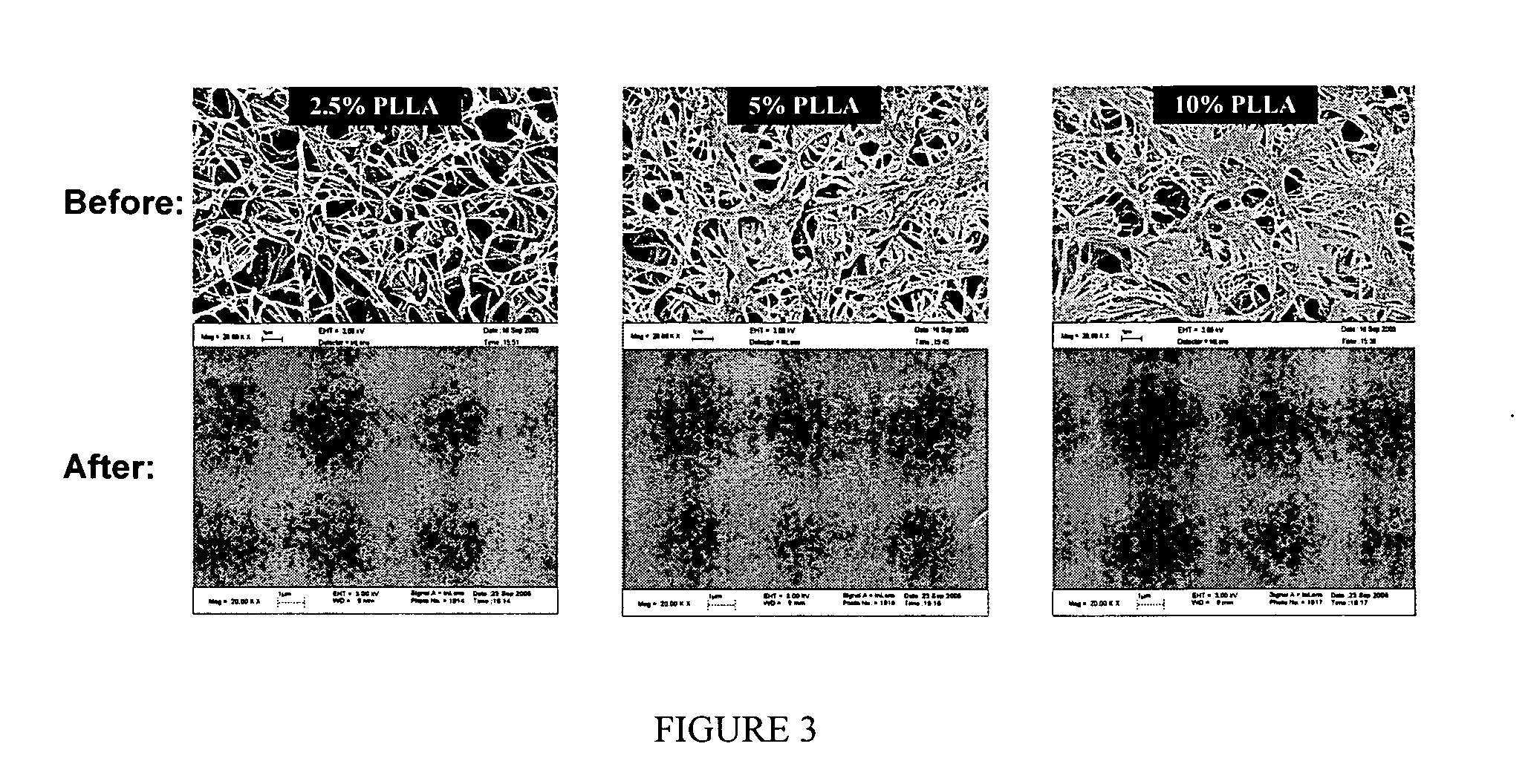

Biodegradable nanocomposites with enhance mechanical properties for soft tissue

InactiveUS20070071790A1Pharmaceutical delivery mechanismPharmaceutical non-active ingredientsMechanical propertyNanocomposite

The present invention is directed to a novel poly(diol citrates)-based nanocomposite materials created using completely biodegradable and biocompatible polymers that may be used in tissue engineering. More specifically, the specification describes methods and compositions for making and using nanocomposites comprised of citric acid copolymers and polymers including but not limited to poly(L-lactic acid) (PLLA) and poly(lactic-co-glycolic acid) (PLGA).

Owner:NORTHWESTERN UNIV

Applications of degradable polymers for delayed mechanical changes in wells

Degradable polylactic or polyhydroxyalkanoate polymers may be used to viscosify aqueous fluids for use in wells, Sand control screen or liner can be coated with a solid degradable polymer during placement in a well. Mechanical changes or flow changes in a well can be caused by solid degradable polymer that changes physical properties after it is placed in a well. Parts of devices or entire devices can be made of solid degradable polymer that converts to a fluid after selected times in an aqueous environment in a well.

Owner:COOKE JR CLAUDE E

Tissue engineered tendons and ligaments

Connective tissue, including neo-tendons and ligaments, has been constructed using biodegradable synthetic scaffolds seeded with tenocytes. The scaffolds are preferably formed from biodegradable fibers formed of a polymer such as polyglycolic acid-polylactic acid copolymers, and seeded with cells isolated from autologous tendon or ligament by means of enzymatic digestion or direct seeding into tissue culture dishes from explants. The cell polymer constructs are then surgically transplanted to replace missing segments of functioning tendon or ligament.

Owner:VACANTI CHARLES A +5

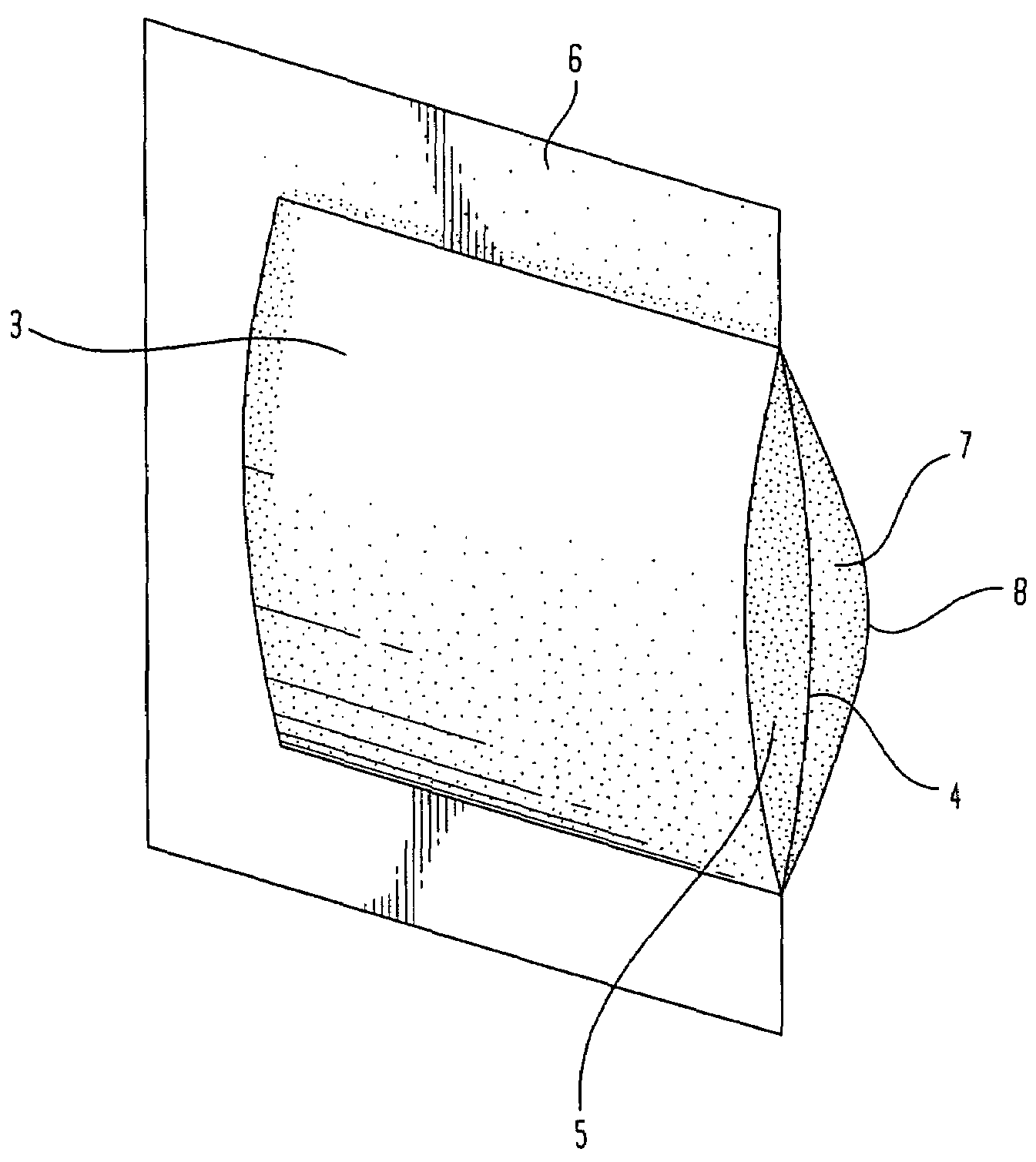

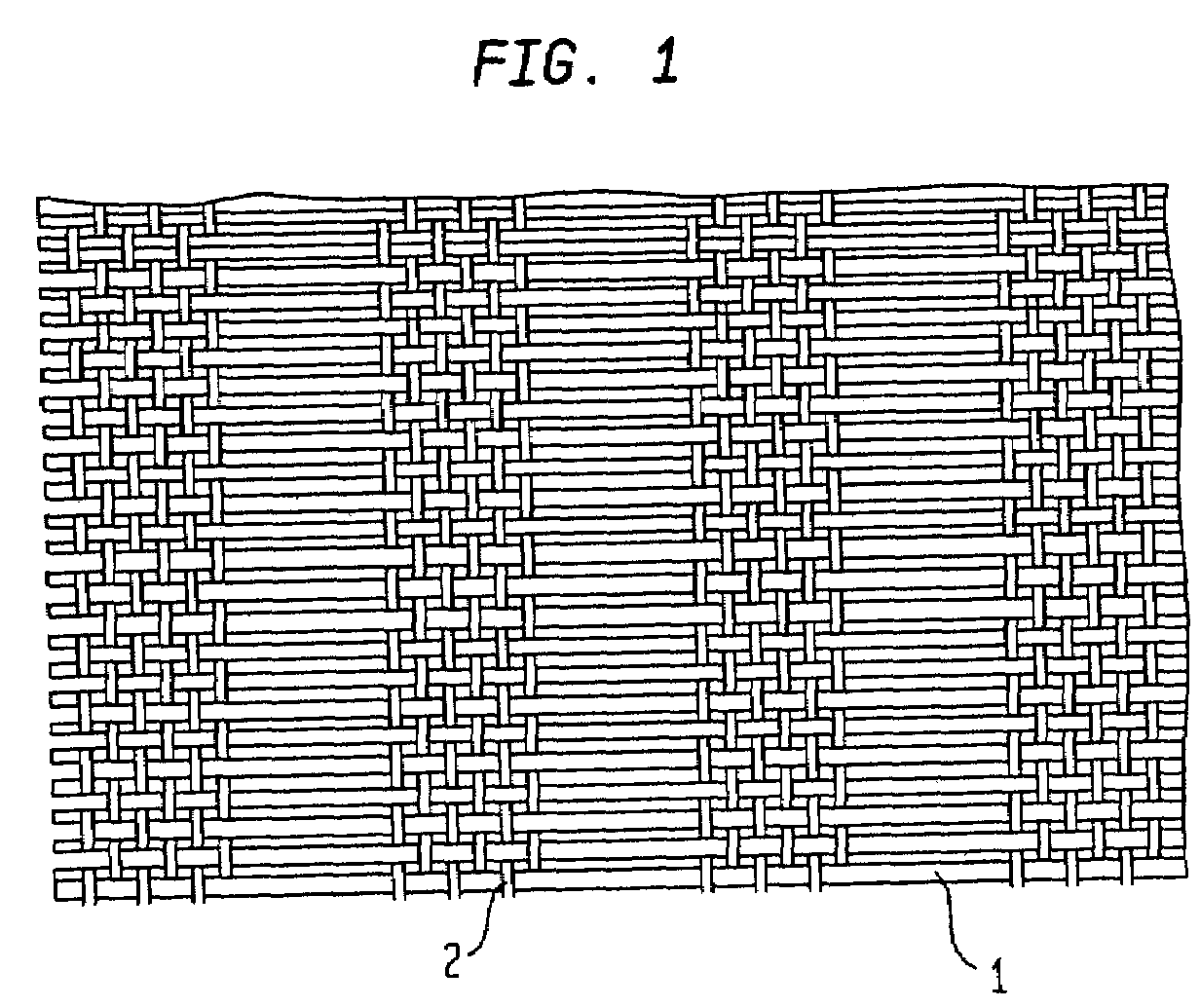

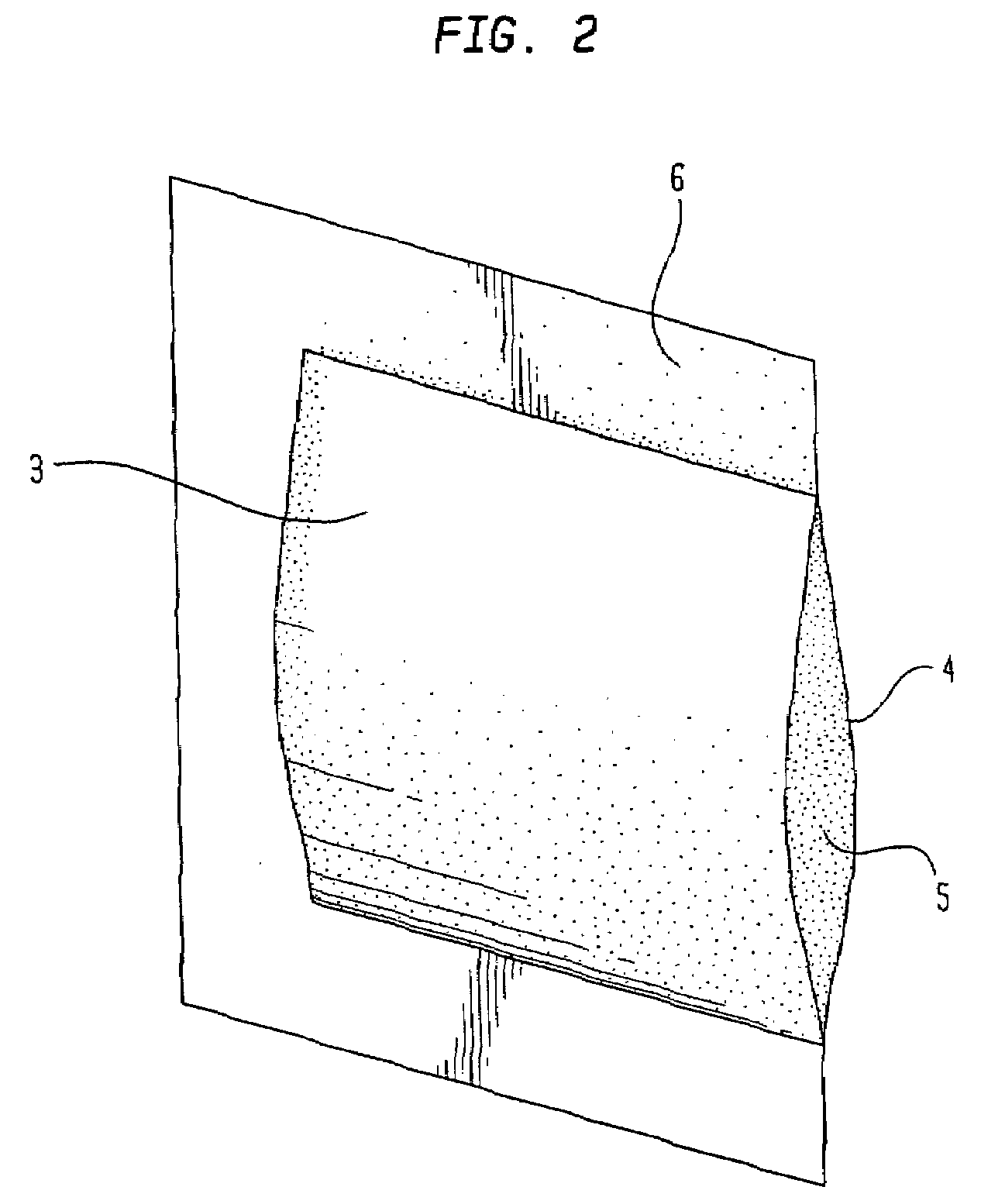

Infusion package

InactiveUS20080095959A1Bio-packagingPedestrian/occupant safety arrangementSynthetic fiberPolylactic acid

The present invention is directed to a material for use in making beverage infusion packages including a plurality of fibers woven with at least one heat-bondable synthetic fiber. Preferably, the fibers are cellulosic fibers such as bamboo and the heat-bondable synthetic fibers are biodegradable fibers, such as polylactides or polylactic acid. The present invention is also directed to beverage infusion packages made from the material and methods of making the infusion package.

Owner:THE REPUBLIC OF TEA

Modified Polylactic Acid Fibers

ActiveUS20120040582A1Improve responseMelt spinning methodsWoven fabricsChain scissionGlass transition

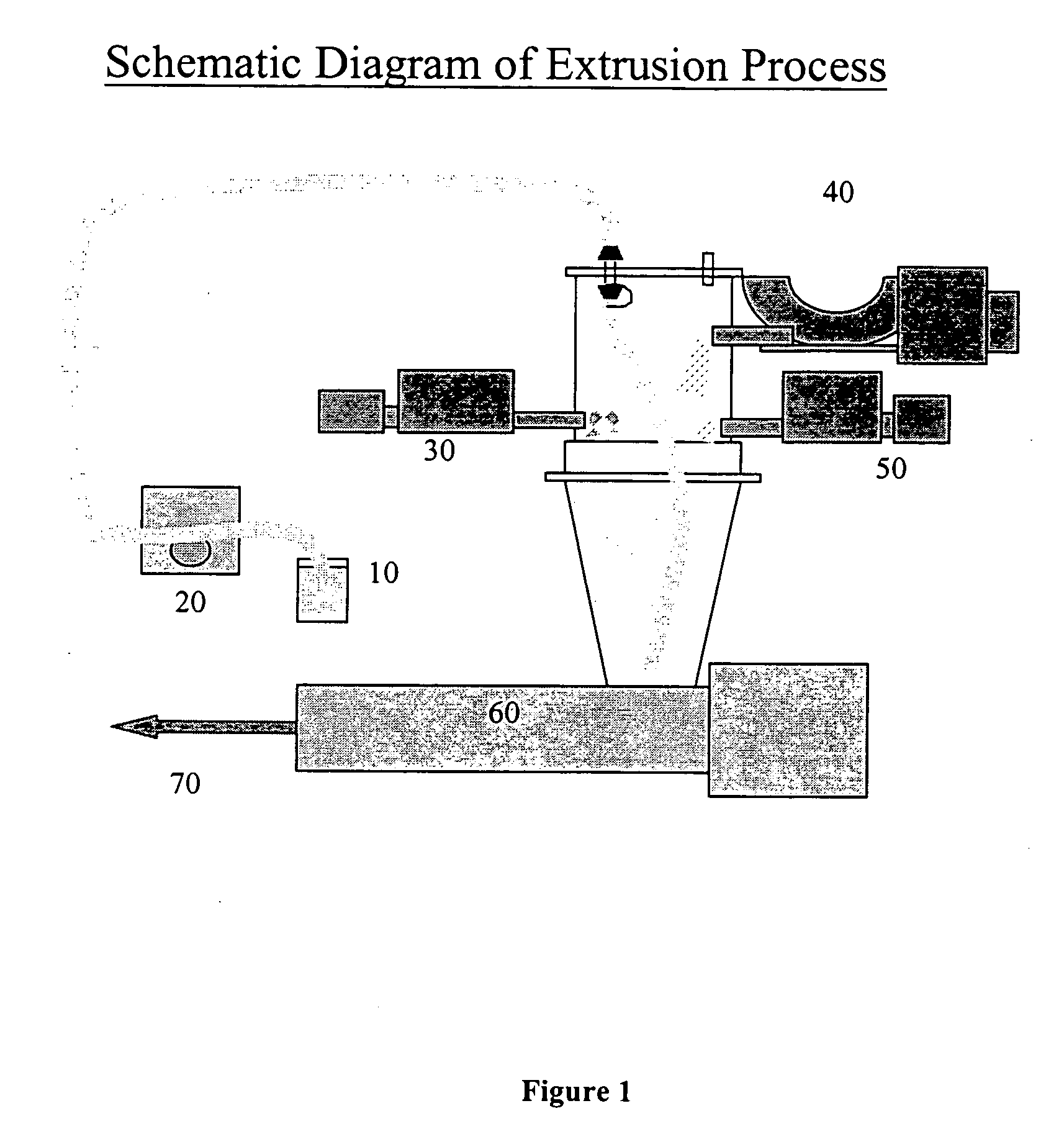

A method for forming biodegradable fibers is provided. The method includes blending polylactic acid with a polyepoxide modifier to form a thermoplastic composition, extruding the thermoplastic composition through a die, and thereafter passing the extruded composition through a die to form a fiber. Without intending to be limited by theory, it is believed that the polyepoxide modifier reacts with the polylactic acid and results in branching of its polymer backbone, thereby improving its melt strength and stability during fiber spinning without significantly reducing glass transition temperature. The reaction-induced branching can also increase molecular weight, which may lead to improved fiber ductility and the ability to better dissipate energy when subjected to an elongation force. To minimize premature reaction, the polylactic acid and polyepoxide modifier are first blended together at a relatively low temperature(s). Nevertheless, a relatively high shear rate may be employed during blending to induce chain scission of the polylactic acid backbone, thereby making more hydroxyl and / or carboxyl groups available for subsequent reaction with the polyepoxide modifier. Once blended, the temperature(s) employed during extrusion of the blended composition can be selected to both melt the composition and initiate a reaction of the polyepoxide modifier with hydroxyl and / or carboxyl groups of the polylactic acid. Through selective control over this method, the present inventors have discovered that the resulting fibers may exhibit good mechanical properties, both during and after melt spinning.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Environmentally friendly polylactide-based composite formulations

Polymeric materials and products, including sheet flooring materials prepared from the polymeric materials, and processes for preparing the polymeric materials, are disclosed. The polymeric materials include a polylactic acid-based polymer in combination with plasticizer and a compatibilizer, and optionally include a filler. The polymeric material can include between about 30 to about 50 percent by weight polyvinyl chloride, polyethylene glycol, polyglycolide, ethylene vinyl acetate, polycarbonate, polycaprolactone, polyhydroxyalkanoates, or polyolefins modified with polar groups, for example, ionomers. The plasticizer is typically an epoxidized vegetable oil or esterified and epoxidized vegetable oil and is typically present in an amount of between about 10 and about 50% by weight. In some embodiments, the compatibilizer is a polyolefin modified with one or more polar functional groups, and is typically present in an amount of between about 5 and about 10% by weight. The material can be used in decorative surface coverings, such as a floor coverings, particularly when it is in the form of a polymeric sheet. The polymeric material can be present in at least one layer of a floor covering, which floor covering can also include one or more additional layers such as wear layers, foamed or foamable layers, top coat layers and design layers. The additional layers can also include the polymeric material.

Owner:AFI LICENSING

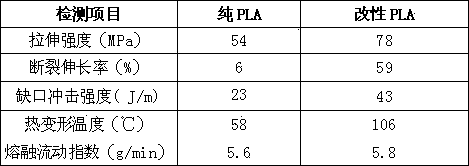

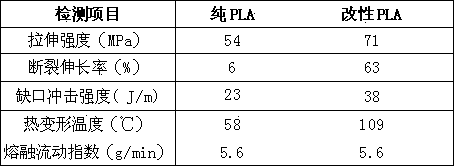

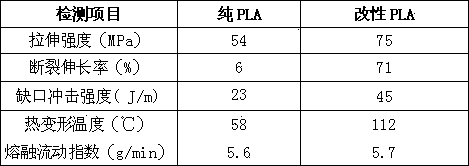

3D printing modified polylactic acid material and preparation method thereof

InactiveCN103467950AIncrease profitSelf-performance has not declinedMonocomponent polyesters artificial filamentArtifical filament manufactureHeat deflection temperaturePolymer science

A 3D printing modified polylactic acid material comprises, by weight, 70-85 parts of polylactic acid, 1-5 parts of chain extenders, 1-5 parts of cross-linking agents, 0.5-1 part of nucleating agents, 5-10 parts of polymers with low molecular weights, 5-10 parts of flexibilizers, 1-5 parts of fortifiers and 0.3-0.8 part of antioxidants. According to the 3D printing modified polylactic acid material, a low-temperature smashing hybrid reaction technology is utilized, modified processing is carried out on polylactic acid, toughness, impact strength and the heat distortion temperature for the polylactic acid are improved to a large extent, and the polylactic acid can have wider application prospects in 3D printing materials.

Owner:佛山市斯太克科技有限公司

Biopsy localization method and device

Owner:ARTEMIS MEDICAL

Polyhydroxylkanoates as well as blending modification for copolymer thereof and polylactic acid

The invention discloses a PHBV with good performance and a copolymer of PHBV and PLA and the preparation technique method. The invention is characterized in that 1 per cent to 99 per cent of PHAs, 1 per cent to 99 per cent of PLA1 and other additives 0-40 per cent are put in a mixer for 1 to 30 minutes, and then put in an electricity hot blast drying oven a temperature ranging from 40 to 100 DEG C for 2 to 48 hours after being mixed equally. The dried compound is plastified in a double screw extruder, the highest temperature of the double screw extruder is between 90 and 180 DEG C according to the the different content of PHAs and the temperature of the mouth mold is between110 to 170 DEG C. The material extruded from a die head is cooled, stretched and grained to form the complete biodegradation aggregate. The resin consisting of PHBV and copolymer of PHBV and PLA is able to be used for producing the thin films, plates and sheet materials and injected mold to plastic materials. The compound has biological degradability and good machining performance. The target product of the compound has excellent mechanical properties and can be used for replacing the petroleum base plastic to be widely used for packing, agriculture, medical material, electron, chemical industry concerning products for daily use, etc.

Owner:深圳市奥贝尔科技有限公司

Fully-biodegradable PLA/PBAT composite film and making method thereof

The invention belongs to the technical field of high-molecular materials, and relates to a PLA / PBAT composite film and a making method thereof. The composite film is made by using the following components, by weight, 10-90 parts of polylactic acid, 10-90 parts of PBAT, 0.04-2.5 parts of a compatibilizer A, 0.04-2.5 parts of a compatibilizer B, 0-3 parts of a lubricant, 0-3 parts of an antioxidant and 1-50 parts of a filler. A blend provided by the invention has a very good flexibility, and the made film can be fully biodegraded, and can be widely used in the field of films.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

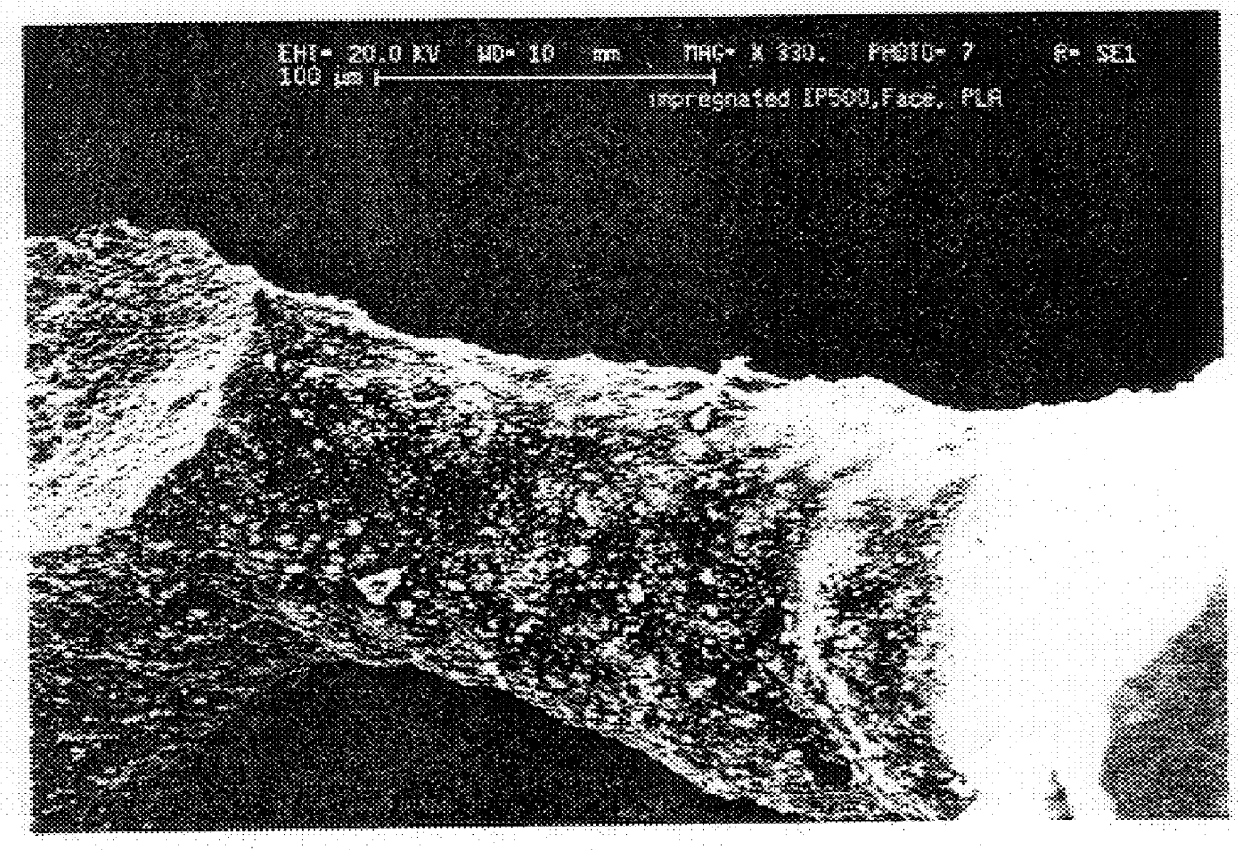

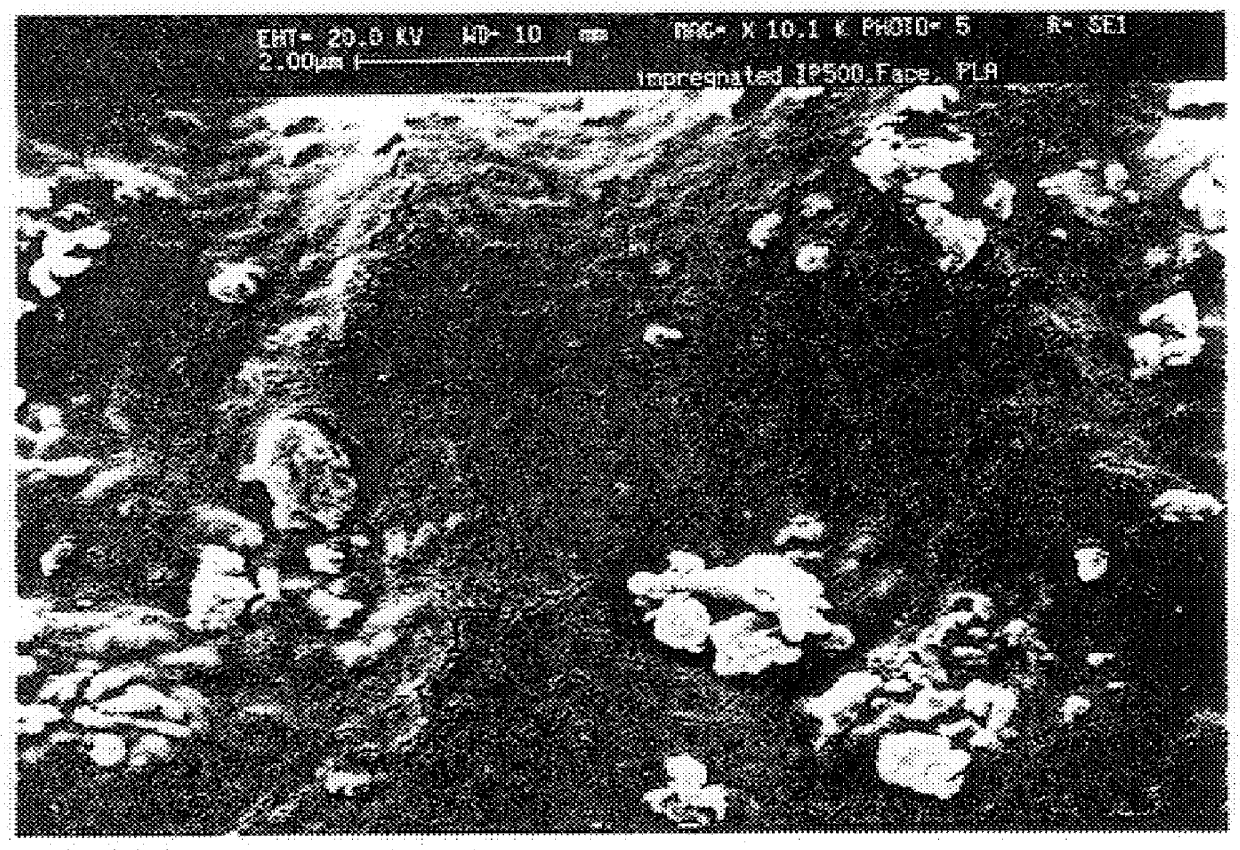

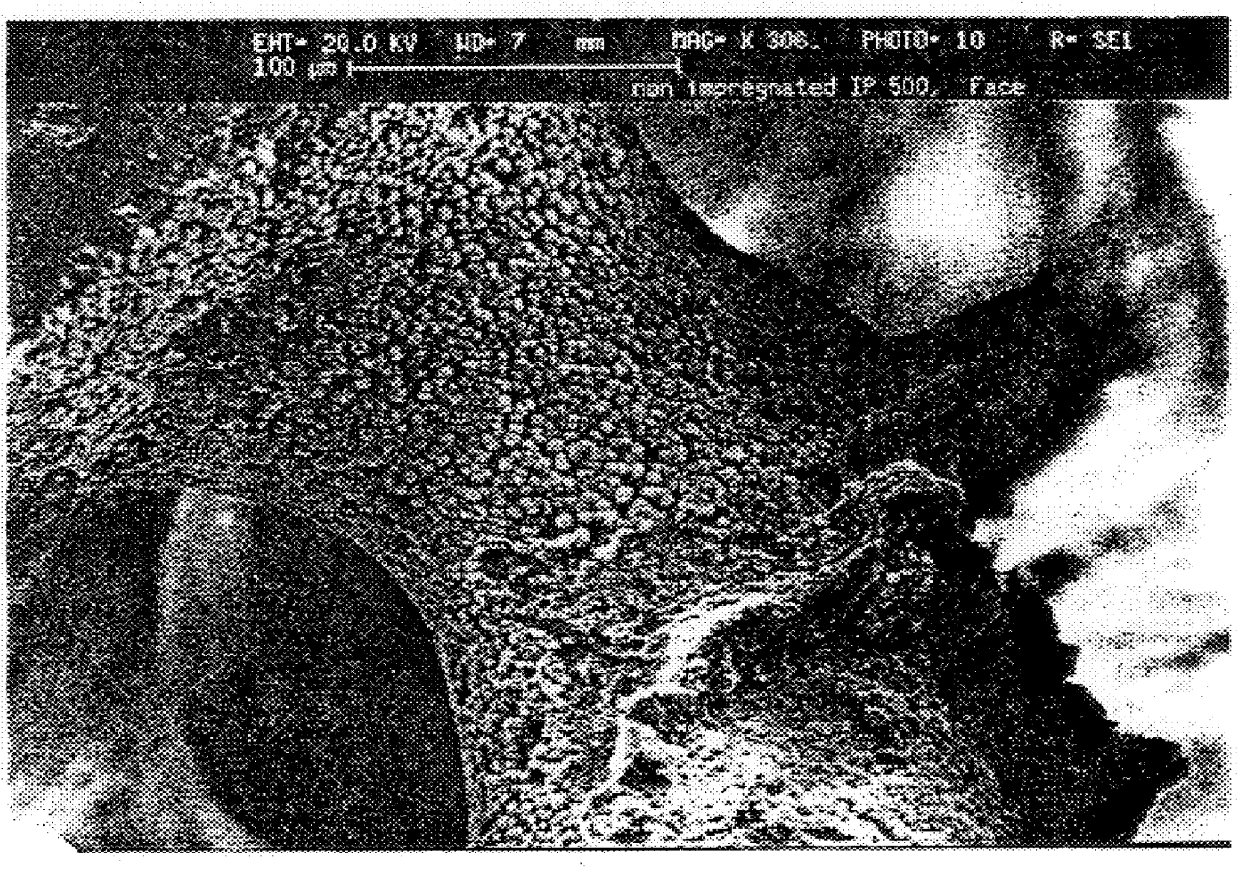

Polylactic acid fibers

A biodegradable fiber that is formed from a thermoplastic composition that contains polylactic acid, a plasticizer, and a compatibilizer is provided. The compatibilizer includes a polymer that is modified with a polar compound that is compatible with the plasticizer and a non-polar component provided by the polymer backbone that is compatible with polylactic acid. Such functionalized polymers may thus stabilize each of the polymer phases and reduce plasticizer migration. By reducing the plasticizer migration, the composition may remain ductile and soft. Further, addition of the functionalized polymer may also promote improved bonding and initiate crystallization faster than conventional polylactic acid fibers. The polar compound includes an organic acid, an anhydride of an organic acid, an amide of an organic acid, or a combination thereof. Such compounds are believed to be more compatible with the generally acidic nature of the polylactic acid fibers.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Biodegradable fibers exhibiting storage-stable tenacity

InactiveUS20060159918A1Desired level of strengthFilament/thread formingConjugated synthetic polymer artificial filamentsFiberPolymer science

The invention provides a drawn and / or crimped fiber comprising a biodegradable polymer, such as polylactic acid, wherein the drawn and / or crimped fiber exhibits a storage-stable tenacity that does not decrease from an initial tenacity upon manufacture by more than about 10% after storage for 120 days in ambient conditions. The polymer composition used to form the fiber may comprise a softening agent. The fiber can be a drawn and crimped bicomponent fiber that is helically self-crimped and which comprises a first biodegradable polymer component and a second biodegradable polymer component, wherein the first polymer component and the second polymer component exhibit different polymer morphology such that each polymer component will undergo a different extent of longitudinal shrinkage upon application of heat. The outer surface of the fiber may carry a water-repellant coating. The invention also provides a method of forming a drawn and / or crimped fiber exhibiting storage-stable tenacity.

Owner:FIBER INNOVATION TECH

Prepn process of polylactic acid-base thermoplastic wood-plastic composite material

The present invention relates to preparation process of polylactic acid-base thermoplastic wood-plastic composite material, which is prepared with polylactic acid and wood powder as main materials, and through reacting and mixing with compatibilizing agent, brightening agent, plasticizer, nucleater, dispersant, stabilizer and other assistant in a high speed stirrer; extrusion pelletizing the mixture in a double screw extruder; cooling and cutting; and drying in a vacuum drier to obtain the polylactic acid-base thermoplastic wood-plastic composite material. The composite material of the present invention has excellent comprehensive performance, is degradable, and may be used as packing material, environment protecting material and decoration material.

Owner:SHANGHAI JIAO TONG UNIV

Method for preparing polylactic acid foam material

The invention relates to a preparation method for an expanded material of polylactic acid; the polylactic acid, a tackifying modifier, a chemical inhibitor, a vesicant, a foaming accessory ingredient, a abscess stabilizer and a parting agent are mixed under high temperature according to a certain proportion to obtain a basic mixture; then the basic mixture is arranged in a die to carry out moulding foaming on a vulcanizing machine with a certain temperature and a certain pressure to manufacture the foaming material of polylactic acid. The foaming material of polylactic acid manufactured by the method of the invention has excellent performances of being biodegradable, controllable density, easy processing as well as good barrier property, has similar foaming shaping performance and shock-absorbing capacity with polystyrene, can replace the foaming material of polystyrene, can be used as the materials for heat isolating, sound isolating and shock absorption and has broad application in the fields of cushion packaging, transportation, electric apparatus, refrigeration, agriculture and forestry and gardening.

Owner:SHANGHAI JIAO TONG UNIV

Resin composition comprising polylactic acid and polyacetal and a molded article, film, and fiber each comprising the same

Disclosed are a resin composition comprising a polylactic acid resin and a polyacetal resin, and such a resin composition in which the polylactic acid resin and the polyacetal resin are kept miscible with each other. The resin composition has good moldability, workability, mechanical properties, heat resistance and transparency, and may be worked into moldings, films and fibers for practical use.

Owner:TORAY IND INC

Entire biodegradation PLA/PBAT composite material and preparing method therefor

The invention belongs to the technical field of polymer materials, and relates to an entire biodegradation PLA / PBAT composite material and a preparing method therefor. The composite material comprises, by weight, 10-90 parts of polylactic acid, 10-90 parts of poly(butylene adipate-co-butylene terephthalate)ester, 10-80 parts of thermoplastic starch, 0.01-1.5 parts of compatilizer A, 0.1-10 parts of compatilizer B, and 1-40 parts of filling materials. The preparing method and an operation process for the composite material are simple, product manufacturing cost is relatively low, the composite material has excellent mechanical properties, is of excellent flexibility, is entirely biodegradable, and can be widely used in the field of consumer products such as packaging materials and disposable tableware.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

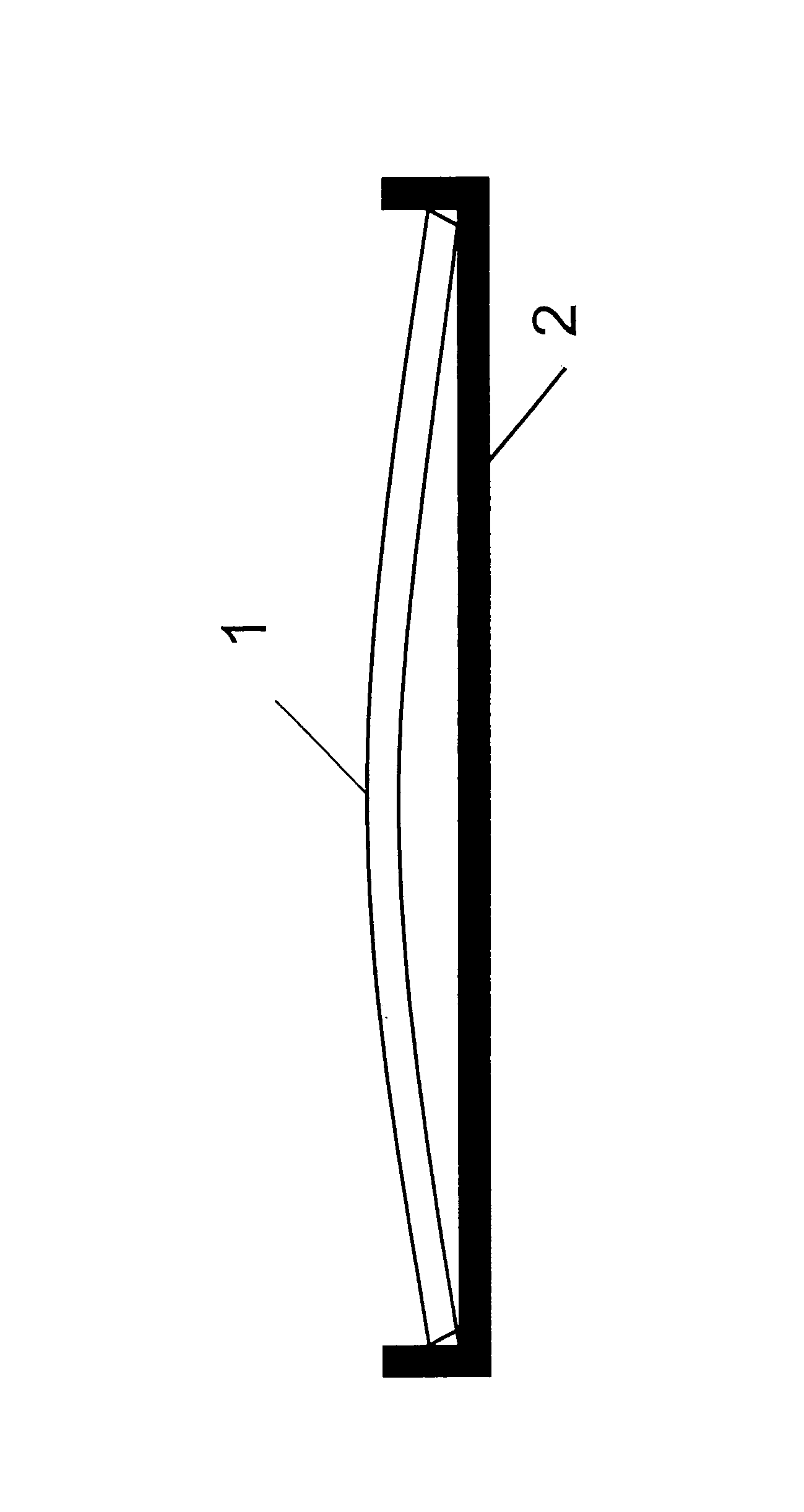

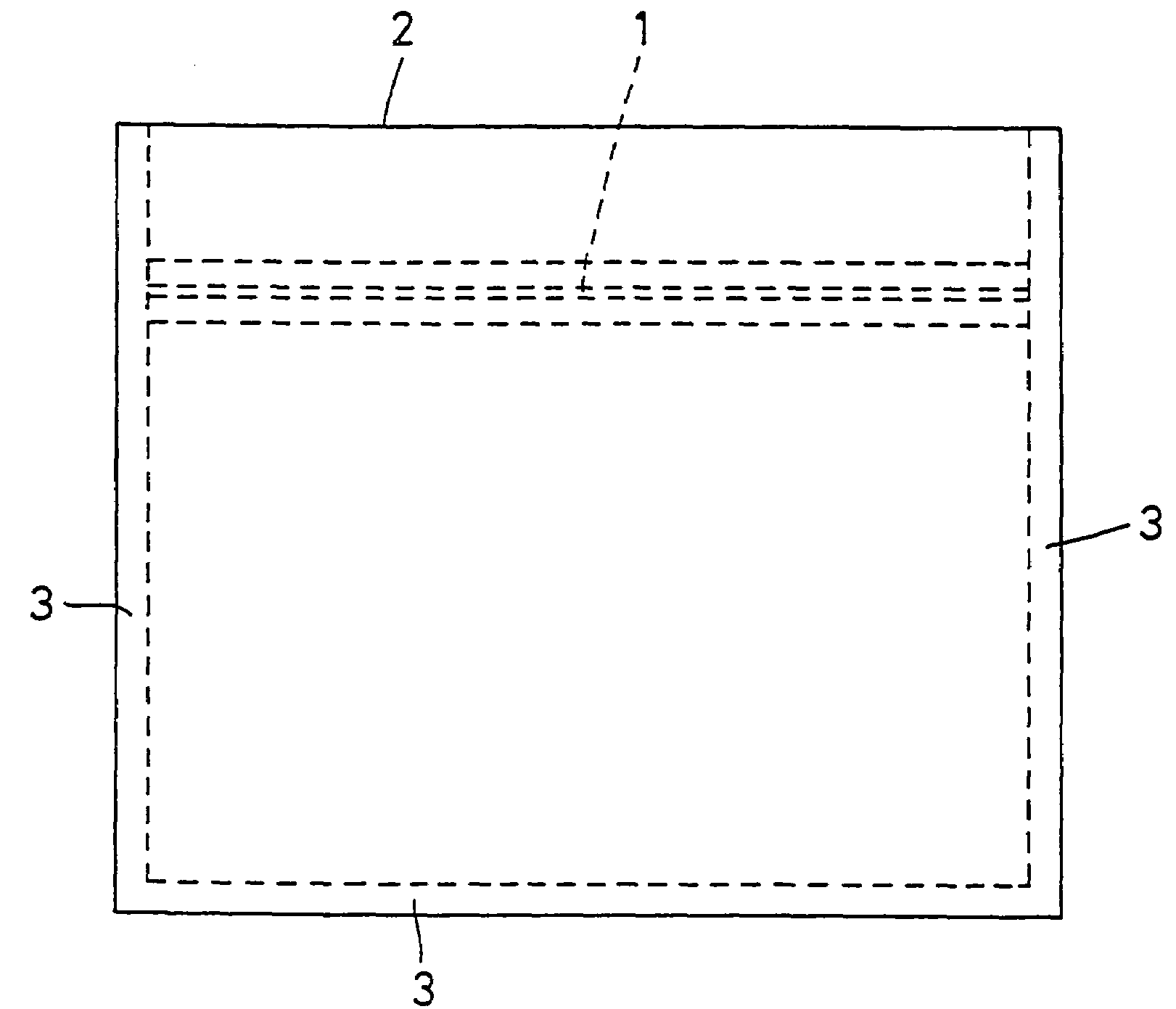

Biodegradable bag

The present invention provides a biodegradable bag which can be heat-sealed at low temperature, does not develop corrugation, has transparency, and has degradability in the natural environment. Laminates including a biaxially oriented film of which the major component is a polylactic acid-family polymer, and a film of which the major component is an aliphatic polyester having a predetermined structure are heat-sealed so that the biaxially oriented film of which the major component is the polylactic acid-family polymer will be an outer layer.

Owner:MITSUBISHI CHEM CORP

Resorbable bone graft materials

Ceramic materials operable to repair a defect in bone of a human or animal subject comprising a porous ceramic scaffold having a bioresorbable coating, and a carrier comprising denatured demineralized bone. The ceramic may contain a material selected from the group consisting of hydroxyapatite, tricalcium phosphate, calcium phosphates, calcium carbonates, calcium sulfates, and combinations thereof. The compositions may also contain a bone material selected from the group consisting of: bone powder, bone chips, bone shavings, and combinations thereof. The bioresorbable coating may be, for example, demineralized bone matrix, gelatin, collagen, hyaluronic acid, chitosan, polyglycolic acid, polylactic acid, polypropylenefumarate, polyethylene glycol, or mixtures thereof.

Owner:BIOMET MFG CORP

Articles Comprising Nonpolar Polyolefin and Polyurethane, and Methods for Their Preparation and Use

ActiveUS20090275690A1Improve adhesionSynthetic resin layered productsCoatingsPolyesterPolymer science

The adhesion between a low surface energy (i.e., nonpolar) material, e.g., a polyolefin such as polyethylene, and a high surface energy (i.e., polar) material, e.g., a polyester, polyurethane, polycarbonate or polylactic acid, is promoted by blending with the nonpolar material typically from 15 to less than 50 wt % of a diol-based thermoplastic polyurethane (d-TPU), e.g., a polydiene diol-based TPU, based on the combined weight of the nonpolar material and the d-TPU. The promoted adhesion allows for the effective painting, printing, over-molding or HF-welding of a nonpolar substrate, e.g., a polyolefin film, with a polar coating, e.g., a paint, ink, etc. Aqueous dispersions can also be made from the blend of nonpolar material and d-TPU.

Owner:DOW GLOBAL TECH LLC

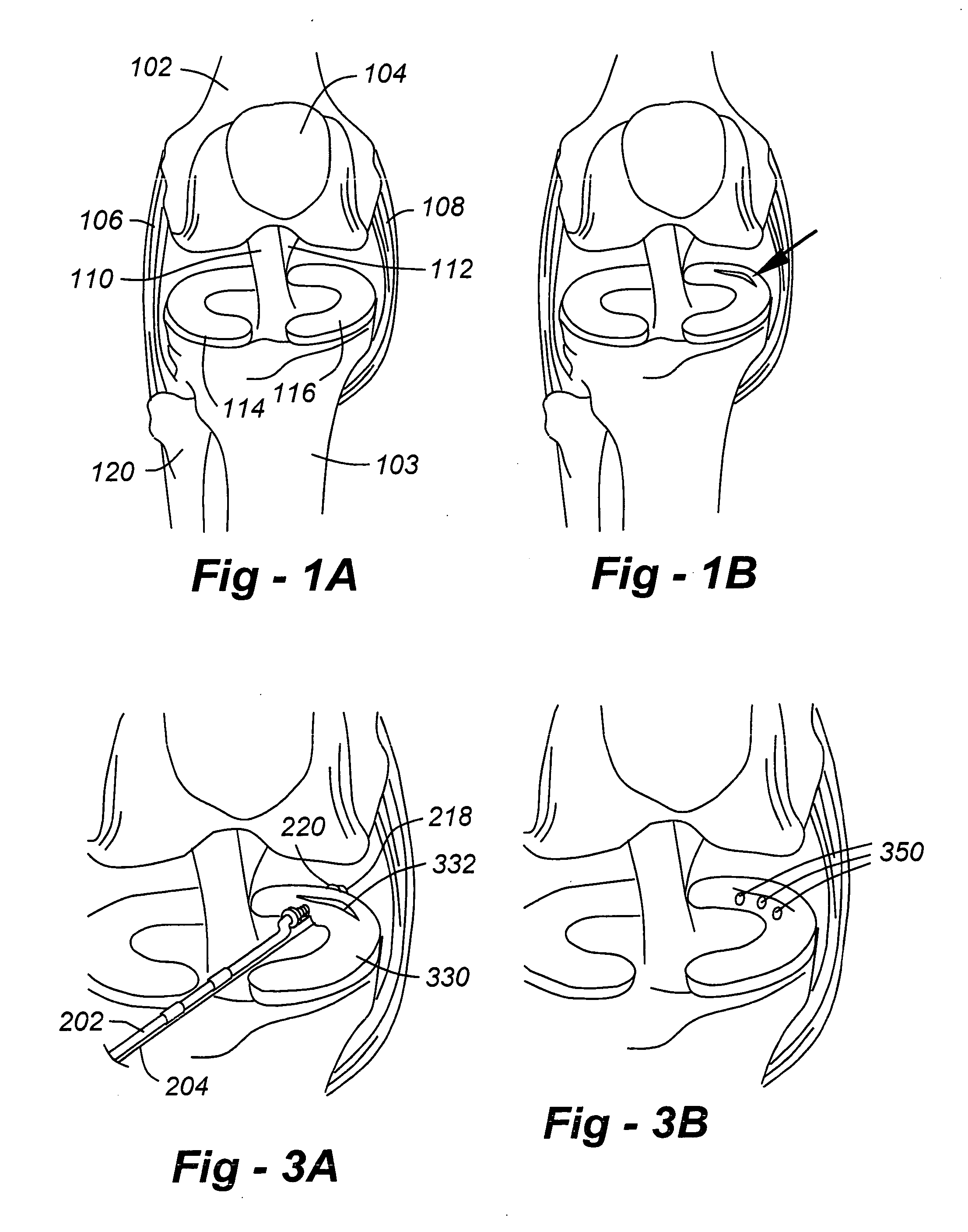

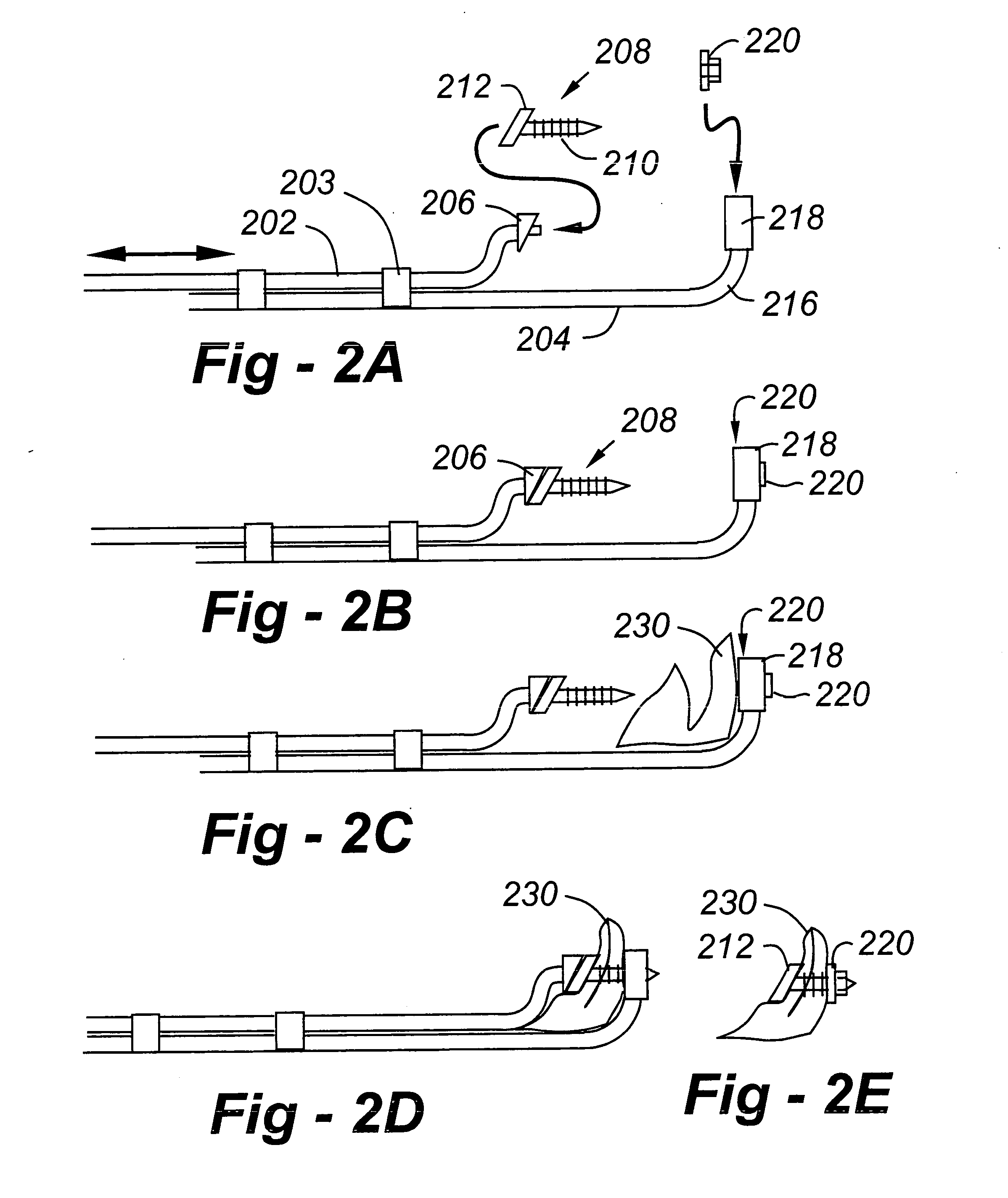

Compression tissue repair apparatus and methods

Instruments and methods facilitate expeditious minimally invasive surgical procedures. A tissue fastener is provided with a female portion and a male portion with a head and a shaft configured to engage with the female portion. A first elongated member is used to hold the female portion of the fastener behind tissue to be repaired. A second elongated member is used to hold the male portion of the fastener in front of tissue to be repaired in alignment with the female portion. The second elongated member is slideable relative to the first elongated member, allowing a user to pierce and compress the tissue as the male portion engages with the female portion. In the preferred embodiment, the male and female portions of the fastener are constructed of a bioabsorbable material such as polylactic acid. The shaft of the male fastener is preferably ribbed or barbed, the female portion of the fastener includes an aperture with features that engage with the ribs or barbs of the male portion, thereby facilitating a desired degree of compression as the portions engage. The head of the male fastener may also be angled for conformance with the outer surface of the tissue undergoing the repair.

Owner:MASINI MICHAEL A

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com